grow, excel April 2022 $12 incl GST APRIL 2022 $12 STRUGGLE TO FILL THE JOBS GAP DAIRY PRICE RECORDS TUMBLE FUELLING OUR BODIES of the crop

THE LIGHTS GO OUT

grow, excel

Learn,

DAIRY INDUSTRY AWARDS REGIONAL WINNERS 2022 WHEN

Learn,

HEAT AND HEALTH MONITORING YOU CAN TRUST.

2 Dairy Exporter | www.nzfarmlife.co.nz | April 2022

Let Tru-Test Active Tag keep an eye on the girls while you get on with your day. Receive accurate, timely updates to your mobile device about changes in behaviour which can signal anything from a silent heat to a potential health concern. They’re easy to set up, easy to use, with training and 24/7 support available every step of the way. Find out more at dairy.farmingmadebetter.com Lets talk. 0800 243 282

Barry Flynn | Farm Manager 620Friesianson195Ha, Methven,Canterbury

TRACTA_DAT64641_TRU-TEST_DE

“We trialled them because of Tru-Test’s reputation. We’re now running with them across the herd because of the results.”

12 Good trumps great, reckons

Pete Morgan

UPFRONT

13 Despite technology, Kiwi farmers will still need migrant labour

16 Market View: Stu Davison watches price records tumble

20 Global Dairy: Farmer flees tyranny of Putin’s war

Dairy Exporter | www.nzfarmlife.co.nz | April 2022 3 CONTENTS Cream of the crop - Dairy Industry Awards 2022 25 Chair’s introduction: Rising to the challenges 26 Northland Dairy Trainee - Macee Latimer 27 Northland Farm Manager - Philip Payton 31 Northland Share Farmer - Antje and Soenke Paarmann 34 Auckland/Hauraki Dairy Trainee - Jamie McDowell 36 Auckland/Hauraki Farm Manager - Jimmy Cleaver 38 Auckland/Hauraki Share Farmer - Danielle Hovmand 43 Waikato Dairy Trainee - Edward Roskam 44 Waikato Dairy Manager - Andrew Macky 46 Waikato Share Farmer - Rachel Bunnik and Brian Basi Page 38 Page 63 Page 13

PLATFORM

the time to

MILKING

10 Jessica Lea relishes

take a break from the farm 11 Automation helps combat risks for Anne-Marie Wells

4 Dairy Exporter | www.nzfarmlife.co.nz | April 2022 Moving house? We can’t help unpack or cat wrangle. But we can help with answers to ‘Is the internet going?’ Give us a call today on 0800 260 196 and make the move to Farmside. When you move house and get Farmside at your new address, you don’t just get great rural broadband; you get award-winning^ service too. Our Timaru-based team will get your broadband connection working quickly, giving you one less thing to worry about. GET 2 MONTHS FREE* when you sign up to a 120GB or 200GB Rural Wireless plan for 24 months. Powered by Farmside.co.nz * Offer is only available to new Farmside RBI customers, signing up to a 120gb or 200gb RBI Wireless Broadband plan, for a 24 month term. See https://www.farmside.co.nz/wireless for eligible plans. 2 months free: only applies to the standard monthly plan charge. Applied when your broadband becomes active and will appear on your first or second bill. Will be debited back if plan is downgraded during the first 6 months of the term or terminated before the end of the term. Early Disconnection Fees apply see https://www.farmside.co.nz/terms. Rural Wireless Broadband and 4G not available everywhere. Connection not guaranteed. Additional charges may apply for Managed Installations & additional travel. For more information call Farmside on 0800 32 76 74. Farmside will supply required equipment. $15 modem postage and handling fee applies. Modem required to be returned at customer’s cost if plan is terminated within 12 months of 24 month term. Offer available until 31 July 2022, unless Farmside, in its sole discretion chooses to extend it. This offer cannot be used in conjunction with any other Farmside promotions. Farmside’s Standard, Broadband and Terms and Conditions apply see https://www.farmside.co.nz/ terms. ^Winner of the 2020 Broadband Compare Awards for Best Rural Service Provider. TRACTA_J64853_HM2022_NZDE

