Air of Doubt

Shipyards uncertain about future demand for offshore CTVs.

Shipyards uncertain about future demand for offshore CTVs.

Each SmartBoat module is an all-in-one gateway that can simultaneously convert multiple NMEA 0183, J1939/J1708/1587 engine interfaces and analog device data to NMEA 2000. Built-in menu-driven software makes network bridging, sensor setup and PGN filtering fast and easy. And the industry’s best alerting allows for custom, user-configured alarms for any device on the network. SmartBoat modules save money and time on every installation.

y-leading Aler ting and PGN Filtering

14 Focus: Evacuation Route Mariners were calm, organized and kept passengers safe during last year’s Staten Island Ferry fire.

20

Amid uncertainties, shipyards vary on offshore wind CTV prospects.

16

• Elliott Bay to design fully electric truckable tug for Miller Marine

• Damen designs 492' WTIV for floating wind turbines • Feeney Shipyard retrofitting 105' tug to run on ammonia • Metal Shark delivers 47' aluminum crewboat to Alaska • American Commercial Barge Line awards contract to Steiner for the design and construction of an environmentally friendly 82'x34' towboat

24 Decked

Adding new winches for inland towing and upgrading old ones

28 Outboard Power Guide

WorkBoatʼs annual directory of outboard engines

8 On the Water: Swell information — Part II.

8 Captain’s Table: Tales from the drydock floor.

9 Energy Level: A deep freeze but lower natural gas prices.

10 WB Stock Index: Index loses 2.4% in February.

10 Inland Insider: Our superheroes are mariners

11 Nor’easter: Offshore wind opponents act locally.

12 Legal Talk: Collision brings attention to ‘proper lookout.’

12 Insurance Watch: Creating a strong safety culture.

13 New Jersey opens third offshore wind solicitation.

13 $12 million available for U.S. Marine Highway Program.

13 BOEM proposes first Gulf of Mexico offshore wind lease sale.

13 Coast Guard commander relieved of duty following collision.

2 Editor’s

6

Most of the talk surrounding offshore wind has been fairly upbeat in recent years, with offshore wind proponents talking about how much power will be produced, how many jobs will be created, and how many new wind vessels will have to be built at U.S. shipyards.

Then reality set in as U.S. offshore wind farm projects began to face delays from regulators, local opponents and others. In February, energized by social media and publicity over winter whale strandings (see page 11), opponents of offshore wind projects almost succeeded in pushing one New Jersey town to literally pull the plug on Ørsted’s Ocean Wind 1 plan.

U.S. shipyards that have broken into the offshore wind crew transfer vessel (CTV) market have differing outlooks on how the emerging sector will shake out (see page 20).

St. Johns Shipbuilding, with seven CTVs either underway or planned, is understandably bullish. “The market is like a freight train and it’s going to be very dif cult to stop. It may slow down a little bit, but it’s not going to stop,” Jim Cutts, who heads up the company’s CTV program, told WorkBoat

But others, such as Peter Duclos, president of Gladding-Hearn Shipbuilding, with a single CTV set for commissioning later this year, sees in ation as a major “opponent.”

“I don’t see the market as being very encouraging at this very time. There’s hesitancy due to in ation and that’s an understandable problem.”

Marcia Blount, president of Blount Boats Inc., which delivered the rst

David Krapf, Editor in Chief dkrapf@divcom.com

U.S.- agged CTV in 2016 and has two CTVs currently under construction, agreed. “My sense is that tenders for CTVs have slowed in coming out mostly because of in ation over the last two years. There’s the supply chain issues in getting deliveries, but it’s mostly due to the increased costs the developers are facing.”

But offshore wind still has a promising future, one that Blount said hinges largely on getting costs stabilized. “There’s de nitely going to be a future. There’s de nitely going to be wind farms built, but I do see a lot of uncertainty.” Thus, as always, the future is anybody’s guess.

simplicity, and durability are within your reach.

NOVEMBER 29DECEMBER 1, 2023

NEW ORLEANS

EDITOR IN CHIEF David Krapf / dkrapf@divcom.com

SENIOR EDITOR Ken Hocke / khocke@divcom.com

CONTRIBUTING EDITOR Kirk Moore / kmoore@divcom.com

CONTRIBUTING WRITERS Capt. Alan Bernstein • Bruce Buls • Michael Crowley

• Jerry Fraser • Pamela Glass • Betsy Frawley Haggerty

• Max Hardberger • Joel Milton • Jim Redden

DIGITAL PROJECT MANAGER / ART DIRECTOR Doug Stewart / dstewart@divcom.com

EDITORIAL DIRECTOR Jeremiah Karpowicz / jkarpowicz@divcom.com

ADVERTISING ACCOUNT EXECUTIVE S

Kim Burnham 207-842-5540 / kburnham@divcom.com

Mike Cohen 207-842-5438 / mcohen@divcom.com

Kristin Luke 207-842-5635 / kluke@divcom.com

Krista Randall 207-842-5657 / krandall@divcom.com

Danielle Walters 207-842-5634 / dwalters@divcom.com

ADVERTISING COORDINATOR

Wendy Jalbert 207-842-5616 / wjalbert@divcom.com

Producers of the International WorkBoat Show and Pacific Marine Expo www.workboatshow.com • www.pacificmarineexpo.com

EXPOSITION SALES DIRECTOR Christine Salmon 207-842-5530 / c salmon@divcom.com

PRESIDENT & CEO Theodore Wirth / twirth@divcom.com

GROUP VICE PRESIDENT Bob Callahan / bcallahan@divcom.com

PUBLISHING OFFICES

Main Office 121 Free St., P.O. Box 7438, Portland, ME 04112-7438 207-842-5608 • Fax: 207-842-5609

MAGAZINE SUBSCRIPTION INFORMATION

cs@e-circ.net • 978-671-0444 (Monday-Friday, 10 AM – 4 PM ET)

© 2023 Diversified Communications PRINTED IN U.S.A.

Don’t forget to mark your calendar for the 2023 edition of the largest commercial marine tradeshow in North America.

Crews on board Offshore Service and Crew Transfer vessels perform a variety of complex operations. Communication is critical to ensure the safe and efficient transport of cargo, equipment and personnel. David Clark Marine Headset Systems offer clear, reliable communications in the harshest marine environments, while enhancing the safety and situational awareness of crew members. Call 800-900-3434 (508-751-5800 Outside the USA) to arrange a system demo or visit www.davidclark.com for more information.

Series 9100 Digital Communication System Scalability • Versatility • Simplicity

When you’re working offshore, keep boat crew communications on course.

Pam Glass’ Inland Insider article in WorkBoat’s January 2023 issue (“Low water, worker shortage plague inland waterways”) could have been written 30 years ago and titled “Offshore Insider.”

Over 30 years ago, I left the U.S. Coast Guard Marine Safety Of ce for an opportunity to head a subcontracting labor company that I had hoped would offer temporary relief to ongoing labor shortages. Since then, I’ve seen labor costs explode as temporary labor shortages became the normal state of affairs for the shipbuilding industry.

My hat’s off to American Commercial Barge Line CEO Mike Ellis for recognizing how his business has been affected by reduced training programs. Now that the average age of a maritime welder is 55, most of our skilled workers are getting ready to trade their

welding rods and shields for shing rods and reels. The forecast that the industry will require 50,000 new workers every year for the next decade guarantees a chronically tight labor pool.

We must have the foresight to plan for and invest in programs that will incentivize new workers to develop journeyman expertise.

Chance McVeay Christian Construction Inc. Mobile, Ala.TheCoast Guard Inspections and Compliance Directorate has released Marine Safety Alert 02-23 to advise mariners to keep their contact information up to date with both the Transportation Security Administration (TSA) and the Coast Guard National

Maritime Center (NMC) to assist in the timely resolution of Transportation Worker Identi cation Credential (TWIC) eligibility issues.

Merchant Mariner Credential (MMC) applicants or holders who have had their TWIC applications denied or revoked because of a TSA security threat assessment (STA) may pose a security threat and have their MMC revoked. Failure to obtain or remain eligible to hold a TWIC may lead to denial of an MMC application or serve as a basis for suspension and revocation (S&R) actions against an MMC.

If an MMC holder receives a TWIC preliminary determination of ineligibility (PDI) letter from the TSA and they intend to appeal TSA’s determination or seek a waiver, they should respond as instructed within 60 days of receipt.

U.S. Coast Guard Inspections and Compliance Directorate

Washington, D.C

Hyundai Welding offers a full range of Flux Cored Wires, for high productivity and superior weldability. Our rutile and metal-cored wires for mild steel applications such as SF-71MC, Supercored 71MAG, SC-420MC, SC-70ML and Supercored 70NS have a proven track record of production savings in top shipbuilding, steel fabrication, heavy equipment and automotive industries around the world. In every kind of application, you can achieve high quality weld profiles with a superior deposition rate and increased welder comfort.

