Learn, grow, excel May 2022 $12 incl GST MAY 2022 $12 The traffic light system for mating Trade’s perfect storm ONFARM EMISSIONS 500kg MS/cow - The Journey DRIVING DOWN

2 Dairy Exporter | www.nzfarmlife.co.nz | May 2022 CONTENTS MILKING PLATFORM 7 Suzanne Hanning is working on the scratch factor. 10 Taranaki’s Trish Rankin looks forward to a well-earned break. 11 Richard Reynolds has gone back to running a discussion group. 12 Persistence with new technology pays off for Hamish Hammond UPFRONT 13 The challenge for pastoral farmers is more than just digital 18 Global Dairy: Ukraine war a threat to UK dairy 20 Market View: Trade’s perfect storm BUSINESS 22 Seeking directions with discussion groups 27 Farmax: Embrace the opportunities 30 Water costs threaten Waimea dairy future SYSTEMS 32 Shining a light on mating 37 Production: Sweet validation 39 Northland: Building drought resistance Page 64 Page 22 Page 30

Page

SPECIAL REPORT:

GHG Emissions

42 Solutions: What’s in the pipeline

47 Proving the theories

50 Magic methane inhibitor

52 Promise with red seaweed ignored

54 Breeding for climate friendliness

55 Making the commitment

ENVIRONMENT

58 Dung beetles: Beetling up the valley

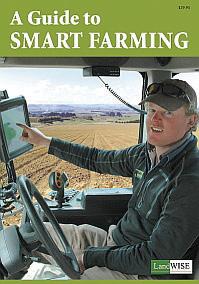

63 Planning for wintering well STOCK

64 Focus on the breeding

68 Dairy Beef: MINDA Beef edition

69 App helps reduce toll on bobbies

70 Dairy Beef: The young ones

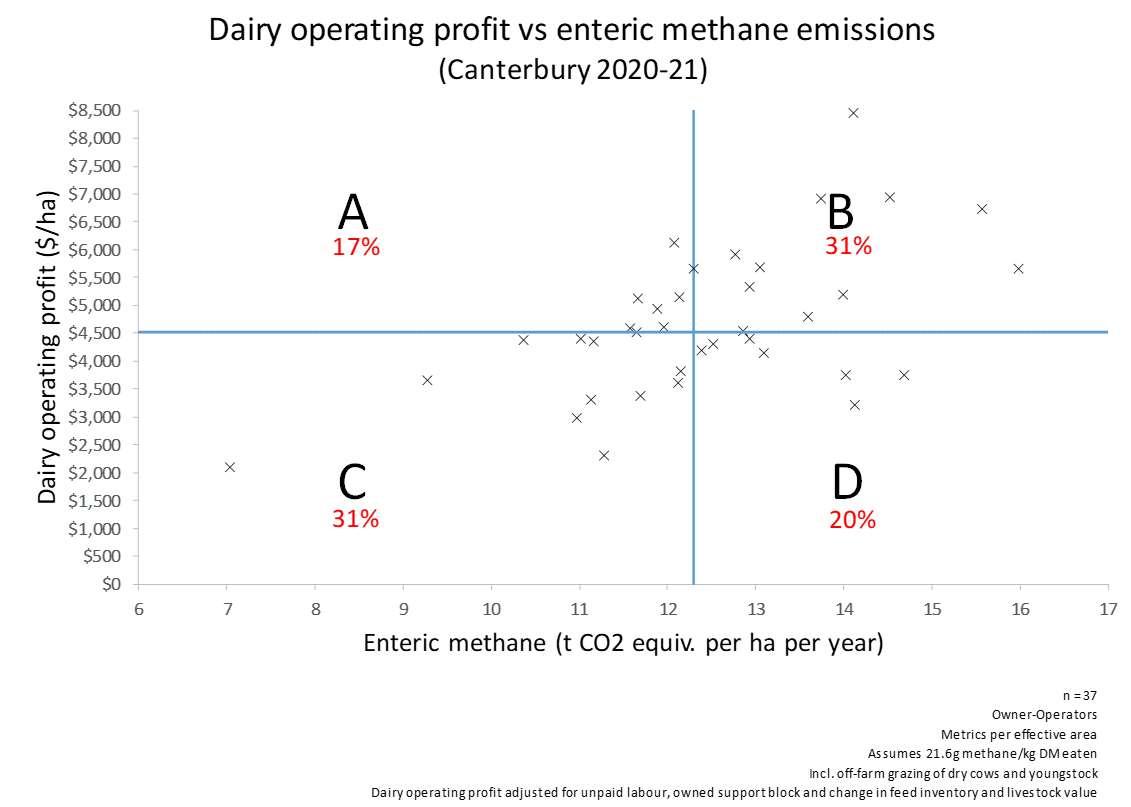

72 Study shows how to drop

GHG 22%

76 Vet Voice: Making the transition

78 Drawn to dairying

80 Wellmates: Overcoming isolation woes

WELLBEING

82 Suffering ‘Nearly there’ syndrome

RESEARCH WRAP

84 The Dry: Coping with drought

85 Microbes: Tiny workers keeping things green

DAIRY 101

86 Those four stomachs

SOLUTIONS

88 Halter expands availability

89 Probiotic supplement cuts methane

OUR STORY

90 50 years ago in the NZ Dairy Exporter

OUR COVER

Page

Dairy Exporter | www.nzfarmlife.co.nz | May 2022 3

78

Page

64

Page

52

Stu and Amy Vanderweg from Pareka farm have proven the theory: GHG emissions can be driven down by reducing stocking rate while staying close to budgeted production targets. Photo by Holly Lee. 58

YOUNG COUNTRY

DAIRY DIARY

May 14 – The Dairy Industry Awards announces its overall winners at the National Awards Dinner in Christchurch. They include New Zealand Share Farmer of the Year, New Zealand Dairy Manager of the Year and the New Zealand Dairy Trainee of the Year. More? visit www. dairyindustryawards.co.nz

June 1 – A Quiet Leadership live webinar between 12.30pm and 1.30pm focuses on the brain-based rhythm and approach of quiet leadership, as well as the power of coaching in leadership. The webinar is run by Dairy Women’s Network with ASB. To register go to register.gotowebinar.com/ register/1984405602444783117

June 8 – The Extension 350 project in Northland is coming to an end after five years and is holding a field day to hear how farmers benefited from the project. The day runs between 10.30am and 1pm on the Giesbers’ farm at Okaihau. More? visit www.dairynz.co.nz/events/northland/ extension-350-public-field-day-june

June 8-9 – The South Island Dairy Event (SIDE) is being held in the Oamaru Opera House. Key speakers include founder and chief executive of Halter, Craig Piggott; doctor and entrepreneur Dr Tom Mulholland; co-founders of 42 Below, Geoff and Justine Ross. Rural commentator Sarah Perriam is MC. The event combines industry experts, networking sessions and practical

workshops in a revitalised format this year. To find out more and to register visit www.side.org.nz

June 8-10 – Ayrshire New Zealand is holding its annual conference in Napier. More? visit ayrshire.org.nz/annualconference

June 9 – The Southland Ballance Farm Environment Awards for 2022 are being held in Invercargill, with other regions following. Dates/locations: June 29, Greater Wellington; July 1, Bay of Plenty; July 6, Taranaki; July 7, Horizons; July 14, Canterbury. More? visit nzfeawards.org.nz

June 15 – Northland’s Future Farm Systems’ trial has a field day to review its first season. The project compares three farm systems that adapt to or mitigate climate change effects. More? visit www. dairynz.co.nz/events/northland/narfnddtfield-day-june

June 15 – The final online episode of DairyNZ’s Farmers’ Forum Series which looks at the bigger picture issues and challenges affecting dairy farming. To register visit www.dairynz.co.nz/ about-us/event-activity/farmersforum-series

June 16 – The Good to Great Primary Sector People and Team Leadership Programme holds its fifth Southland workshop. It provides tools and resources

to build your knowledge, skills and confidence to lead your people. More? visit www.dairyevents.co.nz/ media/2078/final-southland-good-togreat-2022.pdf

June 19-22 – Holstein Friesian New Zealand is holding its annual conference in Palmerston North. More? visit nzholstein.org.nz/event/holstein-friesiannew-zealand-conference-2022-manawatu

July 6-7 – The Primary Industries Summit and Awards is held in Auckland. It brings together representatives from across New Zealand’s primary industries to develop solutions to the multiple challenges they face. Among this year’s themes it will look at cross-industry collaboration, analysis of the evolving geopolitical and economic situation, emissions reductions in action, and safeguarding the future of the primary industries through developing young people. The awards held on July 6 honour the most successful and innovative primary industry producers and supporters. More? primaryindustries.co.nz.

July 7-9 – The FMG Young Farmer of the Year competition holds its grand final in Whangarei where finalists from around the country compete through a range of practical and theoretical challenges for the 2022 title. More? www.youngfarmers.co.nz

TALK TO THE EXPERTS FOR FARMING SUPPORT

HERBAL DIGESTIVE DRENCH

Herbal Digestive Drench is natural health tonic and nutritive, to support a healthy faecal egg count and to maintain a healthy animal. Suitable for calves, cows, lambs, sheep, goats, alpacas and horses.

