Baunntc Pnonucrs Drcnsr Jurv 2009

Nordic Engineered was huilt iding ,the

6f i'iffiFfitBffffitnf i t's'not'&sy tdpt'Uffgryffifffitll%U ""' fiber, Nordic transforms treetips into the key component of its glued laminated product line. ervtno = LAM* is featured in Nordic Lam'" Beams, Columns, Tall Wall Studs, and our latest innovation, the Nl-90x l-Joist Series.

It means inuesting in the future

In addition to our ongoing commitment to sustainable forestry, Nordic continues to invest in advanced manufacturing processes to keep on the cutting edge of technology and product development.

being green

:'=:,,:':. ..:=.,.,t,-. ,f...,t ii!' ' .;'

ENVI

i,= t Industry .:rtu Z|; vto N|IIltI|IC ENGINEERED WOOD fili,,'Jff1il:cHN*Arsrnvr€!' SustALnAbV r 5r4'633'e66r F 514'633'083' w00d s oLv+twvl info@nordicewp.com WOAU ..>Ptt4{ l I AM] \Mww.nordicewp.com

It means understanding that sustainability is more than just a goal

,,.it's a journey

l{,&lX$} *r}d \\

{.}uelttv Yau

td{{;H't. tx{ Can fJuilrl 0n"

i:x1 111i-r;il llar tjll vrars, thc b*sl aruhiterls. huilder.q. ronillltlt:, ;rlii rct;lileri irave rieoended on ReiC & \Al'rrgh1 In d*liverthtr higlt qlrality brik-iinq naterials lh*y want, en{.1 the superior custnmer se rvil* llr*y llcsei"vc Ard rrlw ,#* fr: lalsinq rur rL;$tor'ner s*rvite In nel'r heiilntr.

The new reldwright"*$rn allow$ us tn serve you sven better,

tn ; i *;e 'il iaunch cuf nelr! r,vebsite at wlvw.r*idwriqht.ronr ivhete yf Lr liln.

u V!*w rur rlnpiete pri:iiLrct lrne

n ilsrlrest a qunter sn iin*. any iime , any day.

, kke ucirraiitaqc of *ur 0nlinc Specialn"

* i:rsr: ln-i!ne srfilvare f*r de ck burlrlrnc.

* Antl xti-rie ,,,

filT***c {:}ut www"r*icNwrig}tt"com bsfore &ugust SS, lnne* yGLi esuld ';'r::;l' {.' i ! }iit{ ! :',i,1' Ii ,': I ,'

ilril:ril {r: {.&! d i\

i,, The D"ocI f! So !i tns Con]frdfy

Wolhroys, cro$oyer & plotfomr: Preserved wood plereilet noturc

The susloinobility of the treoled wood induslry

Prospects bright for mointoining the preserving business-ond its products-well into the future.

Downlime ir the dght time lo upgrude youl worchouse or lumberyord

APA Speciol Seclion: Englneered wood & strucfurol ponel updofe

Iwelve-poge report covers the lotest morket forecost, new stondords, soles opporiunities.

long-spon lrusses lemoin ocllve morket lor lominolor ond deolen

(Sister publication Building Products Digest

PUBIISHER Alan Oakes (aioakes@aol.com)

PUBLISHER EMERITUS David Cutler

EDIT0R David Koenig (dkoenig@building-products.com)

ASS0CIATE EDIT0R Karen Debats (kdebats@building-products.com)

C()NTRIBUTIIIG ED|TOAS Carla Waldemar, James 0lsen

ADVERTISING SALES MA}'IAGER Chuck Casey (ccasey@building-prod ucts.com)

ADMINISTRATION DIRECTOR/ SECRETARY Marie 0akes (mlpoakes@aol.com)

CIRCULATI0N Heather Kelly (hkelly@building-prod ucts.com)

How to Advertise

ConlaGl our advertising oflices lor rates: S0UIH, MIDWESI & WEST: Chuck Casey, 4500 Campus Dr. #480, Newpofi Beach, Ca. 92660. Phone (949) 852-1990 Fax 949-8520231 Emailccasey@building-products.com

I{0RTHEAST: Paul Mummolo, 404 Princeton Ave., Brick, N.J.08724. Phone (732) 899-8102 Fax732-899-27 58 mummoloo@comcast.net

lllTERl{ET ADS: Alan Oakes, www.buildingproducts.com. Phone (949) 852-1990 Fax 949-852-0231 Email ajoakes@aol.com.

How to Subscribe

Call Heather at (949) 852-1990 or send a check for the following amount to Building Products Digest,4500 Campus Drive, Suite 480, Newport Beach, Ca. 92660-1872: U.S.A.: One yeat (12 issues), $24

Two years, 939

Three years, $54

FORE|GI{ (Per year paid in advance in Us funds):

Surface-Canada or Mexico. $49

Other countries, $65 Air rates also available.

Single copies, $4 + shipping

Back issues lwhen available), $5 + shipping WWW. BUILDII{G.PRODUCTS. COM

About the Cover

BUILDING PR0DUCTS I)IGEST is published monthly at 4500 Campus Dr., Ste. 480, Newport Beach, Ca. 52660-1872, (949) 852-1990, Fax 949-852-0231, www.building-products.com, by Cutler Publishing, Inc. (a California Corporation). lt is an independently owned publication for building products retailers and wholesale distributors in 37 states East of the Rockies.

Copyright@2009 by Cutler Publishing, Inc. Cover and entire contents are fully protected and must not be reproduced in any manner without written permission. All Rights Reserved. Building Products Digest reserves the right to accept 0r reject any editorial or advertising matler, and assumes no liabilitv for materials furnished to it.

The front cover is a paid advertisement, this month sponsored by Biewer Lumber.

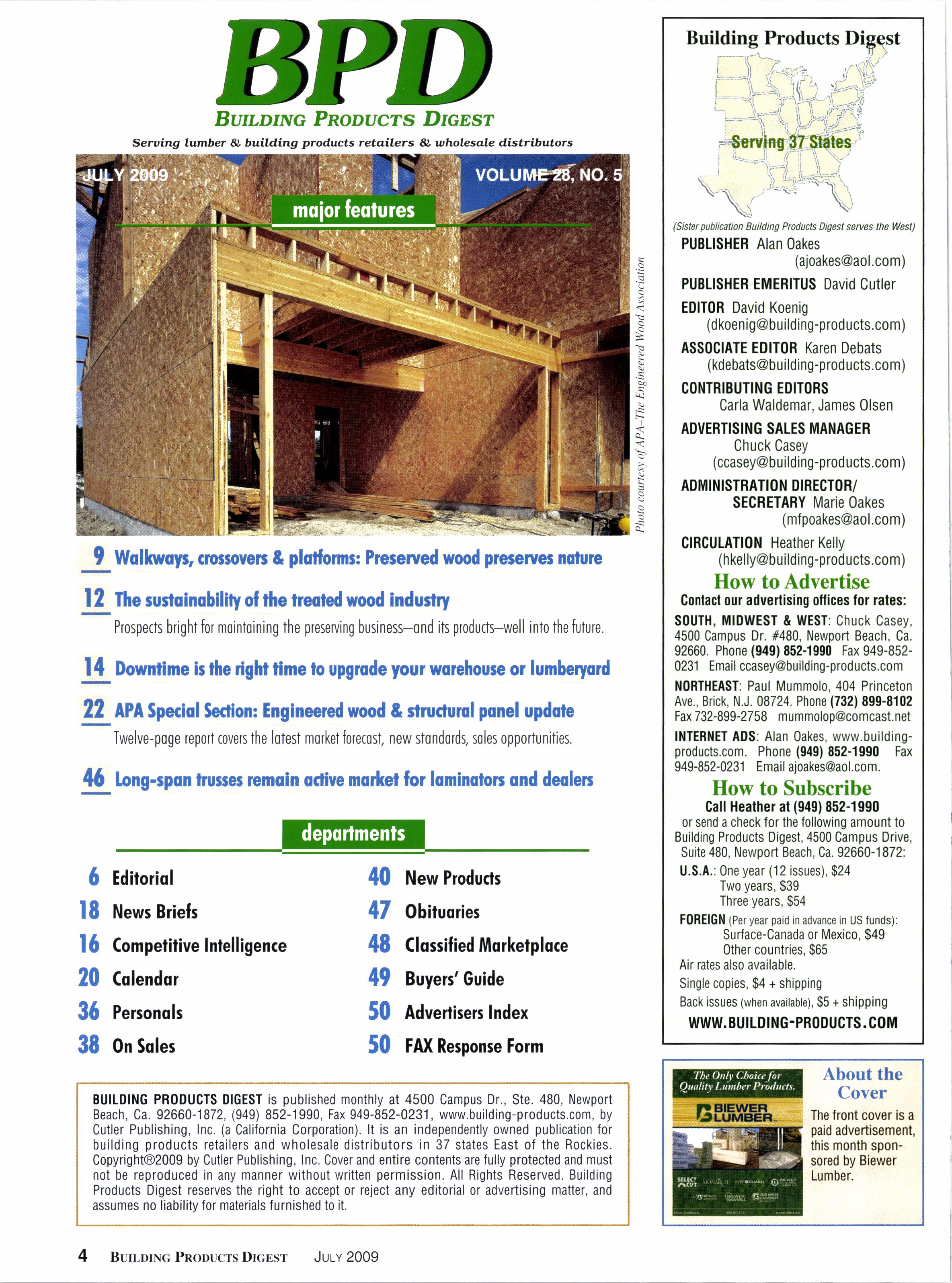

Butt otr,te Pnooucrs Drcpsr s o = \ a I l2 t4 22 45 40 New Products 47 0bituories 48 ClossifiedMorketploce 49 Buyers'Guide 50 Adverlisers Index 50 FAX Response Form

