Biosecurity, before the beginning…

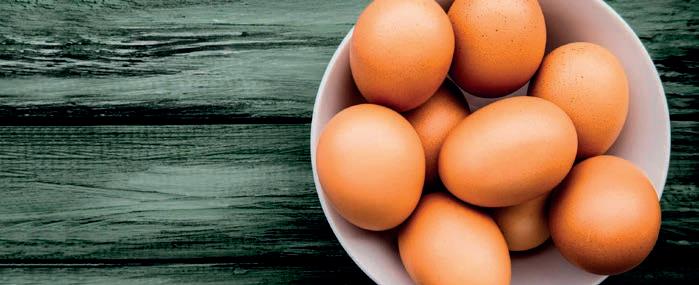

Adding a macroalgae blend to commercial laying hen diets improves egg quality and body weight gain

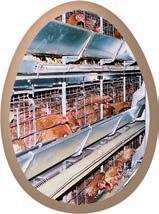

Broiler processing, product quality, and yield

2023

2

Zootecnica International –February 2023 –POSTE ITALIANE Spa –Spedizione in Abbonamento Postale 70%, Firenze

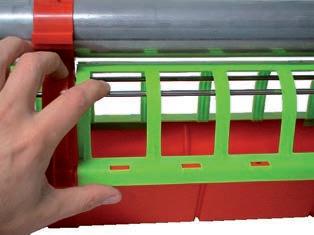

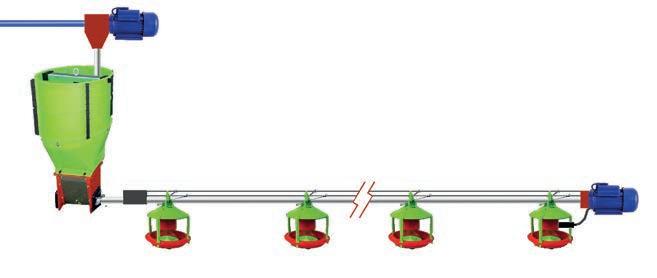

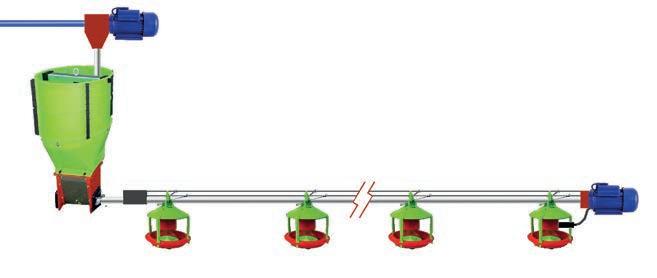

The new feeders of the «Gió» range,

specifically developed for great poultry farms, thanks to the easiness in the regulation of the feed and to the absence of grill (that avoid chicks perching) have many advantages: they are easy to use and their cleaning is extremely easy and fast too, leading to an overall reduction in labour costs.

CODAF Poultry Equipment Manufacturers • Via Cavour, 74/76 • 25010 Isorella (Brescia), ITALY Tel. +39 030 9958156 • Fax: +39 030 9952810 • info@codaf.net • www.codaf.net

for the rearing phase (first 30 days of life)

for the growing phase (no anti-waste ring)

EDITORIAL

“The old year has passed” is the title of a beautiful chorale by Johann Sebastian Bach. The melody is very sweet, nostalgic, and auspicious. 2022 was a storm of painful events, wars, massacres of women and children, weather and nature upheavals, collapse of entire countries due to landslides. In history tragic events have been repeated cyclically but, perhaps never as in recent decades, have we perceived the risks that we will face in the not too distant future, if measures are not taken.

We know that over ten billion people will soon inhabit the earth and that climate change will lead to a sharp increase in the desertification of once arable areas. Even water will become increasingly scarce if adequate and low-cost seawater desalination plants are not built. Undoubtedly, thanks to technology, we will solve many problems by replacing fossil fuels but, however, use of fossil fuels is not the only cause of climate change.

We need a global shared vision incorporating exchanges between climatologists and scientists. Above all, peace is needed along with the recovery of that humanity that we are losing. The recent disappearance of some significant characters in our post-modern era has been a reason for reflection on the subject of the recovery of humanity.

A few examples from some of those lives would be enough to induce us to be more confident. Pope Benedict XVI, emeritus theologian and scholar, not only represents a great model of faith but he also taught us, beyond any religious faith, the importance of one’s independence of thought through study, discipline and respect for others.

Edson Arantes do Nascimento, known as Pelé, was among the best footballers of all times. He taught us style, generosity and fairness. Years ago, he managed to stop a civil war in Nigeria for two days. Gianluca Vialli was also an example of great rectitude, both as a footballer and as a man.

Unfortunately today’s media tend to emphasize matters which cause a stir. We need information to help us swim against this tide and to help us stimulate real and constructive criticism. There are many young and old who are dedicated to volunteering; there are many cultural associations that deal with social issues, art and music.

Infinite sources could be cited to demonstrate what is being done to recover lost values. We should occupy much more of our time dealing with these realities.

for breeding

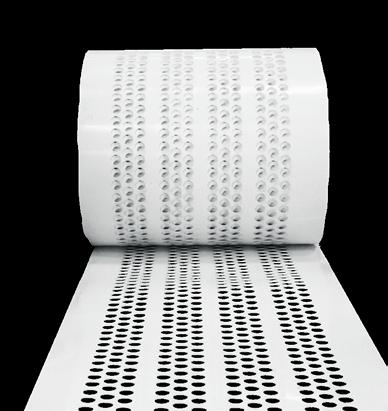

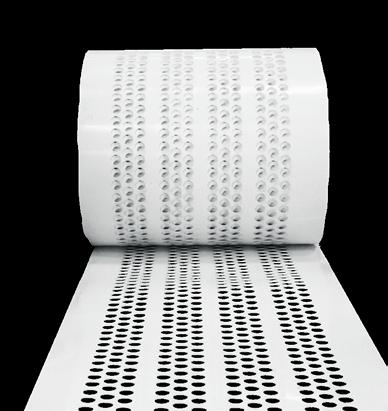

PP Belts

• Egg collection

• Manure drying system

• Manure belt collection

• PP woven egg belts

• PP hole egg belts

4002 H

• 360 degrees opening

• Highly strong and durable material

• “SOFT” action

4626

• Suitable for fattening turkeys

• Perfectly dry bedding

• Simultaneous watering of 2 and more animals

4006 H

• 360 degrees opening

• Highly strong and durable material

• “EXTRASOFT” action

4901 N

• Essential design

• No chicks in the pan!

• Regulation of minimun and maximum feed level

• Available in caged broilers version

Pressure regulator with bypass

INFINITY

CORTI ZOOTECNICI

ARTICLES ACCESSORIES

Corti Zootecnici Srl | Via Volta, 4 21020 Monvalle (VA) Italy| www.cortizootecnici.it |

SUMMARY WORLDWIDE NEWS 4 COMPANY NEWS 10 DOSSIER Biosecurity, before the beginning… 12 FOCUS Cleaning and disinfection of feeding equipment 16 MARKETING Patterns and dynamics of global turkey meat production and trade Part 1 – Turkey meat production 20 TECHNICAL COLUMN A quick breeder farm visit 26 MANAGEMENT Adding a macroalgae blend to commercial laying hen diets improves egg quality and body weight gain 28 NUTRITION Validation of the nutritional matrix of a multienzyme complex through performance and digestibility improvement .................................................... 34 Effects of stimbiotic on performance and intestinal barrier function in broilers challenged with a necrotic enteritis 38 PROCESSING Broiler processing, product quality, and yield 42 MARKET GUIDE 44 UPCOMING EVENTS 47 INTERNET GUIDE 48 42 12 28

Eastern Shore air monitoring effort shows little variation between poultry areas, urban regions

An innovative, partnership-led ambient air quality monitoring project in Maryland has recorded more than two years of data about ammonia and particulate matter air emissions on the Eastern Shore, and has shown little variation in average air pollution levels between areas with no chicken farms, areas with a low density of poultry farms, and areas with many poultry farms.

The Lower Eastern Shore Air Monitoring Project, overseen by the Maryland Department of the Environment (MDE), began collecting continuous data about ammonia, fine particulate matter (PM 2.5), and coarse particulate matter (PM 10) in April 2020 at locations in Princess Anne (designated a low poultry operation density site), Pocomoke City (designated a high poultry operation density site), and an urban Maryland location not on the Eastern Shore with no nearby poultry operations. Delmarva Chicken Association (DCA) and the Keith Campbell Foundation for the Environment jointly supported the effort with more than $500,000 in funds. MDE, along with the University of Maryland Eastern Shore is responsible for collecting and publishing the data gathered by the project, which is ongoing.

The data for the life of the project to date shows average ammonia (NH3) levels for the urban site to be at 1.6% of a MDE-designated 350 parts per billion concern threshold; 1.3% of the threshold level in Princess Anne (lower than in the urban area); and 2.9% of the threshold in Pocomoke City.

Source: Maryland Department of the Environment. Average values for PM 2.5 are based on estimated Design Values calculated with <2 years of data.

The Pocomoke City site, with a high density of poultry operations, saw lower maximum hourly values for each pollutant than the Princess Anne site, with a comparatively lower density of nearby poultry farms. Days when relatively maximum hourly values were recorded in Princess Anne, the low poultry operation density site, coincide with days when commercial fertilizer (which contains nitrogen, the solid form of ammonia) was applied to cropland in the area around the monitoring site. None of the recorded ammonia hourly value spikes at any site have exceeded the 350 parts per billion concern threshold, and the values recorded by MDE during the Lower Eastern Shore Air Monitoring Project are consistent with values recorded throughout the state.

“The nearly 30 months of data recorded and published by the Lower Eastern Shore Air Monitoring Project are valuable to researchers and the public”, said Holly Porter, DCA’s executive director. “We in the chicken community have a shared interest with all Marylanders in better understanding what air quality is truly like on the Eastern Shore and elsewhere in the state.”

Source: Delmarva Chicken Association www.dcachicken.com

4 - worldwide newsWORLDWIDE NEWS

Average Ammonia Average PM 2.5 Urban Area (no poultry operations) 1.6% of MDE threshold 43% of daily NAAQS standard Princess Anne (low poultry density) 1.3% of MDE threshold 44% of daily NAAQS standard Pocomoke City (high poultry density) 2.9% of MDE threshold 40% of daily NAAQS standard

Equal, controlled and immediate distribution throughout the line.

The obstacle-free linear trough feeder allows an easy access for the animals which can easily spot the feed.

WATCH THE VIDEO explaining how the BREEDAZA system works

Manufactured from sturdy light plastic material for easy winching.

