SEMA SHOWCASE

Check out the hot new products fresh off the SEMA stage

Saskatchewan Polytechnic’s

autobody students breathe new

Check out the hot new products fresh off the SEMA stage

Saskatchewan Polytechnic’s

autobody students breathe new

Simplify your body shop processes today.

The 3M OEM Match Family of seam sealing products are engineered to help technicians of all skill levels more easily replicate the appearance and function of a vehicle’s original factory seam sealer.

The system includes our line of seam sealer matching tips and the 2K 3M™ OEM Match Epoxy Seam Sealer in 4 colours –allowing you to replicate the most common OEM seams with one simple application.

The 3M OEM Match Family of seam sealing products are engineered to help technicians of all skill levels

more easily replicate the appearance and function of

In October, Scott Kucharyshen, Saskatchewan Polytechnic auto body program head and instructor, announced the success of this year’s auto body technician students as they refined their skills refinishing a 1959 Impala convertible from being altered almost beyond recognition to better than new.

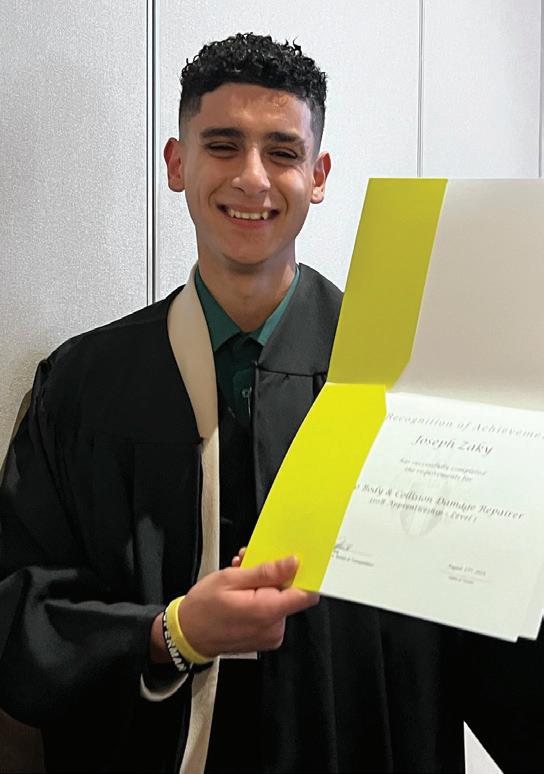

Tropicana Community Services recently celebrated the graduation of its 2023 and 2024 classes in the Auto Body and Collision Damage Repairer 310B PreApprenticeship

Check out the highlights here.

BY DARRYL SIMMONS

As we close the year and look to the road ahead, the collision repair industry continues to inspire with its dedication to craftsmanship, innovation and community. Each page of this issue celebrates the passion that drives us all— be it students restoring the timeless beauty of a 1959 Impala, seasoned professionals

shaping the industry’s future. But we need your help to make it extraordinary. Get involved and send in your nominations— not just for technicians, but for painters, appraisers, office staff and anyone under 40 making a difference in the collision repair world. Let’s recognize the breadth of talent and dedication that defines our

We’re thrilled to announce a special “20 Under 40” edition of Collision Repair magazine, spotlighting young leaders shaping the industry’s future. Let’s recognize the breadth of talent and dedication that defines our industry and ensure every role gets the spotlight it deserves.

mentoring the next generation or forwardthinking innovators reshaping our industry with cutting-edge tools and techniques.

Now, more than ever, it’s essential to spread the word about the opportunities and creativity that collision repair offers. Let this issue of Bodyworx Professional serve as a rallying cry to promote our industry. Share it with your network, hand it to someone curious about their next career move or send a link to our website. Together, we can inspire new talent and encourage more people to discover the rewarding paths available in collision repair.

Next spring, we’re thrilled to announce a special “20 Under 40” edition of Collision Repair magazine, spotlighting young leaders

industry and ensure every role gets the spotlight it deserves.

As we head into a new year, let’s commit to fostering a vibrant, inclusive and innovative collision repair community. By sharing stories like those in this issue and participating in initiatives like “20 Under 40,” we’re not just celebrating our achievements; we’re building a legacy that will attract and retain talent for generations to come.

Here’s to driving forward—together.

