ROADMAP RESULTS

ARC shares plastics survey results

RÉSULTATS DE LA FEUILLE DE ROUTE

L’ARC partage les résultats d’une enquête sur les plastiques

KING OF THE CASTLEGAR ROI DU CASTLEGAR

Stuart Ady has his finger on the pulse of the industry

Stuart Ady a le doigt sur le pouls de l’industrie

WOMAN OF THE INDUSTRY // FEMME DU SECTEUR:

AMANDA JAMES | EMPIRE AUTO

LEGENDS OF THE INDUSTRY // LÉGENDES DU SECTEUR:

ED PLAZEK | PLAZEK AUTO RECYCLERS

Canada Post Canadian Publications Mail Sales Product Agreement No. 40841632 l 86 John Street, Thornhill, ON L3T 1Y2 canadianrecycler.ca

EXPANDS NATIONALLY // EVFRIENDLY SE DÉVELOPPE AU NIVEAU NATIONAL

EVFRIENDLY

SELL MORE PARTS WITH POWERLINK

SELL MORE PARTS WITH POWERLINK

ALL THE TOOLS TO MANAGE YOUR YARD'S SALES, INVENTORY AND OPERATIONS IN A SINGLE, EASY-TO-USE SYSTEM.

ALL THE TOOLS TO MANAGE YOUR YARD'S SALES, INVENTORY AND OPERATIONS IN A SINGLE, EASY-TO-USE SYSTEM.

TAKE CONTROL OF YOUR YARD

TAKE CONTROL OF YOUR YARD

Today's yards face significant challenges — customer demands, competitive pressures, and a challenging economy make it difficult to provide excellent customer service, use resources efficiently, and increase profitability.

Today's yards face significant challenges — customer demands, competitive pressures, and a challenging economy make it difficult to provide excellent customer service, use resources efficiently, and increase profitability.

Powerlink is a salvage yard management system developed specifically for recyclers like you. It provides the broad functionality required to effectively and profitability run your business, including tools to manage your inventory, orders and operations from a single integrated solution.

Powerlink is a salvage yard management system developed specifically for recyclers like you. It provides the broad functionality required to effectively and profitability run your business, including tools to manage your inventory, orders and operations from a single integrated solution.

LEARN MORE ABOUT POWERLINK

www.hollandersolutions.com

LEARN MORE ABOUT POWERLINK

800.825 0644

www.hollandersolutions.com

800.825 0644

COMPREHENSIVE YARD MANAGEMENT

Take unprecedented control over the critical processes at your recycling yard to create more efficiently and run more profitably.

INTEGRATED ECOMMERCE

Connect to our eCommerce platform and eBay to sell your parts to millions of buyers that could be across the street or across the globe.

MODERN INVENTORY

Digitize your inventory and attach images for easy browsing that will help drive your sales.

CONTENTS | SOMMAIRE On the Cover En page couverture FROM DALBERT’S DESK | DU BUREAU DE DALBERT PLAZEK PRIDE | LA FIERTÉ DE PLAZEK EVFRIENDLY’S NATIONWIDE EXPANSION | L’EXPANSION NATIONALE D’EVFRIENDLY YOUR BUSINESS AND ESG REPORTING | VOTRE ENTREPRISE ET LES RAPPORTS ESG 12 54 46 72 FEATURES | ARTICLES VEDETTES 4 CANADIAN AUTO RECYCLERS 2023 50 28 Canadian Auto Recyclers magazine 17-1 Looking for an earnest partner? Look no further than Ernie’s Auto Parts of Castlegar, British Columbia. Owner Stuart Ady has been dedicated to bettering his business since before he even knew it. See what the progressive auto recycler has up his sleeve next in this year’s cover story. Vous cherchez un partenaire sérieux? Voici Ernie’s Auto Parts de Castlegar, en Colombie-Britannique. Le propriétaire, Stuart Ady, s’est consacré à l’amélioration de son entreprise avant même de s’en rendre compte. Découvrez ce que ce recycleur d’automobiles progressiste a dans sa manche dans l’article de couverture de cette année. Fourth-generation auto recycler Amanda James of Empire Abbotsford Used Auto and Truck Parts knows how to hunker down and bolster her business for success. See how she stays prepared in this year’s Woman of the Industry feature. Amanda James, recycleuse d’automobiles de quatrième génération, de Empire Abbotsford Used Auto and Truck Parts, sait comment s’adapter et renforcer son entreprise pour en assurer le succès. Découvrez comment elle se prépare dans la rubrique Femme de l’industrie de cette année.

Eager to learn all things EV? See how you can benefit from the B.C.-born program and its expansion across Canada.

Vous avez envie d’apprendre tout ce qui concerne les VE? Voyez comment vous pouvez bénéficier du programme né en Colombie-Britannique et de son expansion à travers le Canada.

GLORIA’S NOTE | LA NOTE DE GLORIA ASSOCIATION UPDATES | MISES À JOUR DES ASSOCIATIONS NEWS-IN-BRIEF | ACTUALITÉ EN BREF EVENTS | ÉVÉNEMENTS 06 22 14 34 DEPARTMENTS | DÉPARTEMENTS Canadian Auto Recyclers magazine is dedicated to serving the business interests of the automotive recycling industry. It is published by Media Matters Incorporated. Material in Canadian Auto Recyclers magazine may not be reproduced in any form without written consent from the publisher. The publisher reserves the right to refuse any advertising and disclaims all responsibilities for claims or statements made by its advertisers or independent columnists. All facts, opinions and statements appearing within this publication are those of the writers and editors themselves, and are in no way to be construed as statements, positions or endorsements by the publisher. Media Matters Incorporated would like to thank the Ontario Media Development Corporation and the Province of Ontario for the generous support in helping launch Canadian Auto Recyclers magazine. PRINTED IN CANADA ISSN 1707-6072 CANADA POST CANADIAN PUBLICATIONS MAIL SALES PRODUCT AGREEMENT No. 40841632 RETURN POSTAGE GUARANTEED. Send change of address notices and undeliverable copies to: 86 John Street, Thornhill, ON L3T 1Y2. Canadian Auto Recyclers magazine is published by Media Matters Inc. publishers of; Collision Repair magazine, Bodyworx Professional magazine and the 2006 Collision Repair Training Directory We acknowledge the financial support of the Government of Canada through the Canada Periodical Fund of the Department of Canadian Heritage. Collision Repair magazine is published by Media Matters Inc., publishers of: Volume 17 Issue 1, 2023 Volume 17 numéro 1, 2023 Annual Publication / Édition annuelle spécial PUBLISHER / DIRECTEUR GÉNÉRAL Darryl Simmons > publisher@collisionrepairmag.com ASSOCIATE PUBLISHER / ÉDITEUR ASSOCIÉ Orest Tkaczuk > orest@mediamatters.ca EDITOR / RÉDACTEUR EN CHEF Allison Rogers > allison@mediamatters.ca STAFF WRITERS / ÉCRIVAIN Max Reid > max@mediamatters.ca Kate Ng > kate@mediamatters.ca CREATIVE DEPARTMENT/DÉPARTEMENT CREATIF Yvonne Corvers > yvonne@mediamatters.ca VP INDUSTRY RELATIONS & ADVERTISING/ V.P. RELATIONS AVEC L’INDUSTRIE Gloria Mann > advertising@collisionrepairmag.com SALES ASSISTANT/ASSISTANT DES VENTES Wanja Mann > advertising@collisionrepairmag.com DIRECTOR OF SALES & MARKETING/ DIRECTRICE COMMERCIALE & MARKETING Ellen Smith > ellen@mediamatters.ca DIGITAL OPERATIONS MANAGER/ DIRECTEUR DES OPÉRATIONS NUMÉRIQUES Cassie Doyle > cassie@mediamatters.ca AUDIENCE ENGAGEMENT MANAGER / RESPONSABLE DE L’ENGAGEMENT DU PUBLIC James Kerr > james@mediamatters.ca CONTRIBUTORS / CONTRIBUTEURS Steve Fletcher, Becky Berube, Wally Dingman, Emil Nusbaum, Ken Hendricks, Dalbert Livingstone Gloria Mann at 647-998-5677 Pour les demandes de message publicitaire téléphonez à Gloria Mann au 647-998-5677. 317 Reid St, Peterborough, ON t. 905-370-0101 f. 1-888-868-7072

CANADIANRECYCLER.CA 5 Automotive Recyclers of Canada on plastics recycling survey results. Automotive Recyclers of Canada dévoile les résultats de l’enquête sur recyclage des plastiques.

54

64

ONWARD AND UPWARD

Here’s to more thought-provoking conversations in 2023

EN AVANT ET VERS LE HAUT

Autres sujets de conversation qui suscitent la réflexion en 2023

You could feel the passion and excitement in the air at every event.

I can only imagine what 2023 holds!

By/Article de Gloria Mann

Another year—my favourite time of year—and another issue of Canadian Auto Recyclers. Rejoice!

The year put me back in my element. If you know me, you know I’m a social butterfly! I truly missed connecting with all the hardworking men and women in our industry. I visited some industry friends close to home and was treated to a few in-person visits in 2021, but the best gift of 2022 was getting to see you all again, sharing ideas and celebrating the industry at the big events we all missed so much.

The first meeting to return was the Ontario Automotive Recyclers Association’s annual event in March—what a time! It had been three years since we had all gathered for an OARA trade show. The speaker sessions were, as always, highly informative and I walked away with lots to think about.

