PRODUCTS AND ADVICE YOU NEED

FOR COMPLIANCE APPROVAL

EFFLUENT MANAGEMENT SOLUTIONS 2023 Special

HOOFCARE ON FARM STARTS WITH GREAT GEAR!

Handle any animal with confidence and in full safety.

A fast and safe handling job means better production and less stress on you, your staff and your animals.

3 Units to choose from

PREVENT MASTITIS FROM $250 / MNTH

*Farm Ready lease option from $250/mnth

Save time and milk plant running cost

Reduce Milking times

Save labour

Reduce Mastitis

Improve cow health

• New 2021 model

• 1 Payment/month

• Annual Service Included

Neuron Immobilisers are commonly used in Human muscle and nerve pain relieve. In Animals we can use this technology to get the animal to relax and reduce stress levels. This also means much safer handling for the operator

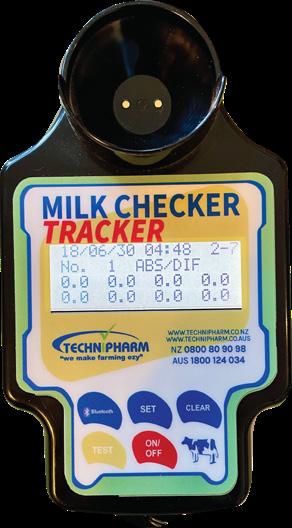

High SCC? Possible penalties and treatment cost? Test for infections with instant results. Instant indication of infection level, instant results on treated and retested milk before it goes back into the vat. Ezy Quik and instant results

2 NZ Dairy Exporter | Effluent Management Solutions | February 2023 EFFLUENT MANAGEMENT SOLUTIONS 2023

PACIFIER ANIMAL CONTROL UNIT MILKCHECKER TRACKER, TEST, CHECK TREAT FAST INSTANT RESULTS “WE

“WE WWW.TECHNIPHARM.CO.NZ 0800 80 90 98 EISELE HIGH PUMPS • From • Long Volume • Efficient • PTO • Quality • EFFLUENT SPREADING • ADVANCE IRRIGATOR • SIMPLE DESIGN • PERFORMANCE TESTED WWW.TECHNIPHARM.CO.NZ

MAKE FARMING EZY”

ANIMAL UNIT MILKCHECKER TEST,

Immobilisers are and nerve use get means handling for Possible treatment infections results. of instant and before

“WE MAKE FARMING EZY”

• EFFLUENT SPREADING

• ADVANCE IRRIGATOR

• SIMPLE RELIABLE DESIGN

• PERFORMANCE TESTED

• Reduce Emissions

• S ave Water

• Reduce effluent

• Massive labour savings

• Save Power

• Create more time for the important jobs

*We

EISELE HIGH VOLUME HIGH PRESSURE PUMPS

• From 600 - 2200 L / Min

• Long distance High Volume Pumping

• Efficient use of Energy

• PTO or electric

• Quality German made

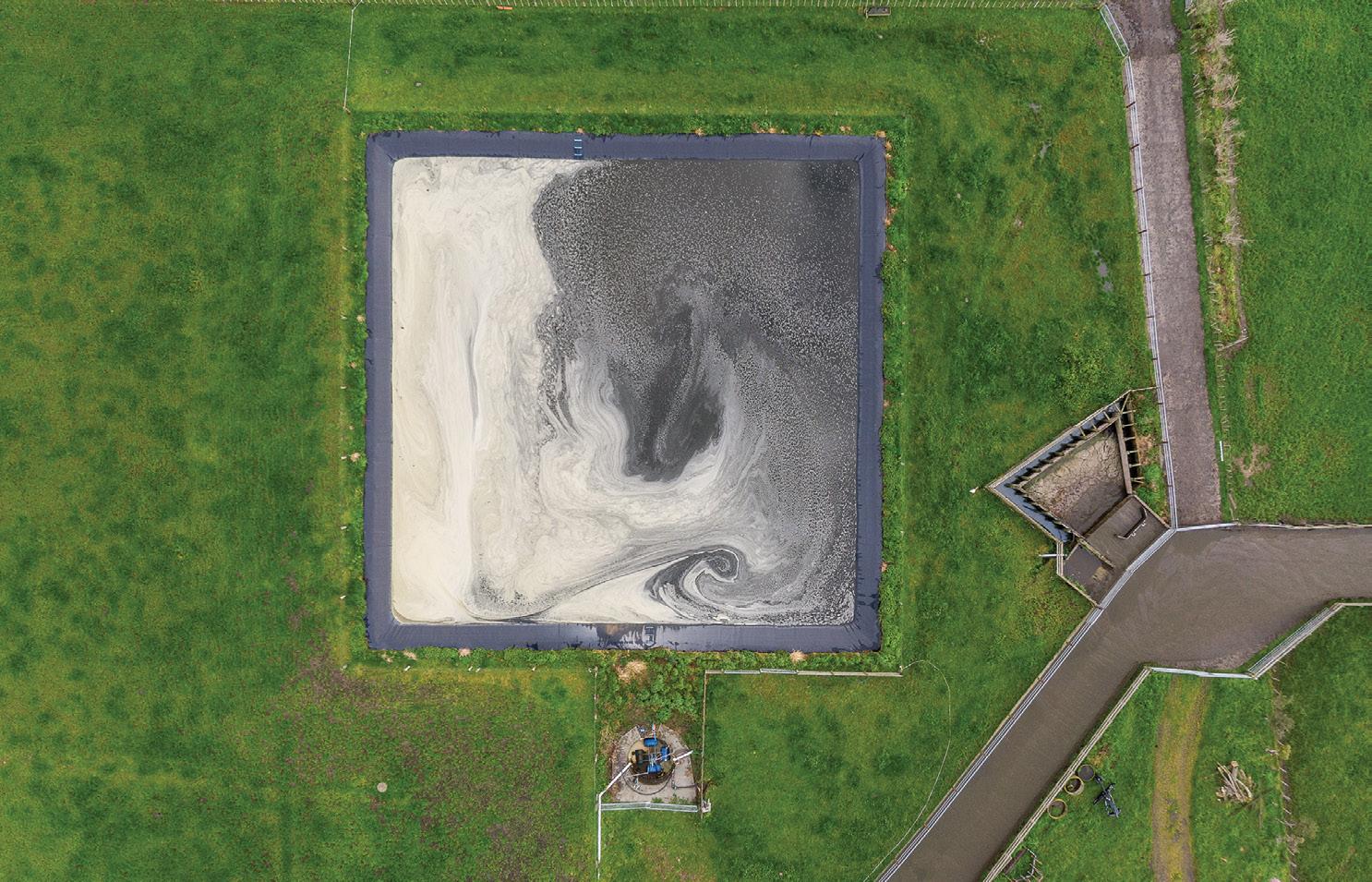

NUTRIENT CAPTURE STORAGE SYSTEM FLEXITANK ROUNDTM

•100% effective storage (no rain water)

• Best capture and re use of Nutrients (No N evaporation)

• Simple Install

• Safe, no one can fall

• Cost effective

• 1000 - 2000 Cube

NZ Dairy Exporter | Effluent Management Solutions | February 2023 3 EFFLUENT MANAGEMENT SOLUTIONS 2023

®

wash your yard by hose ever again!

DUNGBUSTER

Never

do gates and full integrated systems

Wash and Greenwash options Circular Farm your N TH2081 25/01/23 WWW.TECHNIPHARM.CO.NZ 0800 80 90 98 TH2081 25/01/23

*Clean

Waste to

Take control of your power supply.

Bespoke waste-biogas-to-energy power generation solutions for your farmbuilt to last by Eneraque.

Energy independence is achievable with state of the art, engineered solutions that can return your investment in just 5 years. Control your energy costs, get security over your supply and move towards a more sustainable future with our waste to energy solutions. Our team of engineers, project managers and site operations experts have delivered hundreds of projects worldwide.

With a New Zealand based team, we're ready to power your future. Contact us today to discuss your project.

Eneraque Solutions:

Biogas Power Generation

Biogas Scrubbing & Polishing

Biogas Flaring

Biogas Storage

Biogas Upgrading

C02 Liquefaction

Bio-CO₂

Biogas to Hydrogen

t 0800 363 727 (NZ) eneraque.com

energy.

Your herd's manure is your potential on-farm energy source.

TAKE THE NEXT STEP TO FUTURE-PROOFING YOUR FARM

Welcome to our NZ Dairy Exporter special publication, Effluent Management Solutions.

Our aim with this publication is to focus on solutions for today’s effluent management challenges.

We’ve sourced editorial and advertising from a range of national and regional companies who service the dairy farm sector with effluent management products and services. Also included in this publication is advice from DairyNZ and independent advisors on effluent system design and compliance.

The first step to create or maintain a compliant effluent system on your dairy farm could be as simple as contacting one of the advertisers who have supported this publication. They are all committed to providing value to the dairy farm sector.

Achieving compliance is not avoidable. It is a requirement to continue supplying your milk to your chosen milk company. Focus on the future and the rewards are tangible, but so is the financial and emotional pain for those who continue to not meet the standard required for our global dairy markets.

More than ever before, the focus is

on farming to deliver on environmental standards to ensure our dairy produce remains at the top when consumers seek safe food options for their families.

We might be a long way from our markets in the rest of the world but dropping the ball on maintaining our standards onfarm is only a social media post away from a potentially disastrous backlash.

It’s been a challenging summer so far in 2023 for many dairying regions across New Zealand, so here’s hoping for more settled weather from here on.

Like many of you who are second or third generation farm owners with links to the land dating back 100 years, NZ Dairy Exporter is approaching its 100th year of publishing. The first issue was printed in 1925 and we’d love you to join us soon on the journey to another 100 years.

If you’re already a subscriber to NZ Dairy Exporter, we thank you. If you’re not a subscriber, then visit nzfarmlife. co.nz to find out how you can enjoy and benefit from the country’s most-trusted dairy farming publication.

