10064 PINEROLO - ITALIA Tel. +39 0121393127 - Fax +39 0121794480 info@chiriottieditori.it - www.foodexecutive.com Supplemento al n. 3, marzo 2020 di Industrie AlimentariSped. in A.P.D.L. 353/2003 (Conv. in L. 27/02/2004 n° 46) art. 1 comma 1 DCB TOn. 01 anno 2020IP n. 94 - March 2020 ISSN 1590-6515 FOOD & PACKAGING TECHNOLOGY ITALIAN +39 0173 61.05.64 • www.tecno-3.it Headquarter: Tecno 3 S.r.l. - Corneliano d’Alba - ITALY Tecno 3 Switzerland Tecno 3 USA INC FCD CONTINUOUS MELTING, IN A SINGLE PLANT AND IN A SMALL SPACE COCOA AND CHOCOLATE MASS IN BLOCKS BLOCKS OF FAT, ANHYDROUS AND HYDRATED BUTTER 10064 PINEROLO - ITALIA Tel. +39 0121393127 info@chiriottieditori.it www.foodexecutive.com 03, marzo 2024 di Industrie AlimentariSped. in A.P.D.L. 353/2003 (Conv. in L. 27/02/2004 n° 46) art. 1 comma 1 DCB TOn. 106 anno 2024IP n. 106 FOOD & PACKAGING TECHNOLOGY

departments

3

PRODUCT TRENDS - Transforming poultry waste into valuable solutions – Facing the plant-based revolution – EU olive oil production update – The world of coffee

14 FOOD PROCESSING - Process technology advancing: three big trends in focus – Dairy processing equipment: global forecast to 2028 – Sarp at Anuga FoodTec – The world of sieving – The future of chocolate and fat creams: Tecno3 and the P10S – How to design plant protein-based sausages – Ohmic heating-based extraction of biocompounds from cocoa bean shell – The influence of hot-air mechanical drying on the sensory quality of coffee – Effect of pulsed electric field treatment on beef cuts properties – New technology to reduce pathogens in intact eggs

30 PACKAGING TRENDS - Packaging and sustainability: alternative materials and flexible machine concepts – Food and packaging experts dare to look to the future

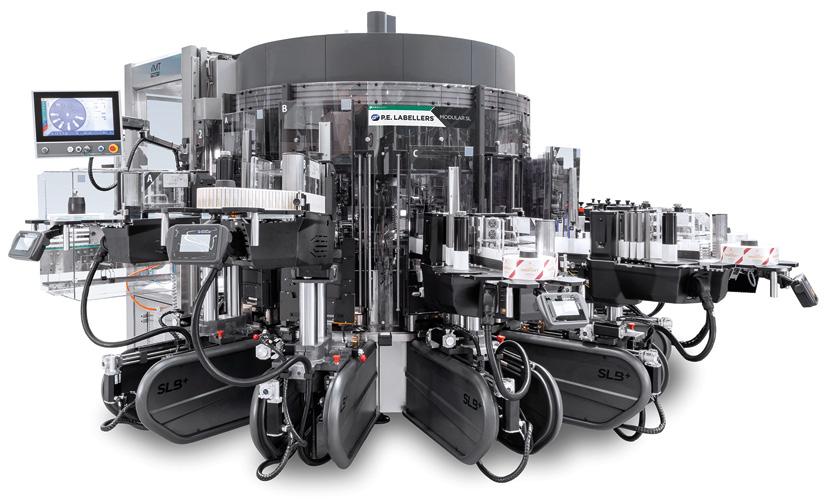

34 PACKAGING EQUIPMENT - Smart intralogistics: innovative solutions for a fully automated supply chain – Innovative solutions for circular packaging (S. Musso) – Innovative packaging solutions from Schubert for high-quality baked goods – P.E. Labellers for Farchioni Olii – Effect of packaging in preventing cholesterol autoxidation in milk chocolates – UVB treatments of packaged ready-to-eat salads

48

NUTRITION - Are all ultra-processed foods linked to cancer and diabetes? – Natural food colors revolutionizing the palate: unleashing the potential of natural ingredients in the evolving food industry – Common food preservatives has unexpected effects on the gut microbiome – Use of cassava flour in the elaboration of ice cream – Ingredient from the fermentation of brewer’s spent grain liquids

56 RESEARCH - Influence of pre-baking and frozen storage on the quality of a multi-seed bread – Upcycling soy processing waste for fat replacement in sweet bread – Replacement of nitrates/nitrites in salami by plant extracts – Extraction technologies to produce food-grade hop extracts – Natural whey starter on cheese whey – Improvement of Robusta coffee aroma by treated spent coffee grounds – Enhancing zein-starch dough and bread properties by addiction of hydrocolloids

62 NEWS - Distillo lands at Simei 2024: together at Milano in November - International events in Italy

64

MARCH 2024 - issue 106

COMPANY INDEX

Four-monthly - ISSN 1590-6515

March 2024

issue 106

Copyright Clearance Center

OUR WEBSITES

www.chiriottieditori.it shop.chiriottieditori.it www.foodexecutive.it www.pasticceriainternazionale.it www.tuttogelato.it

www.alimentifunzionali.it

Chiriotti Editori s.r.l. Viale Rimembranza 60 10064 Pinerolo - To - Italia Tel. 0121 393127

info@chiriottieditori.it www.chiriottieditori.it

Publisher

Alberto CHIRIOTTI

Direttore Responsabile alberto@chiriottieditori.it

Contributing Editors

Laura SBARATO, Simonetta MUSSO, Rossella CONTATO, Matteo BARBONI

Assistant Editor

Chiara MANCUSI

mancusi@chiriottieditori.it

Layout Designer

Anna BOSCOLO

Marketing Manager

Monica PAGLIARDI pagliardi@chiriottieditori.it

Advertising Manager

Luca RUSSO russo@chiriottieditori.it

General Manager

Giuseppe CHIRIOTTI

for free subscriptions

call to +39 0121 378147 or send an e-mail to: abbonamenti@chiriottieditori.it

La riproduzione, anche parziale, di articoli ed illustrazioni pubblicati sulla rivista è riservata e non può avvenire senza espressa autorizzazione scritta dell’Editore. L’Editore non assume alcuna responsabilità per quanto riguarda eventuali errori contenuti negli articoli e per quanto espresso dagli Autori.

All Rights reserved. Reproduction, even partial, of articles and illustrations published in the journal is forbidden and can not take place without written permission of the Publisher. The Publisher assumes no responsibility for any errors contained in the articles and for what is expressed by the Authors and/or by the companies.

PRINTED by La Stamperia Pinerolese srls Pinerolo (To)

COPYRIGHT:

© 2024 Chiriotti Editori srl Supplemento del mensile “Industrie Alimentari”

AUTORIZZAZIONE: n. 262 (19-11-1962) del Tribunale di Pinerolo

PERIODICITÀ:

mensile - sped. in A.P. comma 20/B, art. 2, legge 662/96Torino

INTERNET: www.chiriottieditori.it

PRODUCT TRENDS

Transforming poultry waste into valuable solutions

Rendered poultry products are derived from the rendering process applied to poultry, which includes chickens and turkeys. Rendering is a technique where the raw poultry material is heated to separate & extract the fat & and protein components. Poultry fat is a frequently consumed rendered poultry product obtained by melting the fatty tissues of poultry. Depending on its intended application, poultry fat can undergo further processing to take on different forms, such as liquid or solid fat. It is widely utilized in the food industry for purposes such as cooking, frying, and as an ingredient in various processed food products. The addition of poultry fat in food preparations can enrich the flavor, improve moisture retention, and contribute to the desired texture of the final food items.

Trends in rendered poultry products industry

Increase in global demand for animal-based protein is fueling the market for processed poultry products. With the continuous growth of the global population, there is a greater need for protein sources to fulfill nutritional needs. Chicken and turkey, which are considered valuable protein sources, are in high demand due to their excellent amino acid profile and

nutritional advantages. To address this demand, rendered poultry products such as poultry meal are crucial as they offer a concentrated & cost-effective protein source for animal feed formulas. The expanding livestock, aquaculture, and pet food industries are significant contributors to rise in demand for rendered poultry products.

According a marketing report released by Allied Market Research company, the rendered poultry products market is experiencing substantial growth due to increase in emphasis on waste reduction and resource optimization. Through the rendering process, valuable components from poultry byproducts that would typically be discarded can be extracted and utilized effectively. This process transforms these byproducts into useful products such as poultry fat and poultry meal, minimizing waste and maximizing the value of poultry resources. This approach aligns with the principles of sustainability and the circular economy, which are becoming increasingly important in various industries. The market is benefiting from rise in recognition of rendering as a sustainable solution that reduces environmental impact and promotes efficient resource utilization.

Over the past 50 years, the poultry industry has undergone significant transformations both in the U.S. and globally. While the consumption of poultry

italian food & packaging technology - cvi (2024) - march 3

and its products has experienced a substantial increase, the industry’s structural changes have been even more remarkable. From being a small-scale producer catering to specialty meals, the poultry industry has emerged as a major source of animal protein consumption. This growth is mirrored across the globe, where poultry production has seen a significant expansion. In 2021, chicken production and slaughter in the U.S. reached 9 billion. Furthermore, global chicken slaughter has reached an all-time high, surpassing 70 billion annually.

The demand for rendered poultry products is being propelled by the expanding food processing industry. Poultry fat, in particular, is a versatile ingredient that finds various applications in the food processing sector. It is utilized for cooking, frying, and as an ingredient in processed foods to enhance flavor, improve texture, and provide moisture. With the continuous growth of the food processing industry, there is an increase in the need for dependable and high-quality sources of poultry fat. Rendered poultry fat meets these requirements and provides cost-effective solutions to food manufacturers. Moreover, the convenience and versatility of rendered poultry products make them valuable components in a wide array of processed food products, further driving the growth of the market.

Application of Rendered Poultry Products

Rendered poultry products find diverse applications in different industries. Here are some of the ways these products are used:

• Animal Feed: Rendered poultry products are commonly included in animal feeds such as pet foods, livestock feeds, and aquafeeds. With their high protein content, they serve as valuable ingredients for animal nutrition. These products enhance feed formulations by supplementing protein levels and providing essential amino acids.

• Fertilizer and Soil Amendment: Certain rendered poultry products, such as bone meat and feather meal, are utilized as organic fertilizers and soil amendments. They contain essential nutrients such as nitrogen, phosphorus, and calcium, which contribute to plant growth. These products are commonly used in agriculture and horticulture to enhance soil fertility and foster healthy plant development.

• Biofuel Production: Rendered poultry fat can be transformed into biodiesel, a renewable fuel source. Through a process called transesterification, the fat is converted into biodiesel, which can serve as an alternative to conventional diesel fuel. Rendering plants often supply their poultry fat to biodiesel producers as a feedstock for biofuel production.

• Industrial Applications: Rendered poultry fat finds application in various industrial sectors. It can be utilized in the manufacturing of soaps, detergents, candles, and cosmetics. The fat possesses emollient properties and acts as a natural moisturizer in personal care products.

• Pharmaceutical and Nutraceutical Uses: Certain components derived from rendered poultry products, such as collagen, have applications in the pharmaceutical and nutraceutical industries.

product trends 4 italian food & packaging technology - cvi (2024) - march

Collagen, a protein present in the connective tissues of animals, including poultry, is used in the production of capsules, tablets, and topical formulations. Its potential benefits for skin health, joint health, and wound healing make it a valuable ingredient in these products.

Opportunities for Expansion into Emerging Markets

Expanding into emerging markets presents a significant growth potential for the rendered poultry products industry. As economies in regions such as Asia, Latin America, and Africa continue to develop and disposable incomes rise, there is growth in demand for protein-rich foods, including poultry products. These new markets

offer plenty of chances for selling poultry products that have been processed, especially in the form of poultry meal, which is an important ingredient in animal food recipes. By venturing into these emerging markets, companies can take advantage of increase in demand and establish a robust presence, which will drive the growth of the market.

Technological Advancements and Process Innovations

The rendered poultry products market is witnessing growth opportunities through technological advancements and process innovations. Ongoing R&D endeavors are dedicated to enhancing rendering processes, improving product quality, and increasing the overall efficiency of animal feed. Innovative technologies, including advanced rendering techniques and equipment, have the potential to streamline the rendering process, leading to higher yields and improved product consistency. Moreover, advancements in extraction & and purification methods can contribute to producing rendered poultry products with enhanced nutritional profiles and reduced impurities.

