Engaging your community

Running on empty cows

Grazing by degrees

SMASHING THE TOP OFF INFLATION

Using smart strategies and clever spending to protect your profit margin

$12 incl GST JULY 2022 $12.95

Salmonellosis is over three times more prevalent than in 20131

Salmonella is widespread on New Zealand farms and cases are increasing nationwide1. Striking without warning and spreading quickly, Salmonella can pass from your stock to the ones you care about most.

Vaccinate today to reduce the destructive impact of an outbreak*.

SALVEXIN®+B

NEW ZEALAND’S ONLY SALMONELLA VACCINE FOR SHEEP AND CATTLE

3

For more info watch our Salmonella webinar at: www.msd-animal-health.co.nz/salmonella-roadshows AVAILABLE ONLY UNDER VETERINARY AUTHORISATION. ACVM No: A7886. Schering-Plough Animal Health Ltd. Ph: 0800 800 543. www.msd-animal-health.co.nz NZ-SAL-210500001 ©2020 Intervet International B.V. All Rights Reserved. *Salvexin+B should be used in conjunction with other management practices to help control the risk of Salmonella. 1. Surveillance. Vols 41-47, No. 3, September 2014-2020

4 Dairy Exporter | www.nzfarmlife.co.nz | July 2022 CONTENTS MILKING PLATFORM 10 Jess and Cam Lea have reassessed the financial side of their business. 11 Anne-Marie Wells wonders if farmers should reframe themselves as #1 cow 12 Robert Hodgkins prepares to milk sheep in Hertfordshire, England 13 DairyNZ responds to West Coast issues UPFRONT 14 NZ ag needs to pivot towards modern foods 17 Global Dairy: Netherlands farmers at war with their government 18 Global Dairy: Brazil’s environmental journey 20 Market View: Lower milk prices support stellar milk prices. BUSINESS 22 Cash flow is king 32 Cows running on empty SYSTEMS 38 SIDE: Grazing by degrees 40 Alltech ONE addresses key areas 42 Minimising the wet effect in Southland

32

22 Page 11

Page

Page

SPECIAL REPORT: Smashing the top off inflation

46 Costs crimp record payouts

51 Paying the price

52 SIDE: Control what you can

54 Fertiliser: The right product at the right price

57 Keeping the grain flowing

ENVIRONMENT

60 Wetlands: A farm Taonga

63 Equipping Coast farmers for future

65 Research: Time to take another look at urine

STOCK

68 Calf rearing: Going for gold

69 Colostrum is gold

70 SIDE: Rumination on repro

72 Improving in-calf rates

73 Calves: Back to basics with veal

74 The good grain

75 Wagyu: First Light goes it alone

76 Germany: Organics and Jenseys

78 Vet Voice: The value of a post mortem

Front cover design: Emily Rees

YOUNG COUNTRY

80 Catching the director’s eye.

82 Attracting workers to dairying

WELLBEING

84 Taking a break with the team

DAIRY 101

86 Staffing: Migrants again welcome

SOLUTIONS

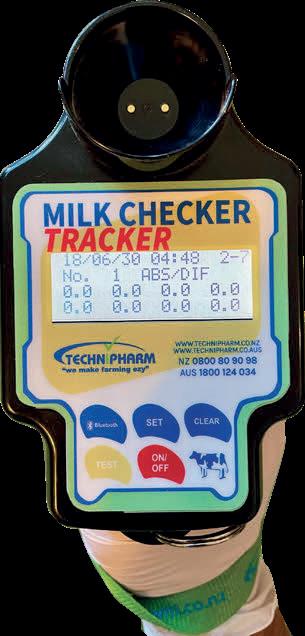

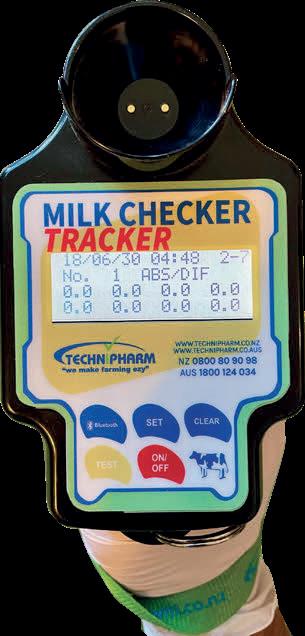

88 Monitoring: Focusing on the heat

89 Know your colostrum powder

OUR STORY

90 50 years ago in the NZ Dairy Exporter

Exporter | www.nzfarmlife.co.nz | July 2022 5

Dairy

Page 80

Page 76

Page 80

DAIRY DIARY

July 25 – Weekly farm walks begin again on the Lincoln University Dairy Farm on Mondays at 9am at the farm on Shands Road. The next focus day will be held on September 29, beginning at 10.15am and will have a focus on mating, managing costs and inflation. For more about the farm, visit www.ludf.org.nz.

July 26 – A relationship property live webinar is being held by Dairy Women’s Network in conjunction with Hammertons Lawyers Ltd. It looks at intergeneration farming operations, constructive trusts and how you can protect against adverse outcomes when a relationship breaks down. For more details and to register, visit register.gotowebinar.com/ register/82950879656517133.

August 14 – Applications close for 2023 Nuffield New Zealand Farming Scholarships. Each year up to five scholarships are awarded in the rural leadership programme to fast track the development of emerging leaders in the agri-food sector. To find out more and apply, go to ruralleaders.co.nz/ nuffield.

September 27-28 – DigitalAg 2022 is being held at the Distinction Hotel in

Rotorua. The formerly MobileTECH Ag brings together technology leaders, agritech developers, early adopters and the next generation of primary industry operators. The real innovation now is in digital platforms that capture realtime data and convert it into practical information that drives productivity. To find out more about the event and to register, go to agritechnz.org.nz/event/ digitalag.

October 2-7 – World Dairy Expo 2022 is held in Madison, Wisconsin. Find out more about the expo at worlddairyexpo.com.

October 6-7 – The New Zealand Landcare Trust is hosting the National Catchments Forum at Te Papa Tongarewa in Wellington which brings together speakers with knowledge and experience in catchment management. It looks at water reforms, integrated farm and catchment planning, and how catchment groups are addressing the climate challenge. For more about the forum visit www.landcare.org.nz/eventitem/national-catchments-forum.

October 28-30 – Waikato A and P Show has been held at Claudelands Showgrounds for more than 100 years and celebrates traditional competitions,

rural lifestyle and bringing communities together. For more, go to waikatoaandp.co.nz.

October 30 – Applications close for the first 2023 Kellogg Rural Leadership Programme at Lincoln which is aimed at developing leaders for the rural and agri-food sector. For more details and to apply visit ruralleaders.co.nz/kellogg.

November 9 – The New Zealand Agricultural Show is held at Canterbury Agricultural Park in Christchurch. Livestock entries open on August 1. For more information about the show visit www.theshow.co.nz.

November 15-17 – The NZ Grassland Association’s annual conference takes place in Invercargill. For more information and to register, visit www.grassland.org.nz.

November 30 – December 3 –Fieldays is a summer event this year at the Mystery Creek Events Centre near Hamilton. Get the details about the Southern Hemisphere’s largest agricultural event at www.fieldays.co.nz.

Dairy Exporter | www.nzfarmlife.co.nz | July 2022

TALK TO THE EXPERTS FOR FARMING SUPPORT FARM SERVICES HOMEOPATHIC farmservices.nz info@farmservices.nz 07 858 4233 @HomeopathicFarmServices

Travel

Easing

Injury Combo Support

Udder Combo Supports sudden onset of udder in ammation with

Combo

the transition for young

for

Staying strong onfarm portrays an innovative programme run by Reporoa dairy farmer and cancer survivor Sarah Martelli, who helps other women find their balance and build strength and wellbeing to be the best they can be.

THE INFLATION WRECKING BALL

Strong Woman is an online community for women to work on their fitness with a workout to do at home, find quick and easy healthy recipes, goal planners and to connect with other women on the same journey. Her philosophy is to help women create healthy, sustainable habits around moving and feeding their bodies and their families.

If women can prioritise their own health and fitness, they can inspire their partners, their children and their community around them, Sarah says (p82).

She is an inspirational woman creating a moment of lift for many women.

Inflation is hot news all over the world at the moment - with the New Zealand rate hitting 7% for the first time in 30 years - so realistically anyone under 45 will not really have seen or been affected by the like in their lifetimes. And it seems the rate of inflation in the ag sector is running even hotter.

(p42). We also cover the Heald family of Norsewood (p52) who have transitioned to organics, OAD and philosophies and are enjoying the less intensive more resilient system they have moved to, along

In this issue we take a look at the regenerative agri journey some NZ farmers are already on, and that the government has signalled they want others to join in on, in our Special Report.

The old, wise and grey heads in the sector will remember the rampant inflation of the early 1980s - spiking at 18% in 1980 and the record high interest rates farmers were subjected to.

milksolids production, from a range of adverse climatic conditions around the country. He puts into context that 4% is only two container ships of our product - out of the roughly 42 that shift a total season’s production, but the chaos in Europe has also led to declining production there and in the United States, so the price is being supported by less product.

The regen debate has divided the farming community in a big way - many scientists are affronted that NZ would need regenerative methods from overseas countries with highly degraded soils - would that then infer that our conventional methods were degenerative?

My first dairy farm job was in the summer of 1984 and the young first farm owners I milked for in eastern Taranaki were struggling with interest rates around the early 20% mark - while I milked the small herd through the little old eight-bail walk-through shed the farm owner rushed around the district baling hay for other farmers, trying to make enough extra cash to cover his mortgage and feed his young family.

Harriet Bremner encourages farmers to get their team off farm during the quiet time to get to know them while doing something fun and different - she took her crew to an escape room challenge.

They say the methods won't work, and that research has already shown that, and also our farmers are already following regenerative practices. Others say that the methods are not prescribed and each farmer can take out of it what they want. It has been called a social movement rather than a science and the claimed benefits of improved soil and stock health and building soil carbon through diverse species, use of biological fertilisers and laxer and less frequent grazing practices along with less nitrogen is something that resounds emotionally with many.

We have taken a snapshot of thinking by scientists in MPI and DairyNZ (p46) and portrayed what farmers using the practices are finding, including ongoing coverage of the comparative trial work by Align Group in Canterbury

Our special report this issue warns farmers against the danger of complacency about cost inflation with a record high payout forecast. Chris Lewis of BakerAg says in these strange times of Covid and the Ukraine war and their affects on the world economy and supply chains, when fuel, fertiliser and feed costs have had a fire lit under them, profit margins will be squeezed by the higher costs.

Dairy Exporter | www.nzfarmlife.co.nz | June 2021

There is more research to be done in the NZ farm system context, says MPI’s chief scientist John Roche, figure out what will and won’t work, but he encourages farmers to engage and learn more, and to embrace regenerative as a verb - saying all farmers could be more regenerative, more resilient, lowering carbon

If you are interested in getting into farm ownership getting out but retaining an interest, read about Moss’ innovative idea for a speed-dating weekend potential partners (p11). We think it could be a

NZ

@YoungDairyED @DairyExporterNZ @nzdairyexporter

We have drilled down into feed, fert and people costs and come up with ways for farmers to help protect their profit margins from the wrecking ball of cost inflation. (page 46).

