10 2022 Zootecnica International –October 2022 –POSTE ITALIANE Spa –Spedizione in Abbonamento Postale 70%, Firenze Dynamics and patterns of the poultry industry in the G19 countries between 2010 and 2020 The ABCs of CDT (Clostridial Dermatitis of Turkeys) Water-saving evisceration process

specifically developed for great poultry farms, thanks to the easiness in the regulation of the feed and to the absence of grill (that avoid chicks perching) have many advantages: they are easy to use and their cleaning is extremely easy and fast too, leading to an overall reduction in labour costs.

The new feeders of the «Gió» range,

CODAF Poultry Equipment Manufacturers • Via

•

ITALY Tel. +39 030 9958156 • Fax: +39 030 9952810 • info@codaf.net •

Cavour, 74/76

25010 Isorella (Brescia),

www.codaf.net

EDITORIAL

For several years we have been talking about human nutrition from a nutritional and dietary point of view. Even if the pleasure of good food is not under discussion, the healthy aspect of it has now become a fundamental prerequisite for eating well while accepting that one aspect does not exclude the other.

The change in eating habits that has taken place in recent decades is not only the logical consequence of different rhythms of life, but is a phenomenon attributable to an undeniable socio-cultural evolution. Once there was the problem of “what to eat”, not in terms of choice, but of availability. Subsequently we wanted to redeem ourselves from past sufferings and meat, in particular, not only responded to nutritional needs, but also represented a status symbol.

In today’s society, where thoughts of well-being are increasingly widespread, meat consumption has decreased. This phenomenon is not surprising if we consider the growing increase in vegetarians and the health beliefs that suggest making moderate use of them, especially red meats.

Analyzing the consumption of different types of meat in recent decades, poultry meat is the only one that has registered a constant increase. This has also happened because white meats have managed to fit into the innovative stream of processed products which are more responsive to the food needs of today.

Unfortunately, in terms of consumer information, the real pluses of poultry meat have neither been exploited, nor has correct information on the subject been successfully conveyed to the consumer. If we ask consumers chosen randomly, many will demonstrate that they know very little about the poultry sector and, not just a few of them, still have biased views due to issues from half a century ago.

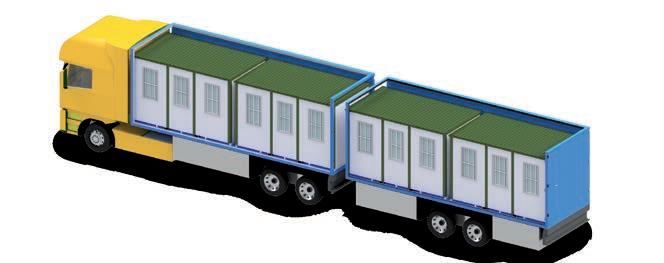

Sanitary Box

4 boxes in one full truckload

Agritech s.r.l. Via Rimembranze, 7 25012 Calvisano (BS) Italy Tel. + 39 030 9968222 r.a. Fax + 39 030 9968444 commerce@agritech.it www.agritech.it

Professional, heavy-duty, insulated box for use on farms. Easy to transport and designed to comply with the health rules.

DOSSIER

Detection and comparative quantification of Gallibacterium anatis and Mycoplasma synoviae strains from layer flocks using qPCR method

FOCUS

Researchers investigate the characteristics of Turkey Hepatitis Reovirus

MARKETING

Dynamics and patterns of the poultry industry in the G19 countries between 2010 and 2020 Part 1 – Egg production

MANAGEMENT

SUMMARY WORLDWIDE NEWS 4

.................

8

........

12

................................................................................

14

...............................................

TECHNICAL COLUMN Controlling water temperature during brooding

20

...............................

................

Dietary approaches to

............................. 32 The

CDT

36 PROCESSING Water-saving evisceration process 42 MARKET GUIDE................................................................................44 UPCOMING EVENTS ......................................................................47 INTERNET GUIDE 48 42 14 32

Game cameras as a biosecurity tool around turkey farms

24 Ammonia control during brooding begins when previous flock ends

28 VETERINARY

control Necrotic Enteritis in broilers

ABCs of

(Clostridial Dermatitis of Turkeys)

MPF Convention announces rebrand to the PEAK

The Midwest Poultry Federation (MPF) Board of Directors is excited to announce that after 51 fabulous years known as the Midwest show, the MPF Convention is changing its name to the PEAK.

The PEAK letters represent all that the MPF Convention has provided to the poultry industry over the past five decades plus gives a nod to the exciting future ahead for the organization and its annual event.

Along with a new name comes a new PEAK Show logo as well as a complete rebranding of its colors, which will be incorporated into the existing MPF website, www.MidwestPoultry.com

The rebranding process began nearly three years ago when the MPF Board met for a strategic planning session in Minneapolis. It was clear at that time that the show had seen tremendous growth and was no longer strictly a show for the Midwest poultry industry. Attendees and exhibitors come from all across the world to take in the largest trade show and convention in the U.S. that

is 100% focused on poultry. After putting the rebrand on hold during the height of the pandemic, the MPF Board rebooted its plans and after much thoughtful discussion over several months, unanimously approved the new name and logo during its May meeting.

“The Board feels strongly that our show name should be reflective of not only our rich history in the Midwest but also provide a solid foundation from which to build our exciting future as the show where North American poultry connects,” said Ross Thoreson, MPF President and long-time exhibitor as President of Best Veterinary Solutions, Ellsworth, IA.

The PEAK show will continue to be powered by the Midwest Poultry Federation, a 501(c)6 organization, whose members are 11 state poultry

organizations in 9 states, including Iowa, Illinois, Indiana, Kansas, Michigan, Minnesota, Nebraska, South Dakota and Wisconsin.

All revenue (after expenses are paid) generated by the PEAK will continue to be donated to various poultry organizations for research, educational, and career activities as well as back to MPF’s member organizations, just as previous MPF conventions have done.

“While our show name has changed, our commitment to showcasing cutting edge information, equipment, technology and services to poultry companies, farmers, and farm managers will only get stronger,” said Thoreson. “In 2023, we are expanding our exhibit hall to offer more booths than ever before and we continue to look for ways to improve our education program, which has al-

4 - worldwide newsWORLDWIDE NEWS

ways been at the epicenter of what our show provides.”

The 2023 PEAK show will be held April 11-13 at the Minneapolis Convention Center, giving the MPF organization the chance to shift its PEAK show dates so that attendees may enjoy spring in the city.

“We are looking forward to our new April dates, which shift us further away from winter weather, spring break conflicts, and other important poultry industry events earlier in the year,” said Thoreson. “It’s a great time of year to get out and enjoy Minneapolis – and meet us at the PEAK!”

About the PEAK and MPF

The PEAK is a name change for the convention only; the Midwest Poultry Federation as an organization, founded in 1971, will continue as it always has. MPF’s website, social media accounts (Facebook, Twitter,and LinkedIn), email addresses, phone number, and office location will remain the same.

Visit www.MidwestPoultry.com to stay up-to-date. You may contact MPF with any questions at info@midwestpoultry.com or 763/284-6763.

2023 Latin American Poultry Summit date announced

The date for the 2023 Latin American Poultry Summit will be Monday, Jan. 23, 2023.

the food, social and economic realities of Latin America. Featured technical topics will cover economic, production and processing issues of highest priority to Latin American poultry and egg producers and processors. Join key business leaders and university researchers to learn, discuss and network. The Summit will also provide several networking opportunities, including a luncheon, coffee breaks and a reception. Special recognition will be given to students and advisors participating in the USPOULTRY Foundation International Student Program during the event.

The date was announced by the International Poultry Expo (IPE), part of the International Production & Processing Expo (IPPE), and the Latin American Poultry Association (ALA). Enthusiastic feedback from 2022 attendees has led to the continuation of the new format developed for the Summit. The program will feature a one-day agenda to allow all attendees as much time as possible to connect and engage with exhibitors on the trade show floor.

The Latin American Poultry Summit will feature sessions focused on the role of poultry and eggs in addressing

If you missed the 2022 event and want to learn about the high caliber presentations that were given, please visit the Latin American Poultry Summit Facebook page at Facebook.com/CumbreAvicoLATAM to view video summaries of some of the presentations. New videos are being added periodically.

The 2023 IPPE show dates are Jan. 24-26, and the event will be held at the Georgia World Congress Center in Atlanta, Georgia. More information on the 2023 IPPE can be found at ippexpo.org, and information about the Latin American Poultry Summit can be found at lacumbreavicolalatinoamericana.org.

- october 2022 - 5 WORLDWIDE NEWS

World Egg Day, a global celebration of the highly nutritious and brilliantly versatile egg

It is celebrated every year on the second Friday in October and is a good opportunity for the global egg industry and egg lovers alike to promote this fantastic product.

World Egg Day is a brilliant opportunity to make sure everyone in the world knows that eggs are an excellent, affordable source of high-quality nutrition, with the potential to help feed the world.

There are lots of ways to get involved in World Egg Day celebrations in 2022, from developing a social media campaign to running an awards programme. This year’s World Egg Day theme ‘Eggs for a bet ter life’ celebrates the incredible egg’s power to support not just human health outcomes, but planetary health and people’s livelihoods too!

