When it comes to the electric power that keeps your critical operations running strong, there is no other option.

With a full power node range of dependable performance, lower total cost of ownership, and expert global support, Perkins electric power solutions help you power ON with confidence.

Find out more at perkins.com/ep Together, we power ahead.

Publisher/Sales DIrector

Neb Saric neb@wipmagazines.com

Publishing & Events Director Richard Teasdale richard@wipmagazines.com

Managing Editor

Aidan Turnbull aidan@wipmagazines.com

Accounts Manager Alison Williams accounts@wipmagazines.com

Sales & Marketing Manager

Sarah Hallows sarah@wipmagazines.com

Far East Sales

Bob Liu Shanghai, China bob.liu@ronco.com.cn

US Sales & Subscriptions

Jelena Milojevic power@wipmagazines.com

Austrian & German Agent Mario Dobresko power@wipmagazines.com

Power Media International Group, The Courtyard, 30 Worthing Road, Horsham, West Sussex, RH12 1SL, UK

Tel: +44 (0) 1403 888019

www.powermediagroup.co.uk © Worldwide Independent Power (ISSN 1468 7100)

The US Government is proposing new limits on greenhouse gas emissions for all coal and gas-fired power plants as part of move to limit carbon pollution from the USA’s second-largest contributor to climate change.

The introduction of a new rule by the US Environmental Protection Agency would make it mandatory for power plants to capture all emissions using filter technology.

The proposed regulation is the first time the federal government has seriously capped carbon-dioxide emissions from power plants, which generate about 25% of U.S. greenhouse gas pollution, second only to the transport sector.

EPA Administrator Michael Regan denied that the power plant rule - or any other regulation - was aimed at shutting down the coal fleet even though he acknowledged: “We will see some coal retirements.”

About 20% of US electricity is produced by using coal, a figure re- duced from about 45% in 2010. Around 40% of US power is generated using natural gas. The remainder comes from renewables such as wind, solar and hydropower and from nuclear power.

The rule would prevent the release of up to 617 million metric tons of carbon-dioxide up to 2042, equivalent to annual emissions of 137 million passenger vehicles, the EPA have revealed.

Coal and gas-fired power plants would have to cut or capture nearly all their carbon-dioxide emissions by 2038 under the terms of the rule, explains the EPA. The power plant rule is one of at least a half-dozen EPA rules which have been designed to limit power plant emissions and wastewater treatment. The EPA rule establishes limits on carbon-dioxide pollution which plant operators have to meet and does not make it compulsory to capture and store carbon emissions. Inevitably, some natural gas plants could start blending gas with another fuel source such as hydrogen, which does not emit carbon.

From 2023-2042 the EPA estimates the net climate and health benefits of the new standards will be worth up to U$85 billion. The technology-based standards EPA is proposing include:

* Strengthening the current New Source Performance Standards (NSPS) for newly-built fossil fuel-fired stationary combustion turbines (generally natural gas-fired)

* Establishing emission guidelines for states to follow in limiting carbon pollution from existing fossil fuel-fired steam generating EGUs (including coal, oil and natural gas-fired units)

* Establishing emission guidelines for large, frequently used existing fossil fuel-fired stationary combustion turbines (generally natural gas-fired).

The EPA believes the proposed standards for existing gas-fired plants and the third phase of the NSPS could achieve up to 407 million metric tons of carbon emission reductions.

AIDAN TURNBULL Managing Editor

AIDAN TURNBULL Managing Editor

“THE US EPA’S NEW RULE WILL HAVE SERIOUS REPERCUSSIONS FOR GAS AND COAL POWER.”

NEW LIMITS ON GREENHOUSE GAS EMISSIONS COULD SHUT DOWN GAS & COAL-FIRED POWER PLANTS

The global diesel generator market size was valued at US$15.16 billion in 2022 and is expected to expand at a compound annual growth rate (CAGR) of 9.4% from 2023 to 2030, reports Grand View Research. Increasing demand for energy globally far outstrips the supply. Factors such as continuous population growth, infrastructure development, and rapid industrialisation in emerging economies are pacing the power demand. Diesel generators still offer companies numerous advantages in 2023.

UK’S LARGEST PAPER MILL HAS A NEW CHP PLANT

The DS Smith plant at DS Smith’s paper mill in Kent, UK, is the largest mill for recycled papers in the UK. Work on the CHP plant began in 2019 with E.ON financing, building and operating the plant. The new CHP plant, which produced its first energy in 2022, has been designed to set the standard in efficiency, sustainability, and reliability.

OPTIMAL MUSHROOM GROWTH THANKS TO GAS-POWERED GENSETS

A CHP plant with an MWM gas genset ensures high mushroom yields all year round at moderate energy costs for the mushroom producer Hajduk Group Sp.z o.o. in Poland. The cogeneration plant with an MWM TCG 2020 V16 gas genset was supplied by the official MWM distributor in Poland, Centrum Elektroniki Stosowanej CES Sp. z o.o..

THE CHALLENGE OF RENEWABLES-BASED ENERGY GENERATION

Lucy Plant, Manager Strategic Partnerships, Energy Solutions at Enel X looks at the transition to renewables-based energy generation presents new challenges for both grid operators and consumers. The intermittent nature of renewable energy generation, which is largely reliant on the weather, calls for flexibility in both demand and generation to balance the grid where the energy mix contains a greater proportion of renewables. . Large energy users like data centres are continuing to adapt to this energy transition.

MICROTURBINES FOR A WEST TEXAS ENERGY PRODUCER

Lone Star Power Solutions, the southern U.S. distributor for Capstone Green Energy Corporation, has been contracted to provide an additional 800-kW C800S Signature Series microturbine to a large West Texas energy company. The contract follows a 3.6 MW Energy-as-a-Service (EaaS) contract with the producer earlier in 2023. According to Capstone, its EaaS solution was selected due to its record of reliability in remote oil and gas fields globally and its extremely low emissions profile.

HYBRID SELF-GENERATION PLANT IN ITALY

KOHLER Engines and Grastim, a JV specializing in high-efficiency technology solutions, have signed an agreement for a new hybrid self-generation plant at the historic Reggio Emilia facility in Italy. The project includes a 2 MW trigeneration plant and an 860 kW photovoltaic park integrated with each other, as well as the possibility of also being powered by hydrogen (hydrogen ready).

DIESEL GENSET SUPPLIED TO A TELECOMS APPLICATION IN MESTRE, ITALY

An emergency diesel generator set has been installed at one of the most important telecommunications nodes of North East Italy. The genset is a Model GS2000BAD/CF nominal power 1600 kWe PRP ISO8528 with a Baudouin engine 20M33SERIES. The engine features a cast iron cylinder block with inspection door per cylinder,

HYDROGEN-READY ENGINE FOR A 1MW PLANT

A 1 MWe combined heat and power plant (CHP) will run on a Jenbacher engine fed by hydrogen produced 100% from solar photovoltaics.

PAN-LEDI d.o.o. (PAN-LEDI) has selected a Jenbacher J420 engine for the project in Nova Pazova, Serbia. The contract calls for the delivery of a containerized CHP unit that will generate about 1 MWe. The electricity will be used by PAN-LEDI for its operations.

