Key things to know about slower growing broiler breeders

A quick review of ventilation and some advice for dusty houses

A projection for the development of global poultry meat production until 2031

2023

5

Zootecnica International –May 2023 –POSTE ITALIANE Spa –Spedizione in Abbonamento Postale 70%, Firenze

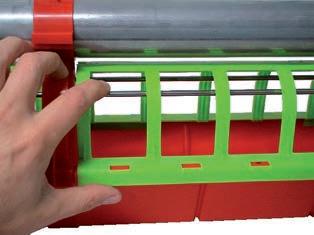

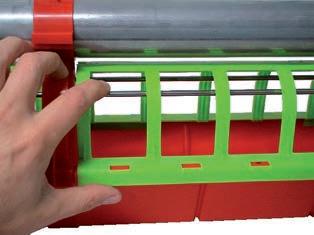

The

new

feeders

of the «Gió» range, specifically developed for great poultry farms, thanks to the easiness in the regulation of the feed and to the absence of grill (that avoid chicks perching) have many advantages: they are easy to use and their cleaning is extremely easy and fast too, leading to an overall reduction in labour costs.

CODAF Poultry Equipment Manufacturers • Via Cavour, 74/76 • 25010 Isorella (Brescia), ITALY Tel. +39 030 9958156 • Fax: +39 030 9952810 • info@codaf.net • www.codaf.net

EDITORIAL

Cell-based food is gaining more and more interest across various media platforms. The so-called “cultivated meat”, is obtained by taking stem cells from live animals or fresh meat, through a complex transformation process, with the end result being synthetic meat.

From one cell, up to ten thousand kilos of meat can be obtained in a few weeks. The first hamburger made in a laboratory at Maastricht University cost 290,000 euros. According to expert forecasts, by 2030 synthetic meat will cost the same as animal meat. By 2040 it could reach 20% of the global meat market, with a turnover of 450 billion dollars. Among the investors who show interest and belief in this activity are Bill Gates, Richard Branson, Tyson Foods, Kellogg’s, Cargill, along with the Governments of Singapore and Israel. In Tel Aviv, the SuperMeat Company already offers synthetic chicken meat. In Italy at the Biology Center of the University of Trento, research is being conducted with positive results. In the United States, Singapore and Israel, the marketing of synthetic meat products has already been authorized. The Italian government on the other hand wants to ban synthetic food, from meat to fish and from milk to animal feed products. Big ethical and biological questions are once again being asked. There are currently trains of thought that see synthetic food as a great opportunity due to its alleged sustainability. For investors this is seen as a great opportunity for good earnings. When considering the future of our planet it is necessary for science to provide us with the right information, first of all in terms of safety. When we then think of an unsustainable population increase, climate change, deforestation and the decreasing availability of water and agricultural land etc, it is reasonable to think carefully about alternative solutions.

Today we are still given the opportunity to choose and the best attitude is always moderation and very varied diets. You don’t need to become a vegetarian to save the world. Daily awareness such as avoiding waste would already help a lot. It would be desirable not to make a “tabula rasa”, by setting aside our history and our food culture.

More opportunities should be given to those small companies that have aligned themselves on the principles of sustainability, respecting tradition and true quality.

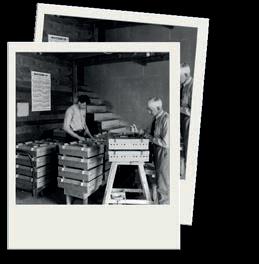

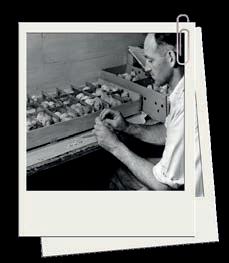

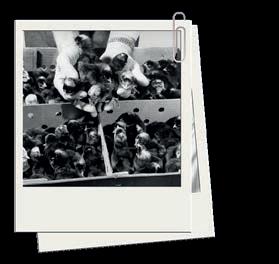

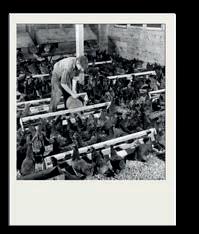

www.hubbardbreeders.com

SUMMARY WORLDWIDE NEWS 4 COMPANY NEWS 8 FIELD CASE The French poultry in the turbulent context of 2022 10 DOSSIER Key things to know about slower growing broiler breeders ............................. 14 FOCUS A quick review of ventilation and some advice for dusty houses ...................... 18 MARKETING A projection for the development of global poultry meat production until 2031 ................................................... 22 TECHNICAL COLUMN The role of HVAC systems in single-stage hatcheries ..................................... 28 MANAGEMENT Machine vision detection of range use by free-range meat chicken flocks 32 NUTRITION Heat stress: vitamin E level and zinc source matter ........................................ 34 VETERINARY Manage litter quality for better paw quality ..................................................... 38 MARKET GUIDE................................................................................44 UPCOMING EVENTS 47 INTERNET GUIDE 48 22 14 18

Two vaccines effective against bird flu

Two of the four vaccines tested for their efficacy against HPAI (highly pathogenic Avian Influenza) type H5N1 bird flu are effective under laboratory conditions.

disease after infection with the current HPAI H5N1 virus found in Europe and can prevent the spread of the virus between laying hens was not tested before.

Each vaccine was administered to ten laying hens. Subsequently, five chickens were infected with the bird flu virus. These were grouped together with the five chickens that were not infected. This study design investigated whether the virus would spread from infected chickens to uninfected chickens.

“The so-called HVT-H5 vaccines offer protection against disease symptoms in laying hens and prevent the spread of the virus”, said Nancy Beerens, head of the National Reference Laboratory for Avian Influenza. The vaccine study was carried out at Wageningen Bioveterinary Research, part of Wageningen University & Research (WUR), in collaboration with Utrecht University, Royal GD and WUR, on behalf of the Dutch Ministry of Agriculture, Nature and Food Quality (LNV).

In the study, three modern vaccines were tested in laying hens: HVT-H5 vaccine from Ceva Santé Animale; HVT-H5 vaccine from Boehringer Ingelheim Animal Health; DNA-vaccine from Huvepharma. In addition, the Nobilis vaccine of Merck Sharp & Dome was included in the study. This is an older type of vaccine and is the only vaccine currently registered as a two-dose vaccine in the Netherlands. The effectiveness of the Nobilis vaccine against the current bird flu virus has not been tested before. In this study all vaccines were applied as a single dose.

“An important selection criterium for the candidate vaccines is the possibility to distinguish between animals that have been vaccinated and animals that produce antibodies due to a bird flu infection. With the three modern vaccines, this distinction can be made; they comply with the so-called DIVA principle”, explains Nancy Beerens. The selected vaccines are already on the market in other countries, or at an advanced stage of development. However, whether these vaccines are effective in preventing

Both HVT-H5 vaccines have been found to be 100% effective in preventing disease and mortality after infection with the HPAI H5N1 virus. This is in contrast to the other two vaccines in which disease was observed. The study showed that both HVT-H5 vaccines prevent virus spread between chickens. For both these vaccines, the calculated reproduction ratio (R-value) was significantly lower than 1. Also, both the reproduction ratios of these two vaccinated groups differed significantly from the control group. The single dose of Nobilis vaccine prevents virus transmission in one of the two groups, but this difference was not significant compared to the control group.

“Our study shows that both HVT-H5 vaccines are effective under laboratory conditions and prevent both disease and virus spread. These vaccines comply with the DIVA principle and are therefore good candidates for further research in practice”, says Beerens. HVT-H5 vaccines can be administered in the egg or to day-old chicks in the hatchery.

The results of the conducted study cannot be extrapolated to the field. “It is important to investigate whether the vaccines work well under field conditions in poultry farms, how long the vaccines protect, and whether one vaccination is sufficient”. The Dutch Ministry of LNV has commissioned a field study that will start this summer. In addition, the vaccines still have to be registered in the Netherlands and the European Union. “There are still some hurdles to overcome, but the results of our research are an important first step towards vaccination against the bird flu virus in poultry”, says Beerens.

Source: Wageningen University & Research

4 - worldwide newsWORLDWIDE NEWS

EFSA, ECDC, EURL: ongoing Avian Influenza outbreaks in birds, low risk to the public

The situation regarding Avian Influenza continues to evolve in Europe and globally, with reports of new outbreaks in birds and occasional infections in mammals. Sporadic human infections have been reported in countries outside the EU, while the risk to the public in the EU remains low. These are some of the findings in the latest report on Avian Influenza by the European Food Safety Authority (EFSA), the European Centre for Disease Prevention and Control (ECDC), and the EU reference laboratory (EURL).

Highly pathogenic Avian Influenza (HPAI) viruses have caused an increase of cases in wild birds, particularly in gulls, in the EU and continue to cause occasional infections in mammals. The number of outbreaks in poultry between December 2022 and March 2023 in the EU has decreased from its high point in November 2022. Abnormal mass mortality in gulls was observed in countries such as France, Belgium, The Netherlands, and Italy. The risk of infection in poultry may increase in the coming months as gulls spread inland, possibly overlapping with poultry production areas. EFSA and EURL recommends that prevention strategies should be implemented in poultry production areas.

Surveillance of susceptible mammals

Mutations associated with genetic adaptation to mammals were detected in some of the circulating viruses in both mammals and birds. In addition, recent mass mortality events in mammals such as sea lions suggest a potential transmission among mammals of the HPAI virus. In this context, EFSA and EURL scientists recommend extending and enhancing surveillance to wild and farmed mammals, particularly American mink and pigs, in certain areas where HPAI is present.

Low risk to the general population

While sporadic Avian Influenza infections in humans leading to severe disease and fatal outcomes have been reported, human infections remain a rare event. Most of the severe human infections reported recently from countries outside the EU were related to people exposed to sick and dead poultry who weren’t wearing personal protective equipment, particularly in backyard farms.

ECDC assesses that the risk to the general public in Europe remains low, and low to moderate for workers and other people in contact with potentially infected sick and dead birds and mammals. ECDC confirms that HPAI viruses currently in circulation are susceptible to antiviral medicines available to humans, and that these viruses preferentially bind to avian-like receptors present in birds and not to human-like receptors.

