ACTA FACULTATIS XYLOLOGIAE ZVOLEN

VEDECKÝ ČASOPIS SCIENTIFIC JOURNAL

Vedecký časopis Acta Facultatis Xylologiae Zvolen uverejňuje pôvodné recenzované vedecké práce z oblastí: štruktúra a vlastnosti dreva, procesy spracovania, obrábania, sušenia, modifikácie a ochrany dreva, termickej stability, horenia a protipožiarnej ochrany lignocelulózových materiálov, konštrukcie a dizajnu nábytku, drevených stavebných konštrukcií, ekonomiky a manažmentu drevospracujúceho priemyslu. Poskytuje priestor aj na prezentáciu názorov formou správ a recenzií kníh domácich a zahraničných autorov.

Scientific journal Acta Facultatis Xylologiae Zvolen publishes peer-reviewed scientific papers covering the fields of wood: structure and properties, wood processing, machining and drying, wood modification and preservation, thermal stability, burning and fire protection of lignocellulosic materials, furniture design and construction, wooden constructions, economics and management in wood processing industry. The journal is a platform for presenting reports and reviews of books of domestic and foreign authors.

VEDECKÝ ČASOPIS DREVÁRSKEJ FAKULTY, TECHNICKEJ UNIVERZITY

VO ZVOLENE 66 1/2024

SCIENTIFIC JOURNAL OF THE FACULTY OF WOOD SCIENCES AND TECHNOLOGY, TECHNICAL UNIVERSITY IN ZVOLEN 66 1/2024

Redakcia (Publisher and Editor’s Office): Technická univerzity vo Zvolene (Technical university in Zvolen); TUZVO Drevárska fakulta (Faculty of Wood Sciences and Technology)

T. G. Masaryka 2117/24, SK-960 01 Zvolen, Slovakia

Redakčná rada (Editorial Board): Predseda (Chairman): prof. Ing. Ján Sedliačik, PhD, TUZVO (SK)

Vedecký redaktor (Editor-in-Chief): prof. Ing. Ladislav Dzurenda, PhD, TUZVO (SK) Členovia (Members): prof. RNDr. František Kačík, DrSc. TUZVO (SK) prof. RNDr. Danica Kačíková, MSc. PhD., TUZVO (SK) prof. Ing. Ivan Klement, CSc. TUZVO (SK) prof. Ing. Jozef Kúdela, CSc. TUZVO (SK) prof. Ing. Mariana Sedliačiková, PhD. TUZVO (SK) prof. Ing. Jozef Štefko. CSc. TUZVO (SK doc. Ing. Hubert Paluš, PhD. TUZVO (SK)

Jazykový editor (Proofreader): Mgr. Žaneta Balážová, PhD. Technický redaktor (Production Editor): Ing. Michal Dudiak, PhD.

Medzinárodný poradný zbor (International Advisory Editorial Board):

Antov Petar Yordanov (Univ of Forestry, BG), Bekhta Pavlo (Ukrainian Nat Forestry Univ, UA), Deliiski Nencho (Univ of Forestry, BG), Hua Lee Seng (UiTM Cawangan Pahang, MY), Jelačić Denis (Univ Zagreb, HR), Kasal Bohumil (Tech Univ Carolo Wilhelmina Braunschweig, DE), Lubis Muhammad Adly Rahandi (Kyungpook Nat Univ, ID), Marchal Remy (Arts & Metiers ParisTech, FR), Németh Róbert (Univ Sopron, HU), Niemz Peter (Bern Univ Appl Sci, Architecture Wood & Civil Engn, CH), Orlowski Kazimierz A.(Gdansk Univ Technol, PL), Pohleven Franc (Univ Ljubljana, SI), Rogoziński Tomasz (Poznań Univ of Life Sci, PL), Teischinger Alfréd (Univ Nat Res & Life Sci, BOKU, AT), Smardzewski Jerzy (Poznań Univ of Life Sci, PL), Vlosky Richard P. (Louisiana State Univ, USA), Wimmer Rupert (Univ Nat Res & Life Sci, AT).

Vydala (Published by): Technická univerzita vo Zvolene, T. G. Masaryka 2117/24, 960 01 Zvolen, IČO 00397440, 2024

Náklad (Circulation) 80 výtlačkov, Rozsah (Pages) 172 strán, 14,63 AH, 14,76 VH

Tlač (Printed by): Vydavateľstvo Technickej univerzity vo Zvolene

Vydanie I. – jún 2024

Periodikum s periodicitou dvakrát ročne

Evidenčné číslo: 3860/09

Acta Facultatis Xylologiae Zvolen je registrovaný v databázach (Indexed in): Web of Science, SCOPUS, ProQuest, AGRICOLA, Scientific Electronic Library (Russian Federation), China National Knowledge Infrastructure (CNKI)

Za vedeckú úroveň tejto publikácie zodpovedajú autori a recenzenti. Rukopis neprešiel jazykovou úpravou.

Všetky práva vyhradené. Nijaká časť textu ani ilustrácie nemôžu byť použité na ďalšie šírenie akoukoľvek formou bez predchádzajúceho súhlasu autorov alebo vydavateľa.

© Copyright by Technical university in Zvolen, Slovak Republic.

ISSN (print) 1336–3824, ISSN (online): 2730-1176

01. NENCHO DELIISKI – LADISLAV DZURENDA – DIMITAR ANGELSKI – PAVLIN VITCHEV – KRASIMIRA ATANASOVA: CALCULATION OF THE THERMAL ENERGY AND ITS COMPONENTS REQUIRED FOR THAWING LOGS 5

02. VIKTÓRIA SATINOVÁ – SILVIA JÁNOŠÍKOVÁ – NADEŽDA LANGOVÁ – ZUZANA VIDHOLDOVÁ – JÁN IŽDINSKÝ: THE EFFECT OF TYPE OF WOOD-BASED RECYCLATE AND LOWQUALITY TIMBER IN PARTICLEBOARD ON MECHANICAL PROPERTIES OF FURNITURE JOINTS 17

03. DOMINIK HRUŠOVSKÝ – ROMAN RÉH: PROPERTIES OF PARTICLEBOARD MADE FROM RECYCLED MUNICIPAL WASTE AND WOOD PARTICLES ............................................................................ 33

04. SERGEI KAZITSIN – ALEKSEY NAMYATOV – MIKHAIL BAYANDIN – NINA GROTSKAYA: EFFECTS OF HYDRODYNAMIC TREATMENT OF WOOD PARTICLES ON MECHANICAL PROPERTIES OF WOOD-POLYMER COMPOSITES 47

05. SLÁVKA POBUCKÁ – LIBOR KALHOTKA – MONIKA LAICHMANOVÁ – KAREL ŠUHAJDA: MONITORING OF MICROCLIMATIC CONDITIONS AND THE OCCURRENCE OF MICROMYCETES IN CRAWL SPACE ....................................................... 59

06 PATRIK ŠTOMPF – JAROSLAVA ŠTEFKOVÁ: INFLUENCE OF MOISTURE CONTENT OF MHM SOLID WOOD WALL CONSTRUCTION MATERIALS ON THERMAL CONDUCTIVITY

75

07. MARTIN HALADEJ: NUMERICAL SIMULATION OF DYNAMIC MOISTURE SPREAD IN COMPACT FLAT ROOFS 91

08. MILENA HENKE – BARBARA LIS – TOMASZ KRYSTOFIAK: RHEOLOGICAL STUDY OF INDUSTRIAL VARNISHES AT VARIOUS TEMPERATURES 105

09. ANNA VILHANOVÁ – NADEŽDA LANGOVÁ: THE EFFECT OF SELECTED FACTORS ON THE MECHANICAL PROPERTIES OF THE SEAMS FOR UPHOLSTERY COVERS MADE OF SYNTHETIC LEATHER 115

10. ANNA JASIŃSKA – MACIEJ SYDOR – GRAŻYNA NIEDZIELA –LAURA SLEBIODA: TECHNOLOGICAL GOODNESS INDEX FOR FURNITURE DESIGN

11. ĽUDMILA TEREŇOVÁ – DOMINIK ŠPILÁK – KATARÍNA DÚBRAVSKÁ – JAROSLAVA ŠTEFKOVÁ: SIMULATION OF A COMPARTMENT FIRE EFFECT ON A LOAD-BEARING WALL MADE OF STRAW

125

139

12. MAREK TRENČIANSKY – RASTISLAV ŠULEK: AN ECONOMETRIC MODEL OF TIMBER DEMAND IN THE SLOVAK

13. MARTIN HALÁSZ – MARIANA SEDLIAČIKOVÁ – ANDREA JANÁKOVÁ SUJOVÁ – JARMILA SCHMIDTOVÁ: EXTERNAL DETERMINANTS OF FAMILY BUSINESS BEFORE AND DURING CORONACRISIS IN

ACTA FACULTATIS XYLOLOGIAE ZVOLEN, 66(1): 5 16, 2024

Zvolen, Technická univerzita vo Zvolene

DOI: 10.17423/afx.2024.66.1.01

CALCULATION OF THE THERMAL ENERGY AND ITS COMPONENTS REQUIRED FOR THAWING LOGS

Nencho Deliiski – Ladislav Dzurenda – Dimitar Angelski – Pavlin Vitchev –Krasimira Atanasova

ABSTRACT

An approach for calculating the thermal energy and its components required for thawing logs intended for veneer production is proposed. The approach is based on the use of two personal mathematical models. The influence of all combinations between 5 values of the initial wood temperature from −1 °C to −40 °C and 3 values of the wood moisture content above the hygroscopic range (0.4 kg·kg-1, 0.6 kg·kg-1, and 0.8 kg·kg-1) on the thermal energy and its four components required to thaw beech logs with a diameter of 0.4 m at operating temperature of the heating medium of 80 °C was investigated. The obtained results show that this energy changes in the range from 31.66 kWh·m-3 (at −1 °C and 0.4 kg·kg-1) to 95.36 kWh·m-3 (at −40 °C and 0.8 kg·kg-1). The approach could be applied to determine the energy required to thaw various frozen capillary-porous materials in practice.

