Simplify your body shop processes today.

The 3M OEM Match Family of seam sealing products are engineered to help technicians of all skill levels more easily replicate the appearance and function of a vehicle’s original factory seam sealer.

The system includes our line of seam sealer matching tips and the 2K 3M™ OEM Match Epoxy Seam Sealer in 4 colours –allowing you to replicate the most common OEM seams with one simple application.

BY DARRYL SIMMONS

Welcome to the 2025 Collision Repair Magazine Buyer’s Guide!

Over the past year, extensive travels through global collision repair markets have revealed a rich tapestry of innovation and creativity within our industry. From bustling trade shows to intimate workshops, the insights gathered reflect a commitment to not only surviving but thriving in an everevolving landscape.

As I navigated various trade shows and industry events this year, I couldn’t help but feel energized by the innovations that can

to provide insights that will elevate your business. I encourage you to explore these offerings and consider how they can fit into your strategy moving forward.

In our fast-evolving industry, staying updated is not just beneficial—it’s essential. The tools and strategies you choose today can shape the future of your business. I hope this guide serves as a valuable roadmap, helping you navigate the complexities of our field and seize the opportunities that come your way.

Collaboration and community are vital to

PUBLISHER

Darryl Simmons publisher@collisionrepairmag.com

ASSOCIATE PUBLISHER

Orest Tkaczuk | orest@mediamatters.ca

EDITOR

Allison Rogers | allison@mediamatters.ca

ART DIRECTOR

Yvonne Maschke | yvonne@mediamatters.ca

ASSISTANT EDITOR

Sarah Perkins | sarah@mediamatters.ca

VP OF INDUSTRY RELATIONS & ADVERTISING

Gloria Mann 647.998.5677 | gd.mann@rogers.com

INDUSTRY RELATIONS ASSISTANT Wanja Mann 647.998.5677 wanjamann1@gmail.com

DIGITAL OPERATIONS MANAGER Cassie Doyle | cassie@mediamatters.ca

AUDIENCE ENGAGEMENT MANAGER

William Simmons | william@mediamatters.ca

MEDIA PRODUCTION SPECIALIST

Dayna Dicuangco | dayna@mediamatters.ca

DESIGN INTERN

Trinity Nguyen | designintern@mediamatters.ca

SUBSCRIPTION

$15.99 For the Special Edition

significantly impact our businesses. Whether your focus is on improving profitability, reducing cycle time, or achieving operational excellence, this Buyer’s Guide is your goto resource for making informed decisions.

The tools and technologies showcased at these events were not just impressive; they embodied the spirit of transformation that fuels our work. From AI-integrated solutions that redefine efficiency to sustainable products that honour our planet, the possibilities are as vast as our ambition. This guide is crafted to be your compass in this dynamic landscape, helping you navigate the myriad options available and empowering you to make choices that will elevate your business.

This comprehensive Buyer’s Guide is designed to equip you with the knowledge you need to tackle any issue that may arise in your operations. From advanced repair equipment to innovative management software, each listing has been carefully curated

our success. I invite you to engage with the content, reach out to vendors, and explore solutions that resonate with your goals. This Buyer’s Guide is more than a catalogue; it’s a catalyst for growth and a resource for operational success.

As you delve into the following pages, I encourage you to envision the possibilities for your business. Embrace the changes on the horizon, and let this guide accompany you on your journey toward transformation. Together, we can tackle the challenges of today and build a brighter future for the collision repair industry.

Thank you for your continued support, and here’s to a successful year ahead!

The Buyer’s Guide is an annual special edition of Collision Repair™ magazine which is published bi-monthly, and is dedicated to serving the business interests of the collision repair industry. It is published by Media Matters Inc. Material in Collision Repair™ magazine may not be reproduced in any form without written consent from the publisher. The publisher reserves the right to refuse any advertising and disclaims all responsibilities for claims or statements made by its advertisers or independent columnists. All facts, opinions, statements appearing in this publication are those of the writers and editors themselves, and are in no way to be construed as statements, positions or endorsements by the publisher.

PRINTED IN CANADA ISSN 1707-6072

CANADA POST CANADIAN PUBLICATIONS MAIL SALES PRODUCT AGREEMENT No. 40841632

RETURN POSTAGE GUARANTEED

“We acknowledge the financial support of the Government of Canada”

Send change of address notices and undeliverable copies to: 317 Reid St., Peterborugh ON K9J 3R2 Collision

Introducing LCS: The first Liner Cup System designed by SATA, optimised for SATA spray guns.

The LCS fits directly on all SATA spray guns with a QCC bayonet connection, eliminating the need for additional adapters. The benefits: Lower center of gravity, reduced weight, and easier cleaning. Also typical SATA: High-quality, particle-free sieves, a comprehensive scale system and a secure, easy-to-use safety lock on the lid.

LCS: 0.40 litre, 0.65 litre, 0.85 litre

INFO on SATA LCS cups www.sata.com/LCS

EIGHT NEW PRODUCTS SHOWN AT SEMA THAT COULD TRANSFORM YOUR WORKPLACE

Story by Allison Rogers

The SEMA New Product Awards are a highlight of the automotive industry, showcasing cutting-edge innovations and tools that push the boundaries of performance and design. This year, a remarkable selection of over 1,600 products competed across 18 diverse categories, each vying for recognition based on criteria such as innovation, technical achievement, quality, and market appeal.

Collision Repair took a deep dive into this year’s New Product Showcase to identify the standout tools that we believe will make the most significant impact in our market. Join us as we reveal our top picks for the coolest advancements that are set to transform the industry.

This limited-edition SATAjetX 5500 Lowrider is a topquality spray gun available in both HLVP and RP compliant technologies. SATA says the spray gun is perfect for spraying all types of topcoats, sealers and clears. Plus, the SATAjet X 5500 Lowrider is a limited production special edition surface coating that will help you stand out. This spray gun is available across the United States and Canada at authorized SATA distributors.

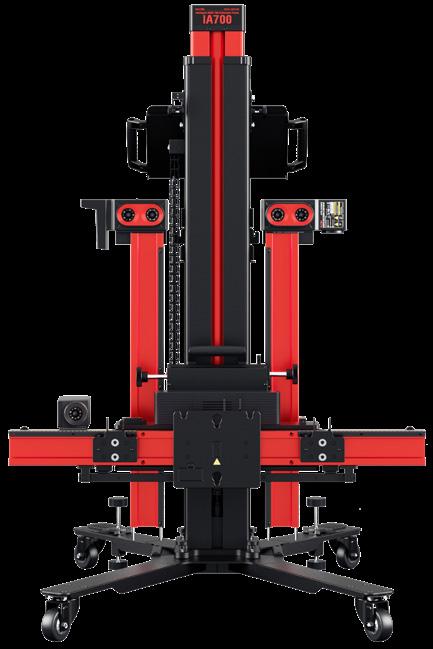

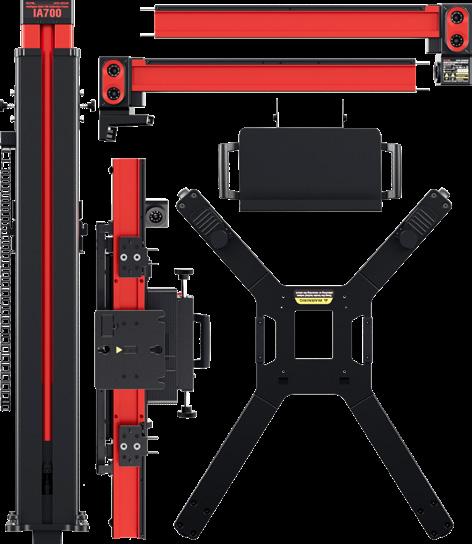

WINNER SEMA BEST NEW ADAS PRODUCT!

BY

REVV ADAS

The revolutionary Pro Spot Ergo Lift Assist™ System (ELA) is the tallest and most versatile motorized boom mechanism for spot welding applications. Designed to reach higher (9.25’ / 2.82 m) and lower (5’ / 1.5 m) than most conventional booms, the ELA makes spot welding any area on today’s high reach/wide footprint vehicles accessible and ergonomic. The Ergo Lift Assist™ is designed for today’s high-profile SUVs, vans and trucks, and the battery-powered ELA has over nine feet of vertical reach.

The winner of the SEMA Best New Product — ADAS Category, Revv ADAS is a SaaS platform that allows collision repair facilities and calibration businesses to identify new revenue streams from required ADAS, safety, steering and functional calibrations on repaired vehicles. According to the company, Revv ADAS Plus delivers a complete calibration identification solution with an advanced rules engine, workflow management, CCC and Mitchell integrations, as well as customizable options for each shop. The program allows for advanced quoting based on labour rates, insurance or vehicle make, plus seamless billing and invoicing via Quickbooks integration.