ECDC, EFSA and EURL recommend the appropriate use of personal protective equipment when in contact with birds. People exposed to infected birds or mammals should be tested and followed-up, in order to early identify potential transmission cases.

Source: EFSA

- may 2023 - 5 WORLDWIDE NEWS

©Mabel Amber

Poultry industry accepting applications for Safety Recognition Award

The Joint Poultry Industry Safety Award Program is currently accepting applications from poultry industry facilities with outstanding safety programs.

The program is open to National Chicken Council (NCC), National Turkey Federation (NTF) and U.S. Poultry & Egg Association (USPOULTRY) members with poultry processing plants, further processing facilities, egg processing plants, hatcheries, feed mills, animal support services and rendering facilities that, through the implementation of innovative and effective programs, have injury and illness rates below the industry average for three consecutive years.

Based on the latest data available from the Bureau of Labor Statistics, the slaughter and poultry processing OSHA total recordable illness and injury rate for 2021 was 5.7 cases per 100 full-time workers. The 2021 rate of 5.7 represents an outstanding 75 percent decrease from 1994.

“The poultry industry depends on a dedicated workforce to produce nutritious and affordable food and is purposeful in investing in processes and procedures to diminish workplace hazards to protect our people,” said Adrienne Allison, director of Safety & Health Services, Poultry Operations, Tyson Foods, and chair of the Joint Industry

Safety and Health Council. “The significant, incremental progress in reducing illness and injury over the last few decades is the result of the poultry industry’s perpetual commitment to worker safety.”

The Joint Industry Safety and Health Council are made up of members from NCC, NTF and USPOULTRY. Collectively, the three organizations represent 95 percent of the nation’s poultry products, and their members generate more than 1.3 million total U.S. jobs. Award program rules, regulations and application forms are available by clicking www.uspoultry.org/programs/employee-safety/ award-programs.

The annual awards will be presented during the National Safety Conference for the Poultry Industry, Aug. 14-16, at the Hilton Sandestin Beach Golf Resort & Spa in Destin, Florida.

Source: www.nationalchickencouncil.org/poultryindustry-accepting-applications-for-safety-recognitionaward

NCC statement on USDA ‘Product of USA’ proposed rule

The U.S. Department of Agriculture (USDA) has released a proposed rule with new regulatory requirements on the “Product of USA” label claim. The proposed rule allows the voluntary “Product of USA” or “Made in the USA” label claim to be used on meat, poultry and egg products only when they are derived from animals born, raised, slaughtered and processed in the United States.

Under the proposed rule, the “Product of USA” label claim would continue to be voluntary. It would also remain eligible for generic label approval, meaning it would not need to be pre-approved by USDA’s Food Safety and Inspec -

tion Service (FSIS) before it could be used on regulated product, but would require supporting documentation to be on file for agency inspection personnel to verify.

The rule-making also proposes to allow other voluntary U.S. origin claims we see on meat, poultry and egg products sold in the marketplace. These claims would need to include a description on the package of all preparation and processing steps that occurred in the United States upon which the claim is made.

Source: www.nationalchickencouncil.org

6 - worldwide newsWORLDWIDE NEWS

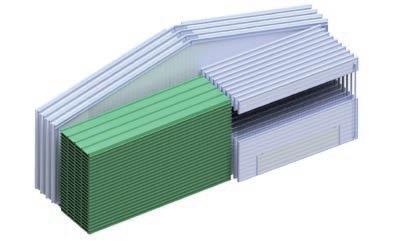

Mobile Poultry Shed

60 m2 Surface Mobile Poultry Shed. Professional design, made in Italy, suitable for free range poultry breeding. 5

- may 2023 - 7 WORLDWIDE NEWS

Agritech s.r.l. Via Rimembranze, 7 25012 Calvisano (BS) Italy Tel. + 39 030 9968222 r.a. Fax + 39 030 9968444 commerce@agritech.it www.agritech.it

unassembled sheds in one truckload

Change in top management: Dr. Frank Hiller to become Chairman of the Big Dutchman Board of Management

From 1 April 2023, Bernd Meerpohl, long-term Chairman of the Board of Management of Big Dutchman AG, was succeeded by Dr. Frank Hiller. Bernd Meerpohl takes over the position of Chairman of the Supervisory Board from 1 January 2024.

happy that Bernd will continue to share his knowledge and remain responsible for the company as Chairman of the Supervisory Board, starting 1 January 2024 after a short hiatus. The outlook for our industry is complex, but promising.

Against this backdrop, we have found an experienced and competent CEO in Dr.-Ing. Frank Hiller. He will successfully lead our globally active company in the next phase,” says Jürgen Steinemann, current Chairman of the Supervisory Board.

After 31 years as CEO, Bernd Meerpohl decided together with the Supervisory Board and the family shareholders of Big Dutchman that the time is right for a change in top management of the Big Dutchman group. Dr. Frank Hiller will bring new and external stimuli to complement the stable and proven management team. With Bernd Meerpohl taking over as Chairman of the Supervisory Board, not only will this position in itself be secured, but Big Dutchman will visibly remain a family enterprise.

“In the past decades, Bernd Meerpohl has shaped the development of Big Dutchman and set the course for the group’s future. He always had all stakeholders in mind and was incredibly committed and dedicated to advancing the family business. The Supervisory Board and the family shareholders want to thank Bernd for all the time and effort he invested in the company and the staff to make Big Dutchman the world leader in livestock farming technology. We are very

Bernd Meerpohl explains: “Taking over my father’s responsibility as CEO 31 years ago was an honour, as was advancing the company for the benefit of our customers all over the world and for the benefit of our staff and their families. The Meerpohl family, my closest colleagues, the Supervisory Board and I believe that someone new should now take over the operational business of Big Dutchman to integrate new stimuli from the outside. Dr. Hiller’s grounded approach fits us very well. With his doctor’s degree in Mechanical Engineering, he brings along a more than solid foundation. In the course of his career, which included positions with some of the leaders of the mechanical engineering industry, for example Meiller, Leoni and, most recently, as CEO of Deutz AG, Dr. Hiller has gained extensive knowledge and proved that he is a team player who is very capable of leading an international company. I would like to thank Jürgen Steinemann, the Chairman of our Supervisory Board, for actively accompanying me personally as well as Big Dutchman in general these past years. I am very pleased that he will remain part of the Supervisory Board as deputy

8 - company newsCOMPANY NEWS

chairman. Personally, I will continue to support the company in my new position, as much as I can and in close cooperation with Dr. Hiller.”

Dr. Frank Hiller adds: “Bernd Meerpohl is a remarkable entrepreneur who has invested much energy and spirit to position Big Dutchman as the international, innovative market leader of an industry that sees its duty in helping to guarantee that the world’s population can be fed. I am looking forward to succeeding him as CEO and securing and advancing the market position of Big Dutchman, together with the Board of Management and all employees, and of course in close cooperation with Mr. Meerpohl as the new Chairman of

- may 2023 - 9 COMPANY NEWS

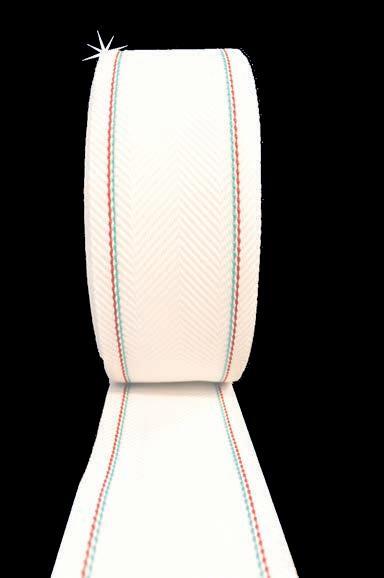

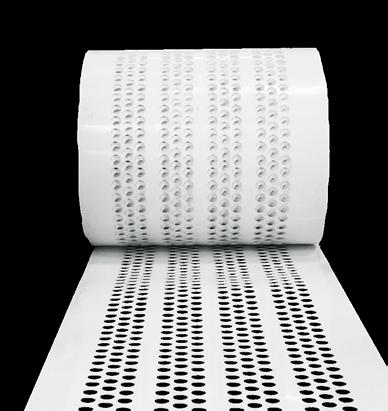

Barbieri srl Via Garibaldi, 54 • 26040 Scandolara Ravara (CR) Italy Tel. (+39) 0375 / 95135 • Fax (+39) 0375 / 95169 • Manu re re moval belt s • Manu re belt wi th hole s for dr yi ng system s

www.barbieribelts.com BELTS and ROP ES for AV ICULTURAL USE BE LT S

info@barbieri-belts.com

Philippe Caldier, independent journalist ph@caldier.fr

The French poultry in the turbulent context of 2022

Hit by an unprecedented Avian Influenza epizootic, concomitant with production costs at their highest (+50% in 3 years for a standard chicken), France saw its overall poultry production fall by -7.6% on 1 year and its imports jumped by +10.6%. In this tormented context,

the French Meat Poultry

Interprofession ANVOL has only one objective: to safeguard the French poultry sector and its exemplary model, unique for its diversity, both in terms of species (chickens, turkeys, ducks, guinea fowl, quail, pigeons) and production methods (standard, certified, organic, Label Rouge).

10 - field reportFIELD REPORT

In 2022, France remains the leading consumer country of poultry meat in the European Union (excluding the United Kingdom) with 1.905 million tonnes of poultry consumed, ahead of Germany (1.763 Mtce - tonnes carcass equivalent) and Spain (1.651 Mtce).

Overall French consumption (at-home + out-of-home consumption) held steady at -0.4% over the year. Each French person consumed 28.2 kg of poultry meat in 2022. Consumption even increased for chickens, at +4.8% vs 2021.

