Schoolʼs In

The first of five dedicated training vessels is delivered.

FEATURES

16 Vessel Report: Riverboat Gamblers

Overnight riverboat cruises have bounced back from the pandemic’s economic woes.

26 Cover Story: Learning Curve

Tote is using a new construction management model for Marad’s training ship program.

BOATS & GEAR

20 On the Ways

16

• Master Boat delivers first U.S. all-electric tug to Crowley • St. Johns Ship Building and Gulf Craft deliver two of five new CTVs for Windea • Brix Marine completes 40' high-tunnel passenger cat for Hawaii • Ribcraft delivers a new 16' RIB to volunteer fire department in Maine.

30 Pushy

A workboat’s most vital equipment package is its propulsion system.

32 Old is New Again

New diesel engine options are coming late this year

AT A GLANCE

8 On

The gambler — Part II

8 Captain’s Table: The negative effects of TWIC.

9 Energy

10

11

11

12

12

NEWS LOG

14

14

14

Is capping LNG exports good or bad?

stocks begin 2024 with a small loss.

Annular Cutters

Training future mariners

If you have been a WorkBoat reader for years, you know all about the critical workforce problems we have had in this industry, especially the shortage of quali ed U.S. mariners.

Now, with the September delivery of the 524.3'×88'6" Empire State, the rst of ve new purpose-built, modern training vessels for U.S. state maritime academies, there is a glimmer of hope.

The Empire State, built at Philly Shipyard Inc., recently completed its inaugural training voyage for SUNY Maritime College, Bronx, N.Y.

The Maritime Administration’s (Marad) new vessel program — known as the national security multimission vessels (NSMVs) — is designed to help provide world-class training for future U.S. mariners and to support humanitarian assistance and disaster relief missions in times of need. Marad has not built ships in more than 50 years.

The goal of these next-generation training vessels will be to address a critical shortage of quali ed of cers necessary to crew government and commercial-owned sealift ships.

While the Marad program may not put much of a dent in the mariner shortage problem in other sectors such as tugs and barges, it’s a start.

These training ships feature several instructional spaces, a full training bridge, and have space for up to 600 cadets to train in a rst-rate maritime academic environment at sea. This training is important. State maritime academies graduate more than half of all new of cers each year — the merchant mariners who help keep cargoes and the

David Krapf, Editor in Chief dkrapf@divcom.com

David Krapf, Editor in Chief dkrapf@divcom.com

economy moving. Many also support U.S. national security by crewing military sealift vessels.

More help is on the way. The next training vessel, Patriot State, destined for the Massachusetts Maritime Academy, is scheduled to be delivered this year. Meanwhile, keel laying for State of Maine (Maine Maritime Academy) and steel cutting for Lone Star State (Texas A&M Maritime Academy) were recently completed. Construction of Golden State (California Maritime Academy) is underway. All vessels are planned for delivery by 2026.

These new vessels provide an excellent training platform, and should attract new talent to the maritime industry.

Krapf / dkrapf@divcom.com

Ken Hocke / khocke@divcom.com

Kirk Moore / kmoore@divcom.com

Capt. Alan Bernstein • Bruce Buls • Robin G. Coles Jerry Fraser • Pamela Glass •

• Max Hardberger • Joel Milton • Jim Redden

Hayden / bhayden@divcom.com

PROJECT

/ ART

Doug Stewart / dstewart@divcom.com

eremiah Karpowicz / jkarpowicz@divcom.com ACCOUNT

842-5439 / mcohen@divcom.com

207-842-5635 / kluke@divcom.com

207-842-5657 / krandall@divcom.com

207-842-5634 / dwalters@divcom.com

207-842-5616 / wjalbert@divcom.com

Jacksonville Ship Repair

Located in Northeast Florida, just two nautical miles from the Atlantic Ocean, BAE Systems Jacksonville Ship Repair offers dry dock facilities to commercial ship operators and owners. Quality service on schedule, within budget and without difficulty.

From start to finish, we are your shipyard of choice. Upfront and honest.

baesystems.com/commercialshiprepair

Work with the Coast Guard inspectors

Thank you for your recent article, “The give and take of dealing with Coast Guard inspections.” (February 2024, Captain’s Table, Capt. Alan Bernstein, page 80)

As a former inspector I’d like to think I respected the judgment of the boat owner and operator. I think most inspectors do, but not all.

When I required a repair, I always listened openly to options and may have accepted as many as I didn’t. I think you are right that retaliation is not a normal response if an inspector’s requirement is overturned. One of my decisions was overturned and I had a normal interaction with the operator the next time I inspected them. In fact, I think the relationship between us was even more professional, with both of us respecting each other’s positions and experience.

I think the key is to work with the

inspector. Both want a safe operation at sea.

Steve Sharpe Westminster, Md.

Coast Guard updating user fees for inspected towing vessels

TheCoast Guard announced in the Federal Register that we are updating the user fees for seagoing towing vessels that are 300 gross tons or more and revising user fees for other inspected towing vessels.

The Coast Guard is issuing these updates because we are required to establish and maintain a fair fee for vessel inspection services and to separate the fees for inspection options that involve third-party auditors and surveyors from inspection options that do not involve third parties.

Under this nal rule, owners and operators of vessels using the Alternate

Compliance Program, Streamlined Inspection Program, or the Towing Safety Management System options will pay a lower fee than vessels that use the traditional Coast Guard inspection option. This nal rule is effective March 27, 2024.

The full notice and associated documents are available at www.regulations. gov under docket number USCG-20180538.

U.S. Coast Guard Washington, D.C.

Something on your mind?

WorkBoat encourages readers to write us about anything that appears in the magazine, on WorkBoat.com or pertains to the marine industry. To be published, letters must include the writer’s address and a daytime phone number. Email: workboat@cox.net

Lubriplate

vessel and other equipment affected by (VGP) Vessel General Permit regulations. Designed specifically for use in harsh marine conditions, these high performance, Environmentally Acceptable Lubricants (EAL)s deliver all the performance and

you need, while maintaining compliance with regulations protecting the environment.

ATB BIOBASED EP-2 GREASE

• This versatile grease meets U.S. EPA Vessel General Permit (VGP) requirements.

• Passes U.S. EPA Static Sheen Test 1617 and U.S. EPA Acute Toxicity Test LC-50.

• ECO-Friendly and Ultimately Biodegradable (Pw1) Base Fluid – 75.2%.

• Designed for use on Articulated Tug Barge (ATB) notch interface, coupler ram and drive screws, above deck equipment, rudder shafts, wire rope, port equipment, cranes, barges and oil platforms.

BIO-SYNXTREME HF SERIES HYDRAULIC FLUIDS

• These fluids meet U.S. EPA Vessel General Permit (VGP) requirements.

• High-performance, synthetic polyalkylene glycol (PAG)-based formula.

• Non-Sheening – Does not cause a sheen or discoloration on the surface of the water or adjoining shorelines.

• Provides long service life and operating reliability, lower maintenance costs, and reduced overall downtime.

• Excellent anti-wear performance - rated as anti-wear (AW) fluids according to ASTM D7043 testing and FZG testing.

• High flash and fire points provide safety in high temperature applications.

• All season performance – high viscosity indices and low pour points.

• ECO-Friendly and Readily biodegradable according to OECD 301F.

• “Practically Non-Toxic” to fish and other aquatic wildlife according to the U.S. Fish and Wildlife Service hazard classification.

VGP COMPLIANCE STATEMENT LUBRIPLATE ATB BIOBASED EP-2 GREASE and BIO-SYNXTREME HF SERIES HYDRAULIC FLUIDS are Environmentally Acceptable Lubricants (EAL)s according to the definitions and requirements of the US EPA 2013 Vessel General Permit, as described in VGP Section 2.2.9

BY JOEL MILTON

BY JOEL MILTON

Joel Milton works on towing vessels. He can be reached at joelmilton@ yahoo.com.

On the Water

The gambler — Part II

Hold

’em or fold ’em? Make your approach and confidently dock the barge “safely” without an assist, because you have the knowledge, experience, ability, and sound judgement to know when you can do so. Or you abort your final approach because things just aren’t going right, or maybe they are not feeling quite right. So, you bail out while still under full control and before you reach the point of no return. This also requires sound judgement. Learning that is a key to success when playing the assist game.

It’s a very serious game to be sure, with many variables — tides, currents, winds, visibility, ice, nearby grounding or allision hazards, the type, condition, location and orientation of the dock, availability of line-handlers, the tug’s and tow’s particulars, vessel traffic, and more. These variables can interact in complex ways, which sometimes makes answering the basic question of whether the planned course of action is “safe” or not very difficult.

