Trends in antibiotic use in New Zealand poultry

Patterns of global egg production and egg trade at the beginning of the current decade

Internal parasites of poultry

4

Zootecnica International –April 2023 –POSTE ITALIANE Spa –Spedizione in Abbonamento Postale 70%, Firenze

2023

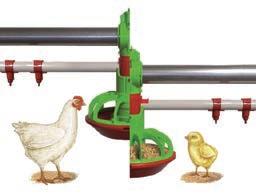

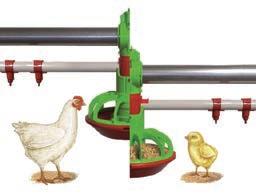

The new feeders of the «Gió» range,

specifically developed for great poultry farms, thanks to the easiness in the regulation of the feed and to the absence of grill (that avoid chicks perching) have many advantages: they are easy to use and their cleaning is extremely easy and fast too, leading to an overall reduction in labour costs.

CODAF Poultry Equipment Manufacturers • Via Cavour, 74/76 • 25010 Isorella (Brescia), ITALY Tel. +39 030 9958156 • Fax: +39 030 9952810 • info@codaf.net • www.codaf.net

for the rearing phase (first 30 days of life)

for the growing phase (no anti-waste ring)

EDITORIAL

With the collapse of the Berlin Wall, we utopianly believed that Europe could play an important role in defending the universal right to have peace. Unfortunately history, as always, has followed her twists and turns and recurrences i.e the Gulf War, the conflicts in Yugoslavia, Afghanistan, Iraq and other countries. Then one year ago the invasion of Ukraine. Russia, China and the United States are contending for the primacy of geopolitics, while in Europe it is now widely believed that they cannot have much influence over peace actions. Each country proceeds like a float in a stormy sea, failing to be cohesive with others.

We must not lose hope for a recovery of the values that lead back to a human dimension.

My deep conviction remains one that each of us can do something positive and I like to recall a verse by the French poet Paul Valéry:

“Le vent se lève!… il faut tenter de vivre!” (the wind rises…we must try to live).

DELIVERING

IMPROVED PRODUCTIVITY AND SUSTAINABILITY for

19

REDUCED

28%LESS

in live weight, shorter grow-out periods and reduced feed production and transport =

%

Progress

19

LOWER ENERGY USE

POLLUTION

FCR = Better nutrient utilization

POTENTIAL Better

NITRATE/ PHOSPHATE EXCRETION

%

GREENHOUSE

FCR and shorter grow-out time = REDUCED GLOBAL WARMING POTENTIAL LESS FEED MEANS...

TRIPS

raw materials and feed for broilers Improved FCR = a 2.5 kg (5.5 lb) broiler consuming... 0.8 kg 1.7 lb LESS FEED required for the production of broiler feed 42% LESS AGRICULTURAL LAND REDUCED LAND USE & TRANSPORTATION

LESS

GASES PRODUCED Improved

FEWER ROAD

delivering

the broiler industry

the past 20 years

THE PLANET FOR FUTURE GENERATIONS while increasing livability, health and welfare through balanced selection The modern broiler is more biologically e cient Per kg of live weight, it requires... IMPROVED PERFORMANCE required per 1.0kg (2.2 lb) broiler 320 g 0.7 lb LESS FEED WATER USAGE BETTER WATER INTAKE = Better gut health Better litter quality Better footpad health More e cient/sustainable water use

over

PROTECTING

VIEW ONLINE 18.3% 40 EXTRA TOTAL EVISCERATED YIELD g 0.09 lb LESS WATER 0.15 US gal 0.57L

Find out more about how Aviagen® protects the planet for future generations

SUMMARY WORLDWIDE NEWS 4 COMPANY NEWS 10 FIELD CASE Trends in antibiotic use in New Zealand poultry 12 DOSSIER The path to 100-week layers ......................................................................... 14 Evaluation of substances affecting turkey spermatozoa motility in vitro 16 MARKETING Patterns of global egg production and egg trade at the beginning of the current decade 18 TECHNICAL COLUMN Heat treatment of hatching eggs during storage 26 MANAGEMENT The importance of water quality in turkey production ...................................... 28 NUTRITION The challenge of reducing crude protein in meat-type chicken diets Second part 32 VETERINARY Internal parasites of poultry 38 MARKET GUIDE 44 UPCOMING EVENTS ......................................................................47 INTERNET GUIDE 48 38 12 18

Feed regulators and industry from around the world discuss critical issues with IFIF and FAO

The 16th annual International Feed Regulators Meeting (IFRM) organized by the International Feed Industry Federation (IFIF) and the Food and Agriculture Organization of the United Nations (FAO) brought together feed industry representatives and government officials from around the world to discuss critical issues facing the feed sector with IFIF and the FAO.

dialogue between the public and private sector are worthwhile and given the current challenges, collaboration among all parties at international and national level to ensure among others, human and animal welfare, and feed and food safety and security is more important than ever,” said Daniela Battaglia, Animal Production Officer, Animal Production and Health Division of the FAO.

At the meeting Ruud Tijssens, IFIF Chairman and Daniela Battaglia, FAO, welcomed IFRM delegates and reiterated their commitment to this longstanding partnership and agreed to continue to strengthen their work together to tackle the challenges facing the feed and food chains. Ms. Battaglia reaffirmed the importance of “collaboration between the public and private sector to support the responsibilities of the animal production sector in a context of sustainable agriculture and food systems worldwide.”

Mr. Tijssens said “I am delighted that we can meet again face-to-face at this unique event and that participants from across the world and from key regulatory bodies joined us at the 16th IFRM. This meeting, yet again, proved to be an important op -

portunity for the global feed industry and feed regulators to discuss key issues for the feed and food chains, including important work on nutritional innovation strategies to improve animal health and welfare, an update of Codex Alimentarius work with relevance to feed, as well as a very timely workshop on emerging feed sources and technologies in a circular bio-economy context.”

Mr. Tijssens added “This dialogue is an important example of the private sector collaborating with the FAO and regulators from around the world and we believe that only by working together can we continue to ensure feed and food security and safety, while meeting the global demands for food sustainably.”

“The success of this meeting is a proof that FAO’s efforts to facilitate

Ms. Battaglia added “feed operators can valuably contribute to make the animal production and food sectors more responsible and sustainable and to achieve other important goals such as the containment of antimicrobial resistance and public, animal and environmental health. The IFRM is an important opportunity to exchange ideas among stakeholders from around the world and to coordinate our efforts towards common goals.”

Other topics discussed at the 16th IFRM included a panel on the successful work of the International Cooperation for Convergence of Technical Requirements for the Assessment of Feed Ingredients (ICCF), which aims towards convergence of technical requirements specific to feed additive/ingredient authorization across regions, as well as presentations on key feed issues in Thailand and Vietnam.

Source: IFIF

4 - worldwide news -

WORLDWIDE NEWS

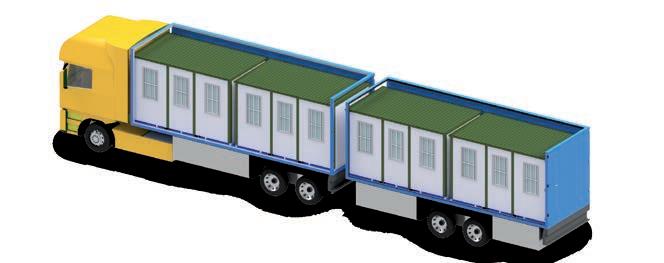

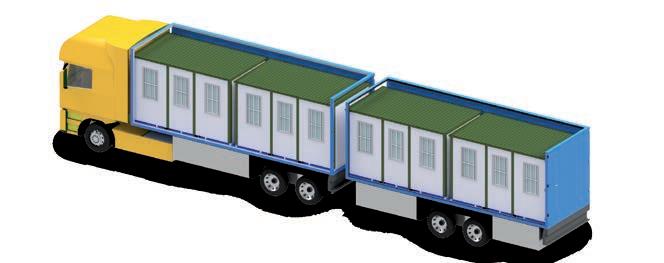

Sanitary Box

Professional, heavy-duty, insulated box for use on farms. Easy to transport and designed to comply with the health rules.

- april 2023 - 5 WORLDWIDE NEWS

s.r.l. Via Rimembranze, 7 25012 Calvisano (BS) Italy

+ 39 030

r.a. Fax + 39

4 boxes in one full truckload

Agritech

Tel.

9968222

030 9968444 commerce@agritech.it www.agritech.it

FAO fully committed to limiting the spread of antimicrobial resistance

Agrifood systems play a key role in limiting the spread of antimicrobial resistance (AMR) and the Food and Agriculture Organization of the United Nations (FAO) is fully committed to tackling what the UN lists as one of the top 10 threats for global health, FAO DirectorGeneral QU Dongyu told the sixth meeting of the Global Leaders Group (GLG) on Antimicrobial Resistance.

approach that aims to sustainably balance and optimize the health of people, animals and ecosystems by recognizing that they are closely linked and inter-dependent.