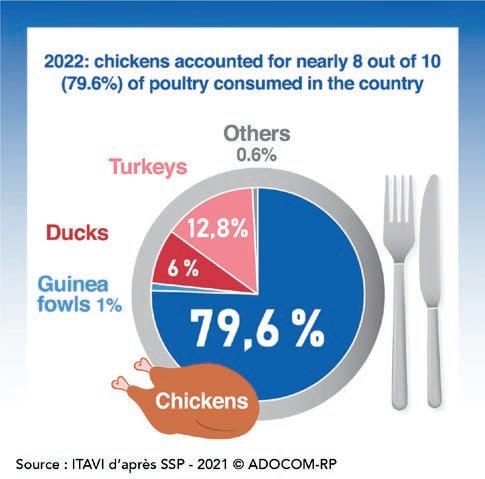

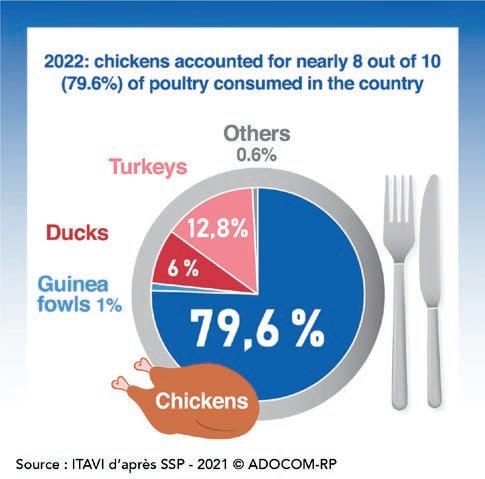

Chickens are the most consumed poultry in France and their share increased significantly in 2022 with the drastic reduction in the supply of other species, which are more affected by Avian Influenza. In 2021, chickens accounted for more than three quarters of poultry consumed in the country (76.1%) and this proportion increased to 79.6% in 2022, i.e. nearly 8 out of 10 poultry.

Turkeys come in second place (14.4% of poultry consumed in 2021 and 12.8% in 2022). The duck occupies the third step of the podium (8.3% of poultry consumed in France in 2021 and 6% in 2022). Less represented species remain stable (see Figure 1).

Influenza, including 860 in Pays de la Loire in 6 months, to which must now be added nearly 300 outbreaks since this autumn. All professionals (farmers, production organizations, feed manufacturers, slaughterhouses, hatcheries, processing companies) have mobilized to stop the spread of the virus, in coordination with state services and veterinarians.

The French poultry industry in figures

• About 14,000 farms and 15,000 related companies.

• Around 100,000 jobs, including around 34,000 on the farms themselves.

• Family farms: on average, a standard French farm has two chicken buildings, for a total area of 2,300 m² housing less than 40,000 birds. In comparison, the size of farms in the European Union is on average three times larger.

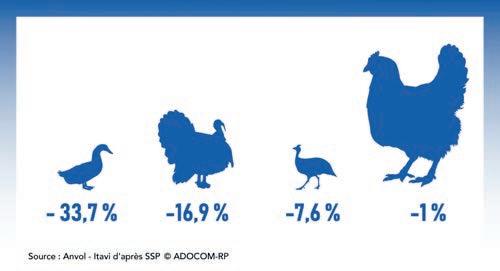

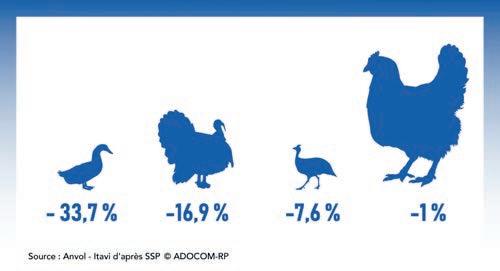

The epizootic led to the disappearance of nearly 20 million poultry, including 12 million meat poultry. Over the whole 2022 year, production fell by -7.6% for all meat poultry compared to 2021. With 1.5 million tonnes of poultry produced in 2022, the French sector has fallen from second place in the EU in 2021 to fourth place in 2022.

Contrasting declines in production depending on the species

2022: a decline in production of -7.6%

The year 2022 was marked by an unprecedented historic health crisis. France has totaled 1,400 outbreaks of Avian

In 2022, while poultry production decreased overall in France by -7.6% compared to 2021 due to the epizoot-

11 - may 2023FIELD REPORT

Figure 1 – 2022: nearly 4 out of 5 poultry consumed are chickens.

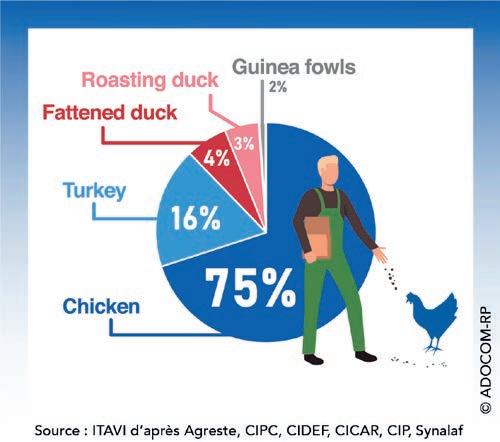

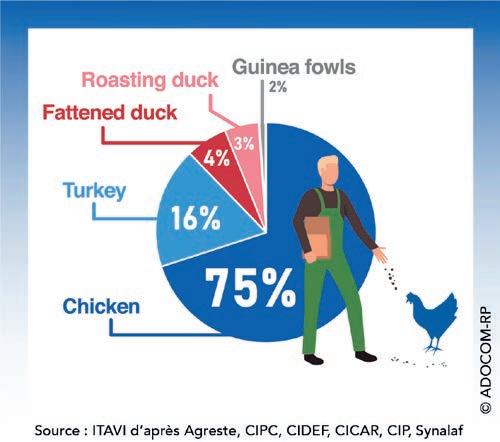

ic, the situations vary depending on the species. Indeed, chicken production is the least slowed down, at -1% (Figure 2). More than 1 million tonnes carcass equivalent (tce) of chicken were produced over the year.

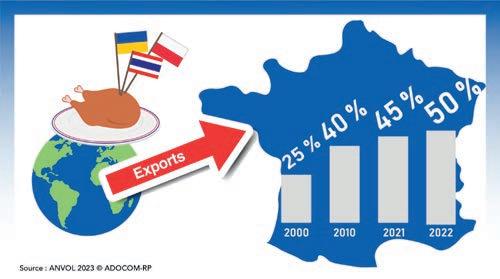

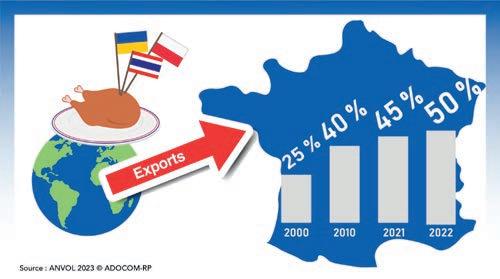

2022: 1 chicken out of 2 imported into France

Of all poultry, chickens are the most affected by imports, mainly used by out-of-home catering and secondary processing companies for the production of processed products.

In 2020, 41% of chicken consumed in France came from other countries; this proportion rose to 45% in 2021 and reached 50% in 2022 (Figure 4). The increase in chicken meat imports from third countries is particularly notable from Ukraine (+114% over 1 year), Brazil (+57%) and Thailand (+6%). However, the largest share of imports still comes from Poland (+26.3% increase over 1 year), Belgium (+12.7%) and the Netherlands (-2.3%).

The production of broiler duck is the one that has experienced the greatest decline in meat poultry, at -33.7% over the year (54,140 tce produced). Turkey is also strongly affected, at -16.9% (around 245,500 tce). The smallest production, that of guinea fowl, is down -7.6%, for less than 23,500 tce over 1 year.

Chicken now accounts for 75% of poultry raised in France, compared to still 70% in 2021. Ducks and turkeys, for their part, see their shares fall when guinea fowl increases its production share from 1% in 2021 to 2% in 2022 (Figure 3).

In this context of rising imports, the ANVOL Interprofession does not understand the recent decisions of the European Union to open the borders to additional imports of low-cost chickens, in particular from Ukraine and Chile.

2023: further reductions in production expected

Consequences of the past epizootic are also to be expected in 2023 since the placement of poultry in farms has been struggling since last April to regain their level of previous years. Indeed, at the end of 2022 vs 2021, there were -4.2% of chicken rearing, -37.4% of ducklings, -13.2% of guinea fowl and -12.3% for turkey poults. Overall, for the different meat poultry species, placement fell by -6.4% over one year. “The decline is more marked for productions under a quality sign”, notes ANVOL: -25% for organic chickens, -9% for Label Rouge chickens.

12 - field reportFIELD REPORT

Figure 2 – Decrease in poultry production in 2022 vs 2021.

Figure 3 – Distribution of poultry production by species in 2022.

Figure 4 – The share of chicken consumed in France and coming from imports reached 50% in 2022

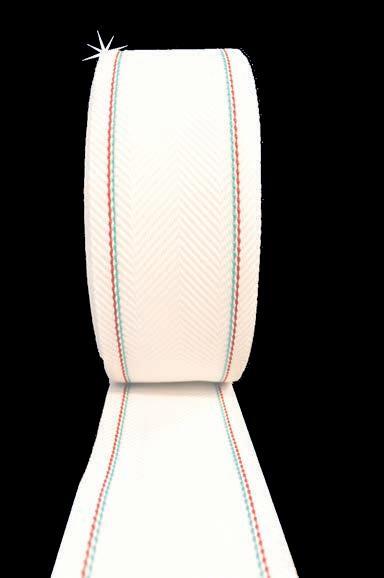

The innovative linear trough feeder

THE REVOLUTIONARY RATIONING SYSTEM FOR BROILER BREEDERS AND LAYERS

Leader in pig & poultry equipment

Equal, controlled and immediate distribution throughout the line.

The obstacle-free linear trough feeder allows an easy access for the animals which can easily spot the feed.

WATCH THE VIDEO explaining how the BREEDAZA system works

Manufactured from sturdy light plastic material for easy winching.

Easy cleaning and no residual feed inside the trough.

- may 2023FIELD REPORT AZA International s.r.l. Via Roma 29 24030 Medolago (BG) Italy Phone (+39) 035 - 901240 - E-mail: info@azainternational.it QUALITY MADE IN ITALY www.azainternational.it

BREEDAZA

AZA!