Easy cleaning and no residual feed inside the trough.

- february 2023WORLDWIDE NEWS AZA International s.r.l. Via Roma 29 24030 Medolago (BG) Italy Phone (+39) 035 - 901240 - E-mail: info@azainternational.it QUALITY MADE IN ITALY www.azainternational.it BREEDAZA

in pig & poultry equipment

Leader

WANT AZA!

The innovative linear trough feeder I

THE REVOLUTIONARY RATIONING SYSTEM FOR BROILER BREEDERS AND LAYERS

ADJUSTABLE ANTI-COCK GRID NO OBSTACLE INSIDE EASY ACCESS TO FEED

GALVANISED STEEL MODEL

National Chicken Council recently filed comments to USDA

USDA’s Food Safety and Inspection Service (FSIS) on October 17 announced a new Proposed Framework for controlling Salmonella in poultry production along with a virtual public meeting.

“As with FSIS,” NCC’s comments said, “food safety is a top priority for the broiler chicken industry, and we support changes in food safety regulations that are based on sound science, robust data, and are demonstrated to positively impact public health. For years the industry has implemented a multi-hurdle approach focused on the continual reduction of Salmonella from farm to fork –implementing robust vaccination, biosecurity, sanitation, and other effective measures.

“While NCC appreciates FSIS’s interest in thinking creatively about food safety issues, the Proposed Framework is not the right approach,” NCC’s comments said.

“First, the Framework appears premised on legally infirm conclusions that Salmonella may be considered an adulterant in raw poultry and that FSIS can mandate on-farm activities,” the comments continued. “Second, the Framework is presented nearly devoid of data, and it lacks the specifics as to how the Agency plans to implement and enforce the proposed changes.”

In addition to the meeting, which provided very limited stakeholder feedback on the wide-ranging proposal, the Agency also made public a comment docket for stakeholders. The Proposed Framework primarily consists of three components that FSIS views as a “comprehensive approach to controlling Salmonella in poultry,” namely:

• requiring that incoming flocks be tested for Salmonella before entering an establishment;

• enhancing establishment process control monitoring and FSIS verification; and

• implementing an enforceable final product standard.

NCC’s comments outlined the enormously successful efforts the industry has made in driving down Salmonella rates in recent years in conjunction with significantly tightened existing Salmonella performance standards, a new scientifically driven modernized poultry inspection system, and numerous new interventions to control Salmonella

There appears to be a “significant misunderstanding about how the broiler industry operates, the industry’s supply chain structure, and current industry practices regarding the control of Salmonella,” the comments said of the Framework.

However, “as written,” the comments concluded, “the Proposed Framework threatens the economic viability of the entire poultry sector and threatens negative impacts on family farmers, company employees, and consumers. It would have negative impacts on both the availability of chicken and the cost of chicken to consumers of U.S. chicken around the world.”

Source: National Chicken Council

6 - worldwide newsWORLDWIDE

NEWS

Aviagen Advantage Innovations

The broiler breeding innovator. Market leader in research and development. Cutting-edge progress in performance, welfare and sustainability. Our innovations will strengthen your success. Let us show you at aviagen.com.

AVEC announces the launch of its first Sustainability Charter

the key attributes leading to the best balance between the 3 pillars of sustainability (Environment, Social and Economy) and guaranteeing the resilience of the sector in the future. The key will be to find a point of equilibrium between the pillars, and not to have an improvement on only one pillar with indirect negative consequences on the other pillars.

form of a list of ambitions put forward by the sector on the following areas of priority: Environmental impact, Packaging, Animal welfare and Use of antibiotics.

This Char ter symbolizes the commitment of the European broiler meat sector to a more sustainable future.

OUR ROADMAP TO A SUSTAINABLE FUTURE FOR THE EUROPEAN POULTRY MEAT SECTOR

The AVEC Sustainability Char ter aims to provide a clear roadmap on

At a time where food security has come back as a major preoccupation in the EU and in the world, following the war in Ukraine, AVEC members are committing to maintain a sufficient level of production to feed the EU and the world population with qualitative and affordable broiler meat. The AVEC Char ter takes the

The AVEC Char ter aims at paving the way for continuous improvement. The journey to sustainability and resilience in each EU country is different and must be considered and respected. It is designed to evolve across the years and amongst AVEC’s members. In parallel, AVEC invited its members to translate and adapt the Sustainability & Resilience Char ter to their national strategy towards sustainability.

Source: AVEC

Zoonotic diseases and foodborne outbreaks on the rise, but still below pre-pandemic levels

In 2021 there was an overall increase in reported cases of zoonotic diseases and foodborne outbreaks compared to the previous year, but levels are still well below those of the pre-pandemic years, reveals the latest annual EU One Health zoonosis report released by EFSA and ECDC.

The general drop compared to prepandemic years in reported cases and outbreaks is probably linked to Covid-19 control measures, which were still in place in 2021. Among the few exceptions are the number of cases for yersiniosis and those of foodborne listeriosis outbreaks, which exceeded pre-pandemic levels. The most frequent cause of foodborne outbreaks was Salmonella, which accounted for 19.3% (773) of

the total. Foodborne outbreaks differ from overall reported disease cases in that they are events in which at least two people contract the same illness from the same contaminated food. The most common sources of salmonellosis outbreaks were eggs, egg products, and “mixed foods”, which are meals composed of various ingredients. The number of outbreaks caused by Listeria monocytogenes (23) was the highest ever reported. This might be linked to the increased use of whole genome sequencing techniques, which allow scientists to better detect and define outbreaks. The report also covers overall reported zoonotic disease cases, which are not necessarily linked to outbreaks. Campylobacteriosis remains the most frequently reported

zoonosis, with the number of reported cases increasing to 127,840 compared to 120,946 in 2020. Meat from chicken and turkeys was the most common source. Salmonellosis was the second most reported zoonotic disease, affecting 60,050 people compared to 52,702 in 2020.

The next commonly reported diseases were yersiniosis (6,789 cases), infections caused by Shigatoxinproducing E. coli (6,084 cases), and listeriosis (2,183 cases).The report also includes data on Mycobacterium bovis/caprae, Brucella, Trichinella, Echinococcus, Toxoplasma gondii, rabies, Q fever, West Nile virus infections and tularaemia.

Source: EFSA

8 - worldwide newsWORLDWIDE NEWS

SUSTAINABILITY

CHARTER SUSTAINABILITY CHARTER

Britain: Salmonella detection in laying hens

As part of the measures to reduce the prevalence of Salmonella in poultry in the UK, National Control Programmes (NCPs) have been implemented. These involve regular statutory testing of poultry holdings to monitor and estimate the prevalence of Salmonella in the national flock population and to control Salmonella on holdings with positive flocks, especially those serovars most identified with human illness: Salmonella Enteritidis (SE) and S. Typhimurium (ST).

The aim of a new study published in “Zoonoses and Public Health” was to estimate the sensitivity of both the Operator and Competent Author-

ity (CA) Official sampling used to detect infected flocks, and to also estimate the true proportion of infected holdings of commercial laying flocks in GB each year of the NCP, along with the trend of any changes in prevalence for both SE/ST and non-SE/ST. Results indicated a very low sensitivity of Operator sampling (~9%), but a much higher sensitivity of CA Official sampling (~44%). Sensitivity of Operator sampling is very low compared to Competent Authority (CA) Official sampling, suggesting that such sampling is relatively ineffective at identifying infected flocks on a single sampling, meaning that the true number of infected flocks is higher than the

number of positive flocks. The true prevalence of Salmonella infected holdings in the UK had a mean average reduction of 10.6% per annum and 15.9% annual reduction for SE/ ST. This has shown the effectiveness of the NCP for Salmonella in commercial laying flocks, with reductions in Salmonella overall more or less equal to the target reduction for regulated serovars of 10% per annum. The true prevalence of SE/ ST was estimated to be below the final target of less than 2% in every year and was below 0.5% at the end of the 10 year period.

- february 2023 - 9 WORLDWIDE NEWS

!lanigirO Per ulteriori informazioni visitate il sito www.lubingsystem.com O scrivete una mail a info@lubing.it

Source: Poultrymed by Nati Elkin

Hybrid Turkeys publishes new European nutrition guidelines

The nutritional guidelines provided by Hybrid Turkeys are essential to ensure optimal performance. Therefore, these guidelines have been updated to meet the needs of the new medium and heavy strains designed for the European market.

The update of these guides pertain to the EMEA zone (Europe, Middle East, and Africa). In 2023 Hybrid Turkeys will finalize the update to the guides for the North American zone. The launch of separate guidelines, based on geographic region, is designed to take into account the unique raw materials used in each zone, the differences in management, and offer different formulations to meet the needs of each customer. In the current economic context, the increase in feed costs due to inflation on the price of raw materials and energy impacts the profitability of all, so these new specification propose a reduction in feed costs without impacting performance.

Commercial turkey nutrition updates

Hybrid Turkeys has established customized ranges for nutrition guidelines, low, medium and high energy diets

The medium energy guideline corresponds to the ideal recommendations, offering customers a more moderate cost, while optimizing performance.

The customized low or high energy ranges are designed to meet varying needs according to the context of each customer. In addition to these new guidelines, various nutrition trials are underway to measure the performance associated with the new Grade MakerEVO and ConverterNOVO strains.

Turkey breeder nutrition updates

The new breeder nutrition guidelines cover both the rearing and the production (laying) phases and include different recommendations based on heavy versus medium strains of turkeys. In the rearing guidelines, the ‘Holding

10 - company newsCOMPANY NEWS

2’ phase is intended to be used if the weight of the flock is below the standard. The goal is to maintain the weight of our animals at the expected level as early as possible in order to improve the laying performance. Similar to the commercial nutrition guidelines, reducing costs and maximizing performance are key components of the changes made. The overall levels of crude protein and amino acids have been reviewed in order to help our animals reach our standard as simply and efficiently as possible.

An important change to the ‘Production’ guidelines is the ‘Female Layer 3’ diet. This diet was added to address the unique needs during the summer period (+30 °C) to ensure optimized performance.

The objective of the updates are to improve feed conversion, while reducing calcium and phosphorus levels. In addition to the cost savings of this change, this solution offers the following performance benefits:

• reduction of litter discharge due to the elimination of excess calcium and phosphorus by renal excretion;

• reduction of locomotor problems related to litter degradation;

• improved animal welfare: better digestive health and drier litter;

• improved FCR due to reduced buffering capacity of the gizzard as a result of reduced calcium;

• reduction of phosphate waste and, therefore, reduction of water eutrophication.

