PLUS ON TRACK IN RAK ON-SITE WITH OCC AND WOLFFKRAN ARABIA

PLUS ON TRACK IN RAK ON-SITE WITH OCC AND WOLFFKRAN ARABIA

The

How LiuGong became a major power access player.

20_A

CMME looks at a project that wants to raise expectations of how to construct in the Northern Emirates of the UAE.

22_MINING REPORT

A major report looks at Saudi’s growing importance in the mining sector.

As we end another season marked by increasingly unpredictable weather patterns, a critical conversation emerges— one that pivots on the urgent need for the construction industry in the Middle East to bolster its preparedness for extreme rainfall events. While our region is predominantly known for its arid climate and sun-drenched landscapes, the sporadic yet severe rainstorms that do occur can wreak havoc on both ongoing projects and existing infrastructure. It’s a scenario that calls for a proactive reevaluation of our preparedness strategies and an adaptation of our construction methodologies.

Recent events have starkly highlighted the vulnerabilities within our industry. From flooded construction sites and delayed projects to compromised structural integrity and increased operational hazards, the repercussions of extreme weather are widereaching. These incidents not only lead to financial losses but also pose significant safety risks to our workforce. As stewards of this critical industry, it is our responsibility to ensure that such risks are mitigated.

The conversation about weather preparedness is not just about risk management; it’s fundamentally about innovation and sustainability. Adapting to more frequent and intense weather conditions necessitates a shift towards building materials and construction practices that can withstand such extremes. It means integrating weather-resilient features into our designs from the ground up, whether it’s improved drainage systems that can handle sudden deluges or the use of materials that are resistant to water damage. Furthermore, technology plays a pivotal

role in enhancing our readiness. Advances in weather prediction models and real-time data collection can dramatically improve our ability to anticipate and react to adverse weather conditions. Integrating these technologies into project management tools will enable more dynamic scheduling and resource allocation, minimizing downtime and enhancing safety.

Training and preparedness are equally critical. Equipping our teams with the knowledge and tools to effectively manage the challenges posed by sudden weather changes is essential. This involves regular training sessions, updated safety protocols, and clear communication channels that can deliver real-time information during crises.

As industry leaders, we must also advocate for stronger regulations and standards that enforce the implementation of weatherresilience measures in construction planning and execution. Collaboration among government bodies, regulatory agencies, and private sector stakeholders is crucial to create a cohesive framework that supports these changes.

The goal is not just to react to these challenges but to anticipate and prepare for them. Let’s pave the way for a more resilient and robust construction industry that stands ready to face the future, come rain or shine.

Stephen White Head of Content, CMME stephen.white@cpitrademedia.com

Stephen White Head of Content, CMME stephen.white@cpitrademedia.com

GROUP

MANAGING DIRECTOR

RAZ ISLAM

raz.islam@cpitrademedia.com

+971 4 375 5471

MANAGING PARTNER

VIJAYA CHERIAN vijaya.cherian@cpitrademedia.com

+971 4 375 5713

DIRECTOR OF FINANCE & BUSINESS OPERATIONS

SHIYAS KAREEM shiyas.kareem@cpitrademedia.com

+971 4 375 5474

PUBLISHING DIRECTOR

ANDY PITOIS andy.pitois@cpitrademedia.com

+971 4 375 5473

EDITORIAL

EDITOR

STEPHEN WHITE stephen.white@cpitrademedia.com

+44 7541 244 377

ADVERTISING

SALES MANAGER

BRIAN FERNANDES brian.fernandes@cpitrademedia.com

+971 4 375 5479

DESIGN

ART DIRECTOR SIMON COBON simon.cobon@cpitrademedia.com

DESIGNER PERCIVAL MANALAYSAY percival.manalaysay@cpitrademedia.com

MARKETING

EVENTS EXECUTIVE MINARA SALAKHI minara.s@cpitrademedia.com

+971 4 433 2856

EVENTS EXECUTIVE PRIYANKA RAINA priyanka.raina@cpitrademedia.com

CIRCULATION & PRODUCTION

DATA & PRODUCTION MANAGER

PHINSON MATHEW GEORGE phinson.george@cpitrademedia.com

+971 4 375 5476

WEB DEVELOPMENT

ABDUL BAEIS

UMAIR KHAN

FOUNDER

DOMINIC DE SOUSA (1959-2015)

PUBLISHED BY

Now you can increase significant savings through a dedicated tool developed and managed by TotalEnergies.

