MACC Attack

American Society of Naval Engineers' conference did not disappoint.

Jacksonville Ship Repair

Conveniently located in Northeast Florida, just two nautical miles from the Atlantic Ocean with unrestricted access, BAE Systems Jacksonville Ship Repair offers professional ship repair and refit services.

• Emergent and Scheduled Repairs

• Refits and Repower

• Subcontract Support

• Project Management

• Facilitator

Quality services, on schedule, within budget, and without difficulty. Honest and Upfront.

Jacksonville, Florida | USA +1-904-431-2227 | jaxshiprepair@baesystems.us

Secure. Professional. Quality. On schedule. baesystems.com/commercialshiprepair

14 Focus: Fearsome Flotsam

In a typical year, more than 2,000 shipping containers are lost overboard.

18 Vessel Report: Small World

Good things sometimes come in little packages.

26 Cover Story: Counter Punch

Technological advances in patrol boat performance and safety.

BOATS & GEAR

20 On the Ways

• LabMar Marine charters first vessel to launch new inland waterways carrier • Conrad Shipyard holds recognition ceremony for US Navy YRBM • Gladding-Hearn delivers refitted ferry to Bermuda

• Eastern to build four new escort tugs for Seattle's Saltchuk Marine

28 Training Wheels

College program specializes in training those who are new to the marine industry

AT A GLANCE

8 On the Water: The heat is on — Part I.

8 Captain’s Table: Growth brings unforeseen business challenges.

9 Energy Level: The maritime industry and the energy transition.

9 Nor'easter: Speed limits to protect whales?

10 Inland Insider: Congress to decide inland waterways cost-share.

12 Legal Talk: Procedural law v. substantive law.

12 Insurance Watch: Legal system abuse.

13 Design flaw and lack of training caused Staten Island Ferry fire.

13 Small Shipyard Grant Program distributes $8.75 million to 15 yards.

13 More than $96 million in illegal drugs offloaded.

10 Tech Watch: Hefring Marine's AI-driven route optimization technology.

SAVE THE DATE

NEW ORLEANS

Housing development

In In August, thousands of college students will descend upon colleges and universities across the U.S. Many of them, mostly freshmen and sophomores, will be staying in dormitories.

That's what I was thinking about at the end of July as I made my way along Hwy. 90 toward Amelia, La. However, those thoughts were interrupted when a south Louisiana summer thunderstorm came barrelling up the highway in the opposite direction. The rain was so intense that I decided to pull onto the shoulder of the road and wait it out. Unfortunately, I couldn't nd the shoulder of the road through the monsoon. Minutes later the storm and I went our separate ways, it toward New Orleans and I to Conrad Shipyard's Amelia shipyard facilities.

I was going there to attend a rst-inclass recognition ceremony for the U.S. Navy's new 151'4"×49'4"×14' yard, repair, berthing, and messing barge — YRBM 57.

I was about an hour early for the ceremony so Conrad's vice president sales and marketing Robert Socha brought me aboard the barge for a tour.

They sure packed a lot into this vessel, although YRBMs are not technically considered Navy vessels.

A YRBM barge provides a temporary home away from home and workplace for service men and women whose vessels are in port for repairs and/or maintenance. In other words, a kind of dormitory.

Among the YRBMs features are a 12-person of cers’ mess, 12-person chief petty of cer mess, 60-person

Ken Hocke, Senior Editor khocke@divcom.com

enlisted mess, ve-person medical examination area, four-person medical of cer’s of ce, ve-person ofcer’s lounge, nine-person chief petty of cers’ lounge, 24-person enlisted lounge, classrooms for 72 personnel, and a 25-person conference room.

The barge has a full load draft of 6'8", an air draft of 60'11", and a full displacement of 1,270 LT. It is an ABS classed A1 accommodation barge, providing pier-side living accommodations capable of berthing 199 duty crew mixed-gender personnel, messing for 300, and space for medical ofces, classrooms, workspaces, laundry rooms, storerooms, and lounge areas. Yes, it rained on the way back home.

Produced by Presented by

Morial Convention Center, Halls B, C, D, E & F

MARINE LUBRICANTS WITH THE POWER TO PROTECT YOUR VESSEL YOUR EQUIPMENT AND THE ENVIRONMENT

Lubriplate is committed to providing you with the right lubrication for your vessel and other equipment affected by (VGP) Vessel General Permit regulations. Designed specifically for use in harsh marine conditions, these high performance, Environmentally Acceptable Lubricants (EAL)s deliver all the performance and protection you need, while maintaining compliance with regulations protecting the environment.

ATB BIOBASED EP-2 GREASE

• This versatile grease meets U.S. EPA Vessel General Permit (VGP) requirements.

• Passes U.S. EPA Static Sheen Test 1617 and U.S. EPA Acute Toxicity Test LC-50.

• ECO-Friendly and Ultimately Biodegradable (Pw1) Base Fluid – 75.2%.

• Designed for use on Articulated Tug Barge (ATB) notch interface, coupler ram and drive screws, above deck equipment, rudder shafts, wire rope, port equipment, cranes, barges and oil platforms.

BIO-SYNXTREME HF SERIES HYDRAULIC FLUIDS

• These fluids meet U.S. EPA Vessel General Permit (VGP) requirements.

• High-performance, synthetic polyalkylene glycol (PAG)-based formula.

• Non-Sheening – Does not cause a sheen or discoloration on the surface of the water or adjoining shorelines.

• Provides long service life and operating reliability, lower maintenance costs, and reduced overall downtime.

• Excellent anti-wear performance - rated as anti-wear (AW) fluids according to ASTM D7043 testing and FZG testing.

• High flash and fire points provide safety in high temperature applications.

• All season performance – high viscosity indices and low pour points.

• ECO-Friendly and Readily biodegradable according to OECD 301F.

• “Practically Non-Toxic” to fish and other aquatic wildlife according to the U.S. Fish and Wildlife Service hazard classification.

COMPLIANCE STATEMENT LUBRIPLATE ATB BIOBASED EP-2

and BIO-SYNXTREME HF SERIES HYDRAULIC FLUIDS are Environmentally Acceptable Lubricants (EAL)s according to the definitions and requirements of the US EPA 2013 Vessel General Permit, as described in VGP Section 2.2.9

MARINE LUBRICANTS

Newark, NJ 07105 / Toledo, OH 43605 / 800-733-4755 To learn more visit us at: www.lubriplate.com

This year at Pacific Marine Expo take some time to explore WorkBoat West; a brand new free educational program designed for shipyards, vessel owner operators and other commercial marine stakeholders. The International WorkBoat show propels the industry forward by bringing together the most important stakeholders in the commercial marine market together each fall in New Orleans. WorkBoat West will bring a piece of that best-in-class maritime tradition to Seattle.

Entry to WorkBoat west sessions is included in your Pacific Marine Expo pass. Please see schedule of events at pacificmarineexpo.com/ workboatwest

EDITOR IN CHIEF David Krapf / dkrapf@divcom.com

SENIOR EDITOR Ken Hocke / khocke@divcom.com

CONTRIBUTING EDITOR Kirk Moore / kmoore@divcom.com

CONTRIBUTING WRITERS Capt. Alan Bernstein • Steve Blakely • Arnie Brennaman • G. Allen Brooks • Bruce Buls • Robin G. Coles • Michael Crowley • Jerry Fraser • Pamela Glass • Max Hardberger • Joel Milton

CONTENT SPECIALIST Benjamin Hayden / bhayden@divcom.com

DIGITAL PROJECT MANAGER / ART DIRECTOR Doug Stewart / dstewart@divcom.com

EDITORIAL DIRECTOR Jeremiah Karpowicz / jkarpowicz@divcom.com

ADVERTISING ACCOUNT EXECUTIVE S

Mike Cohen 207-842-5439 / mcohen@divcom.com

Kristin Luke 207-842-5635 / kluke@divcom.com

Krista Randall 207-842-5657 / krandall@divcom.com

Danielle Walters 207-842-5634 / dwalters@divcom.com

ADVERTISING COORDINATOR

Wendy Jalbert 207-842-5616 / wjalbert@divcom.com

Use code “ ” to secure your free pass to Pacific Marine Expo and start planning today. pacificmarineexpo.com

Producers of The International WorkBoat Show and Pacific Marine Expo www.workboatshow.com • www.pacificmarineexpo.com

EXPOSITION SALES DIRECTOR Christine Salmon 207-842-5530 / c salmon@divcom.com

PRESIDENT & CEO Theodore Wirth / twirth@divcom.com

GROUP VICE PRESIDENT Bob Callahan / bcallahan@divcom.com

PUBLISHING OFFICES

Main Office 121 Free St., P.O. Box 7438, Portland, ME 04112-7438 207-842-5608 • Fax: 207-842-5609

MAGAZINE SUBSCRIPTION INFORMATION

cs@e-circ.net • 978-671-0444 (Monday-Friday, 10 AM – 4 PM ET) © 2024 Diversified Communications PRINTED IN U.S.A. IN

IT’S SHOW TIME!

