WILLIAM BARNET & SON

125 YEARS OF SOLUTIONS

Barnet’s strength today lies in both the commodity business that sustained the company for so long and the more sophisticated specialty products developed in the past thirty years.

Barnet started out making shoddy from discarded wool rags and clippings and today delivers highquality, technical solutions all over the world.

Barnet started out making shoddy from discarded wool rags and clippings and today delivers highquality, technical solutions all over the world.

“To be the world’s most respected, creative, versatile, and sustainable global solution provider to our customers and suppliers.”

— Vision Statement

William Barnet & Son

WILLIAM BARNET & SON

125 YEARS OF SOLUTIONS

Copyright © 2022

William Barnet & Son, LLC

All rights reserved. No part of this book may be reproduced or transmitted in any form or by any means, electronic or mechanical, including photocopying, recording, or by any information storage and retrieval system, without permission in writing from William Barnet & Son, LLC, Spartanburg, South Carolina USA.

William Barnet & Son, LLC 1300 Hayne Street Spartanburg, SC 29301 barnet.com

Donna Dunagin Project Director Book Development Bookhouse Group, Inc. www.bookhouse.net Covington, Georgia

Rob Levin Editor

Jason Spencer Author

Rick Korab Designer

Shoshana Hurwitz Copy Editor and Indexer

Renée Peyton Production Manager

In 1998, to commemorate William Barnet & Son’s one hundredth anniversary, Barnet associates in Aachen, Germany, dressed in turn-of-the-century outfits. This framed photograph now hangs in Bill III’s office in downtown Spartanburg.

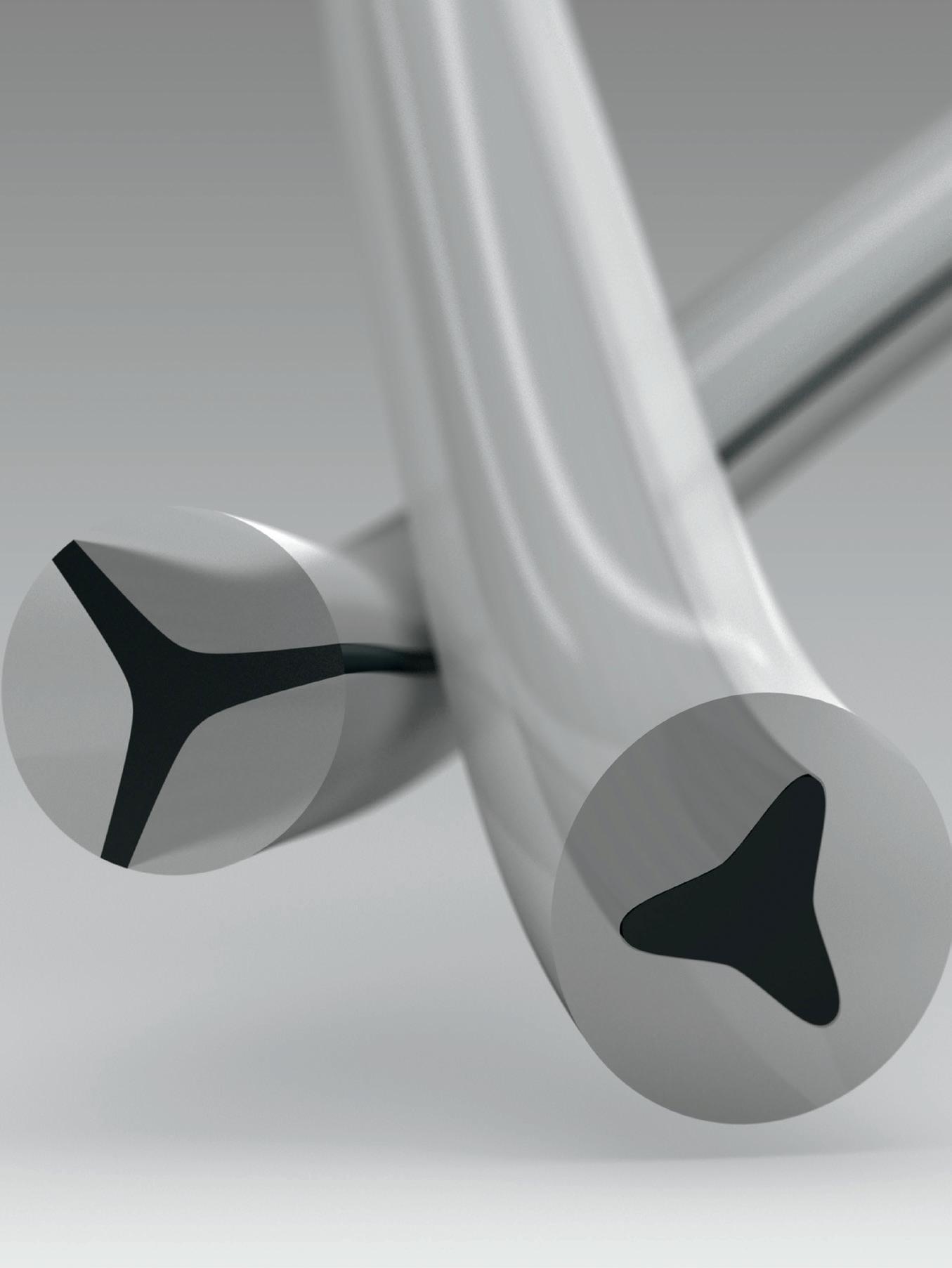

Barnet bought nega-stat® —the company’s first branded product—around the turn of the millennium, which proved to be an increasingly valuable addition to its portfolio in the decades ahead.

XI CHAPTER ONE from humble beginnings to global leader 1

CHAPTER TWO five generations of leadership — and one unique culture

37 CHAPTER THREE sustainability and innovation — barnet hallmarks since day one

57

the next 125 years

For as long as I can remember, our family has celebrated birthdays and special events divisible by five. It was part of our culture! So one can readily understand that in 1948 William Barnet & Son celebrated the fiftieth anniversary of its founding and, as a young man, I was often shown pictures of my grandfather, Henry, leading the festivities. In 1998, many of us gathered to note the one hundredth birthday of the company. So, it seems only proper that 2023 should be celebrated for the remarkable achievement of 125 years of William Barnet & Son’s continuous effort and success.

125 years!

We can all agree, there are many individuals who deserve credit—from the generations before us to hardworking men and women who kept the flame of our mission alive and grew the company through good times and bad. We have been blessed by those who came before us and are certainly equally blessed by those who currently are contributing to the ongoing successes of Barnet.

The Campbell Soup can, which is referenced in this book, was always a standard for those of us who worked at Barnet. It reminded us that every day we had to earn a sale based on raw materials that would not always be perfectly aligned to that product’s success. To this day that is the mantra of this organization as handed down from William Barnet to his son, Henry, to Henry’s sons Pete and Bill, and on to our generation.

We should celebrate as a team, and we have succeeded as a team. We have invested and reinvested in ideas, some very successful and some less so; but, we never stopped applying the energy and values taught to us by those who came before us.

I hope that everyone who reads this book enjoys the history of our company as told by the number of different people who contributed. While I do not recall every detail or every story, I am proud to be a part of the legacy that goes on and prospers to this very day.

My hope is that for many years to come we, and those who follow, will be celebrating just as we are at this special time.

Thank you for sharing a very special moment.

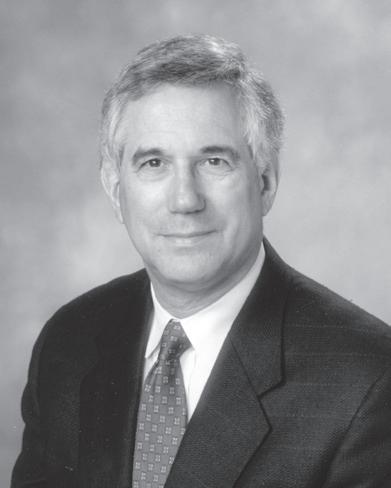

William Barnet III

William Barnet (1852–1932) set out into the American frontier at age eighteen in search of skins that could be sold for their wool. That entrepreneurial spirit has been a driving force for William Barnet & Son for the past 125 years.

William Barnet (1852–1932) set out into the American frontier at age eighteen in search of skins that could be sold for their wool. That entrepreneurial spirit has been a driving force for William Barnet & Son for the past 125 years.

“

In our world, every product that came in the door, and every customer need was always different. So, every day you walked in, and you had a different product to sell with different parameters to a different customer.”

—William Barnet IIIThe story of William Barnet & Son is one of evolution — of creativity and adaptability, determination and innovation. It’s a journey that started 125 years ago by taking wool rags and turning them into something valuable, a trek that has become increasingly technical, with the company today balancing its traditional commodity business with more advanced processes that take first-grade raw materials and create high-value products for critical applications.

“This is creative engineering,” Bill Barnet III said in his office in downtown Spartanburg, South Carolina.

