Publisher/Editor

Ed Haskey

E-mail: ed.haskey@aircraftit.com Telephone: +44 1273 454 235 Website: www.aircraftIT.com

Chief Operating Officer

Scott Leslie E-mail: scott.leslie@aircraftit.com

Copy Editor/Contributor

John Hancock E-mail: john@aircraftit.com

Magazine Production

Dean Cook

E-mail: deancook@magazineproduction.com

AircraftIT MRO is published bi-monthly and is an affiliate of Aircraft Commerce and part of the AviationNextGen Ltd group. The entire contents within this publication © Copyright 2021 AviationNextGen Ltd an independent publication and not affiliated with any of the IT vendors or suppliers. Content may not be reproduced without the strict written agreement of the publisher. The views and opinions expressed in this publication are the views of the authors and do not necessarily reflect the views or policies of their companies or of the publisher. The publisher does not guarantee the source, originality, accuracy, completeness or reliability of any statement, information, data, finding, interpretation, advice, opinion, or view presented.

As we approach the end of 2022, we might be tempted to heave a sigh of relief but maybe we’d better not tempt providence. We started the year still living with the effect of a pandemic and, more importantly, with the changes it had brought about for the airline and operator industry. Solutions and technologies that had once been ‘nice to have one day’ were now ‘must have in order to be able to operate’. Apart from anything else, there has been a significant change in the proportions of fleets that could be described as intelligent aircraft which generate huge quantities of data; but data is of little value if it cannot be sent to the right place and applied usefully. In this issue, we look at several aspects of digital technology, data and connectivity.

Our article from Lufthansa is about their A350 aircraft which use Rolls-Royce Trent XWB engines that generate large volumes of data which Rolls-Royce can use to improve performance and reliability; but the trick is how to get the data from the engines to Rolls-Royce and get the results back to the users. The article examines the high-quality data exchange solution that does the job. Air Tahiti is in a unique situation being geographically distant from almost anywhere else which means that they have to be self-reliant when it comes to MRO and stores. The airline needed a solution that would improve productivity in maintenance planning, stores management, airworthiness and utilization of the fleet.

An integrated M&E system has delivered all of that. With digitalization and mobile working comes a growing fleet of tablets and smart phones as well as the airline’s usual IT devices. From Air Canada you’ll read about the challenges of running several fleets of different devices and how they were resolved by a third-party device management solution that not only controls the devices but also ensures they are all synchronized for efficiency and regulatory compliance. Finally, we have an article about how Air Europa managed to implement a suite of software and mobile apps during the pandemic. Not just that but also what benefits the airline has gained and its plans for the future of the solutions.

The column in this issue, ‘What IT can do’, focuses on the challenge of getting ever larger volumes of data to ever growing numbers of applications which can turn it into useful information and get that information back to the people who need it. As usual, it wouldn’t be Aircraft IT without our vendors and, in this issue, Ultramain Systems, Swiss AviationSoftware, QOCO Systems and Exsyn Aviation Solutions all complete their Job Cards for you. Add to that our regular round-up of news and technology developments and the comprehensive ‘MRO Software Directory’ and you have Aircraft IT MRO: ideas and new developments that will improve your business today.

Wishing all readers a very happy New Year 2023.

Aircraft IT MRO: In so many ways, connectivity is the key component in successful use of IT solutions

Keeping up with what is happening in a complex and evolving business world is a challenge. At Aircraft IT MRO or here in the Aircraft IT MRO e-journal the latest developments are sorted and ready to read.

Keith Dugas, Director, Maintenance AI & Connected Operations, Air Canada

How Air Canada took control of the management of several fleets of devices and how synchronicity was achieved to meet exacting commercial and regulatory requirements.

Rutger Krom, shares the continuing drive within EXSYN to help airlines and MROs manage aircraft airworthiness and maintenance data

In the first of our Q&A pieces, Rutger Krom, Senior Aircraft Data Consultant and NEXUS Solution Architect, Exsyn Aviation Solutions, completes his ‘Job Card’ for Aircraft IT.

Julien Lebeau, Project Manager, Air Tahiti

How an integrated M&E system has enhanced productivity and efficiency for Air Tahiti and how IT has played key role in improving maintenance planning, stores management, airworthiness and utilization of the fleet.

John Warren explains how Ultramain’s pioneering commitment to paperless processes has freed clients to concentrate on what matters

In the next of our Q&A pieces, John Warren, Executive Vice President, Ultramain Systems, completes his ‘Job Card’ for Aircraft IT.

Lena Duken, Airworthiness Engineer, Deutsche Lufthansa AG and Jeff Winter, Senior Consultant, Deutsche Lufthansa AG

Lufthansa has a modern fleet of smart aircraft with connected Rolls-Royce engines and a new MRO/M&E management system. To get the best return from both needed a high-quality data exchange. This is what was implemented.

Andy Graham, knows that honesty and a continuing focus on quality have made QOCO the success it is today

In another of our Q&A pieces, Andy Graham, Chief Commercial Officer and Partner at QOCO Systems, completes his ‘Job Card’ for Aircraft IT.

Juan Miguel Sánchez García and Francisco De Borja Mas Boned

The process and challenges of implementing a suite of software and Mobile Apps during the world’s worst pandemic are covered, along with the benefits Air Europa is seeing from the new system and plans for the future.

Henrik Ollus, Customer Success Manager at QOCO Systems ltd. While unprecedented volumes of data are available to airlines and operators today, getting that data to a place where it can be used is a challenge.

Fabiano Faccoli, shares the enduring commitment to quality and customer service that has made Swiss AviationSoftware successful

In our final Q&A piece, Fabiano Faccoli, CEO of Swiss AviationSoftware Ltd., completes his ‘Job Card’ for Aircraft IT.

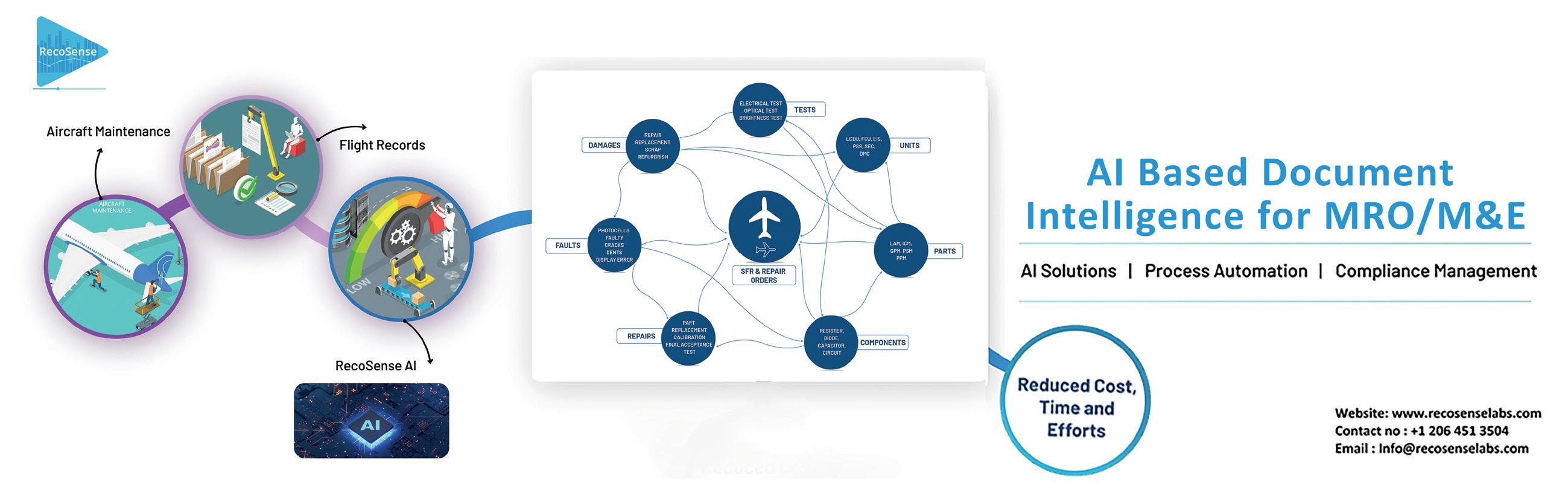

A detailed look at the world’s leading MRO IT systems

We were very pleased to welcome two new vendors to the Aircraft IT panel RecoSense Infosolutions Pvt Ltd offers an AI-powered platform for document analysis and data centralization. The platform powers Process Automations and Compliance Management with MROs in the Aviation Industry. RecoSense works as an Engineering partner with customers to build enterprise-specific solutions. Users can automate processing of manuals, process forms, M&E/MRO Records, job cards (Routine/Non-routine even handwritten), Logbooks, EOs, Technician reports, SFR’s, compliance, inspection reports, etc. with context, and can extract key Aviation metrics for analysis. The NLP-backed DocuSense platform swims through millions of documents to extract and consolidate the most relevant, insightful information for valuable investment data. It automates the process, which might take 1000s of manual hours, thus reducing Turn Around Time (TAT) while increasing operational performance and compliance through user-friendly interfaces. The platform not only evaluates the data but also can understand context through its unique knowledge graph.