FAO is currently preparing a 10-year global initiative to reduce the need for antimicrobials in agrifood systems. FAO has also developed the first version of the International FAO Antimicrobial Resistance Monitoring IT platform to address the existing information gap in agrifood systems. In addition, FAO is hosting the AMR Multi-Stakeholder Partnership Platform, a mechanism to promote collaboration among a wide range of stakeholders at all levels across the One Health spectrum.

The meeting in Bridgetown, Barbados, was the first time that members of the GLG, which is comprised of world leaders and experts, were able to gather in person due to the COVID-19 pandemic. Hosted by the Prime Minister of Barbados, Mia Amor Mottley, the meeting covered critical AMR topics such as financing, research and development, integrated surveillance, the role of the private sector, AMR and the environment and galvanizing political action to address AMR.

“FAO is fully commit ted to working with its partners to create more efficient, more inclusive, more resilient and more sustainable agrifood systems for bet ter production, bet ter nutrition, a bet ter environment and a bet ter life for all,” the Director-General said. Such agrifood systems transformation can now be bet ter suppor ted thanks to the inclusion of the AMR in the Pandemic Fund, he added.

The Director-General underlined the importance of a One Health approach to reducing the use of antimicrobials in the agrifood sector. One Health is an integrated, unifying

Looking ahead, the Director-General invited participants to a UN Food Systems Stocktaking Moment scheduled for July 24-26 at FAO’s headquar ters in Rome, in which AMR will be discussed. AMR occurs when microorganisms such as bacteria, viruses, parasites or fungi become resistant to antimicrobial treatments to which they were previously susceptible.Increasing use and misuse of antimicrobials and other microbial stressors (e.g. the presence of heavy metals and other pollutants) creates favourable conditions for microorganisms to develop resistance. This in turn poses serious threats to human, animal, plant and environmental health, food safety, food security, and pandemic prevention, preparedness, and response. AMR disproportionately affects low- and middle-income countries and contributes to almost 5 million deaths per year, according to the Global Research on Antimicrobial Resistance report

The World Bank estimates that in the next decade, AMR could result in a GDP shortfall of at least $3.4 trillion annually, and an additional 24 million people would be forced into extreme poverty by 2030 if no action is taken on AMR today.

Source: FAO

6 - worldwide newsWORLDWIDE NEWS

FAO Director-General QU Dongyu addresses the sixth meeting of the Global Leaders Group on Antimicrobial Resistance.

©FAO/Enrico Brooks

Veterinary drug residues in food decline again

compliance levels are on the rise, the latest data reveals.

EFSA’s annual report for 2021 includes data reported by Member States, Iceland and Norway. The number of tested samples slightly increased compared to 2020. In 2021, the percentage of non-compliant samples was 0.17%, which is the lowest figure registered in the past 12 years when non-compliance ranged from 0.19% to 0.37%. The figure for 2020 was 0.19%.

Residues of veterinary drugs and other substances found in animals and animal-derived food continue to decline in the European Union and

The overall level of non-compliance in targeted samples (i.e. those taken to detect illegal uses or check non-compliance with the maximum permitted levels) also decreased to 0.24%, compared to 0.27%-0.35%

over the previous four years. The report covers various substance groups including hormones, antibacterials, environmental contaminants, prohibited substances and other veterinary drugs. You can browse the results in more depth using our new interactive data visualisation tool. The full dataset – comprising around 13 million analytical results –is available on the EFSA Knowledge Junction, an open repository that is meant to improve transparency, reproducibility, and reusability of evidence in food and feed safety risk assessments.

Source: European Food Safety Authority

- april 2023 - 7 WORLDWIDE NEWS

FIER VICOLA I N TER N A T IO N A L P OU LTR Y EX HI B I T IO N 3-4-5 MAY 2023 RIMINI - EXPO CENTRE - ITALY TOGETHER WITH cjc

ShowCo: working together to improve poultry trade shows

Poultry trade shows are important events for everyone involved in the poultry sector to make business connections. But with numerous events each year, a strategy is needed to pick when and where to go because it is not possible to attend them all. This is where ShowCo comes in.

ShowCo members are focusing on other international poultry trade shows such as VIV Asia and VIV MEA. Missing out on big shows like IPPE has its drawbacks but ShowCo members buy in to the overall strategy. “Undoubtedly, every trade show has opportunities for ShowCo members,” says ShowCo director Fenny Straat. “But that needs to be considered against the time and financial resources needed to prepare for and attend trade shows.”

More innovation

ShowCo is an association of companies who work together to achieve more from poultry trade shows. ShowCo is made up of various companies from around the world which all sell products and services to poultry producers. Its main tool to get more from events is the Global Exhibition Calendar which maps out trade fairs in the poultry sector. ShowCo discusses and decides which events members will attend in each year.

Every two years

The general rule is that ShowCo members attend each major exhibition every two years. For example, ShowCo attended IPPE in 2022 and will do so again in 2024, but in 2023

“A founding principle of ShowCo is to attend fewer, and work together to make better, trade shows and use the time and resources saved to improve the standard of the products and services we offer customers. By not attending every event, we believe that we offer visitors more innovation and higher quality at the events we do attend.” With this strategy, having a robust method to choose which events to attend is vital. ShowCo members develop collectively a biannual program. For this, ShowCo also works closely with event organizers to learn more about events early in the planning cycle. There is also detailed evaluation of previous events by members. All this information is discussed by ShowCo members collectively to create the Global Exhibition Calendar.

For members and event organizers

“We make sure the Global Exhibition Calendar works for all our members,” says the ShowCo director. “The calendar is a strong recommendation of which events to attend. But member companies are in principle free to attend other shows.” Ms Straat points out that member companies tend to follow the plan because they agree with the ShowCo approach and have been involved all the way with the decision-making process.

“Having a three-year rolling plan makes it easy for ShowCo members and event organizers to plan for events. Everyone focus on delivering events that make an impact. But it is flexible, we continually discuss the plan and make changes if desired or necessary.”

ShowCo in 2023

To find out which companies are members of ShowCo, Ms Straat recommends visiting the website www. showco.org. In 2023, ShowCo members attended VIV Asia in Bangkok in March and will attend VIV MEA in Abu Dhabi in November. A smaller group of ShowCo members will also attend other international regional shows such as, CAHE China and VIV Turkey.

8 - worldwide newsWORLDWIDE NEWS

Leader

THE REVOLUTIONARY RATIONING SYSTEM FOR BROILER BREEDERS AND LAYERS

Equal, controlled and immediate distribution throughout the line.

The obstacle-free linear trough feeder allows an easy access for the animals which can easily spot the feed.

WATCH THE VIDEO explaining how the BREEDAZA system works

Manufactured from sturdy light plastic material for easy winching.

Easy cleaning and no residual feed inside the trough.

- april 2023WORLDWIDE NEWS AZA International s.r.l. Via Roma 29 24030 Medolago (BG) Italy Phone (+39) 035 - 901240 - E-mail: info@azainternational.it QUALITY MADE IN ITALY www.azainternational.it BREEDAZA

in

& poultry

pig

equipment

AZA!

The innovative linear trough feeder I WANT

ADJUSTABLE ANTI-COCK GRID NO OBSTACLE INSIDE EASY ACCESS TO FEED

GALVANISED STEEL MODEL

Aviagen engages with customers, colleagues and future professionals at successful IPPE 2023

For the Aviagen® global team, the 2023 International Production and Processing Expo (IPPE) was marked by sharing, connecting, and strengthening common bonds with likeminded poultry professionals.

“On behalf of Aviagen, I congratulate our five impressive young leaders, and appreciate IPPE for recognizing them in this way,” commented Marc de Beer, Aviagen’s President of North America. “IPPE and Aviagen share a commitment to investing in our next generation. They are our future, and the sustainability of our industry depends on our ability to attract bright, innovative people who have a passion for poultry and for feeding the world.”

Breeding the best

Aviagen employees from around the globe, speaking multiple languages and from various areas of expertise, enjoyed meeting with customers and industry colleagues. A main topic of conversation was Aviagen’s innovative “Breeding for welfare and sustainability.” Due to the company’s balanced breeding approach, welfare, sustainability and performance are all dominant qualities of Aviagen birds. Complementing this strategy is a full portfolio of Arbor Acres®, Indian River® and Ross® conventional breeds, as well as the Rowan Range aimed at slower-growing, organic and free-range markets. These breeds combine to strengthen customer success by enabling them to offer consumer choice.

Aviagen takes every opportunity to connect with our future generation. At the student career section of IPPE, Human Resources representatives were on hand to engage with students and interview them for potential careers at Aviagen. This initiative saw a high turnout of qualified candidates who were enthusiastic about helping feed the world with a sustainable, healthy source of protein.

