The changing preferences for newer colors, patterns and textures is now taking a turn towards more functional features in fabrics. Seeing longer work hours and flexibility of work from home, youngsters are looking for soft, antimicrobial, odourcontrol, wrinkle-free and healthy clothes selections. One of the rising needs from citizens is increasing desire for natural fibers and fabrics.

Focusing on innovative textiles, modern fibers are being developed that are ecofriendly, light, resilient, mechanically flexible and easy to process. They are also blended to acquire properties such as sensory capabilities, electrical conductivity and data transmission. Using hydrophobic cotton, plant-based textiles and shape memory polymers materials are some of the suggestive trends for present day clothes. Some companies are in the process of using post-consumer waste to produce recycled textiles. The technology uses AI and robotics to convert used discarded garments into new clothing threads. Few companies are also carrying out research on printing technology that helps to gently remove the textile design without harming the material. This technology enables multiple decoloring and recoloring of old fabrics. Overall it optimizes the use of water resources and decreases release of number of chemicals in the environment.

In providing latest solutions, textile manufacturers are using microelectronics, biotechnology and nanomaterials to improve the interconnection between components.

Nanotechnology is used in apparels, as nano particles have high surface area to volume ratio, which gives increased affinity for fabric giving improved durability, breathability etc.

Some of the benefits are nano size titanium dioxide, zinc oxide, viscous and nano antimony dioxide, tin dioxide have been found to provide anti-static effect, as they are electrically conducting materials causing the effective decay of static charge.

Moreover nano materials are used as inorganic UV blockers as they have been found to be highly efficient in absorbing and scattering UV radiation.

In effect, smart clothes use a variety of IoT sensors to collect a person’s biometric and physical data for effective health monitoring. Moreover, durable sensors are being developed to withstand multiple wash cycles. This offers the desired technology advantage and also prevents harm to the environment. In conclusion, our clothes that provide attractive look and feel solutions will now become smarter, and take care of our health as well.

For suggestions or feedback write to editorial@worldofchemicals.com

Cover Image Source : freepik.com

The rise of e-commerce and access to new technologies has accelerated counterfeiting and other forms of illicit trade. That makes fighting counterfeit medical products an ever-more urgent priority for pharma companies both in terms of patient safety and brand reputation.

Yann

IschiDirector, New Channels and Partnerships, SICPA

Within the Volkswagen Group, we have a clear strategy for how we want to put battery-electric vehicles into series production across our brands and in many different market segments. However, a major qualification for success in the volume market is more powerful battery concepts. In Volkswagen Group R&D we are focusing on close cooperation, not only with industrial partners but also with the smart minds of the scientific community.

Dr Ulrich Eichhorn

Head, Group R&D, Volkswagen AG.

India is a very important market for polyurethanes and has a wonderful potential for growth. When leaders of the industry from all over the world get together under one roof, it leads to better production and faster growth of the industry

R C BhargavaFormer CEO and current Chairman, Maruti Suzuki.

Indian Solar Manufacturers Association (ISMA) members have expressed positive sentiments as manufacturing and Make in India initiative gathered momentum. The phenomenal growth opportunity of Renewal Energy is unparalleled in the world today, looking at current and future energy consumption in India over the next 2-3 decades. All stakeholders have immense opportunities especially those who make and develop products in India.

K N SubramaniamCEO, Moserbear Solar Ltd and Treasurer, Indian Solar Manufacturers Association (ISMA)

NEW DELHI, INDIA: Cairn Oil & Gas announced the production milestone in the development of its Mangala oilfield in the prolific Rajasthan block, in an onshore play in western India. The subsidiary of the Vedanta group said, it had past cumulative production of 500 million barrels from Mangala Oilfield.

Mangala oilfield was discovered in 2004 and put into production in 2009, has been the object of a huge polymer flood project for enhanced oil recovery. It is part of the complex of oilfields also including Bhagyam and Aishwarya, situated in the Barmer district of Rajasthan.

“We are happy to have achieved this milestone of producing 500 mmbbl of oil from our Mangala oilfield. This brings us closer to our target of doubling our production capacities in line with our chairman’s vision to contribute 50% to India’s domestic oil and gas production, and contribute towards the country’s energy Aatmanirbharta,” stated Cairn Oil & Gas deputy chief executive Prachur Sah.

Mangala is India’s private-sector oil and gas producer, with interests in 62 exploration and production blocks. It also contributes towards the socio-economic development. Cairn aims to achieve net-zero emissions by 2050 while pressing ahead future investments plan.

MUMBAI, INDIA: BASF broke ground on its new Polyurethane Application Development Laboratory in Mumbai, India.

The new lab will have equipment’s in 2,000 square meter space approximately and is expected to be fully operational in 2024. It will offer improved customer support services ranging from troubleshooting to customized formulations, line trials, and customer training sessions and will strengthen the bond between high-growth industries, including consumer appliances, footwear, furniture, and transportation.

This will help drive innovation with customers alongside the Creation Centre, at BASF’s Innovation Campus in Mumbai.

“As a part of the global innovation network, the lab will enable global and regional BASF teams to work closely with local customers in testing and formulation optimization,” said Andy Postlethwaite, senior vice president, performance materials Asia Pacific.

“The new lab reinforces our commitment to strengthening our product development capabilities and providing fast and advanced technical service for our customers,” said Krishnamohan Narayan, Managing Director, BASF India Limited and Head, BASF Group Companies in India.

MUMBAI, INDIA: Reliance New Energy Limited (RNEL) said it has signed an agreement to invest $12 million to acquire 20 percent stake in Caelux Corporation’s perovskite-based solar technology. The transaction will be completed by end of September.

The investment will accelerate product and technology development for Caelux, including its pilot line in the US and for expanding the commercial development of its technology.

Beside the Caelux transaction, Reliance will also set-up a global scale integrated photovoltaic Giga factory at Jamnagar, Gujarat. Through this investment and collaboration, Reliance will be able to produce more powerful and lower cost solar modules leveraging Caelux’s products.

“The investment in Caelux aligns with our strategy to create the most advanced green energy manufacturing ecosystem, backed by world class

talent, and built on the pillars of technological innovation achieved through strategic partnerships,” said Mukesh Ambani, chairman and managing director of Reliance Industries Limited.

“We believe Caelux’s proprietary perovskite based solar technology provides us with access to next leg of innovation in crystalline solar modules. We will work along with team at Caelux to accelerate its product development and commercialization of its technology,” added Ambani.

“Caelux’s ‘perovskite on glass’ architecture is the innovation the solar industry needs to significantly reduce costs and accelerate renewables penetration. As an early backer of Caelux, we have been impressed with their technical progress and are excited to continue working with them as they embark on their commercial journey with Reliance,” said Vinod Khosla, Khosla ventures.

NEW DELHI, INDIA: Taking the pledge of Carbon neutrality, UFlex signed an Memorandum of Understanding (MoU) with CREDUCE – Carbon Credits Consultancy as their consulting partners to achieve ‘carbon neutrality’ and make India strides towards achieving the sustainability goals.

To reduce dependency on fossil fuels and shift the concentration towards plastic waste management and sustainable production process, UFlex and CREDUCE took a stand that will lead to positive environment impacts such as decreasing greenhouse gas (GHG) emissions.

The scope would encompass an analysis on carbon footprint & neutrality, creating and formalizing carbon & plastic credit balances as a part of sustainable roadmap for the future.

“We were always committed to steer our group towards sustainable environmental practices, especially to achieve carbon neutrality in Scope 1 & Scope 2 emissions. We aspire to cut about 175,000 tonnes of

carbon emission equivalent by the end of year 2024, across the group,” asserts Jeevaraj Pillai, joint president of UFlex.

“Socio-Environmental sustainability has always been one of our core organizational values for quite some time now and we have articulated & imbibed the same in all walks of our functioning,” states Manas Kumar Sarkar, general manager– HR & sustainability at flexible packaging business of UFlex.

As a socially responsible corporation, UFlex has been leading the way in creating future-ready, technology-driven sustainable solutions towards a cleaner and greener tomorrow with CREDUCE technologies Limited.

“We would be able to strategize a path towards complete zero carbon footprint. These accruals of carbon credits would be clubbed with community development initiatives like smokeless cook-stoves & clean drinking potable water,” said Shailendra Singh Rao, director at CREDUCE.