Winner of SEMA’s Best New Electric Vehicle Product, Formosa EV’s Vehicle Control Unit (VCU) simplifies EV conversions by acting as a universal translator between components. The company says this eliminates the need for CAN bus programming. Normally, setting up the communication between car parts requires a lot of technical programming, though Formosa says its VCU removes this hassle. The product itself is designed for DIY enthusiasts and is said to offer easy set-up via a user-friendly mobile app. The VCU is said to be automotive-grade and OEM-tested, according to Formosa EV.

Experience hands-on spray painting training without the mess! Developed by expert spray paint technicians, the Sagola SPRAY VR program allows refinishers-in-training to master essential techniques in a safe and eco-friendly environment. Practice repeatedly to refine your skills while saving paint and materials. Receive instant feedback to learn from your mistakes and improve your technique. Discover the perfect gun distance for a flawless finish, adjust your hand positioning for optimal fan patterns, and understand the ideal speed for effective spraying. Elevate your craftsmanship and gain confidence in your abilities with our innovative virtual reality training!

The GPR Star Vortex Cooler is a cooling solution designed to improve the performance of glue pull repair (GPR). It rapidly cools down hot glue, allowing technicians to work faster and more efficiently by minimizing wait times during the repair process. The GPR Star Vortex Cooler—not yet available in Canada—is said to be ideal for shops and locations where ambient temperatures are elevated. The cooling effect of the vortex action reduces temperatures and times between pulls, according to KECO.

Launched in Summer 2024, Hunter University is a new global learning platform designed for easily accessible training for customers, technicians, technical school instructors, students and other interested parties. The Hunter University platform, which is available in 21 languages, collects all of Hunter’s extensive learning content in a single place, offering dozens of free online courses worldwide, as well as streamlined registration for handson, in-person courses at training centres around the United States. Hunter Engineering notes that all existing content was updated and refreshed as part of the nine-month effort, often converting from dynamic modules with narration and video. The online courses are generally presented in five-minute segments, so even a 10-module course can be completed in approximately one hour.

R educe setup time by 6X versus mechanical measurements.

Eliminate failed calibrations due to uneven surfaces.

Ensure your workflow follows OEM-sourced procedures.

The IA700 is an advanced and versatile wheel alignment pre-check and ADAS calibration system engineered for both in-shop and mobile applications – move from bay to bay and shop to shop.

Disassembles into 5 primary parts in less than 90 seconds for easy transport.

3M and Axalta have announced a collaboration to introduce a new training content series focused on automotive refinishing. The series will feature five cobranded training modules, each intended to meaningfully help technicians and shops improve their understanding of repair process practices and drive greater operational outcomes. The first three training modules from the series centred on optimizing process productivity, efficiency and quality in refinishing, are scheduled for release globally on December 2, 2024, and will be accessible through the 3M™ Collision Repair Academy and Axalta Academy platforms. The training content will also be made available on 3M and Axalta’s social media channels. Additional training modules focused on safety and sustainability will become available in 2025.

The companies made the collaboration announcement during Industry Week in Las Vegas, Nevada. Pictured above: Patricia Morschel, vice president of marketing and commercial operations for Axalta global refinish; Troy Weaver, director of global refinish, Axalta; and Dave Gunderson, president, 3M Automotive Aftermarket division.

and

Story by Sarah Perkins

From electric powertrains to selfhealing coatings, advances in modern vehicle tech are such that even the Jetsons would do a double take. While today’s vehicles can’t fly—although, you can look it up and you’ll see that some are working on soaring ahead—current efforts are being made to enhance their safety on the road in the form of automatic emergency braking (AEB) systems.

According to a recent report from the American Automobile Association (AAA) “automatic emergency braking is an advanced driver assistance system (ADAS) that utilizes sensors to detect imminent forward collisions with vehicles or other obstacles. When a potential collision is identified, and driver response is deemed insufficient, AEB systems automatically apply braking pressure to slow the vehicle or bring it to a complete stop, mitigating the severity of the impact or potentially avoiding the collision altogether.”

The report continues that as of 2023, AEB systems are now present in 89 percent of all new vehicles sold, and this number is set to rapidly increase as the United States Department of Transportation (USDOT), the National Highway Traffic Safety Administration (NHTSA) and the Insurance Institute for Highway Safety (IIHS) has outlined that all vehicles sold in the

United States in 2029 must include some form of automatic emergency braking.

As released this April in the document Federal Motor Vehicle Safety Standard (FMVSS) No. 127, this new standard requires all cars be able to stop and avoid contact with a vehicle in front of them up to 62 miles (100 kilometers) and that the systems must detect pedestrians in both daylight and darkness. In addition, the standard requires that the system apply the brakes automatically up to 90 miles per hour (145 kilometers per hour) when a collision with a lead vehicle is imminent, and up to 45

miles per hour (72 kilometers per hour) when a pedestrian is detected.

Furthermore, this new standard is expected to save at least 360 lives and prevent more than 24,000 injuries annually.

While studies by the NHTSA indicate that AEB technologies can lower rear-end collisions by up to 49 percent, AAA’s recent report specifically aimed to determine the performance of older generation tech in comparison to the current generation to see how far automatic braking has to go before it stops at the 2029 finish line.

In order to evaluate the progression of automatic braking technology between older and newer vehicle models, AAA specifically conducted its primary research in a closedcourse simulated environment using vehicles from 2017, 2018 and 2024. All testing focused on preventing forward-motion, rear-end collisions with a stationary vehicle at various speeds under identical test conditions.

The technology systems have commonly relied on front-mounted, forward-looking vision systems; however the industry has more recently begun to shift towards the deployment of a dual sensor approach, using radar and camera to continuously monitor the road ahead and assess potential hazards. The data is gathered and subsequently processed by an onboard computer, which triggers automatic intervention when specific risk parameters are met, the report further notes.

When looking at the difference in performance between older and newer vehicle models, AAA’s data shows that 2024 vehicle models were nearly twice as likely to avoid a collision as 2017 and 2018 models when tested at speeds up to 35 miles per hour (56 km/h).

Moreover, early model vehicles avoided collisions 51 percent of the time compared to 100 percent for the late model vehicles. It was at slower test speeds of 12 miles per hour (19 kilometers per hour) that the early model vehicles were able to perform well, avoiding 73 percent of collisions. When evaluated at slightly higher test speeds, this collision avoidance performance dropped to 47 percent at 25 miles per hour (40 km/h) and 33 percent at 56 km/h.

However, none of the vehicles tested could avoid a collision at speeds higher than 55 miles per hour (88 km/h). Here, vehicles tested from all model years experienced either an aborted test run due to vehicle performance or an impact with the softcar target vehicle used as stand-in for a static passenger vehicle.

The AAA concludes that “as vehicles deploy more advanced electrical and electronic architecture that includes edge node software abstraction into centralized high-performance computers, advancements in machine learning and artificial intelligence will allow AEB systems to detect objects and classify them more effectively in real time. This could enable AEB to tailor braking responses to specific situations based on environmental context, vehicle type and vulnerable road users (VRUs) such as pedestrians and cyclists.”

However, despite this potential, the AAA also reminds that “while there have been notable

improvements in AEB systems over the last few years, drivers should not rely solely on this technology to avoid collisions or expect the vehicle to always brake in the event of a crash. External factors such as vehicle condition, road type and ambient weather can all significantly impact the functionality of these systems.”

With the United States turning its attention to the horizons of 2029, the question remains, where does Canada sit on the issue of mandatory AEB systems? According to an August bulletin from Transport Canada, the Government of Canada has “been studying automatic emergency braking for several years now. The results of this work show that the system slows a vehicle before a collision and helps keep drivers and passengers safe. Our research is consistent with other studies that have found that vehicles with AEB systems are involved in fewer rear-end collisions. Reducing the speed of collisions can also help reduce injuries for vulnerable road users, like pedestrians and cyclists.”

The bulletin continues that “there’s no guarantee that an automatic emergency braking system will always intervene. Some types of weather, like snow or rain, could keep the system

from detecting an obstacle. Even the sun being low in the sky could affect how it operates.”

As a result, “automatic emergency braking isn’t required on new vehicles in Canada, but some manufacturers include it as a standard or as an optional feature on some models.”

Transport Canada concluded that if the country were to move forward with a mandatory adoption, Canadian requirements for pedestrian detection would first have to be developed.

In this way, while advancements in AEB systems are promising, they also underscore a broader responsibility for both drivers and manufacturers. As these technologies become increasingly sophisticated, there must also be an emphasis on public education regarding their capabilities and limitations. Drivers should remain vigilant and not view AEB as a substitute for attentive driving. The potential benefits are significant, but the technology is still evolving.

However, with the continued rise and demand for increasingly technological systems in automotive manufacturing, as governments, manufacturers and collision repairers navigate the changing horizons, one thing remains certain: the pursuit of safer roads is a shared goal that transcends borders, and every step towards innovation is a step towards saving lives.

People choose who fixes their family’s car based on trust.