Keywords: frozen logs; frozen bound water; frozen free water; thawing; thermal energy

INTRODUCTION

For the optimization of different thermal treatment processes, it is required that the distribution of the temperature field in the wood materials and the consumed energy for their heating are known. The intensity of heating and the consumption of energy depend on the dimensions and initial temperature of the wood materials, on the content and aggregate condition of the water in them, on the law of change and the values of the temperature of the heating medium, etc. (Chudinov, 1968; Kollmann and Côté, 1984; Shubin, 1990; Sohor and Kadlec, 1990; Lawniczak, 1995; Trebula and Klement, 2002; Videlov, 2003; Câmpean, 2005; Steinhagen, 2005; Pervan, 2009; Deliiski, 2003, 2004, 2011).

The correct and effective control of the heating process is possible only when its physics and the weight of the influence of each mentioned above and many other factors for the specific wood materials are well understood. The summary of the influence of these factors on the thermal treatment processes of the wood materials is a difficult task and its solution is possible only with the assistance of adequate mathematical models, which have increased complexity in cases where the heated wood contains ice

The development of such temperature-energy models is performed using partial differential equations and requires deep mathematical knowledge. Solving the models without any simplifications, as a rule, is done by developing very complex specialized software packages, using finite difference or finite element methods (Steinhagen, 1986, 1991; Steinhagen et al., 1987; Khattabi and Steinhagen, 1992, 1993, 1995; Deliiski, 2003;

2011, 2013b; Hadjiski, 2005; Deliiski and Dzurenda, 2010; Dzurenda and Deliiski, 2019; Tumbarkova, 2019; Deliiski et al., 2018, 2021; Niemz et al., 2023).

The availability of a simpler and more accessible approach to calculating the energy required for wood thawing would be of particular interest to the development, study, and implementation of science-based energy-saving modes for the thermal treatment of frozen wood materials.

Therefore, the aim of this work is to propose an approach for calculating the thermal energy and its components required for thawing frozen logs intended for the manufacture of veneer. It should offer relatively easy-to-apply (manually or with MS Excel) equations to determine all four types of the individual components of the mentioned energy, namely: for heating the frozen and non-frozen wood itself above the hygroscopic range, for melting the temperature-dependent frozen part of bound water, and for melting all the frozen free water in the wood.

MATERIAL AND METHODS

Material for research

This research was conducted on frozen beech (Fagus sylvatica L.) logs, which are commonly used in veneer production. The calculation of the energy required for thawing frozen logs was carried out for the case of steaming or boiling of such logs in equipment operating at atmospheric pressure and at a temperature of the processing medium of 80 °C

Figure 1 shows the change of the operating temperature tm in the commonly applied modes for heating of frozen wood materials in order to defrost them in equipment operating at atmospheric pressure (Chudinov, 1968; Shubin, 1990; Dzurenda and Deliiski, 2019). These modes consist of two stages, during which tm changes as follows:

Fig. 1 Change of the operating temperature tm in modes for thawing of wood at atmospheric pressure.

▪ During the first stage, in the course of time 0 – τ1, an increase in tm from tm0 to tm1 takes place by fully or partially opening the valve to introduce heat carrier to the thermal treatment equipment;

▪ During the second stage of the modes, in the course of time τ1 – τdefr, dosed introduction of heat carrier into this equipment is carried out in order to maintain a constant technologically permissible value of the operating temperature, equal to tm1 When the temperature at the slowest heating central point of the wood materials reaches 0 °C, this determines the moment of their complete defrosting, τdefr.

The symbols, units, and values of the main parameters of the studied logs, and also of their thawing modes, which were incorporated into the equations of the scientifically validated mathematical models given below, and were used in the computer simulations, are presented in Table 1.

Tab. 1 Main set parameters of frozen beech logs and their thawing modes, which were used during the computer simulations.

Parameter name

1. Diameter of the logs

2. Length of the logs

3. Basic density of the beech wood

4. Density of the ice in the frozen wood

5. Standardized fiber saturation point of the beech wood at 20 oC (i.e. at 293.15 K)

6. Moisture content of the logs (a – at u = 0.4 kg∙kg-1 , b – at u = 0.6

)

,

7. Initial temperature of the logs in the beginning of their thawing process: (d – at tw0 = 1 oC, e – at tw0 = 10 oC, f – at tw0 = 20 oC, g – at tw0 = 30 oC, and h – at tw0 = 40 oC)

8. Temperature of complete melting of the frozen bound water and start of melting of the frozen free water in the wood

9. Temperature of complete melting of the frozen free water in the wood

10.Initial temperature of the modes for logs’ thawing

11.Temperature of stage τ1 τ2 of the thawing modes

fw-end °C 0

12.Time constant for exponential increase of tm from tm0 to tm1 τe s

13.Temperature in the central point of the logs at the end of their complete thawing

Modelling of the 1D unsteady temperature change in frozen logs

When the length of the logs, L, is at least four times their diameter, D, the nonstationary temperature distribution along the radius can be determined using the following experimentally verified 1D model (Deliiski, 2011):

at initial condition

and boundary condition for conductive heat transfer:

Where: cw-eff.1,2,3 are the effective specific heat capacities of the frozen wood during 1st, 2nd , and 3rd temperature ranges of its thawing process, given below, J·kg 1·K 1; w-eff.1,2 effective thermal conductivities in radial direction of the frozen and defrosten wood respectively, W m-1 K-1; ρw – density of the wood, kg m-3; r – coordinate along the log

radius: 0 ≤ r ≤ R, m; R – radius of the log, m; T – temperature, K; Tw0 – initial temperature of the log, K; Tm – operating temperature of the defrosting medium, K; τ – time, s.

The mathematical descriptions of cw-eff.1,2,3, w-eff.1,2, and ρw given in (Deliiski, 2003; 2009, 2011, 2013a; Deliiski, et al., 2018, 2020) were used in solving model (1) − (3).

During the solving of the model (1) – (3), the current average mass temperature of the log, n Tavg , can be calculated according to the following equation (Deliiski, 2011):

The values of Tavg at the moment when the slowest changing temperature in the central point of the logs reaches 0 °C, i.e. values Tavg-end, and this is an indicator of the completion of the log thawing process, are needed below to calculate the energy that was consumed by the logs up to that moment

Mathematical description of the specific heat capacities of wood subjected to thawing

The compresenhive experimental study of the thawing process of logs with an initial temperatureofabout–30 °Cfromdifferentwoodspeciesandvariousmoisturecontentabove the hygroscopic range, which were carried out in (Tumbarkova, 2019; Deliiski et al., 2020b) show that this process can be separated into three ranges. During the first range, the frozen logs are heated at T ≤ 272.15 K (i.e. t ≤ –1 °C) until they reach the state required for starting and gradually melt the temperature-dependent part of frozen bound water in them. During the second range between –1 °C and 0 °C a further heating of the wood occurs until reaching the state needed for starting and melting all the frozen free water in it. During the third range above 0 °C further heating of the wood layers with already fully liquid water in them occurs.

The effective specific heat capacities of the logs during the pointed three ranges of the thawing process of wood above the hygroscopic range, cw-eff.1,2,3, which participate in equation (1) are equal to the following:

Where: cw-fr and cw-nfr are the specific heat capacities of frozen and defrosted (non-frozen) wet wood respectively, J·kg-1·K-1; cice-bw and cice-fw – specific heat capacities of the frozen bound and free water in the wood respectively, J·kg-1·K-1

Mathematical descriptions of the specific heat capacities cw-fr, cw-nfr, cice-bw and cice-fw were given in (Deliiski et al., 2018, 2020a; Tumbarkova, 2019). These descriptions are included below in an appropriate manner in the equations for calculation of the individual components of the energy requred to thaw logs.

Modelling of the energy consumption of frozen logs subjected to thawing

The total specific thermal energy consumption of frozen logs subjected to thawing (in kWh·m-3), Qw-total, can be expressed by the following model (Deliiski, 2013b):

Where: Qw-fr is the thermal energy required for heating of the frozen wood to a condition necessary to melt the frozen bound water in it; Qice-bw – energy required to melt the temperature-dependent amount of frozen bound water in the wood; Qice-fw – energy required

to melt the entire amount of frozen free water in the wood; Qw-nfr – energy required to heat the allready defrosted layers of the wood until reaching 0 oC in the central point of the materials subjected to thawing.

The individual components of the energy required for complete thawing of the frozen logs, Qw-total, can be calculated using the following equations (Deliiski, 2013b):

Where the individual specific capacities cw-fr-avg, cw-nfr-avg, cice-bw-avg and cice-fw-avg are calculated as arithmetic mean values for the respective temperature ranges, which are given in parentheses in the right-hand parts of eqs (6) – (9)

The temperature Tavg-end in eq. (9) is the average mass temperature of the logs at the end of their complet thawing, which is calculated with equation (4) upon reaching 0 °C in the central point of the fully defrosted logs, K.

Solving the models (1) – (3) and (5) – (9)

The numerical solving of the model (1) – (3) in order to determine the duration of the modesforthawing ofthestudied beechlogs, andalso oftheaveragewoodmasstemperature, Tavg, during these modes, is carried out with the help of own software packages in the calculation environment of Visual FORTRAN. An explicit finite-difference scheme was used to transform the individual model equations into a FORTRAN-friendly programming form, which excludes any simplifications of the model (Dorn and McCracken, 1972)

Those specified above in Table 1 were used as basic input data relating to the characteristics of the beech logs subjected to thawing and to the operating temperature parameters of the steaming or boiling modes.