Stu Davison, in his Market View column, covers off the effects of a 4% drop in NZ

Sneak peek

In the next issue:

JULY 2021 ISSUE

• Special Report: Farming/business investment – if you are starting out or bowing out.

August 2022

Reading articles from both here and overseas has made me feel like I was living an escape room challenge this week - from stories of Dutch farmers protesting nitrate directives that will see many of them paid to quit their dairy herds (pg17), to Kiwi journos asking if we should be looking at meat and dairy like tobacco and calls to remove cows from the Canterbury plains… We need to keep reminding ourselves there are farmers all around the country evolving towards building wetlands, planting waterways, concentrating on highly efficient cows in their herds and being smart about nitrogen application. Evolution certainly beats revolution, we need to keep making changes towards more sustainable ways of farming. @YoungDairyED

• Wildlife onfarm

• Ahuwhenua winners

• Governance: Knowing your why, defining your purpose and values

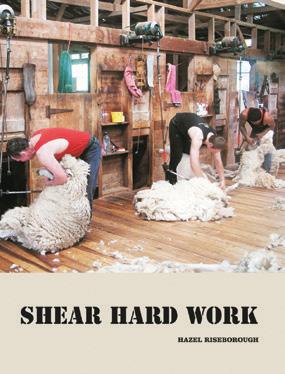

• Sheep milking conference coverage

• More coverage of the Oamaru SIDE conference

• What is sentience, and how does it impact our animal welfare practices?

Dairy Exporter | www.nzfarmlife.co.nz | July 2022 7 Editor’s note

@DairyExporterNZ @nzdairyexporter NZ Dairy Exporter

STRONGER TOGETHER

Dairy

ONLINE

New Zealand Dairy Exporter’s online presence is an added dimension to your magazine. Through digital media, we share a selection of stories and photographs from the magazine. Here we share a selection of just some of what you can enjoy. Read more at www.nzfarmlife.co.nz

IRRIGATION IMPROVEMENTS CREATING RESILIENCE

The Woodhouse family’s irrigation improvements are creating resilience. Good data and investment into spray irrigation that allows lower rates to be applied at shorter return intervals will help maintain pasture production levels as nutrient inputs reduce with regulation.

Take a look:

https://youtu.be/bivsGOWbM9Q

ASB RURAL INSIGHTS

- Succession Series Podcast

PROVING THE THEORIES

Pareka farm has gone through a significant change in farm systems this season with the aim of cutting N losses and methane emissions, paving the way and creating learning opportunities for others.

Take a look:

https://www.youtube.com/watch?v=SV9t9tqB3Kc

COMING SOON:

Welcome to From the Ground Up, a podcast brought to you by Young Country. This is a podcast for the go getters, the big dreamers, the innovators of the primary sector. Host Rebecca Greaves plans to serve up a healthy dose of inspiration, motivation, and maybe even challenge your thinking a little.

NZ Dairy Exporter is published by NZ Farm Life Media PO Box 218, Feilding 4740, Toll free 0800 224 782, www.nzfarmlife.co.nz

Editor

Jackie Harrigan P: 06 280 3165, M: 027 359 7781 jackie.harrigan@nzfarmlife.co.nz

Deputy Editor Sheryl Haitana M: 021 239 1633 sheryl.haitana@nzfarmlife.co.nz

Sub-editor:

Andy Maciver, P: 06 280 3166 andy.maciver@nzfarmlife.co.nz

Reporters

Anne Hardie, P: 027 540 3635 verbatim@xtra.co.nz

Anne Lee, P: 021 413 346 anne.lee@nzfarmlife.co.nz

Karen Trebilcock, P: 021 146 4512 ak.trebilcock@xtra.co.nz

Delwyn Dickey, P: 022 572 5270 delwyn.d@xtra.co.nz

Phil Edmonds phil.edmonds@gmail.com

Elaine Fisher, P: 021 061 0847 elainefisher@xtra.co.nz

Claire Ashton P: 021 263 0956 claireashton7@gmail.com

Design and production:

Lead designer: Jo Hannam P: 06 280 3168 jo.hannam@nzfarmlife.co.nz

Emily Rees emily.rees@nzfarmlife.co.nz

Partnerships Managers: Janine Aish

Auckland, Waikato, Bay of Plenty

P: 027 890 0015 janine.aish@nzfarmlife.co.nz

Welcome to the ASB Rural Insights

- Succession Series podcast, where we’re talking about farm ownership transition from all sides. Thanks to the ASB Rural team for partnering NZ Farm Life Media on this four-part series. Each week Angus Kebbell will be profiling farming families, talking to experts from the advisory sector and investigating new opportunities for farmers thinking about diversifying their farming business. When it comes to ‘what’s next’ for the farm, there’s a lot to think about, so we aim to share success stories, provide useful tips and help you understand more about the many facets of succession planning in the food and fibre sector today.

To listen:

https://nzfarmlife.co.nz/podcasts-2/

CONNECT WITH US ONLINE:

www.nzfarmlife.co.nz

NZ Dairy Exporter @DairyExporterNZ

NZ Dairy Exporter @nzdairyexporter

Sign up to our weekly e-newsletter: www.nzfarmlife.co.nz

Tony Leggett, International P: 027 474 6093 tony.leggett@nzfarmlife.co.nz

Angus Kebbell, South Island, Lower North Island, Livestock

P: 022 052 3268 angus.kebbell@nzfarmlife.co.nz

Subscriptions: www.nzfarmlife.co.nz subs@nzfarmlife.co.nz

P: 0800 2AG SUB (224 782)

Printing & Distribution:

Printers: Ovato New Zealand

Single issue purchases: www.nzfarmlife.co.nz/shop

ISSN 2230-2697 (Print)

ISSN 2230-3057 (Online)

8 Dairy Exporter | www.nzfarmlife.co.nz | July 2022 NEW ZEALAND

NEW ZEALAND

2022/2023 Fonterra forecast price Average $9.34/kg MS $/kg MS 11 10 9 8 7 8.50 8.90 10.38 9.25 10.00 9.00 Fonterra forecast 10.25 Mid 9.50 8.75

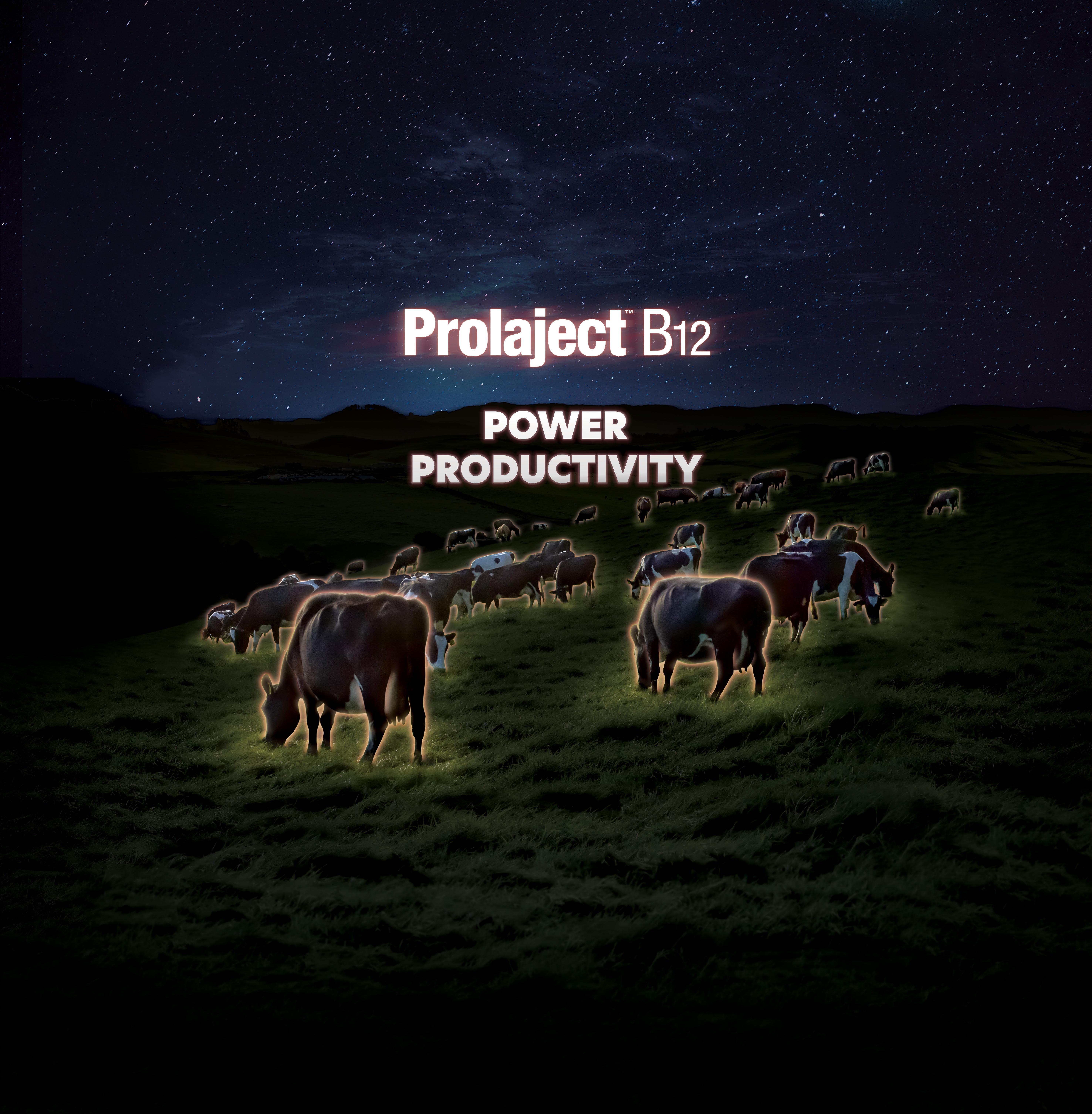

Dairy Exporter | www.nzfarmlife.co.nz | July 2022 9 Long Acting Injectable Selenium 1 SHOT FOR 4 SEASONS 1 SHOT FOR 4 SEASONS For more information visit www.selovin.co.nz or scan the QR code to find out more! Prolaject Coppermax™ and Flexidine™ are Restricted Veterinary Medicines (RVM). No: A004943, A007789, A007790, A007791, A009469, A007866. Only available under veterinary authorisation. Face-Guard™, Prolaject™ and Selovin™ are registered under the ACVM Act 1997. No: A009773, A010198, A010744, A005850, A006170, A006536, A006903, A006139, A009509. Face-Guard, Coppermax, Prolaject, Flexidine and Selovin, Elanco and the diagonal bar logo are trademarks of Elanco or its affiliates. Elanco New Zealand, 106 Wiri Station Road, Manukau, Auckland 2104. www.elanco.com | 0800 446 121. © 2022 Elanco. PM-NZ-22-0110 VetOnly

the status quo RE-EVALUATING

The 2021/22 season brought many interesting surprises. We found ourselves still navigating around Covid restrictions, border closures and a short supply in staff. We also encountered the pressure of change in our farming practices, as the call for a greener New Zealand, along with climate change has seen many farmers stressing about what this means for the future of dairy.

