www.commercialbaking.com

ISSUE Q2 | PARTAKE FOODS’ DENISE WOODARD | REGENERATIVE AG | SIMPLYFUEL APR 2023 DIGITAL EDITION

BARS AND BITES MADE WITH LOVE Bobo’s

Find out more at www.jkingredients.com or call us at 973-340-8700 Keep your labels clean with J&K Ingredients! Our Clean Label line of SOR-Mate products will keep your cakes, cupcakes, muffins, and other sweet goods mold-free without the need for artificial preservatives. Contact our experts to start cleaning up your labels today! CL NG Clean Label Non GMO Kosher Pareve KP Spring cleaning? Don’t forget your labels! Effective alternative to chemical preservatives! Introducing SOR-Mate

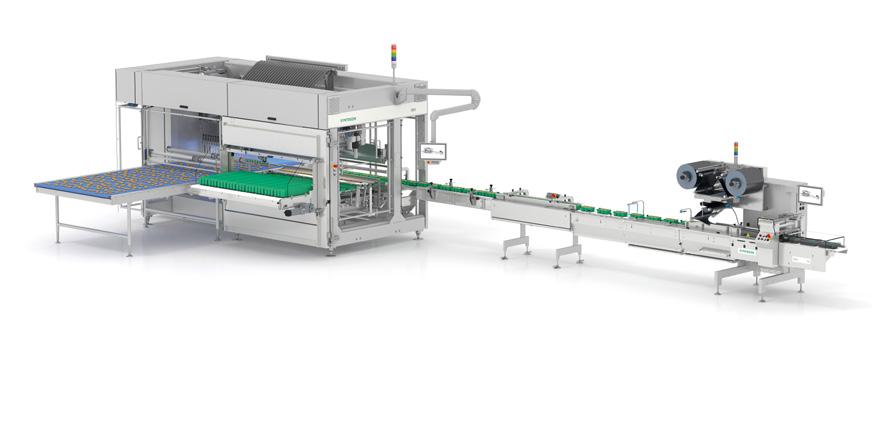

Many players, one team. www.syntegon.com

Many players working hard to ensure the productivity, safety, and sustainability of our machines are always at their best. One team dedicated to providing exemplary service — every time.

Minimize labor issues!

AIM TECHNOLOGY FOR PIZZA

Automation for pizza handling that no one else can deliver.

Active Integrated Motion™ (AIM™) technology transforms frozen pizza handling by enabling automation in washdown environments.

Intralox® AIM solutions include sorting, switching, and merging equipment that deliver maximized, reliable throughput and gentle product handling to your pizza packaging lines.

© 2022 Intralox, L.L.C. 5011057_EN

Scan QR code to learn more.

AVANT FOOD MEDIA

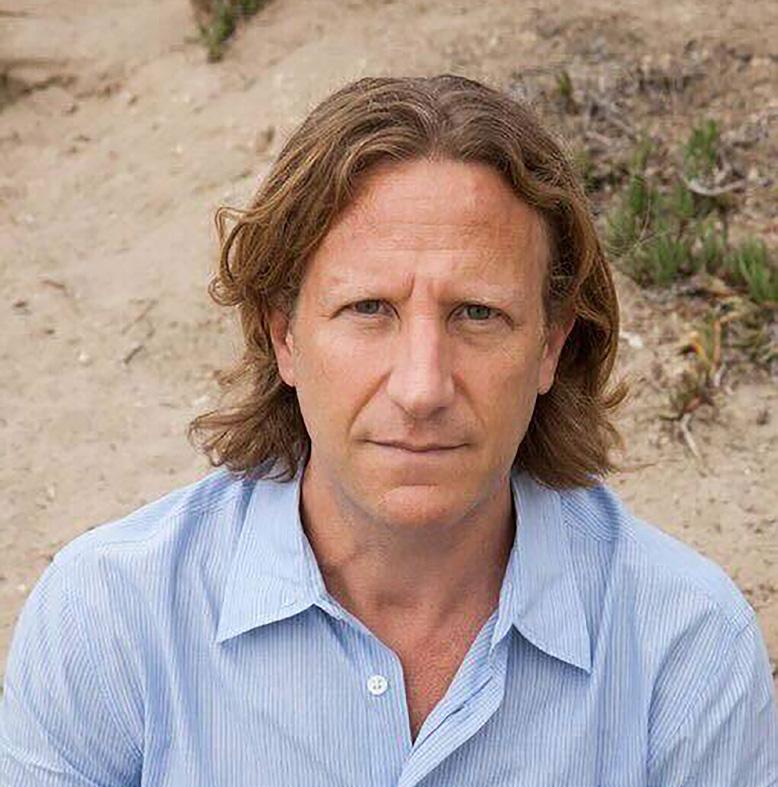

Paul Lattan President - Principal Steve Berne Vice President - Principal

Joanie Spencer Director of Content - Partner

COMMERCIAL BAKING

Paul Lattan Publisher 816.585.5030 | paul@avantfoodmedia.com

Steve Berne Director of Media 816.605.5037 | steve@avantfoodmedia.com

Joanie Spencer Editor-in-Chief 913.777.8874 | joanie@avantfoodmedia.com

Mari Rydings Editorial Director mari@avantfoodmedia.com

Jordan Winter Creative Director jordan@avantfoodmedia.com

Olivia Siddall Multimedia Specialist olivia@avantfoodmedia.com

Annie Hollon Managing Editor annie@avantfoodmedia.com

Evan Bail Associate Editor evan@avantfoodmedia.com

OUR

Commercial Baking is published by Avant Food Media, 1703 Wyandotte St., Suite 300, Kansas City, MO 64108. Commercial Baking considers its sources reliable and verifies as much data as possible, although reporting inaccuracies can occur. Consequently, readers using this information do so at their own risk. Commercial Baking is distributed with the understanding that the publisher is not liable for errors and omissions. Although persons and companies mentioned herein are believed to be reputable, neither Avant Food Media nor any of its employees accept any responsibility whatsoever for their activities. Commercial Baking magazine is printed in the USA and all rights are reserved.

No part of this magazine may be reproduced or transmitted in any form or by any means without written permission of the publisher. All contributed content and advertiser supplied information will be treated as unconditionally assigned for publication, copyright purposes and use in any publication or digital product and are subject to Commercial Baking ’s right to edit.

Commercial Baking , ISSN 2767-5319 / USPS Publication Number: 25350, is published quarterly in February, April, August, and October, with special issues in June and December, in print and digital formats by Avant Food Media, 1703 Wyandotte St., Suite 300, Kansas City, MO 64108. POSTMASTER: Send address changes to Commercial Baking, c/o Avant Food Media, 1703 Wyandotte St., Suite 300, Kansas City, MO 64108.

Circulation is tightly controlled, with print issues sent only to hand-verified industry decision makers and influencers. To apply for a free subscription, please visit www.commercialbaking.com/subscription

FIND US ON APRIL 2023 Q2

6

Maggie Glisan | Bella Foote Contributors info@commercialbaking.com COMMUNITY

MEDIA Magazines Website Newsletters Podcasts Webinars Videos | digital edition

American Society of Baking

OUR

Softase Platinum

Softening + Resilience + Sugar Reduction

Softase now offers a transformational extended shelf life solution to meet multiple demands for today’s bakers Offering state-of-the-art softening with the added benefit of elite resilience and cost-in-use savings, new Softase Platinum meets and exceeds the challenges of the modern bakery.

For customized and traditional baking process solutions and collaborative customer service, you can count on AB Mauri.

©2023 AB Mauri Food Inc.

abmna.com · 1.800.772.3971

+1 (978) 667-0400 | www.wilevco.com | sales@wilevco.com | 10 Fortune Drive, Billerica, MA Take control with Wilevco. Batter MixingTemperature ControlCoating Grill Marking Oil Filtration Integrated Coating System Cool your batter.

Features

PLUS: Look for QR codes that contain exclusive digital content throughout the issue.

22

Bobo’s: For Love and Satiety

After 20 years of growth from a home kitchen to an automated facility, Bobo’s stands strong on its core values and good vibes.

36 Denise Woodard: Setting Standards and Breaking Barriers

42 Emerging Brand: simplyFUEL

49

Kern’s Kitchen: Maker of the Iconic Derby-Pie

COMMERCIAL BAKING 9

IN THIS ISSUE

Cover:

Bobo’s has taken a major step with its new wind-powered manufacturing facility. Read more on page 22.

Photo by Olivia Siddall | Avant Food Media

COMMERCIAL BAKING 11 91 106 TRENDS Critical Issues: 53 NFTs Product Development: 62 Regenerative Agriculture Category Outlook: 71 Sweet Goods Category Outlook: 77 Gluten-Free INNOVATIONS Category Insight: 83 Sweet Goods Category Insight: 91 Gluten-Free Commercial Baking Channel 102 Supplier Solutions 106 Ad Index 112 QUICK READS Editor’s Note 12 Seen and Heard 15 Business Intel 99 The Last Word 114 83 Departments IN THIS ISSUE

Running Up Hills

JOANIE SPENCER Editor-in-Chief | joanie@avantfoodmedia.com

What do you do when the plan goes wrong, and then the backup fails?

The past few years have taught us, if nothing else, to expect the unexpected. But we’re also human and want to assume the best. Well, we all know what they say about the best laid plans … they do, indeed, go awry.

I can say from experience that when plans fail, the reaction — not the failure — will determine the outcome.

In this issue, you’ll see some recurring themes, not the least of which is the undeniable grit that comes with entrepreneurship. When launching a brand, plans can fall apart before they even materialize. But (and I’ve learned this from experience, too) there’s a point where you want to give up … and beyond it is where success lives. That’s the make-or-break moment.

To get beyond the breaking point, you’ve got to have grit, but first, you’ve got to have courage.