AMSTERDAM, NETHERLANDS: AkzoNobel India said it has signed letters of intent with two India start-up challenge winners viz. HyperReality Technologies and Fluid AI.

Bengaluru-based HyperReality Technologies offers a collaboration platform for inspiration, visualization of a space in metaverse. Headquartered in Mumbai, Fluid AI offers multi-channel conversational immersive and interactive AI platform to guide consumers during their painting journey.

AkzoNobel said that winning the ‘Paint the Future’ award opened more doors for these start-ups. Having signed letters of intent to work together on sustainable business opportunities, the two winners now join AkzoNobel’s accelerator program.

“Over the next six months, the goal is clear – to work together with our winners and develop a digital value proposition,” said Oscar Wezenbeek, managing director of AkzoNobel decorative Paints in Southeast and South Asia and chair of AkzoNobel India.

“This startup challenge is about collaborating with equally passionate Indian startups to boost the magic of Dulux and paint the future of paint consumers’ digital experience,” said Rajiv Rajgopal, managing director of AkzoNobel India.

“From the depth of the expert sessions to the sheer amount of industry knowledge we’ve gained, this bootcamp has been a collaborative experience unlike any other,” said Sobin Thombra, CEO, HyperReality Technologies.

“We’re stoked about our win,” said the co-founders of Fluid AI, Abhinav Aggarwal and Raghav Aggarwal. “AkzoNobel’s astute understanding of our artificial intelligence solution is a gateway to bringing new consumer-centric disruptions in the paints sector.”

The India startup challenge is the third regional edition of Paint the Future. Run in partnership with NASSCOM Industry Partnership Program (NIPP), the challenge attracted 207 submissions from 33 cities across India.

the company’s ever expanding internal products pipeline to support its Large-Scale Manufacturing business model.

The facility will feature seven synthetic labs and 55 German-made fume hoods, allowing the company to undertake 110 reactions every day.

Each of the fume hoods has automation to regulate many experimentrelated parameters, allowing for the greatest levels of safety. The R&D centre also has a specialized quality control and assurance lab.

INDIA:

The centre will assist to meet the rising demand in the CRAMS business (Contract research and manufacturing services) areas and will support efforts to increase the efficiency of existing products.

Aether Industries’ newest R&D centre will also enable innovation for

The DCS (Distributed control system) automation system is also included in the pilot plant, allowing the company to test goods at various scales, ranging from a few grams to several kilos to several MTs, employing various technologies such as continuous reactions and highpressure reactions.

The firm has committed roughly INR 330 million to remodel and triple the capacity of the R&D centre to assist the company’s development into new markets through new and creative products and processes for international projects.

TOKYO, JAPAN: Toray Industries announced that it has opened Toray India Water Research Center at the IIT Madras Research Park (IITMRP), in Chennai.

The center will step up R&D into applications for its water-treatment membrane technology to help India meet surging treatment demand in the years ahead and overcome water shortages.

IITM has been ranked first in the Indian government’s National Institutional Ranking Framework for the past four years and has a solid record in water treatment.

The new facility in India will collaborate with the Toray Singapore Water Research Center to support research and development that grows the company’s water treatment business in Southern and South Asia. The Singapore site was inaugurated in August 2009.

About 600 million people experience extreme water stress. This problem will likely worsen as the population grows and the economy develops, with water demand exceedingly twice the available supply by 2030. An urgent need to resolve shortages has propelled efforts around nation to improve the water supply infrastructure and reuse wastewater, stated the company.

FLORIDA, US/ LUTON, UK: Hertz and bp announced the signing of a memorandum of understanding (MoU) for the development for US network of Electric Vehicle charging stations which will be powered by bp pulse (bp’s global electrification and charging solution brand).

bp pulse will build and manage a network for fast-charging hubs to serve Hertz customers, including taxi and ride sharing drivers, as well as the public.

The agreement also involves the management of Hertz’s charging infrastructure by bp pulse and the customization of its Omega software to ensure Hertz’s growing fleet of electric rental cars to recharge quickly and efficiently.

Omega helps fleet operations by automating charging when the energy value is low, whereas offering real-time visibility to electric vehicles, chargers, power usage and lower emission and more.

“Hertz is accelerating the adoption of electrification by investing in the largest rental fleet of electric vehicles in North America and expanding the availability of charging stations. We are excited to partner with bp

pulse to create a national charging infrastructure for the Hertz EV fleet,” stated Stephen Scherr, Hertz ceo.

On the other hand, Hertz has invested in thousands of charging stations across its locations, and its partnership with bp will enhance and enable its US Charging footprint. Hertz’s objective is to make it’s one-quarter of fleet to be electric by the end of 2024.

“Working together to deliver charging facilities and design solutions, we believe we can take the EV driving experience to the next level for US customers,” commented Bernard Looney, bp chief executive.

“This is a landmark moment. It shows the power of bringing together bp’s digital and operational capabilities with a partner like Hertz. Together with its industry-leading electrification ambitions, we can change the future of electric rental cars,” stated Vic Shao, founder of Amply Power and president of bp pulse’s fleet division in the United States.

bp plus is expanding its global network of high-speed charging for card, light commercial vehicles, and trucks, with a global target of more than 100,000 chargers by 2030.

PARIS, FRANCE: TotalEnergies and SARIA said they have agreed to develop and produce sustainable aviation fuel (SAF) at the Grandpuits refinery in France. TotalEnergies is transforming it’s Grandpuits refinery into a zero-crude platform by 2024.

The agreement is a major step towards converting feedstock supply (used cooking oils and animal fats) to sustainable aviation fuel and the conversion will enable SAF production capacity to reach 210,000 tons per year, 25 percent higher than foreseen in the initial project announced in 2020.

TotalEnergies will take 50 percent of SARIA’s production capacity, that will supply animal methyl ester (AFME) and used cooking oils to Grandpuits refinery. On the other hand, SARIA will take an

equivalent share in the biofuel business, which will remain operated by TotalEnergies.

“I am delighted to conclude this strategic partnership with SARIA, which reinforces the conversion of the Grandpuits refinery into a zerocrude platform oriented towards SAF. This is a major milestone in our ambition to become one of the leaders in sustainable aviation fuels,” said Bernard Pinatel, president of refining & chemicals at TotalEnergies.

“SAF is the most efficient solution to immediately reduce CO2 emissions from air travel, and its development is fully in line with the Company’s Climate ambition to get to net zero by 2050, together with society,” added Pinatel.

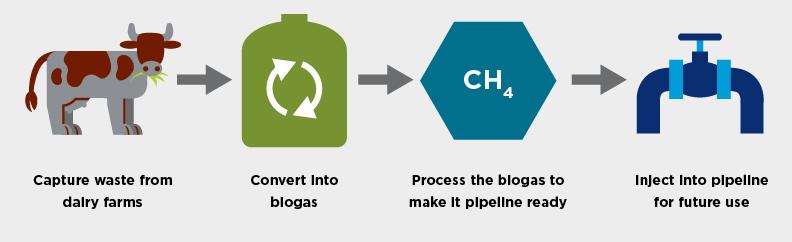

SAN RAMON/VISALIA, US: Finding inspiration in nature is one way Chevron is working to provide an alternative source of power through dairy farms.

Chevron Inc, subsidiary of Chevron Corporation, and California Bioenergy LLC (CalBio) announced a partnership to produce and market diary biomethane as a renewable natural gas (RNG) transporting fuel in California.

The JV is one of the ways to help and protect the environment, provide a renewable energy source, and comply with low-carbon fuel regulations.

The partnership with CalBioGas Hilmar has secured initial funding from Chevron to begin developing infrastructure for biomethane projects in the state’s Merced County.

Manure produces methane as it decomposes and contributes to excess nutrients in waterways.

CalBio’s technology and operational experience will help dairy farmers to build anaerobic digesters and methane capture to convert biomethane to RNG.

Chevron will provide funding to seven digesters and one central upgrading facility across a cluster of diary farms in Merced County.

“This project brings together support from many groups, including seven California Dairy farmers, who are national leaders in milk and cheese production; Chevron, one of California’s largest energy companies; and grant funding from the California Department of Food and Agriculture.

The strong support from these partners will help California with its emission reduction targets,” said Neil Black, president of CalBio.

The diary project will be designed to send biogas to a processing facility where it will be upgraded to renewable natural gas and sent to a local utility via pipeline.