An increased milk payout was a welcome sight, but as the payout increased, a lot of the costs inflated. Not only was this from global pressures as the cost of living has risen significantly, but we also have seen issues in supply chains, the wait times for feed and products impacting our businesses directly.

goals to achieve the final goal of farm ownership. It is also to help us adapt to changing circumstances of fluctuating milk prices and operating costs. Taking time to re-evaluate the companies we use for insurance, gas and power also plays a part in trying to keep costs down.

Along with evaluating the financial side of our business we find the dry period great to assess our whole business structure and focus on our staff’s goals, making training plans so we can see them get the most out of farming and formalising our operations. Catching up on the tasks that were put aside while we were busy but also finding the time to take a bit of time off, so our staff and ourselves can come in refreshed for calving, which is due to commence early July. It has been an interesting challenge going from being mentored to becoming the mentor.

I find myself thinking of my experiences and advice I have been given by my mentors and passing similar advice on to our staff and using that same advice to overcome challenges.

We have finished the season and now can reflect and look at the expenses from the last 12 months. Thanks to great accounting programmes and a good accountant, it is a relatively easy process evaluating where we spent our money and how it compares to previous years.

We find ourselves reassessing the profitability of costs that we deemed as a necessity in previous seasons and finding alternatives or changing how we use them. Our big three increased costs are fuel, imported feed and fertiliser. We do this monitoring to ensure we meet our short-term financial

We are fortunate to come in to farming having built relationships with a great group of farmers around us. They have helped us grow our business and they are also happy to listen to our ideas and let us turn to them for advice. For that we are grateful to them and hope like our predecessors we can also inspire and mentor other generations coming in to farming. The best advice we can give to anyone wanting to advance in farming is to surround yourself with successful people, learn, grow, set goals and be open to a bit of change. Looking to this new season, we find ourselves in a strong position, in a great industry and the outlook where we take each challenge in our stride, knowing that we are getting closer to buying that first farm.

10 Dairy Exporter | www.nzfarmlife.co.nz | July 2022

MILKING PLATFORM BAY OF PLENTY

Taking time to re-evaluate the companies we use for insurance, gas and power also plays a part in trying to keep costs down.

With the big three increased costs of fuel, imported feed and fertiliser, Opotiki farmers Jess and Cam Lea have reassessed the financial side of their business.

Cam and Jess Lea with son James.

no.1 cow BEING

Ialways feel a sense of lethargy once we have dried off the cows and completed all the compliance reporting. The push to finish the season well often feels more challenging than calving – there are so many areas to get right to set up successfully for the season ahead. And despite best efforts throughout the season to make compliance reporting easy, it still takes a while to be sure what we are submitting is correct.

As I read June’s milking platform articles, it struck me just how different a season can be between farming operations.

We are fortunate enough to have had a great season here on the Taieri, everything seemed to align – the weather, the milk price, cow condition.

We have had our challenges, but they have been ones within our control, and we are feeling optimistic as we head into the new season.

With SIDE being in Oamaru this year, it was a good chance for Duncan to get a couple of days off farm and he enjoyed hearing about the latest theories and innovations. While we might not all be ready to invest in these recent technologies, events such as SIDE mean we are able to share in knowledge that is being drawn from them.

We are particularly interested in cow collars at the moment, which was the focus of one of the workshops. As well as finding out more about collars, the workshop also shared what is being learnt from them – such as data from collars are pointing towards the optimum rumination time between calving and moving to twice a day milking. Unlike other industries, this information is not kept secret to help one farm perform better than another, it is shared so that everyone can benefit.

One thing I do find a shame though, is how the number of rural professionals at these events seems to outweigh the number of farmers. By paying levies, fees, and

commission, we fund other people to go, yet struggle to get there ourselves.

As well as taking time off the farm, by the time we have paid for a ticket, accommodation, and transport, it adds up – and this all comes out of our farm expenses. There is an argument that each year our budget should include money set aside for education, but that is easier said than done.

We can justify spending time and money on our cows or infrastructure, but when it comes to ourselves, it is not always as easy.

This point rang true in the Thursday morning SIDE keynote session from Dr Tom Mulholland. Farmers know their cow, production, and environment numbers, yet are not aware of their own health numbers, such as blood pressure and cholesterol.

As we head into the new season, I wonder if it is time for farmers to think of themselves as the number 1 cow in their herd and do all that they can to keep that number 1 cow fit, healthy and productive.

Dairy Exporter | www.nzfarmlife.co.nz | July 2022 11

MILKING PLATFORM SOUTH OTAGO

One thing I do find a shame though, is how the number of rural professionals at these events seems to outweigh the number of farmers.

Anne-Marie Wells wonders if farmers should reframe themselves as #1 cow in their herdand look after themselves accordingly.

- more from less ENTERPRISE STACKING

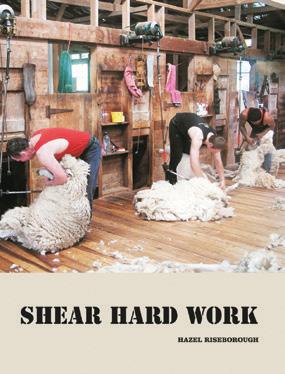

As Robert Hodgkins prepares to start milking sheep in Hertfordshire, England, he describes how his farming operation has adapted to soaring costs.

We’re in the midst of our sheep dairy build at the moment. We received planning permission on April 25 and we hope to start milking around June 15 so it’s pretty full throttle.

Neither of us have ever milked before so we’re relying heavily on our new dairy shepherdess Robbyn, and a lot of our Nuffield dairying friends to direct us.

Only one Holstein and one Jersey dairy farm are left in Hertfordshire - before refrigeration all of our county would’ve been dairy farms because of its proximity to London (50 kilometres to the centre). Dairying has now moved to the west of England where greater rainfall favours ryegrass production, so we’re somewhat bucking the trend, as we were when we set up our sheep flock, at which time only two other significant flocks existed in the county - so why are we so determined to do the opposite to everyone else?

Well, we are large tenant farmers on modern agreements (historically a lot of tenant farmers have been on threegeneration ‘AHA’ tenancies which include buildings, houses and sometimes workers’ cottages at a very reasonable rent). We also have no interest in diversification - most of our tenancies preclude the obvious things neighbours have adopted such as caravan storage, farm shops, holiday cottages, commercial property lets, dog walking paddocks (no seriously), horse stables etc. So to keep paying big commercial rents purely from farming is very unusual, particularly in our part of the world where the soil is not great and there’s no irrigation.

So how do we do it? Enterprise stacking (a very modern version of mixed farming) allows us to produce more from less area. Before we started farming our farms, they only directly employed one person and produced some straw, wheat, barley, oilseed rape, some hay for horses and about 200 ewes. All with a great reliance on inorganic fertiliser and chemicals. Ten years into our management, we are a team of six now, still producing wheat and barley, but also quinoa, borage, oats, grass for seed and peas, running 2500 ewes (with room for more) and milking 300 ewes (should be 600 in two years time). We grow cover crops before spring crops

allowing us to graze sheep over winter and reduce fertiliser inputs. We graze our winter crops allowing a huge reduction in chemicals. We use herbal leys for grazing that receive no fert, weed wipers for low chem use.

An inter-row hoe reduces our herbicide costs and works on our resistant grass weed population we inherited. We only bale spring barley straw as we have no need for straw and neither does anyone in the area (others bale for burning in a power station) but I’d rather return ours to the soil to reduce fertiliser reliance.

And there’s further room for chickens - both meat and egg birds - with little detriment to what we’re producing already.

The modern bit for us is in making each enterprise as profitable and thus sustainable in its own right. Our system has developed over 10 years and this year has brutally highlighted our most sustainable enterprise - the dairy and our riskiest enterprise, arable cropping.

Even with all the steps we have taken, our arable cropping still relies too heavily on unsustainable inputs of inorganic fert propping it up. We use N testers, N sensors, endophyte seed dressings etc to reduce our N requirements, so where our predecessor would have applied 220kg/ha N, we can grow the same yields on 90-120kg/ha N but I believe we need to reduce this further through better-formulated fertilisers perhaps?

We have seen fert prices triple, crop, chem and diesel prices double, we have bought additional fuel tanks, allowing us to make more strategic fuel purchases rather than panic buy.

Last time I did the sums, we needed to find an extra £100,000 (NZ$195,000) to get the arable crops to harvest, and we would receive an extra £100,000 from selling them at the ‘new prices’.

This sum has fluctuated a bit over the spring, but crudely this is the situation, so no greater profit for the arable, just a greater cash demand and many argue greater risk of growing crops. The sheep and dairy systems are far less reliant on ‘bought-in energy’ so we are able to pocket the extra profit increased food prices have created.

• First published in Country-Wide July 2022.