I was also in Orlando for the Automotive Recyclers Association’s annual convention, where Canadians were well-represented; we were the highest turnout of non-Americans at the conference! We had the Atlantic Canada Association of Automotive Recyclers host their 2022 convention in Truro, Nova Scotia, right after Hurricane Fiona hit the east coast! It just goes to show how dedicated this industry truly is.

Finally, we had the Canadian Association of Recycling Industry’s Consumer Appreciation night in mid-October, where all had a great time networking and socializing after so long apart! There were plenty of other visits along the way—too many to name you all here! If 2022 was any indication, we’re in for some real top-notch events and initiatives this year.

It was a spectacular year, full of spectacular memories we’re all the more grateful for post-pandemic. The ideas exchanged were fresh and modern—you could feel the passion and excitement in the air at every event I attended. I can only imagine what 2023 holds!

There are so many initiatives in this industry to be excited about. You can read all about the latest missions in the pages of this year’s issue. From efforts in plastic recycling information, to industry standards, anniversary celebrations and plenty of advancements—it’s all so thrilling to watch.

As always, keep being fantastic. Your hard work as Canadian auto recyclers will never go unrecognized by this magazine. CAR

On pouvait sentir la passion et l’excitation dans l’air à chaque événement. Je ne peux qu’imaginer ce que 2023 nous réserve!

Une année qui commence, mon moment préféré, et un autre numéro de Canadian Auto Recyclers. Réjouissez-vous!

L’année dernière m’a remise dans mon élément. Si vous me connaissez, vous savez que je suis un papillon social! Les contacts avec les hommes et les femmes qui travaillent dur dans notre industrie m’ont vraiment manqué. J’ai rendu visite à certains amis de l’industrie près de chez moi et j’ai eu droit à quelques visites en personne en 2021, mais le plus beau cadeau de 2022 a été de vous revoir tous, de partager des idées et de célébrer l’industrie lors des grands événements qui nous ont tant manqué.

La première activité à reprendre a été l’événement annuel de l’Ontario Automotive Recyclers Association en mars; quel moment! Cela faisait trois ans que nous ne nous étions pas réunis pour un salon professionnel de l’OARA. Les séances des conférenciers étaient, comme toujours, très instructives et je suis reparti la tête remplie de choses à penser.

Je me suis également rendu à Orlando pour le congrès annuel de l’Automotive Recyclers Association, où les Canadiens étaient bien représentés; nous étions le groupe de non-Américains le plus nombreux à la conférence! L’Atlantic Canada Association of Automotive Recyclers a tenu son congrès de 2022 à Truro, en Nouvelle-Écosse, juste après que l’ouragan Fiona ait frappé la côte est! Cela montre à quel point cette industrie est dévouée. Enfin, nous avons eu la soirée d’appréciation des consommateurs de l’Association canadienne de l’industrie du recyclage à la mi-octobre, où tous ont eu beaucoup de plaisir à nouer des contacts et à réseauter après une si longue séparation! Il y a eu beaucoup d’autres visites en cours de route; trop nombreuses pour toutes les nommer ici! Si l’année 2022 a donné le ton, nous nous attendons à des événements et à des initiatives de premier ordre cette année.

Ce fut une année spectaculaire, pleine de souvenirs extraordinaires dont nous sommes d’autant plus reconnaissants après la pandémie. Les idées échangées étaient fraîches et modernes; on pouvait sentir la passion et l’excitation dans l’air à chaque événement auquel j’ai assisté. Je ne peux qu’imaginer ce que nous réserve 2023!

Il y a tant d’initiatives dans ce secteur qui suscitent l’enthousiasme. Vous pouvez lire tout ce qui concerne les dernières missions dans les pages du numéro de cette année. Des efforts en matière d’information sur le recyclage des plastiques et les normes industrielles, en passant par les célébrations d’anniversaires et les nombreuses avancées, tout est passionnant à observer.

Comme toujours, continuez à être fantastique. Votre travail acharné en tant que recycleurs d’automobiles canadiens ne passera jamais inaperçu aux yeux de ce magazine. CAR

6 CANADIAN AUTO RECYCLERS 2023 GLORIA’S NOTE | NOTE DE GLORIA

Your trusted source since 1978 for recycled OEM Parts. Providing quality wheel refinishing for 29 years. Your source for quality recycled OEM parts on all makes and models with 1 million parts guaranteed in stock. 24-48 hour deliveries to many of the surrounding areas including: Toronto | Mississauga | Scarborough | Port Hope | Brampton Barrie | Orillia | Cookstown | Alliston | Tottenham OPEN 8 AM - 5 PM MONDAY - FRIDAY Go to www.carcone.com | Call Toll Free 800.263.2022 Or visit us at 1030 Bloomington Road, Aurora, Ontario L4G 0L7 Our state of the art equipment and quality craftsmanship makes us the industry leader in Wheel Refinishing and CARCONE’S CARCONE’S AUTO RECYCLING & WHEEL REFINISHING WE SHIP CANADA WIDE WHEEL REFINISHING RECYCLED PARTS

Pièces et Mécanique Omerville is a business that has been specializing in automotive recycling for over 50 years.

Pièces et mécanique Omerville est une entreprise spécialisée dans le recyclage automobile depuis plus de 50 ans.

In addition to recycling all vehicle brands, they maintain one of the biggest inventories of Audi, Volkswagen and Hyundai parts in the region. If they don’t have a requested part, they’ll find it for their customer.

Pièces et mécanique Omerville est une entreprise spécialisée dans le recyclage automobile depuis plus de 50 ans.

Officiellement recycleurs de toutes les marques de véhicules, ils détiennent aussi un des plus importants inventaires de pièces Audi, Volkswagen et Hyundai de la région. S’ils n’ont pas la pièce demandée, ils la trouveront pour le client.

Officiellement recycleurs de toutes les marques de véhicules, ils détiennent aussi un des plus importants inventaires de pièces Audi, Volkswagen et Hyundai de la région. S’ils n’ont pas la pièce demandée, ils la trouveront pour le client.

They purchase all kinds of vehicles for resale and recycling, and its general mechanics shop is welcoming, courteous and professional.

Ils font l’achat de véhicules en tout genre pour la vente et le recyclage, et le garage de mécanique générale est accueillant, courtois et professionnel.

The team at the parts counter can find any new and used parts needed. They also have several models of used vehicles in stock.

Ils font l’achat de véhicules en tout genre pour la vente et le recyclage, et le garage de mécanique générale est accueillant, courtois et professionnel.

L’équipe au comptoir des pièces répond à tous les besoins en matière de pièces neuves et usagées. Ils détiennent aussi un inventaire de plusieurs modèles de véhicules d’occasion.

L’équipe au comptoir des pièces répond à tous les besoins en matière de pièces neuves et usagées. Ils détiennent aussi un inventaire de plusieurs modèles de véhicules d’occasion.

21 décembre 2022

Member of / membre de

Pièces & Mécanique Omerville

Pour nous joindre:

735, rue Saint Michel, Magog, (QC) J1X 4J3

Téléphone: 819-868-2135

Sans frais: 1-888-868-2135

Courriel: info@vpmo.ca

A TRADITION OF EXCELLENCE

The Canadian auto recycling industry continues to progress

UNE TRADITION D’EXCELLENCE

L’industrie Canadienne du recyclage automobile continue à progresser

CANADIAN AUTO RECYCLERS 2017 EDITION

With Dalbert and Tabitha Livingstone, Andrew MacDonald, Cherie Cohen and Natalie Miller

“Being featured alongside the up-andcoming leaders of the auto recycling industry in Canada was something I will always remember. I know that we will all be working in close proximity in the decades to come, and I am sure we will talk about the cover story every time we meet.”

“Le fait d’être présent aux côtés des leaders émergents de l’industrie du recyclage automobile au Canada était quelque chose dont je me souviendrai toujours. Je sais que nous travaillerons tous à proximité dans les décennies à venir, et je suis sûr que nous parlerons de l’histoire de la couverture chaque fois que nous nous rencontrerons.”

— Andrew McDonald

CANADIAN AUTO RECYCLERS 2018 EDITION

With Greg Lane, Emile Hogue and George Shae

“Canadian Auto Recyclers has always reflected the spirit of friendly competition that has made our industry such a great place to work. To stand beside Emile and George, my own long time co-petitors really brought that feeling home. After all, we help each other out so much that clients often think we are sister companies!”

“Canadian Auto Recyclers a toujours reflété l’esprit de compétition amicale qui a fait de notre industrie un endroit formidable où travailler. Pour rester aux côtés d’Emile et George, mes propres co-participants de longue date ont vraiment ramené ce sentiment à la maison. Après tout, nous nous entraidons tellement que les clients pensent souvent que nous sommes des sociétés sœurs!”

— Greg Lane

CANADIAN AUTO RECYCLERS 2019 EDITION

With Frank Serravale

“Just read our issue! It looks great. Thank you. It is an honour to have been featured on the cover of Canadian Auto Recyclers.”

“Lisez juste notre publication ! Ça a l’air très bien. Merci. C’est un honneur d’être en couverture de Canadian Auto Recyclers.”

— Frank Serravale

To view past issues of Canadian Auto Recyclers magazine or to advertise or subscribe visit

canadianrecycler.ca

IN YEARS PAST | DE NOS ARCHIVES CANADIANRECYCLER.CA 9

Canadian Auto Recyclers magazine 11-1

Auto Recyclers magazine 12-1

Canadian

Auto Recyclers magazine 13-1

Canadian

CANADIAN AUTO RECYCLERS 2020 EDITION

With Terry Carter

“Being on the cover of Canadian Auto Recyclers[it] was a chance to give the industry a look at my dad’s on-site museum, Al’s Toy Barn and it fifty collector cars.”