NZ Dairy Exporter | Effluent Management Solutions | February 2023 5 EFFLUENT MANAGEMENT SOLUTIONS 2023

Tony Leggett, Publisher AgFirst Engineering 32 Archway Group 13 Aztech Buildings 7, 9 DairyNZ 17, 30 EIDNZ Ltd 26 Eneraque 4 Flexi Tanks NZ 22 Forsi Innovations 16 Hill Laboratories 12 Irri-Max 29 Laser Electrical Putaruru 16 New Holland 31 Nevada 20 Norwood 21 Numedic 23 Plucks Engineering 26 Prime Pumps 10 Pump and Valve Specialties 25 Reid & Harrison Ltd 15 RX Plastics 24 TechniPharm 2/3 Metalform (Tow & Farm) 18 Williams Engineering 27

ADVERTISER INDEX $129 from Incl GST SUBSCRIBE TODAY Be part of the important conversations on the issues facing farmers today. 0800 224 782 subs@nzfarmlife.co.nz www.nzfarmlife.co.nz • Subscribing saves 30% off the cover price • Your subscription is a tax deductible farm working expense • Entry into regular subscriber-only competitions to win great prizes • Access to years of archive content on our website Front cover: K-Line Pods are an ideal option for dispersing effluent on dairy farms. The system is easily towed by a quad bike or side-by-side. Find out more, page 25.

TALK FIRST BEFORE YOU TACKLE EFFLUENT CHALLENGES

BY LOGAN BOWLER

Choosing a new or upgraded effluent system often involves a considerable capital spend, so being involved in the decisions about what will work best for you and your farm is crucial. This is particularly important if you’ve got someone doing your effluent storage calculation for you.

There is not a specific volume of storage your farm needs as it will vary depending on your farm’s location, soils, size, infrastructure and your management.

Take ownership of the decisions being made to ensure the final outcome is a good fit for you and your farm. It’s not all about getting the smallest storage volume, it’s about the ‘right’ storage volume that best fits your farm.

Regional Councils require storage volumes to be calculated using the Dairy Effluent Storage Calculator (DESC). The DESC has a library of more than 30 years of daily climate data (rainfall and evapotranspiration) for most dairying areas throughout the country, and uses this information to model a soil water balance.

The DESC calculates how much effluent is generated each day, and using the historical climate data determines how often soil moisture conditions were suitable for effluent irrigation. If irrigation could take place, it calculates how much effluent would be removed from storage. If effluent irrigation couldn’t take place it calculates how much effluent will be sent to storage. From these calculations it can determine how much storage you will need.

There are many inputs to the DESC that will determine how much storage your farm needs. These include soil risk, water use in the shed, effluent application depths, pump rates, milking season length, herd size, climate, catchment areas, storm water diversions to name a few. Some of

these will be “fixed” on your farm, such as climate, catchment areas, herd size and season length. Others can be variable and up for consideration as a mitigation in reducing storage requirements.

You must get involved with whoever is running the DESC for you. Ask them for a variety of scenarios showing the impact of options on storage and your farm’s management. Where do you want to spend your money; on mitigations or extra storage? Get them to run a number of scenarios that help you decide which options you want to pursue. - make them earn their money! You can cost all the different options to get an idea of what you want to pay for. These are some useful questions to ask yourself as you work through the DESC:

• Do I have any low risk soil on my farm that is not currently in my effluent block?

• What would a low depth irrigation system look like on my farm? How easy or hard would it be to manage?

• What would a storm water diversion cost to install? What reduction in storage volume would it give me?

• How much water does my dairy shed currently use?

• Did they measure/calculate my water use or just use an “industry average”? Using industry average will not result in an accurate calculation for your farm

• What would water reduction look like

on my farm?

• Green water recycling can have huge savings- did my consultant consider this option?

• How much storage would I need if I chose not to irrigate over calving? When you do the cost benefit of all the options - don’t forget to include the time it would take to manage your system as it’s pointless to choose options that give you the smallest possible storage requirement, but are a nightmare to manage. Choose a system that fits you and your farm- both from a labour/time point of view and cost. I have talked to many farmers who have built ponds and wished they had built them a little larger to give better flexibility around effluent irrigation.

Remember the person running the DESC is in your team and are there to help you choose the calculator inputs that best reflect your farm and your desired mitigations. They won’t be running the effluent system once built- you will, which makes your input to sizing storage crucial to the success of a large capital project. Working together you will come up with storage requirements that fit your farm like a glove.

• Logan Bowler is an independent advisor on dairy effluent systems. He is a managing partner in a dairy farm in Rangitikei and was formerly an effluent management advisor with DairyNZ.

6 NZ Dairy Exporter | Effluent Management Solutions | February 2023 EFFLUENT MANAGEMENT SOLUTIONS 2023

Independent effluent management advisor Logan Bowler says it all starts with calculating the unique storage capacity your system needs.

MAKING DAIRY COW WASTE YOUR ASSET

ON FARM WASTE-TO-ENERGY systems are becoming critical assets for farmers seeking to take control over their energy supply – and they’re achieving it by harnessing the power of their own herd’s manure.

Innovation in biogas technology – widely used throughout Europe and now finding application across the Asia Pacific – is offering farmers a way to combat rising energy prices, lower emissions and achieve energy independence.

One company leading the charge is Eneraque, whose waste gas-to-energy technologies are already yielding tangible results for farmers.

Raw biogas is produced through anaerobic waste digestion – this gas is then scrubbed and dehumidified. This

now clean biogas is fed through a closed loop system into gas engines which can provide 100% of the farm’s energy needs.

Waste gas-to-energy technology can be custom designed for any site, and it’s benefits go beyond eliminating reliance on the main grid.

“This technology can radically simplify on farm waste management and improve the fertiliser value of manure and other byproducts,” says Eneraque’s Jeremy Pringle.

“The digestate that remains at the end of the process can be used as a high quality, agricultural fertiliser that has been praised for its higher pH value and lack of odour.”

“The system also provides the benefit of reducing general farm odour and lowering Greenhouse Gas (GHG) emissions,” he says.

Biogas technology doesn’t have to be cumbersome or complex to manage, says Pringle, but it is site specific and needs to be custom designed for your operation.

Eneraque engages in a process of discovery and design for each waste gas-toenergy project.

“It is about efficiency and seamless integration into your existing framework,” he says. “It needs to work for your farm and not the other way around.”

It’s infrastructure that also becomes an asset, with most clients expecting a return on investment in as little as five years.

NZ Dairy Exporter | Effluent Management Solutions | February 2023 7 EFFLUENT MANAGEMENT SOLUTIONS 2023 Struggling with Effluent Management? Need a long term solution? If you are a dairy farmer looking to push the boundaries of production and profitability, and make your effluent work for you, an Aztech Composting Barn is the ultimate solution. Existing feedpad? Talk to us about covering it with a custom Aztech Feedpad Roof. Got questions? Or ready to start? Whether you need more information or looking to kick-off your project, take the next step and contact our friendly team: 0800 298 324 hello@aztechbuildings.co.nz

MORE? Visit www.eneraque.co.nz

Jeremy Pringle.

TECHNIPHARM OFFERS WORLD-LEADING SOLUTIONS ACROSS ALL FARMING TYPES

is not large enough to supply efficient price versus volume, like the Ecobag and Flexi Tank Round systems (internationally certified) and our dairy housing fit out systems, they are obtained in this case from the Netherlands,” says TechniPharm owner Harmen Hessen.

“Like New Zealand, the Netherlands has a very large agricultural industry with scaled up, advanced technology which can benefit NZ farmers. This way our clients get the best of both worlds.”

Many of TechniPharm’s early clients are upgrading the original product solutions they obtained years ago to the latest designs and performance standards now available. Hessen says often the upgrades mean a significant easing of the work load as automation and design experiences shines through in the new solutions.

TECHNIPHARM

OWNS

MANY

patented designs and registered trademarks. Many of its products have received awards for innovation, both in New Zealand and overseas, which is a good indicator of how the industry has judged the product solutions.

Its focus is the dairy, beef and sheep sectors and each category has its own specialised range of product solutions. With winter only a few months away, farmers are encouraged to get in touch to discuss maintenance and new capital investments for the season ahead.

For those in the dairy industry, TechniPharm offers a wide range of products, including the Dungbuster automatic yard washing systems, Ecobag and Flexitank effluent storage solutions, teat sprayers, Dairy Caddy shed trolleys, Hoofcare handlers, and dairy housing systems.

When it comes to meat and wool producing clients, TechniPharm has a real focus on high-performing handling systems and stock yards. Electronic identification systems (EID), weigh recording and drafting systems are all part of the range.

“Most products are locally obtained and manufactured, but where our market

“In the beef sector we are trading in older manual cattle handling systems and upgrading these to hydraulic systems,” says Hessen.

“A drive towards hydraulics in cattle handling is one of our unique selling points in delivering high performance to beef farmers.”

In dairy, TechniPharm is seeing a significant number of upgrades from fresh wash to greenwash and, with reduced emissions from Dungbuster yard washing systems and Bladder storage systems, farmers are winning all the way to the bank.

“Water, labour and emission savings for all farmers is a must these days,” he says. Produce more or the same with less inputs and les impact on the environment is the name of the game.

“For instance, in pond design, we see more and more farmers being aware of nitrogen losses and greenhouse gases, so our closed Ecobag and Flexitank Round options provide great solutions.”

The team at Techni Pharm is highly experienced and dedicated. They enjoy their on-farm connections and the work they carry out.

8 NZ Dairy Exporter | Effluent Management Solutions | February 2023 EFFLUENT MANAGEMENT SOLUTIONS 2023

A Flexitank Round installed at a dairy shed using sump and existing infrastructure to best use.

TechniPharm sells high pressure, high volume PTO or electric Lobe pumps

A Dungbuster yard cleaning system for round and rectangular yards.

www.technipharm.co.nz

MORE?

COMPOSTING BARN JUST ‘EASY’

WEST COAST DAIRY FARMERS

Murray and Gaye Coates can’t speak highly enough about their decision to build a composting barn on their property.

“It’s just so easy, its easy on me, it’s easy on the staff and its definitely easy on the cows,” says Murray.

Their journey started with needing to cover a feed pad but they soon discovered that a composting barn was a superior option so they decided to build two Aztech composting barns, each capable of holding 400 cows.

A major benefit from the new barns is feed utilisation which has increased more than 25% to 97% feed efficiency.

Before their composting barn, Murray was feeding his cows 16kg of feed per cow each day. Thanks to the comfortable, low-

stress environment of the Aztech barn, his cows only require around 9kg, a massive saving. Their cows are in better condition for calving. They achieved an empty rate of 12% which is the best result on the property in 15 years. Over 90% of calving was in the barn, and the calf rearers noticed the calves were more lively, getting on to the feeders much quicker. Under Murray’s management, compost bedding sits at around 30°C50°C, allowing his compost to take care of all effluent left by the cows.

Cows were in the barn 24/7 from June 10 till the beginning of August and no effluent ever drained out of the barn drainage system during that time.

While these benefits are massive, Murray and Gaye say the best is simply the peace of mind. There is no question where cows prefer to be if it’s cold and wet outside.