The egg is a brilliantly versatile protein powerhouse, containing 13 different essential nutrients in one tasty, affordable package. Its all-round goodness delivers a vast variety of benefits to people at every age and stage of life, all around the world. Improving brain function, supporting physical strength, aiding child growth – the egg can do it all!

Along with its many nutritional benefits, the egg is the most environmentally sustainable and affordable animal-source protein available, helping support families around the world as well as the planet itself. Many of the nutrients found in eggs are commonly under-consumed yet are required as part of a healthy diet to help you perform at your best and avoid serious health issues.

The bioavailability and density of their nutrients means eggs have the capacity to directly improve human health outcomes around the world, contributing to a bet ter life for all. The high nutrient density of eggs enables them to support the body’s natural immune system, advance physical growth and aid child brain development.

Eggs are a low impact protein source and have the lowest environmental footprint of common animal protein sources and are comparable to some plant-based foods.

The egg industry remains commit ted to producing nutritious foods in environmentally responsible ways, actively supporting a bet ter life for all. The egg industry is a significant source of income for rural populations around the world.

In low and middle-income countries, women represent a large proportion of egg farmers and rely on their farms to provide a bet ter life for their children.

6 - worldwide newsWORLDWIDE NEWS

Leader

Lower bottom pan from one-day old to slaughtering age. Six feed level adjustments.

COMPETITIVE PRICE. Specific model for cages on request. The feed level adjustment is

FULLY AUTOMATIC

ONE SECOND to open the pan for complete and fast washing.

Only one winching system for two lines. More space in the shed.

Designed from one-day old to slaughtering age. The adjustment of the feed and water level is

AUTOMATIC

- october 2022 - 7 WORLDWIDE NEWS Via Roma 29, 24030 Medolago (BG) Italy - Phone +39 035 901240 - info@azainternational.it www.azainternational.it I WANT AZA!

DUO THE PERFECT COUPLING BETWEEN FEED AND WATER FOR BROILERS

THE BROILER FEED PAN PRATIKA

QUALITY MADE IN ITALY

in pig & poultry equipment

Li č a Lozica a , Silvia Buzaljkob, Željko Gottstein a aDepartment of Poultry Diseases, Faculty of Veterinary Medicine, University of Zagreb, Heinzelova 55, Zagreb, Croatia bFaculty of Veterinary Medicine, University of Zagreb, Heinzelova 55, Zagreb, Croatia

Detection and comparative quantification of Gallibacterium anatis and Mycoplasma synoviae strains from layer flocks using qPCR method

Mycoplasma synoviae is one of the most common preconditions for secondary bacterial infections in poultry.

It causes subclinical infections of the upper respiratory tract, which can develop into systemic infections and result in reduced and poor-quality egg production.

In such cases, Gallibacterium anatis as an opportunistic pathogen often causes clinical infections characterized by depression, diarrhea, respiratory syndrome and decreased egg production. The aim of this study was to determine possible correlation in the prevalence of

8

DOSSIER - dossier -

@Pexels

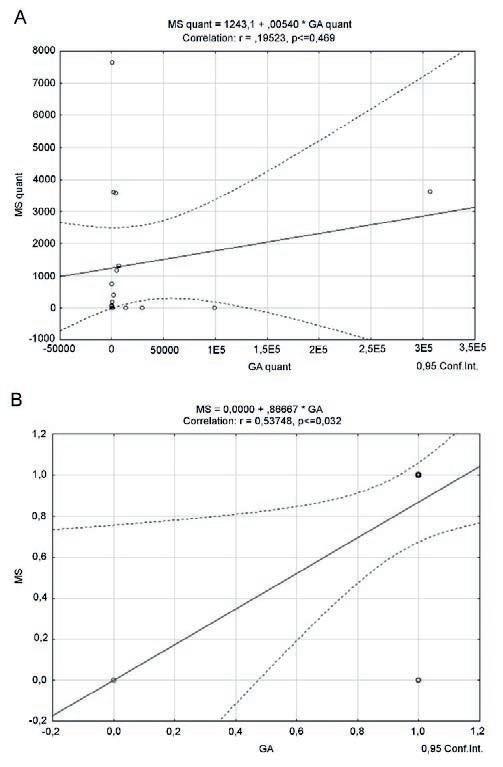

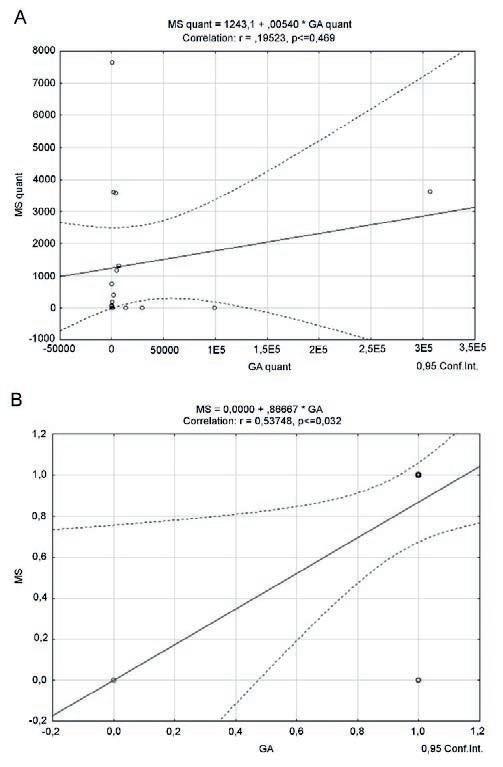

G. anatis and M. synoviae, as well as mutual correlation of their quantity. The research was done on sixteen layer flocks from eight different farms. The tracheal swab samples were analyzed using qPCR assay. The results showed statistically significant correlation in the analyzed samples regarding the prevalence of both pathogens on the farms, with significantly higher average levels of G. anatis compared to M. synoviae. No correlation regarding quantity of each pathogen was detected.

Introduction

Infections caused by Gallibacterium anatis (G. anatis) and Mycoplasma synoviae (M. synoviae) can lead to great economic losses in the poultry production. M. synoviae is one of the most common preconditions for secondary infections, while G. anatis easily spreads from the upper to lower parts of the respiratory system or ascendingly through the oviduct to the coelomic cavity, and causes severe infections.

G. anatis is an opportunistic pathogen that can cause clinical infections characterized by depression, diarrhea, respiratory syndrome and decreased egg production. However, the infection is frequently subclinical and easily overlooked. There are many predisposing factors such as impaired immunity, hormonal status, stress, poor zoohygienic conditions and coinfections, which can lead to systemic infections and high mortality rates. The morbidity and mortality rates vary in naturally infected animals, while in experimentally infected immunosuppressed layers the mortality can increase up to 73%. Due to inadequacy of the conventional diagnostic methods for detection of G. anatis, the pathogen is often difficult to isolate and therefore misdiagnosed. Consequently, a highly specific, sensitive and reproducible qPCR method was developed, which was also used in this study in order to identify and quantify the pathogen.

M. synoviae causes subclinical infection of the upper respiratory tract, which can lead to secondary respiratory and systemic infections. It can also cause decreased egg quality and production, as well as lameness and severe arthritis. M. synoviae strains have tropism for different tissues, but the synergism between arthrotropic and salpingotropic strains and other respiratory pathogens has been documented in several studies. As opposed to the respiratory and arthropathic forms, the last 20 years strains with oviduct tropism, which are associated with

egg deformities, have been increasingly detected. Respiratory form of the disease can be characterized by rales, but is most commonly asymptomatic. Morbidity in chicken flocks varies between 2 and 75%, while mortality is usually less than 1%, which consequently results in high condemnations, decreased weight gains and feed efficiency. Commercial ELISA assays are often used for routine flock monitoring, while the identification is done using different PCR-based methods.

Both bacteria are most commonly located in the upper respiratory system and frequently cause subclinical infections, therefore the aim of this study was to determine their prevalence, as well as mutual correlation of their quantity in the studied laying hen flocks.

Materials and methods

Sampling

and DNA isolation

In this study, sixteen flocks from eight laying hen farms were investigated. The age of the flocks varied from 8 to 66 weeks of age (Table 1). Five tracheal swabs per flock were sampled and stored at -20 °C until the DNA isolation. DNA was isolated from every sample individually using the GenElute Mammalian Genomic DNA Miniprep Kit (Sigma-Aldrich, Co., St Louis, MO, USA) according to the manufacturer’s instructions. Isolated DNA was stored at -20 °C until further analysis.

qPCR analyses

Quantification of the bacteria was done using GoTaq Probe qPCR Master Mix (Promega, Madison, WI, USA). Used primers and probes were specific for G. anatis (gyrB: F-5’-CGATTGTGTCCGTTAAAGTGC, R-5’-TGCAAACGCTCACACCAACTG, P-5’-FAM-CTGGTTTCTTCCGAAGTGAAAAGTGTAGTGGA-BHQ1) and M. synoviae (16S-23S rDNA ISR: F-5’-CTAAATACAATAGCCCAAGGCAA, R-5’-CCTCCTTTCTTACGGAGTACA, P-5’-FAM-AGCGATACACAACCGCTTTTAGAAT-BHQ1).

Quantification protocols were performed as described by Wang et al. (2016), and Raviv and Kleven (2008). The total volume of the reaction mixture was 15 µL. Each sample was analyzed in duplicate, while G. anatis and M. synoviae samples of known concentration were performed in triplicate in parallel for the purpose of absolute quantification. The analyses were carried out using Mx3005P instrument (Stratagene, USA).