11, ISSUE 4, 2024

PUBLISHER

Darryl Simmons publisher@collisionrepairmag.com

ASSOCIATE PUBLISHER

Orest Tkaczuk | orest@mediamatters.ca

EDITOR

Allison Rogers | allison@mediamatters.ca

ART DIRECTOR

Yvonne Maschke | yvonne@mediamatters.ca

ASSISTANT EDITOR

Sarah Perkins | sarah@mediamatters.ca

VP OF INDUSTRY RELATIONS & ADVERTISING

Gloria Mann 647.998.5677 | gd.mann@rogers.com

INDUSTRY RELATIONS ASSISTANT

Wanja Mann 647.998.5677

wanjamann1@gmail.com

DIGITAL OPERATIONS MANAGER

Cassie Doyle | cassie@mediamatters.ca

AUDIENCE ENGAGEMENT MANAGER

William Simmons | william@mediamatters.ca

INTERACTIVE MEDIA DESIGNER

Dayna Dicuangco | dayna@mediamatters.ca

DESIGN INTERN

Trinity Nguyen | designintern@mediamatters.ca

SUBSCRIPTION

One-year $25 / Student Discount is 10%

Bodyworx Professional ™ is published quarterly, and is dedicated to serving the professionals of the collision repair industry. It is published by Media Matters Inc. Material in BodyworxProfessional™ may not be reproduced in any form without written consent from the publisher. The publisher reserves the right to refuse any advertising and disclaims all responsibilities for claims or statements made by its advertisers or independent columnists. All facts, opinions, statements appearing in this publication are those of the writers and editors themselves, and are in no way to be construed as statements, positions or endorsements by the publisher.

PRINTED IN CANADA ISSN 1707-6072

CANADA POST CANADIAN PUBLICATIONS MAIL SALES PRODUCT AGREEMENT No. 40841632 RETURN POSTAGE GUARANTEED

Send change of address notices and undeliverable copies to: 317 Reid St., Peterborough ON K9J 3R2

“We acknowledge the financial support of the Government of Canada.”

Bodyworx Professional is published by Media Matters Inc., publishers of:

When you invest in a Fix Auto franchise, you invest in a business model with a proven track record in 12 countries around the world. You invest in a fully branded business with a roadmap for success. You invest in the same values and work ethic that grew your local business to what it is today.

Drive your business forward with:

• Solid performance-driven operational model and ongoing training.

• Full branding and marketing support for local awareness and promotion.

• Proven experience in winning insurance work.

• Established global supply and fleet arrangements. Our owner started as a franchisee, and this inspires our commitment to the success of the local business owner.

Manitoba is reinstating its one-to-one apprentice-to-journeyperson ratio as of October 30, though collision centres may apply for exemption to keep the two-to-one ratio via the Automotive Trades Association (ATA) of Manitoba. ATA of Manitoba President Norm Bruneau said the organization will link the applicable apprenticeship forms on its website. “We’re happy to assist shops through this change and help them find the resources they need to hopefully run their business with minimal disruption,” he originally told Collision Repair mag. Existing apprenticeship agreements may continue if employers have been permitted to have journeypersons supervise more than one apprentice; apprentices actively demonstrate continued progress; and if journeypersons do not take on additional apprentices.

A new report from CCC Intelligent Solutions titled “Moments of Truth: Customer Satisfaction and Retention in the Auto Insurance Claims and Repair Journey” reveals that customers see the collision process as a unified experience between repairers and insurers. The study specifically looked at responses from 2,400 policyholders involved in an accident between August 2021 and December 2023 who filed a first-party claim and went through the repair process. The study reveals that when it comes to customer satisfaction, “policyholders hold both carriers and repairers accountable for outcomes that are the responsibility of other partners. For example, respondents are more satisfied with their carriers when they perceive overall vehicle repair quality to be high, and they’re also more satisfied with their repairer when they receive clear communications about how the claims process works.”

18.0

Furthermore, the study outlines three moments where the most powerful predictors of customer switching behaviour occur and these include: in a total loss, the policyholder was upside down in their outstanding loan and was able to cover the gap; the presence of an injury in an accident; and being a first-time claim filler with any insurer.

Bill 190, the Working for Workers Five Act, 2024, which aims to create “alternate criteria” for entering the skilled trades, is set to be reviewed and voted on by Ontario members of the Provincial Parliament (MPPs). The bill outlines how alternate pathways would include: introducing the Focused Apprenticeship Skills Training (“FAST”) program for high school students to get apprenticeship training alongside their regular studies; launching an online job portal to help apprentices, journeypersons, and employers to connect easily for networking and job opportunities; and creating alternative paths into skilled trades for career changers based on professional experience, bypassing strict academic requirements. While no date has been set for the most recent vote on Bill 190, the MVRO said it is likely to happen in the coming weeks.

On October 15, Vance Badawey, Member of Parliament, Niagara Centre and Parliamentary Secretary to the Minister of Transport, announced a $365,854 investment from the federal government into Niagara College’s Motive Power program. This funding will be matched by the college through the 2023 Canadian Apprenticeship Strategy ‘Investments in Training Equipment’ program stream. Collision Repair mag reached out to Wayne Toth, professor and program coordinator of Niagara College’s Motive Power program who commented that it is “an innovative program that is giving students the chance to get hands-on experience analyzing and solving complex motive system programs. With the guidance of experienced faculty, students learn to diagnose and repair mechanical, electronic and electrical motive power components and systems in state-of-the-art labs.”

The Shop at Youth Unlimited is using donated used vehicles from the community to help youth at risk of homelessness, addiction and mental illness to receive hands-on automotive repair training. The charity organization has been working with young people in the Newmarket and Cambridge, Ontario area since 2003. Program Director Mark Dean originally told Barrie Today that “we do skills mentoring by training youth between the ages of 15 and 25 in the automotive trade. People donate cars which can be refurbished and then those cars are re-sold to fund The Shop. Youth work alongside us in refurbishing the cars while receiving valuable skills training. The vehicle donations help transform young lives.”