Knowledge sharing – An IPPE show special

Young leaders under 30

Rewarding young talent

Aviagen is proud of its five employees who were recognized with the IPPE “Young leaders under 30” award. These promising young Aviagen professionals, aged 2129, were chosen for their leadership qualities and commitment to the industry. In addition to the experience of engaging in the world’s largest annual tradeshow of its kind, winners were presented with special “Young leaders” plaques at a breakfast held in their honor.

With 28,000 professionals from across the planet in attendance, IPPE was the ideal platform for the exchange of the latest developments and information. Aviagen specialists in genetics, nutrition, veterinary medicine, flock management, hatchery and incubation and more were there to listen to customers and share ideas and advice. Various Aviagen experts also spoke at IPPE-hosted TechTALK events. They addressed the importance of data in improving poultry performance, health and welfare, as well as the usefulness of technology in providing optimal remote support to customers.

“We were pleased with the overall turnout at IPPE 2023, and consider the show an invaluable opportunity to engage with customers and the wider poultry community. A big thank you to poultry producers and visitors to the Aviagen booth. As members of the poultry value chain, we share a common commitment to leveraging the latest innovations to feed current and future generations, while promoting customer success and the sustainability of our planet,” concluded Aviagen CEO Jan Henriksen

10 - company newsCOMPANY NEWS

–

From left: Alexis Sims, Quality Assurance Coordinator; Loretta Chapel, Audit Manager; Wesley Lewis, Farm Manager; Karri Morton, HR Project Coordinator; Lisa Tenny, Associate Veterinarian

AZA INTERNATIONAL, poultry feeding systems and hi-capacity conveyors at Fieravicola 2023

AZA INTERNATIONAL, a long time leading company in the manufacturing of livestock feeding equipment, was founded over 50 years ago. The company’s policy has always been based on customer service, quality and innovation.

the whole line. This considerably reduces the feeding period and the trough feeder is totally cleaned at the end of every daily meal, as there isn’t any obstacle inside the feeding trough.

Self-Dosy pans will also be available on AZA’s stand and are specifically designed for the controlled feeding of roosters. Simple, cheap and easy to manage.

The company will show its wide range of prominent feed pans, such as PRATIKA which gives excellent conversion performances, easy feed adjustment and automatic easy and fast cleaning and MODULA, the sturdy feed pan specifically designed for heavy turkeys from chick to slaughtering age.

The company is proud to introduce its wide range of poultry feeding systems and hi-capacity conveyors at Fieravicola 2023. In Rimini AZA’s customers will be able to see the Breedaza system. BREEDAZA is one hispeed linear trough feed distribution and rationing system particularly suitable for broiler-breeders and layers housed either in cages or on the floor. The system ensures more rapid and even distribution of the feed along

AZA INTERNATIONAL invites you to also see the DUO system, which is a combination of feed pan and drinker on the same line, FLEXA for pullets and MIXTA, the perfect pan for ducks and mixed broiler-turkey cycles. Hi-capacity conveyors diam. 76,102 and 114 mm will be exhibited too. These products are made from top quality materials and are specifically designed for those customers who require hi-capacity transportation. AZA INTERNATIONAL, a winning choice in modern zootechnics!

- april 2023 - 11 COMPANY NEWS

Breedaza

Pratika

Modula

Trends in antibiotic use in New Zealand poultry

The New Zealand Poultry Industry has continued to reduce the use of antibiotics across the national flock since 2016.

Kerry Mulqueen

Zealand

Kerry Mulqueen

Zealand

The poultry industry has four major sectors. The two primary breeding companies, Aviagen and Cobb that own the genetics and provide parent birds to meat chicken companies and farmed to provide the chicken meat in the retail and restaurant food sectors in New Zealand have the potential to provide approximately 20% of the world's demand for meat chicken parents, they are in New Zealand as a protection against Avian Influenza affecting their business.

The meat chicken sector produces 120 million birds per year in New Zealand which supplies the 38 kg of chicken meats/head consumed in New Zealand on an annual basis. There are four major companies in this

sector, and such is the business model that they retain full ownership of these birds and control their diets and processing timings. The farms grow the birds to the companies’ requirements. The farms and processing plants are near to reduce transport times to plants. These birds and breeding birds are all raised and farmed on litter.

The egg layer sector is smaller with four million birds in lay but with one hundred plus farmers own these birds with the business model being small farms with 100 birds of more to corporates owing 500,000 or more. These birds supply the 210 eggs that New Zealand consumers per person per year. In 10 years, this sector has had to completely

12 - field reportFIELD REPORT

PIANZ - Poultry Industry Association of New

change its operating structure from conventional cages to either free range, colony, or barn farming systems. There is also turkey and duck produced in New Zealand, but both these produce less than a million birds per year. This equates to there being on any given day nineteen million birds alive in New Zealand.

New Zealand has a unique avian health status in that we are free of major avian viruses like avian influenza, Newcastle’s disease, infectious bursal disease, infectious bronchitis, and many viruses that are pathogenic in poultry.

The major antibiotic used in poultry and in meat chicken in particular is zinc bacitracin (ZB). The use of this antibiotic has been as a prophylactic for the control of necrotic enteritis (NE). This disease is caused by a clostridia sp. and can affect the whole flock of meat chicken to produce a 90% mortality within 12 hours, this speed renders treatment by inclusion of any treatment in feed or water ineffective. After 60 years of development there is still no vaccine for the control of this agent in poultry, thus the drive to prevent.

In 2022 New Zealand meat chicken grown without zinc bacitracin in their diets will be 95% or 110 million by, 2023 this will be at 99% (PIANZ).

The ability to allow this change in meat chickens has been driven for the USA which now has 69% of its production or 6,427 million (USA chicken Council) meat chickens growing with no antibiotics in their diets. This change in farming practice has encouraged pharmaceutical companies worldwide to develop products that can be classified as gut modulators. These products include

probiotics, prebiotics, botanicals, and phytochemicals, (herbs, spices, and other plants and their extracts), fatty acids, enzymes, immune related products, and vaccines.

A continual issue is the ability to register these products with the ACVM framework. These new products are unavailable to New Zealand poultry as the costs and return economics does not support a complex registration process, an issue that needs addressing to keep poultry health at an elevated level in New Zealand.

This reduction in the New Zealand inc. volumes of antibiotics used will remove approximately 10,000 kg of active when comparing 2016 to 2022. The use of zinc bacitracin is likely to be less than 3,000 kg of active for the year 2022.

The use in the meat chicken, meat chicken and layer breeder sectors are recorded above. These figures are collected by the industry from the companies that produce the feed and the poultry veterinarians that script Antibiotics into these sectors of the industry. These figures are less than that reported in the MPI/ ACVM annual reports and represent actual usage at the level the feed is manufactured.

The use of Abs in the egg layer industry is not as clear as there are many feed mills that are owner op -

erator, but the volumes are low as adult birds are remarkably resistant to pathogens. It is worth noting that the increase of free-range farming has seen a return of diseases that were eradicated with birds being housed.

The ability to compare New Zealand figures with other countries around the world is confused by how other countries register and classify antimicrobial products. New Zealand like USA classifies ionophores as Abs (New Zealand Commerce Department ruling) whereas the European Union classifies these as feed additives and thus makes them available to be classified as able to be used in growing Ab free poultry meats.

The poultry industry will still use antibiotics in the treatment of disease in New Zealand but the usage per bird will be lower than most countries in the world.

References

Peterson A., National Chicken Council Presentation, 31 March 2022

From the Proceedings of 2022 Conference Proceedings of the Epidemiology, Food Safety, Animal Welfare and Biosecurity Branch of the NZVA 25

13 - april 2023FIELD REPORT

Year Oxytetracycline (kg active) Tylosin (kg active) Zinc bacitracin (kg active) Bird numbers (millions) Meat tonnes (thousands) 2019 738 294 16,011 120.745 225,673 2020 471 294 15,634 118.702 217,195 2021 226 49 9,671 120.200 (est.) 219,000 (est.)

Table 1 – AB usage tables for 2019 and 2020 from data submitted to PIANZ.

Active kg of AB used. PIANZ data.

The path to 100-week layers

New research, funded by the Canadian Poultry Research Council, seeks to maintain hen health through longer lay cycle.

For laying hens, strong bones and good egg shell quality both require phosphorus and calcium – two essential minerals that travel from the hen’s body to her eggs over time. As a result, at the end of a 70-week lay cycle, a hen’s supply of minerals in bone may be depleted leading to weaker bones. Now, Marie-Pierre Létourneau-Montminy in Laval University’s Animal Science Department is leading an international multidisciplinary research team on two concurrent projects that aim to un-

derstand how calcium and phosphorus travel through a hen’s body at various stages of the life cycle, and how precision mineral feeding might help meet daily mineral requirements that would allow producers to extend a lay cycle.

