We know cow it just makes sense

The Science of Healthier Animals

We know cow it just makes sense

MSD’s SenseHub package of cow monitoring collars and data management platform is leading the way in New Zealand.

Pauline Calvert says the company is making a considerable investment to continuously develop innovative benefits that will support a successful and sustainable dairy sector in New Zealand.

“It’s great to be part of a company that is not only delivering leading technology to dairy farms right now but has a real eye on the future to continuously build on the strong foundation we have already developed,” she says.

“I believe what’s important to our customers is knowing they will have our support for the life of the solution they are investing in. We are resourcing our team to be able to keep our commitment to supporting our farmers on their journey with technology on farm.

“We are in this for the long haul. We won’t just roll out products and disappear. For us, it’s all about

integrity, innovation and trust so our customers should never have to question anything that we deliver and support in the marketplace,” she says.

MSD Animal Health plans to move all its Monitoring and Automation solutions under the SenseHub brand so farmer clients will be on a single, cloud-based SenseHub Dairy solution.

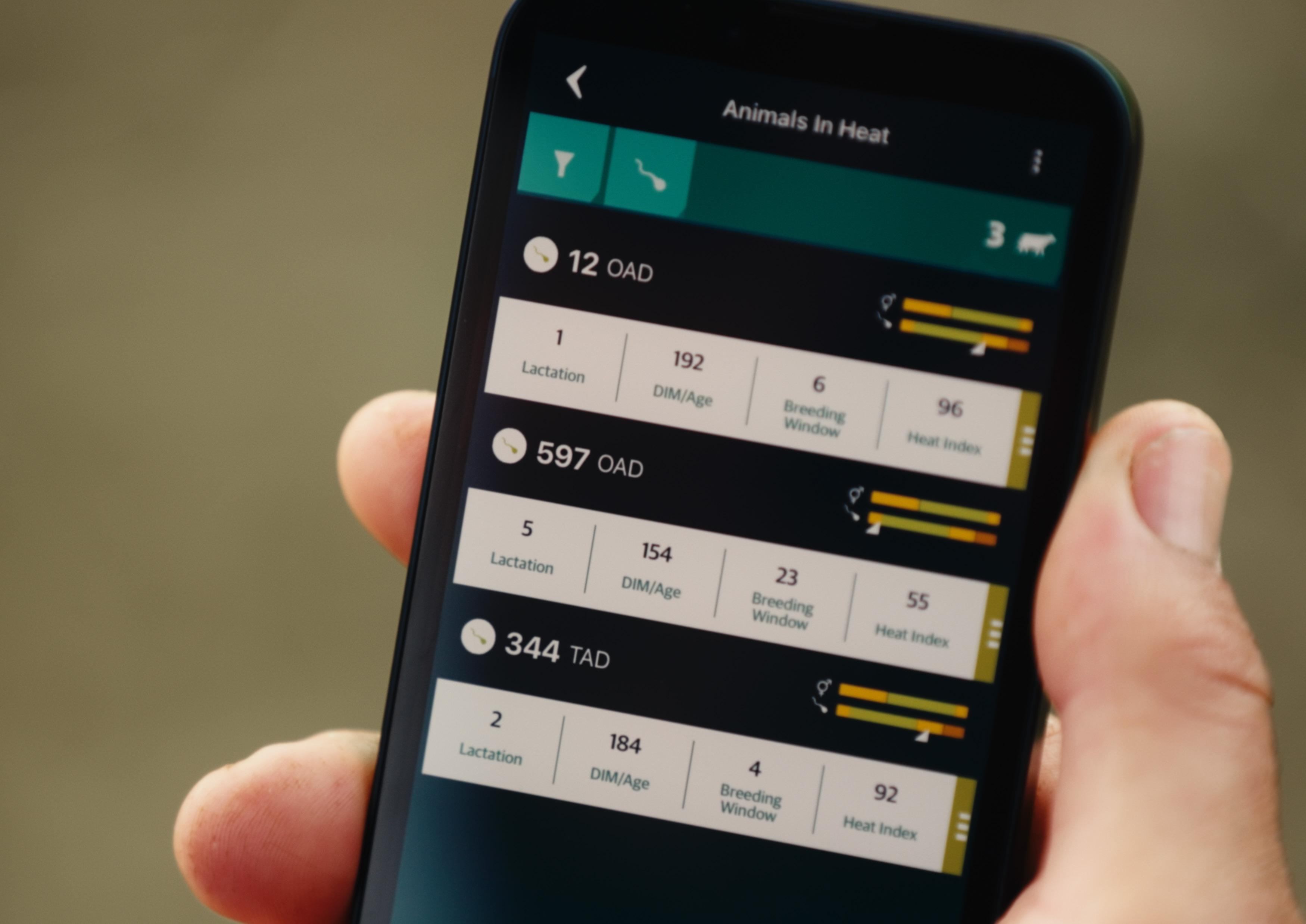

SenseHub combines all the technology into a single platform, accessed through desktop or mobile application. The collars fitted to each cow together with the trusted sales and support teams are unchanged.

“All of the data and information is there on a single device, which makes decisions easy, right down to an individual animal. It doesn’t matter if a herd has 200 or 2000 cows, our system produces real time data that puts farmers, their staff or their veterinarian in the box seat to be proactive.

“There’s lots more to come, so I want to encourage farmers to join us and experience the immediate benefits a SenseHub solution delivers, but know

“For us, it’s all about integrity, innovation and trust.”

that they are investing in a solution that will continue to keep pace with new features to ensure NZ dairy farming is sustainable in the future.”

Later in 2023, individual cow milk quality data such as Somatic Cell Count will be added to the list of SenseHub animal insights.

Calvert joined MSD Animal Health in 2014 as part of the Veterinary Team. She took over the Livestock Business Unit Lead role in 2018 with a team of 18 staff and less than six years on, she’s now managing a team of more than 90 after two game-changing acquisitions – Allflex and Livestock Improvement Corporation’s Automation businesses (LICA).

Calvert says both acquisitions reflect MSD’s global strategy to invest beyond its traditional biopharmaceutical base into technology companies that

Collars for detecting heat and monitoring cow health are just the beginning of a healthy pipeline of new features in development by MSD Animal Health for its Allflex Livestock Intelligence business.

deliver on-farm efficiency and greater productivity down to an individual animal level.

Combining animal health innovation, herd and individual animal data insights drive better animal wellbeing, production and farm sustainability

“MSD Animal Health already has made strong investments to support the farming industry. The significant upgrade of our Animal Health vaccine plant at Upper Hutt in Wellington is a good example of our commitment to develop and produce quality products here in NZ.

“These world-class vaccines are manufactured not only for New Zealand but around the world and MSD is proud to be creating all that right here. It’s a great success story for NZ Inc.”

