Slovenian company Pivka broiler growers join the Ross 420 Club

Aviagen® KFT recognizes the hard work of its customers and believes that acknowledging their achievements promotes mutual success.

keting Assistant; Dejan Bosanac, Regional Technical Manager; and Krisztina Nemeth, Sales Manager. Dejan’s presentation, “From the last broiler to the end of the brooding period,” offered valuable management guidance to ensure a successful transition of chicks to the next stages of production.

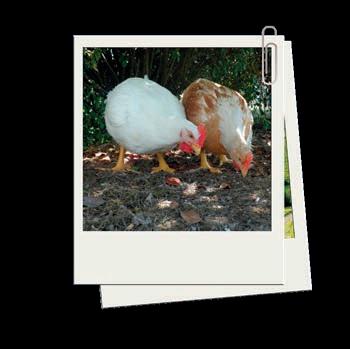

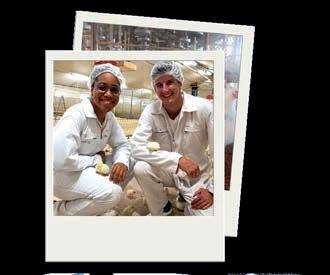

Jasna Perc, Pivka Assistant Production Manager commented, “We are proud of our outstanding broiler growers. The awards prove that we are commit ted to our mission and that our primary focus is the care of our animals.”

Dejan was impressed with Pivka’s accomplishments, saying, “Despite the challenges faced by today’s producers, our birds achieve improved results year on year, and working together with the excellent farm management of Pivka, they continue to reach award-worthy heights in efficiency, sustainability and welfare.” The

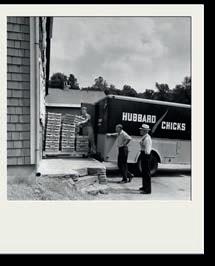

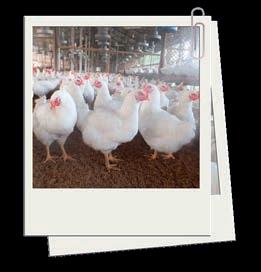

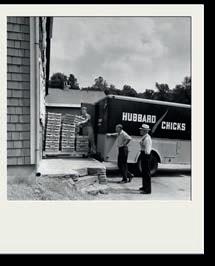

Recently, Aviagen KFT and Slovenian customer Pivka held a special meeting to welcome Pivka’s broiler growers to the Ross® 420 Club. This elite club is reserved for top-performing producers who reach a European Production Efficiency Factor (EPEF) score of 420 or greater. Karl Plut took the top award with an impressive score of 468 EPEF.

The event was at tended by the managing board, production managers, and broiler growers from Pivka, along with Aviagen KFT team members – Barbara Boka, Mar -

6 - company newsCOMPANY NEWS

winners are: Name EPEF Ivan Fab č i č 425 Pavel Gerbec 423 Pavel Gerbec 421 Karl Plut, obj.3 436 Karl Plut, obj.1 468 Karl Plut, obj.4 444 Karl Plut, obj.5 442 Karl Plut, obj.2 438 Karl Plut, obj.3 428 Alenka Rupnik 448 Alenka Rupnik 431 Pivka d.o.o. 468

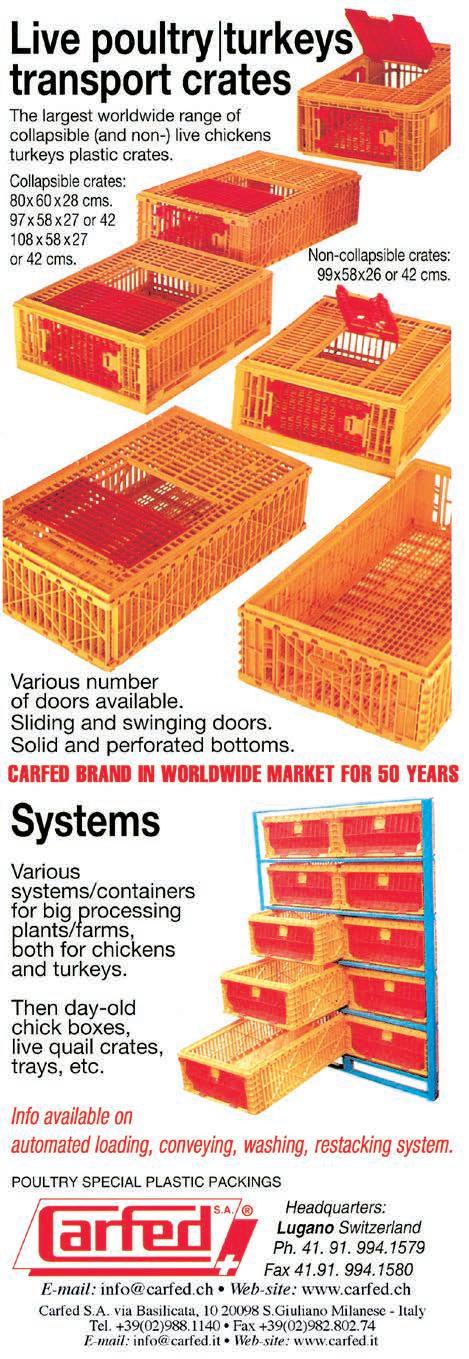

4002 H

• 360 degrees opening

• Highly strong and durable material

• “SOFT” action

4626

• Suitable for fattening turkeys

• Perfectly dry bedding

• Simultaneous watering of 2 and more animals

INFINITY

• Essential design

• No chicks in the pan!

• Regulation of minimun and maximum feed level

• Available in caged broilers version

for breeding

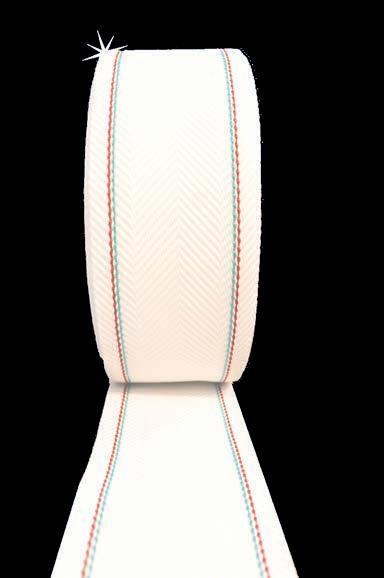

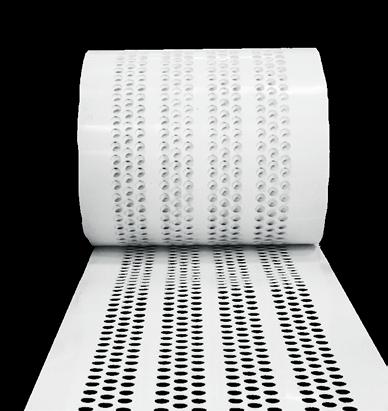

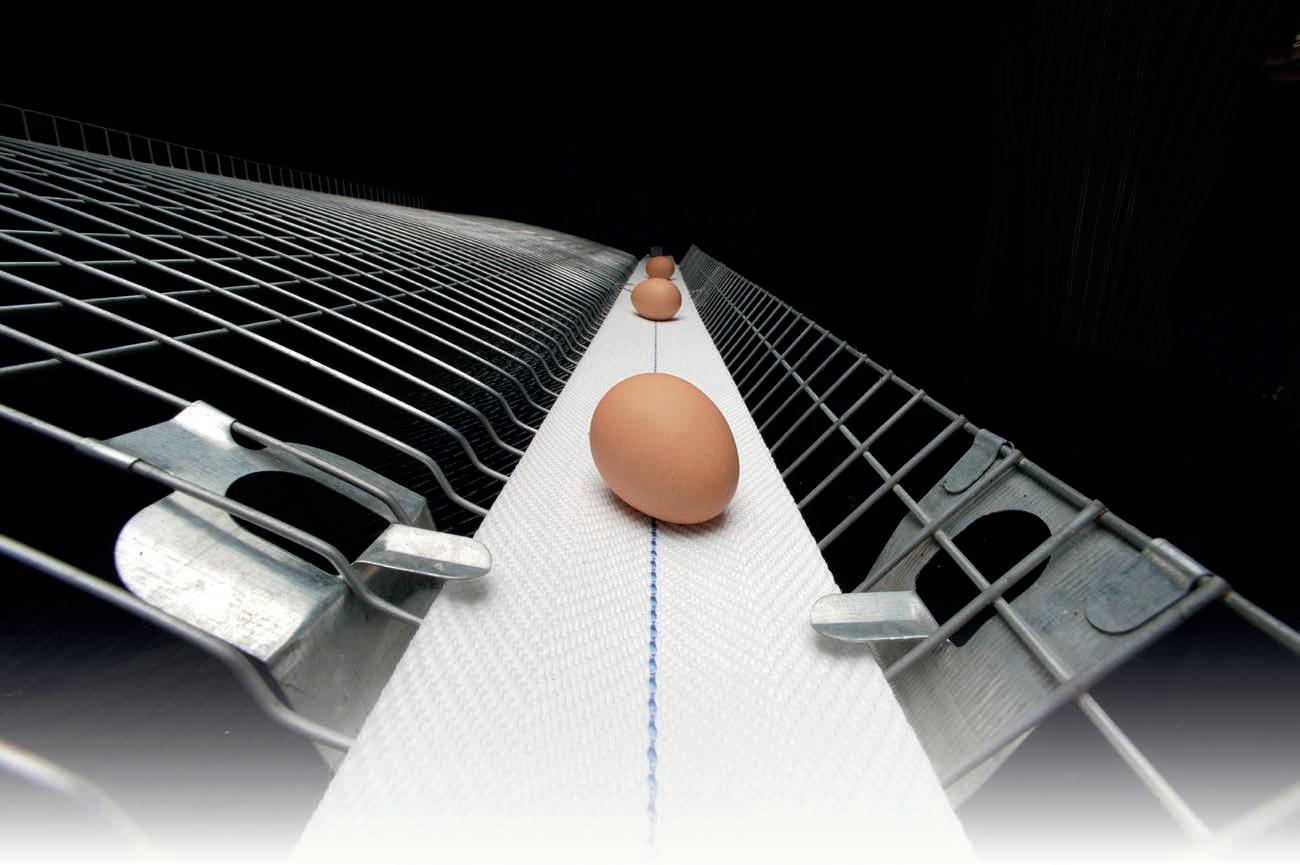

PP Belts

• Egg collection

• Manure drying system

• Manure belt collection

• PP woven egg belts

• PP hole egg belts

4006 H

• 360 degrees opening

• Highly strong and durable material

• “EXTRASOFT” action

4901 N

Pressure regulator with bypass

CORTI ZOOTECNICI

ARTICLES ACCESSORIES

Corti Zootecnici Srl | Via Volta, 4 21020 Monvalle (VA) Italy| www.cortizootecnici.it |

R.J. Atterbury

School of Veterinary Medicine and Science, University of Nottingham, Sutton Bonington, UK

Biological control of Salmonella in the poultry industry: a European perspective

Salmonella remains one of the most important foodborne bacterial pathogens worldwide, and is frequently linked with the consumption of contaminated poultry meat and eggs. Despite some noted successes in reducing particular serotypes and strains, other serotypes have become more problematic. Progress has also been frustrated by increasing resistance to antimicrobials and biocides.

