ACTA FACULTATIS XYLOLOGIAE ZVOLEN

VEDECKÝ ČASOPIS SCIENTIFIC JOURNAL

Vedecký časopis Acta Facultatis Xylologiae Zvolen uverejňuje pôvodné recenzované vedecké práce z oblastí: štruktúra a vlastnosti dreva, procesy spracovania, obrábania, sušenia, modifikácie a ochrany dreva, termickej stability, horenia a protipožiarnej ochrany lignocelulózových materiálov, konštrukcie a dizajnu nábytku, drevených stavebných konštrukcií, ekonomiky a manažmentu drevospracujúceho priemyslu. Poskytuje priestor aj na prezentáciu názorov formou správ a recenzií kníh domácich a zahraničných autorov.

Scientific journal Acta Facultatis Xylologiae Zvolen publishes peer-reviewed scientific papers covering the fields of wood: structure and properties, wood processing, machining and drying, wood modification and preservation, thermal stability, burning and fire protection of lignocellulosic materials, furniture design and construction, wooden constructions, economics and management in wood processing industry. The journal is a platform for presenting reports and reviews of books of domestic and foreign authors.

VEDECKÝ ČASOPIS DREVÁRSKEJ FAKULTY, TECHNICKEJ UNIVERZITY

VO ZVOLENE 66 2/2024

SCIENTIFIC JOURNAL OF THE FACULTY OF WOOD SCIENCES AND TECHNOLOGY, TECHNICAL UNIVERSITY IN ZVOLEN 66 2/2024

Redakcia (Publisher and Editor’s Office): Technická univerzity vo Zvolene (Technical university in Zvolen); TUZVO Drevárska fakulta (Faculty of Wood Sciences and Technology)

T. G. Masaryka 2117/24, SK-960 01 Zvolen, Slovakia

Redakčná rada (Editorial Board):

Predseda (Chairman): prof. Ing. Ján Sedliačik, PhD, TUZVO (SK)

Vedecký redaktor (Editor-in-Chief): prof. Ing. Ladislav Dzurenda, PhD, TUZVO (SK) Členovia (Members): prof. RNDr. František Kačík, DrSc. TUZVO (SK) prof. RNDr. Danica Kačíková, MSc. PhD., TUZVO (SK)

prof. Ing. Ivan Klement, CSc. TUZVO (SK) prof. Ing. Jozef Kúdela, CSc. TUZVO (SK) prof. Ing. Mariana Sedliačiková, PhD. TUZVO (SK) prof. Ing. Jozef Štefko. CSc. TUZVO (SK doc. Ing. Hubert Paluš, PhD. TUZVO (SK)

Jazykový editor (Proofreader): Mgr. Žaneta Balážová, PhD. Technický redaktor (Production Editor): Ing. Michal Dudiak, PhD.

Medzinárodný poradný zbor (International Advisory Editorial Board): Antov Petar Yordanov (Univ of Forestry, BG), Bekhta Pavlo (Ukrainian Nat Forestry Univ, UA), Deliiski Nencho (Univ of Forestry, BG), Hua Lee Seng (UiTM Cawangan Pahang, MY), Jelačić Denis (Univ Zagreb, HR), Kasal Bohumil (Tech Univ Carolo Wilhelmina Braunschweig, DE), Lubis Muhammad Adly Rahandi (Kyungpook Nat Univ, ID), Marchal Remy (Arts & Metiers ParisTech, FR), Németh Róbert (Univ Sopron, HU), Niemz Peter (Bern Univ Appl Sci, Architecture Wood & Civil Engn, CH), Orlowski Kazimierz A.(Gdansk Univ Technol, PL), Pohleven Franc (Univ Ljubljana, SI), Rogoziński Tomasz (Poznań Univ of Life Sci, PL), Teischinger Alfréd (Univ Nat Res & Life Sci, BOKU, AT), Smardzewski Jerzy (Poznań Univ of Life Sci, PL), Vlosky Richard P. (Louisiana State Univ, USA), Wimmer Rupert (Univ Nat Res & Life Sci, AT).

Vydala (Published by): Technická univerzita vo Zvolene, T. G. Masaryka 2117/24, 960 01 Zvolen, IČO 00397440, 2024

Náklad (Circulation) 80 výtlačkov, Rozsah (Pages) 171 strán, 14,07 AH, 14,20 VH

Tlač (Printed by): Vydavateľstvo Technickej univerzity vo Zvolene

Vydanie I. – december 2024

Periodikum s periodicitou dvakrát ročne

Evidenčné číslo: 3860/09

Acta Facultatis Xylologiae Zvolen je registrovaný v databázach (Indexed in): Web of Science, SCOPUS, ProQuest, AGRICOLA, Scientific Electronic Library (Russian Federation), China National Knowledge Infrastructure (CNKI)

Za vedeckú úroveň tejto publikácie zodpovedajú autori a recenzenti. Rukopis neprešiel jazykovou úpravou.

Všetky práva vyhradené. Nijaká časť textu ani ilustrácie nemôžu byť použité na ďalšie šírenie akoukoľvek formou bez predchádzajúceho súhlasu autorov alebo vydavateľa.

© Copyright by Technical university in Zvolen, Slovak Republic. ISSN (print) 1336–3824, ISSN (online): 2730-1176

01. KAZIMIERZ A. ORLOWSKI – DANIEL CHUCHALA – MONIKA SERAFINOWICZ – SYLWIA KOWALSKA: THE EFFECT OF BEECH WOOD DRYING ON HARDNESS IN THE LONGITUDINAL DIRECTION FROM THE BEGINNING TO THE REAR OF THE SAMPLES ...................................................................................................... 5

02. IVAN KLEMENT – TATIANA VILKOVSKÁ – PETER VILKOVSKÝ: CROSS WARPING DURING VARIOUS DRYING PROCESSES OF BEECH WOOD (FAGUS SYLVATICA L.) ....................... 13

03. LADISLAV DZURENDA – MICHAL DUDIAK: THE EFFECT OF STEAMING ON THE COLOR CHANGE OF FALSE HEARTWOOD BEECH 23

04. ZUZANA VIDHOLDOVÁ – GABRIELA SLABEJOVÁ – JOZEF KÚDELA – JÁN SVOCÁK: THE EFFECT OF NATURAL WEATHERING ON STABILITY OF COATING SYSTEM WITH SELFHEALING MICROCAPSULES ..................................................................... 35

05 RICHARD NADÁNYI – MICHAELA DŽUGANOVÁ – ALEŠ HÁZ: OPTIMIZED LIGNIN RECOVERY FROM BLACK LIQUOR FOR ENHANCED MECHANICAL PROPERTIES OF ACRYLONITRILE BUTADIENE RUBBER COMPOSITES .......................................................

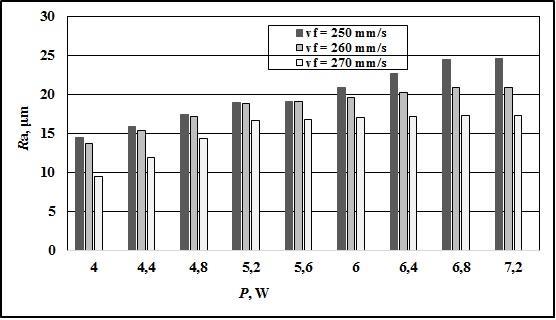

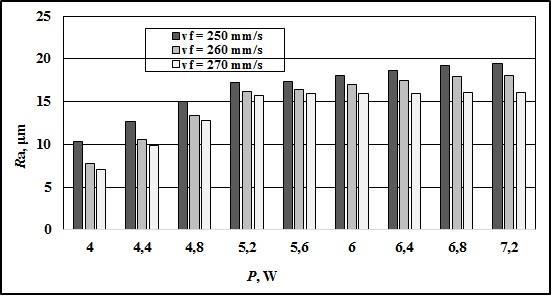

06 LUKÁŠ ADAMČÍK – RICHARD KMINIAK – ADRIÁN BANSKI: COMPARISON OF THE ROUGHNESS OF THE CNC MILLED SURFACE OF SELECTED WOOD SPECIES ............................................. 61

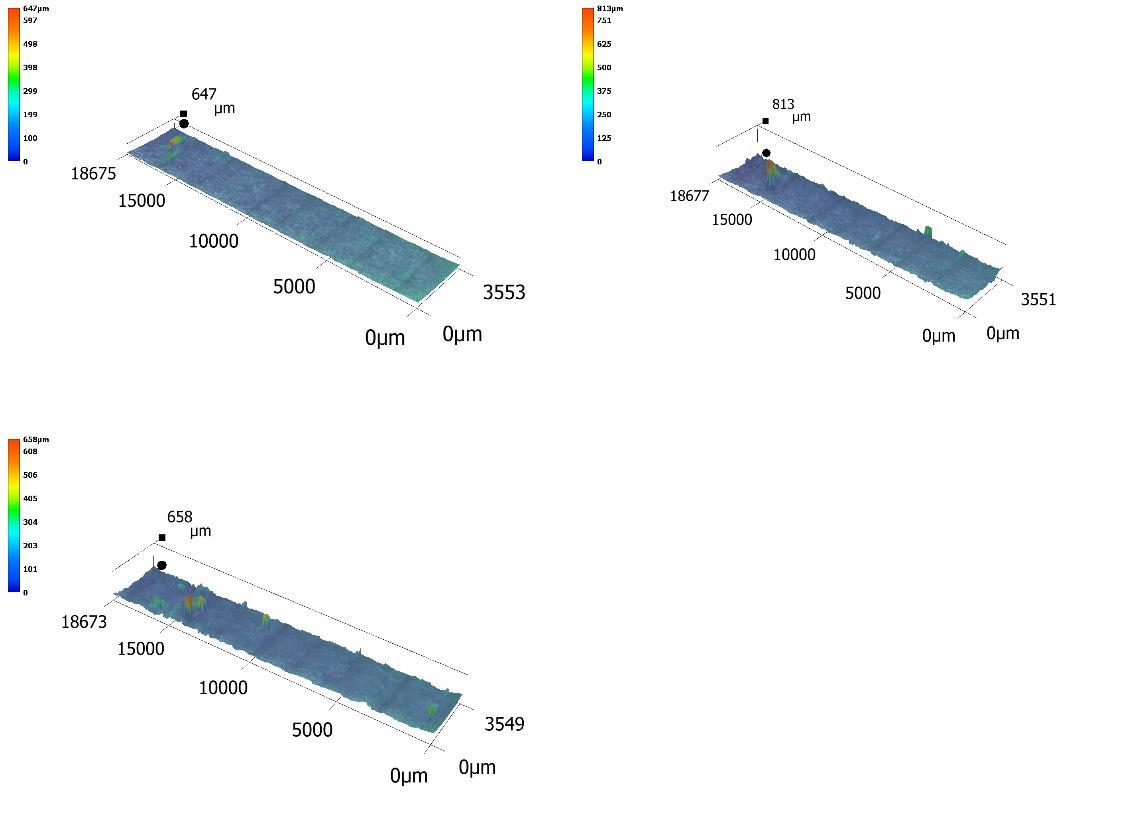

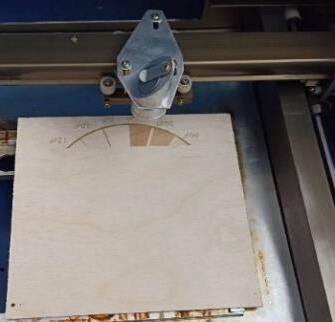

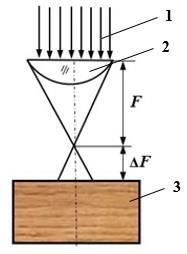

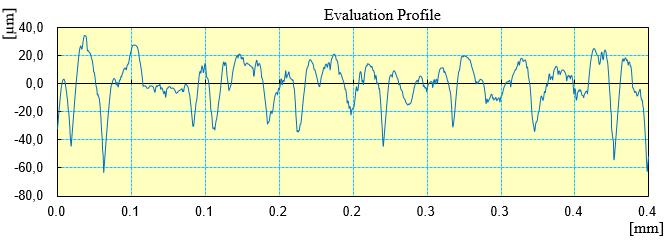

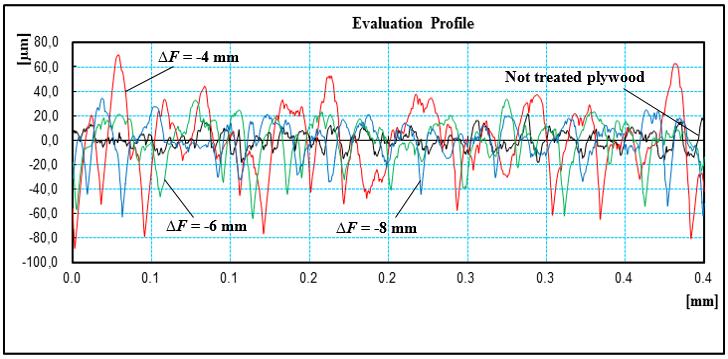

07. ZHIVKO GOCHEV – PAVLIN VITCHEV: THE EFFECT OF THE FOCAL LENGTH POSITION OF THE FOCUSING LENS ON THE DISCOLORATION ROUGHNESS OF PLYWOOD UNDER DIFFERENT CO2 LASER ENGRAVING MODES ...............................................................

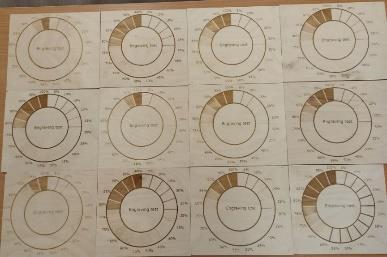

08. MIKHAIL CHERNYKH – ALINA KOREPANOVA – EKATERINA MAKSIMOVA – VADIM SEVRYUGIN – MAXIM GILFANOV –VLADIMIR STOLLMANN: SELECTING COLOR OF MOSAIC PATTERN ELEMENTS FOR LASER ENGRAVING ON WOOD 89

09. MARIÁN IHRING – SIMONA HANES: ALTERNATIVE DESIGN CREATION 103

10. DOROTA MICHALAK – ZDZISŁAW KWIDZIŃSKI – MARTA PĘDZIK – JOANNA BEDNARZ – ŁUKASZ SANKIEWICZ –BARTŁOMIEJ KNITOWSKI – MARCIN DREWCZYŃSKI –TOMASZ ROGOZIŃSKI: THE IMPACT OF DOOR LEAF PARAMETERS ON THE EFFICIENCY OF THE AUTOMATED TECHNOLOGICAL LINE .................................................................................. 115

11. JÁN PAROBEK – HUBERT PALUŠ – MARTIN MORAVČÍK –MIROSLAV KOVALČÍK – MICHAL DZIAN: UTILISATION AND QUANTIFICATION OF WOOD BY-PRODUCTS FROM PRIMARY WOOD PROCESSING 125

12. SILVIA LORINCOVÁ: TRENDS AND CHALLENGES IN MANAGING THE FORESTRY AND WOOD-PROCESSING

13. KATARÍNA MARCINEKOVÁ – ANDREA JANÁKOVÁ SUJOVÁ –MARTIN HALÁSZ: AGILITY ASSESSMENT IN THE WOODWORKING COMPANY

ACTA FACULTATIS XYLOLOGIAE ZVOLEN, 66(2): 5 12, 2024

Zvolen, Technická univerzita vo Zvolene

DOI: 10.17423/afx.2024.66.2.01

THE EFFECT OF BEECH WOOD DRYING ON HARDNESS IN THE LONGITUDINAL DIRECTION FROM THE BEGINNING TO THE REAR OF THE SAMPLES

Kazimierz A. Orlowski – Daniel Chuchala – Monika Serafinowicz –Sylwia Kowalska

ABSTRACT

The objective of this study was to determine the hardness of beech wood samples (Fagus sylvatica L.)in thelongitudinal directionfrom thebeginningto therearofthesamples versus the method of drying. The warm air-steam mixture drying process and the modified airdrying process were used in the experiment. The warm air-steam mixture drying process, in comparison to the modified air-drying process, caused a reduction of the Janka hardness by about 15.4%. Although the hardness along the length of the sample dried with a mixture of air and steam is leveled, this is not the case for the beginning and the rear of the sample, where drops in hardness are observed.