I WANT

ADJUSTABLE ANTI-COCK GRID NO OBSTACLE INSIDE EASY ACCESS TO FEED

GALVANISED STEEL MODEL

Aitor Arrazola, Research biologist, Ph.D. in Animal Behaviour & Welfare

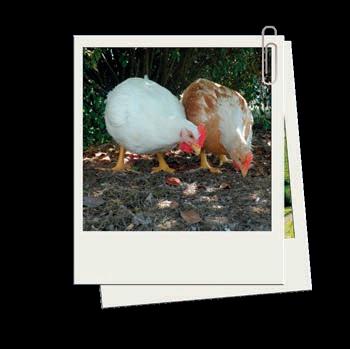

Key things to know about slower growing broiler breeders

Broiler breeders lay hatching eggs that satisfies the need for broiler chicks raised for meat production. Yet, concerns about the poor reproductive performance and welfare issues of conventional broiler breeders question the feasibility and sustainability of these parent stock of meat chickens.

14

DOSSIER - dossier -

Most of these problems associated with limited reproductive performance, health problems, and welfare concerns of conventional broiler breeders are consequence of fast growth rate, excessive body weight, and obesity-related problems. For this reason, alternative lines of broiler breeders with a slower growth rate or less susceptible to obesity-related disorders are unlikely to share these problems. Indeed, according to breeding guidelines and research, the reproductive performance of slower and intermediate growing broiler breeders can exceed that of conventional broiler breeders at a lower cost.

Slower growing broiler breeder lines are currently commercially available and information about these lines suggest that can alleviate welfare concerns associated with chronic feed restriction in broiler breeders and meet the growing public demand for broilers.

On top of this, public pressure and consumer concerns about the health and welfare of conventional broiler strains are moving the meat chicken industry toward using slower growing strains of broilers with better health and welfare outcomes. This increasing interest in using slower growing strains of broilers also requires the use of slower growing strains as the parental stock. Although information about the performance of slower growing broiler breeders needs further research attention, recent studies looking into the performance and welfare of slower growing broiler breeders indeed suggest improved production and welfare outcomes at a much lower feed and water intake than conventional lines.

To produce slower growing broilers, a common strategy nowadays is to breed slower growing broiler breeder hens with faster growing broiler breeder roosters. Due to slower growth, broiler breeder hens from alternative strains are smaller than conventional broiler breeder hens and have lower nutritional requirements for feed intake during rearing and lay. In return, their cumulative feed intake at the end of rearing and lay is remarkably lower compared to that of conventional broiler breeders leading to a lower production cost for broiler breeder producers. Probably due to smaller size as well, livability also seems to improve in slower growing broiler breeder hens because of lower mortality and fewer number of culled birds due to lameness or other health-related problems. These results suggest that slower and intermediate growing broiler breeders may be more efficient, robust, and publicly acceptable than conventional ones.

“To produce slower growing broilers, a common strategy nowadays is to breed slower growing broiler breeder hens with faster growing broiler breeder roosters. Due to slower growth, broiler breeder hens from alternative strains are smaller than conventional broiler breeder hens and have lower nutritional requirements for feed intake during rearing and lay. In return, their cumulative feed intake at the end of rearing and lay is remarkably lower compared to that of conventional broiler breeders leading to a lower production cost for broiler breeder producersˮ

Slower growing strains of broiler breeders, likewise conventional strains, still need feed restriction to control body weight gain and support optimal reproductive outcomes during lay. Yet, in the case of conventional broiler breeders, the reproductive performance of hens and roosters is still low despite strict controlled growth rate and efforts to maintain hens and rooster within healthy body conformation. For example, the laying rate of conventional broiler breeder hens declines gradually soon after reaching peak of egg production at 32 weeks of age. Similarly, the breeding activity of conventional broiler breeder roosters also declines noticeably leading to a fertility decline and hatchability drop in settable eggs around 20 weeks into lay.

15 - may 2023DOSSIER

On the other side, slower and intermediate growing broiler breeders can achieve high, persistent laying rate at a high hatchability during lay under acute/moderate feed restriction throughout the production cycle.

Recent research exploring the performance of alternative strains of broiler breeders suggest that, depending on the strain, slower and intermediate growing broiler breeder hens can start laying earlier, at a higher egg production rate during lay, and maintain laying persistency after the peak of egg production. Looking at their breeding performance, fertility and hatchability in the studied lines were above 95% and 80%, correspondingly, from 30 to 54 weeks of age, when investigation ended. This increase in laying rate, laying persistency, and hatchability shown by alternative strains of broiler breeders translates into higher cumulative chick production than conventional broiler breeders at a lower cumulative feed intake depending on hen strain.

Looking at the reproduction performance of broiler breeders in more detail, susceptibility to obesity-related disorders on laying rate seems to be strain-dependent. These problems often refer to hormonal dysregulation associated with problems establishing future ovulations leading to poor laying persistency and laying cease in overfed hens.

At the flock level, this results in low laying rate during lay, poor laying persistency after the peak of egg production, and inadequate body weight uniformity. Therefore, due to ovary malfunctioning, susceptibility to excessive fat cumulation appears to be responsible for poor reproductive performance in conventional broiler breeder hens while alternative strains may be more resilient. Consequently, although fast growth rate may not be the problem on

its own, improvement in the reproductive performance of broiler breeders may require using strains of broiler breeder hens that are less prone to these negative consequences of excessive fat to overcome poor reproductive performance in the parent stock of meat chickens.

In the case of roosters, fast growing roosters are still used to produce slower growing broilers. However, slower or intermediate growing broiler breeder roosters offer a practical solution to previous welfare concerns and production challenges associated with conventional broiler breeder roosters.

Excessive aggressive behaviour, elevated feeding competition, and reduced breeding activity are major challenges associated with conventional broiler breeder roosters, at least, partially driven by the chronic feed restriction roosters undergo throughout the entire production circle. Much less is known about the performance of alternative strains of broiler breeder roosters but, probably due to slower growth rate, slower and intermediate roosters need moderate levels of feed restriction and have shown improved reproductive performance and fewer behavioural problems. Same as hens, studies looking at the performance of slower growing broiler breeder roosters suggest improved liveability and good foot health which, in return, may explain their active breeding performance and high fertility throughout lay.

Chronic feed restriction in broiler breeders is still a major welfare concern, but needed practice to prevent obesity-related problems, since current selection traits for high performance in broilers impairs reproduction traits and liability of conventional broiler breeders. Alternatively, using broiler breeder strains with slower growth rate can be a welfare-friendly solution to chronic feed restriction for broiler breeders since these alternative strains need low to mild levels of feed restriction to maintain a healthy body weight, slow growth rate, and good reproductive performance.

According to limited research, slower and intermediate growing strains of broiler breeders had high body weight uniformity and exhibited fewer signs of feeding frustration and distress such as good feather coverage and no sings of severe pecking. Therefore, using slower growing broiler breeders can alleviate welfare concerns linked with chronic feed restriction in broiler breeder production while production outcomes are improved at a lower production cost.

16 DOSSIER - dossier -

4002 H

• 360 degrees opening

• Highly strong and durable material

• “SOFT” action

4626

• Suitable for fattening turkeys

• Perfectly dry bedding

• Simultaneous watering of 2 and more animals

INFINITY

• Essential design

• No chicks in the pan!

• Regulation of minimun and maximum feed level

• Available in caged broilers version

for breeding

PP Belts

• Egg collection

• Manure drying system

• Manure belt collection

• PP woven egg belts

• PP hole egg belts

4006 H

• 360 degrees opening

• Highly strong and durable material

• “EXTRASOFT” action

4901 N

Pressure regulator with bypass

CORTI ZOOTECNICI

ARTICLES ACCESSORIES

Corti Zootecnici Srl | Via Volta, 4 21020 Monvalle (VA) Italy| www.cortizootecnici.it |

Dr. Makan Hooshangi (DVM) Veterinarian, Turkey Management Specialist

A quick review of ventilation and some advice for dusty houses

A successful and profitable poultry production needs outstanding controlled environment. A good poultry house provides maximum health and welfare conditions for the birds. One of the most important features is ventilation which has a great role in providing and distributing uniform high-quality air.

The right temperature and humidity, and the right concentrations of O2, CO2, CO and NH3 are the initial measures. To provide high-quality air and maintain the quality of the litter, poultry houses should be ventilated at the right rate.

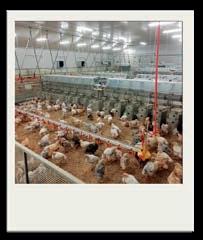

There are different types of poultry houses and ventilation systems. Nowadays, modern houses use combi-tunnel ventilation, which is a combination of three systems of minimum, transitional and tunnel ventilation. Such houses are equipped with automat-

18 FOCUS - focus -

ic controlling systems using plenty of sensors for temperature, humidity, ammonia, CO2, and static pressure, inside and outside the house. The main objective is to control the ideal temperature at the birds’ level with the relative humidity between 50% and 75%, and keep CO2 and ammonia levels below or within the standard ranges. Although it is very expensive to equip such houses, the outcomes cover the costs by decreasing the losses and improving health conditions, livability, FCR, and final weight. The flock density is also highly dependent on the ventilation efficiency.

Minimum ventilation is suitable for cold seasons or when the outside air, entering the house, is cooler than what we need for our birds. For example, we need 30 °C but the outside is 24 °C. Heaters may be used in minimum ventilation. The objective is to remove excess humidity and undesired gases out of the house, and provide uniform high-quality air all over the house (right temperature, humidity, gases’ concentrations, etc.). Providing oxygen is not the priority as oxygen comprises almost 20% of the

air and even in what we call “low-quality air”, there would still be enough oxygen for the birds!

Transitional ventilation is used “whenever temperature sensors or thermostats override the minimum ventilation timer to keep fans running, the minimum ventilation setup will be running in the transitional ventilation mode” (Ross® management). It is also a very useful system when the poults are young and we do not want any drafts in the house. The objective is to cool down the house

Tunnel ventilation is used in summer or hot weather, when the house cannot be cooled by transitional ventilation. In tunnel ventilation, the wind speed is between 2 to 2.5 m/s. Cooling pads are very helpful when the outside relative humidity is lower than 70%. The objective is to cool down the birds with extreme volume of air, and high air speed.

The two T-ventilations (Transitional and Tunnel) work based on temperature changes, and due to the high volume of air exchange, the levels of important gas es will be within ideal ranges.