4 Dairy Exporter | www.nzfarmlife.co.nz | May 2022

TUBERCULINUM Immunity support for the winter season. CAL/MAG

and

farmservices.nz info@farmservices.nz 07 858 4233 /HomeopathicFarmServices FARM SERVICES

To assist in balancing calcium

magnesium

HOMEOPATHIC

Her philosophy is to help women create healthy, sustainable habits around moving and feeding their bodies and their families.

If women can prioritise their own health and fitness, they can inspire their partners, their children and their community around them, Sarah says (p82).

She is an inspirational woman creating a moment of lift for many women.

In this issue we take a look at the regenerative agri journey some NZ farmers are already on, and that the government has signalled they want others to join in on, in our Special Report.

The regen debate has divided the farming community in a big way - many scientists are affronted that NZ would need regenerative methods from overseas countries with highly degraded soils - would that then infer that our conventional methods were degenerative?

CLIMATE DREAD

They say the methods won't work, and that research has already shown that, and also our farmers are already following regenerative practices. Others say that the methods are not prescribed and each farmer can take out of it what they want. It has been called a social movement rather than a science and the claimed benefits of improved soil and stock health and building soil carbon through diverse species, use of biological fertilisers and laxer and less frequent grazing practices along with less nitrogen is something that resounds emotionally with many.

Ihave been reading about climate dread and eco-anxiety, and it’s pretty depressing. It’s prevalent in the younger generation of 16-25-year-olds and research shows it’s the uncertainty of the climate changing and the fear of what the actual change will cause that leads to the condition.

It has been easy to think in New Zealand about climate change as something that is happening to someone else, far away overseas, and that it won’t affect us.

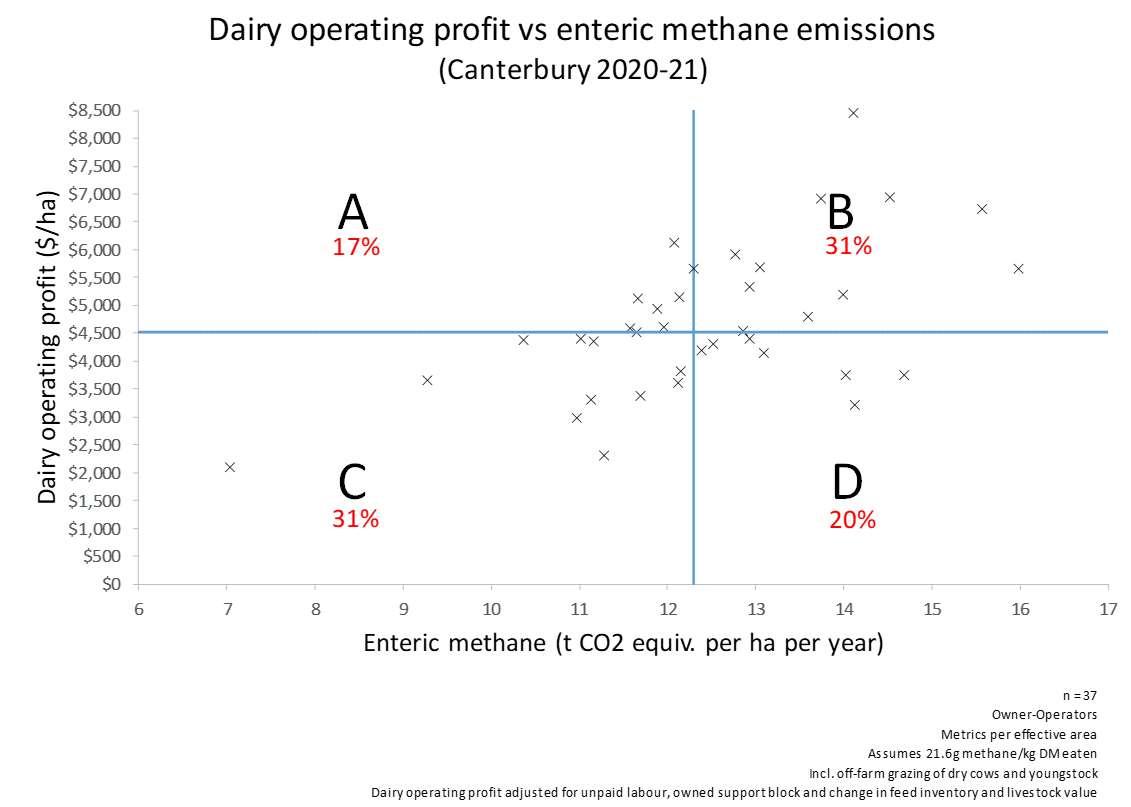

palatable. Read about George’s journey in our special report on GHG emission reductions where we also cover all of the main mitigations coming down the pipeline. We also take a look at how one Canterbury farm has managed to lower emissions by reducing stocking rateachieving significant reductions in methane and nitrous oxide emissions, and nitrogen loss - while also meeting production targets.

We have taken a snapshot of thinking by scientists in MPI and DairyNZ (p46) and portrayed what farmers using the practices are finding, including ongoing coverage of the comparative trial work by Align Group in Canterbury

But then we saw the effects of a pretty rugged summer drought in Southland, and another 1-in-100-year West Coast flood - all in a year, and the news that the sea levels are rising twice as fast as previously thought in some parts of Aotearoa.

And so what if we don’t manage to constrain global warming to 1.5C? That’s a pretty small number - until you start to think about how that’s an average and at the fringes there are going to be some huge increases around the world - like the 47C+ heat waves parts of India are currently experiencing.

It’s here, it’s happening and it’s scary if you think through all the ramificationsstorms, droughts, wildfires, water shortages, global climate refugees.

While He Waka Eke Noa (HWEN) wends its way through the consultation and regulatory process, farmers need to start thinking about how cutting emissions on their farms will work.

The good news is that mitigations are getting closer and there are concrete things you can do in the meantime.

Deciding on a path and taking action is so much better for the planet and for your mental health than catastrophising about the future.

Every journey starts with the first stepMat and Catherine Korteweg started on a journey to 500kg milksolids (MS)/cow and took to a Facebook group in lockdown for support and guidance to reach their goal. (pg22)

A group of farmers investing in dung beetles in the Linkwater Valley in Marlborough are taking action too, with the aim of improving pasture production alongside the environmental benefits of the dung-burying and processing beetles.

Taking action is better than sitting around catastrophising - I’m off to buy an ebike and parking up the car! And I will have to put a lot more thought into what I eat, where I fly and how I shop.

philosophies and are enjoying the less intensive more resilient system they have moved to, along improved profitability.

There is more research to be done in the NZ system context, says MPI’s chief scientist John figure out what will and won’t work, but he farmers to engage and learn more, and to embrace regenerative as a verb - saying all farmers could be more regenerative, more resilient, lowering and building carbon storage.

If you are interested in getting into farm ownership getting out but retaining an interest, read about Moss’ innovative idea for a speed-dating weekend potential partners (p11). We think it could be

Sneak peek

JULY 2021 ISSUE

In the next issue:

June 2022

• Special Report: Farming/business investment – if you are starting out or bowing out.

• Wildlife onfarm

• Ahuwhenua winners

• Sheep milking conference coverage

• Labour-saving onfarm - what’s the latest tech to help farmers save labour and time?

• Deer milking at Pamu

• Getting closer to your consumers’ the local food movement.

WINNER

DairyNZ Climate Change

ambassador George Moss has been committed to the journey for the past five years, and it’s not been easy, nor always successful. (Pg55)

“The reality is that reducing a carbon footprint usually requires decisions that can impact on lifestyles and incomes,” George says, and that’s often not particularly

Dairy Exporter | www.nzfarmlife.co.nz | May 2022 5 Editor’s note

@YoungDairyED @DairyExporterNZ @nzdairyexporter NZ Dairy Exporter Dairy Exporter | www.nzfarmlife.co.nz | June 2021 connect with other women on the same journey.

(p52) who

to organics, OAD

have transitioned

@YoungDairyED @DairyExporterNZ @nzdairyexporter NZ

The lucky winner of the Suzuki DR200SE motorbike subscribers prize is Leanne Browne from Waipu.

ONLINE

New Zealand Dairy Exporter’s online presence is an added dimension to your magazine. Through digital media, we share a selection of stories and photographs from the magazine. Here we share a selection of just some of what you can enjoy. Read more at www.nzfarmlife.co.nz

IRRIGATION IMPROVEMENTS CREATING RESILIENCE

The Woodhouse family’s irrigation improvements are creating resilience. Good data and investment into spray irrigation that allows lower rates to be applied at shorter return intervals will help maintain pasture production levels as nutrient inputs reduce with regulation.

