10064 PINEROLO - ITALIA Tel. +39 0121393127 info@chiriottieditori.it www.foodexecutive.com Supplemento al n. 09, ottobre 2022 di Industrie AlimentariSped. in A.P.D.L. 353/2003 (Conv. in L. 27/02/2004 n° 46) art. 1 comma 1 DCB TOn. 102 anno 2022IP n. 102 - November 2022 ISSN 1590-6515 FOOD & PACKAGING TECHNOLOGY ITALIAN

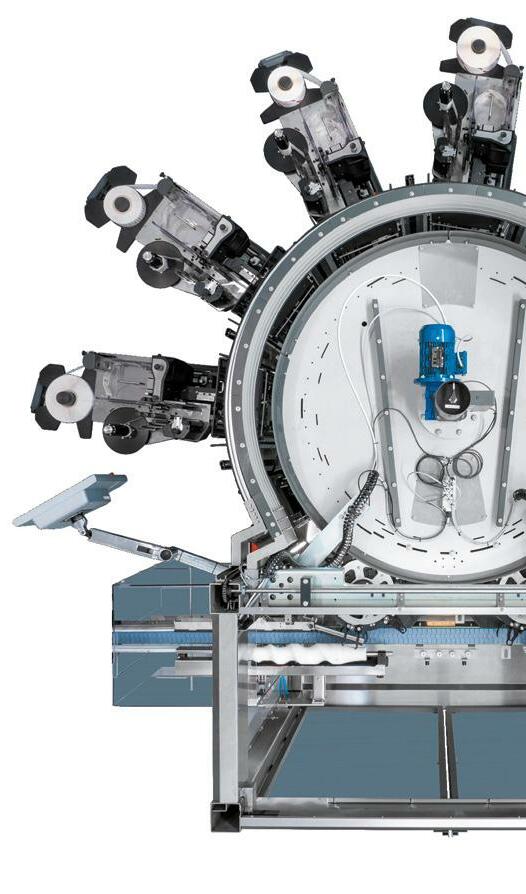

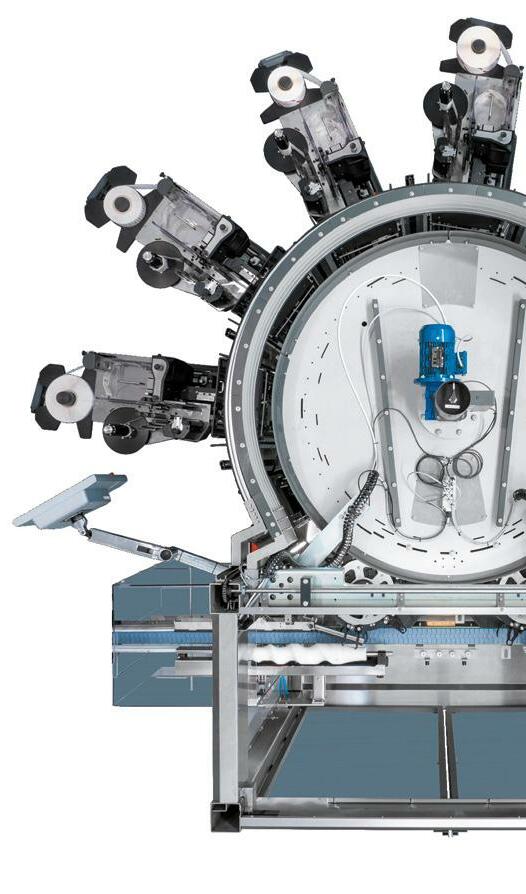

Labelling for Wine & Spirits has never been so effective. CEPQ MODULAR SL SIMEI 2022 is the perfect place to put in the spotlight the best solutions for Wine & Spirits Industry. P.E. Labellers exhibits MODULAR SL fully equipped with labelling stations and special solutions: ◊ new FA-ST 140 m/min units ◊ 6 pressure sensitive labeling stations ◊ the units work in non-stop mode ◊ optical orientation system ◊ capsule presence control device ◊ bottle fall control device Performance, Packaged

PRODUCT TRENDS - Fresh peaches and cherries: world markets and trade - Plant-based meat market worth $8.3 billion by 2025 - Dou bling global potato production in 10 years is possible - Lactose-free products market worth $18.4 billion by 2025 - Spices and season ings market forecast

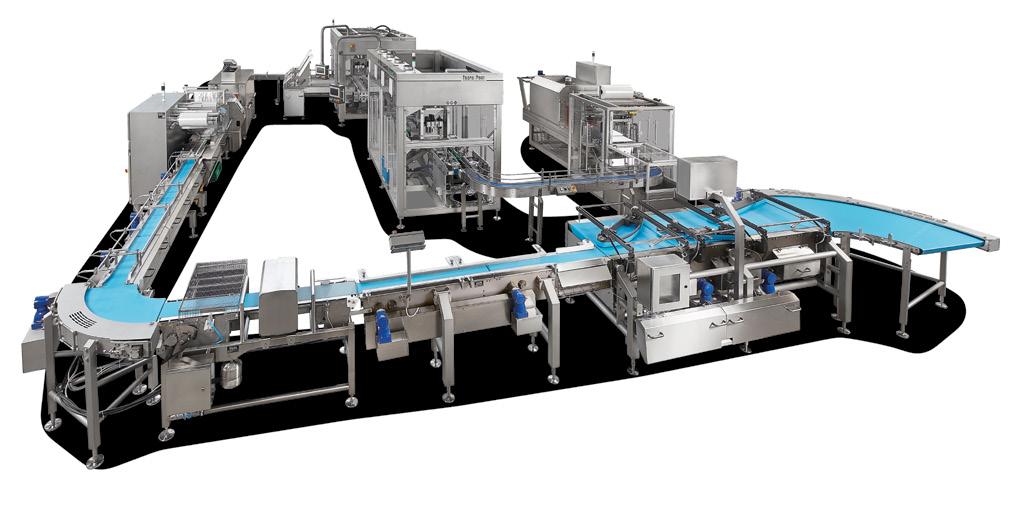

FOOD PROCESSING - Fruit and vegetable processing market worth $11.8 billion by 2027 - Sublimation fits to today’s healthy food re quirements - New solutions for Servomech screw jacks with brush less servomotors - Clip removing and cutting machine - XMD metal and X-Ray detectable timing belt range - SARP, same passion, new graphic - Tailor-made solutions - Melt continuously and in a small space - A mild and innovative solar drying process to provide high quality products - Impact of ultra-high-pressure homogenization of buttermilk for the production of yoghurt - Impact of overhead pres sure during mixing on the quality of sandwich bread

PACKAGING TRENDS - Bioplastics 2023-2033: technology, market and forecasts - Aseptic packaging demand to grow 5.5% annual ly - Capsules growth is slowing down and competition intensifies in aluminium - VTT develops transparent cellulose film to replace traditional plastic - Researchers develop plastic film that can kill vi ruses using room lights - The microperforated packaging design for fresh-sliced mushrooms

PACKAGING EQUIPMENT - Flexible automation solution for card board packaging - Monobloc case packer with pick & place system - P.E. Labellers at Simei: labeling innovation for wine & spirits - In fluence of room layout on airflow distribution in an industrial fruit store - Automatic tray sealing machine - SKIN packaging technology

NUTRITION - Making butter-like spreads healthier - Quinoa sour dough-based biscuits with high antioxidant activity - Canola and olive oil galled emulsions as fat placers in beef burgers - Cistus ladanifer seeds: from ancient snack to novel and sustainable food ingredient - Bread as probiotic carriers - Oral processing behaviours and taste intensity - Effect of freezing treatment of soybean on soymilk nutritional components - Functional oil/vin egar dressing

RESEARCH - Simultaneous detection of four main foodborne patho gens in ready-to-eat food - Natamycin, a biofungicide for managing major postharvest fruit decays of citrus - Use of oleogels to replace margarine in steamed and baked buns - Genome-edited Saccharo myces cerevisiae strains for improving fermented foods - Micellar casein and cheese product storage - The impact of plasma process ing and pulsed electric field on the viability of probiotic yoghurt drink - Smartphone biosensor for detection of ochratoxin A in wine and coffee - Effect of ozone and antimicrobial treatments on the shelf life of packaged cauliflower

NEWS - Sigep 2023, the “dolce”ß communities begin the countdown - Beer&Food Attraction and BBTech Expo to be held in February - In ternational events in Italy - Macfrut 2023 with many new additions

3

14

30

38

48

54

60

64 COMPANY INDEX departments

NOVEMBER - issue 102

Four-monthly

Chiriotti Editori s.r.l.

Viale Rimembranza 60 10064 Pinerolo - To - Italia Tel. 0121 393127 info@chiriottieditori.it www.chiriottieditori.it

for free subscriptions call to +39 0121 378147 or send an e-mail to: abbonamenti@chiriottieditori.it La riproduzione, anche parziale, di articoli ed illustrazioni pubblicati sulla rivista è riservata e non può avvenire senza espressa autorizzazione scritta dell’Editore. L’Editore non assume alcuna responsabilità per quanto riguarda eventuali errori contenuti negli articoli e per quanto espresso dagli Autori.

Publisher

Alberto CHIRIOTTI Direttore Responsabile alberto@chiriottieditori.it

Contributing

Laura SBARATO, Simonetta MUSSO, Rossella CONTATO, Matteo BARBONI

Assistant

Chiara MANCUSI mancusi@chiriottieditori.it

Anna BOSCOLO

All Rights reserved. Reproduction, even partial, of articles and illustrations published in the journal is forbidden and can not take place without written permission of the Publisher. The Publisher assumes no responsibility for any errors contained in the articles and for what is expressed by the Authors and/or by the companies.

PRINTED by Graf Art

COPYRIGHT: © 2022 Chiriotti Editori

Monica PAGLIARDI pagliardi@chiriottieditori.it

Luca RUSSO russo@chiriottieditori.it

Giuseppe CHIRIOTTI

: n.

