Prevent weeds competing with your maize crop with this Nufarm trifecta in one tank mix.

• Primiera® and Latro®WG together deliver outstanding broadleaf and grass weed control with excellent crop safety.

• Latro®WG controls perennial and annual grasses including couch, mercer and summer grasses.

• Bonza Gold® adjuvant improves the deposition, wetting, spreading and uptake of Primiera® or Latro®WG.

Having steps instead of a sloped surface drastically reduces slipping when the ramp is wet or mucky. Te Pari Stepped Loading Ramps have sheeted sides for animal safety and a catwalk with handrail ensures operator safety.

The Te Pari Hoof Handler has superb facilities for hoof paring whilst giving excellent access to all other areas of the cow for vet work and general handling.

• Easy to use overhead winch for back legs & belly support

• Multiple removeable side gates for full body access

• Reliable headbail with a lifetime warranty on locking mechanism

Cover

YOUNG COUNTRY

70 Tangaroa and the Hub

80 Free-range chickens - Keeping it local

RESEARCH WRAP

82 Southland Dairy Hub - Where were the farmers?

82 Answering questions on milk

WELLBEING

84 Harriet Bremner has a chat with Farmstrong’s Gerard Vaughan

DAIRY 101

86 Biosecurity - Keeping vigilant at the borders

SOLUTIONS

88 Managing FE, it’s not just about zinc

89 Practical loader tractors

OUR STORY

90 50 years ago in the NZ Dairy Exporter

November 15-17 – The NZ Grassland Association’s annual conference is being held in Invercargill. For more details go to www.grassland.org.nz

November 17 – A SMASH field day in Northland focuses on hitting your heifer targets. Graziers, local vets and LIC will explore factors that go into producing well-grown heifers. The field day will be held at Waimate North near Kerikeri between 10.15am and 1pm. For details contact Stephen Ball on 027 807 9686 or go to www.dairynz. co.nz/events/northland/smash-hittingyour-heifer-targets-kerikeri-november

November 17 – Owl Farm in the Waikato is holding a focus day. More? go to owlfarm.nz

November 18 – The supreme winner of the NZI Rural Women NZ Business Awards will be presented in Wellington. More? ruralwomennz. nz/nzi-rural-women-nz-businessawards-2022.

November 23 – Dairy Women’s Network is running a live webinar, Handing over the reins, to discuss succession planning. It runs between 12.30pm and 1.30pm. More? register.gotowebinar.com/ register/8987649263449846288.

November 24 – Achieving success in your contract milking business will

be covered in a DairyNZ workshop in Morrinsville. Participants need to register for the workshop which runs between 10am and 2pm. The workshop is aimed at farm managers and contract milkers to help them thrive in their current or future business. More? www.dairynz.co.nz/ events/waikato/achieve-successin-your-contract-milking-businessnovember/ or contact Kylie Brewer.

November 24 – The National Sustainability Showcase brings together the regional winners from the 2022 Ballance Farm Environment Awards to name a national ambassador for sustainable farming and growing. This year’s event takes place in Christchurch. For more details and to read about the regional winners, visit nzfeawards.org.nz.

November 29 – DairyNZ runs a Canterbury workshop on achieving success in your contract milking business. The workshop will be held at Dunsandel between 10.15am and 3.30pm and registration is required. For more details go to www.dairynz. co.nz/events/canterburynorth-otago/ achieving-success-in-your-contractmilking-business/ or contact Amy Chamberlain on 027 243 0943.

November 30 – December 3 –Fieldays is a summer event this year at the Mystery Creek Events Centre near

Hamilton. More? www.fieldays.co.nz

December 5 – Entries close for the 2023 Dairy Industry Awards including the New Zealand Share Farmer of the Year, New Zealand Dairy Manager of the Year and New Zealand Dairy Trainee of the Year. To enter go to www.dairyindustryawards.co.nz

December 7 – An Align Farms

regenerative trial field day is being held at the Hackthorne Road farm in Westerfield, Canterbury. The field day is a chance to hear how the trial is going, ask questions and take part in an optional farm walk, followed by a barbeque. For more details and to rsvp go to www.dairyevents.co.nz/ media/2215/regenerative-trial-fieldday.jpg. For more about the trial go to alignfarms.co.nz/regenerative-study

December 7-8 – Taranaki summer groups are holding onfarm catchups between 11am and 1pm. The Kakaramea group will meet at the Roper farm on December 7, Cardiff at sharemilkers John and Kristina Wyatt on December 8 and Coastal High at Dean Simpson’s farm on December 8. For details on Kakaramea and Cardiff summer groups contact Ashley Primrose on 021 246 5663 and for the Coastal High Summer Group contact Katie Starsmore on 027 1800 3707.

Whakapakari is a Maori word that means to strengthen, to mature and to develop people and I thought that perfectly encapsulated what our special report is about this month.

Development is not just teaching people something new, it’s also about lifting them up, helping them mature and grow stronger - and, as individual team members strengthen, so does your team. Because what is important?…he tangata, he tangata, he tangata (It is the people, it is the people, it is the people).

Developing people is part of the fabric at Kairoa Dairies, part of Canterbury’s Rylib group, where Anne Lee found people are championed, whether it’s building the how-to foundations onfarm, learning more about management and governance or even honing skills for a hobby or interest that’s completely outside the farm.

The family values and people development pays off for the group in staff happiness, retention and progression within or outside of the group. (pg42).

Anne Hardie caught up with Jack Raharuhi from Cape Foulwind, a people person and developer who shares (he says ‘over-communicates’) great insights into how he builds the connection with newbies and makes sure they fit and progress within his teams.

And three people-coaching experts share knowledge about finding out what makes your team tick, how to fill gaps in your team with training and development and how to unlock the hidden potential in every

member of your team, particularly with different cultures.

How timely when grass growth is exploding around the country and the mowers are out making silage, to have coverage of the Pasture Summit field days held in Taranaki and Southland over the past month.