12 Dairy Exporter | www.nzfarmlife.co.nz | July 2022

MILKING PLATFORM ENGLAND

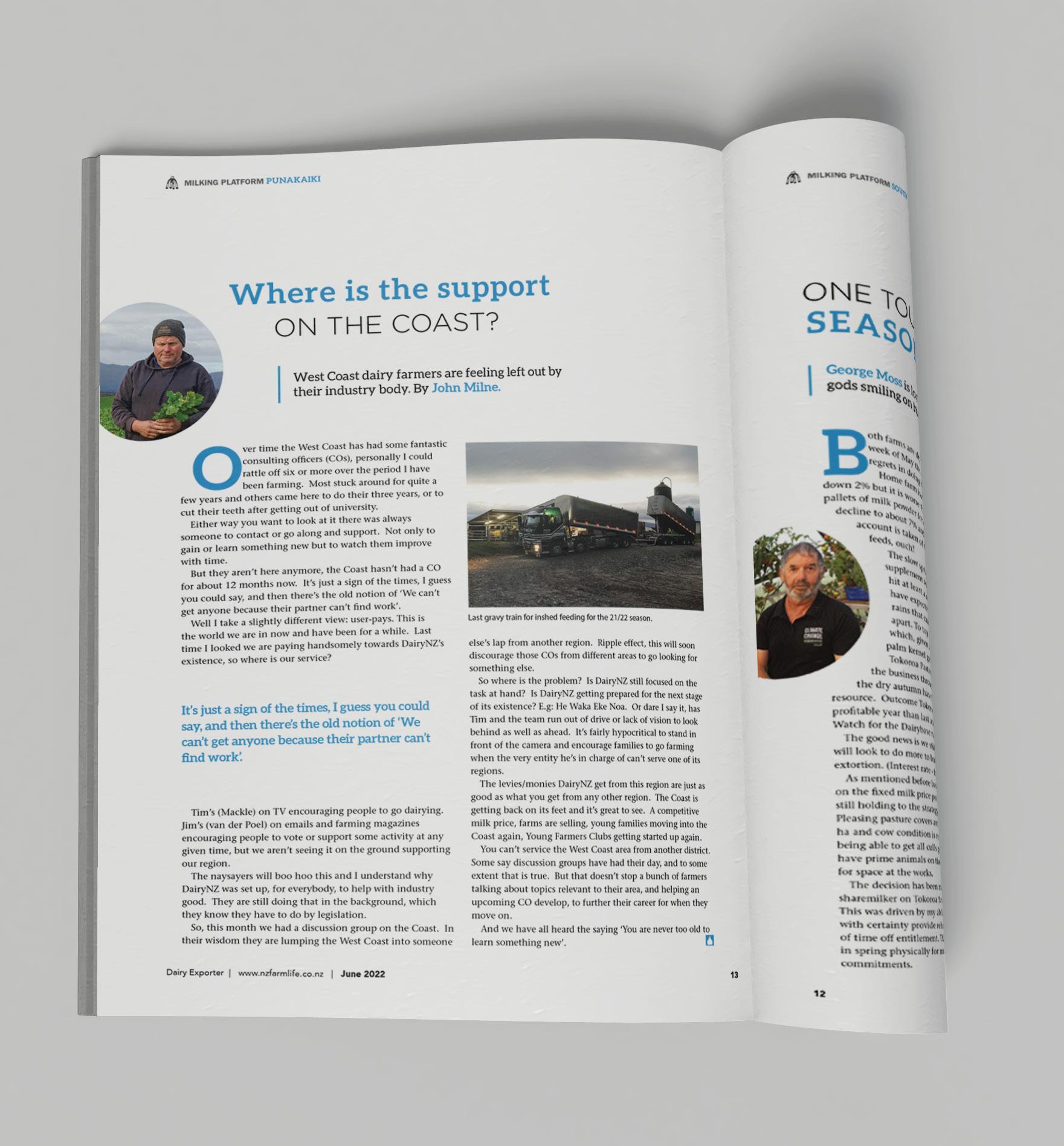

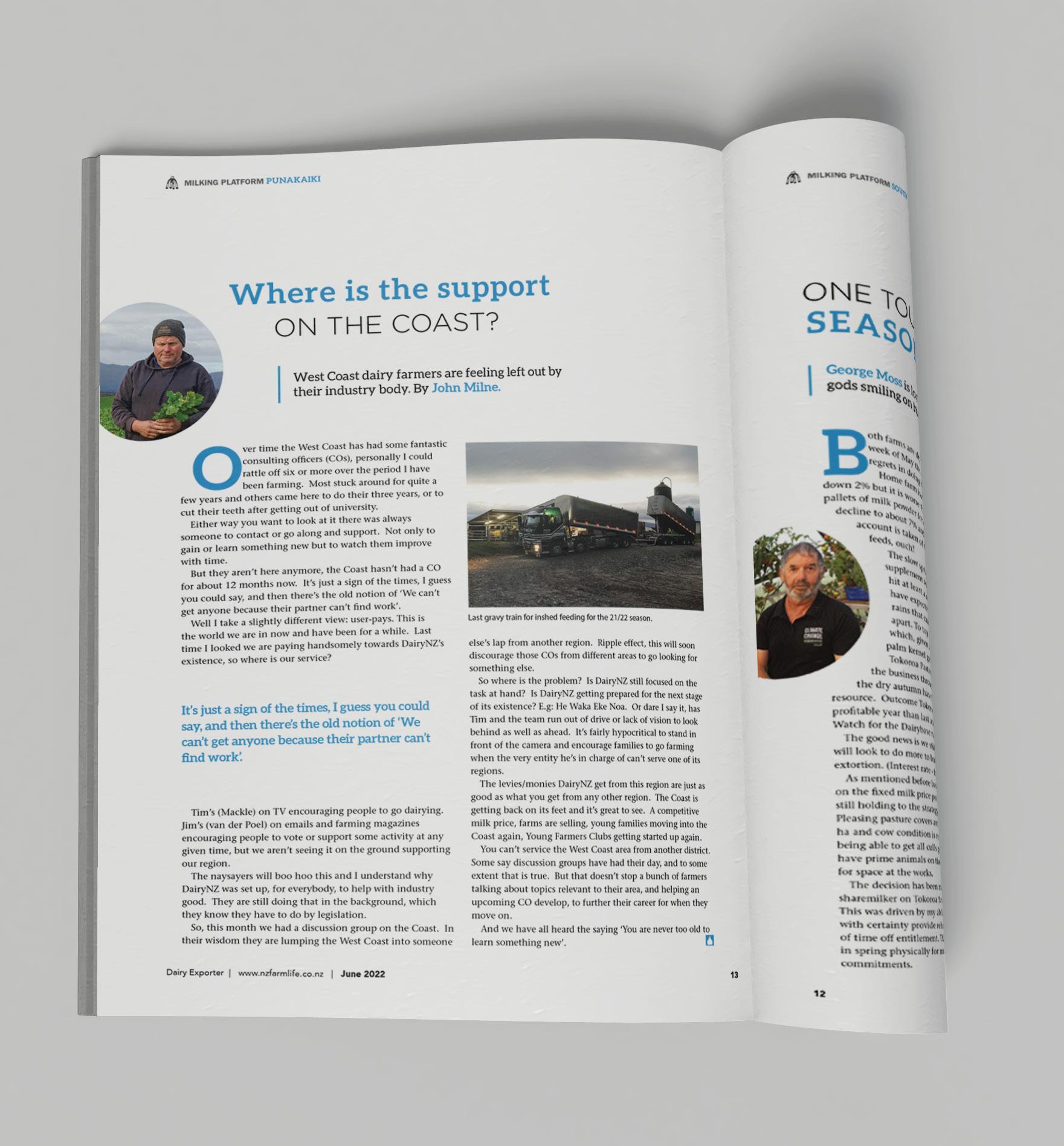

DairyNZ responds to West Coast issues

By: Tim Mackle - DairyNZ chief executive

In the last Dairy Exporter, farmer John Milne shares concerns West Coast farmers have had less support from DairyNZ, since the departure of a local consulting officer.

First, we acknowledge the delay in replacing the local consulting officer is unfortunate and regretted. We have been working hard to find a suitable candidate to replace our former West Coast consulting officer and finding, like dairy farmers, it’s a tough job market out there. We are working urgently to fill this position and looking at how to continue supporting West Coast farmers.

Our Upper South Island regional team has been covering the West Coast and our regional contacts Antoinette Archer, Mark Shadwick and Tony Finch are always happy to chat through any issues you want to discuss.

Meanwhile, I’m pleased to see there’s been a steady flow of activity across the region to support farmers. DairyNZ has hosted or supported 13 West Coast events in the past five months – a solid level of events activity, given the Omicron wave we’ve experienced.

Local events have included discussion groups, drought response meetings, significant SMASH sponsorship, supporting pilot projects within Whataroa, consultation on He Waka Eka Noa and other activities. Over the past season the team has also supported farmers and response teams through flooding response and recovery.

We are committed to continuing and building on that good work on the Coast but also encourage farmers to reach out directly to us, to discuss any queries or concerns they have.

Elsewhere, we continue to work with farmers to make sure their views are heard and understood by the Government on critical issues at national level.

We’ve had some wins with significant changes to winter grazing rules, more international dairy workers allowed into New Zealand, and an alternative and less costly emissions pricing option developed for farmers (He Waka Eke Noa) than going into the ETS.

Farmers have also told us they want our services to be more accessible – so they can use resources when it suits, without leaving the farm. Therefore, we are providing more webinars and podcasts to update farmers on key consultations and topics of interest.

But farming is becoming more complex and we recognise that it’s important to be able to talk through some of the more challenging issues with our team.

Please do reach out to our South Island team directly, we are here to work with all farmers on the Coast – particularly while we appoint a new West Coast based regional partner.

Contact: Antoinette (ph 027 1800 3122), Mark (ph 021 287 7057) and Tony (our head of South Island – ph 027 706 6183).

Dairy Exporter | www.nzfarmlife.co.nz | July 2022 13

Tim Mackle

INSIGHT UPFRONT DAIRYNZ RESPONSE

We’ve had some wins with significant changes to winter grazing rules, more international dairy workers allowed into New Zealand, and an alternative and less costly emissions pricing option

......MOVING TOWARDS MODERN FOODS.......

The middle of the year marks the thinking and planning season, where (some) tools are down and ideas percolate out of reports and conference presentations. This year it’s been particularly prevalent with primary sector thinking bolder and planning more pressing.

Most people are likely to have at least heard of the government’s Fit for a Better World ten-year roadmap, launched in July 2020 to accelerate the economic potential of New Zealand’s food and fibre sector. At a high level, the plan established three goals – that by 2030, the sector will deliver an additional $44 billion in export earnings, reduce biogenic methane emissions to 10 percent below 2017 levels, and employ 10 percent more New Zealanders.

Keen observers will have noted that the initial launch coincided with New Zealand having just eliminated Covid for the first time, and while other countries were still reeling, there was an (albeit false) sense that domestically at least, we were out of the rough and back into it.

Progress updates on the Roadmap in 2021 and most recently in June this year have however

necessitated some adjustments to initial assumptions. While the Roadmap remains intact, uncertainty about the future is explicitly documented with fresh relevance to Covidinspired changes in consumer preferences and even more impetus for technology evolution.

The successive updates have noted that meeting the goals laid out in 2020 will require a change in thinking. Hence (although not directly attributed to the Covid nemesis), the establishment of an associate Think Tank, Te Puna Whakaaronui, designated to propel the Roadmap with direction and ideas that will more likely enable the initial goals to be met.

Now, a Think Tank might conjure up an image of an agenda-fuelled group of people with no immediate stake in, or responsibility for the implementation of its ideas. But it would be wrong to dismiss Te Puna Whakaaronui (a team of eight, including familiar sector leaders Andrew Ferrier, Rob Hewitt, Lain Jager, Spring Sheep Milk cofounder Nick Hammond, AgResearch chair Neil Richardson, and financial investor expert Murray Sherwin) as fitting that cliché. For a

14 Dairy Exporter | www.nzfarmlife.co.nz | July 2022 INSIGHT UPFRONT MODERN FOODS

The roadmap of NZ agri production for the next 10 years requires a huge huge pivot towards producing modern foods demanded by the world’s wealthy to support their wellnessare NZ farmers understanding of and up for the challenge? Phil Edmonds asks.

start it is funded by the government (MPI). While it has prescribed independence, its role is to specifically help lead, co-ordinate and implement transformation. So, in short, we should pay attention because ultimately, its recommended actions will be a pointer to where policy change will occur, and public investment will flow.

Te Puna Whakaaronui was formed last year but has only recently come to prominence with the release of its first Insight report, titled :WELL_NZ, which sets out New Zealand’s food sector opportunities.

Reassuringly, there’s plenty in the report that we know already – we need to invest to implement new methane mitigation technologies, develop natural fibre products, accelerate ocean farming, support the adaption of dairy sector systems and so on.