(19-11-1962)

Tribunale di Pinerolo

mensile

20/B,

662/96

www.chiriottieditori.it

- ISSN 1590-6515 November issue 102

Editors

Editor

Graphics

Marketing Manager

Advertisement

General Manager

Unione

Stampa Periodica Italiana Copyright Clearance Center

Officine Grafiche Artistiche Venaria (To)

srl Supplemento del mensile “Industrie Alimentari” AUTORIZZAZIONE

262

del

PERIODICITÀ:

- sped. in A.P. comma

art. 2, legge

Torino INTERNET:

OUR WEBSITES www.chiriottieditori.it shop.chiriottieditori.it www.foodexecutive.com www.pasticceriainternazionale.it www.tuttogelato.it www.alimentifunzionali.it

PRODUCT TRENDS

Fresh peaches and cherries: world markets and trade

FRESH PEACH AND NECTARINE HIGHLIGHTS

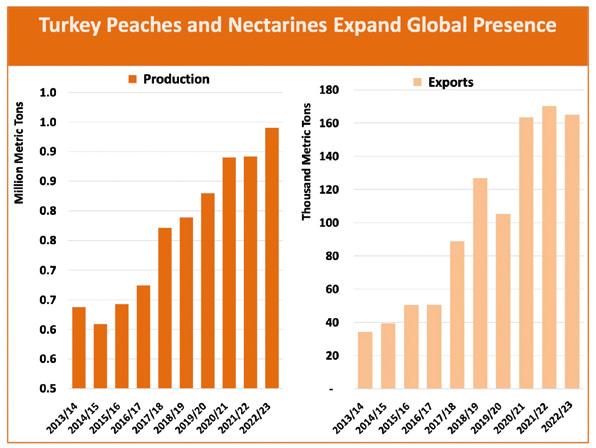

According to the latest report published by the Foreign Agricultural Service of USDA, the world peach and nectarine production in 2022/23 is fore cast to edge up 1.0 million tons to 23.7 million on rising output by China, European Union, and Turkey, the world’s top producers. Exports are expected to be nearly unchanged as higher shipments from Uz bekistan and China offset lower EU and U.S. trade.

China

Here the production is projected up 800,000 tons to 16.8 million due to higher yields on good growing conditions, especially in southern China. However, planted area continues to shrink as declining market returns encourage growers to switch to more profit able crops, including cherries. Exports are forecast to rebound due largely to the resumption of shipments to Russia. Russia banned fresh fruit imports from China, including stone fruit, due to pest concerns in August 2019, lifting restrictions in February 2022. Renewed shipments to Russia are expected to help boost exports 10,000 tons to 55,000. Imports are also anticipated to rebound to a record 43,000 tons on higher shipments from Chile in the beginning of the marketing year (January-December).

EU

The production in EU is forecast to improve to 3.1 million tons as supplies in France and Greece rebound from last year’s weather damage, more than offset ting significant losses in top grower Spain. Aragon and Catalonia experienced intense cold and severe

frosts in April and May, dropping Spain’s output by 30 percent. With the majority of EU exports sourced from Spain, EU shipments are likewise expected to contract, down 12,000 tons to 125,000. Reduced output is expected to boost imports 7,000 tons to 50,000.

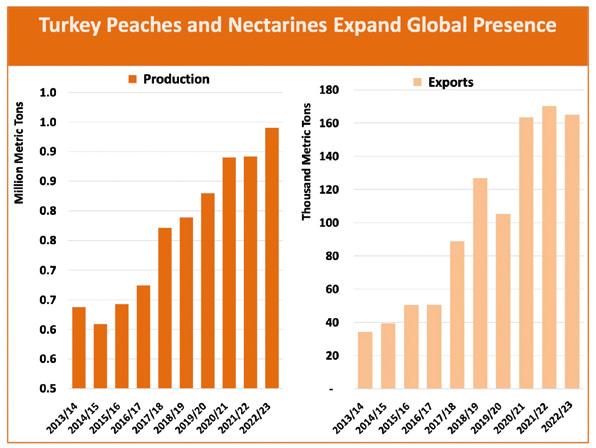

Turkey

In this Country the production is forecast up 48,000 tons to 940,000, an eighth straight year of growth, driven largely by growing nectarine supplies. Peach acreage accounts for the majority of growing area and output, but acreage has remained relatively stable since 2012/13. Nectarine acreage is steadily growing, spurred by an increasing consumer prefer ence for nectarines in domestic and foreign markets.

italian food & packaging technology - cii (2022) - november 3

Despite higher supplies, exports are forecast to con tract slightly to 165,000 tons on reduced shipments to Russia.

U.S.A.

The production is expected to drop over 100,000 tons to 605,000 due to late winter and early spring freezes impacting crops in the top three growing states of California, South Carolina, and Georgia. U.S. production has halved since 2010/11, and is forecast at the lowest level since at least 1982/83 (the earliest year within the USDA Production, Sup ply and Distribution database). Reduced supplies are anticipated to pressure exports lower to 70,000 tons, while imports are up to 35,000 tons, mostly from Chile where output is up.

Chile

Production in Chile is expected to continue its long upward trend, rising to 180,000 tons on favorable growing conditions and improved winter rainfall. Rising nectarine output continues to outpace peach produc tion as growers expand nectarine acreage in response to higher nectarine returns. Exports are forecast up 8,000 tons to 120,000 on higher production.

Russia

Russian imports are forecast down 20,000 tons to 230,000 as reduced shipments from Turkey are only partially offset by gains from Uzbekistan and renewed supplies from China. Despite this second

straight year of declines, Russia re mains the top importer and normally accounts for 30 percent of world trade.

FRESH CHERRY 2022/23 HIGHLIGHTS

Regarding the world cherry pro duction in 2022/23 is forecast up over 220,000 tons to 4.7 million largely on surging output in Turkey and Chile. Great er supplies are expected to lift imports slightly to 630,000 tons on higher ship ments to the European Union and China.

Turkey

In this Country the production is expected to rebound from last year’s weather-damaged crop, surging over 100,000 tons to 980,000 as yields rise on favora ble weather conditions and good rainfall. Though

4 italian food & packaging technology - cii (2022) - november product trends

planted area has been declining for several years, this is being offset by growers replanting orchards with high-density and high-yield varieties. Exports are forecast up 9,000 tons to 80,000 on higher supplies, lifting Tur key past the United States yet again to become the second largest exporter behind Chile.

European Union

The EU production is anticipated to see a recovery from last year’s adverse growing conditions, rising 60,000 tons to 727,000 as good growing conditions in Poland, Italy, and Greece offset heat and drought-induced losses in Spain, Portugal, and Hungary. Consumption is expected to rebound 80,000 tons to over 770,000 propelled by improved domestic supplies and higher imports. Greater shipments from Turkey and Chile are forecast to

boost imports to a record 60,000 tons. Exports are expected to contract again to 15,000 tons as mar kets remain limited following Russia’s 2014 ban of certain EU agricultural production, including fruit.

Chile

Here the production is forecast up almost 20 percent to 467,000 tons as higher rainfall and good growing conditions during the winter boosts yields. Acreage is also up as new plantings contin ue to come online. Higher supplies are expected to drive exports over 50,000 tons to 410,000. The vast majority is still likely to be shipped to China, but exporters are working to diversify markets, such as Vietnam. Shipments to Vietnam com menced in 2021/22 after gaining market access in October 2020. Processing capacity is becoming a concern in the face of increasing output, as the industry works to improve the speed and efficiency of post-harvest processing to ensure fruit quality remains consistently high.

China

Production in China is forecast up 50,000 tons to 650,000. The leading province of Shandong suffered significant losses due to higher temperatures and drought during pollination, but this is expected to be offset by gains in northwestern and southwestern provinces on good growing

italian food & packaging technology - cii (2022) - november 5 product trends

www.fas.usda.gov

Plant-based meat market worth $8.3 billion by 2025

According to the report Plant-based Meat Market by MarketsandMarkets , the global plant-based meat market size is es timated to be valued at USD 4.3 billion in 2020 and it is projected to reach USD 8.3 billion by 2025, recording a CAGR of 14.0% in terms of value.

Growing vegan and flexitarian populations across the world, rising awareness about the health benefits offered by plant-based meat over animal meat, and growth in government initiatives along with significant investments are driving the global plant-based meat mar ket.

The soy segment accounted for the largest share

Based on sources, soy dominated the plant-based meat market. Soy serves as an alternative to meat sources such as pork, beef, and chicken, owing to its high protein content. Traditionally, the consumption of soy and soy products is associated with the Asian population. However, the consumption of soy foods has recently risen in Western countries, owing to the increase in the adop tion of vegetarian diets. Soy-based foods are cholesterol-free against animal protein foods and serve as a source of fibers, vitamins, and other essential nutrients. Plant-based meat

6 italian food & packaging technology - cii (2022) - november

producers are increasingly incorporating soy to make products such as burgers, meatballs, and sausages.

The strips & nuggets segment will mark at a significant growth rate

By product, the plant-based meat mar ket is segmented into burger patties, strips & nuggets, sausages, meatballs, and other products such as slices, fillets, cutlets, slides, fingers, and crumbles.

They are a healthier alternative to meat and are environmentally more sustainable, which is why more food manufacturers are developing plant-based meat products. Several start-ups are going mainstream with the launch of plantbased burgers, nuggets, sausage, meatballs, and other products. Impossible Foods Inc. (US) and Beyond Meat (US) were among the key players to enter the plant-based meat market. These companies are backed by various types of investors, including leading players such as Tyson Foods (US).

The North American region is also expected to grow at the highest CAGR

North America is the fastest growing region in the global plant-based meat mar ket. For American consumers, meat is a very prominent part of their diets. However, as many researches highlighted the health risks related to the consumption of red meat, consumers are increasingly shifting toward plant-based diets as they are a healthier option as compared to animal meat. Further more, Consumers in the region are adopting a flexitarian lifestyle and are incorporating plant-based foods in their daily routine diets.

Along with this, the trend of veganism is gaining momentum in the region, which is further contributing to the growth of the plant-based meat market. Governments are also investing heavily in the plant-based protein industry, as there is a rise of vegan and vegetarian eating.

italian food & packaging technology - cii (2022) - november 7 product trends

www.marketsandmarkets.com

Doubling global potato production in 10 years is possible

Potatoes could contribute even more to world history and global food security, and total pro duction of the food crop could double in the next 10 years, QU Dongyu, Director-General of the Food and Agriculture Organization of the United Nations (FAO), said in his keynote presentation to the 11th World Potato Congress (WPC) convened in Dublin.