ADE is a wholly-owned subsidiary of Capital A Berhad and based in Kuala Lumpur, Malaysia. The business leverages the AirAsia’s Engineering Department’s best practices and unsurpassed combined experience in the region. ADE offers a range of aircraft services focused on the Airbus A320, A321 & A330 for

engineering maintenance services, component and warehouse services, and engineering support services.

Equipped with state-of-the-art infrastructure and facilities and vast experience in airline engineering managing the world’s best low-cost airline, ADE aims to uphold the highest standards when it comes to professional integrity, quality and reliability; driving greater efficiencies and safety, for customers.

The operation is driven by big data, innovation and state-of-the-art digital technologies. Being a fully integrated digital company, ADE strives for operational excellence through enhanced visibility, intelligence, and decision making enabled by data. By combining data from their daily operations with other external data sources, ADE can provide customers with the most comprehensive end-to-end solutions to meet their needs. Supporting customers with the best, tailor-made solutions will always be ADE’s approach.

As a customer-driven company, your satisfaction is always ADE’s number one priority. They will remain nimble and agile to deliver the very best in the market when it comes to safety, reliability and customer service, which are the key components to their success.

Aircraft IT COO, Scott Leslie welcomed the new vendors stating, “Our vendors are the lifeblood of Aircraft IT and what RecoSense and ADE offer are very relevant solutions for our times.”

Perhaps it’s time to consider a new solution…

ENVISION and its mobile apps combine intuitive user-interfaces with streamlined workflows to help your teams work faster and more effectively.

The time saved on day-to-day tasks coupled with efficiencies gained from intelligent planning and analytics, allow you to increase profitability across your operations.

So if you’re ready for an upgrade, why not discover what ENVISION could do for you

in their MRO software as the legacy software was no longer in the position to support today’s airline maintenance requirements. Among others, the airline was looking for fully integrated end-to-end support for all processes for fixed and rotary wing aircraft combined with the capability to support a paperless operation. The operation of their aircraft is far from standard, the mixed fleet brings with it a mixed utilisation with its own challenges. A combination of scheduled, charter medical and SAR flights have to be accommodated when managing all ground activities and supporting business areas. With these requirements in mind, Air Greenland started an in-depth selection process to get a clear picture of the capabilities and gaps on the available software solutions. AMOS was able to

off the requirements and having a proven track record of successful implementations around the world for helicopters as well as fixed wing aircraft so, in late September 2022, Air Greenland and Swiss AviationSoftware were pleased to announce that the airline had chosen AMOS for its new MRO software.

“Air Greenland joins the evergrowing helicopter group within the AMOS Community and their mixed fleet is a perfect showcase of how AMOS allows customers to manage fixed and rotary wing aircraft within one MRO software” stated Fabiano Faccoli, CEO of Swiss AviationSoftware Ltd.

The implementation project is in full swing with workshops and training

being delivered both on-line and on-site. While the project started during the pandemic and all services from Swiss-AS had to be performed online, on-site travel is now possible again to the benefit of both, Swiss-AS and Air Greenland. Flexibility, creativity, and the lessons learnt from the beginning of the pandemic ensured that the travel ban did not block the implementation progress.

As with any project, one of the key paths to success is collaboration. Being able to support the dedicated and highly knowledgeable team from Air Greenland with in-house experts from Swiss-AS Business Consulting and Training, who bring years of experience and expertise, not only in regards to AMOS, but also in rotary wing operations and maintenance as well as airline and MRO activities, has continued to build on the strong foundations built during the selection process.

Greenland is not only a unique project geographical location for Swiss-AS staff, it has also had an impact on the implementation set-up: Contrary to the strong trend within the AMOS Community, and industry, due to its remoteness Air Greenland will not rely on cloud hosting, but will instead run the server on premise.

With the AMOS Airline Edition, Air Greenland will perform most of its maintenance inhouse and rely on the industry best practice processes that come with the MRO software.

AMOSmobile/EXEC is also in the scope of the project and will complete the AMOS user experience in the hangar.

In early October 2022, Ghana’s second largest airline, Pisces Aviation Ltd DBA PassionAir, announced that it had opted for Rusada’s ENVISION software to manage its airworthiness, maintenance, and flight operations.

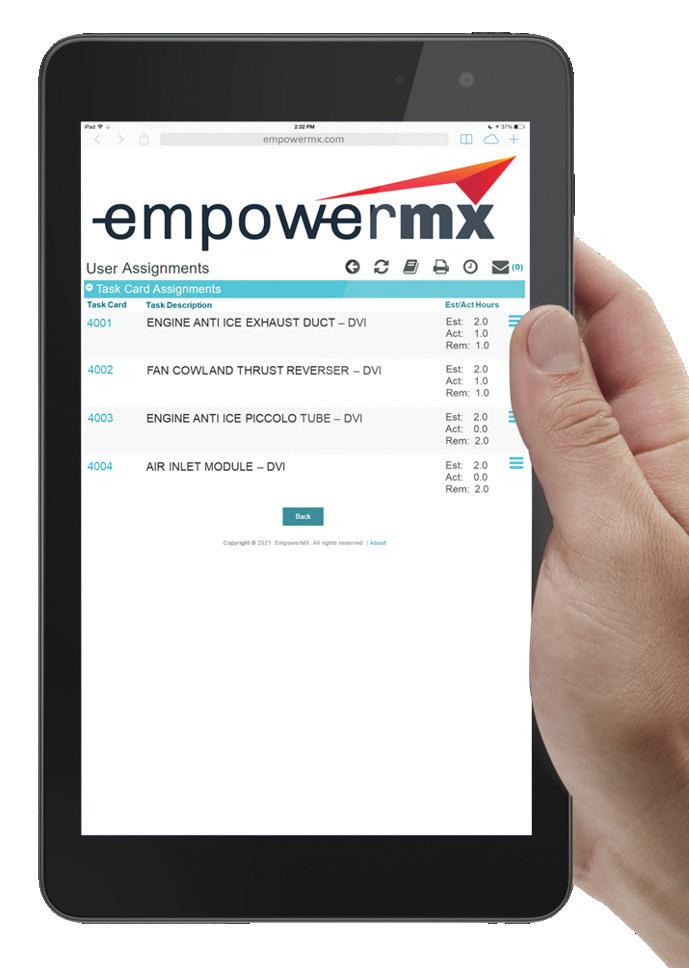

From their base in Accra, PassionAir utilize a fleet of De Havilland Dash 8’s to serve destinations across Ghana. With plans in place to expand their routes and fleet, the operator has selected Rusada’s software solution to manage their operational activities going forward. They will adopt seven of ENVISION’s modules including Fleet Management, Base & Line MRO, Flight Operations, and Human Resources, which will be used to ensure regulatory compliance, effectively manage maintenance activities, and support day-to-day operations.

“We were looking for a more professional system that would bring our airline together and make our activities more efficient as we grow.” said Philip Nartey, Technical Services Manager at PassionAir “We are now looking forward to working with Rusada to get the system in place and prepare for go-live” he continued.

Rusada’s web-based solution will be implemented by their in-house deployment experts, with a view to go live early next year.

“PassionAir are another very welcome addition to our growing customer base in Africa. With their planned growth in mind, now is the

modern software solution that can streamline their operations. I know our teams are eager to get started on what promises to be another exciting implementation project.” stated Julian Stourton, CEO at Rusada.

