Supporting litchi fruit growth and quality

Ideal for early season

Large to extra-large, uniform fruit

Deep red flesh with high brix and excellent taste

Very high yielding with strong vines

Resistance to Fusarium and Anthracnose

Attractive oval fruit with dark green rind and crimson red flesh

Very firm texture, good flavour and brix

Uniform, fruit size of 10kg to 15kg

Very high yield potential

Resistance to Fusarium and Anthracnose

Early maturity

Very high yielding with uniform fruit

Deep red flesh colour, firm texture and high brix

Resistance to Fusarium and Anthracnose

Ideal for early and late season

Large, uniform, seedless fruit

Deep red, firm flesh with long shelf life

Very high yielding with high brix and excellent taste

Strong vines with resistance to Fusarium

Ideal for summer and early season

Large to medium, uniform, seedless fruit

Deep red, crisp flesh with long shelf life

High brix and excellent taste

Vigorous vines with high yield

Ideal for summer season

Large, uniform, seedless fruit

Deep red, very crisp flesh with long shelf life

High brix and excellent taste

Very vigorous vines with high yield

4 Michael Esmeraldo new MD of Netafim SA

4 Citrus grower development company invests R40 million in enterprise development

5 A cold chain can improve business performance

6 R1,1 million donated for rural safety

6 Tenacious, integrated approach secures young farmer of the year title

8 Aartappelboer stap met jongboer-titel weg

8 Boer volhoubaar met betroubare inligting

9 Olive farmer Jo Neser on building dreams and communities

9 Olive oil award winners announced

COVER

Macadamia was first commercially produced on a wide scale in Hawaii, where Australian seeds were introduced in the 1880s. South Africa has been the world's largest producer of macadamia since the 2010s.

EDITORIAL Willie Louw (Group editor)

Carien Daffue (Editor) 018 293 0622 info@mediakom.co.za

ADVERTISING

Jana Greenall 011 476 3702 082 780 9914 mediacom@lantic.net

DESIGN

PO BOX 20250, Noordbrug, 2522

Bly ingelig en volg ons op Facebook. Keep up to date and follow us on Facebook.

- Groente en Vrugte/ Vegetables and Fruit

- www.facebook.com/GroenteenVrugte/

Mercia Venter studio.chatnoir@gmail.com Vrugteverliese

Netafim South Africa announced that Michael Esmeraldo is their new Managing Director. Esmeraldo took over the reins on 1 November 2022 from Adriaan de Lange who joined Netafim SA at the end of 2021. De Lange has made a significant impact to date but decided to pursue a new opportunity.

“I have been offered a very special opportunity in the plant feed industry. The offer was unexpected, and it has been a very difficult decision to make so quickly after joining Netafim SA,” said De Lange. “The position however will allow me the opportunity to deliver on my purpose, which is to create wealth and prosperity in Africa through unlocking the potential of Africa’s abundant agriculture and mineral resources.

“Netafim SA is an exceptional business and I have been privileged to have been part of the team for the last year. It has been a tough time, with serious disruption in the markets, but this awarded us time to refocus and improve various aspects of the business,” said De Lange.

Looking towards the future, an opportunity was created to select a leader from within Netafim’s own ranks. This decision was made keeping in mind continuity within the company, lasting relationships with clients and ensuring a sustainable

future through the next generation. Netafim SA is celebrating its 30-year anniversary in 2022, with the theme of “Celebrating the past, growing the future”.

Michael Esmeraldo joined Netafim SA in January 2015 as an agronomist. In February 2019, Esmeraldo was appointed as Regional Sales Manager working from Netafim’s Nelspruit office and he joined the managerial team in April 2020. He has made an impact and successfully managed the Northern team by driving growth, building trusted relationships with key partners, customers and stakeholders.

Focused on building a strong network in the industry, he joined the South African Irrigation Institute (SABI) early in his career. In 2021, he was elected as the youngest ever president of this industry organisation and has been leading the industry in this position ever since.

“It is an honour to be trusted with the role of Managing Director of Netafim SA,” said Esmeraldo. “I am very passionate about agriculture, irrigation and Netafim, and it is a privilege to have the opportunity to take a leading role. I know that there will be a steep learning curve, but I am excited about the growth opportunity and to be part of the future in the local irrigation industry.”

The Citrus Growers’ Association Grower Development Company (CGA-GDC) has allocated and spent R40 million in 2022 in grant funding towards the successful enterprise development of black citrus growers and their farms across South Africa, through its Enterprise Development Grant Fund (EDGF).

Most notably, the grant funding provides support to growers through the purchase of key production inputs, including fertilizer and chemicals. This is critical following exorbitant price hikes across a number of farming inputs this year, with fertilizer prices increasing just over 56% between 2020 and 2021. These price increases have hit smaller black growers the hardest.

By supporting these growers with funding towards these critical inputs, the CGA-GDC also hopes to help mitigate the impact of other industry-wide challenges affecting the sustainability and profitability of developmental farms in the sector. The challenges include reduced market access (including the highly stringent and costly phytosanitary regulations applied by the EU), decaying public infrastructure, erratic electricity supply and a devastating decline in real export prices.

Long term, the EDGF will assist developmental growers with the capital required to procure production infrastructure, machinery, equipment and a range of horticultural products. The

grant also aims to assist growers with the costs associated with the accreditation required (legal and professional) towards the commercialisation of their fruit for export to foreign markets.

The funding made available to developmental growers is collected through an export levy paid annually by CGA members to the CGA-GDC. The CGA-GDC then administers and allocates the funding through direct payments to service providers towards the successful enterprise development of black citrus growers and producers in South Africa.

The CGA-GDC welcomes the continued support of bigger commercial growers, through their commitment to pay annual levies to ensure that the sector supports smaller, developmental growers, with access to funding to grow their enterprises sustainably.

In Limpopo, the EDGF has already assisted in the successful establishment and growth of Manini Holdings, owned by citrus grower Thabo Moripane. Moripane will be using his grant funding to purchase the inputs he requires to support his planted citrus trees while he works towards the establishment of an additional 70 ha of citrus, including 10 ha of Leanri soft citrus, 10 ha 2PH seedless lemons, 40 ha pr ARC Nadorcott and 10 ha Maayana soft citrus.

Maintaining the cold chain is one of the most important and challenging tasks for businesses in the perishable and fresh food production industry. On average, around 50% of the food produced in African countries becomes unfit for human consumption, due to poor handling and storage conditions experienced along the value chain.

This is according to Dawie Kriel, Head of Business Development at EP Refrigeration – a division of Energy Partners and part of the PSG group of companies, who says that the battle against degradation starts at the moment that any food item is harvested.

“Ensuring that products remain intact and correctly refrigerated throughout the value chain should be a business priority for two reasons: firstly, it reduces unnecessary product losses, thereby improving business performance, and secondly, it ensures that the product reaches the end-consumer in the best possible condition, promoting repeat purchases,” says Kriel. “The key to optimising the cold-chain lies in ensuring the utilisation of technology and equipment and consistently monitoring the temperature data throughout the cold-chain.

“Whether it’s meat or fruit, the goal is to control food temperature as tightly as possible from the time that it is harvested, to the time that it reaches the consumer. In order to do this, it is very important to understand exactly where the weakest points in the chain are. To achieve this, the correct monitoring systems are crucial.”

He adds that there is no going back on degradation once it has started. “Fruit is probably the best example of why it is important to start the process off right. When fresh fruit is harvested, it continues to respirate and convert sugar into energy.

“Add to this, the respiration of most fruit doubles with every 5 °C that the temperature is raised above its ideal storage temperature – just above 0 °C for most fruit and veg. So, the first challenge is to be able to cool the produce as close as possible from where it is harvested (at 25 °C for example) to a tempera ture that will maintain the quality for the longest time.”

He says that the length of time that it takes to load and pack the produce usually means that the product stays at less-thanoptimal temperatures for too long.

“One way in which some farmers have begun to remedy this, is to pre-cool their harvested produce in order to prolong the time that it stays fresh. Another tactic commonly used in the wine industry, is to harvest at night-time when respiration rates are lower.

“Keep in mind that some of the weakest links in the chain

are where the product is passed on to the next operator.”

Kriel explains that in order to find and fix weak links in the cold chain, we need to find ways of measuring temperatures and ensuring that potential refrigeration failures are detected before they affect the product throughout the chain. Real-time monitoring and maintenance of the cooling infrastructure and product involved is essential.

“Energy Partners’ Intelligence and Refrigeration divisions have world-class solutions that make a real difference in efficiency and reliability.

“The rise of servitisation, outsourcing of the ownership, operation and maintenance of cooling infrastructure is a growing global trend and has become one of the most viable ways for businesses to save on capital and operational costs. This is what is referred to as Cooling as a Service (CaaS). In a CaaS scenario, a business does not own any of the refrigeration infrastructure on its premises.”

Kriel adds that the ideal scenario would be if all the businesses along the cold chain adopt CaaS as a part of their operations

Maintaining the cold chain is one of the most important and challenging tasks for businesses in the perishable and fresh food production industry. On average, around 50% of the food produced in African countries becomes unfit for human consumption, due to poor handling and storage conditions experienced along the value chain.