Take a look:

https://youtu.be/bivsGOWbM9Q

Canterbury farm manager Barry Flynn has 100% confidence in collar technology for picking cows on heat. It means he can get off the vet stand and focus on managing pasture, easing staffing pressure. The Trutest Datamars collars are giving him other key data on individual cows that’s helping in other ways too. Check out NZ Dairy Exporter’s special report on reviewing mating to read Barry’s story.

Take a look: https://youtu.be/jQOeNaMG4DA

-

Welcome to the ASB Rural Insights

- Succession Series podcast, where we’re talking about farm ownership transition from all sides. Thanks to the ASB Rural team for partnering NZ Farm Life Media on this four-part series. Each week Angus Kebbell will be profiling farming families, talking to experts from the advisory sector and investigating new opportunities for farmers thinking about diversifying their farming business. When it comes to ‘what’s next’ for the farm, there’s a lot to think about, so we aim to share success stories, provide useful tips and help you understand more about the many facets of succession planning in the food and fibre sector today.

To listen:

https://nzfarmlife.co.nz/podcasts-2/

CONNECT WITH US ONLINE:

www.nzfarmlife.co.nz

NZ Dairy Exporter @DairyExporterNZ

NZ Dairy Exporter @nzdairyexporter

Sign up to our weekly e-newsletter: www.nzfarmlife.co.nz

NZ Dairy Exporter is published by NZ Farm Life Media PO Box 218, Feilding 4740, Toll free 0800 224 782, www.nzfarmlife.co.nz

Editor

Jackie Harrigan P: 06 280 3165, M: 027 359 7781 jackie.harrigan@nzfarmlife.co.nz

Deputy Editor

Sheryl Haitana M: 021 239 1633 sheryl.haitana@nzfarmlife.co.nz

Sub-editor:

Andy Maciver, P: 06 280 3166 andy.maciver@nzfarmlife.co.nz

Reporters

Anne Hardie, P: 027 540 3635 verbatim@xtra.co.nz

Anne Lee, P: 021 413 346 anne.lee@nzfarmlife.co.nz

Karen Trebilcock, P: 021 146 4512 ak.trebilcock@xtra.co.nz

Delwyn Dickey, P: 022 572 5270 delwyn.d@xtra.co.nz

Phil Edmonds phil.edmonds@gmail.com

Elaine Fisher, P: 021 061 0847 elainefisher@xtra.co.nz

Alex Lond lond.alexandra@gmail.com

Design and production:

Lead designer: Jo Hannam P: 06 280 3168 jo.hannam@nzfarmlife.co.nz

Emily Rees emily.rees@nzfarmlife.co.nz

Partnerships Managers: Janine Aish Auckland, Waikato, Bay of Plenty P: 027 890 0015 janine.aish@nzfarmlife.co.nz

Tony Leggett, International P: 027 474 6093 tony.leggett@nzfarmlife.co.nz

Angus Kebbell, South Island, Lower North Island, Livestock

P: 022 052 3268 angus.kebbell@nzfarmlife.co.nz

Subscriptions: www.nzfarmlife.co.nz subs@nzfarmlife.co.nz

P: 0800 2AG SUB (224 782)

Printing & Distribution:

Printers: Ovato New Zealand

Single issue purchases: www.nzfarmlife.co.nz/shop

ISSN 2230-2697 (Print)

ISSN 2230-3057 (Online)

6 Dairy Exporter | www.nzfarmlife.co.nz | May 2022 NEW ZEALAND

NEW ZEALAND

ASB RURAL INSIGHTS

Succession Series Podcast

2021/2022 Fonterra forecast price Average $9.42/kg MS MILK PAYOUT TRACKER: $/kg MS 10 9 8 7 6 9.30 9.50 9.40 9.24 9.60 9.50 9.90 Mid 9.60 2022/2023 Fonterra forecast price Average $9.09/kg MS $/kg MS 11 10 9 8 7 8.40 8.90 9.71 9.25 9.30 9.20

Fonterra forecast

scratch factor DEVELOPING THE

Any calf rearer worth their salt knows that to grow good calves, they need to be fed and cared for well in order to reach their full potential as adult animals. Good quality milk or milk replacer, fresh, clean water, a safe, draft-free, dry bed and a little something to help develop the rumen called “scratch factor”.

This can be supplied in the form of grain/ muesli and or hay or straw. The mechanics behind this and why it’s important is this. Scratching creates tiny abrasions to the papillae or lining of the rumen that stimulate it to develop. Introducing fibre also helps to strengthen the rumen muscles and establish the gut flora which will do most of the digestive work later in life. Without a little “scratching”, the rumen doesn’t develop as well and the animal’s ability to digest grass is delayed, hence resulting in a poorer quality animal.

We humans aren’t so different, however this isn’t in regards to our digestive tract. But more so, the “scratch factor”. In life, we are often delivered less-than-ideal situations which can be trying, annoying or downright scary. We have trials and tribulations which we would rather not go through, but in most cases don’t have a choice. In short, life is far from perfect.

have one) how we look at or perceive unpleasantness goes a long way towards our general wellbeing. If we look at a challenge through the lens of “I give up, turn the lights out, we’re all going to hell in a hand cart”, we are likely going to struggle a lot more to get through it. In contrast, if we perceive the challenge with “okay, I’ll play your little game, let’s dance, I’ll take the first step” we may find the challenge itself is fuel to help drive us to not only rise above it, but become stronger individuals. The “scratch factor” actually helps us to develop strength and that very overused term, resilience.

Of course, the other things that help grow out our little calves are also needed for us humans too. Comfort, good nourishment, safety, and care are all very much pillars which sustain our wellbeing too. These come from family and friends. It’s important we treat these factors like the common cold – when we bring it home, everyone catches it.

Imagine for a minute if it was. Initially you would think “that would be amazing!” However, if we never had anything to stress or challenge us, how would we know what good, or even great, looked like? Everything would be the same and I would wager after a while we would lose our ability to see joy in pretty much anything.

In my humble opinion (and everyone knows I certainly

The coming year will very likely be filled with more fertiliser price increases, Omicron, volatile commodity prices, staff shortages and goodness knows what else. We will get through this because we have no choice. How we get through it is up to us. We have one of the most nimble agribusiness sectors in the world. We are not misled by pseudo-market indicators caused by subsidies.

You scratch my back, I’ll scratch yours. Let’s dance.

Dairy Exporter | www.nzfarmlife.co.nz | May 2022 7

MATAURA

MILKING PLATFORM

The coming year will very likely be filled with more fertiliser price increases, Omicron, volatile commodity prices, staff shortages and goodness knows what else. We will get through this because we have no choice. How we get through it is up to us.

Without a little “scratching”, a calf’s rumen doesn’t develop well and the animal’s ability to digest grass is delayed, Suzanne Hanning writes.

The “scratch factor” helps us to develop strength and resilience.

Salmonellosis is over three times more prevalent than in 20131

Salmonella is widespread on New Zealand farms and cases are increasing nationwide1. Striking without warning and spreading quickly, Salmonella can pass from your stock to the ones you care about most.

Vaccinate today to reduce the destructive impact of an outbreak*.

SALVEXIN®+B

NEW ZEALAND’S ONLY SALMONELLA VACCINE FOR SHEEP AND CATTLE

9

For more info watch our Salmonella webinar at: www.msd-animal-health.co.nz/salmonella-roadshows AVAILABLE ONLY UNDER VETERINARY AUTHORISATION. ACVM No: A7886. Schering-Plough Animal Health Ltd. Ph: 0800 800 543. www.msd-animal-health.co.nz NZ-SAL-210500001 ©2020 Intervet International B.V. All Rights Reserved. *Salvexin+B should be used in conjunction with other management practices to help control the risk of Salmonella. 1. Surveillance. Vols 41-47, No. 3, September 2014-2020

roller coaster TARANAKI

As the season in Taranaki draws to a close, cows and humans are looking forward to a break. It has been an odd season here in the ‘Naki. That’s probably indicative of the season all around New Zealand.

It’s been a roller coaster year. Things start to be going well and then something comes along to make you rethink, replan or change your approach. Yes this is grass growth, weather, fertiliser costs and staffing challenges.

I think it is also more than those onfarm curve balls. It is, should I be looking to grow my business? Should I be looking to diversify? What level will the country be at? Should I go to a meeting or off-farm event which may increase my risk of catching Covid? Should my kids go to school when 20 of the kids in their class are off isolating…

It has been the year of ups and downs. Constant decision making and we are tired. We, being our family, but, I suspect it is most farming and rural families around the place too.

So what next? How do we move back towards feeling like we’re progressing and achieving our goals? As I write this we are taking a few days off farm. This is our first break away and off farm together as a family since… actually I don’t know. One of us has generally had to stay behind on the farms because of one challenge or another.

We know life happens in cycles. There are good times, there are bad times and there are times when you have to draw on your friends, networks and specialists to help keep moving forward and we have been so lucky to have so many good friends and such a great network to rely on over the last few months.

So to all the people out there reading this who have supported someone this year, thanks to you. Thanks to the sector bodies and member organisations who keep planning events even though you don’t know if you can run them.