In summary, the new Hybrid Turkeys nutritional guides will allows for better overall absorption of nutrients, in particular proteins, while maximizing the health and well-being of the animals. The overall objective of this update is to offer solutions to combat the changing economic context, by reducing the costs of breeding while optimizing performance, thus ensuring everyone can maximize their profitability.

Royal Pas Reform appoints Eric Stodel as new CEO

Royal Pas Reform has appointed Eric Stodel as the company’s new Chief Executive Officer (CEO), effective January 1, 2023.

aerospace, machinery, electronics, consultancy and software sectors –both in the Netherlands and abroad. He has a proven track record of achieving profitable sales growth and innovation-driven business transformations across multiple international markets.

Bart Aangenendt, CEO of Hydratec Industries, the parent company of Royal Pas Reform, says: “I am confident about the future of Royal Pas Reform under Eric’s leadership. There is undoubtedly great potential to further strengthen and expand our position as a supplier of integrated hatchery solutions.”

Stodel (57) brings a wealth of management experience to Royal Pas Reform. He has held a wide variety of senior CEO and COO positions over the past twenty years in the

Commenting on his appointment, Stodel says: “Royal Pas Reform is a wonderful company, which distinguishes itself in the global hatchery market with its highly innovative, integrated solutions. The teams’ impressive wealth of knowledge and experience gives me lots of energy to grow the company even further on the world map and to realize our ambitious development plans.”

Stodel holds a Master of Science degree in Industrial Engineering and Business Administration at the University of Twente, is married and has the Dutch nationality.

- february 2023 - 11 COMPANY NEWS

Dr. Makan Hooshangi (DVM) Veterinarian, Turkey Management Specialist

Biosecurity, before the beginning…

Almost all of us, the poultry people, know what biosecurity is about. For the investors, it means spending lots of money to prevent disasters, and for the employees, it means many difficulties to prevent troubles! Taking showers, changing clothes and boots, cleaning and disinfecting, controlling rodents and insects, limiting entrances to the farm and so many other tasks are examples of measures we have to take to decrease the risk of disease occurrences in farms or to prevent the disease from spreading to the other farms.

There are many academic and linguistic definitions for “biosecurity” and there are also many useful approaches found on the web, but how about the preliminaries such as the whole plan design or the materials used in buildings and equipment? How important are such considerations in influencing the whole procedure of biosecurity in a poultry farm? The fact is that of tentimes simple things which we do not pay enough at tention to have huge effects!

12

DOSSIER - dossier -

©cherkizovo.com

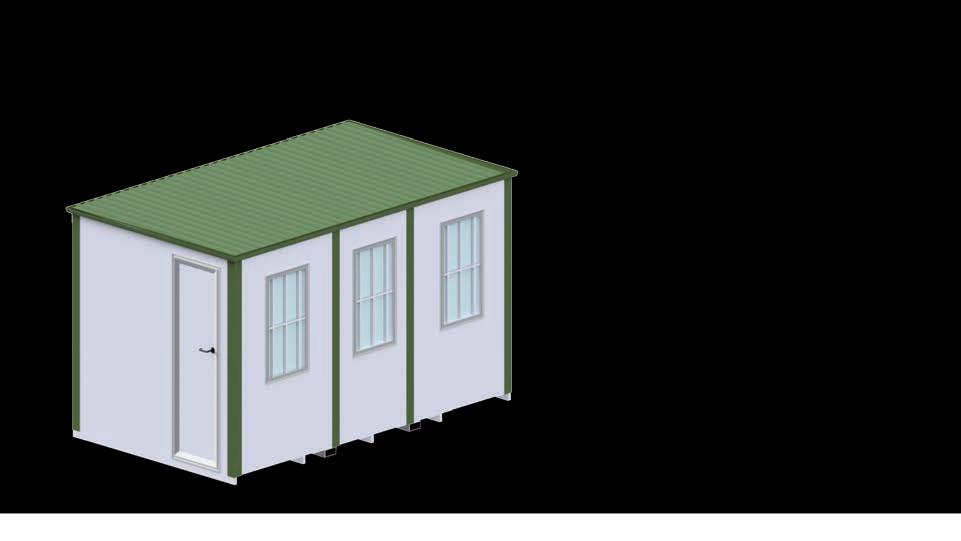

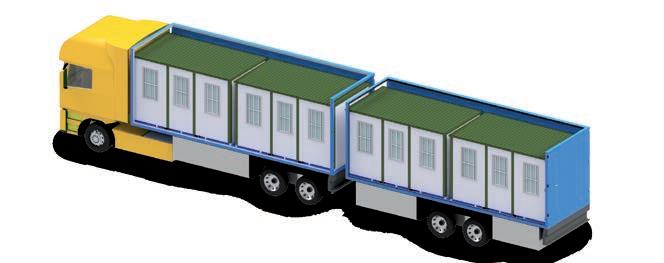

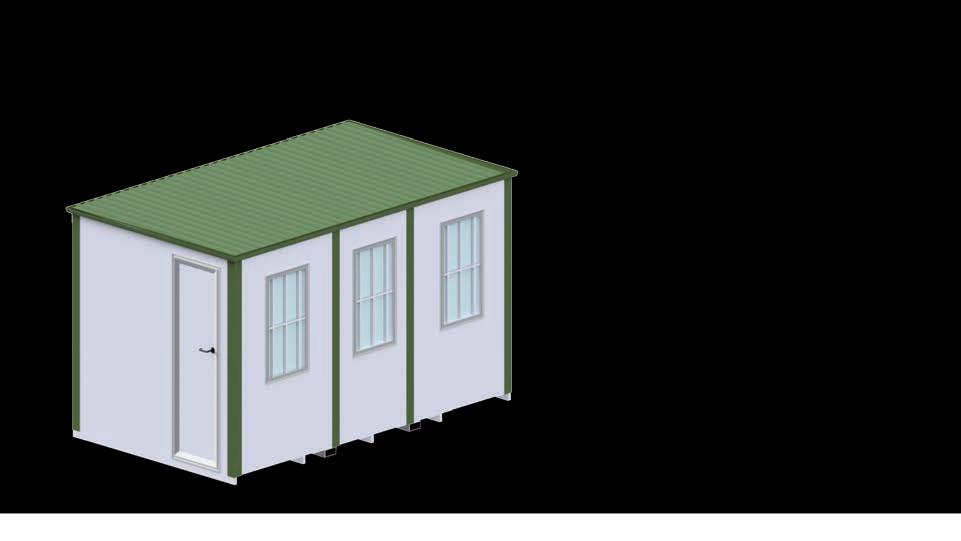

Biosecurity is an expensive practice that starts with the very first steps of establishing a farm or a hatchery

These include the premises’ location considerations including the distance to other farms or high-risk areas, local climate, and the vegetation of the area. As these are the initial requirements of respecting biosecurity regulations, any mistake or miscalculation in these respects will be irreversible! Moreover, the design and the materials of the whole site and the buildings are the next crucial factors for the biosecurity process. Underestimating the importance of these factors will be an expensive mistake and cannot be easily corrected after finishing the constructions, or will not be cost-effective to be corrected. Therefore, it is indispensable that the above considerations be taken seriously prior to the construction phase. The separation of high-risk and low-risk areas in the farm, as the first and second biosecurity zones, the correct design of high-risk access routes (feed trucks, etc.), the houses’ exhaust fans direction, the sewage system, the floor slopes, the isola-

tion type, the surface drainage design, the location and direction of each building and facilities, etc. are issues that must be taken into consideration when designing and constructing poultry sites. In addition, the site should be designed in a way that as far as possible, no CCTV or controlling person be needed for biosecurity watch. Using one-way paths, dividing walls, fixed windows or other similar considerations that can reduce the biosecurity breaches to zero can be easily applied in the designing phase.

13 - february 2023DOSSIER

YOUR CHOICE A RESPONSE ADAPTED TO YOUR SPECIFIC NEEDS OUR COMMITMENT SHARING MORE THAN 55 YEARS OF EXPERIENCE IN PREMIUM BREEDS WORLD LEADER IN SPECIALITY MARKETS! HUBBARD PREMIUM the natural choice! www.hubbardbreeders.com

During construction, it is necessary to carry out regular inspections to ensure correct and precise implementation. Apart from locating, designing, and constructing a farm, one of the most important considerations in biosecurity is the materials used in buildings or in the equipment. On a poultry site, especially in farms and hatcheries, all the surfaces must be washable with the least perforations, seams, joints, or folds. Using wood, PU foam, fabric or glass wool in structures or equipment are mistakes which cannot be corrected easily. None of these materials can be washed or disinfected properly and they will be the causes of continuous disease occurrences in farms, one cycle af ter the other. Usually, correcting such buildings or replacing such equipment is very expensive. On the other hand, continuing the job despite such deficiencies is not cost-effective either. It is an expensive dilemma!

a poultry farm, even seemingly unrelated ones such as engineering tasks be checked and reconsidered by the practical animal science professionals, farm managers, and veterinarians.

The fact is that no practical disinfection can be effective on such surfaces or notches. The microorganisms in organic residues inside wood, PU foam or glass wool, etc. are almost unreachable! That is a big issue in many farms, especially the old ones. So many efforts and resources are wasted because it was not considered before starting the construction or before buying the equipment.

As many businesses, poultry farming is a specialized business, sometimes very complicated, and it needs different professionals to work together to fulfill the needs and comply with the standards, especially biosecurity and hygiene standards. It is crucial for all these professionals to work as a team and look at the job with their different views. However, they must be familiar with the critical points of the job. Mistakes turn into disasters easily and rapidly in this job. All the equipment and facilities are supposed to serve the rearing and growing the birds, so it is important that every single mat ter in

The equipment plays a significant role in complying with the principles of biosecurity in the operating phase. There is a wide range of equipment used in a poultry farm, from clothes and boots to automatic nests and ventilation systems. Equipment helps do the job correctly, quickly, and easily. Without appropriate equipment, the job would be harder, and more energy consuming, so the risk of misperformance would be higher. Almost all equipment used on a poultry site, depending on where they are used, should be washable or cleanable as much as possible. Some equipment such as nests, AI machine, drinkers, feeders, light traps, trolleys, etc. should be washable. Non-washable equipment which are made of fabric, wood, or cardboards, should be changed before the new cycle. Some other equipment such as computers and electronic devices cannot be washed, nor can be changed every cycle. Such equipment must be well-sealed to avoid dust penetration. For cleaning, a high-pressure air pump and a clean tissue or brush can be used. Af ter cleaning, they can either be disinfected by a tissue and disinfecting solution or fumigating by formaldehyde or ozone gas, depending on the type of the equipment and the materials used.

