BEARING INDUSTRY MAGAZINE

How (no-)gravity impacts cage instability in bearings

Publisher

iMotion Media

Louizalaan 523, 1050 Brussels - BELGIUM

Phone

Fax

Web

+32 (0)489 32 85 21

+32 (0)3 303 52 82

info@bearing-news.com www.bearing-news.com : : : :

: linkedin.com/company/bearingnews

: facebook.com/BearingNewscom

: twitter.com/Bearing_News

: youtube.com/channel/

UChCnbcmjFPbLEkLZGdjEXIw

The information contained in this magazine is for general purposes only. The information is provided by BearingNews. We make no representations or warranties of any kind, express or implied, about the completeness, accuracy, reliability, suitability or availability. Any reliance you place on such information is therefore strictly at your own risk. In no event will we be liable for any loss or damage including without limitation, indirect or consequential loss or damage, or any loss or damage whatsoever arising from loss of data or profits arising out of, or in connection with, the use of this magazine.

No part of this publication may be reproduced or transmitted in any form or by any means, electronic or printed, without permission in writing from the publisher/editor.

The BearingNEWS is a member of the EPTDA

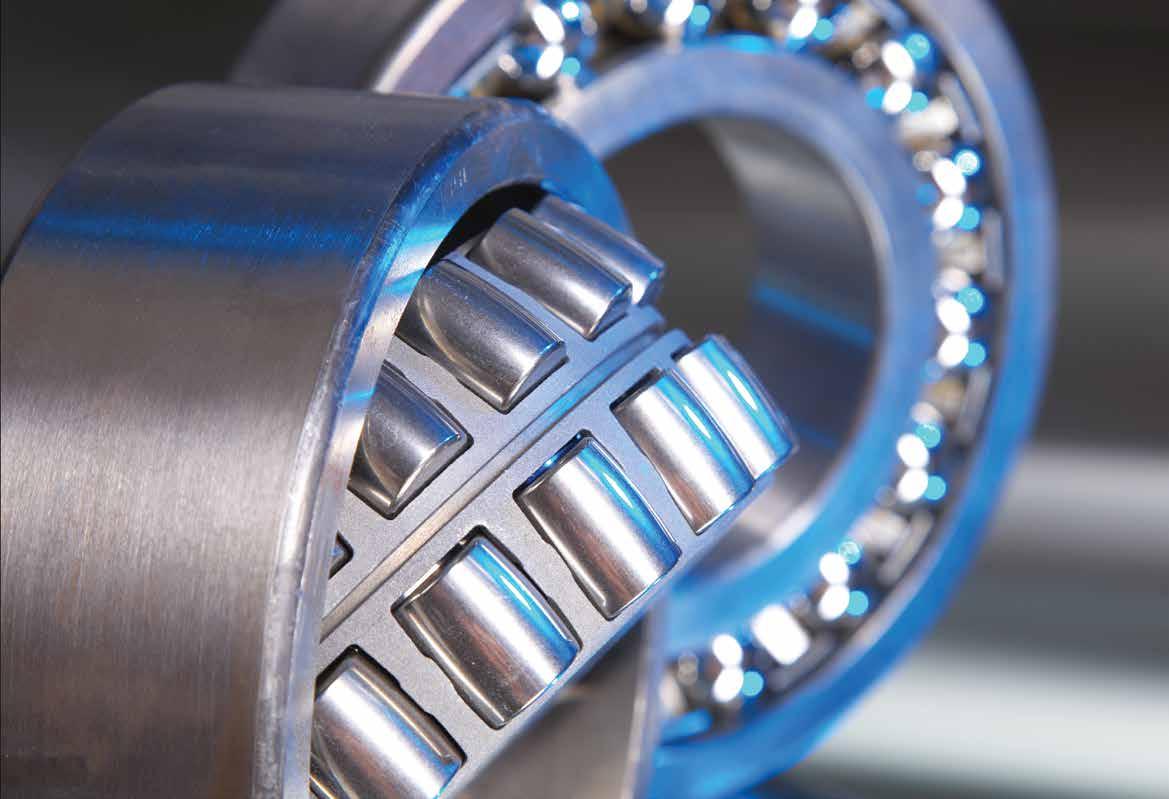

In this issue of Bearing News magazine, we delve into the thriving ball and roller bearing market in LatinAmerica, where robust industrialization and sectoral growth are fueling a steady rise in demand. The region's market, anchored by key players like Mexico, Brazil, and Argentina, is seeing significant momentum due to the technological developments in the manufacturing, mining, and construction industries. As global companies invest heavily in the region, the market is preparing for continued growth, with projections indicating a 4-5% increase over the next decade. You can read more details and a overview per country in this new issue.

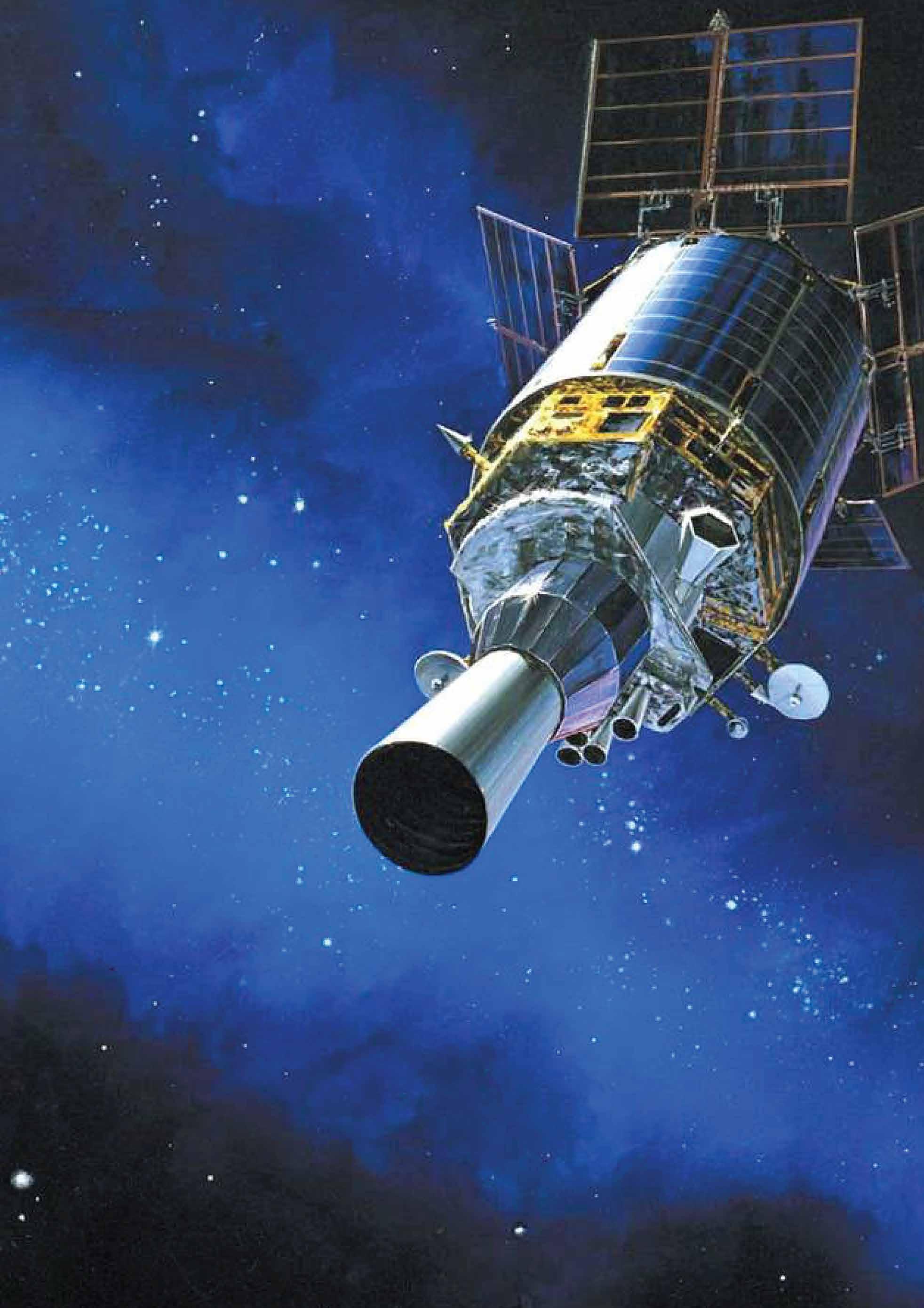

We explore further the critical challenge of cage instability in ball bearings, a phenomenon that has disrupted several high-profile space missions. This unpredictable issue, particularly prevalent in gyroscopes and reaction wheel assemblies (RWAs), generates noise and vibrations that can lead to mission failure. Traditional testing methods on Earth fall short in predicting this instability once in the gravity-free environment of space. However, there is hope on the horizon "Butterfly cage" design, which has been rigorously tested, promises to enhance stability and mitigate these risks, paving the way for more reliable space missions in the future.

In addition, we sit down with Talar Markaroğlu and

The BearingNEWS magazine is published four times a year in March, June, September and December. The online editions are published in 8 languages and can be followed on www.bearing-news.com

Art Director

Diydem Deniz Koç

Photography & Illustrations

Ksenia Shamanaeva

Web & IT

Canbey Bilgili

Birsen Aydın

Onur Uz

Subscriptions info@bearing-news.com

Sesil Markaroğlu, the dynamic leadership duo behind Özevren, which is one of Turkey's leading bearing distributor. With a strategic focus on direct supply to manufacturers and end-users, Özevren has built an impressive local network, boasting a storage capacity of 12,000 square meters across its facilities. The recent launch of Özevren Teknik Makine marks a pivotal transformation for the company, as it expands into offering customized solutions and advanced technological equipment. In our exclusive interview, the Markaroğlus share insights into this exciting evolution and their vision for driving efficiency and innovation in the industry.

Further in this issue, we invite you to explore what’s rolling in the bearing industry. Learn details about key companies and trends, investments, product developments, and other newsworthy advancements. All this and more can be found in this new edition of BEARING NEWS Magazine.

I hope that you will enjoy it!

Related Publications & Network

Editor-in-Chief

Kenan M. Özcan

Editorial Team

Thomas Johnson

Mia Mctigue Rodriguez

Dize Purde

Guest Editor

Mike Brandt

Marketing

Tapaswee Dixit

Victor Vialet

Vincent Yang

Project Coordinator

Merve Zhunuskanova

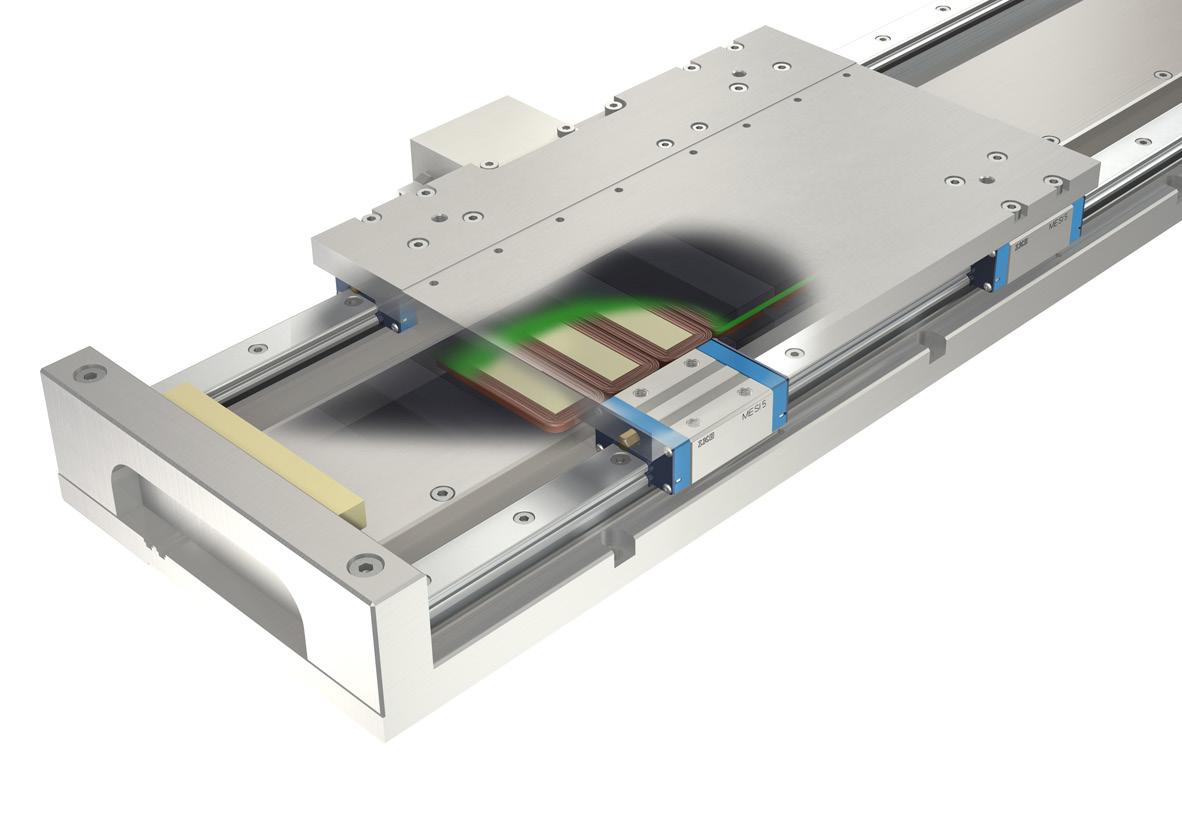

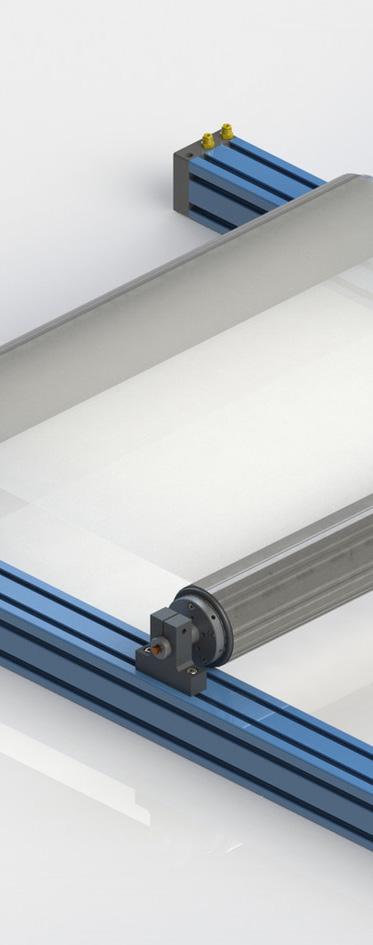

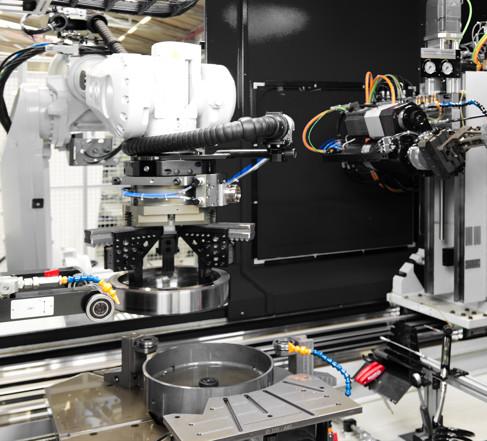

Our specialized finishing with ground end faces allows for seamless joining of individual rail pieces, enabling the installation of rail systems of any length. The precise grinding ensures smooth movement of guide carriages along the rails.