NOV

12-14, 2024 / NEW

Morial Convention Center, Halls B, C, D, E & F

ORLEANS

Register for your free pass workboatshow.com

Underwater Intervention returns in 2024 alongside The International WorkBoat Show!

Underwater Intervention attracts a global audience of engineers, technical specialists, industry leaders, and experts, to share ideas, debate the issues of the moment, and create common agendas for the industry’s future.

Underwater Intervention features some of the world’s leading figures within the upstream oil and gas industry coupled with technical sessions covering the most current challenges and up-to-date strategies and technologies.

MAIL BAG

Committed to rebuilding trust in the Coast Guard

Today(June 11, 2024), I spoke to the Senate Subcommittee on Investigations about our service’s efforts to combat sexual assault, sexual harassment, and other harmful behaviors.

Sexual assault and sexual harassment are crimes that harm our members, and it is not who we are.

I have had the privilege to meet with many victims to hear their stories rsthand. I know that some victims were in the hearing room today. I recognize the harm they experienced, the trust that was broken, and the dif cult journeys they undertook to be heard.

I am so sorry for their pain.

As Commandant, I am committed to rebuilding trust. Our workforce deserves a culture where people feel connected and supported, and the continuing success of our missions depend

on it.

Over the past 10 months, we have taken action to address not only the issues revealed by past investigations, but the broader issues of culture and workplace climate, including efforts to root out toxic behaviors and earn the trust of our workforce.

Every expert we’ve consulted has cautioned that culture change is anything but easy, but it is an undertaking that is critically important to our success as a service organization.

I will not shy from this essential work, and I know our service members are already rising to this challenge.

That’s why I’m con dent this sustained effort will make the U.S. Coast Guard stronger, more resilient, and more responsive to our people and the public we serve.

At issue is the improper handling and secrecy of “Operation Fouled Anchor,” an internal investigation into misconduct at the Coast Guard Academy that occurred between 1990 and 2006. The investigation revealed a pattern of mishandling a raft of sexual harassment and assault cases, leading to perpetrators not being held accountable and victims not being treated with respect or given proper attention to their complaints. The report's ndings were kept secret.

Something on your mind?

WorkBoat encourages readers to write us about anything that appears in the magazine, on WorkBoat.com or pertains to the marine industry. To be published, letters must include the writer’s address and a daytime phone number. Email: khocke@divcom.com

Semper Paratus, Adm. Linda L. Fagan Commandant, U.S. Coast Guard

CORROSION CONTROL

FINGERTIPS

BY JOEL MILTON

Joel Milton works on towing vessels. He can be reached at joelmilton@ yahoo.com.

On the Water

The heat is on — Part I

The heat is on, and it looks to be another cracker of a summer. Heat domes have been working the continent from one end to the other, setting new records, and offering up punishing conditions to anyone working outside.

We’re all familiar with the long-used term “heat index” which is derived from the effects of the relative humidity applied to the actual air temperature, yielding what is sometimes also called the apparent or “feels-like” temperature. The relationship is simple: As actual air temperature, relative humidity, or both, increase the heat index increases, along with the physiological stressors on the human body, while physical comfort decreases, possibly effecting job performance and safety.

It’s very important to understand that actual and apparent temperatures, forecasted and observed, are measured and calculated only in and for shaded locations. Exposure to direct sunlight may

BY CAPT. ALAN BERNSTEIN

Alan Bernstein, owner of BB Riverboats in Cincinnati, is a licensed master and a former president of the Passenger Vessel Association. He can be reached at 859-292-2449 or abernstein@ bbriverboats.com.

Captain’s Table

Improved business brings unexpected challenges

Passenger vessel operators nationwide have experienced outstanding business conditions. In most markets, travel and tourism related activity has surpassed pre-pandemic levels. This is great news for those of us who operate U.S.flagged passenger vessels, and we appreciate the much-improved business climate. However, this continuing business success brings larger passenger numbers and some unwanted challenges.

Rail Jumping is one such problem. As an example, my company, BB Riverboats, recently hosted a party for a school group aboard the Belle of Cincinnati. While underway, one of the students at the party, in a move to show off to his friends, jumped over the rail into the river and swam to shore. Even though the student was lucky enough to survive, he put our passengers and crew in danger by causing us to take evasive action and to initiate a search. In addition, the Coast Guard was immediately notified along with the local fire department and law enforcement.

In another such instance several years ago, I had a jumper while we were underway in the middle

require an upward adjustment of up to 15°F to the standard heat index to compensate.

All temperature measurements of record are necessarily in-the-shade temperatures. This eliminates variability that would otherwise skew all of the data. To accomplish this, a white louvered box called a Stevenson Screen is the semi-standardized instrument shelter used at almost all weather stations, and there are siting and exposure standards for these shelters as well. Among other things, the National Weather Service requires that thermometers be mounted 5 feet (+/- 1 foot) above the ground, and that the ground over which the shelters are located should be “typical of the surrounding area.” That typically means grass or dirt, not asphalt or concrete. Unfortunately, it does not accurately reflect the conditions as we feel them while working in the sun on steel decks.

For 104 years and counting, the official site for measuring and collecting weather data for New York City is in Central Park. It’s a lovely location. But it bears no resemblance to standing in the sun on the deck of a tank barge loading cargo in July.

of the Ohio River near the Cincinnati bridges. The water temperature was 54°F and the river was flowing three miles per hour. There were three towboats and two excursion vessels close by. We launched our rescue boat and my crew was able to save his life. Clearly, this was a dangerous situation for all involved.

At BB Riverboats, we take safety seriously, and we work hard to ensure that our safety and risk management program and practices are secondto-none. We plan, practice, and drill for many different emergencies, including man overboard. But no matter how prepared we are, I always get a shudder when I hear on our internal radio, “We have a jumper.”

In the late 1990s, at the urging of the Passenger Vessel Association, Congress passed legislation permitting the Coast Guard to charge rail jumpers with a violation of federal law and allowing them to assess a civil fine.

I take some comfort in knowing that the Coast Guard can discourage rail jumping through enforcement efforts. But we all must do a better job of discouraging passengers from jumping overboard whether on a dare, to show off, or for some other unknown reason. This begins with communicating the dangers associated with this unsafe practice and the potential for being arrested and fined, if they survive.

Energy Level

The

maritime industry and the energy transition

BY G. ALLEN BROOKS, CORRESPONDENT

bp’s chief economist laments that the world is in an “additive” energy phase where it is consuming large amounts of renewable energies and hydrocarbons. He believes the energy market must quickly move to a “substitution” phase where renewable energies replace hydrocarbons.

The reality is there is no energy transition. Data from the Statistical Review of World Energy shows hydrocarbon consumption is growing faster than renewables despite their privileged status and billions of government subsidies. The intermittency of renewables, their low financial returns, and the necessity of backup energy are slowing the transition.

BY KIRK MOORE, CONTRIBUTING EDITOR

Contributing

Editor Kirk Moore was a reporter for the Asbury Park Press for over 30 years before joining WorkBoat in 2015. He has also been an editor for WorkBoat’s sister publication, National Fisherman, for over 25 years.

These challenges do not deter people from believing we can easily and rapidly transition away from hydrocarbon energy.

A 2022 report from the International Energy Agency (IEA) gave us a roadmap. It estimated how much critical minerals must be mined, refined, and turned into products to drive the transition.

The IEA has two models predicting global emissions in 2040. STEPS (IEA’s stated policies scenario) assumes that the current government climate policies are maintained. SDS (sustainable development level) assumes governments enact new policies to match the emissions targets of the 2015 Paris Agreement. In STEPS, the volume of critical minerals must increase fourfold by 2040. SDS calls for a sixfold increase. EVs, batteries, solar panels, and wind turbines drive the demand.

Can the maritime industry handle such a demand increase? From 20112024, in response to the increased glo-

Nor’easter

Speed limits to protect whales?

Thefederal proposal to designate critical habitat for the endangered Rice’s whale is slowing amid opposition from Gulf of Mexico state leaders, who say any potential restrictions to protect the whales could endanger their maritime industries.

With a population estimated at only around 75 animals, the Rice’s whale is at even more peril than the North Atlantic right whale, believed to number around 360 whales ranging along the U.S. Atlantic coast.

Back in October 2023 the National Oceanic and Atmospheric Administration backed off from a rule proposal that called for local 10-knot speed limits when Rice’s whales are seen in Gulf waters. That plan drew intense criticism from Gulf shipping and offshore energy industries.

