Valmet DNAe is a next-generation distributed control system. As a fully web-based platform, it delivers an industry-leading user experience and cybersecurity by design.

The system brings the process know-how of the world’s leading experts directly to your control applications and improves efficiency. It provides unique data collection and utilization capabilities, enabling informed decision-making.

Valmet DNAe is a catalyst for sustainable practices, and it sets the stage for autonomous operations and a digitalized future. Empower people to perform at their best, reach and exceed your targets, enable path to autonomous operations and evolve throughout the lifecycle with the new DCS. Are you ready to evolve?

For more information, visit valmet.com/dnae

Welcome to the September-October issue of Pulp Paper & Logistics, which includes Green Packaging International covering developments in fibrebased packaging. In this issue you’ll also find a preview of the MIAC show being held at Lucca in Italy which this year celebrates 30 years serving the tissue and paper industries.

Here at Pulp Paper & Logistics, we thank all those readers who took the time to complete their re-registration, so that they continue to receive the magazine. I’m pleased to say that the number has increased to more than 24,000 decision makers in the pulp and paper industry, proving that the magazine’s content is both informative and relevant to today’s mill owners and manufacturing specialists.

Looking forward, we have also taken into account the feedback on the features and subjects that are of importance to our readers. Where possible these will be included in the 2025 schedule.

For the coming November-December issue we invite submissions relating to the following subjects: logistics and handling; paper packaging production technology; and mill safety and security. The deadline for receipt is 15 November and items should be sent to me by email at pulppaperlogistics@virginmedia.com

Vince Maynard, Publisher and Editorial Director

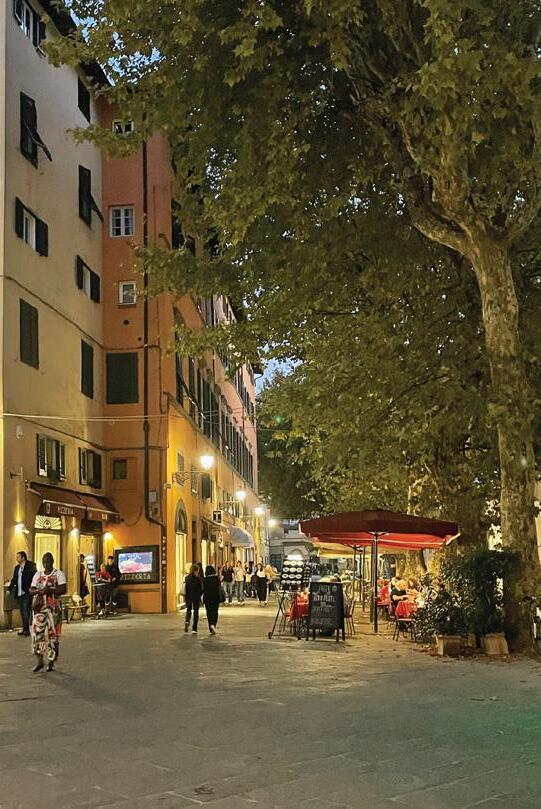

Front cover: Night scene from Lucca, the venue for MIAC 2024. See page 18

Vol. 15 Issue No. 88, September/October 2024

ISSN 2045-8622 (PRINT)

PUBLISHER &

EDITORIAL DIRECTOR

Vince Maynard

Tralee, Hillcrest Road, Edenbridge, Kent, TN8 6JS, UK

Tel: +44 (0) 1732 505724

Mobile: +44 (0) 7747 002286

Email: pulppaperlogistics@virginmedia.com

EDITOR

John Nutting

Tel: +44 (0) 1732 868071

Mobile: +44 (0) 7860 221486

Email: johnnutting47@gmail.com

CONSULTANT EDITOR

David Young

Tel: +44 (0) 1737 551687

Mobile: +44 (0) 7785 796826

PRODUCTION

Anthony Wiffen

Tel: +44 (0) 1460 261011

Mobile: +44 (0) 7851 612799

Email: anton_print_1@mac.com PRINTER

KNOCK OUT PRINT

+44 (0) 1892 823540

Unit 2 The Coppice, Petteridge Lane, Matfield, Kent TN12 7LP

info@knockoutprint.co.uk

http://www.knockoutprint.co.uk

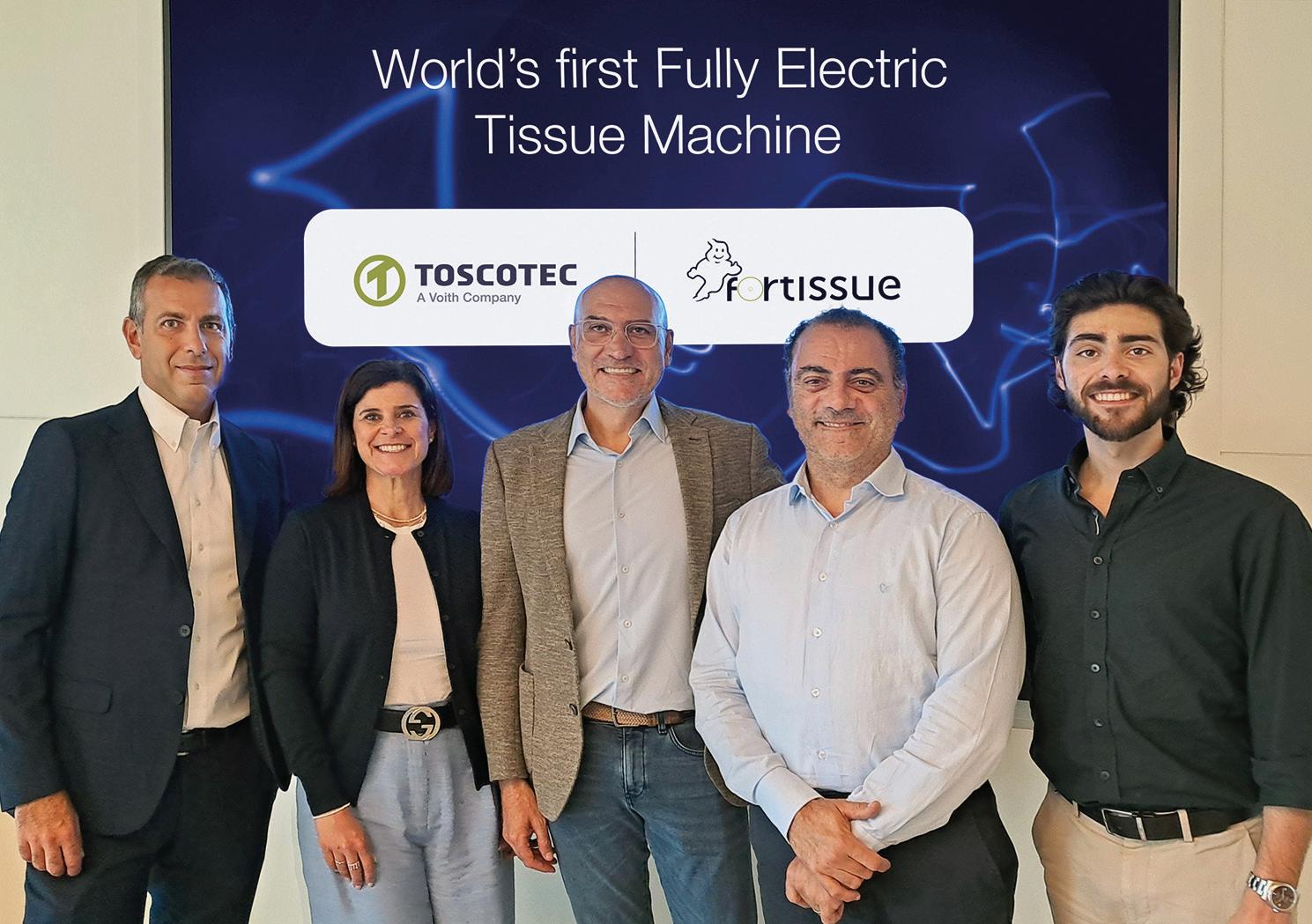

The world’s first tissue machine to operate solely with electricity at 2,000 metres per minute is on course to start up by the end of this year.

First revealed in June, the machine is at tissue manufacturer Fortissue, which is working with Italian engineering firm Toscotec on what is described as a ground-breaking project on PM1 at its Viana do Castelo mill in northern Portugal.

Started up by Toscotec in 2015 as PM1, the Ahead line is being upgraded by the Italian company to run with electrical power.

Equipped with Toscotec’s TT NextPress shoe press, the machine is being upgraded after nine years of operation to meet the goal of making tissue production more sustainable.

Toscotec will install a fully electrically-powered air system including an e-powered TT Hood with several stages of heat recovery. TT Swing will ensure maximum flexibility by giving the choice of the operation modes from full cascading to hybrid depending on the specific production needs. A TT Turbodryer will harness the heat

and Toscotec

recovered from the air system to improve the shoe press dewatering effect and increase post-press dryness.

Finally, the new e-powered TT SteamBooster will generate 100 percent of the steam necessary for the TT SYD Steel Yankee Dryer by recovering the heat present in the hood’s exhaust air together with electric steam generation.

The mill will be able to take electrical power from the local grid in Portugal or by using 100 percent renewable energy taken from its solar and wind plants.

The corresponding greenhouse gas (GHG) emissions will be cut by 20 percent when the tissue line operates from the grid, and net-zero GHG emissions if it runs on renewable energy both for its electric and thermal requirements.

Nuno Ribeiro, owner of Fortissue, said: “At Fortissue we are proud to be spearheading the energy transition of the tissue industry. This groundbreaking project will pave the way for a new generation of production lines with top

performances that also meet the sustainability requirements put forth by tissue consumers in the European market and beyond.”

Gabriele Romanini, sales manager at Toscotec, added:

“Toscotec’s partnership with Fortissue has come a long way in the past 10 years and we are delighted that they selected us for this pioneering project. PM1 was state-of-art when it came on line, and we are now working to take it to a whole new level to become the first high-performance tissue line in the world to run on green electricity.”

Founded in 2015, Fortissue has capacity to produce around 35,000 tons of tissue products. It is part of the Ghost Group, which also includes Suavecel and Nunex Worldwide. With more than 20 years of experience in the personal hygiene market, the Ghost Group employs more than 300 staff and says it focuses its investments on the best available technology worldwide, enabling the delivery of high quality products, while optimising energy and water consumption and guaranteeing zero waste of raw materials.

UPM Communication Papers has been proceeding with the closure of its Hürth newsprint mill and the permanent shutdown of a fine paper machine at Nordland Papier in Dörpen. Both are in Germany. Graphic paper production at the Hürth mill ceased at the

end of August while the PM3 at Nordland Papier was to be shut at the latest by the end of 2024, resulting in annual capacity reductions of 330,000 tonnes of newsprint paper and 280,000 tonnes of uncoated fine paper.

Discussions with representatives of the 338

workers at the mills have been concluded. Antti Hermonen, SVP of operations at UPM Communication Papers, said: “In cooperation with the workers council, we have engaged in a constructive dialogue with the aim of developing responsible solutions for our employees.

The thoughtful and collaborative approach taken by all parties during the consultations resulted in socially responsible solutions for our people.”

The financial impact of the closures is said by UPM to remain materially unchanged from the announcement in May.

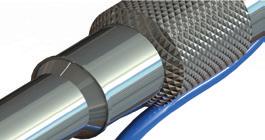

What is being described as a milestone development in press section steam savings, Smurfit Westrock has started up a Voith HighPerformance Press at its Roermond Papier mill in The Netherlands. The success of the project could lead to others at Smurfit Westrock mills.

Installed on the mill’s PM1 line in a rebuild that took 38 hours, the line started up again smoothly and production was subsequently “fully ramped up again”, said Voith.

In a statement, Voith added that the advantages of the new press became immediately clear: The HighPerformance Press increases the dry content of the paper web after the press section and enables Smurfit Westrock to make significant steam savings in the dryer section. As a result, energy consumption and carbon dioxide emissions can be significantly reduced.

Furthermore, the increased dry content after the press section enables an increase in production speed. This in turn can lead to higher production quantities with consistent quality.

