SCHOOL AT CUTTING EDGE OF SUSTAINABLE DESIGN

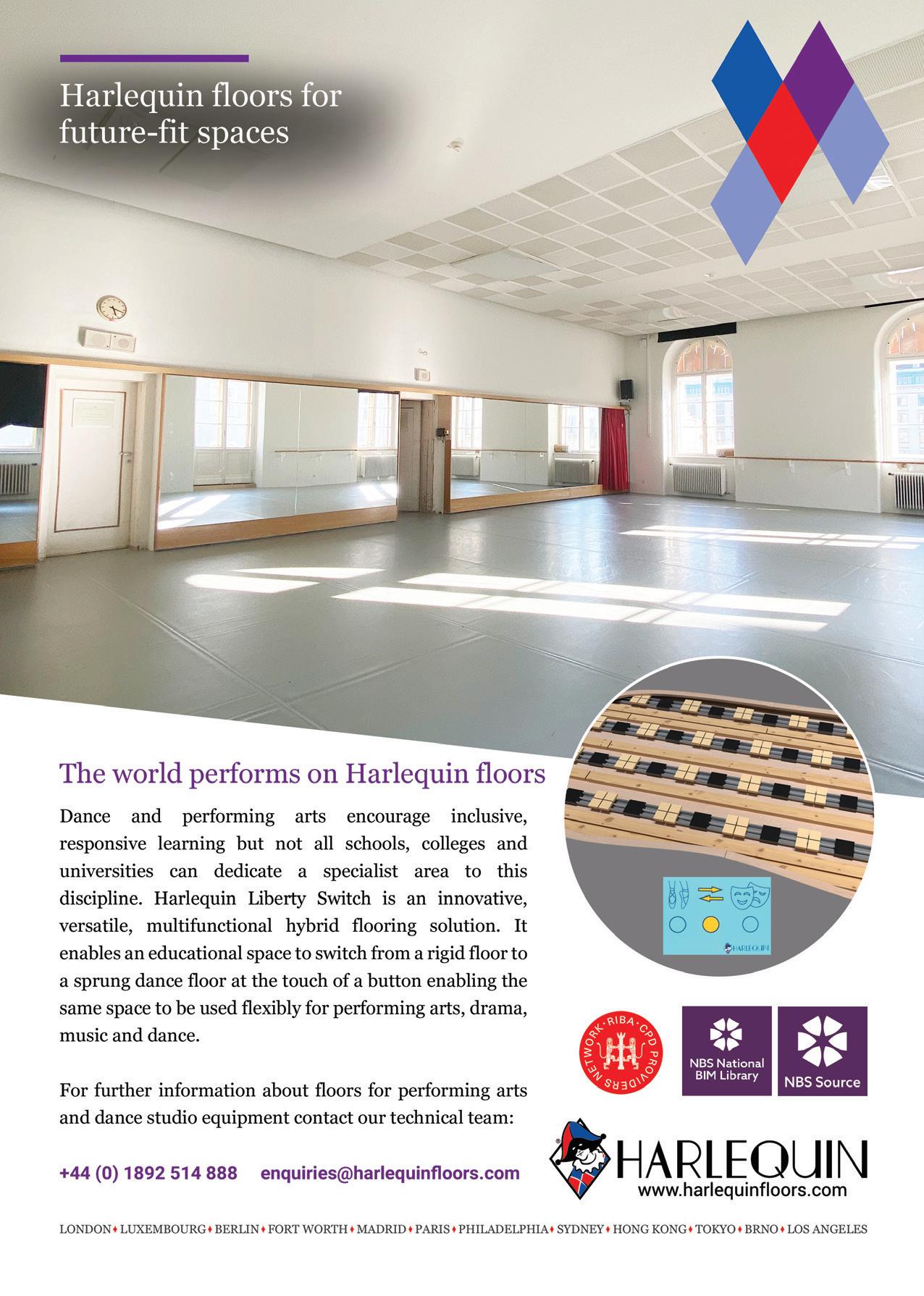

Milton Keynes unveils its first fossil-free school, demonstrating a huge leap forward educationally

REHAU explores how to navigate the changes of the Future Homes Standard

Upgrading the public sector’s built environment goals to circularity

Modern, sustainable school offers a key pillar for a brand-new community

December 2022 Issue 124 Public Sector Build Journal Leisure Housing Education Healthcare psbjmagazine.com

Introducing

Harnessing the power of natural cork, SprayCork wall & roof coatings are an innovative and eco-friendly solution for new build and retrofit public sector buildings.

Cork is one of the world’s most sustainable natural resources with a negative carbon footprint. No trees are felled during its harvest - in fact the bark grows back each time, absorbing much more carbon dioxide than usual, making it a powerful ally against climate change.

It is a strong thermal insulator reducing the dependence on heating systems, which also helps reduce condensation and black spot mould. It has sound dampening properties to improve acoustic comfort, whilst offering natural resistance to fire and high temperatures. Added to this, as it is hypoallegenic it helps to improve air quality against airbourne particles.

02 25 Year Warranty

For more information about using cork on your project, or to book a CPD, please contact our team: www.corksoluk.com | 01484 442420 | info@corksoluk.com

Better for you. Better for the planet.

SprayCork. The Ultimate Building Coating.

Applications: > Mould reduction in social housing > Safe encapsulation of asbestos > Refurbishment of all types of buildings > Fire protection up to 18m

Welcome to the December issue of PSBJ...

Whilst the welcome pages within our December issue from years past might have ‘cheers’d to the season of goodwill, in light of events of the past 12 months, you would be forgiven for not feeling quite so festive. With a notable absence of ‘The Queen’s Speech’ combined with takeaway messages from the recent COP27 in which UN Secretary General António Guterres declared that the planet was “on a highway to climate hell” and anticipation of further protest disruption, ‘Driving Home for Christmas’ may not have quite the same ring to it this year.

Nevertheless, we must remain positive and credit the achievements of the year, specifically the built environment for embarking upon its journey with a collaborative approach to lower the embodied and operational carbon of new buildings and retrofit projects. Being at the editorial helm of this publication for some time, I can confirm that the conversations surrounding climate change are louder than ever. Amendments to Building Regulations, including the proposed Part Z limiting the carbon intensity of buildings, are making considerable headway, or are, at least, getting people to start seriously thinking about the implications of construction, whether they be in the context of social housing, schools, hospitals or recreation and community hubs.

Although it’s unlikely we’ll see immediate action and change from COP27, the UK has plenty to be getting on with in the meantime. Buildings are already reaching completion that are meeting or exceeding targets, which is encouraging to see. In this month’s issue, we reveal one such project that is at the cutting edge of sustainable design. Glebe Farm School is Milton Keynes’ first fossil-free school. Striving for minimal impact on the environment, the building is gas free, utilising air-source heat pumps for heating, whilst hundreds of solar panels generate power to the building. Gas Bunsen burners have also been replaced by electric versions. To read more about this inspiring build and its energy-efficient construction process, turn to page 08

Elsewhere in this edition, REHAU reflects on navigating the changes of the Future Homes Standard, Carlisle Construction Materials urges the public sector to lead by example with a circular approach to sustainability and Zeroignition explores the subject of safeguarding timber from toxic fire retardants.

From all the team here at Public Sector Build Journal, we’d like to wish our readers a very Merry Christmas and a happy and prosperous New Year.

I hope you enjoy this issue. Don’t forget, you can also access the magazine’s features, product news and supplier information on PSBJ’s user-friendly and engaging website. Fully responsive, the website allows you to read all the latest stories on-the-go either on your phone or tablet. Simply visit www.psbjmagazine.com.

03

Glebe Farm School is Milton Keynes’ first fossil-free new-build school, funded and developed by Milton Keynes City Council. See page 08.

us on Social Media: Hannah

are invited and when not accepted will be returned only if accompanied by a fully stamped and return addressed envelope. No

will be taken for drawings, photographs or literary contributions during transmission or

the editor's

the

an agreement the copyright

contributions, literary, photographics or artistic belongs to Red Hut Media Ltd. The Publisher accepts no responsibility

of advertisements appearing

the magazine and the opinions expressed

editorial material or otherwise do not necessarily represent the view

the publisher. The Publisher does not accept any liability

any loss

appearance or non

advertisement. Editor Hannah Woodger hannah@redhutmedia.com Rebecca Kemp rebecca@redhutmedia.com Print & Digital Advertising Sam Ball sam@redhutmedia.com Jim Moore jim@redhutmedia.com Print Design Manager Jack Witcomb jack@redhutmedia.com Digital Design Manager Matt Morse matt@redhutmedia.com Accounts Rachel Pike accounts@redhutmedia.com Sales Support & Statistics Klare Ball klare@redhutmedia.com Publisher Sam Ball sam@redhutmedia.com Published by Red Hut Media Ltd. 5 Mansion Row, Brompton, Kent, ME7 5SE psbjmagazine.com 01622 946150 redhutmedia.com PSBJ is a proud supporter of the Chartered Institute of Architectural Technologists. WELCOME NOTE @psbjmagazine

Hannah Woodger • Editor • hannah@redhutmedia.com

Find

Contributions

responsibility

in

hands. In

absence of

of all

in respect

in

in

of

of

arising from the late

publication of any

06 News

A round up of the latest industry news, including charity events, awarded contracts, completed projects and much more.