51 Bay of Plenty Dairy TraineeThomas Lundman

52 Bay of Plenty Dairy ManagerHayden Purvis

54 Bay of Plenty Share Farmer - Scott and Rebecca O’Brien.

58 Central Plateau Dairy Trainee - Zoe Bryson

60 Central Plateau Dairy ManagerSatveer Singh

63 Central Plateau Share Farmer - Todd and Renee Halliday

68 Manawatu Dairy Trainee - Amit Sujit

69 Manawatu Dairy Manager - Joel Peterson

71 Manawatu Share Farmer - Callum and Megan Bates (Runner-up)

73 Hawke’s Bay Dairy Trainee - Jacob Stolte

74 Hawke’s Bay Dairy Manager - Amarjeet Kamboj

76 Hawke’s Bay Share Farmer - Jonathan and Kerri Robson

78 Taranaki Dairy Trainee - Kate Logan

79 Taranaki Dairy Manager - Nick Besing

81 Taranaki Share Farmer - Murray and Rachel Perks

84 West Coast/Top of the South Dairy Trainee

- Lisa Peeters

86 West Coast/Top of the South Dairy Manager - Robyn Mare

88 West Coast/Top of the South Share Farmer

- Kevin and Kyla Freeman

92 Canterbury Dairy TraineePeter O’Connor:

94 Canterbury Dairy Manager - Jaspal Singh

96 Canterbury Share Farmer - Will Green

100 Otago/Southland Dairy TraineeAidan Roe

102 Otago/Southland Dairy ManagerLaura Murdoch

104 Otago/Southland Share Farmer

- Hamish and Emma Day

WIN A SUZUKI DR200SE

Page 101

BUSINESS

109 Getting the best out of farm IT

STOCK

110 And then came more rain

114 A magic place to farm

118 Vet Voice: That cough may be pneumonia

BUSINESS

120 Monitoring helps hit targets

123 Opening doors to international dairy workers

WELLBEING

124 Food and sleep - Fuelling our bodies

DAIRY 101

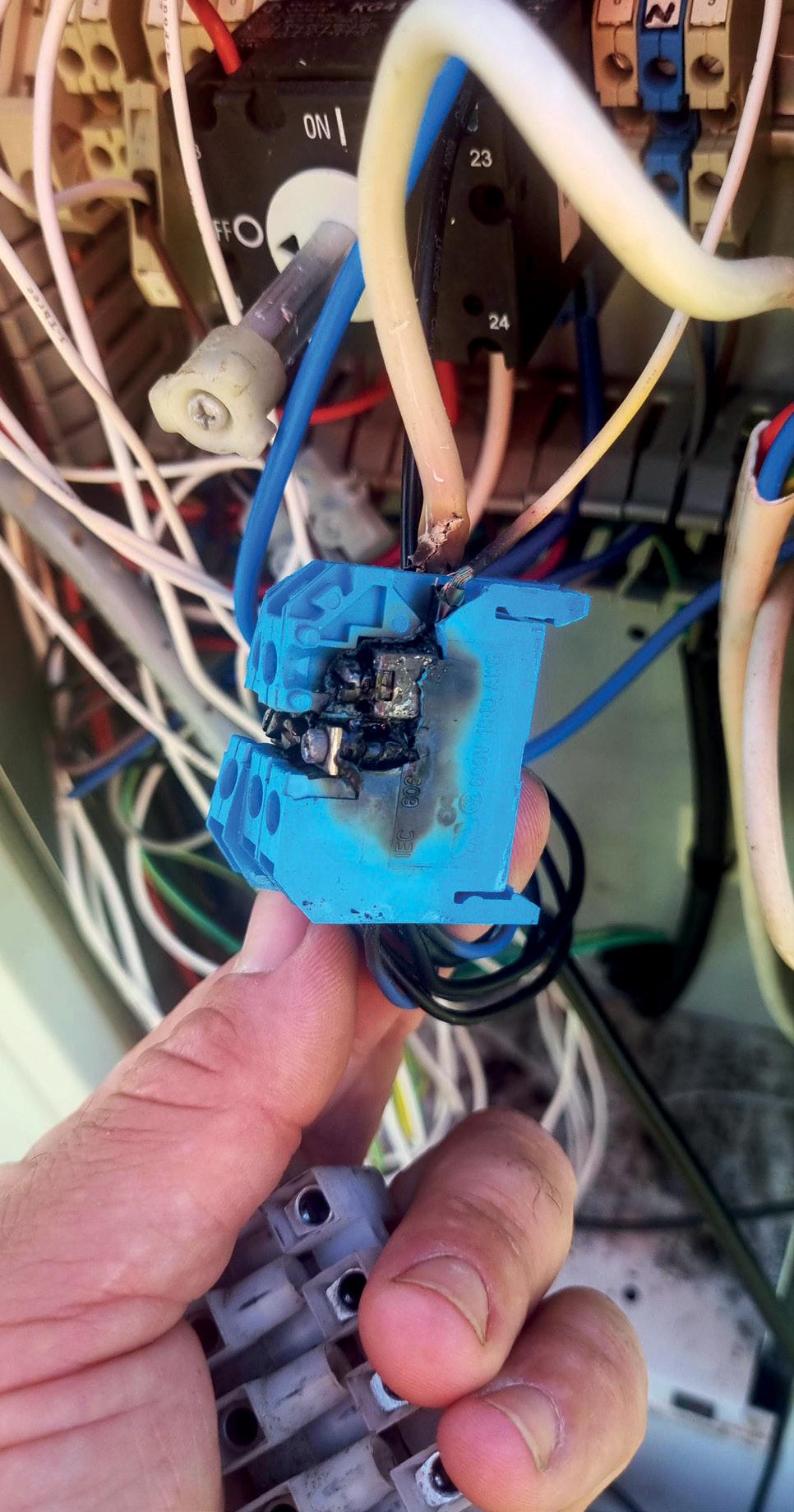

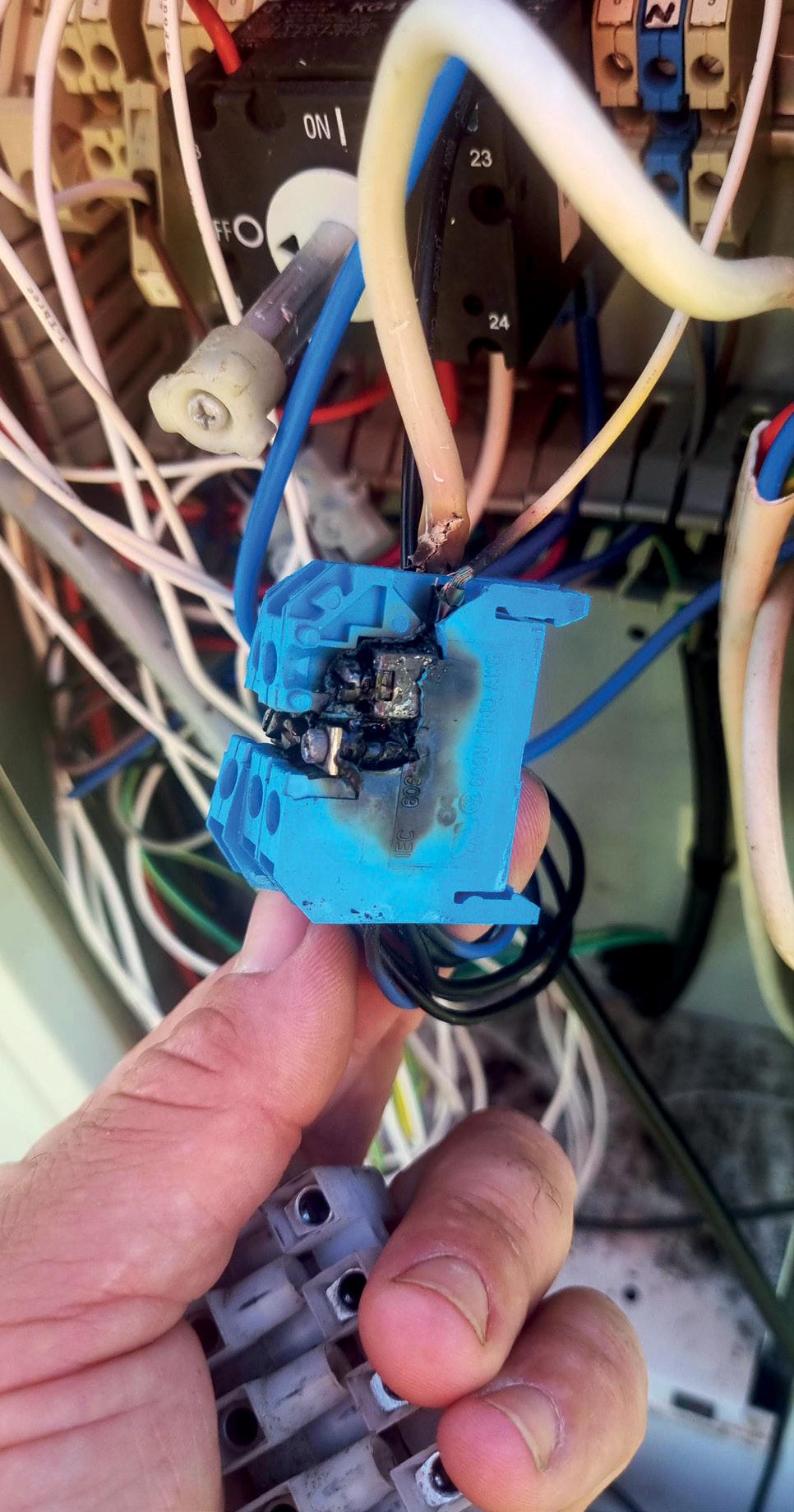

126 Backup power - When the lights go out

SOLUTIONS

128 Control your feed costs

129 Piako Tractors adds dealerships

OUR STORY

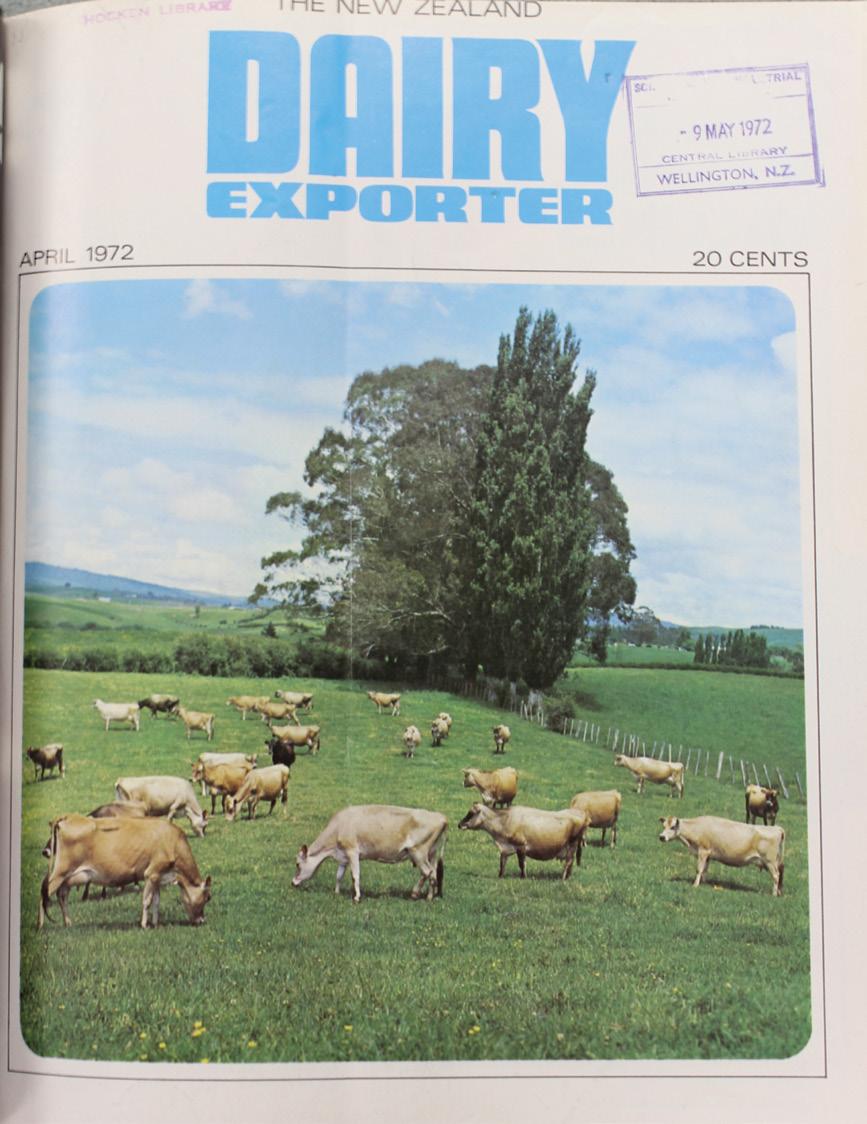

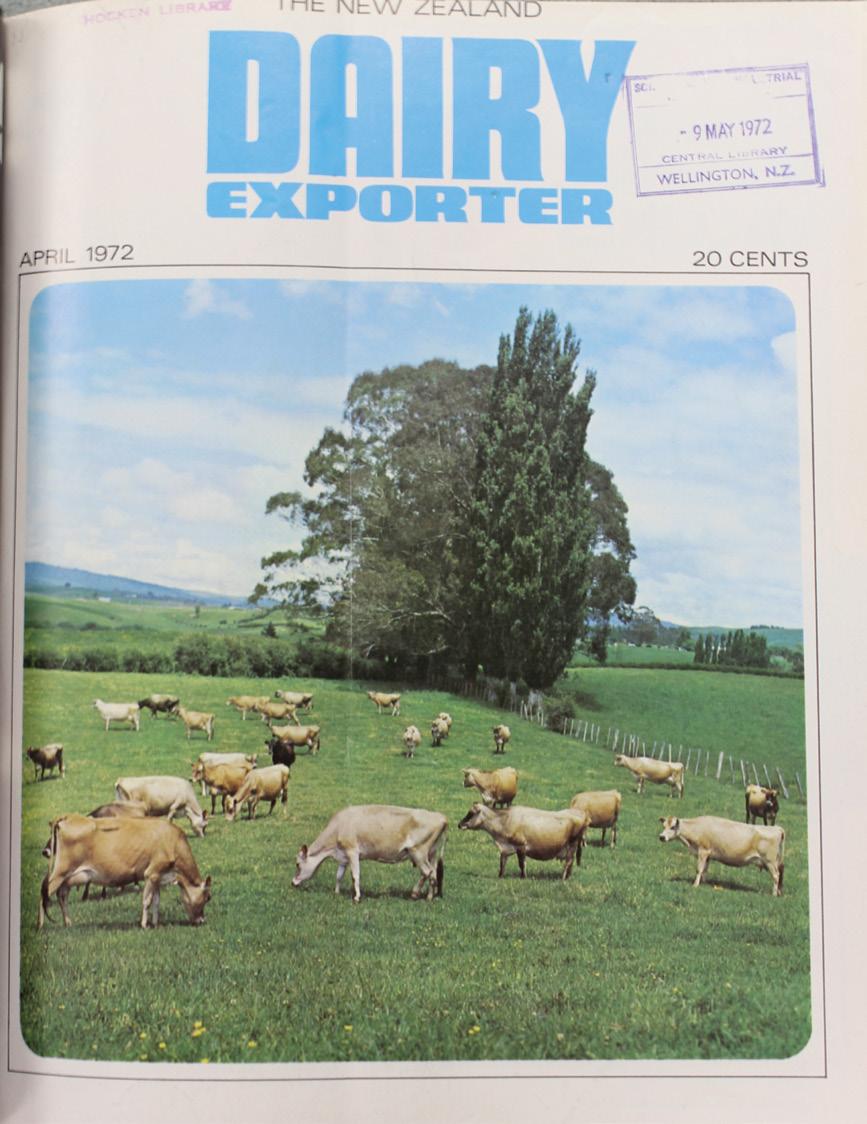

130 50 years ago in the NZ Dairy Exporter

Page 114

Dairy Exporter | www.nzfarmlife.co.nz | April 2022 5

44

Page

DAIRY DIARY

April 14 – SMASH holds a Spotlight on the System field day near Hamilton which will discuss the hosts’ system 5 farm that winters 330 cows. The day also addresses lameness with Neil Chesterton. To register go to www. smallerherds.co.nz/smash-events/field-dayspotlight-on-the-system-hamilton-waikato. SMASH is also holding field days at Hokitika on April 20 with details to be confirmed and then Wyndham in Southland on April 21.

April 20 – The DairyNZ Farmers Forum Series looks at attracting and looking after dairy workers. The series is being run as webinars with recordings of past episodes. The final episode of the series runs on June 1 and looks at the bigger picture issues and challenges affecting dairy farming. For more information and to register visit www.dairynz. co.nz/about-us/event-activity/farmers-forumseries.

April 22 – DairyNZ runs a Lameness and Mastitis Management field day in North Taranaki between 10.30am and 12.30pm. Hear from farmers who have made improvements and from vets for the latest tips and tricks. Other dates/ locations: April 27, Coastal Taranaki; April 28, South Taranaki. Visit www.dairynz.co.nz/ events/taranaki/lameness-and-mastitismanagement-north-taranaki to find out more.