From the obtained change of the temperature field along the radius of the logs, and in particular from the moment of reaching 0 °C in their central point, the durations of the log thawing modes, τdefr, were determined for the investigated three values of the wood moisture content u and five values of the initial wood temperature tw0

The values of the average mass temperature of the logs at τ = τdefr (refer to Fig. 1), Tavgend, calculated with equation (4) were used during the solving of eq. (9).

An Excel program was prepared to solve the eqs (5) – (9) jointly. With the help of this program, the change of all four components of the energy Qw-total required for thawing the investigated logs was calculated

Table 2 gives some of the data obtained for Tavg-end and some of those for the specific heat capacities of the logs, which were used in the calculation of Qw-total and its components. In order to facilitate the analysis of the data in this table, three parameters of the logs, which were previously also indicated in Table 1, are included in it.

Tab. 2 Data on the parameters and thermophysical characteristics of the studied beech logs, which were used in the calculations of the energy Qw-total and its components.

Parameter name

1. Basic density of the beech wood ρb kg∙m-3 560

2. Moisture content of the logs (a – at u = 0.4 kg∙kg-1 , b – at u = 0.6 kg∙kg-1 , c – at u = 0.8 kg∙kg-1) u kg∙

3. Fiber saturation point of the beech wood at 1 °C (i.e. at 272.15 K) ufsp(272.15)

4. Density of the wet beech wood equal to ρb·(1 + u) ρw kg∙m-3

5. Initial temperature of the logs in the beginning of their thawing: (d – at tw0 = 1 °C, e – at tw0 = 10 °C, f – at tw0 = 20 °C, g – at tw0 = 30 °C, and h – at tw0 = 40 °C)

6. Average mass temperature of the logs with u = 0.6 kg∙kg-1 at the end of their complete thawing, depending on tw0 tavg-end °C

7. Average specific heat capacity of log layers containing both frozen bound and free water at u = 0.6 kg∙kg-1 , depending on tw0 cw-fr-avg J·kg-1·K

8. Average specific heat capacity of completely defrosted layers of logs with u = 0.6 kg∙kg-1 , depending on tw0 cw-nfr-avg J·kg-1·K

9. Average specific heat capacity of the frozen bound water in logs with u = 0.6 kg∙kg-1 , depending on tw0

ice-bw-avg J·kg-1·K-1

10. Average specific heat capacity of the frozen free water in logs, depending on u cice-fw-avg J·kg-1·K-1

RESULTS AND DISCUSSION

Figure 2 and Figure 3 present, as an example, the change in the operating temperature, tm, temperature in the central point, twc, and the average mass temperature, tavg,of frozen logs with an initial temperature of –10 oC and –30 °C respectively, calculated with the equations (1) − (4) during logs’ thawing at the three investigated values of the wood moisture content u. Fig.s 4, 5, and 6 show the calculated with eqs. (5) – (9) change in the energy Qw-total and

its components for the cases of log moisture content of 0.4 kg.kg-1, 0.6 kg.kg-1 , and 0.8 kg.kg-1 respectively, depending on tw0.

Beechlogs

tm at tm1=80C

tavgatu=0.4kg/kg

tavgatu=0.6kg/kg

tavgatu=0.8kg/kg

twcat u=0.4kg/kg

twcat u=0.6kg/kg

twcat u=0.8kg/kg

2 Change in tm, twc, and tavg of logs with tw0= −10 oC during their thawing, depending on u.

Beechlogs

tm at tm1=80C

tavgatu=0.4kg/kg

tavgatu=0.6kg/kg

tavgatu=0.8kg/kg

twcat u=0.4kg/kg

twcat u=0.6kg/kg

twcat u=0.8kg/kg

3 Change in tm, twc, and tavg of logs with tw0= −30 oC during their thawing, depending on u.

In Figures 2 and 3 it is seen that complete thawing of the logs occurs as follows:

• for two = –10 °C: after 9.5 h, 12.0 h, and 14.0 h at u = 0.4, 0.6, and 0.8 kg·kg-1 respectively;

• for two = –30 °C: after 11.5 h, 13.5 h, and 15.5 h at u = 0.4, 0.6, and 0.8 kg·kg-1 respectively. At these values of defrosting duration, τdefr, the temperature of the central point of the logs reaches 0 °C, at which the melting of the entire amount of frozen water in the logs was completed. Then, at the end of thawing, the average mass temperature of the relatively most frequently subjected to thermal treatment logs with u = 0.6 kg·kg-1 are equal as follows: tavg-end = 49.7 °C at two = –10 °C and tavg-end = 51.5 °C at two = –30 °C. These and the other values of tavg-end calculated with eq (4) for all studied combinations between two and u were used to calculate the energy Qw-nfr according to eq. (9).

Itcanbenoted,thataspecificalmosthorizontalsectionsofretentionofthetemperature twc for a long period of time in the range from –1 °C to 0 °C in the center of the frozen logs (and also in all calculation points not shown in Fig. 2 and Fig. 3 in the inner layers of the studied logs) was observed. These sections are caused by the extremely small temperature conductivity of these points during the too long melting of the frozen free water in the wood (Deliiski, 2009; Tumbarkova, 2019; Niemz et al., 2023).

Figures 4, 5, and 6 show the change in the energy Qw-total and its components for the cases of log moisture content of 0.4 kg.kg-1, 0.6 kg.kg-1, and 0.8 kg.kg-1 respectively calculated with eq. (5) – (9), depending on tw0.

Beechlogs

=0.4m

m1 =80 oC

=0.4kg.kg-1

Qw-total Qw-nfr

Qice-fw Qw-fr

Qice-bw

Fig. 4 Changes in the energy Qw-total and its components required for thawing of logs with u = 0.4 kg·kg-1 ,depending on tw0.

, kWh.m -3

Beechlogs D =0.4m

tm1 =80 oC

u =0.6kg.kg-1

Qw-total Qw-nfr

Qice-fw Qw-fr

Qice-bw

tw0, oC

Fig. 5. Changes in the energy Qw-total and its components required for thawing of logs with u = 0.6 kg·kg-1 ,depending on tw0.

The analysis of the results presented in Fig. 4 to Fig. 6 allows the following statements to be made about the influence of tw0 and u on the energy Qw-total and each of its components:

• The total energy required for thawing the frozen logs increases with a decrease in the initial temperature of the wood tw0 according to a convex slightly curvilinear dependence Qw-total = f(tw0), as follows:

▪ at u = 0.4 kg·kg-1: from 31.66 kWh·m-3 at tw0 = −1 °C to 58.40 kWh·m-3

at

=

at u = 0.8 kg·kg-1: from 63.39 kWh·m-3 at tw0 = −1 °C to 95.36 kWh·m-3 at tw0 = −40 °C.

;

If the dependences Qw-total = f(tw0) calculated according to Equation (5), are approximated with straight lines, which connect their initial and final points it turns out that

each decrease in tw0 with 1 °C causes an increase in Qw-total with approx. 0.686 kWh·m-3 at u = 0.4 kg kg-1 , 0.751 kWh·m-3 at u = 0.6 kg kg-1, and 0.820 kWh·m-3 at u =0.8 kg kg-1 .

• The energy required to heat frozen wood to a state necessary to start melting the temperature-dependent fraction of bound water in the wood, Qw-fr, increases slightly with an increase in the moisture content u and almost linearly with а decrease in tw0, from 0 kWh·m-3 at tw0 = −1 °C for all u to the following values at tw0 = −40 °C: 16.43 kWh·m-3 at u = 0.4 kg kg-1, 19.33 kWh·m-3 at u = 0.6 kg kg-1, and 22.27 kWh·m-3 at u = 0.8 kg·kg-1 .

Beechlogs D =0.4m

tm1 =80 oC u =0.8kg.kg-1

Qw-total Qw-nfr

Qice-fw Qw-fr

Qice-bw

Fig. 6 Changes in the energy Qw-total and its components required for thawing of logs with u = 0.8 kg· kg-1 ,depending on tw0.

• The energy required to melt the temperature-dependent amount of frozen bound water in the wood, Qice-bw, decreases slightly with an increase in u, and increases according to a convex curved line with a decrease in tw0, from 0 kWh·m-3 at tw0 = −1 °C for all u to the following values at tw0 = −40 °C: 8.21 kWh·m-3 at u = 0.4 kg·kg-1, 7.19 kWh·m-3 at u = 0.6 kg·kg-1, and 6.39 kWh·m-3 at u = 0.8 kg·kg-1

• The energy required to melt the entire amount of frozen free water in the wood, Qice-fw, does not depend on tw0, but increases strongly with an increase in u, reaching the following values: 4.19 kWh·m-3 at u = 0.4 kg·kg-1, 14.30 kWh·m-3 at u = 0.6 kg·kg-1, and 22.27 kWh·m-3 at u = 0.8 kg·kg-1 .

• The energy Qw-nfr required to heat the completely defrosted layers of logs at the moment of reaching 0 °C in the log central point, when the average mass temperature, tavg-end, reaches values around 50±2 °C (see item 6 in Table 2), increases with an increase in u and when tw0 is lowered, as follows:

▪ at u = 0.4 kg·kg-1: from 27.47 kWh·m-3 at tw0 = −1 °C to 29.57 kWh·m-3 at tw0 = −40 °C; ▪ at u = 0.6 kg·kg-1: from 34.28 kWh·m-3 at tw0 = −1 °C to 37.05 kWh·m-3 at tw0 = −40 °C; ▪ at u = 0.8 kg.kg-1: from 41.22 kWh·m-3 at tw0 = −1 °C to 44.53 kWh·m-3 at tw0 = −40 °C

CONCLUSION

The present paper describes an approach for calculating the energy and its components required for thawing logs intended for veneer production. The approach is based on the use oftwopersonalmodels:a1Dunsteadymodelofthetemperaturedistributionalongtheradius

of frozen logs during their thawing, and a stationary model of the energy consumption of the logs subjected to thawing as a sum of its four multifactorial components.

