When you build with EcoliferM Stabilized Weather-Resistant Wood, you'll experience more satisfied customers and fewer callbacks. That means you can reel in more time to fish for more business or spend a day at the lake. And what better way to take back your weekends than winning a2012TrackeP Pro TeamrM 175 TF boat, motor, and trailer? Just enter your Viance Ecolife (EL2) Decks into the "Fish-More Deck Challenge".

Use Ecolife Stabilized Weather-Resistant Wood for your deck projects, and build great-looking decks!

Take quality photos of the finished deck project.

Enter the contest by filling out the online entry form and uploading the photos and the Ecolife (EL2) purchase receipt at www.Ecolife.Fish-More.com.

Enter by the monthly deadline to compete for that month's prize. Enter by the 12/31/12 deadline to compete lor the Grand Prize. The homeowner and builder of a deck may co-register as a team to compete for the Grand Prize!

THAILER! TRACKER' PHtl TEAM" I75TF APPRIIXIMATE RETAIL VALUE llF SIS,Otltl I-..: .^IIIII 1 BUILIIER/H{IME(ITIJ].IER TEAM GRANI| PRIZE: nnlllD lryt eumER u/rl{s 20 I 2 TRAGKER@ PRo TIAMTM 1 75TF v"F H0ME0u/I{ER ultl{S 52500 ,: .nsFr S 1000 EUERY M0NTH |lflfl Try^' TEN SSOO B|JITDER MIII{THLY PRIZES ANl) ".-_ TEN SSOO HOMIOIIII{EB BIY MOI{THLY PRIZES ,i' ii ..,1,t!''. i'l i, : j,i: ,,_ 1r: I dIlIi t. l': i ittri 1 2 3 4 1i. ,i. i.' *, s &' g q !i tl '' 't i: t .*;r 1l'.:t i ,.r1'{* iill til Htlt|l TO

LAN$ YOURSELF A TRACKER.BAS$ BIIAT fi

E]{TER

erc.({e Shbilized Weaher-Besistant Wood \_/ '/ ; i ,1;; .:,i.:t.il ll t I

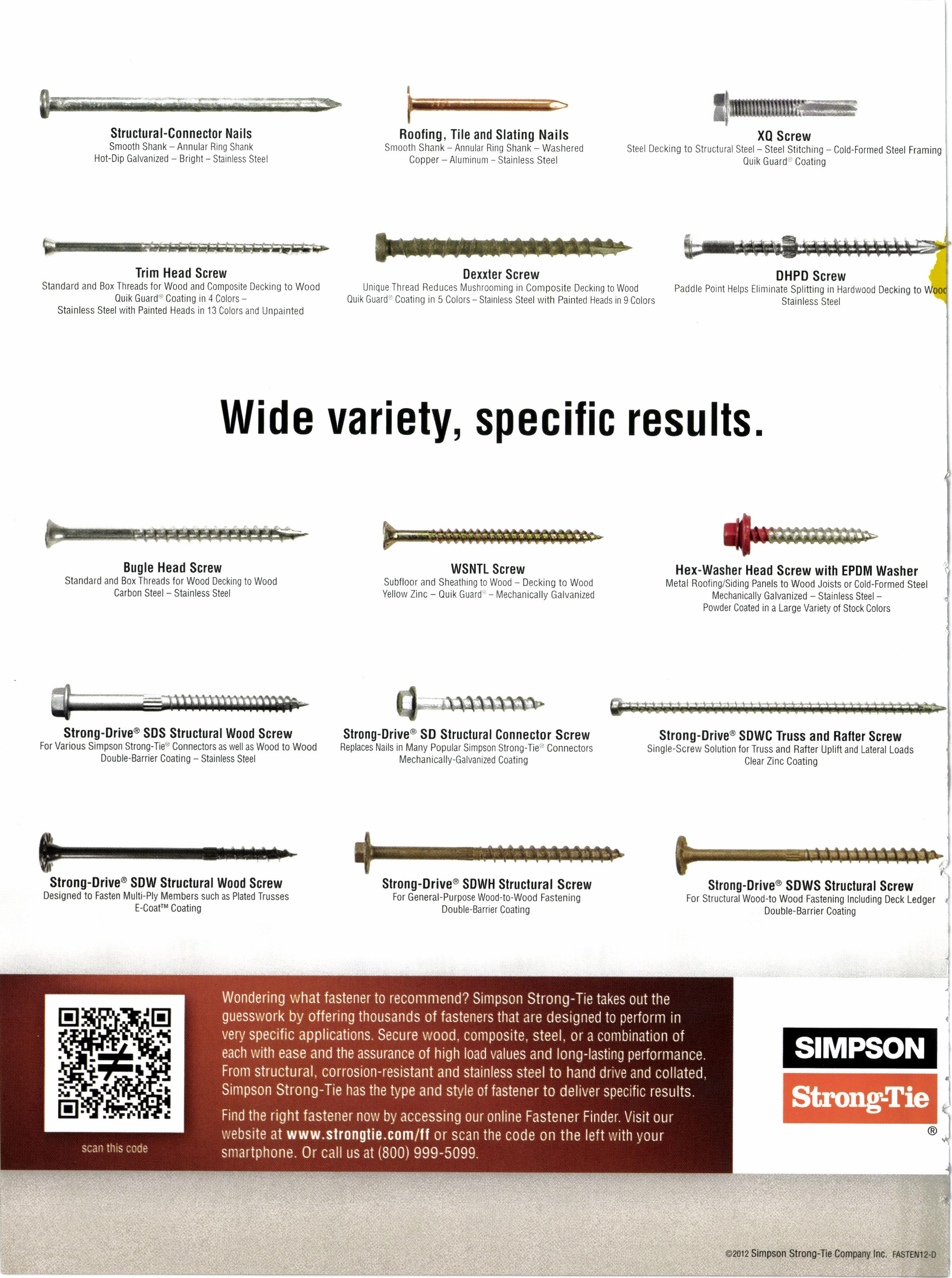

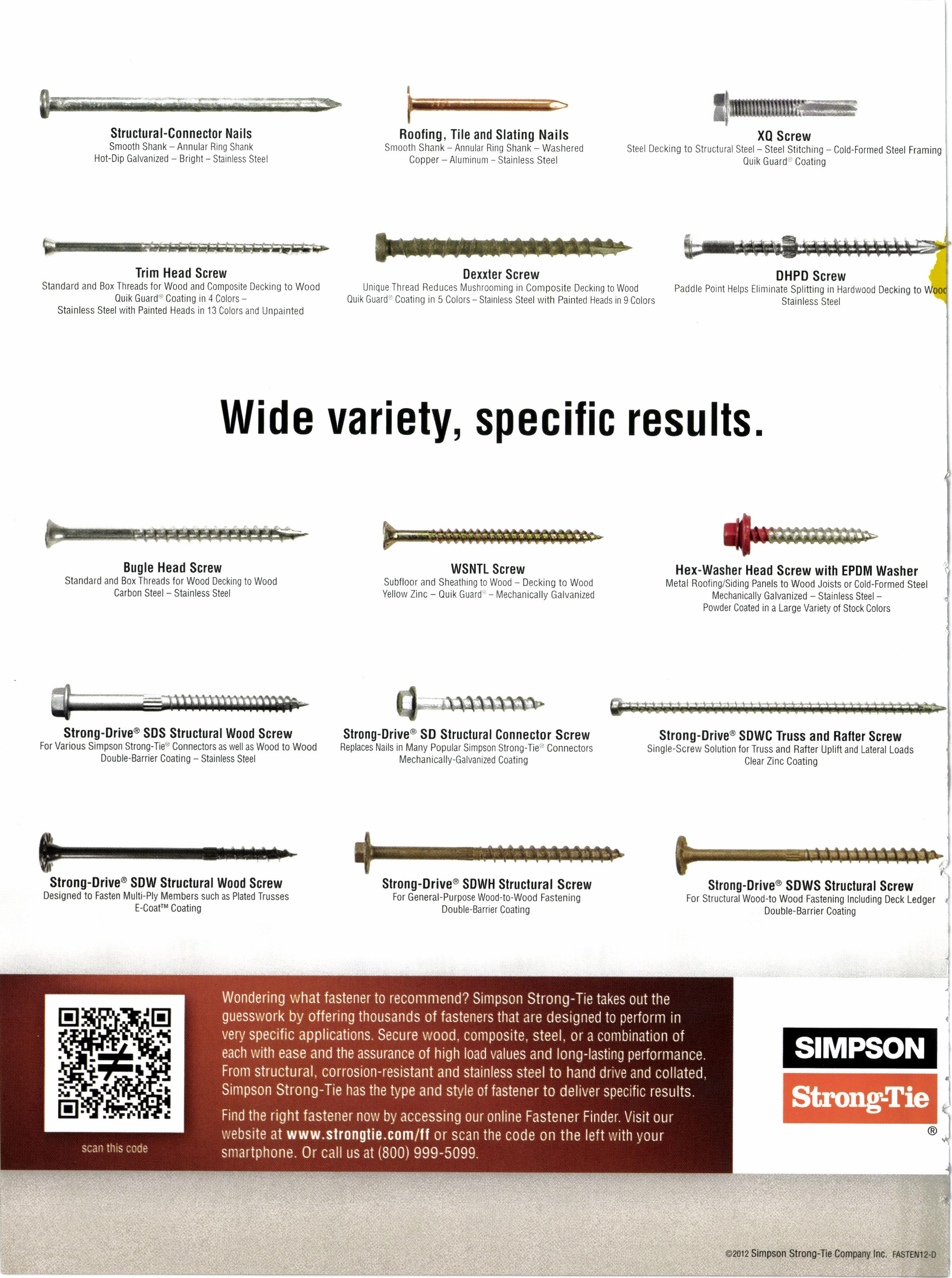

Wide uariety, specific results.