Presenting,

LubAnac is a Fleet Management System, to reduce your vehicle maintenance costs through oil analysis that:

Reduces downtime of your fleet

Optimizes the maintenance Increases the lifetime of your vehicles

Reduces total cost of ownership (TCO)

Emerge to deliver solar energy facility for Dubai Maritime City

Alstom lands Jeddah Airport APM upgrade contract

Arada awards $168mn in contracts for construction of 565 homes

CONSTRUCTION

Peel Ports Group calls for bids for works across portfolio

INFRASTRUCTURE

Implementation phase of railway project between Oman and UAE begins

The project will have a major impact on passenger and cargo movement between the two countries

FINANCIAL

Dubai’s Department of Finance approves $10bn in PPP projects

The CPF programme for managing the PPP ecosystem performance within the Government of Dubai revolves around five strategic objectives

CONSULTANT

WSP Middle East launches Real Estate Advisory services in the region

New entity backed by $4bn funding from Abu Dhabi titan and local investment consortium

CONSTRUCTION

Dubai South and Aldar break ground on new logistics facility

The facility is expected to be completed by the end of 2024

CONSTRUCTION

RFPs announced for Bahrain residential project

Category ‘A’ consultants invited to bid for Phase 3 of kingdom’s flagship housing development

Terex Rough Terrain Cranes has appointed TSM Global (TSM) as authorised distributor for Türkiye (Turkey). With immediate effect, TSM will offer the complete range of Terex Rough Terrain Cranes, while also providing sales, service, and parts to customers throughout the country. Established in 2014, TSM is a major distributor of heavy equipment. Boasting a robust sales and after-sales service network with regional offices in Ankara, Izmir, Adana, Antalya, Trabzon, Diyarbakır and Bursa along with its Istanbul headquarters, TSM’s mission is to become the most efficient, most preferred, high quality construction machinery company that adds value and brings the best solutions in Türkiye. This collaboration not only broadens Terex Rough Terrains presence in the market but also capitalises on TSM’s strong connections to other Terex brands, including Fuchs (material handling equipment) and Finlay (mobile crushing and screening equipment).

“We are delighted to welcome TSM to our distribution network,” said Stefania D’Apoli, Senior Sales Support Manager at Terex Rough Terrain Cranes. “It underscores our ongoing commitment to reinforcing our position as a key player in the lifting industry in Türkiye. TSM have earned a reputation for their commitment to excellence and laserfocused approach. Their dedication to delivering service and support aligns perfectly with our values, ensuring our customers receive expert assistance and access to proven dependable solutions.”

“We are excited about the opportunity to represent Terex Rough Terrain Cranes a global leader in the industry, and to bring their world-class products to our customers in Türkiye,” said Burak ERTUĞRUL, General Manager of TSM.

“Terex’s commitment to innovation and quality aligns perfectly with our values, and we are confident that working with Terex will deliver exceptional value to our customers.”

CRANES TAMIMI RENTALS: ‘NOTHING COMES CLOSE TO GROVE’

BUSINESS

BOOMING IN INDIA, SAYS MYCRANE MYCRANE, the world’s first global platform for online crane rental, has seen a surge in new client registrations and project enquiries in the booming Indian market.

MYCRANE has recently processed customer orders for crawler, rough terrain and telescopic cranes with a capacity of up to 300 tonnes for leading engineering, procurement and construction companies Larsen & Toubro (L&T), Tata Projects and KEC International. The cranes are currently being deployed on a pan-India basis, with MYCRANEenabled lifting projects currently underway in Maharashtra, Gujarat and Rajasthan, among other locations.

Grove rough-terrain cranes have long been the go-to for oil and gas contractors on energy projects worldwide. That’s because when it comes to strength and control nothing comes close, according to Saudi Arabia’s Fahad S Al-Tamimi (known as Tamimi Rentals).

“Grove rough-terrain cranes have very good load charts – typically around 25% better than competitive machines. We appreciate the precise and customizable movements that the Crane Control System (CCS) offers. Having exact control is important when lifting complex and expensive equipment around oil rigs,” says Mohammed Fahad S Al-Tamimi, CEO of Fahad S Al Tamimi & Partners.