There are good times, there are bad times and there are times when you have to draw on your friends, networks and specialists to help keep moving forward and we have been so lucky to have so many good friends and such a great network to rely on over the last few months.

Thanks to the neighbours and friends who answer phone calls and be a listening ear. Thanks to the rural professionals who take phone calls at all hours of the day and evening and weekends!

For my own sanity and break off farm, I am lucky to have secured off-farm work as an Environmental Consultant with Landpro as well as doing some contracting work on one of my passions around improving rural waste outcomes and services for farmers.

It is also great to see Taranaki Catchment Communities have a number of events and really get their catchment group project moving at pace. These are the things that keep me excited about being a farmer and working in the primary food industry.

Most excitingly, I love being part of the Dairy Women’s Network tribe. Having been elected as chair of this fabulous organisation is such an important role.

It’s so important to have a voice in the sector for the women out there holding their families together, keeping the farm ticking along by milking, ensuring other work gets done, or trying to understand the regulatory change that is under way, while also trying to be a wife, mum and their own person too. It really is critical to our famers staying in farming. I hope everyone has some planned time off in the winter and if anyone has any other ideas on how to keep enjoying the roller coaster of farming, make contact and we could catch up over a coffee (or a wine!).

10 Dairy Exporter | www.nzfarmlife.co.nz | May 2022

MILKING PLATFORM TARANAKI

We’re all tired with the constant ups and downs as 2022 throws fresh challenges at everyone, Trish Rankin writes.

habit of repeating HISTORY HAS A

Having been feeling a bit reminiscent this week, I was remembering back to the AGM of a now nonexistent dairy co-op that I was at after a then record $8 payout.

The part we were talking about was the statement from the chief executive that dairy had now reached a new supply level with a price that it cannot fall below. I thought at the time, if this was a listed company I would sell all my shares there and then. The next year we had a $3.98 payout.

This living in the past was also brought about by running two Discussion Groups for DairyNZ on the West Coast. They are suffering staff shortages too.

It was 15 years ago when I last ran groups, and my writing on the whiteboard had not got any better but my belief as to what farmers wanted had changed slightly. There had been a long spell between groups with Covid and a lack of a local CO (extension partner), and coming out of a drought farmers were keen to catch up and decompress with a cuppa. Sometimes just seeing that you are all in the same boat is the value of the day. Rains had come and with good soil temperatures most farmers were feeling confident with the big unknown being getting culls to the works.

The icebreaker question was who had been farming for more than 30 years and therefore experienced inflation. We had one farmer. It is quite a mindset change to get into that things are rapidly getting more expensive and one that up until now, I have luckily avoided.

I have a friend from Zimbabwe that I used to do discussion groups with. My introduction was that he was not taught his 10 times tables but his 1000 times table at school so that he could keep up with inflation.

I then asked how many had not been farming before the 2007 GFC. There were a few hands that went up. These

farmers until now had not experienced interest rate rises. We are now over 7% mid range fixing.

Interest rates have risen 3% very quickly. Average debt per kg milksolids (MS) is about $20 so a 3% rise is a $0.60 increase in costs.

We had some money to fix the day after Lehman Brothers folded. I made the call to fix for two years at 9.9% as there was a high likelihood that banks were not going to lend money. This proved a costly mistake, the advantage of hindsight, and I can still say that I have never paid over 10%.

I have a friend from Zimbabwe that I used to do discussion groups with. My introduction was that he was not taught his 10 times tables but his 1000 times table at school so that he could keep up with inflation.

We also had two couples starting out as contract/lower order sharemilkers who were worrying about cost rises. I hope that with cost rises and labour issues all parties are realistic in their budgets.

After my stint going back to running discussion groups I don’t think I will be going back to the past but I will be holding on to a bit of history as to how farming can change so quickly and there is all likelihood that history will repeat at some time.

Dairy Exporter | www.nzfarmlife.co.nz | May 2022 11

MILKING PLATFORM PUNAKAIKI

Richard Reynolds has gone back to the whiteboard to run a discussion group.

Richard Reynolds in younger times.

Richard Reynolds & Christina Houston: the strange times we live in.

it takes persistence NEW TECH:

After persisting with the installation of new technology onfarm, Hamish Hammond has finally got it right.

Gidday, with a good milk payout many farmers will be doing their best to reduce their looming tax bill by making improvements onfarm and investing in new technology. This is something we have recently done so I thought I’d write about our experience adopting and reaping the rewards of new technology.

Two winters ago, we installed automatic cupremovers (ACRs) with the goal of making our farm system more efficient and productive. The dream was that post-mating we would be able to milk with one worker until the end of the season. This would, in theory, free-up another worker to shift irrigation, load the silage wagon, or do another task while milking was completed.

Now, coming into our third season with the ACRs I can finally say we have achieved our dream situation but boy it took a while to get it ‘right’. You may be thinking, why did it take so long, surely the ACRs weren’t installed correctly?

Sadly no, everything technically was in order from the beginning. The trouble for us was that we were struggling to keep our existing cups on the cows, they were slipping, and

therefore retracting before they were milked out. At times we’d get 50 or more cows with cups slipping each milking. This made for some stressful milkings and a few curses directed at the ACRs.

Initially we thought it was just the cows getting used to the new gear - no worries, they should settle in a few weeks. A few weeks went by, no improvement was seen. Next we targeted the liner size – minor improvement. We lifted the vacuum. We also selectively culled cows with poor udders that would consistently have problems with the new set-up.

In the end, to milk the cows sufficiently, we would run the cups on ‘manual’ mode on ~50 troublesome cows so the ACRs wouldn’t automatically retract as intended. Coupled with this we had a second person at the shed, defeating the purpose of having the ACRs.

Finally, after a year struggling to keep the cups on and looking for solutions, we decided to trial a new set of clusters, the DeLaval Evansa. These modern clusters had an instant effect in reducing cup slippage on cows we previously battled with every milking. They milked out the cows faster and were significantly lighter than our original 30-year-old cups. After a week with no trouble on the trial clusters, the farm owner and I were sold. This meant forking out more coin, on top of what was already spent.

Today with 46 new sets of Evansa clusters in place the shed is running like a well-oiled machine and we have the confidence to trust the ACRs to milk the cows correctly. Our stress levels dropped overnight, we can milk with one person, reaping the intended benefits of adopting ACRs. Hallelujah!

Our experience adopting new technology isn’t unique, in fact I have read that it is normal for performance to drop after adopting a new technology.

The biggest risk is reverting to old practices and not reaping the rewards of improvement. This was our biggest realisation, and it took persistence to find the solution and extra coin to finally get it right. Here’s hoping money invested in technology this season on dairy farms will make for better farming next year and beyond.

12 Dairy Exporter | www.nzfarmlife.co.nz | May 2022

MILKING PLATFORM WAIRARAPA

Pimp our cowshed: getting the ACRs running smoothly

George Hammond out on the farm with Mac the dog.

More than just new gadgets

Pastoral dairy farmers in New Zealand and Ireland share distinct challenges with technology, which tends to be designed for confinement farming, Phil Edmonds writes.

Last month Agritech NZ hosted the New Zealand-Ireland Agritech Summit 2022, which recognised the similarities in focus that both nations have in advancing their respective agriculture sectors. It also offered a reminder of the unique challenges both face in requiring distinct technology solutions to progress their respective dairy industries based on pastoral rather than confinement systems.

Perhaps above the recognition of shared futures in sustaining pastoral dairy industries, it was an opportunity for those engaged to take stock of where NZ’s agritech sector is at, and what its focus is (and should be) compared to other dairy producing countries.

What emerged was a realisation that NZ farmers and the NZ Government want and need agritech to deliver on two different fronts, and that in order to keep making efficiency gains, farmers need to think about innovation and technology as being more than new gadgetry.

13 INSIGHT UPFRONT AGRITECH

First, the summit clearly pointed to the exceptional place New Zealand and Ireland play in dairy production, and the resulting tech deficit they have to cope with as a result.

To date, many of the ‘shiny new things’ that have been developed internationally to enhance dairy production have been modelled for confinement farming. Due to this, uptake of technology in these systems has been both easier and more prevalent. It has also meant that there have been more opportunities for those who operate ‘off grass’, to invest in innovations focused on being more productive.

Speaking at the summit, Dairy Holdings chief executive Colin Glass said “Whether we recognise it or not, as pasture farmers, we are in a race with the rest of the world in dairy.

“Confinement systems, particularly with those based on corn production, are achieving 3.5% compound average gains per annum due to gains from new technologies, compared to pasture at about 0.2%.

“This means every 20 years, corn producing farmers are doubling their efficiencies while pasture farmers take significantly longer.”

New Zealand (and Ireland) then, are compelled to develop and adopt technologies that will increase productivity on pasture, as is the case for confinement farming, but also address the unique challenges that pasture farming faces both now, and into the future.

We’re all aware of the productivity gains NZ dairy farming has made in times with limited investment in technology, but Glass insisted we need to keep getting better every year and try to match other models of farming.