But it is very big on making two frequently referenced (but often not much more than referenced) assumptions the cornerstone of what we need to focus on – that fundamental change (starting yesterday) will be compulsory if our agriculture sector wants to remain viable; and that those populating the highestvalue consumer segments will determine what

and how New Zealand farmers produce, rather than what and how farmers want to provide.

In summary, the :WELL_NZ report says that keeping our eyes on how high value consumers are spending will be the surest way to enable New Zealand to leverage its existing reputation for producing quality food. To support this, the report cites a prediction that over the next decade, 80% of consumption growth in Asia will come from the top two income tiers, contrasting the last twenty years, where consumption growth lay firmly in the middle-income tiers.

What do those in these wealthiest segments want from their food? Wellness, predictably enough. And the demand (and more importantly, the value) of products associated with wellness in a broad sense (well people, well environment etc) have grown fastest since the Covid pandemic set in.

Presenting at the BOMA Summit in Christchurch in June, AERU director Caroline Saunders indicated the findings from its most recent consumer insight work support this. For example, UK consumers of NZ lamb surveyed during the pandemic showed they were increasingly likely to pay more for

Dairy Exporter | www.nzfarmlife.co.nz | July 2022 15

“KEEPING OUR EYES ON HOW HIGH VALUE CONSUMERS ARE SPENDING WILL BE THE SUREST WAY TO ENABLE NEW ZEALAND TO LEVERAGE ITS EXISTING REPUTATION FOR PRODUCING QUALITY FOOD.”

Chair of the Te Puna Whakaaronui leaders group Lain Jager

LINK TO LATEST FIT FOR A BETTER WORLD 2022 UPDATE: fitforabetterworld. org.nz/assets/ publications/2022-Fit-fora-Better-World-progressupdate.pdf

LINK TO : WELL_NZ REPORT ‘REFRAMING NEW ZEALAND’S FOOD SECTOR OPPORTUNITIES’ fitforabetterworld. org.nz/assets/ Te-Puna-Whakaaronuipublications/ReframingNew-Zealands-FoodSector-Opportunities.pdf

natural food, that was good for the environment. Meanwhile, US consumers of NZ wine (especially millennials) were less interested in paying for country-of-origin but more for credence attributes like water quality, biodiversity management and social responsibility. (It’s important to remember that by 2030, millennials will have the biggest wallets).

In terms of the need to adjust to this smartly, :WELL_NZ is littered with language prompts that indicate we’re already falling behind moves made by other countries, and we’re in danger of missing out – not just on getting to choose markets before they’re colonised by others, but simply staying in the game. The report concludes that “we have a short window to invest and make progress”, and “making haste is critical.”

Stepping back for a moment and reflecting on the emotive pleas, you might say all positioning reports of this nature are bound to demand ‘we must act now’. And why, for example, are these pleas more significant than those that have gone before in reports that are now gathering dust?

Based on the collective authors being governmentbacked, as mentioned earlier, and given the esteemed heads behind the report, it’s reasonable to acknowledge there is some urgency.

All well and good, but how urgent are farmers - those who will still be doing the heavy lifting – to adapt with haste and capitalise on the opportunities, as prescribed?

Chair of the Te Puna Whakaaronui leaders group Lain Jager, also speaking at the BOMA Summit, accepts getting all participants in the food producing sector to recognise the opportunities that sit in front of New Zealand is a challenge, not least because its value as a future growth industry is still heavily contested. He noted there are three competing views on this – one that sees the primary sector as a sunset (rather than a growth) industry with an ageing workforce; one that sees food producing industries unavoidably associated with poor environmental outcomes and therefore farmers are not ideal stewards of our land; the third sees the sector as still booming, delivering 80 percent of the country’s mechanise exports based on use of the world’s leading farm systems. But rather than change, farmers need to be left alone to get on with doing what they do well.

Jager says part of the problem is there are justifiable arguments within all. The first two have been alive for some time, but regularly dismissed by those within the sector. The last one however might be the most difficult proposition

to overcome. Around the same time that the :WELL_NZ report was released the 2022 edition of KPMG’s annual Agribusiness Agenda 2022 was published. The authors noted this year it was ‘hard to know where to start’ when trying to distil the array of concerns that were expressed by the sector leaders. For some, the focus was the exceptional export returns (up 9% on 2021) and New Zealand continuing to win on the commodity cycle.

The authors (as does the :WELL_NZ report) indicate the impact of this could delay the motivation to take control of the things we can change to assist in creating a sustainable competitive advantage. Possibly the most challenging, and related finding in the KPMG survey was that respondents were more inclined to look inward than in recent years, and trained on domestic issues than outwards, at what markets were saying. It noted that “The one key element of any plausible future scenario that we might seek to explore does not feature in the Agenda because it did not feature in conversations – That is our current relationship with consumers and markets and things that are disrupting them as we move into a Covid adapted world.”

If the KPMG survey findings hold weight, the chance of a quick call to attention and ‘off we go’ advocated by Te Puna Whakaaronui seems doubtful.

It’s not putting Lain Jager off the task however, particularly the conviction that we must commit to environmental excellence involving a reciprocal relationship between people and the land because the opportunities this will open are huge. “Globally we’re failing to hit milestones and the outcomes of global warming are at the severe end of what was predicted. They’re very pronounced on food and fibre systems. So, there will be strong demand for our supply of natural foods if we take a leadership position on environmental stewardship.” Jager told the audience at the BOMA Summit it is a huge commitment, but Te Puna Whakaaronui is confident about its analysis that backs this up.

He didn’t hold back from emphasising the required rate of change towards producing what wealthy consumers want. Having set the ‘opportunities scene’, Te Puna Whakaaronui will deliver two follow up reports this year New Zealand on how we can orientate towards a producer of ‘modern foods’. This will include positioning on the emerging ‘personalised nutrition’ market as well as alternative proteins, where New Zealand is already falling behind other nations.

At the most basic level, having to contemplate, let alone implement change is a nuisance. Doing so in aid of concepts that we don’t know what they mean (modern foods) requires a huge leap of faith. But maybe not too huge.

Dairy Exporter | www.nzfarmlife.co.nz | July 2022

AERU director Caroline Saunders.

Farmers war in the Netherlands

Dutch farmers are taking to the highways in massed protests against nitrogen plans, Jelle Feenstra reports.

In the Netherlands, farmers are at war with the government. Farmers take to the streets en masse with their tractors. They block roads, supermarket distribution centres and stand on the doorsteps of politicians. They are protesting against the threat of halving their livestock numbers.

The direct reason for the actions are the nitrogen plans of the Dutch government. It wants to significantly reduce nitrogen emissions around 162 nature reserves and is allocating €25 billion ($NZ41.6b) for this. Measures for industry and transport will follow, but it is clear the livestock sector must make a significant contribution to nitrogen reduction. According to a calculation by the National Institute for the Environment, 40% of the nitrogen precipitation on nature reserves comes from livestock farming.

The government plans are causing great confusion. Many farmers, especially in the south and east of the Netherlands, where there are many nature reserves, have to halve their livestock numbers to comply with environmental regulations. According to the proposed nitrogen policy, farmers close to nitrogen-sensitive nature reserves should even quit completely. These are businesses that have been in families for generations. The government threatens to expropriate dairy farms if they do not want to cooperate in the buyout.

Farmers emotional and furious

The farmers are furious, for several reasons. There is great doubt, for example, whether nature really suffers so much from nitrogen. They also doubt that farmers are responsible for 40% of nitrogen emissions. In addition, the standards the Netherlands uses for the amount of nitrogen a nature reserve can have, are many times stricter than in all other European countries.

The standards are so stringent that even if all farmers disappear from the Netherlands, they will still not be met.

The agricultural sector also points out that many proposals have already been made to achieve nitrogen reduction, also in the short term. But these have not been adopted by the government. There is little space for technical innovations, while this is allowed in industry, aviation and traffic. As a result, farmers feel not taken seriously and treated unequally.

More farmers commit suicide

The lack of policy based on facts in combination with a total lack of discussion, participation and future perspective is now leading to strong emotions and protests. The unrest and uncertainty has surged in the Netherlands for a few years now. The suicide rate among Dutch farmers has been alarmingly high.

In the meantime, more and more citizens are joining the protest, because they believe the Dutch government does not listen to the people on other fronts as well. They suspect a double agenda, in which the government is not out to improve nature, but is out to acquire cheap farmland for housing. They fear the whole of the Netherlands will be filled with cities, roads and parks full of windmills and solar panels and that there will be hardly any space left for food production. Many farmers, especially in the south and east of the Netherlands, where there are many nature reserves, have to halve their livestock numbers to comply with environmental regulations. Political opposition parties are fiercely opposed to government policy. They mainly describe the nitrogen problem as a paper problem. While hard clashes are taking place between police and farmer protesters in various places, the government wants to deploy a mediator who should calm things down a bit.

Dairy Exporter | www.nzfarmlife.co.nz | July 2022 17 GLOBAL DAIRY NETHERLANDS

• Jelle Feenstra is an agrijournalist for Dutch pressbureau Langsdemelkweg.

Hard clashes between the police and farmers and other demonstrators are taking place in the Netherlands.

MANY FARMERS, ESPECIALLY IN THE SOUTH AND EAST OF THE NETHERLANDS, WHERE THERE ARE MANY NATURE RESERVES, HAVE TO HALVE THEIR LIVESTOCK NUMBERS TO COMPLY WITH ENVIRONMENTAL REGULATIONS.

Brazil’s environment journey

Brazil’s environmental legislation started in 1934, with early discussions in 1898. Native vegetation must now be preserved, currently at 20, 35 or 80% of the farms, depending on regional biomes (from southern grasslands to the Amazon basin, respectively), as well as hill tops, steep slopes (>45°), wetlands and riverbanks (up to 30m preservation on each side). Unauthorised killing of native animals, destroying native vegetation or illegally trading any of these are considered an environmental crime (1998), non bailable since 2012.

In 1975, Brazil pioneered the first large scale renewable energy programme ever adopted worldwide: PROÁLCOOL, a national programme that promoted the production and distribution of sugarcane ethanol and the creation and sale of 10 million ethanol vehicles. Today, there are no petrol only cars in the country, but flex-fuel cars, running on ethanol or petrol (Brazilian petrol has a mandatory 25% ethanol mixture and diesel has 14% biodiesel).

In 1978, federated states started regulating factory emissions (standardised nationally in 2007). In 1997, vehicle emission restrictions were enforced and became more stringent since 2002.

In early 1980’s, direct drilling was introduced (as part of the no-till agriculture) and is now used in more than 90% of cash crops, winter cereals and temperate pastures (98% in the case of soybean seeding).

During the late 1980’s, crop rotation practices and cover crops (“green manure” as they were called then) were adopted in large scale. Since 1993, burning of vegetation, including that of grasslands and sugarcane plantations, became largely

restricted and have since been replaced by alternative management and harvesting practices. Soil erosion, a major concern in the 1970’s, was thus controlled, with the added bonus of an increase in soil organic matter (“carbon sequestration” had not been coined yet).