COMPANY: RKB BEARINGS FOR EVERY STEP OF THE CEMENT PRODUCTION PROCESS

EVENT: BEARING & POWER TRANSMISSION WORLD MEETINGS 2025

MARKET REPORT: BALL AND ROLLER BEARING MARKET IN LATIN-AMERICA – MARKET OVERVIEW

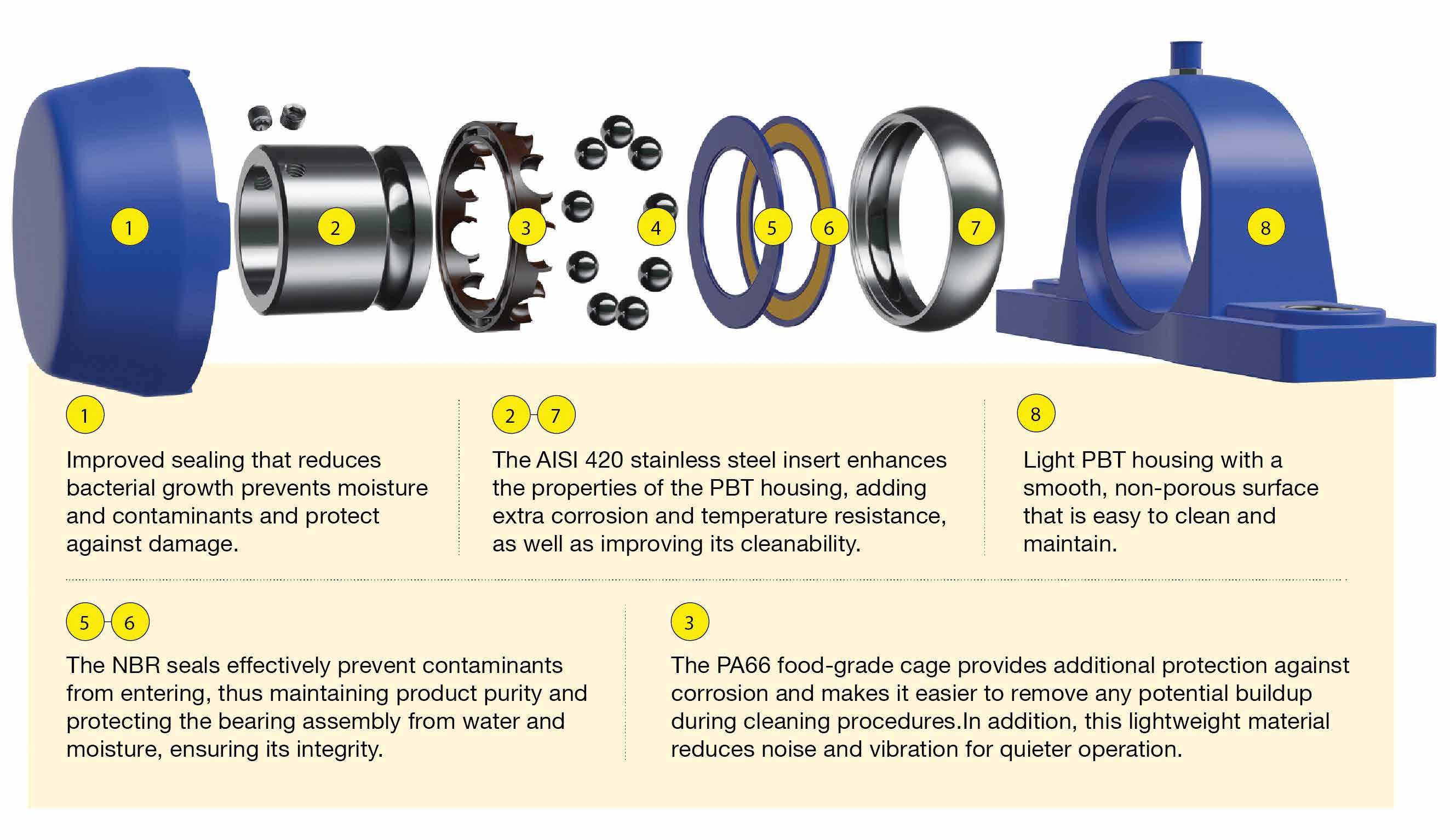

COMPANY: ZEN BEARINGS LAUNCHES ITS NEW FOOD AND BEVERAGE-SAFE LINE

LUBRICATION:

COMPANY: NES’ DIGITAL STITCHING SERVICE ENHANCES BEARING SOURCE QUALIFICATION

TECHNOLOGY: HOW (NO-)GRAVITY IMPACTS CAGE INSTABILITY IN RWA AND GYROSCOPE’S BEARINGS

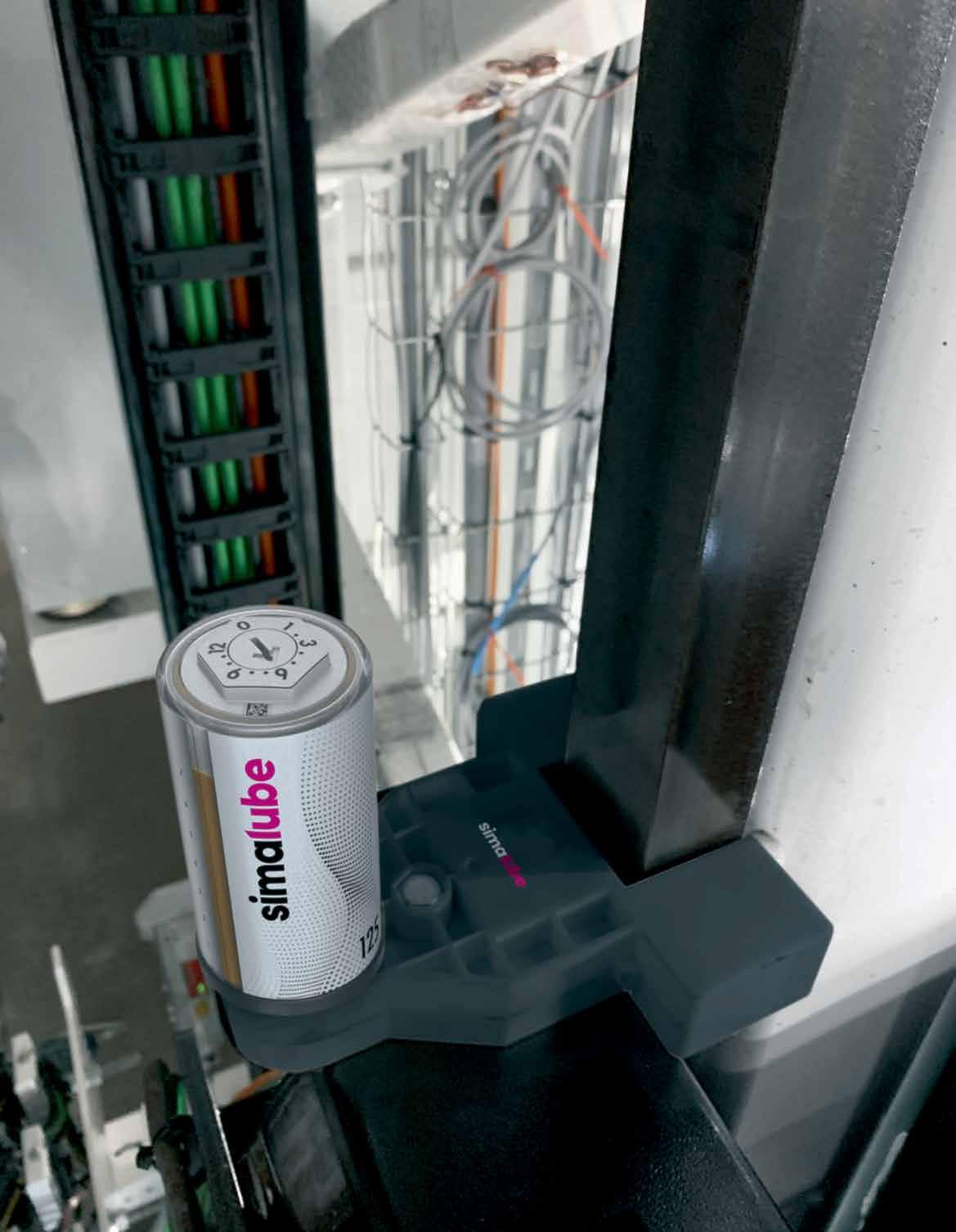

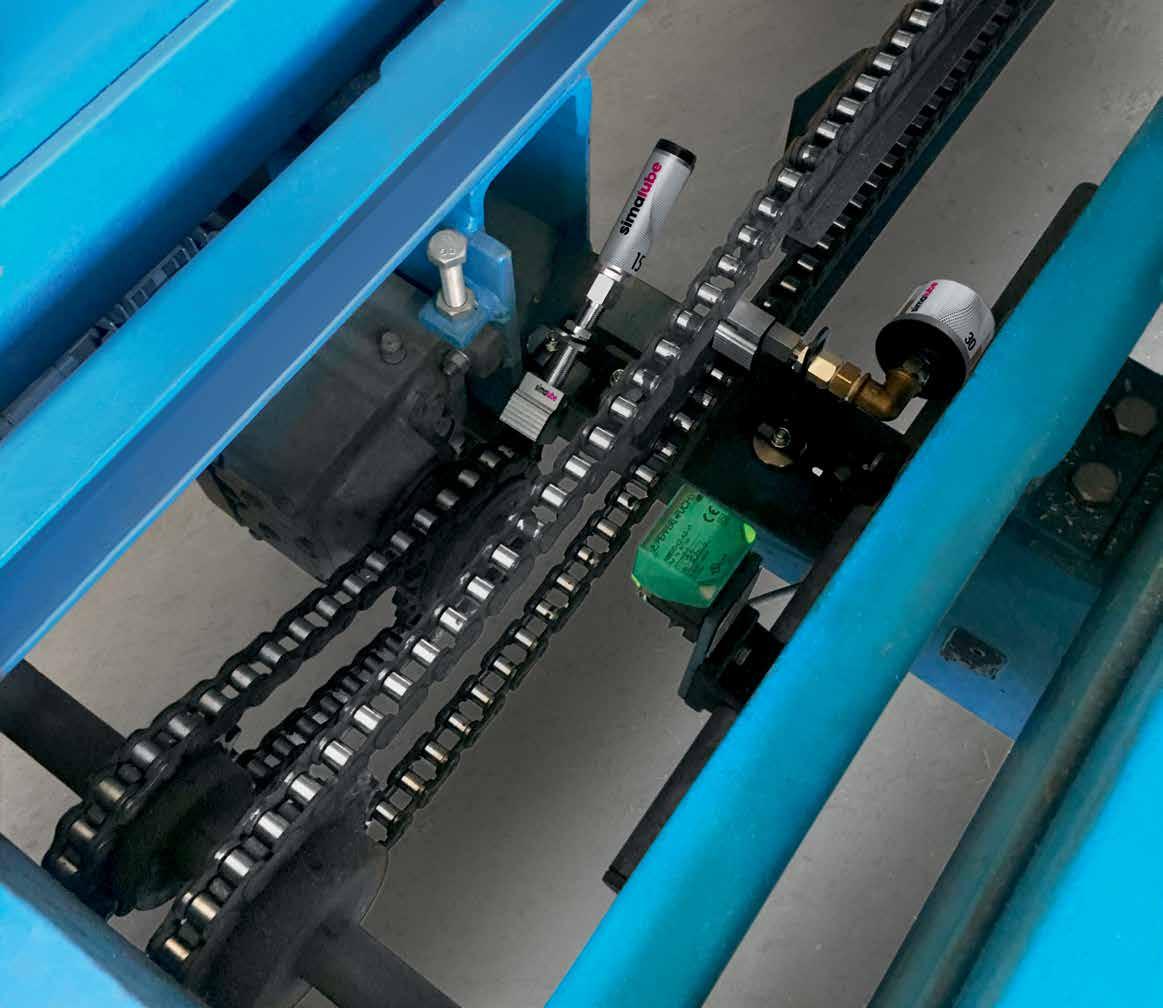

REVOLUTION IN LOGISTICS: AUTOMATIC LUBRICATION SETS NEW EFFICIENCY STANDARDS COMPANY: NTN EUROPE FOUNDATION

INTERVIEW: INTERVIEW WITH GIUSEPPE PANACCIONE

SUSTAINABILITY: SKF AND VOESTALPINE REACH MILESTONE TO DECARBONIZE BEARING PRODUCTION

PREDICTIVE MAINTENANCE: THE ROLE OF ULTRASOUND IN MAINTENANCE 4.0

ENABLING BEARING PREDICTIVE MAINTENANCE

PRODUCTS: SCHAEFFLER'S OPTIME HELPS PREVENT UNPLANNED DOWNTIME AT UK LIMESTONE PLANT

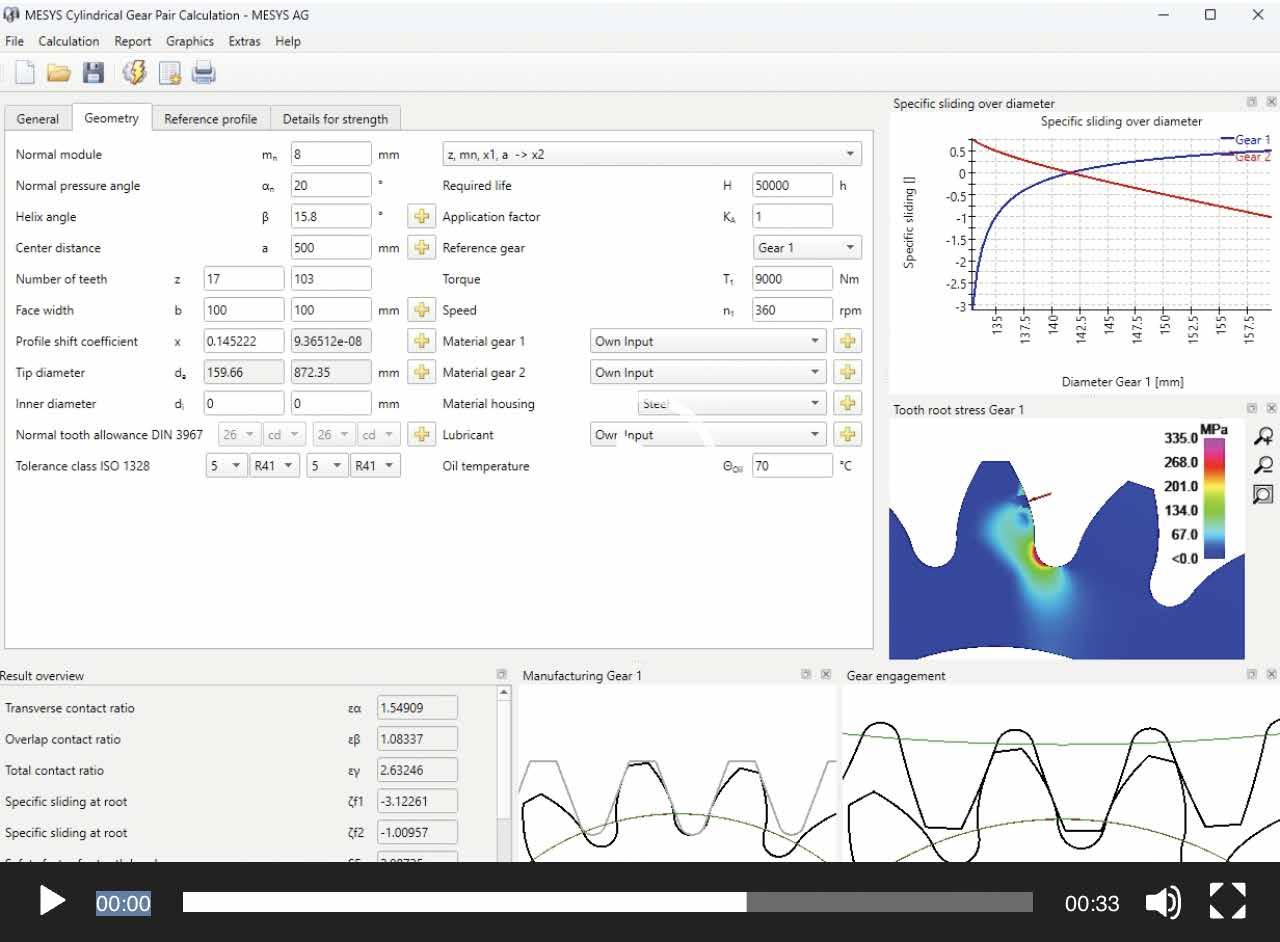

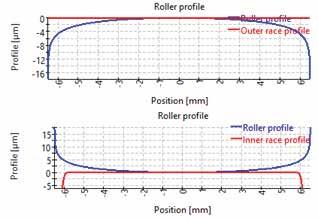

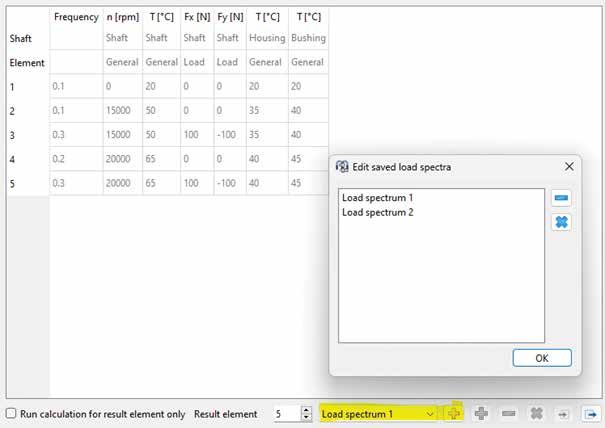

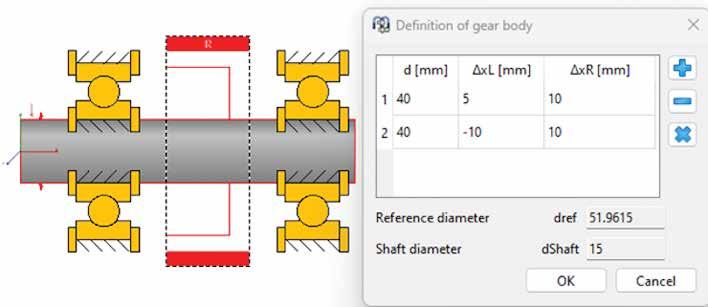

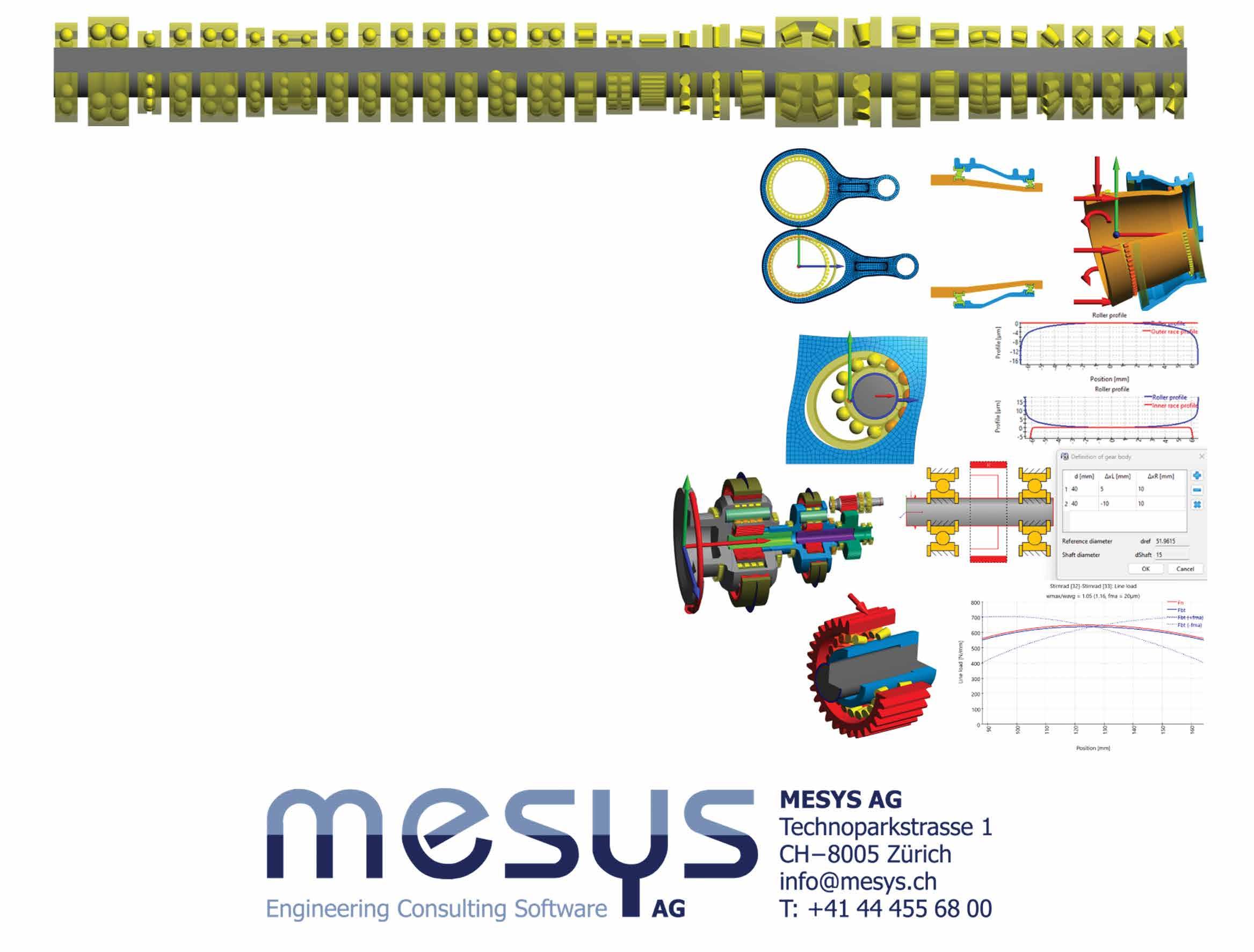

SOFTWARE: MESYS SOFTWARE VERSION 06/2024 IS AVAILABLE

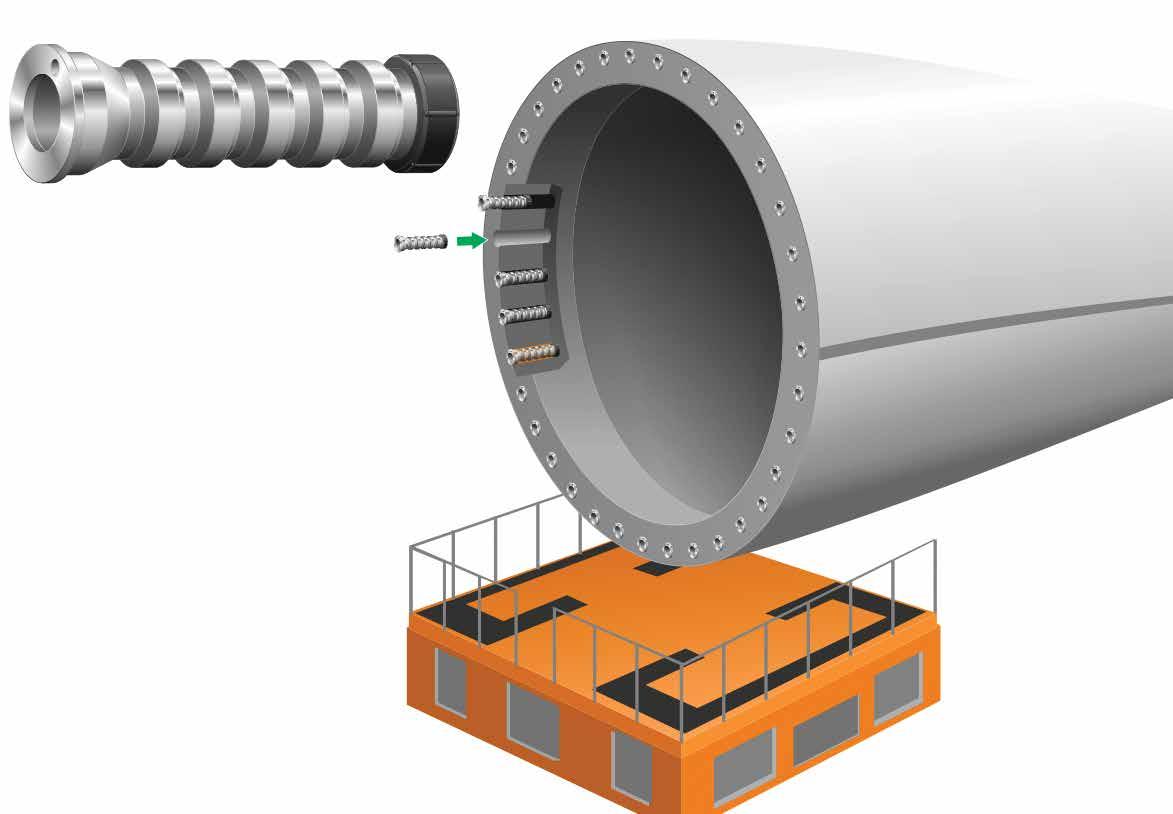

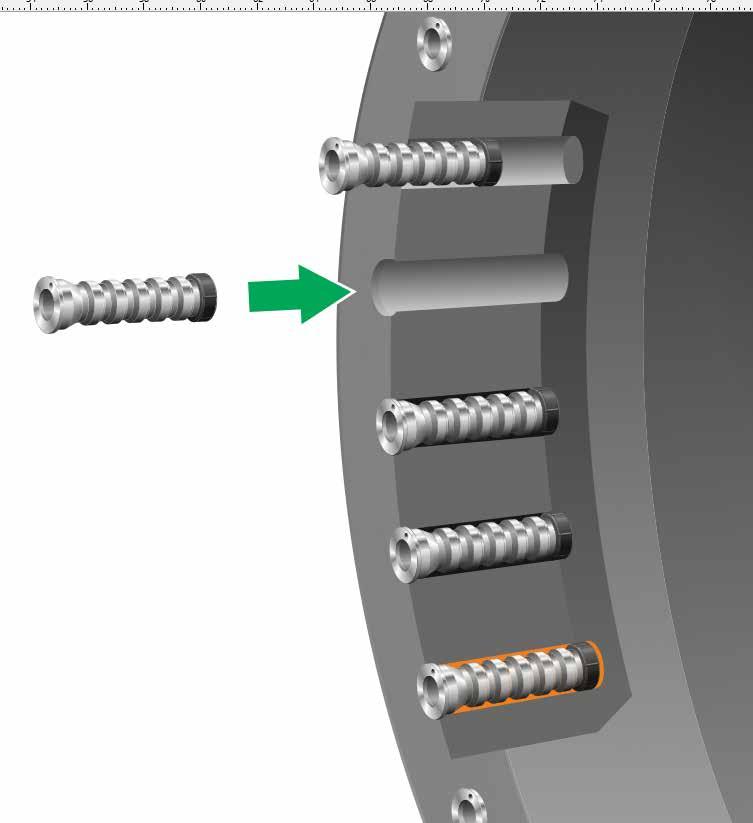

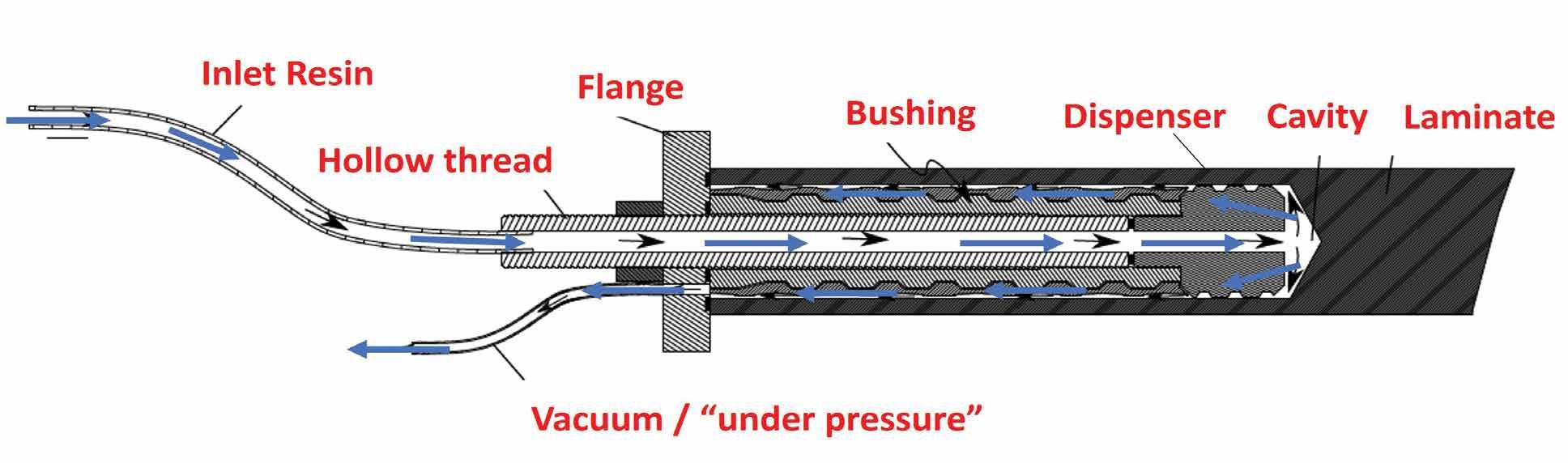

PRODUCTS: WE4CE PATENTS ITS RE-FIT BLADE ROOT BUSHINGS, MEETING DEMAND FOR ON-SITE REPAIR

SUSTAINABILITY: BEARING NEWS GOES GREEN

March 6, 2024 // BearingCloud launches the TradeZone feature! The new function will support distributor companies for checking and posting special offers, specific demands, seeking new partnerships, hiring new talents and many more options. The messages can be shared publicly or anonymously prioritizing user privacy. The details of the new tool can be checked on www.bearingcloud.com.

March 19, 2024 // Crackdown on Counterfeit Bearings are reported. Recent cases in China and India underscore the ongoing battle against these fraudulent products, emphasizing the importance of stringent quality control measures and collaborative efforts between authorities and manufacturers. Ningbo Customs, in a recent operation, intercepted a shipment declared as “bearings and pulleys,” revealing a stash of counterfeit auto parts. Marked with trademarks Koyo and KYMCO, these parts, upon verification, were confirmed as counterfeit by the copyright holders. The seizure, totaling 4,950 units, highlights the dangers posed by counterfeit bearings, which often compromise safety standards and risk equipment failure.

The operation served as a stark warning to counterfeiters, signaling accountability and the commitment to combatting counterfeit products. Meanwhile, in India, National Engineering Industries Ltd. (NEI), a leading bearings manufacturer under the CK Birla Group, intensified its crackdown on counterfeit bearings. Through coordinated efforts with local authorities, NEI conducted raids in Delhi and Agra, seizing counterfeit bearings worth over 2.8 million USD.

March 25, 2024 // The Timken Company has released its 2023 Annual Report, marking another year of revenue growth, expanded margins and record adjusted earnings per share.

“As the company celebrates its 125th anniversary in 2024, our customerfocused innovations are more critical and relevant than ever in addressing the new needs and challenges of a diverse global customer base and end-market mix,” said Richard G. Kyle, Timken president and chief executive officer. “This year’s strong financial performance reinforces that the company has additional runway for profitable growth, driven by our market leading Engineered Bearings and Industrial Motion product platforms, customer-centric innovation, proven business model, long-term strategy and management’s record of excellent execution.”

April 02, 2024 //IKO Nippon Thompson (UK), a global leader in precision motion

technology, and Servo Components & Systems Ltd, a renowned provider of cutting-edge servo systems, proudly announce their strategic partnership aimed at driving innovation and expanding market reach in the realm of motion control solutions, aimed at redefining the landscape of precision motion control. IKO offers a diverse array of precision positioning tables, integrating linear motion rolling guides and ball screws or motors between the bed and slide table. These solutions cater to a wide spectrum of industries, including semiconductor manufacturing, flat panel display manufacturing, and other precision equipment applications. IKO’s Mechatronics series not only offers superior precision and reliability but also streamlines design and assembly processes, thereby enhancing operational efficiency and reducing timeto-market. Established in 1992, Servo Components & Systems Ltd specialises in supplying motion control products to a diverse array of industries, including general industrial applications, production automation, packaging, food processing, life sciences, automotive, and military sectors.

April 05, 2024 // Bartlett Bearing Company, an independent authorized bearing distributor, announces the Q2 opening of its seventh location in Las Vegas, Nevada. Strategically located, the new, fully-stocked warehouse will streamline the company’s distribution network, resulting in faster and more efficient service for our valued clients nationwide. The Las Vegas location will boast more than 8,000 square feet of combined warehouse and office space, inclusive of a Bartlett counter for local pickups. This warehouse will serve as Bartlett’s West Coast distribution hub, offering improved delivery options to

better service the company’s West Coast customers. The opening of this seventh location offers numerous advantages to increase efficiency and provide improved service to valued clients.

April 06, 2024 // New Hampshire Ball Bearings, Inc. (NHBB) has signed Proponent of Brea, CA as an authorized aircraft bearing distributor to support its strategy of increasing business in the MRO sector. Proponent, a leading distributor servicing the MRO market, was chosen by NHBB due to its deep knowledge of the market and broad access to end-users. “This collaboration is intended to help lower our leadtimes and get our bearings into the hands of the aftermarket customers that need them,” said Ted Gentile, NHBB’s Distribution Manager. “Proponent is a great addition to our network of authorized distributors.”

April 07, 2024 // SDT Ultrasound Solutions is excited to announce the release of the LUBExpert ON-GUARD, the newest addition to the SDT Catalog, combining automation with reliability,

simplicity, and safety. Perfectly in line with the SDT mission, the LUBExpert ON-GUARD respects your assets and your work, gives you flexibility by conducting grease replenishment remotely and makes bearing replenishment simple by eliminating the need for extensive training. The LUBExpert ON-GUARD is an online monitoring system designed for smart ultrasound-assisted lubrication with up to 8 channels. The system enables smooth relubrication of assets only when needed, with the appropriate amount of lubricant ensuring your assets consistently perform at their peak. The device promotes a sustainable future with precise control, preventing unnecessary depletion and oversupply as well as reducing lubricant consumption and electrical energy use. This new SDT patented solution helps you keep your workforce safe

by conducting grease replenishment remotely, mitigating any potential risks in hazardous environments.

April 09, 2024 // 2024 The Timken Company Board of Directors has reached an agreement with Tarak Mehta to become Timken’s next president and chief executive officer on Sept. 5, 2024. Mehta is currently president of the Motion business and member of the Group Executive Committee at ABB Ltd., a $32 billion leader in electrification and automation. Mehta will be appointed Timken president and CEO after he completes a transition period with ABB. Richard G. Kyle will remain president and CEO until Mehta’s appointment date. At that time, Kyle will move into an advisory role to assist with the leadership transition. Kyle plans to retire as an employee of Timken following a decade of leadership as CEO but will continue to serve on the Timken Board of Directors. Mehta has 35 years of industry experience, including a 26-year career at ABB. As president of ABB’s Motion business, he has extensive experience accelerating organic growth and innovation across global industrial markets, scaling business portfolios through M&A transactions and helping customers save energy and improve efficiency. While at ABB, Mehta held a variety of global business leadership positions of increasing responsibility, including president of Electrification Products. Mehta will be joining the Timken team in North Canton, Ohio, and is expected to be appointed to the Timken Board of Directors at a future date.

April 11, 2024 // Earlier in April, the Gaotang County Market Supervision Bureau received a notice from local

HUGE STOCK AVAILABILITY

PREMIUM SERVICE AND ASSISTANCE

MULTILEVEL QUALITY CONTROLS

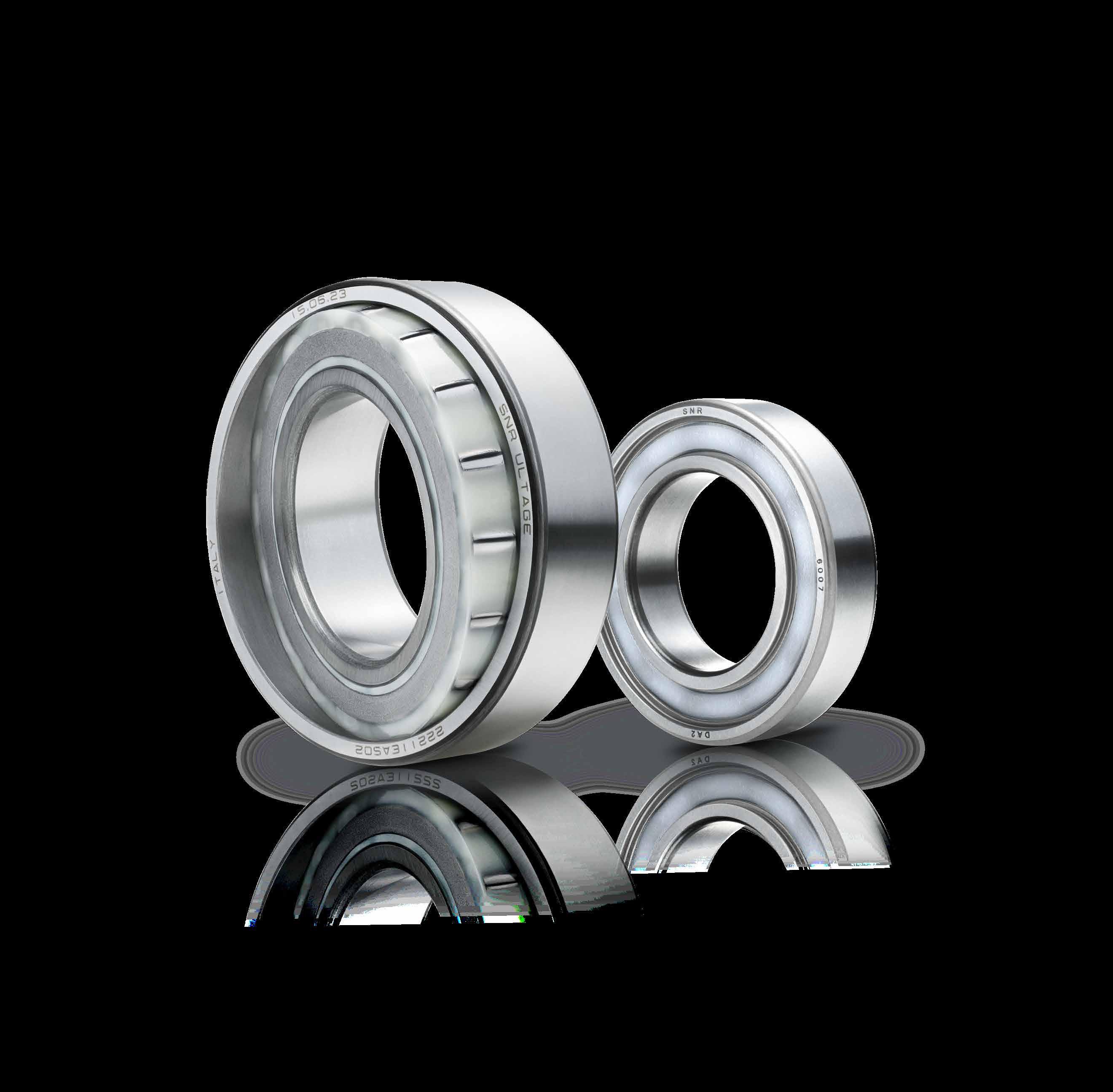

The RKB Bearing Industries Group, a Swiss-based manufacturing organization, has been a key player in the bearing industry since 1936.