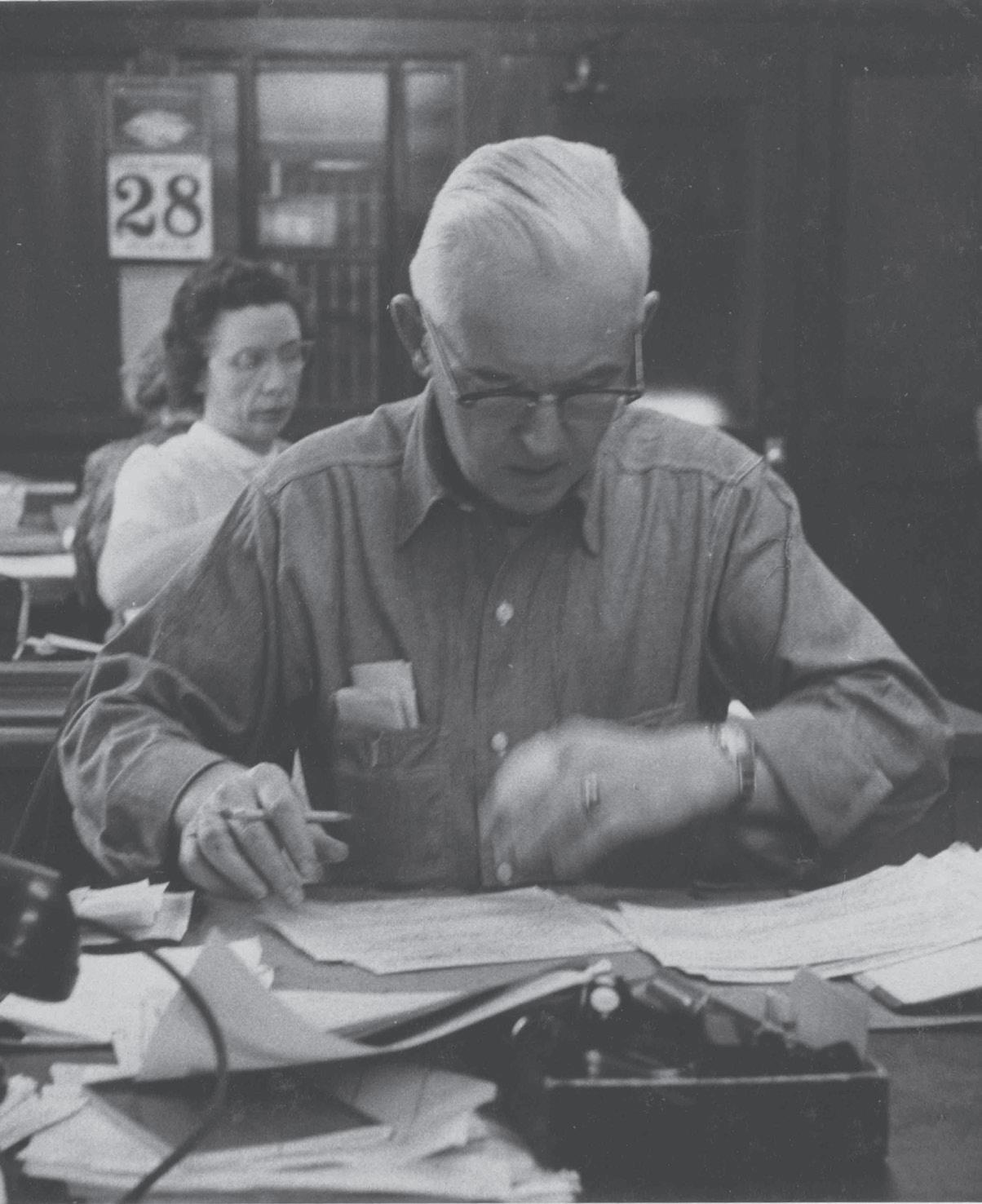

The office is full of memorabilia — scrapbooks, newspaper clippings, handwritten production logs, and much more. Each photo and illustration on the wall has its own story. One was drawn by the cartoonist for the “Times-Union” newspaper in Albany, New York — where William Barnet’s first plant was located — for Bill’s father on his fortieth anniversary with the company. A can of Campbell’s tomato soup is the centerpiece of the illustration. “My grandfather always had a can of tomato soup on his desk. And my father always had it. And I have it,” said Bill III, as he is known in the company.

“The reasoning behind the can was to remind us that we were not selling the same thing every day — meaning a can of tomato soup by Campbell’s, which is always the same and all you have to do is find someone who wants to buy a can of soup. In our world, every product that came in the door, and every customer need was always different. And the fact that we have a product from DuPont or Allied or whatever, there was something about that product that was different. Either they couldn’t sell it somewhere, or it had a deficiency, or it had some other issue. So, every day you walked in, and you had a different product to sell with different parameters to a different customer.”

He continued: “So you were always creatively engineering, and you could never count on every day having the same product in the door and out of the door, like Campbell’s soup. And I think that’s a key story. That’s different than a lot of businesses.”

William Barnet & Son is always creating, answering the riddle of how something that is not being used can be transformed in a way that adds value. Barnet manufactures specialty and niche products, selling that into

“So you were always creatively engineering, and you could never count on every day getting the same product in the door and out of the door, like Campbell’s soup. And I think that’s a key story. That’s different than a lot of businesses.”

— William Barnet III

CHAPTER ONE FROM HUMBLE BEGINNINGS TO GLOBAL LEADER

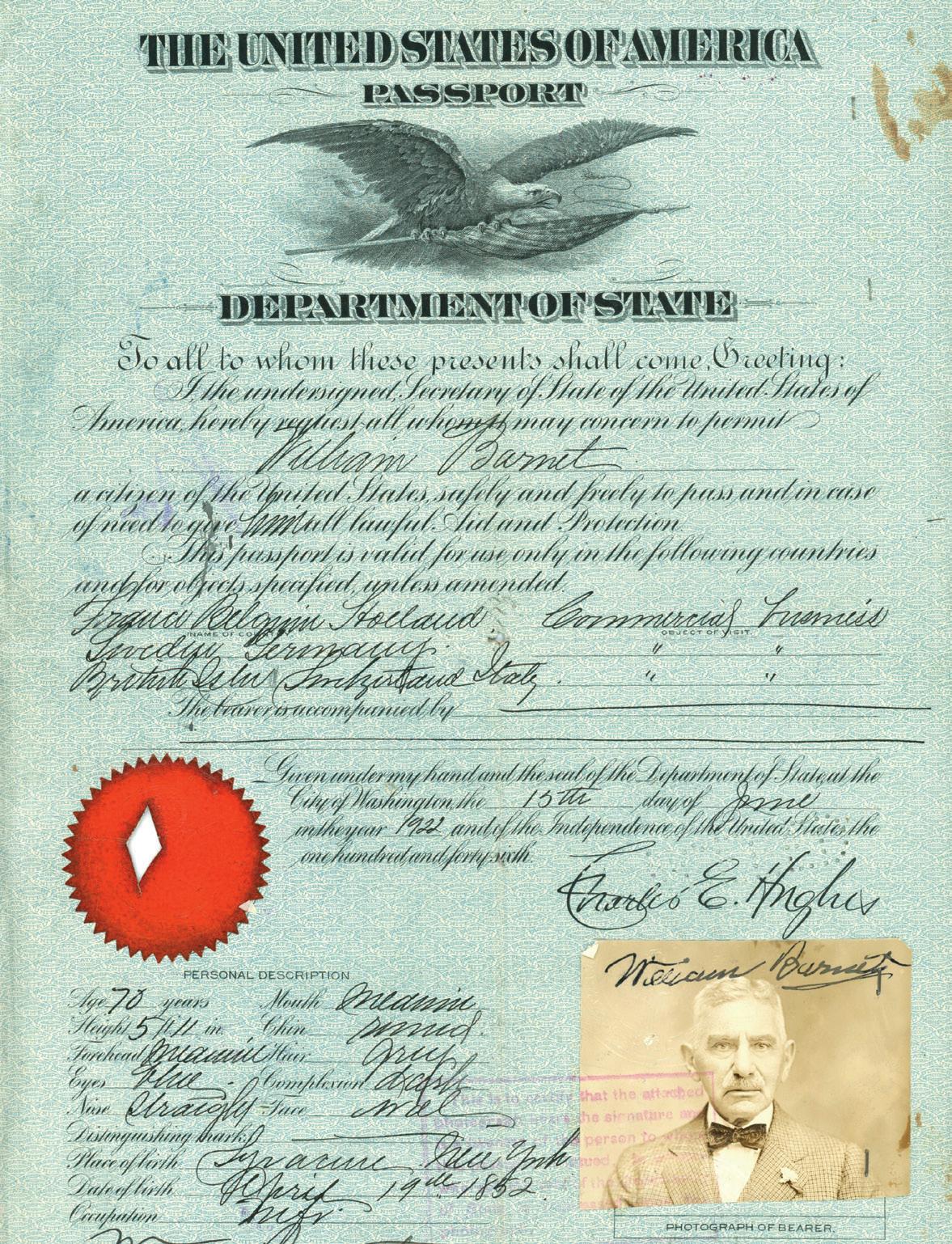

William Barnet’s passport from 1922.

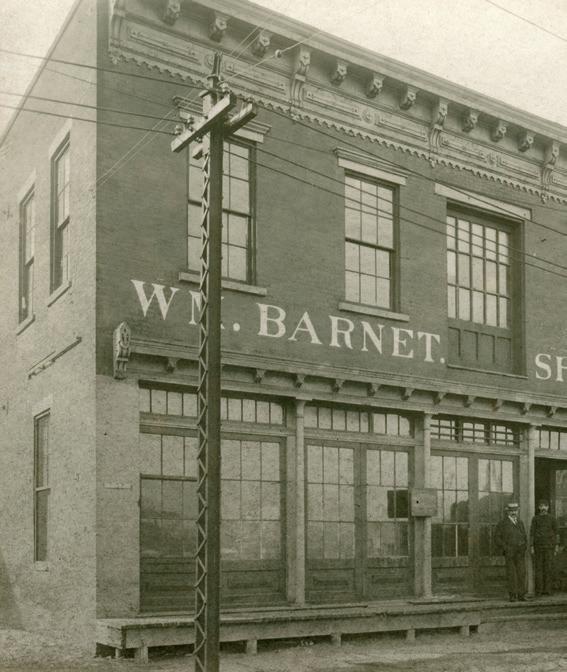

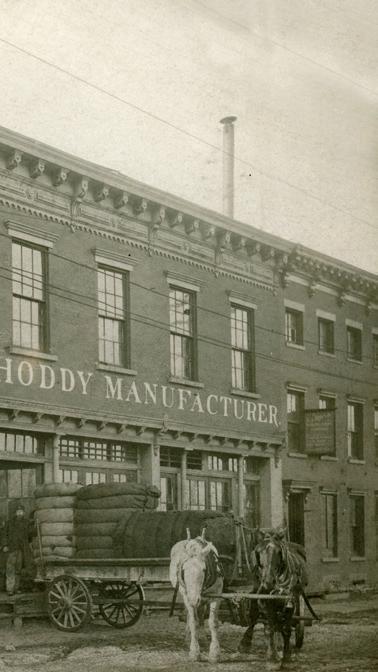

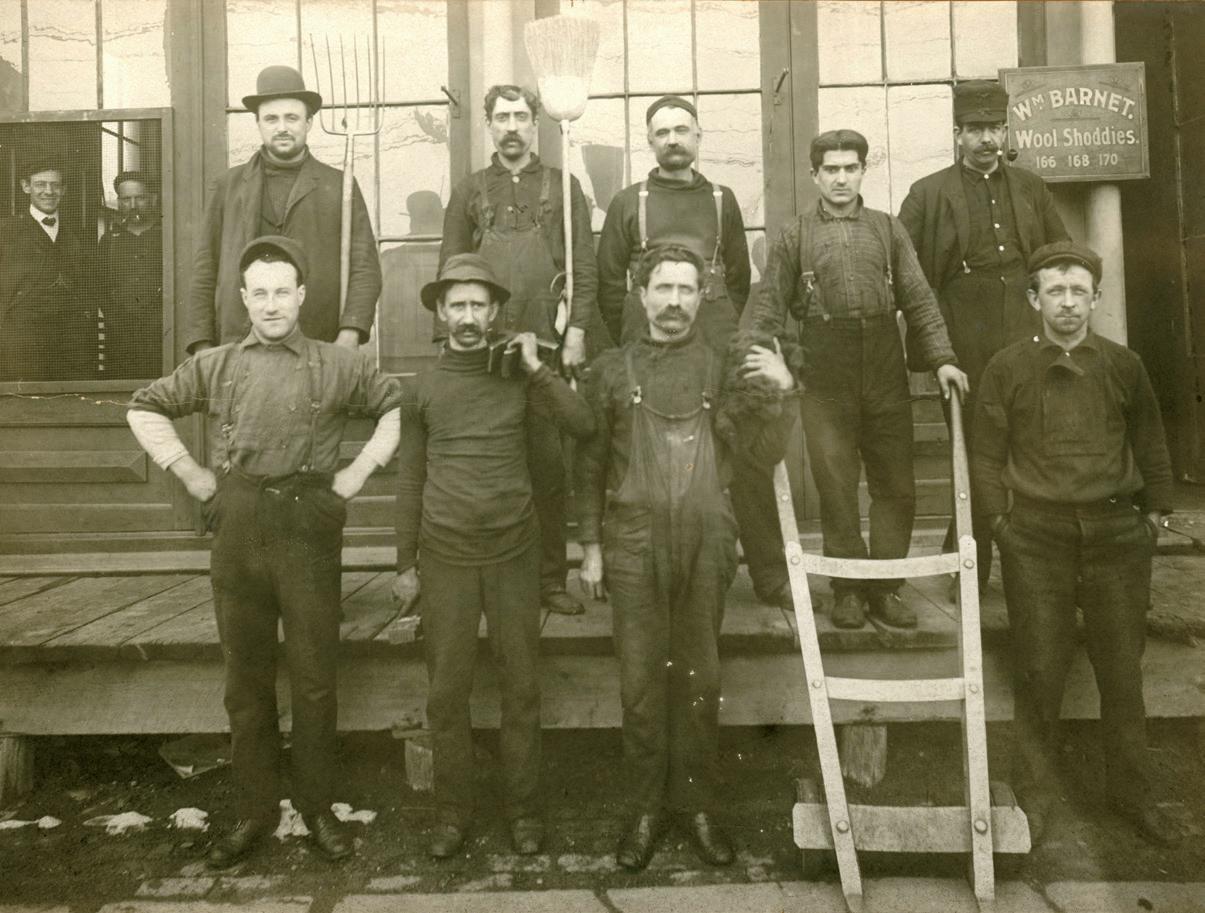

William Barnet launched a textile operation on Westerlo and Arch streets in Albany, New York, on March 22, 1898. William is pictured in the straw hat.