08 Upfront

Glebe Farm School is Milton Keynes’ first fossil-free new-build school, funded and developed by Milton Keynes City Council with building works carried out by the Northern Home Counties team at Morgan Sindall Construction.

12 Healthcare

Simon Briggs of Stepnell believes the key to addressing the care sector’s challenges is to ensure care and health projects are designed and built with sustainability in mind.

14 Legal & Business

Allen Coldrake from Carlisle Construction Materials discusses the need for the public sector to lead by example with a circular approach to sustainability.

16 Education

Seddon has completed a new primary school in Castle Donington, Leicestershire, bringing 210 new school places to the area.

12

18 Security & Building Access

Paul Smith of F.H. Brundle discusses the types of fencing solutions and other security products available for use on public sector sites around Britain.

20 Bricks & Blocks

Scott Denham, Sales Director at IG Masonry Support, looks at how manufacturing expertise and design technology are bringing a new look to traditional brickwork.

22 KBB & Washrooms

Spray heads and hoses are integral to the safety of electric showers, explains Triton Showers, and should not be swapped for aftermarket options without due diligence.

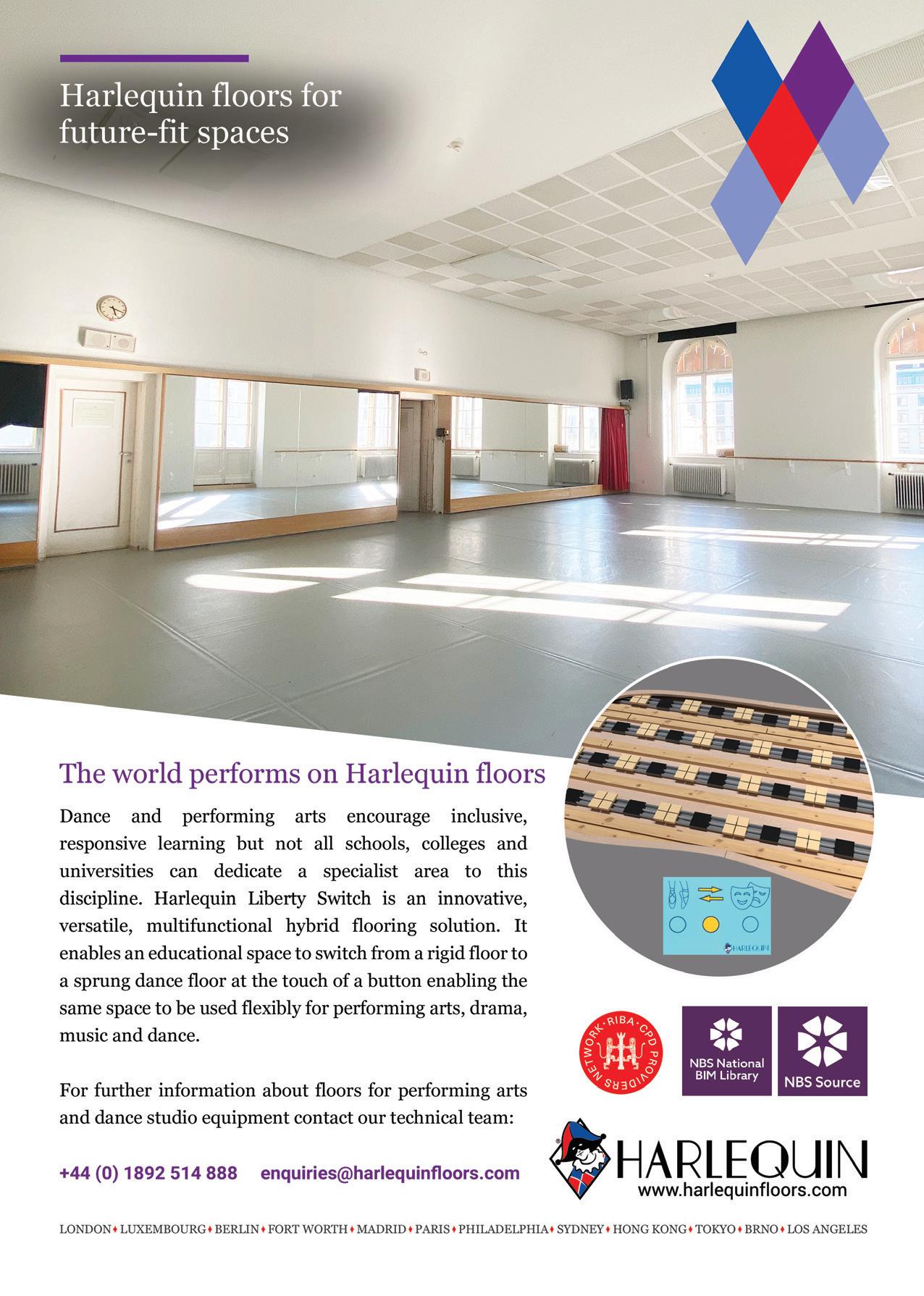

24 Leisure

Two new sporting facilities in Edinburgh, designed by Holmes Miller, were planned not just to nurture the next generation of athletes, but to improve community wellbeing too.

04 CONTENTS

Tel: 0115 941 1126 www.cfa.org.uk Email: info@cfa.org.uk Specifying a CFA member for your next flooring project could mean the difference between success — or a flooring failure. Most of the UK’s largest and best known Manufacturers, Distributors, Contractors and Consultants are CFA members — and for good reason. • CFA members promote high standards, knowledge and expertise • CFA members will maximize your investment and minimize costly flooring failures — which is good for your client, good for your reputation and also helps promote future business • All members have to pass a vetting process See the “Downloads” section at www.cfa.org.uk and download our leaflet TODAY Specify CFA Members_Sep 2021_HP_all sizes.indd 2 24/09/2021 16:25:00

26 Doors, Windows & Balustrades

28 Housing

Public sector buildings have many requirements and factors influencing their design, but one major element that applies to all is selecting a suitable and sustainable roof.

30 Talking Point

Timber construction is on the rise, and while this is good news for the industry, some fire retardants used to protect timber from fire contain harmful chemicals.

32 Technical Focus

Martin Nicholson, Divisional Director of Specification at RWC, outlines how green plumbing technologies can lay the foundations to create the green new builds of the future.

34 Product Showcase

A dedicated focus of industry news, products and case studies to help specifiers and local authorities make informed decisions.

As important as the door

A fire door is an essential part of a building’s passive fire protection system. A critical component of every fire door is the hardware on it. At ZEROplus we have been independently fire testing door hardware for over 20 years, to be able today to offer an extensive range of tested products.

05 CONTENTS

16 20

Steve Tonkiss at REHAU explores the Future Homes Standard’s ramifications, and the role of doors and windows in ensuring compliance with the new, more stringent requirements.

BRUNDLE F.H.BRUNDLE SERVING THE TRADE SINCE 1889 Stand-Offs Wire Rope Frameless Glass Spigots Stainless Handrail Glass Clamps The widest range of stylish Pro-Railing® balustrade & handrail. Whatever the project, we have a cost effective solution. 01708 39 80 22 sales@brundle.com www.fhbrundle.co.uk Order now or request a quote • No trade account required • Competitive prices • Order online 24/7 • FREE delivery on orders over £150 • Delivered from stock PRO-RAILING® BALUSTRADE SPECIALISTS ZERO SEAL SYSTEMS LTD: 01785 282910 FIND OUT MORE AT: WWW.ZEROPLUS.CO.UK

FIRE DOOR HARDWARE

Seals Hinges Locks Euro Cylinders Lever Handles Door Closers Letter Plates Door Stays Vision Frames Louvres Door Viewers Flush Bolts Panic & Emergency Exit Hardware

INDUSTRY UPDATES

National property consultancy Carter Jonas has secured planning consent on behalf of the Perse Upper School for a substantial new sports centre, which will include a swimming pool, sports hall, climbing wall and changing village, together with associated car and cycle parking and landscaping. Consent was awarded by Cambridge City Council on 5th October 2022. The new 2706m2 facility will be located within the Perse School’s existing campus on Hills Road, to the south of the city centre. A Community Access Agreement, to be secured by planning condition, will enable local people to use the facilities either through affiliation with local sports clubs or on a ‘pay-and-play’ basis. This will include early morning and evening swimming two days a week in addition to weekend family swimming session. Each week, local residents will benefit from 45 hours of access, rising to 80 or more during the school holidays. A contractor has been appointed and construction is expected to proceed as soon as pre-development planning conditions are approved by the city council. Alison Shakespeare, Bursar of The Perse, commented: “We are extremely pleased to have achieved planning permission for this exciting project. Carter Jonas have been involved from the outset, and their help and advice has been invaluable.”

Major investment in transformational learning space at East Hunsbury Primary School

Work is underway on a new transformational learning space for Early Years Foundation Stage (EYFS) children at East Hunsbury Primary School. The school has teamed up with Wellingborough-based Timotay Playscapes to plan three distinct areas for pupils aged four and five. Features include a role play village, an outdoor learning zone (with ‘deluxe’ mud kitchen), creative studio area, water play, climbing apparatus and a construction area complete with gravel pit, sand pit, trike and cycle area, as well as a ‘show time’ performance stage and storytelling area. In April 2022, East Hunsbury was confirmed as a ‘Good’ school following an Ofsted inspection, and this investment in its EYFS facilities is another sign of its commitment to building on that success with the quality of learning and teaching going from strength to strength. The EYFS area, which is due to be completed this month, is the latest development in a long-term building and maintenance programme. Recently, the school’s specialist unit that teaches 50 children with profound and multiple learning difficulties, underwent a refurbishment, which included a new sensory room.