NOAA and the Department of Interior “have actively pursued unnecessary measures for the Rice’s whale at the expense of communities along the Gulf of Mexico,” the U.S. senators for Louisiana and Alabama wrote in a May 1 letter to the agencies’ leaders.

balization of commerce, the containership fleet grew by 25% while carrying capacity increased by nearly 80%. Bigger ships dominated the containership fleet expansion.

Critical minerals must be moved from mines to processing plants. The increase in mineral consumption, especially coal and iron ore, drove a bulk carrier fleet growth of 65% over the past 12 years. Since 2020, 1,600 bulk carriers joined the fleet. Over the next 20 years, however, we will need even more ships.

We can build larger carriers, but they take longer to load and unload. We do not know where the critical minerals are located or where they must go. Volumes carried and miles traveled will determine how many more ships will be needed.

To meet the IEA critical mineral demand forecasts, assuming the fleet size mix and trade routes remain stable, we may need to add multiples of the annual newbuilds of recent years.

“While we appreciate that NOAA denied the petition to establish vessel speed measures in the Gulf and that BOEM removed Rice’s whale stipulations from Lease Sale 261, we strongly urge that NOAA, NMFS, and BOEM refrain from advancing regulations that lack sound scientific backing,” wrote Sen. Bill Cassidy, R-La., and Sen. John Kennedy, R-La., and Sen. Tommy Tuberville, R-Ala., and Sen. Katie Boyd Britt, R-Ala.

Off the East Coast, NOAA is still considering a rule change that would extend seasonal 10-knot speed limits in right whale areas to cover vessels between 35' and 65'. In the House of Representatives, Rep. Buddy Carter, R-Ga., is sponsoring bill H.R. 8704, which would lock in NOAA’s current 2008 speed rule applying only to larger vessels.

“NOAA’s proposal was not well thought out and would have the unintended consequences of endangering pilots and pilot boat crews, raising the likelihood of marine accidents in the entrance channels of East Coast ports and negatively impacting the marine supply chain that is relied upon by all Americans," Clay Diamond, executive director of the American Pilots’ Association testified during a June 28 hearing of the House Committee on Natural Resources.

BY PAMELA GLASS

Pamela Glass is the Washington, D.C., correspondent for WorkBoat. She reports on the congressional committees and federal agencies that affect the maritime industry, including the Coast Guard, Marad and Army Corps of Engineers.

Inland Insider

Congress to decide on a new costshare formula for inland waterways

The future of how inland waterways projects will be nanced will soon be determined by a small group of senators and congressmen.

They will be meeting this fall in what Congress calls a “conference committee” to iron out differences between two versions of the Water Resources Development Act. Renewed every two years, WRDA is an important law that sets federal policies and priorities for the nation’s water resources, including modernizing the aging and often crumbling lock and dam system along the nation’s inland rivers.

The two pending bills couldn’t be more different, so decisions negotiated by the committee have important consequences.

The Senate WRDA bill is the most generous to the inland system. It includes a provision that would shift the cost-sharing for costly inland construction and modernization projects more to the federal government with a permanent 75% general revenue and 25% Inland Waterways Trust

Tech Watch

Hefring Marine’s AI-driven route optimization technology

BY BEN HAYDEN, CONTENT SPECIALIST

AFund cost-share adjustment. The current cost-share formula is 65%/35%.

The bill also provides 100% federal funding for projects funded through the Infrastructure Investment and Jobs Act signed into law in 2021, which include Kentucky Lock, Three Rivers in Arkansas, and the Elmsworth Dam on the Ohio River near Pittsburgh.

Waterways advocates call this a “major league win” for the inland waterways as the new formula will accelerate project completion and ensure greater ef ciency for the future of river navigation construction. The Ohio River’s Montgomery Locks in Pennsylvania, for example, would likely be fully funded by FY28 under the new formula, while Lock and Dam 25 on the Upper Mississippi in Missouri could potentially get all its funds in FY30, seven years earlier than projected under the current formula, according to the Waterways Council Inc. (WCI), which advocates for inland infrastructure spending.

Overall revenues from the Trust Fund, which is nanced by a diesel tax paid by the inland towing and barge industry, would jump from the current $125 million to an estimated $1.4 billion in additional project funding available over a decade under the new formula, WCI said.

t this year’s Multi-Agency Craft Conference (MACC), Hefring Marine CEO, Karl Bjornsson, introduced his company’s AI-driven route optimization software.

The product was initially developed for search and rescue operations in Iceland.

Bjornsson highlighted the system’s ability to monitor and analyze realtime data, providing insights into the operational status of vessels. Given this data, fleet managers can make better-informed decisions that enhance a vessel’s performance and safety.

The system employs a combination of center and edge computing, using sensors that accurately monitor impacts and vibrations caused by the vessel’s movement through the water, connected to an IP67 embedded computer to gather the data from each vessel.

The data is accessible through a browser-enabled console compatible with various standard plotters, such as those from Garmin, Simrad, Raymarine, and Furuno which display this information in real-time to the operator, delivering alerts when impact thresholds are exceeded.

The AI-driven software is continuously analyzing that data to provide recommendations for optimal speed

and rpm, improving fuel efficiency and extending the operational range of vessels. Through extensive data collection —over 330,000 nautical miles and growing daily — Bjornsson said the system has demonstrated its effectiveness in reducing impacts and enhancing overall vessel performance. Using collected and real-time data on vessel motions, weather and sea conditions, engines and systems, and operator and vessel response, the system makes continuous predictions and recommends optimal actions for the trip. Depending on the trip mode, the

guidance can either deliver the highest attainable safe speed or the highest fuel-efficient speed.

Fleet managers can now monitor vessels in real-time, viewing live trips on an interactive map with a graphic overlay. The system allows for detailed monitoring of engine hours, fuel rates, battery voltage, water depth, oil temperatures, and pressures. Custom rules and geofences can also be defi ned, triggering alerts for any data collected, from speed and wave impacts to fuel rate or oil pressure violations.

The system also provides detailed statistics for each trip or the entire fleet over selected time periods, allowing managers to study and compare trips, vessels, captains, and aggregate fleet data on interactive charts. Automatically generated reports offer key insights and analysis, helping keep track of fleet performance and individual trip details. Additionally, the platform includes performance ranking for captains, enhancing engagement and data ownership by allowing captains to access their profiles and track their progress.

Made to move you

Volvo Penta provides power solutions for marine and industrial applications, advancing people, businesses, and society. Our Global Dealer Network and 24/7 multilingual support ensure maximum uptime and productivity. Explore our innovative products, all designed to elevate your marine commercial operations:

Hybrid and Electric Solutions

Reduced emissions and fuel consumption contribute to environmental sustainability and compliance with regulations while providing quiet and smooth operation.

Dynamic Positioning System (DPS)

Precise control of vessel position and heading is crucial for operations requiring high accuracy, such as offshore installations, increasing operational efficiency and safety.

Integrated Propulsion Systems (IPS)

Seamless compatibility and optimized performance of engines, transmissions, and propellers simplify installation, reduce maintenance complexity, and ensure reliable operation.

BY TIM AKPINAR

Tim Akpinar is a Little Neck, N.Y.based maritime attorney and former marine engineer. He can be reached at 718-224-9824 or t.akpinar@verizon. net

Legal Talk

Procedural law v. substantive law

Most commercial mariners have a good grasp of practical maritime law. If confronted with an engine breakdown, an experienced tug captain understands how salvage law works when arranging assistance. Similarly, the mate on a towboat has a working grasp of the Jones Act from inhouse company training when writing an accident report for an injured deckhand. The legal issues here are considered substantive law — “big picture” items dealing with things like COLREGs, contracts, crimes, etc.

But on the water, things can become more complex. Beyond these “big picture” concepts are procedural law issues that often arise. For instance, which courts will have jurisdiction over the matter? Which state’s laws apply if there is a conflict of laws? These details involve procedural law.

Procedural law issues are usually not as exciting as substantive law issues, such as the desperate negotiations over salvage terms between the Amoco Cadiz and a commercial tug off the coast

BY DAN BOOKHAM

Dan Bookham is a vice president with Allen Insurance & Financial. He specializes in longshore, offshore and shipyard risk. He can be reached at 1-800-236-4311 or dbookham@ allenif.com.

Insurance Watch

Legal system abuse

Legal system abuse, the exploitation of the legal system for personal gain or to create unfair advantages, has become a significant concern across various sectors, particularly the insurance industry.

Such abuse manifests in various forms, including fraudulent claims, exaggerated damages, frivolous lawsuits, abuse of the discovery process and thirdparty litigation funding. These practices not only burden the legal system but also have profound economic and social implications.

The insurance industry bears the brunt of legal system abuse. The fraudulent claims, exaggerated damages and frivolous or drawn-out lawsuits inflate costs, leading to higher premiums for policyholders. The complex legal environment fostered by abusive practices further burdens insurers with increased legal fees and reputational damage.

