A tribute to Steve Fletcher’s industry acheivements

Un hommage aux réalisations de Steve Fletcher dans l’industrie HOMMAGE À

A tribute to Steve Fletcher’s industry acheivements

Un hommage aux réalisations de Steve Fletcher dans l’industrie HOMMAGE À

Truckmart’s

parcours

MEET OARA’S NEW EXECUTIVE DIRECTOR, MAT DAGONAS VOICI LE NOUVEAU DIRECTEUR GÉNÉRAL DE L’OARA, MAT DAGONAS

WELCOME WILLY DINGMAN AS ARC MANAGING DIRECTOR BIENVENUE À WILLY DINGMAN, ADMINISTRATEUR DIRIGEANT DE L’ARC

WOMAN OF THE INDUSTRY 2025: CANDICE BROWN FEMME DE L’INDUSTRIE 2025 : CANDICE BROWN

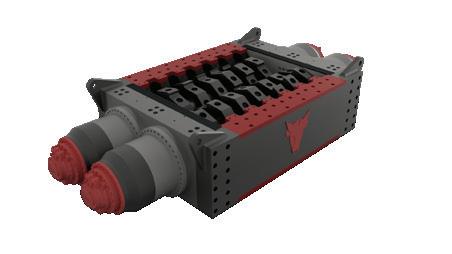

Meet this year’s cover stars from JS Truckmart. American Jeremy Swanson found success in auto recycling, partnering with Christa and Bart Morhart to create JS Truckmart, a Saskatchewan-based company crushing it—literally and figuratively—in the industry.

Voici les vedettes de la couverture de cette année, JS Truckmart. L’Américain Jeremy Swanson a trouvé s’est associé à Christa et Bart Morhart pour créer JS Truckmart, une entreprise basée en Saskatchewan qui connaît un succès monstre dans l’industrie.

Meet Mathieu Dagonas, the new executive director of the Ontario Automotive Recyclers Association (OARA).

Annual Publication / Édition annuelle spécial

Volume 19 Issue 1, 2025 Volume 19 numéro 1, 2025

PUBLISHER / DIRECTEUR GÉNÉRAL

Darryl Simmons > publisher@collisionrepairmag.com

ASSOCIATE PUBLISHER / ÉDITEUR ASSOCIÉ

Orest Tkaczuk > orest@mediamatters.ca

EDITOR / RÉDACTEUR EN CHEF

Allison Rogers > allison@mediamatters.ca

ASSISTANT EDITOR / ASSISTANT RÉDACTEUR Sarah Perkins > sarah@mediamatters.ca

CREATIVE DEPARTMENT / DÉPARTEMENT CREATIF Yvonne Maschke > yvonne@mediamatters.ca

VP INDUSTRY RELATIONS & ADVERTISING/ V.P. RELATIONS AVEC L’INDUSTRIE Gloria Mann > advertising@collisionrepairmag.com

SALES ASSISTANT/ASSISTANT DES VENTES Wanja Mann > advertising@collisionrepairmag.com

Candice Brown of Brown’s Auto Salvage believes this business is a community affair. Hear more about how this emerging leader serves the trade in this year’s Woman of the Industry profile. Candice Brown, de Brown’s Auto Recycling, estime que cette entreprise est une affaire de communauté. Lisez le profil Femme de l’industrie pour découvrir comment cette jeune dirigeante répond aux besoins de l’industrie.

Voici Mathieu Dagonas, nouveau directeur général de l’Ontario Automotive Recyclers Association (OARA). 16 44 54

Canadian Auto Recyclers looks back on Steve Fletcher’s contributions as executive director of OARA and managing director of the Automotive Recyclers of Canada. Canadian Auto Recyclers se penche sur les contributions de Steve Fletcher en tant que directeur général de l’OARA et administrateur dirigeant de l’Automotive Recyclers of Canada.

Wally Dingman, incoming Automotive Recyclers of Canada (ARC) managing director, shares his plans for the association. Wally Dingman, nouveau directeur général d’Automotive Recyclers of Canada (ARC), explique ses projets pour l’association.

Meet the next generation of auto recycling! Young pioneers Tom Charlton, Max Winkler, and Adam Budden share their inspiring journeys and bold predictions for the industry. Faites la connaissance de la nouvelle génération en recyclage automobile! Les jeunes pionniers Tom Charlton, Max Winkler et Adam Budden racontent leurs parcours inspirants et leurs prévisions audacieuses pour l’industrie.

DIGITAL OPERATIONS MANAGER/ DIRECTEUR DES OPÉRATIONS NUMÉRIQUES Cassie Doyle > cassie@mediamatters.ca

AUDIENCE ENGAGEMENT MANAGER/ RESPONSABLE DE L’ENGAGEMENT DU PUBLIC William Simmons > william@mediamatters.ca

CONTRIBUTORS / CONTRIBUTEURS

Mathieu Dagonas, Steve Fletcher Dalbert Livingstone

Gloria Mann at 647-998-5677

Pour les demandes de message publicitaire téléphonez à Gloria Mann au 647-998-5677.

Canadian Auto Recyclers magazine is dedicated to serving the business interests of the automotive recycling industry. It is published by Media Matters Incorporated. Material in Canadian Auto Recyclers magazine may not be reproduced in any form without written consent from the publisher. The publisher reserves the right to refuse any advertising and disclaims all responsibilities for claims or statements made by its advertisers or independent columnists. All facts, opinions and statements appearing within this publication are those of the writers and editors themselves, and are in no way to be construed as statements, positions or endorsements by the publisher. Media Matters Incorporated would like to thank the Ontario Media Development Corporation and the Province of Ontario for the generous support in helping launch Canadian Auto Recyclers magazine. PRINTED IN CANADA ISSN 1707-6072 CANADA POST CANADIAN PUBLICATIONS MAIL SALES PRODUCT AGREEMENT No. 40841632 RETURN POSTAGE GUARANTEED. Send change of address notices and undeliverable copies to: 86 John Street, Thornhill, ON L3T 1Y2. Canadian Auto Recyclers magazine is published by Media Matters Inc. publishers of; Collision Repair magazine, Bodyworx Professional magazine and the 2006 Collision Repair Training Directory

We acknowledge the financial support of the Government of Canada through the Canada Periodical Fund of the Department of Canadian Heritage.

Collision Repair magazine is published by Media Matters Inc., publishers of:

Après Steve Fletcher: écoresponsabilité, appui et mesures de l’industrie

By/Article de Gloria Mann

Here we are again, presenting another edition of Canadian Auto Recycler to our loyal audience! I’m thrilled to share my thoughts on the exciting times ahead.

Let’s start with sustainability and our shift toward climate-conscious actions. This involves ongoing education in safe dismantling and handling of EVs, as well as promoting the use of recycled parts to stabilize CO2 levels.

Auto recyclers play a crucial role in the transition to zero-emissions vehicles. This shift is not just a trend; it requires our immediate attention.

We must also address the potential tariffs from the United States and the impact this could have on our industry. As noted by the Automotive Recyclers of Canada (ARC), it’s vital to support local Canadian parts to strengthen our economy during these challenging times.

On another note, I feel it is necessary to express my gratitude to Steve Fletcher for his contributions to the industry as he moves to the International Roundtable on Auto Recycling. Steve, the team at Canadian Auto Recyclers wishes you the best in this new role.

I’m excited to welcome Mathieu Dagonas as the new executive director of OARA. I look forward to continuing our collaboration to provide valuable content for Canadian auto recyclers.

Additionally, let’s welcome my friend Wally Dingman as the managing director of the ARC. I’m eager to see how his expertise will strengthen our industry.

Thank you, dedicated readers, for picking up another issue of Canadian Auto Recycler. This marks our 19th year, and we’re proud of it. Keep up the great work, stay informed, and let’s continue paving the way toward a sustainable future. CAR

Nous revoici avec un nouveau numéro de Canadian Auto Recycler! C’est une époque tout à fait passionnante qui s’annonce. Tout d’abord, parlons d’écologie et de notre virage vers l’action écoresponsable. Parmi les éléments clés de ce virage, notons la formation continue en matière de démantèlement et de manutention sécuritaires des VE, et la promotion de l’utilisation de pièces recyclées pour stabiliser les émissions de CO2.

Les recycleurs automobile jouent un rôle crucial dans la transition vers des véhicules zéro émission. Ce virage n’est pas qu’une tendance, mais bien d’un mouvement qui requiert notre attention immédiate.

Il nous faut aussi garder à l’esprit les éventuels tarifs des États-Unis et leurs répercussions sur notre industrie. Comme l’a déclaré l’Association des recycleurs automobiles du Canada (ARC), il est crucial de promouvoir les pièces canadiennes pour solidifier notre économie en cette époque difficile.

Dans un autre ordre d’idées, je tiens à exprimer à Steve Fletcher ma gratitude pour sa contribution à l’industrie à l’occasion de son passage à la Table ronde internationale sur le recyclage automobile. Steve, les meilleurs vœux de toute l’équipe de Canadian Auto Recycler t’accompagnent dans ce nouveau rôle.

Je suis ravie d’accueillir Mathieu Dagonas à titre de directeur général de l’OARA et de collaborer avec lui pour continuer de fournir aux recycleurs canadiens un contenu des plus utile.

J’accueille aussi mon ami Wally Dingman au poste d’administrateur dirigeant de l’ARC. J’ai hâte de le voir à l’œuvre; son expertise ne peut que renforcer notre industrie.

Merci à vous, chers lecteurs dévoués, de nous lire une fois de plus. Ce numéro de Canadian Auto Recycler marque notre 19e année, et nous en sommes très fiers. Poursuivez votre excellent travail, restez informés, et continuons ensemble à tracer la voie vers un avenir durable. CAR

We also need to keep in mind potential U.S. tariffs and their impact on our industry.

Les entreprises de recyclage automobile du Canada sont à l’avant-garde du développement durable.

At LKQ, the “R” in P.A.R.T. stands for Recycled OEM parts. LKQ first began 25 years ago through the acquisition of several auto salvage yards, and through the years, LKQ has grown to become the largest recycler of vehicles in the industry. LKQ now operates more than 125 auto recycling yards across North America. Through its state-of-the-art processes, LKQ recycles or re-sells more than 90% of the materials from end-of-life vehicles that would otherwise end up in landfills.

The Canadian auto recycling industry continues to progress

L’industrie Canadienne du recyclage automobile continue à progresser

CANADIAN AUTO RECYCLERS 2019 EDITION

With Frank Serravale, Thorold Auto Parts

“Just read our issue! It looks great. Thank you. It is an honour to have been featured on the cover of Canadian Auto Recyclers.”

“Lisez juste notre publication ! Ça a l’air très bien. Merci. C’est un honneur d’être en couverture de Canadian Auto Recyclers.”

CANADIAN AUTO RECYCLERS 2020 EDITION

With Terry Carter, Aldon Auto

“Being on the cover of Canadian Auto Recyclers[it] was a chance to give the industry a look at my dad’s on-site museum, Al’s Toy Barn and its fifty collector cars.”

« Faire la couverture de Canadian Auto Recyclers [c’était] l’occasion de donner à l’industrie un coup d’œ coup d’œ regard sur le musée sur place de mon père, Al’s Toy Barn et une cinquantaine de voitures de collection. »

To view past issues of Canadian Auto Recyclers magazine or to advertise or subscribe visit canadianrecycler.ca

With Ron Bastarache, Bastarache Auto Salvage

“It was a great honour for our family business, Bastarache Auto Salvage, to be recognized and featured on the cover of Canadian Auto Recyclers. This magazine has made for outstanding exposure of our late father’s dream in visualizing and achieving his goal. The positive feedback of the people who read this interesting story were truly impressed with our remarkable success.”