The Saskatchewan Distance Learning Centre (Sask DLC) has extended partnership agreements with the Saskatchewan Automobile Dealers Association (SADA) and the Saskatchewan Association of Autobody Repairers (SAAR) to help offer work placement options for high school students. Both associations have signed a two-year partnership extension with Sask DLC to enhance learning opportunities through work placement options for students taking online mechanical and automotive or autobody courses. SAAR will provide an annual investment of $20,000 to fund a coordinator position with Sask DLC that will also facilitate work placements enrolled in Sask DLC’s autobody courses. SADA will continue an annual investment of $40,000 to fund the delivery of Sask DLC’s mechanical and automotive program, including a coordinator position to set up student work placements.

Through this initiative, students taking Autobody 10 will be able to do full-online theory or combine it with a 25-hour work placement. Moreover, students in the program’s Autobody A20 and Autobody B20 will be able to complete 50 hours of online theory as well as a 50-hour work placement.

A new report from Clean Energy Canada, “Opening the Door,” indicates that switching to an electric vehicle can lead to significant household savings in all provinces except for Alberta. While the savings vary for detached homes, townhouses and condos, in all provinces except Alberta, households are saving money over time by making sustainable upgrades, the study notes. When looking at Clean Energy Canada’s data, Ontario consumers are positioned to save approximately $551 when making sustainable energy switches in a detached house; $421 for a townhouse; and $220 for a condo. By comparison, Alberta consumers are only looking at approximately $21 in savings for a detached home; $64 in a townhouse; and $51 for a condo.

In October, Durham College announced the launch of its new Electric Drive Vehicle Technician (EDVT) program–one of only two programs offered in Ontario. As noted in a media release, “in addition to technical skills, students will develop critical problem-solving abilities by working on real-world scenarios in state-of-the-art shops, simulating the complexities they’ll encounter in the field. By the time they graduate, they’ll have completed a 56-hour EV capstone project that fuses learning from previous course work in electric and hybrid vehicle technology, offering a hands-on project-based experience.”

A recent report from Bloomberg shares a history of serious health and safety violations at automaker Rivian’s plant in Normal, Illinois, including a former employee claiming to have experienced “Rivian Blue” bile after painting R1T pickup trucks without PPE. Notably, 20-year-old Addison Zwanzig told Bloomberg that within weeks of beginning to work at Rivian in July 2023, she complained of dizziness, alongside other symptoms such as nausea and vomiting, leading to weight loss. After requesting that her supervisor provide her with a respirator—which she reportedly saw other colleagues using—her request was declined. By September, Zwanzig said she was seeing doctors regarding what she described as blue-tinted vomit. Following this symptom, Rivian then provided a respirator the following month and further provided personal protective equipment (PPE) to other employees.

It’s an age-old question: can a Mercury Sable sedan withstand the gravitational force of a giant pumpkin? At this year’s Damariscotta Pumpkinfest and Regatta in Damariscotta, Maine, event organizers attempted to answer this question by dropping a 1,000-pound pumpkin onto said vehicle. This year’s event saw the Pumpkin Drop back in full force when a roughly 1,000-pound pumpkin was dropped by a crane from 200 feet off the ground and onto a Mercury Sable sedan. In a video of the event, the pumpkin successfully crushes the vehicle’s roof panel, buckling the rear doors and bending the A-pillars at a seasonally appropriate scary angle.

FBY SARAH PERKINS

or students pursuing careers in autobody repair, gaining diverse hands-on experience is essential. Engaging with a wide array of materials, techniques and vehicle types— both old and new—not only builds technical skills, but also instills the confidence needed to tackle real world challenges.

In October, Scott Kucharyshen, Saskatchewan Polytechnic Auto Body program head and instructor, announced the success of this year’s Auto Body Technician students as they refined their skills refinishing a 1959 Impala convertible from being “altered almost beyond recognition,” to better than new.

When speaking with Bodyworx Professional magazine, Kucharyshen commented that “at Saskatchewan Polytechnic, each cohort of autobody certificate students undertakes a unique restoration project. This year’s cohort tackled a 1959 Impala Convertible that had endured significant abuse over its lifetime. The car was left outside to face Saskatchewan’s harsh weather, used as a pace car with flagpole holes cut into the quarter panels. A Buick

Nailhead engine and a three-speed standard transmission were haphazardly welded in, and the lower 15 centimetres of the car had nearly disintegrated due to time, abuse and salt exposure.”

Kucharyshen further highlighted how auto body technician students tackled the repair and restoration project, which first began with understanding that, as with almost all vehicles, this 1959 Impala Convertible left the dealership shiny and new but fell into disrepair over time. That is, until the current owner discovered it, recognized its value and decided to restore it to its former glory.