Rusada: Rusada is a leading provider of aviation software with over 35 years of experience in the industry. Its ENVISION software manages over 2,000 fixed and rotary wing aircraft for 150 operators, maintainers, and manufacturers in 45+ countries. With its headquarters in Switzerland and offices in the USA, UK, UAE, India, Singapore, and Australia, Rusada provides global support for a global industry. Specialising in the management of airworthiness, maintenance, and flight operations, ENVISION is developed solely for aviation. Its modern, web-based platform features a suite of integrated modules, enhanced by a series of native mobile apps. ENVISION’s easy-to-use interface provides users with clear, actionable information, enabling processes to be carried out quickly and efficiently, and all without the need for paper or spreadsheets.

Air Atlanta Icelandic has been successfully running its global charter and ACMI operation for 36 years. For 25 of those years Air Atlanta has been a TRAX Maintenance & Engineering software customer. The company is now ready to transition to the TRAX eMRO product to allow its employees to be connected no matter where they are with access to real-time information. So, in early October 2022, Air Atlanta announced that it is turning to eMRO as a proven web-based device-agnostic solution with a modern user interface and a zeroinstall client. It matches how aviation works today.

Air Atlanta has a fleet of 15 Boeing 747-400 aircraft. Its core business has always been ACMI (Aircraft, Crew, Maintenance, and Insurance) leasing of their aircraft to other airlines. They provide their customers with a dedicated aircraft, which is fully crewed, maintained, insured, and managed under Air Atlanta’s Air Operator Certficiates (AOCs) for an agreed period of time. They’ve recently begun setting up a CMI hybrid service that manages the day-to-day operations for a customer’s aircraft. Air Atlanta also has management services that can provide maintenance and planning training, quality, safety and security, as well as the daily operation of multiple types of customer’s aircraft.

Together with the TRAX eMRO cloud-based aviation maintenance

solution, Air Atlanta can continue to provide the efficient and high level of service for its customers that it has been known for these many decades.

Air Atlanta: based in Kópavogur, Iceland, Air Atlanta is a charter and ACMI airline that has been operating for 36 years. It specializes in leasing aircraft on an ACMI and wet lease basis to airlines worldwide needing extra passenger and cargo capacity, as well as taking passengers to the sky with its own airline operation and charter services. The company operates in different countries and has bases worldwide.

TRAX: TRAX provides comprehensive software solutions designed to manage all aspects of aircraft maintenance. TRAX is the premier provider of aviation maintenance mobile and cloud products in the global market today. TRAX products support digital signatures, paperless Workpacks and manuals, RFID-capability for logistics, Biometric security, offline capability for its suite of mobile apps, web-based applications, and the ability for users to work anywhere with easy access to real-time information.

SafetyNet DocuNet

The world’s most trusted solution built to optimise your technical authoring, document distribution and compliance processes.

A single platform that streamlines SMS processes and enables a proactive safety culture.

Vistair Intelligence

A simplified path from data to insight that increases safety and drives decisive competitive advantage.

www.vistair.com

QOCO Systems Ltd were delighted to announce in late October 2022 that Widerøe has chosen to partner with QOCO Systems Ltd and will be using MROTools.io, the most advanced and dynamic tooling management software on the market. Tooling control has often been an after-thought and Widerøe was impressed with how MROTools.io addressed many of the challenges they had around the tooling environment.

MROTools.io will optimize and digitalize Widerøe’s tool management starting in November 2022. Widerøe was seeking better visibility and control of all the tooling processes and a must was a reliable and proven connection to its M&E system, AMOS.

within our core product functionality. We look forward to a long, and mutually supportive relationship with Widerøe”, said Andy Graham, Chief Commercial Office & Partner at QOCO Systems.

Widerøe: Widerøe, is a Norwegian airline, and is the largest regional airline operating in the Nordic countries. Widerøe Technical Services

InForm combines document & content management with process improvement in our tightly regulated industry. InForm seamlessly integrates with OEMs and M&E Systems to reduce any redundant work.

A completely paperless solution, making task card authoring & management highly efficient and requiring minimal technical expertise. InForm takes advantage of the latest OEM digital Maintenance Planning Document (MPD) and Task Card data (AMM). Support for iSpec2200 & S1000D import is built-in to the Task Card template, allowing imports of the entire deck without hassle.

IDMR offers unified Web-based applications with a centralized platform with no installations required. Our secure web application integrates with federated ADFS access and offers fast performance operating across OS, platforms, devices, and terminals.

Our advanced accessibility functionalities allow our applications to be mobile and work anytime, anywhere; key features for inspectors, technicians, and personnel working in hangars.

Management enjoys real-time access to dashboards to track the progress of checks, run reliability reports, and optimize turn-around time.

www.IDMR.com

“QOCO Systems is very proud to be associated with one of Europe’s oldest and most respected airline operations. Widerøe immediately understood the benefits of moving its tooling process to a digital platform, to ensure they have complete visibility across its diverse engineering operations, whilst ensuring connectivity to its M&E platform, AMOS. QOCO was able to demonstrate our superior control around tooling with enriched analytics in order to make critical decisions on operational investments and efficiencies, as well as rich offering

AS is a fully owned subsidiary of Widerøe AS and a daughter company in the Torghatten ASA Group and Fjord1 ASA. Widerøe Technical Services AS provides technical services in five airports and access to 42 airports throughout Norway. WTS provides Heavy Maintenance, Line Maintenance, Component Maintenance, Ground Support, AOG and training. The main office is located in Bodø.

QOCO: QOCO Systems, a trusted partner of leading airlines, MROs, and aircraft OEMs for over 12 years, helps the aviation industry to succeed in the changing world by creating new ways to work, to communicate, and to utilize data. We enable operational excellence and efficiency in the aviation industry with disruptive SaaS solutions. QOCO is committed to a high level of quality and information security, which is supported by ISO 9001 and ISO 27001 compliant management system certification.

IDMR, the leader in aviation document management software, presents a true web-based end-to-end paperless task cards

EXSYN were delighted to announce at the start of November 2022 that ASL Aviation Holdings has expand its relationship with EXSYN to utilize #NEXUS across ASL’s European airlines. The integration of NEXUS will allow ASL to closely manage the migration of #aircraft #data into AMOS and provide ongoing and extensive data #healthmonitoring capabilities. This agreement reflects the growth of a long-standing support arrangement between ASL and EXSYN around AMOS. “The adoption of NEXUS at ASL underpins the long-term relationship between EXSYN and ASL. In addition, it’s a best-practice industry example of how strong aircraft #datamanagement capabilities support an aircraft operator in #airworthiness #compliance as well as #operationalefficiency” said Sander de Bree, CEO of EXSYN Aviation Solutions.

NEXUS: NEXUS is a software solution in conjunction with an operator’s MRO/M&E system landscape to manage, collect and exchange data in

On-time delivery of aircraft parts is the difference between getting your fleet to the air and tens of thousands of dollars in lost revenue.

Skip the RFQ. Get your parts on-time.

We make it happen. www.aerotrade.ade.aero

© ASL Aviation HoldingsAircraft painting specialist Aviation Exteriors Louisiana (AvEx) announced, at the beginning of November 2022, that it has selected Rusada’s ENVISION software to manage its new line of heavy maintenance activities.

With over 30 years of painting experience under its belt, AvEx, located in New Iberia, Louisiana, recently made the decision to expand its service offering by adding heavy maintenance, and aircraft passenger to freighter conversion to its service

This increase in operational activity highlighted their need for a state-ofthe-art system to manage the new business lines. As such AvEx conducted an extensive research project, and after demonstrations and meetings with multiple providers, Rusada’s ENVISION was selected as the solution of choice.

“Our new additional operations will only be able to grow if we are able to manage the increased activity volume, and analyze effectively, something ENVISION will allow us to do with ease.” Said Jerry Hernandez, CEO at AvEx. “We were very impressed with the intuitiveness of the system. This coupled with Rusada’s professionalism and intellectual knowledge base, made ENVISION a sound choice for AvEx.”

AvEx will use ENVISION to manage the planning, assigning, and execution venture. Implementing ENVISION from

the get-go will allow them to make the best possible start with these new service lines. Our teams will now work hard to get the system up and running, to ensure AvEx’s continued growth in the MRO marketplace.” stated Julian Stourton, CEO at Rusada.

