Primed for Ignition

Meet the minds behind the machine that helped pave the way for 2022’s fusion ignition breakthrough.

PAGE 8

Meet the minds behind the machine that helped pave the way for 2022’s fusion ignition breakthrough.

PAGE 8

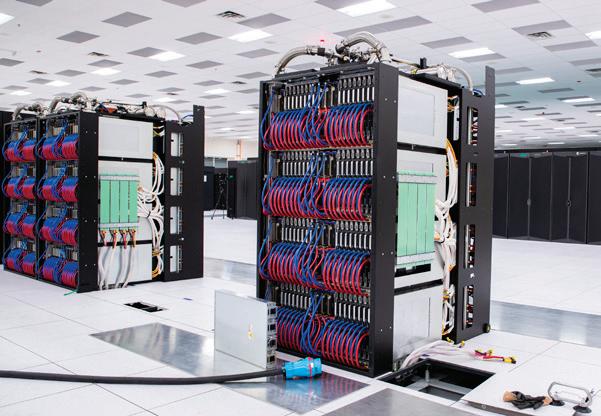

Coming online in 2024, El Capitan is the National Nuclear Security Administration’s (NNSA) premiere exascale-class supercomputer. It is projected to be one of the most powerful and energy-efficient high performance computers in the world, capable of more than two exaflops—or two quintillion double-precision floating-point operations per second.

El Capitan is the flagship supercomputer for NNSA’s Advanced Simulation and Computing (ASC) program, and it will be used by the NNSA Tri-Labs (Livermore, Sandia, and Los Alamos national laboratories) to ensure the safety, security, and reliability of the nation’s enduring and future nuclear stockpile in the absence of underground nuclear testing.

Winners and Finalist

UMap A fast, extensible memorymapping library for diverse datastores

EXUDE Elite concentrates light from multiple lasers with different wavelengths into a single, high-power beam

UnifyFS saves storage time for scientific applications on supercomputers

1952 — 2022

Pele simulates effects of fuel properties on turbine performance Developed

VP, Editorial Director

Paul J. Heney pheney@wtwhmedia.com @wtwh_paulheney

Editor-in-Chief Brian Buntz bbuntz@wtwhmedia.com

Associate Editor Heather Hall hhall@wtwhmedia.com

Senior Editor Rachael Pasini rpasini@wtwhmedia.com

Executive Editor Lisa Eitel leitel@wtwhmedia.com @dw_lisaeitel

Senior Editor Aimee Kalnoskas akalnoskas@wtwhmedia.com @EEWorld_Aimee

Senior Editor Miles Budimir mbudimir@wtwhmedia.com @dw_motion

Associate Editor Mike Santora msantora@wtwhmedia.com @dw_mikesantora

DIGITAL MARKETING

VP, Operations Virginia Goulding vgoulding@wtwhmedia.com @wtwh_virginia

Digital Marketing Coordinator Emily Gillespie egillespie@wtwhmedia.com @wtwh_emily

CREATIVE SERVICES & PRINT PRODUCTION

VP, Creative Services Matthew Claney mclaney@wtwhmedia.com @wtwh_designer

Art Director Eric Summers esummers@wtwhmedia.com

Director, Audience Development Bruce Sprague bsprague@wtwhmedia.com

PRODUCTION SERVICES

Customer Service Manager Stephanie Hulett shulett@wtwhmedia.com

Customer Service Representative Tracy Powers tpowers@wtwhmedia.com

Customer Service Representative JoAnn Martin jmartin@wtwhmedia.com

Customer Service Representative Renee Massey-Linston renee@wtwhmedia.com

Customer Service Representative Trinidy Longgood tlonggood@wtwhmedia.com

SALES

Ryan Ashdown rashdown@wtwhmedia.com 216.316.6691

Jami Brownlee jbrownlee@wtwhmedia.com 224.760.1055

Mary Ann Cooke mcooke@wtwhmedia.com 781.710.4659

Jim Dempsey jdempsey@wtwhmedia.com 216.387.1916

Mike Francesconi mfrancesconi@wtwhmedia.com 630.488.9029

Jim Powers jpowers@wtwhmedia.com 312.925.7793

LEADERSHIP

CEO & Co-Founder Scott McCafferty smccafferty@wtwhmedia.com

Publisher Courtney Nagle cseel@wtwhmedia.com

Since 1963, the R&D 100 Awards have celebrated the world’s most groundbreaking technologies, often recognizing those born from a convergence of disciplines. The 2024 awards continue this legacy, featuring innovations from 16 countries and regions, spanning fields from materials science to AI.

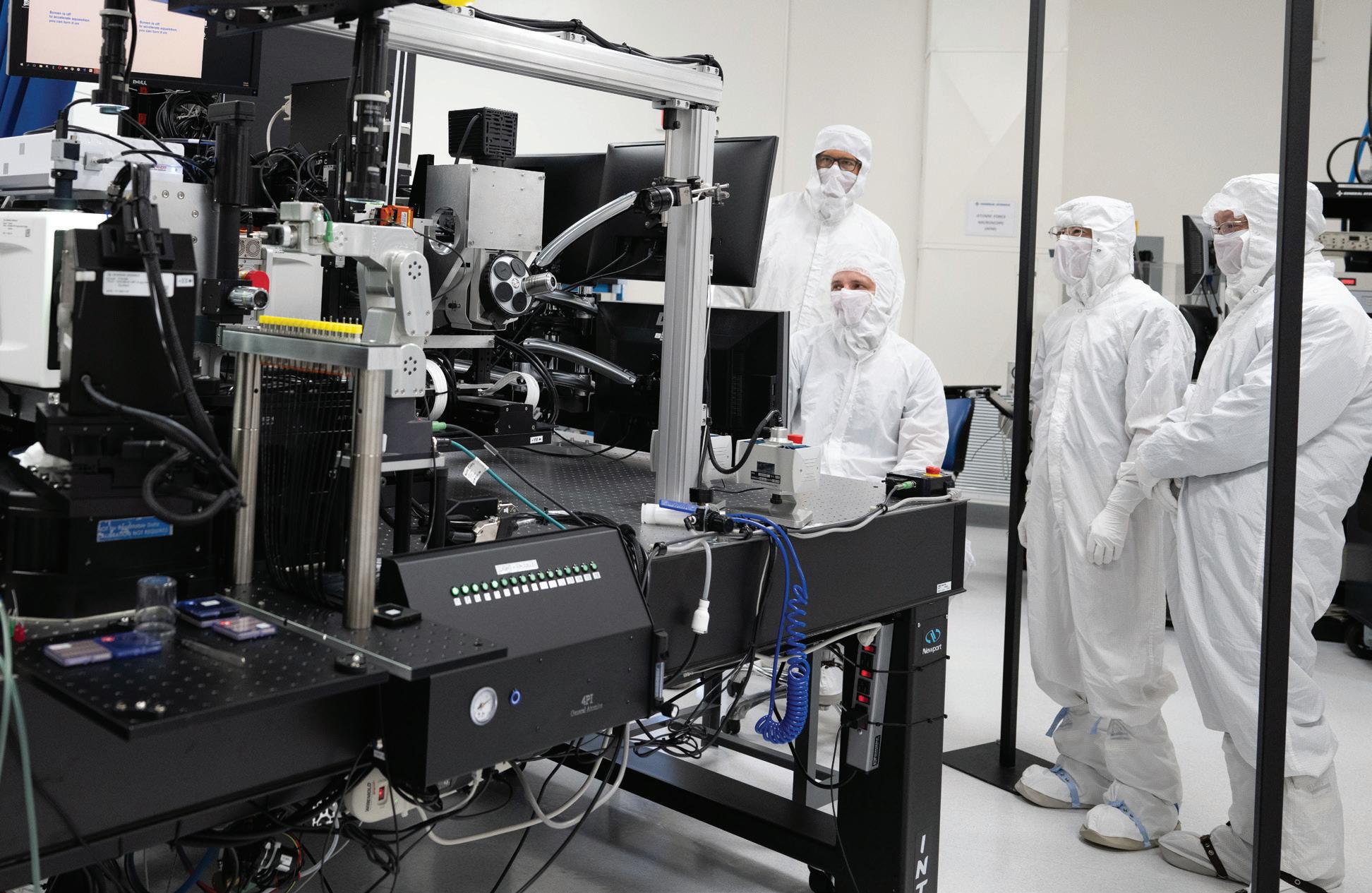

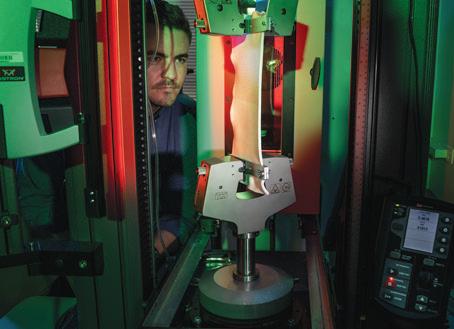

For instance, there is General Atomics’ Metrology Research and Development Team, this year’s “Team of the Year,” exemplifies how the unification of scientific expertise can drive breakthroughs. Its 4Pi Integrated Metrology System, a product of combined expertise in robotics, automation, and AI, has played a role in enabling the first controlled fusion ignitions in history.

On page 9, explore the 4Pi system, a marvel of engineering that combines robotics, automation, and machine learning to examine tiny fuel capsules with sub-micron precision. You’ll meet Haibo Huang, Ph.D., the project lead and a driving force in measurement science, who shares insights on the team’s journey, the challenges they overcame, and the potential of fusion energy.

This year’s winning innovations highlight several key themes. Among them is sustainability. Sandia National Laboratories’ LDAC3 technology exemplifies this trend. LDAC3 uses specialized clays to capture carbon dioxide directly from the atmosphere at a lower cost, making this vital climate change mitigation strategy more accessible. Ames National Laboratory’s BRAWS Technology showcases a synthesis of technologies for a more sustainable future. BRAWS links battery recycling with hydrogen production, recovering valuable materials and generating clean fuel. This innovative approach exemplifies how tackling multiple challenges simultaneously—in this case, electronic waste and clean energy—can lead to powerful win-win scenarios.

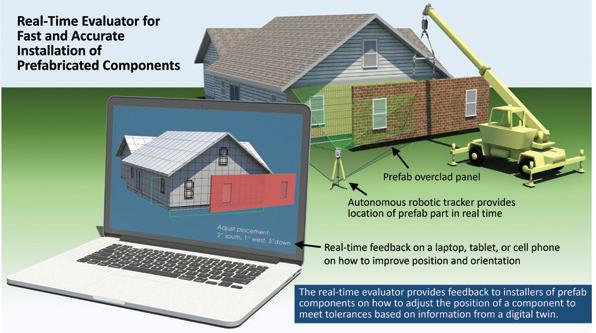

Automation and AI are rapidly becoming intertwined with a range of industrial processes, driving a new era of intelligent systems. As AI technologies mature, innovators are integrating them to boost efficiency, improve safety, and address critical workforce challenges.

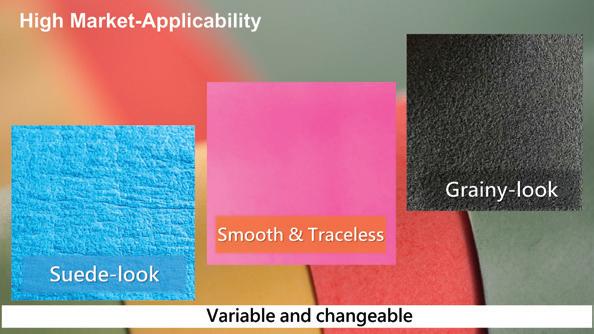

For example, the Taiwan Textile Research Institute (TTRI), in collaboration with AI Machinevision Corp., developed an AIpowered fabric inspection system that revamps quality control. This system uses machine learning to detect defects in real time, boosting inspection speed, accuracy, and overall product quality while minimizing human error.

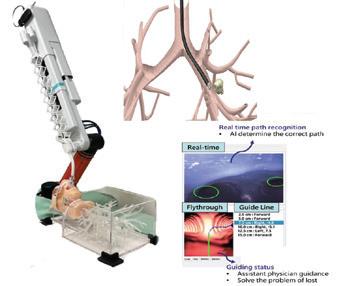

Then there’s ITRI’s AI-driven miniature serpentine robot, which is driving advances in minimally invasive surgery. This tiny robot navigates autonomously within the human body, allowing surgeons to perform complex procedures with greater precision and reduced patient trauma. This innovation demonstrates AI’s potential to significantly bolster healthcare outcomes.

