Biosecurity in poultry farming: an effective tool to fight infectious diseases

Composting daily poultry mortality

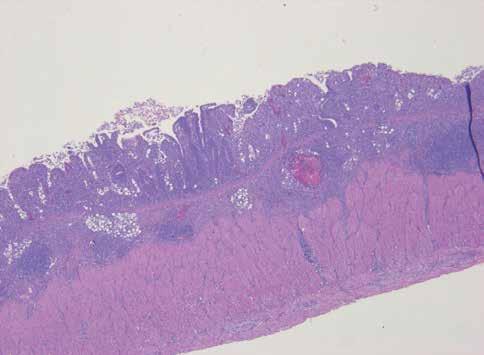

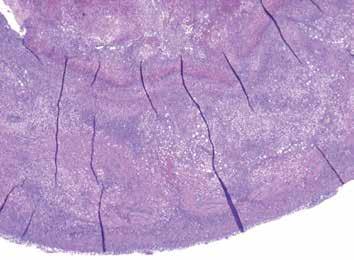

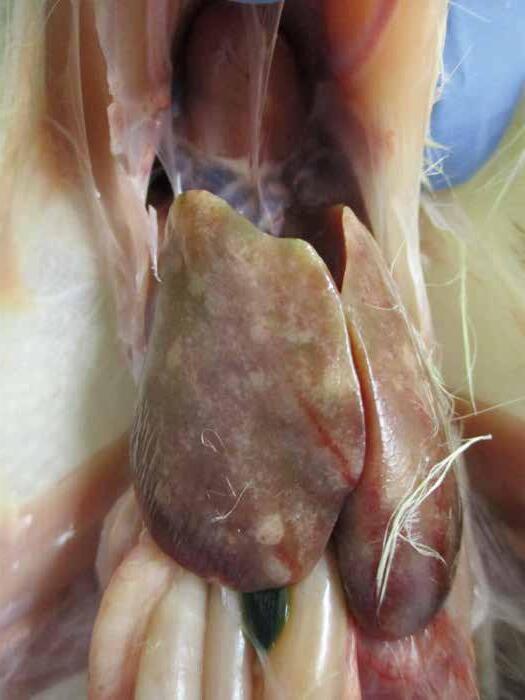

Histopathological evaluation of Histomonas meleagridis on ceca and the bursa of Fabricius in turkeys

2016 2024 Zootecnica International − February 2024 –POSTE ITALIANE Spa –Spedizione in Abbonamento Postale 70 %, DCB Firenze

2

The new feeders of the «Gió» range, specifically developed for great poultry farms, thanks to the easiness in the regulation of the feed and to the absence of grill (that avoid chicks perching) have many advantages: they are easy to use and their cleaning is extremely easy and fast too, leading to an overall reduction in labour costs.

CODAF Poultry Equipment Manufacturers • Via Cavour, 74/76 • 25010 Isorella (Brescia), ITALY Tel. +39 030 9958156 • Fax: +39 030 9952810 • info@codaf.net • www.codaf.net

EDITORIAL

The so-called “convenience and wellness” or “regionality and organic” products have long offered the food industry and consumers increasingly greater guarantees of quality and safety. While these are essential prerequisites in establishing a market presence they also represent an ethical premise which cannot be ignored.

Among the challenges to be faced is the need to optimise production and systems both at local and international levels.

The sector is receiving growing demands for - products suitable to children – for those suffering from food intolerances – those requesting higher quality products – and also from the sector of people who intend to reduce their food consumption for health and sustainability reasons.

Unfortunately the war conflicts that have broken out in some countries also significantly affect good intentions, an example being how the situation in the Red Sea has forced the diversion of merchant ships and has led to incredible increases in transport costs.

However, the efforts made by science, technological evolution and continuous research with aims of saving energy, improving performance and reducing environmental pollution will not be in vain. Fortunately science goes beyond geopolitics. We must not be influenced too much by demagoguery and media terrorism. Doing and acting are more important than words spoken or written in order for us to recover that sense of humanity that we are losing.

for breeding

PP Belts

• Egg collection

• Manure drying system

• Manure belt collection

• PP woven egg belts

• PP hole egg belts

4002 H

• 360 degrees opening

• Highly strong and durable material

• “SOFT” action

4626

• Suitable for fattening turkeys

• Perfectly dry bedding

• Simultaneous watering of 2 and more animals

INFINITY

• Essential design

• No chicks in the pan!

• Regulation of minimun and maximum feed level

• Available in caged broilers version

4006 H

• 360 degrees opening

• Highly strong and durable material

• “EXTRASOFT” action

4901 N

Pressure regulator with bypass

ARTICLES

CORTI ZOOTECNICI

ACCESSORIES

Corti

Srl | Via Volta, 4 21020 Monvalle (VA) Italy | www.cortizootecnici.it |

Zootecnici

SUMMARY WORLDWIDE NEWS ......................................................................... 4 COMPANY NEWS 8 REPORTAGE Biosecurity in poultry farming: an effective tool to fight infectious diseases 10 DOSSIER A practical approach to poultry welfare 16 MARKETING Impacts of the 2022 AI epidemic in the USA on laying hen inventories, egg production and egg prices 20 MANAGEMENT Composting daily poultry mortality 26 NUTRITION Effects of commercial processing conditions of extruded soybean on growth performance and amino acids digestibility of broiler chickens 32 VETERINARY Histopathological evaluation of Histomonas meleagridis on ceca and the bursa of Fabricius in turkeys 36 MARKET GUIDE................................................................................44 UPCOMING EVENTS 47 INTERNET GUIDE 48 36 10 32

WOAH: the animal industry must play its part in curbing the use of antimicrobials as growth promoters

Antimicrobial resistance is a growing concern. Too often, antimicrobials are misused or overused across sectors, creating the conditions for this phenomenon to emerge.

While the majority of WOAH Members have taken strong action in recent years to reduce their use in animals, further efforts are needed as these drugs are still being inappropriately used as growth promoters in some countries.

Taking stock of the use of antimicrobials for growth promotion

In 2016, all WOAH Members committed to definitively ban the use of highest priority antimicrobials for humans, and to phase out the use of antimicrobials in animals for growth promotion purposes in the absence of a risk analysis. How has this commitment been put into practice so far?

• Almost 20% of Members still report using antimicrobials for growth promotion. Of these, it is estimated that 76% have not carried out any preliminary risk analysis.

• More worringly, no less than 11% of WOAH Members still use as growth promoters at least one of the highest priority critically important antimicrobials for human medicine such as colistin.

• At least 50% of the Members using antimicrobials as growth promoters have no regulatory framework in place.

• In some countries, the labelling of certain feed additives intended to increase productivity does not mention the

presence of low doses of antimicrobials, which are then unknowingly administered to animals by veterinarians and farmers.

Such practices are not in compliance with WOAH international standards or the Global Action Plan on AMR.

Competent authorities and the livestock industry must fulfil their responsibilities to phase out the use of antimicrobials for growth promotion in animals

WOAH standards make a clear distinction between veterinary medical use of antimicrobials – which is limited to the treatment, control and, where appropriate, prevention of infectious diseases – and non-veterinary medical use. The administration of antimicrobials for growth promotion in animals is a non-veterinary medical use, and it must not be assimilated to disease prevention use, which requires animals to be at proven risk of disease if the medicine is not administered.

WOAH calls on its Members to restrict the use of antimicrobials solely to veterinary medical use and to actively engage in dialogue with the concerned parties to achieve a total ban on the use of antimicrobials as growth promoters, starting with those that are critically important for human health.

Competent authorities must enact relevant legislation in this regard and are invited to explore and promote alternatives to improve animal productivity, as relevant. These can include, among others, animal health programmes that focus on disease prevention (e.g., deworming and vaccination), biosecurity and good animal husbandry practices. The misuse of antimicrobials in different sectors accelerates antimicrobial resistance. The animal health sector must play its part in curbing this global scourge that threatens animal, human and plant health and adopt sustainable practices.

Source: WOAH

4 - worldwide newsWORLDWIDE NEWS

PRATIKA THE INNOVATIVE FEED PAN FOR BROILERS

Automatic feed level adjustment from chick to adult phase with the window opening system.

Low bottom pan from oneday old to slaughtering age.

No chick trapped in the pan.

Bottom pan designed to avoid feed waste.

FULLY AUTOMATIC

ONE SECOND IMMEDIATE OPENING AND CLOSING OF THE BOTTOM PAN FOR COMPLETE AND FAST WASHING.

- february 2024WORLDWIDE NEWS

QUALITY MADE IN ITALY www.azainternational.it I WANT AZA!

Animal feed probiotics market to hit US$ 12 billion

As per a new Fact.MR analysis, the global animal feed probiotics market is anticipated to expand at a CAGR of 9.1%, increasing from its current value of US$ 5 billion to US$ 12 billion by the end of 2032.

With rising consumption of protein-rich diets across the globe, key players are improving the production of animal feed probiotics. Moreover, to prevent the outbreaks of cattle-based or poultry-based diseases, end users are increasing the adoption of these probiotics. This is resulting in increased research and development activities among leading players to capitalize on growing demand.

As per the study, animal feed probiotics help in maintaining a healthy gut and digestive tract. Consequently, livestock animals are frequently fed animal feed probiotics as vital ingredients. Bifidobacterium and lactobacillus are considered to be the two main sources used in the production of animal feed probiotics. However, rising awareness regarding the health benefits of yeast and fungi consumption will also boost the sales.

Additionally, increasing popularity of organic livestock and advancements in development of animal feed are also expected to drive demand for probiotics. Hence, key manufacturers are focusing on developing new probiotics due to their restrictive effect on digestive diseases.

However, the regulatory bodies such as the U.S. Food and Drug Administration have banned the usage of antibiotics as feed supplements for poultry and livestock animals. Hence, key players such as Evonik, Novozymes, Chr. Hansen, and others are focusing on developing high quality probiotics to gain revenue. On the back of these aforementioned factors, the demand in animal feed probiotics market is expected to surpass US$ 12 Billion by the end of 2032.

Key takeaways:

• India is projected to remain at the forefront in Asia Pacific animal feed probiotics market, generating revenues worth US$ 208.5 Million.

• The U.S. animal feed probiotics market is slated to expand at 4.8% CAGR during the forecast period.