Potatoes are the world’s third most important food crop and are regularly consumed by billions of people. They also generate income for smallscale producers, offer a low-fat, high-fibre source of healthy carbohydrates rich in antioxidants and nutrients, and also generate fewer greenhouse gas emissions than other major crops, said Qu, an acclaimed expert on the food crop. Earlier in his career, he inter alia helped organize the 2015 WPC in China and served as a Trustee of the Inter national Potato Center.

Today potatoes, whose genetic origins are in South America, are cultivated on more than 20 million hectares in 150 countries for a total global output of 359 million tonnes in 2020. By focusing on improving yields and making full use of histor ic potato cultivation areas, worldwide production can be raised to 500 million tonnes in 2025 and 750 million tonnes in 2030, the Director-General said.

8 italian food & packaging technology - cii (2022) - november product trends

“Potato will become one of the advantage crops in the global food security system when the yield of other cereal crops is close to the lim it,” Qu said.

While hailing the genius of the peoples of Peru and Bolivia who domesticated the potato, the Director-General noted that Asia and Africa are the regions with the fastest growth of po tato production today, while output is declining in Europe and North America. Globally, potato output has grown even as the land devoted to their cultivation has decreased, highlighting the role of improved yields, said Qu.

The road ahead

The Director-General called on multiple part ners to help “greatly improve” potato agrifood systems on the national, regional and global lev els.

Noting the importance of providing decent rural employment, offering nutritious food and emphasizing the need for inclusive policies, plans and actions, he called for increasing support for potato genetic improvements and shorter breed ing cycles for potato varieties, and the potential value of virus-free potato seed systems.

The International Potato Center gene bank in Lima has conserved more than 7,000 different native varieties and wild relatives, which have a wide range of traits, including the ability to adapt to different production environments and to resist various pests and diseases. Qu empha sized that the relatively low natural resource requirements of potatoes makes them an im portant food crop for people to survive during famine and disaster relief. In China, potatoes are regarded as the preferred crop for increasing in come and reducing poverty, he said, noting the plant’s spatial distribution in the country closely maps that of formerly poor areas, especially in mountainous areas.

italian food & packaging technology - cii (2022) - november 9 product trends

www.fao.org

Lactose-free products market worth $18.4 billion by 2025

According the latest report by MarketsandMar kets, the global lactose-free products market size is estimated to be valued at USD 12.1 billion in 2020 and is projected to reach USD 18.4 billion by 2025, recording a CAGR of 8.7% during the forecast period. The demand for lactose-free products is increasing significantly due to the rise in lactose intolerant pop ulation across the globe. Moreover, the rise in the consumption of clean label food products is one of the major factors encouraging the growth of the lac tose-free organic products market globally.

The cheese segment is projected to witness significant growth

Based on type, the cheese segment of lactose-free products market is projected to witness significant growth rate during forecast pe riod due to the increase in con sumer interest and importance of lactose-free cheese as an in gredient in the food industry, as it offers similar nutritive values to regular cheese. In addition, it is among the popular and pre ferred breakfast ingredients, which is majorly consumed with breads and offer natural, as well as authentic taste.

The inorganic segment is projected to account for a major share in the lactose-free products

By form, the lactose-free products market is seg mented into organic and inorganic. Low cost of prod ucts and ease in the processing of inorganic products

are the key factors encouraging the high adoption of inorganic lactose-free products across the globe. Furthermore, the price of inorganic lactose-free milk is nearly half the price of organic lactose-free milk, which helps in catering to consumers that are not looking for premium products.

The North America region dominated the lactose-free products market

The lactose-free products market in North Ameri ca is dominant due to the growing demand for differ ent types of lactose-free products such as drinkable yogurt, flavored ice-cream, and flavored milk. Also, the North American population has awareness and self-diagnosis for lactose intolerance. In addition, the increase in no sugar or reduced sugar trends are factors that are projected to drive the growth of the lactose-free products market in the region.

The fastest growing market is Asia-Pacific for lactose-free products market. The increase in disposable income among consumers and the demand for health and wellness products have encouraged the consump tion of lactose-free products. The increase in urbanization in the region has led to a high demand for food security and premium quality food products. Consumers are willing to pay extra for health-enrich ing food & beverage products. These factors are pro jected to encourage the growth of the lactose-free products market in the region.

10 italian food & packaging technology - cii (2022) - november product trends

www.marketsandmarkets.com

FOOD SECURITY

Listeria risks the remedy is HPP

The power of the High Pressure HPP ITALIA, your reliable partner able to provide the innovative hyperbaric HPP treatment for all perishable products.

In HPP ITALIA we treat the products at very high hydrostatic pressure (thousand atmosphere) inducing in this way the bacterial inactivation: an innovative cold process thanks to which food, stabilize and safe, keep unaltered its precious nutritional and organoleptic elements.

Thanks to the HPP technology (High Pressure Processing) your products can increase their shelf life safely!

We were first in Italy to provide the High Pressure Treatment for third parties and we guarantee maximum confidentiality.

Discover more about the extraordinary potential of our HPP treatment booking your free tests on hppitalia.it

HPP Italia srl Parma - Italy - info@hppitalia.it

Brand protection H24 Security Export no limits

Spices and seasonings market forecast

MarketsandMarkets released a report on the “Spices and Seasonings Market where global trends and fore cast to 2026 are analysed.

The global spices and seasonings market is expected to grow from USD 21.3 billion in 2021 to USD 27.4 billion by 2026, at a CAGR of 5.2% from 2021 to 2026. Globally, the spices & season ings market is driven by the growing demand for convenience food prod ucts, clean label trends, and natural preservatives for the meat industry. However, the growing incidences of adulteration and contamination in the spices exported from developing countries such as India and China are prompting regulatory bodies in Eu rope and America to strengthen the safety regulations on imported spices and seasonings. Growth in food prod uct innovations to incorporate natural ingredients, increase in demand for health and wellness products, and rise in demand for ethnic and authentic food products are emerging oppor tunities for the spices & seasonings market.

12 italian food & packaging technology - cii (2022) - november product trends

Ginger is estimated to hold the largest market share

Among product types, ginger account for the largest share in the global market. Spice ginger is obtained from the underground stems or rhizomes of Zingiber officinale, a herbaceous tropical peren nial belonging to the family Zingiberaceae. Ginger is largely a universal spice, although its use is more pre dominant in certain countries such as China. Ginger is used in cooking in various forms, such as immature ginger, mature fresh ginger, dry ginger, ginger oil, ginger oleoresin, dry soluble ginger, ginger paste, and ginger emulsion. It is a popular home remedy for nausea, stomach pain, and other health issues.

Antioxidants and other nutrients in ginger may help prevent or treat arthritis, inflammation, and various types of infection.

Conventional spices, by nature, is estimated to account for the largest market share

The conventional spices segment dominated the spices and seasonings market in 2020. Conventional spices are grown using synthetic chemicals, pesti cides, fungicides, and insecticides for the cultivation process. These chemicals harm the crops and reduce their nutrition level. So before even the processing begins, crops are subjected to harsh chemicals that hinder their quality. To grow more produce, fertilizers are used, but in turn, they damage the land and drain its fertility. Many unfair and unethical trade practices aim to gain more profit in selling the bulk-produced stock of conventional spices. One of them is to add harmful and artificial colors and flavors to the spic es to reduce the cost of production. High-demand spices like turmeric powder and red chili powder are adulterated with food coloring, corn starch, sawdust, brick powder, and lead chromate. These adulterated products are sold at a low cost, but their quality is ex tremely low. These harsh colors and chemicals affect human health and disrupt the normal functioning of the human body. However, since spices are used in really small quantities in food, the consumption of properly tested and certified conventional spices does not pose any threat to human health.

Asia Pacific is estimated to hold the largest market share

The Asia Pacific market accounted for the largest share in 2020. The Asia Pacific region is projected to be the fastest-growing market for spices & season ings, at a CAGR of 4.4% from 2021 to 2026. The us age of spices and seasonings in the industrial sector is less in the Asia Pacific region as compared to that in developed regions, which presents food process ing industries with considerable untapped potential. The overall economic growth in the Asia Pacific re gion has led to an increase in urbanization and rapid industrialization, with a resultant rise in per capita in come. These factors play a major role in the changing preference of consumers towards value-added food products.

italian food & packaging technology - cii (2022) - november 13 product trends

www.marketsandmarkets.com

FOOD PROCESSING

Fruit and vegetable processing market worth $11.8 billion by 2027

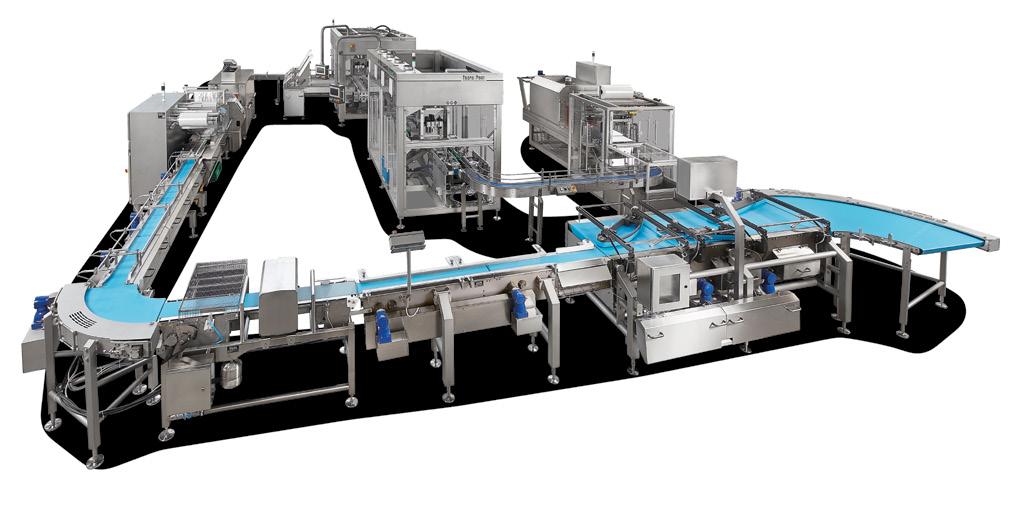

The report “Fruit and Vegetable Processing Market published by MarketsandMarkets shows that this sector is estimated to account for nearly USD 8.7 billion in 2022 and is projected to reach a value of nearly USD 11.8 billion by 2027, growing at a CAGR of 6.4% from 2022.