Calvert says NZ farmers are well ahead of those in many other countries because they are early adopters of animal health innovation and new technologies, and pioneering R&D from trusted animal health company like MSD.

As one of 10 veterinarians in the MSD Animal Health NZ team, she’s particularly excited by the opportunity for the data insights gained from the SenseHub collars to help vets consult on farm and assist with making decisions with their clients.

“We’re actively engaging with industry partners, like vets and milk processors, so that we can maximise

the opportunity to improve on-farm outcomes. By having all the data available on one platform makes it simple for farmers and their veterinarian to review it and assess the need for proactive intervention,” she says.

“That’s what is so exciting about working at a company like MSD Animal Health. It understands the need to invest in research and development to create solutions that really add value behind the farm gate.

“I really encourage people to join us on our journey, it’s exciting, and it’s a journey that we are really committed to. There is so much opportunity to work together to improve the NZ dairy industry for a better future for the animals and the people employed in it.”

Always delivering gold standard service is the reason

MSD Animal Health has developed its own complete package of support and training for its farmer customers to guide them through the installation and ongoing use of its SenseHub technology.

National Training Manager Steph Voice has been working with cow monitoring technology in different capacities for about eight years and joined Allflex in April 2020. She is based at the company’s Palmerston North office and manages the training team of eight full time staff and several contractors across the country.

MSD Animal Health is the market leader in the cow monitoring market in New Zealand, a position built on the quality of its technology plus the training and after-sales support they offer their clients.

“That after-sales support is our biggest point of difference in the market I believe. It’s not just the

training our teams provides to farmers, but the technical side as well,” Steph says.

New trainers take a minimum of two months to learn the basic role required to start helping farmers, but Steph says it is another six to eight months before they are fully proficient.

“Our aim is to train our trainers so they help our clients use the data from our collars to generate the best return on investment they can,” she says.

Training a trainer is not a ‘tick-the-box’ exercise. When fully trained, each trainer has full knowledge of how to use the software, but also understands what the data is showing so they can work with their farmer clients, their vet, consultant or nutritionist, to help them make the best decisions for them.

“We get quite invested in the clients’ success and see the improvements in profitability and reduction in stress levels when the collars are fitted to their herd.”

You’re in safe hands. That’s the phrase that farmers want to hear when they’ve invested time and money in new technology to monitor their dairy cow herd.

is our biggest point of difference in the market I believe. It’s not just the training our teams provides to farmers, but the technical side as well.”

“What I really like to hear is not only did they achieve their best herd mating result, but they also tell me they went away on school camp with their kids over mating.”

Steph says some customers are wary of the technology and wait until the training is underway before they start using it. Others leap in the moment the collars start collecting data.

A typical new install starts with the sales consultant completing a comprehensive site survey, including deciding on the best location for collar readers. Once the paperwork is signed, MSD Animal Health contracts a local dealer to handle the hardware installation.

“They are highly trained at installing the hardware. We use specialists, rural electricians and engineers, to install the readers and equipment at the right points and also any drafting gates required.”

The installation of the computer hub at the shed is overseen by one of the 12-strong technical team which includes people experienced in software, robotics and milking intelligence. This team also

oversees the whole installation process to ensure it meets the high standard required.

After some initial guidance by the farm’s regional salesperson, the collars are normally fitted by the farm staff. Once in place, the trainer assigned to the property connects with the farm owner and gains access to the herd recording information.

“We use a special reader to match up each herd collar with the cow’s EID tag. The trainer then creates

the database in conjunction with the herd recording records, and that is uploaded for the client to use.”

Once the installation is completed, the trainer ensures the system has been properly commissioned and visits the farm within two weeks to start training the farm owner and their staff.

“Each client gets up to four training sessions. Some don’t need all four, but others do. We try to tailor it

“That after-sales support

to each individual farmer and always at the pace each farmer can handle.”

“We’ve worked with farmers typing with one finger through to others that can’t wait to get into the software to see what it’s telling them.”

Steph says the software is very robust, a reassuring fact for clients who fear they might create a problem.

“You can’t break it. There’s nothing that can’t be undone again so we encourage people to try it out,” she says.

Getting started can be daunting when farmers have limited experience with software technology but having the support systems and access to the 0800 after-service freephone means they are never left guessing what to do next.

Steph says farmers only need to provide four facts about a cow to start using the data collected by the SenseHub collars. They are calving date, mating date, pregnancy diagnosis and dry-off date.

“If a farmer can tell the system those four things, it will do heat detection for you and it will tell you when a cow is in distress or declining in rumination activity. These are all things that a farmer can’t always see visually.”

MSD Animal Health also runs regional discussion groups pre-calving and pre-mating to allow farmers

to connect with others using the same technology and share their knowledge, and customers can also attend an annual National Summit which moves between islands each year.

A team of six technical staff operate the New Zealand-based service desk during normal business hours, with an emergency on-call service for after hours and public holidays.

Farmers can call if they have a problem and know it will be answered by someone who understands them and, if necessary, can investigate the situation by logging into the farm’s SenseHub collar system.

Customers also received written service manuals for all the technology systems, for farmers and veterinarians to use. Vets and farmer customers are encouraged to self-learn, using the online resources available to them.

Jo Holter is the Veterinary Technical and After Sales Manager who’s team includes the training team, the service desk and the veterinary technical team.

She says having a small team of experienced vets engaging with rural vets from a technology perspective is unique to the SenseHub business. A rural professional has also been recruited to help support and engage with farm consultants and nutritionists.

“It’s a massive focus for the business to make sure our clients are well supported. Our support structure in behind the collar technology is a real point of difference for us.”

“It’s a massive focus for the business to make sure our clients are well supported. Our support structure in behind the collar technology is a real point of difference for us,” Jo says.

Vets are beginning to embrace cow monitoring technologies and adapting their role to take advantage of earlier intervention when the collars signal health alerts.

“For vets, it’s really a no-brainer to engage in the data their clients are gathering. The collars are not a diagnostic tool, they are telling you that rumination has slowed or stopped so a farmer still needs that vet advice to help her.”

“Our cow monitoring technology is just another tool in the toolbox for the farmer and their vet to create a better health outcome. That opportunity to intervene earlier when an animal is flagged as in distress is better on the animal and the farmer as well,” Jo says.

The sense to know she’s on heat.

The Covid-19 lockdown in early 2020 created the space South Canterbury veterinarian Ryan Luckman needed to tinker with the data generated from cow monitoring collars used by many of his clients.

“I’ve been lucky that I’m in a region of the country where we have some early adopters of the Allflex collars, and that lockdown allowed me to start looking at the possibilities from benchmarking the data from those farms to see where improvements could be made on individual farms,” he says.