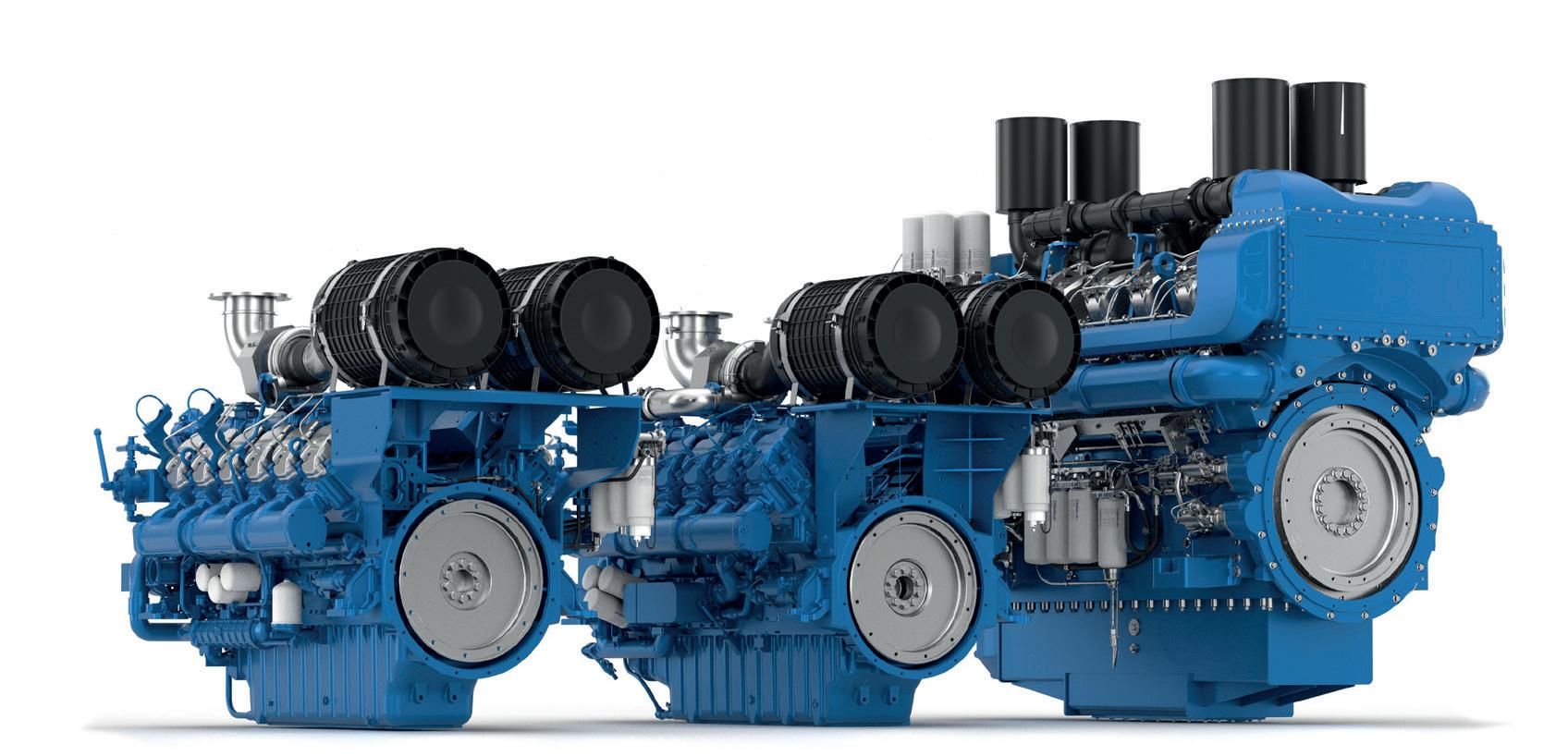

THE NEW 5000 SERIES ENGINES

Optimised turbochargers help deliver outstanding load acceptance to help the new 5000 Series meet ISO 8528-5 G2 and G3 standards. Additionally, the 5000 Series can accept NFPA 100% block load, enabling it to achieve full recovery after the first load step within 13 seconds. The 5000 Series offers high power density in a smaller footprint, delivering optimised fuel and oil consumption.

The latest V-Type alternator has been developed in response to changing market needs and has been built for optimum performance and reliability in harsh marine environments. Having undergone rigorous testing, the V-Type is designed to deliver optimal uptime, so you can be sure of reliable power generation, regardless of the operational conditions and compliant with all marine classifications. With over 75 years in the power generation market we pride ourselves on being the Power from Within the systems and generator sets that our customers produce.

Choose wisely… Choose the V-Type.

The world’s largest independent producer of alternators 1-5,000kVA

Location: The Mere Golf & Spa Club, Knutsford, Cheshire, UK Visitors/Delegates are Free to attend

Opening Time: 10.30-16.30 | Complimentary Pastries/Coffee/Tea & Lunch.

Conference Times: 11:30-15:30

Fifty 250 kW gensets have been purchased to support the UK grid. The power system they will support has been designed so that when one genset is taken offline the other 49 gensets automatically increase output by 2% or 5kW each to maintain an export value of 12.5MW.

The Medium Range 225-938 kVA generator sets can be powered either by an EU Stage IIIa Emissions compliant engine for emissions sensitive territories or a fueloptimised engine where local restrictions are more lenient.

The sets incorporate ComAp InteliGen NT BaseBox. This is a controller for single or multiple diesel gensets operating in stand-by or parallel mode. Intended primarily for switchgear applications, this controller will ensure secure remote monitoring of critical infrastructure installations such as data centres, hospitals or banks. The InteliGen product family has become an industry standard for smart control of single or multiple gensets operating in standby or parallel mode. The units ensure stable power on sites where the main grid infrastructure may suffer a potential failure.

A DE715GC Genset (715 kVA, 50 Hz, 400 V, Standby rating) genset supplied by FINANZAUTO has been installed at a medical building in Madrid (Spain). This building will be finished at the end of 2023.

The GC genset range has been designed primarily for standby power plants offering simplicity and reliability. Producing reliable power 715 kVA at 50 Hz, the DE715 GC generator set is powered by a C15 diesel engine designed to ISO 8528-5 transient response requirements.

SPEAKERS

11.45 – 12.15

Romain Mocaer - 2023-2024 European Generator Market: Impact of the gas crisis and Ukraini-an conflict on the generator market.

12.20 – 12.50

Paul Smethurst – DATA CENTRES - “Powering improved Data centre operation and effi-ciency”. Paul Smethurst takes an abstract look into why gensets are key to operating the IT load and more importantly how to prevent losing the critical load being a total Data Centre disaster.

13.00 – 13.30

Clinton Noble, Senior Sales Manager – Finning – Large Electric Power Sustainability in the power generation industry - A look at the varying options there are to combat the market’s restraints, demand and growth - this includes a look at alternative fuels, what’s possible now and likely options in the future.

13.30 – 14.20

Complimentary Lunch

14.20 – 14:50

John Kerr – Durr Universal – An introduction to acoustics on stationary power generation applications. • What we hear and how sound is measured. • The acoustical characteristics of the sound and how they relate to the applications. • Topography and the effects on sound. • How silencers work and how they are sized.

14:55 – 15:25

Harry Douthwaite – ide Systems Ltd – Looking at Energy Management and Control Tools

15:30 Event Finishes

Provisional speakers: Johnny Rodgers – RODEng Consulting Abird (HSS Rentals)

WHY NOT BE THERE WITH TABLE? – Limited table space to 7 tables. COST of attending the conference with Table: Table tops cost = £600.00 – Limited availability of 7 tables (4 sold) Sponsorship available on request. To reserve your space as visitor/delegate/table top reservation please email your details so we can reserve your delegate/table space/Sponsorship. Email: power@wipmagazines.com

RESERVE NOW

Sponsorship partners: WIP, Power Media International Group, UK Power News, Euro Power News, Power Media International Group Ltd

Deep Sea Electronics Ltd (Hunmanby, UK) and MOTORTECH GmbH (Celle, Germany) have announced the creation of a new Controls and Automation Business Group.

Deep Sea Electronics design, manufacture and supply products into the diesel engine and generator market and MOTORTECH GmbH design, manufacture and supply products into the gas engine and generator market.

The similarities between both businesses and products are extremely complementary in nature and provide the market with access to a range of cutting-edge technology platforms. The formation of the business group delivers a combined workforce of 500+ employees and a total revenue of US$125 million. Both companies will remain separate legal entities, aligning strategically on future growth initiatives.

Rolls-Royce plans to produce green hydrogen at its business unit Rolls-Royce Power Systems’ headquarters in Friedrichshafen, Germany, within the next few years.

The company is keen to test its mtu hydrogen engines and fuel cell systems on its test benches. The project is being supported by the Baden-Württemberg Ministry for the Environment, Climate and Energy Management with a €4.25 million subsidy. The H2Infrastructure funding covers the production of green hydrogen by means of innovative PEM electrolysis, including the necessary infrastructure and the construction of test benches.

DSE’s core market is diesel generators and MOTORTECHs focuses on gas generators. Both companies share similar customer bases to drive continued business growth. DSE and MOTORTECH are both directly involved in the power generation control business and have a wide range of supporting technologies, explained a spokesman.

For privacy reasons, a data centre customer required local, secure data storage from ZWART TECHNIEK and the Xubus Node modular data solutions was ultimately selected as the preferred solution.

ZWART delivered, installed and commissioned the Xubus Node at the customer site and - today - continues to provide a 24/7 support service to ensure uninterrupted performance.

A spokesman commented: “We worked together with our partner Delta to provide our customer with a turnkey data centre solution which delivers the flexibility and scalability that the company required.”

The Xubus Node is an all-in-one, prefabricated data centre (18kW, 35kW, 50kW, 70kW and 90kW) and has been designed ‘to suit an emerging 5G infrastructure intent on opening new opportunities for enterprises and institutions, offering critical services to customers and the public’.