BY CAPT. ALAN BERNSTEIN

BY CAPT. ALAN BERNSTEIN

Alan Bernstein, owner of BB Riverboats in Cincinnati, is a licensed master and a former president of the Passenger Vessel Association. He can be reached at 859-292-2449 or abernstein@ bbriverboats.com.

Captain’s Table

The negative effects of TWIC

My Transportation Worker Identification Credential (TWIC) expires this year. So, I contacted a nearby TSA Enrollment Center to schedule an appointment to renew my TWIC. I did this even though TWIC has little or no use to me, my company, or the passenger vessel industry.

The TWIC program was established after the 9/11 attacks to identify individuals in the transportation industry who may be terrorists or have serious criminal records. All individuals must have a TWIC to gain access to secure maritime facilities. To my knowledge, mariners and truckers are the only ones required to have a TWIC. In the maritime industry, the Coast Guard has confided that there have been few individuals with offenses that disqualified them from getting a TWIC.

While the implementation of TWIC might have seemed logical to federal regulators immediately following the 9/11 attacks, the need for expensive and ineffective TWIC cards in the passenger

Furthermore, every “gambler” is different. Appetites for risk vary, and an operator’s tolerance for risk will vary by situation as well as over the course of a career.

The problem is that variable, changeable nuanced answers may appear to be whimsical or unreasonable. They are often difficult for the other involved parties in the transport food chain to chew, swallow, and digest. This is especially the case if they have little or no relevant and recent direct operational experience, running from vessel dispatchers all the way to the customers whose cargo is in motion, those who regulate or underwrite it, or even an operator that’s in way over their head without realizing it. Existing risk always rises when you don’t know what you don’t know.

The shortest, simplest answer is obvious. Whenever there is any real doubt, just use an assist. Except for dock builders and shipyards, no one involved in transportation comes out ahead after you’ve misjudged the situation, smashed into and damaged a dock, holed a barge, polluted a waterway, or hurt someone. And still there remains much more to this subject.

vessel industry has passed. Today, passenger vessel operators are required to have vessel security plans — also a byproduct of the 9/11 attacks.

These operators, whether they use the PVA Alternate Security Program or other plans approved by the Coast Guard, employ strict security measures which regulate and restrict access to sensitive areas such as the wheelhouse or engine room. These security measures also cover facilities and dock space. I believe that such security measures eliminate the need to also have TWIC cards.

Requiring mariners and other employees to get TWIC cards has been costly for my company and others in the maritime industry. Many potential employees have chosen to work elsewhere rather than endure the hassle of getting a TWIC card to work on my company’s vessels.

TWIC has been costly for mariners and is an added barrier to recruiting in an already tough hiring market.

Mariners must speak out about the negative effects of the TWIC program on our industry and request that their legislators eliminate this ineffective and costly program once and for all.

This column first appeared in the March 2022 issue of WorkBoat.

Energy Level

Is capping LNG growth good or bad?

BY G. ALLEN BROOKS, CORRESPONDENTIt’s election season and the buying of votes by virtue signaling policies is underway. On Jan. 26, the Biden administration announced a temporary pause on pending decisions related to LNG exports in a concession to environmentalists. The administration argues that the energy department’s economic and environmental models are ve years old and no longer adequately account for the effect LNG exports have on domestic energy costs or carbon emissions.

“During this period, we will take a hard look at the effects of LNG exports on energy costs, America’s energy security, and our environment,” President Joe Biden said in a statement. “This pause on new LNG approvals sees the climate crisis for what it is: the existential threat of our time.”

The reality is that Biden needs votes. He is trying to regain the support of young, climate-conscious voters who supported him in 2020 as he plans his 2024 campaign. He disappointed them last year with his decision to greenlight the ConocoPhillips’ Willow oil project in Alaska.

What’s the fallout? Politically, it could upset our allies, especially Germany, which is relying on U.S. LNG exports for a substantial portion of the gas needed to replace Russian supplies. Is the U.S. no longer a trusted source of supply? Energy planners must be wondering.

Economically, the temporary pause, if it leads to a permanent delay in new LNG infrastructure, will signal to E&P companies, including offshore producers, to scale back their drilling for new gas supplies. Already, the Gulf of Mexico (GOM)

has been restricted by the Biden administration’s outer continental shelf ve-year leasing schedule with the least number of sales possible. That is sending GOM drillers overseas.

Who would have thought the U.S. would become the largest crude oil producer in history, a leading global oil exporter, the world’s No. 1 natural gas producer, and the largest LNG exporter?

LNG is replacing coal use, which reduces global emissions. This is something we should be cheering.

These plusses for our domestic energy security and economic growth may be sacri ced to buy votes from people who do not understand how

much of their lifestyle depends on a vibrant oil and gas industry.

"IT'S HARD WORK, WE MIGHT AS WELL HAVE SOME FUN!"

"WE FIX SHIPS, THAT'S WHAT WE DO"

WorkBoat Composite Index

WorkBoat stocks begin 2024 with a small loss in January

The WorkBoat Composite Index mirrored 2023’s performance in January, closing out the rst month of 2024 relatively unchanged.

In January, WorkBoat stocks declined slightly, losing 13 points, or less than 0.4%. For the month, losers topped winners 16-9.

Among the winners was Gulf Island Fabrication Inc. The Houston-based steel fabricator and service provider to the industrial and energy sectors, eked out a small gain in January.

At its third-quarter conference call late last year, Richard Heo, Gulf Island’s president and CEO, told analysts

For the complete up-to-date WorkBoat Stock Index, go to: www.workboat.com/resources/workboat-composite-index

that the company had nally settled its MPSV litigation with Hornbeck Offshore and that the winding down of the remaining shipyard obligations was nearly complete. “We will be able to fully move on to the next phase of our journey,” He said. “We have nearly closed the chapter on a challenged past, and we’re excited to be a pureplay services and fabrication business.”

Heo said was excited by the opportunities that lie ahead for the company. “With the anticipated wind down of the shipyard operations in the fourth quarter, we’ll have removed the signi cant overhang and distractions from our business. Our execution and operations are strong, our end markets are favorable, and we are in a solid nancial position. We’re optimistic that 2024 will be an even stronger year for Gulf Island.”

— David Krapf

BY PAMELA GLASS

BY PAMELA GLASS

Pamela Glass is the Washington, D.C., correspondent for WorkBoat. She reports on the congressional committees and federal agencies that affect the maritime industry, including the Coast Guard, Marad and Army Corps of Engineers.

Inland Insider

Should foreign mariners be allowed to work in the U.S. maritime industry?

As U.S. maritime companies struggle to find viable solutions for filling vacant job positions, one idea that has surfaced recently is hiring foreign mariners.

The concept of creating a pathway for foreign mariners to enter the U.S. legally to work in the industry and be on track for citizenship has gained some steam in recent months. It was discussed briefly at Marine Money’s 2023 Marine Finance Forum held Nov. 30 in New Orleans and has been the focus of growing debate among shipping companies, unions and within the U.S. government.

“There needs to be a national maritime strategy. It won’t be solved without immigration. I think virtually every industry in the U.S. with significant (labor) problems has solved it with immigration,” Sam Norton, president and CEO of Tampa, Fla.based Overseas Shipholding Group (OSG) said at the forum. “There are markets around the world

BY KIRK MOORE, CONTRIBUTING

BY KIRK MOORE, CONTRIBUTING

Nor’easter

Port city fire departments must train on ships

New Jersey’s Port Newark terminals are some of the busiest on the East Coast, frequented by the largest containerships in the world. An ongoing Coast Guard inquiry into the July 5 deaths of two Newark Fire Department captains offers a warning that local emergency responders must be better prepared for waterfront disasters.

Newark Fire Department captains Augusto ‘Augie’ Acabou and Wayne ‘Bear’ Brooks Jr. were trapped as they tried to make their way out of a smoke-filled deck full of vehicles on the Italianflagged 692'×118' ro/ro container vessel Grande Costa d’Avorio.

During January hearings in Union, N.J., Newark firefighters testified that they had no prior experience or formal training for fighting shipboard fires.

with tremendous pools of qualified mariners. I’m not talking about bringing in international labor to substitute for U.S. workers. I’m talking about a sponsorship program for those who have the skillsets that are necessary for this industry.”

The concept, he said, is to develop and implement a targeted visa program that would offer a fast track to citizenship for skilled mariners who would receive wages and benefits equal to those offered on U.S.-flag vessels.

Such a plan has also piqued the interest of the inland barge industry, which has been hit hard by the worker shortage. Norton makes “a pretty good point,” said Del Wilkins, a vice president at Canal Barge Co., and president of Illinois Marine Towing, a CBC subsidiary. “I think there’s something there” to pursue.