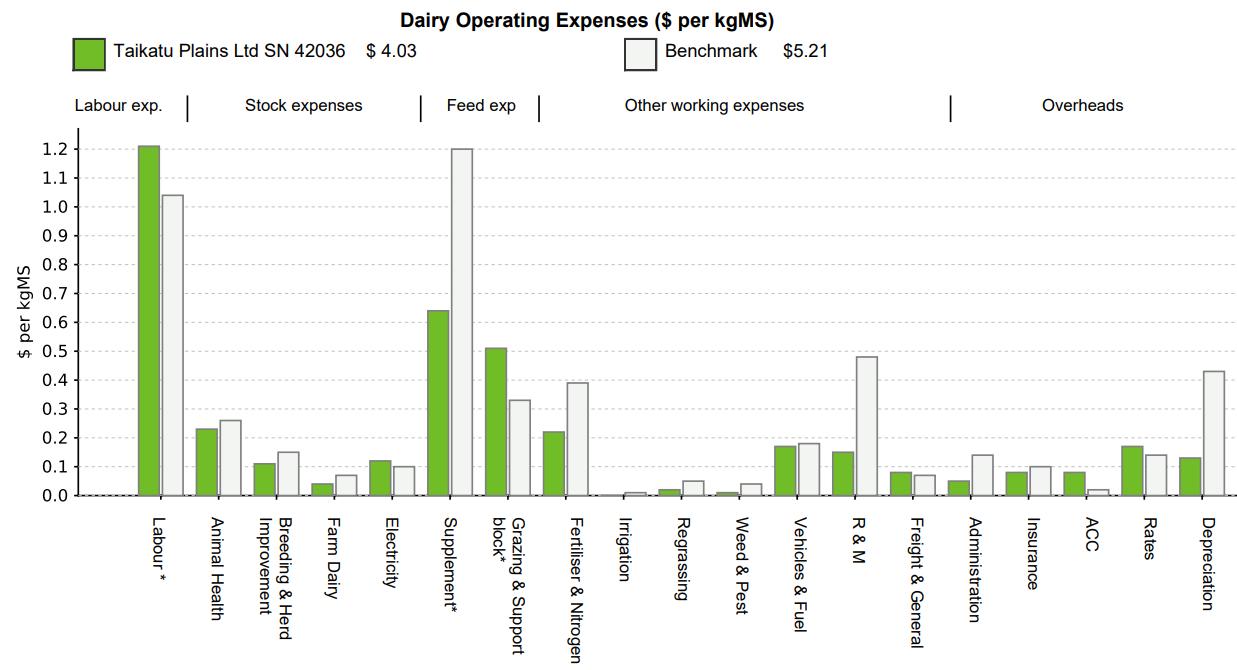

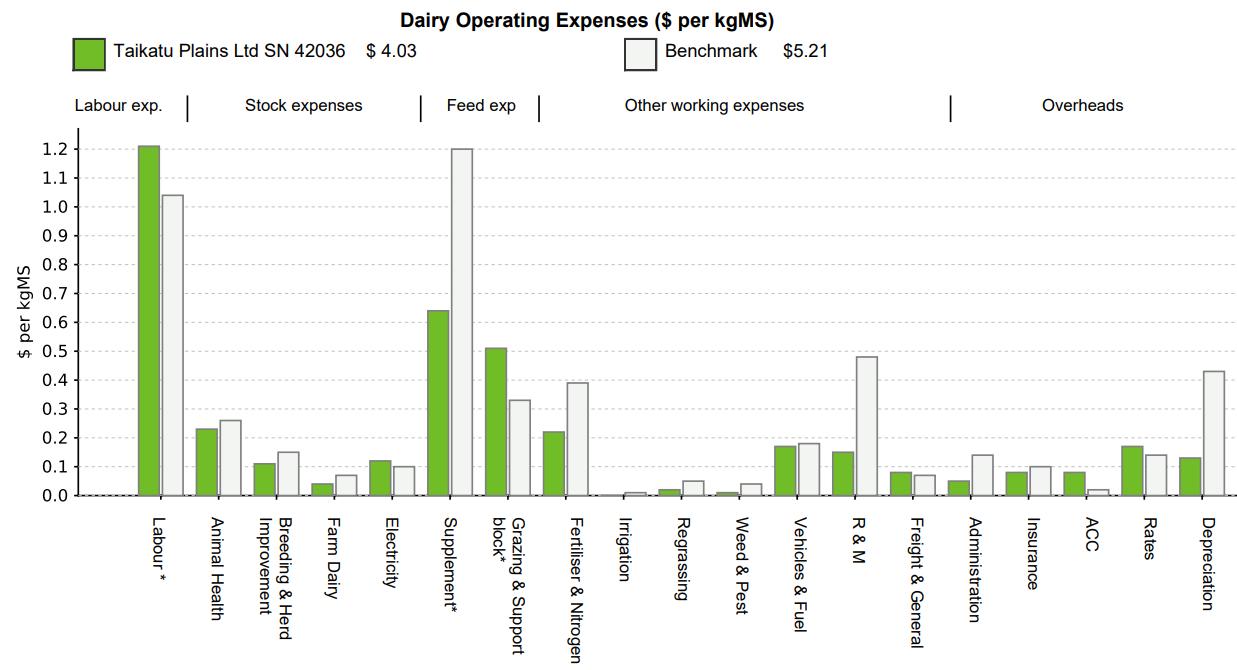

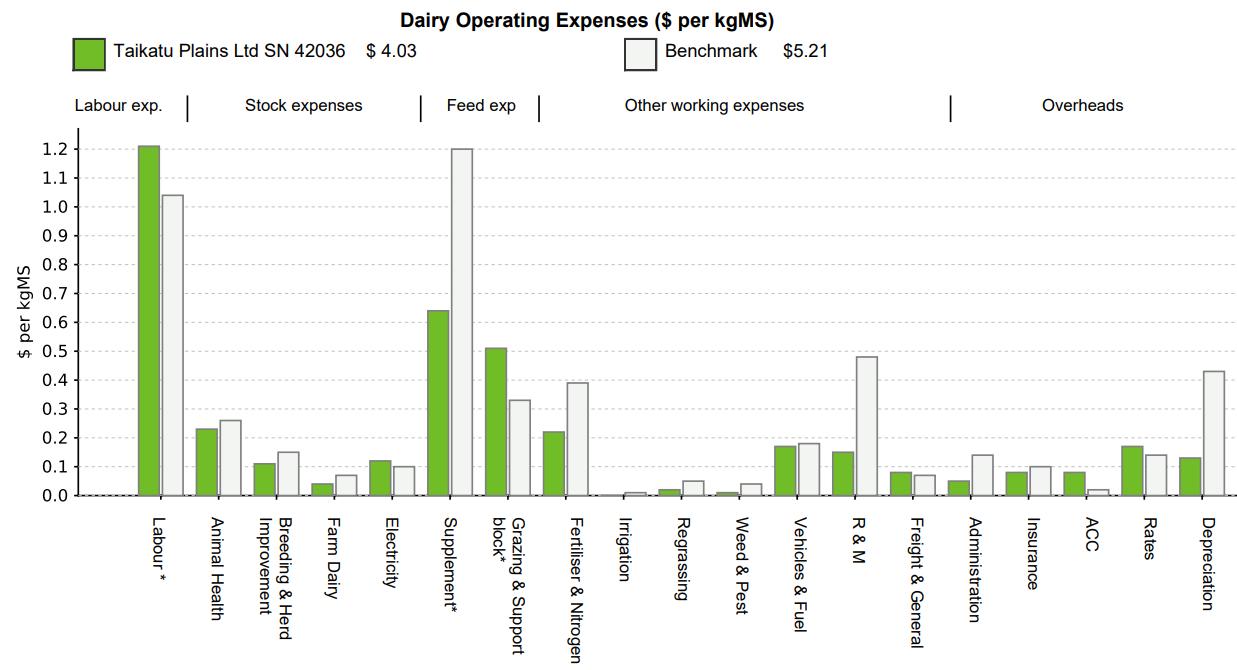

Through maximising growth and utilisation of pasture, and careful cost control, Nathan and Courtney Joyce from South Taranaki are tracking to produce operating profits 40% higher than the South Taranaki benchmark. (pg34).

And in Kimbolton, Manawatu, we follow Darryl and Debbie Coleman who are undergoing a transformation to regen, robotics and recording and interpreting loads of data on their journey to lower-cost, lower-input more-sustainable dairy farming. On the way they are solving some of the cow health issues that have irked Debbie for years, and saving her from sitting behind cows on the quadbike for six weeks of the year! (Pg 68)

Watch out for the Dairy Exporter and Pasture Summit Farmers’ tour to Ireland for 10 days in June/July 2023, details released soon from Farm to Farm Tours. If you fancy a kiss of the Blarney, a peek at the Emerald Isle and a wee taste of the craic, start lining up your ducks and saving those pennies.

It’s a bumper issue, hope you enjoy it! @YoungDairyED

New Zealand Dairy Exporter’s online presence is an added dimension to your magazine. Through digital media, we share a selection of stories and photographs from the magazine. Here we share a selection of just some of what you can enjoy. Read more at www.nzfarmlife.co.nz

Young Country is pleased to announce that episode three of From the Ground Up is now live on all of your favourite podcast providers.

Episode 7: Scott Jimmieson has realised his dream of becoming a farmer, and he’s keeping it local with his new online shop business, Local Food NZ, connecting farms with consumers.

Episode 6: Standing on the sideline watching her daughter play rugby in winter, Charlotte Bell thought she’d love to have a warm wool coat to wear. When she searched, she couldn’t find what she was after, so she decided to create her own.

Episode 5: Edward Eaton and Wilbur Morrison talk all things Buzz Club. The 24-year-olds went from experimenting with different flavour profiles, brewing in their garage on the weekends, to launching a range of premium sparkling mead naturally brewed from native New Zealand honey.

Episode 4: Brad Lake from The Brothers Green talks about harnessing the potential of hemp with a range of value-added products, and they believe the crop could have the potential to tackle some of the environmental and agricultural issues faced by farmers in this carbon era.

Episode 3: The Mangamaire Sunflower Field, established by farmer, photographer and mum, turned sunflower entrepreneur extraordinaire, Abbe Hoare, is turning heads for all the right reasons.

Episode 2: Amanda King founder of By The Horns. They say you should never work with children or animals, but By the Horns photographer Amanda King has carved out a niche for herself doing exactly that.

Episode 1: Delwyn Tuanui from The Chatham Island Food Co about how he chased his dreams from the ground up.

We love highlighting positive stories of young agri-innovators chasing their dreams. Listen to From the Ground Up: nzfarmlife.co.nz/podcasts-2 or scan QR code

NZ Dairy Exporter is published by NZ Farm Life Media PO Box 218, Feilding 4740, Toll free 0800 224 782, www.nzfarmlife.co.nz

Editor

Jackie Harrigan P: 06 280 3165, M: 027 359 7781 jackie.harrigan@nzfarmlife.co.nz

Deputy Editor Sheryl Haitana M: 021 239 1633 sheryl.haitana@nzfarmlife.co.nz

Sub-editor:

Andy Maciver, P: 06 280 3166 andy.maciver@nzfarmlife.co.nz

Reporters

Anne Hardie, P: 027 540 3635 verbatim@xtra.co.nz

Anne Lee, P: 021 413 346 anne.lee@nzfarmlife.co.nz

Karen Trebilcock, P: 021 146 4512 ak.trebilcock@xtra.co.nz

Delwyn Dickey, P: 022 572 5270 delwyn.d@xtra.co.nz

Phil Edmonds phil.edmonds@gmail.com

Elaine Fisher, P: 021 061 0847 elainefisher@xtra.co.nz

Claire Ashton P: 021 263 0956 claireashton7@gmail.com

Design and production:

Lead designer: Jo Hannam P: 06 280 3168 jo.hannam@nzfarmlife.co.nz

Emily Rees emily.rees@nzfarmlife.co.nz

Partnerships Managers: Janine Aish

Auckland, Waikato, Bay of Plenty P: 027 890 0015 janine.aish@nzfarmlife.co.nz

Tony Leggett, International P: 027 474 6093 tony.leggett@nzfarmlife.co.nz

Angus Kebbell, South Island, Lower North Island, Livestock P: 022 052 3268 angus.kebbell@nzfarmlife.co.nz

Subscriptions: www.nzfarmlife.co.nz subs@nzfarmlife.co.nz

P: 0800 2AG SUB (224 782)

Printing & Distribution:

Printers: Blue Star, Petone

Single issue purchases: www.nzfarmlife.co.nz/shop

ISSN 2230-2697 (Print)

ISSN 2230-3057 (Online)

If we’re are going to save our own skin, we are all going to have to make some serious changes, Southland dairy farmer Suzanne Hanning writes.