“What we are seeing now is that our ability to continue lifting production is being challenged on a whole host of fronts, including the need to address water quality and greenhouse gas emissions. Despite this we need to continue looking for efficiencies, and essentially do more with less.”

It goes without saying that NZ needs to keep

up to speed on productivity gains, but in terms of technology development the Government believes the sector has to focus on addressing the broader threats Glass mentioned, rather than helping to pump out more volume with fewer costs.

Minister of Agriculture Damien O’Connor spoke at the summit, and emphasised this point, issuing a reminder that to ensure a sustainable future for our agricultural practices we have to work on mitigating their impact on water quality, the climate and biodiversity.

But given the external nature of these challenges, there seems to be a necessary role for the Government to front up and help enable those technologies to emerge that will provide fixes.

AgritechNZ chief executive Brendan O’Connell agrees, and says agritech development would happen a lot slower in NZ without Government support.

Share the load

The need for the Government to play a role should be obvious, because some of the benefits that will accrue from implementing onfarm technology to solve these challenges are shared ‘downstream’. For example, O’Connell said “you can’t have costs incorporated onfarm and the benefits banked somewhere else”. NZ as a whole will benefit from meeting GHG commitments if onfarm emissions are reduced. So, the costs needing to be borne in the short term, for long-term benefits need to be shared.

What this raises, is the under-acknowledged prospect that the NZ pastoral agricultural sector could start entering an era where its operations start to be subsidised.

O’Connell says MPI is looking at different policy settings to incentivise technology developments that will tackle pastoral farming challenges, which will present a shift in how the sector identifies itself. Most NZ farmers have not operated in a culture of subsidies, but that could be what the future looks like. O’Connell says that “for the Government to get the results it wants, it will have

Damien O’Connor, Minister of Agriculture.

Mark Neal, DairyNZ’s associate strategy and investment leader.

to be creative about how that’s achieved. It can’t just regulate – it will have to incentivise.”

It’s worth comparing for a moment where Irish pasture dairy farmers are on this trajectory, given they face the same external challenges NZ farmers do.

Rather than being new to intervention, Irish farmers have benefited from years of government funding to develop technology solutions via the European Union’s Common Agricultural Policy. They’re accustomed to operating under a wave of regulations on do’s and don’ts. As a result they have lucked-in with much stronger research focus on high productivity under those constraints.

At the Summit, Irish dairy farmer and consultant Paidi Kelly did note however that while its

government had heavily subsidised agritech in genetics and performance management, particularly since the 2008 financial crisis when the country was forced to diversify its economy, there was a now a significant fear that it could abandon farming because of its high greenhouse gas footprint. “We now need support from the Irish government more than ever in order to adapt and innovate.”

So where does that leave the focus for agritech development in NZ?

As mentioned earlier, there are essentially twin drivers in terms of demand for agritech in NZ – on the one hand internal (drive for onfarm productivity) and on the other external (industry’s social licence to operate, and meet market expectations).

Dairy Exporter | www.nzfarmlife.co.nz | May 2022 15

Colin Glass, Dairy Holdings chief executive.

Brendan O’Connell, AgritechNZ chief executive.

Many of the ‘shiny new things’ that have been developed internationally to enhance dairy production have been modelled for confinement farming.

Nearly two years ago a strategy to grow NZ’s agritech sector was unveiled with the release of an Industry Transformation Plan (ITP).

At the time the focus was on both increasing NZ’s agritech exports and advancing our sustainable primary production, with the Government committed to supporting the commercialisation of new products and maximising local adoption of NZ agritech.

Since then, O’Connell said there has been a strong focus on developing ‘weightless’ agri exports in the form of technology rather than just shipping food from our shores. But there is also a greater need to now look at changes needed in the domestic primary sector.

With reference to the Transformation Plan, there has been progress on improving domestic adoption by improving digital access in many areas.

But O’Connell also recognised there are still a lot of individual solutions that don’t talk to each other. Some digital systems onfarm still require double entry.

These could be considered ‘maturity’ challenges which are part of the process of managing a growing industry. There’s likely to be a need for the Plan to evolve, to include better education and support services for farmers using these technologies.

Back to the summit, and Glass’s plea for technology to focus on pasture farming’s productivity gains; this could be helped by NZ farmers thinking more broadly about how their farm business management can help create efficiencies - as much as ‘shiny kit’ can.

It was a point made by DairyNZ’s associate

strategy and investment leader Mark Neal, who said adopting innovative business models should be considered as technological advances in this context.

He said later that DairyNZ is helping to create awareness of the efficiencies that can be made from business planning and development.

“Case studies of budgets and KPIs are provided on the DairyNZ website while targeted events provide advice on farm systems and options to lift profitability. DairyBase supports this with regional benchmarking to compare production and profitability.”

For Glass, he’s seen onfarm efficiencies typically come from the people who use farm systems, not the systems themselves.

“Farmers that have high production tend to be brilliant at everything else, including better herd health, lower lameness and better in-calf performance. Technology has helped identify who those people are by the increase in ability to measure performance.” In this instance, technology is being used as an input into a pasture farm management, rather than effectively ‘driving the bus’, as it might do on a large confinement farm.

There’s no doubt the Government will have an increasing role to play in ensuring agritech development in NZ works to address domestic challenges as much as it expands to reach its potential as an export earner of its own right. For NZ pasture farmers, productivity gains are unlikely to reach unseen heights by watching a machine do all the work as in some other farming models. Persisting with innovative thinking will be as important as ever.

“Farmers that have high production tend to be brilliant at everything else, including better herd health, lower lameness and better in-calf performance. Technology has helped identify who those people are by the increase in ability to measure performance.”

WE NEED TO TALK ABOUT COPPER ― OR THE LACK OF IT. NZ’S COPPER DEFICIENCY IS COSTING NZ AND YOU.

Copper is vital for life and essential for growth, reproduction and immune function. Naturally occurring copper is low in New Zealand agricultural systems and it’s because of this that it’s vitally important to supplement copper in livestock. This is particularly important with your young cattle to ensure they enter the herd in peak condition with strong bones, a strong immune system and ready for a productive life.

Talk to your vet about everything you need to know about NZ’s copper deficiency and the best way to manage it for long term gains.

Dr. Abi Chase

Dr. Abi Chase

PROUDLY AVAILABLE FROM YOUR LOCAL PARTICIPATING VETERINARY CLINIC Restricted Veterinary Medicine; available only under veterinary authorisation. Boehringer Ingelheim Animal Health New Zealand Limited. Level 3, 2 Osterley Way, Manukau, Auckland, New Zealand. COPAJECT® is a registered trademark of the Boehringer Ingelheim Group. Registered pursuant to the ACVM Act 1997, No. A011573. © Copyright 2021 Boehringer Ingelheim Animal Health New Zealand Limited. All rights reserved. NZ-MSP-0001-2021.

Boehringer Ingelheim

BOE 1152 Ensure young stock become future high producers through improved health, growth and energy at: futureproducers.co.nz

Ukraine war a threat to UK dairy

protection costs and a liquid milk market controlled by supermarkets are keeping losses inevitable despite increased dairy prices. Labour is also in short supply with East Europeans no longer available to fill UK farming jobs, which are unpopular with the local population.

costs, National Farmers Union president Minette Batters said: “This is the most serious situation for food production since the Second World War and while we have legislation about tree planting - there’s not even a commitment on ensuring domestic food production.”

Milk prices are pushing beyond 40p/ litre but that’s not enough to cover higher costs. Dairy companies are also preparing shoppers for retail increases between 30 and 50% over the next 18 months. Traditionally, farmers receive only a fraction of any increase in supermarket prices.

“Something has to give and if the milk price doesn’t give, then the producers will,” Oxfordshire dairy farmer David Christensen said in a stark assessment of the peril the dairy industry is facing as soaring costs push farm finances into the red.

“Diesel prices have also gone through the roof. Last year I was paying 62p (NZ$1.2) or 63p ($1.25) for the diesel I use in the tractors; the last load I bought was £1.29 ($2.5),” Christensen said. “It’s come back a bit but notwithstanding that, it is a huge increase.”

David, whose family business runs a 1000-strong herd is a member of Arla, Britain’s largest dairy co-operative, which is itself alarmed that milk production has already dropped more than 4% this year.

The world is at war! Don’t think just because Ukraine is far away from New Zealand that the horrendous atrocity there will not affect you. It can and will.

War in Europe is massively disrupting world food and energy markets and threatening the viability of high-input farming systems –not least the United Kingdom dairy industry.

Based on a high-input fertiliser and concentrate feed model, requiring high yields to pay loans, rents, wages and mounting environmental costs, Britain’s dairy farms were already struggling to break even before Russia invaded Ukraine.

Fast-rising fertiliser prices (doubled), feed (up a third) and energy prices, (up 30%) coupled with high environmental

Add to the mix the aftershocks from the UK leaving the European Union - Brexit - including phasing out productionrelated subsidies, labour shortages, and the collapse of dairy exports to the EU and the scale of woes is all too apparent.

