SF Marina is a world-renowned expert on developing new or existing premium marinas. We provide state-of-the-art floating breakwaters and concrete pontoons to anyone anywhere who plans on building a marina with superyacht berths. And who wants it to still be there after the storm.

www.marinaindustry.net

Paul Barrett

Hartswood Media

8 Lindsey Close, Brentwood, Essex CM14 4PN, United Kingdom Tel: 44 (0)1277 211691 paulbarrett@hartswoodmedia.com

EDITOR AND ADVERTISEMENT

David Young

Young Editorial Services

Tel: +44 (0)1737 551687 youngeditorial1@btinternet.com

Anthony Wiffen

Tel: +44 (0)1460 261011 Mob: 07851 612799 anton_print_1@mac.com

Brown Knight and Truscott

Tunbridge Wells, Kent, TN2 3BW, United Kingdom

Tel: +44 (0)1892 511678

ISSN 2517-7478

©2024 Hartswood Media

recently read a report by Florida-based DockMaster, a supplier of marina management software, which claimed the biggest sustainability challenges in the marina industry to be its rapidly-growing carbon footprint, fossil fuel consumption and other harmful practices. Many facilities were also criticised for their heavy use of plastics, their impact on local ecosystems and their contribution to climate change that is triggered by: dredging and filling of coastal wetlands; construction of large concrete structures; discharge of sewage and other pollutants into the water; and use of toxic chemicals for boat cleaning and maintenance, etc.

Some boat-owners also discard non-biodegradable, unrecyclable substances such as plastic bottles, packaging and other materials into the water, which destroys delicate ecosystems, pollutes the water and harms local wildlife.

The report advises that by following eco-friendly alternatives to these harmful practices will enable marina operators and their clients to be more environmentally responsible and suggests a number of ways in which they can operate more sustainably.

One of the most sustainable practices marinas can follow to lessen their environmental impact is recycling. Customers and visitors should be encouraged

to adopt recycling habits from the moment of arrival. For instance, placing recycle bins everywhere in the facility and installing directions for use may convince boaters to be more eco-friendly. Other areas to consider include reducing energy consumption, minimising waste and using environmentally-friendly materials and products. By switching to renewable energy, such as solar or wind, to meet the energy needs of marinas can help operators to create an eco-friendly image, reduce the cost of electricity and protect the environment. Besides, as boatyards predominantly lack any dense greenery or tree coverage, they’re also the most suitable areas to install solar panels or wind turbines.

The report also advises boatyards to use eco-friendly boat cleaning products and biodegradable oil absorbents, as well as implement a recycling programme for boat parts and materials.

It is in this area that boat builders can play their part by building eco-friendly craft that incorporate sustainable materials that are possible to recycle at the end of a boat’s life – as pointed out on page 13 in our previous issue, there is hope for commercially viable fibreglass recycling in the future.

David Young

One of Europe’s largest marina groups, MDL, is proud to confirm a £2.2 million investment in its flagship Ocean Village Marina in Southampton. This significant investment has enabled the complete replacement of all pontoons along the South side of the marina and the introduction of new smart electric technology.

Beginning in mid-October, 2023, the upgrade works involved installing brand-new pontoons from F through to L (inclusive). This consisted of removing some of the piles, dredging, reinstating the piles and then

installing brand-new pontoons, while maintaining the overall configuration of most of the pontoons. The project was completed in phases throughout May and June. F and G pontoons were the first to be completed and were opened on 10 May.

In addition to the new pontoons, smart meters have been installed across the marina. These meters provide customers with complete control of their electricity accounts, offering 24/7 access for online payments and automatic notifications of any interruptions to their power supply.

Furthermore, the five superyacht

berths, which can accommodate boats from 25-50 metres, have been upgraded with new concrete pontoons, new decking and smart meters supplying three-phase electricity.

MDL Marinas also commissioned works to include enhanced wave attenuation at the entrance to the marina, which acts to dissipate the waves to create a calmer and more comfortable environment for a premium berthing experience. The concrete pontoon sections were transported by land from Ireland to MDL’s Saxon Wharf and then towed to Ocean Village. The old pontoons

and floats were taken away for re-use or recycling, underscoring MDL Marinas’ commitment to sustainability.

Everything spent on these upgrades is focused on maintaining and improving the quality of the customer experience and safeguarding the environment where MDL’s loyal customers come to enjoy their leisure time.

With the upgrades complete, Ocean village Marina can now accommodate all boat sizes from 8-80 metres, enabling small and large boats to enjoy the luxury marina experience year-round.

The Fédération Française de Ports de Plaisance (FFPP) has announced that 53 French marinas have voluntarily signed up to assist boaters with a new system that both broadens and simplifies border controls for yachts travelling to France from outside the EU/Schengen area (and departing from France to a third country).

Using a single generic text document, which can be completed on a mobile phone, boaters can

fill in this form and send it to the participating marinas at least 24 hours prior to arrival or when leaving the previous port outside the Schengen area if the voyage time is less than 24 hours. The marinas will then take care of transmitting documents to the relevant border control authorities and authorise arrival. Entry and departure can be facilitated in each of the participating marinas and

there is no need to arrive and depart from the same location.

Guillaume Nardin, FFPP General Manager, an experienced offshore cruiser himself, announced his satisfaction with the new arrangement. He stated, “We’re very happy to have signed this derogation agreement with the French customs and border control authorities, and would like to express our thanks to the

participating marinas for their interest in helping ease entry procedures for third-country nationals. Naturally, we have just started and given that this is a voluntary operation, we ask for a little tolerance while we get underway! Feedback is welcome and we will collaborate with associations to help channel comments and evaluate and optimise the system”.