Agri Securitas Trust Fund announced a donation of R1,1 million made to the Trust Fund by Corteva Agriscience, Sanlam and NWK limited at the Agri SA 2022 congress. The donation is a vital contribution to the Trust’s work of supporting farming communities in their endeavours to protect themselves against farm attacks and general criminality.

“Farmers worldwide are vulnerable to crime, but in South Africa, the farming community must also contend with brutal farm attacks, a phenomenon peculiar to our environment, compromising the country’s future food security,” said Cobus van Zyl, chairperson of the Agri Securitas Trust Fund.

“The vulnerability of farming and rural communities is therefore not only a farmers’ issue but a community issue and a national imperative.”

The funding will be used to expand the installation of camera systems, expensive technology that has proven to be successful in monitoring vast areas for criminality, and detecting veld fires before they can spread.

The donation underscores the strong partnerships forged between the agricultural sector and corporate world. It builds on the generous donations from other corporate partners, including Nissan SA.

“The Trust Fund was founded by Agri SA in October 1998 as

an initiative started by the late President Mandela after a special summit dealing with rural safety. Since 2017 the trust fund has supported more than 122 rural safety projects improving the safety, lives and livelihoods of almost 8 800 farmers and 183 000 farmworkers and their dependents,” says Van Zyl.

“Corteva Agriscience is on the ground and innovates collaboratively with farmers to help enable their success,” said Tony Esmeraldo. Country Leader, Southern Africa, at Corteva Agriscience.

Karl Socikwa, Group Executive: Market Development and Sustainability at Sanlam, says: “We know how catastrophic it would be to our country, economy and communities if the agricultural sector is unable to offer us enduring food security. As part of our long-standing relationship with the Trust Fund we will continue to support their exceptional efforts in helping increase the security in the vulnerable rural areas. Our purpose as a business is to empower generations to be financially confident, secure and prosperous and we hope this initiative will have an impact in this area for farming communities.”

“The Trust is grateful for these donations. These companies should be recognised and supported for their contribution to the trust fund to ensure a safe and prosperous farming community,” says Van Zyl.

KwaZulu-Natal’s Agricultural Union, Kwanalu, announced that North Coast macadamia and banana farmer, Tammy Williams, is the 2022 KZN Toyota Kwanalu Young Farmer of the Year.

Williams impressed judges with her determination in learning from the ground up to mastering many technical aspects of farming, implementing environmentally conscious applications and driving community upliftment.

Williams (38) will represent Kwanalu in the Toyota SA/Agri SA National Young Farmer of the Year Competition 2022.

“Every year we are astounded at the extremely high standard of our young farmers - a testament to the passion, determination and excellence of agriculture in our province,” said CEO of Kwanalu, Sandy La Marque.

With no prior farming experience, Williams started out as a receptionist at Windemere Estate Farm 12 years ago. Taking an interest in farming and showing a willingness to learn, her potential was recognised and she was promoted to manage a section of the banana farm operations.

Rising to each challenge over the years, she took over the production and management of several banana farms, totalling 120 hectares. In 2013, she expanded into macadamia produc-

tion. Since then, they have grown their macadamia operations to 150 hectares.

“Having been involved in both the technical and administration aspects of the farming, I have learnt that the two go hand in hand in keeping a farming operation efficient,” says Williams.

Striving towards areas of improvement, she has her sights set on fine tuning their macadamia and banana operations towards increasing profitability for the business in the future.

“I believe that the quality of the macadamia nuts produced on our farm will be what sets us apart in future. We have been getting closer to understanding how to do this by trying out new techniques, while also calibrating the ideal conditions for a superior end product,” says Williams.

She is passionate about conservation and is always looking for new ways to minimise the use of insecticides and herbicides.

“I am an avid bee lover and have introduced bee basil and other vegetation to attract good insects for the farm. I also make sure we conserve the natural bush and waterways to take care of the sensitive ecosystems on the farm,” says Williams.

She believes that anyone with a willingness to work hard and to learn can achieve their heart’s desire.

Daniël Opperman van Naboomspruit is as TLU SA se jongboer van die jaar aangewys. Hy boer met aartappels as hoofgewas en met witboontjies, ertjies en groenboontjies. Die wenner van die 2022-kompetisie is by die jaarlikse TLU SA kongres bekend gemaak.

“Dit was besonder moeilik om vanjaar se wenner aan te wys. Elke jongboer wat ingeskryf het, kon wen. Dit is hoe hoog die standaard was en hoe beïndruk ons was met dit wat ons gesien het. Daniël Opperman is waardige wenner,” sê Bennie van Zyl, TLU SA se hoofbestuurder.

Riaan Rossouw van Nigel-boerevereniging en Clemens Senekal van Suikerbos-boereunie was onderskeidelik tweede en derde.

Volgens Opperman het hy besluit om vir die jongboer van die jaar-kompetisie in te skryf om hom deur ’n moeilike tyd te dra. “Dit was iets lekker wat ek kon doen in ’n tyd wat nogal moeilik en uitdagend was. Dit is altyd lekker om erkenning te kry en dit gee mens ook weer moed. Dit is ’n ongelooflike voorreg en eer om as TLU SA se jongboer van die jaar aangewys te word.”

Suid-Afrikaners is met reg trots op hul doen-dit-self, boermaak-‘n-plan-reaksie op die lewe se uitdagings. Wanneer dinge egter ingewikkeld raak, is goeie, onpartydige raad onontbeerlik, sê Janet Lawless van InteliGro.

Tegnologie en toegang tot inligting maak dit toenemend moontlik vir gewone mense om take te verrig wat voorheen as die domein van spesialiste beskou is. Jy kan jou oorsese reis self beplan en bespreek, geen gereg is onmoontlik met die internet wat wemel van resepte nie en Dr Google kom goed te pas om ‘n kwaal te diagnoseer en te dokter.

Een van die groot dryfvere van doen-dit-self is kostebesparing. Daar word geredeneer dat, wanneer die middelman uitgesny word, moet die produk of diens minder kos. Dieselfde denkwyse is tans ‘n sterk tema in landbou. Geoganiseerde landbouliggame vra byvoorbeeld dat die waardeketting korter gemaak moet word om insetkoste laag en die bepaling van pryse deursigtig te hou.

“Produsente kan nie meer bekostig om deel te wees van ‘n ondoeltreffende waardeketting nie,” sê Lawless. Maar, voeg sy by, minder skakels maak nie noodwendig die ketting goedkoper nie. Die sleutel lê in elkeen se waarde.

“Agente wat slegs goeie produkte teen ‘n goeie prys en met goeie diens verkoop, is ‘n skakel wat nie meer plek het in die waardeketting nie,” verduidelik Lawless. “Vandag dring produsente op oplossings aan waarmee hulle komplekse struikelblokke uit die weg kan ruim én wat vir hulle plaas se eiesoortige omstandighede ontwikkel is. Dit is nie iets wat jy met die hulp van die internet kan ontwikkel nie.”

Die oplossings wat produsente nodig het om in die nuwe produksie- en markomgewing te floreer, sluit in:

• Lae- en/of geen-residuprogramme wat toegang gee tot streng gereguleerde markte.

• Betroubare en relevante data vir beter en vinniger besluitneming.

• Opleiding vir plaaswerkers in die korrekte en veilige gebruik

van produkte om aan die vereistes vir volhoubare produksie en rentmeesterskap te voldoen.

• Programme en praktyke wat ontwikkel is vir ‘n spesifieke plaas se grondsoorte, klimaat en bewerkingspraktyke. Dikwels is proewe op plaasvlak die enigste manier om werklik uit te vind wat doeltreffend is.

• Opsies vir finansiering wat spesifieke uitdagings en geleenthede in ag neem.

• Bestaande programme of projekte waarby produsente kan inskakel om hul verantwoordelikhede as rentmeesters na te kom.

Onderliggend aan elk van hierdie punte is die beginsel van onafhanklike advies wat die produsent tot voordeel strek en nie met ‘n verskuilde agenda gedeel word nie.

“Ons het nou die era van vertroude besigheidsvennote betree,” sê Lawless. “Produsente koop nie meer produkte nie, hulle belê in oplossings wat op volhoubaarheid gerig is en die volle kompleksiteit van die produksie-omgewing in ag neem.”

Ten einde aan hierdie vereiste te voldoen, het InteliGro in 2021 ‘n program van stapel gestuur wat sy gewasadviseurs toerus om produsente van relevante, akkurate inligting te voorsien wat hulle in staat stel om munt te slaan uit die transformerende produksie-omgewing.

Met die program wil InteliGro al sy adviseurs en leerlingadviseurs mettertyd tot senior of gesertifiseerde gewasadviseurs (CCAs - Certified Crop Advisors) ontwikkel. Die program is ‘n weldeurdagte kombinasie van gereelde evaluasies, tegniese en kommersiële opleiding en die ontwikkeling van persoonlike en interpersoonlike vaardighede.

