PIM METALS

NEWS UNIVERSAL ROBOTS EVENTS NEW PRODUCTS 2 8 12 18 INCORPORATING IMT VOLUME 2 l ISSUE 9 l AUGUST/SEPTEMBER 2023

Welcome to the August issue of PIM Metals, as we have again started the annual rest -registration reader process, we have already seen a surge in new reader applications over the past 12

With the growth in areas such as renewable energy, manufacturers of items such as wind turbines are now exploring more and more applications for lighter and stronger metal components and raw materials. The use of metal tube, pipe and profiles is also seeing some growth via new district heating and biomass plants that need huge volumes of metals for their construction.

Constructing these plants needs to engage multiple processing applications ranging from cutting, bending, welding, forming and testing, and the use of tube and pipe at these plants is not measured in meters but kilometres which is great news for our industry.

For our next issue October, we will be looking at Sheet metal processing, Bending & end forming. Plus, metals for automotive applications, news submissions should be with us no later than October 19th and sent to imtmagazine@virginmedia.com .

2

Top aluminum producer and recycler Novelis to increase uptime following ABB modernisation

Email: imtmagazine@virginmedia.com

Cover picture: Fronius page 14

VOLUME 2, NUMBER 10 – AUGUST/SEPTEMBER 2023

Contact information

PRODUCTION

Anthony Wiffen

ASTAC Business Publishing

Tel: +44 (0) 1460 261011

Mobile: 0785 161 2799

Email: anton_print_1@mac.com

PRINTING

Brown Knight and Truscott

Tel: +44 (0) 1732 505724

Mobile: +44 (0) 7747 002286

Email: processindustrymatch@virginmedia.com

Tunbridge Wells, Kent, TN2 3BW, UK

Tel: +44 (0)1892 511678

©2022 KVJ Enterprises

8

How collaborative robots are changing the ancient art of welding

UNIVERSAL ROBOTS WELDING

13

BAM spin-off wants to speed up the welding process of wind towers eightfold

11

EVENTS

Sneak peek into UK Metals Expo that opens on 13 -14 September at the NEC

14

NEW PRODUCTS

Ball Screws vs Lead Screws: horses for courses

20 SCHWEISSEN & SCHNEIDEN

More efficiency, digitalisation, safety and health with Messer technology

NEWS 1 PIM Metals August/September 2023

IN THIS ISSUE COMMENT NEWS

COMMENT/IN THIS

Editorial and advertising deadline for the October/November issue of PIM is: October 18th

Top aluminum producer and recycler Novelis to increase uptime following ABB modernisation

Novelis Inc., a leading sustainable aluminum solutions provider and the world leader in aluminum rolling and recycling, is working with ABB to upgrade its third-party drives and controls system as part of a brownfield modernisation project at its hot rolling mill in Oswego, New York, USA.

To futureproof the mill, ABB is replacing obsolete and outdated equipment with new switchgears, transformers, medium voltage drives, medium voltage synchronous motors, motor control centers and auxiliary controls, all integrated with the facility’s existing nonABB control system. This will support Novelis’ ambitions for increased power capacity and reliability. Commissioning of the upgrade is expected by the end of 2023.

The Oswego mill was the company’s first US operation and is today the company’s largest, wholly owned fabrication facility in North America. It produces high-quality aluminum sheet for the automotive, beverage can, and building and construction markets.

Novelis is also the world’s largest recycler of aluminum and seeks sustainability commitments from its supply chain as its customers look for environmentally friendly and circular aluminum products.

“In order to continue to provide our customers with the highest quality, sustainable aluminum sheet, and do so reliably, we are focused on increasingly optimising our production output,” said Ganesh Panneer, Vice President of

Operations, Novelis North America. “ABB is helping to ensure that we continue to have the highest levels of availability in our processes. The expertise of the ABB metals team, together with their commitments on providing the latest, most energy efficient products, will secure Oswego’s future as we maintain our leading position.”

“We’re proud to support Novelis in meeting their production targets, which

promote efficient use of energy and other resources,” said Siraj Boudighar, Sales Manager North America for Metals, Process Industries, ABB. “By leveraging our long-term experience and in-depth knowledge of metals industry processes, including more than 400 references for modernisation projects since the year 2000, we are able to tailor technology packages that meet the specific needs of each customer.”

NEWS 2 PIM Metals August/September 2023

Chevron Mediterranean Limited awards deep water Leviathan field project to Corinth Pipeworks

This is a new award to Corinth Pipeworks from Chevron Mediterranean Limited., building on the success of previous and recent awards, such as the deepwater Tamar project in 2022. This time, to manufacture and supply approximately 118 km of longitudinally submerged arcwelded steel pipes (SAWL) for the deep water Leviathan project.

The Leviathan gas field is located in the eastern Mediterranean, off the coast of Israel, which also hosts the Tamar and Karish-Tanin fields. It is the largest natural gas reservoir in the Mediterranean and one of the largest producing assets in the region. The water depth of the field varies between

1,540m and 1,800m.

The project will provide critical infrastructure as it will connect the subsea manifold to the platform where gas will be processed before being transported to shore in Israel, thus securing the country’s energy needs.

The pipes will be manufactured

at Corinth Pipeworks’ facilities in Greece, and installation work will commence according to schedule within 2024. Scope of supply also includes 3-layer polypropylene, external coating, applied at the same location as pipe manufacturing at Thisvi, Greece.

“The deep-water Leviathan

field project is another milestone that confirms Corinth Pipeworks’ presence in offshore linepipe projects.

We have built a strong track record of successful execution of offshore pipeline projects around the world, enabling interconnections of new fields to existing platforms to be sustainable and to continue to contribute to the energy mix” commented Ilias Bekiros, General Manager of Corinth Pipeworks. Additionally, he emphasized the importance of hydrocarbon exploration in the Mediterranean. “Corinth Pipeworks is already a supplier to major projects in the region, and we are committed to helping existing and new projects be executed as soon as possible.