Using smooth and washable materials for equipment is sometimes hard or expensive, but keep that in mind that the damages will be much more expensive. Most of the pathogens are very sensitive to environmental conditions and can be easily neutralized on a clean surface, but in

14 DOSSIER - dossier -

©Makan Hooshangi

©Makan Hooshangi

the presence of organic residues, their resistance would be significantly higher. Moreover, the effectivity of disinfectants significantly decreases in the presence of organic residues. To have an idea, H5N1 virus can live under two weeks at 4 °C outside the host’s body at best, if protected from sunshine and high %RH; but the virus was found to survive up to eight weeks in dry and wet feces at 4 °C. Apart from the materials used in equipment, the design and manufacturing of the equipment are important as any folds or seams can be a hazard in biosecurity of a poultry site. Such areas cannot be easily cleaned and take lots of time and energy to deal with. Usually, the cleaning team does not put enough efforts on these parts and in an optimistic condition, the responsible supervisor would request repetition of the cleaning process. That means wasting lots of time, energy, and money. In spite of all that, they can still be potential hazards.

Indeed, biosecurity can be respected if you really believe in it; if you think about any details of the job, keeping biosecurity principles in your mind. It is not a play or a show to convince people, it is a necessity for our job, black or white, there would be no gray when the time comes. On the other hand, as said, starting from the base upon biosecurity principles will reduce the high costs of biosecurity procedures. The less detergents and disinfectants are used, the less environmental damage is caused, the more money is saved, and the more money is gained! Work wise!

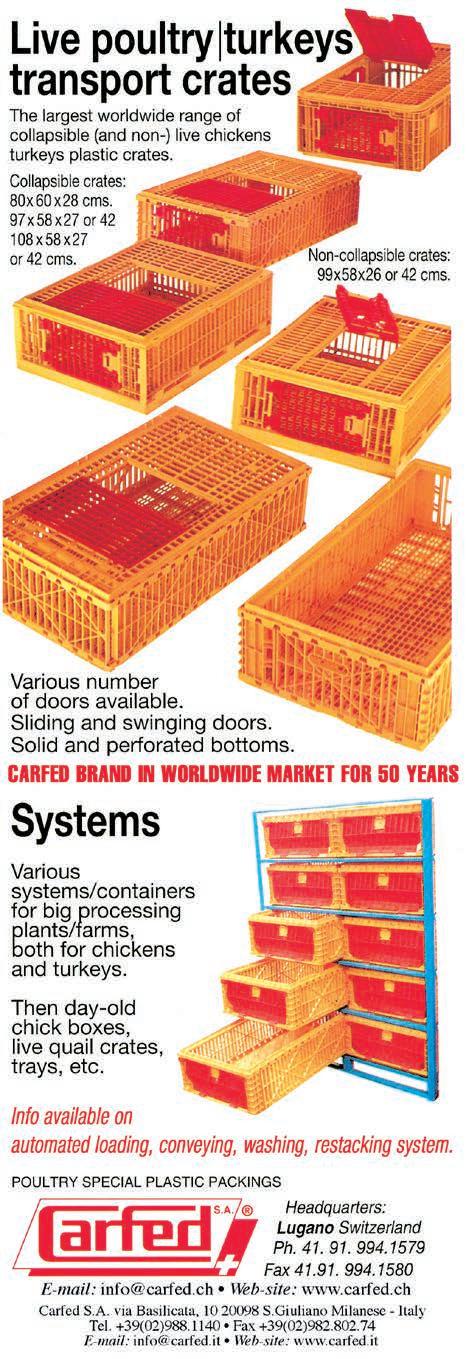

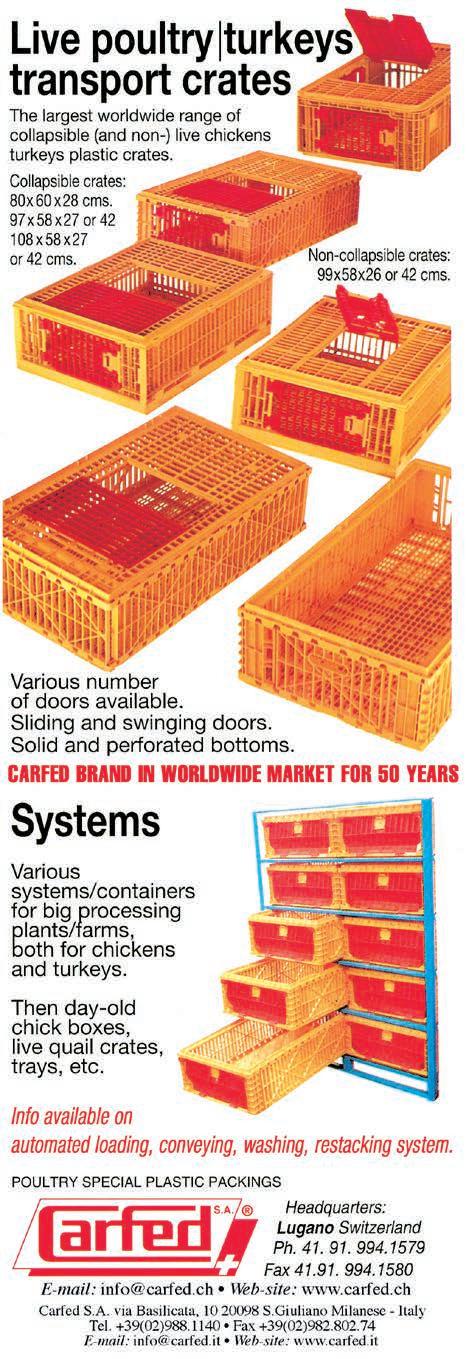

CARFED INTERNATIONAL LTD

Italian headquarters: Piazza Oberdan 3, 20129 Milano (Italy)

Italian warehouse: Via Basilicata 10, 20098 San Giuliano Milanese (Italy)

Ph.: +39 02 9881140 – Fax: +39 02 98280274

Email: carfed@carfed.it – Website: www.carfed.it

UK headquarters: Ground Floor, One George Yard, London EC3V 9DF, England, UK

Ph.: + 44. 20. 7660.0987 – Email: carfed@carfed.co.uk

15 - february 2023DOSSIER

Wooden turkey nests after one production cycle; feathers, litter, and dust penetrated the wooden tissue and cannot be as clean as we need them to be.

©Makan Hooshangi

Andrew Bourne Broiler Specialist, World Tech Services, Cobb Europe

Cleaning and disinfection of feeding equipment

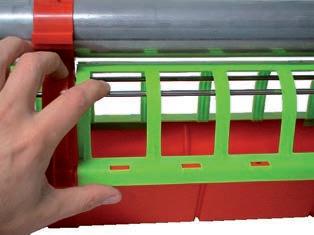

Everyone understands the importance of a precise cleaning and disinfection program on the farm, but one of the most critical parts is the feeding equipment.

From the very start, flocks will spend a large amount of time eating feed. In fact, it will take more time for flocks to eat than to drink even if the volume of feed is half that of the water. If the cleaning of chain or pan feeders has not been thorough, dirt of feed residue from the previous cycle can easily become breeding grounds for microorganisms that may infect the chicks. Furthermore, feed residue can promote the growth of molds that can harm flocks through the production of toxins. Residues of feed inside or outside

of the houses will also attract vermin, which can carry disease.

Good management includes calculating, as precisely as possible, the volumes of feed needed. However, there can be unexpected situations where feed is not consumed and silos remain full with feed. In the case of a disease challenge, feed must be disposed of regardless of remaining volumes. Feed can only be used if mortality is due to heat stress or electrical/mechanical failures. In

16 FOCUS - focus -

©poultrysouth.com

to the manufacturer’s instructions. Apply the disinfectant with water at low-pressure to ensure all surfaces are covered.

After liquid disinfection, apply fumigation. Before fumigating, install supplementary feeders used for brooding so that they are also disinfected. Again, use the correct

- february 2023 - 17 FOCUS

Contact us www.facco.net - info@facco.net Marsango di Campo San Martino Padova - Italy +39 049 9698111 60 years of experience in cage free and free range projects all over the world! Cage Free Contact us www.facco.net - info@facco.net Marsango di Campo San Martino Padova - Italy +39 049 9698111

concentrations and volumes of disinfectant for fumigation (normally calculated per cubic meter of house volume) and apply at the recommended temperature.

Feed distribution tubes are likely to be the most difficult part of the system to clean. Wet washing is normally not an option. One option is using blowers or vacuums inside the tubes to remove dust and dirt. Alternatively, fill the tubes with feed or a feed ingredient such as corn mixed with a high dosage of disinfectant during the days of the cleaning, then completely empty them. This procedure is not the simplest and should be practiced with extreme care to prevent any remaining residue of treated feed.

External silos also need to be cleaned. The most appropriate method will be determined by the age, material and design of the silos. When possible, wet wash and disinfect silos followed by fumigation. If washing or use of liquid disinfectants is not permissible, use vacuums and blowers to remove all dirt and feed residue before fumigation. When it is not possible to wet clean the silos, organic acids blends or a blend of organic acids and disinfectants (i.e., formaldehyde) can be applied to prevent the growth of molds or bacteria. Always verify that these chemicals are approved for use in your region.

Feed will be one of, if not the most, important driver of performance, especially in broilers. Therefore, it is necessary that it is delivered under sanitary conditions to the flock. A proper cleaning and disinfection program of feeding equipment is an important part of a good biosecurity program.

18 FOCUS - focus -

The first step in cleaning feeders is to remove the debris. This can be done using vacuums or blowers.

Pan feeders should be opened to clean and dry.

Sanitary Box

Professional, heavy-duty, insulated box for use on farms. Easy to transport and designed to comply with the health rules.

truckload Agritech

- february 2023 - 19 FOCUS

s.r.l.

Rimembranze,

25012 Calvisano (BS)

+

r.a.

+

4 boxes in one full

Via

7

Italy Tel.

39 030 9968222

Fax

39 030 9968444 commerce@agritech.it www.agritech.it

Hans-Wilhelm Windhorst

Patterns and dynamics of global turkey meat production and trade Part 1 – Turkey meat production

In two papers, the dynamics of turkey meat production and trade will be analysed. The first paper deals with the dynamics in production at continent and country level. The second paper will analyse the development and patterns of turkey meat trade.

Between 2000 and 2020, global turkey meat production increased from 5.5 mill. t to almost 6 mill. t or by 8.6%. Compared to chicken meat, it was a comparatively low growth rate. To the global poultry meat production of 133.3 mill. t, turkey meat contributed 4.5%. Of the total production volume, 871,000 t or 14.5% went into exports.