Rusada: Rusada is a leading provider of aviation software with over 35 years of experience in the industry. Its ENVISION software manages over 2,000 fixed and rotary wing aircraft for 150 operators, maintainers, and manufacturers in 45+ countries. With its headquarters in Switzerland and offices in the USA, UK, UAE, India, Singapore, and Australia, Rusada provides global support for a global industry. Specializing in the management of airworthiness, maintenance, and flight operations, ENVISION is developed solely for aviation. Its modern, web-based platform features a suite of integrated modules, enhanced by a series of native mobile apps. ENVISION’s easy-to-use interface provides users with clear, actionable information, enabling processes to be carried out quickly and efficiently, and all without the need for paper or spreadsheets.

ASQS were pleased to announce at the beginning of November 2022 that Jazeera Airways has taken off with IQSMS.

ASQS’s first customer in Kuwait, is also the first non-government owned airline in the Middle East established in April 2004. Jazeera serves to more than 50 destinations across the Middle East, Central and South Asia, and Europe, operating a reliable fleet of Airbus A320 and A320neo aircraft — all fitted with their signature leather seats.

In June 2018, Jazeera was the first airline in the Middle East to introduce the A320neo into its fleet.

Jazeera owns and operates its own terminal at Kuwait International Airport — Terminal 5 (T5) ensuring an enhanced passenger experience with dedicated check-in, fast immigration and short transfer distances. The IOSA certified operator raises the total number of IOSA certified IQSMS customers

to 64 operators.

IQSMS is therefore pleased to support the Kuwaiti airline with our integrated quality and safety management solution, simplifying vital operational processes for higher efficiency and safety. With the IQSMS core modules for reporting, quality and risk management, including the respective offline applications and the Document Distribution Module, Jazeera Airways is making a deliberate choice to promote a sound communication and safety culture throughout the entire organization. Facilitated reporting procedures and the possibility to file reports even without internet connection strengthens the safety accountability of each and every employee in the company and result in an overall increased operational safety performance.

The ASQS team is pleased to welcome Jazeera Airways as their first Kuwaiti customer on board.

In early October 2022, Seabury Solutions, a market leader in providing Information Technology solutions for the aviation industry, announced the integration of AI solutions through strategic partnerships.

“Aurora’s intelligent scheduling technology improves MRO throughput, resulting in improved transparency and reduced costs, while also resulting in superior operations management. Aurora was developed to help tackle difficult, mission-critical scheduling problems—by using artificial intelligence technologies to encode extensive expert domain knowledge with advanced algorithms to generate more efficient schedules. Today, Aurora manages the most demanding operations for organizations such as The Boeing Company, Mitsubishi Heavy Industries, Bombardier Learjet, Spirit AeroSystems, General Dynamics Electric Boat, Korea Aerospace Industries, and the US Air Force, US Space Force, and US Navy,” said Richard Stottler, President, Stottler Henke.

“Having seen OEMs and Tier 1s invest in predictive maintenance driven AI channels, it was crucial that AI found its way into enhancing data quality and integrity using data driven models. This acts as a segway into helping organizations visualize commercial impact of decisions using an Aircraft, Engine or Component’s Airworthiness and Maintenance data. KeepFlying sees great potential for Airlines, MROs, Lessors and Banks to create financial twins for the Assets they operate, lease, maintain and finance to predict costs, revenues, asset placement commercial potentials and risks using Machine Learning models trained across different Aircraft and Engine types.” remarked KeepFlying CEO, Sriram Haran.

“Our decision to include AI into our Functional Architecture was taken right before the Pandemic started and it was included in our road map together with a 5-year plan to execute it. After understanding the necessity of tools driven by AI in areas such as Scheduling, Planning, Revenue Forecasting (specifically for Airframe and Engines MROs, lessors and Financial Institutions) we took the challenge of inviting specialized strategic partners to deliver a set of solutions that will only improve our digital transformation platform and benefit not only current but also future customers,” stated Seabury Solutions CEO & President, Bijoy Mechery.

State-owned emergency medical operator FinnHEMS, announced in early November 2022 that it has opted for Rusada’s ENVISION software to manage its airworthiness and maintenance activities.

FinnHEMS operates Helicopter Emergency Medical Service (HEMS) flights for hospital districts from its seven bases across Finland. They utilize a fleet of nine helicopters, Airbus H135s and H145s, primarily for the deployment of emergency specialists to incidents, rather than the transportation of patients. As such, their callout rate is typically higher and more frequent than standard air ambulance services. With this high volume of flights and need for constant aircraft availability, FinnHEMS was seeking a greater level of confidence in their operational data and determined that ENVISION met all the requirements for the job.

“We are looking forward to relying on ENVISION to give us more certainty around our operations, as well as increased visibility on the readiness of our fleet.” said Tony Ellonen, Continuing Airworthiness Manager at FinnHEMS. “A key desire was to enable our maintenance teams to effectively plan for upcoming events. With ENVISION, vital information will be readily available to our main base and outlying deployment stations so that our helicopters can be strategically maintained, to be available at a

consolidating their current systems into ENVISION, using its airworthiness and maintenance modules to manage their activities going forward. The solution will be accessible via the cloud from any of their operating locations, and its live dashboards will ensure key information is available and consistent company wide. This will significantly reduce user’s workloads and avoid any potential human factors conflicts.

“Visibility and control are two words we are hearing a lot lately. Operators are finding it hard to manage complex operations with their data and processes spread across multiple different systems. ENVISION has been designed specifically to eliminate this problem, but nevertheless it is always gratifying when dynamic, forward thinking companies such as FinnHEMS select us to help out. In the coming months we will go above and beyond to deliver the oversight and control they seek.” stated Julian Stourton, CEO at Rusada. Read the full story on Aircraft IT Website

Seabury Solutions, a market leader in providing Information Technology solutions for the aviation industry, announced at the start of November 2022, the addition of Sky Airline, Chile, to their growing customer base of Alkym users.

“Through a meticulous evaluation process, Sky Airline chose Seabury Solutions’ Alkym to replace its current Aircraft Maintenance Management tool. It filled us with pride to be chosen by the client most known in the region for their innovation, growth, and adaptive business model. Our teams are currently working on an implementation project that will surely conclude successfully,” noted VP Sales Latin America, Manuel Roche.

“As Engineering & Maintenance Managers, we couldn’t be oblivious to the huge digital transformation process the company is undergoing. All internal processes and passenger-related

processes are being automated and the airline is experiencing remarkable growth. Due to this, we’ve been looking into replacing our current Management Information System (MIS) with a new system that can support our growth and the new challenges we must face as an airline. The system will allow us to streamline all our maintenance processes and, as a result, simplify our daily work and interaction with

our “skyers” through the system. The evaluation process to choose the new system was very thorough. Before launching the RFP, every department that interacted in one way or another with the system was consulted to make an internal list of prerequisites; this way, we could satisfy the diverse needs of our local clients. Alkym stood out as the one who fit most of those prerequisites while also being willing to fulfill all the leftover requirements in the middle-term,” remarked Sky Maintenance and Engineering Director, Cecil Davidson Tölg.

Dir. Davidson continued to comment, “One of the most important features that we need from our new MIS is the ability to work outside of the office and through intelligent devices, meaning it needs a mobile function, which Alkym provides. It is also very intuitive, which makes it easy to use and offers us

the possibility to improve the execution and management processes of our productive areas. Finally, it’s important to mention that Seabury has shown flexibility through the whole process and has worked tirelessly to find a solution that fits our needs. We are sure that the implementation process will provide us with many advantages to develop and smooth our maintenance processes; in that way, Alkym will support us in reaching one of our company goals, which is to continue progressing to a complete digital transformation of our processes.”

“It’s always rewarding to welcome a customer with such fleet growth as Sky Airline, who already has 28 aircraft and is waiting on more to arrive in the near future. It means we are on the right path to becoming the most comprehensive M&E Solution in the market, something that we’ve been striving for the last 20 years. There will be other airlines and MROs that eventually will move away from their existing, outdated M&E Solution, and we will be there to welcome them as well,” asserted Seabury Solutions VP & Head of Sales & Marketing, Carlos Bianchi.

