10,000 BC ~ Howick house. First timber home in the Mesolithic period found in Britain. Were constructed for shelter.

Tools improved with the development of metallic alloys from bronze, to iron, to steel. Steel saws replaced axes as the primary means of shaping timber. 50 AD ~ technique called 'Timber Framing' first developed by the Romans.

1399 AD ~ The Hammer beam roof of Westminster Hall is the largest medieval timber roof in Northern Europe. Hammer beam roofs were the carpenter’s ultimate expression of both technical ability and artistic creativity.

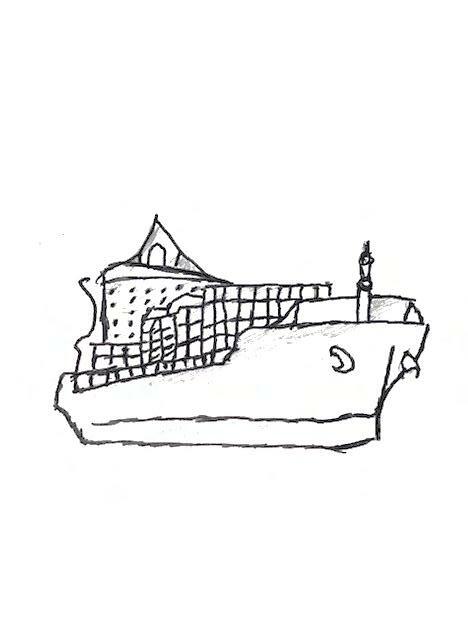

Timber was also used for shipbuilding purposes during the 1700s

21st century With the improvements in CLT (cross laminated timber) there is an increase in popularity in using wood for exterior facade. Trends in innovative finishes like charred wood, also known as shou sugi ban, an ancient Japanese practice arose in the modern world.

5000 6000 BC ~ Neothilic Long House in Balbridie. Rectangular narrow structure, outer walls usually made up of wattle and daub accommodating 20 30 people.

782 AD ~ Nanchan Temple, China. The oldest standing timber frame building in China.

16th Century ~ Wernigerod e Town Hall, Germany. A proliferation of techniques of timber framing came into play across Europe from 14th to 18th century, with many regionally distinct styles developing.

19th century The Granot Loma Cabin, Michigan. Biggest log cabin in the world. The interlocking of timber produces log cabins.

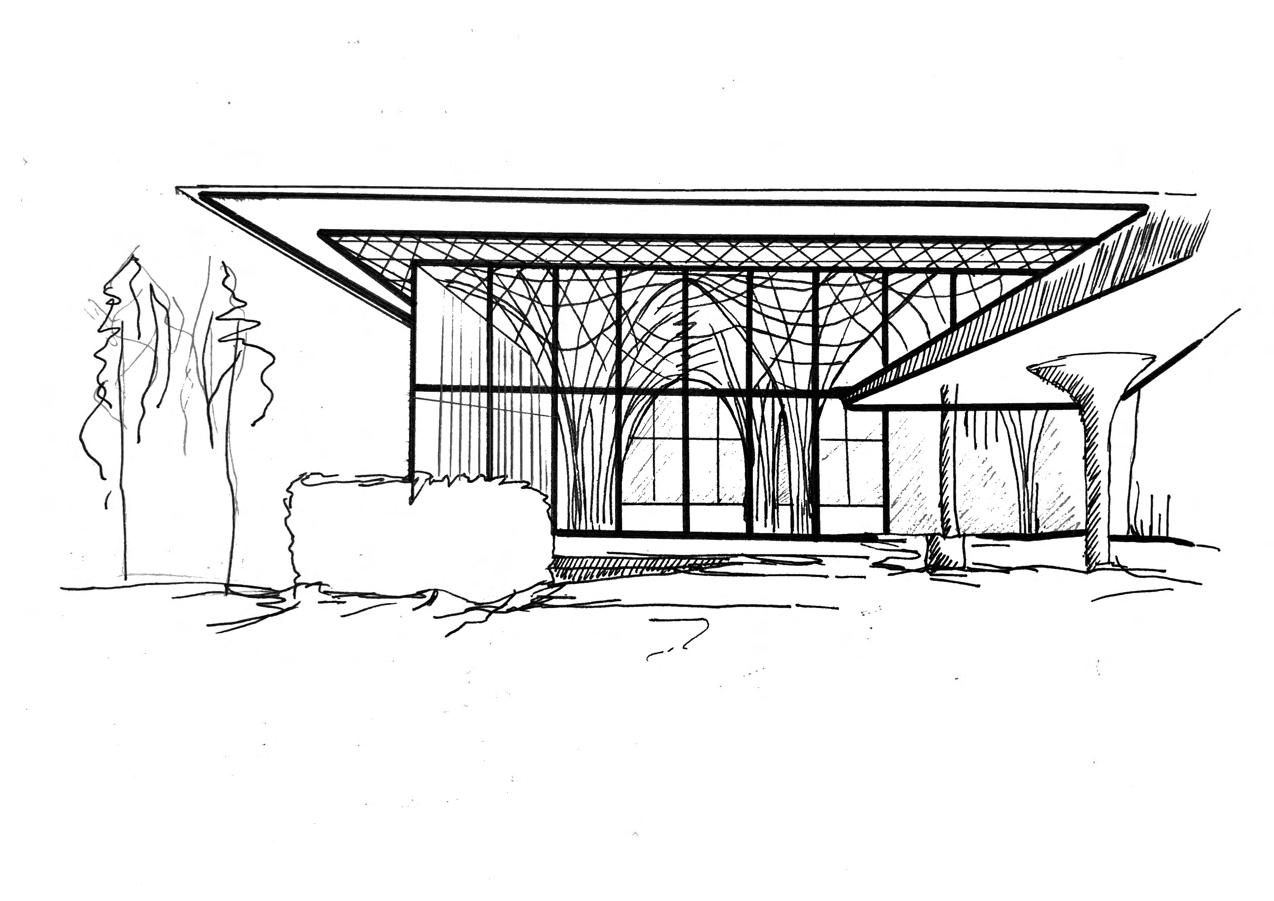

Sunnyhills Café , Kengo Kuma & Associates, Tokyo. Wooden lattice exterior.

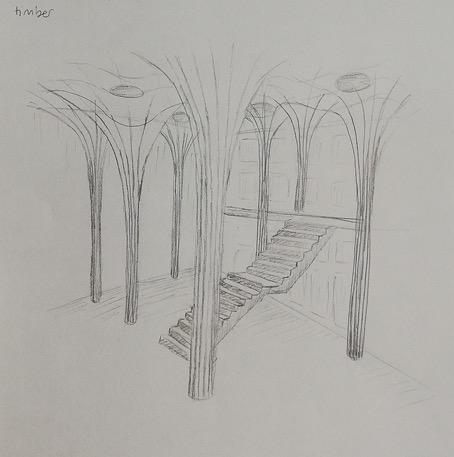

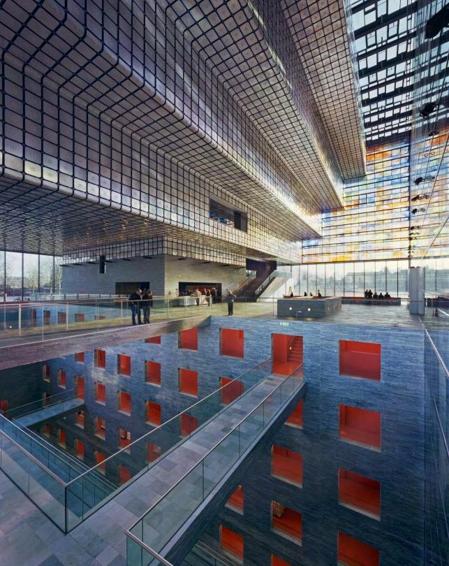

The Nine Bridges Country Club is primarily built out from timber, as its laminated timber columns that climb up to form a hexagonal lattice which forms the roof, is one of its main, most spectacular features.

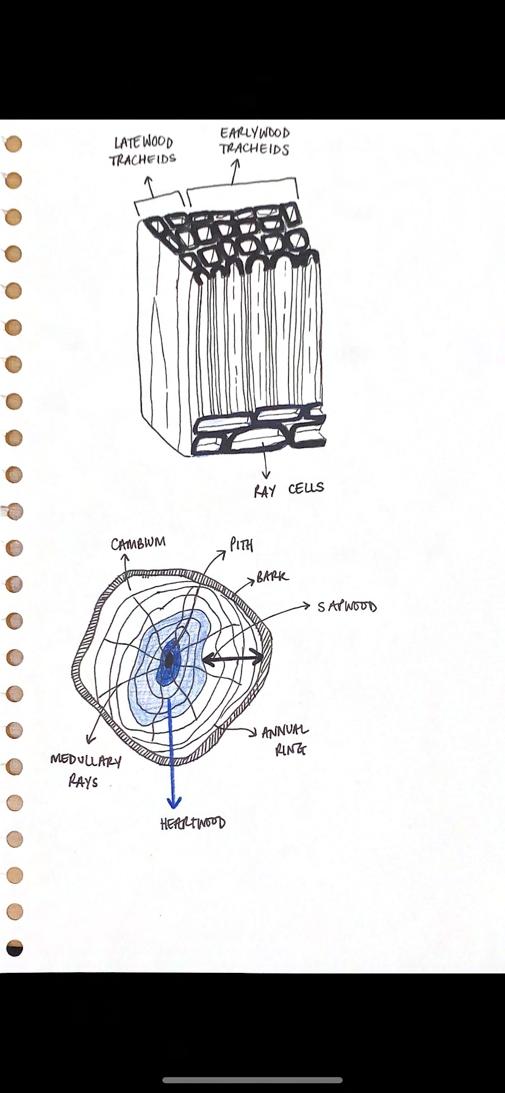

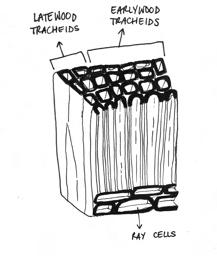

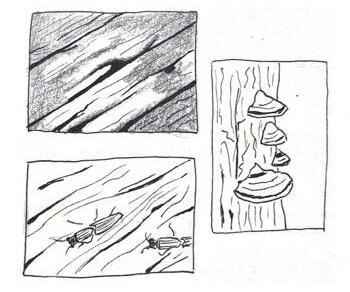

Timber is mostly created from Softwood which originally comes from Gymnosperm trees. This wood is 'converted' into timber when it is split, hewn or sawn into many forms of timber frames for construction. It has been used as an organic material for thousands of years and is truly versatile for construction.

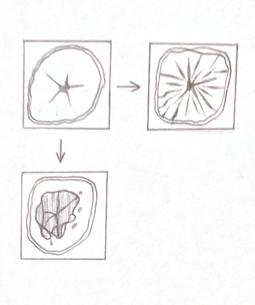

If you were to cut a cross section of a softwood tree, you can easily notice the annual growth rings that form from the center heartwood, to the outer sapwood. More rings are added to older the tree gets, and all these layers are encapsulated and protected by the outer layer of bark.

Heartwood contains less moisture than sapwood, which makes it stronger and more stable, although as a material it is more expensive than sapwood, so from an architect’s perspective the matter of cost over quality would arise

Under a microscope, the cross section would show the cell walls aligned axially on the stem. A suitable analogy of the wood's structure would be a bundle of tubes which act like drinking straws. Depending how central the wood in the trunk is, the thicker the outer cell walls are.

Weight for weight timber is as strong as mild steel

Timber is good at withstanding fracture mechanisms, as its not brittle

It has a wide range of uses in building components e.g., windows and doors, as well as in furniture, MDF

Softwoods are typically less expensive and have a faster growing rate

The stiffness of timber is good, which combined with low density means that it is very efficient in beams and columns (utilized in the Nine bridges Country Club)

If used carefully, the structural performance of wood is not affected by nails and screws.

Timber is prone to deterioration through weathering which can expose the timber externally and it can lose its color or create cracks.

Timber is also combustible so is susceptible to fire Can be affected by fungi Can be infected by insects. Because of these factors, Chemical is vital to protect timber from the effects of fungi and insects.

Knots and shakes are weak points After a long time, repeated stress will usually creep and attain a permanent bend as the amorphous part of the cellulose reacts to changes in humidity and temperature to move away from its

ARYA VAHIDI

Wood is a renewable resource meaning it you will not run out of it as long you keep planting more trees. Producing timber in a sustainable way requires long term planning and for each tree cut for timber, another is planted. Wood is a desirable material as it absorbs the carbon dioxide emitted in the environment." A typical tree can absorb around 21 kilograms of carbon dioxide (CO2) per year" according to Viess Mann

An issue affecting wood is deforestation and when cut trees are not replanted. forests cover 30% of the Earth, but this percentage is decreasing faster and faster. Between 1990 and 2016, the world lost 502,000 square miles (1.3 million square kilometers) of forest. 17% of the Amazon rainforest have been destroyed in 50 years. the main reasons for deforestation are to make space for agriculture, grazing of livestock, mining and drilling. Timber used in construction can also come from this type of deforestation, but most of the time it happens illegally.

The manufacture of wood products requires less fossil fuel than other alternative materials such as concrete.