BPD

y''-..v'-u.. :). 1(i'i Building Products

Seruing lumber St,building products retailers &, utholesole distributors

serues the West)

\

6 Edirotol 18 News

Competitive

20 cobndor 35

38 on soles

Briefs l6

Intelligence

Personols

4 Burlrrnc Pnooucrs Drcpsr Jur-v 2009

...you say "LifeTime Lumber"' (omposite deck and fence products come and go. This one is different. The new line of Litellme Lumber'carries an ASTM E 84 Class A frre rating. Like all of our products, it resists mold, mildew and stains. lt's made of 6570 recycled material bound with a proprietary urethane, making it gentle on the environment and a contribution toward LEED credits. LifeTime Lumber handles like wood, features realistic wood grain, and comes in frve popular colon for decking and LifeTime Fencing SystemsP (heck out new LifeTime Lumbel the deck and fence material engineered to perform, and made to last. Exceptronal performance made to last 1-877-2a5-4338 www.LTlumber.com San Diego, [alifornia

Managing through the crisis

Well, let's assume you have managed through the downturn so far. If you have, congratulations-many have not. Great job! So far, so good! I know fbr myself, with about 40 years of business experience,35 of which have been in cxecutive positions, I have never experienced or seen what we have gone through the past year or so-and hopefully, never will again. I know many in the industry would say the same.

The problem with this type of environment is that it can encourage crazy business decisions. Panic sets in and you start to do business in a way that cannot make you successful short or long term. Giving away the shop now is something you get locked into even when the market turns. So I have learned over a long period that stupid short-term decisions have consequences far beyond what you do today.

That being said, we here at BPD starl to sense a small industry heartbeat. The question is if we are at bottom and if there is a small up-tick (which in my opinion is all it will be for a while), then how do we manage going forward?

We heard all last year about change from our political friends and during the silly season, the term "flip-flopper" was constantly being thrown about. But I am of the opinion that our business models have changed or, if not, should change. If that means doing a business somersault, that is okay. Changing the way we do business, flip-flopping on what we have said in the past is not a moral crime. Indeed, having the bravery to stand up in front of the troops and say, "We have made a mistake and now need to correct it," is perfectly in order. If conditions change or a position becomes outdated, then you as a leader must have the courage, without emotion, to change course.

That being said, change for the sake of change or flip-flopping from day to day on new positions isn't okay. I once worked for someone who would throw the whole company into confusion by changing his position five times in a week, based on who he last spoke to. Not good! Telling one thing to employees and another to investors and the press is also wrong. But, when your perspective changes due to changing circumstances

and unanticipated conditions, it is appropriate to change course-fast!

I have always believed that in times of turmoil there are still many opportunitics. It is a mind-set. But the truly successful companies not only spot the opportunitics, they also know how to act fast to take advantage of them, act aggressivcly, and are unafraid to make change if need be. You may have had to cut costs to survive, but you cannot cut forever. Smart managers eke out new opportunities and invest now for the future at the same time. Recessions cre ate winners and losers just like a boom. Just as in riding waves, getting on and off the board at the right time is a skill that only the best can achieve.

Decisions that were rock solid two years ago may have no relevance today. Many of the companies that went through the boom by taking on large debt by heavy expansion are the ones in deep trouble today as credit has dried up. But the good news is that this past month consumer confidence has shown its first small upward spike in a long while. Together with the comeback of the stock market, evidence is mounting that the worst is behind us.

Those who will succeed going forward are those who have adapted or will adapt to the evolving market. As the number of companies in the industry grows smaller and less-nimble rivals grow weaker, now is the time to take steps to solicit new customers, improve service while others cut theirs, and buy revenue and market share from troubled companies. Strategies in the recent past al many companies included cutting non profitable programs or products, focusing on core profitable products where they hold a unique market position, and looking under every rock to find new opportunity.

Lastly, it has been no surprise to me to see many of the largest companies in trouble. They normally cannot just turn on a dime. The good news is that coming out of the bust many small and mediumsize companies will discover gianl opportunities not possible in yesterday's environment, as by nature they can react faster and more efficiently. I do not know if I am right, but it is time to start thinking of the new end game now!

One-piece &nstruction

"tigsr striping" marks on gutters

. f -800-327-7017 6 Burr,ornc Pnooucrs Drclrsr Julv 2009

GutterGuard--O-

The

BEST WAY to control Gutter Clutter " vr/!vw.guttergua rdpr0. c0m

B00ZEfiBEAM is certified as a distinguished company capable of meeting or excoeding rigoro us sland ards in the manutacture of sate products which bring positive eoonomic impactto the induslry,

ln addition, B00ZEBBEAM is FSC certifted in the use of raw materi als trom well-managed torests. The Eoozerbea m brand with the FSC Label stands for good environmental stewardship,

BOo'ZE BEAilI* l$ $nEEH r

r"ri" '"*. .d" r NEW!

Boozerbeam is an FSC Supplier, Certificate # SCS-C0C-001962 @1996 Forest Stewadship Council A.C.

WalkulilU$, GFo$souens & platloFm$

Pneserueil wooil U's$eFuG$ nature

By Huck DeVenzio Arch Wood Protection

Itr/HEN people say that someone gets "walked all V V over." it is rarelv comolimentarv. But when a structure is walked all over, it can be veiy beneficial for the walker and for the area traversed.

Wood walkways convey people to nature, increasing appreciation for the natural environment and, in many cases, protecting that environment. They enable people to get to places they might not otherwise see, and they limit destruction from foot traffic.

Take, for instance, a crossover stretching from a parking lot, over sand dunes, to the seashore. Not only does the

FLORIDA beach-goers can take different routes across the dunes to get to surf. Treated wood walkways make their trip easier.

walkway make it easier for sunbathers to reach the beach, but it concentrates traffic flow and helps preserve vegetation that anchors the dunes that shield inland property from high seas.

Another example is a walkway through a wetland. By constructing a solid path above the normal water level, vis-

WERE it not for the wooden crossover, sunbathers would likely trample the dunes and the veoetation that anchors them.

] s g \o b {

APPARENTLY, not just humans make use of wood walkways, as evidenced by this scene in Manatee Springs State Park, Fl.

Jut-v 2009 Burr,nrxc Pnouucrs Drcnsr

itors can see wildlife and hear nature's slogging through a fragile environment.

A footbridge on a nature trail allows

sounds without nature-lovers to

takes less energy to produce than comparable building materials; it sequesters carbon, thus reducing greenhouse gases; and its light weight means that it can often be installed with lower-impact construction methods. And, it's a renewable resource.

But even advocates of the environmental features of treated wood often miss a subtle benefit from such structures: walkways, crossovers, and platforms enhance public appreciation for the natural world.

Once, on a trip to the Grand Canyon, I heard people complain about big crowds and the urbanization of the park. But one nature-lover had a very different perspective.

cross a gully without dislodging soil and plantlife and causing erosion.

And one more example, a less obvious situation, is a walkway through an often-visited forest. A walkway keeps people on a hard path and prevents harmful soil compaction around particular trees that may be especially old, large, unusual, delicate, or worthy of crowds for other reaSONS.

Usually these walkways are constructed of woodpreservative-treated wood for durability. Treated wood is

He said that he hoped more people visited Grand Canyon. You can't spend time at the Canyon and not be awed, he said, and the more people who are awed by nature, the more people who will work to protect it.

Treated wood structures help people-of all ages and

plentiful, easy to work, and has an appearance suited to natural settings. It also resists deterioration from termites and fungal decay for decades. Additional life-cycle attributes have been getting increasing attention: treated wood

HIKERS have a wide-angle view ol the Chattahoochee River from this treated wood perch in Atlanta.

TREATED wood bridges allow people to see natural areas with a minimum of etfort and a minimum of impact.

HUGGING the side of a rock wall, this treated wood walkway enables visitors to walk through an othenruise isolated chasm.

NEARLY three-quarters of a mile in length, Wolmanized wood walkway winds its way from a three-tiered observation tower in Boca Ciega Millennium Park. Seminole. Fl.

10 BurLuNc Pnooucrs Drcnsr Jur-v 2009

abilities -become admirers of nature.

Treated wood platforms in Georgia's Okefenokee Swamp enable canoeists to camp in the midst of alligators, cypress trees, water lilies, and great blue herons. Seeing the reflection of red alligator eyes at night can be a lifealtering experience.

Viewing platforms and observation towers allow people to be inspired by scenic views or to add migratory birds to their life lists.