“The investment underscores our commitment to produce 40,000 MMBTU/D of RNG by 2030 and grow the lower carbon businesses that we believe will be a bigger part of the future,” said Andy Walz, president of Americas Fuels & Lubricants for Chevron.

LyondellBasell and Genox Recycling jointly announced they have signed Memorandum of Understanding (MoU) to establish a joint venture (JV) to build a plastics recycling plant in Zhaoqing, Guangdong Province in 2023.

The plastic recycling plant will use mechanical recycling technology to recycle post-consumer plastic waste and produce new polymers sold under the LyondellBasell CirculenRecover product portfolio.

The Joint venture aims to reduce the increasing number of plastic wastes, support the growing demand of circular and sustainable solutions, and promote high-quality development of local recycling, the company stated.

“Advancing a circular economy that enables plastic waste to be transformed into more sustainable solutions for our customers is important to us, and we are pleased to collaborate with Genox Recycling to make this happen,” said Limin Fu, vice president of LyondellBasell China Polyolefins.

“This new joint venture will help develop the local plastics recycling infrastructure in China and is an important milestone for LyondellBasell to contribute to its goal to produce and market two million metric tons of recycled and renewable-based polymers annually by 2030,” added Fu.

“Genox Recycling believes that innovation and collaboration are necessary ways to achieve carbon neutrality,” said Jingfa Jiang, chairman of Genox Recycling.

LEVERKUSEN, GERMANY: Covestro opened a new production facility for the manufacture of aniline at Antwerp, Belgium.

Adding up aniline capacity, the company will strengthen its European production network for methylene-di-phenylene isocyanate (MDI).

Covestro will invest €300 million ($291 million) to build the aniline plant, which is scheduled to be operational, depending on the volatile economic situation in early 2025.

At the beginning of the year, Covestro awarded Maire Tecnimont an engineering, procurement, and construction (EPC) contract for the project.

Aniline is key material for MDI, used to make rigid polyurethane foam. Due to the global trend towards sustainability and climate neutrality, the global MDI market is expected to grow by around 6 percent per year in the medium term.

Covestro says, given the current high electricity and gas prices, especially in Europe, demand for efficient insulation is likely to continue increasing.

“With the expansion of our aniline production, we are addressing the further increase in demand from our customers for energy-efficient solutions for the insulation of buildings and refrigeration appliances,” said Klaus Schafer, chief technology officer at Covestro.

“The capacity expansion of aniline will ensure the sustainable and efficient supply of our MDI network in Europe,” said Georg Wagner, Covestro Antwerp site manager.

The new plant will use technologies that improve energy efficiency. will help to significantly increase the energy efficiency of production in Antwerp.

With the commissioning of the new plant, the share of steam generated from process heat at Antwerp site will double to 40 percent of local demand, and the use of fossil fuels will decline.

The potential savings correspond to up to 27,000 tons of CO2 emissions and craving its path to reach climate-neutral by 2035.

GERMANY: The increasing demand of two Evonik’s coating additive product led the company to increase the capacity for their architectural paints- TEGO Phobe hydrophobing agents and TEGO Viscoplus polyurethane thickeners and will be made available from October.

“The capacity increase is our response to the increased demand for additives for architectural paints. The additional capacity in Europe will not only increase European, but also global supply security,” said Nadia

Lenhardt, head of the decorative coatings market segment in EMEA. Hydrophobing agents are primarily used to give facade paints a water repellent finish. Emulsions based on silicone resins such as TEGO® Phobe 1659 are characterized by a particularly efficient reduction in water absorption.

Polysiloxanes such as TEGO® Phobe 1409 produce a very good waterbeading effect. On the other hand, TEGO Viscoplus products are liquid and contain no organic solvents.

BRUSSELS, BELGIUM/ PERTH, AUSTRALIA: Solvay and Hastings Technology Metals (HAS) has signed a non-binary Memorandum of Understanding (MOU) for the supply of Mixed Rare Earth Carbonate (MREC).

Under the agreement, the supply of an initial 2,500 tonnes of Mixed Rare Earth Carbonate (MREC) will be sent from Hastings’ Yangibana rare earth project in Western Australia to Solvay’s plant in La Rochelle, France.

The Yangibana Project is a significant Australian Rare Earths Project, containing substantial Neodymium and Praseodymium resources.

On the other hand, the La Rochelle plant manufactures around 4000 tons of rare earth-based formulation products each year for the automotive pollution control, polishing and electronics markets.

Solvay recently announced that its plans to expand and upgrade the La Rochelle plant to produce separated rare earth oxides for the permanent magnets market.

“This is a very significant agreement for Hastings. We are delighted that Solvay has chosen to work with Hastings as it re-enters the rare earth oxides separation business at a time when long term demand for NdPr oxides is experiencing strong growth,” said Charles Lew, Hastings Executive Chairman.

“After announcing our plan to make La Rochelle a rare earths hub in Europe, we’re excited to take this next step,” said Solvay CEO Ilham Kadri.

“We want to help Europe power its new economy with more autonomous and sustainable solutions for electric mobility, clean energy generation and sensitive electronics applications,” added Kadri.

next five years, including cathodes, sulphates, carbonates, and oxides of various metals extracted from spent batteries and other sources.

Both the companies same aim to share energy transition and understand to meet the growing demand of Li-ion batteries and support the advancement of circular economy by supplying raw materials back into the battery supply chain.

As part of its mission to expand its recycling footprint, Lohum will procure spent batteries and recycle them at its plant.

“At Lohum, we recognize that Lithium Carbonate extraction through recycling consumes significantly fewer resources than conventional mining. Our partnership with Glencore underpins our global commitment to expanding the availability of existing battery resources through recycling,” state Rajat Verma, founder & CEO of Lohum.

“This major development will directly boost India’s battery industry and energy security, leading to large scale value creation in employment, domestic ecosystem growth, and import savings on LIB raw materials,” added Verma.

DELHI, INDIA: Lohum join hands with Glencore for a strategic partnership to advance circularity in the Li-ion battery supply chain.

The $200 million association between Lohum and Glencore is aligned with the government’s vision of scaling up the Electric Vehicle’s sector.

Under the alliance, Lohum will supply Glencore with 10,000 Metric Ton (MT) of specialty chemicals for the battery supply chain for the

An expanding focus on Li-ion battery recycling is inevitable to meet the raw material demand for the Electric Vehicle adoption.

“Our focus on a greener future is aligned and supports Glencore’s ambition to reach net-zero carbon emissions by 2050. Part of our approach is to seamlessly combine primary as well as recycled feed streams to provide the critical metals needed for the transition to a low carbon future,” commented Jyothish George, co-head of marketing zinc and copper (Metal), from Glencore.

NORWAY: Equinor announced that Al Cook, executive vice president for Exploration and Production International has signed, effective October.

Cook will continue in his current position in Equinor till 1st April 2023, stated the company.

“I would like to thank AI for his contribution to focusing and optimizing our international oil and gas business, and I congratulate him on his new appointment,” said Anders Opedal, president, and CEO of Equinor.

“I am grateful for the opportunity I have had to contribute in shaping and delivering Equinor’s strategy of becoming a broad energy company. And I am particularly proud of the performance improvements we have delivered together. After years of commuting between Norway and the UK,” said Cook.

Al Cook held the position of executive vice president for Global Strategy & Business Development from 2018 until January 2021. Prior to that, Cook was a senior vice president in Development & Production International overseeing operations.

GERMANY: The Management Board of Covestro has extended the contract of board of management member Klaus Schafer by six months until the end of June 2023, effective October.

Shafen has been a member of the board of management of Covestro AG since 2015 and as a chief technology officer (CTO), he is responsible for production and technology as well as all chemical production sites of the company.

Jointly, Schafer and the supervisory board have agreed to extend his contract for the period from January 1, 2023, to June 30, 2023, to ensure personnel stability for Covestro to the upcoming change in market policy.

“We are very pleased that we were able to convince Klaus Schafer to remain on the Covestro board of management beyond his planned tenure. The current geopolitical challenges pose major issues even for a company as resilient as Covestro,” said Richard Pott, chairman, supervisory board, Covestro AG.

“In my more than thirty years of professional life, this industry has never faced greater challenges. For me, continuing to support Covestro in this situation, even against my original plans, is a matter of course,” said Schafer.