Leveraging decades of experience, RKB possesses the specialized knowledge and skills required to design and produce industrial bearings from 1 mm bore diameter to over 2.000 mm outer diameter.

With a global distribution footprint reaching over 70 countries, RKB provides value-driven solutions characterized by impressive operational adaptability, top-tier services, huge stock reserves, quick shipping times, and the hallmark quality expected of a premium-bearing provider.

authorities about a case involving the sale of counterfeit bearings by a suspect identified as Wu Mou. The bearings in question were falsely labeled with the logos of well-known brands such as "NSK," "INA," and "FAG," raising suspicions of trademark infringement. Investigations confirmed that the trademark owners had not authorized Wu Mou to produce, sell, or store products bearing their logos. Wu Mou's actions were found to be in violation of Article 57, Clause 3 of the Trademark Law of the People's Republic of China. As a result, the Gaotang County Market Supervision Bureau decided to take administrative action against the suspect. On April 11, 2024, the Bureau issued a decision ordering Wu Mou to immediately cease his illegal activities. Authorities confiscated the counterfeit bearings and imposed a fine of 40,000 yuan on the suspect. In recent years, China has implemented a range of measures to strengthen intellectual property protection, including the establishment of specialized anticounterfeiting and anti-IPR violation departments within customs. These initiatives aim to protect the rights of trademark holders and prevent counterfeit goods from entering the market.

April 15, 2024 // Acorn Industrial Services is excited to share that it has been appointed as SKF’s Super Precision Bearing Partner – the UK’s first and only of its kind. This partnership is an important milestone for ACORN and will enable the company to offer its clients the highestquality precision bearings available in the market with same-day despatch on hundreds of stocked items. SKF Super Precision Bearings are renowned for their exceptional performance, high-speed capabilities, and system rigidity, making them the ideal solution for any high-speed industry. By partnering with SKF, ACORN can now offer a superior range of stock levels, including single, universally faced bearings that can be easily combined to meet any specific requirements.

Being appointed as SKF’s first-ever Super Precision Bearing Partner offers customers the assurance that they can get the parts they need, when they need them, allowing businesses to achieve optimal performance with the highest quality products, delivered quickly and efficiently.

April 17, 2024 // JTEKT Japan has recently signed a partnership agreement with Team Visma | Lease a Bike (TVL) to supply ONI BEARING® for the 2024 UCI (Union Cycliste International) world tour.

Background of this Partnership with Team Visma | Lease a Bike. Team Visma | Lease a Bike was the winner of the three biggest UCI tours in 2023 – Giro d’Italia, Tour de France and La Vuelta Ciclista a España. JTEKT is excited to start this partnership with TVL to enhance their performances using ONI BEARING®, a low torque performance bearing with an outstanding reputation in Japan.

May 1, 2024 // The Annual General Meeting of Schaeffler has approved the merger of Vitesco Technologies Group Aktiengesellschaft (“Vitesco”) into Schaeffler. After Vitesco shareholders

at their Annual General Meeting had already voted in favour of the merger agreement the day before, the Annual General Meeting of Schaeffler has also given the green light for the merger. The Annual General Meeting also approved all other resolutions proposed by the management. Up to 626 participants attended the virtual event.

May 3, 2024 // European users of NSK’s class-leading linear guides can now take advantage of NSK’s new state-of-theart cutting facility in the Netherlands. Based at the company’s European Distribution Centre in Tilburg, the €1.6 million plant will enhance service levels for customers in key European markets that include Germany, France, Italy and elsewhere. The new NSK linear guide cutting facility in Tilburg offers a seven-

day delivery time anywhere in Europe. Although NSK Europe already has a linear guide cutting facility at its site in Newark, UK, the addition of Tilburg will help to optimise the company’s service level for these popular products across mainland Europe. The opening of Tilburg linear guide cutting facility means NSK can offer a seven-day delivery time anywhere in Europe. This meets with demands from customers using these high-quality products, particularly those manufacturing automated handling systems, packaging equipment and other common industrial machines such as metal shears. In such applications, precise sales forecasting is difficult, so manufacturers will often order linear guides at short notice. A rapid response from NSK is paramount.

May 5, 2024 // Timken reported first-quarter 2024 sales of $1.19 billion, down 5.7 percent from the same period a year ago. The decrease was driven by lower demand, including a significant decline in renewable energy in China, and unfavorable foreign currency translation, partially offset by the benefit of acquisitions (net of divestitures) and favorable pricing.

Timken posted net income in the first quarter of $103.5 million or $1.46 per diluted share. This compares to net income of $122.3 million or $1.67 per diluted share for the same period a year ago. The company’s net income margin in the quarter was 8.7 percent, compared to 9.7 percent in the first quarter of last year. Excluding special items, adjusted net income in the first quarter was

$125.7 million or $1.77 per diluted share. This compares to adjusted net income of $153.5 million or $2.09 per diluted share for the same period in 2023. Adjusted earnings before interest, taxes, depreciation and amortization (EBITDA) in the quarter was $246.4 million or 20.7 percent of sales, compared with $265.5 million or 21 percent of sales in the first quarter of last year.

May 10, 2024 // Axel Johnson

International Acquires a Majority Stake in Royse for Expansion in the Spanish Market. The acquisition of Rodamientos y Servicios S.L., and Royse ISM Servicios Integrales, S.L. (together “Royse”), a leading provider of power transmission products and services in Spain, is significant for Axel Johnson International, and one of the largest in the group’s history. Royse will become a part of the Power Transmission Solutions (“PTS”) business group, strengthening the position in Iberia and is supported by shared values and a mutual vision for the future. Royse, a family-owned company based in Seville, Spain, operates 14 branches, employs over 160 people nationwide and is the largest independently owned company in the Iberian power transmission market. The company was founded by Juan Manuel Ortega Sr. in 1979. It is well-known for its customeroriented approach and its strong offering with bearings, transmission, and value-adding services as core segments. The company’s geographical expansion has ensured high availability of products, a skilled workforce, and efficient logistics from facilities all over Spain, guaranteeing the best possible service and response to the market. PTS’ and Royse’s mutual customer-focused approach and long-term commitment

are important in supporting continued strong customer relationships.

May 15, 2024 // NSK has developed its 7th generation of low-friction tapered roller bearings. This product can help to increase vehicle range through improved fuel/electricity consumption achieved by reducing friction by an average 20% over the entire rotation speed range. NSK aims to achieve annual sales of 15.0 billion yen by 2030 for this product, including existing models.

May 17, 2024 // Eleiko, a leader in premium weightlifting equipment, together with Ovako, a prominent steel manufacturer known for its high-quality clean steel, are excited to announce the strengthening of their historic partnership, which dates back to 1957. This collaboration is set to promote revolutionary low carbon footprint solutions in steel production and products. The newly signed agreement highlights key initiatives including: A firm commitment to supply and utilize world-leading low carbon footprint steel for Eleiko products. Ovako has agreed to reserve production capacity to meet Eleiko’s demand for low carbon footprint steel. The incorporation of CO2e parameters in product specifications, enhancing transparency and sustainability. Joint marketing initiatives aimed at advocating for sustainable industrial practices, particularly in the Nordic region.

An increasing number of tested samples per hour and zero failures are the most important factors in bioscience analysers. Nowadays, linear motion mechanism is an indispensable part in these devices which are used widely in medical and researching facilities. Though dozens of linear bearing manufactures provides small size linear guides in the market, IKO Nippon Thompson brings unique technology and solutions to these high-end devices with our unique technology and the solution we offer:

- Excellent and accurate repeatability

- Maintenance-free

- Made from corrosion resistant stainless steel

The engineer from one of IKO’s Miniature Linear Way ML users who is responsible for designing the precision scanners for their medical devices explains: “Smooth and stable linear movement without a mechanical clearance is absolutely a crucial factor for our device performance. A linear motor-driven table must have zero-compromise speed stability in order to achieve a high quality scanning of the biological membrane. IKO Linear Way brought the solution to our high demands.” During the prototype designing, the engineer and IKO discussed numerous factors and finalized the specification. In addition, the end users or maintenance engineers of the devices are free from a re-lubrication thanks to IKO C-Lube technology. In addition to providing the above mentioned technical solutions, IKO worked together with the customer to plan and arrange optimized delivery control in a recently problematic supply chains system, successfully securing the customer’s on-schedule production.

IKO Miniature Linear Way ML does not stop in the field of mechanical parts, but has evolved to IKO linear motor tables by incorporating their excellent performances. IKO provides the extremely thin and compact structured linear motor tables that are suitable for bio-medical, semiconductor, small automation devices. These positioning tables achieve quick positioning from A to B with more than 80% reduction of the settling time compared to the ball screw driven mechanism.

IKO provides the following size range

Miniature Linear Way ML : 1mm to 42mm in width

Linear Motor Table NT : 38mm to 88mm in width

Linear Motor Table LT : 100mm to 170mm in width

For more information on how IKO can support your new and current projects, visit www.ikont.eu or email nte@ikonet.co.jp, Phone +31 (0)10 462 68 68

IKO Nippon Thompson Europe B.V. Keersopstraat 35, 3044EX Rotterdam, the Netherlands

Make the world move forward*

LUBSOLIDTM is the outcome of our unparalleled proficiency in lubrication development. Through an extensive battery of tests conducted on bearings in the most stringent conditions, this French technology represents the most effective method to combat the causes of premature bearing failure. The solid lubricant solution is highly recommended for numerous industry. It is compatible with most articulated bearings and ensures safety and longevity.

*At NTN, efficiency hinges on a sustainable product life cycle

May 20, 2024 // HVH Industrial Solutions, a renowned provider of industrial products and solutions, has recently announced its strategic acquisition of Metro Industrial Supply. This move signifies a significant expansion for HVH, establishing it as a prominent supplier and distributor of power transmission and motion control parts within the New Jersey region. Adding Metro Industrial Supply offerings to HVH’s portfolio marks a crucial milestone in the company’s dedication to delivering comprehensive industrial solutions. Metro brings a wealth of expertise accumulated since its establishment in 1983. By combining forces, HVH is now equipped to offer an even broader range of products, ensuring it can effectively cater to the evolving needs of its customer base. Vladimir Harutyunyan, CEO of HVH Industrial Solutions, conveyed his excitement regarding the acquisition, emphasizing that it represents a significant milestone in their endeavor to offer comprehensive industrial solutions. He highlighted that through this partnership, they are reinforcing their standing as a premier provider of high-quality industrial products and services, while also improving their capacity to address the changing requirements of their esteemed clients. HVH Industrial Solutions, known for its

commitment to excellence, is a familyowned business dedicated to supplying top-quality industrial products ranging from bearings, belts, gearboxes, electric motors, pneumatics, and more. With a focus on customer satisfaction, HVH serves as a reliable one-stop destination for businesses across various industries.

May 25, 2024 // Motion Technology Company Schaeffler and technology company Siemens have signed a memorandum of understanding (MoU) at the Hannover Messe. Both companies will advance the use of artificial intelligence in the industrial sector and therefore make a significant joint contribution to shaping the digital production of the future. At the Hannover Messe, Schaeffler and Siemens are once again showing the successful collaboration with the “Siemens Industrial Copilot,” an industrial automation solution using AI. It is connected to a production machine from Schaeffler Special Machinery at the Hannover Messe. The AI assistant makes the work significantly more efficient for the employees on the shop floor because complex automation codes for the machine can also be generated with natural spoken words.

May 28, 2024 // C&U Americas, the North American subsidiary of the C&U Group, one of the world’s top eight bearing manufacturers was recognized with a 2023-24 Gold Supplier Award from Bombardier Recreational Products (BRP) for excellence in product quality, manufacturing, and delivery rate. C&U is the primary bearing supplier to BRP for their ATV, watercraft, and motorcycle product lines. The award was accepted by C&U Americas Director

of Sales, Greg Foreman, and Director of Engineering, Rich Peterson. The Gold Supplier Award is earned by achieving specific measurables in supplying parts including a 97% or greater delivery rate and a Production Part Approval Process of over 99%.

August 16, 2024 // SKF UK Announces ERIKS Industrial Services as its First Maintenance Partner for the UK. ERIKS is proud to have been appointed as the first SKF Maintenance Partner in the UK and Ireland. This new status recognises ERIKS’ ability to offer industrial customers more than just a transactional relationship when it comes to SKF products and services. The announcement was made during Maintec, the UK’s longest-standing event dedicated to maintenance, reliability, and asset management,

which took place as part of Smart Manufacturing & Engineering Week on 5-6 June. A SKF Maintenance Partner is SKF’s extended arm on your factory floor. An advisor who helps you pursue maintenance excellence and provides consistent high-quality monitoring, maintenance, and repairs. As the 1st SKF Maintenance Partner, ERIKS uses its industryspecific knowledge to perform services such as root-cause failure analyses and advanced troubleshooting.

June 06, 2024 // Chinese Customs Officers Intensify Efforts Against Intellectual Property Violations. In a recent series of operations, Chinese customs officers have seized numerous batches of counterfeit goods, including bearings, that infringe on intellectual property rights. A notable operation took place at the Meishan Customs Station in Ningbo, where officers discovered 3,140 counterfeit bearings falsely labeled with the "SKF" and "Koyo" brand names. During an inspection of a shipment declared as "rubber bands and printers," customs officers identified undeclared goods bearing the logos of well-known brands. Upon verification with the trademark owners, it was confirmed that all the bearings were counterfeit. Under Articles 44 and 91 of the Customs Law of the People's Republic of China, customs authorities are mandated to protect intellectual property rights related to the import and export of goods. If goods are found to violate Chinese laws and administrative regulations protecting intellectual property, customs have

the authority to confiscate such goods and impose fines. In cases where the violation constitutes a crime, the perpetrators may face criminal charges. This operation is part of a broader effort by Chinese customs to combat intellectual property violations. Counterfeit goods not only infringe on intellectual property rights but also pose risks to consumer safety and the environment.