CHAPTER ONE FROM HUMBLE BEGINNINGS TO GLOBAL LEADER

William Barnet’s passport from 1922.

William Barnet launched a textile operation on Westerlo and Arch streets in Albany, New York, on March 22, 1898. William is pictured in the straw hat.

the market in a way that doesn’t compete with the original supplier. The company also has significant contract manufacturing and trading operations. Each era of growth has ushered in new talent; each acquisition, new sets of knowledge and processes that are absorbed by the larger organization, taking the company another step up the technical ladder.

As Barnet has grown, its core values and philosophy have remained the same, guiding and informing each new stage in the company’s evolution.

“We make solutions,” said Chuck Hall, who became president and CEO in 2021. “And we make them in so many different ways.”

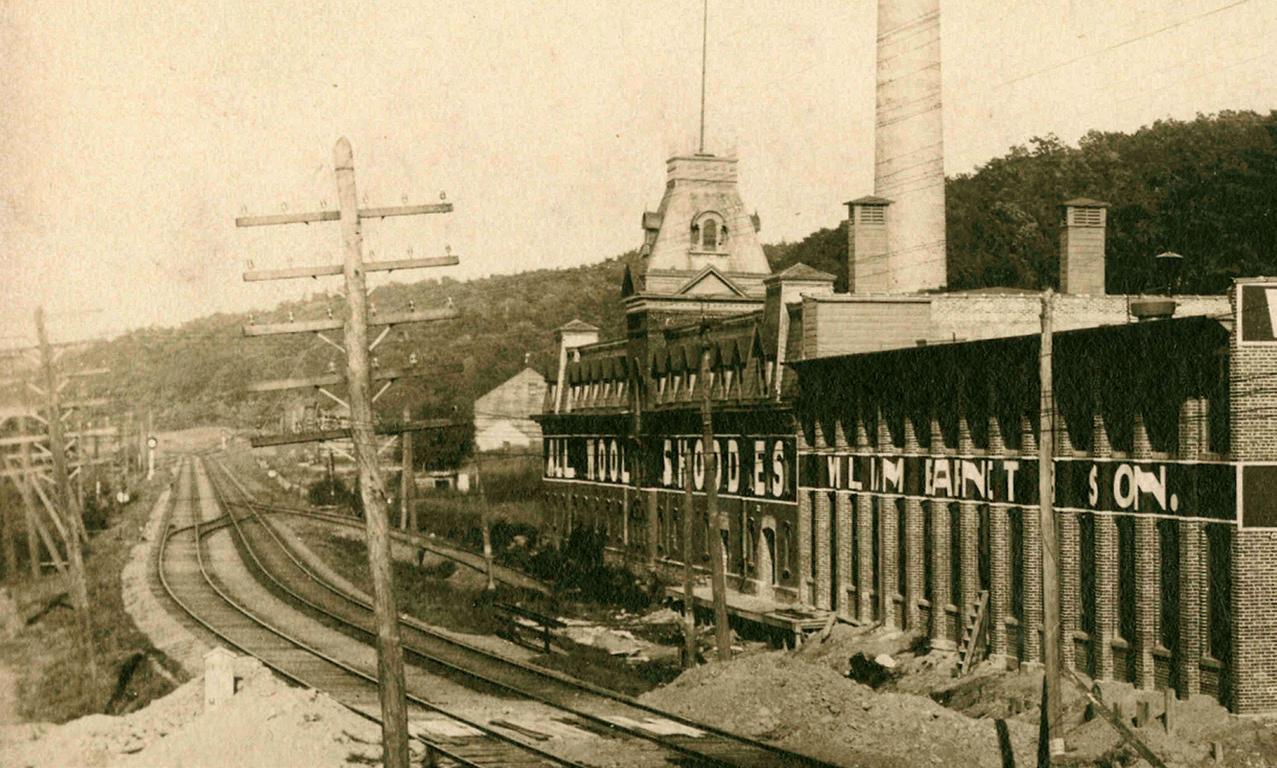

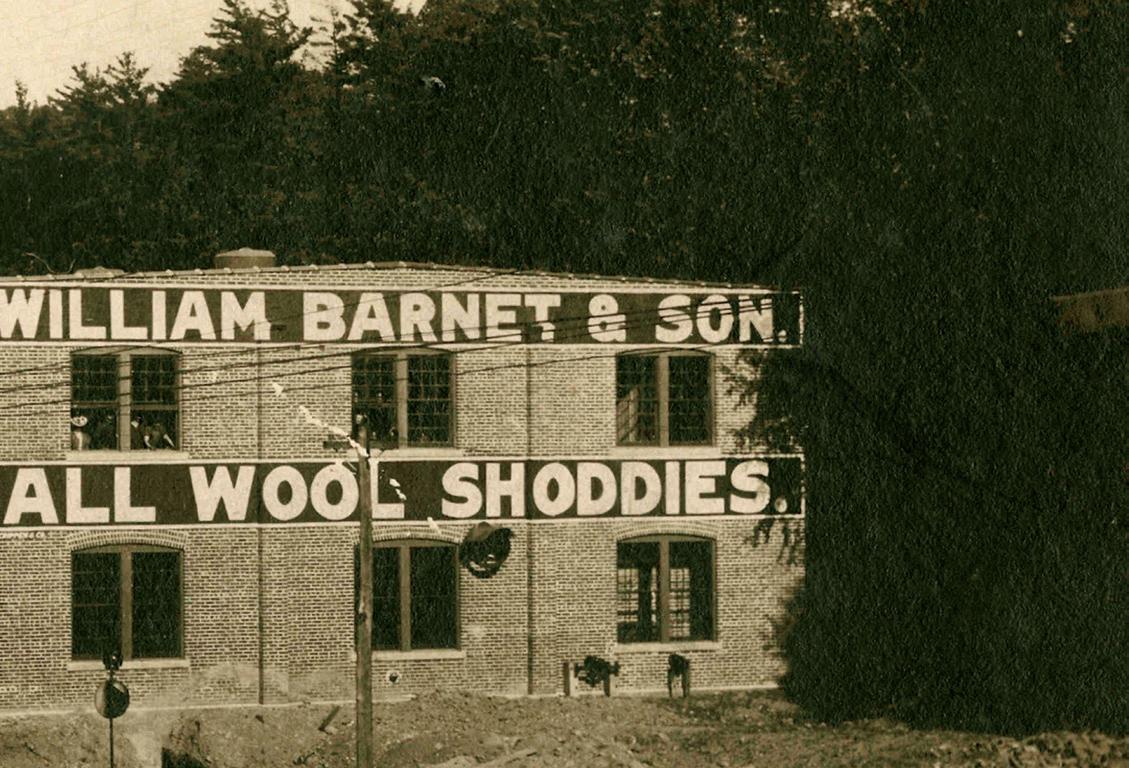

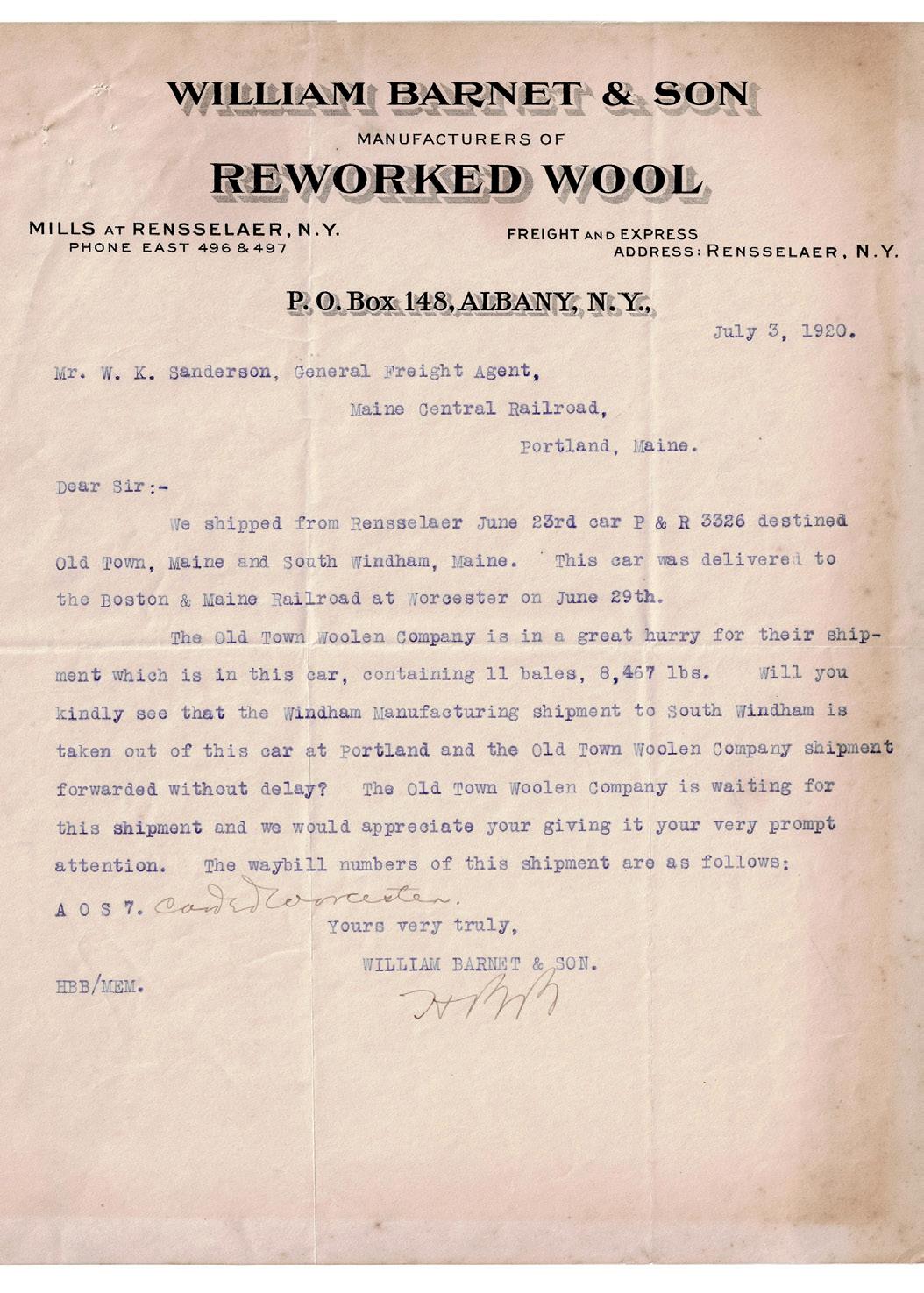

Beneath the ramps leading to the Dunn Memorial Bridge that connects Albany, New York, with Rensselaer once sat Wm. Barnet Shoddy Manufacturing — a modest, two-story brick building at Westerlo and Arch streets whose earliest shipments arrived by horse-drawn wagons.