Keywords: beech wood; specific drying methods; Janka hardness.

INTRODUCTION

Most often, the re-sawing process is done for timber after drying. High quality of sawing, low material losses, and high efficiency are required for this kind of sawing process. Appropriateoptimization ofthesawingprocess allowstheseexpectations tobe metto alarge extent. Accurate forecasting of cutting power allows the sawing process to be optimized and, consequently, the above-mentioned expectations of the process to be met. A precise forecast of the cutting power demand for the sawing process encourages optimally choosing the numberofsawblades and theirspacing, whichensures effectiveuseofthesawingmachine’s capabilities and prevents overloading of these machines. To reduce the drying time, one of the methods is drying with the warm air-steam mixture process proposed in the works by Baranski et al. (2017) and Baranski (2018). The proposed method can reduce the drying time. However, this process affects the granularity of dust during sawing (Orlowski et al., 2019, Rogoziński et al., 2021), and also the mechanical properties of dried wood, such as fracture toughness and shear yield stresses along the shear plane in the cutting zone (Baranski et al., 2014, Chuchala et al., 2020, Muziński, 2021) similarly as the effect of the wood provenance (Hlásková et al., 2018), and colour changes (Barański et al., 2020, Suchta et al., 2024).

The effect of the drying treatment on the planing and moulding properties of wood has been the subject of only a few studies (Hernandez et al., 2001). Sehlstedt-Persson (1995),

Terziev and Daniel (2002), and Hansson and Antti (2006) have reported that no significant effect of the drying temperature was noticed in the case of softwood species, namely Scots pine and Norway spruce. The hardness, planing, and moulding properties of tamarack wood (Larix laricina (Du Roi) K. Koch) from natural forests were evaluated on kiln-dried specimens by Avila et al. (2009) following three types of drying schedules: high temperature, elevated temperature, and conventional. Machining and hardness properties appeared not to be affected differently by the drying process (Avila et al., 2009). They stated that tamarack wood is suitable for the fabrication of flooring products.

While investigating the effect of the drying method of beech wood (Fagus sylvatica L.) on the energy effects during sawing wood on the sash gang saw, lower cutting power values were observed at the beginning of the samples and at the exit of the saws from the cut beam (Muziński, 2021). This phenomenon was not observed during the tests conducted when cutting pine wood (Pinus sylvestrisL.) (Licow et al., 2020). Cutting forces are dependent on raw material provenance and wood density (Chuchala et al., 2014). Moreover, Avila et al. (2009) found that the hardness of tamarack wood was positively related to wood density.

The objective of this study was to determine the hardness of beech wood samples (Fagus sylvatica L.) in the longitudinal direction from the beginning to the rear of the samples versus the method of drying.

MATERIALS AND METHODS

Materials

The investigation was carried out for samples of beech wood (Fagus sylvatica L.) originating from the Baltic Natural Forest Region (PL) (the Pomeranian District, Poland). The wood specimens used in the sawing experiments were prepared as blocks in dimensions of W (Width) = 80 mm × H (Height) = 80 mm × L (Length) = 850 mm (for kiln drying) and 700 mm (for air drying) in the sawmill PHU Drew-Met, Kiełpino, Poland. Samples of beech wood were marked as BS for kiln-drying and BP for air-drying. Examined samples were dried with different modes in industrial and laboratory conditions. Both groups of analysed samples had a moisture content of about 72 % before the drying process. After drying, samples were prepared from the blocks mentioned above for hardness examination on the sash gang saw PRW15M (a prototype designed at the Department of Manufacturing Engineering and Automation. GUT, PL; manufactured by REMA-Reszel, PL) with a hybrid dynamically balanced driving system and elliptical teeth trajectory movement, as described by Wasielewski and Orlowski (2002). The oven-dry density of the air-dried samples averaged 661 kg∙m-3 with a standard deviation SD = 31.35, while the oven-dry density of the kiln-dried samples averaged 631 kg∙m-3 (SD = 17.1).

Warm air-steam mixture drying process

The drying process was conducted in an experimental semi-industrial kiln designed by Gdansk University of Technology employees and manufactured by ASM Elektronik CLP, Szczaniec, Poland. The mentioned kiln is located at the Gdansk University of Technology. The methodologies of the experimental warm air-steam mixture drying process were described in detail by Baranski et al. (2017), Klement et al. (2018), and Baranski (2018). The drying process was carried out in two stages and supervised by a control system. In the first stage, the drying medium temperature in the drying kiln was increased to 65 °C and in the second stage, to 80 °C. The final moisture content was obtained at around 10%. Wood

samples dried in the warm air-steam mixture drying process were additionally marked with S.

The combined air-drying process

This process was conducted outside the workshop at the Campus of the Gdansk University of Technology (Gdansk, Poland). The samples were stored under the sloped roof to keep from rain. Humidity and temperature were variable and dependent on weather conditions. The drying process was carried out in the Pomeranian Voivodeship in Poland and lasted 16 months. It started in late December and ended in April. At the end of the first process stage, the moisture content in dried material was approximately 16%. The second stage of the combined air-drying process was conditioning wood samples in a laboratory room (Gdańsk Tech laboratory), where thermal-flow conditions, such as temperature and air velocity, ensured reaching the final value of moisture content of around 10%. This modification allowed the receipt of moisture content values similar to those obtained from other analysed drying processes.

Hardness measurements

Vörös and Németh (2020) presented the history of the currently practiced static hardness test methods from 1860 till nowadays, considering the applied tool geometry and the definition and calculation of wood hardness. The most common tests for the determination of wood hardness are the Janka hardness test, Brinell hardness test, and Monnin hardness test (in France, according to Chalais – Meudon) (Riggio and Piazza, 2011, Vörös and Németh, 2020, Koczan et al., 2021).

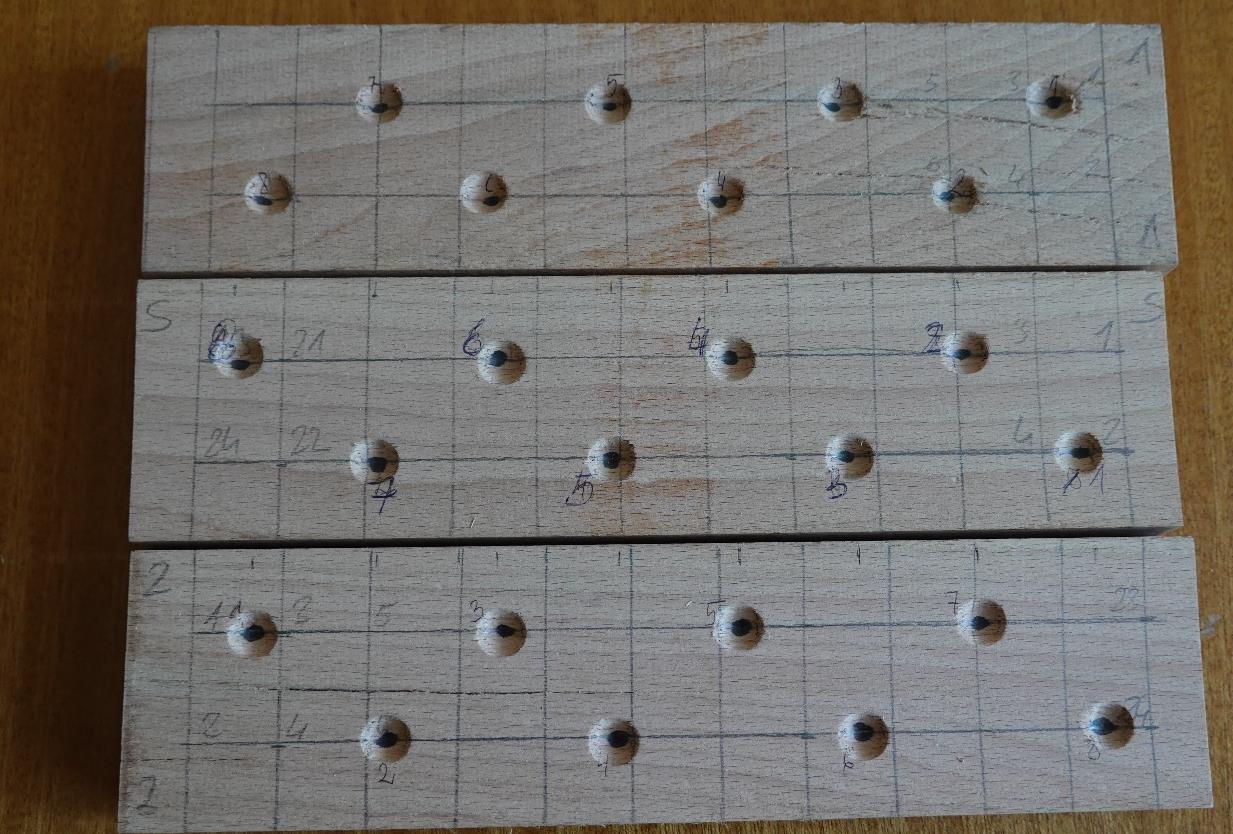

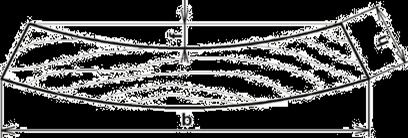

In this study, the Janka test was selected, which is currently applied to assess the suitability of wood species for use as flooring (Riggio and Piazza, 2011, Avila et al., 2009). Before the hardness tests, the planks were divided into three parts: beginning B, middle M, and rear R (Fig. 1).

The hardness test was conducted by the ASTM D143 standard (ASTM, 1994), except for the dimensions of the specimens. The steel hemisphere with a diameter of 0.444 (ball 11.28 mm, projected area of 100 mm2) under the static loading is completely embedded in the wood. Hence, the hardness is always specified as the load H at the penetration of 0.222 in (5.64 mm). To ensure repeatability of penetration, the hemisphere was finished with a special collar; it should be emphasized that the particular hemisphere was CNC–machined. Indentations (Fig. 1) were made on two lines 30 mm apart on specimens with a pitch equal roughly to 28 mm.

The electromechanical Universal Testing Machine manufactured by Instron, model 1195 (capacity 100 kN) (Instron, Norwood, MA, USA), was used in the hardness tests. The hardness tool's penetration rate was equal to 7.5 mm×min-1 in each case. The test set-up allowed continuous recording of load with a sampling frequency of 10 Hz.

Fig. 1 Positions of indentations at the samples in the Janka hardness test, where: B – beginning part of the sample, M – middle part of the sample, R – rear part of the sample.

RESULTS AND DISCUSSION

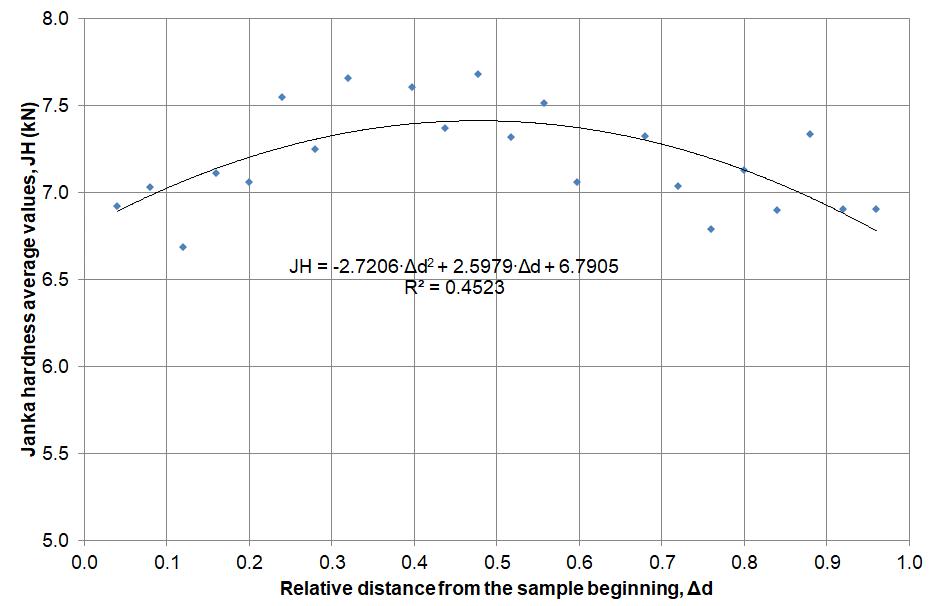

The results of the average Janka hardness values for the modified air drying process samples as a function of relative distances from the sample beginning because of differences in sample total length are shown in Fig. 2. Each point in the graph is an average value of 3 measurements. Analysing the trend line, it can be seen that the changes in hardness are distributed parabolically, with the maximum values occurring at the mid-length of the sample. The average hardness value for the initial sample B (Fig. 1) (relative length range 0.04 - 0.32) was determined to be 7.156±0.135 kN. Confidence intervals were determined at a significance level of 0.05 according to the t-Student test (Kacew, 1978, Sachs, 1984). For the middle part M (relative length range 0.397 - 0.597), the average value was equal to 7.423 ±0.094 kN, and for the rear part, R (relative length range 0.680 - 0.960) was equal to 7.039 ±0.086 kN.