With the benefits they have experienced, the Coates are on track to completely pay off the buildings within five years of completion.

MORE? Visit aztechbuildings.co.nz

NZ Dairy Exporter | Effluent Management Solutions | February 2023 9 EFFLUENT MANAGEMENT SOLUTIONS 2023 Now under the powerful backing of Futura, we’ve innovated our dairy solutions even further. Go on, phone for your free investment guide. 0800 298 324 hello@aztechbuildings.co.nz

The dual composting barns installed at Murray and Gaye Coates’ West Coast dairy unit.

When failure is not an option.

WANGEN agricultural effluent pumps dominate the global dairy industry.

Made in Germany, WANGEN pumps are well-known for their longevity and low maintenance needs. With lifespans measured in multiple decades, they are the pump of choice for agricultural effluent management specialists around the country.

WANGEN progressive cavity pumps maximise effluent pumping efficiency and minimise environmental impact.

They are:

• Highly reliable

• Slow-running, which reduces vibration and wear

• Extremely low maintenance

If you want peace of mind and lifetime value, ask your local effluent management specialist about WANGEN.

10 NZ Dairy Exporter | Effluent Management Solutions | February 2023

www.primepump.co.nz

PUMPS COMBINE PERFORMANCE AND ENDURANCE

GERMAN-DESIGNED AND manufactured Wangen agricultural pumps from Prime Pump have been around the dairy industry since 1969.

Founded on a drive for superior performance, trouble-free operation and a commitment to lowering cost of ownership, their slow-running durability and long service life are legendary.

One Wangen customer in Austria went 35 years without having to dismantle his pump or replace any parts.

Highly engineered, the progressive cavity pumps are also helping New Zealand farmers maximise efficient effluent pumping and minimise environmental impact. Long established in conventional dairy systems they have, more recently, been embraced by the emerging sheep dairy industry.

Feedback from both has been positive, according to Ben Petrie, Prime Pump Agri Team Leader.

“We find that once clients have tried Wangen, they’ll never go back. It’s quiet, it’s reliable, and it runs well which is what you need.”

His comments are backed-up by the general manager of a successful rural trade services business who says he has seen “fairly catastrophic” failings with some other pumps, but none with Wangen.

Petrie says one of the keys to the Wangen pumps’ performance is the Cardan joint; a critical design feature. This knuckle-like system is superior to the conventional pin joint which is subject to rapid wear, resulting in “sloppiness” and ultimately the need for replacement. In contrast the Cardan joint operates smoothly and seamlessly, lasting the lifetime of the pump.

The design, which has the same diameter as the rotor ahead, enables

consistent flow, and avoids the problem of settling, which effectively removes the issues related to fibres becoming wrapped around the shaft.

A one-piece cartridge mechanical seal, filled with oil, rather than a two-piece system, is also easier and quicker to fit while the oil helps extend the life of the pump. Prime Pump’s specialist effluent range also includes world-leading pumps and stirrers from Italian designed and manufactured Faggiolati, Demark’s LJM and Italy’s Varisco providing a complete solution from high-fibre barn effluent transfer to sump and pond management.

MORE? Visit www.primepump.co.nz

DON’T DELAY EMPTYING PONDS

BY LOGAN BOWLER

Don’t leave it too late in the season to empty your effluent storage pond.

Now is a good time to be pumping your effluent pond down as often as possible, while the warm weather ensures soil conditions are dry enough to mitigate the risk of run-off or leaching into waterways.

The bonus with irrigating your effluent this time of year is that it will help with pasture growth and reduce the amount of fertiliser you need to apply. Just continue to keep a close eye to ensure you are doing this in accordance with your region’s rules and consent.

You really should be aiming to irrigate every day weather and soil conditions are suitable to get your levels down before autumn and winter. I’m sure most farmers have been doing this already over the last

two months and this comes as simply a reminder. However, for those who perhaps haven’t had a chance to grasp every opportunity to empty their effluent pond over the last few months, I recommend making this a priority before wet weather limits their opportunity to do so.

Afterall, we never know what autumn has in store for us. If it’s a wet one and you haven’t kept on top of emptying your effluent pond, they’ll be on the back foot heading into winter.

Let’s look at the numbers: A few of you might be thinking, I’ve got heaps of time, what’s the rush?

Here’s an example - A farmer with a 400-cow farm, with average effluent pump rates, would need about 30 days to empty a 2m litre effluent pond (40m x 40m). That’s not too bad right?

Remember, this doesn’t include effluent continuing to be generated in the milking shed. If we factor that in, that’s another 1.2 million litres, which requires 42 days.

Build in rainfall, let’s say 100mm over six weeks, preventing irrigation and adding another 0.25 million litres to the effluent pond, and we’re up to 48 days.

If that farmer left it until early March to start emptying their effluent pond, the process would take until mid-April, and that’s only if they had the right weather conditions.

If they waited until the beginning of April, the chances of getting their effluent pond empty before late autumn rains hit are extremely remote.

NZ Dairy Exporter | Effluent Management Solutions | February 2023 11 EFFLUENT MANAGEMENT SOLUTIONS 2023

• Logan Bowler is an independent effluent management consultant.

STOP WORRYING ABOUT EFFLUENTSIMPLIFY YOUR SYSTEM

HAVING A SIMPLE EFFLUENT SYSTEM is the best thing since sliced bread says John Climo who farms 530 cows at Wharepapa South, Waikato.

John’s previous set up might sound familiar- a manikin tank, sump, and pumped straight to pasture which had to go every day, even if it’s wet.

It was a constant worry. It was a nightmare if the pump broke down, the power was off, or if it blocked and didn’t pump, John says.

“We had to shift the irrigator and manage it every milking, it was so labour intensive, especially when it blocked.”

Now with his Archway Weeping Wall system he doesn’t have to worry.

“We went to the weeping wall because the pumps couldn’t handle the sand,

stones and plastic, but the weeping wall separates everything that goes down the drain and leaves the pond clean.

“I couldn’t believe how long the weeping wall bunkers took to fill and how quick it was to empty them out.

We looked around at a few different systems and we were lucky here with the gravity from the cow shed, so this new system worked out perfectly.” John says.

Archway Group’s Amanda Hodgson says effluent can be one of the most unfavourable jobs on-farm so it’s important to make your system as low maintenance and simple for yourself and your staff as possible.

“We believe that simple systems attract great people. Having a well-designed system which makes these unattractive

tasks easier ultimately takes the pressure off and makes the people on the ground happier.”

The wellbeing of people needs to be part of the design process for a sustainable operation. The effect it can have on people with a good system versus those with an inadequate system is huge.” Amanda says.

NZ Dairy Exporter | Effluent Management Solutions | February 2023 13 EFFLUENT MANAGEMENT SOLUTIONS 2023

www.archway.co.nz

A new weeping wall has simplified the management of effluent for Waikato dairy farmer John Climo.

MORE?