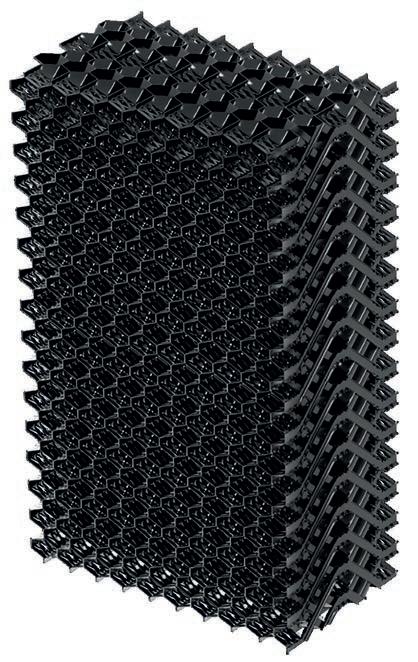

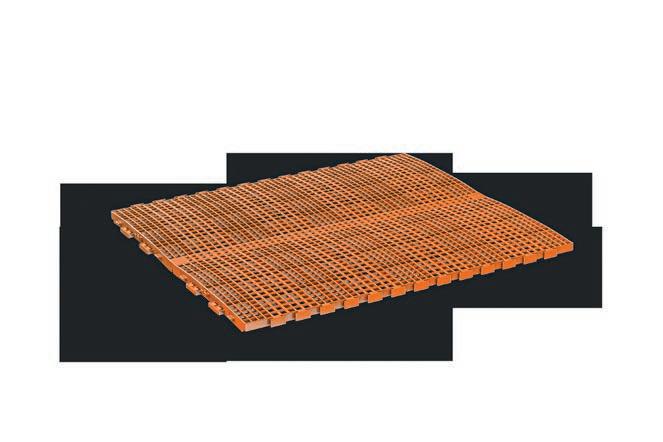

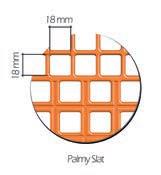

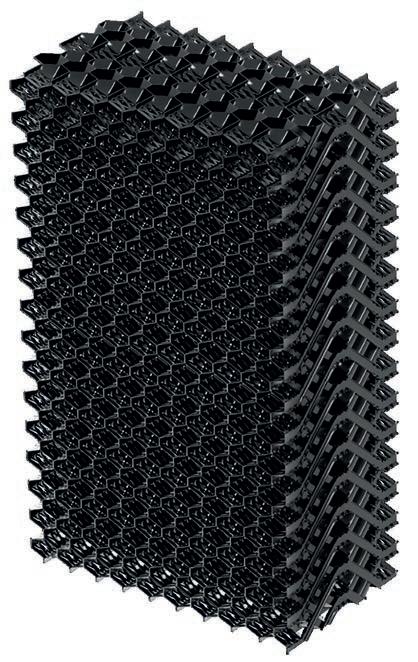

PLASTIC

PADS

FOR THE PAD COOLING

The LUBING Pad Climate system is made entirely of plastic. It is used in systems where highly efficient cooling is required.

•For evaporative cooling of poultry and pig houses.

•Excellent cooling capacity - patented design.

•Easy to clean.

•Long service life.

•Lowest pressure loss.

•High UV resistance.

•Impermeable to light.

•Chemical resistance.

- may 2023FOCUS

!lanigirO

Via Marco Polo, 33 - 35011 - Campodarsego (PD) ITALIA +39 0499202290 - lubingsystem.com - info@lubing.it

Usually, if the ventilation is designed and performed correctly, there would be no problem with high humidity. Nevertheless, there might be problems with low humidity which would lead to a dusty house and respiratory disorders. In transitional ventilations, as there would be no working heater, usually there is no concern about low humidity as in dry climates fogging systems can be used to increase the RH%. In hot conditions, when tunnel ventilation is working, using cooling pads system is an awesome option both for cooling the house and providing moisture in dry climates or dry seasons. By choosing the thickness of the pads and the wind speed passing through them, there are possibilities to control the humidity of the entering air. Nevertheless, minimum ventilation is not that simple and it is very important to have the right equipment and design so that we have the correct flow of high-quality air every square meter of the house by letting as low air volume as needed enter the house. It helps reduce the energy costs and keep the house humidity in range.

Minimum ventilation needs to be operated automatically, because calculating many factors such as unwanted gases levels and air speed at inlets (to reach the peak of the house where the heat is accumulated) with manual equipment or simple timers could not be an easy daily job. In some farms, farmers write very simple protocols for the workers to operate the ventilation system based on their experiences and the protocols. In such situations, insufficient ventilation or overventilation can occur. Improper ventilation has dangerous impacts on respiratory system health.

Inadequate ventilation is one the most common issues in the industry, especially in countries with high costs of energy, or in old farms. This can be easily observed at abattoirs by finding too many Ascites cases during cold seasons. Poor ventilation also increases the house’s ammonia levels, which is considered a great danger for the respiratory system. Ammonia irritates the respiratory ducts mucosal layer and causes inflammatory responses. In this condition, pathogens can easily cause infections. The pathogens can be spread from the respiratory system through the whole body cavity very quickly, and that would be a big challenge for the farmer due to the high costs of antibiotics and also the A.B. restriction programs. Low ventilation rate also increases the house humidity and consequently causes wet litter, which I call “the mother of disasters”! It begins with digestive system disorders, commonly followed by diarrhea, which makes the litter condition worse. Nutrients malabsorption and

growth retardation, CRD complex, and many other issues occur in such condition.

Overventilation, especially in countries with lower energy costs, is mistakenly believed as a plus that provides high amounts of fresh air, and helps birds to grow better and faster. Many farmers think that despite consuming more energy, it can reduce production costs like drugs consumption or mortality damages, and can improve FCR. It is necessary to keep in mind that: “the more, the better” does not apply to ventilation! Overventilation provides excessive volume of fresh air, which is not necessarily desirable or beneficial.

as temperature and humidity

To simply explain the story, consider a farm in an area where the temperature is 10 °C. The preferred inside temperature is 18 °C. In this example, our desired air should be 18 °C with 50-75% RH. When you bring the 10 °C air into the house, you should heat that air for 8 °C. This warming up will reduce the relative humidity. Even in low altitude areas with 80-90 RH%, a rise as small as 8 °C can lower the humidity too much. Now i agine a farm at 1500 meter or higher altitude with a desired inside temperature of 18 °C. The temperature outside is -22 °C and relative humidity is 15%; the density is 15 chickens/m2 at the age of 40 days. The minimum air volume needed is at the highest rate, the elevation is too high and the oxygen concentration is too low (which means more air volume is needed than in the same situation at 100 meter above sea level). At such altitude, vaporizing is much faster and the moisture of litter can be lost more easily. The difference between outside and inside temperature is 40 °C, and there will be almost no humidity in the heaters’ out-coming air. The more you ventilate, the more cold-air will get into the house and the more you will need the heaters to work. You will have a high volume of low-humidity air coming out of the heaters and that will reduce the house’s RH% and consequently the litter moisture. On the other hand, overventilation removes lots of humidity out of the house and makes the situation worse. Low moisture in the bedding leads to increasing dust in the house and this is the beginning of a disaster!

Dust can irritate the respiratory tracts and it is as dangerous as ammonia! Even worse, it carries pathogens! In my experience, in breeder turkey farms, Mycoplasmosis

20 FOCUS - focus -

Fresh air is desirable if it has the desired quality factors such

will be diagnosed in dusty houses after a few weeks. The secondary infections are expected after a while in such conditions. The health and the performance of the workers in dusty houses would be significantly compromised. Most of the house operators, even the experienced ones, choose to increase ventilation rate when facing dusts in the house. Overventilation is the cause of the dusty house and by increasing the ventilation even further, we will make the situation worse. To cure the disease, first we must decrease the ventilation rate as low as possible to avoid the house moisture loss. This will also let the heaters work less, which means less dry air entering the house. This is the only cure. No other accessory equipment can provide enough moisture, if you do not lower the ventilation rate. Some farmers think that their investment on expensive equipment such as fogging systems, can solve the problem, but it really does not work if you ignore the principles. Here is some advice from an old friend, Jean Luc Favennec:

• Try to use as little equipment as necessary;

• Keep the job simple and avoid any unnecessary complications.

Now that we have cured the disease, we can cure the symptoms by increasing the litter moisture.

• Using fogging systems or even irrigating the litter for a week helps a lot. The preferred moisture of the litter is 20-25%.

• Removing excess litter, especially in laying farms or breeder farms, and correcting the thickness (usually 7-10 cm would be enough to protect the feet and provide a tender bedding) is necessary.

• Increasing Na and Cl levels in feed will be a helpful approach that increases the water consumption and leads to more moisture in excretion.

• Increasing hours of darkness, if possible, is another option that can reduce dusty condition of the house and increase litter moisture by keeping the bedding moist under the sleeping birds. Besides, in darkness hours, we need a lower rate of ventilation and that helps to keep more humidity inside the house.

Remember this dusty condition will be managed in less than a week and the symptoms treatment should not be continued after the dusty environment is handled; or else, you will have wet litter issues in a while!

To keep my words concise, in this industry, a tiny mistake can have catastrophic consequences. Experience exchange is key to avoid repeating such mistakes.

- may 2023 - 21 FOCUS

INNOVATION IN VENTILATION +45 75771922 • mail@dacs.dk • www.dacs.dk

DACS climate solutions ensure dry well-ventilated houses with uniform temperatures and perfect climate that vastly improve animal welfare and comfort, allowing animals to grow to their full potential

Hans-Wilhelm Windhorst

The author is Prof. Emeritus of the University of Vechta and visiting Professor at the Hannover Veterinary University, Germany

A projection for the development of global poultry meat production until 2031

The aim of this paper is to analyse the emerging dynamics for poultry meat at continent and country level and to document the underlying steering factors.

The latest OECD-FAO Agricultural Outlook projects an increase in world meat production from 345.2 mill. t in 2022 to 377.2 mill. t in 2031. Of the total increase of 32.0 mill. t, 17.9 mill. t or 55.9% will be poultry meat, 8.1 mill. t or 25.2% pork and 4.2 mill. t or 13.0% beef.

Figure 1 shows that the four main meat types will develop differently. The gap between the production volume of poultry and pork will widen from 15 mill. t to almost 25 mill. t in the decade under review.