9 - october 2022DOSSIER

Table 1 – Mean values of G. anatis (GA) and M. synoviae (MS) genome copies per swab (mean ± SD) with age of the studied flocks.

per swab (Figure 1A). However, results showed statistically significant correlation (p=0.032) in the prevalence of G. anatis and M. synoviae (Figure 1B).

Statistical analysis

The statistical analyses were done in Statistica 13.5.0.17. (TIBCO Software Inc.) software. The normal distribution was tested using Kolmogorov-Smirnov test, and the average number of genome copies was tested using Mann-Whitney U test. Correlation between the pathogen copy number and the correlation between the prevalence of both pathogens on each farm were analyzed using correlation matrices. Statistical significance was set at level P<0.05.

Results

Both pathogens were detected in the majority of the studied flocks, with the exception of Flock 11 (Farm E) and Flock 15 (Farm H) where M. synoviae was not detected, and Flock 8 (Farm C) where none of the pathogens was detected, possibly because of the young age of the flock (Table 1). The results showed higher mean copy numbers per sample for G. anatis, in most cases (Table 1), and a significantly higher average copy number of G. anatis on all farms (data not shown). There was no correlation between the pathogens in regard to the quantity of bacteria

Figure 1 – (A) Correlation between the G. anatis (GA) and M. synoviae (MS) number of genome copies per swab on each farm. (B) Correlation of GA and MS prevalence on each farm.

Discussion

The objective of this study was to determine the possible correlation in the prevalence of G. anatis and M. synoviae, and mutual correlation of their quantity in the tracheal swabs of laying hens.

Both bacteria colonize the respiratory system, which can result in clinical infections with high production losses. Several studies have shown that coinfections with M. synoviae lead to severe clinical symptoms, although no

10 DOSSIER - dossier -

± 534

±

±

3

±

±

4

±

±

5

±

± 158

7 502 ± 640

± 177

8 0 ± 0 0 ±

9 69 ± 71 754 ±

D 10 41 ± 65 51 ± 98

E 11 1126 ± 1838 0 ± 0 33 F 12 1804 ± 2219 400 ± 363 29 13 1800 ± 3266 3615 ± 2991 36 G 14 3974 ± 5222 3578 ± 3914 38

15 99196 ± 197976

±

26 16 6863 ± 8341 1313 ±

Farm Flock GA MS Age (weeks) A 1 388

7645

5166 41 2 307040

683548 3628 ± 2441 41

13596

25438 3

3 49

29374

63502 1

3 49

4856

8633 1175 ± 1114 60 B 6 111

73 ± 127 60

191

19 C

0 8

893 30

66

H

0

0

2599 42

correlation has been detected between M. synoviae and G. anatis to date.

Results of this study showed statistically significant correlation (p=0.032) in the prevalence of G. anatis and M. synoviae (Figure 1B), which confirms the possible link between the studied pathogens. G. anatis was detected in almost all flocks and showed higher titers per sample than M. synoviae, in most cases (Table 1), which is in favor of the fact that G. anatis is a commensal microorganism in the upper respiratory system where it can be found in a high amount without causing a clinical infection. There was no correlation between the quantities of the pathogens in the samples. To our knowledge, there were no clinical manifestations of infections at the time of sampling on any of the studied farms.

Immunoprophylaxis is one of the most important technological measures in the prevention of poultry diseases. Live attenuated M. synoviae vaccine showed high efficacy in the prevention of the clinical infections and elimination of the wild strains on farms. On the other hand, G. anatis strains are characterized by high genetic variability, which complicates the production of a universal commercial vaccine, although different immunogens are being investigated as possible vaccine candidates. The results of this study showed a high prevalence of both G. anatis and M. synoviae, and confirmed the need for regular monitoring on poultry farms. Since M. synoviae most frequently causes subclinical infections, the pathogen is often longitudinally spread through the flocks within a farm, which leads to economic losses. Implementation of the adequate methods for early detection and control of the bacterial pathogens on poultry farms can lead to better prevention of the diseases, which will result in healthier flocks and improved production rates. As the prevalence of Gallibacterium is influenced by the production system and the level of biosecurity measures on farms, more detailed research considering the production management should be conducted.

Acknowledgements

The authors would like to thank the farmers for their cooperation regarding sampling.

References are available on request

From the Proceedings of the 70th Western Conference Disease Conference 2021

11 - october 2022DOSSIER

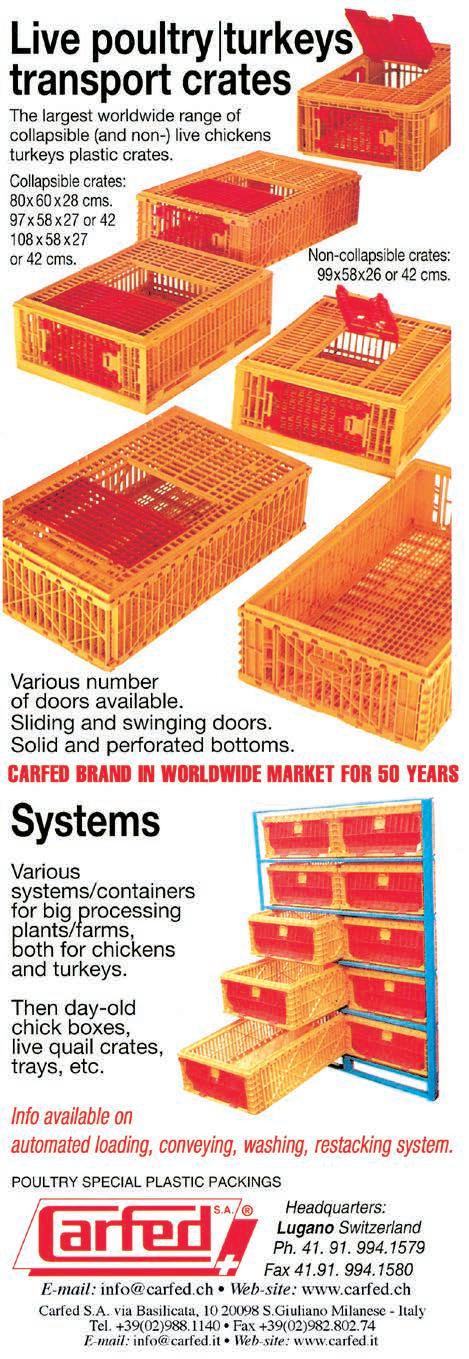

CARFED INTERNATIONAL LTD Italian headquarters: Piazza Oberdan 3, 20129 Milano (Italy) Italian warehouse: Via Basilicata 10, 20098 San Giuliano Milanese (Italy) Ph.: +39 02 9881140 – Fax: +39 02 98280274 Email: carfed@carfed.it – Website: www.carfed.it UK headquarters: Ground Floor, One George Yard, London EC3V 9DF, England, UK Ph.: + 44. 20. 7660.0987 – Email: carfed@carfed.co.uk

Researchers investigate the characteristics of Turkey Hepatitis Reovirus

USPOULTRY and the USPOULTRY Foundation announced the completion of a funded research project at the University of Minnesota in which researchers investigated the characteristics of Turkey Hepatitis Reovirus (THRV). The research was made possible in part by an endowing Foundation gift from the Cooper Family Foundation and is part of the Association’s Comprehensive Research Program encompassing all phases of poultry and egg production and processing.

Dr. Rob Porter, a professor at the University of Minnesota along with colleagues, recently completed a research project investigating the characteristics of Turkey Hepatitis Reovirus (THRV). Findings indicated that THRVs are probably variants of Turkey Arthritis Reoviruses. THRV consistently induced tenosynovitis in inoculated poults. Avian reoviruses (ARVs) are ubiquitous in domestic poultry with most of them being non-pathogenic. However, ARVs have also been associated with enteritis, hepatitis, neurological disease, myocarditis, respiratory disease

and viral arthritis/tenosynovitis in chickens or turkeys. Clinical disease associated with ARV is mostly dependent on age of the affected host, host immune status, virus pathotype and route of exposure. Turkey Reoviral Arthritis is now recognized as a significant cause of lameness in U.S. turkeys and the associated reovirus is referred to as turkey arthritis reovirus (TARV). In 2019, poults began dying from an acute hepatitis and splenitis, and an ARV, termed “ Turkey Hepatitis Reovirus” (THRV), was consistently isolated from liver.

12 FOCUS - focus -

Learning from the experience of TARV, researchers knew it would be important to act quickly to understand the emerging virus so that proper prevention and control measures could be designed to help the turkey industry. An urgent need to answer basic questions about this virus included: what the characteristics of this virus are; where did it come from; how it is different from the other major reoviruses of poultry; and, whether or not the reoviruses were widely distributed. This completed research project addressed the following questions:

• is this THRV different from TARV and Turkey Enteritis Reovirus (TERV);

• are poults susceptible to oral challenge with THRV, and

• do different THRVs differ in pathogenicity.

The specific aims of the study were to sequence the complete genome of a representative number of THRVs to determine space-time distribution of variant viruses, to determine genetic changes associated with tissue tropism of the emerging viruses, and to identify specific strains for pathogenicity study. Further, researchers endeavored to experimentally reproduce the disease to study its pathogenicity in turkey poults.