Formed in 1978, Tamimi Rentals has used its Grove cranes to support companies such as Saudi Aramco, SEC, and SABIC. The company is headquartered in Dammam, in the Eastern Province of Saudi Arabia.

Tamimi Rentals has supplied Grove RT cranes since 1978 to support the world’s largest oil and gas company, Aramco. The two companies have a long history of co-operation based on mutual success. At the end of 2022, Tamimi Rentals received the final deliveries of its most recent order – a giant 50-crane deal for Grove GRT8100 and GRT8120 machines – all destined for major Aramco projects.

Alongside their strength and control, Grove GRT cranes offer manoeuvrability for navigating challenging and unpaved roads, thanks to their compact dimensions and four steering modes. This is hugely beneficial on busy jobsites and in industry where high standards are essential, and risks must be always minimised.

HD Hyundai Infracore has announced the global launch of the ‘DEVELON Uptime Center’ (DUC). The formation of the DUC is based on piloting of the company’s Machine Monitoring Center (MMC) that started in 2021 and officially opened as the DUC at the end of January 2024 with an expanded scope of work to include customeroriented remote services as well as monitoring.

The main central location for the DUC has been established

on the 13th Floor of the HD Hyundai Global R&D Center (GRC) in Seoul in South Korea. The DUC has been launched to enhance customer productivity by comprehensively utilising digital-based service technologies and by quickly resolving remote support requests from customers and dealers/distributors. The main services provided by DUC include Error Code Analysis, VR (Virtual Reality) Simulator, AR (Augmented Reality) Guidance, CAN BLACK BOX* and more.

These are facilitated with remote service functions through various digital technologies.

Jaeyoung Moon, SEVP and also head of the Construction Equipment Division and the company’s team of 28 personnel in charge of digital content development and operation attended the ‘DEVELON Uptime Center Workshop’. The workshop was held to assess the level of competitiveness of DEVELON’s digital services compared to competitors, and shared information on the technologies and roadmaps under development in various departments within the company, including the Electrical and Electronic Development Department and the HD Hyundai XiteSolution Technology Institute. Moon added: “Using this workshop as a platform, we plan to internalize various digital technologies being developed in many fields so that they can be provided as customer-oriented services.

Dubai Municipality deployed approximately 752 vehicles and machinery, including 311 heavy vehicles, 158 light vehicles, 176 rental vehicles, 77 heavy equipment attached to hygiene boats, and 30 light equipment to manage hygiene and community services related to sustainable waste management during Eid Al-Fitr holiday in the Emirate. Integrated Teams Dubai Municipality stated that it has assigned 2,300 cleaners to oversee hygiene services across the Emirate, who worked in four shifts. Additionally, 650 hygiene engineers from the private sector to whom hygiene-related tasks in tourist, industrial, and desert areas were outsourced. The teams included approximately 250 supervisory staff to monitor hygiene tasks and complete the closure of emergency field communications.

The much-anticipated Construction Machinery Middle East Awards 2024 is set to take place in Dubai at the earlier date of the 13th June, 2024; shining a spotlight on the pioneering achievements and innovations within the construction machinery industry. This prestigious event will recognse and honour the exceptional contributions of companies and individuals who are pushing the boundaries of technology, sustainability, and operational excellence. Brought forward to the 13th June, at the Habtoor Grand Resort in JBR, Dubai, the Construction Machinery Middle East Awards 2024 is dedicated to showcasing the latest advancements and best practices that are shaping the future of construction machinery and equipment.

JLG Industries has unveiled the ClearSky Smart Fleet platform in Europe. This groundbreaking platform is set to redefine fleet management and machine interactivity, marking a significant leap from traditional one-way telematics to a comprehensive two-way Internet of Things (IoT) solution, claims JLG.

The ClearSky Smart Fleet, designed as a dynamic and scalable IoT platform, offers unprecedented functionalities, deeper insights, and novel approaches to achieve more efficient operations. As a standard feature on most of JLG’s new equipment, it facilitates direct communication between the machine and its user, elevating the traditional telematics experience to new heights.

The platform introduces a suite of innovative features aimed at revolutionizing customer workflows. These include digitalisation of daily operations for improved efficiency, precise

and effective machine localization, expanded service capabilities for additional equipment, optimized logistics through Automated Site Networks, and accessible, actionable insights on machines and fleets.