Rise in Demand for Specialty & Value-added Products

The rendered poultry products market holds significant growth opportunities due to an increase in consumer demand for specialty & and value-added products. Presently, consumers prefer products with specific attributes, such as organic, natural, or sustainably sourced ingredients. To cater to these preferences, rendered poultry products can be positioned to offer specialty and value-added variations. For instance, producing organic or freerange poultry fat or poultry meal can tap into the niche market of consumers seeking premium and ethically produced ingredients. In addition, the development of value-added products, such as flavored or functional poultry fat, can align with consumers’ evolving tastes and healthconscious preferences. By leveraging these trends and offering differentiated products, companies can target new market segments and drive growth in the industry.

product trends italian food & packaging technology - cvi (2024) - march 5

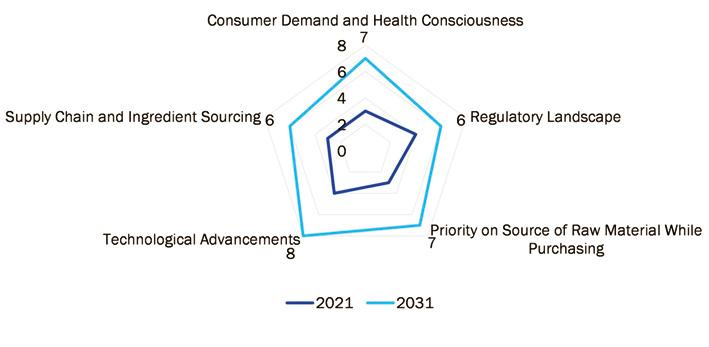

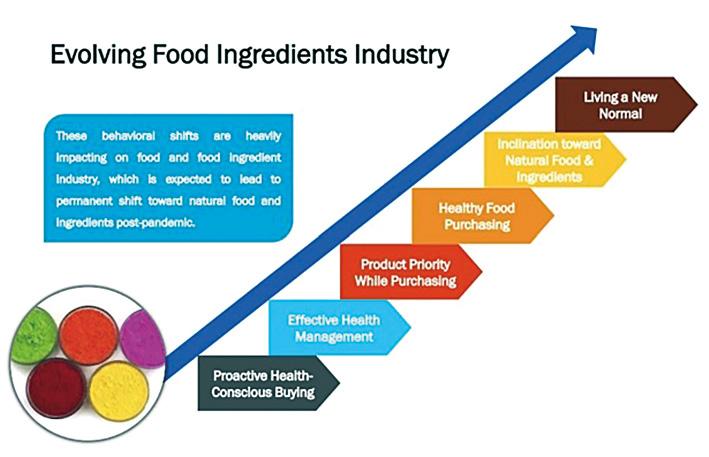

Facing the plant-based revolution

The food industry has now been leaning heavily toward plant-based products. People are looking for healthier choices, making plant-based foods a thriving market. Sustainable choices like meat alternatives and plant-based drinks have become a preferred choice among individuals. This, in turn, is creating great opportunities for businesses to succeed in this domain.

Here are some recent trends in the industry

Dominance of plant-based protein: The demand for plant-based protein sources is on the rise. Beyond traditional sources like tofu and legumes, innovative products like pea protein, hemp protein, and algae-based proteins are gaining much popularity.

Alternative meat revolution: Plant-based meat alternatives are now becoming a favored choice since they imitate the taste and texture of traditional meat products. Companies like Beyond Meat and Impossible Foods have come up with burgers, sausages, and even different chicken substitutes that taste no less than real meat.

Dairy-free craze: On the other hand, plant-based milk alternatives such as almond, soy, oat, and coconut milk have come to the fore. The dairy-free trend extends beyond milk to include plant-based cheeses, yogurts, and ice creams. When it provides delicious alternatives for those with lactose intolerance, it also helps people seeking a vegan lifestyle.

Snacks: Plant-based snacks are also being popular. From chickpea puffs to vegan sandwiches con-

sumers are looking for convenient and tasty plantbased options to cater to their cravings for snacks.

Functional foods: Consumers nowadays look for taste along with nutritional value. There’s a growing interest in plant-based foods with added health benefits. Thus, products added with superfoods and other functional ingredients are becoming popular.

Plant-based seafood: Companies are coming up with plant-based alternatives to conventional sea-

product trends 6 italian food & packaging technology - cvi (2024) - march

food products. This, in turn, offers a cruelty-free and eco-friendly option. As sustainability concerns rise, plant-based seafood options are becoming an instant hit.

Tech innovations: Last but not the least; new technologies in the food industry are boosting the plant-based scenario, especially with the invention of 3D-printed veggie steaks and lab-grown meat. These innovations offer eco-friendly options for foodies.

Plant-based beverage market

One of the key segments leading this charge is the plant-based beverage market. Companies like Oatly and Califia Farms are trying to make the most of the growing consumer preference for dairy alternatives. With an array of options ranging from almond milk to oat milk, these companies are not only meeting the demand for plant-based alternatives but also setting new standards for taste. These healthy choices are meeting the nutritional value too.

Plant-based meat market: Beyond beverages, the plant-based meat market has witnessed significant growth, challenging traditional notions of protein sources. Key players such as Beyond Meat

and Impossible Foods have redefined the concept of meat. They offer plant-based alternatives that are almost similar to the taste and texture of animal-based products. Increasing awareness of environmental sustainability and animal welfare concerns among consumers has driven this shift.

Plant-based seafood market: To cater to the craze for sustainable choices, the plant-based seafood market is also making noteworthy moves. Companies like Good Catch and New Wave Foods are leading the way in making seafood-like dishes from plant-based stuff. When they are providing people with what they want, they’re also helping keep our oceans safe.

Plant-based diet and protein supplements: Eating plant-based isn’t just about specific foods. It’s a whole approach to healthy eating. Companies like Vega and Garden of Life are trying to meet the demand for plant-based options. They provide various products, from protein supplements to meal replacements. This way, they are making it simple for consumers to adopt a plant-focused lifestyle and establish a sustainable market.

Plant-based food ingredients: Simultaneously, the plant-based food ingredients market plays a crucial role in shaping the products consumers see on their shelves. For example, Ingredion and Cargill are providing special ingredients that help improve the flavor, texture, and nutrition of these foods. As more people want plant-based options, these companies are playing an important role in helping food makers create plant-based products that are really good.

Plant-based baby care products: Even babies are getting in on the plant-based trend! Brands like Happy Family Organics and Earth’s Best are making plant-based baby care products such as organic baby food and eco-friendly diapers. They’re catering to parents who want sustainable and cruelty-free options for their little ones.

To sum up, it can be stated that the global plantbased foods market is undergoing a significant transformation driven by high-end innovations. Success in this realm relies on businesses being adaptable and ensuring high quality. Those embracing plant-based foods are not just keeping up with today’s needs but are also influencing the future of the entire food industry.

product trends italian food & packaging technology - cvi (2024) - march 7

www.alliedmarketresearch.com

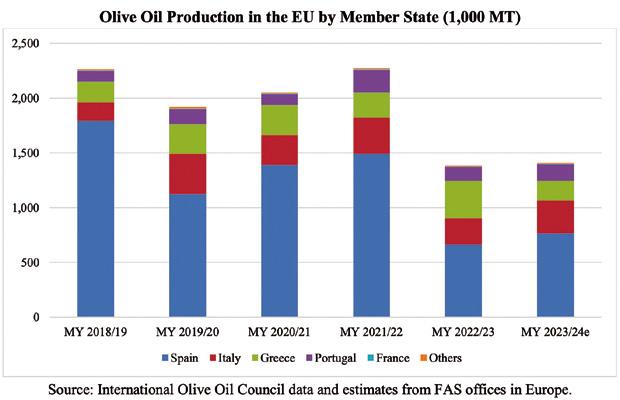

EU olive oil production update

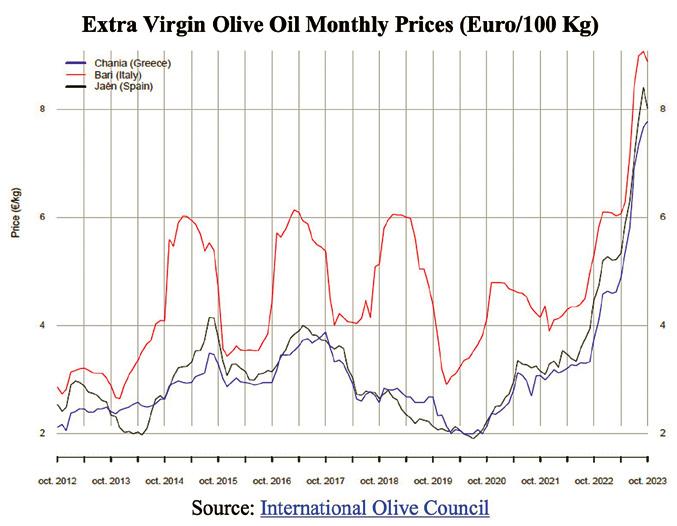

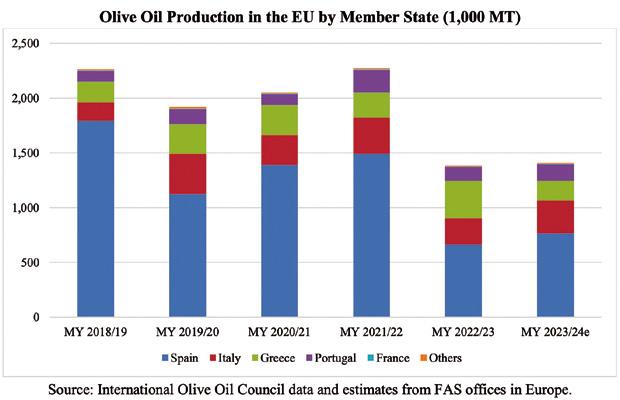

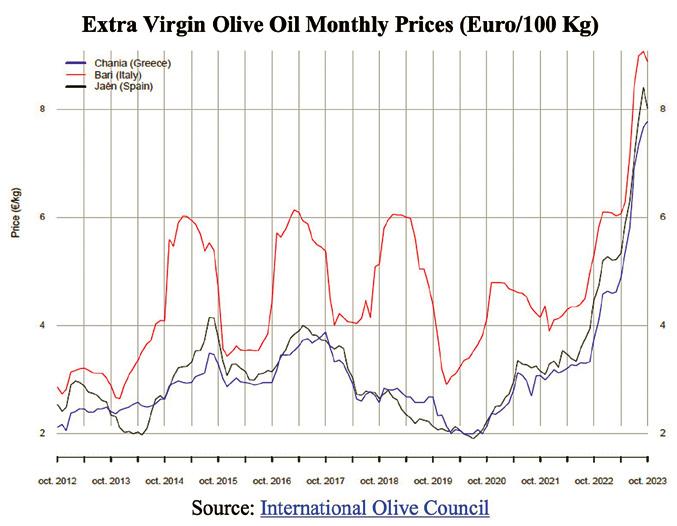

According to the USDA analysis, in 2023/24 the EU is facing a second consecutive short olive oil production crop. Consumer price increases resulting from the limited domestic availability will contribute to reduced consumption, while the short crop will also preempt exports from expanding for the second consecutive year, while also continuing to push stock levels down.

Production

Estimates based on precipitation levels to date, temperatures during the olive trees flowering season, and the subsequent extreme summer heat waves that resulted in unripe fruit dropping, indicate that the European Union’s olive oil output in MY 2023/24 could amount to just above 1.4 million metric tons.

Olive harvest in the EU runs from fall to the beginning of spring. While spring conditions determine flowering and summer temperatures influence fruit development, fall precipitations still play a role in final output levels. Olive tree’s alternative bearing also plays a role in production volumes. New plantations under irrigation entering production also continue to soften the impact of alternative bearing in olive oil production levels across the EU. The EU’s olive oil production is concentrated in a handful of Member States.

The EU is the world’s largest olive oil producer, accounting for over 60% of the world production.

In Spain, which produces about half of the world’s olive crop, extreme weather conditions resulted in short production for a second year. After a spring heat wave impacted flowering, the harvest in Spain was forecast to be only 15% larger than last year, which was the worst olive oil production year in nearly a decade. A series of summer heat waves caused trees to drop unripe fruit to conserve moisture.

product trends 8 italian food & packaging technology - cvi (2024) - march

However, abundant fall precipitation contributed to improve the initially negative production outlook. The latest official estimates indicate that olive oil production in Spain in MY 2023/24 may reach up to 765,200 tons.

In Italy, MY 2023/24 olive oil production is forecasted at 300,000 tons, mainly due to the promising conditions in the regions of Puglia, Calabria and Sicily, which account for approximately 70% of the country’s olive oil production.

Greece’s MY 2023/24 olive oil production could be as low as 180,000 tons. The mild winter did not favor flowering and extensive rainfall in spring further reduced fruit-set. Additionally, extremely hot summer conditions followed by autumn rainstorms ‘Daniel’ and ‘Elias’ reduced the yields in the central Greece area. Chalkidiki in the north and Crete in south Greece also report significant olive oil production decreases.