To order Hyundai Welding's Flux Cored Wires in Spools (11, 33 and 44 lbs) or Drums (551, 661 and 926 lbs) packaging options, please contact:

Phone : +1-770-614-7577

E-mail : orders@hwpusa.com

BY JOEL MILTON Milton

Ihavegreatly appreciated the new swell forecasts that the National Weather Service has released over the course of the winter (or semiwinter) so far. February is about half over as I write this column, and despite a couple of nasty cold snaps, there have been very few instances of real cold on the Eastern Seaboard. This has made some things easier, with icing not being a concern.

Unfortunately, there has been a lot of very chaotic marine weather to contend with in place of the cold, which is unusual. Of course, there is always some natural variation, but spring and fall are generally expected to be the unpredictable disrupters, with summer and winter being the most stable seasons of the year. Once fully established they usually settle into a relatively predictable groove that makes short-to-medium distance coastwise voyage planning simple.

During the winter, the weather normally kicks up preceding the arrival of a cold front, with

For many, it is that time of year to schedule drydocks to conduct hull, tail shaft, and internal structure exams.

unobstructed winds from the easterly quadrant tormenting us the most. Once the fronts pass the winds shift behind them and eventually die down. Sometimes they’re not strong enough to deter us, but other times you need to wait them out. We typically move up and down the coast between these regular systems, pausing as needed to let conditions improve before leaving sheltered waters.

But this winter that pattern has been absent, replaced by no discernible pattern at all, just an endless series of chaotic movements of air masses. The net effect of this has been a lot like playing dodgeball with much more offshore swell than I’m used to seeing in this region in winter. And this affects operations.

When combined wave heights are higher than the freeboard of your barge, you will encounter water on the decks. Too much water on deck for too long, especially “green water,” can lead to equipment damages and possible cargo contamination. The NWS swell forecasts, which provide us with size, direction, and period information, have been a big help in avoiding negative outcomes.

things even more challenging, what date will you receive your credit for? Up to this point, it should have been credited to the last day of the month when the exam was completed, but the Coast Guard guidance update in 2016 created confusion.

BY CAPT. BOB BIJURCapt. Bob Bijur has been with Island Queen Cruises since 1994 and is also a partner of Biscayne Lady Yacht Charters. Bijur is a past president of the Passenger Vessel Association and a member of the PVA Board of Directors.

To begin, you must prepare the vessel to be examined. We power wash and scrape the sea life that has caused us to lose a knot or two over the years. We open sea chests, disassemble the valves, open, and expose shell plating along with anything else that the Coast Guard marine inspectors want to see.

Since this is a scheduled event, we need to be aware of all non-conformities in advance. These items must be disclosed to the inspection team along with a proposed plan of work. It is important that the inspector agrees with your work plan. We all know what lay days and change orders mean in terms of delays. Both need to be avoided.

What happens when there is a gray area or a request from an inspector to x something? What happens when the repair plan exceeds the time you have allotted for the drydock? Also, to make

So, the two-week drydock that started the second week of March, for example, was performed and the required work increased from two weeks to four or maybe six weeks. You could lose a month of credit under the 2016 guidance, which based the next drydock on the previous due date. This was to avoid “drydock creep.” If you are confused and frustrated by this, you are not alone.

Thanks to the Passenger Vessel Association (PVA), the Coast Guard has agreed to simplify the drydock credit process.

During the PVA Annual Convention in Long Beach, Calif., in February, the Coast Guard announced that it had standardized the drydock process to eliminate the loss of credit when drydock exams go longer than planned. In other words, when the vessel goes back in the water, and the inspection is complete, the credit is set to the end of that month.

Those of you who shivered through the historic deep freeze in early February and spent a month’s salary to heat your homes probably will be surprised to learn that an unseasonably warm winter has reined in natural gas prices.

Two days before an Arctic blast sent wind chills to record lows across the Upper Northeast, Enverus Intelligence Research Inc. (EIR) proclaimed that record warm winter weather will send natural gas prices to below $3 million BTUs (MMBtu) this year. The Calgary, Alberta-based analytics firm also pointed to strong U.S. gas stockpiles, aided in part to the continued outage of the Freeport liquefied natural gas (LNG) export facility off Texas, which prevented nearly 2 billion cubic feet per day (Bcfd) from being shipped out of the country.

“Unseasonably warm weather, record high supply and delays to the Freeport LNG restart inflated our end-of-winter natural gas storage estimate,” said EIR Director Bill Farren-Price. “This higher storage projection worsens the oversupply already expected for midyear, pushing our summer price forecast down by as much as $1/MMBtu from previous outlooks.”

To be fair, despite the bitterly cold intermittent spells of late December and the first weekend in February, assessments are based on mean winter temperatures. The National Oceanic and Atmospheric Administration (NOAA), for instance, said that the average January temperature of the 48 contiguous states was 35.2°F, 5.1°F above average, making it the sixth warmest January on record.

“On the demand side, mild weather to kick off the year has seen domestic consumption tail off significantly since the winter storm in December 2022,” Rystad Energy said in a Jan. 24 note. “However, there is some upside

to those figures, as recent weekend weather models are forecasting a ‘cold shot’ in the next few days.”

Rystad expects U.S. dry gas production to grow by around 6.9 Bcfd this year, a 7% jump from 2022.

The WorkBoat Composite Index turned negative for the year, losing 82 points, or 2.4%, in February. For the month, losers topped winners by a 7-5 ratio.

The big percentage gainer in February was Tidewater Inc., which rose 12.5%. The Houston-based offshore service vessel operator announced that

revenue for the three and 12 months ended Dec. 31, 2022, were $186.7 million and $647.7 million, respectively, compared with $105.2 million and $371 million, respectively, for the three and 12 months ended Dec. 31, 2021. Forecasted revenue for 2023 is approximately $900 million, an increase of 39% compared to 2022.

Last year “marked the long-awaited inflection point in the offshore vessel market,” Quint Kneen, Tidewater’s president and CEO, said during the company’s Feb. 28 earnings call with analysts. “Our revenue increased nearly 75% compared to 2021, driven by a major acquisition, but also a significant rise in average day rates. Average day rates improved over $2,400 per day for the full year, a pace of improvement we have not seen during the past 20 years, and we expect that 2023 will reflect a full year improvement of over $3,000 per day.

BY KEN HOCKEFor the complete up-to-date WorkBoat Stock Index, go to: www.workboat.com/resources/workboat-composite-index

What goes on daily aboard inland tugs, towboats, barges, and other vessels that ply the U.S. inland waterways is, to say the least, unique.

Yes, tug and barge companies carry goods up, down, and across our rivers, lakes, and other bodies of water, and they assist ships that need help getting into and out of port. That’s their job.

But what about when things go wrong? That’s when you really want them in your corner. There is something innate about mariners that makes them run to the fire, not away from it.

At the American Waterways Operators meeting in Houston on March 1, AWO announced the inaugural winners of its new American Waterways Honor and Excellence in Rescue Operations (HERO) Award. The award recognizes rescues by AWO member company employees that demonstrate selflessness, skill, and bravery.

The inaugural awardees included six vessel crews from three AWO member companies:

• The crew aboard American Commercial Barge Line towboat Ron Callegan, for rescuing a crewmember from a fall overboard near the

“On a quarterly basis throughout 2023, we expect average day rates to be increasing quarter-over-quarter. And although it’s too early to comment on the full year day rate increases for 2024, we see nothing stopping the day rate acceleration. To put this in perspective, historical up-cycle year-over-year day rate improvements were approximately $1,500 per day.” — David

Krapf

Plaquemine, La., ferry.

• The crew aboard ACBL’s towboat Safety Explorer, for rescuing a crewmember who had fallen overboard from another vessel.

• The crew working for Great Lakes Dredge and Dock who, while working on the Houston Ship Channel Project, rescued three civilians from the water after their boat caught fire.

• The crew aboard the Ingram Barge Co. towboat Mary K. Cavarra, for rescuing a person in the water near the St. Paul (Minn.) riverfront.

• The crew aboard the Ingram Barge towboat Michael J. Granger, for rescuing a distressed automobile driver who had entered the water near Paducah, Ky.;

• The crew aboard the Ingram Barge towboat Midland, who responded to a health emergency on their vessel, rendering immediate care and supporting an airlift evacuation on the Illinois River.