There’s nothing like hard times to fire up the engine — to dig deep, get creative and discover new resources. In fact, I’d say a crisis is a key ingredient for innovation.

It’s always smart to hope for the best and expect the worst. But if the worst sneaks up on you, just remember: We get stronger by running up hills.

APRIL 2023 Q2 12

A NOTE FROM THE EDITOR

Maximize the Life of Your Pans

with Synova & Pan Glo®

Using Synova’s release agents and applicators along with a Pan Glo® pan cleaning schedule, your bakery can take control of oil usage and ensure pans are always achieving their best and longest release life.

SPECIALTY FORMULAS

Synova’sreleaseagentsareformulatedspecifically Synova’s release agents are formulated specifically forbaingandcomeinavarietyofspecialformulas for baking and come in a variety of special formulas.

IMPROVED APPLICATION & RELEASE

Synova’s release agent applicators use precise metering and placement to reduce oil usage while improving pan coverage and release.

PAN SERVICE PLAN*

APanServicePlanprovidesbakerieswitharotating A Pan Service Plan provides bakeries with a rotating supply of clean and recoated pans from Pan Glo to better manage oil usage and keep product quality consistent from the first bake to the last.

*Using DuraShield® coating? We have a plan for that too!

Visit us in Hall B1 - Stand 110! +1.937.652.2151 | info@bundybakingsolutions.com bundybakingsolutions.com Synova | Pan Glo

Seen Heard AND

COMMERCIAL BAKING 15

“We don’t even use those words because they’re confusing. ‘Belonging’ just looks at what it means to have humanity at work — being respected at work and feeling valued at work. That’s belonging.”

Ted Castle | CEO | Rhino Foods Speaking on the belonging aspect of DEI

“There’s a lot of relevancy for today’s consumer across all baked goods, and it isn’t price that motivates their purchases.”

Jonna Parker | team lead, fresh foods | Circana

Photo courtesy of the American Bakers Association

“Bakery is such a basket builder. When people have bakery items, they also have spreads or a protein in the basket. They might not have toothpaste on the grocery list, but they almost always have bread.”

Omar Haque | VP/GM of omnichannel | Bimbo Bakeries USA

During “The Boundaryless Consumer” panel discussion at ABA’s Annual Convention

Photo

courtesy

of the American Bakers Association

WHEN PROOFING FLOOR SPACE IS TIGHT...

SEEN AND HEARD

“If you want to make a food safety culture scale in your organization or your industry, you have to make it real. You have to make it personal. You have to instill a sense of pride and purpose in each person involved in food safety.”

Killian Lapeyre | business unit manager | Intralox On hygienic design and best practices around safe food production

LOOK UP.

If you’re looking for a high capacity proofer that takes maximum advantage of minimum floor space, look no further. Our CapStep Proofer’s only limit … is your ceiling.

When your pans or peel boards enter the CapStep Proofer, they will be raised upward. When the pans reach the top of our system, they are gently moved over to the downward section by a transfer conveyor and lowered one level. This process continues – one Step at a time – until your product is ready to leave the proofer.

CapStep’s PLC controlled temperature and humidity HVAC and mechanical movement system is built for heavy-duty long life.

Call us today at 1.877.222.7929. We’ll help you take the next Step in automated bakery proofing systems.

“Everybody is aware of the fact that we have a climate crisis, and it’s affected everybody in some way, shape or form. The regenerative agriculture story has to be told because it’s a story of hope. And it’s a story of a meaningful solution for problems that affect us all.”

Evan Harrison | CEO | Kiss the Ground

capwayautomation.com

CapStep PROOFER

APRIL 2023 Q2 18

“I can assure you, no leader in an organization wants to put someone in a position that isn’t going to be effective or that leads to a disruption of what’s going on in the plant. It’s about having strategic alignment and being able to say, ‘This is important enough to address so it doesn’t lead to other problems.’”

Brendon Russ | lead, Americas, reliability and asset management engineering services | JLL Work Dynamics

On workforce development at Intralox NEXT

“If we can embrace diversity, equity and inclusion, and get all of our people to understand that what they do out there on that floor matters, that what they do is helping you and you challenge them to keep doing that, everybody just comes together.”

Nathan Norris | director of diversity, equity and inclusion | Highland Baking Co. About the impact of implementing DEI in a bakery

Photo courtesy of the American Bakers Association

“You have to take the opportunities that are given to you, but you also have to create your own. You have to figure out how to get in the room. It doesn’t mean you can make miracles happen. But if there’s a will, there is a way.”

Laura Meyer | owner | Pizzeria da Laura

SEEN AND HEARD

During the Women-Owned Pizzerias panel at the International Pizza Expo & Conference

Pfening’s in-house production capabilities allow full control over our equipment design and quality. www.pfening.com | sales@pfening.com WITH PFENING IT’S ALWAYS Customer First Delivering Superior Value Since 1919 • Water and liquid dosing systems • Dough conditioning systems • Comprehensive engineered systems • Automated ingredient handling systems • Turnkey projects from design to startup • Integrated control systems

APRIL 2023 Q2 20

“If you think about it in-store, we have three to five seconds to make an impression before people decide. They spend two and half hours every day finding recipes, ideas, how to decorate, baking for kids. Those are big opportunities.”

Anne-Marie Roerink | president | 210 Analytics

Photo courtesy of the American Bakers Association

“Being recognized in the Circle of Honor truly has been a really big surprise to me. It’s just a fantastic honor that the industry and the American people would recognize our contribution to the industry.”

Alf Taylor | co-founder and CEO | tna Solutions Receiving the Circle of Honor award from SNAC International

“This is our planet. We need to be resilient, and we need to start taking decisive action because we are all connected.”

SEEN AND HEARD

Irene Espinola Campos | head of net zero carbon and renewable energy | Grupo Bimbo Speaking to ASB BakingTECH attendees on the industry’s need to reach net zero carbon emissions by 2050

The world’s best foods are made on the world’s best equipment.

Since 1913, businesses like yours have relied on Peerless equipment to create delicious food efficiently, consistently — and above all, dependably. You need equipment and a partner you can count on. You need Peerless equipment.

Since 1913, businesses like yours have relied on Peerless to create delicious food and above all, You need and a you can count on You need Peerless equipment

Peerless mixers

Unmatched performance, reliability and productivity. Custom built to your specifications with an extensive range of available options.

Peters sandwiching/ biscuit creamers

Versatile, high-performance machines that accommodate a wide range of base cakes and fillings to create sandwich cookies like no other.

Stop by booth 4C23 at the Interpack show and talk to our helpful associates about your specific needs.

booth 4C23 at the show and talk to our associates about your needs.

And see why you can depend on Peerless.

And see you can on Peerless.

Creams and batters equipment

Ensure fast, accurate production with exceptional quality, from the first mix of the batter to the final coated product.

Peerless Food Equipment | Booth #4C23

Customer service and parts team

Dedicated to providing the highest level of reliability and responsiveness to keep your operations running smoothly and efficiently.

500 S. Vandemark Road, Sidney, OH 45365-0769 USA

(937) 492-4158, (877) 795-7377 | peerlessfood.com

Peerless Food Equipment

OUR WEBSITE

SCAN TO VISIT

APRIL 2023 Q2 22

All photos by David Grossman, Colorado Photography

FEATURED BAKERY: BOBO’S

FOR LOVE AND SATIETY

After 20 years of growth from a home kitchen to an automated facility, Bobo’s stands strong on its core values and good vibes.

BY JOANIE SPENCER

In today’s world of emerging brands, co-manufacturers are in high demand. In fact, it’s hard to find young brands making their own products at scale. Then again, there’s Bobo’s, a Loveland, CO-based oat bar brand.

During its 20 years in business, Bobo’s has mostly relied on making the bars in-house. First, it was in shared k itchens before upgrading to its own small baking facilities in the B oulder area. But today, the company is ready for its next stage of growth, manufacturing its products in a newly completed wind-powered commercial bakery.

How Bobo’s got to where it is today is a tale as old as CPG startups themselves. It all began in founder Beryl Stafford’s kitchen when her daughter Alex — known as “Bobo” to her family — decided to bake some goodies from a recipe she found.

“She started making these treats out of a cookbook,” Stafford recalled.

“They were originally flat little cookies that were dripping with gooey yumminess, and she just kept making them for her friends at school.”

One of Stafford’s close friends, who worked in the natural food industry, took notice and convinced her to adjust the recipe, add oats and make them into bars … and perhaps start a business.

“I didn’t know anything about business,” Stafford said. “I didn’t know anything about food, and I didn’t know anything about sales. But I was newly divorced with two kids, and I knew I had to reinvent myself. So, I thought, ‘Why not? Let’s see if it works.’”

Stafford modified her daughter’s corn syrup and white sugar-based treats, adding oats and replacing the corn syrup with brown rice syrup and nixing white sugar for natural cane sugar, as well as swapping the butter with coconut oil.

She covered them in plastic wrap and took her Bobo’s Oat Bars to a local coffee shop, and soon the bars were a hit in coffee shops and co-ops. Before long, they caught the attention of a Whole Foods bakery buyer … and the rest is CPG startup history.

Two decades and six manufacturing spaces later, Bobo’s Oat Bars

COMMERCIAL BAKING 23

“As an entrepreneur, you never sit back and pat yourself on the back because there’s always more to do.”