Sugle Head Suew Standard and Box Threads lor Wood Decking t0 Wood Carbon Steel - Stainless Steel

Strong-Drive@ S0S Structuml Wood Screw For Various Simpson Strong-Tie& Connectors as well as Wood to Wood Double-Barrier Coatinq - Stainles$ Sleel

Sltong-Drive@ SD $lructural Conneclor Screw

Hex-Washer Head Screur wilh EPDM Washer Metal Rooling/Siding Panels to Wood Joists or Cold-Formed Steel Mechanically Galvanized - Stainless SteelP0wder Coated in a Large Variety of Stock Colors

Sl10ng-Brive@ SDWG Truss and Rafler Screw

Singl€-Screw Solutaon lor Truss and Rafier Uplift and Lateral Loads Clear Zinc Coalino

Strong-Ddve@ SDW $truslural Wood Screw

Strong-Drive@ $OWH $lructural Screw tor General-Purpose Wood-10-Wood Fastening Dorble-Earrier Coatin g

Slrong-Drive@ SOWS $lruclural Screw For Structural Wood-to Wood Fastening Including Deck Ledger Double-Barrier Coatino

Slruclural-Conneclor

Smooth Shank - Annular Rinq Shank Hot-Dip Galvanized

Bright

Stainless Steel

l'lails

-

-

Smooth Shank

Cop!€r

Screw Unique Thread Reduces Musllrooming in Composite Decking t0 W00d Paddle Point Helps Eliminate Splitting in Hardwood Decking to ouik Guard. Coating in 5 Colors - Slainless Ste€l with Painted Heads in g Colors Stainless Steel

Screw

Screw Steel Decking t0 Struclural Steel * Steel Stitching

Quik G[ard.r

Trim Head Screw Standard and Box Threads tor Wood and C0mp0site Decking to Wood Quik Guard'. Coating in 4 ColorsStainless Steel with Painted Heads in 13 Colors and Unpainted

Roofing, Tile and Slaling Nails

- Annular Ring Shank - Washered

- Aluminum * Stainless Sleel DHPD

Dexxler

X0

- Cold-Formed Steel Framing

Coatino

Subfloor and

Yellow Zinc

WSNTL Screw

Shealhing to Wood - Decking to Wood

- 0uik Guard - l\4echanically Galvanized

Replaces

Nails in Many Popular Simps0n Strong-Tiei Connectors [rechanically-Galvanized Coating

to Faslen Multi-Ply Members

Plaled

E-Coatrr

Designed

such as

Trusses

Coatino

J I

Special Features ln

9 Pnooucr Sporucnr

Cvpnrss Hns Co,vurncrnr Coveneo

10 Frnrunr Srony

Ceonns Squ,rnr Orr, rnola Wrsr ro Ensr

1 2 Pnooucr Sporucnr

WRC Srrrles rNro lNorpeNorNcr HRlr

1 3 lxousrny Tnrxos

WHAT's AHrno ron CnreN BurrorNc

'l4 MnncrN Butorns

WHeN Rso ls GnrrN: Tesrs CoNrrnv

Rrowooo's EvrnoNueNrRr SuprnloRrry

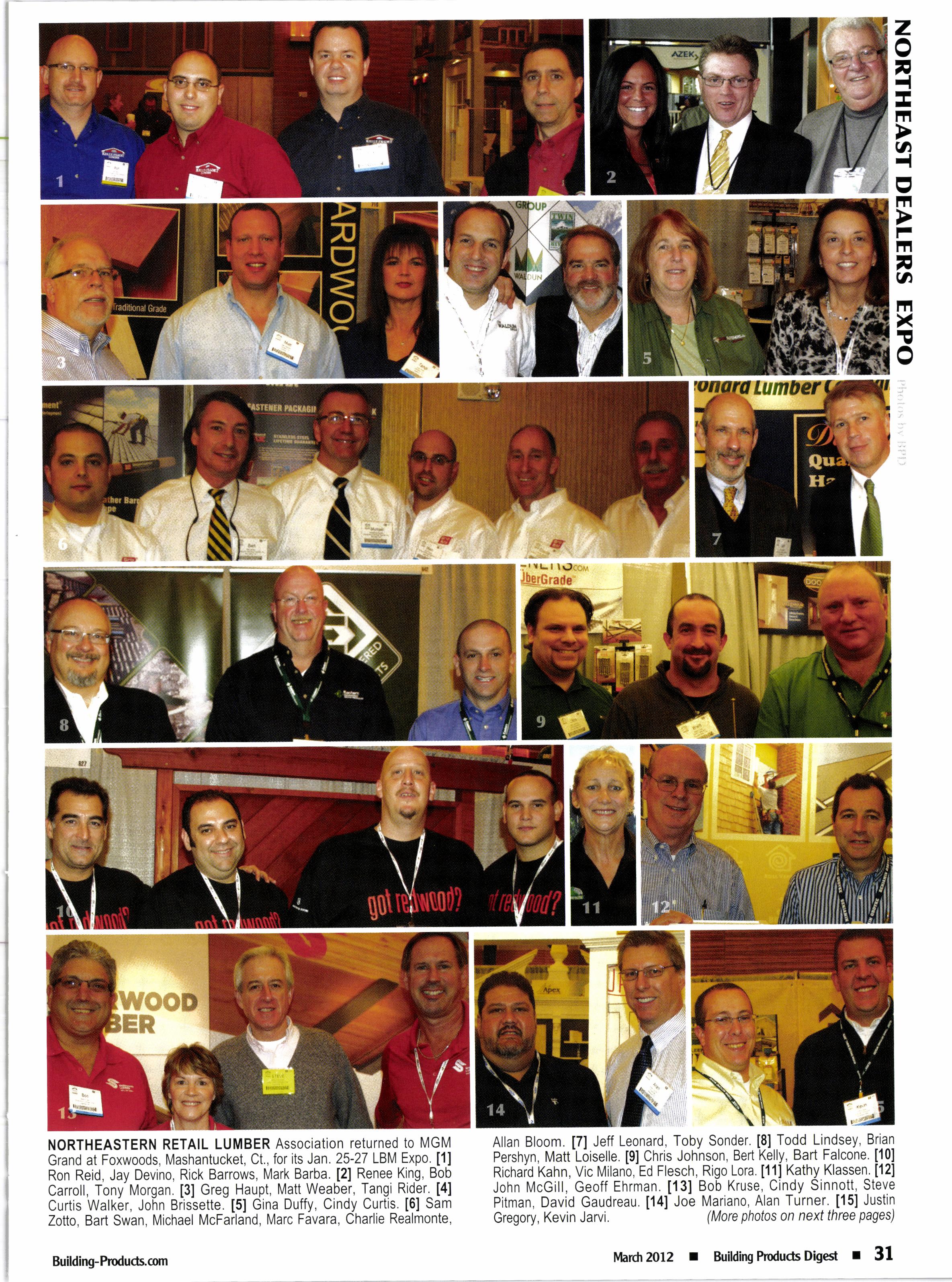

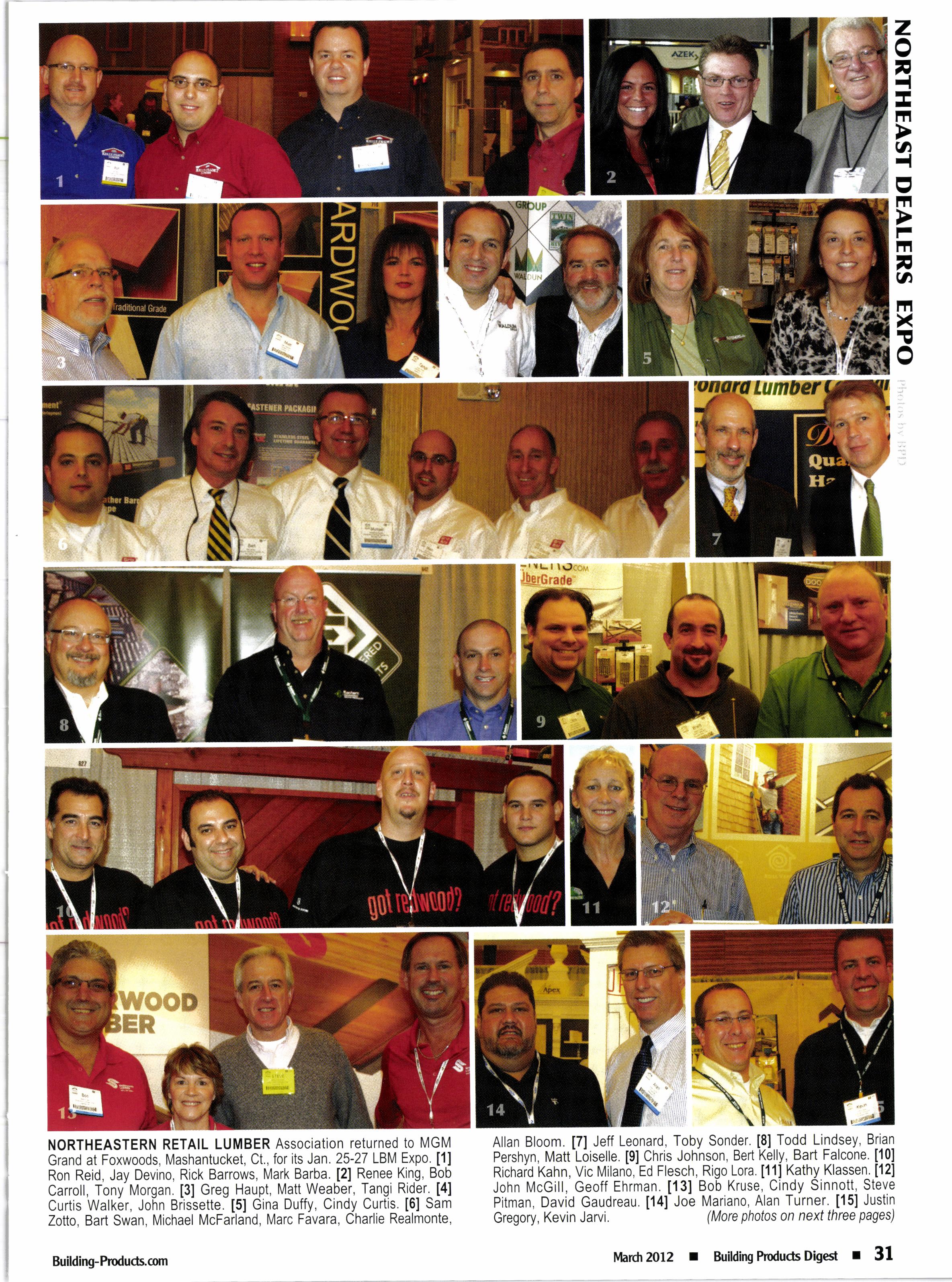

31 Pnoro Rrcnp: NRL{s LBM Expo

35 PHoro Rrcnp: SBMA rN Hrcn PorNr

38 Pnoro Rrcnp: IBS rru OnlnNoo

45 onrr Boox

46 lora Frlr

46 Aovrnrsrns lnorx

Bnrnxrruc lNnusrnv Nrws & lNousrny Pnoro DowHroRos Burror Nc-PnoDUCTS.coM (FoLLow LrNr roR PHoros)

BPD: Drcrnl Vrnsrol. THr Lnrrsr lssur CnN Now Br Vrrwro nr B ur LorNc-PnoDUCTs,coM

BPD

Every lssue 6 Tornlly RnNoom 'l 6 Co,raprnnvt INTnuGENCE 1B oLsrn oH Snlrs 20 CnrrN Rrrnrunc 22 Ftutw BusrNrss 26 Movrns & Snnxrns 28 Nrw Pnooucrs 42 Assocrnnor Uponrr 43 TnLr Brcx 43 lN Mruonrnm 44 CLnssrrrro Mlnrnpucr Mafch 2012 t Votume 31 r Number 1 BuililinA Prnducls Digest

Online

$Recialty GyRress limlers! He can cut Gy[]G$$ tim[orc un l0 f0" lirdryingauailaile. Call us wih allruul needs. Call Us Today - Chuck or Jane 334.793.1527 Custom Lumber Manufacturing Co. www.PlantationCypress.com . www.PlantationPine.com 4 r &rilding Plodu(b Digest I Madr 2012 Building-Produdscom

Comparing Waldun's cedar products to brand X is like comparing Apples to Apples.

as easy to spot from a distance.