GERMANY: Brenntag SE said it is represented in the newly elected presidium of the VCI (German Chemical Industry Association) by Brenntag CEO Christian Kohlpaintner. The general meeting voted on September 29 to elect him as a member of the trade association’s governing body.

“As a representative of Brenntag SE, I look forward to bringing the perspective of chemical distribution to the work of the association and to representing the interests of our industry together with my colleagues on the Executive Committee in these challenging times,” said Kohlpaintner.

“The VCI remains well positioned as a leading business association and an effective industrial policy actor in Berlin and Brussels. As the strong voice of the industry, we will continue to show politicians solutions and demand action. Everything is at stake for us now: the future of our industrial location and sustainable transformation. I am pleased that Christian Kohlpaintner is actively supporting us on our way,” said VCI general manager Wolfgang Grosse Entrup.

chemical giant SABIC and recently stepped down from the board of Swiss specialty chemicals producer Clariant.

During his 17-year tenure at Ineos, the British-born executive was instrumental in the integration of Styrolution, formerly a joint venture between Ineos and BASF, along with the consolidation of the PetroIneos JV.

“We are very happy that Calum has accepted the designated CEO role in this strategic investment and are convinced that his highly relevant experience at both INEOS and Synthomer will be invaluable during the integration and subsequent growth of the engineering materials business. We look forward to working with him and the future executive management team on this exciting venture,” said Ronald Ayles, managing partner at Advent.

“LANXESS and Advent will support Calum during the integration phase as the joint venture establishes itself as a strong global player in this highly attractive market, following merger clearances,” stated Matthias Zachert, CEO of LANXESS.

The new company is expected to have sales of around Euro 3 billion and to be one of the leading suppliers to the attractive and growing automotive, electronics, electrical and consumer goods segments, with a particular focus on environmentally friendly and sustainable products, stated Lanxess.

MacLean has extensive global experience as CEO of companies in the petrochemicals, polymers, and specialty chemicals fields, most recently as head of Synthomer.

He is currently a non-executive board director of Saudi Arabian

“I am truly excited by the challenge and opportunity to lead the merger of equals of two highly successful and complementary businesses with rich heritages from DSM and LANXESS. The combination will create a truly global engineering materials business and an exciting future for both employee teams and customers going forward,” said Calum MacLean, the CEO-designate of the joint venture.

Styrolution has announced the introduction of a comprehensive range of sustainable solutions for its specialty ABS product group Novodur®/ Novodur® High Heat addressing applications in a range of industries including automotive, electronics and household. The individual grades come with a significant product carbon footprint (PCF) saving of up to -71 percent as compared to the respective non-ECO product reference.

Like its non-ECO counterpart, the new Novodur ECO MR P2HAT is a general purpose ABS grade providing high flowability, good stiffness and high gloss. The material is available with a 30 percent, 50 percent or 70 percent post-consumer mechanically recycled content (PCR). The product comes in various colours or in black and offers a PCF saving of up to 57 percent. A product for self-colouring is available as well.

Novodur ECO MR P2H-AT is currently under evaluation by various customers to become a material of choice for various household appliances.

With Novodur ECO P2MC B50 and Novodur ECO HD M203

FC B50, INEOS Styrolution offers two grades with 50 percent contribution of bio-attributed content. Both grades are available in various colours and as an NR (natural) option. PCF savings are up to -71 percent.

Novodur ECO P2MC B50 has been designed specifically for electroplating making it a material of choice for various sanitary and automotive appliances. Novodur ECO HD M203 FC B50 is an attractive offering also suitable for the medical industry.

The Novodur High Heat (HH) family of products includes all ABS products modified to allow thermally stressed components to meet stringent stability requirements. Today, three sustainable grades are introduced in this product group: Novodur ECO HH106 MR30, Novodur ECO H605 MR30 and Novodur ECO H801 MR40. PCF saving is up to -28 percent and the recycled content is 30 percent and 40 percent, respectively.

The products, available in black, are targeting the automotive industry, but may be of interest in other industries as well.

“This announcement for sustainable ABS specialty solutions follows our earlier announcements on sustainable ASA, SAN, SMMA and SBC products. – It will not be the last such announcement. We will continue on our journey to deliver sustainable options for all our product groups,” said Dr. Eike Jahnke, vice president specialties EMEA.

launched four new LNP™ ELCRES™ FST copolymer resins that comply with the European railway standard EN45545 R6-HL 2 for train seating. Designers can benefit from these new material solutions, which not only meet the new regulatory requirements but also provide expanded opportunities to create sleek seating designs.

Compared to thermosets and aluminum, the new ELCRES resins offer lighter weight and efficient processing without requiring secondary operations. To achieve a seamless aesthetic look in an all-inone seat unit or a design with a separate back shell without painting, SABIC offers precision color matching for its extrusion grade (LNP ELCRES FST2732E resin) and injection molding grade (LNP ELCRES FST2432 resin). For customers that require more-sustainable solutions, SABIC supplies bio-based version of each grade.

“Since the EN45545 standard came into effect, the rail industry has faced challenges in obtaining compliant thermoplastic materials – and SABIC has been proactive in providing solutions,” noted Brian Rice, senior manager, global product management, LNP/NORYL, specialties, SABIC. “With our new LNP ELCRES FST products, we not only met customers’ high expectations for compliance, performance, aesthetics and manufacturability, but we also addressed their sustainability goals with bio-based versions. With multiple grades to choose from, manufacturers can once again leverage the advantages of thermoplastics in their seating applications.”

Meeting customer requirements for compliance with stringent EN4 5545 standard

LNP ELCRES FST copolymers address demands from customers like Monte Meao, a Portuguese rail seating provider, for high-performance thermoplastics that help address the stringent requirements of the harmonized European rail fire protection standard, EN45545.

“We needed an injection molding material that complies with the safety requirements set forth in the EN45545 standard for railway seating and offers long-term durability for our customers. SABIC’s LNP ELCRES FST2432 copolymer provided a good combination of physical properties and a flexible processing window,” said Fernando Cerqueira, CEO of Monte Meao.

SABIC’s bio-based versions of both the extrusion and injection molding grades were developed to expand the sustainability benefits of the LNP ELCRES FST materials beyond paint elimination

and weight reduction. LNP ELCRES FST2732EB (extrusion) and LNP ELCRES FST2432B (injection molding) products incorporate 55 percent renewable feedstocks from crude tall oil and other waste products.

Both are potential drop-in solutions that deliver the same high performance and regulatory compliance as the fossil-based grades. An Intergovernmental Panel on Climate Change (IPCC) carbon dioxide (CO2) equivalent analysis showed these bio-based products reduced carbon emissions by 33 percent vs. their fossil-based counterparts.

Custom color and chemical resistance enhance

The new LNP ELCRES FST copolymers offer molded-in color options from a broad palette, including custom colors, to help enable OEMs and railway operators to brand their seats as part of the interior Molded-in color eliminates the need for secondary painting, thereby reducing cost and CO2 footprint.

To maintain the attractive appearance of rail seating over its lifetime, the SABIC materials provide excellent chemical resistance that simplifies graffiti removal, and a good balance of stiffness and impact resistance to improve durability and extend useful life. Also, the increased stiffness of the LNP ELCRES FST grades compared to standard PC allows the same part to be manufactured using less material, for potential cost savings.

“Our new LNP ELCRES FST copolymers are the result of a major technological breakthrough that helps ensure compliance with stringent fire protection requirements of the European railway standard,” commented Luc Govaerts, director, formulation & application, specialties, SABIC.

“By bringing together a proprietary copolymer material and an enhanced additive package, our team delivered the outstanding flame-smoketoxicity performance that customers are seeking. We took this major development effort one step further by formulating drop-in, bio-based versions of both grades to offer the industry new options for increasing the sustainability of rail seating.”

SABIC’s Specialties business will feature the new LNP ELCRES FST materials. Parts to be displayed will include the back of an R6 train seat (injection molded) and a portion of an R6 seat (extruded and thermoformed).

The company will also be featuring a new pelletfed additive manufacturing (PFAM) grade that is well-suited for rail seating and other large parts in Germany.

Evonik aims to make the recycling of lithium simpler, more costeffective, and more environmentally friendly. This metal is essential for the batteries used to drive millions of electric vehicles. At present, however, up to 95 percent is not recycled after use.