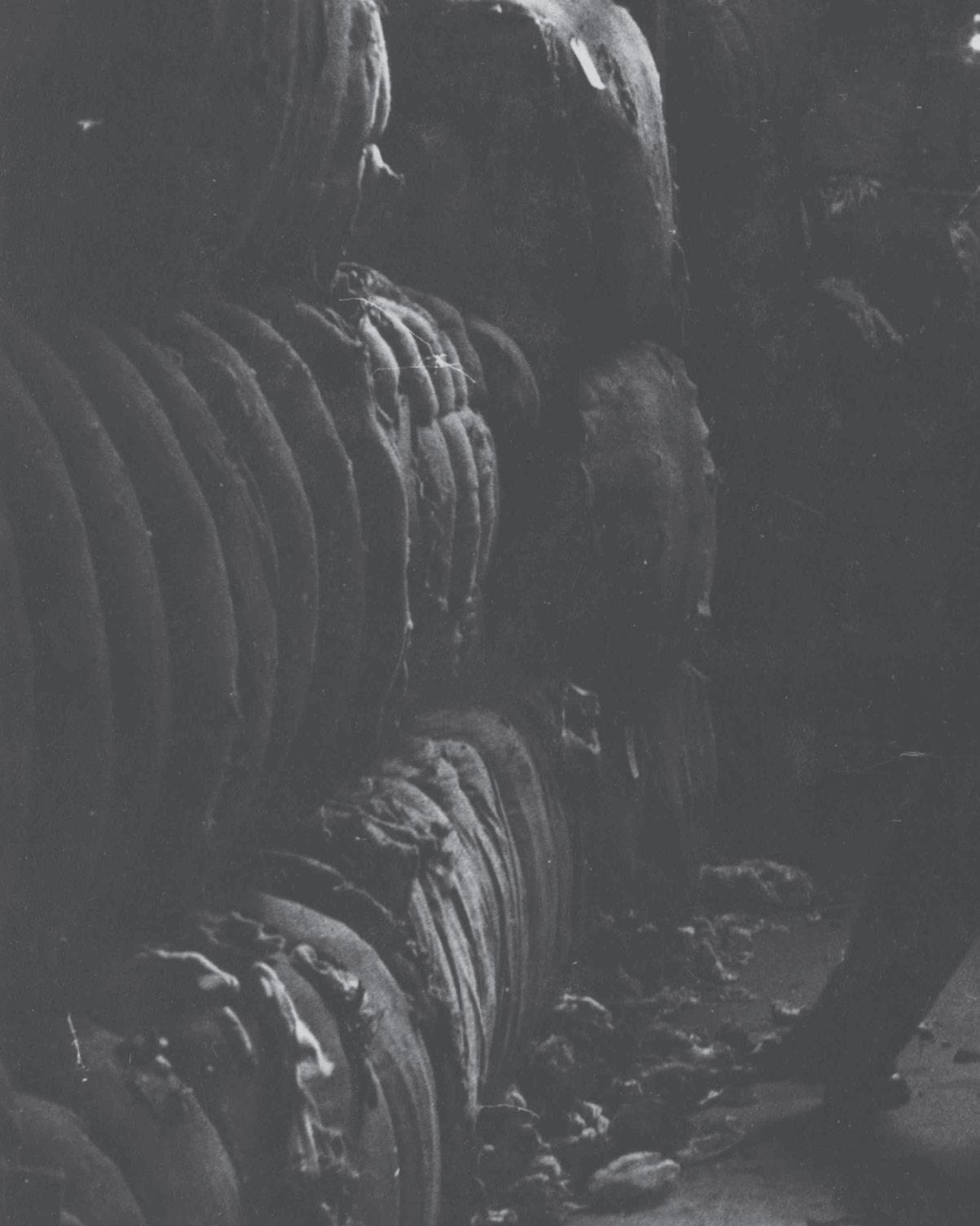

Present-day connotations of the word aside, shoddy — a low-end, non-woven fabric that, in Henry B. Barnet’s operation, was made from wool rags and clippings — became the foundation upon which William Barnet & Son would be built. The reworked wool could be used in garments, blankets, and other applications that were less expensive than their firstgrade counterparts. This first solution provided an alternative to families on tight budgets to fill basic needs.

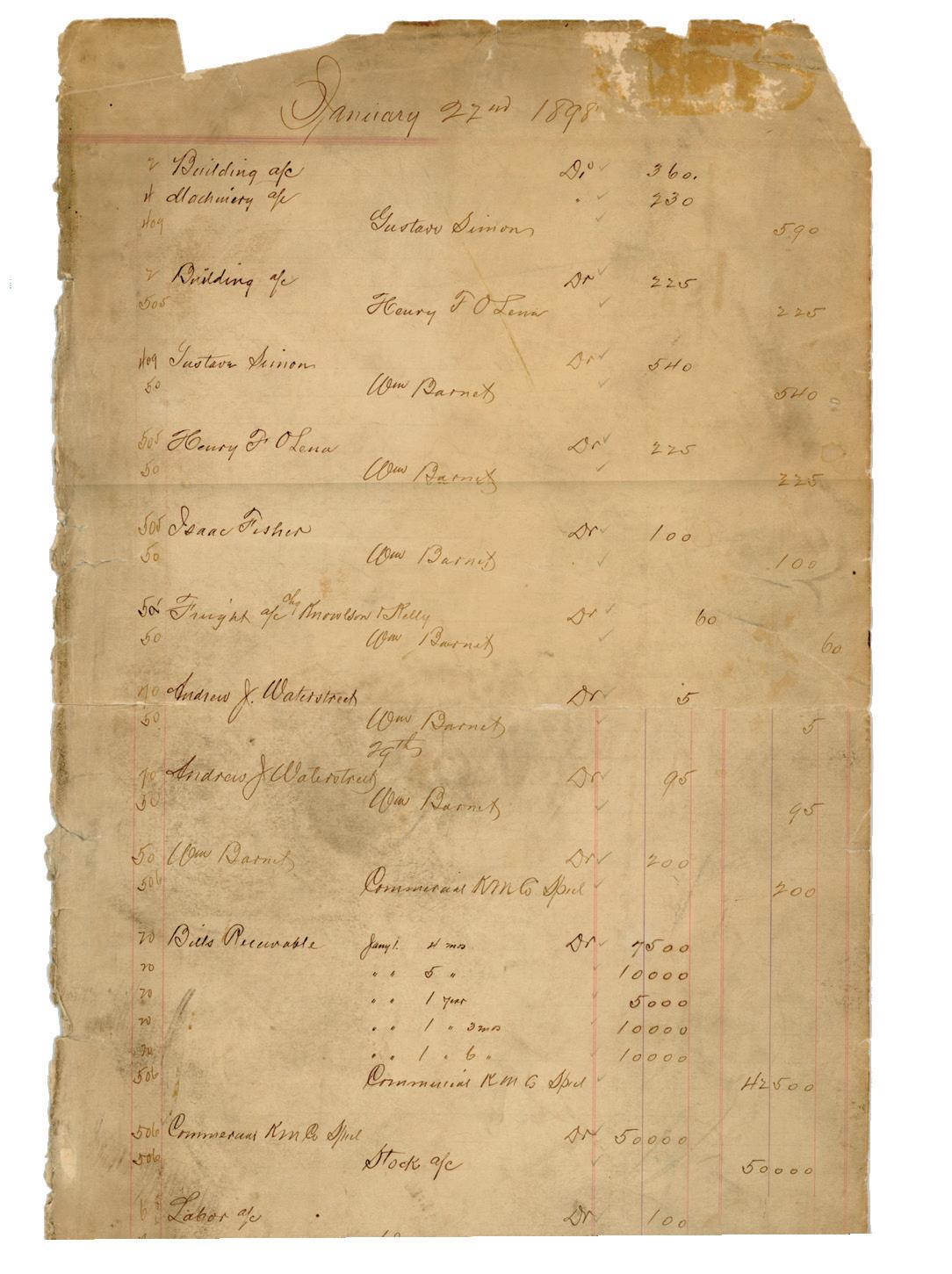

William Barnet, which at the time was not yet incorporated, produced its first pound of shoddy on March 22, 1898, in Albany, according to a company history William Barnet II penned nearly a century later. The company had 10 employees and owed the bank $24,000. It continues to grow and be profitable today, 125 years later.

“We make solutions, and we make them different in so many different ways.”