Walkways at Wilderness on Wheels in Colorado, and at other projects like it, provide access for wheelchair-bound visitors. The organization's motto is "No one should be left out when it comes to experiencing a wilderness envlron-

COLORADO project has docks, picnic areas, and walkway that accommodate passing wheelchairs in a forested mountain area.

ment." An 8-ft.-wide boardwalk follows a Rocky Mountain trout stream, offering a close-up look at nature and an opportunity to enjoy nature-watching and fishing.

At zoos throughout North America, families can experience the joy of viewing exotic creatures. What often assists them? Wood walkways. Treated wood walkways in zoos, botanical gardens, arboretums, and city parks provide some of the same value as walkways in more remote locations. In addition to walkways, treated wood is often used in parks for animal enclosures, benches, fences, picnic tables, sign posts, and other items where a natural but long-lasting building material is desired.

The choice of treated wood provides environmental advantages over alternative materials, while the installation of wood structures can protect habitats and increase respect for nature.

Elnoslng Ufallway lumbsn

Various species of wood can be effectively pressuretreated. Usually the species available are those growing in the region-southern pine in the South and East, red pine or ponderosa pine across the North, Douglas fir or hem-fir out West. All of these species are plentiful and grown on managed timberlands. They have slightly different strength values.

Treating is done at plants where a preservative is driven into wood under pressure. Several different waterborne preservatives may used. Most rely on copper as a primary

pesticide and include a co-biocide to protect against copper-tolerant fungi. Treating companies sell their products to building material outlets. Nearly every lumber dealer stocks preserved wood.

In selecting pressure treated wood, a specifier should consider the type of wood desired (i.e., round poles, timbers, dimension lumber), the grade of lumber (higher grades have fewer knots and other imperfections but usually cost more), and the intended use (e.g., above ground use requires less preservative than wood that will be embedded in the ground or immersed in salt water). To minimize warping and provide other benefits, treated wood can be purchased that is re-dried after treatment or contains builtin water repellent.

URBAN boardwalks, such as this one in a resort city in Uruguay, provide a welcome path.

- Huck DeVenzio is manager of product information at Arch Wood Protection, manufacturer of wood treatments and licensor of the Wolmanized brand of pressure treated wood. He can be reached at (678) 627-22 I 5 or cdevenzio@archchemicals.com.

Jur-v 2009 BuTLDTNG PRoDUcrs Drcnsr 11

MARINA walkway's piles were pressure treated with CCA for saltwater immersion; decking needs less preservative for protection against wood-destroying organisms.

The sustainabilitv of the tre ated r wood industrv

By Dr. Kenneth M. Brooks J Aquatic Environmental Sciences

answer from within industry is likely that you want to sustain your business and that is a reasonable answer-but it is not the answer that the Sustainability Industry wants to hear. In today's world, to sustain your business, you need to consider the following:

. Sustainable over what period of time? Like all industries, the treated wood industry is evolving. Current preservatives will be replaced by new preservatives at some point in the future. The sustainability of those new preservatives will require evaluation of a different set of considerations.

w:l*fr ":: ;#:lili i l";:lJl:

ing what you have into the future.

Although sustainability is an important and worthy goal for insuring that future generations enjoy the same quality and quantity of resources that have been available to us, there is no history of actually achieving sustainable use of resources. We have a history of depleting resources and then looking for alternatives. Sustainability, however, has become a key word in the

lexicon of the politically correct. Many environmental groups emphasize their programs - ostensibly designed to achieve sustainable resources-as mechanisms for funding their activities and paying their salaries. Yet, until we reach steadylevel human population, we cannot even begin to cogently define the term sustainability.

As for the sustainability of the pressure treated wood industry, the first question to be asked is, "What is it that you are trying to sustain?" The

. Are the supplies of commodities used by the industry sustainable? In part, the sustainability of the supply of commodities used to preserve wood depends on competition for those commodities from other users. The development of a middle class infrastructure in China and India will require more copper, leading to increased competition for the metal (higher prices and reduced supply).

Another important commodity for the industry is wood. Will there be the high quality wood necessary to satisfy consumers' demands for residential decking? The quality of the wood sold into the marketplace is as important as the preservative.

. Is the use of pressure treated wood ecologically sustainable? This question could be reformed to ask, "Is the use of pressure treated wood sustainable from a resulatorv noint of

12 Burl.urNrc Pnorucrs Drcesr Jur-v 2009

SEVERAL hundred creosote-treated wood pilings on Fort Ward wharf attracted a greater amount and diversity of aquatic life than could be found around other areas surrounding the island.

view?" The biocides used in pressure treated wood do leach or migrate from the wood into the environment, where they disperse, degrade and/or accumulate in sediments. At low concentrations, copper is an essential micronutrient supporting life. However, as the concentration of copper increases in sediment or water, the metal becomes toxic to many forms of life. In other words, copper-based preservatives need to be managed in sensitive environments.

I have spent a portion ofthe last 17 years studying the environmental response to pressure treated wood and developing models that help manage all of the currently available preservatives. Projects studied included creosote pilings at a wharf on Bainbridge Island, Wa.; CCA and ACZA structures in marine environments in Sequim Bay, Wa.; CCA, ACZA and ACQ viewing platforms in the Wildwood Wetlands on Oregon's Mount Hood, and ACQ- and CCA-treated floats in a pond near Port Townsend, Wa.

In 14 of 15 risk assessments, no significant adverse effects to the environments were documented. In fact. invertebrate communities were more diverse and abundar?t near these structures than at nearby reference locations.

In one case, Darcy Goyette from Environment Canada and I spent l0 years studying the Sooke Basin on the southern end of Vancouver Island in southwestern British Columbia. When we started the project in 1995, Darcy was concerned that creosote-treated structures would likely harm the environment. After the fifth year, he commented that the government should pay people to build with creosote because of the wonderful habitat it creates. We have repeatedly seen higher diversity and abundance of aquatic life on and around treated wood structures than we see at reference locations-not because of the biocides used to preserve the wood, but because the structures diversify the habitat.

So, lacking evidence of significant adverse biological effects associated with pressure treated wood projects located in open aquatic environments. why are some regulatory agencies opposed to the use of such products? As the world's population increases, the size of the "environmental footprint" of each individual or community has to diminish so that the total

footprint remains sustainable. Those in government are demanding that each industry's effect be reduced. For the treated wood industry, that means that there is pressure to reduce the loss of preservative active ingredients, and that is one of the challenges facing this industry if it is to remain regulatorily sustainable.

So. too. we should all be economically sustainable. Since the Second World War, America has built an expanding economy based on borrowed money, relying on other countries to provide the resources and cheap labor to manufacture the goods we crave. My sense is that it is time for America to take responsibility for our own future. Putting America back on track means that we must harvest our own timber and other resources in a responsible way. Manufacture our own goods. Demand excellence from students. And slay the political correctness dragon that prevents real problem solving.

Rather that burdening future generations with huge debts, I believe that this approach will revitalize the middle class by creating new jobs in natural resources and manufacturing.

How does the pressure treated wood industry meet these challenges?

It is a technology-based industry that must continue to evolve. The first generation of alternative preservatives following industries' abandonment of CCA didn't decrease the size of the environmental footprint of treated wood; it significantly increased the contribution of copper from each

structure to sensitive environments. However, newer preservatives dissolve the copper, reducing the impact back to that associated with CCA, making them more environmentally sustainable.

What is the ideal preservative?

From my perspective, it is a preservative that prevents decay and insect attack for at least 50 years. That means the preservative must stay in the wood. When this ideal preservative does leach from the wood, it is quickly transformed to non-toxic endpoints that have little or no potential to adversely affect plants or animals. Some smart wood scientist will eventually develop such a preservative,

In the meantime, pressure treaters currently have tools to help minimize the size of the environmental footprints associated with treated wood structures. They can avoid building structures that will harm the environment. They can employ best management practices in production, designed to minimize the loss of preservative to the environment.

Sustainability is a constantly moving target. Currently available technologies may not be sustainable over the next several hundred years. Yet properly managed forests are infinitely renewable, and pressure treated wood further increases the sustainable use of that precious resource.

- Dr. Kenneth M. Brooks is owner of Aquatic Environmental Sciences, Port Townsend, Wa. He can be reached at brooks@ ohtmous .net.

Jut-v 2009 Buu,urNc Pnopucrs Drcnsr 13

BEST MANAGEMENT Practices, developed in conjunction with the Western Wood Preservers Institute, turn utility poles on the right into sleeker, safer poles on the left.

Downtime is right time for updating your warehouse

"Conrpanies are using downtimc to slinr dou'n and become more efficient." saicl Rick Hogue. Krautel Solutions. Inclianapolis. In. "A well-desi-gncd warchousc allows more work to bc con'rplctccl with l'cwcr ernployees."

A ncw crnphasis on rcmodcling contractol's ancl cl-i-ycls is also cncouragins dcalcr-s to orsanizc thcir yarcls ancl invcst in ncw rack systcrrrs.

"Thc trcncl is to bcttcr scrvc thcsc tvpcs o1' cuslollcrs, cspccially sincc nra.jor honrcbLrilcling is rlown." sairl N4ark Ritz. prcsiclcnt ol' Auto-Stak. Wcstu,oocl N..l . "Thcsc two groups \\'ont t() scc ancl touch proclucts bcfirlc bui'ing. Thcy also buy in srnallcl lots than bi-g honrcbuildcrs. so proper storagc is vcry inrportant."