« C’est un grand honneur pour notre entreprise familiale, Bastarache Auto Salvage, d’être reconnue et de figurer sur la couverture de Canadian Auto Recyclers. Ce magazine a fourni une exposition exceptionnelle du rêve de notre défunt père de visualiser et d’atteindre son objectif. Les commentaires positifs de ceux qui ont lu cette histoire intéressante ont été vraiment impressionnés par notre succès remarquable. »

CANADIAN AUTO RECYCLERS

2022 EDITION

With Pierre Robitaille, Recycleur Duvernay

“Just received my issue of Canadian Auto Recyclers in the mail—very nice. Thank you to Canadian Auto Recyclers magazine for all your hard work on the story. You did a nice job and the story came out great.”

« Je viens de recevoir mon exemplaire de Canadian Auto Recyclers par la poste - très bien. Merci au magazine Canadian Auto Recyclers pour tout le travail que vous avez fait sur l’histoire. eVous avez fait un excellent travail et le produit fini était très bon. »

CANADIAN AUTO RECYCLERS

2023 EDITION

With Stuart Ady, Ernie’s Auto Parts

“Seeing our facility highlighted in the annual edition of CanadianAutoRecyclers was an incredible feeling. To see the story of my career and to look back on how far we’ve come as a business was the greatest part of this feature opportunity.”

« Voir notre installation mise en évidence dans l’édition annuelle de Canadian Auto Recyclers a procuré un sentiment incroyable. C’est principalement grâce à mon expérience professionnelle et au chemin parcouru en tant qu’entreprise que nous avons eu cette occasion. »

CANADIAN AUTO RECYCLERS 2024 EDITION

With Natalie and Chris Miller, Miller’s Auto Recycling

“Last year, being featured on the cover of Canadian Auto Recyclers magazine was more than just an honor—it was a milestone that reflected decades of dedication, innovation, and leadership in the auto recycling industry. At Miller’s Auto Recycling, we take immense pride in our commitment to sustainability, efficiency, and providing top-quality recycled auto parts. Seeing our team and facility recognized in such a prestigious publication was a testament to the hard work and passion that drives us every day. This recognition not only celebrated our achievements but also reinforced our mission to push the industry forward. We are grateful for the support of our customers, partners, and our fellow auto recyclers, and we look forward to continuing to set the standard for excellence in auto recycling across Canada.”

« Figurer en couverture du magazine Canadian Auto Recyclers, l’année dernière, était non seulement un honneur, mais une étape marquante faisant foi de plusieurs décennies de dévouement, d’innovation et de leadership dans l’industrie du recyclage automobile. Chez Miller’s Auto Recycling, nous sommes très fiers de notre volonté d’écoresponsabilité et d’efficacité, ainsi que ne de notre engagement à fournir des pièces automobiles recyclées de qualité supérieure. Le fait que notre équipe et notre établissement soient reconnus dans une publication aussi prestigieuse témoigne de l’ardeur et de la passion qui animent notre travail au quotidien. Non seulement cette reconnaissance a-t-elle permis de célébrer nos réalisations, mais elle a également confirmé notre mission de faire avancer l’industrie. Nous sommes reconnaissants à nos clients, partenaires et collègues de l’industrie pour leur appui, et nous serons heureux de continuer à établir les normes d’excellence du recyclage automobile au Canada. »

By Dalbert Livingstone, Chairman, Automotive Recyclers of Canada

Congratulations on the publication of the 19th issue of the Canadian Auto Recyclers Magazine!

This magazine has chronicled the ongoing development of the auto recycling industry, and has become one of the must-read publications for our sector. The representation of the industry as a collection of professionals has helped propel the industry forward. As much as the technology and equipment utilized in the industry is profiled—it is the people that drive auto recycling ahead. Many of these people have become my personal friends and definitely helped my business. Auto recyclers are all about collaboration, and that shows in this issue and all of the previous Canadian Auto Recyclers publications.

One person has been central to not only this magazine, but many of the progressive initiatives coming out of the professional auto recycling industry in Canada over the last 30-plus years. That is, of course, our long-serving Managing Director, Steve Fletcher.

As many of you know, or will find out, Steve is stepping down from his day-to-day responsibilities with both the Automotive Recyclers of Canada (ARC), and the Ontario Automotive Recyclers Association (OARA). Retiring probably isn’t in Steve’s vocabulary—transitioning is probably a better word. While I reluctantly accept that Steve won’t be our day-to-day guy to solve problems, create solutions and represent our industry, I am heartened by the fact that he will be involved in the industry in some capacity in the future.

Not aware of Steve’s accomplishments? Here is a partial list: founded ARC, OARA’s first Executive Director, Green Recycled Parts branding, CAREC, Retire Your Ride, Car Heaven, Switch Out, Tundra Takeback, VIN branding, Tacoma Buyback, EASR licensing, Grants in Gear, International Roundtable on Auto Recycling (IRT), EV Roadmap, writer of hundreds of articles on auto recycling, ELV Plastics Roadmap, ARA Star Awards, and the startup and editorial advisor to the Canadian Auto Recyclers. Just to name a few.

I was so pleased to see Steve recognized at the 2024 Automotive Recyclers Association (ARA) Convention in Reno with a Lifetime Achievement Award. Another honour, this time bestowed on Steve from our American colleagues, that is so well deserved.

A tribute is being planned for Steve at the OARA Convention in Niagara Falls in March. A couple of hours of recognition for a lifetime of advancement of auto recycling. It doesn’t seem right, but it's what Steve wants.

“I would rather the focus be on the great things within this industry, rather than on what I may have accomplished. Auto recycling and the great people who work hard everyday have been instrumental in anything I have been able to do. Lots of work left to do—let’s all get to it.”

Wise but humble words from a person we have all come to respect and admire. CAR

Par Dalbert

Livingstone,

président, Automotive Recyclers of Canada

Félicitations pour la publication du 19e numéro du magazine Canadian Auto Recyclers!

Ce magazine relate l’évolution constante de l’industrie du recyclage automobile et est devenu l’une des publications incontournables de notre secteur. La représentation de l’industrie en tant que groupe de professionnels a contribué à la propulser vers l’avant. Bien que ce soit la technologie et l’équipement utilisés dans l’industrie qui soient présentés dans le magazine, ce sont les personnes qui font avancer le recyclage automobile. Nombre de ces personnes sont devenues mes amis personnels et ont certainement aidé mon entreprise. Les recycleurs d’automobiles sont des gens de collaboration, et cela se voit dans ce numéro et dans toutes les publications antérieures de Canadian Auto Recyclers.

Une personne a joué un rôle déterminant non seulement dans ce magazine, mais aussi dans de nombreuses initiatives progressistes émanant de l’industrie professionnelle du recyclage automobile au Canada au cours des 30 dernières années. Il s’agit, bien entendu, de notre directeur général de longue date, Steve Fletcher.

Comme beaucoup d’entre vous le savent ou vont le découvrir, Steve quitte ses responsabilités quotidiennes au sein de l’Automotive Recyclers of Canada (ARC) et de l’Ontario Automotive Recyclers Association (OARA). Prendre sa retraite ne fait probablement pas partie du vocabulaire de Steve - le mot transition est sans doute plus approprié. Bien que j’accepte à contrecœur que Steve ne soit plus notre interlocuteur quotidien pour résoudre les problèmes, créer des solutions et représenter notre industrie, je suis encouragé par le fait qu’il jouera un rôle dans l’industrie d’une manière ou d’une autre à l’avenir.

Vous ne connaissez pas les réalisations de Steve? En voici une liste partielle : Steve a fondé l’ARC, il a été le premier directeur général de l’OARA, il a participé à différents programmes, notamment Pièces vertes, CAREC, Adieu Bazou, Autos-O-Ciel, Switch Out, Tundra Takeback, VIN, Tacoma Buyback, licence EASR, Grants in Gear, International Roundtable on Auto Recycling (IRT), EV Roadmap. Il est l’auteur de centaines d’articles sur le recyclage automobile, ELV Plastics Roadmap, ARA Star Awards, ainsi que créateur et conseiller éditorial de Canadian Auto Recyclers. Pour n’en citer que quelques-uns.

J’ai été très heureux de voir Steve récompensé lors de la convention 2024 de l’Automotive Recyclers Association (ARA) à Reno par un prix d’excellence pour l’ensemble de sa carrière. Un autre honneur, cette fois-ci décerné à Steve par nos collègues américains, qui est si bien mérité.

Un hommage est prévu pour Steve lors de la convention de l’OARA à Niagara Falls en mars. Quelques heures de reconnaissance pour une vie entière consacrée à l’avancement du recyclage automobile. Cela ne semble pas normal, mais c’est ce que Steve souhaite.

« Je préférerais que l’on mette l’accent sur les grands aspects de cette industrie, plutôt que sur ce que j’ai pu accomplir. Le recyclage automobile et les personnes formidables qui travaillent dur tous les jours ont joué un rôle déterminant dans tout ce que j’ai pu faire. Il reste encore beaucoup de travail à faire - mettons-nous tous au travail. »

Des paroles sages, mais humbles de la part d’une personne que nous avons tous appris à respecter et à admirer. CAR

Dalbert Livingstone, Président de l’ARC

The year 2024 was active for the BC Auto Recyclers (BCAR), a division of the Automotive Retailers Association (ARA). In 2023, the ARA officially assumed oversight and management of British Columbia’s environmental audit program for vehicle dismantlers. This annual audit is a legal requirement for recyclers in the province that dismantle more than five “wet” vehicles per year. The program is administered by the Automotive Recycler Environmental Association (AREA), a management association established by the ARA in the 1990s, which audits approximately 140 licensed dismantlers across the province.

AREA’s primary auditor and co-founder, Colin McKean, officially retired in 2022, prompting AREA to find a suitable successor. AREA is pleased to announce that Terra West has been selected as the new official auditor for British Columbia. Terra West will play a key role, alongside the ARA, in modernizing the program.

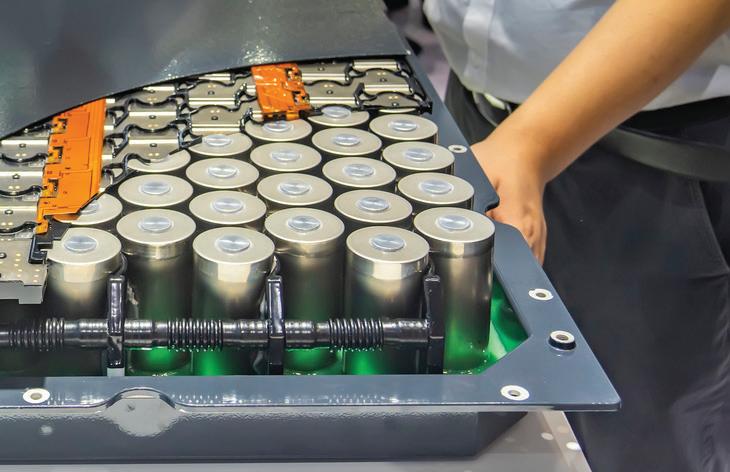

British Columbia continues to lead Canada and North America in the adoption of electric vehicles (EVs). While the rate of adoption has slowed, the market continues to grow, bringing new challenges and opportunities for the industry. Significant uncertainty remains regarding end-of-life solutions for EV batteries, including disposal, re-use, and repurposing potential. The ARA plans to announce new projects and initiatives in the coming year to help prepare the industry as it begins to encounter more of these vehicles on the road.