— Chuck Hall, President and CEO

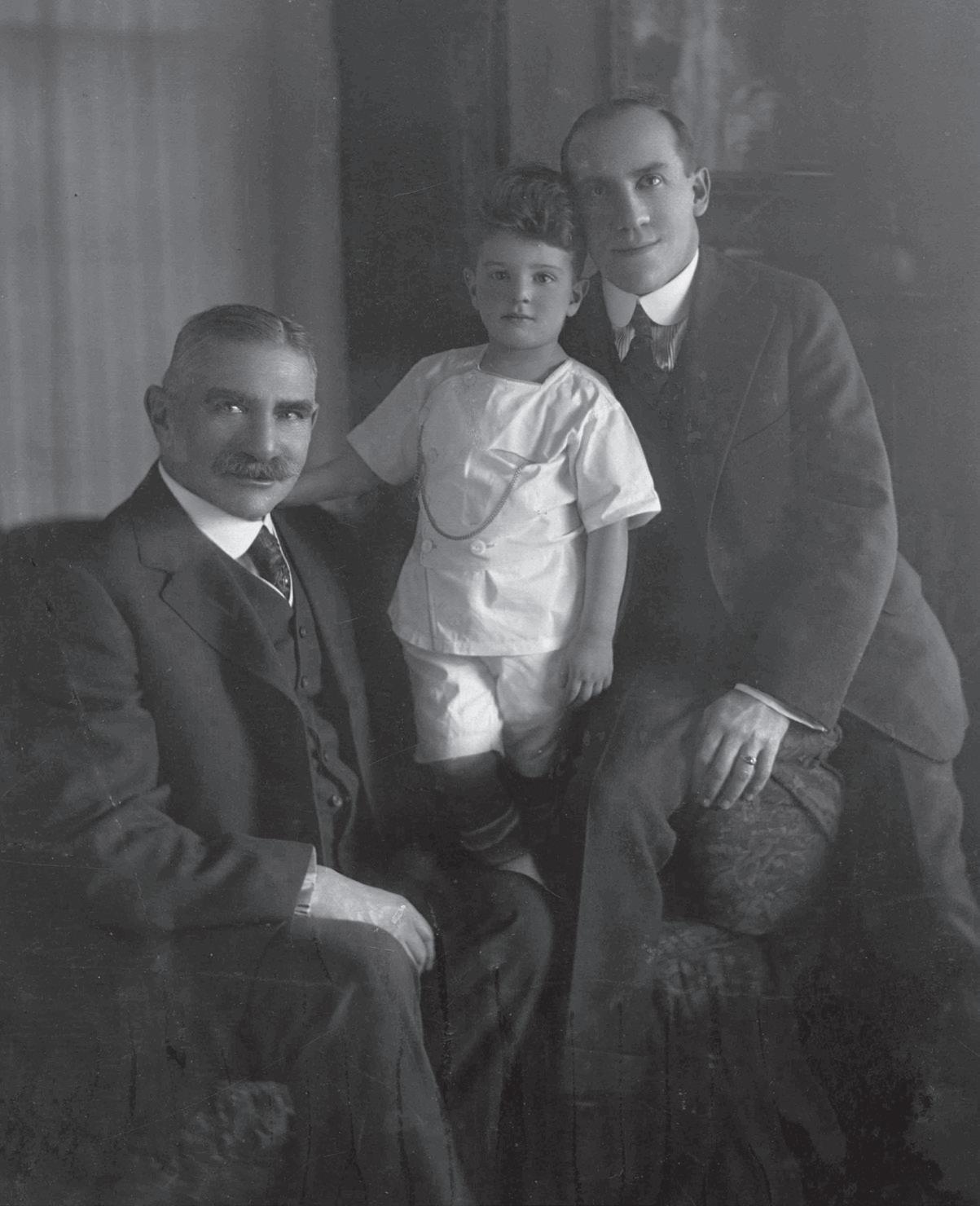

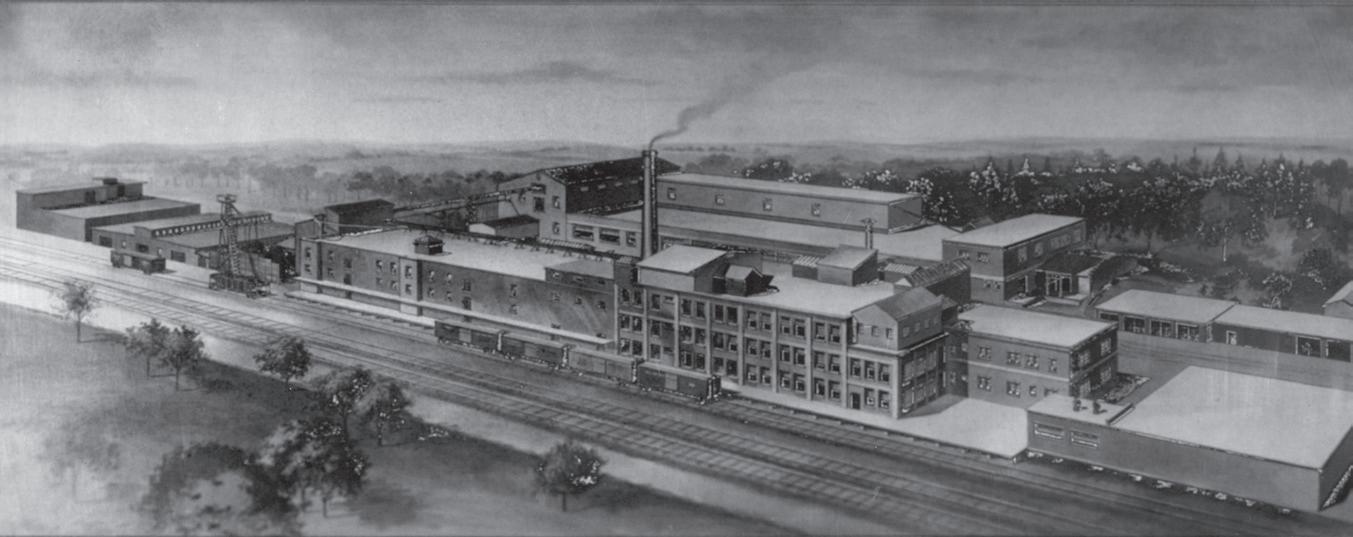

Henry B. Barnet and his father, William Barnet, soon became partners, and William Barnet & Son incorporated in 1920. By then, the firm had converted an old malt plant on the banks of the Hudson River along Forbes Avenue in Rensselaer for its textile operation. Later, Henry’s two sons, William Barnet II — Bill II — and Henry “Pete” Barnet Jr., joined the company and worked with their father to grow the business. Pete was a key contributor to the company until his untimely death from an illness in 1963. The plant on Forbes Avenue still stands today, though it is in need of renovation.

The company did its banking with Norstar Bank of Albany, which counted Bill II (and later Bill III) as a board member. Through a series of acquisitions, Norstar would eventually become part of what is now Bank of America, which the company still banks with today.

Long before the term was used in popular conversation, Barnet was recycling.

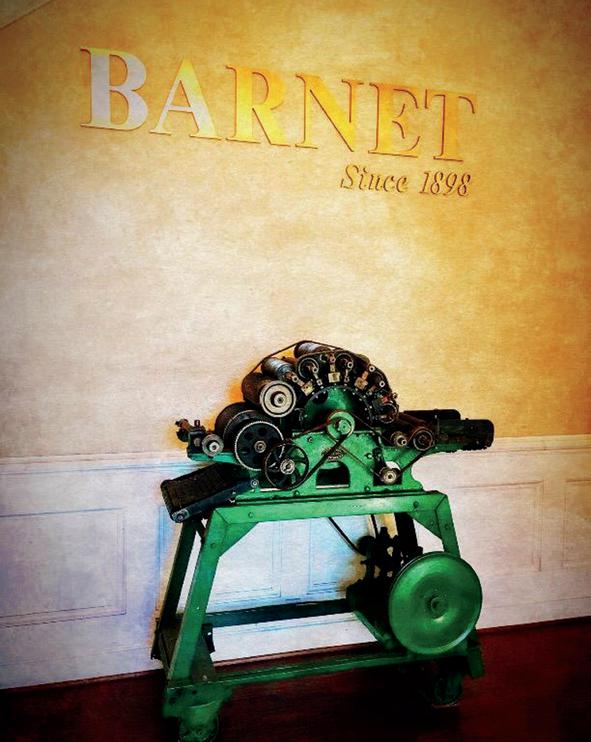

At the time, the process involved picking, garnetting and, where appropriate, dyeing. Picking separates the clippings into yarn, while garnetting reduces that yarn to its original fiber. Today, a miniature version of a card is in the front lobby of the William Barnet & Son headquarters on Hayne Street just outside of Spartanburg.

In the years leading up to World War I, Barnet began selling reworked wool for war materials, like blankets, to foreign countries — up to 60 percent of the plant’s

production. At one point, the plant was destroyed by a fire. The plant was modernized in the rebuilding process.

History marched on. The advent of X-ray technology in the 1920s gave scientists the ability to see and understand the internal structure of natural fibers, which in turn allowed them to begin replicating that with man-made material. DuPont debuted nylon, the first wholly synthetic fiber, at the 1939 World’s Fair, and the synthetic industry began to grow at a rapid pace — particularly in the post-war era.

William Barnet & Son began doing business with Southern textile mills in the late 1940s. It began with strictly woolen operations, though over the next decade it became apparent that the old way of doing business was becoming less practical. The company began making contacts with various synthetic producers, such as American Enka, Phillips Fibers, and Monsanto, which made an acrylic fiber known for its strength, softness, and crease-resistance that was used in clothing, upholstery, and carpets, among other applications.

Already, some of the technology in Albany was becoming obsolete, and new machinery was brought in. High-pressure, stainless steel dye machines were

“All the major chemical companies that made synthetic fibers were somewhere in the South, and therefore it was advantageous to be here because both our customers and suppliers were here.”

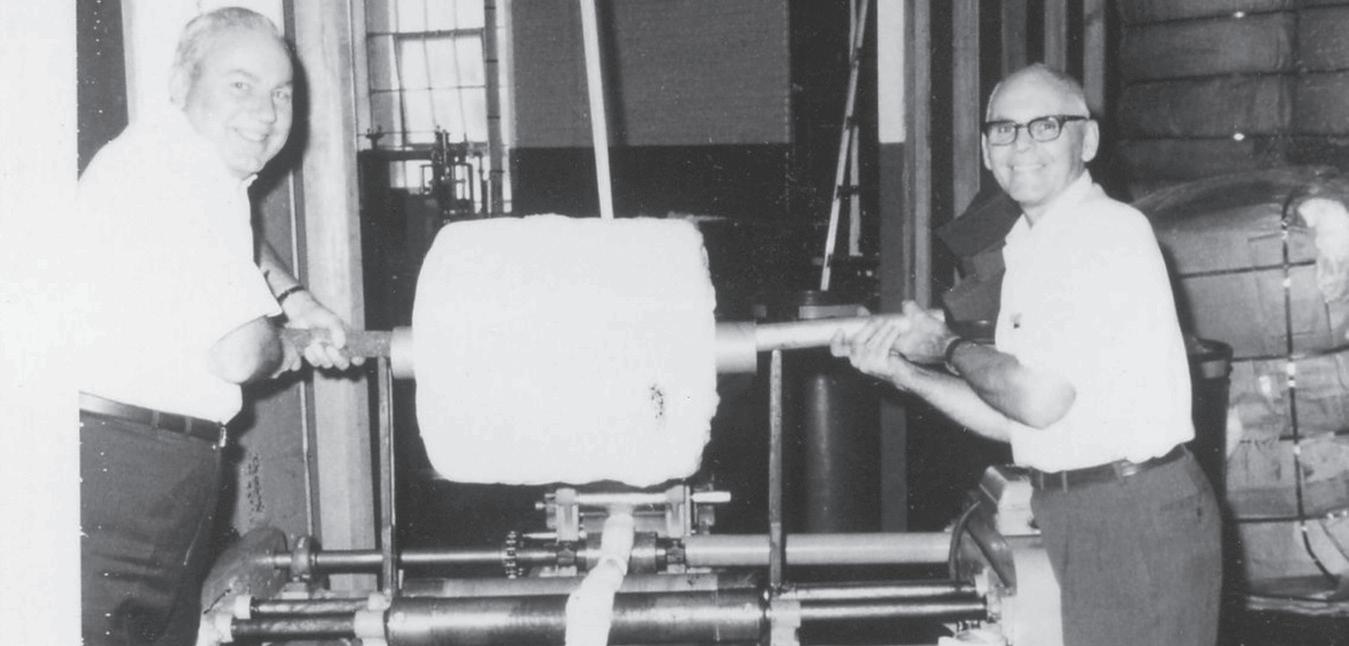

— William Barnet IIIA Barnet employee prepares a bale of wool for processing.

needed to process acrylic fibers, for instance. By 1950, Barnet’s production had shifted to 50 percent wool, 50 percent synthetics.

During this period, the textile industry’s move south was happening in real time. William Barnet & Son hired Vernon McCrary, who after World War II had become superintendent in 1963 of Beacon Manufacturing in Swannanoa, North Carolina, just outside of Asheville.

“All the major chemical companies that made synthetic fibers were somewhere in the South,” Bill III said. “And therefore, it was advantageous to be here because both our customers and suppliers were here.”

Vern McCrary’s Southern roots gave the Barnets some credibility in the South, said McCrary’s son Bill, who would join the company about a decade after his father. Vern became the head of Barnet’s Tryon, North Carolina, plant when it began operation in 1963. The Tryon site — at the time, part of Barnet Southern, which some long-time suppliers and customers still refer to today — was the company’s first foray into the South. ««»»

As the industry changed, a new generation joined William Barnet & Son.

Bill Barnet III joined the family business on December 1, 1969, after graduating from Dartmouth and serving two years in the U.S. Army. Bill’s cousins Hank and Tom joined in 1971 and 1977, respectively, and contributed to the growth of the company for the next two decades.