Biological control using bacteriophages or predatory bacteria is an alternative approach to Salmonella control in poultry which has been effective in laboratory, experimental and/or field trial settings. The European Union is currently considering authorizing the first phage-based commercial product for the treatment of Salmonella in poultry. Questions remain about the regulation and commercial status of such products, as well as their long-term efficacy; but their ability to specifically target multidrug resistant bacteria may provide a new way of reducing our reliance on antimicrobials and decrease the burden of disease in both animals and humans in the future.

8 - field reportFIELD REPORT

Introduction

Salmonellosis remains one of the most frequent foodborne zoonoses, constituting a worldwide major public health concern. Although Salmonella can be acquired from a range of foods, poultry meat and eggs remain prominent (Antunes et al., 2016). Human salmonellosis cases in the US are estimated at 1.35 million per year (Centers for Disease Control, 2019). Likewise, cases in the UK and EU have not changed significantly over the past decade.

Success in controlling some Salmonella serotypes (e.g. Enteritidis) in poultry through vaccination and biocontrol have been punctuated by failure to control other serotypes. A recent example of this was an outbreak of Salmonella Infantis in the United States in 2018, affecting 32 states (Centers for Disease Control, 2019). In the EU, Salmonella Infantis is now the 4th most common serotype from human infections, and the most frequent serotype in broilers flocks (45.6 %) and broiler meat (50.6 %) in Eu-

rope (Alba et al., 2020). More worryingly, multidrug-resistant isolates are becoming increasingly common in Europe, particularly those which have acquired a pESI megaplasmid encoding resistance to multiple classes of antibiotics as well as virulence genes and enhanced tolerance of heavy metals and biocides (Tyson et al., 2021). One alternative approach to Salmonella control is the use of biological control agents; either viruses which specifically infect Salmonella – bacteriophages – or use of predatory bacteria such as Bdellovibrio bacteriovorus. In a recent review of alternatives to antibiotics, funded by the Wellcome Trust and UK Department of Health, bacteriophage-based treatments comprised three of the ten Tier 1 (most promising) new technologies (Czaplewski et al., 2016). Although less developed, Bdellovibrio has been used successfully to control infection in multiple animal models of disease, including the treatment of Salmonella in poultry (At Biological control has unique advantages over antimicro bials. These agents are both self-replicating and self-lim

PLASTIC PADS FOR THE PAD COOLING

The LUBING Pad Climate system is made entirely of plastic. It is used in systems where highly efficient cooling is required.

•For evaporative cooling of poultry and pig houses.

•Excellent cooling capacity - patented design.

•Easy to clean.

•Long service life.

•Lowest pressure loss.

•High UV resistance.

•Impermeable to light.

•Chemical resistance.

- june 2023FIELD REPORT

!lanigirO

Via Marco Polo, 33 - 35011 - Campodarsego (PD) ITALIA +39 0499202290 - lubingsystem.com - info@lubing.it

iting – reproducing only when susceptible bacteria are present. Unlike broad-spectrum antibiotics, they target a specific genus, species or strain of bacterium, avoiding potential harmful dysbiosis in the patient. Likewise, several studies have found that Bdellovibrio can prey upon multidrug resistant pathogens in biofilms (At terbury and Tyson, 2021; Sun et al., 2017). In addition, Bdellovibrio can survive for up to 24 h inside eukaryotic cells without adverse effects, suggesting that it could be applied to control pathogens with an intracellular component to their lifecycle, including Salmonella (At terbury and Tyson, 2021).

Method

Candidate therapeutic bacteriophage are usually isolated from an environment where their bacterial hosts are abundant. In the case of Salmonella, this is of ten poultry feces, wastewater or human sewage. Once purified, these phages are screened against a large panel of tar-

get serotypes and strains which should be chosen to reflect the diversity of pathogens affecting the population. Phages that infect a broad range of bacteria, either separately or in combination (cocktail) are usually selected for genome sequencing and analysis. This step allows the identification of undesirable phage e.g. temperate phage which do not underdo a direct and predictable lytic infection cycle. It also identifies phage carrying undesirable genes such as those associated with virulence. More detailed in vitro characterization of the phage may be performed in parallel, such as determining the burst size and replication kinetics of infection. For promising candidates, the specific phage receptor(s) on the host bacterium may be identified, along with an assessment of how frequently resistance to phage occurs.

Increasingly, bioinformatics is being used to facilitate the characterization and selection of phage. There are tools available to predict the taxonomy, DNA packaging mechanisms (Garneau et al., 2017), lifecycle (McNair et al., 2012), receptor specificity and host range (Zhang et al., 2017) of candidate phage. Once a phage is characterized, online tools can be used to compare it with others uploaded to the database which may be useful for cross-validation (Rangel-Pineros et al., 2021). Further confirmatory tests can then be performed in the laboratory, for example to establish the phage receptors predicted in silico. Thereaf ter, the phage candidates can be tested for efficacy in simple animal models such as Galleria mellonella and their stability in commercial preparations before taking forward to experimental and field trials in poultry.

Bdellovibrio, like phage, is most of ten isolated from environments where their prey are abundant. This is often in aquatic environments or sewage. Unlike most bacteriophage, Bdellovibrio targets multiple genera of Gram-negative pathogens, and resistance to predation is rare and transient (Marine et al., 2020). There is evidence that Bdellovibrio or like organisms are present in the intestinal tracts of a range of animal species, including poultry (Schwudke et al., 2001). However, these bacteria have been difficult to isolate and exploit directly. Bdellovibrio are metabolically active and chemotactic towards their prey. As such, unlike phage they are not reliant on passive diffusion to spread through a bacterial population. However, it also means the options available for therapeutic delivery are more limited than with phage and commercial preparations may be more challenging.

10 - field reportFIELD REPORT

“Bacteriophages have been shown to significantly reduce the intestinal carriage of multiple serotypes of Salmonella in broiler and layer chickens. These reductions were frequently accompanied by improvements in clinical manifestations of disease (reduced perihepatitis, pericarditis, typhlitis) as well as feed conversion ratiosˮ

Results

Salmonella is frequently a target of biological control trials owing both to its importance as a human pathogen and as a cause of significant disease and production losses in livestock. Most effort has been directed towards controlling important non-host-restricted serotypes of Salmonella, such as Enteritidis and Typhimurium which are more significant from a regulatory perspective in the EU and elsewhere.

Cocktails of lytic phage have been used to reduce intestinal carriage of Salmonella by between 1 and 3.5 log10 CFU/g (Atterbury et al., 2007; Sklar and Joerger, 2007). These reductions were often accompanied by marked improvement or elimination of clinical signs of disease (Sklar and Joerger, 2007). Phage therapy has been combined with seeder models of infection to demonstrate how effective phage can be in preventing horizontal infection of chicks by Salmonella. Lim et al. (2012) showed that treatment with up to 109 PFU/g of phage in feed could reduce intestinal colonization by up to 1 log10 CFU/g, while 70% of the contact chickens had no detectable Salmonella Enteritidis colonization. Henriques et al. (2013) significantly reduced the spread of Salmonella Enteritidis in chicks by treating fertilized eggs with a cocktail of two phages. Clinical signs of disease at the end of the eight-day study were not significantly different from the control group.

More recently, two studies have examined the impact of applying therapeutic phage on the chicken microbiome. Kosznik-Kwaśnicka et al. (2022) found that both phage and antibiotics (enrofloxacin and colostin) were all able to reduce Salmonella to below detectable levels in infected chickens. However, antibiotic use was associated with significant and prolonged changes in the microbiome whereas the effects of phage were transient and normalized several weeks af ter treatment. Similarly, Clavijo et al. (2022) used a proprietary Salmonella phage product in a commercial broiler farm to assess the effect on the gut microbiome. No significant effects of phage on the maturation of the microbiome were detected.

Bdellovibrio has been isolated previously from the intestinal tracts of chickens as well as humans and other vertebrates (Schwudke et al., 2001). At terbury et al. (2011) used Bdellovibrio to treat chickens experimentally infected with Salmonella Enteritidis. Significant reductions of over 1 log10 CFU/g were recorded in the ceca of treated birds compared with buffer-treated controls. Bdellovib -

rio -treated birds also had significantly fewer cecal abnormalities compared with both untreated controls and birds treated with a non-predatory Bdellovibrio mutant. Interestingly, in vitro experiments using both phage and Bdellovibrio showed that the combination of both virus and predator was able to eliminate pathogen populations much more effectively than either used independently (Hobley et al., 2020)

Discussion

Bacteriophages have been shown to significantly reduce the intestinal carriage of multiple serotypes of Salmonella in broiler and layer chickens. These reductions were frequently accompanied by improvements in clinical manifestations of disease (reduced perihepatitis, pericarditis, typhlitis) as well as feed conversion ratios. Although phage-resistant variants of Salmonella have been recorded, these phenotypes are often transient, and associated with reduced fitness in animal models of infection. Resistance to Bdellovibrio on the other hand is extremely rare, and only conferred by the presence of an intact S-layer which is metabolically expensive to maintain. Interestingly, when Bdellovibrio and bacteriophage are used in combination, they can act synergistically for a greater reduction in the target pathogen without the development of resistance.

