CONSTRUCTION, QUARRY & RECYCLING MAGAZINE ISSN 2041-7829 PLANT & CIVIL APR-MAY 2023 www.plantandcivilengineer.com £4.95 €6.95 Engineered for power & efficiency Call us on 00353 1 4319839 to discuss your requirements with our expert Blue Fuchs team sales@blueireland.ie | ww w.blueireland.ie Scrap handling Waste handling Port handling Timber handling Engineered for power & efficiency Top-of-the-range material handlers designed for deployment at ports, recycling facilities, scrap yards and timber yards. Each machine is optimally designed to meet routine operational demands and requirements, resulting in outstanding quality and durability, impressive performance and optimum efficiency. Fuchs Cabin - functionality redefined Greater safety and reduced the risk accidents. Large multi-function touch operates all functions. Superior visibility even in wet weather. Ergonomic space utilisation for operator with useful storage compartments. DISTRIBUTORS OF FUCHS, DOPPSTADT, MORBARK AND ROTOBEC IN ASSOCIATION WITH &

The UK's Only Live Demo Construction Equipment & Technology Event in 2023 13-15 June 2023 East of England Arena and Events Centre, Peterborough.

Avoid the queues! REGISTER NOW for your FREE fast track entry badge app.plantworx.co.uk

With emerging technologies featuring alongside construction equipment, live demos, innovation and the latest in machine technology, the show will lead visitors into the future of construction.

For full details, visit www.plantworx.co.uk

FOR THE INDUSTRY, BY THE INDUSTRY

News

28 Terex Ecotec enhances their trommel offering

56 Renault Trucks and TVS Interfleet form partnership to create the ‘E-Mixer’

Regular Features

22 Gordon Best, MPANI

44 Court Report

61 Recycling & Waste Management

100 Auctions & Used Plant

View from the Cab

30 Sany SY155U

Special Features

34 Tippers

45 ‘Reelin’ In The Years’ AG Wilson - 44 Years of Growth Through Experience

72 Highways: More than

No one living and working in Northern Ireland can be left in any doubt that we face a tough year ahead. Whether Chris Heaton Harris’ intention is a ‘punishment budget’ or not, the fact is that the total amount allocated to Departmental budgets will reduce by 0.4%. Combine this with inflationary and increasing pay settlement pressures and the real impacts will be of much greater magnitude. It is welcome news that the capital budget has increased slightly (from £2.1 billion last year to £2.2 billion) but this is unlikely to be of sufficient magnitude to avoid a drop in public works programmes that are so important to many in our sector.

In Ireland, the picture is very different, with the Irish government projecting a budget surplus of €10 billion this year and quarter-on-quarter GDP growth stronger than anticipated at 2.3%. Unquestionably, the North would benefit from a return to the devolved government against ‘indirect’ rule, and from a courtship with the Biden administration that might reap dividends. Notwithstanding, the private sector throughout Ireland is nothing if not robust,

tenacious and self-driven. A quick flick through the pages of this edition bears witness to that. FUCHS features in our cover story with Seaforde Metals taking a brand new MHL 350 and again in a product launch in Ireland for the MHL 434 Timber Handler. Meanwhile, RokBak is delivering on all fronts for the Skene Group with the RA 30 excavator, DAF has launched a full series of new-generation vocational trucks and the Renault C Range from Diamond Trucks is garnering rave reviews from customers. And if you want to read about investment on a scale that speaks of business confidence, read our feature on AG Wilson! Enjoy this edition and keep up to date with all the industry news 24/7 at www. plantandcivilengineer.com. Of course, you should also be getting our weekly newsletter which is emailed out every Tuesday; if not, do subscribe on our website so you don’t miss out. It’s FREE!

Emma Cowan Editor Email: pceeditor@4squaremedia.net

3 PLANT & CIVIL ENGINEER Find us on Find us on facebook Plant & Civil Engineer contents www.plantandcivilengineer.com PLANT & CIVIL APR-MAY 2023 COPYRIGHT NOTICE: © Plant & Civil Engineer 2023. All material in this publication is copyright, including advertisements which have been prepared for advertisers. No part of it may be reproduced in any way whatever or stored in electronic retrieval systems without the written permission of the publishers. We are a completely independent voice and are not connected to any Institutes or Associations within the industry. Our aim is to publish accurate, specific and dedicated information, targeting each sector of the industry, throughout Ireland. The publishers cannot be held responsible for any inaccuracies supplied by the contributors. All rights reserved. 14 Follow us on twitter @PlantandCivil Golda Burrows General Sales Manager David Stokes Group Editor Emma Cowan Editor Phil Eaglestone Commercial Editor Joel Byers Production Manager Zara Beggs Social Media Content Eleanor Blane Accounts Manager Helen Beggs & Garfield Harrison Publishers Plant & Civil Engineer is Published by: 4 SM (NI) Ltd, The Old Coach House, 12 Main Street, Hillsborough BT26 6AE TEL: 028 9268 8888 FAX: 028 9268 8866 Email: info@4squaremedia.net

comment

Aggregate and Asphalt Sales & Services 85 Plant Sales 88 Buyers Guide SEAFORDE METALS INVESTS IN NEW FUCHS MHL 350F FROM BLUE EQUIPMENT IRELAND 70 08 90 Publishing House 4SM has appointed Emma Cowan as editor of Plant and Civil Engineer, taking the magazine over from David Stokes, who remains Group Editor for the company. Emma’s career in journalism goes back to being the school rugby correspondent on her local paper and she has gone on to write for and edit a wide range of trade and consumer magazines over more than three decades. These have included construction, business, engineering, agricultural and automotive market sectors, as well as country sports, food and drink, tourism and hospitality, equestrian and parenting subject areas. PLANT AND CIVIL ENGINEER APPOINTS NEW EDITOR Please be sure to add Emma’s email to your circulation list for stories. Email Emma at pceeditor@4squaremedia.net or phone on +44(0) 7921 787686. PLANT & CIVIL CONSTRUCTION, QUARRY & RECYCLING MAGAZINE AWARDS2023 ENTER NOW 57-60 4SM (NI) Ltd now part of the North West News Group

New Appointment to Board of McHale Plant Sales announced

Construction equipment distributor, McHale Plant Sales has announced the appointment of its Business Development Manager, Darragh O’Driscoll to the Board of Directors of the company.

Announcing the appointment, company chairman, Michael McHale and managing director, Tim Shanahan said that his appointment ‘is in recognition of the professional, innovative and diligent work he has

performed for the company over the last number of years.’ In his role as Director, he will be responsible ‘for multiple projects including the company’s launch in the UK and other key projects in the business development area.’

Terex MP announces purchase of MARCO Conveyors

Terex MP, global manufacturer of materials processing and lifting machinery, has announced the purchase of MARCO, a manufacturer of bulk material handling conveyors, based in Mt. Vernon, Missouri. As part of the transaction, Terex MP will purchase a 100,000-square-foot factory and office space set on a 15-acre site in Mt. Vernon, Missouri. Terex MP plans to expand the site’s manufacturing capacity to support the growing demand for mobile conveying equipment in North America. The site offers a central and local distribution hub in North America while also diversifying Terex MP’s manufacturing footprint and providing access to an additional labour pool. Terex will also assume responsibility for MARCO’s sales and engineering office in the St. Louis area. MARCO was established in 1936 by E.F. Marsh Engineering and has since designed

and manufactured standard, stationary and portable material handling equipment such as stackers, belt feeders, hoppers, and bins. The company was the first conveyor manufacturer to design tubulartruss conveyor frames, which remain to be a signature product for MARCO today.

“This acquisition supports Terex MP’s growth strategy to expand our offering in the Bulk

Material Handling industries with products that complement the existing portfolio,” says Pat Brian, Vice President and Managing Director for Terex Materials Processing’s Crushing and Screening division. “Tubulartruss conveyor frames offer several benefits—they are hardwearing, easily re-configured and can withstand pressures of moving without bending. MARCO also produces equipment sold into the concrete industry, which will also help to expand our presence in this market.”

Terex MP plans to keep MARCO as a brand within Terex MP’s Crushing, Screening and Conveying division that includes Powerscreen, Finlay, EvoQuip and ProStack. MARCO will have substantial growth potential, benefiting from Terex MP’s global distribution network, as well as efficiencies enabled by its global scale and investments in areas such as product development, sustainability, digital solutions, and factories of the future.

Sany Launches New Range of Demolition Spec Machines

SANY UK have announced the launch of two new demolition-spec crawler excavators. The SY215C-XD (24-tonne) and (pictured) the SY390H-XD (40-tonne) tracked excavators are available to order with factory fitted demolition guarding specifically for demolition, waste or arduous applications.