April 27 – DairyNZ’s FarmTune workshops continue, this time in Southland/South Otago. FarmTune is a lean management programme aimed at taking waste out of your business, empowering your people and growing your bottom line. Workshops in the southern region are also being held on May 11, June 14 and July 6. Contact Lynsey Stratford on 021 165 2004 for more information.

May 3 – The Good to Great Primary Sector People and Team Leadership Programme runs a workshop in Mid-Canterbury. Another workshop is being held in Southland on May 5. It is aimed at improving knowledge, growing yor skills and becoming more confident leading people. Contact Lynsey Stratford on 021 165 2004 for more information.

May 3-5 – Lincoln University Dairy Farm (LUDF) is holding focus days in North Canterbury on May 3, Mid-South on May 4 and at the LUDF farm May 5 about technology and cow management options. Find out more at www.ludf.org.nz.

May 14 – The Dairy Industry Awards culminates in the National Awards Dinner at Christchurch where the overall winners will be announced for the New Zealand Share Farmer of the Year, New Zealand Dairy Manager of the Year and the New Zealand Dairy Trainee of the Year. For more, visit www.dairyindustryawards.co.nz.

May 24-26 – DairyNZ holds a Mark and Measure course in Taupo to help you learn key business concepts and skills. A South Island course will be held in Queenstown on June 14-16. Find out more at www. dairynz.co.nz/business/mark-and-measure /?fbclid=IwAR0frOuVcILrhUa_ONaxxbC7_ F73RWzE4qSQrZhnjDko-HxxXR33L7d1T9w.

June 1 – Dairy Women’s Network with ASB runs a Quiet Leadership live webinar between 12.30pm and 1.30pm. It focuses on the brain-based rhythm and approach of quiet leadership, as well as the power of coaching in leadership. To register go to register.gotowebinar.com/ register/1984405602444783117.

June 8 – The Extension 350 project in Northland is holding a field day on the Giesbers’ farm at Okaihau to hear how farmers have benefited from the project. The farmer-led, farmer-focused project is coming to an end after five years. To find out about the field day visit www.dairynz.co.nz/events/ northland/extension-350-public-field-dayjune.

June 8-9 – The South Island Dairy Event (SIDE) is being held in the Oamaru Opera House. It combines industry experts, networking sessions and practical workshops in a revitalised format this year. To find out more and to register visit www.side.org.nz.

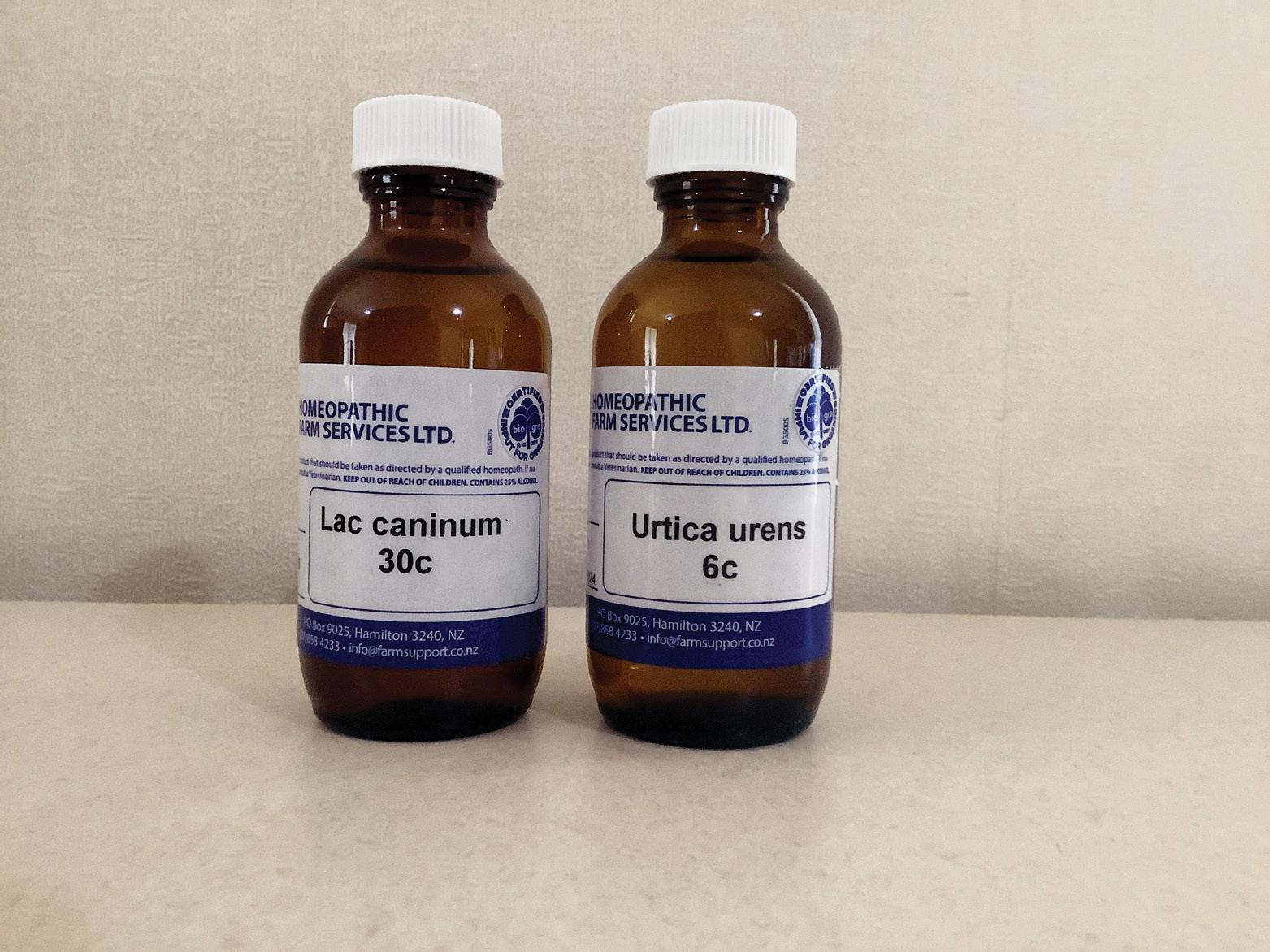

FARM SERVICES HOMEOPATHIC

PRODUCTS TO SUPPORT UDDER HEALTH AT DRY OFF e info@farmservices.nz p 07 858 4233 w farmservices.nz

HOMEOPATHIC

Please check websites to see if events are going ahead under the Covid-19 Protection Framework and what restrictions apply.

Staying strong onfarm portrays an innovative programme run by Reporoa dairy farmer and cancer survivor Sarah Martelli, who helps other women find their balance and build strength and wellbeing to be the best they can be.

Strong Woman is an online community for women to work on their fitness with a workout to do at home, find quick and easy healthy recipes, goal planners and to connect with other women on the same journey.

Her philosophy is to help women create healthy, sustainable habits around moving and feeding their bodies and their families.

EXPERIENCE: IT’S PERSONAL

If women can prioritise their own health and fitness, they can inspire their partners, their children and their community around them, Sarah says (p82).

She is an inspirational woman creating a moment of lift for many women.

In this issue we take a look at the regenerative agri journey some NZ farmers are already on, and that the government has signalled they want others to join in on, in our Special Report.

Throw open the windows and let in the fresh air. I’ve been sitting in the editor’s seat of the Dairy Exporter for almost six years now and every time we put together the Cream of the Crop, Dairy Industry Awards special I always second-guess my life’s journey and wonder if I should’ve pivoted early in my career to become a dairy farmer?

WIN!

(p42). We also cover the Heald family of Norsewood (p52) who have transitioned to organics, OAD and philosophies and are enjoying the less intensive more resilient system they have moved to, along improved profitability.

There is more research to be done in the NZ farm system context, says MPI’s chief scientist John Roche, figure out what will and won’t work, but he encourages farmers to engage and learn more, and to embrace regenerative as a verb - saying all farmers could work be more regenerative, more resilient, lowering carbon and building carbon storage.

The regen debate has divided the farming community in a big way - many scientists are affronted that NZ would need regenerative methods from overseas countries with highly degraded soils - would that then infer that our conventional methods were degenerative?

Growing up on a sheep and beef farm, I was all about the sheep and lambs and wool and riding horses - but I did actually do a couple of stints on dairy farms during my Massey Uni Bachelor of Agri Science degree. The first was milking about 100 cows in a small eight-bail walk-through shed in eastern Taranaki, with lovely young farm owners battling against interest rates in the early 20% range. I really enjoyed the cows, not so much the interminable fencing jobs on the doer-upper farm!

These young farmers are talking about looking after staff, going the extra mile for the environment, focusing on building equity but also on the advancement of their team and the health and efficiency of their stock. And many of them are women farming very successfully on their own account, which is exciting to see.

They say the methods won't work, and that research has already shown that, and also our farmers are already following regenerative practices. Others say that the methods are not prescribed and each farmer can take out of it what they want. It has been called a social movement rather than a science and the claimed benefits of improved soil and stock health and building soil carbon through diverse species, use of biological fertilisers and laxer and less frequent grazing practices along with less nitrogen is something that resounds emotionally with many.

While older and more cynical farmers are perhaps prone to complaining about too much regulation, new taxes and unworkable government initiatives, it’s refreshing that many of the younger award winners stating that despite the challenges faced, they see a path of adapting to changing rules and problem-solving to mitigate adverse effects as key to continuing creating their businesses and fulfilling their dreams.

We have taken a snapshot of thinking by scientists in MPI and DairyNZ (p46) and portrayed what farmers using the practices are finding, including ongoing coverage of the comparative trial work by Align Group in Canterbury

The next practical stint was on a larger farm which was great, but I did have a bout of glandular fever at the time, so I probably wasn’t the most dynamic farm assistant.

So having read this issue, I ponder how different life might have been if I had stayed in the ’Naki, embraced the gumboots and forged a path in the dairy industry.

A sliding door moment.

In terms of building a business and a career, this magazine is overflowing with go–getters and cow-lovers and people dedicated to making it in the dairy industry. Their stories of starting with nothing (many of them totally new to the country, the industry and the language) and building assets and careers are inspirational.

Impressive too, is their dedication to the health and wellbeing of their cows and of their co-workers and staff. Gone are the 12:2 rosters, skinny cows and high empty rates - bobby calves are on their way out too.

“We see ourselves as the new generation coming through and strive to be leaders in the industry who will drive it forward in the most sustainable and ethical way possible,” said Jono and Kerri Robson, 2022 Hawke’s Bay/Wairarapa Share Farmers of the Year.

They are also blessed to have record high payouts to support their initiatives.

Whether it’s wide-eyed innocence or youthful positivity, it’s refreshing to see.

The world is changing, we have to evolve - many of the winners in this year’s Dairy Industry Awards will show it is not only possible, but also profitable.