Sjon Vrieze, technical operations manager at Smurfit Westrock Roermond Papier, explains:

“Thanks to the innovative HighPerformance Press solution from Voith, we can save 7,500 tons of steam and 1,113 tons of CO2 per year. This is an important contribution to our decarbonisation roadmap and shows the potential for converting other Smurfit Westrock paper machines.”

Voith continues to support Smurfit Westrock with

optimisation measures that exploit the maximum potential of the new press.

Bas Noldus, production manager at Smurfit Westrock Roermond Papier, commented: “We were delighted when Voith approached us with its new HighPerformance Press solution. From the very beginning, there was a trusting relationship and close cooperation. It quickly became clear that it was important for Voith to respond to our needs and enable us to achieve

In a move to reduce pulp output to meet ‘market conditions’ UPM is temporarily cutting production at its Kaukas and Kymi pulp mills in Finland.

The move follows negotiations with staff held in March.

“We are adjusting our production as a normal measure in line with market and cost developments, focusing on profitability,” says Marko Sundqvist, vice president of UPM’s Pulp Operations in Finland.

The shutdown of the Kaukas pulp mill started on 9 September and of the Kymi pulp mill on 23 September, and lasted for about three weeks. Maintenance work will be carried out during part of the shutdown period, but

significant production benefits with the HighPerformance Press.”

The press upgrade is the latest of a number of recent improvements made to PM1. These included the installation of a shoe blade gap former, a rebuild of the inrush flow system and an extension of the machine room.

Following the completion of the final phase, the 5-metre wide PM1 was capable of producing 85-135gsm recycled fluting and testliner at a speed of 1,200 metres per minute.

temporary layoffs are possible.

UPM’s pulp mills in Pietarsaari in Finland and at Paso de los Toros in Uruguay will continue to run at full capacity. Deliveries to customers will continue normally during the shutdowns.

UPM Pulp operates four pulp mills worldwide, three in Finland and one in Uruguay, with annual pulp capacity of 3.7 million tonnes.

The chief executive of paper maker DS Smith has called for the new UK government to help make the country a more attractive place to invest, and to align with EU regulations to support trade.

Miles Roberts shared industry insights on trade, investment and what is needed to support UK manufacturing.

Speaking on the Wake Up to Money and Today programmes, Roberts said:

“Support for a vibrant, growing, UK manufacturing base will in turn support economic growth, and right now there is an excellent opportunity to reset and realign with the EU to help make that a reality.

“A failure to maintain the standards of our biggest trading bloc presents a cost, but if we can make sure that standards are common, it will reduce cost to British business, and in turn, the consumer. Unless something is demonstrably not in the UK’s own interest, then we should be asking why we aren’t aligning with EU rules.

“Aside from the need for regulatory alignment, British

businesses need a long-term national industrial strategy that will support higher levels of investment and growth.

“For manufacturers, energy sources are critical – we need to understand the source and cost of energy, how we connect to it, if the power supply is sufficient, and how the grid will support it, before any planning to invest in new technologies or factories can happen.

“For our part, DS Smith has already invested into lower-carbon facilities in Italy and Poland, and into greener technologies

in Germany, France and Spain, because we have ambitious decarbonisation targets and the industrial and energy policy frameworks in those countries are made clear. With a clear plan, the UK can underscore why it is an attractive place to invest, and growth can follow.”

Points that Roberts made during the broadcasts included: Regulatory alignment:

● It is an excellent moment for the new government to reset the relationship with the EU to support trade.

● The EU is developing new

legislation, but the UK is not keeping pace with the new standards which creates automatic divergence with our biggest trading partner, and generates avoidable costs to business.

● We need regulatory alignment –unless something is demonstrably not in the UK’s own interest, then we should be considering aligning with EU rules, so that we have less friction.

Supporting UK manufacturing and making the UK a more attractive place to invest:

● A vibrant, growing, UK manufacturing base could have a very significant and positive effect on the economy.

● Alongside regulatory alignment with the EU, it is crucial that the government set out a longterm plan for infrastructure and energy solutions.

● The UK will be a more attractive option for investment into manufacturing if a clear energy plan is set out.

● Understanding the energy sources and connections, and how the grid’s capacity will be enhanced to accommodate this, is critically important.

Metsä Group’s pulp and sawmill business has again achieved EcoVadis’s highest level of recognition, the Platinum rating, for its sustainability efforts. Since 2019, Metsä Fibre has consistently been among the top one percent of pulp, paper, and cardboard manufacturers evaluated by EcoVadis. The company received particularly

high marks (90 out of 100 points) for its responsible sourcing practices.

“Responsibility and sustainability are integral to our strategy and daily operations. We highly value the Platinum recognition from EcoVadis, which we have now received for the sixth time. We use the feedback from the assessment as a tool for

continuous improvement,” says Ismo Nousiainen, chief executive of Metsä Fibre.

“Metsä Group’s strategic sustainability goals for 2030 pave the way toward a carbon-neutral society. Our objectives include fossil-free factories, 100 percent utilisation of production side streams, and completely fossil-free raw materials by 2030.”

EcoVadis, an organisation that evaluates corporate responsibility, provides a platform for companies to assess their suppliers’ performance in global environmental and social responsibility. The assessment covers four areas: environment, human rights and labour practices, business ethics, and sustainable procurement.

Targeting emissions zero

WE ENABLE OUR CUSTOMERS TO REDUCE CO 2 EMISSIONS

More than €30 million has been invested in solar power systems at Smurfit Westrock’s mills in Spain as part of the paper maker’s mission to cut carbon dioxide emissions by switching from fossil fuels and cutting waste going to landfill.

More than 12,000 solar panels were unveiled at the Sangüesa paper mill. These will augment its biomass and recovery boilers to generate more than half of its annual energy requirements, the equivalent to powering 3,600 homes.

The €6 million photovoltaic system, which is the largest of its kind in the Navarra region, is expected to reduce the mill’s annual carbon dioxide emissions by more than 3,000 tonnes. Since 2005, the Sangüesa paper mill has reduced its carbon dioxide emissions by more than 51 percent.

A €6 million photovoltaic system has been installed at Smurfit WestRock’s Sangüesa paper mill

With a second investment of €27 million, the Nervión paper mill will adopt a fully circular production process involving the biggest landfill reduction project Smurfit has ever undertaken. The project will remove 75,000 tonnes of waste from landfill, and additionally, eliminate around

450,000km per year of road transport.

Javier Rivas, operations chief at Smurfit Kappa Paper & Board Europe, said: “The recent inauguration of both the Sangüesa and the Nervión investments are milestones for the Smurfit Kappa paper division and

Stora Enso is cooperating with the police and other authorities with an investigation into an environmental incident at a wood harvesting site at Kainuu in Finland.

In what was described as an aggravated nature conservation offence, in August forestry machinery crossed a river where there is a population of the highlyendangered freshwater pearl mussels.

Stora Enso said it takes the matter extremely seriously, because the pulp and paper maker adheres to strict responsibility requirements and comprehensive guidelines for the consideration of freshwater pearl mussel in harvesting operations.

“It is evident that our guidelines have not been followed. What has happened is completely contrary to our values and sustainability commitments,” said Seppo Parvi,

country manager for Finland at Stora Enso.

Following its own investigation

Stora Enso said that its guidelines and procedures will be refined to ensure that everyone involved in harvesting in valuable natural areas is aware of them in the future.

“It is our responsibility to ensure that this never happens again. We have taken immediate steps to tighten up our procedures, including forestry planning,

aligned with the EU Green Deal’s transition to climate neutrality through increasing clean energy technologies.”

Chief sustainability officer Garrett Quinn added: “These two projects demonstrate the Group’s continued investment to deliver on its sustainability goals with over €30 million in these two projects alone, delivering reduced emissions, and increasing the circularity of our production process.”

The Sangüesa and Nervión inauguration events were attended by Smurfit WestRock chief executive Tony Smurfit.

Smurfit WestRock’s Nervión mill in Spain where its biggest-ever landfill reduction project has started

environmental training, guidelines and information systems. The police investigation is ongoing, but it is clear that Stora Enso bears its responsibility in this case, both environmentally and financially,” said Parvi.

Stora Enso is supporting the restoration work led by Metsähallitus on site both financially and materially. Stora Enso has also decided to participate in the LIFE Revives programme. “Participation in this programme will not repair the damage already done, but it is the least we can do in this case,” said Parvi.

Despite the continuing threat of missile strikes, a tissue maker in Ukraine has invested in new technology to improve energy efficiency and operational safety.

Kyiv Cardboard and Paper Mill has purchased a TT SYD Steel Yankee Dryer and a high efficiency TT Hood system from Italy’s Toscotec to replace its existing cast iron dryer cylinder and Yankee hoods on PM2 at its Obukhiv mill, south of Kyiv. The project is planned for start-up in 2025.

Ivo Valtchev, vice chief executive

at Kyiv Cardboard and Paper Mill, said, “Despite the war in Ukraine and the current economic situation, we continue to invest in advanced technologies and to modernise production. The new TT SYD and Hood will improve the energy efficiency of PM2, as well as increase our operational safety, which is especially important in this difficult time for the country.”

Compared with the existing cast iron Yankee, the new TT SYD will significantly reduce PM2’s energy consumption and guarantee higher operational safety; the

high-efficiency TT Hood and burner system will considerably optimise the Yankee hoods’ energy consumption. The upshot of the overall project will be substantial energy savings.

Matteo Giorgio Marrano, sales manager at Toscotec, added, “Toscotec is happy to start a new cooperation with Kyiv Cardboard and Paper Mill and we are confident that this technological upgrade will deliver a competitive advantage to drive their market growth. The combination of Toscotec’s key drying equipment – TT SYD and

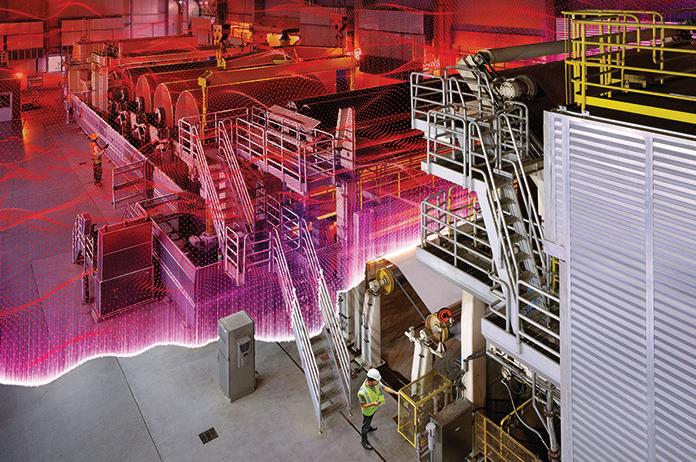

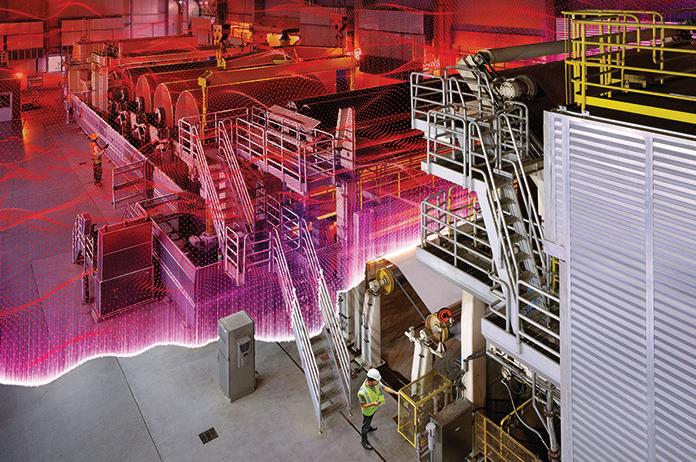

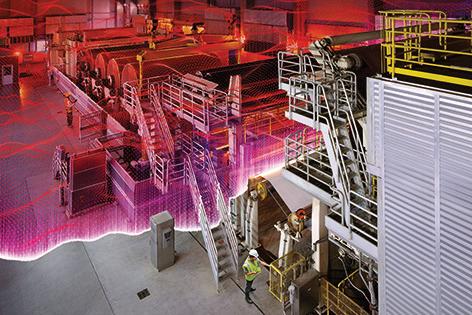

Atlanta-based Georgia-Pacific has completed the US$550 million expansion of its Green Bay, Broadway mill in Wisconsin, celebrating with an opening event in September.