Lastly, Stuart Ady of Ernie’s Used Auto Parts in Castlegar has taken over as Chairperson for BCAR, succeeding Jim LeBrun. Jim LeBrun will continue to serve as BCAR’s representative on the main ARA Board and as a member of the ARC Board of Directors.

L’année 2024 a été dynamique pour les membres de la BC Auto Recyclers (BCAR), une division de l’Automotive Retailers Association (ARA). En 2023, l’ARA a officiellement pris en charge la supervision et la gestion du programme d’audit environnemental de la Colombie-Britannique pour les démanteleurs de véhicules. Cet audit annuel est une obligation légale pour les recycleurs de la province qui démontent plus de cinq véhicules « mouillés » par an. Le programme est administré par l’Automotive Recycler Environmental Association (AREA), une association de gestion créée par l’ARA dans les années 1990, qui contrôle environ 140 démanteleurs agréés dans la province.

Le vérificateur principal et cofondateur de l’AREA, Colin McKean, a officiellement pris sa retraite en 2022, ce qui a incité l’AREA à trouver un successeur approprié. L’AREA a le plaisir d’annoncer que Terra West a été choisi comme nouvel auditeur officiel pour la Colombie-Britannique. Terra West jouera un rôle clé, aux côtés de l’ARA, dans la modernisation du programme.

La Colombie-Britannique reste en tête du Canada et de l’Amérique du Nord pour l’acquisition des véhicules électriques (VE). Bien que le rythme de croissance du marché des véhicules électriques ait ralenti, il se poursuit, ce qui entraîne de nouveaux défis et de nouvelles occasions pour l’industrie. Une grande incertitude demeure quant aux solutions de fin de vie pour les batteries des VE, notamment en ce qui concerne l’élimination, la réutilisation et le potentiel de reconversion. L’ARA prévoit annoncer de nouveaux projets et de nouvelles initiatives au cours de l’année à venir pour aider l’industrie à se préparer à l’augmentation de ces véhicules sur les routes.

Enfin, Stuart Ady, d’Ernie’s Used Auto Parts, Castlegar, a pris la présidence de la BCAR, succédant à Jim LeBrun. Jim LeBrun continuera à représenter la BCAR au sein du conseil principal de l’ARA et à siéger au conseil d’administration de l’ARC.

The Alberta Automotive Recyclers and Dismantlers Association (AARDA) is excited to announce that Trent Hardin has assumed the role of executive direction, also assuming responsibility for the membership’s Canadian Auto Recyclers Environmental Code (CAREC) audits in Alberta.

Hardin has spent 40 years in in industrial operations in Alberta—starting with Syncrude in 1984, through computer chip manufacturing industrial coatings, purchasing for major fabrication projects and rail transload.

Along the way, Hardin has spent stints in the retail, NGO and service sectors and time as an infantry reservist. He then progressed through greater roles of responsibility with proven performance and now operates an operational/leadership consultancy to leverage his experience.

Hardin is also National Construction Safety Officer (NCSO) certified and has had extensive training in hazardous materials, from Workplace Hazardous Materials Information System (WHMIS), through TDG and HAZMAT response, to DG derailment response.

With the assumption of the Executive Directorship of AARDA, as well as direct responsibility for member CAREC audits and within the Automotive Recyclers of Canada (ARC), Hardin commented that he “looks forward to engaging wholeheartedly and being able to make good use of his experience—to increase engagement across the board, with the current membership and by expanding it.”

L’Alberta Automotive Recyclers and Dismantlers Association (AARDA) est heureuse d’annoncer que Trent Hardin a pris la direction de l’association et qu’il est également responsable des audits du Code canadien de l’environnement pour les recycleurs d’automobiles (CAREC) en Alberta.

M. Hardin a œuvré 40 ans dans le domaine des opérations industrielles en Alberta – passant de Syncrude en 1984, à la fabrication de puces électroniques, les revêtements industriels, les achats pour les grands projets de fabrication et enfin, le transbordement ferroviaire.

Au cours de son parcours, M. Hardin a travaillé dans les secteurs de la vente au détail, des ONG et des services, et a été réserviste dans l’infanterie. Il a ensuite gravi les échelons de la hiérarchie grâce à des performances avérées et dirige aujourd’hui une société de conseil en matière d’exploitation et de leadership afin de tirer parti de son expérience.

M. Hardin possède également la certification National Construction Safety Officer (NCSO) et a suivi une formation approfondie sur les matières dangereuses, depuis le Système d’information sur les matières dangereuses utilisées au travail (SIMDUT) jusqu’à l’intervention en cas de déraillement d’un train, ainsi qu’en cas de TMD et de HAZMAT.

En assumant le poste de directeur général de l’AARDA, ainsi que la responsabilité directe des audits des membres de CAREC et de l’Automotive Recyclers of Canada (ARC), M. Hardin a déclaré qu’il était « impatient de s’engager à fond et de mettre son expérience à profit pour accroître l’engagement dans tous les domaines, avec les membres actuels et autres intervenants ».

saskautorecyclers.ca

SARA is headed by Jack Smith of Top Line Salvage in Moose Jaw, Vice-President, Dale Nagel of Dale & Lisa’s Farm & Auto in Mossbank and Secretary-Treasurer Michele Morrison of SGI Salvage in Regina.

SARA’s newest member is JS Truckmart of Estevan, Saskatoon. JS Truckmart was honoured with the Growth and Expansion Award and the Business of the Year award at the 2024 Saskatchewan Chamber of Commerce ABEX Awards Gala. The ABEX Awards highlight the outstanding achievements of Saskatchewan’s businesses, acknowledging their significant role in driving the province’s economic and community development.

This year’s highlight was a joint event held in conjunction with the Auto Recyclers of Canada Board Meeting on October 4 and 5 at the Atlas Hotel in Regina. Our SARA members were privileged to meet the fellow auto recyclers from across Canada that attended. Over the two-day event, we had 33 people attend from six provinces. Attendees were treated to lunch and a tour of JS Truckmart’s new dismantling facility and warehouse in Estevan followed by a dinner and social on Friday night.

SARA’s 2024 Annual General Meeting for members was held the following day. Representatives of 10 of our 17 member yards were in attendance. At the 2024 AGM, SARA elected Christa Morhart of JS Truckmart in Estevan to the board. She joins Brendan Heggs and Dylan Crozier of Southside Auto Wreckers in Weyburn and Shawn Conarroe of 5 Mile Auto Wreckers in Prince Albert.

SARA’s 2025 AGM is planned for April 26, 2025.

SARA members continue to operate in compliance with the Canadian Auto Recyclers Environmental Code (CAREC). Like all auto recyclers, our members are concerned about the impact of electric vehicles on our industry and are closely following the industry updates provided by the Automotive Recyclers of Canada (ARC) and the Canadian Auto Recyclers magazine.

La SARA est dirigée par Jack Smith de Top Line Salvage, Moose Jaw, le vice-président Dale Nagel de Dale & Lisa’s Farm & Auto, Mossbank, et la secrétaire-trésorière Michele Morrison de SGI Salvage, Regina.

Le plus récent membre de la SARA est JS Truckmart d’Estevan, Saskatoon. JS Truckmart a reçu le prix de la croissance et de l’expansion et le prix de l’entreprise de l’année lors du gala des prix ABEX de la Chambre de commerce de la Saskatchewan en 2024. Les prix ABEX soulignent les réalisations exceptionnelles des entreprises de la Saskatchewan et reconnaissent le rôle important qu’elles jouent dans le développement économique et communautaire de la province.

Le point fort de cette année a été un événement conjoint avec la réunion du conseil d’administration d’Auto Recyclers of Canada, les 4 et 5 octobre, à l’hôtel Atlas de Regina. Les membres de la SARA ont eu le privilège de rencontrer leurs collègues recycleurs d’automobiles de tout le Canada. Au cours de ces deux jours, 33 personnes provenant de six provinces ont participé à l’événement. Les participants ont eu droit à un déjeuner et à une visite des nouvelles installations de démontage et de l’entrepôt de JS Truckmart à Estevan, suivis d’un dîner et d’une soirée sociale le vendredi soir.

L’assemblée générale annuelle 2024 des membres de la SARA a eu lieu le jour suivant. Des représentants de 10 de nos 17 chantiers membres étaient présents. Lors de l’AGA 2024, la SARA a élu Christa Morhart de JS Truckmart, Estevan, au conseil d’administration. Elle rejoint Brendan Heggs et Dylan Crozier de Southside Auto Wreckers, Weyburn, et Shawn Conarroe de 5 Mile Auto Wreckers, Prince Albert.

L’AGA 2025 de la SARA est prévue pour le 26 avril 2025.

Les membres de la SARA continuent d’exercer leurs activités en conformité avec le Code environnemental des recycleurs d’automobiles du Canada (CAREC). Comme tous les recycleurs d’automobiles, nos membres sont préoccupés par l’impact des véhicules électriques sur notre industrie et suivent de près les mises à jour de l’industrie fournies par Automotive Recyclers of Canada (ARC) et le magazine Canadian Auto Recyclers

OARA has created a VIN Branding Committee aimed at documenting the incorrect branding of vehicles involved in total losses. While regulations exist to provide specific guidance on what needs to be branded and the differences between Salvage and Irreparable brands, we’ve observed this guidance seems to be consistently ignored. As the media and government pickup on the out of control stolen vehicle epidemic in Canada, with some of that derived from total loss vehicles, the Committee aims to shine a spotlight on bad branding with the goal of improving education and awareness.

OARA’s biggest project, perhaps in a number of years, has been the long and thorough process of replacing our Executive Director of 32 years, Steve Fletcher. The Board was incredibly active over the Summer documenting the opportunity, reviewing candidates, and establishing the protocols to ensure a smooth transition. Mathieu Dagonas is on board, and we are all benefiting from the overlap in Steve staying with OARA and Mathieu’s steep learning curve. We look forward to Mathieu taking over the reins at OARA and taking OARA to the next level representing the auto recycling industry in Ontario. We think we will see that in the planning and execution of the 2025 OARA Convention.

OARA continues to work with Intact Insurance’s recycled parts pilot program to increase the usage of recycled parts. The program is unique in that Intact has brought both frontline staff and planners to the table to work collaboratively. The pilot is showing benefits of recyclers, repairers, insurers and data providers working together.

The Workplace Safety Prevention Service (WSPS) has begun to work with both OARA and the Ministry of Labour to identify risks, processes and suitable training for the proper handling of Electric Vehicles (EVs). This is the first time the Ontario government has recognized the role auto recyclers play in electrification and the need for some level of support.

L’OARA a créé un comité sur le marquage des numéros d’identification des véhicules (VIN) afin de documenter le marquage incorrect des véhicules déclarés « perte totale ». Bien qu’il existe des réglementations qui fournissent des conseils spécifiques sur ce qui doit être marqué et sur les différences entre les marques « Récupérable (Salvage) » et « Irrécupérable (Irrecuperable) », nous avons observé que ces conseils semblent être systématiquement ignorés. Alors que les médias et le gouvernement s’intéressent à l’épidémie de véhicules volés au Canada, dont une partie concerne des véhicules déclarés « perte totale », le Comité a pour objectif de mettre en lumière le mauvais marquage dans le but d’améliorer l’éducation et la sensibilisation.