Accessible via a user-friendly mobile app or a customisable web portal linked to JLG’s 24/7 e-commerce site, Online Express, ClearSky Smart Fleet ensures seamless integration for users. The platform also supports mixed fleets by offering an advanced API data feed, allowing for the incorporation of its data into existing telematics systems.

James W. Hahessy, Product Manager – Connected Solutions at JLG EMEA, expressed the company’s vision behind the

platform: “JLG built ClearSky Smart Fleet to help customers do their jobs faster, more effectively and efficiently than ever before, so that they can reach new heights of productivity and profitability,”

“It’s a robust solution, purposebuilt by JLG from the ground up and using feedback from customers to meet their needs. With more than 25 features, it will make their fleet management tasks easier and more efficient.”

JLG promises to evolve the ClearSky Smart Fleet platform further. This ongoing development aims to provide additional value to customers and maintain an industry-leading, user-friendly experience.

“We’ll adapt as our technology evolves,” added Hahessy.

Anew Bobcat E88 8.9 tonne mini-excavator has been proving its specially modified frame can work alongside the big boys in Sweden with a number of features including remote control, for work on building ventilation shafts for the Förbifart Stockholm (Stockholm Bypass) road tunnel project in Stockholm.

Carried out by main contractor, AF Gruppen, the Stockholm Bypass project is one of Sweden’s largest infrastructure projects, to create a series of underground motorway tunnels between the Kungens Kurva interchange in the south of Stockholm and the Häggvik interchange north of Stockholm. Most of this bypass, more than 17 out of 21 kilometres, is being built underground. The bypass will become the world’s third longest road tunnel in the proximity of a city. Nordkust Maskin AB managed this project in close collaboration with Bobcat Sverige and Bobcat and as a result was able to deliver the heavily modified E88 excavator on time for the customer, Bergteamet AB, a specialist shaft and tunnel contractor, based in Boliden in Sweden. Nordkust Maskin is working on another E88 adapted for the mining industry that will also be used for a drilling application.

that the ability to remote control the excavator was needed to increase the safety of both the work and the environment. The excavator also needed to be modified to protect it for working in the very harsh environment of the underground vertical shafts.

Bergteamet has been using the Bobcat E88 to sink ventilation shafts for the Stockholm Bypass project. One of the first was at Lovön at Drottningholm outside Stockholm. The process used to construct the shafts begins with making a circular hole at ground level using blasting and hauling the material away. The next step is to lift it into place in the hole created at the shaft’s top where the articulated boom allows the machine to fit in the shaft. It can be remote controlled to manoeuvre it into a better position if needed.

The proven Bobcat D24 Stage V engine offers a maximum power output of 48.5kW 48.5KW

As part of the modifications needed on the E88, it was decided

The new R2-Series E88 is designed as a balanced machine in performance, compactness and stability. The rear overhang is only 327 mm (without an addon counterweight), allowing this 8.9 tonne machine to be used in confined space areas. The dynamic and robust design reduces the risk of downtime, with the heavyduty steel side channels and the counterweight acting as a bumper to protect essential components, as well as all the hoses, pipes, valves, lights and other sensitive components that are important for excavator functions.

•

•

January marked a significant milestone for two major construction players in the market when Al Shirawi Machinery and Hyundai Construction Equipment proudly announced their new strategic partnership. The culmination of five years of work, this collaboration wants to redefine industry standards in the United Arab Emirates and spearhead innovations in construction machinery and aftersales.

With the official launch now out of the way, the two companies sat down with CMME to discuss how the the partnership between Al Shirawi Machinery division, and HD Hyundai Construction Equipment, the leading South Korean construction machinery company, represents a fusion of mutual respect, shared goals, and a commitment to technological and ecological

advancements. The new partnership leverages Al Shirawi Machinery’s position as a leading construction equipment supplier in the market, and as the dedicated dealer it can ensure its customers have access to premium HD Hyundai Construction Equipment’s parts and services.

CMME is told the offer to customers is simple: Whether you’re looking to buy an excavator or seek the finest construction machines, Al Shirawi Machinery is your trusted partner with a commitment that extends beyond sales to include comprehensive after-sales support, “making it the go-to destination for construction equipment in the UAE”. When he talks of Hyundai Construction Equipment, Thani Al Shirawi, CEO of Al Shirawi Machinery, vice chairman, and deputy managing director, Oasis Investment Company & Al Shirawi Group, talks of maximising the potential of the brand in the UAE.