NEWS 3 PIM Metals August/September 2023

unisonltd.com

Hybrid, dual-stack tube bending machines Contact us now to discuss your needs: +44 (0) 1723 582 868 I sales@unisonltd.com • 50 mm or 80 mm CNC tube bending machines • Exceptional power and robust mechanical design • Dual-stack bending – for reduced tool changes • Designed for repetitive tube bending tasks • Choice of industry-leading motors and drives • User-friendly Unison touchscreen control • 3D component simulation and measuring interfaces Unison quality and reliability –at a highly accessible price! *Ask for details. 20% Off 10 Machines* 50th Anniversary Offer Hurry! Strictly limited offer

Unison Synergy

Precision Inline Profile Measurement • Full profile measurement • Surface fault detection • 3D image analysis Family owned since 1957, Zumbach is a global leader in the industry. Driven by innovation and experience. We are here for you and ready to build the future together. www.zumbach.com • sales@zumbach.ch

Green Steel: RENK supplies special gearboxes for the production of ‘green steel’

RENK Group, a market leading manufacturer of mission-critical drive technologies, is supplying three high-speed special gear units via RENK-Maag GmbH, a group company, for compressors for the production of so-called green steel to Siemens Energy Compressors GmbH as part of the “SALCOS” (Salzgitter Low CO2 Steelmaking) project of the Salzgitter AG steel group. The three integral gear units will be used in the compressors of a direct reduction plant of the SALCOS project at the Salzgitter site. RENK is thus underlining its position as a key supplier for the energy transition.

“We are very pleased to be part of this beacon project for green steel in Germany,” says Nadine Despineux, CEO of RENK’s Marine & Industry Division. “With our innovative gearbox solutions for the compression of hydrogen, we regularly push the limits of what is technologically feasible

with incredibly high speeds. This way, we are already helping to reduce CO2 emissions in steel production by around 30 per cent. Water is then produced instead of CO2. This way, we support our customers significantly on their way from fossil energies to climate neutrality. And we see great growth potential, because the entire industry is currently converting its production processes.”

“With our technology, our customers are able to switch to hydrogen-rich reduction gas without structural changes to the integral gear compressors. As the name suggests, the gearbox is an integral part of this. We are glad to have RENK-Maag as a strong partner at our side. With this beacon project, we are supporting our industrial customers on their way to decarbonization and are thus an important building block for the steel industry to achieve its CO2 reduction targets,” says Clemens Förster, Sales Manager

of Siemens Energy Compressors GmbH.

“Our high-speed gear units for compressors are an important component for the ramp-up of the hydrogen economy – whether for storage, processing or transport. These turbo compressors are characterized by a high pressure build-up and are suitable for large gas volumes,” says Thomas Fritschi, Managing Director of RENK-Maag in Winterthur.

“Specifically, we are talking about gear units with a speed of 8,000 to 50,000 revolutions per minute – but we have also produced units with a speed of over 60,000 revolutions per minute. Just for comparison, the engine speed of a passenger car in normal driving is a maximum of 2,000 to 3,000 revolutions per minute.”

The gear units are developed and built at the RENK site in Winterthur, Switzerland. They are used in a direct reduction plant in Siemens compressors. In direct reduction, iron ore is converted

into sponge iron with the help of a reducing agent. In the process, the reducing gas dissolves the oxygen out of the iron ore without it melting. This process takes place in the direct reduction plant at overpressure and at about 1,050°C. The iron ore is reduced to sponge iron. Instead of CO2, this technology produces water, which in turn is reused in the integrated process. In a direct reduction plant, both natural gas and hydrogen can be used flexibly as reducing agents. In this way, the natural gas content is gradually reduced and finally completely replaced by hydrogen.

Against this backdrop, RENK is increasingly using the company’s existing industrial know-how in the field of highspeed gear solutions, couplings and slide bearings in new areas of application, including carbon capture technologies and heat pumps in addition to hydrogen.

For further information, please visit: www.renk.com

SMS group and Steel Authority of India Limited (SAIL) join forces to decarbonize steel production in India

SMS group and SAIL (Steel Authority of India Limited), a Maharatna PSU, have drawn up a memorandum of understanding to work together on sustainable steel production and decarbonization efforts. The MoU signifies their commitment to drive developments focused on implementing long-term sustainable steelmaking practices, with a particular emphasis on decarbonizing

steel production in SAIL’s integrated steel plants across India.

This partnership aims at addressing the challenges of reducing carbon emissions and making the steel industry more environmentally friendly. In this respect, SMS will provide its technological expertise for design and engineering activities, equipment supplies, and technical assistance for erection and commissioning projects at SAIL’s facilities

across India.

The signing of the MoU took place at SAIL’s Management Training Institute (MTI) at Ranchi, Jharkhand on August 3, 2023, a significant event that marks a milestone in the collaboration between SMS group and SAIL. It is a positive step towards fostering innovation and sustainability in the steel sector, and it highlights the commitment of both organizations to contribute to India’s

environmental and economic goals.

“We are very proud to team up with a public sector enterprise responsible for steel production in India, and we look forward to collaborating in future,” said Mr. Marco Asquini, CEO, APAC & MEA Region of SMS group. “This is a significant milestone for the decarbonization of the Indian steel industry and aligns perfectly with our mission #turningmetalsgreen”.

NEWS 5 PIM Metals August/September 2023

German laser specialist fires mega laser to mark 100th anniversary

High-tech company TRUMPF unveils one of the world’s most powerful show lasers // Company looks back over 100-year history // TRUMPF products geared to promising future markets

Ditzingen/04, August 2023, this year marks the 100th anniversary of German hightech company TRUMPF, which is based in the Stuttgart region. The special day fell on August 6, 2023 – and the laser experts decided to celebrate it in style! True to its name, TRUMPF set out to trump all previous efforts by firing one of the world’s most powerful show lasers. The laser light shone for the first time on the evening of 3rd August 2023. Under the right weather

conditions, the laser was visible up to 80 kilometers away.

Spectacularly green, amazingly efficient

The green laser light is produced by a particularly energy-efficient laser with three kilowatts of power. Show lasers are not part of TRUMPF’s core business, so its customers would normally use this kind of system for tasks such as welding electricvehicle batteries. The company ships its lasers to industrial companies all over the world. The semiconductor industry, the automotive industry and the medical-device sector are just some of the areas in which TRUMPF lasers play a key role. Alongside its laser business, TRUMPF is also one of the

world’s leading providers of machine tools for flexible sheetmetal fabrication. This is the business in which the company originally made a name for itself.

100 years of innovation

This year marks the achievement of a major milestone. In 1923, Christian Trumpf together with two partners acquired the mechanical workshops previously occupied by Julius Geiger GmbH

in Stuttgart. This laid the foundations for the company, which from 1937 operated under the name TRUMPF. From the mid-1930s, TRUMPF specialized in the production of manual machinery for simple sheet-metal processing tasks. In the 1950s, the company’s focus shifted to stationary machine tools.