The UK’s most outstanding recent building projects went head-to-head for top national accolades at the RICS Awards Grand Final, where the Erne Campus of South West College in Fermanagh, the world’s first educational building to achieve the highest international standard in environmental construction, won the RICS UK ‘Project of the Year’ title. Nominated by Hamilton Architects, Erne Campus, which was completed earlier this year, was chosen by the judges as the overall winner based on its impressive sustainability credentials, which will see it yielding an anticipated 90% reduction in energy costs for the college. Accommodating 800 full-time students, 2000 part-time students and 120 staff, the campus is one of the world’s most sustainable educational buildings, having secured both Passivhaus ‘Premium’ and BREEAM ‘Outstanding’ accreditations. At 8000m2, and representing an investment of £34m, the project has been recognised as one of 26 UN Centres of Excellence for High Performance Buildings, ranking alongside the Apple 2 campus in California. Earlier this year, the landmark building won the Public Sector ‘Project of the Year’ award in Northern Ireland at its regional RICS heat, which led to the project being automatically entered into the national RICS Awards Grand Final.

Leading social housing repairs and maintenance provider, Wates Living Space, has grown its southern property portfolio with three projects on behalf of Brent Council, St Mungo’s and mhs homes. The projects include the refurbishment of four high-rise blocks on behalf of Brent Council, including external wall insulation, heating and lift refurbishments. Work for Brent also includes retrofit installations to increase home efficiency following Wates’ successful retrofit pilot on behalf of Brent Council, which reached completion at the end of 2021. The project saw the Wates Retrofit team install energy-efficiency measures in void properties, taking them from an Energy Performance Certificate (EPC) rating of E to B, exceeding the Government’s 2030 target for social housing. Also included in Wates Living Space’s new contracts is a six-month programme to install new kitchens and bathrooms for 36 properties across north London on behalf of St Mungo’s. The team is also preparing to mobilise a two-year contract to install new kitchens and bathrooms for mhs homes properties in north Kent. The new projects add to Wates Living Space’s current portfolio, which includes repairs and maintenance for 500,000 homes on behalf of 60 social landlords.

06

Each month PSBJ rounds up the latest public sector construction updates, from new contracts to industry awards.

Carter Jonas achieves planning consent for the Perse School in Cambridge

Sustainable Enniskillen college campus is RICS UK ‘Project of the Year’ NEWS

Wates expands southern presence

with

contracts collectively valued at circa £33m

A Victorian street, which was lost to demolition in the 1970s, has been reinstated at Brighton’s newest neighbourhood Edward Street Quarter. Developer Socius alongside investor Patron Capital reopened Mighell Street and has marked the entrance with a public art gateway, which will welcome visitors, residents and workers. Steve Eccles, Director at Socius, said: “Reinstating historic Mighell Street is just one of the major milestones in our development and we are excited that office staff and residents will be able to walk down this road once again. It was important for us to forge links with Kemptown’s heritage and we wanted to bring back this lost street to revive a piece of Victorian Brighton. Mighell Street will be lined with food, beverage and leisure businesses, as well as offices and homes, where our first residents have already moved in, putting this thoroughfare truly on the map once more.” Mighell Street was named after Philip Mighell, who was a local landowner at the end of the 18th century. The new gateway has been designed by master sculptor Casto Solano of British-Spanish studio Solart. Edward Street Quarter comprises 125,000ft2 of Grade A office space, as well as 20,000ft2 of leisure, retail and hospitality units. The development is being jointly developed by Socius, First Base and Patron Capital Partners.

Sleek, sustainable and striking, the recent development by Haslob Kruse + Partners fuses past and present with an expansive wooden exterior made with Kebony wood, which was selected to house over 60,000 precious maritime artefacts at Germany’s National Maritime Museum in Bremerhaven. Clad entirely in sustainablysourced Kebony Character wood and containing 2300m2 of depot space, the German Maritime Museum houses an extensive collection of archival materials and museum objects, preserving Germany’s maritime heritage with a forward-thinking and ecoconscious approach to architecture. Designed with a focus on modernity and eco-conscious construction, the German Maritime Museum has harnessed the latest developments in warehousing, air conditioning and technology, whilst simultaneously making use of sustainable materials in the construction process. The result is a museum depot, which is vast in size, but grounded in environmentally-sound practice that also offers a solution to concerns about limitations in space to contain this precious historical collection.

A Cornish construction and professional services consultancy has generated an added social and economic value of £34.9m as a result of its work with Cornwall Council over the past three years. Mace Ward Williams Joint Venture (MWJV), which is a joint venture between Mace and Ward Williams Associates, has released its annual report. This follows its third year of work with Cornwall Council on the £650m construction and infrastructure capital programme of investment within the Built Environment Professional Services (BEPS) Framework. The added social and economic value has been achieved through the creation of new jobs, facilitated training and via spend with local and small businesses. Jeremy Dunn, MWJV’s Managing Director, said: “In the built environment sector, we know that we can have a more profound impact than is often understood, and this overview of our work to date reinforces that.” MWJV works with its wide network of local and national suppliers to bring expert and costeffective project management, architecture, engineering and surveying support to a range of programmes across Cornwall ranging from transport, schools, town regeneration and housing.

The Centre for Ageing Better is launching a new network of local authorities looking to work collaboratively to address the nation’s inadequate housing stock. Partnering with sector leader Foundations, the Good Home Network will bring together local authorities from all over England to share learning, encourage peer support and motivate innovation in home-improvements services locally. A recent survey carried out by Ageing Better highlights the urgent need for the network with more than four out of five (83%) responding local authorities stating there is a need to address poor-quality homes in their area. The network builds on the work of the Good Home Inquiry to find new ways for local authorities to improve homes in their area. The inquiry identified the need for each local area to provide easy access to information and advice, finance, home repairs and adaptions essential for improving the nation’s housing stock. The Good Home Network will enable local authorities to reflect on the existing situation within their community and share ‘what works’ in addressing poor-quality housing. Health and social care bodies will also be engaged to ensure a holistic ‘whole-home’ approach is adopted.

07

Historic Mighell Street is reinstated at Edward Street Quarter in

Brighton

Cornish construction consultancy and Cornwall Council generate £34.9m in social and economic value

Landmark museum embraces sustainable wood technology to house vast historical collection

NEWS

New network launched to support local authorities in improving poor-quality homes

MILTON KEYNES’ FIRST FOSSIL-FREE NEW-BUILD SCHOOL

At the start of this school year, Glebe Farm School, part of the Inspiring Futures through Learning (IFtL) multi-academy trust, opened its doors to 250 children, and this will eventually rise to over 1530 pupils. As an all-through school, children can enter at reception and stay all the way through to Year 11. There is also a 39-place full-time equivalent nursery. Here, Matthew Shotton, Headteacher of Glebe Farm School, discusses the project.

Nothing new in that, you might be thinking – new schools or new school buildings are opening all the time – but our school is Milton Keynes’ first fossil-free new-build school, funded and developed by Milton Keynes City Council with building works carried out by the Northern Home Counties team at Morgan Sindall Construction.

The driver has been Milton Keynes City Council, which, since 2015, has opened six new schools and expanded 22 others, creating thousands of new local school places. The council is well on track, as part of its MK Futures 2050 strategy, to be carbon neutral by 2030 and carbon negative by 2050 and in each case planners, architects and builders have

aimed to have a positive impact on the environment by using clever designs and greener technologies.

The whole site has been designed to have a minimal impact on the environment. Glebe Farm School is ‘gas free’, with airsource heat pumps (ASHPs), which absorb heat from the outside air providing all the energy needed for air and hot water. All lighting comes from ultra-efficient LEDs, whilst hundreds of solar panels generate power for the building. 840 trees, donated by the Woodland Trust, have been planted on the grounds.

One of the exciting features of this project was the close collaboration from day one of the design and build project between Milton Keynes City Council as the commissioner of the school, IFtL as the appointed multi-academy trust to run the school, and the developer the Northern Home Counties business at Morgan Sindall Construction. Together, they created the vision for a fully-integrated all-through school (under one roof), whilst considering how the sustainable

UPFRONT

08

credentials would be maximised during the build and throughout its operation as a school for years to come.

With construction of the school having started in February 2020, many of the recommended green building processes were immediately underway, reducing any impacts on the local environment. One of the most significant ways emissions were minimised during the build was by using alternative and renewable power sources for the equipment and temporary set up.

This was accomplished by using a solarpowered generator, powered through 32 photovoltaic (PV) panels, to provide clean, off-grid energy for the site’s cabins, canteen, toilets and even the CCTV system. Through embracing new technology, Morgan Sindall Construction used five solar-powered, wireless CCTV cameras around the site.

For those less sunny days, the generator used bio-fuel hydrotreated vegetable oil (HVO) instead of diesel to make sure that the work kept going without any disruptions, whilst also emitting 90% less. Even when not on solar power, this was still a much more sustainable energy source for the team on site, as HVO only creates 0.195kg of CO2 instead of the 2.68kg created when burning red diesel. A solar-powered PV boot wash and electric car-charging parking spaces were also installed for staff.