TRUST Technical Excellence Transparency FAMILY

Story by Allison Rogers

Environmental sustainability and the collision repair industry’s own role in curbing carbon emissions is a topic that has rapidly climbed to the forefront of many industry conversations. In the last year, the Canadian industry has taken several steps to bring the conversation into the spotlight, including the first-ever Canadian Automotive Sustainability Summit, hosted by Solera and Simplicity Car Care this past June.

The question of sustainability, as it relates to collision claims, interrogates what methods are being used to restore the car to pre-accident condition, and how environmentally sustainable those actions are.

In summary, sustainable estimatics measure the amount of carbon that is produced in a collision claim, explained Bill Brower, senior vice president of global industry relations and North American claims.

“When you think about collision claims, the question of sustainability is: how is this car being repaired? At Solera, we have been researching sustainability and working in this space for about three and a half years to create sustainable estimatics,” said Brower.

“In summary, sustainable estimatics measures the amount of carbon that’s generated in a collision repair. Sustainable estimatics provide guidance on how to lower emissions.”

When asked why a collision centre would be interested in pursuing sustainable claims, Brower said Solera’s advice for more sustainable practices—which includes strategies like using green recycled parts wherever possible, and repair over replace—can enable lower cycle times, length of rental and keep technicians happy.

“Plus consumers, in most cases, prefer to go for the eco-friendly collision repair,” he added.

Collision repair facilities should be focused on emissions in three categories, advised Brower. First is scope one, direct emissions;

then scope two, indirect electricity emissions and scope three, external and indirect emissions.

“Scope one is the carbon you produce in your own bodyshop, the emissions that you control. Scope two carbon emissions arise from the energy used in your shop. Your shop may be powered by a local electric company; that could be run by solar power, hydroelectric, et cetera.”

According to Simplicity Car Care’s data, scope one emissions account for between 10 percent and 15 percent of a collision repairer’s emissions. Meanwhile, scope two relates to about 15 percent to 20 percent of the average repairer’s output.

“Scope three is the most difficult to track,” added Brower. “This would be the carbon created in the creation of parts that you, the collision centre, ultimately use in your repair. So, it’s all of the carbon emissions created in that process, from the gathering of raw materials to developing the part and shipping the part.”

According to Alyssa Marchese, ESG manager for Simplicity Car Care, the financial benefits of sustainability can be tangible and compelling.

Simplicity Car Care’s data collection program has revealed that tracking utility usage, waste management, and operational inefficiencies can pinpoint areas where energy is being wasted, resulting in a significant reduction in both costs and emissions.

“For instance, our analysis has shown that embedding a ‘repairover-replace’ strategy can reduce electricity consumption by 7.8 percent,” wrote Marchese in a recent column for Collision Repair magazine.

“This is achieved through technological optimization, but more importantly by changing the way we approach repairs and customer service. When combined with behavioural changes—such as turning off compressors or heating systems when not in use—these savings can reach up to 20.6 percent.

“By simply managing energy consumption more effectively, collision repair centres can cut costs without investing in new technologies or equipment. The goal is to create a culture of awareness where every employee understands their role in managing utility resources and reducing waste,” continued Marchese.

“Simple changes in behaviour and processes can reduce energy costs by over 20 percent, offering the same financial boost as a five percent increase in sales for many collision repair centres, and without the need for significant capital investments in new equipment.”

During Simplicity Car Care and Solera’s Automotive Sustainability Summit, keynote speaker Helle Bank Jorgensen, founder, CEO and environmental social governance (ESG) specialist for Competent Boards stressed that we must focus on the future.

“I want you to skate to where the puck is going to be,” said Jorgensen, using Wayne Gretzky’s famous line. “We can’t say, ‘Let’s wait until we have the regulation,’ or ‘let’s wait until we see the effects of climate change.’ Because it will be too late.”

She added that her top three pieces of advice for businesses keen to pursue sustainable efforts are, first, to “get started”; second, to collaborate and third, to take a look at your data points to deliver a path that gets your business where you want to be.

“You need to get started,” she said. “It would be a stupid thing to just ‘wait and see,’ because this is really happening.”

Jorgensen also emphasized that “for too long, different departments have been working in silos.”

“We need to engage. We need to stop thinking silos—no one is speaking to each other. We as leaders need to step up. The sooner we do it, frankly, the more fun we are going to have.”

Ultimately, the first step is to “buckle up” for waves of change, concluded Jorgensen, adding that the current shift is not unlike the introduction of seatbelt laws in the 1970s.

“Think of how many lives were saved with that proactive action. We can do the same, here and now.”

Story by Sarah Perkins

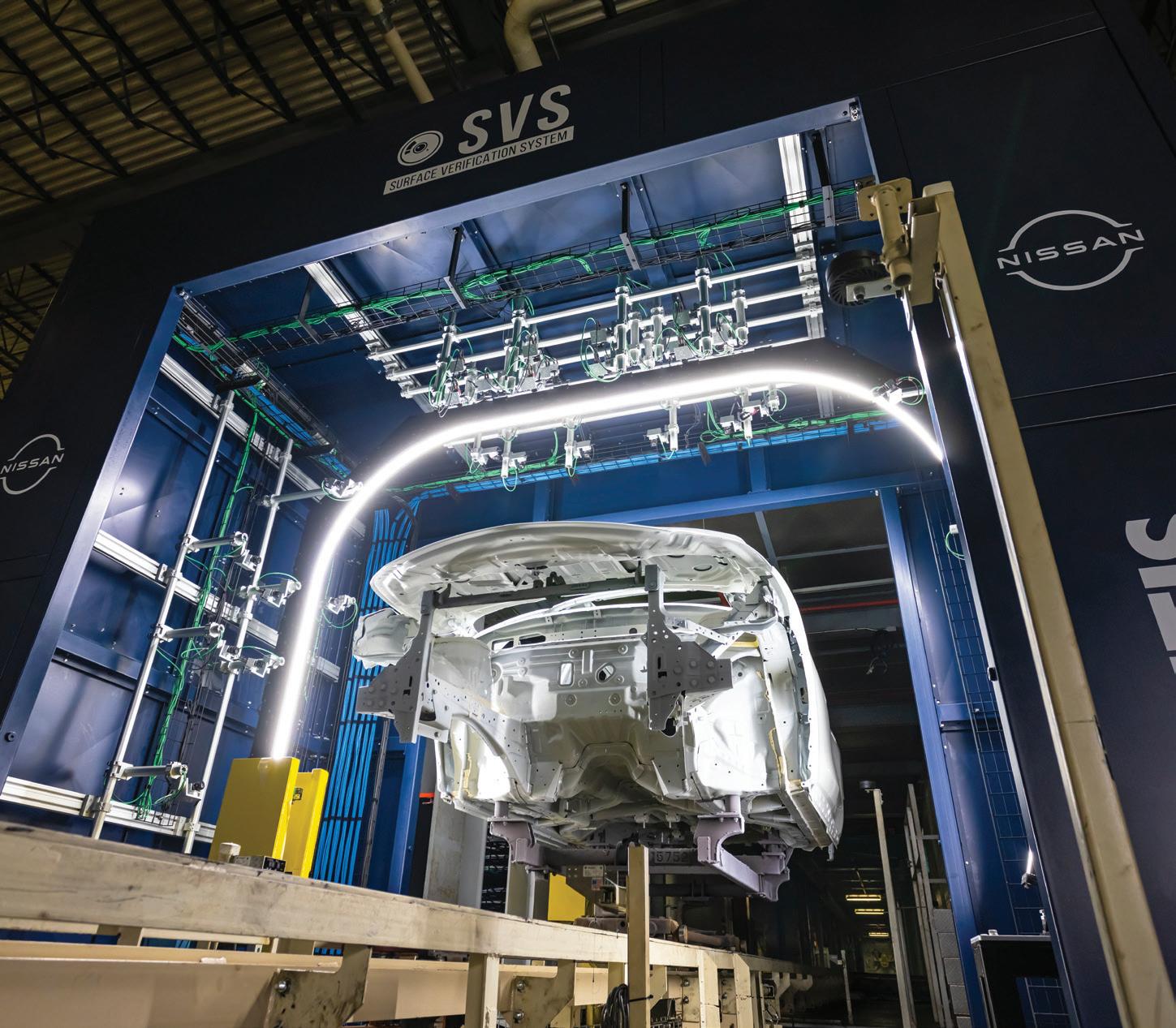

Putting a vehicle together is no small task; from bolts and fasteners to highly sensitive electronic components and increasingly lightweight materials, today’s vehicles are a modern jigsaw puzzle with around 30,000 separate parts.

With manufacturers increasingly looking to grapple with enhanced vehicle sustainability and the ongoing technification of onboard systems, questions of updated production and assembly have also become central within the automotive industry.

And, while automakers have adopted a variety of solutions to the question of how to streamline the production process of the modern vehicle, for many, the answer to tackling the assembly of 30,000 parts into one cohesive ride is one of equally large proportions: gigacasting.