As a vet, he was already very aware of the power of the collars to improve heat detection rates and pinpoint sick cows in the herd much earlier than normal.

“But what I found when I started looking deeper into the data was it quickly filled in so many of the blanks in our knowledge at critical times of the season like transition from calving to early lactation. We know this period sets up the whole lactation, so it is important to get it right.”

“Our collar farms give us real-time, live data feedback, so there’s nothing subjective and that’s what

makes it incredibly powerful as a tool to improve performance,” he says.

His experiences with data and developing his own set of benchmarking reports for his practice’s own customers meant he was an ideal person for SenseHub to collaborate with on its global project to create a set of benchmarking reports and targets. These reports and targets are being tuned for New Zealand’s pastoral farming systems, so vets can work with their clients to compare their herd’s performance and explore ways to improve it.

“So far, we’ve helped to develop a set of benchmarking reports and targets which cover the calving to transition period, and both pre-mating and mating periods. These reports allow farmers to see where their herd sits within the full data set.”

Each farm’s data is compared to quartiles of the total data set, so the herd owners understand how their herd compares and most importantly, what needs to happen for it to improve. Improvements are often immediate and ongoing, he says.

“In the past before cows had collars, we could provide advice and you’d often see a small improvement in say heat detection but then things would plateau or just bubble up and down a bit. But with the collars, the data and benchmarking reports are helping us achieve further improvements.”

He’s particularly excited about the SenseHub benchmarking project which will soon be rolled out to farms in his region before a national launch later in the year.

“When you see the variation in key data, you know there’s so much opportunity for individual herds to improve their performance.”

“I’ve had farmers who have been farming for many years say to me they didn’t really know anything about why their cows were under performing until they fitted them with collars,” he says. Another set of benchmarking reports under development will focus on heifer management. Heifers are particularly vulnerable to poor management.

“In our region, we’ve seen the benefits farmers can get from running a separate heifer mob but with collars we’re seeing the changes they go through in real time.”

“We can literally show our clients the differences that occur in rumination and pre-mate heats based on how they are managed and fed.”

Ryan says any resistance among farmers who fit collars but don’t embrace the data is short lived when they see the opportunities to improve performance.

“We call it the first-year challenge. However, the data is just so easy to explore and everything the data shows plays out in the herd performance which helps eliminates any doubts,” he says.

Many farmers initially buy collars for heat detection and health. Ryan calls these the ‘easy wins’ but says now is the time to take the next step in harnessing the data from these systems to make better realtime and retrospective decisions.

One of the key opportunities posed by collar technology is the ability to monitor and intervene live, before it is too late.

“Instead of getting to the end of mating and finding out that things went poorly, the target should be building in effective monitoring and intervention steps throughout the season to prevent the ship from crashing in the first place.”

Ryan says the dairy sector is only in the infancy stage of how we interact with collars and collar data.

“A huge amount will be gained over and above the core offerings of mating and health monitoring if we are prepared to look for solutions that fit the seasonal NZ market,” he says.

“Our collar farms give us real-time, live data feedback, so there’s nothing subjective and that’s what makes it incredibly powerful as a tool to improve per formance.”

Independent research has confirmed farmers can confidently predict the level of mastitis infection in individual cows using an inline milk sensor which detects the somatic cell count (SCC) within two minutes of the cups going on a cow.

SCC sensing technology was developed around 20 years ago, but it has taken a large investment in research by MSD Animal Health to confirm its accuracy is very similar to herd test SCC when used to identify cows with bacterial infection.

MSD Animal Health sensor project lead Rob Orchard was involved in the development of the world leading SCC and milk yield sensors from the outset and says having independent science to back up their accuracy is reassuring for dairy farmers battling with mastitis infection in their herds.

SenseHub offers a standalone SCC sensor which can be fitted to capture SCC data from milk in a herringbone or rotary shed. Rotary sheds with Protrack software linked to cow identification can be integrated with SCC sensors to provide individual cow results.

He’s now working to link the data generated from an SCC sensor to the SenseHub Dairy software, a project expected to be completed soon and the new integration made available to farmers in the final quarter of 2023.

“Getting a SenseHub link makes it more appealing because it’s part of a bigger eco-system. The big goal now is to translate the data coming off the devices into actionable insights for dairy farmers to use,” Rob says.

The SenseHub sensors are installed in the milk tube connected to a set of cups and automatically take a sample of milk soon after the cups go on. This sample is mixed with a reagent formulation and then the device measures the viscosity of the mixture and interprets the result to estimate the SCC of the sample.

MSD Animal Health recommends fitting SCC sensors to at least 25% of the bails so several estimates can be delivered over a few days to build a more detailed picture of infection among the herd. It’s rare for more than the first few cows entering a rotary to be in the

Rob Orchardsame order every milking so the risk of missing out on testing is minimal.

For sheds with no cow identification system in place, the SCC sensor results are shown on a traffic light warning display above each bail. Cows showing red can have the cups removed immediately and those showing orange can be marked to check next milking. Cows showing green are below a pre-set threshold level for intervention.

Where SCC sensors are integrated with individual cow identification software in Protrack (and SenseHub once the development work is completed later this year), the SCC result is stored and the information

Mastitis is the most prevalent and expensive animal health challenge in dairy herds, but science has just delivered farmers a big helping hand.

used later when treatment options are considered or culling decisions are made.

Automated audio alerts can be set for the next milking so the cow can be inspected to decide further action before cups on.

MSD Animal Health Technical Vet Matt Buckley says linking the SCC sensor to SenseHub will provide a fuller picture of cow health. Automated detection of mastitis will be game-changing for dairy farmers who mostly rely on regular herd testing for that information.

By using SCC sensors, farmers can identify cows that have either clinical or sub-clinical mastitis any day of the season.

Matt says one of the most challenging periods with mastitis infection is leading into the dry off phase.

But the SCC sensors mean farmers can selectively treat infected cows with dry cow therapy rather than blanket treating the entire herd.

“The animal health industry and New Zealand Veterinary Association has a goal of reducing antibiotic use so this has the potential to contribute hugely towards that goal,” Matt says.

Detecting clinical cases of mastitis at milking means they can be treated promptly before infections rise and short-listing cows to check each time becomes a simple, low-labour issue to deal with.

“Our technology has been shown to be superior to the conductivity tests for short listing animals for clinical mastitis. It can rank the animals by cell count, and then shortlist them so culling decisions can be based on the information too,” Rob says.

Rob says any dairy farmer battling with rising bulk tank SCC late in the season knows how difficult it is to find the cows in the herd with mastitis.

“You can easily use our technology to identify the highest SCC cows and remove that risk by milking them into a bucket. So, you’re not stripping a whole lot of cows trying to find those high SCC cows, after getting a report from milk processor which could be three of four days old when milk is being collected every two days nearer the end of the season,” Rob says.