In the late 1990’s, crop-livestock, livestock-forest, and crop-livestock-forest integrated systems were researched, tested in commercial scale and recommended. Crop-livestock systems were quickly adopted, while the other two alternatives only became commonplace in the 2010’s, including some very promising dairy farm initiatives, providing commercial wood, ample shadow for livestock, and carbon sequestration to mention only some of their advantages.

In 2009, Congress approved the National Climate Change Policy (the “PNMC” law), Brazil’s own voluntary attempt at mitigating greenhouse gas (GHG) emissions, which established the need for sectoral discussions and agreements, particularly energy, agriculture and transport sectors.

It also created the Brazilian Market for Emissions Reduction (the carbon market), but these are only considered ready to operate and fully regulated as of May this year, after a new piece of legislation which defined carbon credit, methane credit, stored carbon parameters, the national carbon emissions and reduction ledger, and the workings of credit transactions.

In 2010, Brazil launched the “ABC plan”

(“agricultura de baixo carbono”, meaning low carbon agriculture, in Portuguese), a large national initiative of voluntary adoption setting out guidelines and rules for farmers and growers to access its specific funding scheme (initially 5.5 then 7% annual interest). The programme was very successful, mitigating 170 million tonnes of CO2 eq., in 52 million hectares by 2020, or 327kg of CO2 eq./ hectare/year, a sum that was 46.5% above programme’s goals (note this is agricultural sector alone). Given its success, “ABC+”, a follow up of the original programme, was announced last June, with the aim of reducing the emission of 1.1 billion tonnes of agricultural CO2 eq. by 2030 (interest rates are currently being revised because of inflation, affecting global economies).

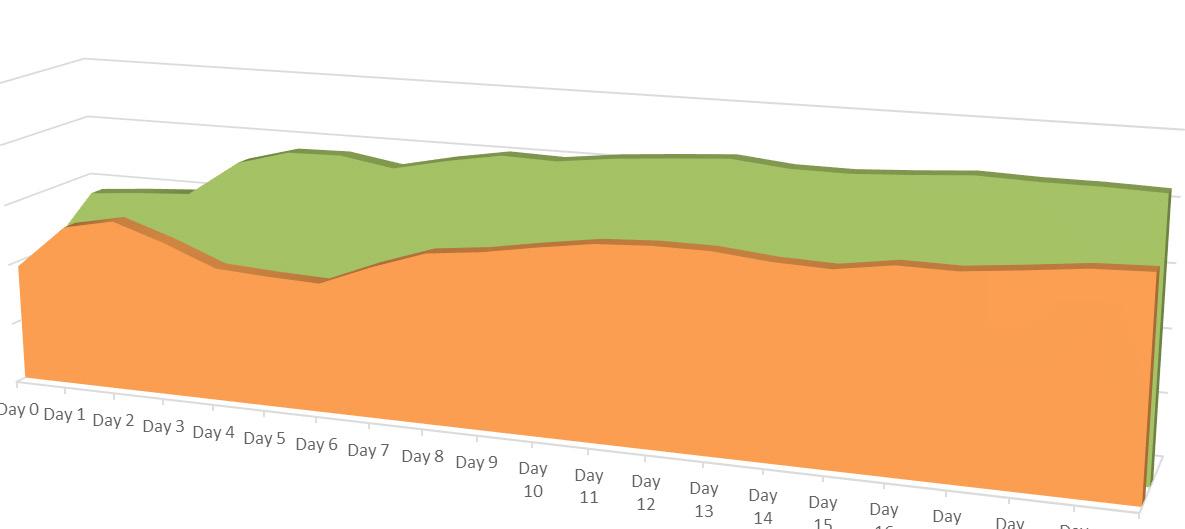

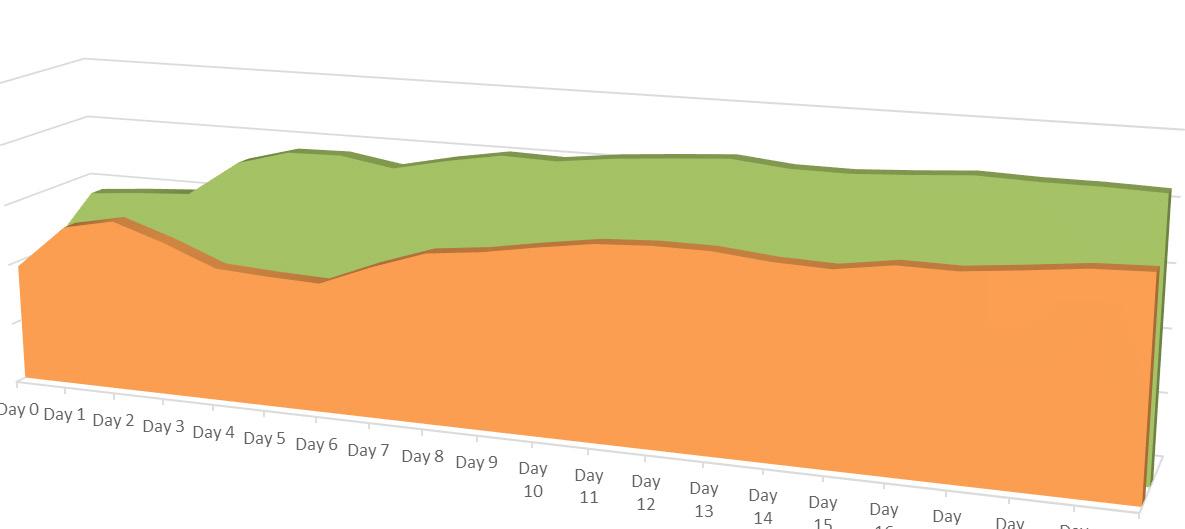

Today, Brazil runs its whole economy on 83% renewable energy, and growing, while the world average is only 27%. This sequence of achievements has not been easy, but it has been done primarily through research, innovation, education, consultation, and legislation. Whenever controversy dominated a discussion, this was overcome before advancing with legislation and in the rare moments when that was not achievable, adoption was made voluntary. Such is the case with carbon emissions in agriculture, and it is working (see graph).

18 Dairy Exporter | www.nzfarmlife.co.nz | July 2022 GLOBAL DAIRY BRAZIL

• Wagner Beskow is a senior dairy researcher and farm consultant with Transpondo, Brazil.

Words by: Wagner Beskow

Trend in per capita GHG emissions (CAIT Climate Data Explorer)

● Wagner Beskow is a senior dairy researcher and farm consultant with Transpondo, Brazil

Trend in per capita GHG emissions (CAIT Climate Data Explorer)

Pasture & Forage News

Picking winners for spring crop

Chances are you’ve already identified which paddocks on the farm need to be put through a crop in spring 2022.

Buffer your feed supply with fast growing oats & Italian ryegrass

How’s your farm feed budget looking for the new season? Have your pastures recovered enough to grow good grass through the season, or are they still showing signs of the hard autumn?

If you have a looming deficit, one way to get ahead is to sow fast growing Catch-crop+ in coming weeks. This will give you a bit of a home-grown feed safety net to reduce your reliance on imported supplement, and help lower your feed bill.

Our mix of Hattrick oats and Tabu+ Italian ryegrass is also – as the name suggests – an ideal catch-crop, soaking up excess nutrients left after cows have grazed winter crops.

Win:win

Extra cool-season growth from oats and Italian ryegrass can be grazed, or will help restore depleted supplements.

If you do run short, that growth will be cheaper than buying in palm kernel, and you don’t have to worry about price volatility or when it might be delivered. Hattrick and Tabu+ can both deliver a bulk of quality feed, just when you might really need it.

Keeps giving

Compared to oats alone, our field

trials show sowing oats and grass together after winter crop gives extra flexibility and better forage quality, with no downsides in cool season dry matter yield or nitrogen uptake. What’s more, you won’t end up with a bare paddock that needs to be resown straight after oats have been cut or grazed! Instead, you’ll have a productive pasture, with good feed quality and excellent yield through spring.

Saves time & cost

Oats on their own are a good catchcrop and provide useful bulk feed in a relatively short period of time, but they’re finished after one or two grazings or silage cuts, and need to be replaced.

Adding grass at sowing gives a high performance pasture for the next 12-18 months. That saves you the time, cost and tractor work needed to immediately re-sow the paddock after oats are finished. Talk to your seed rep about Catch-crop+ today.

For many, these will be the pastures damaged beyond quick repair by prolonged dry weather in summer and autumn. Some of these will have already been re-sown in fast short-term feed for winter and spring, e.g. Tabu+ Italian ryegrass. Others will have been left as they were in autumn, in which case now is the ideal opportunity to make sure they are wellsorted for spring sowing, with everything in place for great crop establishment.

Whether you plan to sow 501 Chicory, Dynamo turnips, Robbos fodder beet, maize or any other crops in a few months, good preparation now will make your life easier come spring.

Key areas to consider at this early stage of the process include soil testing and fertiliser planning. For winter crops, remember to make sure that physical paddock characteristics, like slope for example, meet your regional standards for intensive winter grazing.

Also check for weeds, and spray accordingly, especially if the pasture has really thinned out, and problem species like thistles have taken hold or spread in the bare patches.

Dairy Exporter | www.nzfarmlife.co.nz | July 2022 19

facebook.com/BarenbrugNZ barenbrug.co.nz @BarenbrugNZ

July 2022

Milk production; for dairy farmers, it’s one of the most common conversation topics. It can start from a weather chat or it can finish a weather chat, and no matter the weather, milk production is the key driver of revenue on farm. So, now we have data for the full 2021-22 season, you can all compare your season with the national average. Also, it is worth noting how the rest of the world is tracking on milk production, as it helps to give guidance on expected milk prices going forward.

As I’m sure you’re painfully aware, the 2021-22 season was a tough one; not one part of the country got through unscathed. Southland had a drought, Canterbury and West Coast farmers had floods and Waikato farmers had a gnarly long dry spell, interceded with a cyclone… the list goes on, but it wasn’t easy – not that any season is perfect.

Now, all those weather impacts combined have created a full season production figure of 1,869,078,000 kgMS of milk sent to all processors. This figure is 4.03% lower than the 2020-21 season. That’s a phenomenal figure, 78,548,000 kgMS less than the season prior, and only just squeaking above the 2017-18 season’s total figure. Comparing the 2021-22 season to the season prior isn’t exactly fair. The 2020-21 season was a bumper, potentially the greatest volume of milk to ever be produced in NZ (that is meant to sound like a challenge, by the way!).

