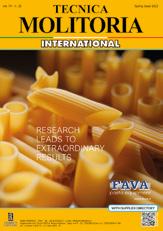

www.fava.it RESEARCH LEADS TO EXTRAORDINARY RESULTS ADV23_Cop_TM International.indd 1 12/04/2023 13:59:13 TECNICA MOLITORIA vol. 74 - n. 25 Spring issue 2023 ISSN0040-1862 10064 PINEROLO - ITALY - Tel. +39 0121393127 - e-mail: info@chiriottieditori.it Supplemento al n° 04 del 2023 di Tecnica Molitoria - Sped. in A.P. - D.L. 353/2003 (Conv. in L. 27/02/2004 n° 46) art. 1 comma 1 DCB TO - n. 1 anno 2023 - IP INTERNATIONAL WITH SUPPLIER DIRECTORY

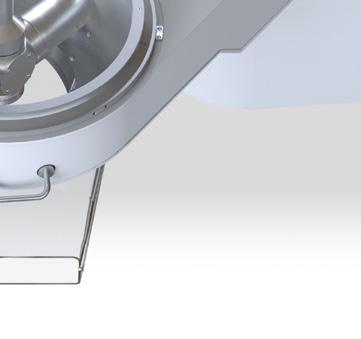

Our results confirm it: Fava’s research leads to exceptional pasta quality levels, guaranteeing extraordinary solutions for the field. The new range of long and short-cut pasta lines, GPL 180 and TCM 100, are proof of the important technical and technological developments which, together with our innovative R&D laboratory and our ever-evolving value-added services, demonstrate the exclusive advantages of our know-how.

www.fava.it

RESEARCH LEADS TO EXTRAORDINARY RESULTS

1

www.ai-lati.com 2

www.paglierani.com www.ocrim.com O u r es s e n c e li e s i n t h e f o r m s t h r o ugh w h i c h w e s h o w o u r s e l v e s . W e offe r j u s t wh a t w e a r e . A l w a y s . 3

5

O.B.R. BULGARELLI srl Via Parri, 3 - 42045 LUZZARA (RE) Tel. +39 0522 976972 - www.obr.it - obr@obr.it * HAMMERS * PLATE * SIEVES

VARIOUS ACCESSORIES FOR FLOUR AND FEED MILLS

*

7

WE CONTINUE TRADITION, ENSURING GREATER PRECISION, EFFICIENCY AND PRODUCTIVITY

www.loporcaro.it S.S.96 Km.78,800 - Z.I. Via del Grano 1 70022 Altamura (BA) Italy

PRESSTRAPEN family

THE INCREASINGLY EFFICIENT CUTTING UNITS.

• NEW HEAD DESIGN WITH DIFFERENTIATED AND OPTIMISED VENTILATION

• BRUSHLESS MOTOR (PATENTED SYSTEM)

• COLOR TOUCH SCREEN

• FRESH PRODUCT DISCHARGE (OPTIONAL)

• MAXIMUM EASE OF OPERATION AND MAINTENANCE

• ALL WITH A SINGLE FAN!

Making our customers’ head spin for over 30 years.

9

Approvedby P ta!

WWW.NICCOLAI.COM

DOWNLOAD OUR CATALOGUES

PATENTED

10

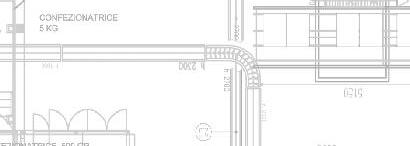

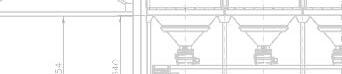

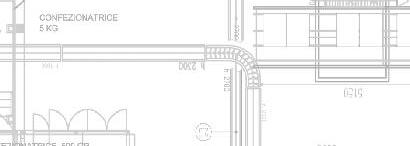

MACHINES AND PLANTS FEED AND

GAMMA PRODUTTIVA

• Impianti completi di stoccaggio prodotti granulari e polverosi.

• Impianti completi di insilamento paste corte ed alimentazione confezionatrici.

• Impianti completi di dosaggio e miscelazione.

• Impianti di presminuzzatura e macinazione sfridi ed archetti di pasta.

• Trasporti pneumatici in compressione ed aspirazione.

• Trasporti meccanici: trasporti a nastro, a catena ed a coclea.

• Elevatori a tazze: verticali, inclinati ed a zanca.

• Filtri autopulenti e statici.

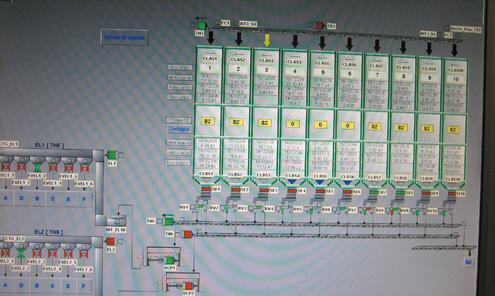

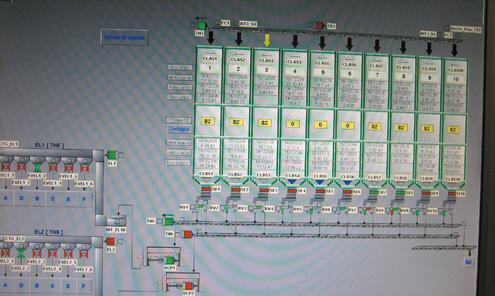

• Quadri di comando con P.L.C. e computer.

12

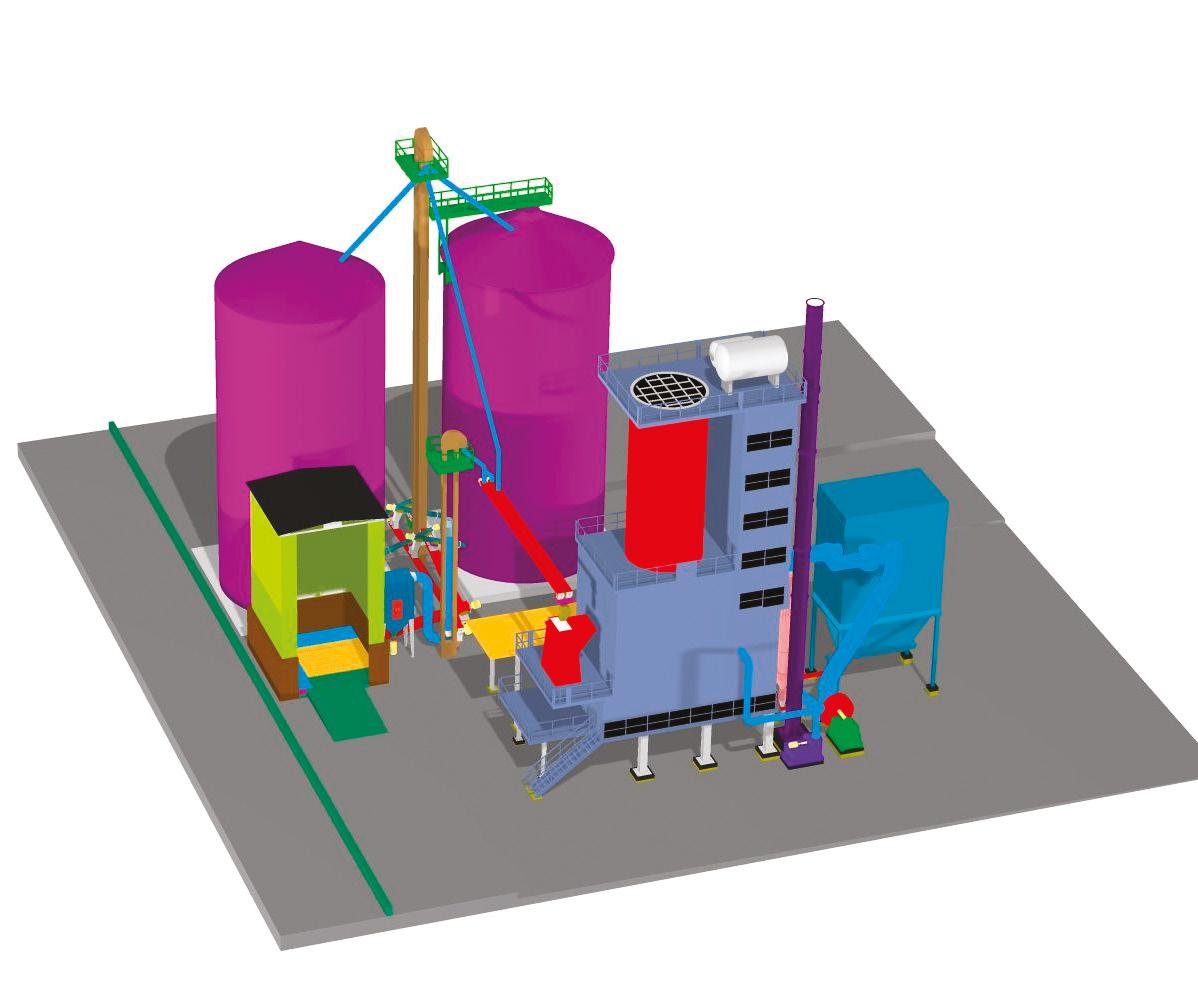

PRODUCTION RANGE

• Systems complete with granular and dusty product stockings.

• Systems complete with short format pasta ensilage and packaging machine feeding line.

• Systems complete with dosing and mixing units.

• Systems for scrap and waste pre-crumbling and grinding.

• Compression and suction pneumatic conveying lines.

• Mechanical conveyance: belt, chain and Archimedean screw conveyors.

• Vertical, sloped and Z bucket elevators.

• Static and self-cleaning filters.

• Control panels with P.L.C. and computer.

S.I.R.C.E.M. C.M. S.p.A. Uffici e Stab.: Via A. Diaz, 19 84018 SCAFATI (SA) ITALY Tel. +39 081 8631205 (r.a.) Fax +39 081 8630301 sircem@sircem.it - www.sircem.it PLANTS

FOR FOOD INDUSTRY, CHEMICAL

13

14 K

M-JET LINK Connection box

15

Tailor-made technology, driven by innovation

Discover Brambati’s experience and continuous research in equipments for raw materials handling in food industry: pasta, confectionery and bakery.