« Faire la couverture de Canadian Auto Recyclers [c’était] l’occasion de donner à l’industrie un coup d’œ coup d’œ regard sur le musée sur place de mon père, Al’s Toy Barn et une cinquantaine de voitures de collection. »

— Terry Carter

CANADIAN AUTO RECYCLERS 2021 EDITION

With Ron Bastarache

“It was a great honour for our family business, Bastarache Auto Salvage, to be recognized and featured on the cover of Canadian Auto Recyclers. This magazine has made for outstanding exposure of our late father’s dream in visualizing and achieving his goal. The positive feedback of the people who read this interesting story were truly impressed with our remarkable success.”

« C’est un grand honneur pour notre entreprise familiale, Bastarache Auto Salvage, d’être reconnue et de figurer sur la couverture de Canadian Auto Recyclers. Ce magazine a fourni une exposition exceptionnelle du rêve de notre défunt père de visualiser et d’atteindre son objectif. Les commentaires positifs de ceux qui ont lu cette histoire intéressante ont été vraiment impressionnés par notre succès remarquable. »

— Ron Bastarache

CANADIAN AUTO RECYCLERS 2022 EDITION

With Pierre Robitaille

“Just received my issue of Canadian Auto Recyclers in the mail—very nice. Thank you to Canadian Auto Recyclers magazine for all your hard work on the story. You did a nice job and the story came out great.”

« Je viens de recevoir mon exemplaire de Canadian Auto Recyclers par la poste - très bien. Merci au magazine Canadian Auto Recyclers pour tout le travail que vous avez fait sur l’histoire. eVous avez fait un excellent travail et le produit fini était très bon. »

— Pierre Robitaille

Pour voir les anciens numéros du magazine Canadian Auto Recyclers ou pour annoncer ou vous abonner, visitez canadianrecycler.ca

10 CANADIAN AUTO RECYCLERS 2023 IN YEARS PAST | DE NOS ARCHIVES LE MUSÉE DE L’AUTOMOBILE Canada Post Canadian Publications Mail Sales Product Agreement No. 40841632 86 John Street, Thornhill, ON L3T 1Y2 canadianrecycler.ca Natalie Miller named woman-of-theyear Tony Carcone on leaving Italy for auto recycling in Canada Bruce Woodbeck’s industry insights The ARA’s cutting-edge convention and MUCH MORE! Natalie Miller nommée femme de l’année Tony Carcone en quittant l’Italiepour le recyclage automobile au Canada Perspectives de l’industrie de Bruce Woodbeck La convention de pointe de l’ARA et beaucoup plus! SURVIVING ARMAGEDDON SURVIVRE À ARMAGEDDON Ron Bastarache on keeping business going through a global catastrophe! Ron Bastarache sur le maintien affaires en cours une catastrophe mondiale! An up-close look at Australia’s auto recycling sector Brace for the battery barrage! OPPORTUNITIES DOWN UNDER STORM WARNING Préparez-vous au barrage de la batterie! AVERTISSEMENT DE TEMPÊTE Un regard de près sur le secteur australien du recyclage automobile OPPORTUNITÉS EN BAS SOUS CAR_Cover.indd Canadian Auto Recyclers magazine 15-1 Canadian Auto Recyclers magazine 16-1 Poles Apart: The global auto recycling sector in 2020 Tout le monde: Le secteur mondial du recyclage automobile en 2020 THE AUTO MUSEUM ON THE PRAIRIE LE MUSÉE DE L’AUTOMOBILE DANS LA PRAIRIE Terry Carter’s visionary transformation of Aldon Auto La transformation visionnaire de Terry Carter de la société Aldon Auto DIAGNOSIS: SCANNING SHOCK THERAPY Can recyclers effectively capitalize on diagnostic tools? Recyclers step forward to solve the EV battery crisis Les recycleurs peuvent-ils tirer parti efficacement des outils de diagnostic? Les recycleurs font un pas en avant pour résoudre la crise des batteries de VE DIAGNOSTIC: BALAYAGE THÉRAPIE DE CHOC Dealing with dangerous drug residue; Auction shops step up their game; Canadian recyclers descend on Alberta; and much, MUCH MORE! Traiter les résidus dangereux de stupéfiants les encanteurs augmentent leurs activités les recycleurs canadiens s’installent en Alberta et bien plus encore, BEAUCOUP PLUS! Canadian Auto Recyclers magazine 14-1

INDUSTRY TORCHBEARERS HÉRAUTS DE L’INDUSTRIE

WELCOME TO 2023

Another standout edition of Canadian Auto Recyclers

Welcome to the 17th edition of the Canadian Auto Recyclers magazine.

The Automotive Recyclers of Canada (ARC) have collaborated with Media Matters since the inception of the CAR Magazine to bring you the best of the world of auto recycling across Canada.

Full of news, industry profiles, and deeper dives into the issues that affect auto recyclers (and, quite frankly, the positive effect that auto recyclers have on stakeholders as diverse as insurers, repairers, auto manufacturers and the environment itself), this magazine has proven to be a showcase for our industry and has opened doors across Canada and around the world.

We are especially proud of the work we are doing on the effect of Electric Vehicles (EVs) on auto recyclers, and the role(s) that auto recyclers need to play in this emerging sector to ensure the completion of the circular economy for EVs. This new breed of vehicles are game-changers for auto recyclers, as it is for every sector that touches vehicles today, and it is critical that we stay on top of and ahead of the issues. This singular issue has brought unprecedented (good) attention to the industry.

In addition to this annual magazine, if you want to receive a more regular update on the industry, sign up for Media Matters’ bi-weekly Canadian Auto Recyclers e-zine—the news you need to know delivered to your inbox twice per month.

On behalf of the auto recyclers—thanks to the team at Media Matters and enjoy this issue!

Dalbert Livingstone Chairman of the Automotive Recyclers of Canada

LETTER FROM THE CHAIRMAN | LETTRE DU PRÉSIDENT 12 CANADIAN AUTO RECYCLERS 2023

Bienvenue à la 17e édition du magazine Canadian Auto Recyclers

L’Association des recycleurs automobiles du Canada (ARC) collabore avec Media Matters depuis la création du magazine CAR pour vous offrir le meilleur du monde du recyclage automobile au Canada.

Riche en nouvelles, en profils d’acteurs de l’industrie et en analyses plus approfondies des questions qui touchent les recycleurs d’automobiles (et, franchement, de l’effet positif que les recycleurs d’automobiles ont sur des intervenants aussi divers que les assureurs, les réparateurs, les fabricants et l’environnement lui-même), ce magazine s’est avéré être une vitrine pour notre industrie et a ouvert des portes partout au Canada et dans le monde.

Nous sommes particulièrement fiers du travail que nous effectuons sur les retombées des véhicules électriques (VE) sur les recycleurs d’automobiles, et sur le rôle que ces derniers doivent jouer dans ce secteur émergent pour assurer la concrétisation de l’économie circulaire pour les VE. Cette nouvelle race de véhicules change la donne pour les recycleurs d’automobiles, comme c’est le cas pour tous les secteurs qui touchent aux véhicules aujourd’hui, et il est essentiel que nous restions au fait des enjeux et que nous soyons proactifs. Cette question singulière a attiré une attention sans précédent sur l’industrie.

En plus de ce magazine annuel, si vous souhaitez recevoir des mises à jour plus régulières sur l’industrie, inscrivez-vous au cybermagazine Canadian Auto Recyclers de Media Matters, qui paraît toutes les deux semaines; les nouvelles que vous devez savoir seront livrées à votre boîte de réception deux fois par mois.

Au nom des recycleurs d’automobiles, merci à l’équipe de Media Matters et profitez de ce numéro!

Dalbert Livingstone

Président de l’Automotive Recyclers of Canada

CANADIANRECYCLER.CA 13 LETTER FROM THE CHAIRMAN | LETTRE DU PRÉSIDENT

BIENVENUE EN 2023 Une autre édition exceptionnelle de Canadian Auto Recyclers Canada Post Canadian Publications Mail Sales Product Agreement No. 40841632 l 86 John Street, Thornhill, ON L3T 1Y2 canadianrecycler.ca KING OF THE CASTLEGAR ROI DU CASTLEGAR ARC shares plastics survey results Stuart Ady has his finger on the pulse of the industry Stuart Ady a le doigt sur le pouls de l’industrie. ROADMAP RESULTS L’ARC partage les résultats d’une enquête sur les plastiques RÉSULTATS DE LA FEUILLE DE ROUTE EVFRIENDLY EXPANDS NATIONALLY // EVFRIENDLY SE DÉVELOPPE AU NIVEAU NATIONAL WOMAN OF THE INDUSTRY // FEMME DU SECTEUR: AMANDA JAMES | EMPIRE AUTO LEGENDS OF THE INDUSTRY // LÉGENDES DU SECTEUR: ED PLAZEK | PLAZEK AUTO RECYCLERS

AUTO RECYCLING ACROSS CANADA

Tracking provincial organization activity in 2022

When this magazine’s editorial team was compiling the 2022 issue of Canadian Auto Recyclers, we heard from more than one party that the year had been one of the best on record for recyclers, where profits were concerned.

Naturally, in our interviews for the 2023 edition, we heard that the ball kept rolling. And, advantageous as this industry is, stakeholders are riding the wave and taking advantage of the times.