In terms of volume produced in the season, production fell

Lower milksolids supports stellar price

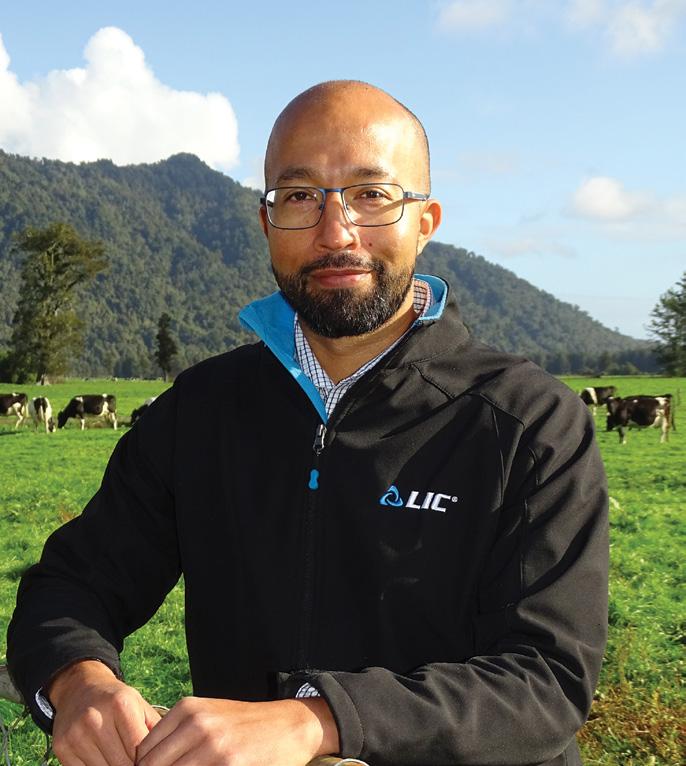

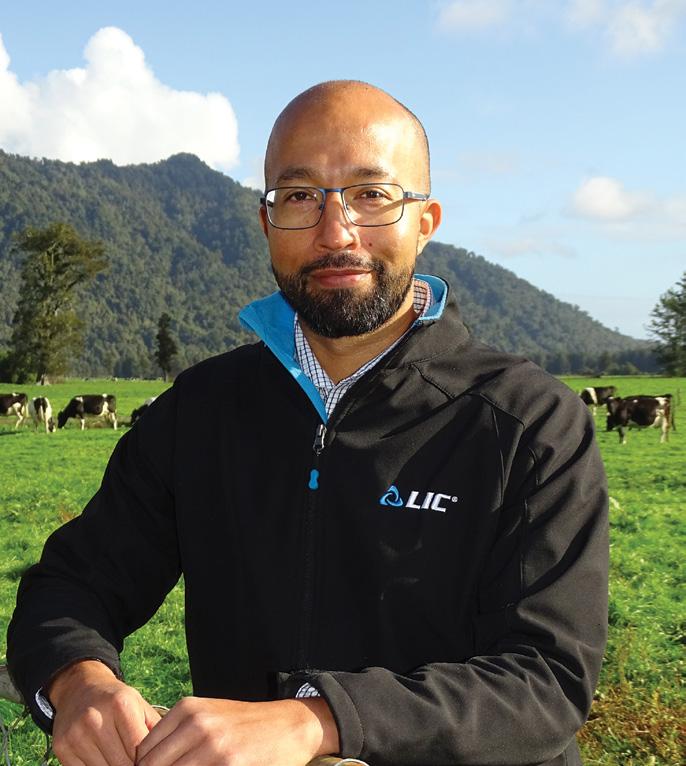

A four percent drop in NZ milksolids production for the 2021/22 year and a tough year for overseas producers is supporting the great milkprice outlook for next season, Stu Davison reports.

4.24%, or 947,000 tonnes. To visualize that volume, that is 37,880 fewer 20ft containers of dairy produced in the season (assuming 25t of dairy per container, it’s not really that exact). And for further clarity, the full 2021-22 season’s production would take 855,720 20ftcontainers to move, very roughly. And with some google data, that would take 42 average container ships to shift the total 2021-22 season’s production, with roughly two ships less than the season prior. Of course this isn’t exact at all, just a guide for scale; what I’m getting at is that 4.03% less milk is a massive reduction!!

So, we had a tough season down here, but it must be noted that this has helped to support dairy prices over the last season also; some good with the bad. Now that we are dealing with winter, and counting the days until the herd starts calving again, what is the rest of the world looking like? Well, our biggest exporting competitor, the EU, is having a terrible time. Their milk production continues to decline; they have posted a year of negative milk production figures also. Key growth countries such as Ireland, Poland and Italy have recently hit a wall, and all countries are posting

negative growth figures. Why? Fuel, feed and fert, the three headline figures everyone is throwing around, are also impacting farmers in the EU. Added to these easy ones, environmental regulations are also punishing milk production expectations. Currently in the Netherlands, regulators are looking to buy farmers out of some areas, to stop farming all together, which will have a forever outcome on milk production in those areas. So, it is unlikely that the global supply of milk will be increased from EU farmers while we are in our milk production lull of the year. Likewise, US dairy farmers are struggling with high input costs, and uncertainty also. The environment isn’t really a big issue in the US, yet. The US is increasing exports of dairy, but are still really only playing in cheese, skim milk powder and whey. Milk production in the US continues to creep along, but not at the rates seen over the four years to 2021. So, overall, milk production globally is very constrained. NZ, the EU and the US are not turning on the taps as expected to the current high prices; there is too much downward pressure for farmers. However, this fact is also a key supporter of milk price expectations for the coming season. So, how did your production compare, and will you be aiming to produce more or less than the farm record this season? More importantly, can you exceed the farm record inside the current regulations?

20 Dairy Exporter | www.nzfarmlife.co.nz | July 2022 INSIGHT UPFRONT MARKET VIEW

Stuart Davison.

0 50 100 150 200 250 300 JuneJulyAugustSeptemberOctoberNovemberDecemberJanuaryFebruaryMarchAprilMay NZ

2017 2018 2019 2020 2021 2022 average

MilkProduction ('000's kgMS)

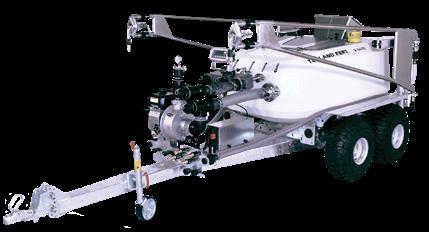

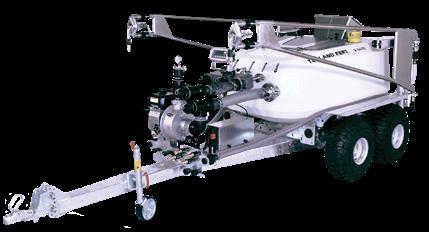

Dairy Exporter | www.nzfarmlife.co.nz | July 2022 21 For more information CALL 0800 337 747 or email us at sales@towandfert.co.nz www.towandfert.co.nz Available in 5 models. Tow and Fert. There is one for your farm. Multi 1000 Multi 500 Multi 2800 Multi 4000 DEMO Make the most of the high milk payout. Reduce your urea, apply multiple products in one-pass, including small seeds, and grow more grass with a Tow and Fert. FREE on-farm Multi 1200 A Tow and Fert is a SMART BUSINESS INVESTMENT We have been able to reduce our synthetic N to almost nothing and we are not tied into a high input system. With the cost of urea now, it’s a really good cost to avoid. Image shows a Multi 1200 in Victoria, Australia spraying a biological brew. Owen Billing, Dairy Farmer Tow and Fert Multi 1200 Owner We have been applying mag oxide, lime flour and other animal health products onto the pasture. We are 6 X less cost per cow in terms of animal health and we have staggering animal health. Geoff Bellamy, Dairy Farmer Tow and Fert Multi 1000 Owner “ “ “ “

CASH FLOW IS KING

Chris and Carla Staples bought their first farm four years ago and it looks immaculate. New shedding has been added, the dairy exterior looks swish and nearly half the 103 hectare (effective) farm has been regrassed. It has all been accomplished from cash flow, in line with their strategy throughout sharemilking and now farm ownership to focus on reducing debt and only spending money when there’s surplus in the wallet.

The couple always hung on to their long-term goal of farm ownership, despite the naysayers along the way who told them they were dreaming.

From a year working on a farm, Chris progressed to four years as a manager and then as a couple with two young kids they took on a lower-order sharemilking contract for four years, followed by seven years in a 50:50 contract.

“There’s a lot of work to get to farm ownership,” Chris says. “To get there you need to have made the decision early on in your career and have clear goals and a pathway to achieve it.”

Milking 360 cows at Whataroa in southern Westland, they won the West Coast-Top of the South Sharemilker of the Year competition in 2014. Winning that competition made them more aware of what they could achieve and that

22 Dairy Exporter | www.nzfarmlife.co.nz | July 2022

BUSINESS FARM OWNERSHIP

Dairy farming on the West Coast proves value for money, say Chris and Carla Staples. Story and photos Anne Hardie.

Chris and Carla grew from sharemilking to owner operators.

they were heading in the right direction for farm ownership.

“We wanted farm ownership and we were strategic in our savings programme,” Carla says. “We’ve always done the work ourselves rather than get staff in – if we could do it.”

Whenever they had extra money they were either buying stock to build up equity or repaying debt. Then four years ago, late in the season, a farm they thought would never be available came on the market at Kowhitirangi in the lush valley inland from Hokitika. It was a difficult time to buy a first farm. Banks were increasingly cautious about lending, especially to first farm buyers. But Carla says their Dairy Industry Award success definitely gave the bank more confidence about their forecasting.

“Our cash flows were always good and when we were buying a farm we could prove we could make money and pay off debt.”

Westland Milk Products was still a cooperative and payout for the 2018-19 season was between $5.80 and $6/kg milksolids (MS). A year later the Staples were milking for Yili after it bought the co-operative, with a 10-year guarantee to match Fonterra’s farmgate milk price, plus the purchase of shares.

For first-farm buyers budgeting on the cooperative’s payout which had been challenging for years, Yili was a lucky break. The cash payment of $3.41 per share went straight into debt reduction and their budgeting suddenly had a higher payout to work with.

They describe West Coast dairy farms as value for money. They have a price tag that is about a third of Canterbury dairy farms and don’t have the cost of irrigation. Production is about half, but overall the return on investment is greater. In Chris and Carla’s view, the West Coast is a good return on investment.

Four years after buying their first farm, they don’t have huge debt which means they are not stressing too much about increasing interest rates, despite being on a floating rate. It’s a risk factor, says Carla, but they are comfortable with that risk.

Each season they have a baseline budget for the business and if the payout is higher than expected, that is a bonus they will use to reduce debt first and then make improvements to their assets. By doing that, they aim to have more flexibility and fat in the business to cope with the unpredictability of payout, climate and government policies.

Dairy Exporter | www.nzfarmlife.co.nz | July 2022 23

‘WE WANTED FARM OWNERSHIP AND WE WERE STRATEGIC IN OUR SAVINGS PROGRAMME. WE’VE ALWAYS DONE THE WORK OURSELVES RATHER THAN GET STAFF IN – IF WE COULD DO IT.’

Chris and Carla decided early in their dairy career to aim for farm ownership.

The Staples had saved hard over the years to achieve their goal and to get the extra equity they needed for the purchase of the farm, they sold 160 of their cows, keeping the young stock with the best genetics in their herd. They had the scope as they were moving from a 360-cow herd to a farm that had been milking 230 Jersey cows.