Maritime labor unions are not onboard, however. “Opening the door for non-U.S. citizens to work aboard U.S. vessels does nothing to solve the root cause of the problem,” Adam Vokac, president of the Marine Engineers’ Beneficial Association (MEBA) said. “In fact, it would be the final nail in the coffin of the U.S. Merchant Marine.”

for over 25 years.

According to testimony, the fire apparently started in a 2007 Jeep Wrangler that stevedores employed as a “push vehicle” to nudge cars up steep ramps to the vehicle decks, where a mix of 1,200 used and new vehicles were bound for Africa.

As the fire spread, the ship’s crew activated a car-

bon dioxide suppression system. When city firefighters arrived around 9:30 p.m., they were briefed by the ship’s chief Benito LaFauci and began ascending stairs to upper decks.

Answering questions from the Coast Guard panel, Newark fire battalion Chief Al Maresca said it was his first time serving as a firefighter on a ship. The Newark firefighters had no experience that he knew of with fires on large commercial vessels, and “just a lack of knowledge of ship [fire] fighting,” he said.

On Deck 10, Newark fire captain Oswald Robetto was with Acabou and Brooks as they made their way in zero visibility, air running low in their oxygen tanks as they traced their way along a fire hose laid on the deck as a lifeline for escape. But the line had been kinked, and the three men became separated, Robetto testified.

Robetto found his way to a wall along the car deck, and to a stairwell door. Rescue teams found Acabou and Brooks trapped amid the cars – apparently victims of carbon monoxide, testified U.S. Navy Dr. Bryan Platt, a U.S. military medical examiner who consulted on autopsy results.

Early findings from the investigation led the Coast Guard to issue a Nov. 20 marine safety alert, noting that city firefighters at Port Newark “had little to no maritime firefighting training, experience, or familiarization with cargo ships of any type.”

BY DAN BOOKHAM

BY DAN BOOKHAM

Dan Bookham is a vice president with Allen Insurance & Financial. He specializes in longshore, offshore and shipyard risk. He can be reached at 1-800-236-4311 or dbookham@ allenif.com.

Insurance Watch

How to be attractive to insurers

How can a workboat company position itself to be attractive to insurers? There’s no one-sizefits-all solution. Insurance is a custom product that considers the specific risks your company faces as well as the strength of your management, procedures, experience, and past claims history.

However, there are some general practices that can help your company stand out when insurance agents, brokers and companies are assessing who is best in class. These include:

• Developing a strong risk management program. This can help to identify and mitigate potential risks, which can make a company more attractive to insurers.

• Maintaining a good financial track record. Insurers are more likely to be interested in insuring a company with a strong and stable financial story to tell.

• Having a clear and concise safety policy. This can help demonstrate to insurers that a company is committed to safety and help to reduce the likelihood of accidents and claims.

Being open and transparent with insurers. Insur-

BY DANIEL J. HOERNER

BY DANIEL J. HOERNER

Daniel J. Hoerner is a maritime attorney with Mouledoux, Bland, Legrand & Brackett LLC. He can be reached at 504-595-3000 or dhoerner@mblb. com.

Legal Talk

Navigational rules violations and manslaughter

Often, the reach of admiralty law affects civil disputes. This includes cases that involve vessel collisions, seamen’s personal injury claims, and disputes relating to shipping and carriage contracts.

From time to time, however, events arise that spill over into the realm of criminal law. Criminal acts are generally governed by state law or “shore-side” federal statutes. But misconduct in vessel operations can also constitute a maritime criminal offense and result in federal prosecution in the courts’ exclusive admiralty jurisdiction.

Such was the case in United States v. Echevarria, which stemmed from a federal involuntary manslaughter indictment for the reckless operation of a powerboat off the coast of the Bahamas that resulted in the deaths of two people. The 2020 boating accident occurred when the defendant’s boat struck a charted high-tide elevation marker while traveling at a high rate of speed.

ers respect companies that are willing to be honest and clear about their operations. This includes providing insurers with all the information they need to assess the company’s risk profile.

Working with your agent to look for the best insurance rates based on your insurance history and current exposures. Often this means getting several quotes (if available), but it can also mean listening when your agent advises you to stay put with your current carrier.

Don’t get a reputation for changing insurance companies too frequently. It takes a while for insurers to learn the ins-and-outs of your business (and to generate a profit − there’s a lot of work up front in a new account). Loyalty is a two-way street in insurance. If you show the same amount of loyalty to your insurer that you expect from them it will pay dividends over time in pricing and claims.

Get certified. There are a several certifications that companies can obtain to demonstrate to insurers that they are committed to safety and risk management. These certifications include the International Organization for Standardization O 9001, ISO 14001, and the Occupational Health and Safety Assessment Series 18001.

The vessel was heavily damaged, and its occupants were ejected. The U.S. Attorney’s Office for the Southern District of Florida, in coordination with the Coast Guard, pursued charges against the vessel operator for failing to maintain a proper lookout and proceeding at an unsafe speed.

The legal authority for these charges is published under Rules 5 and 6 of the International Regulations for Prevention of Collisions at Sea, the companion rules to the domestic Inland Rules of the Road. Both mandate the operating requirements for vessels on navigable waters. The location of the accident and nature of the underlying activity allowed the matter to be tried within the court’s special admiralty jurisdiction.

The defendant operator opted for a guilty plea in lieu of contesting the issues at trial, which precluded litigation of other questions in the case, including whether the operator was impaired by alcohol at the time of the crash. He was sentenced to three years and eight months in prison pursuant to federal sentencing guidelines.

This case serves as a reminder that mariners face the risk of criminal prosecution and jail time, separate and apart from civil liability, when the unsafe operation of a vessel results in death.

Offshore wind developers swap ownership, submit new bids News Bitts

In a urry of actions, offshore wind developers traded joint ventures off New York for sole ownership, rebid into the state’s latest solicitation, and withdrew from previous agreements with Maryland.

Equinor and bp announced in January they will split their joint ventures, with Equinor taking full ownership of the Empire Wind 1 and 2 projects, and bp assuming full ownership of the Beacon Wind project. Equinor said it is rebidding the 810-megawatt Empire Wind 1 project into New York’s fourth solicitation.

Joint venture partners Ørsted and Eversource likewise are rebidding their Sunrise Wind proposal, months after New York utilities regulators rejected all the companies’ requests to renegotiate existing power purchase agreements.

In Maryland, state of cials and Ørsted agreed to terminate agreements for the Skipjack 1 and 2 projects, with an eye toward “future offtake opportunities.”

The moves are part of developers’ and state energy planners’ attempts to recover from widespread turmoil when it became clear that power purchase deals were not nancially viable. Already several years into development, Empire Wind’s contribution to New York’s wind power infrastructure will remain redeveloping the South Brooklyn Marine Terminal as a future hub for East Coast offshore wind. Equinor is taking on bp’s 50% ownership of SBMT as well.

“Empire Wind 1 is ready and so is Equinor,” said Molly Morris, president of Equinor Renewables Americas. “New York has demonstrated its commitment to offshore wind and this project will play a foundational role in driving that commitment forward.”

Empire Wind 1 “is in a clear position to move forward” with a new bid to New York energy planners, “while Empire Wind 2 will be further matured for future solicitation rounds,” according to Equinor. Meanwhile, bp of cials offered few speci cs about the future of Beacon Wind, other than it may pursue a new Offshore Wind Renewable Energy Certi cate (OREC) purchase and sale agreement for the Beacon Wind 1 project.

— Kirk MooreOver 1.3 million more riders boarded WSF ferries in 2023

Over 1.3 million more riders boarded Washington State Ferries in 2023, compared to the previous year, WSF announced in January. The 7.4% spike pushed annual ridership to nearly 18.7 million last year. For the second year in a row, the rise in ridership was fueled by a large jump in walk-on passengers. The number of walkons soared by nearly 487,000, or 14.2%, as tourism and in-person work continue to rebound from the Covid-19 pandemic.

Pilot program to provide San Francisco travelers with water shuttles

Navier, a creator and operator of zeroemission maritime vessels, announced in January a pilot program to provide water transit services to San Francisco Bay Area commuters. Stripe, a financial infrastructure platform for businesses, will be Navier's initial partner in this program, with Navier providing water shuttle services for Stripe employees from Larkspur, Calif., to Stripe's U.S. headquarters in South San Francisco.

New Orleans port awarded $74 million terminal grant

ThePort of New Orleans (Port NOLA) will receive $73.77 million from the federal government to assist in building the Louisiana International Terminal (LIT) project. Port NOLA said LIT will provide an efficient gateway for the movement of cargo on the Mississippi River and the U.S. inland waterways.