We checked in with the provincial auto recycling associations across Canada to hear what they’ve been up to since we last spoke—and what they’re expecting in 2023.

Lorsque l’équipe de rédaction de ce magazine a compilé le numéro 2022 de Canadian Auto Recyclers, plus d’une personne nous a dit que l’année avait été l’une des meilleures jamais enregistrées pour les recycleurs, en ce qui concerne les profits.

Naturellement, lors de nos entrevues pour l’édition de cette année, nous avons entendu que la balle continuait de rouler. Et, aussi avantageuse que soit cette industrie, les parties prenantes surfent sur la vague et profitent de la conjoncture. Nous nous sommes entretenus avec les associations provinciales de recyclage automobile du Canada pour savoir ce qu’elles ont fait depuis notre dernier entretien et ce qu’elles prévoient pour 2023.

AUTOMOTIVE RECYCLERS ASSOCIATION OF ATLANTIC CANADA (ARAAC)

araac.ca

ARAAC is very pleased to host the Canadian Association of Recycling Industries (CARI) along with the ARC Board of Directors at the first Auto Recycler–Scrap Joint Meeting. Taking place June 8-10, 2023 in Halifax Nova Scotia, the event, the first of its kind in North America, is attracting attention from across North America and around the World. Featuring a joint Board session, joint plenary presentations and seminars, facility tours, and a trade show, the event will cater to both the auto dismantling and parts harvesting sectors along with the material recovery and shredding industries.

“Auto recyclers have a growing interest in scrap markets, opportunities and challenges. While we focus on vehicle acquisition, parts recovery and sales - there is a huge overlap with the efficient and safe processing of vehicles with the CARI membership,” said Steve Fletcher, managing director of ARC. “To make it really interesting, some of the shredder’s biggest customers are the large auto dismantlers, and some of the increasing profit opportunities for auto dismantlers are coming from scrap markets from old vehicles. We also have a lot of vendors in common—from insurance to health benefits to equipment providers.

“We are delighted to come together with the members of ARC and ARAAC at this meeting, and to have the chance to learn from and with each other,” said Tracy Shaw, CEO and president of CARI. “Our industries are facing many of the same challenges and opportunities, so now is the ideal time to collaborate.”

L’Automotive Recyclers Association of Atlantic Canada (ARAAC) est très heureuse d’accueillir l’Association canadienne des industries du recyclage (ACIR) ainsi que le conseil d’administration de l’ARC à la première réunion conjointe des recycleurs et des ferrailleurs. L’événement aura lieu du 8 au 10 juin 2023 à Halifax en Nouvelle-Écosse. Cet événement, le premier du genre en Amérique du Nord, attire l’attention de toute l’Amérique du Nord et du monde entier. L’événement, qui comprendra une séance conjointe du conseil d’administration, des présentations plénières et des séminaires conjoints, des visites d’installations et un salon professionnel, s’adressera à la fois aux secteurs du démantèlement automobile et de la récolte de pièces, ainsi qu’aux industries de la récupération des matériaux et du déchiquetage.

« Les recycleurs d’automobiles s’intéressent de plus en plus aux marchés de la ferraille ainsi qu’aux occasions et aux défis qu’ils présentent. Alors que bien que nous nous concentrions sur l’acquisition de véhicules, la récupération et la vente de pièces, il y a un énorme chevauchement dans le traitement efficace et sûr des véhicules avec les membres de l’ACIR, a déclaré Steve Fletcher, directeur général de l’ARC. Pour rendre les choses vraiment intéressantes, certains des plus gros clients de ce marché sont les grands démonteurs d’automobiles pour lesquels certaines des possibilités de profit croissantes proviennent des marchés de la ferraille des vieux véhicules. Nous avons également beaucoup de fournisseurs en commun, des compagnies d’assurances, de soins de santé en passant par les fournisseurs d’équipements ».

« Nous sommes ravis de nous joindre aux membres de l’ARC et de l’ARAAC à l’occasion de cette rencontre et d’avoir la chance d’apprendre les uns des autres, a déclaré Tracy Shaw, présidente-directrice générale de l’ACIR. Nos industries ont de nombreux défis et de nombreuses occasions en commun, c’est donc le moment idéal pour collaborer. »

14 CANADIAN AUTO RECYCLERS 2023 ASSOCIATION UPDATES | DES NOUVELLES PANCANADIENNES

RECYCLAGE AUTO AU CANADA

Suivi de l’activité des organisations provinciales en 2022

ONTARIO AUTOMOTIVE RECYCLERS ASSOCIATION (OARA) oara.com

OARA held its first in-person convention since pre-COVID times in March of 2022, and it was a great success. Members, vendors and stakeholders in the industry thrived in the direct contact environment. Plans are underway for an even bigger and better event in 2023, back at the Mississauga Hilton.

“We always learn from previous events, and we think we have some great changes planned,” said Greg Woodbeck, OARA chairman. “We have hired a professional motivational speaker for the 2023 event to close the convention—we want everyone to leave pumped up and excited by this industry and all the opportunities that exist.”

The trade show is filling up nicely as new and returning vendors plan to get in front of some of Canada’s best auto recyclers. As in past years, OARA extends Member Only pricing to Direct Members from other associations within ARC.

2022 was a real challenge for the continuing implementation of the EASR regulation for auto recyclers. While the rules are in place to oversee everyone engaged in auto recycling in Ontario, without effective compliance and enforcement resources and plans–the regulations begin to be watered down and ineffective over time. COVID kept inspectors out of the field, and a constant turnover in ministry staffing made it difficult to pin down the regulator as to when and how the regulations would be enforced. OARA is committed to working with the Ministry and other stakeholders to make these effective regulations for everyone.

L’Ontario Automotive Recyclers Association (OARA) a tenu son premier congrès en personne depuis l’époque pré-COVID en mars 2022, et l’événement a remporté un franc succès. Les membres, les représentants et les intervenants de l’industrie ont évolué dans un environnement en présentiel. Des plans sont en cours pour un offrir un événement amélioré et de plus grande envergure en 2023, encore une fois à l’hôtel Hilton de Mississauga.

« Nous tirons toujours des leçons des événements précédents qui nous servent à nous améliorer, a déclaré Greg Woodbeck, président de l’OARA. Nous avons engagé un conférencier professionnel motivateur pour l’événement de 2023 afin de clôturer le congrès. Nous voulons que tout le monde reparte gonflé à bloc et enthousiasmé par cette industrie et toutes les opportunités qu’elle recèle ».

Le salon professionnel jouit d’une grande popularité, car les nouveaux représentants tout comme les anciens prévoient réseauter avec certains des meilleurs recycleurs d’automobiles du Canada. Comme par le passé, l’OARA offre des tarifs réservés aux membres d’autres associations de l’ARC.

L’année 2022 a été un véritable défi pour l’application continue du règlement relatif au Registre environnemental des activités et des secteurs (REAS) pour les recycleurs d’automobiles. Bien que les règles soient en place pour

superviser toutes les personnes engagées dans le recyclage d’automobiles en Ontario, sans ressources et plans efficaces de conformité et d’application, le règlement commence à être dilué et inefficace avec le temps. La pandémie a tenu les inspecteurs à l’écart du terrain, et le roulement constant du personnel du ministère a rendu difficile la tâche de l’organisme afin de déterminer quand et comment les règles seraient appliquées. L’OARA s’engage à travailler avec le ministère et les autres parties prenantes pour que ces règles soient efficaces pour tous.

CANADIANRECYCLER.CA 15 ASSOCIATION UPDATES | DES NOUVELLES PANCANADIENNES CANADIANRECYCLER.CA 15

ASSOCIATION OF AUTO PARTS RECYCLERS (ARPAC) arpac.org

ARPAC is proud to have integrated Pièces et Mécanique Omerville as a new member in 2022. Mr. Jacques Boisvert’s recycling center is located at 735, St-Michel, Magog, Quebec, J1Z 4J3, and puts customer service at the heart of its priorities.

ARPAC, in collaboration with the CSMO-Auto, received a $333,445 grant from the Direction du développement des compétences de l’intervention sectorielle (DDCIS) for the development of an online training program that will allow aspiring dismantlers to perfect their skills on the Internet with a cell phone, tablet or computer, in order to master all of the skills specific to the dismantler’s trade.

Insurance companies continue to experience significant rate increases in Quebec for vehicle recyclers in recent years. A project is being studied by ARPAC and its insurance broker to improve the situation.

The ARPAC convention was held on September 17, 2022, in Drummondville and was attended by over 100 people.

ARPAC has a new representative on the Automotive Recyclers of Canada (ARC) Board of Directors, Mr. Gary Johnson, Vice-President of Johnson Auto Wreckers Plus. We thank him for his involvement and wish him all the best in his new position.

ARPAC is very proud to welcome two new members to its Board of Directors. Welcome to Jean-François Allie and Miguel Senécal.

L’ARPAC est fière de compter Pièces et Mécanique Omerville parmi ses nouveaux membres en 2022. Le centre de recyclage de M. Jacques Boisvert est situé au 735, rue Saint-Michel, Magog, Québec, J1Z 4J3, et met le service à la clientèle au cœur de ses priorités.

L’ARPAC, avec la collaboration du CSMO-Auto, a reçu une subvention de 333 445 $ de la Direction du développement des compétences de l’intervention sectorielle (DDCIS), pour le développement d’une formation en ligne qui permettra aux aspirants démonteurs de se perfectionner sur Internet avec un téléphone cellulaire, une tablette ou un ordinateur, afin de maîtriser l’ensemble des compétences spécifiques au métier de démonteur.

