UPPING ADVICE: Growing more farm advisors

SPECIAL REPORT: Labour saving strategies

BUDGET BLOWOUT: Constraining creeping costs

UPPING ADVICE: Growing more farm advisors

SPECIAL REPORT: Labour saving strategies

BUDGET BLOWOUT: Constraining creeping costs

Cartwheel Creamery: Turning local milk into artisan cheeses

Don’t forget what scours can do to your calves – it can be devastating on any farm. Scours make it tough for calves to get a healthy start and causes extra stress for everyone. Help protect your calves from three of the most common causes of infectious scours; Rotavirus, Coronavirus, and E. coli.

So cut the crap, save you and your calves the pain and ask your vet about Rotavec® Corona, your proven scours solution.

As an experienced veterinarian, it was demoralising for Mara Elton Fletcher to watch a severe rotavirus scours outbreak unfold on her own dairy farm.

Mara and her husband, Hayden, milk 930 cows in Culverden, North Canterbury, and despite having top-quality colostrum management and hygiene practices in place, their herd was hit hard with a rotavirus outbreak, prompting them to vaccinate the entire herd last year with Rotavec Corona.

“It was a breaking point for myself as a veterinarian, seeing so many sick animals,” Mara explains. “The decision to preventatively vaccinate going forward was a very easy decision for Hayden, who manages the farm, to make. Having experienced the stress, anxiety, and demoralisation of a full-blown rotavirus scours outbreak, vaccination was a logical next step.”

The common and highly infectious disease was not only damaging the health and potential future growth of their calves but was also taking a serious mental toll on the couple and their staff.

“Experiencing a large scours outbreak was extremely stressful and involved very long hours to treat all of the sick calves and prevent the healthy ones from getting it. The farm staff were having to come off their routine jobs and help our calf rearers… there’s nothing worse than seeing all your staff exhausted and at their wits end.”

Hayden adds the tight labour market postCOVID meant it was really important to get rotavirus under control. “There were no backpackers or casual staff available, and we just didn’t have the manpower to deal with anything like that happening again. So we wanted to remove that risk,” he explains.

“We calve 80 percent of our cows in three weeks so it all happens really fast. It’s all on a knife’s edge as it is, so if you have a rotavirus outbreak, everything can just spiral out of control.”

The couple chose to vaccinate with Rotavec Corona because it was a single shot treatment that had been scientifically proven in the field and peer reviewed.

The vaccination works by transferring antibodies into the colostrum. It must be administered 3-12 weeks before calving begins which Hayden admits is a tricky time of year when cows are wintering off-farm and farmers themselves are trying to take a breather. But Mara says the risk of not giving the vaccine has far greater consequences.

Mara says rotavirus has had an obvious impact on calves who contracted it in terms of growth rates, and their ability to maintain a high immune status as a young growing animal. Post-vaccination, the couple believe their scours free calves are heavier on average than the year before going into their first winter.

“If they don’t get sick when they’re young, their energy is going into growth the whole time and not fighting disease,” Mara says. “We definitely had less sick calves, in general, this year.” She warns farmers not to be complacent about rotavirus or accept it as a fact of rural life.

“Top quality colostrum management and hygiene alone isn’t going to prevent scours. It’s not going to prevent rotavirus. It might

reduce the mortality rates, but it’s not going to prevent the disease. You do everything you can to try and minimise the spread, but it’s always going to spread. It’s as infectious as Omicron or more,” she says. “With a scours vaccine such as Rotavec on board, you can reduce the risk of rotavirus, coronavirus and E.coli.”

Having a well-grown, high producing animal that produces high quality food is the ultimate goal and the couple says there’s “not a chance” they would go through calving again without having first vaccinated all cows and heifers with Rotavec Corona.

“Every season’s different, but I don’t think there’s any question whether or not we’re going to be vaccinating the herd again,” Mara says. “And that’s because we know that it works. Rotavec Corona is now an integral part of our system together with good colostrum quality and hygiene management. Combined this gives us the best chances of preventing rotavirus.”

For more information about vaccinating your cows and heifers with Rotavec Corona before your calving season begins, speak to your veterinarian today.

BUSINESS

26 Artisan cheese: Keeping it local

31 Immigration: Solving staff shortages in time for calving

32 Deer milking comes north

34 A grip on creeping costs

SYSTEMS

36 SMASH Southland: Success with lucerne

38 Winter grazing: Waiting for guidance

41 Clover: Canary in the pasture

Page

SPECIAL REPORT:

Labour saving strategies

44 A sleep-in, even for the cows

47 Making better use of people

50 The future is now

52 10 in 7 milking: Better for body and mind

55 Timer calling

56 Time to outsource

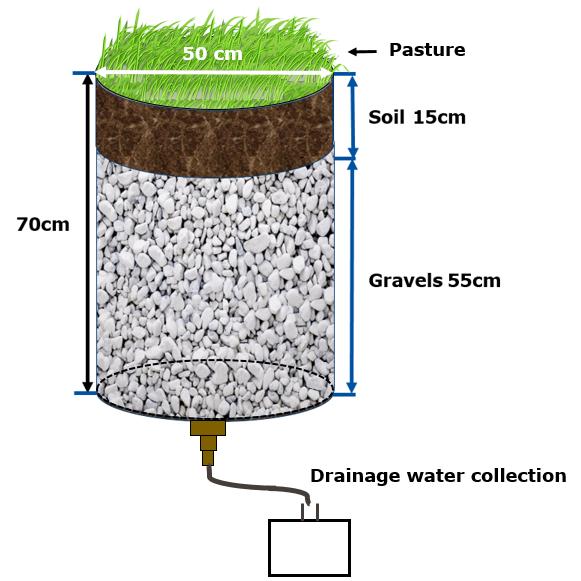

58 Conducting tests for soil water

59 View from on high

ENVIRONMENT

60 Delivering from dilapidation

65 Research: Effluent treatment and tile drains

Page 47

YOUNG COUNTRY

76 Building equity for the next move

80 New rules, new opportunities

WELLBEING

82 Safety of young ones onfarm

DAIRY 101

84 Weighing cows: Keeping on the right track

SOLUTIONS

86 Probiotics make the difference

88 New approach for transition

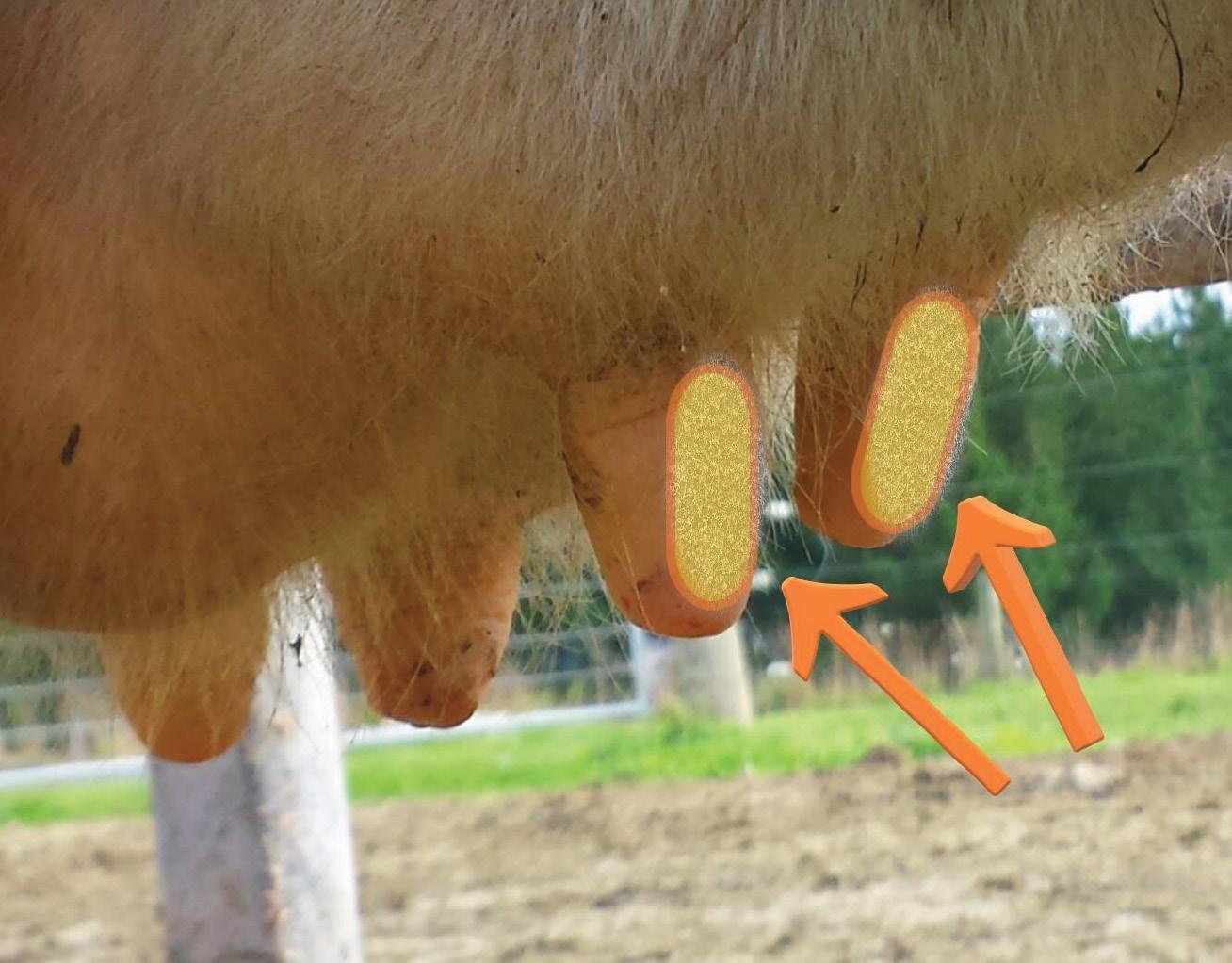

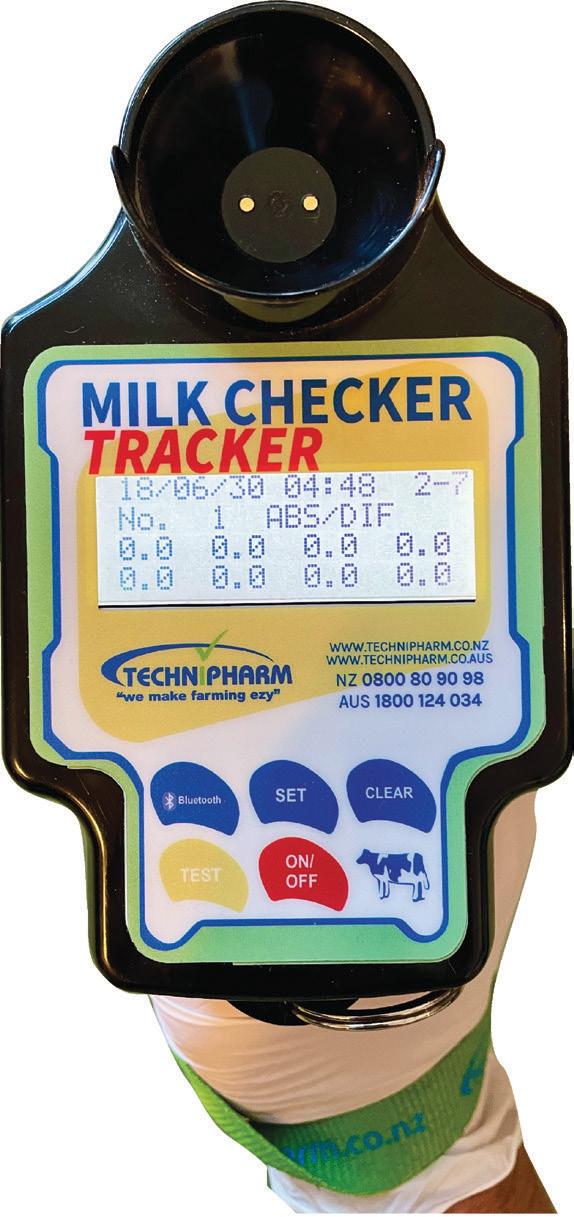

89 Tracking mastitis by the quarter

OUR STORY

90 50 years ago in the NZ Dairy Exporter

Page 82

STOCK

68 Change ahead for animal welfare

70 Calf rearing in a volatile world

74 Vet Voice: Top tips for teat spraying Page

OUR COVER

Jill and Adrian Walcroft are the Pohangina locals behind the Cartwheel Creamery brand, making local milk into artisan cheeses for the locals to love. Photo by Brad Hanson.

June 15 – A DairyNZ winter grazing workshop is being held at Dannevirke. This is a new date for the workshop. For more details visit www.dairynz.co.nz/ events/lower-north-island/winter-grazingworkshop-kiritakitararua-june.

June 15 – Northland’s Future Farm Systems’ field day to review its first season. Visit www.dairynz.co.nz/events/ northland/narfnddt-field-day-june.

June 15 – Final online episode of DairyNZ’s Farmers’ Forum Series which looks at the bigger picture issues and challenges affecting dairy farming. To register visit www.dairynz.co.nz/about-us/ event-activity/farmers-forum-series.

June 16 – A Dairy Trust Taranaki field day visits two of the research farms, Gibson and Kavanagh, for the latest results. The day begins at 10am at the Gibson farm and moves on to Kavanagh in the afternoon. More? visit www.dairynz.co.nz/ events/taranaki/dairy-trust-taranaki-fieldday.

June 16 – DairyNZ field day near Whakatane with Dr Paul Edwards on flexible milkings, its implementation and effects. The field day runs between 10.30am and 12.30pm. More? visit www.dairynz.co.nz/events/bay-of-plenty/ bop-focus-on-dairying-field-day-june.

June 16 – The Good to Great Primary Sector People and Team Leadership Programme holds its fifth Southland workshop. It provides tools and resources to build your knowledge, skills and confidence to lead your people. More? visit www.dairyevents.co.nz/media/2078/ final-southland-good-to-great-2022.pdf.

June 19-22 – Holstein Friesian New Zealand’s annual conference in Palmerston North. Visit nzholstein.org. nz/event/holstein-friesian-new-zealandconference-2022-manawatu.

June 22 – Dairy Women’s Network is running Today’s Calf, Tomorrow’s Cow expo in Matamata. It focuses on proper care and nutrition for calves to set them up for a lifetime of high performance. For more information and to register visit www.dwn.co.nz/events/todayscalf-tomorrows-cow-waikato. Other dates/locations: July 1,Okaihau; July 5, Ashburton; July 7, Invercargill.

June 29 – Dairy Women’s Network is running an on-farm practical calf-rearing workshop at Matatoki in Waikato. More? Go to www.dwn.co.nz/events/calf-rearingworkshop-hauraki-plains.

July 6 – A FarmTune workshop in Southland looks at the lean management programme for farmers. More? Contact Lynsey Stratford on 021 165 2004.

July 6-7 – The Primary Industries Summit and Awards is held in Auckland. It brings together representatives from across New Zealand’s primary industries to develop solutions to the multiple challenges they face. Among this year’s themes it will look at cross-industry collaboration, analysis of the evolving geopolitical and economic situation, emissions reductions in action, and safeguarding the future of the primary industries through developing young people. The awards held on July 6 honour the most successful and innovative primary industry producers and supporters. More? Visit www. primaryindustries.co.nz.

July 7 – A bale grazing and regenerative agriculture field day is being held on a farm near Wendonside in Southland between 10am and 3pm. More? Visit www.quorumsense.org.nz/events.

July 7-9 – The FMG Young Farmer of the Year competition holds its grand final in Whangarei where grand finalists from around the country compete through a range of practical and theoretical challenges for the 2022 title. More? Visit www.youngfarmers.co.nz.

August 14 – Applications close for 2023 Nuffield New Zealand Farming Scholarships. Each year up to five scholarships are awarded in the rural leadership programme to fast track the development of emerging leaders in the agri-food sector. To find out more and apply, go toruralleaders.co.nz/nuffield.

programme run by Reporoa dairy farmer and cancer survivor Sarah Martelli, who helps other women find their balance and build strength and wellbeing to be the best they can be.

Strong Woman is an online community for women to work on their fitness with a workout to do at home, find quick and easy healthy recipes, goal planners and to connect with other women on the same journey.

Her philosophy is to help women create healthy, sustainable habits around moving and feeding their bodies and their families.

If women can prioritise their own health and fitness, they can inspire their partners, their children and their community around them, Sarah says (p82).

She is an inspirational woman creating a moment of lift for many women.

In this issue we take a look at the regenerative agri journey some NZ farmers are already on, and that the government has signalled they want others to join in on, in our Special Report.

The regen debate has divided the farming community in a big way - many scientists are affronted that NZ would need regenerative methods from overseas countries with highly degraded soils - would that then infer that our conventional methods were degenerative?

Richard Branson said every success story is a tale of constant adaptation, revision and change. As you get older, you realise nothing stays the sameyou come up against a problem, you think of a way around it, you change, adapt, and move on to the next issue.

As farmers have become busier, herds have grown bigger, staff has been harder to find and more emphasis has been placed on team health, labour-saving devices have been developed to help solve some of farmers’ issues.

Our deep dive into strategies to save labour in this month’s special report covers the gamut from technological solutions - robotics for milking and feeding calves, satellite-aided pasture measurement, apps and computer programmes for helping in the farm office, through to different milking regimes and an easy way of buying yourself an extra half hour in bed in the morning.

We outline the proposed updates to animal welfare standards that are on the way and are currently open for submissions by farmers. Anne Lee has uncovered some that will have significant impacts on farming practices, and while not enforceable by law, will be looked to by dairy companies and their overseas customers as best practice and minimum standards. (page 68).