Die eerste groep CCA’s het aan die einde van 2021 hul sertifikate ontvang en onlangs het nog 14 gekwalifiseer. “Ons senior gewasadviseurs is volledig toegerus om ‘n verskil op die plaas te maak, want soms is doen-dit-self nie die beste opsie nie,” sê Lawless.

Having worked as a commercial lawyer all his life, Jo Neser traded the corporate world for the great outdoors in 2021 to become a full-time olive and wine farmer. Along with his wife, Tessa, he embarked on this life-long dream. Today, as one of South Africa’s finest producers of olives and olive oil and the recently released Waterleliefontein wine, their farm Waterleliefontein stands a testament to how dreams can flourish while building communities along the way.

“I had a heart attack and a bypass operation in 2010 and subsequently had to make a lifestyle change, so my wife and I looked for a rural piece of land near a river and mountain. And we found this piece of land which we bought.”

But it was only when the Covid-19 pandemic struck that Jo realised that the farm could become his new home. “My wife is also a partner in my former law firm,” he says, “and we learned during the lockdown that we could practice law remotely in a large law firm. So we decided to sell our house in Cape Town and move to the farm.”

At first, the farm wasn’t viable for large-scale operation as it only had about 1 600 olive trees on it. But learning how to transplant mature trees, he has grown the farm to have 4 000 mature olive trees, all in production. Much of the farm’s success, Neser says, can be attributed to the relationship he

has with nature.

“We are not organic farmers,” says Neser, “but we try to farm as organically as possible and we see that our olive trees and vines get as much natural feeding as possible.”

With this approach, he can cultivate some of the region’s finest olives and wine grapes without sacrificing the land for future generations.

But Neser also points to his team on the farm as a larger driver of Waterleliefontein’s success, especially their manager, Johann Hugo, a retired wine farmer from Worcester.

“We provide permanent employment and diversify the workers’ knowledge of skills like being able to prune vines and operate the olive press machinery,” says Neser.

“During harvest time, for a period of three months, we temporarily employ another 30 people from the community per year.”

Additionally, Jo and Tessa’s experience in law has allowed them to get involved in community-based organisations, benefiting people with their knowledge.

Inspired by Neser’s work at Waterleliefontein, the world's oldest workwear brand Sweet-Orr joined him on his farm to see what drives his passion and why, above all, everything he does is a labour of love.

The ten top scoring extra virgin olive oils were announced for the prestigious Absa Top 10 Olive Oil Award, following an additional round of judging after the annual SA Olive Awards. The winners are Altevrede, De Rustica, Falcon's Nest Farm, Het Vlock Casteel, Mardouw Investments, Morgenster, Oudewerfskloof Olive Farm, Porterville Olives, Rio Largo Olive Estate and Zoetigheyd Farms.

The 2022 Absa Top 10 Olive Oil awards took place at Asara Wine Estate in Stellenbosch. As part of an ongoing partnership between Absa and the SA Olive Industry Association,

every year following the annual SA Olive Awards, the highestscoring gold medal winners are entered into an additional round of blind judging.

SA Olive’s CEO, Vittoria Jooste, says they are delighted to be celebrating South African olive oil producers with such a prestigious event. “So much hard work, determination and technical expertise are needed to create EVOOs of the highest quality. South African producers should be duly recognised for producing quality olive oils, year after year, in spite of the many challenges.”

Fruit abscission is a normal physiological process to produce a good crop with quality fruit. External factors can lead to excessive fruit drop and production loss. With orchard management, growers can to a great extent mitigate adverse events.

Schoeman1Although litchi often flowers profusely, only 1-5% of the female flowers set fruit, depending on tree, cultivar, year and environment. Fruit abscission is a normal physiological process to ensure that limited resources are supplied to produce a good crop with good quality fruit.

This self-regulating mechanism is, however, greatly influenced by external factors such as adverse climatic conditions (extreme temperatures, low humidity, drought, strong winds, prolonged rain), lack of nutrients (especially boron and zinc) and competition with vegetative growth, which can lead to excessive fruit drop and production loss.

In addition, flowering and fruit growth are energy costly processes and require ample water, nutrients and carbohydrates. Growers can mitigate adverse events to a great extent and promote fruit quality and production by adequate orchard management.

Pollination and fertilization are the preconditions for sufficient initial fruit set. Plenty of bee colonies (4 hives per hectare) should be introduced to the orchard before flowering. Sufficient initial fruit set is also the best way to suppress summer flush, which competes with the fruit for carbohydrates and can cause heavy fruit drop.

Water and irrigation management plays a significant role to promote uniform flowering, good fruit set and early fruit development. Irrigation is particularly important during the sensitive first six weeks after female flowering. Heat stress and water deficits can lead to excessive flower and fruit drop.

During the cell division stage, these factors will limit potential fruit size and predispose fruit to cracking. If tensiometers are used, irrigation should be initiated when levels in the active root zone reach -30 kPa in heavier soils, and -25 kPa in

lighter soils. In cooler areas, be careful to not over-irrigate at this time.

Flowering and fruit development is a nutrient demanding phase. Fertilization with zinc, boron and calcium is important, because a significant amount of these elements are taken up by the plant during this phase. Foliar sprays of Kelpak or similar products (supplying cytokinins) applied at female flower, boron (maximum 0,5%) applied 15 days after fruit set, and calcium are utilised to support fruit set and cell division.

To support fruit set through to exponential fruit growth, 60-70% of the annual potassium requirement is soil applied between full bloom and after the second fruit drop, while 20% of the annual nitrogen requirement is applied at fruit set. Do not over-apply potassium in the early part of this phase as it could suppress sufficient calcium uptake, especially in cultivars prone to cracking. Sufficient calcium levels are critical for strong cell walls to limit fruit cracking, and promote fruit quality.

Generally, calcium should be maintained throughout the year, but particularly for fruit set, calcium nitrate is commonly applied as foliar spray. If leaf nitrogen levels are high, nitrogen-free calcium sources can also be considered (e.g. calcium chloride).

Girdling is an effective measure to suppress summer flush and root growth and significantly improves fruit set. Girdling for promoting fruit set is done during female flower bloom as a spiral around the trunk. Although very effective, girdling has not been widely used in South Africa.

Synthetic auxins have been proven to assist fruit retention. For the South African market, growers may apply Maxim® (3, 5, 6-TPA) for ‘Mauritius’ at a concentration of 20 ppm (2 tablets/100 L water) at the 2 g fruit mass stage (before the second fruit drop period).

Orchard practices to support fruit quality are aimed at pro-

moting fruit size and colour, and preventing fruit cracking, sunburn and insect damage.

Water management during the exponential fruit growth stage and maturation is important to promote fruit size and prevent sunburn. Trees that are under mild water stress during this stage often have smaller fruit. Moreover, under these stress conditions, fruit can swell excessively and crack after rainfall.

Optimal irrigation with micro sprinklers (depending on soil type) would be to initiate irrigation at 30-40% depletion of easily available soil moisture in the active root zone throughout flowering and fruit development. Trees should be irrigated early in the morning, especially during hot and windy periods, to ensure that the trees start the day with low stress levels. Soil moisture levels should be maintained close to field capacity, particularly when heavy fruit drop is expected.

Mid-canopy or overhead sprinkler irrigation can be used to increase humidity on expected hot days. However, this is only viable if sufficient water is available because atmospheric demand almost always exceed irrigation requirements. Low tree skirts and application of mulch can assist in maintaining good moisture levels in the root zone.

Fertilizer applications suggested in the previous section will also promote fruit quality characteristics. A well-balanced nutrition is required for optimal fruit colouration as various elements play a role in fruit colour development (magnesium seems to be particularly important), as well as in fruit flavour and fruit quality.

Conventionally, leaf samples are taken during the fruit

growth period (October/November) and can assist to determine immediate interventions required, e.g. foliar or soil applications of magnesium, manganese, copper, sulphur and potassium, and to plan the fertilizer requirements for the coming season. Too high nitrogen levels during this period can lead to reduced colour development.

The synthetic auxin Maxim® may also be used for improving litchi fruit size and should be applied at a concentration of 40 ppm (4 tablets/100 L water, applied at the 3-4 g fruit mass stage (after 2nd fruit drop period). Maxim should only be used once per season, either to reduce fruit drop or to improve fruit size.

Because girdling increases the fruit growth rate by increasing the carbohydrate availability to fruitlets, it can also be a valuable aid for increasing fruit size. For this purpose, girdling should be applied at the 2 g fruit mass stage. However, under South African climatic conditions, girdling is only recommended once per season.

Fruit flies, litchi moth and false codling moth can do considerable damage to the litchi crop if left uncontrolled in certain areas and years. Monitoring for these pests should start early in the season and recommended control measures should be applied to protect the crop.

The EU approval period for use of Prochloraz will end at end-December 2023. This means the EU MRL for Prochloraz will be adjusted down to 0,01 mg/kg, and growers will not be able to rely on this post-harvest treatment to manage diseases such as anthracnose. Management must start on-farm with a combination of cultural practices.