Upon completion of the research project, findings indicated that THRVs are probably variants of TARVs. THRV consistently induced tenosynovitis in inoculated poults. The effects were virtually identical to those caused by TARV, further supporting the sequencing evidence that THRVs are variants of TARVs. Real-time PCR results on viral load in different organs of birds in different groups at 14 dpi was lower as compared to viral load in different organs at 7 dpi. The viral load in liver, spleen and tendons was higher than other organs in birds from all the groups. No virus was detected in tissues of the negative control group.

Additionally, the segments encoding outer capsid proteins appear to be evolving/changing at a faster rate as compared to the segments encoding inner core proteins. Serotyping and sequence-based grouping indicate that four main serotypes of THRVs are circulating within the industry.

Source: www.uspoultry.org

- october 2022 - 13 FOCUS

The author is Prof. Emeritus of the University of Vechta and visiting Professor at the Hannover Veterinary University, Germany

Dynamics and patterns of the poultry industry in the G19 countries between 2010 and 2020

Part 1 – Egg production

The G20 (Group of Twenty) was founded in 1999 in Berlin as a forum of 19 individual member countries and the EU1. It substituted the former G8 group. The main goal of the forum is to undertake means, which contributes to the stability of the global financial situation. The heads of the G20 countries hold annual summits to discuss financial and trade matters. Conferences of the finance and foreign ministers hold separate meetings. The composition of the group has been criticised frequently in the past. In this report, 19 instead of 20 countries will be analysed. The EU is omitted as four member countries are among the G19.

¹ Member countries are Argentina, Australia, Brazil, Canada, China, France, Germany, India, Indonesia, Italy, Japan, the Republic of Korea, Mexico, the Russian Federation, Saudi Arabia, South Africa, Turkey, the United Kingdom, the United States and the European Union.

14 MARKETING - marketing -

Hans-Wilhelm Windhorst

The role of the G19 in a global setting

In 2020, the G19 countries shared 58.2% of the global population, 83.0% of the GDP, contributed 70.5% to the global laying hen inventory and 74.3% to global egg production. Their share in global egg trade was much lower. They contributed 34.9% to the global export and 33.8% to the global import volume (Table 1).

Table 1 – The role of the G19 countries in a global setting (2020) (source: FAO database, World Bank; own calculations).

Parameter

Population GDP

Laying hen inventory

Egg production

Egg exports

Egg imports

Share (%) at global level

58.2 83.0 70.5 74.3 34.9 33.8

The difference in their contribution to egg production and egg trade indicates that the efficiency in the egg industry

in most of the G19 was very high. In a detailed analysis at country level, dynamics and changes in the spatial patterns of production will be documented in a first paper. A second paper will deal with egg trade.

The development of the laying hen inventories in the G19 countries

Between 2010 and 2020, the global laying hen inventory increased from 6.5 billion birds to 7.9 billion birds or by 21.2%. In the same decade, the inventories of the G19 countries grew by 1.1 mill. hens or by 25.0%. They contributed 83.8% to the global increase.

Table 2 documents the development of the laying hen inventories between 2010 and 2020 at country level. A comparison of the ranking shows some remarkable changes. Indonesia moved from rank five to rank four, changing places with Brazil. The United Kingdom and Germany reached higher ranks while France and Italy lost two plac-

For further information, please visit www.lubingsystem.com Or send an e-mail to info@lubing.it

15 - october 2022MARKETING

!lanigirO

Table 2 – The development of the laying hen inventories in the G19 countries between 2010 and 2020; data in mill. hens (source: FAO database).

2010 2020

Country Laying hens Share (%) Country Laying hens Share (%)

China USA India Brazil Indonesia Mexico Russia Japan Turkey Korea, R. France Italy Un. Kingdom S. Africa Argentina Germany Canada S. Arabia Australia

2,527 342 304 289 208 186 155 140 71 62 56 50 47 43 38 35 27 20 16

38.8 5.2 4.7 4.4 3.2 2.9 2.4 2.1 1.1 1.0 0.9 0.8 0.7 0.7 0.6 0.5 0.4 0.3 0.2

China USA India Indonesia Brazil Mexico Russia Japan Turkey Korea, R. Un. Kingdom S. Africa Germany France Argentina Italy Canada S. Arabia Australia

3,244 390 314 281 253 209 158 153 123 78 56 49 49 46 45 41 34 33 16

41.1 4.9 4.0 3.6 3.2 2.6 2.0 1.9 1.6 0.9 0.7 0.6 0.6 0.6 0.6 0.5 0.4 0.4 0.2

G19 4,616 *70.7 G19 5,572 *70.5 World 6,520 100.0 World 7,899 100.0

* sum does not add because of rounding

Table 3 – The development of egg production in the G19 countries between 2010 and 2020; data in 1,000 t (source: FAO database).

2010 2020 Country Production Share (%) Country Production Share (%) China USA India Japan Mexico Russia Brazil Indonesia France Turkey Italy Germany Un. Kingdom Korea, Rep. Argentina Canada South Africa Saudi Arabia Australia

es. It is obvious that China was able to fasten its leading position. Worth noting is the fast increase of the inventories in Indonesia and Turkey, resulting from a growth in the per capita consumption in Indonesia and increasing exports in Turkey. Figure 1 shows the share of the ten leading countries in the G19 and the global inventories in 2020. The regional concentration is remarkably high at the G19 as well as at the global level.

A closer look at the absolute and relative changes at country level reveals that China contributed 717 mill. hens or 52.0% to the increase of the G19 inventories in the analysed decade. Indonesia contributed 73 mill. hens respectively 5.3%, Turkey 52 mill. or 3.8%. In contrast, inventories decreased in Brazil by 32 mill. and in Italy by 27 mill. hens.

The development of egg production in the G19 countries

23,483 5,437 3,378 2,572 2,381 2,261 1,948 1,121 947 740 737 662 658 590 554 452 413 219 174

36.6 8.5 5.3 3.9 3.7 3.5 3.0 1.7 1.5 1.2 1.1 1.0 1.0 0.9 0.0 0.7 0.6 0.3 0.3

China USA India Indonesia Brazil Mexico Japan Russia Turkey France Argentina Germany Un. Kingdom Korea, Rep. Italy Canada South Africa Saudi Arabia Australia

29,825 6,608 6,292 5,044 3,261 3,016 2,633 2,492 1,237 985 873 840 774 735 693 604 594 351 241

34.4 7.6 7.3 5.8 3.8 3.5 3.0 2.9 1.4 1.1 1.0 1.0 0.9 0.8 0.8 0.7 0.7 0.4 0.3 G 19 48,727 *74.8 G 19 67,098 77.4 World 64,220 100.0 World 86,660 100.0 * sum does not add because of rounding

Global egg production grew by 22.4 mill. t between 2010 and 2020 and reached a volume of 86.7mill. t. In the same decade, egg production in the G19 countries increased from 48.5 mill. t to 67.1 mill. t or by 37.9%. The G19 countries contributed 18.4 mill. t or 82.1% to the global increase of the production volume. Egg production grew faster than the laying hen inventories. This indicates that the efficiency of production increased considerably, resulting from the use of hybrid races, improved housing technologies, high quality feed and an efficient veterinary surveillance.

Table 4 documents the changes of the G19 countries in the ranking and the shares in global egg production.

16 MARKETING - marketing -

Total: 7,9 billion World Total: 5,6 billion G19

There were no changes in the top three positions between 2010 and 2020. While China lost 2.2% and the USA 0.9% of their contribution to the global production volume, India gained 2.0%. Indonesia climbed from rank eight to rank four, surpassing Japan, Mexico, Russia and Brazil. Japan, France and Italy lost their former rankings while Argentina and Turkey gained higher positions. The change in the ranking partly reflects the dynamics in the laying hen inventories. A comparison of the share of the single countries in the inventories and in production reveals some interesting differences. The USA contributed only 4.9% to the global layer flocks but 7.6% to global egg production. This documents the high intensity of the production systems. A similar relation show Indonesia and India. In both countries, the lead-

Figure 1 – The share of the ten leading G 19 countries in global laying hen inventories and the G 19 inventories (design: A.S. Kauer based on FAO data).

ing egg companies installed modern production systems in the past decade. Figure 2 documents the shares of the ten leading G19 countries in global and G19 egg production. Table 4 lists the G19 countries according to the absolute increase of their egg production in the past de-

cade. China ranked in first place with an absolute growth of 6.3 mill. t, followed by Indonesia, India and Brazil. The four countries contributed 64.4% to the global increase of egg production between 2010 and 2020. Even if China’s absolute growth volume can be challenged, the dominating

17 - october 2022MARKETING

6.8% 1.3% 2.2% 2.7% 2.8% 3.8% 4.5% 5.0% 5.6% 7.0% 58.3% 0.9%

34.2% 1.6% 1.9%

4.9% 41.1%

China USA India Indonesia Brazil Mexico Russia Japan Turkey Korea, R. Others

2.0% 2.6% 3.2% 3.6% 4.0%

IPPE IPPE IPPE IPPE IPPE CREATES NEW EXPERIENCES Let the 2023 IPPE create new experiences for you with thousands of animal food, meat and poultry industry professionals. Don’t miss your opportunity to connect at this powerhouse of a show in January! JAN. 24 - 26, 2023 ATLANTA, GA USA ippexpo.org

China Indonesia India Brazil USA Mexico Turkey Argentina Russia South Africa Germany Canada Korea, Republic of Saudi Arabia Japan United Kingdom Australia France Italy

6,342 3,923 2,914 1,313 1,171 635 497 319 231 181 178 152 145 132 118 116 67 38 - 44

27.0 350.0 86.3 67.5 21.5 26.7 67.2 57.6 10.2 43.8 28.9 33.6 24.6 60.3 4.7 17.6 38.5 4.0 - 6.0 G19 18,428 37.9 World 22,440 34.9

the global population. This indicates that in most of the G19 countries egg production was very efficient regarding breeding, feeding, veterinary surveillance and housing technologies. Together they contributed 70.5% to the global laying hen inventory and even 77.4% to global egg production. It is worth noting that the regional concentration within the group was very high. The four leading countries shared 75.9% in the overall laying hen flocks of the group and 71.1% in egg production. They played a decisive role in the global dynamics of egg production. It can be predicted that the share of the G19 countries in the global production volume will further increase because of the remarkable dynamics in most countries, in particular in China, India, Indonesia, Brazil and Turkey.