Gigacasting, or megacasting, has emerged as a technology that aims to reimagine how vehicles are produced through a process that involves the use of large-scale die casting machines to create significant components of a vehicle in one piece, rather than assembling multiple smaller parts. Using molten aluminum, the vehicle chassis and other structural components are manufactured in one continuous pour into pre-set molds.

In most cases, aluminum is the material of choice for gigacasting due to its lightweight properties, strength and resistance to corrosion. Additionally, during the manufacturing process, gigacasting facilities also often employ advanced automation and robotics to handle high-speed production. Automated systems are capable of managing everything from the handling of raw materials to the casting, cooling and quality control of the finished product.

And, while the technology is attributed to Tesla, it is now used by other automotive companies such as Toyota. Raghunandan Gurumurthy, a global expert in industrial engineering and director of North American operations at Crossover Solutions and Forbes business council member, released in a report that “when Tesla first began gigacasting the Model Y in late 2020, it reduced the number of total parts in the vehicle by 370. Further, the automaker reported a 40 percent cost reduction for the rear of the Model Y using the technology.”

Tesla specifically began using a custom OL6100 CS Gigapress in late 2020 for integrated die-casting production of chassis parts.

During this process, shots of molten aluminum weighing 80 kilograms were injected into a cold-chamber casting mold with a velocity of 10 metres per second, or 36 kilometers per hour.

“A comparison of manufacturing methods for producing 100,000 rear underbody units per year,” Gurumurthy continued, “reveals that steel stamping and joining require $2.3 million to $3.4 million in equipment and tooling, while aluminum gigacasting needs a $6 million high-pressure die-casting machine (HPDC) and $1.2 million to $1.5 million in tooling. However, gigacasting also achieves 27.8 doable jobs per hour versus 24.4 for steel stamping, while also reducing labour costs and indirect costs. With reduced complexity, there are fewer parts to be made, simplifying assembly and quality control processes and requiring fewer operations on the production line.”

For experts such as Gurumurthy, “while gigacasting uses more expensive materials ($151 to $226 for gigacasting versus $75.6 for steel), the overall cost benefits are substantial, and changing mold designs offers more flexible options than modifying hundreds of parts in a complex supply chain.”

Despite the high upfront costs, there are many potential benefits to the gigacasting process:

Reduced Complexity: By consolidating multiple components into a single part, gigacasting minimizes the complexity of assembly. This simplification leads to shorter production times and reduced labour costs.

Weight Reduction: The ability to create large, lightweight components contributes to overall vehicle weight reduction. Lighter vehicles require less energy to operate, resulting in improved fuel efficiency and lower emissions. Moreover, with the ongoing push for electric vehicles, the ability to create lighter vehicles helps to offset the heavier weights that come with incorporating high-voltage batteries.

Enhanced Structural Integrity: Because gigacasting creates components with fewer joints and welds, this has the potential to enhance structural integrity and durability. This reduction in joints also decreases the likelihood of failure in order to improve vehicle safety.

Cost Efficiency: While the initial investment in gigacasting technology can be significant, the long-term cost savings from reduced assembly labour, lower material waste and enhanced production speeds can offset these expenses in the long run.

However, it should be noted that when first installed or when done incorrectly, the potential for incorrect or damaged castings is high and so, equally the potential for material waste.

Collision Repair reached out to Toyota’s manufacturing department to see how the automaker has approached gigacasting. Here, Toyota specifically highlighted how it sees the adoption of gigacasting as allowing for “significant component integration, which contributes to the reduction of vehicle development costs and factory investment.”

For Toyota, the gigacasting process is one in which, “on the manufacturing axis, the car body is constructed from three main components in a new modular structure.” These three main components are designed “for greater variety in the types of vehicles to be designed and produced.”

And, as with other production processes, “Toyota’s gigacasting technology features aluminum die-casting which eliminates many parts and processes.” While the technology “requires the periodic replacement of casting molds, which typically takes around 24 hours, Toyota has been able to significantly reduce this changeover time by leveraging its knowhow in engine manufacturing—including low pressure molding and die-casting. Tapping into this knowledge has allowed Toyota’s engineers to develop an optimally shaped mold that enables replacement in just 20 minutes. The main idea around our gigacasting efforts is to find the best balance between cost (fewer pieces) and repairability (many pieces).”

As a result, while gigacasting has the potential to simplify the automotive manufacturing process and reduce material use, as with all up-andcoming technologies, its future is one that is still migrating from over the horizon. The advantages—such as reduced complexity, weight savings, and improved structural integrity—are compelling, yet the technology faces significant hurdles. High upfront costs and the risk of material waste present ongoing challenges for manufacturers considering its adoption.

While companies like Tesla and Toyota are leading the way, the broader industry must navigate potential pitfalls, including the reliability of largescale casting processes and the implications for existing supply chains. The promise of gigacasting as an innovative approach is undeniable, but only time will tell if it can truly reshape the landscape of vehicle production as envisioned. After all, when it comes to casting new technologies, it’s always a matter of getting the right mold for success.

Story by Sarah Perkins

It’s no secret that precision and efficiency are paramount when it comes to collision repair. Whether it’s a minor fender bender or a major collision, every repair demands a meticulous attention to both detail and skill. However, with the advent of artificial intelligence (AI), the demand for details is quickly gaining a technology-driven-touch. With the modern advances in technology, gone are the days when repair technicians had to rely solely on their experience and intuition to assess damages and execute repairs. Today, AI technologies are entering the body shop from the process of repair diagnosis to completion. Collision Repair magazine reached out to those in the industry to ascertain how artificial intelligence is working on continuously harnessing the power of machine learning and predictive analytics to contribute to the accuracy, speed and process of collision repair, and more importantly, how the industry feels about the tech.

While artificial intelligence, for many, may still seem like something from science fiction, today, there are already many applications for AI in collision repair. From use in damage assessment to helping take phone calls, AI algorithms are working in many shops to try and streamline the repair process.

One prominent application of AI in collision repair is in damage assessment. Traditionally, technicians would manually inspect vehicles to assess the extent of damage—a process that is often time consuming. Today, AI-powered computer vision systems are now capable of analyzing images of damaged vehicles to identify areas requiring repair.

AI algorithms can be used to help estimate repair costs based on the identified damage, parts required and labour involved. For many shops, using AI to help estimate repair costs, can enable more accurate quotes to customers and can help reduce the likelihood of unexpected expenses and disputes later on in the repair process.

Another area where AI can contribute to a shop’s workflow is by helping to identify patterns. AI powered software solutions can analyze historical repair data, such as repair times, parts usage and customer feedback, to identify patterns and optimize repair processes. By identifying inefficiencies and bottlenecks, AI can be used to help reduce turnaround time.

Lastly, in addition to streamlining repairs, AI can also be used to enhance the customer experience. Chatbots powered by AI can assist customers throughout the repair process, answering questions, providing updates on repair statuses and scheduling appointments. Unlike a human, these virtual assistants are also able to offer personalized support 24/7.

However, while artificial intelligence may offer specific opportunities within the collision repair industry, the real question is, are members of the industry ready to use the technology? Collision Repair reached out to industry members via survey who revealed that while they may be aware of the tech, the majority of collision repairers have not yet made the jump to fully embracing AI in the bodyshop.

Specifically, 76.5 percent of industry members polled reported that while they are aware of AI, they do not use it in their day-to-day lives, and this is compared to just 5.9 percent of industry members who instead reported using AI daily and with great familiarity.

Moreover, while 76.5 percent of industry members polled reported being open to the idea of the widespread implementation of AI in the collision repair space, for others, the technology is not without its limitations, challenges and concerns.

When asked about general opinions on the use of AI in the bodyshop, commenters cited the potential for improved efficiency, increases to customer service and better access to information. However, concerns were also raised about the need for education and an understanding of the tech, the potential cost of AI and the loss of human connection that the tech could create.

On the one hand, one surveyee commented that “the world is changing, get on board now or be left behind.” Contrastingly, another surveyee commented that “anyway you look at it, the use of AI will still be ARTIFICIAL.”

With these mixed opinions about the validity of AI as a collision repair tool, Collision Repair magazine reached out to some industry experts to gain a fuller insight into the use of AI.

When speaking with RAVIN AI co-founder and CEO, Eliron Ekstein, he noted that AI “can help streamline bodyshop operations by automating and enhancing traditional processes. AI tools can systematically evaluate vehicle damages, helping to ensure precise documentation and reducing manual oversight.”

Ekstein further noted that “AI tools can help to organize service workflows in order to enhance operational efficiency and so, allowing for a more structured and less chaotic working environment.”

For RAVIN specifically, the company’s AI “works to automate the check-in process and accurately document damages as well as providing detailed insights into each vehicle’s state in order to save time and reduce the likelihood of manual errors.”

When asked about the industry’s anxieties surrounding AI, Ekstein commented that while the “collision industry may harbour misconceptions about AI and view it as a complex, inaccessible technology, it can be used as a practical tool.”