Mukondeleli Munzhedzi SUBTROP SUBTROP JOURNALBACKGROUND

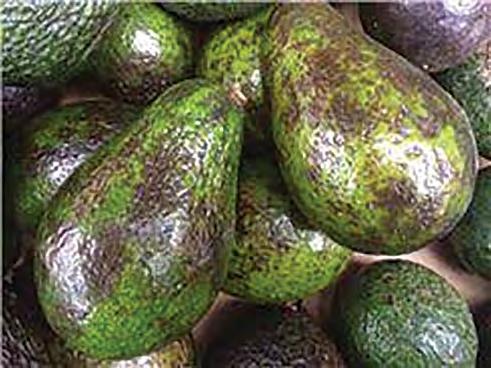

Anthracnose is one of the most severe and widespread post-harvest diseases. Fungi in the Colletotrichum gloeosporioides species complex cause anthracnose in a wide range of tropical plant species including avocado. Anthracnose affects fruit appearance; damaged areas discolour to produce a sour flavour. Decay of infected fruit reduces shelflife and income.

SYMPTOMS

Anthracnose symptoms can develop on fruits, leaves, shoots and flowers. Most fruit damage does not develop until after harvest.

FRUIT

Pre-harvest

Pre-harvest anthracnose occurs mainly on fruit that has suffered mechanical or insect damage. It takes the form of small, dark and disfiguring spots which sometimes occur around the lenticels (natural openings) in the fruit skin.

Post-harvest

• Brown to black lesions < 5 mm diameter develop around lenticels. Lesions appear just after ripening on green fruit with visible blemishes (Fig. 1). Lesions difficult to see on ripe dark skin 'Hass' fruit.

• Lesions become darker, larger and increasingly sunken (Fig. 2). Lesions spread over the entire fruit surface and throughout the pulp. Lesion centre becomes slightly sunken and may develop cracks.

• Lesions produce pinkish, moist masses of fungal spores as

they age (Fig. 3). As the fruit ripens, infection spreads rapidly into the flesh causing a greenish black, firm decay.

• When the fruit is cut in half through one of the lesions, rot extending into the flesh exhibits a hemispherical pattern (Fig. 4). Decayed pulp is initially firm but becomes soft as decay advances.

Fungal spores (conidia) are mainly spread by water (rain/dew), which moves spores from infected branches, twigs (alive or dead) or leaves to fruits. Spores germinate within 7 hours when fruits are wet. Fruits are susceptible from fruit set to harvest. Optimal conditions for infection are temperatures above 20 °C and periods of extended rainfall and/or high relative humidity (63 - 96%). After the fungus penetrates the fruit skin via lenticels, it remains inactive until the fruit ripens. The brown areas that develop from latent infections on the avocado skin are inhibited by anti-fungal chemical compounds in the unripe fruit skin. The fungus can also penetrate via entry portals created by other fungi e.g. Cercospora spot.

Control anthracnose primarily with good cultural practices in the orchard and proper post-harvest fruit handling.

• Use windbreaks in windy areas to reduce fruit scarring and

reduce penetration points for fungi.

• Prune out and dispose of dead wood and old fruit away from trees before flowering to reduce wind damage and remove spores.

• Prune low branches at least 0,5 m above the ground to promote air circulation thereby reducing humidity and dampness within the tree canopy that would promote fungal growth i.e. increase tree skirt height.

• Prune and harvest only during dry conditions to minimise fruit contamination and injury.

• Prune out dead limbs and twigs where fungi can sporulate. If many dead leaves are trapped in the canopy, knock them out of the tree and mulch them with pruned branches.

• Keep calcium and nitrogen levels in balance. A healthy tree and good mineral nutrient status improve fruit resistance to anthracnose.

• A good spray programme using copper-based fungicides and/or other registered products is key to controlling postharvest development of anthracnose.

• Cyprodinil

• Fludioxonil

• Azoxystrobin

• Copper-based products

• Benomyl and carbendazim: NB: not to be used in orchards producing fruit for export.

Because copper-based fungicides are protective, apply these at the right time to ensure they are most effective for anthracnose control. The first spray is especially important. The number of sprays depends on the cultivar planted, the disease pressure in the area, and individual orchard history of Cercospora and pepper spot.

As a guideline, see Table 1 for the number of copper sprays per season. In wet years, or in orchards with a history of anthracnose, additional sprays may be required.

• Avoid picking when temperatures are high i.e. >30 °C especially with late season fruit.

• Avoid picking during or shortly after rain. Lenticels can be damaged resulting in more decay.

• Keep fruit in a cool place, out of the sun; high temperatures can impact ripening and increase decay.

• Minimise delays from time of harvest to cooling.

• Cool fruit to the recommended shipping temperature (± 5.5 °C) as soon as possible after harvest.

• Apply a registered post-harvest fungicide.

FREEMAN, S., KATAN, T. & SHABI, E. 1998. Characterization of Colletotrichum species responsible for anthracnose diseases of various fruits. Plant Dis. 82: 596-605.

MENGE, J.A. & PLOETZ, R.A. 2003. Diseases of avocado. P 35-71. In: R.C. Ploetz (ed). Diseases of tropical fruit crops. CABI Publishing, Cambridge, Mass. 527 p.

HARTILL, W.F.T., EVERETT, K.R. & PAK, H.A. 2002. Stem-end rots: the infection portal. NZAGA Ann. Res. Rep. 2.

NEL, A., KRAUSE, M. & KHELAWANLALL, N. 2003. A guide for the control of plant diseases. Department of Agriculture, South Africa, p 48.

OHR, H.D., COFFER, M.D. & MCMILLAN, R.T. Jr. (primary collators). Diseases of avocado (Persea americana Miller). American Phytopathological Society. https://www.apsnet.org/online/common/ names/avocado.asp (Last update 4/8/03).

PRUSKY, D. & KEEN, N.T. 2011. Involvement of preformed antifungal compounds in the resistance of subtropical fruit to fungal decay. Plant Dis. 77: 114-119.

While crop production is beset with several daunting challenges, herbicides have made significant contributions to sustainable food production. Chemical selection pressure made it inevitable that herbicidal efficacy eventually resulted in weed resistance. Herbicide options in the three subtropical crops are relatively limited, therefore non-chemical weed control practices ought to be given high priority.

Charlie Reinhardt PROFESSOR IN AGRONOMY, NORTH-WEST UNIVERSITY SUBTROP JOURNALThere can be no disputing the fact that herbicides have made significant contributions to sustainable food production since the 1940s with the introduction of the first selective herbicides (2,4-D and MCPA) i.e. synthetic organic chemical compounds with the ability to kill unwanted plants (weeds) without the crop being harmed.

Modern crop production is beset with several daunting challenges, of which the most important are: burgeoning human populations, shrinking of arable land, climate change, genetic limitations of crop yield, scarce water resources, adverse environmental impacts associated with agricultural practices, and herbicide-resistant weeds. Given increased public pressure for absolutely safe agrochemicals, which implies zero risks for human health and the environment, even herbicides, which generally target life processes unique to plants, have come under intense scrutiny.

Organic mulch with wattle bark can also be effective, but then it would need to be better applied than in this picture. Wattle has allelopathic potential.

Weeds and weed control into the future

Humanity’s increased future food needs impose the adoption of intensifed agriculture that is sustainable, not only in the sense of meeting future food demands, but also by ensuring that less land gets converted from natural areas for agricultural purposes. It is generally accepted that sustainable, intensified crop production will long into the future rely on synthetic chemicals for sustaining both high quality produce and high yields (Balmford et al., 2018; Duke et al., 2019).

The global agrochemical industry’s quest for novel che-

mistry to deal with the challenges of public pressure for safer products and environmental safety, is mired in high research and development costs and a ceiling in chemistry innovation (Dayan, 2019). According to Umetsu and Shirai (2020), no herbicides with a novel mode of action have reached the market in 30 years, and only one (cyclopyrimorate) was recently released and another is being developed.

Relatively new weed control technologies, such as sensordirected spraying and drone-operated sprayers, could contrib-

TO PAGE 16

Geformuleer as ’n suspensie konsentraat met ’n waterbasis wat gewasveilig is en nie brandskade op vrugte veroorsaak nie

FROM PAGE 15

ute to a reduction in herbicide use, as could biological weed control through the use of cover crops and organic mulches. The extent to which such technologies and practices will be able to keep weeds in check will be sorely tested by the ability of weeds, relative to that of crops, to cope with climate change.

In general, in terms of plant growth and productivity, weeds are likely to repond more positively than crops can to increased CO2 levels and temperatures, making weeds even more competitive to crops than they currently are.

It is not far-fetched that the natural ability of crop species to produce and release phytotoxic (allelopathic) compounds into the environment can be genetically enhanced for exploitation as bio-herbicides. As early as the 1990s, the International Rice Research Institute embarked on the identification and breeding of rice cultivars with the ability to suppress weeds through the release of allelochemicals into the environment (Olofsdotter et al., 1997; 1998; 2001).