BRAMBATI S.p.A — via Strada Nuova, 37 27050 Codevilla (PV) ITALY tel: +39 0383 373100 | www.brambati.it | info@brambati.it

16

17

18 CONSERVATION, HANDLING AND GRAIN STORAGE SOLUTIONS & SYSTEMS 360° in Your Service 08611

19

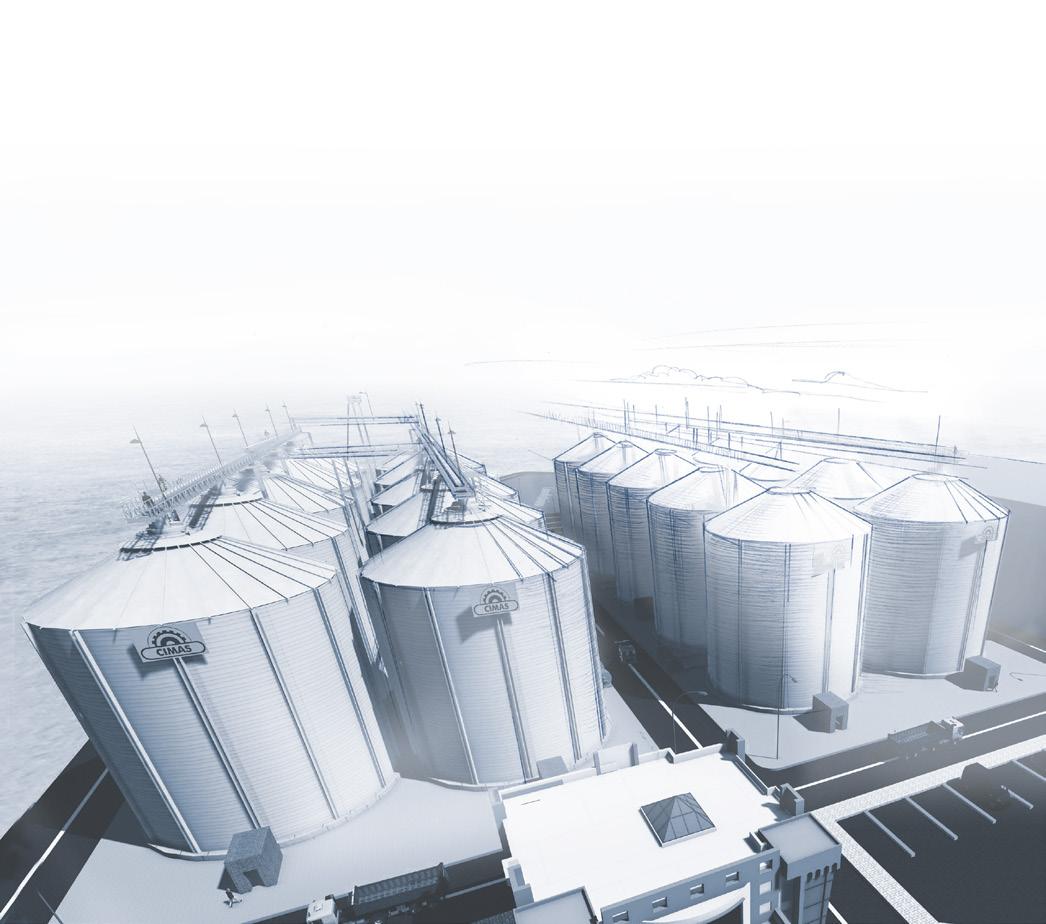

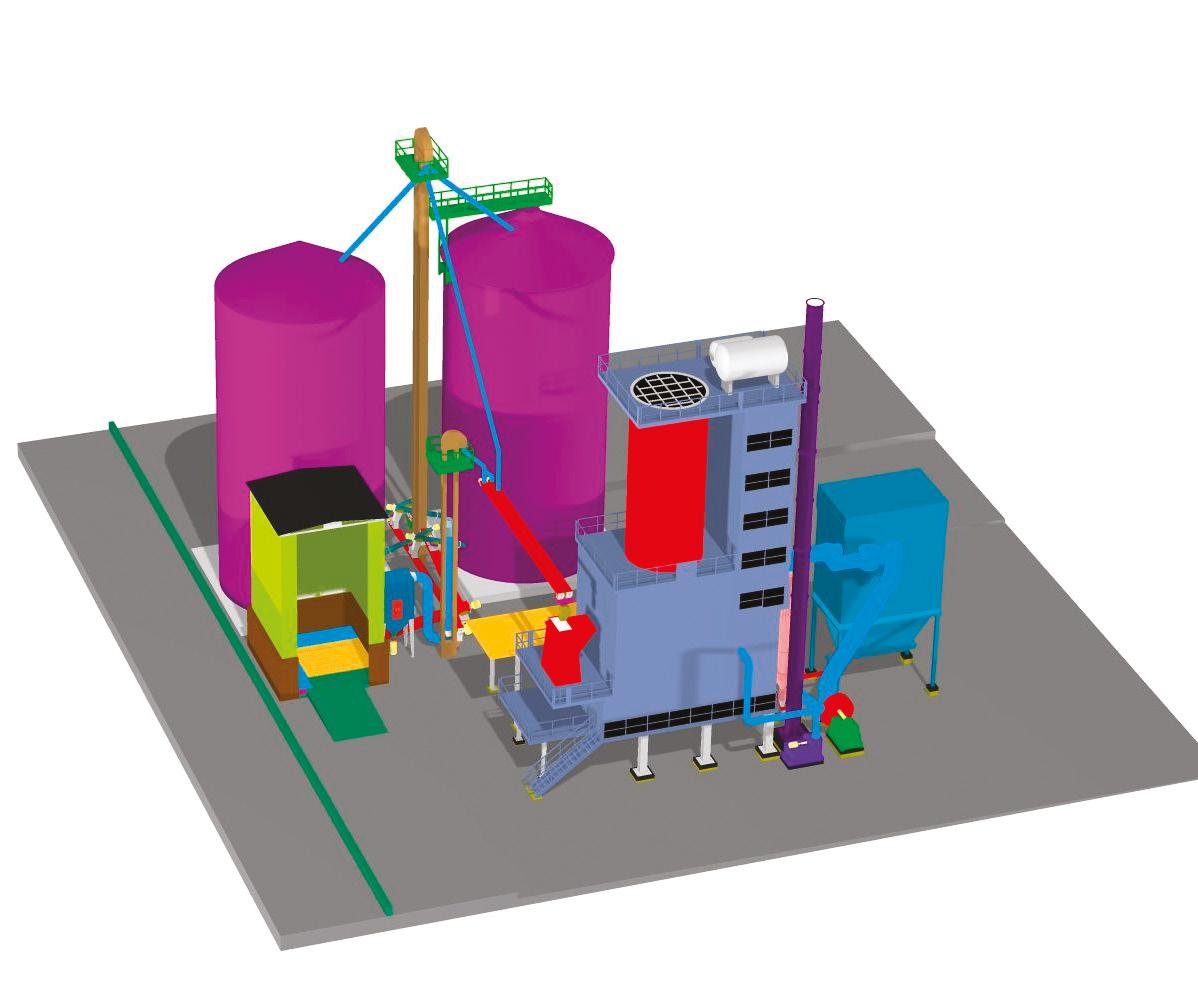

TECHNOLOGIES FOR THE STORAGE INDUSTRY

Technobins srl operates since 1995 in the sector of plant for the storage of granular and powdery products in general and in particular:

• Cereals and oil seed

• Flour and semola

• By products (bran, husk, etc)

• Feed

• Pasta

Technobins supplies all types of metal silos and operate for the supply of silos and steel structures to end customers or to main contractors. We also supply turnkey plant complete of mechanisation and electrical automation.

Technobins has a long experience in the installation of square and round bins integrated in industrial buildings, including the supporting steel structure, cladding and roof cover.

Technobins Srl

Via P. Nenni, 4

42048 Rubiera (RE) Italy

Tel. +39 0522 943002

Fax +39 0522 494105

info@technobins.it

21

C.M.F. Ferrari Carlo s.r.l. Via Venezia, 3 25037 PONTOGLIO (BS) Tel. +39 030 7376774 - Fax +39 030 7470892 www.cmf-italia.it ferrari-giuseppe@cmf-italia.it - ferrari-alberto@cmf-italia.it C.M.F. Ferrari Carlo s.r.l. plants for CEREAL THERMAL FLAKING FLAKES AND CRUSHED CE performing 5-10 T/ho T h e r e p r e s e n t e d m a c h i n e s a r e i n s t a l l e d t o : M O U L I N S C H Y N S S . A .B e l g i u m ollers mm 1000X1200 Total weight: kg 24.000 NEW r l - Vi Ve eziaR our EAL DRIER - ROSTER performing 5-10T/hour COMPLETE Starch Gelatinization! 22

23

We treasure the future of our planet

Agriculture as a restart as a certainty as S.I.M.A.

24

The new generation of food storage*

*Silos for the storage of cereals, flours and semi-finished products for food use, produced according to the standards of the Declaration of Conformity for the M.O.C.A. (Materials and Objects in Contact with Food).

M.O.C.A. is a certification that guarantees compliance with mandatory food hygiene requirements where the products are made in compliance with Regulation (EC) 1935/2004 of the European Parliament and of the Council of 27 October 2004.

STORAGE FEED SEEDS Campo San Martino PD Italy |Via Palladio, 7 | T. +39 0499638211 | mulmix@mulmix.info MULMIX.IT 25

for over 40 years we manufacture:

STORAGE PLANTS AND HANDLING SYSTEMS FOR SHORT- CUT PASTA AND GRANULAR PRODUCTS

BUCKETS ELEVATORS - BELT CONVEYORS - SIEVES -VIBRATOR FEEDERS - LONG- CUT PASTATRANSPORT SYSTEMS

SEMI-AUTOMATIC LINES FOR SHORT-CUT PASTA, LONG-CUT PASTA, NEST PASTA

AUTOMATIC DESTACKER ANDTRAY’S FEEDER,TRAY’S STACKER, TRAY’S DOWNLOADING SYSTEM, STATIC DRYERS

26 VIA GUIDO ROSSA, 13 A 16012 BUSALLA (GE) - ITALY TEL. +39 010 9642386 - FAX. +39

9760838 INFO@PRO-TECHITALIA.COM WWW.PRO-TECHITALIA.COM

010

27

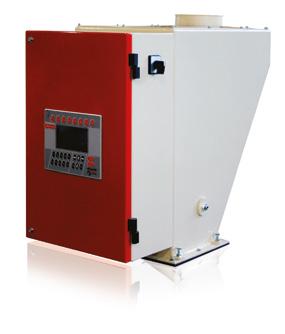

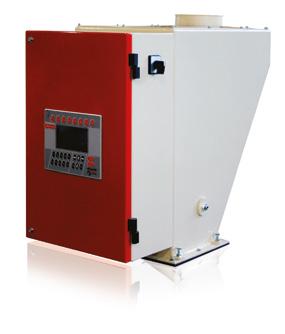

FORTY YEARS OF EXPERIENCE IN PROVIDING THE BEST WEIGHING, DOSING AND PACKAGING SOLUTIONS FOR BULK PRODUCTS IDM Automatic Dampening Controller TSE Electronic Single Weighing Hopper Process Weigher IMECO • Cremona (CR) - Italy (+39) 0372 496826 • sales@imeco.org www.imeco.org Electronic Twin Weighing Hopper Process Weigher DDC Electronic Flow Regulator

SYSTEM OF RECEIPT AND TRANSPORT LOLLA MM MAA ACC CHH HII INN NEE ESS S AA ANN NDD D PP PLL LAA ANN NTT TSS S FF FOO ORR R FF FOO OOO ODD D II INN NDD DUU USS STT TRR RII IEE ESS S I .M.M.A.C. S.r.l. Sede e Stabilimento Via Strada Nuova, 25 27050 Codevilla (PV) Italy Tel. ++39 0383 373044 Fax ++39 0383 73835 www.immacsrl.com E-Mail info@immacsrl.com 30

INNOVAZIONE SENZA FINE

There is a history that for over 70 years has supported customers all over the world in the design and construction of made-in-Italy plants for grinding, mixing, dosing and storing bulk products. It is our story. T Together we build that of your company

31

32

33 Contrada Torre la Macchia 70022 Altamura (BA) Italy | www.molitecnicasud.it | +39 080 310 10 16 | info@molitecnicasud.it

and Agri-food Plants

and 100% Made in Italy

and Agri-food Plants

and 100% Made in Italy

Milling

Customized

Milling

Customized

Milling Culture in the World”

“Spreading

Food and Milling Culture in the World” 001 % M ADEIN ITALYCERTI F I C ETA ITPI

Our Vision: “Spreading Italian Food and

Our Vision:

Italian

Optical sorting is evolution and specialization: a new OPTICA’s generation is born.