Data sources, references and suggestions for further reading

FAO database: http://www.fao.org/ faostat.

G20: https://en.wikipedia.org/wiki/G20.

Windhorst, H.-W.: The Champions League of the egg producing countries. In: Zootecnica International 43 (2021), no. 1, p. 26-29.

roles of Asian and American countries in the dynamics of the global egg industry become evident. The highest relative growth rates showed Indonesia, India, Brazil, Turkey and Saudi Arabia. They were the fastest growing egg producing countries in the decade between 2010 and 2020. While Indonesia, India and Saudi Arabia produced mainly for the domestic market, Turkey became the

second most important egg exporting country behind the Netherlands.

Summary and perspectives

The preceding analysis could show that in 2020 the contribution of the G19 countries to the global laying hen inventory and to egg production was much higher than their share in

Windhorst, H.-W.: The dynamics of the U.S. egg industry between 2010 and 2020. In: Zootecnica International 43 (2021), no. 7/8, p. 22-25.

Windhorst, H.-W.: Patterns and dynamics of the EU poultry industry: a status report. Part 1: Laying hen husbandry, egg production and egg trade. In: Zootecnica International 43 (2021), no. 12, p. 22-26.

Worldbank: https://data.worldbank. org.

18 MARKETING - marketing -

8.6% 1.5% 1.8% 3.7% 3.9% 4.5% 4.9% 7.5% 9.4% 9.8% 44.4% 29.2% 1.4% 1.1% 2.9% 3,0% 3.5% 3.8% 5.8% 7.3% 7.6% 34.4%

China USA India Indonesia Brazil Mexico Japan Russia Turkey France Others Total: 86,7 mill. t World Total: 64,4 mill. t G19 Figure 2 – The contribution of the ten leading G19 countries to global and G19 egg production in 2020 (design: A.S. Kauer based on FAO data). Table 4 – The absolute and relative change of egg production in the G19 countries between 2010 and 2020; data in 1,000 t (source: FAO database; own calculations)

Country Absolute change Relative change (%)

Aviagen Advantage Sustainability

Helping to feed a growing population. Reducing the environmental impact of poultry meat production. Providing efficiencies for sustainable farming. Breeding sustainability is what we do. Let us show you at aviagen.com.

#BreedingSustainability #sdgs #CarbonFootprint

Czarick Brian Fairchild Department of Poultry Science - UGA

Controlling water temperature during brooding

Though there is a wide range of opinions on the optimal drinking water temperature for young chicks, the fact is farm managers actually have a very limited ability to control the temperature of the water their chicks are drinking because, for all practical purposes, it is determined by house air temperature.

20 - technical columnTECHNICAL COLUMN

Michael

©www.tiho-hannover.de

@PexelsAdonyi Gábor

If the air temperature is 90 °F, the water will be around 90 °F. If the air temperature is 80 °F, the water temperature will be around 80 °F, regardless of what temperature the water enters the house. This is the result that due to very low consumption rates, the water within a drinker line moves incredibly slowly, on average less than one foot per minute, which means that it can take over an hour for the water to simply travel the first 50’ of a 200’ - 300’ drinker line! Since the water in a drinker line is almost stationary, and drinker lines are not insulated, the water doesn’t have to travel far before it warms up, or in some rare cases cools down, to room temperature. Typically within 40’ to 60’ of entering a drinker line.

Figure 1 – Water temperatures along the length of a 230’ drinker line.

Figure 1 illustrates water temperatures along the length of a 230’ drinker line during the first week of a wintertime flock in a 40’ x 500’ broiler house. The temperature

of the water entering the house’s control room from the ground was approximately 55 °F. During the 30’ trip from control room to the first nipple on the drinker line, the water warmed from 55 °F to between 70 °F and 80 °F, depending on house air temperature at the time. By the time the water reached the nipples 64’ from the beginning of the drinker line, it had warmed to essentially air temperature. Previously conducted farm studies in which the incoming water temperate was in the high forties or low sixties documented a similar trend.

It may be of interest to note the fact that it typically takes between forty to sixty feet for the water within a drinker to warm to air temperature is the reason that litter beneath the beginning of a drinker line tends to get wet-

21 - october 2022TECHNICAL COLUMN

Want to improve bird performance and reduce wet litter? Check impex nl for more information

“Though it may be potentially beneficial to be able to precisely control the temperature of the water the birds are drinking during brooding, the fact is that house air temperature will tend to determine this temperature”

KEEP UP ON TRENDS AND CHALLENGES of poultry industry with

ter during cold weather than other areas of a house. As warm, moist air comes in contact with the cool drinker line, moisture in the air condenses upon the drinker line and drips onto the floor. The colder the drinker line, the more likely condensation will form on the drinker line and the wetter the litter beneath the drinker line will become. Once the water within a drinker line warms to room temperature, condensation formation ceases and the litter beneath the drinker line becomes drier.

Since the water flows so very slowly along the length of the drinker line, water in a drinker line will actually heat up or cool down depending upon the environmental conditions along the length of the drinker line. Figure 2 illustrates the water temperatures beginning the day before the chicks were placed. House air and drinker

It’s been 50 years since Zootecnica International started serving the poultry industry and professionals. Today the magazine is edited in three languages (English, Italian and Russian) and delivered monthly in 120 countries, reaching around 30.000 readers all over the world.

The target of Zootecnica International includes farmers, egg producers, breeding companies, hatcheries, feed mills, poultry and egg processing companies.

Magazine and website offer a broad overview on the poultry industry, providing in-depth news on international markets, business management, trends and practices in poultry, genetics, incubation, nutrition, veterinary and management.

zootecnicainternational.com

Figure 2 – Water temperatures prior to chick placement. line water temperatures were approximately 70 °F, 36 hours prior to chick placement. Twenty-four hours prior to chick placement (Day 0.8) house air temperature was increased to 90 °F and drinker line water temperatures followed, increasing to between 85 °F and 90 °F, with a notable exception of those near the end of the drinker line, where they only increased to approximately 75 °F. The lower water temperatures recorded near the end of the drinker line were due to the fact that the air temperature near the end of the drinker line was only in the mid-seventies as a result of loose-fitting tunnel fan shutters. When the house’s circulation fans were turned on (Day 0.3) and the air near the tunnel fans warmed to near 90 °F, the drinker line water temperatures increased similarly (Figure 3). The relatively quick recovery of water temperatures after flushing illustrates that

22 - technical columnTECHNICAL COLUMN

Figure 3 – Water temperatures on chick placement day (The sharp drop in water temperature at Day 0.1 was the result of drinker line flushing).

even if the drinker lines are filled within 30 minutes of chick arrival, the water will achieve room temperature by the time the chicks take their first drink. In addition, if water lines are periodically flushed during brooding to assure water freshness/cleanliness, the accompanying short-lived decrease in water temperature would not likely adversely affect young chicks.

The fact that the water within a drinker line is essentially stationary during brooding and drinker lines are not insulated also means that flushing water lines has a very short-lived effect on temperature of the water the birds are drinking. The instrumented drinker line was flushed for five minutes on Days 0, 3, 5, and 7. Flushing the drinker line has the least effect on water temperatures

nearest the end of the line. This is because during flushing, as the water moved from the beginning to the end of the drinker line, it was warmed by the air in the house. That being said, regardless of location along the length of the drinker line, water temperatures returned to within five degrees of their pre-flush levels within 30 minutes.

Though it may be potentially beneficial to be able to precisely control the temperature of the water the birds are drinking during brooding, the fact is that house air temperature will tend to determine this temperature. Whether the incoming water temperature is “hot” or “cold”, it will tend to assume house air temperature within 40’ - 60’ of entering a drinker line. Though flushing drinker lines can decrease water temperatures, the effect is very transitory. This doesn’t mean that there may not be benefits to flushing water lines during brooding (i.e., flushing stagnate water from the line), but controlling water temperature is not one of them.

Source: poultryventilation.com

Figure 4 – Water line temperatures prior to, during, and after flushing (Day 5).