Turkey’s leading chain of marinas, Setur Marinas, has joined the ICOMIA Marinas Group IMG). It operates 11 marinas and one dry dock facility, and is the sector’s leader in the country, with a total yacht mooring capacity of 5,500. Carrying out all its operations

with the aim of improving customer satisfaction, the company achieves a significant increase in customer loyalty every year with the ‘Chain

Marina Programme’ launched at the beginning of 2018.

Setur Marinas has also made a global name for itself with its

sustainability and digitalisation practices. In line with its target to achieve net-zero greenhouse gas emissions by 2050, Setur Marinas makes environmentally-friendly investments, prioritises green technologies to reduce its carbon footprint and works to protect the marine ecosystem.

The world’s largest boat club operator, Freedom Boat Club, has announced the expansion of its UK operations with the addition of its newest location in Chertsey, its sixth in the region. It is centrally located just outside London and will provide members direct access to enjoy boating along the River Thames.

“As a top boating destination in the region, we are thrilled to announce our newest location in

Chertsey,” said Arturo Gutierrez, General Manager, Freedom Boat Club EMEA. “This announcement reflects our commitment to executing on our strategic vision as we continue to expand our international footprint and establish a presence in top boating destinations worldwide.”

Located at Bates Wharf Marina, the Chertsey location will be part of Freedom’s ThamesSolent Hub providing members

with unlimited access to three locations in the region. In addition, the Chertsey location will be owned and operated by Richard Bates, a marine veteran with decades of experience in the industry, who is passionate about expanding the local boating community through Freedom’s shared access model.

“With decades of experience across the full spectrum of boat ownership, marina operations

MA Financial Group’s MA Marina Fund has confirmed completion of its acquisition of East Coast Marina in Manly, Queensland, Australia.

The marina will expand the Fund’s portfolio to 13 high-quality marina locations and will form part of the d’Albora network – the largest marina and hospitality network in the southern hemisphere.

East Coast Marina is located approximately 20kms from Brisbane’s CBD and within the Manly Boat Harbour which is Australia’s largest small-boat harbour. The marina will add 535 additional berths to the d’Albora portfolio including 295 wet berths and 240 premium

and services, I’m ecstatic to be joining the Freedom team and providing a new pathway for boaters to enjoy the on-water lifestyle,” said Bates. “Freedom’s commitment to delivering remarkable member experiences aligns with my passion of growing the UK boating community and I look forward to a successful partnership with Freedom Boat Club now part of our wide range of portfolio offerings.”

dry storage racks. Additional facilities include a full-service boatyard for vessel maintenance, commercial tenancies, waterfront dining, onsite marina office and ample dedicated car parking.

After over 20 years of service, the large centrifugal pump system, which operated the black water pump-out at Anglo Welsh’s Trevor Marina on the Llangollen Canal, had become unreliable and expensive to service, causing challenges all round. So, the marina management called in Warwickshire-based marine sanitation specialist LeeSan to advise on a replacement.

Karl Sutcliffe, Technical Director at LeeSan, commented: “We surveyed the site and made appropriate recommendations. I think that the new, more powerful, quieter and technically more advanced pump came as something of a surprise to the marina as it is about a tenth of the size of the old unit. This means that the boatyard team have now also gained valuable storage space in the pump house”.

The new installation features the latest peristaltic LS30T pump and a dedicated operation panel fitted with its own RCD safety cut-out for

overload protection. The pump is also ‘timer controlled’ to protect it from running dry and to avoid accidental misuse.

The new pump services two separate standpipes, each with an individual suction hose and an

ISO8099 probe valve. Because the marina is next to the world famous Pontcyllte Aquaduct and consequently extremely busy, the site owners expect these to be fully utilised on a regular basis, including servicing their busy boat hire fleet.

As part of the service, Leesan has also organised a comprehensive service contract to ensure that the equipment is always in excellent operational order and should provide another 20 years (or more) of reliable service.

It has been announced that Dura Composites has received a King’s Award for Enterprise in the Innovation category. The supplier of anti-slip decking is one of just 252 organisations in the UK to be recognised with this prestigious award.

At Dura, continuous innovation is central to the company’s ethos

and receiving this award for its sustainability credentials and patented GRP walkway grating products is much appreciated. Through a careful combination of design, technology and manufacturing improvements, its d² Dura Grating range has up to 33% less embodied carbon, whilst also being fully recyclable and lighter than anything else on the market, making installation safer, easier and more cost-efficient. As well as being lower in carbon and fully recyclable, the grating is easier to handle and achieves a better performance-toweight ratio, the highest fire rating, best anti-slip properties and the most proven performance in the GRP grating industry.

The King’s Awards for Enterprise, previously known as The Queen’s Awards for Enterprise, were renamed last year to reflect His Majesty The

King’s desire to continue the legacy of HM Queen Elizabeth II’s by recognising outstanding UK businesses. The Award programme, now in its 58th year, is the most prestigious business award in the country, with successful businesses able to use the esteemed King’s Awards Emblem for the next five years.

Dura has previously received Queen’s Awards for Enterprise for International Trade in 2017 and Innovation in 2020.

Mitan Marina, a 160-berth marina in the Northern Adriatic has been welcomed as a member of TransEurope Marinas by JeanMichel Gaigné, the organisation’s Chair, who expressed the Group’s delight with this ‘state-of-theart Croatian marina in a sailing paradise’.

The family-run marina also offers dry stack services in new and modern hangars covering 6,500 sq m, with video surveillance, which are located 3 km away from the sea.

Berths for large yachts are available on the 240 metre breakwater. Vessels up to 30 metres moor along the inner side of the breakwater, while megayachts up to 80 metres LOA can dock on the outer side. Extremely well-built, the marina has concrete piers that provide additional security.

D-Marin has announced the official rebranding of the esteemed Business Bay Marina in Dubai to Marasi Bay Marina. Following the successful acquisition of the marina by OMINIYAT Group last year, this strategic move marks a significant milestone in D-Marin’s commitment to delivering top quality experiences within Dubai’s vibrant maritime landscape.