Consumption

MY 2023/24 and MY 2022/23 olive oil consumption has been revised down compared to previous estimates in response to soaring EU olive oil consumers’ prices in the main producing and consuming countries. Likewise, olive oil prices in producers’ markets in the EU also far exceed previous season’s levels.

Trade

The second consecutive short EU olive oil crop is expected to limit the bloc’s export potential in MY 2023/24. The EU’s total olive oil export levels in MY 2022/23 also declined significantly, driven by the limited domestic availability. The United States followed by Brazil are the main destinations for EU olive oil exports.

In MY 2023/24, EU olive oil imports are anticipated to recover marginally, provided a production rebound in Tunisia materializes. According to the latest trade data available, in MY 2022/23, the larger olive oil imports originated in Turkey, which saw their production increase in MY 2022/23, nearly countering the reduced imports from the EU’s traditional suppliers such as Tunisia or Morocco, where olive oil availability was lower in MY 2022/23.

Stocks

Despite the somewhat reduced internal consumption and exports, olive oil stocks in the EU are expected to be tight by the end of MY 2023/24 given the two consecutive short crops that have reduced availability of olive oil within the EU.

www.usda.gov

product trends italian food & packaging technology - cvi (2024) - march 9

The world of coffee

The United States Department of Agriculture (USDA) published a report on the global coffee market

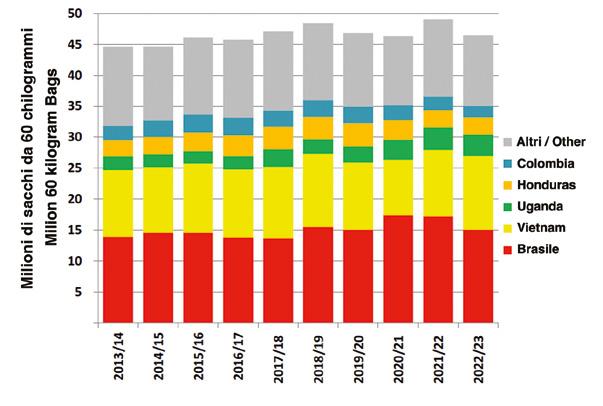

European Union: World’s Top Coffee Importer

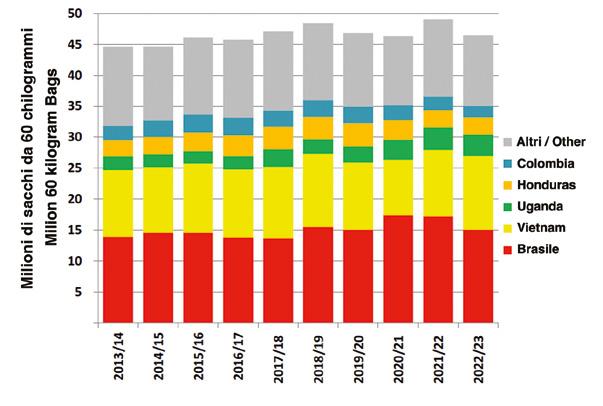

European Union (EU) imports are dominated by unroasted green coffee beans, which accounts for about 90% of trade. Top suppliers in 2022/23 (October through September) included Brazil (32%), Vietnam (26%), Uganda (7%), and Honduras (6%). Imports reached a record 49.1 million bags the previous year but slipped 2.6 million bags this year as lower imports from Brazil more than offset gains from Vietnam. These two countries accounted for 54 to 58% of EU green coffee imports over the last 10 years, leaving limited market share for other suppliers. During this same period, Uganda gained 1.2 million bags to total 3.4 million on rising production while Colombia lost 500,000 bags to total 1.8 million on falling output.

EU imports of roasted coffee totaled just 1.4 million bags in 2022/23, down from a record 2.1 million bags 4 years earlier on reduced imports from Switzerland. Top suppliers included Switzerland (77%) and the United Kingdom (13%). Because coffee beans begin to lose flavor and aroma shortly after being roasted, these imports are mostly limited to neighboring non-producing countries.

product trends 10 italian food & packaging technology - cvi (2024) - march

Imports of soluble coffee rebounded 300,000 bags to 3.7 million in 2022/23. Top suppliers included the United Kingdom (34%), Vietnam (12%), India (12%), and Ecuador (10%). While imports from the United Kingdom have been nearly flat at 1.3 million bags for a decade, imports from India and Vietnam gained about 300,000 bags to each total over 400,000.

EU green coffee imports are forecast to rebound slightly in 2023/24 to 47.0 million bags primarily due to stronger shipments from Brazil, while roasted and soluble coffee imports remain flat at 1.4 million bags and 3.7 million bags, respectively.

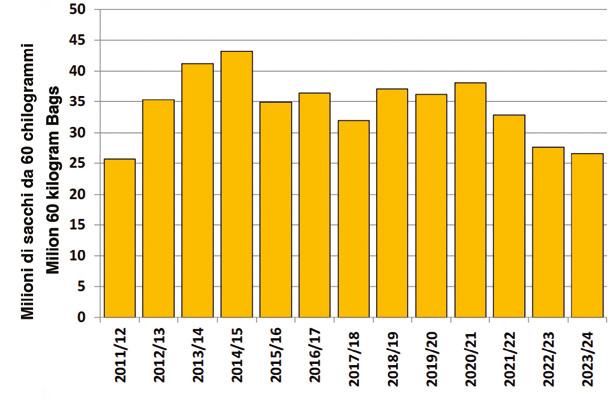

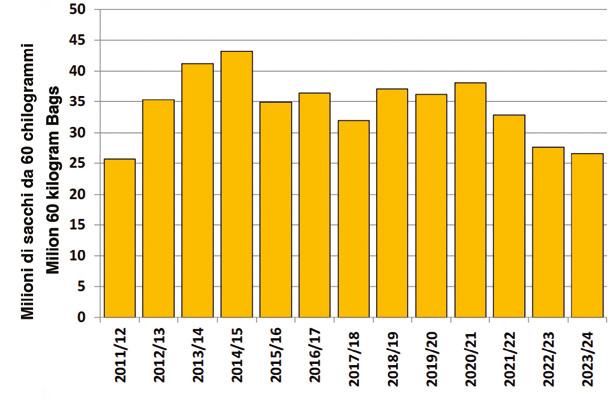

2023/24 Coffee Overview

World coffee production for 2023/24 is forecast to reach 171.4 million bags (60 kilograms), 6.9 million bags higher than the previous year. Higher output in Brazil, Colombia, and Ethiopia is expected to more than offset reduced production in Indonesia. Global coffee bean exports are expected up 8.4 million bags to 119.9 million, primarily on strong shipments from Brazil. With global consumption forecast at a record 169.5 million bags, ending inventories are expected to continue to tighten to a 12-year low of 26.5 million bags.

Brazil combined Arabica and Robusta harvest is forecast up 3.7 million bags to 66.3 million in 2023/24. Arabica output is forecast to improve 5.1 million bags to 44.9 million. In January 2023, coffee trees in top growing region Minas Gerais experienced

product trends italian food & packaging technology - cvi (2024) - march 11

Brazil and Vietnam Drive EU Green Coffee Imports.

higher than average rains during the fruit development stage, causing difficulties for some growers in controlling plant diseases and pests. However, increased precipitation resulted in coarser and heavier beans compared to the last crop, which contributed to production gains. Although output is expected to expand, this quantity is below previous crops that peaked at nearly 50.0 million bags. Arabica trees in many growing regions continue to recover from severe weather that occurred in 2021 including severe frosts, high temperatures, and below average rainfall that lowered production in 2021/22 and 2022/23. Following 6 years of expansion, the Robusta harvest is forecast to decline 1.4 million bags to 21.4 million as reduced precipitation and cooler temperatures leading up to the flowering stage lowered yields in Espirito Santo, where the vast majority is grown. Coffee bean exports are forecast to rebound 7.3 million bags to 39.5 million, fueled by higher supplies and stronger EU and U.S. import demand.

Vietnam production is forecast to add 300,000 bags to reach 27.5 million. Cultivated area is forecast unchanged, with nearly 95 percent of total output remaining as Robusta. However, with lower total supplies due to last year’s stocks drawdown, bean exports are forecast to decline 2.4 million bags to 23.0 million.

Colombia Arabica production is forecast up 800,000 bags to 11.5 million on slightly higher yields. However, yields remain nearly 15 percent below normal because growers limited fertilizer use due to high prices. Bean exports, mostly to the United States and EU, are forecast up 1.2 million bags to 10.8 million on strong demand.

Indonesia combined Arabica and Robusta harvest is forecast down 2.2 million bags to 9.7 million. Robusta production is expected to drop 2.1 million bags to 8.4 million. Excessive rain during cherry development lowered yields and caused sub-optimal conditions for pollination in the lowland areas of Southern Sumatra and Java, where approximately 75% of coffee is grown. Arabica production is seen dipping slightly to 1.3 million bags. Bean exports are forecast to plummet 2.7 million bags to 5.0 million on sharply reduced supplies.

India combined Arabica and Robusta harvest is forecast nearly unchanged at 6.0 million bags. Arabica production is forecast to drop 200,000 bags to 1.4 million due primarily to a prolonged dry spell from December 2022 to March 2023 which was followed by poor pre-monsoon rains. Robusta production is expected to rise 300,000 bags to 4.5 million on slightly higher yields. Bean exports are forecast up 300,000 bags to 4.3 million on a slight inventory drawdown.

www.usda.gov

product trends 12 italian food & packaging technology - cvi (2024) - march

World Ending Stocks Continue to Tighten.

Brazil Arabica Production Continues Rebound as Robusta Slips.

product trends

FOOD PROCESSING

Process technology advancing: three big trends in focus

Whether it is about complete production lines or individual process systems for milk products, cheese, beverages and viscous food – Best Practice technologies are currently called for that ensure both efficiency and product quality. At the same time, these systems must be scalable and flexible, in order to also be able to process new ingredients in future. In advance of Anuga FoodTec, which is taking place from 19 to 22 March 2024 in Cologne, it is becoming clear that the latest generation of process technology systems distinguishes itself through three important trends: digitalisation, sustainability and individualisation.

The goal of sustainably redesigning the food and beverage industries has never been as urgent as it is today. All the more important is it for producers to efficiently and flexibly use systems that are appropriate for this task.

Not least, the consistently high quality of food and food safety is in the focus of developments. “Globally, we are seeing innovations of completely different kinds in process technology. This diversity is also reflected on the Cologne fair grounds at the stands of the exhibitors”, says Matthias Schlüter, Director of Anuga FoodTec . More than a third of the around 1,350 exhibitors from Germany and abroad present solutions in the field of process technology. And these already start with mixing – a complex process that

often takes place at the start of production.

Efficient in every production step

Mixers are the workhorses of the food industry and are indispensable for the standardisation of product masses. Where a simple batch mixer was sufficient 15 years ago to process standard recipes with few ingredients, the situation has fundamentally transformed. The market is now more dynamic than ever before. Manufacturers change recipes several times per day in order to adapt their production to the changing wishes of consumers. A modern mixer must be able to master this complexity and be capable of mixing varied raw materials equally wet and dry, and that without mak-

14 italian food & packaging technology - cvi (2024) - march

ing the process more difficult. At Anuga FoodTec, visitors will find a great variety of models that can be adapted to the respective requirements. An example of this are trajectory mixers. They introduce the shear forces by way of the inertia of the mass through the use of programmable trajectories. The highlight: the product found in the process container processes itself gently with itself, entirely without stirring tools.

However, there is more than one process step behind the manufacture of food. The stirrers, kneaders, mixers, extruders, homogenisers and heat exchangers on the Cologne fair grounds are flanked by a large number of digital solutions that are specifically coordinated to the processes and network these to form a complete line. Recipe and batch management software makes it possible to plan and control fully-automated production. Thanks to central terminals, all functions, such as rotational speeds, vacuum values, exposure to gas or the speed of the conveyor systems, can be monitored and operated by one person. User-friendly designs ensure process-safe and intuitive operation and are also a response to the lack of skilled workers in the industry.

Digital and networked along the entire line

The optimisation of production processes occupies a lot of space at Anuga FoodTec. It is primarily the digital technologies that provide insights into the processes that were not so available in the past. Food manufacturers use this as the

foundation for elevating their own production to the latest standard and to optimise the harmonisation of human being, machine and processes. With their portfolio, the exhibitors in Cologne begin at precisely this point – for example, with intelligent sensor and web-based process control systems that can also be retrofitted on exist-

sorting then subsequently ensure that the products are finally packaged and ready for shipping. With such an integrated complete solution, the individual product components for ready-made meals pass without interruption through the weighing and filling stations and are subsequently filled cleanly into bowls and sealed.

ing systems. They enable comprehensive sustainability management at the central point of the plant control system.