Despite their promise, there remain some technical, commercial and regulatory hurdles which need to be overcome before bacteriophages and Bdellovibrio could be used more widely in the UK/EU. These agents do not fit easily within existing regulatory frameworks which were designed for defined chemotherapeutics. Likewise, the ability to protect intellectual property relating to naturally-occurring biological entities is an open question. Despite these obstacles, commercial phage products targeting food-borne pathogens are available in the United States and the EU is in advanced discussions to authorize the first bacteriophage treatment for livestock in the bloc Given the pressing need to control multidrug-resistant infections, and the reducing efficacy and availability of antibiotics to treat them, biological control agents such as Bdellovibrio and bacteriophage offer a potential solution.

References are available on request

From the Proceedings of the Australian Poultry Science Symposium 2023

11 - june 2023FIELD REPORT

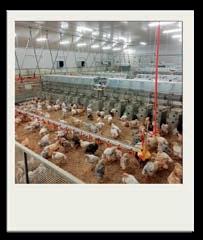

Researchers investigate how laying hens visually perceive the resources in cage-free housing

USPOULTRY and the USPOULTRY Foundation announced the completion of a funded research project at Purdue University in which researchers investigated how laying hens visually perceive the resources in cage-free housing. The research was made possible in part by an endowing Foundation gift from MPS Egg Farms and proceeds from the International Poultry Expo, part of the International Production & Processing Expo (IPPE). The research is part of the Association’s comprehensive research program encompassing all phases of poultry and egg production and processing.

12

DOSSIER - dossier -

Dr. Darrin Karcher, Department of Animal Sciences, Purdue University, West Lafayette, Ind.

©www.soilassociation.org

Project #F095: how does laying hens’ visual perception affect resource usage in cagefree housing?

Dr. Darrin Karcher and colleagues at Purdue University recently completed a research project that investigated how lighting systems can impact hens’ visual perception of their housing environment or of their conspecifics. Researchers were able to show that there were significant differences in the visual systems of brown and white chickens at all ages. Modeling also revealed that the visual environment is often homogeneous and undistinctive, except when highly colored objects are present, potentially increasing the risk of injury to the hens as they move through the aviary.

Geneticists have been trying, with little success, to determine and select egg layer strains that will perform well in cage-free production systems because there are numerous unknown factors which influence a hens’ performance. The unknown factors have resulted in there being no single strain that can perform consistently. Companies that have transitioned to cage-free production are faced with various management and welfare issues including keel bone damage, mislaid eggs and feet pecking. These new welfare issues may be due to the hens’ inadequate or inaccurate perception of their environment due to inappropriate lighting. No previous studies in poultry have determined how lighting systems can impact hens’ visual perception of their housing environment or of their conspecifics.

This project sought to achieve the following objectives:

• develop a chicken-specific visual model through the collection of physiological information,

• evaluate lighting systems for spectral properties among different cage-free housing in commercial settings, and

• explore the relationship between avian visual perception and flock welfare outcomes.

Initial data to develop the visual models was collected from laying hens housed at Purdue University. Researchers partnered with a commercial egg producer to collect light spectra during production in a cage-free housing facility. Models were executed to identify whether high or low conspicuousness of different objects from the hens’ viewpoint could be related with variations in welfare indicators under different cage-free housing and lighting systems.

Due to the highly pathogenic Avian Influenza outbreak across the country during the project period, researchers were unable to visit as many facilities as addressed in objective 2 or assess the welfare indicators initially proposed in objective 3. However, they were able to fully develop the visual models from two strains of chickens (brown and white) at three different ages (17, 25, and 85 weeks of age) to model the visual environment at two different facilities.

The study showed that there are significant differences in the visual systems of brown and white chickens at all ages. The ability of light to transmit through the eye of both brown and white strains decreased with age, reducing the amount of ultraviolet light that reaches the retina. The relative density of cells in the retina consistently differed between the brown and white strains. The sensitivity of cells in the retina did not change with age, however there were unexpected differences found between the brown and white strains.

In cage-free egg laying facilities, modeling revealed that the visual environment is often homogeneous and undistinctive, except when highly colored objects are present, potentially increasing the risk of injury to the hens as they move through the aviary. The ambient light in the egg laying facility impacts how conspicuous objects and substrates are. In certain ambient light conditions, the strain and age of the laying hens determined if an object was easily perceived. Overall, variability in the visual systems of different strains and ages of laying hens should be considered when determining aspects of the visual environments that are utilized in the industry.

The research summary can be found on the USPOULTRY website.

Information on other Association research may also be obtained by visiting the USPOULTRY website, www.uspoultry.org

13 - june 2023DOSSIER

Hybrid Feed - New approach in layer hen feed at start of production

The actual genetic improvements in layer hens are providing the market with a layer hen producing saleable size eggs quicker than before and extending the production life. These two parameters are related to the start of the production. A good feed intake at the start of production assures a good egg size at the beginning of production and a good eggshell quality at the end.

At the start of production, a second bone development happens that will load the bones of the layer hens with calcium, that is critical in the calcification of the egg during production. The hybrid feed is a recommendation of how to approach the layer hen feed at the start of production just after the developer rearing feed phase is finished. This hybrid feed is a mix of concepts of rearing developer feed and production feed; it will stimulate feed intake development and will have enough nutrients to support the body and bone development happening

14 FOCUS - focus -

A. Akpulat1 and X. Arbe Ugalde1

1H&N International, Cuxhaven, Germany

when the first egg is produced and it can be used in any layer hen, brown or white. This feed is meant to be safer and cheaper solution than other traditional approaches of feeding layer hens and it supports the genetic potential of the birds.

Introduction

The continuous genetic improvements are increasing the first commercial egg size produced and extending the production life of the layer hens worldwide. These improvements are related to what happens at rearing and at the start of the production. Early studies showed that while approximately 60 to 75% of the calcium destined for the shell comes directly from intestinal absorption, up to 36% could be traced to bones. This bone source is critical since shell calcification occurs during the dark period, when the hen is not eating. Proper skeletal development is integral during pullet growth, which has a first period of growth during the first 6 weeks of rearing and a second period of growth with long bones reaching their maximum length and cortical bone reaching optimal thickness by week 22 of age. Upon activation of the reproductive axis and in preparation for the laying cycle, increasing estradiol 17-beta (E2) concentrations shift the activity of osteoblasts toward the formation of medullary bone, with cortical bone accumulation terminated before lay. This medullary bone is deposited on the interior, endosteal surface of the cortex in the marrow cavities of long bones, with the largest reserve in the femur, followed by the tibia. This second phase of calcium deposition is very dependent of the feed intake at the start of production. Nutritionists have different approaches when the start of production happens in layer hens and today there is a new option suggested by H&N International called Hybrid Feed that aims to support the start of production better than current and traditional approaches.

Concept of Hybrid Feed

The feed intake development at the beginning of production will allow the bird to have the correct nutrient intake. This feed aims to keep developing the feed intake as it happens at the end of rearing of the pullet and supply enough nutrients to support the bone development and the production of the first egg. The numbers recommended in the Hybrid Feed should be adapted to the different

raw material information sources and to the available raw materials in the market. Here below a description of the principals and recommendations when developing a Hybrid Feed.

Low energy diet: the feed intake of the layer hens is regulated by calories intake. During the developer phase of the pullet the feed should focus in developing the feed intake capacity of the bird, the metabolizable energy content of the Hybrid Feed should be like the developer feed, around 2650-2750 kcal/kg, depending on the source/s of information used to evaluate the energy of the raw materials. This approach stimulates the feed intake at the start of the production, and it will not hurt the start of the production because the production needs are still low, and the feed intake and composition of the Hybrid Feed will provide the necessary nutrients.

Fibre content of the diet: low density diets will be completed by fibre. There are different ways we can classify the type of fibre; it was shown that with the commonly used raw materials in layer hen diet, the increase of the crude fibre has a positive effect in gut development and therefore the feed intake capacity of the birds.

Amino acids level: the amino acids level is like the layer phase 1 recommendation. There will be enough amino acids for body weigh growth and egg production. The amino acids requirements aren’t maximum until week 22-23 of age as the flock is in full production (Table 1). However, due to the low feed intake it is necessary to have a high concentration of the amino acids to be sure that there will be an enough supply.

Calcium level: the average hen requires 2.2 g of calcium for each eggshell formation. At the start of production, we will have a growth of the bones and we will have some

- june 2023 - 15 FOCUS

Week of age Maintenance (Mg D lys / bird) Growth (Mg D lys / bird) Egg mass (Mg D lys / bird) 17 122 209 0 18 129 217 0 19 136 229 52 20 142 226 246 21 149 214 389 22 154 171 486

Table 1 – Requirements of digestible Lysine at the start of egg production, H&N International 2019.

early productive hens. As per the bone development with 2-2.5% of calcium level would be enough, however the early producing bird need more. Therefore, the recommendation is to formulate to 3.8% Ca in browns and 4% in whites layer hens. What is important is the source of calcium, to avoid possible feed refusal the coarse calcium carbonate should be the 60-70% of the total calcium carbonate in the diet. The particle size of the coarse calcium carbonate should be 2-4 mm.

Phosphorus level: the phosphorus level in poultry is related to the feed intake and the growth of the birds, critical in this stage and in layer hens it is related to the calcium deposition in the bones. Therefore, the level of available phosphorus should be as high as in the layer phase 1 recommendation, 0.44% in browns and 0.46% in whites.

High level of salt: the salt is a raw material related to the feed intake in birds. It has been shown that salt stimulates the water intake and feed intake. Therefore, it is recommended to include salt at the level of 0.28%. It shouldn’t be replaced with a level of sodium in the diet. The use of sodium bicarbonate as raw material in the layer diets could complete the needs of sodium requirement in the diet but it doesn’t have the same feed intake stimulation

effect as the salt. Therefore, it will be important to be sure that we have the level of salt in the diet, and we don’t exceed the maximum of 0.34% of chloride as nutrient.

All this parameter will make the diet, but it is also about the use at the farm.

Use of Hybrid Feed

There are challenges at the farm when getting accurate data at the start of production. The long transfer period from rearing to production house and the stress of the arrival make it difficult to calculate the feed intake at the start of production. In addition, the low production of the flock delays the egg collection of the flock, therefore we don’t have an accurate data of the daily production.

The use of Hybrid feed meant to be simple and easy to apply, therefore this is the recommended program:

1. House the pullets in production with Rearing Development feed, as long as there wasn’t a previous light stimulation of the flock at rearing.