Marasi Bay Marina sets a high standard for luxury, with an array of exclusive amenities designed to satisfy its discerning clients, including a five-star hotel, an array of fine-dining restaurants and various offerings for berth-holders.

This landmark destination in the heart of Dubai, highlights D-Marin’s commitment to delivering a premium marina experience.

The significant rebrand of the marina further consolidates its position as a ‘superyacht hub’, setting it apart from the competition.

Marina Projects has been appointed by James Watt Marina in Greenock, Scotland, to develop a new purpose-built operations building and family space that will take customer service to the next level. The new 400 sq m building will be utilised for operations, as well as providing much needed additional facilities in the heart of James Watt Dock.

The development, which will occupy a prominent location within the James Watt Marina, has been designed with customer service leading the key design considerations and to generate maximum future value from the marina building upon completion.

Bottom’s up!

Crick Boat Show’s Real Ale & Cider Festival, which took place from 25-27 May was once again sponsored by Lee Sanitation.

Thanks to LeeSan’s sponsorship, the bars were plastic-free, with drink ‘papers’ instead of glasses, as well as further improvements to speed up service at busy times. The company have named two ales, ‘Khazi’ and ‘Round the Bend’ and two ciders, ‘Double Flush’ and ‘Rhubarb Plunger’ proving that the British sense of toilet humour is still alive and kicking!

Warwickshire-based LeeSan specialise in everything relating to marine sanitation, from on-board toilet systems to marina pumpout equipment, so when boaters or marina-owners have finished drinking and need to ‘go’, the team at LeeSan are the people to call!

Amarina in the Caribbean island of Antigua has enhanced its capabilities by adding a new haul-out facility and an 85BFMII (85 metric ton capacity) boat hoist from Marine Travelift. With the rapidly growing catamaran market, Jolly Harbour Marina & Boatyard is

looking to capture this business of maintenance/storage and identified the Marine Travelift boat hoist as the optimal solution for accommodating these larger beam vessels.

The facility was built in 1992 and has consistently grown and proved to be very successful in

Staff carried out a ribbon cutting ceremony to welcome the new hoist.

hauling and storing vessels. Over the years, the marina has changed ownership twice, in 2010 and 2021, but has remained committed to its top priority: ‘providing excellent customer service’. This dedication is upheld by investing in top of the line equipment and a well-trained staff, many of whom have been with the marina for over a decade, ensuring continuity and expertise.

The new 85BFMII boat hoist joins a Marine Travelift 75 ton already on site and in use since 2015. Ms Jo Lucas, Jolly Harbour Marina General Manager, stated that they began planning for a new haul-out facility in 2023 to tap into the “rapidly expanding catamaran market, focusing on hauling these vessels for maintenance and storage”. The recently purchased boat hoist was also part of the plan and Marine Travelift was chosen due to an already “established relationship with great results”. The new 85BFMII is customised with additional width to accommodate beams up to 34 ft and a sailboat top beam extension to efficiently handle these vessels without removing the mast.

Jolly Harbour Marina’s plans for the new haul-out facility are aided by other customisations on the new Marine Travelift boat hoist, including LED lights, wireless remote control and a jib crane. The 12 LED lights significantly improve visibility when operating at night or in other low visibility conditions. A wireless remote control gives the operator unmatched visibility by allowing them to move around the machine and vessel, eliminating the need for multiple spotters. The jib crane has a capacity of 2,500 lb and can be used for maintenance/ service work removing masts or pulling engines, among other things.

Providing excellent customer service is Jolly Harbour Marina’s top priority, a commitment mirrored by Marine Travelift in its approach to client relationships and delivering results. “We have found working with the team at Marine Travelift to be great,” stated Ms Lucas. “Their effective communication throughout the entire engagement from pre-

sales, production to delivery and now post-sales service stands out.”

In addition to the new boat hoist Jolly Harbour Marina is eagerly anticipating the delivery of their next piece of equipment, a Marine Travelift TM40 transporter with catamaran

boat pads, which is currently on order. “We are looking forward to taking delivery of our hydraulic self-propelled transporter in September. This will further enhance our operation and the service we can provide,” explained Ms Lucas.

These new additions to Jolly

Harbour Marina show the staff’s dedication to maintaining high standards of service and their ongoing partnership with Marine Travelift, ensuring they always put customer satisfaction first. Marine Travelift Inc sales@marinetravelift.com www.marinetravelift.com

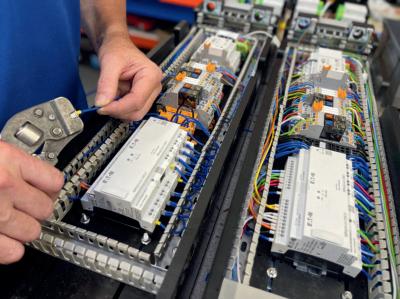

to the Leisure Industry for over 40 years, offering a complete turnkey solution for your electrical infrastructure requirements. Making your needs our priority!

At a marina, there’s no better use of space for storing boats than a dry stack facility, but they can be maintenance and personnel-heavy. Replacing forklifts with a semiautomated CAPRIA Ground-Running Stacker Crane can greatly increase productivity. Launching customers’ boats into the water in a fraction of the time it would take a forklift

contributes directly to profitability, an increased bottom line and happier customers.

Due to the geometry of the crane’s pivot, it can move boats 10 ft longer than a forklift can within the same aisle space. In addition, CAPRIA cranes are electric, so forklift fuel and storage are eliminated. Plus, the quiet, odour-free machinery requires far less maintenance. When

factoring in the 30+ year lifespan of a CAPRIA system versus a ten-year forklift life, it’s easy to see how marinas can quickly recoup their investment.