The numerical solving of the 1D model in order to determine the duration of the modes for thawing of the logs, and also their average mass temperature during these modes is carried out with the help of own software packages in the calculation environment of Visual FORTRAN Professional. Using this program together with the own Excel program for solving thestationarymodel,theinfluenceof all combinations between5 values oftheinitial temperature of frozen beech logs (−1°C, −10°C, −20°C, −30°C, and −40 °C) and 3 values of their moisture content (0.4 kg·kg-1, 0.6 kg·kg-1, and 0.8 kg·kg-1) on the total energy and its components required to thaw logs with a diameter of 0.4 m at operating temperature of the heating medium of 80 °C was investigated.

It was found that the total energy changes in the range from 31.66 kWh·m-3 (at −1 °C and 0.4 kg·kg-1) to 95.36 kWh·m-3 (at −40 °C and 0.8 kg·kg-1).

When expressing the individual components of the total energyas a % of it, a decrease in the initial temperature from −1 °C to −40 °C causes the following change in these components at log moisture content of 0.6 kg·kg-1:

▪ the relative share of the energy required to heat the logs to a condition necessary to melt the frozen bound water in them increases from 0% to 24.8%;

▪ the relative share of the energy required to melt the temperature-dependent amount of frozen bound water in the logs increases from 0% to 9.2%;

▪ the relative share of the energy required to melt the entire amount of frozen free water in the logs decreases from 29.4% to 18.4%;

▪ the relative share of energy required to heat the already defrosted layers of the logs at the moment of reaching 0 °C in their central point decreases from 70.6% to 47.6%.

It can be noted that the approach presented in this work could be applied to determine the energy and its components required for thawing of various frozen capillary-porous materials in practice

REFERENCES

Câmpean,M.,2005.HeatTreatmentsofWood.TransilvaniaUniversityofBraşov,Braşov,Romania, 199 pp.

Chudinov, B. S., 1968. Theory of the Thermal Treatment of Wood. Nauka, Moscow, 255 pp.

Deliiski, N., 2003. Modelling and Technologies for Steaming Wood Materials in Autoclaves. Dissertation for DSc., University of Forestry, Sofia, 358 pp.

Deliiski, N., 2004. Modelling and Automatic Control of Heat Energy Consumption Required for Thermal Treatment of Logs. Drvna Industrija, 55(4), 181 199.

Deliiski, N., 2009. Computation of the 2-dimensional Transient Temperature Distribution and Heat Energy Consumption of Frozen and Non-Frozen Logs. Wood Research, 54(3), 67−78.

Deliiski, N., 2011. Transient Heat Conduction in Capillary Porous Bodies. Ahsan A. (ed.) Convection and Conduction Heat Transfer. Tech Publishing House, Rieka, Croatia, 149-176, https://doi.org/10.5772/21424

Deliiski, N.,2013a.Computationof the Wood Thermal Conductivity during Defrosting oftheWood. Wood Research, 58(4), 637 650.

Deliiski, N., 2013b. Modelling of the Energy Needed for Heating of Capillary Porous Bodies in Frozen and Non-Frozen States. Lambert Academic Publishing, Scholars’ Press, Saarbrücken, Germany, 106 pp., http://www.scholars-press.com//system/covergenerator/build/1060

Deliiski, N., Dzurenda, L.,2010. Modelling of the Thermal Processes in the Technologies for Wood Thermal Treatment. Technical University in Zvolen, Slovakia, 224 pp.

Deliiski, N., Dzurenda, L., Angelski, D., Tumbarkova, N., 2018. An Approach to Computing Regimes for Autoclave Steaming of Prisms for Veneer Production with a Limited Power of the

Heat Generator. Acta Facultatis Xylologiae Zvolen, 60(1), 101-112, https://doi.org/10.17423/afx.2018.60.1.11

Deliiski, N., Dzurenda, L., Tumbarkova, N., Angelski, D., 2020a Mathematical description of the latent heat of bound water in wood during freezing and defrosting. Acta Facultatis Xylologiae Zvolen, 62(1), 41-53, https://doi.org/10.17423/afx.2020.62.1.04

Deliiski, N., Dzurenda, L., Tumbarkova, N., 2020b Modelling of the Two-Dimensional Thawing of Logs in an Air Environment. In Valdman J. (ed.). Modelling and Simulation in Engineering –Selected Problems, Intech Open, London, 19 pp.

Deliiski, N., Dzurenda, L., Niemz, P., Angelski, D., Tumbarkova, N., 2021. Computing the 2D Temperature Distribution in Logs Stored for a Long Time in an Open Warehouse in Winter and during Subsequent Autoclave Steaming Acta Facultatis Xylologiae Zvolen, 63(1), 49-62, https://doi.org/10.17423/afx.2021.63.1.05

Dorn, W.S., McCracken, D. D., 1972. Numerical methods with FORTRAN IV: Case Studies, John Willey & Sons Inc., New York

Dzurenda, L., Deliiski, N., 2019. Thermal Processes in the Woodworking Technologies Technical University in Zvolen, Slovakia, 283 pp

Hadjiski, M., 2003. Mathematical models in advanced technological control systems. Automatics & Informatics, 37, 7-12.

Khattabi, A., Steinhagen, H. P., 1992. Numerical Solution to Two-dimensional Heating of Logs. Holz als Roh- und Werkstoff, 50 (7-8), 308-312

Khattabi, A., Steinhagen, H. P., 1993. Analysis of Transient Non-linear Heat Conduction in Wood Using Finite-difference Solutions. Holz als Roh- und Werkstoff, 51 (4), 272-278, https://doi.org/10.1007/BF02629373

Khattabi, A., Steinhagen, H. P., 1995. Update of “Numerical Solution to Two-dimensional Heating of Logs”. Holz als Roh- und Werkstoff, 53(1), 93-94.

Kollmann, F. F. , Côté, W. A. Jr., 1984. Principles of wood science and technology. I. Solid wood. Springer-Verlag, New York, Berlin, Heidelberg, 592 pp.

Lawniczak,M., 1995. Hydrothermal and plasticizingtreatment of wood. Part I. Boilingand steaming of wood. Agricultural Academy, Poznan, 149 pp.

Mörath, E., 1949. Das Dämpfen ubd Kochen in der Furnier- und Sperrholzindustrie. Holztehnik, No. 7.

Niemz, P., Teischinger, A., Sandberg, D. (Eds.), 2023. Springer handbook of wood science and technology. Springer Nature Switzerland AG, Cham, 2069 pp.

Pervan, S., 2009. Technology for Treatment of Wood with Water Steam. University in Zagreb, Zagreb, Croatia.

Shubin, G. S., 1990. Drying and Thermal Treatment of Wood. Lesnaya Promyshlennost, Moscow, 337 pp.

Sohor, M., Kadlec, P., 1990. Hydrothermal treatment of wood for production of veneer. Drevo, № 2.

Steinhagen, H. P., 1986 Computerized Finite-difference Method to Calculate Transient Heat Conduction with Thawing. Wood Fiber Science, 18 (3), 460-467.

Steinhagen, H. P., 1991 Heat Transfer Computation for a Long, Frozen Log Heated in Agitated Water or Steam – A Practical Recipe. Holz als Roh- und Werkstoff, 49 (7-8), 287-290, https://doi.org/10.1007/BF02663790

Steinhagen, H. P., 2005. Veneer block conditioning manual for veneer and plywood production Maderas. Cienciay Tecnología, 7 (1), 49–56.

Steinhagen, H. P., Lee, H. P., Loehnertz, S. P., 1987. LOGHEAT: A Computer Program of Determining Log Heating Times for Frozen and Non-Frozen Logs. Forest Products Journal, 37 (11-12), 60-64.

Trebula, P., Klement, I., 2002. Drying and Hydrothermal Treatment of Wood. Technical University in Zvolen, Slovakia, 449 pp.

Tumbarkova, N., 2019. Modelling of the Logs’ Freezing and Defrosting Processes and their Energy Consumption. PhD Dissertation, University of Forestry, Sofia, Bulgaria, 198 pp.

Videlov, H., 2003. Drying and Thermal Treatment of Wood. University of Forestry, Sofia, 335 pp.

AUTHORS’ ADDRESSES

Prof. Nencho Deliiski, DSc. University of Forestry, Faculty of Forest Industry Kliment Ohridski Blvd. 10 1797 Sofia, Bulgaria deliiski@netbg.com

Prof. Ing. Ladislav Dzurenda, PhD. Technical University in Zvolen Faculty of Wood Science and Technology Department of Woodworking T. G. Masaryka 24 960 01 Zvolen, Slovakia dzurenda@tuzvo.sk

Prof. Dimitar Angelski, PhD. University of Forestry, Faculty of Forest Industry Kliment Ohridski Blvd. 10 1797 Sofia, Bulgaria d.angelski@gmail.com

Assoc. Prof. Pavlin Vitchev, PhD. University of Forestry, Faculty of Forest Industry Kliment Ohridski Blvd. 10 1797 Sofia, Bulgaria p_vitchev@abv.bg

Assist. Prof. Krasimira Atanasova, PhD. University of Forestry, Faculty of Forest Industry Kliment Ohridski Blvd. 10 1797 Sofia, Bulgaria k_atanasova@ltu.bg

ACTA FACULTATIS XYLOLOGIAE ZVOLEN, 66(1): 17 31, 2024

Zvolen, Technická univerzita vo Zvolene

DOI: 10.17423/afx.2024.66.1.02

THE EFFECT OF TYPE OF WOOD-BASED RECYCLATE AND LOW-QUALITY TIMBER IN PARTICLEBOARD ON MECHANICAL PROPERTIES OF FURNITURE JOINTS