“For five years, we talked about our Project Tiger, well, now we are unleashing the tiger,” he shares with CMME. “We both said we know the opportunities in the market, so now we must grasp it together, but we also know the challenges ahead.”

Eli Park, Managing Director, Middle East & Africa, HD Hyundai Construction Equipment, explains that the alliance will be built on a foundation of enhancing construction efficiencies and pushing forward with sustainable solutions. Hyundai Construction Equipment brings to the table its cutting-edge technology and robust machinery, perfectly complementing Al Shirawi’s deep market penetration and extensive local expertise. When they speak, both Thani Al Shirawi and Park emphasise that, together, the companies are aiming to revolutionise the construction landscape in the UAE.

“This partnership, this collaboration marks a significant milestone for both of us. This is the

end of a long and arduous journey and Al Shirawi has patiently waited for the opportunity to work with HD Hyundai Construction Equipment,” says Park. “Now we can make a remarkable return to the UAE hand-in-hand with our partner.”

Hyundai Construction Equipment, a division of the globally recognised Hyundai Heavy Industries, is a significant player in the construction machinery industry, particularly in the Middle East. Hyundai Construction Equipment itself has established a strong foothold in the Middle East through a combination of direct sales and partnerships with local distributors. The company’s portfolio in the region includes a wide range of machinery suited to the diverse needs of Middle Eastern projects, from construction in the UAE to infrastructure developments in Saudi Arabia and road building in Oman.

Under the terms of the partnership Al Shirawi Machinery is serving as the official distributor for Hyundai Construction Equipment in the UAE. This arrangement allows Hyundai to leverage Al Shirawi’s extensive distribution network and deep market penetration to boost sales and increase the visibility of its construction equipment in the UAE.

Park says the combination of the Korean company’s robust and technologically advanced construction machinery in tandem with Al Shirawi’s determined approach to support and aftersales can meet the growing demands of this dynamic market.

“We can redefine the landscape for construction equipment in the UAE. Our collaboration is not just about machinery, it’s about building relationships and ensuing the successful operations of our customers,” he says.

The critical component of their partnership will be the provision of after-sales support. Al Shirawi’s expertise in service excellence ensures that Hyundai’s equipment users receive timely maintenance and repair services, which is crucial for the longevity and performance of heavy machinery. This support not only enhances customer satisfaction but also reinforces the reliability reputation of Hyundai’s products, say the two companies. The next step for the two companies is to make good on their promise of putting customers at the top of the priority list.

“We understand the importance of reliability and have both committed to providing top-notch service

and products. And we take on the partnership with enthusiasm for the challenges ahead,” says Park.

Thani Al Shirawi echoes Park when he says that by combining Hyundai’s advanced construction technologies with Al Shirawi’s logistical and onground expertise, the partnership can deliver superior construction solutions tailored to the challenging environments of the UAE. With this partnership, Hyundai aims to further solidify its presence while leveraging Al Shirawi’s established networks for deeper market penetration and increased brand visibility. “It’s a shared responsibility. Everybody here is ready to move on and promote the brand,” he says.

Five years in the making both companies agree that a pivotal aspect of the partnership is the emphasis on training and capacity building. By equipping local teams with the necessary skills to operate the advanced machinery from Hyundai, the initiative ensures that the workforce is prepared for tomorrow’s challenges. While this can be a

demanding process, Al Shirawi Machinery’s Deputy Director of Machinery Equipment, Fredrick Victor says the strategic alignment will remain rooted in “a shared commitment to excellence and customer enjoyment which is our vision for the future.”

He adds: “This collaboration represents a blend of pioneering spirit and rich heritage, and is set to transform the construction industry in the UAE through cutting-edge technology. By leveraging our respective strengths, we anticipate creating a synergy that will not only enhance our market presence but also redefine industry benchmarks in the UAE’s construction Industry with this business partnership representing a global leader in construction equipment.”

The Al Shirawi Group is celebrating its Golden Jubilee this year. Fredrick Victor tells CMME that it will now lean into its legacy of five-decades of building a strong foundation in the UAE market to place the Hyundai brand where it belongs in the construction equipment sector.