OI'terr. the l'ilrt tlccision i: to choose the right kind of riicking lbr organizing and storing heavy ancl bulky' items. "Depending on what vou're storing in your warehousc, 1"ou mav \L'ant to choose pallet racks over cantilevcr racks. or vice versa." said Ed Stairrnan. A Plus Warehouse. L1 nn. Ma. "Pallct racks off'cr selectivc pallet lackinc. which is the best solutiort lirr u lrrchousc: whele il is ncec'sarv to kccp a wiclc variety of articlcs in pallcts: cantilcvcl racks arc nrore suitublc lirr storin!. long loacls."

Pallct rlrck shclvirrg of'f'crs caplcitics o1' Lrp to 2,1.0(X) lbs. pcr uplight rnd 6.000 lbs. pcr pail ol'bcarns. Stt'r-rclural pallcl racks havc uplight cupacity to:15.000 lbs. ancl bcant capacity to l-5.(XX) lbs. Both kincls ol'lcr': direct access to all storccl pallcts irnd casy stock control . thc ability to handle one pallct r" ithoul movin-9 others . absolute load storage flexibility.

A SLOWER construction markct -Cl,plus neu federal tax deduction inccntir,es are encouraeinc LBM dealers and distributors to update warehouscs. add more stora-ee. and increasc ovcrall cfficiency. Wr nnn now FSC CrRnrrro, $n lrr Us lletp Ysu Wm Youn Hsxr FS0 lnrunv Your source for LARGE TIMBERS, SPECIALTY PRODUCTS, & npvrnnuracruRrNc . .illrlrywrl . lVcrielrr .ilErl Ced!r . jgujirerrr C'1ptz;; , Duuylu; iir ' Jpj . 9rrrpr leddrrS

TWO KINDS of warehouse racks-A-f rame and pallet -keep LBM products orga nized and accessible.

14 Burror-.'.'c Pnoot'crs Drt;nsr Jurv 2009

both in terms of weight and volume

In comparison, cantilever racks are ideal for tir4bers, beams, profiles and pipes. This tlpe ofrack offers the ability to segregate each type of product by commodity and size, and problemfree, height-adjustment storage that keeps product off the ground.

For vertical display and storage of items up to 16 ft. long, A-frames are the right choice. They are a heavyduty, versatile layback system for vertical display and storage of items such as trim moulding, gutters, piping, etc. Adjustable arms form a divider system that can be manipulated for a variety of compartment sizes.

When it comes to financing warehouse improvements, depreciation deductions in the 2009 economic stimulus program can help. The program extends the $250000 depreciation for companies spending under $800,000. The 5OVo depreciation deduction for new equipment, the so-called "bonus" depreciation, was also extended.

"This has been one of the biggest items I have seen with my clients," said CPA Howard Dorman. He said at least a dozen have used the depreciation write-offs for warehouse equipment, forklifts, trucks and new computers. Although the improvements were needed, he said, the depreciation rules were a major motivator.

"This really is an economic stimulus," Dorman. "The money can be used to defray the cost of the equipment, or help the company keep one or two people employed while they increase their production capacity."

;a€ o q 15 Jut-v 2009 Burlorxc Pnooucrs Drcrsr

CANTILEVER racks provide ideal storage for heavy, bulky items such as timber, beams, profiles, and pipes.

etitive ligence Survival of the fittest

four outside salespeople on the road, with two more in inside-support staff. Each salesperson takes everything from start to finish on a programbringing in the plans, doing the free estimates, on to placing orders, the follow-up and credits. They deal with a contractor's customers for him. too: they answer questions as they come up. This builds relationships and the element of trust that comes along with that. And, once established, those relationships are pretty hard to beat!"

Along with strong independents, there's a Lowe's in Brunswick and a Depot even closer. But Downeast separates itself with both inventory and service. "Contractors can drive up and park 50 feet from the door. We help load their vehicles and show them where things are; this is not a big cavern. We hear a lot from our customers that 'Everybody knows me here, and I know everybody.' They see the same people tomorrow and the next dayno surprises.

If,/HEN folks cheered. "Many V Y happy returnsl" they weren't just talking in the wind. Downeast Energy & Building Supply, owned by the Morrell family since 1908, celebrated its 100th anniversary last year with plans to stand tall in its community for many years to come. And there's a fourth generation of Morrells in training up there in Brunswick, Me., ready to make good on that promise.

The company was founded in 1908 as Brunswick Coal, but soon firewood, lumber, oil and propane joined the mix. A separate Building Supply Division took roots in the '80s, after a disastrous fire "took the whole place down," recalls Peter Bernier, v.p. of the division. "We rebuilt the store and warehouse and made major changes."

Today the division counts 40 employees in addition to the office staff, IT crew, and marketing and training departments it shares with the larger Energy Division, with its l3 outposts in Maine and New Hampshire, allowing the Building Supply force to do what it does best-and that's sell sticks. "Our customers are "15-80Vo contractors, and that's the way we like it-or, liked it," Bernier amends with a rueful joke when faced with the current economic upheaval. "Most of them built two or three houses a year, but, while there's still some new-home activity, they've turned to remodeling."

And that's another niche in which Downeast is well-prepared to help them. The operation boasts a Kitchen Display Gallery, whose staff stands ready to walk a contractor's own clients through their choices, saving the pros both time and patience. The adjoining millwork displays provide margins as bountiful as the choices. "Well, at least they used to," Bernier laughs again. "Even those are more competitive today."

No surprise. In fact, local competition, always vibrant in Maine, has become "even more intense," he notes. But Downeast maintains a strong distinction. "Operationally, our biggest difference-and plus-is that we have

"We carry everything they need, from lumber and plywood to hardware, power tools, Benjamin Moore paints, and Andersen windows. We have two boom trucks for their convenience (costly to purchase, costly to maintain," Bernier adds). "We offer free delivery-which is even more challenging these days," he points out, "because we're reaching farther away, looking for business."

It helps that the Energy and Building Supply divisions are adept at at cross-marketing. "We play up each other's advantages. We also do a fair amount of print advertising-not that it reaches our pros. but it gets our name out to the community, and it pays off. It's happened a number of times that a pro comes in and says,

srlAr+;.: -; "*i#S*;;:=

:;::

GREEN PROMOTION: Downeast invited an arborist in to talk about trees for last vea/s Arbor Dav.

'I've never done business with you, but my client insisted!' Then, after we show them what we can do for them. they're back as some of our better customers."

Downeast takes proactive steps to make them feel valued-everything from hosting weekly, vendor-sponsored barbecues in the summer to contractor cruises with over 150 customers sailing Casco Bay, complete with dinner and band. The company also invests in inviting and transporting them to industry shows and staging green building seminars. "We get a full house, which we can hold in the conference area of the Energy Division, which is otherwise used for staff training," says Bernier. And Downeast's own IT staff also offers customers training on business skills, such as computer software.

The staff is long on tenure. "I started here myself in 1978, right out of college," attests Bernier, and he's not alone in that boast. To foster retention, "We give awards and celebrate years of service. We also offer training in such skills as customer service, using a company in Portland we have on retainer. Right now, we're offering a course in personal development to 25 individuals in things like presentation skills, how to do a PowerPoint."

Indeed, Downeast not only believes in education, it walks the talk. Every year it awards multiple scholarships for children of employees to further post-high school studies. In addition, it offers additional scholarships to kids unaffiliated with the company with interest in careers in the building supply and energy industries to continue their post-high school education in community colleges.

To spark that interest at an even earlier age, the company hosts full-day visits to its yard for area high school classes, called JMG (Jobs for Maine Graduates), to introduce them to job opportunities. "The kitchen department will explain how a designer works, and the yard will show them what a driver does," Bernier says. "We give demonstrations on safety, have speakers about various job functions, and end up with pizza. We emphasize that there are good jobs out there that don't necessarily require college-plenty of opportunities. While we don't know if it's paid off in future employees directly yet, we feel it's a community service, and lets them know that not every student has to mainstream to college."

Speaking of community service, that's an area where Downeast also takes a lead, thanks to the Morrell family's generosity. "We help on library, hospital and church building or renovation, and also in donations of our time. I'm on the board of the United Way, for instance," he adds. "For years, the family wanted donations to remain anonymous, but when folks insisted-'You should tell people!'-they decided that wasn't such a bad idea, after all."

Today, the firm sponsors displays in local home shows and joins in Maine's Green Collaborative Effort, educating consumers in savings to be made in energy and advances in green building products. For its 100th anniversary, a weekend-long celebration attended by the governor, Senator Susan Collins, and radio and tv stations, Downeast held Yard Olympics contests, such as races, nail driving, sawing, and assembling wheelbarrows.

Sure, Downeast is feeling the pain of the times. But it has not laid off a single person. Instead, seeing the way the wind was blowing as early as two years ago, the company started examining savings possible through job attrition. "Plus," Bernier adds, "also

having an energy company allows us to spin off our Building Supply drivers to them during the winter."

Nonetheless, "we're feeling the crunch in every way, and our community has been hit especially hard. A local Naval Air Station is slated to close, which means losing a big piece of the community-700 housing units on base plus other homes up for sale as people move out. But there's a redevelopment committee, which is very active. Still, we'll be hurting long after the national economy recovers," he feels.