• By form, the liquid segment is expected to generate maximum profits in animal feed probiotics market by 2032.

• In terms of source, the lactobacillus, streptococcus, and yeast categories are likely to account for lion’s share in the market.

• Based on animal, the poultry segment is expected to showcase an upward trajectory in the upcoming decade.

Growth drivers:

• Rising prevalence of intestinal disorders among poultry and other livestock animals will improve the demand for animal feed probiotics.

• Growing focus on animal health to prevent animal-based disease outbreaks will aid the growth in animal feed probiotics market.

• Surging production of compound feed and consumption of animal-based products will spur the sales of animal feed probiotics.

Key restraints:

• High research and development costs for the development of new and advanced probiotic strains might limit the sales in emerging economies.

• Presence of stringent international regulations and quality procedures for animal feed probiotics is likely to restrain the growth.

Leading players in the animal feed probiotics market are focusing on launching effective and innovative products to gain competitive edge. Some of the industry giants are forming alliances with mergers & acquisitions and product development related to livestock to generate maximum profits, especially across Europe and East & South Asia. Meanwhile, other players are establishing strong distribution networks through manufacturing facilities across India, China, Japan, Kore, Germany, and other countries in Europe.

Source: Fact.MR

6 - worldwide newsWORLDWIDE NEWS

Till 40 silos in 1x40’ O/T container Till 23 silos in one complete truckload

s.r.l. Via Rimembranze, 7 25012 Calvisano (BS) Italy

Tel. + 39 030 9968222 r.a. Fax + 39 030 9968444 commerce@agritech.it www.agritech.it

Fiberglass

silos: the most practical, effective and durable solution to any bulk storage requirement Agritech

ModularOven+ can adapt to production needs

The Marel ModularOven+ offers state-of-the-art oven technology in a truly modular format. It can be tailored flexibly to meet exact production needs.

The Marel ModularOven+ is designed to meet varied production requirements with unparalleled flexibility and high yield, while also providing machine health monitoring.

ModularOven+ provides customizable, award-winning oven technology that allows processors to begin with essential features and add more capacity or features as needed, such as transitioning from 500 kW to 900 kW heaters.

It cooks, steams and roasts

When it comes to creating the highest rate of reproducible quality of products, maximum yield and unbeatable uniformity are the key words for the ModularOven+. Drawing on over three decades of expertise in heating technology, Marel has designed the ModularOven+ to deliver unparalleled flexibility and control over the production process.

Two-zone versatility

The ModularOven+ has two separate zones, each with independent controls for temperature, dew point and air speed. This provides high versatility for two different climates, whether for steaming, cooking or roasting. For example, one tower may be used for high dew point steaming, while the other is used for high temperature, low dew point roasting.

Product consistency

Equipped with an air regulation system featuring high-tech diffusers and multiple temperature sensors per zone, the ModularOven+ ensures optimal airflow, even heat distribution, and ideal moisture con-

tent. This results in a consistent core temperature and reproducible quality, irrespective of variables like time of day, belt position, or oven loading. The system enables lower core temperature averages, leading to shor ter cooking times and significant energy savings. The combination of separate climate zones and air regulation results in up to 6% higher yield compared to other comparable ovens.

Machine health monitoring

Integrated SmartBase software allows processors to proactively analyze performance, identify areas for improvement, and pinpoint potential issues before they oc cur. This internal digital engine offers the opportunity to (remotely) monitor the health of the oven and allows for (remote) support by Marel. SmartBase goes beyond visualization of the extra data it retrieves on the dashboard.

Combined with predictive, standardized maintenance, SmartBase can really reduce unexpected downtime.

More information: marel.com/modularoven

8 - company newsCOMPANY NEWS

EMEAA Broiler School enhances broiler management focus

Aviagen® was excited to welcome 33 students representing 18 countries to Edinburgh for the 2023 Aviagen® Europe, Middle East, Africa, and Asia (EMEAA) Production Management School Broiler Module.

The students hailed from diverse backgrounds across EMEAA, united by their shared passion for poultry and a strong desire to exchange experiences and knowledge. Discussions centered on finding effective and innovative methods to maximize broiler health and efficiencies, ultimately driving economic benefits for their businesses and contributing to environmental sustainability.

Exploring innovative broiler management

Tutors, consisting of Aviagen experts and guests from the wider poultry industry, shared their insight into crucial broiler topics such as male management and physiology, disease control, and water quality. An interactive biosecurity exercise allowed students to gain practical expertise in an essential aspect of food safety and security.

Interactive, shared learning experience

A highlight of the project was a group exercise, where students navigated a realistic case study, providing collaborative, hands-on learning of key management areas such as veterinary health, house ventilation, and nutrition. To cap off the course, students sharpened their presentation skills by showcasing their findings, with the best presentation receiving special recognition. Students further broadened their skill set by delving into data analysis as a vital tool for improving bird welfare and productivity. Throughout the week, there was a strong emphasis on networking, teamwork, and the exchange of innovative ideas and solutions.

Recognizing potential for excellence

At the graduation ceremony on the final day, the Aviagen team took the opportunity to acknowledge outstanding performance, leadership, and potential.

David Butler award. Alba Sarda Figueras, Veterinarian from Vall Companies, Portugal, received this award in recognition of the exceptional collaborative spirit and leadership demonstrated during the course.

UK Next-Gen scholarship. Thomas Kendal, Area Manager from Forest Poultry Ltd, was the winner of UK NextGen Scholarship to attend the Broiler Module. This scholarship supports promising UK industry colleagues aged 35 or younger in their quest to enhance management skills and knowledge. He commented: “I really enjoyed the opportunity to establish contacts with colleagues from around the world to exchange information and deliberate various topics in interesting discussions. These foundations will help me to enhance my knowledge not only now but further into the future.”

Winning group presentation: The blue team secured the top spot for their outstanding presentation on the case study investigation which utilized their analytical skills as well as information from the tutors’ presentations during the week to interpret and provide solutions for the example company.

Niamh Halley, EMEAA School Director and Global Technical Transfer Manager, said, “We congratulated our class of 2023 and celebrated their success from the week at our graduation ceremony. We appreciate their input and knowledge sharing that emphasizes one of the benefits of the EMEAA Schools. Through this open and transparent communication, we are all able to contribute to the ongoing improvement in bird health, welfare and efficiencies of the global poultry sector.”

- february 2024 - 9 COMPANY NEWS

1 Department of Veterinary Medicine and Animal Science, University of Milan, Via dell'Università 6, Lodi, 26900 Lodi, Italy

2 Department of Comparative Biomedicine and Food Science, University of Padua, Viale dell’Università 16, Legnaro, 35020 Padua, Italy

