November /December 2022 >> Vol.123 Delivering benefits beyond construction Digital twins iRhino launches on the iPad Rhino goes mobile Exciting new tools for AEC workflows New beginnings

Building Information Modelling (BIM) technology for Architecture, Engineering and Construction

Will robotic fabrication change how we plan buildings?

IMAGE COURTESY OF TAL FRIEDMAN, FOLDSTRUCT

The future of architecture engineering and construction technology London 20 June 2023 nxtbld.com PARTNERED WITH Save the date

Building Information Modelling (BIM) technology for Architecture,

MANAGING EDITOR

GREG CORKE greg@x3dmedia.com

CONSULTING EDITOR

MARTYN DAY martyn@x3dmedia.com

CONSULTING EDITOR

STEPHEN HOLMES stephen@x3dmedia.com advertising

GROUP MEDIA DIRECTOR

TONY BAKSH tony@x3dmedia.com

ADVERTISING MANAGER

STEVE KING steve@x3dmedia.com

U.S. SALES & MARKETING DIRECTOR

DENISE GREAVES denise@x3dmedia.com

subscriptions MANAGER

ALAN CLEVELAND alan@x3dmedia.com

accounts

CHARLOTTE TAIBI charlotte@x3dmedia.com

FINANCIAL CONTROLLER

SAMANTHA TODESCATO-RUTLAND sam@chalfen.com

AEC Magazine is available FREE to qualifying individuals. To ensure you receive your regular copy please register online at www.aecmag.com about

AEC Magazine is published bi-monthly by X3DMedia Ltd 19 Leyden Street London, E1 7LE UK

F.

©

All rights reserved. Reproduction in whole or part without prior permission from the publisher is prohibited. All trademarks acknowledged. Opinions expressed in articles are those of the author and not of X3DMedia. X3DMedia cannot accept responsibility for errors

in

Engineering and Construction

Industry news 4

Exyn and Trimble explore fully autonomous surveying; Bricsys makes flexible licensing promise; Allplan 2023 adds precast concrete, plus lots more

Rhino on the iPad 12

With a thriving ecosystem on Windows, Mac and in the cloud, Rhino has now gone mobile with iRhino

The pillars of fabrication integrated modelling 14

Tal Friedman explores how a fabrication centric approach could help impart real change in the construction industry

Bentley Systems iTwin ‘phase two’ 18

The company continues its drive to lead the digital twin infrastructure market with the release of new iTwin products

Q&A: Keith Bentley, Bentley Systems 22

We talk iTwin technology and the ‘platformification’ of the design software world with the Bentley CTO

Monitoring asset health in real-time

26

From reality modelling and IoT, to AI and simulation, Bentley is drawing on a range technologies to monitor infrastructure

Digital twin tech 28

A Trojan horse for systemic and cultural change in AEC?

Autodesk Tandem 30

What’s new and upcoming with the cloud-based digital twin platform?

The Metaverse 34

Roderick Bates of Enscape on how architects can help the Metaverse live up to its hype

Streaming digital twins into Unreal Engine

36

Bentley Systems has a new technology that streams models from its iTwin platform on demand, into the visually rich Unreal Engine environment

A new architecture for Architecture

38

With a major rearchitecting of Archicad underway, Martyn Day spoke with Graphisoft executives to find out more

Modumate: BIM powered by Unreal Engine 42

A San Francisco-based start-up has built an architectural design system on top of Epic’s legendary game engine

SimpleBIM: taking back control with IFC 46

Founded in Finland in 2009, SimpleBIM has played a key role in the rise of IFC standards for data exchange

Swapp: the algorithmic assistant 48

3 www.AECmag.com November / December 2022

This audacious AI tool automates detail design work and produces drawings FREE SUBSCRIPTIONS Register your details to ensure you get a regular copy register.aecmag.com

editorial

or

the

42

T. +44 (0)20 3355 7310

+44 (0)20 3355 7319

2022 X3DMedia Ltd

articles

advertisements within

magazine.

Exyn and Trimble explore fully autonomous surveying with Boston Dynamics Spot robot

ever-changing complexity of construction environments.

The ExynPak mounts and integrates with a robot, supporting level 4 of autonomous exploration missions without requiring the robot to “learn” about its environment beforehand.

The surveyor simply defines a 3D volume for a mission and the integrated robotic solution then handles the complexities of self-navigation without needing a map, GPS or wireless infrastructure.

The Trimble X7 provides 3D laser scanning to capture the state of the environment. The captured data can be uploaded to the Trimble Connect collaboration platform and shared with project stakeholders for further analysis, including a comparison to BIM models and previous scans to monitor quality and progress.

Trimble and Exyn Technologies, a specialist in robotic autonomy for complex environments that can’t access GPS, are exploring the use of autonomous construction surveying technology.

The solution will integrate Boston Dynamics’ Spot robot, the ExynPak portable, real-time 3D mapping ‘SLAM’ solution powered by ExynAI, and the

Trimble X7 laser scanner.

The aim is to enable fully autonomous missions inside complex and dynamic construction environments, resulting in ‘consistent and precise’ reality capture for production and quality control workflows.

Autonomous robots powered by ExynAI, are designed to sense and avoid obstacles, dynamically adapting to the

“Industry has been waiting for reliable and robust autonomous technology to transform difficult and dangerous activities,” said Nader Elm, CEO of Exyn Technologies. “Exyn’s technology is helping to enable a new front in humanrobot collaboration. By working with preeminent leaders such as Trimble, we aim to create adaptable, state-of-the-art systems to tackle the complexities across construction and industrial environments.”

■ www.exyn.com ■ www.trimble.com

Bentley enhances Synchro construction management tool

entley Systems has enhanced its construction management solution, adding new features to Synchro 4D and introducing new tools Synchro Cost and Synchro Perform.

Synchro 4D now offers 4D/5D model authoring with model-splitting tools to create constructible components, the ability to assign construction attributes to the model, mixed reality modelling, construction geometry placement, and web and mobile access to improve team collaboration, status updates, and progress reporting from the field.

Synchro Cost is designed to help project teams control budgets and track financial progress throughout the contract with

support for multi-contract capture, payment application tracking, and change order management.

Synchro Perform supports construction performance management and includes the ability to capture daily progress quantities, diaries, unplanned events, timesheets, tickets, and estimated field costs with a view to providing the shortest cycle time for project feedback.

“Construction teams need to ensure that they are in control of both the schedule and costs of their projects,” said Rich Humphrey, vice president of construction at Bentley Systems.

“The addition of Synchro Cost and Synchro Perform extends Synchro’s

industry leading 4D scheduling and project management solutions to include more capabilities to help contractors manage their costs and effectively connect the planning and tracking of costs and schedule.”

