Shipyard Assist

Grant program aims to keep smaller yards competitive.

Jacksonville Ship Repair

Conveniently located in Northeast Florida, just two nautical miles from the Atlantic Ocean with unrestricted access, BAE Systems Jacksonville Ship Repair offers professional ship repair and refit services.

• Emergent and Scheduled Repairs

• Refits and Repower

• Subcontract Support

• Project Management

• Facilitator

Quality services, on schedule, within budget, and without difficulty. Honest and Upfront.

Jacksonville, Florida | USA +1-904-431-2227 | jaxshiprepair@baesystems.us

Secure. Professional. Quality. On schedule. baesystems.com/commercialshiprepair

16 In Biz: Southern Roots

Content

Alabama shipyard delivers new passenger/vehicle ferry to Maine.

20 Focus: Course Correction

Is a much-needed National Maritime Strategy on the horizon?

30 Cover Story: Scaled-Down Aid

Program helping smaller yards stay competitive is at a crossroads.

34 Construction Survey

A list of vessels under contract, under construction or delivered in the past 12 months.

BOATS & GEAR

24 On the Ways

• Hard Rock Marine delivers dinner cruise vessel to Tampa • ACI Boats delivers new whale watching/eco-tour boat to Washington

• Snow & Company delivers new research vessel to US DOE

46 Leak Detection

New system informs technicians that a leak has occurred at almost any depth

AT A GLANCE

8 On the Water: The heat is on — Part II.

8 Captain’s Table: No-fly zones for drones.

9 Energy Level: The dilemma of positioning.

9 Nor'easter: Offshore wind's first 'spill'.

10 Inland Insider: Another towboat allision to learn from

11 Tech Watch: Volvo Penta's new IPS 40 system.

12 Legal Talk: When engine breakdowns become criminal matters.

12 Insurance Watch: Risk management tips for shipyards.

14 Vineyard Wind blade fracture remains under investigation.

14 Donjon Marine awarded $32.3 million Newark Bay dredging contract.

— 2; public aquarium — 1; no assignment — 1 (the mysterious other).

“Unprovoked bites are de ned as incidents in which a bite on a live human occurs in the shark’s natural habitat with no human provocation of the shark,” the report said.

“Provoked bites occur when a human initiates interaction with a shark in some way,” according to the report.

Ken Hocke, Senior Editor khocke@divcom.com

“These include instances when divers are bitten after harassing or trying to touch sharks, bites on spear sherman, bites on people attempting to feed sharks, bites occurring while unhooking or removing a shark from a shing net, and so forth.”

The 69 con rmed unprovoked shark attacks are slightly above average. Of the 69, the U.S. led the world with 36 (two deaths), followed by Australia with 15 (four deaths), New Caledonia with 3 (one death), Brazil with 3 (no deaths), Egypt with 2 (one death), South Africa with 2 (no deaths), Bahamas with 1 (one death), Mexico with 1 (one death), and Costa Rica, Columbia, New Zealand, Seychelles, Galapagos, and Turks and Caicos with one attack and no deaths.

Morial Convention Center, Halls B, C, D, E & F

Don’t forget to mark your calendar for the 2023 edition of the largest commercial marine tradeshow in North America.

EDITOR IN CHIEF David Krapf / dkrapf@divcom.com

SENIOR EDITOR Ken Hocke / khocke@divcom.com

CONTRIBUTING EDITOR Kirk Moore / kmoore@divcom.com

CONTRIBUTING WRITERS Capt. Alan Bernstein • Steve Blakely • Arnie Brennaman • G. Allen Brooks • Bruce Buls • Robin G. Coles • Michael Crowley • Jerry Fraser • Pamela Glass • Max Hardberger • Joel Milton

CONTENT SPECIALIST Benjamin Hayden / bhayden@divcom.com

DIGITAL PROJECT MANAGER / ART DIRECTOR Doug Stewart / dstewart@divcom.com

EDITORIAL DIRECTOR Jeremiah Karpowicz / jkarpowicz@divcom.com

ADVERTISING ACCOUNT EXECUTIVE S

Mike Cohen 207-842-5439 / mcohen@divcom.com

Kristin Luke 207-842-5635 / kluke@divcom.com

Krista Randall 207-842-5657 / krandall@divcom.com

Danielle Walters 207-842-5634 / dwalters@divcom.com

ADVERTISING COORDINATOR

Wendy Jalbert 207-842-5616 / wjalbert@divcom.com

Producers of The International WorkBoat Show and Pacific Marine Expo www.workboatshow.com • www.pacificmarineexpo.com

PRESIDENT & CEO Theodore Wirth / twirth@divcom.com

VICE PRESIDENT Wes Doane / wdoane@divcom.com

PUBLISHING OFFICES

Main Office 121 Free St., P.O. Box 7438, Portland, ME 04112-7438 207-842-5608 • Fax: 207-842-5609

MAGAZINE SUBSCRIPTION INFORMATION

cs@e-circ.net • 978-671-0444 (Monday-Friday, 10 AM – 4 PM ET)

© 2024 Diversified Communications PRINTED IN U.S.A.

MAIL BAG

Maritime high school memories in New York

Theattached letter is actually submitted on behalf of the rst captain

I ever worked for, A.T. “Tom” Dodrill who, still at this point in life, has an unbelievably keen interest in the goings on around our industry.

As is typical of folks in his vintage, he does not have an easy understanding of how email works, including saving and submitting .PDF les.

Even though his grandkids have him pretty well set up with an iPad, he asked me to help write a letter and submit it regarding your recent cover story (July 2024, page 22) about maritime high schools, particularly in NYC.

He is an alumni of the John W. Brown, the restored WWII Liberty ship, when it was the training campus for the NYC Board of Education from 1946 until 1982.

Tom noticed you hadn't mentioned that history in your article and he wanted to send a letter informing the current generation of the maritime high school he attended and graduated from in 1953.

He had a great career, and by the time I decked for him in the early 1990's he was well into it. Through all these years he maintained that his high school experience on the NYC waterfront in those years prepared him for the lengthy career he ultimately had.

Greg Hanchrow Nyack, N.Y.

Zero emissions?

Benjamin Hayden's August 2024 article (see page 11) on the Seaglider describes it as a “zero emissions” wingin-ground-effect aircraft. I don't buy that analysis.

This reads like a conventional press

release claim that conveniently overlooks the source of the electricity that powers this craft. Whether from likely “dirty” or unlikely “green” sources, either form of electricity is far from totally emissions free. The zero emission claim also fails to consider the legacy emissions from the craft’s construction and operation, let alone the many emission effects associated with its battery metals and materials.

Bruce Pfund Westerly, R.I.

Something on your mind? WorkBoat encourages readers to write us about anything that appears in the magazine, on WorkBoat.com or pertains to the marine industry. To be published, letters must include the writer’s address and a daytime phone number. khocke@divcom.com

Yank Marine, Inc. has built and repaired thousands of boats: private yachts, commercial and fishing craft, military vessels, and a large array of USCG-certified passenger vessels.

BY JOEL MILTON

Joel Milton works on towing vessels. He can be reached at joelmilton@ yahoo.com.

On the Water

The heat is on — Part II

So, if the standard heat index isn’t accurately estimating what it really feels like to labor under the sun, what other options are there? The risks of heat exhaustion and heat stroke, that is to be physically injured internally (notwithstanding sunburn) from environmental heat, are both real and becoming increasingly likely as average temperatures continue to increase.

That includes higher average nighttime lows as well. When the nights get warmer there’s significantly less overnight cool-down from hot days, less possibility for the body to recover from the heat stress, and we feel the difference. It’s cumulative and takes an increasing physical toll.

The National Weather Service (NWS) is in the experimental stages of providing the public with a measurement called Wet Bulb Globe Temperature (WBGT) which they describe as “a measure of the heat stress in direct sunlight, which takes into account temperature, humidity, wind speed,

BY CAPT. ALAN BERNSTEIN

Alan Bernstein, owner of BB Riverboats in Cincinnati, is a licensed master and a former president of the Passenger Vessel Association. He can be reached at 859-292-2449 or abernstein@ bbriverboats.com.

Captain’s Table

No-fly zones for drones

Aspopulations in and around our cities soar, so do problems associated with this growth. Much of this development is on or near water. In my area, the Greater Cincinnati region, thousands of new residents have relocated to both banks of the Ohio River.

We know that our nation’s waterways have become more crowded, and we recognize the potential for accidents has increased proportionately. I have long believed that major marine accidents involving recreational boats and commercial vessels have largely been avoided because of the expertise of our professional mariners. While we have made some headway in managing the known risks of our crowded waterways and avoiding catastrophe, a new hazard has literally risen out of thin air— the proliferation of the public’s use of drones.