Biosecurity in poultry farming: an effective tool to fight infectious diseases

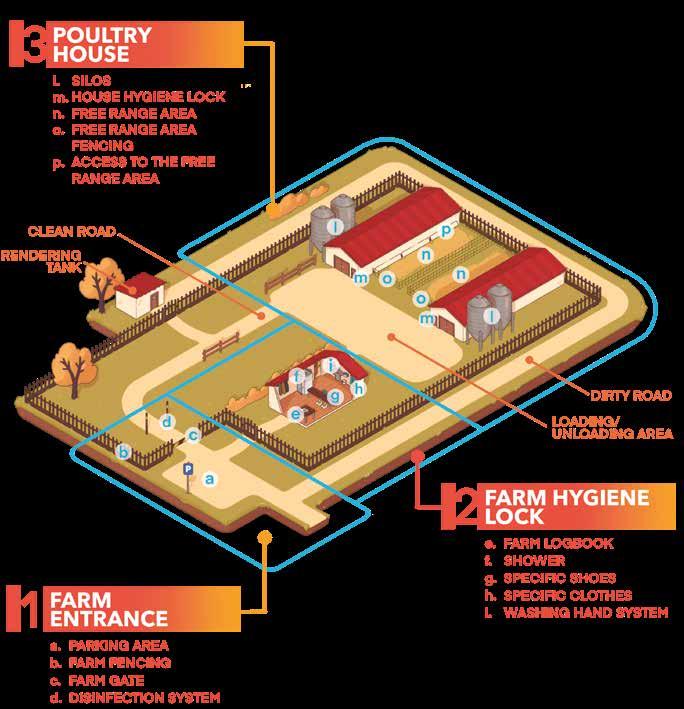

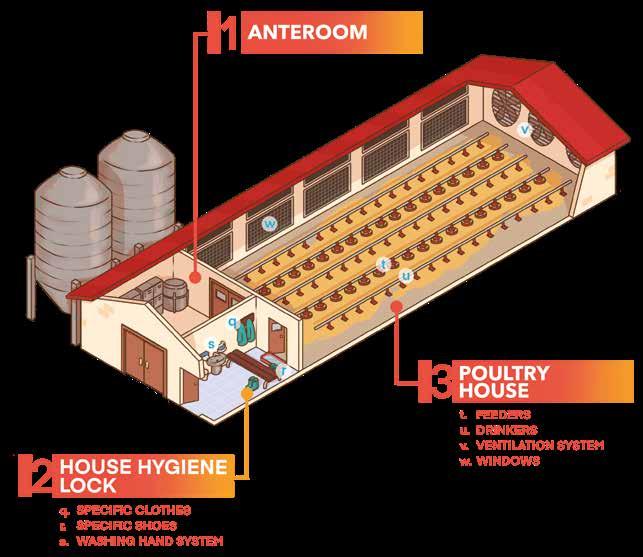

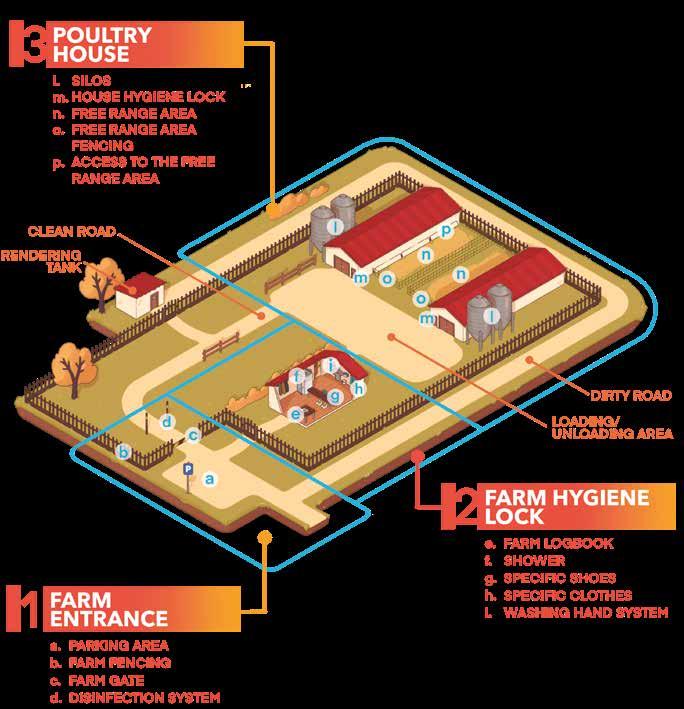

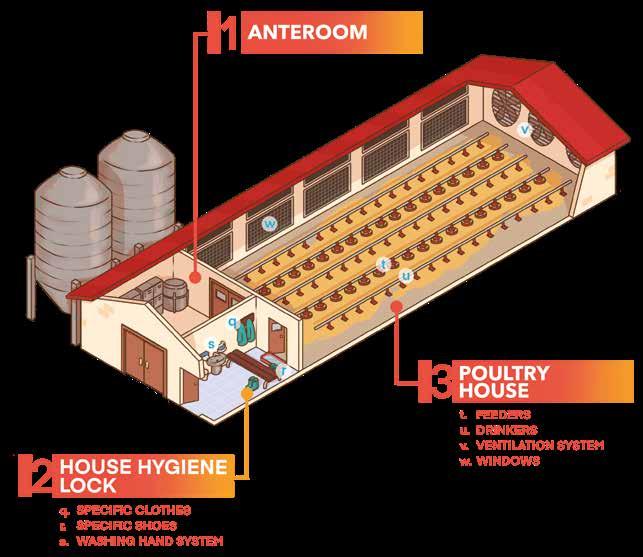

Biosecurity is the set of practices to be implemented in poultry farms to prevent the introduction and spread of infectious diseases. Therefore, biosecurity is a powerful tool for protecting animal health and welfare, as well as food safety. The aim of this article (created within the framework of the “NetPoulSafe - G.A. 101000728” project) is to explain in a simple way the importance of biosecurity in the management of infectious diseases.

Maria Cristina Rapi1, Laura Musa1, Guido Grilli1, Giuditta Tilli2, Alessandra Piccirillo2

10 - reportageREPORTAGE

The term biosecurity refers to the set of all measures designed and implemented in order to prevent the entry (bioexclusion) and spread (biocontainment) of pathogens within and between farms.

Nowadays, biosecurity represents one of the most important tools available for farmers to create, within the production environment, optimal hygienic conditions, capable of protecting animal health and welfare and providing guarantees on food safety by preventing the occurrence of food-borne zoonotic agents in the farm.

Biosecurity therefore represents a key management tool, as well as an essential part, of any successful poultry production system. The onset of diseases in poultry, often caused by negligence or poor management of the farm, reduces productivity, profitability and the long-term financial sustainability of any production sector.

Pathogens capable of affecting and seriously damaging the poultry supply chain are mainly viruses, bacteria, fungi and protozoa; they all possess the ability to cause diseases, which produce significant problems in farms,

This is the first of a series of technical articles on biosecurity in poultry farming produced within the European project

“ NetPoulSafe - Networking European poultry actors for enhancing the compliance of Biosecurity measures for a sustainable production (G.A. 101000728). NetPoulSafe is a thematic network of the European Union with the aim of identifying the best measures to support biosecurity and to stimulate the exchange of knowledge between the various actors in the European poultry sector (France, Spain, Italy, Hungary, Belgium, the Netherlands and Poland). Professor Alessandra Piccirillo and Dr Giuditta Tilli, University of Padua, collaborated on the project representing Italy.

In these articles (3), different issues (principles of biosecurity, new legislation on biosecurity, biosecurity in breeder farms and hatcheries) related to the implementation of biosecurity measures in the context of national poultry farming will be addressed.

For more information: www.netpoulsafe.eu

On the website you will find more information on the project as well as the dissemination materials (podcasts, videos, factsheets, online courses, handbook on supporting measures, etc.) produced within the project. Contents are available in the languages of the countries involved.

L’IGIENE HA UN NUOVO NOME COMBIMASTER

Il CombiMaster, come tutti gli abbeveratoi LUBING, garantisce un flusso d’acqua adeguato agli animali.

• Pareti di maggior spessore: il corpo compatto in plastica offre una resistenza ancora maggiore

• Materiale resistente agli acidi: l'alta qualità dei materiali usati garantisce la migliore stabilità e sicurezza funzionale nel tempo.

• Superficie igienica: le superfici estremamente lisce e levigate dei vari componenti evitano la formazione di depositi

Via Marco Polo, 33 - 35011 - Campodarsego (PD) ITALIA +39 0499202290 - lubingsystem.com - info@lubing.it

- february 2024 - 11 REPORTAGE

Original! The

Figure 1 – Schematic representation of the biosecurity measures to be applied at farm level. Image created by the Digital Learning and Multimedia Office (© University of Padua) within the framework of the “NetPoulSafe” project. This project was funded by the European Union, Horizon 2020 program for research and innovation, Grant Agreement n. 101000728 (NetPoulSafe). For more information: www.netpoulsafe.eu

including the reduction of the productive performance of the animals. To give some examples, viral agents are responsible for diseases such as Newcastle disease, Gumboro disease and Avian Influenza; bacteria are responsible for diseases such as Avian Cholera, Colibacillosis and Salmonellosis; fungi cause problems of Aspergillosis, mould and mycotoxins; protozoa cause, among others, serious coccidiosis problems. All these pathogens, together with lice and mites, represent a huge threat for poultry farming.

How can these harmful microorganisms, dangerous for the production and economic success of the farm, enter?

The identification of the potential routes through which a pathogen can be introduced into the farm represents the first fundamental step to be taken. Producers and operators should pay attention to this, in order to carry out a correct risk assessment, necessary for the implementation of an appropriate biosecurity program in the farm.

The main routes of entry and spread of pathogens are represented by:

• airborne transmission;

• transmission through consumption of contaminated feed and/or water;

• direct transmission from sick, domestic or wild animals to healthy animals;

• indirect transmission through contaminated equipment, materials and vehicles, or through live vectors, mainly represented by pests, such as rodents, insects, but also by staff and/or occasional visitors who do not wear dedicated clothing in the farm area.

The entry routes that microorganisms can use, as well as the paths they can follow to spread throughout the production, are therefore multiple. Hence, the need for every prudent farmer to adopt efficient, robust practices in order to prevent the introduction and circulation of pathogens, thus protecting both the animals and the productivity of the farm.

What are the necessary biosecurity procedures to implement to protect the production?

The procedures to be implemented are located at different levels The construction of physical and conceptual barriers is the necessary basis for the implementation of an effective biosecurity plan on the farm. Usually, the plan is made of three pillars: separation and control of personnel and vehicle’s traffic to/ from the farm, cleaning and disinfection of the facilities and equipment. Poultry farms should be designed in order to prevent the entry of other

12 - reportageREPORTAGE

animals, both domestic and wild, and to limit the access to unauthorized people in the areas adjacent to the houses (fences, nets on the windows). Specifically, the houses should be built in order to prevent access to birds and rodents: all possible entrances should be sealed or covered with metal mesh, which integrity should be periodically checked. Particular attention should be paid to areas of greater risk, such as air inlets, extractors, drains, windows, etc. Rodents, for example, are well known vectors of serious poultry pathogens such as Salmonella Typhimurium, Campylobacter, Escherichia coli, Staphylococcus aureus, Pasteurella etc. and thus their entry should be limited as much as possible according to strict biosecurity practices, including their control.

Insects control is also part of a good biosecurity plan; for example, due to their external hair cover, flies are able to transport Salmonella Enteritidis, Campylobacter jejuni, Enterococcus faecium and other bacteria both inside and outside the farm, including those resistant to antimicrobials. A similar role can be attributed to the mite (Alphitobius diaperinus) and the red mite (Dermanyssus gallinae) which are both widely present in long-living animals’ farms. Insects are also able to maintain infections between one cycle and the following if not correctly controlled, as their lifespan is longer than the period of sanitary break, especially in mild climates areas.

Control of staff and occasional visitors is also of primary importance: those responsible for the animals daily care, veterinarians, truck drivers, external crews, farm workers, etc. represent one of the most important factors in the transmission of diseases within and towards flocks: visits should therefore be reduced to a minimum and allowed only when strictly necessary and carefully controlled. Important biosecurity measures are thus represented, among others, by fencing the farm perimeter, with a single access gate, kept always closed, and with “no access” signs, aimed at making aware unauthorized personnel.

For authorized personnel and/or occasional visitors, at every passage between the ‘dirty area’ (outside the house) and the ‘clean area’ (inside the house), washing and disinfecting at least hands and shoes, as well as changing footwear and clothing in a dedicated room should be compulsory. Vehicles entering the farm should also be disinfected. It is important to underline