From here, Sask Polytech students worked on the body of the car. The owner dismantled it and delivered the body to the Saskatoon campus, where students replaced the floor, repaired the body and rotisserie-painted the car. Students performed a firewall, main floor and trunk floor replacement, complete with bracing. The quarter panels and wheelhouses were partially repaired and replaced, while the rest of the car, including the fenders, doors, hood and trunk, were either repaired, patched or replaced.

“Hands-on experiential learning is the most effective way for autobody students to learn. It directly connects theory to real-life scenarios.”

— Scott Kucharyshen, Saskatchewan Polytechnic Auto Body Program Head and instructor

And, when considering the value of the project, Kucharyshen was quick to outline how this project gave students the opportunity to be part of the overall experience.

“Hands-on experiential learning is the most effective way for autobody students to learn. It directly connects theory to real-life scenarios. As students progress through the program’s learning outcomes, they apply what they learn in the classroom to their hands-on assignments in the shop, ensuring each part of the car is completed correctly. If a task isn’t done properly, they must redo it to meet roadworthy standards.”

Moreover, just as the collision repair industry is a community dedicated to ensuring continued automotive safety, for Kucharyshen, so too is autobody work and education team based.

“Autobody work requires each student to contribute to the projects’ overall progress. Students must work on their communication and teamwork skills throughout the program and to meet the project deadlines. Students are challenged at their individual skill levels,

with advanced students tackling tougher assignments.”

With vehicles becoming more and more technologically advanced, Saskatchewan Polytechnic makes sure to balance the old and the new, so that students can be better prepared for all outcomes. Kucharyshen specifically stressed how special circumstances on vintage cars may arise, providing instructors with opportunities to teach beyond the standard curriculum, offering autobody students valuable extras. This approach builds class camaraderie that can last for years to come.

“Repairing vintage cars, like the 1959 Impala Convertible is a rewarding experience for both students and instructors. We receive many requests to work on and restore vintage cars. To be considered, each car must

meet our Auto Body Technician certificate training requirements, have supplies and parts that we can either produce or purchase, and have the owner who can prepare the car in advance for student work. In the Auto Body Technician certificate program, we also work on late-model, low-mileage collision vehicles. Currently, we have three 2020 and newer collision-damaged vehicles in the shop.”

When asked about the value of restoration projects alongside potential technological training, Kucharyshen concluded that “working on vintage vehicles keeps our faculty excited about the training and connected with industry developments, including parts availability, tool advancements and repair procedures. When students are excited about their projects, so are we. I enjoy staying on campus after hours

with students to help them paint and often spend my evenings researching and planning future projects while learning the history of a bygone era.

“It’s always exciting to see a vintage car restored by Sask Polytech students and reminiscing about our time working on the vehicle is a rewarding experience. It highlights the lasting impact of our hands-on learning experience.”

Ultimately, Kucharyshen is excited for both the future of the 1959 Impala Convertible and the restoration projects to come as students continue to build their skills.

“Once finished and assembled by the owner, we hope this car will be seen on the streets and at numerous car shows, providing students with a lasting memory of their time at Saskatchewan Polytechnic.”

FOR CHRIS CHINN, DRIVING CHANGE IN THE COLLISION REPAIR INDUSTRY HAPPENS IN THE CLASSROOM AS MUCH AS ON THE SHOP FLOOR

BBY SARAH PERKINS

eing an educator and repairing a vehicle—while perhaps not immediately related on paper—involve a foundation of shared characteristics. Both are a process of care, community and an attention to detail that inspires both creativity and passion.

For Chris Chinn, Network Operations Manager at Consolidated Collision Services (CCS) and professor at Centennial College, educating is similarly an effort to create connections within the industry and spark interest for an industry that is constantly evolving.

Bodyworx Professional sat down with Chris Chinn to learn more about what initially brought him into the industry, and what continues to keep him passionate day-to-day.

When asked about his initial journey in collision repair, Chinn highlighted how he— like so many who find their footing working on vehicles—has always had a love of cars.

“I’ve always loved cars and the challenges that fixing them presents. I started working in the collision repair industry in 1982 when my father was able to put me in contact with a bodyshop that he was familiar with.”

“From there, I just continued to explore the industry. I’ve worked at dealerships and independent shops, and I’ve been the owner and manager of my own shop.”

However, it was in 1996 that Chinn formed his first connection with CCS—a decision that would set him on the path to his current role.

“In 1996, I got into the paint side of things and started working with CCS as a paint tech rep, which ultimately led me to where I am today. I had a desire to get into the front-end side of the business, and it was through this process that I also discovered my love for teaching.”

When asked about what it’s like to be an educator in today’s industry, Chinn emphasized that his main challenge is trying to help overcome the ongoing technician and talent shortage.

“I first began working with Centennial as a result of the Covid-19 pandemic. During the pandemic, many colleges had to reduce their class sizes and needed additional professors. A friend of mine who works with Centennial contacted me and asked if I would be interested in teaching.”