2. Hybrid feed should be available to the hens as soon as the light stimulation is given to the pullets.

16 FOCUS - focus -

3. Hybrid feed will be provided until 70% of production is achieved. This will happen around the week 21-22 of age and it will be easy to have an accurate data of the % of production as the egg collection is regularly done at the farm at this age. The feed intake by then will be around 95-100 grams/hen and even higher if the pullet had a good feed development.

4. The next feed should be a 60-58 egg mass target feed as the egg production will reach the peak.

Advantages of Hybrid Feed

There are other approaches during the onset period like using a pre-lay feed and/or a super-starter feed. Both approaches have shortcomings that Hybrid Feed doesn’t and has all the advantages of a pre-lay or super-starter feed.

The pre-lay feed is meant to be a transition feed between pullet and production, however the application at the farm level is very difficult and dangerous. The pre-lay feed use

is recommended to do by two ways, and both are difficult to apply:

• Use of pre-lay until 2-5% of production: this recommendation doesn’t consider that many farms don’t collect the eggs daily when the flock is starting in production. The egg collection is decided by the workload at the farm and how the egg collection belts look like; therefore, a lot of mistakes can happen. The pre-lay diet can be extended too long and early producer hens can become decalcified, stop the production and in the peak of production we will have peaks of production 2- 5% lower than the standard.

• Use of pre-lay 0.5-1 kilogram per bird: this recommendation forgets that there is variation of the feed intake at the pullets due to effect of weather changes and feed development challenges during rearing. This recommendation will have same result as the previous one and even we can have problems of eggshell quality late in production.

- june 2023 - 17 FOCUS

Eurosilos Sirp srl Isorella (BS) Tel. +39 030.9958205 contatti@eurosilos.it www.eurosilos.it WE KEEP YOUR VALUE SAFE Italian manufacturer of fiberglass silos, tanks and augers. Follow us We are Social

Another approach is using a super starter of lay after the developer feed or after the use of the pre-lay. This super starter of lay is highly concentrated feed in nutrients and very expensive; it is designed for supplying all the nutrients needed at this critical moment. However, it creates new challenges: the high energy of this feed restricts the feed intake development of the layers, therefore, many times the birds don’t have enough nutrient intake at the peak of the production; it will lead to production drop at the peak of the production when changing to a layer 1 diet because of lack of feed intake; or it will push the farmer to use an expensive feed until 40 weeks of age because the layer hen doesn’t eat enough nutrients.

The hybrid is a proven alternative that skips the disadvantages of the other recommendations and has all the advantages (Table 2).

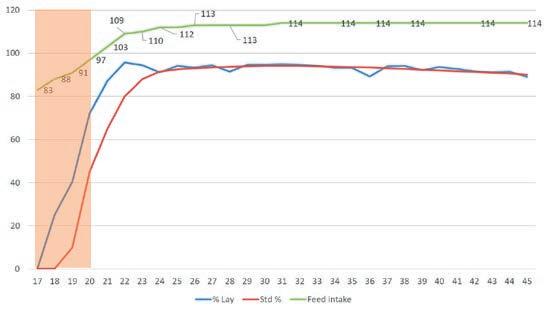

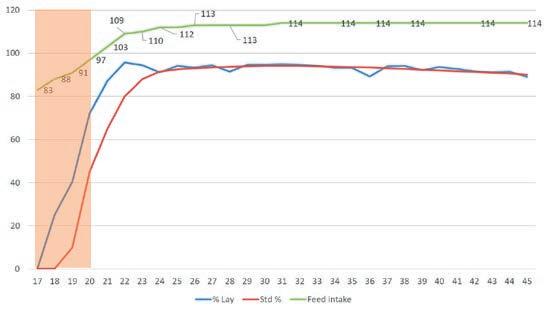

ducers. This feed was tested in Australian conditions in caged brown birds and cage free brown birds; at that time, we could see a good feed intake development, performance of the birds was on standards (Figure 1) with good eggshell quality. There are more positive experiences when using Hybrid feed in brown layer markets like Colombia or Ecuador and in white markets like in USA and Canada.

The use is very friendly for the farmers and it gives a more cost effective solution for the start and peak of the production.

Experience of Hybrid Feed

The use of Hybrid Feed started in 2019 and it keeps increasing the acceptance as it is tested by the egg pro -

In all these experiences using the Hybrid feed we have seen an improvement of the feed intake development and a faster egg size development without affecting the performance of the birds.

Conclusions

The use of the Hybrid Feed is a new approach to the start of production where different challenges happen. This new approach can replace the previous practices that are difficult to apply at farm level or are too costly. The use of the Hybrid Feed should be part of the feed intake development program where first step starts at the develop phase of the pullet. At this stage there should be a feed intake capacity development and later at start the production Hybrid Feed will be the perfect match for having a bone development, sexual maturity growth and first egg production. The Hybrid Feed brings solutions to a critical part of the egg production, the start of production, no matter the breed.

References are available on request

From the Proceedings of the Australian Poultry Science Symposium 2023

18 FOCUS - focus -

Pre -Lay Super Starter Hybrid Feed Application - + + Feed intake development + - ++ Calcification + + + Egg production - + ++ Cost of feed + - +

Table 2 – Comparison of the different effects of the three options at the start of lay.

Figure 1 – Production performance and feed intake when used Hybrid Feed from 17 to 20 weeks.

- june FOCUS www.hubbardbreeders.com

Hans-Wilhelm Windhorst

Part 1 – Global egg production and trade

In two papers the author will analyse the development of poultry over the past fifty years and will document the remarkable growth of global egg and poultry meat production as well as the trade with these commodities.

A remarkable temporal and spatial dynamics

Between 1970 and 2020, global egg production increased from 19.5 mill. t to 87.1 mill. t or by 347%. Table 1 shows that from 1990 on the production volumes grew significantly faster than in the previous two decades. Between 2010 and 2020 alone, it grew by almost 23 mill. t. A closer look at the development at continent level reveals the extraordinary role, which Asia played in the booming development (Table 1, Figure 1). To the absolute growth of 67.6 mill. t in the decades under review, Asia contributed 73.3%, followed by Central and South America with 13.0%. All other continents fell far behind. The relative growth in Africa with 4.5%

20 MARKETING - marketing -

The author is Prof. Emeritus of the University of Vechta and visiting Professor at the Hannover Veterinary University, Germany

The remarkable dynamics of the global poultry industry: 50 years in retrospective

was even higher than in Europe and North America. Until 1988, the egg production volume in Europe was higher than in Asia, from then on the extraordinary growth in several Asian countries began, as will be documented in a later part of the article.

Figure 2 reflects the drastic change in the spatial pattern of global egg production. In 1970, European and North American countries contributed 65.1% to the global production volume, until 2020, their share fell to 21.8%. In contrast, Asia and Central and South America contribut-

ed only 30.7% in 1970, but reached 74.2% in 2020. The far higher relative growth rate in Central and South America in comparison to Europe makes it likely that Europe may lose its second rank during the current decade.

Considerable changes at country level

Over the past fifty years, the composition and ranking of the leading egg producing countries changed considerably (Figure 3).

Figure 3 – The changing composition and ranking of the ten leading egg producing countries between 1970 and 2020 (design: author, based on FAO data).

Until 1985, the USA ranked in first place before it was replaced by China, which in the following years remained the unchallenged number one. A closer look at the dynamics reveals some remarkable changes. Between 1990 and 2020, India climbed from sixth to second place and surpassed the USA. Indonesia, which did not belong to the ten leading countries until 2000 climbed to fourth place and increased its egg production by 4.5 mill. t since 2000. While in 1970 six European countries (Germany, France, Un. Kingdom, Italy, Spain and Poland) belonged to the top group, in 2020, only France was left, ranking in tenth place. A remarkable dynamical development showed also Brazil, Mexico and, since 2010, Turkey. In contrast, Japan fell from third to seventh rank and the for-

21 - june 2023MARKETING

Rank 19701980199020002010 1 2 3 4 5 6 7 8 9 10 D U.K. I PL 2020 China India USA Indonesia Brazil Mexico Japan USSR/Russia Turkey France

Continent 1970 1980 1990 2000 2010 2020 Increase absolute % Africa Asia Europe N America CS America Oceania 585.7 4,630.4 8,290.3 4,388.1 1,342.7 241.1 928.9 7,005.8 10,982.0 4,463.1 2,569.3 255.8 1,534.5 13,650.3 11,663.3 4,351.6 3,628.9 243.3 1,962.1 29,045.5 9,434.0 5,389.4 5,102.3 199.3 2,746.1 37,637.1 10,470.5 5,888.5 7,229.6 245.5 3,607.7 54,190.1 11,283.5 7,263.1 10,397.1 332.1 3,022.0 49,559.7 2,993.2 2,874.9 9,054.4 91.1 516.0 1,070.3 36.1 65.5 674.3 37.8 World 19,478.2 26,204.9 35,071.9 51,132.6 64,217.2 87,074.5 67,596.3 347.0 Africa Asia Europe N America CS America Oceania World 0 23 45 68 90 1970 1980 1990 2000 2010 2020

Table 1 – The development of global egg production at continent level between 1970 and 2020; data in 1,000 t (source: FAO database).

1970 1980 1990 2000 2010 2020 0 25 50 75 100 11.9 11.3 10.0 10.3 9.8 6.9 8.8 9,2 10.5 12.4 17.0 22.5 13.0 16.3 18.5 33.2 41.9 42.6 62.2 58.6 56.8 38.9 26.7 23.8 Africa Asia Europe N America CS America Oceania

Figure 1 – The development of the global egg production at continent level between 1970 and 2020 (design: A.S. Kauer, based on FAO data).

Figure 2 – The changing contribution of the continents to global egg production between 1970 and 2020; data in % (design: A.S. Kauer, based on FAO data).

mer USSR, number two until 1990, showed a deep fall after the political and economic collapse. In 2020, the Russian Federation only ranked as number eight.

A detailed look at the dynamics at country level will show the high regional concentration in egg production and the rise or fall of specific countries.

Figure 4 documents the changing shares of the ten leading countries in global egg production between 1970 and 2020. The lowest value was reached in 1980 with 65.2%, the highest in 2020 with 71.2%. However, the figures do not paint a clear picture of the extremely high regional concentration. In 1970, the four leading countries contributed 49.1%

to the global production volume. In 2000, after the dramatic growth of China’s production volume, they shared 55.1%. In 2020, they contributed even 55.5%, a result of the rapid growth of Indonesia’s egg production.