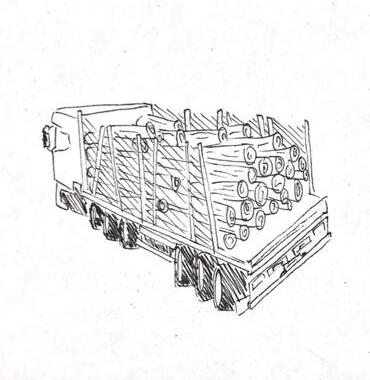

The emissions from transporting timber are the fuel used by trucks. The fuel consumption from trucks transporting timber is usually higher than the average truck, which is the biggest output of greenhouses gases, it is 49% of timber’s greenhouse gas emissions during transportation. The manufacturing and maintaining of timber trucks need to be renewed much more often and this increases 29% of the greenhouse gases emitted during transporting timber and we need to

FERRAIUOLO

FERRAIUOLO

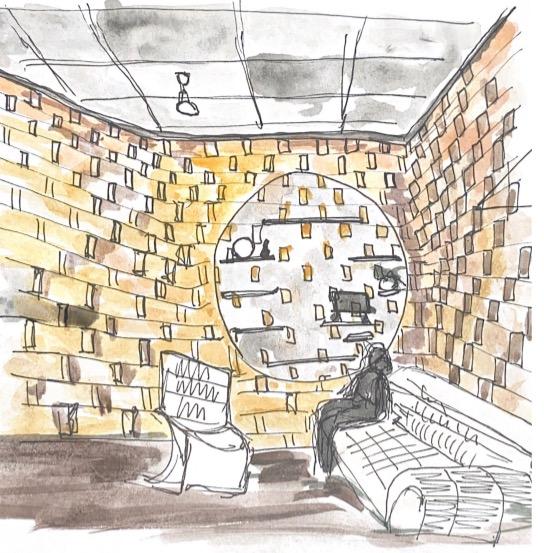

Wood is a good material for assembling of any kind. Building wood is used to make frames of buildings as the material itself its strong and light weight. In addition to being an easy to assemble material, timber is a material that gives a warmer atmosphere unlike materials such as concrete which gives a colder atmosphere. A great example is Grotto Suna,

For the maintenance of wood, some of these causes such as fungi and insect infestation must be treated with chemical treatments, but this can be harmful to the environment.

consider that wood produces "100kg of oxygen per tree per year" (from planet earth.

MELANY FERRAIUOLO where he makes the building of site and assembles on site to reduce time and to make it easier to build it on the difficult terrain This makes the process more sustainable .

ARYA VAHIDI MELANY FERRAIUOLOMELANY FERRAIUOLO

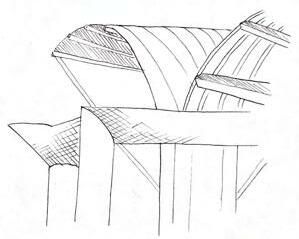

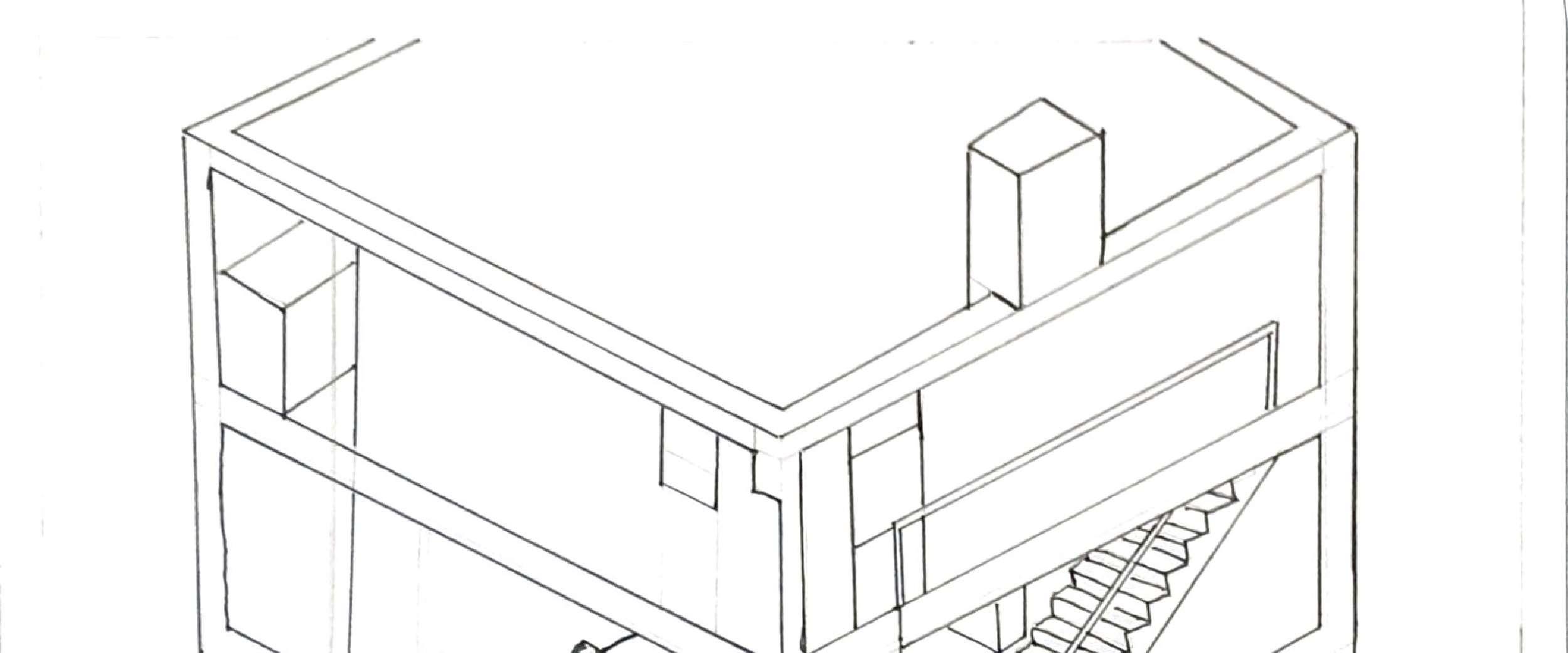

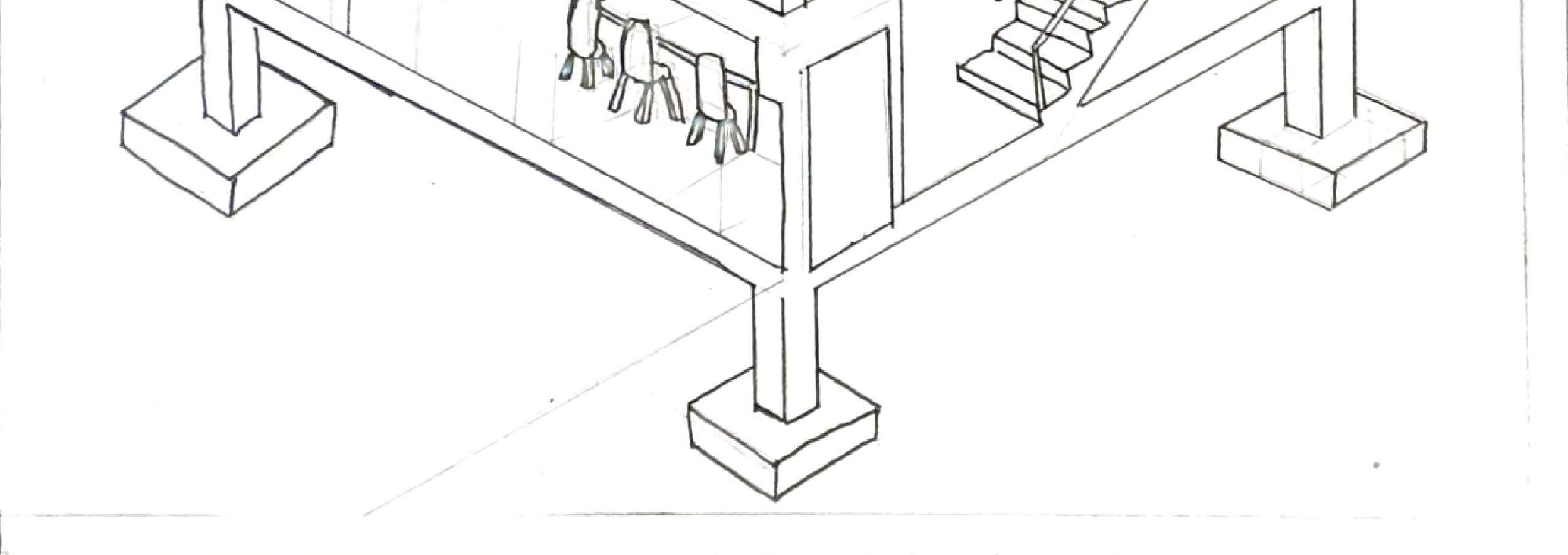

The atrium of the club house is composed of timber columns and roof with glass windows that create an open space.

The timber columns rise and curve to become a horizontal structure made up of hexagons.

Furthermore, the flexibility of the material is shown along with, the beauty of natural and organic materials. The structure is also fire resistant and is built in such a way that it allows skylight and ventilation through.

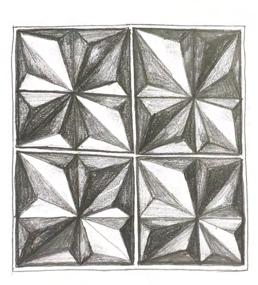

ANA SANCHEZ ARYA VAHIDIThe hexagon grid that forms the ceiling was inspired by the Korean traditional summertime pillow (aka bamboo wife). This feature of the building provides improved aesthetics whilst also serving as structural support from the columns.

ANA SANCHEZ

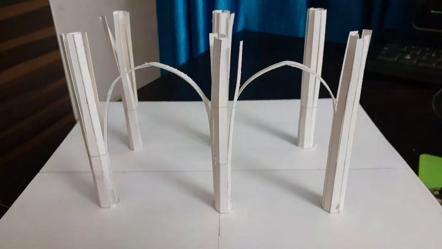

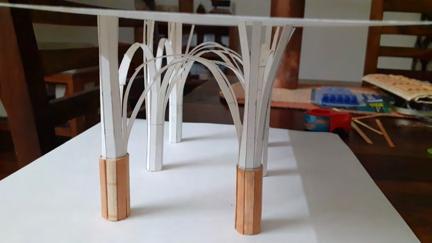

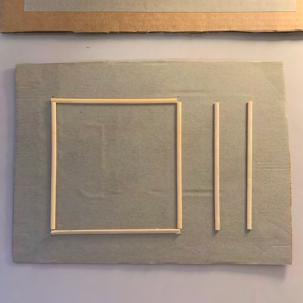

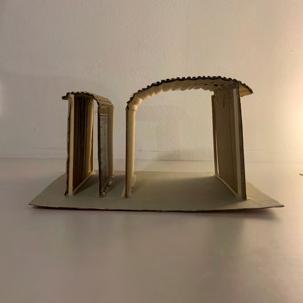

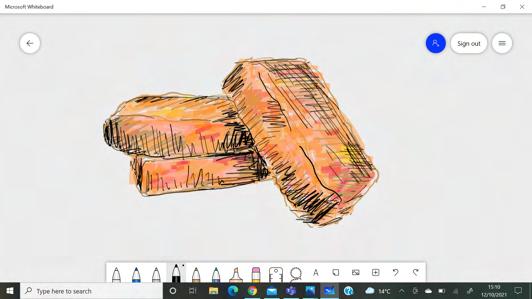

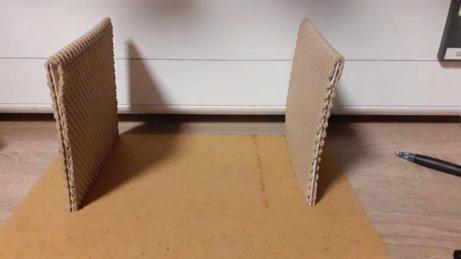

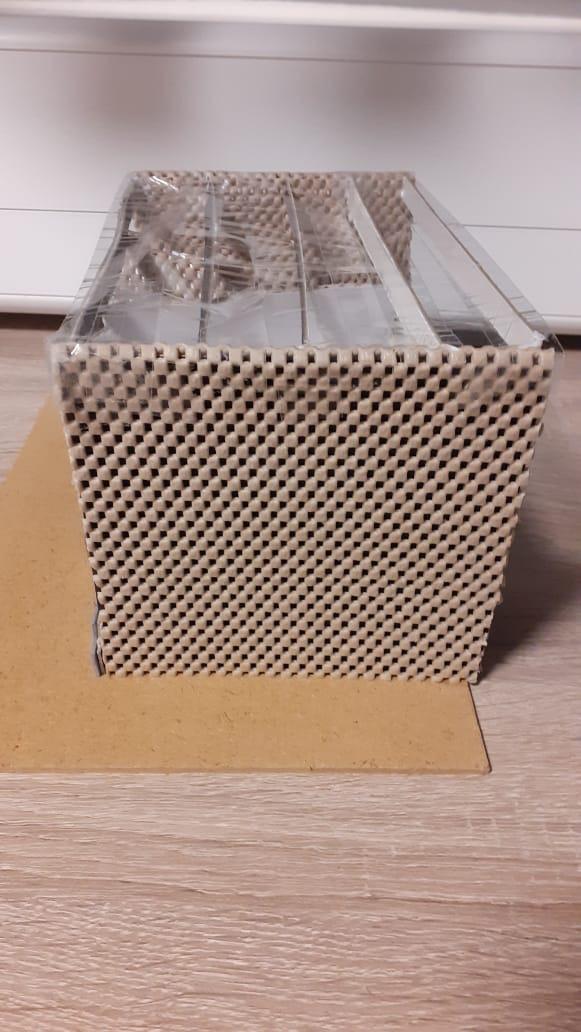

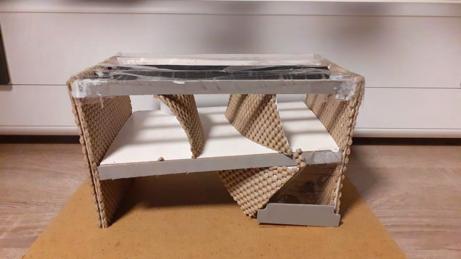

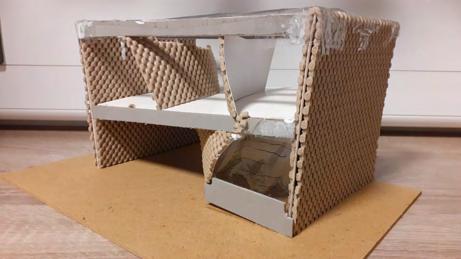

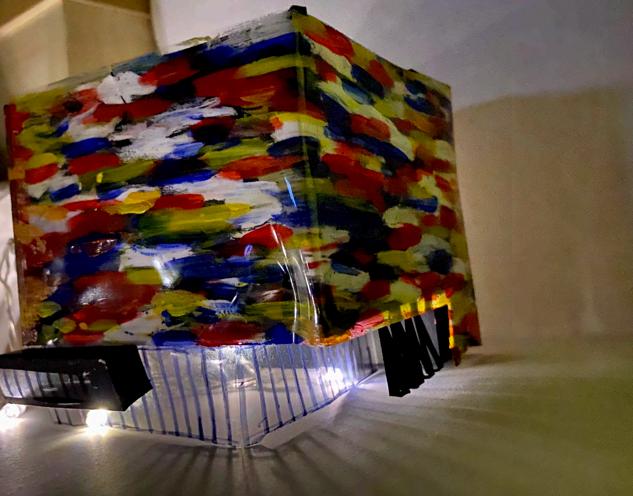

The model was started by using strips of paper to represent the key columns of the building. The strips were then separated at the top and connected to form the structure of the latticed roof. The columns were then stabilized with wood strips and a layer of paper, then clear plastic, was used to show the intricate pattern of the columns.