Beryl Stafford | founder | Bobo’s Oat Bars

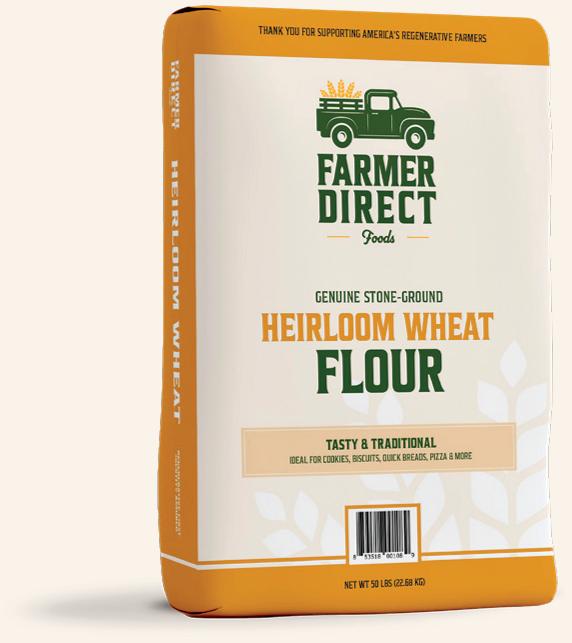

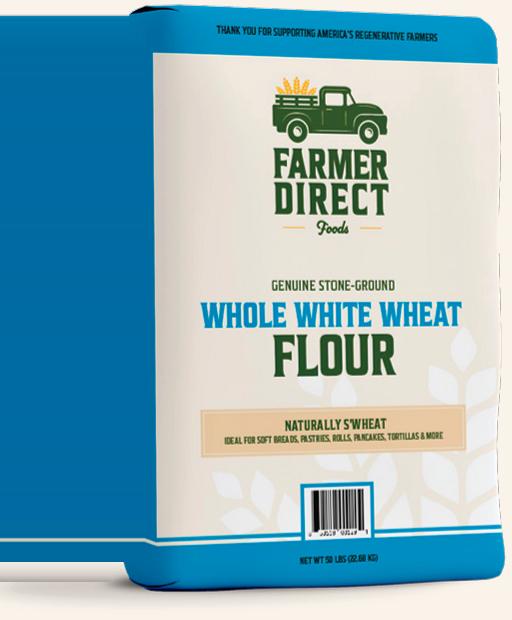

bear the Whole Grains Council stamp and are certified gluten-free, kosher certified, dairy-free and Non-GMO Project verified, and they haven’t strayed far from Stafford’s original modified recipe that included just five ingredients. Only now, the bars, bites and toaster pastries comprise a variety of flavors and are manufactured on four production lines in a 123,000-sq.-ft. bakery.

The company was built, one sale at a time, through good old-fashioned trial and error and, of course, bootstrapping resources. And, for the most part, it’s all been done in-house. After all, Bobo’s was born in the pre- Shark Tank era, before crowdfunding and social media, at a time when co-manufacturers weren’t exactly the most sought-after partnerships in CPG.

In fact, in the early days of the business, Bobo’s Oat Bars were made by hand in shared kitchen space with other notable Boulder-based brands like Justin’s and EVOL. It took about 10 years before Bobo’s was baking bars in its own small facility as it began to enjoy slow, but steady, growth.

Despite the innovative food brands that have emerged from the Boulder area, the lack of industrial space eventually pushed many of them toward co- manufacturing outside the city walls. However, Stafford chose the self-manufacture route, and Bobo’s has maintained control over the process and growth.

“The business was launched in Beryl’s kitchen, and she chose to ‘DIY’ it the entire time,” said T.J. McIntyre, Bobo’s CEO. “That’s become a great legacy that, 20 years later, is woven pretty thoroughly into who we are and how we do things.”

For McIntyre, who joined the company in 2016, Bobo’s manufacturing strategy has been a key factor in its growth.

With executive experience with some of the leading Colorado-based natural brands including Smart Balance, Earth Balance and Boulder Brands, McIntyre is focused on increasing production output through automation and growing the business organically through category and channel expansion.

With 50% market penetration in retail, including rotations in every region of Costco and 15,000 points of distribution for Walmart, opportunities abound for expansion as well as doubling the equivalized items inside the stores where Bobo’s already has a presence.

On supermarket, drug, convenience, military and, of course, big-box store shelves, Bobo’s currently competes in the cereal bar and nutrition bar categories. The most recent product launches — a protein bar, a dipped bar and a PB&J variety — will expand the brand’s presence in both categories.

—Below With its new 123,000-sq.-ft. bakery, Bobo’s is prepared for continued growth.

APRIL 2023 Q2 24

BOBO’S

#WeDoughItAll Rack Ovens •Electric or gas fired Rack Ovens •10-80 pan capacity D Series Deck Ovens •Electric Deck Ovens •4-16 pan capacity Rack and Deck Ovens to meet your Baker’s Needs p p y CREATING CUSTOM SOLUTIONS SINCE 1972 www.geminibakeryequipment.com | 215.673.3520

In c-stores, Bobo’s is on pace with other natural brands as it increases presence in high-end banners such as Wawa, Plaid Pantry, Jacksons, Racetrac and more.

But that’s just the beginning. With new technology now at its fingertips, the runway for growth is still quite long because shoring up production opens up R&D and product development.

In 2022, Bobo’s grew 40%, despite several out-of-stock periods before the company moved into its new facility. Shortly into 2023, February proved to be the bakery’s second biggest month on record.

“It nearly cleaned us out,” said Jason Jimenez, Bobo’s director of operations.

With investments in automation to streamline production and overcome labor challenges, the bakery is on pace to at least match last year’s growth.

The entrepreneurial spirit that started Bobo’s is what keeps the engine revving today.

“As an entrepreneur, you never sit back and pat yourself on the back because there’s always more to do,” Stafford said. “There’s always another place where we can sell Bobo’s. When you start with nothing, and then you get people excited about buying Bobo’s Oat Bars … it’s addictive.”

With many items being baked to order, Bobo’s works with a two-week lead time and a 270-day total shelf life, so the product is constantly on the go … just like Stafford herself.

“Product is never longer than 30 days on our racks,” Jimenez said.

That’s one reason why Bobo’s has, for the most part, focused on making its products in-house, rather than relying on a co-manufacturer.

“We leaned on external manufacturing last year when we were capacity constrained, but it’s just not the same as working with your own team,” McIntyre said. “Even the best co-manufacturers, while they can be an extension of our team, they’re not going to function like our team would internally or have the type of flexibility we have.”

Self-manufacturing, he explained, also helps Bobo’s better control its margins, which has been critical to its growth in a post-pandemic environment.

With the new facility and equipment investments, Bobo’s is better equipped to serve its current customers, avoid the out-of-stock nightmares and focus on its continued growth.

One area where automation is significantly helping Bobo’s keep up with growth is the packaging department. Horizontal flowwrappers run up to

700 pieces per minute for bites, while flowwrappers for bars handle about 250 pieces a minute.

The Westrock packaging automation runs by volume and weight, and it doubles the throughput of the previous location, where all packaging was a manual process.

“It’s been a life saver,” Jimenez said.

Facing typical manufacturing workforce challenges, the packaging automation has helped alleviate some of those labor woes. The operation is set up so that those working on the 24 Revent, Sveba-Dahlen and Gemini/KB Systems rack ovens can shift over to packaging where needed once the bars finish their bake cycle.

The bakery was designed with four central “baking kitchens,” which receive ingredients and house the mixing stations that feed the four production lines. The kitchens are large enough that one can feed two lines when needed for larger runs, such as Costco orders.

APRIL 2023 Q2 26

BOBO’S

“We don’t develop products for a Nutritional Facts outcome. We just bake food. Bobo’s core products are intuitive, good food.”

T.J. McIntyre | CEO | Bobo’s Oat Bars

It’s ingrained in us © 2023 Ardent Mills, LLC. All rights reserved. At Ardent Mills, we are your supplier partner to solve today’s challenges At Ardent we are your partner to solve and stay ahead of tomorrow’s trends. With our nationwide footprint and stay ahead of tomorrow’s trends. With our nationwide and localized support, we help you respond to market dynamics and localized support, we you to market dynamics. And with our best-in-the-business research and resources, like And with our best-in-the-business research and resources, like our Innovation Center, we’re continually developing concepts and our Innovation we’re concepts and products that that can help you seed can you seed growth. Let’s innovate what’s next. next. Visit ardentmills.com/together today. *Ingredients depicted in raw form and not ready for use.

let’s bring ideas to life

Solutions for today. Growth for tomorrow. Together,

BOBO’S

“If we’re running the Apple Pie variety on two lines, we can run them both from just one kitchen,” Jimenez said. “Costco’s main products are Apple Pie and Strawberry, so this allows us to make them both at the same time. In the past, we had to make one flavor, then the other. This layout gives us much more flexibility.”

That flexibility is key for this nimble bakery, but strategic approaches to automation keep it all running smoothly. While one line might still rely on manual work, another line with Reiser automation deposits dough into trays. Additionally, investing in a Vemag extruder has allowed for one of the new products released earlier this year.

The automation has not only increased throughput but also provided greater product consistency.

More than all that, the new bakery enables Bobo’s to keep living out Stafford’s entrepreneurial values and core principles as a mission-driven company.

The wind-powered facility, developed by Colorado-based design-build firm McWhinney Brothers, supports Bobo’s mission of remaining a good steward of the environment.

Although Bobo’s does not own the building, the team worked with the landlord throughout the greenfield process to incorporate sustainable design elements that will benefit not only Bobo’s environmentally friendly production but also whoever occupies the space in the future.

“Of course, the owner wanted to have a building that was environmentally conscious,” said Henry Hughes, Bobo’s EVP of marketing. “But as

we built it out together with the tenant improvement budget we had in the lease, we also could do things that pushed it in that direction.”

Bobo’s rapid growth in recent years — coupled with incremental increases to capacity — casts a light on how operational inefficiencies can impact a company’s carbon footprint. Collapsing three small production spaces into one site allowed Bobo’s to reset and reexamine its environmental impact as a midsize food manufacturer.

“Moving into this facility has enabled us to not only get efficient but also embrace sustainability from an environmental perspective,” McIntyre said, noting that in the first few months after starting up the lines, the operation has established systems to capture the waste stream and calculate natural gas consumption to track and control emissions — which is zero for electricity.