Viktória Satinová – Silvia Jánošíková – Nadežda Langová–Zuzana Vidholdová – Ján Iždinský

ABSTRACT

The effect of particleboard (PB) composition made of recycled or lower-quality timber on the mechanical properties of selected furniture joints is determined in the paper. The tested PBs were manufactured using recycled PB or blockboard from old furniture and lowerquality timber with brown or white rot. The laboratory-produced control PB with particle content of 100% sound spruce wood (Picea abies Karst. L.) and commercial PBs were used for comparison of the results The load capacity and stiffness of corner joints with the confirmat (ø5 × 50 mm) and wooden dowel (ø6 × 30 mm) and the withdrawal resistance and stiffness of the screw (ø3.5 × 30 mm) were tested. The corner joints were loaded under compression by bending moment in the angular plane. In terms of load-carrying capacity, control PB was the most suitable in achieving a load-carrying capacity of 7827.61 N∙mm for the confirmat and PB from recycled blockboard 4072.71 N∙mm when using the wooden dowel. As for joint stiffness, the best values achieved were 1316.00 N∙mm/° and 808.58 N∙mm/° for the PB from recycled blockboard using the confirmat and dowel, respectively. PB from recycled blockboard again showed the highest values of screw withdrawal resistance - for the edge withdrawal 416.61 N and for the surface withdrawal 556.44 N. Considering the values found for the investigated mechanical properties, it was assumed that the tested materials can be used as non-load-bearing elements in furniture construction

Keywords: wooden recyclate; particleboard; furniture joints; joint mechanical properties.

INTRODUCTION

Sustainable product initiatives aim to ensure that by 2030, a significant proportion of products available to consumers in the European Union are designed to be durable, energy and resource-efficient, more environmentally friendly, repairable, and recyclable, and preferably use recycled materials in their production. Eco-design, sometimes referred to as Design for the Environment, is an umbrella term describing techniques used to incorporate an environmental component into products and services before they enter the production phase (Directive 2009/125/EC, Act No. 529/2010 Coll. on Environmental Design and Use of Products) It can be performed by adopting various tools and methods, such as those based on the life cycle thinking principle (ISO 14006: 2020). The design of ecomaterials is changing from the single criterion of environmental consciousness to total life-cycle

considerations in the production and use of products. Life-cycle considerations demand checkpoints at three stages of product life: (1) processing stage: from the extraction of resources to the delivery of products; (2) utilization stage: the period during which products are used as intended; and (3) end-of-life stage: recycling or disposal after use (Halada and Yamamoto, 2001). Life cycle thinking is based on core principles of the Life Cycle Assessment (LCA) methodology according to ISO 14044:2020. The LCA techniques showed that particleboards (PBs) have a minimal impact on the environment, except for global warming if they were not landfilled after use (Rivela et al., 2006; Mohd Azman et al.,2021; Santos et al., 2021). According to the results of the study of Çınar (2005), standard PB had an environmental impact lower than standard fiberboard (72% improvement). For surface and edge finishes, a low-density laminate is preferred to a high-density laminate (36% improvement). Silva et al. (2021) investigated the potential of recycled wood and bioresins to make the PBs The iterative testing and LCA of PB resulted in the fact that the developed PBs were environmentally benign alternatives to conventional PB made of synthetic polymers and wood particles, reducing up to 95% of the environmental impacts of human toxicity, abiotic depletion, and other impacts compared to conventional practices.

Furniture is an apparatus needed in human daily life. The design and construction of furniture is an applied art. The requirements for furniture design are not only appealing appearance and current fashion but also sound functionality and structural safety (Wang and Lee, 2014).

In furniture manufacturing various materials, such as wood and wood-based panels are used. Wood-based panels such as medium-density fiberboard and PBs are widely used in manufacturing case-type furniture because the mechanical, physical, and surface qualities of the engineered panels are comparable to those of solid woods (Kasal et al., 2011). Today, PB is widely used in furniture manufacturing because PB is much cheaper than wood, fiberboards, and plywood (Bardak, 2018). In the past, various sources of wood are used for their production, mainly forest assortments, and secondary sources (edges, cuttings and sawdust). Today, the effort is to use old or recycled wood, or various lignocellulosic materials (Guler et al., 2004; Kwon et al., 2013; Kord et al., 2015; Wronka and Kowaluk, 2019; Iždinský et al., 2020; Iždinský et al., 2021; Wronka and Kowaluk, 2022; Vilkovský et al., 2022; Pelc and Kowaluk, 2023). There is still a need to look for other alternative sources of wood replacement in the production of PBs, such as agricultural residues (e.g., poppy husks, walnut, kiwi prunings, cotton seed hulls, rice straw-wood, vine prunings, pine cone, almond shells, wood flour) and non-wood plant fibers (Kucuktuvek et al., 2017).

However, the employment of fiberboard and PB requires a careful approach to the choice of joints connecting construction elements of such furniture (e.g., particular house furniture for sitting). The application of the same connectors and joints as in the case of solid wood may reduce the stiffness and strength of the construction and increase the time of its assembly, e.g., in particular house furniture for sitting (Smardzewski et al., 2015).

Joints fulfil necessary strength, technological, and operational-aesthetic functions in furniture construction. In general, joints are the weakest parts of a given piece of furniture, and furniture durability depends, first and foremost, on their quality (Podskarbi et al., 2016).

Furniture quality is determined by its form, aesthetics, functionality, ergonomy, rigidity, strength, and durability. The strength and durability of furniture are some of the most essential factors determining furniture value (Smardzewski and Majewski, 2013).

Following the analysis of the literature on the mechanical properties of corner joints for furniture purposes, Majewski et al. (2020) stated various aspects regarding corner joint rigidity, namely theinfluenceofmaterial densityas well as stiffness andrigidity offasteners; the effect of number of fasteners on joint stiffness; the influence of fastener/joint geometry

on joint stiffness; presence, type, and adhesives application technique; the effect of narrow surfaces finishing, use of edge banding, as well as its type and thickness; the effect of a fastener grain orientation changes in relation to the grain direction of the specimen on the pulled-out joint strength; the influence of the back panel assembly method on the strength of thecornerjoints;theinfluenceofthefastenersmountingforceonthejointstrength,theeffect of the guide holes diameter for screwed-in connectors on the joint strength.

It is very important that the newly created materials are suitable and compatible with the conditions of the furniture use. The aim of the study by Antov et al. (2020) was to evaluate the potential of using new eco-friendly recycled wood fibreboard bonded with magnesium lignosulfonate in furniture construction. For this purpose, the bending strength of L-shaped corner joints with mechanical fasteners was determined.

The L-type corner joints made from the developed composites demonstrated significantly lower bending capacity (from 2.5 to 6.5 times) compared to the same joints made from MDF panels. Nevertheless, the new eco-friendly composites can be efficiently utilised as a structural material in non-load-bearing applications.

The withdrawal capacity is based on the composite action between the screw thread of thewoodandhenceisdefinedbythewoodpropertiesandgeometricparametersofthe thread (Hoelz et al., 2022) For board materials, the position of the fastener relative to the plane of the plate plays a role. The effect of the thread pitch of confirmats in pine wood was evaluated by Sydor et al. (2015);they determined littleeffect onloading capacityfor confirmats placed perpendicular to the tangential plane. The load-bearing capacity of confirmats in the tangential plane was 15% higher than in the radial plane. Chen et al. (2016) investigated the pullout resistance of bamboo wood screws with higher resistance compared to that of MDF and PB.

In the work of Taj et al. (2009), the axial screw withdrawal resistance of a 4.8 mm diameter screw for beech is 2690 N, hornbeam 3000 N and poplar 1750 N. The pullout force value for a 6 mm diameter bolt for beech is 6111 N, oak 5307 N and pine 2975 N (Efe et al., 2004). The materials often used in furniture are not only commercial materials such as MDF and HDF, but sandwich materials giving the opportunity to improve the properties of the structures or to reduce the price can be used. For example, the three-layer board is made as a combination of PB, as the core, and layers of HDF or MDF as outer layers.

Jivkov et al. (2017) investigated 10 wood-based sandwich materials and two types of screw, 4 × 40 mm universal screw, and 7 × 50 mm, concluding that the type of wood-based materials (especially the effect of density) has a significant impact on the axial screw withdrawal resistance investigated; there is no correlation between the density of materials and screw withdrawal resistance; the highest withdrawal resistance for both types of screws was in beech plywood (4066 N), OSB, cherry veneered MDF and birch plywood. The lowest values were obtained in PB, a three-layer board with a core of PB sheathed with laminated HDF with a total thickness of 18 mm and MDF. According to this work, the lowest load capacity of the universal screw was in PB (920 N).

Although brown and white rot reduce the mechanical properties of wood, it is still a material that can be used in the production of composite materials. These materials are environmentally friendly and pose no health risk to humans. Since we want to verify the suitability of using PB made of recycled PB and lower quality wood in furniture construction, the aim of this paper is to verify and compare the mechanical properties of the corner joints and the screw withdrawal resistance The quality of the joints is also evaluated through the type and extent of damage to the joint.