“We are proud to recognize the inaugural recipients of the American Waterways HERO Award and we congratulate them on this achievement,” said AWO President and CEO Jennifer Carpenter. “These crews exemplify the purpose of our launching this award: to recognize the heroism of the men and women of America’s tugboat, towboat and barge industry, whose actions prevent harm and save lives on the water every day.”

Energized by social media and publicity over winter whale strandings, opponents of offshore wind projects pushed one New Jersey town to literally pull the plug on Ørsted’s Ocean Wind 1 plan.

The Ocean Wind 1 export cable would come ashore on the barrier island at Ocean City, N.J., go under the back bay and connect to the grid through an electrical substation at Beesley’s Point in Upper Township on the mainland. The connection survives from one of New Jersey’s last coal-fired power plants, the defunct 447-megawatt B.L. England generating station.

Upper Township officials laid out a redevelopment plan for the Beesley’s Point neighborhood, envisioning a waterfront district, potentially with a hotel and marina, on the Great Egg Harbor River. To facilitate the plan, town officials, meeting Feb. 27, proposed moving the substation – Ørsted’s preferred connection to the regional power grid –and faced a standing-room-only crowd of opponents.

“Ocean Wind is clearly labeled on the plan,” said Roseanne Serowartka of Ocean City. “I do understand the people here who want jobs, who want that redevelopment, but not at that cost. Will the people who come to that hotel want to go to a beach with industrialization?”

That future industrial vista had clearly been at the forefront of objections coming out of the beachfront towns. New York State energy planners, who were pounded early on by local political pressure from Long Island homeowners over visual impacts, pressed the Bureau of Ocean Energy Management (BOEM) to keep wind energy areas at least 17 miles off those beaches to reduce visual objections.

“From Cape May to Manasquan, this shoreline will be forever changed,” said Chris Placitella of the group Save Long Beach Island, during a Feb. 11 public meeting in Brigantine, N.J. Both beach communities would look out toward the planned Atlantic Shores turbine field, a few miles north of the Ocean Wind 1 array.

The Atlantic Shores project would erect “375 Eiffel towers” that will be seen from beaches and the back bays along the Jersey Shore, said Placitella.

But opponents received new political momentum with news media coverage of whale strandings on Mid-Atlantic beaches, which they contend could be caused by survey work on offshore wind projects. Marine mammal experts and the National Oceanic and Atmospheric Administration roundly reject those claims, but the story line has gained traction on conservative news media and with Republican elected officials.

The narrative is being promoted by Fox News commentator Tucker Carlson, and U.S. Rep. Jeff Van Drew, R-N.J., whose southern New Jersey constituents in beach towns

would see the offshore turbines on clear days. Van Drew promised to launch a series of Congressional hearings into how federal agencies review wind power plans, and to write legislation to block the projects.

A 2021 New Jersey state law, signed by Democratic Gov. Phil Murphy, affirmed that state utility regulators can override local objections to cable routes. That’s frustrated Ocean City officials who oppose the project and the cable route under their resort town.

Across the bay from Ocean City, Ocean Wind opponents viewed the Upper Township deliberations as one more chance to slow the project. Upper Township Mayor Jay Newman tried to keep the sometimes-raucous proceedings on track, as one objector after another spoke out, pressuring the fivemember Township Committee to delay approval for moving the substation.

BY KIRK MOORE, CONTRIBUTING EDITORContributing Editor Kirk Moore was a reporter for the Asbury Park Press for over 30 years before joining WorkBoat in 2015. He has also been an editor for WorkBoat’s sister publication, National Fisherman, for over 25 years.

“It will align you with the political goals of two persons: Gov. Murphy and President Biden,” warned Michael Dean, a Middletown, N.J., activist who opposes offshore wind. “You’re the only ones to put your political careers on the line … you will be linked.”

Tom Jones of the group Defend Brigantine Beach suggested Upper Township could get “a multimillion-dollar payment from Ørsted” for the substation plan.

With the interest from conservative national media, offshore wind has taken on a markedly partisan cast in New Jersey. The Murphy administration is heavily committed to the Ocean Wind and Atlantic Shores projects and hopes that its New Jersey Wind Port at the mouth of the Delaware River will become a future regional hub for Mid-Atlantic projects.

In turn, environmental groups that support offshore wind are pointing to opponents’ connections to conservative think tanks and legal foundations supported by fossil fuel interests that are backing court challenges to offshore wind plans.

The Protect Our Coast group that promoted the Upper Township protest links online donors to the American Coalition for Ocean Protection, a project of the libertarian Caesar Rodney Institute in Delaware, with a goal of raising $500,000 toward achieving “a permanent exclusion zone 33 miles off the entire Eastern Seaboard of the United States and to ensure any area offered for lease meets all the requirements of federal law.”

In the end, the Upper Township Committee narrowly voted 3-2 in favor of allowing the substation move – perhaps a signal of how local political battles may still ambush New Jersey’s offshore wind ambitions.

A2021 collision in the Bahamas highlighted a fundamental element of collision regulations that appears with regularity in marine collision litigation — the requirement to maintain a “proper lookout.” The collision also brought attention to the rule on overtaking vessels.

The collision occurred some 20 miles northwest of Nassau between the 176' aluminum yacht Utopia IV and the 159' steel product tanker Tropic Breeze

The captain of the Utopia IV was in control of the vessel. The bosun handled navigation and the bridge log. The captain left the wheelhouse a few times to check on passengers. While alone in the house, the bosun saw no radar or AIS targets.

On the bridge of the Tropic Breeze, an able-bodied seafarer (AB) and the master were on watch. The tanker’s AIS had a power issue and only worked intermittently. At around 10 pm, the bow

Astrong safety culture has the single greatest effect on accident reduction in the workplace on land and water.

of the yacht struck the transom of the tanker. The relative speed of the impact was about 15 knots, given the yacht’s speed of 20 knots and the cargo ship’s speed of 5 knots.

The National Transportation Safety Board (NTSB) concluded that visibility was good, at around 10 miles, and the cargo vessel’s stern light should have been seen. The NTSB said it was likely that neither vessel’s crews looked at the radar display for about 12 minutes prior to collision (based on time to cover three miles at a relative closing speed of 15 knots).

As the overtaking vessel, the yacht was required to give way to the cargo vessel. The NTSB concluded that the yacht had not maintained proper lookout. The NTSB also felt that if the tanker had noticed the approaching yacht, it could have signaled the potential danger in some manner, using radio, whistle, or other means.

The NTSB identified the yacht’s actions as the probable cause of the collision. But it also identified the tanker’s conduct as a contributing factor. If there’s a lesson to be learned here, it might be the significance of the concept of “proper lookout.”

or illness.” But human nature is a tricky thing.

BY DAN BOOKHAMWith that in mind, a smart employer will prioritize the creation or reinforcement of a strong safety culture and will often add an incentive program. But what’s the best approach?

Incentive programs fall into two categories.

Calendar-driven programs are incentive programs that reward employees for injury-free time periods such as months or quarters. Action-driven programs recognize employees who take proactive steps to prevent workplace injuries and encourage the reporting of near-misses and safety hazards.

Both approaches are permitted under current OSHA standards, but rate-based programs come with an important caveat. There are concerns that these programs can encourage people to sweep injuries and incidents under the rug. Pressure from coworkers can be significant as well. Nobody wants to be the one to mess up everyone else’s shot at the bonus. OSHA has specifically stated that employers cannot create incentive programs that would “deter or discourage an employee from reporting an injury

The other downside to rate-based programs is that they can make it easy to assume a safety record is a product of an excellent culture rather than a product of luck. We’ve all marveled at boneheaded behavior by a co-worker that surely will result in their being carted off in an ambulance. But people can often engage in unsafe behaviors for a time before an injury occurs. If we throw money at the entire group for avoiding injury, we can inadvertently reward employees who are not actually acting safely.

With action-driven programs, however, the rewards are triggered by proactive efforts to both avoid and acknowledge potential hazards and issues, as well as to ensure there’s no penalty associated with the timely reporting of all workplace injuries. Because sustained safety depends on knowing what injuries are occurring, what the real hazards are, and knowing if employees are engaged in safe behaviors following their training, these data-rich programs feed long-term success.

Also, they incentivize employees to take positive actions to prevent injuries rather than pay them to not be injured.

If you haven’t already, establish a safety program that includes a safety incentive aimed at taking positive actions.

New Jersey energy ofcials moved to open a third round of solicitations from offshore wind energy companies that could double the state’s already aggressive wind power goals.

The New Jersey Board of Public Utilities voted March 6 to open applications for between 1.2 gigawatts and 4 GW of capacity, on top of 3.75 GW already in the pipeline set by Gov. Phil Murphy’s administration.