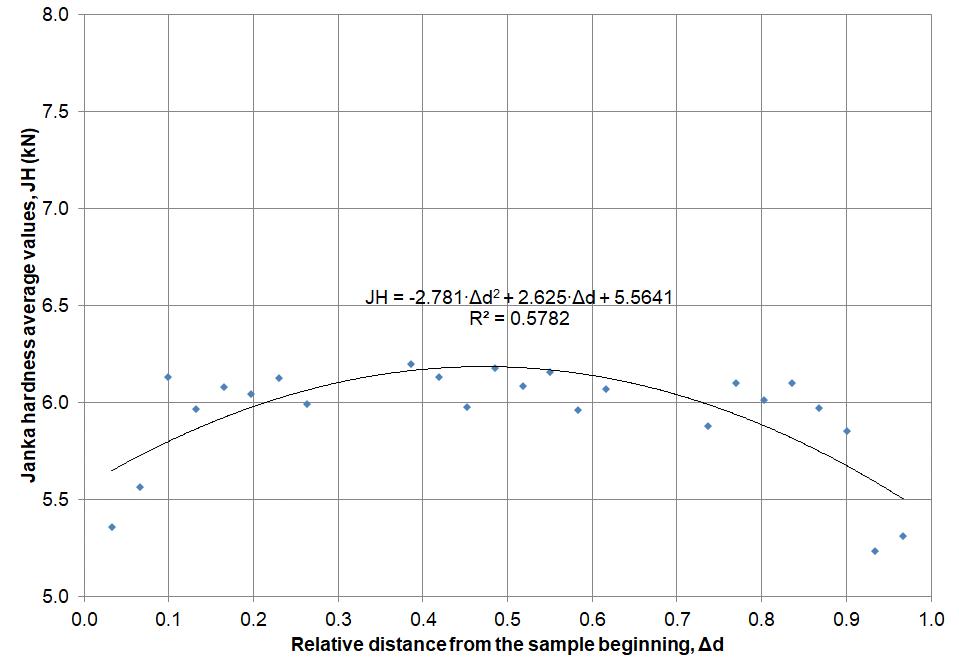

The results of the average Janka hardness values for warm air-steam mixture drying process samples as a function of relative distances from the sample beginning are presented in Fig. 3. Each point in the diagram is an average value of 8 measurements. In this case, it can be observed that in the range from 0.1 to 0.9, the trend of change is rather horizontal, not parabolical, and the hardness values are in the approximate range of 6 kN. For the latter range, an averagevalueoftheJankahardness equals 6.053±0.16 kN. Inboth cases, theJanka hardnesses are approximately 0.6 kN lower at the front and rear faces of the specimen. This phenomenon could be a reason for decreasing cutting power values, which were observed at thebeginningofthesamplesandatthe exitofthesawsfrom thecutbeam whileinvestigating the effect of the drying method of beech wood (Fagus sylvatica L.) on the energy effects during sawing wood on the sash gang saw (Muziński, 2021).

Fig. 2 Janka hardness average values for the combined air drying process of beech samples in a function of relative distances from the sample beginning.

Fig. 3 Janka hardness average values for warm air-steam mixture drying process of beech samples in a function of relative distances from the sample beginning.

The drying method of beech wood (Fagus sylvatica L.) may reduce the Janka hardness in comparison with the hardness of wood dried with the combined air drying method. In the presented study, 15.41% of Janka hardness for the middle part of specimens decreased while the warm air-steam mixture drying process was applied.

The results obtained are difficult to compare with those of other authors, as no articles were found in which changes in wood hardness in the longitudinal direction were studied. Theonly research workconcernedthestudy ofthe physical properties ofbeechwood(Fagus

orientalis Lipsky) from different geographical parts of Greece, which showed that the Janka hardness values were lower than those obtained in the tests carried out (Skarvelis and Mantanis, 2013).As reportedbySkarvelis andMantanis (2013),the averagehardness values were equal to 4.854 kN. The latter authors compared their findings to the values of Bektaş et al. (2002). The opposite result was obtained by Büyüksari (2013), who observed that all of the compressed veneer laminated panels with Oriental beech (Fagus orientalis Lipsky) veneer sheets had higher hardness values compared to non-compressed veneer laminated panel. Thermally compressed veneer laminated MDF panels can be utilized for structural purposes due to higher hardness since the Janka hardness was 8.795 kN to 9.768 kN. These values were higher than ours by approximately 1.5 kN.

CONCLUSION

Based on the carried out analyses, it can be concluded that:

• The drying method of beech wood (Fagus sylvatica L.) while the warm air-steam mixture drying process was applied caused a reduction in the Janka hardness of about 15.41% in the middle part of specimens in comparison with the Janka hardness of wood dried with the modified air-drying method.

• AnalysingthetrendlineoftheJanka hardness forbeech wooddried with the combined air-drying method, it can be seen that the changes in hardness are distributed parabolically, with the maximum values occurring at mid-length of the sample.

• The latter phenomenon was not observed for wood dried with the warm air-steam mixture drying process, in which the Janka hardness was levelled (almost horizontal) on the whole length of the specimen, skipping the beginning and end of the sample.

• In both cases, the Janka hardnesses are approximately 0.6 kN lower at the front and rear faces of the specimen.

• Future studies should be carried out on the samples with larger cross-sections and lengths.

REFERENCES

ASTM D143. American Soc. for Testing and Materials (ASTM), 1994. Standard methods for testing small clear specimens of timber. Annual Book of ASTM Standards Vol. 04.10. ASTM, West Conshohocken, PA.

Avila, C., Hernández, R., Fortin, Y., 2009. Effect of kiln drying on the hardness and machining properties of tamarack wood for flooring. Forest Products Journal. 59(1/2):71-76.

Baranski, J., Chuchala, D., Orlowski, K. A., Muzinski, T., 2014. The influence of drying parameters on wood properties. Annals of Warsaw University of Life Sciences, Forestry and Wood Technology 86, 7-12.

Baranski, J., Klement, I., Vilkovská, T., Konopka, A., 2017. High temperature drying process of Beech Wood (Fagus sylvatica L.) with different zones of sapwood and red false heartwood. BioRes 12(1):1861–1870. https://doi.org/10.15376/biores.12.1.1861-1870

Baranski, J., 2018. Moisture content during and after high- and normal-temperature drying processes of wood. Dry Technol 36(6):751–761. https://doi.org/10.1080/07373937.2017.1355319

Barański, J., Konopka, A.,Vilkovska, T., Klement, I., Vilkovsky, P., 2020. Deformation and surface color changes of beech and oak woodlamellas resultingfrom the drying process. BioRes. 15(4), 8965-8980.

Bektaş, I., Güler, C., Baştürk, M.A., 2002. Principal mechanical properties of eastern beech wood (Fagus orientalis Lipsky) naturally grown in Andirin northeastern Mediterranean region of Turkey. Turkish Journal of Agriculture and Forestry 26: 147-154.

Büyüksarı, Ü., 2013. Surface characteristics and hardness of MDF panels laminated with thermally compressed veneer. Composites Part B: Engineering, Volume 44, Issue 1, pp. 675-678, https://doi.org/10.1016/j.compositesb.2012.01.087

Chuchala, D., Orlowski, K. A., Sandak, A., Sandak, J., Pauliny, D., Barański, J., 2014. The effect of wood provenance and density on cutting forces while sawing Scots pine (Pinussylvestris L.). BioResources 9(3):5349–5361.

Chuchala, D., Ochrymiuk, T., Orlowski, K., Lackowski, M., Taube, P., 2020. Predicting cutting power for band sawing process of pine and beech wood dried with the use of four different methods. BioResources 15(1), 1844-1860.

Hansson, L., Antti, L , 2006. The effect of drying method and temperature level on the hardness of wood.JMaterProcessTechnol.171.467-470.https://doi.org/10.1016/j.jmatprotec.2005.08.007

Hernandez, R.E., Bustos, C., Fortin, Y., Beaulieu, J., 2001. Wood machining properties of white spruce from plantation forests. Forest Prod. J. 51(6):82–88.

Hlásková, L., Orlowski, K. A., Kopecký, Z., Sviták, M., Ochrymiuk, T., 2018. Fracture toughness and shear yield strength determination for two selected species of central European provenance. BioResources 13(3), 6171-6186. https://doi.org/10.15376/biores.13.3.6171-6186

Kacew, P.G., 1978. Kontrola narzędzi skrawających metodami statystycznymi.Wydawnictwa Naukow Techniczne, Warszawa.

Klement, I., Vilkovská, T., Baranski, J., Konopka, A., 2018. The impact of drying and steaming processes on surface color changes of tension and normal beech wood. Dry Technol 37:1490–1497. https://doi.org/10.1080/07373937.2018.1509219

Koczan, G., Karwat, Z. Kozakiewicz, P., 2021. An attempt to unify the Brinell, Janka and Monnin hardness of wood on the basis of Meyer law. J Wood Sci 67, 7. https://doi.org/10.1186/s10086-020-01938-4

Licow, R.,Chuchala, D.,Deja, M., Orlowski, K.A., Taube, P.,2020. Effect of pine impregnation and feed speed on sound level and cutting power in wood sawing. Journal of Cleaner Production, Volume 272, 122833 https://doi.org/10.1016/j.jclepro.2020.122833

Muziński, T., 2021. The effect of drying method on fracture toughness and yield strength when sawing selected wood species (inPolish). PhD Dissertation, Gdansk University of Technology, Faculty of Mechanical Engineering and Ship Technology, Gdansk 2021. https://mostwiedzy.pl/pl/publication/wplyw-sposobu-suszenia-na-wiazkosc-i-naprezeniatnace-przy-przecinaniu-wybranych-gatunkow-drewna,157733-1

Orlowski, K.A,. Chuchala, D., Muzinski, T., Baranski, J., Banski, A., Rogoziński, T., 2019. The effect of wood drying method on the granularity of sawdust obtained during the sawing process using the frame sawing machine. Acta Facultatis Xylologiae Zvolen 61(1):83–92. https://doi.org/10.17423/afx.2019.61.1.08

Riggio, M., Piazza, M., 2011. Hardness Test. Chapter 9, In book: Kasal, B. and Tannert, T. (eds.). In Situ Assessment of Structural Timber. (pp. 87-97). https://doi.org/10.1007/978-94-007-0560-9

Rogoziński, T., Chuchala, D., Pędzik, M., Orlowski, K.A., Dzurenda, L., Muzinski, T., 2021. Influence of drying mode and feed per tooth rate on the fine dust creation in pine and beech sawing on a mini sash gang saw. Eur. J. Wood Prod. 79, 91–99. https://doi.org/10.1007/s00107-020-01608-8

Sachs, L., 1984. Applied Statistics. A Handbook of Techniques. Springer Series in Statistics. Springer New York, NY. pp. 707. https://doi.org/10.1007/978-1-4612-5246-7

Sehlstedt-Persson, S.M.B., 1995. High-temperature drying of scots pine. Acomparison between HTand LT-drying. Holz als Roh-und Werkstoff 53, 95–99. https://doi.org/10.1007/BF02716400

Skarvelis, M., Mantanis, G.I., 2013. Physical and mechanical properties of beech wood harvested in the Greek public forests. Wood Research 58 (1): 123-129 (2013).

Suchta, A., Barański, J., Vilkovská, T., Klement, I., Vilkovský, P., 2024. The impact of drying conditions on the surface color changes of pine wood. BioResources 19(1), 656-669.

Terziev, N., Daniel, G., 2002. Industrial kiln drying and its effect on microstructure, impregnation, and properties of Scots pine timber impregnated for above ground use. Part 2, effect of drying on microstructure and some mechanical properties of Scots pine wood. Holzforschung 56(4), 434-439. https://doi.org/10.1515/HF.2002.067

Vörös, Á., Németh, R., 2020. The History of Wood Hardness Tests. 6th International Conference on Environment and Renewable Energy, IOP Conf. Series: Earth and Environmental Science 505 (2020) 012020, IOP Publishing. https://doi.org/10.1088/1755-1315/505/1/012020

Wasielewski, R., Orlowski, K., 2002. Hybrid dynamically balanced saw frame drive. Holz Roh Werkst 60(3):202–206. https://doi.org/10.1007/s00107-002-0290-4

ACKNOWLEDGMENT

The authors would like to express their thanks to M. Sc. Eng. Lech Targan for his help in preparing the test stand measurement circuits.

AUTHORS’ ADDRESSES

Professor Kazimierz A. Orlowski, Dr. Sc., Ph. D., Eng. Gdansk University of Technology, Faculty of Mechanical Engineering and Ship Technology, 11/12 Narutowicza, 80-233 Gdansk, Poland kazimierz.orlowski@pg.edu.pl

Dr. Sc. Daniel Chuchala, Ph. D., Eng., Prof. of GdanskTech Gdansk University of Technology, Faculty of Mechanical Engineering and Ship Technology, 11/12 Narutowicza, 80-233 Gdansk, Poland daniel.chuchala@pg.edu.pl

MSc, Eng. Monika Serafinowicz

NM Design Office sp. z o. o., Al. Zwycięstwa 96/98 81-451 Gdynia, Poland, nowacka1995@wp.pl

MSc, Eng. Sylwia Kowalska Szkoła Podstawowa w Szonowie, 86 - 320 Łasin 86-320, Poland, tryc-sylwia@wp.pl

ACTA FACULTATIS XYLOLOGIAE ZVOLEN, 66(2): 13 22, 2024

Zvolen, Technická univerzita vo Zvolene

DOI: 10.17423/afx.2024.66.2.02

CROSS WARPING DURING VARIOUS DRYING PROCESSES OF BEECH WOOD (FAGUS SYLVATICA L.)

Ivan Klement – Tatiana Vilkovská – Peter Vilkovský

ABSTRACT

Wood drying does not only consist of removing moisture; the quality of the dried product is the main requirement for the industrial process. Because wood shrinks during drying, deformations and stresses develop, leading to unusable products. When developing drying technologies and methods, the aim is to achieve the shortest possible drying time. The most common defects in wood after drying include cross warping (cup), which significantly affects the efficiency of processing the raw material into products. The research was focused on the impact of different drying conditions (temperature, drying gradient) on the size of the cross warping. The lower values were for the low-temperature drying at 1.4 %. The hightemperature drying process increased values to double from 2.3 to 2.8%. A reduction in the size of the cross warping defects can also be achieved by effectively loading the samples in combination with more precise control of the high-temperature drying process so that smaller values of the moisture gradients of the samples at the end of the drying process are achieved.

Keywords: cross warping; beech wood; high-temperature drying; low-temperature drying; drying gradient.

INTRODUCTION

Wood is a hygroscopic material due to the abundance of hydroxyl groups associated with the cell wall polymers, and the material exhibits dimensional changes with variations in moisture content (MC) and atmospheric relative humidity. The degree to which wood shrinks and swells with changing moisture content is an important property that determines its suitability for different applications. This property, known as dimensional stability, is often a target property for improvement in wood modification research. Its importance makesitacommonlyquantifiedwoodproperty(Sargent2019).Dryingshrinkageiscommon during wood processing and utilization induced by moisture loss (Fu et al., 2022; Ormarsson 1999). The moisture content of a growing tree is high, and it is usually necessary to dry the timber before using it for construction purposes. It is essential to avoid excessive deformation of the sawn timber during wood drying. The deformation process is affected by differences in the moisture and temperature conditions. One may also optimize the conditions during the drying process to minimize unfavorable deformations, such as cup, twist, crook, and bow. A characteristic of wood is that its behavior is strongly orthotropic due to the internal structure of the material and is precisely dependent on moisture and temperature (Miyoshi et al., 2018). In addition, the material is characterized by a substantial

variation of the properties in the radial direction. Furthermore, the behavior of wood is strongly affected by variations in environmental conditions, especially when the trees are exposed to stress.