“SCC counts also form part of the picture of an animal’s value to the farmer so they could be used for breeding and culling decisions as well.”

Knowing which cows in the herd are not infected also gives farmers the option to milk healthy cows for longer if they choose to.

The good news is the SCC sensors are just the start of plans by MSD Animal Health to develop a suite of milk quality tools.

“It’s really a case of watch this space when it comes to new tools to help dairy farmers in the future,” Rob says.

The sense you hold in your hand.

The sense to know she’s unwell.

LOCATION

Hawea Flats, Central Otago

FARM SIZE

3000ha run as five milking units and a young stock unit

HERD PRODUCTION 480kg milksolids/cow average over the total business.

• Individual cow monitoring

• Less pressure on staff

• Better mating performance

• Early intervention when cows need it

General manager Erynne Fildes says installing Allflex Monitoring technology on the entire milking herd and their rising two-year heifers has been transformational for the business.

Her primary initial motivation for adding collars was to improve the welfare of her farm staff, but she says the technology has delivered many more benefits across all five herds and replacement heifers in the Devon Dairy Farms business.

“Watching my staff tail painting cows, climbing up on platforms at milking time and the pressure over

that mating period, I just had to find a better way,” Erynne says.

“I was a little wary of going with collars at first because I thought they would be too big and heavy around the neck of each cow. But after an initial meeting with the Allflex team, I was convinced they were fine.”

“My number one driver was taking the load off my staff, giving them better work-life balance, reducing fatigue and accidents that can result from that. But when I learned more about the health monitoring, I was sold on them.”

Every cow in the 4500 head combined milking herd at Devon Dairy Farms in Central Otago can receive individual attention if she needs it.

She admits not everyone across the five farms embraced the technology immediately. But when the data collected on each cow started to build, everyone could see the advantages of monitoring it so they could intervene earlier than through observing cow behaviour or relying on milk collection data.

One of the Devon Dairy Farms’ managers Jamie Burrows was excited by the installation of SenseHub collars in her herd and says it has been game changing for herself and staff on the unit she manages.

“The support and training provided by Allflex was amazing, especially in those early months while we were building our knowledge of the system,” Jamie says.

The first two herds had collars fitted in May 2021 and immediately proved useful by detecting several cows with udder infections heading into the dry-off phase, and later when they were transitioned from their mainly pasture-based diet on to fodder beet.

“It takes a few days to start gathering the data from each cow, but I soon realised that some cows are very sensitive to infections and that showed up quickly in their rumination data,” Jamie says.

”The data shows me any animal in distress, before you can see it is. By regularly logging into the system to check what’s happening, I was able to save time and money by intervening early.”

By mating time in that first year, Jamie says her confidence in the data made heat detection and mating much easier than the heat patches they had been using.

“You have to trust the alerts completely and let the system auto draft off the cows showing on heat. We soon found they normally were on heat so that saved a lot of time at milking,” she says.

“I wouldn’t want to return to our previous system because by the time you’ve got through 12 weeks

of artificial insemination, everyone’s very tired and struggling to pick up cows that are showing oestrus.”

Jamie says being able to check data from her laptop also reduced pressure over the calving period too. Night checks were only monitored when an alert showed up, reducing pressure on herself and her team.

Based on the success of the SenseHub system in their milking herds, Erynne began to consider installing collars on their rising two year old heifers.

“Using heat patches to detect heats meant running 1200 heifers through the yards every day for several weeks to select out the ones on heat. That was tough on the heifers and our staff.”

She was convinced the collars were worth the further investment so the MSD team installed a new drafting gate in the yards at the young stock farm and the heifers were run through it for almost two weeks so those on heat were removed for mating by artificial insemination. Bulls were then introduced to complete the mating.

“We had an outstanding reproductive performance from the collared heifers last mating, up 10% on the previous year. By comparison a mob of 300 we run on another runoff block over the river were on the old patch system and the results there were like chalk and cheese.”

Having every two-year heifer with a collar also means an extra year of data is collected on each animal.

“So, we’ve captured heats and health alerts on all those heifers entering the milking herds,” Erynne says.

The farm’s regular veterinarian, Caroline Reid from VetLife Wanaka, has access to each herd’s data

“My number one driver was taking the load off my staff, giving them better work-life balance, reducing fatigue and accidents that can result from that.”

and has developed a ‘triage sheet’ which staff use each time an animal shows up with a health alert. The usual routine starts with taking the cow’s temperature. Some cows may be treated with antibiotics or anti-inflammatories, while others may require a vet visit.

“It’s too early to say the collars are helping reduce our animal health costs but we operate a gold standard approach here and we’re now treating fewer cows now and for a shorter treatment period too, so I’m expecting to see that cost drop,” Erynne says.

The vision for Devon Dairy was developed by Erynne’s parents Jim and Jenny Cooper, self-made business owners, who returned to New Zealand from Australia in 2011 to be close to Jenny’s birthplace of Wanaka, Central Otago.

They’d tasted success on several big projects during their decades in Australia and they were looking for another one to sink their teeth into closer to home.

They had to overcome some early negativity from locals in the area when plans to convert their newly acquired sheep station to a large dairy farming venture were unveiled, but their first tanker load of milk left dairy unit number one in 2012. Another four dairy units were commissioned by 2019 along with a purpose-built farm for raising all their young stock and growing supplement for wintering cows.

When Jenny passed away in 2014, Erynne stepped up to take on the management of the farm business. She admits it was daunting at first with no farming experience and being a woman in a male-dominated farming sector.

She initially relied heavily on a team of advisors and staff, including many who are still connected to the business today.

“I took over fully running the farm in 2015 after my parents had previously employed managers to run the operational side of the business. We soon realised the best way that Devon Dairy could be run was by someone in the family,” Erynne says.

“It’s taken me a long time to say I’m a farmer. I’m not a traditional farmer, I prefer to say I’m a science based farmer and it’s the science that I get my motivation from.”

Apart from being close to Wanaka, it was partly irrigated, and had free-draining soils that attracted her parents to buy and convert the property to dairy farming.

“It’s during winter that this land shines through because we’re not up to our knees in mud. We don’t need barns for our cows, they are wintered outside,” she says.

The 3000ha gives them the scale to run five separate dairy units, wintering a total of 4500 cows and milking about 4300 cows at the peak of the season, winter 1050 pregnant rising two year heifers and 1200 rising one year heifers, and grow all the supplement required to sustain all their stock through winter.

The five dairy units plus young stock farm operates separately within the overall Devon Dairy group. Each has its own manager, team of staff and machinery. A set of farm accounts is produced for each unit as well.

“It is surprising how much each farm varies in the balance of soil types, temperatures, and topography.”