Evonik’s researchers have therefore adopted a new approach, focusing highly efficient recycling of lithium using an electrochemical process with a ceramic membrane. The technology is currently being tested on a pilot scale. It is highly efficient and generates high-purity lithium hydroxide that is suitable for the manufacture of new batteries.

Following proof of concept in the lab, the technology now needs to be driven forward—and Evonik is working on that at its sites in Hanau and Marl in Germany. Its specialists are confident that the ceramic membrane process will be market-ready in three to five years.

“In a few years, many lithium-ion batteries will be coming to the end of their service life. As a result, there will be a sharp rise in the volume of spent batteries that can be used to recycle lithium. Moreover,

new production facilities are being set up in Europe for large-scale production of batteries for electric vehicles. That will generate production waste containing lithium,” said Elisabeth Gorman, lithium recycling expert at Evonik.

“A third factor is legislation: The EU, in particular, is pressing for valuable raw materials to be re-used in the production cycle. That is already realistic for cobalt and nickel, but the recycling rate for lithium is less than 5 percent at present,” added Gorman.

Gorman is responsible for market development of lithium recycling at Creavis, Evonik’s strategic innovation unit and business incubator, and is familiar with the legal situation: In the EU, it is stipulated that in four years’ time at least 35 percent of the lithium from spent batteries will have to be recovered. From 2030, the percentage has to be increased to 70 percent. China and the US also have government regulations on the recovery of lithium.

The processes currently used to recover metals from spent batteries are based on smelting (pyrometallurgical process), leaching (hydrometallurgical process), or a combination of the two. These processes have proven effective for the recovery of cobalt and nickel.

Conventional reprocessing of lithium is also based on hydrometallurgic processes. However, the processes are cost-intensive, require large quantities of energy and water, and involve many interim steps and additional chemicals. There are therefore good reasons to look for better alternatives.

Evonik has taken up this challenge. Experts at this specialty chemicals company are working on the development of a ceramic membrane with selectivity for lithium ions, which forms the heart of an electrochemical process. The aim is selective and efficient recovery of lithium salts from spent batteries—while minimizing the use of energy and chemicals.

The starting point is the black mass. This is the term used by experts to refer to what remains of spent lithium-ion batteries when the plastic parts have been removed and the rest has been ground to powder.

The black mass contains a mixture of lithium, cobalt, nickel, and manganese. Processing of this black mass results in lithium leachate. Evonik’s research team processes this leachate electrochemically with the aid of a ceramic membrane with selectivity for lithium ions. Selectivity means that the membrane only allows positively charged lithium cations to pass from the side with the leachate and the positively charged anode to the other side, where there is a negatively charged cathode. Here, the lithium ions are combined with hydroxide to form battery-grade lithium hydroxide with almost 100 percent purity.

Demand for lithium is set to rise as a result of the ongoing shift from combustion engines to electric vehicles. Experts predict that in the long term recycling will contribute around 25 percent of the lithium salts required.

At the same time, this could limit damage to the landscape and greatly reduce dependency on suppliers. Gorman is confident that in a few years Evonik’s newly developed membrane will facilitate efficient recycling of lithium—and be recognized for its sustainability.

BY G S PATNAIK

BY G S PATNAIK

Flexible packaging is a means of packaging products through the use of non-rigid materials, which allows for more economical and customizable options. It is a relatively new method in the packaging market and has grown popular due to its high efficiency and costeffective nature.

This packaging method uses a variety of flexible materials, including oils, plastic and paper to create pouches, bags and other pliable product containers. Flexible packages are particularly useful in industries that require versatile packaging such as the food and beverage, personal care and pharmaceutical industries.

Flexible packaging comes in a variety of materials, shapes, and sizes, and is typically produced in either formed or unformed configurations. Formed products are pre-shaped with the option of filling and sealing yourself in-house, while unformed products typically come on a roll that is sent to co-packers for forming and filling. The materials used in flexible packaging are easy to manipulate and combine into innovative and customizable styles, such as: Sample pouches, Printed Pouches, Sachets, Printed Roll Stock, Stock Bags etc.

Not only does flexible packaging use less material than its rigid counterparts, leading to a lower overall packaging cost, it also creates

less waste. It is said that flexible packaging formats create 50 percent less waste than rigid ones, while also reducing greenhouse gas emissions and BTU consumption.

Flexible packaging is one of the fastest growing segments of the packaging industry, it adds value and marketability to food and nonfood products alike – combining the best qualities of plastic, film, paper and aluminium foil to deliver a broad range of protective properties while employing a minimum of material.

The industry continues to advance at an unprecedented rate. Innovation and advancements in technology have led to the development of lighter weight packaging that enhance flexible packaging’s shelf appeal, strength, product protection, and the ability to be sealed. There are numerous examples of innovation in flexible packaging.

Each one starts from an idea: meat should stay fresher longer, shipping costs should be lower and medicines should be safer for the consumer. With its versatility, custom qualities, efficiency in conserving resources, and sustainability, there’s no better time to consider switching to flexible packaging.

Flexible Packaging entails a package or container of flexible or easily yielding materials that when filled or closed can be readily changed in shape. They are used for consumer and institutional products and in industrial applications to protect, market and distribute a vast variety of products.

As Rigid packaging is made from denser and thicker materials while flexible packaging is mostly made from plastic, film, foil, and paper which makes them less heavy than the rigid packaging. Rigid packaging provides better protection against the heat and other barriers when compared to the other one.

Flexible packaging is a means of packaging products through the use of non-rigid materials, which allow for more economical and customizable options. This packaging method uses a variety of flexible materials, including foil, plastic, and paper, to create pouches, bags, and other pliable product containers.

Flexible packaging can be composed of film, plastic, paper, or foil, to name a few materials.

• Polyolefin (POF) ...

• Low Density Polyethylene (LDPE) ...

• Linear Low-Density Polyethylene (LLDPE) ...

• Polyethylene Terephthalate (PET, PETE) ...

• Polypropylene (PP) ...

• Polyvinyl Chloride (PVC, Vinyl)

Sample Pouches: Sample pouches are small packets composed of film and/or foil that get heat-sealed. They are typically pre-formed for easy in-house filling and sealing.

Printed Pouches: Printed pouches are sample pouches on which the product and brand information is printed for marketing purposes.

Sachets: Sachets are flat packets made of layered packaging material. They are frequently used for single-use pharmaceutical and personal care products. These are great for trade shows where you want to distribute samples.

Printed Roll Stock: Printed roll stock consists of unformed pouch material with product information pre-printed on it. These rolls get sent to a co-packer to get formed, filled, and sealed.

Stock Bags: Stock bags are simple, blank formed bags or pouches. These can be used as blank bags/pouches or you can adhere a label to these in order to promote your brand.

The basic manufacturing process for flexible packaging includes:

1. rotogravure printing. 2. adhesive lamination. 3. flexographic printing. 4. extrusion lamination or coating, and. 5. finishing.

The global flexible packaging market was valued at $182.3 billion in 2020, and is projected to reach $325.6 billion by 2030, growing at a CAGR of 6.2 percent from 2021 to 2030.

Owing to the rising focus on sustainability, traditional rigid packaging solutions are being substituted by innovative and more sustainable flexible packaging. The growing market demand for customer-friendly packages and heightened product protection is expected to boost flexible packaging as a viable and cost-effective substitute.

E-commerce, digital printing, and sustainability are driving market development and growth. Customers are increasingly becoming more eager to pay extra for certain product attributes boosted by flexible packaging. For instance, according to the Flexible Packaging Association, more than 60 percent of consumers in North America are keen to pay more for tangible and functional packaging benefits, such as product protection, shipping friendly, and supply chain efficacy, among others.

Flexible packaging is mainly used for food, which contributes to more than 60 percent of the total market, according to the Flexible Packaging Association. Also brand owners are taking on films, pouches and bags as a go-to packaging solution, acknowledgments in part to extensive acceptance by American consumers1.

The e-commerce retail packaging sector has grown to 65 million monthly unique visitors, accumulating an annual increase of 55 percent. India’s e-commerce revenue is predicted to be the highest rate in the world, growing at an annual rate of 51 percent and increasing to $120 bn in 2020 from $30 bn in 2016, according to an ASSOCHAMForrester report2.

Beauty products manufacturers are also investing in eco-friendly packaging approaches to make more sustainable usage of plastics in the personal care industry.