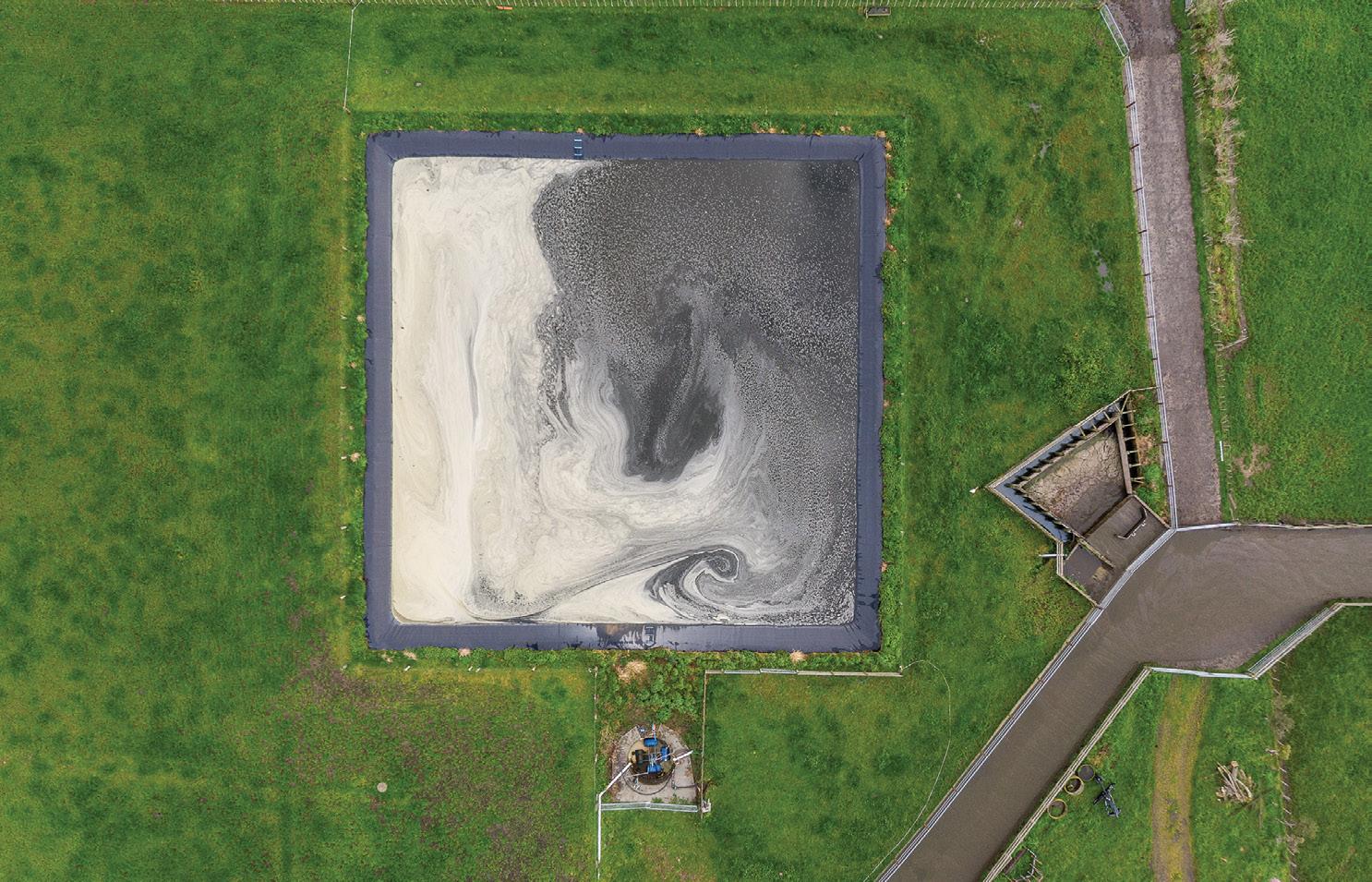

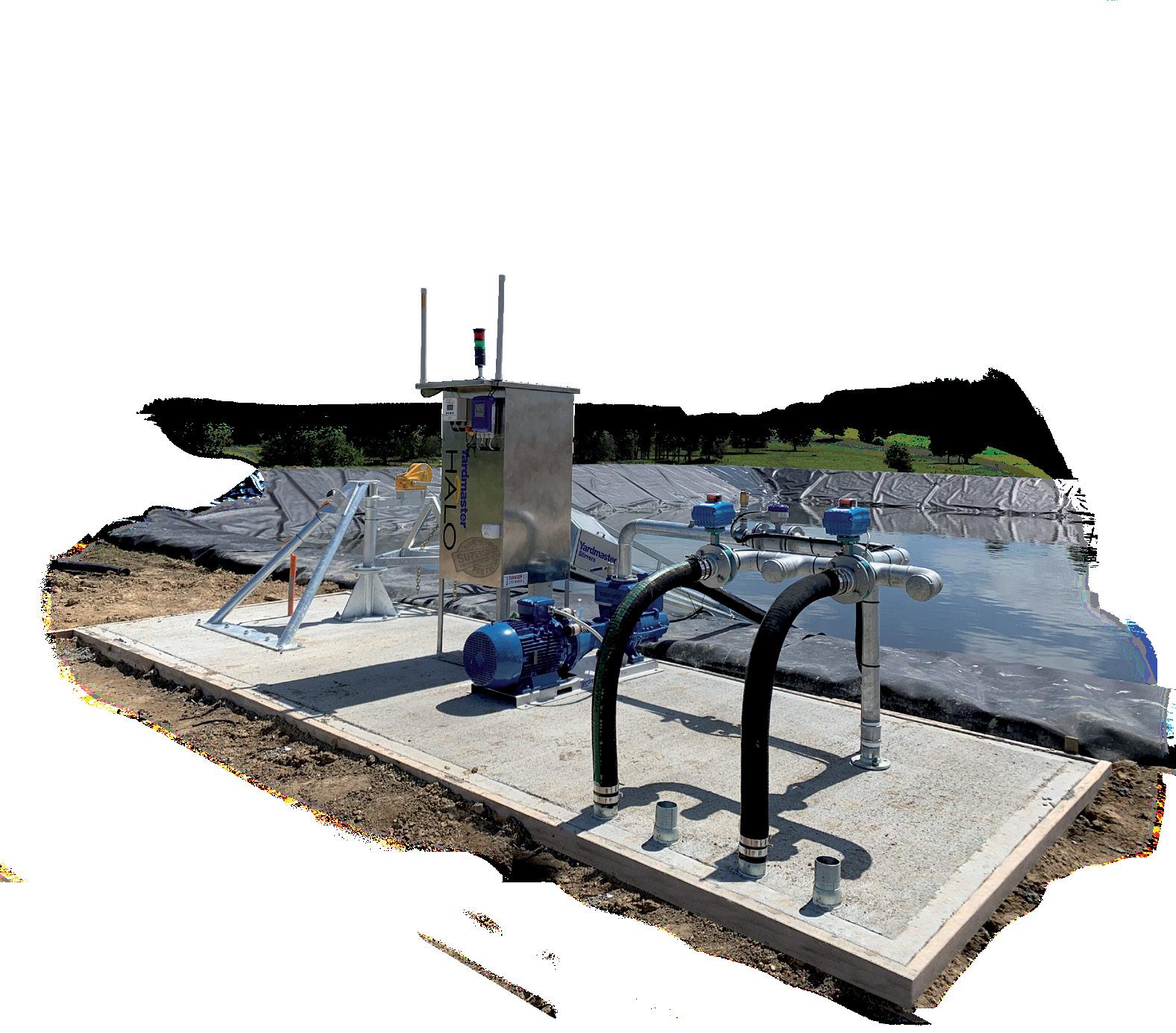

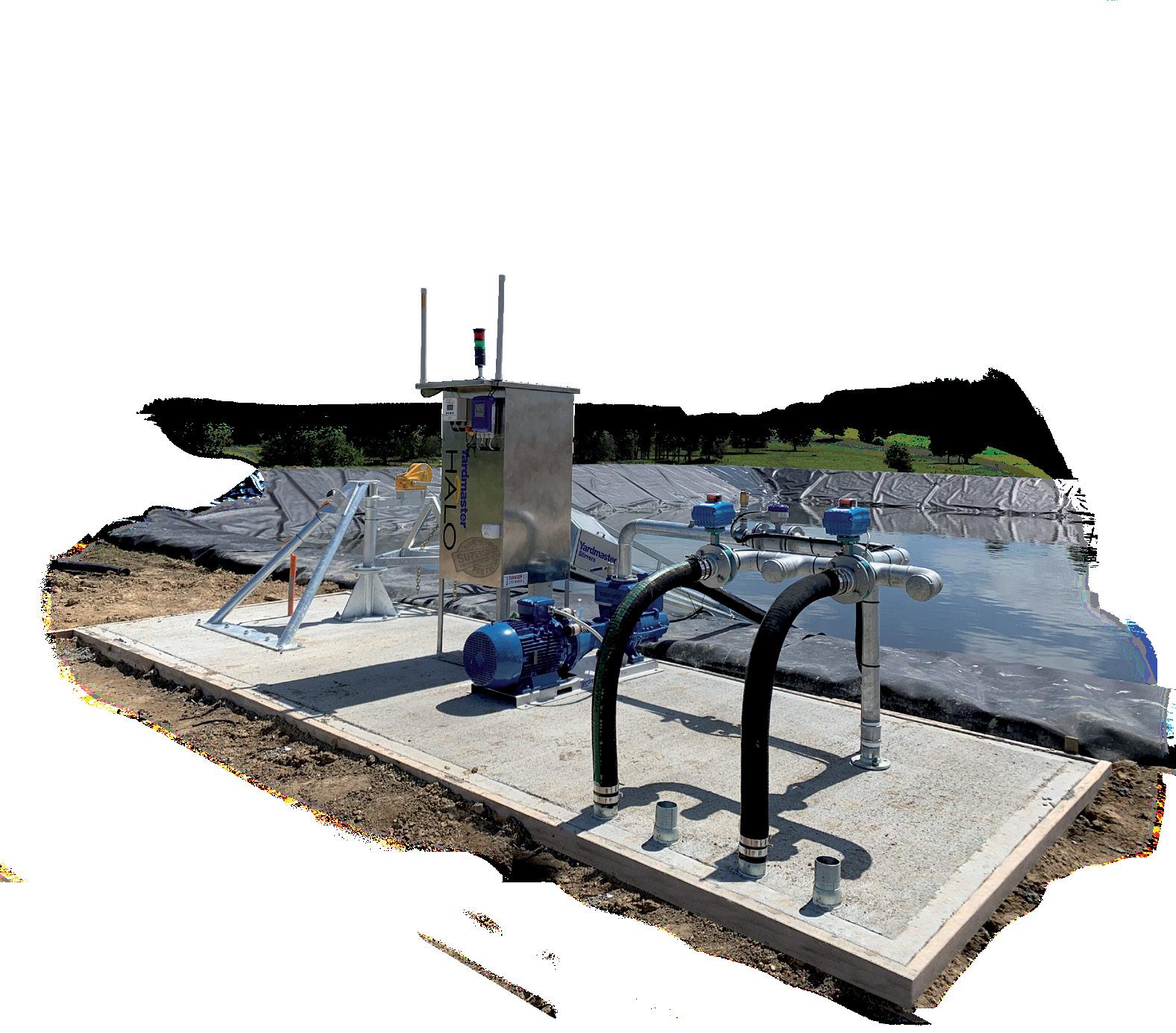

YARDMASTER TAKES ‘FOUR PILLARS’ APPROACH TO CUSTOMER NEEDS

REID & HARRISON HAS ADOPTED a four-pillar approach to support dairy farmers with their dairy effluent system needs.

The Yardmaster brand is well known and proven in New Zealand for their range of products, fit for purpose design, reliable performance, and manufactured in New Zealand. The strategy is simple - have a wide range of products to fit all demands so you are not restricted by what is available. It is also reassuring to know that with a centrally located Matamata factory, support is never far away if any issues do appear.

With all the products available the next pilar is the system design so that a practical and compliant outcome is achieved with the system flow. Being design-accredited also provides assurance that the industry rules and regulations are being followed.

Yardmaster offer this support throughout New Zealand. An effluent system W.O.F service is also available to confirm if optimal system performance is being achieved or where improvements can be made. Once a system is installed, the next challenge is how to control and monitor what is happening.

The collaboration and development of the HALO supersmart automation is the answer to this. Using cloud-based technology, information is available by any smart device.

Ability to set up alarms for events, control equipment including GPS track and Geo Fence are features. This ultimately gives peace of mind to farm owners and managers about their effluent operations.

The last piece of puzzle is local support

via the Yardmaster dealer network. Fully nationwide, certified dealers have access to product information and training. Any system is only as good as the support you get once it is running. Having a local expert makes all the difference.

The combination of the four pillars above, makes a very compelling reason as to why Yardmaster is a leading brand and supplier in the NZ effluent industry.

MORE? Visit www.yardmaster.co.nz

NEW RESEARCH CONFIRMS PLANTAIN’S PROWESS

INNOVATIVE NEW RESEARCH HAS signaled feeding cows plantain can reduce nitrogen leaching from dairy farms by 20-60%.

The results, from the DairyNZ-led Plantain Potency and Practice (PPP) Programme, prove using Ecotain plantain in pasture can significantly reduce nitrogen entering waterways.

Farm trials at Massey University and initial results from a trial at Lincoln University are showing similar trends. The trials are part of the nationwide PPP research and development programme that partners with dairy farmers, industry and Government. The $22 million seven-year PPP Programme is funded by DairyNZ, the Government through the Ministry for Primary Industries’ Sustainable Food and Fibre Futures fund, PGG Wrightson Seeds and Fonterra, working with six additional research and delivery partners.

The programme uses Ecotain environmental plantain from Agricom because it has proven effectiveness. An evaluation system is available to assess the environmental benefits of all plantain cultivars sold by a range of providers.

At the Massey University farm trial, scientists are measuring nitrogen leaching from paddocks grazed by 80 dairy cows. After two years, the trial results have shown reduced nitrogen leaching by 20-60% in perennial ryegrass and clover pastures containing 30-50% Ecotain plantain.