In the 21st century, globali zation has led to an increase in trade and resulted in aggressive R&D initiatives by several food & beverage manufacturers. Ad vanced technologies for food ingredients and food processing include membrane technology, su per-critical fluid technology, and molecular techniques such as Pol ymerase Chain Reaction (PCR) and High-Pressure Processing (HPP) technology. Other new processing technologies use non-thermal preservation techniques such as pulsed electric fields, ultrasound, pulsed light, and hurdle systems to maintain the texture and fresh

ness of the food products. Devel opment of new machinery and enhancement of the existing ones are the key strategies adopted by many players in the fruit and vegetable processing market. In addition, increasing focus on the expansion of facilities, marketing schemes, and information ex change programs to create aware ness and enhance the applications of fruit and vegetable processing is projected to contribute to the growth of the market.

The growth of the processed fruit and vegetable market is at tributed to the increasing trade of ready to eat food among countries such as Mexico, Brazil, Argentina, the UAE, India, and China. Fruit and vegetable processing helps in transforming fresh produce into processed fruits and vegetables with increased shelf life through various physical and chemical techniques. The processed fruit and vegetable is witnessing signif

icant growth due to the increasing consumption of fruits and vegeta bles in developing countries such as India, China, South Africa, and Brazil, compelling manufacturers to increase production.

Drivers: Growth in the demand for convenience food products

The processed food market is driven by the increase in the need for convenience due to the busy customer lifestyles. Further, growth in per-capita income has resulted in greater demand for ready-to-eat and on-the- go food items. This, in turn, has led to an increase in demand for processed fruit and vegetable products. The outlook on the growth of fruit and vegetable processing market is projected to remain positive due to the high growth in the fruit and vegetable processing industry.

Consumers are also benefited by the purchase of processed food

14 italian food & packaging technology - cii (2022) - november

products, as it is easy for them to use, consume, and store for a longer period. Consumer prefer ences in developing countries, such as China, India, Brazil, have wit nessed a gradual transition from traditional homemade breakfasts and snacking meals to ready-toeat products over the last couple of decades.

Opportunities: Growing demand for Vegan food products

Over the last few years, there has been growing interest in the development and production of plant-based alternatives to meat. Manufacturers of plant-based foods are capitalizing on the use of fruits & vegetables, legumes, and pulses; they are also mulling over fruit-based products be cause of their nutritional compo sition and superior functionality, which can bring upon textural and flavor enhancements.

Challenges: Physiological deterioration and infections

The fresh produce value chain is a basic and monumental aspect of agricultural production. Among many other factors, it affects the quality of products for consum ers, profit margins for farmers, and export conditions and conse quences for a country. There can be an increased risk in the rate of loss because of normal physiolog ical changes caused by conditions that increase the rate of natural deterioration, such as high tem perature, low atmospheric humid ity, and physical injury. Fresh pro duce, when subjected to extremes of temperature, atmospheric modification, or contamination, abnormal physiological deteriora tion is often observed. This may

cause unpalatable flavors, failure to ripen, or other changes in the living processes of the produce, making it unfit for use.

The vegetable segment is estimated to account for the largest share in 2022

On the basis of fruit and veg etables type, the vegetable seg ment is estimated to dominate the processed fruit and vege tables market in 2022. In recent years, China is being observed as an emerging country in the pro cessed fruit and vegetables mar ket due to the growing demand for healthy, organic and vegan food products.

The fresh fruit and vegetable segment will be the fastest-growing segment

During the forecast period, the fresh fruit and vegetables segment is projected to grow at the highest CAGR in the pro cessed fruit and vegetables market, in terms of value. This segment is estimated to grow

due to the increasing demand for ready-to-cook produce. Thus, due to the busy consumer lifestyles, demand for convenience food, growth in health awareness, de mand for fresh and fresh-cut fruits & vegetables that save preparation time, and convenient storage & longer shelf life are expected to drive the market for processed fruits & vegetables.

The Asia Pacific is estimated to dominate the market in 2022

The Asia Pacific is estimated to account for the largest market share in the processed fruits & vegetables market in 2022. The fruit & vegetable processing in dustry in developing economies such as Asia Pacific and South American countries has devel oped due to factors such increas ing number of working women and middle-class population, bulk production of various agricultural products, and government sub sidies in countries such as India, coupled with trade liberation.

www.marketsandmarkets.com

food processing italian food & packaging technology - cii (2022) - november 15

Sublimation fits to today’s healthy food requirements

Today, PIGO is one of the few companies in the world that of fers all three main methods of preserving food under one roof: freezing, drying, and freeze drying.

“We have improved existing technologies, obtaining the fi nal product of clearly superior quality”, they explain. “We can define as common request im provement of energy efficiency, preservation of raw material nutritional values and character istics, guaranteed bacteria free processing technology”.

What is the peculiarity of the product sublimation process?

Freeze-drying, or lyophiliza tion, removes moisture from raw,

frozen product through a vac uum system and process called sublimation. The ice contained in the product is sublimated, hence transformed from solid to gas and then trapped inside the conden sation system. At the completion of the process, the treated prod uct will have retained its form, volume and original structure, as well as all its physical, chemical and biological properties.

It can then be stored for an almost indefinite time. As the product is porous, it can be re dissolved by the simple addition of a proper solvent. The process also preserves the actual color and shape of the original raw ma terial, reassuring consumers they are actually getting real fruits and vegetables.

At what stage the product sublimated?

Raw material for freeze drying (sublimation drying) is IQF frozen product. Placing IQF frozen ma terial in vacuum chamber, with proper vacuum, adequate (low temperature) heating, and effi cient sublimated ice vapors catch ing, as result client is obtaining final product completely without water, with almost unlimited shelf life, with outlook of fresh or fro zen product, and with preserved all nutritional values in it.

What make huge difference between PIGO EFD (EASY Freeze Drying) System and other con cepts, is the extraordinary ener gy efficiency, both in heating and cooling part of system, what is easy to demonstrate using the facts and clients experience.

Only available absolutely hy gienic and sanitable system on the market is PIGO EFD, provid ing easy approach to all system components, and fully sanitation provided.

food processing 16 italian food & packaging technology - cii (2022) - november

PIGO technologies for food preservation.

Air-dried, on the left, vs. freeze-dried fruits with PIGO equipment.

Being only system not re quiring fixed “monoral” trolleys transportation system, it is also unique easy transportable freeze drying system, suitable for easy transferring from one location to other. Appart the fact that absence of “monorail” system means also lower investment costs.

What is the drying power?

In order to accelerate drying process, we introduce certain quantity of energy, to help inten sity of sublimation process. Using always indirect (radiation) heat ing at low temperature, it is pro vided minimum energy require ments. It is resulting with total energy consumption of around 2 kW/kg of starting product.

Which products can be processed with the EASY Freeze Dryer technology? How are products prepared before processing?

Freeze drying is suitable and applicable for almost all kinds of products such as fruits, berries, vegetables, spices, milk, meat, fish, mushrooms, coffee, yeast, and ready meals.

Products are simply frozen be fore freeze drying, with possibility also to store them for long period of time before freeze drying pro cess is applied. The advantages are connected with the absence of exposure of the product to high temperatures; this allows to ob tain dry materials without losing their structural integrity and bio logical activity. Most proteins do not undergo denaturation and can be stored for a long time.

Why is it beneficial to sublimate products? How popular are sublimated products in the global market?

It allows frozen foods to be dried directly by vaporizing micro cristals of ice without ever having the water melt; it also avoids the breakdown of cell structure into a mushy product. Freeze dried products are characterised with many years long shelf life (once properly packed after freeze dry ing), preserved taste, colour, nu tritional values characteristics of

fresh product, very light weight (total absence of water inside the product), and no any particular storage conditions requirements.

How do IQF freezing tunnels work?

For the perfect IQF freezing process before lyophilization the best solution is EASY Freeze IQF Freezer. Full controlled fluidisa tion method keeps the product constantly suspended above the belt in a cushion of air. The result is the immediate crust freezing and efficient core freezing of indi vidual pieces, regardless of type, variety or condition of product. Maximized freezing efficiency is guaranteed for each unique product, whether the product is heavy, light, soft, sticky or fragile, thanks to variable speed control of all fans and all other build-inn drives, allowing on-the-fly opti mization of air flow conditions.

(PIGO - Via dell’Edilizia 142 -Vicenza - Italy - Tel. +39 0444 905709 - email: info@pigo.itwww.pigo.it)

food processing italian food & packaging technology - cii (2022) - november 17

Lyophilized berries with EASY Freeze IQF Freezer (PIGO).

New solutions for Servomech screw jacks with brushless servomotors

Among the innovations im plemented by Servomech, a new universal motor adapter is now available to be combined with the range of ball screw jacks and acme screw jacks, thus allowing to combine the high performance mechanics of Servomech with the servomotors of the main brands in trade. The new motor adapters for brushless servomotors, like the whole range of Servomech products, are always made inside Servomech factory in Anzola dell’Emilia (Bologna - ITALY) and are available as standard com ponents with a great advantage in terms of faster delivery times and competitive costs.

Servomech, which has always been at the forefront in the search for new solutions for linear motion, promotes a new concept in lifting systems, with an innova tive approach, focused on the ap plication of its high-performance ball screw jacks, with brushless motors and related drives and controls. Customers and design ers are free to choose the brand of motors and drives they prefer. Thanks to the new universal mo tor adapter, the motor connection is now optimized for the use of servomotors with square flange, allowing a simple and immediate coupling with all the main servo motors on the market.

The next generation of lifting systems proposed by Servomech allow you to reach high linear speeds, high dynamic operations with relevant acceleration and de celeration, high positioning accu racy, exact position repeatability and operations with a continuous

duty cycle. The synchronism be tween the various lifting points is carried out in the electrical axis, with the control in position or in both position and torque. The use of ball screw jacks equipped with servomotors, absolute multiturn encoders and drives capable of managing the motion capability of the motors and the control of the required current, allow for reaching high speed, precision and repeatability performance.

The traditional lifting systems are in low linear speed applica tions, with intermittent operating cycles, preferably with the use of acme screw jacks. Through different configurations depend ing on the needs and dimensions and through the mechanical con nections with connecting shafts, mechanical couplings and motion transmission reducers, the screw jack with motor transmits the movement to the other lifting points through a mechanical syn chronism. This solution has some limits, mostly related to linear and rotation speed, inertia masses in volved and the lost power in the various transmission components, vibrations, noise and play that can be created between the mechani cal connections, and the uncertain accuracy of the positioning of the various lifting points.