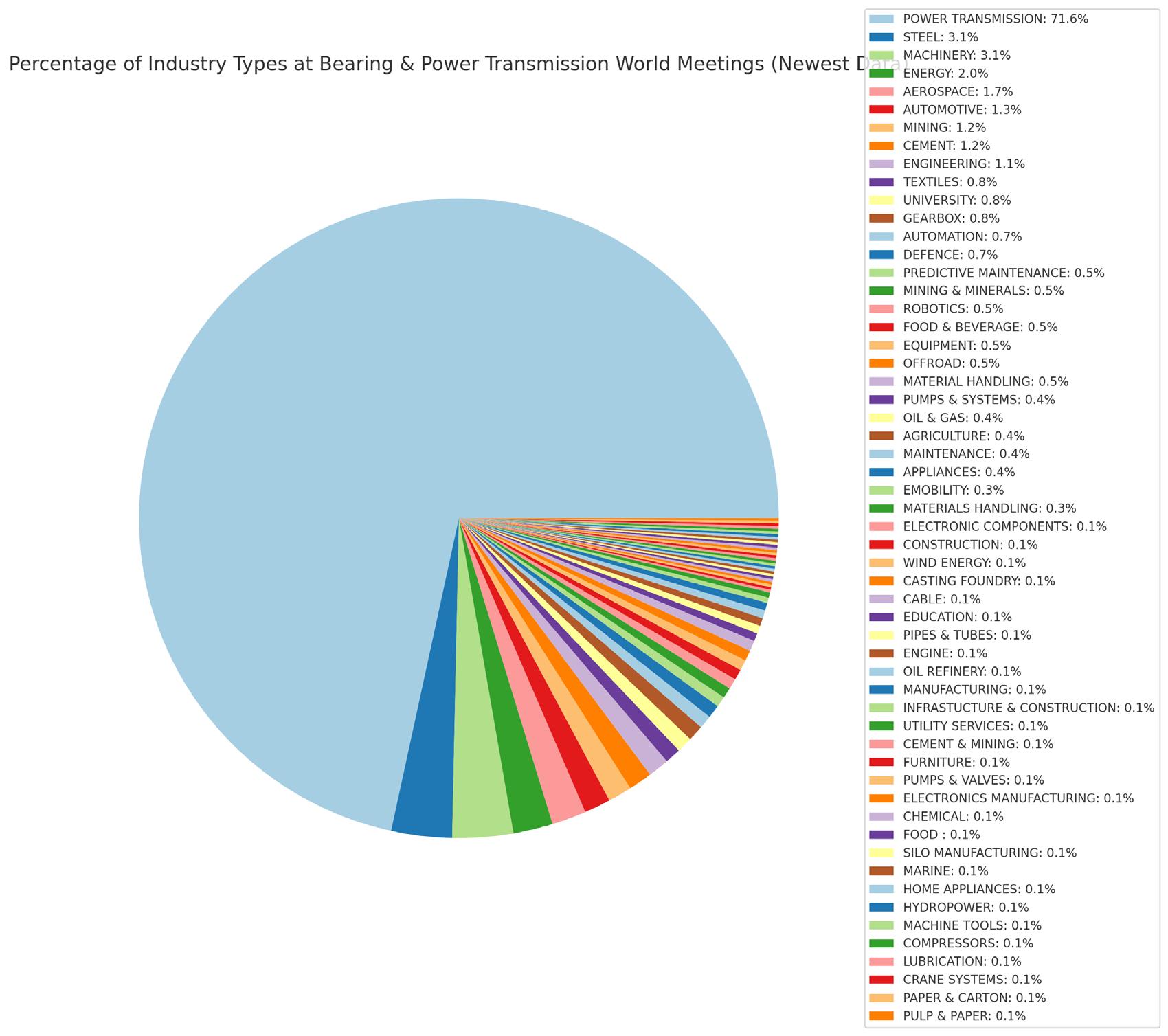

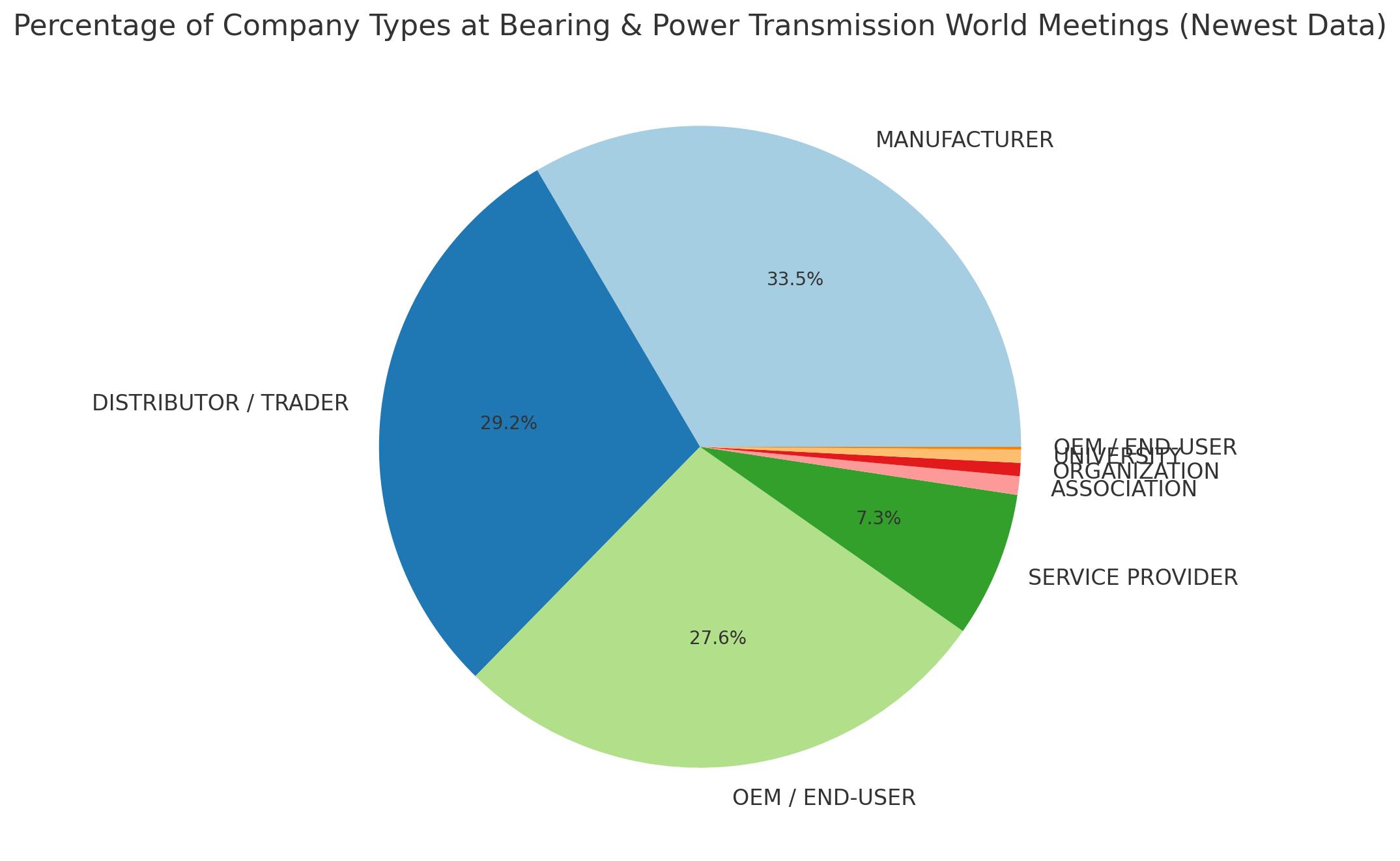

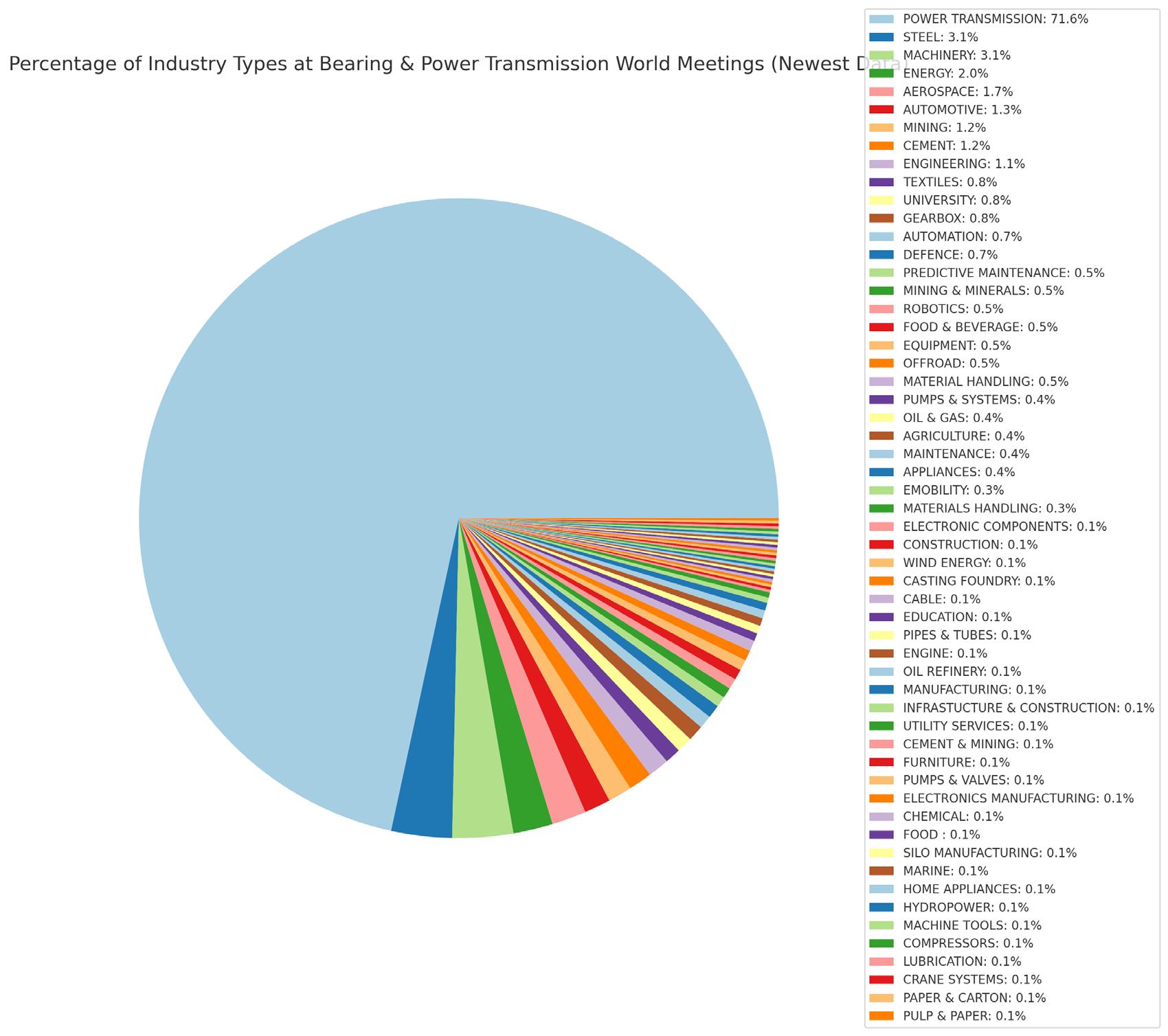

June 15, 2024 // The Bearing & Power Transmission World Meetings, held in Istanbul from June 10 to 12, concluded with remarkable success. The event brought together 502 participants from distributor, OEM, end-user, and manufacturer companies worldwide. In addition to the B2B meetings and the exhibition, various panels were organized, enriching the event’s agenda. A key highlight was the bearing root cause failure analysis workshop, attended by over 100+ reliability and design engineers, followed by several panels where industry professionals had the opportunity to share their valuable insights on market developments and power transmission technology topics.

June 20, 2024 // Bowman International, a leading innovator of bearings and components, has completed the acquisition of Leicester-based Criptic Arvis Ltd – a specialist in plummer blocks and bearing housings. Paul Hancock, CEO of Bowman, commented on the significance of this move: “We are delighted to welcome Criptic Arvis into the Bowman International Group. There are many synergies between our companies and our combined strength will be of genuine benefit to both Bowman and Arvis customers. “The

Arvis plummer blocks for example, compliment Bowman’s portfolio of high-capacity split roller bearings, and their advanced on-site machining capabilities will enable Bowman’s plain bearings division to offer a wealth of additional services to customers around the world.“There are many benefits for Arvis too. They will have access to a far greater global customer base and a skilled sales force to support them. They will be able to grow their business with access to established functions like HR, finance, and global marketing as well as a wealth of technical and engineering skill to leverage as they tackle new markets and new challenges.“Already, our U.S. subsidiary is working with Arvis to establish their offering in North America, while in the UK, we are supporting their team through this transition to ensure it is a positive experience both for Arvis, and their customers.” Wayne Heathcote has been appointed Managing Director of Criptic Arvis and will be assisted by Adam Colford as Technical Director.

June 21, 2024 // A new version of the FVA-Workbench 9.2 has been released! This version introduces powerful new features that significantly enhance the efficiency and reliability of gearbox design. To showcase these new features, we invite you to our free web seminar.

BY

CUSTOM AEROSPACE TOOLS & BEARINGS

LIGHTWEIGHT SLEWING RINGS

CUSTOM & MADE TO ORDER BEARINGS

July 01, 2024 // SKF Reports Resilient Performance Amid Challenging Market Conditions. In the second quarter of 2024, SKF, led by President and CEO Rickard Gustafson, has successfully navigated ongoing challenging market conditions, maintaining a solid adjusted operating margin of 13%. Despite a decrease in organic growth from +8% in Q2 2023 to -7% this quarter, SKF has demonstrated resilience, driven by effective cost management and strategic investments in innovation and regionalization. Gustafson emphasized the importance of these strategic moves, noting that while regionalization and lower production volumes have created short-term cost pressures, they are crucial for bolstering SKF's competitiveness in the long run. The company’s ability to manage significant wage inflation and increased ocean freight costs has been a testament to its effective cost management strategies. SKF’s intensified regionalization efforts, which involve relocating production across different regions, have resulted in higher costs during the quarter. However, these actions are seen as essential for enhancing cost competitiveness and improving lead times to customers, particularly in light of the extensive downsizing actions in Germany. Looking ahead, SKF anticipates continued market volatility and geopolitical uncertainty.

Despite the potential short-term impact on cost efficiency, the company remains confident that its strategic focus on regionalization and innovation will position it favorably when demand improves. For the third quarter of 2024, SKF expects organic sales to remain relatively unchanged yearover-year, with a low single-digit organic sales decline anticipated for the full year compared to 2023. Rickard Gustafson concluded by commending the efforts of SKF employees, whose contributions have been pivotal in managing the business cycle and driving innovation, ensuring that SKF remains an agile and competitive player in the global market.

July 11, 2024 // Serbian Z&S / KLT Bearings Invests in Bearing Production in Hebei Province. This development marks a significant milestone for the region’s bearing industry, opening up new opportunities for growth and innovation. Established in 1987 in Serbia, Z&S Bearings is a prominent supplier of bearings for agricultural machinery across Europe, with a strong presence in the international market. The project, valued at $100 million, is being executed within the industrial park dedicated to high-quality bearings, where the construction of the main facilities has already been completed. This

cooperation is the result of meticulous planning and negotiations, including delegation visits and joint action plans. The Secretary General of the Linxi County Committee expressed confidence that this partnership will significantly enhance the county’s position in the European bearing market, leveraging the Z&S Bearings brand and its established distribution channels. Živko & Sinovi d.o.o. offers bearings under two brands: Z&S and KLT. The KLT brand serves as a more affordable option for secondary installations, while the Z&S brand represents the company’s core product line, developed and produced in both its own and partner facilities. This investment is expected to bolster the bearing industry in Hebei Province, further integrating it into the global market.

August 05, 2024 // NTN EUROPE Foundation Stone Laid for New Head Office and European Technical Centre. Initiated in 2015 and then formally launched in 2020 with a call for projects, the transformation of the NTN Europe site in Annecy is entering a new phase. The foundation stone for the new head office and European technical centre was laid on 10 July. The bearings manufacturer, a leader in the industrial, automotive and aerospace sectors, has decided to modernize this historic site, where the company has been based for over 100 years. This project is part of a modernisation and optimisation strategy aimed at boosting productivity,

entrepreneurship, and interdepartmental exchanges. It is also a further step in the NTN Group’s commitment. to innovation, sustainable development, and local economic growth.

August 08, 2024 // Schaeffler AG has published its interim financial report for the first half of 2024. The Schaeffler Group’s revenue for the first six months amounted to 8,276 million euros (prior year: 8,208 million euros). The 2.0 per cent constant-currency increase in revenue was primarily attributable to higher volumes at the Vehicle Lifetime Solutions division. The Automotive Technologies division contributed slight growth as well. The trend at the Bearings & Industrial Solutions division had an offsetting impact. Revenue for the second quarter of 2024 rose by 4.2 per cent at constant currency to 4,191 million euros (prior year: 4,056 million euros). The 1.5 per cent constant-currency growth at the Automotive Technologies division in the first six months was mainly attributable to higher volumes of the E-Mobility business division (BD) in the Europe and Americas regions. The constantcurrency rise in revenue of 17.6 per

cent at the Vehicle Lifetime Solutions division resulted particularly from the impact of volumes in the Independent Aftermarket business in the Europe and Americas regions. The Bearings & Industrial Solutions division reported a 3.9 per cent constant-currency decline in revenue in the first half of 2024, largely due to the impact of volumes at the Industrial Automation sector cluster in the Europe region, as well as the impact of volumes at the Wind sector cluster in the Greater China region. Trends at the Schaeffler Group’s regions were mixed in the first six months. While the Europe (2.2 per cent), Americas (5.7 per cent), and Asia/Pacific (1.1 per cent) regions reported constant-currency revenue growth, Greater China region revenue for the same period declined by 1.7 per cent at constant currency.

August 10, 2024 // Management Buyout and Buy-In of Renowned German Bearing Manufacturing Business from NSK. The company is pleased to announce the successful management buyout and buy-in of the esteemed German bearing manufacturer Neuweg Fertigung from NSK, the renowned Japanese industrial group. Located between Stuttgart and Munich in Southern Germany, the area is recognised as one of the strongest economic regions in Europe and a centre for engineering development and innovation. This strategic transition aims to unlock the full potential of the factory’s rich heritage, esteemed brand, and unparalleled technical capabilities in a dynamic and growing international market. The buyout and buy-in will be spearheaded by Stephen Lord, a distinguished industrialist with extensive international management and business development experience. Mr. Lord will be joined by two local NSK executives, Mr. Dominik Szell and Mr. Willi Castro Santalla, who bring invaluable expertise and continuity to the new leadership team. NSK, a global leader in the bearing industry, will maintain a good relationship with the Munderkingen business, ensuring a seamless transition and continued collaboration. This continued relationship will enable the new management team continue to benefit from NSK’s extensive network.

August 12, 2024 // SKF Announces Changes to Group Management. Niclas Rosenlew,Senior Vice President and CFO of SKF Group has decided to

Engineering, Bearings, Technology.

Headquartered in Fort Worth, Texas, EBT Bearings showcases a 20,000 sq. ft., ISO Certified warehouse, an in-house quality control (QC) department complete with Zeiss CMM, a complete line of bearings ready for immediate shipment, and humbly speaking, the best team of employees in the industry. In addition to their Fort Worth facility, EBT Bearings, has a global manufacturing footprint which also adheres to the same ISO Quality Management System and allows for a level of customization, flexibility, and control rarely found anywhere else in the marketplace. In addition to manufacturing their own bearings, EBT is also an authorized distributor for many leading bearing manufacturers, including URB.

leave the company and will continue his career outside SKF. Niclas will remain in his current position at SKF until January 2025. ”On behalf of SKF I would like to thank Niclas for his valuable contribution, and I wish him all the best in the future,” says Rickard Gustafson, President and CEO. A recruitment process to identify a successor has been initiated.

August 13, 2024 // The Spanish multinational FERSA, specializing in the design, manufacture, and distribution of high-performance bearings and electromechanical components, has initiated a strategic

transformation that involves a substantial expansion of its global capabilities and a renewal of its corporate identity, which will take place over the coming months. With the arrival of Rafael Paniagua as the company’s new CEO last January, this transformation process began, with the objective of maintaining and enhancing the exponential growth that FERSA has experienced in recent years. To achieve this, the company has invested in opening new production lines in China and India to meet the increasing demand it faces. Specifically, in Jiaxing, where FERSA already operates one

of its six factories worldwide, a new manufacturing plant will start operations by the end of the year. This center will double the capacity of the current plant, bringing the complex to a total of 30,000 m² of capacity, including factory, offices, logistics warehouse, and R&D and quality laboratories.

August 14, 2024 // Timken Company has agreed to acquire CGI Inc., a Nevada-based manufacturer of precision drive systems serving a broad range of automation markets with a concentration in medical robotics. The deal is subject to customary closing conditions, including regulatory approval, and is expected to close in the third quarter. Timken entered the precision drives space in 2018 by acquiring Cone Drive and expanded its capabilities in 2022 by adding Spinea. These acquisitions were a direct result of Timken’s strategy to diversify and expand its capabilities in industrial motion. Cone Drive and Spinea solutions enable a wide range of applications and are helping to drive Timken’s growth in automation, which ranked as the company’s second-largest individual end-market sector in 2023. The addition of CGI will further bolster Timken’s position as a global leader in automation and robotic solutions.