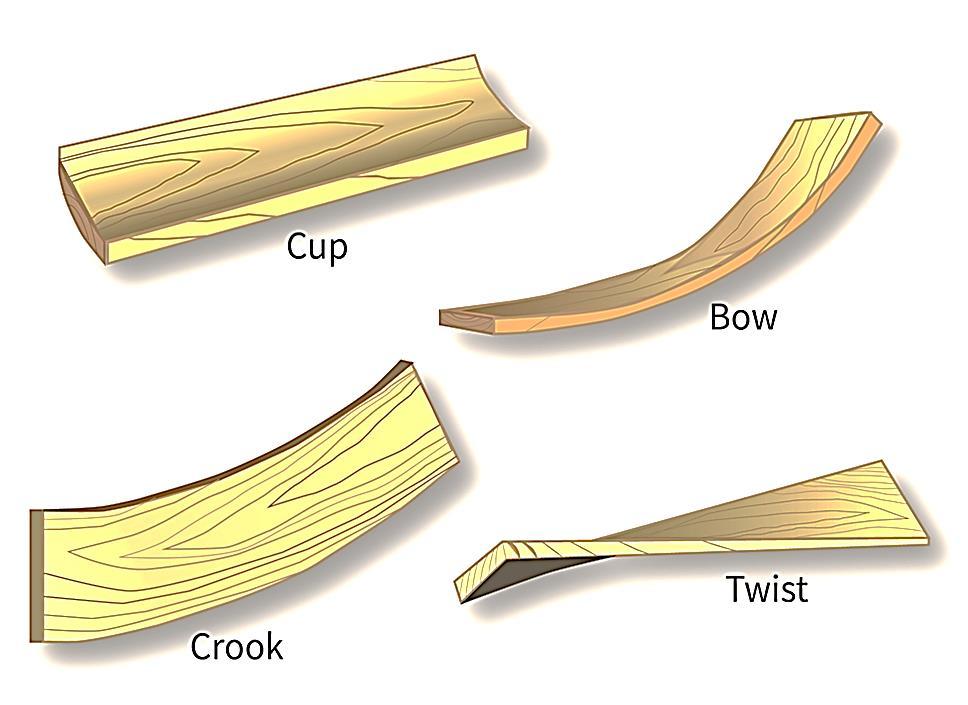

Fig. 1 Different forms of deformation of wood (Hill et al., 2022)

This anisotropy affects many wood species characteristics such as strength, shrinkage, swelling, and thermal and electrical conductivity (Fig.1). As a representative example, wood exhibits different shrinkage levels among tangential, radial, and longitudinal directions. The tangential shrinkage is commonly the greatest, around 6–12%, followed by radial shrinkage at 3–6%, and longitudinal shrinkage is less than 0.1–0.2%. I shall refer to authors Glass and Zelinka 2021; Nocetti et al., 2015. Based on the cited work (Barański et al., 2021; Dudiak et al., 2024), the cup deformation may occur in two directions, the xz- and the yz-plane, respectively. The average cross-warping was in the range of 1.8 to 2.8 %. Statistical analysis of the measured values showed that the thickness of the specimens is an essential factor affecting the size of the cross warping. The drying temperature was not considered statistically significant. Thestandarddeviationvalues werelower for thethickness of 32 mm than for the thickness of 25 mm. It means that the thickness positively affects the size of the cross warping.

The loss of moisture leads to different drying shrinkage in various grain directions of wood; thus, shrinkage anisotropy of wood is one of the reasons for the drying stresses (Bond and Espinoza 2016). Additionally, due to the reliabilities of moisture content between the surface and core layers during the drying process of wood, as well as differences in material properties between heartwood and sapwood or earlywood and latewood, there will be irregular moisture content distribution. The irregular distribution of wood moisture will produce moisture gradient stress, which forms an additional source of drying stresses in wood. Therefore, shrinkage anisotropy stress and moisture gradient stress are the two principal catalysts for drying stresses in wood (Fu et al., 2015; Dudiak and Dzurenda 2021). One type of deformation is a cup, defined as a board distortion in which there is a deviation from flatness across the width of the board (Simpson 1991, Vilkovský et al., 2023).

The main objective of the present paper is to characterize and analyze one of the most common wood defects after drying, namely cross warping. This defect significantly affects the efficiency of the raw material being processed into products. Therefore, the article is

designed to evaluate the effect of drying conditions on the cross warping size during hightemperature and low-temperature drying.

MATERIALS AND METHODS

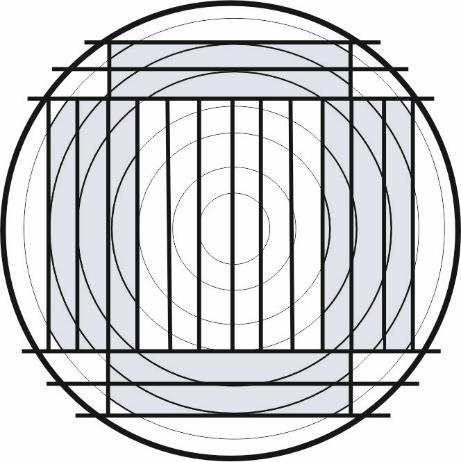

The testing tree species was beech (Fagus sylvatica L.), the most economically important tree species in the forests of Slovakia. The logs were harvested in the University Forestry Enterprise's forests in the Hronská Breznica (altitude 268 m n. m.) location. Logs with a diameter at the thinner end of 50 to 56 cm and a length of 4 meters were used. The logs were sawn from the ground part of the tree. The logs were sawed by a cant log sawing pattern (Fig. 2 ) to produce the tangential lumber. Subsequently, the prisms were cut into 25 mm thick sawn timber. The dimensions of the samples were 25 × 120 × 1000 mm. Specimens were cut from the center of the lumber so that their net dimension was 1000 mm (marked grey color Fig. 2 a.)). Specimens with annual circles with a slope of 0 to 30° tangential sawn timber were selected for test specimens. At regular time intervals, the selected samples were weighed. Based on this moisture content, the drying process was controlled.

Drying mode

Twodryingmodeswereused.Thesamples weredriedin thedryingkilnin thedrying laboratory at the Department of Wood Technology, Technical University in Zvolen, Slovakia,forhigh-temperatureandlow-temperaturedrying.Alow-temperaturedryingmode with constant drying environment parameters was used for low-temperature drying (40°C). Two drying modes were used for high-temperature drying (HT), which differ in the maximum temperature used in the last mo stage (130 and 150 °C). The parameters of the drying modes are given in Table 1. The samples were dried to a final moisture content of 10 ± 1 %.

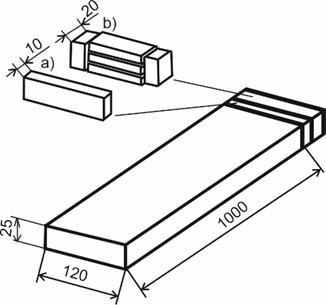

Tab. 1 Parameters of used drying modes.

High-temperaturedrying process Low-temperaturedrying process

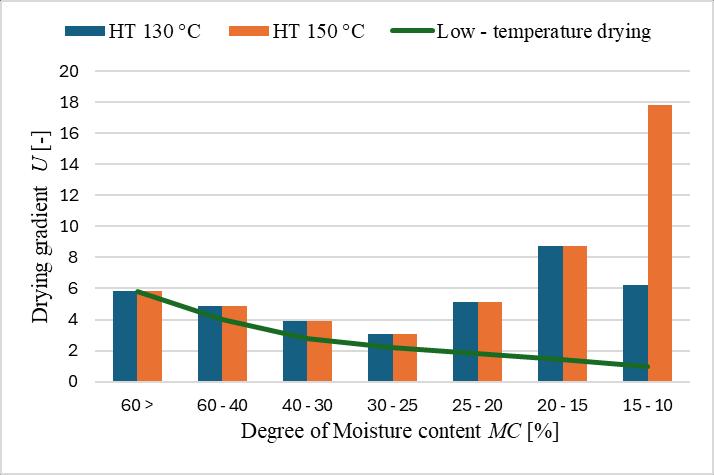

Figure 3 shows a graphical representation of the average values of the drying gradients for the moisture stages and each drying mode. The drying gradient characterizes the drying intensity and is the ratio between the actual wood moisture content w and the equilibrium moisture content wr Moisture measurement was carried out using the oven dry method according to STN 49 0103.

Fig. 3 Average values of drying gradient U in moisture levels and drying modes.

During drying, the drying samples were weighed at regular time intervals to determine the actual moisture content of the wood.

The moisture gradient characterizes the moisture distribution in the wood crosssection. The samples for the determination of the moisture gradient were processed, as shown in Figure 4. The moisture content of the individual layers was determined using the oven dry method. The level of the moisture gradient was calculated according to the equation:

Cross warping

The value of the cross warping level was evaluated using relative warping. Relative warping is the ratio of the maximum deflection f to the width of the sawn timber b (Fig. 4) and is expressed as a percentage.

Fig. 4 Measurement of cross warping

Due to the small volume of the dried samples in the dryer, their relative loading was small and did not affect the size of the measured cross warping. The values of cross warping K were calculated according to Eq. (2):

Where: f – maximum deflection [mm], b - width of timber [mm].

Measurement of density in the absolutely dry state

Density in the absolutely dry state was determined for each sample. The measurement was performed under laboratory conditions. Density in the absolutely dry state was calculated by equation (3) according to the Slovak standards norm STN 490 103

Where: m0 is the weight of oven-dried moisture samples (kg) and V0 is the volume of oven-dried moisture samples (m-3).

RESULTS AND DISCUSSION

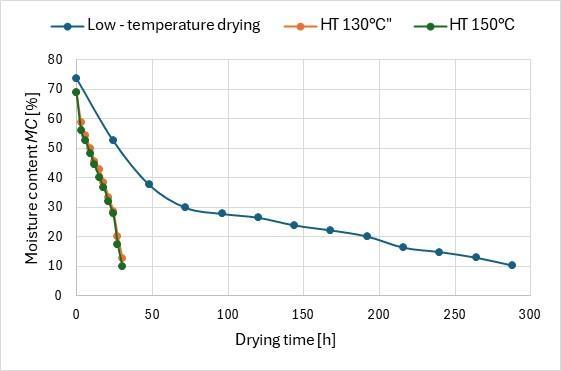

Table 2 shows the average values of the samples' moisture contents, drying times and rates, and densities at the dry state. Figure 5 graphically shows the samples' moisture loss as a function of time.

Tab. 2 Basic drying characteristics for individual modes.

Fig. 5 Moisture content change of beech samples in high-temperature and low- temperature drying.

The initial moisture contents of the samples varied from 68 to 74.2 %, and the final moisture contents ranged from 9.4 to 12.8 %. With high-temperature drying and a drying temperature of 130 °C, the final moisture content was higher than initially planned, averaging 12 %. In the high-temperature drying, the curves were linear. This means that the moisture loss was proportional to the drying time. The average drying time was 30 hours, corresponding to the drying rate, which was slightly higher when a drying medium at a temperature of 150 °C was used.

The resulting drying times are very short compared with low-temperature drying of this wood due to the high drying intensity around the removal of bound water. In lowtemperature drying mode, the drying time was 288 hours, and the drying rate was ten times shorter compared to high-temperature drying.

This corresponds to the drying gradient values for the drying modes used. All modes started with the same value (5.82), and the drying gradient gradually decreased.

For a high-temperature drying process with an average moisture content of 25 %, the drying gradient increased to 8.5. At the last moisture content stage, at a drying medium temperature of 150 °C, it reached almost 18. The drying gradient values decreased for lowtemperature drying in the evaporation section of the water bound from the samples (below 25%). At the last moisture content stage, the drying gradient value was 1.

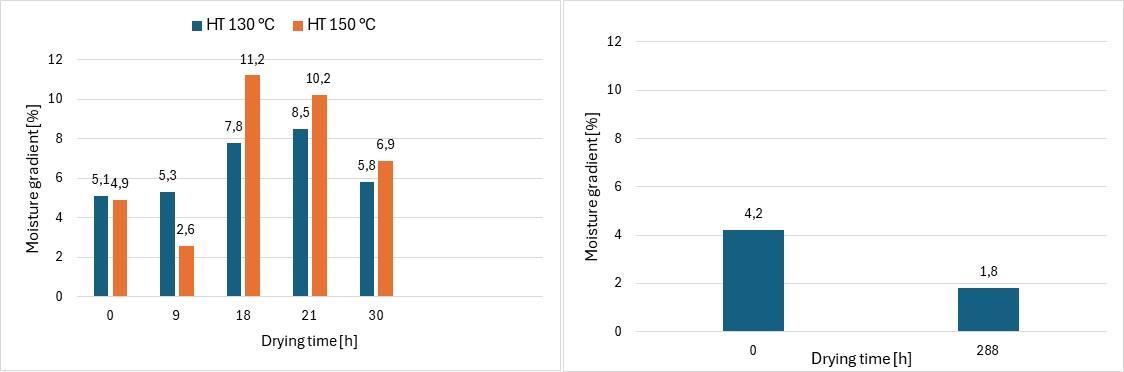

Moisture gradients were measured at three-hour intervals for both high-temperature drying modes. In the low-temperature drying process, the moisture gradient was measured at the beginning and the end. The calculated average values are shown in Figure 6.

Fig. 6 Average values of moisture gradients of samples (a) High-temperature drying (b) Low-temperature drying.

After drying experiments, the absolute value of the cross warping (f) was measured at the center of the samples with a mechanical device and then converted according to equation (2) to the relative warping (K), considering the width of the samples. The converted mean values and their basic statistical characteristics are shown in Table 3.

Tab. 3 Mean values and basic statistical characteristics of the cross-sectional grading of the samples

The changes in the shape of the samples were small for both drying methods. The average values of relative cross-warping ranged from 1.4 to 2.8 % (Table 4). The lower values were for the low-temperature drying at 1.4 %. The high-temperature drying process increased values to double from 2.3 to 2.8%. Statistical analysis of the measured values showed that drying temperature or drying method was a moderately significant factor influencing thesizeofthe crosswarping.Besidesthedryingtemperature,thedryinggradient positively affected the size of the cross warping. The drying gradient in the low-temperature drying method decreased significantly from a critical wood moisture content of 40 %. In high-temperature drying, the value of the drying gradient was increasing (Fig. 3).

Assessing the effect of the drying method on the amount of cross warping based on the drying gradient is a more complex assessment, which also includes the impact of the relative humidity of the drying environment. Our findings are in concordance with authors Hill 2022; Sargent 2019). Asalso shownin theresearchof Xiang et al., (2012)crosswarping happens because the shrinkage parallel is more significant than that perpendicular to the growth rings. In other words, cupping results from tangential shrinkage of wood being more excellent than radial shrinkage, and the more significant the difference, the more severe the degree. Our observations are consistent with authors Konopka et al., 2017 made comparable

measurements of cross-warping where the drying process was carried out at 150 °C. The effectofthesizeofthecrosswarpingwas analysedforloadedandunloadedbeechspecimens ("lamellas") at an initial moisture content of approx. 40% and a final moisture content of approx. 10%. The values of K of the cross warping were 1-5.5%, and the slope of the annual rings was also determined. Higher values were for tangential samples. Our observations about reducing the size of the warping are also possible by efficient loading of the samples in combination with more precise control of the high-temperature drying process so that smaller values of the samples' moisture gradients at the end of the drying process are achieved are in accordance with other cited authors.

Between130and150 °Cdryingtemperatures,therewasastatisticallynon-significant effect on cross-warping. High-temperature drying showed a positive impact of the high temperature on the amount of drying of the wood and, thus, on the size of the cross warping. When high temperatures are combined with the moisture content of the wood, partial plasticization occurs, which positively affects the formation of internal stresses in the wood and, ultimately, the size of the cross warping. Longitudinal warping was also observed in the samples, reflected by longitudinal bowing and twisting. Overall, it can be concluded that the values of cross-warping for both drying methods are positive, even because it was not possible for technical reasons to load the samples during drying, which eliminates the crosswarping further. Based on the cited work by Miyoshi (2014), it was revealed that the mechanical properties of wood in the lateral direction were significantly affected not only by the density but also by the structural features such as deformation of cell shapes, arrangement of rays or vessels, and the degree of the transition from the earlywood to the latewood.