Riverboat Gamblers

Overnight riverboat cruises have bounced back from the pandemic’s economic woes.

By Ben Hayden, CorrespondentThe Covid-19 pandemic brought the passenger cruise industry to a standstill for nearly two years. But fast forward to 2024, and passenger numbers are expected to surpass the pre-Covid levels of 2019. Ocean-based cruises dominate the overnight cruise sector of the maritime industry, but overnight riverboat cruises on the nation’s

rivers and other waterways have carved out their own niche, offering a distinct and intimate exploration of America’s waterways.

The U.S. river cruise market, valued at $95.4 million in 2022, anticipates a 20.8% compound annual growth rate from 2023 to 2030, according to market analysis by Grand View Research. The U.S. river cruise market is expected to reach $431.1 million by 2030.

Regionally, the U.S. market

is segmented into the Mississippi, Columbia, and Snake rivers; Alaska; and the Great Lakes. The Mississippi River, holding a 68.2% market share in 2022, remains dominant with a high penetration rate and growth potential.

American Queen Voyages (formerly American Queen Steamboat Company) operates three vessels on the Mississippi, while American Cruise Lines (ACL) has ve. In 2022, Viking Cruises introduced the 386-passenger

Viking Mississippi to the waterway for voyages between New Orleans and St. Paul, Minn.

Operating on the Mississippi River has its challenges, especially when it comes to water levels. Lack of rainfall along the Mississippi from Minnesota to New Orleans in 2023 led to record low water levels for the river and its tributaries.

“My understanding is that the Mississippi River levels have been challenging to the overnight riverboat operators,” said John Groundwater, executive director of Passenger Vessel Association. “It is because of their level of professionalism and training that they have been able to operate successfully.”

AMERICAN QUEEN

AQV owns four paddlewheel overnight riverboat cruise vessels. The six-deck, 418'×89' American Queen is the largest steamboat in the fleet, built in Morgan City, La., at McDermott Shipyard, in 1995 and refurbished in 2017.

The American Duchess, a four-deck, 341'×98 vessel, was built by Nichols Brothers Boat Builders, Freeland, Wash., in 2017 and refurbished in 2023.

The American Countess, a 318'×79' paddlewheeler, was built in Houma, La. by Gulf Island Shipyard, Houma, La.

These vessels offer passenger capacities of 436, 166, and 246, respectively, and paddlewheel experiences along the Mississippi, Ohio, and Tennessee rivers.

The only AQV riverboat that doesn’t operate on the Mississippi River is the American Empress, formerly

Riverboat Cruises

known as the Empress of the North. The 360'×59'×12.5' diesel-electric paddlewheeler was built in 2002 by Nichols Brothers and refurbished in 2014. It navigates the Columbia and Snake rivers, accommodating 217 guests.

AQV announced last year that the cruise line would exit the Great Lakes market after the 2023 season and focus on river cruises.

After the season ended in late November, AQV said it would sell the Ocean Navigator and Ocean Voyager coastal cruise ships.

The ships, first named the Cape May Light and Cape Cod Light, were built in the U.S. in the early 2000s for Delta Queen Coastal Voyages

AMERICAN CRUISE LINES

American Cruise Lines, with 19 vessels ranging from 90 to 180 passengers, focuses on small-ship cruising. The Guilford, Conn.-based company has been expanding its eet since the cruise

line’s rebirth in 2000 and currently has ve more new ships under construction, all scheduled for delivery over the next two years. These are in addition to the three ships built by ACL’s Chesapeake Shipbuilding in Salisbury, Md., last year.

Of the ve underway, two are coastal cats. ACL christened the second of four 100-passenger coastal cats, the Ameri-

can Glory, in Key West, Fla., in January. The coastal cats boast shallow drafts of 6'6".

“Their shallow draft is really the key to a lot of the new itineraries,” said Charles B. Robertson, ACL’s president and CEO. “This can be a low-speed hull form which really allows us to get creative with the draft.”

Robertson said his company has recovered quickly from the pandemic. “We’re now signi cantly past pre-Covid levels. We lost the entire 2020 season during Covid, but we really focused on the shipyard production, and have doubled the production capability of the shipyard since the pre-pandemic level.”

Since the pandemic, the shipyard has delivered six ships to ACL. “That has been absolutely enormous for transforming American Cruise Lines,” Robertson said. 2023 was the rst time the shipyard delivered three ships to ACL in a year.

Going forward, Robertson and ACL are optimistic. He sees the cruise line’s potential for growth. Domestic travel is increasing, and consumers like small ships. “We really believe the difference between a 180-passenger boat and a 100-passenger boat is substantial in the consumer’s mind,” he said. “They really value the smallest cruise ships out there.”

VIKING CRUISES

Viking’s 450'×75', 386-passenger riverboat, the Viking Mississippi, built by Edison Chouest Offshore (ECO) at its La Ship shipyard, Houma, La., was delivered in the summer of 2022. The vessel was purpose-built for the Mississippi River.

“It is a proud moment that this new

ship has met an American waterway for the rst time,” Torstein Hagen, chairman of Viking, said when the vessel was oated out in March 2022 at La Ship, noting that Viking passengers had been clamoring for a Mississippi excursion.

Nonetheless, Viking’s move in 2022 into the Mississippi River overnight market was not without controversy.

Since Viking is a Swiss-owned company, some in the industry questioned whether it would try to operate in the U.S. in violation of the Passenger Vessels Services Act, which, like the betterknown Jones Act, prohibits foreignflagged vessels from sailing from one U.S. port directly to another without calling on a foreign port in between.

But Chouest created River 1 LLC, an affiliate, that would time-charter “a cruise vessel that it would construct, own and operate, to Viking USA, a non-citizen,” for an initial term of eight years with contract options extending to 30 years, according to documents on Marad’s site from 2022.

U.S.-flag operators questioned Marad’s initial opinion that the deal was a time charter and not a bareboat charter. Their interests must be considered before the agency “acts to change the standards and processes it has historically applied in ‘time charter’ determinations,” operators told Marad.

“Here, the economic consequences are substantial, since approval of the charter means entry into the Jones Act coastwise passenger market by a large foreign cruise line.”

In the end, Marad came down on the side of Chouest and Viking.

Apparently, all is going well. As of early February, the company listed nine Mississippi River cruise itineraries on its website — seven in 2024 and two in 2025. Six will depart from New Orleans, one from St. Louis, one from St. Paul, Minn., and one from Memphis, Tenn.

WorkBoat reached out to Viking, but the company declined to comment.

GO WEST

In the Pacific Northwest, Grand View Research projects a 20.4% growth rate for the Columbia and Snake rivers region from 2023 to 2030. The Pacific Northwest Waterways Association (PNWA) noted that river cruise ship

STACKING THE DECKS

Riverboat Cruises

demand has steadily increased over the last 15 years and represents a growing market in the region. Each summer, thousands of passengers see the Columbia and Snake rivers from cruise vessels traveling the 325 river miles between Astoria, Ore., and Clarkston, Wash. Over 20,400 passengers and crew visited in 2023 and contributed over $21 million to communities along the two rivers, PNWA said.

Overall, the overnight riverboat cruise industry has experienced a remarkable resurgence despite the challenges posed by the pandemic. The Mississippi River remains a dominant force in this market, while it’s expected that the Pacific Northwest will contribute to the rising demand for river cruises. This growth reflects a broader trend in the industry. With an aging U.S. population, the riverboat cruise industry should continue to attract passengers that are seeking more intimate ways to experience America’s scenic waterways.

CONSTRUCTION ACTIVITY AT WORKBOAT YARDS

Master Boat delivers fi rst US all-electric tug to Crowley

Master Boat Builders, Coden, Ala., has delivered the 82'x40'x17'9" eWolf, the rst all-electric, ship-assist harbor tugboat in the U.S., to Jacksonville, Fla.based Crowley

The eWolf was designed by Crowley’s engineering services team with a 16'5" draft. It will operate with zero emissions while providing the complete performance capabilities of a traditional tug.

Crowley said it is committed to improving air quality through battery energy for the vessel and port technology, including a shoreside, microgrid charging and storage station at the Port of San Diego, where the tug will operate.

The industry has been anticipating the new tug’s delivery for more than two years. During a visit to Master Boat in September, Garrett Rice, the shipyard’s president, explained that part of the delay was a result of the Coast Guard’s never having had to sign off on

this kind of tug. There has never been a similar tug up for certi cation in the past. “Our industry has to be pushed to build toward innovation,” he said. “Our government doesn’t work fast.”