If you are interested in getting into farm ownership getting out but retaining an interest, read about Moss’ innovative idea for a speed-dating weekend potential partners (p11). We think it could be a winner!

Sneak peek

JULY 2021 ISSUE

In the next issue:

May 2022

• Special Report: Farming/business investment – if you are starting out or bowing out.

• Wildlife onfarm

• Ahuwhenua winners

• Greenhouse gases - How are mitigation options shaping up?

• Sheep milking conference coverage

• Bobby calves - What’s happening in markets, the products, the regulations?

• LUDF: Wrap up of this season’s research programme into 10 in 7 milking and plantain.

• 500kg/MS/cow – The Journey. A discussion group founded from interactions within a closed Facebook group during the first Covid lockdown has helped steer a significant boost in production.

Congratulations to all the winners and good luck for the National Awards, @YoungDairyED

Dairy Exporter | www.nzfarmlife.co.nz | April 2022 7 Editor’s note

@DairyExporterNZ @nzdairyexporter

Exporter

NZ Dairy

Dairy Exporter | www.nzfarmlife.co.nz | June 2021

@YoungDairyED @DairyExporterNZ @nzdairyexporter NZ Dairy

SUBSCRIBE TO

GO TO PG 101 FOR MORE DETAILS

WIN A SUZUKI DR200SE

ONLINE

New Zealand Dairy Exporter’s online presence is an added dimension to your magazine. Through digital media, we share a selection of stories and photographs from the magazine. Here we share a selection of just some of what you can enjoy. Read more at www.nzfarmlife.co.nz

IRRIGATION IMPROVEMENTS CREATING RESILIENCE

The Woodhouse family’s irrigation improvements are creating resilience. Good data and investment into spray irrigation that allows lower rates to be applied at shorter return intervals will help maintain pasture production levels as nutrient inputs reduce with regulation.

Take a look:

https://youtu.be/bivsGOWbM9Q

ASB RURAL INSIGHTS

- Succession Series Podcast

Canterbury farm manager Barry Flynn has 100% confidence in collar technology for picking cows on heat. It means he can get off the vet stand and focus on managing pasture, easing staffing pressure. The Trutest Datamars collars are giving him other key data on individual cows that’s helping in other ways too. Check out NZ Dairy Exporter’s special report on reviewing mating to read Barry’s story.

Take a look:

https://youtu.be/jQOeNaMG4DA

NZ Dairy Exporter is published by NZ Farm Life Media PO Box 218, Feilding 4740, Toll free 0800 224 782, www.nzfarmlife.co.nz

Editor Jackie Harrigan P: 06 280 3165, M: 027 359 7781 jackie.harrigan@nzfarmlife.co.nz

Deputy Editor Sheryl Haitana M: 021 239 1633 sheryl.haitana@nzfarmlife.co.nz

Sub-editor:

Andy Maciver, P: 06 280 3166 andy.maciver@nzfarmlife.co.nz

Reporters

Anne Hardie, P: 027 540 3635 verbatim@xtra.co.nz

Anne Lee, P: 021 413 346 anne.lee@nzfarmlife.co.nz

Karen Trebilcock, P: 021 146 4512 ak.trebilcock@xtra.co.nz

Delwyn Dickey, P: 022 572 5270 delwyn.d@xtra.co.nz

Phil Edmonds phil.edmonds@gmail.com

Elaine Fisher, P: 021 061 0847 elainefisher@xtra.co.nz

Alex Lond lond.alexandra@gmail.com

Design and production:

Lead designer: Jo Hannam P: 06 280 3168 jo.hannam@nzfarmlife.co.nz

Emily Rees emily.rees@nzfarmlife.co.nz

Partnerships Managers: Janine Aish Auckland, Waikato, Bay of Plenty P: 027 890 0015 janine.aish@nzfarmlife.co.nz

Welcome to the ASB Rural Insights

- Succession Series podcast, where we’re talking about farm ownership transition from all sides. Thanks to the ASB Rural team for partnering

NZ Farm Life Media on this four-part series, Each week Angus Kebbell will be profiling farming families, talking to experts from the advisory sector and investigating new opportunities for farmers thinking about diversifying their farming business. When it comes to ‘what’s next’ for the farm, there’s a lot to think about, so we aim to share success stories, provide useful tips and help you understand more about the many facets of succession planning in the food and fibre sector today.

To listen:

https://nzfarmlife.co.nz/podcasts-2/

CONNECT WITH US ONLINE:

www.nzfarmlife.co.nz

NZ Dairy Exporter @DairyExporterNZ

NZ Dairy Exporter @nzdairyexporter

Sign up to our weekly e-newsletter: www.nzfarmlife.co.nz

Tony Leggett, International P: 027 474 6093 tony.leggett@nzfarmlife.co.nz

Angus Kebbell, South Island, Lower North Island, Livestock

P: 022 052 3268 angus.kebbell@nzfarmlife.co.nz

Subscriptions: www.nzfarmlife.co.nz subs@nzfarmlife.co.nz

P: 0800 2AG SUB (224 782)

Printing & Distribution:

Printers: Ovato New Zealand

Single issue purchases: www.nzfarmlife.co.nz/shop

ISSN 2230-2697 (Print)

ISSN 2230-3057 (Online)

8 Dairy Exporter | www.nzfarmlife.co.nz | April 2022 NEW ZEALAND

NEW ZEALAND

2021/2022 Fonterra forecast price Average $9.49/kg MS MILK PAYOUT TRACKER: $/kg MS 10 9 8 7 6 9.30 9.50 9.40 9.61 9.60 9.50 9.90 Mid 9.60 2022/2023 Fonterra forecast price Average $9.15/kg MS $/kg MS 11 10 9 8 7 8.40 8.90 10.75 8.50 9.30 9.20

Fonterra forecast

Dairy Exporter | www.nzfarmlife.co.nz | LET’S CUT TO THE CHASE... PROUDLY NZ OWNED Available exclusively through veterinary practices nationwide. Visit www.alleva.co.nz for more information. TURBO® is a registered trademark of Alleva Animal Health Ltd. TURBO® Pour On (A011722) is registered pursuant to the ACVM Act 1997. See www.foodsafety.govt.nz for registration conditions. *Available while stocks last. TURBO® is the rain-resistant pour on that delivers better potency and a broader spectrum in a world-first formula for growing cattle. www.alleva.co.nz Purchase 7.5Ls of TURBO® Pour On and receive an Oleo Mac Pole Saw* Visit your local veterinary clinic for details.

Time to take a break FROM THE FARM

Getting out to the beach, going for a family walk or a day at the lake can do wonders for your mental health, leaving the farm behind just for a few hours, Jessica Lea writes.

To say the season has been a roller-coaster is an understatement, we’ve had crazy weather, staff shortages, a pandemic and inflation soaring. One thing that has been consistent is farmers have kept trucking on.

It is very sobering to see that we are looking at a record payout, that the hard yards should be worth it.

We’ve had our most testing season for Cam and myself. With taking on the neighbouring farm, it has had its challenges, running two sheds, two herds, calving down both farms, finding everything is double the costs and costs have risen.

Hiring staff has been challenging especially when you are looking at mid-season. Our previous manager we employed when we took over next-door had a pre-existing injury that became more detrimental to his health as the season unfolded. This left Cam and me having to do a lot of the work ourselves and relying heavily on casual help. This gave us no time away from the farm as one or both of us were in the sheds.

Fortunately, we were able to hire someone in January making a huge difference and taking some of the stress off. It has been a common thread - staffing issues have been consistent throughout the industry.

Reading posts on social media or talking to other farmers, finding staff has been challenging and a lot of people were also doing everything themselves. We also find when you live in a small town, it can be hard for people new to the area to integrate into the community.

We offer a competitive salary, upskilling and perks with the job, as staff are essential to our business running smoothly. Like the opportunity we have had, we encourage our staff to grow and further themselves in the dairy industry, setting goals and working towards reaching them. Although we are a few hours away from any major city, our area in the Bay of Plenty offers a lot of great off-farm activities. I can attribute taking time off the farm to being able to carry on, especially having three kids in tow.

We ensure the weekends are low maintenance (when we’re not in the midst of calving).

Getting out to the beach, going for a family walk or a

day at the lake can do wonders for your mental health, leaving the farm behind just for a few hours. Spending your weekends at home, it’s easy to nip down to do something on the farm and end up home a couple of hours later.

Having employed a new staff member has freed us up to be able to have a bit of down time on the weekends and spend time with the kids. We also encourage our staff to ensure their weekend on is low maintenance, so feeding out is done prior to the weekend and all you have to do is milk and move the cows.

We also go to once-a-day milking as soon as it starts getting dry around Christmas. This takes some pressure off, we find at this time of year we don’t drop a huge amount in production. This also allows us and our staff to enjoy a bit of lifestyle around summer.

Farming can be tough at the best of times, you will have your hard days and it takes its toll especially when there’s always something to be done, but ensuring we have happy staff and taking the time to get off the farm keeps us thriving.

10 Dairy Exporter | www.nzfarmlife.co.nz | April 2022

MILKING PLATFORM BAY OF PLENTY

Above: Ayla, 9, and Kensi, 7, enjoying some family time off the farm.

Following the cows.

Left: Weekends are minimal work only.

QUESTIONS

of risk

What would you consider to be your main business risk? Was this your main risk six months ago? Do you think it will be your main risk in six months’ time?

Because of our business setup, we have a risk register which is reviewed each month with our shareholder reporting. Not only does this process get us to think about what we would do in a situation before it arises, we also benefit from other shareholders imparting knowledge if they have experience that can help.

Risk-register or not, we can probably measure our biggest risks by the main topic of conversation at the dinner table. For a while, this was dominated by work bubbles and what to do if we catch Covid-19. Now staffing and consistency is very much the main discussion. Staffing has been on our radar for some time now, but until recently it was more of a niggle than our top risk.

Duncan is also a dab hand at fixing things, so this is a risk we are prepared to take on. Perhaps it is time to think about the risk of booking a holiday abroad over the winter?

We are fortunate that our location makes it possible to employ people who can travel in rather than live-in. After a big recruitment drive, we now have eight casual team members, seven of whom come in only for milking. As with many solutions there is a knock-on effect, in this case, it is the risk of inconsistency. The first area of inconsistency is the yard wash. The yard always gets cleaned, but how much water and time that takes depends on who is doing it – I will embarrassingly confess to having run us out of water recently in my enthusiasm!

Secondly there is the plant wash. This is not a simple process, and we feel it is best done by staff who are here more often, which limits the number of people trained to carry out the task. How the cows are milked differs with

each person in the shed. We have automatic cup removers but prefer to have someone at cups off to keep an eye on whether cows have milked out properly or look like they may be developing mastitis. Someone experienced at cups off makes very different decisions to someone who is new or not often milking.