This enables cross-process automation from the preparation of raw materials with mixing and reduction through processing with portioning, dispensing, molding or extrusion to options like gripping and insertion of the products into the packaging. Intelligent feeds and precise

Gentle processing for higher quality

Food manufacturers face not only the challenge of continually improving the efficiency of their processes. They must at the same time ensure the durability and the quality of their products. Against this background, non-thermal preservation processes remain the trend. The solutions to be found in Cologne

food processing italian food & packaging technology - cvi (2024) - march 15

are bundled under the term “Minimal Processing”. These include, for example, high pressure processing (HPP). This enables the gentle preservation of food at 6,000 bar, without heat or additives. The products are treated

ily used to date with vegetables and fruit. When producing French fries, PEF pretreatment has become the standard in the meantime. It results in a better cut appearance, reduced loss of raw material and starch losses

directly in the final packaging. Because high temperatures are unnecessary, the products remain fresh and of a high quality. That works as well for vacuum and modified atmosphere packaging (MAP) as it does with PET bottles.

New application areas in food processing are also always arising for pulsed electric fields (PEF). The technology is primar-

for manufacturers. The process can be combined with conventional drying methods like hot air, freeze, vacuum, microwave or infrared drying and increases the attractiveness of the dried products – with reduced consumption of water and energy. The technology has recently promised great potential for the manufacture of wine or native olive oil. The principle of electro-

poration and the resulting discharge of cell sap is applied here to extract valuable ingredients.

The future of food production

From 19 to 22 March 2024, Anuga FoodTec will show what levers food producers can apply to elevate their production processes to the next level of resource efficiency and product quality. The exhibition programme will be complemented by conferences with prominent guests, interactive forums, panel discussions and lectures, special events, guided tours as well as the presentation of the International FoodTec Award 2024. The Main Stage Responsibility (Hall 9, B080/ C081) and the Innovation Stage (Hall 5.2, C100/D119) revolve around themes like automation, digitalisation, robotics, sustainability and process optimisation. “This overarching perspective of Anuga FoodTec on developments of the industry thereby helps with reaching investment decisions for new technologies”, according to Matthias Schlüter. The Best Practice technologies shown at the trade fair offer trade visitors valuable stimuli in this regard.

Anuga FoodTec is the leading international supplier fair for the food and beverage industries. Organised by Koelnmesse, the trade fair takes place from 19 to 22 March 2024 in Cologne and places the emphasis on the key theme of Responsibility. The professional and industry sponsor is the DLG, the German Agricultural Society.

www.anugafoodtec.com

food processing 16 italian food & packaging technology - cvi (2024) - march

“RAPID” PUMPS

Sanitary - Self priming. Both for liquid and for thick products (Creams and Sauces).

“FARMINOX” FILTERS

Packingless plate filters. Working through paperboard filter-sheets.

HYGIENIC DESIGN

for an easy cleaning.

SAFETY

FDA certified materials, suitable for the use in contact with foods.

ENDURANCE

made of stainless steel machined from bars, NO CAST PARTS, NO WELDINGS.

info@wolhfarth.it - www.wolhfarth.it V. Cavour, 31 - 26858 Sordio (LO) - Italy - Tel. +39 02 9810153 - Fax +39 02 98260169

THE MOMENT FOR A NEW BEGINNING!

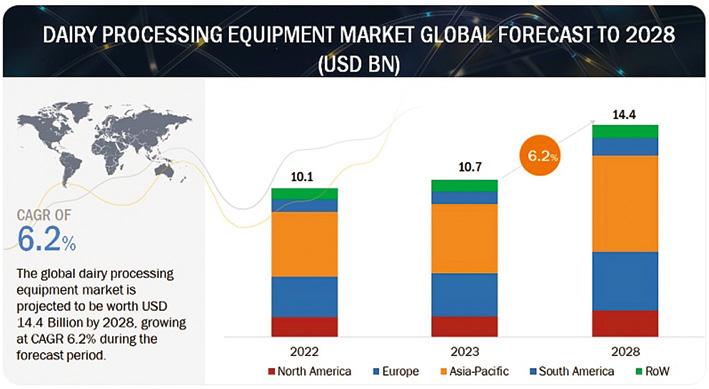

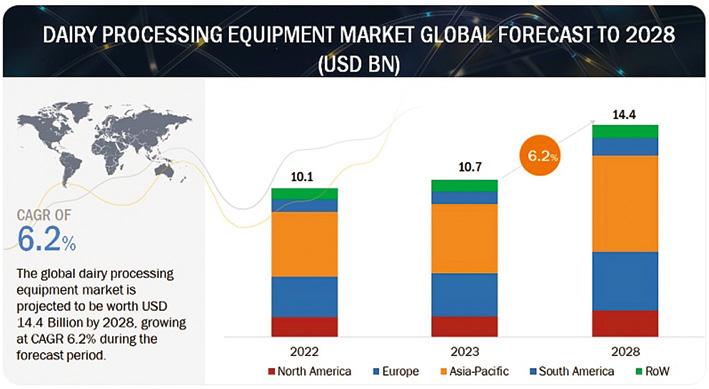

Dairy processing equipment: global forecast to 2028

According to MarketsandMarkets agency, the global dairy processing equipment market is projected to reach USD 14.4 billion by 2028 from 10.7 billion in 2023 at a CAGR of 6.2% during the forecast period, 2023-2028, in terms of value.

The growth of the dairy processing equipment market is notably influenced by the diversification of dairy product portfolios. Dairy processors are actively expanding their product offerings to meet evolving consumer preferences and capture a broader market share. This diversification necessitates versatile processing equipment capable of handling a wide array of dairy products efficiently. The demand for equipment that facilitates

flexibility in processing different products, such as varied types of milk, cheese, yogurts, and other dairy derivatives, is on the rise.

Furthermore, investments in emerging markets, particularly in Asia Pacific and South America, play a pivotal role in propelling the dairy processing equipment market. As economies in these regions experience significant growth, there is an increased focus on developing robust dairy processing infrastructure to cater to both local and global demands. The investments aim to enhance production capacities, improve processing efficiency, and ensure compliance with stringent quality standards, fostering the overall expansion of the dairy processing equipment market.

MARKET DYNAMICS

Drivers: growing demand for dairy products

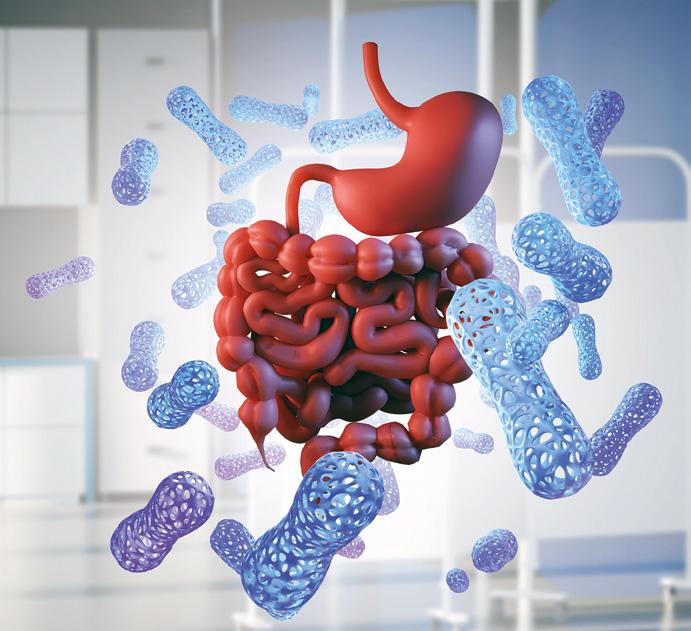

The escalating demand for dairy products is a key driver fueling the growth of the dairy processing equipment market. Changing dietary preferences and an increasing awareness of the nutritional benefits associated with dairy consumption propel the demand for diverse dairy products. Moreover, lifestyle shifts, including a rising preference for convenience and readyto-eat dairy items, contribute significantly. The global popularity of dairy-based snacks and beverages further amplifies the demand. Additionally, evolving consumer trends favoring specialty and functional dairy products, such as probiotic-rich offerings, contribute to the market growth. To meet this heightened demand efficiently, dairy processors invest in advanced processing equipment to ensure enhanced production capabilities, maintain product quality, and comply with evolving hygiene and safety standards, collectively fostering the expansion of the dairy processing equipment market.

Restraints: increasing energy costs

Increasing energy prices amplify operational expenses for dairy processing facilities, impacting their overall profitability. Energy-intensive processes, such as pasteurization and refrigeration, substantially contribute to operational costs, prompting a need for more energy-efficient equipment. In response to environmental concerns, strin-

food processing 18 italian food & packaging technology - cvi (2024) - march

gent regulations also drive the adoption of sustainable and eco-friendly practices, influencing dairy processors to invest in energy-efficient equipment. The focus on reducing the carbon footprint and adhering to stringent emission norms adds an additional layer of complexity. As a result, dairy processors navigate the delicate balance between technological advancements and cost-effective solutions to mitigate the impact of rising energy costs, thereby influencing the trajectory of the dairy processing equipment market.

Opportunities: support by the government and non-government bodies in terms of funding for SMEs and startups

Government and non-government support for funding small and medium-sized enterprises (SMEs) and startups in the dairy sector presents a significant opportunity in the global dairy processing equipment market. Initiatives like the Common Agricultural Policy (CAP) in the EU and the Dairy Business Innovation (DBI) Initiatives in the US play a crucial role in fostering innovation, development, and expansion within the dairy industry. The availability of funding through schemes such as the School fruit, vegetables and milk scheme, direct payments under the European Agricultural Guarantee Fund, and the European Agricultural Fund for Rural Development provides financial backing for small companies to invest in advanced dairy processing equipment.

In the US, the DBI Initiatives offer direct technical assistance

and subawards to dairy businesses, encouraging diversification, promoting innovation, and supporting regional milk production. This financial support becomes an opportunity for SMEs and startups to modernize their operations, specialize in niche dairy products, and enhance their value chain. The allocation of approximately USD 23 million for DBI projects creates avenues for dairy businesses to invest in state-of-the-art processing equipment, facilitating improved efficiency, quality, and sustainability. Overall, government and non-government funding initiatives act as a catalyst for the growth and technological advancement of SMEs and startups in the global dairy processing equipment market, fostering a more competitive and dynamic industry landscape.

Challenges: high capital investment

High capital investment poses a significant challenge in the global dairy processing equipment market, affecting both

existing players and potential entrants. The dairy industry demands sophisticated and technologically advanced equipment to ensure efficiency, quality, and compliance with stringent hygiene standards. Procuring and implementing such cutting-edge machinery requires substantial financial resources, creating a barrier to entry for smaller enterprises and startups. High capital expenditure is particularly challenging for businesses in developing regions or emerging economies, limiting their ability to adopt state-of-the-art processing equipment.

For established players, the need to continually invest in upgrading and expanding their processing capabilities adds financial strain. The dairy processing industry is evolving rapidly, with advancements in automation, sustainability, and quality control necessitating ongoing investments. This creates a competitive landscape where companies with limited capital may struggle to keep pace with their well-funded counterparts, impacting their overall market standing.

food processing italian food & packaging technology - cvi (2024) - march 19

Moreover, the dairy sector often operates on tight profit margins, making it challenging for businesses to allocate substantial funds for capital investment without compromising their financial stability. High capital requirements can hinder the modernization and optimization of processing facilities, affecting operational efficiency and limiting the adoption of eco-friendly and energy-efficient technologies. In essence, the challenge of high capital investment acts as a potential roadblock to the widespread adoption of cutting-edge dairy processing equipment, influencing the market dynamics and competitiveness within the industry.

Based On Type, The Pasteurizers Segment Is Estimated To Hold The Largest Market Share During The Forecast Period Of The Dairy Processing Equipment Market

Pasteurizers are poised to hold the largest share in the dairy processing equipment market due to their crucial role in ensuring the safety and quality of milk products. Pasteurization is a key process in the dairy industry, involving the heating of milk to specific temperatures to eliminate harmful bacteria, thereby preventing diseases and enhancing the shelf life of milk. The significance of pasteurization in sterilizing raw milk is paramount for delivering high-quality and safe dairy products to consumers.

In dairy processing plants, pasteurization machines play a vital role in the destruction of

tubercle bacillus and the thermal destruction associated with cream separation. The versatility of pasteurizers allows for two main processing methods: longterm low treatment temperature and short-term high-temperature treatment. The low-temperature treatment, typically around 60 degrees Celsius for half an hour, is the preferred option due to its effectiveness in preserving milk quality.

Moreover, pasteurization machines are integral in treating bagged milk, ensuring the collection of fresh milk at low temperatures for superior quality and extended shelf life. The complexity of the process underscores the importance of these machines in maintaining the overall hygiene and quality standards of the dairy processing industry.