OPTICA HD: higher resolution, doubled detail, suitable for all applications.

OPTICA RISO: expressly designed for an accurate selection of any kind of rice.

34 3U Vision Srl Via Ugo La Malfa 20 40026 Imola, Italia 0542 1881791 info@3uvision.com www.3uvision.com

EVOLUTION OF SPECIES

Viale Rimembranza, 60 - 10064 Pinerolo - TO - Italy Tel. +39 0121 393127

info@chiriottieditori.it www.chiriottieditori.it shop.chiriottieditori.it

PUBLICATION MANAGER Alberto Chiriotti

EDITOR-IN-CHIEF Livia Chiriotti

EDITOR CONTRIBUTING EDITORS Simonetta Musso, Laura Sbarato, Elena Folco, Chiara Mancusi, Rossella Contato, Matteo Barboni

EDITOR Federica Diaferio: diaferio@chiriottieditori.it

CIRCULATION Monica Primo: primo@chiriottieditori.it

SUBSCRIPTIONS Marilù Cianflocca: Tel. +39 0121 378147 - abbonamenti@chiriottieditori.it

GRAPHICS Anna Boscolo

MARKETING MANAGER Monica Pagliardi: pagliardi@chiriottieditori.it

ADVERTISEMENT Luca Russo: russo@chiriottieditori.it

GENERAL MANAGER Giuseppe Chiriotti

PRINTED BY La Stamperia Pinerolese srls - Pinerolo (To)

COPYRIGHT © 2023 Chiriotti Editori srl - All rights reserved

Supplemento a Tecnica Molitoria n. 4 Aprile 2023 - ISSN 0040-1862

Spedizione in abb. postale Torino

Autorizzazione n. 172 (5-5-1950) e n. 233 (30-1-1961) del Tribunale di Pinerolo

Aderente a: Copyright ClearanCe Center

Unione Stampa Periodica Italiana

Socio Sostenitore:

CHIRIOTTI EDITORI MAGAZINES

Tecnica Molitoria the Italian milling journal since 1950

“Tecnica Molitoria International” is the English language son of the Italian monthly magazine “Tecnica Molitoria” published by Chiriotti Editori, which enjoys worldwide prestige as the most complete journal dealing with all branches of pasta making, wheat milling, feed mills, silos, and cereal research.

Tecnica Molitoria

The Italian language “Tecnica Molitoria” journal first appeared in 1950, and now runs 12 issues each year. Technical and scientific articles by Italian and foreign experts

36 ˙ Spring issue 2023 Tecnica Molitoria International riempitivi TM per sito.indd 1 17/04/23 10:56

The web page www.tecnicamolitoria.com where “Tecnica

updated

Molitoria”

indexes can be found.

(with English abstracts), descriptions of new machinery, equipment, technologies and services, economical and legislative news, exhibition and congress reportages, and current activities are regularly published each month. The summaries of the technical and scientific articles published in the last and in the past issues of “Tecnica Molitoria” can be viewed at the English language web page www.tecnicamolitoria. com. Further to the subscription of “Tecnica Molitoria” hard copy by air-mail, they are available the PDF for tablet and PC as well the iPad and iPhone subscriptions.

Tecnica Molitoria International

Since the year 2000 “Tecnica Molitoria International” is published as well. It is issued once a year completely in English language. This magazine is sent abroad for free, in order to promote the Italian technology, machinery, and research worldwide.

“Tecnica Molitoria International” is also available on-line for free, together with several other English language technical magazines of Chiriotti Editori publishing house, at the web page www.chiriottieditori.com (click “Digital magazines”).

(Chiriotti Editori - Viale Rimembranza 60 - Pinerolo - TO - ItalyTel. +39 0121 393127 - www.chiriottieditori.com)

tecnica molitoria Tecnica Molitoria International Spring issue 2023 ˙ 37

“Tecnica Molitoria International” is freely available on-line to be downloaded at shop.chiriottieditori.it

riempitivi TM per sito.indd 2 17/04/23 14:33

CONTENTS

Tecnica Molitoria

36 - Tecnica Molitoria, the Italian milling journal since 1950

Marketing

39 - The maize flour market to 2031 - Feed premix market trend

Cereals

44 - Updates on the world cereal market - FAO forecasts on cereal supplies in 2022/23 - New purple and red rice varieties - To enhance wheat yield - Europe’s first GE wheat trial produces less acrylamide - Strengthening sorghum against a fungal threat - Grain silage rehydrated with water or acid whey

Milling

54 - Preharvest and flour quality - Variability of carbohydrate composition and pasting properties of oat - Increases iron and zinc concentrations in wheat flour - Hydrothermal treatment parameters on oat grindingComparative study of separate and mixed fine grinding methods

Feedstuff

60 - Polyphenols, isoflavonoids, and their metabolites in milk samples - Exhausted bergamot by-product for pigs - Protein sources for cattle diet - Energy reduced diets for broiler - Feed supplementation with silage in pigs - Sustainable business models for insect-fed poultry production

Pasta

66 - Addition of high-amylose wheat - Raspberry powder as a functional ingredient - Rapid detection of common wheat flour addition to durum wheat flour - Spirulina enriched gluten free protein maize (QPM) pastaOptimization of pasta supplemented with tef and chickpea flours - Gluten-free pasta enriched with protein

Bread

72 - Sodium chloride substitution with Salicornia ramosissima powder - Properties and in

vitro digestibility of a bread enriched with lentil flour - Addition of wheat bran - Bran particle size on rheology properties and baking quality of whole wheat flour - X-Ray microtomography of a white bread from plasma functionalized flour - Effect of wheat and barley malt addition - Gluten composition and baking quality of wheat

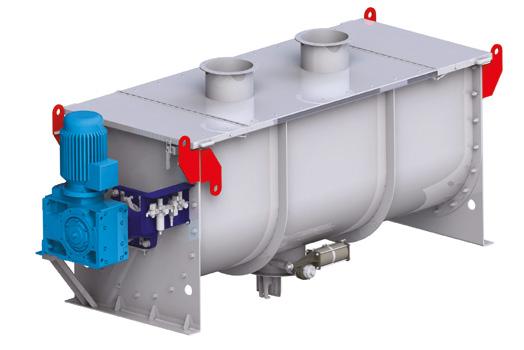

Machinery and equipment

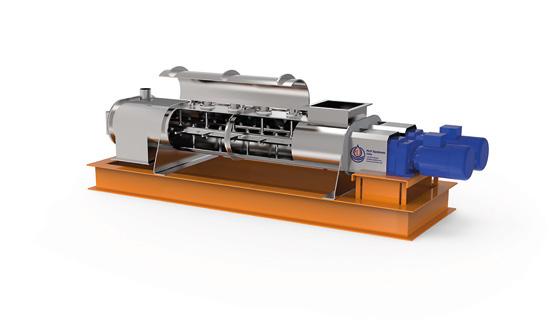

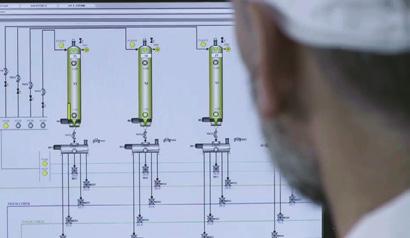

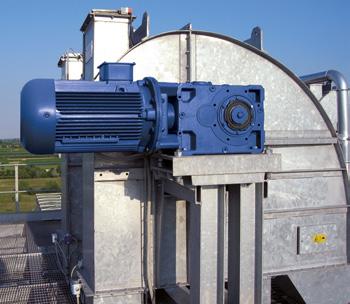

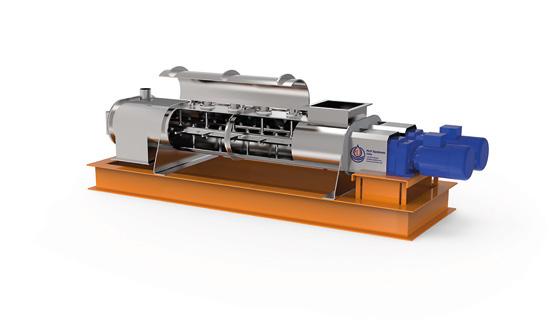

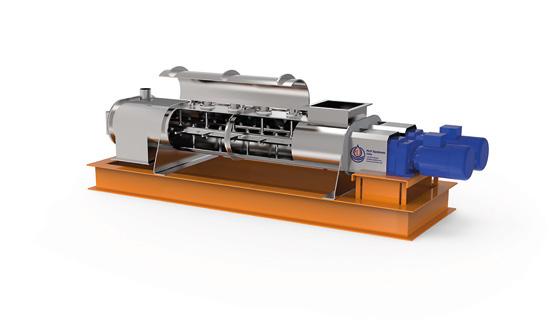

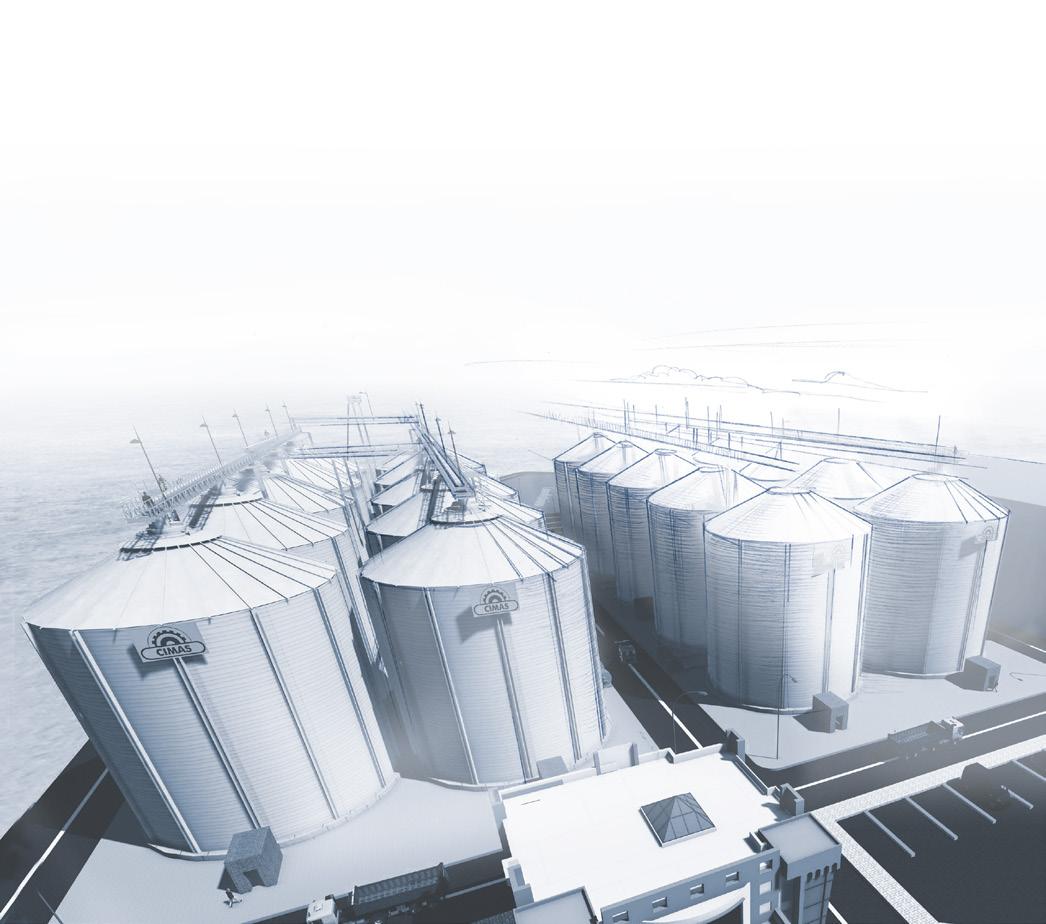

80 - Molitecnica Sud: Italian milling and food culture around the world - Production lines for pasta, couscous and snack pellets - Single Shaft Ribbon Blender - Pasta scraps recovery - New complete plant for storage and rapid bulk return of meat flour - Business between the Rummo pasta factory and Cusinato has been strenghtened - Mobile hopper - New automatic bagging machine - Brushes for milling - Complementary systems for pasta production lines - Avantgarde packaging machines - New goals in Africa for OcrimThe solution for sorting and grading cereals with maximum accuracy - Micro powder dosing systems - Hygienical storage systems and handling systems - Semi-automatic spre sampler - Fava’s research achieves new objectives - Creativity and professionality, the winning combination - Cimas in a strategic continent - Accessories for milling industry