Depuis quelques années, les recycleurs de véhicules au Québec subissent des hausses importantes au niveau de leurs assurances d’entreprise. Un projet est actuellement à l’étude par l’ARPAC et son courtier d’assurance pour améliorer la situation.

Le congrès de l’ARPAC a eu lieu le 17 septembre 2022 à Drummondville et plus de 100 personnes y ont participé.

Association des recycleurs de pièces d’autos et de camions a un nouveau représentant pour siéger au conseil d’administration de l’ARC, monsieur Gary Johnson, vice-président de Johnson Auto Wreckers Plus. Nous le remercions de son implication et lui souhaitons le meilleur des succès dans ses nouvelles fonctions.

L’ARPAC est très fière d’accueillir deux nouveaux membres au sein de son conseil d’administration. Bienvenue à Jean-François Allie et Miguel Senécal.

AUTOMOTIVE RECYCLERS OF MANITOBA (ARM) arm.mb.ca

The ARM are happy to report that its current executives have all agreed to stay on board for another year so thanks to Greg Lane, president; Emile Hogue, vice-president; George Shea, treasurer and Paul Jaihel, secretary.

For the vast majority of members, 2022 meant it was time for a Canadian Auto Recyclers Environmental Code (CAREC) audit. The organization said its participation in this process was seamless as every recycler wanted to score well and have bragging rights for the next three years.

This year, ARM also had the opportunity to celebrate the Motor Vehicle Industry of Manitoba (MVIM) 20th anniversary. ARM awarded two scholarships in the amount of $1200.00 each to deserving applicants. We look forward to working with the MVIM for many more years to come.

“We have seen our industry come full circle and have never been a more valued integral part of the repair process while assisting repair facilities with their parts request and quite often salvaging the cycle times that are more important now than ever,” concludes ARM.

L’Automotive Recyclers of Manitoba (ARM) est heureuse d’annoncer que ses dirigeants actuels ont tous accepté de rester à bord pour une autre année. Merci à Greg Lane, président, Emile Hogue, vice-président, George Shea, trésorier et Paul Jaihel, secrétaire.

Pour la grande majorité des membres, 2022 signifiait qu’il était temps de procéder à une vérification du Code environnemental des recycleurs automobiles du Canada (CERAC). L’organisation a déclaré que sa participation à ce processus s’est déroulée sans heurts, car chaque recycleur voulait obtenir un bon score et avoir le droit de se vanter pour les trois prochaines années.

Cette année, l’ARM a également eu l’occasion de célébrer le 20e anniversaire de la Motor Vehicle Industry of Manitoba (MVIM). L’association a attribué deux bourses d’études d’un montant de 1 200 $ chacune à des candidats méritants. Nous sommes impatients de travailler avec la MVIM pendant de nombreuses années encore.

« Nous avons vu notre industrie boucler la boucle et n’avons jamais été aussi appréciée en tant qu’intervenant au processus de réparation, tout en aidant les installations de réparation à demander des pièces et, bien souvent, en récupérant les temps de cycle qui sont plus importants que jamais », conclut l’ARM.

16 CANADIAN AUTO RECYCLERS 2023 ASSOCIATION UPDATES | DES NOUVELLES PANCANADIENNES

ALBERTA AUTOMOTIVE RECYCLERS AND DISMANTLERS ASSOCIATION (AARDA) aarda.com

At the close of 2022, AARDA listed 59 full members and 23 associate members. As with many associations, AARDA was very pleased to be able to hold the annual conference after having to cancel it for the past two years due to COVID restrictions. The event was held in Red Deer in September with guest speaker Paul D’Adamo providing lots of information in addition to being a great entertainer! It was well attended, and everyone took something back to their business that they could profit from. The 2023 Conference was Set. It will be held in Calgary at the Blackfoot Hotel on September 15 and 16.

One of the key accomplishments from 2022 was creating a good relationship with Arthur J Gallagher Insurance. While many insurance companies are dropping recycling businesses, or drastically raising the rates, they are working to provide affordable coverage for members.

AARDA is also working with Chatterhigh to create a program for high school students that outlines the automotive recycling industry. This will be one of the options available through the life skills program that is used in Schools in Alberta.

AARDA is looking forward 2023 as there are exciting ideas and plans members want to association to look at.

À la fin de l’année 2022, l’Alberta Automotive Recyclers and Dismantlers Association (AARDA) comptait 59 membres à part entière et 23 membres associés. Comme de nombreuses associations, l’AARDA était très heureuse de pouvoir tenir sa conférence annuelle; après avoir dû l’annuler ces deux dernières années en raison des restrictions liées à la COVID. L’événement a eu lieu à Red Deer en septembre et le conférencier invité, Paul D’Adamo, a fourni beaucoup d’information en plus d’être un excellent amuseur! L’événement a attiré beaucoup de monde et chacun a rapporté quelque chose à son entreprise dont elle pourra tirer profit. La date et l’emplacement de la conférence de 2023 ont été fixés. Elle aura lieu à Calgary, à l’hôtel Blackfoot, les 15 et 16 septembre.

L’une des principales réalisations de 2022 a été de créer une bonne relation avec Arthur J Gallagher Insurance. Alors que de nombreuses compagnies d’assurance abandonnent les entreprises de recyclage ou augmentent radicalement les taux, cette compagnie s’efforce de fournir une couverture abordable aux membres.

L’AARDA collabore également avec Chatterhigh pour créer un programme destiné aux élèves du secondaire qui présente l’industrie du recyclage automobile. Ce programme sera l’une des options disponibles dans le cadre du programme d’apprentissage de la vie utilisé dans les écoles de l’Alberta.

L’AARDA se tourne vers 2023, car il y a des idées et des plans passionnants que les membres veulent que l’association examine.

B.C. AUTOMOTIVE RECYCLERS (BCAR)

ara.bc.ca/b-c-auto-recyclers-division

The British Columbia government is proceeding with its plans to bring electric vehicle lithium-ion batteries under its extended producer responsibility (EPR) framework. Beginning in 2023, lithium-ion batteries will become incorporated into the Recycling Regulation with full implementation starting in 2026. The Automotive Retailers Association (ARA) is working on its own plans to bring lithium-ion batteries under the scope of the province’s Vehicle Dismantling Regulation and is working on redesigning and modernizing its environmental audit system to work within an EPR framework.

A recent survey was sent out to B.C. auto recyclers regarding disposal of Toyota Prius hybrid electric vehicle batteries. Many recyclers in the province were unaware that Toyota operates a take-back program for its HEV batteries. However, according to the survey, only a small percentage of the total Prius batteries were being left in storage.

The Insurance Corporation of British Columbia (ICBC) has moved to a new pricing system for its recycled parts suppliers. In September of 2021, ICBC replaced the Allied recycled parts procurement system with Car-Part. Almost 50% of the recyclers in the province do not list their prices on the system with only a small percentage listing the majority of their inventory. The new policy will now only pay a collision repair shop for the listed price and all shipping costs to be included. Since shipping costs in BC vary with postal codes, including all the variations in with one listed price is seen as onerous.

Le gouvernement de la Colombie-Britannique va de l’avant avec son projet d’intégrer les batteries au lithium-ion des véhicules électriques dans son cadre de responsabilité élargie des producteurs (REP). À partir de 2023, les batteries au lithium-ion seront incorporées dans son règlement sur le recyclage et la mise en œuvre complète commencera en 2026. L’Automotive Retailers Association (ARA) travaille sur ses propres plans pour intégrer les batteries au lithium-ion dans le champ d’application du Vehicle Dismantling Regulation de la province et s’emploie à remanier et à moderniser son système de vérification environnementale pour qu’il fonctionne dans le cadre de REP. Un récent sondage a été envoyé aux recycleurs d’automobiles de la Colombie-Britannique concernant l’élimination des batteries des véhicules électriques hybrides Toyota Prius. De nombreux recycleurs de la province ne savaient pas que Toyota avait mis en place un programme de reprise de ses batteries de véhicules électriques hybrides. Cependant, selon l’enquête, seul un petit pourcentage de l’ensemble des batteries de Prius était laissé en entreposage.

L’Insurance Corporation of BC (ICBC) a adopté un nouveau système de tarification pour ses fournisseurs de pièces recyclées. En septembre 2021, l’ICBC a remplacé le système d’approvisionnement en pièces recyclées Allied par Car-Part. Près de 50 % des recycleurs de la province n’inscrivent pas leurs prix dans le système et seul un petit pourcentage d’entre eux y inscrivent la majorité de leurs stocks. Selon la nouvelle politique, le prix payé à un atelier de réparation de carrosserie sera désormais le prix indiqué et tous les frais d’expédition seront inclus. Étant donné que les frais d’expédition en Colombie-Britannique varient selon les codes postaux, l’inclusion de toutes les variations dans un seul prix affiché le rendrait onéreux. CAR

CANADIANRECYCLER.CA 17 ASSOCIATION UPDATES | DES NOUVELLES PANCANADIENNES

CANADIANRECYCLER.CA 17

TIME TO PLUG IN

ARC notes EV gaps for recyclers, key strategies in new report

By Steve Fletcher, managing director, Automotive Recyclers of Canada

By Steve Fletcher, managing director, Automotive Recyclers of Canada

The official Roadmap and Implementation Plan for the Management of End-of-Life (EOL) Electric Vehicles (EVs) in Canada has been prepared by the Automotive Recyclers of Canada (ARC) with the financial support of Natural Resources Canada’s Canadian Minerals and Metals Plan. The project began on May 1, 2022 and was completed on July 31, 2022. ARC is now communicating the results of this work and the next steps to its membership, other auto sector influencers, potential funders and beyond.