Designed to meet the demands of the most challenging demolition projects, the machines are equipped with advanced hydraulic systems, reinforced structures, and heavy-duty attachments, making them capable of handling even the toughest demolition jobs. They are equipped with reinforced structures including heavy-duty

belly plates, ram guards and side impaction protection, to withstand the demands of the

demolition industry. They also feature hammer shear and rotate lines and advanced hydraulic

systems that enable easy change over of attachments in line with whatever the application requires.

“Following our announcement last year that we had joined the NFDC (National Federation of Demolition Contractors, it’s great to launch our new range of demolition machines which have been specifically designed for the UK,” said Leigh Harris, Business Development Director of SANY UK. “Our machines are built to the highest standards of quality and reliability, and we are confident that they will exceed the expectations of our customers”.

The new range of demolition machines is now available for purchase though SANY’s authorised dealer network and come with an industry leading 5-year / 5000-hour warranty for complete piece of mind as well as a comprehensive range of service and support packages. Demolition modifications to other existing SANY tracked excavators, the SY265C, SY305C and SY500H will follow later this year.

news 4 PLANT & CIVIL ENGINEER

Darragh O’Driscoll.

ACTIVELY , PRACTICALLY , WE’LL HELP YOU THRIVE AGAIN Close Brothers Commercial Finance provide asset based lending, invoice finance and asset finance solutions to businesses across Ireland. We can help you access the working capital you need. Contact us today on (0)28 9099 5701 / +353(1) 901 5224 or visit closecommercialfinance.ie

Topcon Launches Easy-to-Use Digital Layout Software for Fast-Paced Building Construction Industry

Topcon Positioning Systems has launched Digital Layout, a simple, easy-to-use building construction software app to enable more contractors to adopt a digital layout workflow for increased efficiency, accuracy, and productivity.

The software is designed to provide a distinct competitive advantage in the fastpaced building construction industry for general contractors, concrete contractors, mechanical, electrical and plumbing (MEP) contractors, steel erectors, fire suppression companies and more. Designed to help both first-time and experienced users of digital layout technology, this cost-efficient building construction field software works

in combination with a 3D laser - the Topcon LN - or a Topcon GT robotic total station, providing a step-by-step guide to streamline routines and workflows.

Additionally, the software can be used with the Point Manager plug-in for Autodesk Revit or AutoCAD to create point files in the office and seamlessly transfer as-built data back to a contractor’s design software. It is compatible with 2D, 3D and BIM workflows, and is supported by Microsoft Windows and Android operating systems. Users can easily generate real-time PDF reports to summarize work progress for stakeholders. Topcon MAGNET Enterprise web service is also included, enabling users to easily share data between the office and field.

Hillhead 2024 website is now live!

The brand-new Hillhead 2024 show website is now live at www.hillhead.com

Freshly designed and updated for the 2024 event, the site contains stunning video footage and a review of last year’s show as well as all the details you need for next year’s event including stand packages and pricing. The site is fully responsive meaning you can view it wherever you are through a tablet or mobile, as well as at home or in the office on your laptop or PC.

Hillhead 2024 takes place at Tarmac’s Hillhead Quarry, near Buxton, Derbyshire from 25-27 June. Expressions of interest should be directed to Event Manager Harvey Sugden: harvey.sugden@qmj.co.uk

McHale Plant Sales opens UK base in Tamworth

Resulting from their appointment as UK distributors of Metso Outotec stone crushers – first announced last January – McHale Plant Sales has established its first UK base in the Staffordshire town of Tamworth. From there, the company will initially service Metso customers across England, Scotland and Wales with an additional outlet in Scotland to follow next year.

Chosen for what McHale says is its ‘strategic location’ the new Tamworth base is situated on the Lichfield Road Industrial Estate in the town where it will accommodate offices, machine storage, parts warehouse and a repair and maintenance workshop.

Commenting, the company’s sales director, Denis McGrath said: “of the many locations we examined, Tamworth stood out as one from which we could reach-out to machinery owners and operators whose priorities in terms of technical back-up and after-sales support we fully understand.”

to

on-going responsibility

“In Tamworth we will implement an approach to customer service proven in Ireland and Northern Ireland where sales, service and parts operate in lockstep,” McGrath added.

news 6 PLANT & CIVIL

ENGINEER

Metso Outotec officials Adam Benn (left) and Anthony Bouvié (second right) pictured with a group of McHale Plant Sales officials (left to right) Darragh O Driscoll (Head of Business Development), Tim Shanahan (Director), Denis McGrath (Director) and Anthony Ryan (Aftersales Director) during a visit to their Dublin base ahead of the announcement by Metso Outotec to extend their distribution remit to include England, Scotland and Wales in addition

their

for Ireland and Northern Ireland markets.

Topnet Live is a real-time GNSS correction service that delivers high-quality data to GNSS receivers around the globe. Sold through aftermarket, system integrators and OEM channels, the service can be used in a variety of applications including survey, construction, GIS, mapping, and agriculture.

Increase your reliability with seamless, global network coverage. Truly global precise positioning Tailored business model Seamless, borderless service Reliable coverage Flexible subscriptions Topnet Live is now live in Ireland, contact us to discuss one of our subscription services. Dublin: 01 8975900 · Antrim: 028 79659299 info.ie@topcon.com · topconpositioning.com/ie

Next level precision

10,000th ADT IN NORWAY FIRST IN DEVELON COLOURS IN EUROPE

8 in profile PLANT & CIVIL ENGINEER

In February 2023, Doosan celebrated the production of the 10,000th Articulated Dump Truck (ADT) from the company’s plant at Elnesvågen outside Molde in Norway. There was even more to acknowledge with the 10,000th unit as it is the first machine in Europe to officially carry the colours of the company’s new DEVELON brand. As well as the DEVELON branding, the 10,000th ADT also carries an extra special design, which harks back to the origins of the ADT range. A time well before Doosan and even the Moxy era, back to the Viking ADT model, 12 of which were produced by the company, Øveraasen, in the time before Moxy

took over production. This is recognised by a Viking ship motif on the tailgate of the 10,000th unit, a DEVELON DA45-7 model. Over the years, several different ADT models have been produced at Molde, including the D15, 5222B, 6225B, 7235, MT40, MT41, DA40 and now, today’s models, the DA30-7 and the DA45-7. Rosendal Maskin AS, the Authorised Dealer for Norway, has supplied ADTs since 1987, and has delivered a total of almost 500 of the 10,000 so far produced! According to the Molde Plant Manager, Jan Roger Lindset, the 10,000th ADT with production number 851951 has been purchased from Rosendal Maskin AS by the Rental Group in Norway.

Production began at the Molde plant in 1972 when the business was called Glamox. Since then, the brand has had several names such as Moxy, Moxy Industrial, Brown Engineering, Moxy Trucks, Moxy Engineering and in 2008, the name changed to Doosan when the South Korean manufacturer bought the factory and the product. In 2021, Hyundai Heavy Industries bought the Doosan construction equipment

9 in profile PLANT & CIVIL ENGINEER CONTINUES ON NEXT PAGE

CONTINUED

range including the ADT line, and the name of the business was changed to Hyundai Doosan Infracore (HDI). There are currently 150 employees at the Elnesvågen plant, but with both DEVELON and Hyundai ADTs now being produced at the factory, the workforce is expected to expand to meet an expected 40% growth in production.

THE DEVELON ADT RANGEBEST-IN-CLASS PERFORMANCE

The DEVELON ADT range comprises two 6x6 models - the DA30-7 and DA45-7 Stage V compliant machines - the DA30-7 has a payload of 28 tonne, while that of the DA45-7 is 41 tonne. The range was extended at Bauma 2022 with the launch of a new 4x4 version of the DA45-7 ADT, intended to compete with rigid dump trucks (RDTs) in the 40-tonne class. Like all DEVELON ADTs, the DA30-7 and DA45-7 models feature an articulation hinge positioned behind the turning ring to provide equal weight distribution to the front axle even during maximum steer articulation. This combined with a free-swinging rear tandem bogie, ensures equal distribution of weight to each wheel and guarantees permanent 6-wheel contact and drive for equal power distribution and excellent performance, particularly on difficult terrains such as soft ground, uneven surfaces, very steep slopes, tight turns or a combination of all of these difficult conditions.

Collectively, the forward turning point, the unique tandem bogie and the sloping rear frame result in ‘best in class’ rough and soft terrain capabilities. The unique body shape and sloping frame ensure equal load distribution on all the wheels making these machines the best haulers for soft terrain work. The design of the articulation also provides equal load distribution on the wheels on both the left and righthand side when turning, which is very important for the traction and stability of

the machines. All of these outstanding features are available on the DEVELON Stage V DA30-7 and DA45-7 ADT models. In the new 4x4 ADT, the front truck and cab unit is the same as in the original 6x6 model, with modifications being made on the rear dumper unit only. Featuring a ZF EP8-420 transmission, the 4x4 DA45-7 is a two-axle ADT with twin wheels at the rear, and with a dumper section similar to that on RDTs in the 40-tonne class.