23 - october 2022TECHNICAL COLUMN

including www.eurotier.com THE WORLD’S LEADING TRADE FAIR 2022 | 15 – 18 NOVEMBER | HANOVER, GERMANY TRANSFORMING ANIMAL FARMING Guiding Theme 2022

Game cameras as a biosecurity tool around turkey farms

The

Erin

1 Bioproducts and Biosystems Engineering, University of Minnesota, Saint Paul, MN, USA

2 Veterinary Population Medicine, University of Minnesota, Saint Paul, MN, USA

3 Animal Science, University of Minnesota, Saint Paul, MN, USA

Introduction

The focus areas for Salmonella risk reduction usually involve several farm biosecurity measures such as rodent control, especially on breeder farms, and controlling entry of people or equipment in an attempt to limit transmission of infection between houses and between the inside of houses and the environment. Visual observations of wild birds and other fauna on the premises by workers and managers are limited to their time spent on farm. Furthermore, there are likely periods of changing exposure dynamics for turkey farms depending on the type of farm and the time of year. In particular, during the fall and spring seasons, there is an increased frequency of wild bird movements.

Camera traps, or trail cameras, are well known for animal and bird detection for private use (i.e. hunting and trapping). The research community has also made significant use of camera traps, for example, to quantify the availability of vertebrate hosts to ticks, monitoring scavenger visits as a disease transmission risk, and habitat occupancy. In order to evaluate the

24 MANAGEMENT - management -

Cortus1, Marie Culhane2, Sally Noll3 and Chloe Beaudoin1

objective of this presentation is to present quantitative and qualitative summaries of camera trap image data from six turkey farms in Minnesota and discuss findings relative to visitor logs and rodent trap records.

source of Avian Influenza infection into poultry facilities, researchers in the Netherlands used cameras that were strategically placed during one visit and set to record images for a full year with little interruption to the farm operation. Although camera image review is time-consuming and generally a fixed position view, the data captured can be used to identify types of pathogens potentially transmissible from wildlife to poultry based on the types of wildlife seen.

The objective of this presentation is to present quantitative and qualitative summaries of camera trap image data from six turkey farms in Minnesota and discuss findings relative to visitor logs and rodent trap records. Our longterm goal is to use this data to help poultry farmers refine biosecurity measures to reduce the risk of Salmonella spp. and other pathogen introduction from interactions with wild species or increased traffic on the farm.

Method

There were camera traps at six poultry farms in MN during three migration seasons (Fall 2018, Spring 2019, Fall 2019). Three of the farms were breeder farms and three were commercial grow-out farms. The cameras were Bushell B-12 12 MP Trail Cameras. The cameras were set in motion-sensor mode, taking a picture when motion was detected and every 5 minutes thereafter if the movement continued. The camera position and view angle were stable within a season for each barn, but did change between seasons on some farms. The number of images was limited by the view angle for each farm and was not wholly indicative of all movement on the farms. Each image was 12 megapixels with date, time, and temperature stamps. The memory cards were emptied every 2 weeks and photos stored for subsequent review. A team of reviewers sorted the images based on traffic type (mammals, birds, humans, vehicles and no traffic) and documented the number, type (as best possible), and location (i.e. on ground, perched on barn ridge, flying overhead, etc.) of traffic in each image in a spreadsheet. Birds included wild and domestic avians (i.e. escapees). All reviewers signed a confidentiality agreement.

The farm veterinarians provided visitor logs and rodent trap records for the camera-monitored periods at the three breeder farms. The farm veterinarians reviewed the summary of images and engaged in discussion about

Results and Discussion

Across the six barns and three seasons, the cameras captured over 9,000 images. Following review, approximately 5,500 images contained at least one form of “Traffic”. Snow, blowing vegetation, or other non-traffic movement triggered photos that were ultimately removed from the dataset, but still consumed time and energy during the review process.The number of images differed between sites and seasons (Table 1). There were 73 total images of mammals on all farms in the view angles, and 79% of the instances occurred outside of typical working hours. On Farm 2, the mammals tended to be housecats, raccoons, coyotes, or other small animals during Fall 2018 and Spring 2019; there were frequent instances of white-tailed deer in Fall 2019. The greatest frequencies of birds were in the Spring 2019 season on all but Farm 4. The majority of bird images occurred during working hours. Farms 3 and 5 view angles’ included a service road, resulting in higher frequencies of human and vehicle traffic images.

Visitor and rodent/pest logs are recommended biosecurity measures for any farm. These logs were available for the breeder farms only. The format of and the entries

25 - october 2022MANAGEMENT

what the camera and image quantification did and did not tell us.

Table 1 – The number of images with traffic types for six turkey barns in Minnesota during three migration seasons. The number of images are limited by the view angle for each farm, and are not wholly indicative of all movement on the farms.

Number of images

Breeder

Grow-out

Mammals

Birds

Humans

Vehicles

in the rodent logs varied over time. All rodent/pest logs suggested regular maintenance of and checking of rodent traps and/or bird nests. Periodically, there were notations of mice trapped and bird nests. At some of the farms, based on view angle, we expected to see more human traffic corresponding to rodent trap maintenance along the exterior of barn walls. There was no significant agreement between the images and the logs for many reasons, particularly view angles. This suggests the two record types may serve more in complementary roles rather than as validation measures.

Recommendations

Camera traps were easy to install, but the time for image review was considerable. Each image took approximately 60 s to review and code in this project. Camera trap technology is evolving, and video may prove more useful for some situations than still images. Recording image types is not necessary, but recommended for pattern detection and comparison to management records. View angle is critical for several reasons.

If view angles change periodically and randomly, the ability to detect patterns is lost. Additionally, when placing

cameras, it is obviously necessary to avoid structures that block the view of the camera but of equal importance is placement of the camera to avoid detecting “non-traffic” motion, e.g., swaying tree branches and fan baffles opening and closing.

Finally, when placing the cameras, the goal of camera trap use should ultimately guide camera placement. If the goal is to detect wild mammals, for example, place cameras to capture motion near points of entry to the feed or compost piles. However, if the goal is to monitor entry and exit of people and equipment on the farm, placement of cameras to detect motion at the line of separation will likely yield useful images.

Regardless of camera angle and placement, if the images are to be used to determine pathways of pathogen introduction into a turkey barn, regular and timely review of the images is highly recommended, not only to decrease the backlog of images to review but to also provide more immediate feedback to the farm managers who can then make corrections to biosecurity protocols as needed.

References are available on request From the Proceedings of the Midwest Poutry Federation Convention 2022

26 MANAGEMENT - management -

Farm 1 Farm 2 Farm 3 Farm 4 Farm 5 Farm 6 Total

Fall 2018 4 22 0 6 1 1 34 Spring 2019 7 10 0 0 5 0 22 Fall 2019 0 16 0 1 0 0 17

Fall 2018 1 0 32 12 137 40 222 Spring 2019 16 9 393 28 208 584 1238 Fall 2019 0 1 63 87 101 53 305

Fall 2018 27 18 59 13 373 23 513 Spring 2019 48 81 52 16 489 79 765 Fall 2019 24 23 557 44 129 83 860

Fall 2018 41 17 248 10 382 29 727 Spring 2019 60 78 188 22 700 122 1170 Fall 2019 21 31 1013 58 413 114 1650

Fall 2018 total 73 57 339 41 893 93 1496 Spring 2019 total 131 178 633 66 1402 785 3195 Fall 2019 total 45 71 1633 190 643 250 2832 Total 249 306 2605 297 2938 1128 7523

27 - october 2022 -

Michael Czarick, Extension Engineer Connie Mou, UGA Poultry Science (PhD 2020)

Ammonia control during brooding begins when previous flock ends

The level of ammonia young chicks will be exposed to during the first week of their lives is determined to a large extent by what was done to the litter between the flocks.

Towards the end of a flock the birds are adding thousands of gallons of water to a house each day. During cold weather, reduced ventilation rates, in attempt to keep heating costs to a minimum, can result in a large percentage the moisture remaining in the litter. The most prevalent location for moisture build-up in litter is near a house’s drinker lines. If fact, it is not uncommon at the end of the flock for the moisture content of the litter within a couple of feet of each drinker line to be 40% or greater.

28 MANAGEMENT - management -

Since water is one of the key building blocks for ammonia, the increased moisture content leads to increased ammonia production from the litter near the drinker lines. In fact, research has shown that the ammonia production of the litter in the vicinity of the drinker lines can be four times or more than that in other areas of the house where the litter is drier.

After a flock leaves a house during cold weather, the temperature of the air in a house quickly drops. Though this fact may seem trivial, it can cause problems for the chicks that will be showing up in a couple of weeks. This is because both the evaporation of water and generation of ammonia from the litter are temperature-dependent. The colder the house becomes, the lower the amount of ammonia generated, and the lower the amount of moisture removed from the litter. In a sense, the colder a house becomes, the deeper the litter tends to go into a state of hibernation. If heat is added to a house a week or so later, it can seem like the birds just left. The ammonia generation process starts back up and the ammonia levels rapidly increase. As a result, one of the keys to keeping ammonia levels to a minimum at the beginning of a flock is to remove as much of the ammonia-producing cake from a house as possible and then work on drying the litter that remains. The sooner the cake is removed, the more time you have to dry the remaining litter and the easier it will be to control the ammonia at the beginning of the next flock.

Delaying the removal of cake from a house for a few days after the birds leave effectively reduces a house’s downtime a few days because little drying of the cake and the litter beneath the cake will occur. Figure 1 shows the av-

erage litter moisture taken from multiple locations near the drinker lines from three broiler houses on the same farm. The day after the birds left the litter moisture was 45%. Over the next seven days there was no significant decrease in the moisture level of the caked litter near the drinker lines.