Tim Price

Tim Price

Future UK farm support will be in the form of payments for environmental enhancement. Delivered through the Environment Land Management Scheme, the new system will reward farmers for protecting wildlife. It does not support food production. However, it’s the attitude of a government fixated on net-zero emissions and seemingly impervious to food production and security which worries dairy farmers most. After failing to persuade the government to take action to avoid production cuts by stabilising input

Surprisingly perhaps, farm land continues to sell for record prices. With a limited supply of good farming land in Britain and little coming to market, there’s a continuing demand from farmers desperate to take on extra land. As a result, prices sit way beyond a level consistent with profitable returns. Grazing land averages NZ$32,549 to NZ$42,771 a hectare, up 10% in 2021, with far higher prices paid for desirable blocks to bulk up existing holdings.

Whether retail price rises will be enough to put herds back in the black remains to be seen. High gas prices look set for the long-term, making generous fertiliser use unviable. In this environment, the money’s on low-geared grass-fed systems with the New Zealand model well-placed for growth. In the short-term, Britain’s dairy farmers are working all-out to maximise grazing and silage crops using fertiliser bought before prices rocketed beyond $1250 a tonne.

18 Dairy Exporter | www.nzfarmlife.co.nz | May 2022 GLOBAL DAIRY UNITED KINGDOM

Costs were already rising for UK farmers before Russia invaded Ukraine. Now they are rocketing.

By Tim Price.

Pasture & Forage News

Play it safe with transition

If anything is going to go wrong with your transition this year, it will most likely happen in the first week of changing animals from one diet to another.

Give yourself one less thing to worry about this spring!

Imagine starting spring with the confidence of knowing exactly which paddocks are going to be cropped, and even better, knowing they are all ready to deliver great yields of winter or summer feed.

No last-minute stress, or missed opportunities; just the reassurance of having a solid plan that gives you (and your animals) every chance of a successful outcome.

Is such a thing possible?

Sometimes, but not always! Details of the plan may have to change because the weather between now and then is – as always – a law unto itself. But you will come much closer to achieving this, simply by starting now. Even if you have to change some detail within your plan as the year progresses, you’ll still be better off than if you leave those paddock decisions until later.

Lime takes time

Lime is a great example of the kind of thing you might need to grow great crops on your selected paddocks. It takes months to work.

By putting it on now, if required, you know it will have time to do its job before the seed drill even gets near the soil.

Fall back option

Hopefully winter will be kind. If it’s not, however, your girls may need somewhere to stand off, take shelter and be fed.

Paddocks that you already know are destined to be cropped in spring can be useful for this, especially when it comes to protecting pastures and soils that might otherwise be damaged. So looking ahead can help your wintering plan, too.

Numbers don’t lie

You may already have a feel for which paddocks need to be cropped in spring. But the definitive answer lies in your paddock records. How many times was each one grazed during the year? You might be surprised at the difference!

Once you’ve got your short list, make sure you know why each paddock is under-performing, and take steps to correct any issues. We can help; book your free Pasture Health Check at www.barenbrug.co.nz today.

That is the time when most animal health issues – and sometimes deaths – occur, so there’s no such thing as being too careful when it comes to preparing for this. And that includes bringing the whole farm team on board, so everyone who needs to know about the risks is up to speed. The first step is to allow enough time for animals adapt to a different feed source. The rumen is a complex fermentation system, full of billions of microbes, and they do not like sudden changes. You can transition onto brassicas in a shorter time than fodder beet. But in both cases, a gradual introduction of the new feed is all-important.

Putting hungry animals onto any crop is very risky – they will eat too much, too fast, so they always need to something in their bellies first, whether it’s hay, silage or straw.

Watch them carefully – things can go wrong very quickly, and some animals just don’t do well on crop, meaning they will need to be removed and put back onto pasture.

Dairy Exporter | www.nzfarmlife.co.nz | May 2022 19

facebook.com/BarenbrugNZ barenbrug.co.nz @BarenbrugNZ

May 2022

Trade’s perfect storm

Have you seen the movie The Perfect Storm? It’s got a stellar cast, and they go fishing; a great premise for a movie. Now if you haven’t seen the movie, things turn to custard when they’re out fishing, and go from bad to worse: the boat sinks, and Mark Walhberg’s character watches the boat sink while in the punishing seas.

The captain thought everything was going to be golden, not accounting for how much risk he was actually sailing into. And at this point, you’re asking, how does this relate to dairy, Stu, or are you writing movie reviews on the side now? Well, the reason is, the last six-weeks in the dairy industry have been the perfect storm, a storm no one saw coming, and something that really turned into something bigger than expected.

This storm arrived in the form of three key dairy markets having their own issues, with demand issues arising from two of them, and geopolitical issues from the other.

China’s zero covid approach always had the ability to create harm to economies outside of their own, considering where China is placed in the web of world trade.

The lockdowns in Shanghai alone are having bigger impacts to the world than anyone ever expected or accounted for, and these impacts are being felt in the dairy world especially.

The Shanghai population is locked into their houses, not even allowed to leave to go to supermarkets, thus their consumption of every product has been stymied, and dairy is no different.

This lockdown created what can be seen as a rapid supply chain stall: nothing leaving shelves in a normal fashion, creating a logjam of products. This has seen Chinese dairy processors drying all the milk arriving at factories into whole

milk powder instead of into consumer goods such as yoghurt.

At the same time, some Chinese ports and logistics are in their own logjam, creating stranded product and ships unable to unload, creating issues for exporters to get product on to ships from origin regions. Long story short, a market that was traveling with some large momentum came to a sudden stop. And we all know that when things come to a sudden stop, they end up in a mess. This is where the Chinese market finds itself. In a mess, everyone is unsure how this situation will iron itself out. Will the Chinese government die on the hill of Covid zero or accept that biology is impossible to beat? These situations have different outcomes for the Chinese economy, which the New Zealand economy is so heavily tied to, and most importantly the NZ dairy industry.

The other interesting market dynamic is Sri-Lanka’s financial issues. Now, another long story short: Sri-Lanka took very brave steps to change their country, and they all backfired. These steps included banning all agri-chemicals, which halved their rice yields in one year, and plunged the country into a food security issue - woke politics at their finest.

Now their economy is on its knees, with the country defaulting on debt, which interestingly enough is mostly owned by Russia. This means Sri-Lanka doesn’t have the ability to buy any imported products, because they can’t pay for them. So, this creates a hole in demand in the South East Asian market for NZ dairy.

Sri-Lanka’s demand isn’t something to sneeze at – they aren’t massive buyers, but they take good regular volumes of our exports, and even at recent high

prices of dairy commodities, they were buying right up until their economy tanked, and everyone stepped back knowing they wouldn’t be paid.

The other part of this storm is the on-going war in Ukraine. I hope by the time you read this, the war has settled, but I doubt it.

The outbreak of the war has actually been bullish for the global dairy market, with the expected disruption to grain exports from Eastern Europe creating downwards pressure for milk production in the rest of Europe, due to higher costs of production. The impacts will whiplash into the future longer than most are measuring, and even though markets have been in flux following the outbreak, there is more to be measured yet.

Who would have expected that these three factors would occur all at the same time, and create the reaction that the industry has had to traverse over the last two months? No-one, it would seem, but some made a call to protect some of their own risk. The biggest day of trading for milk price futures was the day before GDT 306. Prior to this auction, expectations of a downfall were painted on the wall, with the above three factors outlined clearly by Fonterra. Following the GDT auction, milk price forecasts were slashed by 50 cents/kg milksolids (MS) for the coming season, while the cloud of uncertainty has returned to the dairy market.

Measuring risk in any market is a very hard thing, no one has a working crystal ball. But the last two months have painted the perfect picture of how quickly a commodity market can flip, and how important it is to have some risk management in place; even if that is having the paperwork completed with your broker.

20 Dairy Exporter | www.nzfarmlife.co.nz | May 2022 UPFRONT MARKET VIEW

Stuart Davison.

War, Covid and mis-guided policy have combined for a perfect picture of how quickly a commodity market can flip, writes Stuart Davison

Dairy Exporter | www.nzfarmlife.co.nz | May 2022 21 For more information CALL 0800 337 747 or email us at sales@towandfert.co.nz www.towandfert.co.nz Available in 5 models. Tow and Fert. There is one for your farm. Multi 1000 Multi 500 Multi 2800 Multi 4000 DEMO Make the most of the high milk payout. Reduce your urea & save $$$, meet the 190 units/ha regulations and grow more grass with a Tow and Fert. FREE on-farm Multi 1200 A Tow and Fert is a SMART BUSINESS INVESTMENT grass growth We have managed to reduce our N inputs from an average of 246 units to 173 units Image shows a Multi 4000 in Southland, New Zealand spraying Urea

Seeking

directions

what could be possible. They took him on as their farm advisor.

“Over the years we’ve had a strong focus on staff development and training, and we saw using a consultant as an opportunity to focus on and invest in ourselves.”

And the couple have cracked it – for the first time their cows are on target to produce 530kg MS/cow by season’s end in May.