“It is our firm belief that this partnership will not only contribute to the growth and success of our organisations but also serve as a testament to the power of collaboration in navigating the challenges and opportunities that lie ahead,” he says.

“We wanted to ensure that we give a clear and strong message in the UAE market that HD Hyundai Construction Equipment is back in the UAE strongly after their absence of the last few years,” he remarks. “With the proven aftersales reputation of Al-Shirawi Group in this market, we are proud to say that we are making this comeback legacy as an unstoppable force with unrivalled reach - Hyundai returns with Al Shirawi!!”

“This partnership, this collaboration, marks a significant milestone for both of us”

“The business goal of LiuGong has changed, our products are no longer just simply construction machinery”

wants to provide a complete settle set of products and services to meet customers’ demands; and satisfy them with global-leading technology and services,

With 65 years of expertise in heavy machinery and a growing presence in over 170 countries, LiuGong is now setting its sights on becoming a leader in the Access Work Platform (AWP) industry — an area marked by its high demands for safety, efficiency, and innovation.

LiuGong, a company traditionally known for its robust construction machinery, is now making significant strides in the sector, emphasises Alan Hou, Marketing Director –Overseas Business, LiuGong AWP.

“Even though we are a new player of AWP business, we are open, innovative, and ambitious,” says Hou.

LiuGong’s entry into the AWP market comes as part of the company’s broader strategy to diversify its product offerings beyond traditional construction equipment. This includes the development of mining machinery, agricultural machinery, and notably, aerial work platforms. This shift represents LiuGong’s response to evolving market demands and its ambition to offer a comprehensive range of products and services that meet the nuanced needs of modern customers.

“The business goal of LiuGong has changed, our products are no longer

just simply construction machinery,” he says. “Therefore, we have shifted from construction machinery to equipment for the future. LiuGong will provide a complete set of products and services to meet customers demands, satisfying them with global-leading technology and services. The upgrade on this mission has expanded our business.”

This vision to become a global leader in equipment and technology solutions is an ambitious goal underpinned by a commitment to technological innovation, operational efficiency, and a strong customer-first philosophy. LiuGong has built a comprehensive global industry value chain to support its diversification, including R&D, manufacturing, marketing, and aftersales support, ensuring a robust support system for its products worldwide.

According to Hou, the AWP sector, in particular, stands to benefit from LiuGong’s emphasis on smart and green technology. The company is pioneering the development and application of electric AWPs, which are more environmentally friendly, efficient, and suitable for urban and enclosed spaces. These innovations are not only a response to increasing environmental awareness but also aim to meet the rising market demand for more sustainable and cost-effective solutions.

“LiuGong was the earliest enterprise in the industry to develop and apply electric products with years of experience and development,” he explains. “We now have

matured electric technology and products,” he says, adding that electric products have many advantages, such as being more environmentally friendly, more efficient, more energy saving, more reliable and more convenient.

Ultimately, LiuGong has fully embraced the potential of electrifying its AWP range and Hou believes that the company will be a particularly strong player as demand for greener equipment increases.

“Firstly, electrical equipment is more environmentally friendly. It is more suitable for cities and rentals as well as enclosed spaces such as terminals and shipyards, for instance. Secondly, their more efficient hydraulic and transmission systems in tandem with independent controls are increasing work efficiency by at least 20%.

“They are cost effective compared to internal combustion products and the cost of ownership is reduced by approximately 60%. And the purchase price for LiuGong electrical AWP is lower than the diesel ones,” he explains.

The machines are much more reliable than their more traditionally powered alternatives, he stresses.

“The mechanical part is greatly simplified making maintenance easier and more reliable. It is more convenient too by integrating motor battery and electric control technology which are used to achieve digital and intelligent collaborative development. The application cases in China will be similar all over the world and also in the Middle East and UAE. “

While it boasts a strong green lineup, LiuGong is determined to enhance its competitive edge by focusing on

customer-centric approaches, including actively integrating feedback from users to refine its products, such as the LT16jE boom lift, which boasts significant competitive advantages in terms of total cost of ownership and operational efficiency.

“The electric boom lift has, in terms of safety, electrical sensors and the balance valve of the variable amplitude oil cylinder, a dual redundancy design providing double protection. The arm system adapts a z-shaped connecting rod with the centre of gravity allowing the design of an overall layout which is stable and lightweight.”