I’ve heard it argued that because insurances companies are the ones dealing with the front lines of this issue this is somehow a victimless crime. Setting aside the troubling implication that it is somehow OK to defraud an entire sector of the economy, it is important to remember that the insur-

of France on a fateful afternoon in March 1978. The court decision there reads like a terrifying thriller, describing a 1,096' tanker being battered by mountainous seas and gale force winds. But the less-exciting procedural law issues can often decide the outcome of a case. A recent Supreme Court case illustrates this.

The matter involved a vessel running aground. The Supreme Court’s decision reads like an essay question designed to confuse first-year law students. We have an insurance company organized in Germany. It is headquartered in the UK. We have a vessel owner headquartered in Pennsylvania. The contract between the vessel owner and insurance company states that New York law will apply to future disputes. The vessel runs aground in Florida.

Following the grounding, the insurance carrier filed a declaratory judgment in the U.S. District Court in Pennsylvania. The vessel owner brought claims under Pennsylvania law. But the Supreme Court held that the choice-of-law provisions (New York law) are enforceable. Procedural law is every bit as important as the “more-exciting” substantive law issues we often focus on in legal settings.

ance industry is underpinned by what we pay for our coverage, so if costs climb so do our premiums. When it comes to legal system abuse, we are all suffering.

Additionally, the repercussions of legal system abuse extend far beyond the insurance industry. Legal system abuse distorts the economy, leading to higher prices, reduced economic growth and job losses. The legal system itself suffers from eroded public trust, overburdened courts, and weakened deterrence. Moreover, individuals and businesses face increased anxiety, reduced access to justice, and a diversion of resources from critical social needs.

A relatively new — and currently entirely legal — phenomenon driving expenses and claims in addition to more fraudulent practices is third-party litigation funding, where outside investors finance lawsuits in exchange for a share of potential awards.

To give some context, the largest third-party litigation fund in the U.S., funded by both private equity and overseas sovereign wealth funds among others, has a $6 billion war chest to help push lawsuits to as expensive a conclusion as possible. In essence, there’s a massive thumb on the scale against businesses facing lawsuits and claims.

Design flaw and lack of training cause Staten Island Ferry fire

The design of a new passenger ferry’s engine and inadequate followon training for engineering crewmembers led to a 2022 re aboard a Staten Island Ferry, the National Transportation Safety Board said in July.

The re broke out in the engine room of the passenger ferry Sandy Ground in New York Harbor with 884 persons aboard on Dec. 22, 2022. The crew’s actions to contain and extinguish the re, combined with a quick response from good Samaritan vessels, resulted in the safe evacuation of all onboard. Damage to the vessel totaled $12.7 million.

As a result of the investigation, NTSB issued a safety alert and ve safety recommendations, including recommended regulatory changes to design requirements for diesel engine fuel oil return systems.

While attempting to manage fuel oil levels as the vessel was transiting between Staten Island and Manhattan, oilers aboard the Sandy Ground closed both day tank fuel oil return isolation ball valves, which caused the overpressurization of the fuel oil system. The fuel oil lters on the main engines ruptured, leading to the spray of fuel oil that ignited a re. A delay in shutting down the main engines led to fuel oil continuing to spray and increased the severity of the re.

The Sandy Ground is the second of three Ollis-class ferries built for the New York City Department of Transportation and was put into service six months before the re. The Ollis-class ferries were not originally constructed with fuel oil return isolation valves. Instead, isolation valves were added after delivery to regulate the day tank fuel oil levels. The Ollis-class vessels did not have a means to relieve the pressure in the fuel oil return lines if both fuel oil return isolation valves were closed, and the relief valves in the fuel oil system did not have independent return lines. These design aws led to the overpressurization.

News Bitts

Small Shipyard Grant Program distributes $8.75 million to 15 yards

The U.S. Department of Transportation’s Maritime Administration (Marad) announced that it has awarded $8.75 million in grants to 15 small shipyards in 12 states through the Small Shipyard Grant Program. The funds will help shipyards modernize, increase productivity, and expand local job opportunities while competing in the global marketplace. The full list of this year's recipients can be found at https://www. workboat.com/shipbuilding/small-shipyardgrant-program-distributes-8-75-million-to15-shipyards

More than $96 million in illegal drugs offl oaded

Thecrew of the 270' Coast Guard Cutter Forward offloaded more than 7,302 lbs. of cocaine with an assessed street value of approximately $96 million in Port Everglades in July. Coast Guard crews, working alongside interagency and international partners, interdicted the illegal drugs in the international waters of the Caribbean Sea during three separate cases.

Chinese naval vessels spotted near Alaska

The U.S. Coast Guard in July detected multiple People’s Republic of China (PRC) military ships transiting the Bering Sea, according to a statement issued by the agency. The encounters involved the crew of the USCG Cutter Kimball and an HC-130J aircrew from USCG Air Station Kodiak. The Kimball crew identified three Chinese vessels approximately 124 miles north of the Amchitka Pass in the Aleutian Islands.

The NTSB recommended the Coast Guard require diesel engine fuel oil return systems on U.S.- agged vessels be designed to have either unimpeded return ow or a pressure relief valve. For now, the NTSB recommends the Coast Guard develop and disseminate design guidance for new construction diesel engine fuel oil return systems to have free ow from the engine or other arrangements to stop overpressurization.

All 884 passengers were evacuated safely.

Average container losses for the three years between 2020-2022 were 2,301 containers overboard per year.

Fearsome Flotsam

In a typical year, more than 2,000 shipping containers are lost overboard.

By Stephen Blakely, Correspondent

At 3 a.m. on June 23 during the 2024 Newport Bermuda sailboat race, in the pitchblack and boisterous Gulf Stream, the 41' yacht Alliance smashed into an unseen oating object. The collision destroyed the rudder and ripped open

the hull, sinking the boat within half an hour. The highly trained crew issued a mayday call, grabbed their ditch bags and other essentials, squeezed into the in atable life raft, and watched their sailboat go under the waves. A nearby competitor quickly rescued all nine sailors on board.

“Based on the fact that the people on

watch felt two impacts, they feel it was a submerged container that bounced off the keel and slammed the rudder and caused catastrophic damage,” said Mary Martin, co-captain of the boat, in a post-race video interview. “There was total structural damage. There was no way we could repair it.”

The World Shipping Council (WSC), whose member companies operate more than 90% of the global containership capacity, estimates that in the 15-year period between 2008-2022, an average of 1,556 containers are lost at sea each year. Average losses for the three years between 2020-2022 were 2,301 containers overboard per year.

HIDDEN DANGER

Shipping containers may not seem like the stuff of drama — unless you’re in a small boat at sea. If you are, as I experienced during a recent 1,700-mile

voyage from the Caribbean to New York in a 50' sailboat, they’re impossible to ignore, even if you never see one in the water.

The actor Robert Redford, in his 2013 lm All is Lost, brought this particular nightmare vividly to the big screen: A solo sailor far offshore in the Indian Ocean collides with a jettisoned shipping container oating just above the surface, launching him on a drawnout ght for survival.

The lm garnered various awards (with just one actor and only 51 spoken words) but was criticized in the sailing world for certain inaccuracies (such as the lack of some basic safety equipment and questionable actions by the captain). Whatever its aws, it brilliantly portrays how cascading accidents and bad luck can overwhelm the very best of human ingenuity and tenacity. And it skillfully portrays how vulnerable mere mortals are when we

Doug Stewart

Containerships, like this one moving through the Port of New Orleans, must report boxes lost in U.S. waters. That is not the case in international waters.

go down to the sea in ships, despite the best planning and equipment and technology we can take along with us.

Our boat differed from Redford’s in several ways. Redford’s, like the vast majority of recreational boats both power and sail, was plastic. Ours, Cour de Lion, had a heavy-gauge aluminum

hull designed for Arctic exploration and dealing with ice (not, however, with corrugated steel). Redford’s boat lost its radio communications, while we had a satellite phone to the outside world, in addition to VHF radios. Redford was utterly alone, while we had four experienced sailors aboard,

FOCUS Rogue Containers

providing not just company but different skill sets, and a long list of modern safety equipment.

But in one important aspect, we and every other small-boat sailor at sea are all the same: at night, we are completely blind to anything ahead of us that ies, literally, under the radar — such as a semi-submerged shipping container washed off a ship in a storm. Almost every time I came on deck for a night watch, my only view of the world outside the cockpit was red and green spray sweeping across the bow running lights as the boat plowed into the waves ahead.

In the night, a sailboat runs only on wind, diesel, and hope that nothing is waiting in the water dead ahead.