"Fortunately, Downeast is well established and doesn't carry a lot of debt. We're very careful of spending, so we can withstand this for a long time. We did see a little spike in the past three or four weeks, but those will come and go. Summer is flat, but that's okay. But next winter will be very difficult around here. I'll be surprised if all the players are left standing a year from this time...."

Expect Downeast, however, to be standing tall.

- A former award-winning LBM trade magazine editor, Carla Waldemar writes frequently on the industry. Contact her at cw aldemar@ c omc as t.net.

Proudly grown and manalactured. bythe Colville Indian Tribe PnpcistoN'Prnp Co. Manufacturerc of hlgfi 'qmli$ Ponderosa pine boards''&"-' ' industrials; Douglas fir. lamstock, dimension & induStiials'iiom Omak, Wa. Edir (iile) 422-'7iia" Fax 509-422-7fl1 Producerc of high qaality '- PIyWood & Dry Ven66r from Ornak, Wa. Cail AflU Sunn (5O9)l 22.7tHtt Fax 5tl9-4122:7.11311 s, Jut-v 2009 Buu,nrxc Pnopucrs DrcBsr 17

R:rln:ns

Housatonic Lumber, Derby, Ct., closed May 29 af\er 102 years

Medina Lumber & Hardware has been opened by Tom and Warren Snyder at the former site of Somerset Lumber, Medina, N.Y,; they hope to add a lawn & garden center next summer

Coastal Lumber & Supply, Niceville, Fl., has closed after 25 years...

Iverson's Lumber, Highland, Mi., is operating its Milford, Mi., branch as a clearance center as it tries to sell the property

Goodale Hardware. Grandview Heights (Columbus), Oh., is being opened this summer by Jeff T,ettler and his son, Jeffrey T,ettler

Matthews & Fields Lumber Co., Henrietta, N,Y., agreed to lease tlree acres of the former Babcock Lamber Co. yard in Lancaster, N.Y., to warehouse wood products as its prepares to open a sales office in nearby Buffalo, N.Y. ...

Island Hardware & Lumber is the new name for Arnold Transit's hardware and fuel operations on Mackinac Island, Mi., after their acquisition by Kirk Lipnitz; he will keep the store open year-round

Marvin's moved to a new, larger location in Demopolis,Al.

84 Lumber reopened its mothballed W. Houston, Tx., yard and engineered wood products centers in Houston and Dallas, Tx.

Rylee's Ace Hardware broke ground on a $4-million replacement store with lawn & garden center in Grand Rapids, Mi.

Builders FirstSource has closed its branch in Cincinnati, Oh.

Frontier Lumber, Erie, Pa., added a 2,000-sq. ft. Frontier Home Products & Design Center ...

Bradco Supply opened a new branch in Wauconda, I1.

BMC West parent Building Materials Holding Corp. filed Chapter 11 bankruptcy ...

Bradco Supply Corp., Avenel, N.J., acquired Dynamic Roofing & Siding Supply, Warminster, Pa.; Ray Ace was named branch mgr., and Dynamic's Barbara Krumins will stay on to ensure a smooth transition period ...

Lowe b unveiled a new store June 19 in SE San Antonio, Tx., and expects a 3rd quarter 2010 opening in Salem, N.H. ...

MarJam Supply Co. signed a l0-year lease for a 65,518-sq. ft. warehouse on 4.5 acres in N. Miami Beach, Fl.

Habitat for Humanity opened a replacement ReStore May 18 in Kannapolis, Md.; a new 3,000-sq. ft. ReStore June 13 in Danbury, Ct. (Joanne Bosshardt, coordinator), and, a24p00-sq. ft. outlet June 1l at an old 84 Lumber vard in Newnan, Ga. (Sharon Hazel,mgr.)

Wnor:sm:rs/trrutrcrur:rs

Hager Group (f.W. Hager Luntber), Grand Rapids, Mi., is closing after 81 years

Lee Roy Jordan Lumber,Dallas, Tx., moved into a new facility, nearly a year after a speeding car crashed into the old building and it burned to the ground (see JuIy 2008,p.41)...

North Paciftc, Springfield, Ma., had four forklifts worth $120.000 stolen in late May

Lo ui s i ana - P ac ifi c temporarily laid off 43 workers at its LSL plant in New Limerick, Me. ...

International Paper Co. shuttered its Franklin, Va., lumber mill May 3l

Clopay Building Products is closing its gargage door plants in Russia, Oh., and Baldwin, Wi., consolidating production in Troy, oh....

U.S. Lumber Group, Atlanta, Ga., has installed new lBM business intelligence sofware to gain in-depth reporting capabilities in real time vs. the daily reports of its previous system

JeId-Wen next month will close its door manufacturing plant in Oshkosh,Wi....

Arch Wood Protection and Arch Treatment Technologies moved to new offices in Atlanta, Ga. ...

Temple-Inland is closing its sawmill in Buna, Tx., for an undetermined period of time ...

Bonsal American has renovated and expanded its Sakrete manufactwing facility in Cincinnati, Oh. ...

Sherwin Williams Co. will close its Olive Branch, Ms., paint plant by year's end

Masonite International Corp. has restnrctured and emerged from Chapter 11 bankruptcy, 85 days after its filing

Boston Cedar & Millwork, Holbrook, Ma., is now distributing the Azsx Deck Terra Collection in Long Island, eastern N.Y., and six New England states

Atlanta Hardwoods Corp. is now distributing Contact Industries' veneer-wrapped mouldings in Ga., Al., Tn,, Ms., and northern Fl. from its five Hardwoods Inc. DCs and from White County Mouldings,Cleveland, Ga. ...

Parksite, Batavia, Il., is now distributing Circulation Solutions roofing ventilation products from its 10 DCs

Advantage Trim & Lumber Co., Grover, N.C., has received FSC chain-of-custody certification for its ipe and Tigerwood decking and hardwood flooring

Anniversaries: Lyons Do it Best Lumber & Hardware, Brighton Park and Frankfort, Ky., 100th Schade Builder's Supply, Helena, Oh., 50th ... Duncan Builders Supply, Duncan, Ok., 45th .,.

Housing starts in May jumped L7.2Vo to a yewly rate of 532,000, thanks to a 61 .7% spike in multifamily regionally, starts rose ZVo in the Northeast, 11.17o in the Midwest ll.IVo. and 16.87o in the South ... permits were up 4Vo to a 5l8,000 rate.

briefs

18 BT.nLDNG PRooucrs Drcrsr Julv 2009

&RHH;* WTw $RKKFT

THE FIRST VIABLE SUBSTITUTE FOR PRESSURE TREATED PRODUCTS.

TimberSlL' is a non-toxic fusion of two natural materialswood and glass, producing the ideal, natural product and a combination of properties never achieved before. More than wood and more than glass, TimberSlL@ combines the best of both bringing a transformation to wood. DRY TimberSlL@ Wood is VERY GREEN, and we're not talking color.

TIMBERSIL@ COMBINES THE BEST PROPERTIES OF WOOD: paintable/stainable, strength, beautiful look and feel, easy to cut and machine, and cool to the touch.

WITH THE BEST PROPERTIES OF GLASS: Class A Fire Retardant (30 min extended test),insulator, unaffected by seawater, unaffected by heat, barrier to rot, decay or insects.

AND ENHANCES BOTH WITH THE TIMBERSIL@ GLASSWOOD FUSION PROCESS: nontoxic, structural stability, extra strong non-corrosive fastener hold, effective carbon sequestering,up to 50% stronger, twice as hard, lower maintenance, sustainable, multiple life cycles.

TimberSlL@'s revolutionary chemistry and proprietary process transforms wood -inside and out - into a superGlassWood product that is great for the environment, a great value for the consumer, durable, sustainable, and helps fight global warming.

TimberSll'is Proud to Announce a Historic EPA Determination: TimberSllo is a Nontoxic, EPA Exempt Barrier Product

Heavy Metals: 0% Pesticides: 0%

Fungicides:0% Performance: 100%

Available Exclusively From Hood Distribution, M&uesten Group.

Locked in for life.

Servicing AII of New England. TimberSil Hotline: 800-752-0129 McQuesten Group

Timberslf ^.l\ Hood tll Distribution

North Billerica, MA 800-752-0129 o Manchester, CT 800-468-8220 . Milton, VT 800-955-2677

Listings are often submitted months in advance. Always verify dates and locations with sponsor before making plans to attend.

tutY

Oklahoma Lumbermen's Association - July 10-11, convention, Tanglewood Resort, Pottsboro, Tx.; (800) 444-177 1

Construction Suppliers' Assn. - July 10-12, summer management conference, Hiawassee, Ga.; (800) 351-2255.

North American Retail Hardware Association - July 13-15, Marriott Rivercenter, San Antonio, Tx.; (317) 290-0338.

Central New York Retail Lumber Dealers Association - July 14, golf outing, Pompey, N.Y.; (800) 292-6752.

Northern New York Lumber Dealers Association - July 15, board meeting, Norwood, N.Y.; (800) 292-6'752.