As early as 1985, TRUMPF launched its first own laser, laying the foundation for its rise as a laser expert. Today, the TRUMPF brand stands not only for machine tools and laser technology, but also provides solutions for promising technologies that hold the key to the future, such as e-mobility and the EUV lithography systems used to produce cutting-edge computer chips.

NEWS 6 PIM Metals August/September 2023

Photo: TRUMPF

Photo: TRUMPF

Solar power to be a major focus at the UK Metals Expo 2023

Perfect Sense Energy (PSE) are excited to be part of the UK Metals Expo of 2023, an event that brings together the best of the UK’s metal industry. The expo will take place from September 13th to 14th, 2023, at the NEC Birmingham.

Perfect Sense Energy has been a key presence in ethical solar and energy-saving technologies since 2010, providing robust solutions that continue to deliver real and proven energy savings for businesses and organisations all over the UK.

Operating in the world’s fastest-growing energy sector, PSE makes a difference by helping to rebuild the UK economy to meet the challenges of Net Zero, whilst placing corporate social responsibility at the forefront of their business.

The UK Metals Expo 2023

recognises the importance of renewable energy sources in reducing carbon emissions and mitigating climate change. As such, solar panel power is a major part of the Expo, and Perfect Sense Energy are excited to showcase the latest advancements in this field.

Luke Rowson, Head of

Sustainability & Strategy at Perfect Sense Energy, said:

“We’re excited to be an exhibitor at this year’s UK Metals Expo, showcasing our renewable solar technologies to help the metal industry reduce its reliance on fossil fuels and move towards a greener future. Perfect Sense is well-placed to

Intoco- excellence every day

In 1972 Intoco were established and quickly became leaders in the global supply chain for precision engineered products and set a standard for quality and excellence in customer service.

In 2001, Intoco invested heavily to develop as a distribution centre for special metals. Beginning with grade 440C, then adding 904L & F44 before moving into the Duplex (F51) and Super Duplex (F55 & F53) grades.

Over the last two decades, the business has grown to now stock 20 grades, including nickel alloys such as 718, 625, K500, 400,C276,

which complement the steel grades offered to industries such as oil and gas, energy, chemical & petrochemical, valve, and fastener markets.

Surpassing 50 years of trading, Intoco have built an international

reputation and become the byword as one of Europe’s largest independent, dependable stockists and distributors of high integrity stainless steels and nickel alloys supplied to worldwide destinations.

tackle this challenge, and we look forward to highlighting the latest advancements in solar technology.”

Perfect Sense Energy has already worked with countless businesses throughout the UK, including household names such as Holiday Inn, to help them move towards a fully sustainable future - significantly reducing their energy bills in the process.

With the UK metal industry’s increasing focus on harnessing renewable energy, PSE is committed to promoting sustainable energy solutions and believes that solar power has a vital role in achieving this goal.

Perfect Sense represents a convenient and reputable choice of partner in the rapidly evolving world of green energy. For more information about Perfect Sense Energy and their services, visit perfectsenseenergy.com.

By implementing an ISO 9001:2015 quality management system, Intoco continue to set new standards by committing to continually improve operating systems and efficiencies, investing in people, developing relationships with suppliers and customers, accepting only the highest standards in specified and certified materials, Intoco continue to provide exceptional value to their customers.

Intoco continue to invest in people and processes, working with our supply chain to ultimately be the chosen solution provider to our customers in the UK, Europe and worldwide.

NEWS 7 PIM Metals August/September 2023

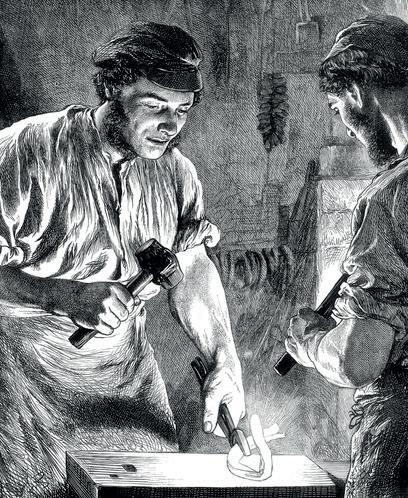

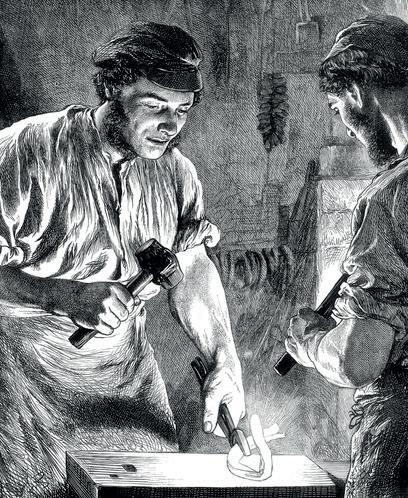

How collaborative robots are changing the ancient art of welding

By Will Healy III, Global Welding Segment Manager at Universal Robots

By Will Healy III, Global Welding Segment Manager at Universal Robots

The biggest ongoing construction projects in the UK include the HS2 Railway, Hinkley Point C, and the final stage of Crossrail. All are expected to generate billions for the UK economy when complete. However, the average onlooker often fails to appreciate the individual skills and components required to make these types of projects a reality.

All these projects rely on welders to bond and fuse the metals integral to their structure and design. And with welding jobs being crucial for communities across the world, demand for welders is only set to grow over the next decade. According to one market research report, the industry is set to reach a market size of around $28.66 billion globally by 2028.

Some of us can appreciate that without welders the world would fall apart. Literally. But the industry’s workforce has an uncertain future. In the UK, the number of welders has fallen by a quarter in five years, according to the Capital City College Group, the largest FE college in London. Similar shortages are felt across the world. According to the American Welding Society, by 2026, 336,000 new welding professionals will be needed in the US.

The art of welding

Welding is by nature both technical and creative, requiring a trained human eye and impressive manual dexterity for the most complex metal welds. Welders know it takes years to master and acquire sufficient

experience to gain the trust and accolade of companies and fellow experts. With the creativity and passion that it constitutes, welding is worthy to be called an art form.

Welders also recognise the challenge involved in their trade. The work itself can be dangerous in nature and if a task requires long simple welds or hundreds of identical welds, very time consuming.

Perhaps due to some of these challenges, there are fewer young people going into welding and developing the skills required. This is leading to a skills shortage, and as the ageing welding workforce retires, it’s becoming harder to meet rising demand. This is a huge problem given how critical welding is to so many different industries. A

shortage of welders could even threaten the implementation of major infrastructure projects, such as laying new pipes for district heating or building wind turbines.