With a CAPRIA dry stack solution, the crane operator is always at eye level with the vessel, eliminating blind spots a forklift driver often faces. Clearer sight lines reduce the potential for accidents and angry

boat owners. Installing a CAPRIA Ground-Running Stacker Crane into an existing dry stack shed is also very straightforward. Rails are placed on both sides of the aisle, on gravel, asphalt or concrete.

Once the boat is pulled from the shed, it’s placed on a CAPRIA launcher. Three versions accommodate virtually any water access. Frontal Launchers are perfect

for sites with steep embankments and/or extreme tidal fluctuations.

For narrow waterways with limited space, such as a canal, Lateral Launchers lower the boat parallel to the water’s edge. Finally, Rotary Launchers are ideal for marinas that have pedestrian and vehicular traffic

between the shed and the shore as the boat is moved up and over obstacles.

A typical CAPRIA dry stack solution consisting of one crane and two launchers per 250-300 boats can move up to 30 vessels per hour. Manufactured to ISO 9001

standards, CE-certified, the system accommodates vessels up to 13 m in length and weighing up to 9,980 kg. Available worldwide, a system can be installed and operational in only ten days.

CAPRIA S.A. has manufactured precision heavy machinery for over

50 years, including marine systems for over 20 years and with low-cost, dry stack installations around the world, it has a proven record of solidly improving profits for its customers. CAPRIA SA

info@thestackermachinery.com www.thestackermachinery.com

“The majority of yachtsmen say that it is one of the best pontoons they’ve ever moored on. Stable, non-slip and a high freeboard so they do not have to jump from their yachts on to the pontoon.”

Scott Ferguson, Harbour Master, Berwick

By Dan Natchez CMP*

Whether you call it rack storage, dry stack or vertical marine storage, it has come a long way over the years, having evolved from the early approach using wooden posts for two levels of boats with converted front

loaders and extended forks to now fully enclosed buildings that can be multiple stories high with steel racks, specialised lifts and even fully-automated systems.

I am delighted to co-author this article with Brett Roof – second generation from Roof and Rack

Products, one of the early entrants into and a continued leader in boat rack storage systems.

Of course, the biggest argument for rack storage is that it allows for efficient revenue producing use of upland real estate by allowing for multiple layers of boat storage within the same footprint. It started with lighter boats in the 15

ft to 20 ft (4.6 m to 6.1 m) range and has evolved to where boats up to 60 ft (18.3 m) long, with weights that can be upwards of 40,000 to 50,000 pounds (18,144kg to 22,680 kg), can now be handled. As rack storage system options have increased, the types of boats

that may require rack storage also have dramatically changed. They have gone from the relatively shallow flat or shallow ‘V’ bottom runabouts with an outboard motor

to boats with deep ‘V’ bottoms and multiple outboards with trim taps, inboards with rudders and skegs, longer boats with higher freeboards or fixed towers and even cruising

boats – along with dramatic weight increases.

When contemplating rack storage, one must understand the surrounding user market as it is

today, as well as the boating trends for tomorrow, and always keeping in mind the climate, in every sense of the word. Some typical boat size trends being seen in the industry

include moving from what may have been the historic maximum of 28 ft to 35 ft (8.5 m to 10.7 m) to often having a minimum of 30 ft (9.1 m) and going up to more than 55 ft (16.8 m), particularly in coastal areas, including large lakes. In the inland river and smaller lakes, the target seems to be towards a minimum of 25 ft to 30 ft (7.6 m to 9.1 m) boats, with a growing presence of boats and a corresponding need for boat rack storage in certain areas for 35 ft to more than 40 ft (10.7 m to 12.2 m) boats. Yes, the width, length and weight requirements continue to be on the upswing and there seems to be a trend to including larger boats with non-collapsible binny tops and towers, which require taller racks. These then require more thought and potential flexibility, while

offering the potential for more revenue.

From the boater’s point of view there can certainly be advantages to rack over in-water storage, including: one does not have to paint the bottom of the boat; it prevents fading of the gelcoats and other materials; one doesn’t have to cover the boat; and someone else gets the boat ready so one can just jump in and head out, as well as puts it away, which can include important valet services such as rinsing the bottom, flushing the engines and cleaning the rest of the boat. Of course, there can also be perceptions of disadvantages, including: dripping from boats above; not as convenient or easy to work on or putter around in the

boat; may have to wait for the boat to be put in the water; having to call ahead to arrange a launch time; and perhaps biggest of all, one cannot just sit in the boat at its berth and enjoy the day or sleep in the boat at the dock for the weekend!

Is rack storage for every site? The simple answer is no. Can it be meaningful – yes! It can be very effective and economically desirable, but one has to do their homework and understand the various yin-yangs. We always say that every site is site-specific and that goes double for rack storage. While every site is site specific, as a general approach there are two major pieces to the rack storage jigsaw puzzle: is it compatible with the location; and is it economically desirable for the site?

Many do not consider this upfront and then get very frustrated when going through the regulatory process. In most areas, there are zoning regulations and in many places quite restrictive regulations, including bulk and height constraints, as well as parking, architectural treatment and setback requirements, which can significantly limit the size and height and economics of the rack storage structure(s). Then one may be faced with Not In My Back Yard issues. Surrounding residents may come out in force with the NIMBY arguments at public hearings. Some communities, such as Fort Lauderdale, Miami and several in the Florida panhandle, have found ways to have peaceful co-existence… at least more often

than not, but as areas become more populated and built up with residences, NIMBY typically becomes more prevalent. Many communities, particularly in suburban areas, have height restrictions of 35-40 ft, translating to two to four racks high depending on the size and type of boats one desires to place in the racks. Of course, there are some notable exceptions, particularly in more urban/city settings, such as Fort Lauderdale, where a recently opened facility is six racks high and 135 ft high!