Sky Airline: Sky Airline, is based at Comodoro Arturo Merino Benítez International Airport in Santiago, Chile and at International Airport Jorge Chavez de Lima, Peru. It is the second largest airline in both countries, behind LATAM Airlines and the first airline to operate under a low-cost model in Chile. It serves international routes to Argentina, Brazil, Chile, Colombia, Peru, Mexico, the Dominican Republic, and The United States of America. It also operates charter flights in Chile and South America.

Seabury Solutions: Seabury Solutions is a leading global aviation software

Eauthority® (a safety management software for aviation authorities), and a range of airline performance analysis tools within the Enterprise Performance Analysis System (EPAS). The EPAS® suite has models that include capabilities in determining current and future route profitability, maintenance performance, budget planning, fuel planning and distribution channel performance. Read the full story on Aircraft IT Website

„Implementing AMOS as our M&E software was a strategic project for Lufthansa and Lufthansa Cargo. We now have a solid platform to continue our digital push towards more increased mobility, leaner processes and easier data integration across our multiple systems.”

says VP Technical Fleet Management Lufthansa

Lufthansa and Lufthansa Cargo are live with AMOS, the worldclass M&E software solution. Both carriers have implemented AMOS including AMOSmobile, enabling paperless maintenance operations from the beginning.

The close cooperation of the Lufthansa group members will be further promoted by AMOScentral, which enables the exchange of data between AMOS instances while nevertheless allowing each group member to keep control over their individual AMOS environments.

At the endo of November 2022, Aviation software leader Comply365 was pleased to announce that its newest partner, Spright, will leverage Comply365’s document and compliance management system to support its growing drone operations, delivering medical supplies for rural and underserved communities across the US.

Spright uses state-of-the-art UAS technology to provide advanced BVLOS drone solutions tailored to medical delivery and utility inspection applications.

Drone pilots at Spright will use Comply365’s mobile app to access their operational manuals, flight safety, and maintenance documents and provide compliance to required content.

“Commercial drone operators must meet many of the same requirements and certifications as

commercial airlines to ensure safe and reliable operations, so it made sense for us to turn to a longtime, proven solution in the aviation industry with Comply365. We needed a system to manage our operational content and compliance and be able to target the distribution of these documents to our pilots, and we found Comply365 to be a perfect fit.” stated Spright President Joe Resnik

Pilots will always have the most updated content with revision control and automated syncs, and they’ll be able to quickly find content and easily filter and search across all their manuals. They’ll also be able to personalize their documents with annotations, bookmarks, and highlights, which are retained when files are updated. Users will be able to easily see what’s changed in a document and can read and sign in the same place, providing automatic compliance tracking for Spright, with built-in

reporting for regulators.

Spright is the second drone-based operator to join the community of Comply365 users, which includes many major airlines around the globe.

“While we’ve previously transformed existing industries with our solutions, it’s exciting to be part of the new, rapidly growing drone industry. We are thrilled to welcome the innovative team at Spright to our global community of users,” Comply365 CEO Tom Samuel said. “Spright is solving many access and efficiency challenges with the latest technology, and we are proud to partner with them to offer a solution that will scale with Spright as they grow their operations to serve critical needs.”

Comply365: Comply365 is the leading provider of enterprise SaaS and mobile solutions for content management and document distribution in highly regulated industries. Having played an

instrumental role in the FAA’s approval of replacing the traditional, paper-based, pilot flight bags with electronic flight bags (EFBs), Comply365 partners with clients to transform their industries.

Spright: Spright is the drone division of Air Methods, helping to solve many of the toughest challenges facing communities across North

America. This innovative, drone-based solution is tasked with leveraging emerging aeronautical technology to create operational solutions that can be implemented locally. Based in Gilbert, AZ, Spright is a stand-alone Part 135 Operator with a leadership team with more than 70 years of aviation operational experience.

Read the full story on Aircraft IT Website

Towards the end of November 2022, OASES was pleased to announce the launch of OASES Knowledge Base, the ultimate resource for all things OASES related. Initially the new platform will offer articles, product information, instructional videos, updates, webinars and FAQs with added customer interaction and networking in a community environment including:

• Training content accessible 24/7/365;

• 10 October 2022Access to Live Streaming sessions;

• Archive of all webinars and OASES online events;

• A safe environment for content related questions and feedback;

• We will continue to upload and create insightful content in collaboration with our customers and will be offering;

• Self-learning online courses;

• Individual product modules;

• Customised material for organisations.

OASES Knowledge Base will be accessible for free but will also offer ‘advanced content’ with a pay-as-yougo or subscription model offered to customers.

“We’re looking at diversifying our training offer at OASES to embrace more flexible solutions that allow customers, wherever they are, access to a world-class suite of training content based on their needs.”

Explained OASES Operations Director, Alessandra Palmer-Tilley.

“In addition we believe that by presenting this information in a collaborative, community-based environment we can achieve a much better understanding of our customers’ requirements and as such better improve and evolve our product portfolio.” he continued.

OASES Customers that haven’t already received their invitation to access OASES Knowledge Base should contact their Customer Success Manager directly.

Read the full story on Aircraft IT Website

Since switching to Aerros, our customers have:

• Increased fleet size with minimal increase in overhead

• Increased plan detail by 9x and plan length by 4x

• Reduced time to budget by half

Learn how Aerros can dramatically improve your planning results today.

aerostratsoftware.com info@aerostratsoftware.com

■

face in a post-pandemic world is the shift to automating key operational processes such as maintenance auditing and vendor interpretation issues.

South East Asian Airlines, a reputed name in the aviation industry, announced in early October 2022 that it had entered a Maintenance Repair and Overhaul (MRO) agreement with Collins Aerospace for its fleet of 55 Boeing 787s, which also extends to the airline’s budget carrier section, Scoot. The airline has clocked an impressive journey throughout its growth trajectory and has won several accolades for its high in-flight service standards. The airline even runs a subsidiary, the South East Asian Airlines Engineering Company (SIAEC), which undertakes MRO for

began its digital transformation journey in 2018. Since then, they have made extensive progress. However, they were yet to digitize and automate maintenance audits and vendor interpretation. Due to missing data, the sale encountered difficulties when the airline found it challenging to process aeroplane maintenance records. Maintenance checks needed to be completely redone to help plug the gaps. The entire process would need to be undertaken from scratch, resulting in an unnecessary expense and a mammoth effort. Another challenge was the lack of an incumbent mechanism to validate the Shop Finding Reports provided by the vendors. There was no way to check whether the assessed damages were

airline saw it as an opportunity to course-correct and avail itselfof an AI-based solution to address the issue.

This was when AI-solutions provider RecoSense stepped in. After detailed discussions with South East Asian Airlines, RecoSense identified key areas where smart solutions could be applied to simplify the entire aircraft maintenance audits and vendor analysis process and bring efficiency and cost-effectiveness to the process. This comprised AI-based auditing of hand-written maintenance records, standardisation of damages and their classification, and detailed vendor analysis.

The maintenance records at South East Asian Airlines had all been manually created and managed, causing several gaps in the information. Due to inefficient maintenance audits, gathering corresponding MRO data proved

susceptible to inefficiency and data gaps. The second challenge was addressing vendor interpretation to curb unnecessary expenditures. There was no way to tell if the vendors’ Shop Findings Report submitted was accurate. The damages mentioned in the reports often exceeded the actual scope of work, thus resulting in overbilling and revenue leakage, which impacted the airline’s profitability.

Automation via a unified, simplified platform could bring end-to-end transparency and accountability to maintenance audits and vendor interpretation processes. RecoSense implemented its AI Transformation and Content Intelligence Solutions, specifically customised for the aviation industry. The tools used created a niche knowledge graph, interlinking various stages and activities of the MRO and vendor-related operations. This formed the foundation for Natural Language Processing (NLP) and the cognitive engines to function.

When we think about a paper logbook on an aircraft, we think about a piece of paper that is accessible by 1 person at a time. The paper logbook usually consists of notes handwritten by the pilot, technician, or cabin attendant which various parties then transport to the back-office system, hangar, MRO, or relevant destination. Copies must be created, faxed, or emailed and records should be stored or returned to the aircraft. This process can create issues with illegible handwriting, errors, and vital missing information. A digital replacement, in this case the Electronic Tech Log, maximises time efficiency when completing mandatory documents and the app can be configured to input repetitive data or pre-fill date/time automatically. The completed documentation can then be sent to a handler on the ground when the device has a connection. It is no longer necessary to store paper copies (although paper can always be used as a

backup). The data can be structured clearly and easily read.