Waldun roofs have 30-50 vear real warranties because the products created at Waldun are crealed by people who care.

Waldun is FSC and PEFC Cerltfted.

Waldun sells 100% Bureau product and has warranties unmatched by any mill in the industry At Waldun tn every bundle we guarantee 1007" coverdge. Many mills will put in less inches of wood to compensate fora low price.

Mills that run with c Bureau label are mills that run wtth nothing to hrde.

By Alan Oakes

Are we off to the races... or back to the kennels?

ala*o MoNTHS INro 2012,I've been trying to get a handle on the year ahead. As I wrote a I couple of months back, we have been hearing better news, although perhaps more regional in nature. Recent trade shows have shown a mixed picture of how everyone is doing, but overall there are good signs that this year will be better than last, especially on the remodeling side of the business.

I just returned from IBS with a mixed view. On the one hand, the show footprint appeared to be the smallest in memory. But afier a quiet first day, the second seemed like old times. As well,l thought the energy and positive news I saw and heard in the Northeast a couple of weeks back at NRLA was very encouraging, although I think everyone agreed the news had better be better with the great weather this year compared to last. And, much to my surprise, I actually got there this year, after being stranded in Chicago at the same time last year (although only my GPS had any clue as to where I actually was staying).

Many of you last year reported a sudden jump in business in March, but one that by May had petered out. For others, there was no real spring business due to the bad weather. For the decking industry in particular, that business could never really catch up. So here's hoping that the good weather continues and we all have a great spring this year.

If this feeling is for real-along with the continued stock market revival, the apparent increase in new jobs, and declines in unemployment-then perhaps we are seeing the first dawn of revival. I hope so! I have always argued you cannot have a U.S. revival without a housing revival, and we are nowhere near that yet. However, I believe we will get there in small steps. Hopefully, the job picture will continue to improve, meaning more money in pockets, more spending, and a continued improvement in sentiment, which will then feed on itself. But there is very fragile psyche with the American consumer about spending. It does not take much to send us into a tizzy. My fear is that all the good news sometimes flies in the face of what many feel is not the reality.

Today, I spoke with an industry veteran who has been looking for a job without much success. Gone are the days I could name four or five companies to call. The recession has changed many things and none more so than the ability to find a job. No longer can you expect multiple job offers, a signing bonus, and a great increase on what you earncd before.

The old ways of sprinkling your resume around no longer seem to work. Fewer jobs mean more competition. Job seekers must be pro-active like never before. The Web can notify you of every job posting that might be a fit through job boards, job search engines, and social media. According to the Bureau of Labor, in 2007 there were I .8 persons per job opening, compared to 4.2 today (at least better than 6.1 in 2009). The reality is that for every prized position, there are probably 100 or more resumes to sift through. You need to be thick-skinned, more energetic, and use great initiative to unearth opportunities.

And yet we still look the same old ways, including sending the same resume to everyone. The reality today is that you need a resume tailored to every position you apply for. Every job and every company have different needs, and with each job you need to sell your ability to fit those requirements. That's easily achieved with your computer. No longer do you have hundreds printed at a time. As in any business situation, you must differentiate yourself and avoid being dismissed when your resume goes through word checking-not only for grammar and spelling, but for identifying key words that outline your skills. Do not believe that every word you write is read. You have about 10 seconds to make an impression on the typical recruiter. And watch out for your low credit scores and drunken stupor pictures posted on Facebook. All today are part of your picture.

Lastly, your best bet for a job is using the network you have developed through your career and socially. It can be no fun to have to call peers asking for help, but these contacts can help open doors.

To that end, you are part of my network and have helped me greatly over the years. If your company has a job opening in management, purchasing, sales or marketing, I am happy to offer you a $60 credit to advertise your position in the classffied section our April issue. Fax to 949-852-0231 or email dkoenig@ building-products.com. This means any help wanted ad under 40 words is free. Again, I want to see my friends back to work!

Alan Oakes, Publisher aioakes@aol.com

BPII

Building Ploducts lligest

www. bu ld i n g-prod ucts. com

A publication of Cutler Publishing 4500 Campus Dr., Ste.480, Newport Beach, CA 92660

Publisher Alan Oakes ajoakes@aol.com

Publisher Emeritus David Cutler

Director of Editorial& Production David Koenig dkoenig@building-products.com

Editor Karen Debats kdebats@building-products.com

Contributing Editors

Carla Waldemar, James Olsen, Jay Tompt

Advertising Sales Manager Chuck Casey ccasey@building-products.com

Administration Director/Secretary Marie Oakes mfpoakes@aol.com

Circulation Manager Heather Kelly hkelly@building-products,com

How to Advertise

Chuck Casey

Phone (949) 852-1990 Fax 949-852-0231 ccasey@building-products.com

Alan Oakes www.building-products.com

Phone (949) 852-1990 Fax 949-852-0231 ajoakes@aol.com.

CLASSIFIED MARKETPLACE

David Koenig

Phone (949) 852-1990 Fax 949-852-0231 dkoenig@building-products.com

How to Subscribe

SUBSCRIPTIONS Heather Kelly

Phone (949) 852-1990 Fax 949-852-0231 hkelly@building-products.com

or send a check to 4500 Campus Dr., Ste. 480, Newport Beach, CA 92660 U.S,A.: One year (12 issues), $24 Two years, $39 Three years, $54 FOREIGN (Per year, paid in advance in US funds): Surface-Canada or Mexico, $49 Other countries, $65 Air rates also available.

SINGLE COPIES $4 + s5;Op,nn BACK TSSUES $5 + shipping

BUILDING PRODUCTS DIGEST is oublished monlhly at 4500 Campus Dr., Ste. 480, Newport Beach, Ca. 92660-1872, (949) 852-1990, Fax 949-852-0231, www.buildingproducts.com, by Cutler Publishing, Inc. (a California Corporation). lt is an independently owned publication for building products retailers and wholesale distributors in 37 states East of the Rockies. Copyright@2012 by Cutler Publishing, Inc. Cover and entire contents are fully protected and must not be reproduced in any manner without written permission. All Rights Reserved. BPD reserves the right to accept or reject any editorial or advertising matter, and assumes no liability for materials furnished to it.

TOTALLY Random

6 r Buildirng hoducb Digest I Madt 2012

&rilding-Prcdudscon

OUR PREMIUM IDAHO FOREST GOLDTM LINE is in demand the world over - including Cedar, Idaho White Pine, Ponderosa Pine and Export.

!."', iet; t*3,.\ili ! i it j; ; r

I

PALMITER GARTH

I *f',. ''uil, r .l ",.r It r,tl lt l, 1r " ['.. ,til \ | r, ]i {) L l, 208.762.6630 | idahoforestgroup.com

RIcK

WTLLTAMS

Gypress has buildings covered

f\avnNn FoR cypRESSs remains stable, even as the lumLlber industry as a whole continues to struggle. Part of this demand can be credited to the increased use of cypress siding in institutional and commercial projects.

"Building professionals are looking for resource- and energy-efficient materials," says Ernie Pyle, Ontario Hardwoods, Keysville, Va., and president-elect of the Southern Cypress Manufacturers Association. "However, they also are looking for locally sourced and competitively priced materials, and cypress addresses all their needs."

On the outskirts of Dallas, horizontal tongue-and-groove cypress was used to clad part of the 22000-sq. ft. Trinity River Audubon Center. Brown Reynolds Watford Architects' Gary DeVries said, "Cypress was selected for its beautiful appearance as well as its natural rot resistance and longevity." Because the cypress was sourced from within 500 miles, it contributed points to the project's LEED Silver certification.

"Design professionals who are looking for a natural alternative to cedar and redwood, with superior qualities at a competitive price, are turning to cypress," Pyle explains. "Cypress products add warmth and beauty to any project, and their popularity is spreading across the country.

The durability of cypress was a requirement for Jackson Hole Airport in Jackson, Wy. Situated between the Teton

mountain range to the east and the Gros Ventre range to the west, the facility required exterior siding materials that were durable enough for Wyoming's drastic winter weather-dry and often reaching minus 30o-while adding beauty and aesthetic warmth to the project.

The design team wanted to utilize wood's natural attributes on the building's exterior and interior. "We originally specified Douglas fir, but we substituted it with cypress, which is considered more rot-resistant," explains Brent Mather, design director and senior associate of Gensler's Denver office. "The extreme weather exposure of the exterior was the major driver behind the change."

The project was Mather's first experience working with cypress, but it left a positive impression. "It stacks up to other wood for value, price, and quality," he notes. "It looks great, and the owner and the design team are very pleased."

Chuck Harris, Wholesale Wood Products, Dothan, Al., says he has seen a number of inquiries for cypress come across his desk in the last 60 days. "We recently received an order for cypress to be used on a new school," Harris adds. "A large portion of the exterior is select grade cypress siding, and they are using cypress timbers as well. I met with the architects on this job to help them with the specs and learned they had two more commercial jobs they wanted to use cypress on."

Nancy Tuck, Gates Custom Milling, Gatesville, N.C., says she is supplying select grade cypress in a special profile to clad a 50000-sq. ft. facility for the University of North Carolina Coastal Studies Institute on Roanoke Island. "Cypress is capitalizing on the lack of cedar logs and lumber available in the marketplace," she says. "Cypress is becoming a much bigger piece of what we do."

- To learn more about building with cypress, visit SCMA's website at www.cypressinfo.org and download its updated brochure, " Cypre s s Siding Installation Guidelines."

PRODUCT Southern Cypress

NEW AIRPORT required exterior siding that could withstand harsh conditions in Jackson Hole, Wy.

&rildingPrcducts.orn

Photo by Mafthew Millman

CYPRESS SIDING in T&G format clad part of a new 22,000-sq. ft. nature center near Dallas, Tx.

Photo by Michael Lyon Photography

Madr 2Of2 r BuiHiry hoducbDig€d r 9

From west to east, cedars square off

f) rcnlv ARoMArrc, highly decay l\resistant. and all beauties to behold, North American cedars grow from coast to coast. But each type has its own strengths, making it best suited for certain applications and markets.

Western red cedar is the most abundant cedar available in the U.S. and Canada. Primarily grown in British Columbia, it also can be found in western Washington and Oregon.

Western red is also the clearest and most decay resistant cedar and. because it comes from the largest trees, it can yield a larger variety of dimensional lum-

ber. Its sapwood is nearly white, its heartwood fragrant reddish or pinkish brown to dull brown.