Bill McCrary, who grew up in Asheville and had earned his undergraduate degree at Duke University, came on board in 1970 after two years at Lockheed Martin; what he thought was going to be a summer job ended up being a fifty-

year career. The company was beginning to grow at the time, said McCrary, who served as a key contributor for three decades before taking over as CEO himself.

“We were all in our thirties,” Tom Barnet said. “And there was an energy and an optimism that comes with youth . . . that I think was a catalyst for growth.” This infusion of new energy would happen again and again, almost cyclically, in the decades to come.

The company was growing, but Tryon was landlocked. It was costprohibitive to expand there. Barnet bought sixty-three acres in Inman, South Carolina, in 1970 with plans to build a new plant there; shortly afterward, though, a building on Hayne Street in the Arcadia community just outside the

Spartanburg city limits became available from North American Rockwell Corp. It had been used to store and distribute metal castings produced on South Pine Street in Spartanburg.

Vern McCrary found the building, and the company bought the site. “Two or three weeks later, the folks who sold it decided they made a mistake and wanted to buy it back,” Bill McCrary said. But the deal was done; Barnet had found what would later become its corporate headquarters.

Bill III moved South on May 1, 1976, assuming the role of chief executive officer soon afterward. He had visited the Tryon facility with his father in 1962 while still in college. They stayed at the Pine Crest Inn. When Bill III made the permanent move, he knew only the people at that plant.

Bill was single at the time, and he settled in Spartanburg, thinking it more cosmopolitan than Tryon, and began to adjust to life in the South as Barnet Southern operations began to shift from Tryon to Arcadia.

“It was hot. And I was trying to learn what I was supposed to do, and I wanted people to think I was a hard worker,” Bill III said. “So, I worked hard that first year. I lived in an apartment in Spartanburg and went back and forth between the Tryon plant and the Arcadia plant.” Those who know Bill III today would likely argue that he never stopped working hard.

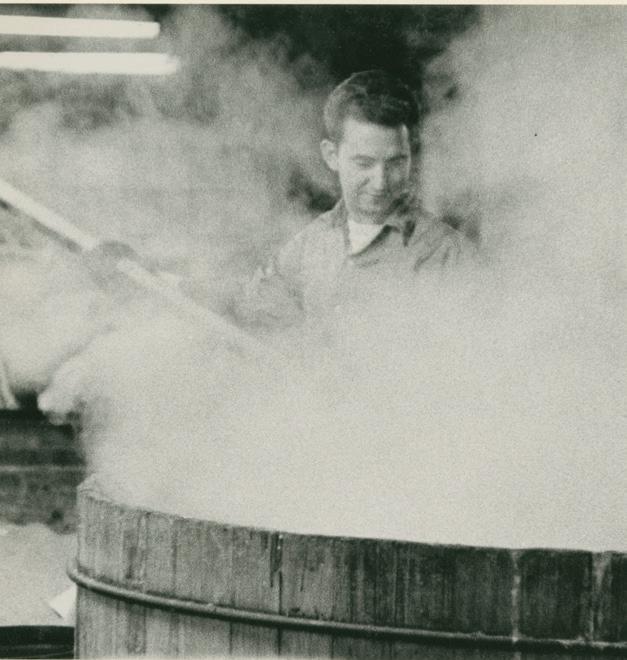

As synthetics entered the market, Barnet had to upgrade its machinery in Albany, including purchasing stainless steel dye machines to process acrylic fibers.

Barnet’s interests in the South continued to expand, while the focus on New England began to dwindle. The Rensselaer plant closed in 1976, and the company opened an office and leased warehouse space in Albany for a time. Meanwhile, drawing, crimping, and cutting operations in Tryon gradually shifted to Arcadia; a new dye house opened in Arcadia.

Bill III remembers the dying machines looked like rotisserie chicken cookers. Vern McCrary discovered that Milliken had some of these machines for sale at its Hatch Plant in Columbus, North Carolina, just a few miles from Tryon. They were used, but when Barnet looked at them, they were quoted a price as if they were brand new. Bill III asked why they were priced new and was told, “Roger Milliken isn’t going to let anybody enter into business on his nickel.” Barnet ended up simply buying new machines.

The Arcadia dye house remained operational until Barnet acquired the Allatoona Dye Works facility in Cartersville, Georgia, in 1973 — an 80,000-squarefoot plant that tripled Barnet’s capacity. The Cartersville acquisition, due to its proximity to Dalton, Georgia, known as the Carpet Capital of the World, opened the door for Barnet to step into the carpet trade.

Barnet implemented a noncontributory annual profit-sharing plan in 1957.

Barnet operated the Cartersville site until 1994, when the company opted to sell it to the Italian firm Piana Nonwovens. Barnet supplies fiber to the Piana operation to this day.

Always adapting means always learning. And sometimes the learning curve was steep. Suppliers weren’t often interested in explaining the differences in the off-grade materials they would unload onto Barnet; they just wanted the materials gone. As the inflow of raw materials into Barnet became more technical and of higher quality over the years, Barnet would invest time and resources into testing and identifying these materials. But in the early days, some lessons were learned the hard way.

Jack Porter came to Barnet in 1977 from Collins and Aikman in Charlotte, North Carolina, where he was in charge of purchasing synthetic fibers. He recalls one story where Barnet had bought what it thought was optically

Barnet

“The Tryon location was by definition very much what the company was built on. Some of the same equipment out of Rensselaer, New York, came down to Tryon and was put into that plant.”

— Chuck Stokes

brightened fiber from a fiber producer in the 1970s. The fiber would arrive with codes listed on the inventory. They knew some of these codes — one designated tenacity, for instance — but not all of them. Some of this fiber made its way to a customer in North Carolina, a friend of Porter’s who bought train cars full of it in hopes of using the lower-cost fiber to reduce his overall blended cost.

The customer called Porter to complain, and Porter went to North Carolina to see what was wrong. The customer waved a blacklight over the fiber, and it was immediately apparent that one of the codes must have stood for mixed luster. It was not optically brightened. Porter offered to have the inventory returned, but the customer growled, “I’ll make it work.”

“It was a tremendous learning process,” Porter said. “We very quickly started learning that industry, what you could and couldn’t do. But that was really kind of the beginning of our becoming involved in polyester staple. It was very early on. Those were the kind of things we went through in the early days. Every time we would jump into something new, these guys wouldn’t tell you everything you needed to know. You had to learn it on your own. But we salvaged that deal.”

The symbiotic relationships that Barnet would develop with its customers and suppliers then, such as companies like Monsanto, DuPont, Allied, and Enka, have guided the company’s growth throughout its history.

“In this business, your supply is just as important as your sales customers,” Bill McCrary said. “And wool as a process was declining, and synthetics were growing in the South. I started calling on certain companies, and Bill III started calling on companies. I called on, for instance, DuPont, and established relationships, and this relationship has been a very important one to us for over 50 years. Another would have been Allied, which became Honeywell. These were enormous relationships that supplied us with a lot of raw materials that we could process and add value. And so those relationships led us to things like Kinston.”

“You had to go to Marilyn to get anything. Because we did everything manually, Marilyn was involved in every move.”

— Jack PorterMarilyn Honeycutt joined Barnet in 1971 at age eighteen after graduating from Landrum High School. Marilyn retired in 2019 with over forty-seven years of service.

DuPont opened the world’s first plant devoted to producing commercial polyester in 1953 in Lenoir County, North Carolina, not far from the small town of Kinston, which bolstered the surrounding area’s population and economy in a relatively short amount of time.

The plant made partially oriented yarn (POY) that could be woven into textile fabrics. But if the yarn was not 100 percent up to specification, it wasn’t useable; it wouldn’t dye evenly, for instance. DuPont produced a massive amount of yarn, and so the company had a considerable amount of fallout.

Former DuPont employees established Precision Cutting and Winding Co. (PCW) in Kinston in 1972 with DuPont’s blessing to turn that fallout into staple fiber that could be used in other applications. But after a few years, that relationship began to sour. DuPont was ready to end its contract with PCW, which would have had a negative impact on Barnet.

Barnet Intelligent Materials became the company’s face to the market in 2021 to emphasize Barnet’s role as a technical solutions provider.

Barnet had relationships with DuPont and PCW. In 1978, for instance, Barnet supplied up to eight million pounds of industrial fiber for reprocessing in Kinston.

William Barnet & Son bought PCW in June 1979 — a major acquisition that solidified the Barnet-DuPont relationship that continues today. The plant was about 100,000 square feet at the time; it would eventually grow to six times that size spread over multiple buildings.

The sale happened quickly. On June 29, 1979, Bill III and a team from Barnet went to Kinston, stayed in the Kinstonian Motel — at $13 per night, it certainly wasn’t the most luxurious place in town — and stayed up all night cutting checks to PCW’s creditors so that it didn’t go into bankruptcy and the deal could close. By July 1, Barnet owned the plant.

This was Barnet’s first major acquisition, one that still pays major dividends today. The ongoing relationship with DuPont has been a key relationship in the company’s history.

“DuPont made no guarantees, but said, ‘If you take over the contract, we will work with you, and if you perform, we’ll see where it goes,’” said Chuck Stokes, who would later become senior vice president of sales and manufacturing. Over time, the PCW plant would run almost 100 million pounds per year for Barnet, plus whatever DuPont needed processing.

In 1985, Barnet’s Kinston facility began processing higher value functional fibers — a critical business to this day. The plant ran 24/7 in the 2000s, peaking at about 375 employees. Kinston has remained the largest Barnet site since becoming part of the company. It has been led by outstanding plant managers from Tom Parker to Ray Deane to Dee Parker today.

“The Tryon location was by definition very much what the company was built on. Some of the same equipment out of Rensselaer, New York came down to Tryon and was put into that plant,” said Stokes, who joined Barnet in 1981. “And that was true waste reprocessing. It was very labor intensive, and very hands-on. As opposed to Arcadia, which was a step up the ladder in terms of technical processing, and Kinston was even more so.”

The Barnet-DuPont relationship is an example of how one company can be both a customer and supplier. DuPont supplied off-grade polyester yarn to Barnet, and Barnet supplied manufacturing services to DuPont.

Another new technology was soon introduced: computers.

Up until the early 1980s, all information was logged manually. Big ledgers — the “Barnet Bible” — would be in the plants, with a master ledger in the Arcadia headquarters. And Marilyn Honeycutt, who joined Barnet in 1971 at age eighteen after graduating from Landrum High School, kept what was known as the “big black book,” which recorded the company’s inventory.

“You had to go to Marilyn to get anything,” Porter said. “If you wanted to sell something, you had to dig through the book to see if we had any and if you could sell it. Marilyn controlled that black book. If you wanted to sell something, Marilyn had to make sure it was not committed to another sale first. She held the lock and key to our inventory in that black book. Because we did everything manually, Marilyn was involved in every move.”

At first, just three terminals were installed — one in sales support, one in accounting, and one in the Arcadia warehouse — said Jeff Brady, a psychology major from the University of South Carolina Spartanburg who joined the company in 1979. Brady still remembers running the massive cables underground to install the system.

As often is the case with new technology, some employees resisted. The warehouse clerks could type, they just weren’t comfortable with the new system. When training began on the green-screen, menu-driven system, clerks initially tried to memorize the order of keystrokes. To pull up a packing list, for instance, they may have to select three, two, and then seven. Brady told them that wouldn’t work, because the screen and menu

options could change; they needed more familiarity with how the system worked.