Their own cows are Friesian crossbreds and so they have dropped numbers to 205 to compensate for Friesian-type cows on the heavy soils. It also fits their philosophy of fewer cows for more production. They begin the season on twice-a-day milking, dropping to 3in2 about March to lengthen the round and then once-a-day for the last month to build up condition and feed going into winter.

With limited inputs and pasture production about nine tonnes drymatter (DM)/ha/year, they reached 880kg milksolids (MS)/ha during the 2020-21 and 430kg MS/ cow. This past season it was back a bit to about 410kg MS/ cow after a particularly wet spring and ended up with a total of 84,000kg MS which is down a bit on their best season of 89,000kg MS from 210 cows.

In the past four years, Carla has detailed much of their progress through their Dairy Exporter’s Milking Platform column – and they have accomplished a lot. Apart from buying the farm, they have baulked at taking on more debt and everything has been done from cash flow. Though they recognise that down the track if they have to make a big purchase such as a new tractor, that won’t come out of cash flow.

Regrassing programme

In their first season, they upgraded the dairy building, including a new roof, cleared drains and subsoiled a lot of the farm to aerate and drain the fertile, but heavy soils. The effluent pond was enlarged to 600,000 litres and they began a major regrassing programme, much of it following the winter swede crop that is used to keep the cows at home. Much of the farm had not been regrassed for 20 years and regrassing is their way of becoming less reliant on imported feed.

In their regrassing programme they have trialled various ryegrass-clover mixes and this past season they have sown 10ha of the tetraploid ryegrass Forge, plus the diploid, Maxsyn, with a couple of different white clovers. It is more regrassing than they planned this year, but after the wet spring, they had a great summer and decided to keep regrassing while the going was good.

“It made us a bit short of feed in early autumn, but we’re fine now as the new grass has really taken off,” Chris says.

He likes to try the newer pasture species to find out what works best on the farm. The Italian ryegrasses weren’t lasting and he has high hopes for Forge. It is a new hybrid that is hard to source after a poor harvest of the seed in Canterbury, but they have enough to also sow this winter’s swede crop back into pasture.

Paddocks are sprayed out and fully cultivated before regrassing and are drilled using their own seed drill. They have purchased

Dairy Exporter | www.nzfarmlife.co.nz | July 2022

Nearly half the farm has been regrassed in the past four years.

all of their own equipment as the weather can often restrict the time available to get the job done. Most of the farm has been aerated in their four years of ownership to help drainage and reduce compaction.

In their first year on the farm, they soil tested every paddock which showed up a few areas that needed attention and fertilised each paddock according to the results. Last year they tested the entire farm again and the results showed the benefits of targeted fertiliser applications.

“It saves you money in the long run because you aren’t applying any more fertiliser than you need,” Carla says.

Last spring was so wet they couldn’t drive over the paddocks for a month and had to spread DAP over the farm by helicopter. It only took 45 minutes to get fertiliser on which Carla says was great for time management, but another cost. A high-rainfall climate means applying fertiliser little and often, including their nitrogen applications which are on target for the 190kg/ha/year cap.

They have also used the plant-growth regulator ProGibb SG which has enabled

them to halve the nitrogen applications in April and May. Chris premixes ProGibb and sprays it on the pasture, so it is a bit of work, but it is only for two months of the year and it gives the pasture a good boost for winter grazing.

Cows graze on grass and a break of the 6ha of swedes through winter with the swede crop yielding 16-18t DM/ha. If it gets wet in autumn, Chris says they start feeding the cows on the crop in May to build their condition going into winter.

They also make wet silage on the farm to feed to the cows whenever they need it through the year and this past season they made 210t to feed out on the concrete feedpad.

They have looked at putting a roof over the feedpad, but at this stage feel it would over-capitalise the small farm. Troughs on the feedpad enable them to feed an imported feed such as palm kernel if required.

Chris says they buy in feed if it is needed, but don’t want to be reliant on it, especially with rising costs. Like the price of fertiliser which has soared

Farm Facts

• Owners: Chris and Carla Staples

• Farm: 103 effective hectares at Kowhitirangi near Hokitika

• Herd: 205 Friesian crossbreds at peak

• Milking regime: Twice-a-day to March, then 3in2 and drop to oncea-day for May

• Production: 430kg MS/cow in 2020-21 season, 410kg MS/cow in 2021-22 season

• Wintering: Cows wintered on and fed grass, silage, palm kernel and swedes

• Bought-in supplements: 430kg DM/cow palm kernel, 239kg DM/ cow molasses in shed.

• Silage made: 210t pit silage

in the past season – doubled for the Staples - the price of palm kernel has risen dramatically. Since October it has risen from $300/t to $500/t for them. Though they still intend to feed some palm kernel through the year, it won’t be as much as the 100-150t per year they have been feeding between April and October. That covers preparation for calving and then mating.

Throughout the season, the cows are fed molasses in the dairy which helps cow flow and gives the cows extra energy when the weather is cold and wet.

Before the increase in palm kernel costs, supplements cost them 84c/kg MS for the 2020-21 season and that included making silage, calf feed, palm kernel and molasses.

It was part of their farm working expenses that tallied a moderate $3.73/kg MS – with this season still to be worked out and expected to increase due to higher costs of just about everything.

“We are really honing in on everything and being careful of what we spend,” Carla says.

Dairy Exporter | www.nzfarmlife.co.nz | July 2022 25

Chris and Carla have upgraded buildings from cashflow.

Better calves with ad-lib milk feeding

The Staples have never been afraid of trying something new and last season Carla decided to give the calves ad-lib access to milk. It meant the calves drank 70% more milk, but they grew faster and were weaned three weeks early.

“Seventy per cent more milk sounds phenomenal! But we had better calves that were quieter because it was like being reared by their mothers.

“When you typically go to a calf shed in the morning they are all going for it, but when they are ad libbing there’s absolute silence.”

The calves were fed whole milk that wasn’t destined for the vat, such as milk from the previously teat-sealed heifers. The calves were kept inside as long as possible, which was about five weeks, then transitioned on to the calfetaria in the paddock which took about three days. By early November they were all weaned because they had reached 90kg liveweight and that saved money on meal.

“The key for ad-lib feeding is never let them run out of milk. I always go over in the morning and top it up and then again in the afternoon. It’s a lot easier and time wise it’s a lot better. I had a pen of newbies so I could teach them to drink and then it’s just making sure they look like they have had a feed. They don’t overfeed because it’s more natural.

70% MORE MILk

Three seasons ago they began teat sealing the heifers to avoid mastitis. The heavy soils on the farm are great for holding moisture through summer but resulted in more mastitis cases in the spring due to their 4m-plus annual rainfall. Teat sealing has helped eliminate mastitis and its associated losses.

“It’s a nightmare of a job though. We do it when it has been dry for a while so the heifers are nice and clean. You have to be really careful about hygiene and we use lots of methylated spirits.”

It worked so well Carla intends to ad-lib feed the calves again this coming season. The calves stay on the farm until May 1 and through autumn where they have ad-lib access to the latest paddocks of new grass. By the time they head down to a grazier at Whataroa, they are huge. The same day, the in-calf heifers return to the farm for winter where they graze with the main herd. Chris says it gives the heifers time to adjust to the herd before the season begins.

“We put the whole lot through the shed once a week in winter and check their teats and teat spray and sometimes just let them walk through the (24-aside herringbone) by themselves.”

“Fun times in the shed,” Carla adds. Then at calving, each teat has to be stripped to completely remove the seal. It’s a hassle and a cost to teat seal each heifer, but Chris says the cost pales in comparison to possibly losing heifers from spring mastitis or having to cull because of lost quarters for the same reason.

The heifers calve toward the end of July, about 10 days before the rest of the herd so there’s a bit of time to “muck around with them” in the dairy before the rest of the herd calve and time is short.

Chris and Carla employ no labour, with a relief milker only brought in when they are away, so early spring is full on.

This season they have extended their calving to 10 weeks to get more cows in calf but will still have the same calving spread by using semen from shortgestation bulls for the last eight days of mating. They are strongly driven by breeding worth (BW) and production worth (PW), always nominating a bull to a particular cow to improve genetics in the herd. They reason that it isn’t a big cost to nominate a bull and you get what you want. Any cows they don’t want replacements from get Hereford straws at AI. The Hereford straws ensure a market for the calves and fewer bobby calves, with the same buyers taking their Hereford-cross calves for the past eight years.

The heifers have been artificially inseminated for the past eight years to improve genetics. This year they went one step further and used sexed semen for 75% of the heifers after a double PG programme and 60% of those resulted in successful pregnancies. They used frozen sexed semen which doesn’t get results as high as using fresh semen, but the heifers were in Whataroa so frozen semen was the only practical way of doing it.

“It costs about $55 for the sexed semen compared with about $25, but you only need one more heifer on the ground and it’s paid for itself,” Chris says.

26 Dairy Exporter | www.nzfarmlife.co.nz | July 2022

They aim at 50 heifer replacements a season which gives them good selection pressure for genetic gain and a younger herd.

Bulls go over the cows that are still cycling after five weeks of AI and that results in a small number of bobbies. They have looked at Hereford sexed semen to create more bull beef calves, but have decided to carry on the way they are for now. Carla says they are always looking at ways to improve everything they do, so they will keep their eye on options.

For the past two years the herd has had no intervention at mating. Cows are tail painted as they calve with different colours for each calving batch and that helps identify calving dates for then being metrichecked for uterine problems. Post insemination they then rely on Estrotect heat detection patches and that tail painting to identify any cows recycling. This season they also used

teaser bulls to help identify cycling cows.

Now that they have a smaller herd and there are just the two of them onfarm, they feel they have more consistency in identifying cycling cows and can record all natural matings after AI. When the cows are pregnancy scanned they also establish the age of the calf so they know whether the AI was successful or whether it was a pregnancy from a bull. Mating is an area they are always trying to make improvements by tweaking different things but mother nature sometimes has other ideas.

They’re happy with the way the season finished up though, considering the severity of spring and are now working on preparing the herd for calving and next season. As the farm improves and their debt goes down, they reckon it can only get better.

Dairy Exporter | www.nzfarmlife.co.nz | July 2022 27 dairynz.co.nz/wintering Let’s winter well for a better future Lying surfaces Fresh water Balanced diet Are your cows comfortable?

They dropped cow numbers to compensate for their Friesiancrossbred cows on heavier soils.

Engaging

your community

chairperson. “They came and went in an hour and we were able to engage with so many people and tell a good story. It’s much easier than people think.”

The dairy industry’s contribution to the economy through the early stages of Covid created a halo effect that was welcomed by farmers. Some feel that is waning now the talk has returned to environmental regulations, but DairyNZ’s chief executive Dr Tim Mackle says the organisation’s surveys show the public still looks favourably on the industry.

a photo on a Golden Bay community facebook page of the sunflowers blooming in their crop, 1,000 people liked the photo – nearly a third of the community’s population. When they posted an invite to the public to head to the farm for photos in the sunflowers and watch the cows head in for milking, more than 50 people turned up.