Producing accurate, consistent and near real-time data means that the recipient of this data has an easier job. Let’s look at maintenance engineers as this is an area that can produce costly delays. A pilot that is using an electronic tech log can enter faults, defects or squawks as they happen (or soon after). These updates are transmitted to the relevant maintenance department, either in real-time or when the aircraft touches the ground. This transmission simplifies the control of maintenance on the line and decreases the chance of parts being wrongly replaced whilst also enabling faster turnaround times. The Electronic Tech Log provides a system that can manage the more dynamic needs of line maintenance by sending timely data in an organized fashion. Longer-term analysis of data can also reveal

accordingly. Finally, there are also benefits to external maintenance teams planning to accept an aircraft at a remote station.

Handwritten entries cannot be searched, used in analytics, or mined for information. The data inside of an ATL is useless until it reaches the hands of the next person in line. An Electronic Tech Log provides a connected system that can be used by multiple people, from anywhere, at the same time. The full influence of an eTechlog can only be seen when we

look at all the areas it affects in an airline. It has often been described as the ‘beating heart’ of an airline due to the range of departments that are affected. An effective eTechlog allows a pilot to communicate with the airline’s MCC both directly or indirectly, line maintenance, 3rd party maintenance and aircraft records without these departments having to depend on each other to pass on data. Not to mention providing back-office teams with real-time views of the Electronic Tech Log in the cockpit, connecting all mission-critical personnel on any given day of operations.

The fact that more stakeholders can see an up-todate view of the aircraft’s status allows for anticipation and forward planning for upcoming maintenance activity. The Electronic Tech Log replaces the paper-based ATL complete with the capability to record approved signatures (under EASA NPA/2016-12), license numbers and to sign off on the airworthiness the aircraft. It can therefore be

treated like the ATL when it comes to the airline’s designated CAA. The recording of defects and MEL items is also something that gets closely monitored by the regulator. The REDiFly Electronic Tech Log comes equipped with a fully searchable digital MEL which automatically provides deferral processes and related information at the click of a button. Furthermore, we at REDiFly use our experience and expertise to provide support for the air operator through the entire approval process.

Although an Electronic Tech Log is not free, its implementation can result in significant cost reductions and savings throughout the entire organization. Paper-based systems can be expensive, time-consuming and physically heavy. Time and money are spent on the storage, printing, entering, and processing of data as well as searching for errors and identifying trends for analytics. Digital data entry is significantly faster, more accurate and instantly searchable, saving team members time and

minimizing costly errors. Data is automatically transferred and stored, meaning technicians get defect information directly and office staff no longer engage in time intensive data entry and processing. The efficiency of defect management is enhanced with access to real time data giving technicians the ability to identify and resolve defects with greater speed and accuracy, resulting in less delays and quicker turnaround times.

Maintaining records, allotting task cards, and extracting detailed information from the records is a laborious task for the aviation maintenance team. The amount of time and resources taken to run the maintenance process and update the records leave the aviation maintenance team wondering if only an automation system exists to help them.

A leading aviation leasing entity came to RecoSense with the same requirement. They needed an intelligent automation system that could analyze the incoming work pack, split the work packs into task cards. Post completion to process/validate the task cards for quick engine dispatch there by optimizing TAT’s.

RecoSense is one of the fast-growing AI-powered data intelligence solution providers. With the

proprietary NLP engine and efficient machine learning & intelligent deep learning system, RecoSense’s AI solution helps organizations better handle tons of data, structure them, and get better insights accurately in a shorter time frame.

• Automated Compliance

• Reduced Turn Around Time (TAT)

• Plugging of Revenue Leakage

• Accelerating Process with higher accuracy

When the aviation leasing entity receives the engine or other major aviation component, a work pack containing thousands of pages regarding the tasks to be performed will be given. Then the maintenance team has to manually extract the data point and add it to the MRO software and Planner excel sheet. Similarly, all the updated task cards from various

technicians during the engine/other major aviation component visit must be collected. Then the task cards must be manually scanned, reviewed, and clubbed together as one whole set for engine dispatch.

Since various human resources are used at each stage, the consistency of the end result varies. It takes months to plan the resources for maintenance, and the team has to wait for the entire set of task cards to arrive to complete the engine dispatch process.

Using legacy systems caused high operational costs, manual errors, and revenue leakage for the leading aviation leasing entity. To overcome the shortcomings, the entity required —

1. Automation for analyzing the incoming Work Packs.

2. Automation in processing the completed Task cards.

While the legacy system takes months to complete and despatch an engine, the AI system can perform the same tasks in a relatively shorter duration. Once the aircraft maintenance team collects the flight records, the records will be fed into the AI system. Later the AI system will-

• Extract data from the records

• Analyze the data and correlate them

• Execute the desired automation task

The task card may contain unstructured data like handwritten data, stamp seals, signatures, etc.; This is where the cognitive AI engine & Natural Language Processing (NLP) engine kicks in. Irrespective of the format, language, and information structure, the NLP engine extracts the proper information without any errors.

The AI system uses deep learning to analyze the extracted data and get progressively higher-level features from the data. These extracted data will be used to perform data classification and correlation, which will help the AI system to automate the desired task, such as extracting the

data and updating the info on MRO software.

Let’s see how RecoSense’s AI-based solution helped the leading aviation leasing entity accomplish its goal.

The goal is to leverage NLP’s full potential to process the work packs and split work packs in a logical order based on the Task card number. Later the extracted data points should be uploaded to the MRO software & Planning excel sheets. Typical process followed on receipt of Work Pack is:

• Print the entire Work Pack.

• Segregate the Work Pack into individual Task cards.

• Populate the Planning XLS.

• Update Task Card Data into MRO Software.

All this work is manually done by the Planning Engineer. A senior resource doing manual work is an anachronism in today’s world.

Thankfully the DocuSense AI platform from RecoSense is powerful enough to perform the complex task of processing the docs and extracting all types of structured and unstructured data. Since the Docusense platform handles thousands of data regularly using high-end Optical Character Recognition (OCR), the system can effortlessly identify the key entities and tag them.

Read the full story on Aircraft IT Website

Air Canada is the largest airline in Canada by fleet size and passengers carried. Keeping aircraft in optimal condition is a critical part of everyday operations. For that, the Maintenance team must optimize aircraft maintenance procedures to ensure security and meet regulatory requirements while minimizing turnaround time between flights to limit the costs of having an aircraft grounded. Essential to meeting regulatory requirements is ensuring that maintenance engineers have mobile tools with the latest documentation always available plus achieving optimal aircraft security. However, maintaining synchronicity across all devices throughout multiple sites presents numerous challenges which can add significant costs and delays that can result in longer aircraft turns.

With the challenges of managing mobile devices, Air Canada looked for a partner to help ensure that their teams always had up-to-date and ready-to-use devices. The best match identified was M3 Solutions and this case study explains how that worked. Of course, different airlines will have different needs but this article highlights the fundamental reasons for having a solution to manage devices, how one such solution works and was implemented plus, of course, what Air Canada gained from implementing the solution.

teams always had up-to-date and ready-to-use devices. The best match identified was M3 Solutions…”

Air Canada first introduced iPads on its Boeing 787 Dreamliners for their entry into service. The goal was to maximize flying time for the 787, which meant maintenance turnaround time needed to be the lowest it could be for any widebody aircraft. To achieve that, gaining as many efficiencies as possible was essential.

Prior to the introduction of iPads, when an aircraft landed, the engineer would take the aircraft defect paper logbook to the closest desk-top terminal to look up the applicable references and determine whether the defect could be deferred and the aircraft dispatched or whether the aircraft would have to be grounded until that defect was resolved. Mobility allowed the adoption of Apps to access information pertinent to the airworthiness of the aircraft; and offered the flexibility to complete all maintenance tasks safely on board the aircraft (as images above) without having to disembark or lose time walking to a desktop computer. It has allowed engineers to fix or legally defer defects faster, which has led to an increase in ‘first-time fix’ rates and a reduction in deferrals into the planning process; ultimately improving aircraft reliability.

The 787 represented a step change in aircraft technology and was well suited to the introduction of a proof of concept for new technologies and processes. As a result of successful implementation of the proof of concept, Air Canada rolled out these new technologies and solutions to all other aircraft types.