Remarkable dynamics in Asia and Latin America

A detailed analysis of the production development at continent level reveals that Asia and Latin America will show the highest absolute increase (Table 1), Africa the highest relative increase in the production volume. In Europe, production is projected to grow by only 588,000 t or 2.7%. In North America, the relative growth rate will also be lower than the global average.

22 MARKETING - marketing -

©www.rspcaassured.org.uk

The trend also reflects the red-white-shift in meat production that has been observed for several decades (cf. Windhorst 2021), which, however, has developed differ-

ently in the continents. Because of the favourable feed conversion rate of poultry, especially broilers, this aspect is becoming increasingly important regarding rising feed costs. In addition, there are no religious barriers to the consumption of poultry meat, which explains the rapid increase in production, particularly in Islamic and Hindu countries with high population growth rates and a growing per capita income. A comparison of the continents’ shares in global production growth shows that Asia will be the undisputed leader with 58.8%, followed by Latin America with 16.4% and Africa with 11.0%. Europe and North America will lag far behind at 2.7% and 10.4% respectively. In addition to the slowly growing population, the already very high per capita consumption, which permits only small rates of increase, is an important steering factor.

The expected different dynamics in production development will have an impact on the shares of the individual continents in the global production volume. As can be seen from Figure 3, Asia (+2.3%) and Africa (+0.7%) can increase their contribution to global production, while Europe (-1.5%), North America (-1.0%) and Latin America (-0.5%) will have to accept losses. A closer look at the development at country level will show which countries can benefit from the emerging dynamics and which tend to lose in importance.

Developing countries1 will determine the future development

An analysis of the expected production development according to the development level of the countries shows that the developing countries will be the driving force behind the dynamical development in the current de -

23 - may 2023MARKETING

Continent 2022 2031 Change absolute relative (%) Africa Asia Europe N America L America Oceania 6,954 52,579 22,081 24,272 28,371 1,671 8,912 63,108 22,668 25,969 31,315 1,872 1,963 10,529 588 1,692 2,944 201 28.2 20.0 2.7 7.0 10.4 12.0 World 135,928 153,844 17,921 13.2

Table 1 – Projected development of global poultry meat production between 2022 and 2031 at continent level; data in 1,000 t (source: OECD-FAO Agricultural Outlook).

Africa Asia Europe N America L America Oceania [mill. t] 0 17.5 35 52.5 70 2022 2025 2028 2031

Figure 2 impressively illustrates as well the general trend towards increased production on all continents as the outstanding role of Asia.

Figure 2 – Projected development of global poultry meat production between 2022 and 2031 at continent level (design: A.S. Kauer based on OECD-FAO Agricultural Outlook data).

Total: 135.9 mill. t 1.2% 20.9% 17.9% 16.2% 38.7% 5.1% 2022 Total: 153.9 mill. t 1.2% 20.4% 16.9% 14.7% 41.0% 5.8% 2031 Africa Asia Europe N America L America Oceania

Figure 3 – The share of the continents in global poultry meat production in 2022 and 2031 (design: A.S. Kauer based on OECD-FAO Agricultural Outlook data).

[mill. t] 0 40 80 120 160 2022 2025 2028 2031 Sheep Cattle

Pig Poultry

1 I

Figure 1 – Projected development of the production volume of the four leading meat types between 2022 and 2031 (design: A.S. Kauer based on OECD-FAO Agricultural Outlook data)

n the OECD-FAO Agricultural Outlook emerging countries are included in the class of group of developing countries.

cade (Figure 4). The share of the developed countries in global poultry meat production will decrease from 38.9% to 36.3%, while that of the developing countries will increase from 61.1% to 63.7%. In 2022, the gap between the two country groups was 30.3 mill. t; it will increase to 42.2 mill. t or by almost 40% in 2031. This reflects the expected population development. Between 2022 and 2031, the global population will increase from 8 billion to 8.4 or 8.5 billion. Asia and Africa will be the continents with the highest population growth. For the current decade, an annual increase between 65 million and 68 million is projected. In 2031, of the expected increase of 68 mill., 37 mill. will be contributed by Africa and 26 mill. by Asia. For the Americas, an increase by about 6 mill. is expected, in Europe the population will decrease by 1.1 mill.

2031. They will account for 50.4% of global production growth. The ranking of the countries with the highest relative growth rate differs from that with the highest absolute increase. It is worth noting that four of the six leading countries with the highest absolute growth will be located in Asia, also four with the highest relative growth rates. The different dynamics in the countries will change their shares in global production and their ranking (Figure 5). China will replace the USA in first place and be the country with the highest production volume in 2031. The USA, Brazil, Russia and Mexico will lose shares, while Asian

2 – Projected development of poultry meat production in the 15 leading countries (without EU (27) member countries); data in 1,000 t (source: OECD-FAO Agricultural Outlook).

Table 2 documents the projected production development at country level. Of the 15 countries considered, five are developing countries, eight are emerging countries and only two are developed countries.

Table 3 lists the six countries with the highest absolute increases in poultry meat production between 2022 and

24 MARKETING - marketing -

[mill. t] Developed countries Linear (Developed countries) Developing countries 0 25 50 75 100 2022 2025 2028 2031 Linear (Developing countries)

Figure 4 – Projected development of global poultry meat production at country development level (design: A.S. Kauer based on OECD-FAO Agricultural Outlook data).

Country Absolute increase (1,000 t) Country Relative increase (%) China India USA Indonesia Brazil Pakistan 3,169 2,078 1,524 841 770 649 India Pakistan Peru Turkey Columbia Iran 48.3 33.4 27.3 26.7 25.8 24.2 6 countries 9,021 - -

Table 3 – The six countries with the highest expected absolute and relative growth rates in poultry meat production between 2022 and 2031 (source: own calculations based on OECD-FAO Agricultural Outlook data).

Country 2022 2031 Change absolute relative (%) China* USA Brazil * India* Indonesia* Russia Mexico* Turkey* Iran Pakistan South Africa* Thailand* Peru Columbia Viet Nam 21,279 22,797 14,818 4,301 4,090 4,589 3,705 2,347 2,306 1,942 1,923 1,892 1,807 1,759 1,565 24,448 24,321 15,588 6,379 4,931 4,821 4,068 2,973 2,865 2,591 2,300 2,197 2,301 2,212 1,924 3,169 1,524 770 2,078 841 232 363 626 559 649 377 305 494 453 359 14.9 6.7 5.2 48.3 20.6 5.1 9.8 26.7 24.2 33.4 19.6 16.1 27.3 25.8 22.9 15 countries 91,120 103,919 12,799 14.0 World 135,929 153,850 17,921 13.2

Table

* emerging country

countries will be the winners. They will be able to increase their shares in world production significantly, India alone by 0.9%. In 2031, India and Indonesia will rank ahead of Russia, which will fall to sixth place. These shifts again document the outstanding role which Asian countries will play in the future development of global poultry meat production.

Will alternative poultry meat become a competitor?

Regarding the dynamic development in the production of plant-based meat substitutes and the emerging possibility to produce meat from cell cultures and to introduce it to the market, the question arises which impacts this may have on conventional meat production. In 2021, the global sales volume of plant-based meat substitutes reached 5.7 billion US-$. Western Europe and North America shared 4.7 billion US-$. Meat from cell cultures (poultry meat) was only approved for sale in Singapore and has not generated any significant sales there so far. Overall, meat substitutes accounted for just 0.5% of the $1,071 billion in meat and meat products sales worldwide. At the COP27 in Egypt in November 2022, companies and organisations had the opportunity to present their technologies and products in an official pavilion and to present arguments for their importance in feeding a growing world population. These activities received wide media coverage.

25 - may 2023MARKETING

Total: 135.9 mill. t 39.5% 1.4% 1.7% 1.7% 2.7% 3.0% 3.2% 3.4% 10.9% 15.7% 16.8% 2022 Total: 153.9 mill. t 39.7% 1.7% 1.9% 1.9% 2.6% 3.2% 4.1% 3.1% 10.1% 15.9% 15.8% 2031 USA China Brazil Russia India Indonesia Mexico Turkey Iran Pakistan Others

Eurosilos Sirp srl Isorella (BS) Tel. +39 030.9958205 contatti@eurosilos.it www.eurosilos.it WE KEEP YOUR VALUE SAFE Italian manufacturer of fiberglass silos, tanks and augers. Follow us We are Social

Figure 5 – The share of the ten leading countries in global poultry meat production in 2022 and 2031 (design: A.S. Kauer based on OECD-FAO Agricultural Outlook data).

The provision of funding in several countries and political statements show that the opportunities by using these technologies have been recognised. Despite the increasing acceptance of alternative products by consumers, meat substitutes and meat from cell cultures will only account for a few percent of total meat consumption in 2031. One reason is that for the scaling up of production capacities high investments are required, a second that meat from cell cultures was approved in Singapore only and the technology for cell-cultured production in the USA. In addition, there are still many technical problems to be solved, resulting from the enlargement of the bioreactors for the production of quantities that are of interest for the market. Added to this are the high production costs, which oppose a price parity with conventionally produced poultry meat in the predictable future (cf. Windhorst 2023).

A preliminary conclusion

Poultry meat will show the highest absolute and relative growth rates of all meat types in the current decade. The favourable feed conversion of poultry, especially broilers, compared to pigs and cattle, and the lack of religious barriers to consumption will be the key steering factors behind the emerging dynamics. Other advantages include the versatility of poultry meat, its position in quick-serve restaurants and a lower price for consumers compared to beef and pork. In addition, the short succession of gener-

The OECD-FAO Agricultural Outlook only projects data for the overall development in the EU (27). The production volume is projected to increase from 13.6 mill. t in 2022 to 13.9 mill. t or by 2.0%, which is well below the 2.7% expected for Europe. If the member states of the EU had been considered, Poland would have been 8th and Germany 15th among the 15 leading countries in 2022. In 2031, only Poland is likely to remain in the top group because of the lower growth rates in Germany in comparison to several developing countries.

ations in poultry allows a faster reaction to market changes compared to the significantly longer periods in pig and cattle farming. Developing and emerging countries in Asia and Latin America will be the main drivers behind the expected increase. The industrialised countries of Europe and North America will lose market shares despite increasing production because of a slow-growing and even declining population. The already high per capita consumption does not allow a rapid expansion of production. However, export opportunities are likely to arise for some countries because in many developing and emerging countries the demand for poultry meat will grow faster than the possibility to increase the domestic production.