■ www.bentley.com/software/synchro

4 www.AECmag.com November / December 2022

News

B

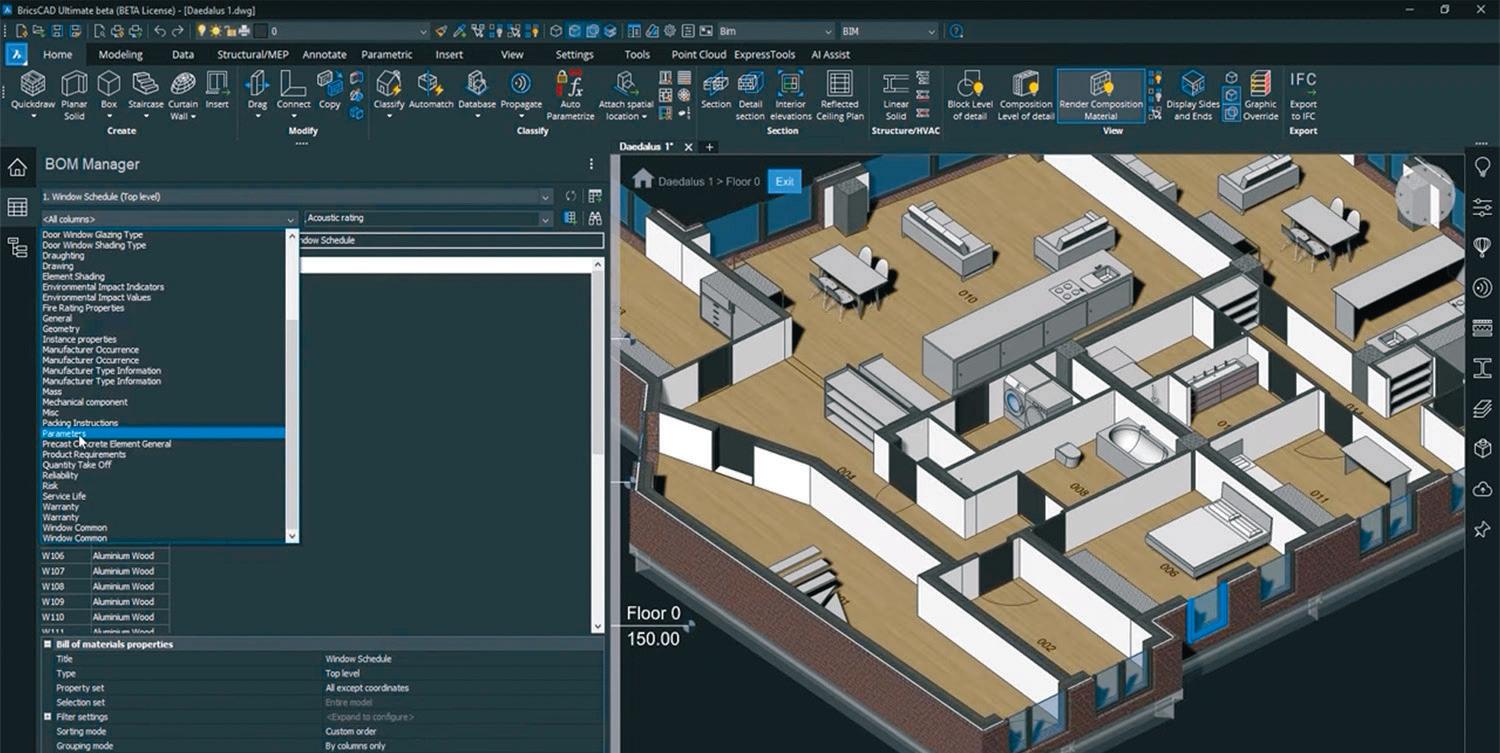

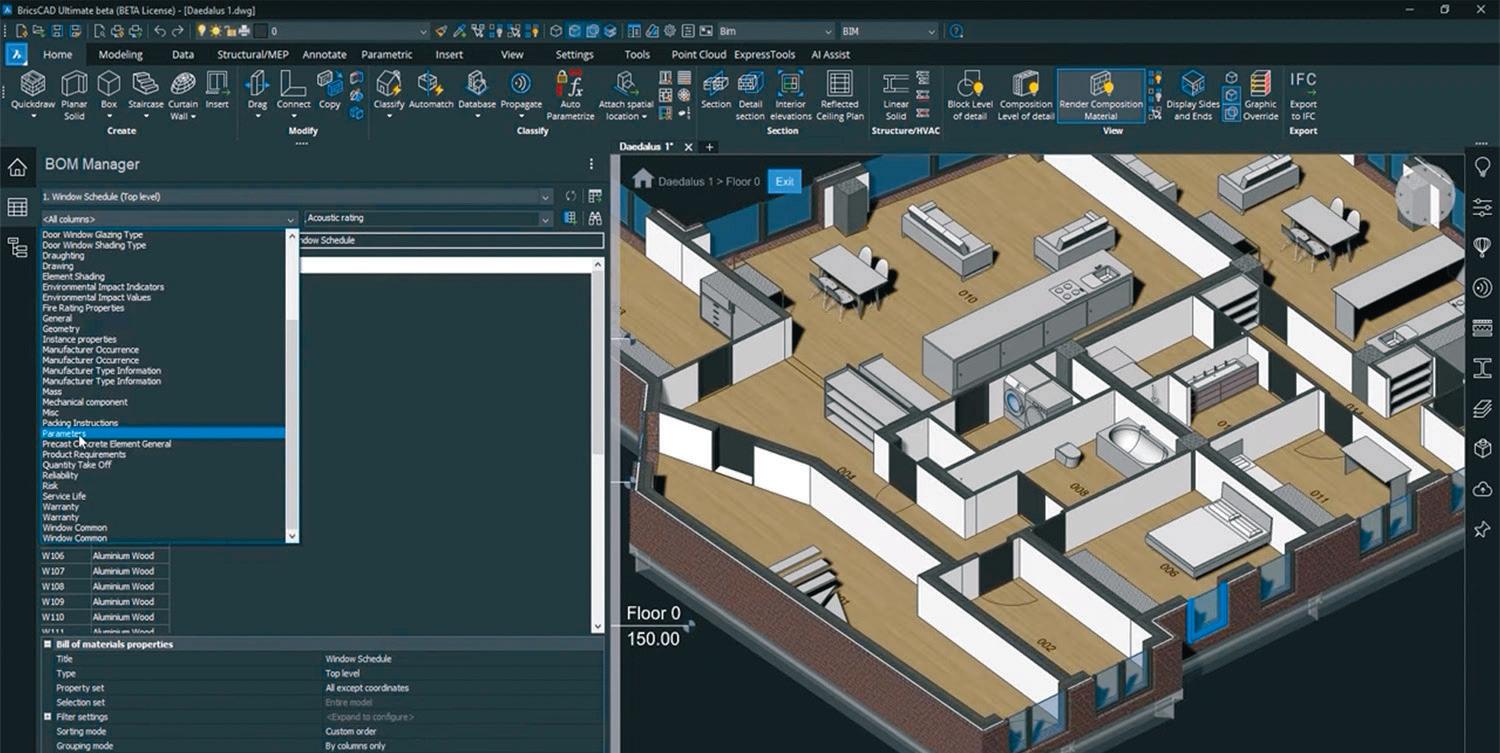

BricsCAD v23 launches with flexible licensing promise ROUND UP

Streamlining Revit

Microdesk has integrated its BIMrx product line into Symetri’s Naviate. The expanded and rebranded suite of tools aims to improve workflows for AEC professionals by streamlining Revit project setup, model management, and documentation ■ www.microdesk.com

Scia Engineer 22

Version 22 of structural analysis software Scia Engineer has been designed to give users better insight into the economy of their designs. The extended AutoDesign report helps users save material by evaluating the weight of reinforcement per cubic metre of concrete ■ www.scia.net

Telecom digital twins

Axians France has partnered with Pix4D to provide operators and telecom infrastructure managers with infrastructure digital twins. Pix4D technology will be used to automatically identify telecom assets and their dimensions. BIM models will then be created for use in 5G antenna installation and maintenance ■ www.pix4d.com

CICES BIM paper

A new white paper from the Chartered Institution of Civil Engineering Surveyors (CICES) ‘Transforming the civil engineering surveyor’ aims to help improve understanding of BIM and how it relates to civil engineering during site operations

■ www.cices.org/publications/white-papers

13th Gen for BOXX

BOXX Technologies’ APEXX S3 workstation now features 13th Gen Intel Core i7 and i9 processors. The new CPUs are said to offer exceptional performance for CAD, 3D design, motion media, and other professional software applications

■ www.boxx.com

NBS subscriptions

NBS has launched a ‘cost-effective’ subscription option for its specification platform, NBS Chorus. NBS Chorus Designer enables users to annotate design models in Revit, Vectorworks or Archicad directly from the specification, view guidance and add notes

■ www.thenbs.com

At the Bricsys Digital Summit 2022 last month, Bricsys introduced BricsCAD v23, the latest release of its DWG-based family of CAD tools, which includes BricsCAD BIM, its ‘AI-powered’ BIM software.

Speaking at the event, Rahul Kejriwal, CEO, also addressed inflexible licensing models for CAD software, “Bricsys will never trap your data in walled gardens, and we will offer new and flexible business models to serve users who need the best, most accessible design, modelling and collaboration software,” he said.

New features for BricsCAD v23 include drawing health management tools and a ‘significant expansion’ of the drawing recovery tools. There have been updates to the Optimize 3D command for

correcting errors in 3D models, and CopyGuided 2D, which offers a ‘smarter way’ to copy entities. For the civil sector, BricsCAD also includes civil and point cloud capabilities.

BricsCAD BIM v23, which now offers compatibility with IFC, RVT and RFA, includes an improved stair 2D representation and a new type plans feature, which allow elements of scan-toBIM modelling to be automated.

Bricsys 24/7, the company’s CDE for managing project data and exchanging multi-format documents, has also been enhanced. Demonstrations at the Summit included workflows for tender documents, building drafts, building models, site plans and bills of materials.

■ www.bricsys.com

Bentley launches Infrastructure Cloud

Bentley Systems has launched the Bentley Infrastructure Cloud, a combination of enterprise systems powered by its iTwin Platform and infrastructure schemas, which ‘seamlessly integrate’ with Bentley’s engineering applications. According to the company, Bentley Infrastructure Cloud will enable better creation, delivery, and ongoing operation of infrastructure, through complete and evergreen digital twins.

Bentley Infrastructure Cloud encompasses ProjectWise, for project delivery; Synchro, for construction; and AssetWise, for asset operations. Now

powered by iTwin, Bentley explains that these enterprise systems are becoming fundamentally data-centric without disrupting file-based workflows.