As an entirely new concept in aircraft design and the ‘smartest’ aircraft to date at its time, the 787 presented a challenge in the maintenance turnaround and, as Boeing acknowledged, Air Canada achieved the highest levels of reliability among operators of the type. Much of that has to do with the amount of time that has been given back to the aircraft maintenance engineers who can now stay with the aircraft throughout a turn as opposed to spending time on a desk-top terminal.

Initially, the Proof of Concept (PoC) was to showcase the benefits of having all maintenance procedures/recordings done on the wing. The benefits were clear, but the PoC helped iron out several core issues.

One of the biggest criteria for any aviation regulatory body is to maintain synchronicity across all technical publications. Working from the latest and same documentation is a requirement of Transport Canada. Once the OEM publishes a revision to the aircraft maintenance manual, it would be impossible for the revision to be adopted across every platform that an airline operates that same day. When those revisions are sent, operators will also add airline specific content to the revisions and then publish them. This set of documentation can be as large 35GB, making it virtually impossible to synchronize a large fleet of devices seamlessly and efficiently. With the 787’s entry into service, Air Canada found that maintaining synchronicity on all iPads in the fleets was much too cumbersome. In addition, the IT team needed to plan the OS update and the application update, and ensure their compatibility. This is where the partnership with M3 Solutions and their Platform was introduced. It fully automated all of these processes.

Notwithstanding that, the original business case was proven in the sense that our technical dispatch reliability improved. Engineers no longer had to spend time returning to the desktop computer to ensure compliance when deferring defects: now, everything can be done on wing. Engineers have all the maintenance manuals in their hands, with the ability to action a defect on wing which has increased our proficiencies.

We discovered that it would take an IT resource one week to implement revisions or updates on just 25 devices. Air Canada sees approximately three revisions per month (36 per year) for different fleets. That fact alone supported a good business case to introduce third-party management of the devices even before taking account of the regulatory aspect.

Today, Air Canada Maintenance has more than 500 iPads in operation making it simply impossible to manage that large a fleet without appropriate automation enabled by the M3 Platform. Also, although this article refers to the Technical

“One of the biggest criteria for any aviation regulatory body is to maintain synchronicity across all technical publications. Working from the latest and same documentation is a requirement of Transport Canada.”

publication updates, there are, of course, many more to consider such as the software suite of Trax (Quickturn and Task Control), updated daily, as well as iTIMS which is an app built by Interfacing to allow for the housing of our component maintenance manuals as well as our engineering authorization work flow.

Running several fleets of different devices poses several challenges for IT management.

Today’s aircraft are increasingly sophisticated and technically advanced. The amount of documentation needed to outline every aspect of an aircraft’s maintenance has increased tenfold since the days of printed maintenance manuals. Aircraft manufacturers are constantly updating their maintenance documentation to ensure compliance and adherence to safety regulations. In addition to monthly technical publications which are regularly supplied by aircraft manufacturers, there are also unscheduled releases as often as required to catch critical maintenance deficiencies in the equipment and prevent any failures. In both instances, the challenges surrounding how the information is transmitted and how quickly it can be distributed across MRO teams, in every location around the world, to ensure proper compliance across the entire fleet of aircraft, become critical.

With Air Canada maintenance crews operating in multiple locations worldwide and servicing several aircraft models, maintaining synchronization across all of their mobile devices can pose a significant challenge. This is not only to ensure the aircraft’s maintenance documentation is up to date, but that the devices’ OS matches the requirements of the mobile app which provides that information, most often provided from the aircraft manufacturer. If different tablets have different OS versions, then errors may occur which can impact the smooth operation of maintenance teams and result in longer aircraft turns, not to mention added strain on IT resources tasked with resolving those errors.

Updating every device so they have the right operating system, app version and latest documentation is often a time-consuming process. Doing this manually can put an enormous strain on any I.T. department and require multiple people to achieve it in a timely manner. Furthermore, because of the delays associated with this update process, ensuring that maintenance crews all have synchronized documentation on their device, right when the update is scheduled for release, is virtually impossible.

also be able to track each device and have detailed reports of where it was used and by whom.

M3 Solutions’ innovative technology eliminates the legwork involved in synchronizing a mobile device ecosystem by streamlining content deployment, complex data structures and installations required for maintenance crews to perform their jobs. The platform hosts each device and is uniquely tailored to process updates, install certificates, wipe clean after each use, charge the devices, and much more. The moment a user picks up the device they know it will have the same installations and same version of technical documentation that any other user would have in their organization. Within the M3 platform, access is controlled to devices via RFID, barcode and NFC readers – ensuring all devices are physically secured and traceable (figure 1). Ultimately, it’s a platform that bears the load of an IT team, with a worldwide support network ready to troubleshoot from anywhere.

Figure 1

Air Canada saw significant gains as a result of using the M3 Platform, including current functionality:

• Seamlessly manage multiple device-types including tablets and UMD running different OS, in the same installation.

• Deploy new OS or configuration images remotely and unattended, across the entire network. Manage the content on all devices and ensure it is complete and always up to date.

• Gate the deployment of new revisions of apps to ensure compatibility with the OS version deployed.

• Physically control access to portable devices, monitor the users and their usage with administrator permissions and the system management dashboard.

• Schedule or deploy content in real-time, to some or all devices, anywhere in the world, within minutes and without IT resource intervention (remote and unattended content deployment).

• Retrieve accurate device and system monitoring, ad-hoc reporting, and transaction auditing.

• Reduce IT and device inventory costs immediately. Overall system ROI (return on investment) was achieved within months of installation.

The requirement to maintain synchronicity with technical publications and the latest reference documents is a Transport Canada requirement. With 35

gigabytes of monthly updates, we quickly discovered it would not be possible to maintain synchronicity unless we had a controlled mechanism such as the M3 Platform.

In addition to physical security, access control, and inventory tracking capabilities, deploying the M3 Platform significantly helped streamline Air Canada’s maintenance operations by eliminating delays to synchronize all devices for various teams to use. We would be hard-pressed to find another industry where the adage, ‘time is money’ is as applicable as it is in aviation. For Air Canada, the M3 Platform helped us save both time and money.

Keith Dugas, Director, Maintenance AI and Connected Operations has the current mandate to build AI solutions for Air Canada’s Operations. Keith has worked for Air Canada for 14 years, where he has had business lead responsibility for Air Canada’s Supply Chain transition to Trax from the airline’s legacy maintenance system, as well as responsibility for deployment of logistics and operations continuous improvement initiatives. Most recently, before AI, Keith was the business lead to digitalize Air Canada’s line maintenance paper-based processes, having started his career in AOG operations and progressed into management from there.

Air Canada is Canada’s largest airline, the country’s flag carrier and a founding member of Star Alliance, the world’s most comprehensive air transportation network, celebrating its 25thanniversary in 2022. Air Canada provides scheduled passenger service directly to 51 airports in Canada, 51 in the United States and 86 internationally. It has a fleet of more than 332 aircraft (179 mainline, 39 Rouge and 114 Express), which is also one of the youngest, most fuel efficient and environmentally friendly in the world. It includes, Boeing 737, 767, 777 and 787 types; Airbus A220, A319, A320, A321 and A330; Embraer 175; Mitsubishi CRJ; and De Havilland Dash 8-400.

“The moment a user picks up the device they know it will have the same installations and same version of technical documentation that any other user would have in their organization.”

Rutger Krom is Senior Aircraft Data Consultant at EXSYN Aviation Solutions, being responsible as Lead Solution Architect on EXSYN’s flagship solution NEXUS. As Lead Solution Architect, he oversees all development activities of NEXUS and supports customer onboardings onto NEXUS. Rutger joined EXSYN in 2014 as a graduate intern and has ever since played a vital role in the continued development of the business, various high profile airline data migration projects and EXSYN’s overall footprint in the aviation industry.

Aircraft IT: Your name, your job title, and the name of the business?

Rutger Krom: Rutger Krom, Senior Aircraft Data Consultant and NEXUS Solution Architect

Aircraft IT: How did EXSYN get started?