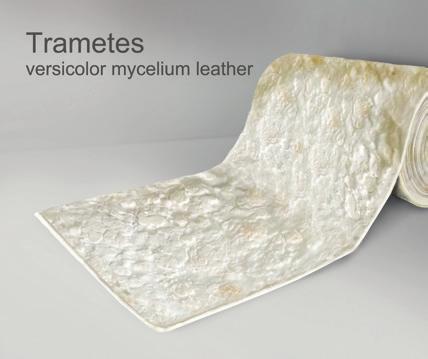

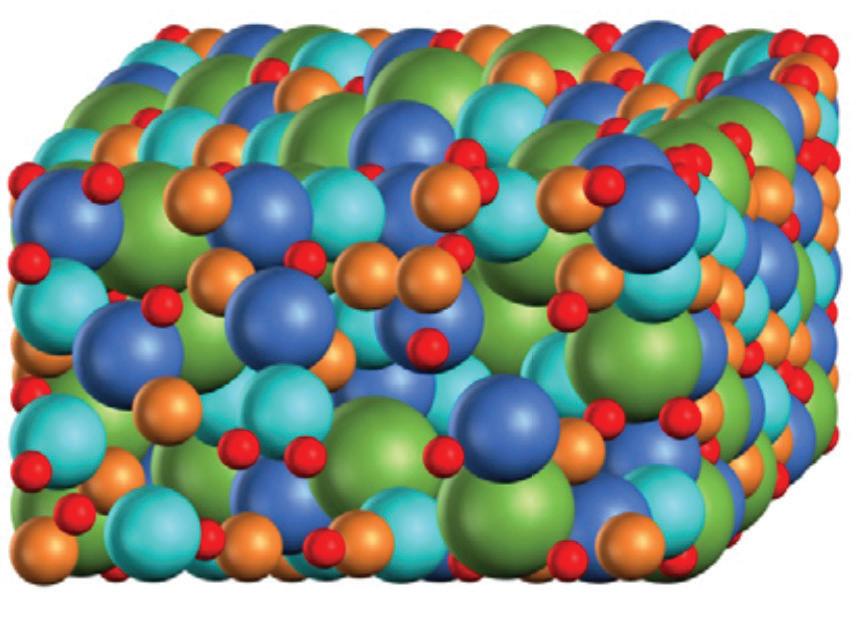

Material science often lies at the heart of convergent innovation, providing the building blocks for new technologies. A prime example is the Nanocrystalline Axial Flux Electric Motor developed by CorePower Magnetics and Carnegie Mellon University. This motor leverages nanocrystalline soft magnetic materials to achieve greater efficiency and power density compared to conventional motors. The innovative design reduces energy loss and allows for a smaller size, potentially impacting the development of electric vehicles and renewable energy systems.

Sandia National Laboratories has developed Self-Healing Refractory High-Entropy Alloys (RHEAs), which represent a significant development in material durability. These alloys can withstand extreme temperatures and radiation, making them wellsuited for applications in aerospace, nuclear reactors, and other demanding settings. The self-healing properties of RHEAs offer the potential to extend component lifespans, enhance safety, and improve cost-effectiveness.

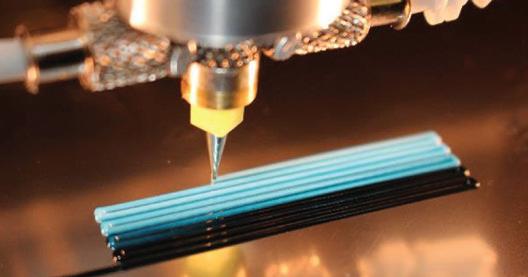

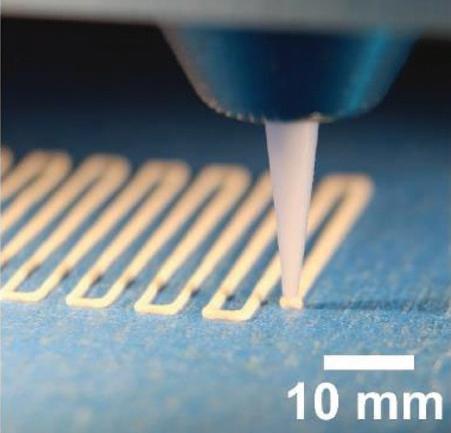

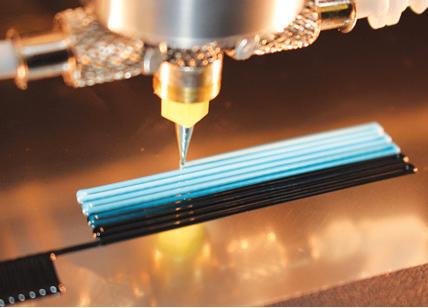

MIT Lincoln Laboratory and Harvard University are helping guide the future of 3D printing with their Nanocomposite Inks. These inks allow for the creation of advanced devices with graded dielectric properties, opening up novel possibilities in electronics manufacturing, from customized antennas to electromagnetic shielding.

Portable and modular technologies are driving a powerful shift toward decentralization, enhancing both resilience and accessibility. Los Alamos National Laboratory’s MENDS system embodies this shift. This flexible, modular system decontaminates surfaces on-site, eliminating the need for large-scale infrastructure. Its portability allows rapid deployment in various settings, improving safety and reducing environmental impact.

Oak Ridge National Laboratory’s MBE-DAC system takes a similar approach, integrating carbon capture directly into building systems. This localized approach allows individual buildings to participate in emission reduction, promoting a more distributed and effective fight against climate change.

Another example of convergence comes courtesy of the University of Pittsburgh. Partnering with the National Energy Technology Laboratory and Sensible Photonics, they developed UltraSonic Photonics, a system that merges ultrasonic and photonic technologies for structural health monitoring. This integration enables real-time, autonomous flaw detection in critical infrastructure, enhancing safety and preventing catastrophic failures in pipelines, bridges, and more.

Similarly, NenoVision s.r.o.’s LiteScope 2.5 seamlessly integrates Atomic Force Microscopy (AFM) with Scanning Electron Microscopy (SEM). This powerful combination grants researchers unparalleled insights into materials, enabling simultaneous observation of surface topography and composition at the nanoscale. This multidisciplinary tool is accelerating research and development in fields like nanotechnology and biotechnology.

These examples are but a handful among many. The 2024 awards feature a wealth of innovations that demonstrate the power of interdisciplinary collaboration and knowledge sharing. Let us break down silos, forge new partnerships, and create ecosystems where ideas can flow freely and empower humanity to solve its greatest challenges.

BRIAN BUNTZ Editor, R&D World

BY BRIAN BUNTZ

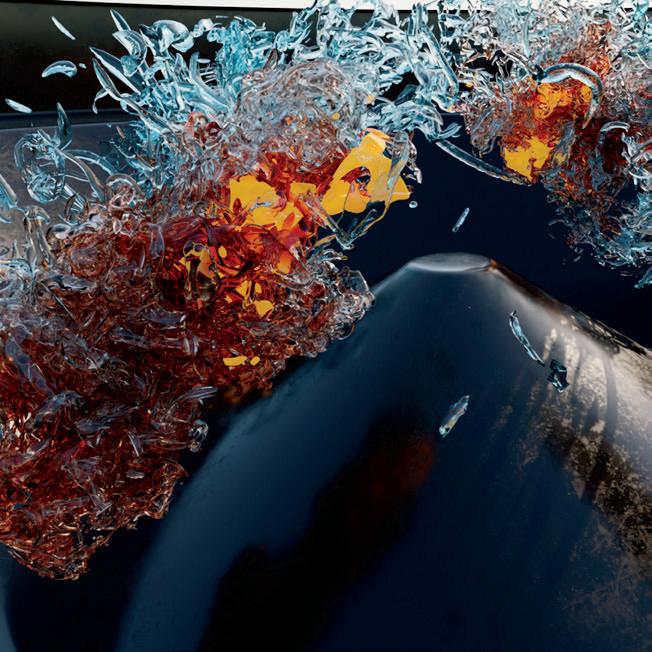

It’s no wonder that a team of scientists at General Atomics won the “Team of the Year” R&D 100 Professional Award for their development of the 4Pi System. This metrology tool played a pivotal role in the historic achievement of fusion ignition at the National Ignition Facility (NIF) in December 2022. Scientists demonstrated for the first time that a controlled fusion reaction could produce more energy than it consumed — a feat long considered the “holy grail” of clean energy research, pursued since the 1940s following Nobel laureate Hans Bethe‘s research.

The 4Pi System’s ability to analyze the tiny fuel capsules used in Inertial Confinement Fusion (ICF) experiments helped pave the way for this breakthrough. Haibo Huang, Ph.D., director of the Center of Excellence for Advanced Diagnostics and Sensors at General Atomics, highlighted two specific challenges the system addressed:

First, 4Pi helped solve the wall thickness variation problem. The 4Pi System can accurately measure and map the wall thickness of fusion target capsules made of nanocrystalline diamond (HDC), which appear opaque to visible light. While X-rays can see through, it can’t measure to the nanometer sensitivity required. Huang’s team turned to mid-infrared wavelengths to accurately measure and map the wall thickness. Huang explained: “If it’s lopsided, then after the X-ray energy impinges on the surface, it’s going to drift in one direction, and that drift deprives the energy that could otherwise be used to compress the capsule to a higher temperature and pressure,” he noted. “So this is one key reason why ignition was not achieved for almost a decade.”

Second, it can detect and map surface defects. The 4Pi System can identify and quantify tiny surface defects, such as pits, on the capsule surface. These defects, even at microscopic scales, can cause instability growth during the implosion process. Huang described the problem: “Nuclear fusion is an unstable problem… There’s something called Rayleigh-Taylor instability growth, and because of that, any small imperfection in the ablator material itself will cause exponential instability growth during the implosion, injecting a spike of ablator material into the DT ice layer inside. The mixed-in material becomes so hot, it behaves like “meteors” radiating away the much needed energy, thereby quenching the ignition.”

Huang describes the impact of the instrument as “transformative.” “It can be applied back and forth. You can select the best capsule,” he said. “You can feed the information back to the shell production team so that they can improve their fabrication process. You can give the results to the PIs (principal investigators) of the experiment so they can simulate performance and predict the yield and enable them to improve their code.”

“Our team brings together a diverse range of expertise, allowing us to tackle complex challenges and innovate in ways that wouldn’t be possible individually.”

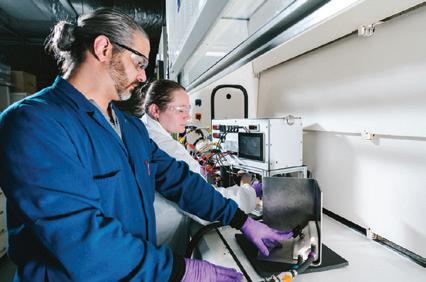

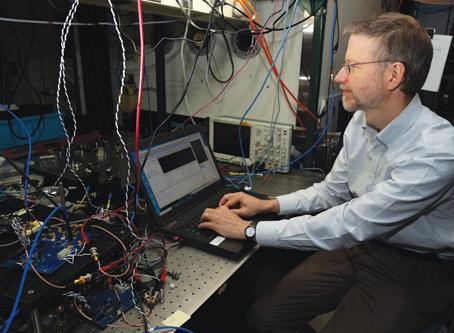

Central to the 4Pi System’s success is the team’s multidisciplinary expertise. Kurt Boehm, Ph.D., serves as the engineering project manager. He has a background in mechanical engineering and system design and translating complex physics requirements into practical specifications.

Kevin Sequoia, Ph.D., contributes as a data scientist, developing algorithms for processing the vast data sets generated by the system. His work was instrumental in identifying the best target capsules for experiments.

Pavel Lapa, Ph.D., and Masashi Yamaguchi, Ph.D., both Instrumentation physicists, combined their experience to refine instrument control systems and ensure seamless data acquisition.

“Our team brings together a diverse range of expertise, allowing us to tackle complex challenges and innovate in ways that wouldn’t be possible individually,” Huang said.

The team not only collaborated internally, it also worked with external teams extensively, sometimes at customer sites.

“Our mission and vision is to be at the nexus of comprehensive solutions for anything measurement-wise that people need,” Huang explained. “I would just say our desire is to be a one-stop shop for metrology solutions, supporting our customers to accomplish their missions.”

General Atomics operates the Department of Energy, Office of Science, DIII-D National Fusion Facility, which is unique for a private company. Huang emphasized that General Atomics is a “true scientific partner of the national labs,” investing millions annually in metrology research and target fabrication.

The partnership between General Atomics and national labs goes beyond building instruments. They also

collaborate on fundamental research. For example, Huang mentioned collaboration with National Institute of Standards and Technology (NIST) to refine X-ray fundamental parameters in support of the national program investigating how a material’s opacity changes under extreme conditions—research that has implications for both fusion energy and astrophysics.