One of the most significant eco-friendly design changes came with the decision to remove the school from the gas grid, with all the heating to be provided instead by renewable energy via roof-mounted ASHPs. The emission-reducing effectiveness of this move was highlighted by the Committee on Climate Change, which stated that carbon emissions for a home can be up to 90% lower for a house and 80% lower for a naturally-ventilated office when using ASHPs instead of gas.

Unlike most developments, this decision has an interesting knock-on effect for a school, as typically every science lab will require gas-powered Bunsen burners. To solve this issue, Milton Keynes City Council installed electric Bunsen burners instead, so that no part of the building would require a gas connection for any reason.

This is a good example of how this project is ahead of the curve, as gas Bunsen burners are still routinely specified for new schools despite the construction industry veering away from this fossil fuel. The move to drop gas is especially evident in the recent Future Homes Standard and its directive to take new homes off the gas grid – a direction that is likely to be keenly felt in public sector construction in the coming years.

Integrating underfloor heating (UFH) into the school’s ground-floor slab provided an energy-efficient heating method while saving time when compared to using a sand and cement screed. The manner in which UFH heats an entire space from the ground up means that heat is used in a more efficient manner compared to traditional methods such as radiators.

09 UPFRONT

10 UPFRONT

The green design changes did not stop at construction. In operation, renewable power became an ever-more prominent part of the project, with the number of solar panels increasing and with six electric charging points added to the car park. When it came to the components used to construct the school, the Green Guide for building materials was consulted to inform sustainable specification choices, which included choosing ecofriendly PVC-free hoarding instead of a traditional option. 360m of carbon-neutral hoarding was installed around the site, saving 12 tons of carbon.

The Morgan Sindall Construction Northern Home Counties business worked closely with Milton Keynes City Council and IFtL to ensure that the school’s design would continue to effectively minimise emissions during its day-to-day use. A key way this has been achieved is by designing a building envelope with very low air permeability to retain heat and reduce the energy required to warm the classrooms. While regulations state that schools should meet an air leakage

rate of 5m 3/hm 2, the school benefits from a much better air permeability rate of only 3m 3/hm 2

Externally, the school’s grounds were made to be green in more ways than one. Not only will 840 saplings donated by the Woodland Trust be planted, but all the mulch and topsoil will be reused instead of being moved, saving the emissions that would otherwise be incurred through transportation. The levels of the school’s ground were carefully redesigned and raised to accommodate this additional material. In operation, this now saves 40 tons of CO2 each year.

Beyond the design of the building and its eco features, the school is a huge leap forward educationally. Underpinned by our strong values of Integrity, Responsibility, Endeavour, Bravery and Empathy, our school will be the ‘beating heart’ of a new and developing community. Serving children and young people from the immediate residential area and nearby towns and villages, we will offer unrivalled curriculum and enhancement opportunities, enabling pupils and students

from all backgrounds to pursue their interests and fulfil their potential. As a centre of innovation, equipped with the latest education technology including 1:1 devices, and a commitment to outstanding pastoral support, our school will give every learner the tools needed to be successful in the ever-evolving and challenging modern world.

As David Rowsell, Area Director for Morgan Sindall Construction in the Northern Home Counties, summarised himself for this article: “This project is a great showcase for how to rapidly create a high-end educational environment that is not just at the cutting edge of sustainable design, but which has been delivering tangible social benefits to the local community at every stage of its development. Thanks to this combination of factors, the local area has a significantly-increased student capacity and the school’s pupils will go through their educational journey in Milton Keynes’ first fossil-free school.”

11

www.glebefarmschool.co.uk

UPFRONT

BUILDING CARE HOMES FOR A CHANGING WORLD

With more than 1.9 million requests for support and 841,000 people receiving state-funded long-term care showing in the most recent statistics, social care is in significant demand. Combine that with the ongoing financial crisis and the ambitious national targets for carbon emission reduction, and you have a perfect storm for public sector care homes to weather. Simon Briggs, Energy Lead at complete construction partner Stepnell, believes the key to addressing this daunting series of challenges is to ensure care and health projects are designed and built with sustainability in mind.

ith nearly 500,000 residents currently in care homes across the country and a rapidly-ageing population, there is rightfully an ever-increasing focus on residential care for older people. On top of this, better diagnosis of developmental challenges and childhood traumas have seen a significant rise in those under 18 requiring social care.

This increase of pressures on the system have seen the value of the care sector overall increase to more than £16bn, and – with the rise in the cost of utilities like energy and the ongoing cost-of-living crisis showing little sign of easing – more and more responsibility falls on the public sector care providers to scrutinise the efficiency of their existing facilities and planned builds.

If care homes are going to invest in new or refurbished buildings, they must ensure that it will be able to provide the best environment for often vulnerable members of society that must be well looked after.

Along with this duty of care, the high energy expenditure that often comes with providing it must also be carefully managed to ensure that the building remains efficient and won’t cost unnecessary amounts to keep warm or cool.

An engaged supply chain

An important element of executing these design ideals is having the contractor involved at the earliest possible stage. In its simplest sense, early engagement means that conversations about buildability can be had while the project is still in the design stage, and a contractor can lend its expertise to the process to aid the client’s decision making.

Another major benefit of this is that the supply chain and key material suppliers are also brought to the table early, which helps maximise efficiencies and allows for early purchasing of materials. This is something that has become increasingly important in the past year in particular, with significant material shortages caused by a combination of Brexit regulations, the long tail of the COVID-19 pandemic and the war in Ukraine.

One of the ways the public sector is able to achieve early engagement is by procuring projects through frameworks. Frameworks help to ensure quality and cost effectiveness and can support the public sector by providing a faster route to project delivery.

Through our work procured through several framework agreements, including specifically for the public sector, Stepnell has found that they provide a collaborative platform for all parties with shared success factors, bringing greater efficiencies at project and programme level while safely delivering innovation, on time and to budget.

While this is the case for new buildings, there is still a significant challenge with the existing public estate and retrofitting its respective infrastructure. Again, early engagement here is key to finding the right solution, and any actions taken need to be based on the particular energy usage profile. This can only properly happen when there are open and honest conversations between clients, contractors, consultants and end users. Bringing these stakeholders together will allow informed decisions to be made, generating realistic and achievable decarbonisation plans.

The energy question

It’s no secret that care home running costs can be astronomical. With the essential heating and lighting – not to mention any medical equipment required – there is a real need for efficiencies to be found wherever possible.

12 HEALTHCARE

W

The elimination of wasted energy should be the priority in the first instance, and this can be achieved at the design stage by ensuring the building fabric is as energy efficient as possible, with high levels of insulation and airtightness, high-quality windows and doors, as well as smart controls for lighting and heating systems.

While this approach is best practice, it isn’t always practical or possible, meaning that the focus shifts to energy efficiency, achieved through installing appliances that have a beneficial effect on the building and its individual usage. For care settings, this approach is especially relevant when it comes to heat recovery, making sure the building remains heated by recirculating the warm air that would be extracted under more conventional systems.

Looking longer term, there is a real need in the care sector for a concerted push to use more renewable and sustainable energy solutions. With the current high energy costs showing no sign of abating, some of the most common renewable plant and machinery solutions have significantly reduced payback periods for the initial expenditure of installing them compared to traditional methods.

The design answer

This push towards more energy-efficient approaches to building fabric is reflected in some of the changes in design we’re seeing from our work in both the public and private sectors. Heating solutions are now leaning more towards the use of air-source heat pumps, and incorporating systems powered by solar PV, rather than traditional gas central heating.

At Stepnell, we have committed to supporting projects early on with the right energy-efficient design and installation solutions through ‘Step Energy’. This is an in-house offering providing commerciallysound, bespoke energy-saving and carbon-reduction strategies throughout the lifecycle of projects.

As well as carefully factoring in low-carbon heating solutions, material choices are key in this equation – whether that’s getting the right amount of glass to provide natural light without leaking heat, or looking at more sustainable material solutions for buildings such as the timber and zinc Stepnell used at The Forge (pictured) – a residential care home for children in Warwickshire.

Functionality is naturally the priority when it comes to health and care facilities, but it’s important to remember that they need to be living spaces that inspire residents and staff alike.

A better way

The priority for construction partners needs to be on ensuring not just that the right technologies are being offered to suit client requirements,

but that they are installed, commissioned and monitored to make sure they are continuing to perform.

In fact, the public sector is in a prime position to be the client of best practice and, with the right engagement and support, can debunk the ‘lowest price wins’ mindset, which doesn’t factor in the longer-term savings associated with creating schemes that consider the embodied carbon of a building long after the initial build.

The ultimate key to doing this effectively is understanding the whole scheme and how each element aligns with the other – something that can only truly be achieved by engaging early and working with suppliers that have a true understanding of energy usage.

13

HEALTHCARE www.stepnell.co.uk

UPGRADING THE PUBLIC SECTOR’S BUILT ENVIRONMENT GOALS FROM SUSTAINABILITY TO CIRCULARITY

Allen Coldrake from Carlisle Construction Materials discusses the need for the public sector to lead by example with a circular approach to sustainability, highlighting a best-practice approach in The Netherlands that the UK could learn from.