With respect to the racks themselves, today there are many choices, which include: Open Racks that have no side walls, including smaller individual ones that can

be portable and can be viewed as equipment as opposed to a structure for approval purposes; Roof Covered Racks, which are the first step towards protecting the boats from the outdoor elements such as sunlight; Roof and Walls Covered Racks, providing better protection from the elements and more security for the boats and which can be very helpful when the land available does not lend itself to a full aisled building with racks on each side; and Fully Enclosed Rack Buildings, which keep the boats protected from the outdoor elements, as well as being the most secure from theft or damage. Enclosed buildings in colder climates keep the boats free of snow and ice, and many buildings today are heated, which adds longevity to the boats and their equipment. If hurricane-rated, they also help both in obtaining boat insurance, as well as better insurance coverage and rates. Most rack systems are designed as rectangular or square with normally a perpendicular boat entry and exit. However, particularly in a retrofit project, the racks can be made angular, allowing longer boats to fit in spaces designed for shorter boats.

Adding to the puzzle there are two basic types of storage systems – mechanical with

From the boater’s point of view there can certainly be advantages to rack over in-water storage, including: one does not have to paint the bottom of the boat; it prevents fading of the gelcoats and other materials; one doesn’t have to cover the boat; and someone else gets the boat ready so one can just jump in and head out, as well as puts it away

a negative forklift system or automated systems. All need to be maintained and serviced although the issues and costs of each system vary greatly in terms of costs, availability of replacement parts, service response times and so on. A marina needs to consider the market and know the number of boats that can be moved/ launched/retrieved in an hour. If one cannot keep up with the

demand, then one is losing money and upsetting the customer base.

The forklift system is relatively simple and conceptually is less expensive to implement. A basic system is usually quicker to get up and running and can be expanded relatively easily over time. It does not need a different piece of equipment for hauling and launching. More than one forklift provides back-up in case one has a mechanical problem and allows for more than one truck to move boats in and out at the same time. We find that once a facility exceeds roughly 60 boats, that second forklift becomes more of a necessity than a luxury. Forklifts need OSHA-certified operators (the certification is not overly difficult to obtain), with a skilled eye to place the boats in and out of the racks, and a heavy reinforced concrete surface to operate over. The forklift does make noise (beeping) when moving in reverse, requires wide turning areas to move the boats, and has greater weight limitation (more so than length) on how high boats, especially heavier boats, can be safely lifted. The forklift operator is on the machine, usually at the ground level, and the line of sight is diminished as the boats are lifted higher into the air.

Automated options have not been as prevalent in the industry to date, but are continuing to evolve and there are any number of impressive new facilities. Currently there are four basic types: overhead crane; overhead cables; bottommounted crane; and a potential new automated vehicle transport system (similar to the automated pallet car elevator systems). Each has its attributes and limitations. Some use traditional racks, some use five-walled cubicles and there are variations upon a theme. Some can increase the heights and boat weights that can be lifted to the higher storage levels well over the more traditional three to four levels, reaching as high as six to eight levels or even higher. All use various types of sensors and electronic controls and run from semi-automatic to fully automatic (just press the button).

The automated systems do have a narrower turning aisle than the

forklift systems and reduce or eliminate the reinforced concrete turning isle within the building. They reduce manpower labour (payroll) and human error either by having an operator at eye level with the boat at all times or being fully automated, essentially eliminating the operator altogether. They can place heavier boats at higher elevations and can be placed using less space for moving the boat in and out of the racks. They are quieter than forklift operations. However, automated systems often seem to have multiple vendors involved, including for the traditional building components, but then adding software, sensors and other equipment. They often use a second piece of equipment to haul and launch the boats, and then transfer to the main automated system. The logistics of the building placement usually are more restrictive due to the need to be close to the water’s edge. Many

do not have the ability to have a staging area for boat maintenance as part of the system. They are powered by electricity, making them vulnerable to associated disruption issues.

One definitely wants to consider a back-up generator. Almost all of these systems will involve higher upfront costs than some form of forklift-based system, but where they can increase efficiency, overall boat capacity and so forth, they certainly can make sense – and can even prove less costly in the long run.

So, what are the typical costs? That’s a question often asked, but not easily answered. In our conversations with various suppliers of the different types of systems over the years, we find that there is no real consensus as to generic costs per boat. There are just too many variables that influence the

calculations, from the number and, more importantly, the types of boats, with their respective weights and heights, the height of the buildings, and site development costs, including, but not limited to, the all-important soil conditions. The one thing that all of the suppliers seem to have in common is that they all agree that each facility is unique for pricing and we absolutely agree.

That being said, and recognising that there is no average facility, we have taken a stab at it. What follows are very rough estimates of the cost per boat for the different systems, arrived at by eliminating land acquisition, development costs, regulatory and other associated costs, and assuming only a bare bones building (with no fancy architectural treatments), and the boat handling equipment/systems.

Forklift systems. Simple outdoor forklift/rack system: $20,000-

$40,000 per boat.

Traditional indoor forklift/rack system: $35,000-$55,000 per boat. Automated systems. Overhead crane system: $55,000-$110,000 per boat.

Overhead cable system: $70,000-$110,000 per boat.

Bottom-mounted crane system. Traditional racks: $35,000-$70,000 per boat.

Five-walled rack system: $45,000-$100,000 per boat. Automated vehicle transport system. $75,000-$100,000 or more per boat.

These compare to the similar rough average bare bones cost of an inwater berth of $40,000-$75,000.

Again, these figures are far from gospel, and do not include other major development costs, which are real and will significantly change the economics of a project. The type, height and weight of boats, as well as the number of levels of the building will significantly alter the cost benefit and payback ratios.

Also note that many vendors are talking in terms of higher buildings to capture one’s interest in a particular system. However, at present, there are relatively few areas in the world that would either allow or welcome six to ten level boat storage buildings. To date, as a general rule, the automated systems have tended to make the most sense for big, and particularly taller, buildings, while forklifts have traditionally dominated the smaller and/or less tall buildings, open racks, etc, but as the classic Dylan song almost goes, the times they are (always) a-changin.