News

111 - The seek for nutrient-dense foods - A new identity - Olocco joins the VDL Groep

Agenda

114 - Retail Plaza by TuttoFood, the format to discuss the future of retail - Trade show Solids gets Italian flair - Host 2023, where innovation gets a sneak preview - In Rome the Symposium on gluten free cereals - Diary of international events in Italy and worldwide events

119 - Supplier directory

128 - Advertisers index - Companies index

SPRING ISSUE 2023

The maize flour market to 2031

According to a research by Allied Market Research, the global maize flour market was valued at $32.7 billion in 2021, and is projected to reach $51 billion by 2031, growing at a CAGR of 4.6% from 2022 to 2031.

Maize flour is derived from the ground and desiccated seeds of maize or corn plant. Vast majority is made of yellow and white maize flour. Maize flour is healthier and tastier as compared to other flours. In addition, it is suitable for patients with high cholesterol as it has been shown to have an anti-atherogenic effect on cholesterol levels, which reduces the risk of various cardiovascular diseases.

The pandemic disrupted the food & beverage industry all across the globe. Consumers’ buying behavior has changed by their perception of the risk associated with Covid-19. To reduce the risk of infection, consumers preferred online services for acquiring daily essentials. As a result, buying foods from restaurants and hotels was discouraged. Global trade restrictions, on the other hand, put strain

on regional economy. The closure of restaurant and food chains further caused setbacks to the market.

In long term, as the situation begins to stabilize, consumers are focusing on appropriate solutions for food items made up of maize flour. Maize flour firms are rethinking their strategy, rationalizing their product lines, and evaluating the robustness of their supply chains and route-to-market networks, going to simplify and optimize e-commerce. Manufacturing companies will be looking to set up their business into an omnichannel to cater to the market demand and increase their sales.

Consumer preference toward food is changing, and preference for nutritionally enriched is increasing as people are now more concerned about their health. The high cost of raw materials may affect the growth of the maize flour industry as the cost of corn, the main raw material used in the production of corn flour, has been steadily increasing in recent years. This has made corn flour less affordable for consumers, resulting in a slowdown

Tecnica Molitoria International Spring issue 2023 ˙ 39

marketing

in market growth. According to the United States Department of Agriculture National Agricultural Statistics Service, the price of corn for June 2022 is 7.37 $/ bushel, which is at an all-time high. The global maize flour market analysis is segmented on the basis of product type (yellow and white), end-user (commercial and household), distribution channel (hypermarkets/supermarkets, convenience stores, online retail...), and region (North America, Europe, Asia-Pacific, and LAMEA). On the basis of product type, the

white maize flour segment dominated the market in 2021 due to its use for various dishes like cornbread and other baked items. As for the market size, the commercial segment has the highest maize flour market share with $18,541.3 million and is expected to dominate throughout the forecast period at a CAGR of 5.0%. For the distribution channel, hypermarkets/supermarkets would be the fastest growing segment over the forecast period, and, of region-wise, North America dominated the global market in 2021.

40 ˙ Spring issue 2023 Tecnica Molitoria International

Feed premix market trend

According to a research by Allied Market Research, the global feed premix market was valued at $5.1 billion in 2021, and it is projected to reach $11.4 billion by 2031, growing at a CAGR of 8.8% from 2022 to 2031.

Premix is a mixture of feed additives or a mixture of one or more feed additives with feed materials or water employed as transporters, not intended for direct feeding to animals. Typically, this premix is added into the compound feed at a rate of 0.2 to 0.5%.

For the growth and development of farm animals, an increase in the demand for and consumption of livestock-based products such dairy and dairy-based products, meat, and eggs is anticipated to boost the use of feed additives. The FAO reports that by 2025, the world’s meat production is expected to increase by 16%. Due to its great demand, low production costs, and low product pricing in both, developed and emerging nations, poultry meat is the main factor driving the expansion of global meat production. According to statistics provided by the FAO, the output of chicken meat reached 120.5 million tons in 2017, compared to 118.7 million tons for swine, 70.8 million kilograms for cattle, and 14.9 million tons for ovine. There is a growing trend for animal-sourced protein in the form of meat, eggs, or milk because of the expanding understanding of the dynamics of food nutrients, particularly protein, on total physical and mental growth and development.

Due to the overuse or improper usage, antibiotic use decreased after the EU im-

posed its prohibition in several nations globally, particularly in China, India, and the U.S. companies were obliged to discontinue using antibiotics in feed premixes because of restrictions on the use of antibiotics as a growth booster in feed in many countries. This poses a significant obstacle for producers of feed premixes based on antibiotics.

In 2017, the combined demand from emerging economies in the Asia-Pacific and Latin America regions represented 47% of global consumption. According to the FAO report, “World Agriculture: Towards 2015/2030”, the population of developing nations in the Asia Pacific region, including India, China, Indonesia, Vietnam, and Thailand, is predicted to consume meat at a rate of 2.4% annually until 2030. To improve the meat weight and quality of the animals, the

marketing Tecnica Molitoria International Spring issue 2023 ˙ 41

demand for premium feed concentrates and premixes have boosted. To fulfill the rising demand for feed premixes, major players to start premix production facilities in these areas. Similar to this, Brazil had the greatest population of cattle in South America in 2017 with a headcount of 330 million, and the FAO anticipates that it will continue to increase faster than the average for the region. A high Feed Premix Market Demand is anticipated due to increased consumer awareness of nutrient-dense foods and the need for meat products of export quality.

The feed premix market is segmented into livestock, type, form, and region. Depending on livestock the market is divided into swine, ruminants, poultry, aquatic animals, and others. On the basis of type, the market is segregated into vitamins, minerals, amino acids, and antibiotics. On the basis of form, the market is bifurcated into organic and conventional. Region-wise, the market is analyzed across North America, Europe, Asia-Pacific, and LAMEA. North America accounted for more than 35% share of the total revenue in 2021, followed by Europe and Asia-Pacific.

Poultry

This segment dominated the global market in 2021: population expansion, urbanization, and rising wages in developing nations have been the main drivers of growing demand. Due to its widespread affordability, low-fat content, and lack of significant religious and cultural barriers, chicken dominates the Feed Premix Industry.

Type

In 2021, the vitamin segment established itself, having to act on vitamin deficiencies. Although just a tiny portion of dietary nutrients, such as vitamins, are necessary for normal physiological processes like growth, development, and reproduction as well as animal welfare and general health status, vitamins are vital micronutrients.

Form

The conventional segment had the major Feed Premix Market Size in 2021 and it is likely to be the fastest-growing segment during the Feed Premix Market Forecast year. Many governments, especially those in North America and Europe, are now concerned about feed safety. Consumers are becoming more knowledgeable and conscious of the external characteristics of the meat they eat. These elements have increased the value of organic feed among consumers globally. For instance, in 2017, Belgian and Dutch authorities discovered eggs contaminated with the insecticide, fipronil; problem with the quality of meat and eggs surfaced in Germany in August 2017; Aldi, a large grocery chain, removed eggs from its shelves after tests revealed the potential for insecticide contamination. In the same year, stores and warehouses in these nations had to recall millions of eggs, and other nations, including Slovakia and South Korea, prohibited the importation of pork from Germany in the same year. These occurrences have increased the need for wholesome, secure feed, including organic feed premix that gives

42 ˙ Spring issue 2023 Tecnica Molitoria International

animals a balanced diet and shields them from such dangerous threats. In addition to preserving the integrity of feed items, organic feed premix provides nutrients that increase livestock output. To protect animals from pesticide contamination, growers in this region are concentrating on manufacturing organic feed, which is expected to fuel the expansion of the global organic feed premix market.

Region

North America led in terms of Feed Premix Market Share in 2021 and is expected to retain its dominance during the forecast period. According to the International Health, Racquet & Sports Club Association (IHRSA), due to the growth of the U.S. health and fitness industry, the consumption of animal protein is likely to increase and is expected to grow at a faster rate during the forecast period. This is attributed to the rising number of U.S. consumers adopting a healthy lifestyle or indulg-

ing in activities that promote an active and healthy lifestyle. Presently, about 20% of U.S. adults have fitness club memberships, and the number is expected to increase in the future, boosting the demand for better feed premix in the process.

The study provides Porter’s five forces analysis to understand the impact of various factors such as competitive intensity of competitors, the bargaining power of suppliers, the threat of substitutes, the threat of new entrants, and the bargaining power of buyers of the Feed premix market.

The players operating in the global feed premix market have adopted various developmental strategies to increase their market share, gain profitability, and remain competitive in the market. Between them, DSM, BASF SE, Cargill, Incorporated, Nutreco N.V., InVivo Group, Jubilant Life Sciences, Koninklijke Coöperatie Agrifirm U.A., Phibro Animal Health Corporation, Archer Daniels Midland Company, Agrofeed, and Novus international.

marketing Tecnica Molitoria International Spring issue 2023 ˙ 43

cereals

Updates on the world cereal market

According to the latest bulletin from the US Department of Agriculture USDA, global production for 2022/23 is forecast higher this month on larger crops in Kazakhstan, Australia, and India. Global trade is forecast up with higher exports,

mainly from Kazakhstan, Australia, and Brazil, more than offsetting smaller exports for Argentina and India. Imports are forecast up mostly on higher demand from Kazakhstan, Saudi Arabia, and Azerbaijan. Global consumption is

44 ˙ Spring issue 2023 Tecnica Molitoria International

raised with more consumption for food, seed, and industrial use in India and more feed and residual use in Kazakhstan.

Stocks are forecast lower, continuing a multi-year decline. The U.S. seasonaverage farm price remains at 9.00 $/ bushel.