India is Expected to Witness Significant Growth in the Asia-Pacific Region. The packaging is the fifth largest sector in the Indian economy and is one of the highest growth sectors in the country. According to the Packaging Industry Association of India (PIAI), the sector is growing at 22 -25 percent per annum.

With the rising population, increasing income levels, urbanization, changing lifestyles, increasing internet penetration, and growing economy, the demand for packaging has been growing. According to the World Bank, approximately a third of the total population in the country lives in cities.

In recent years, India has witnessed sustainable packaging growth owing to the increase of packaged food consumption and awareness, and demand for quality products. Consumer awareness surrounding packaged food, specifically packaged food deliveries, has heightened.

The packaging industry in the country is moving towards flexible packaging owing to its multi-fold energy and environmental benefits. Flexible packaging uses the best characteristics of plastic, paper, and aluminium foil, without compromising on the product’s freshness, barrier protection, durability, printability, and ease of use.

Looking into the demand for environmental protection, it has become a concern for all to stop using plastic / foils for packaging. Plastic is not degradable and affecting the environment and health of flora and fauna. Toxic chemicals leach out of plastic and are found in the blood and tissue of nearly all of us. Exposure to them is linked to cancers, birth defects, impaired immunity, endocrine disruption and other ailments.

The biodegradable and recyclable materials used in eco-friendly packaging can take a variety of different forms: Bioplastics, or plantbased plastics. Recycled paper and plastics. Post-consumer products, such as recycled bulk bags.

There are various eco-friendly food packaging options that are better for the planet and health of living beings.

• Paper & Board packaging which are bio-degradable

• Glass containers. Glass has a multitude of uses and benefits for daily life

• Stainless steel

• Bamboo

• Rice husk

• Wood Dust

• Gelatine films

As the variety of foods containing grease is abundant, the types of oilresistant materials used in food packaging has diversified in recent years. Environmental protection and safety issues continue to be important, and as a result, scholars have paid increasing attention to paper packaging materials. Oil and grease resistant paper is one of them, which imparts barrier properties for oil and grease.

The oil and grease resistance of paper after surface sizing with aqueous dispersions composed of film forming polymers, their mixtures with fluorinated polymer or fluorinated polymer and silver nanoparticles were compared. The oil and grease resistance of paper was regulated by changing the composition and intake of aqueous dispersions and paper grade, and it was evaluated by the content of fine surface pores, contact angle, oil absorptiveness, grease resistance, oil repellence on the inclined surface and oil penetration time.

The aqueous dispersions were applied on one side or on both sides of paper surface in the size press. The film forming polymer has created a physical barrier against oil and grease, while combination with the fluorinated polymer developed a physical and chemical barrier.

The papers sized with aqueous dispersions containing a mixture of film forming and fluorinated polymer with the addition of silver nanoparticles, achieved high oil and grease resistance even with lower consumption of the fluorinated polymer, and also achieved an antimicrobial surface. The more porous paper has achieved the required oil and grease resistance at higher polymers intake. Compounds such as PE, EVOH, and palm wax are often compounded with cellulose to reduce the porosity and wettability of paper materials and thereby improve their oil resistance. However, these composite papers lose some of their biodegradability and recyclability. Consequently, coating derived from biomass polymers have great research potential in food packaging applications3

The rapid surge in e-commerce sales has led to an increase in package waste. These brands are incorporating sustainable packaging into their fulfilment processes.

E-commerce sales jumped a whopping 49 percent in April in response to COVID-19, and since then, online retailers have been scrambling to keep up with the increased demand in shipments. In addition to using more boxes or bags, there is also more in-thebox protection used to make sure the package contents make it safely to its destination. If the materials are not properly disposed of, this additional packaging may lead to a rise in consumer waste.

In spite of all this increased consumption, online shoppers still care about the environmental impact of their purchases. In a recent survey, 83 percent of consumers said they considered the environment at the checkout screen, including the excessive waste it might be generating, and the increase in their carbon footprint. In that same study, 78 percent of respondents said that companies could be doing more to mitigate packaging waste.

More and more brands are becoming conscious about their impact on the environment. Eco-friendly products in the fashion, personal care, and other sectors have been popular for years. But now those same values are being extended to their packaging and fulfilment strategies, and mainstream companies are joining them.

With the uncertainty of in-person retail is amplified by COVID-19, deliveries and the unboxing experiences are becoming one of the primary ways for brands to build a relationship with

their consumers. And part of that relationship is about honouring the sanctity of the environment.

In recent years, India has seen sustainable packaging growth due to the increase of packaged food consumption and awareness, and demand for quality products. Consumer awareness surrounding packaged food, specifically packaged food deliveries, has heightened.

Earlier this year, the Food Safety and Standards Authority of India (FSSAI) announced new packaging regulations to replace the former 2011 provisions. The new regulations comprise of a migration limit of 60mg/kg or 10mg/dm2 and migration limits for specific contaminates in plastic packaging materials. Looking into threat to environment and negligible possibilities of recyclability, Recycled plastics and newspaper used for food packaging have also been banned. New labelling regulations were also revised.

In terms of India’s beverage packaging, materials such as glass and rigid plastics account for 70 percent of the total packaging market. PET is the material most used to package water, accounting for around 55 percent of India’s packaged water sector.

Projected to reach a CAGR of 4.17 percent to $142.2 bn by 2023, it is predicted that the nation will see continued demand for PET bottles, along with a new demand for liquid packaging cartons due to their longer shelf life and ease in transportation.

Author: G S Patnaik is General Manager (QA & TS) at J K Paper Ltd.