“We are working to predict daily nutrition requirements of laying hens in calcium and phosphorus,” says Létourneau-Montminy. “We have a modeling project that, for the

14 DOSSIER - dossier -

first time, collates all available published data to give us a better understanding of the fate of calcium and phosphorus in the gastrointestinal tract and then at metabolic levels. And simultaneously, we are able to test the model’s predictions in a 100-week research trial.”

Limestone particle size matters

To simulate the fate of these minerals, the team first had to understand the extent of work that had already been done to track phosphorus and calcium in the digestive tract of a laying hen. The researchers faced an unexpected hurdle when they realized there was no information relating to the interaction between limestone particle size (a source of calcium) and phytase in laying hens, an enzyme that makes phosphorus from plants. Research partners in France performed a trial that provided information to address the gap.

“We confirmed large limestone particles interact less with phytase, and fine particle size will reduce the efficiency of the enzymes,” says Létourneau-Montminy. “Larger limestone particles stay in the gizzard longer, and since eggshells form at night when the hen eats less, they are an available source of calcium. This is particularly important as a hen ages, and makes less efficient use of calcium.”

From there, the researchers were better able to predict phosphorus and calcium absorption. In general, the hen has to take some calcium from the bone to deposit in the egg’s shell during the night, and that process delivers phosphorus, which is then lost in manure. With the modelling study data, the team was able to predict daily nutrition requirements throughout a hen’s life cycle – and even optimal time of day.

Measuring bone health

For the second part of Létourneau-Montminy’s project, the researchers are putting the model predictions to the test by raising laying hens to 100 weeks with two different dietary phosphorus levels. The team is using a bone scanner tool commonly used in human medicine for osteoporosis diagnosis to test the hens’ bones for mineral content as well as body composition in fat and lean. Létourneau-Montminy hopes the project will give a better understanding of how bone evolves, and the amount of calcium that transfers to eggs as hens age.

“With age, the birds enter osteoporosis and they make less efficient use of calcium,” says Létourneau-Montminy. “We also tend to see a reduction of phosphorus.”

The importance of precision phosphorus

Létourneau-Montminy notes with world phosphorus reserves affected by rising prices and scarcity, producers face increasing pressure to be precise with this non-renewable resource. When the trial completes in November 2022, she hopes to have a better understanding of exactly how phosphorus and calcium are used in the hen’s body over time.

“We know that with aging, hens use more of their bone reserves, so we are looking at different strategies,” says Létourneau-Montminy. “With this trial we will have important information about how mineral requirements change, and we will have many data points to help us fill in some of the knowledge gaps.”

Birds typically lay 350 eggs by the end of their 52-week cycle. By extending to 70 weeks of lay or 100 weeks of age, the aim is to get to 500 eggs, as long as the data supports the birds are in good physical shape. She notes the team is gathering information about bone composition, bone marrow density, mineral content in eggs and bones, as well as hormone levels in bloodwork over time.

Both the modeling project and the research trial will be completed by early 2023. Létourneau-Montminy hopes to complete a similar trial using the same design looking at vitamin D concentrations in diet and in layer hens.

This research is funded by the Canadian Poultry Research Council as part of the Poultry Science Cluster which is supported by Agriculture and Agri-Food Canada as part of the Canadian Agricultural Partnership, a federal-provincial-territorial initiative. Additional support was received from Egg Farmers of Canada, DSM and Avimix Nutrition.

15 - april 2023DOSSIER

P. Massanyi, T. Slanina and M. Miskeje

Slovak University of Agriculture in Nitra, Faculty of Biotechnology and Food Sciences, Institute of Applied Biology, Tr. A. Hlinku 2, 949

76 Nitra, Slovak Republic

AgroBioTech Research Centre, Slovakia

Evaluation of substances affecting turkey spermatozoa motility in vitro

Artificial insemination is a necessary and exclusive means of breeding turkeys in large farms. For optimal fertility outcomes, breeders must focus also on the quality of collected semen.

Artificial insemination is currently a necessary and exclusive means of breeding turkeys in large farms (Di Iorio et al., 2020; Slowinska et al., 2018). For optimal fertility outcomes, breeders must focus not only on the insemination itself, but also on the quality of collected semen. The culture medium is one of the main factors influencing semen quality and turkey spermatozoa in in vitro conditions. The aim of the study was to evaluate the impact of selected additive substances with potential stimulatory effects on spermatozoa motility of turkeys

16

DOSSIER - dossier -

©Petersime

(Meleagris gallopavo), during in vitro incubation. Specifically, we analyzed the effect of different concentrations of trehalose, fructose, caffeine and taurine diluted in the physiological solution as the culture medium.

The primary aim of the study was to develop a new semen extender usable in practice based on obtained results. The individual motility parameters were analyzed by CASA system (Computer Assisted Semen Analyzer) at 5 °C and 41 °C in different time periods.

The highest monitored concentrations of trehalose (10 mg/ml) and fructose (20 mg/ml) showed a relatively balanced value of motility parameters. At the lower concentration of trehalose (5, 2.5, 1.25 mg/ml) and fructose (5, 10, 15 mg/ml), a negative effect on the individual motility parameters of turkey spermatozoa was observed. Significantly (P<0.01, P<0.001) higher motility and progressive motility of spermatozoa, respectively, were detected in the samples containing caffeine ranging from 0.16 mg/ml to 7.5 mg/ml in comparison to the control sample at 5 °C.

At cultivation temperature of 41 °C the positive effect of caffeine was demonstrated only at the beginning of incubation (time 0 and 1h). The concentration of taurine above 10 mg/ml had a negative effect on spermatozoa motility. A significant stimulatory effect of taurine on motility parameters was observed in the samples containing 7.5, 5 and 2.5 mg/ml of taurine. Following the continuous results three new semen extenders were prepared. At the cool media incubation (5 °C) all three extenders showed significantly higher values of all CASA motility parameters from 1 to 6 hours during in vitro incubation. After 24 hours of incubation, significantly higher values of motility parameters were measured in extender three compared to the control.

In conclusion, we can state that we have successfully developed new turkey semen extenders (registration in process), which not only maintain spermatozoa motility during short-term storage in in vitro conditions, but also have a stimulatory effect on turkey spermatozoa motility.

Acknowledgements: This publication was supported by the Operational program Integrated Infrastructure within the project: Creation of nuclear herds of dairy cattle with a requirement for high health status through the use of genomic selection, innovative biotechnological methods, and optimal management of breeding, NUKLEUS 313011V387, co- financed by the European Regional Development Fund. This work was supported also by

“The aim of the study was to evaluate the impact of selected additive substances with potential stimulatory effects on spermatozoa motility of turkeys (Meleagris gallopavo), during in vitro incubation. Specifically, we analyzed the effect of different concentrations of trehalose, fructose, caffeine and taurine diluted in the physiological solution as the culture mediumˮ

project of the Scientific Grant Agency of the Ministry of Education, Science, Research and Sport of the Slovak Republic (projects VEGA 1/0539/18).

References

Di Iorio M., Rusco G., Iampietro R., Colonna M. A ., Zaniboni L., Cerolini S. & Iaffaldano N. (2020) Animals (Basel) 10: 421.

Slowinska M , Liszewska E , Judycka S , Konopka M & Ciereszko A (2018) Poultry Sci. 97: 3709- 17.

From the Proceedings of the Australian Poultry Science Symposium 2022

17 - april 2023DOSSIER

Patterns of global egg production and egg trade at the beginning of the current decade

In December 2022, the FAO published data on global livestock production and trade in livestock products. This makes it possible to document and analyse the patterns of global egg production and egg trade at continental and country level at the beginning of the current decade.

Asian countries dominated global egg production

Hans-Wilhelm Windhorst

Emeritus

Hans-Wilhelm Windhorst

Emeritus

Remarkable growth of global egg production

Between 2011 and 2021, world egg production increased from 65.5 million tonnes to 86.4 million t, or by 31.9% (Table 1). In 2021, the continuous upward trend was interrupted by the Covid-19 pandemic and outbreaks of Avian Influenza in several countries (Figure 1). This trend continued in 2022, when severe AI epidemics were reported not only in Europe and North America, but also in other regions of the world.

Figure 2 documents the changes in the continents’ shares in global egg production between 2011 and 2021. With the exception of Asia and Central and South America, all continents lost shares, Europe 3.3% and North America 0.7%. These dynamics reflect the absolute and relative changes in production volume over the decade under consideration. With a relative growth of only 4.9%, Europe lagged far behind all other continents. The already high per capita consumption, a declining population and the impact of AI epidemics were the main reasons for the comparatively low growth rate. Asia contributed 73.8%, Central and South America 14.1%, North America 6.2% and Europe only 2.5% to the absolute growth in global egg production of 20.9 million tonnes. The observed regional concentration in egg production over the past decades also continued until 2021. The share of the ten leading countries in the global production volume increased from 68.4% in 2011 to 71.2% in 2021 (Figure 3).