Wisconsin Retail Lumber Association - July 16-17, summer board meeting, Neenah, Wi.; July 22, golf outing, Onalaska, wi.; (262) 250-1835.

Eastern New York Lumber Dealers Assn. - July 20, summer outing, Wiley Bros., Schaghticoke, N.Y.; (800) 292-6752.

New Jersey Building Materials Dealers Association - July 20, annual golf outing, Battleground Country Club, Manalapan, N.J.;(800) 269-9603.

Northeast Window & Door Assn. - July 20-21, summer meeting, Maniott Seaview Resort, Galloway, N.J.; (609)799-4900.

New Hampshire Retail Lumber Association - July 23, board meeting, Hooksett, N.H.; (800) 292-6752.

Southeastern Lumber Manufacturers Association - July 2325, annual conference, Ritz Carlton, Amelia Island, Fl.; (770) 63r-6701.

Moulding & Millwork Producers Association - July 28-Aug. 1, summer meeting, Naples, Fl.; (800) 550-7889.

Southeast Building Conference - July 30-Aug. 1, Orange County Convention Center, Orlando, F1.; (800) 261-9447

Southern Building Material Association - July 30-Aug. 2, summer conference, Wyndham Oceanfront Resort, Virginia Beach,

Auousr

Appalachian Hardwood Manufacturers Association - Aug. 14, summer conference, The Homestead, Hot Springs, Va.; (336) 88s-831s.

Massachusetts Retail Lumber Dealers Association - Aug. 3, golf outing, Watertown, Ma.; (800) 292-6752.

Temperate Forest Foundation - Aug. 4-7, teachers tour, catskills, N.Y.; (503) 445-9472.

Lumber Dealers Association of Connecticut - Aug. 5, board meering, Rocky Hill, Ct.; (800) 292-6752.

Indiana Lumber & Builders Supply Assn. - Aug. 6, golf tourney, Oak Tree Golf Course, Plainfield, In.; (317) 875-3'737

Michigan Lumber & Building Materials Association - Aug. 6, golf outing, Hawk Hollow Golf Course, East Lansing, Mi.; (517) 394-5225.

Vermont Retail Lumber Dealers Association - Aug.6, board meeting, Fairlee, Vt.; (800) 292-6752.

Northern New York Lumber Dealers Association - Aug. 12, fishing derby, Clayton, N.Y.; (800) 292-6752.

Mid South Building Material Dealers Assn. - Aug. 14-15, midyear meeting, Hampton Inn, Natchez, Ms.; (877) 828-3315.

Vermont Retail Lumber Dealers Association - Aug. 19, annual meeting and golf outing, Killington, Vt.; (800) 292-6752.

Wisconsin Retail Lumber Association - Aug. 19, golf outing, Fennimore, Wi; (262) 250-1835.

Florida Building Material Association - Aug. 20-22,meeting & expo, Gaylord Palms, Kissimmee, Fl.; (352) 383-0366. Orgill Inc. - Aug,20-22, market, Boston, Ma.; (901) 754-8850.

20 BurluNc Pnolucrs Drcnsr JULY 2009

I 0 0 I I I I

7 TREATEDWOOD PRODUCTS, TTVC. Sales: 80G531-5558

WThe FSC ldentlfleslogo pro<Juds from wcll-managed Support 8OGTEC-WOOD (832-9663) Web: www.FRTW.com

Seminars: www.leamaboutfrtw.com

Building code standards require deck railing posts to be able to resist a 200-lb. load in any direction. Many common railing-post connections that attach only to the rim joist don'l oass this test. The new Simpson Strong-Tie@ DTT Deck Tension Tie connects the railing post back into the I deck traming, not just to the rim ioist, creating I a connection that meets the code standard I and results in a saJer deck. And since the DTT

I installs quickly with Simpson Strong-Tie@ I SDS screws, a safer solution doesn't have to I take more time. I I

Share product and deck salety information

I with your cuslomers, including the Simpson Strong-Tie Deck Framing Connection Guide, aur 0nline deck classes and local workshops. Visit www.slr0nglie.c0m/deck or call {800) 999-5099 tor more details.

Interior Fire Retardant Treated Lumber and Plylood Exterior Fire Retardant Treated Lumber and Plpntood

Nationwide Stocking Distributors Superior to Paint or Coatings

and Decay Resistant Pressure Treated and KDAT Strongest FRTW Warranty Competitive Pricing Available in RED ,AO Y'u, FSC

Termite

'HOOVER

Jur-v 2009 Burlpluc Pnooucrs Dtcssr 21

Ei

MaFket Outlook

Looking for the Iight at the end of the tunnel

r|'IHIS year is expected to mark the I- low point of the long and protracted recession that began with the housing downtum and was officially recognized as a recession in December 2OO7 , according to APA's annual spring forecast.

That expectation comes with some cautions and caveats, however, notes APA market research director Craig Adair. "Our forecast assumes that at least some of the many programs thrown at the economy and the housing market by the federal government will stick and get the economy moving again," he said.

The key factors required for a turnaround are affordable homes, a recovered credit system, renewed consumer confidence, and at least moderate job

growth, the forecast notes. The first three of those four criteria have shown some promising signs recently. Home prices in most parts of the U.S. have come down to pre-boom levels. Once buyers believe the bottom has been reached, the huge inventory of unsold housing should begin to recede. The Treasury Department's recent banking "stress test," although showing billions of dollars in anticipated losses through the end of the year, at least provided a measure of the problem, a critical first step in repairing the system. And consumer confidence has been on the rise for the last three months, signaling new hope for an increase in consumer spending.

The unemployment rate, at approximately 9Vo. remains the most trou-

Get monthly housing, production reports

Subscriptions to APA's monthly housing market and quarterly engineered wood production reporls are now available.

The housing markel report is in the form ol a PowerPoint presentation and includes housing starts and permit data, new and existing home sales, home inventories and months of supply, mortgage rate trends, and a housing starts forecast. Also included are data on nonresidential construction spending, industrial production and remodeling, consumer prices and spending, and U.S. and Canadian gross domestic product. Based on data compiled through a comprehensive review of industry and government reports, the report is emailed to subscribers, The annual subscription is $600.

The quarterly industry production reports, published about two weeks after the end of each quarter and encompassing both the U.S. and Canada, cover softwood plywood, OSB, glulam timber, wood l-joists, and LVL. The reports provide data on U.S. panel production by region as well as panel import and export data and mill closures and openings for all engineered wood prod-

uct categories. Annual subscriptions to the quarterly production reporl are $250. The report is delivered by email as a PDF file.

APA also issues an annual Structural Panels & Engineered Wood Yearbook that provides a wealth of historical demand and production data, including U.S. and Canadian softwood plywood and OSB production and capacity, U.S. regional production, panel imports by country of origin, panel exports by destinalion, U.S. and Canadian production of glulam, wood ljoists and LVL, product consumption by end-use markets, panel and EWP producing mills in North America, producers ranked by size, panel production by state, mill starts and closures, and much more.

The reference tool includes data up through 2008, with estimates for 2009. In some cases, the historical data go back as far as 1990.

Prepared by APA's Craig Adair, the yearbook (APA Economics Report E175) is $250 as a PDF only. To view the table of contents or to order online, go to the Publications section of www.apawood.org.

bling of the challenges still ahead.

Taking all those factors into account, APA's spring forecast is for U.S. GDP to return to growth by the fourth quarter and for the seasonally adjusted annual rate of U.S. housing starts to begin a long slow rise during the second halfofthis year.

U.S. housing starts, including manufactured units, are expected to total just 540,000 this year, down 45Vo from 2008 and a staggeringT5To from the 2.2 million at the peak of the housing boom in 2005. Starts next year, however, are forecast to rebound to 755,000 and to continue climbing in the ensuring years, up to 1.8 million in 2013. That expectation is based in part on the formation of an estimated 1 million households annually, representing a pool of pent-up purchase demand.

Since new residential construction under normal conditions is the single largest market for structural wood panels and other structural engineered wood products, the rise in housing starts is expected to lead the way to recovery for the panel and engineered wood industries. U.S. and Canadian softwood plywood and OSB production is forecast to rise next year to approximately 27.7 billion sq. ft. (3/8" basis), up l4%o from 24.2 billion ft. this year. Almost 80Vo of the increased production is expected to result from growing demand in the new residential construction market.

Industry production of glulam timber, wood I-joists, and LVL also is expected to climb next year, up 2lVo, 66Vo and 3 5Vo, respectiv ely

The forecast is for the remodeling and industrial markets also to show improvement next year, with structural panel demand in those sectors tp 7Vo and 6Vo, respectively. Panel demand in the nonresidential construction, on the other hand. is forecast to be down

22 Blrr.uNc Pnopucrs Drcnsr Jur-y 2009

again slightly next year, following a l2%o decline this year.

Industry production is expected to total less than 6O7o of capacity this year, among the lowest ratios in the industry's history. That ratio is expected to climb to 657o next year and to reach 907o in 20 13, when industry production is forecast to reach 41 billion sq. ft., a level last reached in 2005. The average ratio over the 15 years prior to 2008 was almost 917o. The substantially changed market supply and demand mechanics have made structural wood panels and other engineered wood products good bargains over the past several months.