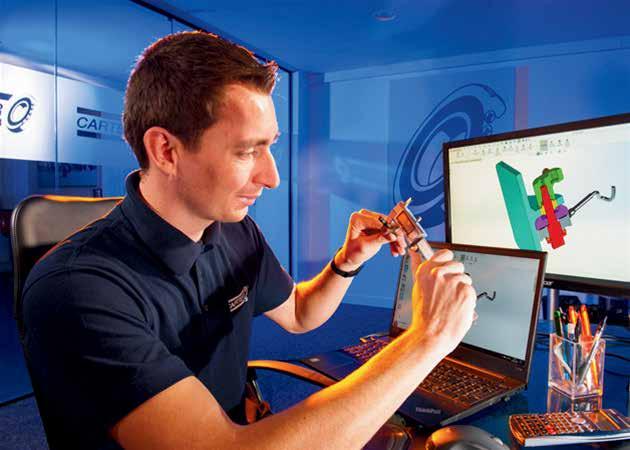

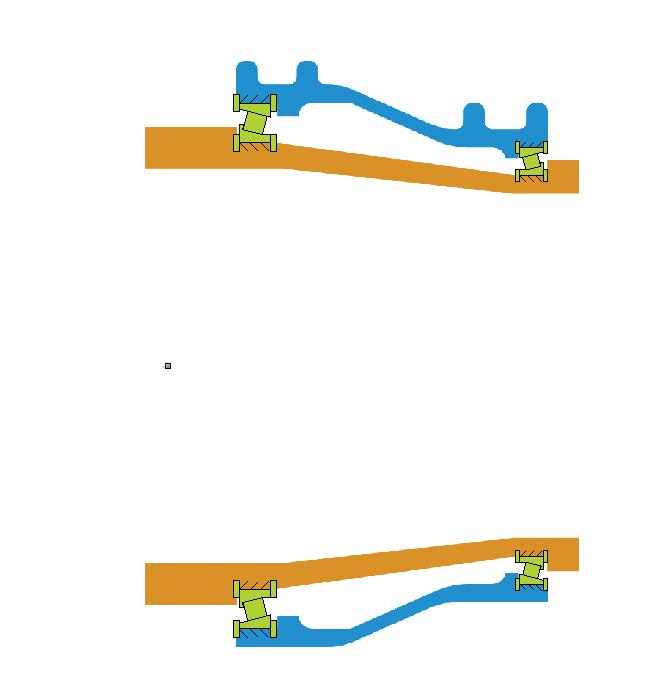

We would like you to take advantage of our design co-operation service from initial application appraisal, through costing and prototypes, to ISIR and PPAP approval and production supply of your rod based Linkage assemblies. They can be supplied loose for final adjustment at the point of fit, alternatively, where required, by using length setting gauges and tooling, linkages can be supplied to pre-determined fixed centres. The flexible manufacturing techniques used in the production of linkage components allow non-standard derivatives to be readily manufactured. We produce hundreds of customer specials with varying dimensions, thread forms and features. We welcome your enquiries - please contact us at sales@btl-uk.com

BTL-UK is proud to be a committed European manufacturer of Dunlop brand Bearings, Power Transmission and Linkage components. We believe in the future of European manufacturing and will continue to focus and further enhance the requirements and expectations of our customers globally. As a proud manufacturer we want to help Europe’s industry flourish and to meet the world’s evolving appetite for innovative designs and responsibly produced quality manufactured products.

Dunlop linkage components such as Rod Ends, Spherical Bearings & Ball Joints are proudly manufactured in the UK and are used to transfer mechanical motion. Whether that motion is shifting the cutting height in a lawnmower or controlling the exhaust valve on an articulated lorry, we specialise in the supply of these products to bearing distributors and to some of the World’s most well-known original equipment manufacturers.

A wide range of materials are available, steel, stainless steel, plastic, bodies with options of bronze, nylon, PU and PTFE liners and with over 100 plating specifications we are sure to meet your customers heat or corrosion resistant requirements.

We believe our range of Dunlop rod ends, spherical bearings & ball joints are the largest range available throughout Europe.

Please visit www.btl-uk.com for further information.

BTL-UK LTD - Head office & European Distribution Centre MPT House, Brunswick Road, Cobbs Wood Industrial Estate, Ashford, Kent, TN23 1EL United Kingdom

BTL-UK LTD - Production Site Units 6&7 Hilton Road, Cobbs Wood Industrial Estate, Ashford, Kent, TN23 1EW United Kingdom

BTL-UK LTD - Production Site Unit 22, Albert Drive, Burgess Hill, West Sussex, RH15 9TN United Kingdom

Only bearing manufacturer in the world to win Deming Grand Prize

Bearings for wide range of applications: from 20 mm to 2000 mm

Exports to 30+ countries worldwide

Major suppliers to Global Automotive OEMs and Railways

R&D and technology centres in Germany, Slovakia and India

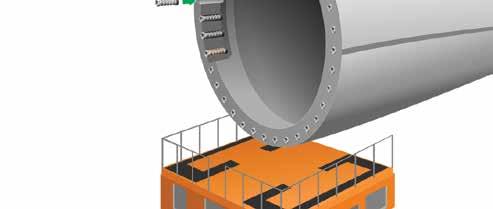

• The segmented slewing bearing with an outer diameter of 23.4 metres is the largest slewing bearing produced by Liebherr to date

• In operation on the high seas, the slewing bearing will rotate a heavy-duty crane by GustoMSC BV on an installation vessel

Liebherr's Components product segment is further expanding its portfolio in the area of segmented slewing bearings. The segmented roller slewing ring, which was developed and manufactured at the site in Biberach (Germany), has an external diameter of 23.4 metres.

GustoMSC BV has developed a heavyduty crane for a new type of installation vessels. For the positioning of wind turbines on the high seas, transport ships are able to deliver individual parts directly to such a vessel. This allows for continuous work at sea without having to fetch new parts from the harbour. And it

is in this heavy-duty crane that Liebherr's segmented slewing bearing takes over a vital task. Once in place, the bearing is the core element that turns a ship crane with a lifting capacity of 2,000 tonnes, responsible for the installation of offshore wind turbines. The slewing bearing is a real masterpiece by Liebherr-Components

Biberach, consisting out of 68 segments, the total diameter of which is almost as large as six small cars placed in a row. During its service life of about 25 years, the 23-metre bearing will help to erect offshore wind farms and contribute to sustainable power generation.

The segmented slewing bearing was designed as light as possible to increase the load capacity of the ship. "The crucial features thereby are the inductionhardened raceways of the segments,

which offer a more efficient bearing cross-section than inlaid raceway plates, and thus add to weight reduction," explains Benjamin Schmid, head of sales maritime applications at Liebherr-

Components. "In this way, Liebherr supports the further development of offshore mechanical engineering, which is advancing into ever larger dimensions."

Elevate your machinery’s performance through innovative ultrasound measurement technology and automatic bearing lubrication. Ultrasound Solu ons

The seasoned engineered products leader has been leaning in since day one

As he approaches his 100th day as Chief Executive Officer of Solve Industrial Motion Group (“Solve”), Ernie Lauber has been busy building his leadership team and implementing operational improvements.

“I look forward to building on what Solve has already achieved in developing a go-to platform for engineered power transmission products so that we can double the size of the business in the near future,” says Lauber.

“Delivering an unmatched customer experience is critical to ensuring we can achieve that ambitious goal. My job is to keep the Solve team laser-focused on creating a robust and competitive product portfolio, leveraging data to make better decisions, and maintaining strong strategic partnerships."

Lauber arrived at Solve in June after four years as Group President for the Engineered Products Group at ParkOhio Holding Corp, overseeing a $500 million sales business and 2,000+ employees across 40 locations.

He succeeds Lisa Mitchell, who now serves as Chairperson of the Solve board of directors after more than five years with the company where she also held the positions of CFO and COO.

“Ernie brings a compelling mix of leadership and management experience combined with a strong vision for the future of the company. He is an experienced changemaker who the board believes can help take Solve to new heights,” says Mitchell.

“He’s hit the ground running and the leadership transition couldn’t have gone any smoother. I look forward to working closely with him as he plots a course toward an even brighter future for Solve.”

Over the last three months, Lauber has taken steps to implement lean principles across the company, laying the foundation for a cultural transition focused on high expectations and empowered employees.

“We’re working to change the conversation from 'I can't' to 'How can we get to yes?'” says Lauber. “We've already started to

deploy an operating system to help us better pinpoint specific challenges we need to address. I’m a big believer in embracing a culture of continuous improvement.”

In the months ahead, Lauber plans to focus on innovation and product development as well as improving overall operational performance. He expects continued progress toward the company's goals to come through a combination of organic growth and strategic acquisitions.

“I continue to acquaint myself with all aspects of Solve’s business and build trust with employees as we work together to improve performance and meet our growth targets for next year,” he says.

“Every growth journey is by definition a learning journey, and I look forward to traveling the road ahead with the talented team here at Solve.”

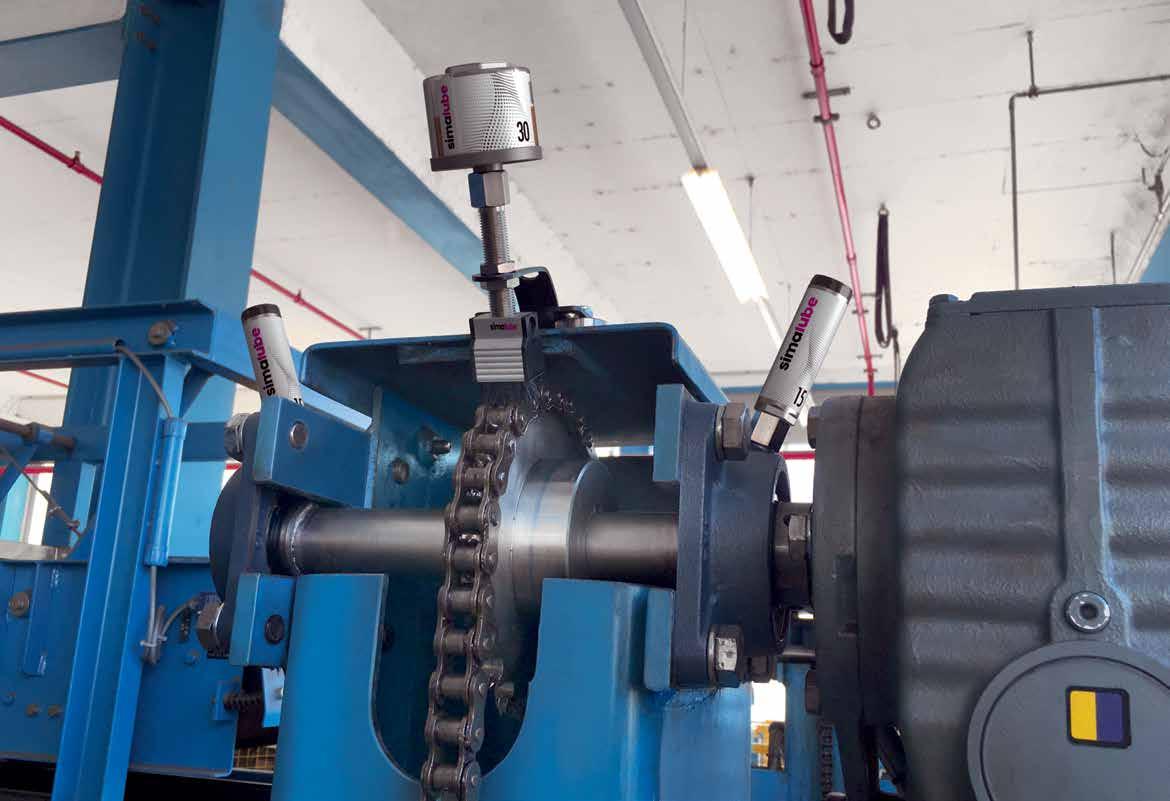

Explore the next level of automatic lubrication: simalube IMPULSE connect

The «simatec World of Maintenance» app is the overarching digital simatec platform: simatec products can be controlled by the app, taking simatec another step into the

Features

Monitoring of lubrication points

Creation of electronic lubrication schedules in Lubechart (available in the App)

Digital ordering process

Calculation Pro: Calculation programme for the correct setting of your lubricators. Available in the app «simatec World of Maintenance» only Download the simatec app now:

NSK is developing a world-first: a high-accuracy way of rapidly and accurately diagnosing the remaining life of lubricant grease. The company will provide the solution as a mobile app, enabling users to perform the on-site analysis of lubricant condition in bearings and linear motion systems. This innovative capability will reduce the need for grease inspection and replenishment costs, and help companies implement condition-based maintenance strategies. NSK’s is currently seeking customer input and feedback ahead of launching its new app.

A broad spread of machinery and equipment, from machine tools to railcars, utilise greaselubricated products like bearings, ball screws and linear guides. However, grease degrades over time as machinery operates, so on-site lubricant inspection is vital to help maximise uptime and OEE (overall equipment effectiveness). In recent years, more and more companies are switching their equipment maintenance strategy from time-based maintenance to condition-based maintenance. A need therefore exists for a grease degradation diagnosis method capable of rapid and highly accurate deployment on site. Such an app would also help combat labour shortages and support carbon neutrality efforts.

— The new NSK mobile app uses grease deterioration diagnosis tech

As a consequence, many companies replenish lubricant unnecessarily early to ensure stable operation, resulting in wasteful grease usage.

Existing high-accuracy diagnosis methods rely on laboratory analysis, but this comes with high cost, a lack of suitability for on-site use, and a long wait for results. Visual observation or densitometer methods are thus more common, but suffer from low accuracy.

With these thoughts in mind, NSK set about developing a far more convenient, costeffective, fast and accurate method of grease degradation diagnosis. Importantly, the new NSK app can analyse the level of lubricant degradation using just a small sample of grease. Chemical changes to the base oil and additives of the grease occur due to heat from operation and oxidation with the passage of time. These chemical

changes cause the molecular structure of the lubricant to change and absorb more short-wavelength light, affecting its colour. Grease itself starts off white when new, turning yellow or orange with use and eventually becoming black, which indicates zero remaining life. The NSK app quantifies grease by its colour to calculate remaining life.

NSK has a 40+ year history of inhouse grease development, allowing the company’s to base its new grease degradation diagnosis technology on a deep understanding of the chemical composition of lubricants.

Lubrication management is a cornerstone of industrial maintenance, encompassing a range of tasks far beyond the simple application of oil or grease to machines. It involves meticulous selection of lubricants, proper storage and filtration, vigilant monitoring of bearing health, and prevention of over- and under-lubrication.

In the pursuit of operational excellence, the importance of effective lubrication supervision cannot be overstated. Yet, despite its essential role in ensuring the longevity and optimum performance of machinery, lubrication practices often lack focus, leading to costly downtime and equipment failure. Fortunately, thanks to technological advances, new lubrication management tools have emerged, promising greater efficiency and reliability. In this regard, the LUBExpert ON-GUARD is a revolutionary solution that is about to improve automatic bearing lubrication and set new standards in reliability, simplicity and safety.

Understanding the lubrication challenge

Inadequate lubrication can wreak havoc on machines, with incorrect replenishment rates and the wrong type of lubricant posing significant risks. Choosing the right lubricant isn't enough, you also need to ensure that the replenishment rate is correct. Too little grease accelerates

wear, while too much leads to overheating and potential bearing failure. Striking a delicate balance is essential to maintaining optimum performance and extending equipment life.

One of the most pressing challenges in lubrication management is over-

lubrication, recognized by many experts as a ubiquitous problem in industrial plants worldwide. The consequences of excessive grease application are disastrous: heat generation, agitation and, ultimately, solidification, leading to clogging of the fresh lubricant and, with no surprise, bearing failure. Bearing

failures, mainly due to lubrication problems, lead to unplanned downtime, hampering production and incurring significant costs. Clearly, meticulous lubrication practices are essential to the smooth running of industrial operations.

Conventional approaches to lubrication, while seemingly logical, are often unreliable. Many technicians still adhere to time-based, preventive lubrication methods, administering grease at regular intervals. While this strategy aims to limit under-lubrication and the resulting malfunctions, it often overlooks the risks associated with over-lubrication, which can accelerate bearing deterioration.