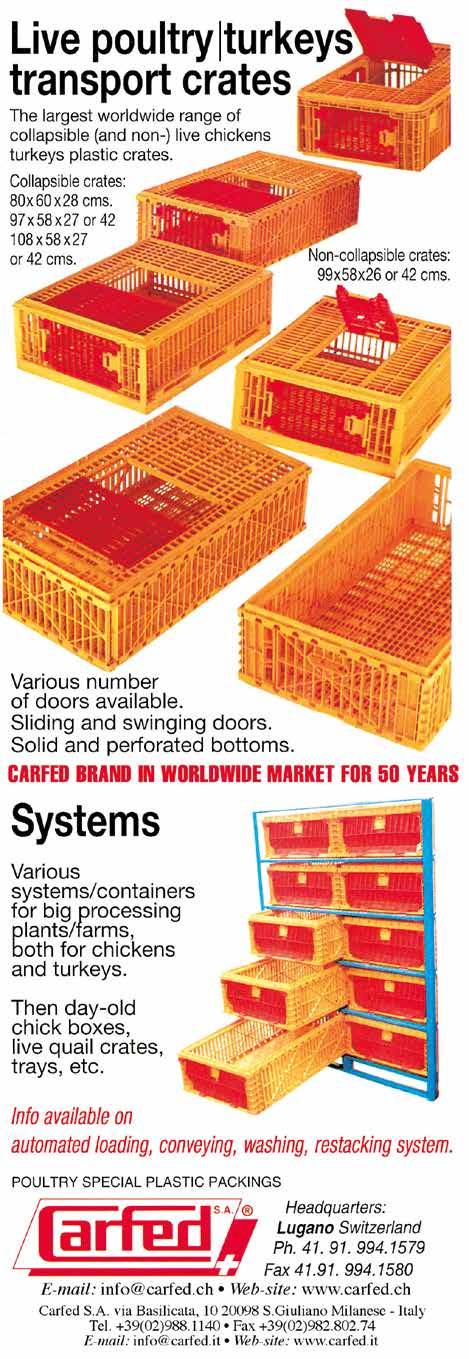

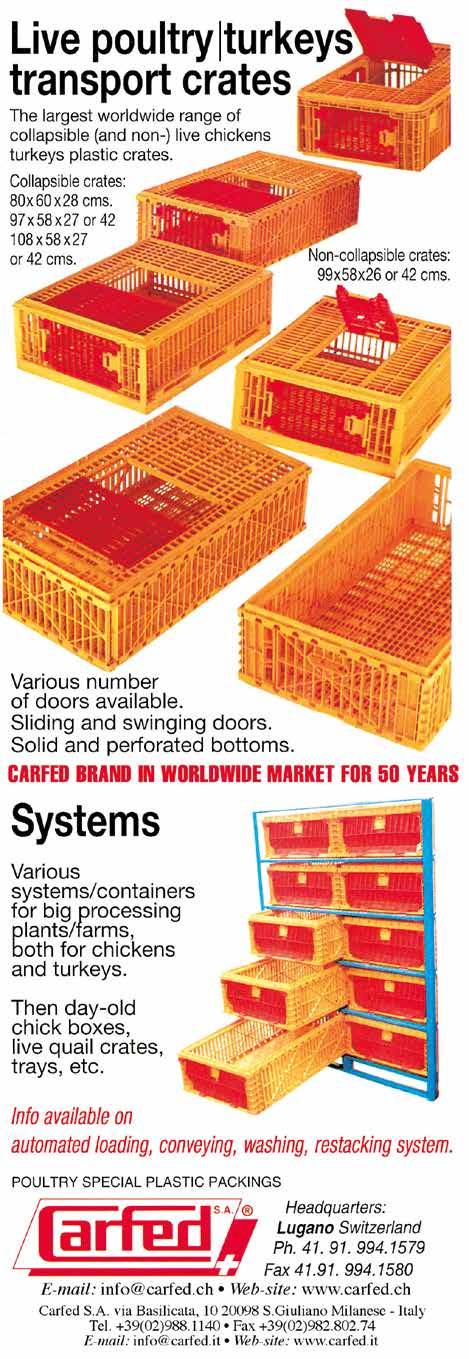

CARFED INTERNATIONAL LTD

Italian headquarters: Piazza Oberdan 3, 20129 Milano (Italy)

Italian warehouse: Via Basilicata 10, 20098 San Giuliano Milanese (Italy) Ph.: +39 02 9881140 – Fax: +39 02 98280274

Email: carfed@carfed.it – Website: www.carfed.it

UK headquarters: 2nd Floor Gadd House, Arcadia Avenue London, England, N3 2JU, United Kingdom Ph.: + 44. 20. 7660.0987 – Email: carfed@carfed.co.uk

- february 2024 - 13 REPORTAGE

Figure 1 – Schematic representation of the biosecurity measures to be applied at farm level. Image created by the Digital Learning and Multimedia Office (© University of Padua) within the framework of the “NetPoulSafe” project. This project was funded by the European Union, Horizon 2020 program for research and innovation, Grant Agreement n. 101000728 (NetPoulSafe). For more information: www.netpoulsafe.eu

that, within the area surrounding the farm, only vehicles whose access is essential for farm activities should be allowed; all the other vehicles should be parked outside the farm perimeter.

Other important procedural barriers to prevent the spread of pathogens on farms are represented by effective cleaning and disinfection of all facilities and equipment, following the complete removal of all organic material, at the end of each production cycle and before repopulation of the farm: the objective is to reduce the load of pathogens present in the environment and, consequently, to minimize the risk of the occurrence of health problems in the following cycle. To apply a correct cleaning and disinfection plan is fundamental, especially if there have been cases of salmonellosis, as it is able to survive in the litter for several months. Feeders, drinkers and water distribution lines should also be included in these plans. It is also necessary to periodically clean and disinfect the feed silos, since minor salmonellae, entering the house through feed, can stay for long periods, as well as mycotoxins if

“The construction of physical and conceptual barriers is the necessary basis for the implementation of an effective biosecurity plan on the farm. Usually, the plan is made of three pillars: separation and control of personnel and vehicle’s traffic to/from the farm, cleaning and disinfection of the facilities and equipment.”

there is feed left between one cycle and the following one. In order to have effective results from these practices, it is necessary that all materials have precise requirements, such as easiness of washing, cleansing and disinfection. Finally, it is important to underline that, to implement an effective and successful biosecurity program, all measures should be simple, understandable, acknowledged, usable, through specific indications placed in various areas of the farm, by all the poultry workers and regularly monitored.

All these aspects are crucial in poultry farms and, for this reason, require great attention: indeed, it should always be remembered that diseases significantly increase production costs and losses, leaving the farmer with little or no profit and representing a potential risk to public health.

14 - reportageREPORTAGE

A practical approach to poultry welfare

Improving poultry welfare on-farm may seem challenging, yet manageable. Due to industry responsibility and consumer expectations for poultry health and wellbeing, rising attention has focused on developing venues to practically improve poultry welfare by avoiding stressful conditions, allowing birds to cope with challenging situations, and supporting flock comfort.

Aitor Arrazola

Research biologist, Ph.D. in Animal Behaviour & Welfare

Finding a definition for animal welfare is far away from straight forward. Indeed, animal welfare can be seen as a multifaced concept that includes physical health, mental health, and behavior. Within this interplay, animals with good welfare are also likely to function well and be economically efficient, either due to low product cost, optimal production outcomes, or both. Still, regardless of the approach, birds with good welfare refer to healthy, comfortable animals. Although this understanding of welfare appears to be easy at first sight, applying this concept practically is particularly difficult in poultry industry. Table-egg layer and broiler barns

16

DOSSIER - dossier -

DOSSIER

hold thousands of birds within each building, and there is a wide range of production systems worldwide from cage to multitier and free-rage systems, including breeder and production flocks. Due to this diverse structure of the poultry industry, safeguarding the wellbeing of each bird is definitely challenging as well as assessing how chickens perceive their production systems, environments, and management practices. Yet, another difficulty when evaluating and improving poultry welfare is recognizing the relationship between animals’ wellbeing and their genetic background. Because of differential genetic selection for table-egg and meat production, management practices that benefit layer welfare may not work for broilers or dual-purpose chickens. Nonetheless, best management practices to enhance flock and individual welfare should reduce and avoid stressful conditions, allow birds to deal with that stress, and find venues to support birds’ wellbeing.

Avoiding stressful conditions

A core component of on-farm welfare improvements is to mitigate instances of negative experiences like distress, pain, and suffering. To do so, identifying possible resources of stress, pain or suffering is the first step to develop an action plan to enhance poultry welfare. For example, environmental conditions, health problems, behavioural problems, and access to resources can put at risk birds’ wellbeing and also jeopardize production outcomes and profitability. The first step is to guarantee that birds’ physical needs are covered by ensuring, for example, that all chickens have access to water and feed without fighting over it. Environmental conditions such as temperature, relative humidity, and quality of air and litter also play a key role on birds’ health and welfare. Extreme temperatures can lead to thermal stress, inhibit feed intake, and increase flock mortality due to hypo- or hyperthermia. Chicks are particularly susceptible to suboptimal temperatures, and producers should check that ground temperature is suitable for chick placement at least few days before arrival. Additionally, poor air and litter quality can cause air-borne diseases and lesions in skin, legs, and foot, respectively, that are associated with pain and suffering. Avoiding, as much as possible, instances of distress, pain, suffering, and discomfort is consequently the first, go-to step to make poultry welfare improvements on-farm.

Allowing birds to cope with

stressful conditions

Avoiding stressful conditions in poultry may sometimes be difficult and inevitable on farms. For example, dealing with an outbreak of acute diseases can be challenging and producers need a period of time for flock diagnosis, treatments, and recovery. Also, due to rising temperatures and more frequent extreme weather events associated with climate change, managing environmental conditions within poultry barns during heat waves is becoming tough for most producers in temperate climates. In both scenarios, birds are likely to experience acute or mild stress due to the unpredictable nature of these events. However, continuous monitoring of birds’ health and behaviour is the best preventive approach to foresee challenges and act on it as quickly and duly as possible. Current scientific knowledge on animal behaviour also supports the idea that birds sometimes need to undergo instances of negative experiences to motivate the performance of survival-related behaviours. For example, birds need to feel full to stop eating before they collapse, need to feel exhausted after exercising before they have a heart attack, and need to feel tired to have a break and rest peacefully for recovery.

Freedom from stress and discomfort is therefore unattainable sometimes under commercial conditions. In these cases, birds will attempt to cope with these challenging conditions to the best of their capabilities. However, if birds cannot successfully cope with these ongoing challenges, stress can indeed build up internally and result in further stress-related problems over time that may take a toll on birds’ health and performance. For this reason, allowing birds to release stress can help mitigate the negative, side consequences of stressful conditions on their health, performance, and welfare.

Birds deal with stress in various ways. Chickens will naturally avoid external stress by moving away from its source, and these should be taken into account when considering housing densities. Under internal stress, chickens tend to become more active and increase pecking activity toward objects and other birds. These behaviours are stress-release activities for chickens, and producers can support these behavioral changes by providing scratching areas and pecking objects. The resources allow birds to redirect these oral activities toward environmental enrichments instead of pecking themselves, other birds,

17 - february 2024 -

or feeders. In cage systems, for example, scratching mats can support pecking, scratching, and dustbathing behaviours and reduce problems associated with feather pecking. In aviary systems, perches, platforms, or vertical barriers can help victims of severe pecking move away from aggressors. However, although these enrichments can help improve poultry welfare, they don’t solve the problems behind those undesirable behaviours. Yet, allowing birds to engage in these stress-release behaviors certainly supports their stress resilience capabilities.