The release of plant-produced biochemical compounds that are phytotoxic i.e. allelochemicals, from living plants and plant litter, specifically their utility for weed control, is seldom given due credit for weed control achieved by cover crops and organic mulches. The latter practices’ role in weed control is often attributed solely to the physical suppression of weed growth and to preventing light from reaching covered weeds and the soil surface. In reality, both biochemical (allelochemical) and physical phenomena explain the weed suppressing roles of cover crops and organic mulches.

“once-in-a-century”

Glyphosate first came onto the world market in 1974/75, also in South Africa, and has since become the mainstay herbicide for use in important annual and perennial cropping systems globally. Duke and Powles (2008) extolled the virtues of glyphosate and coined the phrase “a once-in-a-century herbicide” for it.

A particularly mutually beneficial association has been glyphosate use in zero-tillage systems devoted to glyphosatetolerant (Roundup ReadyTM) crops such as maize, soy and cotton. Glyphosate is also an important tool for weed management in perennial crop systems such as orchards and vineyards, as well as in forestry.

The phenomenal popularity of glyphosate has turned it into the world’s best-seller herbicide, which also means it was used in high volumes and high frequency in various crop systems, thus exposing many weed species to it. High use levels, coupled with high chemical selection pressure due to its phenomenal herbicidal efficacy, made it inevitable that glyphosate eventually ran into the difficult problem of weed resistance.

Being implicated in weed resistance is not unique to glyphosate; currently, 512 cases of herbicide-resistant weeds have been reported globally, and 266 weed species have evolved resistance to 21 of 31 known herbicide sites of action involving 165 different herbicides (The International Herbicide-resistant Weed Database, www.weedscience.org accessed 7 April 2022).

Worrying to those who depend on glyphosate are the threats to its continued use because of the unabated controversy raging over its safety for humans (Beckie et al., 2020). This situation is worsened by recent substantial price increases due to shortage of product in the market. This begs the question posed by Beckie et al. (2020): is farming without glyphosate possible?

We are already seeing restrictions being placed on the use of glyphosate, and its registration is even revoked in certain countries. As Beckie et al. (2020) so eloquently puts it: “In developed countries most voters live in urban centres; politicians naturally cater to eligible voters of whom farmers are becoming a smaller and smaller percentage over time (usually <5% nationally)”. Globally, the agri-food research and development sector is taking stock of such developments and contingency plans are being made.

It is difficult to contemplate a world without glyphosate. It has many virtues, and from a weed management pespective, even weed resistance can be countered by measures such as supporting glyphosate with additional and different herbicide modes of action in a particular programme.

Furthermore, alternative non-chemical weed control methods such as mechanical, biological (cover crops and organic mulches) and cultural (cropping practices) should always be considered for augmenting chemical control. One thing is certain – increased costs for weed control are inevitable if herbicide resistance is to be dealt with successfully.

In subtropical fruit crops the weeds to look out for with regard to their ability to evolve resistance to glyphosate, include: Conyza spp. (tall fleabane; hairy fleabane; horseweed), Bidens pilosa (common blackjack); Parthenium hysterophorus (parthenium; famine weed), Amaranthus hybridus (pigweed); Sorghum halepense (Johnsongrass) and Eleusine indica (goosegrass). Close scrutiny of orchards for the presence of South Africa’s latest crop-debilitating, glyphosate-resistant alien invasive species, Amaranthus palmeri (Palmer amaranth), is strongly advised (Reinhardt et al., 2022).

Herbicides registered for use in mango, avocado and litchi orchards, based on Subtrop/SALGA January 2022 information, show that litchi production is in the most precarious situation with regard to diversity (lack thereof) in herbicide mode of action, given that only five herbicide types are registered,

Duke and Powles (2008) extolled the virtues of glyphosate and coined the phrase “a once-in-acentury herbicide” for it.

including glyphosate and paraquat. If the latter two herbicides should fall away, it would create a crisis situation for litchi production as far as sustainability of effective weed management is concerned.

Although avocado and mango production are better off in terms of diversity in herbicide mode of action, the only herbicides registered for broad-spectrum control of sedges, broadleaf and grass weed species are glyphosate, paraquat and glufosinate-ammonium. Again, in the event of glyphosate and paraquat exiting the scene, over-reliance on glufosinate-ammonium will, sooner rather than later, promote the evolution of weeds that are resistant to it.

In general, herbicide options in the three subtropical crops are relatively limited compared to the situation in many annual crops. Therefore, non-chemical weed control practices ought to be given high priority, and weed management strategies should integrate chemical (herbicide) control with as many other methods as possible.

The subtropical fruit industry is advised to do all in its power to retain glyphosate; fundamental to such an effort is responsible use that calls for strict adherence to registered dosages and use frequencies, as well as combining different herbicide modes of action in a particular herbicide programme.

BALMFORD, A., AMANO, T., BARTLETT, H., CHADWICK, D., COLLINS, A., EDWARDS, D., FIELD, R., GARNSWORTHY, P., GREEN, R., SMITH, P. & WATERS, H. 2018. The environmental costs and ben-

efits of high-yield farming. Nat. Sust. 1: 477-485.

BECKIE, H.J., FLOWER, K.C. & ASHWORTH, M.B. 2020. Farming without glyphosate? Plants 9: 96.

DAYAN, F.E. 2019. Current status and future prospects in herbicide discovery. Plants 8: 341.

DUKE, S.O. & POWLES, S.B. 2008. Glyphosate: a once-in-a-century herbicide. Pest Man. Sci. 64: 319-325.

DUKE, S.O., POWLES, S.B. & SAMMONS, R.D. 2018. Glyphosate –How it became a once in a hundred year herbicide and its future. Outl. Pest Man. 29: 247-251.

OLOFFSDOTTER, M., NAVAREZ, D. & REBULANAN, M. 1997. Rice allelopathy – where are we and how far can we get? Brighton Crop Prot. Conf. – Weeds. Proc. Int. Conf., Brighton, UK. 1997, 3A-3, pp 99-104.

OLOFFSDOTTER, M. 1998. Allelopathy in rice. In: Oloffsdotter M (ed): Allelopathy in rice, International Rice Research Institute, Manila, Philippines, pp 1-5.

OLOFFSDOTTER, M. 2001. Getting closer to breeding for competitive ability and the role of allelopathy – an example from rice (Oryza sativa). Weed Tech. 15: 798-806.

REINHARDT, C., VORSTER, J., KÜPPER, A., FALCO, P., SIMELANE, A., FRIIS, S, MAGSON, J. & ARADHYA, C. 2022. A non-native Palmer amaranth (Amaranthus palmeri) population in the Republic of South Africa is resistant to herbicides with different sites of action. Weed Sci. 70: 183-197.

UMETSU, N. & SHIRAI, Y. 2020. Development of novel pesticides in the 21st century. J. Pest. Sci. 45: 54-74.

Charlie Reinhardt is professor in agronomy at North-West University, and project lead in the South African Herbicide Resistance Initiative (SAHRI) at the University of Pretoria. He can be reached at 083 442 3427 or dr.charlie.reinhardt@gmail.com

We are entering our 50th year of commercial Macadamia tree propagation. We are highly experienced, using Mother-Material from our own commercial blocks, which form one of the oldest Plant-Improvement schemes in South Africa. We offer our Growers high-yield potential from the start.

We offer West Indian / Guatemalan Avocado rootstocks grafted to your cultivar of choice. Data from source b.i. Agriculture Data Analytics shows the role of rootstocks in the yield and quality of Avocado production. Over a 7-year period, seedling rootstocks yielded the same average tonnage per hectare as clonal rootstocks.

An exciting addition to your Subtropical agricultural development. SWEET-tasting Dragon Fruit selections for local and export markets. Excellent returns per hectare. Optional: Join the Marketing Company and be part of the Amorentia Sweet Dragon Fruit Brand!

Its good news for the nut loving South Africans as ZZ2 subsidiary Cape Almonds (Pty) Ltd launches 50 tonnes of locally grown almonds through South Africa’s national fresh produce markets under the Al Monde brand name. Fresher, crunchier, tastier and locally grown, this healthy super food is always available.

Charged with goodness, Al Monde almonds are packed in unique boxes in different sizes as well as smaller quantities that are contained in recycled plastic bags which stand proud proclaiming their wholesome contents and 100% ‘Made in South Africa’ stamp. Consumers will be confident in their purchase, knowing that the produce is locally grown and has incurred a considerably reduced carbon footprint in its delivery.

More good news comes because Cape Almonds has formed licensed agreements with more than 50 Western Cape farmers to grow and produce the almonds, which in turn helps upskill the farmers in making a locally grown crop commercially viable and helps create demand for more in the future. The Al Monde almonds are raw (not roasted, salted or treated in any way) and are available at the national fresh produce markets in Johannesburg, Pretoria, Durban and Cape Town.