Drones have become more than just an annoyance to mariners and others. They have become a significant safety and security threat. A drone flying close to or above a commercial passenger

sun angle and cloud cover (solar radiation).”

By taking these other environmental variables into continuous consideration it promises to be a far better tool for calculating heat stress and managing the risks of working outside — exposed to the sun and the other elements — as temperatures climb from warm through hot and upwards into the realm of dangerously hot. The old heat index just doesn’t cut it.

Spending days working in the sun on the steel decks of barges is to be barraged with solar radiation from above, and both radiant and conductive heat from the decks. Throw in high humidity or a hot, dry, desiccating wind and it can and will cook you as if you were placed in either a steamer or an air fryer.

To prevent heat-related illnesses and fatalities WBGT is already in use by our military for determining which activity-level and water-intake guidelines apply to those who are acclimated or unacclimated to the local conditions at a base. It’s also used by universities and school systems to protect student-athletes.

Go to www.weather.gov/tsa/wbgt to check out the prototype tool for determining WBGT for your general area and learn more.

vessel, for example, is not only a distraction to the captain and crew but also a possible danger to all aboard the vessel. It is also suspicious from a security standpoint and poses a potential hazard to all aboard should it accidentally or intentionally crash into the vessel. A large drone can cause a great deal of damage to a vessel and can cause severe bodily harm to a passenger should it crash.

The Federal Aviation Administration has rules and certifications for operating drones in the U.S. For example, there are flight height restrictions and rules against flying drones over people. There are laws against using drones to interfere with aircraft.

I believe it is time for the federal government to establish rules that prevent drones from interfering with passenger vessels, towboats and other commercial vessels for safety and security reasons. Essentially, such rules would establish no-fly zones for drones around these vessels, and especially around those vessels that are operated using MTSA security plans.

If a commercial or private drone operator wished to fly a drone over a commercial vessel, for marketing or other reasons, it would have to seek permission from a regulatory authority such as the Coast Guard before doing so. And the vessel operator would have to agree with the request.

Energy Level

The dilemma of positioning

BY G. ALLEN BROOKS

Should you focus on managing near-term volatility or be positioned to capitalize on long-term oil industry trends? CEOs must be wondering what to do given the high level of market volatility of the past few weeks. Stock markets crashed after a weak U.S. employment report, setting off recession fears. Panic ensued and investors clamored for an immediate Federal Reserve interest rate cut — even as much as a 150-basis point reduction.

The reality was the stock market crash was set off by a margin call on the Japanese yen carry-trade — borrowing in a low-interest rate currency. Hedge funds had been borrowing costless yen, converting them into U.S. dollars, and investing in the stock market, mostly the tech-heavy Nasdaq. They made substantial pro ts until the Bank of Japan raised interest rates for the rst time since 2008 and crushed the $4 billion carry trade.

At the same time, the Energy Information Administration revised its gasoline demand gures for May. Instead of consumption falling, it set a post-pandemic record. Oil traders were confused and now question the validity of U.S. data. The uncertainty about global oil demand was further tweaked by OPEC trimming its 2024 and 2025 demand forecasts, although traders remain the

most aggressive about consumption growth.

Natural gas prices are under pressure because an early forecast suggests winter will be mild. Meanwhile, in Europe, hedge funds are betting that gas supplies will experience a disruption. However, U.S. Gulf of Mexico supplies have yet to be disrupted by a hurricane, and Middle East geopolitical tensions have failed to disrupt Qatari LNG supplies.

Is a correction waiting to happen?

U.S. oil output continues to set records, while China’s oil imports are weak. Does the oil price go down? But what happens to future demand if governments pump their economies to offset possible recessions? And if oil compa-

BY KIRK MOORE, CONTRIBUTING EDITOR

Kirk Moore was a reporter for the Asbury Park Press for over 30

nies cut back exploration and production spending, where will the supply come from? Should prices go up?

Do you count on key industry players — OPEC, domestic producers, government monetary authorities — to make the right moves to protect against further oil price downside? Or do you focus on positioning to capitalize on the longterm need for more hydrocarbons to sustain the global economy and improve human lifestyles?

History has shown that companies that do their best to protect against disastrous downturns but remain committed to making the right long-term moves have done the best for their shareholders. Follow that playbook.

Nor’easter

Renewable

energy advocates used to joke that unlike offshore oil production, the worst that could happen with turbine arrays would be a “wind spill.”

No more. The July 13 turbine blade failure on Vineyard Wind’s machine AW38 dropped parts of 57 tons of berglass, balsa wood and resin coatings into the sea, with fragments washing up on beaches — rst from Nantucket, Mass., then onward from Cape Cod to Montauk, N.Y., at the height of summer tourism.

One month after the fracture, the federal Bureau of Safety and Environmental Enforcement (BSEE) issued an “updated suspension order” to allow some work to resume on the planned 62-turbine, 806-megawatt rated array. The order continued to block new blade installation or power production at the 24 GE Vernova turbines installed before the break.

AT-A-GLANCE

Reports of broken blade pieces drifting across southern New England waters were cited by opponents off the Atlantic Shores project off New Jersey as proof of their fears that building turbine arrays starting 8.7 miles off their beaches will endanger their own tourism industry.

“We saw what happened in Nantucket. God only knows what would happen when we get a cat [category] 3 or any hurricane,” said Rep. Jeff Van Drew, R-NJ, a erce critic of the Bureau of Ocean Energy Management (BOEM) and the wind industry. He predicted “a blizzard of berglass” if turbine blades break apart in a severe hurricane.

The Vineyard Wind incident is “offshore wind’s version of Three Mile Island,” said Amy DiSibio, a board member of ACK for Whales, a Nantucket-based group that sued in federal court attempting to stop Vineyard Wind construction.

Wind energy supporters offered scant pushback to the furious reactions.

“Those who are responsible for the problems with the wind turbine should obviously x it, clean up their mess, and make sure it doesn’t happen again. But it’s a heckuva lot better than an oil spill,” said Johanna Neumann, senior director of Environment America’s renewable energy campaign.

Nantucket municipal of cials Aug. 13 posted a 25-point summary of the crisis –an explainer of their community’s position, and a critique of the developers as well as BOEM.

“We have seen little balance in BOEM’s permitting approach to offshore wind, which signi cantly favors industry developers, including foreign-government owned developers...” the Nantucket Select Board wrote.

BY KEN HOCKE

Inland Insider

Another towboat

allision to learn from

Continuing my periodic look back at maritime accidents since the catastrophic ship allision this year between the 984'x157' container ship Dali and the Francis Scott Key bridge on March 26 in Baltimore Harbor, I offer the case of the 160'x40' towboat Anne Holly and the Eads Bridge over the Mississippi River at St. Louis in 1998.

The towboat was pushing a barge tow northbound on the river about 10 p.m. The tow consisted of the boat and 11 200'x35' barges and three 195'x35' bottoms.

Capt. John O. Johnson used full power going under the

bridge, making about 3 mph against a stiff current. About 800' of the tow cleared the bridge before the tow abruptly stopped. The Anne Holly’s engines continued at full power, but the tow stalled, the current pushing the tow into the center span of the bridge on the Missouri side.

Eight of the tow’s dry cargo barges broke away and were taken southbound by the current. Three headed for the permanently moored casino boat Admiral, slamming into it and severing all but one of its 10 mooring lines. Johnson disengaged the towboat from the rest of the tow and sped (if a towboat can speed) toward the drifting casino boat. Placing the towboat’s bow against the Admiral’s bow, he was able to hold the casino boat against the shore.

Within an hour, all the barges had been rounded up and deposited to eeting areas. No major injuries or deaths were reported.

The Eads Bridge allision reinforced the tug and barge industry’s move toward implementation of an industrywide safety management system (SMS), which is now part of Subchapter M.

After the accident, the National Transportation Safety Board (NTSB) recommended that an SMS be a part of every company’s operating pro le.

When I rst revisited this story in 2013, Jennifer Carpenter, who at the time was the American Waterways Operators’ senior vice president (currently, she’s the organization’s president and CEO) told me that the inland industry needed to be more proactive when it comes to safety and not just reactive once an accident occurs.

“After the accident there was a new wave of tying industry and government together to increase safety,” Carpenter said. “In addition to that, industry said, ‘Let’s take a look at ourselves and try to put into place a real safety culture.’ What we need now is to have the wheels of government move a little bit faster.”

Accidents do happen, and they usually happen quickly. Unfortunately, they are part of the industry.