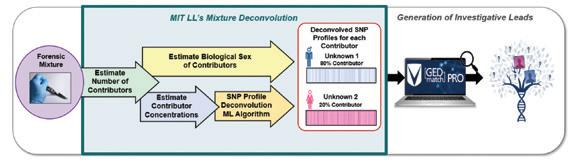

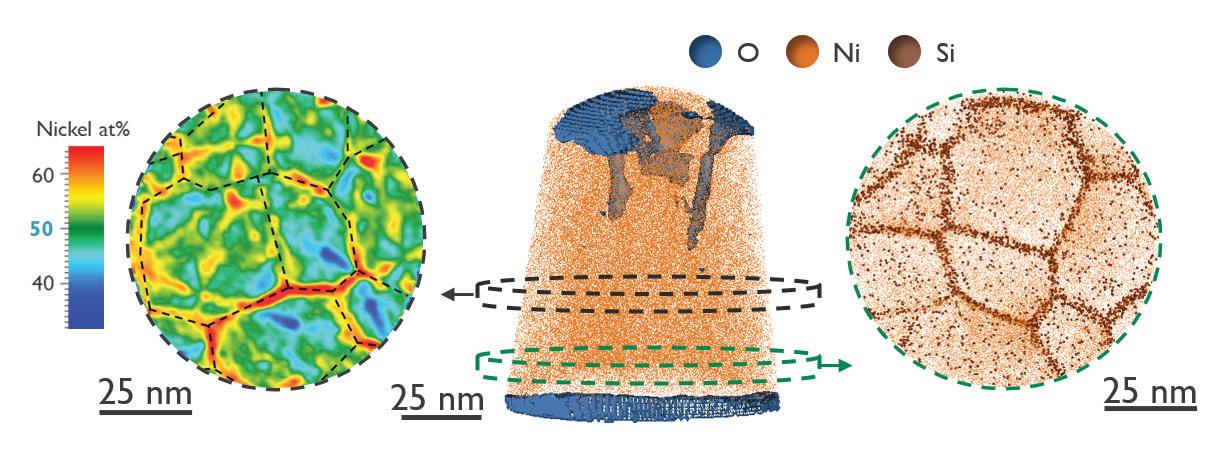

The quest to achieve fusion ignition presented a significant challenge: the need for precise and comprehensive measurement of the inertial confinement fusion (ICF) capsules used in experiments at the National Ignition Facility (NIF). Traditional metrology methods were insufficient, as they typically involved sampling or measuring only parts of the capsule’s surface. Dr. Haibo Huang recognized this limitation early on. “Going forward, we would need to have a full-body analysis of the entire ablator capsule, not just sampling. In addition, different instruments will be used to map different properties of the capsule, and present the data on a common coordinate system to gain deeper insight.”

This realization led to the conceptualization of the 4Pi Integrated Metrology System. The name “4Pi” references the total solid angle in a sphere—symbolizing the system’s ability to analyze the entire surface area of the spherical capsules. “We want to measure the whole surface instead of doing a trace, want to quantify all imperfections inside a capsule. This led to the development of the 4Pi System,” says Huang.

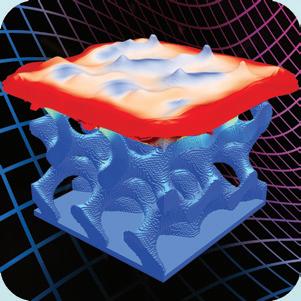

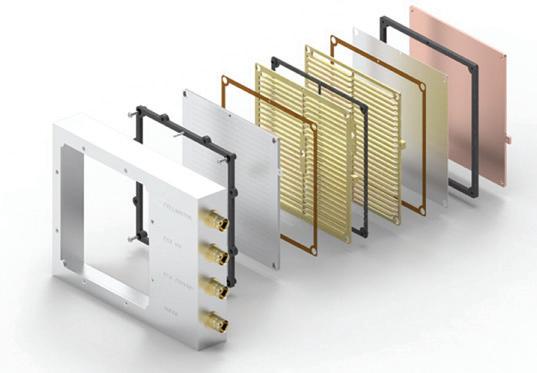

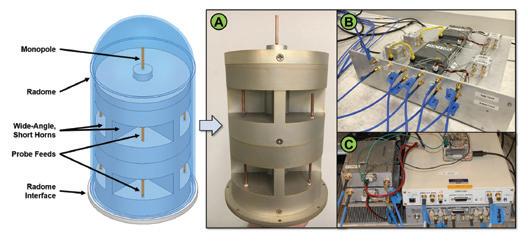

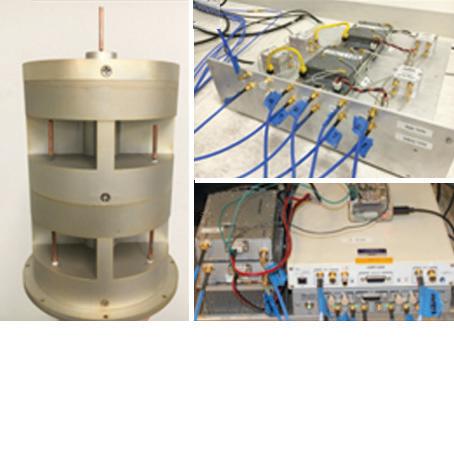

The 4Pi Integrated Metrology System represents a significant advance in the field of inertial confinement fusion (ICF) research. This sophisticated platform provides full 4Pi surface coverage of ICF capsules, enabling comprehensive

analysis not possible with traditional methods. By combining data from multiple instruments, including holography, FTIR, X-ray tomography, AFM, and microscopy, within a common (theta, phi) coordinate system, the 4Pi System allows for data fusion from various metrology tools.

Notable metrology tools integrated into the 4Pi System include the Lyncee Tec Digital Holographic Microscope for rapid full-surface defect detection in high-density carbon (HDC) capsules, a compact Fourier transform infrared spectroscopy (FTIR) for measuring wall thickness and variations in capsules, a near infrared microscope specialized in measuring thin wall thickness, a second generation digital microscope with 3-laser wavelengths for improved step height measurement and integrated AFM for detailed local defect mapping, a darkfield microscopy for inspecting interior defects on transparent capsules, and a Lasik tool for removing protruding defects or writing engineered structures onto otherwise perfect capsules.

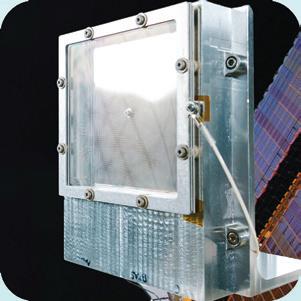

The 4Pi system is a 12-axis platform that provides full surface coverage of ICF capsules. Each capsule is approximately 2mm in diameter—about the size of a BB— and is fabricated at sub-micron tolerances. The system achieves high precision, with 2μm positional repeatability and less than 1μm wobble control.

The most recent development is the addition of a robotic batch loader which enabled 24/7 production operation, and more than quadrupled the 4Pi metrology throughput. This allows every capsule in a production batch to be fully measured by multiple instruments and select out the very best capsule for high yield experiments. Since the robotic automation, ignition has been achieved at least four more times, at much increased tempo.

One key challenge was integrating various advanced instruments into a cohesive system capable of analyzing ICF

capsules at sub-micron tolerances. “We designed the entire post-processing software on our own because we wanted to suppress the artifacts we don’t want and maximize the signals that we care about,” Huang noted.

Looking ahead, Huang and his team are exploring new frontiers in capsule analysis. “In the future, what if we have a capsule that’s so opaque that we cannot see through it with X-ray or infrared? Can we now start to ‘hear’ it? Similar to how LIGO brings “hearing” to astronomy as opposed to “seeing” using telescopes,” Huang mused. “We are investigating ultrasound spectroscopy to “hear” the thickness of targets too opaque for photons to go through. On another front, we will apply the FTIR microscope to ‘map oxygen variations’ in Glow Discharge Polymer (GDP) capsules. According to national lab simulations, GDP has potential to outperform HDC enabling the NIF yield to increases by another ten times to 30MJ.”

The team is also investigating ways to compensate for imperfections in capsule geometry. As Huang explained, “We have been talking about the possibility… let’s say if the wall thickness is lopsided, can we align it in such a way that we can use laser to offset that lopsidedness?” This approach could potentially “achieve a spherical implosion with specific laser power distribution, as long as we know how the shell is oriented,” he said.

“Our mission is to make science fiction come true and become science. So we always think ahead and try to solve problems ahead of time,” Huang concluded.

ANALYTICAL/TEST CATEGORY

Simurgh: AI-Powered Framework for Fast and Accurate Computed Tomography of Dense and Complex Components, Oak Ridge National Laboratory, ZEISS Industrial Metrology LLC

A High-Temperature, Radiation-Endurance Ultrasonic Transducer for Nuclear Harsh Environment Applications, X-wave Innovations Inc.

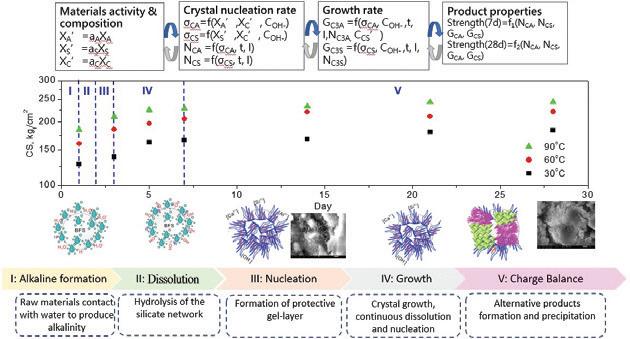

REBEL Concrete Strength Sensing System, WaveLogix Inc., Purdue University

Lil’ CO2: Real-Time Insights into Stem Growth and Respiration of Trees, Lawrence Berkeley National Laboratory

Key Functional Cell Identity (KFCI), Industrial Technology Research Institute (ITRI)

IT/ELECTRICAL CATEGORY

Flexible Circuit Board Superior in High-Speed and Low-Loss Data Transmission, Nano and Advanced Materials Institute, Chung Yin New Materials (H.K.) Company Limited

HARMONIE-SPS, Sandia National Laboratories

MECHANICAL/MATERIALS CATEGORY

Printable Blue and Green Light Emitters with Near-Unity Photoluminescence for Next-Generation Displays, Lawrence Berkeley National Laboratory, University of California, Berkeley

Sustainable Acrylic Polymer Emulsion for Super Dirt Repelling Waterborne Exterior Coatings, The Dow Chemical Company

NASA Langley’s Adjustable Compact Vibration Damper, NASA Langley Research Center

Reducing Risk of Fire and Advancing Safety for Urbanization through Innovative Materials, SABIC Microfabricated Optical Microbaffle for Stray Light Rejection, MIT Lincoln Laboratory

MELLT: Mechanochemical Extraction of Lithium from α-Spodumene at Low Temperatures, Critical Materials Innovation Hub/Ames National Laboratory

AIR2CO2 DAC Process, National Energy Technology Laboratory (NETL), GE Research

Heat Exchanger for Low-Conductivity Phase Change Materials, Oak Ridge National Laboratory (ORNL)

Relocatable/Resiliency Alternative Power Improvement for Distribution – Microgrid-in-a-Box (RAPID-MIB), Idaho National Laboratory, Aberham Solar

Tough and Recyclable Carbon Fiber Composites, Oak Ridge National Laboratory

NEOLAST Elastoester Polymers Enabling the Production of Sustainable NEOLAST Elastic Yarn –NEOLAST is the Future of Stretch, Celanese, Under Armour

Self-extinguishing EV Battery with In-situ Quasisolid Electrolyte, Nano and Advanced Materials Institute, Contemporary Amperex Technology Co., Limited

VC Lid Cooling technology for Kilowatt-Level Chips, VLiCo, I-CHIUN PRECISION INDUSTRY CO. LTD., Industrial Technology Research Institute (ITRI), National Tsing Hua University

LCCF-Blade: Fully Recyclable, Lightweight Wind Blade from Low-Cost Carbon Fiber and its Lightning Protection Methodologies, Oak Ridge National Laboratory

Highly Efficient Multi-Functional Nanoporous Composite Adsorbent, Industrial Technology Research Institute (ITRI)

Low Attenuation Polypropylene for Beyond-FifthGeneration (B5G) wireless communications (LAPB5G), Industrial Technology Research Institute (ITRI), Formosa Plastic Group Corporation

Interlocking Metasurfaces, Sandia National Laboratories, Texas A&M University

OTHER CATEGORY

E Ink Spectra 6, E Ink

PROCESS/PROTOTYPING CATEGORY

Short-Chained Digital Ink: shorten supply chain process with better ink effects, Taiwan Textile Research Institute (TTRI)

Lactide Technology for Polylactic acid (PLA) production - the sustainable plastic of the future, SULZER

A Revolutionary Energy-Efficient, Cost-Effective, and Environmentally Sustainable Process for Lithium-Ion Battery Recycling, Oak Ridge National Laboratory, Momentum Technologies Inc.