Main propulsion comes from 6.2MWh battery power and two 2,100-kW electric motors spinning two azimuth thrusters. There are two switchboards — a DC grid and AC switchboard. For longer transits, the new tug has twin 300-kW generators. (Propulsion manufacturers’ names were not provided by Crowley.)

The tug will have a running speed of 12 knots.

“The eWolf will provide services through its advanced vessel control technology and rst-in-class energy features, while providing the safety, quality and reliability that Crowley and our mariners are known for,” James Fowler, senior vice president and general manager of Crowley Shipping, said in a statement. “We are thrilled to reach this important achievement for our company

and the U.S. maritime industry through the collaboration with our partners.”

Crowley said the all-electric tug will generate 178 fewer tons of nitrogen oxide (NOx), 2.5 tons less of diesel particulate matter and 3,100 metric tons less of carbon dioxide (CO2) over the rst 10 years of its operations — the equivalent of removing 350,000 gals. of gas from use, according to EPA calculations. The vessel uses ABB’s integrated electrical propulsion system.

Keegan Plaskon, director of business development at the American Bureau of Shipping (ABS), said during a conference session at the recent International WorkBoat Show that the eWolf complies with U.S. shipping industry standards and will be the rst Jones Act-compliant all-electric tug.

So, what is the future? Battery-driven electric motors cannot be retro tted and placed in existing tugs, but alternative fuel engines can be retro tted. Master Boat’s Rice said during the eWolf session at the WorkBoat Show that “it’s costly to retro t an already existing vessel fully. Federal and state grants can help fund new fully electric vessels.”

On deck will be a Markey Machinery DEPC-48-50-hp electric render/ recover winch.

“The eWolf demonstrates where the maritime industry can go, in terms of both innovation and sustainability, with solid partnerships between owners, designers, suppliers and shipyards,” said Rice. “We are proud to have partnered with Crowley in the construction of the eWolf and look forward to seeing her at work in San Diego very soon.”

The 200-grt eWolf has an estimated bollard pull of 70 short tons. Tankage includes 9,800 gals. of fuel and 750 gals. fresh water.

“We attract people to the marine industry with these new developments,” Crowley Engineering’s Coulston Van Gundy said during the WorkBoat Show panel session. “We must provide innovative, sustainable vessels for this industry to stay ahead for our customers and the next generation.”

— Ken Hocke and Carli Stewart

St. Johns Ship Building, Gulf Craft delivers two of five CTVs for Windea

Incat Crowther, Lafayette, La., recently announced the delivery of the rst two of ve 99'×33'×5' aluminum crew transport vessels (CTVs) for Windea CTV LLC, a partnership between Hornblower Wind and MidOcean Wind

St. Johns Ship Building, Palatka, Fla., delivered the Windea Courageous and Gulf Craft, Franklin, La., delivered the Windea Intrepid. The vessels are already onsite in New Bedford, Mass., supporting the construction of the Vineyard Wind 1 project. The new Bureau Veritas-classed vessels are the largest newbuild CTVs delivered to the offshore wind industry in the U.S. to date.

The construction of this series of Incat-designed vessels at St. Johns’ kicks off the shipyard’s new dedicated focus on the building of high-speed aluminum vessels. The groundwork was laid more than two years ago through multiple facility modi cations and the acquisition of new production equipment such as a CNC router for the processing of nonferrous metals and composite materials.

St. Johns’ holding company, Americraft Marine Group, was launched to support and strengthen the U.S. shipbuilding industry and infrastructure and envisions St. Johns Shipbuilding as a center of excellence in Jones Act shipbuilding, shipyard of cials said.

“This delivery marks a proud moment of validation,” said Ed Sheets, executive vice president and director of business strategy for Americraft Marine Group.

The USCG Subchapter L-certi ed CTVs, which have a depth of 14'3", can transport 24 technicians. There are also accommodations for a crew of six.

In addition to spacious seating, the main deck level of the superstructure features a large galley and mess area, two bathrooms and dedicated internal storage space.

The upper deck level features a large, elevated wheelhouse as well as two single cabins, two double cabins and

BOATBUILDING BITTS

Ribcraft , Marblehead, Mass., recently delivered a 16' Ribcraft 4.8 to the Greene Volunteer Fire Department in Greene, Maine. The specialized RIB expands the department’s response capabilities while providing a safe platform for rescue missions. Funded by a grant through Firehouse Subs , Ribcraft worked with the department to build a boat that met all their operational requirements. Powered by a 50-hp Yamaha outboard, the boat reaches speeds of more than 25 mph. With a dark gray, multi-chambered, heavyduty Hypalon tube, the Ribcraft 4.8 is designed to provide a durable, stable, and seaworthy platform regardless of the operational waters and sea conditions. The 4.8 features a deep-V hull, high-swept bow, and excellent open deck space for rescue operations, personnel, and equipment.

Austal USA , Mobile, Ala., handed over the Cody (EPF 14) fast transport vessel to the Navy recently. Austal and the Navy’s expeditionary fast transport (EPF) program team completed acceptance trials on the EPF 14 in the Gulf of Mexico in December. The trials involved the execution of intense comprehensive tests by the Austal-led team while underway and demonstrated to the Navy the successful operation of the ship’s major systems and equipment. Cody is the first EPF Flight II vessel Austal has delivered to the Navy. EPF Flight II vessels feature enhanced afl oat medical capability and will provide critical combat care in austere and contested operating environments. The EPF’s main propulsion comes from four 20V8000 MTU diesel engines that turn four Wärtsilä steerable, reversing waterjets through four ZF 60000 NRTH gearboxes. The system gives the Cody a speed of 33 knots with 380 metric tons of cargo and 10 knots in sea state 5.

Key West, Fla.-based Yankee Freedom has awarded a contract to Gladding-Hearn Shipbuilding, Duclos Corp. to build a 300-passenger, highspeed catamaran. The new cat will provide passenger service

ON THE WAYS

three bathrooms for up to six crew. A large, 1,080-sq.-ft. forward deck and a 378-sq.-ft. aft deck provide ample space for carriage of cargo to offshore wind installations. Each vessel can transport a deadweight of 50 metric tons.

Main propulsion comes from four Volvo Penta D13 marine diesel engines with a quad Volvo Inboard Propulsion System

(IPS). Each vessel is also future-proofed and ready for the retro t of the Volvo parallel hybrid system. The boats have a total of 2,760 hp at 2,250 rpm each. The CTVs have a running speed of 25 knots and a maximum speed of 27 knots.

Transfer capability is enhanced by the Incat Crowther resilient-bow technology, which reduces impact forces applied

during wind turbine boat landings.

Ship’s service power is the responsibility of two Kohler 40EKOZD gensets.

“The delivery of these two new CTVs builds on Incat Crowther’s proven track record of designing state-of-the-art, operationally ef cient and exible CTVs for operators servicing the expanding global offshore wind industry,” said Incat Crowther’s U.S. managing director Grant Pecoraro. “The design and construction of these 30-meter CTVs has been a collaborative effort with MidOcean Wind and the respective builders ensuring the design is tailored speci cally to meet the unique set of domestic regulations in the U.S.”

Tankage includes 9,510 gals. of fuel oil and 925 gals. fresh water.

The third and fth vessels in the series are under construction at St Johns, and construction of the fourth vessel is well underway at Breaux Brothers Enterprises, Loreauville, La.

— K. Hocke

Brix Marine delivers 40' high-tunnel passenger cat for Hawaii

Brix Marine, Port Angeles, Wash., has delivered a 29-passenger, 40'×14' high-tunnel catamaran (HTC) aluminum tour boat to Haleiwa Shark Tours, Oahu, Hawaii.

The open-cabin Kamohoali’i is powered by twin Volvo Penta 380hp D6 diesel engines. With a Seastar Optimus inboard steering system and EPS smart cylinders, the vessel is designed to ensure dynamic propulsion, optimal performance, and precise maneuverability through Hawaiian waters.

Brix said a standout feature of Kamohoali’i is the Garmin navigation system, including a 12" Volvo glass cockpit screen and a 7" multifunction display. The Kamohoali’i also has a GPS, AIS Class B transponder and a VHF radio.

The vessel is equipped with two helm stations: the main station and a second station on the starboard side cabin aft. The design allows for enhanced visibil-

ity and control, providing the crew with exibility and ensuring optimal positioning for the best shark encounters.

The dimensions provide ample space for 29 passengers and two crew, offering an experience that aligns with the company’s commitment to sharing Hawaiian culture and the signi cance of sharks.