As part of the platform, Bentley has introduced new AssetWise Asset Health Monitoring Solutions that use reality modelling and IoT to deliver real-time asset health monitoring (see page 26)

Bentley also expanded its iTwin platform with iTwin Experience, for visualising and navigating digital twins; iTwin Capture, for capturing, analysing, and sharing reality data; and iTwin IoT, for acquiring and analysing sensor data (see page 18).

■ www.bentley.com

6 www.AECmag.com November / December 2022

Allplan 2023 adds precast concrete to material range

Carbon assessment for digital twins

Bentley Systems has linked Building Transparency’s Embodied Carbon in Construction Calculator (EC3) to its iTwin platform to streamline embodied carbon calculation in digital twins.

EC3 is a no-cost, open-access tool that allows benchmarking, assessment, and reductions in embodied carbon, focused on the upfront supply chain emissions of construction materials.

llplan has expanded the range of materials supported in its core BIM software with the 2023 version now including precast concrete as well as masonry, cast-inplace concrete, steel and timber.

According to the developers, the ability to coordinate different materials and construction methods in one common model enables architects to better consider the economical and sustainable use of building materials, earlier, and in accordance with environmental requirements. It also means engineers and construction companies can build directly on the architects’ design and use it as the basis for structural analysis and detailing, MEP engineering, prefabrication and construction.

Allplan 2023 has also been enhanced to better harness graphics card processing. According to the developers, this helps process large volumes of data more

reliably, in particular terrain surveys or point clouds with millions of points.

For structural design, enhancements include: new tools to make it easier to create and adjust openings in walls and slabs; automated reinforcement modelling with the ability to reinforce several identical walls and columns at the same time; a new precast design and detailing feature for creating complex precast components in one platform; and new tools for accurately modelling steel framework.

For construction planning there are new functions for bored pile, and soldier pile walls, as well as ground anchors, and the ability to ‘intelligently place’ cranes, containers, or fences, complete with collision detection and capacity checking.

For infrastructure design, there are new productivity tools for users working on terrain and road plans, while bridge design also get a boost.

■ www.allplan.com

FineHVAC helps cool World Cup venue

ineHVAC software from 4M was used in the design the HVAC system for the Qatar Foundation Stadium, one of the host venues for the 2022 FIFA World Cup.

The piping and air-duct installations serve the free space under the stands of the “Diamond in the Desert” sports complex, comprising an air-conditioned area of 55,000m2 structured in four levels.

One of the considerations for the design was that many of the existing spaces are

to be reconstructed into a mall complex as soon as the World Cup is over.

The HVAC design was carried out by GKA engineers on behalf of Salfo & Associates SA. According to 4M, FineHVAC was selected for three reasons: smart BIM modelling of the HVAC installations; automatic generation of the final drawings and calculation reports; and accuracy in calculations, complying with the latest international standards.

■ www.4msa.com/brands/finehvac

WSP is applying both the EC3 database and the Bentley iTwin platform on infrastructure projects. “Implementing this link will significantly reduce the time and cost of generating EC3-based detailed embodied carbon analysis and reports along the design and construction stages,” said Thomas Coleman, vice president of WSP USA.

■ www.buildingtransparency.org

Avvir joins Hexagon

Hexagon has acquired construction reality capture and analysis specialist Avvir, and is integrating the company’s AI-powered technology stack into its portfolio of solutions, including BricsCAD and the hxGN Smart Build suite.

Avvir’s reality analysis platform compares BIM models to onsite reality capture data using AI algorithms that compare thousands of elements at a time to determine what is built and whether it is built in place. Construction firms can then use the results to keep schedules up-to-date, verify subcontractor payment applications, or update the BIM model to reflect as-built conditions.

■ www.avvir.io

7 www.AECmag.com November / December 2022 News

F A

Trimble Construction Cloud powered by Azure launches

Trimble aids HP in robotic site layout

Trimble and HP are working together to integrate the Trimble Ri robotic total station with HP SitePrint, a robotic layout solution that prints 2D plans on construction site floors.

SitePrint can avoid obstacles and print lines and complex objects with ‘pinpoint accuracy and consistent repeatability’. In addition, text printing capabilities are designed to bring additional data from the digital model to the construction site to prevent errors.

Trimble has launched Trimble Construction Cloud, a new platform powered by Microsoft Azure to link project teams, data, processes and multiple stakeholders –including general contractors, subcontractors, designers, engineers and owners – across all phases of construction projects.

Trimble Construction Cloud takes advantage of Microsoft Azure services including Logic Apps, Azure DevOps, and Azure Kubernetes Service.

A Common Data Environment (CDE) connects the office with site operations tools, enabling Trimble and non-Trimble solutions to ‘automatically integrate’ into one usable data set.

Configured and Custom Workflows

help project teams automate different aspects of their business. There are three pre-configured workflows: a model-toprocurement built for Mechanical, Engineering and Plumbing (MEP); a model-to-fabrication for structures; and a civil bid-to-build for site management.

Meanwhile, Live Data/Model Sharing (pictured above) allows for ‘real-time’ model collaboration for both Trimble and nonTrimble solutions. Trimble explains that multiple users can be in several Trimble solutions—such as Quadri, Trimble Connect and Tekla—and view model changes as they happen. According to Trimble, those with non-Trimble solutions, such as Microsoft Teams can also collaborate in the same modelling process.

■ www.trimble.com

DotProduct launches iOS scanning app

DotProduct, a provider of realtime, handheld 3D capture solutions, has released a professional scanning app for Apple iOS, which runs on all iPhones and iPads equipped with a built-in LiDAR scanner.

Dot3D 5.0 features what Dotproduct describes as ‘ultra-large scene capture’ thanks to the rebuilt core engine.

According to the company, with Dot3D’s new intelligent streaming technology, users

are now able to scan and optimise entire small buildings, roadways, landscapes, infrastructure, and other outdoor spaces all in one go, with virtually no limits to scan time or scale, outside of practical considerations.

This new core also includes a fully rebuilt optimisation engine, which performs full global loop closure, tight alignments, surface reconstruction, and reference constraint satisfaction, all on-device.

Dot3D 5.0 is available as a free 7-day trial and there is an indefinite free version for testing without export. Subscriptions start at $49/month or $299/year. ■ www.dotproduct3d.com/ios

Using optical technology, the precise positioning and navigation of the HP SitePrint robot is driven by the Trimble Ri total station. Equipped with automatic level detection, selfcalibration, and Trimble Vision technology for advanced tracking, the Trimble Ri helps the robot achieve autonomous, highaccuracy indoor layout work. ■ www.hp.com ■ www.trimble.com

DroneDeploy acquires structionSite

Aerial reality capture platform DroneDeploy has acquired ground reality capture specialist structionSite with a view to delivering a complete reality capture platform for construction.

structionSite helps contractors capture photo documentation of their jobs in 360-degrees. Photos are automatically organised by date and floor plan location. DroneDeploy offers autonomous drone flights and ground-based walkthroughs to help contractors virtually document construction projects. Captured data includes 360 tours and reality models.

■ www.dronedeploy.com

www.AECmag.com November / December 2022

News

Intel® Arc™ Pro A40 GPU unites fluid viewports, the latest in visual technologies, and rich content creation in a condensed half height, half length form factor. • Ray Tracing Hardware Acceleration • Dedicated AI Acceleration • Industry First AV1 Hardware Encode • 6GB High Speed Memory • Software Certifications • Up to 4x Displays, with Audio Support and Latching Mechanism • Single Slot, Tiny Form Factor • Premium Components • Extended Warranty Professional Graphics Begins Here Intel.com/ArcProA40 © Copyright 2022 Intel Corporation. All rights reserved. Intel, the Intel logo, and other Intel marks are trademarks of Intel Corporation or its subsidiaries. Intel Arc Graphics is a trademark of Intel Corporation in the U.S. and/or other countries. Other names and brands may be claimed as the property of others.

Solibri Inside to check BIM models as you design

Solibri Inside is a new cloudbased service that allows users of Nemetschek authoring tools Graphisoft Archicad, Allplan, and Vectorworks to check BIM models as they design. The SaaS-based offering uses a plug-in to work as a native feature within the authoring tool. It means the designer no longer needs to export the model and open other software to perform basic model checking.

According to the developers, Solibri Inside ensures that every model can be checked upfront before submitting the model to the coordination workflow.

“Today, more models are created than ever, yet many lack the essentials of a good BIM: the information. This missing information makes Quality Assurance impossible to deliver,” said Ville

Kyytsönen, Solibri CEO. “Solibri is improving the quality of models by bringing quality checking as part of the model authoring process. With Solibri Inside, we improve the process by enabling more QA early in the process before coordination takes place.”

The first release of Solibri Inside allows the checking of Door and Window clearances and the supporting Level of Information (LOI). The service is a standard free package within Graphisoft Archicad, Allplan and Vectorworks. By registering, more features are unlocked, and the Premium paid package allows the customisation of rule checks to suit a designer’s specific project need – to help ensure everyone in the team works with the same requirements.