3S Yoga : Stretch, Smart, Safety, Taiwan Textile Research Institute

Isostatic Pressing Approaches for Conventional Liion and Solid-State Battery Technology, Oak Ridge National Laboratory, Quintus Technologies

Micro Complex Internal Pipe Coating System Technology, Metal Industries Research & Development Centre (MIRDC)

SOFTWARE/SERVICES CATEGORY

Hardware Assisted Kernel Compartmentalization (HAKC), MIT Lincoln Laboratory

Behavior, Energy, Autonomy, Mobility

Comprehensive Regional Evaluator (BEAM CORE) for Flexible Modeling of Transportation Scenarios, Lawrence Berkeley National Laboratory, National Renewable Energy Laboratory (NREL) UrbanSim Inc., SimRise LLC, University of California, Berkeley, University of California, Santa Cruz, Technical University Dortmund, Graphhopper GmbH

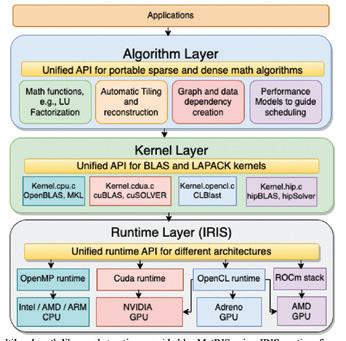

OpenMxP: Open-Source Mixed-Precision Computing, Oak Ridge National Laboratory

DeepHyper: Efficient Multiobjective Optimization of Learning Workflows on high performance computing systems, Oak Ridge National Laboratory, Argonne National Laboratory, Lawrence Berkeley National Laboratory, Pennsylvania State University, and Université Paris-Saclay

IRAD: Ion–Matter Interaction Calculations, Oak Ridge National Laboratory, University of Tennessee, Knoxville

National Economic Resilience Data Explorer (NERDE), Argonne National Laboratory

Cooking with Quantum Fire: Quantum-in-theLoop, National Renewable Energy Laboratory, Atom Computing Inc.

Pele Suite of Reacting Flow Simulation Codes, National Renewable Energy Laboratory, Sandia National Laboratories (SNL), Lawrence Berkeley National Laboratory (LBNL), and Oak Ridge National Laboratory (ORNL), with additional inputs from staff at Argonne National Laboratory (ANL) and Lawrence Livermore National Laboratory (LLNL)

Autonomous Air-ground Cooperative Tunnel Inspector, Hong Kong Productivity Council, Civil Engineering and Development Department (CEDD), HKSAR, and Hyder-Meinhardt Joint Venture (HMJV)

SolarAPP+: The Automated Solar Plan Review and Permitting Solution Powering Through Administrative Gridlock, National Renewable Energy Laboratory

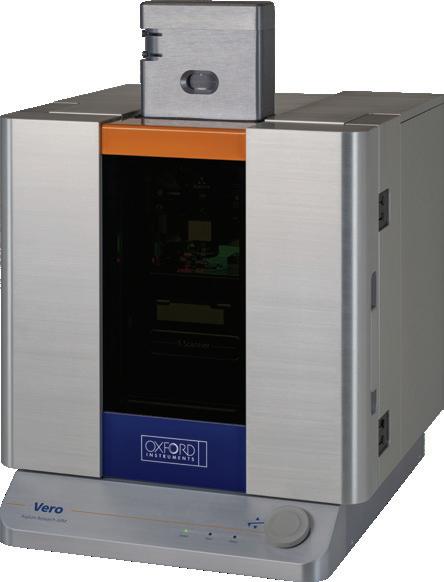

Oxford Instruments Asylum Research Inc.

Co-developers: Université de Lyon ENS de Lyon, CNRS, Laboratoire de Physique

In the field of atomic force microscopy (AFM), there have been many incremental improvements, but relatively few new products have emerged with transformative new technologies and capabilities. Asylum Research has been in the AFM industry since the company’s founding in 1999. The MFP-3D AFM (2002) significantly advanced AFM imaging metrology accuracy through the implementation of closed-loop scanning. The Cypher AFM, a 2009 R&D 100 Award winner, was the first commercial fast scanning and the highest resolution AFM. In 2013, the blueDrive photothermal excitation dramatically improved on performance. Each of these innovations reshaped the AFM industry. The introduction of QPDI (Quantitative Phase Dynamic Imaging) on the Vero AFM offers further advances. QPDI’s AFM cantilever motion improves the accuracy of quantification and measurements. Oxford Instruments Asylum Research says that the Vero AFM with QPDI technology will redefine how AFM measurements are done in diverse fields, including piezo and ferroelectrics, 2D materials, quantum materials, and polymers.

908 Devices

MAVERICK is a platform designed specifically for biologists, using Raman spectroscopy to streamline bioprocess development and optimization. It offers out-of-the-box capabilities for real-time monitoring of variables like glucose, lactate, and biomass, all through an intuitive touchscreen interface. This platform supports automation, remote access, and compliance with cGMP standards for pharmaceutical industry applications. While Raman spectroscopy itself is not new, MAVERICK transforms its application by offering a turnkey offering that simplifies bioprocess workflows, accelerating drug development and enhancing data science efforts. Traditionally, configuring Raman spectroscopy for bioprocesses required costly equipment, extensive customization, and a steep learning curve. MAVERICK eliminates these barriers with its pre-configured system, reducing time and expense by incorporating a novel de novo model for immediate bioprocess analysis. This platform bridges the gap between research and application, enabling pharmaceutical developers to scale efficiently from pilot production to full GMP production, all while improving predictive modeling for better product quality and yield.

Idaho National Laboratory

SHINE is transforming neutron detection with its ability to be shaped into any size or form within minutes at room temperature, while offering detection capabilities comparable to current technologies. This material addresses the helium-3 (3He) shortage, thus aligning with national security considerations and helping prevent the entry of illicit special nuclear materials (SNM) into the U.S. SHINE’s ecofriendly, first-of-its-kind scintillation polymer gel detects thermal neutrons, with high lithium chloride (LiCl) content enhancing its neutron capture capability. The inclusion of indium phosphate quantum dots (QDs) makes the gel wavelength-tunable, increasing light yield through a larger surface area. The QD core/shell design, featuring a semiconductor core and a zinc sulfide shell, prevents self-absorption of light, offering better performance than current detection technologies.

NenoVision s.r.o.

LiteScope 2.5 represents a novel AFM-in-SEM technology, especially for nanoscale analysis. Its unique integration of AFM and SEM capabilities allows for site-specific, multimodal correlative analysis, making advanced research accessible to a broad range of industries. Key features include selfsensing probe technology, seamless SEM integration without modifications, and AI-driven image correlation, enhancing precision, efficiency, and user experience. The system is compatible with 80% of scanning electron microscopes (SEMs) from major manufacturers, allowing for rapid deployment and interchangeability. LiteScope 2.5 also features a unique load lock probe and sample exchange, protecting sensitive materials and speeding up throughput. It is thus suited for applications like battery materials research and semiconductor failure analysis. Institutions such as Arizona State University, Thermo Fisher Scientific, and CEITEC Nano Research Infrastructure have backed the LiteScope 2.5’s feature set.

MIT Lincoln Laboratory

Co-developer: MIT

Detailed knowledge of seafloor topography is valuable for applications ranging from locating missing objects and undersea resources like oil and minerals to tracking human impacts, monitoring marine life, and modeling deep-ocean currents’ climate effects. Yet, most of the Earth’s oceans remain largely unmapped. The challenge lies in the lack of technology capable of producing high-resolution, meter-scale bathymetry at scale. While ocean-mapping ships with multibeam echo sounders provide broad coverage, they only deliver low-resolution data. Mapping areas deeper than 1,000 meters, which cover 85% of the ocean, requires sending underwater vehicles near the seafloor, a method that limits coverage and adds significant costs.

The MIT Lincoln Laboratory’s sparse-aperture sonar technique bridges this gap by offering a novel approach — delivering seafloor maps at 100x the resolution of surface vessels and 50x the coverage rate of underwater vehicles.

Hemolysis accounts for up to 70% of all unsuitable specimens and can falsely elevate potassium by up to 152%. Potassium is critical in managing cardiac function. Misdiagnosis due to hemolysis can significantly affect the management of the patient, causing repeated blood draws, delays in care, or unnecessary medical interventions. Studies demonstrate hemolysis prevalence throughout acute care settings, including in whole blood measurements on blood gas analyzers where potassium is reported. Until now, hemolysis detection on entire blood has not been available on blood gas analyzers. The GEM Premier 7000 provides integrated hemolysis detection on whole blood, with no additional sample volume/time required at the point of care. Using acoustophoretic technologies with laboratory-standard photometric measurements, the system separates whole blood to determine the degree of hemolysis in a sample, simultaneously reporting blood gas, electrolytes, CO-Oximetry, and tBili results. Designed for use throughout the hospital — from the lab to acute care settings — the system can improve patient care while reducing costs associated with undetected hemolysis.

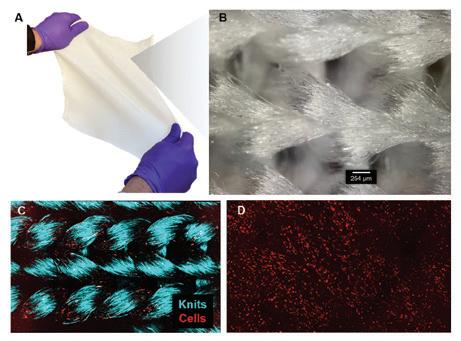

MIT Lincoln Laboratory Co-developer: MIT Department of Mechanical Engineering

Stem cell therapy holds promise for healing damaged tissues, but current scaffolds often fall short in mimicking the natural flexibility of human tissue. This can lead to cell detachment, death, and even secondary injury during recovery. Researchers have developed a new type of scaffold that addresses this limitation. The scaffold, made from bioabsorbable knitted yarns like polyglycolic acid (PGA) and polylactic acid (PLA), can be tailored to match the biomechanical properties of different types of tissues. The unique design allows the scaffold to “uncrimp” rather than stretch, preventing cell damage during motion. Tests have shown that these knitted scaffolds maintain a high cell survival rate even under significant strain, exceeding the performance of traditional scaffolds made from similar materials. This innovation holds great promise for enhancing the effectiveness of stem cell therapy, allowing for more robust healing and faster recovery.

CytoTronics Inc.

The Pixel Primo is an advanced device for multiplexed measurements at singlecell resolution. It combines unique measurements, using varying electrical field geometries and frequencies, with the highest electrode density on the market. This allows it to provide unparalleled information on cellular morphology and function, surpassing other live cell impedance devices. The Pixel Primo is the only instrument capable of multiplexing measurements. Researchers can concurrently perform electrical imaging and electrophysiological measurements, studying structure and function in electrogenic cells. Later this year, the same electrodes will measure redox potential, providing insights into cellular metabolic activity. The device’s circuits can also be configured to produce electrical signals for cell manipulation, with applications in wound healing and macromolecule delivery expected after 2024. Built with scalability in mind, the Pixel Primo is introduced with 96-well and 384-well plates, allowing flexible assay design. Later in 2024, the Pixel Octo, an 8-plate reader, will be launched, compatible with the same microplates. This enables easy scaling of assays developed on the Primo for higher-throughput applications such as screening.

Los Alamos National Laboratory

Co-developer: Golden Engineering

Since the discovery of X-rays, there have been two classes of radiographic sources: medical below 100 kV and industrial above 1 MV. Medical sources are blind beyond a thin sheet of metal, and industrial sources are enormous and typically occupy an entire room.

X-ray imagers, up to the present day, have not exploited the in-between “orthovoltage” (500 KV to 1 MV) spectrum. For that reason, X-rays are underused in various potential applications. Researchers at Los Alamos National Laboratory have developed PHOENIX. This X-ray source allows users to see at depth with unprecedented fine detail and leverages wellunderstood, commercial, off-the-shelf technology to generate tunable X-rays in a man-portable package powered by a drill battery and controlled with a simple on/off switch. Beyond bomb detection, its original purpose, PHOENIX can be reliably deployed in any application requiring deep vision in a portable, user-friendly package, whether in the ocean, oil fields, or industrial inspection.

Thermo Fisher Scientific

The Orbitrap Astral mass spectrometer is modernizing the field of proteomics, allowing researchers to analyze biological samples with speed and depth. This powerful instrument can identify over 8,000 protein groups from a human cell line digest in just eight minutes, dramatically increasing the scale of experiments and improving statistical power. The Orbitrap Astral combines the power of three advanced technologies: a high-resolution quadrupole mass filter, the Thermo Scientific Orbitrap mass analyzer, and the novel Thermo Scientific Astral mass analyzer. This combination allows for the accurate and rapid acquisition of high-quality, high-resolution mass data with exceptional sensitivity and broad range. The Orbitrap Astral is poised to accelerate drug discovery, treatment development, and therapeutic breakthroughs by providing faster, more comprehensive, and more accurate analysis of biological samples. This instrument has the potential to fundamentally change our understanding of complex biological systems and drive the development of new therapies and cures.