Bringing on Jim Stewart as director of environmental health and safety was the natural first step in that reset.

“Jim has done a lot of work to help us understand our baselines with CO2 emissions and how we can minimize it, as well as help us look at how we handle waste in the facility,” Hughes said. “Now we have a lot of opportunities to get smarter and more thoughtful about our emissions and how we can offset those.”

With a goal of becoming carbon neutral by the end of the year, Bobo’s is taking a holistic approach to sustainability through LED lighting, water reduction and efficiency in transportation.

The baking technique required for these bars relies on gas-fired ovens, so while the gas usage currently prevents Bobo’s from eliminating its carbon footprint, the bakery is exploring partnerships for purchasing carbon credits.

APRIL 2023 Q2 28

Automation is helping Bobo’s expand its product varieties and channel reach.

keto friendly solutions

Together, let’s bring keto friendly ideas to life

Keto and lower net carb diets are no longer a fad

Keto and lower net carb diets are no longer a fad, they’re a way of life. , a way of life. In fact, carb management products are growing at 12% CAGR In carb management are at 12% CAGR.1 With a a simple swap to our keto certified flour blends and custom solutions, swap to our keto certified flour blends and custom solutions, you can bring new you can new great-tasting keto friendly products keto to market to quickly and easily, and without changing your processes, equipment or without your processes, or signature recipe. Let’s innovate what’s next. next.

Visit ardentmills.com/ketofriendly today.

© 2023 Ardent Mills, LLC. All rights reserved. 1 Innova Market Insights

recipes. Streamlined operations.

On-trend

Meanwhile in the packaging department, Bobo’s is managing cardboard use by recycling or selling unused materials.

Additionally, the Bobo’s engineering team, led by Charles Nichols, director of engineering, worked hard to develop packaging that was environmentally friendly yet sturdy enough to withstand robotic case-packing machinery.

“We worked really closely with the packaging engineers to maximize the efficiency of the cartoners,” Hughes said. “They understood our goals of not only keeping our cardboard usage down but also having something that we could run through the equipment efficiently.”

Sometimes, all it takes is a small change to make a big impact.

“People don’t always think about it, but if you could make a box just a millimeter thinner, it saves money and still gets the customer their product but in a more sustainable way,” Jimenez added.

Bobo’s has also invested in postconsumer recycle board, and the package design includes messaging about how to properly recycle the wrapper. The bakery has also enrolled in the “How 2 Recycle” program, which will be added to product packaging later this year.

“A lot of people will bring their waste to a compost/trash/recycle stand and not know what to do,” Hughes said. “So, I spent a lot of time learning about it so we can help make it easier for consumers.”

And speaking of consumers, Bobo’s also stands on a foundation of the people the bakery feeds. The company has come a long way from Stafford’s kitchen, but the sentiment is still the same.

“We talk a lot about bringing people home and feeding them,” McIntyre said. “That’s a way that Bobo’s has stood out from the very beginning.”

Bobo’s partners with There With Care, a Boulder-based nonprofit that provides

a range of fundamental services to children and families in critical health crisis.

“This group shows up and helps them,” McIntyre said. “They really descend on families who have a child facing terminal illness and attend to their needs. That feels really good to us.”

Service like this is foundational to Bobo’s culture, and it shows in how the bakery develops its products.

“We don’t develop products for a Nutritional Facts outcome,” McIntyre said. “We just bake food. Bobo’s core products are intuitive, good food. It’s satiating, but at the same time, it reminds you of coming home from school and smelling

WATCH NOW: T.J. McIntyre expands on the core benefit of Bobo’s Oat Bars beyond nutrition.

APRIL 2023 Q2 30 BOBO’S

As a commercial bakery, Bobo’s stands on a foundation of values that were established two decades ago when founder Beryl Stafford was just getting started.

Together, let’s bring ideas to life © 2023 Ardent Mills, LLC. All rights reserved. *Results will vary based on manufacturer's application. Any carb,“net” carb, keto, or any other claim is the responsibility of the manufacturer. When it comes to blends, we’re the only supplier partner you’ll need When it comes to blends, we’re the partner need. Streamline your operation with our ready-to-use options, or work Streamline your with our or work with us to create custom blends designed for your specific needs with us to create custom blends for your needs. From grain and seed to keto certified and gluten-free flour blends From and seed to keto certified and flour blends— our unique expertise enables the highest level of integrity and our enables the level of and quality So, you can lead today and be ready for tomorrow quality. So, you can lead and be for tomorrow. Visit ardentmills.com/betterblends to find your ideal solution. Highest quality. Maximum efficiency. done better

cinnamon and raisins baking in your mom’s kitchen. That’s the benefit we bring: Love and satiation.”

That love is what brought Stafford and her daughter joy from the very first iteration of a Bobo’s bar, when Bobo herself was just 14 years old.

As Bobo’s continues its category and channel expansion, the bakery is spreading that love through products like its Pride Bar line, which has run as a limited-time offer (LTO) for three consecutive years. In celebration of Pride Month in June, Bobo’s donates 100% of the profits to organizations such as PFLAG National and The Center on Colfax. While the LTO launches in conjunction with Pride Month, it remains available direct to consumers on the Bobo’s website.

“These are the things that are interwoven into the fiber of who we are as a company,” McIntyre said.

Twenty years ago, her friend sketched a caricature of Bobo into a logo, and Stafford set off on an adventure selling the plastic-wrapped bars she made in her kitchen. Stafford’s had successes and made mistakes along the way, and she’s learned how to improve with every step.

Today, Bobo’s is a mission-based business that’s bringing the same good vibes to consumers that the original gooey treats brought Bobo’s classmates all those years ago. Not bad for a single mom who didn’t know a thing about food or business. It just goes to show, people really can do anything if they want it bad enough. CB

INNOVATIONS FROM THE BAKERY FLOOR

In Loveland, CO, Bobo’s Oat Bars have settled into its environmentally friendly 123,000-sq.-ft. plant. Collapsing three small bakery spaces into one facility with four production lines increased Bobo’s capacity while reducing its carbon footprint and the need for additional labor. Below is a list of supplier innovations that can be found in the bakery:

AMFEC mixers

Fanuc robotic tamping unit

Lantech pallet wrappers

IMA/Delta flowwrappers

PMI Kyoto horizontal | vertical cartoners

Revent rack ovens

Sveba-Dahlen rack ovens from Gemini

Vemag depositors

WestRock case packers

APRIL 2023 Q2 32 BOBO’S

While Bobo’s relies on gas-fired rack ovens, the bakery is exploring options for purchasing carbon credits.

the

Sustainable oven solutions from Reading Bakery Systems.

Put our latest advancements in baking technology to work for you.

Reading Bakery Systems ovens feature advanced technology that delivers the flexibility, consistency, and efficiency you need to perfect your process and your products. Our oven engineering team employs sustainable and sanitary design principles, energy-efficient materials, as well as valuable data gathered by our exclusive SCORPION® 2 Profiling System to optimize production. RBS outbakes the competition, so you can too.

• Reduce carbon footprint with alternative fuel and electric ovens.

• Reduce energy costs with better insulation, stack heat reclamation, lighter oven belts, and recipedriven baking profiles.

• Improve product quality and efficiency using hybrid ovens.

• Increase product output with better baking technology.

• Reduce sanitation time with SafeShield® design protocols.

• Increase operational sustainability with fully automated controls.

For more information, call (01) 610-693-5816 or visit readingbakery.com. VISIT RBS. Hall 1. Stand B70.

Engineered to outbake

competition.

YOUR RECIPE AUTOMATED TO PERFECTION

Whether it’s storing, sifting, metering, weighing or transferring, Shick Esteve is your complete flour recovery and ingredient automation system provider.

FOLLOW US

shickesteve.com VISIT US AT INTERPACK HALL 04/STAND 4C23 SCAN ME

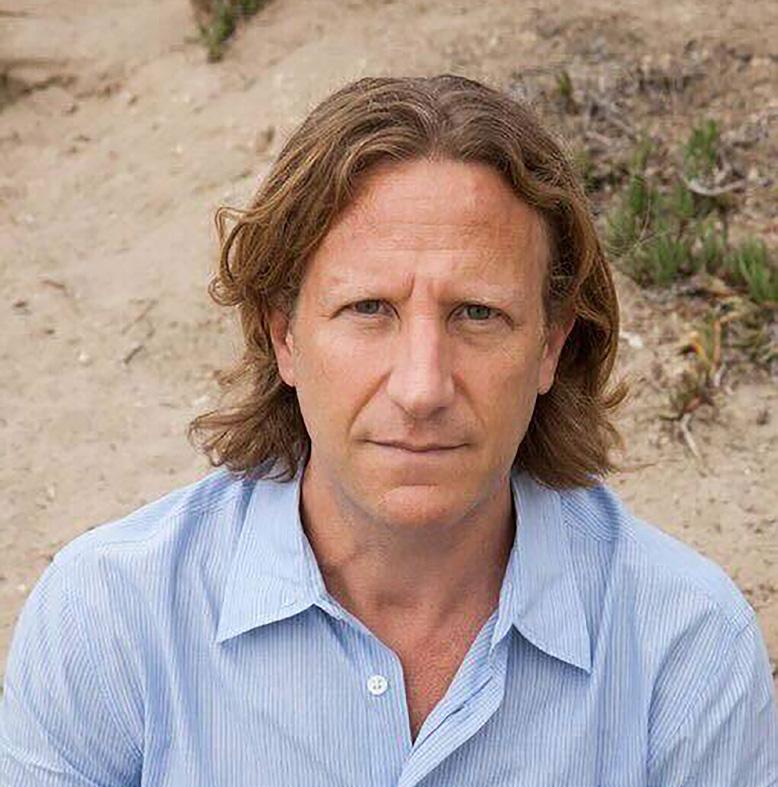

The North Star

Partake Foods founder and CEO Denise Woodard is setting standards and breaking barriers — and doing it for all the right reasons.