“I had attended Centennial as a student in the 80s, and so I really see the opportunity now as a chance to try and give back to the community that has supported me.”

Despite the ongoing challenges in advertising the industry to youth, for Chinn, he sees his unique position as the chance to “try and bring a different perspective to students as someone who is still closely involved in the industry, and who can provide real world case studies.”

He also frequently volunteers at women in the trades events to try to bring interest in the industry across a diverse range of prospective students.

And, when asked what his biggest achievement has been so far, Chinn was quick to comment that it’s all about seeing his students succeed.

“The best part, for me, about being an educator is seeing my students get jobs within the industry. That’s one of the benefits of my position. As someone who still works closely with the collision repair industry, I am able to help students make those vital connections needed to get their first start.”

In order to do this, Chinn further noted that it’s vital for those already well-established in the industry to continue to stay educated.

“I want to keep students aware of the constant changes within the industry—especially when it comes to vehicle technology—and to do this, I also take courses and work on achieving I-CAR Platinum standards in all categories. Learning is a constant journey.

My advice for educators, or for those in a similar position, ‘always strive to be a better and more informed version of yourself than you were the day before.’”

Finally, when asked how CCS University—a platform that aims to share information and education between members—helps in maintaining a strong knowledge base, Chinn outlined how it’s all about creating integration.

“CCS University offers recorded training— well over 100 videos on different topics—that can help members stay up-to-date on industry trends and repair knowledge. Members are able to dial in from all over the country and in doing so, are able to more easily network together to share what they’ve learned,

“In 1996, I got into the paint side of things and started working with CCS as a paint tech rep, which ultimately led me to where I am today. I had a desire to get into the front-end side of the business, and it was through this process that I also discovered my love for teaching.”

—

or what they’re experiencing in their section of the industry.”

“I believe,” Chinn concluded, “that I have been fortunate to have had many people in my career that have helped me, guided me, and annoyed me enough to help me succeed. CCS has encouraged me and allowed me the flexibility to share my time and experience with students to contribute to the sustainability of our trade. If you’re in the industry, no matter in what capacity, be a mentor. Share your knowledge and experience with the next generation. We all play a part in the future. I have yet to see a computer or any type of artificial intelligence that can fix a collision damaged vehicle, we still need people! Let’s all try to do what we can where we can.”

BY ALLISON ROGERS AND SARAH PERKINS

This year’s SEMA Show——which took place from November 5 to 8, 2024—may have come and gone, and with it, the afterimage of the bright lights of Las Vegas, Nevada in attendees eyes, but when it comes to the hottest products for the collision repair industry, the glitz and glamour of the spotlight stage is never far behind.

More than just a showcase of the latest products and innovations, the SEMA Show is a vibrant gathering of like-minded professionals eager to share knowledge and insights.

When looking at all the SEMA showroom had to offer, Bodyworx Professional’s first visit was a special unveiling at AkzoNobel’s Central Hall booth. Here, the coatings company once again hosted brand ambassador, custom car builder and designer and painter Dave Kindig—owner of Kindig-It Designs and star of Motor Trend’s Bitchin’ Rides.

Alongside some truly impressive car designs, on the scene Bodyworx reporters also had the opportunity to see PPG’s Moonwalk automatic paint mixing system in action.

Held at the ‘Moon Walk’ van outside of the convention centre, PPG representatives discussed how digital tools are helping to reshape the way paint is mixed and applied in the collision repair sector. The exclusive

media tour further allowed attendees to engage directly with the representatives to discuss the impact of technology on paint processes.

And, when considering the future of technology within the industry, another highlight of the event was the announcement of the 2024 winners of the New Product Showcase. Here, I-CAR Academy walked away with the top prize as the best new Collision Repair/Refinish product. Runners-up were Sagola SPRAY (Sagola by Elcometer) and the RTS app from I-CAR, respectively. Additionally, the best new ADAS product was awarded to Revv ADAS Plus by Revv ADAS. Here, runners-up were Revv ADAS Mechanical by Revv ADAS and Solar Wireless Driving Assistant by Vision Automobile Electronics Industrial.

Overall, more than 1,600 products were entered into the 18 different Showcase categories to be considered for a SEMA New Product Award. Winners were selected based on a variety of factors, including superiority of innovation, technical achievement, quality and workmanship, consumer appeal and marketability and more.

So, while the glitz and glamour may be finished for another year, relive the highlights by checking out exclusive photos and product descriptions here.

This limited-edition SATAjetX 5500 Lowrider is a topquality spray gun available in both HLVP and RP compliant technologies. SATA says the spray gun is perfect for spraying all types of topcoats, sealers and clears. Plus, the SATAjet X 5500 Lowrider is a limited production special edition surface coating that will help you stand out. This spray gun is available across the United States and Canada at authorized SATA distributors.