Ken Hocke has been the senior editor of WorkBoat since 1999.

BY BENJAMIN HAYDEN

Tech Watch

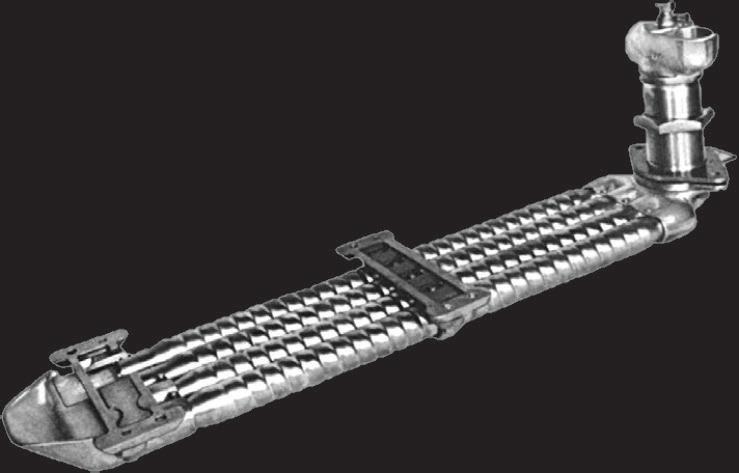

Volvo Penta's new IPS 40 system

As I write this, I’m sitting at Volvo Penta’s (VP) test center in Krossholmen, Sweden. After extensive sessions detailing the company’s inboard propulsion system (IPS), the attending media group got behind the wheel (and joystick) of two smaller monohulls ranging in size from 34'-37', where we tested the company’s dynamic positioning system (DPS) and dock-assist features, as well as its D4-DPI electric, hybrid and diesel modes.

With the push of a button, Volvo’s DPS system allows the vessel to maintain its positioning, ac-

counting for strong winds and current. The docking assist allows the operator facilitated control and maneuverability of the vessel, also removing wind and water current from the equation. Experiencing this feature rsthand was impressive, as media with little-to-no maritime experience could dock boats on the windy Archipelago of Gothenburg.

Though the IPS system is nothing new, Volvo said the company’s largest model, the IPS 40, is suitable for vessels up to 180', coming in twin, triple, or quad con gurations. The media group witnessed the IPS 40 in action on one of Volvo’s testing vessels, a 122'x33'x6.5' catamaran ferry, repowered with quad IPS 40s.

Stainless Steel Cable Ties

Keep Getting STRONGER!

Ben Hayden is a Maine resident who grew up in the shipyards of Massachusetts.

BY TIM AKPINAR

Tim Akpinar is a Little Neck, N.Y.based maritime attorney and former marine engineer. He can be reached at 718-224-9824 or t.akpinar@verizon. net

Legal Talk

When engine breakdowns become criminal matters

The March 2024 Francis Scott Key Bridge accident has heightened the maritime community’s alertness in tracking large commercial vessels in con ned waters. On Aug. 2, 2024, the 55,000-ton vessel Denebola lost steering after leaving Baltimore for Beaumont, Texas. Reacting promptly, the Maryland Transportation Authority closed traf c on the Chesapeake Bay Bridge. Fortunately, the steering issue was resolved and the ship continued toward its nal rendezvous with the breaker’s torch. Although the incident was uneventful, failures involving propulsion, steering, or towing gear can sometimes be catastrophic, as in the case of a parted towline that caused American Star to founder on the shores of the Canary Islands in 1994. Readers may prefer to remember that ship’s better days as SS America, smaller cousin of SS United States. Although

America proudly carried the same livery and sampan funnels of her younger running mate, it was “Big U” that shattered speed records with her 240,000 horses.

But getting back to the issue at hand, when large vessels suffer loss of power or steering that results in damage, it’s likely that the incident will receive close scrutiny. The 2004 grounding of the bulk carrier Selendang Ayu illustrates this. En route from Seattle to China, Selendang Ayu encountered violent sea conditions after transiting the Straits of Juan De Fuca. In the Bering Sea, she suffered a crack in the no. 3 cylinder of the main engine, resulting in a loss of power that caused her to founder off Unalaska Island.

The U.S. attorney for Alaska believed that thermal loading related to failure to adequately clean and seal the cylinders was a major cause of the crack, aggravated by poor adjustment of variable injection timing and turbocharger issues. The exhaustive investigation included input from the NTSB, Coast Guard, FBI, and other agencies. This ultimately resulted in guilty pleas to violations of the Refuse Act and the Migratory Bird Treaty Act.

BY CHRIS RICHMOND

Chris Richmond is a licensed mariner and marine insurance agent with Allen Insurance and Financial. He can be reached at 800-439-4311 or crichmond@allenif. com

Insurance Watch

Risk management tips for shipyards

Today’s shipyard is inherently dangerous workplace. Implementing a sound risk-management program is an important part of managing your employee workers compensation and Longshore and Harbor Workers’ Compensation Act (USL&H) costs, thus reducing claims and limiting injuries. And there’s the added bonus of avoiding possible nes and penalties imposed by safety violations or hazardous waste clean-up. Here are some items to consider.

• Implement regular assessments of your safety plan and see if it still re ects your current operations. Your initial plan should be based on a comprehensive risk assessment identifying hazards and the potential for accidents. There are risks everywhere, and they are major and minor. You should keep them all in mind. As your business grows and evolves, so should your risk assessment plan. Don’t make the mistake of doing the work to create one and leaving it to gather dust.

• Conduct period safety training with your employees. Insurance companies and government agencies have material available but don’t be afraid

to develop your own manuals outlining speci c jobs and procedures. Topics can include emergency response plans, safe work practices and hazard identi cation. And don’t keep trainings only in the classroom. Real-life scenarios and employee involvement, such as demonstrating a proper response to a re or chemical spill, can increase the learning potential.

• Personal protection equipment should be readily accessible to your employees and its use should be as common as putting on a pair of pants. Steel-toed shoes, hard hats, hearing protection, safety glasses, respiratory masks and gloves are all great examples. And don’t stop with just making this equipment available. Conduct proper- t tests for masks and make replacement lters available.

• Have you reviewed procedures for potential pollution threats? Prevention is obviously the best response, so have proper handling procedures in place. But in the event of a misfortune, have a proper response plan in place. Maintain proper waste management practices and don’t forget about storm runoff. Keeping up with compliance with environmental regulations and standards will not only save you the headache of a pollution claim but can also save you the nes and penalties associated with them.

Vineyard Wind blade fracture remains under investigation News Bitts

One month after a wind turbine blade broke on the Vineyard Wind project off Massachusetts, the federal Bureau of Safety and Environmental Enforcement (BSEE) in mid-August allowed the developers to resume installing towers and nacelles. But power production and installing new blades remained on hold, as the investigation into the July 13 blade fracture continued.

The blade break sent tons of berglass and foam fragments into the sea, some collected by Vineyard Wind’s response teams. But fragments drifted to beaches in Nantucket, Mass., to Cape Cod, and west to Montauk, N.Y.

Opponents of Vineyard Wind and other offshore projects portrayed the accident as a harbinger of threats from the still-emerging U.S. industry, with as many as 20 East Coast projects now in various stages of planning.

“Vineyard Wind is a menace to our sheries. Floating berglass shards remain a navigation and safety risk for mariners over a month after the blade disaster. We have no idea what effects this industrial litter will have on local food chains,” said Jerry Leeman, CEO of the New England Fishermen’s Stewardship Association, which organized a protest cruise by shing boat Aug. 25 past the crippled Vineyard Wind turbine. “Fishermen understand the volatility of the North Atlantic better than anyone, and we are not con dent these turbines and blade components will survive a winter squall or a hurricane in light of July’s catastrophe.”

About 20 commercial and recreational shing vessels sailed from Massachusetts and Rhode Island ports for the protest event. Vineyard Wind and turbine manufacturer GE Vernova worked for weeks to assure they are making a maximum response to the incident.

Another hit came Aug. 22 with news that a similar GE Venova Haliade turbine suffered a blade failure Aug. 22 on the Dogger Bank A offshore wind project in the North Sea.

Austal pleads guilty, agrees to $24 million to settle fraud charges

Austal

USA LLC, Mobile, Ala., pleaded guilty and agreed to pay $24 million to settle with the U.S. Department of Justice over charges that the company engaged for years in an accounting fraud, illegally inflating profits on ships it built for the Navy. The fraud charges stem from 2013 to July 2016, when “Austal USA and its co-conspirators conspired to mislead Austal Limited’s shareholders, independent financial statement auditors and the investing public about Austal USA’s financial condition,” DOJ officials said.