Every dominant species in an environment will have a direct effect on that environment.

Whether you believe in climate change or not, one cannot argue that humans as a species are not only dominant, but are having an effect on our world.

For people then talking about saving the world, the world doesn’t need saving. In the words of John Dutton “There will be a time when Earth sheds us like dead skin.” It’s not the survival of the world that is at stake, it’s ours. Of course, to sell a message like that would come across as selfish, so, the message put out taps into the inner wanna-be hero.

That message is gold to a person’s perceived image and those that market to them. It’s all designed to remove guilt, make people feel they are doing something meaningful and that makes them feel good. It gives a little bit of meaning and purpose in an otherwise too big, meaningless world. People can’t do much about the war in the Ukraine, but they can still be a hero by buying shampoo in a 100% recycled plastic bottle.

This leads me to the biggest hero gig out. The Emissions Trading Scheme with emphasis on the word Scheme. Not to be confused with He Waka Eke Noa, in which funds are intended to be circulated back to farmers.

Rod Carr explicitly advised the New Zealand Government that we cannot plant our way out of this. But our powers that be appear to be strongly supporting just that.

“Any time anyone plants enough trees to sequester a tonne of carbon, we automatically generate an NZU, which is a permit to pollute a tonne of carbon into the atmosphere.

“Which means, technically, unlimited forestry allows unlimited pollution.”

But those trees only sequester carbon while they are growing. The carbon is stored in the wood and once the wood rots or is burnt, that carbon is released back into

the atmosphere. Hence, future generations will need to continue to plant more trees to absorb carbon being emitted historically.

As NZ allows 100% of a companies’ pollution to be offset with forestry, buying a few carbon credits means it can be business as usual for emitters and they can claim they are “carbon neutral” even though they haven’t done anything except a little virtue signalling. Those customers buying their products can then have a guilt-free purchase and feel they’re “saving” the planet when the reality is mere smoke and mirrors and couldn’t be further from the truth.

No wonder it’s easier for the majority to point the finger at agriculture, then they don’t have to do much because they’re buying their almond milk latte in their commercially compostable cup and feeling like a hero for doing it.

The reality is, if we’re are literally going to save our own skin, we are all going to have to make some serious changes. In a literal sense, all the carbon (fossil fuels) that has been dragged out of the earth for the last 100+ years needs to somehow go back there.

Think about all the stuff made from those fossil fuels –it is mind-boggling to think of the sheer volume of stuff consumed, burnt, used and thrown out. No wonder it’s easier for the majority to point the finger at agriculture, then they don’t have to do much because they’re buying their almond milk latte in their commercially compostable cup and feeling like a hero for doing it.

How we climb out of this, I have no idea. But some people will end up paying for it and some will make a lot of money on the way.

In October, I got off farm for five milkings (yes, like many of you, time off is measured in milkings) and attended the Agri-FoodTech Oceania Summit 2035 thanks to AGMARDT. Spending two days with AGMARDT general manager Lee-Ann Marsh and trustee Ben Tosswill, digesting and hearing from international presenters on the topic of agri-food and tech was good for the soul.

In order to feed 9.8 billion people by 2050, the key themes from all the speakers that resonated with me were:

• Collaboration (in fact one speaker said ‘radical collaboration)

• Net zero mindset, full utilisation of the product/circular economy model and reducing food waste

• Understanding your ‘capitals’ (as in not just finance but in six capitals)

• Capturing hearts and minds is vital

• Vision is important and the story of farming is the story of people.

Not one speaker said more regulation would help the planet or people to manage climate effects, a growing population or the myriad of challenges sitting in front of the agri food and tech sector. However, more than one, spoke about the place the government can have to foster the right people to do the right thing with support.

All speakers said farmers were smart and with some help would keep going from strength to strength in the land and farm management practices.

Collaboration (or radical collaboration) is required. No longer can we be all things to all people.

One crown research institute representative stood up and said they have great scientists but who in the room could partner with them on entrepreneurship, venture capital and going to market.

They have new cultivars of products (some already on the market) that could have had accelerated progress with the right collaborations.

The seaweed industry was another. Agrisea have been around for 26 years, and only in the last few years have the rest of the sector realised seaweed could have methane-

reducing properties. They now have great collaboration to bring a product to market.

If we approached everything we did as a net zero or no waste or full utilisation of product approach, then we would move quickly towards reducing our emissions and growing our businesses and communities. Not waiting for legislation or regulation, just us, thinking about how we can mitigate our impacts on the world around us.

Our business capital is far more than just the money we have or the asset in our name. We could have KPIs for financial, intellectual, human, social/relationship (communities), manufacturing (how we buy, use or make) and natural (land/water etc). What if we set our own business plans up to have goals in each of these areas just as we do to have financial targets? Just focusing on one capital will likely have an adverse effect on the others so having a plan on how to manage all capitals will be vital.

Capturing hearts and minds, making ag feel trendy by having the right tools and tech will assist our agri food sector to grow and farm. There are so many tools like digital twins, machine learning, emissions modelling, circular economic tools that will help make better decisions now in order to keep improving.

Finally, the vision. We know our sector has a vision, as do a number of food or tech systems in NZ. I’m not talking about the big visions created by others that we can’t even remember as a one-liner. I’m talking about your vision for your land or farm or business or family.

We all have them, we may not write them down on letterhead (maybe we should!) but we know deep down we want to do right for the people, the land, and the sector.

Maybe if we own our own vision for ourselves, and work on that daily then the flow-on effect will be that we do have improvements in our water, climate, land, business and people outcomes too. I particularly like the mindset of taking sustainability beyond regulatory compliance and turning risk and challenges into opportunities.

(And yes, like most of you, Taranaki has had a terrible spring. I can’t remember what the sun looks like but I didn’t want you to have to read about it when most of you have been living and breathing it too!)

Taranaki dairy farmer Trish Rankin reckons the world has never been a better Petrie Dish to try new things.

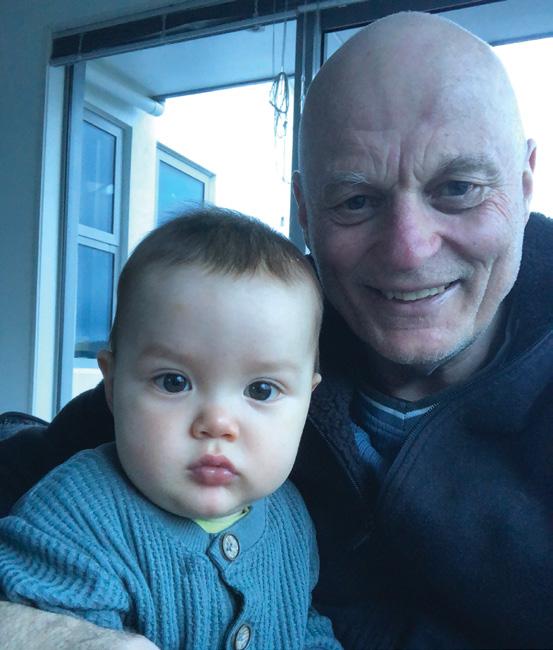

Rachel Hammond gets used to shoe-horning daily life into becoming a new mum onfarm.

As I watched my toddler smear his sticky hands across the fridge door, I heard Hamish say “Can you write that article for Dairy Exporter? It’s due tomorrow, and I need to do the GST”. Just as I was collating my excuses of why I won’t have time to do it, the door shuts and he was gone, off to do the rest of his farm jobs for the day.

Initially, I thought I could write a farmer’s scientific review on “how to stop climate change, while still feeding the world”, however I quickly thought otherwise for a number of reasons:

First, I have what is self-diagnosed as “Mum Brain” – commonly referred to as forgetfulness and brain fog experienced after the birth of a child. And secondly, there appears to be few solutions to climate change that will have enough of an impact except, maybe, getting rid of the humans? That, of course wouldn’t win any votes.

So, here goes: an honest review of being a firsttime farm mum, during the busy spring period. Farm mums can be put into two categories: The “working farm mum”, this is the mum who needs to manage daily childcare and house chores, while working fulltime on the farm (these women are superheroes); and the “farm stay-at-home mum (SAHM)”, which I would describe as the townie version of SAHM, but on crack. I would put myself in the latter category.

Since having a child, I have realised the time required to get ready to do a job usually takes as long as the job itself. For example, when feeding the calves in the morning, I need to:

1. Prep a nutritious breakfast for the child grizzling at my feet

2. Let the child self-feed – this can take anywhere between five minutes (to pick each item up individually and throw it on the ground) and 30 minutes (breakfast well enjoyed).

3. Clean up

4. Change

5. Repeat steps 2, 3, 4 (any order)

By this stage the chorus from the calf sheds is getting louder, and the pet lamb is pawing at the door and you realise you are not ready yourself.

Once you have made it out the door, you must expect the job to take twice as long as it did before having the child. Or, if you’re fortunate like us, you can call on the grandparents from time to time. If that’s the case, then all the steps outlined above (and more) may be skipped. In addition to the farm SAHM morning routine, you must not forget the cooking, washing, gardening, entertainment, HR management and the “last-minute” farm call ups.

I am not going to lie, it can be tough and it is easy to compare ourselves with families that have every weekend off and 8am – 5pm jobs. I’m very guilty of this, but we must remind ourselves how lucky we are for our children to grow up with endless space, rural experiences, and opportunities to watch their role models at work. I am only fortunate to be a SAHM because of the farming life we live. It allows me to have the flexibility to enjoy farm jobs (with a special helper), attend playgroups and be present. Here’s to those families that do it with four or more in tow!