Delta Xubus Node solutions are said to the perfect answer for supporting 5G needs, offering turnkey data centres available in five different IT load configurations from 18 to 90kW, reports the company. It is an all integrated, plug-and-play solution for rapid deployment with excellent reliability and flexibility – ready to deliver on the promise of 5G. The Xubus Node is a modular data centre which is available in a variety of configurations from 18 to 90kW. It is available on short or long-term lease and purchase terms and can be installed & supported 24/7, 365-days by ZWART. A Tier III certified data centre is concurrently maintainable with redundant components as a key differentiator, with redundant distribution paths to serve critical environments.

An investment of US$6 million up to 2025 will enable power systems supplier Kohler Energy to upgrade its production site in Brest, Brittany. The plan is to meet increasing demand for generators in the data centre market.

The 42,800 sq m plant offers expanded manufacturing and logistics facilities and upgraded dock infrastructure to support higher-capacity shipment by sea.

Kohler manufactures around 17,000 generators per year in Brest, with power nodes ranging from 7.5 to 4,500 kVA.

The investment will allow it to increase the number of large generators it produces per annum, while introducing a new range of walk-in enclosures.

“The Brest plant

provides a one-stop-shop approach to generator supply from design and manufacture to testing and inspection, all under one roof,” said a spokesman.

The first phase involved the enlargement of main docks to accommodate larger generator designs.

The second phase involved expanding manufacturing, test, and logistics warehouse floor space to support the growth in leading markets.

Expansion at the site has allowed Kohler to introduce a new range of walk-in enclosures to house >4,000 kW generators in outdoor environments.

EXPANSION AND IMPROVEMENT OF GENSET MANUFACTURING SITE LOCATED IN BREST, FRANCE

MORE GREEN HYDROGEN WILL SOON BE PRODUCED IN GERMANY

DTGen has been appointed to provide an emergency power solution at Datavita’s new data centre located at 177 Bothwell Street in Glasgow’s city centre. The company has supplied two FG Wilson 2.5MVA generators complete with a control system to cover switching between both dual mains supplies and the back-up synchronising generators. The generators are located high in the city centre skyline on the building rooftop in bespoke acoustic enclosures. Each generator runs off its own day tank with an auto fuel fill system in place from ground floor bulk storage tanks.

The new data centre is a highly resilient, purpose-built facility, and of tier III design, with 130 racks worth of space. It is said to offer excellent fibre connectivity and highly efficient cooling using green energy.

A 600 kW diesel genset is now operating at the Sydney Harbour West wastewater treatment plant. Delivered by SANSOM in late 2022, the 600REOZVB, 60 Hz Industrial Diesel Generator has a Standby Range (kW/kVA) 485-600/606-750 and a Prime Range (kW/ kVA) of 485-555/606-694.

It has a Frequency of 60 Hz and a Speed of 1800 RPM. The engine is a Volvo with an Alternator Type Brushless, Permanent-Magnet Pilot Exciter.

The T60 Hz generator set meets NFPA 110, Level 1, when equipped with the necessary accessories and installed per NFPA standards. The generator set accepts rated load in one step. There is a speciallydesigned controller for guaranteed system integration and remote communication.

A low coolant level shutdown feature prevents overheating while an integral vibration isolation eliminates the need for under-unit vibration spring isolators. An electronic, isochronous governor delivers precise frequency regulation. The set also features multiple circuit breaker configurations and there is a 186 mph wind load rating on a robust aluminum enclosure. A pilotexcited, permanent-magnet (PM) alternator provides the set with key, superior short-circuit capabilities.

CMP Products, leading manufacturer of cable glands, cleats and accessories, has been awarded ISO 50001-energy management certification by Bureau Veritas, demonstrating the company’s commitment to responsible energy management and efficiency.

To achieve ISO 50001 certification, CMP was required to establish its processes, procedures and set benchmarks to ensure efficient energy usage and to implement continuous improvement when it comes to energy management.

Three third parties audited CMP over a five-day period, who visited the company’s manufacturing headquarters based in Cramlington, UK to analyse all the documentation and processes relating to energy management, speaking with various team members and witnessing processes in practice. The ISO 50001 certification now forms part of CMP’s integrated management system, which covers ISO 9001, ISO 14001 and ISO 45001.

Michael Walton, Health Safety and Environmental Manager, said: “CMP is committed to achieving net-zero by 2040, and this certification forms an important part to demonstrate that we are making progress towards achieving this goal, through responsible energy management.

“As part of this certification, we must continue to monitor and develop our energy management with third party audits on a yearly basis to ensure we continue to adhere to the standards.”

Gravity energy storage can form part of ‘virtual power plants’ – helping deliver stable power as many of Europe’s top countries strive to decarbonise their electricity grids.

Underground energy storage specialists

Gravitricity have signed a collaboration agreement with Czech electricity flexibility aggregator Nano Energies to develop commercial routes to market for their gravity storage technology.

Gravitricity - the Edinburgh storage firm - has unveiled plans to transform the former Darkov deep mine in the Czech Republic into a massive gravity energy store – which could be a pathfinder for projects Europe-wide.

Gravitricity plans to store energy by lowering and raising a single massive weight suspended in the Darkov mine shaft.

Stanislav Chvála, CEO of Nano Energies, explains: “Gravitricity’s technology is able to respond to grid fluctuations very quickly and flexibly in terms of megawatt volume. We could thus involve them in our virtual power plants, which help balance the grid in the way that nowadays primarily coal and gas-fired power plants are able to do. He says: “It is a long-life technology, well suited to integration with existing grid infrastructure. It can cycle rapidly from charge to discharge without any loss of performance over many years, and it delivers extremely fast response times of less than a second.

GRAVITY ENERGY STORAGE FOR A DECARBONISED GRID COULD HELP THE NATIONS OF EUROPE

CABLE GLAND MANUFACTURER IS AWARDED ISO 50001 ENERGY MANAGEMENT CERTIFICATION BY BUREAU VERITAS

GE and RWE have just celebrated the inauguration of the Biblis power plant, which began operation for Germany’s transmission system operators in early March 2023.

The plant uses 11 units of GE’s flexible LM2500XPRESS aeroderivative gas turbine technology and GE’s advanced gas-insulated-substation (GIS) equipment.

The 300 megawatt (MW) plant is a so-called special grid-technical equipment located in Biblis, a municipality in the Southern Hesse region of Germany, and will only operate when needed – aiming to deliver power in under 30 minutes upon request from a transmission system operator - to help ensure continual grid stability.

Grid flexibility is important to the German government which is committed to achieving 80% of renewable energy generation for the country’s electricity mix before the end of the decade after exiting nuclear and ideally phasing out coal power generation. Dispatchable gas power – gradually decarbonised through hydrogen or carbon capture solutions – shall cover the remaining 20% of power generation.

“With the plant in Biblis, we can feed in electricity quickly and flexibly at the request of the transmission grid operators and thus help to stabilise the grid in southern Hesse. With this project we’re adopting GE’s flexible and modularly designed aeroderivative gas technology and advanced protection, control, monitoring, and diagnostic technologies and software to monitor the safe condition of the plant”, said Roger Miesen, CEO of RWE Generation.

GE’s turbines are connected to the grid via a 380 kV high-voltage substation at the Biblis site. The T168 gas-insulated-substation (GIS), the first outdoor GIS in Germany, can help address the challenges of networks up to 550 kV for all applications including power generation, transmission, and heavy industry.

“Countries like Germany are committed to working on grid digitization and modernisation to make grids smarter and well positioned to meet growing demands by adding advanced distribution networks, hybrid systems, energy storage and grid stability power plants,” said Joseph Anis, President & CEO, Europe, Middle East & Africa, GE Gas Power.

“GE’s aeroderivative fleet and grid solutions will provide RWE with a reliable energy supply, support Germany’s grid reserve, and help manage the complex grid requirements of tomorrow’s renewables-heavy grid.”

Apex Clean Energy is developing and building two new battery storage projects in Texas, USA, which will feature Powin hardware and software.

Angelo Storage, co-located with the 195 MW Angelo Solar Project, and Great Kiskadee Storage are designed to each deliver 100 MW/200 MWh of capacity to the Texas grid with a 2-hour battery duration.

The battery systems will use Powin’s StackOS platform to provide energy arbitrage and ancillary grid services to the ERCOT market.

The Powin Stack™ and StackOS™ energy storage platform is a vertically integrated and purpose-built solution designed for the demands of utility-scale, commercial and industrial, and microgrid applications. Powin’s Stack hardware also features a modular architecture and streamlined installation process allowing for efficient scaling from MWhs to GWh scale.

The storage systems will absorb excess solar or wind generation when demand is low and discharge when energy usage is high, ensuring adequate power supply while allowing the grid to operate more efficiently and flexibly. The Angelo and Great Kiskadee storage projects are expected to begin commercial operations in late 2023 and 2024. Powin’s Centipede battery energy storage platform is the company’s first fully modular design, complete with pre-integrated segments containing batteries, thermal management equipment, and safety systems.