Port of Seattle hit by cyberattack

The Port of Seattle, including the SeattleTacoma International Airport, was hit by a cyberattack in late August. The incident forced the government agency to shut down its systems to mitigate the impact. Three days after the attack, the port's websites remained offline, and phone system outages persisted. The port's and the airport's websites, along with email and phone services for port staff, were also affected. A 2022 Jones Walker LLP survey on ports and terminals cybersecurity revealed that cybersecurity remains a top concern within the maritime industry.

Donjon Marine awarded $32.3 million Newark Bay dredging contract

The U.S. Army Corps of Engineers (USACE), New York District, has awarded a $32.3 million contract for the Maintenance Dredging of Newark Bay to Donjon Marine Co. The maintenance dredging will restore channel depths, preventing shoaling that can create navigational hazards and disrupt shipping.

The Dogger Bank incident is the second blade failure on that project after one in May. All three involve Haliade 13-megawatt generators, marketed by GE Vernova as an industry standard as wind developers go big in a quest for ef ciency. — Kirk Moore

Commercial fisherman organized a protest close by the site of the crippled turbine near Nantucket.

Southern Roots

Alabama shipyard delivers new passenger/vehicle ferry to Maine

CHARLES NORMAN SHAY SPECIFICATIONS

By Ben Hayden, Content Specialist

Steiner Shipyard, Bayou La Batre, Ala., recently delivered the new passenger/vehicle ferry Charles Norman Shay to the Maine Department of Transportation (MaineDOT) in Portland before making its way to its new homeport in Rockland, Maine. There it will serve the Matinicus Island route under the Maine State Ferry Service (MSFS), a subchapter of the MaineDOT serving the island communities of Vinalhaven, North Haven, Islesboro, Swans Island, Frenchboro, and Matinicus.

The new ferry is a signi cant upgrade to the service and will provide a vital link for the island communities off the coast of Maine. The new 104'x28'x11' steel-hulled vessel replaces its larger predecessor, the 154'x38' Capt. Richard G. Spear. That change in length proved challenging in the newbuild.

“Each one of Maine’s ferries is unique,” said Tara Marshall, Steiner Shipyard’s owner. “That boat hasn’t been built before, so anytime you build a one-off, you have a little bit more work with the naval architect, and Maine, and even the Coast Guard. So that boat being a unique vessel and being that it’s a small boat, it has all the same equipment as the bigger boats. I think one of our guys’ biggest struggles was tting all the equipment into that small area.”

THE PARTICULARS

Charles Norman Shay was designed by Gilbert Associates, Braintree, Mass. With a 7' draft, the new 149-passenger ferry has room for a single tractor trailer and four light

Vessel Name: Charles Norman Shay

Builder: Steiner Shipyard Inc.

Designer: Gilbert Associates

Owner: Maine Department of Transportation

Length: 104' Beam: 28' Depth: 11' Draft: 7'

Main Propulsion: Caterpillar C18, 600 hp @1,800rpm

Ship’s Service Power: Cat C4.4 coupled with Caterpillar generator (three phase, 240 VAC, 60 Hz, 99 kW)

Marine Gear: Twin Disc MGX-516, close-coupled 4.04:1

vertical offset gears

Propellers: Sound, 4 bladed, 52” diameter

Controls: Twin Disc ec6000

Thruster: Veth VT-50, 64 kW tunnel bowthruster

Steering System: EMI

Speed (Knots): 13

Hull Construction: Steel

Crew Capacity/Passenger Capacity: 149 passengers

1 tractor trailer and 4 small trucks or 8 cars or light trucks.

Capacities (gals.): Fuel oil, 3200; potable water, 1,900; lube oil, 300

Classification/Certification: USCG Classed, Subchapter T

Delivery Date: June 2024

Doug Stewart

Mike

Cohen

Charles Norman Shay under construction at Steiner Shipyard.

trucks or eight cars or light trucks.

Main power for the vessel comes from twin Caterpillar C18 diesel engines coupled with Sound 4-bladed 52" diameter wheels through Twin Disc MGX-516 close-coupled vertical offset gears with a 4.04:1 reduction ratio. The vessel has a running speed of 13 knots.

To enhance maneuverability, a Veth VT-50 64-kW tunnel bowthruster has been installed, providing the necessary agility for docking and navigation in tight spots. The vessel is also out tted with an advanced electronics suite, a steering system from EMI, and Twin Disc ec6000 controls.

The Charles Norman Shay offers capacities for 3,200 gals. of fuel oil, 1,900 gals. potable water, and 300 gals. lube oil. The vessel is classi ed under the stringent Coast Guard Subchapter T regulations, ensuring that it meets all safety and operational standards for ferry operations in the region.

EMI steering, and Twin Disc controls enhance maneuverability.

TEAM EFFORT

Marshall’s son, Gregory Marshall Jr., Steiner’s project manager and purchasing assistant, spoke to the complexities involved in building a vessel that adheres to modern Subchapter T regulations, primarily.

“Being able to get reinvolved with Subchapter T regulations, and relearning that.”

“It’s been a few years since we built a

Subchapter T vessel, and the regulations are much stricter now,” he continued.

“To be able to come in and have a naval architecture group like Gilbert Associates to work through some of that stuff with us was bene cial in the long run and hopefully for future ferry jobs.”

Tara Marshall reinforced the strong partnership with Gilbert Associates, sharing insights into the construction process and noting the unique collaboration with

Four Generations of Excellence

Steiner Shipyard is a family-owned and operated 4th generation shipyard located in Bayou La Batre, Alabama.

Steiner builds passenger/cargo ferries, inland river tow boats, ASD tugs and offshore supply vessels to commercial fishing trawlers

The vessel is powered by twin Caterpillar C18 diesel engines.

Mike Cohen

BOATS & GEAR Maine Ferry

the Maine State Ferry Service during the project. “While Maine didn’t have a representative on-site, the owner’s reps, alongside John Gilbert and his team, were instrumental in the process,” she said.

The Charles Norman Shay is a custom-built ferry designed to meet the specific needs of the MSFS, which transports nearly 500,000 passengers and 190,000 vehicles annually. The ferry will primarily serve the 23-mile route between Rockland and Matinicus Island, the longest in the MSFS system, providing a critical connection for the island’s residents and visitors.

“I mean the boat is beautiful,” Marshall said. “It’s a pretty boat. It’s got a lot of character. It’s not a cookie-cutter ferry.

“I can’t wait to go up and see the run.”

Looking ahead, Steiner Shipyard continues to expand its capabilities. In addition to ferry construction, the shipyard is currently working on two 76' pushboats for John W. Stone Distribu-

tors LLC., and a 94' towboat for Golden Barge Line

The shipyard also has plans of ramping up its repair division. Currently outfitted with a 400-ton travel lift, there are plans in place to enhance its facilities

around the beginning of next year.

Marshall, who recently purchased the shipyard from her retiring father, expressed pride in the company’s achievements and optimism for the future.

“We’re excited about the growth of our repair division and the projects we have lined up,” she said. Marshall noted that her son Gregory and nephew Jason are both fourth-generation workers at the yard. Jason was part of the delivery crew that brought the Charles Norman Shay up from Alabama to Maine.

The Charles Norman Shay gets its name from a heroic Maine veteran and member of the Penobscot Nation. Shay, who is now 100 years old and living in France, served as a combat medic during the D-Day invasion in World War II.

At just 19 years old, he was drafted while living on Indian Island and was later sent to the front lines, where he saved many lives on Omaha Beach. His efforts on that day earned him the Silver Star.

Gregory Marshall Jr., Steiner’s project manager, oversees the construction progress of the vessel.

Doug Stewart

McDermott Light & Signal

Dredge Lights

Meets 2 mile requirement for marking of dredge pipelines

Solar Marker Lights

Navigation

Barge

1 to 3 mile visibility for aids to navigation and applications such as buoys, docks, barges, and temporary lighting

Lights

Permanent mount LED lighting for bridges, docks, and barges

For vessels greater or less than 50 meters Certified to meet UL 1104 and Subchapter M Platform Marker Lights

Solar or battery powered barge navigation lights for unmanned barges per UL1104 Regulatory

Buoys

Available for all applications

*Available with or without lighting*

Course Correction

Is a much-needed National Maritime Strategy on the horizon?

Pamela Glass, Washington Correspondent

ANational Maritime Strategy has been a long time coming, and it’s still not here yet.