Though the moisture content of the litter under the cake was not measured, it would be highly doubtful if there would have been any change due the fact that the mois-

29 - october 2022MANAGEMENT

Pas Reform Integrated Hatchery Solutions www.pasreform.com pas2020_adv-Zootecnica-180x61mm.indd 1 25-02-2020 11:16

“Research has shown that the ammonia production of the litter in the vicinity of the drinker lines can be four times or more than that in other areas of the house where the litter is drier”

Royal

post sale

Figure 1 – Litter moisture near drinker lines past sale.

ture content of the caked litter above it didn’t change. In this case, since the houses were not decaked for roughly seven days after the end of the flock, from a litter-drying standpoint the 21-day downtime became a 14-day downtime.

Though acid-based ammonia control products can be used to effectively lower ammonia prior to chick placement, how long an ammonia control product will last depends upon the ammonia-generation rate of the litter when it is applied. There is a precise amount of ammonia that each pound/gallon of litter treatment will eliminate. The higher the ammonia-generation rate, the faster any litter control product will be used up and ammonia levels will start to rise. If prior to chick placement caked litter has not been removed and the

litter hasn’t not been dried sufficiently, the ammonia-generation rate can be so high that the ammonia binding capability of a litter treatment can be overwhelmed.

To help assure chicks will not be exposed to excessive ammonia during brooding, caked litter should be removed soon after the previous flock’s departure, then house should be closed up and ventilated in a manner similar to that if there were birds present. Minimum ventilation fans should be controlled by a timer. Ideally, the average house relative humidity would be kept below 70%. If daytime temperatures are moderate (+50 °F) minimum ventilation fans should be operated continuously. If excess litter moisture is not removed from the house then little moisture will be removed from the litter and the ammonia generation rate at the beginning of the next flock is more likely to overwhelm any ammonia-control product applied. In addition, if a house is not ventilated properly between flocks, excessive humidity/condensation and high ammonia levels can end up damaging a poultry house’s structure and equipment.

In the end the goal quite simple: don’t let the moisture and the cake from a previous flock adversely affect the current flock’s performance and health.

This article was originally published in Poultry Housing Tips, Volume 34, Number 2, 2022. University of Georgia, College of Agricultural and Environmental Sciences Cooperative Extension

30 MANAGEMENT - management -

55 50 45 40 35 30 25 20 15 10 5 0 Day 1 Day 3 Days

From the Proceedings of the Midwest Poultry Federation Convention 2022 Litter Moisture (%) Day 5 Day 7

Sturdy and easy to manage. Designed from one day-old chicks to heavy and nervous male turkeys. No chick inside the pan. Fast and easy cleaning. High quality product at

31 - october 2022MANAGEMENT I WANT AZA! QUALITY MADE IN ITALY

MIXTA THE FEED PAN FOR TURKEYS OR MIXED CYCLES

Flexible

shock-proof cone

Feed pan for turkeys or mixed cycles (turkeys,broilers, ducks). No chick inside the pan. The feed level adjustment is FULLY AUTOMATIC.

ONE SECOND to open the pan for complete and fast washing.

rubber

PRICES

Model

cover

FEED PAN FOR TURKEYS MODULA Leader in pig & poultry equipment Via Roma 29, 24030 Medolago (BG) Italy - Phone +39 035 901240 - info@azainternational.it www.azainternational.it

COMPETITIVE

.

without

Young birds

Dietary approaches to control Necrotic Enteritis in broilers

Necrotic Enteritis (NE) occurs in broilers due to an overabundance of C. perfringens and is usually associated with predisposing factors which include coccidial challenge, poorly digested feed, and immune suppression. Coccidiosis is often considered a primary predisposing factor for the onset of NE development in both commercial and research settings.

toxin most often associated with NE is the α-toxin, though Keyburn et al. (2006; 2008) questioned the original α-toxin research and published a paper describing “NetB” as a new toxin that should be considered. A review by Rood et al. (2016) suggested that the onset of NE is complex, with multiple contributing factors, and not simply the presence of a specific toxin.

Clostridium Perfringens life cycle and calcium

Multifactorial causes of NE

Coccidiosis effects on mucosal permeability can lead to plasma protein leakage into the intestinal lumen which can increase intestinal pH, decrease gut motility, and increase the potential for a secondary bacterial infection. Eimeria spp. can also increase intestinal mucus production. Though mucus is an essential part of the primary barrier against invading pathogens, overproduction is a source of nutrients for mucolytic bacteria including Clostridium perfringens

There has been considerable discussion on which toxin(s) produced by C. perfringens is primarily responsible for NE in chickens. The

Clostridium perfringens is a commensal bacterium that can exist in the intestine and the environment (litter, soil, water, feces, food, etc.). The life cycle of C. perfringens begins with a spore which will germinate under favorable conditions into a vegetative cell. The vegetative cell replicates and subsequently sporulates. A C. perfringens spore can survive for years and is resistant to heat, cleaning, and disinfectants. The composition of the spore coating includes components that help facilitate germination and these include Ca and dipicolinic acid (DPA). Recent in-vitro research has demonstrated that C. perfringens germination also requires exogenous calcium. This was previously demonstrated with C. difficile, a Clostridium species with implications for human health. The presence of Ca in the intestine (especially at higher levels) can theoretically circumvent the need for endogenous Ca and DPA from the spore coating. Once a vegetative cell has formed, C. perfringens replicates via binary fission to produce two vegetative cells. The production

32 - veterinary scienceVETERINARY SCIENCE

Alamanda Calvert, M.S. Research Manager, Biomatrix International

of the α- and netB toxins occurs when C. perfringens is a vegetative cell. When C. perfringens encounters enterocytes in the intestinal lumen it produces α-toxin. Higher concentrations of C. perfringens (109 CFU) and limited nutrient availability stimulate NetB production through quorum sensing and both toxins utilize Ca.

The third life stage, sporulation, results in the formation of an endospore. The induction of sporulation can occur in response to increased C. perfringens density and unfavorable conditions such as lack of nutrients. Though Ca is not needed for sporulation, increased Ca during spore formation can increase the protective capacity of the endospore. Spores with increased Ca and DPA are more resistant to heat and thus harder to kill. Sporulation also responds positively to phosphorus in the intestinal environment as it counteracts the inhibitory effects of glucose and subsequently facilitates sporulation. Previous research suggests that increased Ca levels in the diet increases the activity of both toxins resulting in increased NE mortality. Our hypothesis is that reducing dietary Ca may decrease mortality related to NE by reducing the availability of Ca needed for multiple life stages of C. perfringens. Both hypotheses require additional research.

Effects of Bacillus DFM’s in broilers with Necrotic Enteritis

A summary of published broiler studies using supplemental Bacillus DFMs (direct-fed microbial) with a NE challenge are shown in Table 1. These trials suggest an inconsistent effect of DFM on body weight and gain. Seven trials report no effect of the DFM whereas six show an improvement in gain. In the six with improved gain, three

occurred in the phase immediately after challenge while the other three reported an overall improvement at the end of the trial. This inconsistent effect of Bacillus DFM on body weight and gain is similar to research studies in birds that are not challenged. Feed intake was not affected by DFM supplementation in previous challenge studies (Table 1) whereas in studies with no challenge feed intake effects of DFMs are inconsistent, some show no effects, while some demonstrate improvements that may be age or phase dependent. Bacillus DFM supplementation improves feed conversion ratio in most research trials with NE challenge (Table 1). Nine trials reported an improvement while in three other studies, there was no effect or improvement was age dependent. In trials without an NE challenge, approximately half the studies demonstrated no effect and the other half an improvement of DFM on feed conversion ratio.

Eight studies with broilers challenged with NE reported NE lesion severity scores (Table 1). Five reported reduced NE lesions with DFM, and two observed reduced lesions in the duodenum but not in the ileum or jejunum. The one remaining trial reported no effect of DFM on lesions though all lesions were noted as mild. In nine NE challenge studies where mortality data was reported, there was reduced mortality with DFM supplementation in five studies, three reports with no effect and one with a transient effect but no overall effect at the end of the study (Table 1). In summary, dietary DFM inclusion in broilers with NE appears to have a somewhat positive effect on FCR (feed conversion ratio). Bacillus DFMs may reduce NE lesions and mortality though effects on BW (body weight) and FI (feed intake) should not be expected, though transient effects may occur in broilers affected by NE.

- october 2022 - 33

VETERINARY SCIENCE

MADE IN ITALY WEB R www.valli-italy.com quality you can depend on Area Baby Area Bellavita Castello Casa Piramide Plus Vita VLV Plus Via Cimatti, 2 47010 GALEATA FC -ITALY ALTERNATIVE SYSTEMS

Table 1 – Performance effects of Bacillus DFMs with NE challenge in broilers.