”The data shows me any animal in distress, before you can see it is.”

Technology is playing an increasing role in delivering a more sustainable level of performance for Canterbury dairy farmer Darcy Bishop.

LOCATION

Oxford, Canterbury

FARM SIZE

270ha milking platform, 335ha total area including 10ha water storage pond

HERD SIZE

930-950 cows at peak

• Peace of mind – more certainty cows are well fed

• Quicker genetic gain through more use of sexed semen

• Future proofing farm business

• Less pressure on staff, better retention

Technology is playing an increasing role in delivering a more sustainable level of performance for Canterbury dairy farmer Darcy Bishop.

He bought his 320ha (effective) partly-irrigated dairy farm in 2014, heading south from Waikato to Oxford to build scale and milk a herd of 930-950 cows at peak each season.

He just bought 50ha of adjoining land and 10ha of it will be included in the milking platform. Replacement stock will graze the balance, reducing the time replacements are grazed off farm.

After several years of pushing production, he’s content with production of around 445,000kg milk

solids per season and feels he’s found the farm’s sweet spot is 3.5 cows/ha.

“Our idea is not to milk more cows but do everything better and take some pressure off so we’re not living on a knife edge all the time,” Darcy says.

Canterbury’s label as a consistent dairy performer has been challenged in the past two years.

In their 2020-21 season, they produced 449,000kg MS but last year production dropped to their worst season ever of 429,000kg MS when the climate delivered a run of wet cool months. This season, they are on track to hit 445,000kg MS.

“It’s made everyone happier in the team too. We’re all a little busier than usual, but it’s more manageable now.”

Allflex Monitoring collars and readers were installed in September 2021. In spite of two consecutive difficult mating periods since, Darcy says the collars have been a very worthwhile investment. One of the most significant developments since adding the collars is a switch to using sexed semen for the first time. At around $50/ straw, he always felt it was too expensive.

“But with the collars, you know a cow is cycling, and you know if she’s in calf 35 days later, so you feel like that $50 straw you’re using is worth the investment.”

Using sexed semen for the first three weeks of mating also means he has been able to double the number of cows mated to beef sires from 20% to 40% of the herd and gain extra income from the sale of more beef-cross calves.

“Switching to using sexed semen is game changing for me because if the rules ever change for us in the future, I’ve already done a decade of breeding only from my top cows in the herd so if we have to reduce cow numbers, I can keep 800 of the best cows in the country and milk from them,” he says.

“The collars have given me a big hand to fast track genetic gain in my herd.”

He works with his LIC rep to combine herd testing and monitoring data to produce a mating plan which is colour-coded for ease of visual selection and links straight to his Protrack drafting system. He’s aiming to lift the conception rate to sexed semen from last season’s 49% to 52% for the 2023 mating with better feeding leading into mating this spring.

With Allflex monitoring technology in place, mating has become a less stressful period in the year for Darcy and his team of three full-time staff.

“The first three weeks are still full on busy, and I like to be at the shed to make sure the right decisions are made. But I’m not having to get up at 4am every morning and spend three hours-plus on the stand

“I literally don’t need to do anything now. I can get up in the morning, have a coffee, go to the shed and there’s a group of maybe 50 cows waiting for me. I go through their data and generally most will be on heat. It’s that simple.”

“It’s made everyone happier in the team too. We’re all a little busier than usual, but it’s more manageable now.”

Darcy likes to use the rumination data to back up his own subjective assessments of how feeding is going.

“If you know in your gut that you’re not feeding cows properly, the rumination data shows it. We’re able to make better decisions on feeding and we can make them earlier than we would just on gut feel.”

Almost at the end of his second season with the collars on his herd, Darcy says he is gaining more confidence in using the data they deliver in his dayto-day feeding management of the herd.

“What I realise now is you learn so much more in the second year from the rumination and health reports, and if you really want to make a great return from them, you have to be prepared to put some time into it.”

“Like all technology you only get out of it what you put in. But it’s amazing when you do that.”

The farm’s veterinarian has direct access to the monitoring data and checks in weekly, especially at critical times of the year.

On the advice of their veterinarian and after getting information from his Allflex Training Specialist, Darcy

“The collars have given me a big hand to fast track genetic gain in my herd.”

has introduced a two-stage transition approach to prepare cows for the twice-a-day milking mob.

Cows enter a colostrum herd for the first four days after calving and then move to a transition herd for six days where they are milked once each day, before entering the main mob and being milked twice a day.

“With collars, you can monitor their rumination data so you know when they reach the right level to move on. Cows need longer to recover from having their calf so giving them 10 days means they hit ground running when go into the twice-a-day herd.”

“If they drop rumination once they get to the main herd, you can pull them back out to the transition herd again if required.”

Darcy says the collars have helped him find a better balance between work and home life.

“I’ve gone from often feeling tired through the season to being able to spend more time with my

family. I have three children so it’s a lot easier for me to support them with sport and take time off the farm now.”

Darcy considered two other cow monitoring technologies before settling on the Allflex Monitoring option. In the end, he eliminated one on cost and rejected the other on inferior compatibility with his existing Protrack auto-drafting gate at the dairy shed.

“For me, choosing Allflex was the easy option and I knew it was fully compatible with my existing Protrack drafting gate and I had all the technology in my shed from LIC.

Training and support from his local Allflex trainer have been exceptional.

“Allflex Monitoring collars gives me peace of mind. I know when my cows are well fed and when you get that right, you don’t have to intervene.”

• More proactive decision making

• Better detection of heat stress

• No more ‘lost’ cows

• Heat detection now a one-man job

“We’re right on the boundary of Egmont National Park so we’re as far up the mountain as you can farm. Our biggest farming challenge is the 4-5m of rainfall the farm gets each year,” he says.

Most of the soil is free draining ash over metal and it slopes away, so a lot of the surface water runs off. But the rainfall heightens the risk of animal health issues like lameness and mastitis occurring, so Kane has to be vigilant for early warning signs.

He is in his first year of contract milking for the farm’s owners Hamish and Emma Lawn and expects to produce 147,000kg milk solids for the 2022-23

season, a pleasing improvement on the previous season’s result under different management. Two Herd Homes are a haven for the cows especially in winter. Most cows calve in one of the homes so they are monitored closely through that risky period. Kane had seen cow monitoring technology in action at other farms and when he found a source of second-hand Allflex collars, the farm owners agreed to buy them and he contacted Allflex to start the installation process.

Farming just under the bush that rises up the mid slopes of Mount Taranaki might seem a picturesque location, but contract milker Kane Brisco measures annual rainfall in metres.

The SenseHub Dairy hardware with Allflex collars was operational from November 12 last year, about 14 days into the 2022 mating.