West Coast diary farmer Richard Reynolds contemplates livestock emissions proposals.

Well done Tim and Jim, we won, we truly beat Beef and Lamb. I had my doubts about your plans around He Waka Eke Noa. When the climate commissioner’s report was released on the ability of farmers to change their gas production, there were glaring mistakes and nontruths presented around mitigation measures, but you supported the report in its whole.

I thought this was a bit strange, but now I understand you were just waiting your time.

Now you will have so much “levy” recycled for research, mitigation and extension that there will be no need for you to collect any DairyNZ levy. So for dairy farmers on a levy basis I may not be paying any more than I am at the present, very clever. I am looking forward to receiving payments from the rest of the agriculture industry paying me for my mitigation. If science is to save us, as all the reports say it will, feed additives and vaccines will work better for dairy than beef. Very interesting research is coming out around breeding in sheep for lower methane - this is positive.

If it works with cattle with our science-backed and directed breeding companies compared to beef breeders we will be able to prove and breed low methane cattle very quickly.

How did you keep the tweed-jacket wearers arguing over whether Angus or Hereford were better and not looking at how this was going to affect them? You could have suggested that they finish dairy cross stock but that is not real beef farming. Now they will be farming pine trees which are not even stock. You have let them keep on selling their land to foreigners with no restrictions to be planted in carbon sinks for a one-off gain to be of no value to New Zealand after 80 years. But dairy farmers can’t sell to foreign buyers. I know you will work on this.

I also thought it was clever not to educate the minister of agriculture and prime minister. I listened to the whole

announcement. Minister Damien O’Connor said He Waka was not a big deal for farmers, all they had to do was put some solar panels on the roof and have some EV vehicles and change some pasture species.

How did you keep the tweed jacket wearers arguing over whether Angus or Hereford were better and not looking at how this was going to affect them?

The first two have nothing to do with He Waka and the pasture species through regrassing may increase your He Waka tax. The prime minister talked about the premiums Silver Fern Farms is receiving from its carbon-zero beef. The problem is this works with onfarm offsetting that is not going to be allowed.

Take care that the talk of transition payments or subsidies Jacinda talks about don’t affect our free trade agreements. Those two may have been easy to hoodwink but watch that smiling James Shaw.

He is playing the long game - the 10% reduction target by 2030 may be easy for the agricultural industry but he knows the real game is the 2050 reduction target of 24% to 47% is the real kicker. Also keep an eye on that bearded commissioner not wanting agriculture to have offsetting of biological gases with biological tree planting, I don’t know what he is up to but you two will.

I like how you are now complaining how nitrogen is under the ETS and the government sets the level of the tax. You knew you never were going to get these things your way, but it looks good to complain so farmers support you.

Well done, you played the game with a straight bat. And we won!

New Zealand farmers have a long-held reputation for innovation. But a recently released report shows a large proportion of farmers are not yet convinced by the merits of the latest available, innovative farm technologies.

In September AgritechNZ published a ‘baseline’ report of Digital Adoption in Primary Industries, the purpose of which was to better understand the motivations, pressures and barriers faced by farmers and growers in adopting digital tools.

In many ways the initiative was needed as a way of ‘putting to bed’ common but unscientific stereotypes around why farmers do or do not engage with digital technology in NZ. As chair of AgriTechNZ Bridgit Hawkins identified in the report’s introduction, falling back on stereotypes and generalisations are easy but not helpful when trying to support positive change. It was a necessary step to take to help the fledgling agritech sector understand what it needs to do to most effectively serve farmers.

The top-level findings show 59% of farmers lean towards the adoption of digital technology, with 41% not seeing much value in using it to run their businesses. This latter stat represents a sizable chunk and is higher than outside the primary sector, but not unexpected given knowledge levels are low.

In terms of farmer motivations, there were few surprises identified in the survey (efficiency and ease of use are key determinants). The barriers were also predictable - cost, a reluctance to move from manual systems that still work, and (lack of) proof of return on investment.

But several of the considered conclusions and lessons drawn from the survey of 1000-plus farmers revealed under-recognised truths. These included:

Farmers struggle to see the value in the onfarm data and particularly the value of sharing that data; 77% of farmers would be happy to share data if it benefited them, but the fact that only half of farmers do so indicates the benefits are not widely appreciated.

Use of digital technology is prevalent in farm business management (accounts, payroll etc). But there is lower uptake in operational, onfarm solutions. In fact, farmer investment intentions for the shiny gadgets most often associated with ‘agritech’ is low.

Farmer interest in digital technology is not ultimately determined by farmer age, but farm business stage (whether a farm business is growing/ expanding vs. declining/existing).

On the first lesson, Rezare Systems Farm Systems specialist Graeme Ogle confirms failure to see value in data is driven by a lack of belief in its ability to create practical improvements.

While most Kiwi farmers are keen to adopt digital technologies onfarm, a sizeable minority don’t. Phil Edmonds reports.

“There’s a huge amount of data that is flowing around and there to be captured, but the data that will have an effect on production is pretty scarce. Too often developers assume their challenge is just to make sure farmers get the ‘value’ a particular solution will create, and the improvements that flow to a farmer’s business from adopting it.”

Rather than trying to convince farmers on the value of a digital innovation, they should recognise farmers are most likely going to view agritech as a cost. When it comes to software, farmers are probably going to see it as having problems, Ogle says. Using it is going to take longer than the system they use and will require a lot more effort to get used to using it. As a result, farmers will attribute a discount to its nominal value, and determine whether it is worth putting their time into this technology.

“If agritech developers ask a farmer if they’d be interested in their new software, what they are actually doing is asking for a big commitment in time.”

Federated Farmers board member and rural connectivity spokesperson Richard McIntyre not only shares concerns on the time cost of adoption but also the ability of those tasked with using new technology to be willing to do so.

“As an employer, the tech we choose to uptake will be determined by our employees’ willingness to use it. There is no point having technology if no one will invest themselves in learning how to use it.”

Any increase in acceptance that farm data holds value will only come when it can be captured efficiently, Richard says.

“Farmers are frustrated having to input data for reporting requirements but unsure how it is used. There are cases where the same data needs to be entered into different software three or four times. Fertiliser applications are a good example of that. Farmers wouldn’t mind sharing data if they could enter it once. The frustration comes from the inefficiency.”

As noted in the baseline report, efficiency is one of the key considerations in adoption.

Part of the still suspicious view of digital technology among a large minority of farmers is that for many, they have started their journey of adoption by coercion. A good example of this has been the emergence of farm environment plans in parts of the country.

“Being confronted with a need to use a digital portal is a massive hurdle for farmers who might have a computer but have only ever used it for email,”

AgFirst consultant Erica van Reenan says. “There haven’t been a lot of resources available to provide education on digital technologies. This contrasts with other countries where governments have proactively subsidised adoption. When this happens, the chances of adoption will be higher.”

The second lesson identified above (business software yes, onfarm gadgets less so) should be no surprise. The baseline report found that where farmers are willing to engage with digital technology is when it has already been ‘de-risked’ by other sectors (desktop-based admin, for example) and where there are people on hand to support its use (accountants, farm advisers etc).

The successful uptake of the latter can be attributed to having a human able to offer advice and service rather than be at the mercy of a list of frequently asked questions to scroll through. Graeme Ogle says farmers are well accustomed to using financial software but that’s because they feel supported doing so. Richard McIntyre makes the same point.

“Farmers are experts on cows and grass. We don’t intimately know how software works; we just want it to work. If the support is not there, it is going to be so much harder to adopt and bring people on the journey.”

To this point it’s easy for developers to forget that farm businesses are generally family businesses that don’t have HR or IT departments that can be called up by dialling 0. If farmers can’t easily troubleshoot problems, then it’s going to struggle to fly. In terms of the relatively modest appeal of shiny gadgets in the field compared to those in the office, there is a sense that the agritech industry has failed because it has focused on ‘disruption’ where the most successful technology advances are about continuity. Ogle says about 1% of technology is about disruption, and about 1% of that succeeds. If you have 100 disruptor innovations in NZ, one might succeed.

Some of the most talked about agritech advances are those that require whole system changes, van Reenan adds. But what has most appeal will be those innovations that can be built into existing systems to make life better – automatic cup removers being a good example,

rather than large-scale revolutions, such as shifting your whole operation towards virtual farming.

The other ‘truth’ demystified in the baseline report survey around a farmers’ age determining their interest in agritech points to farmers being far more pragmatic than they are given credit for. Ogle says it’s misleading to think of farmers as laggards. It’s more that agritech is not often top of their minds. When it is, they’ll be open to listening irrespective of age. But not all farmers are in the market.

“In my experience, a large proportion of farmers are busy with other hurdles in their business, such as farm succession, farm maintenance, health issues and so on,” Ogle says. “It’s only when these types of pressing issues are taken care of that farmers will be able to seriously consider the value proposition of new technology.”

All told, there are plenty of good reasons why farmers are cautious about adopting new technology. And the baseline report documents what might be obvious to most – that there remains a disconnect around developers understanding farmers’ motivations. But perhaps we need to accept that the agritech industry has still got its trainer wheels on, and it is unrealistic to expect it to have got everything right. A couple of years ago an Australian AgriFutures report on the challenges and opportunities for effective value proposition design in agtech was published, which (possibly reassuringly) identified many of the issues presented in the AgriTechNZ baseline document. It showed there is nothing unique in NZ farmers’ perceived reluctance to see value in digital technology.