Our May 2024 passage had two legs, taking three weeks: Some 900 miles from the Virgin Islands due north to Bermuda, followed by another 800 miles — crossing an unfriendly Gulf Stream — on our way to landfall on Block Island, R.I. Several shipping lanes cross this route.

We passed only a half dozen large commercial vessels during the entire trip, none of them containerships: bulk carriers, tankers, freighters, and one massively ugly cruise ship that lit up the night. Only one ship was vectored so close while we were under sail one night that we radioed the captain asking him to change course.

While we didn’t see or encounter any oating shipping

containers, we knew they were out there — because containerships were out there. Which meant that some of them inevitably had gone overboard in rough weather along the way.

That was dramatically con rmed by the unlucky sailboat Alliance only one month later, in the very same waters we had just sailed through.

As the loss of Alliance and similar cases demonstrate, collisions with submerged containers are dif cult if not impossible to prove, since — unlike in Robert Redford’s movie — they are likely to happen at night in zero visibility, in rough weather, and they disappear quickly if they are seen at all.

A day after Alliance was sunk, another sailboat in the same race suffered a catastrophic leak and sank in nearby waters (reason unknown), the crew also rescued.

In a more clear-cut case in 2016, a 52' sailboat off the Canary Islands slammed into a big submerged metallic object in the middle of the night that stopped the boat dead in the water, causing severe damage to the keel. Boat and crew managed to limp into port, but the captain puts the blame squarely on a submerged shipping container.

THE DATA

In 2023, according to the World Shipping Council (WSC), 221 containers went overboard out of 250 million transported, the lowest percentage since recordkeeping began in 2008. Of the 2023 amount, 33% of the containers were recovered (these being in port; containers lost at sea are gone for good). WSC claims “containers lost overboard represent less than one thousandth of 1% (0.001%) of the roughly 241 million packed and empty containers currently shipped each year.”

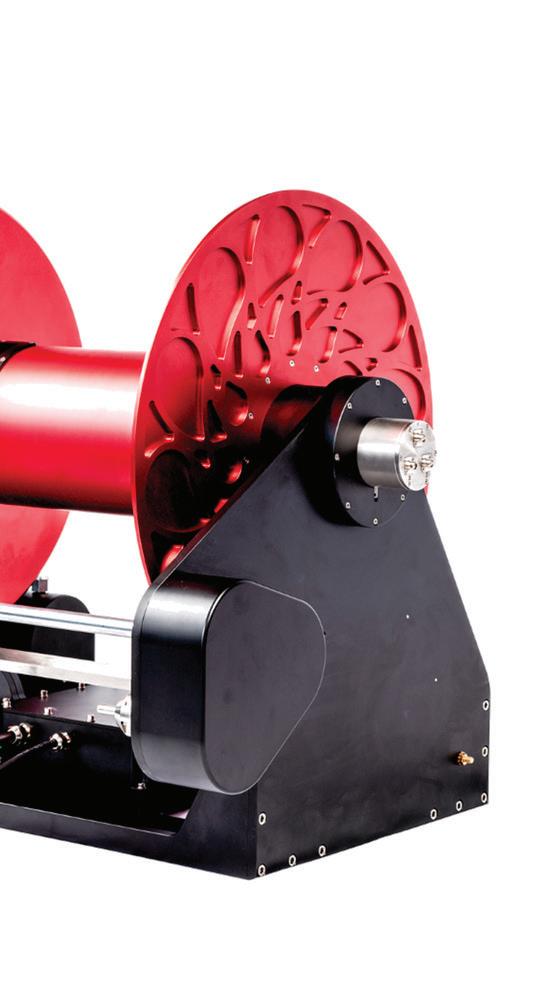

REEL ADVANTAGE

Integrated FORJ or slip ring; Modular design: motorized or manual; Designed for harsh environments; ROVs, tethered drones, portable systems

Whatever the statistics, oating containers are a threat to other vessels, contribute signi cantly to the planet’s alreadyheavily polluted oceans, and create local environmental disasters when they wash ashore and break apart, spewing plastic insulation and whatever toxic materials may be inside.

Losses can vary wildly from year to year driven largely by the weather. In 2021, just one vessel — the One Apus containership — lost about 2,000 containers in rough weather off Hawaii. The same year, an estimated 750 containers went overboard from the containership Maersk Essen during a storm sailing from China to Los Angeles. The largest single container loss was in 2013 when the MOL Comfort broke up in the Indian Ocean, shedding just under 4,300 containers.

Marine engineers say the trend stems from various causes, beyond aging containers, inadequate restraints, and the lack of uniform standards.

As the shipping business has boomed, containerships have become massively larger and the number of boxes they carry on deck keeps getting stacked higher. This makes them increasingly vulnerable to a condition called “parametric rolling,” when waves hit the bow at an angle and start a rolling motion exacerbated by the ship’s normal pitching. In big, fully loaded ships, traditional restraint systems can get overwhelmed by this effect even when waves aren’t that high.

While the majority of containers that go in the water are

said to sink fairly quickly, some do not — especially those that are empty or refrigerated with a tight seal and can oat near the surface for an extended time. Experts predict the number of lost containers will inevitably grow, since shipping is so crucial to global trade and as ever larger and fully packed containerships encounter bigger, more violent and more frequent storms because of climate change.

About 90% of the global trade in goods is transported in ships, and there are currently more than 50,000 merchant ships operating in the world’s oceans, according to the International Chamber of Shipping. As of this writing, the two biggest containerships on Earth, both built in China, are the ultra-large container vessels MSC Irma and the MSC Loreto, each 1,312' (more than four football elds) and capable of holding 24,346 containers (based on the volume of a standard 20-foot-long intermodal box).

REGULATIONS

There are currently no global safety standards for the prevention of container losses, since regulations vary by the ag state of individual ships. In response to the losses, the Marine Institute of the Netherlands several years ago started the Top Tier Joint Industry Project, supported by a consortium of shipping interests, with the goal of creating widely accepted (but voluntary) restraint and safety standards for containerships. The project has

Rogue Containers

The two largest containships in the world each measure 1,312' and can hold 24,346 containers.

issued technical ndings and warnings, including about parametric rolling, but it notes that the existing hodgepodge of international safety rules “does not suf ciently cover…the newest classes of ultra-large containerships.”

The International Maritime Organization (IMO) has been working on new rules to prevent, detect and — especially — report containers lost at sea; in certain cases, even today, depending on where the loss occurred (or if the loss was at least noticed) shippers do not have to alert authorities that containers have gone overboard or to identify what was in them (such as hazardous cargo).

In U.S. waters, according to the Coast Guard, a regulation in effect since 2016 requires “the reporting of

the loss or jettisons of any container or other cargo that could adversely affect the safety of any vessel, bridge, structure, or shore area or the environmental quality of any port, harbor, or navigable waterway of the United States.”

“The Coast Guard is not currently working on new regulations for mounting and securing containers,” a spokesperson told WorkBoat, and “there is no domestic regulation that standardizes the cargo securing con guration.”

Currently, the standard is that any U.S. or foreign- agged vessel of 500 gt. or greater on an international voyage must have a cargo-securing manual approved by a recognized classi cation society and that complies with Coast Guard Cargo Stowage and Securing regulations.

Small World

Good things sometimes come in little packages.

By Michael Crowley, Correspondent

department in Irvine, Calif. It’s probably not a coincidence but a little more than three months later, the Mexican Port Authorities purchased nine Oceanbotics SRV-8 ROVs to deploy in ports for security and monitoring.

The SRV-8 is Oceanbotics’ agship ROV and its rst underwater drone, introduced in 2017. It’s designed to be easy to use “for people that aren’t necessarily trained on high-tech marine equipment,” such as police of cers, re ghters and divers, said Nagle. The SRV-8 has an operating depth of 1,000', weights 41 lbs., is portable for one person, can be set up with its own software, and put in the water in three minutes.

Oceanbotics uses its own SubNav software to view different screens and video record the mission for later analysis.

About three years later, Nagle said representatives from the oil industry came to Oceanbotics inquiring about an ROV that could go deeper and operate in stronger currents. That led to the SRV-8X, which is about 15 pounds heavier than the SRV-8, goes down to 1,640' and has more sonar, camera and detection devices.

Discussions regarding innovations in the workboat industry don’t always center on the big things — the 180-passenger riverboat, the 364' trailing suction hopper dredge or even the 198', 11,000-hp towboat.

How about something measuring 19.5"x17"x13", weighs 41 lbs. that spends most of its time underwater. That’s the SRV-8, an Oceanbotics remotely operated vehicle (ROV). It’s a remotely operated, highly maneuverable, tethered, underwater vehicle used for deepwater work and rescue systems. ROVs are getting an increasing amount of attention. What follows is the story of two ROV companies, Oceanbotics and Poseidon Robotics.