Compared to previous generations of Powin’s Stack™ products and smart enclosures, Centipede requires 50% less time to procure and deploy and 30% less space onsite, while also reducing lifecycle costs and providing superior reliability.

The Stack750E will be the first modular Stack purpose-built for the Centipede platform and is well-suited for 2-hour to 4-hour applications, including solar and storage use cases. Building on Powin’s core technology, Centipede’s simplified design offers enhanced scalability, supporting more than 200 MWh-AC per acre and a simple augmentation strategy. Centipede is said to accommodate a wide range of system configurations and energy specifications.

Exergy International, a specialist in Organic Rankine Cycle based plants, has signed a contract with Hez Enerji for the supply of a 24 MWe geothermal binary plant, the Bilecik Hez Morali JES-1 unit.

The new plant will draw energy from a geothermal field in Aydin, Turkey. The ORC power plant is planned to be delivered in early 2024, with commercial energy production slated for 2024.

Hez Enerji is an energy company with 9 geothermal licence areas under development in the Aydin, Manisa, Denizli, Bilecik and Nigde regions. The geothermal potential of its licence areas that has been estimated at around 300 MWe of total capacity. Exergy will be responsible for the design, engineering and supply of the power plant. The design of the binary system consists of a cycle utilising two radial outflow turbines (ROT) of 12 MWe each and an air-cooled condensing system.

Researchers in China have proposed the building of a super grid designed to connect northeast Asia’s major economies and make renewable energy as cheap as coal. China, Russia, Mongolia, South Korea, North Korea and Japan would all be connected. The region currently consumes a third of the world’s electricity, with demand set to double by 2050.

Zhang Ning, professor of electrical engineering at Tsinghua University, has said that the grid could “significantly increase the proportion of clean energy in electric power supply systems.”

In 2018, a study by Kepco, the state energy utility of South Korea, estimated that it would cost around US$6-$7bn to install the transmission lines required. The main interconnector - Kwepco proposed - would be a US$2.6bn, 370km undersea power line linking the Chinese port of Weihai with Incheon in Korea. Another US$2.1bn would be needed to link Vladivostok to North Korea by some 1,000km of landlines. The transmission lines would be accompanied by battery storage facilities to smooth fluctuations in power output.

With the exception of North Korea, the five nations that would benefit from the grid have signed a number of agreements in principle in recent years.

Many experts see this as an opportunity to link fossil-fueldependent countries such as Japan and South Korea with relatively cheap wind energy from Mongolia, solar power from the Gobi Desert and hydropower from Russia.

Gateway will be humanity’s first space station in lunar orbit and serve as an essential element of NASA’s Artemis missions. As astronauts live and work on Gateway to enable sustained exploration and research in deep space, their efforts will be made possible by the Power and Propulsion Element (PPE).

PPE will provide Gateway with power and allow it to maintain its unique orbit around the Moon. PPE will generate 60kW of electrical power, which will power Gateway’s subsystems and its solar electric propulsion (SEP) system to keep the station in orbit around the Moon, reports NASA.

A spokesman commented: “PPE leverages technology advancements from past successful electric propulsion missions – such as the recent DART mission – to help NASA push the boundaries of what’s possible in deep space.

“PPE’s SEP system provides greater fuel economy, enabling lower-cost missions which can carry more cargo. This is because the spacecraft’s propellent mass can be reduced up to 90% by being augmented with energy from the Sun.”

Once deployed, PPE’s two large, yoga-mat-like roll-out solar arrays – which are approximately the size of a football field’s endzone – will generate power to ionize and accelerate Xenon gas, using a tenth of the propellant required by conventional chemical propulsion systems. As the powerhouse of Gateway, the PPE will also provide capabilities for high-rate communications between the station, the lunar surface, and Earth.

ABB Energy Industries is embarking on an ambitious venture in collaboration with Lhyfe and Skyborn to bring to life one of the world’s most impressive renewable hydrogen projects: SoutH2Port.

This nmew project aims to combine the expertise of Lhyfe, a pioneer in renewable hydrogen production, and Skyborn, a global leader in renewable energy.

The location for the new hydrogen production plant, operated by Lhyfe and Skyborn, has been chosen as the municipality of Söderhamn in Sweden. This is conveniently connected to Skyborn’s 1 GW offshore wind farm at Storgrundet.

Once fully operational, this plant is projected to yield approximately 240 tons of hydrogen per day, boasting an impressive installed capacity of 600 MW. This accomplishment will establish it as one of

Europe’s largest suppliers of renewable hydrogen.

Brandon Spencer, President of ABB Energy Industries, emphasised the significance of this collaboration. He said: “This partnership aligns perfectly with our strategic goals in both the hydrogen and offshore wind sectors.

“To expedite the energy transition, it is vital to establish seamless supply chains through efficient collaborations like these. Hydrogen plays a pivotal role in achieving global climate goals, particularly in the decarbonization of industrial and transportation sectors.”

SOUTH2PORT WILL BECOME ONE OF THE WORLD’S MOST AMBITIOUS HYDROGEN PROJECTS

PPE WILL PROVIDE POWER FOR GATEWAYSOON TO BE BE BUILT IN LUNAR ORBIT

The global diesel generator market size was valued at US$15.16 billion in 2022 and is expected to expand at a compound annual growth rate (CAGR) of 9.4% from 2023 to 2030, reports Grand View Research.

Increasing demand for energy globally far outstrips the supply. Factors such as continuous population growth, infrastructure development, and rapid industrialisation in emerging economies are pacing the power demand.

Diesel generators have numerous advantages such as low operating costs and better fuel efficiency. Thus, they are much more popular in developing regions, especially in the Asia Pacific region.

Along with its advantages, it had many other drawbacks which include noise pollution, and emissions of hazardous gases.

The World Nuclear Association has projected that the electricity requirement is expected to double the current consumption. According to the U.S. Department of Energy, solar energy will be the most abundant energy source available.

Significant growth in the economies of major developing nations such as India, Brazil, and others is expected by 2050.

India is expected to grow from being the third largest to the second largest economy in the world, only after China in terms of GDP at PPP (purchase power parity). Countries such as Brazil, India, and South Africa are already suffering due to low power supply. Emerging economies are expected to account for 65% of the global economy.

The market in the U.S. is anticipated to witness substantial growth owing to rising costs of power outages across several IT-enabled service firms and data centers along with growing consumer awareness toward the requirement for reliable emergency power supply. In addition, the market is also driven by the rising vulnerability of grid power stations to disasters caused by changing weather conditions across the region.

Solution providers across the diesel generator market are primarily responsible for generator system manufacturing, installation, maintenance, and repair. Generator dealers or electrical contractors establish product supply and maintenance contracts with end-market consumers present across commercial places, residential places, and small-size companies using generators as emergency power backup systems. Moreover, companies also assign an in-house monitoring engineer to supervise a large number of

THE MARKET IN THE U.S. IS ANTICIPATED TO WITNESS SUBSTANTIAL GROWTH OWING TO RISING COSTS OF POWER

OUTAGES ACROSS IT-ENABLED SERVICE FIRMS AND DATA CENTRES.

generators in industrial-scale operations.

Stringent government regulations regarding the reduction of harmful carbon emissions are expected to boost the penetration of gas-based generators over diesel generators.

This trend is anticipated to restrict the market demand for diesel generators across all the end-use sectors.

However, low operating costs and low initial investment are among the key factors sustaining the current requirement for diesel generator sets.

The low power generator segment accounted for a significant revenue share of 44.0% in 2022 owing to the presence of a wide application base in commercial and residential sectors.

Generators with a capacity below 80 kW are used as power backup solutions in residential homes to power devices such as water pumps, water purifiers, AC units, geysers, and others.

Furthermore, the low cost of these generators is expected to play a crucial role in boosting product demand over the forecast years.

The high power generator segment is expected to attain a significant CAGR over the forecast period owing to its rising demand in power, manufacturing, and the marine

industry, where there is a huge requirement for continuous power supply.

High-power diesel generators are installed for power generation and distribution across off-grid remote areas, as it is not economically feasible to supply direct grid power to several remote places.

The commercial application segment occupied the largest market share of 45.34% in 2022 and is projected to register a substantial growth rate over the forecast period. The high growth rate can be attributed to the wide application scope including several industries such as data centres, government centres, educational institutions, healthcare, hospitality, telecom, agriculture, and others.

Diesel gensets are used across commercial establishments to back up sudden power interruptions such as voltage fluctuations and electrical outages, if not tackled, add up to financial losses.