MATERIALS AND METHODS

Manufacturing of PB

In the laboratory conditions at the Technical University in Zvolen, three-layer PB type P2 was produced for interior use. Four variants of PBs and one variant of control PB were produced (Tab. 1). The PBs contained particles from (a) old laminated PB furniture, (b) old veneered blockboard furniture, (c) lower-quality timber spruce wood (Picea abies, Kart. L.) with inactive brown rot (Famitopisi pinicola /Sw./ P. Karst.), or (d) lower-quality timber spruce wood (Picea abies, Kart. L.) with inactive white rot (Armillaria ostoyae /Romang. /Herink). The quantity of brown and white rot in timer is analyzed in Satinová et al. (2022). Only particles from sound spruce wood species (Picea abies, Kart. L.) were used for manufacturing the control PB

The particles were bonded with urea-formaldehyde (UF) adhesive with hardener and paraffin from KRONOSPAN s.r.o. The adhesive mixture was applied to the particles in a rotary mixing machine. The layered particles were cold-pressed in a low-temperature machine at a pressure of 1 MPa. The pressing was carried out in a CBJ 100-11 press (TOS, Rakovník, Czech Republic) according to a three-stage pressing diagram – maximum pressing plate temperature 240 ºC, maximum specific pressing pressure 5.23 MPa and with a pressing factor of 8 s·mm-1

PBs were subsequently conditioned in an environment with a temperature of 20±2 ºC and a relative humidity of 65±5%. The manufactured boards were 400 × 300 × 16 mm in size. A total of 6 pieces of board were manufactured for each type. The specimens were cut from the parts prepared this way. The control specimen was made in order to compare the production technology in the laboratory and commercial conditions. The commercial PB was supplied by JAF Holz Slovakia, s.r.o. The raw PB FunderMax E1E05 Homogen was type P2 with a density of 719 kg·m-3 (Tab. 1), which is suitable for the interior. An overview of the density of the PB used in the experiment is given in Tab 1. The density was determined following the requirements of the standard STN EN 323.

The test specimens of 50 × 150 × 16 mm were stored in an air-conditioned room at a temperatureof20±2 °Candrelativehumidityof60±5%foronemonth.Themoisturecontent of the specimens was determined following the requirements of standard STN EN 322.

Tab. 1 Density of commercial and laboratory manufactured PB used in the experiment.

Determination of the mechanical properties of the corner joints

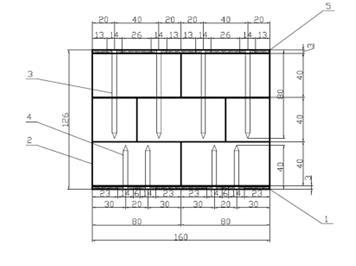

When determining the load capacity and stiffness of the corner joint, the following scheme (Fig. 1a) for loading the corner joint subjected to bending moment in the angular plane by compression is used. All geometric parameters for determining the mechanical properties of the corner joints can be derived from loading diagram (Figs. 1a and 2b). The load progression of the corner joints was executed according to force deformation diagram (Fig. 1d). Two types of furniture fasteners were tested: a) confirmat with the dimension of ø5 × 50 mm and b) wooden dowel with the dimension of ø6 × 30 mm. The dowels were glued with Technobond polyvinyl acetate adhesive of resistance class D3. It is a one-

component copolymer adhesive with good moisture resistance and is suitable for furniture from PB

Fig. 1 Specimen for stiffness and load capacity (a) dimensions of the specimens, (b) loading scheme with geometrical characteristics (c) execution of the test and (d) force deformation diagram.

r1, r2 – arms of the joint, the distance of the center of loading force from the pivot point (mm); l – force arm (mm); F – compression loading force (N); a – arm span (mm); c – displacement of the joint arms under load (mm); φp – joint angle before loading (°); φd – joint angle after loading (°)

The strength characteristics were investigated in the range from 10% to 40% of the maximum load of the joint. Based on the recorded forces and their associated displacements, the deformation, stiffness and load capacity were calculated using the following equations:

(a) Joint load capacity:

(b) Joint stiffness:

Where:Mu – load capacity (N∙mm)

Fmax – maximum loading force (N)

l – arm of the force (mm)

t – joint stiffness (N∙mm/°)

Δφ – angular deformation at load from 10% to 40% Fmax (°)

Determination of the withdrawal capacity and stiffness for the screw

When determining the axial screw withdrawal capacity, the methodology of STN EN 26891:1995 was followed. The test procedure requires estimating the maximum Fest load to be determined by experience, calculation, or preliminary tests. The procedure for loading the test body is shown in Fig. 2a. The dimensions of the test specimen for determining the screw withdrawal resistance are w x h x d (mm). The fasteners used in this test were ø3 5 × 30 mm screws. Pre-drilled holes of ø2.5 mm to a depth of 16 mm were drilled at the screw location. The size of the specimens was 50 × 50 mm. The screws were mounted in two directions on the surface and on the edge of the plate as shown in Fig. 2b

The determined strength characteristics are:

Screw withdrawal capacity: ���� =�������� (N)

Deformation at maximum withdrawal capacity: �� =�������� (mm)

Withdrawal stiffness (modulus of displacement) of the screws in the material (when it is pulled out) expresses the amount of force required to induce a unit length deformation (displacement). It is expressed by the steepness of the force-deflection curve. The withdrawal stiffness of the screw is determined by following equation:

Where: T – withdrawal stiffness (N∙mm-1),

ΔF – load capacity difference at 40% and 10% of maximum load (N),

Δu – displacement difference at 40% and 10% of maximum load (mm)

RESULTS AND DISCUSSION

Mechanical properties of the corner joints

The average values of the mechanical properties for corner joints loaded by compressive bending moment for the individual materials and connector types tested, are given in Tab. 2 and 3. The load-carrying capacity Mu (N∙mm) and stiffness of corner joints t (N∙mm/°) were evaluated. Based on the preliminary tests, it was found that for all materials and dimensions of the confirmat tested, the bending moment stress in the angular plane in tension exhibits a higher load-carrying capacity than the bending moment stress in the angular plane. Both the stiffness and the load capacity of the confirmats reach higher values of mechanical properties compared to pin joints, when stressed in the angular plane by compression. The highest values of these mechanical properties were achieved by the joints for PB with recycled block boards. The load capacity of the pin joint is 33% lower compared to the confirmat. The stiffness of the pin joint is 39% lower compared to the confirmat. Comparing the joints forPB with recycled block board with commercial PB, the commercial PB achieves higher values. The values of mechanical properties for the glued pin joint are smaller by 57% and for the confirmat by 35%.

Tab. 2 Mechanical properties of of the corner joint using wooden dowel and confirmat for tested PBs.

Mechanical properties of corner joint

Wooden dowel

PBs type:

Note: Value at parenthesis is coefficient of variance.

Confirmat

(a) (b)

Fig. 3 Force-displacement diagram of stress loading in the angular plane – average value (a) wooden dowel joint, (b) confirmat joint.

Tab. 3 One-way analysis of variance for the load-carrying capacity under compression bending and joint stiffness.

Effect

Note: DOF – Degree of freedom, F – Test value, p – Probability

Tab. 3 shows that at the significance level of 0.05, all investigated factors, i.e., type of fastener (p=0.000) and type of material or density (p=0.000), as well as their interaction (p=0.000), were significant for both the load capacity and stiffness of corner joints. It means that a change in any of the investigated factors will result in a change in the load capacity or the stiffness of the corner joint, respectively.

Withdrawal resistance and stiffness of the screw

The average values of the mechanical properties, the withdrawal resistance F (N) and withdrawal stiffness T (N∙mm-1) for screws ø3 5 × 30 mm loaded by axial force embedded in the tested materials at their surface and edge are given in Tab. 4.

Tab. 4 Mechanical properties of axially loaded screws ø3.5 × 30 mm embedded in the tested materials.

Note: Value at parenthesis is coefficient of variance.

Tab. 5 One-way analysis of variance for withdrawal stiffness and resistance of ø3.5 × 30 mm screws.

Sigma-restricted parameterization

Effective hypothesis decomposition Withdrawal stiffness

Note: DOF – Degree of freedom, F – Test value, p – Probability

Following the one-way analysis of variance (Tab. 5), the effect of selected factors on the withdrawal resistance of the screw ø3 5 × 30 mm was determined. The effect of all factors, density of materials and load direction acting simultaneously was statistically significant at the 5% significance level (p=0.007) when evaluating withdrawal stiffness. The effect of all factors, density of materials and load direction acting simultaneously, was statistically significant at the 5% significance level (p=0.001) when evaluating withdrawal resistance.

Higher withdrawal resistance and withdrawal stiffness was achieved when the screw was embedded in the surface of the specimen (perpendicular to the plane of the plate). The highest values of withdrawal resistance were achieved by the screw embedded in the surface of PB from recycled blockboard at the level of 556.44 N, which is 25.13% higher than for edge embedding with a capacity of 416.61 N. Compared to commercial PB (863.59 N), the withdrawal resistance for PB from recycled blockboard is 35.56% lower for surface embedding and 33.34% lower for edge embedding. The smallest withdrawal resistance values were performed by the brown rot specimen. Compared to the commercial PB, the values for the surface were lower by 60.69% and for the edge were lower by 64.88%. The screw withdrawal stiffness was also the highest for the PB from recycled blockboard compared to other tested materials. Compared to commercial PB, the withdrawal stiffness of PB from recycled blockboard withdrawal resistance for this material was lower, with a difference of 11.40% for surface embedding and 35.31% for edge embedding.

Fig. 4 shows characteristic damage of a glued wooden dowel joint and Fig. 5 shows damage of a confirmat joint.

(a) (b)

Fig. 5 Failure modes in some of the studied cases – confirmat at: (a) commercial PB and (b) PB with recycled blockboard.

The lower quality of the recycled PB and lower-quality timber was also reflected in the extent of damage around the fastener. According to the work (Langová and Jočšák, 2018), the extent of the damage for ø5 × 50 mm confirmat for spruce and beech joints was 10 mm in diameter around the fastener header. This damage was up to 30 mm in diameter for commercial PB and MDF materials. In the case of the materials tested in this study, the damage was manifested through the entire width of the specimen (50 mm). For a glued ø6 × 30 mm wooden dowel, the material was visible to be torn out at a distance of 18 mm from the centre of the dowel. Although the difference in densities between commercial PB and boards made of recyclate or using lower quality timber was negligible, there was a visible difference in damage at the glued joints. In commercial PB, the dowel breaks, while in the tested specimens thematerialaroundthe gluedjoint was tornout. Forthe confirmatdesigned for bonding PB when joining commercial PB, there was a bending of the confirmat, which was typical damage to the joint, in our tested specimens there was a breakage of a part of the structural board. This type of damage is related to the quality of bonding in the production of PB.