The change from paper to clear plastic was very useful as it really allowed the intricate pattern of the columns to stand out and specifically show the details of the structure.

MODEL AND PHOTOS FROM SOHAM

MODEL AND PHOTOS FROM SOHAM

Timeline:

1. Timber Framing History - A Timeline | Carpenter Oak. (2021) Carpenter Oak. [Online] [Accessed on 26 September 2021] https://carpenteroak.com/timber_framing_history_timeline/?gclid=CjwKCAjwwsmLBhACEiwANq-tXBLTXeQTfFD7FQhkxtDGPz6vbjW9hnwCqEZJC13qVwPHlyILYe2qRoCSJIQAvD_BwE.

2. Nanchan Temple Wikipedia. (2021) En.wikipedia.org. [Online] [Accessed on 26 September 2021] https://en.wikipedia.org/wiki/Nanchan_Temple.

3. The Hammer Beam Roof. (2021) Parliament.uk. [Online] [Accessed on 26 September 2021] https://www.parliament.uk/about/livingheritage/building/palace/westminsterhall/architecture/the hammer beam roof /.

4. Wernigerode Village, Germany Embark On An Adventurous Journey. (2021) Mynews28. [Online] [Accessed on 27 September 2021] https://mynews28.com/wernigerodevillage germany embark on an adventurous journey/.

5. Timber: The past, present and future | International Timber. (2021) International Timber. [Online] [Accessed on 27 September 2021] https://internationaltimber.com/resources/timber-the-past-present-and-future/.

6. 10 x examples of amazing wood facades Accoya Blog. (2021) Accoya. [Online] [Accessed on 27 September 2021] https://www.accoya.com/uk/10 x examples of amazing wood facades/.

Material:

1. BA1 Materials Lecture 1 In the Beginning, https://architizer.com/blog/practice/materials/softwood cladding/

Structure:

1. Haesley Nine Bridges Golf Club House. (2021) Worldarchitecture.org. [Online] [Accessed on 25 September 2021] https://worldarchitecture.org/architecture projects/fgng/haesley_nine_bridges_golf_club_house project pages.html.

2. lunga, n., lunga, n. and profile, V. (2021) Nine Bridges Country Club.. Myarchitecturalblog102.blogspot.com. [Online] [Accessed on 26 September 2021] http://myarchitecturalblog102.blogspot.com/2014/04/nine

1820 Stoddard, Pierre Berthier, and Faraday recognized in 1820 that iron chromium alloys could withstand some acids, but it was Clark and Woods who developed an acid resistant iron alloy that later became known as stainless steel.

1875 Brustlein documented the importance of low carbon content in making corrosion resistant steel.

Only 100 years ago, stainless steel was introduced to the world of materials science. This may be hard to believe due to the material’s ubiquitous nature as it is almost in every aspect of modern life. This goes to show what an important breakthrough stainless steel was.

Additionally, it has outperformed more traditional competing materials like copper, aluminium, and carbon steel.

1911 Philip Monnartz of Germany published the first detailed work on the topic of corrosion resistance of stainless steel.

stainless steel with a combination of 21% chromium and 7% nickel. Often used in high or low temperatures, Austenitic steel has a higher chromium content than ferritic (also known as "Martensitic").

1912 Additionally, this same year in Sheffield, while seeking a corrosion resistant alloy during his work at the Brown Firth research laboratory, Brearley discovered a martensitic stainless steel alloy.

Ana Sanchez Ana Sanchez1915 Brearley achieved the patent for this, along with Elwood Haynes who had previously applied for a patent on martensitic stainless steel alloy.

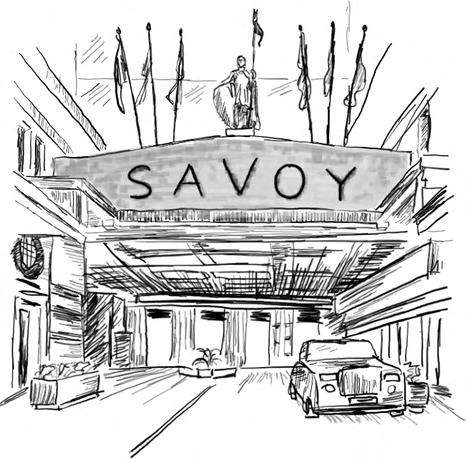

1929 One of the prominent uses of Stainless steel was the entrance canopy for the Savoy Hotel in London.

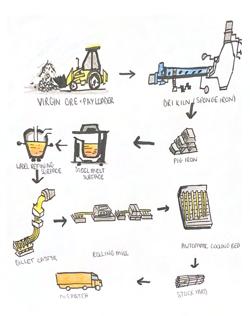

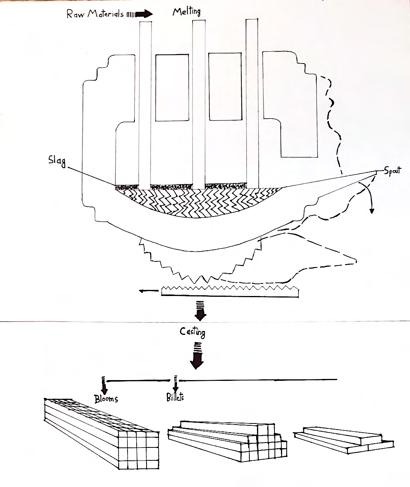

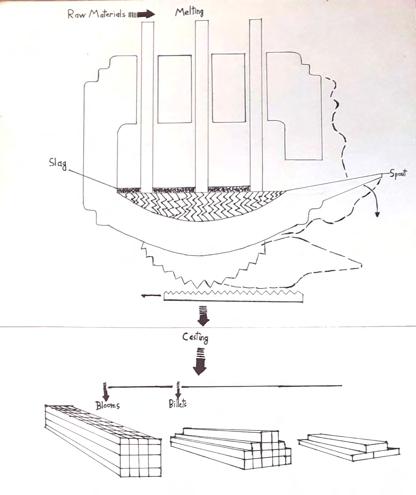

Steel is made by mixing carbon and iron at very high temperatures, as it's an alloy. Steelmaking is a process that creates steel from a product called “pig iron.” Pig iron is smelted iron, from an ore. Stainless steel is made by, using at least 10.5% of chromium, which makes the steel stainless. Stainless steel is by far one of the most widely used material in the construction industry today.

shiny finish +polish

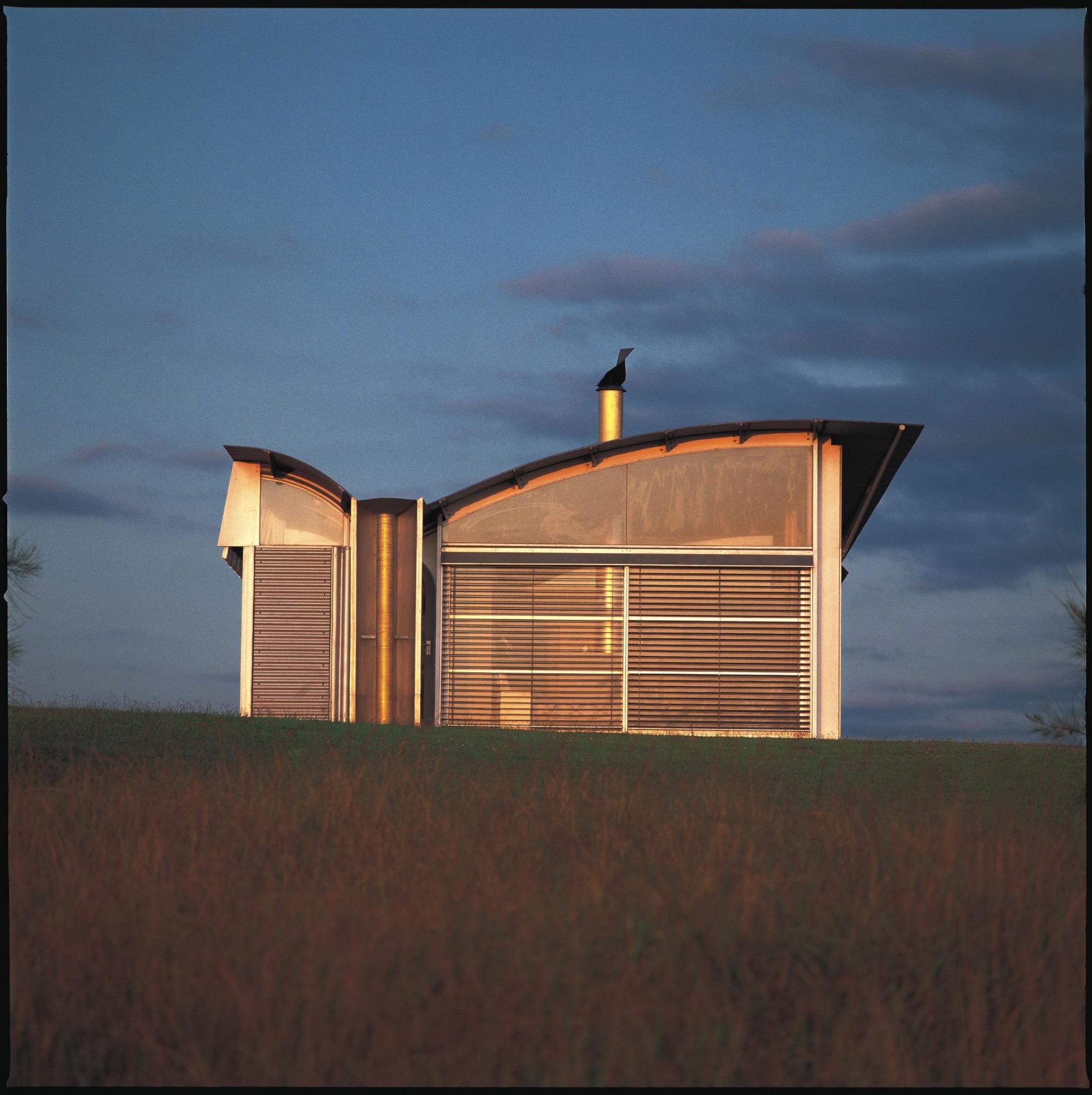

The material used for the Magney House, is best suited due to its response to the site and surrounding environment. The use of stainless steel makes is delightfully reflective when the sun hits the corrugated sheathing.

Steel melts around 2700°F

In the manufacturing process, stainless steel is melted and then it is molded into solid form. After various forming steps, the steel is heat treated, cleaned and polished to give it the desired shiny finish. Next, it is packaged and sent to manufacturers, who shape the steel to produce the desired shapes ready for construction.

• It's reusable and endlessly recyclable. Which makes it a very reliable material to adopt.

• Enables energy efficiency in buildings and construction projects.

• High tensile and compressive strength to weight ratio which means it can provide large spans, more space with smaller size sections.

• Light wight , requiring reduced foundations.

• Fast on site build for prefabricated buildings. This is perfect projects that have short time limit to construct buildings.

• Does not rust or corrode easily.

• Appearance. The appearance of steel without the use of cladding or false ceiling is considered to have a poor aesthetic appearance particularly in residential and office buildings.

• Susceptible to buckling.

• High cost especially when considered as initial expense.

• In need of high quality machines to handle the metal

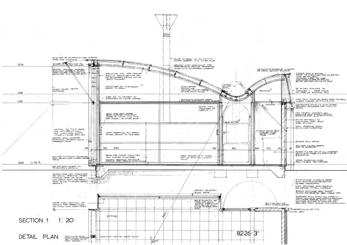

The structure was designed considering the position and the climate, in fact it protects from southern winds and is open to the north for the sun angles.

The roof is proportionally thin and has the shape of a V, this allows to collect

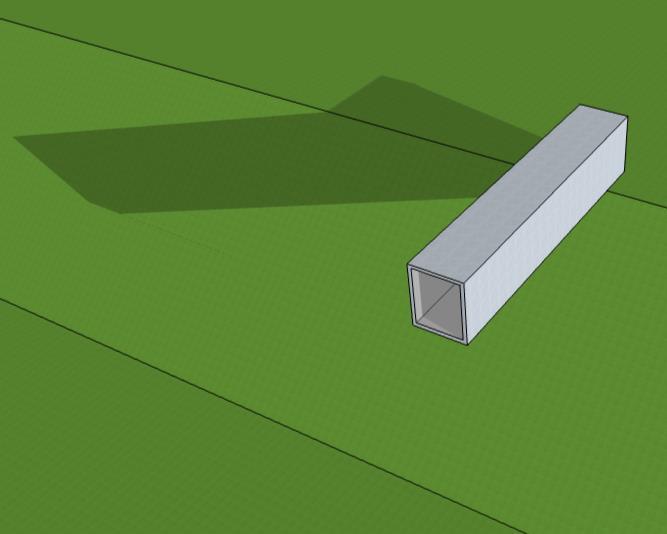

The structure of the house is light thanks to the tubular steel frame.

The owners' main use of land was camping, so they wanted a permanent structure that reflect the lightness of a tent.

The inside of the house is covered with single brick interior skin,

while on the outside corrugated aluminum was used. Between the brick wall and the aluminum part there is a 37cm cavity which has been filled with Insulwool insulation.

To control the temperature and light were used Louvered blinds at the window.

MELANY

Stainless steel is an iron alloy that contains iron and carbon. The raw material is melted together, this first step requires 8 to 12 hours of intense heat this will impact the environment negatively because of the carbon dioxide emissions

Hot worked stainless steel

Cold worked stainless steel

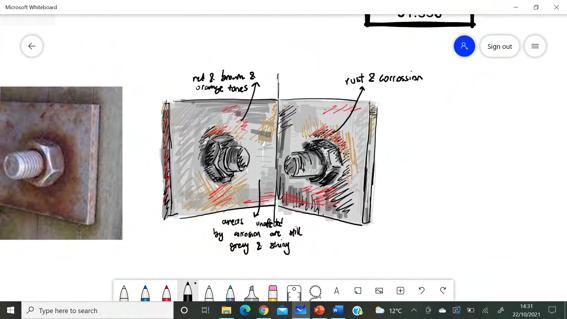

The diagrams show how the structure of stainless steel changes Depending on the process is used.