■ www.solibri.com

Datumate boosts analytics for Procore

Datumate, the developer of construction analytics platform DatuBIM, has partnered with Procore, the construction management software provider, to provide civil construction teams with enhanced infrastructure site analytics and progress monitoring.

The integrated solution is said to solve a key industry challenge by giving project stakeholders up-to-date data for better decision making, improved efficiency and accelerated project delivery.

“DatuBIM complements the Procore

portfolio – providing owners and contractors with a complete lifecycle management solution and the field data they need to better control budget planning and ensure project quality,” said Dror Friedman, CEO of Datumate.

Datumate’s DatuBIM analytics platform is designed for large-scale civil and infrastructure projects. It helps teams access a single source of truth for design, plans, and as-built data, run advanced analytics, and overlay design plans to check for deviations and potential quality issues.

■ www.datumate.com

Resolve breaks down model barriers in VR

Resolve, an XR-based collaborative design review tool for AEC, has introduced the ‘Wellington Engine’, a custom 3D engine designed to render BIM models with millions of polygons on standalone VR headsets.

Supported devices include the new Meta Quest Pro, which also enables Resolve to add AR capabilities to the software by taking advantage of the headset’s colour passthrough cameras.

According to the developers, the ‘Wellington Engine’ uses virtualised geometry, occlusion culling, and adaptive partitioning to enable the review of complex files without having to stream data from an external workstation/server or devoting hours to model clean up.

■ www.resolvebim.com

DDScad gets boost from Graphisoft

Graphisoft Building Systems (formerly Data Design System) has released version 18 of the building services planning software DDScad.

The new release features a new user interface with re-designed buttons, function icons and input windows. Electrical installations can now be modelled faster and more precisely thanks to new routing, configuration and calculation options. In addition, electrical planning can be based on room information from an IFC reference model.

The software also has a connection to Graphisoft’s interactive app BIMx, allowing 3D models and project info to be viewed on a variety of mobile devices and operating systems.

■ www.dds-cad.net

11 www.AECmag.com November / December 2022

News

Rhino on the iPad

The Apple iPad has been on a journey. It started life back in 2010 as a giant iPhone that didn’t make calls (unless they were via VoIP), but went on to finally cement a tablet market that had previous ly failed to attract many customers.

Today, with desktop-class Apple sili con, the iPad continues to provide porta bility, along with long battery life and pretty decent pen input.

We have already seen some great AEC application developments for the iPad, but historically, these have been mainly for the consumption of AEC data – via Autodesk BIM 360, Graphisoft BIMx and so on — rather than the creation of designs. If you go back to around 2010, you’ll find that iRhino 3D also started life as a navigator/viewer.

A lot has changed since then. Today’s reality is that the iPad is now pow erful enough to run design-based desktop applications. One only has to look at Shapr3D (www. shapr3d.com), the excellent Spaces by Cerulean Labs (www.spacesapp.io) and SketchUp for iPad (www. tinyurl.com/sketchup-ipad) to see how the iPad has become a viable laptop replacement for creatives.

This fact has not escaped McNeel Associates CEO Bob McNeel or the compa ny’s lead on business development, Scott Davidson. In response, iRhino 3D has been relaunched with the full Rhino tech stack underneath and offering big possi bilities. It requires the latest operating system, iOS 16. And, as it runs on an iPad, it obviously also runs on an iPhone, but you would have to be pretty desper

ate to do anything on such a small screen. For now, the 12.9-inch iPad would be ideal and there are rumours of an even bigger device in the works, with the pos sibility of a 16-inch model at some point in the future.

Rhino has not been ‘ported’ from the desktop. Instead, it was completely rewritten from the ground up and per forms exactly like other versions, but with an interface that makes the most of a touch environment.

New horizons

Before readers get too excited, it’s impor tant to stress that the initial version is intended for model viewing and mark-up only. But we have been assured by McNeel executives that, under the hood, the entire functionality of desktop Rhino is there already. Over time, that functionality will be exposed as the company finds out how users want to use the system and what new addi tions make sense in product development terms.

Apart from the power of the processor, Apple has with each generation of chip included more and more direct memory cache and expanded the addressable memory per application. This allows bigger programmes to run, working with bigger data sets. In other words, with each generation, the iPad is becoming increasingly usable for professional modelling use.

One of the original ‘melon twisters’ of the original iPad was its complete lack of a file system, or rather, its lack of expos ing a file system to the user. This has been addressed over time, but even for long-time users, finding where the device

stores files can sometimes be an absolute mystery. The safest option is to link the iPad to a cloud storage service. iRhino 3D supports iCloud, Dropbox, Google Drive, Box and other cloud storage providers. There’s a built-in file browser, too.

When models are loaded, they can be displayed in shaded, wireframe, ren dered, ghost and X-Ray display modes. This is for all object types, breps, curves, meshes, point cloud, text and annota tions. You can pan, zoom and orbit by dragging your fingers on the screen, pro viding instant and accurate control of the viewing position. The software supports any previously set up layouts (page views) and objects can be selected and queried for information.

There’s a built-in mark-up tool that works with the pen, which allows drawn highlights, text mark-ups, and some dimensioning. The software also sup ports an augmented reality (AR) mode.

Community feedback

In common with most McNeel products, iRhino is a work in progress and with the active user community, the company real ly listens to feature requests on its forums (www.tinyurl.com/iRhino3D). Moreover, developers actually reply back to posts.

While it may not initially seem that iRhino 3D has made dramatic steps for ward, the company has had to go back to the drawing board in order to support Apple silicon and the new Metal graph ics. While that work was being done, adding in the Rhino engine for later exposure and usage made sense.

Now, the question is, will iRhino 3D remain a handy portable viewing and mark-up tool, or play a wider, more crea tive role in conceptual design? That, of course, will be down to users. I wonder how far away we are from Grasshopper running on an iPad?

12 www.AECmag.com November / December 2022

In AEC, McNeel Associates is a familiar and much-loved brand, along with its product Rhino. With a thriving ecosystem on Windows, Mac and in the cloud, Rhino has now gone mobile, as Martyn Day reports

Software

‘‘ The question is, will iRhino 3D remain a handy portable viewing and mark-up tool, or play a wider, more creative role in conceptual design? ’’

SOLIBRI PUTS YOU IN CONTROL OF MODEL QUALITY

Solibri

The right tools for the right people.

Solibri Anywhere

Model viewing and access to the digital information flow for free.

Solibri Site

Get the information you need, right when you need it.

Solibri Office

The complete solution to meet the toughest QA/QC needs.

Solibri Enterprise

Customized solution for maximum scalability.

With Solibri you can take your quality assurance to a whole new level and ensure that the information flows seamlessly from design to build. No more hiccups – the future of building better is here.

DISCOVER MORE AT SOLIBRI.COM

The pillars of Fabrication Integrated Modelling (FIM)

Tal Friedman explores how a fabrication centric approach, one where the entire building process is considered holistically, could help impart real change in the construction industry

It is a common notion in the AEC industry that building is a linear process. It begins with conceptual design, moves into compliance, then analysis, and finally, fabrication. That process can take months, and sometimes years, every single time.

But FIM (Fabrication Integrated Modelling) offers to reverse the equa tion, allowing us to get fabrication right from the start.

Looking at the construction software

industry roadmap in past years, it is evi dent that the design/engineering process is perceived as a ‘solved’ issue by the mainstream CAD/BIM companies that dominate the market. In the eyes of exec utives at these companies, the next stop on the journey to conquering the entire construction value chain is project man agement and procurement.

But I would like to propose an alterna tive perspective. To my mind, procure ment and project management are not a

‘continuation’ of the design process, but a derivative of it. Instead of running for ward, perhaps we need to go back to basics, and think about the building pro cess more holistically. In the age of FIM, the one who controls the initial design/ engineering process controls the rest of the value chain, too.

Though BIM’s original concept was to simplify the design process and cut resources, current methodologies demand special BIM managers and experts and

14 www.AECmag.com November / December 2022

Opinion

more planning time and costs. It is no won der, then, that only an estimated 20% of projects use even the basic capabilities of BIM. A much smaller fraction is actually implementing detailed, high-level model ling, as seen in BIM Level 3.

In today’s construction world, space layout planning is not enough. Design teams (architects, engineers, consultants) often reside in ‘masstopia’ or ‘renderland’, their thinking dominated by virtual envi ronments and documents nested as far

away from a real-life work site as possible. As a result of this fragmentation, the level of control that design teams exert on the fabrication supply chain is diminishing.

In an age where the biggest challenge the construction industry faces is adopting advanced industrialised methods, smart materials and sustainable supply chains, why do these considerations come last, when it’s already too late to make changes?