The public sector is the benchmark for the commercial sector to follow when it comes to sustainability.

From BIM to Energy Reduction Plans, initiatives that are pioneered in the public sector provide the blueprint to demonstrate what is achievable for commercial development projects. ‘Green’ buildings are no longer just a way for the public sector to trailblaze a principled example of environmental responsibility, however; they are an essential part of netzero strategies and long-term commitments to driving down both energy consumption and maintenance/repair/replacement costs for built assets.

A role model for sustainability

Sustainable construction and property asset management strategies align with both the principles of best value and the need for improved transparency on environmental performance and budget

responsibility. We have seen a focus on consolidating local authority sites into fewer locations, investing in new sustainable buildings, and improving existing property assets, all of which have contributed to much more environmentally-responsible public sector estates.

The term ‘sustainability’ still means different things to different organisations. Hopefully, however, we have now moved beyond box-ticking exercises because the public sector has begun to reap the rewards of more sustainable buildings in terms of energy and maintenance costs, fuelling a culture of greener design and specification.

The roadmap to circularity

But more can be done. In addition to selecting products that last longer, thereby reducing the environmental impact of construction by enabling longer replacement

intervals and extending the service life of the building, public sector decision makers also need to consider what happens to construction materials at the end of their service life. Can they be recycled or re-used? How can they be given a second life? Who will be responsible for ensuring that reincarnation?

It is those questions that lie at the heart of circular sustainability; a philosophy that is seeing the drive for reduced construction impact come of age. It’s a simple concept: rather than considering the environmental credentials of a material solely in terms of how green it is at the time of use, circularity requires a cradle-to-cradle approach to selecting materials that deliver reduced embedded carbon emissions, improved performance and extended service life, along with the ability to be returned to the value chain at the end of their initial lifecycle.

Pioneering circularity in The Netherlands

It’s an approach that is being pioneered at the highest level in The Netherlands, where a Dutch Government initiative has been devised to enable developers or building owners to recoup up to 12% of the cost of both building materials and labour, based on circularity criteria. To enable the client to qualify for these financial measures, the product supplier must promise to take back the materials at the end of their service life and recycle them or reprocess them so that they can be re-used.

Reducing raw material consumption is integral to improved circularity and, while the UK does not have a Government-led scheme to drive this approach, the public sector and the construction industry in the UK can still learn from the best practice we’re seeing in The Netherlands.

The benefits of circularity may not be felt for a while –particularly for materials like EPDM that have a long service life – but making the right choices matters now.

The devastating effects of summer heatwaves this year have reiterated that there really is a climate crisis and the public sector needs to lead the way in delivering on our collective responsibility to take a cradle-to-cradle approach to circularity.

www.carlisleconstruction materials.com

14

LEGAL & BUSINESS

Allen Coldrake is Director of Marketing and Technical Services at Carlisle Construction Materials; a company that specialises in waterproofing systems for the building envelope. He has more than 20 years’ experience in the built environment supply chain.

15

A MODERN SCHOOL FOR A MODERN COMMUNITY

Seddon has completed a new primary school in Castle Donington, Leicestershire, bringing 210 new school places to the area. Situated in the heart of a newlyconstructed housing development, it represents a key pillar for a brand-new community with a sustainable mindset ingrained into its modern design.

The creation of what would become Foxbridge Primary School was delivered across a 52-week period, with its construction necessitated in Section 106 provisions. As outlined by Leicestershire County Council, the building of the new school was key to the planning approval of the surrounding 895-home development to ensure the housing project extended beyond just housing. The 210 new school places it provides will help meet the demands of the new development, delivered by a tri-consortium of housebuilders

– Miller Homes, Redrow and Clowes Developments – has naturally created. The contractor was appointed for the project by The Scholars Academy Trust on the strength of its comprehensive experience in the education sector and commitment to sustainability, with environmental measures a key component of the project. Seddon, which is in its 125th year of business, has invested heavily in sustainable construction methods and brought to fruition over £70m of educational facilities across the North West and Midlands in the last six

years. Previous projects include Phase 1 works for Stockport College, renovating the flat roofing of the University of Derby’s West Wing and constructing the 57,000ft 2 Keele Veterinary School over a 70-week period. It also completed a £1.8m refurbishment and extension project for Bolton Sixth Form in its hometown. These projects successfully showcased Seddon’s ability to navigate a myriad of education construction projects on time and to budget, making the contractor an ideal delivery partner for the development’s tri-consortium.

Community-powered project Plans were drawn up for the single-storey, 1332m² building to be situated on Welsted Road. It would sit nestled within the heart of the new development. Sensitive to what this means for its residents, Seddon, driven by its belief that ‘people make places’, worked closely with the surrounding community during the planning stages.

The key aim was to gain a thorough understanding of the community’s views on the project and to maintain a positive relationship with the neighbouring houses while the project was in development. This approach was continued throughout the 52-week build, with Seddon accommodating feedback from global property and construction consultant, Gleeds, Academy and Leicestershire County Council, on the back of regular site visits.

Acting upon the learnings of consultations and discussions, Seddon executed an adaptable construction model throughout the project to make sure the school became a valuable addition to the new development and the community it is sewing. With close links to a neighbouring high school, Castle Donington College, the new primary school’s importance within the local community and the stepping stone it represents for the community’s next generation, could not be understated.

16

EDUCATION

Designed and delivered

The school was designed by Glancy Nicholls Architects. The single-storey building was designed as a kinked block, with mono-pitch roofs to primary teaching areas with flat roofs connecting these sections. Lined with trees and a high green weldmesh fence, the design allows the building to blend in with the two-fold aesthetics of the local landscape, characterised by green fields and the grey aircraft hangars of the neighbouring East Midlands Airport.

Large windows to classrooms allow for views between internal and external spaces with good passive surveillance around the site to ensure a school-wide approach to health and safety. The windows are a dark grey, chosen to match the cladding, with key opening windows also coloured accordingly. A light grey metallic standing seam was wrapped vertically to both the walls and roof to soften the building’s edges.

To comply with new Building Regulation laws, put in place during the construction phase, plans were also integrated to install two electric car-charging ports in a 24-space car park. These plans were tailored with flexibility, ensuring there was the ability to facilitate more in the future.

Green minded for green fingers

Just like the school it was building was to become, Seddon ensured its operations were green minded. Of the waste produced during the project, 98% was recycled off site, with 85% of subcontractors located within a 30mile radius of Derby to minimise its carbon footprint. To the same end, after the onsite topsoil failed testing, Seddon sought out a local farm for the topsoil to ensure its supply chain was locally sourced. Recycled wood was also repurposed in the structure of the school’s reception and the soft play area.

The school grounds include a football pitch, soft social area, playground, hard games court and a habitat area, all of which encourage socialising and exercise from its

pupils, alongside being ideal platforms for further, outside-the-classroom learning. The habitat area, especially, which will be managed by select pupils, will be a valuable source for hands-on learning about nature and responsibilities for the area’s next generation, which greatly echoes the school and contractor’s mutual commitment to the environment. The pupils’ green uniform is a further reflection of this, with the school’s ethos of underlining the importance of outdoor learning, meaning a great deal of emphasis was put in the creation of outdoor spaces the school had to offer.

Mark Barrington, Chief Operating Officer at the Scholars Trust, said that “Seddon is firmly in our legacy” as a result of the project. He said: “From the outset, it was clear that the project team at Seddon had the best interests of the most important stakeholders in this project at heart – the pupils who would be using the school.

“As a trust, this is the first time we have opened a brand-new school, so to be able to draw upon the extensive knowledge of the Seddon staff was vital. Every question was

answered quickly and efficiently, and we always felt like our thoughts and opinions were heard and mattered. Throughout every step of the build process, we were kept fully up to speed with progress through regular meetings, both on site and remotely. The local community has responded really positively to the quality of the school design and build, and we are so excited for the future of our school and for the families that will benefit from it.”

Construction of the 10990m² site was completed in summer 2022, with Foxbridge Primary School moving into the property ahead of the new school year. Seddon’s ability to deliver the £4.2m project in time for the new school year represented a major coup for the local community as the wider development nears completion. The school was officially opened by the Lord-Lieutenant of Leicestershire, H.M Mike Kapur OBE, in early October, with parents, local businesses and the press in attendance.

17

EDUCATION

www.seddon.co.uk

WHICH PUBLIC SECTOR SECURITY SOLUTION IS RIGHT FOR YOU?

Paul Smith of F.H. Brundle discusses the types of fencing and other security products available for use on public sector sites around Britain.

It’s a sad but unavoidable fact – public buildings are highly visible, likely to be full of expensive equipment, and that makes them an obvious target for thieves and vandals.

Fences are one of the most fundamental forms of security we have available to us in modern construction.

There’s little more effective at preventing burglaries than

a physical barrier a would-be criminal can’t pass through and finds hard to climb.

But while everyone probably has a very clear picture in their mind when they hear the word ‘fence’, the reality is surprisingly complicated.

There’s an extensive range of different security fencing solutions on the market today, all of which are suited for different situations.

Here’s our guide to some of the options available, and where they excel.

Palisade gates and fencing

For heavy-duty perimeter protection applications, palisade gates and fencing are an excellent choice – in fact, it’s thought the Romans used wooden versions to secure their army camps.