OCEANBOTICS

To start with, publicizing cocaine traf cking is not something most lawabiding companies would do, unless you are talking a cocaine bust and sending the bad guys to jail.

That’s what happened on Aug. 9, 2023, when the Australia Border Force, which was in the habit of deploinging an Oceanbotics SRV-8 ROV to survey the hulls of cargo ships arriving in Melbourne, detected a suspicious compartment below the waterline on the outside of a ship’s hull. A diver went down and found 200 kg of cocaine worth $80 million in the compartment.

“It’s called parasite smuggling and it was good exposure for us,” said Mira Nagle with the Oceanbotics marketing

That was followed by the SRV-8X MDV, with basically the same specs as the SRV-8 along with some extra technology, seeing that it’s a mine disposal ROV designed to “detonate mines underwater,” said Nagle. Once a mine is located, the SRV-8X MDV is moved up to the mine where it places a shock tube over the explosive, “then ies backward away from it” and the mine is detonated. “The shock tube has to be replaced but the drone is ne.”

The last ROV in the Oceanbotics lineup is the SRV-8X Optimus ATS with an acoustic tracking system, which is directed toward the military and search and rescue operations. The ROV detects underwater pingers and transponders, such as those in the blackboxes of commercial aircraft, and using a signal strength meter shows the target’s exact location.

A difference between Oceanbotics ROVs and others is the that the Oceanbotics ROV is offered with X-box controls as the primary form of control. “As

Oceanbotics

Some Oceanbotics ROVs weigh as little as 41 lbs., making them portable.

far as I know, we are the only one that uses X-box controls,” said Nagle.

Its advantage is “there’s not necessarily any training involved” to use it. “Its functionality is pretty basic, not taking more than 10 minutes to learn to fly it. You are not fiddling with a bunch of different buttons.” Oceanbotics also offers flight-stick controls.

Moving beyond law enforcement, search and rescue and the military, there are a couple of underwater worlds where Oceanbotics is working to develop a presence. “We’re breaking into the offshore oil and gas market, doing pipeline inspections,” said Nagle.

Another application is marine science where Oceanbotics is working with different aquariums.

The National Oceanic and Atmospheric Administration (NOAA) is using an Oceanbotics ROV in the Gulf of Mexico to study coral populations. The Oceanbotics ROV is sent into the Gulf once a year or biannually to record video data showing what’s happening to the coral.

POSEIDON ROBOTICS

Versatility and cost savings are two forces driving the continual evolution of ROV technology. A good example is Poseidon Robotics Maui Gen 2 that was launched in June. It’s a slightly larger version of its predecessor, the Maui, and with more camera space.

“It’s designed to do the kind of survey work that a very large ROV would do, something like a 3- to 4-ton vehicle from a large boat,” said Peter Schubert, director of engineering at Poseidon Robotics.

An ideal customer for the new Maui Gen 2 ROV, said Schubert, would be a company doing route surveys for oil and gas pipelines, bathymetric seabed surveys for science, salvage or environmental work, or wind farms that want to run a cable 10 miles to the nearest beach but need a survey to see what kind of bottom the cable will be on in 500' or maybe 1,000' of water. Running a multibeam echo sounder over the intended cable path won’t show anything much smaller than a 20' boulder. “There could be an unexploded mine, and you would

never notice it” and out in the open ocean, maybe not see that 100' vessel lying on the bottom where you want to lay the fiber cable,” said Schubert.

The solution is mounting sonar under an ROV, lower the ROV to just above the seabed, say 10' to 50', and then driving the ROV across the seabed.

It used to be that ROVs employed in bottom mapping work were extremely large and couldn’t be carried on a 30’ boat. “You had to have a 300-foot boat with an enormous A-frame and several people to launch the ROV,” said Schubert.

But over the years, ROVs used for underwater exploration are midgets compared to their predecessors. Facilitating the reduced size of ROVs has been the shrinking of equipment that ROVs carry. “We feel strongly that ROVs must shrink with them to remain competitive,” Schubert noted.

He offers a good example, the pipe tracker, an ROV mounted metal detector used to locate buried cables and pipes on the seabed. In the past a pipe tracker consisted of “a set of detector coils almost 8 feet across, large housings for the electronics, and the whole system required an ROV of a few thousand pounds and a lot of space for accessories just to carry it to the seabed." In contrast, a new pipe tracker version from Teledyne weighs less than 30 lbs. in water “and is easily carried by smaller vehicles,” said Schubert.

Compared to the very large ROVs of the past, the new Maui Gen 2 ROV weighs 114 lb. and measures 33.8”x20-

1/2"x20-1/2". There are eight fully vectored T500 thrusters with a full 9 kW of power to maneuver the Maui Gen 2 in any direction while maintaining a set altitude to monitor objects being surveyed. It can perform cable-route surveys for wind farms and pipeline surveys for oil and gas lines and be set out with a small davit winch or A-frame from the back of a 40' boat by a crew of four or five, all at an initial lower cost than earlier systems.

BEST AVAILABLE TECHNOLOGY

The ROV market continues to expand as potential users understand ROV’s possible versatility and ROV manufacturers learn to take advantage of smaller, lighter-weight equipment. Sometimes that comes out to be, as Schubert acknowledges, plagiarizing from other industries, or put another way, utilizing the best available technology.

“We’ve been able to take a lot of technology from the aerial drone market. ROVs are about where drones were 10 years ago when they were just starting to become a little more mainstream,” he said.

The electrical vehicle market is another industry ROV manufacturers have been borrowing from, especially from Tesla and Ford. In the underwater marine world that technology is a necessity when “a lot of electricity is needed to drive these propellers under water,” said Schubert. Electric vehicle parts are available now. Maybe the upgraded ROV parts will be available next.

Poseidon Robitics

Poseidon Robotics new Maui Gen 2 ROV with a Teledyne TSS 660 pipe tracker, a metal detector that can calculate how deep a pipe or cable is buried under the seabed.

ON THE WAYS

CONSTRUCTION ACTIVITY AT WORKBOAT YARDS

LabMar Marine charters first vessel to launch new inland waterways carrier

Laborde Marine Management LLC, New Orleans, announced in July the creation of a new affiliate, LabMar Inland LLC, that will focus on the U.S. inland marine market, providing towing and pushboat services.

The initial vessel to be placed in service will be the 78'x34'x10' Ivy Steiner, a new 2,000-hp pushboat. The company intends to expand its presence in the inland marine market, using the same management techniques used to grow Laborde Marine Management.

“We are very pleased to announce our entry into the inland marine market through our new affiliate, LabMar Inland LLC and our initial charter of the Ivy Steiner. We intend to grow this new facet of our operations with additional towing and pushboat vessels, which is a natural extension of our many years of serving the offshore waters of the Gulf of Mexico,” Ashton Laborde, president of Laborde Marine Management, said in a statement announcing the new company’s existence. “We have the in-house expertise, strong management team and skilled crews to quickly build our presence inland.”

Built by Steiner Construction, Bayou La Batre, Ala., with an 8'6" maximum draft, the Ivy Steiner’s main propulsion comes from twin Caterpillar C32 diesel engines each producing 1,000 hp at 1,800 rpm. The Cat engines connect to stainless steel props through Reintjes WAF reverse reduction gearboxes supplied by Karl Senner LLC, Kenner, La. The propulsion package gives the new pushboat a running speed of eight knots.

“LabMar Inland is bareboat chartering the Ivy Steiner. This arrangement allowed us to take delivery of a new vessel immediately and to best respond to the demands of our customers,” Laborde

told WorkBoat. “We plan on growing LabMar Inland and will consider doing so through additional bareboat charters, new construction programs, or by acquiring existing fleets.”

Laborde Marine Management owns or operates a fleet of 21 vessels which service the offshore oil industry and other marine support activities.

“Our management and business development teams have been following the inland market, especially the lower Mississippi region, for several years. We made several steps towards entering the market over that period, but for a variety of reasons, we elected to hold off,” Laborde said. “Although costs are at an all-time high for new vessels, we see charter rates adjusting to levels that support the higher construction costs. We also have the advantage of having excess crew capacity by drawing from our various operating arms. Between our offshore and ferry divisions, we have a number of crewmembers that have previous inland experience, a strong working knowledge of the industry, the

appropriate licenses and endorsements, as well as a desire to help the company form a new division.”

On the Ivy Steiner’s deck are two 40-ton capacity Nabrico DF-1-40H winches.

Accommodations include three single-person rooms and two twoperson rooms.

“As of now our focus is on the lower Mississippi, but we would certainly be open to expanding our geographical footprint in the future,” Laborde said.

The electronics suite is made up of two Furuno DRS6AX radar and Furuno loudhailer, FA 170 AIS, and GP39 GPS. Standard Horizon supplied the four VHFs.

Ship’s service power is the responsibility of two John Deere-powered gensets, each sparking 65 kW of electrical power.