The expansion included a new through-air-dried (TAD) paper machine and three converting lines that will produce Brawny brand paper towels and other premium private label brands for the retail market.

Construction on the 600,000sqft site began in July 2022, helping to

support Georgia-Pacific’s own retail towel brands, and the growth of premium private label brands. It also reduces manual ‘touches’, a critical part of the new paper machine’s production process, the associated converting equipment, and the overall infrastructure.

With the production process nearly 85 percent automated, the technology-focused jobs as part of this project will manage high levels of automation across the entire product system.

The new TAD machine increases

TT Hood – represents the best available technology in tissue for its value in energy efficiency.”

Founded in 1982, Kyiv Cardboard and Paper Mill is one of the largest producers of full-cycle cardboard and paper products in Eastern Europe. It is part of the Austrian group Pulp Mill Holding.

tissue capacity to the Broadway mill, which already operates seven other paper machines and several converting operations.

“Today is an exciting day for Georgia-Pacific,” said John Nundahl, manufacturing chief at Georgia-Pacific during the opening. “After more than two years, it is wonderful to see the results of this new investment in the form of more than 100 full-time jobs, enhanced levels of technology and automation, and production capabilities that will produce Brawny paper towels

and other premium private-label brands.”

Since 2006, around $1.2 billion has been invested in GeorgiaPacific’s Green Bay facilities, including the Broadway mill. Many of the investments were focused on high-tech equipment and technology, including the latest in automation, laser-guided vehicles, artificial intelligence, and robust data analytics that it says help operations run safely and efficiently. Georgia-Pacific has five facilities in Wisconsin, which provide almost 2,000 direct jobs in the state.

Flow Link Systems (FLS), a Voith subsidiary that supplies customers with valves, strainers and high-quality steel castings, has won an award recognising its commitment to the use of renewable energy in industrial activities.

Efforts to integrate renewable energy into the India-based company’s energy mix include optimising energy consumption and improving energy efficiency through continuous monitoring, measurement, and control.

Commenting on the EQ Solar Award, Dr Nithyanandan Devaraaj, chief executive of Flow Link Systems, said: “FLS is amongst the early users of renewables for its energy needs in India. The recognition has

come in at the right moment for the commitment of the

Compensation of almost US$500 million has been awarded to Smurfit Holdings after its operations were ‘unlawfully expropriated’ by the Venezuelan government in 2018.

The award on 28 August against the Bolivarian Republic of Venezuela was made by the arbitral tribunal of the World Bank’s International Centre for Settlement of Investment Disputes (ICSID).

Smurfit Holdings BV, a wholly owned subsidiary of Smurfit Westrock, will receive compensation in excess of US$468.7 million, plus legal costs of $4.5 million, plus interest from the end of May 2024 until the date of payment.

The case involved the

breaking of the treaty that provided reciprocal protection of investments between the Netherlands and Venezuela.

Following the government occupation in August 2018, Smurfit Kappa Group’s Venezuelan operations were deconsolidated.

By majority, the Tribunal dismissed Venezuela’s objections to its jurisdiction, and held that Venezuela breached the treaty’s protection against unlawful expropriation and Venezuela’s seizure of Smurfit’s business there.

The tribunal concluded that Venezuela’s occupation of Smurfit’s Venezuelan subsidiaries in 2018 “constitutes an expropriation that was not taken

in the public interest and was not compliant with due process of law”.

Smurfit Westrock said it will now pursue the full value of the award from Venezuela.

Tony Smurfit, chief executive of Smurfit Westrock, commented: “We are pleased with the award of the ICSID tribunal. It validates our assertion that our Venezuelan business was unlawfully expropriated in 2018. While the award cannot compensate us for the full loss in relation to our operations in Venezuela, including the significant impact it had on our people and the wider community there, we will now pursue the full value of this award from the Venezuelan government.”

organisation and the team to a small carbon footprint. This award is deemed special given the across-industry competition and FLS specifically belonging to an energyintensive sector. We wish to continue this success journey of decarbonisation in meeting corporate expectations.”

The award is given by EQ International Magazine with the participation across the industry to encourage the adoption of renewable energy sources to decarbonise industrial activities. By striving for low-carbon emissions, companies contribute significantly to ecological sustainability.

The 56th Pulp and Paper International Congress and Exhibition, a gathering of the forest base industry organised by Brazilian Pulp and Paper Technical Association (ABTCP), includes a robust technical programme coupled with an exhibition featuring the latest technological trends in the sector.

It is being held from 1-3 October at the Expo Transamérica, in São Paulo (SP).

“The opening ceremony, which traditionally occurs on the morning of the first day of the congress, always gathers important participants to discuss current issues regarding all players in this extensive production chain, and is definitely worth blocking your calendar to attend it,” says Darcio Berni, executive director of ABTCP.

Swedish analyser and measurement technology company

PulpEye has been acquired by Andritz. The acquisition is said to complement Andritz ’s capabilities by adding the core pulp quality analysers and measurements into the group’s automation and digitalisation portfolio.

PulpEye focuses on online applications and services for the global pulp and paper industry. The Swedish company provides pulp, paper and board producers with a wide range of online pulp analysers, measurements and controls ranging from chip quality,

kappa to fibre properties and more throughout the process. Since 2002, PulpEye products have contributed to stabilised and higher pulp quality, process efficiency and reduced energy consumption in pulp production. Andritz will continue to invest in the further development of the PulpEye product line and will establish a dedicated service network to provide customers with global support. The acquisition complements the extensive portfolio of Smart Series, Andritz Intelligent Instruments, and leverages the group’s position to provide total solutions combining

measurements, analysers, advanced process control and optimisation, as well as a broad range of services.

Stephan Keuschnigg-Zingl, senior vice president for pulp and paper automation and digitalisation at Andritz , says: “We are very pleased to welcome the PulpEye team with its excellent analyser portfolio to Andritz. This acquisition further strengthens our offering in automation and digitalization and allows us to provide reliable analysers to measure all the main quality parameters of pulp processing, as well as new solutions and services leveraging them.“

● In a second acquisition, Andritz has taken over Finnish company Procemex, which specialises in web monitoring and inspection for the pulp and paper industry. The value of the deal was not revealed.

Procemex’s smart camera-based solutions help customers ensure product quality and minimise costly production downtime. With 20 years of industry experience, Procemex has delivered more than 1,000 systems worldwide. It has a team of more than 100 vision systems experts and operates from Finland and subsidiaries in Germany, Japan, and the US.

With the launch of DNAe, Valmet redefines what a distributed control system can be in a connected digital world, particularly in pulp and paper mill operations. Report by Ralf Salonen and Randel Wells

The future holds remarkable prospects for process industries. Every challenge is a catalyst for innovation and growth. The pressures of globalisation and demographic and climate change are reshaping expectations. As technology leaps forward, Valmet is creating solutions that transform complexity into simplicity, enabling a new generation of workers to navigate and excel in a digital landscape.

Transformative times for process industries

“The world around us is changing rapidly. Industrial systems like the DCS need to embrace this digitally-connected world,” explains Jukka Ylijoki, vice president of R&D for Automation Systems at engineering group Valmet.

“Building a truly open yet secure and sustainable DCS that would last for decades required a complete overhaul. No aspect of

our recently launched Valmet DNAe was left untouched. We had to be sure it delivered the reliability, performance, flexibility, and security our customers needed.”

A foundation for digitalisation and autonomous operations

“Compared to 20 years ago, the requirements for a DCS have changed dramatically,” says Harri Mustonen, director of control systems at Valmet. “The primary purpose of a DCS is still to connect field devices to process controls, but over the last few years, digitalisation initiatives everywhere have pushed the DCS toward higher levels of connectivity and automation.”

The common thread is better data utilisation. To enable greater autonomy, the DCS needs to collect, manage, analyse, and share highquality data across operational technology (OT) systems at the facility and the information technology (IT) systems of the back office.

“Valmet DNAe makes this possible as a single

unified system,” says Mustonen. “In addition to real-time process controls, Valmet DNAe brings structured high-quality information

management tools for advanced analytics and reporting to the core of the DCS. This enables customers to improve their digital intelligence at every level to achieve higher targets while reducing production costs.”

Cybersecurity meets open connectivity

Making the digital transformation smooth for customers was a key ingredient in the development of Valmet DNAe. “Customers need to be able to open their DCS in an easily controlled manner to combine systems and data sources,” says Ylijoki.

“Our networking and connectivity goals for Valmet DNAe were far more ambitious than anything we had done before. How do you secure a system designed to be open and adaptable? To answer that, we maintained a laser-like focus on cybersecurity.

“This was perhaps our biggest insight when we started developing Valmet DNAe,” Ylijoki

continues. “The need for a platform that is fundamentally cybersecure is proving itself time and again.”

Valmet DNAe ensures cybersecurity measures from the operating field layer up to IT-level communication. The system’s different network

A common controller and I/O family enables a smooth transition from Valmet DNA to Valmet DNAe over a plant’s lifecycle. Additionally, Valmet has introduced a new modular controller and a single-channel I/O as new hardware options for Valmet DNAe

layers and technical features have been developed based on certified Security Development Lifecycle Assurance (SDLA) methodologies, ensuring security from the first line of code.

At the core of the Valmet DNAe distributed control system is the Trusted Information Framework (TIF), which serves as the backbone for communication and data management. The TIF framework provides a robust foundation for system security and integrity. Built on the TIF foundation, Valmet DNAe architecture is cybersecure by design, and it includes measures such as role-based access control, authentication, encryption, endpoint protection, and comprehensive audit trails. IT security integration helps security teams stay alert to potential threats, and the Valmet DNAe system also enables the implementation of intrusion detection.

Every user counts more than ever “Industries face a silver tsunami of retirement,” says Mustonen.

Attracting new recruits and keeping them is hard, adding to the pressure to optimise and do more with less. Smaller and smaller teams need to be able to run processes in larger, more complex operations.

Valmet DNAe empowers teams to collaborate seamlessly across process areas, sites, departments, and organisations by implementing a design philosophy that focuses on usability. Users get an intuitive holistic view of processes, sites, and fleets for best situational awareness and cross-team collaboration.

more users into the DCS realm is the key to success.

“The most experienced people are leaving the workforce. New recruits lack the expertise from 30-plus years in the same job, and they don’t even want such a career. Changing jobs after a few years is the norm now. Even though the DCS role is bigger, the system needs to be much easier to learn and use to counter high turnover.”

“Valmet DNAe is as much about bringing people together and new ways of working as it is about connecting systems,” says Ylijoki. “We want the best experts to be available for our customers and work seamlessly to analyse data, resolve issues, and optimise process performance.”

All users can now easily access and leverage process data to improve and accelerate datadriven decision making. Bringing

With the DCS taking on an increasingly important role, high availability is a must for a fully digitalised DCS. “System reliability is critical because the primary function of a DCS is to secure continuous, trouble-free production,” notes Mustonen. Fault tolerance and redundancy have been at the core of Valmet DNAe development, ensuring continuous availability of real-time high-quality data. This enables precise control of the process and faster response times to both unexpected disturbances and planned changes.

“You can eliminate process variability and run at the optimal operating point to produce the targeted production and quality with the minimum input,” says Mustonen. “This is critical for long-term sustainability. Valmet DNAe delivers the controls, data, analytics, and diagnostic

intelligence to confidently towards more efficient use of resources and lower emissions.”

The future starts now Valmet keeps its lifetime systems compatibility promise to customers with Valmet DNAe. Existing Valmet DNA customers can benefit now from the latest

Valmet DNAe is inherently cybersecure by design. The innovative system core and architecture provide multi-layered protection to shield operations from cyber threats.

Developed following the industry-leading IEC 62443-4-1 standards and independently verified with Security Development Lifecycle Assurance (SDLA) certification, Valmet DNAe delivers hardened defenses against cyber threats.