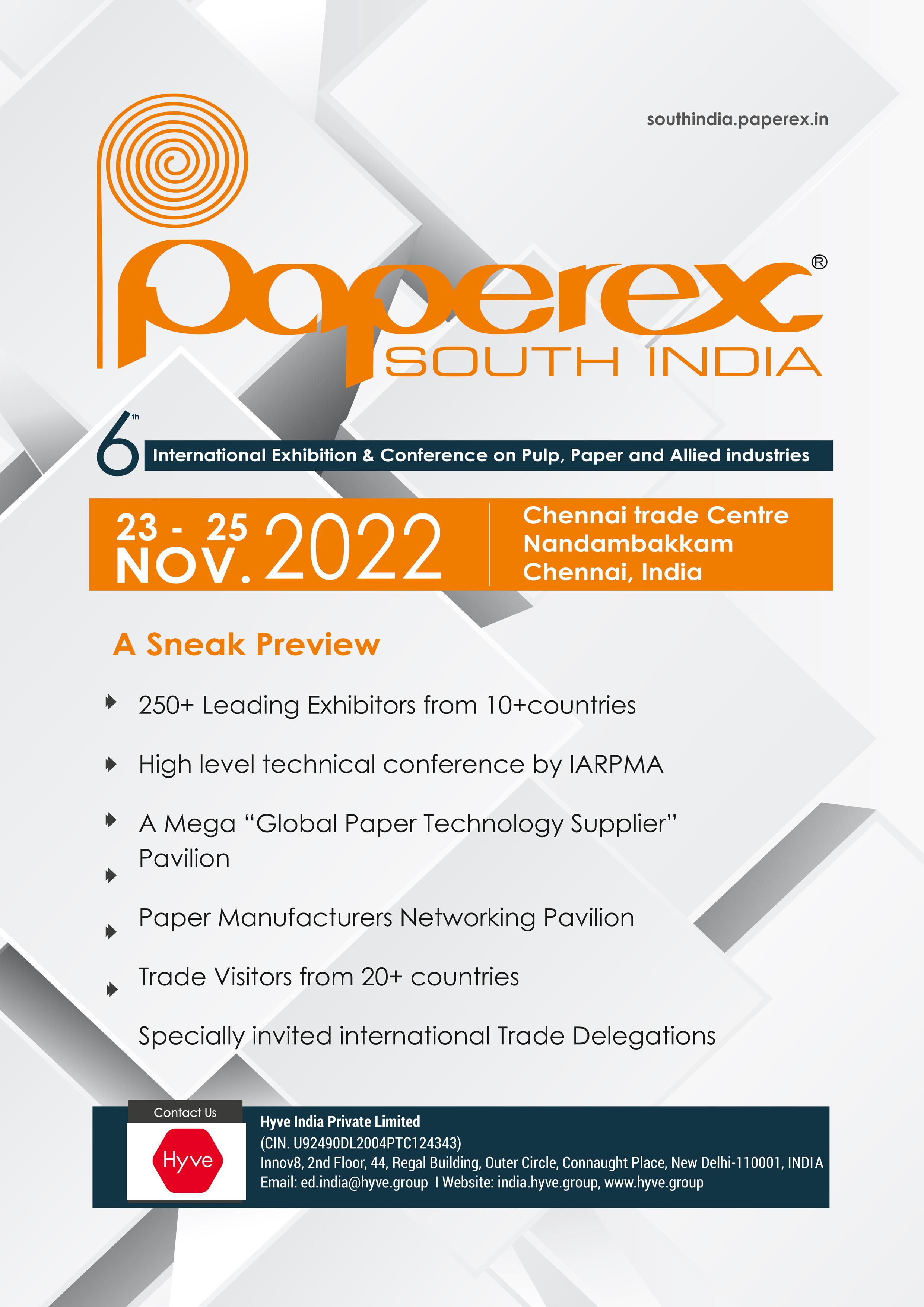

During 1990s and the years that followed, office spaces were getting rapidly computerised internationally. In this backdrop, the demand of Writing & Printing (W&P) papers was expected to be adversely affected. But during this one and half decades, the consumption continued to grow across geographies. Ironically, the demand for copying papers outgrew any other type of paper or paperboards during these years, which should have been the immediate victim of workplace computerisation.

Finally, these predictions came true in 2008 and thereafter. The financial crisis triggered a sustained contraction in demand for W&P grades. While this contraction was most severe in mechanical and

semichemical grades, the woodfree varieties were also significantly affected. However, this contraction was confined to developed economies only while the rest of the world continued to witness demand growth.

As digitization made rapid inroads into our life and work, over last one decade, the demand growth has been decelerating gradually in practically all geographies including India. Perhaps, like sub-prime crisis of 2008, another trigger was needed to push the W&P grades from deceleration to demand contraction; that trigger could well be the pandemic of 2020.

Our generation and the ones preceding it were mostly comfortable with reading from a sheet of paper. But the younger generations are at home reading or interacting with a screen even for long hours. This fundamental change in the way people consume printed content is guiding the fate of writing & printing papers. The pandemic and its repercussions have boosted this trend in multiple ways:

1. Work from home culture is here to stay, at least in part

2. On line education will take away another slice of W&P demand

3. Publishing industry is rapidly driving shift towards digital books. It reduces production and distribution cost as well as the turn-around time

4. eCommerce has killed a big part of commercial printing eg, POP material, leaflets etc

While energy and food prices are at high level, globally most of the manufactured commodity prices have begun to soften and this includes paper. Sometime in 2023, the dust will settle on global supply chain disruption. Prevailing demand supply contradictions in pulp, waste paper and paper will ebb and extent of damage to demand by the pandemic will become clearer.

When such a scenario unfolds, the industry will be forced to make quick and drastic changes to its business to remain relevant or even survive. As always, the survival kit will not be a silver bullet but will have to be a multi-pronged strategy:

1. New products and new markets

2. Calibrated sales & marketing initiatives

1. New Product and new markets: This is existing default reaction of most mills in times of difficult market conditions. Here it is pertinent to note that new products are not created by change of recipe or materials or significant intervention in manufacturing in upstream stage of the process. Downstream interventions like same product offered to new segment or markets thru different SKU or formats in new brands can be equally or more effective.

For manufacturers of printing papers, test-liner, kraft-liner, fluting, absorbent kraft are good examples of upstream intervention. But for upstream strategy to succeed, it is important that chosen products have large and growing markets to accommodate new players. Absorbent kraft may be of limited value from this perspective. On the other hand, relatively bigger and wider deckle machines needed to be competitive in containerboard market. It is important to note that success in new business will require more than the ability to manufacture a product with given specs.

The best case for downstream intervention is segments like flexible packaging and food service packaging. Like in any other segment, product and price are just basic qualifier for success. We will discuss some of these factors in the following parts.

2. Calibrated Sales & Marketing Initiatives: A product backed by a well calibrated sales and marketing initiatives ensures that the product enjoys faster acceptance, gains higher share and remains stable during periods of market downturns. Depending upon customer spread and market dynamics, suitable marketing initiatives, sales strategy and channel mix is required to get optimal results.

Business development is often said to be the “product management” function for B2B domain. This critical tool is waiting to be exploited by W&P industry in multiple segments like flexible packaging, containerboard, e-commerce shipping,

app-based food delivery services etc. Unfortunately, the industry has no experience or talent and will be best advised to acquire resources from other industries like packaging to succeed in business development endeavours.

Food delivery and single use disposables are largely unorganized and fragmented segments. Therefore, focussed development of the sales channel will be an essential element for gaining lead share in the market.

3. Building Supply Chain Competencies: This is perhaps the least acknowledged and the most potent of all tools for gaining competitive edge. This activity requires running several small initiatives to align outbound supply chain of one’s business to that of inbound supply chain priorities of one’s customers.

Some examples:

- Supply lead time is amongst most important requirement not just for paper but across industries and W&P industry is badly out of sync on this. There is an urgent need to bring down lead time to 1-2 weeks for some important segments

- Special sizes; never before opportunity today exists to accommodate larger number of special sizes. Wider machine deckle, better trim optimization software and market side opportunity for special size aggregation can enable the industry to access more markets and generate value

- Customer supply chain compatible product formats eg, flexible mix of reels, ream and skid packaging.

- Paper may be sold in weight but is used in area and length. Ability to supply in specific length and exact number of sheets are relevant in the age of digital printing.

The interests of the industry will be served best if it shifts away from investment led value creation to a knowledge and innovation led value creation model. The options and choices discussed above can be smartly deployed to generate superior value for the business and raise invisible barriers for the competition. Being pro-active and prepared is the best way to ride over the looming crisis.

Attention on ocean-friendly Personal Care is intensifying beyond packaging to the formulations, as consumers increasingly demand biodegradable cosmetic ingredients, and regulatory initiatives to ban microplastics in rinse-off products take shape.

Opacifiers are among the cosmetic additives impacted by these shifts. Used to impart a creamy white appearance and rich visual viscosity that many consumers find luxurious and caring for shampoos, conditioners, and liquid hand/body washes, formulators’ needs for alternatives to the most traditionallyused opacifiers for surfactant-based rinse-offs - styrene/ acrylates copolymer – are accelerating. These conventional water

dispersible solutions are non-biodegradable and considered as microplastics under an EU/EEA legislative proposal, meaning they will be banned in rinse-off formulations if restrictions take effect as expected in 2022.

To widen choice for the industry, Clariant has recently extended its natural ingredients portfolio with a 95 percent renewable carbon index (RCI), readily biodegradable, microplastic-free opacifier to support Personal Care formulators in minimizing the impact of rinse-off hair and body products on marine and river life.

“Because rinse-off formulation ingredients will usually end up in waterways and oceans, providing readily biodegradable solutions to this cosmetics sector is an important focus of our product development,” commented Hermann Bach, head, Strategic Marketing and Innovation, Clariant BU Industrial & Consumer Specialties. “The percentage of biodegradability in a final formulation depends on its proportion of readily biodegradable ingredients, therefore we are pleased to now offer a drop-in natural-derived option to support the sector in addressing this evolving priority without compromising on visual appeal.”

New Plantasens® OP 95 (INCI: Sodium Methyl Cocoyl Taurate (and) Glycol Distearate) offers a range of attributes that create an easy-to-use solution for opacifying a wide range of hair and body care applications and for supporting eco-conscious consumer behavior. In addition to its microplastic-free profile, it is sulfatefree, non-irritant, and non-hazardous to aquatic life. The product is based on coconut oil and palm (kernel) oil and can be purchased as a Roundtable on Sustainable Palm Oil (RSPO) certified grade. The feedstock comes from Malaysia, Indonesia or the Philippines.

The following assessments highlight the new ingredient’s ability to answer formulators’ needs on multiple fronts from performance to sustainability.

Samples in the visual test of Figure 1 show particularly effective opacifying performance from Plantasens OP 95 even at low concentrations. Comparisons to a sulfate-free benchmark are shown at 0.2 percent active and at 0.6 percent active. Unlike the sulfate-free benchmark product, the same level of creamy whiteness is achieved with Clariant’s new ingredient at both concentrations.

over a 12 week period at room temperature. A standard formulation composition already used in the past with pearlizers was selected as the basis for the evaluation (Figure 2). To replicate current opacifier options for formulators, Plantasens OP 95 was compared to respective market benchmark products: two sulfate-free blends (one anionic / one amphoteric); a sulfate-based blend; and a styrene/ acrylate copolymer. The results over time can be seen in the Figure 2 graph.