During the first Covid-19 lockdown, Mat Korteweg and his wife Catherine started thinking about what they wanted to get out of discussion groups.

With contact with other dairy farms limited to phone calls and online, they went to social media and started a Facebook group: 500kgMS/cow – The Journey.

“We were about to go 50:50 sharemilking with 550 cows. We’d been on the farm in South Otago as lowerorder since 2014 and we were thinking about tools we could use to help us reach our goals,” Mat says.

“Before coming here we had worked on a dairy farm in Australia, in Gippsland, Victoria, and the owner there had beautiful cows, high input, and he was enjoying measuring the cows’ potential.

“We had a good idea of the direction we wanted to take the home farm. We grow a lot of grass here but we weren’t getting to where we wanted to be. I knew it was time to start reaching out to hear what other people were doing.”

The Facebook group caught the attention of interested farmers and after lockdown a discussion group was held on Caleb Holmes’ farm on the Taieri with DairyNZ, vets, nutritionists and other rural professionals including consultant Howard de Klerk.

“He gave a presentation about the potential of the New Zealand grazing system with the use of the right supplement at the right time.”

Afterwards, Howard showed Mat and Catherine ways to use the data they had been collecting for years on the Stirling farm on the banks of the Clutha River and

Since their first year on the farm, when they produced 420kg MS/cow, they have consistently increased per-cow production each season but reached a ceiling of 470kg MS/cow for the past two.

Supplementary feed inputs were also increasing, with the 470kg MS/cow production reached with in-shed inputs of 700kg to 800kg DM/cow/year.

“I just didn’t think we could do more production and still get the cows in calf. I wanted to get there but I thought there was no way,” Mat says.

“I’m really conservative with budgets and when we came up with this target of 500kg MS/cow I thought, oh yeah, whatever,” Catherine says. “I’ll believe it when it happens. But now I have the confidence.”

And that confidence is given by one thing they both say – sticking to the plan.

It starts with transitional feeding. With their calving data they worked out a spring rotation plan and instead of beginning transitional feeding four to five days before calving, they started 21 days beforehand giving the springer mob as much adlib hay and straw as they could eat on the calving pad and silage in the herd home to get the DCAD minerals into them.

Before heading into the herd home each day, the springers would go on the rotary platform to eat 1kg of their milking cow ration to start getting their rumen ready for their post calving diet.

It also allowed them to be teat sprayed daily which helped to reduce spring mastitis.

“With Protrack drafting and their inshed feeding programme which allows you to feed individual cows, it was easy to do and when the cows did come in for

22 Dairy Exporter | www.nzfarmlife.co.nz | May 2022 BUSINESS DISCUSSION GROUPS

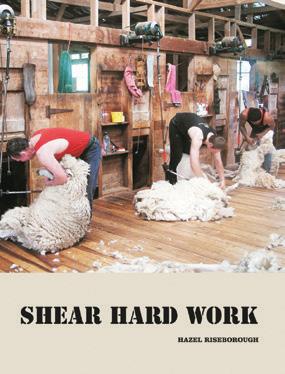

A discussion group founded from interactions within a closed Facebook group during the first Covid lockdown has helped steer a significant boost in production. Photos and story by Karen Trebilcock.

Dairy Exporter | www.nzfarmlife.co.nz | May 2022 23

milking they were used to being in the dairy and were super settled,” Mat says.

Making it easier too, they had installed Allflex collars for the herd, putting them on in the autumn so they were ready for the planned start of calving on August 10.

And it gave them new data to work with.

“If anyone is thinking about buying collars, I would tell them to go for it but only if you’re going to use the data. Don’t just use it for drafting cows for mating. They’re too expensive for that. Tail paint is cheap.

“But if you want to go to that next level and really understand what is happening with your cows then consider them.”

It was the rumination time the collars were showing that caught Mat and Catherine’s attention.

“After calving, we couldn’t get it over that magic 400 minutes a day. It was down at 300 minutes and at 200 minutes they’re crashing so we were really worried.

“This went on for two weeks after the start of calving. The cows were on grass and supplement in the dairy but they weren’t looking great and the collars were telling us they weren’t happy and then we had a light bulb moment.

“They had been on silage before calving and now they were on grass. We started feeding out balage on their allocated break based on the spring rotation planner and their rumination went up straight away to 400 minutes.

“Their rumen wasn’t used to fresh grass and it needed

time to adapt. Even though we were feeding out when we had a lot of spring grass, which seemed crazy, it worked.

“Transition feeding is all about getting the rumen ready.”

“It makes us cringe now,” Catherine says. “All these years we’ve been doing that to our poor cows and they couldn’t tell us what they needed.”

Their cows lost less body condition than usual after calving, metabolic issues stopped and suddenly they had time on their hands because they weren’t lifting downer cows. As each cow calved, its individual supplement (a mix of barley, palm kernel and DDG) was increased week by week from 1kg/day until at five weeks post calving it was at 4.5kg/day.

“The cows were still cleaning out the grass in the paddocks.

“Howard got us to work backwards from our daily production and we worked out they were eating, as well as the 4.5kg of supplement, 18.5kg DM of pasture which

24 Dairy Exporter | www.nzfarmlife.co.nz | May 2022

‘Over the years we’ve had a strong focus on staff development and training, and we saw using a consultant as an opportunity to focus on and invest in ourselves.’

Mat and Catherine Korteweg with Leo (1) and Beau (5) on the farm by the Clutha River.

With Moving Day on the way, we are encouraging Farmers to do their bit to maintain the integrity of our biosecurity system.

1 Create a new NAIT location number.

2 Create a movement within 48 hours of moving.

3 Deactivate the old NAIT location number. Register any new grazing blocks you are in charge of and record movements in NAIT for any animals sold or sent away to grazing.

If you have followed all of the instructions to update your NAIT details and are still struggling, our Support Centre is geared up to assist you. Call 0800 482 463

Complete and sign a PICA change form at your current NAIT location and make sure you become the registered PICA if you are moving to another farm.

For more Moving Day information see OSPRI.co.nz

Dairy Exporter | www.nzfarmlife.co.nz | May 2022 25

NAIT is an OSPRI programme

Moving with the herd?

Moving farm without the herd?

Failure to comply with NAIT obligations may result in fines or prosecution issued by the Ministry for Primary Industries. For more information about your obligations as a PICA, please visit our website ospri.co.nz.

was exactly what we were measuring in the paddock as well. It all lined up with the spring rotation plan as well.

“The cows peaked at 2.55kg MS/day.

“This was real. There’s no bullshit. We worked all the figures and they all said the same thing.”

Body weight of the Friesian cross herd is about 500kg so they are on target to do more than the cow’s body weight in milk this season.

“By the start of November, at mating, the cows were pumping. The inshed feed bins were licked clean and the grass was always decked in the paddocks.”

The 10-week mating was AB for five and a half weeks with the bulls going out afterwards before a final week of short gestation semen to tighten the calving spread.

Their six-week incalf rate is 79% and their empties is 9%.

“The collars captured all the premating heats so we could target cows who needed help, instead of just doing a blanket synchro. We could spend the money where it was actually needed.

“And in the past the cows calving with metabolic issues always had trouble getting back in calf. With hardly any metabolic issues we didn’t have that problem.”

Usually the farm goes to three in two milkings mid-December, to give the staff, Mat, Catherine and their young family an easier summer, but with the cows still producing 2.2kg MS/cows, they had to delay it to mid-February.

In March, they were doing 2kg MS/cow and condition scores looked great.

“We dry off at a body condition score of five for the two- and three-year-olds and at 4.5 for the older cows.

“We want our covers at 2200kg DM/ha and then we can be assured we’ll be at 2300kg DM/ha at calving, unless there is a major flood or something.”

About 300 cows are wintered on silage in herd homes with the rest on fodder beet and balage at a neighbouring potato farmer’s block.

The Kortewegs own their own baling gear so any surpluses, however small, can be made into balage.

“We can control the quality of what we’re making too that way. We’re not waiting for the contractor to get here as we watch the quality go.”

Mat’s parents Stephen and Rhonda still live on the farm and although there have been a few raised eyebrows as feed trucks arrive every couple of weeks, they’re happy with how things are going.

“They wouldn’t be comfortable if what we were doing was on guesswork. But we’ve got the figures and we know it’s working. They trust Howard’s plan and our execution.”

Peak cows milked on the 175ha effective dairy platform had been 630 in the past when Mat’s

brother Blake ran the farm and was building numbers to go 50:50 sharemilking.

“Although those high numbers were a once-off, we can see that calving 550 cows is a better number for the farm,” Mat says.

“There is increased efficiency with less cows. It means increased profitability, less time needed to milk, we’re able to concentrate on individual cows and it’s better for the farm.

“We’ve really noticed how the paddocks have improved with less hooves on the ground.”

And with dairying coming under scrutiny for greenhouse gases, the system works there too.

A 500kg cow producing 500kg MS will eat about 6200kg DM per year. The same cow producing 400kg MS will eat 5550kg DM per year (including when they’re dry). Although the cow which eats more and produces more will produce more GHGs than the lower producing cow, on a per MS basis the GHG emissions will be about 10% less for the high producing cows.