The industrial diesel generator segment accounted for the second-largest revenue share in 2022.

The segment includes the manufacturing and construction sector, electric utilities, mining, transport & logistics, and oil & gas sector, these sectors draw huge product demand citing their heavy power consumption operations. www.grandviewresearch.com

• Presetting per G99/98, values as per the standard pre programmed

• Under and overvoltage monitoring 40…520 V

• Under and over frequency monitoring 45…65 Hz Monitoring of Rate of Change of Frequency (ROCOF, df/dt) Monitoring the voltage quality (10 minute average value)

• Response time adjustable 0.05 … 130.0 s, individual setting for each limit

• Fail-safe, with monitoring of the connected section switch (can be switched off) 2 automatic restarts on error

• Supports the mains synchronisation when using generators

• Measurement 3 phase 3 or 4 wire systems or single phase

• Self-test

Third Part Independently tested Compliant to G99/98 by Bureau Veritas

Header tank heat exchangers

For engines rated up to and in excess of 1 MW.

Water cooled intercoolers

For engines rated up to 850 kW.

Engine & transmission oil coolers

Heat recovery for engines rated up to 8900 kW, with up to 30 bar oil pressure.

Exhaust gas heat exchangers

For engines rated up to 1 MW, recovering up to 673 kW of heat.

Efficient, cost effective cooling solutions for Engine Driven Gen-sets, Pumps, HPU’s and Compressors; Co-Generation Systems; Off Highway Vehicles; Fire Protection Systems, plus Marine Engines, Transmissions and Gen-sets.

Visit www.ej-bowman.com for full details of the extensive range, call our technical sales team on +44 (0) 121 359 5401, or email sales@ej-bowman.com

DS Smith, a leading supplier of sustainable packaging solutions, and energy provider E.ON unveiled a new state-of-the-art combined heat and power (CHP) plant at DS Smith’s paper mill in Kent, the largest mill for recycled papers in the UK. Work on the CHP plant began in 2019 with E.ON financing, building and operating the plant.

The new CHP plant, which produced its first energy in 2022, has been designed to set the standard in efficiency, sustainability, and reliability – reducing CO2 emissions by 36,000 tonnes a year, the equivalent of 30,000 medium-sized cars driving more than 6,000 miles a year.

It boasts an electrical capacity of 73MW, generating steam and power to help the Kemsley mill manufacture around 830k tonnes of recycled paper every year.

To commemorate the plant’s official opening in May 2023, a ribbon-cutting ceremony was attended by senior leaders from DS Smith and E.ON, including Niels Flierman, DS Smith’s Head of Paper and Recycling, Rogier Gerritsen, Managing Director of Paper Europe at DS Smith and Manfred Wirsing, Managing Director of E.ON Energy Projects.

The ceremony marks the continuation of the long-term partnership between DS Smith and E.ON. Both companies have been working together in the field of energy supply for several years and – with Aschaffenburg paper mill in Germany and Kemsley –are currently realising two large projects together.

In addition, E.ON’s IQ Energy system has been deployed at the new CHP plant, an intelligent, energy supply solution that has been specially developed for energy-intensive industries.

It features an automated, self-controlled power plant based on patented hardware and a digital control concept that uses artificial intelligence to optimise the supply in real time. Data from the operation of the power plant and production facilities, the grid, and commodity markets help make the energy supply efficient and flexible.

E.ON and DS Smith cutting ribbonNiels Flierman, Head of paper and Recycling at DS Smith commented on the new facility: “We’re excited about the sustainability and operational benefits this state-of-the-art plant brings to our flagship mill in Kemsley.

“Leading the way in reducing the impact paper-making has on our environment is something we are passionate about - it’s important to us, our customers and the communities in which we operate. This is one of a number of projects we have across Europe and

North America that will help us to reduce Green House Gas emissions by 46% on an absolute basis by 2030, compared to 2019 levels, and to reach Net Zero emissions by 2050.”

Manfred Wirsing, Managing Director of E.ON Energy Projects, said: “We are delighted the new site for our partner DS Smith here in Kemsley has come on-line.

“This successful project is another example of how we are driving decarbonisation for our industrial customers and their production processes across Europe.

“The new energy solution we have implemented on site will make DS Smith more independent and flexible and, with a high degree of automation, optimally positioned for the future.”

DS Smith is a leading provider of sustainable fibre-based packaging worldwide, which is supported by recycling and papermaking operations.

It plays a central role in the value chain across sectors including e-commerce, fast-moving consumer goods and industrials.

Through its purpose of ‘Redefining Packaging for a Changing World’ and its Now and Next sustainability strategy, DS Smith is committed to

leading the transition to the circular economy, while delivering more circular solutions for its customers and wider society – replacing problem plastics, taking carbon out of supply chains and providing innovative recycling solutions. Its bespoke box-to-box in 14 days model, design capabilities and innovation strategy sit at the heart of this response.

Headquartered in London and a member of the FTSE 100, DS Smith operates in 34 countries employing around 30,000 people and is a Strategic Partner of the Ellen MacArthur Foundation. Its history can be traced back to the box-making businesses started in the 1940s by the Smith family.

Manfred Wirsing, Managing Director of E.ON Energy Projects, comments: “This successful project is another example of how we are driving decarbonisation for our industrial customers and their production processes across Europe.

“The new energy solution we have implemented on site will make DS Smith more independent and flexible and, with a high degree of automation, optimally positioned for the future.”

www.eonenergy.com

ACHP plant with an MWM gas genset ensures high mushroom yields all year round at moderate energy costs for the mushroom producer Hajduk Group Sp.z o.o. in Poland. Polygeneration makes it possible.

Poland is the world’s leading exporter of mushrooms and truffles, ahead of China (Statista 2022), and the market leader in European mushroom production.

One of Poland’s leading mushroom and mushroom substrate producers is the Hajduk Group Sp.z o.o. . Hajduk Group produces around 160 tonnes of mushrooms per week in four cultivation plants.

As mushrooms are energy-intensive in production, the company already invested in a CHP plant in 2018. The cogeneration plant with an MWM TCG 2020 V16 gas genset was supplied by the official MWM distributor in Poland, Centrum Elektroniki Stosowanej CES Sp. z o.o..

Using polygeneration, the plant produces electricity and heat but also cooling and steam for mushroom cultivation.

For a year-round harvest, mushrooms need stable growing conditions with the proper humidity and temperature.

Typically, this means cooling in summer and heating in winter with the help of air conditioning. Mushrooms are energy-intensive to produce.

The energy costs of the production facilities, therefore, significantly impact the mushrooms’ final price.

To keep these costs as low as possible, the polygeneration plant supplied by Centrum Elektroniki Stosowanej CES Sp. z o.o. is based on CHP. Liquefied natural gas is used as fuel.

Agricultural production plants far from conurbations and large cities often have limited connection options to the natural gas grid. To operate a CHP plant, Hajduk Group relies on LNG for its CHP plant with a capacity of over 1.5 MWe. With this solution, polygeneration plants can be installed almost anywhere.

Thanks to the additional equipment, the CHP plant generates steam and cooling, electrical energy, and heat. The plant is powered by an MWM TCG 2020 V16 gas genset with an electrical output of 1,560 kW and a thermal output of 1,580 kW.

In the cooling halls where the mushroom substrate is produced, an absorption chiller uses the exhaust heat from the MWM gas genset to generate cooling for the halls.

The absorption chiller has a capacity of 720 kW. Steam is used to sterilise the refrigeration halls between production cycles.

For this purpose, the hightemperature heat of the exhaust gases is used in the steam generator, which supplies 1,060 kg/h of steam at nine bar pressure. The hot water is also used for washing and other technical purposes.

conditions for the popular edible mushrooms all year round while saving energy costs through the combined production of the different media.

Features of the MWM TCG 2020

V16 gas genset

The gas genset offers the highest ratings in ecology and economy:

- Output range from 1,000 to 1,560 kWel

- Best electrical and thermal efficiency in its output class

- Runs on all gas types: natural gas, biogas, landfill gas, sewage gas, mine gas, etc.

CHP

In typical operation, the CHP plant with the MWM gas genset covers the entire demand for heating, cooling, steam, and electricity of the production facility at Hajduk Group.

Part of the electrical energy is used on hot summer days for additional cooling. In winter, the halls can, in turn, be heated with heat from the CHP plant.

The polygeneration system offers flexibly controllable energy generation with a heat and cooling supply. This allows Hajduk Group to maintain optimal production

- Low operating costs.

The TCG 2020 is mainly used for CHP plants in Europe and for biogas worldwide.

The MWM gas gensets of the TCG 2020 series are perfectly geared to the challenges of a dynamic market environment.