Seeking poultry comfort

Improvements in poultry welfare require a forward-thinking mindset in which birds feel comfortable within their production systems. Most work on animal welfare from couple of decades ago has primarily focused on reducing negative experiences in poultry. However, since keeping animals absolutely stress free is unachievable in reality, new animal welfare approaches are focusing on promoting positive experiences that can outbalance the experience of stressful ones. Chickens en-

joy scratching and foraging on the ground even when sated, exploring their surroundings while pecking new objects, staying physically active engaging in social and object play, and rest in comfortable areas. All these behaviours are rewarding, boost their immune system, and enhance their overall health and well-being that, in return, benefits production outcomes. Consequently, providing birds with resources or physical space so they can perform these behaviours is a highly recommend on-farm practice to promote poultry welfare across multiple production systems. For example, motivating layer or broiler chicks to exercise can support a healthy skeletal development and reduce the prevalence and severity of leg/toe malformations and bone fracture later in life. Other venues to support poultry wellbeing include proper management practices such as maintaining adequate environmental conditions within barns, euthanizing birds that are in pain or suffering humanely, and promoting low-stress handling techniques.

This approach of promoting positive experiences is more practical and feasible on poultry barns than aiming merely to avoid the experience of stressful events. Rather than only neutralizing or abolishing negative experiences, efforts to care for poultry wellbeing should focus on providing animals with opportunities to perform behaviours that rewarding for them, so birds can have a comfortable life within their production systems. These advancements in poultry welfare should be implemented not only throughout the production of breeder and production flocks, but also considered during transportation and processing.

18 DOSSIER - dossier -

MODULA THE SPECIFIC FEED PAN FOR TURKEYS

STURDY AND EASY TO MANAGE

Designed from one day-old chicks to heavy and nervous male turkeys.

Simple washing of any component of the feed pan.

Safe and fast assembly/ disassembly of the antiwaste ring without tools.

Leader in livestock feeding systems

QUALITY MADE IN ITALY www.azainternational.it I WANT AZA!

Impacts of the 2022 AI epidemic in the USA on laying hen inventories, egg production and egg prices

After 2015, a devastating outbreak of the Avian Influenza virus (AI) hit the United States again in 2022. In the first half-year of 2022, there was still a certain resemblance to what happened in 2015, but the further course showed significant differences.

Hans-Wilhelm Windhorst

The author is Professor Emeritus of the University of Vechta, Germany

A more detailed analysis of the timeline showed that, strictly speaking, these were two separate waves, which also showed different spatial patterns. The aim of this article is to document the impacts of the epidemic in the mainly affected states on laying hen inventories, egg production, the value of produced eggs at farm gate and the egg price in retail stores. The analysis was possible after the publication of the Chicken and Eggs 2022 Summary and the Poultry Production and Value 2022 Summary by the National Agricultural Statistics Service of the USDA.

The timeline of the AI outbreaks in egg farms

Figure 1 documents the timeline of the outbreaks in layer farms and the respective animal losses per outbreak. In 2022, a total of 45 outbreaks on laying hen farms was recorded, 27 of them in the first and 18 in the second half-year. The highest animal losses occurred between calendar week 11 and 17. The average flock sizes of the affected farms differed considerably, 13 of the 45 affected farms had a size of less than 100,000 hen places. These were mainly breeder

20 MARKETING - marketing -

farms for laying hens and broilers. In contrast, 21 farms had more than 1 million places, two even more than 5 million. It is worth noting that farms with more than 5 million places were not infected in the second half-year. This is probably due to the fact that, after the experiences in the first halfyear, farm managers improved the biosecurity of their farms, and on the other hand that, if they were infected again, they may not have been fully restocked when the epidemic flared up again. Of the 57.6 million birds that died from the infection or were culled, 44.3 million were laying hens. In the first half-year 31.4 million hens were lost, in the second halfyear 12.9 million. This difference is reflected in the development of the egg value at farm gate and on egg prices at retail stores.

21 - february 2024MARKETING

Figure 1 – The timeline of AI outbreaks in layer farms and resulting animal losses in 2022 (source: Windhorst 2023).

Laying hens Cases 0 5 10 15 20 25 30 35 Weeks 6 8 10 12 14 16 18 20 22 24 26 28 30 32 34 36 38 40 42 44 46 48 50 52

del grafico Animal losses [1,000] 0 1.000 2.000 3.000 4.000 5.000 6.000 7.000 8.000 9.000 Weeks 6 8 10 12 14 16 18 20 22 24 26 28 30 32 34 36 38 40 42 44 46 48 50 52 2nd half-year 1st half-year 1st half-year 2nd half-year Eurosilos Sirp srl Isorella (BS) Tel. +39 030.9958205 contatti@eurosilos.it www.eurosilos.it WE KEEP YOUR VALUE SAFE Italian manufacturer of fiberglass silos, tanks and augers. Follow us We are Social

Titolo

Table 1 – The development of the laying hen inventories between 2021 and 2022 in the mainly affected states by the AI epidemic; data in 1,000 hens (source: USDA, NASS Chicken and Eggs 2022 Summary).

Impacts on inventories differ considerably at state level

When analyzing the impacts on the laying hen inventories1 one must differentiate between the actual losses of hens during the epidemic and the annual changes. As can be seen from Table 1, the inventories at country level decreased by 11.9 million birds between December 1st, 2021 and November 30th, 2022, while during the epidemic 44.3 million birds were lost.

7

Table 2 – The development of egg production between 2021 and 2022 in the mainly affected states by the AI epidemic; data in million pieces (source: USDA, NASS Chicken and Eggs 2022 Summary).

Table 3 – The development of the value of egg production between 2021 and 2022 in the seven mainly affected states be the AI epidemic; data in million US-$ (source: USDA, NASS Poultry Production and Value 2022 Summary).

A closer look at state level reveals that the inventories of the seven most affected states declined by 17.3 million hens or 14.9%. This documents that because of the high losses in these states, egg farmers in other states placed more pullets to participate in the increasing egg prices.

A closer look at the data in Table 1 reveals that Iowa showed the highest absolute loss with 8.7 million birds, followed by Pennsylvania and Colorado. The highest relative decrease occurred in Colorado with 31.6%, followed by Wisconsin and Iowa. It is worth noting, that Iowa shared more than 50% in the reduction of the inventories in the seven most affected states.

Considerable impacts on egg production and egg value

A comparison of Tables 1 and 2 shows that egg production decreased at a lower percentage than the hen inventory. The production volume in the seven most affected states fell

* sum does not add because of rounding

1 The statistics at state level do not differentiate between laying and hatching hens. The total number of hatching hens in 2021 was 65.5 million and in 2022 66.1 million. This equalled 16.5% respectively 17.4% of the total inventory. Of the hatching hens, 95% were broiler type hatching hens. They were mainly concentrated in the South East.

22 MARKETING - marketing -

State 2021 2022 Decrease absolute % Iowa Pennsylvania California Nebraska Wisconsin Colorado S. Dakota 14,980 8,107 4,019 2,396 2,182 1,557 699 12,198 8,340 3,823 1,990 1,798 1,046 593 - 2,782 + 233 - 196 - 406 - 384 - 511 - 106 - 18.6 + 2.9 - 4.9 - 17.0 - 17.6 - 32.8 - 17.6 7 states 33,940 29,788 - 4,152 - 12.2 USA 111,395 109,514 - 1,881 - 1.7 State 2021 2022 Decrease Value cents/egg absolute % 2021 2022 Iowa Pennsylvania California Nebraska Wisconsin Colorado S. Dakota 852.1 431.5 372.4 155.4 129.4 89.4 37.2 1,968.8 1,278.1 856.8 324.2 292.9 162.0 59.2 1,116.7 84.6 484.4 168.8 163.5 72.6 59.2 131.0 243.2 130.1 108.6 126.4 181.2 159.2 17.4 14.2 26.6 19.1 17.6 17.5 16.8 49.0 47.4 64.1 46.9 49.5 46.2 50.6 7 states *2,067.3 *4,979.1 2,911.8 140.8 17.8 50.4 USA 8,713.2 19,352.4 10,639.2 122.1 22.3 51.0

State 2021 2022 Decrease absolute % Iowa Pennsylvania California Nebraska Wisconsin Colorado S. Dakota 48,877 30,360 13,993 8,131 7,356 5,117 2,216 40,157 26,988 13,358 6,912 5,921 3,502 1,905 8,720 3,372 635 1,219 1,435 1,615 311 17.8 11.1 4.5 15.0 19.5 31.6 14.0

states 116,050 98,743 17,307 14.9 USA 391,242 379,304 11,988 3.1

by 12.2%, in the USA by only 1.7%. Although the decline at country level seems to be marginal at first sight, the analysis of the egg price in retail stores will show that it increased dramatically. This is due to the fact, that the production volume in several states, which played a major role in interstate egg trade, decreased considerably, i.e. Iowa, Colorado and Nebraska.

Table 2 documents that Iowa’s production volume fell by 2.8 billion eggs or 18.6% in the period under consideration. Colorado was even confronted with a relative decline of 32.8%. Wisconsin, Nebraska and S. Dakota also showed high reduction rates. It is surprising at first glance that in Pennsylvania the production volume increased. A look at the timeline of outbreaks reveals that all outbreaks occurred in the first half-year. The farms could be completely restocked again and production reached full capacity earlier than in states with later outbreaks. In California, egg production decreased much less than in other affected states because only 715,000 hens were

tic increase in the value of total egg production and the value per egg (Table 3). In the seven most affected states, the value grew by 140.8%, in the USA by 122.1%. The development differed, however, considerably between the states. The highest relative increase showed Pennsylvania with 243.2%, followed by Colorado and South Dakota. In the seven states, the average value per egg increased from 17.8 cents to 50.4 cents or by 283.1%. In the USA as a whole, the growth rate was lower with 228.7%, but had far-reaching impacts nevertheless on the egg price in retail stores. It is worth noting that in 2022 the value per egg was highest in California with 64.1 cents. This is due to the state’s low egg self-sufficiency. About two thirds of the demand has to be imported, and in addition, the regulation of Proposition 12, which does not permit the sale of eggs produced in conventional cages, contributed to the worsening of the situation. Companies and farmers, which were not hit by the Avian Influenza virus made high profits. The net income of Cal Maine, the largest U.S. egg producing company, soared from 39.5 million US-$ in March 2022 to 323.2 million US-$ one year later.2

https://edition.cnn.com/2023/03/29/business/egg-profits-cal-maine/index.html.