SUPERIOR PERFORMANCE IN DIFFICULT CONDITIONS COMPARED TO RDTS

“With superior operation on poorer roads, smoother surfaces and steeper terrain, the aim of our new 4x4 machine is to challenge RDTs in the 40-tonne class, by providing a dumper product that delivers much more than RDTs,” says Beka Nemstsveridze, ADT Product Manager at DEVELON.

As well as performing better in conditions that are tough for RDTs, the new 4x4 DA457 ADT has a width of less than 4 m to avoid the need for special transportation and offers a better turning radius than a comparable RDT. The shorter turning radius and the design of the rear dumper unit, which is more suited to carrying flat and heavy rocks, provide particular advantages in the mining and tunnelling industries. These latter are growing markets for ADTs, and include pioneering, short-term mining projects, quarrying and contract mining industries, especially those in southern Africa, the UK and Australia. Construction and bulk earthmoving contractors involved in roads, dams, airports, landfills and development projects are also large users of ADTs. Together these areas make the ADT market a wide and varied one, ensuring a large customer base.

PLANT & CIVIL ENGINEER 10 in profile

Doosan Construction Equipment is now

Same quality products maximum productivity outstanding value continuous innovation

Find out more: eu.develon-ce.com

Kilwaughter Doubles Larne Football Club Brighter Futures Support

Kilwaughter Minerals has committed a further £20,000 to Larne Football Club’s official charity, the Brighter Futures community fund programme. The donation doubles the amount contributed to the scheme by the leading minerals processor since it commenced the partnership in 2021. The money will go towards group and community projects throughout Larne and the surrounding area. Dozens of projects across the borough have already benefited from grants through the programme, which are made available in four categories including Sport and Recreation, Business Enterprise, Education and Training and Community Needs.

Gary Wilmot, CEO, Kilwaughter Minerals said: “As a business,

we are very mindful that we are also part of our community and we are proud to help support others through a variety of different programmes and initiatives. Brighter Futures makes an incredible impact across Larne and the wider east Antrim borough, and we’re privileged to play a part.

“Throughout our partnership, it has been a pleasure to see first-hand the tangible difference the grants have made to many. We are delighted to renew our support with this very worthy scheme and look forward to seeing further positive impact from the subsequent awards.”

Kilwaughter Minerals was recently named the winner of the Business in the Community category at the Larne Times Business Excellence Awards and was awarded Silver Status as part of the latest Business in the Community (BITC NI) Environmental Benchmarking Survey.

Gregg Humphrey, Brighter Futures Chairman added: “Brighter Futures acts as the charitable arm of Larne Football Club and has been in operation since 2019. The scheme has been tremendously well received across the borough with a huge take up from a wide variety of groups and individuals. “Quite simply, the success of Brighter Futures would not be possible without the backing of corporate partners and thanks to Kilwaughter Minerals for its continued valuable support.”

Egis Expands in Ireland with Major Acquisition of Civil Engineering Firm JB Barry & Partners

Egis, a leading global consulting, construction engineering and operating firm has acquired JB Barry & Partners, a Dublin-headquartered civil engineering business. Together, Egis and JB Barry & Partners will form one of the largest multidisciplinary consultancy, engineering and operations firms in Ireland.

For both organisations, the move will accelerate growth in the country and enable both Egis and JB Barry & Partners to better support clients in delivering important major infrastructure projects as part of Project Ireland 2040, such as smart cities, climate change programmes and updates and improvements to critical transport, water and energy infrastructure.

Egis and JB Barry & Partners have significant existing alignment including operating across the full lifecycle of major infrastructure projects from design to construction oversight and operations. Egis has had a firm base in Ireland for 20 years, employing more than 500 staff and delivering major infrastructure projects such as the operation, maintenance and asset management of 470km of Ireland’s strategic road network, including the Dublin Port and Jack Lynch Tunnels.

For over 60 years, JB Barry & Partners has been delivering landmark projects spanning 25 sectors including water services, development and structures, transportation and energy. A few projects of note include upgrades to the

iconic Ringsend Wastewater Treatment Plant, the largest treatment facility in the country, planning the development of the N/M20 Cork to Limerick multimodal transport corridor, and acting as Contractors Designer for the N22 Baile Bhuirne to Macroom Road Development, the largest construction project nationally. The two organisations are currently partnered on several projects in the rail and light rail sectors, including the planning and detailed design of the Luas Finglas in Dublin and the Galway-Athenry Capacity Feasibility Study.

JB Barry & Partners employ over 180 people across four office locations in Ireland. The organisation’s current leadership team and expert staff are expected to stay in post with no anticipated changes to the delivery of JB Barry & Partners existing projects.

Full completion is subject to Competition and Consumer Protection Commission approval.

Laurent Germain, CEO, Egis Group said:

“We are delighted to welcome JB Barry & Partners to Egis. This significant investment in Ireland will support our continued growth and enable us to deliver world-leading civil engineering projects at a greater scale for our clients. I extend my warmest welcome to the JB Barry & Partners team”.

Steve Preece, Managing Director, Egis in Ireland said: “There are many synergies between Egis and JB Barry & Partners, and a history of success and mutual respect in our markets. In joining Egis, we are supporting JB Barry & Partners in the next stage of its impressive journey and together we’ll unlock new capabilities and services for our clients. As part of Egis, there will be new opportunities for JB Barry & Partners to play a role in a pipeline of leading projects around the world.”

Liam Prendiville, Managing Director, JB Barry & Partners, said: “Joining Egis is a natural next step in our organisations development and will give us the capacity to respond to larger domestic and international tenders and offer our existing clients new added value services, particularly in digital transformation, asset management, smart cities and sustainability. We are immensely grateful to our clients and supporters over our long history and we hope you will join us in embracing the next chapter in our development. We sincerely believe that it is good news for clients and staff alike”.

news 12 PLANT & CIVIL ENGINEER

Gary Wilmot, CEO, Kilwaughter Minerals and Gregg Humphrey, Brighter Futures Chairman.

Laurent Germain and Liam Prendiville.

Aer Rents acquires Hudson Lifting Ltd

AER Rents, an O’Flaherty Holdings group company, is pleased to announce the acquisition of Hudson Lifting Ltd, a leading independent provider of Hire, Sales, Service and Testing of lifting equipment in the United Kingdom.

Founded by Jeff Hudson & Danny Smalldridge in 2018, the company has grown steadily and is already considered as one of the leading providers of lifting equipment and accessories in the UK. Shortly after its inception Kevin Lewis also joined the team and the business has grown steadily from its base in East Tilbury, with the opening of further depots in Dartford and West Drayton. In addition to hire, Hudson also sells a wide range of lifting equipment and accessories from leading suppliers and is also able to provide bespoke, designed lifting gear solutions for one-off requirements through their in-house design team. This latest acquisition significantly strengthens AER Rents specialist services, allowing the group to offer a widened range of products and services to its customers in tandem with the general rental offerings from Mr Plant Hire, Drogheda Hire & Sales, Mainline & Chippindale Hire & Sales. AER Rents & Hudson Lifting will execute an agreed growth plan which will see Hudson establish a UK-wide network of 12 depots over the next 5 years. O’Flaherty Holdings is an organisation well known in Ireland, primarily through its role in

the development of the Irish motor industry. Founded in the 1940s by legendary motor industry entrepreneur, the late Stephen O’Flaherty, the group continues to be owned and managed by members of the O’Flaherty family. Its subsidiaries include Motor Distributors Limited, distributors in Ireland of Mercedes-Benz passenger cars and commercial vehicles and MSL – a network of independent motor dealerships providing sales and after-sales service for Mercedes-Benz, Mazda & Skoda. The group first invested in plant hire in 2014 with the acquisition of Londonbased Mr Plant Hire and in 2020 also

acquired Ireland-based Drogheda Hire and Midlands-based Mainline Group. AER Rents will continue to expand its presence in the plant hire market through a combination of strategic acquisitions and organic growth, offering its customers access to a wider offering of modern products and services. The group was advised by KPMG Corporate Finance & Legal Services, Dublin, with legal support from Shoosmiths in Manchester. Hudson Lifting were supported by Nelsons Law LLP, located in Nottingham & Denmark Forrester located in Heybridge in Essex.

news 13 PLANT & CIVIL ENGINEER

TRUSTED FOR THE JOURNEY STERTIL KONI VL TEST SYSTEMS SAMOA MAJORLIFT SALES TEAM (028) 7131 2225 WWW.SWSNI.COM

Ireland’s leading workshop specialist for haulage, transport, plant and fleet

STERTIL KONI VL TEST SYSTEMS SAMOA MAJORLIFT SALES TEAM (028) 7131 2225 01 506 0572 sales@swsni.com www.swsni.com Export & Freight_SWS_Half Page_July 2022.indd 1 20/07/2022 09:35:11

SWS is Ireland’s leading garage fit-out and workshop equipment specialist. With over 40 years’ experience and access to the world’s leading brands, we are trusted by operators who value our expertise, reliability and exceptional value.