The number of U.S.- agged vessels has dropped to less than 200, and the eet’s share of the international shipping trade is in serious decline as well. American ships moved half of the world’s cargo in 1950; now it hauls only 1%. About 98% of cargo moving in and out of the country is now on foreign-owned and -crewed ships, a gure that is alarming from a national security standpoint. Many shipping companies now register their vessels with foreign countries to take advantage of less stringent regulations, fewer labor protections and lower taxes, thus saving millions in operating costs.

Across the country, shipyards have consolidated or closed, leaving only a handful able to build large ocean-going vessels, most of which are for the military.

The number of American mariners has also tanked, down from some 200,000 during World War II to about 12,000 today. As of 2017, according to the Maritime Administration (Marad), the U.S. faced a shortfall of about 1,800 quali ed licensed and unlicensed mariners to crew its sealift vessels for a prolonged period of time. Since then the need has likely grown given the current shortage of quali ed mariners.

“The competition between the United States and Communist China will de ne the 21st century and nowhere is this

con ict more prevalent than in the maritime domain,” said Sen. Marco Rubio, R-Fla., an author of a 2024 report, Congressional Guidance for a National Maritime Strategy. “The United States must move quickly to revitalize our maritime industrial base, reinvest in a robust workforce and advance innovative technologies to project strength and security in the world’s waterways, oceans and seas.”

CHINA CONNECTION

Enter China, with its state-supported shipyards and a national policy to grow its global maritime dominance. By some accounts, China has poured nearly $132 billion into its shipping and shipbuilding industries. It has bought many ports around the globe, controls roughly 15% of the global commercial eet, and its shipbuilders have captured about 50% of global vessel construction orders.

While the U.S. has less than 200 U.S.- agged oceangoing vessels, China has 7,000 active in world trade. The U.S. shipbuilding workforce is about 153,000, while China employs more than 600,000. There are 12,000 U.S. merchant mariners; China has 1.7 million seafarers.

These staggering differences have drawn the attention of Congress and government of cials from many non-maritime agencies. The National Maritime Strategy report sounded an urgent alarm for reforms.

Danish vessels of the Maersk Line, numbering more than 700 ships, loom over U.S. container ports.

First, it offered a framework to strengthen the maritime workforce and shipbuilding as well as promote energy innovations at sea and fund modernization of the inland waterways. It also proposed creating a “National Maritime Adviser,” a presidentially appointed position that would have the authority to coordinate maritime policies across the federal government and oversee a new National Maritime Council, similar to the National Security Council, that would give the maritime adviser a permanent seat at the table in the White House.

Numerous studies over decades have well documented the steady decline of the U.S. bluewater shipping and shipbuilding industries. This trend has created worrisome challenges for national and economic security and made the country vulnerable in times of crisis when maritime services are needed.

Efforts to create a viable, long-term

Numerous studies over decades have well documented the steady decline of the U.S. shipping and shipbuilding industries.

plan that would address the many shortfalls in the once-thriving American maritime domain go back to at least 2014 when Congress mandated that Marad start creating a strategy.

At that time, more than 200 maritime stakeholders convened at a symposium in Washington and offered ideas on how

best to reinvigorate the industry. Since then, there have been more studies, delays in issuing the mandated plan, more meetings with stakeholders, three presidents from different political parties (Obama, Trump, Biden), more congressional mandates and several Congresses led by different leaders.

FOCUS America’s Shipbuilding

Despite a few false starts, a decade later, there is still no national maritime strategy.

In the meantime, concerns about America’s maritime prowess have deepened, and the industry slips deeper into a labor crisis and a wide ocean of uncertainty about its future.

But now the tide might be turning, thanks to China.

FORCED TO ACT?

Outpaced and spooked by the aggressive maritime ambitions of China, Congress is revving up efforts to produce a broad plan to rebuild the once globally dominant U.S. ag eet and shipbuilding industry.

But the task ahead won’t be easy or inexpensive and could take years, given

how far behind the country’s maritime sector has fallen and will require the cooperation and healthy budgets of several federal agencies, most notably defense and transportation.

The U.S. oceangoing and shipbuilding industries currently generate over $150 billion in annual economic output and keeps 650,000 people working in goodpaying jobs.

Building world-class vessels requires a world-class crew. Thank you to our dedicated team for putting in the work every day to produce the industry’s best-performing boats.

But that’s only a small fraction of the economic punch and prominence it once had. At the end of World War II, thanks largely to a private sector and federally supported expansion of shipbuilding to serve wartime needs, the U.S. ag eet was the largest in the world with nearly 4,500 ships of all types and sizes, according to Marad.

Since then, the merchant marine both domestically and internationally has drastically shrunk. Shipyards have consolidated or closed across the country, leaving only a handful able to build large oceangoing vessels, most of which are for the military under government contracts.

Since 2014, Congress has continued to push Marad to produce a workable, comprehensive strategy that incorporates many of the above recommendations. When Marad nally sent a strategy document to Congress, lawmakers felt it was weak and told the agency to hire a federal research center to do a study that would inform a more robust plan. In September 2023, Marad selected the Center for Naval Analyses to conduct the study and the wait is on.

Meanwhile, the House Transportation and Infrastructure Committee continues to gather reform ideas, and in July held a roundtable that brought together maritime stakeholders to discuss elements of a maritime strategy.

The federal government plays an important role in the industry, mostly through several key programs and laws. The 1920 Jones Act, which requires that cargo shipped between U.S. ports be carried by U.S.-owned, crewed and built ships, has helped shipyards and protected the domestic shipping market. The law is considered the cornerstone of the U.S. industry, and supporting and

enforcing it should be the cornerstone of any national maritime policy, many at the roundtable said.

The Maritime Security Program, the Tanker Security Program, and cargo preference laws assure that U.S. ships carry certain cargoes around the world. In addition, the Small Shipyard Grant Program and demand generated from the Jones Act, help sustain the shipbuilding industry. Marad also operates a ship nancing program (Title XI) to support construction projects and the Small Shipyard Grant Program, which offers assistance to small yards for infrastructure improvements and workforce development.

Advocates at the roundtable said Congress must continue to fully fund these programs and expand and ensure full compliance with cargo preference requirements. In addition, they said, Congress must not only protect the Jones Act, it must ensure that it is applied to emerging green-energy sectors like offshore wind.

China was on everyone’s mind at the roundtable.

“It is absolutely essential that we take note of the existential threat that is posed by China’s attempts to expand its power globally using the maritime industry as a key weapon,” said Jennifer Carpenter, president and CEO of the American Waterways Operators, which represents the tug and barge industry. She also heads the American Maritime Partnership, a coalition that supports the Jones Act. “The Jones Act ensures that our domestic supply chain can’t be held hostage and weaponized against us.”

Also discussed were changing the maritime culture to make it more welcoming and tolerant of women and minorities, creating maritime prosperity zones for investment, and improving mariner recruiting and retention. These are big-picture ideas, Carpenter said, but Congress can make small changes that would improve the lives of mariners like those she represents in the towing industry by reforming the Coast Guard’s antiquated mariner credentialing system.

There’s a lot of work ahead. Decisions must be made on goals and key reforms,

how changes will be implemented across federal agencies, and how a plan will be nanced. No big movement is expected this year due to the elections and other pressing congressional business, observers said.

While a new president, combined with an infusion of new members of Congress after the elections might slow the process, it might also offer new opportu-

nities for moving a strategy. And as long as China shows no plans of curtailing its maritime ambitions, the heat will remain on Congress to act.

“There’s a serious attempt to grapple with this on the part of U.S. policy makers that I haven’t seen previously,” AWO’s Carpenter said, citing alarmed voices from the military, national intelligence and economic sectors.

GEAR FAILURE DOESN’T WORK FOR THE UNITED STATES NAVY.

For commercial marine applications, gearbox failure isn’t an option either. Philadelphia Gear created Onsite Technical Services™ (OTS) to support all our marine customers, including the U.S. Navy and Coast Guard, to install, rebuild, and maintain critical rotating equipment anywhere they go.

Get Navy-trusted OTS for your commercial marine vessels: Visit PhilaGear.com/Marine today.

ON THE WAYS

Hard Rock Marine delivers dinner cruise vessel to Tampa

Hard Rock Marine Services, Jean Lafitte, La., delivered the steel-hulled 130'x31'x5' dinner vessel Craft to Yacht Starship Dining Cruises, Tampa, Fla. The boat was delivered in March and since then, has been taking up to 150 passengers on culinary and cocktail river journeys along the Hillsborough River through the heart of downtown Tampa, Fla.

Designed by Dejong and Lebet , Jacksonville, Fla., with a 3'6" draft, Craft is fitted with an Imtra side power AC 208/240, 60-hp electric thruster for additional maneuverability.