BY JOANIE SPENCER

In the US, women are starting businesses at a much faster rate than men. However, they’re only raising a fraction of the venture capital funding. According to TechCrunch+ citing the latest PitchBook data, women-founded startups raised less than 2% of all venture capital funds in 2022. And for women of color, the slice of the pie is even smaller.

Enter Denise Woodard, the first Black woman to break $1 million in startup funding for a packaged food or beverage company. New York City-based Partake Foods is a brand of allergy-friendly cookies and baking mixes that is breaking ground for not only consumers with food allergies but also marginalized entrepreneurs. Some might call Woodard a North Star for women and people of color, but the truth is, she followed a star of her own.

A former sales and marketing executive for well-known CPG brands, Woodard developed an affinity for entrepreneurialism when she was named director of national sales for venturing and emerging brands at The Coca-Cola Co.

“I got to work with high-growth, missionoriented beverage brands, and that gave me a glimpse into entrepreneurship,” she recalled. “I saw how a seemingly regular person with a big dream could make a change.”

36

All photos courtesy of Partake Foods

APRIL 2023 Q2

Woodard didn’t realize it, but that was a foreshadowing of her own career path.

On the surface, her story isn’t new: She’s a mom who started making allergy-friendly treats after her daughter, Vivienne, was diagnosed with several food allergies. It’s often the origin story for many emerging brands in the betterfor-you food space. But the way Woodard built the brand made her a hero in more ways than she could have expected … and not just for Vivienne, though she was the driving force.

When you start a food company for your child’s nutritional needs, failure is not an option. Vivienne was her North Star.

“It would be one thing if I started any other business and it failed,” Woodard said. “But there was no way I could have looked at my daughter and said, ‘Mommy started a company to make things better for you. And then it got really hard, and a lot of people said no, so I quit.’ That was not going to be the example I set for her.”

In some ways, developing the product was the easy part. And while having sales and marketing experience with one of the country’s biggest beverage brands looks great on a resume, marketing is only a small piece of what it takes to launch a CPG startup.

“I started the business in a very small way and had to learn on my feet,” Woodard recalled. “I was bootstrapping and delivering cookies out of my car. But that gave me the opportunity to learn every facet of building the company.”

Because it’s almost impossible for largescale brands to be nimble, the boom in emerging CPG stemmed from the fact that big companies are innovating via

acquisition. Woodard used that insight to shape how she innovates in her own product development.

Learning the hard way about innovation and scale, she’s self-taught in developing a formal Stage Gate innovation process and food safety in manufacturing.

“A lot of times, entrepreneurs think a brand revolves around packaging or a logo,” Woodard said. “But through my experience at Coca-Cola, I know it’s every single touchpoint a consumer has with your business.”

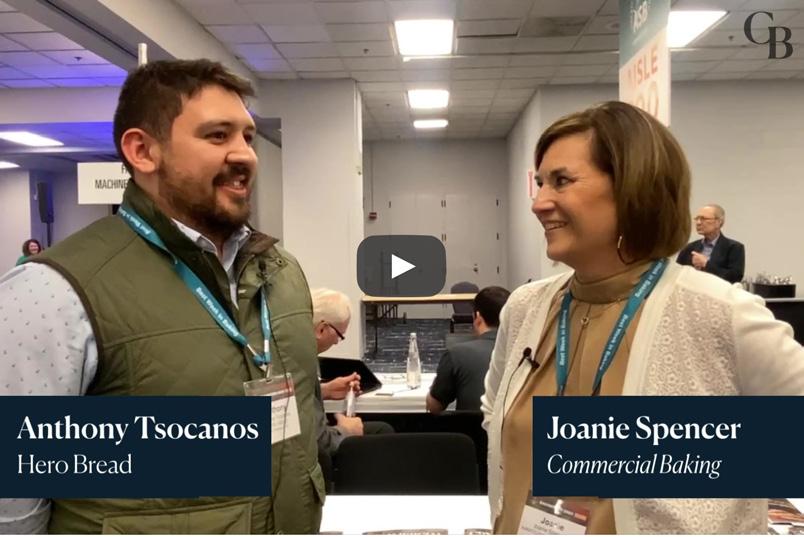

WATCH NOW:

Denise Woodard shares her journey from bootstrapping Partake to production at scale.

To that point, much of what Woodard has learned about the criticalities of creating an allergy-friendly product didn’t come from her time at Coca-Cola, in securing co-manufacturing deals or in building the business at all. It came from being a mom.

“It’s really scary for food allergy parents when companies aren’t particularly clear about things like the type of facility where their products are manufactured,” Woodard said, noting that it’s unnerving when labeling isn’t clear about what potential allergens are in a facility.

“Through that experience, I’ve learned how important it is to be as transparent as possible with our consumers,” she added. “That includes transparency about our supply chain and where we’re sourcing our ingredients from, what testing we’re doing on our finished products so that our consumers can make an informed decision about

37 COMMERCIAL BAKING

“I have a responsibility — a privilege — to support other women and people of color as they build their companies. Because the inequity shouldn’t be like this. It just shouldn’t be the case.”

EXECUTIVE PROFILE: DENISE WOODARD

Denise Woodard | founder and CEO | Partake Foods

whether our product is right for them. I care more about the safety of our consumers than I do making the sale, and I learned that from being a part of this community.”

The implications of making an allergy-friendly product — Partake cookies and mixes are free from the Top 9 allergens — finding a co- manufacturer when it was time to scale proved to be one of the hardest challenges for Woodard’s burgeoning brand.

The only thing harder than finding the right co-manufacturer was securing the funding, especially when manufacturing is so costly. But overcoming those challenges eventually put Woodard on a path to break the ceiling for Black businesswomen in manufacturing and beyond.

“There are not many allergy-friendly manufacturers that exist in the US,” Woodard said. “Getting [co- manufacturers] to work with a company that was just a woman with an idea — and making a cold phone call — was a huge challenge.”

After running a Kickstarter campaign that finished in the top 1% of food Kickstarters at that time, Woodard deployed what she called an “I told you so” strategy to get a co-manufacturer on board with Partake. The company still uses the same partner today.

The Kickstarter campaign was just the beginning. Partake was in Wegmans and Whole Foods in the brand’s first year, and managing that high growth rate is expensive. Once Woodard was all-in from a personal finance perspective, it was time to seek funding. After

exhausting the “friends and family” capital, she added some fuel to her fire.

It was 2019 when Woodard became the first Black woman to raise $1 million in public funding for a packaged food or beverage startup. That funding was led by Marcy Venture Partners, a venture fund co-founded by Jay-Z. Partake has since raised more than $19 million in capital, achieving one of the largest food and beverage startup funds led by a Black woman.

“Every time I hear that, it makes me feel even more committed to change,” Woodard said.

Looking at the statistics of inequity in access to capital, Woodard has recognized a calling. She may look to her daughter as her North Star for creating

APRIL 2023 Q2 38

EXECUTIVE PROFILE

With a self-taught venture capital accumen, Denise Woodard is the first Black woman to raise $1 million in public funding for a packaged food or beverage startup.

www.formostfuji.com 425-483-9090 sales@formostfuji.com “Quality is: First and Formost” Got cookies? We’ve got you covered! Flow Wrappers, Bagging Machines, and Automation Partnerships, Customization, and Service are just a few advantages of doing business with

a successful business, but in doing so, she has become a North Star for other entrepreneurial women of color.

“I have a responsibility — a privilege — to support other women and people of color as they build their companies,” she said. “Because the inequity shouldn’t be like this. It just shouldn’t be the case.”

Woodard is leading the charge with a self-taught venture capital acumen that’s stemmed directly from building Partake one “no” at a time — 86 no’s, to be exact.

“My experience with Marcy was eye opening to me because up to that point, I was just a number,” she said. “I learned that relationships with investors are longterm. They shouldn’t be transactional; they should be a partnership. You want investors who are aligned with you and your mission and vision for your company.”

Beyond the hard data of revenue and gross margin is where the innovation lives. Finding the right partner who will invest in more than the bottom line is the key to relationships that can truly drive a business forward. It is a sea change that, through Partake, Woodard wants to drive.

“Don’t get me wrong, business metrics are important,” she said. “But there’s also something qualitative that goes with it, and people hadn’t been as concerned about that previously. It’s a reason why I’m so passionate about mentorship today.”

Woodard believes that the venture capital system is designed in such a way that entrepreneurs with groundbreaking ideas could be overlooked simply because they don’t speak the language, and that’s having a big impact on women and minorities in particular.

Through mentorship and teaching others the lessons she learned the hard way, Woodard is helping those who are coming up behind her to increase that success rate in gaining access to capital. She volunteers her time to several mentoring programs, including one through Target, with whom she’s had a partnership for three years. The retailer’s Forward Founders accelerator program organizes cohorts of 30 women and minority entrepreneurs for networking and career guidance.

“If I can share the mistakes or landmines that we’ve come across and help someone else go further and faster,” Woodard said, “that’s what I want Partake to be.”

Now, she’s creating those opportunities earlier through Partake’s Black Futures in Food & Beverage fellowship, built in 2020 and designed to help HBCU students find jobs and internships in the food and beverage industry.

“Throughout my career, I’ve seen a lack of women and minorities in leadership, and I thought, ‘If I start my own company, I’m going to change that,’” she said. “When I went out to hire for Partake, the applicant pool was so homogeneous, so we started the fellowship to create more diversity in the industry.”

Woodard started Partake for the sake of her daughter, and she kept it going as a show of unconditional love. The result was a product that people with allergies — or without — can safely enjoy. But she created more than a company; she started a movement.

When marginalized entrepreneurs hear “no,” they can look up and see Woodard. The success of Partake shows proof of the reward that lies beyond perseverance.