Additionally, Kamohoali’i’s advanced safety features, including watertight hatches, bilge pumps, and emergency systems contribute to creating a secure environment for passengers and crew, allowing unforgettable experi-

BOATBUILDING BITTS

between Key West and the Dry Tortugas National Park. Delivery of Yankee Freedom IV is planned for 2026. The 112.5'x31.61 all-aluminum catamaran will draw 6.9'. It will be powered by a pair of MTU 12V-4000M65R EPA Tier 4-compliant diesel engines, each delivering 2,000 hp at 1,600 rpm. The engines will turn nibral propellers through ZF 8000 gearboxes. The ferry will be equipped with an Atlantic Detroit Diesel-Allison 80-kW EPA Tier 3 genset with the addition of exhaust gas treatment. A Humphree active interceptor ride control system will be installed to control vessel pitch and roll. Top speed will be over 28 knots, with a deadweight of 29.5 metric tons. Netherlands-based Damen Shipyards has been awarded a contract to build four fully electric car ferries for BC Ferries. The new ferries will be used for short-range services in the coastal waters of British Columbia. The order will raise the total number of ferries that Damen has supplied

ences that foster a connection between visitors and the spiritual essence of sharks, Brix said.

“Kamohoali’i is a testament to Brix Marine’s commitment to pushing the boundaries of marine innovation,” Perry Knudson, managing director of Brix, said in a statement. “Our goal is to not only design and build great vessels, but also to support ventures like Haleiwa Shark Tours in their mission to educate and inspire through responsible marine tourism.”

The new tour boat is Coast Guard certi ed, Subchapter T

to BC Ferries in recent years to 10. As opposed to the previous ferries, these latest additions will be the first to use 100% electrical power. The vessels will be based on Damen’s double-ended Islandclass RoRo 8117 E3 design. Each will be capable of carrying up to 47 vehicles and 390 passengers. Battery packs with a capacity of 2,000 kilowatts will supply the electricity for the power trains.

Learning Curve

By Ben Hayden, Correspondent

By Ben Hayden, Correspondent

In September, Philly Shipyard Inc., Philadelphia, delivered the 524.3'×88'6" Empire State, the rst of ve new purpose-built, modern training vessels for the U.S.’s state maritime academies.

The U.S. Department of Transportation’s Maritime Administration (Marad) new vessel program — known as the national security multimission vessels (NSMVs) — was designed to provide world-class training for future U.S. mariners and to support humanitarian assistance and disaster relief missions in times of need. Marad has not built ships in more than 50 years.

With a draft of 24.6', the Empire State, which can berth up to 760 people, will serve SUNY Maritime College, Bronx, N.Y.

This next-generation training eet will address a critical shortage of quali ed of cers necessary to crew government and commercial-owned sealift ships.

The NSMVs feature numerous instructional spaces, a full training bridge, and have space for up to 600 cadets to train in a rst-rate maritime academic environment at sea. State maritime academies graduate more than half of all new of cers each year — the merchant mariners who help keep cargoes and the economy moving. Many also support U.S. national security by crewing military sealift vessels.

In addition to being a state-of-the-art training and educational platform, each ship will feature modern hospital facilities, a helicopter pad, and the ability to accommodate up to 1,000 people in times of humanitarian need. Adding to the NSMVs’ capabilities, the ships will provide roll-on/roll-off and container storage capacity for use during disaster relief missions.

COMMERCIAL MINDSET

Tote Services Inc., the prime contractor for Marad’s NSMV program, has brought a commercial mindset to the program. Tote’s approach involves aligning government requirements with commercial shipyards, resulting in substantial efficiencies. Tote is experienced with building U.S.-flag ships using commercial design standards and commercial construction practices that are consistent with the best interests of the federal government.

In a recent conversation with WorkBoat, Ben Christian, head of the NSMV program at Tote, shed light on the company’s innovative vessel construction management (VCM) model, highlighting the benefits and challenges of overseeing the construction of these ships.

“The difference was that when the government looked at it, they figured in doing the government process, and looking at similar government programs. It’s probably a $750-million-plus vessel. And the average cost under the job services as the VCM was $320 million per ship,” Christian said. “It’s not necessarily apples to apples, because they would be different ships, right? We went and built a commercial vessel because that was the need. But the government could have overbuilt it to a government standard, to a MIL-SPEC (military specification) standard and spent a whole bunch more money that added no useful functionality as far as the end user is concerned.”

Herbert Engineering Corp. provided the guidance design, close to a fully developed contract design, covering ship structure, full ship finite element analysis (FEA), arrangements, machinery sizing, piping diagrams, electrical load analysis, one-line diagram, high voltage switchgear specifications, and intact and damage stability. Herbert engineering used AutoCAD for the drives, including a full-scale finite element model using Maestro ship modeling software.

Empire State’s main propulsion comes from four Wabtec 16V250MDC diesel engines producing 5,625 hp each. The mains are connected to GE Power Conversion N3HXC 1250L/10 4,500-kW

propulsion motors.

“We have a contract for the construction of all five ships to provide technical oversight and assistance to Marad,” said Eugene van Rynbach, vice president at Herbert Engineering. “As part of that we carry out monthly visits to check on the construction of the ships to make sure they are meeting the intent of merit and the intent of the guidance design, and also to provide input to Marad on schedule and progress and quality of construction.” Van Rynbach is responsible for issuing Marad a monthly status report.

ACADEMY INPUT

Capt. Morgan McManus, Empire State’s master, discussed the involve-

ment of the academies in the early stages of design.

“Herbert Engineering got input from all the SMAs early in the design process on what was needed. “If you had your dream training ship, what things would you need on it? It’s funny, simple stuff comes back like more public bathrooms, more laundry machines. You have 500 cadets on board,” said McManus. “One thing was the engine control room (ECR). On the first design, the ECR space was pretty small. It was more based on commercial space, and our engineering departments noted we need to have a bigger ECR because we need to fit more students in there. We needed to have an ECR that can fit like 20 people

COVER STORY

EMPIRE STATE SPECIFICATIONS

Builder: Philly Shipyard

Designer(s): Herbert Engineering and DSEC

Owner: Maritime Administration

Vessel Construction Manager: Tote Services LLC

Mission: Cadet training and disaster response

Length: 525'1"

Beam: 88'7"

Depth: 55' 1 1/2"

Maximum Draft: 24' 1 3/8"

Main Propulsion: (4) Wabtec 16V250MDC, 5,625 hp (4,200 kW)

Propulsion Motor: (2) GE Power Conversion N3HXC 1250L/10, 4,500 kW

Propeller: Nakashima, 5.85m, fixed pitch 5.4285 m, 5-bladed, nickelaluminum bronze

Steering System/Controls: Kongsberg, 1 x RV650-3, rotary vane

Speed (knots): 18

Hull Construction: Steel

Cargo Deck: Aft container deck, RoRo garage

Crew/Passenger Capacity: 600 cadets; 100 officers, crew, faculty and staff; and 60 supplemental

Electronics/Navigation Equipment: (2) Furuno FAR-3330S radar; (2) FAR-3320 radar; (6) FMD-3300, ECDIS; (2) SDD GM Rack (2S), GMDSS; (3) GP-170, DGPS; DS-60, speed log; FE-800, echo sounder; VR-7000 voyage data recorder; (2) YDK (Yokogawa) CMZ900D gyro compass; (2) PT900A-P-N2-2S autopilot

Tankage: Fuel (MGO), 2,167 m3; salt water ballast: 3,551 m3; fresh water ballast, 1,275 m3; fresh water, 1,324 m3; lube oil, 28 m3

Ancillary Equipment/Systems: Bowthruster: combination type, tunnel/azimuthing; Kawasaki Rexpeller: KST-180LC/EMR, 1,800 kW; stern thruster: tunnel thruster type; Kawasaki side thruster: KT-88B3, 890 kW

Classification/Certification: American Bureau of Shipping (ABS) +A1, Training Ship, AMS, ACC, SPS, UWILD, CRC, CPS, ENVIRO, IHM, BWT Delivery Date: Sept. 8, 2023

in there. Okay, so they modified that.”

McManus also noted that the academy’s food service workers provided input to the flow of the galley layout.

“Philly Shipyard is an excellent yard. But their experience is and has been cargo ships where you have a small accommodations block and a lot of steel and paint throughout the ship.” Christian said.

Input from the academies paid off. “By the time we delivered one, we were already incorporating lessons learned into the steel fabrication in the early stages of construction for number two,” Christian said. “You can just rinse and repeat going forward.”

In addition, he said, “A lot of those things that are of a higher programmatic level, we were able to work through collaboratively between the shipyard and the government.”