14 cover story PLANT & CIVIL ENGINEER

FUCHS MHL 350F SCAN THE QR CODE TO WATCH THE VIDEO. VIDEO STORY

SEAFORDE METALS INVESTS I N NEW FUCHS MHL 350F FROM BLUE EQUIPMENT IRELAND

When John Killen of Seaforde Metals decided it was time to replace his equipment handler, he made a change from his previous brand and went to Blue Equipment Ireland and their FUCHS range.

Seaforde Scrap Metals is a long-established family business, founded by Peter Killen in 1920. The company specialises in reprocessing ferrous and non-ferrous metals for a wide range of customers from the general public to multi-national companies and its professional, expert services are highly valued and fully accredited. Seaforde Metals is a fully-licensed waste

carrier, waste management facility and authorised treatment facility (ATF).

The material handler needed to be up to long hours of work, both on-site processing scrap metals into bales and at Warrenpoint docks, loading bales for freight shipping. “over the years we have tried different management approaches to our machinery,” said John. “We’ve tried driving the machine until it’s totally done but, when you count the repair bill it’s cheaper to change the regularly used machine every four or five years. It was time for a new material handler and the extra tax relief this year was an added incentive to invest.”

Although he had never previously purchased a FUCHS, John was first attracted to the brand in 1995, when a delegation from the Northern Ireland scrap industry was invited out to the FUCHS factory close to Heidelberg in Germany.

“I was very impressed by the factory and, since then periodically the sale people from Blue would pop in for a chat and cup of tea, even though I was using another brand,” continued John.

“When it came time to update our fleet I found Blue Equipment Ireland was

FUCHS ENGINEERED FOR POWER & EFFICIENCY

AT A GLANCE

Outstanding stability for the toughest jobs.

Operating weight without attachments (t) 33.0-35.5

Engine power (kW) 160

Electric engine power (kW) 132

Loading equipment (m) 14.7-16.0

Operator David Howard enjoying the comfort of the cab in the new Fuchs MHL 350F they recently took delivery of.

really good coming back with answers to my questions. Our family has been in the scrap metal business for 103 years and I have been working in the

15

PLANT & CIVIL ENGINEER

cover story

CONTINUES ON NEXT PAGE

business full-time since 1989. I’ve also travelled a lot to the various machinery shows in Europe and the USA I know what I am looking for. Even so, there are always things you don’t know (every day is a school day). I liked the MHL 350F I was very impressed with Blue Equipment Ireland’s response time – possibly the best in my 34 years’ experience. What’s more, if the sales team are fast, the parts department will be efficient and that is important so that maintenance downtime is minimised.”

THE 350F: A STANDOUT MATERIAL HANDLER

State-of-the-art engine technology paired with pioneering hydraulics make the MHL 350F one of the fastest and most sensitive picking and loading machines in its class. Its robust 36 tonne operating weight, a 16-metre reach and a 3-metre undercarriage, coupled with a powerful 160 kW turbo diesel engine and high-performance hydraulics operating on an efficient dualcircuit make it possible for loads weighing several tons to be moved effortlessly, quickly and precisely. This is an agile machine with smooth high to

low manoeuvrability and, utilising the range of grabs available, can collect anything from large single items like a car chassis to mixed small materials. Scrap metal, timber and port handling as well as recycling operations lie at the core of the MHL 350F’s design and it is a genuine multi-tasker.

In the MHL 350F, the stage V diesel engine fully conforms to Tier 4 Final legislation without any compromise on performance. It is more fuel-efficient than earlier models and even features an Eco-Mode option reducing fuel consumption by up to 27% depending on application and loading.

The Fuchs 350F also boasts a maintenance-friendly design and a FUCHS service platform enabling easy access to the main components to minimise downtime, an important factor for Seaforde Metals.

IMPRESSIVE MACHINE

The FUCHS MHL 350F ticks all the boxes for Seaforde Metals’ owner, John Killen and it is also a big hit with its operator, David Howard. David operates the handler processing scrap metal alongside co-worker John, who operates the baler/shearer.

David also operates the MHL 350F for loading at Warrenpoint dock. Even though the 350F arrived less than two months ago, he’s had plenty of time in the cab to assess the machine’s comfort and capabilities.

“I have a lot of experience using other brands and some much older machines, but this is the first time I’ve driven a FUCHS and the first time in my working life that I’ve been lucky enough to drive a brand new model, straight from the factory. I’m definitely enjoying it,” says David. “In terms of my job, the 350F does everything I want it to do and it does it well. It can definitely lift the weights I need, even though the grab adds 1.5 to 2 tonnes to the weight. It’s a powerful, well-balanced machine and can handle heavy loads, even with the arm stretched right out. It’s agile too, the outswing design makes it capable of fitting into smaller spaces without taking away from its lifting and manoeuvring capability, the MHL 350F feels so much better, more comfortable, more competent and more easily operated than older handlers I’ve driven in the past. The FUCHS has a six-cylinder engine, so it’s

also much quieter than other handlers that I’ve driven.” David spends long hours in the cab so comfort and easy access to controls is important. “The cab is very comfy. It has it all really, DAB radio, USB ports, cameras. We’ve currently got two cameras connected, one at the back and one at the right-hand-side where the arm extends, so my visibility is great,” says David. “Everything in the cab is easily adjustable and the display screen lays out all the controls and information within easy visibility and reach. David concludes: “At times, especially when I’m working on the dock, I can be in the cab for fairly long periods, maybe three hours and this machine is so comfortable to work in and so good at doing what I need it to do that it’s just a great place to go work.”

PLANT & CIVIL ENGINEER 16

cover story CONTINUED

www.blueireland.ie

Ashbourne Truck Centre, Ballymadun, Ashbourne, Co. Meath, Ireland

Tel: 00353 18350573 Josef: 0035387 255 66 77 Sarah J: 0035386 255 66 77

New Faymonville 4-axle hydraulic widening bed low loader, extendable in width from 2.54m to 3.2m at the push of a bu on, also extendable in length, double ip hydraulic ramps, rear steer axles, hydraulic rear legs, full spec. In stock available immediately.

2022 Faymonville 4 axle 9ft wide, heavy duty spec on 19.5” wheels, trough, extendable, double flip ramps, BPW axles, greaser, marker boards, available with immediate delivery IN STOCK

New Schmitz Bulk Tipping Trailer, 70 cubic yard, step frame design, steel galvanised chassis, roll over cover, grain hatch and sock, sealed tail board, front lift axle, ina stock, available immediately.

2022 Schmitz 8.2m tipping trailers, standard size and higher side wall for waste etc, steel body, galvanised steel chassis, front lift axle, auto dump on suspension, manual cover, sealed tail board, fully thermal insulated in stock also. available with immediate delivery IN STOCK

New Schmitz Cargobull insulated tar spec pping trailer, 8.2m, steel body, electric cover, front li axle. In stock available immediately.

New Faymonville 4 axle fixed bed low loader, two rear steer, double flip ramps, marker boards, 9ft wide plus out riggers, coming into stock within 2 weeks. Available on short delivery (same spec as trailer shown)

New Schmitz Cargobull

Aluminium pping trailer 9.6m, electric cover, rear steer axle, front li axle. In stock available immediately.

New Faymonville MAX 3 axle step frame low loader, double flip ramps (timber or grid floor), in stock available immediately.

2022 Faymonville 4 axle 9ft wide, choice in stock, extendable with trough, or full extension no trough, double flip ramps, hydraulic rear support legs, marker boards, top spec, available with immediate delivery, IN STOCK New Schmitz tipping trailers, in stock & on short delivery times, various specs, 8.2m steel 1460mm side or 1860mm side, manual or electric covers, various other options available.

www.ashbournetruckcentre.com

www.ashbournetruckcentre.com

Tel: 00353 18350573 Josef: 0035387 255 66 77 Sarah J: 0035386 255 66 77

Ashbourne Truck Centre, Ballymadun, Ashbourne, Co. Meath, Ireland

PUMA accreditation scheme from TSA creates a national standard for utility surveys

More than four million excavations take place across the UK every year. Many of these take place without a detailed search for pipes and cables being carried out first. Striking of these underground assets can cause injury and death, as well as millions of pounds worth of damage and delays to major projects. Raising standards in utility surveys is essential to prioritise safety, drive efficiency and save money. To achieve this, The Survey Association, the trade association representing land surveyors in the UK, has launched an accreditation scheme for its members who carry out utility surveys. Named PUMA (PAS128 Utility Mapping Accreditation), the new accreditation scheme will be run by LRQA, a global leader

in assurance, certification and inspection services. PUMA is designed to assess the ability of surveyors to deliver to the PAS128 specification. It will

provide a benchmark and create a national standard for best practice for underground surveys. Membership of the scheme will give accredited

surveyors a competitive edge and will be a tangible means of demonstrating their continuous professional improvement.