BY HUNTER ENGINEERING

Launched in Summer 2024, Hunter University is a new global learning platform designed for easily accessible training for customers, technicians, technical school instructors, students and other interested parties. The Hunter University platform, which is available in 21 languages, collects all of Hunter’s extensive learning content in a single place, offering dozens of free online courses worldwide, as well as streamlined registration for hands-on, in-person courses at training centres around the United States. Hunter Engineering notes that all existing content was updated and refreshed as part of the nine-month effort, often converting from dynamic modules with narration and video. The online courses are generally presented in five-minute segments, so even a 10-module course can be completed in approximately one hour.

Experience hands-on spray painting training without the mess! Developed by expert spray paint technicians, the Sagola SPRAY VR program allows refinishers-in-training to master essential techniques in a safe and eco-friendly environment. Practice repeatedly to refine your skills while saving paint and materials. Receive instant feedback to learn from your mistakes and improve your technique. Discover the perfect gun distance for a flawless finish, adjust your hand positioning for optimal fan patterns, and understand the ideal speed for effective spraying. Elevate your craftsmanship and gain confidence in your abilities with our innovative virtual reality training!

The winner of the SEMA Best New Product — ADAS Category, Revv ADAS is a SaaS platform that allows collision repair facilities and calibration businesses to identify new revenue streams from required ADAS, safety, steering and functional calibrations on repaired vehicles. According to the company, Revv ADAS Plus delivers a complete calibration identification solution with an advanced rules engine, workflow management, CCC and Mitchell integrations, as well as customizable options for each shop. The program allows for advanced quoting based on labour rates, insurance or vehicle make, plus seamless billing and invoicing via Quickbooks integration.

The revolutionary Pro Spot Ergo Lift Assist™ System (ELA) is the tallest and most versatile motorized boom mechanism for spot welding applications. Designed to reach higher (9.25’ / 2.82 m) and lower (5’ / 1.5 m) than most conventional booms, the ELA makes spot welding any area on today’s high reach/wide footprint vehicles accessible and ergonomic. The Ergo Lift Assist™ is designed for today’s high-profile SUVs, vans and trucks, and the battery-powered ELA has over nine feet of vertical reach.

3M and Axalta have announced a collaboration to introduce a new training content series focused on automotive refinishing. The series will feature five co-branded training modules, each intended to meaningfully help technicians and shops improve their understanding of repair process practices and drive greater operational outcomes. The first three training modules from the series centred on optimizing process productivity, efficiency and quality in refinishing, are scheduled for release globally on December 2, 2024, and will be accessible through the 3M™ Collision Repair Academy and Axalta Academy platforms. The training content will also be made available on 3M and Axalta’s social media channels. Additional training modules focused on safety and sustainability will become available in 2025.

Winner of SEMA’s Best New Electric Vehicle Product, Formosa EV’s Vehicle Control Unit (VCU) simplifies EV conversions by acting as a universal translator between components. The company says this eliminates the need for CAN bus programming. Normally, setting up the communication between car parts requires a lot of technical programming, though Formosa says its VCU removes this hassle. The product itself is designed for DIY enthusiasts and is said to offer easy set-up via a user-friendly mobile app. The VCU is said to be automotive-grade and OEMtested, according to Formosa EV.

The companies made the collaboration announcement during Industry Week in Las Vegas, Nevada. Pictured above: Patricia Morschel, vice president of marketing and commercial operations for Axalta global refinish; Troy Weaver, director of global refinish, Axalta; and Dave Gunderson, president, 3M Automotive Aftermarket division.

The GPR Star Vortex Cooler is a cooling solution designed to improve the performance of glue pull repair (GPR). It rapidly cools down hot glue, allowing technicians to work faster and more efficiently by minimizing wait times during the repair process. The GPR Star Vortex Cooler—not yet available in Canada—is said to be ideal for shops and locations where ambient temperatures are elevated. The cooling effect of the vortex action reduces temperatures and times between pulls, according to KECO.

WINNER

SEMA BEST NEW EV PRODUCT!

Tropicana Community Services recently celebrated the graduation of its 2023 and 2024 classes in the Auto Body and Collision Damage Repairer 310B PreApprenticeship Program. Marking 14 years of the organization’s dedication to skills development in the Canadian collision repair industry, the ceremony highlighted the program’s role in addressing the skilled labour needs of Ontario’s autobody sector.

Having taken place at Centennial College, this year’s ceremony held special significance as, for the first time, graduates were awarded Certificates of Achievement from the college, recognizing their technical training and readiness for careers in collision repair. Tropicana’s President & Chair of the Board, Anthony Grey, and leaders from Centennial College joined family, friends and industry stakeholders in honouring the hard work and dedication that each graduate brought to their studies and hands-on work placements.

The Pre-Apprenticeship Program, funded by the Government of Canada as well as Ontario’s Ministry of Labour, Immigration, Training and Skills Development, provides tuition-free training to participants aged 18 years to 30 years, including academic upgrading; 12 weeks of technical instruction and valuable paid work placements. This rigorous 30-week program has equipped graduates with not only the skills required for entry-level work in autobody repair but also the confidence and experience to excel in a competitive field.