New Jersey has opened a third round of solicitations from offshore wind companies, as developers continue to survey lease areas in the New York Bight.

“Today marks a pivotal next step toward accomplishment of our offshore wind development goals,” according to a statement from Murphy, who has talked of building out to 11 GW of potential power offshore – rivaling the goals of neighboring New York state.

“Offshore wind constitutes a crucial component of our journey to 100 percent clean energy by 2035, a benchmark that solidi es our position at the national forefront of climate action,” said Murphy. His administration is building infrastructure initiatives like the New Jersey Wind Port near the mouth of the Delaware River to position New Jersey as a hub for building projects off the Mid-Atlantic coast.

The solicitation comes as the Murphy administration and federal agencies are under re from offshore wind critics, who contend a series of whale strandings on the state’s beaches require a pause in offshore wind geotechnical surveys using sonar and sea oor drilling.

The Ocean Wind and Atlantic Shores turbine arrays planned off New Jersey already had local opposition from residents and businesses in beachside towns. The whale deaths since December have energized their effort, and generated publicity from Fox News and other conservative commentators who have picked up the critics’ narrative that survey noise could have disoriented the whales’ sense of hearing.

The National Oceanic and Atmospheric Administration maintains that there is no evidence that offshore wind operations have done anything to affect whale strandings, which have been elevated among humpbacks along the East Coast since 2016.

Conservative media coverage has fed a partisan edge to the offshore wind debate. Rep. Jeff Van Drew, R-NJ, whose southern New Jersey coastal district would look out to the planned wind turbine arrays, had a March 16 public hearing planned at the Wildwood, N.J., convention center hall, that could be the rst in a series of inquiries by the Republican-controlled House of Representatives into the Biden administration’s offshore wind push.

In announcing their new solicitation, New Jersey state of cials say the third round will call on developers to commit more money toward assessing the environmental impacts of wind power. — Kirk

MooreThe Maritime Administration (Marad) announced in March that $12.4 million is available in fiscal year 2023 funds through the U.S. Marine Highway Program (USMHP), previously named America’s Marine Highway Program. The USMHP seeks to increase the use of navigable waterways in the U.S., especially where water-based transport is the most efficient, effective, and sustainable option. Applications must be submitted by April 28, 2023. Contact the USMHP staff via email at mh@dot.gov or by phone at 202–366–1123.

InFebruary, the Department of the Interior proposed plans for the first-ever offshore wind lease sale in the Gulf of Mexico. The proposed sale includes a 102,480-acre area offshore Lake Charles, La., and two areas offshore Galveston, Texas, one comprising 102,480 acres and the other 96,786 acres. These areas have the potential to power almost 1.3 million homes with clean energy, the Interior Department said.

Thecommander of the Puerto Ricobased Coast Guard cutter Winslow Griesser was formally relieved of his duties in February, as an investigation continues into the cutter’s August 2022 collision with a fishing vessel. Lt. Cmdr. Benjamin Williamsz was relieved “due to a loss of confidence in Williamsz’s ability to effectively command the cutter,” the Coast Guard said.

When an engine room re broke out on the Staten Island Ferry Sandy Ground shortly before 5 p.m. on Dec. 22, a cold, rainy afternoon, it could have been a disaster. Instead, it was a textbook example of how mariners, working together, kept everyone and everything safe.

The 330'×70' Sandy Ground, the newest Staten Island Ferry built at Eastern Shipbuilding Group in

Florida, went into service in June 2022. It was on a routine 5 ½-mile passage from the Whitehall terminal in Lower Manhattan to St. George, Staten Island, with 868 passengers aboard. Part way though the trip, crew saw re in the engine room.

They immediately evacuated, closed off the space and released 3M Novec 1230 re protection uid, a clean agent re extinguishant, which effectively put the re out, said Capt. Barry Torrey,

assistant commissioner for ferry operations for the New York City Department of Transportation (NYCDOT). Torrey worked with Sandy Ground

Capt. Joseph Ajar, and the 15-member crew by cell phone during the incident.

The re, he said, was caused by a fuel leak that turned into a machinery space re. There were no ames and minimal smoke throughout the vessel. The ferry had no propulsion so both anchors were dropped in a channel near Bayonne, N.J., as Ajar radioed for assistance. Police, re, and Coast Guard vessels arrived along with ve tugboats and several small passenger ferries. Another Staten Island Ferry stood by.

Evacuating the passengers safely was the main priority. Many were frightened at rst because they did not know what was going on. One said she feared the boat would blow up. The passengers calmed down as the crew kept them informed, helped them move to the ends of the vessel away from the midships re zone, and assisted with life preservers.

Of cials decided the safest way to of oad people was to use smaller ferries from NYC Ferry (operated by Hornblower) and NY Waterway in bow-to bow-transfers. The 80'×27', 2,600-hp tug Mister Jim from Carver Marine Towing, and the 77'×26', 2,400-hp Charles James from Stasinos Marine LLC, tied up on either side of Sandy Ground, creating a virtual slip that buffered the smaller ferries from wind and waves.

The 85' NYC Ferry, River Sprinter, under the command of Capt. Paul Radzewsky, put its bow against the Sandy Ground and tied off. Crew from the Sandy Ground, River Sprinter and the tugs helped 138 passengers aboard. River Sprinter dropped them at St. George and relayed land-based re ghters to the Sandy Ground.

NY Waterway’s Franklin Delano Roosevelt, with Capt. Tom Beckedorff at the helm, was standing by, and snugged up to the Sandy Ground as soon as there was space. Crews from

the ferries and tugs tied things off and guided passengers, almost all wearing lifejackets, aboard the Roosevelt The decks were at the same height, so passengers could walk from one vessel to the other, rather than step down or jump. The Roosevelt, at 110'×32.5', is one of NY Waterway’s largest ferries, with a capacity of 500 passengers. In this case it took 568 evacuees. A video showed that the atmosphere on the boat was calm, even jovial, as a crewmember picked up a mike and started singing. Some passengers joined in.

There were still 50 or so people waiting to leave the Sandy Ground as the Roosevelt pulled away. “We’ll be back,” a crewmember said. But with the pressure of the tugs and the wind picking up, Sandy Ground’s anchors started to drag, so they decided, Torrey said, to end the transfers and keep the remaining passengers aboard as they raised anchor and tugs guided the big ferry into a slip at the St. George ferry terminal.

“We can’t undo the fire,” Torrey said, “but we can be pleased how crews worked together. Together we evacuated 868 people, safely, with just five minor injuries.”

The success was the result of constant training with weekly safety drills on the smaller ferries, and regular coordination with police, fire, and Coast Guard. “This is New York Harbor,” Torrey said. “These guys talk to each other regularly on the radio. It’s not the first time in New York Harbor that professional mariners have come together to respond to a rescue without having done that exact event.” He referenced the 9/11 boatlift and the Miracle on the Hudson rescue of passengers from US Airways flight 1549 in 2009.

“This was not a lucky event,” Deputy Assistant FDNY Chief Frank Loeb said in a briefing after the evacuation. “This is years and a long time of preparation and training. The crew acted as the crew was supposed to act.”

The Coast Guard and NTSB are investigating the Sandy Ground fire. Hearings took place in late February. As of press time, the results had not been published. The vessel is awaiting repairs at Caddell Dry Dock and Repair Co. Inc. on Staten Island.

The Sandy Ground is the second of three $85 million Ollis-class ferries

built for New York City by Eastern Shipbuilding. The first, the SSG Michael H. Ollis, went into service in February 2022. It was WorkBoat ’s 2022 Boat of the Year.

The Sandy Ground had been operating without incident until the fire. The third Ollis-class ferry, the Dorothy Day, is on site in New York Harbor, but the Department of Transportation has not yet taken delivery.

Immediately following the fire Staten Island Borough President Vito Fossella and members of a ferry workers union suggested that the Ollis-class ferries be taken out of service until a full investigation could be done. After consultation with the Coast Guard, NYC Fire Commissioner Laura Kavanagh said there’s “no concern at all” about there being a problem on ferries with a similar design.

The Coast Guard was scheduled to host a ceremony March 9, honoring the crews and vessels that assisted in the Staten Island Ferry evacuation, including the NYPD Marine Unit, FDNY Marine Unit, Coast Guard Station New York and the tugboats Charles James, Eastern Dawn, Mister Jim, Paula Atwell, and Robert Burton, along with ferries Franklin Delano Roosevelt and River Sprinter

challenge, said Mike Complita, a principal with EBDG. “Although the hull itself is easily adapted to an all-electric option, the biggest challenge is to work with multiple smaller component providers who don’t offer a complete integrated solution, which means picking each component individually and ensuring everything communicates together properly and effectively,” he said.