He immediately stopped tail-painting but continued monitoring cows for another two weeks on the stand to double-check each one showing oestrus in the

Dairy software was also backed up by rubbing of the tail paint.

“I was blown away. When the data on heats started to come through, it was 100% accurate,” he says.

Tag numbers still have to be entered manually into the auto-drafting gate over mating, but the shed

became a one-man operation overnight once the collars were fitted and the SenseHub system began collecting data.

The herd empty rate from the 2022 mating was only 7%, a result Kane believes was heavily influenced by the heat detection capability of the collars and movement data they collect.

The six-week in-calf rate was 74% and he adopted a full artificial insemination strategy with no back up bulls.

One of his big motivations for installing cow monitoring was to reduce the extra labour unit he needed in the dairy shed each morning during mating.

“We’ve got a 35 bale rotary shed with auto-drafting so it’s set up for a one-man operation. But before the collars went on, my worker had to be in the shed through mating with me,” he says.

“It’s pretty full on here with 305 cows in two Herd Homes, and it’s quite a big cost having two people in the shed every morning,” he says.

Installing collars had an immediate effect on workload for them both. “It was a massive relief because the collars mean one of us can have a sleep in each day.”

“I’ve been dairy farming for 14 years and I’ve never taken time off during that mating period until now. Farming’s like an ultra-marathon but this sort of

technology is game changing because it frees up time for me to spend with my family, reduces fatigue and makes everything more enjoyable.”

Kane was also keen to improve overall herd health by picking up cows under stress earlier than through observation. Although he takes pride in his own stockmanship skills, he believes the collar data gives him 24-48 hours earlier warning and he can intervene much quicker.

When a cow shows up with a health alert, the policy is to draft her out next milking and check her for any obvious signs of illness or disease. Her temperature is taken and a paddle test is done on a sample of her milk. Most receive an anti-inflammatory injection and return to the paddock, but those with elevated temperatures may require a check by the farm’s veterinarian.

“Farming’s like an ultra-marathon but this sort of technology is game changing.”

“I was blown away. When the data on heats started to come through, it was 100% accurate.”

“The anti-inflammatory injections are amazing. Most cows go back to the paddock and their rumination levels rise almost straight away,” Kane says.

“With the SenseHub system operating, it means we can take cows out of the milking herd earlier, give them the TLC they need to recover and get them back into the main herd quicker too.”

Kane’s collar system is also set up to send an alert if a cow misses being seen at the shed for 24 hours and this feature has picked up three cows that had gone missing.

“Two had found their way into drains and were less than a day away from dying. The other cow had slipped through a fence into the bush and may not have found her way back to the herd.”

“But losing three cows at $2k each is expensive, so that’s been another win from having the collars on.”

Through last summer he also monitored heat stress in the herd using the rumination data. By adjusting feeding times in the Herd Homes, using the sprinklers in the holding yard before milking and changing afternoon paddocks so they were closer to the shed, he was able to minimise it.

At calving next spring, Kane is planning to set a rumination threshold for cows to reach before they move into the main milking herd after their calf is born.

“Just having that extra data set can really back up your decision whether that’s a feeding or health issue.”

Kane says the back-up service from the Allflex team has been superb.

“They bent over backwards to help us all the way through the installation. I can text my trainer with a question and she’s usually back to me really quickly with the answer.”

“They are happy to come to the farm to upskill us, and the hotline you can call anytime from 4am to 7pm and someone will always answer the call.”

After just a few months with the collars on his herd, Kane says it would be difficult to move to another farm to manage a herd without them.

“I’d much rather go to a place that has collars on the cows. It would be a selling point for me in the future if I ever move,” he says.

He likes the phone app which allows him to check into the data in just 5-10 minutes a day.

“If something’s not right with a cow, you can match that up with what you’re seeing visually in the paddock or the Herd Home.”

“I can be anywhere in the country, check on my phone and know if I need to make a phone call or not. I’m always in control but I don’t need to be at the farm to make sure anymore.”

575 Kiwi-cross cows milked at peak

• Less demand on labour over mating period

• Happier, healthier cows from closer monitoring

• Entry to milking mobs guided by cow rumination levels

Technology has to become every farmer’s best friend, says Waikato contract milker Jeff Peek.

He and wife Jasmine are in their third season contract milking for farm owners Stephen and Penny Sanson at Maihiihi, south-east of Otorohonga, milking 575 cows at peak on their 190ha (effective) unit.

Their first season produced stellar production of 228,000kg milksolids, but last season it dipped to 210,000kg because of a long period of very dry weather. Their 2022-23 season has been just as tricky to manage, but for different reasons.

“It’s been very wet but I’m pleased to say our production looks on track to finish the season at about 225,000kg, thanks to some tweaks we’ve made to our system,” Jeff says.

SenseHub Dairy technology and Allflex collars were installed in August 2021 and provided immediate benefits, particularly reduced pressure on staff at mating time and early detection of health issues in the herd.

The need for an extra labour unit in the shed during mating to pick cows on heat was eliminated when the collars went on.

“Instead of having to be on the stand in the shed for more than three hours at every morning milking selecting cows on heat over several weeks, I became a productive labour unit overnight.”

Jeff and his two full time staff now have regular sleep-ins and more time off during mating. A break away from the farm during mating last spring was a first for Jeff in many years of dairy farming.

“My wife and I were able to head south and do the Lake Dunstan cycle trail during mating last year.

That’s never been able to happen before,” he says.

“My eldest son also has a birthday during mating and in the past, I’ve never been able to be there when he wakes up and opens his presents in the morning. But having the collars has changed that.”

The 2021 mating period was particularly challenging because of the prolonged and unusually dry period the Waikato region endured that year. Jeff says the reproductive performance suffered, though he’s quick to acknowledge the SenseHub system and collars performed as expected.

“I can’t fault the collars for any of it. They did a fantastic job picking up the cows on heat each day. It was really just feeding that caused the lower six week in-calf rate that year.”

There was a dramatic improvement in the 2022 mating in spite of the wet cool conditions that

“When mating started, our cows were a lot healthier and happier than previous years and that showed in our results.”

prevailed leading into and through the mating period. Empty rate dropped by 7% on the 2021 result and the herd’s six week in-calf rate lifted by 10%. Conception rate rose by 5% too.

“We have the luxury of being later in the morning on the AI run so we get the opportunity to draft off cows showing on heat and then double-check them before our technician arrives.”

He operates a total artificial insemination policy with no bulls on the farm. Replacement heifers are produced from the first five weeks of mating, before another six week block of short gestation Kiwi-cross or beef semen is used. A bottom cut of 10% (on Breeding Worth) of cows go to beef bull semen.

After a second year of having the SenseHub Dairy technology in place, Jeff feels he’s now gaining extra value from the data and reports as his understanding and experience grows from using it.