The results are compared to traditional perennial ryegrass and clover paddocks (the most common pasture types in New Zealand). There was no difference in milk production between the plantain and control pastures in the trial.

The amount of reduced nitrogen leaching depends on the quantity of

plantain in the pasture, the soil type, climate and farm system. The Massey University trial will continue for a further two years.

Initial results from the programme’s Lincoln University study in Canterbury, on lighter soils under irrigation, show similar trends to the Massey University trial, with a 38-50 percent reduction in nitrogen leaching from pasture containing 24 percent Ecotain plantain. More data are being collected to confirm these results.

Ecotain environmental plantain reduces nitrogen leaching by increasing cows’ urine volume, therefore diluting the nitrogen in urine and reducing the total amount of nitrogen excreted in urine. It also retains nitrogen in the soil, preventing it entering waterways.

MORE? Visit dairynz.co.nz/ plantain-programme

14 NZ Dairy Exporter | Effluent Management Solutions | February 2023 EFFLUENT MANAGEMENT SOLUTIONS 2023

A recently completed installation by Reid & Harrison, based on its four-pillar approach to providing a complete system backed by ongoing service.

Trusted by generations of New Zealand farmers, our equipment is purpose designed for effluent, and performs reliably where others can’t.

Every farm is unique. Reliable effluent systems that work every day in the real world need experience, expertise and an integrated design approach. Yardmaster® systems provide a total solution that works for you.

NZ Dairy Exporter | Effluent Management Solutions | February 2023 15 EFFLUENT MANAGEMENT SOLUTIONS 2023 www.yardmaster.co.nz Waihou St, Matamata. Ph: 07 888 8224 REID & HARRISON™

& Systems

PROVEN EFFLUENT AN EFFLUENT SYSTEM THAT'S RIGHT FOR YOU EFFLUENT SYSTEM MANAGEMENT A STRONG DEALER NETWORK

Pumps

smart device. See what’s going on in real time and receive alerts wherever you are. Options include Proof of Placement, which provides valuable feedback and compliance data.

WASTEWATER RECYCLED USING KIWI KNOW-HOW

A SMALL FAMILY-BASED COMPANY in Matamata has showcased its ability in the overseas market to effectively recycle effluent.

FORSI Innovations owner Terry Hawes and his sons Darren and Craig, entered the water and wastewater filtration industry in 2010, after branching from their parent company AG-WORX (J.S Jobe Ltd).

In 12 years, FORSI has moved beyond iron, manganese and effluent, to installing water recycling systems in orchards, wineries, laundromats and car washes.

A dairy consultant, who assists with major dairy projects around the world, was looking for a specialised company to deal with the dairy effluent in a university on the outskirts of Hong Kong.

After learning about FORSI’s unique and custom-built effluent systems in place throughout New Zealand, the consultant

approached FORSI’s sales rep Derek Piper and told him about the project.

This would be FORSI’s break into the overseas market. The FORSI effluent recycling system is broken up into three end products - clean filtered water, dry matter and a concentrated liquid – just what was required in Hong Kong.

This resulting trifecta creates a sustainable system with very little waste. The clean filtered water can be reused to wash down yards or stored to spread on pastures during dry seasons, the dry matter can be composted and the nutrient rich concentrate can be spread on pasture at a low rate where it can soak into the soil and won’t contaminate water ways.

The system would meet the needs of 75 head of stock and filter an estimated 5000 litres a day (600 litres/hour).

“The flow rate was minimal compared to

WATE R

what other FORSI systems manage, which are around 10,000 litres/hour,” said Piper.

Managing a lower flow rate was one of the many challenges as part of the Hong Kong project, which gave the FORSI team many opportunities to think outside the box.

To have cows on site, the university was required to filter the effluent to drinking

How do you manage and control your Effluent System?

Have you ever wanted to have full control of your effluent pumping equipment locally and remotely, wanted fail safe security in case of burst pipe or no movement at irrigator as well as offering placement data on Google Maps, wanted to have the flexibility to set flow rates, pumped quantity or pumping times?

“Control

How do you manage and control your Milking Plant and Vat Wash System?

16 NZ Dairy Exporter | Effluent Management Solutions | February 2023 EFFLUENT MANAGEMENT SOLUTIONS 2023

Forsi is taking its technology to the world after this successful installation in a Hong Kong dairy unit.

Street | Matamata | Ph 07 880 9479 | Fax 07 880 9486 | www forsi.co.nz ● Iron, Manganese, Arsenic, Turbidity Rem ● ● C ash cling s tion eparation e water rec ycling ● pH Correction

Call Laser Electrical • A Laser Electrical Representative will call around to discuss your application. • A tailored control solution can be created • Preliminary costings can be provided.

Ascertain loading requirements for new installations and offer solutions around this.

•

Milking

and Vat Wash System

to

the

Have you ever wanted to have your

Plant

fully automated and free up valuable time

do

things that matter?

automation

your Plant and Vat Wash system

our integrated automation solution” (07) 883 7677 • www.laserelectricalputaruru.co.nz Continues p19

your effluent system with our integrated

solution” “Control

with

HELP IS AT HAND WITH EFFLUENT

WHEN THINGS ARE NOT GOING TO plan with your effluent system, or the time to make a change has arrived, you can get back on an even keel with the help of DairyNZ by following this simple three step process.

“Year on year dairy farmers nationwide have invested considerably in effluent infrastructure and management processes to ensure they comply 365 days of the year, achieving better flexibility for irrigation, increased nutrient utilisation and peace of mind,” says DairyNZ solutions and development lead advisor Adam Duker.

“However, some farmers still need to make some changes, whether that’s creating an effluent management plan or investing in an upgrade.”

Often the hardest part is making a start, so here’s a simple process to help you get going:

Step 1: Go to: dairynz.co.nz/effluent

The DairyNZ website has a range of effluent management resources to give you a core understanding of all things related to farm dairy effluent.

Step 2: Review your effluent management

Now that you have found the DairyNZ effluent resources you’re one click away from the staff guides for the operation and maintenance of effluent systems. If you don’t have an effluent management plan, give the poster a go with your farm team, then pin it in the farm office as a visual prompt.

Step 3: Assess your infrastructure

No two farms are the same, so before any upgrade is considered it is best to make a sound evaluation on the existing

LOST YOUR PADDLE?

infrastructure to determine what will stand the test of time and where upgrades could be considered. You can make your own assessment using the “Planning the right system for your farm” guide.

There are many industry advisors ready to help you. But building your own knowledge using DairyNZ resources will help you ask the right questions in the first place before making any decisions.

The DairyNZ website is your go-to place to find trusted advice – look for the green tick for accredited companies, or the WOF sticker for certified effluent system assessors.

MORE? Visit dairynz.co.nz/effluent

EFFLUENT MANAGEMENT SOLUTIONS 2023

DON’T GET STUCK UP THE CREEK LEARN ABOUT ALL THINGS EFFLUENT Self-help Management Guides Infrastructure Guidelines WOF Assessors Accreditation Designers DAIRY EFFLUENT WARRANT OF FITNESS WOF’ ’ dairynz.co.nz/effluent

Adam Duker, DairyNZ

18 NZ Dairy Exporter | Effluent Management Solutions | February 2023 EFFLUENT MANAGEMENT SOLUTIONS 2023 Powerful, efficient pond stirring for maximum value.

Effluent management has never been so easy. Call 0508 747 040 or visit www.pondstir.co.nz Another quality product from the makers of Tow and Fert Shrouded propeller creates an energy efficient jet-stream saving power and increasing thrust. 2.3 cubic meters of concrete in the foundations and counterweight allow for quick and easy setup. Available in 8m and 10m lengths State-of-the-art propeller and motor for increased pressure and efficiency A powerful yet energy efficient TBM motor available in 4kw and 7.5kw options A 180 degree swiveling boom means the propeller and system can be swung out of the pond for easy servicing and movement within the pond PondStir pivoting counterweight. Installed in under 4 hours - no builders needed*. * Concrete is required to be delivered to site for pouring into premade counterweight boxing.

Once the PondStir is assembled, concrete is poured into the counterweights and left to set for 24 hours. With the concrete set the PondStir can now be connected to an existing mains power source and stirring can begin.

PONDSTIR MAKES EFFLUENT EASY TO MANAGE

EFFLUENT SHOULDN’T BE A DRAIN on your dairy farm. The right stirrer will help you to fully capitalise on this valuable resource.

The pond stirrer you choose is instrumental in determining the nutrient value of the effluent you apply to your pasture. Insufficient stirring can lead to the build-up of sludge at the base of your pond inhibiting the microorganisms that break down effluent creating a nutrient rich fertiliser.

Metalform’s PondStir uses specialised design and production to greatly increase the efficiency of the stirring achieved, using less power while increasing thrust and stirring capability.

A PondStir can be assembled in less than a day without any excessive digging or specialist equipment. The head of the PondStir is mounted on a pivoting boom that allows it to be serviced a safe distance from the pond.

The adjustable height, pivot and engineered head make the PondStir

From p17

water standards before being released into the wastewater network, with 32% dry matter. The space the FORSI system was to be housed in hadn’t been built – so the team could only work from schematics and trust the space wouldn’t change during construction. Every inch of the workable space would be used for not one, but two identical systems.

“Having two systems was a requirement to act as a failsafe. The systems could work independently or at the same time.”

They also needed to know what the cows were eating, how often the yards were being washed down and the elements already in the water. All this information provided the basis for how the water recycling system would manage the requirements for the solid matter.

Design and construction of the two systems took over two years to complete. Despite two COVID-19 lockdowns and

effective in a wide range of pond types. The ability to swivel the mixer head completely out and away from the effluent pond makes this one of the safest models on the market.

The unique shrouded head on each PondStir requires less energy to get the effluent moving by creating increased efficiencies. This means it gets the job done faster using less power, saving you money over time.

Thorough mixing prevents stagnation

and the formation of a crust while also supporting anaerobic activity. The result is a higher quality fertiliser for you to apply to your pasture.

Two PondStir mixer types are available in 4kw and 7.5kw outputs in either 8m or 10 lengths depending on the size of the pond, allowing for efficient stirring regardless of your pond or tank size.

MORE? Visit www.metalform.co.nz

other projects on the go, the system left the Matamata based workshop and flew out to Hong Kong by deadline. Piper and filtration engineer Kevin Bayly followed closely behind to oversee the successful two-week installation. The system is completely automated from New Zealand, with an on-site consultant overseeing any necessary hands-on issues.