“We’re in discussions now with multiple customers, several of which we have long histories with on the upstream side of their businesses, to provide barges, and will consider growing

Laborde Marine Management

The first vessel to be placed in service by LabMar Inland will be the 78'x34'x10' Ivy Steiner, a new 2,000-hp pushboat.

that division through the same avenues we’re considering utilizing to expand the vessel eet,” Laborde said.

— Ken Hocke

Conrad Shipyard holds recognition ceremony for US Navy YRBM

Conrad Shipyard LLC, Morgan City, La., held a rst-in-class recognition ceremony in July at Conrad’s Amelia, La., shipyard for the new 151'4"×49'4"×14' yard, repair, berthing, and messing (YRBM) barge — YRBM 57 — for the U.S. Navy.

Back in 2022, Conrad signed a contract worth up to $140 million to build up to eight YRBMs.

A YRBM barge provides a temporary home away from home and workplace for service men and women whose vessels are in port for repairs and/or maintenance.

Though Conrad Shipyard has been in existence since 1948, this is the yard’s rst U.S. Navy contract. YRBMs are not technically considered naval vessels.

“What you guys out here are doing matters,” the Navy’s Capt. Gregory Mitchell told the shipyard’s workers during his remarks. “This barge will take the place of a barge that’s 60- to 70-years old.”

Conrad’s YRBMs incorporate functional spaces which are designed to allow the sailors to work, sleep and eat comfortably.

YRBM 57, which has a full load draft of 6'8", an air draft of 60'11", and a full displacement of 1,270 LT, is an American Bureau of Shipping A1 accommodation barge that provides pier-side living accommodations capable of berthing 199 duty crew mixed-gender personnel, messing for 300, and space for medical of ces, classrooms, workspaces, laundry rooms, storerooms, and lounge areas.

“We went through builders’ trials recently,” said Mitchell, “and it was one of the best builders’ trials I’ve ever been a part of. Our expectations were far exceeded.”

Among the YRBMs features are a 12-person of cers’ mess, 12-person

BOATBUILDING BITTS

St. Johns Ship Building, Palatka, Fla., delivered the first of two Jones Act-compliant crew transfer vessels (CTV) ordered by Atlantic Wind Transfers. The delivery marks the third CTV built by St. Johns Ship Building (two different customers) within the past six months. The 80'x28.4' aluminum catamaran, Atlantic Resolute, was designed by UK-based naval architect Chartwell Marine Ltd. as part of its Ambitious-class. St. Johns has now built and delivered both Incat Crowther and Chartwelldesigned CTVs. Main propulsion comes from two MAN V12-1400CR engines connected to HM651 Hamiltonjet waterjets through ZF 3050 marine gears. Ship’s service power come from twin Cummins Onan 29kW generators. The Atlantic Resolute has a passenger capacity of 24, including three-to-four crewmembers, and it will operate under USCG Subchapter L.

Moose Boats LLC, Vallejo, Calif., has delivered a customized M3-36 monohull to the Woodbridge Fire District. The M3 will serve as a fireboat in the San Joaquin (Calif.) Delta. Main propulsion comes from twin 300hp Mercury outboards, which have a heavy-duty outboard protective guard, tow line guides, a tow post, and an integrated towing spool. The boat has a dedicated fire pump to flow through two 1,500 gpm Typhoon RC TFT monitors, one cabin-top mounted and one on the bow with VUM for attack hose connection. The fire pump is powered by a Volvo Penta V8 engine providing ample power for the Darley pump.

New fireboat is powered by twin 300-hp Mercury outboards.

The boat also features Moose Boats’ proprietary integrated dive platform door on the port and victim retrieval door on the starboard side. Electronics include a Blue Sea System electrical panel, Lifeline house and start batteries, Furuno 14" MFD integrating radar, chart plotter, depth sounder, and FLIR. The cabin is heated with a Webasto heating system.

All American Marine (AAM), Bellingham, Wash., announced in July that it has signed a contract to construct a 65'x24' patrol vessel for the Los Angeles Port Police. Teknicraft Design, Auckland, New Zealand, designed the dive and patrol vessel. The boat will be powered by

80' CTV for Atlantic Wind Transfers.

St. Johns Ship Building

Moose Boats

chief petty officer mess, 60-person enlisted mess, five-person medical examination area, four-person medical officer’s office, five-person officer’s lounge, nine-person chief petty officers’ lounge, 24-person enlisted lounge, classrooms for 72 personnel, and a 25-person conference room.

“This is an historic event in the history of Conrad Shipyard,” Dan Conrad, the shipyard’s senior vice president, said in his remarks. “These barges are built to a level of quality unrivalled in shipbuilding.”

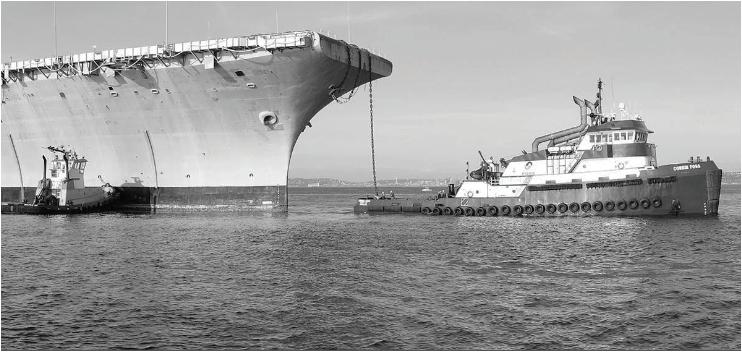

YRBM 57 will move on to San Diego for additional outfitting before eventually making its home in Japan.

— K. Hocke

Gladding-Hearn delivers refitted ferry to Bermuda I

n July, the government of Bermuda’s Marine and Port Services took delivery of the 105'x31' passenger ferry Bermudian after a major refit at Gladding-Hearn Shipbuilding, Somerset, Mass., that took about a year. If all goes as planned, the work done at Gladding-Hearn will give the 700-passenger ferry another 15 years before the vessel will be replaced.

“It’s the first time it’s had any major work done,” said Gladding-Hearn’s president Peter Duclos. The Bermudian’s main job is transporting passengers just getting off large cruise ships that have tied up to what was once the

BOATBUILDING BITTS

twin Cummins QSM11-715 engines with fixed-pitch propellers, providing a combined power output of 705 hp at 2,500 rpm, giving the new patrol vessel a cruising speed of 20 knots and a maximum speed of approximately 25 knots. The vessel is designed to meet the standards of the U.S. Coast Guard Subchapter T regulations.

Royal Naval Dockyard and shuttling them on a 10- to 15-minute run from the dockyard into Hamilton, the capital of Bermuda. “There are 5,000 to 6,000 people on a cruise ship. They want to go somewhere in a hurry,” noted Duclos. Thus, cosmetic changes were kept to a minimum when overhauling the Bermudian, an exception was made in the main cabin that seats 150 passengers. The work included new ceiling, new carpet, new wall linings and air conditioning. “That was considered a good value in terms of cosmetics,” said Duclos. “That’s part of the service they are providing when passengers come on and you want a pleasing environment.”

Critical changes involved replacing the twin Detroit Diesel 12V-71, 460-hp main engines with Caterpillar C-18, 600-hp, Tier-2 diesels and replacing the generators with 99-kW Caterpillar generators. “They were just old and inefficient,” said Duclos, speaking of the engines and generators, “and dirty and hard to get parts for, becoming a real problem for their reliability.” A little more engine power came with the Caterpillar C-18s, “but basically it wasn’t a goal to get more speed; it wasn’t something that was very important.”

Most of the work on the Bermudian done at Gladding-Hearn centered on the vessel’s bilge area: engines, generators, shafts, propellers, whole new steering system, bow thrusters, new

Bollinger Shipyards, in collaboration with Mississippi Gulf Coast Community College (MGCCC), the South Mississippi Planning & Development District, and AccelerateMS, announced the launch of the inaugural Shipfitter Bootcamp, a workforce development initiative. The comprehensive program is designed to equip current and future Bollinger employees with the essential skills and knowledge required to advance their careers. Through a blend of classroom instruction and hands-on experience, students will learn the essential functions required to become a shipfitter in the 14-week program. The first 12 weeks will be taught at MGCCC, with the final two weeks on-site at Bollinger Mississippi Shipbuilding, Pascagoula, Miss.

65' patrol boat being built at All American Marine.

Ken Hocke

New accommodation barge will be homeported in Japan.

engine cooling systems, “all the things that will make this thing run every day for the next 15 years,” said Duclos. “Those were things that were just really worn out, tired, and corroded.”