A closer look at the dynamics at country level shows not only the changed composition of the countries, but also their ranking (Table 2). In 2021, no European country was in the top group any more. Turkey and Pakistan replaced EU member states France and Spain, and India replaced the USA in second place. Japan fell from fourth to seventh place, Russia from sixth to eighth; Brazil, on

18 MARKETING - marketing -

The author is Prof.

of the University of Vechta and visiting Professor at the Hannover Veterinary University, Germany

the other hand, improved by two ranks. Although China had the highest absolute growth in the decade studied, the increase in production volumes of India and Indonesia is remarkable. China contributed 5.1 million t or 24.6% to global growth, Indonesia 4.1 million t or 19.7% and India 3.2 million t or 15.5%. Population growth and rising per capita consumption, especially in Indonesia and India, due to the increasing per capita income of the growing middle class, were the main factors behind this remarkable momentum.

Europe and Asia dominate global egg trade

Compared to meat, the share of traded table eggs in egg production was very low. In 2021, only about 2.5% of the eggs produced were traded, even 0.3% less than in 2011. The low trade volume is due to the fact that shell eggs cannot be frozen and have a comparatively short shelf life. Table eggs are produced almost exclusively for the domestic market.

Figure 4 shows the development of global exports and imports of eggs between 2011 and 2021. In the decade under consideration, the export volume increased by 328,000 t or 18.1%. A closer look at the graph shows that it was not a continuous upward trend. In 2015 and 2016, and again in 2019 and 2020, export volumes declined. In 2015 and 2016, this was a result of massive outbreaks of the Avian Influenza virus in Europe and North America; in

19 - april 2023MARKETING

[mill. t] 0 23 45 68 90 20112012201320142015201620172018201920202021 S America N America Europe Asia World

Figure 1 – The development of global egg production between 2011 and 2021 (design: A.S. Kauer, based on FAO data).

Continent 2011 2021 Increase absolute % Africa Asia Europe N America CS America Oceania 2,884.5 38,211.9 10,598.9 5,934.1 7,587.4 275.7 3,471.8 53,655.1 11,117.5 7,254.4 10,529.5 359.8 568.8 15,443.2 518.6 1,320.3 2,942.1 84.1 20.3 40.4 4.9 22.2 38.8 30.5 World 65,474.5 86,387.8 20,913.3 31.9

Table 1 – The development of global egg production between 2011 and 2021 at continent level; data in 1,000 t (source: FAO database).

Total: 65.5 mill. t 0.4% 11.6% 9.1% 16.2% 58.3% 4.4% 2011 Total: 86.4 mill. t 0.4% 12.3% 8.4% 12.5% 62.4% 4.0% Africa Asia Europe N America CS America Oceania 2021

Figure 2 – The share of the continents in global egg production in 2011 and 2021 (design: A.S. Kauer, based on FAO data).

31.4% 1,3% 1.3% 1.6% 3.1% 3.5% 3.8% 3.8% 5.3% 8.4% 36.5% China USA India Japan Mexico Russia Brazil Indonesia France Spain Others Total: 65.5 mill. t 2011 Total: 86.4 mill. t 2021 28.8% 1.2%1.4% 2.9% 3.0% 3.5% 3.8% 6.0% 7.7% 7.8% 33.9% China India USA Indonesia Brazil Mexico Japan Russia Turkey Pakistan Others

Figure 3 – The share of the ten leading egg producing countries in global egg production in 2011 and 2021 (design: A.S. Kauer, based on FAO data).

2011 2021 Country Production Country Production China USA India Japan Mexico Russia Brazil Indonesia France Spain 23,897 5,475 3,466 2,483 2,459 2,284 2,037 1,028 866 819 China India USA Indonesia Brazil Mexico Japan Russia Turkey Pakistan 29,316 6,710 6,643 5,156 3,317 3,047 2,574 2,496 1,207 1,000 10 countries 44,814 10 countries 61,466 World 65,474 World 86,388

Table 2 – The ten leading countries in global egg production in 2011 and 2021; data in 1,000 t (source: FAO database).

2019 and 2020, the onset of the Covid-19 pandemic and numerous new AI outbreaks caused the decline (Böckmann 2021, Windhorst 2016, 2022). Global egg imports increased faster than exports. In the period studied, the volume increased by 434,000 t or 25.7%. The fluctuation was similar to that of egg exports.

Europe and Asia dominated both exports and imports of eggs. In 2011, Europe accounted for 61.8% of the global export volume, followed by Asia with 30.6%. In the following ten years, Europe lost 7.1% of its former share, while Asia gained 3.3%. In terms of egg imports, Europe’s share fell from 58.7% to 53.2% during the decade under review, while Asia’s share increased from 33.8% to 37.0%. A detailed analysis of the dynamics at country level will document which countries were able to consolidate their position or were confronted with a loss of market share. In 2021, only North America (+167,000 t) and Europe (+40,000 t) recorded an export surplus, while all other continents had a negative trade balance.

High regional concentration in egg exports and imports at country level

Tables 3 and 4 document the ten leading countries in exports and imports of eggs in 2011 and 2021. Figures 5 and 6 show the shares of the ten leading countries in global export and import volumes respectively. Both the tables and the figures show the still high regional concentration in the global egg trade, even if it has decreased in the decade under review.

The Netherlands has been the undisputed leading export country for eggs for decades. However, Table 3 and Figure 5 show that its export volume fell by 30,000 t between

2011 and 2021 and its share in global exports declined by 4.7%. Of the top ten countries, only four (Uzbekistan, USA, Belgium and Spain) gained shares. The rapid growth of Uzbekistan’s and the USA’s exports is remarkable. A comparison of the composition and ranking of the countries shows considerable changes. While the Netherlands and Turkey were able to consolidate their top positions, Poland, Germany, Malaysia and China were unable to maintain their previous positions. Uzbekistan replaced Saudi Arabia and was in fourth place in 2021, the USA even made up five ranks.

Similar to the Netherlands in egg exports, Germany has been the leading egg importing country for decades. Close bilateral trade has developed between the two countries,

20 MARKETING - marketing -

[mill. t] 0,0 0,6 1,2 1,8 2,4 20112012201320142015201620172018 Exports Imports 2019 2020 2021

Figure 4 – The development of global egg exports and imports between 2011 and 2021 (design: A.S. Kauer, based on FAO data).

2011 2021 Country Exports Country Exports Netherlands Turkey Poland Germany Malaysia China Spain USA Belgium S. Arabia 381.3 206.3 174.0 138.6 137.7 102.2 96.2 94.0 46.4 41.5 Netherlands Turkey USA Uzbekistan Poland Spain Germany Malaysia Belgium China 351.2 221.2 201.4 190.0 147.7 123.7 117.5 114.2 93.4 73.6 10 countries 1,428.2 10 countries 1,633.9 World 1,809.4 World 2,137.4

Table 3 – The ten leading egg exporting countries in 2011 and 2021; data in 1,000 t (source: FAO database).

2011 2021 Country Imports Country Imports Germany Iraq Netherlands China Hong Kong Singapore France Belgium Switzerland Un. Kingdom 416.6 188.2 155.7 112.2 103.1 75.5 63.0 56.7 32.1 31.1 Germany Netherlands China Hong Kong Belgium Un. Arab Emir. Mexico Singapore Russia France 325.3 252.1 198.8 183.9 124.1 98.5 82.5 80.6 72.5 48.0 10 countries 1,234.2 10 countries 1,466.3 World 1,686.2 World 2,120.2

Table 4 – The ten leading egg importing countries in 2011 and 2021; data in 1,000 t (source: FAO database).

which will be presented in a later part of the analysis. Table 4 shows the top ten egg importing countries in 2011 and 2021, Figure 6 their share in the global import volume in the respective years. A comparison of the composition and ranking of the countries reveals some notable changes. Iraq, Switzerland and the United Kingdom have been replaced by the United Arab Emirates, Mexico and Russia. While Iraq still ranked second behind the Netherlands in

2011, it was no longer part of the top group in 2021. This is mainly due to the withdrawal of US troops from Iraq from 2020 on. The United Arab Emirates increased its egg imports significantly, but re-exported some of its imports to other countries on the Arabian Peninsula (Bahrain, Kuwait, Oman). Mexico had to import more eggs due to a growing population, consistently high per capita consumption and the impact of AI outbreaks. Russia increased its egg imports because of the decline in pig meat production caused by the severe outbreaks of the African Swine Fever. The change in import volumes is reflected in the countries’ changing contribution to world egg exports.