CONCLUSION

When developing drying technology and methods, the aim is to achieve the shortest possible drying times; one way this can be achieved is by increasing the temperature of the drying environment. However, the dried wood must be protected. Cross-warping is one of the most common defects in the wood after drying, which considerably affects the efficiency with which the raw material can be processed into products. The following conclusions can be made from the measured results of the research:

- The high-temperature drying process is a very rapid drying method. Compared to the low-temperature drying method, the resulting drying times are, on average, 10 to 15%, corresponding to a drying rate approximately ten times higher.

- The drying curves for both modes of high-temperature drying were very rapid and linear. When a temperature of 150 °C was used in the last moisture level, the final moisture content of the samples was achieved more precisely.

- Thevaluesofmoisturegradients at theend of thehigh-temperaturedrying process were large (5.8 - 6.9%), which had a negative effect on the size of the cross-warping of the samples.

- This indicates that a more optimal control of the drying process based on achieving the average required moisture content could be achieved. For low-temperature drying, the moisture gradient was 1.8 %.

- The average values of the cross warping were lower in the low-temperature drying process by 1.4 % compared to the high-temperature drying process, increasing values to double by 2.3 to 2.8%. The differences between the high-temperature drying modes (130

and 150°C) and the statistics were insignificant.

- Research into the effect of drying conditions on the size of wood warping is essential to increase the efficiency of processing raw materials into final products.

REFERENCES

Barański, J., Suchta, A., Barańska, S., Klement, I., Vilkovská, T., Vilkovský, P., 2021. Wood Moisture-Content Measurement Accuracy of Impregnated and Nonimpregnated Wood. Sensors 21, 7033. https://doi.org/10.3390/s21217033

Bond, B.H., Espinoza, O., 2016. A Decade of Improved Lumber Drying Technology. Curr Forestry Rep 2. 106–118. https://doi.org/10.1007/s40725-016-0034-z

Dudiak, M., Dzurenda, L., 2021. Changes in the physical and chemical properties of alder wood in the process of thermal treatment with saturated water steam. Coatings - Vol. 11, issue 8 art. no. 898.

Dudiak, M., Kminiak, R., Banski, A., Chuchala, D., 2024. The Effect of Steaming Beech, Birch and Maple Woods on Qualitative Indicators of the Surface. Coatings 2024, 14, 117. https://doi.org/10.3390/coatings14010117

Fu, Z., Zhao, J., Huan, S., Sun, X., Cai, Y., 2015. The variation of tangential rheological properties caused by shrinkage anisotropy and moisture content gradient in white birch disks. Holzforschung 69. 573–579. Review on Wood Deformation and Cracking during Moisture Loss.

Fu, Z., Wang, H., Li, J., Lu, Y., 2022. Determination of Moisture Content and Shrinkage Strain during Wood Water Loss with Electro-chemical Method. Polymers 14. 778.

Glass, S., Zelinka, S., 2021. Moisture relations and physical properties of wood. Chapter 4 in FPLGTR-282; U.S. Department of Agriculture Forest Service: Washington. DC. USA.

Hill,C., Kymäläinen, M., Rautkari, L., 2022. Reviewofthe use of solidwood as anexternal cladding material in the built environment. J Mater Sci 57, 9031–9076. https://doi.org/10.1007/s10853-022-07211-x

Konopka, A., Barański, J., Vilkovská, T., Klement, I., 2017. The influence of the drying process on the deformation of the beech and oak wood samples Annals of WULS, Forestry and Wood Technology, 99, Article 99.

Miyoshi, Y., Kojiro, K., Furuta, Y., 2014 Deformation properties of wood in lateral tension effect of tensile direction to the annual rings. moisture. and temperature on lateral tensile deformation of hinoki (Chamaecyparisobtusa) (in Japanese). Mokuzai Gakkaishi 60:241–248

Miyoshi, Y., Kojiro, K., Furuta, Y., 2018. Effects of density and anatomical feature on mechanical properties of various wood species in lateral tension. J Wood Sci 64. 509–514. https://doi.org/10.1007/s10086-018-1730-z

Nocetti, M., Brunetti, M., Bacher, M., 2015. Effect of moisture content on the flexural properties and dynamic modulus of elasticity of dimension chestnut timber. Eur. J. Wood Prod. 73. 51–60. https://doi.org/10.1007/s00107-014-0861-1

Ormarsson, S., Dahlblom, O., Petersson, H., 1999. A numerical study of the shape stability of sawn timber subjected to moisture variation Part 2: Simulation of drying board. Wood Science and Technology 33 407–423 https://doi.org/10.1007/s002260050126

Sargent, R., 2019. Evaluating dimensional stability in solid wood: a review of current practice. J Wood Sci 65, 36 https://doi.org/10.1186/s10086-019-1817-1

Simpson, W. T., 1991. Dry Kiln Operator’s Manual. USDA Forest Service. Agricultural Handbook 188.

STN 490 103: 1993. Wood. Determination of the moisture content of the physical and mechanical testing. Slovak Standards Institute, Bratislava, Slovakia. Vilkovský, P., Klement, I., Vilkovská, T., 2023. The impact of the log-sawing patterns on the quantitativeandqualitativeyieldofbeechtimber(Fagussylvatica L.).AppliedSciences13(14). 8262. https://doi.org/10.3390/app13148262

Xiang, Z., Peralta, P., Peszlen, I., 2012. Lumber drying stresses and mitigation of cross-sectional deformation. Wood and Fiber Science 44(1). 94-102.

ACKNOWLEDGMENT

This work was supported by the Slovak Research and Development Agency under contract no. APVV-21-0049. This work was supported by the Scientific Grant Agency of the Ministry of Education Science Research and Sport of the Slovak Republic and the Slovak Academy of Sciences project VEGA no. 1/0063/22.

AUTHORS’ ADDRESSES

prof. Ing. Ivan Klement. CSc. Ing. Tatiana Vilkovská. PhD. Ing. Peter Vilkovský. PhD. Technical University in Zvolen Faculty of Wood Science and Technology Department of Wood Technology T. G. Masaryka 24 960 01 Zvolen Slovakia klement@tuzvo.sk tatiana.vilkovska@tuzvo.sk peter.vilkovsky@tuzvo.sk

ACTA FACULTATIS XYLOLOGIAE ZVOLEN, 66(2): 23 33, 2024

Zvolen, Technická univerzita vo Zvolene

DOI: 10.17423/afx.2024.66.2.03

THE EFFECT OF STEAMING ON THE COLOR CHANGE OF FALSE HEARTWOOD BEECH

Ladislav Dzurenda – Michal Dudiak

ABSTRACT

The work presents the results of the color change of false heartwood of beech wood during the steaming process in a pressure autoclave in individual modes in the temperature interval t = 90 to 120 °C. The color of the wood of the false heartwood, depending on the steaming conditions, changes in oppositeways, while at temperatures up to t ≈ 105 °C it becomespale, and at temperatures above t ≈ 115 °C it becomes darker.

Based on the results of the research on the color change of the false heartwood wood in the steaming process, 3 steaming modes were proposed to achieve a targeted change in the color of the false heartwood beech. By steaming the wood with saturated moist air tI = 90 ± 2.5 °C for τ = 8 h, the color of the wood lightens, which is numerically expressed in the color space CIE L*a*b*: L* = 69.2 ± 2.9, a* = 12.7 ± 1.6 and b* = 19.7 ± 1.4. Steam mode II with saturated water steam tII = 115 ± 2.5 °C during τ = 16 h, slight darkening of the wood color of the false heartwood reaches the following values: L* = 56.0 ± 2.4, a* = 12.4 ± 1.4 and b* = 19.2 ± 1.5. The dark brown color described in the color space CIE L*a*b* by the values: L* = 50.0 ± 2.1, a* = 12.4 ± 1.3 and b* = 18.5 ± 1.4 is achieved by the vaporization mode III. at the temperature of saturated water steam tIII = 120 ± 2.5 °C during τ = 24 h.

Keywords: beech wood; false heartwood; wood color; wood steaming; color difference; color dispersion.

INTRODUCTION

The beech wood belongs to the scattered-porous, coreless woods with the possibility of forming a false heartwood. In some older trees, there is wood of a different color in the middle of the trunk, from brown-yellow to red-brown to brown-red-gray, the so-called false heartwood.Afalseheartwood is agrowth defect in thezoneofmaturewood,whichis caused by the penetration of air into the tree trunk through wounded places of the trunk or branches of the tree and the subsequent oxidation of soluble carbohydrates and starch contained in living or partially dead parenchymal cells with the formation of polyphenolic compounds that penetrate into neighboring mesh and wood are colored by (Nečesaný 1958, Požgaj et al. 1997, Bauch and Koch 2001, Račko and Čunderlík 2006, 2010, Barański 2020, Vilkovský 2023). In extreme frosts lasting several consecutive days with temperatures below -30 °C, the parenchyma begins to die in the growing tree and conditions are created to form the socalled of brown-yellow to brown-red frosted false heartwood (Gorczynski 1951) According to the shape and position of the false heartwood on the cross-section of the trunk, the false

heartwood is divided into types: Round, Mosaic, Star, Flame (centric, eccentric) (Mahler and Höwecke 1991, Trenčiansky et al. 2017).

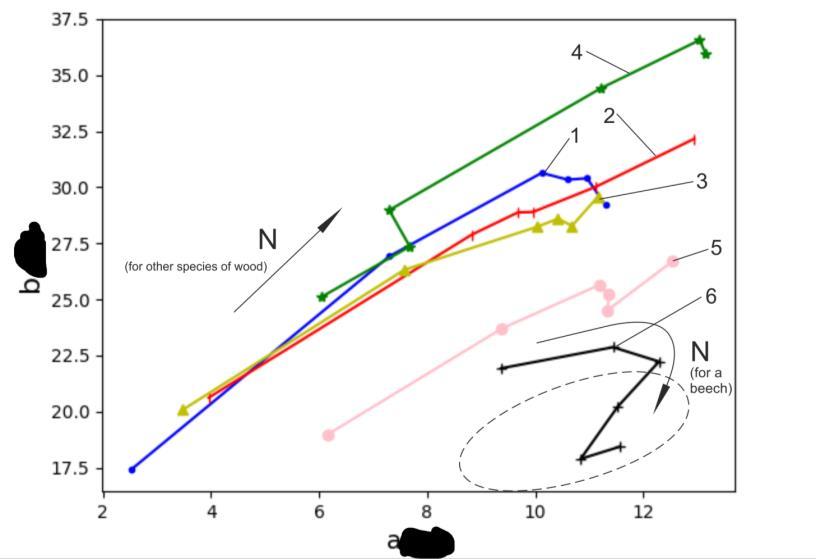

In contrast to sapwood, the wood of false heartwood is significantly more colorful. In the works of Dzurenda (2023), Dzurenda and Dudiak (2023), visual differences in the darkness and variety of yellow-brown-red shades of wood of individual types of false heartwood are quantified in the color space CIE L* a *b* in the form of the total color difference ΔEsx *. The color in mosaic wood of false heartwood with values on the lightness coordinate L* = 65.2 ± 6.9 and on the chromatic coordinates: red color a* = 13.2 ± 2.3 and yellow color b* = 19.2 ± 1.9 is the most diverse with a dispersity value of ΔEsx * = 7.5. The wood of round, flame and star false heartwood is more homogeneous in color with dispersity values in the interval ∆Exs * = 3.9 - 4.3.

Steaming of wood is a technological process in which wet wood is heated by the action of heat in the form of saturated moist air or saturated water steam and changes its physical, mechanicalandchemical properties.Whiletemporaryphysical-mechanical changes areused in the production of veneers, plywood, bent furniture, or pressed wood, permanent chemical changes manifested, among other things, by a change in color, serve to purposefully change the color of the wood into more or less distinct color shades (Deliiski 1991, Tolvaj et al. 2009, Dzurenda 2014, Milić et al. 2015, Geffert et al. 2017, Dzurenda and Dudiak 2021, Dzurenda et al. 2023, Dudiak 2023)

The aim of the work is based on experimental research aimed at monitoring the color changes of the false heartwood in the color space CIE L* a *b* in the steaming process with saturated atmospheric moist air at a temperature of tI = 90 ± 2.5 ° C, or of saturated water steam at atemperatureof tII =105 ± 2.5 °C,at temperaturetIII =115± 2.5 °C andtemperature tIV = 120 ± 2.5 °C.

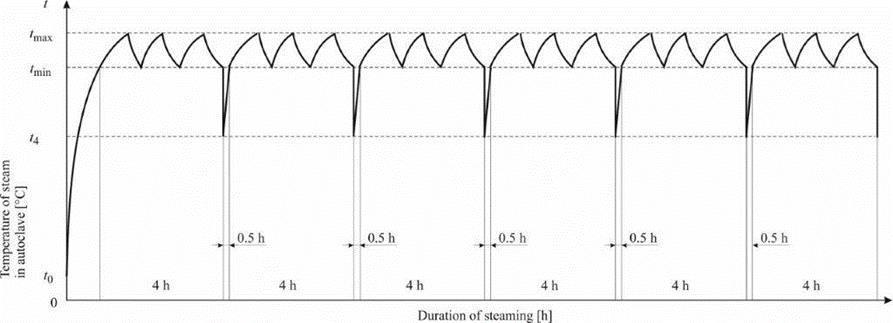

MATERIAL AND METHODS

Blanks with dimensions of 40×50×800 mm were made by longitudinal and transverse sawing from the central lumber of thickness h = 40 mm from logs with a round and star false heartwood. 375 blanks of false heartwood were randomly selected. The blanks were divided into 25 groups, so there were 15 blanks. The blanks of the 1st group were unsteamed. The other blanks were steamed with saturated atmospheric moist air at a temperature of tI = 90 ± 2.5 °C, or with saturated water steam modes: mode II with a temperature of saturated water steam tII = 105 ± 2.5 °C, mode III with a temperature of saturated water steam tIII = 115 ± 2.5 °C and mode IV with the temperature of saturated water steam tIV = 120 ± 2.5 °C. Individual sets of steamed wood were taken from the steaming autoclave after steaming τ = 4 h, τ = 8 h, τ = 12 h, τ = 16 h, τ = 20 h, and τ = 24 h. Steaming of wood was carried out in a pressure autoclave AZ 240 (Himmasch AD, Haskovo, Bulgaria) installed at Sundermann s.r.o. Banská Štiavnica (Slovakia). The conditions of steaming the false heartwood of beech wood with saturated water steam with marked time intervals of sampling during thermal treatment v are shown in the diagram in Fig. 1.

Fig. 1 Diagram of the steaming process of wood in a pressure autoclave.

The temperature of the steam-air mixture (Mode I), or of saturated water steam in steam Modes IIto IV is listed in Table 1. Temperatures tmax and tmin are temperature intervals in which saturated water steam is supplied to the autoclave for the implementation of the technological process. Temperature t4 is the temperature of the saturated water steam after reducing the pressure to atmospheric pressure, enabling the safe opening of the pressure device and selecting a group of steamed blanks in the specified steaming time.

Tab. 1 Technological conditions for the homogenization of the color of beech wood in a pressure autoclave.

Wood color homogenization time

Note: * taking a group of steamed blanks from the autoclave at planned intervals took 0.5 h. The actual steaming time compared to the planned steaming time was extended by the time of technological breaks.

Unsteamed and steamed beech wood blanks of the false heartwood were dried in a hot air oven according to Dzurenda (2022) mode in order to preserve the original color of the wood achieved by the technological process of steaming. The bedding surfaces of the dried lumber were machined on a FS 200 horizontal plane milling machine.