But what if welders could find better tools to make their conditions and workload more satisfying? This is where collaborative robots – or cobots –come in.

The evolution of welding: what’s next?

As many of us know, automated welding has existed for several decades, though for a long time it was available only for specific use cases. For example, huge robots were created to help weld the inside of ships in the 1980s. Industrial automation, when it first became available to welding,

NEWS 8 PIM Metals August/September 2023 TUBE BENDING UNIVERSAL ROBOTS

was initially only viable for large companies operating in highvolume, low-mix environments. Nowadays though, automation is widely used by welders. According to the International Federation of Robotics, welding applications represented almost one in five of all new robot installations in 2021 with most uses in the automotive industry.

But, with so much nuance required on the job, tackling the skills shortage by completely replacing humans with automated welding machines is not the answer. The industry needs a collaborative approach; one that can help augment welders’ productivity.

A collaborative automation approach, where welders work alongside smaller, cost-effective robots, called cobots, could help solve the skills shortage.

We’re already seeing this have real impact in the UK market. For example, Olympus Technologies Ltd, one of Universal Robots’ UK partners, helps manufacturing companies deploy robotics.

With new collaborative welding robots going into commission every month, they have helped companies like Storth Machinery, an agricultural management company, develop and build easyto-use robotic welding solutions that can be quickly integrated into their existing workflows.

As Adam Swallow, Director and Co-Owner at Olympus Technologies, says, ‘”Storth Machinery, like a lot of engineering companies, came to us as it was struggling to find a team to carry out its more advanced, higher margin welding jobs. A shortage of qualified

welders meant the professionals it had employed were spending too much time on basic and repetitive welding tasks.

“Working with Storth and Universal Robots, we created a turnkey robotic welding solution that was fully operational within two months – and the results

EVENTS 9 PIM Metals August/September 2023 TUBE UNIVERSALBENDING ROBOTS

speak for themselves. Not only did Storth double productivity, but two skilled welders were released onto higher value welding processes. The two cobot solutions we’ve designed have taken on basic welding tasks such as producing scraper parts, and their qualified welders have been reallocated to specialist fabrication jobs with much higher margins. Retention is better, and the team is able to focus on much more interesting work.”

After all, welding is not just about meeting production demand: manufacturing demands creativity and problemsolving skills to create quality output. This is where a robot collaborating with a skilled human welding workforce can add real value, while also creating safer working environments.

Unlocking the power of collaborative welding

Yet, even with widely available technology in place, the use of collaborative automation for welding has been relatively

slow to take off. When smaller collaborative robots were first introduced to industry in the early 2000s, welding was thought to be an impossibly difficult task for lighter robots. Collaborative robot (cobot) welding has only started to become more widespread in the last five years, following impressive innovation across a number of different

welding companies.

Delayed adoption is partly a matter of awareness and partly due to the highly skilled nature of welding. It’s arguably harder to see the role of automation in a craft like welding, than in some other manufacturing activities, such as lifting, packing and dispensing. But in reality, a cobot is just a tool, similar to a painter and his brush, or a baker and his mixer. Its main purpose is to complete repetitive tasks, rather than taking over the artistic element of the role.

With the demand for highmix and low-volume metalwork rising, and a growing shortage of skilled workers, manufacturers should put collaborative welding at the forefront of evolving their sector.With accessible technology in place, the trade will be well placed to meet future challenges head on.

Sparking a welding revolution

For an industry that’s thousands of years old, welding has remained in many ways surprisingly traditional. Now, in the face of an ageing workforce and low numbers of new trainees entering the profession, welders have opportunity to shape

the future of the industry by combining forces with cobot technology. Industry experts see arcwelding, MIG and TIG welding as the first focus for collaborative welding techniques, with plasma-cutting, grinding and laser and spot-welding fast following.

Not only can cobots empower welders to make more of their art, they are also improving job satisfaction for welders. They are removing the repetitive and dangerous parts – putting skilled tradespeople first so they can get on with the task at hand. Welders using cobots keep their creative freedom, while teaching the cobot where to weld and what weld parameter ‘recipes’ to apply –something only a welder can do.

By easing the physical strain and monotony of certain welding work, cobots could help to tackle workforce shortages in the profession by keeping experienced welders working for longer and bringing in younger talent that is excited by the prospect of using collaborative technology. Because of this – and similar to all good welds – the welding industry could have a very bright and solid future ahead of it.

EVENTS 10 PIM Metals August/September 2023

TUBE BENDING UNIVERSAL ROBOTS

Sneak peek into UK Metals Expo that opens its doors on 13th and 14th September at the NEC Birmingham

UK Metals Expo (www.ukmetalsexpo. com) is just around the corner, and it is the ONLY event that brings together the entire metals supply chain with the manufacturing and engineering sectors on the 13th and 14th of September 2023 at the NEC Birmingham.

UK Metals Expo is a free-toattend exhibition and conference that promises to deliver a wide range of innovative products, services, and interactive sessions led by top experts such as JCB, Jaguar Land Rover, Stellantis, Boeing, Spirit AeroSystems, ADS Group, Rolls-Royce, Ford Motor Company, Ricardo, Network Rail, The Royal Mint, RWE, Algeco, OCEA Shipbuilding, Bryden Wood, Tata Steel, Make UK, Outokumpu, Norsk Hydro, ThyssenKrupp, CRU, and many more.

UK Metals Expo is the premier marketplace for both domestic and international exhibitors in the industry. With over 200 leading companies participating, including Ace Polishing Services, Acerinox, Alloy Sales, AMEG (Amari), AMG Analytical, AMPCO Metal, Apurvi Industries, Arcus, Arun Technology, Behringer, Brown McFarlane, Combilift, Hindustan Inox, Hitachi High-

Tech Analytical Science, Hydro, Jonas Metals, Smiths Centre, Taylor Forgings, Trimble, Truva, Wedge, and many more, the expo features live demonstrations, product launches, and interactive displays, providing attendees with an immersive experience of the industry’s most innovative solutions.

The conference program, with over 60 sessions and 100+ leading practitioners spread across 4 stages, provides attendees with valuable insights into the current state of the metal industry and the emerging technologies and strategies that are shaping its future.

“It is a timely event and totally free to attend! The UK has significant challenges and opportunities in achieving net zero through advanced materials and manufacturing. A thriving home-based metals sector is a prerequisite for success. This event will help to foster collaborations and signpost the way to get there,” said Lord Rupert Redesdale, UK Metals Expo Chair.