Los Alamos National Laboratory

Co-developer: United States Air Force Academy, i2 Strategic Services

A key objective for the space weather community has long been to predict space weather with the same reliability as terrestrial forecasting. The Compact Space Plasma Analyzer is a small, durable, and cost-efficient sensor designed to measure ion and electron energy, density, and temperature, as well as spacecraft charge. This data is crucial for mitigating the risks posed by the highly charged space environment, which affects satellite design, development, and operation, and can lead to dangerous differential charging and signal interference for GPS and communication systems. Its compact, rugged design offers a low SWaP-C solution that can serve as a primary payload on CubeSats or as an auxiliary payload on larger satellites. By providing affordable and widespread space-environment measurements, this sensor enhances our understanding of solar wind, magnetospheric and ionospheric processes, improves space weather forecasting, and aids in spacecraft anomaly resolution.

Elegen Corp.

Elegen has developed a custom synthetic DNA product that is changing genetic medicine development. This new technology, which uses a combination of molecular biology, chemistry, and microfluidics, produces linear, double-stranded DNA in a fraction of the time compared to traditional methods. ENFINIA DNA boasts a 20x higher accuracy and lengths up to 20,000 base pairs, exceeding the capabilities of existing synthetic DNA technologies. The process eliminates the need for cells or cloning, offering a more streamlined approach to DNA synthesis. Custom synthetic DNA is essential for developing genetic medicines, engineered crops, and synthetic biology products. Elegen’s technology has the potential to accelerate research and development in these areas by reducing the time and cost associated with DNA synthesis and scale-up. Elegen’s approach to DNA synthesis is gaining recognition, collaborating with pharmaceutical giants like GSK. This technology is poised to transform the way genetic medicines and vaccines are developed, potentially leading to faster and more efficient breakthroughs in healthcare.

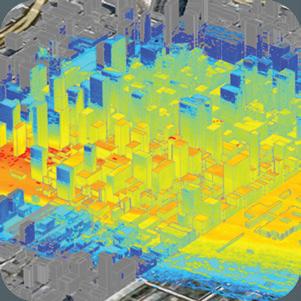

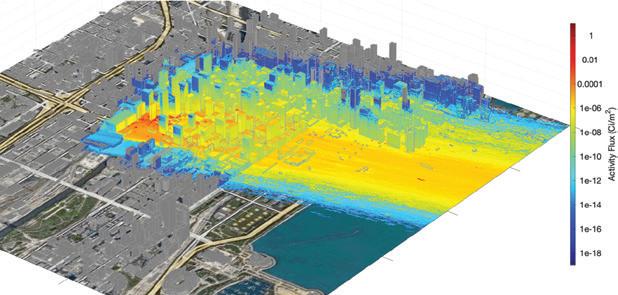

Los Alamos National Laboratory

All unexpected radiological releases concern human health, economic well-being, and global stability. QUIC-DEPDOSE is an inventive tool that is the first to calculate personalized radiation doses for people downwind from a radioactive plume. Unlike other plume-modeling software, it provides far more accurate and realistic results on an average laptop within minutes. QUIC-DEPDOSE uses precise topography to model the spread and deposition of radiological particles from the scale of kilometers across a city to the scale of microns within the human respiratory tract. QUIC-DEPDOSE incorporates the effects of terrain and cityscapes, employs a building infiltration model, and includes 888 radionuclides, making it a crucial tool to guide evacuations and emergency response while minimizing harm to civilians and responders. The software is user-friendly, portable, and fast — a nonexpert can run it at an emergency site in under half an hour. QUIC-DEPDOSE is the new, necessary software tool to support policymakers, emergency planners, and emergency responders as they plan for and respond to radiological releases.

Curiosis Inc.

Pacific Northwest National Laboratory

The MSP 320 is a new digital pathology scanner designed to improve the efficiency and accuracy of cancer diagnosis. This device can scan up to 320 slides per session with exceptional resolution, ensuring every detail is captured for accurate diagnoses and improved patient outcomes. It also incorporates advanced artificial intelligence (AI) and machine learning algorithms to analyze pathological features, identifying potential issues and supporting pathologists with reliable data. This reduces human error and enhances diagnostic accuracy. The MSP 320 supports the transition towards digital health records by digitizing slides, which facilitates remote consultations, collaborative research, and secure management of vital medical information. Its scalable design ensures it can adapt to the growing needs of healthcare systems globally. The MSP 320 is a significant advancement in pathology, promising greater efficiency, improved accuracy, and ultimately, better outcomes for cancer patients.

The AXES Complete Advanced X-ray Emission Spectrometry

Solution, a new advanced X-ray emission spectrometer, is modernizing material analysis with its unique combination of high-performance spectroscopy and AI-powered imaging processing capabilities. It is the only XES spectrometer capable of simultaneously measuring up to seven emission lines, generating massive amounts of data. This data is processed in real-time by powerful software, eliminating the need for significant human intervention. The spectrometer features an innovative rotating crystal holder that can hold up to 72 different crystals, providing flexibility and versatility. This “crystal-on-demand” system allows researchers to analyze a wide range of elements simultaneously, maximizing signal strength and enabling in-situ measurements. With over 3,000 potential combinations, AXES offers the equivalent of more than 3,000 traditional XES spectrometers, making it a powerful tool for a wide range of applications in materials science, chemistry, and other fields.

A new tool combines AI with automation to examine materials at the atomic level with unprecedented speed, precision, and efficiency. Applications range from clean energy to life sciences. The patented Autonomous Electron Microscope (AutoEM) is modernizing materials research by equipping electron microscopes with “human-like reasoning.” This novel system combines machine learning software, a custom central controller, and automated data collection and analysis to rapidly pinpoint key characteristics of materials under examination. With AutoEM, researchers can now identify complex material defects that were previously impossible to observe manually, conducting studies in a fraction of the time with less human error. The results are swift, comprehensive insights into the structure of materials that can be used to develop new batteries, semiconductors, solar cells, and pharmaceuticals. This powerful tool promises to accelerate scientific discovery and innovation, leading to faster development of crucial technologies for a sustainable future.

The Electromagnetic Spectrum Management System (ESMS) offers a solution for controlling radio frequencies in sensitive areas. It identifies and “manages” unwanted signals, effectively silencing them while allowing authorized communications to pass through. This is achieved by removing the modulation of hostile signals, essentially rendering them unintelligible while preserving the intended data and voice communication on friendly channels. The ESMS is particularly valuable for bomb disposal technicians, allowing them to safely disable explosives without disrupting their own communications. Unlike traditional jamming methods that block all signals, ESMS selectively silences only hostile signals, ensuring safe and effective operations. This technology has numerous applications across national security, law enforcement, and even civilian sectors. From secure computing facilities to hospitals limiting cell phone usage, ESMS provides a flexible and adaptable solution for managing the electromagnetic spectrum. This paradigm shift in signal control offers a powerful new tool for ensuring safe and secure communication in a world increasingly reliant on wireless technology.

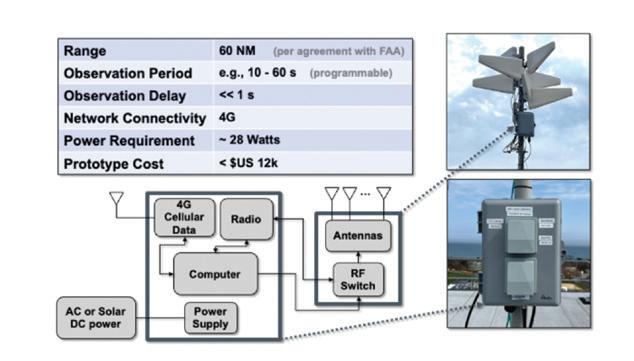

Weather forecasts are important for national safety, economic performance, and environmental management. Aircraft-derived observations (ADOs) are especially valuable, offering more impactful data for weather models than traditional sources like ground stations or satellites. ADOs help estimate current atmospheric conditions to help generate accurate forecasts. However, the current NOAA system, MDCRS, is installed on only a small percentage of aircraft, limiting the resolution and timeliness of the data. To address this gap, MIT Lincoln Laboratory developed the Portable Aircraft Derived Weather Observation System (PADWOS), which significantly increases atmospheric observation data by using Mode S Enhanced Surveillance transponders found on a larger range of aircraft. PADWOS gathers real-time data at lower altitudes and in data-sparse regions, improving weather forecast accuracy and enabling better decision support for air traffic controllers and aviation operations. With a 60-nautical-mile range and the ability to sample more aircraft, Portable Aircraft Derived Weather Observation System (PADWOS) offers a cost-effective way to deploy weather observation systems, particularly in regions lacking data, like the Midwest.

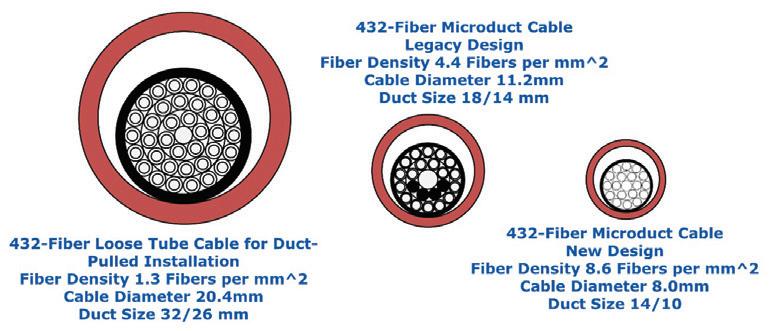

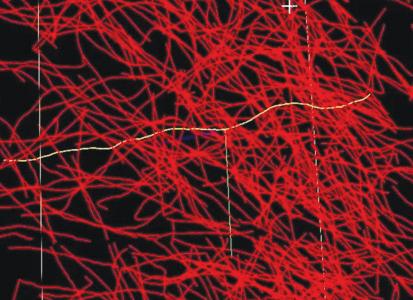

Nuclear energy is poised to reduce the world’s carbon footprint. TRIPWIRE’s breakthrough approach to managing and mitigating radiological risk is vital to building public trust in nuclear energy as a sustainable, low-carbon power source for a clean energy future. The groundbreaking radiation-monitoring system enables the safe, secure, and cost-effective long-term storage of nuclear material — any material that emits gamma radiation. It uses ruggedized scintillating fibers, the size of a pencil lead, to provide continuous, real-time monitoring of radiation levels over large areas at a fraction of the cost of conventional solutions. TRIPWIRE’s advanced methods leverage low-cost and readily available optical fibers to significantly reduce personnel exposure to potentially dangerous radiation and maintenance costs of long-term nuclear storage facilities. TRIPWIRE also has applications beyond repositories, including monitoring the natural background radiation along oil and gas pipelines, monitoring radiation at ports of entry for national security, and perimeter awareness for emergency response.

MIT Lincoln Laboratory Co-developer: Kumu Networks

In Taiwan, traffic violations, especially those involving motorcycles, remain a problem. In 2022 alone, traffic accidents resulted in 3,085 deaths and nearly 500,000 injuries, the highest in a decade. Limited police resources make traffic violation enforcement difficult, leading to a gap between issued penalties and actual infractions. Traditional enforcement methods pose safety risks to officers, with an average of one traffic officer injured in a traffic accident every nine days. To address these issues, the Institute for Information Industry (III) has developed AI-based recognition technology capable of detecting traffic violations in real time. The “Traffic Violation Catcher” application uses sensors and deep learning to automatically identify violations such as running red lights and failing to yield to pedestrians. Compared to traditional methods, AI-powered traffic enforcement reduces the workload of officers, minimizes their exposure to danger, and ensures fairness. The system operates 24/7, providing concrete evidence and facilitating penalties.

With over 18 billion wireless devices worldwide, the demand for greater bandwidth and faster data rates is increasing. In-Band Full Duplex (IBFD) technology is poised to meet this challenge by effectively managing interference from multiple sources. This allows for a more robust and deployable solution for modern networks. IBFD technology, through advanced interference mitigation techniques, supports significantly more devices, improved data rates, and extended communication range. These breakthroughs include antenna nulling to suppress self-interference, RF/ digital cancellation to reduce onboard interference, and adaptive beamforming to eliminate external interference. Real-world demonstrations have shown that the novel system supported 68x more devices, delivered data rates 10x higher, and extended communication range four times compared to current 4G LTE systems. The technology offers significant performance gains over emerging 5G NR networks. IBFD’s versatility makes it suitable for integration into smart vehicles, base stations, and handheld devices, paving the way for the next generation of connectivity and addressing the growing demands of wireless users globally.