Valmet DNAe was developed with a design philosophy that empowers people to perform and collaborate better across their organisation. The system provides a common user interface for controls, analytics, configuration, and maintenance. Intuitive workflows simplify operations and enable users to manage larger process areas with less effort. With role-based access control and support for global

technology and innovations in Valmet DNAe.

“We have well-defined upgrade paths for existing Valmet DNA customers to transition to Valmet DNAe on a timeline that best fits their production and investment plans,” says Mustonen.

“Whether it’s a hydrogen production or power plant, paper

expert networks, Valmet DNAe also enables global collaboration and multisite operations to increase operational flexibility and ease recruitment. The new user interface enables significantly easier onboarding for the new generation of DCS users.

Process insight is included in Valmet DNAe and can be run onpremise in an edge server or fully in the cloud. Easy-to-use trending, analysis, and filtering allow users to follow, study, and troubleshoot processes, while powerful reporting and self-service data visualisation help cross-team collaboration.

Advanced analytics and reporting solutions provide actionable insights to all users from control room personnel to analytics teams and office stakeholders. The easyto-use dashboarding and analysis tools and advanced monitoring and prediction applications are specifically designed for industrial data and provide a comprehensive

machine, or whiskey distillery, tremendous process expertise has gone into those applications,” adds Ylijoki. “They’re the strongest foundation to build on. We introduce innovative technology while securing customers’ existing assets by migrating control functions without changing their behaviour.”

view of production processes or sites.

Valmet DNAe is a scalable automation system that grows with a business. It adapts to evolving operational needs and technological advancements. Valmet’s commitment to lifetime system compatibility guarantees that there’s always an upgrade path available.

Predictable lifecycle costs and long-term commitment are ensured through lifecycle plans. Service agreements provide performance guarantees and expert support for continuous performance improvement.

Upgrading an existing Valmet DNA can be started smoothly through the user-friendly Valmet DNAe User Interface.

Since the 1960s, Valmet has been pioneering digital solutions for industrial customers. Valmet’s first DCS arrived in 1978, one

Customers are able to jump-start optimisation and performance enhancement through a library of industry-specific applications for Valmet DNAe. Valmet also provides a reference network with ready-made templates to significantly reduce project times and ensure the final Valmet DNAe network design adheres to cybersecurity requirements.

Securing the present is as important as securing the future.

“One of the key advantages of the Valmet DNAe system is that it can evolve. This is pivotal to our customer promise,” says Ylijoki. “More than that, though, our system is designed to adapt and remain competitive in the future.”

of the very first on the market. Since then, all its distributed control system generations have had industry-leading release compatibility.

Valmet’s controllers and I/Os are built for reliable real-time operation, ensuring uninterrupted performance. The adaptable hardware family offers a wide range of options to perfectly fit to specific needs, regardless of the current system.

● Common hardware family between Valmet DNA and Valmet DNAe

● A new modular controller and a single-channel I/O as new hardware options for Valmet DNAe

● Easy migration from existing DCS or PLC systems

● Open connectivity to third party systems and devices

● Scalability to expand the system’s size and functionality

● Redundancy options maximise uptime in mission-critical processes

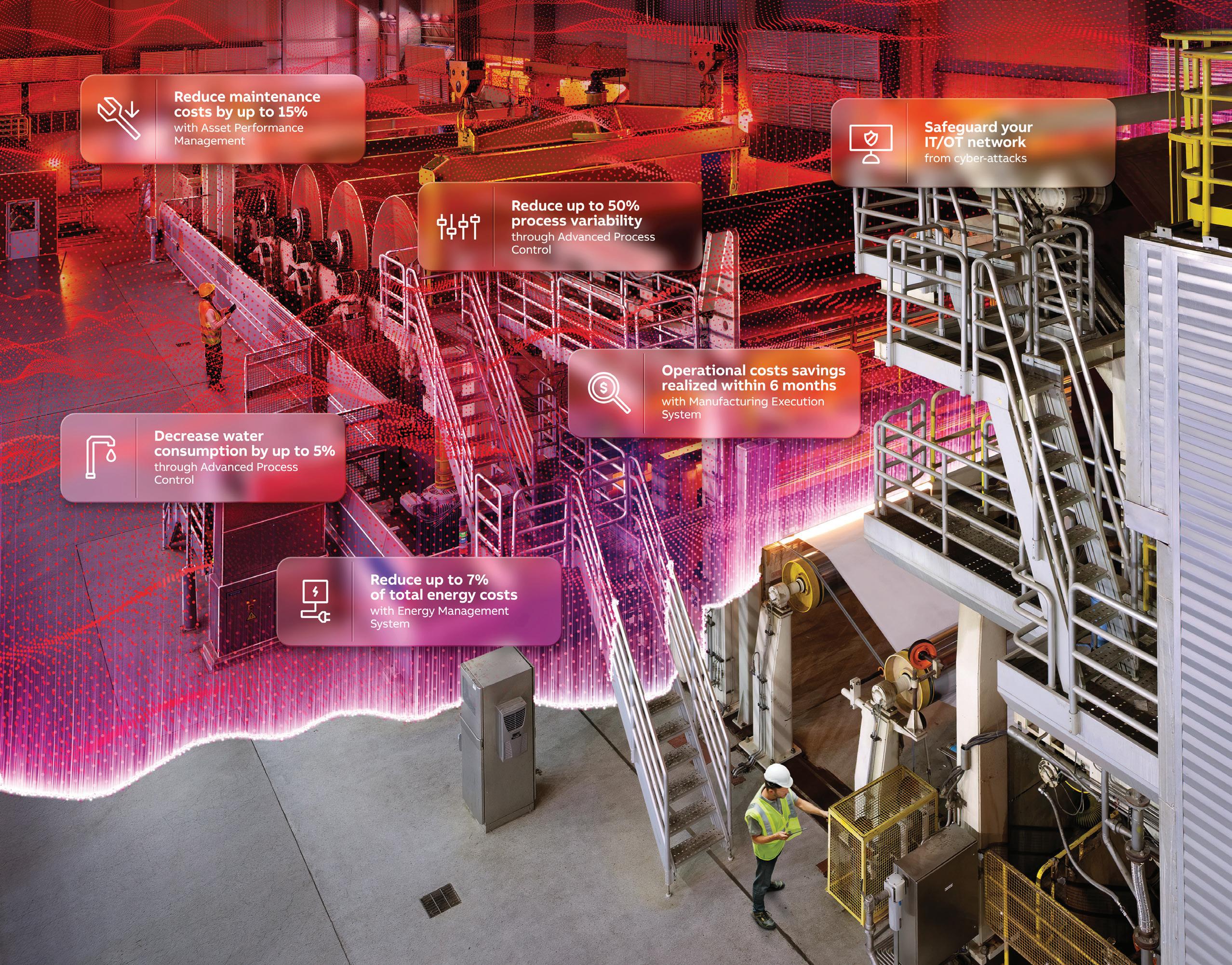

ABB is calling on process industries, and especially pulp and paper, to evolve their operations by leveraging advanced solutions that bridge digital gaps and is drawing on expert teams assembled across five disciplines to deliver insights to build on successes in energy management, process safety, skills retention and process performance results. PPL reports

Global technology leader ABB has launched Do

More With Digital, a global campaign that highlights the opportunities for process industries to realise their full potential through digital transformation.

Leveraging its deep ties across pulp and paper, mining, metals and cement, ABB recognises a significant opportunity to continue equipping these sectors with advanced industryspecific solutions, driving their digitalisation journey and allowing

them to accelerate their adoption curve in a shorter timeframe. While these industries will continue to be enhanced through technology development using the likes of generative artificial intelligence (Gen AI), data analytics, machine learning (ML),

cloud and edge computing, they are also considered hard-to-abate due to the volume of production, location of operations, energy and heat chemistry, and many other factors.

The World Economic Forum reports that digital solutions can

accelerate efforts to reach net zero in high-emission industries, delivering up to 20 percent of the total reduction that the International Energy Agency says is needed by 2050. ABB is leveraging its experience of previous energy transitions, its recent record in industrial software development, and its 140 years of heritage across a range of industries to guide customers on their digitalisation journeys. ABB has worked with customers

ABB’s advanced suite of digital offerings is empowering mills to overcome its most pressing challenges by enabling datadriven decision making

within the process industries for decades, supporting with the deployment of digital solutions such as advanced process control (APC), energy management systems (EMS), and manufacturing execution systems (MES).

These have evolved from original packages to become variations used for distinct industries, with their own tools and libraries, and remain the foundation for advanced technology progression.

Customers recognise that they are at different stages of their digitalisation journey, often with starters (those embedding digital for the first time), stallers (those piloting a new advanced solution, often with a start-up) or scalers (those moving to the next level, perhaps with a technology company). ABB is currently working across this ecosystem to jointly design and develop new solutions for current and future needs.

“Adoption of advanced digital technologies is still much slower than one might expect in the process industries,” says Sanjit Shewale, global business line manager for digital at ABB Process Industries. “Customers are facing new challenges in proving and scaling up solutions that will drive real, transformative change.

“However, there are opportunities for all parties to use technologies to retain knowledge of processes in their business as people retire or move on in shorter timeframes than was typical in the past. Through co-creation, there is the chance to show more and do more for positive investment decisions that quickly result in unprecedented

levels of energy management, efficiency, sustainability, safety and service.”

ABB reports that it is also working with fellow global technology companies to integrate the likes of Gen AI capabilities into the ABB Ability suite of industrial software, supporting industrial companies to improve data collection, unlock insights hidden in operational data, and enable significant gains in efficiency and productivity. Partnerships also exist for initiatives to accelerate the adoption of digital solutions to help industries meet their goals on net-zero emissions. One such example is real-time data transmission using cloud-based software integrated with ABB systems.

In the pulp and paper industry, ABB’s advanced suite of digital offerings is empowering mills to overcome its most pressing challenges by enabling data-driven decision making. A holistic view of operations, leading to reduced waste, minimised downtime, and stable production profiles for mills, ensures that ABB can deliver exceptional results to meet its customers’ expectations.

Alongside Jujo Thermal in Finland, part of the Nippon Paper Group, ABB’s team was able to transform the thermal paper maker’s operations by understanding its complex production needs and implementing ABB Ability Manufacturing Execution System (MES) for pulp and paper. Jujo Thermal achieved reduced production costs within just six months through improved utilisation of overproduction, while also improving overall efficiency with more integrated workstreams.

“The significance of the pulp and paper industry in our everyday

lives cannot go understated, nor can the problems that the industry is currently facing,” says Stefano Cinquina, global business line manager for pulp and paper at ABB Process Industries. “Working to tighter margins than ever, incremental gains in productivity and efficiency make a huge difference. For decades, we have been a trusted advisor to the pulp and paper industry. This deep domain expertise, coupled with our expertise in implementing digital solutions at scale, allows us to co-create a digital roadmap that unlocks a new era of efficiency for the industry.”

ABB’s team embraces what it refers to as five key pillars –operational excellence, process performance, asset performance, sustainability, connected workforce – all with embedded cyber security. ABB considers such a framework when advising industries that need to keep up the rapid pace of innovation, optimise efficiency and, in turn, minimise energy waste and reduce costs.

ABB’s Process Automation business automates, electrifies and digitalises industrial operations that address a wide range of essential needs – from supplying energy, water and materials, to producing goods and transporting them to market. With around 20,000 employees, along with leading technology and service expertise, the company helps customers in process, hybrid and maritime industries improve performance and safety of operations, enabling a more sustainable and resourceefficient future.