So where should you start if you want to explore rack storage?

There is no one answer, but we suggest that among the first steps would include: a) determining the local regulations that might apply in terms of limitations on height, coverage and parking, as well as any other zoning/land use regulations that could affect the implementation of a rack system/ building; b) reviewing the site for

what areas could be used and what the soil conditions are; and c) analysing the local boating market and trends. Thereafter, try to determine what might be best for your area, such as traditional rack or an automated system. Next, come up with a concept approach of how high and how big the facility is that you would ideally desire, including the types of boats –width, height and length. Talk to different providers and ask them to provide a spreadsheet analysis of all of the component costs that would be included for what you are contemplating. Some will even provide a spreadsheet with their interpretation of competitive systems. Land and site development costs may or may not be included in their spreadsheets, but should be as part of your overall homework.

So, the bottom line is dry stack can be meaningful but, like most development projects, one needs to really do their homework and

fully understand the project, and not only the obvious, but all of the site development costs, as well as the potentially tangential costs. We would also suggest looking at the track record of the system being considered and having candid discussions with the potential supplier, as well as with others that are actively using the system for hands-on input. Each system has its own advantages, as well as issues, and one’s location (physical, as well as market) is typically most important in determining which system might be better than others, including for the rate of return.

*Dan Natchez, CMP, is President of Daniel S. Natchez and Associates Inc, an international environmental waterfront design consulting company specialising in the design of marinas and marina resorts throughout the world.He can be contacted on Tel: +1 914 698 5678, by WhatsApp at +1 914 381 1234,by E-mail: dan.n@dsnainc.com or on his Website: www.dsnainc.com

Aworldwide shortage of superyacht berths has reached a critical point whilst growth in superyacht development shows no sign of slowing down. This has led to strong competition between owners looking for permanent ‘home berth’

locations. Introducing Habacoa, a new superyacht marina in South Abaco, which is expected to open in 2027, Ra’anan Ben-Zur, founder and CEO of Habacoa, announced: “This project will truly redefine super-yachting and luxury living, creating an upscale, sophisticated lifestyle”.

The developer has described this project as North America’s largest and most comprehensive superyacht marina and luxury residential community. It will feature 150 berths ranging from 18 metres to over 200 metres, complete with service pedestals alongside berths, as well as diesel refuelling, customs and immigration, a one-stop provisioning centre and a dry stack facility for 200 boats.

Developed by globally-renowned marina engineers Moffatt & Nichol, the marina is built to withstand a

once in 100-year storm event. Yearround tranquillity is ensured as the 110 acre basin has been designed on the leeward side of the Bahamian island, featuring a sizable protective breakwater.

A private, members-only Yacht

Club of approximately 2,320 square metres will feature a unique roof, restaurant and bar, open-air terraces and a hub for curated events and programming. The architectural concept revolves around undulating forms that connect with the marina

and define all the covered outdoor spaces housing luxurious facilities, including a night club, casino and a five-star hotel. There will also be a spa, wellness and fitness centre, and superyacht crews will be provided with their own dedicated crew club.

Each building will integrate sustainable technologies and use environmentally-responsible materials. An important focus will be placed on blurring the lines with nature, as the near-transparent design ensures seamless connection to the island’s inherent beauty, whilst flooding the space with natural light and ventilation.

“Respecting the natural beauty and integrity of South Abaco, we envisioned our design through a sustainable lens,” said Juan Ignacio Aranguren, Associate Director, Zaha Hadid Architects (ZHA).

Habacoa’s developer is also committed to sustainability in The Bahamas and aims to minimise disruption to marine habitats, use sustainable construction methods and incorporate extensive solar power and rainwater harvesting infrastructure. “This project has been deeply influenced by meticulous attention to environmental considerations,” added Aranguren of ZHA.

Finally, it is anticipated that the project will offer many socioeconomic benefits to the region by providing significant infrastructure improvements and employment for local people. Habacoa inquire@habacoa.com www.habacoa.com

l Services for superyachts

l Security gates and lighting

l Tenders and workboats

l Marina visit to Italy

Deadline: Monday, 5 August

Whether looking to stay for the day, the night or the year, this 400-berth member of the Yacht Havens Group takes pride in its Five Gold Anchors customer service and the safety of its berth-holders, visitors and their boats. Troon Yacht Haven’s sheltered location on the waters of the Clyde makes Troon the ideal stop-over when venturing North into the Firth of Clyde or South to Northern Ireland, England or Wales. The marina can provide berthing for boats up to 50 metres in length and a maximum beam of 8.5 metres. Its modern pontoon berths provide quick and easy access to boats and they are all fully-serviced with electricity (16 and 32 amps), water and free Wi-Fi. In fact, the marina recently announced its completion of a major connectivity upgrade across the site, bringing the latest Wi-Fi 6 technology to berths throughout the marina.

As the next generation of Wi-Fi technology, Wi-Fi 6 is designed to comfortably handle a higher number of devices compared to the previous Wi-Fi 5 technology – perfect for

a busy marina like Troon Yacht Haven. Most importantly, Wi-Fi 6 can deliver greater Wi-Fi coverage at faster speeds. This upgrade is complemented by 19 new access points across the marina. Diesel and Calor Gas available is available 24/7 and within the marina there is round-the-clock security and CCTV surveillance, as well as secure bridgehead access.

Ashore, there is a modern hotel on-site, a fantastic restaurant and bar. The Salt Lodge at Troon Yacht Haven offers contemporary, comfortable and flexible accommodation overlooking the harbour at the heart of the facility. Its one and two-bedroom suites

offer flexible, stylish living spaces, with a kitchen and dining area, and the option of great food and drink at Scotts restaurant, which is adjacent to the hotel.