Our solution to achieving consistency in these areas is automation. Thanks to a good year of production and milk price, it was an easier decision to make some investments.

Over the last two weeks, our shed has been a hive of activity with the installation of an automatic yard wash and automatic plant wash. In the coming few weeks, in-bail milk meters will also be installed.

Both automatic washes are simple to use and achieve consistent and quality results. The list of advantages keeps building – less water, less electricity, less time, removing the health and safety risk of handling chemicals at each wash, less training, less experience needed.

It was not quite as clear cut making the decision to install milk meters, especially given we are considering using collars in the not-too-distant future. Meters provided a less expensive stepping-stone towards understanding more about the production and udder health of each cow, and we can also use it to identify possible cluster faults, enabling a less-experienced eye at cups off.

By relying on automation, the conversation at the dinner table moves to the “what ifs” of machine failure. Well, the yard hoses are still in place, the plant wash can still be done manually, and we still usually have someone at cups off.

Duncan is also a dab hand at fixing things, so this is a risk we are prepared to take on. Perhaps it is time to think about the risk of booking a holiday abroad over the winter?

Dairy Exporter | www.nzfarmlife.co.nz | April 2022 11

MILKING PLATFORM OUTRAM

Automation of a range of tasks has helped solve some of the potential risks of dairy operation.

By Anne-Marie Wells.

Top: Yard wash before and above, yard wash after.

Good trumps great

Ultimately,

Give me good any day. Payout, weather, stock prices, public opinion and even staff. We hang out for the perfect ones but are they realistic or good for us?

Payout will cycle through the years under the influence of exchange rate, surplus dumps from other nations, droughts and now pandemic and war. High payout distorts expectations and drives up costs.

many expressions Shakespeare left littered in our everyday language, I find myself using words and concepts in my farming life that they seeded.

We don’t need to be great to run a sound, profitable, robust business. Or to have good mates, a family that loves me and to live a meaningful life.

We do need a mindset necessary for managing risk, a resilience for change and a clarity or direction. We get security in controlling what we can by running consistent cashflow and feed budgets. Financial feed surprises are rarely good. Managing feed surpluses are often more difficult than a deficit.

Election cycles, social consciousness and trends see our standing as farmers kicked up and down the field. We must always earn the right to farm as the New Zealand public have the dual role of voters and consumers so their perception of us counts.

As an industry we have never been keen on dairy company buffering of payout. I can hedge if I want but weathering and learning from the tough years and being prudent in the good ones is the lesson reality gives us.

There’s no chance of the weather staying the same particularly as we witness the effect of climate change. We are having amazingly mild and dry winters now. Great for dairy farming but the more extreme cyclone events and brutal summer dry periods are unfortunately also normalising.

There are many great farmers. They inspire us and trail blaze with performance, leadership or innovation. They become so often by circumstance and their influence varies for all of us and so by focusing on being good at what we do, chance may see others benefit from our actions.

“Some are born great, some achieve greatness, and others have greatness thrust upon them.” William Shakespeare, Twelfth Night.

First bosses have an enormous influence on building your skills and experience as well as imprinting expectations and farming philosophies. My first two employers, Gordon and Ken were exceptional. Good farmers that gave me the time to grow and the responsibilities to learn from. Just like the

Ultimately we, as farmers, just have two main roles. Caretakers of the land and animals and providers of their food. Proving we are good at it maintains that trust. Visitors to ours and other farms often voice surprise that they didn’t expect we cared so much for that which we are responsible for. That we love working with our cows, tend the land carefully, value our people and have great belief in the quality and value of our milk. Food security is vital to the stability of a society.

Staff turnover is very costly to us and impacts the industry. Select carefully, support their learning, review constructively their job performance regularly and be happy to be a stepping-stone for them in the industry. Constantly good staff performance is always linked to alignment of expectations.

We always turn the table and have our people assess themselves and how well the job is living up to what they expect. It is powerful to be known for encouraging them to move up, within or beyond your farm. Train and retain good people. The great ones will only be with you briefly so wish them well.

Being a good farmer is a great legacy to leave.

12 Dairy Exporter | www.nzfarmlife.co.nz | April 2022

MILKING PLATFORM WAIKATO

farmers just have two main roles. Caretakers of the land and animals and providers of their food. Proving we are good at it maintains that trust, Pete Morgan writes.

Pete Morgan and his wife Ann Bouma milk 630 cows at Pokoru in the Waikato.

We don’t need to be great to run a sound, profitable, robust business. Or to have good mates, a family that loves me and to live a meaningful life.

Struggle to fill the job gaps

Amongst the wave of challenges facing the dairy sector, farmer advocates have recently stuck closely to pressuring the Government into creating exemptions for migrant dairy workers to address the wellcharted problem of industry staff shortages.

Not all farmers are feeling the same pain on this, but it is likely to be affecting all to some extent, even if through difficulties in accessing off-farm contractors. In light of this unresolved workforce deficit, are there realistic opportunities for farmers to reduce their labour needs by adopting new technology?

The dairy industry workforce is undoubtedly stretched and has been for a number of years. The 2021 Federated Farmers Farm Confidence Survey pinpointed the sector’s struggle to fill workforce gaps as a huge issue, with nearly half of respondents stating it was harder to recruit skilled and motivated staff.

The most recent version of the survey published in March this year reported no change in the proportion of respondents who

specifically identified the difficulty in recruiting staff as a major challenge.

The degree of concern in the farming community that there are not enough people willing to take on available jobs is backed up by DairyNZ research that has indicated the industry is short of more than 4000 workers.

The general shortfall is not new, and its underlying causes are well documented. But they have been exacerbated by the Covidera’s border closures and resulting inability for migrant workers to enter New Zealand to address skill shortages. The ever-declining NZ unemployment rate has also continued to decrease the pool of potential workers, who have a much wider range of job opportunities than in the past.

In the current context, DairyNZ expressed ‘bitter disappointment’ that in March the Government decided to allow only 300 international dairy farm workers into NZ to help address the immediate shortage, despite being asked for 1500. This comes after the Government created a temporary class

Dairy Exporter | www.nzfarmlife.co.nz | April 2022 13 INSIGHT UPFRONT MIGRANT WORKERS

While technology can fill many of the gaps, New Zealand dairy farmers are likely to have an on-going need for migrant labour.

By Phil Edmonds

.

As with any sector, there is a need for a backup workforce that may well be transitory or part-time. This is particularly important for dairy farming as it enables employers to offer the kind of conditions necessary to attract good workers.

exemption in November 2021 for 200 dairy workers to enter the country.

These (albeit modest) exemption spots had been hard fought for, and there has been some surprise that after the first 200 were enabled, farmers were slow in coming forward to accept the offer (particularly given the rhetoric from DairyNZ and farmers via the confidence surveys).

The Government indicated the latest exemption would be the last before July when the new visa regime takes hold.

After July, employers wanting to bring migrant workers into New Zealand will have to be accredited and meet minimum standard requirements and commitments, which will include a labour market test to ensure New Zealanders get the first chance in the job market ahead of migrant workers, and employers will have to pay the median wage (currently $27 per hour). Could the initial slow uptake of entitlement to migrant dairy workers signal the problem is not as chronic as has been argued?

Possibly, although there are also some reasonable explanations for the hesitancy. The 2020-21 season was well underway by November and most farmers who had been short of labour are likely to have already stitched together a means to get through it. In addition, those migrant workers that were sanctioned to come into NZ to work on dairy farms would still have needed to go through managed isolation for two weeks, at the employers’ expense, and

have their availability delayed. Beyond that, there may be wider factors that have made farmers think twice about recruiting offshore dairy workers.

Part of the shortfall identified by DairyNZ is unlikely to be just about advertised jobs not being filled. As with any sector, there is a need for a back-up workforce that may well be transitory or part-time. This is particularly important for dairy farming as it enables employers to offer the kind of conditions necessary to attract good workers. Where there is a lack of people on hand to do casual milkings, for example, there is not the same opportunity to offer a favourable work roster and more days off. It is possible that other sectors are ‘pinching’ dairy farming’s back-up.

In terms of wages, there should be less concern than in the past about escalating expectations of pay rates and conditions (and now median wage mandates) as a reason to be cautious about taking on new staff.

The revenue gains dairy farmers are making with record high milk prices will have eased those qualms. However, given what farmers know about milk price volatility, they will also be thinking about higher wage costs in seasons ahead when prices inevitably fall. International milk prices are not determined by a function of farmers’ ability to service their fixed onfarm costs. Wages don’t fall in line with prices. There may be a proportion

of farmers who are vocal about staffing deficits but in the same breath not as eager to add higher costs to their business.

Understanding why the initial quota of migrant workers was not filled on day one (despite the reportedly dire need) requires a more nuanced consideration of what the vacant jobs are within the industry, and where they are located rather than simply accepting the industry is short of a bald 4000 workers.

DairyNZ says its data indicates “the greatest need is for farm assistant positions, which is the most common role onfarm. There are also a number of herd manager positions available. Highly skilled roles of assistant managers and farm managers are also vacant on some farms”.

Looking at the pinch point though, DairyNZ says “as calving approaches, farmers will be looking to fill fixed-term calf rearing positions”. This suggests the most sought-after workers are those who would be ‘temporary’ farm assistants. They are also workers that might previously have been paid closer to the minimum, rather than the median wage. The elevated (effectively regulated) wages that will need to be paid to migrant workers filling farm assistant roles (before July at 1.5 times the median wage, and at the median wage from July onwards) could be considered an imposition by some.

In terms of where those jobs are, and what type of farm operations are most in need of workers, DairyNZ says “farms in

14 Dairy Exporter | www.nzfarmlife.co.nz | April 2022

all regions have been affected by staffing shortages, regardless of whether they are close to towns or cities.

eliminating specific tasks, some of which are seasonally specific – essentially feeding calves, spraying weeds, putting up fences and putting cups on cows.

transition from season to season.

Scott Townshend, chief executive of onfarm

“While all farm sizes are affected by staff shortages, larger farms with more staff are more likely to have vacancies. Larger farms tend to be located in Canterbury, Otago and Southland, and farmers in these regions have reported being more likely to have vacancies.”

There will of course be exceptions, but the above suggests that for established farmers with average sized operations based in the traditional North Island dairying regions, worker shortages might not actually be top of their minds.

It also suggests that if technology is to play a role in de-escalating the industry’s need for supplementary international workers, it would need to be focused on

Suppliers of robotic milking machines would argue they’ve got the latter covered, and that their technology has been developed specifically to help farmers working with labour uncertainties and shortages. The promotion of DeLaval’s VMS milking system includes a pitch to farmers who want to have a normal family life and their employees to have normal working hours.

But uptake of robotic milking in NZ has possibly not reached a level that reflects an unsustainable dependency on hardto-attract farm assistants. Among other things, including business investment priorities, this is likely due to farmer perception that it requires a whole-farm system change that they’re not prepared for.