Awards were also handed out during the ceremony, including the Toyota Canada scholarship, facilitated through the Black Business and Professional Association (BBPA). Through this two-year scholarship, recipients can access funds to further their education and training toward obtaining a Red Seal Ontario Apprenticeship in the trade of Auto Body and Collision Damage Repairer 310B Apprenticeship. This year’s recipient is Nya Excell.

Tropicana also awarded the Class of 2024 Tropicana Community Services Student Success Scholarship to Dylan Christensen, Jay Patel, John Paul Mukhwan and Nkili Codrington. The Tropicana Community Services Student Success Scholarship is a cash award, paid towards the recipient’s level 2 administrative fees, if they continue their apprenticeship career path. It is awarded to graduating students who have achieved a cumulative GPA of 4.0 or greater.

Finally, the Community Award was given to retired auto body professor Jim Miles and Alan McClelland, retired dean at Centennial College. This award celebrates years of dedicated service, hard work and other valuable contributions toward the success of the Auto Body & Collision Damage Repairer 310B Pre-apprenticeship Level 1 program.

Tropicana’s community-focused approach extends to its industry partners, whose contributions play a vital role in supporting graduates through scholarships, employment

Having taken place at Centennial College, this year’s ceremony held special significance as, for the first time, graduates were awarded Certificates of Achievement from the college, recognizing their technical training and readiness for careers in collision repair.

opportunities, and hands-on industry exposure. The partnership with the industry is crucial and Tropicana’s collaborative efforts have paved the way for these graduates to begin fulfilling careers. As the demand for skilled trades grows across Canada, programs like Tropicana’s, continue to fuel the collision repair industry’s future, preparing graduates to lead with professionalism and skill.

For more information on Tropicana Community Service’ Auto Body & Collision Damage Repairer 310B Pre-apprenticeship Level 1 program, visit tropicanacommunity.org/auto-body-collisiondamage-repairer-pre-apprenticeship

BY SARAH PERKINS

In an industry traditionally dominated by men, achieving excellence often requires not just skill and dedication, but also an unwavering commitment as a stand out woman. This is particularly true in the collision repair industry where technology and innovation are driving transformative changes. At the forefront of this evolution stands Cynthia Vilez, CSR at CARSTAR Torcam Group, whose contributions are not just helping to shape the industry but also setting new standards of excellence.

Like so many who come to find themselves developing a long-lasting passion for the collision repair industry, Cynthia originally started her role by taking a chance on a new opportunity.

“I originally got into the industry through a friend,” she reported to Collision Repair magazine. “He was hired at another shop associated with CARSTAR Torcam Group and he told me that I would be a good fit for helping to run the front of a shop.”

“I’ve been in customer service for a long time,” Cynthia further reported, “and I ran the front of a hair salon for years before beginning to work in the front of CARSTAR Torcam Group . But, when I first entered the industry 15 years ago, I didn’t start with a

strong knowledge base of collision repair and so that has definitely been a continuous learning curve.”

As a result, when she first began in the role, Cynthia worked hard to build up a strong knowledge base and notes that her expertise today would not have been possible without the help of coworkers and the collision repair community.

“Having originally entered the collision repair industry without a lot of background knowledge, I’ve found that there are always a lot of people willing to help and to offer support.”

“At CARSTAR Torcam Group, we have a great team, and we always work together to help customers.”

When looking at a typical day in the industry, Cynthia outlined how while “there’s a lot of paperwork involved, the interaction with customers is always a high point.”

Here, Cynthia and Sebastian Torres, owner and General Manager of CARSTAR Torcam Group even jokingly discussed how one long term customer occasionally brings the shop wine to thank them for their quality service and then later comes back to retrieve and return the bottle.

And, in having been a part of the collision repair scene now for almost two decades, Cynthia has also been able to observe noticeable shifts in the industry.

One of the main differences that she has seen is shifts in generational expectations between older generation customers versus younger generation customers’ expectations of service.

Another notable shift has been in the diversity of vehicles now entering the shop’s doors, such as an increase in the number of electric vehicles needing repairs.

However, for Cynthia, rather than customer interaction or changes in technology, the biggest challenge in the industry has been being a woman in a traditionally male dominated space.

“While it’s not so much a challenge now, when I first started out, I found it difficult to be a woman in the industry. This was especially the case with more traditional clientele who were used to, at the time, interacting with a man.”

“This is something that has definitely shifted in a more positive direction,” Cynthia commented. “The office at CARSTAR Torcam Group is now mostly women and we’re currently trying to grow the back and get more women here too.”

On this note, Sebastian further commented that “in my experience, some of the best managers I have seen over the years have been women. We really lean into this because the women we have at CARSTAR Torcam Group right now can do it like no other.”

And, in doing it like no other, Cynthia has successfully grown the shop’s charity initiatives into a large-scale event.

“My biggest achievement is definitely getting to work on our charity initiatives. At the shop, we do an annual car wash every year and we’ve watched it grow from me being alone, essentially running and organizing the car wash to Sebastian and I running the car wash today with a committee.”