One example is proprietary shore power plugs, which are being developed by several companies and must be treated differently than land-based applications.

The tug will be made up of two pieces — a shoe box-looking hull and a customizable superstructure with an enclosed steering station. Both pieces can be loaded separately on a single atbed trailer and towed anywhere in the U.S. without the need for any special permitting or road closures. Construction is scheduled to begin in the summer with the rst tug completed and put in operation by the rst quarter of 2024.

Elliott Bay Design Group, Seattle, and Miller Marine, Deltaville, Va., announced late last year that the two companies would design and build the rst fully electric truckable push tug.

The 26' tug is designed as a multifunctional utility boat that services marine construction sites, tends dredges and buoys, and can handle short range ferry operations and other near-shore operations such as crew transportation or line handling, EBDG said. The tug will be a test case to understand the market demand for an all-electric vessel, EBDG added.

Last year, Miller Marine reached out to EBDG to discuss partnering on development of a battery-electric option for Miller’s popular truckable tug design.

The shipyard saw a market opportunity for an electric version of a design

they had been building for several years — a result of new Environmental Protection Agency regulations and government grants for zero- and low-emission vessel construction. Also, other states are starting to follow California’s lead in issuing credits to low-emission or zero-emission operations.

For EBDG, the new electric tug is another step in its goal to become a market leader in green and alternate fuel technologies, as well as an industry- rst test case to gauge market demand for an all-electric option. The electric tug will be built with a lot of room in the hull for batteries. EBDG will incorporate an electrical propulsion system into Miller Marine’s truckable tug design. Miller Marine will build the vessel at its 15,000-sq.-ft. production facility.

Designing electric or hybrid vessels is a bigger and more complex design

The 26' vessel will be powered by two permanent magnet (PM) motors with a total power of over 300 kW (400 hp). The new tug will not only be truckable, but 26' is also the cutoff for Subchapter M inspection by the Coast Guard.

Shore power will be used to recharge the vessel’s battery banks overnight, taking about eight hours. On a full charge, the vessel will operate for 12plus hours. A closed-loop uid cooling system will provide temperature control for the batteries, motors and electronics, maximizing their lifetime. The con guration is ideally suited for shallow and silty water operations, EBDG said. —

Eric van Rees

Damen has developed the FLOW-SV vessel concept that can accelerate the development of oating wind farm installation, the

company said. The Damen 492'×105' FLOW-SV is specially designed to install ground tackles for offshore turbine oaters.

The vessel can load the immense lengths of chain needed to install and secure nine anchors or suction piles, Damen said. Instead of mooring one oating windmill in a mission, three can be secured.

Secured at all three corners, a oater needs three ground tackles.

“With the FLOW-SV, we have developed a vessel which covers the entire process of attaching mooring lines,” Wijtze van der Leij, Damen’s sales manager, offshore wind, said in a statement. “This vessel, combining the supply, installation, securing and inspection of the ground tackles for oating turbines in one vessel, introduces a big step forward towards large-scale installation of oating windfarms.”

The anchors and chains needed for installing offshore oating wind turbines are so big that a vessel larger than existing anchor handlers is needed. Since the FLOW-SV will be designed to take all the materials and equipment needed to install three oaters, it is also being designed to save time on transits and loading.

When Damen engineers de ned the amounts of gear that the FLOW-SV needs to take onboard to be able to install three oaters in a base case of 328' of water, their calculations added up to ve kilometers (3.1 miles) of 152-mm dia. chain links, 4.5 kilometers (2.8 miles) of 112-mm dia. ber rope, nine anchors each weighing 15 tons, approximately 100 clump weights of 10 tons each, D-shackles, tensioners, as well as steel cable.

Getting the gear to the place of operation means the vessel carries a load of more than 4,000 tons. Depending on seabed conditions, depth and windfarm operator requirements, anchors can be replaced with suction piles to provide a secure ground tackle.

When deploying the anchors at sea, the chain is guided to large winches on the forward end of the large open aft

Metal Shark recently delivered the 47'x12' welded aluminum 45 Defiant crewboat Triumph VII to Anchorage Launch Services Co., Portland, Ore. The company provides launch, line, pilotage, and cargo services to vessels on the Columbia and Willamette rivers. Designed by the Metal Shark engineering team and built at the company’s Jeanerette, La., facility, the new boat has already been placed in service. Main propulsion for Triumph VII comes from twin Cummins QSM11 marine diesels — producing 705 hp each. The mains connect to HamiltonJet HJ-364 waterjets through Twin Disc marine gears. The propulsion package delivers a cruise speed of about 30 knots and a top speed of approximately 40 knots. A 500-gal. fuel capacity allows for a cruise speed range of more than 300 nautical miles.

American Commercial Barge

Line (ACBL), Jeffersonville, Ind., has awarded a contract to Steiner Construction Co., Bayou La Batre, Ala.,

for the design and construction of an environmentally friendly 82'x34' towboat. After delivery late this year, ACBL’s new towboat will support barge operations in the Houston Ship Channel. With a 10' operational draft, the new towboat will be equipped with twin Mitsubishi diesel engines producing 2,600 hp.

Global investment firm Carlyle and private equity firm Stellex Capital Management has agreed to sell Titan Acquisition Holdings to an affiliate of Lone Star Funds. Titan is made up of Vigor Industrial LLC, a shipbuilding and ship repair company based in Portland, Ore.; MHI Holdings LLC, a ship repair and maintenance company based in Norfolk, Va.; and Continental Maritime, San Diego. Key Titan customers include the Navy, Coast Guard, Military Sealift Command, Boeing, cruise lines, and barge and ferry operators.

Austal USA officially opened the Mobile, Ala., company’s new San Diego waterfront ship repair facility in February. The new facility, located adjacent to Naval Base San Diego, provides full-service repair, maintenance, and modernization services for small surface combatants, unmanned and autonomous vessels, and auxiliary

deck, from where it leads over the deck to the stern where it is deployed into the water. A 250-ton crane with a 41' reach and active heave compensation is installed along the aft deck’s starboard side while two smaller cargo rail cranes are available for handling gear on deck. A triple-drum anchor winch can deploy 600 tons pulling force.

One unique feature of the FLOW-

SV is the combination of bollard pull generated by the thrusters and added pulling force from the bow reaction anchor winch, which adds up to 1,000 tons of force. The FLOW-SV deploys the bow anchor and embeds it by reversed bollard pull. The boat then moves to the spot where the anchor for the oater needs to be installed. After letting out enough chain, the

anchor for the oater needs to be proof loaded, ensuring a secure seabed connection. Using the four thrusters, the FLOW-SV has 400 tons of bollard pull. Pulling strength is enhanced by the forward anchor handling winch, which generates another 600 tons. At that moment, approximately 1,000 tons of proof-load is acting on the turbine oater anchor.

Two xed propellers in nozzles and two azimuthing thrusters at the stern propel the FLOW-SV and provide forward bollard pull. The propellers in nozzles turn 180° to provide ample reverse bollard pull when the bow anchor is set. The azimuthing thrusters are also engaged for dynamic positioning, together with the retractable azimuthing thruster and tunnel thrusters in the bow section of the vessel.

In line with the purpose of installing

Feeney Shipyard, Kingston, N.Y., is retro tting a 105'x27'x15' tug for Amogy Inc., Brooklyn, N.Y. The ammonia-powered, zero-emission vessel is scheduled to be delivered in late 2023.

Ammonia is predicted to become the leading fuel source for the world’s giant cargo ships by 2050, according to the International Energy Agency.

The tug was originally built in 1957 at Brooklyn-based Jakobson Shipyard and uses diesel generators and electric motors, with its ammonia-topower system.

Main propulsion will be the responsibility of a 1-MW version of Amogy’s 600 kW powerpack. The boat will also be out tted with two auxiliary diesel generators.

Amogy’s ammonia-to-power technology feeds liquid ammonia through its cracking modules integrated into a hybrid fuel cell system, which powers the electric motors for zero-carbon shipping, the company said.

Amogy plans to launch the tugboat later this year in upstate New York after further safety testing.

“We’re incredibly proud of unveiling the rst ammonia-powered vessel later this year — especially because of the hope, promise and anticipation that ammonia has built as a zero-emission fuel in the heavy transportation industry — speci cally in regard to maritime shipping,” Seonghoon Woo, Amogy’s CEO, said in a statement.

“This is the rst milestone of many you will see from Amogy in accelerating the accessibility and scalability of clean energy in the global maritime industry.”

Yara Clean Ammonia (YCA), one of the world’s largest ammonia producers and the world’s largest trader and shipper of ammonia, will be providing green ammonia for the demonstration.