Dan Coetzee, CEO of Cape Almonds, says the launch of local almonds in South Africa comes at a critical time. “Due to the oversupply of almonds in the US, South Africa is getting flooded with cheap poor-quality stock. As an Association, our main aim is to protect producers and the almond market as a whole and to ensure South African consumers get better quality local almonds at competitive prices.

“People are becoming increasingly aware of the need to support local farmers and they also want to know where their food comes from. So, knowing they are buying a product that is fresh, and not 6-12 months old as it is when it arrives from California – will be a major factor in their purchasing decision. Until now, very few almonds sold in South Africa are grown locally.”

Almonds need a Mediterranean-type climate to flourish and the Western Cape, where most of the farmers are, match-

es this perfectly. The Al Monde growers are mostly farming the Independence almond varietal, which is self-pollinating.

Most commercial almond cultivars rely upon natural pollinating, by bees, to ensure successful cross-pollination and fertilization. The Independence cultivar, however, is the first self-compatible and self-fertile almond cultivar developed by the Californian breeder, Zaiger’s Inc. Genetics. In 2016, ZZ2 subsidiary, Cape Almonds, was granted the exclusive masterlicence to cultivate ‘Independence Almonds’ in Southern Africa from Zaiger’s Inc. Genetics and Zaiger SA. Since then, Cape Almonds, in partnership with around 50 sub-licensee growers, has planted approximately 700 ha of ‘Independence’ almond trees throughout the Western Cape Province.

Coetzee, also head of marketing of the newly formed South African Almond Association says farmers and consumers alike in this country need to know that the industry is committed to long-term sustainability.

“The almond Association will not only be a hub of information, but also a body of mutually interested peoples who will collectively ensure that the local industry thrives over time. Together with ZZ2, we began researching and creating the Al Monde product around four years ago, because we believe the future is in unlocking the natural goodness available right here in South Africa and to delivering an excellent natural product to local people.”

There is good news in the offing for SMEs and the SA economy too. As the local almond industry matures, it will help support and create new industries from the bi-products of raw almonds which are not fit for packaging - those that are chipped or broken in half will be sold to third parties. In time, this will develop into a burgeoning bi-product industry producing almond flour and almond milk.

Enjoy the fresh, delicious taste of local. Grown in the Cape, our Al Monde Cape Almonds are tasty, healthy and abundant. Grab a handful now and enjoy home-grown goodness.

The local macadamia industry grew from around R800 million in 2012 to just short of R4,8 billion in 2021, with some 55% growth in total volume when measured nut in shell. The Bureau for Food and Agricultural Policy (BFAP) recently highlighted that South Africa is now the world’s largest macadamia producer and the world’s largest exporter of macadamias. But would an international visitor to our country know this?

Mariana Purnell CONTRIBUTORMacadamias are produced in KwaZulu-Natal (43%), Mpumalanga (36%) and Limpopo (16%). With recent expansion in planted area that is still to enter production, substantial growth in total volumes and specifically exports are expected. Considering the lag between planting and production, this industry could well double over the next 10 years. Demand growth for these almost-niche nuts will be an important factor in price stability and farm level sustainability in the future.

Years ago, in 1986, I was fortunate enough to visit Hawaii as a young pineapple researcher. The aim was rapid clonal propagation of selected cultivars, but I also took the time to look around. Their pride and obvious success in processing of agricultural commodities was an eye opener. Six years later, I was back as an invited speaker at the very first international pineapple symposium.

I was amazed at the numerous upmarket shops in the foyer of the hotel. America's 50th state has perfected the marketing of brand “Hawaii”. In fact, everywhere you go promotes everything Hawaiian and the spirit of Aloha. Hotels, airports and high-volume tourist destinations like the aquarium and traditional village boast displays of Hawaiian products.

What left a lasting impression on me was their macadamia industry’s amazing approach to value adding. The interesting thing is that the marketing of their processed products has been so successful that many people think macadamias originate from Hawaii, but they are actually indigenous to Australia.

China is South Africa’s most important trade partner for uncracked nuts with an uptake of 80% of in-shell macadamia. There has been a gradual shift in macadamia exports, with a greater share going directly to China in the last five years, as opposed to Hong Kong while some 19% of nutin-shell macadamias are destined for Vietnam. In 2021, 57% of total macadamia exports were kernel based (shelled nuts), mainly destined for the EU, the US and the UK, with some shelled macadamias also exported to Vietnam.

Growing consumer demand for macadamia nuts in raw

as nut-in-shell or shelled will play a critical role in sustaining current prices. Striking though, is the lack of South African macadamias in processed form. This is where huge potential lies for this industry that has expanded tremendously over the past decade, with an area growth rate around 200%, or a 13% average annual growth rate from 2012 to 2021. There is a latent opportunity for South Africa to, just like Hawaii, also develop an integrated macadamia value chain and add much needed jobs to the South African economy.

Apart from the obvious natural and dry roasted macadamias, Hawaiian companies also coat macadamias in chocolate, chocolate-toffee, coffee-glazed, honey-glazed, mangochipotle or flavour the nuts with salt, onion & garlic, wasabi & teriyaki, and chili-spice. In addition to the traditional chocolate box presentation, a whole range of individual packaging types are used.

But that is not where it stops. Cookies, or biscuits as South Africans call them, is a frequent accompaniment to their famous local coffee. The macadamias are also transformed into macadamia cookies – macadamia and chocolate chip, dark chocolate macadamia, macadamia and coconut, pineapple and macadamia as well as macadamia nut shortbread and even macadamia pancakes.

Other products are macadamia nut butter, similar to peanut butter and macadamia oil.

In South Africa there is a glaring absence of macadamia nut products in areas that tourists frequent, in 5-star restaurants with exotic menus and even from local supermarket shelves. With on-line purchases and a world-wide distribution system being the norm after Covid, international gifts comprising healthy snacking and gourmet treats as well as offering new options to vegans could be a winner.

There could also be the possibility of gift packs with smaller packages in a variety of tastes, pouches and cans to tempt taste buds. Airlines flying into South Africa, wine estates and luxury game lodges could be major off-takers for sample-size packs of tasty flavoured macadamia nuts or even cookies.

South Africa needs to market macadamias as brand “South Africa”. Let’s do it to ensure price stability and farm level sustainability going forward. Let’s go nuts!

Die weer is seker die onderwerp waaroor die meeste gepraat word. Almal word skielik kundiges wanneer hierdie onderwerp ter sprake kom en elke persoon het ‘n storie om te vertel oor die invloed van die weer op sy of haar lewe. Die weersomstandighede verander ons gedrag en bepaal grootliks wat ons doen en hoe ons dit doen.

Johan Stronkhorst en Carmen Scholtz SAKATAAs mense kan ons gelukkig warmer aantrek wanneer dit koud is, die lugversorger aanskakel wanneer dit te warm is, of binne die huis bly wanneer dit reën. Wanneer ons egter nie die opsie het om ons omstandighede te verander nie, besef ons die ongemak wat die weer kan veroorsaak en sal ons vinnig begin kla indien dit te warm, te koud of te nat is.

Dit is om hierdie rede dat ons moet besef plante word ook deur weersomstandighede beïnvloed. Plante wat geplant word of sade wat gesaai word in ‘n spesifieke gebied, kan nie verskuif word nie. Net soos mense nie optimaal kan funksioneer wanneer die omstandighede nie ideaal is nie, word plante ook negatief beïnvloed deur negatiewe klimaatsomstandighede.

Produsente begin dus toenemend strukture oorweeg om

plante teen die uiterstes van die natuur te beskerm, soos teen sonbrand, windskade en hael. Nethuisstrukture is ‘n gewilde opsie vir produsente, omdat dit ‘n omgewing skep waarbinne plante kan groei en optimaal produseer. In baie gevalle kan gewasse oor ‘n langer tydperk in nethuise groei as in die oopland en verder verleen dit beskerming en kan as ‘n opleistruktuur dien.

Nethuisstrukture bied ook verskeie voordele vir plante, waarvan die skadu-effek seker die belangrikste is. Skadunet beskerm plante teen die son en veral ultravioletbestraling.

Skadunetstrukture bestaan gewoonlik uit tussen 10% en 40% skadunet. Verskeie kleure kan gebruik word, hoewel grys of wit geweefde nette die algemeenste is. Indien verskeie gewasse onder die strukture verbou gaan word, is ‘n skadunet van 20% ‘n goeie keuse.

Tamaties en rissies verskil in verskeie opsigte van mekaar en rissies kan onder ‘n digter skadunet verbou word as tamaties.

Indien tamaties se persentasie netskadu te hoog is, kan die plante se internodes te lank raak. Dit maak die bestuur van die plante moeiliker, dit kan meer arbeid vereis en ook ‘n negatiewe uitwerking hê op die plante se vrugset, wat ‘n laer opbrengs tot gevolg het.

Ander voordele van skadunetstrukture sluit die volgende in:

• Dit verminder windbeweging binne die struktuur en kan die tekort aan dampdruk verminder. Dit beteken dat plante gedurende die dag langer fotosinteer, wat tot hoër opbrengste en beter uitpakpersentasies lei.