20 MARKETING - marketing -

The author is Prof. Emeritus of the University of Vechta and visiting Professor at the Hannover Veterinary University, Germany

Moderate growth of production

A closer look at the long-range development of global turkey meat production between 2000 and 2020 reveals that it was not a continuous growth. The upward trend was interrupted by the economic crisis between 2003 and 2006 and then again because of various outbreaks of the Avian Influenza (AI) virus in the USA and in Europe (Figure 1).

A comparison of the dynamics in North America and Europe shows that the production volume hovered between 1.5 and 2.2 mill. t. While it

increased from 2017 onward, the opposite was the case in North America. The massive losses caused by the AI virus in 2015 in the Midwest are still visible in the recent development of the turkey flocks and in production.

The analysis of the dynamics at continent level (Figure 2) documents the dominating role which North American and European countries play in global turkey meat production. In 2010, they shared 82.9% in the production volume, in 2020 81.7%.

A comparison of the continents’ shares confirms the upward trend in Europe and the downward trend in

North America. While Europe gained 1.9% in its share, North America lost 3.1%. A positive development showed Central and South America (+0.4%) and Africa (+0.9%); production in Asia increased only slightly and was negligible in Oceania.

The downward trend in North America reflects the decreasing per capita consumption in the USA from 7.1 kg in 2008 to only 6.3 kg in 2020. In the EU, the per capita consumption grew from 3.5 kg to 4.1 kg in the same time-period.

High regional concentration in production

Turkey meat production is highly concentrated. Table 1 shows that the ten leading countries contributed 88.2% (2010) respectively 88.8% (2020) to the global production volume, the three top-ranked countries over 60%. The dominating position of the USA is unchallenged (Figure 3). Although their share in global production decreased, their production volume was still more than four times higher than that of Brazil.

A closer look at the dynamics at country level documents the fast

21 - february 2023MARKETING

[mill. t] 0.0 1.6 3.3 4.9 6.5

20002002200420062008201020122014201620182020 World North America European Union (27)

Figure 1 – The development of global turkey meat production between 2000 and 2020 (design: A.S. Kauer based on FAO data).

pas2020_adv-Zootecnica-180x61mm.indd 1 25-02-2020 11:16

Royal Pas Reform Integrated Hatchery Solutions

www.pasreform.com

* sum does not add because of rounding

growth in Poland. Between 2010 and 2020, turkey meat production increased by 306,800 t or 306.8%. A growth in production also showed Brazil (+99,000 t), Spain (+96,600 t) and Tunisia (+37,900 t). In contrast, production fell by 83,600 t in France and by 19,000 t in the United Kingdom. In Germany, ranked in third place, the production volume decreased by 2,500 t.

Figure 4 documents the relative changes for the ten leading countries in turkey meat production. With a relative growth of 5.0%, Poland showed a remarkable dynamics, followed by Spain (+1.5%) and Brazil (+1.0%). The highest relative decrease occurred in the USA with 2.9%, followed by France (-1.9%) and Germany (-0.8%). The remarkable dynamics in Poland is based as well on the engagement of the leading US American and Western European breeding companies, the transfer of technology and knowhow from the USA and other EU member countries and on foreign capital investments. The leading companies are vertically integrated and use the latest technologies in production and processing.

Lower regional concentration of production in the EU

While turkey meat production in the Americas is concentrated in the USA and Brazil (cf. Figure 3), 14 of the 27 member countries of the EU produced turkey meat in 2020. Figure 5 shows that despite the diversified spatial pattern, the five leading countries shared almost 90% in the total production volume. With a contribution of 24.4%, Germany was in a

22 MARKETING - marketing -

2010 2020 Country Production Share (%) Country Production Share (%) USA Brazil Germany France Italy Un. Kingdom Canada Spain Poland Israel 2,560.2 485.0 478.5 404.6 298.5 162.0 158.2 129.4 100.0 90.0 46.4 8.8 8.7 7.3 5.4 2.9 2.9 2.3 1.8 1.6 USA Brazil Germany Poland France Italy Spain Canada Un. Kingdom Tunisia 2,697.4 584.3 476.0 406.8 321.0 313.3 226.0 158.3 143.0 85.7 43.5 9.8 7.9 6.8 5.4 5.2 3.8 2.6 2.4 1.4 10 countries 4,844.4 *88.2 10 countries 5,321.8 88.8 World 5,517.2 100.0 World 5,992.8 100.0

Table 1 – The ten leading countries in turkey meat production in 2010 and 2020; data in 1,000 t (source: FAO database).

13.5% 1.8% 2.3% 2.9% 2.9% 5.4% 7.3% 8.7% 8.8% 46.4% 12.6% 6.8% 3.8% 2.6% 2.4% 5.2% 5.4% 7.9% 9.8% 43.5% Total: 5,517 mill. t 2010 Total: 5,993 mill. t 2020 USA Brazil Germany France Italy UK Canada Spain Poland Others

0.4% 11.5% 49.3% 33.8% 2.4% 2.6% Total: 5,517 mill. t 2010 Total: 5,993 mill. t 2020 0.3% 11.9% 46.1% 35.6% 2.5% 3.5% Africa Asia Europe N America CS America Oceania

Figure 3 – The share of the nine leading countries in global turkey meat production in 2010 and 2020 (design: A.S. Kauer based on FAO data).

Figure 2 – The contribution of the continents to global turkey meat production in 2010 and 2020 (design: A.S. Kauer based on FAO data).

leading position, followed by Poland with 20.9%. Considering the remarkable

however interrupted by the Covid-19 pandemic because of a lower demand in the main countries of destination for its exports. The second paper will analyse this in detail.

Summary and perspectives

The preceding analysis showed that North America and Europe dominated turkey meat production in 2020. The two continents shared over 80% in the global production volume. The high regional concentration is also reflected in the ranking and composition of the ten leading countries. In 2020, they contributed 88.8% to the global production volume of almost

23 - february 2023MARKETING

USA Brazil Germany Poland France Italy Spain Canada UK Tunisia -6.0% -3.3% -0.5% 2.3% 5.0% 0.5% -0.5% -0.3% 1.5% -0.2% -1.9% 5.0% -0.8% 1.0% -2.9%

Figure 4 – The development of the leading countries in global turkey meat production between 2010 and 2020 (design: A.S. Kauer based on FAO data; own calculations).

Barbieri srl Via Garibaldi, 54 • 26040 Scandolara Ravara (CR) Italy Tel. (+39) 0375 / 95135 • Fax (+39) 0375 / 95169 • Manu re re moval belt s • Manu re belt wi th hole s for dr yi ng system s info@barbieri-belts.com www.barbieribelts.com BELTS and ROP ES for AV ICULTURAL USE BE LT S

KEEP UP ON TRENDS AND CHALLENGES of poultry industry with

Total:

1,947 mill. t

It’s been 50 years since Zootecnica International started serving the poultry industry and professionals. Today the magazine is edited in three languages (English, Italian and Russian) and delivered monthly in 120 countries, reaching around 30.000 readers all over the world.

The target of Zootecnica International includes farmers, egg producers, breeding companies, hatcheries, feed mills, poultry and egg processing companies.

Magazine and website offer a broad overview on the poultry industry, providing in-depth news on international markets, business management, trends and practices in poultry, genetics, incubation, nutrition, veterinary and management.

zootecnicainternational.com

The USA and Brazil ranked in the top two positions, followed by Germany and Poland. Production in Poland showed a remarkable dynamics during the past decade with the highest absolute und relative growth rates. Negative rates showed the USA, France and Germany. Obviously, the Covid-19 pandemic resulted in stagnating or even decreasing production volumes because of a lower demand. If the per capita consumption will recover from this interruption in the demand, is a still open question. In some countries, it has been decreasing for years, in others it is more or less staggering or shows only moderate growth. Turkey meat lost market shares to chicken because of higher production costs and retail prices. Higher slaughter weights of broilers also contributed to the success of this meat type.

References

Berkhout, N.: EU: Poland continues in turkey production. In: Poultry World 16. 12. 2020. https://www.poultryworld. net/poultry/eu-poland-continues-to-lead-in-turkey-production.

FAO database: https://www.fao.org/faostat.

OECD-FAO (Ed.): Agricultural Outlook 2021–2030. https://stats.oecd.org.

USDA, Gain Report PL2020-048: Poland: Turkey and Products Market Brief_Warsaw_Poland_11-13-2020-4. pdf.

Windhorst, H.-W.: Patterns and dynamics of global egg and poultry meat trade. Part 2: Poultry meat trade. In: Zootecnica International 44 (2022), no. 3, p. 24-27.

24 MARKETING - marketing -

4.0% 2.4% 4.1% 11.6% 16.1% 16.5% 20.9% 24.4% Germany Poland France Italy Spain Hungary Portugal Others

Figure 5 – The share of the seven leading EU (27) member countries in turkey meat production in 2020 (design: A.S. Kauer based on FAO data).

25 - february 2023 -

Eline Holtslag, Incubation Specialist, Royal Pas Reform

A quick breeder farm visit

Egg quality is a very important part of incubation. And, as we often say, bad input equals bad output.

We simply cannot create good quality chicks from poor quality eggs, as one of my recent hatchery visits proved. While looking at the transfer, I noticed that one flock in particular had a lot of clears, even though this was a prime flock! The hatchery manager said this flock was known for having lots of clears, but when I asked whether they knew why, there was no answer.

So, I placed myself at the end of the conveyor belt that takes away the clears, and played a game of catch the egg during the

drop towards the hopper. Many of the eggs I caught had hairline and/or star cracks. This required further investigation of the fresh eggs coming from the breeder farm. The farm from which these eggs came was relatively new; this flock was the first round in this barn and neither the owners nor the personnel had any previous experience with poultry. So, while it is easy to look at the eggs and draw your conclusions, we all know that being completely new at something is always hard. As we discussed this,

26 - technical columnTECHNICAL COLUMN

the opportunity was presented to go and visit the farm. While incubation specialists often go to hatcheries, they do not always get the chance to visit breeder farm, so of course I jumped at the chance.

As we made our rounds through the different barns, we applied the same rules that I often tell our customers: keep your eyes, nose and ears open, and your brains switched on! And of course, if you spot something, don’t be afraid to get your hands dirty. Only one of the basic five senses is left, but when it comes to breeder eggs and day-old chicks, I prefer to skip the tasting part!

This easy trick saved us a lot of time as it immediately pointed us in the right direction. While standing in the barn, our ears picked up the familiar sound of eggs colliding. We walked towards the source of this sound: the laying nests. As the eggs rolled down towards the conveyor, they picked up so much speed that they collided into the edge of the conveyor.