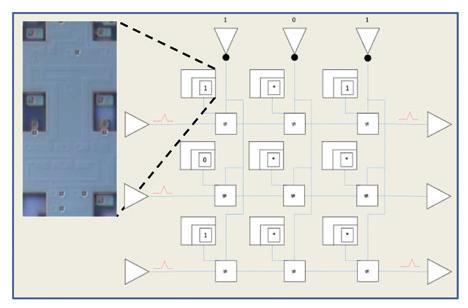

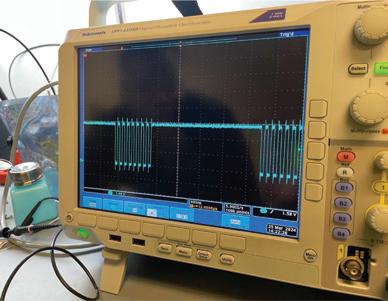

MIT Lincoln Laboratory

Lincoln Laboratory has developed superconductive circuits that store and compare more than two discrete states using the quantized magnetic fields from superconductive materials. This advancement enables digital logic to move beyond binary (base-2) to ternary (base-3) logic, enhancing memory throughput without increasing device count or circuit surface area. Their ternary content-addressable memories (TCAMs), based on superconducting technology, are expected to achieve high throughput with clock frequencies near 15 GHz and pattern matching throughput of 16.8 Tbps. At this speed, a superconducting TCAM could pattern match the entire digital Library of Congress (23 petabytes) in roughly three hours, nearly 30 times faster than CMOS-based TCAMs with 0.5 GHz clocks. These superconductive circuits are foundational for ultra-high-speed, lowpower digital logic, particularly for demanding pattern-matching applications.

MIT Lincoln Laboratory

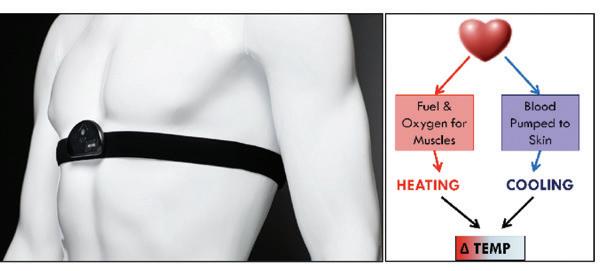

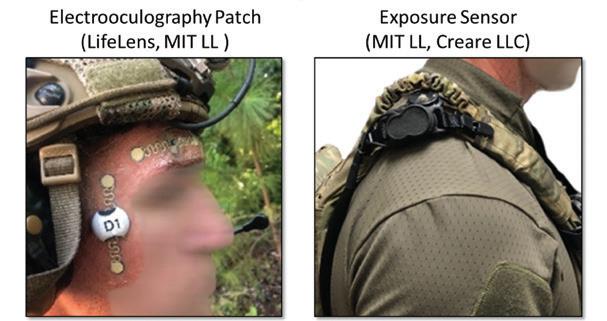

Co-developer: US Army Medical Material Development Activity, US Army Research Institute of Environmental Medicine, Georgia Tech Research Institute, Odic Inc.

Heat-related injuries are the primary cause of weatherrelated loss of worker productivity, disability, and death of individuals. Most at risk are those who work outdoors (for example, construction and industrial workers, the military, first responders, and athletes). Each year, there are hundreds of heat stroke deaths in these at-risk populations worldwide. These injuries are an under-reported danger that is increasingly deadly with climate change. The HIPS system can provide accurate early warning of heat stroke several minutes before visible symptoms. The high accuracy of this system results in accurate prediction of heat injuries, with false alarms limited to <=10%, a rate found acceptable by users. The HIPS system offers a dramatic improvement over earlier technologies, estimated to have a 40% false alarm rate. Significant advantages in affordability and user acceptability have contributed to a high user acceptance and integration of HIPS into the operational environments for which it was designed, leading to a 100-fold increase in data collected that enables the development of dramatically more accurate predictive, individualized algorithms.

SAFE is an information barrier technology that meets a need that alternative devices do not address. It rigorously safeguards sensitive data against dissemination by automatically executing a triple-overwrite deletion without human action. This safeguard is essential in a potential violation, such as tampering with a device, removing it from a secure area, or cutting its power. Upon initial power-up, new data collection is disallowed until the independent, supercapacitor-powered deletion circuitry is fully charged and ready. While suitable for protecting private medical or financial data or proprietary industry secrets, SAFE was designed to meet the exacting standards of international nuclear arms inspections, including a critical security and longevity requirement to maintain zero energy in the system after deletion (rendering batterybased systems unusable). It allows discerning measurements of classified technology to verify treaty compliance without revealing the measurements themselves, even to the inspectors. Rather than maintaining current analog means to achieve this, SAFE enables detailed digital data analysis because data protection and erasure are inherently guaranteed.

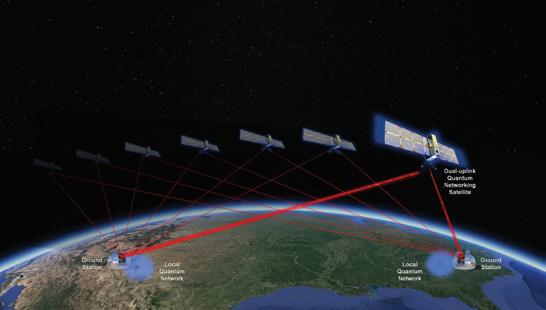

Quantum networking has the potential to advance connectivity across the globe, unlocking unprecedented capabilities in computing, sensing, and communications. To realize this potential for a range of applications, entangled photons distributed across a quantum network must arrive and interact with other photons in precisely controlled ways. The Precision Photon Synchronization System is the first to provide a low–size, weight, power, and cost solution to synchronize space-to-ground quantum networking links to subpicosecond precision. Unlike other technologies, the system performs free-space quantum entanglement distribution through a satellite without needing to locate complex entanglement sources in space. These sources are instead located on the ground, providing an easily accessible test environment that can be upgraded as new quantum entanglement generation technologies emerge. NASA seeks to employ this system in future field demonstrations that could lead to advances such as interconnected metropolitan quantum networks (a building block of a future global quantum internet) and swarms of satellites equipped with quantum sensors for precise navigation of space vehicles.

CorePower Magnetics

Co-developer: Carnegie Mellon University

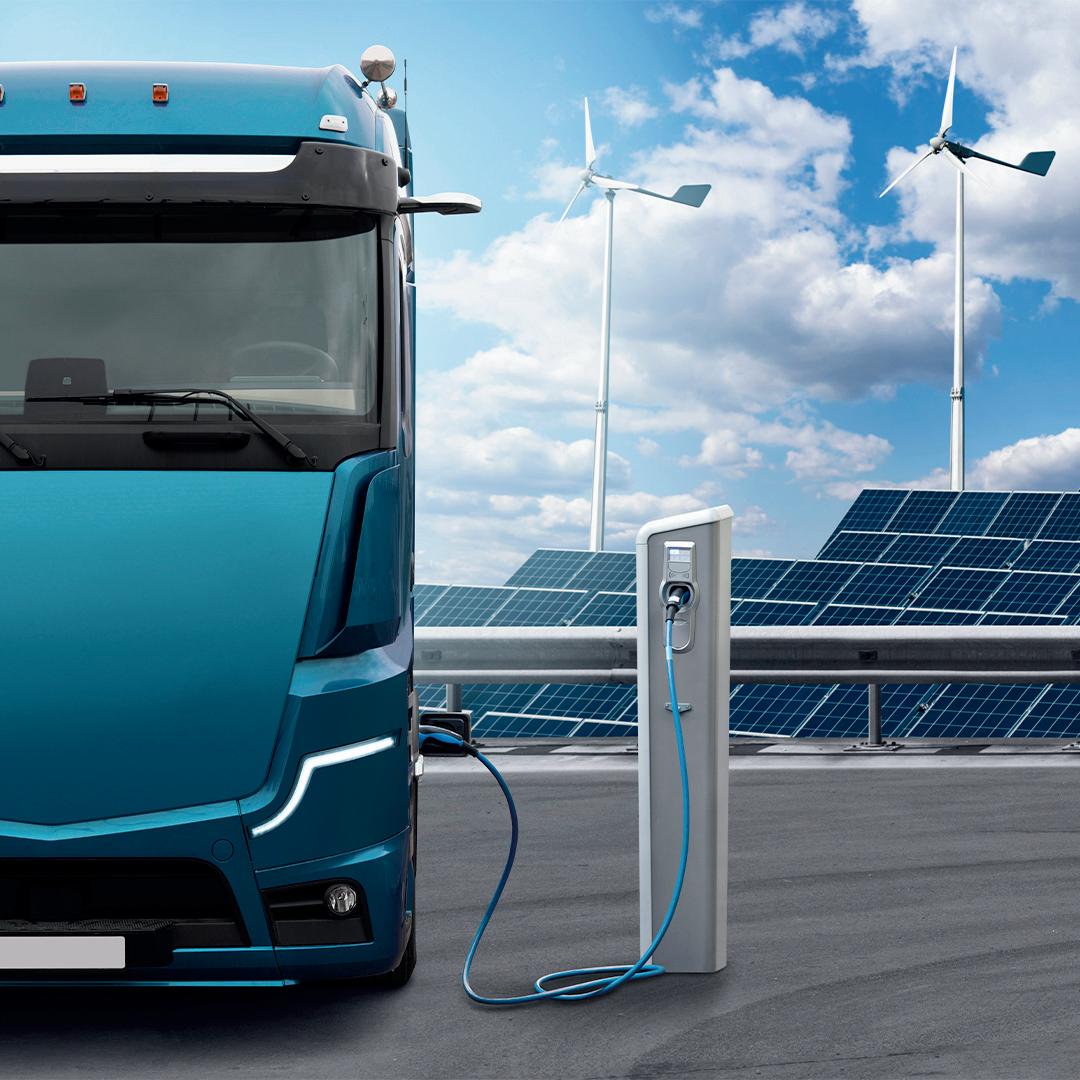

The rapid shift towards electric vehicles is driving a demand for more powerful and efficient electric motors. Traditional electric motors lose a significant amount of energy due to losses in their soft magnetic cores, which are typically the bulkiest components in these systems.

CorePower Magnetics has developed a new electric motor that addresses this challenge by using nanocrystalline soft magnets, which exhibit extremely low losses at high frequencies. These materials, combined with a novel electric machine design, result in a motor that converts electrical energy into mechanical motion with significantly higher efficiency than conventional motors. This breakthrough has the potential to significantly improve the performance and range of electric vehicles. By minimizing energy losses, the new motor can increase efficiency and reduce reliance on battery power, extending driving range and enhancing the overall performance of electric vehicles. This advancement in motor technology is a key step towards a more sustainable and efficient transportation future.

MIT Lincoln Laboratory

Co-developers: Creare LLC, Lifelens LLC

Military/law enforcement personnel are often exposed to blast overpressure in training and operational settings, which can lead to short-term cognitive impairments and increased risk of conditions like anxiety and depression. The Electrooculography and Balance Blast Overpressure Monitoring System (EYEBOOM) is a wearable monitoring system that provides early warning of blast exposure risk. It combines measurements of environmental overpressures produced by weapon systems and the resulting physiological responses observed in changes in gait, balance, and eye movements. Unlike current technologies that only provide an early warning based on peak exposure levels, EYEBOOM offers continuous data that can be used in real time to adapt training and reduce injury risk. Its adoption by U.S. Special Forces units has led to changes in training practices and the possible identification of individuals at greater risk of injury. This technology could help protect our service members and law enforcement personnel from the long-term consequences of blast exposure.

Los Alamos National Laboratory

Co-developer: Advent Technologies Holdings Inc.

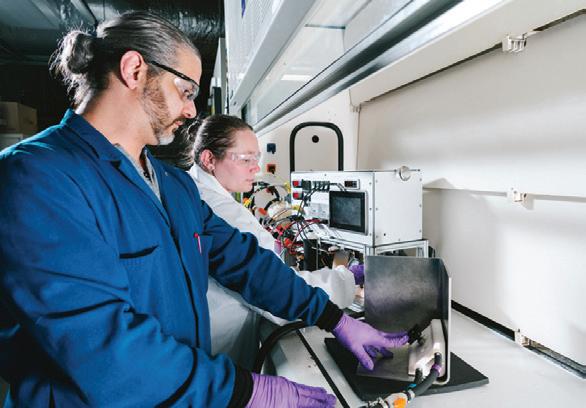

Los Alamos National Laboratory (LANL) and Advent Technologies collaborated to develop Ion Pair membrane electrode assemblies (MEAs) for fuel cell-powered heavy-duty vehicles. This technology aims to improve fuel cell performance, rated power, and durability.

As part of the collaboration, Advent Technologies licensed patents from LANL and established a fuel cell research, development, and manufacturing facility in Massachusetts. The Ion Pair technology is intended to address challenges in heavy-duty vehicle electrification, where batteries face limitations and conventional fuel cells may not meet power requirements. Reported advantages of Ion Pair technology include a wider operating temperature range, increased power generation, greater tolerance to hydrogen fuel impurities, and a simplified design that may reduce costs compared to conventional fuel cells with similar power output.