They say the methods won't work, and that research has already shown that, and also our farmers are already following regenerative practices. Others say that the methods are not prescribed and each farmer can take out of it what they want. It has been called a social movement rather than a science and the claimed benefits of improved soil and stock health and building soil carbon through diverse species, use of biological fertilisers and laxer and less frequent grazing practices along with less nitrogen is something that resounds emotionally with many.

(p42). We also cover the Heald family of Norsewood (p52) who have transitioned to organics, OAD philosophies and are enjoying the less intensive more resilient system they have moved to, along improved profitability.

There is more research to be done in the NZ farm system context, says MPI’s chief scientist John figure out what will and won’t work, but he encourages farmers to engage and learn more, and to embrace regenerative as a verb - saying all farmers could be more regenerative, more resilient, lowering carbon and building carbon storage.

If you are interested in getting into farm ownership getting out but retaining an interest, read about Moss’ innovative idea for a speed-dating weekend potential partners (p11). We think it could be a

JULY 2021 ISSUE

In the next issue:

We have taken a snapshot of thinking by scientists in MPI and DairyNZ (p46) and portrayed what farmers using the practices are finding, including ongoing coverage of the comparative trial work by Align Group in Canterbury

New technologies almost always have heaps of potential to save time, labour and even cost, but there is usually a pain threshold to get over, in terms of bedding in the new system, training people and animals to use it and tweaking it to get the best performance out of it.

The family motto that my husband brought to our life together was ‘perseverance furthers’, he always taught our kids to keep trying and success will come. Success doesn’t come to those who give up.

The winners of the Fonterra Responsible Dairying Award for 2022, Craigmore farming, have invested in new technologies with labour-saving potential - but have been careful to match the different options to the needs and capabilities of the team running their farms, thus stacking the odds for success. (page 47).

Last word goes to Frances Coles, our contributor from South Canterbury who encourages you all to ‘lighten the Invisible Load’ that you carry. She says the invisible load is the stress we carry, that no one sees, that drives how we think and feel. While labour-saving strategies go some way towards helping to lighten the load, on the other side we have increasing compliance, regulation and worry about what might come next that make the invisible load heavier.

Frances suggests some great strategies for all farmers to use with the coming of Matariki and the new season to make the farming load less invisible, better understood and more well-supported. (pg16).

July 2022

• Special Report: Farming/business investment – if you are starting out or bowing out.

• Wildlife onfarm

• Ahuwhenua winners

• Special report: KPIs: The numbers driving your business

• Sheep milking conference coverage

• What metrics should you be aiming for to drive your business forward

• Progression pathwaysclimbing the mountain to first farm ownership

Something of a reset, over the winter dry period, to rebalance and refocus on the things that are important. Wishing you luck with that. @YoungDairyED

• Coverage of the South Island Dairy Event: Dynamic conference

Salmonellosis is over three times more prevalent than in 20131

Salmonella is widespread on New Zealand farms and cases are increasing nationwide1. Striking without warning and spreading quickly, Salmonella can pass from your stock to the ones you care about most.

Vaccinate today to reduce the destructive impact of an outbreak*.

SALVEXIN®+B

NEW ZEALAND’S ONLY SALMONELLA VACCINE FOR SHEEP AND CATTLE

New Zealand Dairy Exporter’s online presence is an added dimension to your magazine. Through digital media, we share a selection of stories and photographs from the magazine. Here we share a selection of just some of what you can enjoy. Read more at www.nzfarmlife.co.nz

IRRIGATION IMPROVEMENTS CREATING RESILIENCE

The Woodhouse family’s irrigation improvements are creating resilience. Good data and investment into spray irrigation that allows lower rates to be applied at shorter return intervals will help maintain pasture production levels as nutrient inputs reduce with regulation.

Take a look:

https://youtu.be/bivsGOWbM9Q

ASB RURAL INSIGHTS

- Succession Series Podcast

Pareka farm has gone through a significant change in farm systems this season with the aim of cutting N losses and methane emissions, paving the way and creating learning opportunities for others.

Take a look:

https://www.youtube.com/watch?v=SV9t9tqB3Kc

NZ Dairy Exporter is published by NZ Farm Life Media PO Box 218, Feilding 4740, Toll free 0800 224 782, www.nzfarmlife.co.nz

Editor

Jackie Harrigan P: 06 280 3165, M: 027 359 7781 jackie.harrigan@nzfarmlife.co.nz

Deputy Editor Sheryl Haitana M: 021 239 1633 sheryl.haitana@nzfarmlife.co.nz

Sub-editor:

Andy Maciver, P: 06 280 3166 andy.maciver@nzfarmlife.co.nz

Reporters

Anne Hardie, P: 027 540 3635 verbatim@xtra.co.nz

Anne Lee, P: 021 413 346 anne.lee@nzfarmlife.co.nz

Karen Trebilcock, P: 021 146 4512 ak.trebilcock@xtra.co.nz

Delwyn Dickey, P: 022 572 5270 delwyn.d@xtra.co.nz

Phil Edmonds phil.edmonds@gmail.com

Elaine Fisher, P: 021 061 0847 elainefisher@xtra.co.nz

Alex Lond lond.alexandra@gmail.com

Design and production:

Lead designer: Jo Hannam P: 06 280 3168 jo.hannam@nzfarmlife.co.nz

Emily Rees emily.rees@nzfarmlife.co.nz

Partnerships Managers: Janine Aish Auckland, Waikato, Bay of Plenty P: 027 890 0015 janine.aish@nzfarmlife.co.nz

Welcome to the ASB Rural Insights

- Succession Series podcast, where we’re talking about farm ownership transition from all sides. Thanks to the ASB Rural team for partnering NZ Farm Life Media on this four-part series. Each week Angus Kebbell will be profiling farming families, talking to experts from the advisory sector and investigating new opportunities for farmers thinking about diversifying their farming business. When it comes to ‘what’s next’ for the farm, there’s a lot to think about, so we aim to share success stories, provide useful tips and help you understand more about the many facets of succession planning in the food and fibre sector today.

To listen:

https://nzfarmlife.co.nz/podcasts-2/

CONNECT WITH US ONLINE:

www.nzfarmlife.co.nz

NZ Dairy Exporter @DairyExporterNZ

NZ Dairy Exporter @nzdairyexporter

Sign up to our weekly e-newsletter: www.nzfarmlife.co.nz

Tony Leggett, International P: 027 474 6093 tony.leggett@nzfarmlife.co.nz

Angus Kebbell, South Island, Lower North Island, Livestock P: 022 052 3268 angus.kebbell@nzfarmlife.co.nz

Subscriptions: www.nzfarmlife.co.nz subs@nzfarmlife.co.nz

P: 0800 2AG SUB (224 782)

Printing & Distribution:

Printers: Ovato New Zealand

Single issue purchases: www.nzfarmlife.co.nz/shop

ISSN 2230-2697 (Print)

ISSN 2230-3057 (Online)

George Moss is looking forward to the climate gods smiling on his Tokoroa operation.

Both farms are dry now, home farm in the first week of May the other farm in mid-April and no regrets in doing that despite the record milk price.

Home farm is down 5% and the other farm down 2% but it is worse than that, as it purchased three pallets of milk powder for calves, which takes the real decline to about 7% and it is worse than that again when account is taken of the six-figure sum of purchased feeds, ouch!

The slow spring meant the expected amount of supplement was not harvested, the dry summer hit at least a month earlier than we would have expected in the south Waikato and what rains that came, while significant, were too far apart. To top it off we took a hit from eczema which, given the amount of crop, silage and palm kernel going in, caught us by surprise.

Tokoroa Pastoral purchased maize silage to get the business through the winter and fortunately the dry autumn has meant good utilisation of that resource. Outcome Tokoroa Pastoral will have a less profitable year than last and largely saved by milk price. Watch for the Dairybase numbers later.

The good news is we still smashed a lot of debt and will look to do more to buffer against the rising rates of extortion. (Interest rate - for the uninitiated).

As mentioned before both farms are out of the money on the fixed milk price position (45% at $7.50) but we are still holding to the strategy as certainty is important to us. Pleasing pasture covers are over 2100kg drymatter (DM)/ ha and cow condition is reasonable. We were fortunate in being able to get all culls gone by mid-March, but we still have prime animals on the dry block waiting and waiting for space at the works.

The decision has been made to put a lower order sharemilker on Tokoroa Pastoral for the coming season. This was driven by my ability or inability to adequately and with certainty provide relief cover for the almost 90 days of time off entitlement. This was especially challenging in spring physically for me as well as juggling my other commitments.

I may have bitten off more than I can chew – I feel happy with my understanding of risks and mitigations but my ability to get it into a comprehensive report with the all appropriate referencing and acknowledgements is challenging – due date May 23 and only quarter done. Should have waited for next year.

Silly me, I decided I should exercise my brain a bit more by doing the Intermediate Farm Environmental Planning Course through Massey University. It is a good course but I really found my limitations in terms of time and computer competency and I suspect I may have bitten off more than I can chew – I feel happy with my understanding of risks and mitigations but my ability to get it into a comprehensive report with the all appropriate referencing and acknowledgements is challenging – due date May 23 and only a quarter done. Should have waited for next year.