Color measurement was performed with a Color reader CR-10 Plus colorimeter (Konica Minolta, Japan) with a 400-700 nm reflection spectrum. A D65 light source was used and the diameter of the optical sensing aperture was 8 mm. The color measurement was performed on the milled surfaces of each blank at three points.

The results of the measured values: lightness L*, red color a*, yellow color b* on the coordinates of the color space CIE L* a *b* , are presented in the form of writing the average measured value �� and the standard deviation sx

Where: x – average value, sx – standard deviation.

The color dispersion of unsteamed and steamed wood beech wood of the false heartwood is determined through the standard deviations from the measured values at individual coordinates in the color space CIE L* a *b* and quantified by a modified equation of the total color difference Dzurenda (2023), Dzurenda and Dudiak (2024) in the form:

Where: ���� – value of standard deviation of lightness, ���� – value of the standard deviation on the red color coordinate, ���� – value of standard deviation on the yellow color coordinate.

The differences between the color of the sapwood and the color of the heartwood before steaming and after steaming are evaluated by the total color difference ΔE* :

Where: ��1, ��1, ��1 – average values on the coordinates of lightness, red and yellow color of unsteamed beech wood, ��2, ��2, ��2 – average values on the coordinates of lightness, red and yellow color of steamed beech wood.

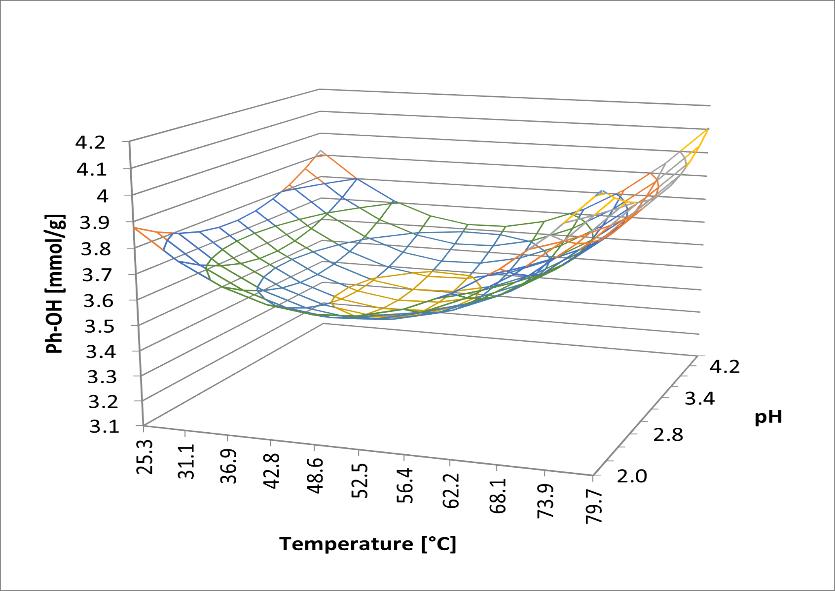

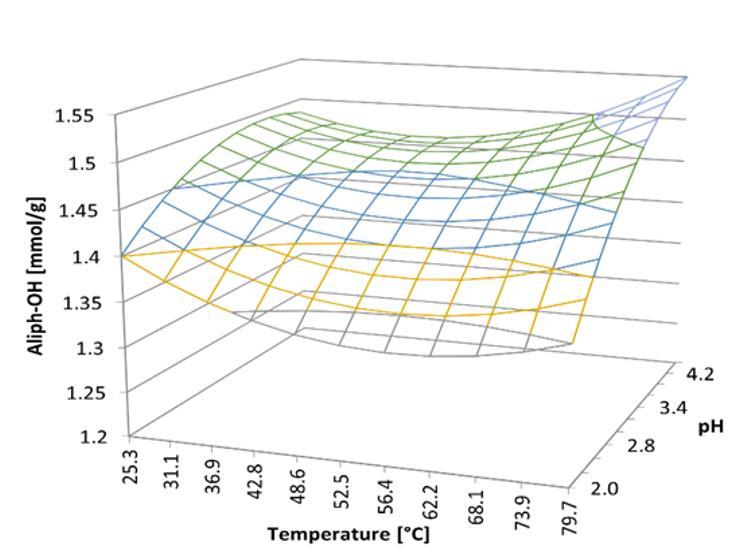

RESULTS AND DISCUSSION

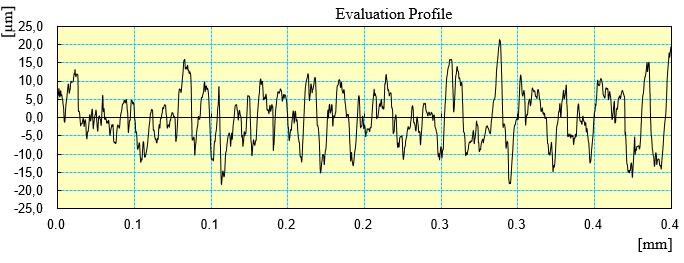

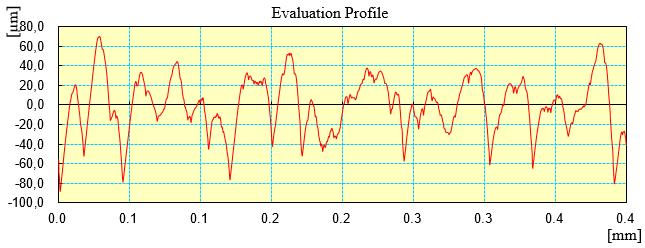

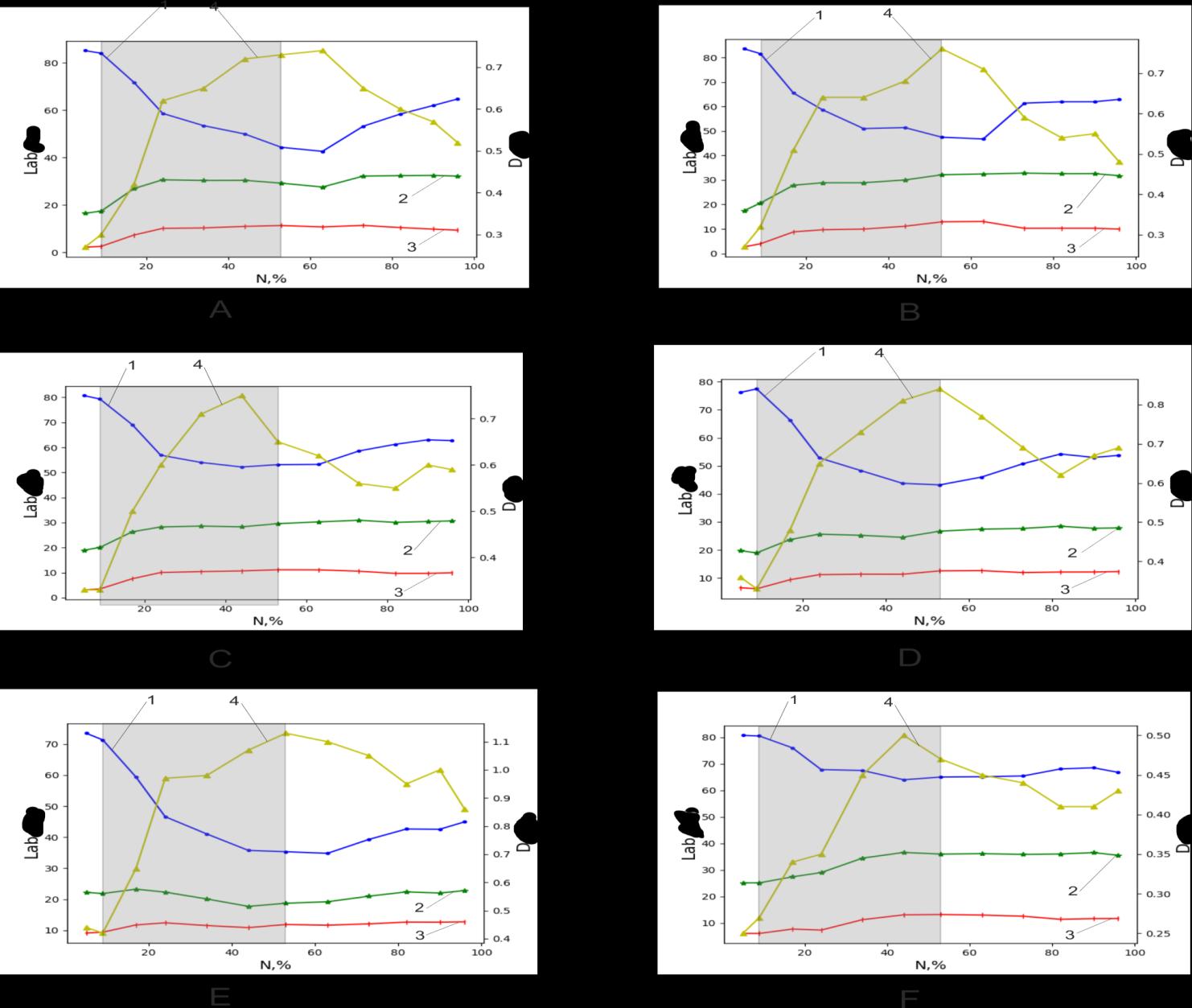

The course of changes in the color of the false heartwood on the individual coordinates of the color space CIE L* a *b* during τ = 24 h vaporization with saturated moist air at temperature tI 90 ± 2.5 °C and saturated water steam at temperature tII 105 ± 2.5 °C, temperature tIII = 115 ± 2.5 °C and temperature tIV 120 ± 2.5 °C are shown in Fig. 2 to 4.

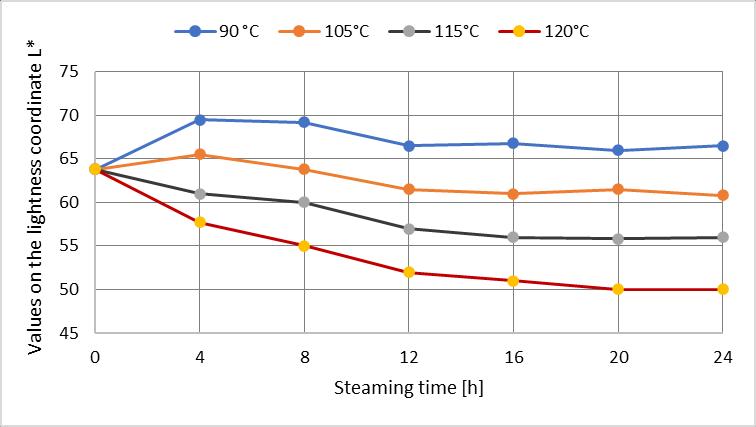

Fig. 2 Color changes on the lightness coordinate L* within 24 h steaming of wood of the false heartwood at individual temperatures.

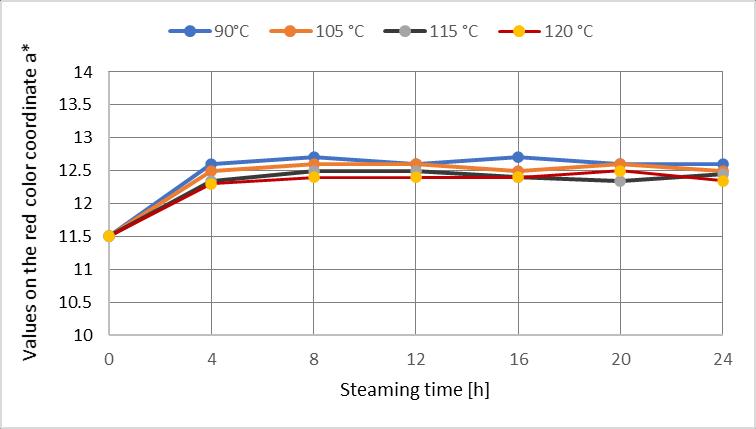

Fig. 3 Color changes on the chromatic coordinate of red a* within 24 h steaming of wood of the false heartwood at individual temperatures.

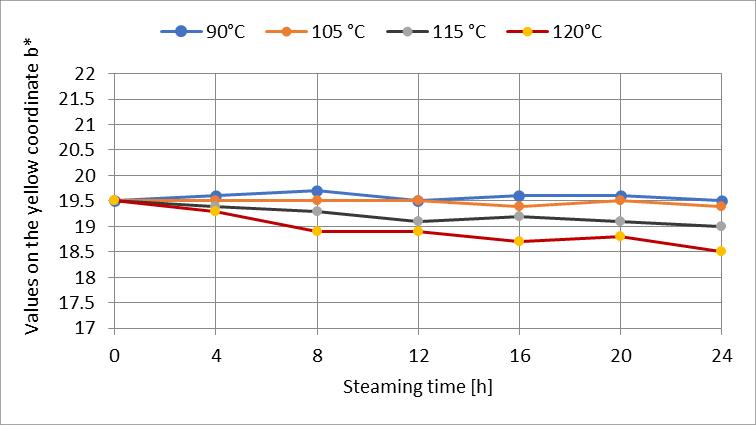

Fig. 4 Color changes on the chromatic coordinate of yellow b* within 24 h steaming of wood of the false heartwood at individual temperatures.

Changes in the lightness coordinate L* and the chromatic coordinates of red color a* and yellow color b* indicate changes in the color and color diversity of the wood of the false heartwood, which the wood acquires at individual temperatures during the steaming process. The most significant changes are on the lightness coordinate, minor changes on the chromatic coordinate of the red color a* and the chromatic coordinates of the yellow color b*

The wood color of the false heartwood by steaming at tI = 90 ± 2.5 °C during the first 8 h of steaming, as documented in Fig. 2. fades out. The fading of the color of the wood declares an increase in the lightness of the wood from the value L0 * = 63.7 to the value LI-4 *= LI-8 *= 69.3. Due to the further application of heat in the steaming process, the fading of the wood not only stopped but gradually darkened, which documents the decrease in lightness values to LI-24 *= 65.5.

At the steaming temperature tII = 105 ± 2.5 °C, the wood of the false heartwood also lightens at the beginning of steaming. Within 4 h of evaporation, the value on the lightness coordinate increased from L0 * = 63.7 to LII-4 * = 65.5. Due to the subsequent heat action, the wood darkens similarly to the steaming temperature tI = 90 ± 2.5 °C, which is reflected in the lightness coordinate by a decrease to LII-24 * = 60.8.

The lightness of the wood of the false heartwood at the steaming temperatures tIII = 115 ± 2.5 °C and tIV = 120 ± 2.5 °C during the entire steaming time decreased from the lightness value L0 * = 63.8 to the value LIII-24 * = 56.0 and at temperature tIV = 120 ± 2.5 °C to the value LIV-24 * = 50.0. The steamed wood darkened, and the rate of darkening increased as the temperature of the steaming process increased.