• Dit kan die plant en grond se waterverbruik en verdamping verminder.

• Plante word teen hael beskerm. Indien die struktuur goed ontwerp is, kan die struktuur sélf ook minimale haelskade opdoen.

• Skadunet kan voordelig wees ten opsigte van grondtemperature. Laer grondtemperature lei daartoe dat grond-organismes en organiese materiaal nie so vinnig afgebreek word nie – grondsiektes en die afbreek van weerstand deur, onder meer, nematodes, kan dan ook kleiner probleem wees.

Skadunetstrukture kan egter ook verskeie uitdagings skep vir produsente:

• Skadunetstrukture hou nie insekte uit nie – inseknette kan wel gespan word, maar selfs dan verseker dit nie algehele uitsluiting nie.

• Die omstandighede waarin plante groei beïnvloed die plante. Plante wat onder gunstige omstandighede groei kan weens laer lig en temperature sagter wees.

• Nethuisstrukture verminder lugbeweging, wat kan lei tot

die verhoging in humiditeit – dit kan weer lei tot hoër siektedruk.

• Met ‘n vaste struktuur, wat nie rondgeskuif kan word nie, is dit belangrik dat gewasrotasie steeds bestuur moet word. Tamaties en rissies is nie goeie rotasiegewasse nie, terwyl boontjies en brassicas beter doen. Verskeie kruie kan ook suksesvol onder nette verbou word - die kwaliteit en smaak is goed.

Gewasrotasie

Gewasrotasie is ‘n baie belangrike onderwerp vir produksie onder enige strukture waar dieselfde area jaar vir jaar gebruik word. Om probleme met plae en siektes in die grond so ver as moontlik uit te skakel en om minerale in die grond te herstel, word aanbeveel om nie gewasse van dieselfde familie binne ‘n tydperk van drie tot vier jaar op dieselfde stuk grond te verbou nie.

Vir verbouing onder ‘n permanente struktuur soos skadunetstrukture waar die spasie beperk is, is dit baie belangrik om gewasse met die korrekte plantfamilies vir optimale produksie te roteer. Gewasse van die Solanaceae-familie (tamaties, rissies en eiervrug) neem baie voeding uit die grond en moet dus geroteer word met gewasse wat voedingstowwe in die grond aanvul.

Kenmerkend van peulgewasse is dat hulle stikstof in die grond “terugsit” en die balans van voedingstowwe in die grond kan verbeter. Rankbone is ‘n baie goeie keuse vir die produsent om tussen aanplantings in te sluit, om die volgende redes:

• Rankbone het ‘n vinnige groeisiklus van 60 tot 65 dae van saai tot oes.

• Gesonde plante kan oor ‘n verlengde tydperk van tot twee maande geoes word.

• Produksiegebiede met subtropiese wintertemperature kan groenbone oes wanneer die markpryse hoog is.

• Siektes wat onder die Solanaceae-familie voorkom het geen invloed op peulgewasse nie.

• Minder insetkoste, deurdat die groenbone stikstof terugplaas in die grond wat deur die volgende gewas gebruik kan word.

Gesonde grond verskaf die korrekte balans tussen noodsaaklike voedingstowwe, water, suurstof en mikro-organismes wat gesonde wortelontwikkeling, plantegroei en uiteindelik optimale oeste tot gevolg het.

Wenke vir die oprigting van skadunetstrukture

• Die oprigting van skadunetstrukture is ‘n groot ekonomiese oorweging - begin eerder klein, maar met die beste kwaliteit.

• Kontak verskillende verskaffers van skadunet en maak seker dat die verskaffer betroubaar is. Baie nette word vir buitelandse klimaatstoestande ontwikkel en die Suid-Afri-

Onaanvaarbare groei van onkruid in die nethuisstruktuur.

kaanse son en veral UV-strale veroorsaak dat die skadunet slegs ‘n beperkte leeftyd het. Die meeste produsente begroot om nette elke 10 jaar te vervang.

• Maak seker die netstruktuur is hoog genoeg sodat masjiene binne kan beweeg. Indien moontlik moet nette kan oprol sodat implemente kan deurbeweeg.

• Oplei-strukture moet verkieslik nie aan die netstruktuur verbind wees nie. Die plante kan tydens reën swaar word en die nethuis tydens ‘n storm omtrek.

• Probeer om grond in die nethuis so gelyk as moontlik te maak of maak seker dat geen versuipkolle in die nethuis ontstaan nie.

• Sorg dat die strukture gereeld deeglik geïnspekteer word om die uitbraak van siektes en insekte betyds te beheer.

• Verdeel die strukture in blokke, indien moontlik, sodat verskillende aanplantings afsonderlik bestuur kan word.

• Probeer om so lank as moontlik in die grond te plant – dit bied meer moontlikhede om voedingstowwe aan plante te voorsien en dit verhoog ook opgaring vir die wortels.

• Hou die gebied binne en buite die nethuise so skoon as moontlik deur alle onkruid te verwyder – onkruid dien as gashere vir insekte.

• Sekere chemiese middels kan ‘n invloed hê op nette se leeftyd – bespreek hierdie punt met verskaffers voor die toediening van hierdie middels.

Skadunetstrukture is nie ‘n towerstaf om die produsent se probleme op te los nie. Dit verg deeglike kennis om die bestuur só aan te pas dat die uitwerking die grootste moontlike voordeel vir die produsent sal inhou.

VRYWARING: Die inligting in hierdie artikel is op Sakata se waarnemings gebaseer en/of op inligting van ander bronne. Aangesien gewasprestasie afhang van die interaksie tussen die saad se genetiese potensiaal en fisiologiese eienskappe en die omgewing, insluitend bestuurspraktyke, gee Sakata geen uitdruklike of geïmpliseerde waarborg vir gewasse se prestasie in verhouding tot die gegewe inligting. Sakata aanvaar geen aanspreeklikheid vir enige direkte of indirekte verlies wat te wyte aan enige oorsaak mag ontstaan nie. Lees eers Sakata Seed Southern Africa (Pty) Ltd se verkoopsvoorwaardes voordat saad bestel word.

Ÿ Bevorder aktief die agroekonomiese en omgewingsverantwoordelike kunsmis,- en aglime-praktyke;

Ÿ Ontwikkel 'n positiewe publieke bewustheid en aanvaarding van die behoefte aan kunsmis, bio-kunsmis en landboukalk-gebruik in voedselproduksie;

Ÿ Verbeter die bedryfsomgewing waarbinne sy samestellende nywerhede funksioneer in 'n gees van vrye onderneming en billike handel;

Ÿ Assimileer, voeg waarde toe tot en versprei kunsmis, biokunsmis en landboukalk verwante inligting;

Ÿ Voorsien 'n gespreksforum vir sy lede en ander partye oor alle aspekte wat verband hou met kunsmis, bio-kunsmis en landboukalkverspreiding, agronomiese advies en produkkwaliteit.

Fertasa en sy lede is verbind tot die bevordering van volhoubare grondvrugbaarheid en verbeterde plantvoeding.

In ground breaking research work, the presence of iodinated proteins in higher plants has been described and for the first time 82 iodinated proteins have been identified

Based on scientific phenotyping, genomics and protein studies, it is shown that plants need iodine for leaf and root growth, efficient photosynthesis (the plant’s factory), timely flowering, increased seed production, stress resistance along with increased yield and better harvest quality.

Many areas have deficient levels of iodine in both soil and water which will lead to reduced crop quality and yield.

SQM International are now introducing an iodine enriched potassium nitrate (Ultrasol®ine K Plus*). It has been well proven to be safe and effective for growers to apply the necessary iodine in conjunction with the plant’s nitrogen and potassium requirements, enhancing both yield, quality and return on investment benefits. These trials can be viewed on: https:// sqmnutrition.com/

The iodine containing proteins are involved in important biological processes such as Rubisco for efficient photosynthesis in the leaves, peroxidase enzymes defending plants from biotic and abiotic stress and the ATP energy enzymes supplying energy for plant growth and nutrient transport.

Iodine is considered a micronutrient, as it is required in small quantities by plants. Not too little, not too much is very important. Typically, iodine is found in the oceans at an average concentration of 0,5 micromole iodine per liter of sea water. Rainwater, soil solution and irrigation water typically have iodine concentrations of less than 0,2 micromoles per liter of water.

Iodine is considered deficient in most countries around the world and as we know, iodine is essential in human nutrition too, for the effective function of the thyroid gland. Thus, in most countries table salt is fortified with iodine to meet the requirements in humans.

The optimal iodine requirement in a nutrient solution for plants has been found to be in the 5-10 micromole per litre range, in other words, in much higher concentrations than in the water examples mentioned in the previous paragraph.

SQM’s Ultrasol®ine K Plus contains two essential plant macronutrients - potassium and nitrate nitrogen - and iodine from natural resources. Since potassium and nitrate nitrogen are applied in well-defined application rates, the product ensures that a well-defined range of iodine is applied as well. This makes it easy for the grower to maintain an effective and safe concentration of iodine in the root-zone. Ultrasol®ine K Plus will therefore prevent iodine deficiency in the crop, with-

out the risk of application of excessive iodine.