PUMA is the culmination of ten years of development work by TSA. Sam Roberts, Technical Committee Chair at TSA, who has spearheaded the campaign to create PUMA, commented: “Installing and maintaining the UK’s four to five million kilometres of buried assets requires accurate utility data to understand the networks that may be present within a survey area, below and above ground. Previously, survey companies could claim to deliver to the PAS128 specification but did not have to provide any proof of their capability and there was no recognised standard for them to work to. Now, thanks to this new scheme, anyone seeking a utility survey, who sees that a survey company has PUMA accreditation, can have complete confidence in the level of service and the quality of data that will be provided to them.” For more information about PUMA, go to https://www. tsa-uk.org.uk/pas128accreditation/TSA and LRQA

Kieran Holohan appointed Managing Director of Saint-Gobain Ireland

Saint-Gobain Ireland is pleased to announce the appointment of Kieran Holohan as its new Managing Director. Kieran will begin his tenure as Managing Director on May 1st, 2023, succeeding Pádraig Barry who is retiring after a career with Saint-Gobain Ireland spanning more than 16 years

Kieran joined Saint-Gobain in 2007 and has spent the last nine years as Marketing Director for Saint-Gobain Ireland. Prior to this, he held the positions of Marketing Manager with Moy Isover and Strategy Manager for Saint-Gobain Ireland. During this time, he has been instrumental in the development of Saint-Gobain’s Gyproc and Isover businesses and played a pivotal role in the organisation’s wider success. Throughout his career at Saint-Gobain, Kieran has been an integral part of the leadership team and has amassed extensive experience of the Irish construction market and the competitive dynamics that shape it. In his new role as Managing Director, Kieran will be responsible for developing and executing business strategies for the Saint-Gobain brands Gyproc and Isover in Ireland. He will oversee the company’s executive team, manage the company’s business operations, as well as continuing to grow and enhance

Saint-Gobain’s brand profile as leaders in the Irish building materials market.

A Laois native, Kieran holds a Bachelor in Business Studies from the Atlantic Technological University and was recently awarded an MBA from the South East Technological Institute in 2022. An all-round sports enthusiast, Kieran is a passionate

Gaelic games and soccer fan, and currently enjoys mountain biking. He is also the vice chairperson of the development committee for his local football club, Mooncoin Celtic. Speaking on his appointment as Managing Director of Saint-Gobain Ireland, Kieran Holohan said: “I am delighted to be appointed Managing Director of Saint-Gobain Ireland.

I want to thank Pádraig for the stellar work done under his leadership and the substantial contribution he has made to this organisation during his sixteen years of service.

“As a key contributor to the construction of safe and sustainable buildings in Ireland, I have a huge passion for our organisation and its ability to do an enormous power for good. As a worldwide leader in light and sustainable construction, we have a key role to play in building a carbon-neutral economy in Ireland. I look forward to leading our exceptionally talented team to continued success and further growth as we play our part to ensure Irish buildings are efficient, safe, sustainable and great places to live and work.

“I will dedicate myself to ensuring the growth ambitions for the organisation are realised and that we build on our strengths to deliver the best possible service to our loyal customer base.”

news 18 PLANT & CIVIL ENGINEER

Kieran Holohan.

Carved by a lifetime of hard work, Rokbak articulated haulers are built to perform. Day after day. Decade after decade. From the heat of the desert to the cold of the arctic, you can rely on Rokbak.

rokbak.com Contact your local dealer for more information.

ROKBAK RA30 DELIVERS ON ALL FRONTS FOR SKENE GROUP

Down the road from Rokbak’s Motherwell HQ, a renowned familyowned Scottish construction materials business has shopped local and adopted a RA30 into the fold.

As Rokbak continues to build a global reputation for robust and reliable articulated haulers, just 50 miles directly east of the company’s headquarters in Motherwell, Scotland, Skene Group Construction Services Ltd has put an RA30 to work. Skene Group is a proud family business started in 1968 by the now-retired Donald Skene, with his son Neil later taking over as Chairman and daughter Jill as a Director. Today, it operates a much-valued 100-person workforce,. For Skene, it’s always about bringing in the best people, and best equipment, to each aspect of its operations. “Our partnerships are dictated first and foremost by attitudes and relationships –it’s all about the people that we deal with,” says Skene Group Managing Director Darren Forrester, who has been with the company for a quarter of a century. “Our customers know that we deliver. And, manufacturing in the outdoors, whatever the weather. our product quality remains consistently high.” Well-known around the local area for having its own weather-system, Soutra Mains Quarry in Pathhead, Midlothian, has provided the conditions to demonstrate the best of the Rokbak RA30. Skene Group exracts material from this site for a concrete plant through on-site wash plants and crushing trains –primarily as fill materials and the coarse recycled aggregate of crushed concrete stone. As one of the leading independent quarry operators, Skene currently supplies pre-cast concrete blocks to around 50% of Scotland’s housing market.

LOADED WITH PRIDE

“The RA30 has been a very good, strong asset to Soutra Mains,” says Quarry Operations Director Kevin Hill. “It’s rugged and robust, it can stand up to

the conditions it’s subjected to, and it suits the type of rock we’ve got here.”

The RA30 (arranged through Molson Group) arrived on site in late September 2022. “When we needed to find an articulated hauler manufacturer, we were already attracted by Rokbak’s proximity to us,” explains Darren. “Initially we were speaking to our contact at Molson, but we soon discovered that we could also have close contact with Rokbak, which helped us to fine-tune the product to our specific needs.”

“It was great to have that connection with the Motherwell factory, to be able to see the workforce passion – you can tell the Rokbak products mean something to them.

“But what most impressed me about Rokbak as a manufacturer is that they allowed us to try both the RA30 and RA40 to see what would suit us personally on-site. Rokbak actually invested in Skene Group before we had even placed an order.”

THE RA30 AT WORK

At Soutra Mains, the RA30 is utilised predominantly in the lower benches of the quarry for load and haul, from the bottom level up to the concrete aggregate wash plant. The loading shovel fills the hauler in three passes before the RA30 sets off on an 800-metre round trip across different site levels to the plant and back. “They’re generally dirty conditions for a dumper,” explains Skene Group Services and Quarry Manager Alex Brodie. “The Rokbak is running on compacted Type 1 sub-base with a few ruts here and there, but it’s nothing the machine can’t cope with. We’ve had no issues – the RA30 goes everywhere and does everything we’ve asked it to do.”

TAILORED TO YOUR NEEDS

Skene Group’s RA30 customisation involves the popular tailgate and a green safety beacon. Side extensions on the truck

in profile 20 PLANT & CIVIL ENGINEER

Kevin Hill, Quarry Operations Director.

maximise payload and help prevent spillage while travelling on the haul roads. An autolube system ensures everything is greased at the right times, saving operation time and providing safe maintenance. Heated mirror arrangements offer greater visibility down the side of the machine, and an additional mirror on the bonnet as per Skene Group’s request grants even greater safety while manoeuvring. “Given winter condition, this customisation is specific to the demands of Skene Group and the Soutra Mains Quarry,” says Kenny Price, Rokbak’s Regional Sales Manager for EMEA.

OPERATORS PRAISE THE RA30

“I’ve been using the Rokbak since it arrived and it’s really nice to operate,” says Quarry Operative Robert Robertson. “When I first arrive on site in the morning, I check over the machine and do the initial checks with the oil, water and hydraulic levels. The layout makes everything quick and clear to see. “The rear-view camera makes my life a lot easier when you’re reversing the hauler, and the large windows offer a lot of visibility. With any operation, comfort is very important, and it is a very comfortable truck to drive. Personally, I like the amount of room the cabin offers, as well as the stereo of course!”

The RA30’s spacious ROPS/FOPS certified cabs have been designed to avoid fatigue –with low noise, air-conditioning, cushioned steering and tough suspension. Easy

operation and service data extraction is gained through clear instrumentation and an LCD display for operational and service feedback, including fuel consumption, while smart data identifies any faults and damage before they cause downtime.

MEETING REQUIREMENTS

“When Skene Group was considering replacing an existing hauler, we were able to demonstrate how the RA30

met all of their requirements including safety, efficiency, productivity and operator acceptance,” says Mark Proudfoot, Managing Director, Molson Group. “Feedback for the RA30 has been extremely positive in terms of performance, efficiency and reliability –customers including Skene Group like that it’s modern but down-to-earth.”