More information from: go.abb/ processautomation

As markets demand more environmentally-friendly raw materials, mills need to be able to change between producing kraft and dissolving pulp. This is how Andritz makes the process more accessible. PPL reports

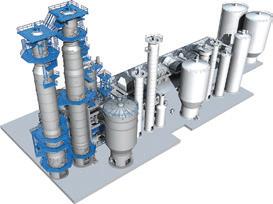

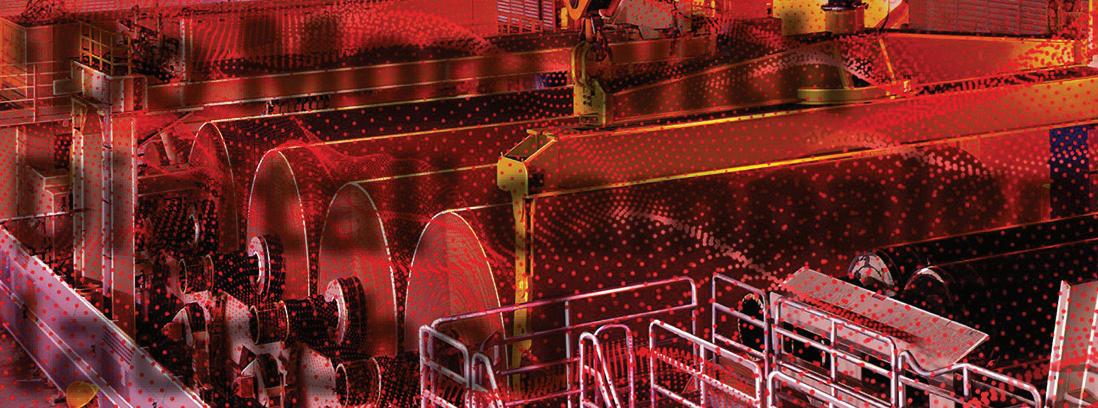

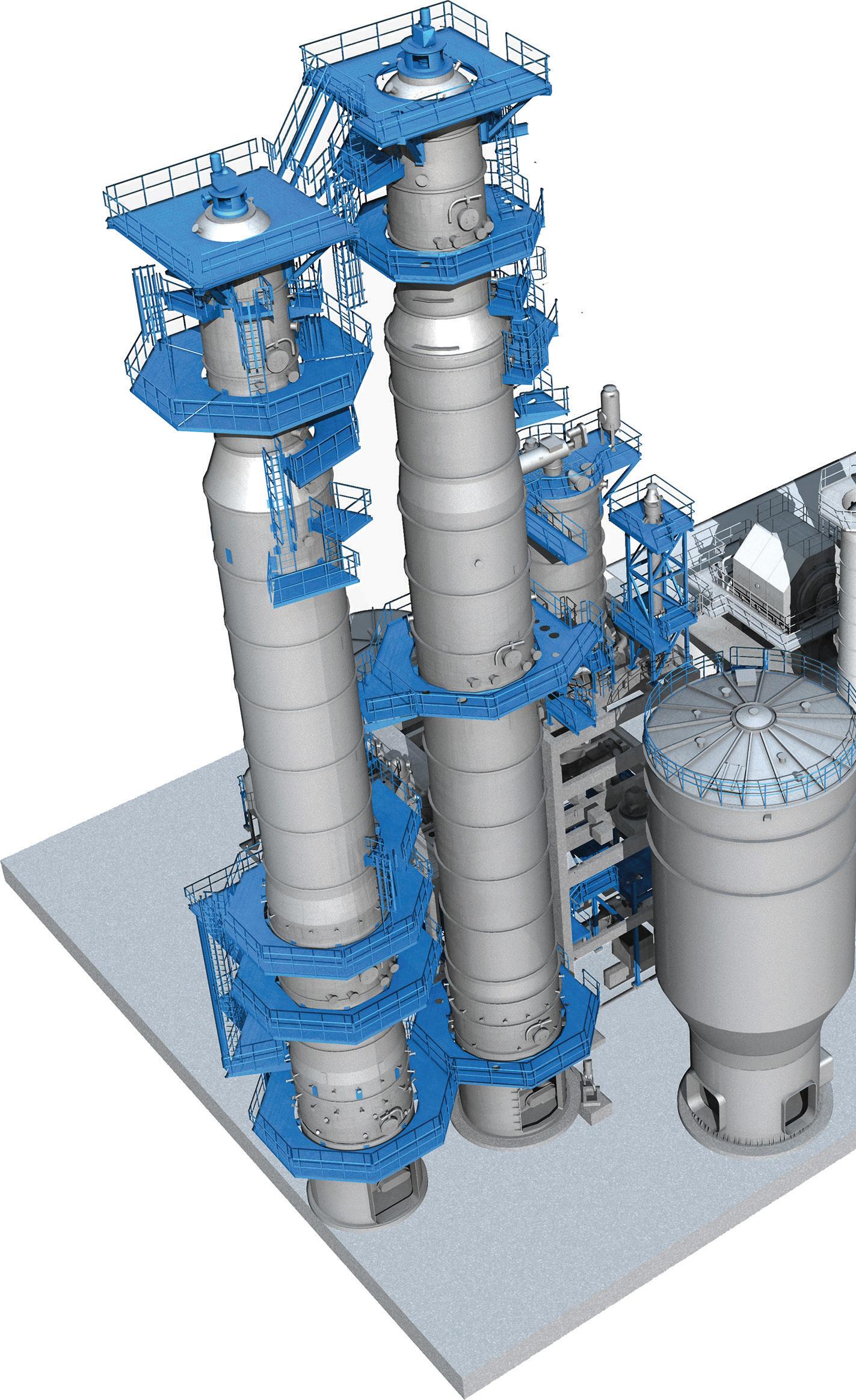

Cellulose fibres are becoming increasingly important to the textile industry as the world moves away from fossil-fuel derived products and seeks more environmentally-friendly raw materials. Andritz has developed the A-ConFlex continuous cooking method for bleached dissolving pulp production to simplify the process for pulp producers switching between dissolving pulp and kraft pulp according to market demand.

Andritz says it has made it easy for pulp producers to switch between producing kraft and dissolving pulp, but adds that it is by no means a simple process. There are major differences between the two pulps when it comes to qualities and production processes. However, with the A-ConFlex concept, Andritz has taken a complex challenge and transformed it into a user-friendly and reliable solution.

A-ConFlex is the only potential system available on the market for continuous dissolving pulp production and is already a proven technology with 10 systems delivered to Andritz customers around the world.

Key changes to a kraft mill fibre line

There are a number of differences in the production of kraft pulp and dissolving pulp. Viscosity is the main one as it needs to be much lower in dissolving pulp than in kraft pulp. Another difference is

that the pulp needs to be much cleaner. All hemicellulose has to be removed along with all traces of metals and impurities, such as sand. The third main difference is that the water supply needs to be changed to purified waters, to ensure purity of the final pulp.

“Basically the quality of the dissolving pulp needs to be at a much higher quality level, when compared to kraft pulp,” says Michael Bloder, head of product and technology management for wet end at Andritz

To address these differences, a number of adaptations need to be made on a kraft pulp fibre line to enable the production of dissolving pulp. Sampsa Laakso, technology manager for fibre line cooking, explains: “The most important change to the fibre line is the installation of a pre-hydrolysis vessel before the digester; this is for the removal of hemicellulose. This is carried out by adding steam and heat to the chips with the reaction, then hydrolysing the hemicellulose.”

When it comes to lowering the viscosity, the process has been adapted to reduce the level by up to half at the oxygen delignification stage. Taneli Alajoutsijärvi, technology specialist for fibre line washing and bleaching at Andritz, says: “In dissolving pulp we want to have a low viscosity, around 400-500 ml/g, whereas in kraft pulp we want as high viscosity as possible, around 800-850 ml/g. So, we have to significantly reduce the viscosity

levels. This we do in various ways on the fibre line, including the possibility of introducing an ozone stage, which gives more flexibility to the control of viscosity.

“The viscosity issue is very important as, if it is too high, the dissolvability of the pulp is reduced.”

Andritz DD-Washers in the fibre line are also put to good use in the production of dissolving pulp, Alajoutsijärvi says: “Production rates are higher for kraft pulp and lower when it comes to producing dissolving pulp, so we use DD-Washers more efficiently

by adding more washing stages for dissolving pulp production. For example, there can be two washing stages per DD-Washer for kraft and three for dissolving pulp due to the lower production level. These changes can be flexible according to quality parameters and are carried out by the operators on the run.”

difference is that the drainability is far higher as the dissolving pulp is cooked for longer and does not hold as much water as in the kraft process. Also, adaptations can be made to ensure that the pulp is as clean as possible with minimised traces of metals or foreign particles such as sand.

removes heavy particles such as sand and silicates in a very efficient way.”

drying line

When it comes to pulp drying, much of the drying machine remains unchanged with just some minor adaptions. The main

“The biggest change we need to make in the drying area is to replace the post screening installed for the kraft process with a pure cleaner plant to ensure that silicates and any other heavy impurities are removed,” says Bloder. “The cleaner plant

Cleanliness of the pulp before drying is further ensured by adding a hot shower in the forming section, as well as a final berol surfactant spray. Bloder explains: “In kraft pulp production, we usually add steam to the pulp to heat it up in the forming section. However, when switching to dissolving pulp, we usually add a hot water shower instead, again to make sure that remaining metals such as magnesium and calcium can be removed properly.”

Just before the sheet enters the dryer, a berol spray is added which produces a chemical reaction with the fibre itself. This is important when it comes to the production process of dissolving pulp end user products.

Due to the changes in properties and conditions when operating with dissolving pulp, the risk of creating dust increases. The dryer is designed for minimum dust creation including, for example, the blow boxes, which are from the beginning designed and manufactured for optimum performance and runnability for different types of fibres.

When it comes to the bale finishing, the duo wrapper is usually replaced or bypassed and a so-called ‘paper wrapper’ is installed.

Once the pre-hydrolysis vessel is heated, and the chip feeding and transfer lines are in dissolving mode, the switch from producing kraft pulp to producing top quality dissolving pulp takes place. The time taken during this part of the process is dependent on the grade of dissolving pulp required. “First, we fill up the pre-

hydrolysis vessel with chips while making room in the digester,” says Laakso. “Pre-hydrolysis chip filling is the only time when the digester blowline is closed. After the pre-hydrolysis vessel is full of chips, we then start transferring the chips to the digester. At the same time the digester blowline is opened again. It depends on the digester size, but normally it takes a couple of hours before dissolving pulp comes out of the digester.”

Alajoutsijärvi continues:

“Transition from the cooking plant drying machine takes about 24 hours. It takes some time to fine-tune the process to meet the prime quality properties of the dissolving pulp. However, with the A-ConFlex concept, you can continuously control the reaction degree of the hemicellulose hydrolysis, adjust the viscosity of the pulp, and ensure cleanliness of the pulp to meet the highest criteria of dissolving pulp, such as Lyocell grade which can be produced with the Andritz concept.”

In the drying process, there are only minor adjustments to be carried out. Bloder confirms: “In the pulp drying area, there are only small adjustments, such as adapting the production and basis weight, to be made, which are usually done within the few hours before the dissolving pulp arrives in the pulp drying area.

“This is not a totally easy process, but with the A-ConFlex technology we have developed a solution that works really well,” concludes Alajoutsijärvi. “Most importantly, we can continuously make a change from kraft to dissolving pulp and back, without stopping the process.”