A first interim balance can be summarised as follows. Global egg production more than quadrupled between 1970 and 2020, reaching a volume of 87.1 mill. t. Parallel to this remarkable increase, a drastic change in the production centres occurred. Europe and North America lost their leading positions to Asia and Central and South America, which in 2020 contributed almost three quarters to the global production volume. During the dynamical development, the composition and ranking of the leading countries changed considerably. While in 1970, the USA and the USSR were the leading egg producing countries, China and India occupied the first two ranks in 2020. In 1970, six European countries belonged to the top ten group, not counting the USSR. In 2020, only one European country remained with France in tenth place. This comparison graphically describes the drastic changes in the spatial pattern of global egg production.

Egg trade volume comparatively small

In contrast to poultry meat, the volume of traded shell eggs is comparatively small. In the decades under review, only between 1.8% (2000) and 2.8% (1980 and 2010) of the production was exported. The reasons for the low trade volume are the fact that shell eggs cannot be frozen

22 MARKETING - marketing -

29.4% 2.0% 2.4% 3.1% 3.4% 4.6% 6.0% 7.7% 9.1% 11.5% 20.8% USA USSR Japan China Germany U.K. France Italy Spain Poland Others 34.9% 2.5% 2.6% 3.0% 3.1% 3.3% 4.3% 7.6% 8.5% 14.5% 15.7% USA USSR China Japan Germany France U.K. Brazil Spain Mexico Others Total: 19.5 mill. t 1970 Total: 26.2 mill. t 1980 33.5% 1.9% 2.5% 2.8% 2.9% 3.3% 3.5% 6.9% 11.5% 13.1% 18.1% China USSR USA Japan Brazil India Mexico Germany France Spain Others 29.4% 1.7% 1.8% 1.8% 3.0% 3.5% 3.7% 4.0% 5,0% 9,8% 36.3% China USA Japan India Russia Mexico Brazil France Germany Turkey Others Total: 35.1 mill. t 1990 Total: 51.5 mill. t 2000 30.9% 1.2% 1.5% 1.7% 3.1% 3.5%3.7% 3.9% 5.3% 8.5% 36.7% China USA India Japan Mexico Russia Brazil Indonesia France Turkey Others 28.9% 1.1% 1.4% 2.9% 3.0% 3.5% 3.7% 5.9% 7.6% 7.7% 34.3% China India USA Indonesia Brazil Mexico Japan Russia Turkey France Others Total: 64.2 mill. t 2010 Total: 87.1 mill. t 2020

Figure 4 – The share of the ten leading egg producing countries in global egg production between 1970 and 2020 (design: A.S. Kauer, based on FAO data).

Fiberglass silos: the most practical, effective and durable solution to any bulk storage requirement

Agritech s.r.l. Via Rimembranze, 7 25012 Calvisano (BS) Italy

Tel. + 39 030 9968222 r.a.

Fax + 39 030 9968444

commerce@agritech.it

www.agritech.it

23 - june 2023MARKETING

Till 40 silos in 1x40’ O/T container

Till 23 silos in one complete truckload

and have a relatively short shelf life. Most of the eggs are produced for domestic consumption. Nevertheless, exports respectively imports are of a considerable economic importance for several countries. The following analysis will document the trade patterns at continent and country level.

Table 2 provides an overview of the development of egg exports and imports and the trade balance at continent level. It is obvious that Europe dominated egg trade over the past fifty years. It was not before 2000 that Asia reached higher volumes in egg exports. In all other continents, egg trade was only of minor importance. Europe showed a trade surplus over the whole time-period under review, North America since 1980. Africa and Central and South America had a negative trade balance in all decades, Asia with the exception of 2010.

Considerable fluctuations in egg exports at country level

Figure 5 shows the considerable fluctuations in the composition and ranking of the top ten exporting countries. The Netherlands after several years of competition with Belgium, have been the leading egg exporting country since 1975. Belgium, number one until 1974 fell to rank nine in 2020, China from rank three to rank ten. Several countries only belonged to the top group for a short time period, such as Denmark, Romania, Hungary, the United Kingdom, France, the USSR, Iran, Belarus or Syria. Other countries were able to reach a stable po -

sition among the leading exporting countries, such as the USA, Germany, Spain and Malaysia. In 1970, Poland played an important role as an egg exporting country as a member of COMECON (Council for Mutual Economic Assistance), but could not maintain its position after the collapse of the system. It was not before 2010 that after the remarkable development of the poultry industry as an EU member state, Poland became one of the leading egg exporters again. A similar development occurred in Turkey, which became the

second most important egg exporting country in 2011 after years of an extraordinary dynamics in its poultry industry. The regional concentration in egg exports was even higher than in production. Figure 6 documents that the concentration increased between 1970 and 1990 and then decreased in the following decades. In 1990, the ten top ranked countries contributed 89.1% to the global export volume. In 2010, the lowest value was reached with 74.6% before it climbed to 78.6% again in 2020. In 1990, the Netherlands contributed

24 MARKETING - marketing -

Continent 1970 1980 1990 2000 2010 2020 AFRICA Export Import Balance 3.6 2.7 +0.9 3.2 53.2 -50.0 2.1 11.9 -9.8 6.2 25.7 -19.5 11.4 51.4 -40.0 17.6 35.9 -18.3 ASIA Export Import Balance 57.1 83.7 -26.6 72.1 175.3 -103.2 92.7 170.2 -77.5 204.1 235.8 -31.7 536.8 499.3 +37.5 627.2 787.0 -114.8 EUROPE Export Import Balance 321.9 283.8 +38.1 594.7 471.1 +123.6 689.3 591.1 +98.2 640.7 557.5 +83.2 1,158.7 1,060.0 +98.7 1,264.4 1,228.0 +36.4 N AMERICA Export Import Balance 14.5 18.5 -4.0 60.6 12.1 +48.5 38.4 21.5 +16.9 66.7 26.9 +39.8 88.7 28.3 +60.4 159.5 30.7 +128.8 CS AMERICA Export Import Balance 3.7 6.8 -3.1 11.7 17.7 -6.0 7.1 15.1 -8.0 26.4 39.1 -12.7 26.1 34.2 -8.1 17.6 73.8 -56.2 OCEANIA Export Import Balance 2.7 0.5 +2.2 1.4 0.6 +0.8 0.3 0.3 0.0 0.9 0.5 +0.4 4.8 2.4 +2.4 1.7 2.7 -1.0

Table 2 – The development of global egg trade at continent level between 1970 and 2020; data in 1,000 t (source: FAO database).

Rank 197019801990200020102020 1 Netherlands 2 Turkey 3 Poland 4 USA 5 Uzbekistan 6 Spain 7 Germany 8 Malaysia 9 Belgium 10 China F SF BG PL DK RO LB E U.K. H CSSR USSR IR BY SYR

Figure 5 – The changing composition and ranking of the ten leading egg exporting countries between 1970 and 2020 (design: author, based on FAO data).

50.9% to the global egg exports. Until 2020, the country’s share declined to only 19.9% despite an increase in the export volume. The growing production in Turkey, Poland, the USA, Uzbekistan and Malaysia challenges the dominating role of the Netherlands.

Considerable fluctuations also in egg imports at country level

The composition and ranking of the ten leading countries in egg imports fluctuated also considerably (Figure 7 ) with the exception of Germany. Worth noting are the changes in the ranking of several EU member states in the decades under review, such as France, the United Kingdom, the Netherlands and Italy. In 1970, France ranked in third place then fell to rank ten

in 1980, climbed to rank five respectively four in 1990 and 2000 before it again fell to rank nine in 2020. A similar dynamics showed the United Kingdom. Belgium and Singapore began to import eggs in 1990, in 2020 they ranked as number four respectively five. Of particular interest is the Netherlands. While they resided as number eight in 1970, they became the second largest egg importing country in 2020. This is due to the fact, that Dutch investors bought respectively built large egg farms in eastern Germany after the reunification of the country. They transferred the eggs, which were produced in these farms, to the Netherlands either to export or to further process them. This transfer appears as imports for the Netherlands respectively exports for Germany in the FAO database. Until 1980, the USSR imported eggs from other COMECON countries, but stopped imports after the collapse of the political and economic system. In 2020, the Russian Federation began to import eggs again to supply the population with animal proteins due to the dramatic decrease of pig meat production, which resulted from outbreaks of the African Swine Fever. Because of the war, Iraq’s egg industry was severely hit so that imports became necessary to meet the domestic demand. From 2010 on, the country ranked in second place among the top ten importing countries. When egg production began to recover, imports decreased from 2020 on. In 2020, the United Arab Emirates and S. Arabia imported large amounts of eggs for domestic consumption and for further exports to other countries on the Arabian Peninsula.

The regional concentration in egg imports reached similar values as

25 - june 2023MARKETING

15.4% 3.6% 4.2% 4.3% 4.8% 5.6% 5.6% 6.8% 8.2% 19.7% 21.8% Belg./ Lux. Netherl. China Bulgaria Hungary Poland Denmark Romania Finland Lebanon Others 14.6% 3.0% 3.1% 3.6% 3.8% 3.9% 4.5% 7.1% 7.2% 7.3% 41.9% Netherl. USA Belg./ Lux. China Spain France Germany U.K. Finland Hungary Others Total: 743,600 t 1980 Total: 403,600 t 1970 10.9% 1.4% 1.8% 2.3% 3.0% 3.4% 4.4% 4.4% 5.9% 11.6% 50.9% Netherl. Germany Belg./ Lux. France USA China Malaysia Finland CSSR USSR Others 16.4% 3.9% 4.1% 4.6% 5.1% 5.9% 6.8% 6.8% 7.0% 8.1% 31.3% Netherl. Belgium Germany China USA Malaysia Spain France Iran Belarus Others Total: 944,800 t 2000 Total: 829,900 t 1990 25.4% 4.2% 4.3% 4.7% 4.9% 5.5% 6.3% 6.7% 7.2% 22.4% 8.4% Netherl. Poland Turkey Spain Germany China Malaysia USA Belgium Syria Others 21.4% 3.5% 4.5% 5.5% 5.7% 6.0% 6.0% 7.6% 9.5% 10.4% 19.9% Netherl. Turkey Poland USA Uzbekistan Spain Germany Malaysia Belgium China Others Total: 2,088,000 t 2020 Total: 1,826,400 t 2010

Figure 6 – The share of the ten leading egg exporting countries in global egg exports between 1970 and 2020 (design: A.S. Kauer, based on FAO data).

in exports, it decreased, however, between 2010 and 2020, a result of the fast growth of imports by Russia and western Asian countries. Between 1970 and 1990, the first three leading countries shared over 50% in the global imports with a peak of 55.1% in 1980. In the following decades, the regional concentration was lower and in 2020, the three top countries only imported 38.3% of the eggs, which were traded globally (Figure 8). Worth noting is the changing share of Germany in global egg imports. Between 1970 and 1990, the country imported between 32.0% and 39.5% of the eggs, which reached the global market. From then on, the share fluctuated between 28.7% in 2010 and only 17.7% in 2020. From 2010 to 2020, the import volume fell by 100,000 t despite an increase of the per capita consumption. This was possible because of the considerable growth of the inventory by more than 10 mill. hens in that decade.