Stainless steel has low maintenance you only need the surface to be clean the rest does not need much maintenance .But to try to modify an existing building will not be efficient and will require a lot of work, it's also 100% recyclable but you will have to repeated the manufacturing process this is good as you will not have to worry about the material ever running out, but this is still not environmentally friendly.

Image from google

These are tools used to make modifications on stainless steel

The transport sector contributes to 27% greenhouse gasses released to the atmosphere; this sector is also the biggest producer of the greenhouse gases. This can be avoided or reduced by using manufactured material produced by your country that you are working on rather than imported material.

You can easily assemble your parts because you can weld two different parts together this process in not expensive and it is a suitable way to assemble your parts for the building together, but you will not be able to separate the parts once welded. Stainless steel can also be assembled by screwing bolts together this can be bad because in the future the harsh environment could make the bolt loose and this could be very damaging to the building structure and possibly even break

ARYA VAHIDI

ARYA VAHIDI

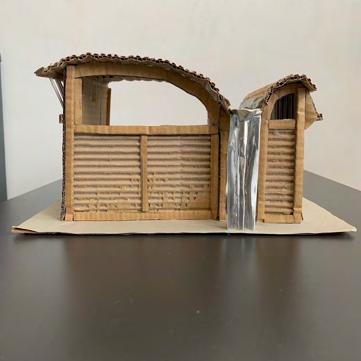

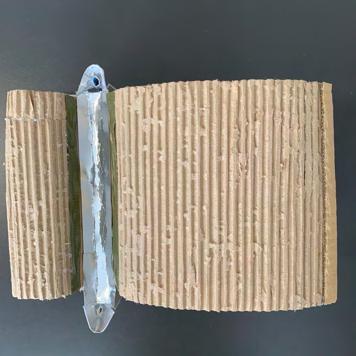

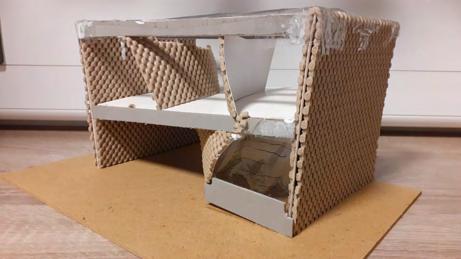

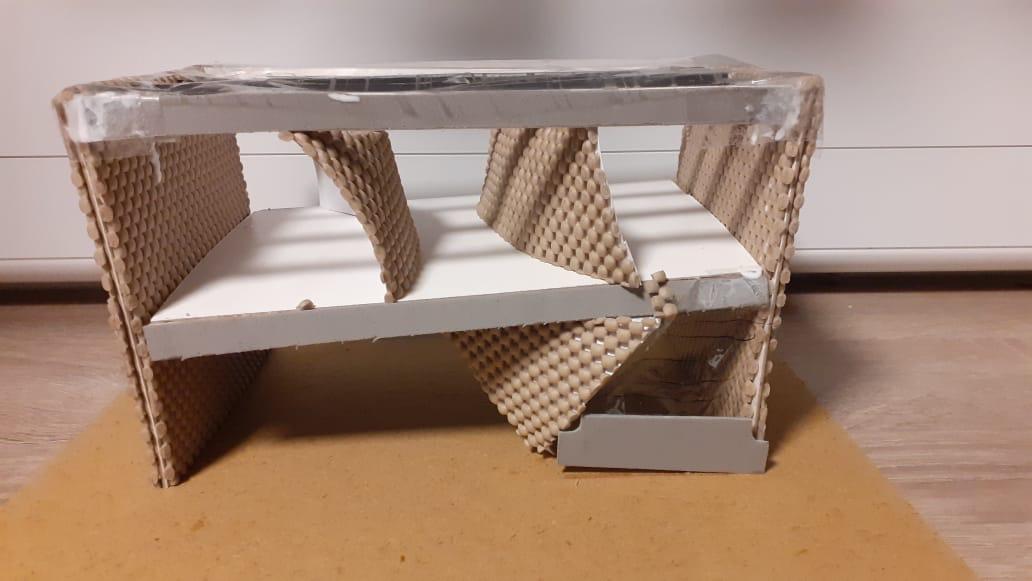

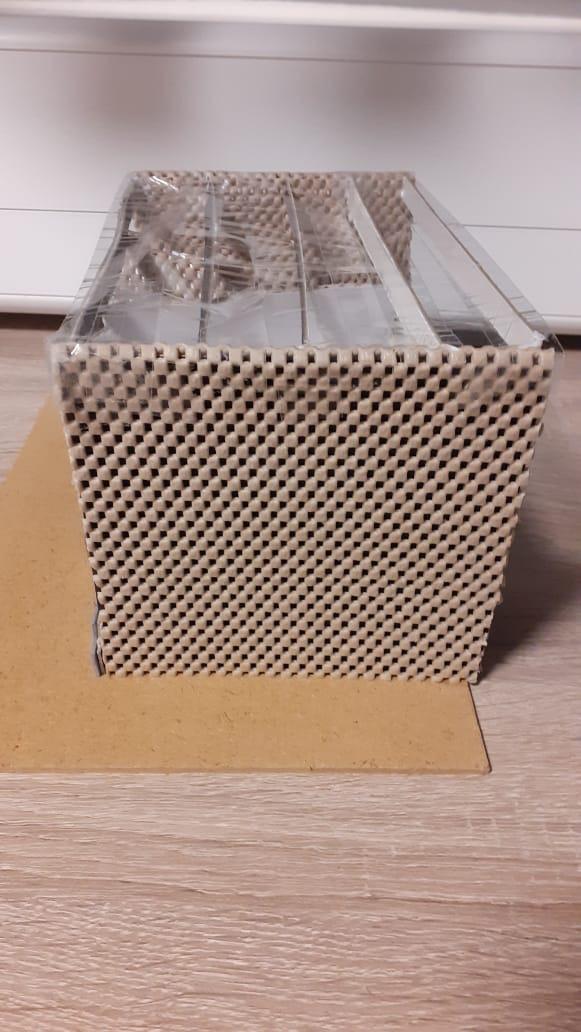

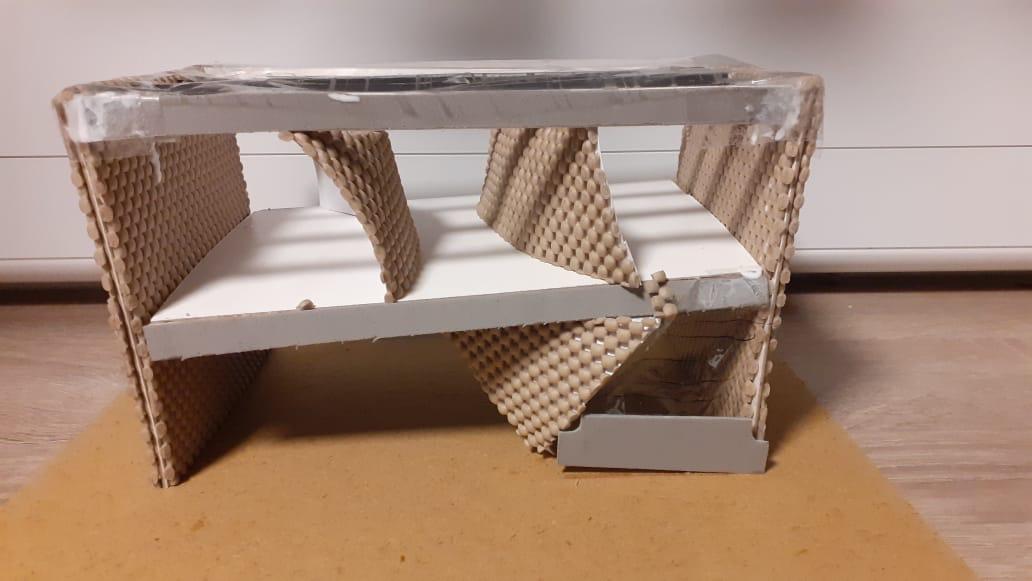

When I initially researched the structure of the Magney house, and its sustainability through the genius design of the roof, I wanted to explore this feature through my model. I used corrugated cardboard to represent the corrugated stainless steel and used card to show the buildings main irrigation system. This was the main feature I wanted to emphasize. The roof collects the Australian rainwater so it can be reused for drinking and heating, I wanted to show this through the shape of the roof and its texture, as shown in the aerial view photos. Steel tubing is also used as an internal frame which adds a lightness to the building and acts as a very light skeleton.

ARYA VAHIDI

ARYA VAHIDI

Ancient Egyptian bricks made of Clay mixed with Straw. Paintings on tomb walls of Thebes depicted Egyptian slaves tempering and making these bricks.

27BC – 395AD

The Romans preferred to make their bricks in spring, then they stored them for two years before selling or using them. They only used white or red clay to manufacture bricks.

Bricks were re-introduced to Northern Germany and Northern Italy with the brick gothic period with buildings mainly built from red clay bricks.

In the Renaissance and Baroque periods, exposed brick walls became less popular, brickwork was covered in plaster instead. In the mid 18th century brick walls started to regain their popularity.

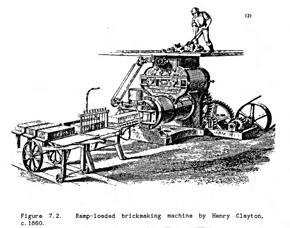

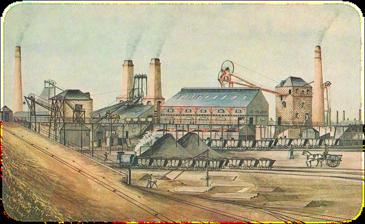

During the industrial revolution, brickmaking machinery broke out, by 1925 one machine made 12,000 bricks a day. Because of this brick structures could be made quicker and cheaper. During this time when more than 10 million bricks were made annually.

Many American Cities like New York favored locally made bricks. In Victorian London, Red bricks were also very popular as it was visible in the heavy fog.

Invention of fired brick, made from the heat of the sun and became popular in cooler climates.

These advances show the first signs of how climate and environment impacted materials and therefore design.

When the Roman Empire fell in 395AD, the art of brickmaking almost vanished but remained in Italy and the Byzantine Empire, where they used it for its figurative qualities. century, brickmaking spread from these regions to France.

Brick Gothic was replaced by Brick Renaissance architecture

This shift was huge as bricks became a symbol of material wealth within architecture.

Bricks were made by hand. Handmade brick production ranged to 36,000 bricks per

Used by famous architects such as Le Corbusier, F. L. Wright and Louis Khan. Today brick is still a very common material, mainly used in domestic construction.

Sanchez

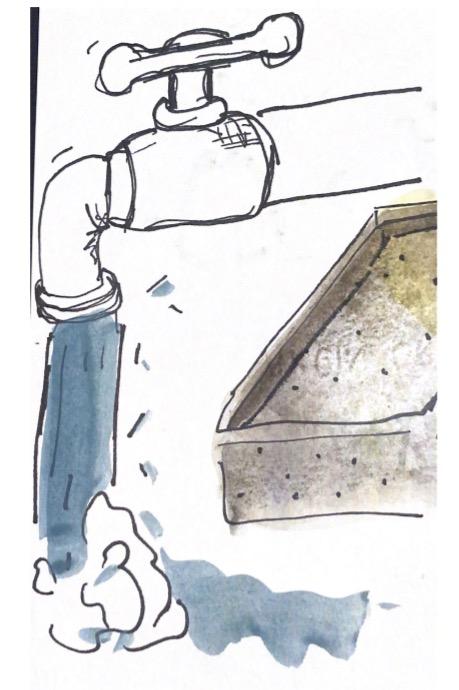

Manufacturing: the clay is mixed with water by a pugmill, the mixture is then poured into a mold and then dried. the bricks are then fired at 300-400 degrees F.

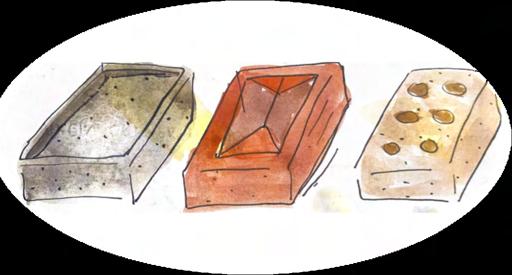

Brick is a product used since ancient times to work in construction. It usually has the shape of a parallelepiped, with well defined dimensions.

There are different types of bricks, and these can have different functions in construction.

Common bricks: this type of bricks are used for various purposes in construction such as columns, walls, foundations, etc.

Firebricks: they have a high resistance to fire and heat for this reason they are used for fireplaces, building brick grills or making fire pits

Hollow bricks: this type of bricks are very light, 1/3 of a common brick, in addition they reduce the transmission of heat, sound and humidity.

Sun dried bricks: used since 7000BC in Turkey, these bricks are not very strong and are mainly used in temporary structures

.

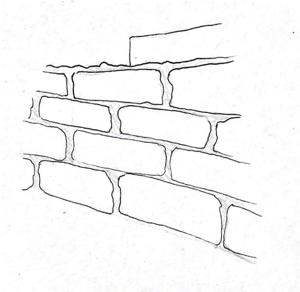

Construction/Assembly: components needed for brick wall construction are labor, scaffolding, mortar mixing machines, and hand trowels.

Maintenance/Repair: high maintenance is not needed for decades if there are no noticeable cracks.

Engineering brick: are mainly used for basements due to their properties such as compressive strength, low porosity and resistance to chemical and water damage.

Perforated Brick: thanks to the holes, less clay is needed for the preparation of these bricks. They are mostly perforated in the panel of lightweight structures and multi-Storey framed structures.

Fly ash Bricks: Properties of this type of brick are strength and durable, also they are made by reusing toxic metal byproducts in coal-fired power plants, this helps reduce toxic waste.

Concrete bricks: this type of brick can save costs and time as it can be produced by professional manson at the construction site. it is used for facades, internal walls and external walls.