Day 1 of the expo, on September 13th, will commence with an Opening Keynote by Stephen Kinnock, the Labour MP for Aberavon. He will discuss the critical role of steel as a

foundation industry for a modern manufacturing renaissance.

Following this, a thoughtprovoking panel discussion on the importance of a robust industrial strategy for the UK will take place, featuring distinguished panellists such as Gareth Stace (UK Steel), Neil Hodgson (Department for Business & Trade), and Tom Jones (The Aluminium Federation). These experts will share insights into economic growth, innovation, and long-term sustainability.

Other engaging sessions on Day 1 include “Circular EconomyThe Practical Aspects” with Alison Jones (Stellantis), which explores the implications and opportunities for manufacturers, suppliers, and customers. The discussion on “Decarbonisation of the UK Steel Industry” will feature industry leaders Ben Burggraaf (Net Zero Industry Wales), John Barrett (University of Leeds), Peter Quinn (Tata Steel Europe), and Russ Hall (HMVC), who will delve into strategies to achieve Net

Zero emissions. Additionally, the session on “Sustainable Mobility: Future for Aerospace and Automotive Sectors, a Challenge for SMEs?” will address sustainability challenges and the potential for SMEs to collaborate with larger stakeholders to drive innovation.

The event will also cover a range of topics such as the Carbon Border Adjustment Mechanism (CBAM), the transformative power of aluminium in various industries, metals sourcing strategies in a decarbonising world, and forecasting raw materials prices, among others.

Day 2, on September 14th, will carry forward the momentum with sessions focused on supporting the growth of the offshore wind sector, unlocking the economic viability of recycled metals in manufacturing, improving training and skills, advancing metallurgy for sustainable manufacturing, and exploring the future of steel construction.

These sessions are just a glimpse of what the UK Metals Expo has to offer.

For the full conference agenda, exhibitor list, and floor plan, and to receive your free badge, please visit www.ukmetalsexpo.com

EVENTS 11 PIM Metals August/September 2023

Unison’s flagship all-electric tube bender for FABTECH 2023 to go to Sharpe Products

Sharpe Products, one of North America’s leading specialists in custom tube and pipe bending and tube laser cutting, has ordered the all-electric Unison Breeze CNC tube bending machine that will form the centrepiece of Unison Tube LLC’s display at FABTECH in Chicago, September 11 – 14.

The machine, a 100 mm (4”) single-stack model, will be on display at Unison’s FABTECH Booth - # D41930 - after which it will be installed at Sharpe Products’ Wisconsin-based manufacturing plant. It will be the ninth Unison Breeze tube bender that has been purchased by Sharpe Products since 2003 and will be used to provide additional capacity for bending tubular components for the company’s extensive customer base.

Sharpe Products and UKbased tube bending machinery manufacturer Unison Ltd have a long and proud history of working together. Sharpe’s President and CEO, Paul Krickeberg, was an early convert to the idea of allelectric tube bending and bought one of the very first British-built Unison Breeze machines in the United States.

“This latest Unison Breeze tube bending machine will help to support our ability to offer short lead times and consistent results – attributes that are essential to our customers,” says Mr Krickeberg. “We’ve worked with Unison for numerous years and look forward to installing this next generation machine at our plant.”

“We’re absolutely delighted that Sharpe Products has chosen to purchase yet another Unison Breeze all-electric tube bending machine,” says Stuart Singleton,

VP of Unison Tube LLC. “As you can

imagine, such impressive repeat orders are an incredible testimony to the faith a customer places in our machine technologies, operating software and product support. The new 100 mm Breeze machine will bring valuable extra capacity to one of our longest-standing customers in the US. Equipped with the latest version of our Unibend control system, it will deliver cycle time speed improvements in the region of 25% compared to earlier versions. It also incorporates innovative new teach routines and simulation features.”

UK-based Unison Ltd invented ultra-precise, all-electric tube and pipe bending, and the Breeze 100 mm (maximum tube diameter) machine is one of its flagship models. Just like all Unison Breeze tube bending machines, the 100 mm/4” Breeze

offers rapid setup, fast tooling changes, exceptional power, rigid mechanical design, and all-electric control for right-firsttime repeat sub-contract work, or immediately after producing a single trial part. These are all attributes that Unison Ltd believes make its Breeze models the ultimate tube manipulation machines for businesses specialising in frequently

changing, small-to-medium batch production runs.

Other single-stack Unison Breeze machines operated by Sharpe Products include 80 mm (3”) and 100 mm (4”) variants. Sharpe also has 76 mm (3”), 80 mm (3”) and 130 mm (5”) multistack Breeze machines – each able to accommodate several tools for rapid changeover between bending cycles.

About Unison Tube LLC

Unison Tube LLC is the North American division of Unison Ltd, the UK’s leading manufacturer of tube and pipe bending machines, offering the largest range of all-electric benders for diameters from 4 mm (5/32”) to 275 mm (10”). Unison Ltd manufactured the world’s first all-electric tube bender in 1994, followed by the world’s first allelectric multi-stack tube bender, then the world’s largest all-electric tube bender for the shipbuilding industry. Available in single-stack, multi-stack and right/left varieties, Unison machines are delivered to more than 20 countries globally. Written and supported by Unison, the company’s tube bending software is widely recognised as the most user-friendly control system for tube bending machines. www.unisonltd.com

EVENTS 12 PIM Metals August/September 2023

BAM spin-off wants to speed up the welding process of wind towers eightfold

Aspin-off of the Bundesanstalt für Materialforschung und -prüfung (BAM) has developed a groundbreaking approach that revolutionises the welding process in the manufacture of steel towers for wind turbines. The new technology could secure important competitive advantages for the German wind industry and could also be used in the construction of hydrogen pipelines or liquid gas tanks.

In a modern steel wind tower, the welds add up to a length of about 700 metres. Steel sheets up to 30 millimetres thick have to be joined together in several layers using the so-called submerged arc welding process. At present, this takes a total of almost 100 hours. This alone limits the capacity of the four remaining German production sites to about 520 steel towers per year - only about half of what the German government’s expansion targets for onshore wind energy envisage. Further steel towers are bought from abroad, mainly from China, where they can be produced particularly cheaply due to low labour costs.