Is that a greater gift to Vivienne than the products themselves? It’s hard to say. But today, when Vivienne sees a problem, she simply suggests, “We should start a company and fix that.” So, perhaps, one gift couldn’t exist without the other.

“When Marcy said yes to me after 86 other people had said no, that changed the trajectory of my business,” Woodard said.

The dedication that led to Partake’s funding is what has kept the company alive, and that is what Woodard intends to pay forward.

“I hope we can do similar things for other entrepreneurs,” she said. “I hope we open doors for them.” CB

APRIL 2023 Q2 40

EXECUTIVE PROFILE

“If I can share the mistakes or landmines that we’ve come across and help someone else go further and faster, that’s what I want Partake to be.”

Denise Woodard | founder and CEO | Partake Foods

www.reiser.com Reiser • Canton, MA • (781) 821-1290 Reiser Canada • Burlington, ON • (905) 631-6611 Reiser UK • Milton Keynes, Bucks • (01908) 585300 2021 At Reiser we have the experts, the experience and the equipment to help you produce the bar you envision – precisely portioned and efficiently produced. Come run your product with us at the Reiser Customer Center. Your bar. We’ll help you make it.

The Curveball of Protein Snacks

When it comes to building simplyFUEL, it’s all about the hustle.

BY MARI RYDINGS

Most emerging brands — nicknamed “challenger brands” for their reputation of upsetting the status quo — attempt to disrupt an established market with an innovation created to solve a problem that mainstream brands aren’t addressing. Sometimes, though, a brand develops organically, which is exactly what happened for Leawood, KS-based simplyFUEL.

The motivation behind creating simplyFUEL was to feed a passion for healthy living through better-for-you protein balls to a wider consumer audience.

When founder and chief fueling officer Mitzi Dulan, RD, CSSD, was a newly minted registered dietitian fresh from a highly competitive dietetic internship at the University of California San Francisco Medical Center, she dove straight into the entrepreneurial world, launching her own nutritional consulting company. She built an impressive client base that has included the likes of the National Honey Board, the Kansas City Chiefs and the Kansas City Royals. The partnership with the National Honey Board served as a catalyst for the popularity of her signature protein balls after the recipe appeared on Dulan’s America’s Nutrition

Expert Pinterest page. With about 3.5 million followers, the recipe went viral.

Over the next two years, Dulan continued developing protein ball recipes out of her home and sharing them on social media. The balls are formulated with the same base ingredients — oats, honey, peanut butter and protein powder — with inclusions such as chocolate chips and almonds for variety.

The 2015 World Series was the game changer that would give simplyFUEL its first base hit.

“By 2015, I had been the team sports dietitian for the Kansas City Royals for 10 years,” Dulan recalled. “I was out at the ballpark, and I told the guys I was going to bring them my protein balls the following week. It was the first time I ever made the team food from my kitchen as I always worked with the chef. They absolutely loved the balls. I kept having to make more, eventually quadrupling the recipe. The players kept eating them, loving them — and winning games.”

Baseball is a superstitious sport, and the players connected their winning streak with the protein balls.

APRIL 2023 Q2 42

In the early days, simplyFUEL relied on a network of friends to help fulfill orders.

“I got lucky … six weeks later, we won the World Series,” Dulan said.

A chance meeting with a sports reporter after a celebratory party in the Royals clubhouse during the playoffs led to a series of appearances on all the local TV networks, which were already familiar with Dulan’s work from her appearance as an expert for nutrition segments.

“My protein balls became a little bit famous in KC, and people started asking, ‘How can I buy these?’” Dulan said. “That’s how the company got started.”

The brand began as an online store in 2016 while Dulan made products in her kitchen to fulfill digital and word-of-mouth orders. In those early days, the simplyFUEL production team was a bit unconventional as Dulan called on a network of friends to help fulfill orders from customers like the US Men’s National Soccer team and the Los Angeles Lakers.

The 2017 Natural Products Expo West show was the next big play for the company when simplyFUEL drew big-name attention.

“We ran out of samples the first day and had to make more protein ball dough that night,” Dulan recalled. ”We had so many people coming to the booth that we were rolling protein balls in the booth as fast as we could.”

At the show, the brand caught the attention of Los Angeles-based Pressed, a manufacturer of cold-pressed juice and plant-based foods that sells its products in its own retail stores. Pressed became simplyFUEL’s first large-scale client, adding the protein balls to the 68 locations it had at the time. The retailer has since grown to 114 locations in California, Texas, Arizona and New York City.

43 EMERGING BRAND: SIMPLYFUEL

All photos courtesy of simplyFUEL

COMMERCIAL BAKING

A Los Angeles-based buyer from Costco also noticed simplyFUEL at the show. But with no co-packer, that opportunity quickly turned into a challenge.

That didn’t stop the fledgling brand. Before long, simplyFUEL secured a co-packer and — after more than a year of searching — invested significant capital into a protein ball extruder that could help the brand scale up production while maintaining the integrity of the product.

“I wanted to keep the sphere shape of the protein balls intact,” Dulan explained. “I wanted to keep the integrity of the product so that all the ingredients are blended into small pieces together. I wanted it to look and feel like it was still handmade.”

Yet, by the time the necessary pieces were in place, the Costco buyer from Los Angeles was out on medical leave. Then the COVID-19 pandemic hit. Like so many early-stage brands, the forward momentum all but evaporated in a matter of weeks.

“I was supposed to meet with a buyer from Costco’s Midwest region in March 2020, and it was cancelled because of COVID,” Dulan said, reflecting on one of the brand’s biggest challenges.

“It was a really tough year because I had made the decision that we were going to go through some major growth, and I was ready for it. I was going to use a distributor in LA to hit Southern California hard. It was going as planned for January, February and early March. We were adding 50 locations a month, but I had to back out of the California situation from a financial perspective and just try to hold on and make it through COVID.”

At the time, simplyFUEL’s customer list included NFL teams like the Dallas Cowboys and New York Jets. But when the pandemic prevented teams from getting together, the orders stopped.

“It’s hard to make it in the industry in general,” Dulan acknowledged. “But I’ve always been an entrepreneur and owned my business. I’ve bootstrapped my company, and I operate lean.”

In 2020, the brand used a convertible note to securing funding, and it has plans to fundraise in the third or fourth quarter

44 EMERGING BRAND

APRIL 2023 Q2

—Below simplyFUEL launched in 13 Costco stores in the Texas region earlier this year, with additional distribution planned.

From the flower, to the bee hive, to you. A natural source of a wide array of nutrients, including trace amounts of 7 vitamins, 11 minerals, 5 antioxidants and 17 amino acids. A familiar flavor that everyone loves. Consumers are looking for an all-natural sweetener they can trust. Give them honey.

Contact keith@honey.com to learn how to formulate with honey.

HONEY IS A NaturalWonder

this year, which will help grow the brand and expand the product line.

The return of in-person tradeshows is helping get the name out there again.

Dulan returned to the Natural Products Expo West show in 2022 with the goal of reigniting some of the momentum that started before the pandemic. This time, when Costco came calling, simplyFUEL was ready.

The VP for Costco’s Texas region stopped by the booth at the Expo and offered to introduce simplyFUEL to the buyer in the snacks category. It was just a few weeks later that the brand had secured its first Costco protein ball purchase order.

As a result, simplyFUEL protein balls launched in 13 Costco stores in the Dallas/Ft. Worth area earlier this year and in Costco stores in Oklahoma and Wichita, KS, also part of Costco’s Texas region. The protein balls have performed so well, in fact, that Costco is expanding distribution to the entire Texas region, which includes Houston and Austin. The emerging brand is set to launch in the San Francisco Bay Area this month.

Currently, simplyFUEL protein balls are available in three flavors: Chocolate Coconut Peanut Butter, Brownie Batter and Peanut Butter Honey Almond.

The brand also offers keto granola and a one-ingredient chickpea protein

EMERGING BRAND

Altering the integrity of the product was non-negotiable when simplyFUEL looked to scale production.

powder and plans to expand the line with a second protein powder.

One thing that’s definitely in simplyFUEL’s favor — the market. Dulan was in the protein-packed, better-for-you products game when the only people interested were athletes. Now that everyday consumers are seeking these products, simplyFUEL is well-poised to shift from the emerging brand roster to mainstream player faster than expected — and by the bootstraps. CB

—Right

Securing a co-packer and investing in equipment helped simplyFUEL scale up production quickly.

—Right

Securing a co-packer and investing in equipment helped simplyFUEL scale up production quickly.

QUALITY OVER QUANTITY

With

BY EVAN BAIL

When most people think of the Kentucky Derby, they probably think of horse racing, mint juleps and ornate hats. Two weeks prior to the famous two- minute race held each May, however, is the Kentucky Derby Festival, a grand celebration designed to increase anticipation for the race. Over the years, the festival’s partnership with Louisville, KY-based Kern’s Kitchen, makers of the iconic Derby-Pie chocolate nut pie, has become a tradition.

The partnership began in 1990 when the Kentucky Derby Festival was searching for a new pie partner. Kern’s Kitchen was eager to gain that title.

“We had been ready to get involved with the Kentucky Derby Festival ever since we heard about them,” said Alan Rupp, president of Kern’s Kitchen.

The roots of the company’s Derby-Pie chocolate nut pie run deep through Kentucky, dating back to 1954 when Walter and Leaudra Kern — or Grandma Kern — began managing the Melrose Inn restaurant with their son George. It was there that the first-ever Derby-Pie chocolate nut pie was created, named and sold. Little did the Kerns know, by creating the Derby-Pie chocolate nut pie, they paved a path for a business that would last for generations to come.

As business picked up and Derby-Pie chocolate nut pie production rapidly hit major milestones, such as 1,000 pies sold in 1960, Walter and Leaudra knew that at the pace their business was increasing, they couldn’t continue to work out of the restaurant kitchen.