“Alarms alert us to any problems, which through cameras, we can assess immediately.

“All our systems have the latest cuttingedge technology. We never look back – we always improve on what we have done. We are using this system through the automated settings to try new things, without disrupting the process – it’s a cool learning opportunity for the team.”

It’s this meeting of the minds that keeps Piper coming back to work each day.

“There’s a lot to be said for how the FORSI system works,” said Piper. “I have

been with the company for 17 years and I am incredibly proud of how far we have come and the different ways the FORSI system has been used.

“Different industries are now coming to us and we are evolving with them. I am really motivated by what we are doing. We can branch out – there’s always new ways of doing things, new technology is always being developed.

“You never know what’s around the corner and I am excited to see what’s next.”

Since the success in Hong Kong, FORSI have been approached to install an effluent recycling system for another overseas client, at the other end of the spectrum with extremely high flow rates.

“This project has 3000 head of cattle. But there’s nothing we haven’t been able to put our hand to – so watch this space.”

MORE? Visit www.forsi.co.nz

NZ Dairy Exporter | Effluent Management Solutions | February 2023 19 EFFLUENT MANAGEMENT SOLUTIONS 2023

A PondStir in action, showing the efficient mixing of dairy effluent.

PRECISION FROM PICHON

SLURRY TANKERS

Pichon provides high quality, robust and high performance slurry and muck spreading products. Today, Pichon offers a wide range of spreading solutions for agriculture including muck spreaders, slurry tankers, drip hose booms, incorporators, injectors and more.

The agriculture of tomorrow needs to combine soil conservation and high yields. To achieve this, you need precision and efficiency. With this in mind, Pichon manufacture and market slurry tankers and muck spreaders for precision farming, designed to take the best value out of liquid and solid organic fertilisers.

From the smallest model (single axle 3 050 L) to the largest (tri-axle 30 000 L), Pichon has a range of capacities to meet your needs. All Pichon tankers are fully galvanised inside and out, guaranteeing the tanker ultimate corrosion resistance and longer lifespan.

The tankers are between 5 and 8 mm thick depending on their diameters. There is no risk of damage to your tanker during the sequences of air pressure loss.

Pichon slurry mixers are equipped with a spiral-shape mixing screw for perfect mixing and chopping. Two sharp blades are attached to the base of the screw and an adjustable counter blade is attached to the end of the chassis. This design helps to avoid build-up of materials around the main shaft ensuring the pond contents are mixed efficiently. With a capacity of 8 to 24 m3 and with a working width up to 20m, Pichon muck spreaders are specially designed for intensive use. The Pichon MK series solid organic fertiliser spreaders have an excellent reputation thanks to its perfect combination of robustness and versatility

The narrow body is paired with a high

rear frame and large diameter vertical beaters. This design prevents the manure from being stuck in the body during spreading. The body design optimises the load volume and facilitates the spreading operation. Standard on all models, the floor chain is made of rectangular slats with Ø16 mm marine chains. The chain’s pulling resistance index reaches 32 tonnes. Centralised the greasing points on all models make maintenance easier.

TankSTIR 710

20 NZ Dairy Exporter | Effluent Management Solutions | February 2023 EFFLUENT MANAGEMENT SOLUTIONS 2023

NEW

A Pichon slurry tanker in action.

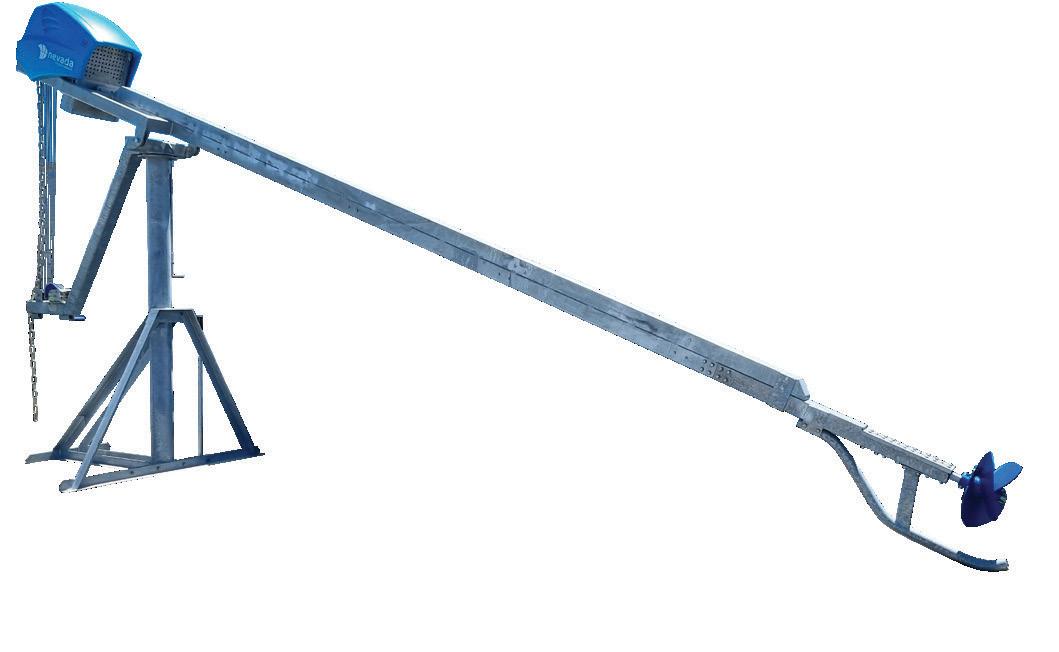

Nevada

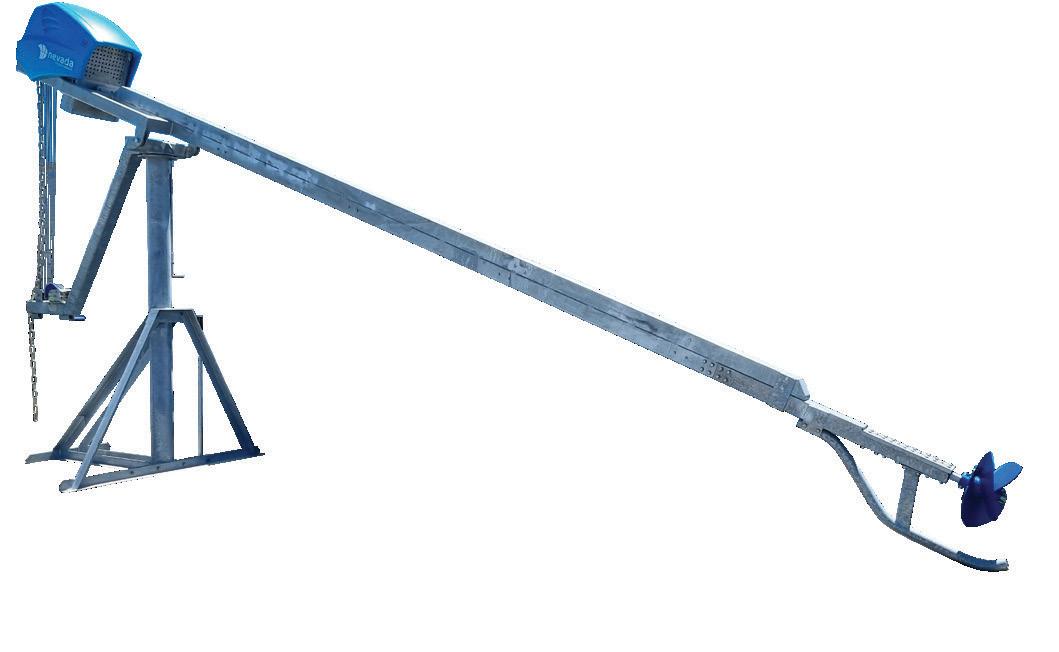

KEEP EFFLUENT STIRRED

ABOVE-GROUND EFFLUENT storage tanks require a good slurry stirrer, says Nevada effluent specialist Michael Prestidge.

Above-ground effluent tanks need a good stirrer to keep the effluent well mixed, he says.

Pumps alone are insufficient for dealing with effluent – particularly floating solids. If the effluent is not mixed well enough,

solids accumulate at the bottom of the tank or form a crust on top, making it difficult to harvest and grow grass. Prestidge says other issues include solids that are not mixed in causing blockages in pumps, settled solids reducing the storage capacity, potentially affecting council requirements, and solids left sitting in the tank will decrease in nutrient value.

“Who wants to have to clean out a tank,” he asks?

An electric stirrer is recommended where possible. They are cost and time efficient and can be set on an automatic timer for even more efficiency.

Shore mounted horizontal stirrers are the preferred option as the angle is important for drawing in solids from around the pond.

Where previously electric stirrers needed to be mounted on a pedestal to reach over the wall of an above ground tank, Nevada has developed a new electric stirrer with extended mast.

This allows the stirrer to be operated from the ground while reaching over the wall of the effluent tank. Ground operation is a much safer and convenient option, while still providing powerful performance, he says.

If electricity is not available, many farmers are choosing hydraulically driven stirrers that can mount onto fro

MORE? Visit www.nevada.co.nz

Precision. Productivity. Performance

Pichon provides a variety of slurry tanker systems, featuring capacities from 2,600 to 30,000L and a selection of axle options.

• Auto filler left and right operation

• Fully welded and galvanised inside and out for long life protection

• Rear attachment injection and application options

• Fully integrated oiler system for long life of vacuum pump

EFFLUENT MANAGEMENT SOLUTIONS 2023

Contact your local Norwood dealership for more information or a demo. norwood.co.nz I 0800 66 79 663

A Nevada hydraulic slurry stirrer in action.

HASSLE-FREE EFFLUENT MANAGEMENT

IF YOU NEED A NEW EFFLUENT system or an update to your existing one, you want a solution that is compliant, reliable, cost effective and future-proof. Correct effluent management can deliver savings on fertilising costs, increased grass growth and ensure environmental compliance.

Numedic’s team, trusted by farmers in New Zealand and worldwide for many years, has been helping customers with their effluent management requirements and equipment to ensure efficiency, compliance, and high productivity.

Numedic is Farm Dairy Effluent System Design accredited, which means that farmers can rest assured that its systems meet the Farm Dairy Effluent (FDE) Design Code of Practice and Farm Dairy Effluent (FDE) Design Standards.

We can help with resource consent applications, renewals, system design and implementation, and servicing.

Numedic recently added the self-priming HP series of Progressive Cavity pumps to its range.

Numedic’s locally manufactured product range includes pumps, stirrers, hydrants, and irrigators, designed and developed by highly skilled engineers working with farmers to deliver products that deliver the desired outcome.