“It was painful at first, but like anything else, once they were used to it, it was fine,” he said. As computers became more prevalent companywide, Brady remembers Bill III would occasionally stress test the system, calling three different people to ask for the same information to see if the three answers were the same. That initial computer system served Barnet well for over thirty years. In 2022, Barnet converted to a new global cloud-based enterprise resource planning (ERP) system.

Kinston and subsequent acquisitions not only expanded Barnet’s footprint, but increased the overall volume of materials the company was handling and, by some accounts, bolstered Barnet’s legitimacy in an industry that was relatively crowded at the time.

Barnet acquired Meadows Industries in Milledgeville, Georgia, in August 1984. The state-of-the-art, 220,000-square-foot facility added 275 employees to the Barnet roster. It was the largest independent twist and heat-set mill in the United States at the time. Al Gandy was general manager, and he stayed on to manage the plant until his retirement.

The plant was hot and loud and busy. At one time, it had sixteen heat-set tunnels, but saw little turnover in its workforce. The Barnet team members were loyal to the company. The plant ran four shifts, 24/7.

Compared to today, the carpet industry looked much different then. Barnet went about it a couple of different ways: The plant would take yarn — from Candlewick, for instance — twist and heat set it and simply charge a conversion fee; or, as was the case with Allied, Barnet would buy the company’s off-spec BCF (bulk continuous filament) yarns, process that raw material and sell it as a package into the marketplace.

“We focused on establishing programs with our customers,” said Rick Powell, who started in the carpet business working in a mill in 1970 at age twenty and was brought on as an independent sales representative for Barnet. “So, when you have a plant that can make 35 million pounds a year, you have to know that you’re going to be able to sell that capacity and, knock on wood, we were very fortunate. Our goal would be to go in to, perhaps Columbus Mills, for instance, and say, ‘We have a product here that you can use, and we know we can provide you two hundred thousand pounds a month. Can you utilize that?’ So, we knew every week that we had to have their yarn on X number of machines to provide the pounds. We worked off programs, and we were pretty consistent with knowing that we had the place sold up.”

The industry would see significant consolidation in the 1990s when Mohawk, Shaw, and Beaulieu began buying up Barnet’s customers. Barnet sold the Milledgeville operation to Mohawk in 1999.

As Barnet followed the shift of the domestic textile industry to the South, company executives began traveling the world — Israel, South Africa, Europe, Asia, and Australia — in search of new suppliers and customers. But it was the acquisition of Cherotan Fibers located in Aachen, Germany, that transformed the company into a global player.

“We focused on establishing programs with our customers, so, when you have a plant that can make 35 million pounds a year, you have to know that you’re going to be able to sell that capacity and, knock on wood, we were very fortunate.”

— Rick Powell

Accompanying this new era on the world stage was a new generation filling the ranks in the home office. Next-generation technology was starting to appear, too, with fax machines and laptops changing how and where business could be done.

“When I left Fiber Industries to come here,” Stokes said, “several of the engineers pulled me aside and said, ‘You’re making a big mistake.’ They said, ‘What these people are telling you they’re doing can’t be done. It’s physically not possible. It is technically, chemically, physically not possible.’ Well, I had been here, and I had visited with Bill Barnet, and I had seen what they were doing. And I knew that it was possible.”

“The people I had worked for sold their byproduct to Barnet because they couldn’t do anything with it. And Barnet found applications where that same material brought value.” ««»»

Bill Steuber joined Barnet in 1986. Steuber had been working for a startup polyester filament company in Costa Rica when Bill III asked him to “poke around” Central and South America. Steuber essentially became a one-man trading office. Steuber said the first time he went to Ecuador, he only knew

two companies. He turned to the textiles section in the Yellow Pages and started going down the list making calls.

John Avinger (sales and business development) and Joe Eskridge (domestic sales) joined the company in 1990. Robbie Vannoy, who had spent ten years at Milliken, joined Barnet in 1991 and soon became the head of the company’s international operation. Byrd Miller, who previously had a ten-year banking career, came on board in 1992 to later replace Vern Lamp as chief financial officer. Ken Eubanks, who spent seventeen years with Michelin before joining Barnet in 1993, became general manager of the Arcadia Division and would later run the company’s new polymers venture. Bernd Lenzen joined Cherotan Fibers in 1994.

Bertold Schmid, a textile engineer, founded Cherotan Fibers in Aachen, Germany, in 1975. He worked for Enka Glanzstoff, the largest synthetic fiber producer in Europe, from 1965 to 1972. Enka had been simply acquiring warehouse space to store its off-spec material; by the mid-1970s, the company likely had tens of thousands of tons of waste. Storing it was becoming expensive. It wasn’t unusual for companies to simply put the off-grade material into a landfill just to get it out of the way.

Enka had been looking for new end uses for post-industrial waste since the 1960s, and Bertold was entrusted with the task of searching for and, if possible, finding ways to reuse raw materials discarded in the company’s plants.

Later, from 1972 to 1975, Bertold worked for a Dutch company in a similar field.

And then, against the tide of a global oil crisis and recession, Bertold bought two draw frames from Phillips Fibers in the United States and had them shipped to Aachen, Germany. Phillips had tried unsuccessfully to process post-industrial waste, but Bertold was able to draw on his experience and modify the machines to make them work. He founded Cherotan and began to draw, crimp, and cut polyester. They called it “upcycling.”

Over the years, Cherotan grew, adding facilities in Belgium, the Netherlands, and two in Italy. Frederic Huppermans, Bertold’s right-hand man since 1978, helped drive that growth.

The volume of available raw materials was high, and it was growing. Machines weren’t as advanced as they are today; some plants had as much as 10 percent fallout. The sale of this off-grade polyester was so lucrative that at one point, Bertold wondered if he should dig in the landfill for more inventory. (He didn’t.)

In 1978, Cherotan moved to a new location on Eisenbahnweg in Aachen and doubled production. The company built its next two draw frames itself. Cherotan also began selling some of the Nylon 66 fallout it was receiving from Enka Glanzstoff to customers in Sweden, Switzerland, Denmark, and the United States. It wasn’t long before Cherotan realized all of that Nylon 66 was ending up with Barnet.

“I’m not sure whether we found Barnet, or they found us,” said Bertold’s son, Notker Schmid, who joined the company in 1985. “We met and started selling directly to them.

While Barnet was growing by acquisition in Europe, the company would grow more organically in Asia.

Barnet Pacific opened in 1995, with Bess Yeung starting the office in Hong Kong, which was then the biggest trading port into China. The main objective, going in, was to source materials —either raw materials to run or trade goods — for Barnet USA and Barnet Europe. Barnet Pacific was paid a commission on the materials the company bought.

Chuck Hall, a chemical engineer from Georgia Tech, joined Barnet in 1998. He had wanted to eventually enter into pharmaceuticals, and started at the Hoechst plant in Spartanburg, drawn to its training programs. But when Hoechst became Hoechst Celanese, the training program ended. Soon after,

That’s how it started. And at one point, Barnet was one of our most important suppliers, as well as one of our most important customers. Bill Barnet and Bill McCrary visited us, and Bill Barnet started the meeting by saying, ‘Hey, Bertold, why don’t you buy Barnet?’ And Bertold smiled and said, ‘Well, that might be a little too much for me to handle, but would you be interested in buying us?’ And this is how we start.”

Bertold said selling Cherotan to Barnet in October 1990 was not a difficult decision; it was something that needed to happen for the security of his sixty employees. The companies were similar in what they did; Cherotan was just doing it on a smaller scale.

Barnet kept the name Cherotan for several years after the acquisition since it was a known player in the European market. Cherotan eventually became Barnet Europe. Notker Schmid became managing director after his father’s retirement in 1994.

Bertold’s grandson, Roman Schmid, has since joined Barnet. Bertold goes into the Aachen office once or twice a week, has coffee and checks his mail. He said he’s proud that a third generation of his family has joined the business.

“I have a very good feeling what happened there,” Bertold said. “And it’s a nice feeling for me still.”

Hoechst Celanese began the process of selling its fiber business to KoSa.

Hall wasn’t interested in staying for that deal to close. His first supervisor at Hoechst, Bill Mayrose, reached out to Bill Barnet about the situation and soon after, Hall met with Bill III, Byrd Miller and Bill McCrary, and they offered him a job as vice president of manufacturing. Drawn by Barnet’s global reach and opportunities to enhance the company’s manufacturing practices, he accepted the offer.

His first major task was to work with the team at the Milledgeville operation to make that site a world-class manufacturing asset. After that, he took on Barnet’s nascent polymer trading operation. He would end up spending quite a bit of time growing the polymer business.

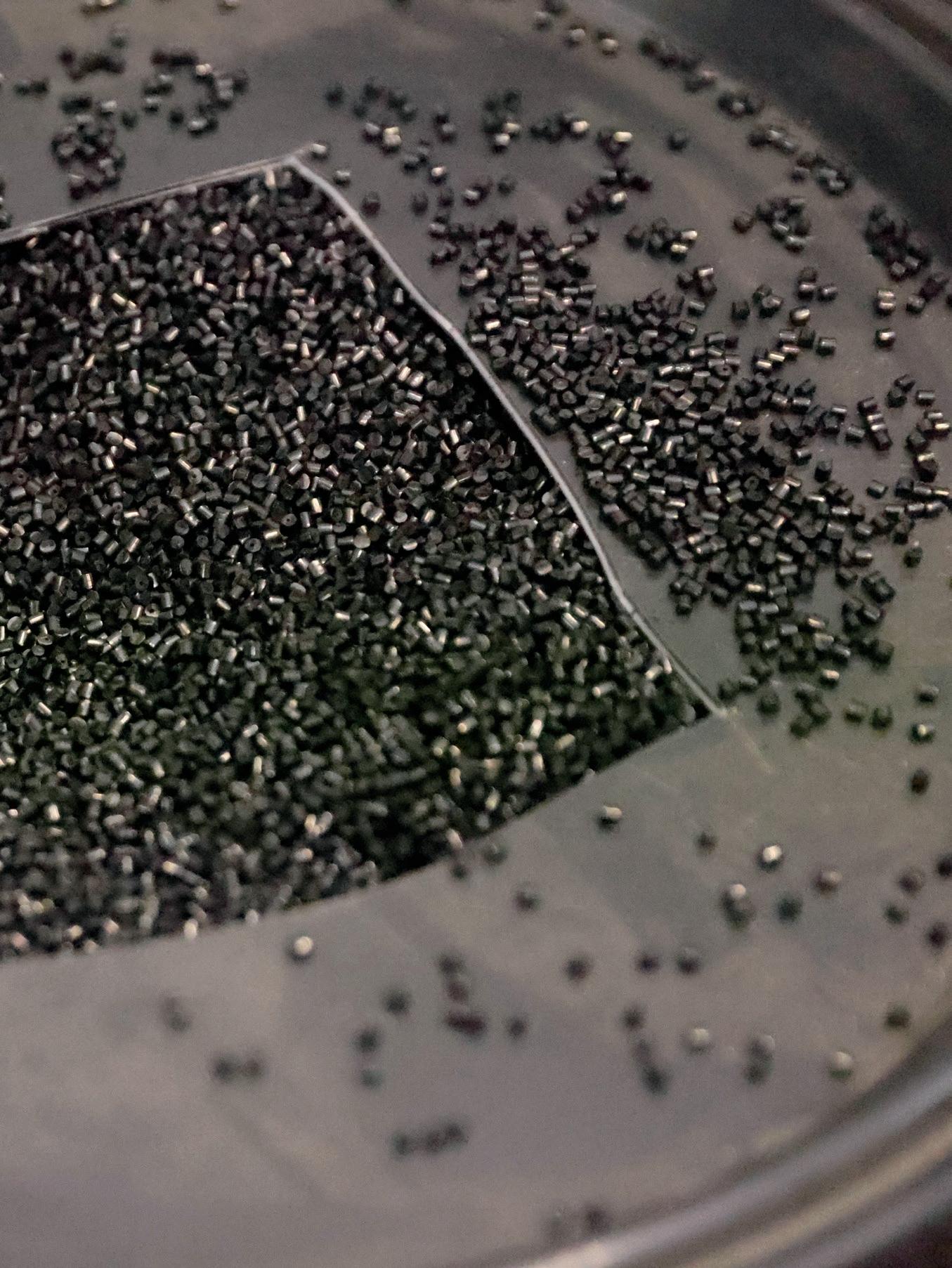

While Barnet was expanding globally, it was also expanding in scope. For nearly a century, the company had been focused on fibers and yarns. In 1996, the company invested in densification equipment and launched the Barnet

“There were significant safety issues that had to be addressed,” Eubanks said. “And it was every day. You had to live it. Because if this polymer touched you, you were burned.”