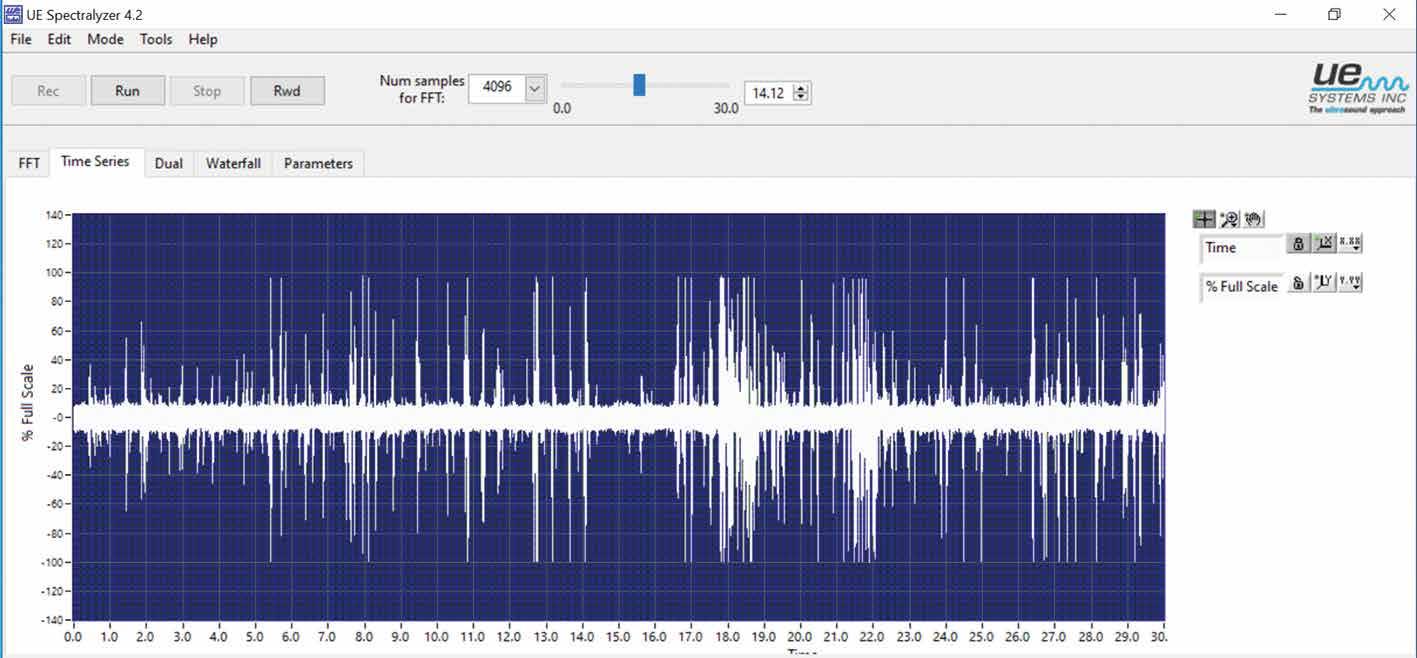

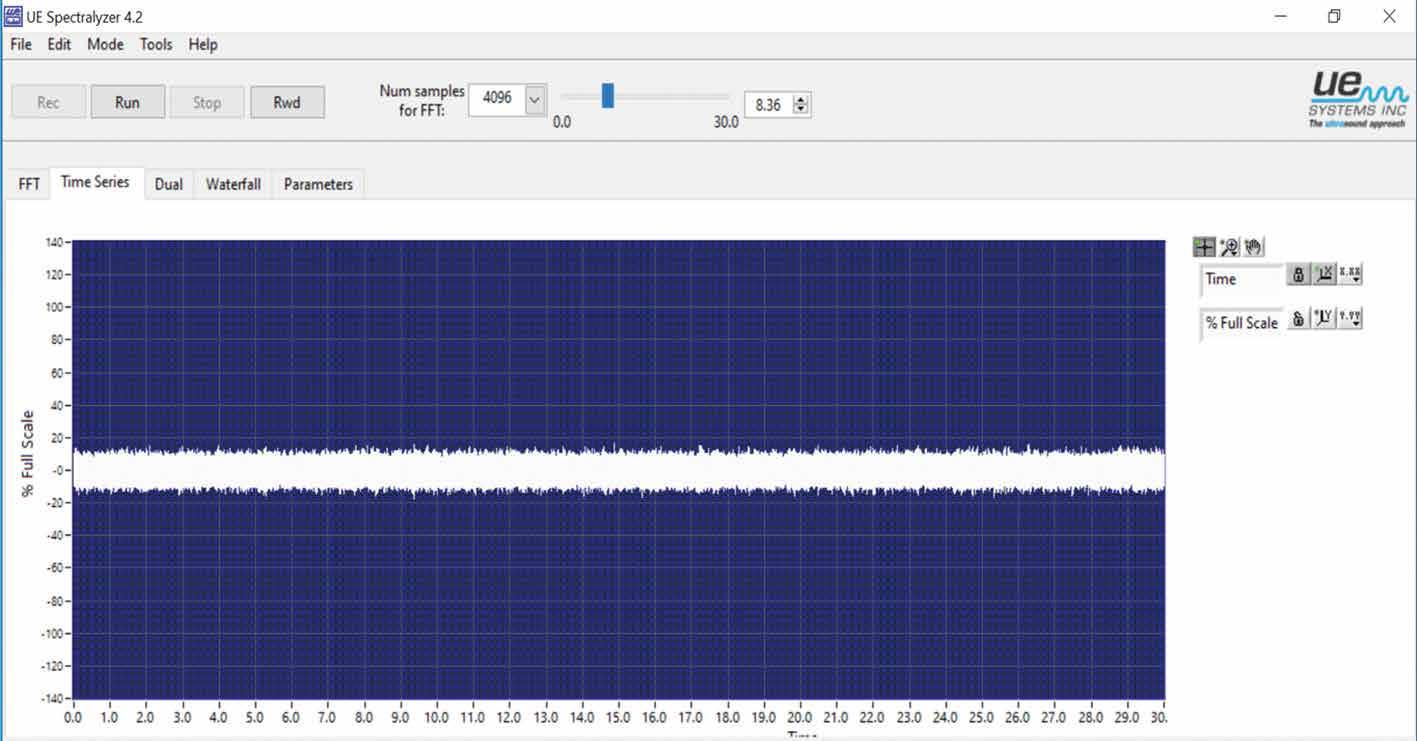

The role of ultrasound in lubrication

Lubricating bearings using ultrasound has long been considered good practice, as it provides valuable information on friction levels and the quantities of grease required. Ultrasound is a reliable indicator of bearing health, enabling maintenance professionals to accurately assess the effectiveness of lubrication efforts. By assessing friction levels, ultrasound helps

determine the precise amount of grease required, mitigating the risks associated with both over- and under-lubrication.

The LUBExpert ON-GUARD represents a new step in maintenance technology, harnessing the power of ultrasound measurement to deliver targeted lubrication solutions with unrivalled precision.

Long gone are the days of relying solely on time-based calculations, guesswork or manual intervention. With the LUBExpert ON-GUARD, the lubrication process is automated, ensuring that the right amount of grease is applied at precisely the right time. This device functions as a virtual "nutritionist" for machines, developing personalized, autonomous, data-driven maintenance plans that preventively address potential problems.

Imagine the peace of mind knowing that you no longer need to constantly visit each machine to ensure proper lubrication. With the LUBExpert ON-GUARD, the intricate task of bearing grease replenishment is

seamlessly managed, eliminating the need for manual intervention. This not only reduces workload and minimizes grease waste but also guarantees optimal machine performance.

But what makes this device a real added value that can change the whole of a plant's practices, is that its benefits are not limited to individual machines. It's actually a versatile solution capable of transforming entire plants and lubrication programs, instilling a culture of reliability and efficiency.

Indeed, the LUBExpert ON-GUARD serves as a comprehensive solution for your entire plant and lubrication program. By automating lubrication tasks with precision, thanks to the SDT LUBrain’s advanced algorithm, the device ensures that every machine receives the right amount of grease precisely when needed.

The idea is not to improve the performance of individual machines. Rather, it's about revolutionizing your entire approach to maintenance. Implementing the LUBExpert ON-GUARD solution means a change of

culture and methodology. No longer bound by traditional time-based practices, you'll be able to take condition monitoring and lubrication strategies to the next level.

In other words, it's not just another set of components assembled and installed on machines. The LUBExpert ON-GUARD represents a complete solution to combat poor lubrication practices and promote reliability in your operations. It's an all-in-one package designed to establish new quality practices, where precision, efficiency and reliability come together to deliver unrivalled performance.

Key features and benefits

• Reliability Through ConditionBased Lubrication: The LUBExpert ON-GUARD addresses the vulnerability of 80% of machine bearings prone to failure due to improper lubrication practices, ensuring consistent peak performance and eliminating downtime concerns.

• Simple, Smart, and Automatic

Operation: With its built-in web server and intuitive interface, the LUBExpert ON-GUARD simplifies maintenance tasks, allowing users to connect and control the device from anywhere. The SDT LUBrain algorithm automates lubrication, optimizing machine performance while minimizing workload and grease waste.

• Safety and Flexibility: Prioritizing safety, the LUBExpert ON-GUARD offers remote grease replenishment capabilities, mitigating risks in hazardous environments. Its allinclusive options empower users to tailor lubrication strategies to their specific needs, ensuring sustainable operations and data security.

• Sustainability: The LUBExpert ONGUARD offers significant advantages in two key areas: lubricant consumption and the use of electrical energy. By reducing over-lubrication, it cuts costs and environmental impact. Moreover, it extends bearing life, reducing the need for frequent replacement. On the energy front,

it improves efficiency by reducing friction, resulting in significant electrical energy savings, particularly beneficial for large-scale operations.

Embracing the future of lubrication

With industries facing all the challenges of modern machinery, the LUBExpert ON-GUARD ensures bearing longevity and optimum performance of critical assets. Leveraging the latest advances in ultrasound technology, it redefines precision maintenance, enabling companies to thrive in today's innovative and efficient environment.

Get more information about the LUBExpert ON-GUARD by scanning the following QR code.

www.sonotec.eu

Located in Bochum, Germany, Friedrich PICARD GmbH & Co. KG stands as one of Europe’s premier wholesalers of rolling bearings and linear technology, exclusively serving the specialized technical trade. Their expansive warehouse spans approximately 10,357 sq m (111,481 sq ft) and stocks over 55,000 items from all premium and high-quality alternative brands, readily available for immediate dispatch.

PICARD is renowned for its tailored linear motion technology solutions and exceptional customer service, a reputation bolstered by its in-house Linear Motion Technology Centre. This state-of-theart facility occupies roughly 600 sq m (6,500 sq ft) and is equipped with two fully automated cutting machines, as well as two horizontal milling machines and one end surface grinding machine,

all operated by expertly qualified personnel, ensuring first-class service.

Situated in Germany's Ruhr region, the centre excels with a comprehensive stock of linear guide rails and shafts from premium manufacturers. They provide matching carriages, traceable rails via data matrix codes (DMCs), a userfriendly linear technology configurator available in their online shop, and remarkably fast delivery times.

PICARD’s extensive linear product range includes ball & roller guide rails, miniature rails, shafts, linear ball bearings (+ units), threaded spindels, carriages, ball screw nuts, shaft trestles and more from renowned brands such as BOSCH Rexroth, Schaeffler (INA and EWELLIX), THK, NSK, SCHNEEBERGER, SNR, SAMICK and ZEN.

Using the linear configurator available in the PICARD online shop, customers can easily specify their requirements by entering the needed rail types, quantities, precise lengths, and offset space ahead of the first borehole. Prices and availability are displayed instantly, and the ordered rails are precisely cut and securely packed. Each rail cut in their centre is chamfered, facilitating the insertion of guiding carriages that protect the seals.

All linear rails supplied by PICARD are lasered with a data matrix code label, corresponding to the WBA manufacturers' article identification. These DMCs ensure precise traceability and providing detailed product information such as dimensions, boreholes, illustrations, and manufacturer details.

PICARD now offers butt machining, catering to customers needing exceptionally long rails beyond standard lengths. This method allows for a seamless connection of rail sections, theoretically enabling assembly to infinite lengths.

In contrast to conventional separation, the end faces of the rails are precisely ground during the butt machining process, ensuring there is no gap and a tolerance of just 0.02 mm. This precision is crucial for allowing the individual elements to be seamlessly fitted together later by the user, ensuring smooth operation of carriages on the rails. After machining, the matching end points are marked with a laser device, indicating

to the fitter which rail elements are compatible with each other.

Butt machining not only facilitates the creation of very long rails but also frequently reduces shipping costs and makes storage easier. Currently, PICARD offers this specialized service upon request and subject to availability.

PICARD’s logistics operations are both sophisticated and incredibly swift. Orders placed by 7 p.m. CET from Monday to Friday are guaranteed to be shipped the same day. For even faster needs, PICARD offers courier delivery options by air, sea, and land, including direct delivery to endcustomers.

Setting benchmarks in linear technology, the company excels with its extensive product range, customized solutions, and innovative machining techniques. Combined with efficient logistics and exceptional customer service, PICARD remains a top choice for specialized technical trade partners seeking reliable and fast solutions.

Contact: +49 234 53993 130 post@picard.de shop.picard.de

31 MAY - 04 APRIL 2024

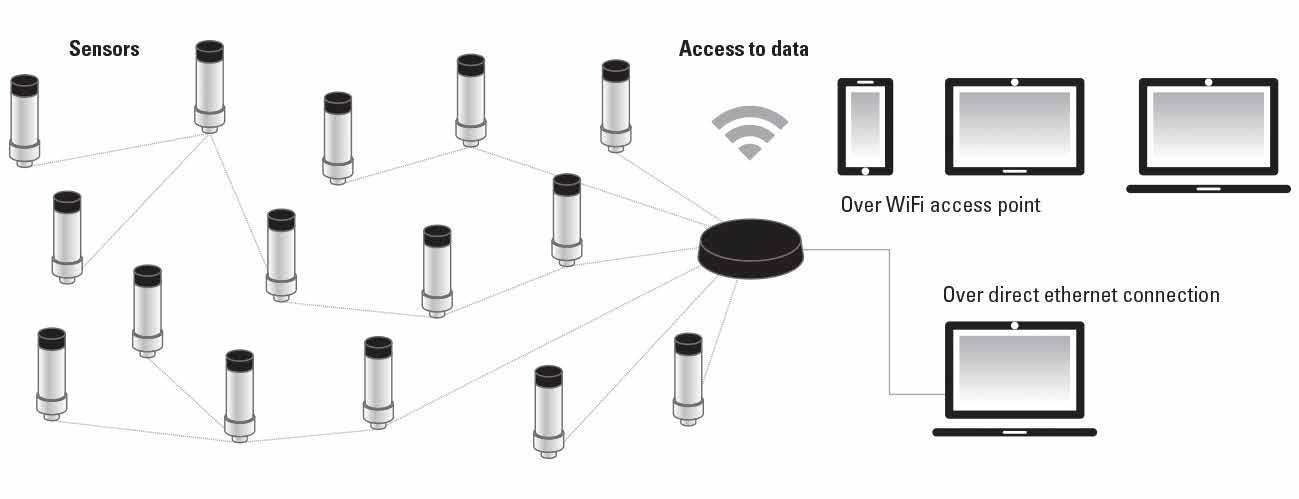

The Timken Company has launched a new wireless sensor and condition monitoring solution to help users detect a failure or major change before it happens through temperature and vibration monitoring.

“Solving challenging application problems is at the core of what we do,” said John Szarka, Vice President Product Management – Engineered Bearings.

“Our wireless sensor and monitoring solution can indicate potential performance issues before they happen, saving our customers from experiencing unplanned downtime.”

Initial network set-up for the gateway and sensors is simple and intuitive,

allowing for either a WiFi or Ethernet connection. The wireless sensors are designed to be installed into the equipment the user wishes to monitor. Next, temperature and vibration data are transmitted to a gateway receiver through mesh technology. With this technology, sensors can transmit data both directly and through each other, allowing sensors to link to a single gateway receiver over an expanded distance.

The data remains in the user’s control on-premise, enhancing data security. With no recurring fees, users can then visualize, access, and receive alerts about the data through the intuitive dashboard.

More information about Timken’s Wireless Sensor and Monitoring Solution is available at timkensensor.com

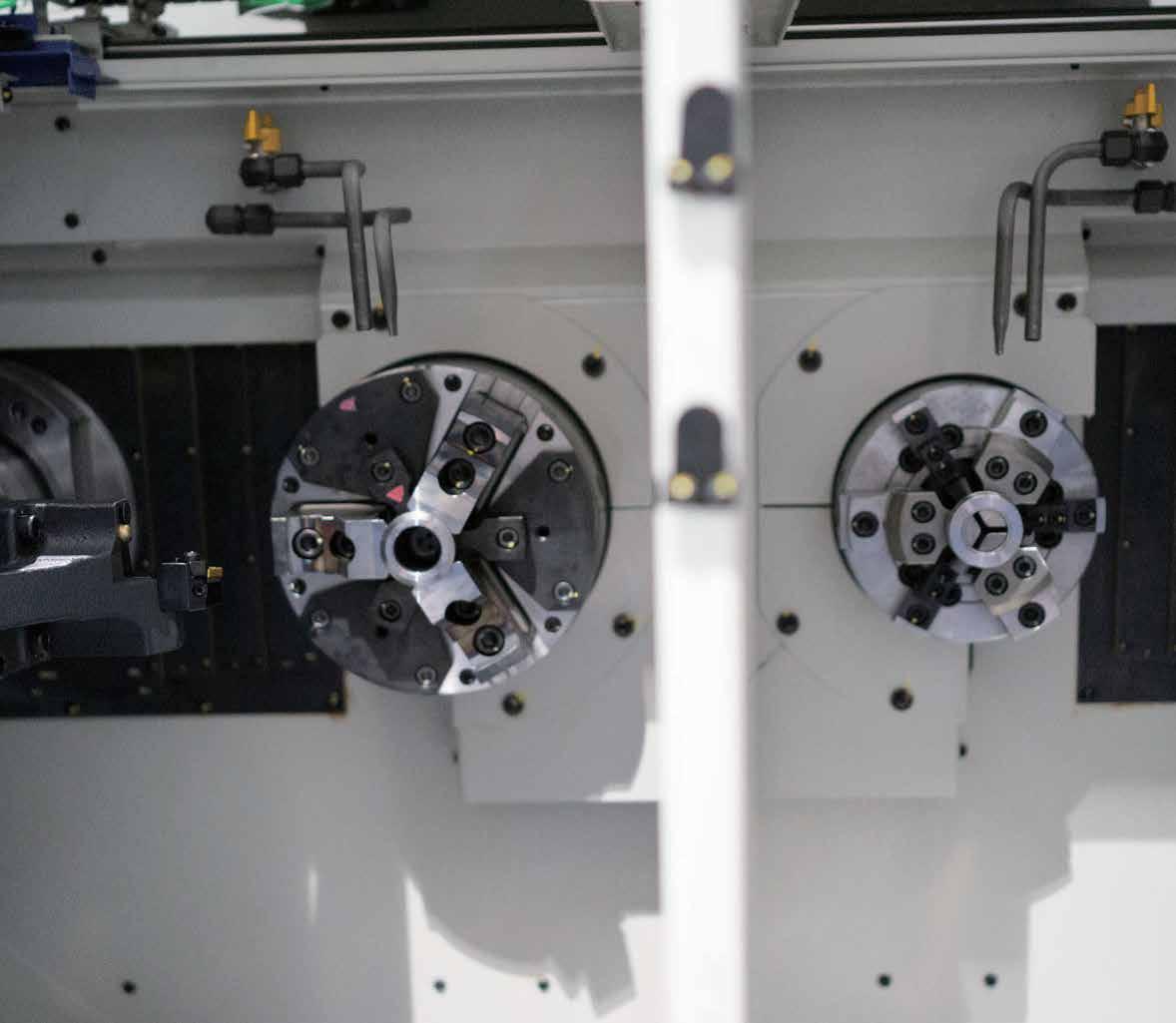

Özevren Rulman A.Ş., one of the largest bearing distributor companies in Turkey, has always prioritized supplying manufacturers and end-users directly as its main strategy. This approach led to the establishment of branches in key industry locations with significant industrial activity. With its Head Office, European Side Coordination Center, Logistics & Operation Center and 5 branches with a combined storage capacity of 12,000 square meters, Özevren Rulman A.Ş. stands out as the regional leader in terms of local network, logistics, and capacity.