Technology is, however, readily available that is helping farm teams become more efficient, and within that, farm businesses to adjust to what has become a fluid labour market as staff (at the assistant level)

Scott Townsend, chief executive of onfarm data company Trev, says that while a tool like Trev doesn’t directly reduce the farm head count, data tools can be used by anyone regardless of their tech literacy, which helps mitigate the challenges of rotating staff.

“Our farmers are using Trev to provide business continuity by storing all necessary information in a structured way so when there are personnel changes, they can understand how your farm operates, and manage your data before the next person steps in to pick up where they left off.”

The prospect of reducing the number of assistant roles on NZ dairy farms still looks like a long-term, rather than a short-term goal.

Without farm system changes, migrant workers are still going to be required to fill seasonal gaps for some time, particularly in the South Island.

Technology will increasingly ease the disruption that transitional staffing creates, but at this stage there’s no immediate danger that gumboot makers are going to go out of business.

Dairy Exporter | www.nzfarmlife.co.nz | April 2022 15

data company Trev.

Dairy commodity prices are traversing the high section of the commodity cycle, with record prices being broken across the complex. New Zealand cheddar prices have never been higher, and butter continues to be in hot demand, hitting prices not seen before.

Milk powders are moving in the right direction, with skim milk powder prices streaking higher over the first three months of 2022. Whole milk powder prices have surged, with a few bumps in the road, but in very favorable territory. From dairy commodity prices we know that the farm gate milk price for the 2021-22 season is relatively baked in, which means the risk has shifted strongly into the coming season. So, what are the chances commodity prices can remain high for another season, and deliver another high farm gate milk price in NZ?

As I’m sure you’re aware, while we deal with winter in NZ, Northern Hemisphere farmers are delivering peak milk flows.

Dairy price records

The level of milk flows across United States and European farms has a serious impact on global dairy prices, which we as Kiwi farmers are directly exposed to. So, for insight into what the coming season’s milk price is likely to be, it’s important to get a good handle on what milk flows are likely to be, so let’s take stock of how Northern Hemisphere milk flows are likely to track this year.

Basically, is the current imbalance of supply and demand going to persist throughout the coming season?

The easiest place to explain this is with the European Union, where uncertainty in all markets is still rife, and milk flows tracking below last season’s figures, which were below the season before.

What’s driving these low milk flows? Onfarm costs are pushing higher than milk prices, with the things impacting in NZ hitting the Europeans in the same way.

Fuel costs are proportionally a larger part of a European farmer’s operating costs, due to the way they farm; tractors and machinery are used far more for their milk production than in our pasture-based systems.

Fuel costs have streaked higher over the first three months of 2022 and look unlikely to settle in the near term. Feed costs have tracked the same path, shifting sharply higher, with constrained feed supplies likely to persist.

But you’ve read this sort of discussion about six times over the last three months, and you’re asking “surely if supply and demand is out of kilter as much as you’re saying, why would EU farmers not just ramp up milk supply as dairy commodity prices drag farm gate milk prices higher and then make the most of high prices?”

Well, something that can’t be measured on a commodities market, or via crude oil prices, is the impact of changing

16 Dairy Exporter | www.nzfarmlife.co.nz | April 2022 INSIGHT UPFRONT MARKET VIEW

Stuart Davison.

As external pressures impact world dairy commodity prices, New Zealand producers have never seen prices so high. By Stu Davison.

tumble

Trusted for decades and proven to perform, you can always rely on Boehringer Ingelheim products to keep your stock at their best. And to help get everything else done right, we’ll throw in these DeWalt tools.

Ensure young stock become future high producers through improved health, growth and energy at: futureproducers.co.nz

Dairy Exporter | www.nzfarmlife.co.nz | April 2022 17

Purchase qualifying cattle drench products this season and you’ll receive either a FREE * DeWalt 18V Cordless Drill Set, Lockable Tool Box or a 35-piece Screwdriver Set. *Promo ends 30th April 2022. While stocks last. Ask in clinic for qualifying products. PROUDLY AVAILABLE FROM YOUR LOCAL PARTICIPATING VETERINARY CLINIC. Boehringer Ingelheim Animal Health New Zealand Limited. Level 3, 2 Osterley Way, Manukau, Auckland, New Zealand. ECLIPSE®, EXODUS®, GENESIS®, MATRIX® and EPRINEX® are registered trademarks of Boehringer Ingelheim Vetmedica GmbH, used under license. Registered pursuant to the ACVM Act 1997. No’s A010222, A011151, A007191, A009222, A010131, A009270, A011138. © Copyright 2022 Boehringer Ingelheim Animal Health New Zealand Limited. All rights reserved. NZ-BOV-0089-2021. GET IT DONE RIGHT

environmental regulations on European farmers. The EU has for many years been very vocal about the changes required, especially by European dairy production.

Over the last two years, herd sizes in the Netherlands alone have been dramatically reduced to be able to comply with these environmental regulations. Simply put, if you have fewer cows, there’s an upper limit of how much production can be extracted from each cow and thus each farm.

The Dutch are world renowned for being sharp dairy operators, so being restricted on cow numbers has directly restricted their potential milk flows; Dutch cows were already producing at high levels prior to the restrictions, with little potential for more capacity to be extracted in a short time frame. The Dutch, with their vulnerable soils, some recovered only over the last century, are at the pinnacle of environmental restrictions, but similar limitations have been placed across all other EU dairy farmers. What this means to world dairy supply, is that the environmental regulation enforced has created a ceiling on cow numbers, which has directly impacted EU dairy farmers’ ability to ramp up milk production quickly, even if they wanted to chase prices.

So, EU farmers have regulations stopping them from chasing milk production at any cost. Yes there is an associated economic impact to the EU from these restrictions, but the EU population pays for this via subsidies. The upside is that Kiwi farmers are likely to see the dairy market remain supported in the short term.

Meanwhile in the US, a massive force in the world of dairy, environmental regulations are not as restrictive just

YOY growth, weekly milk production

Superior design for comfort and safety

yet, but they will undoubtedly be in the pipeline. Their milk flows are being driven by restrictively high and very variable onfarm feed, fuel and fertiliser costs, with milk prices not keeping up with these rapid market changes.

So, the same question needs to be posed, will US dairy farmers respond to high global prices? Not in the short term. Do they have the capacity to ramp up production? Yes. Why are these two factors not aligning? US processors are struggling with factors greater than milk prices or commodity prices. Logistics and packaging in the US are having massive issues in the processing side of the equation – if processors can’t get product into a bottle or on a ship, it becomes very hard to keep

pushing prices higher when you can’t sell the product. So, the US market is restricted by factors off farm. This adds to onfarm issues, creating real downward pressure on milk flows out of the US.

Altogether, it seems very unlikely global milk flows will be able to respond in the short term, leading to an expectation that dairy commodity prices will remain supported. The supply demand imbalance is unlikely to be resolved in the short term, at least from the supply side of the equation. The risk of demand falling is always real, but it would seem the biggest factor to impact demand right now is further geopolitical tensions.

18 Dairy Exporter | www.nzfarmlife.co.nz | April 2022

The WOPA keeps you in control and out of harm’s way. Supporting farmers to be the best they can be. Hoof Trimming Services Canterbury, Otago, West Coast, and Southland. We use state of the art equipment for fast and comfortable trimming. Freephone 0800 833 463 The crush your cows prefer

Email info@veehof.co.nz www.veehof.co.nz One stop shop for hoof care products Advice Trimming Products -6.0% -4.0% -2.0% 0.0% 2.0% 4.0% 6.0% 26-Apr-20 26-May-20 26-Jun-20 26-Jul-20 26-Aug-20 26-Sep-20 26-Oct-20 26-Nov-20 26-Dec-20 26-Jan-21 26-Feb-21 26-Mar-21 26-Apr-21 26-May-21 26-Jun-21 26-Jul-21 26-Aug-21 26-Sep-21 26-Oct-21 26-Nov-21 26-Dec-21 26-Jan-22

Hoof Trimming Crush

Germany France UK

• Stuart Davison is an NZX Dairy Analyst.

Pasture & Forage News

April

Picking winners

There is a huge amount of variation in new pasture performance right across New Zealand – between regions, between farms, and even between different paddocks on the same farm, in the same year.

What’s the fuss? Why pampering baby pasture pays off, big-time

Anyone can sow and grow an average pasture. For new grass to make your neighbours green with envy, however, you need to go just a little further.

A bit of tender, loving care at this early stage works wonders when it comes to lifetime pasture growth and longevity. You’ll be happier, and so will your cows.

Why bother?

Seed sown this autumn holds the power to fuel your business for years to come. It’s packed with genetic potential, ready to deliver hundreds of tonnes of cost effective, renewable, home grown feed, season after season.

The only way it can do this is with your help. But here’s the good news – you don’t have to do much, and the payback is generous.

Space invaders

Right now, weeds are poised to pounce and take a big bite out of your new pasture’s future performance. Weeds are fast, super-competitive and hungry for space, sunlight, nutrients and moisture.

They’re also stealthy! Especially from the seat of a farm bike zooming down

the race. So turn off the motor, and get your nose (close) to the ground in those newly sown pastures. The sooner you spot any invaders, the faster you can get rid of them.

Ready to eat

Once they’ve got their little roots firmly in the ground, grass seedlings in particular need to be grazed. Not too heavily – just enough to take the tips off. This tells the young plant to make more tillers, and you need lots of tillers for thick, healthy pastures.

A light nip at the right time saves clovers and herbs from being shaded to an early death, too. Clover grows slower than ryegrass, and suffers without sunlight.

Feed me

New pasture isn’t always yet equipped to source enough nitrogen from the soil to help it re-grow after grazing.

Some new pastures seem to be winners from the get-go; others never hit their straps. What can we learn from this? Quite a lot. For a start, it’s helpful to note what might have led to a good outcome, so hopefully this can be repeated in future.

Just as important, however, is finding out what might have led to a poor or disappointing outcome. What went wrong; when, and why? What could be done differently next time?

If you can record these observations, so much the better. They might be clear to you now. But next autumn’s pasture renewal is nearly 12 months away, and by then it’s easy to forget the detail. Working out what went wrong –or right – with new grass can be tricky. There are many interlocking factors at play. If you’d like a hand, book a free Pasture Health Check at www.barenbrug.co.nz today.

Dairy Exporter | www.nzfarmlife.co.nz | April 2022 19

facebook.com/BarenbrugNZ barenbrug.co.nz @BarenbrugNZ

A light snack of nitrogen (30 kg/ ha, for example), if needed, will give new pasture enough energy to keep growing after grazing. 2022

Farmer flees tyranny of Putin’s war

he world is at war! Don’t think just because Ukraine is far away from New Zealand that the horrendous atrocity there will not affect you. It can and will.