— Ken EubanksThe acquisition of the Precision Cutting and Winding facility in Kinston on July 1, 1979, solidified Barnet’s relationship with DuPont, a key relationship in the company’s history that still pays dividends today.

Processing Center in what was known as the Landmark site, a 400,000-squarefoot warehouse outside of Spartanburg. The company was moving into the plastics business.

The BPC had a capacity of about thirty million pounds per year and was founded largely to provide services to one of the company’s largest suppliers, Allied. But the technology quickly became obsolete; it did not filter the fiber that was fed into it, so it required very clean material.

The market was not moving in that direction, so Barnet switched gears.

Barnet began a joint venture with Hartley Oil, a family-owned business out of Ravenswood, West Virginia: BH Polymers initially was housed in an old Fiber Industries building near Woodruff Road in Greenville, South Carolina.

After about a year, Barnet bought out Hartley and moved the operation to a facility in Duncan, South Carolina. Barnet Europe made similar investments in a sister plant in Obernburg, Germany — and later in Humenne, Slovakia — and from that formed a global polymer business.

In their travels, Robbie Vannoy and Notker Schmid came to know all types of manufacturers. At one point, a Swiss trading company introduced them to what would become a big supplier out of Belarus, a company called Mogilev. Vannoy remembers the first time Mogilev’s managing director came to the United States.

He described the man as a 5-foot-6 “cinder block” with flat top hair, probably in his mid-sixties. Sturdy. Didn’t speak much English.

“We were standing there together, and we were talking and being translated by the Swiss. And I just reached over and grabbed his bicep and squeezed it, and I went, ‘Hmm.’ And he was just so excited. He took his jacket off and dropped down on the floor and he did about ten pushups. And then he threw his arm behind his back and did one-arm pushups,” Vannoy said.

“And then he stood up, and he looked at me and he goes, ‘You!’ And I could do pushups, but I’m not sure I’d ever done a one-arm pushup. But, I thought, all I have to do is one. So, I cranked out one, and he loved it. He laughed. It just kind of had everybody laughing and loose. But those are the kind of things that made the job fun.”

Later that day, Bill III took him to lunch near a Home Depot in Spartanburg — and he just had to go inside. “He just threw stuff in the cart, hammers and drills and things like that. And Bill paid the bill. The guy had never seen anything like it,” Vannoy said.

Barnet Polymers in Duncan, South Carolina. As the polymers business grew around the turn of the millennium, it began to rival Barnet’s more traditional fiber and yarn business units in terms of profitability.

The business grew, becoming “a very significant player in the plastics recycling and plastics compounding world,” Hall said. “We were a fiber-yarn company, and all of a sudden this polymer business was coming up and rivaling those two businesses in terms of the ability to generate profits for the company.”

The evolution of Barnet’s fiber and yarn focus to include a polymer focus was in line with what the company had always done — taking byproducts, filtering them and, in this case, recovering the polymer in the form of 1/8-inch pellets.

It was the next step up the technical ladder in the recycling world. This recycled plastic has major applications in the automotive industry. As Bill McCrary later recalled, “This helped us move up the value chain, as our recycled polymer could be used as-is in a recycled component or, in some cases, as a firstquality item.”

Eubanks was tasked with managing the BH Polymers site and, as the business grew, finding a new location for it. He found the 100,000-squarefoot facility on Highway 290 in Duncan, which Barnet acquired and launched an expansion to bring the plant up to 250,000 square feet.

The polymer business was a new frontier. Quality control and safety systems were incredibly important. Labs had to be certified. Customer visits increased. Safety, in particular, was a constant concern. The process involved heating material to approximately 480 degrees Fahrenheit to melt properly.

“There were significant safety issues that had to be addressed,” Eubanks said. “And it was every day. You had to live it. Because if this polymer touched you, you were burned.”

Barnet began participating in the Occupational Safety and Health Administration’s voluntary Star Program and showed significant results. Incident rates were less than half of that for the industry. OSHA recognized Barnet for its safety results, eventually getting to the point where inspections were no longer needed.

When Barnet designed the new plant, the company focused on creating a work environment that addressed the many challenges associated with operating a polymer recycling operation. Ample space was provided for

each workstation and production line, for instance, and lighting was greatly improved. Lines were laid out in a way that reduced the physical demands on operating team members, increasing efficiency. Several provisions were made to address the heat such an operation generates, improving the working environment. In short, Barnet was able to use its experiences from BH Polymers and use it to build a better facility.

“We considered it a world-class recycling center,” Eubanks said. “Because it’s tough to keep a place clean when you’re handling yarn and melting it. But we always were complimented by the people that visited about how good it looked, and that went with the safety program, with the quality program, and it went with employee retention. Generally, we had very little problem keeping people in a tough environment.”

Barnet Polymers became the company’s first site to successfully register its quality system against the ISO 9001 quality standard. It was not Barnet’s first efforts to implement a quality system; In 1998, the company’s centennial year, Target 98 was implemented to drive an intentional focus on quality. Today, all Barnet manufacturing sites’ quality systems have been certified against the ISO 9001 standard.

With the exceptions of Thanksgiving, Christmas Eve, and Christmas Day, the polymer plant ran 24/7. In its heyday, it was churning out up to seventy million pounds per year and more than one hundred Barnet associates worked there.

As Barnet started growing its polymer business, China was becoming a big polymer user. China’s goal was to become the manufacturing center of the world, and it needed raw materials to do that. Barnet Pacific, which was meant to source goods, turned into a sales office — polymers became an export business for the company, while fiber and yarn would be imported from China.

The turn of the millennium was another period of change. Barnet bought nega-stat®, an anti-static yarn created by DuPont. This brand would become increasingly important in the decades ahead. The Tryon plant closed in 2001 after thirty-eight years.

Ironically, global expansion didn’t always highlight how big the world is, but rather how small it can be.

Uday “Bobbie” Grover grew up in textiles. His family owned Modella

“My father was raving about Barnet. He said, ‘What a company! And the warehouses, I’ve never seen anything like this in the world. They just go on and on.’”

— Uday “Bobbie” Grover

Woolens, which had a large manufacturing center near Bombay, India, and a presence in other cities as well. As a teenager, Grover would go to the plant and get pieces of fabric to make his own suits.

After college, Grover and his father established a textile recycling business, but that shuttered after a few years — it was a little ahead of its time in India, Grover said. In 1992, Grover’s father visited William Barnet & Son in the United States.

“My father was raving about Barnet,” Grover recalled. “He said, ‘What a company! And the warehouses,’ he said, ‘I’ve never seen anything like this in the world. They just go on and on.’ He said, ‘You have to go and see them.’ And so, when he died, it was something he left me — that idea in my mind that I have to know this company. I wanted to figure out what this is all about, because he left this huge picture in my mind. And then I did find out. And I thought, I am going to be partnered with them eventually.”

Grover began to establish a relationship with Robbie Vannoy at Barnet, buying raw material and selling it in India. It wasn’t long before he was Barnet Europe’s exclusive agent, and Vannoy and Grover developed a relationship

with the Reliance Group, one of the largest private businesses in India, with interests in telecommunications, power, financial services, infrastructure, media, and healthcare. Today, Reliance is among Barnet’s biggest suppliers of raw materials.

By the late 1990s, Grover was supplying more than one hundred tons of raw materials per month to Barnet from Reliance. Barnet soon asked Grover to join the company; Barnet India was incorporated in 2002, with Barnet owning the majority interest. Barnet India began as a sales and trading office, eventually opening its first warehouse, and in the mid-2000s it began importing and distributing products in India.

Hall made a fifteen-day visit to Barnet India in 2008, and he brought with him the opportunity to sell recycled, off-grade, and first-grade polymer in India. At the time, Barnet was recycling and selling Nylon 66, an important base resin in the polymer industry, in the United States, Europe, and China. An opportunity was presented by Ascend Performance Materials to sell their Nylon 66 products in India. Nylon 66 is heat resistant, strong and lightweight,

and is used in the automotive and electrical industries. Barnet India was able to develop this opportunity into a profitable business by 2010, which Grover said has helped give the company its own identity. Today, Barnet India has about twenty employees.

Barnet Pacific, in Hong Kong, remained an important office for the company, but when the British transferred control of Hong Kong to China in July 1997, it became clear over the next few years that China wanted to make Shanghai its key port. Barnet began conceptualizing an office location in Shanghai.

In early 2003, DuPont spun off its textile fibers division into Invista, which was later acquired by Koch Industries. Invista shuttered the yarn operation in Kinston, which forced Barnet to look elsewhere for raw materials. That year, Barnet decided it was time to establish that office in Shanghai – Barnet Trading. Hall and Bradley McCrary — Bill’s son — moved to Shanghai in 2007 to grow that business, selling plastics into China and buying the raw materials needed in Kinston.

Hall said his goal was to make Barnet’s Asia operation self-sufficient, including manufacturing. By the time Barnet Fibers Manufacturing opened in Qingpu, a suburban area in western Shanghai, in 2012, Barnet had become a global leader in the production of precision-cut specialty fibers.

In the last twenty years, the company has developed a substantial precisioncut business, made major strides in the realm of carbon fibers, and, with the acquisition of The Davy Group in 2017, begun a major push into the technical fibers market.

The company managed to weather the COVID-19 pandemic in 202021 thanks to its diversification. While some sectors took an initial hit, other markets took off, such as medical, barrier fabrics, and wipes. nega-stat®, for instance, is used extensively in medical gowns and masks, which proved to be in high demand as the world adjusted to its new normal.

For sure, the Barnet universe of 2023 is a long way from 1870, when William Barnet, at age eighteen, “headed west with a gun on his hip” to buy skins in Kentucky and Missouri. The wool would be separated from these skins in Albany and sold to merchants in Boston. He and various family members would operate two knitting mills before William Barnet joined his son in 1898 for the venture that would become a global solutions provider.

Today, William Barnet & Son has six plants, five sales offices and approximately five hundred employees worldwide. Like the original William Barnet, the company is still venturing out into the frontier.