More information from Taneli Alajoutsijärvi by email: taneli. alajoutsijarvi@Andritz.com

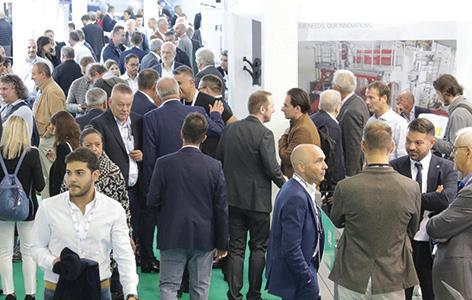

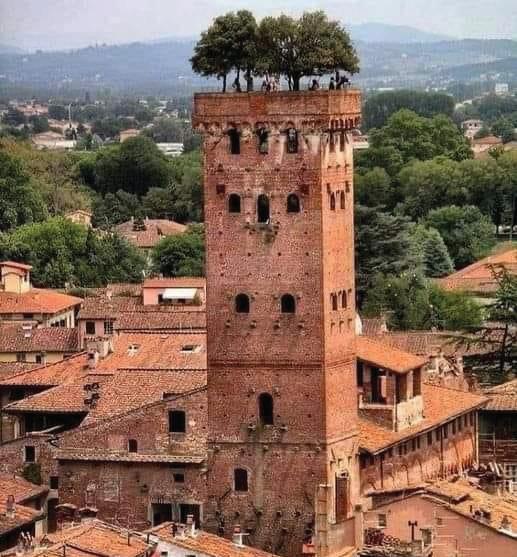

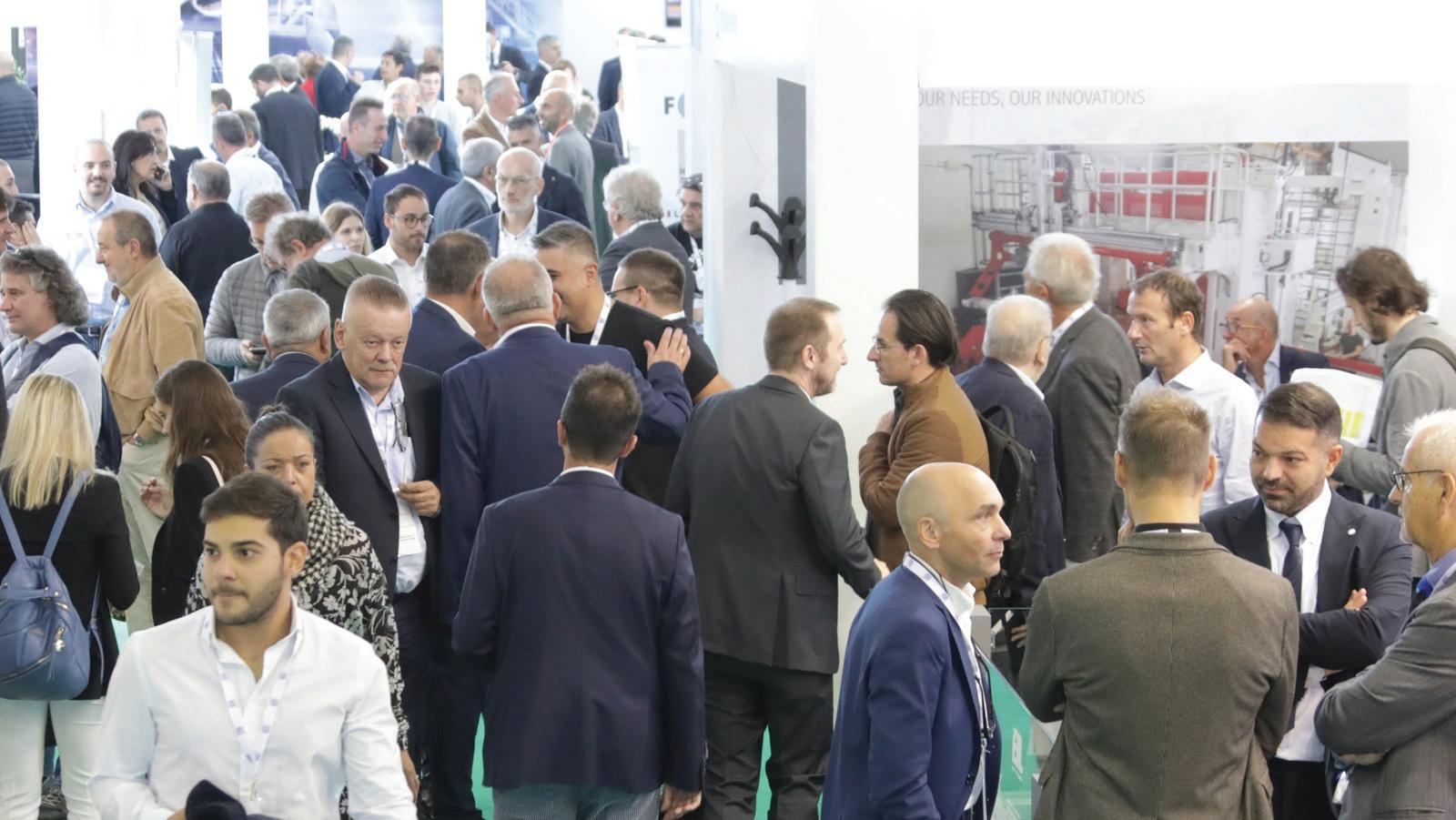

The paper and tissue industries meet at Lucca in Italy in October for the annual MIAC exhibition and conferences. Pulp Paper & Logistics will be there

This year the MIAC show – the premier event in the tissue industry –celebrates 30 years of being held in the centre of the business at Lucca in northern Italy.

See the following pages for the list of exhibitors – this year they number 254 companies at the time of publication – and the floor plan for the show at the Lucca Exhibition Centre from 9 to 11 October, which offers the latest in technologies and services for those working in the paper and cardboard sectors and the tissue manufacturing world.

The show and conferences are free to participating professionals provide that they register. They will find that there will be networking opportunities for discussing the significant changes in the global paper industry.

The tissue industry has shown resilience facing these challenges by responding to customers’ needs by optimising its processes and products. These needs and the industry’s responses will be addressed in the two MIAC Tissue Conference mornings where new technology and innovation that supports the industry will be showcased.

Meeting the demand of a new industry that operates with higher standards of sustainability and lower carbon emissions requires a range of approaches, from energy saving to efficient energy production from renewable sources. In MIAC Energy these new technological approaches will

be explored.

Visiting MIAC 2024 provides a complete overview of the technology and equipment available to the paper industry sector, from the production of paper and cardboard to the converting of tissue.

As a media sponsor Pulp Paper & Logistics will be at Lucca and publisher Vince Maynard will be pleased to meet exhibitors and industry professionals alike. Email Vince at pulppaperlogistics@ virginmedia.com to make an appointment.

Located in central Italy, Tuscany is one of the world’s most popular regions for tourists with beautiful landscapes, artistic heritage and key cities. Places to see after MIAC Exhibition should include a visit to Lucca and other cities such as Pisa, Viareggio, Montecatini Terme, Forte dei Marmi and Florence.

The city of Lucca is one of the major tourist destinations in Italy, and well known worldwide for the unique Walls of Lucca that surround its historical centre.

Another famous symbol of the city of Lucca is the charming Anfiteatro Square built on the ruins of the Roman amphitheatre. Within walking distance there is the medieval Fillungo street, which is the main thoroughfare of the town centre and heart

of the city’s shopping. Other architectural and cultural attractions in Lucca include the Church of San Michele and the famous San Martino Cathedral. Lucca is rightly called ‘The city of 100 churches’.

In Europe, Lucca is the leading area for tissue production (24 per cent); Italy is also one of the leading countries in the corrugated cardboard sector.

The paper industry in Italy has 165 paper mills, producing nine million tons of paper products a year, and employs 20,000 people. Italy is one of the top four producers in Europe with annual sales of almost €7 billion.

Lucca itself is home to a number of leading companies in the paper industry that have total sales of

€2.6 billion with more than 8,000 employees.

How to get to Lucca

MIAC 2023 is located at the Lucca Exhibition Centre, Via della Chiesa XXXII 237, 55100 Lucca, Italy.

To reach the free parking of MIAC Exhibition it is advisable to look on your satnav for ‘Vitricaia street – Lucca’.

Activities covered at MIAC 2024

l Machinery and plant for the production of paper and board

l Components and part of paper machines

l Converting machines for tissue

l Instruments and systems to measure, test, control and manage plants

l Machinery and plants for water treatment

l Plants, machinery and electrical control

l Chemicals, additives and raw materials

l Machinery and plant for drying, filtration and energy recovery

l Laboratory, diagnostics, logistics, services and plant optimisation

Three conferences are offered at MIAC covering tissue in two sessions, paper and board in another and finally on the third day an energy conference. Participation is free to all conference sessions although online pre-registration recommended. A simultaneous translation service is provided.

Conference programme

Session 1.

Wednesday 9 October, MIAC Conference room

14.00: Massimo Rammuni –Assocarta

Opening remarks

14.10: Francesco Pasquini –Lucart

The tissue overview in Italy and Europe

14.30: Denny Di Vita – A.Celli Paper

Smarnip-T – The Shoe Press Excellence

14.50: Mickey Lindevall – Valmet Real results. Reel innovation. New generation Valmet Advantage SoftReel

15.10: Stefan Federling – Andritz Revolutionising tissue production. Advanced automation and digitalization in Brazil’s most autonomous plant

15.30: Sebastiano Goddi –Toscotec Digital technologies for sustainability. Innovative upgrade of TT Brain DCS

15.50: Mika Suojärvi – Trimble Forestry Europe Finding answers to questions by using process data

16.10: Dominik Stempfle – Voith Paper

Successes at Saica with predictive and AI-based monitoring

Session 2.

10.00: Massimo Rammuni –Assocarta Opening remarks

10.10: Christoph Euringer – Afry Tissue industry trends –opportunities and challenges for value creation

10.30: Giovacchino Giurlani –Valmet Tissue Converting The state-of-the-art in tissue converting technology

10.50: Alessandro Viani – Futura

Setting a goal of 1000m/min for the Away-From-Home/ Professional sector

11.10: Alberto Colombo – Omet New boundaries in the world of interfolding

11.30: Andrea Rodolfi – IBS Papertech

Advancing Tissue OOE with AIbased web inspection and unwind automation technology

11.50: Veljko Zlatanović— Stax Technologies

Folded tissue packaging solutions

12.10: Matteo Giardini – Plusline

The end-of-line revolution using Plusline’s solutions

MIAC Energy Conference

Thursday 10 October

14.00-16.30 MIAC conference room

Energy efficiency and decarbonisation paths for the paper industry

The challenges of decarbonisation for the paper sector start from energy saving and efficiency, as well as the use of renewable

sources. During the conference the latest technological advances and the most innovative solutions will be discussed.

14.00: Alessandro Bertoglio –Assocarta Opening remarks

14.10: Arne Kant – Afry

Towards climate neutrality – a plan for the Italian paper industry: a talk with paper mill representatives

14.50: Paolo Della Negra –Valmet

Is a fully electrified mill a utopian idea? It is not!

15.10: Chiara Spinelli and Giuseppe Bonforte – Renovit Technical feasibility and economic benefits in considering the New ETS2

15.30: Erika Sboarina – ANDRITZ

Revolutionizing efficiency. An approach system rebuild delivering major environmental and economic advantages

15.50: Paolo Masiero – Solar Turbines

Digital Twins – the contribution of AI for a more efficient, flexible and sustainable energy future