At first glance, it is surprising that the Netherlands is the second most important egg importing country, despite its top position in egg exports. This is due to the movement of eggs from East German layer farms owned by Dutch companies to the Netherlands. These eggs were classified as exports from Germany and imports from the Netherlands. Germany reduced its imports by 91,000 t in the reporting year, resulting in a 9.4% decrease in its share of

IT’S WHAT YOU DON’T SEE THAT SETS US APART

B.U.T. Premium

The B.U.T. Premium poult box is the start of something special. It’s the home of our well-bred and developed poults that will deliver top-performing results aimed at enhancing your bottom line. With high productive performance, exceptional welfare, enhanced liveability and improved FCR, B.U.T. Premium is your best choice for top profits.

For more information about our entire range, visit www.aviagenturkeys.com

Our top-performing birds deliver direct to your bottom line

21 - april 2023MARKETING

Total: 1.81 mill. t 21.6% 2.3% 2.6% 5.2% 5.3% 5.6% 7.6% 7.7% 9.6% 11.4% 21.1% 2011 Total: 2.14 mill. t 23.7% 3.4% 4.4% 5.3% 5.5% 5.8% 6.9% 8.9% 9.4% 10.3% 16.4% 2021 Netherlands Turkey Poland Germany Malaysia China Spain USA Belgium S. Arabia Others Netherlands Turkey USA Uzbekistan Poland Spain Germany Malaysia Belgium China Others

Figure 5 – The share of the ten leading egg exporting countries in global egg exports in 2011 and 2021 (design: A.S. Kauer, based on FAO data).

the global import volume. A considerable increase in the laying hen population allowed for lower imports despite rising per capita consumption.

Patterns of trade flows

In this part of the analysis, the trade flows for the leading egg exporting and importing countries are analysed in detail. This will make it possible to identify the driving factors behind the different patterns.

Figure 7 shows the trade flows for egg exports of the Netherlands, Turkey and Poland. In 2021, the Netherlands exported 351,200 t of shell eggs, of which 62.8% went to Germany. A closer look at the composition of the top ten destinations shows that the EU (27) Member States dominated. Obviously, in addition to the absence of customs duties, short transport distances played an important role. Saudi Arabia, Iraq and Russia became attractive markets only a few years ago. The trade flow pattern of egg exports from Turkey was very different. The regional concentration was almost identical to that of the Netherlands, but there was no dominant country of destination. Nine of the top ten countries were Islamic countries, five of which were on the Arabian Peninsula. In addition to the Islamic denomination, short transport distances were an important steering factor. The countries of the Arabian Peninsula were accessible by lorry. Poland exported almost 148,000 tonnes of shell eggs in 2021, of which 82.1% were imported by EU (27) Member States. A closer look at the composition of the countries shows that distance, tariff regulations and Poland’s former membership of COMECON (Council for Mutual Economic Assistance) were the main steering factors in the trade flow pattern.

Figure 8 shows the trade flows of egg imports by Germa-

ny, Hong Kong and the United Arab Emirates. In 2021, Germany imported more than 325,000 tonnes of shell eggs. Of the import volume, 82.7% came from the Netherlands, reflecting the long-standing trade relationship between the two countries. The top five countries of origin, all EU (27) Member States, accounted for 97.0% of total imports.

The regional concentration of Hong Kong’s egg imports was also very high. China was the leading country of origin with a share of 44.2%. Four of the top five countries of origin were in Asia. Imports from Malaysia, Japan and Thailand showed high growth rates between 2019 and 2021. Egg imports from the USA have fluctuated considerably in recent years. The severe Avian Influenza outbreaks

22 MARKETING - marketing -

Total: 1.69 mill. t 26.8% 1.8% 1.9% 3.4% 3.7% 4.5% 6.1% 6.7% 9.2% 11.2% 24.7% 2011 Total: 2.12 mill. t 30.8% 2.3% 3.4% 3,8% 3.9% 4,6% 5.9% 8.7% 9.4% 11.9% 15,3% 2021 Germany Iraq Netherlands China Hong Kong Singapore France Belgium Switzerland U.K. Others Germany Netherlands China Hong Kong Belgium U.A.E. Mexico Singapore Russia France Others

Figure 6 – The share of the ten leading egg importing countries in global egg imports in 2011 and 2021 (design: A.S. Kauer, based on FAO data).

Total: 351,200 t 5.5% 0.8% 0.8% 0.9% 1.1% 2.3% 4.6% 5.8% 14.6% 62.8% Netherlands Germany Belgium Switzerland S. Arabia Iraq Poland France Russia Austria U.K. Others 0.8% 17.8% 2.0% 3.2% 3.3% 3.8% 4.3% 6.8% 7.5% 8.1% 21.1% 22.1% Germany Netherlands Hungary Singapore Czechia Romania Belgium France Italy Liberia Others Total: 147,700 t Poland 5.4% 2.1% 3.4% 3.6% 4.5% 4.9% 7.3% 12.3% 14.8% 16.0% 25.7% Turkey U.A.E. Syria Kuwait Qatar Oman Iran Iraq Russia Bahrain Afghan. Others Total: 147,700 t

Figure 7 – The share of the ten leading countries of destination for the egg exports of the Netherlands, Turkey and Poland in 2021 (design: A.S. Kauer, based on FAO data).

The feed pan for turkeys, ducks and mixed cycles

FULLY AUTOMATIC

Flexible rubber shock-proof cone

No chick inside the pan.

Automatic feed level setting with the window opening system.

ONE SECOND, Immediate opening and closing of the bottom pan with one simple CLICK-CLACK for complete and fast washing.

Suitable for mixed cycles (broilers and turkeys).

The innovative combined feeding and drinking system

- april 2023MARKETING AZA International s.r.l. Via Roma 29 24030 Medolago (BG) Italy Phone (+39) 035 - 901240 - E-mail: info@azainternational.it QUALITY MADE IN ITALY Leader in pig & poultry equipment I WANT AZA! www.azainternational.it

DUO MIXTA

Only one winching system for two lines with more space in the shed. Designed from one-day old to slaughtering age. Automatic feed level setting with the window opening system.

AUTOMATIC ADJUSTMENT CLACK ONE SECOND TO CLOSE CLICK ONE SECOND TO OPEN EASY CLEANING

in 2015 led to a sharp drop in the volume of imports, which only returned to previous levels in 2018. The AI epidemic in 2022 may have caused a further drop.

The UAE imported 98,500 tonnes of shell eggs in 2021, of which 75.0% came from Turkey and Ukraine, with Turkey being the undisputed leader with a 56.6% share. At first sight, it is surprising that Brazil and the USA are among the top countries of origin. Apparently, the close trade relations in chicken meat imports allowed both countries to export shell eggs as well. In 2022, the war in Ukraine will have significantly reduced the volume of exports. Considering the trade flow patterns in context, it is clear that transport distances, tariff regulations, religious denominations and political tensions or close relations were important steering factors for the respective patterns.

Summary and perspectives

Between 2011 and 2021, global egg production increased by almost 21 million tonnes and reached a volume of 86.4 mill. t. Asia contributed 73.8% to the absolute increase, Europe only 2.5%. The regional concentration at country level was very high. In 2021, the ten leading countries accounted for 77.1% of world egg production, with China alone accounting for 33.9%. The rapid growth in India and Indonesia is noteworthy. No European country was left in the top group. European and Asian countries dominated egg trade. However, the regional concentration in exports and imports was lower than in production. In 2021, the Netherlands and Turkey were in the top two positions, accounting for 26.7% of world exports. For imports, Germany and the Netherlands ranked first and second, together accounting for 27.2% of the world import volume.

The trade flow patterns of the leading egg exporting and importing countries were quite different. Transport distance, tariff regulations, religious denomination and political tensions were the main steering factors.

The dynamics observed in the past decade are expected to continue in the current decade. Asian countries will consolidate their dominant position in egg production, although there may be changes in the regional pattern due to the remarkable development in India and some other countries in South-East Asia. The volume of eggs traded will increase, but its share in production will remain low, as the vast majority of eggs will continue to be produced for domestic consumption.

Data source and suggestions for further reading

FAO database: https://www.fao.org/faostat/en.

Windhorst, H.-W.: Patterns of the poultry industry in the MEA region: Part 1: Egg production and trade. In: Zootecnica International 44 (2022), no. 7/8, p. 30-33.

Windhorst, H.-W.: Dynamics and patterns of the poultry industry in the G19 countries. Part 1: Egg production. In: Zootecnica International 44 (2022), no. 10, p. 26-31.

Windhorst, H.-W.: Dynamics and patterns of the poultry industry in the G19 countries. Part 2: Egg trade. In: Zootecnica International 44 (2022), no. 11, p. 26-30.