- Strength: bricks can have a compressive strength of 9N/mm² for a twostory building, for taller buildings it can reach 13 N/mm² .

End of Life/Disposal: bricks last for years and can either be recycled as bricks or are downcycle to aggregate.

- Durability: bricks have a durability that can last hundreds of years if they are properly manufactured.

- Absorption: bricks can absorb water. Ordinary building bricks do not have an absorption of more than 25%.

- Fire resistance: the temperatures at which the bricks are fired are greater than the fires that can occur in a building, which means that the bricks have a resistance to fires.

- Time consuming construction

- Cannot be used in high seismic zones

- because it absorbs water easily, it causes fluorescence when not exposed to air.

- Rough surfaces of bricks may cause mold growth if not properly cleaned.

MELANY

Brick kilns in Trivandrum is a dying industry with people opting out for wire-cut machinemade bricks, this was also an attempt to promote this local agriculture-based industry that is on the brink of extinction.

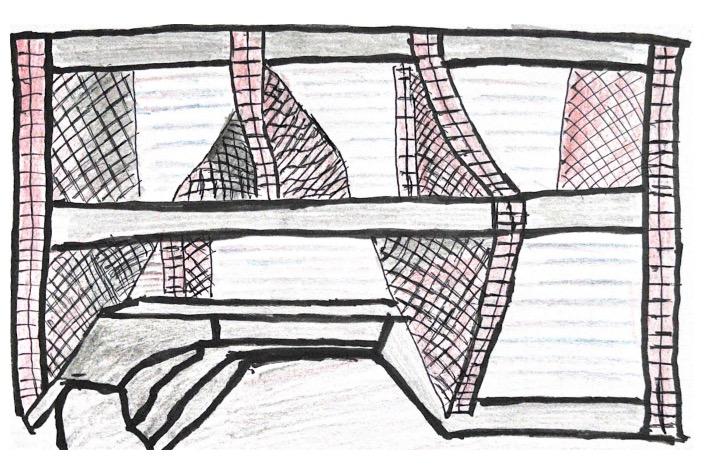

The structured used to lay out the bricks is known as the ‘rat trap bond’ technique in which bricks are laid with a rotated vertical orientation, creating a cavity within the wall that increases thermal efficiency and cuts down on the total volume of bricks used.

The house is aligned in the East-West direction with openings facilitating for maximum cross-ventilation. This is very important as this is carefully considered by the architect to decrese the tempricure becouse india has an avrage temprature of 25 degrees Celsius

They fire clay bricks to over 1000C which is energy -intensive. This can be seen as quite negative for the environment as it's using high volumes of energy.

• Not affected by temperature changes.

• Bricks can store heat from the sun well.

• Brick is a maintenance-friendly product ,the impact of construction on the environment is much smaller.

• 100% recyclable.

Switching from higher CO2 emitting fuels (like coal) to natural gas and other lowcarbon fuels like hydrogen and electric-firing aids as it reduces levels of CO2 emissions.

When it's time to knock down brickwork as it reaches the end of its life, it can be crushed or recycled on site – and old lime mortar bricks can be cleaned up and re-used.

Water is needed in the brick manufacturing process to help shape bricks before they are dried and fired. There has been recent changes to water abstraction regulations to reduce reliance on potable mains water to maximize efficiency of water use where it is required. This ensures a more environmentally friendly approach to the manufacturing of brick. Carbon emissions released due to transport can be reduced. This can be avoided or reduced by using manufactured material produced by your home country or using material that is more prevalent in the country you are going to build your structure/building

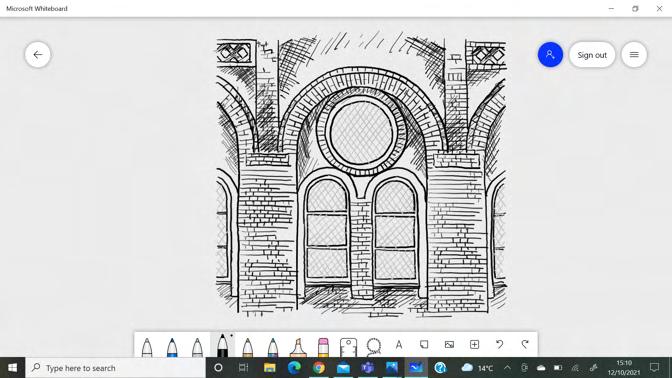

We wanted to focus on the exterior structure of the building as there isn’t a clear differentiation between the indoor and outdoor spaces, which is what we found the most interesting about the building. We used textured card to show the intricate brickwork pattern that wraps and warps itself throughout the building. It was this feature which stood out the most to us and we believe the model showcases that.

SOHAM SENGUPTA

SOHAM SENGUPTA

GROUP 17E: PATIENCE BAFFOUR ATA, MELANY FARRAIUOLO, ANA SANCHEZ DE MIGUEL, SOHAM SENGUPTA, ARYA VAHIDI & HASSAN UL HAQ

Archaeologists have found evidence of first uses of glass that dates to 4000 BC . This took the form of glazes used for coating stone beads.

The library of the Assyrian king Ashurbanipal contains the first recorded recipe for making glass: "Take 60 parts sand, 180 parts ash from sea plants and five parts chalk." This formula dates to the year 658 BC.

In the 7th century the romans were renowned for their skills across Europe after the fall of the empire UK began glass industry's.

In the 12th century they discovered the principle of crown glass that brought light into the castles and cathedrals of the Gothic period. The glass blowers pressed gobs of glass into flat discs and used lead to join their central parts to form bigger areas.

Around 1500 BC, the Egyptians produced the first hollow glass containers, which they used for ointments and

oils. These containers can be seen in the State Collection of Egyptian Art in Munich.

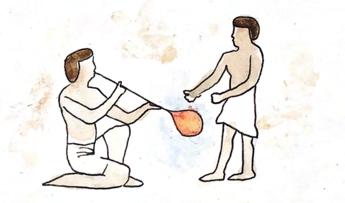

100 BC, the glassmaker invented the blowpipe.

And this is a tube about 1.2 to 1.6 m long, with a mouthpiece at one end. With the other end, the glassblower picks up the gob of molten glass, turns and rolls the once the glass starts to cool the glassmaker will blow air into it.

From the 11th century. Venice became the center of glassmaking in the Western world.

The glassmakers there they began the use of pure crystal glass, and they developed the elegant Renaissance glass style within the Venetian glassmaking tradition.

In the French town of Saint Gobain that glassmakers first poured molten glass on to a table and rolled out the molten mass until it was the same thickness all over. This was ideal for making mirrors

In the 1903 the American Michael J. Owens invented the fully automatic bottle blowing machine, a masterpiece of engineering. It used the suck and blow process and 2,500 bottles an hour could be produced using this miracle machine.

In 1925, the engineers Ingle and Smith invented IS machine. This produces hollow glass using the blow and blow technique, a production method that is still used to this day. A gob is pre blown in a metal mold, then the pre shaped gob is delivered into a second mold where blowing is completed.

In 1867, Friedrich Siemens introduced a new method to make the process of smelting glass faster continuous basin furnace. These tank furnaces still consist today of a melting end and a working end and are operated day and night without interruption. It was a milestone in the mechanical production of glass containers.

In these times we primarily the use electronically controlled machines this made the process much more efficient. This process allowed for making lightweight glass help protect the environment because it is used in communications technology, architecture and solar systems.

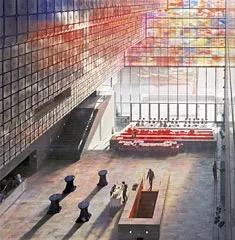

Glass plays a huge role in the making and outcome of the building. The main façade of the Netherlands Institute for Sound and Vision is how the building is wrapped in an envelope of glass, each depicting a relief of Original TV- images taken from the archives of the institute and translated into 2100 different coloured high relief glass panels, composed by graphic designer Jaap Drupsteen.

As a material, Glass is rigid and is an amorphous, non crystalline solid. It is usually transparent and has been used globally for its many decorative, practical and technological uses.

Jaap Drupsteen’s designs were imprinted onto the glass through a technique called Glass Slumping. Traditionally this is done by heating up the glass and using gravity to let it melt into a mold shape.

The typical process of forming glass is by heating a mixture of dry materials to a viscous state then cooling them quickly to stop a regular crystalline structure from forming. As it cools the structure of glass is neither a liquid or solid, as the colder it gets, the atoms become locked in a disordered state before forming the perfect crystal arrangement of a solid.

The Colored Glass dissipated the light beautifully and paired with the slumped glass pattern it creates a very tactile surface.

Depending on the time of day, the light reveals and conceals the different reliefs making them appear and disappear throughout the day.

ARYA VAHIDI ARYA VAHIDI ARYA VAHIDIGlass is a sustainable, fully recyclable material that provides many environmental benefits, including reducing the effects of climate change and the conservation of precious natural resources.

Glass is endlessly recyclable as it can be reused repeatedly. This is because today's waste glass can be melted down, reshaped, and repurposed as new products for tomorrow.

Nevertheless, different types of glass are recycled differently and not all of them are as easily recyclable. Hence, recycling coloured glass is not as simple as one might think.

Nowadays most glass formulas use recycled content in place of other raw materials meaning that not all colours of glass can be recycled together, especially because mixing hues reduces the quality of the recycled finished product and therefore, the ability to sell the glass in the future.

Ø Regardless, the fact that almost all glass formulas include recycled glass is very economically efficient and saves resources. But this technique only works if the recycled glass is recycled by colour, reflectivity and other important characteristics.

All of this leads us to question the extent to which this building's choice of materials are the most sustainable.

• Firstly, using glass is a way to reduce energy cost as glass provides natural light into buildings which is a great sustainability advantage.

• Additionally, glass buildings are also proven to contribute to people's well being and improve health conditions, whilst also enhancing the working and living environment this is another sustainability advantage since sustainability refers to a balance between the environment, the people and the economy.

In that sense, glass as a chosen building material is a great and sustainable choice. However, as we discussed earlier, the fact that the glass used in this building is coloured glass, more specifically, slump glass, it makes it a less sustainable option since it's harder to recycle properly and efficiently.

ANA SANCHEZThe Netherlands Institute has many different functions, therefore many different spaces, so structure had to be considered.

The Building is not only an accommodation for a large, safe and professional archive, but also a public information center, a service institution for professionals and a museum that holds a huge audience.

Neutelings Riedijk makes this clear in his work as each space fits its function very visibly. All users of the building enter in the same entrance. They then all enter the atrium of the building which connects to all the different areas of the building: the depots, the museum and the offices. The one thing that connects all these spaces together is the immense amount of light that flows through the entire building.

ANA SANCHEZTogether with glass company Saint Gobain and TNO, graphic designer Jaap Drupsteen created the coverings for the four glass facades. The interiors of the building are visible from the outside. For the outer walls, Drupsteen abstracted 768 images from the Sound and Vision collection in order to keep them from becoming too anecdotal. Each one of the 2244 glass panels has a distinctive relief and color pattern. The purpose of these glass panels is to form a kind of ‘second skin’ around the building. Additionally, the panels can also be rotated to enable them being cleaned. On the office side there are completely transparent glass panels between the colored panels; this way, the employees are provided with sufficient daylight in their offices.

When making the model, I wanted to emphasize the colours used in the unique glass façade of the institute. To do this I used strokes of acrylic paint on acetate, resulting in the blurred and dynamic effect. The concept behind the low visibility of the images embedded in the glass façade, implies the daily bombardment of the media, however in this building they're frozen in time ironic manner. Which is why I decided not to depict these images in my model, but if I could change one thing, it would be incorporating these subtle relief images to showcase this concept.

During my research I found this interesting statement on the Flow Journal that influenced my model making too. "The designers, meanwhile, hoped that the façade, viewed from a distance, would have “the aura of a flickering TV set in a typical Dutch living room." I definitely think the designers achieved their hopes in the structure and the colours of the façade. I 'm really fond of the TV like structure (box) , I believe it excellently delivers the concept of a 'flickering TV' and helps me as an individual to incorporate my surrounding environments in my future projects.