The new generation of lifting systems proposed by Servomech therefore broadens the applica tion horizons of lifting systems in general with a modern and ad vanced approach. Lifting systems can now be used for continuous operations, for process functions, with also heavy load working cy

Universal motor adapter (Servomech).

cles, with highly dynamic condi tions, high speed, high accuracy and control.

Servomech Spa was founded in 1989 and from the very be ginning has followed the entire production cycle internally within its factories in Anzola dell’Emilia, in the Bologna area. Specialized in linear actuators, acme and ball screw drive, ball screw jacks, acme screw jacks, bevel gearboxes, ball screws and nuts. Appreciated in all European Union countries and industrialized countries around the world, Servomech provides to the market a wide range of high quality and performances prod ucts for the linear motion, and ensure top flexibility and care for its customers.

(Servomech - Via Monaldo Ca lari, 1 - 40011 Anzola dell’Emilia -BO - Italy - Tel +39 051 6501711 -email: info@servomech.comhttps://servomech.com)

food processing 18 italian food & packaging technology - cii (2022) - november

THE MOMENT FOR A NEW BEGINNING! info@wolhfarth.it - www.wolhfarth.it V.Cavour, 31 - 26858 Sordio (LO) - Italy - Tel. +39 02 9810153 - Fax +39 02 98260169 HYGIENIC DESIGN for an easy cleaning. SAFETY FDA certified materials, suitable for the use in contact with foods. ENDURANCE made of stainless steel machined from bars, NO CAST PARTS, NO WELDINGS. “RAPID” PUMPS Sanitary - Self priming. Both for liquid and for thick products (Creams and Sauces). “FARMINOX” FILTERS Packingless plate filters. Working through paperboard filter-sheets.

Clip removing and cutting machine

Fava Giorgio Axel presents TDSAL, an automatic machine for clip removing and/or cutting in half, 45° or 90° angle for cooked and seasoned products.

A loading conveyor, working in step and controlled by a brush less motor, allows the precise positioning of the products in the clip removing station. The two de-clipping heads lean against the product, centering it transversally and acting in order to optimize the aesthetic result after the removal of the clips, with the least possi ble product removal. The products are then transferred to the cut ting device, which divides them into two parts of approximately equal length and/or equal weight, depending on the characteristics of the product, and transfers them onto a conveyor belt, which can be customized, for transfer to subsequent processes. The clip removing heads and the cutting unit are equipped with easily re placeable parts to adapt to the size of the products and to obtain the desired result. The product’s dimensions vary from 30 to 90 mm in diameter and from 250 to 600 mm in length, and productiv ity ranges from 15 to 20 pcs/min.

It is possible to have machines for clip removing only, model DSAL, with one or two clip remov ing units, with a productivity rang ing from 18 to 30 cycles/min. The DSAL can also process, depending on the model, products with diam eter from 120 mm to 180 mm and length from 300 to 800mm.

A special version for cooked or roasted products in net, per forms the removal of the clips and of the relative portion of net, elastic or not elastic, with

dimensions from 120 mm to 240 mm width, from 120 mm to 180 mm height, from 250 mm to 600 mm length. Productivity is 12 or 24 pcs/min, in the versions with one or two clip removing units. An operator touch screen panel allows the management of the various types of machines and it provides operators with the nec essary information, from use to maintenance. The machine’s PLC allows both the connection with the company’s management soft

ware, for production program ming and product traceability, and the remote connection with technical assistance service.

TOVAD model is also available for mortadella (bologna sausage) with diameters from 80 to 160 mm and lengths from 120 to 240 mm, capable of performing the best and quickest clips removing and cutting into two parts with minimum weight differences.

(Fava Giorgio Axel - Via Cerati 19/A - 43126 Parma - Italy - Tel. +39 0521 293734 - email: info@fava giorgioaxel.com - favagiorgioaxel. net)

food processing 20 italian food & packaging technology - cii (2022) - november

Clip removing and cutting machine (Fava Giorgio Axel).

XMD metal and X-Ray detectable timing belt range

For the food industry, noth ing is more important than food safety, and contamination from belt or cleat fragments is one of the clearest threats to prod uct purity and brand trust. At the same time, processing lines need to operate at peak produc tivity to achieve business suc cess. The Megadyne XMD range of Metal and X-Ray detectable timing belts and accessories are designed so that belt fragmen tation and contamination from belt particles can be identified quickly and efficiently, without compromising on superior per formance.

Megadyne, a global leader in belting and a member of the AMMEGA Group of companies, introduced these new belts at this year’s IFFA, the world’s showcase for the Meat Indus try as slicers up to the primary packaging equipment needs.

How it works

Megadyne’s XMD belts – in cluding open end, endless joined, and truly endless belts from the popular Megalinear and Megaflex families – and their accessories are manufactured using a special blue polyurethane; in fact, the belts are made entirely in blue, a colour that contrasts best with most food products for further hygiene benefits. The polyure thane compound can be picked up by Metal and X-Ray detectors, meaning that fragments not readily visible to an onlooker will be spotted by the Food Safety system in place, alerting end us ers to potential contamination and belt fragmentation.

Test cards to proof detection and identify the minimum size

To ensure that this detection is taking place, and to operate at your company’s standard level of efficiency, Megadyne has devel oped test cards that come with the XMD belts. With the help of the test cards, and the presence of the special compound in all the belts and accessories of the XMD ranges, food companies can truly say they’re doing their utmost to

fight against product contamination due to belt issues, all while partnering with a Food Grade glob al standard-setter in high-perfor mance belting solutions.

Giuseppe Allais, Global In dustry Segment Manager Food, points out that: “With Metal and X-Ray detectable belts and a test card toolkit that enables end users to fine-tune their de tection systems, the Megadyne XMD range helps prevent product contamination, and brand dam age from expensive recalls. In this way, these belts protect the consumer and the industry at the same time.”

For further information, please contact Megadyne Team at: info@megadynegroup.com

XMD timing belt with gusset. (Megadyne).

(Megadyne Group - Via S. Lucia 114 - 10075 Mathi - TO - Italy - Tel +39 011 9268052 - email: info@ megadynegroup.com - www. megadynegroup.com)

food processing italian food & packaging technology - cii (2022) - november 21

XMD timing belts. (Megadyne).

SARP, same passion, new graphic

For over 30 years Sarp has been operating in the food prod uct market, with a passion for technology and innovations. It always thinks about what is be hind a good plate of pasta or the hidden process behind ice cream or fruit juice and they think about putting their own ideas, with their customizations and with their knowledge.

We are never satisfied with the final result; we constantly de velop to have the best product.

and plants for pasta and ther mal treatment plants for food products.

But if the separation between fresh and dry pasta is clear for the pasta itself, presenting the specification of the machines and the production, such as presses, cookers, and coolers, the thermal treatment systems are much more complex to un derstand immediately.