Excluding shipments from Canada, U.S. imports of structural plywood are forecast to total just 430 million sq. ft. this year, down 24Vo from last year

and more than'75Vo from 2005. OSB imports are expected to be up slightly this year, to approximately 60 million ft., but down more than 9O7o from the 2005 peak of 744 million. The overall decline of panel imports extends a trend that began in 2006 with the col-

lapse of the housing market and resulting excess domestic production capacity. Panel imports are expected to begin rising again next year and to continue climbing in ensuing years in response to increased demand generated by the improving housing market.

& Canadian StructuralWood Panel & Engineered Wood Production Forecast (2008 - 2010)

U.S.

$oftW.q q Pfiwood tnitton sq, ft., oE basb) OSB (mittion sq. tt.,3/8 basis) Total $tructural Wood Panels lmirior q. n.y Glulam Timber (miuion uo. tt.) lfrtood I'rfOiete (mittion tinsar fr.) Laminated Veneer Lumlter (mirion cu. ft.) 2008 12,206 18,505 30,711 279 615 51.9 2009 2010 10,500 1a,927 13,700 16,735 24.2A0 27,fi62 213 257 350 , ,: 580 31.6 44.6 23 Jur-v 2009 Burr,orNc Pnooucrs Drcnsr

From mouement to mandate The grovuth of green building legislation

By Mark Rossolo

or small, has looked at ways to increase green building practices through public policy.

For its part, the federal government has recently debated a number of bills regarding energy efficiency in schools and other buildings, while agenciessuch as the Department of Interior, Environmental Protection Agency, General Services Administration, and Department of Health & Human Services-have either adopted or proposed formal green building policies for all o[ their buildings.

Itr/HILE green building may once V V have been a fringe movement embraced by a select few architects and building owners, it is fast becoming common practice-and is now being driven, not only by design and building professionals looking to make their projects more sustainable, but by a staggering increase in government legislation.

Whether it's a city councilperson, state representative or U.S. senator, politicians are under pressure to facilitate the adoption of green building practices. In political speak, proposing a green building policy is viewed as "win-win" for legislators, who see it as a way to address climate change, reduce our dependence on foreign oil, and ensure that our children have a

better place to live-all while saving the government money through energy and water efficiency. It also allows elected officials to position themselves in the eyes of the public as environmentally conscious and willing to act on important issues for the benefit of their community and country.

For these and other reasons, there has been an explosion of legislative activity, particularly at the state and municipal levels over the past three years. In 2001,for example,32 states debated more than 170 bills related to some aspect of green building, an already incredible number that grew to 33 states and over 200 bills in 2008.

The municipal numbers are just as impressive. as nearly every major population center across the countrv. large

To date, the vast majority of legislation has focused on the new construction of publicly funded buildings. This isn't a surprise when you consider that most public entities are under severe pressure to reduce their budgets; the potential operational savings associated with high performance buildings are simply too attractive to ignore. The most common type of legislation currently mandates publicly funded buildings over a given size threshold-typically between 5,000 and 10,000 sq. ft.-to meet or exceed guidelines set forth by a green building rating tool. The Green Building Initiative's Green Globes standard and the U.S. Green Building Council's LEED tool are the most common rating systems named, though there are many other programs in existence.

At the same time. an increasing amount of green building legislation is also being targeted toward the private sector, where governments are choosing either to incentivize or mandate energy efficiency and other aspects of building performance. Incentives, which have been the more popular choice so far, vary widely-from lowcost measures such as expedited per-

GREEN BUILDING legislation, once aimed primarily at public buildings, is now making inroads in the private sector. Builders working to earn recognition under the green building standards can earn points by using engineered wood products and efficient wood-frame construclion systems.

24 Burr,orNc Pnooucrs Drcnsr Julv 2009

ffigpwffi ffi pffiffiffi ffi ffiryreK& ffi tuK&tuem'* ffiffiffi &ruw ffiffituK$ffiffiffi -'M &ffiwtu#ffiruw ii,..r i ri liri?,.r*,,.,,,.,,,,,d r,,,, i,i;:..r i ,,,:r::i ,. i.lii,i :ri iii ilii;liii I iilliir,r rl il tll:-,ilt,i :lfir:',:i,,: '"t e@ e#, FF '' '" ' f ^$ln " r r*t q& --df *H

mit processes and fee rebates for those who meet certain requirements, to more costly measures such as property tax refunds. However, some governments, such as the city of Washington D.C., have also chosen to mandate green building within their jurisdictions, and recent history has shown an increasing willingness among legislators to require certain practices.

legislation E the Wood Industry

For the wood industry and other manufacturing sectors, the most significant potential impacts of green building legislation are not related to energy efficiency or other similar mandates, but the requirement to use certain rating systems and the specifics of what those systems entail.

It is the position of the GBI, for example, that legislation should never mandate one rating system exclusively. In addition to the fact that multiple credible systems exist in this country-and, given that, the inappropriateness of a government body creating a monopoly-it is unreasonable to expect that one system can meet the needs of every design and building professional, type of building, and budget. As in other segments of the

economy, competition among rating systems also drives the improvement of each and lowers costs. somethins

we've already witnessed as Green Globes has gained increasing market acceptance alongside LEED.

From a wood industry perspective, the issue is how different rating systems treat competitive building materials. For example, both Green Globes and LEED award points for wood that is certified as having come from sustainably managed forests, but Green Globes recognizes a number of credible systemssuch as the Forest Stewardship Council, Sustainable Forestry Initiative, American Tree Farm System, and Canadian Standards Association- while LEED recognizes only FSC. Independent research has shown all of these systems to be effective. But, aside from that, an FSC-only approach creates an issue of supply, since the vast majority of forests in the U.S. are certified to other systems.

Green Globes is also the only rating tool to strongly emphasize and encourage life cycle assessment, or LCA, which is a method of scientifically analyzing building materials and assemblies over the course of their entire lives and assigning an unbiased score that reflects their true environmental impacts. As part of the recently completed process to establish Green Globes as the first American National

Pourform-O5" Concrete Forming Panels

Pourform-OS, an AinsworthEng i nee red@ OSB substrate designed specifically for cost-effective concrete forming. lts enhanced MDO overlay, moisture resistant edge-seal, and a kali-resistant finish outperform B-B plyform every time

-at a competitive price.

l{nln:

IultnfiRsrr lfitil1ffi Inunou

"WOOD: Sustainable Building Solutions," an eight-page brochure that can be downloaded free from the APA website, describes the environmental benefits of engineered wood products, compares wood to other structural products, explains scientific research demonstrating the sustainability of wood, and orovides links to other valuable sources of information on green building.

OS" is a trademark of Ainrwo{h Corp. -9 Aansworth9 AintwotthEngineeted9 Poufform-Os? and Engineercd Pefomon.efot the Woild ofWoodaate rcgistered trademafks. 26 Burrrnrc PRoDUCTS Drcpsr Julv 2009

Releases Easlly for Farter Clean-up Thanks to its enhanced paper overlay,the 05* panel releases cleanly and eliminates wood fiber transfer, for improved concrete quality with less clean-up.

Standard for commercial green building, GBI commissioned a tool that provides instant LCA results for hundreds of common building assemblies. That tool has been incorporated into the Green Globes standard and is also free, under the name Athena EcoCalculator for Assemblies (www.athenasmi.ca).

By allowing designers to impartially evaluate and compare design scenarios based on their environmental impacts, LCA helps to ensure that a building meets its sustainability objectiveswithout infl uence from pre-existing biases that have long been an accepted part of green building. A relevant example would be rewarding the use of a product with recycled content without considering the embodied energy actually required to extract, manufacture, transport, install and maintain that product over time.

Making Sure You're Heard

The legislative and regulatory environment surrounding green building is evolving quickly-and the current economic challenges will only serve to increase the desire for operational and other savings associated with building sustainability. Elected officials nationwide are in the process of deciding what is considered green, whether to put in place incentives or mandates, which rating systems will be used to determine success, and other issues affecting everyone involved in the building industry for years to come.

Organizations such as the American Forest & Paper Association are active in the legislative arena on the wood industry's behalf, but the only way to ensure that all levels of government understand the importance of issues such as competition and LCA is for the industry to participate en masse in the debate. Joining a green building organization,

participating on a committee working to expand green building within your state or municipality, or submitting comments on proposed policies and legislation all help to ensure your voice is heard.

- Mark Rossolo is the director in charge of state outreach for the Gr e e n Buildin g Initiat iv e ( www.the gbi.or g ).

The orticle appeared originalLy in the spring 2009 issue o/t/re Engineered Wood Jotmal arul can be viewed toqether with atlditional information on green building rqtinB systetns at wttw.mtbook.com/nxtbookslnaylor/EWAB0l09/#10. Readers also may subscribe to the electronic edition ofthe biannual Engineered Wood Joumal Dy sending name, company name and email address to kim.sivertsen@apuw,oodorg.

Industry's green strategy

A broad-based task group ol North American wood products industry stakeholders has begun work on a new plan to advance the credentials of wood products as a green building material.