It pointed to inherent challenges in gaining trust when an industry such as agritech is new.

“New industries often experience a flood of new products hitting the market simultaneously, and often in unpolished states, because of the potential commercial rewards that come from being first to market. Also, because of how new the industry is, entrepreneurs entering for the first time lack information about their users.

“Further, they are trying to build never-made and never-seen-before products, rather than incrementally better versions of existing products. Therefore, by definition, there is no knowledge about what makes a product good or bad, or what is desirable.

“Entrepreneurs lack the time and budget to go slowly and carefully to ‘get it right’ on the first try. They deploy products rapidly and adapt based on customer feedback: a ‘get it out and see how it goes’ approach.”

With this in mind, farmers might not have more sympathy for obvious agritech industry failings, but it could recalibrate expectations. The disconnect that farmers see between what an innovation says it does on the box, and how easily it is operationalised effectively represents industry growing pains. A lasting, slightly suffering lesson might be ‘give it time’.

The top-level findings show 59% of farmers lean towards the adoption of digital technology, with 41% not seeing much value in using it to run their businesses.Rezare Systems Farm Systems specialist Graeme Ogle. AgFirst consultant Erica van Reenan.

A new generation of dairy farmers is adopting new business models to succeed in red-tape Britain.

By Tim Price.Britain’s dairy farmers dream of a future without the red tape which governs their lives.

It’s why so many farmers voted for Britain to leave the European Union six years ago and now blindly support politicians who promise ‘a bonfire’ of red tape.

It’s also why motoring-journalist-turnedfarmer Jeremy Clarkson has become the farmers’ guardian angel. His forthright style and cavalier attitude to rules has made Clarkson’s Farm a huge hit on Amazon Prime and earned the heart-felt thanks of farmers for ‘telling it like it is’.

Now Clarkson’s latest gimmick, a pop-up restaurant in a redundant farm building, has been closed by the local council for breaking planning laws.

Farmers’ dismay at their hero’s failure to

beat the bureaucrats coincides with the disastrous attempt by recent Prime Minister Liz Truss to transform Britain into a low-tax, light-regulation state.

one throw of the dice was doomed to fail. The Chancellor of the Exchequer (Finance Minister), only in post for days, was sacked and Truss’s raft of policies and tax cuts reversed, following massive falls in the financial markets. Within days, Truss was also out the door.

The message for dairy farmers is that you can’t beat the system. Rules and regulations will continue to multiply.

Get out or adapt to constant change and ever-tighter regulation are the stark options.

However, it’s not all doom and gloom. A new generation of dairy farmers is springing up, ready to take up the slack from an increasing number of traditionally run units exiting the industry.

For a nation with a large ageing population facing massive hikes in energy costs, betting the country’s economy on

Farming in England’s Midland dairy belt, Jimmy Pritt of JWP Farming is one of these, using a flexible business model to help JWP survive in today’s fast-changing

‘OUR GOAL IS TO PRODUCE MILK PROFITABLY, ACHIEVED THROUGH GOOD MANAGEMENT AND UTILISATION OF THE GRASSLAND, 70% OF WHICH WAS RESEEDED USING CULTIVARS SUITED TO OUR SYSTEM.’Above: Jimmy Pritt with cows on his farm in the English Midlands.

marketplace. Jimmy, who graduated from Harper Adams University in Shropshire in 2006, contract-farms Whetstone Pastures supplying milk to a local Stilton cheese manufacturer from a 370-head herd run on 107 hectares. The herd is run on a flying herd basis with in-calf heifers and some cows purchased as replacements (no replacements reared).

Yields average 6163 litres with 3927 litres from forage, at 4.5% butterfat and 3.7% protein. In 2017, a New Zealand-style 24-aside herringbone parlour complex was built to replace the old parlour, along with a slurry lagoon and limestone cow tracks. Furthermore, two buildings were converted to increase cubicle numbers to a total of 346. Maize and grass silage is grown on contract with a nearby arable farm. Regular soil sampling enables them to tailor fertiliser use, and slurry is spread after grazing to reduce input costs.

Cows calve from the end of February to the end of May, with all animals put to short-gestation beef sires.

Boldly, Jimmy has just taken over another 405ha unit nearby with 650 autumn-calving cows. Their milk is sold to Tesco and Mueller.

“Our goal is to produce milk profitably, achieved through good management and utilisation of the grassland, 70% of which was reseeded using cultivars suited to our system.

“Britain’s dairy farmers face labour shortages, huge feed and energy costs. With farmers’ average age now reaching 68, and many dairy units urgently

requiring major investment, the pace of farmers going out of dairy is increasing.

“This offers great opportunities for my generation who have the enthusiasm and resources to meet future challenges while farming in an environmentally safe way.

“Our business model is designed to cope with challenges – we just didn’t expect to be facing them all at once. We’re rising to the challenges and finding alternative ways to stay in profit in our dairy units.

“With fertiliser costing £1000 a tonne we’ve got to use it well and make slurry work more effectively to maximise our grass and clover mixes and maize crops. It’s now possible to measure slurry nitrogen content as it is applied, which helps us to fine-tune how we balance fertiliser use.

“Finding and keeping good staff is a huge problem for many farms. Today’s farm staff live amongst people whose jobs provide good pay and conditions with regular time off and decent holiday provision. People will no longer accept that farm work means the low wages and very long hours.

“It’s a challenge to find and retain good staff, but by offering good remuneration, working conditions and training we’ve got a settled team with good quality housing provided.”

Despite anti-dairy pressures and group XR (Extinction Rebellion) targeting British dairies, Jimmy maintains a social media presence to promote what he sees as a sustainable farm business producing healthy food while working towards carbon net zero. While fully committed

to achieving net zero in the future, Jimmy is pleased to see that the Government’s policy of future subsidy payments only rewarding farmers’ environmental improvements is softening.

Following Eco Zealot Boris Johnson’s dismissal as Prime Minister, the new regime has announced a review of its Environmental Land Management Schemes (ELMS) - but following multiple false starts and ‘U’ turns, farmers aren’t letting hopes get too high.

Jimmy’s experience and knowledge has been gained through previous positions, such as managing and driving improvements on a high-yielding herd and driving system changes as a partner in a mixed-family farming business.

His next move was to join his family partnership, where he learned more about business finances and managing a grassbased system. He also got involved in First Milk’s development group, giving him a greater understanding of the industry, and introducing him to a network of farmers and contacts. As chairman and member of the local Profiteers discussion group he shares experiences and ideas with a group of forward-looking dairy farmers, including new starters and herdsmen.

Alongside carrying on a small amount of dairy consultancy, Jimmy plans to continue to grow JWP Farming by taking on more opportunities.

“In the future I hope to achieve the dream of farming in my own right, to own a dairy herd and to be proud of a profitable business.”

The pasture landscape is changing...

Inflation remains high in most places In NZ we had a bit of a shock earlier in the month, with headline inflation coming in at 7.2% for Q3 - down only very marginally from Q2, and much higher than anyone had anticipated If it hasn’t yet, inflation must hit consumers’ pockets some time soon, and sellers are therefore concerned about how much demand there will be

102% year on year, with China again taking increased volume, up 350% year on year. Cheese exports were up 58%, with 79% more sent to China in September and 116% more to Japan. Whey was one of few categories to see a fall, down 12% year on year. The United States is NZ’s main destination for whey, and exports to the US fell 20% year on year.

Now to the less-positive news.

Prices fell at both Global Dairy Trade (GDT) events in October. The overall GDT index was down 3.5% at the October 4 event, and fell another 4.6% at the October 18 event. In addition, GDT Pulse events trended down. There’s only one grade and contract on offer at the Pulse events – C2 regular grade WMP – but as a key product, ongoing falls in prices aren’t a great sign for the wider GDT complex.

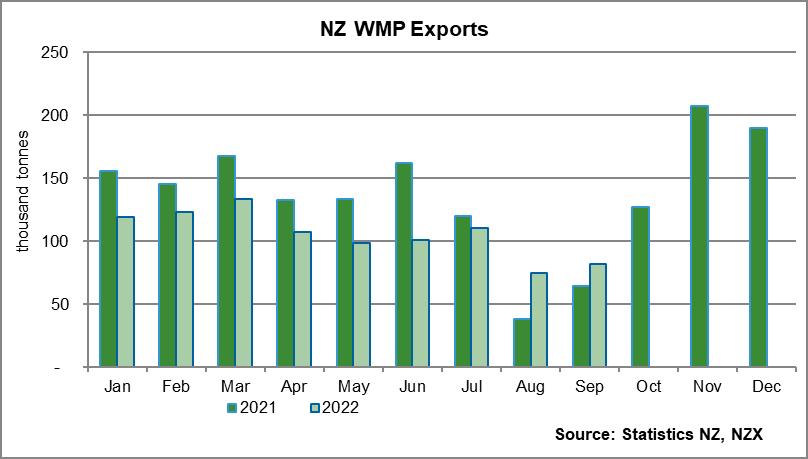

New Zealand’s dairy exports grew again in September, following growth in August. The total volume of all dairy products was up 32% year on year, though year-todate exports are still down 6%.