You can also rely on backup service and

parts being available when you need it. Whether you are looking at a complete system, an upgrade, or an extension, get the ball rolling by contacting Numedic experts to discuss your requirements.

MORE? Visit www.numedic.co.nz

22 NZ Dairy Exporter | Effluent Management Solutions | February 2023 EFFLUENT MANAGEMENT SOLUTIONS 2023

RAIN? NO PROBLEM FOR A FLEXI TANK Andre: 027 706 3633 | info@flexitanksnz.com www.flexitanksnz.com | Cambridge, NZ Pump effluent, not rain

FLEXI TANKS NZ IS THE NEW Zealand distributor of the flexible tank which are made by French company, Labaronne-Citaf, which invented and has been manufacturing them since 1959.

Based in Waikato, Flexi Tanks NZ works closely with industry professionals and farmers to provide storage solutions that are simple to install and require little maintenance.

• Unmatched reliability of your

• Maximised Profitability

The Flexi Tank is an enclosed, selfsupporting bladder that stores anywhere from 25,000-litres and up to 2 million litres of dairy effluent. They can be installed and operational within hours of arriving on farm – without the need or expense for permits.

The tank can simply be rolled out on top of a 100mm horizontal bed of sand and has proved very popular with dairy farmers

since it was introduced to New Zealand a decade ago.

In contrast to other forms of liquid storage, the enclosed Flexi Tank is constructed of a rip-stop, UV stabilized fabric guaranteed for 10 years but expected to last more than 20 years.

Being enclosed, it is extraordinarily safe and only requires a stock fence as opposed to a pond’s security fencing system. The tank features overflow vents, which can also be used to harness bio-gas, and multiple valves with camlocks on the sides of the tank to allow for regular stirring of contents before pumping out to irrigation.

Flexi Tanks NZ General Manager Andre Meier says repeat business is the best endorsement of the tanks’ efficiency and cost-effectiveness.

“The practicality, safety, efficiency and cost-effectiveness of the tanks resonates with farmers and has resulted in significant demand and repeat business,” he says.

MORE? Contact the Flexi Tanks team on info@flexitanksnz.com or Andre on 027 706 3633.

• Lower Operating costs

• Performance exceeding your expectations

• No Nonsense Equipment Advice

•

• Easy to Manage

NZ Dairy Exporter | Effluent Management Solutions | February 2023 23 EFFLUENT MANAGEMENT SOLUTIONS 2023

Unmatched reliability of your effluent system

Maximised Profitability

No Nonsense Equipment Advice Futureproof your Farm Effluent Management

Lower Operating costs

Performance exceeding your expectations

•

•

•

•

•

Easy to Manage 0800 686 334 | info@numedic.co.nz | www.numedic.co.nz Or contact your nearest Numedic stockist. Effluent Pipe Technology for the Future Experience the Numedic difference PTO Pumps Travelling Irrigators Stationery Irrigators Pond Mixers Vertical Effluent Pumps Horizontal Effluent Pumps

Unmatched reliability of your effluent system

Maximised Profitability

No Nonsense Equipment Advice Futureproof your Farm Effluent Management

Lower Operating costs

Performance exceeding your expectations

Easy to Manage 0800 686 334 | info@numedic.co.nz | www.numedic.co.nz Or contact your nearest Numedic stockist. Effluent Pipe Technology for the Future Experience the Numedic difference PTO Pumps Hydrants Travelling Irrigators Stationery Irrigators Pond Mixers Vertical Effluent Pumps Horizontal Effluent Pumps Unmatched reliability of your effluent system • Maximised Profitability • No Nonsense Equipment Advice Futureproof your Farm Effluent Management Lower Operating costs

Performance exceeding your expectations Easy to Manage 0800 686 334 | info@numedic.co.nz | www.numedic.co.nz Or contact your nearest Numedic stockist. Effluent Pipe Technology for the Future Experience the Numedic difference PTO Pumps Hydrants Travelling Irrigators Stationery Irrigators Pond Mixers Vertical Effluent Pumps Horizontal Effluent Pumps

•

•

•

•

•

•

•

system

effluent

Futureproof

Farm Effluent Management

your

0800

info@numedic.co.nz

Or contact your nearest Numedic stockist. Effluent Pipe Technology for the Future Experience the Numedic difference PTO Pumps Hydrants Travelling Irrigators Stationery Irrigators Pond Mixers Vertical Effluent Pumps Horizontal Effluent Pumps FARMERS ENDORSE EFFLUENT STORAGE BLADDERS

686 334 |

| www.numedic.co.nz

One of the Flexi Tanks NZ tanks installed within hours of arrival on the farm.

CLEVER DESIGN IMPROVES RELIABILITY FOR SABRE PUMPS

PUMP & VALVE INTRODUCED SABRE effluent pumps to the New Zealand market about 10 years ago.

Sabres are heavy duty industrial grade pumps, set up for NZ dairy effluent pumping conditions.

As well as the usual features expected from an industrial style pump, Sabre has one unique design that gives them an edge over competitors.

To understand how they work, PC pumps use a ‘single’ helix SS rotor, which turns inside a ‘double’ helix rubber stator, to transfer liquid through the pump.

This rotor and stator look like a threedimensional sine wave (see image).

It fits tightly into the stator, making it the key wearing part.

This compression fit enables it to create excellent suction and to pump high pressures, while requiring relatively low kilowatts.

Sabre pumps have a simple but clever design – they have extended the length of the rotor/stator geometry - which reduces the rotor’s diameter.

Reducing the diameter of the rotor means the rubbing velocity within the pump is reduced.

Every time the rotor turns 360 degrees, it travels 20% less distance than other pumps. Lower internal rubbing speeds are a key factor in the Sabre pump’s reliability.

You will note that when promoting PC pumps, special attention is paid to this

MANAGE EFFLUENT BETTER.

speed, and rightly so, because this has traditionally been the gauge to indicate rubbing velocity inside the pump.

With Sabre’s extended geometry design, they can run at the same speed – or slightly faster - and still be wearing the components at a lesser rate.

Pump & Valve have seen pumps in service for more than seven years without a change of stator.

Lower internal rubbing speeds are key to Sabre’s reliability.

It is worth noting that farmers currently using a centrifugal type pump, irrigating uphill, can often save about 50% on power requirement with a PC pump.

• Preferred by installers.

• Flexible when dragging.

• Easy shifting for large pods.

• Strong enough to prevent kinking.

• Easy fit to hydrants, camlocks & compression fittings.

•Low application rate avoids leaching.

EFFLUENT MANAGEMENT SOLUTIONS 2023

MORE? Visit pumpandvalve.com

K-LINE SYSTEM COPES WITH EFFLUENT CHALLENGES

WHEN SETTING UP YOUR EFFLUENT dispersion system, it is important to get the right advice to ensure you are compliant and efficient.

Factors such as the shape and size of your property, the available dispersion area, the quality and quantity of effluent, the effluent rotation and soil type all determine which option is best.

RX Plastics (RXP) recommends solid separation to achieve best results and flexibility. With RXP’s K-Line tm system, all the parts are designed to work together and because RXP manufacture and distribute all parts farmers can be assured of a complete, reliable solution the company will stand behind. There is a range of pipe and K-Line™ pods available depending on the type of solid separation system in place on farm. K-Line irrigation pods are used for effluent dispersal with

a simple change of sprinklers depending on the varying levels of solids and liquid in your effluent. Equally if farmers are needing to mix and match, then K-Pipe™ is ideal because of its flexibility yet high resilience in the effluent environment.

All effluent pipes are not created equal. K.Pipe is a good example. The K.Pipe technology resulted in producing an extruded compound flexible enough to be dragged around the farm behind a quad bike, yet strong enough to withstand being trod on or twisted. K.Pipe is available from 32mm to 75mm to suit all your needs.

The irrigation pods, known as K-Line Pods, are perfect for effluent dispersion. At times when the soil is too moist for a travelling irrigator the K-Line Pod can still be used. This is due to the low, instantaneous application rate meaning there is virtually no ponding

on the pasture. Run off and leaching are minimised, and farmers can meet their regional council requirements.

The K-Line Pods are very easily moved, modular and have a lower level of health and safety risks. They cost less than a travelling irrigator and due to the K-Line pod only having the sprinkler as the moving part, maintenance is a breeze. They are built using high-impact engineering-grade thermoplastics and top quality stainless steel components for strength and durability with a pressure range between 1.5 bar and 3 bar.

MORE? Visit www.rxp.co.nz

NZ Dairy Exporter | Effluent Management Solutions | February 2023 25 EFFLUENT MANAGEMENT SOLUTIONS 2023 SCANME The Green EffluentPump 0800786774 www.pumpandvalve.com

Towing K-Line tm into place is easy with a quad bike.

COMMITMENT TO RESEARCH AND DEVELOPMENT

PLUCKS ENGINEERING WAS established in 1966 and is a family owned and operated business specialising in the manufacture, supply, installation, and servicing of dairy effluent products.

From our base in Rakaia, MidCanterbury, and through our distributor network, we offer our specialist effluent products anywhere in New Zealand. With an extensive and proven product range, we can supply, install, and maintain everything needed for an efficient and reliable dairy effluent system, whether from green-field or utilising existing infrastructure. Products in our range include:

• Civil works covering Enviros Saucer™ storage ponds, stone-traps, screeningbunkers, leachate-pads and aprons.

• Effluent screening systems utilising our

self-managing ADR500 rotary-screen or Yardmaster screw-press separators.

• Access-walkway/pump-raft systems for storage ponds and sumps, which provide safe and secure access to off-shore pumps.

• Shore and raft-mounted centrifugal effluent-pumps, and high efficiency progressive-cavity pump effluent pumpstations.

• Stirrers for sumps, ponds and tanks with high-efficiency and low power requirements.

• Travelling irrigators with exceptional distribution uniformity that complies with Dairy NZ effluent standards. All our products have proved themselves in providing reliable and effective performance over 33 years in the field.

Over the 33 years, Plucks has been

involved in dairy effluent the company has invented and developed a number of important effluent products.

These include the Enviro Saucer, which is a primary pond design and shape that never builds up with solids and always cleans itself out to nearly empty every time it is used, and a range of effluent pond stirrers specifically for dairy effluent and very low kW with huge blades turning over the liquid within the pond seven times per hour. Another important dairy effluent product Plucks developed is the effluent screen with the concrete and electronic infrastructure to support the screen’s function, where the screen filters the dairy effluent down to particle sizes of no greater than 0.9mm so there are no blocked nozzles on the irrigator when spreading effluent.