“Craft was a challenging marine design project, as there were limits on the air draft to get under the bridges and limits on the hull draft to meet USCG stability requirements,” said naval architect Andy Lebet. “Addi-

tional design and regulatory challenges included lengthening an existing hull, adding large overhangs to create added exterior deck space, gas cooking, creating separate propulsion engine and generator spaces, as well as ballasting to limit the air draft and keeping the gross tonnage below 100 to remain a Subchapter T vessel.”

Propulsion comes from twin Volvo Penta D-4 175I main engines connected to two Michigan Wheel 20"x23", 4-bladed bronze propellers through Twin Disc MG-5050SC marine gears with 3:1 reduction ratios, giving the boat a running speed of 10 knots.

Ship’s service power is the responsibility of two John Deere 4045 gensets, sparking 99 kW of electrical power each. The steering system is a Kobalt 2-7065B1237T-2 and the controls are

Volvo Penta EVC 2.0.

The electronics suite includes two Standard Horizon GX1400B VHF, Garmin AIS800 and Garmin 743xsv GPS.

Additional features include capacities for 50 crew, 750 gals. of fuel, 1,500 gals. water, and a Seahorse M-1500 MSD.

“Craft has exceeded all expectations,” said Lebet. — Ken Hocke

ACI Boats delivers new whale watching/eco-tour boat to Washington

ACI Boats, Port Townsend, Wash., has delivered a new 60'x20'x5.67' whale watching, eco-tour boat, Blackfish VI, to Outer Island Excursions, Orcas, Wash. Designed by the shipyard and Coastwise Corp., Anchorage, Alaska, the new boat will operate in Washington state’s San Juan Islands.

The USCG-classed, Subchapter T, 80-passenger vessel, with a draft of 1.9' light, is an all-aluminum symmetrical planning catamaran whose upper cabin will feature four dinettes, bench seating, and an enclosed helm station, and accommodate up to 16 passengers. The main floor is designed to accommodate 54 passenger seats, three dinettes, a galley, and two head compartments.

Main propulsion comes from six (two clusters of three engines) 400hp Yamaha Marine XTO outboards with stainless steel props. Yamaha also handled the controls — Yamaha Helmaster EX with joystick — and steering system — Yamaha helm and helm-follower system — responsibilities. Blackfish VI ’s cruising speed loaded is 28 knots.

“ACI Boats was thrilled to win this contract with Outer Island Excursions. With construction commencing in the winter of 2023, the duration was approximately 15 months,” ACI officials said in an email. “During construction, a decision was made to change the propulsion from quad 600-hp outboards to six 450-hp Yamaha XTO outboards.

Yacht

130' passenger vessel can carry up to 150 people for dinner and cocktails.

This unique propulsion package for a boat of this size was achieved by modifying the outboard brackets to accommodate two clusters of three engines per hull and setting up a fully redundant Coast Guard-approved steering system using a helm-follower system that is designed and fabricated to the satisfaction of the OCMI and Yamaha Marine.”

The new tour boat’s electronics suite is equipped with two Garmin 861XSV 16 MFDs, ush mounted in the dash, Garmin 18xHD 4 kW radar, Garmin cameras, Garmin Class B AIS transceiver, and public address systems with wireless microphones.

Tankage includes dual 500-gal. fuel tanks and 150 gal. freshwater tank. The boat has a 24-ton deadweight.

The new boat will be operating tours out of Lopez Island, Wash., Orcas Island, Wash., and Anacortes, Wash.

Some additional features include stadium-style seating on the bow, direct bond windows, a galley with concession booth, mounted televisions, and passenger seating for 80. — K. Hocke Snow & Co.

delivers new research vessel to DOE

Seattle-based Snow & Co. has delivered a 49.7'x15.9'x7.54' hybrid catamaran aluminum research vessel to the U.S. Department of Energy’s Paci c Northwest National

Laboratory (PNNL).

Resilience was designed to demonstrate Incat Crowther and Snow’s abilities in designing and building lowemissions vessels that deliver practical solutions for their scienti c mission requirements.

Incat Crowther’s design features a

28-sq.-meter main deck equipped with a 5,000-lb. capacity A-frame, 1,000lb. capacity boom crane and a 500-lb. capacity movable davit in addition to access to a foldable swim platform, in an effort to extract maximum functionality from the space. A set of stairs offers direct access from the main deck to the upper deck and ybridge, which affords all-round visibility.

“What attracted us to this project was the opportunity to tackle the complexities of hybrid systems amidst the growing trend of electri cation,” said Chris Watson, the shipyard’s project manager. “We aimed to expand our knowledge of this emerging technology by pushing the boundaries in design, installation, and integration alongside our partners, Incat Crowther and Paci c Power Group. The result is a vessel capable of high-speed transit in diesel mode and quiet, ef cient operation in electric mode, enabling the client to conduct research with minimal noise disruption and reduced transit time to

ACI

Boats

60' whale watching/eco tour boat will operate around the San Juan Islands.

ON THE WAYS

The new cat will be able to support the research of six scientists in a tailored layout containing multiple research workstations and convertible sleeping arrangements, providing PNNL a capable platform to efficiently carry out its research.

The vessel, which has a 3.5' draft, is powered by a parallel hybrid-

electric propulsion system consisting of two Volvo Penta D8-510 main engines capable of producing 501 hp at 2,850 rpm each and supplemented by two Danfoss Editron EM-PMI375T200-2600 motor-generators. The mains connect to wheels (manufacturer unspecified) through Twin Disc MGX5075 SC gearboxes. The electric propulsion mode allows the vessel to oper-

ate quietly on electric power between 1-6 knots for four hours, and cruise at 20 knots using diesel power. Resilience has a maximum speed of 23 knots. Power will be stored using a 113kW Spear Trident battery system, allowing the vessel to operate quietly in a zero-emission electric state while engaged in a mixture of survey operational modes. Onboard electronics include a Garmin electronic suite. “During our testing of the electrical drive, it was very remarkable how quiet it is in the cabin and on the working deck,” said Watson. “Throughout this project, we gained extensive insights into hybrid technologies, which we are now leveraging to assist new clients interested in hybrid and electric drive vessels.”

Pacific Northwest National Laboratory is one of the U.S. Department of Energy national laboratories, managed by the Department of Energy's Office remote areas.”

BOATBUILDING BITTS

The 416' liquified natural gas (LNG) bunker

Tankage will include 840 gals. of fuel and 80 gals. fresh water. The boat has accommodations for a two-person crew.

barge Progress was delivered to Crowley, Jacksonville, Fla., after construction was completed at Fincantieri Bay Shipbuilding, Sturgeon Bay, Wis. The Progress will provide LNG fuel bunkering services for ship operators at the Port of Savannah (Ga.) after commissioning there, according to a statement from Crowley. Shell NA LNG LLC signed a long-term agreement with Crowley to operate the barge. Designed by Crowley’s engineering services group, the barge has a capacity of 12,000 cubic meters (3.17 million gals.) and features a design that enables efficient and dependable supply of LNG to fuel ships, according to the statement. Shell and Crowley’s engineering services group worked together to flexibly deliver LNG to various types of LNG containment

systems. LNG is the lowest carbon fuel currently available to shipping at scale, emitting up to 23% less greenhouse gas (GHG) emissions (well-to-wake) compared to very/ ultra-low sulfur fuel oil.

Thoma-Sea Marine Constructors LLC, Houma, La., launched the 244'6"x51.25' oceanographic research vessel Oceanographer for the National Oceanic and Atmospheric Administration (NOAA) in August. Oceanographer and its sistership Discoverer will support a wide variety of missions, ranging from general oceanographic research and exploration to marine life, climate and ocean ecosystem studies. Missions will include shallow coastal, continental shelf and worldwide ocean survey and data collection. Both ships will incorporate emissions controls and high-efficiency diesel engines that have the potential to save 15,000 gals. of fuel per

New oceanographic research vessel was launched in Houma, La., in August.

Chris Cerullo

Snow & Company

New research vessel will carry up to six scientists and two crewmembers.

The new bunker barge was chartered by Shell. Crowley

of Science. The main campus of the laboratory is in Richland, Wash.

— K. Hocke

A&M Manufacturing delivers Texas tour boat

A&M Manufacturing, Alachua, Fla., designed and delivered a new event-space/tour boat

to DFW Boat Ride, Rockwall, Texas, earlier this summer.

The 67'x28' Sapphire Star can carry 149 passengers and two crewmembers and is designed for hosting wedding cruises, company outings, diner cruises, and other private events.