We attended an excellent SMASH day on Henry and Nicki Hendriks’ farm. They achieve outstanding reproductive performance with their herd of 3% MT’s and eight days to calving midpoint, all from eight weeks’ mating – brilliant! This is a real opportunity for us in our quest to reduce GHGs and improve overall performance.

Those there felt the performance was from the excellent management of transition cows. Clearly this has a significant role, along with the rising plane of nutrition, but I do wonder whether keeping the first-born heifer calves over several years has bred a “super fertile” herd? This year we will give serious consideration whether it is the firstborn calves we keep or the highest indexed ones?

A close look at our transition cow management is also in order. Neil Chesterton on lameness was excellent as always and the take-home message for me was that we do not give our cows enough space on the yard when milking, necessitating overuse of the backing gate.

Let’s hope the climate gods smile till next time, and remember, it can always be worse.

Over time the West Coast has had some fantastic consulting officers (COs), personally I could rattle off six or more over the period I have been farming. Most stuck around for quite a few years and others came here to do their three years, or to cut their teeth after getting out of university.

Either way you want to look at it there was always someone to contact or go along and support. Not only to gain or learn something new but to watch them improve with time.

But they aren’t here anymore, the Coast hasn’t had a CO for about 12 months now. It’s just a sign of the times, I guess you could say, and then there’s the old notion of ‘We can’t get anyone because their partner can’t find work’.

Well I take a slightly different view: user-pays. This is the world we are in now and have been for a while. Last time I looked we are paying handsomely towards DairyNZ’s existence, so where is our service?

else’s lap from another region. Ripple effect, this will soon discourage those COs from different areas to go looking for something else.

So where is the problem? Is DairyNZ still focused on the task at hand? Is DairyNZ getting prepared for the next stage of its existence? E.g: He Waka Eke Noa. Or dare I say it, has Tim and the team run out of drive or lack of vision to look behind as well as ahead. It’s fairly hypocritical to stand in front of the camera and encourage families to go farming when the very entity he’s in charge of can’t serve one of its regions.

Tim’s (Mackle) on TV encouraging people to go dairying. Jim’s (van der Poel) on emails and farming magazines encouraging people to vote or support some activity at any given time, but we aren’t seeing it on the ground supporting our region.

The naysayers will boo hoo this and I understand why DairyNZ was set up, for everybody, to help with industry good. They are still doing that in the background, which they know they have to do by legislation.

So, this month we had a discussion group on the Coast. In their wisdom they are lumping the West Coast into someone

The levies/monies DairyNZ get from this region are just as good as what you get from any other region. The Coast is getting back on its feet and it’s great to see. A competitive milk price, farms are selling, young families moving into the Coast again, Young Farmers Clubs getting started up again.

You can’t service the West Coast area from another district. Some say discussion groups have had their day, and to some extent that is true. But that doesn’t stop a bunch of farmers talking about topics relevant to their area, and helping an upcoming CO develop, to further their career for when they move on.

And we have all heard the saying ‘You are never too old to learn something new’.

It’s just a sign of the times, I guess you could say, and then there’s the old notion of ‘We can’t get anyone because their partner can’t find work’.West Coast dairy farmers are feeling left out by their industry body. By John Milne. Last gravy train for inshed feeding for the 21/22 season.

Application of new technology has allowed Nic and Kirsty Verhoek to ride out the challenges of the season.

Entering our third year of writing for the Dairy Exporter, it has been good to look back on our past articles. June 2020 was about ‘logistics in lockdown’ where the excitement of a new season, new farm and new home was turned on its head with the emergence of Covid-19. June 2021 was about ‘breaking barriers’ and finding opportunities in the face of challenges within the industry. And then there is June 2022: ‘limping into next season’.

The 2021-22 season has been a challenge for us and continues to be so with the lack of any significant rainfall since late December in the Waikato.

Pasture and winter crop growth rates are flailing, pasture covers are well behind target for planned start of calving, production for the season is down by 10%, and expenses are up by 10%.

We are now four months into having Halter onfarm and it is really coming into its own, especially with the wintering of dry cows. No more break fences! No longer are fences and reels being balanced on motorbikes.

We were fortunate that we got in some early winter crops which, despite the lack of rain and moisture stress, have at least provided us with some feed for dry cows. Most importantly, cows are drying off at target body condition. This is satisfying knowing we have almost reached our goal of relying on 100% homegrown feed and by-products while still being a system 5.

If you were to ignore our seasonal challenges, one aspect on the up has been onfarm technology.

We are now four months into having Halter onfarm and it is really coming into its own, especially with the wintering of dry cows. No more break fences! No longer are fences and reels being balanced on motorbikes.

It has meant we are able to back fence animals efficiently and therefore get a second go at growing additional feed by redrilling behind the cows. We still have people slowing down and doing a double-take with cows keeping behind a virtual fence that isn’t visible to the eye.

No longer do cows bellow or come to the gate when it comes to shifting as they no longer associate human presence with a new allocation of feed. Staff hours have already decreased markedly with the use of the technology onfarm –which ticks one of our goals of being able to give time back to our staff. We are excited to be going into calving and seeing what Halter can do for us and our farm.

We are entering our third season of 50/50 sharemilking and while we have had our challenges, we have been fortunate to have a great relationship with our farm owner and his full support. We are also entering the second year of our lease block which we use for grazing heifer replacements and beefies.

Again, we are fortunate to have a great relationship with

our lease block owner. The ability to have full control over the feeding and therefore growing of our heifer replacements is crucial to having them come into the herd at a target exceeding 500kg liveweight. Even while in a drought, we can feed them to their requirements (even if it does make our pockets lighter in the process) which will pay dividends down the track.

As tradition has dictated, we also got off-farm for the

opening of the duck hunting season. This is always met with much enthusiasm by the whole family. There is nothing quite like kids racing around blowing duck callers all day. This time away always freshens us up and gets us ready for the new dairy season ahead. The only downside was coming home to find it drier than when we left. Fingers crossed the break in the weather is around the corner.

Have you ever heard of a concept called ‘The Invisible Load’?

A very wise woman named Dr Libby Weaver has even written a whole book on it, saying “The invisible load is the stress we carry, that no one sees, that drives how we think and feel. From the physical load on our body, to the emotional load on our mind, this invisible load is what really sits at the heart of our stress.” How heavy are farmers’ invisible loads right now? (Apologies guys, but I’ll be slanting this from the female perspective – not to in any way diminish the weight of the loads you are all carrying, but might I suggest you check in with your wives/mothers/sisters/ friends).

Farming is by nature tough, with many variables beyond our control – weather, prices paid for our goods and costs of inputs to name just three. But it feels like it is getting mentally tougher by the year too, in ways invisible to many outside the sector.

Traditionally the females in a farming partnership often take on responsibilities in the areas of finances, HR and compliance. All alongside any role they may play in the business such as being hands-on over the busy period of calving, relief milking at weekends, or being the general farmhand/delivery-person/errand-runner.

Then they may be caring for children, older parents, migrant staff adjusting to life in a new country… Often there are also voluntary roles in the community to be filled too –PTA, sports coach, fundraising co-ordinator… the list goes on.

And all of this comes with so many thoughts! From the moment our eyes open in the morning until long after they should have been shut again at night for the mythical eight hours of beauty sleep.

‘Did I get all of the kids’ hockey uniforms through the wash? I’d better check what time their game is so I can put a message up in the team group chat for the other parents. Then I’ll need to swing past the supermarket to grab a few

things for that baking I need to do for the fundraising cake stall. Oh and the car will need to be fuelled up since the light came on during the drive home from the BOT meeting last night. What’s the date today? Dammit! The FEP audit is on Monday and I still haven’t had that certificate emailed back from the water meter installer yet, better follow up with them…’ and on it goes…

When I first married Aaron and was introduced to dairy farming life, autumn could be relatively relaxed if the weather was kind, and winter was downright quiet. Now the dairy season seems unrelentingly busy. The compliance workload is never-ending. The dry period is filled with workshops, audits and checklists to be completed. There are expectations/ standards/obligations to be met for our land, animals, people, dairy companies, regional authorities… and it all has to be documented in ever-increasing detail.

Farmers are seen as the glue that holds the community and economy together – they keep on keeping on - even through a global pandemic, weather extremes of near-biblical proportions, and financial pressures that haven’t been seen for a generation or more.

It’s exhausting, and I wonder, who has the farmers’ interests at heart? Do you feel like you are being understood and more importantly, well-represented?

We’re coming to the start of a new season, and with Matariki holiday near, a spiritual new year of sorts. Let’s all set some intentions to make ourselves better heard this year, so we don’t get to the end of this coming season even more invisibly loaded than ever before.

Ask for help when you need it. Be honest about how challenging farming is. Push back against any pointless compliance and bureaucracy. Make sure the rural sector has a voice at the table – be it your local business association, chamber of commerce, community board, council, or seat in central government. If you can’t be that voice, then at least vote well for someone who can be.