Fabrication first

Getting started with ‘FIM thinking’ requires a mind shift at every stage of the pro cess. Below, I outline the current situation and then the necessary shift to be made at each of those stages.

Design phase

Current situation: Architecture starts with a sketch and moves towards detailed design, regulation and building

15 www.AECmag.com November / December 2022

A midjourney, AI-inspired vision of the future for Fabrication Integrated Modelling (FIM)

permits. Fabrication, sustainability and supply chain considerations come at a later stage.

FIM thinking: Building details and regu lation compliance are integrated as part of the design process using AI. This ensures that everything we design is ready for construction from the get-go.

Supply chain and procurement

Current situation: After planning is approved and permits are given, the design and plans are ‘frozen’ in place and the search for methods, procurement and detailed fabrication drawings begins. This makes it impossible to adjust to any meth od or system that requires design optimi sation, ruling out most industrialised methods by definition.

FIM thinking: Supply chains and bestpractice methods are an integrated part of initial design and decision-making. FIM methodology creates best-fit results using big data gathered from supply

chains to help planners make the right choices from the start.

Cost analysis

Current situation: Costs are assessed as general numbers and after a design is fin ished, it goes to tendering. This creates many unknowns and a tendency to design for the lowest common denominator in order to reduce risk.

FIM thinking: Costs are embedded in the planning data and connected to a realworld supply chain, turning your BIM model into a shopping cart.

One offs vs. network effect

Current situation: A building is designed once and lives in a vacuum. It is a one-off in every sense of the word and lacks interaction with external supply chains, knowledge bases or other projects in its surroundings.

FIM thinking: Building plans live in a smart network. They learn from one

another and share a unified supply chain. Not only do they all have access to pro curement data, but they can also be opti mised, to achieve economies of scale and reduce costs.

A digital revolution

Construction, the largest industry on the planet, is going through a digital revolu tion. If we want to see more sustainable, affordable and efficient cities, a radical approach is needed to break the current bottlenecks.

FIM offers such an approach — but it also demands that we push back the boundaries of our comfort zone in order to get there. This means letting go of old hierarchies, business models and work flows, leading the way to true human/ machine integration.

In my work with Foldstruct, these prin ciples are being applied on a daily basis in a constant battle to expand architectural horizons with artificial intelligence (AI). ■

www.AECmag.com Opinion

www.foldstruct.com

‘‘

In the age of FIM, the one who controls the initial design/ engineering process controls the rest of the value chain, too ’’

and machine learning capabilities, the Lenovo ThinkPad® P16 Mobile Workstation is now powered by the Intel® Arc™ Pro A30M Mobile GPU. Uniting fluid viewports, the latest in visual technologies, and rich content creation in a portable 16” mobile workstation. This system combines a fresh, modern look with powerful professional graphics. • Ray Tracing GPU Hardware Acceleration • Dedicated GPU AI Accceleration • 4GB High Speed Graphics Memory • 16:10 Aspect Ratio with 4x Display Options • Lenovo ThinkShield Security • All-new 12th Gen Intel® Core™ HX processors • Software Certifications for Professional Apps Introducing the All New Lenovo ThinkPad® P16 Mobile Workstation intel.com/ArcProA30M © Copyright 2022 Intel Corporation. All rights reserved. Intel, the Intel logo, and other Intel marks are trademarks of Intel Corporation or its subsidiaries. Intel Arc Graphics is a trademark of Intel Corporation in the U.S. and/or other countries. Other names and brands may be claimed as the property of others. P16

Bentley Systems iTwin ‘phase two’

It is almost four decades since Bentley Systems was founded — or 38 years, to be precise. It’s almost as long since the 1986 launch of MicroStation for DOS, and yet MicroStation continues to be the base platform for the infrastructure software company’s wide range of vertical prod ucts. These cover areas as diverse as plant, rail, roads, bridges, dams, telecom, electricity, and water systems.

Having achieved its long-awaited Initial Public Offering (IPO) in 2020, the company recently passed $1 billion in annual revenue, and while its products remain emphatically desktop-based on Microsoft Windows, the Microsoft Azure cloud is now an option, too, when that

option makes sense for customers.

Over the past five years, Bentley Systems has been on a mission to per suade infrastructure owners and opera tors to invest in digital twins of their assets using its iTwin technology, on the promise of better lifecycle management for those assets, as well as to extend their use of asset information, whether it is designed in CAD or modelled from the field using reality-capture technology.

That message seems to be getting across, especially with customers in Asia, with entrants for the company’s Year in Infrastructure (YII) 2022 awards using the iTwin technology significantly out numbering those from other regions. As CEO Greg Bentley pointed out, 50% of

the world’s infrastructure projects are currently happening in Asia.

These Asian companies are using digi tal twins to address three critical areas, according to Greg Bentley. The first is ‘digital context’, the ability to use and deploy 3D and 4D technologies to capture the physical reality of an asset being twinned. The second is ‘digital chronolo gy’, which focuses on maintaining a data base or record throughout the lifecycle of an asset to create what Bentley refers to as an ‘evergreen’ digital twin. The third area is ‘engineering technology’, the abili ty to model and simulate a facility over the lifetime of a project in order to opti mise its efficiency.

But this focus on digital twins is by no

18 www.AECmag.com November / December 2022

In mid-November, the first post-Covid, in-person gathering on all things Bentley Systems took place at YII in London, where the company continued its drive to lead the digital twin infrastructure market with the release of new iTwin products

Feature

iTwin Experience for visualising and navigating digital twins

means confined to Asia. According to a survey of infrastructure CEOs conducted at the event by AEC Advisors, when asked about their main concerns over the next three years, it was clear that respondents are worrying less about 2D drawings and more about 3D models. Almost one in five said their companies were evaluating and deploying digital twins.

This interest comes at a time when many customers are having to do more with less, as chief operating officer Nicolas Cumins explained. Infrastructure investment is on the rise, to support eco nomic recovery, ensure energy security and tackle climate change, he said. But such projects must play out against a backdrop of extreme labour and skills shortages, which are causing considerable work backdrops and, in some cases, forc ing companies to turn down projects.

One way that Bentley can help, said Cumins, is to give firms the digital tools they need to mine data held in many dif ferent file formats and in hard-to-access data silos. Hidden away, that data goes stale and ‘dark’, he said.

CIOs estimate that around 70% of the data produced by their organisation is never used, and in the infrastructure sec tor, the picture may be even worse — as high as 95%, according to Bentley Systems. If only 5% of an infrastructure organisation’s data is being analysed to derive actionable insights from it, then decision-makers are likely making underinformed decisions on critical infrastruc ture on a regular basis.

Bentley’s goal, then, is to make this ‘dark data’ more accessible, more usable and available to more people.

Technology evolution

From a Bentley perspective, the signifi cant interest in digital twins demands a fundamental shift from files to databases and thus a fundamental change in soft ware architecture and its ability to sup port very large digital twin models. Both Greg Bentley and his brother and chief technology officer Keith Bentley touched on this, while stressing that files continue to be useful, logical and here to stay.

At the same time, Keith Bentley explained to attendees how the company’s view of digital twins has changed and matured since the 2018 launch of iTwin. Back then, he said, “I thought that the prospect of digital twins would add more value than all the progress that had been made since the beginning of Bentley Systems, back at the beginning of the PC. I thought that the opportunity around digital twins was a once-in-a-lifetime

opportunity and I was extremely excited.” He is still excited, he said.

From the start, he added, openness was a key theme for the product, which is why iTwin was made open source early on. In that way, he said, customers “can use the iTwin platform without paying a licence to Bentley Systems at all, downloading the entire source code to the iTwin platform.”

That’s still true today, he says, and now the company has plans to create a lot more open-source projects around iTwin.

In ‘Phase Two’ of the company’s iTwin initiative, the company will work harder to help users understand how iTwin can assist them in their day-to-day work and integrate iTwin services into the desktop products they use. That won’t mean replatforming, reimplementing or repro gramming of existing products, he stressed: “They are what they are.”

In other words, customers can move to iTwin-enabled versions of the core prod ucts, without losing any of the capabilities to which they are accustomed. But they will improve in three key ways, he promised: first, in the input to those products; second, in their operation; and third, in their output.

Building on reference files, MicroStation will be able to add a reference iTwin — not only files on a desktop or server, but also in the cloud – and the iTwin itself can connect to many other sources. Bentley Systems is also working on incorpo rating interactive tools like Slack, Microsoft Teams and Zoom with MicroStation, for collabo rative design sessions. Finally, digital twins will be updated directly by design applications, not via some convoluted check in/check out document management system.

“Phase Two is about empowering our existing user base to become digital twin natives,” said Bentley. In the long term, he promised, “nobody will be thinking about their role in the project. They will be thinking about how they contribute to everything that every body else is doing at the same time.”