21 PLANT & CIVIL ENGINEER in profile

FROM THE DESK OF: GORDON BEST, REGIONAL DIRECTOR, MPANI

STRONGER TOGETHER WITH ONE VOICE

Our recent MPANI annual general meeting and question time session was a great success and my thanks go to everyone who attended the event at the Dunsilly Hotel. In his address our Chairman, Paul Brogan, highlighted the importance of MPANIs collaborations with other Industry bodies and Associations in engaging with the Government on issues such as Brexit, red diesel rebate removal, energy costs, planning and skills.

As he said, “We are stronger together with one voice”. “Likewise, there are matters in all our sectors where, by working together through MPANI, all our companies can benefit from the strength of having one representative voice”. Paul also highlighted the ongoing unfortunate position we still find ourselves in relation to the lack of an Executive and no functioning government. As an Association we cannot point the political finger on what any party should or should not do. We would strongly recommend, though, to the MPANI membership to engage with your local MLA’s and give them your perspective, as business people, as to what you consider is in the best interests of the country. The dire predictions for 2023 that were given back in the latter half of 2022 thankfully have not come to pass and while the market in NI has taken a downturn it is not as bad as many had feared. Those sectors, such as highway maintenance, are being impacted by the lack of an executive and confirmation of budgets thus endangering the retention of a skilled and heavily invested-in workforce.

The continuing impact of the turbulent energy markets created by the war in Ukraine is having a significant and alarming impact on contracts with the costs of some materials, particularly bitumen, not being reflected in the monthly price fluctuation indices. MPANI has written to the Office of National Statistics and BEIS seeking information on a freedom of information basis asking how the price fluctuation indices information is collated and processed.

BIOCHAR IN CONCRETE

The MPANI Concrete Development Group recently met with QUB and the Agri-food and Bio-science Institute (AFBI) to discuss the use of Biochar in concrete and cement products in NI. Biochar is a lightweight black residue, made of carbon and ashes, remaining after the pyrolysis of biomass. According to Professor David Rooney and Thomas Cromie, this material can be a lower carbon alternative to be used by the Industry. QUB has written a report, the second draft of which has been submitted to the Department for the Economy. MPANI has reviewed the report and we are excited about the positive aspects the use of biochar can bring to reducing the carbon footprints of concrete products in NI.

Given that NI Agriculture produces enough food to feed 8 million people and we only have 2 million people we have enough biochar and biomethane from the biomass process to meet the needs of the NI Concrete Industry.

MINERAL PLANNING FOR MINERAL PLANNERS

On the planning front, I recently facilitated a presentation on Mineral Planning for Mineral Planners by Julian Smallshaw of IoQ at the Strategic Planning Group meeting on 16th March in Mid Ulster Council Offices in Magherafelt. The course is aimed at local authority planners and is an updated version of the course we delivered to council planners some 5 years ago.

I am delighted to say Julian’s presentation was very well received and it was agreed the course will be delivered later this year to local council planners dealing with mineral planning applications. Also on the 26th April, our MPANI / NIEA liaison group held a Mineral Planning workshop to which council planners dealing with mineral applications regularly were invited. It was an excellent engagement and sharing of ideas and no doubt will help all stakeholders engaged in the mineral planning process towards a better understanding

essential materials sustainable solutions

22 PLANT & CIVIL ENGINEER

Gordon Best, MPANI

Our AGM Question time panel from left, Gordon Best (Regional Director MPANI), David Surplus MBE, B9 Energy, Claire Sullivan, CBI NI Policy Director, Stuart Anderson, NI Chamber and Chair of the NI Business Brexit Working Group, Nichola Mallon, Logistics UK, Paul Brogan, MPANI Chairman.

of each others position. More events and site visits are planned for later this year.

One of the key messages I made to the Senior Planners on the Strategic Planning Group was that MPANI were keen to engage with local planners to ensure a secure and sustainable supply of minerals for NI into the future. “Supply should never be assumed”.

“Mineral products represent the largest material flow in the economy, with the vast majority of supply used in NI construction but also supporting a variety of agricultural, industrial and manufacturing activities. As such, these resources are of strategic importance to the economy.

“The continued decline in aggregate reserves, nationally and regionally, is a stark reminder that the future ‘steady and adequate’ supply of these essential minerals cannot be assumed. It requires effective planning, management and monitoring and there is a continued clear desire from both local authorities and from industry for the National and Sub-national Guidelines for aggregates provision to be updated to support the Managed Aggregate Supply System (MASS). The case for a national statement of need has never been stronger and we will continue to press DLUHC Ministers for this.

“The under-replenishment of mineral reserves over the last decade represents an unsustainable position, and the fact that the decline continues, despite two years of reduced aggregate sales, should ring alarm bells given the role of these minerals underpinning Government ambitions around net zero, green recovery and ‘levelling up’. Looking forwards, there is certainly no evidence that demand for these strategic resources will reduce over the next decade and beyond. As such, the pressures on the reserve base will only increase unless something changes. “To secure the most sustainable and costeffective supply of these materials will require active support and management, backed by data to monitor performance, to ensure the right resources can be made available in the right place and at the right time.”

PMI POINTS TO PRIVATE SECTOR GROWTH MOMENTUM

The recent Ulster Bank Purchasing Managers Index pointed to growth gaining momentum in the Northern Ireland private sector. Output, new orders and employment all increased at sharper rates. However, rates of inflation in both input costs and output prices continued to ease. Richard Ramsay commented, “Construction was the only NI sector not in expansion mode in March. The lack of a Stormont Executive and a paralysis in decision-making is being felt and will continue to be felt in this sector. This is reflected in the new orders indicator which has indicated declines for 21 months running. In the latest report, construction was the only sector not to see new orders growing, in fact recording a marked fall”.

He added “One of the few bright spots for construction is employment, with headcounts growing as firms fill vacancies that they perhaps were unable to fill when the labour market was tighter. Indeed, employment was strong across all sectors, growing at the joint-fastest pace on record and one that exceeded all other UK regions.

SAFE QUARRY MAKEOVER AND TOOLBOX TALKS

Last but by no means least, can I again recommend to all readers our SafeQuarry.com, which has recently had a makeover. Safequarry is a longestablished website, managed by MPA as a resource for the whole industry. It provides an important central hub which includes circa 1,200 examples of good practice from the MPA Health and Safety Awards, guidance, incident alerts, toolbox talks, hot topics, over 400 videos and other resources that are relevant to all product sectors within the mineral products industry. Updated versions of both the Safequarry and QNJAC websites were jointly launched on 1st March at an industry health and safety forum. MPA has launched a series of nine toolbox talks that deal with isolation from energy sources on mobile plant. The toolbox talks cover a wide range of earthmoving plant including excavators, loading shovels, dump trucks as well as road vehicles including tipping lorries, and tankers. The resources were developed by the MPA Fatal 6 working group that considers Isolation and Entrapment and are an essential resource for operators and engineers who may be required to carry out maintenance on mobile plant. The guides consider all sources of energy that are typically found on mobile plant and go beyond motive power. Other sources of energy include hydraulic, gravitational, and pneumatic. A significant proportion of fatalities in the industry

have been as a result of contact with moving machinery, often associated with reactive maintenance and a failure to correctly isolate all sources of energy. Much work has been done to reduce the risks from unintended start-up of plant that has not been correctly isolated; these guides are a useful tool to illustrate other sources of energy found on mobile plant that could cause serious injury or death if they are not identified and correctly isolated. The new toolbox talks on isolation can be found on Safequarry.com. Please go to Fatal 1 – Contact with moving machinery and isolation section of the website and click on the Orange Toolbox Talk rectangular button, that can be found at the bottom of the page. Safequarry is now similar in appearance to the main MPA website and features improved functionality and navigation. Whilst content can be searched using criteria based on specific product sectors, experience has shown that vital lessons and experience can be gained by reviewing content, such as incidents alerts and good practice, generated from across all the product sectors. We are all Safer by Sharing. We look forward to seeing as many members as possible at our Local Member Forum on May 25th in the Seagoe Hotel Portadown, kindly sponsored by the Norman Emerson Group. To all our Affiliate Members please remember that if you want to put up a stand please do so early as space will be in high demand.

If you’re interested in becoming a full or affiliate member of MPANI and get access to up to date Industry news and guidance don’t hesitate to give me a call on 07876136929. It would be great to have you on board.

essential materials sustainable solutions 23 PLANT & CIVIL ENGINEER

More short tails for Takeuchi

New for 2023 is an addition to the extensive Takeuchi line up of short tail excavators.