The couple moved all baking to their home kitchen, where they had a 5-quart KitchenAid mixer to handle the mixing. Back in those days, they could only bake two pies at a time.

As product demand grew, the Kerns upgraded their resources to a Hobart

140-quart mixer but kept their commitment to quality.

“Our main focus has been that pie coming out the same way it did when Grandma was baking two at a time,” Rupp said.

Growing demand often leads to a need for more production space. Kern’s Kitchen has moved locations multiple times, with production currently run out of an 11,000-sq.-ft. space the company moved into in 2014.

The team prides itself on being very hands-on in the process of creating

49 FEATURED BAKERY: KERN’S KITCHEN

a storied history, Kern’s Kitchen has stuck with its iconic chocolate nut Derby-Pie.

The Derby-Pie chocolate nut pie is made with premium chocolate and choice walnuts that are folded into a decadent filling and baked into Grandma Kern’s crust.

All photos courtesy of Kern’s Kitchen

COMMERCIAL BAKING

its own pie dough. However, if they get backed up, one of the perks of being a “somewhat small business,” as Rupp described it, is the versatility to make changes on the fly.

When the team needs to increase production quickly, it uses a Colborne Double Arm mixer combined with a Colborne portioner.

Kern’s Kitchen is built on the foundation of family business, purpose and passion. In fact, a sign on the way into the bakery’s production floor reads, “Purpose and Passion.” It’s important that everything related to creating pies is done with intent. Because Kern’s relies on many old school techniques for crafting the pies, several quality control procedures are required to ensure the highest standard.

“Our walnuts come in already handpicked and machine cleaned,” Rupp shared. “We still dump those on a table and hand sort before we present them to our production manager for mixing.”

The Derby-Pie chocolate nut pie recipe is extremely proprietary, making it one of the most sought-out desserts in the region. New hires who will be working with the recipe have to sign a noncompete and confidentiality agreement. The bakery’s new production manager is only the third person outside of the Kern family to know the complete recipe.

Beyond the Derby-Pie chocolate nut pie, the Kern’s Kitchen product portfolio only extends to one other product, the Golden Pecan Pie. Added to the lineup in 2010, the recipe was also taken out of Grandma Kern’s recipe box.

As a business dating back to the ’50s with only two products in its portfolio, “quality over quantity” is something

Kern’s Kitchen takes very seriously. Plans of expanding the lineup had been tossed around internally. However, just like many other companies, COVID-19 hit the bakery hard, so any plans to grow the product line are at bay for now.

“These last three years have been quite a challenge with COVID,” Rupp said. “Restaurants shut down and distributors really locked down. We have been in survival mode for a couple of years, and we are just coming out of that.”

As Kern’s Kitchen gears up for the 149th Kentucky Derby, held May 6 at Churchill Downs Racetrack in Louisville, preparation to produce enough of the two pie types has been a long, extensive process. Projections for spring began in January, and days are counted in ovens at Derby-Pie. Currently, the bakery uses three rotary tray ovens that can bake 80 pies at a time. The projections for the spring and

Kentucky Derby Festival totaled nearly 64,000 pies.

With any business, there is often a push to expand and increase profit. Kern’s Kitchen continues to grow, but expanding just for the sake of profit is not what this family business is about.

“It’s not that we want to make a bazillion pies a year,” Rupp said. “I want to make sure we are doing things right and we are making a good quality product. Everything that comes out of Kern’s Kitchen is top-notch quality. That’s where we want to grow our space.”

It is easy to zoom through tasks and prioritize quantity over quality. However, at Kern’s Kitchen, the Derby-Pie chocolate nut pie production process serves as a reminder that slowing down, going back to the basics and remembering your core values can lead to a better end result. CB

50 KERN’S KITCHEN

APRIL 2023 Q2

Quality control is something that is prioritized at Kern’s Kitchen to ensure every pie meets the bakery’s standards.

YOUR BAKERY. YOUR MIXER. 937.652.4480 | info@shaffermixers.com | shaffermixers.com FOLLOW US 24/7 PARTS & SERVICE +1 888.508.1298 service@shaffermixers.com Automatedaddition Automated addition of spongedo sponge dough and discharge d an ischarge offinishe of finished dough fini d Compa Compact foot print andlow and lower height Height restrictions inbak in bakery Efficient operation and simple maintenance a d t n n High-efficiency belt-drive design Sanitary design ita ySanitar d sign with easy washdown sy Water-tight ght enclosures es Keep bun eep dough cool ughdo h o Refrigerated frigerated agitator and itatorag a o VerTech® rTech® bowl jacket wl j c et Two-Way Two-Way Tilt, 140° forward/4 forward/45° reverse Contact us to design your custom solution today!

Marketing in the Metaverse

Are

NFTs a fad … or the future?

BY MAGGIE GLISAN

When you hear “NFT,” what comes to mind? Is it digital art sold for millions at a Christie’s auction? Maybe it’s something about brands like Nike, Adidas and Budweiser releasing digital collectibles for major dollars. Or perhaps it conjures up other techy buzzwords like cryptocurrency, blockchains and the metaverse — all of which are hard to get a handle on.

Consumer interest in non-fungible tokens (NFTs) remains relatively low. According to a survey by Maru Group, nearly one-third of US adults have not heard of them, and the aftermath of the 2021 NFT boom may have left those who are familiar with them feeling less enthusiastic. But now, as this technology enters a new stabilizing phase, brands are shifting their focus to explore how NFTs could offer greater utility for consumers and serve as a game-changing marketing tool for building community, brand awareness and loyalty. And that starts with the emergence of Web3.

53 CRITICAL ISSUES: NFT

© Two Pixel on Adobe Stock

COMMERCIAL BAKING

In the early days of the World Wide Web, content was delivered in one direction. Information was uploaded and then accessed by users — not unlike an online encyclopedia. Then came Web2, which allowed users to create their own websites and connect to others via social media apps like Twitter, Facebook, Instagram and TikTok. The latest iteration, coined Web3, ushers in a new era of worldwide connectivity based on a decentralized online ecosystem that utilizes blockchain technology.

“Web3 describes the future of how we will connect, communicate and collaborate online,” said Ben McDougal, a tech founder, author and entrepreneur. Put simply, “If Web1 is read-only, and Web2 is read and write, Web3 is all three — read, write and own.”

Because Web3 is still very much in its infancy, it’s easy to be put off by some of the jargon — and much of the language is still being shaped by innovators and early adopters. However, there are a few must-know terms and concepts that make exploring the world of Web3 far less overwhelming.

First is the idea of decentralization, a key component to the next generation of the web.

“[Decentralization is] sufficiently transitioning from single authorities to proportionately deliver verifiable ownership, access, control, transparency, communication and governance to many stakeholders,” McDougal said.

This means that in the future, the internet will be controlled less by big tech, and more by individual users.

Web3 runs on the blockchain, a digital decentralized ledger that records

information in a way that makes altering or cheating the system nearly impossible. Since the data cannot be changed and is completely transparent, it enables cryptocurrency, a digital decentralized currency that works around the traditional financial system using the blockchain’s cryptography. Bitcoin and Ethereum are two of the most well-known cryptocurrencies. Either can be purchased from a cryptocurrency exchange such as Coinbase, then transferred into a digital wallet — the tool for accessing Web3.

That brings us to NFTs. It’s important to first distinguish between what’s fungible and what’s non-fungible. Fungible items can be replicated and are not unique (e.g., a $1 bill has the exact same value as any other $1 bill). Non-fungible items, on the other hand, are unique and irreplicable (e.g., a signed rookie baseball card).

Therefore, NFTs are original digital assets that can be verified on the blockchain, and because they are uniquely coded, they serve as a digital record of ownership. NFTs can represent almost anything and can be used for collectability, event or community access, and crowdfunding, among other things. Users can receive, buy and sell NFTs on marketplaces such as OpenSea (the largest NFT marketplace), with new utilities and applications constantly emerging.

McDougal said now is a good time to help shift perception about what NFTs are and what they can do.

“I think because of the way they hit the mainstream through digital art, it created a false assumption that that’s all they are,” he said. “Focusing solely on what an NFT looks like is a quick way to get misguided.”

54

Web3 provides a unique opportunity for CPG brands to connect with consumers.

NFT credit APRIL 2023 Q2

© ArtemisDiana on Adobe Stock

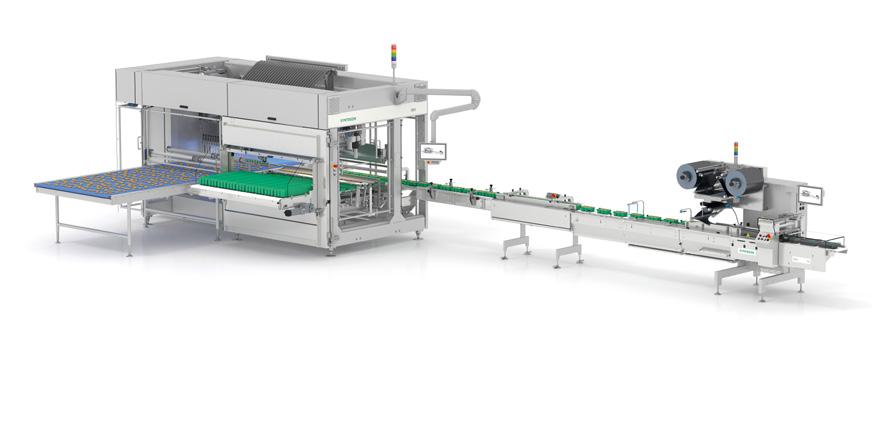

New Top Load Case Packers using Gravity

A simplified, flexible approach to automated end-of-line case packing

With this top load case packer, a layer of product is indexed and positioned over a set of doors prior to dropping the layer into a basket or case. This solution combines mechanical simplicity with flexibility – you can quickly changeover EOL packaging to handle multiple SKU’s under either approach. It is also well suited to constrained plant footprints often associated with manual loading.