The next release of MicroStation, due in 2023, will be powered by many new iTwin features, he said.

New iTwin Products

As mentioned, the iTwin platform was officially launched in 2018. While this

built on the open iModel database work that Bentley had done in previous years, iTwin provided a host of services on which to build digital twins. There was one main omission: applications to ease the creation and management of twins. Five years later at YII 2022, we saw the first three iTwin applications launched: iTwin Experience, iTwin Capture and iTwin IoT, which are all available immediately.

iTwin Experience is a new cloud prod uct for owners and operators which gives them ‘a single pane of glass overlay’ to their engineering, operational and enter prise data. It enables users to visualise, to query and to analyse critical infrastruc ture data at any level of granularity, at any scale, all geospatially referenced. It will also be used by engineering firms as a platform to offer their own digital twin solutions to their owner/operator clients by adding their proprietary algorithms.

iTwin Capture, which has evolved from ContextCapture, will be used to create 3D models of existing infrastructure assets derived from photograph or point clouds with engineering level precision. These will be used in engineering workflows, leveraging artificial intelligence and machine learning to auto matically identify, locate, and classify reality data.

Adobe is already using iTwin Capture as part of its Substance 3D solutions, to help designers leverage their own pictures to create photorealistic 3D environ ments. When it comes to Infrastructure, the majority of digital twins will be derived from capturing their existing infrastruc ture assets by using a reali ty model and not a BIM model. This makes iTwin Capture probably the most important on-ramp to cre ate infrastructure digital twins.

iTwin IoT does what it says on the tin, enabling the seamless incorporation of Internet of Things (IoT) data from sensors and moni toring devices. IoT devices are being used increasingly in both construction and operations for real time safety and condi tion monitoring, to measure and visualise any change in the environment of an infra structure asset, to look for changes to the structural condition and to know when to perform repairs.

Dustin Parkman, VP of Mobility, gave an example here of a workflow that focus

19 www.AECmag.com November / December 2022

‘‘

Producing a model to generate dumb drawings may well be a means to an end today, but Bentley figures that there are many more benefits to be had in talking to and repurposing a virtual model ’’

1

2

es on an elevated road section. In a single environment, he brought in a GIS map, a modelled asset created via a reality cap ture of the actual structure. BIM informa tion was then added to this, and GPR (Ground Penetrating Radar) data over laid to identify pitting and to assess hydroplaning risks on the bridge as cap tured. Subsurface data was also added and IoT sensor feeds were placed for realtime performance analysis. AI was then run over the photogrammetry of the sec tion, to assess visible cracks, rust and critical deterioration to the structure.

New tech, new insights

Other executives speaking at the event also focused on the integration of differ ent types of data to inform more insightled decision-making.

For example, according to Julien Moutte, vice president of technology, Bentley Systems is creating a sensor data service to manage connectivity to smart devices and analyse the data they collect, brought in from Azure IoT Hub or Amazon IoT Edge.

The company’s experience with integrat ing enterprise systems, such as enterprise resource planning or asset management systems, is enabling it to create an enter prise data federation service, to expose a simple yet secure API to connect custom ers’ enterprise data to their digital twins.

Bentley also has a new mesh export service, which will enable digital twins to appear in the Metaverse and in game engines. It will use the best format depending on output, whether that is USD for Nvidia Omniverse, DataSmith for Epic Games’ Unreal Engine, glTF for Unity, and many more.

The problem with digital twin data, Moutte pointed out, is that it is usually very large and any changes require a complete reload into these game engines. The solution to this challenge comes in the format of 3DFT – 3D Fast Transmission. The technology uses

streaming, meaning users no longer download entire models, but only that which is visible in the viewport. See page 36 for more on this.

That’s a wrap

At Bentley Systems, digital twins are the new BIM. Now that’s a loaded sentence if ever there were one, so I will explain fur ther. Producing a model to generate dumb drawings may well be a means to an end today, but Bentley figures that there are many more benefits to be had in talking to and repurposing a virtual model. More benefits, in fact, than today’s somewhat limited workflows support.

The vast majority of BIM models, after all, are created to produce drawing sets and then not reused. Bentley wants to drive that digital thread on throughout the life cycle, and digital twins is the next destina tion after adopting a modelling-based view.

This is a technology approach where Bentley Systems enjoys an impressive industry head-start. Autodesk’s Tandem, for example, only came out last year with an embryonic feature set, limited to deal ing with BIM twins from Revit.

With that in mind, the three iTwin

applications that have been released by Bentley look set to simplify and lower the barrier to entry for more resistant cus tomers, enabling them to experiment with the iTwin platform.

Bentley’s vision makes a lot of sense of its 2015 acquisition of Acute3D, which led to the ContextCapture capabilities that allow customers to ‘grab’ data relat ing to existing real-world assets, ready for its inclusion in digital twins. After all, the vast majority of assets don’t cur rently have a corresponding BIM model at the ready to drive their digital twin, so most of them will still need to be cap tured by drones using photogrammetry and some laser scans.

But what about Bentley customers with no plans at all to get into ‘twinning’? Here, there is good news, because the new iTwin features due to arrive in Bentley’s desktop software portfolio will still benefit existing workflows, extend ing their connectivity and collaboration capabilities. And, if such customers do feel the need to explore twinning further down the line, every application will be ‘twin ready’ in the coming years.

■ www.bentley.com

20 www.AECmag.com November / December 2022

Feature

iTwin IoT for acquiring and analysing sensor data

iTwin Capture, for capturing, analysing, and sharing reality data

1 2

All images courtesy of Bentley Systems

Q&A: Keith Bentley, Bentley Systems

At Bentley Systems’ recent ‘Year in Infrastructure’ event, we got the chance to catch up with CTO Keith Bentley and get his perspective not only on the company’s iTwin technology, but also the ‘platformification’ of the design software world

Astudy of Bentley Systems’ cur rent marketing output could easily bamboozle the reader with its terminology and fool them into thinking that the company’s only focus is now digital twins. For any one led down that path, it’s important to keep in mind that the company is still sol idly built around a single platform (MicroStation), its core DGN format, and its broad array of design and project management tools.

At the same time, the digital twin mes saging and focus on iTwin services are about more than just marketing. In fact, they signify an important technology pro gression, from file-based, project mile stone workflows to live databases that can ultimately be integrated with Internet of Things (IoT) and Bentley iTwin services for infrastructure lifecycles.

The first stage of this transition came with the introduction of the iModel back in 2007. An iModel is Bentley’s informa tion container for data exchange — a self-

describing, geometrically precise, portable and secure entity, containing the history of file changes and encapsulating informa tion regardless of its original source, be that a Bentley tool or software from anoth er vendor. Then, in 2017, Bentley launched iModel.js, version 2.0 of its iModel tech nology, providing spatial and unit align ment between the contents of iModels. At the same time, iModelHub was also intro duced, in order to handle change manage ment, time stamping and allocating chang es to team members to support managed digital workflows.

As iModel.JS developed, it became clear that it was going to contain and do a lot more than just manage iModels. Its new roles included connecting to IoT devices, connecting and streaming geometry to Unreal Engine, storing reality data, and so on. It was renamed iTwin.js to reflect this expanded vision — a move that has caused some understandable confusion.

From there, Bentley open-sourced iTwin.js on Github under an MIT licence.

The thinking here was that an open approach to users’ data is necessary because digital twin information will never come from a single source, requires a fusion of formats and has many layers. With this methodology, it’s possible for anyone to leverage the open-source code to create, query, modify and display infra structure digital twins.

At Bentley Systems’ ‘Year in Infrastructure’ (YII) event, held in London in November 2022, we sat down with the company’s CTO and co-founder Keith Bentley to get his views on how this signif icant technology progression is unfolding.

Martyn Day for AEC Magazine (MD): Keith, I’d like to start by asking whether you can define a Bentley data lake work flow without concentrating on iTwins?

Keith Bentley for Bentley Systems (KB): We purposely use the iTwin brand to describe what I call ‘Phase Two’. Here’s what’s going to happen: You are using

22 www.AECmag.com November / December 2022

Interview

MicroStation, just plain old MicroStation. It’s the lowest common denominator. Everybody understands MicroStation — and here, I’m not saying you need a prod uct like OpenRoads to get any value out of iTwins. What I am saying is you can be using products, and I expect many people will be using STAAD and other products that they have bought, where there is no such thing as a digital twin.

Over many years, you’ve built up a workflow that works. Of course, it involves DGN files for our products, mostly DGN. It might involve creating, exporting, importing SketchUp files etcetera. There’s a workflow that people use today to get their jobs done, and the output of their job is not a digital twin. In fact, it is largely drawings. So, what we’re going to do is deliver a version of MicroStation next year. It will have, with in it, an engine, but it’s the iTwin plat form embedded inside MicroStation.