Plucks is committed to research and development of dairy effluent products and the team is always looking at new and better ways to make a farmer’s day better.

MORE? Visit www.plucks.co.nz

Effluent and Irrigation Design™ looks at all aspects of your farm including topography, nutrient budgeting, and preferred management to recommend the best solution for you.

We understand the concerns relating to how much work managing an effluent system can be. With years of experience, technical training, contact with farmers and understanding of industry requirements our consultants have a wealth of knowledge to call upon.

Because Effluent and Irrigation Design™ is made up of independent consultants, we have the ability to provide different system designs. We work with all manufacturers of effluent disposal solutions available in the New Zealand market. Multiple outcomes are often reached allowing farmers to make choices that best suit their farming needs. Rather than simply being sold a specific product, our process allows farmers to become educated buyers of designs precisely suited for their farm.

26 NZ Dairy Exporter | Effluent Management Solutions | February 2023 EFFLUENT MANAGEMENT SOLUTIONS 2023

How we work with you Let’s talk... 0800 856 544 www.effluentandirrigation.co.nz Distributors throughout NZ Effluent Pond Stirrers Self cleaning screen and ponds • Two year warranty on motor and planetary No greasing required All bearing above the

A 40-YEAR FOCUS ON EFFLUENT

WILLIAMS ENGINEERING, BASED IN the Waikato, have been effluent-focused for 40 years, manufacturing products that have not only taken the brand throughout New Zealand, but to many countries around the world.

The Spider range of travelling irrigators have been an undisputed machine on thousands of farms, known for their reliability, simplicity and ongoing service to the dairy industry.

Williams say they have a travelling irrigator to suit every farm including the GB Magnum with a static rain gun that delivers a wetted area that is more than twice as wide as a standard travelling irrigator.

The company’s largest irrigator, the Greenback Spider, provides an even spread pattern with its wide boom design.

The Spider Deluxe is a smaller version, suitable for most average-sized farms, followed by a Deluxe Junior, with shorter

arms, designed for smaller farms. With a proven range of products from irrigators to hydrants and filters, William’s has become a complete one-stop-shop for all farm effluent needs.

Being Farm Dairy Effluent Design accredited, Williams has designers in-house who work directly with the farm owner to get an effluent plan in place.

The whole installation is managed by the company, working with the farmer’s preferred contractors e.g. electrical and earthworks.

Williams work closely alongside a pond lining crew and manufacture their own precast panels for bunkers, weeping walls and stone traps, having diggers/trenchers to install mainline systems and hydrants.

Williams Engineering has a NZ-wide dealer network, with a 24/7 Waikato-wide service team for all effluent breakdowns, with proven experience and expertise to solve any effluent problem - big or small.

NZ Dairy Exporter | Effluent Management Solutions | February 2023 27 EFFLUENT MANAGEMENT SOLUTIONS 2023

0800 4 EFFLUENT www.williamsirrigation.com Farm Effluent Equipment Full System Design Installation Service New Zealand Wide Dealer Network

SUBSCRIBE TODAY

BENEFITS:

• Choose from print or digital subscription options

• Subscribers save between 17% and 22% off the cover price, depending on your subscription term

• Share your magazines with team members to grow their knowledge or subscribe them all and each have a copy

• A great reference tool to refer back to time and time again

• Your subscription is a tax deductible farm working expense

• Entry into regular subscriber-only competitions and giveaways

• Access to years of archive content on our website

12 MONTHS $129

24 MONTHS $252

36 MONTHS $360 3*

28 NZ Dairy Exporter EFFLUENT MANAGEMENT SOLUTIONS 2023

AND 6-MONTH SUBSCRIPTION TERMS ARE AVAILABLE, VISIT OUR WEBSITE FOR DETAILS.

CARD PAYMENT ONLY Use RuralcoFarmlandsyouror card and SAVE 10%

224 782

• www.nzfarmlife.co.nz

*CREDIT

0800

subs@nzfarmlife.co.nz

POWER AT THE FINGERTIPS IN CHALLENGING SEASON

IT HAS BEEN A CHALLENGING SIX months for dairy farmers when it comes to effluent dispersal, says Irri-max boss Clem Powell.

He says authorities often focus on the storage capacity available on each farm. This is important, but Irri-Max has always been a proponent for powerful effluent systems which can quickly evacuate the collected effluent in any small window of opportunity given by the weather.

“This season has clearly shown that storage capacity is only working if the pond or tank is empty to begin with and also that once filled it needs to be emptied rapidly and lightly enough to prevent runoff,” he says.

Irrimax’s specialty is providing irrigators which apply a linear spray of effluent at controlled travel speed and application rate

to avoid the overlap effect of placed sprinklers and drag pipe Irrigators. Computer control along with monitoring via GSM provides accuracy and oversight to keep farmers “in the drivers seat even when not on farm” he says.

“Although diesel may seem a dirty word to some, our Iveco and CAT powered pump units give performance that would be impossible for many farm power supplies.”

He says many users have remarked on the fuel saving over PTO pump systems. This is due to not powering auxiliary tractor systems at same time as pumping but more importantly it reflects our ability for targeting the required pumping performance and supplying

CUSTOMERS TOP OF MIND AT NEW HOLLAND

bespoke pump units to match.

“In pumping bigger is not always best,” Powell says!

MORE? Visit irrimax.co.nz or visit site O120 at CD Field Days in March.

CNH

INDUSTRIAL (CNHI) HAS ANNOUNCED

THE establishment of a new retail footprint for New Holland Agriculture machinery in New Zealand. Following the conclusion of a distribution agreement between CNHI and CB Norwood Distributors in July last year around the wholesaling of Case IH and New Holland machinery to CNHI’s New Zealand dealerships, the two companies have now announced their plans to go in different directions in 2023.

“We feel this decision for Norwood to leave the CNHI dealer network will allow both businesses to forge new paths and capitalise on additional opportunities in this dynamic market. We have appreciated the support and commitment of Norwood and its staff over many years and wish them all the very best into the future,” says New Holland Agriculture Australia-New Zealand general manager Bruce Healy,.

“Of course, our customers are also front of mind at this time and their ongoing needs and requirements are being prioritised.”

The change will come into effect immediately, with CNH Industrial’s Case IH dealerships serving as caretaker dealers for New Holland machinery until the new dealer structure is finalised. A small number of Case IH branches which were operated by Norwood are also impacted. Existing New Holland dealers Agricentre and R&R Tractors will continue to support their customers. New Holland customers with sales, service, warranty or maintenance requirements, can either phone 0800 333 340 or contact their closest Case IH dealership, which can be found at the dealer locator: www.newholland.co.nz

NZ Dairy Exporter | Effluent Management Solutions | February 2023 29 EFFLUENT MANAGEMENT SOLUTIONS 2023

A diesel powered pump installed by Irri-Max to clear effluent quickly when conditions allow.

SiteO-120CDFIELDAYS Life’s great, especially when your Effluent system works! Come and see how we can make your Effluent job easier! 0800 426 296 IRRI-MAX LTD www.irrimax.co.nz offers high performance pumping and irrigation equipment designed to reduce the headache, cost and time of Effluent dispersal. We have Computer controlled irrigators, Electric, Diesel or PTO pumping Systems and we import most of our product to keep it competitively priced!

CLEVER TEAM ON HAND NATIONWIDE

AGFIRST ENGINEERING SPECIALISES in design and construction of dairy effluent systems.

The company is renowned for its highlevel design knowledge, experience in the industry and capability to deliver the highest quality solutions.

AgFirst Engineering has system designers, engineering work shops and installation/service crews located in Te Awamutu, Te Puke, Gisborne and Hastings. AgFirst Engineering staff work predominantly in the greater Waikato, Taranaki, Bay of Plenty, Gisborne, Hawkes Bay and Manawatu regions. It is also involved in projects nationwide by client demand. Davieth Verheij leads the Waikato Engineering team and is head of Dairy Effluent solutions nationally for AgFirst. Davieth is supported by two of the AgFirst Engineering workshops located on Bond

Road, Te Awamutu and King Street, Te Puke. From Te Awamutu, effluent irrigation equipment is manufactured in house along with importation of key products such as irrigators, pumps, stirrers, hoses, and fittings.

A key product developed by Davieth and the AgFirst team is the Weta low-rate travelling rain-gun irrigator. The Weta can achieve low application depths at low speeds which provides major operational advantages.

The Weta irrigator is self-propelled via a highly efficient turbine-driven hydraulic winch system. The turbine drives a hydraulic pump and winch motor. This drive system requires a lot less energy than a conventional gearbox solution often

LOST YOUR PADDLE?

found on low rate irrigators. The Weta has speed control via a speed selection dial (in meters per hour) and turbine by-pass valve. Given the efficiency of the hydraulic winch system, most of the flow can be directed to the rain gun itself thus reducing flow and pressure loss through the turbine and providing more flow and pressure to the gun itself. This in turn increases wetted width of the irrigator, reduces application rate/depth and required travel speed.

EFFLUENT MANAGEMENT SOLUTIONS 2023

DON’T GET STUCK UP THE CREEK LEARN ABOUT ALL THINGS EFFLUENT Self-help Management Guides Infrastructure Guidelines WOF Assessors Accreditation Designers DAIRY EFFLUENT WARRANT OF FITNESS WOF’ ’ dairynz.co.nz/effluent

The Weta’s low application at low speeds is a major advantage over other travelling irrigators.

NATIONWIDE DEALER SUPPORT MEANS YOU’LL NEVER WORK ALONE

Every New Holland dealer knows what farmers face season after season. That’s why we’re committed to being there to deliver what you need when you need it. From world class products and genuine parts to personal service - it’s all about nationwide on-demand support to lighten the load and get the job done.

NZ Dairy Exporter | Effluent Management Solutions | February 2023 31 Newholland.co.nz WITH WHAT YOU NEED BEFORE YOU NEED IT. FIND Existing New Holland dealers Agricentre and R&R Tractors will continue to support their customers, for all other New Holland customers with sales, service, warranty or maintenance requirements, either phone 0800 333 340 or contact their closest Case IH dealership, which can be found at the dealer locator on: www.newholland.co.nz

• Low rate effluent irrigation made easy.

• Even nutrient application with automated irrigator speed control and hydraulic winch system. Even spread from 50m-100m

ACCURATE | DURABLE | USER FRIENDLY | EFFICIENT

32 NZ Dairy Exporter | Effluent Management Solutions | February 2023 EFFLUENT MANAGEMENT SOLUTIONS 2023