Summary and perspectives

The preceding analysis showed the remarkable increase in global egg production and the drastic spatial shifts. Which were the decisive innovations respectively steering factors behind the success story?

A first innovation was the use of the hybridisation technology in the breeding of laying hens. It started in 1950 in the USA and was in the late 1950s transferred to Europe. Specialised breeder companies began to market hatching eggs and chicks worldwide. A second innovation was the construction of cages with automatic feeding, water supply, egg collection and manure handling. It

26 MARKETING - marketing -

18.8% 2.5% 2.9% 3.3% 3.5% 4.8% 6.1% 6.3% 8.5% 11,3% 32,0% Total: 396,000 t 1970 Germany Hong Kong USSR France Switzerland Austria USA Netherl. U.K. Italy Others Germany Hong Kong Algeria USSR Italy Switzerland U.K. Iran Iraq France Others 21.2% 2.4% 2.5% 3.0% 3.3% 3.4% 3.5% 5.6% 6.5% 9.1% 39.5% Total: 730,000 t 1980 20.1% 2.9% 3.3% 3.9% 3.9% 4.4% 5.0% 5.4% 6.9% 9.7% 34.5% Total: 810,100 t 1990 28.6% 2.7% 2.8% 3.3%3.7% 4.6% 6.3% 6.9% 7.1% 9.2% 24.8% Total: 885,500 t 2000 Germany Hong Kong Belg./ Lux. U.K. France Italy Singapore Switzerland Netherl. Spain Others Germany Hong Kong Italy France Netherl. Singapore U.K. Belgium UAE Switzerland Others Total: 1,675,600 t 25.7% 2.0% 2.2% 2.4% 3.2% 3.6% 4.5% 5,7% 10.1% 2010 Total: 2,158,200 t 32.8% 2.5% 2.7% 3.7% 4.1% 4.7% 5.0% 6.2% 8.5% 12.1% 11.9% 17.7% 29.7% Germany Netherl. Hong Kong Belgium Singapore UAE Afghanistan Russia France S. Arabia Others 2020 Germany Iraq Netherl. Hong Kong Singapore Belgium France Italy U.K. Switzerland Others

Rank 19701980199020002010 1 2 3 4 5 6 7 8 9 10 I DZ A USA NL IRQ U.K. IR USSR CH E UAE IRQ 2020 Germany Netherlands Hong Kong Belgium Singapore Un. Arab Em. Afghanistan USSR/Russia France S. Arabia

Figure 8 – The share of the ten leading egg importing countries in global egg imports between 1970 and 2020 (design: A.S. Kauer, based on FAO data).

Figure 7 – The changing composition and ranking of the ten leading egg importing countries between 1970 and 2020 (design: author, based on FAO data).

reduced the necessary labour input drastically and allowed much larger flocks. The very efficient housing system spread parallel with the hybrid hen. A third innovation was the development of vaccines against the Newcastle Disease (1954) and Marek’s Disease (1972). They improved the health status of the laying hens and reduced the mortality rates to less than 5%. A very important steering factor was the development of a compound feed with special additives, which improved the nutrition of the hens. This also contributed to the health of the hens and increased the laying rate considerably.

The combination of these factors made it possible to produce large amounts of eggs with a high nutritional value to a reasonable price for the constantly growing global population. Worth noting is, that similar forms of the organization of egg production developed worldwide: vertically integrated companies. As no religious barriers

While in 1970 European and North American countries contributed almost two thirds to the global production volume, their share fell to 21.8% in 2020. In contrast, Asia and Central and South America contributed only 30.7% in 1970, but reached 74.2% in 2020, China and India together shared 42.0%. Of the six European countries, which belonged to the top ten group in 1970, only one remained in 2020. This graphically describes the drastic change in the global pattern of egg production.

Although the volume of egg trade only accounted for a share of less than 3% in global egg production, it reached a considerable economic importance for the leading exporting and importing countries. Europe was the dominating continent in egg trade over the time-period which is analysed in this paper and it was not before 1990 respectively 2020 that Asia reached a higher share in exports and imports. Europe was also the only continent with a positive trade balance over the past fifty years. North America showed a trade surplus from 1980 on and

27 - june 2023MARKETING

Barbieri srl Via Garibaldi, 54 • 26040 Scandolara Ravara (CR) Italy Tel. (+39) 0375 / 95135 • Fax (+39) 0375 / 95169 • Manu re re moval belt s • Manu re belt wi th hole s for dr yi ng system s info@barbieri-belts.com www.barbieribelts.com BELTS and ROP ES for AV ICULTURAL USE BE LT S

A personal note

“In 1970, I started my academic career at the University of Vechta and immediately began to study the dynamics in intensive animal production at different spatial levels. While my empirical studies initially dealt with Lower Saxony, in particular the counties of Cloppenburg and Vechta, the focus soon widened to EU member states and the USA. The close contacts with leading companies, which produced and marketed equipment for intense animal production, especially for pig and poultry husbandry, and with globally active breeder companies gave me the opportunity to study global patterns and dynamics”

Hans-Wilhelm Windhorst

At the turn of the century, new challenges began to confront the egg industry. One is the animal welfare discussion, which in the EU already led to a prohibition of conventional cages from 2012 on and the introduction of new housing systems, such as enriched cages, floor and freerange systems. It will in the coming two decades also reduce the number of hens kept in conventional cages drastically as the development in the USA, Canada and New Zealand show. A second is the threat of the Avian Influenza virus, which has caused disastrous epidemics since 2015 and obviously become endemic in many countries. The success of the vaccines against the Newcastle and Marek’s diseases could show a way out of this existential threat.

Despite these challenges, egg production and the volume of egg trade will further increase because of a grow-

ing demand in several threshold and developing countries. The spatial pattern will remain stable. European and North American countries will lose shares in production but Europe will be able to maintain its leading position in egg trade. Although several companies and startups have been successful in the production and sale of plant-based egg substitutes, they will not be able to reach shares in the two-digit percentage before 2030.

Data sources and suggestions for further reading

FAO database: www.fao.org/faostat/en.

Windhorst, H.-W.: Die Industrialisierung der Agrarwirtschaft (The industrialization of agriculture). Ein Vergleich ablaufender Prozesse in den USA und der Bundesrepublik Deutschland. Frankfurt a. M. 1989.

Windhorst, H.-W.: Changing patterns of global egg trade: Dynamics at continent and country level in detail. In: Zootecnica International 41 (2019), no. 11, p. 24-29.

Windhorst, H.-W.: The forgotten continent: Patterns and dynamics of the African egg industry: Laying hen inventory and egg production. In: Zootecnica International 42 (2020), no. 9, p. 24-27.

Windhorst, H.-W.: The Champions League of the egg producing countries. In: Zootecnica International 43 (2021), no. 1, p. 26-29.

Windhorst, H.-W.: The forgotten world: the egg industry in the least developed countries. In: Zootecnica International 43 (2021), no. 2, p. 22-25.

Windhorst, H.-W.: The dynamics of the U. S. egg industry between 2010 and 2020. In: Zootecnica International 43 (2021), no. 7/8, p. 22-25.

Windhorst, H.-W.: Patterns and dynamics of the EU poultry industry: a status report. Part 1 - Laying hen husbandry, egg production and egg trade. In: Zootecnica International 43 (2021), no. 12, p. 22-26.

Windhorst, H.-W.: Patterns and dynamics of global egg and poultry meat trade. Part 1 - Egg trade. In: Zootecnica International 44 (2022), no. 2, p. 22-28.

Windhorst, H.-W.: A documentation and analysis of the AI epidemic in the USA in 2022. In: Zootecnica International 45 (2023), no. 3, p. 8-17.

28 MARKETING - marketing -

IMPROVED

19

REDUCED

28%LESS

Progress

19 % LOWER ENERGY USE

29 - june 2023MARKETING

in live weight, shorter grow-out periods and reduced feed production and transport =

POLLUTION POTENTIAL Better FCR = Better nutrient utilization

NITRATE/ PHOSPHATE EXCRETION

LESS FEED MEANS...

for

Improved FCR = a 2.5 kg (5.5 lb) broiler consuming... 0.8 kg 1.7 lb LESS FEED required for the production of broiler feed 42% LESS AGRICULTURAL LAND REDUCED LAND USE & TRANSPORTATION

% LESS GREENHOUSE GASES PRODUCED Improved FCR and shorter grow-out time = REDUCED GLOBAL WARMING POTENTIAL

FEWER ROAD TRIPS delivering raw materials and feed

broilers

the

THE PLANET FOR FUTURE GENERATIONS while increasing livability, health and welfare through balanced selection The modern broiler is more biologically e cient Per kg of live weight, it requires... IMPROVED PERFORMANCE required per 1.0kg (2.2 lb) broiler 320 g 0.7 lb LESS FEED WATER USAGE BETTER WATER INTAKE = Better gut health Better litter quality Better footpad health More e cient/sustainable water use

DELIVERING

PRODUCTIVITY AND SUSTAINABILITY for the broiler industry over

past 20 years PROTECTING

Aviagen®

VIEW ONLINE 18.3% 40 EXTRA TOTAL EVISCERATED YIELD g 0.09 lb LESS WATER 0.15 US gal 0.57L

Find out more about how

protects the planet for future generations

Brendan Graaf, Broiler Specialist, Cobb Europe

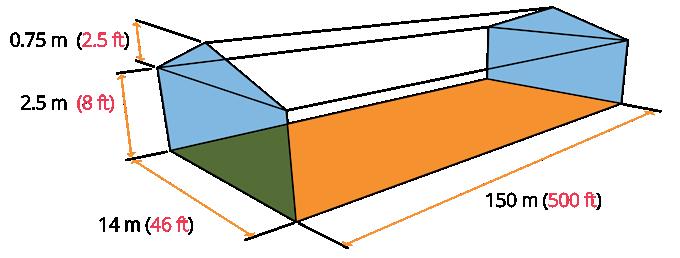

The importance of minimum ventilation and how to calculate it

Providing birds with the correct house environment is key to unlocking the full genetic potential and performance of a flock. Poultry growers often focus on limiting house energy and heating costs. In most cases, this is a false economy as it leads to a sub-optimal environment which is detrimental to final bird performance and therefore overall profit. Performance damage due to poor minimum ventilation in the early stages of the flock are realized towards the end of the cycle when it is too late to correct.