Let’s work together to make the farming load less invisible, better understood and definitely more well-supported. It’s time for change!

has a hope for Matanki, to ease the load.

Family folklore has Murray’s grandfather proclaiming that Haupiri would be the perfect place to farm if only a roof could be put over it.

No doubt this assertion was made during a downpour and with 3.3 metres of annual rainfall, there was plenty of opportunity for this statement to be made. Two generations later, we have this year somewhat achieved that vision of creating a perfect farming spot – quite literally, the roof is on.

Last year we embarked on a project. Our feed pad was not fit for purpose. It was one of those landmarks onfarm that we weren’t keen on promoting. It complied but we knew, not well.

Our problem again, was water; still too much of it, resulting in a compromised feed platform, exacerbated by 800 quartets of feet. We needed to keep the water off for the cows, the integrity of the farm and for us – it is hard work feeding out in mud. So, what started as a rather innocuous project, morphed with deliberation into a large-scale plan to build two composting shelters, dubbed affectionately in farming commentary as “Mootels”.

Why? Ultimately when we refined the issue, we wanted something that was going to respond broadly in the longterm to both weather and farming demands, regardless of season.

it address that perpetual issue of winter grazing. We needed a bigger roof over a more multi-purposeful space.

There were a number of cow housing options that could have achieved this; other farmers were generous in sharing honestly their experiences and opinions. Simply put, “Mootels” ticked our requirement boxes.

The cows would be able to feed, shelter, rest, walk around, calve and mate all under the one roof at any time of the year, if being out on the pasture was detrimental to them or to the land.

Most importantly our emphasis could remain on feeding grass. Ironically, as the roof went on, the rain stopped and the heat turned up. We were presented with hot and dry conditions not usual for our district. Summer growth rates plummeted and pasture quality disappeared, limiting milk production and challenging cow condition. Summer and early autumn became a frenzied juggle of managing feed demand and securing feed supply.

While only one of the two barns was completed, the responsiveness of the shed was instantly demonstrated. Every day from the end of October, the cows went into the barn for supplementary feed and to shelter from the intense heat. They wanted to go in there.

It was amazing to watch from a distance, the clouds of dust stirred up from the dry laneways as the cows determinedly, fast-paced their entry. There was no feed wasted. All that was left on the concrete feed lanes were a few stones and some unpalatable dock stems. Cows rested.

There is still a bit to learn about the composting process and maintaining the activity of this. And still a bit of fine tuning required to align the shelters with our farming system and practices. We’re learning and there is a whole community of cow barn farmers and professionals who can mentor this.

We wanted the solution to reflect our values of caring for our cows, our land and our people. We farm in a high rainfall area in the direct path of an easterly wind notorious for its damage. Farming in the basin of a valley can present extremes of both cold and heat.

We are bounded by a large river and have several creeks running through the property. The realities presented by this topography meant simple additions to the feed pad weren’t going to deliver us a future-proof solution and in no way did

But, when we see cows content, well fed, in good condition, with clean udders and producing milk; a pasture rested and recovering; and a happy team of people, despite the disorder delivered by the weather outside, there is a sense of accomplishment; a feeling that we’ve made a contribution to securing the future of farming for NZ. (Thanks Richard Pierce, Southland farmer and motivator, for those words).

• First published Country-Wide June 2022.

“It was amazing to watch from a distance, the clouds of dust stirred up from the dry laneways as the cows determinedly, fast-paced their entry. There was no feed wasted.”

When you farm on the West Coast, water can be a problem. So the family has built a Mootel, Gaye Coates writes.

The Government has recognised the need to boost the agricultural advice sector, as well the need to broaden the potential interest in becoming a farm adviser, Phil Edmonds writes.

Last month the Government announced it would be investing more than $25 million to expand and strengthen the primary industry advisory sector. This represented the latest spend on lifting the appeal of primary sector jobs.

To date, the focus has been on boosting numbers at farm-level (Taratahi and Telford taster courses, and the Opportunity Grows Here campaigns including GoDairy). This latest dump of cash looks to be less speculative, more mission-focused and with that,

on surer footing to deliver on its projected aim. It might also help illuminate a professionalised and internationally envied sector of farm environmental experts.

To those in the business of advising farmers, this intervention by the Government will be welcome, but not unexpected. Since the middle of 2021 when Ministry for Primary Industries published its approach to ‘Good Farm Planning’ in the form of a 28-page guidance document ‘Towards Integrated Farm Planning’, it has been abundantly clear the

One option that might help buffer the effects of the dry autumn is undersowing Hattrick oats, with or without Tabu+ Italian ryegrass.

If you’ve spent more on supplements than you budgeted for recently, you’re not alone. It’s been a really challenging season feed-wise.

But every challenge comes with opportunity. In this case, it’s a chance to strengthen your system for the season ahead, and ideally bake some more security into your home-grown feed supply for 2022/23.

Where’s the risk?

One way to tackle this is to look closely at when, how and why onfarm feed growth failed to meet cow demand during the season just finished. Was the system compromised at one single point, or were there multiple, compounding causes of feed shortages?

Is your ‘normal’ plan for spring sowing still fit for purpose in today’s unreliable climate? If there’s one thing you could have done differently to grow feed last season, what would it have been?

With spring sowing coming up, now’s the time to look at all the options for reducing imported supplements, and rebuilding or enhancing your

productive base. Happily, there may be more options than you think! As well as the summer standards of 501 Chicory and Dynamo turnips, for example, kale can grow good summer feed. Or you might find oversowing Captain plantain into run-out pastures is a better fit for you.

Plus there’s grass

Forage crops and herbs are only part of the potential package. Different ryegrasses may well help balance future gaps between farm feed supply and cow demand, too. Depending on your requirements, perennial, Italian and hybrid ryegrasses offer a wide range of seasonal growth, persistence and flexibility.

We’re here to help

It’s not always easy to work out what’s needed to restore farm feed supply after a hard season. For more ideas, book a free Pasture Health Check today at www.barenbrug.co.nz.

Our window for sowing is closing as temperatures drop. But it’s not too late to quickly stitch in next season’s crop paddocks to provide flexible feed supply from late winter onwards. Results will depend on the weather, and this approach may not suit all farms. The one thing we do know for certain, however, is that if the seed is not in the ground there’s no way it can grow!

If you don’t find yourself facing a feed pinch in late winter and early spring, extra cool-season growth from Hattrick and Tabu+ will help restore depleted supplements. If you do run short, that growth could be invaluable for calving. Both Hattrick and Tabu+ have the potential to deliver a bulk of quality, cool season feed, just when you might really need it. The beauty of oats in a situation like this is that they will establish and grow at lower temperatures than ryegrass. Likewise, Tabu+ will out-grow perennial ryegrass in cool conditions.

capacity of existing farm advisory firms was not going to be able to carry the load that would be required to meet farmers’ need to have a functioning farm plan established by 2025.

A year later, the Government has come to that very conclusion, as well as recognising there is also a need to broaden the potential interest in becoming a farm adviser. In April the Careers Pathway Scheme was born to achieve the goal of ensuring farmers and growers can adapt and innovate in order for the value of New Zealand primary sector exports to grow and be sustained.

The scheme has the primary aim of increasing the number and diversity of skilled farm advisers by up to 100 (the number determined by research undertaken

It is well understood that farming has an ageing workforce and is struggling to attract a new generation of workers. But it’s less often recognised that the advisory sector is suffering from the same phenomenon. It needs new blood and new faces as well.

for MPI by Landcare Research and Scarlatti) in the independent farm advisory sector.

As is conditional with government funding, there will be an emphasis on attracting more advisers from people outside the current network. Specifically, the target is more women, new graduates, Māori and career-changers. This isn’t just about promoting diversity for diversity’s sake.

It is well understood that farming has an ageing workforce and is struggling to attract a new generation of workers. But it’s less often recognised that the advisory sector is suffering from the same phenomenon. It needs new blood and new faces as well.

In terms of the nuts and bolts, the Government will help fund salary and training costs for new and early career advisers with less than three years advisory experience - $22,500 per year (for up to three years) will be available. It will also provide one-off contributions towards integrated farm planning-related training costs, which can be made to experienced advisers with more than three years’ advisory experience. This latter category is for advisers who want to upskill to support farmers with integrated farm planning.

Independent advisory firms are encouraged to apply for funding, particularly if they want to grow their team’s diversity and can support professional development with a steady workflow.

For those still suspicious of the need for mandated farm plans, the Government’s stock answer remains focused on it being a necessary response to what the customer wants, as well as an attempt to reduce (yes, reduce) the amount of time spent by farmers on compliance. Announcing the Career Pathway Scheme, Minister for Agriculture Damien O’Connor said integrated farm planning is being adopted to “make meeting consumer, market, environmental and business needs easier and less timeconsuming for farmers and growers”.