16.10: Francesco Del Medico –Glayx

Pshave Platform. The optimisation of energy assets in real-time

9.Septembar – Tissue Converting stand B63

ACE Tissue Technologies stand A18

A.Celli Paper stand B88/B108

Acquaflex stand B83

Aermec stand A5

Aerothermic stand B67

Africa Pulp&Paper stand MP

AFT Aikawa Fiber Technologies stand B82

Officine Airaghi stand C21

Albany International stand B107

Amotek stand B37

ANDRITZ stand B29/B43

A. Piovan stand B87/B109

A-SAFE Italia stand C34

AstenJohnson stand C7

Atlas Copco Italia stand B100

Axchem Group stand B91

Azmec stand B89

Babbini stand A21

Baosuo Paper Machinery Manufacture stand B5

Baroncini Nello stand A6

Bellmer stand B23/B49

B.F.G. Rapp.ze Ind.li stand B83

BHM Ingenieure – Engineering & Consulting stand C30

BIM Kemi Sweden stand C23

BM Group Polytec stand C49

Böttcher Italiana stand B56

Bolzoni stand A1

Bretting Manufacturing stand B2/B3/B4

BTG stand B64/B72

Buckman stand B84

Calpeda stand A5

Camozzi stand B100

Cannon Artes stand A20

Cannon Bono Energia stand A20

Carta&Cartiere stand MP

Cascade Italia stand A8

Cellwood Machinery stand B10

Centrax Gas Turbines stand C29

Centro Aria Compressa stand B100

CHT Germany stand C26

Coincart stand A14

Comertek stand B27

CPS Company stand B38

S.A. Giuseppe Cristini stand B83

CTP stand B86

Daxing Paper-Making Machinery stand C39

Henan Dazhi Paper Machinery stand C38

De Iuliis Carlo & Alfonso stand B33/B40

Debem stand A22

Deublin Italiana stand B73

Devasol stand B19

Di Marco stand B65/B71

D.M. Progetti stand C3

Dystar stand B83

E80 Group stand B58

Ecol Studio stand B66

Ecoverde stand B23/B49

Effebi stand A5

Eigenmann & Veronelli stand C6

EIL stand B24/B48

Elettromar stand B14

Elio Cavagna stand B45

El Papel stand MP

emtec Electronic stand C22

Enfasi stand C19

Enrico Toniolo stand B16

EOC Group

stand A2

Eurofins Lamm stand C44

Euroimpianti stand C2

Euroincis stand B21

Eurotronix stand B31

Euwid stand MP

Fan Separator stand B32/B41

Fife-Tidland stand B25

Filtereco stand C18

Firefly stand B98

Fis Impianti stand B111

FMW Förderanlagen stand B82

Food Contact Center stand A24

For-Tech stand C8

FPZ stand B55

F.lli Frediani stand B32/B41

Futura stand B44

Gambini stand B74

Ghetti 3 stand A10

Giotto Technologies stand B5

Giuliani stand B87/B109

Glayx stand C32

GTK Timek Group stand C20

Hannecard Tissue & Paper stand B113

Henkel stand A19

HERGEN – Máquinas e Equipamentos stand C16

Hoerbiger Italiana stand B73

IBS Austria stand B32/B41

ICM Makina Ve Muh. stand B52

IFP Packaging stand C2

IM Converting stand B22

Indexa Italia 2 stand B57

Infinity Machine & Engineering stand B15

Ingersoll Rand stand B9

Inox BF stand A15

Intecom stand C35 ipw stand MP

Italmatic Presse Stampi stand B69

Italprogetti stand B47

Jaeger stand B32/B41

Julia Utensili stand B99

Jungheinrich stand A13

Kadant Group stand B116

Kairos stand B42

Kansan Materials stand C33

Kapp-Chemie stand B23/B49

Kappa stand C14

Kawasaki Gas Turbine stand B32/B41

Kemira stand B79

La Papeterie stand MP

Lario Energy stand B28

L.B.Z. Lavorazioni Meccaniche stand C21

Le Maitre Papetier stand MP

Linde Material Handling Italia stand A3

L&M Pumps stand C25

Lotus stand C4

Maanshan Songlin Doctor Blade&Saw Manufacture stand C13

MacDue stand B117

Maflex stand B12

MAN Energy Solutions stand A26

Mapro International stand C9

Mare stand B18/B53

Mario Cotta – Zincometal Group stand B114

Martin Lohse stand B82

Gruppo Martinelli Industriale stand A5

Maxima stand B85

Metissue

Mevas

Microline

Mingazzini

Mink Bürsten

Movingfluid

Multipack

MWN

Zhejiang Onepaper Smart Equipment stand C37

Oradoc MTK stand B120

Organik Kimya stand C27

Overmade stand B1

Paper Advance stand MP

PaperAsia stand MP

Paper Desk stand MP

Paper Market stand MP

Paper Market.eu stand MP

Paper Middleast stand MP

Paper Technology – PITA stand MP

Paper360 stand MP

Paper First stand MP

Papnews stand MP

Parason Machinery stand B87/B109

PastaePapel stand MP

Paul Wegner stand B82

PCHEM stand C10

PCMC – Paper Converting Machine Company stand B112

Petrofer stand B83

Pfannenberg Italia stand C28

Plastylenia stand B76

PL di Lazzari stand A22

Plusline stand B6

Pneumax stand C24

PNR Italia stand A25

Polimek stand B87/B109

Powermade

stand B1

Proxitalia stand C15

Pulp Paper & Logistics stand MP

Pulsar Engineering stand B39

Foshan New PURUI Industrial Textile stand C41

Renova stand B103

Renovit stand A16

Replus Tissue stand B24/B48

RIF stand B59

Robopac stand B75

Robuschi stand B9

Rolco Europe stand B46

Rotocalco Mediterranea stand B97

Runtech Systems stand B9

Rynek Papierniczy stand MP

SABA Automation stand B95

Sadas stand B122

Sael stand B80

Safem stand C17

Sauer stand B30

Saueressig stand B13

S.B.R. Solutions stand C14

SchäferRolls stand B78

SDF stand B50

Sei Sistemi stand B36

Senning stand B2/B3/B4

Service AMS stand C46

serv-o-tec stand C43

Sicem Saga stand B35

Sicma stand B81

Sinergy-SL stand B80

Slittec stand C45

Solar Turbines stand B20

Solenis stand B23/B49

Shanghai Soontrue Machinery Equipment stand C42

Sorgato stand C36

Sotemapack stand B75

Spares Service & Machinery stand B90

ST Macchine stand B106

STAX Technologies stand B112

Stiavelli Irio stand A4

STILL stand A6

S.TO.R.I. stand B92/B104

Sulzer Pumps stand B32/B41

Svecom-P.E. stand C1

Tamburini stand C5

Tasowheel stand B87/B109

Tau Machines stand B118

Techno Paper stand B82

Technowrapp stand B51

Techpap stand C47

Tec.Mec. stand B17

TC Rolls & Covers stand B101

Tecnofer Ecoimpianti stand C48

Tecno Paper stand B54

Tip95 stand B119

Tissue Tec Sales & Service stand B26

Tissue360 stand MP

TissueMAG stand MP

Tissuenet stand B34

TKM stand B11

IMA TMC stand B68

Toscana Spazzole Industriali stand A12

Toscotec stand B92/B104

Toyota Material Handling Italia stand A11

Trimble stand C11

Tubicom stand B62

Turkiye Kagit Sanayii stand MP

Unimatec stand B121

Vakuo – vacuum pumps and systems stand B110

Valmet stand B93/B102

Ve.Car stand A3

VEGA

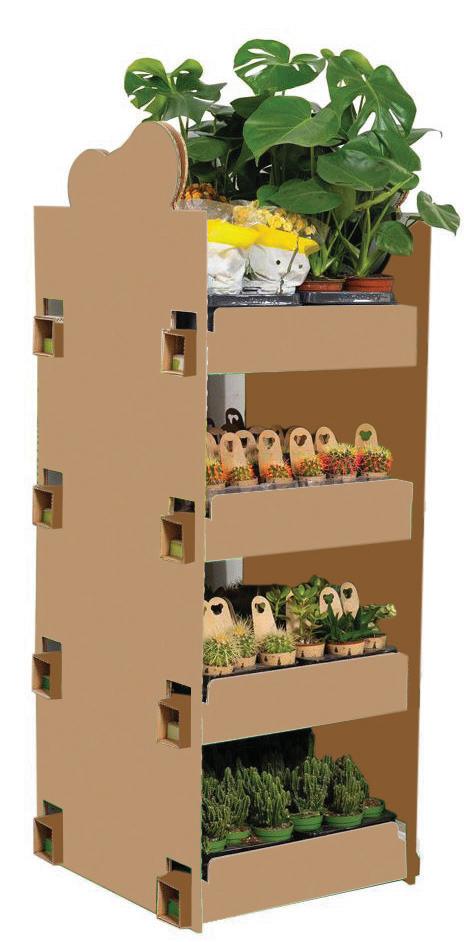

Mondi has been recognised with a number of awards at this year’s Crescents and Stars for Packaging competition in Turkey.

Commenti ng on the successes, Markus Gärtner, chief executi ve of Mondi Corrugated Packaging, said: “We are incredibly proud of our team’s achievements and the recogniti on we have received at the Crescents and Stars for Packaging 2024. These awards are a testament to our relentless pursuit of excellence and our commitment to providing our clients with sustainable, innovati ve packaging soluti ons that not only meet, but exceed their expectati ons.

Mondi’s winners are: Koala Display, Mondi Adana; Corrugated Packaging for Premium Umbrellas, Mondi Ansbach; Doorbell Guard,

Koala Display is a pioneering corrugated packaging solution for potted flowers, the Koala Display is 100 percent recyclable and provides a visually appealing, practical alternative to traditional wooden stands

British packaging and equipment

manufacturer Antalis is offering MetsäBoard Prime FBB EB, a recyclable and compostable barrier board for fresh food packaging.

Using a dispersion barrier, the coated paperboard is a costefficient replacement for singleuse plastic packaging. Easily recyclable in paper or paperboard waste streams. MetsäBoard Prime FBB EB is ideal for premium packaging, especially in food and food service uses, where a medium grease and moisture barrier is needed.

Prime FBB EB is a bright OBAfree board that is lightweight, strong and has excellent printability. It is made without fluorochemicals and optical brighteners (OBA), making it suitable for direct food contact.

MetsäBoard Prime FBB EB is biodegradable and can be composted. The industrial compostability certification complies with DIN EN 13432 and ASTM D6400 standards, while the home compostability certification complies with NF T 51-800 – all DIN CERTCO certificates. It accelerates

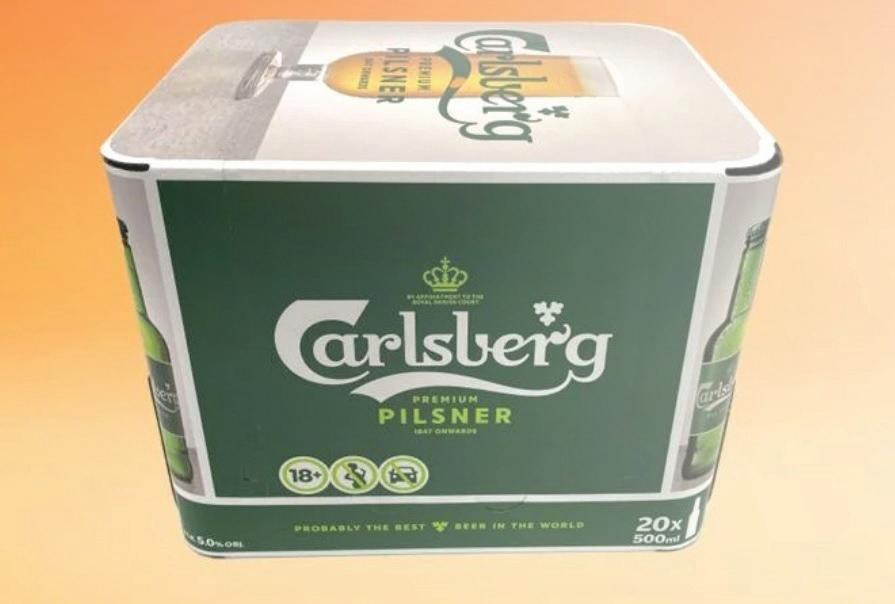

Mondi Bad Rappenau; Eco Cage Paper Basket, Mondi Bupak; Plate Protector, Mondi Eschenbach; TopLock Box, Mondi Gebze; Beer Arena, Mondi Grünburg; Bott le Protector, Mondi İzmit; Display Guard, Mondi Tire; 3-in-1 Separator, Mondi Tire; and Beer Cool Box, Mondi Warsaw.

Operati ons chief at Mondi Corrugated Soluti ons Armand Schoonbrood added: “Each of our award-winning products refl ects our strategy to integrate customer feedback into our design process, ensuring that we address both the practi cal and environmental challenges our clients face. This recogniti on fuels our drive to conti nue innovati ng and leading the industry towards

Designed to resemble a football stadium, ‘Beer Arena’ is distinctive packaging for beer cans and bottles, created for football fans

more sustainable and effecti ve packaging soluti ons.”

The winners will be presented with gold, silver and bronze trophies at the Crescent and Stars for Packaging 2024 awards ceremony to be held in Istanbul later this year.

More informati on from www. mondigroup.com

MetsäBoard Prime FBB EB from Antalis is biodegradable and can be composted

from www. antalis.com

To help drinks brands eliminate plastic from their supply chains, James Cropper has launched tops and bases for inner bottle packaging made from moulded fibre.

Specifically designed for the champagne and whisky market, the tops and bases are made from Colourform. Using bespoke moulds, the tops and bases fit the

bottle shape and are placed within rigid boxes to ensure product protection.

Replacing traditional plastic and foam parts, the fibre products have been developed to support brands in their efforts to meet the European Commission’s proposal to regulate packaging waste, which states that (a) all packing shall be recyclable by 2030 and (b) weight and volume of packing

are reduced to the minimum necessary while still ensuring functionality.

The Colourform inserts help brands reduce, or even eliminate, non-sustainable materials from their supply chain, and are said to be five times lighter than the alternatives, thus helping reduce carbon emissions in transit.