A well-stocked chandlery is on-site, open seven days a week.

A Morrisons supermarket and cash points can be found in the nearby town of Troon.

If repairs are needed, a 55 ton boat hoist operates from the marina’s slipway from Monday to Friday all year round. There is also a 24-hour emergency call-out service. Boats can be lifted and held in the hoist for an hour or overnight for small jobs or stored ashore for a longer period. Vessels can be lifted to and

from road transport as required. The marina’s mobile crane can also be used for other tasks, including mast-stepping and engine lifts as required.

There is space ashore for 120 boats, all supplied with power and water. Vessels are safely positioned in cradles or on chocks; both of which can be hired from the marina. All boats are pressure-washed before being stored ashore, with the yard being designed to ensure boats are easily accessible at all times. Perhaps the best reason for visiting Troon Yacht Haven is its knowledgeable, friendly and efficient team, which is always ready to help.

Troon Yacht Haven troon@yachthavens.com www.yachthavens.com/troonyacht-haven

The innovative Pelican Lift BL70 MDC mobile dockside crane on wheels allows hauling and launching operations of boats to be carried out in maximum safety and reliability. Due to its innovative and patented design, the dockside wheeled crane enables boats to be moved to and from the water even where there is no waterfront infrastructure, such as

basins or ramps.

The front cantilever beam is balanced with counterweights on the rear of the crane and ensures that hauling and launching operations can be achieved well beyond the edge of the dock, with its ‘boat hoist style’ slings system.

The Pelican Lift crane is equipped with a dynamic electronic steering system for exact wheel alignment

under any circumstances. Thanks to this system, it is possible to choose between various modes (four steering wheels, two steering wheels and two skid steering – concentric rotation – crab steering) using either remote control or with an operator on board.

Boat Lift Srl info@boatlift.it www.boatlift.it

As superyachts continue to increase in size and complexity, so do their onboard power requirements. Keeping pace with demand, Hubbell Marine, a manufacturer of safe, high-amperage electrical connection products, is the only supplier to offer 200 amp ship-to-shore devices that are listed to UL 1682 standards and UL-classified.

Made in the USA, heavyduty 200 amp ship-To-shore fittings are designed to be fully interchangeable with Crouse-Hinds Arktite and Appleton Powertite receptacles. The four-pole, fivewire 200 amp system is 600 volt AC/250 volt DC, 50-400 Hertz and accepts a cord range of #1 AWG to 250 MCM. A unique interior clamp and swivel/pressure pad design protects conductor strands while securing the cable at four separate points for superior retention.

For durable performance, the housing employs copperfree aluminum, with an electrostatically-applied epoxy/ polyester finish. These are Type 3, 4 and 4X-rated per UL 50 standards for superior water resistance.

The UL-listed and CSAcertified pins and sleeves of the connector are made of nickelplated tellurium copper for superior corrosion and heat resistance.

Hubbell Marine Electrical Products custserv@hubbell.com www.hubbell-marine.com

Internet of Things (IoT) sensor technology called ‘marinaSCAN’ from SMBL GmbH consists of a robust, seawater-resistant housing. All data is transmitted wirelessly to the supplier’s servers. This is done either via a dedicated wireless network or via mobile radio, which also makes it possible to obtain an overview of smaller and remote jetties. Various sensors identify the current status of the berth and transmit the information directly to the marina’s software. The modules use their own radio network for this purpose.

Any public WiFi network in the vicinity is not affected. The modules can be integrated into a wide variety of software solutions via interfaces. It is not necessary to change the marina management software as ‘marinaSCAN’ simply adds real-time data and the option of LED control to the software. The modules can be conveniently addressed via the software to indicate the current berth status (free or bookable = GREEN/occupied or booked = RED).

The system is able to use the collected data to identify the length of absence of a permanent berth-holder. This results in potential resources, which in turn can be used/ booked by guests. Each unit is energy selfsufficient and requires no connection to external power sources. This makes installation simple and freely scalable.

SMBL GmbH info@smbl.eu www.smbl.eu

The Aquablast ® line is a device for cleaning and decoating vertical or vertically-inclined surfaces. It is particularly suited to treating rusted areas and/or surfaces with similar damage.

The system can be mounted on various suitable carriers such as hydraulic lifts, baskets, working platforms, etc. Pre-loaded springs ensure contact stability and a

The Model GSB18V-800CB24 brushless hammer drill/driver kit from Bosch features a Rapid Mode Selector, which rapidly shifts between hammering, drilling and driving modes without the need to adjust the clutch. The precision

clutch is switchable and, when turned on, stops the tool when clutch slippage is detected. There are 20 clutch settings for driving accuracy and reduced fastener damage.

Two speed settings allow the tool to be used for both high-speed and high-torque applications, and the all-metal chuck gives enhanced durability.

Ergonomic design promotes comfort and balance on the job, and an integrated LED light illuminates the working area for better visibility.

Bosch 18 volt cordless power tools are covered by a five-year limited warranty. Bosch bosch.servicecentre@uk.bosch.com www.bosch-profesional.com

smooth start-up.

Other features include vacuum suction connection and the gimbal and pre-loaded springs, which ensure stable positioning on the surface of the hull.

Versions with electric or manual oscillating movement are available.

Hammelmann GmbH mail@hammelmann.de www.hammelmann.de

One of Heskins first marinespecific products is an anti-slip adhesive tape tailor-made for use on anything from pleasure craft to racing yachts. H3460 marine tape is the first product to be 100% guaranteed saltresistant.

It was felt necessary to have this feature due to the long amounts of time the tape will be applied on a vessel out in the open sea, as while the company previously used Safety-Grip™ and its non-abrasives, with the exception of its chemical resistant Safety-Grip™, full salt resistance could not be guaranteed. Subject to correct application on to a clean, dry surface, the service life of this

salt-resistant tape will be exceptional.