Usually made of galvanised steel, palisade fencing is supplied in kit form, with the vertical pales fixed to two rails running horizontally.

The design allows the fence to be erected so that it can follow the contours of the ground, making it ideal for uneven land.

Palisade fencing presents a formidable barrier to thieves and other intruders, especially when installed at heights of up to 3m.

Available in W or D profiles, it’s topped with a spike that offers a clear deterrent to would-be thieves, and some incorporate other forms of anti-vandal scaling barrier as a way of further discouraging potential intruders.

Mesh gates and fencing

Mesh represents another versatile security fencing solution. Thanks to their welded intersections, mesh gates and fencing are robust and durable, and require little maintenance.

However, they achieve all this without obstructing views – meaning they’re great for areas where you need to retain reasonably good visibility into or even through the fenced area, or where you want a barrier that security cameras can still see through.

However, mesh fencing is also widely used in contexts where safety is a major concern.

‘Safe Top’ mesh fencing features a closed-beam section located along the top and bottom edge of the panel with no sharp or raw edges. As such, it’s used extensively in public spaces, schools, sports grounds and playgrounds.

Mesh gates come in single leaves, for pedestrian access, or double leaves, for vehicles and keeping people and vehicles apart.

Controlling access

Another aspect of securing a public sector site is controlling who is allowed in – and that means doors and locks.

Increasing numbers of public buildings are now investing in more high-tech access control systems like keypad locks.

One of the biggest challenges around lockable gates in a public sector environment is the need to keep intruders out of sensitive areas, but allow building occupants to move around the site, and quickly and easily escape in an emergency.

That’s why we’ve seen the development of products that present external users with a sturdy lock, often with combinations, but internal ones with a clearly-labelled push pad to allow for speedy egress.

Get some friendly guidance

At F.H. Brundle, we’re able to offer an extensive array of fence, gate and lock products suitable for an array of public sector applications.

18 SECURITY & BUILDING ACCESS

www.fhbrundle.co.uk

19

EVOLUTION OF MASONRY SUPPORT SOLUTIONS HELPS PUT A STYLISH NEW FACE ON PUBLIC BUILDINGS

Reliable, weather resistant and age proof, brick remains an ideal building material. Innovation, in terms of masonry techniques, means brick can be used in evermore inventive ways, allowing a solid, stylish finish to homes and a range of buildings. Here, Scott Denham, Sales Director at IG Masonry Support, looks at how manufacturing expertise and design technology are bringing a new look to traditional brickwork.

Due mainly to its consistent shape, compressive strength and ability to absorb water, many generations of architects have selected the brick as their go-to building material. Its popularity hasn’t gone unchallenged, however, with the past decade or so seeing the emergence of solutions such as cladding. But in-keeping with the well-known phrase, ‘form is temporary, class is permanent’, brick is back in vogue as an inspiration to property owners and designers looking to emulate modern interpretations of classic architecture.

Architecturally, the intricate detailing that brickwork enables is without compare. Brick detail in the form of brick soffits, brick feature arches, deep reveals and flying beams continually make for stunning exteriors, enabling architects to create truly unique facades. Brick’s popularity in the UK and Ireland as a triedand-trusted building source was unrivalled until modern composite cladding systems containing materials such as steel, concrete and aluminium offered a quicker, cheaper route to creating bright, contemporary-looking buildings. Such convenience comes at a cost, however. Aesthetically, modern cladding systems can begin to look tired and dated over time, thus regular and potentially costly maintenance can be needed to upkeep or upgrade them. This brings into question their long-term cost efficiency, but not-so brick-built facades, which will retain their impressive look many years after their initial construction.

20

BRICKS & BLOCKS

A bespoke solution

At IG Masonry Support, not only do we understand that architects need to be given creative authority over prefabricated brick features, we realise the importance of regulatory compliance and quality.

Achieving deep brick soffits and intricate brick bonds around window heads and openings is quick, easy and cost efficient to achieve with our Brick On Soffit Systems (B.O.S.S. and B.O.S.S.+). These tailor-made bespoke solutions are designed and manufactured to meet the client’s specification. The systems are highly adjustable, enabling architects to design various shapes and depths of brick soffits whilst accommodating a wide range of bond patterns.

To meet changes to Building Regulations, IG Masonry Support engineered B.O.S.S.+, an A2 fire-rated system suitable for use on projects that require Building Regulations Document B compliance. The second generation of its original B.O.S.S. system, B.O.S.S.+ comprises a stainless-steel framework with a cement particle board backing element to which the brick slips are adhesively bonded and mechanically fixed. In short, this BBA-certified solution ticked the boxes in all of the required areas and was available to the market in 2019.

Not resting on its laurels, IG Masonry Support’s next step was to create a fully non-combustible and carbon-neutral product. The BBA-certified B.O.S.S. A1 system is ‘A1’ fire rated and has been subjected to hygrothermal testing. The

product passed the rigorous examination with ease. As well as meeting current fire regulations regardless of the building’s height or purpose, the manufacturing process and environmental impacts will be significantly reduced.

Marlborough Primary School

IG Masonry Support’s B.O.S.S. system was selected as the ideal solution to create a stunning brick detail around large, circular windows, which form part of a major redevelopment at Marlborough Primary School in west London. The window feature, designed in conjunction with the project’s lead architect Dixon Jones, required IG Masonry Support to prefabricate a series of imposing circular-form B.O.S.S. deep soffit systems containing green-glazed slip bricks. The soffits’ shape and colour acknowledge the polychromy of a nearby 1911 Michelin building. In situ, this magnificent brick detailing brings an exciting, creative energy to the refurbished school’s vibrant new learning environment.

Alison Gingell Building, Coventry University

A new health and science building at Coventry University offers a fine example of how innovative masonry techniques have revolutionised brick’s use as a design accessory. The Alison Gingell Building was created to provide students with ‘world-class facilities’, enabling them to learn in situations that mirror real-life scenarios. Following consultations with

architect Broadway Malyan, IG Masonry Support supplied the building’s standout architectural feature: 23 large-scale brick slip fins, which appear throughout the health and science block’s south elevation. The prefabricated fins were designed and manufactured by IG Masonry Support using slip bricks within a brick panel system, which the company developed to allow designers and specifiers to achieve a deeper soffit that blended seamlessly with surrounding brickwork.

Time and cost savings

No matter how ambitious the design, IG Masonry Support’s easy-to-install solutions deliver significant reductions in installation time by up to 90%. Any higher initial costs can be offset by saving time and money in terms of labour. A quality finish that meets the required aesthetics and blends seamlessly with the surrounding brickwork can also be achieved.

As with a beloved work of art, brick is a design classic that will continue to be rediscovered by future generations. It will ensure brick’s relevance to private homes and public buildings that will gain in style but lose nothing in terms of stature and safety by the additional design possibilities it now allows. This is due in part to companies such as IG Masonry Support and their commitment to developing solutions that enable brick, a staple construction material, to be used in ways that fire the imagination of architects and builders alike.

21 www.igmasonrysupport.com BRICKS & BLOCKS

SHOWERHEADS AND HOSES: ESSENTIALS FOR SAFER ELECTRIC SHOWERING

Spray heads and hoses are integral to the safety of electric showers, explains Martyn Brown, Contracts and Technical Manager at Triton Showers. Here, he discusses why these elements should not be swapped for aftermarket options without due diligence.

lthough sometimes overlooked, shower accessories are a key element in any shower set up, as not only do they form an important part of an interior scheme but they are also critical to safety and performance.

This is especially pertinent for electric units, which can cut out and cause unsafe showering when showerheads and hoses are damaged, worn or blocked.

The dangers of disrupted flow

Many of the risks stem from the movement of water through the shower being interrupted. An electric shower is a vented appliance and consistent flow through the head is critical. If water spends too long in the heating element, its temperature can rise rapidly and become dangerously hot by the time it reaches the person showering. For vulnerable users, like the young, elderly or disabled, this outcome can be particularly hazardous as they are more susceptible to scalding.

One reason for flow disruption is original showerheads being swapped for novelty alternatives. Examples include LED-emitting or mineral stone bead showerheads. There are also options that feature a button to stop water flow, which is perilous when paired with an electric shower.

Be aware that incompatible and poorquality products may not have been tested to appropriate standards, meaning they can prevent water from continually flowing from the unit. These risks also apply to hoses when twisted or kinked during use – the shower could even stop completely due to triggering the thermal cut-out function or pressure relief valve.

Think before changing components

When looking after showers and their accessories, best practice is to consult the manufacturer’s guidelines and confirm that products are fit for purpose before replacing.

For hoses, it’s crucial that a robust product is selected. Look for ‘anti-kink’ options to avoid blocking the flow when twisted and turned. For example, Triton’s hoses feature anti-twist cones and double interlocked-stainless steel and have been tested to withstand up to 141kg of weight before breaking.

Meanwhile, Triton’s showerheads are designed to consistently maintain a steady flow, as well as being quick and easy to fit. These options are compatible with most electric units in the UK, along with suitable mixer and digital units too.

Maintain to stay safe

A vital piece of advice is that shower accessories should be regularly cleaned to ensure the product operates as intended. A simple fix is to remove the head, insert into a sealable plastic bag or container and fully immerse in white vinegar for two hours. A quick brush or wipe of the nozzles will then remove any remaining limescale and deposits, before rinsing with water – this process can be followed to clean hoses as well.