Recognizing the need for customized solutions to reduce production costs, increase efficiency, and enhance Total Cost of Ownership (TCO), the company has launched Özevren Teknik Makina. While bearings, reducers, linear products, chains, belts, and other power transmission products constitute the core of its product portfolio, Özevren Teknik Makina was brought to life to offer customized solutions and more technological equipment to its partners.

We discussed the transformation of the new activities with the General Manager and CEO Talar Markaroğlu and Sesil Markaroğlu.

Özevren Rulman A.Ş. has a well-deserved reputation in the bearing and power transmission industry for many years. What were the motivating factors behind establishing Özevren Teknik Makina A.Ş.?

Thank you for your kind words. As Özevren Teknik Makina A.Ş. we’re proudly one of the most respected, reliable and strongest brands in the Turkish bearing industry. We can say that bearings are one of the most critical and indispensable intermediate products used in the industry all over the world. Similarly, bearings are indispensable items of the industry in Turkey.

The market we serve has a highly competitive structure and we work in a highly dynamic environment. According to a report I’ve seen recently, 80% of companies established in Turkey are closed within the first 5 years and the average lifespan of companies is around 25 years.

In this regard, only those who know their job best, love and respect the most can be a part of a journey that will last for generations. As Özevren Rulman A.Ş. we have become

a company which serves the sector and add value by constantly growing in a balanced manner for more than 40 years. We have the invaluable experience and hard-earned pride that this brings with.

As a result of analysis of the business trends, our experience has shown us this: In the market; there is a growing need for companies which position themselves as customers' solution partners and can quickly respond to their expectations. New expectations require more detailed information and support by specializing with a sector-focused approach.

This was our basic motivation behind the establishment of Özevren Teknik Makina A.Ş. We want to find fast, efficient and longterm solutions to customers’ problems. The added value that Özevren Teknik Makina A.Ş. will create can be briefly summarized with this strategy.

Today while it seems very easy to access information; we are very well aware that accessing accurate information is more difficult and costly than ever.

In addition to providing quick and simple solutions to day-to-day problems, we want to provide in advance support in areas that our customers cannot foresee with an approach that we can describe as “preventive medicine”.

What kind of products and services will it offer? Which sectors and markets do you aim to reach with these products and services?

As I just mentioned, it would be more accurate to position Özevren Teknik Makina A.Ş. as a supporter and solution partner of our companies that produce in Turkey, we call them the dynamo of production.

We want to move forward in a sector-focused manner and specialize in different sectors that we have selected and see big potential. We follow a strategy of becoming a crucial solution partner in the Turkish Industry. Of course, we are aware that this is a long-term project.

When we closely look, we see our industry often competes with the world's leading companies in their fields, sometimes they collaborate with biggest ones. We believe,

the need for those companies to have more holistic solutions will gradually increase in order for them to keep up with the global competition.

We analyze problems customers face and generate tailored solutions. Each problem and each solution will accumulate in an ever-increasing pool of knowledge, and over time, we will have a memory that can offer solutions to similar problems much faster.

For example, if there is a chronic malfunction experienced by our customers, we will also offer options on the most optimum bearing arrangement while solving this malfunction. We will create business processes in which we will review together with our customer in order to reduce total costs.

During these processes, many of our services, from product supply to field supervision, will improve over time. As I said, these will become much more efficient over time, we wanted to take the first step without any more delay.

Özevren Teknik Makina A.Ş. in what location and in what kind of structure?

As Özevren Rulman A.Ş. we have 5 branches on different locations all over Turkey and we are one of the most accessible companies with our widest network. Özevren Teknik Makina A.Ş. will be able to reach our customers from all these locations. As human resources, we have an experienced staff, mainly engineers, who know the problems and aware of the expectations of the sector. Our primary principle will be accessibility and a free from bureaucracy in this field.

As a part of our long-term strategy mentioned above, we are also proud to share some good news that we will move our Headquarters to its new location.

We’ve just hired a new place with 900 m2 in total space in Acarlar Plaza in Istanbul / Kavacık. As of September 1, 2024 we have started our activities in our new headquarters and it will be referred as GENERAL DIRECTORATE of ÖZEVREN RULMAN A.Ş.

In order to meet our customers’ expectations in terms of faster delivery

times, our current location in OrhanlıTuzla will be transformed into a Logistics Center. This center will be serving much faster in terms of logistics and we’ll strengthen our logistics capacity. Our Orhanlı-Tuzla campus will referred as LOGISTICS & OPERATIONS CENTER.

What kind of goal did you set for 2024? Could you share your business agenda?

We decided to move forward with sector focused strategy for years 2024 and 2025. Many sectors in Turkey are globally strong and have a large production capacity, we know this. We are one of the leading countries in Europe in many sectors we focus on.

However, we also see that there is still a long way to go in terms of using the right technology in the most efficient way. In general, our country has a work culture that is not resistant to changing technologies and can adapt quickly.

We have seen closely that some companies have come a long way to complete this transformation when they believe it is ecessary. We’ve decided to focus on various sectors in order to both support

these companies and encourage all other companies in the same direction. Since the beginning of this year, we have visited almost all the major companies in our focused sector and we aim to reach the rest till the end of the year. We want to be the first company that comes to mind when in the field of bearings and technical solution.

Özevren Rulman A.Ş., which has the strongest bearing stock in Turkey is our biggest supporter. Additionally, we will be explaining our current products and services at the fairs we will attend in the last quarter of 2024.

Could you detail your product groups? How do you contribute to increasing efficiency and quality in factories?

Our main product group is bearings, bearing heating devices, seals, belts, couplings, chains, gears, etc.

The products we offer minimize downtime that causes unplanned costs and contribute significantly to the efficiency of factories. In addition, we ensure maximum efficiency from bearings with Arcanol greases produced only for bearings.

With segmented spherical roller bearings in critical fan bearings or critical conveyor bearings and similar products, we can significantly shorten bearing replacement times and minimize costs.

In general, our approach is to support manufacturers in making long-term and predictable production plans and to prevent unforeseen costs.

What kind of services will you offer for after-sales customer satisfaction?

By offering Field Supervision service, we provide our customers with field support service from the most reliable and knowledgeable source. We know we need to be solution-oriented and offer fast service without creating bureaucracy.

We have an understanding that the structure we have established will always be flexible according to the demands of our customers. We can make the necessary changes anytime. There is another important point that I would like to underline: One of the critical issue is using original materials.

Unfortunately, we have seen and continue to detect many defective products in the field we are authorized distributor of. And I would like to state that we attach great importance to this issue. Perhaps this issue could be the subject of a separate interview.

As a result of our sensitivity on this issue, one of the important parameters of customer satisfaction has been the complete elimination of our customers' concerns about the products we sell, whether this product may be defective or not.

Using defective products unknowingly or consciously is one of the heaviest setbacks to our country and our economy. Our most important request from our customers is to carefully investigate the source they purchase and make sure they are authorized distributors.

We also provide training to our customers to prevent potential work accidents and downtime.

Our goal is to keep large stock of special bearings used in specific sectors and to provide instant service on 7/24 basis in case of sudden factory stoppages. We already

are taking firm steps towards this goal. If support is requested from us in terms of assembly of large bearing items we will be providing supervision service in this field and eliminate risks that may arise due to assembly errors.

What is your message to the industry?

As a sector all together; we believe we should improve continuously day by day, learns new solutions and transfers this knowledge to the field. In this way, we can meet at a point where we are constantly learning, developing, making significant contributions to our industry and creating added value. In today's world where accessing accurate information is so valuable, being able to provide added value to our valuable industrialist friends is our company's greatest source of motivation.

Walking hand in hand with the industry is the most invaluable goal for us.

More information can be found at www.ozevren.com

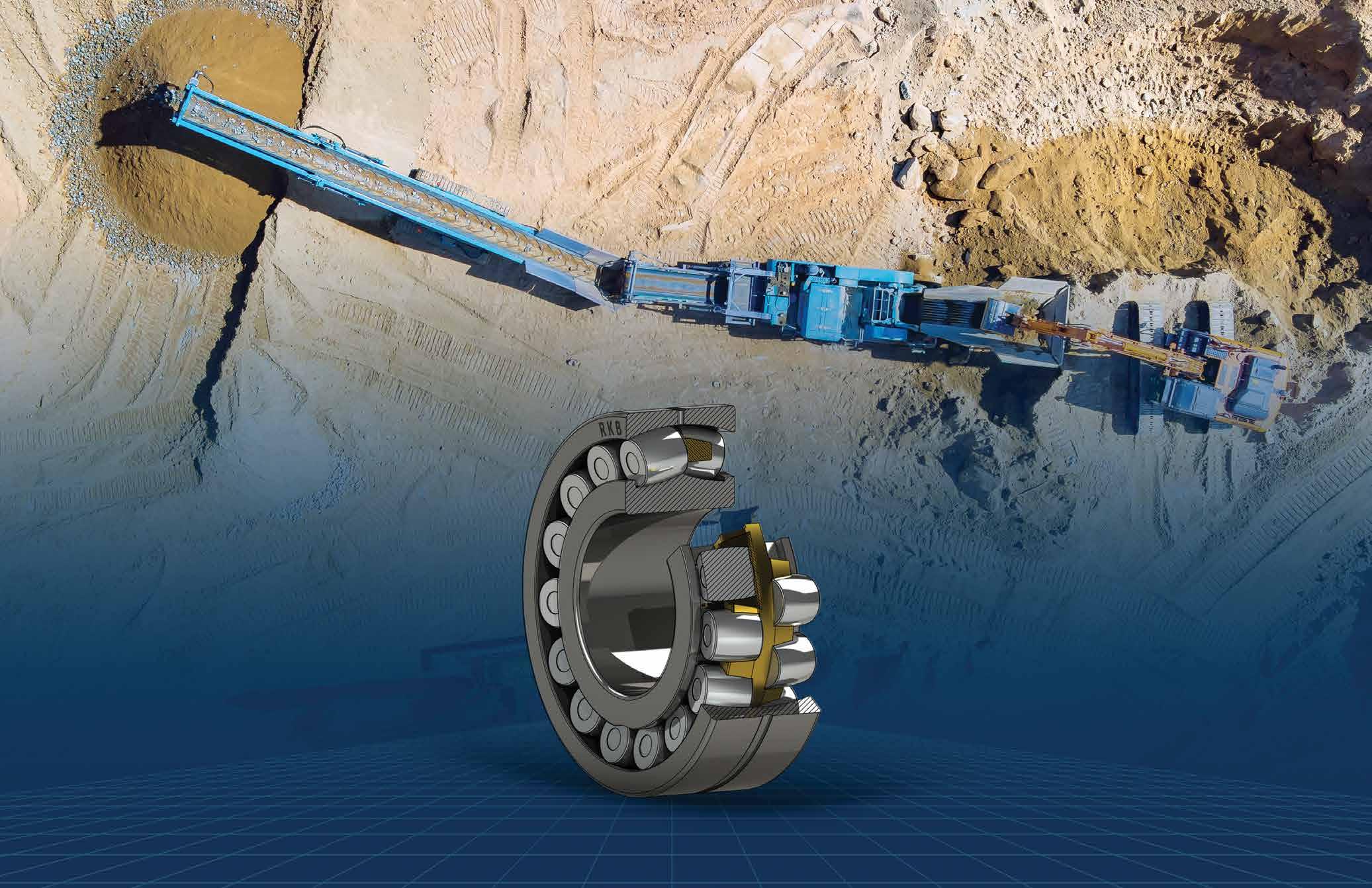

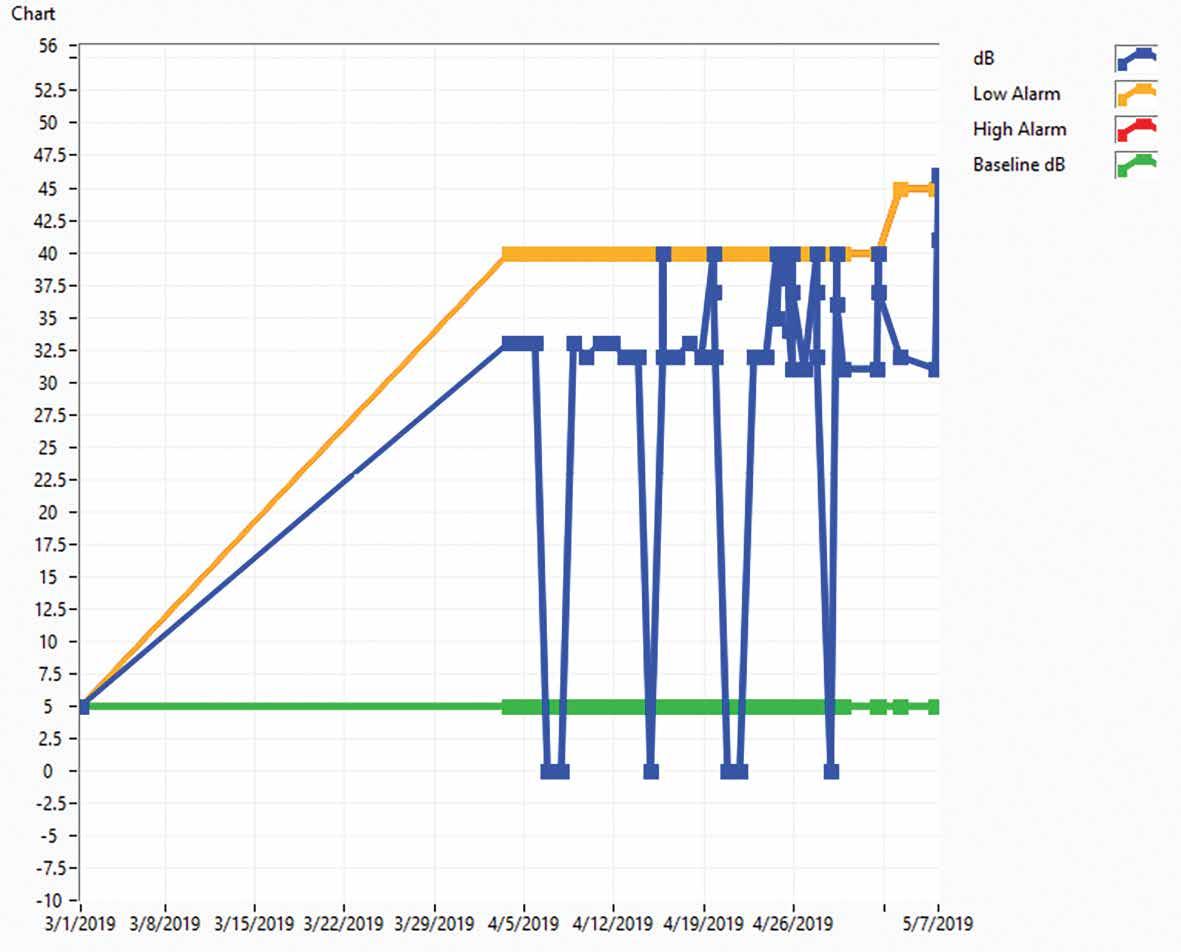

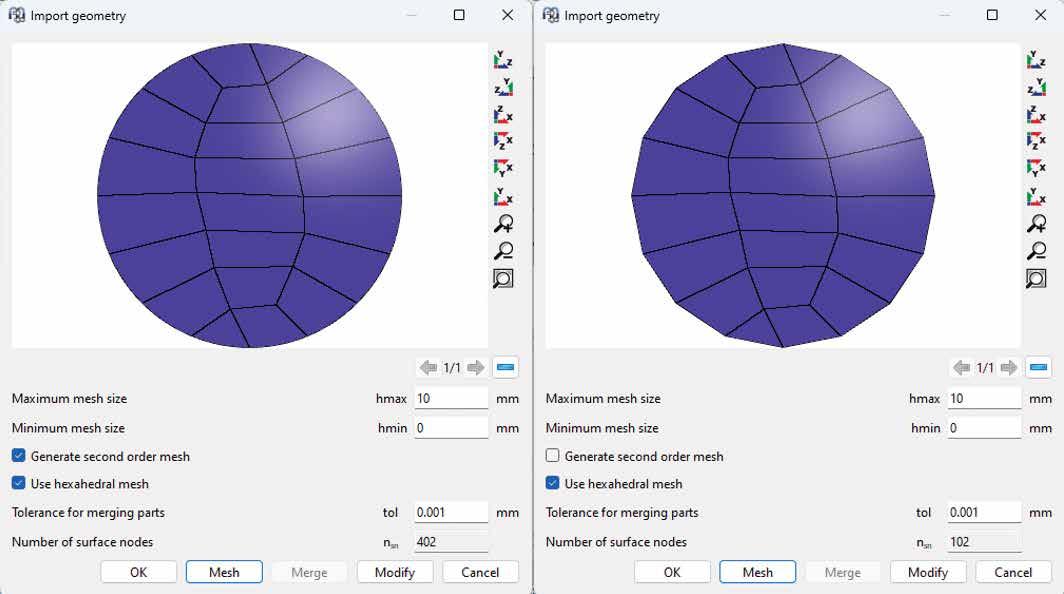

RKB manufactures bearings that offer efficiency and reliability at every step of the cement production process, from the initial stages of mining and quarrying to the final product. RKB products are integral to various stages, ensuring seamless operations and optimal performance. Consequently, over the years, the cement industry has become a significant sector in terms of sales share for the RKB Group.