“Just being able to drill into those reports in a lot more detail helped with feeding and getting on top of a lot of the health issues coming into mating last spring. When mating started, our cows were a lot healthier and happier than previous years and that showed in our results.”

SenseHub Dairy data also allows him to manage freshly calved cows more closely than just by checking them in the paddock. They are held close to the dairy shed and their rumination data is checked regularly so any health alerts are promptly investigated.

Jeff has introduced a once-a-day-mob comprising mainly first and second-calving cows and some older cows recovering from a difficult calving, ill health or lameness. About 40% of all cows are in this mob.

“My wife and I were able to head south and do the Lake Dunstan cycle trail during mating last year.”

Next calving, his plan is to more closely monitor each cow’s rumination data to help determine when it is ready to move from the freshly calved mob into one of the milking mobs.

The SenseHub Dairy data reports are increasingly being used by the farm’s vet who recently completed a training module with an MSD/Allflex Technical Vet

Jeff says allowing their vet access to the system remotely when cows are showing health alerts is the obvious next step so he can intervene earlier and have a health report available on the animal before arriving at the farm to treat her.

He and his second-in-charge are both running the mobile phone app which provides access to the SenseHub Dairy reports any time of the day or night.

Jeff has no hesitation in recommending the technology and the ongoing training and support offered by the Allflex team. “I really can’t fault them; it’s been excellent all the way through.”

“If we do strike a problem, we know we can call the after service number and know we’ll get an answer from someone who understands what we’re after.”

The collars are simple to fit to each cow and Jeff says he’s only had an issue with one collar in the past two years.

“Our internal rotary was actually ideal for the collar fitting because all the cows are facing out and we got through the fitting really easily and smoothly. Our trainer couldn’t believe how well it went,” he says.

Jeff Peek 39

Jeff Peek 39

• Low-stress heat detection

• Early intervention for animal health issues

• Reduced pressure on single labour unit farms

• No need for back-up bulls

Mark and his wife Louise are 50-50 sharemilking on her parent’s 65ha (effective) property just outside Morrinsville, managing a milking herd of 230 Jersey and Jersey-cross cows plus 60 heifer calves reared and grazed on farm.

They are in their seventh season on the property which supplies local dairy company Tatua.

“I don’t know how I could farm without collars now, especially being a one-man unit,” Mark says.

Within two months of installing them, Mark knew it was a great decision when six cows showed up with alerts to say they were empty.

“We got our vet in to check them, and five out of the six had lost their calves. That’s huge for me to know the data from the collars picked up something was wrong before we could see it, and we could get in early to investigate it.”

“It was a massive win for us to be able to deal with those empties straight away, rather than not realising they’d lost their calves until much later,” Mark says.

When he started investigating cow collar options, his primary motivation was saving time identifying cows on heat during the entire mating period and maintaining consistent reproduction results when a labour unit is eventually employed in the future.

After installing SenseHub collars, Mark found that heat detection accuracy was maintained compared to traditional methods but the real benefit came from removing the stress and pressure that builds up during the mating period.

“The conversations I used to have with myself about cows on heat were pretty intense. I’d be constantly thinking ‘is this cow actually on heat, what’s her tail paint like, who is she next to on the row, is she in the right row and the right place in the row’, stuff like that.”

Mark’s mating plan used to involve a full fiveweek pre-mating programme, maintaining tail paint twice a week, followed by six weeks of artificial insemination with LIC nominated semen, then three more weeks of mating using Jersey bulls.

“I don’t know how I could farm without collars now, especially being a one-man unit.”

“By the end of the five week pre-mating and six weeks of nominated AB, I was always really exhausted. But now, with the SenseHub technology creating a list of cows on heat each day, all the pressure has come off,” he says.

Last season, he decided to go to a full artificial breeding system for the first time because of the consistent heat detection accuracy from the collars.

“That period leading into mating and the first six weeks of AB was a heap easier last spring. I’d never go back to life without the collars on my cows,” he says.

The tags of cows selected by SenseHub as being ready for mating are still manually entered by Mark for drafting off through his Protrack autodrafting gate.

“With the drafting accuracy of our Protrack system running at damn-near 100%, I still prefer to just punch each tag number in manually so I know it will be drafted off.”

“That’s just me being a control freak, but when Protrack is drafting cows like it is, I’m not prepared to sacrifice that level of accuracy for the slight convenience of auto-drafting.”

Mark says it is not hard to justify the investment in the collars when you put a realistic value on your own time.

“When I’m not here, the system is still running 24/7, so I’m still in touch with it from the SenseHub app.”

“Time is money in my world, especially as I run this as a one-man operation,” he says.

“When I’m not here, the system is still running 24/7, so I’m still in touch with it from the SenseHub app on my mobile phone. If there’s a distress alert for a cow or something untoward happens to the herd, then I know about it straight away and it’s only a phone call to the relief milker to get them to check what’s happened.”

Installation of the readers and fitting of the collars was straightforward, and Mark says the training and back-up has been excellent.

The long, narrow shape of the property meant he chose to install a second aerial away from the base unit at the dairy shed to get close to full farm coverage.

“There’s about six paddocks at the back of the farm that I don’t get complete coverage in, but that’s not really an issue because the cows are at the shed twice a day except when they have been dried off.”

“As soon as they reach the point where the coverage kicks in on their way to the shed, the data is pinged off to the base unit anyway, so it’s not causing me any problems at all.”

The initial training and back-up service since the collars were installed has been excellent, he says. “My local rep, Shaun Killalea, has been great to work with. He’s always available which is really reassuring especially in those first few months when you’re still learning.”

From people to animal health, management to mating, you’ll have a bunch of reasons why you need SenseHub cow collars. Just know that no matter what your ‘why’ is, we’ve got your back.

Catch silent heats, non-cyclers and identify the precise moment you need to inseminate for optimal breeding.

Let your workers take a break. SenseHub monitoring system gives your staff the right information at their fingertips, regardless of where they are.

Keep your herd healthy. Get notified of any issues early – before they cause major problems.

Don’t miss any rumination changes. You can monitor your entire farms wellbeing – so there’s no guesswork.

NO MORE TAIL PAINT IMPROVE ACCURACY OF SUBMISSION RATES

REDUCES MORTALITY RATE ON AVERAGE

CONDENSE YOUR CALVING WINDOW

MORE DAYS IN MILK

REDUCE YOUR EMPTY RATE

ALLOWS REGULAR BREAKS OVER BUSY EVENTS OF THE SEASON

INCREASE YEARLY MILK PRODUCTION PER COW

These are just some of the results farmers are achieving with our collars

Each year, over half a billion animals are identified using our intelligent visual and electronic identification solutions.