Rice

For 2022/23 global rice production is up, due to a larger crop in India. Global consumption is forecast up, also mostly in India. Exports are projected higher, largely from India, and imports are up particularly for China, Nigeria, and Vietnam. U.S. rice exports are forecast at the lowest volume since 1985 due to loss of U.S. market share in key markets, includ-

ing Mexico and several other Western Hemisphere countries.

Global stocks are forecast higher, most notably in India as well as China.

Corn

For 2022/23 global corn production is forecast lower with a substantial cut to Argentina exceeding increases in India, Paraguay, and Turkey. Global trade is forecast lower as lower exports from Argentina and the United States are only partially offset by increased exports from Brazil, India, and Ukraine. Global imports are also forecast lower with cuts across a number of importing countries led by Iran, Malaysia, and Turkey. The U.S. season-average farm price is down 10 cents to 6.60 $/bushel.

FAO forecasts on cereal supplies in 2022/23

According to FAO, the benchmark index of international food commodity prices declined in January for the tenth consecutive month. The FAO Food Price Index averaged 131.2 points in January, 0.8% lower than the previous month and 17.9% below its peak reached in March 2022. The index tracks monthly changes in the international prices of commonly-traded food commodities. The price indices for vegetable oils, dairy and sugar drove the January decline, while those for cereals and meat remained stable.

In January, the FAO Cereal Price Index was unchanged (up a mere 0.1 percent) from December and stood 4.8% above its level of one year earlier. International wheat prices declined by 2.5% as production in Australia and the Russian Federation outpaced expectations. World maize prices rose marginally due to strong demand for exports from Brazil and concerns over dry conditions in Argentina. International rice prices, however, jumped by 6.2% from December, influenced by tighter availabilities, strong local demand in some Asian ex-

Tecnica Molitoria International Spring issue 2023 ˙ 45

cereals

porting countries and exchange rate movements.

The FAO Vegetable Oil Price Index declined by 2.9% in January. World prices of palm and soy oils dropped amid subdued global import demand, while those of sunflowerseed and rapeseed oils declined due to ample export availabilities.

The FAO Dairy Price Index averaged 1.4% lower than in December, with prices trending down for butter and milk powders on lighter demand from leading importers and increased supplies from New Zealand. World cheese prices rose, driven by a recovery in food services and retail sales in Western Europe following

the New Year holiday, as well as currency movements. The FAO Meat Price Index moved in January (edging down just 0.1% from December), as ample export availabilities weighed on poultry, pig and bovine meat prices, while ovine export prices rose due to stronger import demand. The FAO Sugar Price Index dropped by 1.1% from December. Strong harvest progress in Thailand and favourable weather conditions in Brazil outweighed the impact on prices due to concerns over lower crop yields in India, higher gasoline prices in Brazil, which support demand for ethanol, as well as the Brazilian real’s appreciation against the United States dollar.

46 ˙ Spring issue 2023 Tecnica Molitoria International

New purple and red rice varieties

USDA’s Agricultural Research Service (ARS) releases newly-developed purple and red varieties of rice. In addition to being beautiful, the novel grains pack a nutritional punch, and offer farmers a distinct new opportunity. The latest addition is a purple variety, named USDA-Tiara. Anna McClung, research geneticist at the Dale Bumpers National Rice Research Center in Stuttgart, AR, developed the pigmented purple and red varieties to enable American farmers to enter an important market: “This is an opportunity for our domestic growers to have access to that market, which has greater economic potential than white milled rice”. With conventional rice, the bran, which contains most of the nutrients, is removed during the milling process. When the bran is removed, only the starch is left. In the pigmented bran varieties, McClung and her team found that, in addition to the basic nutrients that brown bran possesses (vitamin E, fiber, and other vitamins), there is additional nutritional value in the pigmented bran. The pigments purple and red are like those that you find in grapes and berries and dif-

ferent fruits and vegetables, and some of those compounds — tannins, flavonoids, and phenolics — have been shown to have antioxidant properties, which have a potential health-beneficial effect.

Originally from China, the purple rice made its way to Brazil via a scientist who recognized its potential, improved it through breeding, and ultimately brought it to McClung’s attention. Over the last 15 years, she has worked to breed an improved version of that strain from Brazil. It has since been released in the U.S. and commercialized; it is the parent of the new Tiara strain.

The Scarlett rice is the first red rice ever bred for commercial production in the United States, and, in the past, it was regarded as a weed. The geneticist has discovered that the weedy species had yield-enhancing genes and she identified several farmers willing to try growing the new varieties. Relative to conventional varieties, it was found that the flavor and aroma expression is more relevant.

Tecnica Molitoria International Spring issue 2023 ˙ 47 cereals

New purple (left) and red (right) rice varieties developed by ARS.

Life sciences technicians Luis Coral (left) and Laduska Sells (right) shell USDA-Tiara purple rice.

To enhance wheat yield

Scientists from the Chinese Academy of Sciences and Peking University reported that gene editing of an APETALA2/ethylene responsive factor (AP2/ERF) transcription factor, DUO1, could lead to better wheat grain yield.

Wheat is one of the most important food crops worldwide. To help improve food production, it is vital to pinpoint new locations in the wheat genome that can help improve its yield. Thus, the researchers analyzed the key genes involved in spikelet number. They investigated Brachypodium distachyon spikelet mutant bdduo1, which has an increased number of spikelets per spike. They further clari-

fied the role of BdDUO1 in the regulation of spike shape in Brachypodium distachyon through a series of tests. Then, using CRISPR-Cas9, they edited the gene and came up with wheat plants exhibiting multiple spikelets in the lower middle part of the spikes. Furthermore, live imaging showed that there were more and larger cells in the basal spikelet primordia of the gene-edited wheat compared to the wild type which may imply that the gene is involved in regulating cell division. Field tests showed that the gene-edited wheat plants developed more grains per spike than the wild type, indicating an increase in yield per unit area.

48 ˙ Spring issue 2023 Tecnica Molitoria International

Europe’s first GE wheat trial produces less acrylamide

The results of Europe’s first ever field trial of a gene edited (GE) variety of wheat have shown a reduction of the potential carcinogen acrylamide when the flour is baked.

A study appeared on Plant Biotechnology Journal in which researchers at Rothamsted Research in the UK used a geneediting technology called CRISPR to “knock out” a gene in the wheat which they hoped would lower formation of asparagine. When cooked, this amino acid is converted to acrylamide – a potential carcinogen that food processors are keen to control.

Levels of asparagine (acrylamide’s precursor) in the GE wheat were up to 50% lower than the control variety Cadenza. Once ground into flour and cooked, the amounts of acrylamide formed were also reduced by up to 45%.

The field trail was an important step in determining whether the new GE wheat would be viable. Indoor trials under glass had proved successful, but only by planting out in experimental fields could the research team be sure that the new strain could deliver for farmers.

Prof. Nigel Halford, who led the research, says: “The study showed that gene editing to reduce asparagine concentration in the wheat grain works just as well in the field as under glass. This is important because the availability of low acrylamide wheat could enable food businesses to comply with evolving regulations on the presence of acryla -

mide in food without costly changes to production lines or reductions in product quality. It could also have a significant impact on dietary acrylamide intake for consumers”.

Regulatory framework could put brakes on GE in Europe

While Halford was bullish on the potential impact gene editing could have in helping the food sector develop health-

ier products, he warned that an uncertain regulatory environment could limit the development of the technology: “GE plants will only be developed for commercial use if the right regulatory framework is in place and breeders are confident that they will get a return on their investment in GE varieties”.

The results of the trial are timely as the Genetic Technology (Precision Breeding)

Tecnica Molitoria International Spring issue 2023 ˙ 49 cereals

Bill, which will make provision for the release and marketing of GE crops, is in the final stages of its passage through the UK Parliament. Some scientists suggest CRISPR represents an exciting development for the food industry that will become increasingly important to keep up with the changing environment, but regulation has limited the use of the technology in agriculture.

Both gene editing and genetic modification are banned by the EU, although Brussels is reviewing its stance on CRISPR crops.

CRISPR can be used as an advanced plant-breeding tool that facilitates crop breeding by making cuts at specific locations in a plant genome. Subsequent repair of the cut by the cell’s endogenous repair mechanism can introduce precise

changes. Unlike GMOs, no new genetic material is added.

The UK Department for Environment, Food and Rural Affairs believes gene editing techniques, such as CRISPR, have the potential to produce abundant, healthy food and to reduce the environmental impact of a growing global population. It further believes gene editing techniques, when used to breed crops that could have been developed using traditional methods, should not be regulated as GM crops. It complains that despite the differences between genome editing with CRISPR and GM, genome edited plants are currently treated in the same way as GM under EU regulations, essentially blocking the use of a technology that is gaining official approval in many other parts of the world.

Strengthening sorghum against a fungal threat

A gene discovered by a team of Agricultural Research Service (ARS) and Purdue University scientists could help fortify the defenses of sorghum to anthracnose, a disease of the cereal grain crop that can inflict yield losses of up to 50%. The study opens the door to breeding disease-resistant sorghum cultivars that are less reliant on fungicides to protect them, reducing growers’ production costs and safeguarding grain yields and quality, among other benefits.

Sorghum is the fifth-most widely grown cereal grain crop worldwide, providing consumers not only with a source of food

containing 12 essential nutrients, but also forage for livestock and material for bio-based energy. However, unchecked with fungicides or other measures, anthracnose will attack all parts of a susceptible cultivar, often forming reddish lesions on leaves and the stem as well as causing damage to the plant’s panicles and grain heads.

Genetic-based disease resistance is the most effective and sustainable approach to combating anthracnose in sorghum. However, how this resistance works in the plant is poorly understood, according to Matthew Helm, a research

50 ˙ Spring issue 2023 Tecnica Molitoria International

molecular biologist at ARS’s Crop Production and Pest Control Research Unit in West Lafayette, Indiana. That knowledge gap is worrisome because of the genetic variability among different races (or types) of the anthracnose fungus and their potential to overcome a cultivar’s resistance genes over time. Additionally, anthracnose resistance can be temperature-dependent, leaving a sorghum crop vulnerable to infection if temperatures soar above a certain threshold.

A team of Purdue University scientists have begun to close this gap. They identified a disease-resistance gene that orchestrates a series of defense responses to early infection by the anthracnose fungus, preventing its spread to the rest of the plant and grain heads.

Additionally, sorghum plants carrying the resistance gene, known as “ANTHRAC-

NOSE RESISTANCE GENE 2” (ARG2), successfully withstood the fungus even when greenhouse temperatures were increased to 38°C. This temperature stability could be a boon for sorghum production regions of the world where growing season temperatures can reach those levels.

The team also determined that ARG2 helps make (“encodes for”) a protein that is concentrated in the plasma membrane of resistant sorghum cells. There, it acts as a kind of intruder alert that’s triggered by certain proteins used by the anthracnose fungus to infect the plant. ARG2 and its protein don’t protect sorghum from all races of anthracnose. However, combining ARG2 with other similar genes could help broaden that protection—either through conventional plant breeding methods or biotechnological ones.

Tecnica Molitoria International Spring issue 2023 ˙ 51

cereals

Grain silage rehydrated with water or acid whey

A Brazilian study appeared on Semina: Ciencias Agrarias, aimed to evaluate the effects of rehydration with water or acid whey, as well as the effects of bacterial-enzymatic inoculant on fermentation losses, aerobic stability, and chemical composition and in vitro digestibility of corn grain silages.