Its abundance and properties make the spccies popular across the country. "Western red cedar is king in this part of the Northeast," said Phil Payne, Vermont Wholesale Building Products, Williston, Vt. "The natural characteristics of the product make it very stable, durable and weather resistant. WRC is twice as stable as other softwood species. The natural oils are resistant to insects and decay. Best of all, it looks great. It is a great product when left natural. Today's high-tech coatings, when used properly, will provide the best looking and performing exterior wood products on the market. The good availability of such

a broad range of products makes it very easy to maintain a sellable inventory."

WRC is perfect for clear products-siding, decking, paneling, fascia, trim, shakes and shingles, and appearance grade timbers.

Due to its superior qualities and availability, western red is the only cedar sold by many companies. including Boston Cedar, Holbrook, Ma., and TMI Forest Products, Morton, Wa. "For the last six years, we have cut only coastal western red cedar," said TMI's Jeffrey Cook. "TMI has tried five alternative cedar species, but each proved to be less desirable for the finished product."

Inland red cedar is the same botanical species as western red cedar, but hails from the interior slopes ofthe Rocky Mountains in Idaho, Montana, and into eastern B.C. and Alberta. Grown in drier, higher-elevation forests, IRC trees are small and their wood lighter, more striped, and with less clarity and color variation than its coastal-grown kin.

Enyeart Cedar, Tigard, Or., supplies WRC for clears and IRC for tight-knot orders. "The (IRC) trees grow farther inland, are slower growing, and develop tighter fiber. The knots are small, tight and firm," said Enyeart's Linda Elliott. "But the primary difference is the color of the board. There is less iron in the soil where these trees are grown. As a result, the color of the board is blonder in naturemore creamycaramel with vanilla swirls."

Uses are fewer,

Cedar Comparisons

l0 r BuiHing Producb Digest I Madr 2Or2

ALTHOUGH western red is the most popular and plentiful of the cedars, other varieties offer their own strengths and applications.

including smaller dimensional lumber, siding. and split-rail fencing.

Incense cedar is native to the mountains from western Oregon to southern California and the northern Baja Peninsula of Mexico. Its saPwood is creamy white, its heartwood light brown to light reddish brown. Decay resistance and dimensional stabili' ately low.

p.. ty are high, yet ! k strength. shock resisF tance, stiffness and ":, hardness are moder-

C&D Lumber Co., Riddle, Or., manufactures incense cedar because of its versatility. "It can be used in many applications, including decking, pergolas, T&G paneling, and timbers," said Leslie Southwick. "When dried to less than 197o, it is very stable and durable. It has excellent stain-holding properties and is virtually splinter free."

Hall Forest Products, PuyalluP, Wa.. distributes C&D's kiln dried incense cedar in addition to WRC, because, according to Marty Frost, "it's a less expensive option in a very similar quality and grade. All is reversible material, graded all four sides. Kiln drying ensures all our decking is stable prior to finishing or prefinishing. Performance properties are very similar to WRC, but it but comes in a less expensive price point. And once it's got a nice oil finish on it, it's difficult to tell the difference between incense cedar and western red cedar. They do have a slightly different odor."

C&D manufactures Port Orford cedar because of its uniqueness. "No other cedar is like Port Orford cedar, and C&D Lumber is one of the few manufacturers that mills it," Southwick said. "Port Orford is the strongest of all cedars and an excellent choice for both interior and exterior use. Historically, it has been the preferred wood for fine boatbuilding because of its strength and natural oils that make it rot and decay resistant. It is ideal for manufacturing laminated beams because of its superior strength. It is also widely used for decking that turns the outdoors into a unique outdoor living area."

Alaskan yellow cedar, also known as Pacific yellow cedar and Sitka cypress, grows slowly along a coastal patch from southern Alaska to southern Oregon, limiting its availability. Its rarity is unfortunate, considering it is the hardest of all cedars and boasts easy workability and exceptional resistance to weather, decay, disease and insects.

Popular applications are boat building, shingles, sauna boards, trim, fascia and paneling. Although some wholesalers, like Van Arsdale-Harris Lumber Co., Brisbane. Ca.. stock some Alaskan yellow cedar, most handle it on a special-order basis.

tremendous amount of northern white cedar goes into siding, decking, and log home construction. It's very dry and lightweight due to its cellular structure. The lower density provides the best insulating value in walls. For homes, cedar is the Cadillac."

She cited the wood's limitations as difficulty to find long lengths, wide boards, and clarity.

Atlantic cedar has similar properties, though is less porous and is found along the coastal plain of the eastern '"' U.S. The , saPwood is nar-

wood light brown with a hint of red.

Appl ications include siding, paneling, boat planks, fencing, decking and shingles.

Southern red cedar grows along the East Coast, from northeast North Carolina to central Florida and west to southeast Texas. With a dull-red heartwood, it is lightweight, soft and weak, but highly durable and works and finishes well.

is found in a Pacific coast, to northwest

Port Orford cedar compact zone near the from southwest Oregon California. It's one of the easiest cedars to identify, due to the distinctive yellow tone of its sapwood and the hints of yellow in its browning heartwood. Decay resistance is high, texture fine and even. The wood is somewhat lightweight and shock resistant, and will shrink slightly when dried.

Eastern white cedar, also known as Northern white cedar, grow in eastern Canada and the North Central and eastern forests of the U.S. In Part because most of the tallest trees were harvested over a century ago, eastern whites are typically not as prized as the larger cedars in the West. Yet the wood is still naturally resistant to rot and insect infestation, lightweight, and easy to work. The sapwood is white, tinged with yellow. The heartwood is light brown, occasionally with a red hue.

The wood is soft and has low mechanical properties. More significantly, it reportedly has the lowest density of any commercial domestic wood, making it a natural for canoe building.

According to Colleen Goodridge, Goodridge Lumber, Albany, Vt., "A

In addition to stocking WRC siding, timbers and paneling, Wholesale Wood Products, Dothan, Al., also makes its own aromatic paneling from locally grown southern cedar, for use as closet lining. Wholesale Wood also markets cypress-a softwood that grows amid the hardwood forests of the South-as "Southern cedar."

"Cedars" are also imported from overseas, most notably Chinese cedar (a fast-growing wood popular for fencing, but structurally closer to fir) and Spanish cedar (a mahogany-like hardwood used in cigar boxes and humidors). Both species are attractive and highly aromatic, explaining why exporters are hapPy to trade on the reputation of authentic cedar.

' ''

tt"'#

,n

Mardr2012 r BuildingProducbDigest r 11 log "r1,

, ,f, a.j-

4"

Building-Produdsom

Western red ce Independence

!tf.aflVlV: Old-taper split roof is assessed by Bradco Supply's Kerry Mole-ski (/eft) and Capital Forest Products' Mark'Carroll, who'dpirarhead'ed efforts to involve the various suppliers.

f, s wonrvEN pur the finishing touches on a l4-week la.restoration of Philadelphia's Independence Hall, western red cedar is leaving its mark at the site of the signing of the Declaration of Independence.

The $4.9-million pioject included replacing damaged brick masonry; painting window frames, doors, and all exposed wood decorative features; refurbishing copper urns; installing new clock faces, bracings, and lightning protection system; applying borate fungicide treatment to interior structural elements, and replacing wood shingles and flashings.

As much as possible, new materials were selected to match the old and products were sourced locally, such as using Horsham, Pa.-based Benjamin Obdyke's Cedar Breather ventilating roof underlayment-a product not yet invented at the time of the last renovation in the 1980s.

Roofing was provided by Bradco Supply, Malvern, pa., and wood products by Capital Forest Products, Annapolis, Md. Pro-East, Essington, Pa., supplied the fastenersdomestically produced by Maze Nails, Peru,Il.

For the cedar roofing, however, Bradco and Capital had to call on British Columbia to find older-growth trees with sufficient density. "Western red cedar was chosen for its durability and beauty," explained Curtis Walker, of B.C.based Waldun Group. "The existing roof was cedar, and we had to match it with high quality cedar roofing. The old roof was still in great shape after 30 years, but because the extensive scaffolding was up, it made sense to re-roof."

He said, "Originally, the product for this U.S. landmark was to be lOOTo American made. There was an excention

made to have Waldun product installed. This specification was changed because the consistency of the Waldun product is unmatched in the industry, and the product was cut from first growth."

Walker traveled to Philadelphia to ensure Waldun would provide an exact match. "When we first got to the project, I was literally lying on the platforms 15 stories up to examine the underside of the shakes to see if they had a split back face or a resawn back face," he recalled. "We m-easured exposures and even met with a government official, who was overseeing the particulars, to see the archive room and take samples from the old roof."

Waldun supplied 2,000 sq. ft. of custom-made cedar shakes for the project. Its mill split the 18- and 24-inch shakes, while an old-world craftsman from Washington State hand-split the 36-inch by 314-inch shakes. In toral, cedar shakes were installed on four ofthe hall's nine levels.

PRODUCT Western Red Cedar Shakes & Shingles

t2 r &rildingProducbDipd r Mad20l2

BuiHing-hoducts"can

WALDUN'S Curtis Walker gets a close look inside the bell tower shorfly before new cedar shakes and shingles are installed. The first home of th6 Liberty Bell, the 14-story tower now houses the Centennial Bell.

Whatts ahead for green building

f\esrtre A sl-ow economy, green building is alive and lrfkicting. Key areas of interest include green remodeling, retrofitting, and zero-net-energy homes-which produce as much energy as they consume.

"The big home builders are starting to put on 2- or 3kilowatt systems as a standard feature, and it's just part of the price of the house. There's no add-on cost, so that's a real breakthrough," says Jerry Yudelson, whose consulting firm, Yudelson Associates, Tucson, Az., has specialized in green building and sustainability for the past 25 yeats.

"The real trick is to make the home so efficient that it can heat itself with internal loads such as lights and refrigerators and natural sunlight coming through highly efficient windows," he says. "Different kinds of coatings can make them more energy-efficient than even the best doublepaned windows, almost as energy-efficient as walls."

Although Yudelson predicts modest growth in construction this year, he believes the emphasis will be on what he calls frugal green.

"In the past, there was a feeling that you could spend money to add green features," he says. "Today, the real challenge for construction and design professionals is, 'How do I do this on the same budget?' and I think that's the core trend."

Other trends to watch include:

Green Retrofitting. More property owners will retrofit to LEED for Existing Buildings: Operation & Maintenance, which is fairly painless when a building is already Energy Star rated. Businesses want to be able to market their ecofriendliness.

Government Projects. Although funding is tight, existing buildings will need to be upgraded, projects in the pipeline will move forward, and schools-which are funded by bonds-will need to be built.

The federal Better Buildings Initiative was passed last year to accelerate private sector investment in energy efficiency and encourage commercial and industrial buildings to become 2OVo more energy efficient by 2020.

Water Conservation. Rainwater-capture systems, as well as graywater and blackwater on-site treatment capabilities, will become more pervasive-even in what Yudelson calls "water wet areas." He predicts that "instead of toilet to tap, we're going toilet to toilet."