Discussion

The density values of the control PB were lower, which may be due to the production technology in laboratory conditions.

The measured and calculated load capacity values of corner joints PB made from recycled material and lower quality timber with commercial PB and solid timber can be compared. According to the work of Langová and Jočšák (2018), the assumption that the mechanical properties are influenced by the density of the material and the bolt dimension but also by the thickness of the material was confirmed. For comparison, the values of the strengthpropertiesofø5 ×50mmcompression-loadedcornerscrewedjointswerepresented

The highest load capacity values were achieved by the PB made from recycled blockboard 6113.94 N∙mm, which is comparable to the load capacity of commercial MDF with 12 mm thickness, ρ = 680 kg m-3 (6890.00 N mm). In the case of our recycled PB, the loading capacity was 3312.32 N∙mm, which is comparable to that of commercial PB with 12 mm thickness (3600.00 N mm) or to that of a joint made from spruce lumber with 12 mm thickness, ρ =392 kg∙m-3 (4580N∙mm).According to theworkof Antov et al. (2020), corner joint with ø7 × 50 mm confirmat made from eco-friendly boards, produced in the laboratory with a density of 720 kg m-3 and 15% magnesium lignosulfonate gluing content, based on the dry fibres, achieved a loading capacity value of 6950 N∙mm.

The effect of the diameter of the fastener and the density of the material to be bonded wasalsoconfirmedinthecaseofbondedjoints.In ourcase,ajointofPBmadefromrecycled blockboard (ρ = 649 kg m-3) with a glued wooden dowel ø6 × 30 mm achieved a loading capacity of 4072.71 N∙mm. In the work of Antov et al. (2020) a joint made of eco-friendly boards (ρ = 726.5 kg m-3) with a glued wooden dowel ø 8 × 30 mm achieved a two times more loading capacity of 8020.00 N∙mm. The highest stiffness values were achieved in the case of the PB made from recycled blockboard 1316.00 N∙mm/°, which is comparable to the stiffness of commercial PB with 12 mm thickness (1279.50 N mm/°) and 12 mm thick commercial MDF, ρ = 680 kg∙m-3 (1805.01 N∙mm/°). For both commercial materials, with 18 mm thickness, the joint stiffness was almost three times higher compared to the PB made from blockboard recyclate, which showed the best strength properties for both types of fasteners among the tested materials.

The axial screw withdrawal resistance is influenced by the density of the material. Higher values were achieved for screws stressed to pull perpendicularly from the surface of the specimen, which is also suitable from a practical point of view when attaching furniture fittings. In terms of the axial screw withdrawal resistance of ø3.5 × 30 mm screw, the best results were achieved by the PB made from recycled blockboard (556.44 N), which is almost 1.5 times less compared to commercial PB. Compared to spruce parallel to the grain in the tangential and radial directions (1117.00 N) and perpendicular to the grain (1034.00 N), it is 2 times less.

In the work of Pereira et al. (2018), panels reinforced fibers reached about 74% of the maximum strength achieved by MDF samples. Panels reinforced with pejibaye showed the worst mechanical performance. However, hybridization between pejibaye and fibers resulted in a performance improvement of approximately 50% in the maximum withdrawal load comparing with panels reinforced only with pejibaye fibers. The results of Yorur et al. (2020) indicated that the average direct screw withdrawal resistance ranged from 695 N to 2076 N for frontal test blocks, while for lateral in MDF it ranged from 79 N to 1634 N. For PB frontal test blocks, the average direct screw withdrawal resistance ranged from 474 N to 1646 N, while for lateral it ranged from 190 N to 1313 N. The results of Sackey et al. (2008) studies indicate that not only the content of fine particles, but also the ratio of all fractions with particle size strongly influences the efficiency and strength of the bond. In three-ply particleboards with a low target density, replacing 20% of the fines content of the total slurry with coarse particles increased the internal joint strength by 40% and the screw adhesion by 18%. Wronka and Kowaluk (2022) reported that the screw withdrawal resistance decreases with subsequent re-milling of the PB to produce the PB out of recovered particles. The progressive milling of the PB leads to achieving a fraction of the fine-size particles of growing bulk density,whichinfluences the density profile ofthepanels produced, especially of the face zone. This local densification allows the surface soundness to be kept high, irrespective of the decrease in other mechanical parameters, such as internal bond and screw withdrawal resistance.

In the event of a decrease in forest resources, it is possible to produce PB from various rawlignocellulosicmaterials. Several studies have dealt with this area.Basedonthefindings ofthesestudies, we can concludethatsources ofagricultural rawmaterials suchas cane stalk (Kord et al., 2015) and lignocellulosic particles of raspberry Rubus idaeus L. (Kowaluk et al., 2019) or rice husks (Kwon et al. 2013) meet the standard and in some cases PB had improved physical and mechanical properties, therefore, they are a suitable material for the production of PB.

CONCLUSION

• Comparing results for tested mechanical properties of this study with other works carried out under the same loading conditions and dimensions of the test bodies, it can be concluded that particleboard made from recycled materials and lower-quality timberachieves significantlylowerstrength properties comparedto commercial PBs. These properties are evaluated through the mechanical resistance of the joints. Therefore, these materials find application in non-load-bearing elements of furniture structures In the case of brown rot, the boards can be used as part of decorative interior elements.

• The influence of the proportion of recycled or reduced quality timber is reflected in the density of the material and subsequently in the strength properties of the joints, with the highest values achieved by the PB made from recycled blockboard. Based on the determined strength characteristics of the joints, producing structural boards by adding recyclate and not by adding timber of lower quality is recommended. When using a proportion of timber with brown and white rot, the strength properties of the joints show the lowest values.

• The extent of damage around the fastener highlights the need to reconsider the spacing of fasteners in structural joints but also the correct choice of fastener. A larger wooden dowel diameter is recommended for bonded joints.

• Asthematerialisrecommendedfornon-load-bearingordecorativeinteriorelements, examining the adhesion of decorative veneers or foils is advisable.

REFERENCES

Antov, P., Jivkov, V., Savov, V., Simeonova, R., Yavorov, N., 2020. Structural application of ecofriendlycompositesfromrecycledwoodfibresbondedwithmagnesium lignosulfonate.Applied Sciences 10(21), 7526. https://doi.org/10.3390/app10217526

Bardak, S., 2018. Predicting the impacts of various factors on failure load of screw joints for particleboard using artificial neural networks. BioResources 13(2), 3868–3879. https://doi.org/10.15376/biores.13.2.3868-3879

Çinar,H., 2005. Eco-designandfurniture: Environmental impactsofwood-based panels, surface and edge finishes. Forest Products Journal, 55(11), 27–33.

Directive 2009/125/EC of the European Parliament and of the Council of 21 October 2009 establishing a framework for the setting of ecodesign requirements for energy-related products. [Access 2023-11-28]. Available: https://eur-lex.europa.eu/eli/dir/2009/125/oj

Efe, H., Erdil, Y.Z., Kasal, A., Imirzi, H.O., 2004. Withdrawal strength and moment resistance of screwed T-type end-to-side grain furniture joints. Forest Products Journal, 54(11), 91–98.

EN ISO 14044:2020. Environmental Management - Life Cycle Assessment - Requirements and Guidelines.

Guler, C., Ozen, R., 2004. Some properties of particleboards made from cottonstalks (gossypium hirsitum l.). Holz roh werkst 62: 40-43.

Halada, K., Yamamoto, R., 2001. The current status of research and development on ecomaterials around the world. MRS bulletin, 26(11), 871–879. https://doi.org/10.1557/mrs2001.227

Hoelz, K., Doerner, P.T., Hohlweg, J., Matthiesen, S., 2022. Influence of thread parameters on the withdrawal capacity of wood screws to optimize the thread geometry. European Journal of Wood and Wood Products 80(3), 529–540. https://doi.org/10.1007/s00107-022-01792-9

Chen, Y., Zhu, S., Guo, Y., Liu, S., Tu, D., Fan, H., 2016. Investigation on withdrawal resistance of screws in reconstituted bamboo lumber. Wood Research 61(5), 799–810.

Iždinský, J., Vidholdová, Z., Reinprecht, L., 2020. Particleboards from recycled wood. Forests, 11(11), 1166.

Iždinský, J., Reinprecht, L., Vidholdová, Z., 2021. Particleboards from recycled pallets. Forests, 12(11), 1597.

Jivkov, V., Kyuchukov, B., Simeonova, R., Marinova, A., 2017. Withdrawal capacity of screws and confirmat into different wood-based panels. in Proceedings of the The XXVIIIth International Conference Research for Furniture Industry, Poznan, Poland, 21–22.

Kasal, A., Yüksel, M.F., Fathollahzadeh, A., Erdil, Y.Z., Yildirim, N., 2011. Ultimate failure load and stiffness of screw jointed furniture cabinets constructed of particleboard and mediumdensity fiberboard. Forest Products Journal 61, 155–160. https://doi.org/10.13073/0015-747361.2.155

Kord, B., Roohani, M., Kord, B., 2015. Characterization and utilization of reedstem as a lignocelulosic resource for particleboard production. Maderas. Ciencia ytecnología 17(3): 517524.