Like the rest of the boat, the bottom plating was aged, though Duclos said it “was in pretty good shape. They had done a good job of maintaining it.” But there were areas that weren’t easy to maintain. That’s where significant deterioration occurred. Thus about 20% of the bottom plating had to be cut out, along with some framing. “It’s not unusual for a nearly 40-year-old boat.”

Looking back on the work done over the past year on the Bermudian, Duclos compares it to “kind of like an archeological dig, because after 40 years of

service things get changed and modified and not necessarily documented.”

Thus, there’s a lot of discovery of mechanical systems that weren’t even envisioned when the Bermudian pulled into Gladding-Hearn. “But that’s just the way it goes,” said Duclos. “It’s why it takes so long.” — Michael Crowley

Eastern to build four new escort tugs for Seattle's Saltchuk Marine

Eastern Shipbuilding Group (ESG), Panama City, Fla., has been awarded a contract to build four new 84'x42'x14' ship assist/escort tugs for Saltchuk Marine, Seattle. The vessels will be built at

ESG’s Allanton and Port St. Joe facilities, with delivery expected in 2026.

The tugs were designed by Robert Allan Ltd., Vancouver, British Columbia, with 18'7" drafts and accommodations for eight.

Over the past 20 years, ESG has successfully delivered 35 ship assist tugs. This contract marks the beginning of Saltchuk Marine’s long-term fleet renewal project, with the new tugs set to support West Coast port operations and comply with EPA Tier 4 and California Air Resources Board (CARB) environmental requirements.

“We are pleased to partner with Saltchuk Marine on this significant fleet renewal project. Our team is dedicated to delivering high-quality, reliable vessels with industry leading low lifecycle costs that meet stringent environmental standards and support our customer’s missions for many, many years,” Joey D’Isernia, chairman and CEO of ESG, said in a statement announcing the new contract. “This contract award is more solid evidence that ESG is able to successfully design and build both government and commercial vessels while remaining highly competent and competitive in both arenas.”

Main propulsion will come from two Caterpillar 3516E, Tier 4 diesel engines each producing 3,500 hp at 1,800 rpm. The Cats connect to Schottel rudder propellers (SRP 510). The propulsion package will give the new tugs a running speed of 12 knots and a bollard pull of 95 short tons.

“The combination of the Robert Allan team’s naval architecture and engineering experience and ESG’s proven history of building best-in-class vessels will ensure that we continue to provide our customers with the most reliable service on the West Coast, Hawaii, and Alaska,” said Jason Childs, Saltchuk Marine’s president and CEO.

On deck equipment will include a Markey Machine DEPGH-52, 75-hp single drum, class II winch.

The new tugs will offer harbor towage and operate under Saltchuk's AmNav and Foss Maritime brands.

— K. Hocke

The new tugs will operate in California under the AmNav and Foss Maritime brands.

The focus of the refitting was below deck: engines, generators, shafts, propellers, whole new steering system, bow thrusters, and new engine cooling systems.

Counter Punch

Technological advances in patrol boat performance and safety.

Military patrol boats are used in a variety of different missions — coastal defense, maritime security, border control, anti-smuggling operations, counterterrorism, disaster relief, shery patrols, law enforcement, search and rescue missions, and drug interdiction.

In all of these missions, the ability for a vessel to operate at high speeds and in any type of sea state is top of mind. What’s not often considered are the operators of these patrol boats, either rst responders or military personnel, and the damage that running at high speeds in rough water can do to the human body.

PROJECT PERFECT STORM

At this year’s Multi-Agency Craft Conference (MACC) in Portsmouth, Va., put on by the American Society of Naval Engineers (ASNE), the gap between vessel design and operator safety was addressed in a presentation led by of cials from Ocean Craft Marine (OCM). MACC is an open forum for the exchange of operational and technical information on small boats and craft between government agencies and the

maritime community.

“My father is a 100 percent disabled combat veteran who bears the scars of over 300 combat missions on small patrol craft in the U.S. Navy,” said Ryan Salus, OCM’s director of business development in his presentation of Project Perfect Storm, a mission that holds deep personal signi cance. “These experiences, along with those who served, like Ron Carpenter, have been a driving force behind our project.”

Members of the innovative collaboration Project Perfect Storm brought OCM’s 11.5-meter (37.7') Offshore Interceptor to MACC, highlighting the project’s mission to build boats that exceed current standards for safety, comfort, and performance. The team emphasized the integration of technologies aimed at minimizing the impact of high-speed maneuvers and reducing G-forces on rst responders and military personnel and addressing the lack of innovation on current military patrol boats.

The project’s multi-phased approach began with phase one testing, a rigorous data collection of the vessel’s existing con guration, measuring shock impacts, accelerations, vessel pitch, and roll using up to a dozen Inertial Measurement Units (IMUs). These tests recorded G-forces up to 23 Gs at speeds

By Ben Hayden, Content Specialist

Doug Stewart

WorkBoat's Ben Hayden (right) gets a water demonstration aboard Ocean Craft Marine's Offshore Interceptor.

of 60 miles per hour in challenging sea conditions. In Phase 2 testing, the vessel was stripped down, and a new strakeless running surface was sculpted onto the aluminum hull for a second round of identical testing to compare results.

Phase 3 of the project included the addition of the Porta Products Hydraulic Transom Lift System for additional data collection, followed by phase 4, which included the addition of the Seakeeper Ride system. Additional phases will include a collaborative effort of over 15 companies from the maritime industry, showing how competition was set aside to achieve a common industry wide maritime goal.

The integration of various technologies from all the Project Perfect Storm partners aims to create the ultimate high-speed pursuit vessel, combining safety, speed, and cutting-edge technologies. The cooperation serves as a model for future industry projects, demonstrating the potential of united efforts in advancing maritime capabilities. The various companies involved include Ullman Dynamics, Sharrow Marine, Skydex, Military Systems Group, and Hefring Marine, resulting in features like shock-mitigating seats, articulated weapon mounts, shockabsorbing deck pads, a recon gurable deck layout, and AI-based optimal routing technology.

Todd Salus, co-founder and vice president of OCM, detailed the Offshore Interceptor’s working deck space, twin

diver notches, and specialized shockmitigating seats that ensure operator comfort and safety. Salus also emphasized the importance of data collection and collaboration, inviting new partners to join the project.

“We’re here to collect as much data as we can, and then give it all away for anybody to use. I’m not doing this to sell boats. I want to offer this as a legacy project to protect future operators,” said Salus.

Scott Porta, owner of Porta Performance, was heavily involved in the hull recon guration of the vessel. Porta holds 11 world and national offshore points championship titles in the APBA Super Stock Catamaran offshore racing class. “I’ve been in this stuff since I was a kid, and I absolutely love making things work better and go faster,” he

said. Porta Performance also provided the hydraulic transom lift system for the project.

Porta spoke about the advancements in technology being used to measure ef ciency in Project Perfect Storm, making mention of his old method of hanging over a boat’s transom traveling at 100 mph. “The technology that I’m hooked up with, with these guys (Project Perfect Storm), is just phenomenal. And for a change, I’m looking up. I’m looking at other people that have educated themselves tremendously.”

Keith Hubble, principal engineer at TMS Group, provided data on the OCM Offshore Interceptor’s performance, showing signi cant reductions in vertical, lateral, and forward accelerations due to the technologies employed. This model of the stabilizer system is a prototype for larger vessel applications.

The gyrostabilizer was tested in various sea conditions, which demonstrated control over vessel roll and pitch, leading to a more ef cient, smoother, and safer ride for all onboard. The combined technologies on the modi ed vessel resulted in a 26% to 77% reduction in vertical accelerations, in various sea conditions, and compared to stock con gurations. All of these improvements to the boat’s ride, comfort, safety, reduced operator fatigue, and situational awareness are known in the industry as “Human Factors.”

The presentation concluded with a message about the potential impact of

OCM's 11.5m Offshore Interceptor at MACC 2024.

Doug Stewart

Various small craft on the docks in Portsmouth, Va. awaiting water demonstrations at the Mutli-Agency Craft Conference 2024.

Doug Stewart

such advancements, suggesting that if these technologies had been available 20 years ago, many injuries and disabilities among patrol boat operators could and would have been prevented.

The team at Project Perfect Storm will be presenting their project’s results in an educational session at this year’s International WorkBoat Show in New Orleans this November.

In a follow-up discussion, Ryan Salus reflected on the current trends in military patrol boats and the pressing need for innovation. “A lot of what the Navy and the Coast Guard are buying are larger aluminum boats. So that’s why we’re really pushing the innovation on the aluminum side… And that’s kind of where the seed for Project Perfect Storm came about. Everyone was kind of staying in their competitive silos, and they’re not really innovating their hull forms. And operators are continuing to get beat up out there. So that’s why our focus is really pushing the innovation of getting aluminum hull forms up to speed to where they’re just as good (as fiberglass).”

OLD PROS