Global Programs. There are more than 90 national Green Building Councils throughout the world, and LEED projects have been registered in 161 countries. Last year, 44Ea of total LEED registrations were outside the U.S.

Performance Disclosure. Already popular in Europe and Australia, requirements for buildings to disclose energy use are gaining traction in the U.S. Next month, Seattle, Wa., will require buildings of more than 10000 sq. ft. to disclose energy usage. California will begin requiring disclosures starting next year. Yudelson says such disclosures will have a market impact because they allow prospective tenants to compare energy costs of different buildings'

"This is going to happen everywhere, particulady in big cities, because it's the easiest move to take politically," he says. "It doesn't say you have to retrofit the building. It just says you have to disclose."

Buitding Management. Thanks to wireless sensors and controls, it's getting increasingly easier to locate and fix maintenance problems, and to do so remotely.

"You make money if you go green," Yudelson counsels. "If you don't go green, you're at a marketplace disadvantage. Doing nothing is not an option."

The Coming Year in Green

BulldingrRodudscom

Madr 2OP r Bullding hoducb D[ed I 13

By Charles fourdain, California Redwood Association

When red is green Tests confirm environmental superiority of redwood

fl nseN. cREEN. cREEN. Everywhere \Iyou look. you see the green building message. But how should "green" really be measured?

The emerging answer appears to be that building with sustainable, environmentally responsible materials is the one, true "green" way to build. A truly natural, renewable resource, redwood is a material that can actually reduce the greenhouse gases that contribute to global warming.

California Redwood Association enlisted help from the independent Consortium for Research on Renewable Industrial Materials (CORRIM) to conduct a life cycle assessment (LCA) to better understand and compare redwood decking to plastic composite decking. CORRIM is a nonprofit research consortium with members from l6 universities and research institutions such as the USDA Forest Products Laboratory. CORRIM has been involved in the field of LCA for well over a decade and is among the most respected institutions performing such work.

Life cycle assessment has emerged as the internationally recognized standard for establishing the environmental burdens associated with the manu-

facture and use of a product from cradle-to-grave. LCA is a prime decisionmaking tool for use by specifiers and consumers to compare the carbon footprints of various building materials. It is being rapidly incorporated into building standards such as LEED.

The table below shows relative values for important environmental impacts. Results of the LCA are conclusive, showing that considerable differences exist between redwood and alternative decking products such as plastics and plastic composites. In terms of global warming potential , plastic-based decking materials are

Environmental lmpact Assessment for Decking Products

contributors, while growing, harvesting and using redwood for decks do not contribute to global warming.

Regarding other important environmental impacts, plastic-based decking contributes anywhere from twice as much to 100 times as much negative effects as redwood. Redwood decks store the carbon that was originally absorbed as CO, from the atmosphere while the trees were growing. In fact, the average redwood deck may store over half a ton of carbon. Once the redwood deck has reached the end of its lifespan, it is easily recycled or reused for other purposes, or reabsorbed into the earth as nutrients for new plants. On the other extreme are plastic composites, which will stack up for decades in landfills.

Detailed data was collected from CRA member mills on such items as raw material production (harvest), manufacture (energy usage), product distribution (transportation), product installation and use (lifespan), and final product disposal at end of life (reuse vs. landfill).

According to Dean Kerstetter, v.p. of operations for Mendocino Forest Products, "The quantity and detail of information gathered by the CORRIM team was truly amazing. Rick Bergman, CORRIM team member with the USDA Forest Products Lab in Madison, Wi., visited our manufacturing facilities in Ukiah, Ca., for two days collecting detailed data on log storage and handling, type of sawmill equipment, dry kilns, boiler, planer-basically anything that consumed energy."

Water usage, packaging such as strapping and lumber wrap, and byproducts for fuel or soil amendments are also examples of the extent to which the LCA looks at all inputs

)

MARGIN Builders

Environmental lmpact Global Warming Potential Ozone Depletion Smog Contribution Acidification Water Pollution Respiratory Effects Fossil Fuel Use Plastic vs, Redwood 126 times more 100 times more 2 times more 20 times more 6 times more 25 times more 7 times more Composite vs. Redwood 90 times more 70 times more 2 times more 30 times more 12 times more 30 times more 9 times more 14 ! Building hoduds Dipst r Mardr 2012 Building-hodudsorn

and outputs of production.

Han-Sup Han, professor of forest operations & engineering at Humboldt State University, Arcata, Ca., is the CORRIM researcher who spent daYs visiting forestlands of CRA member mills throughout the redwood region. According to Professor Han, the forest resource data collection phase of LCA integrates site preparation, stand establishment, stand management, and timber harvest factors associated with forest management into a presentation of total cost, fuel consumption, and carbon footprint for various levels of management intensity.

"The redwood lumber industry has known for years that we have an outstanding environmental record and a great green message to tell consumers," said Janet Webb, president of Big Creek Lumber Co., Davenport, Ca.. and current chair of the CRA. "Operating in accordance with the strict provisions of the California Forest Practices Act places any industrial or non-industrial forest landowner or timber operation at the forefront of environmental responsibility. This new LCA reinforces our beliefs that redwood is a world class product in terms of environmental performance."

Combine redwood's world class environmental performance with its legendary beauty, stability and durability, and why would anyone choose anything other than redwood? Educate your customers about the true environmental strengths of redwood. The next time your employees or customers ask what is the greenest product for use in deck construction, tell them that red is green- redwood, that is.

- Charlie Jourdain is president oJ the California Redwood Association. Reach him at charlie@calredwood.org or (888) CAL-REDWOOD.

Redwood Decking Growing in Northeast

Redwood decking is slowlY making a comeback in the Northeast, thanks in part to efforts by producer The California Redwood Co., Eureka, Ca., and distributor Feldman Wood Products, Garden City Park, N.Y.

Last May, Feldman began suPPlYing Classic Heart redwood to LBM dealers in New York, New Jersey, and Connecticut.

"ln about 1989. 1990, with the advent of the spotted owl, dealers in the Northeast were unable to get the quality grades of redwood they expected," said Richard Kahn, sales manager for Feldman. "We are reentering the market with a different kind of product-construction heart grade for deck-

ing and backyard structures."

Feldman's challenge has been re-educating dealers about the species and, Kahn said, "to convince people it's not going to disappear like it did 20 years ago."

The distributor enjoyed a successful first season selling redwood, signing 13 dealers to stock inventory on the ground.

Feldman carries 5/4 and 2xO easededge Classic Heart redwood decking up to 20' long, plus 2x2 cuts for balusters and 4x4 cuts for oosts. The hand-selected, heartwood-only boards feature a deep red, uniform appearance. The heartwood contains properties that resist insects and decay.

Mary's Rlver Western ReCl Cedar Decklng is all-naturalwood with a smooth texture and soft tone that makes it a pleasure and comfort to touch. Nol only is it naturally beautiful, but it feels as good as it looks. Red Cedar's natural insulative characteristics make it cooler to the touch on a hot day and warmer on a cool day. Afler all, nobody ever said, "ll's hot enough out there to fry an egg on a cedar deck."

Mary's River manufactures a full line of Western Red Cedar, including siding' decking, railing, boards, trim, fascia and paneling. Our Red Cedar is preci' sion milled and quality controlled tor unmatched commitment to customer satisfaction. Mary's River Red Cedar is manufactured from abundant' sustainable, fast growing, second-growth resources, making it the green choice for decking.

Call us at t-800-523-2052 lor outstanding service and quality in Western Red Cedar oroducts.

4515 NE Elliott Circle Corvallis, OR 97330

Toll Free 800-523-2052 Fax541-752-5143 www.marysrvr.com

t a t I

It.

frRlr \:"TP-t/

Lumber

Mary's River

ComPanY

It. It. Proudly Made In Tbe U.S.A. &rildiryPrcdudscom Mardr 2012 r Building Pnducb Digest r 15

By Carla Waldemar

From first phone to first phone app

cultural base, so the company grew by supplying pole barns, hog houses, even building trusses. Today, Woodford serves custom builders, remodelers and commercial accounts. Thanks to this commitment to gazing into the future, the operation has newly remodeled and expanded its retail space and showroom to encourage homeowners to stop in, too. In fact, despite the economic turmoil that, yes, has hit Clear Lake's builders as well, Jan has just hired another staffer-"an opportunity too good to pass up"another woman with strong design background, bringing Woodford's total personnel to seven.

"They're experienced, they know what they're talking about, and"-here's the clincher-"they're customerfocused. In this work environment, they see they're appreciated and feel they make a difference," Jan emphasizes. "And that carries over to the satisfaction gained from helping customers on what will probably be the most important undertaking of their lives."

Thus, Woodford offers clinics for do-it-yourselfers in skills such as painting, and steers key vendors to its con-

tTt"t Crvrl Wen was recent history when Woodford

I Lumber & Home was founded in Clear Lake, Ia., back in 1869. Five generations later, it's still flourishing in this bump in the road (pop. 8,300) off Interstare 35.

Looking back upon company achievements is intriguing, and good for bragging rights. Two years after Alexander Graham Bell secured his patent, Woodford's owner was pivotal in bringing telephones to town, along with that other radical, new amenity, electricity. After making do with horse-and-buggy deliveries, he was among the first to take advantage of the new railroad connection, which also brought celebrity orators like William Jennings Bryant, Booker T. Washington, evangelist Billy Sunday, and prohibitionist Canie Nation to Clear Lake's buzzing summertime Chautauqua circuit. But while company history fills fascinating scrapbooks, it doesn't do much for survival in 2012.

"Evolve?" fifth-generation president Jan Lovell reacts to a reporter's question. "You have to! Every business has to reinvent itself to meet changing customer needs. That's how we've survivedl"

In the heyday of the Seventies, this was a strong agri-

COMPETITIVE In

STAND.UP GUY: President Jan Lovell looks for inspiration from the company's heritage, starting with her greafgrandfather Charles "C.R." woobfoid.

16 r BuildingProdudsDigest r Mardt20t2

&ildiryrhodudscom

recent "reinvention" of

INSTALLING NEW signage was part of the Woodford Lumber & Home, Clear Lake, la.

tractor customers to impart savvy, too. But it gets even more personal: "We believe in relationships," insists the president. "To strengthen those relationships with our contractors, we sit down with them and beg for feedback: What are we doing well? What can we do better? We learned, for instance, about their delivery needs. We used to promise 'As soon as we can,' but we've learned from them that they need us to be much more specific."

Woodford recently added a drive-through for their convenience. And inside the store, there's a special contractor corner with coffee and peanuts and conversation' "Plus, we recently upgraded the power tools selection and joined a national buying co-op. You've got to keep moving forward," she reiterates.

pany undertakes to educate its customers on the importance of environmental concerns, and the mission is becoming easier every year: "People are understanding the low-VOC part, so the interest has really grown in the past couple of years. It used to take a lot more effort to promote. "

(Jan continues to walk the talk; she's designated the store as a drop-off point for Habitat's ReStore recycling project in Mason City, eight miles away and eight miles too far for many a homeowner's minivan to carry.