Given the paramount role of pasteurization in ensuring milk safety, quality, and longevity, pasteurizers are expected to dominate the dairy processing equipment market, reflecting their indispensable position in the overall dairy production process.

Asia Pacific To Have The Fastest Growth In The Dairy Processing Equipment Market

Asia Pacific commands the largest share in the global dairy processing equipment market, driven by the substantial contributions of key players like India and China. India’s status as the leading global milk producer, contributing 24% of the total milk production, underscores its pivotal role in the regional and global dairy industry. The signif-

icant growth of the dairy sector in India, with a remarkable 61% increase in milk production over eight years, positions the country as a major market influencer.

According to the Dutch Bank, in China, the self-sufficiency rate for dairy products fluctuates between 70% and 80%, necessitating a focus on imports and domestic production to meet rising demand. The Chinese government’s initiatives, such as the five-year plan for the dairy sector, emphasize the promotion of large- scale modern dairy farms and digital transformation. The concentration of milk production in regions like Inner Mongolia and Heilongjiang further consolidates China’s position in the Asia Pacific market.

The growth in the Asia Pacific dairy processing equipment market is also fueled by the shift in food security awareness, geopolitical considerations, and strategic government actions. With a rising percentage of dairy herds on farms with more than 1,000 head and a focus on improving breeding capabilities and vertical integration, Asia Pacific is poised to dominate the global dairy processing equipment market, reflecting the region’s dynamic and evolving dairy industry landscape.

Key Market Players

The key players in this market include GEA Group (Germany), SPX Flow (US), Tetra Laval (Switzerland), ALFA LAVAL (Sweden), JBT (US), Bucher Industries (Switzerland), Krones (Germany), and The Middleby Corporation (US).

www.marketsandmarkets.com

food processing 20 italian food & packaging technology - cvi (2024) - march

Sarp at Anuga FoodTec

It’s trade fair season once again, a time for personal exchanges and intensive networking, to showcase the business and technologies in an even more innovative manner, pushing the boundaries of progress. Join Sarp and experience their latest advancements in food processing technology at Anuga FoodTec from March 19th to 22nd in Cologne.

Anuga FoodTec is the most important information and business platform for new concepts and innovative developments in the international food and beverage industry. It is the world’s only supplier fair that competently covers all aspects of food and beverage. For the first time in 2024, as a new sector, there will be an exhibition area for environmental technology and energy.

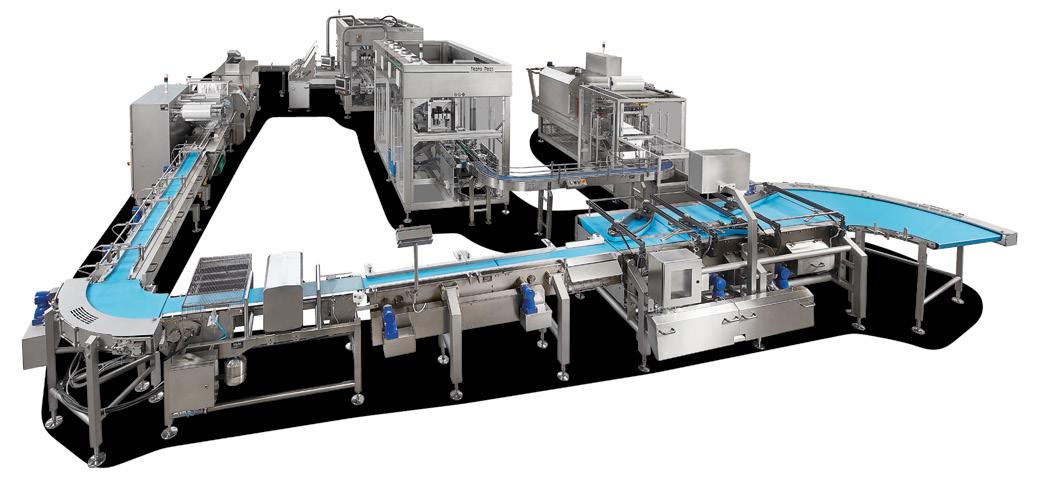

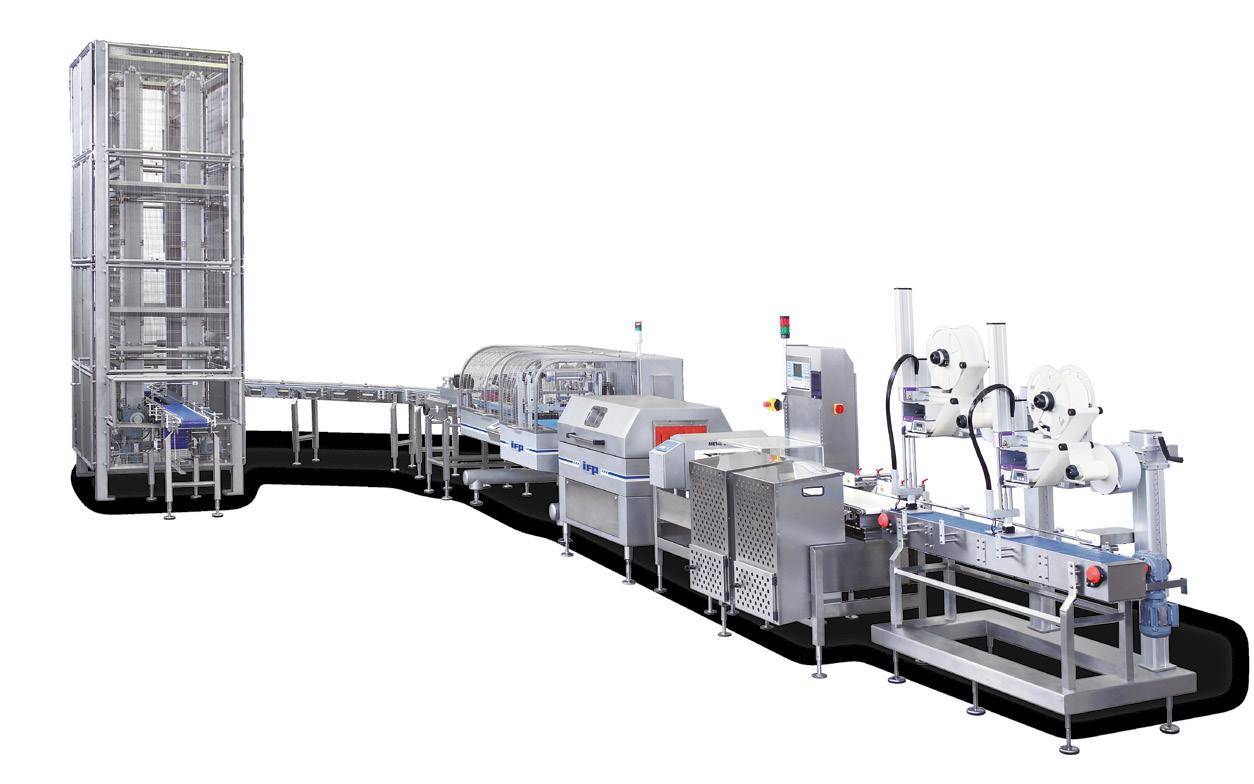

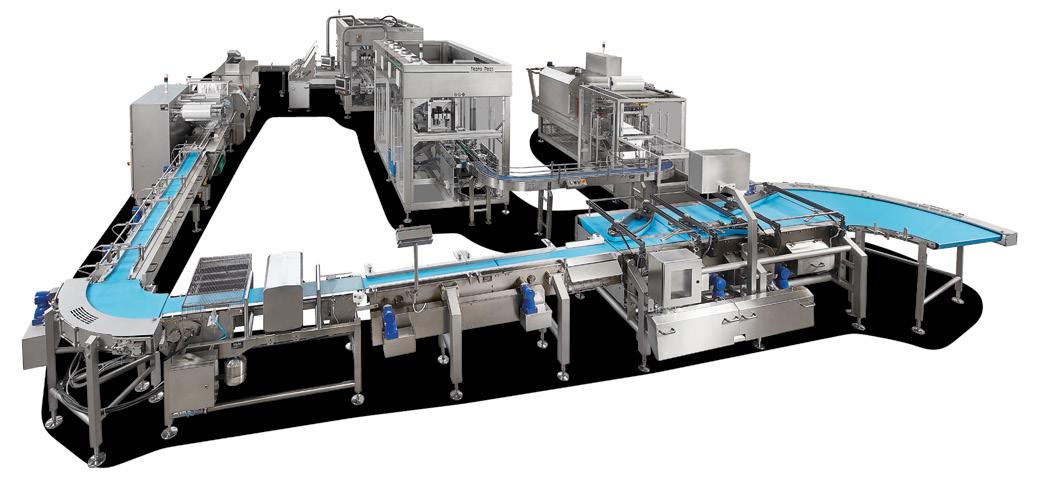

For Sarp, this event is a prime opportunity to showcase its diverse range of technologies spanning food processing and complete lines for pasta technologies, including the Spiral Division for cooling, freezing, pasteurizing, proofing, and cooking various food products such as bakery items, dairy products, processed fruits and vegetables, meats, ice cream, desserts, and beverages.

At Anuga, the company will be highlighting its Cooling and Freezing Spiral for Bakery Products, capable of reaching temperatures as low as -40°C. The engineers will analyze your product’s characteristics and recommend the most suitable spiral freezing tunnel, custom-designed for your requirements. Sarp offers flexibility in spiral

shape (circular, oval, eight), conveying speed, loading and unloading systems, as well as inlet and outlet positions of the product, and belt direction.

The cooling treatment can occur at room temperature or, with the use of an insulating cell, at a controlled temperature. Through airflow studies conducted by Sarp, it ensures uniform temperature distribution in the environment, expediting the heat treatment process and enhancing its effectiveness in preventing moisture build-up. Sarp is committed to energy efficiency, providing customers with the option to combine insulated cell advantages with evaporation systems that utilize and filter external air, optimizing air recirculation and reducing heat treatment energy requirements.

Visit Sarp booth at D11-Hall 10.1 and discover all the specific construction details that differentiate their machines, including the welded cell, washing system, and numerous belt options tailored to your production needs.

Here is where Sarp will be displaying for the rest of the year: Appex, Melbourne, AU 12-15 March 2024

Pastaria, Firenze, IT 20-21 May 2024

Fispal Tecnologia, Sao Paolo, BR 18-21 June 2024

Anutec, Mumbai, IN 28-30 August 2024

Gulfood Manufacture, Dubai, UAE 3-5 November 2024

(Sarp - Via Montebelluna di S. Andrea 43 - 31033 Castelfranco Veneto - TV - Italy - Tel. +39 0423 482633 - email: sarp@sarp.itwww.sarp.it)

food processing 22 italian food & packaging technology - cvi (2024) - march

Cooling and freezing spiral equipment for bakery products (Sarp).

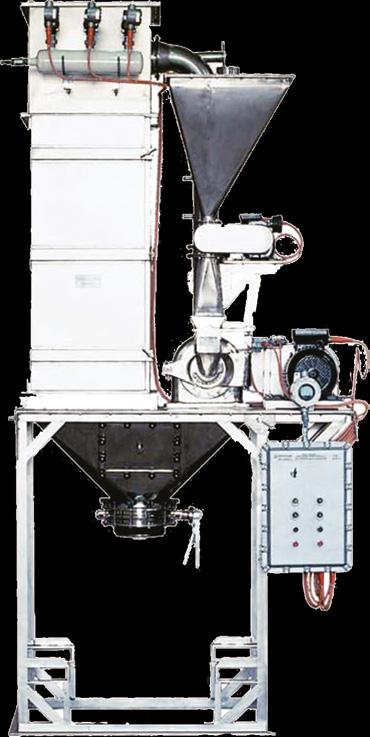

The world of sieving

Emilos passion for sieving was born at the end of the 70’s and is the result of the will and commitment of Luigi Solimè, the founder. He has always been characterized by intuition and enthusiasm, thanks to which the company has been able to establish itself in the world of sieving.

The structure is characterized by a strong flexibility, which allows to obtain significant immediate results. Direct contact with the customer’s problems constantly stimulates the planning.

In Italy, Emilos offers free sieving tests, thanks to which it is possible to precisely define the type of vibrating screen most

suitable for the result desired by the user. With its processing cycle it is possible to create entirely customized vibrating screens,

offering an absolute quality, and always guaranteeing the best functioning of the tailor-made vibrating screen; in fact, loyalty of the customers is an element of pride.

The range of the vibrating screens goes from 450 to a maximum of 1,800 mm diameter and they are capable to deal with very difficult sieving and high hourly flow rates, thanks to the special vibrators designed to work continuously 24 hours a day, 365 days a year.

The strengths that distinguish Emilos are the design and manufacture of customized vibrating screens, the quality of the materials used, the precision of the workmanship, the longevity of the machinery produced, and the short execution and delivery times; moreover, it’s always been focused on Made in Italy and each of the vibrating screens is entirely manufactured in-house.