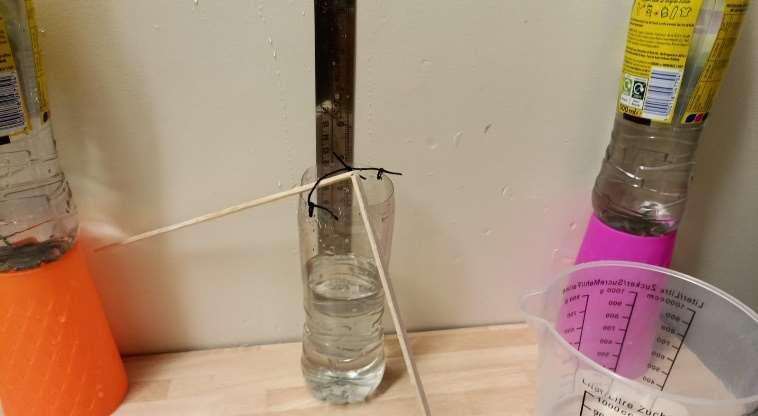

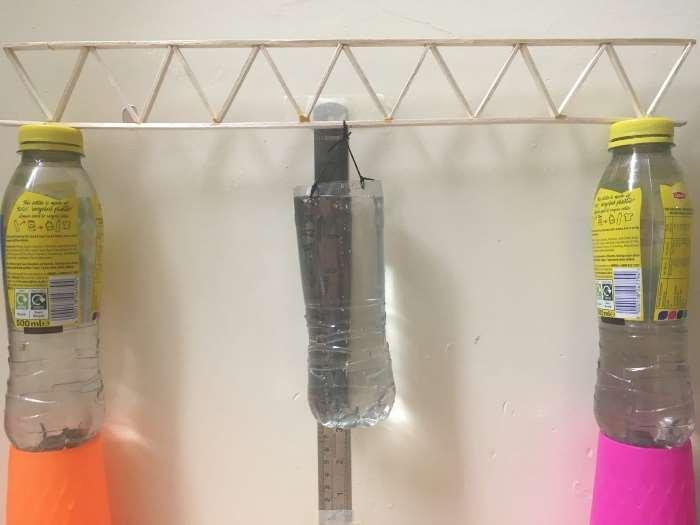

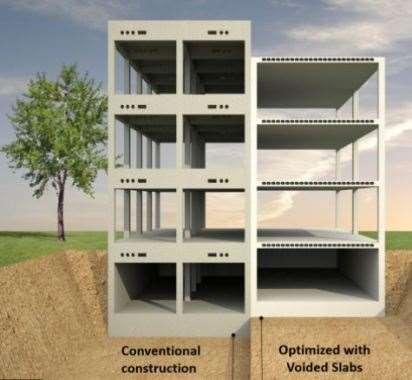

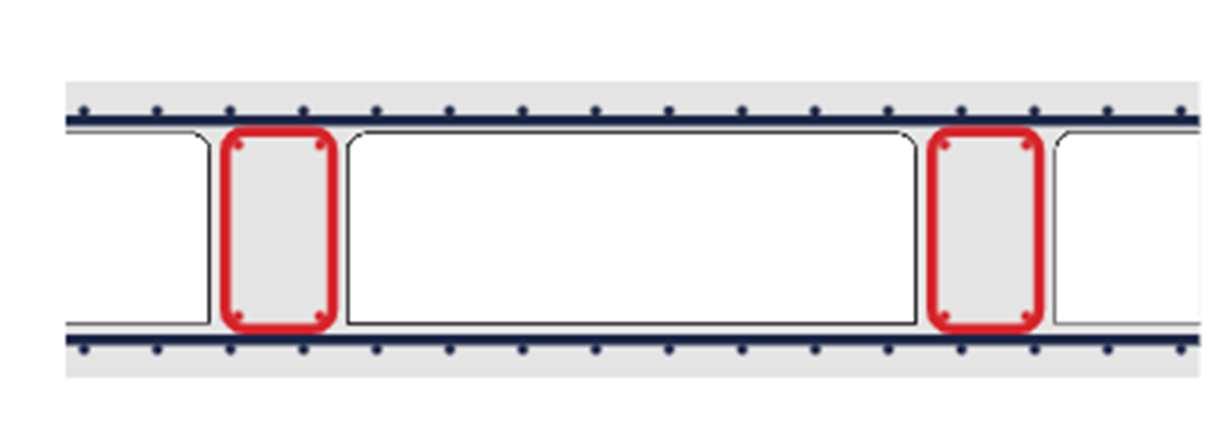

Avoidedconcreteslabisasystemthatremovesthenon-workingorexcess concretefromthestructuralslabandreplacesitwithvoidformers.Oneof themaindisadvantagesofconventionalsolidslabsistheirweightwhichnot onlyimposesastrainonitselfbutalsoputsahugeburdenonthebuilding andthefoundation.Thevoidscreatedwithinasolidslabsystemhelpto reducetheoverallweightoftheslabsystem.Thevoidedslabsystem providesahugeopportunitytoreducethecostandenvironmentalimpact withoutcompromisingtheperformanceofthestructure.Unnecessary concreteisremovedtomakevoidedslabs,thisreducestheweightofthe slabandimprovesthestructuralcapacityandspanlengthoftheslab.

Steelmesh

Thevoidedslabsystemincorporatesanarrayofvoidsthatcontainair,these voidsmadeupofplasticandotherrecycledmaterialsfromtheslab.Asteel meshiscommonlyusedtocreatetheframeworkuponwhichConcreteis pouredduringcasting.Thisarrangementcreatesanarrayofhollowcubesin theslab.Thishelpsitprovidesupportbybeingabletotransferloadvertically andhorizontally.Thisiswhyitiscalledabiaxialslab.

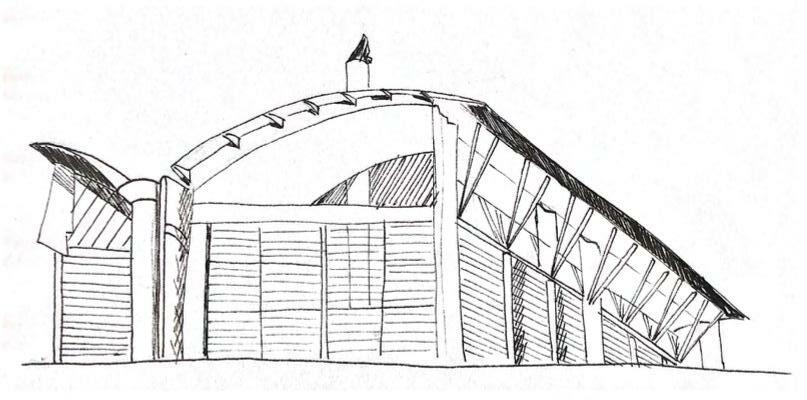

Architects:KSPEngelGmbH

Location:Klingenberg,Germany

YearofCompletion:2021

Purpose:InnovationCenterfortheWIKAcompany.

TheWIKAInnovationCenterwasaprojecttakenbyKSPEngel Architectstobringthreefields;production,developmentand progressintolineforWIKA.Eachofthesefieldshaditsown requirementsandstandards.Tocombatthisissuethearchitects usedgreatopennessandtransparencybetweenthedifferent workingareas,thusconnectingallthreeusages.

Thebuilding,constructedwithCobiaxtechnology,createsgreat opennessandtransparencybetweentherespectiveworkareas.

Thebuildingusesclearstructures,meetingpointsandlinesofvision betweenthedepartmentsandviewsoutoverthebeautiful countryside.Thecomb-shapedfootprintaffordsviewsoutoverthe vineyardsandthusforgesattractivelinksbetweennature, architecture,andtechnology.Thebuildingintegratesall departmentsinvolvedinproductionandsolutionsincludinglabs andmachinery.Flexibleofficestructuressupporttheconceptof keepingeverythingcloseandensuringeffectivecommunication. Theentranceareaisafoyer,assemblyhall,andexhibitionspace rolledintoone.Themarketplacefunctionsasapresentationand eventarea,offeringplentyofspaceforinteraction,forstaff meetings,andevents.Italsoshowsthecompany’sdevelopment efforts.

•Weightreductionofslabsisachievedbythevoided slabsystem.Thiswouldhelptoachievelongerspans, lighterfoundations,andsmallercolumns.

•Thissystemsimplifiesformworkbytheeliminationof thebeamsandrelatedlabour.Thishencesavestime andbringsapositiveimpacttotheprojectschedules.

•Saferincaseofanearthquakelessseismicforcesacting onthebuildingduetoitslightweight.

•Avoidedslabsystemreducestheamountofconcrete andsteelreinforcementconsumedbythebuilding.This systembringssavingsintheformofmaterialsand costs.

•Maximumconservationofresources.

•Thevoidedslabsystemprovidesdesignfreedomin buildingconstruction.Ithelpstoprovideanopenfloor platewithlessernumbersofcolumnsandbeams.The systemhencepreparesthebuildingtoadapttofuture changes.

•Easytoassembleon-sitebyattachingfullyfinished parts.

•Thinnerceilingsandwalls.

•Higherprofitability.

•Significantlyincreasedusability.

•Easyhandling.

•Reductionofdeliverytraffic.

•Safeconstruction.

•Availabilityislowasonlyafewcompaniesmanufactureit.

•Itisnotsuitableforasmallbuilding.

•Itcanbeexpensiveasonlyahandfulofmanufacturersproduce itandcanchargeapremium.

•Requiresconcreteforconstructionwhichstopsitfrommoving towardsconstructionfullyoutoftimber.

•Notsuitableforlongcantilevers.

Cobiaxhascontinuedtooptimizetheshapeofthe structuralelementstocomeclosetothestatically idealconcreteshapebetweenthemodules. TheX-shapedconcretestructuregivestheCobiax hollowcoreslabstheiruniquestabilityandtherefore safety.Nootherhollowelementsarethisstrongand secure,theyallneedadditionalreinforcement.

CobiaxresearchedanddevelopedtheidealX-zone. Todothis,theyturnedawayfromrectangularhollow bodiesanddevelopedasphericalorellipsoidal hollowbodythatformedaconcretestructurestrong enoughwithoutanyreinforcements.

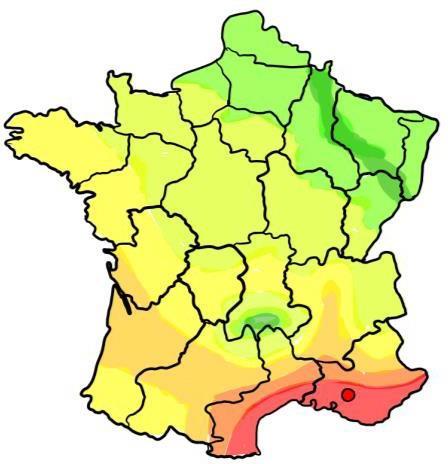

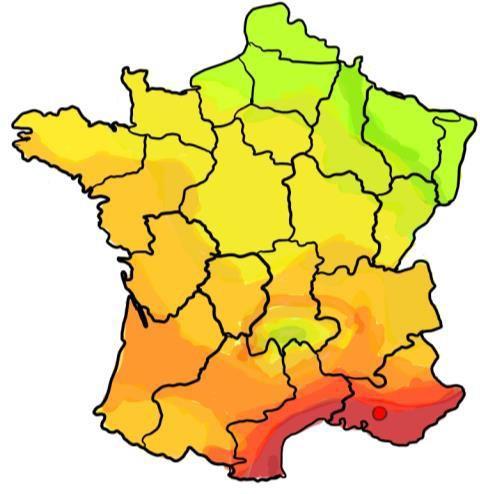

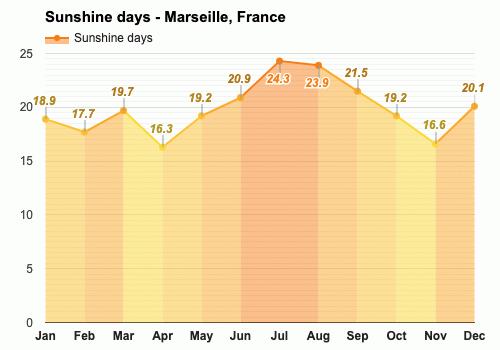

Marseille located in the southern part is in the hottest part of the country. The city is the hottest in July with a peak temperature of 28ᵒC and the coldest is January with the lowest temperature of 2ᵒC.

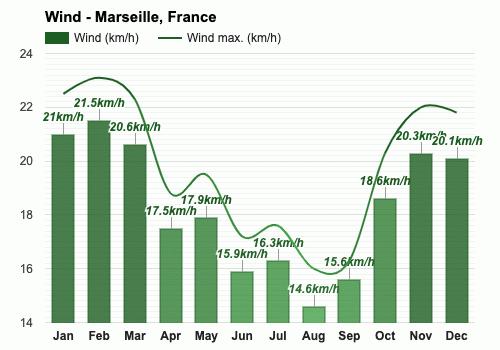

Wind February is the windiest month with average

speeds of 21.5Km/h, meanwhile August is the least with only 14.6Km/h

speeds

November receives the highest precipitation with an average of 108mm of rainfall, whereas, July is the driest with only 25mm of precipitation on average

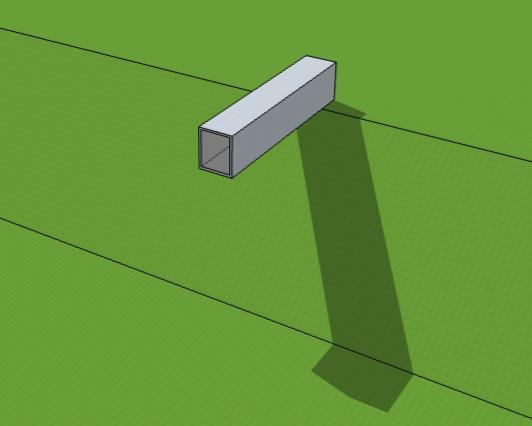

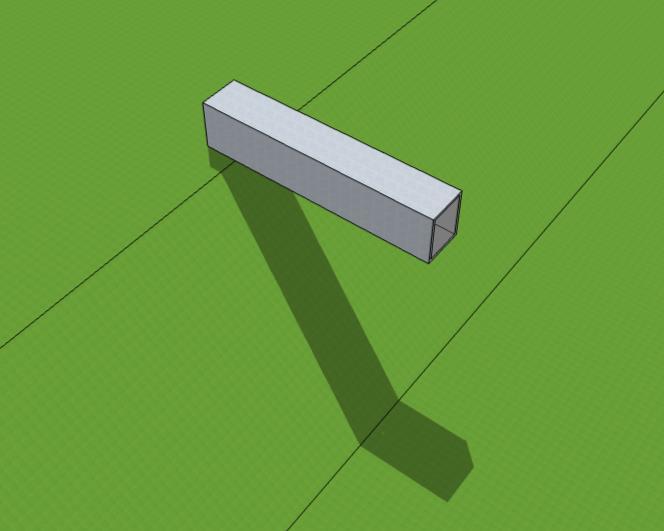

The 3D render on the left shows how the 27m long cantilevered gallery the interesting shadows the building makes throughout the day. The shadow starts in the west, is directly under the building around 12:00 PM and moves to the east in the evening.

July receives the most sunshine with 24.3 days. Meanwhile, April has the least sunshine with only 16.3 days. The Gallery’s glass façade faces the sun path and illuminates the gallery at different angles.

The gallery’s main purpose is to provide stunning views of the beautiful French countryside.

It consists of no furniture, no seating, no activities and no display. The gallery sticks to its purpose and provides these beautiful views by hanging 27m of the terrain as a cantilever and has complete glass exteriors on both sides so that light can pass through unobstructed and provide the view not only from the inside but also the outside. The view of the countryside through the gallery in perspective see from outside the entrance through the main door draws more interest and draws you in to have a better look.

The gallery could also function as an art display, a restaurant, a minor exhibition hall, etc.

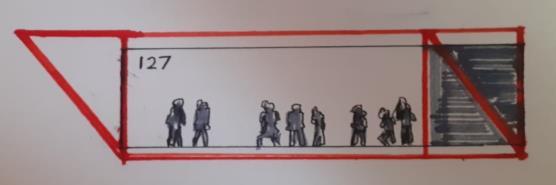

Area=

If each person takes up 10sft or 1m ^2 then the gallery can accommodate 127 people.

Light plays a crucial role in the gallery. The architect has played with the light in his design.

During the day the gallery faces the sun’s path and natural light enters the gallery at different angles at different times of the day and illuminates the gallery in spectacular fashion. This also saves energy.