The models in the output range of 1,000 – 1,560 kWel are said to meet the high requirements of a broad range of applications and offer efficiency, reliability, flexibility and environmental sustainability, together with low lifecycle costs and high profitability. www.mwm.net

The transition to renewables-based energy generation presents new challenges for both grid operators and consumers, explains Lucy Plant, Manager Strategic Partnerships, Energy Solutions at Enel X.

The intermittent nature of renewable energy generation, which is largely reliant on the weather, calls for flexibility in both demand and generation to balance the grid where the energy mix contains a greater proportion of renewables.

Large energy users like data centres are continuing to adapt to this energy transition. Data centre operators have already tackled energy efficiency savings by optimising servers and cooling equipment.

To become even better grid citizens and to achieve a low-carbon agenda they must work in partnership with the grid to help keep their systems running and the lights on for the rest of us.

There are many pathways to low-carbon energy and data centre operators must decide which strategy is right for them.

Options include participating in flexibility services like demand response, battery storage, and contractual agreements with green energy suppliers.

Each option helps data centres become good grid citizens, plus there’s an added bonus that participating in demand response presents revenue generating opportunities.

While renewable energy sources are intermittent, they are largely predictable.

To modulate fluctuating generation and demand, grid operators need active participation from their largest energy users to increase grid security and stability of supply.

Demand Side Response (DSR) is a powerful and effective strategy that incentivises data centres to free up grid capacity when it is needed most.

For data centres, DSR participation can look like switching to their own backup generation and battery storage to reduce demand during peak period emergencies.

This might be on a cold, still winter evening when wind generation is low and demand is high.

Through DSR, data centre operators can offer flexibility to help balance the grid and accommodate more green energy on the system.

DSR also provides a safe way for data centres to test back-up systems while the grid is available, increasing their resilience should an unexpected grid outage happen.

Data centre operators that participate in DSR programmes see it as a way to mitigate interruptions to the power source, rather than a threat to uptime.

The reward for data centres is a revenue opportunity for simply being available. This valuable income can help offset energy costs or invest in further low-carbon measures. DSR has proven to be a successful, cost-effective strategy for grid operators for several years and, when managed effectively, doesn’t adversely impact data centre operations.

A highly versatile asset for any data centre is its battery energy storage system (BESS). It solves multiple challenges from operational needs, providing standby power for

resilience and recovery during a power failure, improving the quality of power, or storing energy generated on site. If the stored energy is not required by the data centre or there is spare capacity, it can be used to support the grid. Microsoft has successfully used battery storage at one of its data centres in Ireland to support EirGrid. It has participated in a market for grid services that prioritises noncarbon-emitting solutions. Microsoft participates in this market through Enel X, which aggregates industrial and commercial energy consumers into virtual power plants.

Data centre operators are also showing strong leadership on corporate renewable procurement with many looking to buy Power Purchase Agreements (PPAs). PPAs enable data centres to procure long-term contracts with operators of renewable assets. These contracts help data centres to move towards decarbonisation targets and enhance their corporate reputation. PPAs also directly support the development of renewables infrastructure and an increase in renewable generation on the grid system.

As large energy consumers, data centres have the potential to make a tremendous impact on grid innovation and sustainability.

Working with a skilled energy management partner ensures that appropriate plans and technology are in place to help data centres optimise their energy flexibility and become good grid citizens. Support can help to monetise the flexibility of energy assets, reduce costs, optimise revenue from onsite energy storage and generation and implement other efficiency measures like power purchase agreements.

www.enelx.com

THROUGH DSR, DATA CENTRE OPERATORS CAN OFFER FLEXIBILITY TO HELP BALANCE THE GRID AND ACCOMMODATE MORE GREEN ENERGY ON THE SYSTEM. DSR ALSO PROVIDES A SAFE WAY FOR DATA CENTRES TO TEST BACKUP SYSTEMS WHILE THE GRID IS AVAILABLE, INCREASING THEIR RESILIENCE IF AN UNEXPECTED GRID OUTAGE HAPPENS.”

Lone Star Power Solutions, the southern U.S. distributor for Capstone Green Energy Corporation, has been contracted to provide an additional 800-kW C800S Signature Series microturbine to a large West Texas energy company.

The contract follows a 3.6 MW Energy-as-a-Service (EaaS) contract with the producer in the spring of 2023.

The C800S is part of the Capstone range of clean and green turbines, which are scalable from 30kW to 30MW and can operate on a variety of gaseous or liquid fuels.

The West Texas energy producer is currently using the microturbine energy systems to power production loads using the onsite gas produced from its day-to-day operations.

According to Capstone, its EaaS solution was selected due to its record of reliability in remote oil and gas fields globally and its extremely low emissions profile, as the energy producer looks to decarbonize its operations.

As part of the rental contract, all maintenance is included, enabling the customer to benefit from fixed operating costs for the term of the rental.

Doug Demaret, president of Lone Star Power Solutions, comments: “With emissions which are 90% lower than our customer’s previous solution and a cutting-edge onsite power generation technology which requires only six hours of planned maintenance per year, we have enabled our customers to focus on their core business and not worry about power reliability.”

Capstone Green Energy president and CEO, Darren Jamison, believes both new and existing customers are finding value in the EaaS rental offerings.

He said: “We are seeing repeat orders from core industry segments like oil and gas while also expanding interest from new areas like Electric Vehicle (EV) charging providers,” he noted. “EaaS is proving itself to be a win-win solution as it meets the Capstone customer need to manage capital investment while delivering reliable, lower emissions energy, and it meets Capstone’s need for higher margins and predictable revenues and cash flow.”

The C800S is the microturbine model also previously chosen by the Burbank Water and Power (BWP) company of California. In the early 2000s when the organisation was faced with a need for greater power reliability. They also had a keen interest in reducing emissions from their power generation, and so they worked with Capstone’s distributor for California, Capstone California, to develop an onsite power system which converts landfill gas collected at the Burbank Landfill into electricity. This project was a unique partnership between BWP and the South Coast

Air Quality Management District (SCAQMD). Today, the site is Capstone’s largest microturbine project running on landfill gas in California.

The original system, built around ten C30 microturbines, was installed in 2001, followed seven years later by the installation of an R250.

The power generation process starts at the Burbank Landfill where waste from the community is collected and delivered. As the waste is compacted, it decomposes, and methane gas is produced.Once the gas is conditioned to remove impurities, a portion of it is flared off, while the rest is directed to the microturbines where it is used as a renewable fuel to make electricity.

In 2020, BWP worked with Capstone’s Western U.S.distributor, Cal Microturbine, to replace the original system with a new C800 configuration. In total, the system produces 800 kW of renewable generation and sends it back to the grid, supplying enough power for approximately 500 homes.

The contract also includes a 15-year Factory Protection Plan (FPP), which covers the cost of all parts and labor for both planned and unplanned maintenance, providing BWP with power reliability assurances and

predictable maintenance costs.As one of over 90 Capstone systems used in biogas applications across North America, the Burbank system is highly-efficient, reliable, cost effective, and environmentally beneficial. The operation allows the Burbank system to fall well below emission standards set by the SCAQMD.

Furthermore,the conversion of landfill methane gas, which would otherwise be released into the atmosphere, is free fuel. This application eliminates approximately 10,000 pounds of greenhouse gas emissions annually, which is roughly the equivalent of removing 500 cars from California’s highways.

The project was a success on other levels, too, having been completed on-schedule and under budget.

“The landfill gas-to-energy project is a great example of BWP’s commitment to providing reliable, affordable and sustainable services to the citizens of Burbank. With increasing costs to produce electricity, we are confident that this technology will continue provide benefits for the City of Burbank for years to come,” comments Sean Kigerl, Landfill Gas-to-Energy Project Manager Burbank Water and Power.

www.capstonegreenenergy.com

Kohler Engines, a Kohler company which has specialized in engine production for over a century, and Grastim, a JV specializing in highefficiency technology solutions, has signed an agreement for a new hybrid self-generation plant at the historic Reggio Emilia facility in Italy.

The project includes a 2 MW trigeneration plant and an 860 kW photovoltaic park integrated with each other, as well as the possibility of also being powered by hydrogen (hydrogen ready).

The two plants together, trigeneration and photovoltaics, will have important environmental and economic impacts: they will ensure a CO2 reduction of up to 1,300 t/year, equal to almost 20 percent (19.5 percent) of the site’s energy emissions, and energy cost savings of up to 15 percent.

At the core of the plant is a Jenbacher natural gas engine, distributed by another Kohler company, Clarke Energy. It is a new state-of-the-art engine which compared with others on the market provides even more flexibility in fuel choice, more efficiency, and cost and CO2 emission savings.