On February 24 an idiotic, unstable little despot president in Russia decided to unleash a war of terror on the innocent people of Ukraine.

As that war continues thousands of innocent Ukrainian men, women and children have lost their lives, and for what?

While the fighting continues in Ukraine the aftershocks are being felt worldwide and are hitting people’s pockets as energy and food prices escalate.

Dairy farmers, especially, around the world are bearing the brunt of increased input costs on top of what already were high costs. One dairy farmer in Northern Ireland has reported his electricity bill alone has almost doubled from £1500 to £2800 in one month!

The hearty, courageous Ukrainians are fighting for their lives, their country, their freedom and democracy, goals taken for granted by most people.

Farms in Ukraine are being torn up by the Russian army’s tanks and other military vehicles. The main sowing season for grain crops starts at the end of March but for many farmers this will not be possible.

The Russian soldiers are fast running out of food and fuel, and are raiding farms to replenish stocks. Ukrainian farmers are hiding fuel in the fields and processing as much food as they can from stocks and delivering it to their soldiers. The one big plus stalling the Russian advance, and something Vladimir Putin did not figure into his masterplan, is that land in Ukraine is very muddy and sticky in spring. Tanks, armoured personnel carriers and missile launchers are being swallowed up by what the Ukrainians call “the mud of spring” and are subsequently bogged and abandoned by the Russians, or blown up by the Ukrainian army. Some farmers in the besieged regions are fleeing as the Russians take up positions in their fields. Other farmers are evacuating before the Russians turn up.

For the past 20 years Dutch

20 Dairy Exporter | www.nzfarmlife.co.nz | April 2022 GLOBAL DAIRY UKRAINE

As the Russian army gets bogged in ‘the mud of spring’ in its assault on Ukraine, Chris McCullough reports on the effects on one farm in ‘the breadbasket of Europe’.

Dairy Exporter | www.nzfarmlife.co.nz | April 2022 21 For more information CALL 0800 337 747 or email us at sales@towandfert.co.nz www.towandfert.co.nz Available in 5 models. Tow and Fert. There is one for your farm. Multi 1000 Multi 500 Multi 2800 Multi 4000 DEMO Make the most of the high milk payout. Reduce your urea & save $$$, meet the 190 units/ha regulations and grow more grass with a Tow and Fert. FREE on-farm Multi 1200 A Tow and Fert is a SMART BUSINESS INVESTMENT grass growth We have managed to reduce our N inputs from an average of 246 units to 173 units Image shows a Multi 4000 in Southland, New Zealand spraying Urea

farmer Kees Huizinga, with his two business partners, have run their large 15,000-hectare crop, dairy and pig farm near Cherkasy, 200km south of the capital, Kyiv.

Their farm TOV Kischenzi runs 2000 Holstein Friesian cows as well as 450 sows, and has been performing very well over recent years with excellent commodity prices.

When Kees heard about the invasion he immediately sent his wife Emmeke and their two young daughters home to the Netherlands via Romania. One week later Kees followed his family to be a voice in the west for Ukrainian farmers, leaving his farm in the capable hands of the 400 staff.

“We started out there with 1000 hectares and grew that up to 15,000 hectares, mostly leased, as foreigners cannot own land there,” Kees, who is also fluent in Ukrainian and Russian, says.

“When I became a farmer, I knew I would have to wage a figurative war against the traditional enemies of food production such as pests, weeds and disease, but I didn’t expect to be in a real war zone with a deadly enemy.

“The Ukraine Agrarian Association has around 1100 members farming a total 3.5 million hectares in Ukraine,” he says. “They asked me to go to the west and be their voice in case we lose internet connection in Ukraine.”

Work on the farm continues and the 2000 cows still need to be milked, although a big review of the cropping programme is under way.

“Just before I left the cows were yielding

34 litres each per day,” Kees says. “We milk them in an 80-unit rotary parlour twice per day. Cows are fed a mix of corn silage, alfalfa hay, soybean, sunflowers, sugar beet pulp and the minerals, most of the ingredients we grow ourselves.

“Our milk goes to Molikija where it is processed into liquid milk, butter, cheese and yoghurts. We are on a premium with the factory receiving around 43 euro cents per litre, as we produce high quality milk all year round. Thankfully, the trucks collecting the milk are still running for now, but I do not know what will happen.

“For the world market we grow corn, wheat, barley and sunflowers that are exported out of the Black Sea ports, but the Russians have closed those ports now. Incidentally, Ukraine is the biggest sunflower exporter in the world and accounts for over 50% of global sunflower

production.” While the area Kees farms in is relatively quiet, some of the farm staff have gone to fight the Russians.

“Around 25 of our staff have gone to fight the Russians. Some others are working as local security to keep an eye out for saboteurs. Our farm, like most farms and local villages, are preparing food and sending it to the Ukrainian army and to Kyiv.”

So just imagine, what would you do if you woke in the morning and found a hostile foreign army platoon setting up a base there and barbecuing your cows?

Slava Ukraini!

• Read more about the Dutch farmer Kees Huizinga in Ukraine: https://www. dutchfarmerinukraine.nl/en/blog/what-aweek-it-was

22 Dairy Exporter | www.nzfarmlife.co.nz | April 2022 ACTIVATING PEAK ANIMAL HEALTH

OPTIMISE

FOR BOVINE Fixine Check our facebook agribionz | agribio.co.nz Special offer - use Promo Code dairyfix *Optimate ACVM registration No A011800

Fixine is a special formulation of 7 species of fresh probiotics blended with a natural toxin binder* for cows and calves

HERD PERFORMANCE BY USING

Dutch dairy farmer Kees Huizinga in his Ukrainian dairy farm barn.

Dairy Exporter | www.nzfarmlife.co.nz | April 2022 23 26 Northland regional winners 34 Auckland / Hauraki regional winners 43 Waikato regional winners 51 Bay of Plenty regional winners 58 Central Plateau regional winners 68 Manawatu regional winners 73 Hawkes Bay / Wairarapa regional winners 78 Taranaki regional winners 84 West Coast / Top of the South regional winners 92 Canterbury / North Otago regional winners 100 Southland / Otago regional winners

of th e c r o p

CREAM OF THE CROP | NZ DAIRY INDUSTRY AWARDS 2022

www.nzfarmlife.co.nz | April 2022 What you put in today will pay dividends tomorrow. By taking an integrated approach to the health, growth, energy and vitality of your young cattle, you’re setting them on a path to become future high producers. Go to futureproducers.co.nz for all you need to know about young cattle health management, including how to integrate the product suite below into a 360° health programme for maximum results. PROUDLY AVAILABLE FROM YOUR LOCAL PARTICIPATING VETERINARY CLINIC Boehringer Ingelheim Animal Health New Zealand Limited. Level 3, 2 Osterley Way, Manukau, Auckland, New Zealand. MARKS-MIN , COPAJECT , ECLIPSE & IVER MATRIX are registered trademarks of the Boehringer Ingelheim Group. Registered pursuant to the ACVM Act 1997, No’s. A011687, A011573, A011151 & A011065. © Copyright 2021 Boehringer Ingelheim Animal Health New Zealand Limited. All rights reserved. NZ-BOV-0001-2021. Ensure young stock become future high producers through improved health, growth and energy at: futureproducers.co.nz

RISING TO THE challenges

of the crop

Welcome to the season’s much-anticipated edition of ‘Cream of the Crop’! On behalf of the NZ Dairy Industry Awards and the NZ Dairy Exporter, it is my honour to introduce to you our 2022 National Finalists.

As we move into our third year of running our programme through the disruptions and challenges that a global pandemic has brought, it is incredible to look back and see how far we have come. We have learnt to be nimble, adaptable, and open-minded as we continue to navigate this challenging time in our history.

But as they say, “The bigger the challenge, the bigger the opportunity for growth” and with that in mind it was exhilarating to roll out some substantial changes this season in our Dairy Trainee of the Year and Dairy Manager of the Year programmes.

Although early days signals show these changes have been well received and over the next few weeks, we look forward to gathering feedback on how we can improve again for next season.

Our programme would not be what it is today without the support and dedication from our national sponsors, regional and national judges, our large family of volunteers and our management team who together enable us to deliver a thriving and successful programme each year.

In a few short weeks our regional winners will come together in Christchurch to take part in the highlight of our programme “Nationals Week”. The week is an opportunity for all of our finalists to continue their journey of learning, connecting and growing. We are thrilled to be heading down south this year and to be able to host our Nationals week in Christchurch for the first time since 2008.

The National Awards dinner will be held at Te Pae, Christchurch, on Saturday, May 14, I extend a warm invitation to join us in celebrating some incredible people of our industry. I look forward to seeing you there. (At the time of writing Covid-19 restrictions prevent us from holding our National Awards dinner so we wait in eager anticipation for these restrictions to lift).

AMBER CARPENTER Executive Chair NZ Dairy Industry Awards

Dairy Exporter | www.nzfarmlife.co.nz | April 2022 25 A high performance residual insecticide for the control of a wide range of pests Ripcord Insecticide Xtra NOW AVAILABLE For more information on Ripcord Xtra visit pest-control.basf.co.nz or contact your local BASF representative on 0800 932 273 ALWAYS READ AND FOLLOW LABEL DIRECTIONS. © Copyright BASF 2022 ® Registered trademark of BASF. 211453 03.2022 DAIRY INDUSTRY AWARDS | EXECUTIVE CHAIR’S INTRODUCTION

A farming team that has got your back

Our rural consultants and agri-business advisors are proficient in driving on-farm profit. Our expertise in onfarm management, linked with our deep knowledge of the financial and technical aspects of running a farming business, will help support you and your aspirations.

Have a yarn with one of the team if you’re keen to understand what we can do for your farming business.

Now, for tomorrow

Philip Macey

Taranaki

06 757 3155 021 275 8096

philip.macey@bakertillysr.nz

Steve Vollebregt

Waikato

07 834 6814 021 220 0282

steve.vollebregt@bakertillysr.nz

The Baker Tilly team has become a strategic partner in our diverse farming business, supporting us with various financial processes and strategic decision making — enabling us to continue to grow. We only deal with #goodpeople and this team fits into that bracket.

Ed Whiting Airport Farm Taranaki

26 Dairy Exporter | www.nzfarmlife.co.nz | April 2022

A KIND HEART WINS THE DAY

DELWYN DICKEY

Having just taken out the 2022 Northland Dairy Trainee of the Year award, 18-year-old Macee Latimer, sees dairy farming as her future.

Raised on her parents’ dairy farm at Mangakahia, west of Whangarei, it’s hard to get past Macee’s enthusiasm for dairying at such a young age.