Le plus grand projet de l’OARA, peut-être depuis un certain nombre d’années, a été le long et minutieux processus de remplacement de notre directeur général des 32 dernières années, Steve Fletcher. Le Conseil d’administration a été incroyablement actif au cours de l’été pour documenter l’exercice, examiner les candidats et établir les protocoles pour assurer une transition en douceur. Mathieu Dagonas est monté à bord et nous bénéficions tous du fait que Steve soit resté à l’OARA pendant l’apprentissage de Mathieu. Nous attendons avec impatience que Mathieu prenne les rênes de l’organisation et qu’il l’amène à un niveau supérieur en tant que représentant de l’industrie du recyclage automobile en Ontario. Nous pensons que nous constaterons le résultat dans la planification et l’exécution de la Convention de l’OARA de 2025.

L’OARA continue de collaborer au programme pilote d’Intact Assurance sur les pièces recyclées afin d’accroître leur utilisation. Ce programme est unique, en ce sens qu’Intact a réuni à la fois le personnel de première ligne et les planificateurs pour travailler en collaboration. Le projet pilote montre les avantages d’une collaboration entre les recycleurs, les réparateurs, les assureurs et les fournisseurs de données.

Le Service de prévention de la sécurité sur le lieu de travail (WSPS) a commencé à travailler avec l’OARA et le ministère du Travail pour identifier les risques, les processus et la formation appropriée pour la manipulation adéquate des véhicules électriques (VE). C’est la première fois que le gouvernement de l’Ontario reconnaît le rôle que jouent les recycleurs automobiles dans l’électrification et la nécessité d’un certain niveau de soutien.

ARPAC has appointed Steve Lemm as fire prevention advisor. Lemm owned a recycling centre, Pièces d’autos M.S., for many years, was a member of ARPAC’s Board of Directors, and was also a firefighter beforehand. He had the opportunity to visit all of ARPAC’s members in 2024 to observe fire prevention good practices, identify any issues and advise owners on potential improvements to prevent fires in their businesses.

Insuring a car and truck recycling business is increasingly costly, and to slow down the increase in insurance premiums, ARPAC also published a fire prevention checklist with 32 control points for fire prevention. Each point is associated with one of 5 intervention timelines: 1) at all times, 2) daily, 3) monthly, 4) every six months upon time changes, and 6) annually. As an example, the list includes item 27: Site monitoring policy in the hour following the shutoff of oxycutting; this is to avoid seeing your business go up in flames when you return from your break or lunchtime.

L’ARPAC a nommé Monsieur Steve Lemm au poste de conseiller en prévention des incendies. M Lemm a été propriétaire d’un centre de recyclage, Pièces d’autos M. S., durant de nombreuses années, il a siégé au conseil d’administration de l’ARPAC et a aussi exercé les fonctions de pompier. Il a eu l’occasion de visiter tous les membres de l’ARPAC en 2024 afin de constater les pratiques exemplaires en prévention des incendies, d’identifier les enjeux potentiels et de conseiller les propriétaires concernant les solutions d’améliorations possibles pour prévenir les incendies dans leurs entreprises.

Assurer une entreprise de recyclage d’autos et de camions coûte de plus en plus cher et, afin de ralentir la hausse des primes d’assurances, l’ARPAC a également publié une grille de vérification « Zéro incendie » en 32 points de contrôle pour la prévention. Chaque point est répertorié dans 5 catégories d’intervention, soient, 1) en tout temps, 2) journalière, 3) mensuelle, 4) aux six mois lors du changement d’heure et 6) annuelle. Voici à titre d’exemple l’article 27 : Politique de surveillance des lieux dans l’heure qui suit le coupage à l’oxygaz; qui vise à éviter de voir votre garage ravagé par les flammes en revenant de la pause ou de votre heure du lunch.

The June meeting of Automotive Recyclers Association of Atlantic Canada (ARAAC) is always a highlight of the auto recycling calendar in Atlantic Canada. The 2024 did not disappoint. Hosted Island Auto Supply in Charlottetown PEI, the two-day event saw 60 attendees from all corners of the industry. Topics covered included green recycled parts, insurer-repairer-recycler relations, electric vehicles (EVs), plastic bumper recycling research, CAREC audits, parts procurement, inventory management, and much more.

La réunion de juin de l’Association des recycleurs d’automobiles du Canada atlantique (ARAAC) est toujours un moment fort du calendrier du recyclage automobile au Canada atlantique. L’édition 2024 n’a pas déçu. Organisé par Island Auto Supply à Charlottetown (Î.-P.-É.), l’événement de deux jours a attiré 60 participants de tous les secteurs de l’industrie. Parmi les sujets abordés figuraient les pièces recyclées écologiques, les relations entre assureurs, réparateurs et recycleurs, les véhicules électriques, la recherche sur le recyclage des pare-chocs en plastique, les audits de CAREC, l’approvisionnement en pièces, la gestion des stocks et bien d’autres choses encore.

The biggest highlight was the presentation by Intact Insurance discussing their Sustainability Plans and how auto recyclers fit in. They also participated in an open panel discussion with recyclers and repairers discussing the opportunities and challenges with accessing more recycled parts on their estimates.

The event wrapped up with the always popular tour and BBQ at Dalbert Livingstone’s Island Auto Supply facility, with more hands-on learning, networking…and fun.

The Mini-Ductor Venom HP is the highest powered Mini-Ductor at 1800 watts. This handheld induction heater generates high-frequency magnetic fields to produce a flameless heat™ that releases ferrous metal from rust, corrosion and thread lock compounds.

APPLICATIONS:

> Seized Lugnuts

> Fuel Tank Straps

> Exhaust Manifold Bolts

> Suspension

L’événement le plus marquant a été la présentation par Intact Assurance de ses plans de développement durable et de la manière dont les recycleurs automobiles s’y intègrent. Les représentants d’Intact ont également participé à une table ronde avec des recycleurs et des réparateurs afin de discuter des occasions et des défis liés à l’accès à davantage de pièces recyclées sur leurs devis.

L’événement s’est terminé par la visite de l’installation Island Auto Supply de Dalbert Livingstone et un barbecue; deux activités toujours très appréciées, et avec encore plus d’occasions d’apprentissage pratique, de réseautage... et de plaisir.

> Seatbelt Bolts

> O2 Sensors

> Inline Connectors

> & 100’s more!

Story by/par Allison Rogers

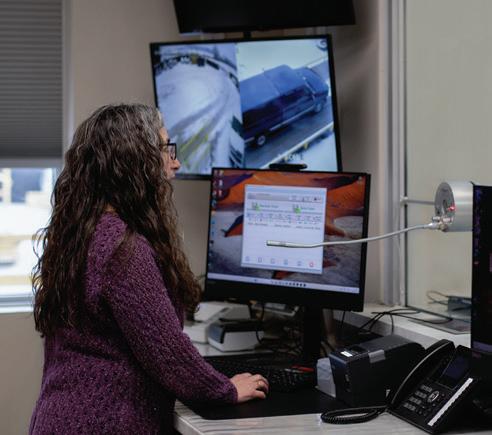

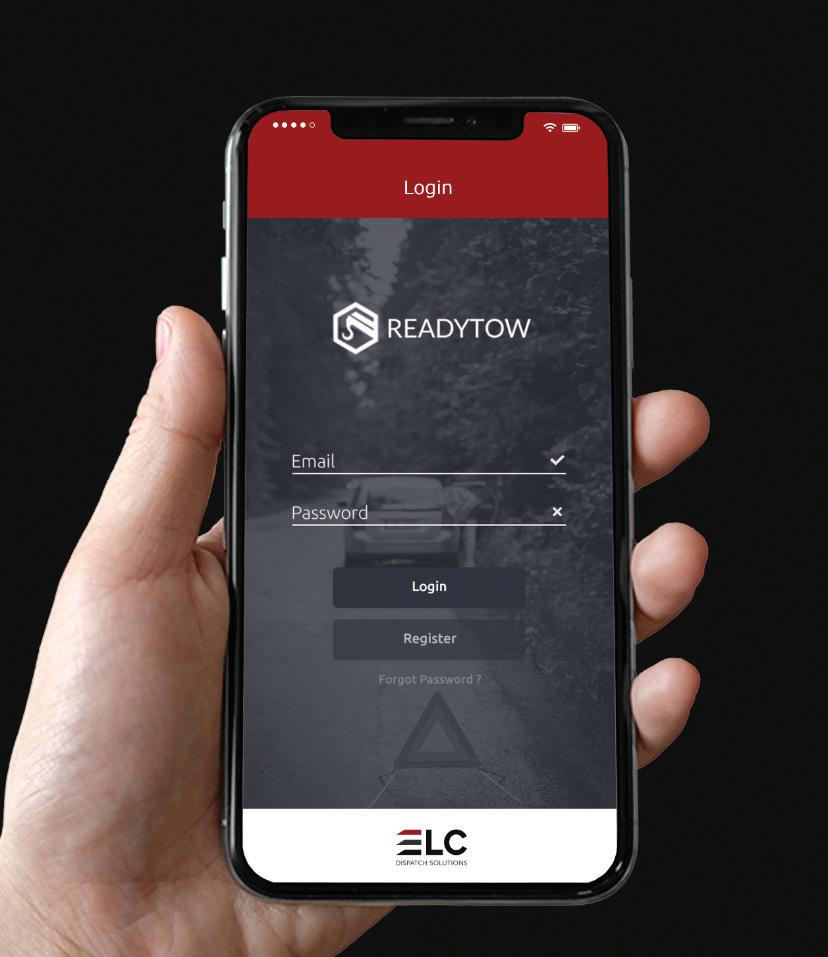

After an exhaustive search for a new Executive Director upon Steve Fletcher’s departure, the Ontario Association of Automotive Recyclers (OARA) has selected Mathieu P. Dagonas as its next executive director.

With Dagonas’ assumption of the role of Executive Director of OARA, Steve Fletcher, long-serving Executive Director will be stepping away from his Ontario role at the 2025 OARA Convention and Trade Show in Niagara Falls in March. Until then, the press release notes, Dagonas and Fletcher will be sharing the Executive Director role to ensure a seamless transition.

Trust that Dagonas understands that he has big shoes to fill—he jokingly told attendees during a November meet-and-greet that he’d heard the phrase at least a dozen times during the recent Automotive Recyclers’ Association (ARA) Convention and Expo. But the former non-profit warrior is ready to put his all in to OARA to bring the association into a new and exciting era.

OARA, meet your new Executive Director: Mathieu Dagonas.

[Q&A]

Canadian Auto Recycler: Will you tell us about your previous work experience, Mat?

Mathieu Dagonas: I started my career in politics after studying at the University of Toronto. I advised several cabinet ministers and spent seven years learning how the government functions.

I left politics because I wanted to make a difference. So, I started working in the non-profit sector, where my work focused on at-risk youth.

After a few years helping these charitable organizations, I transitioned to lead an association called the Documentary Association of Canada, where I served as executive director to all Canadian documentary filmmakers.

I did this for two years, but the association was hit hard by the pandemic. I fell upwards, and landed at the ombudsman for telecommunication: the Commission for Complaints for Telecom-television Services (CCTS). I was there for four years as their director of communications and stakeholder affairs. My day-to-day meant I was the lead on all files that dealt with the Government of Canada and the Canadian Radio-television and Telecommunications Commission (CTRC), as well as Bell, Telus, Rogers and Videotron.

I sit on a number of boards as well: previously with Firefighters Without Borders and, more recently, with the Canadian Centre for Housing Rights.

Après une recherche exhaustive, l’Ontario Association of Automotive Recyclers (OARA) a choisi Mathieu P. Dagonas à titre de directeur général pour remplacer Steve Fletcher.