Stable opacity is an important consideration in order to ensure the high visual expectations of Personal Care consumers are reached. The new Plantasens OP 95 biodegradable opacifier is able to sustain a high whiteness over time for microplastic-free formulations with only minimal loss in opacifying effect, achieving performance comparable to sulfate-based and acrylate-based opacifiers.

Transmission over time was determined by evaluating shower gel formulations containing different opacifiers at 1 wt. percent active,

Soft caring shower cream formulation & transmission over long time at 22ºC (room temperature)

More detailed testing was performed on the same formulations at 12 weeks at various temperatures: 5 degrees Celsius; 22 degrees Celsius; 40 degrees Celsius. In Figure 3, we observe that there is a constant opacifying effect at 5 and 22 degrees for sulfate-free solutions. Sulfate-free solutions lose slightly in their opacifying effect after 12 weeks at 40 degrees, however the difference is not visible to the eye.

The new opacifier has been assessed on a number of key parameters relevant to ease of use for formulators. It supports low formulation complexity by providing a liquid drop-in solution for formulators who want to work with cold processes. Thanks to its strongly shear thinning behavior, it rapidly finds the necessary viscosity level to be efficiently dispersed in the formulation, delivering a homogenous appearance to the final product.

Its ability to maintain viscosity level of the formulation has been demonstrated by addition of the product to various commercial formulations (Ghul, Axe, Garnier). The viscosity level changed only by +/- 10 percent and remained stable over 3 months of storage at room temperature and 40°C.

The drop-in opacifying performance attributes can be seen in practice in the following videos on Clariant.com

To demonstrate the relevance and suitability of the new opacifier for hitting rinse-off product performance and sustainability attributes, the development team evaluated and compared renewable carbon content, readily biodegradable and microplastic-free profiles of the

assessed opacifiers versus key performance parameters. Figure 4 provides an overview.

Addressing trends & sustainability claims

Appearance is a key driver for consumer choices in Personal Care. For rinse-off formulations, Plantasens OP 95 achieves a high level of opaque creamy whiteness to meet consumer perceptions regarding luxury, mildness, and care. At the same time, it is readily biodegradable, microplastic-free, and sulfate-free which makes it a viable alternative for enabling shifts towards more aquatic-friendly hair and body care applications. The new opacifier can aid product manufacturers in addressing trends and extending new sustainability claims to their rinse-off formulations, while formulators can also benefit from its ease of use.

Xenia® Materials has introduced the XECARB® ST, a new family of supertough carbon fiber composites custom-engineered to close a performance gap in the market and provide superior impact strength performance.

“There is a growing demand for lightweight composites in various new markets, such as sustainable mobility and unmanned aerial vehicles (UAVs), where we have identified a need for higher impact resistance than previously offered by carbon fiber reinforced composites,” said Cristian Zanchetta, technical manager for R&D at Xenia® Materials.

“Our new XECARB® ST family meets these challenges while at the same time opening new opportunities for innovative applications in existing market segments, such as sports equipment, appliances, supercars and even additive manufacturing.”

XECARB® ST builds on the proven mechanical strengths of Xenia®’s successful XECARB® range, but shows significantly higher notched impact resistance, low temperature ductility and tensile elongation at break. With slightly lower density, the new carbon fiber composite technology offers these unmatched advantages together with further lightweighting possibilities.

Major customers seeking to improve the impact and cold impact performance of carbon fiber composite applications are already

evaluating the added potential for weight reductions, lower material and energy consumption, associated cost savings and reduced environmental impact.

XECARB® ST thermoplastic composites are based on selected polyamide matrix materials – PA66, PA6, PA11, PA12, PA6.10, PA6.12 and PA4.10 – addressing different mechanical, thermal and physical requirements. Standard carbon fiber content is 30 percent (CF30).

The PA6-based composites are also available as CF20, CF25, CF35 and CF40 grades. In addition, the portfolio includes two highmodulus materials for enhanced flexural strength, and provides a wide engineering window for further customization depending on specific application needs.

“Beyond winter and mountain sports equipment from boots and running shoes to bikes, these new high-impact carbon fiber composites will help us reach into other markets and further expand our customer base in Europe, APAC and North America,” said Enrico Mancinetti, sales manager. “Driving this growth, Xenia® Materials will also increase its European sales force with a strong focus on qualified local customer support and service.”

The mobility and automotive industries are in a time of rapid transformation. The industry is pushing not only for a more sustainable future for vehicles, but also for one that is safer, more connected and, of course, still profitable. With well over half a billion dollars of announced global investment into production of electric vehicles (EV) and EV batteries, OEMs and their Tier networks are moving at an accelerated pace to design, validate, and produce low and zero emission vehicles, while simultaneously transforming vehicles into some of the most electronically advanced devices in our daily lives.

The first half of 2022 saw light vehicle production and sales in key markets around the world, including China, Europe and the US, roughly flat compared to the same time frame last year, due to continued supply chain challenges, ongoing pandemic impacts, chronic labor shortages, and the conflict in Ukraine. The transition to electric vehicles, however, continues to accelerate with penetration in China up over 10 percent compared to last year, with EV sales representing almost a quarter of new vehicles purchased in 2022.

This fundamental change in powertrain technology continues to present substantial opportunities for materials science companies, like Dow, as we rapidly innovate to meet the needs of battery assembly and safety, new noise and vibration profiles, vehicle autonomy, and occupant experience.

In terms of things to come, we’re hyper-focused on enabling and partnering with our customers to succeed in delivering low-carbon mobility. This means developing new materials that will help our customers meet, and often exceed, new performance requirements and increasingly stringent sustainability regulations from world governments and expectations from their citizens. It requires enabling new levels of circularity to reduce waste and catalyze innovation.

It means engineering materials that increase the efficiency and consistency of vehicle production, while delivering the more comfortable, more satisfying, and safer cars that consumers desire. This is what gets our MobilityScience™ team excited and what is pushing us to accelerate continuing materials science innovation for OEMs and Tiers.

We see several megatrends that are impacting the mobility industry: electrification, enhanced safety like battery fire protection, connectivity and autonomy, and circularity and sustainability. Dow MobilityScience™ was created to provide OEMs and tiers with simplified and straightforward access to Dow’s full breadth of solutions and capabilities and address these megatrends.

Sustainability is one of the top priorities for our customers. Innovations in materials science present a huge opportunity for them to enable new levels of recyclability and circularity across the entire vehicle lifecycle. Collaborating with customers early in the design phase enables our MobilityScience™ team to recommend and create tailored, validated solutions that unlock efficiencies from design to end-of-life, using the least materials possible while delivering the highest performance.

The other megatrend I’d note is connectivity. The boundaries between industries are blurring, with vehicles becoming a computer on wheels. We see some of the most famous consumer electronics and software brands partnering with, or (potentially) becoming Mobility OEMs. The transistor count per vehicle continues to increase, and combined with governmental investment in the chip industry, opportunities exist across the value chain in many geographies for Dow materials in this segment.

Potential for mobility, auto industry materials manufacturers in Asia Pacific and India.

China in particular is leading the way in electric vehicles (EV) through their generous investments. For example, CATL, despite its small beginnings, has now grown into the world’s largest EV battery producer, having formed partnerships with several global OEMs and is investing across the globe. Rising incomes across APAC, combined with governmental incentives and mandates to go electric, drive expectations of tremendous growth in the region over the coming decade.

In India, we see materials developed for EV batteries and passenger vehicles being applied to two- and three-wheelers. These smaller vehicles have distinct materials needs but also benefit from innovations in lithium-ion battery technologies developed for larger vehicles. This segment represents additional growth opportunities for Dow as their vehicle electrification rate accelerates.

Scope for materials innovation in the e-mobility segment.

We believe there are opportunities for sustainable innovation at every phase of the vehicle life cycle, whether we’re talking about electric, autonomous, or ICE vehicles. Our MobilityScience™ team is focused on engineering solutions for sustainable disassembly, exploring new adhesive/sealant/coating technologies to create parts that can be reused, repaired or recycled, and we’re committed to generating value from waste. Dow is also investing in lower-carbon material offerings.