Still in its early stages, the effort has two objectives-first, to inventory existing industry data, research, communication programs, and tools in an effort to better coordinate their effective use, and second, to develop and then implement a strategic plan that addresses the education of key user, specifier and other stakeholder groups on the environmental merits of wood products, with an ultimate goal of helping lo increase sales of North American wood products. The group made final recommendations for the scope of work and agreed to retain a consultant to complete the inventory of data and develop the strategic plan at a recent meeting in Chicago.

Group members are Ken Skog, U.S. Forest Service/Forest Products Laboratory; Jennifer O'Connor, FP-lnnovationsiForintek; J.P. Martel, Forest Products Assn. of Canada; Bob Glowinski, American Forest & Paper Assn.; Dave Bischel, Calilornia Forestry Assn. and Forest Industry Assns. Council; David Anderson, Natural Resources Results; Cees de Jager, Binational Softwood Lumber Council; Jeff Howe, Dovetail Partners, and Dennis Hardman, APA and Wood Producls Council. Hardman also chairs the task group.

i

Julv 2009 Burr.nrnc Pnooucrs Drcnsr 27

Setting the standard Work progressing on new, updated rules

Panel Laheling lnswers

Questions and answers pertaining to the panel thickness labeling issue in California are contained in an Technical Topics publication prepared by APA last year. The four-page publication provides background on the matter, answers to several frequently asked questions, and a facsimile of an APA trademark showing the supplemental mill thickness label that many mills are now using to comply with California Weights & Measures requirements. Quesflons & Answers Regarding Panel Thickness Labeling, Form No. TT0548. is free from www.aoawood.oro.

A PA and industry stakeholders are .Cl,well along on efforts to develop and update key structural wood panel product and performance standards.

The standing committees for Volttntctrt, Product Standard PS I: Structttral Plywood and Voluntary Product Standard PS 2: Performance Standard Jbr Wood-Bosed StructuralUse Panels were recently reconvened and have met to address possible changes pertaining to product thickness Iabeling, fastener and concentrated load provisions, and other testing, label ing and certil'ication issues.

PS 1 is a prescriptive standard that sets requirements for producing, marketing and specifying softwood plywood used in a wide array of construction and industrial applications. It was last revised in 2007. PS 2. last revised in 2004, is a performance-based standard resulting from efTorts to harmonize U.S. and Canadian standards under the U.S.-Canada Free Trade Agreement. The standing committees of both standards are comprised of members representing panel manufacturers. suppliers. regulatory agencies. government, academia and inspection agencies. APA serves as a non-voting sponsor and technical advisor.

Thickness labeling changes, if adopted, would be designed to achieve consistency between provisions in PS 1 and PS 2 and those found in hand-

$iding Gets listed

Two varieties of APA 303 plywood siding are now listed in the California Wildland Urban Interface Products handbook as products complying with new California Department of Forestry & Fire Protection regulations for fire-resistive construction assemblies in state urban-wildland intedace areas.

The products include: (1) 303 siding with shiplap edges, nominal 19/32" thick and grooves spaced 4" on center, manufactured wilh veneers of all southern pine or Douglas fir face, back and center with hemlock or Douglas fir cross plies, measuring 4x8 ft., and (2) 303 reverse board and batten, nominal 19/32" thick and shiplap edges, grooves spaced 12" on center, manufactured with face, back and center of Douglas fir veneers and cross ply veneers of hemlock or Douglas fir, measuring 4x8 ft. The new regulations went into effect January 1, 2009. The listings are based on the results of a series of fire tests that APA sponsored at the Western Fire Center, Inc., an accredited fire test laboratory in Kelso, Wa.

,Trtffl * \ \ I 1lt i{ :rri?it?i \tl'. SolarPly'" Prevents Up ta 97Y" of the Sun's Heat from Entering the Attic. t Attic temperatures reduced by as much as 30e I Reduees workload on your A/C unit

Lowers cooling bill up to 20%, reducing energy consumption - saving you money Tiaditional Sheothing Allows Radiont Iteot to EnterYour Home. I Extreme attic temperatures I Heat transfers through the attic into the living areas I lncreased workload on A/C & system I Electric bills soar rtal pany

more information. call 1-800-3s9-6432 www.coastalplywood.com 28 Br rlornc PRoDU( rs Dlcnsr Jurv 2009

I

For

books published by the National Institute of Standards & Technology. The differences have resulted in the red tagging of plywood at retailers in California by that state's Division of Measurement Standards. APA and industry allies developed an interim solution last year with the California Department of Food & Agriculture that provides for a supplemental marking system-the normal PS I and PS 2 marks with reference to a thickness "category," and a separate mill stamp designating panel thickness in accordance with NIST tolerances. That partial fix does not assure adherence by local regulators, however, and the matter was therefore referred to the standing committees. The committees have considered several options, and proposed revisions are now being drafted for further review and public commenl later this year.

Completion of revisions to both standards is expected in 2010.

A new Standard Jbr PerformanceRated Engineered Wood Siding (ANSI/ APA PRP-210), meanwhile, was completed late last year under APA's recognition as an American National Standards Institute-accredited standards developer and is now available

from APA.

The new siding standard, based on APA's proprietary PRP- I 08 Performance Standards & Policies for Structural-Use Panels, covers the manufacturing, qualification and quality assurance requirements for engineered wood siding products. APA served as the secretariat of the consensus committee that oversaw its development.

APA is also utilizing its ANSI accreditation to spearhead development of a national consensus standard

for structural insulated panels in cooperation with the Structural Insulated Panel Association and recently began developing a new national consensus standard for rim board. Additional standards under consideration by APA include concrete form and fiber-reinforced glulam.

APA's recognition as an accredited ANSI standards developer helps elevate standards as national consensus standards, which can significantly expedite building code acceptance.

i I t -{

Ti'uPour Form Panels bgineered To /t{eet The Toughest Dem ands WE'RE READYTO BUILD! When Your Shovel Ready Projects Get Going, Call Swanson Group Sales. 1-800-331-0831 www.svvansongroupinc.com Aror*" Yffitr#l ,# Jut-v 2009 Burr-ornc Pnopucrs Drcrsr 29

A C0NSENSUS standard for engineered wood panel siding was recently completed under APA's recognition as an American National Standards Institute (ANSI) accredited standards developer.

Strategic Target

Raised wood floors constitute major market opportunity

hESPITE the current state of the I-fhousine market and overall economy, pockels of opportunity still exist for expanding wood product demand. One such strategic target is the raised wood floor market in the Gulf Coast region, where the risks of storm flooding and expansive soils make raised wood floors a natural choice over traditional concrete slab-on-grade construction.

The Southern Pine Council. APA. their member manufacturers, and other industry partners have been working together for months under a program called Raised Floor Living to deliver construction strategies, product support, and educational outreach to

home builders and buyers in a broadbased effort to increase awareness, acceptance and use of raised wood floors, as well as other wood construction systems, from Texas to Florida to North Carolina.

Although SPC has promoted raised wood floors along the Gulf Coast and elsewhere for years, the system gained a major spike in interest and wood industry attention following the massive flooding and extensive property damage caused by hurricanes Katrina and Rita in late 2005. Compared with other options-such as concrete slab atop dirt fill, slab on backfilled perimeter wall, or ring levee-the raised floor system often is the most

practical and cost-effective way to protect buildings and meet local building ordinances in flood-prone areas. The system provides other benefits as well, including excellent insulating properties. ease of improving or repairing utility lines, durability, uplifting comfort, and classic style, among others.

APA activities in the region are aimed at educating builders, framers, designers and building code officials about the merits of wood construction, while SPC is working both to create consumer awareness of raised wood floor features and benefits and to complement APA's design and construction education efforts. (Visit www. raisedfloorliving.com for more information.)

The prospects for increasing wood industry share of the residential floor market is strongly supported by the results of a consumer preference survey released last year by the National Association of Home Builders. For the U.S. as a whole, 42Vo of consumers prefer wood framed first floors, compared with 25Vo for concrete slab, according to the survey results. The remaining one-third had no preference, were unsure, or didn't know. And while the preference for concrete slabs was only 25Vo, concrete represents 537o of total first floor area, suggesting a wood floor promotion campaign such as that now being conducted by APA and SPC in Gulf Coast states could yield positive results.

The preference for wood varies widely by region, with the highest popularity in the North Central region and lowest in the West South Central region, where concrete has a longstanding tradition. Those findings provide support for the view that the

30 Burr,lrNc Pnooucrs Drcrsr Julv 2009

RAISED WOOD floors provide a variety of builder and homeowner benefits, including better protection from flood damage.

raised wood floor effort could also make inroads in other regions.

The Raised Flooring Living program employs a wide variety of promotional tactics, including professional seminars and training events, demonstration projects, trade and consumer publicity, advertising, local television coverage, publications and website information. Cost and performance studies also are under way to develop data to help overcome misperceptions about the economies and long-term performance advantages of wood construction.

APA's activities also place special emphasis on wind-resistant structural panel sheathed wood walls. Structural wood panel share of the residential wall sheathing market stands at approximately 707o, which means there is substantial volume at risk, but also potentially to gain.

APA, which has conducted high wind and seismic load tests at its Tacoma. Wa.. research center for years, has in recent months also installed new state-of-the-art combined shear and uplift test equipment, launched a three-dimensional whole house test program, developed a wall bracing website (www.wallbracing.