C’est dans le cadre du congrès et de la foire commerciale de l’OARA 2025, prévus à Niagara Falls en mars, que Steve Fletcher cèdera son poste de longue date à M. Dagonas. Le communiqué de presse précise par ailleurs que, d’ici là, que M. Dagonas et M. Fletcher se partageront les tâches du directeur général, afin d’assurer une transition en douceur.

M. Dagonas est bien conscient qu’il aura du pain sur la planche — il a plaisanté qu’on le lui a répété maintes fois lors du récent congrès et salon de l’Association des recycleurs automobiles (ARA). Mais cet ancien héros de l’action à but non lucratif est prêt à s’investir pleinement dans l’association pour la guider dans une ère nouvelle et passionnante.

OARA, voici votre nouveau directeur général : Mathieu Dagonas.

Canadian Auto Recycler: Pouvez-vous nous parler de votre expérience professionnelle, Mat?

Mathieu Dagonas: J’ai commencé ma carrière en politique après mes études à l’université de Toronto. J’ai conseillé plusieurs ministres et j’ai passé sept ans à apprendre le fonctionnement du gouvernement.

J’ai quitté la politique parce que je souhaitais faire de grandes choses. Je me suis donc engagé dans le milieu caritatif, ou j’ai d’abord œuvré auprès des jeunes à risque.

Après quelques années de contribution à ces organismes, j’ai dirigé l’Association des documentaristes du Canada, où j’étais le directeur général de tous les documentaristes canadiens.

J’ai exercé cette fonction pendant deux ans, mais l’association a été durement touchée par la pandémie. J’ai alors pris du galon et je me suis retrouvé au bureau de l’ombudsman des télécommunications : la Commission des plaintes relatives aux services de télécom-télévision (CPRST). J’y suis resté quatre ans dans le rôle de directeur des communications et des relations avec les intervenants. Mon travail quotidien consistait à piloter tous les dossiers touchant le gouvernement du Canada et le Conseil de la radiodiffusion et des télécommunications canadiennes (CRTC), ainsi que Bell, Telus, Rogers et Vidéotron.

Je siège également à plusieurs conseils d’administration : précédemment avec Pompiers sans frontières et, plus récemment, avec le Centre canadien du droit au logement.

CAR: Quelles sont vos priorités depuis votre entrée en fonction au poste de directeur général de l’OARA?

MD: Mon objectif premier a été de me plonger dans l’organisation et sa mission, de comprendre les besoins uniques de nos membres et d’établir des relations avec les principales parties prenantes.

J’ai passé beaucoup de temps à écouter le Conseil d’administration et les membres de l’OARA, à visiter des chantiers et, avec l’aide de Steve, à reconnaître les priorités et les possibilités immédiates.

CAR: What have you been focused on since stepping into the role of OARA Executive Director?

MD: My focus has been immersing myself in the organization and its mission; understanding the unique needs of our members and establishing relationships with key stakeholders. I’ve spent a lot of time listening to the Board, to OARA members, visiting yards and, from time t to time, receiving guidance from Steve to identify immediate priorities and opportunities.

I also attended the Automotive Recyclers’ Association (ARA) 81st annual Convention and Expo in Reno, Nevada, which provided invaluable insights into the latest trends and challenges for the industry, albeit with an American spin.

I am also participating on monthly OARA board calls and have begun to meet with association members as well as other associations like the Used Car Dealers Association of Ontario (UCDA) and the Automotive Industries Association of Canada (AIA Canada). We’re also working on a strategic planning retreat in April with the Board and Steve.

CAR: What has your first impression of the automotive recycling industry been?

MD: Well, my first impressions of OARA have been that this is a passionate, forward-thinking organization with an incredibly dedicated membership base. I’ve been impressed by OARA’s commitment not only to advancing the auto recycling industry but also fostering a sense of community and collaboration. That’s what I saw in Reno; that’s what I’ve heard from OARA Board members and that’s what I’ve seen firsthand in my meetings.

As for the auto recycling industry, it is far more dynamic and complex than I initially imagined. I have a lot to learn still, but I am impressed by the technical expertise, innovation and environmental stewardship that are integral to this field.

Perhaps most surprisingly, I’ve been impressed by the stories I’ve heard of deeply rooted family-run businesses: their tribulations, their perseverance, their successes. I also know I have big shoes to fill when Steve [Fletcher, outgoing OARA executive director] departs, so I am looking forward to downloading all of your knowledge to service our members.

CAR: What goals and activities to your envision tackling in your first few months at OARA Executive Director?

MD: In the immediate term, my goals are centered on building a solid foundation and establishing our strategic priorities. I plan to focus on a few key areas.

First, member engagement and support. I plan to work closely with OARA members to ensure they have the resources and support they need. This includes actively listening to their feedback and identifying new ways OARA can add value.

I also plan to tackle marketing and advocacy. With the new marketing committee, I hope to refine and amplify our messaging to better promote OARA’s impact, both within the industry and the broader public. Strengthening connections with industry allies and government stakeholders to explore opportunities that can benefit our members and support sustainable practices.

Finally, I have been working with Steve to put on the biggest OARA Convention in March in Niagara Falls. We’ve toured the hotel and casino as well as Thorold Auto Parts and Miller’s Auto Recycling for our yard tours. I truly believe members will remember this one.

CAR: What do you do for fun outside of work?

MD: Outside of work, I enjoy staying active—swimming, golf—and travelling with my family. My wife’s name is Rachael and my two kids, Nikolas and Aria, are nine-years-old and almost two-years-old. Spending quality time with family and friends is important to me, like many of you.

CAR: Do you have any other words for OARA members?

MD: I am genuinely excited to be part of OARA and to support our members. I am thrilled I get a mentor like Steve to help me succeed, and I’m thankful to the board members for their confidence in me. I believe I can make a big impact here. CAR

J’ai également participé au 81e congrès et salon de l’Association des recycleurs automobiles (ARA) à Reno, dans le Nevada, au cours duquel j’ai recueilli des renseignements extrêmement utiles sur les dernières tendances et les défis courants du milieu, quoiqu’à l’américaine.

Je participe aussi aux réunions mensuelles du conseil d’administration, et j’ai entrepris de rencontrer les membres et d’échanger avec d’autres associations, comme la Used Car Dealers Association of Ontario (UCDA) et l’Association des industries de l’automobile du Canada (AIA Canada). Le conseil s’affaire par ailleurs à planifier une retraite de planification stratégique avec Steve au mois d’avril.

CAR: Quelle a été votre première impression de l’industrie du recyclage automobile?

MD: Au premier abord, l’OARA me semble une organisation passionnée, tournée vers l’avenir et dont les membres sont incroyablement dévoués. J’ai été impressionné par l’engagement de l’OARA à non seulement à faire avancer l’industrie du recyclage automobile, mais aussi à stimuler un sens de la communauté et de la collaboration. C’est là ce que j’ai constaté à Reno, ce que j’ai entendu des membres du conseil de l’OARA et ce que j’ai observé lors des réunions. Quant à l’industrie du recyclage automobile, elle est beaucoup plus dynamique et complexe que je me l’imaginais au départ. Il me reste encore beaucoup à apprendre, mais je suis impressionné par le savoir-faire, l’innovation et la conscience écologique qui animent le secteur.

Ce qui me surprend peut-être encore davantage est à quel point je suis touché par le récit des tribulations, de la persévérance et des réussites des entreprises familiales profondément enracinées.

Je sais aussi que j’aurai fort à faire lorsque Steve [Fletcher, directeur général sortant de l’OARA] nous quittera, donc je me réjouis d’apprendre le plus possible et de mettre toutes ces connaissances au service de nos membres

CAR: Quels objectifs et activités envisagez-vous pour vos premiers mois en tant que directeur général de l’OARA?

MD: Dans l’immédiat, mes objectifs sont d’établir une base solide et de déterminer nos priorités stratégiques. J’ai l’intention de m’attarder à quelques domaines en particulier.

En premier lieu : la participation et le soutien des membres. Je compte travailler en étroite collaboration avec les membres de l’OARA pour m’assurer qu’ils disposent des ressources et du soutien dont ils ont besoin. Notamment, il s’agit d’être à l’écoute de leurs commentaires et d’élaborer de nouveaux moyens pour l’OARA d’apporter une valeur ajoutée.

Je compte aussi m’attaquer au marketing et à la défense des intérêts des membres. Avec le nouveau comité de marketing, j’espère peaufiner et amplifier notre message afin de mieux promouvoir les retombées de l’OARA, à la fois au sein de l’industrie et auprès du grand public.

Je veux renforcer nos liens avec les alliés du secteur et les acteurs du gouvernement afin d’explorer les possibilités pour nos membres et promouvoir des pratiques écoresponsables.

Enfin, avec l’aide de Steve, je me suis efforcé d’organiser le plus important congrès de l’OARA en mars, à Niagara Falls. Nous avons visité l’hôtel et le casino, ainsi que Thorold Auto Parts et Miller’s Auto Recycling pour nos visites de chantier. Je suis convaincu que les membres se souviendront de ce congrès.

CAR: Que faites-vous pour vous amuser dans vos temps libres?

MD: Dans mes temps libres, j’aime bien rester actif, notamment grâce à la natation et au golf, de même que voyager avec ma famille. Mon épouse se nomme Rachael et j’ai deux enfants — Nikolas, neuf ans et Aria, qui aura bientôt deux ans. Comme beaucoup d’entre vous, je trouve très important de passer des moments de qualité en famille et entre amis.

CAR: Avez-vous autre chose à dire aux membres de l’OARA?

MD: Je suis vraiment ravi de m’intégrer à l’OARA et de soutenir ses membres. Je suis reconnaissant d’avoir un mentor comme Steve pour m’aider à réussir et je remercie les membres du conseil pour la confiance qu’ils me témoignent. Je crois pouvoir accomplir de grandes choses ici. CAR

In June, Lithion Technologies (Lithion) announced the completion of construction of its first commercial critical minerals extraction plant, Lithion Saint-Bruno, located in St-Bruno-de-Montarville, Quebec. Lithion is now in the commissioning phase to ensure that its processes operate safely and efficiently. The plant will extract the critical mineral concentrate, a black mass composed of lithium, nickel, cobalt, manganese and graphite. The second stage consists of a hydrometallurgy process to separate and purify the black mass to produce higher-quality materials that can be re-injected into the production of new batteries. Lithion plans to continue implementing the next stages of the recycling process.

En juin, Lithion Technologies (Lithion) a annoncé l’achèvement de la construction de sa première usine commerciale d’extraction de minéraux critiques, Lithion Saint-Bruno, située à St-Bruno-de-Montarville, au Québec. Lithion est maintenant en phase de mise en service afin de s’assurer que ses procédés fonctionnent de façon sécuritaire et efficace. L’usine extraira le concentré minéral critique, une masse noire composée de lithium, de nickel, de cobalt, de manganèse et de graphite. La deuxième étape consiste en un processus d’hydrométallurgie visant à séparer et à purifier la masse noire afin de produire des matériaux de meilleure qualité qui pourront être réinjectés dans la production de nouvelles batteries. Lithion prévoit poursuivre la mise en place des prochaines étapes du processus de recyclage.

Hyundai Canada has appointed Lithion as its official partner for the recycling of electric vehicle batteries across the country, with the aim of creating a more circular economy. The agreement, which was announced earlier this month, is multi-year and builds on an initial collaboration established in 2021 to validate Lithion’s mineral extraction technology. As stated in a Hyundai press release, under the partnership, Lithion’s responsibilities “encompass the entire recycling process, including logistics, collection, dismantling and recycling. The company’s advanced technology can recover up to 98 percent of the minerals contained in electric vehicle batteries, contributing to a more circular economy for battery materials”.