Globally, SQM documented use by more than a hundred growers who had included the product in their nutrient solu tions instead of the normal – iodine free – form of potassium nitrate. Growers’ experience confirms the benefit of iodine for improved root growth, above ground plant growth, photosyn thesis, nitrogen conversion, tolerance to abiotic stress, flower ing and fruit quality with less fruit rot and better shelf life.

In 34 farms located in nine countries, and including ten dif ferent crops, the circumstances allowed to compare Ultrasol K Plus to potassium nitrate without iodine, in the same crop, of the same planting date and the same fertilizer programme. On average, 10% more marketable yield was recorded in the sec tors using Ultrasol®ine K Plus. Crops included: tomato, lettuce, sweet pepper, cucumber, musk melon, sugarcane, pomegran ate, papaya, banana and coffee.

Ultrasol®ine K Plus is shown to ensure an easy application of iodine to improve crop performance, leading to higher yield and quality for better revenues.

**All claims in this article can be substantiated with references which can be made available on request.

Disclaimer: The information herein contained is given to the best of SQM’s knowledge and is believed to be accurate. The conditions of your use and application of the suggested recommendations are beyond our control. No warranty is made as to the accuracy of any data or statements contained herein. SQM specifically disclaims any responsibility or liability relating to the use of the recommendations and shall under no circumstances whatsoever, be liable for any special, incidental or consequential damages arising from such use.

Die aartappelbedryf se hoë insetkostestruktuur maak dit besonder kwesbaar en in 2022 sal insetkoste-inflasie na verwagting aartappelprysstygings verbysteek. Dit word verder vererger deur die rol wat binnelandse faktore speel in onbestendige pryse, wat dikwels daartoe lei dat pryse van internasionale siklusse afwyk.

Mariana Purnell MEDEWERKERModelle wat finansies op plaasvlak naboots is nuttig om die uitwerking van stygende insetkoste op die winsgewendheid van aartappelprodusente te evalueer. Volgens dr Tracy Davids, BFAP Bestuurder van Kommoditeitsmarkte by die Bureau vir Voedsel- en Landboubeleid (BFAP, Bureau for Food and Agricultural Policy) kan hierdie modelle help om die potensiële gevolge te bereken, gelykbreekvlakke en alternatiewe projeksies te verstaan en om die uitwerking van spesifieke ingrypings te demonstreer.

Vir die BFAP se vooruitskouing in die volgende 10 jaar tot en met 2031 het dr Davis twee prototipe-aartappelplase in die Oos-Vrystaat (droëland) en Sandveld (besproeiing) ontleed om die koste-effek op plaaswinsgewendheid na te boots en die potensiële uitwerking te toon in ’n projeksie waar plaashekpryse daal. Dit is belangrik om daarop te let dat die ontleding die finansiële simulasieresultate van ’n prototipe plaas in die Oos-Vrystaat en Sandveld verteenwoordig en nie ’n gemiddelde is vir hierdie streke nie. Wisselvallighede in opbrengs, prys, insettoekenning en koste sal van plaas tot plaas verskil en behoort in ag geneem te word.

In 2020 was die wêreldwye aartappelproduksie 359 miljoen ton met Oekraïne (20,8 miljoen ton, 5,8%) en Rusland (19,6 miljoen ton, 5,5%) onder die top aartappelprodusente en -verbruikers (FAOSTAT, 2022). Weens onsekere tye as gevolg van die voortslepende oorlog in die Swartsee-streek het dr Davids ’n vooroorlogse en voor-COVID-era vergelyk met die huidige toestand waar hoë insetkoste aan die orde van die dag is. Die prototipe boerderye volg 'n heelplaas-benadering wat direkte uitgawes behels, asook oorhoofse koste, insluitend koste van finansiering en skuldterugbetalings.

Die modelle vir die prototipe Oos-Vrystaatse plaas (Figuur 1) toon dat direkte uitgawes met R28 000 per hektaar sal toeneem, vergeleke met 2020. Dit verteenwoordig ’n styging van byna 40%. In 2020 het kunsmis 12% tot die totale direkte

koste bygedra, maar met die onlangse stygings sal hierdie aandeel tot bykans 20% in 2022 toeneem.

Met ’n tendens in opbrengs van ongeveer 31 ton per hektaar, is die gelykbreekprys vir direkte uitgawes in 2022 meer as R3 200 per ton (R32,00/10 kg sak). Weens die stygings in die koste van insetmiddele toon die indeks in 2022 ’n netto afname in plaasinkomste (van 100 in 2021 tot 46 in 2022). ’n Projeksie word ook aangebied indien die prys vir vars aartappels daal tot by vlakke voor die oorlog en COVID, waar dit gewissel het tussen R32,20/10 kg sak en R34,70/10 kg sak. In hierdie projeksie word bo-koste ook verreken en die ernstige uitwerking op plaaswinsgewendheid is duidelik uit die grafiek.

Die ontleding vir die Sandveldstreek (Figuur 2) toon dat direkte insetkoste in die meer intensiewe insetstelsels van besproeiingsprodusente in 2022 met bykans R55 000 per hektaar sal styg, relatief tot 2020. Dit is ’n toename van 34%. Onder die huidige basislyn sal netto boerdery-inkomste onder erge druk wees, met die indeks wat nul nader. Indien die streeksprys vir vars aartappels tot vooroorlogse en COVID-vlakke daal (gemiddeld R40,62/10 kg sak) vanaf 2022 tot 2025, sal netto plaasinkomste aansienlik daal en negatief wees.

BFAP meen Suid-Afrika se aartappeloppervlakte sal na verwagting in 2022 met 4,7% tot 49 900 hektaar afneem, ondanks ’n jaarlikse verhoging van 4,1% in die nominale prys tot R49,69 per sak van 10 kg. Dit sal na verwagting in 2021 ’n afname van 2,8% van 2,6 miljoen ton in produksie teweegbring tot 2,5 miljoen ton in 2022. Die korttermyn-afname in oppervlakte kan toegeskryf word aan die toename in insetkoste wat aartappelprodusente in 2021 en 2022 in die gesig staar. Brandstof en kunsmis behels gemiddeld 25% van produsente se insetkoste.

Dr Davis projekteer dat die oppervlakte onder aartappels oor die komende dekade sal uitbrei sodra wêreldwye insetmarkte begin normaliseer, om teen 2031 byna 3 miljoen ton op 51 400 hektaar te lewer. Die nasionale gemiddelde opbrengs kan teen 2031 57,5 ton per hektaar bereik, weens gemiddelde jaarlikse opbrengsverbeterings. Sodanige op-

OOS-VRYSTAAT

Figuur 1. Finansiële modelle illustreer die bykomende direkte koste per hektaar vir die Oos-Vrystaatse droëlandplaas as gevolg van die onlangse stygings in insetkoste. Die grafiek aan die linkerkant vergelyk die toename in direkte koste in 2021 tot 2023, relatief tot 2020. Die grafiek aan die regterkant illustreer die netto plaasinkomste-indeks (basis = 2021 = 100).

SANDVELDSTREEK

Figuur 2. Finansiële modelle vir die Sandveldstreek bied ’n soortgelyke ontleding as by die Oos-Vrystaatse droëlandplaas om die uitwerking op besproeiingsprodusente te illustreer, tipies geassosieer met ’n meer intensiewe insetstelsel (basis = 2020 = 100).

brengsverhogings word hoofsaaklik aangespoor deur kultivarontwikkeling, verbeterde produksiepraktyke en beter gewasbeskermingsprodukte.

Uit ’n verbruiksperspektief het die vraag afgeneem en dit sal na verwagting in 2022 tot 2,38 miljoen ton daal. Die versnelde afname in verbruik weerspieël beperkings in

verbruikersbesteding en word vererger deur stygende pryse. Gedurende die vooruitsigtydperk gaan die totale verbruik na verwagting toeneem om 2,64 miljoen ton teen 2031 te bereik, aangespoor deur 'n toename van 1,3% in vars verbruik, 1,6% in verwerking en konstante saadgebruiksvolumes as gevolg van die redelik stabiele area.

Kelpak, die natuurlike suiwer seewierekstrak stimuleer ‘n toename van 34.7% addisionele inkomste met 2 toedienings van 0.4% op avokado’s. Die unieke verbindings in Kelpak verbeter vrugset, vrugretensie asook meer bemarkbare vrugte.

The yellow pecan aphid is an indigenous pest of pecans in the United States of America but has been introduced into Egypt, Sicily and South Africa. It has been considered an important pest of pecans in South Africa since 1977, after its introduction in 1976. Host plants of this pest include pecan, hickory and other members of the Juglandaceae (walnut) family.

Nozibusiso Maphumulo IPM-PROGRAM, NORTH-WEST UNIVERSITYYellow pecan aphid classification:

Class: Insecta (insects)

Order: Hemiptera (bugs)

Family: Aphididae

Genus: Monelliopsis

Species: Pecanis