MSD Animal Health provides New Zealand farmers with a wide range of animal health products, available through veterinary practices and your local rural retailers.

The boldest, blackest, easiest-to-read livestock identification.

LaserInk pitch black ink

Laser marking for proven durability

Advanced shiny, non-stick surface

As permanent as a tag tattoo

Multiple marking options available including a wide variety of letter and number combinations, this paired with our multiple tag colour options provides flexibility for customised on farm identification management.

Allflex Tissue Sampling Units (TSU) take an ear punch, which can replace tail hair, blood, semen or other sample types used for DNA, Pestvirus or other serology testing.

Quick, easy, reliable DNA sampling

• Take an ear punch, instead of tail hair, semen or other DNA testing methods

• Sample is sealed in a specifically designed preservative

• Tissue samples contain large quantity of high quality DNA for genetic analysis, yielding excellent lab results

• Fully sealed and positively identified with both a 2D barcode and ID panel

• Can be paired to matching visual and management tags

• TSU applicator used to take samples

HDX tags are the best practice EID tag

• LaserPlus marking for easy to read numbers

• Advanced, shiny, non-stick surface, preventing tags from warping or fading

Allflex HDX Electronic tags are the High-Performance EID tag solution. Record, measure, improve livestock performance with Allflex EID tags.

• HDX equals high performance, suitable for weighing stock regularly

• Suitable for cattle and deer

• Visual tags colour available in white, orange, green, purple, pink, yellow, red, blue, black and brown

HDX Premium calf pack

• TSU pre-matched to the birth ID

• Save time - tag and tag your TSU sample at the same time

• Reduce recording errors

• Convenient - all components packed together in a robust tray

• Easy and accurate

Allflex Birth Packs consist of a pre-paired Visual ID Tag, NAIT Tag and TSU (Tissue Sampling Unit) providing even more convenience.

Our vaccines can help farmers protect cattle from production losses and disease. These tried and proven vaccines give farmers greater control of their herd health by helping protect against the following:

• BVD

• Rotavirus, Coronavirus and E. coli – the 3 most common causes of infectious calf scours

• Salmonellosis

• Clostridial diseases

Our team knows what it is like to run a farm business, and all the costs and cashflow challenges that go with it. So, we’ve developed a simple and affordable way for you to access our monitoring and automation solutions, designed specifically for you, the New Zealand Dairy farmer.

• Continuous warranty & software upgrades on collars & application plans including free replacement and uninterrupted renewal of collars when needed.

• Affordable small monthly payments, which helps with your budget and farm cash flow.

• Simple and easy to understand billing statement.

• Unlimited access to NZ based training service and support team.

• Access to knowledge base and digital resources.

• Full warranty for the first 5 years.

• Access to NZ based training service and support team.

• Access to a knowledge base and digital resources.

• Automatic software upgrades and backups for the warranty period.

• Additional 2% discount when charged via your Farm Source Account.

• Farm Source Reward Dollars.

• No deferred payment terms.

Events like the Annual 2-day Monitoring Summit

8x NZ based trainers

2x technical vets on staff dedicated to monitoring

Service desk operating during normal business hours with an after hour emergency on call schedule for after hours and public holidays.

Nationwide dealer network

15 in our technical support team and 6 Service Desk Specialists

Dedicated online hublearn.allflex.co.nz

Resources customised for NZ Pastural farming

NZ based R&D team

Global software support and development from MSD Animal Health

So, if you’d like more information on SenseHub® Dairy monitoring or our automation solutions, give your local specialist a call.

NORTH ISLAND SOUTH ISLAND

North Waikato / Northland

Craig Midgley

North Island Sales Lead

M 027 222 86 22

E craig.midgley@merck.com

North Waikato / Northland

Kate Stewart

M 027 227 2611

E kate.stewart@merck.com

Waikato

Shaun Killalea

M 027 430 3413

E shaun.killalea@merck.com

South Waikato / BOP

Fleur Dickie

M 027 347 3344

E fleur.dickie@merck.com

King Country / Taranaki

Mark Ward

M 027 252 7373

E mark.ward2@merck.com

Wairarapa / Manawatu / Hawke’s Bay

Trevor Ward

M 027 556 7779

E trevor.ward@merck.com

Southland / South Otago

Laura Christensen

South Island Sales Lead

M 027 536 7967

E laura.christensen@merck.com

Upper South Island

Trevor Green

M 027 244 6144

E trevor.green@merck.com

South Canterbury / Otago

Gordon Keown

M 027 306 8201

E gordon.keown@merck.com

Canterbury / West Coast

Tyler Jones

M 027 533 0282

E tyler.jones2@merck.com

Our friendly team are here to help, so call 0800 255 353 (0800 ALLFLEX)

Monitoring & Automation Sales Option 4

For more information visit www.allflex.co.nz

Allflex/MSD

Animal Health

Allflex Livestock

Identification

MSD Animal Health Global Vaccine Manufacture

Trainer location

Office location

Allflex Livestock Intelligence is the world leader in the design, development, manufacturing and delivery of solutions for animal identification, monitoring and traceability. Our data-driven solutions are used by farmers, companies and countries to manage hundreds of millions of animals worldwide. By putting intelligent, actionable management information into farmers’ hands, our solutions empower them to act in a timely manner to safeguard their animals’ health and wellbeing, while achieving optimal production outcomes for a healthy food supply. Allflex

Livestock Intelligence is a livestock portfolio of digital products within MSD Animal Health.

Our milking automation technologies drive advanced milking solutions that are highly reliable, accurate and require little maintenance. They improve milking, save time, increase accuracy and improve cow and worker wellbeing. Based on unique development started over 40 years ago and continually improved over the years, our milking automation technologies have become the leading standard in the market.

Through its commitment to the Science of Healthier Animals®, MSD Animal Health offers veterinarians, farmers, pet owners and governments one of the widest ranges of veterinary pharmaceuticals, vaccines and health management solutions and services as well as an extensive suite of digitally connected identification, traceability and monitoring products. MSD Animal Health is dedicated to preserving and improving the health, wellbeing and performance of animals and the people who care for them.

This product is not intended to diagnose, treat, cure, or prevent any disease in animals. For the diagnosis, treatment, cure, or prevention of disease in animals, you should consult your veterinarian. The accuracy of the data collected and presented through this product is not intended to match that of medical devices or scientific measurement devices.

Copyright© 2023 Merck & Co., Inc., Rahway, NJ USA, and its affiliates. All rights reserved. The information contained herein is subject to change without notice. The only warranties for Allflex’s products and services are set forth in the express warranty statements accompanying such products and services. Nothing herein should be construed as constituting an additional warranty. Allflex Livestock Intelligence shall not be liable for technical or editorial errors or omissions contained herein.

NZ-NON-230500006