The roadmap report is a summary report that presents the business case for a national training and capacity-building program (including estimated three-year budgets and timelines) for Canadian auto recyclers/dismantlers to support their ability to manage and properly and safely dismantle the anticipated rapid growth of EOL EVs. The roadmap also contains five specific EV research, development and demonstration (RD&D) project opportunities that were identified through the project research and key informant interviews. Sections 5 through 8 provide background, context and other information that are used to inform the roadmap itself, which is described in detail in Sections 9 to 13.

The appendix contains ten brief research papers that address specific questions regarding the growth in EVs in Canada and the impact of this growth on the current and future EV recycling and dismantling sector across the country. These research papers (including a detailed survey with 122 ARC member companies—and several follow-up and key informant interviews) were key inputs to the development of the roadmap.

La feuille de route officielle et le plan de mise en œuvre pour la gestion des véhicules électriques (VE) en fin de vie au Canada ont été préparés par Automotive Recyclers of Canada (ARC) avec le soutien financier du Plan des minéraux et des métaux du Canada de Ressources naturelles Canada. Le projet a été lancé le 1er mai 2022 et s’est terminé le 31 juillet 2022. L’ARC dévoile maintenant les résultats de ce travail et les prochaines étapes à suivre notamment à ses membres, à d’autres influenceurs du secteur automobile et à des bailleurs de fonds potentiels.

Le rapport de la feuille de route est un rapport sommaire qui présente l’analyse de rentabilisation d’un programme national de formation et de renforcement des capacités (y compris les budgets et les échéanciers estimés sur trois ans) pour les recycleurs/démanteleurs d’automobiles canadiens afin de soutenir leur capacité à gérer et à démanteler correctement et en toute sécurité les VE en fin de vie qui devrait connaître une croissance rapide. La feuille de route contient également cinq possibilités de projets de recherche, de développement et de démonstration (R-D-D) propres aux VE qui ont été identifiées par l’étude sur le projet et les entrevues menées avec les principaux informateurs. Les sections 5 à 8 fournissent des renseignements de base, le contexte et d’autres éléments qui sont utilisés pour élaborer la feuille de route, décrite en détail dans les sections 9 à 13.

L’annexe contient dix courts documents de recherche qui abordent des questions précises concernant la croissance des VE au Canada et l’impact de cette croissance sur le secteur actuel et futur du recyclage et du démantèlement des VE à travers le pays. Ces documents de recherche (y compris une enquête approfondie menée auprès de 122 entreprises membres de l’ARC et plusieurs entrevues de suivi et avec les principaux informateurs) ont été des éléments clés dans l’élaboration de la feuille de route.

ELECTRIC EDUCATION | FORMATION SUR LES VE 18 CANADIAN AUTO RECYCLERS 2023

IL EST TEMPS DE SE BRANCHER

L’ARC note les lacunes des recycleurs en matière de VE et les principales stratégies à mettre en place dans un nouveau rapport.

The core recommendation from the roadmap is that, over the next three years a comprehensive, bilingual, in-person and online End-of-Life Electric national Vehicle Dismantler’s training program be designed and delivered to at least 400 dismantlers across Canada. The research for this report clearly shows that:

• The flow of EOL EVs to dismantlers is currently low, but is expected to grow in the coming years;

• ARC member companies are for the most part eager to take on this challenge, but are not yet ready or trained to properly do so;

• There is time to prepare for the coming EV transition but those preparations need to begin immediately;

• The safety and well-being of dismantlers (and others) may be at risk if the EV transition is not managed properly; and,

• The uncertainty regarding the economics of EOL EV recycling and dismantling is a concern.

The comprehensive training program includes five specific short ter complementary actions:

• Design, develop and deliver program materials and training to help ensure the safe, environmentally and cost-effective dismantling of all EOL EVs in Canada;

• Provide program materials and training both on-line and in-person formats, made available in both official languages and delivered across Canada;

• Given that the EV battery platform and design varies significantly from one EV brand to another, in-person training is considered essential to provide hands-on practice and experience to training program participants; on-line training will also be a key element of the overall long-term capacity-building program;

• Solicit the support of Employment and Social Development Canada (ESDC)—and other government departments and auto aftermarket sector leaders–in the design and delivery of EV training programs that offer direct subsidies to ARC/other businesses and individual dismantlers to ensure safe and environmentally sound practices; and

• Form a multi-party oversight organization (led by ARC) to guide the national expansion and on-going management of EV dismantler training, while also supporting the development and delivery of other related EV training materials at the national level as needed (e.g., for first responders; EV auto-mechanics, EV sales staff; EV trainers, supervisors, etc.). ARC’s recently created ZEV Alliance could serve this function.

There is still time to prepare for the coming EV transition; but those preparations need to begin immediately.

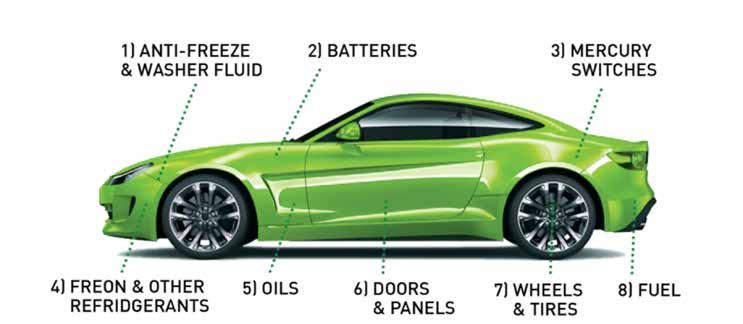

While there are knowledge gaps related to the range of metal and materials in EVs from different OEMs, EVs will have more copper and aluminum than internal combustion engine vehicles.

Bien qu’il existe des lacunes dans les connaissances relatives à la gamme de métaux et de matériaux dans les VE de différents équipementiers, les VE contiendront plus de cuivre et d’aluminium que les véhicules à moteur à combustion interne.

Il est encore temps de se préparer à la transition vers les VE, mais ces préparatifs doivent commencer immédiatement.

ELECTRIC EDUCATION | FORMATION SUR LES VE CANADIANRECYCLER.CA 19

The projected three-year cost for the training development/delivery and capacity building for the national dismantler training program is $3.9 million.

Le coût triennal prévu pour l’élaboration et la prestation de la formation et le renforcement des capacités pour le programme national de formation des démonteurs est de 3,9 millions de dollars.

La principale recommandation énoncée dans la feuille de route indique qu’au cours des trois prochaines années, un programme de formation complet, bilingue, en personne et en ligne, destiné aux démonteurs de véhicules électriques nationaux en fin de vie doit être conçu et offert à au moins 400 démonteurs au Canada. Les recherches effectuées pour ce rapport montrent clairement que :

• Le flux de VE en fin de vie vers les démonteurs est actuellement faible, mais devrait augmenter dans les années à venir.

• Les entreprises membres de l’ARC sont pour la plupart désireuses de relever ce défi, mais ne sont pas encore prêtes ou formées pour le faire correctement.

• Il y a du temps pour se préparer à la transition vers les VE à venir, mais ces préparatifs doivent commencer immédiatement.

• La sécurité et le bien-être des démonteurs (et d’autres personnes) peuvent être mis en danger si la transition vers les VE n’est pas gérée correctement.

• L’incertitude concernant l’économie du recyclage et du démantèlement des VE en fin de vie est une préoccupation.

Le programme de formation complet comprend cinq volets complémentaires particuliers à court terme :

• Concevoir, élaborer et offrir du matériel de programme et de la formation pour aider à assurer le démantèlement sécuritaire, écologique et rentable de tous les VE en fin de vie au Canada;

• Fournir du matériel de programme et de la formation en ligne et en personne, dans les deux langues officielles et dans tout le Canada;

FAST FACTS

• 122 respondents across Canada + additional 150 ARC industry contacts

- 45 percent from Ontario; 16 percent from Alberta; 11 percent B.C.

- Responses received from every province, says ARC

• 76 percent of ARC members currently handle EVs

- Six percent of respondents (four companies) reported storing 20+ batteries; two are storing 40+

- 60 percent report removing batteries and storing inside; 35 percent said they leave battery in vehicle and outside

- 49 percent report keeping batteries on-site as primary action with EV batteries; 35 percent report reselling battery as-is; 25 percent send for recycling and 13 percent said they’ve resold for repurposing

• The four most common EV parts sold by respondents: batteries, drivetrains, motors and inverters

• Étant donné que la plateforme et la conception de la batterie des VE varient considérablement d’une marque de VE à l’autre, la formation en personne est considérée essentielle pour fournir une expérience pratique aux participants du programme de formation; la formation en ligne sera également un élément clé du programme global de renforcement des capacités à long terme;

• Solliciter l’appui d’Emploi et Développement social Canada (EDSC) et d’autres ministères et chefs de file du secteur du marché secondaire de l’automobile, pour la conception et la prestation de programmes de formation sur les VE qui offrent des subventions directes aux ARC/ autres entreprises et aux démonteurs individuels afin d’assurer des pratiques sécuritaires et respectueuses de l’environnement; et

• Former un organisme de surveillance multipartite (dirigée par l’ARC) pour guider l’expansion nationale et la gestion continue de la formation des démonteurs de VE, tout en soutenant également le développement et l’offre d’autres matériels de formation liés aux VE au niveau national, selon les besoins (par exemple, pour les premiers intervenants, les mécaniciens de VE, le personnel de vente de VE, les formateurs de VE, les superviseurs, etc.) La ZEV Alliance, récemment créée par l’ARC, pourrait remplir cette fonction.