RG: EXSYN started out in 2011 as a consultancy company focused on supporting airlines implementing MRO systems. Over the course of several projects, use cases were encountered that triggered the development of what is now EXSYN’s aircraft data management platform. Within this platform we provide solutions to manage aircraft data, analytics to drive business value, and technical support services to help clients adopt our technology. The platform itself is centred around the two core applications, NEXUS and AVILYTICS. This resulted in EXSYN’s unique positioning as being a niche leader in offering digital solutions for aircraft maintenance and engineering data

Aircraft IT: What is the guiding business principle that drives EXSYN?

RG: Transparency and flexibility have been at the core of our team since the beginning. Whatever we do, we strive towards a full cooperation to achieve the project’s goals, instead of two entities sitting on different sides of the table. Everyone in the business is encouraged to speak their mind, both internally but also externally, to ensure nothing is missed and all ideas have been heard.

Aircraft IT: What has EXSYN’s greatest business achievement been to date, and why?

RG: During the pandemic, the aviation industry was, as a whole, hit hard. At EXSYN we have been able to continue to support our customer base during this difficult time. As well as keeping our entire team on board, we have simultaneously invested heavily in our technology to even better support airlines and MROs to manage data in critical airworthiness processes.

“EXSYN offers the AOG risk monitor that uses data from MRO systems as well as onboard aircraft data to create risk profiles of aircraft in the fleet and the probability of component failures.”

Aircraft IT: What have been your disappointments and what have you learned from them?

RG: Predictive maintenance is a hot topic within the aviation industry. Within Avilytics, EXSYN offers the AOG risk monitor that uses data from MRO systems as well as onboard aircraft data to create risk profiles of aircraft in the fleet and the probability of component failures. However, we had to accept a rather slow adoption as we underestimated that data at many airlines is not yet ready to really adopt predictive analytics and a predictive maintenance philosophy. Based on this experience, our focus in this area is now more helping airlines to manage their aircraft data and have a continued level of data accuracy to become ready for using predictive analytics. To achieve this, we offer our customers data health checks to continuously validate their system, ensuring their system remains clean, up-to-date and

Aircraft IT: In a sentence, how would you summarize what EXSYN does for aircraft maintenance customers?

RG: We help our customers to efficiently manage aircraft data, retain continued trust in the accuracy of their data and empower digitization of their technical operations to derive value from their aircraft data.

Aircraft IT: What do you feel will be the next big thing in maintenance Aviation IT?

is still too much ‘waste’ in these processes, where data is registered manually in different places/ systems. This is not only a next step for individual airlines per se, but something that will happen industry wide and between all stakeholders in the aircraft maintenance value chain.

Aircraft IT: What do you want your customers to say about EXSYN

RG: That EXSYN made a difference and is a valued partner that seeks the best solutions together with the customer.

Aircraft IT: Rutger Krom, thank you for your time.

“…we offer our customers data health checks to continuously validate their system, ensuring their system remains clean, up-to-date and efficient.”

Julien Lebeau, Project Manager, Air Tahiti

Julien Lebeau, Project Manager, Air Tahiti

As with any case study, a key part of the story will be the subject of the article which, in this case, is Air Tahiti. So, before we look at the case study, let me first tell you something about Air Tahiti.

Operating from and in French Polynesia, in the middle of the Pacific Ocean, halfway along a line between San Francisco and Sydney, Air Tahiti works in a unique environment. The network is as large as Europe but largely over water (figure 1). To travel to anywhere outside of the territory always entails a five- or six-hour flight — in short, it’s quite remote. There are 1,200 people working in the company and just ten aircraft. The reason why there are so many employees is that we undertake all of the ground handling for the network as well as the catering plus the usual airline divisions of Flight Ops and Technical department to do the maintenance with our own C-checks and Heavy checks, because it’s easier for the airline to do its own work in such a remote place. Air Tahiti carries almost 800,000 passengers a year, twice the population of French Polynesia, with a fleet of nine ATR-72 and one -42 aircraft.

•

•

•

•

Figure 1

Tahiti itself is right in the middle of the territory with the Marquesas Islands as far away as Sweden is from Paris. Air Tahiti connects 48 destinations within the 120 islands of French Polynesia; we have ETOPS (Extended Twin Engine OPerationS) flights as well as having both the shortest (at just seven minutes) and the longest (at four hours) flights operated by ATR aircraft. Because of the wide variation in flight lengths, the aircraft are rotated to different flights in order to roughly

equalize wear and tear across the fleet. The airline has only one maintenance base in Tahiti with around 90 people working there. All maintenance is carried out at that base; there is no line support to the other destinations but we do carry out our own C-checks, as I mentioned above.

Working with a legacy system to manage maintenance and stores, Air Tahiti experienced a number of pain points (Figure 2).

Multiple disparate systems data inconsistencies and repeated data entry

Figure 2

We were using multiple disparate systems which led to data inconsistencies and the need for repeated data entry. There were also capability voids when it came to the airline’s adherence to regulatory requirements; as well as planning and execution of maintenance, the upkeep of the manuals was the responsibility of the Hangar department. Finally, there was a lack of real-time stock visibility.

“We were using multiple disparate systems which led to data inconsistencies and the need for repeated data entry. There were also capability voids when it came to the airline’s adherence to regulatory requirements…”

that can be used to repair parts or from where uses can purchase, for example, a starter generator, with all of the suppliers and their costs plus some historical information with links to go into historical transactions for more information, also some parts on the screen where users can see the parts that are on order as well as where parts have been used. This was a game changer for us with its good visibility of the data and history allowing users to focus on their work.

There are also some workflows that users can reconfigure in the application to set authorization levels for purchasing and repairing parts (figure 5).

Figure 5

Some workflows can be defined to include, depending on the price of the part, who can authorize its procurement. Workflows can also be defined for purchase and repair orders. Ramco empowers the user to configure each warehouse and segregate, for instance, serviceable and not serviceable parts as well as to define some strategies for the warehouse in terms of picking parts when they are required for mechanics or the planning department (figure 6).

“Some workflows can be defined to include, depending on the price of the part, who can authorize its procurement. Workflows can also be defined for purchase and repair orders.”

Versatile Warehouse Configuration

• Full control on stock: Ability to set part conditions and transactions applicable to a Warehouse

• Warehouse level definition of Part Planning parameters to ensure automatic completion of the stock

Figure 6

Some screens, that are called Hubs, offer a good view on activity (figure 7.1)

Hubs : Activity at a Glance

Figure 7.2

Users can see that it focuses on external receiving for several warehouses and if the user picks one warehouse, as illustrated in the figure, it can be seen that there are three transactions to be inspected with the transactions and what they are about. This helps give a very good view of activities at a glance but it also it allows end users to work directly from the screen, so they can launch the transaction for, say, inspecting the part, direct from the screen. It can be used by management but also by end users to pick up that transaction that they have to do.

Having implemented a system, the question always has to be, how has the business benefitted? I’m glad to report that we can see clearly the benefits that the Ramco solution has delivered for Air Tahiti (figures 8.1 and 8.2).

Figure 7.1

For example, figure 7.1 shows the fleet availability with all the aircraft on one screen. Users can see the next due date for the aircraft’s maintenance and some later dates. That’s one example and another one is for the inventory operations (figure 7.2).

“… with all the aircraft on one screen. Users can see the next due date for the aircraft’s maintenance and some later dates.”

Figure 8.1

Maintenance

•

Effective Discrepancy deferral process

• Management workflows to monitor user authorizations based on the transaction & its total value Figure 8.2

For the future, having this system which is running smoothly gives Air Tahiti confidence, should we need to grow the fleet and/or increase the number of destinations. We are also considering going more mobile, using Ramco tools, and would like to reduce paper in the business because paperwork is timeconsuming. The Ramco application is modular and is what we are looking for, because it could help in reducing paperwork, plus the application provides some AI/ML (Artificial Intelligence / Machine Learning) functionalities that Air Tahiti does not use right now but that could help the processing of the mechanics’ work.

I hope that this article will inform readers and encourage any who face particular and non-standard challenges such as those faced by Air Tahiti, to consider that step to a more modern way of doing things. At Air Tahiti, we have enjoyed considerable benefits from our solution.

Julian joined Air Tahiti in 2006 to manage the transition between an old legacy IT system and an off-the-shelf. He is experienced at implementation and administration of M&E/MRO systems into an operational environment. He also has knowledge of various functional areas from engineering and planning through maintenance reporting and fixing to logistic and store management. Julian has also worked on the analytic and KPIs side of such projects.