Data sources and suggestions for further reading

OECD-FAO Agricultural Outlook 2022-2031. https://stats. oecd.org.

UN World Population Prospects 2022. https://population. un.org/wpp.

USDA Agricultural Projection to 2031. https://www.ers. usda.gov/publications/pub-details/?pubid=103309.

Windhorst, H.-W.: The Champions League of the chicken meat producing countries. In: Zootecnica International 42 (2020), no. 7/8, p. 22-26.

Windhorst, H.-W.: The forgotten world: the chicken meat industry in the least developed countries. In: Zootecnica International 43 (2021), no. 3, p. 28-32.

Windhorst, H.-W.: The red-white-shift in global meat production. In: Zootecnica International 43 (2021), no. 5, p. 32-37.

Windhorst, H.-W.: Patterns and dynamics of global egg and poultry meat trade. Part 2: Poultry meat trade. In: Zootecnica International 44 (2022), no. 3, p. 24-27.

Windhorst, H.-W.: Patterns of the poultry industry in the MEA region: Part 2: Poultry meat production and trade. In: Zootecnica International 44 (2022), no. 9, p. 32-35.

Windhorst, H.-W.: Dynamics and patterns of the poultry industry in the G 19 countries between 2010 and 2020. In: Zootecnica International 44 (2022), no. 12, p. 22-27.

Windhorst, H.-W.: The revolution is taking shape. In: Fleischwirtschaft international (2023) no. 1, p. 34-39.

26 MARKETING - marketing -

SELF-DOSY

The automatic feed pan for cocks

NO WEIGHING SCALE REQUIRED

EVERYTHING IS DONE BY THE SELF-DOSY PAN

Automatic adjustment of the feed volume throughout the line.

Centralised opening for the simultaneous feed distribution in all the pans.

Sturdy, easy to manage and designed for aggressive birds. Simple washing of any inner and outer component of the feed pan. It works with flex auger.

HOW SELF-DOSY WORKS

Example : 80 kg of feed must be distributed throughout one line with 50 pans

80 kg: 50 = 1,6 kg of feed per pan

Adjust the feed volume at 1,6 kg with the centralized winch

Feed pans are filled according to the adjusted volume and the limit switch stops the line

The automatic opening is used to drop simultaneously the feed in all the pans

Leader in pig & poultry equipment

- may 2023MARKETING AZA International s.r.l. Via Roma 29 24030 Medolago (BG) Italy Phone (+39) 035 - 901240 - E-mail: info@azainternational.it QUALITY MADE IN ITALY Watch all information about Self Dosy www.azainternational.it

I WANT AZA!

SENSOR TO STOP THE LINE 1,6Kg 1,6Kg 1,6Kg 1,6Kg WINCH Set to: 1,6Kg N°1 N°2 N°49 N°50 Tot 80Kg

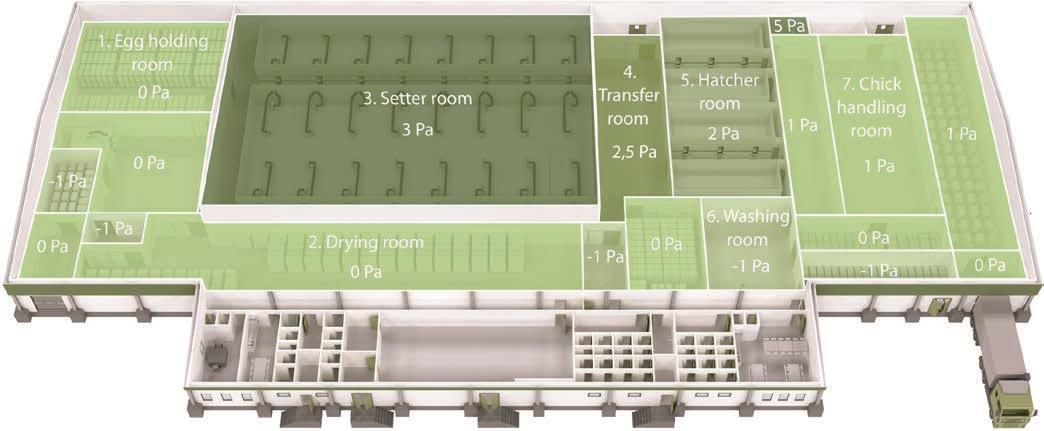

The role of HVAC systems in single-stage hatcheries

Since the evolution of the hatchery industry from multistage to single-stage incubation, Heating, Ventilation and Air Conditioning (HVAC) systems have become an indispensable part of hatchery operations.

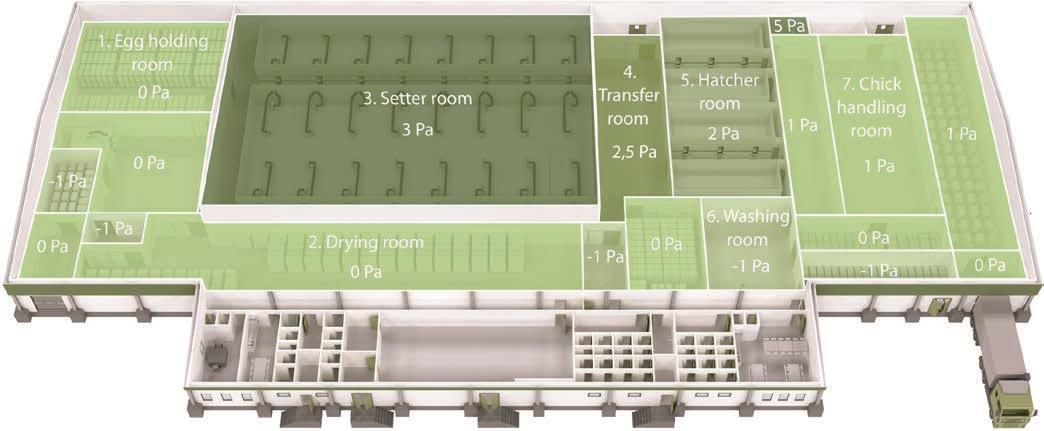

In essence, the HVAC system does the heavy lifting when it comes to climate control in single-stage hatcheries, and thereby helps the incubators achieve an optimal yield. The importance of climate control stretches far beyond the conditioning of the air for setters and hatchers, as controlling the air conditions in every room, from the reception of eggs to the dispatch of chicks, in a single-stage hatchery is essential to achieving optimal hatchery results.

Single-stage incubation relies on HVAC

Even though the commercial incubation industry had long adhered to the multi-stage incubation methodology (and successfully so), a new approach was required to both fulfil the worldwide demand for more poultry meat while meeting ever-stricter levels of biosecurity, and optimize the industry’s efficiency and return on investment.

28 - technical columnTECHNICAL COLUMN

Apart from retraining the personnel to the single-stage way of working, it also requires adapted machinery and equipment, including a properly-dimensioned Heating, Ventilation and Air Conditioning system. An effective and customized HVAC system is indispensable for efficient single-stage operations, as this technology does the heavy lifting when it comes to heating, cooling, humidifying and dehumidifying the fresh air supply that feeds the incubators. This makes it easier for the incubators to finetune the embryo’s environment for optimal hatchery results.

In this article, we focus on the four ways an effective climate control system impacts a single-stage hatchery for the better.

1. The right air supply at every stage

Arguably the biggest advantage of single-stage incubation is that environmental conditions can be adjusted to

the needs of the embryo at every development stage, from egg to chick. Not only does this improve the hatchability and chick uniformity as a result of an improved hatch window, but it also makes it easier to guarantee the biosecurity within the hatchery.

The HVAC system ensures that the correct volumes of air, conditioned both in terms of temperature and humidity, are delivered to the setter and hatcher room at all times. This allows the actual setters and hatchers to finetune the temperature and flow of the air and provide optimum and uniform environmental conditions inside the machines.

2. Any location, any climate

Outside climate conditions not only vary from region to region, but from season to season and even from day to night as well. That is why Petersime designs and engineers HVAC systems based on historical geographical

29 - may 2023TECHNICAL COLUMN

VISIT OUR WEBSITE zootecnicainternational.com FOR A DEEP INSIGHT INTO THE POULTRY INDUSTRY! and latest technical and scientific advances at zootecnicainternational.com! NEW PRODUCTS COMPANY NEWS INTERVIEWS FIELD REPORTS MARKET TRENDS EVENTS PROFILES

climate data, that take into account the actual minimum and maximum temperature and variations in humidity levels during a given time span.

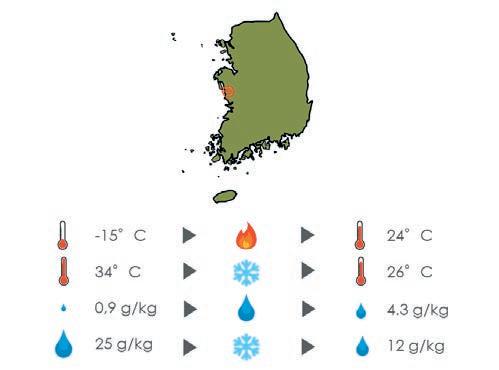

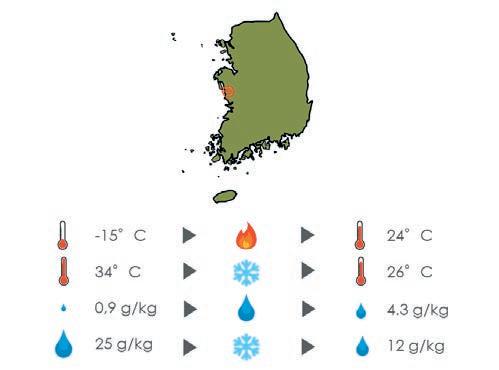

Example: A hatchery in South Korea

In South Korea, temperatures can easily range between -15 °C and 34 °C, while absolute humidity levels can rise from 0.9 g/kg up to 25 g/kg. A well-designed HVAC system will adjust the air conditions in the hatchery by heating the air in winter and cooling it in summer, while at the same time adjusting the level of humidity as required by the incubation process.