“The fiberglass multihull vessel is designed to host events and up to 149 passengers which required assembly,

year for each vessel, resulting in an estimated reduction of approximately 5,700 tons of carbon dioxide. The acquisition of these two ships is part of NOAA’s effort to revitalize and modernize its fleet of research and survey ships. Oceanographer will be homeported in Honolulu and Discoverer in Newport, R.I.

San Francisco Bay Ferry recently released design renderings for what it said will be the U.S.’s first highspeed, zero-emission, battery-electric vessels. The boats will be the first of the agency’s Rapid Electric Emission Free (REEF) ferry program. The vessel design is a part of SF Bay Ferry’s efforts to seek bids from American shipyards for procurement of its first five battery electric ferries including two 400-passenger vessels that will operate on the system’s Central Bay routes and three 150-passenger vessels that will serve San Francisco’s rapidly growing Treasure Island and Mission Bay neighborhoods. The new boats have been designed to provide riders with views of the San Francisco skyline along a trip that will connect Treasure Island and Mission Bay to Downtown San Francisco. SF Bay Ferry expects a transit time of 15 minutes.

Canadian multinational shipbuilder, Davie, announced its intention to make a significant, long-term commit-

disassembly, transportation from Florida to Texas, and reassembly on-site for a lake in Dallas, Texas,” said A&M’s sales manager Geoffrey Lardy. “The boat was delivered without rigging and rigged by the owner on location.”

The Sapphire Star has a 12" draft and is powered by twin Honda BF 150 outboards, giving the vessel a running speed of 6 knots.

Delivered in June 2024, the boat has an electric/hydraulic steering system, and capacities for 100 gals. of fuel and 80 gals. fresh water. —

K. Hocke

All American Marine to build North Carolina research vessel

All American Marine (AAM), Bellingham, Wash., has a new contract to build a 73'x26.7' research vessel for the University of North Carolina Wilmington (UNCW). Designed by Teknicraft Design, Auckland, New Zealand, the aluminum catamaran will serve in marine science research and education along the

ment to the U.S. shipbuilding industry. Pending final site and partner selection, Davie noted its decision coincides with a series of actions announced by the U.S. government to boost the efficiency, resilience, and competitiveness of U.S. shipbuilding. The production of superior U.S. ships for both domestic and international markets is also anticipated to revitalize American sea power, spur economic growth, and create many skilled jobs for American workers, the shipbuilder said in a statement.

Davie noted its plans are also aligned with the ICE Pact, a trilateral collaboration between the U.S., Canada, and Finland, announced on July 11. The ICE Pact is expected to enhance the production of in-demand polar icebreakers in participating countries boosting economic, climate and national security, while supporting vital shared interests in the contested polar regions. The U.S. Depart-

67' event space/tour boat is located about 20 minutes east of Dallas.

San Francisco is looking for a shipyard to build it five new passenger vessels.

San Francisco Bay Ferry

ON THE WAYS

Atlantic Coast.

The twin-engine, propeller-driven boat will be built to Coast Guard Subchapter T standards as a multipurpose research vessel for scienti c missions, including oceanographic surveys, biological studies, and educational outreach programs.

For example, the boat and its crew will be conducting oceanographic surveys using multibeam side scan, magnetometer, and sub-bottom pro ler surveys, as well as deploying oceanographic instrumentation and moorings.

For biological studies, the group will employ marine mammal monitoring, deploy trawl nets, and conduct water quality and sediment sampling.

As for educational outreach, the plan is to engage students and the public in marine science through hands-on educational programs, supporting up to 20 participants on day trips.

“Our collaboration with UNCW is a signi cant advancement in our commitment to supporting marine research and education by building this next-gen research vessel,” Ron Wille, the shipyard’s president and COO, said in a prepared statement. “This vessel will offer the faculty, students, and partners at UNCW a cutting-edge platform to explore and study the marine environment, greatly contributing to their mission of advancing marine science.”

The design incorporates Teknicraft’s hydrofoil-assisted hull to reduce drag, enhance fuel ef ciency, and enhance passenger comfort by optimizing stability in various sea conditions.

Main propulsion will come from twin Scania Di16-082M EPA Tier 3 engines, each producing 800 hp at 2,100 rpm, for a transit speed of 21 knots. Fuel capacity of 1,500 gals. will ensure extended operational range and endurance.

The electronics suite will include a Kongsberg ADCP electronics suite and a fixed WASSP multibeam system for use in oceanographic and biological research. The research vessel’s design will include wet and dry lab spaces, comfortable live-aboard quarters for up to 10 personnel, and the capacity to accommodate 20 passengers for day trips.

Research vessel will be built to have a 30-year lifespan.

It will also support dive operations and the deployment and retrieval of remotely operated and autonomous underwater vehicles.

The vessel is expected to have a 30year lifespan.

“All American Marine remains steadfast in our commitment to advance

manufacturing techniques and integrate the latest technology, producing reliable and ef cient research vessels,” said Daniel Zech, All American’s business development manager. “We have re ned our designs over the past ve years through multiple vessel builds with specialized research missions.”

BOATBUILDING BITTS

ment of Defense (DOD) launched its 2024 Arctic Strategy on July 22, outlining steps DOD will take, in collaboration with allies and partners, to preserve the Arctic as a secure and stable region.

The ICE Pact is expected to enhance the production of in-demand polar icebreakers.

Austal USA, Mobile, Ala., has successfully launched the future USS Pierre (LCS 38), the last ship of the Navy’s Independence-variant littoral combat ship program. Following launch, Austal USA’s test and activation team will spend the next several months preparing it for sea trials later this year. The 421'6"x103.7' LCS is designed to be an agile, mission-focused platform able to operate in near-shore environments. Each aluminum trimaran LCS has a displacement of 3,200 MT, a 15.1' draft, and is powered by a pair of 12,200-hp Rolls-Royce 20V8000 diesel engines and two 29,500-hp GE LM2500 gas turbines. Pierre is the Navy’s 19th and final Independence-variant LCS to be christened. Following delivery, the new LCS will join its sisterships homeported in San Diego and deploying to the INDO-PACOM region.

Dee Burch, a veteran of the heavy/civil and marine construction industry, is now the sole proprietor of Gunderson Marine & Iron, the company announced Aug. 5. During the past year Gunderson has made a substantial increase in its workforce, shipyard officials said. Notable projects included the completion of the Makani Loa barge for Lynden Inc., and the construction of a new drydock at the shipyard in Portland, Ore.

All American Marine

Davie

IT’S SHOW TIME!

NOV

12-14, 2024 / NEW

Morial Convention Center, Halls B, C, D, E & F

ORLEANS

Register for your free pass workboatshow.com

Underwater Intervention returns in 2024 alongside The International WorkBoat Show!

Underwater Intervention attracts a global audience of engineers, technical specialists, industry leaders, and experts, to share ideas, debate the issues of the moment, and create common agendas for the industry’s future.

Underwater Intervention features some of the world’s leading figures within the upstream oil and gas industry coupled with technical sessions covering the most current challenges and up-to-date strategies and technologies.

Scaled-down Aid

Program helping smaller shipyards stay competitive is at a crossroards .

By Ben Hayden, Content Specialist

Small shipyards have always played an essential role in the U.S. maritime industry, often providing specialized services and craftsmanship that larger shipyards do not offer. However, staying competitive has become increasingly challenging. Yards have to contend with regulatory pressures, in ation, supply chain issues, and a shrinking skilled workforce.

Multiple shipyard owners have emphasized the extensive regulations that their yards must follow to stay compliant, along with the costly need for legal and consulting support throughout the process. These regulations have been deemed by many as nonproductive and no longer just about building ships.

Yet, for these smaller shipyards, a crucial lifeline remains — the Small Shipyard Grant Program.

SCHOLARSHIP MONEY

Administered by the U.S. Maritime Administration (Marad), small shipyard grants have been a reliable resource

for many shipyards across America, helping them modernize their facilities, purchase new equipment, and invest in workforce training. The program has also proved to be critical in maintaining the competitiveness of these smaller shipyards.

Given that, the survival and success of this program hasn’t always been guaranteed, and much of its continued relevance can be attributed to the efforts of the Small Shipyard Grant Coalition — a group formed to advocate for the program’s funding and support.

Dave Matsuda, a maritime industry veteran who served as Marad’s 17th maritime administrator, previously worked on Capitol Hill as a policy adviser and founded the coalition in an effort to help revive the program after Congress cut its funding in 2014 and 2015.