Industrial Technology Research Institute (ITRI)

The rapid advancement of AI is hampered by the “memory bottleneck,” a challenge stemming from the separation of memory and processing units in the von Neumann architecture. This bottleneck is particularly pronounced in generative AI applications, where memory-intensive operations exacerbate the issue. Over the past two decades, the growth of computing power has outpaced memory bandwidth, further intensifying this challenge. Generative AI also consumes significant energy, with a recent study highlighting the high energy footprint of generating AI images. MOSAIC, a new technology, addresses this challenge by integrating a 3D DRAM hierarchy directly onto the logic chip, reducing data transfer distances and energy consumption. This approach also simplifies yield control for high-performance computing (HPC) chips, lowering costs. Powerchip Semiconductor Manufacturing Corporation (PSMC) is leading this integration, combining memory and logic technologies to enhance chip performance while minimizing costs. With multiple wafer fabrication facilities and a new 12-in. fab under construction, PSMC continues to advance semiconductor manufacturing.

Satellite communications, known as non-terrestrial networks (NTN), are bridging the gap in cellular coverage, bringing connectivity to remote areas and disaster zones. NTN technology allows devices to remain connected even when outside the range of traditional cell towers, enabling users to communicate, receive emergency warnings, and navigate. Ameba RAN, a software-defined cellular base station, is at the forefront of this technological advancement. It leverages commodity hardware and flexible software to accommodate a variety of base station types, including emerging direct-to-cell satellite communication services. Ameba RAN allows for seamless transitions between terrestrial (TN) and NTN services, ensuring uninterrupted connectivity for mobile users even in remote areas. The system supports both broadband and narrowband NTN services, providing a cost-effective solution for expanding communication coverage. Beyond emergency communication, Ameba RAN also offers a range of features for traditional TN applications, including urban communication, AR/VR, smart factory, and online gaming. Its flexible design allows for software configuration to optimize performance for specific applications, addressing the unique needs of each sector.

University of Pittsburgh

Co-developer: National Energy Technology Laboratory, Sensible Photonics

UltraSonic Photonics is a sensor system that monitors large-scale infrastructure under stress, offering unprecedented capabilities in detecting potential failures before they occur. The technology uses ultrasonic waves and optical fiber cables to “listen” for changes in the structural integrity of monitored systems, such as pipelines, nuclear canisters, and bridges. By analyzing ultrasonic signals, the system can detect cracks, corrosion, or other forms of degradation that could lead to catastrophic failures. UltraSonic Photonics combines advanced data analytics with physics-based models and machine learning algorithms, enabling the system to analyze vast amounts of data and identify potential problems with greater accuracy and earlier detection than traditional inspection methods. It can operate in challenging environments, including high temperatures and radioactive zones, helping to prevent explosions, infrastructure failures, and radioactive leaks. Its simple installation and operation make it a cost-effective solution for ensuring the safety and reliability of critical infrastructure.

Infinitum

Data centers are facing a growing energy challenge as demand for computing power, particularly for AI applications, continues to surge. According to Goldman Sachs Research, data center power demand is projected to increase by 160% by 2030. This growing demand translates into increased heat generation and, consequently, higher cooling requirements, putting a strain on energy consumption and sustainability efforts. Infinitum’s Aircore EC Motor for Data Centers is designed to tackle this challenge. This advanced motor is significantly smaller and lighter than traditional motors, requiring 66% less copper and no iron. It also boasts a 10 to 15% reduction in energy consumption and a 30% decrease in carbon emissions. Infinitum’s Aircore EC Motor is specifically designed to meet the precise horsepower, speed, and torque requirements for cooling equipment in data centers, reducing the need for oversized motors and minimizing electrical infrastructure and utility demand. The motor’s reusable components can remain in service for decades, reducing waste and contributing to a more sustainable future.

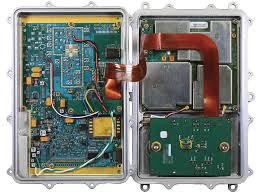

Co-developer: Johns Hopkins Applied Physics Laboratory

NASA missions with limited mass and power budgets have driven the development of innovative communication systems. In response, Johns Hopkins Applied Physics Laboratory (APL) created Frontier Radio, a low-power, low-mass, modular S/Ka-band software-defined radio that launched on NASA’s Van Allen Probes in 2012. Over the past two decades, Frontier Radio has become essential for numerous near- and deep-space missions, enabling small spacecraft to reliably transmit data and receive commands. The latest iteration, Frontier-X, commercialized in 2023, expands the reach of smaller satellites while providing enhanced connectivity and faster data transmission at a lower cost. Frontier-X represents a significant advancement in spacecraft communications technology, meeting the critical radio communications needs of numerous near- and deep-space missions. The technology has been used on multiple space missions, including the Van Allen Probes, the Parker Solar Probe, and others. Rocket Lab has licensed the technology for Frontier, enabling the creation of software-defined radios for the commercial industry.

Oak Ridge National Laboratory

Co-developer: Volkswagen Group of America, Volkswagen Group Innovation, Volkswagen Group Components, Hyundai-Kia North America Technical Center

Current wireless charging technology for electric vehicles is limited by the bulky and heavy nature of high-power systems. While light-duty vehicles are limited to 11 kW charging, systems capable of 100 to 250 kW are too large for practical use, even in heavier vehicles. This new wireless charging technology development offers a solution by significantly increasing power density while reducing size and weight. This advancement achieves a surface power density of up to 1,530 kW/m2, an 8 to 10-fold increase compared to existing systems, making it a transformative leap in wireless power transfer. Furthermore, the new technology addresses concerns about electromagnetic field emission. Using a polyphase design, the system operates below international guidelines and standards, minimizing energy losses and boosting efficiency to over 95%, compared to existing systems operating between 85 and 92%. This advancement holds immense promise for the future of electric vehicles, paving the way for more powerful, efficient, and compact wireless charging solutions.

Berxel Photonics Co. Ltd.

A new 3D camera, utilizing PolarizationStructured Light (PSL), is transforming depth perception in challenging environments. Traditional 3D cameras struggle with reflective surfaces like glass, mirrors, and water, often producing inaccurate depth readings. The PSL 3D camera overcomes these limitations by leveraging the polarization properties of light. It employs highcontrast-grating vertical-cavity surface-emitting lasers (VCSELs) in the transmitter and an HCM polarizer integrated with a CMOS image sensor in the receiver. This unique design enables accurate depth measurements even in complex environments by minimizing the effects of multipath noise. This technology is poised to transform a range of applications, including robotics, logistics automation, and advanced manufacturing. Humanoid robots will be able to navigate and interact with their surroundings more effectively, while automated systems in warehouses and factories will gain the ability to handle reflective materials with greater precision. The PSL 3D camera represents a significant step forward in 3D imaging, offering enhanced accuracy and robustness in environments where traditional systems falter. This breakthrough has the potential to significantly impact the development of future robots and smart technologies.

Shanghai Institute of Optics and Fine Mechanics

The automotive industry faces a challenge in balancing the need for fuel-efficient lightweight materials to improve the range of electric vehicles with solid and safe vehicles to protect passengers. Aluminum-silicon-coated press-hardened steels (PHS) are a promising solution, but these materials pose a unique challenge in laser welding. The presence of the Al-Si coating often leads to the formation of brittle delta-ferrite phases during welding, compromising the strength and integrity of the weld. Traditional methods require a costly laser ablation process to remove the coating before welding, significantly increasing manufacturing costs. PANGUJ developed a new solution eliminating the need for this expensive step. Their innovative filler wire, featuring a unique chemical composition, enables sustainable laser welding of PHS, regardless of coating thickness, strength grade, or thickness combinations. PANGUJ’s filler wire not only eliminates the need for laser ablation, but it also significantly improves weldability, reducing manufacturing costs by more than 15%, lowering energy consumption, and boosting productivity by 2-3x. This breakthrough technology has opened new possibilities for the automotive industry, with a potential market value exceeding $11.6 billion annually.

Thermo Fisher Scientific

As cell therapy approvals continue to grow, new technologies and evolutions in cell therapy manufacturing are needed to get these therapies to patients. Despite the promises of the therapy class, many challenges remain within the manufacturing process that can potentially delay getting critical therapies for diseases such as cancer to needing patients. Current hurdles in cell therapy manufacturing include contamination risks, overall efficiency, scalability issues, and higher production costs. The Gibco CTS

Detachable Dynabeads offer a new, effective way for cell therapy manufacturers to actively detach Dynabeads from a target cell at any point during manufacturing, allowing greater control over the process and consistently delivering target cells with desired characteristics. CTS

Detachable Dynabeads help manufacturers alleviate pain points in flexibility, compatibility, and scalability to help bring cell therapy innovations to patients faster.

Nano and Advanced Materials Institute

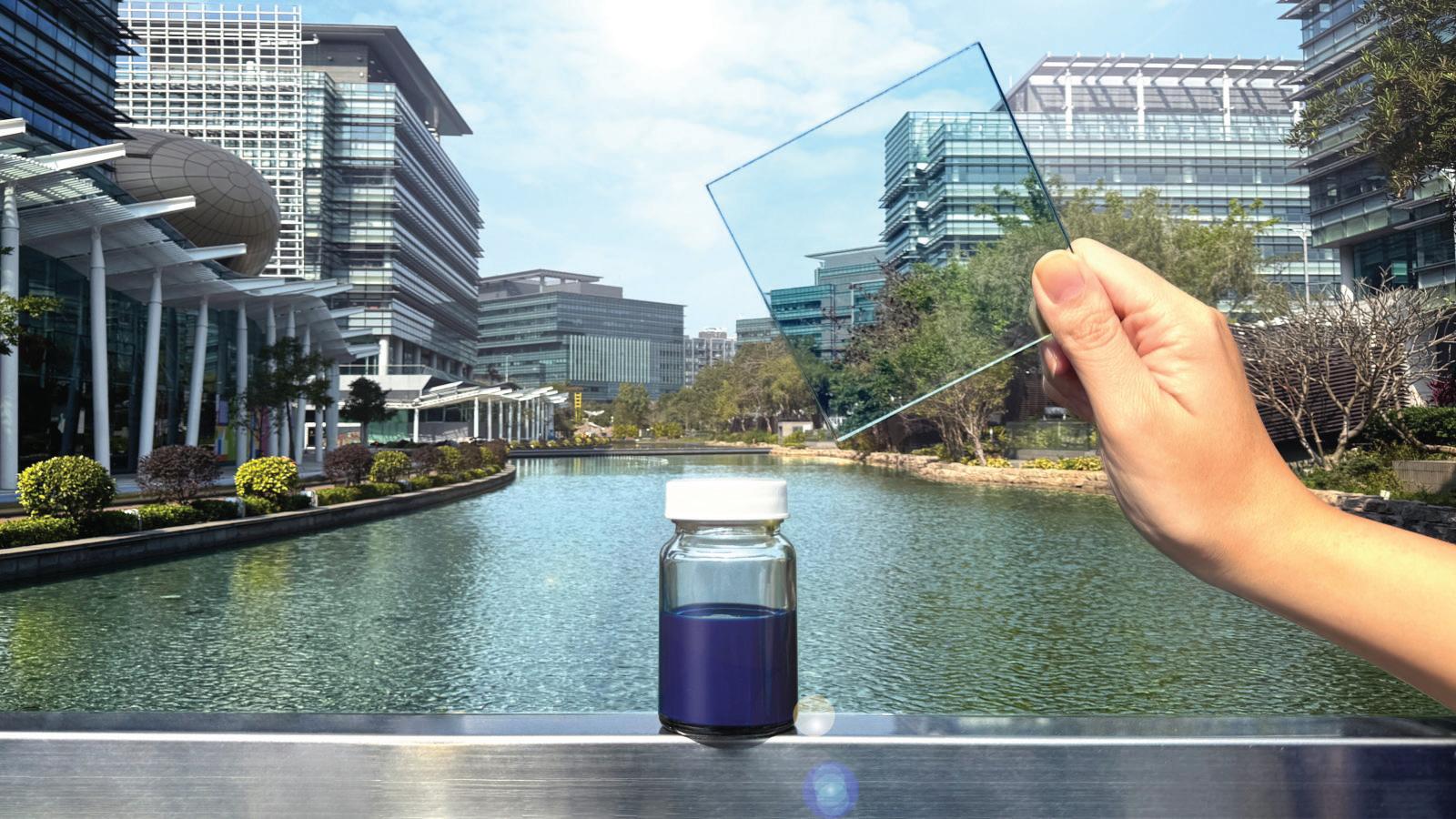

Co-developer: Harvest Time Facade Limited

SABIC’s Specialties Business

NAMI’s Transparent Sun Nanocurtain offers a durable, cost-effective solution for improving energy efficiency in windows of various shapes and curvatures. The product blocks 50% of solar energy while allowing over 60% of visible light to pass through, and it reflects less than 6% of light, making it one of the top-performing window treatments globally. Unlike bulky Low-E windows, which are limited to new buildings and raise road safety concerns, or expensive window films with short lifespans that only apply to flat surfaces, the Transparent Sun Nanocurtain is easy to apply to any window and lasts over 12 years. In addition to reducing glare, it provides significant energy savings by lowering indoor temperatures caused by solar radiation, cutting electricity use, and reducing carbon emissions by 20% annually. This makes it a highly efficient and sustainable option for enhancing energy performance in both residential and commercial buildings.