She's served as chair of Clear Lake's Earth Day for the past 15 years, following in the footsteps of her grandparents, environmental activists who donated the island in Clear Lake to the state. The company has also saved a mile-long natural stretch of the lake's heavily-developed shoreline by gaining a conservation easement to allow folks to enjoy its natural beauty. "People need a balance in their lives," Jan advocates.

From low-impact to high tech: Looking at the future once again, Woodford has become adept at electronic marketing. It boasts a Facebook page and interactive website that includes a homey family history "written" by C.R. Woodford, who arrived here at age 18 in 1879 to join his uncle's business. (Jan admits that "in my first life" she worked as a newspaper reporter and editor before returning to Clear Lake 25 years ago, so it's possible that she's the one, um, channeling C.R.)

The website also features a photo gallery ofprojects and salvos by their uber-satisfied owners. "Working with Woodford was an awesome experience! They went above and beyond the line of duty when it came to finding unique products and solutions for our new home," attest Scott and Julie. "It was a wonderful experience working with the Woodford staff. They came to our home and helped us design our new deck. We couldn't be happier!" glow Tom and Janice. Architect Randall Cram adds a professional appraisal: "Woodford has always provided me with the expertise, knowledge and quick service to make informed decisions as a designer. The quality of their materials... is unsurpassed."

"We're also helping these builders become more proactive in using technology to help themselves; they can email us, and we have a Woodford app that makes it easy to contact us 24 hours a day." To woo commercial accounts, Jan sends out letters of introduction, then sets up personal meetings, involving vendors in the conversation who can ease and speed their business, too.

She keeps tapped into the pipeline on product trends to assure that Woodford's lines keep on evolving, too. And when that meant adding more retail space, fine-even at the expense of pride and history. "We removed my father's office," she laughs-"a big step, both literal and figurative, because times are changing and we needed room to put in a signature paint store for Benjamin Moore-which is helping us attract new customers."

Another reason to partner with Ben Moore, Jan feels, is because paint represents a project every homeowner can afford. "Remodeling is where the activity is, these days. Even when money is tight, everybody still wants to spruce up."

Because these "incredible pioneers," as she deems the outfit, offer no- and low-VOC paints is another reason they're a good fit with Woodford, where going green is more than a marketing plan, it's a moral stance. The com-

Attracting new business, of course, is crucial to any company, especially one that boasts 143 years in operation' Jan uses direct mail to her pro list. Mass mailing to homeowners, however, has run its course. "Now, we're more targeted-more bang for the buck," she explains. We also participate in the annual home show in Mason City as a way to attract clients. And we're training our staff to pay more attention to cross-selling"-maybe the brush and drop cloth to go with the Benjamin Moore paints. Hey, even new kitchen cabinets or replacement windows. Or, how about a steel roof?

Looking into the future of the company, "we're very positive," Jan declares. "We've remodeled, we've added staff. There's a growing population here. We just need to keeP listening to people's needs, to do things better. "

Finally, I just had to ask: generation six? "My son is 19," she says. "But we don't want to push..."

Carla Waldemar cwaldemar@comcast.net

WOODFORD LUMBER employees Meni Matteson and Mike Ritter at the store's grand reopening.

BniHingiProductrom

Madf mr2 I Buldlry Produds Dlgest t 17

What do I do?

fl u" WALKS lNro the doctor's \foffice. "Doc. I broke my arm in five places, what do I do?" The doctor thinks for a moment and says, "Stay out of those places."

Many salespeople come to me asking for help on problems that are at best mitigate-able but almost never winnable. Let's take steps before these situations happen.

" I talked to my customer last Friday. He assured me he would give me the order on Monday. Now I can't get him on the phone." What do I do?

Sell the whole account. Many sellers save all their charm and attention for the buyer. This is insincere, and the other people at the account know it. Make a conscious

effort to get to know everyone at the account. In this way, when we need allies-and we will-we will have them. If we make the minimum of effort with the receptionists, they will bend over backwards to help us. They live to help those who recognize their importance (and respect their power).

Create urgency in your closes. To overcome customer procrastination, use urgency, "John, I would love to wait until Monday, but these great salespeople I work with will have this sold by then. Let's just do it now."

"My biggest account continually grinds me down to the last penny. He holds the price of our cheapest competitors over our head at negotiation time and we always cave." What do I do?

Be precise on value. The earlier in the relationship, the better! If you charge more money than your competition, it may be because: You always ship on time. Instead of telling the customer you always ship on time, ask your customer if there is a penalty for late shipment. If they ask why, tell them because you make on-time delivery seem easy, but in fact it costs you money to ship on time every time, but you appreciate the erstwhile unknown ability to ship late without consequence. This forces the customer to decide. Of course they want your level of service, quality, expertise and charm at the same price as the cheap guy-but it is our responsibility to sell the difference.

. Your product is always right the first time. Ask your customer if there is a penalty for poor product. "But they always make it right" will be a common response. yes, but

what is the price of the hassle and loss of momenlum? In any case. is there a penalty? If your product is always right the first time, force customers to answer these questions. Make sure you are not in denial. Just because you say you are better doesn't make it so. The same goes for quality, integrity and the rest. Make sure you are selling a value that truly differentiates you and, more importantly, that your customers will pay for.

o Prospect. If we do not prospect, our current accounts own us-and they know it. If we find ourselves in this situation, it will be difficult to win negotiations. If we always upgrade our account base-the lifetime activity of the seller who wins negotiations-we will get better prices.

"She only wants to communicate by email." What do I do?

Speak to your customers by email as you would in a conversation.

Always ask questions that demand-or ask for, depending on your and your customer's style-a response. IJse teasers. Give them a list of five products, listing the price of four. For the product they need/want the most put "Too good to put on the Internet. Call for secret price."

. Leave great phone messages. Practice and polish. Our phone message in the age of email and texting is vital. Keep it under l0 seconds. Be bold (not loud or bombastic) and confident in your value. "Hey, Pete, this is Bob. I've got some great de.als on the ,#,, items we have been emailing about. Call me. I only have five left."

. Persistent and consistent. Keep calling. There are those who only communicate by email, but to really get close to an account, we will have to talk to them. Be consistent and persistent-they will pick up.

James Olsen Reality Sales Training (503) s44-3572

By |ames Olsen

lE r Buildiqt Producb D(pst I Madr 2Ol2

.6 q,

Building-Productrorn

james @ real itysalestraining.com

Green spring training

ll fiencn rs My FAVoRrrp month. IVIWhy? Spring is in rhe air, ar least in some parts of the country. And baseball is just around the corner. And now, some market research has come out demonstrating that green building is poised to lead this industry out of the doldrums.

Things aren't back to normal, or back to a new and different normal, not just yet. But if you've been working to bring your retail or wholesale operation into the green big leagues, this could be your breakout season.

The study from McGraw Hill reports some interesting numbers that should inspire optimism. The share of new single-family homes built to a LEED or equivalent standard reached lTVo and is expected to become about a third of the market in five years. Builders report that marketing green homes is easier and the majority of customers are willing to pay a little more. Among builders who are doing some green projects,3g%o report that green work is having a positive impact on their bottom line, compared to 90Eo of builders who are fully dedicared to green. There were similar results for green remodelers.

I want to focus on one takeaway from this. The reason dedicated green builders and green remodelers report better results-and are looking forward to better prospects, too, I might add-is because they are focused. They have the knowledge and skills, and therefore the credibility. They know what they're doing and they believe in it. These are the companies driving green forward and these are the companies getting the bigger share of the projects. If you're looking to grow your green business, these are the pros you want on your team.

Given the strength of this trend, making green building an increasing focus of your own business is an obvious forward thinking strategy. Equally important is building strong relationships with the leading green builders and remodelers in your market area. To build productive relationships, these four key points are worth repeating:

First, be prepared to walk your talk. No amount of schmoozing will win customer loyalty in this arena without expertise and knowledge to back it up. Don't rely on manu-

facturers and product knowledge to see you through. Go the extra mile and develop internal expertise in LEED or other residential ereen building programs.

Second, go to them. Don't expect them to come to you. Visit them at their office, their job site, green building association meeting, trade shows and conferences. Most regions have a USGBC chapter or equivalent-join it.

Third, bring value to the relationship, right away. If you can help them win a new project. introduce them to a talented new sub, point them to an innovative new solution, they will come to see you as vital part of their business ecosystem. When this happens, they will bring start bringing value to you.

Fourth, dig deeper and find experts: builders, remodelers, retrofitters with specialisations that in-store events, and develop referral programs. At the end of the dav. it's customer relationships that sustain any business, especially during lean times. This industry is adopting green building at an accelerating pace and demand is showing signs of picking up. It's the leading builders and remodelers who are winning an increasing share of the business. By getting together you can build a solid team and make this a winning year.

make sense for you and your region. Energy retrofitting, rainwater harvesting, green roofs, and solar are all hot areas-maybe they're ripe for building new relationships, too. Develop the right product categories they need, host

Jay Tompt Managing Panner William Verde & Associates (415) 321-0848

williamverde.com

GREEN Reta

By lay Tompt

20 r &rilding hoducb Digest I Madr 2Or2

fuilding-Produdscom

info@

/UIAZE NAILS r00% ilf,D[ IN T[[ www.mqzenqils.Gom 0ur 1.800.435,5949 Division of W.H. Maze ComPanY Helping to build America since 1848 Use the RIGHT nails to get the BESI performance! * PVC MOLDINGS AND TRIM * DECKING * LOG HOMES AND TIMBER FRAMES Get to mazenails.com FAST! Scan this barcode using an application on your mobile device. teIutation is on the line WiTh EUERYTHING WG MAKC! Maze Naits is America's Largest Manufacturer of Specialty Nails Ultimate corrosion resistant nails in double hot-dipped galvanized and stainless steel for the following applications' * FIBER CEMENT SIDINGS AND TRIM * ROOFING * CEDAR AND REDWOOD SIDINGS * GUTTERS AND TRIM * PRESSURE TREATED LUMBER * FENCING * POST FRAME BUILDING t{lAzE NAILS

By fames Olan Hutcheson

Dealing with a death in the fiamily business

f 've eean woRKrNG as a family-busi- lness consultant full time for more than l5 years. In 2006, three of my clients died, which is more deaths than I've experienced during my entire career. With every family I work with, I take steps to prepare their business for a death, setting up succession plans and buyout agreements. But all the planning in the world couldn't have prepared me for how to handle the aftermaths of these three deaths.

Like each family, I was put to the ultimate test following each death. My counsel and wisdom were quickly shown to either work or not work. Until you've lived through a death in a family business, you just don't know what's going to happen. And the effects on the business will vary depending on the way the family deals with the loss: Reactions can range from temporary shock to falling apart to continuing to function relatively normally.