Having worked for Sen. Frank Lautenberg, D-N.J., who initially authored the legislation to create the program, Matsuda’s experience in both the legislative process and the maritime industry led him to develop the coalition, unifying shipyards and equipment manufacturers across the country. His efforts have been instrumental in keeping the Small Shipyard Grant Program alive, particularly during times when

million for the program. For example, in scal year 2023, 27 different shipyards across 20 states split a purse of $20.4 million to improve their facilities and upgrade their equipment.

its funding was at risk. Sen. Tammy Baldwin, D-Wis., and Sen. Bill Cassidy, R-La., now lead the funding efforts in the Senate.

“When I left government, one of the staff at Marad said, ‘you know, you really ought to help those small shipyards, because nobody’s really helping them,’” Matsuda recalled.

The coalition’s efforts have helped secure millions of dollars in federal grants for small shipyards, allowing them to make critical upgrades that have, in many cases, transformed their operations.

UNDER THREAT

Now underfunded and under threat, the Small Shipyard Grant Program nds itself at a crossroads. For the past six years, Marad has offered around $20

But 2024 saw a steep cut to $8.75 million. “Even $20 million is a drop in the bucket in the scheme of the federal budget, but it has an outsized impact to the small shipyard industry,” Matsuda said, With the reduced funding, there are fewer grants and smaller awards, leading to a signi cant decrease in transformative projects like travel lifts and drydocks — essential elements for shipyard operations. This year, only one drydock was funded, and zero travel

lifts, a sharp contrast to last year’s provision of four each. Matsuda notes that the shortfall is most telling in the absence of haul-out equipment, the backbone of any shipyard’s functionality, but he remains positive. “This is a critical year,” he said. “If Congress comes back and gives us the 8.75 number again, we might be stuck at that for a while. And if they come back at 20, then it just kind of shows that [20]24 was an aberration, and that was just a one-time thing. We can go back to a funding level that’s more stable. It was funded every year, and it still is, so glad they didn’t cut it all together.”

The take home message from coali-

SMALL SHIPYARD GRANT REQUIREMENTS

Eligible Small Shipyard Grant applicants include the operating companies of shipyard facilities, which:

• Must be in a single geographic location;

• May not have more than 1,200 production employees;

• Must construct, repair, or reconfigure vessels 40' in length or greater for commercial or government use; or

• Must construct, repair, or reconfigure vessels 100' in length or greater for non- commercial vessels.

Source: Small Shipyard Grant Coalition

Colonna’s Shipyard , Norfolk, Va., used a 2008 Small Shipyard Grant to purchase a travel lift.

Doug Stewart

Colonna's lift was the world's most powerful when it was delivered in 2010.

tion-to-industry is that this is a critical time for the program. “If you care about this program, if you want to see it continue, you’ve got to be engaging with us, with your members of Congress, to let them know how important this is, and that we want to see the funding restored,” Matsuda said.

“We still come across folks who are new to the program or aren’t aware of the opportunities it provides,” he continued. “Our job is to keep spreading the word, helping shipyards secure the funding they need, and ensuring that this vital program continues to support the industry for years to come.”

BEST PRACTICES

Matsuda had never written a grant before starting this coalition. After one shipyard asked for assistance, he obliged, likening the process to writing a college term paper. “I spent two or three nights pulling late nighters. But we got the grant, and the next year I got smart and created a small team,” he said.

Over the years, Matsuda has developed a deeper understanding of what makes a grant application successful. “One of the unique things about this grant program is they require quantitative analysis, and I think generally grant writers have a hard time with that,” he said. “It requires a detailed understanding of how a specific project will

lead to measurable improvements in efficiency.”

Marad is keen on funding training grants. Understandably, most shipyards apply for equipment; however, one way to have your application stick out is to include a training component. The Maritime Administration wants to see workforce development, Matsuda said, adding that many of the jobs created through the program are still around today. “This is not a jobs program, nor is it designed to be, but in effect, it is. It helps create and retain jobs long term. It helps companies grow,” he said.

As the program continues to evolve, the success stories of shipyards that

have benefited from the grants are powerful testaments to its impact.

GRANT SUCCESS

Senesco Marine, North Kingstown, R.I., is currently working on two hybrid ferries bound for the Maine coast, and the final two-of-six WindServe Marine LLC crew transfer vessels (CTVs). The shipyard recently began work on a 140'x50' deck barge, which they are building on spec with the intent to sell or charter in the future. The deck barge construction marks a new development for Senesco, as it is advancing in the commercial barge industry and can build to suit any customer’s needs, the company noted.

Last year, Senesco was awarded a $738,289 grant through the Small Shipyard Grant Program to support the purchase and installation of a one-sided submerged arc welding system that consists of three integrated digital systems to load, fit, and weld multiple-plate panels, upgraded network servers and software, an all-terrain lift with variable reach, and a Tier 4 compressor.

“This machine runs a bead and can weld two (40'x40') plates together in about an hour and a half,” Ted Williams, Senesco Marine’s president, said in describing the benefits of that grant and the sub arc welder as an asset to the yard. “It would take a human about three-to-four days to do it,” he said,

Ben Hayden

Senesco Marine's arc welder, purchased with a Small Shipyard Grant, can weld two 40'x40' plates together in about 90 minutes. It would take a person three to four days to do the job. All American Marine

In 2023 All American Marine was awarded a $916,000 grant which it used to purchase two 30' router tables and a 550-ton capacity CNC brake press.

highlighting where the better part of the grant was allocated.

Mike Foster, Senesco’s general manager, mentioned the increased capabilities that the new welding head will provide.

“This one’s capable of welding up to five-eighths of an inch thick,” he said. “Whereas the new machine’s three-quarters to one-inch, so it allows us to weld thicker materials with less distortion.”

“Most importantly, we were awarded about half of a million dollars out of that grant to get a new head, that yellow head right there,” he said, pointing to the arc welder. “We’re going to replace that in a few months as that comes in. That’s an old analog system. We’re going to get a new digital system, which will make it even better, more accurate, and more refined.”

Williams emphasized the impact the Marad program has had since its inception. “That’s a great thing for shipyards to be able to tap into something like that and get that support.”

Further down the coast sits Colonna’s Shipyard, Norfolk, Va., a repair and refit yard that, next year, celebrates its 150th anniversary. The shipyard has received a number of grants through the program over the years, none more important than its 2008 grant that funded a new travel lift.

“Marine travel lifts are just transformative. Colonna’s is probably one of the best examples because of what they did. They were a yard that was limited to drydock or railway technology,” said Matsuda. “The travel lift is a force multiplier. All of a sudden, you’ve got six times, seven times, 10 times the amount of business.”

For a shipyard and industry what does that mean? For a lot of vessel owners, it means, they don’t have to travel as far out of their way to get service.

In 2017, Colonna’s was awarded $387,500 to support the purchase of a Link-Belt 110-ton rough-terrain crane. In 2020, the shipyard received $800,000 to purchase welding machines.

In 2023, All American Marine (AAM), Bellingham, Wash. was awarded $916,000 to purchase and install two 30' router tables and a CNC press brake. The shipyard recently delivered a 75'x27.5' patrol boat to the California Department of Fish and Wildlife. The yard is currently working on two research vessels, one headed to Cal Poly Humboldt and the other to the University of North Carolina, Wilmington. Also under construction is a Los Angeles port police boat, a 108' monohull, and a number of other vessels under contract.

“We went from one router to two, so it’s more than doubled our capacity, said Ron Wille, AAM’s president, “because if one’s tied up on a given job, we’re able to then use the other one. So, it’s been really helpful for us.”

It took some time for the staff to get properly trained on the new CNC press break, but it’s been worth the effort. “We already had an old CNC router, but what we didn’t have was a CNC press brake,” said Wille.

The new CNC press brake, with its 550-ton capacity, allows All American to handle heavy-duty forming tasks more efficiently and accurately. The ability to program the machine for repeat tasks has reduced production time and

improved precision. The company’s previous press brake was manual and less efficient, especially for complex tasks like forming hydrofoils.

The new equipment has already been utilized in several projects, particularly those involving thick aluminum plates. “We build our own hydrofoils for a number of our projects,” said Wille. “In the years that we’ve been working with Teknicraft Design, it’s been 25 years now, we’ve built more than 75 Teknicraft-designed vessel hulls, and more than 40 of those boats have been equipped with a hydrofoil. That foil is a wing that spans between the two hulls.

“We are making those wings out of a much thicker plate now. Until we got this press brake, there were pieces of plate that we had to send to third parties to get formed because our machine was not powerful enough to actually bend aluminum that thick,” Wille continued. “And so, it’s pretty amazing to go out there now and watch this six, seven-foot piece of inch-and-a-half plate form up.”