The TB335R is a stylish new short tail that weighs in at 3.8-tonnes. One of the new 3-Series Takeuchi excavators, it is packed full of value-added features offered as standard for maximum safety and productivity.

The new model sits in the 3-4-tonne weight class. Stage V ready with 18.2kW and Eco operating mode this short tail delivers maximum versatility on-site. The larger than average track frame and optimised counterweight provides excellent stability and just 75mm maximum track overhang. The compact size offers maximum accessibility where space is limited.

The 3-Series styling comes with a very comfortable large styled cab with high back suspension seat and good foot room. A highlight is the 3-Series automotive styled Jog-Dial and large colour touch screen for easy machine operating. Designed for maximum all day operating, climate control comes as standard in the TB335R along with skylight with sun shade and

rainguard. The in-cab DAB radio, microphone socket, Bluetooth, and a 12V charging socket provides all the support operators need for a “working office”.

The TB335R is designed with attention to safety on site. Visibility is enhanced with all around LED work lights – front, back and internal. The blind-side window is larger and lower for maximum dig and slew area visibility. Holding check valves are fitted as standard along with audible warning lift alarm. The steel hitch pipework is factory fitted with easy hand/ foot activation switches. Regular attachments can be pre-set and password secured. Service access as always is first class. The swingout engine hood and large side panels provide full 270° access for daily checks and servicing. The electric re-fuelling pump provides fast fill-up and has a cradle for safe storage. The in cab easy lift floor

panels combined with a new front of cab service panel give maximum access to hydraulic components and test points. The TB335R combines all the proven characteristics of Takeuchi excavators: smooth hydraulics, power performance, proven durability, high resale value, with maximum operator comfort and serviceability.

Mobile Screen for Coarse Elements - More flexibility and efficiency on site

Kleemann

The new MOBISCREEN MSS 802(i) EVO offers users a mobile, efficient screening plant that was designed to meet changing challenges in different application areas. With its well-thought-out plant design and flexible conversion options, Kleemann demonstrates how a high material flow can be guaranteed in natural stone and recycling applications. With the development of the MOBISCREEN MSS 802(i) EVO, a new generation of screening plants and successor of the MS 15 Z, Kleemann consciously places the focus on the user perspective. The technology behind the screening process must be easy and safe to use for all users. The new plant impresses not only with technological highlights in the process sequence, but also through its ergonomic design, optimised operation and the userfriendly maintenance concept.

Improved mobility and flexibility

With its proportionally controlled running gear, the plant can be quickly relocated either by a lowloader to the job site or within the building site. Apart from other improvements of the new MSS 802(i) EVO, folding of the side discharge conveyors without the need for disassembly clearly

reduces set-up times. Increased application variability is provided by a hopper rear wall that can be folded to three heights, which permits feeding of crushing plants with a lower discharge height. The simple adjustment of the screen parameters rapidly adapt the MSS 802(i) EVO to a very wide range of feed materials, reduce set-up times and thus

personnel requirements and costs. The screen casing angle with a wide adjustment range from 15.4 – 20° makes optimises the screening capacity possible, allowing the MSS 802(i) EVO to produce and discharge two or three final grain sizes, Efficient and precise process sequences for optimum material flow

An optimised material flow is a central aspect of all screening plants. With its new mobile screen for coarse elements, Kleemann demonstrates what screening plants of the latest generation can achieve. This includes a wide crusher discharge conveyor on which, like all of the other conveyors, the speed can be steplessly adjusted, as well as a large material transfer system to the screen deck for optimum utilisation of the screening surfaces. High discharge heights and thus higher stockpiles thanks to the optionally available extended crusher discharge conveyor and telescopic side discharge conveyors guarantee ideal processes on the building site. The new MOBISCREEN MSS 802(i) EVO can be operated through line coupling with all EVO and PRO crushing plants integrated in the process and safety system.

news 24 PLANT &

ENGINEER

CIVIL

|

PLANT & CIVIL www.plantandcivilengineer.com

The MSS 802(i) EVO impresses with a feed capacity of up to 500 t/h in natural stone and in recycling.

Sod is turned on ‘pivotal’ new wastewater project in Athlone and the Midlands Region

A sod turning to signal the start of construction on one of the largest capital investment projects to date by Uisce Éireann took place in Athlone, on the banks of the River Shannon. The €114 landmark project to upgrade the town’s wastewater collection system is pivotal to meet the growing needs of homes and businesses, while providing capacity for current and future growth and development. Crucially, the new scheme will also protect the environment and enhance water quality in the Shannon while significantly reducing the risk of sewer flooding to homes and businesses.

Commenting on the importance of the project, the CEO of Uisce Éireann, Niall Gleeson said: “This is a landmark project for Athlone and its surrounding communities, and we are looking forward to delivering it on their behalf.

“The project itself is one of the largest capital investments by Uisce Éireann to date and will bring numerous benefits to the local community and environment. It is a massive undertaking for us and our delivery partners, and today marks another major milestone in our work to ensure that wastewater is adequately treated and meets appropriate standards before being safely discharged to the environment.”

Uisce Éireann is responsible for delivering public drinking water and wastewater services for the people of Ireland. It is committed to enabling communities to thrive by continuously upgrading and developing critical infrastructure to support sustainable growth and development, providing safe drinking water, and enhancing the environment.

news 25 PLANT & CIVIL ENGINEER Heavy-duty radar sensors designed to detect people and objects. Radar Object Detection. Built by Brigade. 01322 420 300 brigade-electronics.com Scan for more information

PLANT & CIVIL FOLLOW US ON

Minister for Housing, Local Government and Heritage, Darragh O’Brien TD and Niall Gleeson, CEO of Uisce Éireann, with pupils from St Peter’s National School at the sod turning of the €114 landmark Athlone Main Drainage Scheme project which will safeguard the environment and enhance water quality in the Shannon while significantly reducing the risk of sewer flooding to homes and businesses.

DEVELON to show DL280-7 Wheel Loader at WasteExpo 2023

DEVELON, formerly known as Doosan Construction Equipment, will display a next-generation wheel loader during WasteExpo in New Orleans, Louisiana in the USA from 2-4 May 2023. The DEVELON DL280-7 wheel loader will be in booth 2512 during the trade show at the Ernest N. Morial Convention Center. The DL280-7 wheel loader offers durability and manoeuvrability for loading and carrying construction materials, transporting scrap or working at agricultural facilities. Durability features include optional stronger axles, increased lift capacities, wider radiator fin spacing and a standard reversible fan to clear dirt, dust and other large debris to reduce clogging. Featuring a roomier, more comfortable cab, the DL280-7 includes relocated controls for more intuitive use. Increased glass area, a

full-glass door, larger mirrors and optional LED work lights offer all-around visibility. In addition, the exclusive Transparent Bucket option provides a supplemental visual perspective by allowing operators to ‘see through’ the bucket from an in-cab display. An upgraded heating and air conditioning system is designed to keep wheel loader operators comfortable when working long days. The Smart Guidance System provides tips for operators to achieve more efficient machine use.

NTA to Brief Domestic & International Construction Sector on Sustainable Transport Plans

The National Transport Authority (NTA) is to brief contractors and consultants in Ireland and abroad on opportunities that will arise as a result of National Development Plan (NDP) investment in sustainable transport over the next decade.

The briefing will take place by way of a two-hour Zoom webinar on 26 May. Interested parties from Ireland and abroad will be invited to attend.

The meeting will be chaired by NTA CEO Anne Graham and addressed by Minister for Transport Eamon Ryan along with Minister for Public Expenditure, NDP Delivery and Reform Paschal Donohoe. Representatives of Iarnród Éireann and Transport Infrastructure Ireland will also participate in the event.

The meeting will hear of NDP plans to invest in public transport, active travel and the

connectivity of communities to the tune of €35bn, including €15.3bn allocated to the NTA between now and 2030.

Sustainable transport programmes earmarked for funding in the NDP include BusConnects, MetroLink and DART+ along with an ambitious

Engine: 139 kW (189 HP)

Operating weight: 15673 kg

Bucket capacity: 3 m3

Static tipping load, full turn: 10820 kg

Dump height: 2819 mm

Dump reach, 45 degrees: 1.14 m

programme of active travel schemes around the country. NTA CEO Anne Graham said: “We’re looking to hear from contractors, designers, consultants, and any other interested parties involved in the construction supply chain.