The treatments consisted of corn kernels (Zea mays) ground through a 3-mm sieve and rehydrated with chlorine-free water or unsalted whey (NaCl) combined or not with bacterial-enzymatic inoculant. This was a 2x2 factorial randomized design with sources of rehydration (water or whey) and absence and presence of bacterial-enzymatic inoculant with eight replications. Water and acid whey were added to ground corn with 12% mois-

ture in order to increase it to 35%. Rehydrated corn was ensiled in Polyvinyl chloride (PVC) minisilos and stored for 60 d. The bacterial-enzymatic inoculant used was composed of Lactobacillus curvatus, L . acidophilus, L . plantarum, L . buchneri, L . lactis, Pediococcus acidilactici, Propionibacterium acidipropionici and Enterococcus faecium, in concentrations of 1,010 CFU g-1 and 5% cellulose-based enzyme complex. The aerobic exposure of silages was evaluated for 120 hours. There was interaction (P=0.02) between the sources of rehydration and the use or not of the inoculant on the values of silage temperature during aerobic exposure. There was a difference for dry matter (DM) losses (P=0.38) between rehydrated corn silages with and without inoculant. DM losses were 37.51% higher in silage without inoculant compared to silage with inoculant (3.84% DM). There was no difference between the sources of rehydration on DM losses (P=0.39), with a mean value of 4.99%. Corn rehydration using acid whey (P<0.01) increased 2.19 and 31.36% DM and ash content compared to water, an average of 66.14 and 1.28%. There was no interaction (P=0.30) between the sources of rehydration and the use of inoculants on the in vitro digestibility of DM (mean of 79.26%). The use of the bacterial-enzymatic inoculant improved the fermentation characteristics, aerobic stability and nutritional value of corn grain silage rehydrated with water or whey.

52 ˙ Spring issue 2023 Tecnica Molitoria International

We reciprocate everything... ...especially your confidence.

SAVIGLIANO (CN) • WWW.AGRINOVA.IT • INFO@AGRINOVA.IT • TEL. 0039 0172 71 54 88

ARTICLES & SPARE PARTS FOR MILLS, AGRICULTURE & INDUSTRIES

OFFICIAL DEALER

Preharvest and flour quality

Preharvest sprouting (PHSing) of wheat induces more heterogeneous germination in the field than in a controlled laboratory setting.

In a Korean research published on Cereal Chemistry, the impacts of field-weathering (FWing) /PHSing in soft wheats on resulting flour quality and baking performance, for soft wheat-based baked products, were explored for twelve soft wheat cultivars. FWing/PHSing in soft wheats affected test weight, break flour yield, falling number, alpha-amylase activity, and solvent retention capacity. Starch-pasting profiles for flour samples with different wheat harvest

times appeared to show four groups of behavior. However, the impacts of FWing/ PHSing in the wheats studied were negligible on the resulting baking performance of pancakes, cookies, and crackers, but were dramatic for Japanese-type sponge cake. Effects of FWing/PHSing in soft wheats on resulting wheat and flour quality, milling performance, and baking performance were confirmed.

The set of tested flours in the study, milled from field-weathered (FWed) /PH sprouted (Sed) soft wheat grains, exhibited four groups of behavior in starch-pasting profiles, which varied with wheat genotype.

54 ˙ Spring issue 2023 Tecnica Molitoria International

milling

Variability of carbohydrate composition and pasting properties of oat

A Finnish study appeared on Food Chemistry characterised the starch and dietary fibre properties and their significance to the pasting characteristics of oat flakes and flours produced from 30 Finnish pure cultivar oats with or without the industrial scale milling process. Variation in carbohydrate characteristics was observed, the insoluble dietary fibre content of flours was 2.45.7 % and soluble dietary fibre was 4.98.0 %. The oat milling process induced a significant amount of starch dam -

age (p<0.05), a fourfold increase from 1 to 4% in average was observed. The pasting properties of both flakes and flours were interlinked (p<0.05) with the chemical composition of oats, i.e., high starch content of flours was connected to higher paste viscosity values. The milling process increased the peak, trough, setback, final and time to peak viscosities of oat flours.

The results show the significance of oat milling process, including kilning, to the carbohydrate quality of oats.

Tecnica Molitoria International Spring issue 2023 ˙ 55 milling

Increases iron and zinc concentrations in wheat flour

Dietary deficiencies of iron and zinc cause human malnutrition that can be mitigated by biofortified staple crops. Conventional breeding approaches to increase grain mineral concentrations in wheat (Triticum aestivum L.) have had only limited success, and the understanding of the genetic and physiological barriers to altering this trait is incomplete. In England, a study appeared on Plant Physiology was conducted, which demonstrated that a transgenic approach combining endosperm-specific expression of the wheat vacuolar iron transporter gene TaVIT2-D with constitutive expression of the rice (Oryza sativa) nicotianamine synthase gene OsNAS2 increases the total concentration of zinc and relocates iron to white-flour fractions. In two distinct bread wheat cultivars, we show that the so called VIT-NAS construct led to a twofold increase in zinc in wholemeal flour, to

~50μg g-1. Total iron was not increased, but redistribution within the grain resulted in a three-fold increase in iron in highly pure, roller-milled white flour, to ~25 μg g-1. Interestingly, expression of OsNAS2 partially restored iron translocation to the aleurone, which is iron depleted in grain overexpressing TaVIT2 alone. A greater than three-fold increase in the level of the natural plant metal chelator nicotianamine in the grain of VIT-NAS lines corresponded with improved iron and zinc bioaccessibility in white flour. The growth of VIT-NAS plants in the greenhouse was indistinguishable from untransformed controls. The results provide insights into mineral translocation and distribution in wheat grain and demonstrate that the individual and combined effects of the two transgenes can enhance the nutritional quality of wheat beyond what is possible by conventional breeding.

56 ˙ Spring issue 2023 Tecnica Molitoria International

Hydrothermal treatment parameters on oat grinding

In a Finnish research on LWT - Food Science and Technology, the role of hydrothermal treatment (steaming and tempering) parameters on oat groat, flake, and flour properties was studied by us-

Three untreated oat groat cultivar samples with varying native groat hardness were studied. Among the studied factors, tempering temperature influenced both groat hardness and flour particle size in all samples. High temperature led to fragile groats and fine flours, while low temperature resulted in hard groats and coarse flours. The treatment parameters affected groat and flour properties in a similar way, but sample-specific

ing experimental design and response surface modelling approach. The modelled properties were oat groat hardness, oat flake hardness, and oat flour particle size milled from oat groats and oat flakes. In the design of experiments, the studied factors were moisture content, temperature, and duration of the hydrothermal treatment using the central composite face-centred design (CCF).

Tecnica Molitoria International Spring issue 2023 ˙ 57

milling

Via Tessara 9/11 35010 Curtarolo (PD) Italy Tel +39 049 557094 - cell. +39 3287753783 info@rambaldoantonio.com www.rambaldoantonio.com

RAMBALDO ANTONIO 2022.indd 15 22/09/22 16:38

NEW ALUMINIUM, POLYPROPYLENE OR STEEL FRAMES FOR ANY MODEL OF PLANSIFTER

differences remained in groat hardness and flour particle size after identical treatments. In the sample with the softest native groats, also the moisture content influenced groat hardness and flour particle size.

The results suggest that with a proper selection of the native groats and by adjusting the hydrothermal treatment parameters, the milling properties of oat could be optimised for specific uses.

Comparative study of separate and mixed fine grinding methods

In a Chinese study published on Food Science and Technology, the wheat millfeeds (bran, shorts, and germ) were ground separately and mixed with an ultrafine pulverizer, and the fine powders of 80, 100, 120, 160, and 200 mesh were obtained through the measurement and

adjustment of the laser particle size analyzer. The pulverizing ability of the two methods were compared, and the fine powders obtained by the two methods were added back to the wheat flour according to the original wheat milling proportion. The quality characteristics of recombined whole wheat flour obtained by two grinding methods were compared. The results showed that the shorts were easier ground than the bran and germ, and the temperature rise and energy consumption were lower. The moisture content decreased with the reduction of the ground particle size, the whiteness was increased, and the damaged starch content was increased. The water absorption of the obtained whole wheat flour was increasing, and the development time, stability time, quality index, and various extensigraph properties were decreasing. When the grinding particle size was 100 mesh, the whole wheat flour obtained by the separate grinding method had a longer stability time, higher quality index, and stronger extensigraph properties, which could be used to make whole wheat products better.

58 ˙ Spring issue 2023 Tecnica Molitoria International

QUALITY SYSTEMS FOR FLOUR AND GRANULAR PRODUCTS PROCESSING

• STORAGE SILOS

• EXTRACTORS FOR SILOS AND DISTRIBUTORS

• DOSING, MICRODOSING AND MIXING MACHINES

• GRINDING AND PRE-GRINDING MACHINES

• DUST ASPIRATION SYSTEMS WITH AUTOMATIC FILTERS

• CRUSHING MACHINES FOR SCRAPS

• SIEVING, SELECTION AND DISINFESTING MACHINES

• PNEUMATIC CONVEYING SYSTEMS IN PRESSURE OR VACUUM

• MECHANICAL CONVEYING SYSTEMS BY SCREW, CHAIN, BELT CONVEYORS AND BUCKET ELEVATORS

Since 1948 we have been designing, manufacturing and installing customized, high quality systems and machines for pasta, feed, milling and chemical industries.

INNOVATIVE CONVEYING AND STORAGE TECHNOLOGIES CMB srl - Via Monte Pelmo, 8 - 35018 San Martino di Lupari (PD) IT Ph. +39 0424 780 176 - info@cmbsrl.it - www.cmbsrl.it cusinato.com

feedstuff

Polyphenols, isoflavonoids, and their metabolites in milk samples

In a work made by the Department of Animal Science, Food and Nutrition of the Università Cattolica del Sacro Cuore of Piacenza, Italy, published on Dairy, milk samples collected in a cohort of intensive dairy farms of the Po Valley (Italy) were screened for their (poly)-phenolic profile to check the occurrence of phenolic metabolites of biological interest. The selected dairy farms were classified on the basis of their cow feeding system, considering the utilization of corn silage as

the main ingredient of the rations. Overall, high-pressure liquid chromatography coupled with mass spectrometry using an Orbitrap analyzer, followed by unsupervised and supervised statistics, allowed identifying clear different phenolic distributions in the milk samples. Accordingly, a great variability in the phenolic profiles of the different milk samples was observed, with two main phenolic clusters outlined by the unsupervised hierarchical clustering approach and not fully correlated to the nutritional strategy considered. The variables’ importance in the projection approach allowed selecting the most important metabolites, resulting in samples’ discrimination. Among the most discriminative compounds, they had been found phenolic metabolites (such as hippuric acid and 4-hydroxyhippuric acid), followed by lignans (such as enterolactone) and isoflavonoids (such as equol and O-desmethylangolensin). The results suggested that both the feeding systems and the ability of dairy cows to process parent phenolic compounds were the main factors providing the final (poly)-phenolic profile of the milk samples.