DFM Challenge

Baymix grobig

B. subtilis 1.1 x 10 6 spores/g diet

B. lichenformis

3.2 × 10 9 CFU/g diet

CloStat, B. subtilis

2 × 107 CFU/g Gallipro Tech B. subtilis 4 × 10 9 CFU/g

B. amyloliquefaciens

2 x 10 8 CFU/g diet

16 d: 10 8 CFU/bird

C. perfringens

Floor pens: 1 d: high dose Coccivac b52 (anti-coccidial vaccine) C. perfringens spores known to be present in the barn

Cages with oral gavage: 15 d: 4 x 10 8 CFU/g C. perfringens

Cages with challenge via water/ feed: 9 d: 20x anticoccidial vaccine in drinking water (8,000 oocysts per bird) 14 and 15 d: In feed, 1.76 x 10 8 CFU/mL at 1:1.5 Vol/ Weight C. perfringens

BW or Gain FI FCR

NE Lesions Mortality Author

26 d: increased 34 d: not improved No effect 19-26 d: improved 1-34 d: improved Not done Not reported

14 d: increased 42 d: no effect 14 d: increased 42 d: no effect 14 d: no effect 42 d: improved

35 d: both increased

35 d: no effect (no effect of challenge either)

14 d: reduced in duodenum not in jejunum or ileum

14 d: reduced 42 d: no effect

Eid et al., 2020

Emami et al., 2020

35 d: both improved Not done 35 d: both reduced Hussein et al., 2020

No effect No effect 21 d: improved 21 d: reduced No effect Shini et al., 2020

DSM 32315

B. subtilis 1 x 10 6 CFU/g of diet

DSM 32315

B. subtilis 4.5 × 1011 CFU/g diet

Floor pens with infected feed: 0 d: Coccivac-B52 (anticoccidial vaccine) 18, 19, and 20 d: 10 8 CFU/bird C. perfringens (NetB field strain)

Floor pens with oral gavage 12 d: Eimeria maxima 5,000 oocysts 16 d: 0.5 to 1 x 10 9 live cells/bird C. perfringens (field strain)

28 d: no effect 42 d: increased No effect 28 d: improved 42 d: improved

21 d: reduced with DFM 28 d: no effect 42 d: reduced Bortoluzzi et al., 2019

35 d: no effect 35 d: no effect 35 d: improved Not done 35 d: reduced Whelan et al., 2019

Sporulin B. subtilis 1 × 10 6 CFU/g diet

Cages with oral gavage: 14 d: E. maxima 5,000 oocysts 19, 20 and 21 d: 10 8 CFU/bird C. perfringens

No effect (of DFM or challenge)

No effect (of DFM or challenge)

14-28 d: improved with DFM 21 d: reduced with DFM 28 d: reduced with DFM Kuttappan et al., 2018

Reducing dietary calcium

in

broilers with Necrotic Enteritis

As alluded to previously, there is some research suggesting that a reduction in dietary Ca levels in broilers with NE may reduce mortality. Paiva et al. (2013) reported that mortality was reduced from 20% to 5% in birds fed reduced Ca diets (0.9% vs 0.6%) at 21 days of age when source of Ca was calcified seaweed and dicalcium phosphate. In birds fed Ca from limestone and dicalcium phosphate with similar Ca differences, mortality was reduced from 12% to 7% at 21 days of age. In a second trial mortality was reduced from 20% in birds fed standard Ca diets to 10% in birds fed reduced Ca diets at 35 days of age. The Ca source was calcified seaweed and dicalcium phosphate and standard or low dietary Ca treatments stepped down with age (starter: 0.9% or 0.6%, grower: 0.8% or 0.52%). The NE challenge in the trials by Paiva were from exposure to C. perfringens in the litter (from a previous flock with NE) after live coccidiosis vaccine. Zanu et al. (2020)

compared dietary Ca levels using an induced NE challenge where broilers were given three Eimeria spp. on day 9 followed by a NetB positive strain of C. perfringens orally gavaged on days 14 and 15. Treatments were standard or low dietary Ca that was stepped down with age (starter: 1% or 0.6%, grower: 0.9% or 0.5%, and finisher 0.8% or 0.4%). Mortality at 42 d was reduced from 7% in birds fed standard Ca diets to 3% in those fed low Ca diets. Intestinal lesions were higher in challenged broilers but there was no effect of Ca on lesion scores. Lesion scores were not determined by Paiva et al.

Current dietary formulation utilizes total Ca though formulating diets on digestible Ca values has recently been reviewed by Walk et al. (2021a). Limestone and other calcium sources can vary in solubility. More specifically, as particle size increases, solubility decreases in-vitro, and digestibility increases in-vivo. In a trial with broilers from 0 to 10 days of age, diets were formulated on digestible Ca. Tibia ash % was optimized in diets with close to 0.5% digestible Ca (1.01% analyzed total Ca). Though diets as

34 - veterinary scienceVETERINARY SCIENCE

Table 1 (continued) – Performance effects of Bacillus DFMs with NE challenge in broilers.

DFM Challenge BW or Gain FI FCR NE Lesions Mortality Author

B. coagulans

4 × 10 6 CFU/g diet

Sporulin B. subtilis

1 × 10 6 CFU/g diet

Cages with oral gavage: 14 d: 20x attenuated anticoccidial vaccine 18, 19, and 20 d: 10 8 CFU/bird C. perfringens

Floor pens with oral gavage: 15 d: 10x anti-coccidial vaccine (brand/spp. not specified)

15-21 d: increased 22-28 d: increased (with challenge) 29-42 d: no effect

22-28 d: no effect (challenge reduced) 29-42 d: no effect

No effect (of DFM) No effect (of DFM)

Avicorr B. subtilis

1.5 × 105 CFU/g diet

PB6 B. subtilis

4.5 x 1011 CFU/g diet

Reused litter (10x) known to contain Eimeria spp. and Clostridium spp. (No NE symptoms reported)

Cages with oral gavage: 16 d: 10x dose Paracox-8 (anticoccidial vaccine) 18 and 20 d: 4 x 10 8 CFU/bird C. perfringens (MicroBiologics)

PB6 B. subtilis 2.8 × 1011 CFU/g diet

QST 713 B. subtilis

1 x 10 6 and 1 x 10 5 CFU/g diet

Floor pens with oral gavage: 14 d: Eimeria spp. 30,000 oocysts 19, 20 and 21 d: 10 8 CFU/bird C. perfringens (field strain)

Cages with oral gavage: 14 d: E. maxima 5,000 oocysts 19, 20 and 21 d: 10 8 CFU/bird C. perfringens

15-21 d: improved 22-28 d: no effect 29-42 d: no effect

14 d: improved 21 d: improved 27 and 41 d: no effect

28 d: reduced in duodenum not in jejunum or ileum

Not reported Wu et al., 2018

28 d: mild, no effect Low, no effect Yan et al., 2017

No effect Not reported Not reported Not done No mortality Lee et al., 2014

No effect No effect No effect Not done No effect Abudabos et al., 2013

No effect (of DFM or challenge)

No effect (of DFM or challenge) 35 d: improved 28 d: reduced with DFM No mortality Jayaraman et al., 2013

28 d: improved (DFM 10 6) Not reported 28 d: improved (DFM 10 5 and 10 6)

low as 0.3% digestible Ca (0.64% analyzed total Ca) did not significantly reduce tibia ash % when compared to the reference diet (0.89% analyzed total Ca).

Combining multiple dietary approaches to reduce Necrotic Enteritis in broilers

A research trial was completed by Calvert et al. (2015) which included three dietary Ca levels (0.90%, 0.75% and 0.60%; from limestone and dicalcium phosphate) with or without a Bacillus subtills DFM. The NE challenge utilized the same method as Paiva which was exposure to C. perfringens in the litter (from a previous flock with NE) after administering a live coccidiosis vaccine at the recommended dosage. Mortality related to NE at 28 d was reduced from 16% to 6% when dietary Ca level was reduced from 0.90% to 0.60% (P≤0.05).

Mortality in broilers fed 0.75% dietary Ca was intermediate at 10%. Feed intake was depressed as dietary Ca level increased likely due to the more severe NE challenge present in broilers fed higher levels of Ca. Body weight and gain were improved in broilers fed the DFM with 0.60% dietary Ca compared to broilers fed the 0.90% dietary Ca without DFM (P≤0.05). No effect on feed con-

22 d: reduced (DFM 10 5 and 10 6)

28 d: reduced (DFM 10 5 and 10 6)

Tactacan et al., 2013

version ratio occurred related to either Ca level or DFM supplementation. This is likely due to the increased variability given the natural NE challenge that was utilized in this trial compared to most previous trials with DFMs that have utilized known amounts of C. perfringens administered to each bird. Ileal Ca digestibility was reduced as dietary Ca increased from 0.60% to 0.90%. Percent tibia ash was not different between 0.6% and 0.75% Ca diets though it was higher in chicks fed 0.75% Ca versus those fed 0.90% Ca at 18 days (P≤0.05). During an NE challenge it appears that chicks may adjust Ca absorption and utilization to prevent signs of deficiency.

Reducing dietary Ca level reduced mortality related to NE and when combined with a Bacillus DFM improved body weight gain. Reducing Ca levels in diets to below industry standards may be one dietary approach to manage the severity of NE though it may not be sufficient to improve performance without the use of other methods as demonstrated in this trial by the inclusion of a DFM with lower Ca diets.

References available on request From the Proceedings of the Midwest Poultry Federation Convention 2022

- october 2022 - 35 VETERINARY SCIENCE

The ABCs of CDT (Clostridial Dermatitis of Turkeys)

Clostridial Dermatitis of Turkeys (CDT), also referred to as Cellulitis, remains a major disease issue across all geographic regions of the US; the annual industry 2021 survey average score for CDT changed slightly to 3.9 (from 4.0 in prior year) and increased in rank from #3 (2020) to #2.

Steven R. Clark, DVM

Peachtree City, Georgia