Kowaluk, G., Wronka, A., 2019. Influence of density on selected properties of furniture particleboards made of raspberry rubus idaeus l. Lignocellulosic particles. Annals of warsaw university of life sciences sggw forestry and wood technology, vol. 105, pp. 62-70. https://doi.org/10.5604/01.3001.0013.7719

Kucuktuvek, M., Kasal, A., Kuskun, T., Erdil, Y. Z., 2017. Utilizing poppy husk-based particleboards as an alternative material in case furniture construction. BioResources 12(1), 839–852. https://doi.org/10.15376/biores.12.1.839-852

Kwon, J. H., Ayrilmis, N., Han, T. H., 2013. Enhancement of flexural properties and dimensional stability of rice husk particleboard using wood strands in face layers. Composites Part B: Engineering, 44(1), 728-732.

Langová, N., Joščák, P. 2018. Mechanical properties of screw of furniture constructions. 1st edn. ed. Publishing House of the Technical University, Zvolen (in Slovak)

Majewski, A., Krystofiak, T., Smardzewski, J., 2020. Mechanical properties of corner joints made of honeycomb panels with double arrow-shaped auxetic cores. Materials 13, 4212. https://doi.org/10.3390/ma13184212

Mohd Azman, M.A.H., Ahmad Sobri, S., Norizan, M.N., Ahmad, M.N., Wan Ismail, W.O.A.S., Hambali, K.A., Hairi, M.H., Hermawan, A., Mohamed, M., Teo, P.T., Taharin, M. R., Noor, N.A.M.,2021.Lifecycleassessment (LCA)of particleboard: investigationoftheenvironmental parameters. Polymers 13, 2043. https://doi.org/10.3390/polym13132043

Pelc, O., Kowaluk, G., 2023. Selected physical and mechanical properties of particleboards with variable shares of nettle Urtica dioica L. lignocellulosic particles. Annals of Warsaw University of Life Sciences SGGW Forestry and Wood Technology, vol. 123, pp. 30-40. https://doi.org/10.5604/01.3001.0053.9307

Pereira,A.A.,d'Almeida,J.R.,2018.Mechanicalandphysicalscrewwithdrawalpropertiesbehavior of agglomerated panels reinforced with coir and pejibaye fibers. Wood Material Science & Engineering, 13(5), 286-295.

Podskarbi, M., Smardzewski, J., Moliński, K., Molińska-Glura, M., 2016. Design methodology of new furniture joints. Drvna industrija 67(4), 371–680.

Rivela, B., Hospido, A., Moreira, T., Feijoo, G. 2006. Life cycle inventory of particleboard: A case study in the wood sector. The International Journal of Life Cycle Assessment 11, 106–113. https://doi.org/10.1065/lca2005.05.206

Sackey, E., Semple, K., Won Oh, S., Smith, G.D., 2008. Improving core bond strength of particleboard through particle size redistribution. Wood Fiber Sci 40(2): 214-224. https://wfs.swst.org/index.php/wfs/article/view/752

Santos, A., Carvalho, A., Barbosa-Povoa, A., 2021. An economic and environmental comparison between forest wood products–Uncoated woodfree paper, natural cork stoppers and particle boards. Journal of Cleaner Production 296, 26469. https://doi.org/10.1016/j.jclepro.2021.126469

Satinová, V., Hlaváč, P., Iždinský, J., Reinprecht, L., 2022. Rot evaluation in spruce logs and rot reflection into dimensions of chips for particleboards. Acta Facultatis Xylologiae Zvolen, 64(2), 5-16.

Silva, V.U., Nascimento, M.F., Oliveira, P.R., Panzera, T.H., Rezende, M.O., Silva, D.A.L., de Moura Aquino, V.B., Lahr, F.A.R. and Christoforo, A.L., 2021. Circular vs. linear economy of building materials: A case study for particleboards made of recycled wood and biopolymer vs. conventional particleboards. Construction and Building Materials 285, 122906. https://doi.org/10.1016/j.conbuildmat.2021.122906

Smardzewski, J., İmirzi, H. O., Lange, J., Podskarbi, M., 2015. Assessment method of bench joints made of wood-based composites. Composite Structures 123, 123–131. https://doi.org/10.1016/j.compstruct.2014.12.039

Smardzewski, J., Majewski, A. 2013. Strength and durability of furniture drawers and doors. Materials & Design 51, 61–66. https://doi.org/10.1016/j.matdes.2013.03.101

STN EN 322: 1995. Wood-based panels. Determination of moisture content.

STN EN 323: 1996. Wood-based panels. Determination of density.

STN EN 26891: 1995 Timber structures. Joints made with mechanical fasteners. General principles for the determination of strength and deformation characteristics.

Sydor,M.,Zmyślony,G.,Pinkowski,G.,Szymański,W.,2015.Theinfluenceofpitchontheholding power ofscrewsinscotspinewood. Annalsofwarsawuniversityoflifesciences-sggw.Forestry and wood technology 90, 193–197.

Taj, M. A., Kazemi Najafi, S., Ebrahimi, G , 2009 Withdrawal and lateral resistance of wood screw in beech, hornbeam and poplar. In European Journal of Wood and Wood Products (Vol. 67, Issue 2, pp. 135–140). Springer Science and Business Media LLC. https://doi.org/10.1007/s00107-008-0294-9

The Act No. 529/2010 Coll. on Environmental design and use of products (“Eco-design Act”) [online]. [Access 2023-11-28]. Available: https://www.slov-lex.sk/pravnepredpisy/SK/ZZ/2010/529/

The Act No. 529/2010 Coll. on Environmental design and use of products (“Eco-design Act”) [online]. [Access 2023-11-28]. Available: https://www.slov-lex.sk/pravnepredpisy/SK/ZZ/2010/529/

Vilkovský, P., Vilkovská, T., Klement, I., Čunderlík, I., 2022. The Analysis Effect of Selected Factors on the Shear Strength of Woodbark at Different Wood Species. Forests, 13, 637. https://doi.org/10.3390/f13050637

Wang, Y., Lee, S. H., 2014. Design and analysis on interference fit in the hardwood dowel-glued joint by finite element method. Procedia Engineering 79, 166–172. https://doi.org/10.1016/j.proeng.2014.06.326

Wronka, A.; Kowaluk, G , 2022. The Influence of Multiple Mechanical Recycling of Particleboards on Their Selected Mechanical and Physical Properties Materials 15, 23: 8487. https://doi.org/10.3390/ma15238487

Yorur, H., Birinci, E., Gunay, M. N., Tor, O., 2020. Effects of factors on direct screw withdrawal resistance in medium density fiberboard and particleboard. Maderas. Ciencia y tecnología, 22(3), 375-384.

ACKNOWLEDGMENT

This work was supported by the Scientific Grant Agency of the Ministry of Education, Science, Research, and Sport of the Slovak Republic Grant No. 1/0665/22 (50%) and 1/0264/22 (50%)

AUTHORS’ ADDRESSES

Ing. Viktória Satinová, PhD. Ing. Zuzana Vidholdová, PhD.

Ing. Ján Iždinský, PhD.

Technical University in Zvolen Faculty of Wood Sciences and Technology, Department of Wood Technologies

T. G. Masaryka 24 960 01 Zvolen Slovak Republic xsatinova@is.tuzvo.sk zuzana.vidholdova@tuzvo.sk jan.izdinsky@tuzvo.sk

Ing. Silvia Jánošíková

doc. Ing. Nadežda Langová, PhD. Technical University in Zvolen Faculty of Wood Sciences and Technology, Department of Furniture and Wood Products

T.G. Masaryka 24 960 01 Zvolen Slovak Republic xvanikova@is.tuzvo.sk langova@tuzvo.sk

ACTA FACULTATIS XYLOLOGIAE ZVOLEN, 66(1): 33 46, 2024

Zvolen, Technická univerzita vo Zvolene

DOI: 10.17423/afx.2024.66.1.03

PROPERTIES OF PARTICLEBOARD MADE FROM RECYCLED MUNICIPAL WASTE AND WOOD PARTICLES

Dominik Hrušovský – Roman Réh

ABSTRACT

Particleboard consumption in the furniture industry is high, and the wood raw material costs required for particleboard production are also high. Therefore, the incorporation of cheaper recycled raw materials into the particleboard structure is welcome and the economic costs of their production are reduced. The aim of this research was to find out the possibilities of processing recycled municipal waste in a commonly produced structure and incorporating it into the particleboard in an optimal proportion. Another goal was to determine the effect of the recycled material proportion on the selected particleboard physical and mechanical properties so that boards can be used for common furniture interior applications. Singlelayer particleboard with 10%, 15%, 20%, 25% and 30% of recycled waste were produced, followed by three-layer boards with the proposed optimal 15% recycled waste in their core layer. The following properties of particleboard were tested: flexural strength, swelling, water absorption, density (according to the relevant provisions of EN). The effect of the proportion of recycled waste on board properties was manifested in comparison with the control samples, the reduction of the mechanical values was moderate. The bending strength values of three-layer particleboards with a 15% recycled waste content in their core layer were at an average level of 9.7 N/mm2. The required level of bending strength of 11 N/mm2 was not achieved. It was caused by the recycled elements manufactured shapes which were not slim enough and, in combination with the slim wood particles, worsened the properties of the manufactured particleboard. Adjusting the recycled elements' shape and pressing conditions makes achieving the standard required values of the particleboard properties possible.

Keywords:particleboard;recycledplasticwaste;physicalproperties;mechanicalproperties

INTRODUCTION

Technologies in the woodworking industry are considering a number of innovations and advances in the use of recycled materials, as the conservation of natural resources and recycling become an increasingly important issue. The trend of today is the recycling of man-made waste, which is suitable, even necessary, to be processed and thereby reduce its volume (Irle et al., 2012, Barbu et al., 2014).

Even manufacturers of wood composite boards are influenced by new trends and increasingly strict ecological criteria. In order to reduce the cost of input raw materials, they are forced to process recycled waste, and therefore the technological equipment and tools used in woodworking plants are adapting to this trend, becoming flexible in processing

different input materials (Maloney 1993, Ihnát et al. 2020, Lübke and Ihnát 2018, Adeniran 2021).