• Manu re re moval belt s

Manu re belt wi th hole s for dr yi ng system s

info@barbieri-belts.com www.barbieribelts.com

23 - february 2024MARKETING

Barbieri srl

Via Garibaldi, 54 • 26040 Scandolara Ra vara (CR) Italy Tel. (+39) 0375 / 95135 • Fax (+39) 0375 / 95169

•

and ROP ES for AV

BE LT

BELTS

ICULTURAL USE

S

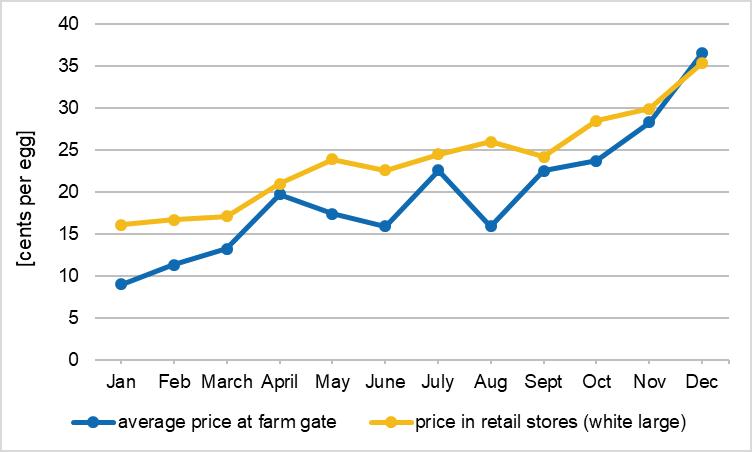

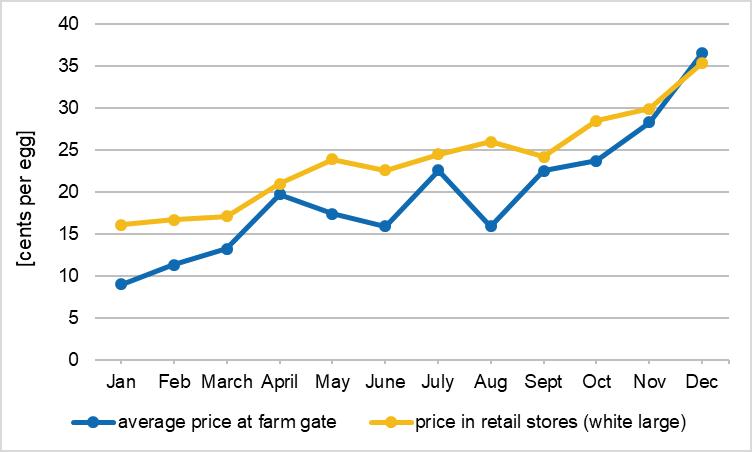

Figure 2 – The development of the average egg value at farm gate and the egg price for large white eggs in retail stores between January and December 2022; data in cents per egg (design: A.S. Kauer based on data of the Egg Industry Center).

Figure 2 – The development of the average egg value at farm gate and the egg price for large white eggs in retail stores between January and December 2022; data in cents per egg (design: A.S. Kauer based on data of the Egg Industry Center).

Drastic increase in egg prices

The shortage of shell eggs for consumption and for further processing resulted in a drastic increase of egg prices paid at farm gate and for consumers in retail stores. Figure 2 shows that the price at farm gate increased from 9.0 cents per egg in January 2022 to 36.6 cents per egg in December. While the absolute growth during the first wave of the epidemic until June was only about 10 cents per egg, further outbreaks in the second half-year and the not completed restocking of infected farms in earlier months added to the critical situation, especially for the egg processing companies, which were even forced to import eggs from abroad. The sharp increase in November and December was a result of the higher demand around Christmas and of AI outbreaks in large egg farms in Colorado. Over the whole year, the egg price at farm gate increased by almost 307%.

The two waves of the epidemic are also reflected in the egg price which consumers had to pay in retail stores. In the first half-year, the price grew between 6 and 7 cents per egg. After a short plateau, prices increased again and reached a maximum with 40.2 cents per egg in January 2023. But it was not before March 2023 that the price decreased considerably.

Consumers in California had to pay up to 6.72 $ per dozen in December 2022 due to the particular situation in that state. Because of the high price, the per capita consumption decreased from 280.5 eggs in 2021 to 277.5 eggs in 2022.

Summary and perspectives

During the Avian Influenza epidemic of 2022, over 44 million laying hens either died from the infection or were culled to prevent a further spread of the disease. The drastic decrease of the laying hen inventories in the most affected states led to a sharp reduction of egg production. This resulted in a considerable increase in the value of produced eggs at farm gate and the price, which consumers had to pay in retail stores. The changing prices over the year reflect the two waves of the epidemic in the first respectively second haft-year. It was not before the early months of 2023 that the situation began to stabilize. To prevent future epidemics of this dimension it will be necessary to discuss the possibility of a preventive vaccination.

Data sources and references

USDA, NASS (ed.): Chicken and Eggs, 2022 Summary. Washington, D. C.: February 2023.

USDA, NASS (ed.): Poultry – Production and Value, 2022 Summary. Washington, D.C.: April 2023.

U.S. Egg Industry Center: Cost and Prices Report. Costs and Prices for March 2023 mailed by April 2023.pdf.

Windhorst, H.-W.: A documentation and analysis of the AI epidemic in the USA in 2022. In: Zootecnica International 45 (2023), no. 3, p. 8-17.

24 MARKETING - marketing -

* sum does not add because of rounding

CHOOSE HOW YOU WANT TO

ENJOY

It’s been 50 years since Zootecnica International started serving the poultry industry and professionals. Today the magazine is edited in three languages (English, Italian and Russian) and delivered monthly in 120 countries, reaching around 30.000 readers all over the world.

The target of Zootecnica International includes farmers, egg producers, breeding companies, hatcheries, feed mills, poultry and egg processing companies.

Magazine and website offer a broad overview on the poultry industry, providing in-depth news on international markets, business management, trends and practices in poultry, genetics, incubation, nutrition, veterinary and management.

Subscribe by money transfer:

1. effect a money transfer to: Zootecnica International, Vicolo Libri, 4 50063 Figline Incisa Valdarno (FI), Italy; bank: UNICREDIT, BIC: UNICRITM1OU9 Iban: IT 81 H 02008 38083 000020067507

2. send us your complete shipping address by email: subscription@zootecnica.it.

PRINT ONLY

DIGITAL ONLY

(digital magazine sent to your mailbox)

(print magazine delivered to your door) € 49

€ 99

€ 109

DIGITAL

PRINT +

Composting daily poultry mortality

Tom Tabler, Department of Animal Science, University of Tennessee Shawn Hawkins, Department of Biosystems Engineering and Soil Science, University of Tennessee

Pramir Maharjan, Department of Agricultural and Environmental Sciences, Tennessee State University

Victoria Ayres, School of Agriculture, Tennessee Tech University

Jonathan Moon, Department of Poultry Science, Mississippi State University

Jorge Urrutia, Department of Poultry Science, Mississippi State University

Composting, the biological decomposition of organic matter under purposefully controlled conditions, is the most widespread method used to manage normal daily mortalities on commercial poultry farms. Composting is a safe and efficient disposal method if the proper procedure and timeline are followed.

To use composting successfully for daily mortality management, it helps to understand that composting is a natural, aerobic process (meaning oxygen is required) that is carried out by microorganisms that metabolize organic wastes as an energy source for growth, in this case transforming poultry mortality into a stable final product that has added value as a fertilizer and soil amendment. Although this process can be highly effective, attention to management detail is essential for success. Failure to properly manage poultry carcass composting will create odors and flies, attract unwanted scavengers and other vermin to your farm/compost site, and leave you with a material that is not stable in final storage and not suitable to land apply without creating nuisances. Proper mortality compost management is critical in order to avoid nuisance complaints. Successful composting requires following a recipe and the orderly mixing of ingredients for the microorganisms to do their job and completely break down carcasses in a timely and efficient manner.

26 MANAGEMENT - management -

MANAGEMENT

A few pertinent facts

Composting daily poultry mortality on the farm has several advantages, including:

1. Averts the potential for groundwater pollution that, in the past, was associated with burial or the continuous use of open disposal pits;

2. Avoids the high fuel cost and potential air pollution concerns associated with incineration; and

3. Prevents potential disease transfer caused by moving poultry carcasses off the farm.

In recent decades, across the country, the number of farms has significantly decreased. This is true in the poultry sector as well as other agricultural enterprises. The farms that remain have significantly increased in size. Many integrated commercial broiler farms today have six to eight or perhaps even more production houses on a single farm, whereas a generation ago two to four houses were common. In addition, the size of individual production houses has increased substantially versus a generation ago. The increase in the production capacity of commercial poultry farms means more normal daily mortality must be managed, often in a smaller geographic area.

While normal daily mortality losses are small, they are continuous throughout the flock grow-out cycle. Therefore, dead bird disposal is an essential daily management chore. Composting these daily mortalities is cost-effective, environmentally sound and a biosecure management technique that also produces a valuable and useful soil amendment. However, there are requirements and specific procedures to consider for the composting process to be successful.

Compost recipe

Creating good compost of any kind is like baking a cake; a specific recipe must be followed, otherwise the end product will not have the desired characteristics, including notably a lack of offensive odors. In mortality composting, this recipe is designed to accommodate and allow the microorganisms that break down carcasses to flourish. These microorganisms require carbon, nitrogen, oxygen and moisture in the proper proportion to efficiently degrade carcasses. Any ingredient lacking or in excess will slow down decomposition and microbial growth, resulting in inadequate heat production and a generally poor com -

posting environment. Generally speaking, the recipe is to add twice the volume of a bulking material to carcasses; this bulking material can be recently de-caked litter and/or a largely carbonaceous bedding material such as wood shavings/chips. This recipe/mixture provides the ideal carbon to nitrogen (C:N) ratio that compost microorganism need to grow rapidly. Critically, the added bulking/carbon materials provide voids through which air can flow to the microorganism degrading the carcasses. Because the degradation process produces heat, continuous airflow occurs through the compost material as hot air rises and induces a draft that draws in replacement air through the compost materials.