“All cows have to eat to maintain themselves, so the more you can feed them to produce more, then the more efficient they become. It’s obvious.”

Catherine says they had titled their Facebook group ‘The Journey’ and it had certainly been one.

“You have to have the perspective of how one thing can affect the whole system,” she says. “It doesn’t just happen. This is something we planned to do and once we had the plan we had to follow it. We had to get so many things right.”

So far the private group has about 350 members from throughout New Zealand with a few in Australia.

“We use photos a lot on it of real data so there’s credibility and that’s what gets the discussions going,” Catherine says.

“At calving it goes a bit quiet then something will pop up and there is a discussion going again.”

ABOVE: Looking great – these cows are doing more than their bodyweight in milksolids.

26 Dairy Exporter | www.nzfarmlife.co.nz | May 2022

Embrace

........ the opportunities

Almost everything New Zealand grows is plant/grassbased compared to most countries using grains to raise animals, Elaine Fisher reports.

New Zealand farmers need not be afraid of ‘modern food’ or alternative proteins, but instead should embrace the opportunities they offer, says Scottie Chapman managing director of SLC Ocean Ltd and co-founder and executive director of Spring Sheep.

“New Zealand agri-business is far too defensive and worried about what is coming,” he told the Farmax Conference, ‘Advancing the New Zealand farm system of the future’ held online over two days in early March.

“Many consumers want to eat plant protein and we are in a good position because almost everything New Zealand grows is plant/grass based compared to most countries using grains to raise animals. New Zealand also has the supply chains and access to customers. We should embrace the opportunities which enable us to feed more of the globally growing population in an environmentally friendly manner.”

Scottie compared what was happening with food to the car industry. “Carmakers don’t necessarily want to produce electric and hydrogen vehicles. They have perfected the combustion engine, but consumers want electric and hydrogen so that is where the money, research and development and manufacturing is going.”

New Zealand cannot just rely on its image of being excellent in the production of high-quality foods. “We think everyone thinks New Zealand is great and dismiss

Dairy Exporter | www.nzfarmlife.co.nz | May 2022 27 PROBIOTICREVOLUTION.CO.NZ LET’S CHAT CHRIS: 027 459 1061 MATT: 021 234 1713 DO IT ONCE, DO IT RIGHT ONCE A DAY FEEDING WITH A probiotic of great strength Live yeast stabilises rumen supporting digestion Digestive enzymes increase meal hay and grass intake Five powerful bacteria for health BUSINESS FARMAX

.......

that our customers think some other countries are exceptional also.

“Sports teams don’t stop when they are good enough. We are a tier one provider of some of the best food in the world, but it is not enough to tell everyone we are already good enough. Standing still is going backwards.”

Consumers had more power and were becoming increasingly pragmatic in their demands including around the environmental, animal welfare and social sustainability performance of food producers. Due to increased scrutiny, farmers not in the top 25 per cent for performance in those areas should think hard about whether they had a long-term future in continuing to do what they do, Scottie said.

“Increased use of technology in the form of sensors and artificial intelligence means there will be transparency everywhere and nowhere to hide.

“The average consumer wants to research to find out for themselves if a company is authentic and has the science to support the claims it makes.”

Spring Sheep had 24 million data points about the sheep it milked but it talked to customers, not about the animals, but about what was in it for them in terms of superior nutrition, superior taste and environmental sustainability. “A lot of work has been done in the background and if we are challenged, we can explain it.”

Scottie said it was important to understand the modern consumer. “While those over 40 know where their meat and dairy products come from, the modern urban consumer, (and remember everyone under 41 years old is a Gen Z or Millennial), has a different attitude.”

The term ‘meat industry’ was not appealing to these consumers. Many of these consumers also had issues when they researched and believed that they were, “drinking a secretion from another animal which stopped its baby having its mother’s milk”. It was important to market dairy and meat products in ways that better appealed to those consumers.

Increasingly consumers were also seeking natural and whole foods. “With Spring

Sheep, we looked at infant formula and did a lot of research to find out what people wanted added to it. The answer was that consumers want ‘free-from’ and ‘purity’.”

The Covid pandemic had led to people taking more responsibility for their own health, along with an increased understanding of the importance of gut health and the gut’s relationship to overall wellbeing.

When it came to marketing New Zealand foods, Scottie said diversification was important, but for Spring Sheep and many other New Zealand producers, China remained a vital market.

“Spring Sheep started in three to four smaller markets before entering China. We have a lot of ambition and want to be a global industry. With infant nutrition you have to be in China.”

Free trade agreements negotiated by successive New Zealand governments in the past 20 years had been fantastic and exporters should look at how the FTAs

suited their businesses and ambitions.

Geopolitical risks should also be factored in. “There are lots of other markets. If you have a product which is holistic, then the western world is your market. If it’s more pragmatic, then head to Asia.

“In New Zealand we have so many options. Don’t put your head in the sand. Front foot it. Remember the fast eat the slow.”

Scottie, who describes himself as an “explorer of modern food; investor in the future”, has had a career taking Aotearoa New Zealand food products to the world both for corporates and his own entities.

“With Spring Sheep Milk Co I continue to do that and know Aotearoa New Zealand has a place as the premium producer of traditional food products.”

Spring Sheep is a joint venture between SLC Ventures and Pamu (Landcorp), New Zealand’s largest Government owned farming group.

“Now through SLC Ocean I am surrounding myself with more talented individuals who believe we have an obligation to create environmentally accretive modern food to compliment traditional food and sustainably feed the ever-growing number of people on the planet,” said Scottie.

The company’s aim is to; “make New Zealand a better country for the world by harmoniously utilising our ocean plants while increasing bio-diversity”.

28 Dairy Exporter | www.nzfarmlife.co.nz | May 2022

Nothing

to fear from modern foods - says Scottie Chapman managing director of SLC Ocean Ltd and co-founder and executive director of Spring Sheep.

Spring Sheep has 24 million data points about the sheep it milks.

Dairy Exporter | www.nzfarmlife.co.nz | May 2022 29 get your herd performance ready Registered pursuant to the ACVM Act 1997, No. A9374. Copyright © 2022 Virbac New Zealand Limited. All rights reserved. Virbac New Zealand Limited, 26-30 Maui Street, Pukete, Hamilton 3200. 03/22. Enhance immunity and improve fertility1,2 this season. Visit performanceready.co.nz and ask your vet.

The cost of water is making it harder to justify dairying on the Waimea Plains near Nelson where the Waimea Community Dam build continues to blow its budgets.

Just three small dairy farms remain on the plains where horticulture returns have increasingly driven land use over the decades. Now the dam, which is integral for future production on the plains, will make it even harder for those farms to hold their ground.

The dam has been plagued by continual cost blowouts, but Waimea Irrigators Ltd (WIL) chairman Murray King says it is an intergenerational project that will enable horticulture to develop on the Waimea Plains.

King owns one of the three remaining dairy farms and has long been a proponent of the dam in the Lee Valley. Along with other proponents, he has worked on the project for 20 years and though the increasing cost of the dam is disappointing, he says the benefits will still be significant for the region.

When the project was first put to the public in 2017, it had a price tag of $75.9 million. By the time it was commissioned in 2019 it was $105m and since then the

WATER COSTS threaten dairy future

project has been assaulted with problems from geology to Covid. The latest increase takes the project to $185m and there is a risk it will go higher as the remaining 30% of the build is completed.

The biggest hurdle for the build and cause of increased costs was the discovery of highly fractured rock on the site, with multiple large shear zones (areas of ground rock and clay) bisecting the top of the spillway, plus weak rock under the plunge pool. Added to geology problems was the high inflation on the cost of materials and global supply chain disruptions, materials in short supply and the ongoing impact of Covid-19 on staff and productivity. The mechanical and electrical works alone is now expected to cost $19m more than the original 2018 budget.

The irrigators who bought shares in WIL own 49% of the dam, with some of the larger irrigators paying hundreds of thousands of dollars each to secure water for the future and buying surplus shares to

get the dam over the starting line. Tasman District Council owns 51% and will fund that percentage of the operating costs with just over half of those costs attributed to insurance, rates and consent compliance. The remaining costs cover ongoing dam operations, maintenance, engineering, staff and company costs.

The council needs the dam to service its existing communities and future residential and commercial growth. Waimea Water, which is the councilcontrolled organisation responsible for managing the construction, operation and maintenance of the dam, expects it to be completed by early spring which means it could begin filling and be commissioned by early 2023.

Initially, irrigators were looking at paying annual operating costs of about $500/hectare or just over, but that could double and King admits it is an unknown at this stage until extra funding is sorted and costs shared. Council has stated it proposes to use income from its enterprise activities to cover interest related to the irrigators’ share for 2022-23 as other funding options are investigated. A targeted rate on irrigators will not come into effect until the 2023-24 year.

30 Dairy Exporter | www.nzfarmlife.co.nz | May 2022 BUSINESS WATER

Murray King.