The tops and bases are 100 percent recyclable, with no

dismantling required, making it easy to dispose of the product quickly and correctly with household recycling.

As with all James Cropper Colourform products, the tops and bases are offered in white, black or bespoke shades on request. Customers can also choose to emboss or deboss a logo.

More information from www. jamescropper.com

A partnership between kraft paper maker Mondi and Italy’s CMC Packaging Automation is aiming to meet growing demand for sustainable eCommerce paper and packaging.

By building synergies between CMC’s packaging on-demand technology and Mondi’s expertise in sustainable kraft paper products, the partnership says it is primed to change the market with innovative packaging alternatives.

“We are thrilled to join forces with Mondi, a company that shares our unwavering commitment to sustainability and innovation,” said Luigi Russo, general manager of CMC Packaging Automation.

“This partnership enhances our machine performance and enables us to provide our customers with responsible and sustainable eCommerce packaging solutions that meet the highest performance requirements and standards.

After successful trials with Mondi kraft paper on our machines, we are confident in its exceptional runability, ensuring our customers receive a seamless and efficient solution.”

Mondi’s wide range of paper products (such as Advantage eCom Kraft, EcoVantage eCom Mailer Pro and EcoVantage eCom Mailer) is produced to operate on CMC’s machines.

“It’s an honour to become CMC’s preferred paper partner,” said Silvia Hanzelova, sales

director for speciality kraft paper at Mondi. “Our joint efforts will focus on creating innovative kraft paper solutions that support the circular economy and meet the needs of the eCommerce sector. Together, we can drive significant positive change in the packaging industry, combining our in-depth technical kraft paper knowledge power and our partner CMC’s long history of machine expertise.”

More information from www. cmcsolutions.com

Fibre-based, e-commerce packaging has been developed by DS Smith with an innovative secondary use for Funzy, a manufacturer of modular play sofas for children. The Funzy packaging, intended for online retail, has been designed with a range of secondary uses for consumers. While corrugated cardboard provides a protection for the customer’s products during transportation and storage, and it can also be converted into a shelf and toys for children.

The bottom flap of the packaging is comprised of diecuts for children to assemble into plug-in figures, including rockets and rocking horses, and the craft-friendly material can then be personalised with paint and stickers.

Furthermore, the compact corrugated cardboard packaging can be transformed into a shelf for a child’s bedroom or play area. Overall, the packaging design is intended to create a learning process for both children and adults as they are exposed to the possibilities

provided by this simple concept in upcycling.

Christian Emeka, supply chain manager at Funzy, said: “We are impressed by the initiative, the high-quality advice and creative solutions that the team at DS Smith have given us. We finally have beautiful fibre-based and recyclable packaging, and this embodies our core brand values. Our customers will also be thrilled and after successful test shipping, the DS Smith packaging is ready for series production”. More information from www. dssmith.com

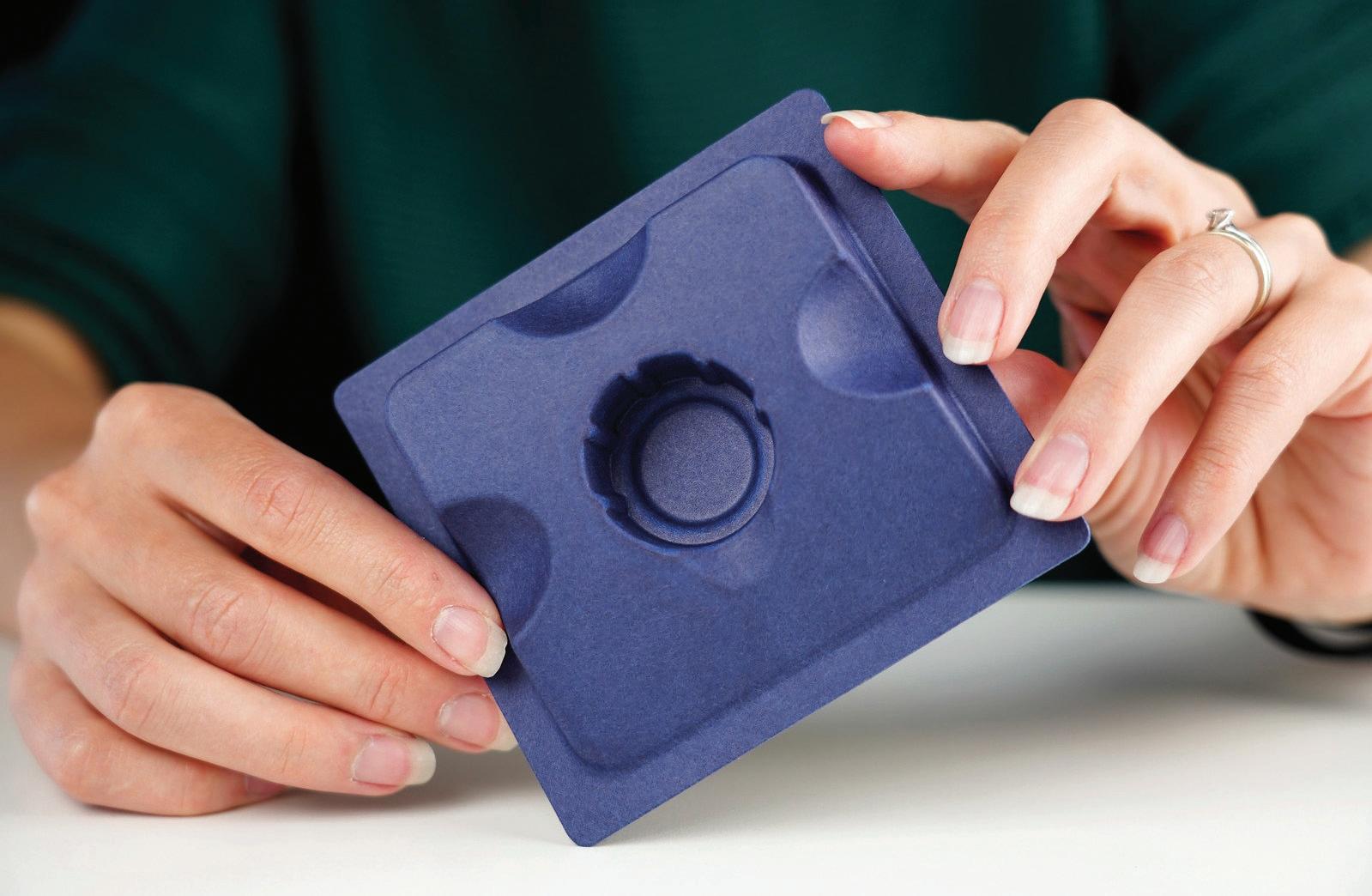

‘Pre-commercialisation’ of Muoto, the three-dimensional wood-based packaging developed by Metsä Spring, has started for a small number of pilot customers.

Suitable for a range of applications Muoto packs can be used for anything from takeaway food to industrial packing. Its fibre composition ensures safety and non-toxicity, while being lightweight, durable and sturdy.

Muoto products have been made at a demo plant operated by the innovations arm of Metsä Group and Valmet at Äänekoski in Finland since May 2022 and if the results of pre-commercial sales are successful, in 2025, Metsä Group will be in a position to evaluate investing in a commercial manufacturing plant.

“We have been extremely pleased with the early results of Muoto. In wood-based product development, it’s quite rare to have a product ready after only a few years of development. Designed for durability and safety,

Muoto is ideal for a wide range of uses, from serving dishes to food containers, so we are ready to expand co-operation with pilot customers,” said Jarkko Tuominen, vice-president of projects at Metsä Spring.

A key benefits of Muoto production process is that it removes many of the supply chain steps that are required for other types of packaging. In the Muoto process, pulp slurry is fed into a mould, formed, dried and cut, thereby making products for shipping directly

to customers, ready to be used in food packaging. The process also requires a minimal amount of water and other resources on one production line; it is largely automated and uses machine learning in multiple touchpoints, making it safe and reliable.

“By offering early access, we aim to gather valuable feedback and insights from customers to further refine our product. Together, we can explore new applications based on the market and customer needs,” explained Tuominen.

Due to the EU directive on single-use plastics, food packaging manufacturers in Europe are searching for affordable and more sustainable alternatives to current packaging solutions. In addition, the European Commission’s proposal for the Packaging and Packaging Waste Regulation (PPWR), when accepted, will force companies to promote circularity and reduce packaging’s environmental impact.

“At Metsä Group, we are constantly looking into potential innovations that could bring more wood-based alternatives into everyday products, thus replacing, among others, various fossil-based products. With Muoto, we can offer an alternative to the plasticdominated market, proving that functionality, responsibility, profitability and design can go hand-in-hand,” added Niklas von Weymarn, chief executive of Metsä Spring.

More information from www. metsaspring.com

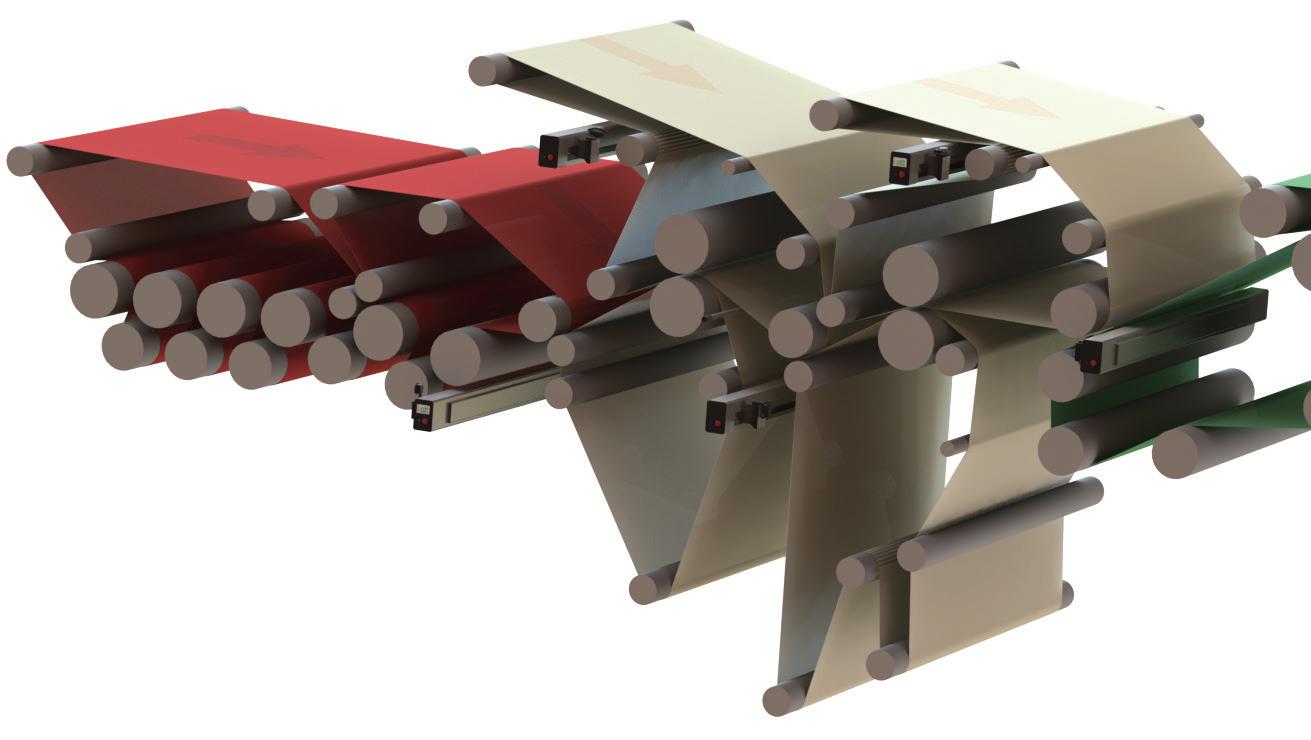

Cardboard and paper packaging maker DS Smith is developing a corrugated board collator for beverage and food cans that it says will offer better recycling and security properties than other secondary packaging options. The product is being developed at the company’s research and development facility at Redditch in the UK.