24 MARKETING - marketing -

3.0% 0.8% 2.9% 3.4% 7.2% 82.7% Netherlands Poland Belgium Denmark Spain Others Total: 325,300 t Germany 8.1% 4.8% 4.8% 7.3% 18.4% 56.6% Turkey Ukraine Brazil Oman USA Others Total: 98,500 t United Arab Emirates 3.3% 5.1% 10,2% 14.0% 23.2% 44.2% China USA Malaysia Japan Thailand Others Total: 183,900 t Hong Kong

Figure 8 – The share of the five leading countries of origin for the egg imports of Germany, Hong Kong and the United Arab Emirates in 2021 (design: A.S. Kauer, based on FAO data).

4002 H

• 360 degrees opening

• Highly strong and durable material

• “SOFT” action

4626

• Suitable for fattening turkeys

• Perfectly dry bedding

• Simultaneous watering of 2 and more animals

INFINITY

• Essential design

• No chicks in the pan!

• Regulation of minimun and maximum feed level

• Available in caged broilers version

for breeding

PP Belts

• Egg collection

• Manure drying system

• Manure belt collection

• PP woven egg belts

• PP hole egg belts

4006 H

• 360 degrees opening

• Highly strong and durable material

• “EXTRASOFT” action

4901 N

Pressure regulator with bypass

CORTI ZOOTECNICI

ARTICLES ACCESSORIES

Corti Zootecnici Srl | Via Volta, 4 21020 Monvalle (VA) Italy| www.cortizootecnici.it |

Gerd de Lange, Senior Poultry Specialist Pas Reform Academy

Heat treatment of hatching eggs during storage

The best hatch results and chick quality are achieved when eggs are set that have been correctly stored for three to five days. However, longer storage cannot always be avoided, and in fact is common practice in GPS hatcheries. Eggs that are stored for longer should be kept at a lower temperature and turned four to six times a day.

An increasingly popular method for minimising the negative impact of prolonged egg storage is to apply one or more heat treatments during the storage period, especially if the eggs are stored for over seven days.

The procedure for heat treatment during egg storage involves three steps:

• Pre-heating: The aim is to warm all eggs from storage room temperature to a uniform internal temperature of 25 °C / 77 °F.

• Heating: The aim is to reach and maintain an eggshell temperature of at least 32 °C / 90 °F for 3.5-5 hours (but no longer than 6 hours).

• Cooling: The aim is to cool the eggs to as close as possible to storage room temperature, and at least to below 27 °C / 81 °F.

The first round of heat treatment, also called pre-storage incubation, is usually applied

26 - technical columnTECHNICAL COLUMN

three to four days after oviposition. The advantage of this is that it can be done after the eggs arrive at the hatchery. The aim of this treatment is to bring the embryos of eggs that were cooled too quickly after oviposition to storage-resistant stage XII–XIII.

If the eggs were not cooled too quickly in the breeder house and the embryos are well advanced, the first step should either be skipped or the period that the eggshell temperature is maintained above 32 °C / 90 °F should be kept short.

Otherwise, the embryos may overdevelop and reach the ‘point of no return’, which is the start of gastrulation. Eggs that have reached this stage can not be stored any longer and the result is massive, very early mortality.

Subsequent rounds of heat treatment may be carried out every five to six days. The aim of this is to replace cells that have died and revitalise cells that have started to degenerate.

Some incubator manufacturers supply a special incubator with sufficient heating and cooling capacity for this treatment, which can be kept near the egg storage room. However, heat treatment can also be carried out in empty single-stage setters. Typical multistage setters have a limited heating and cooling capacity and are therefore unsuitable for this treatment, as both heating and cooling will take too long.

Advice

• Apply heat treatment to eggs placed on setter trays and in setter trolleys.

• Monitor the time that eggshell temperature is above 32 °C / 90 °F using data loggers or the rule of thumb from incubator manufacturers based on measured air temperature.

• Start with relatively short heat treatments that cause no harm, but perhaps too little benefit. If no harm is observed, extend the period of treatment the next time for greater benefit.

• Open some eggs after treatment to check that it did not

accidentally lead to the ‘point of no return’.

• Monitor the effect of heat treatment on hatch results; consider withdrawing a few setter trays from the batch for comparison.

• Avoid returning warm eggs to the egg storage room; maintain a stable temperature in the egg storage room.

• Understand that stored, heattreated hatching eggs do not need extra incubation time.

Avoid the ‘point of no return’; the typical doughnut shape is no longer visible as the translucent centre of the embryo is filled-up with migrating embryonic cells

27 - april 2023TECHNICAL COLUMN

Figure 1 – A climate graph showing the three steps of heat treatment during egg storage

Wiebke Oellrich Aviagen Turkeys Ltd.,

Chowley Oak Business

Park, Tattenhall, Cheshire, CH3 9GA, UK

woellrich@aviagen.com

The importance of water quality in turkey production

In contrast to turkey feed where fine-tuning of feed formulations is based on years of research, the quality of the water as the most important nutrient for the birds is often overlooked.

Water is involved in every aspect of the bird’s metabolism. It has a role in virtually every physiological function in the body, for example regulating body temperature, digesting food, and eliminating body wastes. It is a major component of blood, and a necessary medium for many chemical reactions that help to form muscles and eggs.

At normal temperatures turkeys consume approximately twice as much water as feed and in hot environmental conditions, water consumption can double or even quadruple. A safe and adequate supply of water with acceptable physical, chemical, and microbiological parameters is therefore essential for efficient turkey production as these parameters can influence the performance of birds. Hence it is important to avoid substandard water quality.

28 MANAGEMENT - management -

The role of water and the impact of water quality

Water is the most single important nutrient in its own right and 68-75% of the body mass consists of water. It is an ideal transport medium with great solvent qualities and can pass through biological membranes freely resulting in rapid liquid and material exchange. Water acts as a reagent in the process of digestion, hence feed and water intake are linked. Water can be used for the transport and dissipation of heat as it has a high heat capacity and high evaporative heat. It must be consumed to maximise the genetic potential for feed consumption, feed utilisation, and ultimately feed conversion. Reduced water intake, e.g. due to it being tainted, will negatively impact on flock performance.

As many birds have access to the same water source quality problems will consequently affect a great number of animals. Some of the most common poultry diseases are transmitted by water. Therefore, important factors in preventing waterborne diseases in turkey production are the protection of supply sources, water disinfection, and the quality control of microbiological, chemical, and physical characteristics.

There is a trend that farms with consistently poor performance tend to have higher microbial levels in their water systems, and there is a trend that farm performance improves after thorough and effective water line cleaning, provided management and environment are also good. Water needs to be available (physically accessible at the right quantities with a suitable flow rate and pressure), palatable (flavour), and safe to drink (free of or low in nitrates, nitrites, micro-organisms like E. coli, Pseudomonas, acid levels, and heavy metals e.g. lead).

Water should not contain micro-organisms which predispose to disease such as viruses, bacteria, yeast, mould, and protozoa. Pathogens can be easily introduced and rapidly spread through a flock via contaminated drinking water supplies.

Difficulties of water management

Poultry houses are ideal environments for growing microorganism: it is a warm environment; has relatively low flow rates of water through the lines at certain times of the production cycle, particularly during the early rear

CARFED INTERNATIONAL LTD

Italian headquarters: Piazza Oberdan 3, 20129 Milano (Italy)

Italian warehouse: Via Basilicata 10, 20098 San Giuliano Milanese (Italy)

Ph.: +39 02 9881140 – Fax: +39 02 98280274

Email: carfed@carfed.it – Website: www.carfed.it

UK headquarters: Ground Floor, One George Yard, London EC3V 9DF, England, UK

Ph.: + 44. 20. 7660.0987 – Email: carfed@carfed.co.uk

29 - april 2023MANAGEMENT

and at night facilitating sedimentation and colonisation; and provides substrates microbes can thrive on like probiotics, citric acid, vitamins, organic acids, and vaccines. A symbiotic relationship between bacteria, yeasts, and moulds leads to the formation of a biofilm. The complexity of water supply systems makes effective cleaning and disinfection (C&D) challenging; and delivery systems can be old and poorly/incorrectly maintained. Furthermore, the turkey growing cycle is long with lots of opportunities for waterlines to become contaminated.

Flow rates have to be considered particularly at the start of the rearing period of the birds when turkeys are only drinking small amounts of water resulting in very low flow rates. In a larger house with multiple brood rings, the brood rings at the far end of the house will be supplied with water which has travelled the length of the shed. With low flow rates, the water will be as warm as the ambient house temperature and any bacteria will have had time to multiply and form biofilms.

Biofilms are not just bacterial layers embedded within a slimy extracellular matrix, but biological systems. Microorganisms organize themselves into a coordinated 3-dimensional functional community (“cities for microbes“); and they can be a single species or a diverse group of microorganisms. The biofilm microorganisms are able to share nutrients, and are sheltered from harmful factors in the environment, such as antibiotics or disinfectants.