At night artificial lighting is used to illuminate the hall. This creates a mysterious effect as the interior walls being smooth reflect the light and shine up the hall. The glass at the end shows the contrast to the bright uniform white walls and pulls you in appearing as a cave or a water body for you to seek more into the dark and mysterious.

View of countryside seen from outside the entrance of the gallery.

The 27m long cantilevered gallery gives users the feeling as if they are floating. The minimum contact with the ground enhances this feeling.

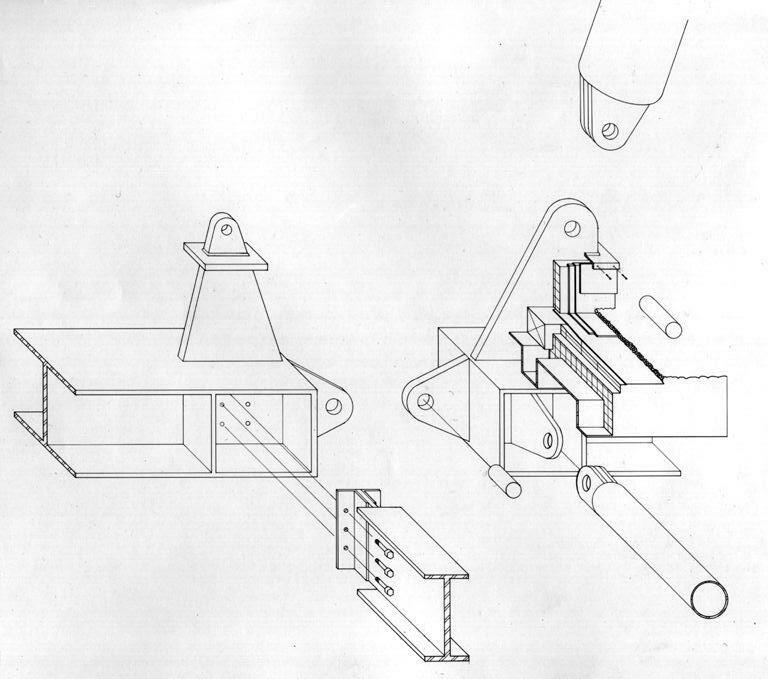

The load gets greater as the distance from the two connecting points increases.

The tension In the metal wires holds the entire structure in place. The tension varies with the load primarily the number of people inside.

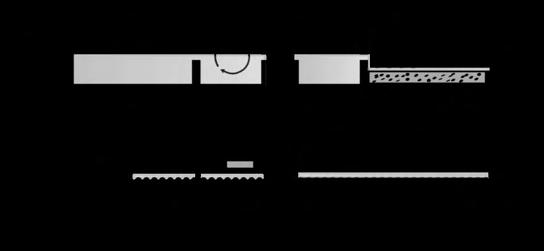

This hand drawn diagram shows the different forces the structure experiences.

All the load of the structure is taken by the four points which are connected to the earth. The forces and loads are transferred to these two points via the beams and other structural support.

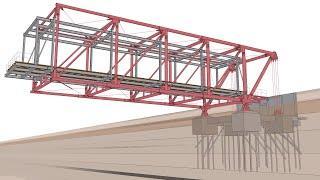

This steel structure was fabricated by Bysteel as a lightweight kit of parts that could be transported to the site and assembled by hand.

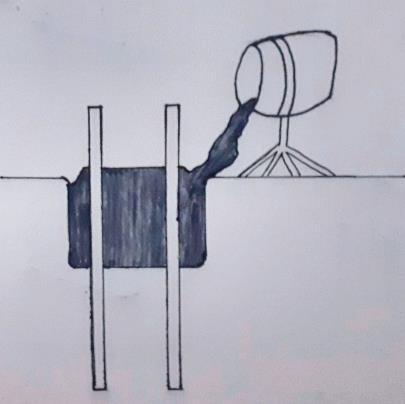

The first step is laying the foundation under the ground as this will bear the entire load of the gallery and keep it in place. Steel rods were buried at 4 points making 4 main connections to the ground.

Concrete was then poured to hold everything together.

The prefabricated steel frame and supports by Bysteel are assembled on site and fixed in position.

The prefabricated kit which can easily be assembled in the site reduces cost and time drastically as the site is a hilly, remote area where carrying heavy equipment is difficult.

The final step involves finishing up the interior such as interior walls, ceiling and windows. Lighting is also an important part of the finishing touch.

After the main structural element, the frame has been put in place, work begins on the internal walls, floor and ceiling.

Completed Gallery

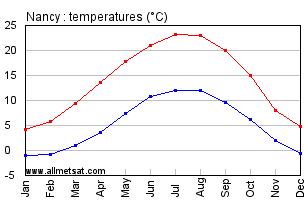

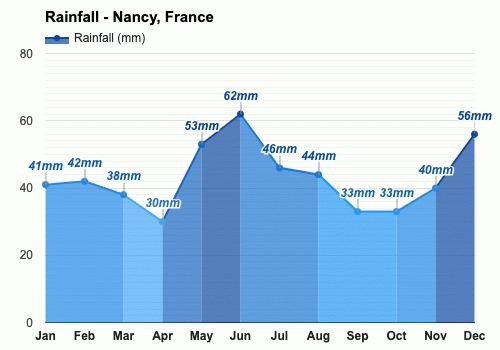

Nancy Lorraine is located in northeastern France. The climate of Nancy is semi-continental characterized by cold and grey winters, which are often accompanied by snowfalls, there are also warm summers with a few thunderstorms.

The city’s elevation is 200m(650ft) above sea level, in the north east of France is the coldest region of France in winter.

The average temperature of the coldest month, January is 2.7 °C, and that of the warmest month, July is 20 °C.

July receives the most daily hours of sunshine with an average of 10.8 hours of sunshine.

January has the fewest daily hours of sunshine in Nancy with an average of 2.86 hours of sunshine a day.

December is the wettest month list with 80mm of rainfall.

April is the driest month with 48mm of precipitation.

The best time to visit Nancy runs from mid May to mid September, since it is the warmest and sunniest period of the year. Sometimes, it can get hot in July and August, while in other circumstances, nights can be cool or even a little cold even in these months. The weather is pleasant with an average high of 24°C and an average low of 14°C between June to September.

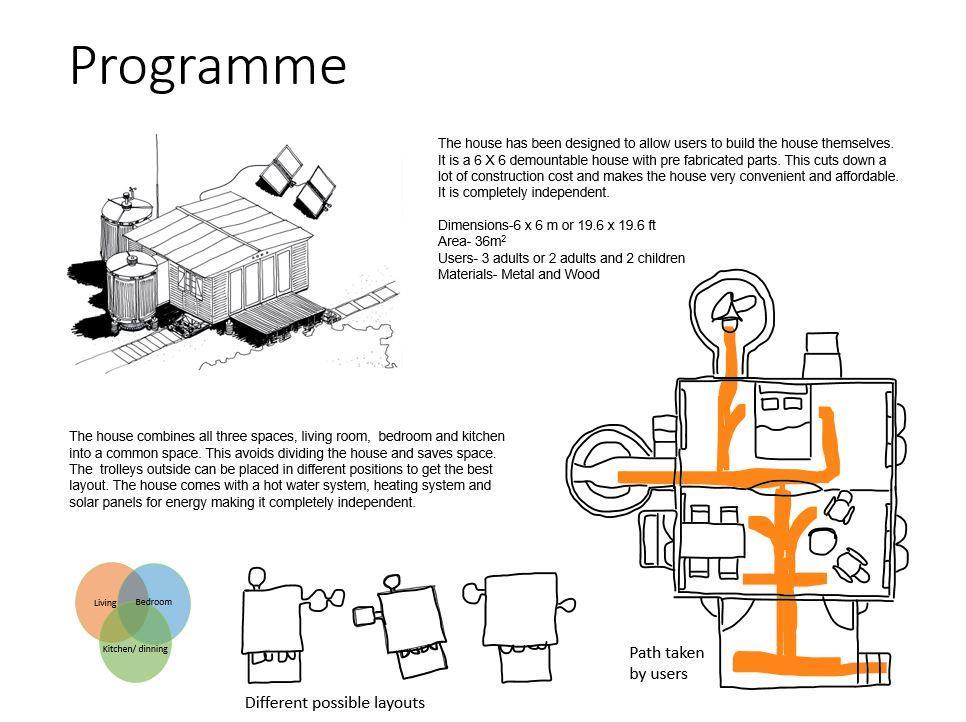

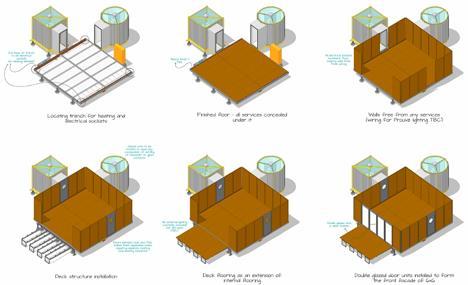

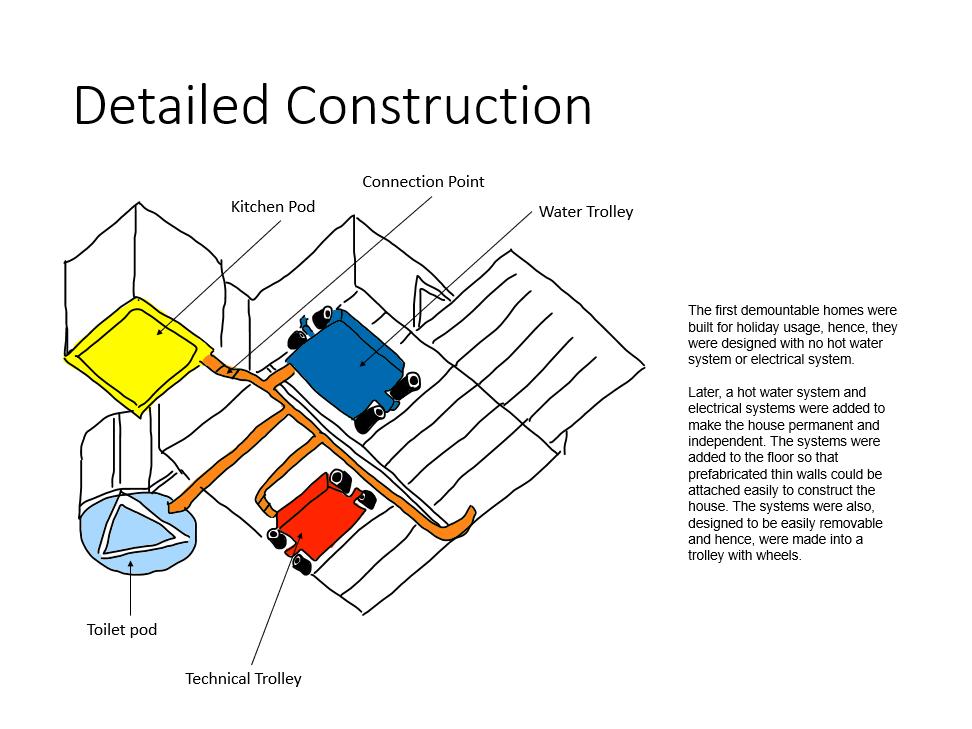

The structural frame transfers all the load of the house to the earth through the load bearing structures. 10 of these heavy stilts hold the house up on any terrain, they are heavy so they are unable to move easily.

The ceiling is slanted so that water doesn’t collect on it and increase the load. Water supply and electric power equipment are attached under the floor of the house.

The house is made up of lightweight materials, which makes it easily transportable and easy for the structure to hold together. The main structural frame runs through the ceiling, the walls and the A-shape structure in the centre.

The house has no foundation and the lightweight steel frame which is then covered with wooden panels is held up by load-bearing supports under the house.

The house is prefabricated and put together on the site. It includes attachable kitchen and toilet pods. This also includes a wall and floor panel which can be put together easily to make the house’s walls and floor.

The wooden floor is prefabricated and includes electric sockets in it. The insulation in between the wood and the steel frame keeps the house warm inside.

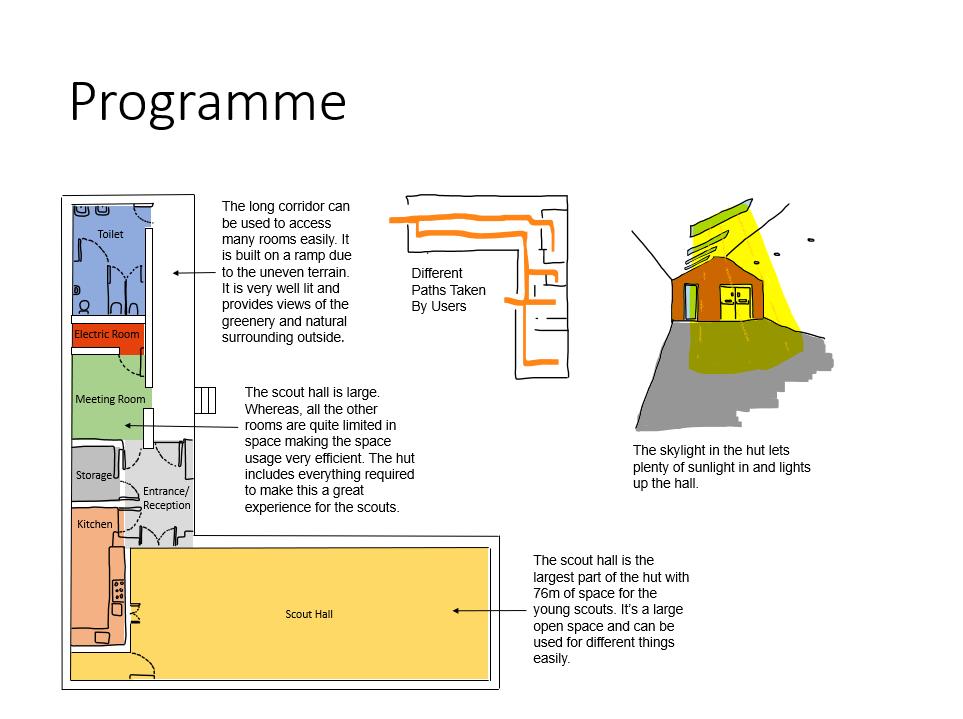

The illustration on the left shows the sun path around the hut. The hut receives plenty of natural light through the skylight.