So you’re using MicroStation, you’re opening up a DGN. These DGNs are being

managed in ProjectWise, or you are using another file share service. The digital twin doesn’t change the way you start. You start with that DGN file and you’re going to end your session with that DGN file.

During your session, you modify a bunch of elements, you add a bunch of elements. The iTwin engine is running in the background and you either select to synchronise - or it can happen automati cally, when you exit at the end of your session. Now, you’ve got an iModel. This is synchronised with all the changes that you’ve made and your DGN files are still your master file.

Now you have an iModel sitting on your desk, updated with the changes you just made to the DGN file. What good does that get you? For one thing, it gives you the ability to invite somebody else who has a web browser to look at the changes you just made. They are my changes, they haven’t been published by anybody other than me. I can now syn chronise with the iTwin server.

Today, the way it works in the demos that we’ve been showing at YII, with our iTwin format, customers change the data on their desktop, they push that up to the cloud, where we run a copy of a pro gramme that effectively mirrors MicroStation in the cloud and it updates the iModel in the cloud.

The phase lag can be minutes, hours, depending on many things — but usually, people don’t do it often. Instead, they only do this at project milestones, only when they then generate the PDFs for the milestone. The iModel is always out of sync, it’s not up to date, nobody has it on their desk. So nobody thinks of it when you’re using MicroStation as being rele vant to the job.

But because you now have an iModel, you don’t have to do any extra work and use a different tool to create the iModel. You didn’t end up with a different DGN file. It’s the very same DGN file. Now, when you’re at the point where you’re going to push your changes to

23 www.AECmag.com November / December 2022

‘‘

Drawings are stupid and the goal of BIM is to automate drawing creation ’’

ProjectWise, we push them into an iMod el on your desktop. So now there’s an iModel that exists that includes all the users’ changes — but only the changes between milestones get recorded. They don’t include the changes in between milestones. But now the iModel has the ability to store the whole team’s collabo ration history.

MD: Will this support real-time collabo ration?

KB: In MicroStation or OpenRoads today, you have a DGN file, you have it locked, perhaps I have a copy of it. But I can’t make any changes. We can’t change the way that that works. Those locks are there so we don’t conflict. It doesn’t change that. This iModel is merely a jour nal of what happened. It doesn’t include new capabilities for you and to be on the same model at the same time. It’s a cache, but it’s more than a cache, as it’s been transformed and combined.

If we were working on a project togeth er, people segregate their data into files, for locking purposes. We have to decide who takes what file and what part of the

can do. We can give you the tools that we’ve written to do carbon footprint anal ysis, clash detection, consistency checks, etcetera. We can run that against the iModel on your desktop. And it didn’t cost you anything, because you already paid for that computer. If you don’t use the cycles, they go to waste. If we run it in the cloud, somebody’s got to charge you and give you feedback. The iModel tells you when someone else just changed something that affected the thing you’re working on. So we can start improving the process of creating the data, even though the master copy is still a DGN file. People will start to recognise that iModel isn’t ‘an output’, it’s just sort of ‘always there’. It’s a second copy of my data. So why do you need two copies of your data? Well, because we can’t change the way that OpenRoads works with DGN data, as well as other data files and stuff.

MD: Will you start rewriting the apps to use iModel as the new format?

KB: If you have been using OpenRoads for a long time, you are now going to have some new features that are going to be in

KB: Covid didn’t really hurt us. When you think about adoption of new technologies, people were way more interested in doing things differently during Covid. They had to do things differently. If it hadn’t been for Covid, I don’t think we would have been able to convince people to start to have digital design review meetings. Online meetings were necessary because they couldn’t physically be in the office. They were presented with a fact: the old way couldn’t be the current way.

We need to go fast. But we should expect that only incremental change gets adopted. But what I hope is that, in the mental world view of the designer using MicroStation, they think their purpose in life is not to modify the DGN, but to mod ify the iModel. Even though to modify the model, they first modify the DGN file, DWG or RVT, even if they’re going to use a different tool. But when they’re done, they’re going to look at what’s in the iModel, what’s in the digital twin.

I know you think “There’s that term” — that term ‘digital twin’, which you say that not many people want to hear. But I don’t think they don’t want to create a digital twin. When they get paid for it,

‘‘

project will be done in that file. And another user is going to work on a differ ent project — otherwise, you can’t write to them at the same time. In the iModel, they’re all combined. They’re geo-located, so that if you’re using five different tools inside the same iModel, I can do a query and find everything in this volume of space - and that’s really hard to do in a DGN. They’re also synchronised, right, so that you have this journal of change and you can push that to the cloud.

So, for now, the iModel someone else creates for me is on my desk. Now what? Well, there are some really cool things we

the iTwin model. Maybe it’s in a separate window, but wouldn’t it be really cool if we then start adding some new capabili ties that are in the iModel part of it? Over time, the iModel part of it grows and the DGN part of it shrinks, and by the time we are done, you’ve gone through the transition and you are only working on iModels. It’s not going to happen all at once. It’s going to take years. It has taken us five years to get us to where we are now. Do you think that’s quick for the AEC industry? [laughs]

MD: Was this because of Covid?

they will care about it. When we start giving them ways that they can be more productive, add more value, they’ll wish for a digital twin.

MD: But people naturally switch off when a message gets repetitive. It’s always about change. How about them getting value from the stuff that’s already been paid for and delivered?

KB: I do concede that. But I think a digi tal twin is a big thing. Drawings are stu pid and the goal of BIM is to automate drawing creation. And here’s an easy

24 www.AECmag.com November / December 2022

Interview

When people say files are bad, they mean that loose files, lots of files, are bad. One big file, like an iModel, is still a file and it’s a big file — like a gigabyte file — but they are in a database and that means they are as open as we can make them ’’

step forward. I want the world view to be that, at the end of a design session or after a period of work, users think: “I’m going to commit my changes now and modify the digital twin.” And, in the case of our users, an iTwin.

DGN files are of course important. You can’t throw them away — but everyone who’s looking at my work and comment ing on whether or not a change had some kind of positive or negative impact, they’re going to evaluate the iModel. We have to get people using smart tools to analyse the current state of projects and looking at past stages of other similar projects to get feedback. I don’t think that’s going to happen with a bunch of loose DGN and RVT files being the input for machine learning, especially not when they’re all in different coordinate systems.

MD: At our NXT BLD event, and in AEC Magazine, we’ve been covering industry initiatives to get data out of proprietary file formats and into data bridges that span the silos and deliver entity-level exchanges. What’s your view on that?

KB: Well, that’s another reason why I assert that automatic creation of iModels is better. With OpenRoads and DGN, it’s a great product — but while the product is called ‘Open’, the data is not. It’s open

by interface but, in reality, there’s noth ing we can do to make DGN files open, even if we wanted to. To publish the for mat of a DGN file, we would have to pub lish a bunch of code. It’s miserable, because even if we documented it all, it wouldn’t make sense, as it’s kind of defined internally to represent the data in memory that OpenRoads uses.

When people say files are bad, they mean that loose files, lots of files, are bad. One big file, like an iModel, is still a file and it’s a big file — like a gigabyte file — but they are in a database and that means they are as open as we can make them.

So another large difference between iModels and let’s say Revit RVT files is that I don’t send you my iModel, I just send you my changes. And these transac tional changes are small, even if the data base is big. I don’t even know what kind of change it would be that would end up having touched every object making a modification to every object.

Looking ahead

While our conversation mainly wan dered around in the weeds of industry data structures, these are fundamental concepts when it comes to understanding how the AEC industry is likely to change over the next five to ten years.

Platforms being designed today cannot

deliver productivity enhancing capabili ties if they are based on old data schemas. As Keith Bentley pointed out, drawings are dumb.

For Bentley to help its customers tran sition to an iTwin outlook, iModels are fundamental to future direction, and it was fascinating to return to this topic. Somehow, this point has got somewhat lost in the deluge of messaging around iTwin and the wider digital twin focus.

The move to build in automated/paral lel iModel creation perhaps indicates that previous innovative work at Bentley has failed to gain traction, in an industry that can be notoriously slow to adopt new technology.

If the success of the iTwin technology relies on the uptake and proliferation of iModels, things need to change. Over the next few years, iModel looks set to quiet ly replace DGN-centric workflows at the core of MicroStation, bringing new capa bilities and features. Even customers that are not explicitly planning to deliver digi tal twins will nevertheless be ‘digital twin ready’.

Bentley executives are keen to point out that files will never disappear from the process — and this is a company that I have only ever seen change its core file format once. So I trust Bentley to deliver this tran sition without disruption to customers. ■ www.bentley.com

25 www.AECmag.com November / December 2022

Monitoring asset health in real-time

Bentley is starting to carve out real niches in the AECO sector apply ing its broad portfolio of technol ogies to solve specific problems. In recent years, monitoring and inspection has become a big focus - assessing the health of a wide range of infrastructure assets from telecommunication towers and bridges to rail and dams.