Significantly faster - and at the same time more cost-effectivethe systems could be produced using the laser hybrid welding process. It requires only a single welding layer. But so far, this process has only been approved for sheets up to 12 millimetres thick in industrial use. The reason: when welding thicker sheets, drops form from the liquefied metal underneath the weld seam due to gravity. They endanger the stability of the later plant and would have to be reworked at great expense.

A team from BAM’s Competence Centre Wind has now found a smart solution to this long-known problem: The scientists have developed a system of electromagnets that is attached to the welding zone. The magnets release a so-called Lorentz force that counteracts gravity. This prevents any drop formation at the weld seam. At the same time, the system works completely contactless. The innovation makes it possible to use the faster laser hybrid welding process without compromising safety, even for the thick steel sheets used in wind turbines.

Now the four scientists are setting up their own spin-off company. They want to develop their invention into a marketable system for industry in the next two years. They are supported by the EXIST funding programme of the Federal Ministry of Economics and Climate Action (BMWK).

At the same time, they have access to the excellent research infrastructure of BAM, which has the most powerful high-power laser in Europe with 60 kilowatts.

According to Christian Brunner-Schwer, who is responsible for finance and sales in the team, the potential time and cost savings from the innovation would be enormous for a modern 120-metre wind tower: by using laser welding, which the magnet system makes possible, the welding time could be reduced from 96 to just under 12 hoursan acceleration by a factor of 8. At the same time, only 900 instead of 4000 kilowatt hours of energy would be needed. The costs for welding could be reduced by a total of 90 per cent. The CO2 emissions from the production of a wind tower would even be reduced by 93 per cent.

“Experts already confirm that our system could become a game changer for the wind industry,”

explains Fatma Akyel, who is responsible for research and development in the team. “At the same time, steel wind towers are only one field of application for our innovation. There is further potential wherever, thick-walled steel sheets are joined together: in the construction of hydrogen pipelines, of containers for liquid gas or chemicals, in ship and bridge construction.”

Further Information:

l Division Welding Technology at BAM

l Competence Centre Wind@ BAM

l EXIST funding programme of the Federal Ministry of Economics and Climate Action MWK)

Contact: Oliver Perzborn

Head of Communication, Marketing

Phone: +49 30-8104-1013

E-mail: oliver.perzborn@bam.de

WELDING 13 PIM Metals August/September 2023

Efficient welding with the iWave

Big success stories often begin in small garages. This is also the case with Ferrum.at. In 2009, Hannes Holl founded a small metalworking company in Schwertberg, Upper Austria, which evolved into a renowned contract manufacturer for industry and commerce within just a few years. Today, the company, which holds multiple certificates, manufactures a variety of metal components for well-known national and international clients. In search of intelligent, multifunctional welding systems for MIG/MAG applications, FERRUM. AT Metallverarbeitung GmbH found the right partner in Fronius, not only to improve welding quality and efficiency, but also their own competitiveness.

Combined design and welding competence

The medium-sized company is not only known for its immense flexibility in high-quality contract manufacturing work, but also supports the development of new products and prototypes that are ready for series production.

Aluminum, steel, stainless steel, brass, and copper are welded in different sheet thicknesses. Dedicated professionals, Solid Works 3D software, and high-quality machinery including laser, rolling, and bending systems, as well as digital high-tech welding systems are all available for this purpose. Many of the often challenging tasks begin with extensive feasibility checks, during which the experienced FERRUM.AT experts evaluate the weldability of components in terms of design, material, and dimension, the suitability of welding processes, or the effect of welding sequences on component distortion. Even complex clamping devices are designed.

The cross-industry service and product portfolio is extremely broad and ranges from outdoor facilities to roof components, facade and steel construction elements, pressure vessels, machine and wagon components, and designs for bridge construction. The

company welds for customers from Germany to Greece.

MIG/MAG

& TIG—two

welding systems were one too many

Time and again component accessibility, material, and design require that individual components be welded using both the MIG/MAG and TIG processes at FERRUM.AT. Before the newly acquired multifunctional welding systems from Fronius were used, two different device types were required: one MIG/ MAG and one TIG. The space needed was enormous, and the constant switching between the two welding systems was inefficient. Therefore, they had been looking for efficient and reliable multifunctional welding

systems for quite some time. These systems should provide significant time savings and therefore increase efficiency, without compromising on welding quality and causing downtimes.

As a long-standing Fronius customer, the Ennsdorf-based

metalworking company was one of the first to test the new iWave AC/DC 400i digital multiprocess device for a month, and the result was impressive. The metalworking company did not have to lower any of their expectations—neither in terms of

WELDING 14 PIM Metals August/September 2023

FERRUM.AT Metallverarbeitung GmbH plant in Ennsdorf, Austria

Hannes Holl, Managing Director

operation nor the welding results, quite the opposite:

“We now have two unrivalled machines that allow us to rapidly switch between the two welding processes of MIG/MAG and TIG,” says managing director Hannes Holl enthusiastically. “At the same time, we benefit from a considerable time saving, paired with a huge increase in convenience and weld quality. This represents our next step forward as a company. Stagnation is not an option to remain competitive.”

FERRUM.AT increases productivity

The ultra-fast SpeedNet communication between the system components in combination with the high computing power of the iWave enables the use of new advanced welding processes that lead to excellent weld results. Innovative functions such as CycleTIG (for TIG) or PMC (Pulse Multi Control for MIG/MAG) stabilize the arc, optimize the droplet detachment, and reduce the heat input, while at the same time ensuring high deposition rates and constant penetration.

The gap-bridging ability is exemplary, with gap tolerances being automatically compensated for. Even for out-of-position welding, such as in the case of vertical-up seams, 100% control of the weld pool is assured. Higher welding speeds shorten cycle times and significantly increase the already high productivity of these metalworking professionals—all in the interest of FERRUM.AT customers, who benefit from faster lead times.

The visually perfect welds also help to shorten the manufacturing time by preventing time-intensive rework such as removing spatter or grinding off weld reinforcements and, in turn,

promoting resource-conserving work.

Time savings of up to 50% when tacking

With the help of the tacking function, the weld pool briefly oscillates at the beginning of the welding process. As a result, tacking takes place in a single step because both component

edges merge beautifully—without burning the edges. Very little to no temper coloration occurs at the tacking points. In addition, the filler metal is not required for air gaps up to 1.5 mm. Particularly for chrome-nickel and steel applications, the tacking function leads to a significant increase in efficiency.