That said, there was no time for dawdling. The next training vessel, Patriot State, destined for the Massachusetts Maritime Academy, is scheduled to be delivered in 2024. Meanwhile, keel laying for State of Maine (Maine Maritime Academy) and steel cutting for Lone Star State (Texas A&M Maritime Academy) was recently completed. Construction of Golden State (California Maritime Academy) is underway. All vessels are planned for delivery by 2026.

“We’ve got two in the water, three and four on the dock, and we’re about to cut steel on number five,” Christian said in January. “So, you have to pretty quickly take the ideas and move them back into the system.”

Christian emphasized that these NSMVs are sisterships, enabling them to be physically identical with interoperability for diverse operational scenarios. SUNY Maritime’s mariners have thus far cited the NSMV’s outstanding performance, stability, and maneuverability.

TRAINING

McManus discussed the vessel’s inaugural training voyage to Puerto Rico in January. “The vessel has a tremendous amount of flexibility,” he said. “We’re able to go through different permutations of running with all four engines online. You know, running a training ship with just two diesel generators online and having the others offline.

“The redundancy of the ship is great. You have two propulsion drive units to one shaft, so if you have a problem with one you can take it offline and you still have power. You’re still able to do 12-14 knots in trainee ship mode.”

McManus said he is impressed with the overall safety of the ship. “The high fog system for the accommodations, the internet system for the machinery spaces, a lot of integrated passive safety systems that students don’t even know about, or they now know that they’re there because they’re learning about it. But they’re just there in the background. So that makes it a great platform.”

McManus said the ship moves along almost effortlessly. “It’s so smooth. The diesel electric is so smooth that when we’re underway, you would barely notice you’re moving. Sometimes you look at satellite and say, ‘Okay, we’re moving along at 14 knots.’ This is a very smooth ride,” he said.

Empire State’s modern equipment and enhanced training environment was also mentioned by the SUNY mariners. One ongoing adjustment included the need for faster internet connectivity in times of humanitarian crisis. “If you

think about having 1,000 people on board in a disaster scenario, that can suck up a lot of bandwidth,” Christian said.

The NSMV program also addresses the shortage of quali ed of cers for government and commercial-owned sealift ships. With state-of-the-art technology, crew comfort, and safety enhancements, these NSMVs provide a superior training platform, attracting new talent to the maritime industry. “What we’ve heard from the schools is that this is a fantastic recruiting tool. When they’re doing campus tours and folks are showing up to SUNY Maritime College, they’re seeing (the vessel) before they even get on campus because it’s right there,” said Christian.

Tote Services envisions its model being adopted for noncombatant ships needed by the Department of Defense, the Army Corps of Engineers, and other services, driving a more commercial

approach to building the ships.

As the NSMVs set sail, they represent not just vessels, but a new way to approach government-sponsored shipbuilding programs. “This is the key to this collaboration,” Christian noted.

Whether you’re powering an offshore service vessel, a

vessel, or an inland pushboat, Louisiana Cat has

for your hard working fleet. We focus on you, the

and

reliability, safety and profitability of your business. Let us help you navigate every waterway. Visit us online to request an engine quote for your next project: www.LouisianaCat.com/Marine

“We had a shipyard that was willing to collaborate and saw us as a bene t, not as a hindrance to what they wanted to do. And we had a government team that saw value in having a commercial entity and were responsive.”

Pushy

A workboat’s most vital equipment package is its propulsion system.

By Ken Hocke, Senior EditorAccording to Merriam Webster, the word propulsion comes from the Latin word propellere, meaning “to push or thrust forward, compel to go forward.” Whatever the workboat, it must be able to thrust forward, be compelled to go forward. Otherwise, the boat is just a large metal object oating in the water.

Luckily for workboat owners, there are many methods of propulsion available — propellers, azimuth thrusters, Z-drives and L-drives, waterjets, controllable pitch propellers (CPP), tunnel thrusters, outdrive propulsion units — to name a few.

HUNDESTED PROPELLER

Hundested Propeller has operated out of Seattle for over 35 years. A couple of years ago the company went looking for a dealer that could sell its products on the East Coast. That’s how AB-Marine in Providence, R.I., got involved.

“Hundested is one of the rst to

pioneer the controllable pitch propeller technology,” said Brendon Prior, one of AB-Marine’s founders. “They were looking for someone to handle their equipment on the East Coast. That’s us.”

Prior said a CPP has blades that can be rotated around its long axis to change the blade pitch.

With its pitch varied to absorb the maximum engine power, the CPP is ef cient for the full range of rotational speeds (RPM), operational conditions (load) and vessel speed. The result is reduced fuel consumption, reduced emissions, and less noise.

the required vessel speed.

Commercial vessels need more power when they are fully loaded then when they’re empty. By adjusting the propeller to the optimal pitch, the engine can operate at maximum power without overloading the system. At lower than maximum vessel speed, fuel consumption can be considerably reduced, and cruising range extended, by lowering the

When maneuvering a vessel with CP propellers, the engines will be on a xed RPM. Only the pitch is changed, providing instant acceleration, quicker speed from a standstill and more effective deceleration, making stopping quicker and safer.

AB-Marine sells controllable pitch (CP) systems for a variety of workboats such as ferries, tugs, coastal towing vessels, reboats, and small tankers.

“Among the CP systems we’ve installed are on a ferry in Miami, a ferry in Massachusetts, a sludge boat in New York and a reboat in New York,” said Prior. “The controllable pitch system is like changing gears in a car. The most important points are the controllability, fuel ef ciency, and reliability.”

Hundested’s CP gearboxes are designed and produced in house with builtin pitch control for the propeller. The hydraulic system of all CP gearboxes includes a double oil pump. One pump is utilized exclusively for the pitch control and the other is utilized for the clutch, a

possible shaft brake, and lubrication.

The gearboxes are manufactured for vessels from 300 hp to 4,500 hp, depending on engine RPM and the reduction ratio. All sizes have ground, case-hardened, helical gear wheels. “A lot of people don’t know about controllable pitch,” said Prior. “People who do have it, love it.”

Depending on what you want to do, you increase or decrease the pitch. Prior said many of the bigger, slower workboats have their CPPs in nozzles.

“With controllable pitch, you can ne tune your maneuverability and usually increase your fuel ef ciency by 30 percent, leaving your engine at cruise speed,” he said.

STEERPROP

Late last year, Finland-based Steerprop was chosen to supply advanced ice-class bowthrusters to the Canadian coast guard’s new polar icebreaker.

The ship is being designed and built at Seaspan Shipyards. When completed, the ship will be one of the most powerful icebreakers in the world.

The 492'×92' multimission icebreaker will have a displacement of 27,876 metric tons and accommodate up to 100 people.

With a Polar Class 2 (PC2) rating, the second highest ice class according to the International Association of Classi cation Societies (IACS), it will be able to operate in more dif cult ice conditions (including in multiyear ice) and for longer periods than any other Canadian icebreaker.

“The Arctic conditions require extreme reliability — reliability is always the most important thing. Our R and D has always taken this kind of ultimate dependability to be the foundation of everything we do,” said Steerprop’s Juho Rekola, director, sales and project management. “The propulsion system must be able to perform, day in and day out.”

Steerprop will equip the polar icebreaker with two arctic tunnel thrusters specially designed to meet the most demanding ice conditions, even without the protection of tunnel grids. This will be Steerprop’s rst delivery of this type

of ice-strengthened tunnel thruster. The delivery package also includes a bridge control system and an of ine oil ltering system.

Steerprop said it has designed an optimal solution for the scope and operational pro le of the icebreaker based on the company’s decades-long experience of delivering ice-classed solutions, and “ t for purpose” resolve.

In addition to optimizing operational performance, the fully integrated propulsion solution will be designed to increase reliability and safety, while reducing lifecycle costs and keeping maintenance requirements at a minimum.

ZF MARINE

ZF Marine announced in November the launch of the latest product in its azimuth thruster (AT) series, the ZF AT 90.

The new, well-mounted, Z-drive thruster is compatible with a wide range of commercial vessels, supporting max power of 1,978 kW/2,651 hp, increasing the power and thrust capabilities of its AT series.

Fully customizable to nearly any hull shape or vessel pro le, the ZF AT 90 is designed to be one of the most exible products on the market. It also supports auto-trolling. In combination with ZF’s ThrusterCommand, the system is designed to ensure precise and ef cient propulsion control, ZF said.

The ZF AT 90 can be used as part of a hybrid or fully electric system, requir-

ing reduced engine power during vessel operation, full electric sailing, dynamic positioning, and slow cruising while in electric mode, and more, ZF said.

“Whether a client is operating vessels in the inland waterways or has tugboats, ferries or any number of specialty vessels, such as dredgers, the ZF AT 90 offers signi cant advantages,” said ZF’s product manager, Walter Fienco.