Early solutions focused solely on pho togrammetry, applying machine learning (ML) and object recognition to 3D reality meshes captured by drones. But through acquisition and investment, Bentley has been expanding the technologies that can contribute to the ‘digital twin’ from design to construction.

In 2021 Bentley acquired sensemetrics and Vista Data Vision, providers of soft ware for Internet of Things (IoT) applica tions that allow digital twins to incorpo rate real-time sensor data. The tools sup port interfaces to hundreds of different sensors and related data types, including inclinometers, piezometers, strain gaug es, crack meters, and many more.

These tools have now been integrated into Bentley’s iTwin platform in the form of a new product - iTwin IoT - that can be used to monitor, in real time, a range of environmental changes, such displace ments, vibrations, deterioration, settle ments and more; the idea being that any change on the condition of an asset can prompt interventions when necessary.

Bentley is now marrying iTwin IoT with iTwin Capture (a new product for capturing, analysing, and sharing reality data) to create two new solutions designed for real-time health monitoring - AssetWise Bridge Monitoring and AssetWise Dam Monitoring.

These solutions are not necessarily designed to eliminate in situ rope access inspections, but help consultants keep a

close eye on the asset and develop a more informed inspection plan from the com fort of the office.

Monitoring dams

AssetWise Dam Monitoring employs a particularly diverse range of technolo gies, starting with the obligatory reality model captured by all manner of drones to create the foundation for a digital twin.

Early iterations of the product were able to use sensors to provide specific feedback about the dam, such as how much settle ment was happening in a certain place or how much flow was causing pitting on the concrete. But, according to Santanu Das, chief acceleration officer, Bentley Systems, it was missing one big element, “We couldn’t predict where these cracks were, how deep the cracks were and what kind of crack propagation would cause prob lems in the future - the insights.”

Bentley looked to Niricson, a Canadian startup that had developed an AI-based predictive analytics SaaS platform designed to verify the structural integrity of concrete structures. The company has several hydro dam owners and engineer ing consulting firms as clients.

Rather than pursuing an acquisition, Bentley made an investment in Niricson through Bentley iTwin Ventures, a $100m corporate venture capital fund specifically set up to invest into AEC startups.

Niricson’s technology uses acoustic sensors on drones to go deep behind the concrete where the rebar is, then applies AI and ML to the reality model to figure out exactly where the spalling is happen ing. This is in stark contrast to traditional on-site methods, which leave a lot to interpretation, as Das explains, “Today, inspectors use a hammer, they listen for that void to see exactly where a lot of this delamination or cracking is happening.”

Armed with this information, engi neering consultants can then precisely locate IoT sensors to monitor the dam moving more effectively forward.

With the open nature of the iTwin plat form, data from Niricson’s Autospex soft ware can then be fed into Bentley’s AssetWise Dam Monitoring product, then married with the reality model and sensemetric IoT data to see cracking anal ysis superimposed with temperature, dis placement, vibrations and other metrics.

“An operator of a dam now has the abil ity to get information from disparate dif ferent repositories and sources under a single pane to look at some insightsexactly what’s happening to their asset,” says Das.

Closing the loop

The story doesn’t end there. Bentley is also exploring how simulation can be used more effectively to study the future impact of cracks and other forms of degradation on dams and other concrete structures.

Bentley recently acquired Finite Element Analysis (FEA) software devel oper Adina, whose non-linear technology is well suited to analysing existing struc tures. “[Adina] shines when you have an asset, and this is how it really is - it’s degraded, it’s spalled, it’s cracked, it’s cor roded. It can answer the question - what is the strength that remains?” said Raoul Karp, VP engineering simulation, Bentley Systems.

Results from simulations could be married up against data from sensors that have recorded the response of the structure over time. This allows the model to be calibrated more precisely so it can more accurately predict future events, and what needs to be done to min imise their impact, further closing the loop on the digital twin.

26 www.AECmag.com November / December 2022

From reality modelling and IoT sensors, to AI and simulation, Bentley is drawing on a vast portfolio of technologies to monitor infrastructure assets, such as dams, over time, writes Greg Corke

Technology

Why BIM? Better results Improve collaboration and productivity. Our leading expertise in Building information management (BIM) according to ISO 19650 enables us to offer a choice of routes to BIM certification for both individuals and businesses. Less stress Reduce waste, rework and errors. Faster & more efficient Better information for improved decision making over a building or assets life cycle Why BRE? Guided by experts Audits are performed by experienced construction professionals. Boost reputation BRE’s 100-year history of research and innovation behind these schemes. Comprehensive Training and certification schemes developed by industry experts. ISO 19650: BIM Essentials training. ISO 19650: Delivering information management training. BOOK TODAY BIM ISO 19650 training

Digital twin technology:

a Trojan horse for systemic and cultural change in AEC?

By Bola Abisogun OBE, digital director, BIM Academy

When it comes to diversity of thought, technology has created something of a level playing field. In construction, it’s getting tougher and tougher to achieve true competitive advantage, in both the design and con struction phases and beyond.

The business case for digital twin tech nology is that intelligence collected, mined and shared in the twinning pro cess translates to reduced risk and great er return on investment. These are clear ly desirable outcomes — so why then has the adoption of this technology been so slow in construction, especially when compared to other industries?

The client-facing decision to construct an asset ‘with the end in mind’ is based on the idea that it is possible and advan tageous to first design and build an asset virtually. But when faced with tight schedules and insufficient time to pro cure a design team, the level of detail achieved in the traditional design process often falls far short of the goal of ‘asbuilt’ information. In other words, we’re

still not delivering detailed, asset-tagged, data-rich 5D models prior to construc tion. This objective has never been fully understood and embraced by the indus try and remains vastly undervalued by commissioning clients. A full under standing and appreciation of the princi ples of end-to-end, whole-life cycle, design management must be pri oritised by the client if we are ever to achieve a net zero future.

The critical component of a successful project is typically measured across three key pil lars: cost, time and quality.

During the traditional construc tion delivery process, it is often difficult to ensure that the right design informa tion is continuously provided across the entire value chain and acted upon accordingly.

It’s a shameless challenge to tradi tional ways of

working, this notion of a digitally ena bled, data-driven solution, complete with visualisation, that captures granular detail in real time. The cultural behav iours of project participants typically result in one of two responses across the ecosystem of actors: fear or inspiration.

But here’s the thing: while digital twins have been used for years in other sectors — for example, in avi ation and manufacturing— the global construction sector con tinues to push back when it comes to this innovation. The real value to project participants, funders and wider society is gravely misunderstood.

Fit for purpose

A digital twin is a virtual represen tation of a sys tem, asset or pro cess. It can collect real-time infor mation about the

28 www.AECmag.com November / December 2022

asset via an architecture of sensors and other interdependent technologies. Using advanced analytics, artificial intelligence (AI) and machine-learning (ML) algo rithms, it is possible to gain detailed insights into the function of a building dur ing design, construction and on through to occupation. (In the case of Grenfell Tower, for example, this might be the fitness for purpose of a proposed specification.)

In essence, the proposi tion here is that the value of a physical asset becomes greater thanks to its connec tion with a virtual twin.

While the global market for digital twin technolo gies is expected to grow by up to 40% cumulatively year on year, achieving an estimated market value of between $16 billion and $20 billion by 2023, the real challenge remains a cultural one.

For many clients/stakeholders, be they development or investment companies, a better understanding of project constraints is needed in order to determine and expe

dite project viability, as part of the wider risk-evaluation process. And here, the real challenge is the ability to collaborate close ly, openly and seamlessly.

To my mind, there is no better environ ment than a virtual one in which to under take this informed and collaborative pro cess. In effect, a digital twin represents the possibility of a ‘try before you buy’ offer.

In fact, I would go one step further. A digital twin workflow, robustly built on a common data environment (or CDE), can be used to assemble a detailed history of the entire decision-making process, in a way that provides complete confidence for any third parties who seek to acquire the asset in future.

In the UK, the post-pandemic business case for digital twins (an argument forti fied by the tragic events at Grenfell Tower) has been further strengthened by the Building Safety Act 2022. We are now looking at the very real prospect of the ‘pre-construction’ digital twin becoming a day-to-day reality in our industry.

But real questions remain. In a post-Grenfell environ ment, where cost of capital will be directly correlated with the net carbon intensity of all project-level opera tions, will digital twin tech nology become the only fea sible way to deliver projects that command whole lifecy cle metrics on actual performance beyond the construction phase?

And perhaps more importantly, will the sector be ready and adequately skilled to deliver on this ambition, in a world where accountability for our actions as qualified professionals may become a real indicator of project viability?

29 www.AECmag.com November / December 2022

■ www.bimacademy.global

‘‘

Opinion