SABIC’s LNP STAT-KON is fast emerging as a technology of choice for replacing metal-based bipolar plates in redox batteries for energy storage, thus enabling mass production of batteries for traditional and renewable energygenerating systems. This thermoplastic solution offers a balance of electrical and thermal conductivity, higher mechanical strength, better corrosion resistance to the electrolyte for an extended life, cost, use of available raw materials, and greater manufacturing ease than their metal-based counterparts. SABIC’s LNP STAT-KON can serve the redox battery market and other adjacent opportunities where highly electrically conducting materials can be used for applications involving metal replacement, EMI shielding, and thermal conductivity. Applications that can stand to benefit from the use of SABIC’s LNP STAT-KON technology include but are not limited to, plates of frame-and-plate heat exchangers where thermal conductivity is of critical importance, electromagnetic shields of automotive radar sensors for advanced driver-assistance systems (ADAS) applications and of printed circuit boards of electronic components where strong EMI shielding is required, and also in bipolar plates of fuel cells for electric vehicles.

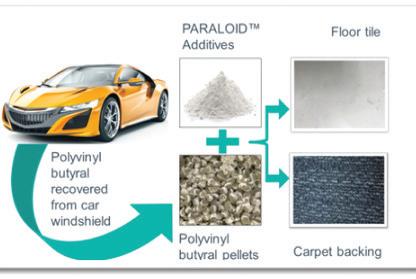

The Dow Chemical Company

Every year, millions of windshields are replaced around the world, leaving behind a significant amount of waste in the form of the polyvinyl butyral (PVB) interlayer, a material responsible for keeping shattered glass together. Currently, recycling this material is a complex and costly process, often resulting in low-quality materials unsuitable for reuse. The sheer volume of PVB waste is substantial – over 175 million pounds are landfilled annually, and this doesn’t even account for PVB used in solar panels and architectural windows. A new solution developed using PARALOID Additives, a patented and commercially available technology, offers a practical and sustainable alternative to landfilling PVB. It allows for the upcycling of both virgin and recycled PVB into a variety of applications, including flooring, films, adhesives, and coatings. Further reducing environmental impact, PARALOID Additives also enable the creation of foamed PVB carpet backings, which require less material, resulting in lighter carpets for transport and installation. This innovative technology is poised to transform the way we manage PVB waste, promoting a more sustainable future.

Lawrence Berkeley National Laboratory

Axalta Coating Systems

Automotive coating company

Axalta is committed to developing sustainable and energy-efficient solutions. The company’s latest innovation, Primerless Consolidated Coating System, simplifies the traditional multi-layer painting process while enhancing both performance and sustainability. Axalta’s new system eliminates the need for a separate primer layer, achieving the desired color effects and coverage in a single basecoat application. This consolidated process streamlines the painting process, reducing cycle time by up to 10%, energy consumption by up to 25%, and reducing carbon emissions by up to 21%. The primerless paint system has been successfully launched at the Chery Anqing II plant, demonstrating its effectiveness in achieving aesthetic, sustainability, and productivity targets. It underscores Axalta’s commitment to developing smarter, more sustainable surface solutions for the automotive industry. The new system not only streamlines the painting process but also reduces the need for primer spraying equipment, further minimizing energy consumption and contributing to a more sustainable future.

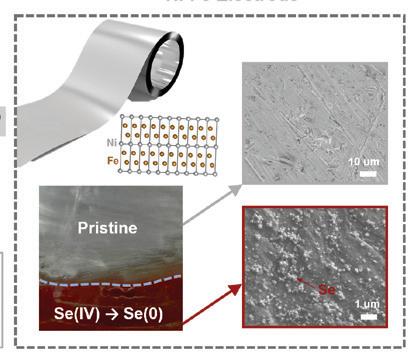

Dow (Shanghai) Holding Co.

Selenium (Se) pollution, which harms aquatic ecosystems and wildlife and can be toxic in humans and animals, is found in natural water bodies worldwide. Current biological treatment to remove Se from wastewater is expensive, produces non-biodegradable sludges, has a large carbon footprint, and is sensitive to chemical and environmental limitations. Direct electrochemical reduction using gold or graphite electrodes offers advantages, but gold is too expensive, and graphite cannot achieve the Environmental Protection Agency (EPA)’s maximum contaminant level for reduction. LBNL’s Nickel-Iron Electrode effectively removes aqueous selenite from wastewater at a cost substantially lower than its competitors. It is easily manufactured and processed, has high catalytic activity and selectivity, is stable in aqueous environments, uses less energy than competing products, and creates no pollution. The Fe-Ni foil that can reduce Se(IV) concentrations to the EPA’s limit is commercially available, ensuring material scale-up. Replacing the Au electrode with Ni-Fe significantly decreases capital and operational costs, making the global adoption of this technology possible, especially in developing countries.

Coatings for cookware and grills face a tough challenge: withstanding high temperatures and repeated cleaning cycles while maintaining a smooth finish. Silicone resins offer heat resistance but lack strength and are costly, while polyesters provide good strength but struggle with heat. Silicone Modified Polyester (SMP) aims to combine the best of both worlds, but current production methods have limitations. Traditional solvent-based processes pose safety and environmental concerns, while solvent-free methods result in undesirable “sandy-like” finishes. Dow has developed DOWSIL 2080 Resin, a new, patented silicone molecule that solves these challenges. This innovative resin reacts directly with polyester in solvent-free conditions, creating a highperformance, sustainable SMP powder coating. DOWSIL 2080 Resin offers exceptional heat resistance, durability, and a smooth finish. It also provides a sustainable alternative to fluorocarbon-based coatings. This new technology promises to transform the coatings industry, providing a high-performing solution for demanding applications.

CHIMEI Corporation

Co-developer: Industrial Technology Research Institute (ITRI)

Industrial Technology Research Institute (ITRI)

As the global polycarbonate market size increases, using captured CO2 as a chemical raw material to produce polymers has an obvious ecological advantage over conventional polymers. The development of FCO2PC technology marks a significant step forward for the chemical industry. The entire process is close-looped, zero waste, and non-toxic, and the sophisticated catalysts used effectively solve the common environmental problems in traditional methods. This technology avoids toxic chemical feedstock and recycles all solvents and wastewater, significantly reducing energy consumption and overall carbon emissions. The FCO2PC facility is cost-effective to install, and the cost of production is comparable to or lower than that of conventional polycarbonate. ITRI has shown that FCO2PC technology works and is economically beneficial on an industrial scale. FCO2PC successfully implemented the 3Rs (Reduce-Reuse-Recycle) green policy and demonstrated an exciting, practical pathway for the industry to follow.

Oak Ridge National Laboratory

Co-developer: Enginuity Power Systems (EPS)

A new 8-kW micro combined heat and power (micro-CHP) system is poised to transform energy efficiency and reduce carbon emissions in residential and commercial buildings. This inventive system uses a highly efficient opposedpiston engine (OPE), which boasts 60% fewer parts than traditional engines, leading to lower manufacturing costs and increased durability. The OPE can run on a variety of fuels, including natural gas, propane, and even hydrogen, making it adaptable to both conventional and carbon-free energy sources. The system also features a sophisticated waste heat recovery system that captures heat from the engine’s exhaust and coolant to provide hot water, further increasing its overall efficiency. This micro-CHP system achieves 93% overall and up to 35.2% fuel-toelectricity efficiency, surpassing the 30% limit of conventional micro-CHPs. This technology offers a cost-effective and sustainable solution for building decarbonization, potentially accelerating the adoption of micro-CHP systems in both residential and commercial settings. It also holds promise for providing energy to remote and underserved communities.

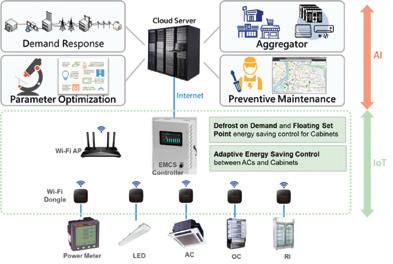

AADREMS is the first energy management system (EMS) to leverage deep reinforcement learning (DRL) for energy-saving services. The team behind AADREMS has made significant strides in accelerating DRL’s learning speed, making the technology practical for real-world applications. The system excels in managing interactions among multiple components, achieving 15 to 20% energy savings within a short period without compromising service quality. Its quick setup, plug-and-play functionality, and independent maintenance algorithm, which predicts maintenance with 93% accuracy, make it highly efficient. AADREMS also offers a demand response service, allowing for a 5% shift in power demand over an hour with minimal effort. In the AI era, AADREMS demonstrates the potential to save substantial amounts of energy through efficient processing. Its adaptability and effectiveness make it a valuable tool for businesses seeking to reduce energy consumption and contribute to a Net Zero emissions future.

Ames National Laboratory

Co-developer: Iowa State University

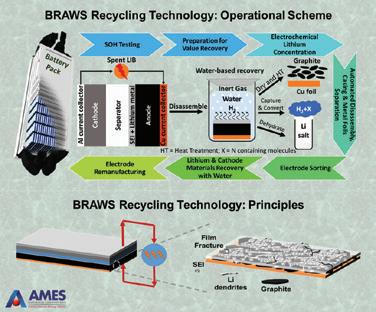

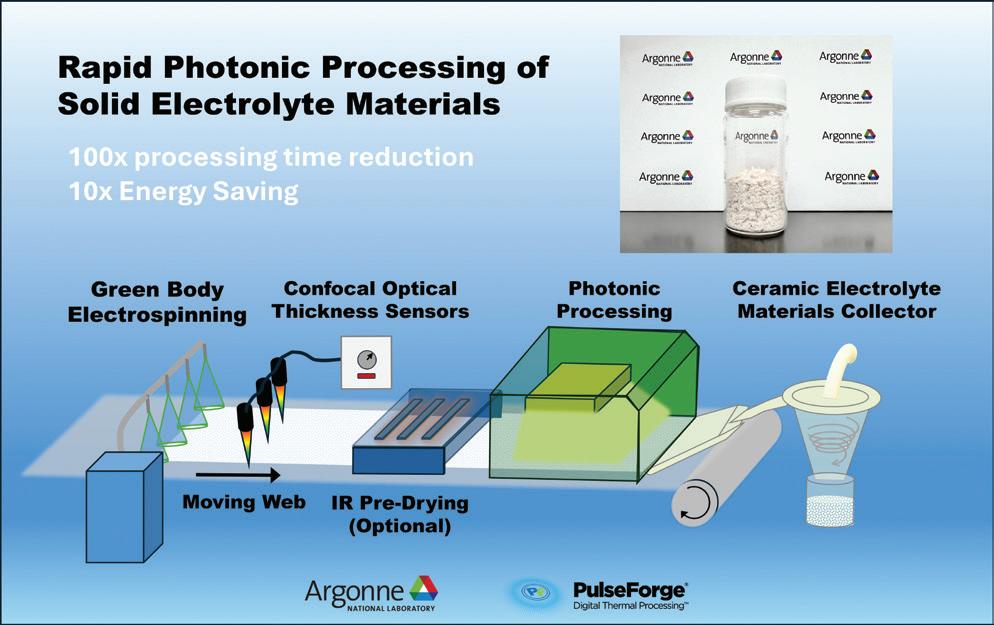

The Rapid thermal processing of solid-state lithium battery ceramic electrolyte materials (BRAWS) technology enables full-value recovery of materials from lithium-ion battery waste streams. It offers environmental and economic advantages by recovering lithium, graphite, cathode materials, current collectors, and separator materials from end-of-life lithium-ion batteries without harmful solvents. Unlike traditional recycling methods that rely on acids and other toxic solvents, the BRAWS technology uses water as the sole solvent. This eliminates the need for expensive and hazardous chemicals, resulting in cost savings. The process is more energy-efficient compared to conventional methods. By avoiding complex, high-energy-consuming processes, the BRAWS technology reduces operational costs. The full-value recovery of materials from lithium-battery waste ensures no valuable components are lost, which maximizes the economic benefits. The carbonnegative feature of the BRAWS technology aligns with sustainability goals and may even lead to potential carbon credits or incentives. Green hydrogen is generated, which can have additional economic value, mainly because of the growing interest in hydrogen-based energy systems.

Industrial Technology Research Institute (ITRI)