60 ˙ Spring issue 2023 Tecnica Molitoria International

Exhausted bergamot by-product for pigs

A study by the Dipartimento di Agricoltura, Alimentazione e Ambiente (Di3A)-Università di Catania appeared on Animals, in which an investigation was carried out on the effect in pig diet of supplementation with exhausted bergamot by-product, stemming from pharmaceutical industry after extraction of phenolic compounds, on growth performance and on the quality of meat and meat products. Twenty pigs were assigned to two dietary treatments and fed a conventional concentrate (control) or a concentrate including exhausted bergamot by-product at the level of 15% on a DM basis (EB). No differences between dietary treatments were found for

final weight (p=0.243), carcass weight (p=0.679), dry matter intake (p=0.321). In EB pork, the proportion of docosapentaenoic acid was increased (p<0.05); it tended to have a greater proportion of n-3 PUFA (p = 0.09), and the n-6/n-3 PUFA ratio was lower in EB treatment (p=0.01). In salami from EB pigs fed, the proportion of alpha-linolenic acid and the total n-3 PUFA were higher than in the control group (p<0.001). In salami, the TBARS value was lower after 5 days of storage (p<0.001) in the EB group. The results suggest that the inclusion of exhausted bergamot by-product in pig diet offers a qualitative improvement of meat and meat products.

Tecnica Molitoria International Spring issue 2023 ˙ 61 feedstuff

Protein sources for cattle diet

Replacing imported soybean meal (SBM) by protein sources such as grain legumes, food industry by-products or novel resource-efficient feeds is a current research focus to enhance the sustainability of ruminant production systems. In addition, grass silage replacing maize silage can contribute to dietary crude protein (CP) supply as well and complies with the natural diet of ruminants.

Animal Feed Science and Technology published an experiment with 30 Limousinsired beef bulls, performed with diets in which SBM was replaced by alternative protein sources when feeding a diet composed of, per kg dry matter (DM), 500 g grass silage, 300 g maize silage and 200 g concentrate. In the concentrate, SBM (control diet) was replaced by faba beans, pumpkin seed cake, or spirulina ( Arthrospira platensis) to result on average in 226 g CP/kg concentrate dry matter (DM). A fifth group served as negative control, which received a grain-based

concentrate with only 135 g CP/kg DM. Bulls were fed the experimental diets for the entire fattening period starting from an initial body weight (BW) of 164±2.3 kg and 4.3±0.06 months of age. At an average body weight (BW) of 275±5.6 kg and 7.4±0.17 months of age, each animal underwent a 9-day sampling period to determine individual N and energy intake and excretion (7 days of urine and faeces collection) as well as methane emission (2 days in respiration chambers). The diet had no effect on DM and nutrient intake. Apparent fibre digestibility was affected by diet, being numerically lowest with faba beans instead of SBM. Compared to the other groups, the bulls fed no additional protein had the lowest urinary N excretion (25.1 vs. 40.3g/bull/day; 366 vs. 460g/kg total faecal and urinary N). Digestive and metabolic energy utilisation were comparable among diets. Methane (CH4) production adjusted to body weight differed among groups, being numerically highest in bulls fed faba beans (547 vs. 513mg CH 4/kg BW/day in the other diets).

The results show that none of the tested protein sources, including SBM, was of benefit when feeding a diet containing 500g/kg DM grass silage complemented with maize silage and concentrate. Feeding such a diet seems to provide an adequate supply with metabolisable protein. Omitting the common protein supplementation therefore mitigated urinary N losses and thus likely N emissions from the manure at unchanged N and energy utilisation.

62 ˙ Spring issue 2023 Tecnica Molitoria International

Energy reduced diets for broiler

Protein sources obtained from co-products might provide an alternative to soybean meal (SBM), counteracting the dependency on other countries and increasing the sustainability. In an Austrian research that appeared on Journal of Applied Poultry Research, in an energy reduced broiler diet (-0.72 MJ AMEN), a mixture of DDGS, sunflower meal and rapeseed meal was applied as alternative fiber rich protein source (APS) to replace 100% of SBM. Furthermore, the diets were supplemented with 0.04% of a lignan-rich phytogenic component derived from bark to improve the performance. The experimental diets were fed to 3,600 broilers (Ross 308, mixed sex) from day 11 to 36 posthatch (grower and finisher phase). Overall, the broilers responded to APS diets with a increased daily feed intake and decreased body weight (P<0.05), which resulted in an impaired F: G ratio (P<00.05).

The apparent total tract digestibility of dry matter, organic matter, and gross energy with APS diets decreased. The replacement of SBM by APS resulted in higher gizzard weights (P<0.05), proventriculus weights (P<0.05) together with a decreased gizzard pH (P<0.05) and improved foot pad dermatitis score of broiler chickens (P<0.05). The results suggest that the replacement of soybean meal with alternative protein sources in energy reduced diets destined for broilers negatively affects performance and digestibility, however, improves food pad health and upper intestinal tract characteristics. The supplementation with a phytogenic component, decreased feed intake in finisher phase, however improved F: G ratio and increased the breast weight (P<0.05). Furthermore, it indicated a positive statistical interaction with APS diets regarding certain digestibility values (P<0.05).

Tecnica Molitoria International Spring issue 2023 ˙ 63 feedstuff

Feed supplementation with silage in pigs

In organic pig husbandry, the use of roughage is mandatory as dietary supplement.

In a study appeared on Annals of Animal Science, Spanish researchers studied the effects of oat silage on the fatty acid composition, in entire males and gilts, as well as indole and skatole levels in perirenal adipose tissue of entire males. Entire males and gilts (forty-five to forty-eight pigs/sex) were assigned to two dietary roughage feeds (control with straw vs. oat silage). There was no effect of silage or sex on total SFA and MUFA in pork fat. However, the oat silage increased the total PUFA n-3 and decreased the PUFA n-6/n-3 ratio.

The content of boar taint compounds (skatole and indole) in the entire male pigs did not differ between diets, although human nose scoring rejected in a greater extent more pork fat from entire males supplemented with oat silage, compared with those only supplied with straw. Approximately 50% of the entire males (90 to 97 kg of carcass) had low skatole values (<=0.1 mµg/g), that were below the range of boar taint detection, regardless of the feeding regime.

These results indicate that more studies should be performed to avoid the problem of taint detection in entire males under organic production.

64 ˙ Spring issue 2023 Tecnica Molitoria International

Sustainable business models for insect-fed poultry production

During the last decade the potential of insects for human nutritional protein is increasingly recognised. Direct consumption of insects contributes to a reduction of the ecological footprint of human food production and is claimed

sociated with insect-derived protein for feeding poultry.

A Dutch research published on Journal of Insects as Food and Feed explores the insect-fed poultry production value chain through an interdisciplinary approach.

to have health benefits. An alternative is feeding poultry (broilers and layers) with insect-derived protein. This offers several additional advantages, e.g. a more extensive use of (new sources) of organic by-products of food industry for insect production. Implementation of a People-Planet-Profit (PPP) sustainable way of utilising these opportunities requires the development of sustainable business models. Such business models need to be based on the opportunities of insect-derived protein in feeding poultry but should also include the risks as-

First, the essential features of this value chain are described. Then, an inventory and classification is made of the main opportunities and risks of this value chain. Finally, the opportunity-risk trade-offs are discussed, as well as their implications for developing sustainable business models. For PPP-sustainable business models, management of the asymmetric tradeoffs between opportunities and risks related to possible contamination of organic by-products used as substrate for insect production should receive prime attention.

Tecnica Molitoria International Spring issue 2023 ˙ 65 feedstuff

pasta

Addition of high-amylose wheat

In a study by the Università Campus Bio-Medico of Rome, Italy, which appeared on International Journal of Food Science & Technology , pasta samples were produced by replacing durum wheat semolina with high-amylose bread wheat semolina-type flour in

proportions of 30%, 50% and 70%. Resistant starch content in uncooked pasta samples varied from 4.9% of total starch in high-amylose pasta with 30% substitution of semolina, to 15.3% of total starch in 100% high-amylose semolina pasta, achieving the lev -

66 ˙ Spring issue 2023 Tecnica Molitoria International

els established for the health claim. The high amount of resistant starch in cooked pasta caused a reduction of starch digestion rate in all samples with high-amylose flour substitution compared to control. The expected glycaemic index lowered from 53.8 in control pasta (durum wheat semo -

lina) to 48 in 100% high-amylose pasta (bread wheat semolina). The inclusion of high-amylose flour in proportion of 70% combined the best cooking and nutritional properties, but it is expectable a further improvement in pasta quality with the adoption of tailored processing protocols.

Raspberry powder as a functional ingredient

Raspberry powder consists mainly of raspberry peels and seeds, rich in polyphenols and fibres. The recovery of this waste by drying and fine grinding gives a powder suitable for many applications.

A study by the Dipartimento per la Innovazione nei Sistemi Biologici, Agroalimentari e Forestali-Università della Tuscia, published on International Journal of Food Science & Technology, is aimed to assess the technical quality, functional properties, and consumer acceptability of five pasta samples produced by replacing durum wheat semolina ( Triticum durum) with 3.70, 5.61, 7.69, 9.88, and 12.00% raspberry powder. The control sample was 100% hard semolina pasta.

The cooked pasta (RP) with 7.69% raspberry powder replacement showed higher acceptability values, a slight decrease in hardness, compactness, and time of optimal cooking (OCT) than the control semolina pasta (CP). Furthermore, the “half of the maximum

inhibitory concentration” (IC50), evaluated through the 2,2-diphenyl-1-picrylhydrazyl (DPPH) and 2,2’-Azino-bis (3-ethylbenzothiazoline-6-sulphonic) acid (ABTS) tests, showed an increase of about twice the antioxidant activity compared to the semolina paste, both before and after cooking.

Tecnica Molitoria International Spring issue 2023 ˙ 67 pasta

Rapid detection of

common wheat flour addition to durum wheat flour

Attenuated total reflectance Fouriertransform infrared spectroscopy (ATRFTIRS), near-infrared spectroscopy (NIRS), and synchronous fluorescence spectroscopy (SFS) combined with chemometrics, were used in a Turkish study,

of determination (R 2) values of the prediction curves for ATR-FTIRS were found as 0.900 and 0.903 for flour and pasta samples. Similarly, R 2 for the prediction of NIRS was 0.867 and 0.895 for flour and pasta samples. Since, NIR spectros-

published on Journal of Cereal Science, to determine common wheat (Triticum aestivum) flour in durum wheat (Triticum durum) flour and common wheat farina addition to durum wheat pasta. The main objective was to determine the most suitable spectroscopic methods to predict adulteration level in flour and pasta. It was found that among the spectroscopic methods tested, ATR-FTIRS had the lowest limit of detection (LOD) values for blended flour (0.68%) and pasta samples (0.49%). The coefficients

copy is used in food industry for quality control, it might have a good potential to detect the adulteration of common wheat flour in durum wheat flour and farina in the durum wheat pasta. SFS demonstrated a weaker predictive ability for low levels of adulteration with its higher root mean square error of prediction (10.750).

The study demonstrated that ATR-FTIRS had better specificity and accuracy compared to other spectroscopic methods for the detection of adulteration.