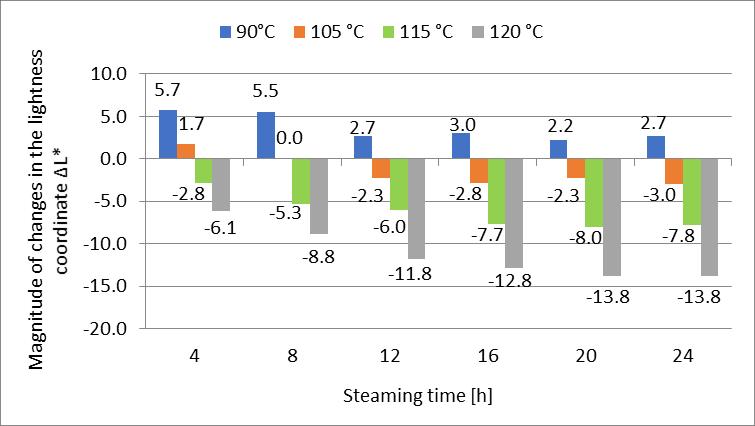

Fig. 5 shows the magnitude of changes in the lightness coordinate ∆L* at individual temperatures of the steaming process in bar diagram form at time intervals of 4 h.

Fig. 5 The magnitude of changes in the lightness coordinate ∆L* over time at individual temperatures of the wood steaming process.

The lightening of the steamed wood of the false heartwood at the steaming temperature tI = 90 ± 2.5 °C and at the steaming temperature tII 105 ± 2.5 °C in the first 4 h point to the instability of the chromophoric system of the wood of the false heartwood formed by the enzymatic processes of peroxidase and polyphenoloxidase, which are responsible for the oxidation of phenolic compounds and the characteristic coloration of the wood of the false heartwood (Hofmann et al. 2004, Albert et al. 2003, Tolvaj et al 2009).

Wood darkening after 4 h steaming at temperature t = 105 ± 2.5 °C, or at higher steaming temperatures t ≥ 115 °C is consistent with the opinions of Bekhta and Niemz (2003), Geffert et al. (2017), Laskowska et al. (2020), Dzurenda and Dudiak (2021), who darken they attribute the decrease of hemicelluloses caused by hydrolysis processes and thus the increase of the lignin content in the steamed wood.

The values on the chromatic coordinate of the red color a* of beech wood of the false heartwood showed a slight increase during the first hours of steaming, independent of the steaming temperature, from thevaluea0 * =11.6to thevaluea* ≈ 13.5.However,thesevalues remained stable and did not change further during the steaming process, providing a clear picture of the color changes during the process.

The values on the chromatic coordinate of the yellow color b*of the wood of the false heartwood did not change at the steaming temperature tI = 90 ± 2.5 °C and the steaming temperature tII = 105 ± 2.5 °C. The measured values of the yellow color b* during the

steaming show the values oscillating around b* ≈ 19.5. The stated finding is similar to the works ofTolvaj et al (2009), andDzurendaand Dudiak(2024).At the steamingtemperature tIII = 115 ± 2.5 °C and the temperature tIV = 120 ± 2.5 °C, a slight decrease is recorded during τ = 24 h in the interval ∆b* = 0.5 - 1.0.

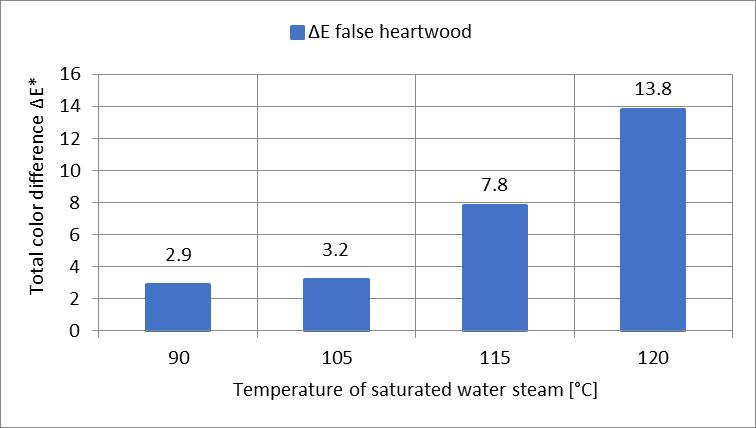

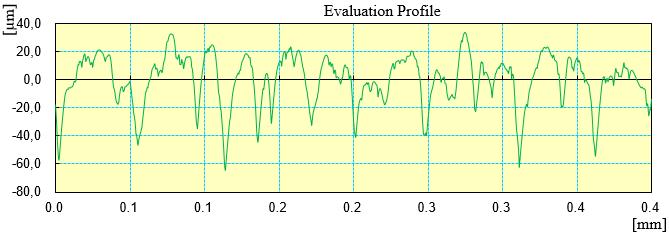

The influence of the steaming conditions on the chemical changes of beech wood in the steaming process is comprehensively expressed by the overall change in the color of the steamed wood. In Fig. 6 shows the change in the color of the wood of false heartwood during τ = 24 h of the steaming process, shown as the total color difference ∆E*.

Fig. 6 Sizes of changes in the color of the false heartwood achieved by the steaming process during τ = 24 h for individual temperatures.

The lower values of the total color difference ∆E* = 2.9 – 3.2 at steaming temperatures t = 90 °C – 105 °C point to the partial resistance of wood ef the false heartwood to the influence of heat on the color change manifested by opposite changes in the lightening and darkening of the color of the wood. The effect of heat on the steaming process with temperatures above t ≥ 115 °C is more favorable for continuous changes in the color of the wood manifested by the darkening of the wood. Numerically, this is evidenced by a 2.5 to 4.5 fold increase in the values of the total color difference ∆E* compared to the value of the total color difference at temperature t = 90 °C.

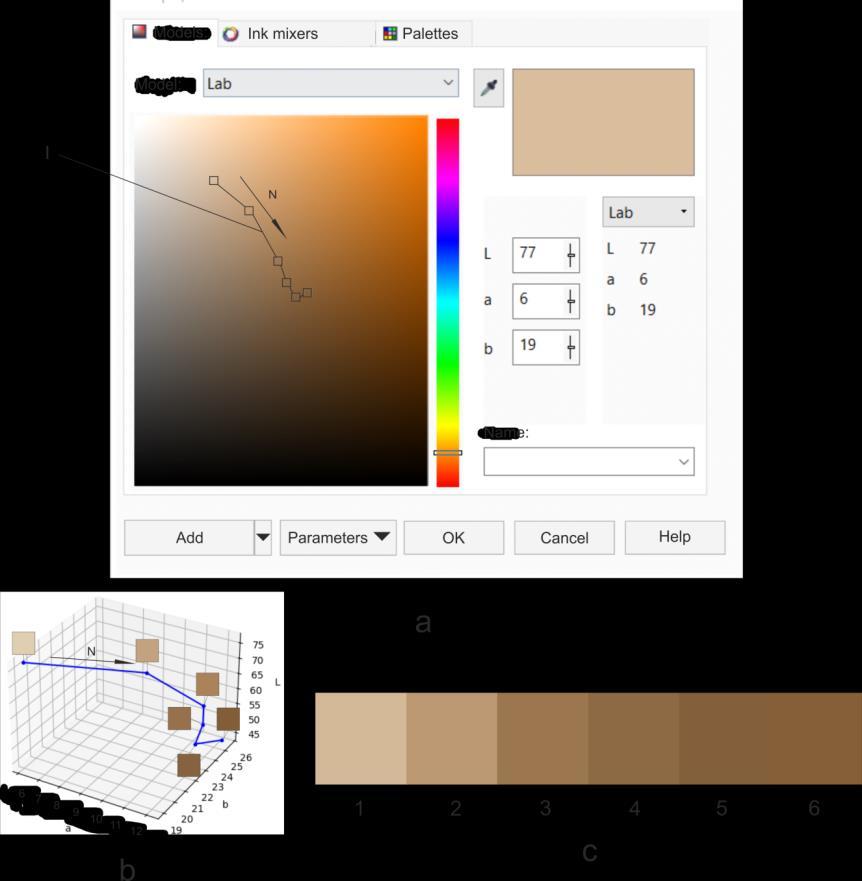

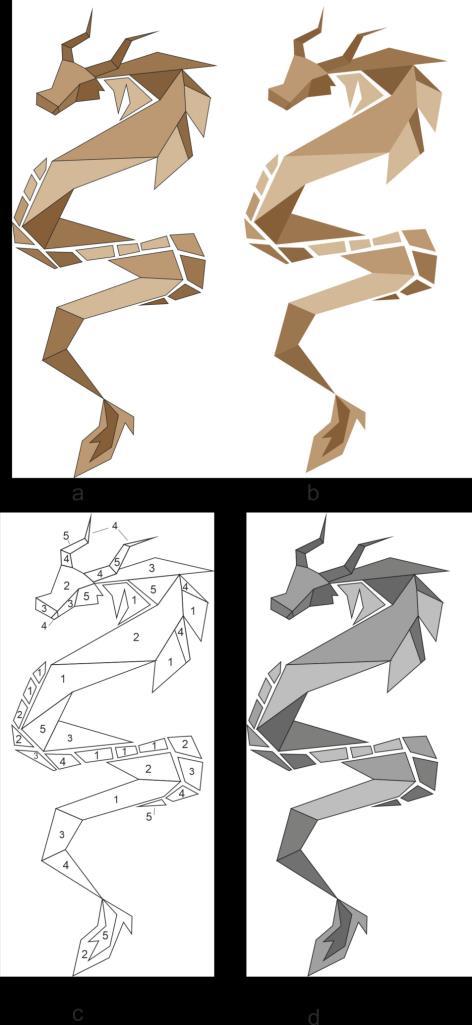

Based on the presented results of the lightening of the wood color of the fake heartwood during the steaming process, fig. 7b, respectively darkening fig. 7c and fig. 7d the technological conditions of steaming were proposed. Technological conditions of steaming to achieve the targeted color of steamed wood, such as steaming temperature, the minimum steaming time required to achieve the targeted wood color, the steamed wood color identified by values on the coordinates of the color space CIE L* a *b*, the dispersion of the steamed wood color ∆Esx * is given in Tab. 2.

Tab. 2 Technological conditions of steaming to achieve the targeted color of steamed wood.

Beech wood of false heartwood

Steamed with mode I

with mode II

with mode III

Steaming time Values on the color space CIE L* a *b* coordinates Color

The color of the wood of the false heartwood before cooking and after steaming according to the proposed technological conditions is shown in Fig. 7b to 7d.

7 Color of unsteamed and steamed wood of false heartwood.

Changes in the color of steamed wood of false heartwood achieved by the proposed steaming modes are characterized by the following facts:

• Steaming mode I enables lightening of the wood color of the false heartwood of saturated atmospheric moist air at a temperature tI = 90 ± 2.5 °C during τ = 8 h. On the coordinates color space CIE L* a *b* values: L* = 69.2 ± 2.9, a* = 12.7 ± 1.6 and b* = 19.7 ± 1 4. The given coloring of steamed wood reaches the value on the lightness coordinate by ∆L* = +5.5 and the values on the chromatic coordinates of red color by ∆a* = +1.2 and yellow color by ∆b* = +0.2. A decrease in the color dispersion value from ∆Esx * = 4.4 before steaming to ∆Esx * = 3.6 points to the homogenization of the wood color of the false heartwood by the steaming process.

• The steaming mode II carried out by saturated steam with a temperature of tII = 115 ± 2.5 °C during τ = 16 h causes the wood to slight darkening and acquire a brown color with values on the coordinates of the color space L* = 56.0 ± 2.4, a* = 12.4 ± 1.4 and b* = 19.2 ± 1.5. The change in the color of the wood of the false heartwood is accompanied by a decrease in the value on the lightness coordinate by ∆L* = -7.7 and an increase in the value on the red color coordinate by ∆a* = +0.9 and a decrease in the value on the yellow color coordinate by ∆ b* = -0.3.

• Steam mode III with saturated steam with temperature tIV = 120 ± 2.5 °C during τ = 24 h changes the original color of the wood to a dark brown color. In the color space CIE L* a *b* it is identified by the values at the coordinates L* = 50.0 ± 2.1, a* = 12.4 ± 1.3 and b* = 18.5 ± 1.4. The stated steaming conditions not only contribute to the most significant darkening of the wood of the false heartwood, but also contribute to reducing the color dispersion of the steamed wood characterized by the color dispersion value ∆Esx * = 2.8.

CONCLUSION

Results of analysis of the effect of temperature on the steaming process of beech false heartwood within 24 h point to a relatively wide range of color changes from pale brown to dark brown color.

False heartwood steamed with saturated atmospheric moist air at a temperature of tI = 90 ± 2.5 °C in the first 8 h, or with saturated water steam at a temperature of t = 105 ± 2.5 °C in the first 4 h, fades from the original brown-red color to a pale brown color and then gradually darkens to a brown color. The mentioned facts point to a certain instability of the chromophoric system of false heartwood formed during the growth of the tree against the action of heat.

Steaming false heartwood core with saturated water steam with a temperature of t = 115 ± 2.5 °C and with a temperature of t = 120 ± 2.5 °C, the wood gradually darkens to brown to dark brown. The rate of wood darkening increases with increasing steaming temperature. Qualitative differences in wood color in the wood steaming process of false heartwood at temperatures above t ≥ 115 °C declare the values of the total color difference ∆E*, which are 2.5 to 4.5 times higher than the color changes at the steaming temperature t = 90 ° C.

On the basis of the presented results of the color changes of the false heartwood in the steaming process, the technological steaming conditions for 3 color changes of the false heartwood by the steaming process were proposed for the targeted color changes of the false heartwood.

Steaming mode I allows the color of the wood to lighten. By steaming wood with a saturated atmospheric moist air at a temperature of tI = 90 ± 2.5 °C for τ = 8 h, the original color of the wood changes to a pale brown color with coordinates in the color space CIE L* a *b*: L* = 69.2 ± 2 .9, a* = 12.7 ± 1.6 and b* = 19.7 ± 1 4.

Steaming mode II a slight darkening of the wood color is achieved. Steaming of wood of the false heartwood is carried out with saturated water steam with a temperature of tII = 115 ± 2.5 °C during τ = 16 h. The acquired wood color in the color space CIE L* a *b* is identified by the following values: L* = 56.0 ± 2.4, a* = 12.4 ± 1.4 and b* = 19.2 ± 1.5.

Steaming mode III it changes the color of the wood of the false heartwood to a dark brown. It is realized with saturated water steam with temperature tIII = 120 ± 2.5 °C during τ = 24 h. The dark brown color is in the color space CIE L* a *b* described by the values: L* = 50.0 ± 2.1, a* = 12.4 ± 1.3 and b* = 18.5 ± 1.4.

REFERENCES

Albert, L., Hofmann, T.,Németh, ZS.,Rétfalvi, T.,Koloszár, J., Varga,Sz.,Csepregi, I. 2003 Radial variation of total phenol content in beech (Fagus sylvatica L.) wood with and without red heartwood. Holz als Roh- und Werkstoff (61) 3: 227–230

Barański, J., Konopka, A., Vilkovska, T., Klement, I., and Vilkovsky, P., 2020 Deformation and surface color changes of beech and oak wood lamellas resulting from the drying process," BioResources. 15(4), 8965-8980.

Bauch, J., Koch, G., 2001. Biologische und chemische Untersuchungen über Holzverfarbungen der Rotbuche (Fagus sylvatica L.) und Möglichkeiten vorbeugender Maßnahmen. Abschlussbericht, Bundesforschungsanstalt für Forst- und Holzwirtschaft, Universi-tät Hamburg, 2001.

Bekhta, P., Niemz, P. 2003 Effect of high temperature on color change, dimensional stability and mechanical properties of spruce wood. Holzforschung 57 (5): 539-546.