It may be convenient for the Government to point to consumers rather than its own needs as the reason for all this work is necessary. But there’s no point dwelling on ulterior motives. Recent announcements on the way forward for measuring greenhouse gas emissions onfarm (as proposed by the farming sector itself) is a reminder that the farm plan train is well in motion.

Wairarapa-based BakerAg dairy consultant Chris Lewis says farmers are engaged and broadly understand what lies ahead. In terms of existing commitment to planning, he says “There are differences throughout the community. Dairy farmers for example have had compliance requirements through their dairy companies for some years now, and so they’ve already started the journey.

“There are others who are only just coming on board. But the consensus is farm plans are not going away and best that we start at least learning about it and understanding the implications for our farms.”

With all that in mind, New Zealand Institute of Primary Industries Management (NZIPIM) chief executive Jo Finer says the 100 additional advisers the Government is effectively funding into the sector is probably shy of what the real number required is.

O’Connor made a point of noting the Government had worked with organisations including NZIPIM to determine the most effective way to develop capacity in the sector, and there is definitely support for the

Damien O’Connor, Minister of Agriculture.

New Zealand Institute of Primary Industries Management (NZIPIM) chief executive Jo Finer

Damien O’Connor, Minister of Agriculture.

New Zealand Institute of Primary Industries Management (NZIPIM) chief executive Jo Finer

funding approach. However, Finer says “The extra 100 might deal with the initial work on regulation around freshwater farm plans, but by the time you start adding in GHG, and the requirements that will come out of the He Eke Waka Noa plan and then potentially indigenous biodiversity reporting then that number is looking conservative.”

With 2025 around the corner, the need for more people who have environmental skillsets and knowledge of integrated farm planning will be invaluable. This is the clear basis for getting the scheme underway now. Lewis says consultancies in some regions - Canterbury, Southland and Waikato – have seen a significant shift already in their workloads and needed to take on people to deal with environmental needs.

“Other regions have been a bit slower in bringing on the demand for compliance reporting, including Greater Wellington and Horizons but as that increases the need for people will grow.”

On one level you could say bolstering the advisory sector with new talent is breeding bureaucracy – if you happen to struggle with the justified need.

But with a more positive lens, it could be viewed as a fresh means to open new career opportunities for those with existing farm experience. In fact, it is likely to add more appeal to starting a career in the primary sector, with some visible evidence that a transition from gumboots to loafers is a realistic propositionbased on the work experience gained wearing gumboots.

“It will be highly advantageous to have people coming into this work with onfarm experience,” Finer says. “In a lot of cases, it will require tertiary qualifications, but we want to push the onfarm knowledge necessary for the job and highlight the professionalism of those who are (and will become) advisers on integrated farm planning.”

Not only that, but these types of jobs also show that career progression from farm work can lead to overseas opportunities – something other sectors make a strong play for when promoting the benefits of entering their industries.

While the link wasn’t specifically made between the $339 million the Government said it would be pumping into ag emissions mitigation research in May and the global opportunities NZ would have to capitalise on its advisory expertise, the political reaction was reasonably unified on the benefits of us becoming the world leader on solving agricultural emissions. Jump forward to NZ churning out the world’s most sought-after farm

advisers.

As in any situation where the Government chips in with cash, it’s right to ask whether the investment is worthy and will lead to net positive outcomes. For example, given the spotlight on Government spending and its beneficiaries, questions might be asked as to whether the independent advisory firms (those already identified as winners) should be investing themselves to take advantage of the work that lies ahead.

Lewis suggests however there are plenty of checks to make sure the funding achieves both its desired outcome, and the recipients of funding play their part.

“Firms are expected to take responsibility for the training, and they have to demonstrate that there’s an existing in-house programme with milestones that demonstrate the progress being made by the career pathway nominee.

“On the whole, the initiative is well measured, and it will make a difference to a range of businesses. It could make all the difference in their decisions to employ an extra person.”

Wairarapa-based BakerAg dairy consultant Chris LewisIt is likely to add more appeal to starting a career in the primary sector, with some visible evidence that a transition from gumboots to loafers is a realistic propositionbased on the work experience gained wearing gumboots.

The only way to get food during the early stages of the lockdown was by buildings and apartment complexes getting together and organising group buying, which is a large quantity of food.

Locked down inside a 20th floor apartment building in downtown Shanghai is not much fun, especially with a couple of young kids. On top of this it was a huge challenge to purchase food at the start of the latest lockdown.

Being worried about the food supply is one thing I didn’t think would happen in a modern city like Shanghai. We have been lucky as we did not run out of food but the food supply has been a bigger issue for many Shanghai residents.

This is Shanghai’s first full lockdown since the initial Covid-19 lockdown in early 2020. A full lockdown in China means just that. No leaving your apartment building at all. This time all shops (including food suppliers and all deliveries) were closed.

It started as an initial “four-day” city-wide lockdown and more than two months later it is still going without an end in sight.

In mid-March and for the first time ever in 15 years, I started to see logistics issues with some items in supermarkets.

There was some panic buying late March and full lockdown started April 1 for many. Our building lockdown occurred

a few days earlier than that. The panic buying focus was not on toilet paper, but dairy products, meat, fruit and vegetables.

Luckily I did panic buy some British butter as usual supermarkets had run out of Fonterra butter and cheese, well before April 1.

With all the standard places to buy food - supermarkets, wet markets, online shops all closed, buying food became a major issue and challenge for everyone.

The larger distributors, who usually supplied the retailers, were able to deliver in large trucks. There had to be a large volume or high value of orders for them to deliver. This is a very inefficient way to do things but many people, locked down, had the time to organise this. Also the quantity of food items were a lot larger than they normally would buy, so storage became an issue for some products.

Our refrigerator and freezer space is very limited, as in most Chinese kitchens. Storage space in general is limited within apartment buildings. We always make tradeoffs with products in “normal” times. We always use milk powder - Fonterra’s 1kg whole milk powder is our go-to option, instead of fresh milk. This means we freeup refrigerator space.

Our chilled storage space is now used for fresh vegetables and fruits. Our milk powder supply has now been used up, and we have moved to UHT dairy products.

UHT milk and yogurt are enormous markets in China and the range of products available always seems to be growing. Without needing to be refrigerated it’s the ideal product when supply chains are having issues. We would always buy about four times as much as anyone else in our building when there was a UHT milk or yogurt group order. Many people in the building found that a bit strange, but with a couple of young growing kids, you can never have too many dairy products available.

When China does lockdowns, everyone must stay home. Hunter McGregor describes his family experience of Shanghai’s latest lockdown.UHT packs we are currently drinking: UHT Yogurt 205g = NZD $0.95 each pack - it is a drinking yogurt (made by Yili). UHT Milk 200g = NZD $1.25 each pack (made by Adopt a cow company) Far left: Empty street in Shanghai in the middle of the day. It should be full of traffic and people… Left: A delivery driver dropping off a group order. It’s in a large truck, not the usual ebike.

Omicron-caused lockdowns in Shanghai and other major Chinese cities have skewed imports to New Zealand’s biggest dairy market, but it’s not all gloom, Stu Davison reports.

Exports and imports are the truth standards behind perceived demand signals, especially when looking at our largest export market. With lockdowns in Shanghai and other cities in China, long-term Chinese demand for dairy is being questioned.

Import data has now been printed negative for a run of consecutive months, the truth of demand can be seen in the numbers. There is lower demand, but it’s not catastrophic for the longer term, as some are suggesting. It’s not a complete decline either, it’s a reduction. Demand has not dropped on 2008 import figures: more like 2020 figures.

Now for the numbers. Whole milk powder (WMP) imports into China in April 2022 were 8.4% lower than the same month a year prior, with a total import figure of 60,177 tonnes. Now 8.4% seems a significant number when talking about a reduction, and it is, but there is always more to the data than a single data point during the year.

By the end of April 2022, Chinese imports of WMP were 7.9% higher year to date, than the same period last year. The biggest increase in WMP import volumes was in January, which was also a record volume of WMP imported in any month ever.

It is not unusual for China’s biggest import month to be January, as NZ and China have a free trade agreement, with a zero-tariff quota at the start of each year for milk powders. This protective tariff finishes after January 2023, by the way, which will see changes to the way Chinese buyers import their WMP. But right now, this large volume of imports helps to explain why I think demand is still strong in the Chinese dairy market.

This large import volume of WMP at the start of the year was impressive at the time. It was a good indication of how strong Chinese demand is for imported dairy products. WMP wasn’t the only product seeing good demand levels at the time; liquid milk and cream products continue to see solid demand, milk protein products continue to be in demand as health foods gain popularity in China and cheese volumes keep growing.

However, these large levels of imports are now a bit of a headache. Inventories in China were well-bolstered prior to the draconian Zero-Covid lockdowns put in place; these high levels of importation were because Chinese buyers expected demand to continue the same trajectory; this trajectory was interrupted with

government policy stopping normality in its tracks.

So now we know where we are: China’s underlying demand was hot prior to the lockdowns, but lockdowns have created logistical and consumer issues and as a result imports of dairy products have fallen like a rock in China, compared to the year before.