“During next month’s event, attendees will be encouraged to message NTA facilitators to schedule one-to-one followup sessions with ourselves or with some of the other key stakeholders, either for later that day or in the following days or weeks.”

news 26 PLANT & CIVIL ENGINEER

PLANT & CIVIL FOLLOW US ON

DL280-7 Wheel Loader Specs

180° www.terex.com/ecotec SHREDDING | SCREENING | HANDLING | SEPARATING | CONVEYING

SUPERIOR SCREENING WITH TEREX ECOTEC’S NEW PHOENIX 2100T TROMMEL SCREEN

Leading environmental equipment specialist, Terex Ecotec, has further enhanced its trommel offering with the launch of the new Phoenix 2100T. A tracked variant of the market leading Phoenix 2100 trommel, it has been intuitively designed offering operators unrivalled throughput, application flexibility and serviceability. Fully equipped with a Stage V/ Tier 4 Final engine and the latest intelligent screening technology, the Phoenix 2100T delivers superior screening efficiency. Ideal for medium sized operations the Phoenix 2100T can accurately screen a variety of materials including compost, biomass, soil, green waste, C&D waste and aggregates.

Pawel Kononczuk, Sales Director commented: “The Phoenix 2100T is the latest trommel to be launched by Terex Ecotec and will complement our strong range of trommels already in the market. Whilst maintaining the key features of the existing Phoenix trommel range, it has been purposefully engineered

to provide improved service and maintenance access. Manoeuvred via heavy duty crawler tracks, the Phoenix 2100T offers increased site mobility and is a great solution for difficult terrain.”

With a rapid set up time the Phoenix 2100T is ready to work in minutes with no tooling required. The user-friendly control system with push button start/stop offers simple operation and diagnostics, allowing the operator to effortlessly configure the machine to suit the required application. The fully proportional, hydrostatic feeder combined with an

trommel screen 28 PLANT & CIVIL ENGINEER

www.terex.com/ecotec

intelligent control system continually monitors the machine adjusting the feeder speed to optimise screening performance and throughput.

The Phoenix 2100T is fitted with a 1.94m x 6.45m screening drum with heavy duty mesh or punch plate options available ensuring that all application requirements are met. Equipped with a powerful hydrostatic fourwheel drive system the Phoenix

2100T offers unrivalled start up torque and screening efficiency. With a fully independent track subframe the drum screening angle can be adjusted from 0° - 7° whilst in operation. Maintenance and inspection can be carried out with ease due to the side drum access. Powered by a 102kW (137HP) CAT C4.4 Stage V/Tier 4 Final engine, the Phoenix 2100T offers the perfect blend of power

and efficiency, reducing operating costs. Both noise and emission levels are reduced due to the machine running at a lower engine RPM. The swing out power unit provides unprecedented service access enabling daily checks and maintenance to be carried out from ground level. The 180° radial fines conveyor with a variable discharge height of up to 5.3m can be remote controlled whilst in operation,

maximising stockpile capacity. Both the radial fines and oversize conveyors lower to ground level hydraulically for maintenance.

The Phoenix 2100T is available to purchase now via Terex Ecotec’s world class dealer network that provide the sales and aftermarket service demanded for in the market. To learn more and to locate your nearest dealer visit www.terex.com/ecotec

trommel screen 29 PLANT & CIVIL ENGINEER

IDEAL FOR MEDIUM SIZED OPERATIONS THE PHOENIX 2100T CAN ACCURATELY SCREEN A VARIETY OF MATERIALS INCLUDING COMPOST, BIOMASS, SOIL, GREEN WASTE, C&D WASTE AND AGGREGATES.

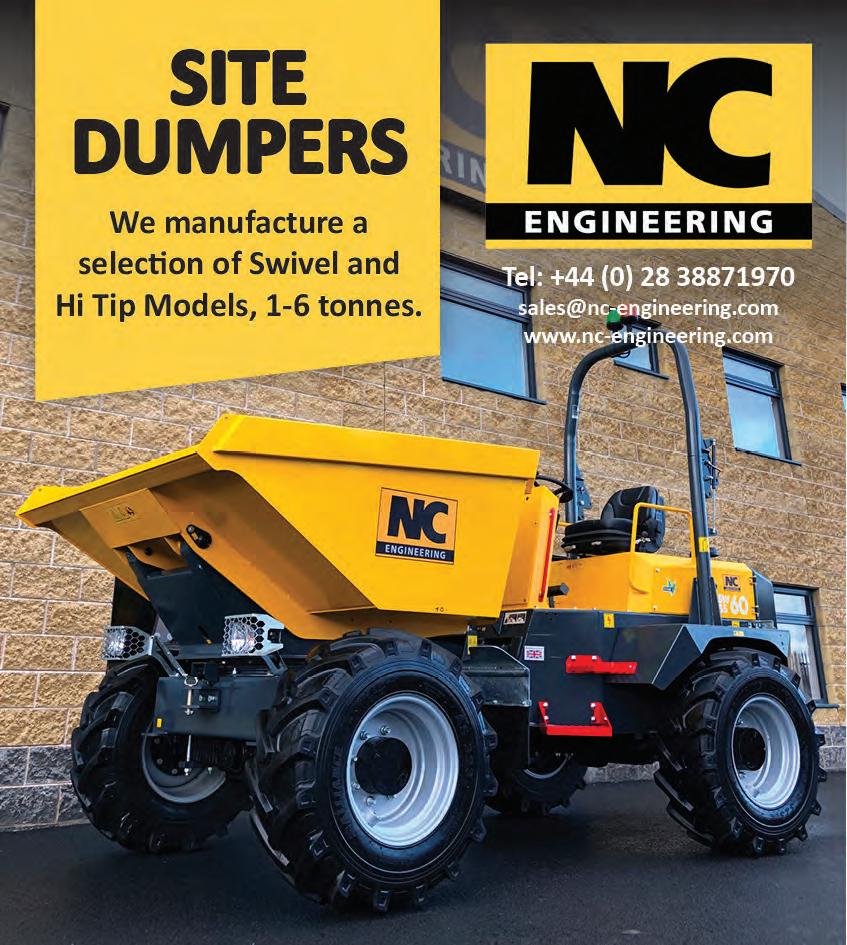

SENSATIONAL SANY STEPS UP TO THE PLATE AT KM PRODUCTS

30 view from the cab PLANT & CIVIL ENGINEER

SANY SY 155U SCAN THE QR CODE TO WATCH THE VIDEO. VIDEO STORY

A key member of the team at KM Products in Laurencetown, Paul McMullen is a professional digger driver with thirty-five years’ experience, but he’d never met a SANY before. That was until Kevin Murphy of KM Products bought a SANY SY155U from Sleator Plant. Plant and Civil Engineer caught up with Paul to get the verdict on the compact zero tail-swing excavator. Paul does all of KM Products’ digging and excavating works and he is also contracted by other companies. He’s driven just about every excavator brand but he’d

never met a Sany before. He’s liking the experience.

“Kevin is expanding his site considerably, and he decided to buy his own excavator as an investment and for ongoing work,” says Paul. “The site to be excavated was 18 metres by 35 metres, so we wanted a compact machine but one that could handle any job. We both went to Sleator Plant in Mallusk to try out the Sany SY155U. We liked it, Kevin bought it and I’ve been working away with it since it arrived about six weeks ago.”

“It’s a real tidy, compact machine but, at 16 tonnes, it punches plenty of power, thanks to the Stage V ISUZU

engine. The zero tail-swing really improves its ability to work in smaller spaces and load-sensing hydraulics means you’ve always got the power you need, while at the same time increasing fuel efficiency. Its capabilities are unbelievable for its size it’s well capable of doing the same work as a 210. It’s as good a digger as I’ve ever driven; it can handle heavy work, it can get into tight spaces, it’s good on sloping ground and it is very economical to run. It’s also relatively quiet, which is a bonus. So far, I’ve clocked 130 hours on it and there have been no issues or glitches at all, the SY155U just

keeps on getting on with the job.”

WHAT ABOUT LIFE INSIDE THE CAB?

“It’s very comfortable,” says Paul. “It’s got everything you’d want and then some. There’s a great view from the cab and a rearview camera, so I feel confident I can see everything going on.

The seat’s air suspension makes it very comfortable and it can be heated for working in colder weather. The screen and instrument panel are very easy to read and there are LED

31 view from the cab PLANT & CIVIL ENGINEER CONTINUES ON NEXT PAGE

work lights which make it easy to work on as the daylight is fading.

“There’s plenty of storage space inside and the sound system is excellent, which is a bonus for me as I’m driving it from 7 am to 9 pm on Saturdays and Sundays. Even taking all your breaks, that’s a long day in the cab but the design and finish are very comfortable, even on long shifts.”

THE BUSINESS CASE FOR THE SANY SY155U

Kevin Murphy established KM Fuels in 2010, originally as a fuel, oil and gas distributor, but the business has expanded considerably into timber, aggregates and building supplies. Already KM Products can service any construction or DIY project from stock, however, the range and stock holding capacity will increase significantly with the new space currently being created with the Sany machine.

“This was my first excavator purchase, so I didn’t have any set ideas about which brand I wanted, I was more interested in getting the right size of machine

with the capability to do anything I might want it for,” says Kevin.