Deliiski, N. 1991. The method extends the assessment of the degree of beech sawn timber during its drying process. Current problems and perspectives of beech lumber drying 1991. ES-VŠLD in Zvolen (Slovakia), 37−44.

Dudiak, M. 2023. Density of beech (Fagussylvatica L.) wood through a cross-section of the trunk. Acta Facultatis Xylologiae Zvolen. Zvolen, 65(2), 5-11.

Dzurenda, L. 2014. Colouring of Beech Wood during Thermal Treatment using Saturated Water Steam. Acta Fac. Xylologiae Zvolen 2014, 56, 13–22.

Dzurenda, L., Dudiak, M. 2021. Cross-correlation of color and acidity of wet beech wood in the process of thermal treatment with saturated steam. Wood Research 66 (1): 105-116.

Dzurenda, L., 2022. Mode for hot air drying of steamed beech blanks while keeping the colours acquired in the steaming process. Acta Facultatis Xylologiae Zvolen. Zvolen, 64(1), 81-88.

Dzurenda, L. Dudiak, M. 2023. Color diversity of beech wood with a false heartwood in the color space CIE L*a*b*. Wood Research 68(4): 68(4): 792-801.

Dzurenda, L. 2023. Natural Variability of the Color of Beech Wood in the Color Space CIE L*a*b*. Forests 14, 1103.

Dzurenda, L., Dudiak, M., Kučerová, V., 2023. Differences in Some Physical and Chemical PropertiesofBeechwoodwithFalseHeartwood,Mature Wood and Sapwood. Forests,14,1123.

Dzurenda, L., Dudiak, M. 2024. Homogenization of the color of beech sapwood and false heartwood by the steaming process. Forests 15(6):1009.

Geffert, A., Vybohová, E., Geffertová, J. 2017. Characterization of the changes of colour and some wood components on the surface of steamed beech wood. Acta Facultatis Xylologiae Zvolen 59(1): 49−57.

Gorczynski, T. 1951. Comparative anatomical studies on common beech wood (Fagussylvatica L.). Rocz.demdr.Polsk. Tow. Bot.7. 3-114.

Hofmann, T., Albert, L., Rétfalvi, T., Bányai, É., Visiné Rajczi, E., Börcsök, E., Németh, Z S. 2004 Quantitative TLC Analysis of (+)-Catechin and (-)-Epicatecin from Fagus sylvatica L. with and without Red Heartwood. Journal of Planar Chromatography (17): 350–354.

Laskowska, A. 2020. The influence of ultraviolet radiation on the colour of thermo-mechanically modified beech and oak wood. Maderas, Cienc. tecnol. Vol. 22 no.1 Concepción ene. 2020.

Mahler, G., Höwecke, B., 1991. Verkernungserscheinungen bei der Buche in Baden- Württemberg in Abhängigkeit von Alter, Standort und Durchmesser. Schweiz. Z. Forstwes. 142: 375−390. Makovíny I., 2010. Useful properties and use of different types of wood. TU Zvolen, Zvolen.

Milić, G., Todorović, N.;, Popadić, R. 2015. Influence of steaming on drying quality and colour of beech timber. Glas. Šumar. Fak. 112, 83–96.

Nečesaný, V., 1958. Beech false heartwood, structure, origin and development. Publishing House of the Slovak Academy of Sciences, Bratislava. 256 p

Požgaj, A., Chovanec, D., Kurjatko, S., Babiak, M., 1997. Structure and properties of wood. Bratislava, Slovakia, Príroda, 1997, 485 p.

Račko, V., Čunderlik, I. 2006. Qualitative and quantitative evaluation of false heartwood in beech logs of various age and qualitative structure. Wood Research, 51(3): 1−10.

Račko,V.,Čunderlík,I.,2010.Maturewoodasalimitingfactorintheformationofafalseheartwood beech (Fagussylvatica L.). Acta facultatis xylologiae Zvolen,52 (1), 15 – 24.

Tolvaj, L., Nemeth, R., Varga, D., Molnar, S.2009 Colour homogenisationof beech woodby steam treatment. Drewno, 52, 5–17.

Trenčiansky, M., Lieskovský, M., Merganič, J., Šulek, R. 2017. Analysis and evaluation of the impact of stand age on the occurrence and metamorphosis of red heartwood. ForestBiogeosciences and Forestry, 10(3):605-610.

Vilkovský, P., Klement, I., Vilkovská, T., 2023. The Impact of the Log-Sawing Patterns on the Quantitative and Qualitative Yield of Beech Timber (Fagussylvatica L.). Appl. Sci. 2023, 13, 8262. https://doi.org/10.3390/app13148262

ACKNOWLEDGMENT

This experimental research was prepared within the grant project: APVV-21-0051 Research of false heartwood and sapwood of Fagussylvatica L. wood in order to eliminate color differences by the process of thermal treatment with saturated water steam as the result of work of author and the considerable assistance of the APVV agency

AUTHOR ADDRESS

Ladislav Dzurenda

Michal Dudiak

Technical University in Zvolen

T. G. Masaryka 24 960 01 Zvolen, Slovakia dzurenda@tuzvo.sk xdudiak@tuzvo.sk

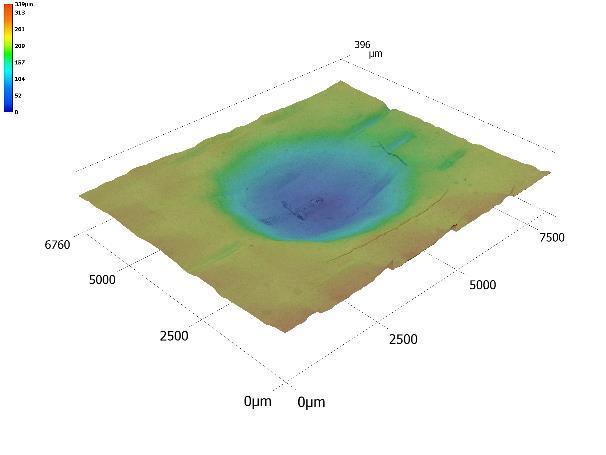

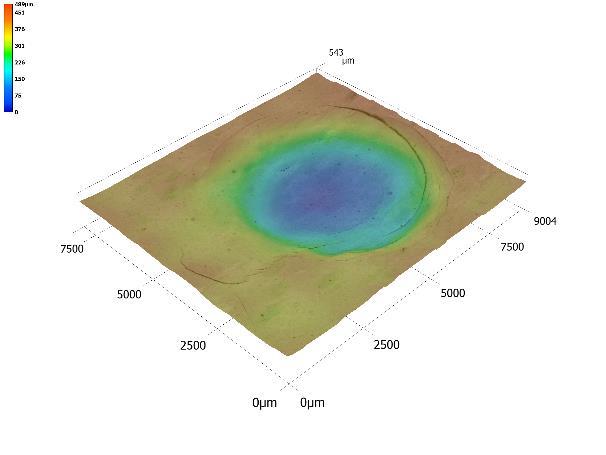

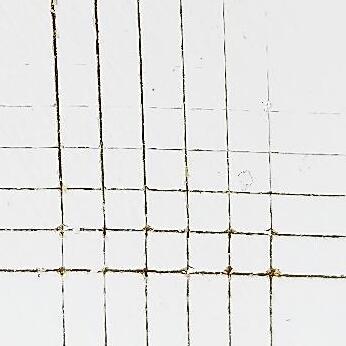

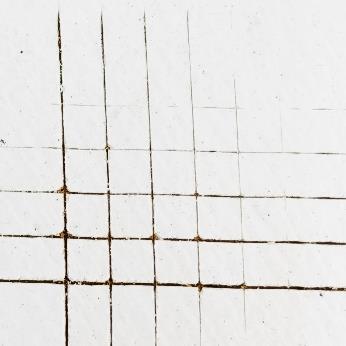

ACTA FACULTATIS XYLOLOGIAE ZVOLEN, 66(2): 35 49, 2024

Zvolen, Technická univerzita vo Zvolene

DOI: 10.17423/afx.2024.66.2.04

THE EFFECT OF NATURAL WEATHERING ON STABILITY OF COATING SYSTEM WITH SELF-HEALING MICROCAPSULES

Zuzana Vidholdová – Gabriela Slabejová – Jozef Kúdela – Ján Svocák

ABSTRACT

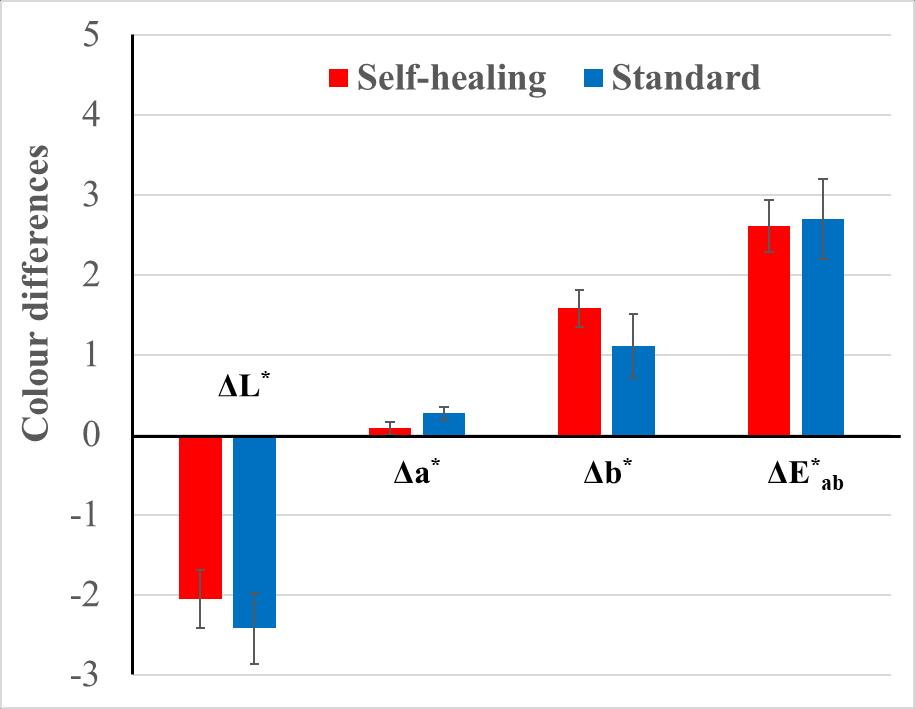

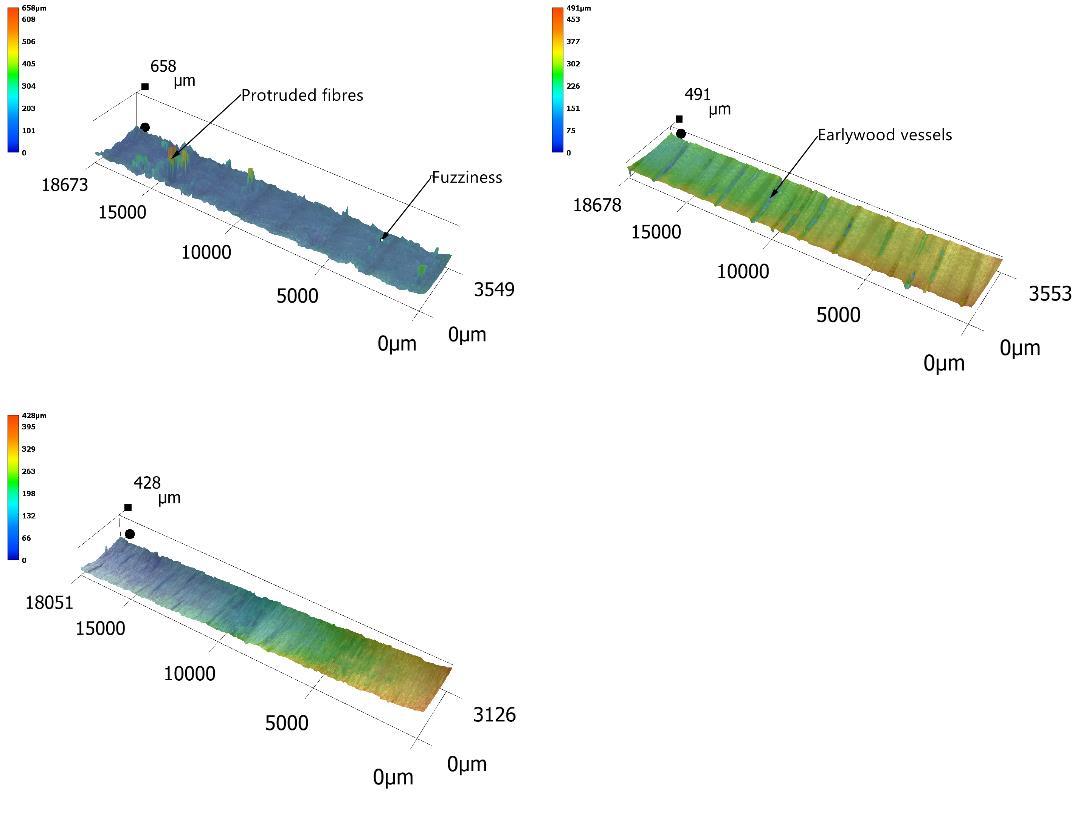

The performance of self-healing and standard coating systems on oak wood exposed to natural weathering for two years is investigated in the paper. The changes in coating thickness, colour coordinates L* , a *, b*, total colour difference ΔE* ab, impact resistance, and adhesion by Pull-off and Cross-cut tests are evaluated in the study. The results show that while both coating system types displayed slight colour alterations, the self-healing coating system containing microcapsules exhibited more colour stability, maintaining a colour difference (ΔE* ab) of 2.6. The primary factors contributing to colour change were variations in lightness (L*) and, to a* lesser degree, the b* coordinate leading to subtle darkening and yellowing of the coatings. However, the self-healing coating system exhibited lower impact resistance indicating increased brittleness and susceptibility to cracking corresponding to the standard coating system. Regarding adhesion, the self-healing coating system showed no changes after weathering, as measured by the Pull-off and Cross-cut tests. In contrast, the standard coating system experienced a 32% reduction in adhesion in the Pull-off test. These findings suggest that although self-healing coatings may offer advantages in colour retention, their application on exterior wood surfaces, particularly those exposed to mechanical stress, requires careful consideration.

Keywords: adhesion properties; colour stability; impact resistance; self-healing coatings, weathering.

INTRODUCTION

Mechanical damage and crack formation belong to the most harmful defects in wood surface coatings, as they compromise the integrity of the coating film, which leads to a significant reduction in its protective capabilities against environmental factors, particularly water, UV radiation, chemical agents, contamination, andbiological organisms suchas fungi and algae (Bulian and Graystone, 2009; Viitanen and Ritschkoff, 2011; Hochmańska et al., 2014; Reinprecht and Pánek, 2015; Kúdela et al., 2017, Liu et al., 2017; Vidholdová et al., 2017; Cogulet et al., 2018; Slabejová et al., 2019; Jirouš-Rajković and Miklečić, 2021; Hasanagić et al., 2024). These disturbed areas act as starting points for further degradation, mainly through moisture absorption, which induces swelling in the surface layers of the wood. The resulting tension at the wood-coating interface promotes crack propagation, accelerating the coating breakdown (Lagaňa et al., 2021). This process impairs adhesion between the coating and the wood substrate, leading to peeling, and necessitates frequent

and costly maintenance of the damaged surface. Considerable research efforts are focused on mitigating these negative effects to extend the lifespan of surface coatings.