Ammonia, which does not emit

CO2 when used as a fuel, is expected to become a next-generation fuel as it contains properties ideally suited for the hydrogen economy, Amogy said. Furthermore, green ammonia produces with zero greenhouse gas emissions from well to wake, Amogy added.

Other partners in the project include Seam, Amogy’s electrical systems integrator, and C-Job Naval Architects.

Amogy is also working with Unique Technical Solutions (UTS) for the electrical and systems work involved in scaling up the powerpack for precommercial use.

To date, Amogy has raised $70 million in funding from strategic investors such as Amazon, Saudi Aramco, SK Innovation, AP Ventures and DCVC

— Ken Hockeships. Austal USA has invested over $100 million in facility upgrades and a new fl oating drydock. Also in February, Austal USA delivered the 338'x93'6" expeditionary fast transport vessel Apalachicola (EPF 13) to the Navy. EPF 13 is now the largest surface ship in the Navy fl eet with autonomous capability.

Bollinger Shipyards LLC, Lockport, La., recently delivered the 154'x25'5"x9'6" Maurice Jester to the Coast Guard in Key West, Fla. The cutter is the 178th vessel Bollinger has delivered to the Coast Guard

over a 35-year period and the 52nd fast response cutter (FRC) delivered under the current program. FRCs have a fl ank speed of 28 knots, stateof-the-art C4ISR suite (command, control, communications, computers, intelligence, surveillance, and reconnaissance), and stern launch and recovery ramp for a 26', overthe-horizon interceptor cutter boat. Bollinger is using a design based on the Damen Stan Patrol Boat 4708. Main propulsion comes from twin MTU 20V4000 M93L diesel engines, producing 2,900 hp each.

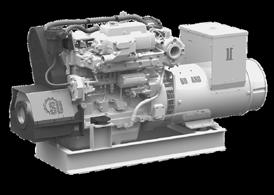

With some U.S. offshore wind farms facing delays or worse, shipyards engaged in the construction of crew transfer vessels (CTV) have contrasting visions on how the emerging sector will shake out over the next few years.

At one end of the spectrum, St. Johns Shipbuilding, with seven aluminum CTVs either under construction or in the hopper at its Palatka, Fla. shipyard, is understandably bullish. “The market is like a freight train and it’s going to be very difficult to stop. It may slow down a little bit, but it’s not going to stop,” said Jim Cutts, who heads up the company’s CTV program.

At the other end, Peter Duclos, president of GladdingHearn Shipbuilding, Somerset, Mass., with a single CTV set for commissioning later this year, sees an inflationary cloud blocking near-term prospects. “I don’t see the market as being very encouraging at this very time,” he said. “There’s hesitancy due to inflation and that’s an understandable problem.”

For sure, project delays, at best, are likely as prominent East Coast wind developers attempt to renegotiate power purchase agreements (PPA) that were signed with states when costs were more tolerable. Four-decade high inflation rates have since put the viability of some approved wind farms into question, creating uncertainties throughout the

infrastructure.

“My sense is that tenders for CTV have slowed in coming out mostly because of inflation over the last two years,” said Marcia Blount, president of Blount Boats Inc., Warren, R.I., which delivered the first U.S.-flagged CTV in 2016 and has two CTVs currently under construction. “There’s the supply chain issues in getting deliveries, but it’s mostly due to the increased costs the developers are facing.”

Duclos believes supply chain bottlenecks will ease once the economics are sorted out. “I think we have a commitment issue, resulting from the [PPA] renegotiations. I think the supply chain will fall into place when all the commitments are made, but we’re not there yet.”

Gladding-Hearn is set to deliver an 88.5' Incat Crowther CTV to Patriot Offshore Marine Services, New Bedford, Mass., this fall. The vessel will have the capacity to ferry up to 24 technicians to and from the Vineyard Wind Farm off Massachusetts, which remains on track to begin delivering power late this year.

Unlike developers, shipyards do not have the option of renegotiating boat contracts to deal with spiraling costs. “I’m shocked to see the size of the material increases and my labor rate increases, especially for ABS-certified welders. We’re under fixed price contracts so it’s getting very uncomfortable,” Blount said. “The wind farm developers

Amid uncertainties, shipyards vary on offshore wind CTV prospects.Atlantic Wind Transfers has ordered six Chartwell Ambitious-class CTVs from St. Johns Ship Building in Palatka, Fla.

are seeing their margins tightening, so they’re demanding that the vessel operators tighten, and this filters down to the shipyards. There are other types of boats to build besides CTVs, but it would be unfortunate as we are at the right place at the right time, and we understand these boats.”

St. Johns President Jeff Bukoski said aluminum prices have spiked, primarily due to the Ukrainian war and the accompanying tightness in the bauxite feedstock. “That’s a challenge for advancing medium and long-term pricing for aluminum vessels,” he said. “Machinery and equipment vendors also seem to be able to raise their prices without regard and shipyards do not have that same flexibility. We have to walk a little bit of a tightrope.”

He agreed with Blount that labor, specifically aluminum-qualified welders, ranks as a significant constraint.

“Aluminum welding is a bit of a niche even within our market and certification of those welders becomes more challenging and expensive,” he said.

The National Renewable Energy Laboratory (NREL) estimates no less than 58 Jones Act CTVs will be required for the wind farms now permitted and in various stages of development. Cutts, for one, believes that projection is well on the conservative side.

“I think it could jump to 70 and maybe even 100 boats off the East Coast in the next 10 to 15 years. It’s huge and there’s enough work to go around for all the yards capable of building these boats,” said Cutts, who came to St. Johns from his native UK where he was heavily involved in the world’s premier offshore wind industry.

Blount said her 74-year-old familyowned shipyard is one of about 10 U.S. yards in the north and south capable of mass-producing aluminum catamarantype CTV.

Despite the headwinds, St. Johns, which was acquired by Americraft Marine Group last year, is well un-

Asconstruction begins on the newest U.S.-flagged service operations vessel (SOVs), companies looking to get a deal on a stacked platform service vessel (PSV) suitable for conversion for offshore wind service are finding the pickings a lot slimmer “With the oil and gas industry picking up in the last 12 months, I believe there will be less and less opportunities to convert these PSVs, as they are now becoming valuable assets,” said Liviu Galatanu, managing director of Romanian naval architecture and marine engineering firm GOL Marine

Conversion made perfect sense when those vessels could be picked up for a relative song. However, as the offshore industry regains its footing after the Covid disruption, high-end PSVs once idled throughout the Gulf Coast and elsewhere are now nearly fully booked with offshore oil and gas work. According to the National Renewable Energy Laboratory (NREL), a new SOV costs upwards of $100 million or more and takes two to three years to build, while a conversion can cost half as much with a much shorter timeline.

GLO Marine has completed two PSV-to-SOV conversions, each requiring about eight months to complete. As for the actual cost differential “it’s hard to tell with today’s steel prices,” Galatanu said in an email.

Converting a PSV for offshore wind projects is far from a straightforward proposition, given the complexity of an SOV underdeck, which typically requires removal of all drilling fluid and completion brine tanks. The underdeck of an SOV has been likened to a giant warehouse, connecting to an elevator system that goes up to an articulated gangway that transfers technicians and their equipment directly to the transition piece of the wind turbine.

Unlike a PSV, SOV technicians are also on station for extended periods, making crew accommodations a primary design consideration. “This ‘warehouse’ is connected to an accommodation area, which for the first time in ship design history is aligned with a two- or even three-star hotel standard,” Galatanu said. “The major issues are coming from the need to accommodate a large number of technicians on board. This means adding a SPS (special purpose ship) class notation to existing PSVs which has a major impact on vessel’s stability and thus the existing arrangements and tank layout.” –

J. Reddenderway on a major expansion that includes more covered tents required for aluminum construction and an underground gas distribution system. A recently modified Maritime Administration grant is funding 50% of the expansion, which will enable the yard to produce up to eight CTVs a year.

“Generally, we’re revamping almost our entire infrastructure to support individual build slots for CTVs while still maintaining our steel line. We haven’t set an exact percentage yet, but it’s fair to say that we’ll maybe be in the 75 percent to 25 percent range of aluminum versus steel,” Bukoski said.

St Johns has two 82.8' Chartwell CTVs and two Incat Crowther 98.4' CTVs set for delivery this year to Atlantic Wind Transfer (AWT) and Windea, respectively. Windea is a U.S. joint venture of Hornblower and MidOcean Wind. Construction will begin this year on two additional AWT vessels and another CTV for an undisclosed customer.