Similarly, when speaking to Bill Brower, Senior Vice President, Global Industry Relations and North America Claims Sales, Solera, he outlined how “there are numerous opportunities for AI to increase efficiency and improve the customer experience in bodyshops. While there may be some skepticism and resistance, AI can be a very effective tool in the broader toolbelt if implemented properly.”

Moreover, “AI can significantly improve bodyshop operations by transforming work intake procedures, leading to lower administrative costs, more streamlined processes and improved customer outcomes. Integrating AI can also expedite workflows by reducing time spent on non-productive work, which helps bodyshops operate more efficiently and increase the number of repair deals.”

Brower also outlined how in improving efficiency, “this allows technicians and estimators to focus more on delivering timely, high-quality repair services, especially amid surging costs and worker shortages.”

“While there is some misunderstanding about what AI is, what it is not, and what it’s intended to do, the perception, especially, that AI threatens job security, tends to overlook the benefits AI tools can bring. AI is not replacing human workers but augmenting their existing capabilities by automating repetitive and mundane work. This shift allows for a more customer-centric approach, where technicians and estimators can provide more personalized services and promptly address customers’ needs, underscoring the importance of their role in the repair process.”

For Solera, AI is being used in multiple ways across each business unit. Brower discussed how Solera “recently launched a Sustainable Estimates tool that leverages extensive data, technology and partnerships to measure, analyze and offset carbon emissions, while also giving insight into emissions activities throughout the repair process.”

When speaking to James Spears, Head of Automotive and Property at Tractable AI, he told Collision Repair that the issue is not that the industry misunderstands AI, but that “in

To help show the potential of AI in the bodyshop, Ryan Taylor and Bodyshop Booster are offering readers the chance to try it out for themselves. Calling the featured number will connect readers with an AI phone assistant in order to demonstrate how the technology can be used to help facilitate customer interactions.

the automotive world, the whole ‘perfect or nothing’ attitude about AI seems to be slowing things down.”

“AI is crazy powerful, but it is not perfect and won’t be for a bit. But even with its limits, things like ChatGPT are showing people just how much AI really can do, and helping everyone across the general public understand the potential.”

Spears also noted that from his own experience, “some of the most functional ways I see AI streamline operations are by helping shops schedule and triage work at first notice of loss (FNOL) and by reviewing and generating estimates from pictures, ensuring all damage, calibrations and repair procedures are instantly captured.”

On this note, Tractable AI described how it uses the technology to “offer a service that lets (shops) streamline estimates. This way, shops can figure out which repairs to do first and when, and customers can decide whether they want to pay for repairs themselves or go through insurance.”

Ultimately, when it comes to AI, Spears said, “it’s all about giving folks the information they need to make smart choices.”

Finally, when speaking with Ryan Taylor, CEO of AMP Bureau and Bodyshop Booster, he commented that currently within the automotive industry, AI is at a stage of early adopters. Through the use of AI, Bodyshop Booster has reportedly seen a 27 percent reduction in admin tasks, and the company specifically uses it for customer first contact through phone, texting and website conversations.

“I think that AI can be difficult for the industry to understand until they use it. The shops that do not adapt to this technology will quickly get left behind.”

Calling the featured number will connect readers with an AI phone assistant

432-465-2978

Story by Sarah Perkins, Allison Rogers

Insurance companies are embracing technologically advanced trends like generative AI and machine learning to address industry challenges.

According to Reuters’ recent report, titled The Future of Insurance in Canada: Top Technology Trends in 2024, the majority of Canadian insurance representative respondents indicated that their companies have already invested in “established technologies,” with 79 percent saying their companies have invested in data analytics and 72 percent saying they’ve invested in automation.

The report further notes that exactly 50 percent of Canadian insurers said their organizations are planning to adopt automated technologies like generative AI. Thirtythree percent of respondents indicated their companies are testing scenarios where AI can be used, compared to just 22 percent of insurers globally.

In total, 37 percent of Canadian survey respondents indicated their organization had already used generative AI in test-use cases; had evaluated potential vendors or even moved on to full-scale implementation.

According to Reuters’ analysis, generative AI and machine learning will be the top trending investment by insurance representatives come 2027. In 2024, generative AI and machine learning are the eighth and ninth-most invested in technology by insurers. As of 2024, data analytics are the top-ranked insurer investment, followed by digital portals and automation. Despite these widespread investments and clear interest in new technologies, 63 percent of respondents indicated that automated claims management systems are particularly difficult to implement. More than half of

respondents highlighted delays in implementing technology. A further 46 percent said there was a lack of understanding regarding technology implementation, either on the industry’s part or on the business and vendor side.

“It’s essential that investments [in AI, particularly generative AI] are supported by strong governance frameworks and the adequate training of our people,” noted Markus Glese, chief compliance officer for Zurich. “While AI has the potential to revolutionize operations, it’s ethical and effective implementation depends on ensuring that employees are well-equipped to manage and utilize these advanced tools responsibly, maintaining trust and meeting regulatory standards.”

Comparing both Reuters’ global insurer and Canadian insurer samples, the technologies delivering the best return on investment are data analytics, automation, digital portals and claims management systems.

“Data analytics is unsurprisingly number one in most businesses,” said Brady Aarssen, VP of operations, strategy and transformation for Canada Life. “The industry has a unique and comprehensive data repository that historically we haven’t been able to fully leverage. With new tools and technologies, it opens up a world of possibilities by providing the knowledge needed to run a better business and make better decisions.”

Reuters further points out that data analytics is being applied across multiple insurance processes, unlike other new technologies. Across Canadian respondents, 32 percent apply data analytics to claims; 45 percent apply them in underwriting; 36 percent use data analytics in actuarial practices; 45 percent in pricing and 32 percent in marketing. For comparison,

The Reuters Events Insurance Technology Benchmarking Survey 2024 was conducted between March and April 2024. Among the 47 respondents from Canada, 45 percent are in senior management positions, reporting directly to organizational leadership. A further 34 percent of Canadian respondents are in C-suite or equivalent sector leadership and board membership roles, while 13 percent are in mid-management capacities.

aren’t employing literal robots (yet), but they are investing in new technologies like generative AI and machine learning, especially in Canada.

PERCENT SHARE OF RESPONDENTS INDICATING THEIR ORGANIZATION HAS INVESTED IN SPECIFIC TECHNOLOGIES OVER THE LAST 12 MONTHS:

PERCENT SHARE OF RESPONDENTS RE: SPECIFIC TECHNOLOGIES DELIVERING THE BEST ROI IN THE LAST 12 MONTHS

18 percent said they’ve used automation in claims; 14 percent have used automation in underwriting; zero percent in actuarial; two percent in pricing and 14 percent in marketing.

More than half of Canadian respondents (57 percent) said data analytics is delivering the best return-on-investment today. Globally, respondents ranked data analytics to have the second-best ROI, behind automation. Generative

AI and machine learning are ranked to have the lowest ROI, both in Canada and globally, indicating a shared perception of this novel technology across markets.

“Generative AI and other more advanced tools may simply be too novel and unknown for demonstrable implementation plans, while employees may take longer to develop an understanding of them,” noted the report.

Think of it as a smart machine that learns from lots of examples and then uses that knowledge to make something new. For instance, if you show it many pictures of auto damage and “teach” the program what it is looking at, it can begin to learn and identify auto damage on pictures you upload to the system.

In the insurance world, generative AI could help to write policies, answer customer service inquiries, perform risk assessments or detect fraud.

There’s no need to grit your teeth when it comes to automotive abrasives—this year’s technology developments will be sure to make you grin.

In 2024, a confluence of technological advancements and material innovations are continuing to reshape the way collision repairers approach surface preparation and finishing processes. Notably, the introduction of advanced abrasive materials—such as ceramics and hybrid composites—has led to enhanced cutting performance and durability, allowing for faster, more efficient repairs while reducing the risk of surface damage.

Furthermore, the integration of digital technologies in the abrasive sector is also transforming traditional practices. Automated abrasive systems and precision sanders equipped with sensors are now capable of optimizing pressure and speed in real-time, providing consistent finishes and minimizing waste.

In tandem with these innovations, the increasing complexity of modern vehicle surfaces—including the use of high-strength steels, aluminum and composite materials—demands a more

tailored approach to abrasives. Understanding the specific materials is essential for collision repair professionals to select the appropriate abrasive solutions that ensure superior adhesion and finish quality.

Some advancements in technology specifically include the use of 3D printing in the production of abrasives; the development of multi-abrasive materials made from a combination of components, allowing for more complex structures and more precise machining; and the introduction of ‘smart’ abrasives that range from self-adjusting products to those that monitor their own conditions and recommend adjustments as necessary.