In one scenario, two of the family's three sons had been locked in a long conflict, causing the business to suffer, and I had been hired to help resolve it. But then the son who wasn't involved in the conflict died. One of the two rival brothers tried to leverage the death to gain an advantage, by suggesting that the actions of his rival brother caused the death and refusing to join hands with his family in mourning. The elderly parents, who still served as leaders of the business, weren't prepared for this and my work salvaging the business took a major step backward.

The whole experience showed me that in a deeply conflicted family, tragedy can drive members further apart instead of bringing them closer together.

An Incomplete Bequest

In the second family, the father and founder of the business died unexpectedly. While the business was prepared for his death, with wills and other arrangements already in place, the family wasn't. And to make matters worse, the founder's spouse enforced certain terms in his wiil to lash out at the couple's son-in-law, who hadn't worked for the family business because he hadn't gotten along with the founder. But what was in the will wasn't what the founder had ultimately intended. That's because after the son-in-law and the founder had gone their separate ways businesswise, emotions cooled and their relationship had improved.

Unfortunately, the founder died without having changed

his will to reflect his change of heart. As a result, the surviving spouse took action to give the business to her children, who weren't involved in it and didn't live in the state, probably not the best outcome for the business. The experience showed me that even when all the proper succession planning steps are taken, a death can bring out the most unexpected reactions in family members. In fact, their actions can foul up what seem like welllaid plans. The hard-earned lesson is to review estate plans on at least an annual basis or upon each significant life event.

In the third family, the father had sold his family business and collected a sizable payout. This is what I think of as a natural evolution, a sunrise-sunset scenario. He had planned appropriately by transferring assets, obtaining suitable life insurance, and otherwise managing his estate to prevent estate taxes from gutting the business. Sadly, he died shortly after he had completed the sale and was unable to enjoy the fruits of his hard work.

Expecting the Unpredictable

I found myself acting almost as a grief counselor to his widow. It wasn't a role I had filled before but one I fell into because I was considered a source of stability as the family's longtime business consultant.

The reactions of the three families taught me that there's more to the game of family business consulting than I had realized, despite my years of experience I realized the job isn't just about installing the right procedures and plans. I learned that when clients are vulnerable, a good bedside manner is worth more than an business-school MBA. That was my takeaway. Perhaps it seems pretty obvious.

Family members aren't billiard balls you can spin a certain way and consistently expect a certain result. In my consulting engagements from now on, I'll continue to get the processes and policies in place to produce the result that seems appropriate. But I'll also be ready to adapt to the unpredictable needs of the family members during the unexpected tough times.

FAMILY Business

22 I Buitding Producb Diget r Madr 2Ol2

Building-hodudsorn

- James Olan Hutcheson is managing partner and founder of Dallas, Tx.-based family business specialist ReGeneration partners. Reach him at (800) 406-I I 12 or regeneration-partners.com Reprinted with pennission of ReGeneration Purtners. No portion oJ this article mat be reprodut'ed without its permtsston.

A FEW EXTRA FEET cAN MEAN so MUcH [ess. LESS rnaterial utAste. LESS labor time. LESS oaerA.II cost. With sizes in 9 ft.,10 tt. & 12 ft.,Tutfstrand@ extended-length sizes cut down on material waste and valuable labor time when compared to traditional I ft. panels. Eclipse'" Radiant Barrier 0SB panels are available up to 109 /a in. ASK FON .'t .:tl .:i .:: ..aa.. Co tt'myomatn.eom 0r scan this 0R code to leam more about all of rour s(ce$i;tal nnoO groO.ucG and dglnload literature lor your next proleet; TIAME. u 68 tlldt e ndLlt fr6l $mratli Csil" (,SCO} 4tlil3l |lr h lt l3l E III lll,-E,*59 WIOD hiOrRXS*rat$rallf" 800,299,5174 | royomartin,com

GSWP Takes Over Rocky Top

(ireat Southern Woocl Prcsen'ing. Abbevillc. Al., the narion's larscsr tfeated wood produccr, has purchascd the asscts of the Rocky Top Building Proclucts citmpanies from Thc Franklin Group. Rockv Mount. Va.

With thc acqr,r isition o1'Rockv Top's lrr'rrtirrg planls irr Roekl Mt,uni. Hagcrstown. Md.. and Fombell, Pa., (lreat Southcrn now operatcs l-5 l'acilitics, supplying 27 statcs from thc Fkrrirla Keys to Texas to Canada.

"This reprcsents the contbination ol' two lcadcrs in the builclin-l products inclustry "" saicl J irnml' Ranc. chairntan prcsiclcnt and c.e.o. of Great Southcrn. "Therc are man)' sintilaritics bctween our two companies. but our distributiou li)otprints ale adjacent althou-sh they don't ovcrlap.."

Carcl' Garst, c.e.o. of RockY Top. sititl Crerr t Sorrthcrn'. \) \tcnl\. rcsourccs and ability to source proci-

ucts on an intcrnational scale il,ill bencfit Rocky Toll's custctmcrs.

Although Grcat Southern uses Osmosc's micronized copper azolc in its Yellawood brand proclucts, Rocky Top has utilizcd Wolmanizecl prcser\.ativcs in its PmSclect. Vista Dcckins. ancl Vista Railing products. Great Southern has acquired thc three lradenrarks and. at lcast initially. "n'ill cctntinuc to ofl'er the santc products that have becn offercd in the past."

lP Closes Temple Acquisition

International Paper Co.. Memphis. Tn.. has cornplered irs g3.tJ-billion acquisition of Tcmple-lnland, Austin. Tx.. alter agrceing to sell three facilities to satisty antitrust concerns.

IP agrccd to scll the forntcr Terrrple containerboard ntills in Waverly. Tn.. ancl Ontario. Ca.. ancl its ntill in Oxnard, Ca., or Henderson. Ky.. ctver the next four ntonths.

Short & Paulk Supply Co, Tifton. Ga., has acquired Laing Hardware, Dawson, Ga., as its fourt6 retail location.

The new location is supoosed to reopen early this month after a threeweek remodel, featuring an updated, full-line hardware center, lumbervard, and millwork showroom.

Sutherlands Lumber Co. is closing its east Columbus, 0h., store, but expects to reopen at a new location in central Ohio once a suitable site has been found.

Carter Lumber's Holmes

Lumber divrsion has acquired DSD Builders Supply Co. Canton, oh., from Stark'Tru-ss Co.

Mike Thomas is the new mgr.

Duncan Box & Lumber Co., Huntington, W.V., has been sold by retiring Jim Duncan to Norman Taylor, Mike Taylor, and Teresa Klaiber.

Scott Adams, ex-84 Lumber, is now general mgr.

Alexander Lumber Co. is closing its Gibson City, ll.. lumberyard Ints montn.

The yard was purchased from Hager Lumber in'1999.

Locust Lumber Co. is opening its third location, a 26,000-sq. ft. facitity Southern Pines, N.C. (J.D. Cuff, mgr.)

DeWitt Lumber, Btanchard, Mi., relocated its door and window showroom from Mt. Pleasant, Mi,, to a new lumber sales center in Midland, Mi.

Gurtis Lumber Bailston Spa, N.Y., applied to remodel its nearly 40year-old location in Schodack, N.Y.

Plans call for the existing steel structure to be replaced by a drive{hru lumberyard, 20,300-sq. ft. retail store, and 100-space parking lot.

American Builders Supply, Sanford, Fl., has acquired 67-year-old Clermont Builders Supply, Clermont, Fl.

As part of the deal, CBS executives David Wallace and Tad Wolfe wilt serve as v.p.s of ABS.

Fleeger's Pro Hardware, Toledo, Oh., is closing by the end of the month after 65 vears.

-

Your soune for 1ARGE TrfilBrRt SPECTAT.TY PR0DUCTI & REIIIANUFACTURING ilerllvegd l/Ve;iarl .iterl C:rJlr iuujj.rerlt !'1prz;; Duujt; iir Jp'j a a o a a 24 r Building Products Digest r Marci 2012 Building-Producb.com

r DEALER Briefs

Williams Ace Hardware opens a new store late this month in Goddard, Ks., and another next month in a former Ace storefront in Andover, Ks.

Manchester True Value Hardware, Manchester, Mi., is reopening this month, 10 months after an electrical fire destroyed its prior building.

E&H Hardware Group recently opened its 8th Ace Hardware store, in Rocky River, Oh.

Store manager Lisa Bird and nine other emplovees had been with recently shutteied Ingersoll Hardware, Rocky River and Westlake, 0h.

Handyman Ace Hardware has takenbver the former Ballweg Hardware, New Carlisle, 0h.

Phelps Do lt Best Hardware, Louisville, Ky., has added a contract post office.

Annie's Ace Hardware, Washington, D.C., opened Feb. 7. lt is owner Anne Strom's first store.

Vassar True Value Hardware, Vassar, Mi., recently added UHaul truck and trailer rentals.

Brookings Ace Hardware, Brookings, S.D., closed afterfive years.

Owner Bryan Miller continues operating Dakota Ace Hardware, Viborg, S.D.

Do-Cut True Value Hardware, which lost its Canfield, Oh., store in a Sept. 14 fire, is reopening this month in Boardman, Oh.-minus the hardware.

Since the new facility is smaller, it will concentrate on outdoor Power equipment, as does its location in Wanen,0h.

Habitat for Humanit! recently added a ReStore discount LBM outlet in Arlington, Tx.

VALU Home Centers, Buffalo, N.Y., was honored as the 2011 Outstanding Philanthropic Corporation by the regional chapter of the Association of Fundraising Professionals.

The 41-unit chain has raised more than $4 million for charitable organizations over the past 20 years.

Texas Dealer Opening DC

Cassity Jones Lumber, Longview, Tx., has purchased an existing 25-acre lumber distribution facility in Terrell, Tx., where it plans to consolidate distribution for its North Texas operations.

Located outside Dallas, the site has a 36,000-sq. ft. warehouse and office.

According to c.e.o. Jeb Jones, the chain is increasingly targeting custom home builders.

Cassity Jones operates seven yards, six floor covering operations, four equipment rental units, a commercial flooring firm, and a finance company.

MJB Priming Composite Trim

MJB Wood Group, Irving, Tx., has developed a new coating and priming process for the MoistureShield exterior trim and mouldings it distributes.

The primed composite products can be painted and will hold the paint under normal circumstances.

More FSC for RoyOMartin

RoyOMartin and its subsidiaries now offer an even wider range of Forest Stewardship Council-certified building products.

In January, RoyOMartin/Colfax Treating Co.'s treated poles and piling, made in Pineville, La., earned FSC certification.

Six months earlier, the Rainforest Alliance presented Roy O. Martin Lumber with an FSC certificate covering multi-site chain-of-custody and controlled wood. The certificate, which previously covered only RoyOMartin's OSB and plywood products,

extended coverage to lumber and timbers manufactured at its Rocky Creek Lumber Co. mill in Mexia, Al.

Hood Expands Milling

Hood Industries, Hattiesburg, Ma., leased a74,240-sq. ft. plant in Ayer, Ma., for expansion of its custom milling operations.