This was probably where the hairline cracks were being formed. Later on, when we took a look at the point where the eggs left the barn conveyor and were passed onto the central egg conveyor, we heard even more noise. Here, we saw that the eggs were forced to make a small jump before landing on the central conveyor, leaving a star crack. By slightly raising the central conveyor, the eggs rolled gently without any problems. So, by making a couple of simple adjustments, the incidence of hairline cracks decreased from 3.1 to 0.7% and both the breeder farm owner and the hatchery experienced a change for the better.

“As we made our rounds through the different barns, we applied the same rules that I often tell our customers: keep your eyes, nose and ears open, and your brains switched on! And of course, if you spot something, don’t be afraid to get your hands dirty. Only one of the basic five senses is left, but when it comes to breeder eggs and day-old chicks, I prefer to skip the tasting part!”

Pioneers in future proof solutions

27 - february 2023TECHNICAL COLUMN

PT02, PT03, PT04, PT05

UNIQUE BLEND STRONGER THROUGH INNOVATION

SMART, CHOOSE SAFETY!

INTRA HYDROCARE DOES COMPLY WITH THE LATEST REGULATIONS

BE

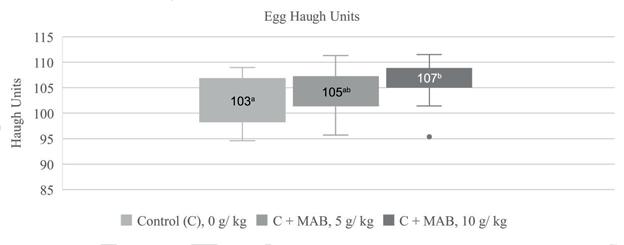

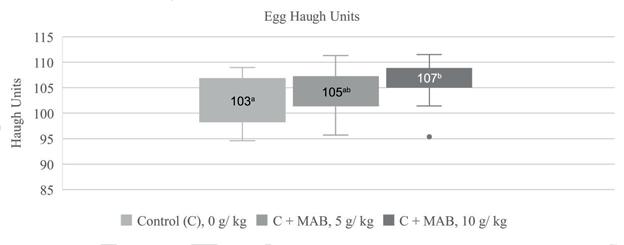

Adding a macroalgae blend to commercial laying hen diets improves egg quality and body weight gain

The effect of a selected blend of brown, green and red macroalgae on egg production and egg quality was evaluated as a functional ingredient in diets fed to commercial laying hens from the onset of laying (22 weeks of age) for a period of 168 days.

A total of 288 Hy-Line, point-of-lay pullets were randomly allocated to 72 cages. The birds were fed one of 3 dietary treatments with increasing concentration of a proprietary macroalgae blend (MAB): Control (0 g/kg), Control plus MAB at 5 g/kg feed and Control plus MAB at 10 g/kg feed. Diets met or exceeded the NRC requirements (1994) for laying hens and were presented as mash with hens having ad libitum access to feed throughout the study. Diets were assigned to replicate cages using a completely randomised design, with each group

28 MANAGEMENT - management -

J.S. Sands1, L.R. Park 2, D. Currie2 and H. Graham1

1 Ocean Harvest Technology Ltd., Heaton House, Fareham, Hampshire, UK PO16 8AA

2 Roslin Nutrition Ltd., Longniddry, East Lothian, Scotland EH32 0PX

consisting of 24 replicate cages of 4 birds. Under the conditions of the study, MAB did not have a significant influence on egg production rate or egg weight (P>0.05). However, hens offered diets with MAB had higher (p=0.04) body weight gain than the Control group offered diets without the MAB. Egg albumen height and consequently Haugh units were significantly higher (P=0.02) for eggs from hens offered the MAB. These findings suggest MAB may have a positive impact on egg quality factors.

Introduction

Ingredients other than in-feed antimicrobial compounds can offer a sustainable approach to improving gastrointestinal (GI) health and animal performance. Efficient egg production and egg quality are of major importance to the poultry industry, but their optimisation is dependent on numerous factors. Nutrition and disease factors are among the most common factors affecting egg production and quality (Roberts, 2004). It follows that a healthy GI tract is required for efficient digestion and absorption of nutrients and, consequently, for egg production and egg quality. Marine macroalgae represent a promising feed ingredient, due to the presence of several bioactive components that have been repor ted to benefit GI health (Salehi et al. 2019). These bioactive compounds including polysaccharides, peptides, essential fatty acids, antioxidants such as polyphenols and other phytogenic compounds vary significantly between macroalgal species (Salehi et al., 2019). This variation in content of bioactive compounds between algae species provides opportunities for selection of different species to vary the amounts of specific categories of bioactive compounds that benefit GI health in laying hens. The authors hypothesised that a blend of marine macroalgae containing varying proportions of selected brown, green and red algal species may convey benefits that improve egg production and egg quality in commercial hens.

Methods

Wheat and soyabean meal-based diets were formulated to be iso-nutritive and to meet the recommended nutrient requirements of the NRC (1994) for layers (Table 1). Three dietary treatments were produced by increasing the concentration of a proprietary, marine macroalgae blend (MAB, OceanFeedTM, supplied by Ocean Harvest

1Details of vitamin, mineral and enzyme premix available on request

Technology Ltd.) to provide a Control (0 g/kg), Control plus MAB at 5 g/kg feed and Control plus MAB at 10 g/kg feed. Diets were fed in two phases, weeks 1-12 and weeks 13-24. The diets were presented to the birds in mash form and were prepared without the inclusion of growth promoting antimicrobials. Diets were analysed for nutritional homogeneity prior to the start of the trial.

29 - february 2023MANAGEMENT

Ingredients, % 0 – 12 Weeks 13 – 24 Weeks Wheat 49.1 49.4 Soybean meal, 48% CP 22.2 24.3 Maize 15.0 12.5 Soya oil 2.67 2.26 Dical-Aliphos 40 1.40 1.66 Salt 0.37 0.37 Limestone 8.47 8.70 L-Lysine HCl 0.005 –DL-Methionine 0.195 0.230 L-Threonine 0.055 0.068 Roslin pigment 0.150 0.150 Vitamin and mineral Premix1 0.319 0.319 Calculated analyses ME Poultry, MJ/kg 11.5 11.2 Crude protein, % 17.2 18.0 Crude fat (acid hydrolysis), % 5.1 4.6 Crude fibre, % 2.1 2.2 Ash, % 12.6 13.1 Dig. Lysine (poultry), % 0.724 0.770 Dig. Methionine (poultry), % 0.422 0.465 Dig. Meth+cyst (poultry), % 0.669 0.722 Dig. Threonine (poultry), % 0.557 0.597 Calcium, % 3.64 3.80 Total phosphorus, % 0.590 0.648 Digestible P Layers 0.471 0.452 Sodium, % 0.160 0.160 Potassium, % 0.746 0.785 Chloride, % 0.264 0.263

Table 1 – Composition and calculated analyses of basal diets for phases 1 and 2.

The hens were allowed continuous access to feed and water throughout the study.

This study was conducted in accordance with Regulations (EC) No. 1831/2003 (EC, 2003) and No. 429/2008 (EC, 2008) as outlined in the European Food Safety Authority’s (EFSA) technical guidance document on the assessment of efficacy of feed additives (EFSA, 2018). A total of 288 Hy-Line pullets (Gallus gallus domesticus) at the point-oflay were randomly allocated to 72 cages, 4 birds per cage in 3 blocks of 24 cages. Three dietary treatments were randomly allocated to cages within blocks providing 24 replicate cages per block. The house was cleaned prior to placement and was equipped with programmable artificial lighting, automated gas heating and forced ventilation. The temperature inside the building was maintained as per breeder recommendations. A 24-hour lighting programme of 16 hours light and 8 hours dark was maintained throughout the trial. The 3 dietary treatments were

allocated at random to cages with blocks. Each 4-bird cage served as an experimental unit, providing 24 replicates per treatment. Zootechnical performance parameters measured included: feed intake, egg number, egg weight, average egg weights, egg mass, hen body

weight, feed conversion efficiency and incidence of cracked, softshelled, and dirty eggs. Egg production (%/hen/day) was calculated as [total egg number per (number hens * number of days hens were alive) x 100]. Feed conversion efficiency (FCE) was calculated as [Egg mass (g/cage/day) per average daily feed intake (g/cage/day)].

Prior to statistical analyses, the data were assessed for outliers using the Box Plot method of JMP ® PRO 14.2 (SAS Institute Inc., Cary, NC) and assumptions of Analysis of Variance (ANOVA) using Shapiro–Wilk test for testing normal distribution and Welch test for testing equal variances, respectively. Where data met the assumptions of the ANOVA test, data were analysed as a randomised completely block design by JMP ® PRO 14.2 using the Fit Model. Treatment was included as a main effect and block as random effect in the model.

Table 2 – Egg production, average daily feed intake, final body weight, body weight change and feed conversion efficiency of laying hens fed a wheat-soybean meal-based diets with the addition of a marine macroalgae blend* at 0, 5 or 10 g/ kg of feed over a period of 24 weeks.

*A selected blend of green, brown and red macroalgae optimised to deliver a range of soluble, non-starch polysaccharides. SEM = Standard error of mean;

a, b, c Denotes significance within a row (P≤0.05);

1 Data analysed using parametric tests (ANOVA) with P-value shown;

2 Data analysed using non-parametric tests (Wilcoxon test) with Chi-square estimate shown

30 MANAGEMENT - management -

Concentration of Macroalga e Blend Paramete r 0 g/kg 5 g/kg 10 g/kg SEM P-value Egg Production Rate (%/hen/day)1 92.6 93.4 93.4 0.43 0.50 Average Daily Feed Intake (g/ cage/d)2 513 513 516 2.5 0.68 Body weight (g, week 0)1 1938 1921 1904 10.9 0.13 Body weight (g, week 24)1 2208 2220 2232 16.7 0.48 Body Weight Gain (g, weeks 0-24)1 243 271 299 13.1 0.04 Feed Conversion Efficiency1 0.458 0.459 0.459 0.004 0.88

“Efficient egg production and egg quality are of major importance to the poultry industry, but their optimisation is dependent on numerous factors. Nutrition and disease factors are among the most common factors affecting egg production and quality. It follows that a healthy GI tract is required for efficient digestion and absorption of nutrients and, consequently, for egg production and egg qualityˮ

CHOOSE HOW YOU WANT TO

ENJOY

It’s been 50 years since Zootecnica International started serving the poultry industry and professionals. Today the magazine is edited in three languages (English, Italian and Russian) and delivered monthly in 120 countries, reaching around 30.000 readers all over the world.

The target of Zootecnica International includes farmers, egg producers, breeding companies, hatcheries, feed mills, poultry and egg processing companies.

Magazine and website offer a broad overview on the poultry industry, providing in-depth news on international markets, business management, trends and practices in poultry, genetics, incubation, nutrition, veterinary and management.