As a result, with the continued rate of advancements, it’s clear that when it comes to automotive abrasives, technology has only scratched the surface of the product’s full potential. Check out the next few pages to see how these innovations are driving the industry forward. After all, in the world of automotive abrasives, it’s important to keep your edge—because when it comes to repairs, there’s no room for rough spots!

www.prospot.com

www.indasa-abrasives.com

The Dust-Free Pro sanding system is an all-in-one sanding station that provides a detachable, easy-to-move dust extractor designed to perform in the most demanding bodyshops while providing clean and safe dust extraction. The sanding system is completely air-powered and contains no electrical parts making it safe for use in all paint booths, prep areas and on steel or aluminum materials. The patented air improvement module increases vacuum performance, says Pro Spot, and operates on extremely low air flow at 5-7 CFM compared to competitor systems that use 40-50 CFM. Visit link https://prospot.com/products/dust-free-sanding-systems/

www.eagleabrasives.com

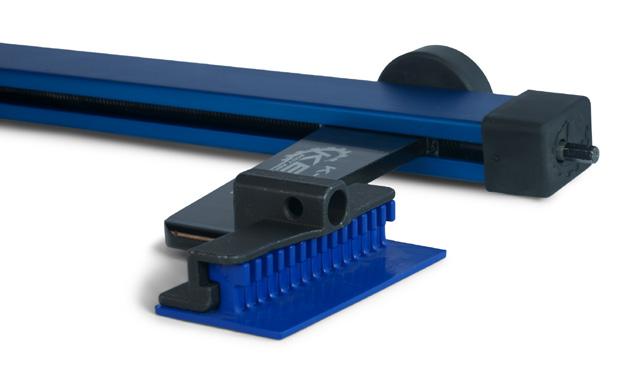

Introducing the advanced DRY Sanding System! Super Assilex features fast and uniform coverage with extremely shallow scratches, as a result of a combination of an Ultra Flexible bonding and Super Sharp abrasives. Ideal for light sanding on all types of surfaces and that demand shallow scratches and a uniform finish that can be done in the shortest time. Save up to 50% in labor by utilizing Super Assilex for prep sanding, basecoat scuffing, clearcoat correction, and polish sanding. Super Assilex available in grades K-240 to K-1500. Super Buflex utilizes the same technology for fine polish sanding in grades K-2000 to K-3000.

Maximize your productivity by virtually eliminating dust with the Rhyno Grip Mesh Line by INDASA. This product has been developed to transform your sanding and extraction capabilities by keeping dust contaminants out of your job. Featuring an open mesh structure that helps to provide excellent dust extraction, an electrostatic coating provides superior sanding performance. The Rhyno Grip Mesh Line is a durable abrasive that is thermally modified for long lasting sanding. Designed for use on old paint, fibre glass, plastic, fillers, topcoats and much more. The Rhyno Grip Mesh Lines are available in a variety of forms, dimesions and grits.

www.3mcanada.ca

3M™ Cubitron™ II Hookit™ Clean Sanding Abrasive Disc 737U can be used to remove paint, shape body filler, fine feather-edging, final prep before priming or even surface structure removal of clearcoats and preparation of blending areas. The product features 3M™ Precision Shaped Grain technology. This triangular-shaped grain is said to cut 30 percent faster and last at least 30 percent longer than traditional ceramic abrasives. 3M states the combination of the multi-hole pattern on the abrasive disc offers excellent dust extraction, further increasing the cut rate and disc life. When used with a 3M™ Clean Sanding Disc Pad, the disc holes do not require alignment with the pad holes, making switching the discs fast, easy, and convenient.

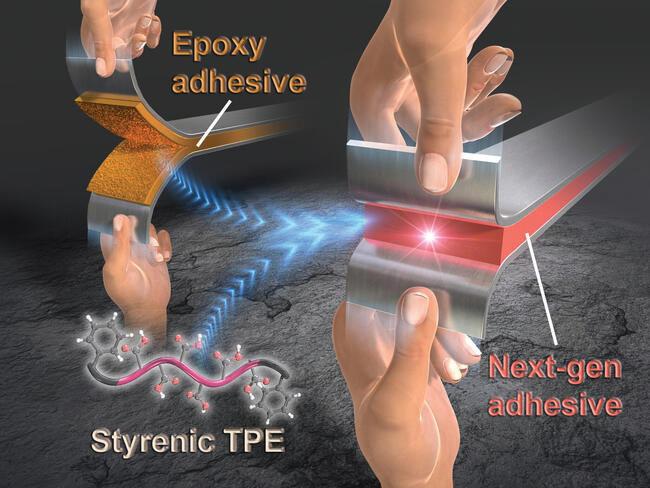

With the continued rise of electric vehicles and the push for more lightweight materials, the role of adhesives in collision repair is more critical than ever as vehicle components are glued, rather than fastened together.

Modern adhesives are designed to provide stronger bonds to accommodate the use of materials like aluminum and composites—so much so that today’s cars are more than 40 pounds of adhesives. These adhesives can also withstand higher temperatures while providing resistance to environmental factors.

Additionally, like other areas of the industry, as sustainability becomes a central focus, eco-friendly adhesives are emerging as a viable option for collision repair, with many manufacturers now offering adhesives made from renewable plant-based sources and with reduced volatile organic compounds (VOCs).

And, when looking at tech trends, innovations such as automated dispensing systems and smart application tools are being adopted to ensure the precise and consistent application of adhesives. These advancements help reduce waste, improve efficiency and minimize the risk of human error during repairs.

However, it is in the continued rise of electric vehicles where adhesives are demonstrating their full potential as a critical component of automotive manufacturing. Here, adhesives are often used to bond and seal the lid of the battery pack of an electric vehicle to the chassis. Adhesives also help to maintain thermal temperature to reduce the chances of thermal runaway.

In the OEM race for lightweight vehicles, some modern cars can contain more than 40 lbs. of adhesive.

One recent innovation in the world of automotive adhesives comes from researchers at Nagoya University in Japan who claimed in October to have created an adhesive that is 22 times stronger than traditional epoxy-based alternatives. The new adhesive—made from hydrogen-bonded styrenic thermoplastic elastomers—was created in collaboration with Aisin Chemical Company with support from the New Energy and Industrial Technology Development Organization (NEDO) and is a polymer that exhibits rubbery properties, allowing it to stretch and return to its original shape.

So, while this magazine may not be able to stretch without ripping, the products on the next few pages should be able to bond you together with all the best of what modern automotive adhesives have to offer.

Fusor® 800HD Plus series is used to duplicate factory seams where a non-sag, toolable/brushable seam sealer is required. Fusor® 800HD Plus Series is a single-component, direct-to-metal (DTM), non-sag cosmetic sealer/adhesive that has excellent adhesion to bare metal, cold rolled steel, e-coat, and aluminum. The features and benefits include holding brush marks without die back, indirect UV resistant, having low VOC, and can be welded with no burn back.

Call: +1 877 ASK LORD (275 5673) to learn more.

At SRP, we take pride in offering the finest quality windshield repair resins that are designed to meet the highest industry standards. A cutting-edge solution designed to enhance visibility and safety of your car windshield on the road. Our advanced windshield resins are crafted with state-of-the-art technology, providing superior performance and durability in all driving conditions. Not only do our windshield fillers restore functionality, but they also enhance the aesthetic appeal of your vehicle. The crystal-clear finish leaves your windshield looking as good as new, providing a seamless, unobstructed view of the road ahead.

go.3M.com/CA-seamsealing

3M™ OEM Match Epoxy Seam Sealer is a versatile family of epoxy seam sealers designed for use on bare metal or primed surfaces. Available in black, beige, white, and gray to match the most common OEM-applied seam sealer colors. Compatible with many leading automotive paint systems, they are set and ready to paint after 15 minutes. These sealants are caulkable, toolable, brushable, and sprayable—meaning they can be used in a variety of applications, including door skins, floor pans, trunk floors, roof seams, and many others.

go.3M.com/CA-seamsealing

Available in four tip styles (Sprayable, Wing, Wide Stream and Ripple) to match OEM seams, door skins & hem flanges or textures like caterpillar and lasagna beads.

For more information visit go.3M.com/CA-seamsealing

‘LET’S JUST EYEBALL IT’ IS ARCHAIC

As vehicles become increasingly complex, the demand for precision in repair processes has never been greater, and bodyshops continue to be aligned with tech trends as modern vehicles require more and more calibrations.

Jeff Labanovich, vice president of operations for Fix Network Canada, originally outlined for Collision Repair magazine that the complexity of vehicle parts is greater than ever before.

“Take the headlamp for example. Before, a vehicle’s headlamps were just for lighting the road, but now, they serve multiple functions and feature complex technology like sensors and advanced driver assistance systems.”

With this complexity in mind, when looking at emerging technologies and trends for automotive alignment and measuring, collision repair shops increasingly make use of 3D wheel alignment systems. Utilizing high-definition cameras and advanced software, these systems provide precise measurements of a vehicle’s alignment angles.

Additionally, laser alignment systems further help to project beams onto the vehicle, allowing technicians to see alignment issues clearly and make necessary adjustments with greater precision.