Hyundai Canada a nommé Lithion à titre de partenaire officiel pour le recyclage des batteries de véhicules électriques à travers le pays, dans le but de créer une économie circulaire. L’accord qui a été annoncé au début du mois est pluriannuel et s’appuie sur une collaboration initiale établie en 2021 pour valider la technologie d’extraction minérale de Lithion. Comme l’indique un communiqué de presse de Hyundai, dans le cadre de ce partenariat, les responsabilités de Lithion « englobent l’ensemble du processus de recyclage, y compris la logistique, la collecte, le démantèlement et le recyclage. La technologie avancée de l’entreprise permet de récupérer jusqu’à 98 pour cent des minéraux contenus dans les batteries des véhicules électriques, contribuant ainsi à une économie plus circulaire pour les matériaux des batteries ».

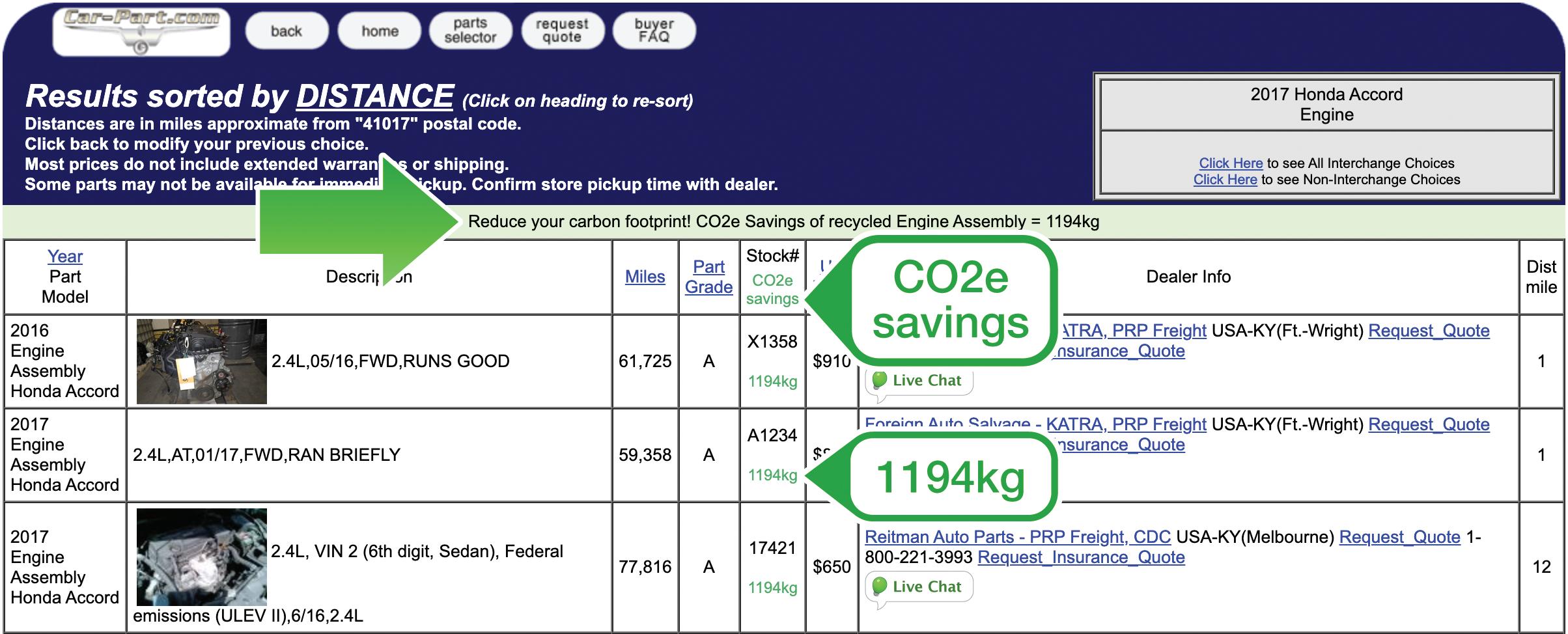

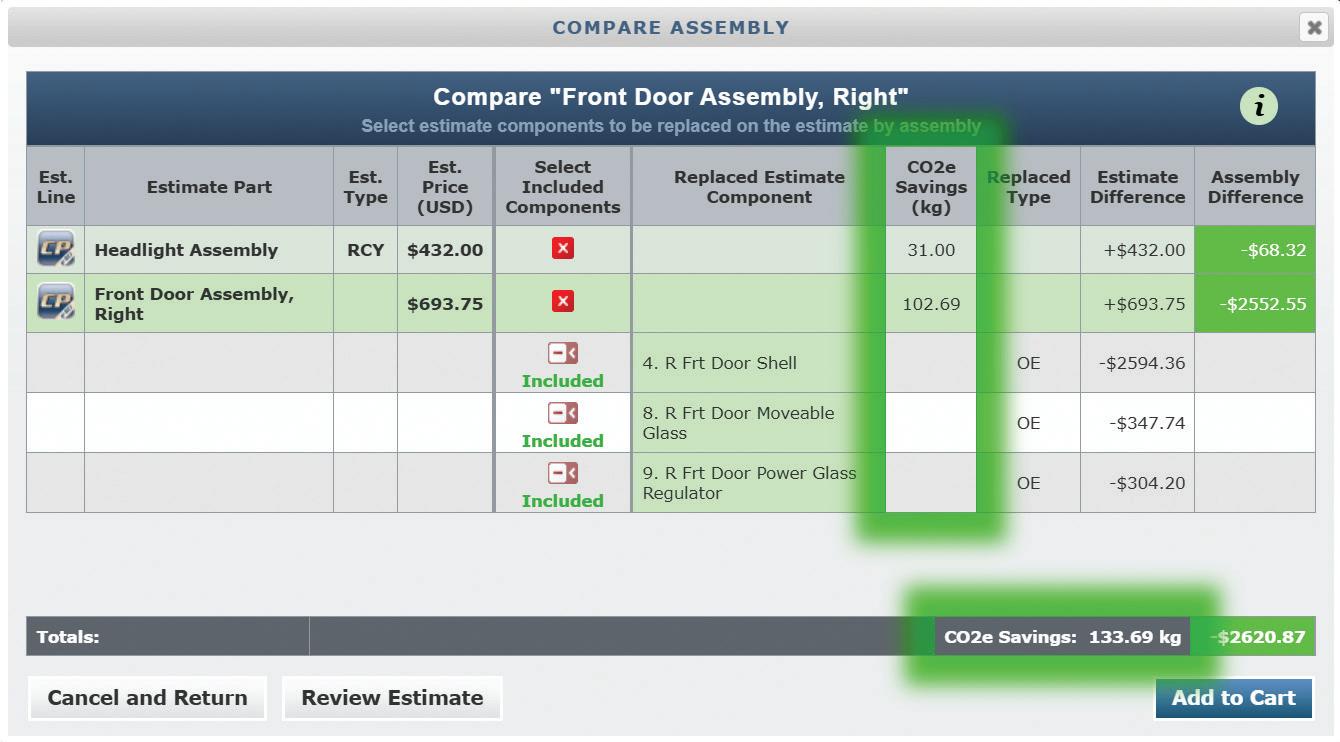

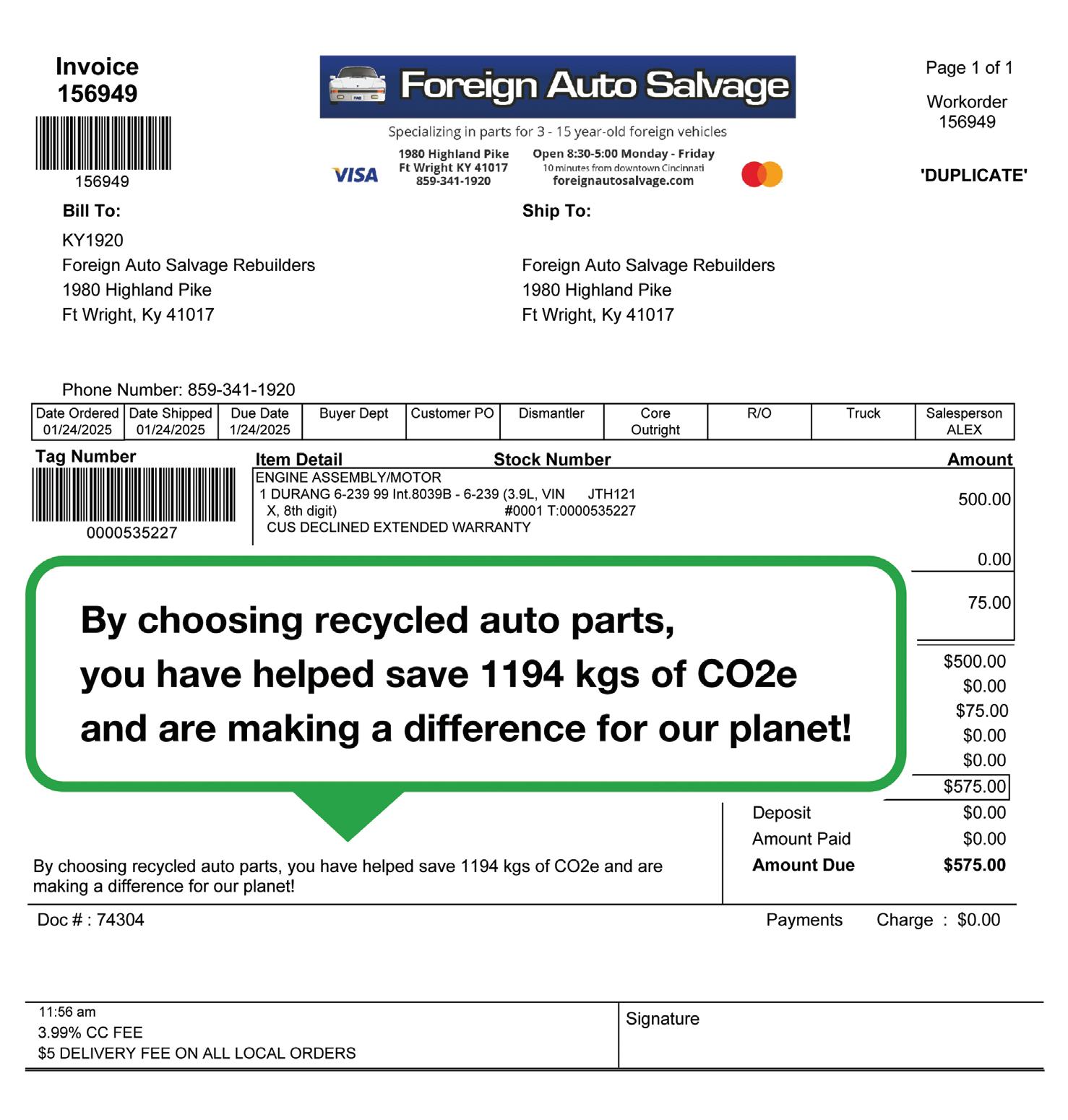

According to data from Car-Part.com’s North American marketplaces, quoting for high-quality recycled parts instead of new parts results in an estimated reduction of 35 million metric tons of CO2e emissions per year. This is equivalent to 32 percent of the annual emissions produced by Canadian vehicles,” notes Tim Schneider, Managing Director of integrated marketplace Car-Part Pro. This is great news for the companies in the body repair sector who are committed to zero emissions, and for the auto recyclers who are responsible for the CO2e savings.” The data used in the iPro Analytics reports is based on CO2e savings data from a recent Ontario Automotive Recyclers Association (OARA) environmental impact study of major recycled parts in the Ontario market.