Biofilms are the product of a microbial developmental process. The process is summarised by five major stages of biofilm development: Initial attachment, Irreversible attachment, Maturation I, Maturation II, and Dispersion (Monroe, 2007). During the dispersion stage, huge numbers of bacteria can be released into the drinking water which can have a sudden and significant impact on flock health.

Water sampling

Laboratory testing of the birds’ drinking water is undoubtedly necessary as sensory perception is not sensitive enough. Water has to be tested for the presence of bacteria and other microbes, for the levels of minerals that occur naturally in the water, and for other chemical and physical factors. Water quality requires regular monitoring and this should be part of the routine farm operating procedures.

A good starting point for identifying weaknesses in the system is the sampling of water for TVC testing at different points on the farm including at source and at the end of the line.

TVC stands for “Total Viable Count ” and is the measure of the total number of live bacterial organisms. Measurements are given in CFU “Colony Forming Units ” per ml. This does not identify non-bacterial organisms or bacteria hidden in the biofilm; it does not identify the type of bacteria nor does it differentiate probiotics. TVCs may underestimate bacterial numbers due to clumping or chain of cells.

Two different types of water sampling methods can be employed: The most common method is the “Standard” method where a sterile pot is used to collect water at various locations. This is a quick, easy, and cheap method; however, the existing biofilm may not be releasing organisms when taking a standard water sample not reflecting the true situation. Another option is the “Swab” method where a sterile sponge saturated in Butterfield’s Phosphate Diluent solution is inserted into the line and tested for Aerobic Plate Count (APC), E. coli/coliform, yeast, and mold. More details about this method can be found online (Scantling and Watkins).

A comparison of “Standard” versus “Swab” method samples for evaluating water lines on a farm showed considerable differences between these two methods employed. Five tests were performed in which results taken under the “Standard ” method ranged between 0-4 CFU/ ml and 5,900-191,000 CFU/ml for the “Swab” method.

Some literature state that “Standard method ” samples should have results of <100 CFU/ml and “Swab method ” samples of <10,000 CFU/ml. Others believe that “a TVC <300 CFU/ml should help support production, and a TVC <750 CFU/ml should support better liveability.”

Keeping water lines clean

A clean water system is the starting point: The terminal C&D must remove the biofilm as any remaining organisms can multiply and start building a new biofilm. However, as water will not be sterile efforts need to focus on minimising the multiplication of already existing microorganisms and slowing the re-colonisation of the water systems. Once birds are in the house only a limited amount of C&D is possible.

30 MANAGEMENT - management -

It is important to understand the limitations of treatments used during a flock’s life. Monitoring water quality (TVC testing) and conducting ORP (see below) testing will help to understand what is going on and if necessary the terminal C&D needs to be modified accordingly.

A lot of different products and systems are in use for water sanitation. If systems are relying on chlorine than it is vitally important that the pH value of the water is considered due to the dissociation of the product. An effective chlorination requires a pH of <7.0 as hypochlorus acid is 80-300 times more effective as a sanitiser than a hypochlorite ion. Free chlorine is not considered to be effective unless it is 85% hypochlorus acid. However, a pH of <5.9 can lead to poor performance as birds are less keen to drink due to poor palatability.

Conclusions

Water is the most important single nutrient and offering good quality, safe, potable fresh water with sufficient

availability is an essential tool in maximising production, welfare, and profitability.

Minimising microorganism contamination of water lines is vital to this process. Hence a regular water sanitation program on the farm is absolutely necessary to ensure a good flock performance.

Water lines require a targeted and tailored cleaning regime at terminal disinfection; they require regular monitoring and may require cleaning through flock life.

Furthermore, if systems rely on chlorine products for water sanitation, than it is vitally important that the pH is considered due to the dissociation of the product.

References

Monroe, D. (2007). Looking for chinks in the armor of bacterial biofilms. PLoS Biol. 2007. Nov;5(11):e307

Scantling, M., and Watkins, S. Identify Poultry Water Sys tem Contamination Challenges. FSA8011- PD-2-13N

PLASTIC PADS FOR THE PAD COOLING

The LUBING Pad Climate system is made entirely of plastic. It is used in systems where highly efficient cooling is required.

•For evaporative cooling of poultry and pig houses.

•Excellent cooling capacity - patented design.

•Easy to clean.

•Long service life.

•Lowest pressure loss.

•High UV resistance.

•Impermeable to light.

•Chemical resistance.

- april 2023MANAGEMENT

!lanigirO

Via Marco Polo, 33 - 35011 - Campodarsego (PD) ITALIA +39 0499202290 - lubingsystem.com - info@lubing.it

2 Poultry Research Foundation within the University of Sydney, 425 Werombi Road, Camden, NSW, 2570, Australia

3 Evonik Nutrition & Care, Rodenbacher Chaussee 4, 63457, Hanau-Wolfgang, Germany

The challenge of reducing crude protein in meat-type chicken diets

Second part

The second part of the paper focuses on the digestive dynamics of lipids and starch, on the dietary electrolyte balance and the role of phytate.

Lipid, starch and digestive dynamics

As dietary CP reduces, without the use of unusual or “novel” ingredients, the grain content of the diet increases and added lipid tends to decrease in diets that are iso-energetic in terms of apparent metabolisable energy (AME). The proportion of energy derived from dietary starch will increase whilst the dietary energy contribution from lipid and, to a lesser extent, from protein, decrease. In van Harn and van Krimpen (2016) CP in the control grower diet was reduced from 208 g/kg by increments of 10 g/kg to create 3 additional trial diets of 198,

©Big

32 NUTRITION - nutrition -

Dutchman

Peter V. Chrystal1,, Sonia Y. Liu2, Amy F. Moss2, Dafei Yin2, Victor D. Naranjo3 and Peter H. Selle2

1 Baiada, 642 Great Western Highway, Pendle Hill, NSW, 2145, Australia

188 and 178 g/kg CP, respectively. Similarly, the control finisher diet of 198 g/kg was decreased by the same 10 g/kg increments and resulted in 3 additional trial diets of 188, 178 and 168 g/kg CP, respectively. All birds were on a standard starter feed to 10 days of age and the grower diets were offered from 11 to 28 days post-hatch and the finisher diets were offered from 29 to 35 days post-hatch. All EAA’s were maintained at the same levels within the grower and finisher phases and the SID Gly + SID Ser ratio to SID Lys was maintained at 142% in the grower diets and 138% in the finisher diets. Experimental diets were based on wheat and maize which increased as CP (and soyabean meal) decreased. Added dietary lipid also decreased and the variation is shown in Table 2.

analysis method.

Many examples of similar dietary changes that occur when CP is reduced are available in the literature but the example of van Harn and van Krimpen (2016) was selected, since the diets are commercially feasible as commercial diets and overall bird performance in birds offered reduced CP diets was comparable to Ross 308 2014 performance objectives (Table 3).

In practice, reduction of supplemented dietary lipid increases feed dust in the feedmill and reduces throughput within the pellet press, because added lipid acts as a lubricant during the pelleting process. The influence of dietary lipid concentrations on pellet quality, and/or gastric emptying also needs to be considered in the context of reduced CP diets because of its potential to alter feed intake and feed passage rate in the GIT.

In diets where “novel” ingredients such as maize starch are used to replace maize grain in reducing dietary CP, in iso-energetic (AME) diets with equal EAA contents, the

direct impact of starch can then be considered. Selle et al., (2018) compared a standard diet (219 g/kg protein, 269 g/kg starch) and a low-protein diet (190 g/kg protein, 439 g/kg starch) offered to male Ross 308 broilers from 7 to 28 days of age post-hatch. The transition to the low-protein diet significantly increased ileal starch digestibility by 10.8% but decreased digestibilities of EAA’s and CP by 6.1%. In this study, replacing maize with maize starch also compromised GIT development shown by a higher pH in gizzard contents and a decreased relative pancreas weight compared to the control. These authors suggested that there was interaction between the digestion of starch and protein and/or absorption of glucose and AA’s. Furthermore, paradoxically, the reduced CP diet significantly increased free concentrations of Lys, Met, Thr and Val in plasma taken from the anterior mesenteric vein. Selle et al., (2018) suggested that several Na+-dependent (and independent) transport systems may be involved with the absorption of AA’s and conclude that Arg, Ile and Phe appeared to be the AA’s most likely to have their digestibility compromised by a large dietary concentration of readily digestible starch and competition with glucose for intestinal uptakes. Clearly there are dynamics of digestion that need to be considered when reducing CP in meat-type chicken diets, particularly as dietary starch increases and large volumes of free crystalline AA’s are supplemented.

Digestive dynamics may be considered as a three tier process: digestion of protein and starch in the gut lumen, absorption of amino acids and glucose along the small intestine and their transition across the gut mucosa into the portal circulation and it may also hold relevance when

33 - april 2023NUTRITION