Unlike Heskins’ abrasive products featuring aluminium oxide, H3460 marine anti-slip tape comprises granules applied to the surface. The S2 grit, akin to small glass beads rather than sharp-edged granules, ensures comfort when traversed barefoot while delivering effective slip resistance in demanding environments. Ideal for leisure craft, providing both slip protection and comfort, it excels in rigorous applications such as competitive boat or yacht racing.

Heskins Ltd mail@heskins.com www.heskins.com

Naval Tecno Sud Boat Stand specialises in the design, production and supply of equipment for use in boatyards and to store and transport leisure craft in marinas.

It offers a high quality range of cradles, boat stands, safety steps, work platforms dry stack storage racks and fixed and mobile booths for painting and other maintenance tasks. Versatile boat trailers, both self-propelled and towable, are also available.

Naval Tecno Sud Boat Stand, Via Pino Pascali 28, 70010 Valenzano BA, Italy. Tel: +39 393 5493586 E-mail: navaltecnosudboatstand@gmail.com

Step into the heart of maritime innovation at the Marina & Yard Pavilion, a central hub for marinas during METSTRADE, the largest marine equipment trade show. For over a decade, the pavilion has been the epicenter of cuttingedge marina-specific equipment, featuring everything from pontoon systems to dock fenders. Join global marina professionals at the ultimate networking for marinas. Don’t miss your chance to explore the forefront of marine technology!

The Organisers of the Thailand International Boat Show

A Luxury Lifestyle Event and Thailand Boat Festival have announced they have formed a strategic alliance to host a single boat show in Phuket Yacht Haven from 9-12 January, 2025. The event name will remain ‘Thailand International Boat Show’ as the two organisers aim to leverage their complementary experience and scale up the 2025 show to be the biggest yet.

David Hayes, CEO of Thailand International Boat Show organisers JAND Events, said, “We know the industry only wants one show, and this strategic alliance with M Vision will deliver just that - together we aim to deliver the best possible boat

and lifestyle show in 2025. M Vision’s experience organising large-scale Thai consumer events complements our boat show and luxury events experience, and while we look to further grow international visitors we will also build on our Thai visitor success this year and supercharge our efforts for 2025.”

Businesses and partners of the Thailand Boat Festival will join the stellar line-up of boat and luxury brands from around the world that are already confirmed to be participating in the 2025 Thailand International Boat Show. Speaking of the alliance, Opas Cherdpunt, CEO of M Vision Public Company Ltd, commented, “Aligning our efforts with the Thailand International Boat Show makes a lot

It has been announced that METSTRADE, has established the Superyacht Content Board, which is aimed at fostering stronger ties with the most significant associations in the superyacht sector. With 1,540 exhibitors and 18,630 professional visitors, METSTRADE stands as one of the foremost B2B gatherings in the industry, showcasing innovation, networking opportunities and advances in leisure marine technology and equipment.

With the recent acquisition of The Superyacht Forum, METSTRADE has strengthened its commitment to address the educational needs of the entire superyacht value chain. It is imperative to actively engage the voices of these key industry associations in shaping the show’s agenda and delivering content that propels the superyacht industry forward.

Comprised of leading trade associations in superyacht building, brokerage, refit and operations,

Daniel S. Natchez and Associates Inc 17 www.dsnainc.com

Dura Composites 6 www.duracomposites.com

Inland and Coastal Marina Systems Ltd 11 www.inlandandcoastal.com

LeeSan 5 www.leesan.com

of sense for the industry and hosting it at Phuket Yacht Haven is the ideal location. This gives us more space in-the-water and opportunities to add more lifestyle displays and activities on land. And with direct access to Phang Nga Bay, boat exhibitors have the possibility to take potential buyers on sea trials during the show.”

The Thailand International Boat Show A Luxury Lifestyle Event will also include the second annual Thailand Yachting Conference on the 8th January, 2025 and the yachting awards and gala dinner that evening.

Thailand International Boat Show info@thailandinternational boatshow.com www.thailandinternational boatshow.com

the board will gather biannually in April/May and November during METSTRADE. On 7 May, the Superyacht Content Board convened for its inaugural meeting in Amsterdam, providing guidance on METSTRADE, including its Superyacht Pavilion and The Superyacht Forum, with a focus on the most recent industry developments. This collaborative approach ensures that the show’s content programme is curated by industry professionals, for industry professionals, ensuring optimal alignment with the sector’s evolving needs.

METSTRADE registration@rai.nl www.metstrade.com

www.mppengineering.co.uk

Tecno Sud Boat Stand

www.navaltecnosud.it

Please check websites for up-to-date information before booking hotels or confirming travel plans.

Sydney International Boat show

Darling Harbour, Australia 1 August-4 September, 2024 www.sydneyboatshow.com.au

Southampton International Boat Show Southampton, England 13-22 September, 2024 www.southamptonboatshow.com

Salone Nautico Genoa, Italy 19-24 September, 2024 www.salonenautico.com

Grand Pavois

La Rochelle, France 1-6 October, 2024 www.grand-pavois.com

IBEX Tampa, Florida, USA 1-3 October, 2024 www.ibexshow.com

METSTRADE Amsterdam, The Netherlands 19-21 November, 2024 www.metstrade.com

Abu Dhabi International Boat Show ADNEC Marina, Abu Dhabi 21-24 November, 2024 www.adibs.ae

Thailand International Boat Show Phuket, Thailand 9-12 January, 2025 www.thailandinternational boatshow.com

Boot Düsseldorf Düsseldorf, Germany 18-26 January, 2025 www.boot.de

Miami International Boat Show Miami, Florida, USA 18-26 February, 2025 www.miamiboatshow.com

ICOMIA World Marinas Conference Venice, Italy 15-17 October, 2025 www.worldmarinas conferencevenice.com