Some of the iffy demand lately may be due to reluctance to hold on to any inventory if consumer demand suddenly plummets

September milk production was weak, coming in at -3 8% on a milksolids basis This puts season-to-date production at -4% Pasture growth conditions haven’t been particularly favourable, along with continued labour shortage issues, not to mention the ongoing concerns with environmental regulations NZX expects another negative result for October and that full season milk production will remain quite negative this season In theory this should provide support to prices, but for now demand issues seem to outweigh supply issues

Whole milk powder (WMP) exports lifted 26% year on year. Year -to-date WMP exports remain down 16%. WMP exports to China fell 33% year on year in September, with the lift coming from increased exports to other destinations. NZ sent more WMP to South East Asia, the Middle East and South America.

Skim milk powder (SMP) was up just 2%

year on year. Year-to-date, SMP exports are up 3.6%. Again, exports to China fell, down 25% year on year. The increase was largely made up by more volume sent to South East Asia, with a little more also sent to Saudi Arabia and Japan.

Butter exports lifted 48% year on year. There were increased butter exports to China, up 46%, with increased volume also sent to most of NZ’s other top destinations for butter. Anhydrous milkfat (AMF) soared

The fall in prices seems to be due to softened demand, though outside of GDT, demand is still sometimes being described as ‘firm’. There is nervousness about the global macroeconomic situation. Inflation remains high in most places. In NZ we had a bit of a shock earlier in the month, with headline inflation coming in at 7.2% for Q3 - down only very marginally from Q2, and much higher than anyone had anticipated. If it hasn’t yet, inflation must hit consumers’ pockets some time soon, and sellers are therefore concerned about how much demand there will be. Some of the iffy demand lately may be due to reluctance to hold on to any inventory in case consumer demand suddenly plummets.

September milk production was weak, coming in at -3.8% on a milksolids basis. This puts season-to-date production at -4%. Pasture growth conditions haven’t been particularly favourable, along with continued labour shortage issues, not to mention the ongoing concerns with environmental regulations. NZX expects another negative result for October and that full season milk production will remain quite negative this season. In theory this should provide support to prices, but for now demand issues seem to outweigh supply issues.

While the Government’s recently released proposal for pricing agricultural emissions stops short of stating the likely price for methane (CH4), discussion in the document still focuses on 11cents/kg CH4

That was the price used by the He Waka Eke Noa agricultural sector partnership in its modelling.

The Government commissioned its own modelling that included work on both the processor levy and the farm-level levy.

It looked at three price scenarios for methane to estimate the possible emissions reductions in 2030 comparing the modelled scenarios with a scenario with no pricing system.

The prices used:

• A low price – 8 cents/kg CH4

• A medium price - 11 cents/kg CH4 (suggested by the partnership as the starting price)

• A high price – 14 cents/kg CH4

Even at the low price, the modelling has found total agricultural emissions are expected to reach the targeted 10% reduction from 2017 levels by 2030, with methane emissions alone dropping by 12%, the Government’s consultation

document says. (page 59 of the consultation document)

For dairy farmers the models suggest the farm-level levy will mean a drop in revenue of 6-7%, significantly less than the impact borne by sheep and beef farmers who are expected to lose 18-24% of their revenue. (see table A on page26) Milksolids (MS) production is expected to drop by 4-5%.

For the red meat sector the drop in production and revenue is significant and harsh with sheep and beef revenue likely to take an 18% hit at the low levy price and drop by almost a quarter (24%) at the high price.

Lamb production is predicted to tumble by 16% at the 8c/kg CH4 farm level levy and 20% at the14c/kg CH4 price.

However, beef production is modelled to increase by 8% at the low levy price and 5% at the medium 11c/kg CH4 price but drop by 14% at the high price.

That’s because more cost-effective mitigation technologies are assumed for beef cattle compared with sheep which would allow a degree of switching from running sheep to running beef cattle, the consultation document says.

It’s uncertain what the effect emissions

pricing will have on the dairy sector’s push to cut bobby calf numbers.

DairyNZ says He Waka had recommended emission price levies would be set by Government ministers on advice from a system oversight board, a collaborative governance approach between government, Māori, and the agriculture sector.

He Waka proposed a price for methane, nitrous oxide, and carbon dioxide.

“The methane price would be set based on a broad set of pricing criteria which considers progress towards legislated emissions targets, but also social and economic impacts.

“Nitrous oxide price would be set at the level needed to fund sequestration, research and development, incentives, and administration of the scheme.

“The price for methane should be guided by a wider set of criteria than just targets alone.

“It needs to also consider the availability of mitigation technologies, social and economic impacts, and potential emissions leakage alongside target trajectories.

“The price should only collect enough levy to deliver on the scheme’s intended purpose and outcomes.

“Prices should not be linked to the NZ ETS and should be set every three years to provide stability and certainty,” DairyNZ says in its review of the consultation document.” (link below)

At the Lincoln University Dairy Farm (LUDF) focus day in October, just before the release of the Government’s consultation document, Lumen Environmental resource management adviser Nicole Mesman walked farmers through the likely cost of emissions pricing using the LUDF as an example farm.

The calculations are based on LUDF’s 2025/26 obligations using its 2021/22 season results.

They are based on He Waka pricing of 11c/kg CH4 and a nitrous oxide price of $4.25/tonne.

The new Government proposal also has 11c/kg CH4 but uses $10.86/t CO2e for nitrous oxide (N2O) as the 2030 price.

LUDF’s methane emissions, based on cow numbers, milk production and feed

eaten are estimated at 1655t of carbon dioxide equivalent (CO2e).

To convert tonnes of CO2e to kg CH4 divide by 25.

1655t CO2e = 1,655,000kg CO2e

1,655,000 CO2e ÷ 25 = 66,200kg CH4

66,200kg CH4 x 11cents/kg CH4 =$7282

LUDF N2O emissions = 539t CO2e

539t CO2e x $4.25 = $2291 (He Waka price)

539t CO2e x $10.86 = $5853.54 (Government 2030 modelling price)

Total cost for LUDF based on He Waka N2O price = $9573

If the Government’s 2030 N2O model price is used the total cost is $13,135.54

Nicole says one of the key issues for farmers under the Government proposal is that the price of emissions is unclear and that the methane price will largely be based on progress towards emissions reduction targets.

Without cost-effective mitigation technologies and the ability to offset cost with sequestration “credits” reductions will require reduced feed inputs and/or reduced stocking rates.

DairyNZ’s view - A good summary of what the sector proposed through He Waka Eke Noa and the Government’s recently released proposal which is open for consultation until November www.dairynz.co.nz/environment/agricultural-greenhouse-gases/pricingagricultural-emissions/governments-proposal-to-price-agricultural-emissions/

The full Government consultation document on pricing agricultural emissions environment.govt.nz/assets/publications/Pricing-agricultural-emissionsconsultation-document.pdf

The Government commissioned report on the impacts of emissions pricing on the rural sector www.mpi.govt.nz/dmsdocument/53632-Imapcts-of-CC-mitigatin-policies-onthe-primary-sector

Nicole Mesman Lumen Environmental analysis LUDF www.ludf.org.nz/assets/Handout-4-GHG-Lumen-NicoleM-28Sep22.pdf

LUDF methane and costs – Jeremy Savage analysis www.ludf.org.nz/assets/Handout-4a-GHG-MRB-JSavage-28Sep22.pdf

The sheep and beef sector is expected to bear the brunt of the hit on profitability because those livestock emit more greenhouse gases relative to the overall net revenue.

LUDF farm consultant Jeremy Savage from Macfarlane Rural Business says at the starting price of 11c/kg CH4 will equate to 2.4c/kg MS or 0.2c/kg drymatter (DM) fed or $20/t DM.

That’s based on it taking 10kg DM to produce 1kg MS and research putting methane production at 0.22kg CH4 for every kg MS produced.

Analysis across Macfarlane Rural Business clients shows that for every tonne of DM harvested, clients lifted profit by $820 in the 2021/22 season and over the longer term they boosted profit by $600/t DM harvested.

For a high-input system where supplements are fed all season to support the higher stocking rate where supplement costs are 59c/kg DM total feed costs for every kg of milksolids will be $5.90 (the response rate of 1kg MD/10kg DM). If cow running costs or core cow cost is $3/kg MS produced the cost to produce that marginal milk (milk produced through supplement rather than pasture production) will be $8.90/kg MS. (see link for cow running cost details)

The methane price will add another 2.4c/kg MS to that.

The additional feed costs are still the biggest cost for that marginal milk but what we don’t know is where the emissions price will go to.

With the aim to use pricing to drive emissions down to reach the target the price could rise but what this shows is that at current milk prices dairy is significantly better placed than sheep and beef to bear the additional cost, supporting modelled predictions of a 16-20% reduction in lamb production compared with a 4-5% reduction in dairy production.

The New Zealand dairy sector may already be among the most greenhouse gas (GHG) efficient in the world but doing nothing is not an option when it comes to reducing greenhouse gas (GHG) emissions, Fonterra chairman Peter McBride says.

In a statement to shareholders issued on the day tractors rolled to town in the Groundswell-organised, nationwide protest against emissions pricing, McBride says the co-operative supports the intent of He Waka Eke Noa but the Government’s proposal differs from what the He Waka partnership recommended on a number of key points.

“The primary sector worked on He Waka as a total package, to achieve equity on emissions reductions and pricing.