The entire hybrid plant is already set up for the future: photovoltaics could be extended over parking areas and other buildings for up to an additional 2 MW, and the cogeneration module is already hydrogen ready, meaning it is capable of being powered by up to 20 percent hydrogen in the fuel mix.

Green hydrogen would also potentially be produced onsite by electrolysis, in case of excess PV production, and then be reused in the trigenerator.

With this development Kohler Engines confirms its strategy of increasingly focusing on environmental sustainability, investing in multiple technological solutions on the road to energy transition.

For its part, Grastim further expands and integrates its high-efficiency technology solutions for large industrial players committed to decarbonising their major manufacturing operations.

“At Kohler, we believe everything can constantly be improved, consistent with our belief which underlies the ‘Believing in Better philosophy’ declares Vincenzo Perrone, President of Kohler Engines.

“After achieving the ISO 50001 certification, our Reggio Emilia facility is further accelerating its decarbonization and energy efficiency path.

“We are investing in renewable and diversified energy sources: a renewal that concerns not only the development of environmentally advanced technologies for our engines, but also the programs to reduce our operational environmental footprint of our production facilities.”

Baldo Pavolini, Investments and Operations Director of Grastim, comments:. “After so many international experiences, it is a source of pride for Grastim to set foot in the heart of Italy’s very own Motor Valley; we do so by proposing a hybrid solution, and above all a versatile one, to make room for subsequent technological evolutions, with a view to decarbonisation and energy transition, already in the timeframe of the agreement just signed.”

Alex Marshall, Group Business Development and Marketing Director US at Clarke Energy, explains: “This project demonstrates the potential for hydrogen-ready gas

engine CHP to combine with other low carbon power generation technologies and support cost and carbon reduction for manufacturers.”

Kohler has been manufacturing engines for more than a century and has continued to grow its product portfolio ever since its inception to increasingly bring ease and convenience to the lives of end users worldwide.

The company offers a wide range of diesel, petrol and gas engines up to 140 hp of power – adopted globally by machine and equipment manufacturers.

Clarke Energy, a KOHLER Company, is a leader in the engineering, design, installation, and long-term maintenance of distributed energy solutions. Clarke Energy can delivery complex installations and microgrids incorporating gas engine CHP units, battery energy storage systems, biogas upgrading systems and solar photovoltaic units.

Clarke Energy can supply energy solutions including a range of low carbon or decarbonized fuels including biogas, renewable natural gas (RNG) and hydrogen.

Clarke Energy operates in 27 countries and has over 8GW of power generation, 1.4GW of which is from biogas, a renewable fuel.

www. kohlerengines.com

www.clarke-energy.com

An emergency diesel generator has been installed by EUROGEN in one of the most important telecommunications nodes of North East Italy. EUROGEN is a member of the Italian DataCenter Association.

The genset is a Model GS2000BAD/CF nominal power 1600 kWe PRP ISO8528 with a Baudouin engine 20M33 SERIES.

The engine features a cast-iron cylinder block with an inspection door per cylinder, cast iron cylinder liners, wet type and replaceable valves guides and seats and separate cast iron cylinder heads with 4 valves.

Other points of interest include a hardened steel forged crankshaft with induction-hardened journals, crankpins and radius, lube oil-cooled light alloy pistons with high performance piston rings and an advanced cooling system.

Radiator and hoses are supplied separately. There are two separate circuits and the high temperature circuit is equipped with a thermostatically-controlled system with two gear-driven coolant pumps.

The Baudouin engine has 20-cylinders, Bore & Stroke 150 X 185 mm, a total displacement of 65.4 litres and a counter-clockwise engine rotation. The Rated Speed is 1500/ 1800 RPM.

The engine’s lubrication system includes full-flow screwable oil filters, a lube oil purifier with replaceable cartridge and a water-cooled lube oil cooler.

The engine’s fuel elements include a high pressure common rail system with one high pressure electrical driven coolant pumps in the V-angle of the cylinder block.

Two rails are mounted on the sides of the engine, double wall, under inlet manifold. There is a duplex fine filter and water separation filter assembly with transparent cup for better efficiency. An electric fuel priming pump ihas been ntegrated into the filter support. There is also a special rear mounted air filter with restriction indicator, plus an exhaust manifold shield for heat isolation.

In the Air Intake and Exhaust System 4 compressors are feeding a single water-air intercooler, mounted over the exhaust system flywheel housing, with vertical flow. There is a special rear-mounted air filter with restriction indicator.

The engine’s electrical system has a 24V DC electric starter motor and battery charging alternator, with low oil pressure & high water temperature sensors. There is also an SAE 00 flywheel housing and 21”

Ratings definitions

Emergency Standby Power (ESP):

This is the maximum power available for a varying load for the duration of a main power network failure. The average load factor over 24 hours of operation should not exceed 70% of the engine’s ESP power rating.

Typical operational hours of the engine is 200 hours per year, with a maximum usage of 500 hours per year. This includes an annual maximum of 25 hours per year at the ESP power rating.

Data Centre Power (DCP)

Data Centre Power is defined as being the maximum power which is the generator set is capable of delivering to a Datacenter, while supplying a variable or continuous electrical load and during unlimited run hours.

Prime Rated Power (PRP)

Prime Power is the maximum power available for unlimited hours of usage in a variable load application. The average load factor should not exceed 70% of the engine’s PRP power rating during any 24 hour period. An overload capability of 10% is available, however, this is limited to 1 hour within every 12 hour period, according to the manufacturer’s specs.

www.eurogenpower.com

Innio will provide a 1 MWe combined heat and power plant (CHP) which runs on a Jenbacher engine fuelled by hydrogen produced 100% from an array made up of solar photovoltaics.

A Jenbacher J420 engine has been chosen by PAN-LEDI d.o.o. for the project in Nova Pazova, Serbia. The contract calls for the delivery of a containerised CHP unit built to generate about 1 MWe.

The electricity will be used by PAN-LEDI for its electric vehicle (EV) charging station, with excess energy provided for the Serbian grid and the engine waste heat sold to a nearby commercial customer.

The CHP unit consists of a Jenbacher container and a complete heat recovery system. The Jenbacher CHP plant is expected to be delivered and commissioned in late 2023.

The Jenbacher J420 is based on Innio’s proven Type 4 platform of more than 6,000 delivered engines generating about 7 GW of power worldwide.

Leading the way with next-generation technology innovation, the J420 delivers as much as 4% more output - up to 1,560 kW - and up to 1% point of additional electrical efficiency compared to respective J420 B versions.

The J420 D/E genset, for example, delivers a robust concept with a compact footprint with a 0.6-metre reduction in length compared to previous Type 4 genset versions.

The CHP plant at Nova Pazova, will be fuelled by hydrogen generated via an electrolyzer which, in turn, is powered by a solar photovoltaic (PV) plant located near Cuprija.

The electrolyzer is used to produce green hydrogen for interim storage before the hydrogen is transported from Cuprija to Nova Pazova.

This achieved in the following process: water molecules (H2O) contain hydrogen (H). The H2 is separated from the O in a process called the electrolysis of water. Electrolysis is the technique used to produce hydrogen which consists of “breaking” the water molecules using an electric current in an electrolyzer in order to extract the dihydrogen H2. The electricity must itself be carbon-free in order to consider this hydrogen as green or renewable.

Most of the hydrogen will be produced during the summer in Serbia when the output produced by solar plants is high.

In times of low hydrogen supply, the CHP plant will run on natural gas, to ensure the continuous provision of energy. The Jenbacher team will work with its distributor, STI d.o.o., to implement, install and service the hydrogen CHP unit.

Combined Heat and Power Module (CHP Module) solutions like these allow customers to generate power and heat simultaneously at a very high total efficiencies, reaching 90% and even more.

Advanced design features

Jenbacher Type 4 engines have the same design, emissions control, and waste gas-to-energy capabilities as their Type 2 and Type 3 counterparts, plus high power density and outstanding efficiency in their power range.

The high-power turbocharger allows optimal operation at higher air intake temperature and altitude.

A four-valve cylinder heads f eatures enhanced swirl and channel geometry using advanced calculation and simulation methods, resulting in optimal cooling and combustion conditions. The Type 4’s connecting rod reduces bearing wear and is easy to maintain.

Combined Heat and Power Module (CHP Module) solutions incorporating Jenbacher Type 4 engines allow customers to generate power and heat simultaneously at a very high total efficiencies, reaching 90% and even more, says Innio.

Such CHP Modules can generate hot water or steam at various parameters and can be integrated with existing heat infrastructure.

Clients can select the option whch fits a project’s needs from among the various heat recovery schemes provided by Jenbacher.

The scope of supply can be extended further with various

balance of plant options (BOP)offered by Jenbacher.