PRINT ONLY

(print magazine delivered to your door)

DIGITAL ONLY

(digital magazine sent to your mailbox)

PRINT + DIGITAL

Subscribe by money transfer:

1. effect a money transfer to: Zootecnica International, Vicolo Libri, 4 50063 Figline Incisa Valdarno (FI), Italy; bank: UNICREDIT, BIC: UNICRITM1OU9

Iban: IT 81 H 02008 38083 000020067507

2. send us your complete shipping address by email: subscription@zootecnica.it.

€ 109

€ 99

€ 49

- february MANAGEMENT

The results were presented as the least squares means. Statistical significance was declared at P≤0.05. The Tukey-Kremer test was used to separate differences between means. Data that did not meet the assumptions for ANOVA were transformed to facilitate meeting of the assumptions or non-parametric analysis was employed if assumptions for ANOVA were not met. For all response criteria, cage served as the experimental unit.

Results

Body weight of hens were not different among dietary treatment groups; however, the change in body weight during the trial period tended to be higher in hens offered diets containing MAB (p=0.065, Table 2). Egg production, egg mass, egg weight and feed conversion efficiency were not significantly affected by diet over the 168-day study period. However, for egg quality parameters, the average albumen height (mm) and Haugh units were increased by in eggs from hens fed diets containing the MAB (Table 3 , Figure 1).

Discussion

While egg production was similar, hens offered diets with MAB tended to have higher body weight gain af ter consuming the diets for 168 days. An increase in weight suggests a more efficient extraction of nutrients; however, this was not confirmed by improved feed conversion efficiency. Haugh Units (HU), which combines the egg mass with the albumen height, is generally accepted as an indicator of egg quality (Eisen et al. 1962). An improvement

Table 3 – Egg Quality (egg weight, egg mass, albumen height and yolk colour) from laying hens fed a wheat-soybean meal-based diets with the addition of a marine macroalgae blend* at 0, 5 or 10 g/ kg of feed over a period of 12 weeks.

*A selected blend of green, brown and red macroalgae optimised to deliver a range of soluble, non-starch polysaccharides. SEM = Standard error of mean; Different superscripts denotes significant differences between means within a row (P≤0.05);

1Data analysed using parametric tests (ANOVA) with P-value shown;

2Data analysed using non-parametric tests (Wilcoxon test) with Chi-square estimate shown

HU was measured using the formula: HU=100log (H-1.7W0.37+7.6) where H is the height (in millimeters) of the albumen, and W is the weight of the egg. Values shown are means +/- SEM; different superscripts, denotes significant differences between means (P≤0.05).

in albumin height and in HU noted with dietary MAB in this trial suggests an improvement in overall egg quality. Given HU is widely accepted as a key indicator of egg quality and freshness (Eisen et al. 1962, Williams 1992), it is an important value metric for egg producers. Further studies involving supplementation with the MAB used in this study, to greater numbers of laying hens over longer periods of time are proposed to confirm the possible benefits for laying hen welfare and productivity. Further, a more detailed assessment of the quality factors and the composition of eggs from hens fed diets containing MAB should be included in future studies.

References are available on request

From the Proceedings of the Australian Poultry Science Symposium 2022

32 MANAGEMENT - management -

Figure 1 – Haugh Unit (HU, an index of egg quality) of eggs from hens fed diets containing a marine macroalgae blend at 0, 5 and 10 g/ kg of feed.

Concentration of Macroalga e Blend Parameter 0 g/kg 5 g/kg 10 g/kg SEM P-value Average Egg Weight (g/egg)1 62.6 62.5 62.9 0.29 0.60 Egg Mass (g/cage/day)2 234.9 235.8 235.4 2.05 0.55 Albumin Height (week 12)2 4.43a 6.00 b 6.01b 0.438 0.016 Yolk Colour (week 12)2 5.75 5.96 5.46 0.410 0.58 Average Haugh Units 102.9a 104.5ab 106.8 b 0.80 0.004

The automatic feed pan for cocks

NO WEIGHING SCALE REQUIRED

EVERYTHING IS DONE BY THE SELF-DOSY PAN

Automatic adjustment of the feed volume throughout the line.

Centralised opening for the simultaneous feed distribution in all the pans.

Sturdy, easy to manage and designed for aggressive birds. Simple washing of any inner and outer component of the feed pan. It works with flex auger.

HOW SELF-DOSY WORKS

Example : 80 kg of feed must be distributed throughout one line with 50 pans

80 kg: 50 = 1,6 kg of feed per pan

Adjust the feed volume at 1,6 kg with the centralized winch

Feed pans are filled according to the adjusted volume and the limit switch stops the line

The automatic opening is used to drop simultaneously the feed in all the pans

- february 2023MANAGEMENT AZA International s.r.l. Via Roma 29 24030 Medolago (BG) Italy Phone (+39) 035 - 901240 - E-mail: info@azainternational.it QUALITY MADE IN ITALY Watch all information about Self Dosy www.azainternational.it

in pig & poultry equipment

SELF-DOSY Leader

I WANT AZA!

SENSOR TO STOP THE LINE 1,6Kg 1,6Kg 1,6Kg 1,6Kg WINCH Set to: 1,6Kg N°1 N°2 N°49 N°50 Tot 80Kg

1 Kemin Animal Nutrition and Health, Herentals, Belgium

2 Department of Animal Nutrition and Feed Management, Poznan University of Life Sciences

Validation of the nutritional matrix of a multienzyme complex through performance and digestibility improvement

It is well known that feed represents the most important cost in poultry production. Together with variable costs, it can reach up to 80% of the total cost in a poultry operation. Then it seems reasonable that improving feed efficiency should be the very first target of every poultry producer.

There are multiple tools to optimize feed cost, being feed enzymes one the most cost effective and most widely accepted by nutritionists. They should provide a well proven and reliable nutritional matrix for the most cost-effective feed reformulation.

When evaluating nutritional matrices for feed enzymes we should pay attention not only to figures but mostly to how these figures were obtained. Feed enzymes should offer to poultry nutritionists a reliable and well researched matrix value for different nutrients of interest. Ide -

34 NUTRITION - nutrition -

David González-Sánchez1 and S.A. Kaczmarek 2

ally obtained from a safely corrected average improvements of nutrient digestibility recorded in different poultry trials. This would allow to build a trustful and reliable nutritional matrix to optimize feed cost without impairing poultry performance. Aiming to further validate the proposed matrix value of a commercial multi-enzyme complex (MEC) the following investigation was proposed.

Material and methods

320 one-day-old male Ross 308 chickens (average initial weight 41.2 g) obtained from a commercial hatchery were randomly assigned to 4 treatments that were replicated 8 times:

• T0: positive control (PC) without enzymes.

• T1: negative control (NC), PC reformulated to reduce apparent metabolizable energy, digestible aminoacids and crude protein by 65 kcal/kg and 2% respectively (reduced the feed cost by 12 €/ ton compared to the PC)

• T2: NC + MEC (xylanase + betaglucanase + cellulase + amylase + protease) at 250 g/ ton.

• T3: NC + a commercial xylanase + betaglucanase complex (XBC) at 50 g/ton.

Birds were housed with 10 per pen and the experiment lasted for 35 days. The trial was divided into 3 feeding periods: (starter 1-11d), grower (12-24d) and finisher (2535d). The composition of experimental diets and calculated value is presented in Table 1. Average pen weight and feed intake was recorded at the end of every feeding phase. Feed conversion, daily growth rate,

35 - february 2023NUTRITION

Starter (1-11d) Grower (12-24d) Finisher (25-35d) Ingredients (%) PC NC PC NC PC NC Maize 43.10 26.08 45.11 27.77 50.23 32.86 SBM (45% CP) 39.13 34.33 36.82 31.53 31.61 27.37 Wheat 10.00 20.00 10.00 20.00 10.00 20.00 Triticale - 10.00 - 10.00 - 10.00 Sunflower Meal (34% CP) - 2.28 - 3.00 - 2.00 Soybean oil 3.42 2.88 4.24 3.81 4.71 4.25 Limestone 1.40 1.42 1.27 1.28 1.13 1.15 MCP 0.94 0.91 0.76 0.73 0.62 0.60 NaCl 0.26 0.25 0.25 0.24 0.23 0.23 Sodium Bic. 0.12 0.13 0.06 0.07 0.05 0.05 HCl-Lys 0.20 0.28 0.13 0.20 0.12 0.18 DL-Met 0.33 0.32 0.30 0.28 0.24 0.23 L-Thr 0.10 0.12 0.05 0.08 0.04 0.07 Premix (vit/min)1 1.00 1.00 1.00 1.00 1.00 1.00 Phytase 50002 0.01 0.01 0.01 0.01 0.01 0.01 Nutrients (%) PC NC PC NC PC NC Crude Protein 22.50 22.15 21.50 21.15 19.50 19.15 Crude Fat 5.74 4.81 6.59 5.75 7.13 6.28 Crude Fiber 3.19 3.45 3.12 3.49 2.98 3.30 Ca 1.00 4.00 0.91 0.91 0.82 0.82 dig P 0.49 0.49 0.45 0.45 0.41 0.41 Na 0.18 0.18 0.16 0.16 0.15 0.15 Cl 0.24 0.25 0.22 0.23 0.21 0.22 DigLYS 1.24 1.22 1.126 1.100 1.000 0.980 DigMET 0.618 0.598 0.579 0.551 0.500 0.480 DigMET+CIS 0.910 0.890 0.862 0.833 0.760 0.740 DigTHR 0.800 0.788 0.730 0.718 0.650 0.638 DigTRP 0.244 0.236 0.232 0.224 0.207 0.20 DigVAL 0.912 0.877 0.874 0.84 0.790 0.756 DigILE 0.851 0.811 0.813 0.772 0.727 0.690 DigARG 1.376 1.317 1.312 1.256 1.170 1.111 AME (Kcal/kg) 2950 2885 3035 2970 3125 3060 Feed cost (€/ton) 294.7 282.0 294.7 281.6 288.5 276.9 1 mineral and vitamin premix provides per kg diet: IU: vit. A 11250, cholecalciferol 2500; mg: vit. E 80, menadione 2.50, vit. B12 0.02, folic acid 1.17, choline 379, D-pantothenic acid 12.5, riboflavin 7.0, niacin 41.67, thiamin 2.17, D-biotin 0.18, pyridoxine 4.0, ethoxyquin 0.09, Mn 73, Zn 55, Fe 45, Cu 20, I 0.62, Se 0.3. 2 phytase 5000 provides 0.15% dig P, 0.165% Ca and 0.035 Na.