(Emilos - Via Della Costituzione

6 - 42025 Cavriago - Re - ItalyTel. +39 0522 575010 - email: info@emilos.it - www.emilos.eu)

food processing italian food & packaging technology - cvi (2024) - march 23

SV series vibrating screen (Emilos).

CRX series vibrating screen (Emilos).

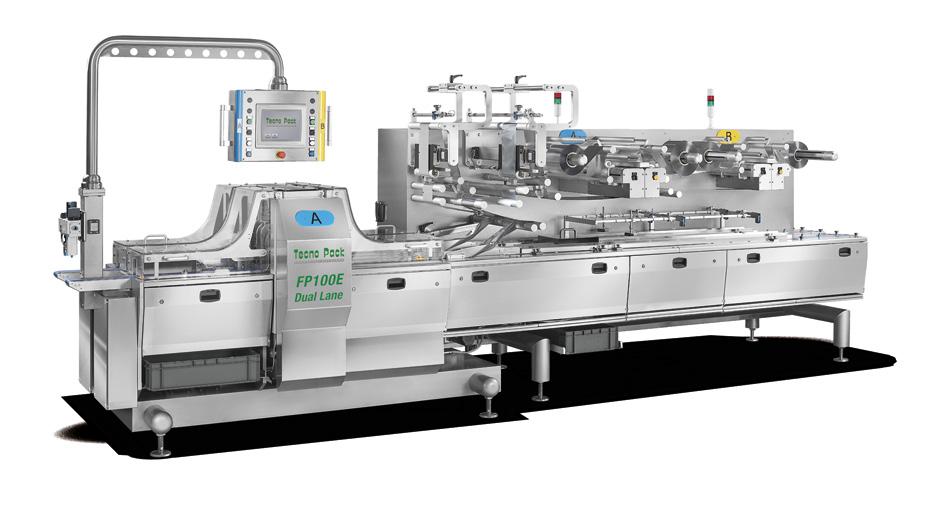

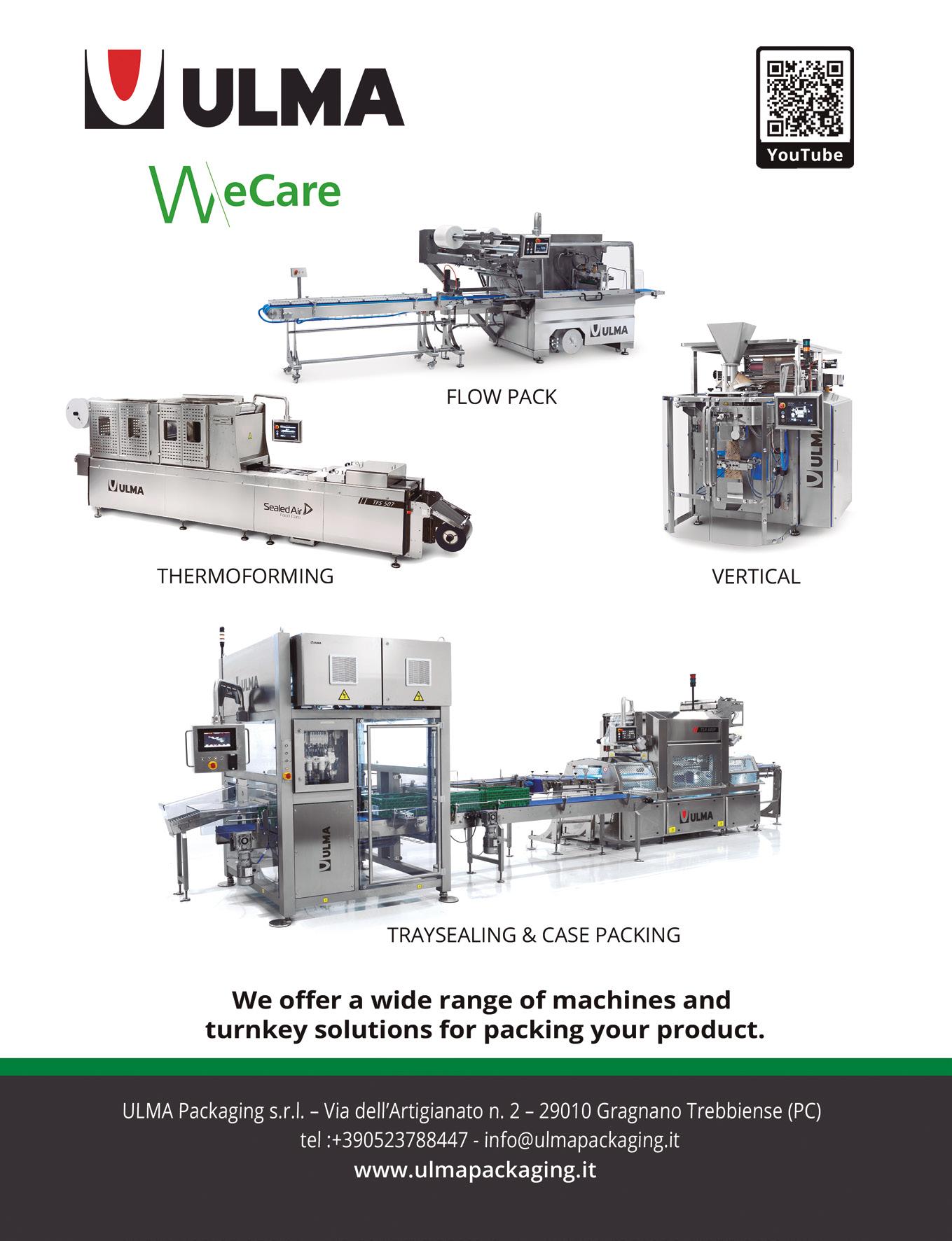

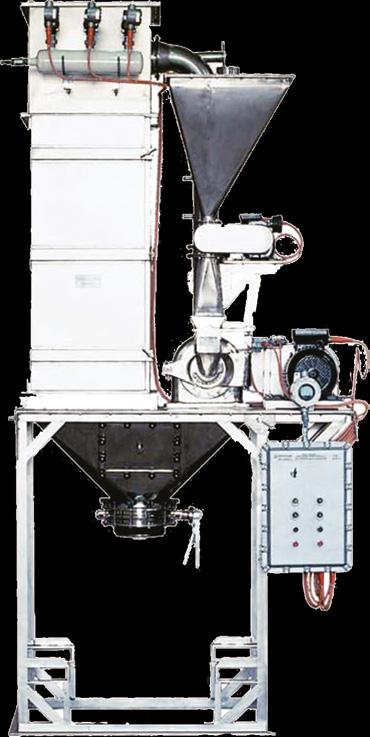

The future of chocolate and fat creams: Tecno3 and the P10S

In the increasingly competitive landscape of chocolate and fat cream production, efficiency and innovation are not only desired, but essential. Tecno3 , at the forefront of processing technology, presents the P10S plant, a revolutionary solution that meets modern requirements with optimal performance and respect for the organoleptic characteristics of the products.

P10S: a plant that rewrites the rules of continuous refining

The P10S is not a simple plant; it is a guarantee of quality, efficiency and precision. Tecno3 has

focused its expertise on creating a system that combines grinding and refining in a single process. This approach not only simplifies the workflow, but also ensures a significant reduction in physical footprint and considerable energy savings.

The machine consists of three distinct stages, each designed to optimise a specific part of the process:

• Pre-refining with two horizontal cylinders: this stage prepares the product for refining, ensuring that the grain size is ideal for subsequent stages.

• Vertical roll refining: further refines the product, improving consistency and particle size distribution.

• Ball refining: last but not least, it guarantees maximum fineness of the product, preserving its organoleptic and sensory qualities.

The beating heart of the plant is without doubt the intelligent process control.

Tecno3 has implemented a monitoring and management system that regulates critical parameters such as product flow rate, rotor speed, working temperature and internal pressure. This not only guarantees the quality of the final product, but also prevents the formation of excessively fine particles, preserving ideal rheological properties.

Tecno3: an ideal partner for reliability and innovation

Over and above the P10S, Tecno3 stands out in the industry for its ability to innovate and offer solutions that arise from actively and deeply listening to the needs of each customer. That is why the company speaks not only of systems, but of complete processes customised to each production request.

In this context, Tecno3’s P10S represents both a further step forward in the field of chocolate and fat cream processing and a symbol of the company’s progress and innovation.

(Tecno3 - Via Mastri Cestai 2 - 12040 Corneliano d’Alba - CNItaly - Tel. +39 0173 610564 - Fax +39 0173 619494 - e-mail: a.mattis @tecno-3.it - www.tecno-3.it)

food processing 24 italian food & packaging technology - cvi (2024) - march

P10S grinding and refining plant (Tecno 3).

GRINDING MILLS AND PLANTS

ITALO DANIONI manufactures grinding mills, mixers and crushers since 1918. The Company also produces closed circuit, refrigerated and conditioned and explosion proof plants for products in powder Customers have at their disposal a test room with industrial machines for verification of functioning and capacity

Via Mecenate, 78/b 20138 Milano - ITALY Tel. +39 02 504095 +39 02 504195 Fax +39 02 5062646 info@danioni.com w w w . d a n i o n i . i t Upgrading to existing installations

How to design plant protein-based sausages

The synergistic effect of lactic acid fermentation and high-moisture extrusion processing of pea protein on the microbiological and sensory properties of plantbased sausages was investigated by Finnish Researchers.

Plant-based sausages were formed by combining ferment-

ed pea protein concentrate (PPC) biomass with high-moisture extruded pea protein isolate (PPI). Pea protein concentrate (PPC) was fermented with Lactococcus lactis subsp. lactis and Lactiplantibacillus plantarum to improve the perceived structure, texture, and flavour (specifically via expression of glutamic acid which is connected to umami flavour) of plant-based sausages. The sausages were prepared by stuffing the mixture of extruded PPI and fermented PPC (addition level 70:30) inside vegetarian casings followed by steam cooking. After preparation and cooking of the sausages, a trained sensory panel evaluated the inten-

sities of ten selected attributes defining the flavour, odour, colour, and texture. In addition, dry matter content, acidification, microbial quality, and glutamate contents were analysed. The results published in LWT - Food Science and Technology journal demonstrated that fermentation decreased the pea-like odour and improved the texture of the sausages. In addition, yeast-like odour and umami taste were observed.

The study was able to demonstrate novel clean-label processing approaches by combined fermentation and extrusion to generate in-situ meat-like flavour and texture based on plant protein ingredients.

Ohmic heating-based extraction of biocompounds from cocoa bean shell

Cocoa bean shell (CBS), a by-product of the chocolate industry, was employed as substrate for the sustainable recovery of bioactive compounds using ohmic heating (OH). In a Portuguese study published in Food Bioscience journal, the total phenolic content and antioxidant activity of the treated CBS were optimized by experimental design.

Maximum extraction of antioxidant phenolic compounds (23mg GAE/g CBS) was obtained at 67°C, 50 min and 44% ethanol (v/v). The antioxidant activity of the extracts obtained under of the central point conditions

was 284.5muM Fe2+/g extract (FRAP) and 36.4muM TE/g extract (DPPH). The use of OH increased the extraction of bioactive phenolic compounds when compared to the conventional process (CH) (approximately 40%). An increased on the chemical antioxidant activity was also observed, ranging from 4 to 20%. The metabolic activity of the extracts obtained by the two methods (OH and CH) was evaluated in non-tumoral (HEK293T and L929) and tumoral cell lines (Caco-2, HT-29, and HeLa). The CBS extracts presented low toxicity in non-tumoral cells and ROS preventive effects.

These characteristics make them ideal to be used in food processing and formulation, as well as nutraceutical products due to their antioxidant protection. The use of OH results in an extract with higher phenolic content and higher antioxidant activity and low environmental impact.

food processing 26 italian food & packaging technology - cvi (2024) - march

The influence of hot-air mechanical drying on the sensory quality of coffee

The main aim of this Colombian study published in AIMS Agriculture and Food journal was to evaluate the impact of mechanical drying on the sensory quality of specialty coffee produced on three Colombian coffee farms.