Blount, likewise, is looking at increasing covered capacity at its six-acre shipyard but is awaiting more clarity on the economic front. “We have approval for a 45-foot addition to our large hull shop and additions to our smaller shops where we do the prefab,” Blount said. “But I’ve got to see if it’s worth it to do the capital investment and then wait for a return. If inflation had been kept at bay, I think we all would have been fine, both the developers and the shipyards.”

Since delivering the 65' 12-passenger Atlantic Pioneer CTV to service Rhode Island’s Block Island Wind Farm seven years ago, Blount has had a ground-floor view of rapidly evolving designs. The company has two new generation U.S.specific G-class CTVs scheduled for delivery in 2024 and early 2025 to Massachusetts-based American Offshore Services (AOS), a joint venture of Sweden’s Northern Offshore Services (NOS) and SEA.O.G Offshore, Seattle. The 100' hybrid ready CTVs are designed by NOS and have capacity for 24 passengers, excluding crew.

“It’s amazing how fast these vessels have increased in size and complexity. We call them the beasts in the hull shop,” Blount said. “These are big boats and very robust with a very complicated bow section and all the bells and whistles a lot of the developers want.”

The problem is those bells and whistles can change from developer to developer, which further tightens the margins, especially on one-

off projects, Duclos said. Awarding shipyards multiboat contracts with like designs would reduce costs, time, and risks, he said.

“They’re trying to standardize to a degree, but it’s a little frustrating that every developer seems to have their own idea of what the perfect boat is. The differences in what they’re asking for won’t make a lot of difference at the end of the day, when you consider the cost of building a semi-custom boat for every single contract and every single customer, said Duclos. “Then they’re splitting the boats up [between shipyards], so we’re starting from scratch to fit their designs. For the moment, we’re pretty happy with Patriot. They’re great to work with, so I’m not complaining. I’m just concerned about the future.”

That future, as Blount sees it, hinges largely on getting costs stabilized.

“There’s definitely going to be a future. There’s definitely going to be wind farms built, but I do see a lot of uncer-

Latethis year, the 472' Charybdis is expected to leave the Keppel AmFELS Brownsville, Texas, shipyard and begin work as the only Jones Act-compliant wind turbine installation vessel (WTIV) in U.S. waters, while a uniquely engineered foreign-owned installation vessel is set to follow two years later.

“Charybdis is expected to be in service ahead of the 2024 turbine installation season,” said a spokesman for Dominion Energy Inc., which ordered the vessel to install up to 180 turbines at its Coastal Virginia Offshore Wind (CVOW) project off Virginia Beach, Va. First, however, the Charybdis will deploy to New London, Conn., where it has been subchartered to Ørsted and Eversource for installation work at the Sunrise and Revolution wind farms off New York and Connecticut, respectively. Both projects are slated to go online in 2025, while construction of the CVOW project is expected to be completed by year-end 2026, the spokesman said.

The Charybdis is a start, but a far cry from what will eventually be needed to install the 2,100 wind turbines the Department of Energy (DOE) said will be required to meet the Biden administration’s objective to generate 30 gigawatts of offshore wind power by 2030. The DOE estimates that will require the delivery of up to six Jones Act-compliant WTIVs annually.

Meanwhile, Maersk Supply Service is building a wind

tainty. I think if inflation can be tamed, then the cost structures can stabilize and that would help everybody.”

installation vessel in Singapore destined for the East Coast. The vessel, which is slated to mobilize in 2025 under contract to the Equinor-BP joint venture to install the wind turbines for New York’s Empire Wind and Beacon Wind projects, represents a stark departure from the conventional jackup design.

The new WTIV incorporates a proprietary load transfer system that Maersk claims to be over 30% more efficient than standard installation vessels and allows the vessel to remain on location throughout the installation. “This enables the WTIV to be deployed solely for the purpose of the turbine installation. The solution is also less weather dependent, enabling installation to continue all yearround,” Maersk said in a statement.

To comply with the Jones Act, the Danish company has teamed up with Kirby Offshore Wind, Houston, to provide feeder barges and tugs. – J. Redden

standards.

By Michael Crowley, CorrespondentJust because a winch has been used for a long time — try 27 years — it doesn’t mean it needs to be replaced. Perhaps it just needs a little modernizing. Twenty-seven years is how long three Markey Machinery DESH-5 deep-sea research winches have been on the 274'×52' Ronald H. Brown, a NOAA research vessel.

Bollinger Mississippi Shipbuilding, Pascagoula, Miss., awarded Seattlebased Markey a contract to upgrade the Ronald H. Brown’s deck equipment “to current standards and current practices,” said Scott Kreis, Markey’s vice president of sales. That includes the three Markey DESH-5 winches that the company designed a few decades ago for the oceanographic industry.

Markey’s engineering department is upgrading the level-wind system on the winches by replacing the three-sheave level wind with a two-sheave instrumented mechanical driven level wind. The original level wind “created slight backbends as the cable (conductor cable with metal armor sheathing on the outside and inside coaxial electrical cable or multiple conductor wires protected by insulation) went through the guide in the level wind,” said Kreis. Now, the two-sheave level wind “has zero back bends.”

The winch project has been an ongoing process with upgrades taking place when the Ronald H. Brown is hauled at the boatyard. The estimated delivery date of the refurbished winches is in the

spring of 2024.

Smaller Markey winches aren’t giving up any options just because of their size. For example, take Markey’s compact 7H hydraulic winch. The winch is on the 60'×18' Piping Plover, a harbor survey vessel with twin 670-hp Caterpillar C18s, built by Aluma Marine, Harvey, La. The Piping Plover was delivered to the New York City Department of Environmental Protection in January.

The 7H hydraulic winch (an electric model is also available) is not only the lone aluminum winch in Markey’s lineup, but it is also the smallest research winch, at 50"×50"×60" and 1,350 lbs. without its wire. The 7H winch includes

“features almost never found even on deep-sea research machines 500 times larger,” said Kreis, including instrumented level wind with load monitoring showing how much cable is out.

The winch comes with two drums, which allows different types of wire on each drum, thus drums can be swapped out as needed. “That’s something you don’t see very often,” said Kreis. There are also two control stations, load monitoring and a slip-ring assembly. The slip-ring assembly allows cable with electrical conductors to be wound in on a winch drum or let out without the rotating cable losing its electrical connection to the onboard electrical outlet.

Arcosa Marine & Industrial builds towboat deck gear at two of its subsidiaries, Nabrico in Gallatin, Tenn., and Wintech International in Bossier City, La. Both Nabrico and Wintech recently introduced new winches for inland barge towing.

Nabrico’s winch is the hand-operated FASST 40 winder winch that Nabrico began marketing in early 2022. It’s the next generation Nabrico winder winch. The rst was the DF-356 FASST winder winch introduced in 2019 for connecting two or more barges or bringing barges up to a towboat, allowing them to operate as a single hull.

The process starts with spooling-up loose wire on the deck of a barge or towboat by turning the hand wheel on the side of the FASST 40. Then, by using the ratchet handle, the winch’s foot pedal and a combination of your arm and leg power, the tow line between barges reaches full tension. No other form of leverage, such as extension bars, is needed. Up to 15,000 lbs. of line pull can be obtained, according to Nabrico. There’s a drum capacity of 85' of 7/8"

line or 70' of 1" line.

The original DF-356 FASST winder winch was built to move large tank barges, say 298'×55' with a 30,000-bbl. liquid capacity. The new FASST 40 winder winch is designed for smaller dry cargo barges, under 200’, that haul less weight.

The new FASST 40 winder winch has a compact design with “the industries smallest footprint,” said Clint Bryan, Arcosa’s director of product development. It is 21 1/2"×20 1/2"×41 1/4". The FASST 40 weighs 565 lbs., is hot-dipped

galvanized with stainless steel drive shafts, winch guards, and brake drums with an 80,000-lb. holding capacity.

Wintech’s newest winch, the HW Series harbor winch, model HW30-E5, was introduced to the towing industry at the 2022 International WorkBoat Show in New Orleans. It’s primarily designed for eet boats or harbor boats that make up groups of barges for larger inland towboats. The major issues addressed by Wintech when designing its harbor winch were safety and ef ciency.

Prior to the development of the harbor winch, most harbor boats had two winches mounted near the center of the forward deck with a line going from each winch drum, around a roller or stainless-steel chock and out to the barges. Thus, ropes and winches took up much of a harbor boat’s limited deck area.

Wintech’s solution was to put two winches in a single housing and mount it next to the tug’s bulkhead. The two lines leaving the winch follow the bulkhead, turn through starboard and port rollers or stainless-steel chocks, and then follow the edge of the superstructure back to the barges.