Finally, the integration of alignment systems with vehicle diagnostic tools is a growing trend. This connection allows technicians to analyze not only alignment issues, but also other electronic systems that may have been affected during a collision.

As a result, while traditional repair methods may have relied on heating and pulling damaged areas to ensure they fit back to their original shape, as vehicles become more sophisticated, the relationship between technology and repair processes becomes increasingly intertwined.

Ultimately, the future of collision repair is not just about fixing dents; it’s about achieving alignment on all fronts. After all, when it comes to keeping vehicles in line, precision really is the name of the game—no ifs, ands or buts!

www.hunter.com

Ultimate ADAS® combines Hunter’s standard-setting alignment technology with an efficient and easy-to-use guided target placement system for aroundthe-vehicle coverage. Gimbal-mounted lasers are the key component, replacing the inexact guesswork of strings, plumb bobs and tape measures to cut setup time by 70 percent for some procedures. The onscreen guidance provided by Hunter’s award-winning WinAlign® software dramatically increases target placement precision by automatically compensating for non-level floors. For more information, visit https://www.hunter.com/ alignment-machines/ultimate-adas.

www.accuvision-3d.com

www.car-o-liner.com

Arslan Automotive keeps it simple with the Accuvision 3D® measuring system. The system features no moving parts, no lasers, targets, adaptors, magnets, arms, extensions, wires, Wi-Fi, or Bluetooth—but it also requires no calibration, making it a quick and simple yet accurate 3D measuring system, according to Arslan Automotive. The Accuvision 3D® is durable, versatile, universal, mobile, and user-friendly, saving operators time and money. According to Arslan Automotive, everything you need for measuring and alignment can be done easily with the Accuvision 3D® measuring system.

Unlock the future of collision repair with the Car-O-Tronic® measuring system. Equipped with advanced digital technology, it offers precise 3D measurements and real-time data analysis. The wireless Bluetooth connectivity ensures seamless integration with your existing systems. Its intuitive software interface simplifies complex tasks, while the extensive vehicle database guarantees accurate repairs. Enhance your workshop’s capabilities with Car-O-Tronic®, the pinnacle of precision and efficiency. For more information visit https://car-o-liner.com/en-us/product/caro-tronic/

Ensure your workflow follows OEM-sourced procedures.

Revolutionize your workshop with the industry-leading John Bean® Tru-Point™ advanced drive assistance system (ADAS) calibration tool. Utilizing advanced camera and target technology, it ensures precise placement of ADAS targets and fixtures. The award-winning accessories, including the TGT-05, enhance 360-view calibrations for manufacturers using vinyl mats, surpassing traditional methods. Additionally, the BKT-16 advances ADAS accessory placement for blind spot calibrations, streamlining the entire process.

www.arslanauto.com

Arlan Automotive introduces the 45-DBLE, an electrohydraulic lift with a minimum travel height of 96 cm and double platforms connected by a torsion beam for synchronization. It features a double redundant hydraulic circuit with four pistons for overload protection, along with a shut-off valve. The lift includes self-lubricating axle bearings and polyethylene sliding pads, requiring no maintenance. A compensation valve controls the lowering speed for safe and precise operation.

For more info visit www.arslanauto.com/auto/sect/45/45-DBLE.shtml

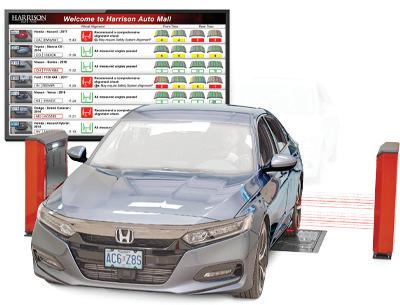

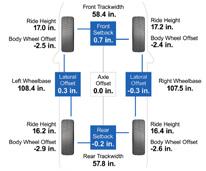

Alignment and ADAS callibration collide through streamlined alignment measurements with the Hunter’s Collision Alignment System. Featuring collision blueprints, full diagnostic scans, ADAS callibration support and documented results, the Hunter’s Collision Alignment System automatically guides the technician through a workflow of five essential diagnostic measurements before work begins. These specific measurements eliminate extra days of cycle time when problems are discovered too late, such as a damaged subframe or lower control arms, shifted axles, or bent spindles. Use your existing frame or collision repair rack and save time and expenses by keeping all services in-house.

www.hunter.com

Opportunity doesn’t knock; it rolls: Vehicles need alignments and new tires, but you won’t know unless you look. Quick Check® Drive from Hunter Engineering is a fully autonomous inspection system that finds the opportunities you need. Twelve cameras and 32 laser sensors provide accurate alignment and tire tread measurements in seconds, displaying the easily understood results on the large Flightboard™ video monitor for convenient customer discussions. For more information visit www.hunter.com/vehicle-inspection/quick-check/

As technology continues to evolve, it’s clear that the future of automotive glass repair is not just looking bright—it’s positively transparent. From changes in materials to the rise in smart windshields, the glass used in today’s vehicles is shaping up to be anything but dull.

In 2024, one of the most notable updates in the industry is the continued introduction of advanced driver assistance systems within vehicle windshields. With many vehicles incorporating glass that can display vital information onto the screen, such as navigation, speed and traffic updates, technicians must be able to perform precise calibrations during repairs or replacements to ensure that safety features function correctly.

Additionally, auto glass manufacturers are developing new types of laminated glass made from recycled materials and less energy-intensive processes. These innovations aim to reduce carbon output while also maintaining strength and durability of the vehicle.

And, alongside changes in materials and manufacturing processes, from a collision repair perspective, mobile services have also become more sophisticated. With the ability to cover a wider range of repairs, including more complex fixes, mobile services now offer technicians the chance to more easily perform calibrations and ADAS sensor alignment.

When looking at modern technologies, augmented reality is not just limited to smart windshields, but is making appearances within the repair scene—or in this case, screen.

Technicians can now utilize augmented reality technology to precisely locate and assess damages to the windshield. This ensures a more accurate repair process, reducing the likelihood of errors and providing a faster turnaround time.

So turn to the next few pages and take a look. Just as a rise in digital diagnostic tools are allowing auto glass technicians to accurately and effectively determine the best course of action when it comes to a safe repair, so too will the products featured on the next pages help you to see clearly into the future of what glass repair has to offer.

www.novusglass.com

Join the millions of customers who are winning the war against fading, scratching, and dulling of plastics before their time. With 50 years of experience and innovation, Novus Plastic Polish is as easy as 1, 2, 3! From microwave doors to your car and everything in between, Novus plastic polish will have your surfaces looking like new!

For more information about this product call (450) 433-1414 or email communications@novusglass.com.

www.novusglass.com

NOVUS Glass’ patented repair method is a safe and effective way to repair your windshield. A part of Fix Network, with a repair first, replace when necessary commitment, NOVUS Glass is dedicated to repairing windshields with improved optical clarity and structural integrity. With over 40 years of experience working with large insurance companies and small independent agents, NOVUS Glass aims to continue providing clients with the highest possible technical service. We service your glass right, the first time and every time.

For more information, visit https://www.novusglass.com/en-ca/services/

Equalizer® Transformer® is a drill powered auto glass removal tool that works with your existing Visual Vacuum Cup! The Transformer® is a multiuse tool that serves as a dual-cutting, cord removal tool as well as two quarter glass removal tools that attach to the door striker when separated. The TFM1000 Transformer® Tool-only includes; The Transformer® tool, screw/studs (4) to convert your Visual Vacuum Cup, the SideStriker™ for quarter glass removal, 3/8” ratchet, a drill bit and protection pad. www.equalizer.com

UPGRADING PPE FOR AN ELECTRIC WAVE

When it comes to collision repair, keeping technicians safe is not unlike patching a dented body panel—it’s essential and requires the right tools. As technology rapidly develops, personal protection equipment (PPE) continues to evolve from basic equipment to high-tech threads and tools.

From smart helmets equipped with augmented reality, to advanced respiratory protection that monitors air quality, to high tech paint booths equipped with advanced ventilation and temperature controls, today’s PPE is increasingly designed to meet the industry’s unique challenges.

Moreover, the rise of wearable technology is reshaping how technicians interact with their tools and surroundings. Wearable technology can now track vitals and alert workers to potential hazards in real time.

And, with the continued rise of electric vehicles, it is more important than ever for repairers to stay ahead of the electric learning curve. Here, David Giles, co-founder of ALL EV CANADA originally told Collision Repair magazine that safely repairing an electric vehicle “requires some specialized tools and equipment. PPE includes insulated gloves, face shields, safety glasses and arc flash clothing to protect against high-voltage risks. Diagnostic tools like high voltage multimetres and insulation testers are crucial to help test and verify repairs.”

Additionally, when it comes to respiratory protection for technicians, Mike Ruston, creator of the Air Clarity Solutions (ACS) Workflow 5000, told Collision Repair magazine that when it comes to working on vehicles in any capacity, quality air filtration is paramount.