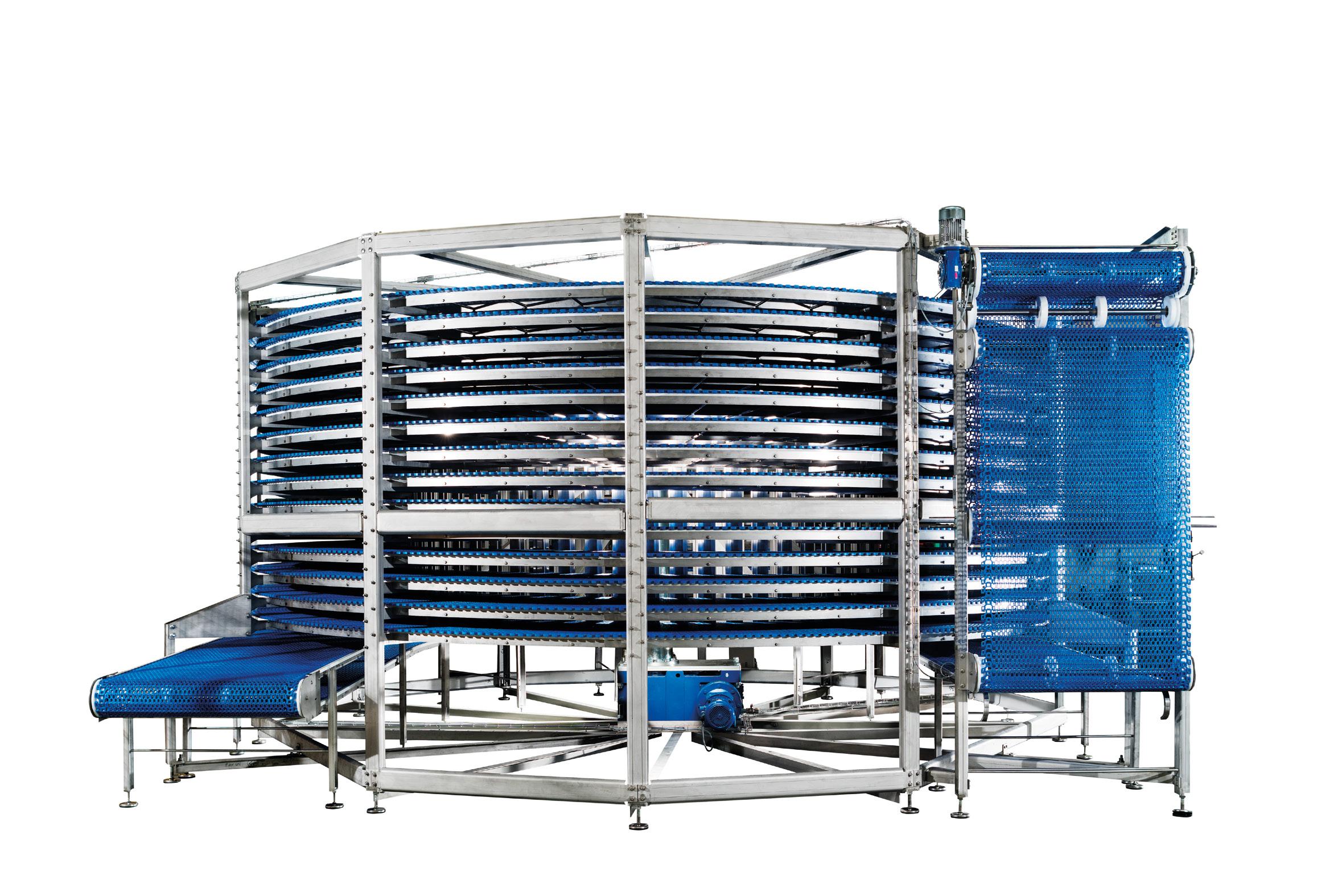

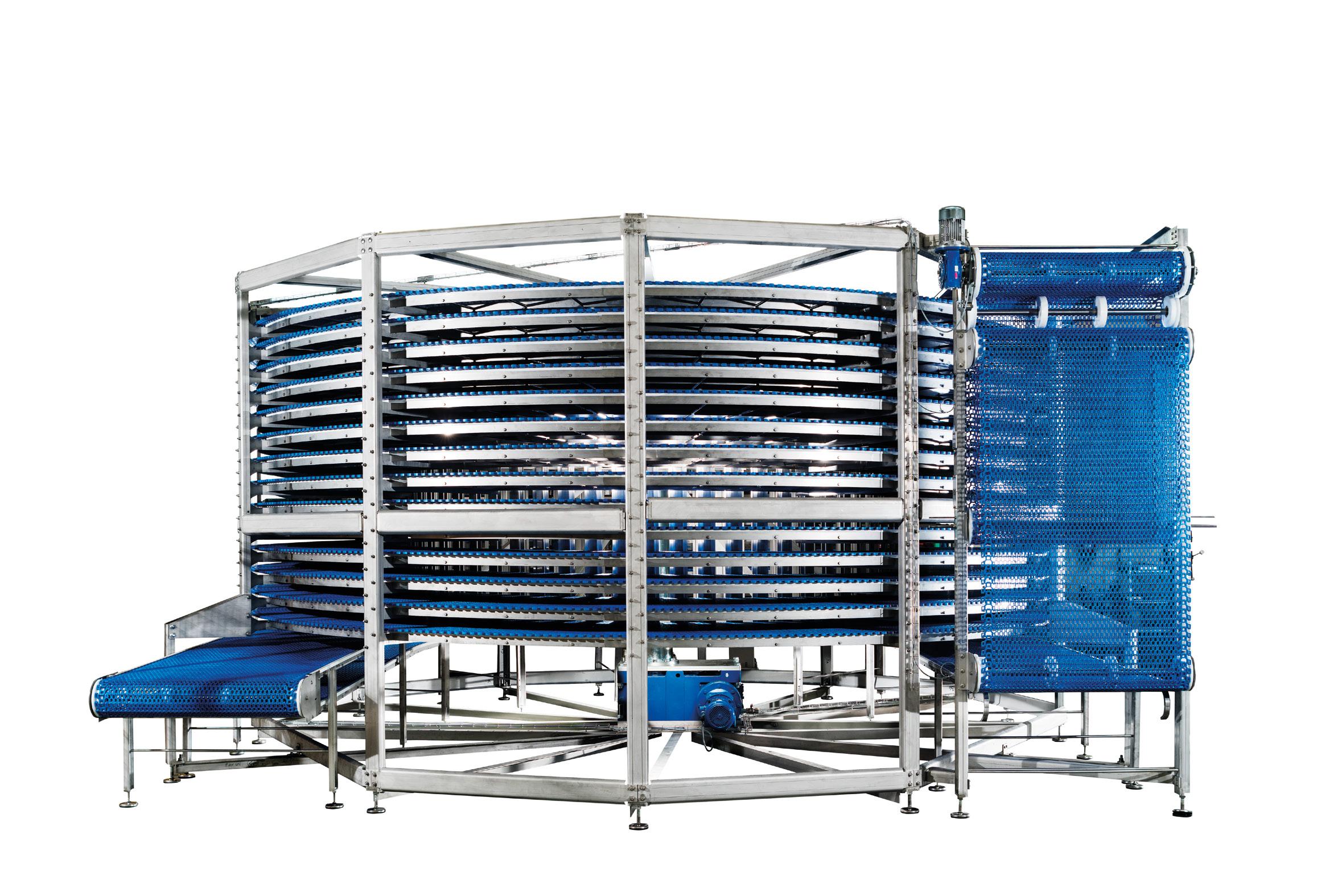

In the spiral systems sector, Sarp is talking about treatments

and hence the specification of the applications used: bakery, meat, fruit and vegetables, dairy products, ice cream, and other food products.

The graphic restyling was intended to make the website more attractive and at the same time usable, eliminating the signs of aging, and continuing to represent the idea of a company that is always in technological evolution.

Designed to be highly us er-friendly, responsive, and studied in every detail for the customer, the new website has revised and enriched contents, able to offer all the necessary information and answer the questions that may arise, quickly and easily, minimizing the doubts about our products.

The applications where the products are used are shown and the products themselves are il lustrated in their detail, showing the technical points necessary to answer the main questions of the customer.

This time we wanted to renew ourselves by thinking of a new interface for the website

The challenge was to present everything Sarp produces clearly and interestingly, trying to make it clear immediately what the products are and where the ma chines can be applied.

It is clear that Sarp’s pro duction is primarily divided into two macro sectors: machines

with different temperatures combined with different types of products: from bread to cheeses, from fruit juices to meat.

It was necessary to create a web navigation system that would highlight the different types of treatment: cooling, freezing, pasteurization, and proofing. Each type of treatment is directly related to the type of food product to which it refers

Sarp has worked for a website able to best express its profes sionalism and able to represent then in a more complete and ex haustive way, which best conveys the work and the way they do it: with passion, dedication, and product and customer oriented.

Come and visit Sarp at Gul food Manufacturing 2022, Dubai, November 8-10 - stand S3-C12Shk Saeed Hall 3.

(Sarp - Via Montebelluna di S. Andrea 43 - 31033 Castelfran co Veneto - TV - Italy - Tel. +39 0423 482633 - email: sarp@sarp. it - www.sarp.it)

food processing 22 italian food & packaging technology - cii (2022) - november

Tailor-made solutions

EBARA Pumps Europe, located in Gambellara Italy, is part of the Japanese multinational EBARA Corporation, founded in Japan in 1912 by Issei Hatakeyama to de velop products according to the theory of centrifugal pumps of Prof. Ariya Inokuchi.

Through its core business, the EBARA group has taken on a leadership role in the water, air and environmental sectors to meet its customers’ and society’s needs and it is recognised as one of the world’s leading manufac turers of pumps.

The spirit of the EBARA Corpo ration is to work with Passion and Dedication (Netsu to Makoto). This value lives also in EBARA Pumps Europe (EPE) which represents an important hub for the market of industrial and domestic elec tric pumps. To realize products with high quality and high level of performance, EPE constantly

investing in research, technology and quality. It’s an important ex ample of the Industrial Business Unit (IBU) department, which was officially launched in February 2016 and comes from the idea: to bring together in one department all the skills needed to provide ef fective, qualified, and timely sup port to OEM (Original Equipment Manufacturers) clients, i.e. those manufacturing companies that use electric pumps as a ‘compo nent’ within their finished prod ucts (machinery, systems).

The IBU department is much more than a group of engineers. In fact, the team has experts in all areas including planning, codification, order processing, assembly and testing to ensure best service to customers. For urgent complex technical mat ters, All OEM sales staff in Eu rope have direct access to the IBU department in Italy. Mean

while, being part of EBARA’s global headquarters, the IBU is offering its service for EPE products to EBARA group com panies as well.

Thanks to this highly special ised department, EBARA is able to realise the 3LMZC SERIES (AISI 316L) with tri-clamp connection DIN32676. These pumps, with an excellent design, are also availa ble with steel housing to protect the motor from indirect water splashes.

The pump body is made of AISI 316L through the renowned hy droforming process, which uses a high-pressure fluid (up to 1200 bar) to form the metal.

The hydraulic fluid, in this case water under increasing pressure, pushes the stainless steel to copy the shapes of the template until it comes into contact with the internal walls of the matrix that forms the mould. Hydroforming, which combines the power of a press with the force of water, has significant advantages over tradi tional processes, namely perfectly smooth shapes and eliminating welding points.

The impellers, completely in AISI 316 steel, are dynamically balanced in order to reduce vi brations.

3LMZC SERIES offer high qual ity, perfect design and are suita ble for pharmaceutical and food & beverage fields.

For more infor mation visit www. ebaraeurope.com or scan the QR code

(EBARA Pumps Europe S.p.A. - Via Torri di Confine 2/1 int. C36053 Gambellara VI - Italy - Tel. +39 0444 706811 - email: industry@ebaraeurope.com - www. ebaraeurope.com)

food processing 24 italian food & packaging technology - cii (2022) - november

Melt continuously and in a small space

TECNO 3 presents the FC se ries continuous melters suitable for continuous melting loaves of fat, anhydrous butter and hydrated fat (vegetable fat, cow butter, etc.) for the confectionery, dairy and food industries, as well as cocoa mass and chocolate in loaves for the confectionery industries.

This equipment features a special innovative technology system that ensures high pro ductivity, reduced energy costs and labor savings.

The efficiency of heat ex change is excellent as a result of the mechanical work of hot rotors, which operate a scrap ing action on the surface of the loaves, fed automatically on the inclined and hot loading surface spontaneously slide to the heat ed rotors, equipped with a thin spiral that acts as a scraper and continuously renews the area to be melted in contact with the hot part.

A double filter system is inserted before the product transfer pump to retain any foreign matter, and then a ne odymium system allows further metal impurities to be inter cepted. If necessary, at the end of processing or for a product change, the melt tank can be completely discharged, total ly eliminating residual melted product.

The melting cycle is signif icantly shortened without the use of excessively high temper atures, thus allowing the quality characteristics of the raw materi al to be respected.

The overall dimensions are small, and as a result, continuous

melters can be installed even in small spaces.

Constructed entirely of AISI 304 stainless steel, meeting hy gienic and sanitary standards and complete with insulation, FC series continuous melters are equipped with a double thermoregulation circuit controlled by PLC to keep the operating temperature con trolled and constant. In addition, an additional melting unit can be integrated to increase produc tivity. The removal and melting rotors can be equipped with wear-treated and replaceable

bushings, this keeps spare parts costs down.

The innovative technological concept is complemented by an integrated system of monitor ing and reporting of predictive maintenance operations with the possibility of remote control, ensuring the correct and con stant operation of the plant over time.