This article will cover the key considerations and basic calculations for minimum ventilation. The minimum ventilation system is designed to ensure good air quality and moisture control

30 - technical columnTECHNICAL COLUMN

©Val-Co

throughout the life of the flock, thus helping to achieve both optimum performance and bird welfare.

Minimum ventilation

Minimum ventilation is the minimum amount of ventilation (air exchange) required to maintain the full genetic potential of the birds by ensuring an adequate supply of oxygen while removing moisture, waste products, and combustion from the environment. Table 1 is a reference guide for air quality standards that must be maintained by the minimum ventilation system.

ture control should supply adequate air quality for the birds and ensure carbon dioxide levels remain below 3000 ppm.

The preferred cycle time for minimum ventilation is a 5-minute (300 sec) on/off cycle with a minimum run time of approximately 20% of this time (five minutes = cycle of one minute on, four minutes off). Any time the air quality begins to deteriorate, small increases (10 to 15 seconds) to the ON time must be made, but the total cycle time should always remain the same i.e. if you increase the ON time by ten seconds you need to remove ten seconds from the OFF time so that the total cycle length remains at 300 seconds. The minimum time the fans are turned on needs to be approximately 60 seconds to ensure

adequate mixing of the cold incoming air with the warm internal air and adequate extraction of moisture through the exhaust fan. However, if your house only has large (1.2 to 1.5 m/ 50 to 60”) tunnel type ventilation fans as opposed to the smaller (600 to 900 mm /24 to 36”) minimum ventilation fans then the cycle on time can be lowered to achieve similar air exchange rates.

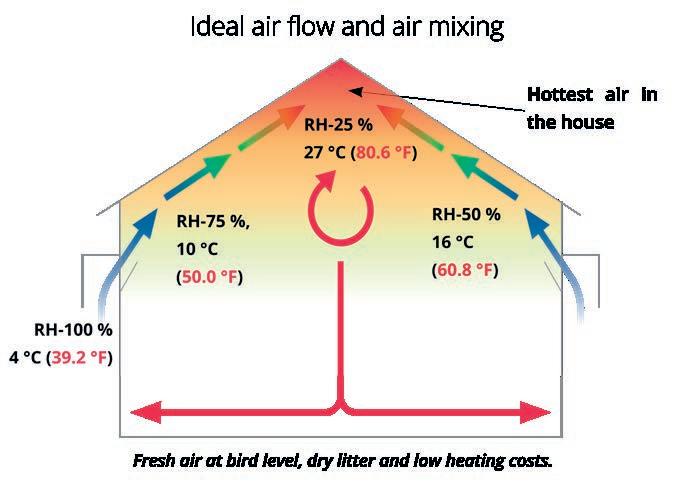

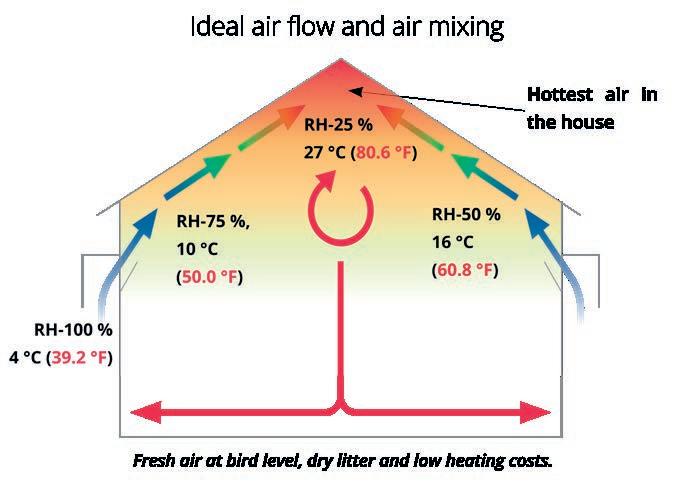

The incoming cold air must be conditioned correctly by easily attaching to the ceiling, moving towards the peak of the house where it is heated, expand and its relative humidity reduced. The air jet must then start detaching from the ceiling near the centre of the house generating a return movement at floor level in the opposite direction. This return movement towards the side walls will ensure distribution of the warmer dry air thus bringing fresh air to the birds while also removing moisture and waste gases from the litter, the birds, and the heating system (Figure 1). The stale moist air is then extract-

The system uses fans on a cycle timer and is independent of temperature control. Poultry houses need sufficient heating capacity (Table 2) to maintain house set-points on the cold days, while still allowing sufficient minimum ventilation, since the minimum ventilation system is the primary source of heat loss from the house. The minimum air exchange is linked to the amount of moisture added to the house by the birds, the drinking system, heating system and ventilation system. Under most conditions, maintaining good mois-

31 - june 2023TECHNICAL COLUMN

Air quality guidelines Oxygen > 19.6% Ammonia < 10 ppm Respirable Dust < 3.4 mg/m³ Relative Humidity < 65% Carbon Monoxide < 10 ppm Carbon Dioxide (CO2) < 0.3% / 3,000 ppm Air exchange (with minimal air movement at chick level) <0.30 m/s (60 fpm)

Table 1 – Air quality guidelines for broiler houses.

Table

Forced Air Heating System Requirements kW/m3 Tropical climates 0.05 Temperate climates 75 Cold climates 0.10

2 – Heating capacity requirements.

Figure 1 – Ideal air flow for negative pressure ventilation in a broiler house.

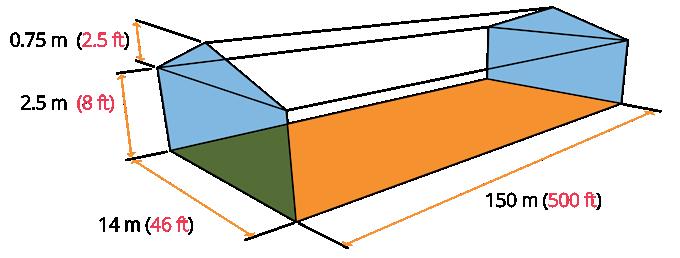

House dimensions used in example:

150 m long, 14 m wide and 2.88 m average height.

Average height = 2.5 m + (0.5 x 0.75 m) = 2.88m

House floor area: 150 m × 14 m = 2,100 m²

Fans used for example:

Fans capacities used in the examples are rated at 25 Pa Exhaust or side wall fans: 900 mm, working capacity of 340 m³/min.

Air exchange range: 0.3 to 0.60 m³/min per m² of floor area

Note: These fans can be fixed volume or variable speed. The 0.61m3/min per m2 of floor area fan capacity is only needed in cold climates.

ed from the house through the fans. The system runs when the house is at or below set point temperature and will operate on a timer program – see the example of a simple timer fan program below (Table 3).

The timer fan capacity should be a minimum of 0.3 m3/min per m² (1.0 cfm per ft²) in hot climates where outside temperatures rarely drop below 20 to 25 °C (68 to 77 °F). In cold climates a timer fan capacity of 0.61

How many fans to install or allocate for minimum ventilation:

Number of fans required = (House floor area X Air exchange rate) ÷ Working capacity 2,100 m² × 0.3 to 0.61 m³/min per m² of floor area = 630 to 1260 m³/min 630 to 1260 ÷ 340 m³/min = 1.85 to 3.70 or 2 to 4 fans

to 0.77 m3/min per m2 (2 to 2.5 cfm/ ft 2) of floor area, will be needed. The challenge will always be matching the requirement with fans available in the market. Do not use large tunnel fans for the minimum ventilation system, smaller capacity fans will always afford more stable environmental control and flexibility.

Some ventilation systems do not use cycle timer programs for minimum ventilation, but instead run a contin-

uous ventilation system using variable speed fans. These systems are designed to produce a more uniform house environment, but it is strongly dependant on the fans pressure stability at low rpm. In practical terms can the incoming “air jet” attach to the ceiling to provide effective conditioning of the cold incoming air? These systems will require good quality environmental controllers, perimeter inlets and fans. They are not suitable for older (leakier) houses and will generally require a higher level of technical knowledge.

The sizing and run times should be adjusted to suit an individual house but the basic principles remain the same. The minimum ventilation cycle run times are only guidelines and daily adjustments should be made based on air quality and maintaining humidity below 65 % where possible. If the number of fans works out to be less than 1, then cycle on time can be adjusted to less than 60 seconds to maintain correct air exchange rates and not over ventilate the house. Some newer controllers use m3/bird/hr as an input setting for their minimum ventilation rates. In order to convert to these units, first calculate the total ventilation capacity at each age based on the number of fans used and the cycle timer program and then divide by the number of birds in the house.

E.g. Capacity of 2 fans = 40,800 m3/hr

Cycle time at day 0 = 60s ON; 240s OFF = 20% run time

Total capacity on cycle time = 20% of 40,800 m3/hr = 8160 m3/hr

House has 40,000 birds, so = 8160 m3/hr ÷ 40,000 birds = 0.20 m3/bird/hr

32 - technical columnTECHNICAL COLUMN

Minimum ventilation timer settings (5 min (300 sec) timer) Day ON (seconds) OFF (seconds) 1 45 to 60 (20 %) 240 3 45 to 60 240 5 75 225 8 90 210 11 105 195 14 120 180 18 135 165 22 150 150 25 165 135 30 180 (60 %) 120

Table 3 – Minimum ventilation timer program.