Final thoughts

In public sector-managed buildings, especially in housing, healthcare and education where vulnerable users could be using the facilities, safety should be a top priority. Here, using good-quality spares and accessories for electric showers and following manufacturers’ guidelines is critical. This will not only prevent units from being damaged unwittingly and warranties becoming void, but most importantly, will ensure people are not unnecessarily put in harm’s way.

22 KBB & WASHROOMS

www.tritonshowers.co.uk

A

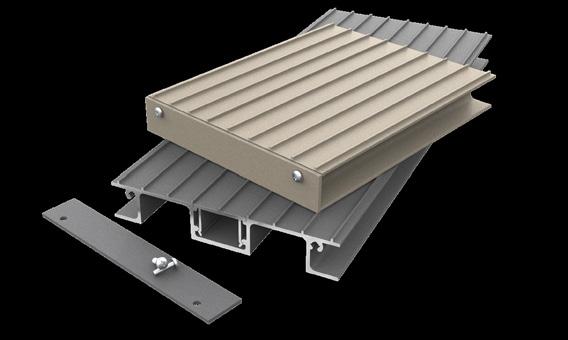

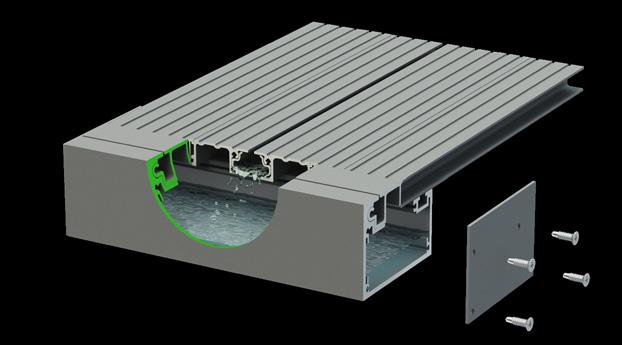

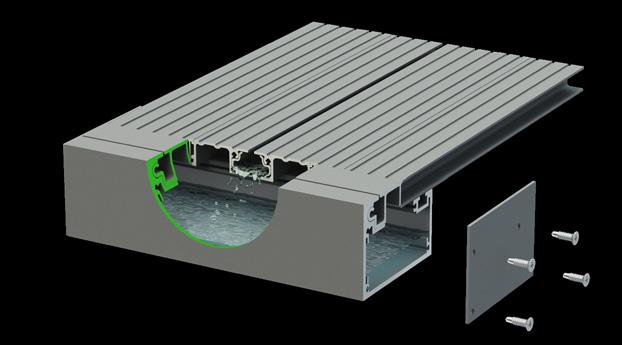

23 • Fire Rated to A2-s1, d0 & A2fl-s1 • Aluminium construction to 6063 T6 grade • Slip-resistant and wear-resistant • 30-year manufacturer product warranty To find out more about the AliDeck System, call our team today! THE UK’S ORIGINAL FULLY COMPLIANT ALUMINIUM NON-COMBUSTIBLE BALCONY DECKING SOLUTION Call: 01622 534 077 Email: info@alideck.co.uk www.alideck.co.uk ALIDECK BALCONY DRAINAGE SYSTEM ALIDECK JUNIOR BALCONY BOARD This innovative drainage solution delivers positive drainage to balconies, with our Drainage Channel between the deck boards capturing and directing water to the Drainage Gutter for controlled evacuation to a specified outlet. The 20mm AliDeck Junior Board is our most popular decking board, available in ridged and flat specification. Spanning up to 600mm, the cost-effective Junior Board requires less underside support than traditional decking and is non-combustible. IDEAL FOR EWS1 Aluminium Decking TM DRAINAGE GUTTERING DRAINAGE CHANNEL STANDARDS COMPLIANT SOLUTION BALCONY BOARD HINGED ACCESS GUTTER LID

COMBINING COMMUNITY WELLBEING AND SPORTING EXCELLENCE IN EDINBURGH

Two new sporting facilities in Edinburgh, designed by architecture firm Holmes Miller, were planned not just to nurture the next generation of elite athletes, but to improve community wellbeing too.

Both funded by City of Edinburgh Council, Meadowbank Sports Centre and the Trinity Academy Sports Campus represent more than £50m of investment into the city’s sports capacity.

Participation, accessibility and sustainability are at the heart of the facilities, which will bring huge physical, mental and social benefits to the people of Edinburgh.

Integrating community benefit and wellbeing into environmentallyconscious sports and leisure buildings is a core brief Holmes Miller is getting used to working to, as more urban local

authorities look for creative ways to cut vehicle use by meeting the needs of their residents within a short walking distance of their homes.

The practice is also seeing a growing trend towards community involvement in the design process.

A long history of sporting excellence

Meadowbank Stadium has been the home of elite sport in the Scottish capital for decades. Built to host the 1970 Commonwealth Games, it was something of an Edinburgh icon. Many renowned athletes spent their

early days training there, including former Olympic 100m champion Alan Wells, and long-distance favourite Liz McColgan.

The city’s professional rugby team had been based there, as had a Scottish professional football side.

Trinity Academy, much like its more famous neighbour, also has a proud sporting track record. The school has helped develop the potential of several world-class athletes in recent years, and hopes to continue inspiring many more.

Replacing an icon

After more than 50 years of active service, Meadowbank urgently needed updating into a facility fit for purpose in a modern, environmentally-conscious world. In 2017, with plans in place for a new centre, the old building was decommissioned.

Holmes Miller’s Director Ian Cooney, Lead Architect on the project, wanted to ensure the local landmark was replaced with something worthy of the Meadowbank name.

“Revitalising such an iconic facility was a huge responsibility as well as a privilege,” he said. “We had to be certain it could deliver professional and elite sports competitions well into the future, as well as provide best-inclass training and leisure facilities for the local community.

“This meant not only working with sporting bodies, such as Scottish Athletics, to meet some very exact technical specifications, but also designing spaces that both professional and amateur athletes would enjoy.”

24

LEISURE

A home for local clubs

As well as providing world-class indoor and outdoor training facilities for Edinburgh-based elite athletes including 1500m world champion Jake Wightman, who grew up in the city, Meadowbank has also become home to numerous local sports groups and teams thanks to its two outdoor 3G football and rugby pitches.

The re-opening allowed FC Edinburgh to return home after five years spent playing at Ainslie Park on the outskirts of the city. It also now serves as home to Hibernian FC’s women’s team for their Scottish Women’s Premier League home fixtures.

An eight-court indoor hall features seating for around 1000 spectators, and to widen use of the building to more participants, facilities were included to cater for netball, boxing, squash, martial arts, trampolining and dance.

Trinity Academy Sports Campus also welcomes a host of local sports clubs, like Waverley Inveresk Hockey Club and Trinity Academicals Rugby Club, to its professional-standard playing fields, and boasts a four-court sports hall, gym hall, dance studio and fitness suite.

Creating community hubs

Although primarily designed to continue work as a venue for elite-level sporting competition, Meadowbank is equally embraced as an important community hub.

The venue supports accessible participation and has much-improved indoor facilities, including two multi-sport games halls, two fitness studios, a cycle studio and a gym with triple the number of exercise stations as its predecessor.

Local people can also use the centre’s cafe, meeting rooms, hospitality suite and event facilities.

Trinity Academy Sports Campus makes a similar investment in the local area, with public facilities like a cafe, community learning centre, fitness suite and a workshop for the repair and storage of bikes and

kayaks, which were included in the design after close consultation with local people.

Lead Architect Ryan Holmes, a Director at Holmes Miller, explained: “From the beginning, we knew the local community wanted to benefit from the centre, so we listened to their desires and were flexible in our approach. During the consultation process, direct feedback from residents helped us prioritise open, well-designed spaces, adjusting our plans to make sure their expectations were delivered.”

Green credentials

In line with the council’s ambitions to cut carbon emissions, Holmes Miller embraced the very best elements of green design, both at Meadowbank and Trinity Academy.

Meadowbank is an accessible centre for community sport, with impressive sustainability credentials which include a low-velocity air displacement system, which helps create a calm and fresh environment with low energy consumption, and HFO-based (hydrofluroolefins) chillers rather than conventional HFC (hydrofluorocarbons) to reduce greenhouse-gas emissions.

Both facilities also serve as linchpins in City of Edinburgh Council’s plans for low car use, low-carbon communities,

supporting its commitment to creating ‘20-minute neighbourhoods’ – where residents can find most of their daily needs within a 20-minute return walk from home.

The importance of wellbeing and community

“As a practice, we’ve learned a lot through our work on these two buildings, especially about the importance of wellbeing in community-led projects, and how sports and leisure can be a catalyst for change and renewal,” says Ian Cooney. “Meadowbank, especially, has sparked a wider regeneration of its local area, as it is such a strong, visible statement of the council’s investment in local wellbeing and sustainability.

“More and more local authorities across the country are beginning to strengthen their commitment to environmentallyconscious design and to creating neighbourhoods where it’s easier to leave the car at home, because facilities that enhance lives have been brought closer to the people.

“If things continue in this direction, I am genuinely excited about the future of community architecture.”