“There is no magical solution to totally eliminate airborne pollution in bodyshops,” Rushton said, “but reducing it as best as we can is key.”

In this way, keeping technicians safe in the collision repair industry is all about finding the right balance—just like a well-done paint job. After all, when it comes to protecting our skilled workers, it’s essential to “coat” them with the best PPE possible, because safety should never take a backseat!

www.sata.com

SATA’s latest filter series, the SATA filter 500 is said to enable a higher absorption of contaminations and enhanced durability due to the optimized position of the charcoal filter. 100% technically clean air for perfect finishes. The SATA filter 500 series is available either as a one-stage sintered filter with water and oil separator, as a two-stage combination filter with sintered and fine filter, or as a three-stage filter unit with additional sintered activated charcoal filter. Changing the filter is simple and straightforward and filter maintenance is now only necessary every 6 months.

www.breathingsystems.com

Quality Air Breathing Systems are designed to provide Grade “D” breathable air, from an existing compressed air source. Systems are available from 50 SCFM to 150 SCFM panels, to fit the end users particular needs and facilities, and can service from one to fourteen people at the same time. Custom systems are also available to fit your facilities.

www.kent-automotive.com

A first line of defence against dangerous high-voltage systems, the Novax® Rubber Insulating Gloves Kit is rated at Class 0 and provides a necessary PPE when working with energized parts. Manufactured in a natural latex state to provide a much softer feel and greater dexterity when in use, the Novax® Rubber Insulating Gloves Kit helps lessen hand fatigue while also offering top protection. Each glove is tested prior to shipment and the kit is rated for a protection test of 2,500 volts. With a clear finish that makes it easier to identify any scratches or tears from use, the Novax® Rubber Insulating Gloves Kit ensures that no shocks are in your repair future.

www.sata.com

The SATA air vision 5000 offers a completely redesigned way of supplied breathing air. The respiratory hood not only ensures high breathing air quality but also a low noise level. The modern, ergonomic design fits with almost any head shape and can be individually adjusted in size, height, and position. Absolute safety through external supply of clean air to the hood and suitable for continuous use. Available add-on modules for heated or cooled air. With the SATA air vision 5000 breathing protection system, you can be sure that your health and comfort are both efficiently catered for. NIOSH approved.

Automotive repair remains a vibrant canvas of both ongoing technology and talent. Gone are the days of guesswork, when automotive paint was a process of continuous trial and error. In 2024, automotive paint technologies continue to act as a blend of cutting-edge technology with artistry, transforming the paint booth into a place for true innovation.

To paint a picture: imagine waterborne systems that can not only reduce VOC emissions but can also offer superior adhesion and finish quality. Consider colour-matching systems that can analyze the exact hue of a car’s paint and feature software that can calculate the perfect formula. And who can overlook the advancements in curing technologies? Ultraviolet-cured paints and infrared drying systems allow repairers to go from spray to finish in record time.

While these features may feel like trends that are just emerging on the hue-rizon, they’re happening now.

Take, for instance, Nissan’s recent and ongoing development of an automotive paint that can cool vehicle interiors by twelve degrees Celsius. The paint, developed in partnership with Radicool, a specialist in radiactive cooling products, incorporates metamaterial synthetic composite materials and functions by reducing the transfer of heat into surfaces such as the roof, hood, doors and vehicle panels of a treated vehicle. The paint is also resistant to salt and chipping, peeling, scratches and chemical reactions.

Moreover, when looking from technology to talent within automotive paint, at the end of April, Fix Network and its Calgary, Alberta Training Centre partnered with the Alberta-based CAREERS to host a young woman in trades and technologies day, where a group of high school students with no prior autobody experience learned about opportunities in the trade.

During the day, students learned about painting gear and suits, prepped panels, applied tack and spray sealer and base coat, airbrushed with stencils and finally, applied clear coat during a panel painting project.

Led by Jeff Francis, Fix Network’s technical trainer for Western Canada, the students took to the tasks of the day with flying colours. One such student, fourteen-year-old Olivia Gagnon commented that while she “didn’t really think the trades and technology were interesting,” she was excited about “the aspect of painting and stencils” in the automotive industry, “and the opportunity to add your own creativity and individuality to your projects.”

In this way, as repairers continue to paint the road ahead, it is key to continue embracing the dynamic interplay of innovation and creativity.

Look to the pages ahead and check out the products that are contributing to a palette that is rich and diverse.

www.axalta.com

Easy to mix. Easy to match. Easy to apply. Cromax® EZ is a waterborne basecoat system that makes life simpler-without compromising the integrity of your craft. It’s easy to mix. Easy to match. Easy to apply. With less material consumption and essentially no flash time between basecoat and clearcoat, Cromax® EZ is designed to deliver better coverage and speed than competitive waterborne systems. It’s not just better for your customers, it’s better for your bottom line.

Visit Axalta website: https://www.axalta.com/ca/en_CA.html

www.spraymax.com

www.ppgrefinish.com

SprayMax 1K E-Coat Primers

SprayMax 1K E-Coat Primers are designed for direct to steel and aluminum applications. They are paintable, corrosion resistant and compatible with OEM basecoats. Perfect for inner body panels, engine compartments, trunks, support rails, bodyfiller, fiberglass and SMC. They replicate OEM gloss levels, are fast drying and durable, while offering excellent adhesion. Now available in eight colours: White, light green, olive green, gray, black, tan, field drab, and olive brown.

For more information contact: order@Kwasny.us | 844.426.6330 or visit spraymax.com

ONECHOICE® UV-Cured Primer Surfacer from PPG achieves a high film build of 2.0-2.5 mils per coat and can be cured and ready to sand in two minutes. It’s the ideal solution for high production shops seeking to save time and increase the throughput of their paint operation. Available in spray gun ready quart or aerosol can.

For more information visit ppgrefinish.com.

www.akzonobel.com

Sikkens Autowave

Sikkens Autowave® MM sets a new standard in waterborne basecoat performance with major advances in binder and pigment technology. It provides excellent coverage, metallic control and sprayability when duplicating OEM solid, metallic and pearl effect colors—with remarkable ease of use, first-time-right color reliability and reduced process time, Sikkens Autowave® MM is the right step in setting a solid foundation.

For more information on Sikkens products visit https://sikkensvr.com/us-en

www.dominionsureseal.com

Dominion Sure Seal’s 3 in 1 Primers are quick to dry, easy to sand, and paintable in as little as 30 minutes. Apply direct to metal, aluminum, plastic, fibreglass and SMC. Surfaces can be sanded just 15 minutes after priming, and can be painted 30 minutes after. The products offer great flexibility, a film build, large paint gun style fan pattern, and great filling characteristics. They are suitable for metal, aluminum and plastics. The 3 in 1 Primers are available in black, grey and white.

For more information visit dominionsureseal.com

www.spraymax.com

SprayMax offers a complete range of Clear Coats to meet every repair need. From 1K Clear Acrylic to the 2K series of glamour, satin, and matte finishes, SprayMax has you covered. SprayMax 1K Spot Blender is a perfect addition to any professional paint spray operation. SprayMax 2K 2 in 1 Headlight Clear is ideal for fixing scratched and yellowed polycarbonate automotive headlights. Add convenience and reduce cycle time with SprayMax Clear Coats.

For more information contact: order@Kwasny.us | 844.426.6330 or visit spraymax.com

www.ppgrefinish.com

Efficiency, sustainability, and ease of use – these are just three of the reasons why PPG’s Envirobase® High Performance waterborne paint system is the trusted choice of more than 40,000 body shops around the globe. But the benefits don’t stop there. The Envirobase® High Performance paint system supports fully digitalized repair processes and is compatible with every tool in the PPG LINQ™ digital ecosystem, making it the perfect solution for modern collision centers.

To learn more, visit envirobase.com

www.globalfinishing.com

Enabling automotive body shops to attain real-time visibility into their filter loading, production levels and paint booth usage data, Global Finishing Solutions is proud to introduce Booth Connect. Providing remote access and monitoring for paint booths from the convenience of a computer, tablet, or smart phone, Booth Connect allows painters, paint shop managers, owners and corporate decision makers to view reports and track booth performance from anywhere at anytime. On-demand insight into booth cycles, filler loading and power usage trends allows shops to build a portfoilio-level dashboard and KPIs, while also offering the knowledge needed to keep businesses and equipment running at peak perfomance.

Since 2010, we have designed and developed custom Membrane Nitrogen Generators with heater controllers and heated hoses for automotive and industrial use. With over 3,000 units in operation globally, we provide a product that boosts efficiency, reduces costs, and supports a cleaner environment.

Nitrogen generators for spray painting are designed to enhance efficiency, reduce cycle times, and improve finish quality in spray painting environments.

Our Nitrogen on Demand system provides nitrogen for tire filling stations 24/7, eliminating the need for costly nitrogen tanks. Simply connect it to your compressed air source to access all the nitrogen you need.