Selon les données des places de marché nord-américaines de Car-Part.com, l’utilisation de devis pour des pièces recyclées de qualité supérieure au lieu de pièces neuves permet une réduction estimée à 35 millions de tonnes métriques d’émissions de CO2e par an. « Cela équivaut à 32 pour cent des émissions annuelles produites par les véhicules canadiens, note Tim Schneider, directeur général de la place de marché intégrée Car-Part Pro. C’est une grande nouvelle pour les entreprises du secteur de la réparation de carrosserie qui se sont engagées à atteindre l’objectif zéro émission et pour les recycleurs automobiles qui sont à l’origine des économies de CO2e. » Les données utilisées dans les rapports d’iPro Analytics sont basées sur les données relatives aux économies de CO2e d’une récente étude d’impact environnemental de l’Ontario Automotive Recyclers Association (OARA) portant sur les principales pièces recyclées sur le marché de l’Ontario.

Selon les données des places de marché nord-américaines de Car-Part.com, l’utilisation de devis pour des pièces recyclées de qualité supérieure au lieu de pièces neuves permet une réduction estimée à 35 millions de tonnes métriques d’émissions de CO2e par an.

According to data from Car-Part.com’s North American marketplaces, quoting for high-quality recycled parts instead of new parts results in an estimated reduction of 35 million metric tons of CO2e emissions per year.

Understanding the importance of time within your transportation strategy, means you can move at the speed of your customer, not your carrier. Cardinal’s Pre 8am transportation solutions and unique night network provide a competitive advantage where first to market comes standard. Expect Cardinal’s night network with unattended pickups and deliveries to deliver a competitive advantage to your business.

Cardinal is a wholly owned Canadian company that has built its reputation as the most reliable Pre 8am delivery service for time-sensitive goods and parts, servicing communities across Ontario and Quebec.

After more than 35 years, the Institute of Scrap Recycling Industries (ISRI) has announced that it is now the Recycled Materials Association (ReMA). The new brand was unveiled at the closing general session of the ISRI 2024 Convention & Exposition, held in Las Vegas, Nevada, April 15-18. In addition, the organization’s new identity includes a new slogan - Sustainable. Resilient. Essential. Before unveiling its new name and logo, the association also celebrated its history by launching several initiatives. Earlier this month, the organization launched an online timeline featuring historic milestones in the recycled materials industry, as well as memorable moments from its 30-year history. Alongside this move, the association also launched a digital mosaic in which members have worked to share memories of ISRI and various events over the years in the run-up to ISRI 2024.

Après plus de 35 ans, l’Institute of Scrap Recycling Industries (ISRI) a annoncé qu’elle était désormais la Recycled Materials Association (ReMA). Cette nouvelle marque a été dévoilée lors de la session générale de clôture de la convention et de l’exposition ISRI 2024, qui s’est tenue à Las Vegas, au Nevada, du 15 au 18 avril. En outre, la nouvelle identité de l’organisation comprend un nouveau slogan - Durable. Résilient. Essentiel. Avant de dévoiler son nouveau nom et son nouveau logo, l’association a également célébré son histoire en lançant plusieurs initiatives. Au début du mois, l’organisation a lancé une chronologie en ligne présentant les étapes historiques de l’industrie des matériaux recyclés, ainsi que des moments mémorables survenus au cours de ses 30 années d’existence. Parallèlement à ce changement, l’association a également lancé une mosaïque numérique dans laquelle les membres ont travaillé pour partager des souvenirs de l’ISRI et de divers événements survenus au fil des ans dans la perspective d’ISRI 2024.

The Institute of Recycling Industries (ISRI) will henceforth be known as the Recycled Materials Association (ReMA).

L’Institut des industries du recyclage (ISRI) sera désormais connu sous le nom d’Association des matériaux recyclés (ReMA).

An active member of the Recycled Materials Association (ReMA), Lotzkar has worked with government officials in Canada and the U.S. to defend the interests of the recycling and manufacturing industries.

Membre active de l’Association des matériaux recyclés (ReMA), Mme Lotzkar a collaboré avec des représentants du gouvernement au Canada et aux États-Unis pour défendre les intérêts des industries du recyclage et de la fabrication.

The Canadian Association of Recycling Industries (CARI) is pleased to announce the appointment of Jacqueline Lotzkar as President and CEO. Ms. Lotzkar will take up her new position on February 3. Lotzkar brings a wealth of experience in the recycling industry to her new role. She has received worldwide recognition and was recently named one of the 100 most inspiring and innovative leaders in recycling by Recycling International magazine. For the past four years, Ms. Lotzkar has held the position of Vice President of Pacific Metals Recycling International, where she was instrumental in the sale and transition process of this 112-year-old family business. An active member of the Recycled Materials Association (ReMA), Lotzkar has worked with government officials in Canada and the U.S. to defend the interests of the recycling and manufacturing industries. She holds a Master of Business Administration and a Bachelor of Commerce from the University of Victoria.

L’Association canadienne des industries du recyclage (ACIR-CARI) a le plaisir d’annoncer la nomination de Jacqueline Lotzkar au poste de présidente-directrice générale. Mme Lotzkar entrera en fonction le 3 février. Mme Lotzkar apporte à son nouveau rôle une vaste expérience du secteur du recyclage. Elle a été reconnue à l’échelle mondiale et a récemment été nommée parmi les 100 leaders les plus inspirants et les plus novateurs dans le domaine du recyclage par le magazine Recycling International. Au cours des quatre dernières années, Mme Lotzkar a occupé le poste de vice-présidente de Pacific Metals Recycling International, où elle a joué un rôle essentiel dans le processus de vente de et de transition de cette entreprise familiale vieille de 112 ans. Membre active de l’Association des matériaux recyclés (ReMA), Mme Lotzkar a collaboré avec des représentants du gouvernement au Canada et aux États-Unis pour défendre les intérêts des industries du recyclage et de la fabrication. Elle est titulaire d’une maîtrise en administration des affaires et d’une licence en commerce de l’Université de Victoria.

Story by/par Allison Rogers

Businesses can be formed in a variety of ways. In the auto recycling industry, many professionals are part of a rich legacy, family businesses that have been passed down two, three or even four generations. Though not every journey in this sector follows this path; JS Truckmart has one of those stories.

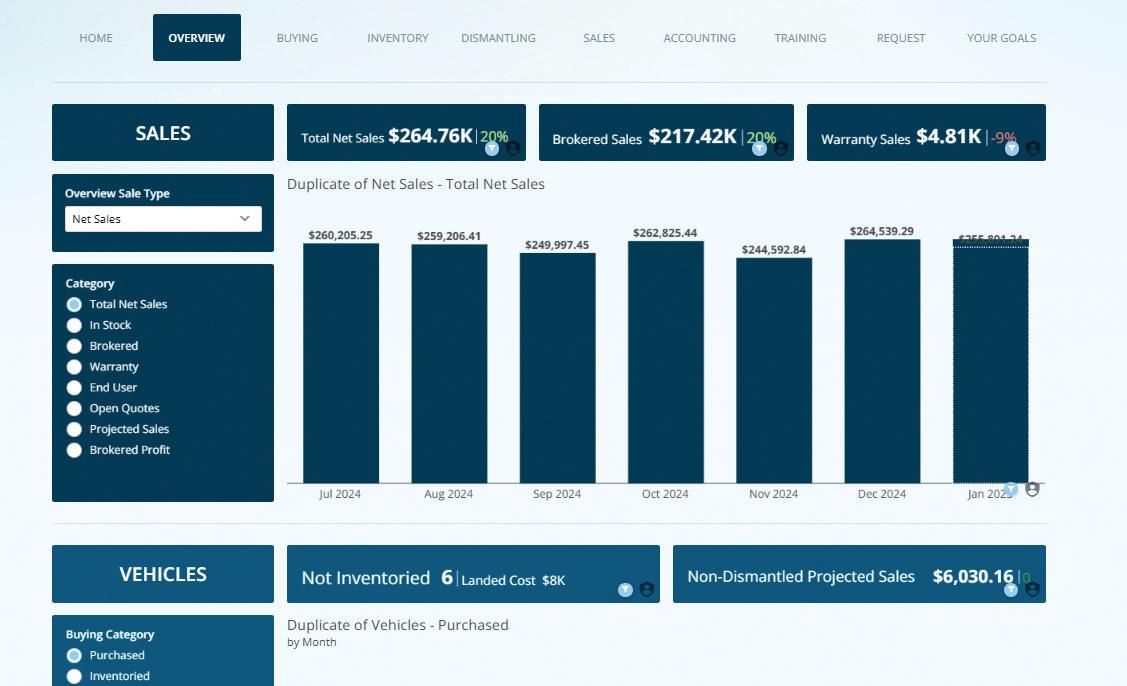

The tale begins with a team of well-rounded individuals who recognized a gap in the market in Southeast Saskatchewan for an automotive recycler. The ownership team bring a unique set of skills to the table that complement each other well, with Jeremy Swanson focusing on business growth and sales; Christa Morhart focusing on the recruitment, retention, finance and cross-border transactions, and Bart Morhart focusing on the production and logistics side. The hiring department managers—who handle warranty, dismantling and shipping—have also been key in the overall success of JS Truckmart. Warranty and sales manager Robert Herrington has also proven to be an integral part of the management team since joining JS Truckmart a number of years ago.

Since its establishment, JS Truckmart’s ownership team quickly embarked on what would quickly become an incredibly impressive automotive recycling facility offering OEM and premium remanufactured parts across all of North America.

The first home to JS Truckmart was much different than what we see today. JS Truckmart quickly outgrew their humble beginning in 2017 with a dynamic growth from their leased property, small warehouse and one dismantle hoist.

Les entreprises se forment de diverses manières. Dans l’industrie du recyclage automobile, de nombreux professionnels s’inscrivent dans un riche héritage, celui des entreprises familiales transmises sur deux, trois ou même quatre générations. Bien sûr, toutes les entreprises du milieu n’ont pas cette chance, comme JS Truckmart.

Tout a commencé grâce à une équipe de personnes polyvalentes ayant remarqué que le marché du sud de la Saskatchewan avait besoin d’un recycleur automobile. L’équipe de propriétaires contribue à l’entreprise un ensemble unique de compétences qui se complètent bien : Jeremy Swanson apporte son savoir-faire en matière de croissance et de ventes, Christa Morhart est chargée du recrutement, de la fidélisation du personnel, des finances et des transactions outre-frontière, et Bart Morhart est responsable de la production et de la logistique. Les gestionnaires du service d’embauche, qui gèrent les garanties, le démantèlement et l’expédition, ont également joué un rôle clé dans le succès général de JS Truckmart. Robert Herrington, gestionnaire des garanties et des ventes, s’est révélé un atout précieux de l’équipe de direction depuis son arrivée il y a quelques années.

À la création de JS Truckmart, l’équipe de direction s’est lancée dans ce qui allait devenir une entreprise de recyclage automobile absolument remarquable offrant des pièces d’origine réusinées de qualité supérieure dans toute l’Amérique du Nord.

Le premier site de JS Truckmart était très différent de ce que l’on connaît aujourd’hui. À ses modestes débuts, en 2017, l’entreprise disposait d’un petit entrepôt et d’un unique palan de démontage, le tout sur une propriété louée.