25 www.holmesmiller.com LEISURE

FUTURE HOMES STANDARD: NAVIGATING THE CHANGES

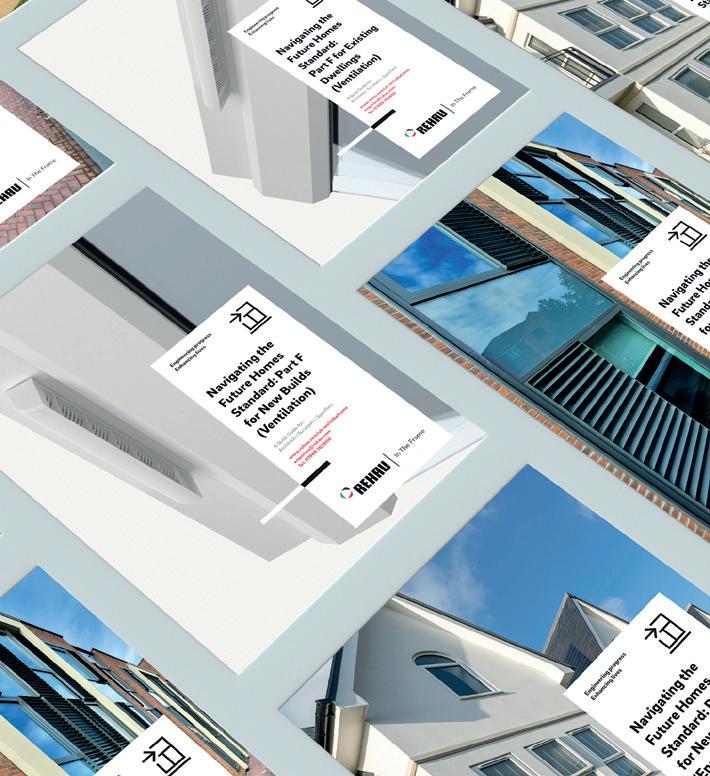

Energy efficiency and ventilation regulations in construction have come under the spotlight at local authorities since uplifts to Building Regulations under the Future Homes Standard. Implementing sustainability-minded changes is a pressing challenge for council specifiers, architects and contractors working on public sector projects. With this in mind, Steve Tonkiss, Head of Sales at REHAU, explores the legislation’s ramifications, and the role of doors and windows in ensuring compliance with the new, more stringent requirements.

The long-awaited Future Homes Standard (FHS) came into force earlier this year, causing significant upheaval for local authority construction. Specifically, clear ramifications are expected on the design and product selection of new-build local authority projects and the refurbishment of existing properties, to ensure new standards of ventilation and energy efficiency.

Though the standard’s launch date was advertised well in advance as part of the Government’s 2019 Spring Statement, this push for clarity has had the opposite effect. Namely, years of debate on the topic has led to conflicting information and advice. It is, therefore, understandable that specifiers at local authorities may not know where to start when looking for marginal gains in areas, such as windows, that will be required to hit the standard’s thermal performance targets.

Yet, in order to achieve the FHS’ requirements, local authority specifiers must first cut through the noise and understand what they entail, and why they have been implemented. The UK’s goal of achieving net zero by 2050 is the overarching reason behind the updated rules, with new homes built from 2022 needing to produce 31% less carbon emissions, and further drops of 75 to 80% expected by 2025.

Specifier steps

Consequently, architects, surveyors and specifiers working with local authorities are under pressure to consider new, sustainability-minded factors when choosing products for new-build or refurbishment projects. While all building components have a part to play in decarbonising structures, windows provide an especially effective avenue through which important gains can be made.

This can be seen in findings published by the Energy Saving Trust in March 2022, which demonstrated that installing high-performance double glazing to a semi-detached gas-heated property could result in annual savings of up to £175 and 410kg of carbon dioxide. Applied across larger local authority properties, these benefits have the potential to be further scaled up.

The key aspects of the FHS relating to windows are uplifts to Part L and F of the Building Regulations, pertaining to energy-efficiency and ventilation requirements respectively. Changes to Part L have involved optimising window U-values. Specifically, under the updated requirements, the target U-value for windows has been set at 1.2W/m 2K, restricting the lowest specification allowable – the limiting U-value for SAP calculation – to 1.6W/m 2K.

When it comes to doors in new builds, those with a glazed area greater than 60% must similarly achieve a target U-value of 1.2W/m 2K, alongside doors below the 60% benchmark at 1.0W/m 2K. Furthermore, replacement windows within existing dwellings must attain a Window Energy Rating (WER) of B or higher, with a maximum U-value of 1.4W/ m 2K. Replacement doors with a glazed area larger than 60% must achieve a WER C, or B for those less than that figure.

Futureproofing

Importantly, these uplifts are part of a longer process – further technical consultation is expected on FHS requirements in spring 2023, and targets could be adjusted again. As such, it is vital to select frames and materials that offer best possible futureproofing. Of the options available, polymer has become an increasingly attractive choice, especially as the material eliminates the thermal bridging that can be a major issue in new-build properties insofar as heat loss is concerned.

Additionally, advances in frame foil technologies mean that project stakeholders can enjoy the performance benefits of polymer while convincingly imitating the aesthetic appeal of other materials, including aluminium and wood. Alongside this, it is important to note that polymer solutions already exist that meet and exceed FHS requirements, such as REHAU’s TOTAL70 window and door system, with the company’s GENEO solution able to meet Passivhaus requirements.

Appropriate ventilation

The significant upheaval in energyefficiency requirements under the FHS is mirrored in Part F of the Building Regulations, covering ventilation for both new projects and refurbishment works. Specifically, old windows with trickle vents must be replaced by windows that

26 DOORS, WINDOWS & BALUSTRADES

have trickle vents that are at least the same size or larger and be controlled automatically or by the dwelling’s occupants.

Ventilation standards are contained in Part F of the FHS. As with windows’ energy efficiency covered in Part L, ventilation applies to both new housing and refurbishment projects. The ventilation standard states that old windows with trickle vents must be replaced by windows that have trickle vents that are at least the same size or larger and be controlled automatically or by the dwelling’s occupants.

If the frames being replaced do not have trickle vents, then the new windows must meet minimum Equivalent Air Area requirements (EQA) – the metric specifying the minimum amount of air passing through new vents. For existing buildings, approved under test conditions, a minimum EQA of 8000mm 2 is specified for habitable rooms and kitchens in multi-floor dwellings, with 10,000mm 2 required for single-floor dwellings. For bathrooms without a toilet or habitable rooms with continuous mechanical extract ventilation, excluding wetrooms, the EQA standard is 4000mm 2

System types

Three types of ventilation systems are required for new builds – System 1, System 2 and System 3. System 1 is known as ‘natural ventilation,’ in which trickle vents are used in dwellings defined as ‘less airtight’ during design stage calculations – showing an air permeability higher than 5m 3/hm 2 at 50Pa. If airtightness tests are carried out after the build, air permeability must be higher than 3m 3/hm 2 at 50Pa.

System 2 uses continuous mechanical extraction, meaning trickle vents with a minimum EQA of 4000mm 2 can be used in each habitable room. The amount of vents used on a property depends on the number of bedrooms – two more of the former are required than the latter (three for a one-bed project, four for a two-bed dwelling, etc.).

System 3 requires a mechanical ventilation system with heat recovery and no provision for background ventilators. Once the system type has been chosen, minimum EQAs can be implemented. For habitable rooms and kitchens in multiple floor housing, the EQA is 8000mm 2. For single-floor (bungalow) counterparts, 10,000mm 2 is required. An EQA of 4000mm 2 is shared across bathrooms in either type of property, with no requirements for utility rooms or sanitary accommodation.

Additional assistance

The technical specifications with the updated FHS standards is causing disruption in public sector construction, with project stakeholders needing to keep track of upheaval across multiple building components. With this in mind, it is incumbent on solution suppliers to provide as much technical support as possible to architects, surveyors and specifiers working with local authorities if they are to remain compliant.

REHAU, for example, are offering free CPD courses to ensure specification teams are compliant and understand the new requirements for windows and doors. Alongside this, the organisation have developed a series of four fact sheets aimed at those working with architects, specifiers and surveyors, which aim to provide a brief introduction to the changes, projected timeline and targets.

27

WINDOWS & BALUSTRADES www.rehau.com

DOORS,

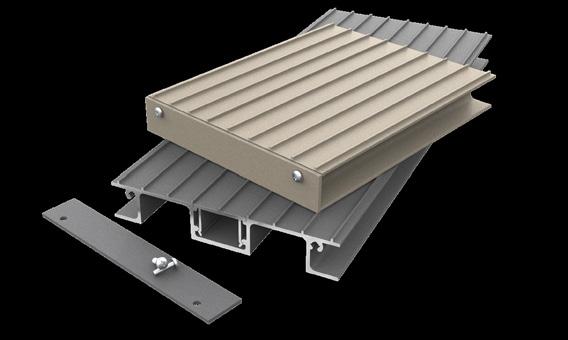

SUSTAINABILITY IN THE PUBLIC SECTOR

The public sector encompasses a wide range of buildings from local authority housing, schools and hospitals to Government buildings and transport infrastructure. Public sector buildings have many requirements and factors influencing their design, but one major element that applies to all is selecting a suitable and sustainable roof.

The choice of the roofing system, design and even the materials used are crucial in the construction of sustainable buildings as this can greatly help to restrict the environmental impact of the building throughout its lifespan.