Harpak-ULMA’s Top-Load Gravity Case Packers utilize a common conveyor and pattern former with side pushers to condense and orient a complete product layer of fresh baked goods, or the corrugated cases typically used for frozen products. Historically, producers have either utilized manual loading to achieve such flexibility or invested in separate basket and/or case end-of-line (v) automation. A single solution that offers both capabilities in the same footprint helps justify automation by significantly improving ROI.

// Different mosaics

// Small footprint

// GCP100 model packages at a speed of up to 60 bags per minute

// GCP200 model packages at a speed of up to 90 bags per minute

© 2023 Harpak-ULMA Packaging, LLC, 85 Independence Drive, Taunton, MA 02780 USA H RP K-ULMA.COM • 800-813-6644 Contact Us Today to Learn More!

Instead, he said, NFTs should be considered digital properties that have the potential to add immense value and utility.

How are food and beverage brands thinking about NFTs? As expected, some of the largest global players were among the first to jump on the bandwagon. At the start of 2021, big names like McDonald’s, Coca-Cola and Taco Bell made flashy headlines with an onslaught of high-profile releases.

To mark the relaunch of its McRib sandwich, McDonald’s gave away 10 McRib NFTs as part of a sweepstakes promoted on Twitter. The chance to obtain one of the exclusive digital art pieces was aimed at superfans hoping to own a piece of the McRib’s 40-year history.

Coca-Cola’s inaugural NFT collection dropped just in time for International Friendship Day with proceeds from the auction benefiting Special Olympics International. The four unique multisensory NFTs reimagined some of the brand’s most notable features for the metaverse including a custom-designed jacket wearable and sound visualizer that brings to life a Coke’s iconic audio cues.

Taco Bell hopped on the NFT train by selling taco-themed GIFs and images, which were also accompanied by a $500 digital Taco Bell gift card reserved only for the NFT’s original owner.

Despite the buzz generated by these campaigns (and apparent demand: Taco Bell’s 25 tokens reportedly sold out in just 30 minutes), brands don’t appear to be in a hurry to repeat these efforts with similar initiatives.

“There was this feeling that brands were saying, ‘Hey, we’ve got an NFT collection,

and it’s really cool,’ but beyond that, it was difficult for consumers to understand why they’d really want it,” McDougal said, noting that giant brands could only entice their audience with Willy Wonka’s golden ticket so many times before they caught onto the gimmick.

But it’s not just the world’s most massive brands that have dipped a toe in the NFT pool. Baking and snack brands big and small are also experimenting.

The Kellogg Co. and General Mills were two of the bigger players to test the NFT waters in early 2021. Kellogg’s joined the NFT frenzy with a limited-edition release of CryptoCrisp Pringles, a virtual flavor of the popular chip rendered in the form of digital art by Ukranian artist Vasya Kolotusha (proceeds from the auction of the 50 artworks went directly back to Kolotusha). Despite the fact that consumers couldn’t actually “taste” the exclusive new flavor, early bids for the collectibles went for upwards of $800 on Rarible, an Ethereum-based NFT marketplace, after starting at just $2.

General Mills, on the other hand, took a page from McDonald’s’ playbook and leveraged interest in the tech to support nonprofit Feeding America. To mark the return of chocolate Dunkaroos, the company auctioned off 10 original digital artwork NFTs dubbed “new frosting tokens” inspired by Dunkaroos artwork from the 1990s, when the snack was in its heyday. All proceeds from the Rarible auction went to Feeding America’s network of food banks, and the highest bidders also scored an exclusive first taste of the nostalgic snack before it hit store shelves.

While many of these early NFT campaigns leaned heavily into scarcity and collectability — and the hope that

56

NFT

“For us, it’s about creating something that builds a longterm relationship with our guests; food is perishable and can be fleeting, and once you’ve eaten it, it’s gone. With an NFT, it lives on, and we can keep building and growing that community.”

APRIL 2023 Q2

Dominique Ansel | French pastry chef, owner | Dominique Ansel Bakery

Webinar: Improving Sustainable Practices in Your Bakery

May 24, 2023 12PM CST

Register Today!

Scan the Code Below

Re:

Redefine Your Expectations for Preservation

We believe food preservation is about more than simply cutting costs. It’s about keeping food out of landfills, reducing waste and ensuring sustainable practices. It’s about keeping consumers safe and healthy and doing what’s right for the planet. If you think improving the way we make food improves the course of nature, you think like we do. Together we can redefine preservation.

corbion.com

food@corbion.com

CorbionFood

©2023 Corbion

the collectible NFTs would increase in value over time — they lacked utility, which McDougal said is crucial for mainstream adoption.

According to Maru Group, only one in four US adults said they were aware that some NFTs could provide real-world benefits, so increasing awareness about the more practical uses could encourage greater consumer interest.

“If you have a huge audience with a ton of reach and brand loyalty, collectability is a realm you might want to experiment with,” McDougal shared. “But if you are a small baker and your bandwidth is already maxed out, you don’t need to make a big gimmicky splash with NFTs or try to make a bunch of money off Web3. Instead, just start to consider how NFTs can provide value to your customers — whether that’s a loyalty program that delivers exclusives to NFT holders or access to unique events. They need to be more than just a digital token to collect.”

Some of the smaller bakery brands that were quick to explore the NFT space did include this additional layer of utility to build consumer interest

San Francisco-based Love + Chew, a plant-based superfood and protein cookie company, launched a crypto cookie NFT collection in March 2022 to honor International Women’s Day. Designed by female artist Fatemeh Monfared, the NFTs were not just collectible digital art pieces. They also unlocked access to upcoming launches, cookie subscriptions and recipes exclusive to NFT holders.

Las Vegas-based Freed’s Bakery, which was recently acquired by Cafe Valley, was among the first small bakeries to dabble in NFTs when it created the world’s first NFT wedding cake — a collectible GIF of one of its handmade cakes — in September 2021. Since then, Freed’s has expanded its NFT collection to 50 colorful cake collectibles

available in its Sprinkle Iced Cake Depot on OpenSea. Each cake NFT unlocks gated content and presents exclusive offers and benefits.

No stranger to scarcity and exclusivity, in May 2022, French pastry chef Dominique Ansel celebrated nine years of the Cronut with an inaugural NFT collection consisting of 60 Cronut tokens in five former flavors voted upon by fans.

“We’ve always been excited to try new things that we thought are worthwhile, whether it’s regularly changing our menu or, in this case, developing our very first collection of NFTs,” Ansel said. “For us, it’s about creating something that builds a long-term relationship with our guests; food is perishable and can be fleeting, and once you’ve eaten it, it’s gone. With an NFT, it lives on, and we can keep building and growing that community. This will be a new way to keep in touch and give our guests that extra bit of hospitality.”

APRIL 2023 Q2 58

© popaukropa on Adobe Stock

NFT

Cavanna: scalable Flowpack, Cartoning & Casepacking CAVANNA PACKAGING USA INC. 3400 Corporate Way | Suite F | Duluth GA 30096 Phone: (770) 688-1501 Fax: (770) 810-3528 sales@cavannagroup com www cavanna-usa com Cavanna Packaging specializes in: • Turn-key Flow Wrapping, Cartoning and Casepacking solutions • Sanitary Design Systems for the Food Industry • Easy to clean toolless Poke Yoke solutions • Fully Caustic Washdown Flow Wrapping lines • Unique space and labor saving Flow Wrapping solutions Turn-key Flowpack & Cartoning

Each Cronut NFT also came with special perks, including early access to new pastry launches and a free pass to “skip the line” when visiting a Dominique Ansel Bakery.

McDougal said he sees lots of opportunities for companies to test similar NFT strategies that include exclusive access to help consumers feel a deeper bond and loyalty to a brand through unique experiences.

“Along the way, you’ll find things that might not fit what you’re trying to do long term,” he said. “But there may be ways that you can weave in something fresh and activate not only your existing audience but also maybe introduce channels for new awareness.”

One way marketers might want to consider NFTs is as a tool for deeper storytelling, whether that’s unlocking content that connects with customers who care about where their food comes from, establishing traceability through the supply chain or improving transparency around safety protocols. It’s all possible with NFTs via smart contracts, which act as the bridge between digital assets and the blockchain.

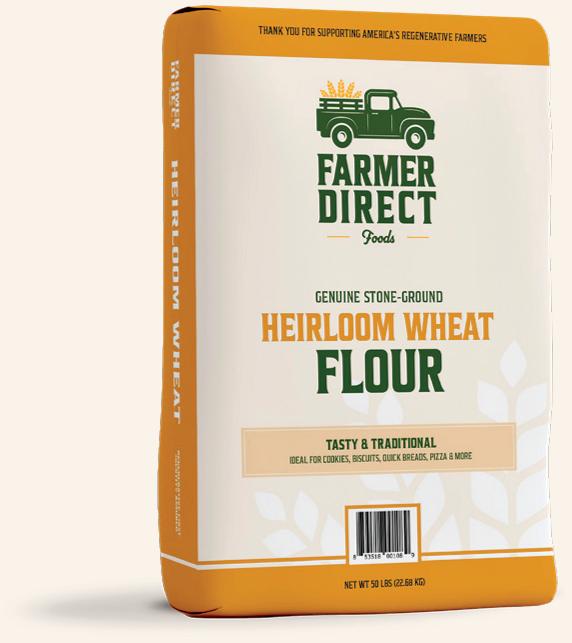

A key element of Web3 is its community lead, meaning it diversifies the pool from which stories are told. As power in advertising continues to shift toward influencers and real-life consumers, marketers can use the decentralized NFT space to think outside-the-box for new ways to connect with customers.