Static pressure test

The number of fans to run for minimum ventilation has been calculated and a timer program for their run time has been designed. Next, it is important to achieve correct air conditioning. First, we need to ensure the house is as air tight as possible in order to effectively generate a negative pressure and ensure air enters through the inlets and not through leaks or gaps around the house. Conducting a static pressure test will let you know how tight or leaky your house is. Once a tightly sealed house has been established it is important to ensure correct inlet management.

Inlets

Important points about inlets:

• Minimum ventilation inlets should be sealed especially at the hinge, sides and along the leading edges, to prevent the cold air being directed down to the floor.

• When open, the air should only enter over the top of the inlet and not from the sides or through the bottom of the inlet

• All minimum ventilation inlets should direct air towards the peak of the house. The pressure drop across the inlets should be adjusted to ensure that the incoming air reaches the peak where the heat has accumulated.

• The pressure drop selected will depend on the width of the house or how far the air must travel once it enters the house.

• Correct air pressure is achieved by matching the inlet area and the fan capacity.

• Air inlets should be pressure controlled to maintain constant air speed throughout the ventilation stages.

• Table 4 can be used as a reference for the correct static pressure/inlet air speed required to ensure incoming air stays as close to the ceiling until it reaches almost half way across the house.

• The pressure drop selected will depend on the house width, how far the incoming air jet must travel once it enters the house, and the outside temperature.

• When outside temperatures are below 5 °C the inlet pressure drop, and opening size will need to be increased. The ability of the incoming air jet to

33 - june 2023TECHNICAL COLUMN

INNOVATION IN VENTILATION +45 75771922 • mail@dacs.dk • www.dacs.dk

DACS climate solutions ensure dry well-ventilated houses with uniform temperatures and perfect climate that vastly improve animal welfare and comfort, allowing animals to grow to their full potential

attach to the ceiling depends on the temperature differentials between outside and inside the house.

• Always use a smoke test to ensure that the incoming air reaches the centre of the house. Smoke tests should only be done when the outside temperatures are significantly colder than inside, and when there is no wind.

• Inlets need to open enough to achieve the required static pressure and airflow. Depending on inlet design, a minimum opening of 2.5 to 5 cm is required to ensure cold air reaches the centre of the house.

• Inlets should be installed as close to the ceiling as possible – about 30 cm below the eaves

provided there is no interruption of airflow.

• In open truss houses, the angle of the inlet opening must be such that the air is not directed onto a purlin which will redirect the air down to the floor.

• Any obstructions (electrical conduit/concrete or wooden beams) should be removed because they interrupt the air flow, forcing air to the floor.

• In the case of existing obstructions, a directional flap can be used on top of the inlet and/or a solid “air ramp” to aid the air in passing the obstruction.

• When using a negative pressure ventilation system, it is not the placement of the fans which dictate uniformity

of air distribution but rather the placement of the inlets.

• To achieve uniform air distribution, inlets should be evenly spread throughout the house and open the same amount.

• Houses over 100 m (330 ft) should have the inlet drive units installed in the centre of the side wall to reduce any inlet opening variation. Solid 5 to 8 mm (0.2 to 0.3 in) steel rods eliminate any stretch and twisting.

• It is common for cables to stretch and twist and can cause variability in perimeter inlet openings. Inlets closer to the drive unit are open more than those at the end of the house. This can be minimized by ensuring a sufficiently sized counterweight or spring. Guide pulley position and size is very important for efficient closing and sealing of inlets.

• All inlets require wind proofing covers on the outside of the house. The inlet cover should be at least 30% more than the cross-sectional area of the inlet to minimize air restriction. These inlet covers also help to reduce natural light entering the house.

When it comes to minimum ventilation, there is rarely a one size fits all solution.

However, by applying the information from this article together with good stockmanship, such as making daily adjustments to minimum ventilation based on air quality, humidity, and bird behaviour, will greatly assist with providing an optimum environment to achieving excellent bird performance.

34 - technical columnTECHNICAL COLUMN

Required inlet airspeed and pressure di erence House width Pascals (Pa) Inches of water (in wc) Airspeed Distance air travels m ft m/s fpm m ft 10 30 20 0.08 5.7 1,112 5.0 16 12 40 25 0.10 6.5 1,280 6.0 20 15 50 31 0.12 7.2 1,417 7.5 25 18 60 37 0.15 7.8 1,535 9.0 30 21 70 43 0.17 8.4 1,654 10.5 35 24 80 49 0.20 9.0 1,772 12.0 40

Table 4 – The required inlet airspeed and pressure difference.

Specific feed pan for turkeys

- june 2023TECHNICAL COLUMN AZA International s.r.l. Via Roma 29 24030 Medolago (BG) Italy Phone (+39) 035 - 901240 - E-mail: info@azainternational.it QUALITY MADE IN ITALY Watch all information about Modula www.azainternational.it MODULA Leader in pig & poultry equipment

I WANT AZA! Designed from one day-old chicks to heavy and nervous male turkeys. Safe and fast assembly/ disassembly of the anti- waste ring without tools. The bottom cap is easy to remove and assures simple and complete washing of any component of the feed pan. STURDY AND EASY TO MANAGE NO CHICK INSIDE THE PAN EASY CLEANING SAFE AND FAST ASSEMBLY

1The University of Sydney, Plant Breeding Institute, Sydney Institute of Agriculture, School of Life and Environmental Sciences, Faculty of Science, Sydney NSW 2006, Australia

2The University of Sydney, Poultry Research Foundation, Camden NSW 2570, Australia

Heat stress and the quality of wheat grains

Increasing temperature and consequent changes in climate adversely influence plant growth and development, resulting in loss of wheat productivity. High environmental temperature may influence crops in different ways and such effect varies depending on the crop’s genotype and phenological stages.

The aim of the present research was to study the contributions of genotypes, and year of sowing and their interaction on the physico-chemical quality of wheat cultivars.

Four wheat cultivars, EGA Gregory (E), Lancer (L), Trojan (T) and Borlaug 100 (B) were sourced from Narrabri during the 2019

and 2020 growing seasons. Starch, protein, viscosity, and mineral contents (P, Ca, Na and K) were analysed. The data showed that starch, and mineral contents and viscosity were significantly impacted by environmental factor (year) and genotype. However, the interaction of year and genotype

36 MANAGEMENT - management -

A. Khoddami1, V. Messina1, D. Tan1, R. Trethowan1, R. Thistlethwaite1, P. Selle2 and S. Liu1,2

did not show any significant changes on the quality of tested grains.

Introduction

Wheat is the predominant feed grain in Australia and other dry regions in the world. Typical broiler diets in Australia contain 60-70% wheat. Climate -induced factors, including elevated temperature, have been repor ted as depressing crop production around the globe during the last few decades and there is limited understanding of how climate -induced factors may influence the nutritional quality of wheat.

The sowing time of wheat is the most important factor for temperature-sensitive cereals. Late sowing normally

physical and nutritional quality of wheat grains such as grain number, size, grain weight, hardness and the composition of protein and carbohydrate content.

The chemical quality of wheat grain is mainly explored by measuring the content and composition of protein and carbohydrates in response to heat stress. The protein content is increased by heat stress, particularly during the grain-filling period.

Carbohydrate concentration and composition are critical measures of grain chemical quality and have important implications for the functionality of wheat flour. Starch is the main carbon reserve in wheat, which comprises up to 75% of total grain dry weight and heat can inhibit the efficiency of starch biosynthetic enzymes, affecting starch deposition in developing grains. Post-anthesis heat also

MANAGEMENT

Nuova-i Evisceration enters the digital era. Nuova-i‘s innovation and connectivity offer data-driven optimum performance. • Highest yield and quality in eviscerated carcass and giblets • Best-in-class pack removal, with uniform, compact viscera packs • SmartBase machine health monitoring for performance insight • More efficient and easy operation and maintenance Contact us to find out more: +31 485 586 111 info.poultry@marel.com marel.com/nuova-i Intelligent evisceration management

Method

Four wheat grains cultivars (EGA Gregory (E), Lancer (L), Trojan (T) and Borlaug 100 (B)) were sourced from crops grown in Narrabri during 2019 and 2020. The 2019 harvest experienced higher temperatures compared to the grains harvested in 2020. Wheat grains were milled using a Cyclone Sample Mill (UD Corporation Boulder Colorado USA) to a particle size of 500 µm and transferred to a small zip-lock bag, stored in the refrigerator at 4 °C until analysis.

Total starch was measured using an assay kit from Megazyme (K-TSTA).

The total protein content of milled wheat flour was determined using a nitrogen/protein Vario MACRO Cube analyser (Frankfurt, Germany). Thirty mg of samples were prepared in 12 x 6 mm pressed aluminium capsules. Samples were combusted with oxygen and nitrogen oxide. The measured nitrogen content in this method was conver ted to total protein content by applying a conversion factor of 6.05.

Pasting property was measured using a Rapid Visco Analyser (RVA)

(Newport Scientific). 3.5 g of the ground wheat sample was added to 24.5 g of water and ran using 50 °C as base temperature to 95 °C and then back to 50 °C within 13 min cycle.

Mineral content (Ca, K, P, and Na) was analysed using a Perkin Elmer Avio Inductively Coupled Plasma Optical Emission Spectrometer (ICPOES). The results are analysed by two- way ANOVA to check the impact of genotype, year of harvest and G xY interaction.

Results

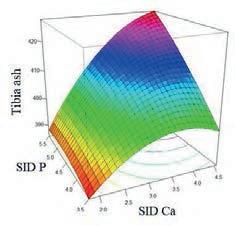

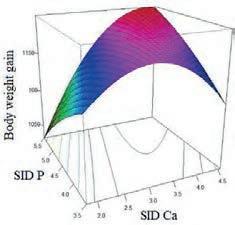

The starch, protein, viscosity, and mineral contents were determined to check the impact of the year of harvest, genotypes and their interaction (G x Y) (Table 1). The impact of year or genotype was significant on quality attributes of all tested samples. However, the obtained results showed no significant difference in the protein content among different genotypes (P=0.071). The results also indicated that the year of harvest had no impact on the final viscosity of the tested grains (P=0.314). The starch content increased in grains harvested in 2020 while significantly higher protein content was observed in 2019. The highest level of starch and the lowest level of protein were for Trojan.

The results showed that the genotype remarkably impacted the RVA final viscosity (P=0.002). The greatest viscosity belonged to the Trojan.

The results obtained in the experiments showed that the mineral content level was significantly impacted by all of the factors including, genotype, year and G x Y interaction.

38 MANAGEMENT - management -