(Tecno3 - Via Mastri Cestai 2 - 12040 Corneliano d’Alba - CN - Italy - Tel. +39 0173 610564 - email: a.mattis@tecno-3.itwww.tecno-3.it)

TECNO 3 FC series continuous melter loaves of fat, anhydrous and hydrated butter - cocoa mass and chocolate in loaves.

food processing italian food & packaging technology - cii (2022) - november 25

A mild and innovative solar drying process to provide high quality products

In developing Countries post harvest loss of fruits is very high due to the perishable nature of fruits, poor postharvest handling, and lack of cheap and appropriate postharvest technology. Ade quate solar drying techniques may be a promising sustainable technology for transforming local products to obtain foods easily storable at room temperature.

Five pilot innovative mild so lar drying processes on fruit and vegetable products were carried out at the Research Centre for Engineering and Food Transfor mation (Milan, Italy) to verify the influence of the process on some physico-chemical properties of fruits and their shelf life, for a process scale transposition.

Samples were analysed for water activity (aw), colorimetric

parameters and VIS spectral pro files. Solar drying allowed the pro duction of dehydrated products with attractive visual characteris tics and microbiologically safe due to low a w values. Dried product can be used as both final products ready to direct consumption and food ingredients in their milled form in fortified foods.

The possibility to store the products at room temperature can support the rural sector of the Developing Countries by re ducing food loss, poverty, and improving nutritional status of the population.

This work was published in the Journal of Food Measurement and Characterization.

Impact of ultra-high-pressure homogenization of buttermilk for the production of yoghurt

Despite its nutritional prop erties, buttermilk (BM) is still poorly valorized due to its high phospholipid (PL) con centration, impairing its tech no-functional performance in dairy products. Therefore, the objective of the study carried out by Canadian Researchers was to investigate the impact of ultra-high-pressure homog enization (UHPH) on the tech no-functional properties of BM in set and stirred yoghurts.

BM and skimmed milk (SM) were pretreated by convention

food processing 26 italian food & packaging technology - cii (2022) - november

al homogenization (15 MPa), high-pressure homogenization (HPH) (150 MPa), and UHPH (300 MPa) prior to yoghurt production. Polyacrylamide gel electrophore sis (PAGE) analysis showed that UHPH promoted the formation of large covalently linked aggre gates in BM. A more particulate gel microstructure was observed for set SM, while BM gels were finer and more homogeneous. These differences affected the water holding capacity (WHC), which was higher for BM, while a decrease in WHC was observed

for SM yoghurts with an increase in homogenization pressure. In stirred yoghurts, the apparent viscosity was significantly higher for SM, and the pretreatment of BM with UHPH further reduced its viscosity.

Overall, the results published in Foods journal showed that UHPH could be used for modulating BM and SM yoghurt texture proper ties. The use of UHPH on BM has great potential for lower-viscosi ty dairy applications (e.g., readyto-drink yoghurts) to deliver its health-promoting properties.

Impact of overhead pressure during mixing on the quality of sandwich bread

A paper published in Food and Bioprocess Technology journal by French Researchers presented the impact of overhead pressure (con stant pressure and pressure mod ulation) during mixing on impor tant mixing parameters (maximal power level and the correspond ing time (tPEAK)), dough properties after mixing and fermentation (dough voidage and growth rate), and bread characteristics (such as specific volume, void fraction, and crumb microstructure).

The overhead pressure during mixing, which was done with air as overhead pressure, did not significantly affect the maximal power level and tPEAK , but signifi cantly impacted dough and bread characteristics. Mixing at high pressure, i.e., 0.5 bar above at mospheric pressure, led to higher dough voidage at the end of mix ing, resting, and sheeting. More

over, high-pressure mixing led to higher dough growth, resulting in the attainment of desired expan sion ratio of 3.5 much early (after 70 min fermentation). The bread obtained from this condition

had the largest specific volume of 4.29ml/g and void fraction of 82.98% and possessed one of the largest crumb cell sizes. On the other hand, mixing under atmospheric pressure (1 bar) and step decrease to partial vacuum (i.e., 0.2 bar below atmospher ic pressure) from atmospheric pressure and high pressure led to dough with relatively low void fraction and slow dough growth rate during fermentation. For the same fermentation time (i.e., 70min), these conditions resulted in bread with similar characteris tics but had significantly smaller measured parameters than oth er conditions. Moreover, dough mixed under these conditions had to be fermented for an addi tional 10 min (i.e., total of 80 min) to attain bread with specific vol ume and void fraction similar to that of other studied conditions.

Overall, it was found that overhead pressure during mixing mainly impacted the dough void fraction which, in turn, impacts the dough growth rate during fermentation and the final bread characteristics.

food processing italian food & packaging technology - cii (2022) - november 27

How can you package confectionery and baked goods flexibly in a wide variety of pack formats? With pick & place robots that accurately position each product and systems that effortlessly switch between different packaging materials. Saving precious resources –with virtually no waste. This is our Mission Blue. A true benefit for the climate and the many FMCG manufacturers who have been relying on us since 1966. And for you too. www.schubert.group/en/confectionery-snacks.html

A CONFECTIONERY JUNGLE PACKAGED AUTOMATICALLY. BROUGHT TO LIFE WITH SCHUBERT.

PACKAGING TRENDS

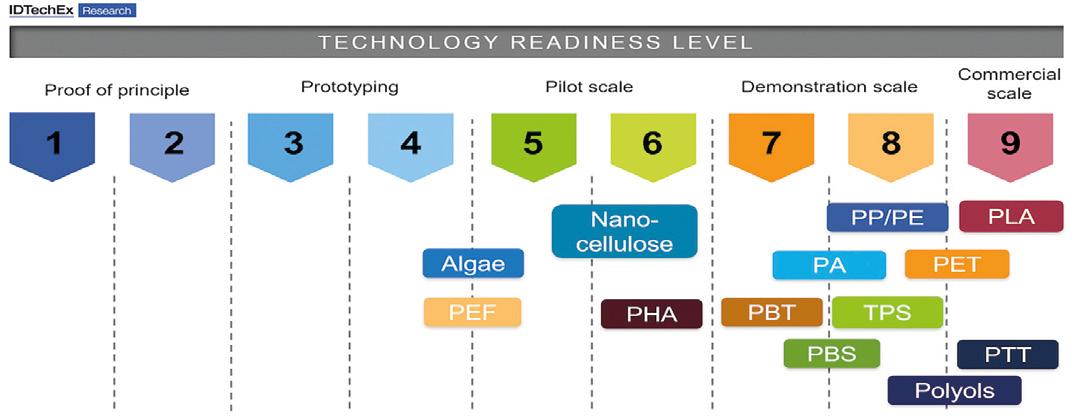

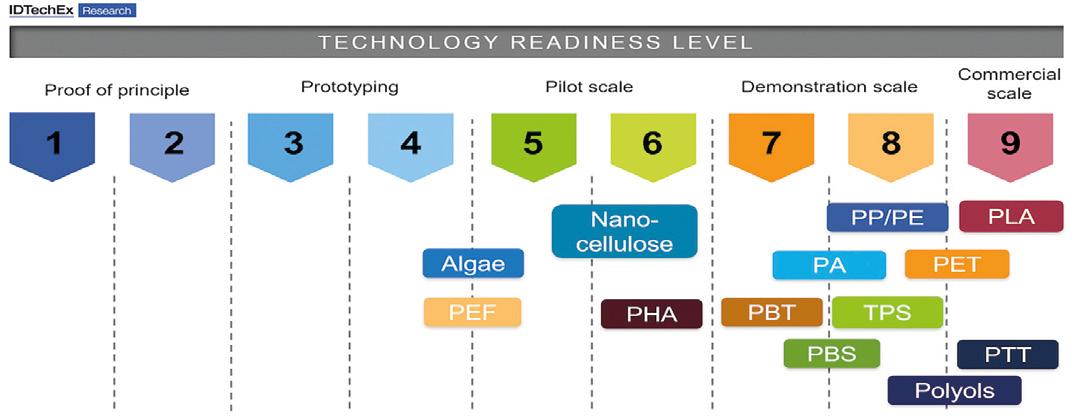

Bioplastics 2023-2033: technology, market and forecasts

Bioplastics manufacturers are scaling produc tion rapidly and the industry is expected to grow by 10.1% CAGR in the next ten years. Manufacturers are driven by brand-owner pull to meet decarbonization commitments, consumer demand for sustainability, and single-use fossil-based plastic ban laws. In this report, IDTechEx explores the drivers of the bio plastic market’s growth, analyses key and emerging technologies, examines end-of-life options, discuss es applications, and forecasts the opportunities and growth of the market.

Plastic demand grows

Plastic demand continues to grow even as we become increasingly aware of the threat that plas tics pose to our environment. Global consumption of plastics will double by 2050. To combat the impact of plastic on environment and climate change, the

industry is transitioning towards a circular economy. Yet, even if all the plastic produced every year was 100% recycled, there would still be a need for virgin feedstock to meet growing consumption. Bioplastics - plastics which are synthesised from biobased feed stocks - can replace incumbent fossil-based plastics here. Given their biobased origin, these plastics are a lower carbon footprint and sustainable option to incumbent fossil-based plastics.

Climbing out of the valley of death

The bioplastics industry began decades ago, but during the 2010s the industry fell deep into the val ley of death, indicated by a string of bankruptcies and business repositioning away from the space. This slump was driven by recoil from bullish initial investment in the space, and a significant bottleneck when it came to scaling production to commercial level. Furthermore, the high relative cost of bioplas tics compared with a substantial drop in the price of Brent crude made bioplastics poor competition against conventional plastics, reinforcing the decline.

Yet, recent changes have turned the tide in the bioplastics industry, revitalizing its growth mode. Foremost, there has been a shift towards sustaina bility demand from brand-owners themselves. This is driven from both sides: by consumer pull that contin ues to strengthen, and by legislation changes (plus anticipation for future changes) towards sustainabil ity- such as single use fossil-based plastics bans. The cornerstone COP26 conference, supported by the IPCC report, fuelled brand-owner commitments to decarbonization, too. This surplus demand is pushing

30 italian food & packaging technology - cii (2022) - november

manufacturers to expand their capacities faster, with many brand-owners forming partnerships to acceler ate the scaling-up process.