When a welding system thinks

for itself

Top-quality manual welding requires years of experience and dexterity. This is especially true for TIG welding. The more intuitive and convenient a welding system is to operate and the more it supports welders with their welding work through intelligent functions, the better they can focus on the actual task: the

WELDING 15 PIM Metals August/September 2023

MIG repair welding with the iWave

TIG welding with the iWave

perfect weld result. The iWave makes things much easier for the professionals at FERRUM. AT. The menu navigation is selfexplanatory and available in more than 30 languages. Operating the touch display and adjustment wheel even while wearing gloves is easily possible.

“RPI auto” takes TIG welding ignition behavior to a whole new level. Adapted to the different electrode diameters, this function enables fast and reproducible ignition without any manual adjustment of the ignition parameters, regardless of the material characteristics.

If the professionals at FERRUM.AT want to repeat certain welding parameters, they can create “Jobs” in the iWave and subsequently call up to 1,000 of them on the JobMaster welding torch. This eliminates the need to move back and forth between the component and the welding system as soon as new welding parameters are needed. Recurring jobs can be saved in iWave as favorites, five of which can be set as so-called “Easy Jobs” on the welding torch. This is an enormous gain

in convenience for welding tasks that have to be performed over and over again.

Depending on the job, the

iWave itself recognizes when it has to change from MIG to TIG for certain applications and vice versa. It automatically changes

the necessary parameter settings and lowers the main current slowly and in a controlled manner for a clean weld toe. All these functions support the welding professionals in achieving the desired weld seam quality.

Above all, welding engineer Stefan Aumayr would not want to be without the handy WeldConnect app: “As soon as I enter the base material, filler metal, shielding gas, weld seam profile, and the desired speed into the app, I receive sensible welding parameters for the next welding task in a split second. I then transfer these from my cellphone to the iWave via Bluetooth in no time. If I’m still not satisfied with the weld result, I only need to do some finetuning. My many years of experience help me with this. I save the welding parameters found this way in the iWave and can access them at any

WELDING 16 PIM Metals August/September 2023

Intuitive touch display—even while wearing gloves

Stefan Aumayr, Metal and Sheet Metal Engineer

time. I simply make the selection on the JobMaster welding torch when I need it.”

Ready for large tasks at any time

At FERRUM.AT, the focus was on development from the start. Within twelve years, the company

evolved from a small contract manufacturer to a renowned, nationally known, and soughtafter partner for high-quality welded constructions. There are hardly any limits in terms of components and industries. The company is certified according to EN 1090-1EXC3, ISO 3834-3,

and EN 15085-2.

“We rise to just about any challenge. This is also in the interests of my employees, of whom I am particularly proud and on whom I can rely one

hundred percent. They are with me through thick and thin. They also don’t shy away from any task, no matter how difficult it may be, quite the opposite: they seek it out,” explains Holl.

Welding is carried out in accordance with a WPS (welding procedure specification), which is usually prepared by in-house experts or by the company’s own welding coordination personnel for the individual tasks. And when it comes to expanding skills and the range of services offered, they do not shy away from either welding or process tests, true to the motto “Stagnation is not a recipe for success!”

Holl concludes: “In addition to professional qualifications, the health of my staff is of great importance to me. That’s why we provide the best personal protective equipment possible, such as respiratory protection systems with a fan filter unit, and I meticulously make sure that it is actually being used.”

This news release and the images can be downloaded from: https://www.fronius.com/en/ welding-technology/info-centre/ press

WELDING 17 PIM Metals August/September 2023

Photos: Fronius International GmbH; reprints free of charge

TIG application

Laser system

iWave multiprocess welding system

Ball Screws vs Lead Screws: horses for courses

By Japh Humphries, UK Sales & Commercial Manager, Matara UK Ltd.

When it comes to linear motion systems, one question that gets repeatedly asked is ‘which should I use – ball screw or lead screw?’ They both perform the same task, converting rotational motion into linear movement. However, assuming they are interchangeable because of this would be a mistake, and a potentially costly one at that. Their design and subsequent operation differ, providing each with its own set of advantages and disadvantages; weighing these up against the application at hand is essential to ensure your linear motion system performs to the specified criteria.

Design & operation compared

Both lead and ball screws feature a threaded shaft which acts as the screw element of the unit. A lead screw - the simpler of the two options when it comes to design – has a threaded mating nut which is in direct contact with the screw. Rotational motion turns the screw, causing the nut to move along in a linear motion, thereby converting the motion from rotary to linear. Lead screws come in different formats with one of the most popular for industrial applications being trapezoidal lead screws. The screws are manufactured from steel and the nuts are available in a variety of materials from steel through to bronze, brass and plastic.

In the case of ball screws, a threaded shaft is also used, but it features a helical path around which ball bearings move. The ball assembly behaves as the

nut. Ball screws are available in different formats, with rolled and ground types mostly favoured by manufacturers.

Lead screws: pros & cons

As mentioned above, lead screws are the more basic design of the two and that is reflected in the cost. Lead screws have a lower capital outlay than ball screws; ball screws can be two to three times the price of a comparable lead screw. They also do not require a braking system as they are self-locking, which is a

further plus point when it comes to total cost.

This price differential often makes lead screws the first port of call, but this could be a false economy as it may not operate well in your specific application; it’s horses for courses, as the saying goes!

Apart from a lower purchase cost, lead screws have the advantage of generally being self-lubricating and they tend to be quieter in operation than ball screws. They are compact with minimal parts, and are easy to design into a system.

Where they don’t score so well is efficiency, which runs between 20% - 25%, as lead screws require greater torque and a larger motor and drive. They also have higher friction and therefore run at a hotter temperature.

Ball screws: pros & cons

With ball screws relying on point contact to support a load, as opposed to line contact, less friction is produced during use. This means that ball screws typically operate at a minimum of 90% efficiency, plus they run at cooler temperatures, and they produce a considerably smoother movement.

Due to recirculating balls supporting the load, ball screws have a higher load capacity than lead screws of a similar size.

Ball screws are also more versatile than lead screws. They are available in higher accuracy grades for greater positional accuracy, and they can be

NEW PRODUCTS 18 PIM Metals August/September 2023

adjusted to increase/decrease preload.

But there are some drawbacks. Obviously cost is one, as outlined above, which is further increased by the need for braking mechanisms to eliminate the risk of back driving. Back driving occurs when the motor shuts off and the ball screw free-falls as a result. Brakes must be fitted as

a safety precaution in this case. This is particularly pertinent if the load is to be carried vertically. With moving balls within the mechanism, it is likely to be noisier than a lead screw, and will also require regular lubrication to ensure the balls move freely. Furthermore, the overall size of ball screw device is larger than a comparable lead screw due

to the need for the balls to be recirculated.