“The Government’s changes now create an imbalance within the (agricultural) sector that needs to be addressed during consultation,” he says.

Having a farm-level, split-gas levy that aligns with the desires of Fonterra’s customers and communities for low-carbon dairy production is a better outcome than what might have been achieved through the Emissions Trading Scheme – the default outcome - by 2025, he says.

Fonterra’s key concerns echo those of DairyNZ, in particular how the levy price is to be set and the governance of the whole process.

The Government’s proposal for what can and can’t be included in sequestration accounting differs from the He Waka proposal and is a major issue for all farmers, in particular the drystock sector.

McBride says Fonterra will be working with DairyNZ to support farmers to engage in the consultation process and will be seeking changes on sequestration, levy pricing and governance for the process. While he acknowledges the unease the Government’s proposal is creating in rural communities, he says it is important conversations are based on facts.

DairyNZ chair Jim van der Poel says while the proposal has adopted many key recommendations from the He Waka Eke Noa Partnership, that were informed by farmer feedback, the Government has made significant changes that will be a focus for the sector during the six-week consultation.

“The Government has accepted a lot of what farmers told us was important to them during our sector consultation earlier this year,” said Mr van der Poel.

“This includes a farm level levy and a split-gas approach that prices biogenic methane separately – recognising that its warming impact differs from that of long-lived gases, such as carbon dioxide.

“It is still proposed that any revenue generated through emissions pricing will be reinvested back into the sector to

support R&D and incentivise action on-farm, that will reduce emissions – this is significant for farmers too.”

However, DairyNZ strongly disagrees with some of the changes made to limit the recognition and reward farmers will get for their on-farm planting, by removing classes of sequestration like shelterbelts, woodlots and scattered trees.

DairyNZ is also disappointed the Government has removed the ability for farmers to form collectives to work together to report, reduce or offset their emissions – a key mechanism that would drive the change that is needed.

“These are material changes that will be of real concern to most farmers, and we will be raising them directly with the Government on farmers behalf over the coming weeks,” said Mr van der Poel.

“The Partnership’s recommendations to Government were finely balanced so they would work for all sectors, and we stand behind the whole-farm system approach we and our partners put forward.

“We know how important it is for New Zealand to move on climate change, but we also know the importance of moving at a pace that doesn’t leave our farmers, families and rural communities behind.

“Emissions pricing needs to be practical, pragmatic and fair for farmers, and there is still a lot that needs to be improved to make what the Government have announced today workable for farmers,” said Mr van der Poel.

Government consultation is now open and will run for six weeks, with the final decision to be announced in December.

DairyNZ will be making a detailed submission on behalf of dairy farmers but are encouraging dairy farmers to engage with the process too. It’s important that the Government hears from farmers and understands what’s important to the sector.

The Government has released its proposals for agricultural emissions charges as part of climate change mitigations. Joanna Grigg reports on the proposals and their conflicts with the industry’s He Waka Eke Noa suggestions from the standpoint of the sheep and beef industry.

On the table from the Government is a proposed scheme for agriculture. It puts a cost against every sheep, cattle beast and deer on the farm each day, based on their gas output. Farmers are expected to start paying this cost from 2025.

It aims to reduce methane emissions on farms, by 10% by 2030. According to Prime Minister Jacinda Ardern, it will “carve out a high value space for our exporters”. Nicky Hyslop, South Canterbury farmer and Beef + Lamb NZ Director, says there may be some validity in this claim, long term.

“But our sector must be viable in the short and medium term and changes the Government has proposed to He Waka Eke Noa, puts this at risk.”

“We cannot accept this proposal as it stands.”

This is the consultation doc: https://environment.govt.nz/assets/publications/ Pricing-agricultural-emissions-consultation-document.

This is DairyNZ’s view on the whole proposal. It clearly sets out the differences for He Waka and what the issues are with each. https://www.dairynz.co.nz/environment/agriculturalgreenhouse-gases/pricing-agricultural-emissions/ governments-proposal-to-price-agricultural-emissions/

Commitment to reducing emissions is important for access to markets, she says, and for multinational customers like McDonalds and Nestle, but it may not attract premiums in the short term.

She thinks the scheme should deliver moderate emission reductions that reflect warming impact, while allowing farms and rural communities to be sustained.

“The Government proposal on the table and their modelling, clearly shows this will not be achieved and disproportionately impacts hill country farming.”

To ensure, as she puts it, “the guts of our farm communities are not hollowed out” she wants to keep the He Waka model. This is all farm sequestration recognised, ongoing industry involvement in governance, and emission price setting that reflects progress to targets.

“No-one else in the world is doing this, so a cautious approach is critical or we will simply be replacing New Zealand food with high-emissions food which is counterproductive for reducing global warming.”

Ignoring this consultation (closing November 18) and hoping it goes away with a 2023 election is not realistic. Christopher Luxon, National Party, says: “National supports New Zealand’s emissions targets, including reaching carbon net zero by 2050. And that means reducing agriculture emissions over time.”

National’s difference seems to be that they may allow farmers to earn credit for all forms of onfarm carbon capture. Hyslop says while farmers are rightly frustrated and disappointed, they should not panic.

“All the He Waka industry partners are collectively focused on getting changes to this.”

• First published in Country-Wide November 2022

Words by: Joanna Grigg

Farmer and Beef + Lamb NZ Director, Nicky Hyslop, says the price put on methane must be conservative.

She encourages farmers to tell the Government this by submitting on the agricultural emissions proposal.

“Even the Government modelling shows that at 8c, it will have a significant impact on many sheep, beef and deer farms.”

The model in the consultation document shows that 8c by 2030 would reduce methane emissions by 12% (and meet a total 10% target). See Table A.

It comes at a cost. At 8c (Table B) the model predicts an 18% drop in sheep and beef farm net revenue, from 2020 to 2030. This is likely to be made up of a 16% drop in lamb production, 14% drop in wool, 13% fall in deer, and 4% drop in milksolids. Beef production increases in some scenarios, because more cost-effective mitigation technologies are assumed for beef cattle compared with sheep. The large drop in sheep includes afforestation, the impact of emissions pricing and some farmers switching from sheep to beef, Hyslop says. The Government modelling didn’t include sequestration and any future mitigations, so is a worst-case scenario.

Table A: Model results of emissions reductions in 2030, compared with 2020. It shows eight cents per kg methane would see a 12% methane reduction.

Table B: Ouch: Changes in sector net revenue and agricultural production, if methane levy is at $0.08/kg, relative to baseline.

Note: Mitigation and sequestration are not included in the model, and these are likely to help to some small degree.

Source: Pricing Agricultural Emissions Consultation Document.

‘The Government proposal on the table and their modelling, clearly shows this will not be achieved and disproportionately impacts hill country farming.’

Concern about this drop in production and profitability is the type of comment farmers should put in their submission, Hyslop says.

Farmers may think comments will fall on deaf ears. Hyslop says consultation, along with other actions, are all valid options to get the message across. She suggests making a powerful submission, farmers get together with neighbours or their catchment group and make a joint submission.

“Describe your farm or catchment, your ongoing commitment to stewardship, your plantings, your estimated carbon sequestration (using the calculator) and the likely emission costs.”

“If we lobby and submit and talk to local and central government, we can be effective and get changes.

“This scheme is the farmers’ scheme, it’s our money being collected and reinvested or paid in sequestration, so they need to listen.”

There are 15 questions to answer in the consultation.

Question Five is the guts of how the levy price will be set. He Waka wanted a committee, including farm industry members, to advise on the price. The Government proposal is for ministers to set the price for both long-lived gas levy and biogenic methane levy. When it comes to short-lived gas (i.e: methane) the Government wants to set the price based on whether emissions are dropping. This is quite different to what He Waka proposed, which was a price based on just bringing in enough levy to pay for sequestration, a share of administration, incentives to farmers and research into reducing emissions. The consultation states ministers would periodically assess whether methane emissions were on- or off-track regarding the target. If over- or under-achieving, ministers could update the biogenic methane price. Hyslop says the sustainability of rural communities and local economies must be included in pricing discussions.

“What about the potential loss of rural community, infrastructure, food production capabilities and economic

returns – we can’t ignore these in the single-minded drive for overall methane reductions?”

In Section Five there is discussion on ‘pain relief’ for farmers during the transition. The Climate Change Commission had not finished writing specific proposals on what schemes, payments, they might be, so nothing concrete is here. An example may be methane levy relief if an adverse event struck. But the bottom line from the Government is it mustn’t “undermine the intended price signal”.

When it comes to using the levies collected, He Waka recommended levies collected from Māori landowners (e.g: collective agribusiness) go to a dedicated fund and be administered by Māori. The Government proposes to do this by setting a minimum percentage of overall revenue that must go into the dedicated fund.

What’s unclear is how this would actually help Māori-owned sheep and beef farms, especially as they face the same issues of low profitability/hectare and few mitigation options as non-Māori sheep/ beef farms. If Māori levy income comes off lower-stocking-rate land, then the pool of funds is likely to be smaller than average/

hectare. The minimum percentage may provide some top-up. In the same way, the sheep and beef industry relies on methane levy payments from intensive dairy to create a pool of funds for sequestration, which is largely on sheep and beef farms.

Hyslop says the Government has tossed out the hard work He Waka did on balancing the different farming partners, and the conversations about wealth transfer using sequestration.

“We need to be careful we don’t divide our sector and tip the scales one way.”