The technique involved a study of the coffee bean drying process parameters, such as temperature (35°, 45° and 55°C), airflow (100 m3/min.m2) and thickness (0.2 m) for mechanical drying, vs conventional drying in the open sun until 11% of moisture content was reached. For mechanical drying, the effective diffusion coefficient, electrical conductivity and drying kinetics were evaluated. A sensory test was performed for three storage periods (3, 6 and 9 months) using the Specialty Coffee Association (SCA) protocol. The results

showed that the effective diffusion coefficient varied from 3.21 to 8.02 x10-7 m2/s for mechanical drying and from 4.21 x10-11 m2/s for drying in the open sun. The time drying time was established at 20.35 ±0.06, 29.10 ±0.09 and 71.52 ±0.11 hours for mechanical drying at 55°C, 45°C and 35°C respectively and 54.48 ±11.37 hours for drying in the open sun system. The average moisture content at the end of all drying operations was 12.5%. Electrical

conductivity rose from 11.71 to 16.86 microS/cm.g at drying temperatures ranging from 35 to 55°C. The sensory test revealed that storage duration had no effect on the quality of the coffee drink when in touch with the drying process, with mechanical drying yielding higher sensory ratings. The coffee beans were dried at 55°C, yielding coffee samples with SCA scores more than 85 points.

In overall, it is determined that the convective mechanical drying method is a viable approach for the processing of specialty coffee beans since it allows for the retention of high-quality sensory qualities, allowing it to command higher market pricing.

Effect of pulsed electric field treatment on beef cuts properties

The effect of pulsed electric field (PEF) treatment on beef cuts was performed by Czech Researcher based on two consecutive experiments and the results were published in the Innovative Food Science and Emerging Technologies journal. In the first experiment, the effect of PEF treatment (100 pulses, 5 mus, 100 Hz) of different voltage intensities (0.5; 0.75; 1.0; 1.5; 2.0; and 4 kV.cm-1) was evaluated in M. psoas major (PM). A significant effect of treatment on meat colour, texture, drip loss, and electrical conductivity was confirmed (P < 0.01), but no effect on pH value, and water activity. The electrical voltage of 0.75 kV affected the beef cuts most significantly, due to this finding the second ex-

periment was designed. Colour, texture, cooking loss, and drying were evaluated to assess the number of pulses of PEF treatment on M. longissimus thoracis (LT), M. psoas major (PM), M. semitendinosus (ST), and M. brachiocephalicus(BC).

In addition to significant effect on colour and cooking loss, PEF has accelerated the drying process of LT cuts (P < 0.01).

food processing italian food & packaging technology - cvi (2024) - march 27

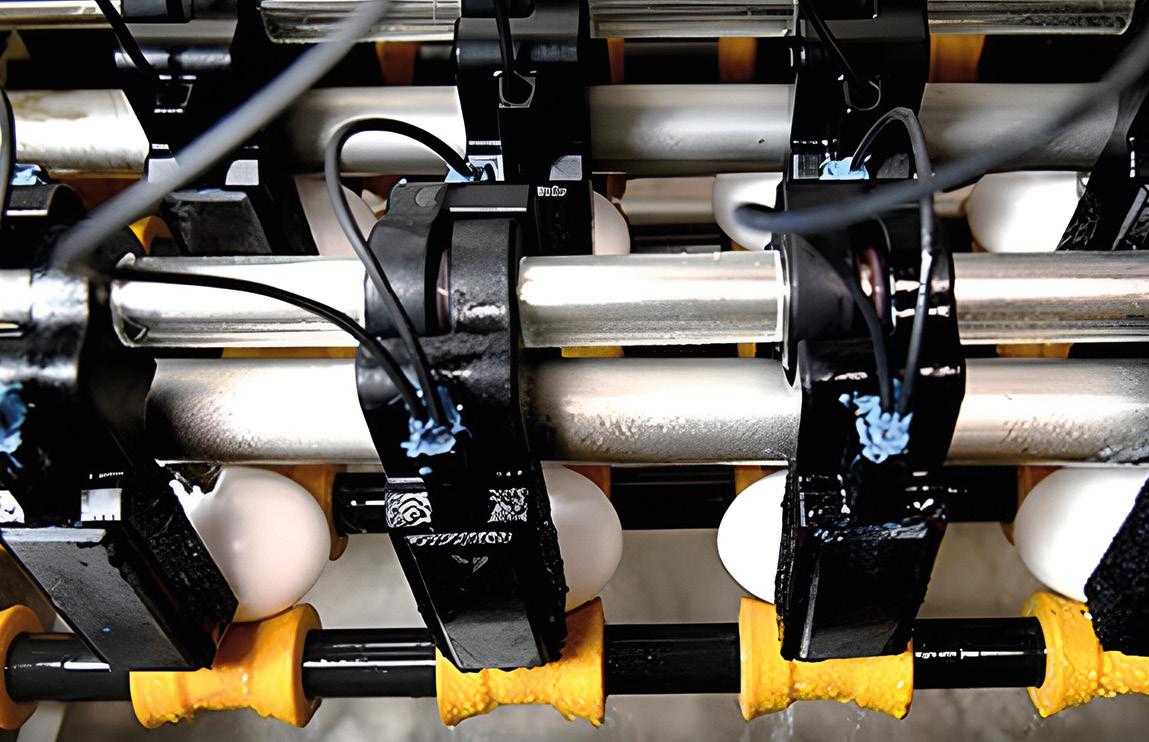

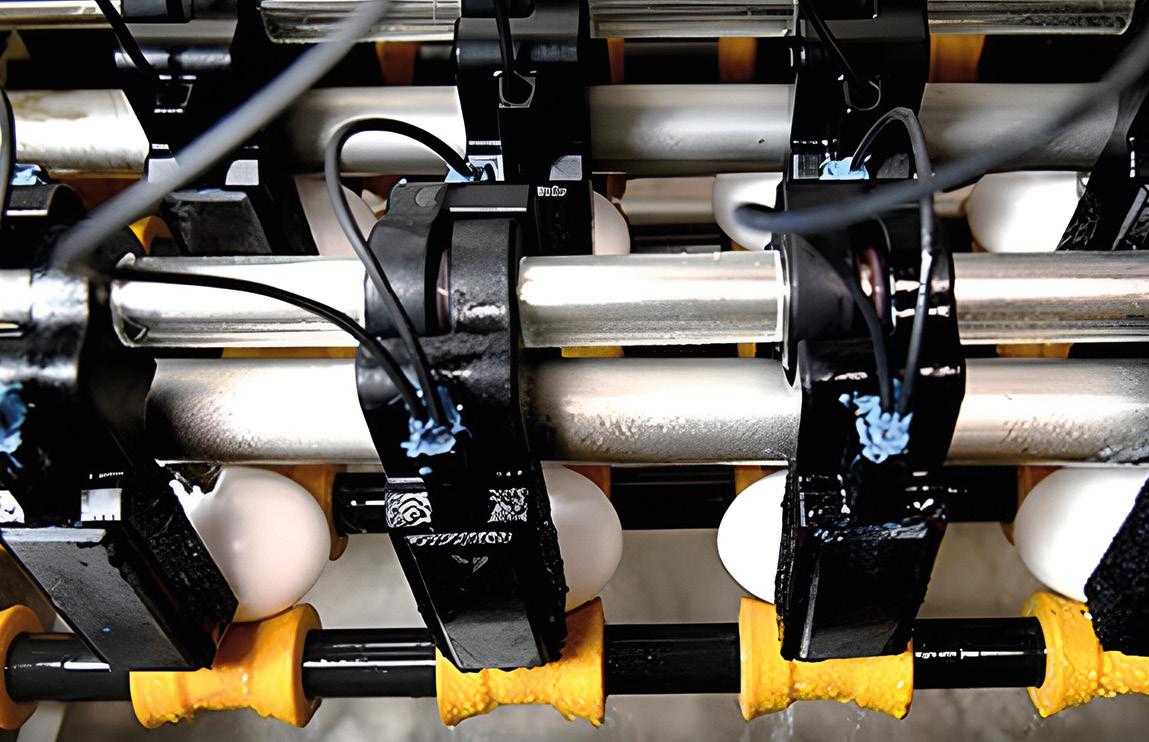

New technology to reduce pathogens in intact eggs

Salmonella bacteria causes about 1.35 million infections, 26,500 hospitalizations, and 420 deaths in the United States every year. Despite their appearance in everyday meals and snacks, the truth is that raw

less than 3 percent of commercial eggs are pasteurized in the United States. Conventional thermal pasteurization of intact eggs is usually a long process that involves submerging eggs in hot water for more than 57 minutes

eggs and egg products can carry Salmonella and cause foodborne illness and outbreaks, and even death, in some circumstances. But researchers at the U.S. Department of Agriculture (USDA) recently found a way to combat this through Radio Frequency (R.F.) technology.

A simple solution to foodborne pathogens in eggs would be to pasteurize all raw eggs before they are consumed; however,

to inactivate Salmonella cells. Researchers at the Agricultural Research Service›s (USDAARS) Eastern Regional Research Center in Wyndmoor, Pa., used a novel thermal technology that pasteurizes eggs and inactivates Salmonella cells with a short processing time.

During the study, the water molecules inside the egg rotate and align with the RF instrument’s electric field. This molecular fric-

tion causes the liquid inside the egg to heat up quickly and subsequently reduce Salmonella by 99.999% within 24 minutes. The R.F.-processed eggs were transferred to the refrigerator and kept at 7°C for seven days to simulate the commercial cold chain temperature.

“After treatment with the system, no intact Salmonella or sub-lethal Salmonella cell remnants were recovered, and no cell recovery was found in the R.F.treated eggs when stored at retail refrigerated temperature,» said USDA-ARS Research Food Technologist Daniela BermudezAguirre. “The egg quality, such as the color and other parameters, were also preserved through the processing.”

This technology has shown several advantages when used in food, all without a negative effect on food quality. Statistics also show that Americans consumed a total amount of 93.1 billion eggs in 2023. So, this is a promising advancement for small farmers or egg processors and can ensure food-safe eggs while minimizing Salmonella. Consumers will also benefit from this technology since it preserves the quality of the eggs that can be used for special markets such as nursing homes, hospitals, or schools.

ARS researchers will continue to develop this technology’s capabilities and expect it to be commercially available in the near future.

www.ars.usda.gov

food processing 28 italian food & packaging technology - cvi (2024) - march

PACKAGING TRENDS

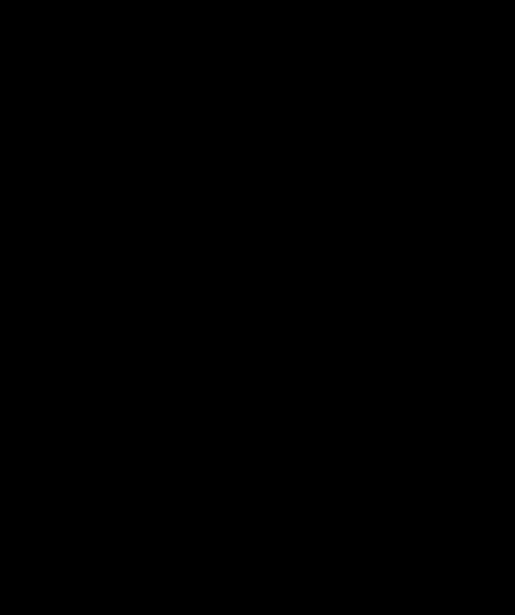

Packaging and sustainability: alternative materials and flexible machine concepts

The current packaging development trend is evident at ProSweets Cologne: Wherever it is possible to dispense with plastic for packaging, paper or cardboard are being used instead. There will be many examples of this during the Sweet Week at the Cologne fair grounds, especially in the halls of the co-staged ISM, the world’s largest trade fair for sweets and snacks. As a duo, ISM and ProSweets Cologne, represent the entire industrial value chain of the international sweets and snacks industry. Increasing the recyclability and reducing the weight of the packaging are important aspects that are at the top of the agenda of the sweets industry. During the Sweet Week the industry’s most important producers, suppliers and decision-makers all engage in an exchange in one location at the same time - to bring about synergies in the areas of networking, knowledge transfer and business.

Recyclable and functional alternatives to petrochemical plastics of the linear economy

“We very much welcome the consumers’ increased awareness for sustainability,” confirmed Prof. Dr. Markus Schmid. “This awareness leads to a heightened interest in environmentally-friendly packaging. However, it is important that well-founded decisions are taken concerning the choice of material. We often see that well-intended initiatives lead to hasty solutions without their functional restrictions and the actual ecological footprint being taken into

full consideration. In our work at the Sustainable Packing Institute (SPI) at the Albstadt-Sigmaringen University we strive to develop holistic solutions that are both functional and sustainable. Our aim is to improve the life cycle assessment of bio-based plastics, i.e. by using residual plant matter and thus being able to offer really more sustainable packaging materials.” The recent successes achieved in current and completed projects will be presented interactively in the scope of the Sustainable Packaging Special Show in Hall 10.1 during ProSweets Cologne.