What to use where: the rule of thumb

So, which should it be – ball screw or lead screw? Whilst a definitive answer isn’t practical – each application will have other factors and trade-offs that may need to be taken into account – generally speaking, lead screws are more suitable for transfer applications for which speed, accuracy, precision and rigidity are not as critical. That’s because most lead screws are not well suited to high throughput, high speed applications or those with continuous or long cycle times. Typically, you will find lead screws in use in fluid handling, data storage applications and life science equipment.

Ball screws, on the other hand, are mostly better for high precision applications where

accuracy and control are critical. They are also a good option for high load applications and for where thrust force is required to move those loads across a distance in a smooth motion, whilst maintaining speed. Examples of applications include 3D printers and automobile and aeroplane manufacturing.

So, when deciding on whether a ball screw or lead screw is right for your machine, whilst they both perform the same task of converting rotational motion into linear movement, the way in which they realise this and type of end result you achieve are markedly different.

Matara designs, manufactures and supplies pneumatic and linear automation products, including lead screws and ball screws.

www.matara.com

sales@matarauk.co.uk

01684 850000

NEW PRODUCTS 19 PIM Metals August/September 2023

Gain the cutting edge. nukonlasers.co.uk • 2D, 3D and tube fibre laser cutting machines from Europe • Accessible high power and high performance • American-made nLIGHT fibre lasers • Advanced Lantek CAD/CAM nesting software • From the exclusive Nukon distributors for the UK and Ireland Contact us now to discuss your needs: +44 (0) 1723 582 868 I sales@nukonlasers.co.uk UK

More efficiency, digitalisation, safety and health with Messer technology

Cutting and digitalisation solutions increase productivity

The World’s international experts in gouging, cutting and coating will gather this year from September 11th to 15th at the SCHWEISSEN & SCHNEIDEN in Essen. The cutting experts from Messer Cutting Systems also could not fail to be there. Together with their colleagues from Messer Gas they will be presenting their newest innovations and tried and tested solutions for process optimisation in cutting technology. Efficiency, digitalisation, decarbonisation, safety, health protection – a rich, multifaceted programme awaits the fair visitor on the joint stand B13/23 in Hall 8 on about 530 m².

One of the main attractions from Messer Cutting Systems on the SCHWEISSEN & SCHNEIDEN will be the live demo of the ELEMENT 400. Equipped with oxyfuel and plasma technology as well as two additional marking tools, this thermal cutting machine is suitable for the largest variety of applications with the highest quality demands. The plasma bevel head Bevel-S promises maximum flexibility: complex contours, holes of bevels for weld preparations can be cut effortlessly.

Optimum conditions for automation in laser cutting technology

Automation is the key to increased productivity and the answer to the challenges of our time, such as lack of skilled personnel and resources. With its newest developments in laser cutting technology, Messer Cutting Systems has created outstanding conditions for successful automated production and is presenting these at the

SCHWEISSEN & SCHNEIDEN. Often it is small things which bring the decisive advantage, for example in handling: To be able to handle components better after processing, Messer Cutting Systems have made it possible, for example, to leave micro bridges between the cut parts and the scrap frame. Thus, each part does not have to be picked up separately, rather the plate can be removed as one piece with a loading/ unloading system or a shuttle table. This significantly reduces nonproductive times. The bridges are so fine that they can be separated easily from the frame later.

To experience the laser cutting machine ELEMENT 400 L in action should also visit the Messer Cutting Systems stand. The experts will switch over to the factory in Groß-Umstadt for a live demonstration.

Bring orders into production faster and more economically

Production planning brings an astonishingly large potential for increasing the efficiency in production significantly, simply and fast. Messer Cutting Systems demonstrates with an exhibition premiere at the SCHWEISSEN & SCHNEIDEN impressively how this can be achieved excellently and with little effort.

With the new version of OmniFab, the software suite for the digitalisation of production, cutting jobs can now be directly placed on the machine from the pre-calculation of customer quotations. With automatic component nesting, the step of CAD/CAM nesting software can be shortened or even completely bypassed. This increases the speed and significantly accelerates the process from submitting quotations to starting the order in production. For some applications this is a revolutionary and new way of working. It is made possible by the direct linking of the software to the Global Connect machine control. With the integration of the CAD/ CAM software OmniWin, nesting plans can now also be transferred in real time to the machine. The user saves significant time, especially through the automatic pre-selection of all the parameters necessary for production.

As well as the emphasis on work preparation, the visitor to the fair will also experience on a total of four workstations how the digital solutions for production gain additional competitive advantages.

More safety in oxyfuel technology with S.A.T.

Visitors to the SCHWEISSEN

& SCHNEIDEN fair can also experience live and close up the complete world of oxyfuel equipment from Messer Cutting Systems with various combination torch systems for welding, brazing, heating, flame straightening and cutting. With the innovative new development S.A.T. (Safety Advanced Technology), the experts will offer a live demo highlight.

Sustainability with Messer Gas Solutions

The welding and cutting experts present on their joint stand innovative and proven gas solutions for process optimisation. With new gas mixtures and technologies from Messer, users can increase efficiency, increase safety, and improve their environmental balance. Sustainable production, health and operating protection and reduction of the CO2 footprint are increasingly the focus today. At the same time economical and productive solutions are as important as ever. This also has its effect on cutting technology and the selection of cutting gasses. HyCut is here a new, powerful and sustainable alternative to conventional oxyfuel application technology. On their joint stand there will be a quite special highlight for this: Messer and Messer Cutting Systems will present live at various stations which possibilities and advantages arise with HyCut.

See how production can be optimised with solutions from Messer has the chance to do this from the 11th to 15th September 2023 in Essen at the SCHWEISSEN & SCHNEIDEN: Hall 8, Stand B13/23.

EVENTS 20 PIM Metals August/September 2023 SCHWEISSEN & SCHNEIDEN

x 200+ Supply Chain Exhibitors x 5,000+ visitors x 100+ Speakers x 50+ Seminars x 4 Theatres FREE to attend - www.ukmetalsexpo.com The ONLY event that brings together the entire metals supply chain 13 – 14 SEPTEMBER 2023 6 NEC K METALS EXPO U Sponsors, partners, exhibitors and speakers include

By Will Healy III, Global Welding Segment Manager at Universal Robots

By Will Healy III, Global Welding Segment Manager at Universal Robots