“We discussed, as management, that we wanted to focus on culture, and capitalize on hiring personalities, attitude, and loyalty over skillset, with a focus on culture.”

— Christa Morhart, partner, J.S. Truckmart

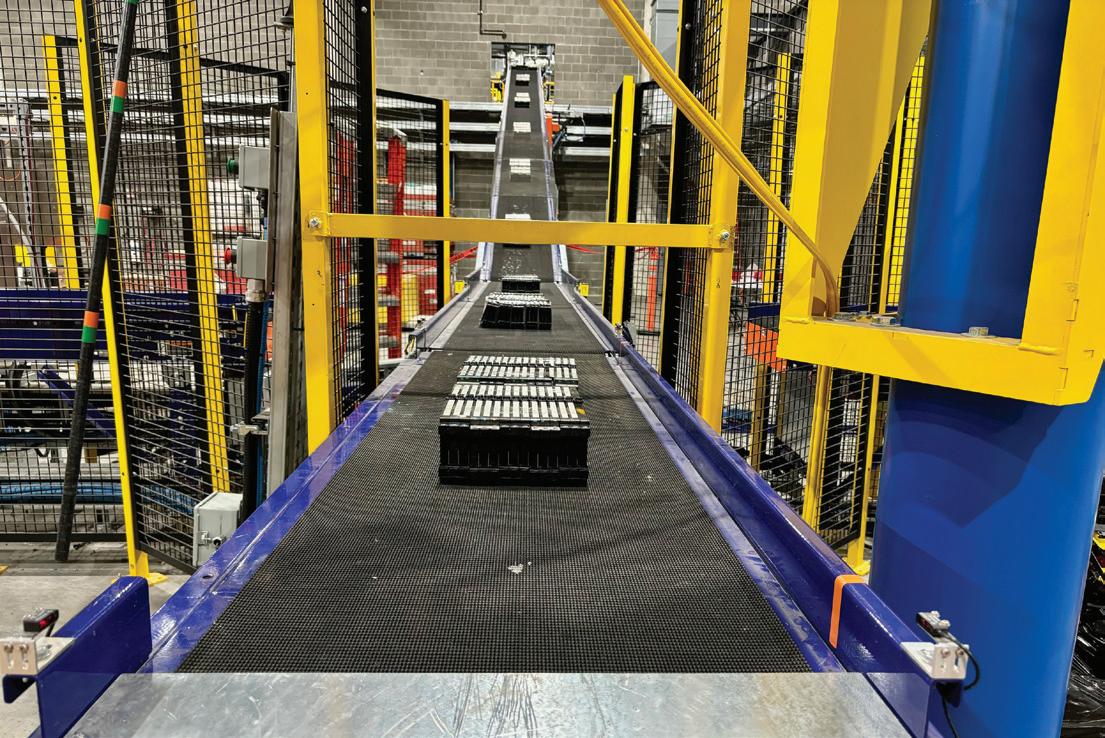

The expansion to a new facility with five hoists, 19 acres of land, and over 12,000 square feet of warehouse space has allowed for explosive growth in just a few years—not just in space, but also in manpower.

Today, JS Truckmart has fifty-two employees rounding out their team; including some key players who have stuck with them from the very beginning.

Investing in their business, with a state-of-the-art facility, up to date equipment and training for the entire team is of huge importance to JS Truckmart. Consistently developing, reviewing and implementing processes and procedures in all departments to improve efficiency has provided the building blocks for the growth for the company.

Diversity in the workplace, capitalizing on recruiting positive attitudes with a willingness to train the skillset, and providing opportunities for employees to grow within the company has been integral to employee retention. JS Truckmart is known for their award-winning customer service, a direct result of the recruitment and process implementation.

The managing partners attribute their overall success to their unique business model, with a strong focus on breaking through age-old barriers. Being open to tearing down the walls of cross border trading and shipping across Canada and the United States are strong key points of the business model.

Reaching out to other auto recyclers and working together to gain trust and a valued relationship in trading has also been a key point in the business model.

One hundred percent of JS Truckmart’s sales team works remotely, adding another unique factor in their success.

« L’équipe de direction souhaitait miser d’abord sur la culture et embaucher des personnes qui, au-delà des compétences, se démarquent par leur personnalité, leur attitude et leur loyauté. »

— Christa Morhart, partenaire, JS Truckmart

En seulement quelques années, l’entreprise a connu une croissance explosive, tant en espace qu’en main-d’œuvre, et elle exploite maintenant ses propres installations comptant cinq palans et plus de 12 000 pieds carrés d’entrepôt sur 19 acres de terrain.

Aujourd’hui, l’équipe de JS Truckmart compte cinquante-deux employés, dont quelques acteurs clés qui sont restés fidèles depuis le tout début.

JS Truckmart doit son succès, entre autres, à ses installations et ses équipements de pointe, de même qu’à sa volonté de veiller à la formation de tous les membres de son équipe. Pour favoriser sa croissance, l’entreprise a misé sur la création, la refonte et la mise en œuvre de processus et de procédés dans tous les volets de l’entreprise.

Par ailleurs, elle encourage la diversité dans le milieu de travail, recrute des gens à l’attitude positive enclins à apprendre et offre à tous la possibilité d’évoluer au sein de l’entreprise, ce qui contribue grandement à fidéliser le personnel. JS Truckmart est reconnue pour son service à la clientèle primé, un résultat direct du recrutement et des processus établis.

Les partenaires dirigeants attribuent le succès général de l’entreprise à son modèle d’affaires unique, qui mise sur l’élimination d’obstacles de longue date. Par exemple, l’élimination des barrières au commerce transfrontalier et l’expédition à travers le Canada et les États-Unis constituent des éléments essentiels de ce modèle d’affaires.

L’entreprise mise aussi sur la collaboration avec d’autres recycleurs automobile pour établir des liens de confiance.

La totalité de l’équipe de vente de JS Truckmart travaille à distance, ce qui est un autre facteur unique de sa réussite.

« L’équipe de vente est concentrée comme un laser. La productivité, l’efficacité... c’est tellement impressionnant que beaucoup de nos clients

“Our growth has not been about luck; it’s about hard work, vision and believing what you can achieve.”

— Jeremy Swanson, partner, J.S. Truckmart

“The sales team are laser-focused. The productivity, the efficiency…it’s so impressive that many of our customers don’t even realize the salespeople are not physically here in the building,” added Jeremy.

“I love having our salespeople work remotely,” added Christa. “Of course, it’s nice when we get together and see them, but the focus is there; the efficiency is there, and how great is it that they don’t have to endure the stresses of a Saskatchewan commute, especially in the frigid Winter temperatures?”

“We have added positions over the years that have enhanced the customer service component of JS Truckmart and we pride ourselves in our quality control processes, as well as ability to ship any part across Canada and the USA. Our teams have worked hard and followed us through change to ensure we continue to meet our company goals,” said Bart.

JS Truckmart are also active members of a number of associations, continuously learning and implementing new processes to standardize their approach to dismantling vehicles and processing the premium recycled parts. These associations include URG, Team PRP, QRP Canada, SARA, ARA, and the Automotive Recyclers Association of Canada. Having a voice in the industry and aligning their vision with other like-minded recyclers is important to the management team at JS Truckmart.

At its core, JS Truckmart was built on dedication, strong team dynamics, and a clear vision. Like other automotive recyclers, JS Truckmart remains committed to improving their carbon management, with a strong focus on their recycling processes and end-of-life materials recovery.

“We’re here to stay,” concluded Jeremy, the confidence clear in his voice. “It’s not about luck; it’s about hard work, vision and believing what you can achieve.” CAR

The JS Truckmart team accepting their Achievement of Business Excellence (ABEX) award. The company won the ABEX Business of the Year and the Growth and Expansion Award; they were also a finalist for the diversity, equity and inclusion award.

L’équipe de JS Truckmart recevant son prix « Achievement of Business Excellence » (ABEX). L’entreprise a remporté le prix ABEX de l’entreprise de l’année et le prix de la croissance et de l’expansion ; elle était également finaliste pour le prix de la diversité, de l’équité et de l’inclusion.

« Notre croissance n’est pas attribuable à la chance, mais bien à un travail acharné, une vision et la conviction de ce que l’on peut accomplir. »

— Jeremy Swanson, partenaire, JS Truckmart

ne réalisent même pas que les vendeurs ne sont pas physiquement dans le bâtiment », a déclaré Jeremy.

« J’adore que nos vendeurs travaillent à distance, a ajouté Christa. Bien sûr, c’est agréable de voir tout le monde en personne, mais la concentration est là, l’efficacité aussi, et quelle chance nous avons de pouvoir éviter le stress d’un trajet en Saskatchewan, surtout lorsque les températures hivernales sont glaciales! »

« Au fil des ans, nous avons ajouté des postes précis pour rehausser le volet du service à la clientèle, et nous tirons une grande fierté de nos procédés de contrôle de la qualité, ainsi que de notre capacité à expédier n’importe quelle pièce depuis n’importe où au Canada ou aux États-Unis. Notre équipe a travaillé dur et nous a épaulés pendant les changements pour veiller au respect des objectifs de notre entreprise », explique Bart.

JS Truckmart joue un rôle actif au sein de plusieurs associations — comme RG, Team PRP, QRP Canada, SARA, ARA et l’Association des recycleurs automobiles du Canada —, toujours pour apprendre et établir de nouveaux procédés dans le but de normaliser la démarche de démantèlement des véhicules et le traitement des pièces recyclées de qualité supérieure. L’équipe de direction de JS Truckmart considère qu’il est important de se faire entendre dans l’industrie et d’harmoniser sa vision avec celle d’autres recycleurs partageant les mêmes valeurs.

Le dévouement, une dynamique d’équipe robuste et une vision claire sont les fondements de JS Truckmart. Comme d’autres recycleurs automobile, JS Truckmart est déterminée à améliorer la gestion de son empreinte carbone et, pour ce faire, mise principalement sur ses processus de recyclage et la récupération des matériaux en fin de vie.

« Nous sommes ici pour de bon », conclut Jeremy, d’une voix forte et sure. « Ce n’est pas une question de chance, mais bien de travail acharné, de vision et de confiance en ce que l’on peut accomplir. » CAR

Describing Steve Fletcher’s impact on the automotive recycling industry might seem straightforward, especially considering the significant transformation the sector has undergone since he joined the industry more than 30 years ago.

Upon closer reflection, it becomes clear that Steve Fletcher’s contributions to the automotive recycling industry are too numerous to fully capture. His efforts in promoting a nationwide regulatory framework and modern practices have set new standards, while his warm and thoughtful mentorship has guided many in the field.

Steve has also introduced inter-industry panels that foster vital conversations among insurers, repairers, recyclers, and other stakeholders, enhancing collaboration across the sector. Moreover, his international outreach continues to expand his influence, connecting recycling communities around the globe.

Summing up Steve’s remarkable impact on the automotive recycling industry is indeed a challenging task, as he has left an indelible mark that will be felt for years to come. The most fitting way to honor Steve’s tenure with ARC and OARA is encapsulated in the Lifetime Achievement Award he received from the Automotive Recyclers Association last October.

Over the past 18 years, we at Canadian Auto Recyclers magazine have had the privilege of working closely with Steve. His unwavering commitment to advancing the interests of auto recyclers in Canada has been nothing short of inspiring. From organizing impactful events to driving policy initiatives, Steve has been a driving force in our industry, championing sustainability and innovation.

As we celebrate Steve’s accomplishments, we also look forward to seeing him thrive in his new role at IRT. We are confident that his expertise and dedication will continue to elevate the standards of automotive recycling worldwide.