If carbon offsets through sequestration are narrowed, there will be more imbalance. Question Seven is where farmers need to put their case for pricing.

Hyslop suggests farmers review their numbers and work out the likely cost at the medium-level price of 11c/kg CH4 as this is important for the submission. Some farmers had very high cost estimates as they used the carbon equivalent methane emission tonnes and plugged in the ETS price of $80/tonne, she says, which is not the right price.

“Eleven cents is a conservative approach and a useful place to start.”

• First published in Country-Wide November

Managed indigenous vegetation (with stock excluded but not necessarily fenced) that can show specific management interventions. Can be planted, regeneration or combo. Additional sequestration only.

Fenced Riparian margin plantings after 2008, alongside waterway of minimum size. Set a reward rate for a specific period.

Likely to be low reward as sequester only about four units/ha.

Pre-1990 indigenous forest at NZ ETS rates. May need to align to current ETS 1ha rules.

Exotic shelter belts. Potentially highest sequestration ability.

Mixed exotic/native shelter belts

Riparian margins fenced before 2008. Early adopters miss out.

Exotic shelterbelts are only eligible for NZ ETS if more than one hectare and the right shape and right species.

The freshwater regulation roll-out debacle, showed up embarrassing government shortfalls in implementation. This 2022 experience is likely to be one reason behind the Climate Change Commission’s push for pragmatism in designing an onfarm sequestration scheme.

The Government has picked up the vibe and taken pruning shears to He Waka’s extensive work on sequestration recommendations.

Out go exotic plantings (mainly shelter belt shapes) even though they can’t be included in the NZ ETS, primarily due to being narrower than 30 metres. Managed indigenous forest and post-2008 riparian plantings are in, although size and age and type specifications are undefined. Those early adopters of riparian planting (pre2008) miss out. Farmers can respond to sequestration proposals in Question 8 of the consultation.

Nicky Hyslop, Farmer and Beef + Lamb NZ Director, says she has just planted a shelter belt with a mix of natives and exotics. The exotics were chosen to provide faster shade and shelter than less-reliable, slower natives.

“This wouldn’t be counted within ETS farm sequestration as the size is too narrow, yet it couldn’t meet the proposed Government/He Waka scheme as the plant choice is wrong.

“I have issues with the Government promoting wide-scale exotic plantings across whole farms through their ETS policy, when they say they want integrated plantings within working farms, yet don’t reward farmers for it.”

She is also concerned that a figure floated for indigenous sequestration is only 0.5 tonnes/hectare – a very low rate.

Riparian vegetation is not known as a high carbon sink. The 2018 Landcare report Carbon Sequestration On Farms, listed riparian vegetation as sequestering about 3.4 tonnes of C02/hectare/year. Exotic woodlots in a shelter belt, for example, would be streets ahead. This pruning of offset options for farms has raised issues of fairness and has become the most disliked aspect by farmers. Ironically, inequity for non-farming landowners was listed by the Climate Change Commission as a reason for their stance. But isn’t this an agricultural scheme?

The commission suggested creating another scheme altogether – where additional non-NZ ETS plantings could be rewarded alongside biodiversity and water quality. Then, add categories to the NZ ETS. He Waka had always batted for as much onfarm sequestration as possible, even if it means a gradual addition of categories, with a full scheme by 2027. The original industry He Waka recognised that over time, if the ETS was reformed, this sequestration could be transitioned to the ETS. The Government proposal followed the commission’s approach, and favours the NZ ETS as the home for sequestration. Into this will go new categories like pre-1990 indigenous forest (previously ineligible).

While the bean-counters get this sorted, the Government proposes a short-term option where farmers can take a contract with the government for additional native vegetation, counted from 2025. This would transition, in time, to the ETS. No modelling is provided on whether the contract cost would be worth the offset. An example price is provided of 75% of the NZU price. After the contract ends, there would be no ongoing liability requiring the vegetation to be maintained as it was for the duration of the contract. The

Government shows some vision here, in that the payment could be designed to align with biodiversity incentives being developed.

Farmers with pre-1990 forest may like the idea of an ETS category being opened for them. They will likely get higher payments per hectare via the updated ETS, than discounted rates through the ag emissions scheme. This reward for managing pre-1990 indigenous forest onfarm as a carbon sink, has been a long time coming and will be welcomed. However, farmers don’t have a lot of confidence in NZ ETS recognising regenerating onfarm sequestration. Any new categories will have to prove themselves to be workable for farms.

The early-movers on riparian fencing and planting (pre-2008) are disadvantaged by the proposed 2008 cut-off. The cut off is because satellite imagery was better from this date. Other methods of proving planting are not discussed.

In 2022, Country-Wide drew attention to problems with the initial HWEN proposal that required full stock exclusion via fencing to get sequestration status for an area of bush/forest. This didn’t recognise that natural boundaries could exclude stock. The new proposal is far more realistic, defining stock exclusion to “include fencing, geographic boundaries and/or dense vegetation that stock cannot access”.

Beef + Lamb NZ said, in their initial email to levy-payers after the proposal release, that there is a lack of detail on sequestration from the Government (including what the sequestration rates could be) and they will be pressing for additional information and clarity over the coming weeks. DairyNZ strongly disagrees with some of the changes made to limit the recognition and reward farmers will get for their onfarm planting, by removing classes of sequestration like shelterbelts, woodlots and scattered trees.

MfE and MPI will host a webinar consultation on the topic on Wednesday, November 9.

• First published in Country-Wide November 2022

Use Bovilis BVD for 12 months of proven foetal protection1. The longest coverage available.

Exposure to BVD could mean your unborn calves become Persistently Infected (PI’s) - spreading BVD amongst your herd. It is estimated that up to 40% of dairy herds are actively infected with the BVD virus at any given time. The convenience of the longest coverage available along with flexible dosing intervals2 means you can protect this season’s calves no matter when they are conceived.

Avoid an outbreak. Ask your vet about vaccinating with Bovilis BVD or visit bovilis.co.nz

Danish dairy farmers have had a hard time in recent years. The trust in dairy cooperative Arla Foods is high, but there are fears of a pending carbon tax and unwilling banks. Sjoerd Hofstee reports.

Denmark has among the highest milk production per cow in the world. An average of 10,518kg milksolids were produced in 2021 at the country’s 2575 dairy farms that are still active. The number of dairy farms has fallen dramatically in the last 10 years, with at least 40% closing.

A major factor for that rapid decrease was the large land price drop Denmark was confronted with in 2007-2008. In the years before, land prices had risen to an average of about €45,000/hectare (about $NZ77,000/ha). In one fell swoop, prices crashed to average just over €20,000.

Many dairy farmers saw their equity evaporate, along with the surety for bank loans they had taken out. In the following years, many Danish dairy farmers went bankrupt. And that still doesn’t seem to be over, with a leading role for the Danish banks. More about that later.

Most remaining Danish dairy farmers are now running relatively healthy businesses. Record milk prices have been fluctuating between €55 and €60 per 100kg in recent months.

Farm sizes vary greatly, but on average farms carry more than 200 cows. In total, the country has about 560,000 dairy cows, of which few are grazed.

Holstein-Friesian is the dominant breed in Denmark, but you will also find many Jerseys, especially at organic farms.

Dairy cows at organic farms must be able to access grazing, but by far the bulk of Danish dairy cows are in stables all year round.

This helps to account for the aforementioned high average milk production. Another reason for high milk production is the relatively high percentage of replacements. That is still above 40% due to the availability of

relatively large farms with feed grown onfarm. Many Danish dairy farmers keep all their young cattle and often select them as replacements as soon as a cow shows problems and suffers a lower milk production.

Dairy farming in Denmark differs greatly from that in New Zealand without the use of grazing. The comparison is large at another point. Just as in NZ, the Danes are the first country in Europe where their government is preparing a law to tax greenhouse gas production.

While the amount of tax to be levied on carbon dioxide emissions is yet to be decided, farmers fear that for their farms would face an extra cost of several hundred thousand euros and bankruptcy of the entire sector. Later this year it will become clear whether the problem is really that big or whether the height of the tax is not that bad.

Where Denmark deviates from other dairy countries, is the way most farms are financed. It is possible to finance up to 70% of the farm from loans via a credit fund. This is the property of the largest Farmers Union. The remaining 30% of

financing must come from equity or a loan through a bank.

Banks in Denmark often finance relatively small amounts for dairy farms, yet their influence is big. Dairy farms are classified as having a high-risk profile. For that reason dairy farmers, who, according to the banks do not perform well enough, can be declared bankrupt overnight, in contrast to other northwest European countries. Danish dairy farmers who have a loan at a Danish bank are often heard to say they fear “the bank can make and break you.”

In addition, a few years ago, Danish banks also worked with loans that were linked to swap financing.

These SWAPs had to protect companies against the interest rate rise, but when the interest rate dropped, a lot had to be paid. Thousands of Danish dairy farmers have lost hundreds of thousands of euros and hundreds of farmers have ended up in bankruptcy.

The structure of the Danish dairy industry is also comparable to NZ, characterised by the enormous dominance of one party. In Denmark that is Arla Foods. About 90% of all Danish milk goes to this large cooperative which is based in Denmark but is active in seven countries with factories and collecting members milk. Arla processes a total of 13.6 billion kg milksolids, in Denmark that is 4.9 billion kg of a total of 5.6 billion.

Four other milk processors of serious size are also active in Denmark - two private companies and two that focus on organic