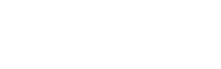

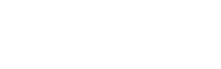

This recipe is fixed regardless of the method used to compost poultry mortalities. In the past, bin composters (Figure 1) that included primary and secondary bins were a popular mortality management methodology. More recently, alleyway composters (Figure 2) have become a popular choice because they ease material handling. In-vessel rotary drum composters (Figure 3) are the newest method to compost poultry mortalities and can significantly increase efficiency and decrease the time required to produce a high-quality compost end product.

Factors affecting mortality composting

Although the recipe is relatively simply, it is important to consider that the composting process is directly affected by several critical factors, including:

• Moisture: 50-60%, when squeezed into a ball compost holds shape; very little free water.

• C:N ratio: 25-30:1, about a 2:1 volumetric ratio of bulking/carbon material to mortality

• Temperature: Should peak between 130-150 °F.

• Oxygen: Voids are required to promote airflow, refreshed with mixing/turning.

27 - february 2024 -

Figure 1, 2 and 3 Static-bin composter (1), alleyway composter (2) and in-vessel rotary drum composter (3).

• Amendment particle size: Avoid old, finely divided litter which will inhibit air flow.

• Pile surface area: Large piles have a low surface area promoting poor airflow.

• Microbial population and activity level: Heating (temperature) is the key indicator.

• Mortality size: Large birds require more carbon and decomposition time.

If the recipe is followed correctly, the correct carbon-to-nitrogen ratio (C:N) is achieved, but the moisture content and oxygen level in particular must still be managed carefully, otherwise the composting process will work inefficiently as indicated by lower than expected temperatures (<110-120 °F). Improper compost management is an environmental concern because the end product that is land applied is capable of spreading disease and causing nuisances as a result of soft carcass tissue decomposition. On the other hand, high temperatures, which are achieved with the right compost recipe and good management, will kill disease organisms and fully decompose 100% of soft carcass tissues. Temperature of 122 °F maintained for 24 hours, or equivalently a temperature of 142 °F for 1 hour (both achieved throughout a compost pile), is required to kill pathogenic bacteria, viruses, and insect and worm larva. The right recipe and proper compost management, which result in these high temperatures, will not attract scavengers, flies, or vermin that dig into the compost material and drag potentially diseased partially degraded carcasses onto neighboring property. Without proper heating, flies and malodors are sure to be issue that results in neighbor complaints.

While all the factors are ultimately critical to produce a high-quality end product, the moisture content is likely the most important factor. The moisture level primarily controls whether the compost process occurs under aerobic or anaerobic (without oxygen) conditions. A moisture content in the 50-60% range work wells. Composting slows significantly at a moisture content less than 40% (when squeezed into a ball, the material readily falls back apart). Anaerobic conditions, which are indicated by noxious odors, generally occurs at a moisture content greater than 70% (when squeezed into a ball, free water is readily released).

The C:N ratio is also critical to the composting process because it affects biological activity of the microorganisms. A C:N ratio of 25-30:1 works best. Nitrogen will be lost as volatilized ammonia if the C:N ratio drops well below 25:1, a process that reduces the compost fertilizer value and results in noxious odors and neighbor complaints and even lawsuits if not resolved. Table 1 lists common bulking agents and their C:N ratios. Note that the wood products tend to work best as carbon sources because of their high C:N ratios. However, de-caked litter is often used successfully as a bulking agent, particularly in combination (50:50 volumetric ratio) with carbon materials. In any case, older and drier litter should not be used in mortality composters. For reference in examining Table 1, a broiler carcass has a C:N ratio of approximately 5:1.

Generally speaking, it is better to add more bulking material or carbon material than you think you need — do not skimp on the bulking/carbon material. This seems like a simple enough process to manage, that is, adding enough bulking/carbon material, but is more difficult than one might think. Birds are constantly increasing in size each day and therefore, adjustments to the amount of bulking material must continually be made to balance for this size increase. While a low 1:1 ratio of bulking material to mortality may work for one-week-old chicks, it can take a 5:1 ratio (or more) for large market-age birds. Extra bulking/carbon material is needed for large birds to absorb the moisture in the daily mortality losses. While week-old baby chicks will release very little water per bird as they degrade, each eight-pound market-age broiler can release ¾ of a gallon of water. Therefore, growers must constantly adjust bulking material amendment rates not only to fluctuations in daily mortality losses (5 birds vs. 25 birds per day), but also for individual bird size (baby chicks vs. market-age birds). With practice, com -

28 MANAGEMENT - management -

Source C:N ratio Softwood shavings 641:1 Hardwood chips 560:1 Sawdust 442:1 Wheat straw 127:1 Rice hulls 121:1 Straw (general) 80:1 Corn stalks 67:1 Finished compost 40:1 Horse manure 35:1 Hay (general) 24:1 Cattle manure 19:1

litter 12:1

Broiler

Table 1 - Common composting bulking agents and their C:N ratios.

posting is a process that anyone can learn to manage so long as you carefully observe and react to temperature, odors and the presence of noxious leachate, for example

One thing to keep in mind is that composting is a somewhat forgiving process. If you mess it up, given a little time, you can fix it. For example, if your mortality compost gets too wet, say, due to wind-blown rain, you can mix in some additional dryer bulking material to absorb the excess moisture and the process will go back to working again. If the material gets too dry in summer, adding the right amount of water to bring the moisture content back into the 50-60% range will result in improved composting you can easily measure as a temperature increase. Note that while it is possible for the compost to become too dry, most growers that fail with composting poultry mortality fail because the material gets too wet . Excessively wet compost is usually caused by not using enough carbon material to soak up the fluids released from decomposing carcasses or because proper layering for mortality in compost bins (see below) is not followed.

One common mistake that leads to excessively wet compost is to place mortalities into compost bins in a layer that is too thick. This effort to try to improve the space efficiency of composting results in a very low C:N ratio and poor air flow, which in turn adversely affects the activity of the microbial population degrading the carcasses.

Composter management

Bin and alleyway composters require similar management practices. Each consists of one or more bins of various size constructed of treated lumber set on a concrete

slab with a roof overhead. The slab prevents the compost material and any draining fluids (known as leachate) from seeping into soil or groundwater. The walls keep the compost contained. The roof protects the material from precipitation. For each of these types of composters, ingredients should be layered as illustrated in Figures 4 and 5 below. Failure to do so will result in only partial composting and yield a product that is not suitable for land application. The steps to successful composting in bins and alleyway composters include:

• First, begin a new mortality compost cycle by placing an initial 12-inch layer of de-cake or fresh cleanout liter or carbon material on the concrete slab floor. Litter will supply bacteria to start the composting process, will help absorb carcass fluids or excess water that may be added to the composter by wind-blown rainfall, provides voids through which air can flow to the carcasses as they are being degraded, and insulates the compost material from excessive heat loss through the concrete floor.

• Do not dump mortalities into a compost bin in a heap! Rather, add a single bird thick layer of carcasses arranged side by side, touching each other. Place carcasses no closer than six inches to the walls of the compost bin because heat loss from the composting material is high where it touches the walls. Carcasses placed too near the walls will not compost as rapidly because of the lower temperatures near the walls; this can cause noxious fluids (leachate) to seep from the compost bin.

• Do not skimp on the carbon material, which can be litter, carbon bedding material or a mixture of litter and carbon material. This layer should be twice as thick as the layer of carcasses underneath. If only a partial layer of birds is placed for that day’s mortali-

29 - february 2024 -

MANAGEMENT

MADE IN ITALY WEB R www.valli-italy.com quality you can depend on Area Baby Area Bellavita Castello Casa Piramide Plus Vita VLV Plus Via Cimatti, 2 47010 GALEATA FC -ITALY ALTERNATIVE SYSTEMS

Figure 4 - Bin composting diagram. Side view of mortality and bulking/carbon material layers in a compost bin. The bin is 6-7 feet wide and 5-6 feet high. The bin sets on a concrete slab which eliminates vermin burrowing. A 12-inch layer of litter/carbon source is placed on top of the slab to begin composting. Single bird thick layers are then alternated with 6-8 inches of litter and/ or carbon material. Finally, a 12-inch cap of litter is placed on the final layer of birds. Note that there is 6-8 inches of space between the bird carcasses and the bin sidewalls on all four sides.

ty, all the birds must be adequately covered when they are placed, otherwise you will create a prolific breeding ground for flies. The rest of the layer can be used for mortality in the coming days. To emphasize these points again, you cannot dump a front-end loader bucket of dead birds into the composter and cover them with just enough bulking material so that they are out of sight. This will not work, it is not composting, and it will not produce a suitable product for land application

• Continue to add subsequent single bird layers of carcasses and litter/carbon source until reaching a height of 5 to 6 feet. A stacking height of 5 to 6 feet, with adequate porosity and moisture is not a fire hazard. However, excessive height can induce compost temperatures that exceed 170 °F and increase the chance of spontaneous combustion and a shed fire.

• Cap the final layer of birds with a layer of 12 inches of litter/carbon source. This final cap is critical to retain heat and moisture and avoid attracting flies.

• It is important to measure compost temperature regularly because it is an excellent method to gauge performance and detect recipe and management problems early on, when they can be fixed. It takes just a few minutes, and you only need two things: a 3- foot-long compost thermometer and a clipboard to record data. Record the temperature of your compost bins frequently, ideally twice a week. For alley way composters, record temperatures along the length of the alleyway as

Figure 5 - Alleyway composting diagram. Side view diagram of an alleyway composter. Width is usually 12-18 feet with a wall height that should not exceed 5-6 feet. The bin sits on a concrete slab to prevent burrowing vermin. Leave 6-8 inches of space between bird carcasses and the alleyway back and sidewalls

it is filled with compost.