So, let’s put some colour on these numbers and create context of where things really are. China’s imports of WMP in April 2022 were lower than in 2021, similar to 2020, but significantly higher than in 2019 and 2018. Skim milk powder imports are now tracking at levels of around 2020 and 2019, butter imports over the last three months are above the last three years, and cheese imports are behind 2021, but much stronger than 2020 and 2019.

The way we’re currently looking at this situation is: if this is the demand that Chinese buyers are willing to register while some of the country is locked within their homes, what will demand be like when life returns to normal for the Chinese population? Strong is my bet.

We saw the same demand drag during the early stages of the Wuhan lockdowns, with demand exploding following that. Then pull the lens out a little and look to the wider world.

Demand is very strong elsewhere for dairy, all while milk production keeps slipping globally. Fundamentally it’s hard to be bearish in the current market. When China returns to normal is unknown, but when they do, I expect to see fuel added to the dairy industry fire.

Maybe the origins of Adrian and Jill Walcroft’s cheese-making business were working for a year in France as research scientists and falling for the slow food movement, or being given three sheep as a wedding present by Jill’s aunty, or Ade doing a cheese-making course and creating artisanal fromages on the kitchen table early in their marriage.

Regardless of the origins, when Ade decided to chuck in the crown research scientist life, in 2011, the couple wanted to start a small business and set up a small creamery in the Pohangina Valley, Manawatu.

Their 13-hectare smallholding on a former dairy farm in the valley gave them a base and setting up a creamery in a couple of kitted-out Portacoms on the property was a great choice, Jill told farmers at a Smaller Herds (SMASH) field day at Pohangina in April.

“During cheese-making things need to happen at odd hours - it’s a 24/7 process - so it’s great to be able to pop across to the creamery and do the various processes,” Jill said.

“The question was, how much cheese did we need to make to make a living? And how much equipment did we need to get started but also to allow us room to grow?

“The portacoms give us the ability to remove, repurpose or add-on and being the DIY kind of people that we are, we spent a couple of years setting up the cheesemaking process and equipment and designing our risk management plan (RMP).

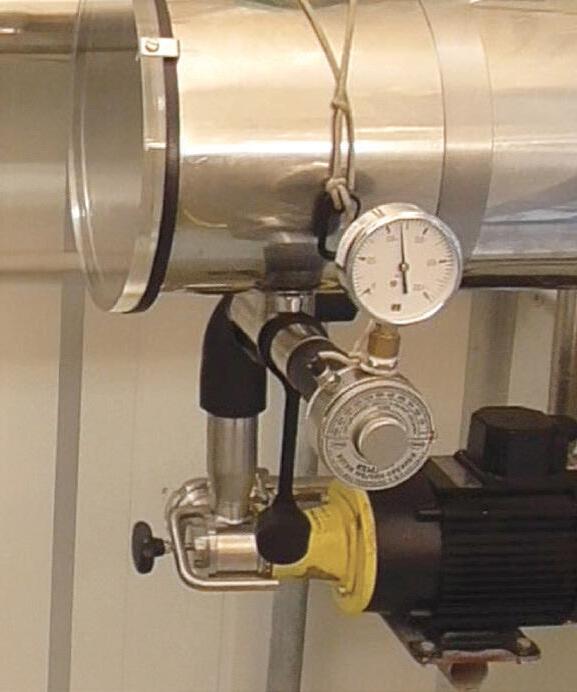

“Our 400 litre milk vat is like the mothership - and while it was expensive, it is triple-layered stainless steel and can pasteurise the milk and then make the cheese in it.

“We decided not to milk our own animals, but to concentrate on making the cheeses so we have been super grateful to connect with local farms for milk supply.

“Our RMP is a beast, but it’s been worth taking time to set it up well - the annual audit has been pushed out to 18 months.”

The company also has a rigorous testing regime for pathogens, alongside access to milk test data from their milk suppliers’ results.

They began making cheese in 2014 and have slowly ramped up production and built up their suite of artisan cheeses. The cheese offering now ranges from soft cheeses Marama and Coppermine (similar to camembert and washed-rind brie) and a soft goats’ milk Opiki Ma and Do Rei Mi, semi-hard tommetype cheese Epitome, made from lower fat milk, (also with cumin and smoked, truffle and fenugreek seed flavourings), blue cheeses Blue Rhapsody and Nanny Blue (goats’ milk) and brined cheeses Fiesta (feta) and halloumi (also made in garlic, chilli and original flavours).

After a career in science a Manawatu couple are using local milk to make a range of artisan cheeses. By Jackie Harrigan.Left: Say cheese: the Cartwheel Creamery team: Adrian Walcroft, Wicki Pask, Alison Leber and Jill Walcroft. Above left: The Walcrofts set up their creamery at their small Pohangina property. Above right: Epitome, a lower-fat tomme style cheese.

Having decided not to try and supply their own milk, the couple have built numerous supply arrangements with local farmers and love that their milk is produced so locally that they can pick up a vat of it and be making it into cheese the same day.

They have four main suppliers of milk, Jersey milk for the soft cheeses from Ian and Aly Passey’s Pohangina Valley herd (see story page 30); Friesian lower-fat milk from the Stewart Dairylands herd at Bunnythorpe for the Epitome tomme-style cheeses; winter milk from Arran Farm of Feilding from their main herd through the winter and their A2 herd for a special range of A2 cheeses sold out of their farm shop; and milk from the Henson’s herd at Rongotea for the goats’ cheeses. Alongside locality, the quality of the milk is the most important factor the Walcrofts look for.

“All of our suppliers have very low cell counts - high counts change the quality of the flavours and the yield of the cheese,” Jill explained.

“They also let us know if they are feeding the cows on a crop of turnips or brassicas - because they can change the flavour profile of the milk and of the cheese.”

The couple tend to make cheese twice a week and have a cycle of production that sees the making, ageing, wrapping and marketing of the different cheese varieties depending on their individual ageing needs - followed by marketing at the regular markets the couple attend to sell their products.

They have been regulars at the Friday Feilding Farmers Market and Saturday morning Whanganui Riverside Market for many years now, and attend two Palmerston North farmers

markets each month, along with numerous regional fairs and shows around the Manawatu and the Wellington Food Show. Cheeses are also sold through more than 25 delis and cafes around the country and from the Creamery door by appointment.

The 2020 onset of Covid-19 encouraged them to set up an online shop to sell the full range of single cheeses along with a range of goodie boxes with artisanal crackers and preserves. Whole cheese rounds for weddings and parties are the latest product Jill has developed. She is active on social media, building awareness of the brand and using it as a way to keep followers abreast of new products and news of wins at the cheese awards, which have been plenty over the past few years.

She draws on the local themes - local milk made into local cheeses by locals, the beauty of the beautiful Pohangina valley through the seasons, new ways to enjoy the cheeses, flavour matching, and brand building messaging.

As with any small business the Walcrofts have been mindful of sustainable growth and have recently taken on some part-time labour to give a hand and take some of the manufacturing and marketing load.

“We have been slowly ramping up production, despite the Covid pauses and it’s great to have the freedom to organise an extra milk pickup whenever we need it. Its just a matter of making a phone call to the Passeys the night before,” Jill said.

“We are planning to move to making cheese four days a week and the ability to double production will allow us to grow the team and give us more time off and remove some key risk - by having another cheesemaker available.

“Eventually we might like to step back and keep an involvement but be more hands-off - Adrian has fallen for sailing so he wants to have more time to explore that.”

The cheesemaking process 101:

• Cows eating grass produce very fresh milk

• Into the vat for pasteurisation (65.1C for 10 minutes then chilled to 32C)

• Making: Cultures are added to the vat, producing acid that changes the flavour and profile of the milk, a coagulant (vegetarian rennet) turns it from a liquid to a gel, and the enzyme reaction forms curd

• Cutting the curd - cutting into cubes releases whey, curds are stirred and held at temperature

• Whey is drained and curds scooped into shapes and pressed or not - depending on the cheese - lots of turning of the rounds

• Salt added as preservative and for flavour, some are brine salted

• Added seeds/spices/smoked/rounds washed in beer to form rind using local ales

• Into the culture room - steady temperature and humidity. Matures and grows rind, ready for packaging and marketing

*

‘During cheese-making things need to happen at odd hours - it’s a 24/7 process - so it’s great to be able to pop across to the creamery and do the various processes.’Top: And the compliance goes on… Above: Salting the cheese

The Passey family have been locals in the Pohangina Valley for four generations now, and their high fat Jersey milk is featuring in a range of local cheeses.

Ian Passey’s ancestor was sponsored to come out from Shropshire to become a farmer by Bishop Monrad, an ex-Premier of Denmark who settled at Karere just out of Palmerston North with his family in 1866. The bishop only stayed in New Zealand for three years before returning to Denmark but his sons stayed on and farmed with their families.