SCHOTTEL

In January, Washburn & Doughty, East Boothbay, Maine, delivered the 93'×38' tug Grace McAllister to New York-based McAllister Towing.

Main propulsion comes from two Caterpillar 3516E Tier 4 engines delivering a total of 6,770 hp to twin Schottel SRP 490 Z-drive units, giving the tug a bollard pull of 85 metric tons.

Schottel’s RudderPropeller (SRP) is a 360° steerable Z-drive designed to combine maximum maneuverability and bollard pull with course stability during free sailing, always providing powerful thrust in the chosen direction, according to Schottel.

The company said it has installed more than 15,000 SRP systems in lowto medium-speed vessels.

The main distinguishing feature of the SRP is its combination of propulsion unit and azimuth steering, making a rudder superfluous and converting engine power into maximum thrust.

Old is New Again

New diesel engine options are coming late this year.

By Michael Crowley, Correspondent

By Michael Crowley, Correspondent

Workboat operators that are hankering for something new after years of relying on the same old diesel propulsion system often need time before making a major move in another direction. In the meantime, these operators have some diesel options to consider that won’t start to become available until the end of this year.

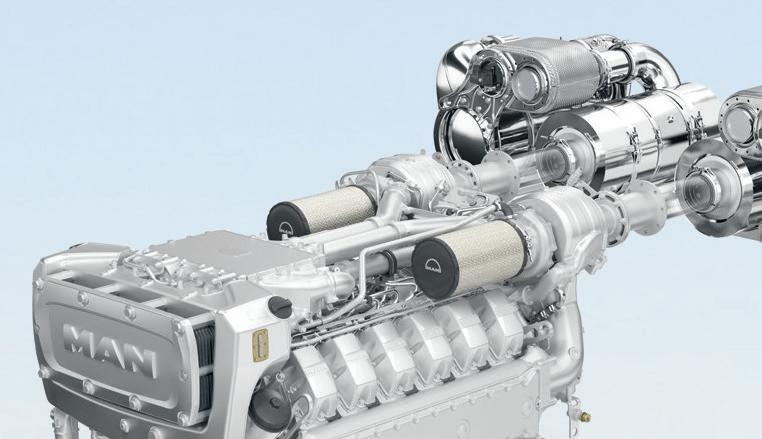

One of those will be part of a new MAN lineup of V12 diesels that are particularly appropriate for ferries, large pilot boats, pushboats and larger

crew transfer vessels (CTVs). Compared to MAN’s current V12 lineup, the new engines come with numerous improvements, including larger displacement, increased crankcase wall thickness, a new coolant pump, an optimized thermostat housing, reinforced engine block and a new crankshaft with larger bearing surfaces. These improvements make the engine “more reliable and more robust for workboat applications and increase durability before major overhauls,” said Jason Blume, sales manager, MAN Engines & Components in Pompano Beach, Fla.

The rst of the new engine lineup for the workboat market will be the 30-liter displacement, 1,650-hp MAN D3872, followed by a 1,450-hp version and lastly, a heavy-duty 1,250hp diesel. These are not spinoffs of MAN’s current V12 engine. They are based on “a completely new engine,” said Blume. The D3872 is currently undergoing eld trials.

The three new engines will take advantage of MAN’s compact exhaust after-treatment system that is being used with MAN’s current V12 engines. Blume describes it as “a really great aftertreatment system.” Custom-

Diesel Engines

ers “need more power, but also need a very compact aftertreatment system.”

The new V12 engines will be more powerful — up to 1,650-hp — but will be able to “keep the same compact modular aftertreatment system because the engines are so fuel ef cient.” The MAN D3872 will be available at the end of 2024. The MAN 1,450-hp model will be out in 2025 and the MAN 1,250-hp engine in 2026. All three new engines will be certi ed EPA Tier 4.

More immediately, MAN’s current V12 diesel, the D2862LE, with power ratings from 1,000 hp to 1,450 hp, had been out tted with a selective catalytic reduction aftertreatment system for EPA Tier 4, but in the past two months a diesel particulate lter was added to the exhaust aftertreatment package. This allows the D2862LE to meet core California Harbor Craft emission requirements set by the California Air Resources Board (CARB) for vessels desiring to operate in California harbors such as San Francisco Bay. That quickly opened the state’s harbor business to MAN. “In San Francisco Bay we have some potential pilot boats and ferries” that could now be powered with the V12, said Blume. In Europe, the V12 is already powering vessels along inland waterways.

YANMAR

Yanmar is another marine engine manufacturer not content with doing what has previously been done.

“It was time to upgrade technology, and develop a replacement engine for our older design,” said Carl Micu, Yanmar’s division manager of power solutions. Thus, the introduction of the

6GY135W diesel with a 500 hp (continuous) rating in the 14.6-liter category, which goes up to 803 hp at the EPA Tier 3 cutoff. “We’ve not had an engine in this displacement size for a while.”

Nathan Stabile, a Yanmar marine engineer, said the new engine “is heavy-duty purpose built. It’s not an ultra-light truck engine.”

because “Yanmar tries to pay attention to bringing the cost of ownership down in the long run and bringing up reliability.” A multistage fuelinjection system reduces emissions by 80% with the common-rail system.

Micu feels that the new engine will work well in several workboat markets including smaller twin-screw tugs and towboats in the 1,000-hp range, as well as shing boats and passenger vessels. For tugboats, especially, Stabile emphasizes that the 6GY135W “has a very good torque curve. It’s going to hold its rpm and hold its power where a tug typically operates — 1,200- to 1,400-rpm range.” That’s also “the best fuel consumption area for the engine.”

Serviceability is a feature of the 6GY135W diesel. For instance, the 6GY135W engine features side panels for individual cylinder heads allowing direct access to connecting rods and crankshaft. “You can change a single kit out without having to take 97% of the engine out,” noted Micu. That reduces the amount of time spent servicing the engine.

“Side panels are new in this engine size,” added Stabile. “It makes quicker service time and lowers the cost of operation.”

If the engine does have to be rebuilt, “it’s designed to be rebuilt in place, without having to pull the engine.” That, Micu said, is

An added bene t of choosing Yanmar is the gearbox. “Yanmar is the only manufacturer to build the engine and gearbox,” said Micu. When an engine and gearbox are purchased together “they are coupled together and tested together” at the factory. The bene t to that arrangement “is you only have to call one organization to do the service,” said Stabile.

About 20 6GY135W engines are operating in Japan. The 6GY135W should be commercially available in the U.S. and Canada in the fourth quarter of 2024. The rst engines released will be IMO Tier II compliant, followed by IMO Tier III with an SCR system.

AIRMAR

Beating that fourth quarter 2024 MAN and Yanmar release date is Airmar’s digital SmartFlex Diesel Flow Meter, which was product ready in June. The sensor is designed to work with an Airmar SmartBoat Module as a single or dual-chamber ow meter with a ow rate reading from six to up to 4,000 liters per hour, depending on the model. The dual-chamber model combines measuring chambers for supply and return fuel lines in a single housing. The difference between ow rates is the fuel consumption. A single-chamber ow meter can be matched up with another singlechamber ow meter for fuel burn and consumption data.

Airmar’s fuel- ow sensor is a kind of slip-ring technology, made up of a pivot post and around it a ring. “As the fuel enters the chamber it turns the ring,” said Airmar technician spe-

BOATS & GEAR Diesel Engines

cialist Zack Floyd. “It’s very dif cult to clog, and is highly accurate, within 1%, because of the way it senses the rotation of the ring.”

The Airmar SmartBoat Module “is the gateway” for the fuel sensor’s ow data, rst interpreting the data and “then pushing it out to NMEA 2000,” said Floyd, making it accessible on various displays. Installation is nearly effortless, requiring no hardwiring. “It takes three minutes to set up. It’s all done through the SmartBoat box (module).”

The fuel ow information includes instant and total fuel consumption. This should be especially meaningful to workboat operators “that want to bring older engines into digital and see the actual fuel consumption and want the real-time burn. This will allow them to do that,” Floyd said. “Knowing how much fuel they consume they can determine how far

they can go and have enough fuel to make it back.”

With newer engines fuel consumption is calculated. The engine computer knows how much the fuel injectors should be sending and can adjust the fuel volume based on load and the amount of air and rpm. “The problem is,” said Floyd, “you are relying on

the computer to calculate that, and the assumption is all systems are good and working in an ideal spot.” But if there’s, say, a leaky injector, “and the leak is pushed into the exhaust and shot out the back of the boat, you never know that” because the computer doesn’t measure the supply rate and how much fuel comes back to the tank. “You have no real way to know the ef ciency at a given rpm because the margin of error is so high.”