The new nine-acre site with double rail spur joins Hood's two PlYwood plants, three lumber mills, and 18 specialty wood product DCs in 13 states.

New Cabinet Maker Formed

Private equity investment firm and US LBM Holdings founder Building Industry Partners, Fort Worth, Tx., has partnered with kitchen & bath cabinet industry veterans Terry Dickey and Michael Arnaud to form United Cabinet Holdings, Greensboro, N.C.

UCH will acquire or invest in North American regional K&B manufacturers. Its first is Touchstone Fine Cabinetry, formed via the recapitalization of Geppetto Kitchens, Rutherfordton, N.C.

Dickey serves as president and c.e.o. of UCH, Arnaud as executive v.p. of sales and marketing.

Ex-Manager Sues Over Age

A former general manager has filed an age discrimination suit against Foxworth-Galbraith Lumber, Fort Worth, Tx.

Rhett King claims that at age 55 he was fired after 32 years on the job, allegedly due to the performance of the branch, but was replaced by a 38year-old with less experience.

Buildlngrhodudsom

British Columbia WESTERN RED CEDAR' D Fir, Hemlock FSC /PEFC CERTIFIED Rough, Finished & Engineered Products (jp.clcL)FoRo C;Rte,ek Lr.lrrrlleeR co. Lxo.Surrey, BC . fax 888.620.3964 t craw{ordcreek@shaw.ca 604 -53 I -7 600 . www.crawfordcreeklumber.com Mad 2012 r Buildtuu Ptoduds Dge* t 25

@akers

Ed Bouverat, commercial engineered wood products mgr., Boise Cascade, Auburn, Ga., has retired after 40 years in the industry.

Robert Carson, ex-Allied Building Stores, is now v.p.-business development for ENAP, New Windsor, N.Y., directing the regional operations for the buying group's new sales office in Monroe. La.

LeRoy "Jack" Skriden has retired after 54 years with Metropolitan Lumber, Warrenville, Il.

Ted Fitch, ex-Secor Lumber, has joined the outside sales team at North Main Lumber, covering the Savannah, N.Y., area.

Chuck Mooney has rejoined Henry Poor Lumber Co., Lafayette, In., in building materials and fireplace sale. Eric Miller is new to building material and roofing sales.

Brian Anderson, ex-Midwest Hardwood, is now wood products sourcing mgr. for Olam International. He is based in Park Falls. Wi.

Cory Rougeaux, ex-84 Lumber, is a new contractor sales rep at CBS Builders Supply, Clermont, Fl.

Major Allred, ex-American Lumber, is now SPF dept. mgr. at Birmingham International Forest Products, Birmingham, Al.

Ben Guzzone joined the sales team at Dyke Industries, Jacksonville, Fl.

Jeremy Stout, ex-US Lumber, is now Delta Gulf Region sales mgr. for Bluelinx Corp., Mobile, Al., overseeing logistics centers in New Orleans, La.; Pensacola, Fl., and Jackson, Ms. Michael Miller, exONeTree Distribution, has joined Bluelinx's sales team in Bellingham, Ma.

Randy Binkley, ex-Diamond Hill Plywood, has rejoined ProBuild, Charlotte, N.C., as an engineered wood designer. Bud Johnson, exLiverpool Lumber. is new to outside sales in Liverpool, N.Y.

Ken Butler, ex-Bloch Lumber, now focuses on industrial and truss accounts at Sitka Forest Products USA, Chicago, Il. Gregg Riley, exBloch Lumber, was named general mgr. of U.S. operations.

Kevin Jimmar, ex-Norandex, is now sales mgr. for Siding Supply, Macon, Ga.

Mark Sanacore, ex-Bluelinx, is a new engineered lumber trader-sales mgr. for Georgia-Pacific, Atlanta, Ga.

Len Barker, ex-UCM Timber. has joined Elof Hansson Timber, Suwanee, Ga.

Cheryl Seitz, ex-Old Fort Building Supply, has joined the sales team at Mid-City Supply Co., Michigan City,In.

Peter Kotiadis, ex-Tech-Wood North America, has joined Fiberon, New London, N.C., as director of product development. Also new are Anne-Marie Davis, v.p./senior controller; Rob Long, ex-Lowe's, director of channel marketing; Mike Coombs, e-media mgr.; James Gunning, territory sales mgr.; Tim Thornton, product specialist for Maine, New Hampshire, and Vermont; Chris Sanders, exAssociated Materials, product specialist for Illinois, nofthern Indiana, and southeast Wisconsint Nate Courtney, ex-Moore's, product specialist for northern Kentucky, Ohio, and southern Indiana, and Brad Hurst, ex-Wolp, product specialist for Georgia.

Addie Atkins, ex-Mid-State Lumber, is now territory sales mgr. for TruExterior Trim at Boral. Boston. Ma.

Glen Akins was promoted to president of Harper Chambers Lumber Co., Tuscaloosa, Al. Ben Uzzell is a new structural engineer.

Dave Walsh, Calvert Manufacturing, Longwood, Fl., is retiring after 43 years in the plywood business.

David Johnson has been promoted to director-national accounts for ABC Supply, Beloit, Wi.

Michael Clark has been promoted to v.p. of information technology for Andersen Corp., Bayport, Mn.

Sam Huff has been promoted to territory sales & business development mgr. for western Pennsylvania at Do it Best Corp., Fort Wayne, In.

Richard Dreiling, c.e.o., Dollar General, was elected to the board of Lowe's Cos., Mooresville, N.C.

Shawn Baumbaugh, ex-Headwaters Stone, is now regional sales mgr. for Great Lakes and eastern Canada at ProVia, Sugarcreek, Oh.

Michael Holmstrom, ex-Pella, is a new window and door specialist for Shepley Wood Products, Hyannis, Ma.

Brett Boyum has been promoted to v.p. of marketing for Marvin Windows & Doors, Warroad, Mn. He succeeds Tom Angelis, who is retiring after l5 years with the firm.

26 r Building hoducb Diged r Mad 2012 Building-Rodudscom

Ben Battle is new to ECi Software Solutions, Fort Worth, Tx., as chief technology officer.

Mary Jo Wenzel has been named v.p. of finance and chief financial officer for Eggers Industries, Two Rivers, Wi.

Douglas Morin, ex-Milgard, has been named division mgr. of ChamPion Windows, Richmond, Va.

Alexander Toeldte, chairman/c.e.o., Boise Inc., Boise, Id., was elected chairman of the American Forest & Paper Association, succeeding Jim Hannan, c.e.o./president, GeorgiaPacific, Atlanta, Ga. Nancy Clark, ex-American Chemistry Council, has joined AF&PA as director of air & cliimate programs.

Kristen Manos has been named president of Wilsonart International , Temple, Tx. She replaces Bill DiGaetano, who is retiring after 33 years with the company.

Witl Telligman has been named government & regulatory affairs mgr. for the Southeastern Lumber Manufacturers Assoc iation.

Pat Edwards, president, R.P.M. Lumber, Yulee, Fl., is running for a seat on the countY commission.

Barb E. Dahl is now modeling products at trade shows for MungusFungus Forest Products, Climax, Nv., report owners Hugh Mungus and Freddy Fungus.

Fires Plague Eastern Mills

Over a four-week span, a rash of fires struck sawmills throughout the East.

Black Creek Lumber's VolneY, N.Y., sawmill burned to the ground Feb.20.

On Feb. 11, Eagle Lumber Co., Stamford, Vt., lost its 15,000-sq. ft. processing plant and Twin Pines Lumber, East Kingsford, Mi., lost its sawmill.

Reeves & White Manufacturing, Salt Lick, Ky., saw an estimated $500,000 in equipment and $100,000 in hardwood stock go up in flames in a Feb. l3 blaze.

Linden Lumber Co., Linden, Al., expected its sawmill to be down for about two weeks, following a Feb. l0 fire that began in the hydraulic room.

Fires also inflicted significant damage to Weyerhaeuser's planer mill in Plymouth, N.C., on Feb. 14 and to American Walnut Co., St. Joseph, Mo., on Jan.24.

On Jan. 18. a sawdust fire hit J.B. Mill Lumber, Hickory Township, Pa.

Ghester Wood Products, Chester, S.C., has applied to amend its air emigsion permits to allow its plylvood plant to expand operating hours.

Boston Gedar, Mansfield, Ma., is distributing Perennial Wood decking from Eastmal, Binghampton, N.Y.

BlueLinx is now distributing Weyerhaeus€r'S engineered wood products, including Trus Joist TJI joist, TimberStrand LSL, Microllam LVL, Parallam PSL, and TJ Rimboard, throughout New England, from its DCs in Bellingham, Ma.; Portland, Me.; Burlington, Vt., and Buffalo, N.Y.

Warren Trask, Stoughton, Ma., now distributes Claymark's Solid Gold trimboards.

Jeld-Wen is shuftering its window and door manufacturing and distribution facility in North Wilkesboro, N.C.

LS Building Products' distriuution center in Morton, ll., was damaged by a Feb. 11 fire of undetermined origin.

Midwest Fastener, Kalamazoo, Mi., paid $1.1 million for a 65,000-sq. ft. facility in Gloversville, N.Y., to open its SEVCNIh DC.

Nisbet Brower, Cincinnati, has opened its first retail location-a 4,000sq. ft. LifeStyle Kitchen Designs showroom in Centerville, Oh.

Soft-Lite LLC, Streetsboro, oh., aoreed to acquire the product lines of dorell Windows & Doors, Indiana, Pa., a week after Gorell entered receivership.

Polymera has begun production at its 160,000-sq. ft. plant in Hebron, 0h., producing wood-polymer composites for use in decking, window/door frames, and outdoor furniture.

Pleasant River Lumber, Dover-Foxcroft, Me., received a SHARP safety award from the state.

PAL honored three of its founding members-Jonesville Lumber, Jonesville. Mi.: Fulton Lumber, Charlotte, Mi., and DeWitt Lumber, Blanchard, Mi.-during the co-oP's recent 75th anniversary conference.

WRCLA MEMBERS

Downie Tinrber/Selkirk Specially

Enyeart Cedar Products

Giibert Snrlth Forest Products Ltd.

l-laida Foresl Products Ltd.

ldaho Forest Group

ln te rfor

Mary's Rrver Lumber Co.

Mrd Vatley I unrber Specia ties

North Enderby Tinrber Ltd

OrePac Building Products

Power Wood Corp.

Ouadra Wood Products

Sawarne Lumber Conrpany Ltd.

Shakertown

Skana Forcst Products Ltd.

Twin Rivers Cedar

West Bay Forest Products

Western Forest Products, inc.

AFFI LIATE MANU FACTU RERS

BW Creative Wood lndustrres

Cedarshed Industrtes

Outdoor Living Today

Synergy Pacific/Ouattro Timber

&rilding.Rodudsom

Are Creoted Equol Buy your Western Red Cedar from these quality producers.

Not All Suppliers

www. reolced0r.org

Mardr 2012 r Building hoducb Digest t 27