3. Increased biosecurity: no more airborne cross-contamination

A well-designed HVAC system will increase the hatchery’s level of biosecurity, as a pressure-controlled airflow is able to create different pressures in different rooms.

The highest pressure should be maintained in the setter room and the vaccine room — where cleanliness is paramount — while the lowest pressure is reserved for the washing rooms and areas that house dirty baskets. If ever a door opens, the air will always flow from the most vital and clean rooms to the dirty rooms, and especially never the other way around.

The HVAC system also filters the fresh incoming air. In fact, Petersime recommends using two levels of air filtra-

30 - technical columnTECHNICAL COLUMN

“An effective and customized HVAC system is indispensable for efficient single-stage operations, as this technology does the heavy lifting when it comes to heating, cooling, humidifying and dehumidifying the fresh air supply that feeds the incubatorsˮ

tion: first, a G4 pre-filter to keep out particles visible to the eye (>10μm); and secondly, a main F7 filter which blocks out fine dust and particles larger than 1μm. In this way, the hatchery only draws in clean air, while dirty air is contained in the designated rooms until being exhausted from the building.

4. Keeping energy costs in check

A well acclimatized hatchery does not necessarily consume more energy. Provided it has been properly engineered, a customized HVAC system can even help hatcheries consume the lowest amount of energy possible. In fact, the same pressure control system monitors how much air is required and will only provide that specific volume of air, so no conditioned air is wasted.

Moreover, in cold climates, it is possible to recover heat from the developing embryos, as from day nine onwards, the embryos are in their ‘exothermic phase’ (which means they start to produce more heat). A sustainable HVAC system can use this heat to pre-heat the cold fresh air entering the hatchery, thereby dramatically reducing the boiler’s and chiller’s energy consumption; indeed for the latter, this can sometimes be brought down to zero.

Leave your hatchery’s HVAC to Petersime

There is no single, standard solution for HVAC. Hatcheries in hot, humid climates, for example, require an air conditioning system designed for cooling and dehumidification,

whereas heating and humidification is a must in cold environments. Petersime has extensive experience in designing and installing tailor-made HVAC systems for hatcheries in the most varied climates. We are therefore ready to custom-build each of our HVAC systems to suit the conditions that prevail in your area. Please don’t hesitate to contact us for more information.

Petersime’s new X-Streamer™ brings incubator intelligence and performance to the next level. The X-Streamer™ is the first intelligent incubator that turns data into maximum hatchery performance. It knows which eggs are on board and uses this knowledge to help you maximise incubation performance, while minimising operational costs.

This ensures you get the best economic return out of your hatchery; not just right now, but during its entire lifetime. Maximum profit for life is what we stand for.

Let’s keep in touch!

31 - may 2023TECHNICAL COLUMN

X-Streamer™

www.petersime.com

Scan for more information: Built-in intelligence Unique Embryo-Response Incubation™ technology Designed for minimum operational costs The intelligent incubator that turns data into maximum hatchery performance © Petersime 2020All rights reserved.

1 Centre for Agricultural Engineering, University of Southern Queensland

2 Environmental and Rural Science, University of New England

3 South Australian Research and Development Institute

Machine vision detection of range use by free-range meat chicken flocks

Quantification of range use in commercial meat chicken flocks is desirable so that farmers can objectively assess meaningful range access, including number of chickens using the range and how far chickens roam from the shed.

Currently there is no cost-effective technology for quantifying range use in commercial conditions, and farm staff perform assessments based on visual inspection. A proof-of-concept machine vision system was developed for automated range use assessment, using simple

32 MANAGEMENT - management -

C. Mccarthy1, P. Taylor 2 and C. Dekoning3

and low-cost camera hardware with visibility of the length of the range area. A colour camera with solar panel and power bank was used to monitor a free-range site in South Australia in March 2022. The camera was placed at one end of the range adjoining a meat chicken shed, midway across the 12 m width of the range, and oriented towards the far end of the range. The camera was positioned at a height of 1.8 m and programmed to capture one image per minute during daylight hours. Image resolution was 1600 × 1200 pixels. Images were captured for 14 days on which pop holes were open, spanning flock age of 21 to 42 days.

Captured images were a one-point perspective scene, with the edge of the shed and the boundary fence of the

range receding to a vanishing point at the middle top of the image. Plant ground coverage was 85%, comprising green kikuyu grass, dry annual grasses, and isolated broadleaf weeds. The shed was oriented east-west such that shadows cast by the shed onto the range were relatively short. However, there were silos behind the camera on the eastern end of the range which cast a long shadow onto the range in the morning. Hence, image analysis was required to detect chicken pixels for sunlit, shaded and overcast conditions. After chicken pixels were detected, number of chickens and their distance from the shed were automatically calculated taking image perspective into account.

Image analysis counts of chickens achieved R2 of 0.85 to 0.94 when compared with manual counts of 120 images across four days with variable natural lighting. Reduced image analysis accuracy occurred within 1 m of the shed where chickens were seated closest together. Image analysis and visual inspection both indicated that range use was highest at approximately 09:00 - 09:30 h for the observed flock, with range use declining after about 10:30 h for sunny days.

Based on image analysis, it was common for chickens to range up to 4 m from the shed. Chickens appeared to prefer ranging in the shadow cast by the silos, as chickens that were the greatest distance from the shed (i.e. more than 4 m) were always seated or standing in the shadow cast by the silos, where that same shadow also reached within 3 m of a pop hole.

It was concluded that a single low-cost colour camera with a viewpoint along the range was suitable for image analysis algorithms to quantify range use. Automated counts were accurate compared to manual counts from images. The algorithms could distinguish chickens under the different lighting conditions of overcast, sunlit and shaded, indicating potential for further research of meteorological and environmental conditions and ranging behaviour.

Further work should evaluate and refine algorithms for segmenting chickens from the background for various ground covers, sunlight directions and flock ranging routines, through trials for a greater number of farms, shed orientations and times of year.

From the Proceedings of the Australian Poultry Science Symposium 2023

33 - may 2023MANAGEMENT

Dr Cibele Torres, Poultry Nutritionist at Zinpro Corporation

Heat stress: vitamin E level and zinc source matter

Zinc and vitamin E are vital antioxidants that protect the gut and support broiler growth and health during heat stress conditions. The biggest wins are reached by supplying them during the early days post hatch and new research showed that more is not always better.

High feed prices alone are a huge challenge to tackle. But when poultry producers are faced with added challenges, such as heat stress, it puts even more pressure on controlling feed efficiency, animal performance and farm profitability. Gut health plays an important role in making birds more resilient, healthy and on target during all the challenges they face, including heat stress. And the sooner the gut maturation is positively modulated, the bigger wins can be achieved. Early intervention is key because the chick’s gut development is develop -

34 NUTRITION - nutrition -

ing fast during early life. In the first 3 days after hatch, the absorptive nutrient area of the intestines increases by 70% (increase of villi length). This is essential because the chick needs to adapt fast from a diet based on lipids (yolk lipids) to a solid carb/protein-based diet. Gut development is complete by 10 days and the mature gut microbiome is established around 17 days.

Zinc and vitamin E

Over the years, the industry has gained a lot more insights on how to determine and measure ‘intestinal health’, and how to positively influence it through nutrition and certain feed additives such as zinc and vitamin E. Zinc and vitamin E are both vital antioxidants that protect the gut through different modes of actions. But not all zinc sources that are on the market are the same and have

35 - may NUTRITION

Nuova-i Evisceration enters the digital era. Nuova-i‘s innovation and connectivity offer data-driven optimum performance. • Highest yield and quality in eviscerated carcass and giblets • Best-in-class pack removal, with uniform, compact viscera packs • SmartBase machine health monitoring for performance insight • More efficient and easy operation and maintenance Contact us to find out more: +31 485 586 111 info.poultry@marel.com marel.com/nuova-i Intelligent evisceration management

“Over the years, the industry has gained a lot more insights on how to determine and measure ‘intestinal health’, and how to positively influence it through nutrition and certain feed additives such as zinc and vitamin E. Zinc and vitamin E are both vital antioxidants that protect the gut through different modes of actions. But not all zinc sources that are on the market are the same and have the same performanceˮ

ronmental temperatures, to the best of our knowledge, interactions of different zinc sources and vitamin E level have not been investigated under heat stress conditions in broilers. A study by De Grande et al. (2021), published in the Journal of Animal Physiology and Animal Nutrition,

therefore looked at different levels of vitamin E, in combination with different zinc sources. The trial looked at two sources of zinc, 60 mg/kg of Zn as ZnSO4 or 60 mg/kg of Zn as zinc amino acid complexes1 (hereafter called ZnAA), combined with two levels of vitamin E (50 or 100 IU/kg). Performance was measured from day 0-36. From day 28 until day 36 (finisher period), all birds were subjected to chronic cyclic high temperatures (32 °C ± 2 °C and Relative Humidity 55–65% for 6 hours daily).

Annatachja De Grande obtained her PhD at the University of Ghent in Belgium where she focused on the effects of dietary zinc source on growth and intestinal health in broilers. In 2021, De Grande et al published new insight, as discussed in this article. She currently works as a postdoctoral researcher at ILVO (the Flanders Research Institute for Agriculture, Fisheries and Food).

De Grande explains: “During heat stress, broilers have an increased need for several nutrients and trace minerals. This requires adaptation of the poultry farmers and the nutritionist to change the formulation when a rise in temperature is expected. But at the same time, you don’t want to make the diet unnecessary expensive and only provide the extra nutrients when the animal really needs them. In our trials we showed that strong antioxidants such as zinc and vitamin E should definitely be part of a ‘summer diet’, as they have an important role in gut health and reducing oxidative damage in the muscle tissue. Using a zinc as zinc amino acid complexes increases the availability and uptake of the trace mineral, reflecting in reduced drip loss, one of the most important parameters for meat quality and better growth and performance, due to better gut health and nutrient uptake in the gut. Surprisingly, these results were achieved in combination with the lower level of vitamin E, something we didn’t really expect, yet very welcome in these times of high feed prices. It would be interesting to delve deeper into the complex interaction of zinc and vitamin E in the near future”.

More is not always better