Many companies are beginning to overcome the commercial scale bottleneck and as technology de velops bioplastics are being produced for lower costs. Additionally, consumers are more willing now to pay the premium for sustainable bioplastics. Overall, these factors are driving bioplastics towards being more affordable and competitive against conven tional plastics. This is supported by a spike in Brent crude prices recently, which make bioplastics a more attractive alternative.

Challenges for bioplastics

Yet, there are still many challenges for several bio plastic types to overcome. To be truly sustainable and become part of the circular economy, bioplastics must be designed for end-of-life processing. For example, PLA, the most widely produced 100% biobased plas tic material can be industrially composted, however this provides no value to the compost so there are few off-takers in the industry. Meanwhile, recycling PLA, unlike drop-in biobased PET, requires dedicated infrastructure that is uncommon and very expensive to adopt. Instead, most PLA is mismanaged or goes to landfill.

Drop-in disruptors

A major factor for bioplastic adoption to disrupt the plastics industry is the drop-in materials. These are biobased feedstocks or building blocks that can be a direct substitute for incumbent feedstocks. By substituting with drop-ins, manufacturers can easily facilitate the transition from fossil to biobased. The same processes can be used, rather than establishing entirely new plants, and end-product properties are unchanged. This also means that the well-established end-of-life options of incumbent plastic products can be used, particularly recycling streams which mas sively improve the sustainability of a plastic product. Using drop-ins, the biobased material can be traced with chain-of-custody models like mass balance, which create transparency and trust throughout the value chain regarding sustainable material origins and processes. Overall, the plastics market will more readily adopt drop-in bioplastics which have a strong advantage over other bioplastics.

The largest groups of plastics worldwide, PP and PE, remain without a major bioplastic solution. Bio-naphtha is used to make biobased PP and PPE, but synthesis of bio-naphtha from bio-alcohols and oxygenates is inefficient (because of waste oxygen in the process). Furthermore, this puts chemical manu facturers into competition for feedstock with biofuel and bioenergy. On the other hand, bio-naphtha can be made from plant oils, however these raw materials suffer from price fluctuations resulting from geopolit ical instability.

Younger bioplastic types that are still in demon stration or pilot scale show promising properties. However, they have yet to develop a significant range of applications, critical to developing demand for the materials. Companies in these niches need to form partnerships with brand-owners and formulators to expand their application portfolios.

packaging trends italian food & packaging technology - cii (2022) - november 31

www.idtechex.com

Aseptic packaging demand to grow 5.5% annually

A new Freedonia Group analysis forecasts de mand for aseptic packaging for food to increase 5.5% annually to $2.3 billion in 2026. Aseptic processing will increasingly be preferred over more traditional thermal processing methods such as retort and hot fill due primarily to its shorter heating times, which better maintains the flavor, texture, and nutrition of food that these other processing methods.

Strong gains in aseptic packaging demand

Through 2026, aseptic packaging will continue to see strong demand growth in the packaging of milk and milk alternatives, soups, tomato products, and other foods. However, growth will lag significantly in the juice market – the largest application of aseptic packaging – due to market maturity and a declining interest in the overall ambient juice category, which

faces intense competition from fresh and coldpressed juices and other lower sugar beverages.

Aseptic cartons remain most popular

Aseptic cartons account for the largest share of aseptic packaging, and they are increasingly taking share from traditional shelf stable packaging such as cans in applications such as soups, stocks, broths, and sauces. The advantages aseptic cartons offer over cans include their lower weight, more modern aesthetic, and greater shelf appeal. However, the higher cost of these prod ucts and issues surrounding their recyclability will re strain even further penetration into these applications.

Sustainability remains a key innovation driver

Sustainability remains a key issue in the packaging industry as a whole and especially for aseptic packag ing. The composite material used in the manufacturing of cartons and pouches to extend shelf life is difficult to recycle in practice due to lack of adequate recycling infrastructure and difficulty in separating the materials. However, aseptic packaging producers are addressing this by focusing on material improvements. Carton pro ducers are eliminating the aluminum barrier layer typi cally found in aseptic cartons to increase their recycla bility, while monomaterial pouches are being developed that are still compatible with aseptic filling.

Aseptic Food Packaging provides historical data (2011, 2016, and 2021) and forecasts for 2026 for aseptic food packaging demand for in current dollars (including infla tion) by product, application, and material.

www.freedoniagroup.com

packaging trends 32 italian food & packaging technology - cii (2022) - november

Capsules growth is slowing down and competition intensifies in aluminium

AMI has published its 4th report mapping the glob al Single Serve Capsules industry. The report aims to support the development of robust participation strategies by equipping industry players and investors with a comprehensive understanding of scale of po tential for future development, growth dynamics per system, market drivers and competitive pressures.

Over 80 billion capsules were filled in 2022 global ly, both aluminium and plastic formats. Single serve capsules are a dynamic market segment with a com plex value chain. The changes in this industry are fast, and driven by growing sustainability pressures and end-of-life scenarios, brand positioning as well as organic consumption trends.

The context of 2020-2021 pandemic lockdowns boosted the demand for single serve capsules in Eu rope and North America. Both retail and online sales of capsules sharply increased, anecdotal industry feed back being 30-50% growth in lockdowns. Operationally, throughout the first 2 lockdowns filling was working at near capacity and in shifts to assure safety of per sonnel. Some SKUs were sold out, which was to do with prioritisation of lines and optimal operations to limit changeover times. The second half of 2021 and 2022 resembled more of a normal sales pattern, and the spikes in consumption had settled down. The growth is now largely slowing down. Unlike previously, there was a significant volume increase for original capsules between 2020 and 2022. Nestlé has been managing its portfolio of products extremely well - increasing sales of Nespresso via the Starbucks brand, which was pop ular in conventional retail. Still, the share of compatible capsules is rising. The Nespresso compatibles include both private label (retailer own brand) and branded of fering (L’Or, Café Royal, Dallmayr Capsa).

Penetration of compatible single serve capsules in 2022 (AMI).

The compatibles’ need for differentiation result ed in capsule material and barrier spec adjustments, impacting positioning. To this end, L’Or was success fully relaunched in aluminium capsules in 2017. Given L’Or’s aluminium victory, post 2018 the market had gone through the process of dramatic transition from plastic to aluminium Nespresso compatibles.

The growth of aluminium was a result of both the organic growth of consumption of Nespresso and Nes presso compatible capsules buoyed by system ration alisation, but also by inter-material substitution trend away from high barrier plastics in particular. As previ ously experienced with plastic Nespresso compatibles, there is a current need for differentiation of aluminium compatibles. This can be delivered with aesthetics – not only a variety of lacquers, but also embossing, design features, pre-printed patterns, etc.

The aluminium opportunity had beckoned new entrants and the competition has intensified.

www.ami.international

packaging trends 34 italian food & packaging technology - cii (2022) - november

VTT develops transparent cellulose film to replace traditional plastic

Food packages fulfil their most important tasks when they protect food and minimise waste. Thin plastic films are nevertheless difficult to recycle, and they often end up in the wrong places after use.

VTT has developed a solution to the problem of plastic packaging. Regenerated or recrystallised cellulose can replace plastic films. “We can produce transparent and flexible cellulose film. The consum er cannot distinguish between the crystal-clear ma terial and traditional oil-based plastic. Cellulose film can resist dampness, but in nature it disappears as completely as a sheet of paper does. The product is biobased and biodegradable”, says VTT Research Professor Ali Harlin.

In addition to their protective properties, plastics are important because consumers want packages that allow them to see the product itself. Howev er, once they have been used, many packages are sources of problems. If a package has both paper and plastic, the consumer may wonder if it can be recycled with cardboard, or if the plastic needs to be torn off first. Some of the materials have alter nating layers of fibre and plastic. Many packages are placed among mixed waste by people who cannot think of a better way of dis posing of it. Plastic that ends up in a cardboard recycling bin can be removed, but the plas tic usually ends up incinerated.

“The cellulose film devel oped by VTT can replace plas tic as a more climate-friendly solution. It also makes recy cling easy, as it can be placed in cardboard recycling along with other packages”, says Atte Virtanen, Vice President, for Biomaterial processing and products at VTT. Finland re mains far from the goals set by the EU for reducing the environmental harm caused by plastics. At present about 20% of plastics are collected, and even less ends up recy

cled. Under the EU target, 55% of plastics should be recycled by 2025.

Plastic film market worth 110 billion dollars

Finland is currently more of a packaging material country than a printing paper country. Last year the value of sales of cardboard exceeded that of paper for the first time. The forest industry is looking for new products with a big market, which bring val ue-added. Flexible, transparent cellulose film is one such product. The world market for plastic films was about 110 billion dollars last year.

VTT’s unique expertise has been used in cel lulose film as a replacement for plastic. “VTT has researched cellulose films for more than ten years, and for more than six years on regenerated cellu lose in transparent films”, Virtanen says.

The production of packaging material is in the pilot phase, and it could be in extensive industrial use in 5–7 years.

packaging trends italian food & packaging technology - cii (2022) - november 35

www.vtt.fi

Researchers develop plastic film that can kill viruses using room lights

Researchers at Queen’s University Belfast have developed a ground-breaking plastic film that can kill viruses that land on its surface with room light. The self-sterilising film is the first of its kind – it is low cost to produce, can be readily scaled and could be used for disposable aprons, tablecloths, and curtains in hospitals. It is coated with a thin layer of particles that absorb UV light and produce reactive oxygen species – ROS. These kill viruses, including SARS2.

The technology used to create the film also en sures it is degradable - unlike the current disposable plastic films it would replace, which is much more envi ronmentally friendly.

The breakthrough could lead to a significant re duction in the transmission of viruses in healthcare environments but also in other settings that uses plastic films – for example, food production factories.

The Queen’s researchers tested the film for an ti-viral activity using four different viruses – two strains of influenza A virus, a highly-stable picorna virus called EMCV and SARS2 – exposing it to either UVA radiation or with light from a cool white light flu orescent lamp. They found that the film is effective at killing all of the viruses - even in a room lit with just white fluorescent tubes.

The research, which has been published in the Journal of Photochemistry and Photobiology B: Biology, was carried out by Professor Andrew Mills, Dr Ri Han and Dr Christopher O’Rourke in the School of Chemistry and Chemical Engineering at Queen’s University Belfast and Dr Connor Bamford and Dr Jonathon D. Coey at the Wellcome-Wolfson Institute for Experimental Medicine in the School of Medicine, Dentistry and Biomedical Sciences at Queen’s.