30 italian food & packaging technology - cvi (2024) - march

Peter Désilets, Chief Operating Officer of Pacoon Sustainability Concepts GmbH, knows which materials and technical innovations promote the change process. Whether for jelly items, toffee, caramel or bonbons: Whilst the consumers are pleased about the huge variety at the point of sale, the sweets and snacks manufacturers have to find the right interplay between packaging material and the packaging technology for their products. Materials that display the best possible machinability from the start are the prerequisite for this,” according to the expert. Especially in the concept phase of a new machine there is a lot of scope for designing the packaging with sustainability in mind. Fibre-based packaging is a preferred and in many respects forward-looking option for Désilets: “As a contact person for the companies we are presenting among others selected samples of fibre-based packaging at the Sustainable Packaging Special Show.”

Flexible machines for a wide variety of packaging

The trend towards paper-based packaging and monomaterials made from plastic is clearly noticeable among the machine builders who are exhibiting at the fair grounds in Cologne. They are supporting the producers in switching over to recyclable alternatives with innovative technologies that enable more economical cuts, improved material utilisation and optimised formats. Solutions that are found at ProSweets Cologne also guarantee perfectly sealed packaging in the case of very thin films made of polypropylene or polyethylene. In this way, stand-up pouches for snacks can be recycled as a true “single material solution”. Schubert offers its customers more flexibility for transverse sealing with the box motion unit in the Flowpacker, for example. The ultrasonic method makes it possible to seal more hermetically overall because the seam displays a consistent high quality across the entire width. Thick films that require longer sealing times can be easily processed as well as recyclable tubular bags made from monofilms or paper-based films.

In the meantime, sustainable materials can be processed in many other machines - what’s more with full format flexibility. An example of this is the Kliklok ACE by Syntegon. The carton erector folds paper trays without glue and thus enables conventional plastic trays to be replaced by paper-based materials. Moreover, sustainable packag-

ing is demonstrated in concrete form by the FPC5 of Theegarten Pactec. The modular packaging machine for the production of bars in a tubular bag has been further developed so that paper-based packaging can be processed: On the one hand using a conventional cold seal process, but on the other hand also using a much more complex heat seal process. The machine has a capacity of 90 m per minute for paper-based packaging. That corresponds to 600 larger 40-g bars of chocolate per minute. And Loesch’s LTM-DUO fold wrapping machine is both flexible regarding the choice of format and the packaging material: From smaller bars through to 300-gram bars, from biofilm, to monofilm and composite material, through to aluminium foil, everything can be processed unproblematically. The outer wrapper of the bar of chocolate can be designed as a paper label from the stack or reel or also as a carton label. The examples show how the machine builders unite the themes sustainability and process integration with one other.

A look into the biocircular future

Hence the turnaround towards sustainable packaging solutions is in full progress – this will also be demonstrated in the Cologne exhibition halls from 28 to 31 January 2024. Hon. Prof. Dr. Sascha Peters, founder of the Haute Innovation Agency will be addressing scenarios for the markets of the future at ProSweets Cologne in his lecture entitled “Biocircular packaging for the sweets industry.” The solutions will also be presented in the scope of the Sustainable Packaging Special Show. The potential of regrowing alternatives to plastics is nowhere near exploited, he explained. Packaging that is made out of regrowing raw materials and residual organic materials are in demand. As a resource-saving alternative to con-

packaging trends italian food & packaging technology - cvi (2024) - march 31

ventional paper made of fresh fibres, grass paper is for instance developing into an ever-increasingly important packaging material. Depending on the usage it can replace the wood fibre content by up to 50%. “One can achieve an innovative advantage with alternative packaging,” according to Peters.

ProSweets Cologne is a trade fair for the entire industry-specific supply spectrum of the sweets and snacks industry. This ranges from the packaging of sweets and snacks and packaging technologies, to the raw materials and ingredients needed especially for the production of sweets and snacks, through to process technology. Secondary sections like refrigeration and air conditioning technology, operating and auxiliary equipment as well as the themes food safety and quality management for the sweets and snacks industry round off the portfolio.

www.prosweets.com

Food and packaging experts dare to look to the future

A breakfast in the year 2040: the porridge comes from a 3D printer which, thanks to your smart watch, has your current vital data and links it to a nutritionally optimized recipe. The basic raw materials required for this, such as rolled oats, nuts, and dried fruit, have already been processed for the 3D printer and are delivered to your home every week in a subscription box. But the user doesn’t notice much of this, “after all, thanks to technology, everything runs autonomously”, says Daniel Anthes, describing his scenario of the future. He is a startup founder, food expert, and keynote speaker at the Zukunftsinstitut.

Andreas Milk, who runs an agency for packaging design, has inspired Anthes to develop a joint “Future Food Trend Radar”. The two people from Frankfurt have been working on innovative and sustainable packaging materials for years. The radar not only sheds light on the future of eating and cooking, but also on packaging in the food sector.

Milk and Anthes venture a look into the future and predict that some packaging and systems, such as the compostable film Traceless and the Loop recycling project, will become game changers, while oth-

ers, such as packaging made from seaweed, may no longer have a secure future.

The radar provides inspiration and guidance on the question of which food and packaging materials and concepts – metaphorically speaking – are relevant today and will be tomorrow (2030 to 2040) or the day after tomorrow (from 2040). Companies from the food or packaging industry can have an individual radar created on this basis. They can therefore develop an individual brand image for the future and start the process for new products and packaging solutions based on this.

Change in Nutrition

“With our ‘Future Food Trend Radar’, we want to illustrate the transformation of nutrition in all its complexity and multi-layeredness and invite you to think about the future in an entertaining and inspiring way”, says Andreas Milk. “The focus is on the topics of food, kitchen, marketing, and packaging and, therefore, on what we eat, how and where we prepare and cook it, how and where we produce and transport the necessary food, and also on how we package it.”

Who Are the Game Changers?

In the Loop project, Procter & Gamble, Unilever, Nestlé, PepsiCo, Danone, and other consumer goods giants are working together on solutions to reduce waste. This is a completely new way of shopping in which reusable packaging plays the main role. Such naïve fallacy in which the packaging goes back to the retailer, are the future, say Milk and Anthes.

Further leaps in material reduction can be made with other approaches such as the “Flow Pack” from Adapa, which is already on the market. In Adapa’s innovative example, the special mono-material solution for improved recyclability is the decisive piece of the puzzle for contemporary packaging. The experts also see the edible protective layer Apeel as a gamechanger that is here to stay, it can be applied to citrus fruits or avocados, for example, and extends the shelf life of the food.

packaging trends 32 italian food & packaging technology - cvi (2024) - march

AS FAR AS YOUR EYES CAN SEE: INFINITE OPTIONS FOR PACKAGING FOOD. BROUGHT TO LIFE WITH SCHUBERT.

Being flexible is good, being fast and flexible is even better. Schubert packaging machines are leading the way. Intelligent control and precise robotics can now replace complex mechanics to ensure maximum flexibility in all packaging processes. In fact, 80% of the leading FMCG companies count on us and our flawless packaging combined with the lowest possible consumption. In line with our Mission Blue Sustainability Initiative: A winning proposition – for our planet and for you. www.schubert.group/en/food.html

MAR 19 - 22, 2024 HALL 7.1 BOOTH C-071 WELCOME

ANUGA FOODTEC COLOGNE

PACKAGING EQUIPMENT

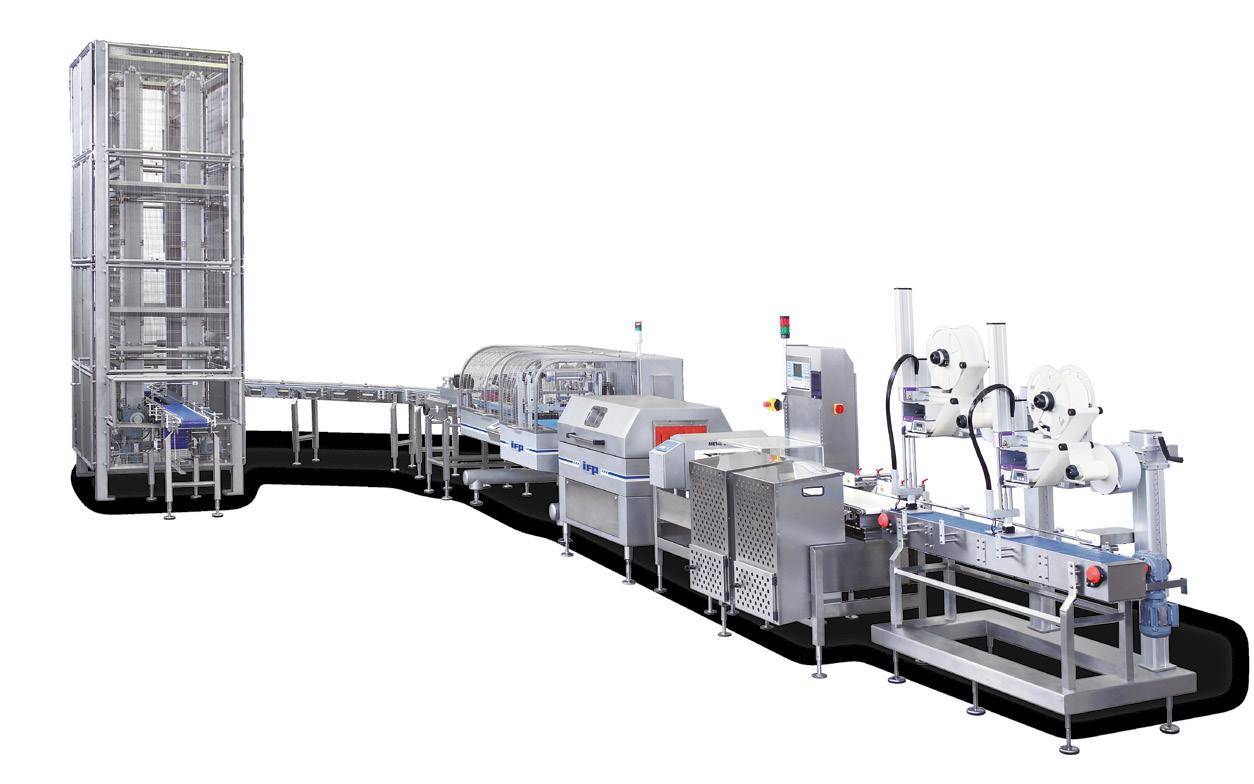

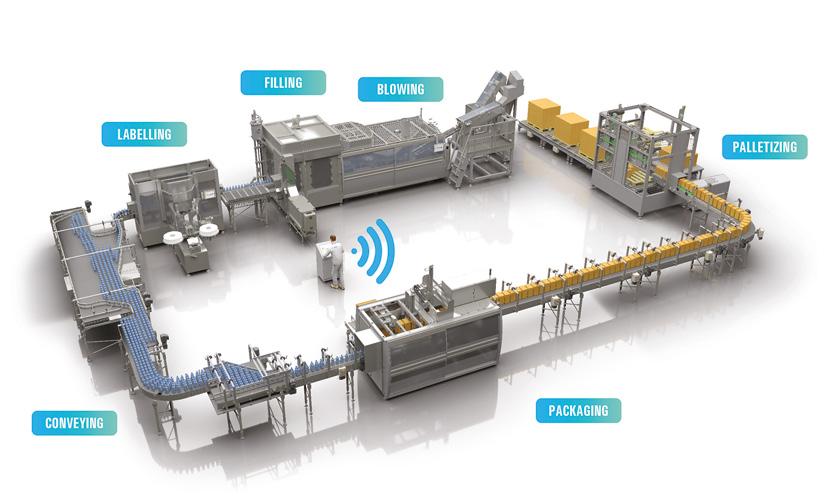

Smart intralogistics: innovative solutions for a fully automated supply chain

Almost nothing can happen in the modern warehouses and cold storage facilities of the food companies without plastic containers. Durable pallet boxes and robust containers that guarantee hygienic transport and product-compatible storage are therefore just as much in focus at Anuga Food Tec as conveyor belts and mechanisms. Around 120 exhibitors present holistic intralo-

gistics solutions on the Cologne fair grounds.

The technology providers are embarking on new paths, particularly when it’s about improving the internal material flow: the goal is the seamless transition from production to distribution. Modern automation solutions are at the same time expanding the production facilities into storage and distribution centres thanks

to artificial intelligence (AI). A theme that the lectures of the Main Stage Responsibility in Hall 9 also address, for example, in the framework of the panel discussion “Process optimisation in logistics” on 20 March 2024. Driverless transport systems thereby play just as important a role as picking and palleting solutions or conveyor systems that ensure optimal area use.

Systems for the “warehouse of tomorrow”

The warehouse of tomorrow must meet high requirements for connectivity. All of the systems used must not only communicate with one another, but also with external systems and processes. The requirements actually involved in practice are shown by a project realised by Anuga FoodTec exhibitor Westfalia for Spaichinger Nudelmacher. The intralogistics specialist replaced the forklifts used to date in the warehouse area of around 4,000 square metres in 2022 with an

34 italian food & packaging technology - cvi (2024) - march