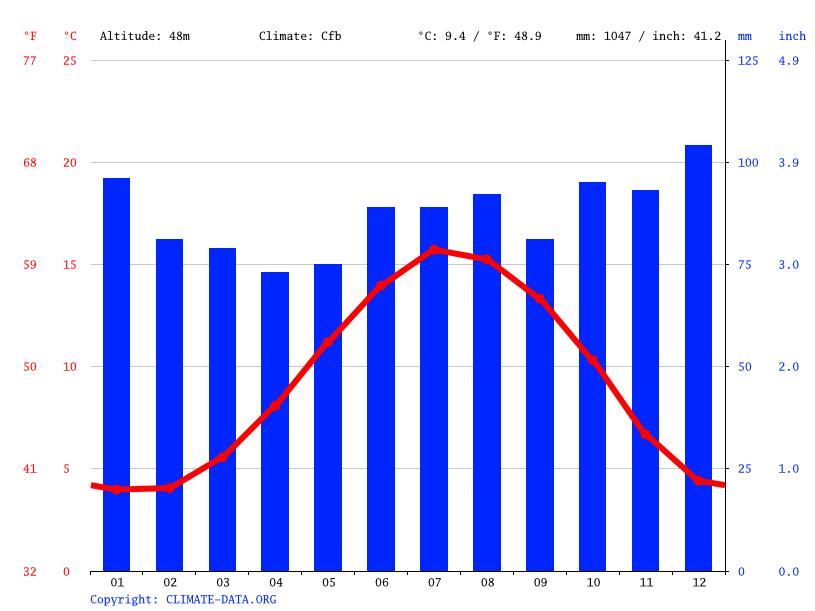

Manchester, located in Northern England is known for its cold climate and frequent showers.

July is the hottest month with an average temperature of 15.7 °C. January is the coldest month with an average temperature of just 4.0 °C.

April receives the lowest precipitation with an average of 73mm. Meanwhile, December receives the highest precipitation with an average of 104mm.

The highest number of daily sunshine is in May with an average of 7.48 hours a day, whereas, the lowest sunshine is in January with an average of only 2.96 hours a day.

The building has clearly been designed according to the climate of Manchester. Manchester is a rainy city and hence, the sloped roof prevents water from collecting on the roof. The skylight has also been placed to let the occasional but healthy and beautiful natural light into the hut.

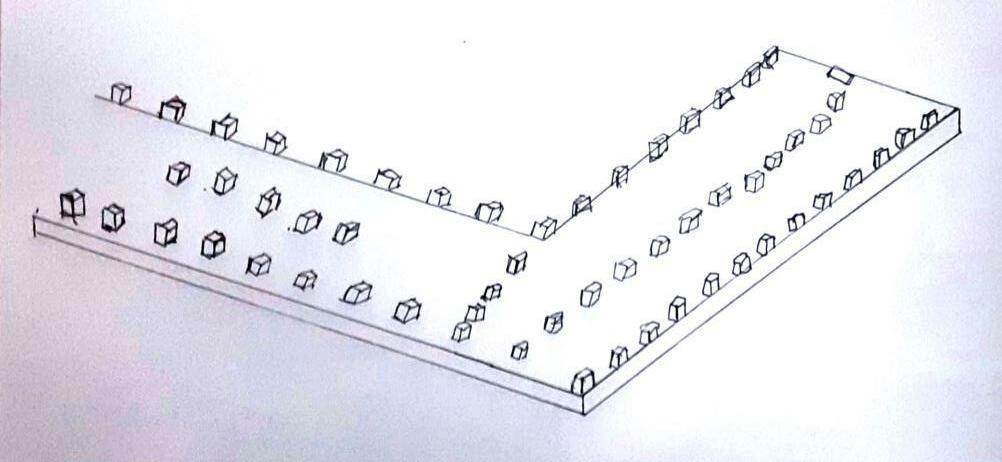

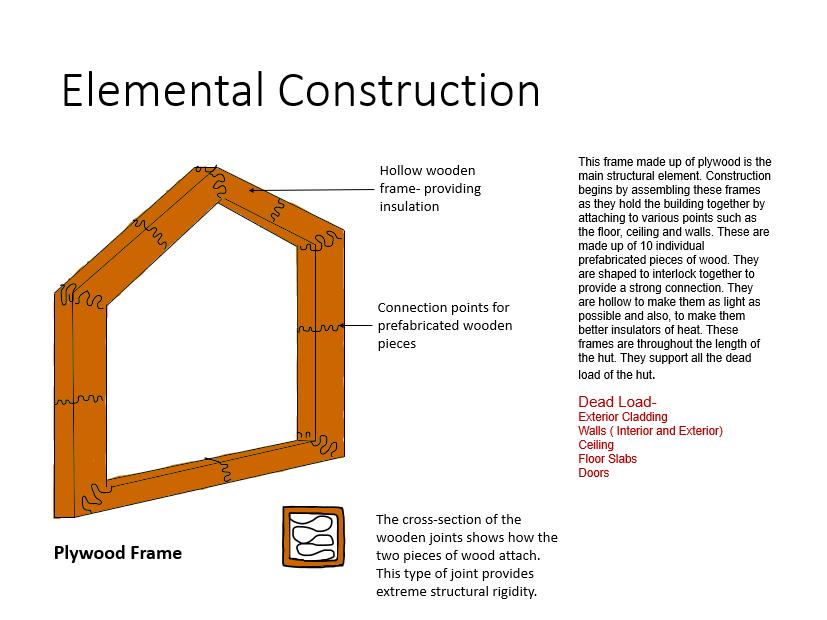

The foundation holds the building above ground level on any even terrain. They are placed along the edges and centre and take the entire load of the hut.

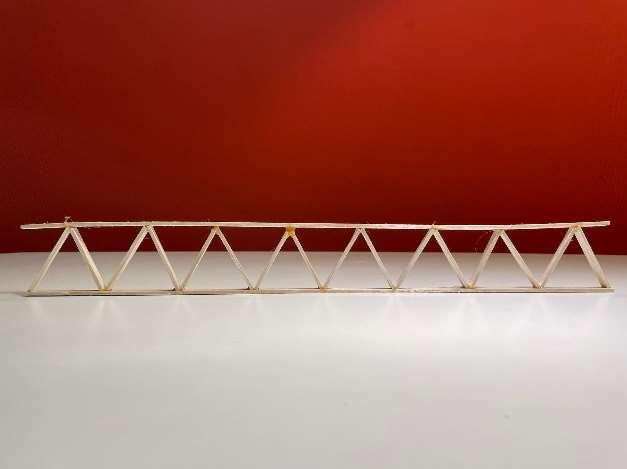

The wooden frames take the load of the ceiling, and the walls and transfer it down to the foundation. They form a grid together and spread the load evenly. The beams and columns are hollow and hence, lighter.

Additional load is put on the structure by furniture and people. This load is primarily spread through the floor and taken by the foundation.

The construction of this hut is made simple by using prefabricated parts. These can be attached by hand and avoid relying on machines.

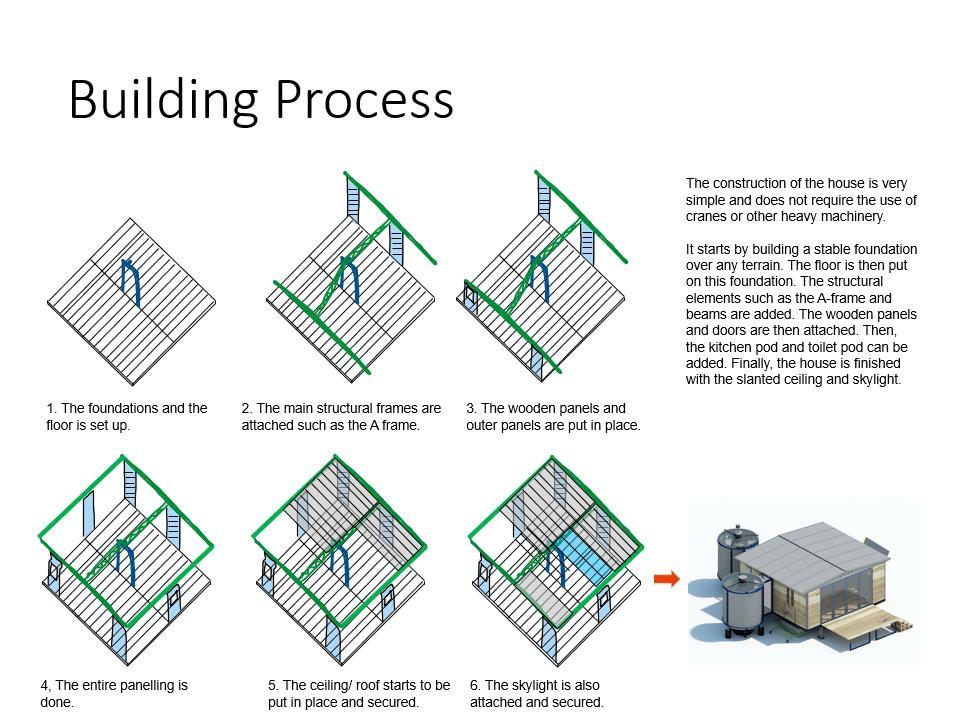

1. The foundations and the floor is set up.

2. The prefabricated parts are put together to form structures.

3. The wooden frames are erected.

The process starts by making the foundation and floor. This will be the base for all the construction. Wooden pieces are cut in a way to interlock and are then attached to form the frames. These frames are put together and further made stronger by adding beams and columns. Finally, the exterior is completed by attaching the wooden panels as walls, doors, and windows.

4, All the frames are put up together to form the internal structure.

5. The frames are connected. The structure is made stronger by adding beams and columns.

6. The exterior is completed by adding cladding, exterior walls, windows and doors.

Both cottages receive ample sunlight as they face the sun path.

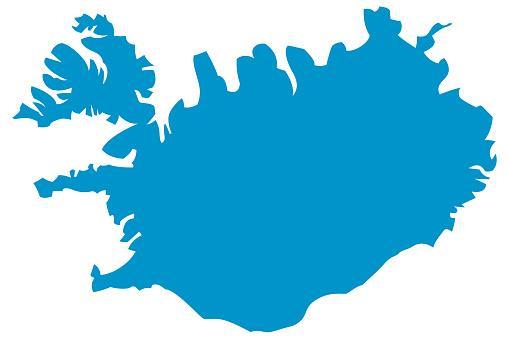

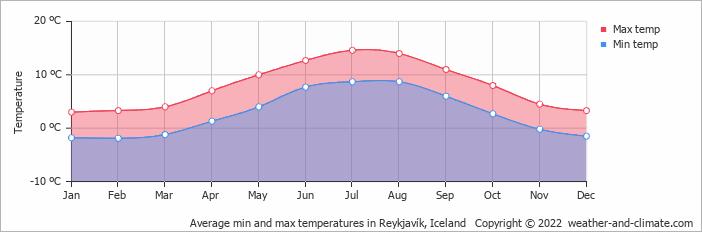

Brekkuskogur is located 90miles southwest of REYKJAVIK. It has a harsh climate with extremely low temperatures and strong winds.

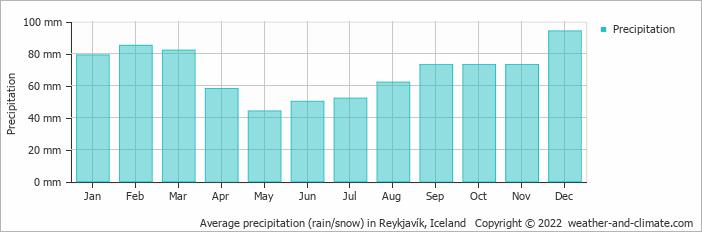

The lowest temp. is in January with an average of 3 °C. The highest temp. is during July with a temp of 15 °C. December receives the highest precipitation with an average of 94mm of rainfall. Whereas, May receives the lowest precipitation with only 42mm of rainfall.

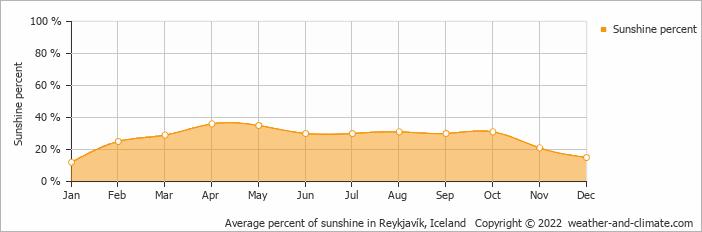

Brekkuskogur receives very little sunlight.April receives the highest sunshine hours a day with an average of 9.6. Meanwhile, January receives the least sunshine with only 4.5 hours of sunshine a day.

The cottages are built using concrete and timber. The structure rests upon concrete foundations. The main structure of the cottages is constructed using timber frames. The structure bears all the load of the cottage by transferring the loads through the walls to the floor and foundation. These loads include dead loads as well as live loads.

Dead loadsRoof Walls ( internal and external)

https://www.weather - atlas.com/en/france/marseille - weather - june https://worldarchitecture.org/article - links/egmfn/richard - rogers - new - gallery - supported - byorange - steel - beams - cantilevers - out - 27 - meters - over - hillside.html

https://www.dezeen.com/2021/02/15/richard rogers drawing gallery cantilevered art gallery chateau la coste france/ https://architecturetoday.co.uk/richard rogers stirk habour partners drawing gallery chateau - la - coste/

https://weather and climate.com/average monthly Rainfall Temperature Sunshine,Nancy,France https://weatherspark.com/y/53724/Average Weather in Nancy France Year Round https://en.wikiarquitectura.com/building/prouve-house/ https://www.dezeen.com/2015/06/11/richard-rogers-updates-jean-prouve-6x6-demountable-house-design-miami-basel-2015-galerie-patrick-seguin/

https://www.climatestotravel.com/climate/england/manchester https://en.climate-data.org/europe/united-kingdom/england/manchester-3621/ https://www.2ndwhalleyrangescouts.org.uk/newhut/

https://weather-and-climate.com/average-monthly-Rainfall-Temperature-Sunshine,blaskogabyggo-is,Iceland https://divisare.com/projects/270733 arkibullan brekkuskogur cottages