68 ˙ Spring issue 2023 Tecnica Molitoria International

Spirulina enriched gluten free protein maize (QPM) pasta

The gluten-free Quality Protein Maize (QPM) and pasta made from such grains would have far-reaching implications for achieving nutritional stability. The aim of an Indian study appeared on Emirates Journal of Food and Agriculture was to check whether QPM combined with legume flours could be used to make gluten-free pasta (pasta without gluten protein). Furthermore, the effect of adding legume flours and spirulina to QPM pasta (2, 4, 6, 8 and 10%) on color, appearance, cooking, physical, nutritional and sensory quality was examined. The best-accepted combination of QPM (QPM flour 60%, black gram flour 30%, defatted soy flour 8%, and guar gum 2%-Q) and QPM pasta enriched

with spirulina (QPM flour 60%, black gram flour 30%, Spirulina 6%, defatted soy flour 2% and guar gum 2%-S) were compared to the control (100% whole wheat flour-C). The functional and cooking parameters such as bulk density (0.54 kg/m3), swelling index (1.3 g/g), and cooked weight (11.0 g) of the spirulina pasta were higher with a cooking loss of 7.6%. The nutrients such as protein (21.6%), calcium (44 mg%), iron (8.6 mg%), lysine (3.1 g/100 g protein), and tryptophan (0.81 g/100 g protein) were reported in the dietary composition of QPM pasta enriched with 6% spirulina (S). Further addition of spirulina resulted in 16-fold increase in the carotenoid content.

Tecnica Molitoria International Spring issue 2023 ˙ 69 pasta

Optimization of pasta supplemented with tef and chickpea flours

Durum wheat semolina is the preferable ingredient for pasta products, but it has low protein quality, micronutrient and fiber composition.

In a study conducted in Ethiopia and published on International Journal of Food Properties, response surface methodology was applied to optimally formulate a pasta by supplementing durum wheat semolina with tef (0 to 40%) and chickpea (0 to 15%) flours. The aim was improving the nutritional quality of the product while maintaining the cooking quality. Supplementing the durum wheat semolina (S) with tef (T) and chickpea (C) flours improved the Water Absorption Capacity and Index (WAC and WAI) (p<.05). Among the 11 flour blending ratios of S:T:C, ([60: 40: 0%], [85: 0: 15%], [60: 25: 15%], and [68: 28: 4%]) improved the WAC and WAI

of the semolina flour by 36, 8, 25, 7, 32, 9, and 31, 3%. With the same blending ratios, the cooking weight and the WAC of the control macaroni increased by 15, 15, 10, 19, 17, 18, and 22, 23% (p<.05). Interestingly, these blending ratios reduced the wet gluten content of the semolina by 58, 28, 53, and 42% (p<.05). With higher tef and chickpea incorporation, the pasta had lower and higher firmness. The macaroni prepared with incorporation of chickpea 3.5-15% appeared to have better color and comparable overall acceptability score with control.

The optimum formulation of pasta for desirable sensorial and cooking quality (better firmness, lower stickiness and cooking loss) was 73.46 g/100 g semolina, 11.55 g/100 g tef flour, and 14.25 g/100 g chickpea flour.

70 ˙ Spring issue 2023 Tecnica Molitoria International

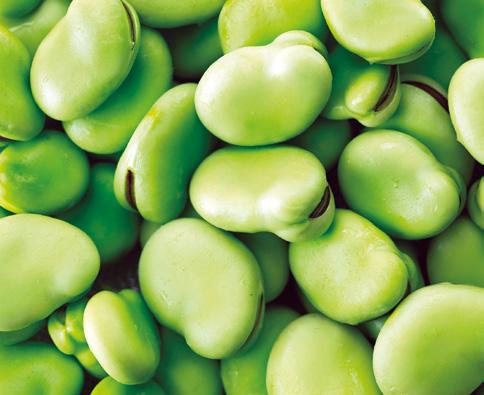

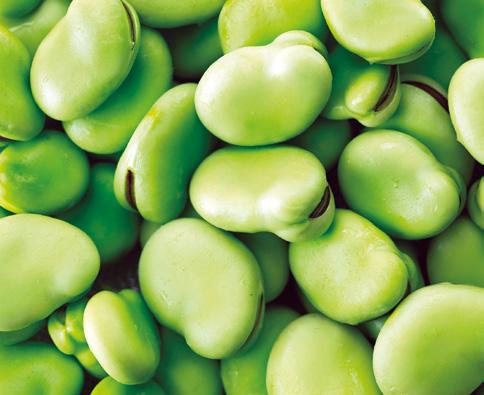

Gluten-free pasta enriched with protein

The objective of an American work appeared on Journal of Culinary Science & Technology was to optimize the formulation of a protein enriched gluten-free pasta. A mixture design of experiments (MDOE), using isolated protein from pea (PPI) and fava (FPI) as the protein sources, was used to optimize the pasta formulation. Formulations were tested for extrusion feasibility, optimal cooking time, cooking loss, swelling index, color, and hardness. Two optimized protein ratios, 30:70 and 43:57 PPI:FPI, resulted from the MDOE analysis. The optimized formulations were compared to semolina pasta for the same properties. Hedonic sensory evaluation of the optimized formulations, semolina, and whole wheat pastas was conducted: glutenous pastas showed higher liking scores. The results shows that, by using PPI, FPI and MDOE, it is feasible to formu-

late protein enriched gluten-free pasta, while further optimization is needed to fully mimic their regular glutenous counterparts.

Tecnica Molitoria International Spring issue 2023 ˙ 71 pasta

shop.chiriottieditori.it RIEMPITIVO LIBRI 2023_TM.indd 2 02/02/23 10:35

bread

Sodium chloride substitution with Salicornia ramosissima powder

Sodium chloride is known to influence several technological and sensory characteristics of bread, but the high dietary daily intake of sodium, however, raises concern because of serious health implications.

In a study by the Dipartimento di Scienze dell’Agricoltura-Università di Sassari, published on Journal of Functional Foods, response surface methodology was used to optimize the extent of sodium

chloride reduction (0.6-1.2-1.8%) and its replacement with Salicornia ramosissima powder (0-50-100%), to achieve the best low-sodium wheat bread, while meeting dough quality standards. Mixing, viscoelastic, extensional, and fermentation properties of doughs, as well as specific volume, textural, and color features of breads, were evaluated as response variables. After applying optimization criteria via desirability function, results

72 ˙ Spring issue 2023 Tecnica Molitoria International

evidenced that, using 1.8% salt with a substitution ratio of 65.24%, is the best combination to obtain both doughs with longer development times, high stability, better viscoelastic properties and similar

fermentation capacity, and breads with higher specific volumes, softer and less chewy crumbs, but higher green tones, than those containing only sodium chloride.

Properties and in vitro digestibility of a bread enriched with lentil flour

An article by the Dipartimento di Agricoltura-Università di Napoli appeared on Food Structure, regarding the effects of three leavening times (60, 105 and 150 min) on structure and some physico-chemical and nutritional properties of bread added with 20% of green lentil flour were investigated. Leavening time affected bread physicochemical properties, leading to a reduction in moisture content, an increase in weight loss and a darker appearance of bread crumb as leavening time increased. Besides, crumb of bread leavened for the longest time (B150) showed a compact structure and the highest resistance to the compression, while the Young’s modulus increased with the rising of leavening time. By contrast, breads leavened for shorter times (B60 and B105) had a more porous structure with more circular bubbles compared to B150, exhibiting lower deformation resistance. Different bread macrostructure had an impact on the in vitro protein and starch digestibility. The alpha amino nitrogen release and the estimated Glycemic Index (eGI) at the end of digestion reached the lowest values in bread leavened for the longest time (B150).

In particular, eGI showed a linear correlation both with the Young’s modulus (R 2 =-0.926) and macrostructural properties (R 2 =0.902), suggesting that modelling bread structure by acting on leavening time can be a novel approach to develop healthier products.

bread Tecnica Molitoria International Spring issue 2023 ˙ 73

Addition of wheat bran

The functional and nutritional properties of bread could be improved by incorporating wheat bran. However, there are disadvantages technological, sensory and rheological associated with the use of wheat bran directly in bread processing. To eliminate these problems, wheat bran can be subjected to different pretreatments.

The aim of a Turkish research published on Journal of Cereal Science was to apply hydrothermal treatment to the wheat bran at different temperatures and investigate the effect of the hydrolysates of the pretreated wheat bran on the rheological properties of dough. The hydrothermal treatment process was applied at 130°/160°C for 30 min. The amounts of reducing sugar, fur -

fural, acetic acid and phenolic substances in the hydrolysate increased with the increase of the hydrolysis temperatures. It was determined that the addition of the hydrolysate obtained at 150°C to dough had a positive effect on its rheological properties.

It reduced the dough development time and increased the water holding capacity. However, some drawbacks started to occur in the dough’s rheological properties with the use of the hydrolysates obtained at higher than 150°C.

The results showed that hydrothermal treatment had the advantage of eliminating the technological and rheological problems caused by the direct addition of wheat bran.

74 ˙ Spring issue 2023 Tecnica Molitoria International

Bran particle size on rheology properties and baking quality of whole wheat flour

In an American study published on LWTFood Science and Technology the effect of bran particle size on whole wheat flour (WWF) bread-making performance was investigated using four different varieties with protein levels of 9-15 g/100 g. Five different bran particle size ranges from 590.5 to 159.7 mµm were obtained using various milling methods. Mixolab tests revealed that white flour had a lower water absorption (56.2-59.2 g/100 g) than the corresponding whole wheat flours (63.2-67.0 g/100 g). Larger specific loaf volume was observed for white bread

with a higher flour protein content, but this was not always associated with the trend for the WWF. For most wheat varieties, the bread from WWF with the fine bran had the lowest specific loaf volume, darker crumb color, and larger hardness value than bread made with white flour or with WWF of other particle sizes. Overall, WWF with medium to coarse bran size was more suitable for bread production. The findings contribute to the standardization of whole flour bran particle sizes for quality assessment and effective industrial production.

bread Tecnica Molitoria International Spring issue 2023 ˙ 75

X-Ray microtomography of a white bread from plasma functionalized flour

Cold plasma (CP) technology has emerged as a novel non-thermal technology with the potential to improve food quality or impart functionality to ingredients. The previous studies on wheat flour demonstrated how the structure and functionality of wheat flour might be modified using CP to provide an alternative to chemical additives (Chaple et al ., 2020). However, understanding of the further effects of plasma functionalized ingredients in existing or new product formulation is limited.

In a study published on LWT - Food Science and Technology , Irish researchers investigated the effects of CP treatment of wheat flour on traditional white pan bread development. The bread was formulated using plasma functionalized flour (PFF), and critical product characteristic responses were analyzed. Plasma treatment of flour positively affected the bread expansion ratio, crust color, and water activity. Farinograph analysis suggests improvement in water absorption capacity, dough development time, and dough stability.

76 ˙ Spring issue 2023 Tecnica Molitoria International

X-Ray Microtomography (XRMT) analysis was conducted to understand how plasma functionalising the flour impacted the microstructure of bread. The 3D scans suggested no macro-change in the bread matrix compared to control; however, the porosity decreased in line with the increasing plasma treatment duration of the flour.

The texture profile analysis showed an improvement in the gluten network developed in the dough developed from

PFF. Sensory analysis results showed overall acceptance for bread formulated with PFF compared with a commercial sample.

Overall, CP treatment of the flour improved the functionality in relation to dough and bread preparation and can thus provide an alternative to chemical additives in bread making. The CP processes may be modulated to deliver tailored effects for bread product development.

Effect of wheat and barley malt addition

Wheat grain obtained from agricultural overproduction is stored for along time ingrain warehouses, which reduces its baking value.