• When you observe a temperature decline below 120 °F in your newly formed compost pile (generally after 2-4 weeks), you must then rotate the material to a new bin. This newly mixed material should be covered immediately with 8-12 inches of fresh litter or carbon-based bulking material to avoid excessive heat and moisture loss and to avoid attracting vermin and flies. This process of mixing the compost materials adds oxygen to reinvigorate aerobic decomposition of all the carcass soft tissue. Turing the compost at least once is critical to make sure pathogen destruction occurs throughout all the compost materials. Approximately 4-6 weeks after turning, the compost should be inspected to verify soft tissue has been consumed (ideally any remaining bones will be soft). If necessary, the compost can be returned to provide an improved end product.

In-vessel rotary drum composters

The process of turning mortality compost is automated with rotary drum composters, but these devices still require a similar ingredient recipe as traditional bin and alleyway composters.

Because the turning process occurs daily or perhaps multiple times daily, and the drums use controlled forced aeration from blowers, oxygen easily infuses throughout the compost materials near continuously which greatly speeds up the composting process. A nice feature of these devices is that they have built-in thermometers

30 MANAGEMENT - management -

MANAGEMENT

used to control the mixing and aeration process and which allow you to constantly monitor the temperature of the material inside the drum. The drums also greatly reduce the ill effects of weather on the composting process because the product is contained inside the drum. This protects the compost from blowing rainfall and cold winds which can increase heat loss. The drums are also more aesthetically pleasing than a bin or alleyway composter, enhancing public perception of the task of composting dead birds. Public acceptance of agricultural practices is increasingly important today. Every commercial poultry farming operation needs to recognize this and take public perception of on-farm mortality management seriously.

Diagnosing morality compost problems

Even with good management, you can expect problems and difficulties to arise. These problems will be most evident in the temperature data you collect, which will show poor or very slow heating performance. Use Table 2 below to categorize and correct these problems and get your mortality compost system back to working efficiently.

Summary

Composting is the most common method of managing daily poultry mortality losses on commercial farms, and the process works well when it is managed properly. Commercial poultry producers should view mortality composting as a value-added process that produces a beneficial product. This realization justifies the daily attention and invested management time the process requires. Composting is a recipe, a properly proportioned mixture of poultry mortality and a bulking agent or carbon source to achieve the correct C:N ratio, which then requires oxygen and right amount of moisture to turn large quantities of instable organic matter, in this case dead birds, into an inoffensive and useful soil amendment in a short period of time. Mortality compost must be properly managed, otherwise bad odors, flies, scavenging and vermin will plague you as well as your neighbors. These problems can be easily avoided by monitoring compost temperatures and using the troubleshooting guide in Table 2. Following the composting recipe and attention to detail on a daily basis will ensure that your finished compost product is safe, free of disease pathogens and suitable for land application as a valuable soil amendment.

Problem/symptom Potential cause Correction

Improper temperature Too dry

Too wet

Low C:N ratio

Improper layering of ingredients

High heat loss

Failure to decompose

Low C:N ratio

Carcasses layered too thickly

Carcasses at outside edges

Bad odors Too wet

Low C:N ratio

Inadequate cover over carcasses

Inadequate cover over carcasses

Add water

Add bulking material and turn pile

Increase bulking/carbon material amendment rate

Layer birds in single bird thick layers covered with adequate bulking material (see Figure 3 and 4).

Ensure adequate bulking material is used for cover and base

Increase bulking/carbon material amendment rate

Carcasses must be placed in a single bird thick layer

Maintain 6-10” between carcasses and edges

Add bulking material and turn

Increase bulking/carbon material amendment rate

Cover every layer of carcasses promptly with 12 inches of bulking material

Cover every layer of carcasses promptly with 12 inches of bulking material

Too wet

Failure to reach proper temperature

Scavenging animals

Inadequate cover over carcasses, inadequate final cover

Add bulking material, turn pile, cover pile with 12 inches of carbon material; avoid leaching from pile, cover leachate with carbon bulking agent promptly if this occurs

Assess C:N ratio and layer management

Place 12 inches of bulking material cover promptly over fresh mortalities layers. Avoid initial entry with a fence, barrier or cover where vultures are a problem.

By courtesy of The University of Tennessee Institute of Agriculture and UT Extension

31 - february 2024 -

Flies

Table 2 - Troubleshooting guide for carcass composting

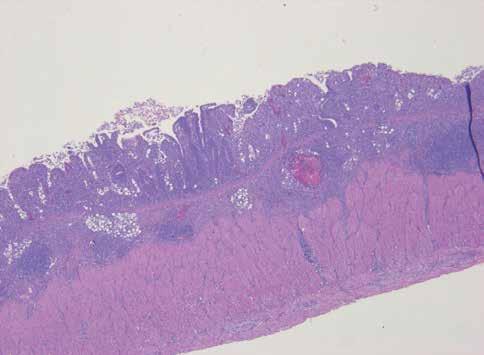

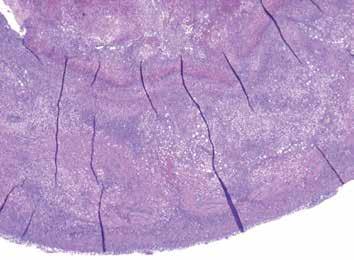

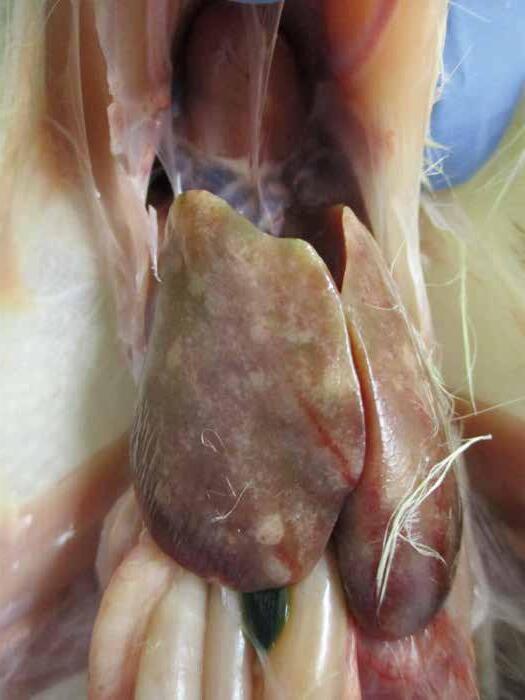

A.M. Villegas1,2, N. Yacoubi3, A. Menconi2 and T.J. Applegate1

1 Department of Poultry Science, University of Georgia, Athens, GA 30602, USA

2 Evonik Corporation / Nutrition & Care, Kennesaw, GA, 30144, USA

3 Evonik Operation GmbH / Nutrition & Care 63457 Hanau, Germany

Effects of commercial processing conditions of extruded soybean on growth performance and amino acids digestibility of broiler chickens

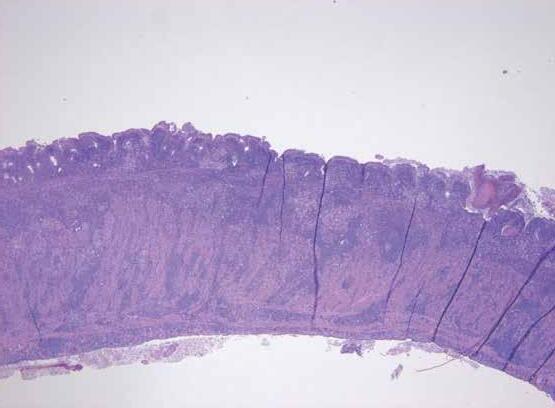

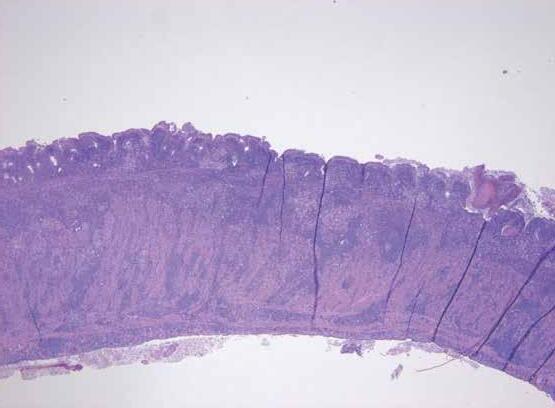

Coccidiosis is a disease with substantial economic impact, particularly due to the push to ban anticoccidials. Vaccines are available but can be expensive, and are often implemented for free range and breeder flocks only. Thus, it is imperative to find effective nutritional alternatives to reduce the impact of coccidiosis on broiler chickens.

A total of 1,860 male Cobb 500 broiler chicks were randomly allocated to the 3 different treatments with 10 replicate floor pens (62 birds/pen) from 0 to 35 d of age. The 3 expeller SB batches were processed with different extruder temperatures of 182, 199, and

154 °C for normal-control (NC), overcooked (OC), and undercooked (UC) SB, respectively. Performance parameters, body weight gain (BWG), feed intake (FI), and feed-togain ratio (FCR) were recorded on d 0, 14, 28, and 35. Intestinal integrity was assessed

32 NUTRITION - nutrition -

in one bird per pen by determining serum fluorescein isothiocyanate- dextran (FITC-d; 4 kD) concentrations for gut permeability at d 16. The relative weights of the right pectoralis major (RPM) were determined at 35 d of age. Intestinal permeability increased in birds fed the OC SBM (P<0.05). On d 14, 28, and 35, birds given the OC SBM diet had the lowest BWG and FI and the highest FCR, as well as the smallest RPM (P<0.05). Both OC and UC expeller SB reduced the mean apparent ileal digestibility (AID) of all non-essential and essential amino acids at d 14 (P<0.05) by 3.8% and 3.2%, respectively. The AID of Lys was 7% lower (P<0.05) in birds fed the OC SBM batch compared to the NC treatment at d 14 and 28. The adverse effects of OC expeller SB on BWG were driven by digestible amino acid (AA) intake, which was lower (P<0.05) for Lys, Met+Cys, and Thr in the OC treatment compared to the NC and the UC treatment groups. In conclusion, these results showed that inappropriate SB processing can lead to a lower AA digestibility resulting in lower growth performance and economic losses. Extruded soybean results from mechanical extraction of oil from soybeans (SB). During processing, soybeans are exposed to heat treatment to remove antinutritional factors and to increase the nutritional value of extruder SB for optimal bird growth performance. Variations in SB processing conditions, such as moisture, drying time, and toasting and drying temperature, lead to variability in the trypsin inhibitors (TI) amount ingested by poultry between SB batches.

Introduction