After a long involvement with Young Farmers TeenAg at school, Macee recently joined Whangarei Young Farmers, unfazed at being one of the youngest at meetings. She also completed a Farming A&P Internship course last year, seeing her studying and learning practical level 3 agriculture skills. She hopes to continue this year with the level 4 agriculture studies.

Now employed on a farm on the Wairua River, “just over the hill” from home, working with the stock is where Macee shines, recognising what is good for the animals is often also good for business, like reducing lameness by letting the cows walk at their own pace to and from the milking shed.

But a shift in farming is needed, she says. Higher animal welfare standards, more sustainable practices and lowering greenhouse gas emissions is where dairy farming in New Zealand is heading.

She is frustrated with farmers who don’t treat their stock well, who don’t care about sustainability or the environment.

“Some farmers shouldn’t be farming,” she says.

Reducing nitrate runoff into waterways with more riparian planting is needed, she says. We need to look at cropping alternatives that will survive the increasing dry and heat as Northland is impacted by climate change more, along with being more water-smart.

She’d like to see trees incorporated into farming more, not just in riparian

planting, but also to reduce heat stress in cows.

And while she would love to see zero methane cows she is also frustrated at the costs of being more environmentally minded and at the small number of options available for farm equipment – like electric farm bikes and quads - needed to achieve this lower emissions future.

Better animal welfare, sustainability and the environment will help change the public’s perception of farming, but farmers should take care not to add to the negative views, she feels.

“Don’t put sick cows in paddocks next to the road,” she says, as most people don’t understand that no matter how well you treat your stock, every farm is going to have sick animals.

Macee has always loved the freedom and adventures that came from exploring her parents’ farm with her siblings.

But it is possibly her love of animals that has been behind her decision to look at dairy farming the most. Knowing their behaviour well has seen a strong empathy develop.

She has also tried her hand at handrearing hurt birds, had a pet possum as well as a pukeko. Her current menagerie includes Marty, a wild kitten she found on the farm, a boisterous dog Digger - too noisy around stock to work on the farm, and a handful of chickens.

Her collection of very healthy carnivorous house plants should end any notion Macee is a complete softie.

MERIT AWARDS

RUNNERS -UP

DairyNZ Practical Skills Award: Bill Hamilton

Northern DIA Emerging Talent

Award: Shaniah Flood

MilkBar Farming Knowledge

Award: Michael Everitt

Piako Tractors Northland

(Bryant Tractors 1983 Ltd)

Communication & Industry Involvement Award: Macee Latimer

Dairy Exporter | www.nzfarmlife.co.nz | April 2022 27 NORTHLAND | DAIRY TRAINEE OF THE YEAR

WORDS & PHOTOS BY

Dairy Trainee Macee Latimer with her cheeky chicken Karen.

Michael Everitt from Kaitaia and Bill Hamilton from Titoki was third placegetter.

CHANGING DIRECTION

WORDS BY DELWYN DICKEY

Winner of the 2022 Northland Dairy Manager of the Year category is 35-year-old Phillip Payton.

When Phillip Payton was 20 years old he injured his back, and at that moment his future changed. Surgery would be needed to fix the problem properly.

With no heavy work during rehabilitation, his engineering apprenticeship ended.

Instead he found himself working for a year as a security guard in Hastings, mostly at the local freezing works. While he enjoyed it up to a point, sometimes working 12-hour shifts from 6pm to 6am could be tough.

With his future uncertain Phillip thought of his father.

Phillip had grown up in Te Awamutu on the dairy farm his father worked on. His father had loved working on the land but had also suffered a back injury and was never cleared for full-time work again. But he stayed as a relief worker - as his rehabilitation. Soon after Phillip left home at 18, his father went back to just milking.

Phillip had loved growing up in the countryside and his pathway now became clear again.

A dairy assistant job in rural Napier came up, he moved to farms in the Waikato for seven years and then secondin-charge jobs in Taranaki. While he enjoyed the work, the hours were long.

Then back to the Waikato and a move into dairy goat farming for 18 months. It was all in-house with shed feeding and a cut-and-carry operation and Phillip enjoyed doing a bit of everything.

Wanting to be closer to his partner Leef’s family saw the couple move north a year ago on to Greg and Ingrid McCracken’s farm at Te Hana, Phillip taking on the farm manager’s role.

He is enjoying a good work/life balance here and feels he has a good working relationship with Greg, both having a fairly easy-going style.

“Calving is the most stressful time of year and everyone’s tired. A more laid back approach is needed then,” he says. “You have to stop and think rather than being reactionary.”

The farm has only just come back into dairy production after a 10-year break when the previous owners removed the milking apparatus and instead ran cattle, young animals and grew maize.

A refurbished 40-head rotary milking system has now been installed for the herd of 350 cows.

Maize is no longer being grown on the property with supplements being bought in instead. Greg has put a lot of work

28 Dairy Exporter | www.nzfarmlife.co.nz | April 2022 NORTHLAND | FARM MANAGER OF THE YEAR

‘WITH GLOBAL RESTRICTIONS COMING ON FARMING EXPANSIONS GENERALLY, THE AMOUNT OF MILK BEING SUPPLIED WILL DECREASE. BUT THE DEMAND WILL STAY THE SAME OR INCREASE SO PRICES WILL GO UP.’

Above: A move north to be closer to family sees Phillip Payton managing a farm at Te Hana.

BOE 1063 ENSURE THEY REACH THEIR PEAK POTENTIAL Ensure young stock become future high producers through improved health, growth and energy at: futureproducers.co.nz The essential building blocks for optimal health including vitamin B12 in one convenient injection. PROUDLY AVAILABLE FROM YOUR LOCAL PARTICIPATING VETERINARY CLINIC Boehringer Ingelheim Animal Health New Zealand Limited. Level 3, 2 Osterley Way, Manukau, Auckland, New Zealand. MARKS-MIN® is a registered trademark of the Boehringer Ingelheim Group. Registered pursuant to the ACVM Act 1997, No. A011687. See product label for full claim details and directions for use. © Copyright 2021 Boehringer Ingelheim Animal Health New Zealand Limited. All rights reserved. NZ-BOV-004-2021.

getting elements back into the soil, Phillip says.

In response to a changing climate, they are looking at moving away from ryegrass pastures. Next summer, they will be using alternative pasture mixes like tall fescue and cocksfoot for persistence over the hotter, drier months.

Fortunately, with two dams on the farm, along with a connection to the Te Hana water supply, water has never been an issue on the farm even during the last big drought.

In an effort to lower greenhouse gas emissions, stocking rates are being kept low – just over two per hectare. This reduces the amounts of nitrates they use, which should keep nitrate runoff to a minimum. Phillip sees this as an inevitable trend in New Zealand.

“Stocking rates are coming down – it’s just how it is.”

They have also doubled the effluent area so that’s not so condensed in one area, which will also help reduce nitrate leaching.

A wetland has been fenced off and will be allowed to regenerate at its own pace.

Shade trees which should combat heat stress in stock have been planted in some areas of the farm, and Phillip is planning on planting up some unproductive areas in trees for carbon sequestering and financial carbon rewards.

“We should look at the positives and move forward,” he says, “Change what you can for the better, but you have to adapt to what you can’t change.”

“With global restrictions coming on farming expansions generally, the amount of milk being supplied will decrease. But the demand will stay the same or increase so prices will go up.”

Work-life balance, appropriate pay, a safe and supportive work environment for staff especially around mental health, along with adequate housing should be seen as investments in any farming operation’s future, he says. He is pleased to be on a wage now so that when he works long hours, he is paid appropriately for them.

Milking platform area: 175ha

Silage/hay

Nitrogen: 96kg/ha.

DeLaval Livestock Management Award:

Phillip Payton

Fonterra Dairy Management Award: Phillip Payton

NorthTec Environmental Sustainability Award:

Brant Julian

MERIT AWARDS

Northern Wairoa Vet Club Association Ltd Pasture & Feed Management Award:

Daniel Richards

Webb Ross McNab Kilpatrick

People & Leadership Award:

Phillip Payton

Northland DIA Personal Planning & Financial Management Award:

Daniel Richards

Pacific Motor Group Emerging Talent Award: Daniel Richards

Perhaps because of the missed opportunity of his own apprenticeship, education for farm workers is also important to him, and he is supportive of his own farm assistant going through agricultural ITO training.

With plenty of experience but no qualifications Phillip is also looking at doing a level 5 ITO course, recognising this is becoming more important to farm owners.

PHYSICAL FARM

Cows: 350-400 next season

Production: 601.1kg

MS/ha to date

Pasture eaten: 8.5t

Milking supplement:

Cows/labour unit: 175/1

Farm Dairy: 40 bail rotary shed Dairy Automation: Auto cup removers and teat spray

Ultimately Phillip and Leef are aiming at farm ownership. Along with calf rearing they’d also like to incorporate teaching and education, and have a viable contracting business providing short-term relief staff capable of running the entire operation.

“We’ve encountered many challenges these past few years and some have altered the path, but we have reassessed, overcome what was within our abilities, made peace with what wasn’t, and kept ticking off our goals.”

30 Dairy Exporter | www.nzfarmlife.co.nz | April 2022

DATA

Left: Phillip’s future pathway includes farm ownership and a business able to connect farmers with relief workers.

CHASING THE DREAM

WORDS AND PHOTOS BY DELWYN DICKEY

Antje and Soenke Paarmann from Okaihau have been named winners of the 2022 Northland Share Farmer of the Year.

The win continues a successful dairying career that has seen them move from their first position in Rotorua where they had just a farm bike to their name, to being 50/50 sharemilkers in the Bay of Islands with 450 cows.

But there is more to their story than a progression up the farming ladder.

Antje and Soenke arrived in New Zealand in 2006 with all their belongings packed into 24 boxes. They were young, not long out of university and had left their families behind in Germany - a pretty daunting step for anyone.

But they were coming back to a country

$FINANCIAL FARM DATA

Sharemilking: 50/50.

Gross farm income: $3.96/kg MS

Operating expenses $2.91/kg MS

Operating profit: $1.05/kg MS

Farm working expenses: $2.24/kg MS

Animal health: $0.17/kg MS

they had fallen in love with and had a dream that was unattainable back hometheir own dairy herd, and ultimately their own farm.

German farms usually stay in a family, says Antje, passed on from generation to generation. So while you can work on a farm you’ll never own one if your family doesn’t already have one.

“A manager’s position would probably have been the highest we could have achieved,” she says.

Both Antje and Soenke have agricultural degrees, Antje majoring in animal welfare and Soenke in business and economics.

Before they met, and while a university student, Antje travelled to New Zealand with a friend. She worked on several farms for a six-month practical semester for her degree, as well as seeing the country, She remembers them as some of the best days of her life, she says.

Soenke, meanwhile, had to make a choice young Kiwi men no longer face. Conscription still applied in Germany at that time, and saw young men having to serve nine months in the army.