As part of the CARSTAR banner, CARSTAR Torcam Group raises money for Cystic Fibrosis Canada, and this year, the shop raised $12,000 for the charity.”

In describing her efforts, Sebastian was quick to make sure that Cynthia refrained from selling herself short.

“It wasn’t until Cynthia started at the shop and started running the committee that we really started to see the increase in the amount

“It wasn’t until Cynthia started at the shop and started running the committee that we really started to see the increase in the amount of funds that we’ve raised for Cystic Fibrosis Canada. It’s been all through her relationship with vendors and customers. Cynthia is and always has been someone who shows what best practices are to achieve success.” --- Sebastian Torres, owner and General Manager of CARSTAR

“My biggest achievement is definitely getting to work on our charity initiatives. At the shop, we do an annual car wash every year and we’ve watched it grow from me being alone, essentially running and organizing the car wash to Sebastian and I running the car wash today with a committee.”

The Mini-Ductor Venom HP is the highest powered Mini-Ductor at 1800 watts. This handheld induction heater generates high-frequency magnetic fields to produce a flameless heat™ that releases ferrous metal from rust, corrosion and thread lock compounds.

“My advice,” said Cynthia, “would be, don’t be afraid to ask for help. It’s always okay to ask questions and to remember that everyday is a learning curve. I still learn something new everyday and have found that knowledge is everything.”

of funds that we’ve raised for Cystic Fibrosis Canada. It’s been all through her relationship with vendors and customers. Cynthia is and always has been someone who shows what best practices are to achieve success.”

In looking towards the future, Cynthia hopes to continue cultivating her collision repair knowledge and using the best practices that have for so long made her a vital part of the CARSTAR Torcam Group team.

“Going forwards, I am definitely looking to go into a leadership role with Sebastian, who is in the process of developing a back office,

and I would love to be part of it in order to continue growing with the company and do a customer service management role.”

“We’ve just acquired a fourth location to the group,” Sebastian said. “With that fourth location, we’ve found the need for shared centralized services. One of the main things we were talking about was ‘what does a training centre look like?’ and this year, we’ve started performance groups for different aspects of the business. Where Cynthia will come in is that we’re going to be doing a performance group for CSRs and I asked her to help me lead

it. As early as November this year, Cynthia is going to help me teach best practices so that everything is consistent among the stores.”

Finally, when asked about advice she has for those looking to enter the collision repair industry, whether this be as a repairer or on the customer service end, Cynthia concluded that it’s all about “just being positive.”

“My advice would be, don’t be afraid to ask for help. It’s always okay to ask questions and to remember that everyday is a learning curve. I still learn something new everyday and have found that knowledge is everything.”

Looking for your next career move or top talent to join your team? Our job board is the perfect place to connect candidates with the right opportunities and help employers find exceptional talent. With a streamlined design, advanced search features, and updated listings across industries, we make job hunting and hiring easier than ever.

Whether you’re a job seeker ready for a fresh start or a company looking to build your dream team, our platform is designed to meet your needs. Explore opportunities, post jobs, and take the next step in your career journey with us!

BY ALLISON ROGERS

As we wrap up this issue of Bodyworx Professional, let’s take a moment to reflect on the wild ride we call the collision repair industry. From paint mismatches to dent dilemmas, we’ve all navigated the ups and downs. Some days, it feels like we’re living a never-ending episode of a reality show, complete with drama and unexpected plot twists.

Yet, through it all, one thing remains clear: this is our passion. Even when the going gets tough—and trust me, it can get pretty tough—we find joy in the art of restoration. Whether you’re a painter bringing a vehicle back to life, a bodyperson making dents disappear or a customer service rep turning frowns into smiles, each of you plays a crucial role in this world. You are the backbone

Through it all, one thing remains clear: this is our passion.

of this industry, and your hard work does not go unnoticed.

In the stories shared throughout this issue, you’ll find reminders that every job has its ups and downs. Some days will test your patience more than others, but don’t let frustration overshadow your passion. Remember that the satisfaction of seeing a job well done is worth the struggle. It’s those moments—the rush when you nail that perfect colour match or the joy of handing a satisfied customer their keys—that remind us why we chose this path.

And let’s not forget the unsung heroes in the customer service department, who juggle complaints and requests with a smile.

Your ability to turn frustrations into laughter is nothing short of legendary. You’re the glue that holds everything together, making sure our customers feel valued and understood.

As you head back into the shop, remember to stick to what you love. Hone your craft, embrace the chaos, and take pride in the incredible work you do. We truly have it pretty good, despite the challenges we face.

Together, let’s continue to celebrate our passion and lift each other up. After all, it’s not just about fixing cars; it’s about the community we build along the way. Keep pushing forward, and let your passion guide you through the tough days.

Happy 2025, team. This year will be one for the books.

The SATAjet X 5500 and limited. The special edition pays tribute to Lowrider car culture began in Los Angeles, California, in the midto-late 1940s, and has now spread worldwide.

Now available from SATA Canada in 1.3 “I” and “O” nozzles in both RP and HVLP technologies – while stocks last.