The right auxiliary equipment is of critical importance in ensuring that a power solution is economically feasible and provides a particular business with the most benefits in terms of reliability, availability and efficiency, says Innio.

Delivering carbon-free electricity when hydrogen is available Dr. Olaf Berlien, president and CEO of INNIO, commented on the Nova Pazovaproject:“Our H2-engines provide the flexibility and sustainability to meet PAN-LEDI’s pioneering requirements. INNIO’s technology will deliver carbon-free electricity when hydrogen is available, while maintaining continuity of power generation when hydrogen is scarce.”

Slobodan Vujovic, CEO PAN-LEDI d.o.o. concludes“Using hydrogen or natural gas to operate our combined heat and power plant is critical for our EV charging station strategy. INNIO’s Jenbacher CHP solution will provide our operation with the flexibility required for a sustainable EV mobility and use hydrogen at high CHP utilisation rates.”

www.innio.com

www.jenbacher.com

With our MWM container solutions, you have everything under one roof – precisely aligned with your needs. Benefit from our assistance in planning, configuring and installing comprehensive plant concepts. Thanks to digital possibilities such as a highly developed, secure data analysis, these steps can be tailored to maximize your profit.

www.mwm.net/en

Engineered for the power generation market, the Perkins® 5000 Series is said to be packed with features and the performance to match customer demands.

Designed to supply electrical power when and where needed, whether to critical power applications, prime continuous or standby power, the 5000 Series has been optimised and tested to deliver cost-effective, reliable performance no matter the location or demand.

The 5000 Series engines have been designed from the ground up to deliver power when you need it, says Perkins.

The power demands of critical applications like data centres and hospitals drove the development of a platform that is compliant with NFPA 110 Type 10 as well as G2 and G3 standards – enabling a fast ramp up to full load.

The Perkins 5000 Series range includes inline six- and eight-cylinder models (23- and 30-litre), together with V12 and V16 (46- and 61-litre) versions.

The engines have been engineered specifically for the power generation market, delivering prime or standby power for applications including data centres and hospitals.

The 5000 Series is described as the largest and most powerful fully-electronic engine range yet delivered by Perkins.

The engines have been designed to support the need for quick, reliable and cost-effective power. Power output for the new turbocharged engines extends from 750 to 2500 kVA (2250 kVA prime). Delivering high efficiency and low fuel consumption.

EMEA sales director for Perkins, Richard Hemmings, comments: “With multiple engine models offering a substantial power output of up to 2500 kVA, every aspect of the new 5000 Series engine range, from its outstanding load acceptance capabilities to custom-created components and innovative engineering techniques, has been designed to optimise our customers’ needs for quick, reliable and cost-effective power.”

All models (5006, 5008, 5012 and 5016) feature electronic fuel injection and an overhead camshaft and are compliant to US EPA Tier 2.

The smaller engines can operate for up to 750 hours/2 years before requiring oil and primary fuel filters.

The larger models can operate for up to 500 hours/2 years. They offer remote monitoring, operation at altitude and ease of integration, reports the manufacturer.

The Perkins® 5008C-E30TAG - for example - has been specifically designed to offer reliable power for the emergency standby and critical applications market, including data centres and hospitals among others.

Engineered and built specifically for the power generation market, the Perkins 5000 Series is certainly a power-packed engine range built to be dependable, versatile and offer lower emissions to meet regulatory standards.

Benefits include: 100% block load capability; Up to 750 hours / 2 years service interval; and up to 1107 kW from its 30 litre engine (36.9 kW/l).

A spokesman for Perkins comments: “The 5000 Series delivers maximised productivity through excellent load acceptance, achieving NFPA110 Type 10 and ISO 8528-5 G2 and G3 performance class.

“The engine build and performance has been designed with ultimate productivity and dependability in mind, so customers can be confident that power will be available when required.

“They have been tested around the world, in the harshest environments imaginable, to ensure the best performance, no matter the conditions.”

www.perkins.com

The Government has made a series of announcements outlining its plans to achieving net zero carbon emissions by 2050 and setting out steps to strengthen the UK’s long-term energy security and independence.

The announcements include pledges of continued support for heat networks and energy efficiency deployment, two of the ADE’s workstreams.

The ADE’s Director of Policy and Research, Caroline Bragg, said: “The Great British Insulation Scheme marks an important step forward, but to be truly great, the ADE would have liked to have seen new money committed - the £1 billion it includes has already been pledged.

“Despite this, the scheme will play a critical role in driving much-needed energy efficiency investment up until March 2026, and is a long overdue step towards reducing bills, delivering net zero and boosting energy security. It will support around 300,000 of the UK’s least energy-efficient homes, saving each household as much as £400 each year.”

He concludes: “The Government’s commitment to improving owneroccupied homes, privately rented homes and through lenders, as well as reducing demand from large businesses and greening industrial processes through the Industrial Energy Transformation Fund (IETF), demonstrates progress.

“Much more action on energy efficiency is urgently needed. While the announcements mark a clear step in the right direction, keeping the UK’s homes warm, safe and comfortable will require bolder actions and more dedicated funding.”

Guto Davies, head of policy at the Association for Consultancy and Engineering (ACE) and also the Environmental Industries Commission (EIC), reflects on a series of announcements made by UK government on climate action.

Guto said: “ACE and EIC welcome the focus of the Government on providing more policy clarity and certainty to the infrastructure sector, particularly in light of Chris Skidmore MP’s earlier review of Net Zero.

“The newly-published strategy sets out some important steps to reach net zero by 2050 through clarifying finance, the UK’s role in international leadership and influence, strategic policy aims and the future direction of innovation and research.

“But there remain many unanswered questions. This has already been a lengthy process, so implementation is now crucial given our 2030 and 2050 targets.

“The team is looking at the detail in these documents to see whether they support long-term delivery of Net Zero. In the meantime, ACE and EIC look forward to working with the newly formed Department for Energy Security and Net Zero to take forward many of the actions set out today, including our own policy positions.”

He concludes: “The CCC’s latest report paints an alarming picture. The government has an opportunity to lay a solid foundation for delivery through an updated Net Zero Strategy, which is expected in the coming days.But the government must work closely and in good faith with industry, including ACE and EIC, to establish and maintain a confident and robust non-partisan long-term policy approach.”

An IPowerE One Day Seminar Diverse Solutions for De-Carbonisation’ will be held on 27th September 2023 - IGEM House, Kegworth.

This one-day Seminar is aimed at examining today’s energy challenges demand a full range of solutions to de-carbonise the power sector. Conventional gas fired plant will continue to support the Energy Transition, with changes to despatch, control, and fuels used.

Energy storage will, be it in battery or grid scale solutions, be used to complement renewable systems, deployed at increasing scale. Grid control and management will assume great importance as today’s energy transmission and distribution systems are adapted to meet tomorrow’s requirements. This seminar will bring many of these themes together, providing information and the opportunity for discussion and debate amongst your Power Engineering peers. With the added opportunities for networking and discussions in smaller groups during the day and the excellent venue, this should be both an informative and enjoyable day.

Meetpoint Midlands is a quiet, relaxed and friendly meeting centre based in Kegworth in the East Midlands. Conveniently located just off junction 24 of the M1, three miles from East Midlands Parkway train station and four miles from East Midlands Airport allowing easy access for delegates and free parking.

Please contact the office for more information Tel +44 (0)1234 214340 or email: enquiries@ipowere.org

Key points: Registration is from 9:00am and the Keynote Speaker talk will be commencing at 9:15am. Morning Presentations will be followed by a Buffet lunch. After lunch the Afternoon Presentations will commence, followed by a Panel Discussion and a Finish- approx 16:00pm.

The UN Climate Change Conference (COP26) has highlighted that an unprecedented shift in progress will be needed to enable governments worldwide achieve Net Zero Strategies by 2050. In the lead up to COP26 the UK’s Net Zero Strategy has been discussed as part of the most recent IPOWERE Webinar Series during which the UK’s ten-point plan for a green industrial revolution was discussed by industry experts.

NEW

NEEDED TO MAKE GREAT BRITISH INSULATION SCHEME TRULY

Generac has released a new series of stationary battery energy storage systems (BESS).

The SBE series battery systems will be available with lithium iron phosphate (LFP) and nickel manganese cobalt battery chemistries, are designed to complement Generac’s line of gas and diesel generator sets for full-facility resilience during long-duration blackouts.

Systems like these can also be installed with onsite solar energy systems to help reduce both carbon footprint and energy costs. There are two versions of each model. The NMC units are available with storage capacities of 500 kWh and power ratings of 125, 250 and 500 kW and 1000 kWh and power ratings of 250, 500 and 1000 kW.