“It keeps everything tucked in, so you aren’t tripping over things,” said Bryan. Wintech’s double-drum deck winch is “fully serviceable from both sides,” and inspections can be conducted by removing two latches that hold aluminum guards in place.

The Wintech HW30-E5 winch introduced at the WorkBoat Show is the rst of three models. The remaining two will be introduced to the market later. The HW30-E5 is 44"×18 1/4"×44 1/2".

Since 1858 Patterson Manufacturing in Pittsburgh has been coming up with labor saving technology for barge operators. Some of the most notable include the River Ratchet in 1871. It was the first ratchet able to link barges together. More recently was the YoYo Winch in 2010, a one-person manually operated winch that would not bind up when making barge connections.

“Fifteen thousand to 16,000 have been sold in the past 10 years,” said Taylor Grapes, Patterson Manufacturing’s president, Patterson’s latest innovation is the Patterson davit crane, introduced in early 2020 to make lifting operations safer and faster on river boats. “It’s 100-percent galvanized, stainless steel, zinc plated,” said Grapes. “Corrosion prevention is one thing we do differently” than other crane manufacturers.

There are no plastic pulleys or sheaves, and the davit crane comes with an electric winch. Each end of the electric winch’s galvanized drum is supported by pillow block bearings that absorb the forces generated during a lifting operation, thus minimizing the stresses placed on the gearbox.

The davit crane’s boom, when in a horizontal position, is 56" off the deck and 107" when fully extended at a 45° angle. That should get the deck crane’s load over most obstructions. The davit crane has either a half-ton lifting capacity when using 1/4" wire rope or a one-ton lifting capacity with 5/16" wire rope. The boom length on the half-ton model extends from 29" to 59" and from 39" to 74" on the one-ton crane. If a vessel operator needs a longer boom, the davit crane can be modified. A robust brake ensures that the boom and its load stay at the desired height.

“A better-quality brake is a point of focus for us,” said Grapes. “No creeping on the brake.” If a vessel operator has a particularly heavy metal object that needs to be moved and the deck crane’s standard lifting arrangement won’t work, Patterson’s optional magnetic attachment with a 2,000-lb. capacity will do the lifting.

Late last year, Mercury Marine, a division of Brunswick Corp., introduced its V10 outboard with the ofcial launch of its all-new 5.7L 350 and 400-hp Verado outboard engines. Mercury of cials said the engine is the rst of its kind in the industry.

Designed to run quieter, the new Verados are not only compatible with the latest Mercury SmartCraft technologies but will also be offered with an optional dual-mode 48V/12V alternator. This will enable it to seamlessly pair with Navico Group’s (a division of Brunswick) Fathom e-power system, an integrated lithium-ion auxiliary power management system that permits the elimination of onboard generator systems.

“The all-new Mercury V10 Verado outboards are exactly what boaters have been asking for in a 350- and 400-hp platform,” Chris Drees, Mercury Marine president, said in a

statement.

Cox Marine unveiled new green technology advances and a strengthened U.S. presence at December’s International Workboat Show in New Orleans.

Cox presented documentation of the CXO300’s high performance using HVO fuel propellent, which, unlike traditional fossil derived diesel, is synthesized from 100% renewable raw materials such as vegetable oils, animal oils and fats, which is designed to reduce net CO2 greenhouse gas emissions by as much as 90%. The CXO300 runs on HVO out of the box with no modi cation, and all existing warranties and service schedules are maintained whether the engine runs on diesel or HVO.

The company’s internal testing has shown a 28% fuel savings over an equivalent 300-hp gasoline engine and net CO2 emissions reductions with HVO100 fuel.

The Cecil Pashley Building, Unit 8, Cecil Pashley Waym Shoreham (Brighton Way) Airport, Lancing, West Sussex, UK Bn43 5FF +44 (0) 1273 454 424 / www.coxmarine.com / info@coxpowertrain.com

10101 Science Dr., Sturtevant, WI 53177 800-901-3228 / www.evinrude.com

HONDA MARINE

4900 Marconi Dr., Alpharetta, GA 30005-8847

770-497-6400 / www.marine.honda.com

W6250 Pioneer Road, P.O. Box 1939, Fond du Lac, WI 54936-1939 920-929-5040 / www.mercurymarine.com

Manager 985-215-1520 730 / www.dieseloutboards.com / david.l@dieseloutboards.com /

info@oxe-diesel.com, Diesel Outboards LLC, David LeBlanc, Regional

1855

3251 E. Imperial Hwy., Brea, CA 92821-6795 714-996-7040, ext. 2322 / www.suzuki.com / dgreenwood@suz.com

670 S. Freeport Parkway, Suite 120, Coppell, TX 75019

469-771-3740 / www.tohatsu.com

171 Erick Street, Unit D-2, Crystal Lake, IL 60014 815-444-8806 / www.torqeedo.com/us/en-us

1270 Chastain Road, Kennesaw, GA 30144 866-894-1626 / www.yamahaoutboards.com

Laborde Products, 74257 Hwy. 25, Covington, LA 70435/7410 • Miller Road 2, Building 4, Houston, TX 77049 800-628-9882 / labordeproducts.com / ccerullo@labordeproducts.com

*Due to space constraints, not all engine models are included. See your local dealer for a complete list of all the engine manufacturers listed.

WELDERS: COMBO-FITTERS

PAINTERS/SANDBLASTERS

The Boat Company is now accepting applications for USCG licensed Deckhand (minimum OUPV) for their 2023 season. We offer a competitive salary and guaranteed minimum tip amount. Equal

For full job description and to apply: https://www.workboat.com/resources/ jobs-marketplace/welders-painterscarpenters-deckhands

Has Immediate Openings!

Derrick Barge Deck Foreman

Leadermen

Rigger

Derrick Crane Operator

Deck Crane Operator

Tower Operator

Welding Foreman

Welder (6 GR Certified)

Clerk

Chief Engineer

Chief Electrician

Mechanic

Oiler

Electrician

Steward

Night Cook

Galley Hand

Tug Boat Captain

Able Body Seamen

QMED/OILER

VANUATU FLAGGED TUG CREWS:

Able seafarer deck–II/4 or II/5

Chief engineer III/3

Able seafarer engine III/4 or III/5

All deck officers must hold valid Vanuatu GMDSS– General Operator’s Certificate (GOC) (IV/2)

Minimum 2 years offshore experience onboard a derrick barge required. Applicants must have a valid TWIC card.

Email resume to: jobs@shoreoffshore.com

To

wjalbert@divcom.com

WM RESOURCES STAFFING L.L.C.

Experienced Utilities, Preps, Bakers, Cooks & Painters for Offshore.

Must have T.W.I.C. Miniumum 2 years offshore experience Must pass drug test

Email Resumes to: wmresource206@yahoo.com

A great opportunity for an experienced technician with a desire to join an engineering-backed group as a Field Service Engineer servicing the West Coast This position is geared toward mechanical or electrical technicians with at least 2 years of related experience and a high drive for learning and problemsolving The role will conduct field service engineering work and related activities

https://palmer-johnson-enterprisesinc.rippling-ats.com/job/543183/fieldservice-engineer

2023 Spring-Summer-Fall Season! We love boats and the ocean!

We are passionate about taking people out and sharing the waters we love and enjoy We are located on Mount Desert Island, Maine.

JOB POSITIONS :

CAPTAIN ENGINEER (Unlicensed) MATE / SENIOR DECKHAND DECKAND

FOR MORE DETAILS & TO APPLY

https://www.barharborwhales.com /employment/

Email: larry@barharborwhales.com

Dann

NO

As our fleet continues to grow, we are looking for experienced wire boat:

- Captain - Engineers - Mates - AB Deckhands

We Offer:

A company committed to safety

Competitive Day Rates

Equal Time Opportunities

Paid Travel

Apply online: www.dannoceantowing.com

Email: hiring@dannoceantowing.com

McAllister Towing, “Leading the Way” for over 150 years, Has positions available:

Captains, Mates, Engineers, AB & OS Deckhands

Captains: Need a minimum of 200 Ton Near Coastal License with Master of Towing, 1600 ton preferred, with a valid TWIC, USCG Medical Certificate, NY harbor experience is preferred. Coastwise towing experience on wire tugs and /or Tractor tug experience is a plus

Mates: Need a minimum of 200 ton Near Coastal License with Mate of Towing, 1600 ton preferred, with a valid TWIC, USCG Medical Certificate, NY harbor experience is preferred. Coastwise towing experience on wire tugs and /or Tractor tug experience is a plus

Engineers: Need a valid MMC, TWIC, USCG Medical Certificate, We prefer a Licensed Engineer with Tug experience, but will consider unlicensed personnel that have tug experience.