ELECTRIC EDUCATION | FORMATION SUR LES VE 20 CANADIAN AUTO RECYCLERS 2023

VIEW THE FULL REPORT AT: www.autorecyclers.ca/about-arc/ev-roadmap

The full report also identifies longer term EV training needs and opportunities and–as noted–five specific EV research, development, and demonstration (RD&D) project opportunities that were identified through the project research and key informant interviews. A three-year timeline and detailed budget estimates are contained in the final report. The projected three-year cost for the training development/delivery and capacity building for the national dismantler training program is $3.9 million.

Several potential funding and organizational support partners are also identified in the report including Employment and Social Development Canada; Environment and Climate Change Canada; Natural Resources Canada; BC’s EVFriendly Program (the developer of Canada’s first comprehensive EV training program) and various auto sector and after-market key players. ARC plans to begin outreach to each of these organizations in the coming months with the hope of an early 2023 national, three-year EV training program launch.

The development of an EV ecosystem in Canada is a once-in-a-lifetime opportunity to de-carbonize our vehicle transportation system and support long term Canadian prosperity. Dismantler training is a central element of the rapidly developing EV ecosystem. ARC member companies are very concerned about the safety and well-being of their dismantler staff and other auto aftermarket agents.

There are significant personal and business risks if the EV transition across Canada is not managed in a timely and proper manner. CAR

FAITS RAPIDES

• 122 personnes à travers le Canada + 150 autres contacts de l’industrie de l’ARC ont répondu au sondage

- 45 pour cent de l’Ontario; 16 pour cent de l’Alberta; 11 pour cent de la C.-B.

- Des réponses ont été reçues de toutes les provinces, selon l’ARC

• 76 pour cent des membres de l’ARC traitent actuellement des VE

- Six pour cent des répondants (quatre entreprises) ont déclaré stocker plus de 20 batteries; deux en stockent plus de 40.

- 60 pour cent des répondants ont indiqué qu’ils retiraient les batteries et les entreposaient à l’intérieur; 35 pour cent ont dit qu’ils laissaient les batteries dans le véhicule et à l’extérieur.

- 49 pour cent des répondants ont indiqué que la conservation des batteries sur place était la principale mesure prise à l’égard des batteries de VE; 35 pour cent ont indiqué qu’ils revendaient les batteries telles quelles; 25 pour cent les envoyaient au recyclage et 13 pour cent ont indiqué qu’ils les revendaient pour les réutiliser.

• Les quatre pièces de VE les plus vendues par les répondants sont les suivantes : batteries, transmissions, moteurs et onduleurs.

Le rapport complet énonce également les besoins et les possibilités de formation à plus long terme en matière de VE et, comme indiqué, cinq possibilités de projets de recherche, de développement et de démonstration (R-D-D) propres aux VE qui ont été mis en évidence par l’étude sur le projet et les entrevues avec les principaux informateurs. Un calendrier triennal et des estimations budgétaires détaillées figurent dans le rapport final. Le coût prévu sur trois ans pour l’élaboration et la prestation de la formation et le renforcement des capacités pour le programme national de formation des démonteurs est de 3,9 millions de dollars.

Plusieurs partenaires potentiels de financement et de soutien organisationnel sont également identifiés dans le rapport, notamment Emploi et Développement social Canada, Environnement et Changement climatique Canada, Ressources naturelles Canada, le programme EVFriendly de la Colombie-Britannique (qui a élaboré le premier programme complet de formation sur les VE au Canada) et divers acteurs clés du secteur automobile et du marché secondaire. L’ARC prévoit entreprendre des démarches auprès de chacune de ces organisations au cours des prochains mois dans l’espoir de lancer un programme national de formation sur les VE au début de 2023.

Le développement d’un écosystème de VE au Canada est une occasion unique de décarboniser notre système de véhicules de transport et de soutenir la prospérité canadienne à long terme. La formation des démonteurs est un élément central de l’écosystème des VE qui se développe rapidement. Les entreprises membres de l’ARC sont très préoccupées par la sécurité et le bien-être de leur personnel de démontage et des autres agents du marché secondaire de l’automobile.

Il existe des risques importants aux niveaux individuel et commercial si la transition vers les VE au Canada n’est pas gérée de manière appropriée et en temps opportun. CAR

ELECTRIC EDUCATION | FORMATION SUR LES VE CANADIANRECYCLER.CA 21

VOIR LE RAPPORT COMPLET À L’ADRESSE SUIVANTE :

www.autorecyclers.ca/about-arc/ev-roadmap.

GONE TOO SOON

Tesla has been talking big about its in-house insurance platform recently, and how it is providing insights on potential design improvements, but some recent reporting from Reuters has found that far too many of the electric automaker’s vehicles are turning up as salvage prematurely. In a compilation of 120 Model Y vehicles found on salvage auction listings, Reuters found that a “vast majority” of the listed vehicles had less than 10,000 miles (approx. 160,000 km.) on the odometer, according to data obtained from Copart and IAA. All the Model Ys in the analysis were 2022 or 2023 models, and were built at either the Fremont, Calif. or Austin, Texas, plant, according to Reuters. Of the 120 listed vehicles, 14 of them were identified as long-range variants of the Model Y that were likely only built within the last year. Recent comments made by Tesla execs during a Q4 earnings call point to an effort on the part of the company to use data collected from its insurance division to make design changes that make the vehicles cheaper to repair, and therefore, out of an early grave in a salvage yard. “Previously we didn’t have good insight into [the cost of repair]. The other insurance companies would cover the cost, and the cost in some cases would be unreasonably high. So, we have actually adjusted the design of the car, and made changes in the software of the car, to minimize the cost of repair,” said Tesla CEO, Elon Musk. “We’re actually solving how to get somebody’s car repaired very quickly and efficiently and back in their hands quickly.”

DISPARU TROP TÔT

Tesla a beaucoup parlé de sa plateforme d’assurance interne récemment, et de la façon dont elle fournit des informations sur les améliorations potentielles de la conception, mais un rapport récent de Reuters a révélé que beaucoup trop de véhicules du constructeur électrique sont récupérés prématurément. Dans une compilation de 120 véhicules Model Y trouvés sur des listes d’enchères de récupération, Reuters a constaté qu’une « grande majorité » des véhicules listés avaient moins de 10 000 miles (environ 160 000 km) au compteur, selon les données obtenues de Copart et IAA. Tous les modèles Y analysés étaient des modèles 2022 ou 2023, et ont été construits dans l’usine de Fremont, en Californie, ou d’Austin, au Texas, selon Reuters. Sur les 120 véhicules répertoriés, 14 d’entre eux ont été identifiés comme des variantes à longue portée du Model Y qui n’ont probablement été construites qu’au cours de l’année dernière. Les commentaires récents des dirigeants de Tesla lors d’une conférence téléphonique sur les résultats du quatrième trimestre indiquent que l’entreprise s’efforce d’utiliser les données recueillies par sa division d’assurance pour apporter des modifications à la conception des véhicules afin de les rendre moins coûteux à réparer et, par conséquent, de leur éviter une tombe précoce dans une cour de récupération. « Auparavant, nous n’avions pas une bonne idée [du coût de la réparation]. Les autres compagnies d’assurance couvraient le coût, et dans certains cas, le coût était déraisonnablement élevé. Nous avons donc ajusté la conception de la voiture et modifié son logiciel afin de minimiser le coût des réparations », a déclaré Elon Musk, PDG de Tesla. « Nous sommes en train de résoudre la question de savoir comment faire réparer la voiture de quelqu’un très rapidement et efficacement et la remettre entre ses mains rapidement. »

PROGRESS FOR PROGI

Progi has announced that going forward, Quebec vehicles sold on the ProgiPix car auction platform will be made available to all buyers with a Canadian operating license. The Quebec-based company is opening the floodgates to all accredited auto recyclers operating in Canada with this news, which operations director Frederic Miceli says plays into an ongoing shift of Progi’s overarching business model. “Our vision has always been to provide a platform designed by and for automotive recyclers and that is the direction we are heading in. We invite new buyers to the table with a desire to create more opportunities for Canadian recyclers,” said Miceli.

PROGRÈS POUR PROGI

Progi a annoncé qu’à l’avenir, les véhicules québécois vendus sur la plateforme d’enchères automobiles ProgiPix seront accessibles à tous les acheteurs possédant un permis d’exploitation canadien. La société québécoise ouvre les vannes à tous les recycleurs d’automobiles accrédités exerçant leurs activités au Canada avec cette nouvelle, qui, selon le directeur des opérations Frédéric Miceli, s’inscrit dans le cadre d’un changement continu du modèle d’affaires global de Progi. « Notre vision a toujours été de fournir une plateforme conçue par et pour les recycleurs d’automobiles et c’est la direction que nous prenons. Nous invitons de nouveaux acheteurs à la table avec le désir de créer plus d’occasions pour les recycleurs canadiens », a déclaré Miceli.

Alongside this news, Miceli added that Progi is launching a new project in Quebec that will see recyclers working alongside insurers to help them source parts, and by extension, help them compete in new markets. “The goal is for Progi and the Canadian recycling community to move forward together as we have since our founding,” he said.