The Passey’s bought their own farm in the Pohangina Valley in 1912 from the Wagstaff family who had cleared much of the land - they planted the 120 year old oak tree still growing near the woolshed and another, much older remnant totara tree was too large for the cross-cut saw to fell. The Passeys’ roots go deep in the valley and Ian has been on the family farm since a summer dairying job in the late 80’s, while he was a Massey student, “flicked a switch” for him and convinced him to take on the family farm. He and his wife Aly run 200 ‘Kiwi-cross leaning towards Jersey’ cows on the river terraces of the Pohangina river, and run 105 breeding ewes, all replacement dairy stock and 15-20 dairy beef steers on the steeper sidings between terraces.

The 90ha milking platform is run by Ian on his own with a part-time worker and while he says it’s busy with the two operations, he is passionate about low-input farming and loves the interaction with his animals and farming Jersey cross cows that will produce at an efficient level for 10-12 years. Of the changing times in the dairy industry, Ian told visitors at the April SMASH day that the farming industry has always been a place of change - solving problems throughout

the history of agriculture is what Kiwi farmers do, and have always done, well, he said.

On his own operation, he and Aly have changed to Once-ADay (OAD) milking in the 2021/22 season, which he says has been a mixed bag with a very poor spring season.

“We used to milk OAD for six weeks each spring and then go TAD, but I thought that this would be a good season to change, because the high payout will buffer the loss of production.”

Twice a day production was 79,000kg milksolids (MS) in the last season, about average for the herd, Ian said.

“We are 13% down on last season, but I think we would’ve been 5-7% down anyway, with the difficult season - but we hope to get back to 75,000kg MS production levels over the next three seasons.”

“There is quite a different feel to the season though, just milking OAD - there is less pressure, even though the daily milking is longer and the grazing has changed - I have more time to monitor and change things if I need to pull the cows out of a paddock or move them along.

“I was surprised at how many changes OAD has created.

“The cows are certainly happy on OAD, they have adjusted very well, and they have a cruisy life.

“Just having the morning milking is easier on them in the summer heat, they can stay under the shade and I think its better on the land.”

The supply partnership with Cartwheel Creamery came about after a phone call with Adrian and Ian said it is really nice to see his product being processed locally.

For the past four years Ade rings Ian in the evening before he needs milk.

“He turns up with his trailer and vat, listening to RadioNZ, I hear the dog bark and he’s gone again.

“He has been coming regularly a couple of times each week and the small volume means we are only selling about 1-1.5% of our total production to them for the cheese-making.”

“It does mean we have an audit with MPI as they require Cartwheel Creamery to have their own RMP for this farm as a supplier of milk for cheesemaking so we have to comply with that.” But the couple really enjoy seeing their milk being made into artisanal cheeses and sold locally, saying it’s a great local partnership.

With calving just around the corner, filling any gaps in your team is likely to be top of mind.

Unemployment is at a historical low and many sectors (including dairy) are finding it tough to get staff. Getting both Kiwis and international workers on to dairy farms in time for calving is a priority for us all.

To help attract Kiwis, DairyNZ’s new GoDairy Go Now campaign is highlighting the benefits of working in dairy and the opportunities available to job seekers. It also points candidates to the latest sector vacancies.

The campaign is helping raise the profile of the jobs available and it’s then up to farmers to ensure those are great jobs.

In such a competitive job market it’s important your job ad is accurate and appealing. As people increasingly seek work-life balance, there’s a growing expectation that roles will offer good rosters and hours. Adding in factors like flexible milking, development opportunities and a competitive salary package will make roles more appealing and help attract quality staff.

Coming up with fresh ideas on how to improve your workplace – to both attract new staff and keep the ones you have – is a challenge. But I encourage you to explore what you could do to attract, and keep, good people.

DairyNZ has a webinar on recruitment and retention online that has some great tips from other farmers and a rural recruitment specialist. Visit www.dairynz.co.nz/ffseries.

Where farmers are struggling to fill a position locally, workers can come into New Zealand through the dairy border class exception.

Sustained advocacy by DairyNZ led to the Government increasing the number of international dairy workers. For 2022, the number increased from 300 to 800. The minimum wage requirement for these international workers is $28/hour.

The process is much simpler than last year – as there are no isolation or MIQ requirements. There is also no cap on farm assistant numbers. With air travel opening up again, booking flights is becoming easier too.

If you will need an international worker on board this spring, we recommend you apply now to allow time to work through immigration processes.

To find out more visit www.dairynz.co.nz/border

If you have an onfarm dairy role available, list it at nzfarmsource.co.nz/jobs. You can list a vacancy, even if you’re not a Fonterra supplier. The campaign underway now directs job applicants to farm positions advertised on Farm Source. If you’re having trouble filling a role, and want to apply to bring an international worker into NZ, the dairy class exception visa is a good option. The visa is currently the only pathway to bring in international workers. To find out more and apply, visit www.dairynz.co.nz/border

0094320

60x267

CW Sheep 1/3 Page Multi

A PETA dispenser is the simplest way to dispense magnesium, trace elements and salts to treat grass staggers or trace element deciencies. Developed by agricultural scientists at Ruakura Research Centre, the correct amount of treatment is dispensed per-animal per-day. Available in 24 hr and 48 hr models. Simply place in the trough and the job is done.

Purchase a PETA Dispenser from your local rural supplies store or veterinarian.

www.peta.co.nz

Pāmu have led the way with their innovative farming from the beginning, so it was no surprise when they decided to expand their deer milking empire into the North Island.

Deer milk has proven to have significant health, nutrition and skincare benefits compared to regular milk, and provides an opportunity for the farming sector to expand into new areas of the world while driving the milk industry forward.

So, who better to head the experiment

than Mason Jones, a current Pāmu farmer with five years experience with deer after starting as a junior shepherd on their Te Anau farm. Mason spent time working with deer both in Te Anau and later in Rangitaiki, and said this previous experience was invaluable when it came to him deciding to take on the job of managing the milking side of things.

“Milking definitely doesn’t come naturally to me, being from a dry stock background, but having experience with deer and knowing how to behave

around them is far more valuable. Deer can be unpredictable at times and so it is important that we have a good team who behave accordingly.”

Picking the right staff is extremely important when working with deer, and Mason said he has been very lucky so far. Alongside him he has his 2IC Scott and a team of milkers with previous experience milking sheep, which helps when it comes to having a calm attitude around the stock.

Both Scott and Jo, another milker, came over from other Pāmu farms which meant that they already knew the high standards that Pāmu set and aim to achieve.

The team have started off milking 90 hinds once a day through their brand new seven-aside herringbone shed on Tukairangi Road, just outside of Taupo, and soon hope to expand this number to 140. Choosing the deer that are transitioned into milking is the hardest part, Mason said, made easier by the fact that the deer all come from within Pāmu and are chosen mainly on temperament rather than milk production.

“Sometimes it can be difficult choosing because you don’t know how an animal is going to act until they are in the milking facility. The great part is that there is no waste; if a hind does not adapt well to being milked, she simply dries herself off and returns to another Pāmu farm.”

Mason wasn’t completely in the dark about what he was signing himself up for, and spent time with Pete and Sharon McIntyre in Gore before starting the job. The McIntyres are a fifth-generation farming family, and Mason said his time with them was extremely valuable in preparing him for what was to come. While the industry is still learning, it is important that fellow deer farmers have each other’s backs, because we all want each other to succeed and show the world how beneficial deer milk can be, Mason explains.

Another advantage to milking deer is the handling of young stock. With the help of Jamie Ward from AgResearch, Mason has developed an efficient way to rear fawns and guarantee accurate recording of replacements. Fawns are currently born between November and December, and

while the hinds are still adjusting to the milking procedure, fawns are left at foot which has proven a natural success.

They are weighed and then tagged and weaned over 30kg, while anything under this is left with the hinds to continue to naturally grow. The fawns are all DNA tested ensuring the most accurate results in regards to keeping everything in house, and Mason hopes they will be able to accurately produce replacement hinds from those that prove themselves to be the best overall milkers.

“Our best hinds are producing 1.1 litres/ day, which is quite impressive considering that’s just once a day and looking at the size of their udders. It is important that they are milked out properly, and we pride ourselves on having zero mastitis issues so far after two short seasons milking.”

At the end of the season (usually about the end of April) the hinds dry themselves off naturally, and then they are scanned at the end of May. While it is very much still a case of learning on the job, most hinds won’t cycle until the middle of March,

which is why scanning happens so much later. This works well with drying off being earlier and gives the hinds time to adjust, while relieving stress both for the deer and the staff.

Developing the system to work well onfarm has been easy so far, Mason said, and the smaller milking window alongside a 6/2 staff roster has kept everyone happy.

All the milk produced is frozen and transported off farm fortnightly to be used by Pāmu for a variety of products.

These include cosmetic products mostly sold in South Korea, but also as milk and powder to restaurants in New Zealand, Australia and Hong Kong.

The plan in the future is also to make products available to buy direct from the Pāmu website.

Deer milk’s rich nutritional profile lends itself to foodservice, but other components useful for skincare and healing service have also been identified.

The latest venture is research into the benefits of deer milk in regards to healthy ageing, something already strongly

supported by traditional Asian beliefs among the older population.