Table 1 – Composition of experimental basal diets and calculated nutritional value.

bird-days and daily feed intake per bird was calculated per feeding phase and for the overall trial. Digestibility was determined during the grower period from 18th to 21st day using titanium oxide as indigestible market. Collection trays were installed in floor pens on day 18 to 21 allowing excreta collection; eight excreta samples per treatment were collected. One excreta sample represented one pen (10 birds).

Results

Performance

The effect of supplementing different enzyme preparations to broiler diets on feed intake (FI), body weight gain (BWG) and FCR is presented in Table 2.

For the whole experimental period (1-35 d), no statistical difference was found between PC (T0) and NC + MEC (T2) birds for FI, BWG or FCR, whereas FCR of NC (T1) and NC + XBC birds was significantly worse (P<0.05) compared to PC (T0) and NC + MEC birds (T2). Overall feed intake was the highest (P<0.05) for NC birds (T1) and NC + XBC birds (T3). There were no differences in growth performance during starter period (1-11 d). During grower period (12-24 d), the highest feed intake (P<0.05) and worst FCR (P<0.05) was recorded for NC birds (T1). For finisher period (25-35 d) worst FCR (P<0.05) was recorded for both NC (T1) and NC + XBC birds (T3).

Digestibility

The effect of supplementing different enzyme prepara-

tions to broiler diets on nutrient retention and total tract digestibility is presented in Table 3

There were significant differences (P<0.05) in dry matter and nitrogen retention. Birds from PC treatment (T0) were characterized by the highest DM retention, while NC + MEC birds (T2) showed higher dry matter retention compared to NC (T1). Nitrogen retention of the NC birds (T1) was the lowest compared to all other treatments (P<0.05). There were no differences in total tract crude fat digestibility. NC + MEC birds (T2) were characterized by the highest starch total tract digestibility (P<0.05) while birds from negative control treatment (T1) were characterized by the lowest. Total tract digestibility of GE was significantly better (P<0.05) in birds from PC (T0) and from NC + MEC (T2) compared to the NC (T1).

AMEn of diets fed to PC (T0) and NC + MEC birds (T2) was not significantly different despite of the gap created by reformulation with the proposed nutritional matrix. This effect is consistent with the lack of significant differences in FCR and BWG. AMEn of the diet fed to NC (T1) and NC + XBC birds (T3) was not different and it was lower (P<0.05) compared to PC (T0) and NC + MEC birds (T2), which is also consistent with the FCR results (Figure 2).

The results of the present study confirm the previous findings that a MEC helped in improving growth and FCR when added to broiler diets (Adams, 1993). Feed enzymes are commonly added to poultry diets to counteract the potential anti-nutritional effects caused by non-starch polysaccharides (NSP). In the early life of the chicken, its digestive capacity is not yet fully developed. According to

positive control (PC) without enzymes; T1: negative control (NC), PC reformulated to reduce apparent metabolizable energy, digestible aminoacids and crude protein by 65 kcal/kg and 2% respectively; T2: NC + MEC (xylanase + betaglucanase + cellulase + amylase + protease) at 250 g/ton; T3: NC + a commercial xylanase + betaglucanase complex (XBC) at 50 g/ton

a–c Means without a common superscript differ significantly at P<0.05.

*FCRa is adjusted FCR at 2.2 kg BWG calculated per Ross 308 Management Handbook 2014.

36 NUTRITION - nutrition -

Star te r (1-11 d) Grower (12-24 d) Finisher (25-35 d) Total (1-35 d) BWG FI FCR BWG FI FCR BWG FI FCR BWG FI FCR FCR a * T0 234 269 1.152 837ab 1531a 1.830a 1106 1519ab 1.381a 2177b 3319a 1.526a 1.531 T1 223 266 1.190 812b 1600 b 1.976 b 1054 1753 c 1.666 c 2089a 3618 c 1.732c 1.757 T2 225 266 1.183 829ab 1552a 1.877a 1092 1507a 1.380a 2146ab 3325a 1.549a 1.561 T3 228 274 1.200 866a 1599 b 1.850a 1039 1596 b 1.539 b 2132ab 3468 b 1.627b 1.642 P 0.358 0.681 0.253 0.142 0.0067 0.0020 0.164 <0.0001 <0.0001 0.087 0.0001 0.001T0:

Table 2 – Growth performance of broiler chickens fed different diets supplemented with different enzymes.

T0: positive control (PC) without enzymes; T1: negative control (NC), PC reformulated to reduce apparent metabolizable energy, digestible aminoacids and crude protein by 65 kcal/kg and 2% respectively; T2: NC + MEC (xylanase + betaglucanase + cellulase + amylase + protease) at 250 g/ton; T3: NC + a commercial xylanase + betaglucanase complex (XBC) at 50 g/ton

a–c Means without a common superscript differ significantly at

Conclusions

The MEC when added at 250 g/ton of feed in reformulation (reducing apparent metabolizable energy, digestible amino acids and crude protein by 65 kcal/kg and 2% respectively) reduced the feed cost by 12 €/ton of feed compared to the PC diet, without compromising broiler performance. The XBC did not show the ability to recover the nutritional gap following reformulation.

Bibliography

Adams, C. A. and R. Pough, 1993. Non-starch polysaccharides digestion in poultry. Feed Compounder, 13: 1921.

Bedford, M.R. (1995): Mechanism of action and potential environmental benefits from uses of feed enzymes. Anim. Feed Sci. Technol. 53: 145-155.

Bedford, M.R. (2000): Exogenous enzymes in monogastric nutrition. Their current value and future benefits. Anim. Feed Sci. Technol. 86: 1-13.

CVB Feed Table 2016. Federatie Nederlandse Diervoederketen (FND)

Noy and Sklan (1995) net duodenal secretion of amylase, trypsin, and lipase is low at 4 d and increased 100-, 50-, and 20-fold, respectively, by 21 d. A MEC containing NSP degrading enzymes together with amylase and protease could increase the digestive capacity of the chicken: by supplying multiple NSPases to attack different portions of the cell wall at once and by providing other hydrolases such as protease and alpha-amylase, enhancing the action of the endogenous digestive enzymes to ensure the most efficient energy and amino acid release from the feed.

Noy, Y. and D. Sklan. 1995. Digestion and absorption in the young chick. Poult. Sci. 74:366-373.

Tony, M.A., A. Meeusen, H.A. Abdellatif (2007): Effect of multi-enzyme systems with increasing levels of protease activity on broiler performance. Proceedings of the 16th European Symposium on Poultry Nutrition, August 26 –30, 2007 Strasbourg, France.

From the Proceedings of the Mediterranean Poultry Summit 2022

37 - february 2023NUTRITION

Rete ntion Total tract digestibility Dry mat te r Nitrogen Crude Fat Starch Gross Energy AMEn(kcal/kg) T0 70.9 c 62.9 c 79.6 95.4b 73.4 c 3034b T1 67.0 a 56.8a 77.8 93.2a 68.9a 2826a T2 68.8 b 60.8 bc 80.6 97.0 c 71.6 b 2991b T3 68.1ab 60.2b 79.2 95.7b 70.4ab 2879a P-value 0.0001 0.0002 0.396 <0.0001 <0.0001 <0.0001

Table 3 – Digestibility and retention of nutrients from 18 to 21d of age.

1,5 1,55 1,6 1,65 1,7 1,75 2050 2070 2090 2110 2130 2150 2170 2190 PC (T0)NC (T1)NC + MEC (T2)NC + XBC (T3) BWG FCR b ab a ab BWG FCR a c a b Figure 1 – Overall trial BWG (g) and FCR 1,4 1,45 1,5 1,55 1,6 1,65 1,7 1,75 2700 2750 2800 2850 2900 2950 3000 3050 PC (T0)NC (T1)NC + MEC (T2)NC + XBC (T3) AMEn FCR b a b a a c a b FCR AMEn Figure 2 – Overall trial FCR and AMEn

P<0.05.

2 Cherrybro Co., Ltd. Jincheongun 27820, South Korea

3 AB Vista, Marlborough, Wiltshire, United Kingdom

Effects of stimbiotic on performance and intestinal barrier function in broilers challenged with a necrotic enteritis

Two experiments were conducted to evaluate the efficacy of stimbiotic (STB) supplementation in necrotic enteritis (NE) challenged broilers.

Introduction

Necrotic enteritis (NE), caused by Clostridium perfringens (CP) and exacerbated when birds are co-infected with Eimeria spp., is one of the most severe and common diseases resulting from intestinal mucosal damage (Bae et al., 2021). The stimbiotic (STB) concept has been recently introduced as a non-digestible and fermentable additive that stimulates the development of a microbiome comprising bacterial species that are principally involved in fibre degradation (Cho et al., 2020). It was reported that a low concentration of STB resulted in a better fermentation activity in colonic samples compared with 10-20 times higher doses of commercially available prebiotics. To successfully test the proposed mode of action, it is

38 NUTRITION - nutrition -

J.H. Lee1, B.K. Lee2, X. Rousseau3, G.A. Gomes3, H.J. Oh1, Y.J. Kim1, S.Y. Chang1, J.W. An1, Y.B. Go1, D.C. Song1, H.A. Cho1, J.C. Kim3, M.R. Bedford3 and J.H. Cho1

1 Department of Animal Science, Chungbuk National University, Cheongju 28644, South Korea

critical to develop an experimental infection model that will mimic a commercial outbreak of NE. Therefore, for successful NE induction in Experiment 1, a pre-screening study was performed to determine the optimal dosage of vaccine (coccidia and infectious bursal disease) and CP for inducing damage of the intestinal mucosa and instigating an NE infection model. Then in Experiment 2, the effects of STB on performance and intestinal barrier function in broilers challenged with the NE infection model were evaluated.

Methods

The experimental protocol for this study was reviewed and approved by the Institutional Animal Care and Use Committee of Chungbuk National University, Cheongju, Korea (CBNUA-1477-20-02).

Experiment 1

1. Oral administration of Vaccine and C. perfringens

Coccidia vaccine (Hipra Evalon ®, Laboratorios Hipra, Girona, Spain) and infectious bursal disease (IBD) vaccine (IBD Blen ®, Boehringer Ingelheim Animal Health USA Inc., Georgia, USA) were used in this experiment. These vaccines were diluted in sterile water and, when broiler chickens reached 14 days of age, 10 times or 20 times the recommended dose was administered orally through a sterile pipette. Clostridium perfringens (CP) type A NCTC 8798 (NCTC, National Collection of Type Cultures, London, UK) was used in this experiment. Four days after vaccination, a total of 3 ml of CP at 2.2 × 107 colony forming units (CFU)/mL was orally administered twice daily for 3 consecutive days (09:00 and 17:00; on days 18, 19, and 20).

2. Experimental animals and treatment