Parallèlement à cette nouvelle, Miceli a ajouté que Progi lance un nouveau projet au Québec qui permettra aux recycleurs de travailler en collaboration avec les assureurs pour les aider à s’approvisionner en pièces, et par le fait même, à être concurrentiels sur de nouveaux marchés. « L’objectif est que Progi et la communauté canadienne du recyclage progressent ensemble, comme nous l’avons fait depuis notre fondation », a-t-il déclaré.

NEWS | NOUVELLES 22 CANADIAN AUTO RECYCLERS 2023

Leading Buyers of scrap aLuminum WheeLs Call us today for a quote www.eccomelt.com www.houseofmetals.ca (888) 356-WHLS (9457) Michael Horowitz: michael@eccomelt.com • ext 105 Chad Hayes: chad@eccomelt.com • ext 104 Eneida Di Giorgio (purchasing coordinator): eneida@eccomelt.com • ext 114 Locations: 45 Commercial Rd, Toronto, Canada M4G 1Z3 101 Delano Dr, Manchester, Georgia, USA 31816-1832 6605 Rankin Rd, Humble, Texas, USA 77396 Like Primar y. Only Better. Competitive Prices • Prompt Payments • Quick Delivery

WE’LL MISS YOU, MARY

Mary Poirier from Valley Automotive in Pembroke Ontario has stepped down from the Automotive Recyclers of Canada Board of Directors after an incredible run of service. Poirier was appointed to the Board of ARC as one of the Ontario representatives in 2009 and has held the position of Recording Secretary since that time. “I’ve been on the ARC Board for quite a while. I’ve seen a lot of changes, and had the joy of working with some of Canada’s best auto recyclers. But it is time to hand the reins over to the next generation of auto recyclers. Big changes are coming to the industry, and the younger generation needs to have their say and be involved.” Poirier continues to serve on the Board of Directors of the Ontario Automotive Recyclers Association (OARA) in the position of Treasurer. Poirier’s replacement on the Board is Corey Earl from Hotch’s Auto Parts in Prince Edward County Ontario. Corey brings with him decades of experience in automotive recycling as a second-generation auto recycler.

MOST RELIABLE PRE 8AM DELIVERY SERVICE

Understanding the importance of time within your transportation strategy, means you can move at the speed of your customer, not your carrier. Cardinal’s Pre 8am transportation solutions and unique night network provide a competitive advantage where first to market comes standard. Expect Cardinal’s night network with unattended pickups and deliveries to deliver a competitive advantage to your business.

Cardinal is a wholly owned Canadian company that has built its reputation as the most reliable Pre 8am delivery service for time-sensitive goods and parts, servicing communities across Ontario and Quebec.

Mary Poirier served on the ARC Board of Directors for 13 years.

Mary Poirier a siégé au conseil d’administration de l’ARC pendant 13 ans.

TU VAS NOUS MANQUER, MARY

Mary Poirier, de Valley Automotive à Pembroke (Ontario), a quitté le conseil d’administration d’Automotive Recyclers of Canada après un incroyable parcours. Mary a été nommée au conseil d’administration de l’ARC en tant que représentante de l’Ontario en 2009 et a occupé le poste de secrétaire de séance depuis cette date. « Je siège au conseil d’administration de l’ARC depuis un bon moment. J’ai vu beaucoup de changements et j’ai eu la joie de travailler avec certains des meilleurs recycleurs d’automobiles du Canada, a déclaré Mary. Mais il est temps de passer les rênes à la prochaine génération de recycleurs d’automobiles. De grands changements s’annoncent dans l’industrie, et la jeune génération doit avoir son mot à dire et s’impliquer. » Mary continue de siéger au conseil d’administration de l’Ontario Automotive Recyclers Association (OARA) au poste de trésorière. Son remplaçant au sein du conseil est Corey Earl, de Hotch’s Auto Parts, du comté de Prince Edward, en Ontario. Corey apporte avec lui des décennies d’expérience dans le recyclage d’automobiles en tant que recycleur de deuxième génération.

NEWS | NOUVELLES 24 CANADIAN AUTO RECYCLERS 2023

Pre 8am Package Delivery Dedicated Logistics

Call 1-(800)-387-3199 | cardinalcouriers.com 6600 Goreway Dr., Unit D Mississauga, ON L4V 1S6

Pre 8am LTL Delivery

AND STAY THERE

Nissan executive Nic Thomas claims that almost all of the EV batteries the OEM has ever made are “still in cars.” “We haven’t got a great big stock of batteries that we can convert into something else,” said Thomas, who serves as the U.K. marketing director for Nissan. “It’s the complete opposite of what people feared when we first launched EVs—that the batteries would only last a short time.” Nissan has only collected a “relatively small” number of Leaf batteries, according to Thomas. The stock has largely come from collision total losses or warranty issues, and some of the recovered batteries were recycled into solar panels to supply backup power to the Johan Cruijiff Arena in Amsterdam. Other Leaf batteries will be dismantled and reused in consumer-level portable energy storage packs—that is, “when [Nissan has] got some batteries to go into them,” said Thomas. “But by far the easiest thing to do is take the complete battery out of the vehicle, put it in a shipping container in a rack and plug that into a solar farm,” he added. The International Energy Agency estimates that the world has enough global capacity to recycle 180,000 metric tons of used EV batteries annually—but recycling analysts believe that EVs bought in 2019 alone will eventually generate more than 500,000 metric tons of battery waste.

Une batterie de Nissan Leaf. Nissan affirme avoir collecté un nombre « relativement faible » de batteries de Leaf.

ET RESTEZ-Y

Nic Thomas, cadre de Nissan, affirme que la quasi-totalité des batteries de VE que l’équipementier a fabriquées sont « toujours dans les voitures ». « Nous n’avons pas un grand stock de batteries que nous pouvons convertir en autre chose, a déclaré M. Thomas, qui occupe le poste de directeur du marketing de Nissan au Royaume-Uni. C’est tout le contraire de ce que les gens craignaient lorsque nous avons lancé les VE, à savoir que les batteries ne dureraient que peu de temps. Nissan n’a collecté qu’un nombre « relativement faible » de batteries de Leaf, selon M. Thomas. Le stock provient en grande partie de pertes totales dues à des collisions ou de problèmes de garantie, et certaines des batteries récupérées ont été recyclées en panneaux solaires pour fournir une alimentation de secours à la Johan Cruijiff Arena d’Amsterdam. D’autres batteries de la Leaf seront démontées et réutilisées dans des packs de stockage d’énergie portables destinés au grand public, c’est-à-dire lorsque [Nissan aura] des batteries à mettre dedans, a déclaré M. Thomas. Mais le plus simple, et de loin, est de retirer la batterie complète du véhicule, de la placer dans un conteneur d’expédition et de la brancher sur une ferme solaire », a-t-il ajouté.

NEWS | NOUVELLES CANADIANRECYCLER.CA 25

A Nissan Leaf battery. Nissan says it has collected a “relatively small” number of Leaf batteries.

ENOUGH FLUFF

A Toronto-area auto recycler has received some mainstream attention for his calls to automakers to develop recycling procedures that properly account for non-metal waste, which often winds up in a landfill. In a story published in the Toronto Star, president of Scarborough’s Standard Auto Wreckers’ David Gold spoke on how, much like with the aftermarket’s Right to Repair movement, Canada’s auto recycling sector needs a framework in place to allow dismantlers to be able to do their jobs as thoroughly and sustainably as possible. “Plastics, fabrics, foams are all shredder ‘fluff’ that is bound for landfill because the economics of it doesn’t make sense,” said Gold, who said he wants to see automakers engage with recyclers to advise on how best to deal with end-of-life vehicles. “They don’t provide any information on dismantling their vehicles,” he said. “We’re working on a Right to Repair Act. Maybe it’s time for a Right to Recycle Act, as well.”

SUFFISAMMENT DE DÉCHETS

Un recycleur d’automobiles de la région de Toronto a attiré l’attention du grand public en demandant aux constructeurs automobiles d’élaborer des procédures de recyclage qui tiennent compte des déchets non métalliques, qui finissent souvent dans les décharges. Dans un article publié dans le Toronto Star, le président de Standard Auto Wreckers de Scarborough, David Gold, a expliqué que, tout comme le mouvement Right to Repair du marché secondaire, le secteur canadien du recyclage automobile a besoin d’un cadre pour permettre aux démonteurs de faire leur travail de manière aussi complète et durable que possible. « Les plastiques, les tissus, les mousses sont tous des déchets de broyage qui sont destinés à être mis en décharge parce qu’ils ne sont pas rentables, a déclaré M. Gold, qui souhaite que les constructeurs automobiles collaborent avec les recycleurs pour les conseiller sur la meilleure façon de traiter les véhicules en fin de vie. Ils ne fournissent aucune information sur le démantèlement de leurs véhicules, a-t-il déclaré. Nous travaillons sur un projet de loi sur le droit à la réparation. Peut-être est-il temps d’adopter une loi sur le droit au recyclage également. »

A report from Environment and Climate Change Canada found that only 35 percent of end-of-life vehicles are properly dismantled and recycled, while the rest usually end up in the hands of metal shredders, whose job it is not to separate metal from non-metal materials, or on ships to foreign markets.

Un rapport d’Environnement et Changement climatique Canada a révélé que seulement 35 pour cent des véhicules en fin de vie sont correctement démantelés et recyclés, tandis que le reste finit généralement entre les mains de broyeurs de métaux, dont le travail n’est pas de séparer le métal des matériaux non métalliques, ou sur des bateaux à destination des marchés étrangers.