A hydraulic system adapts low sensitive flooring-matching technology to achieve composite action of the boom with high efficiency, he adds.

“Optimised control algorithms achieve higher power output and greater energy efficiency. Better TCO is a reflection of the LiuGong’s products’ competitiveness and is also the design requirements of the products. Taking the LT16JE as an example, we are significant significantly competitive with both the electric and diesel products at the same level in the market.”

Safety features, such as upgraded anti-

“We are committed to using smart and green equipment and technology to help human society to become a better world”

291,000

Global AWP sales reached 291,000 units, a year on year increase of more than 12%

collision devices and low battery voice prompts, are now standard in LiuGong’s newest scissor lifts, reflecting the company’s aim of meeting the highest safety standards in the industry.

“LiuGong scissors lifts focus on safety. For scissors, high attitude compression can cause serious injury and even death. The new generations of the LiuGong scissors are equipped with upgraded anticollision height limit devices as a standard configuration. Besides this, the battery life has always been a problem for rental companies. If users do not charge properly, deep discharge will reduce the battery life. To solve this problem, our entire series of scissors has added a standard low battery voice prompt function, at the same time the iLink application will send a reminder when the machines need to be charged.”

The innovation driving the development at the company all ties, once again, with a recognition that putting the customer first must be the most important core value at the heart of the business, explains Hou.

“‘Customer first’ emphasises meeting customer’s needs as top priority and addressing them as the most important and urgent matter. Starting from the management teams we are driving from top to bottom to make the most of all our resources. Only by putting customers first, can there be opportunities to survive. And when we design the products, we keep innovating while meeting customers’ demands in order to achieve a better TCO for AWPs.”

2023 marked the 65th anniversary of

LiuGong and the 20th year since it founded its AWP subsidiary. It has enjoyed rapid growth ever since.

As LiuGong continues to expand its footprint in the AWP market, its approach of leveraging advanced technology, customer insights, and a robust global network must position it as a formidable player in the sector. By prioritising innovation and customer satisfaction, LiuGong aims to not only meet but exceed the expectations of its clients, thereby shaping the future of the AWP industry and establishing itself as a leader in the global market, says Hou.

He explains that from January to September 2023, the global AWP sales reached 291,000 units, a year on year increase of more than 12%. The global market has experienced a strong rebound after the pandemic in 2022, he adds, and steadily grew by 12% last year. By the end of 2023, the global inventory reached 2.4 million units including 30,000 units in Africa and the Middle East.

“It is inevitable that in 2024 that Chinese enterprises exporting will further increase. The number of boomlifts exported from China will continue to maintain high speed growth. The proportion of electric boom lifts will keep rising too. It is also predicted that the global AWP sales will be over 400,000 units, and the Middle East ,arket will further expand.”

He continues: “2023 was our 65th anniversary but it was also the 20th anniversary of the subsidiary which produces AWP. For two decades, we have rapidly grown by establishing of subsidiaries and after sales facilities all over the world. And now LiuGong is continuing by building part centres and localised offices in its global network to provide better and better support to customers.”

With over 16,000 employees, of which 10% of them are overseas, LiuGong now has over 30 overseas subsidiaries and offices in 12 regions, three overseas manufacturing bases and five global R&D centers and more than 300 dealers in over 130 countries.

“LiuGong will be there: when wherever and whenever the customer need us.”

All the Nice Features of Previous Model Bodily Succeeded, Even Nicer Things to Come.

Heavy Duty 4.7 m3 Loading Bucket 4.265 m Bucket Pivot Pin

Quick Coupler Read

Piping Auto Boom Kickout & Return to Dig

Telematic Service

Access FOC For Life

Tier IlI Scania Engine with 345 HP 1,664 Nm @ 1,800 rpm

Load Sensing Hydraulic System Providing Power on Demand

Ultra Web Filter (Oil Washed Pre- Cleaner Rear View Cam Automatic Reverse Fan

Base

MOBILE CRANE SPECIFICATIONS LIEBHERR LTM 1150

Mobile Crane Size: 150 ton

Outrigger Span: 8.050m x 7.600m

Counterweight: 45 ton

Boom Configuration: 47.2m Main Boom

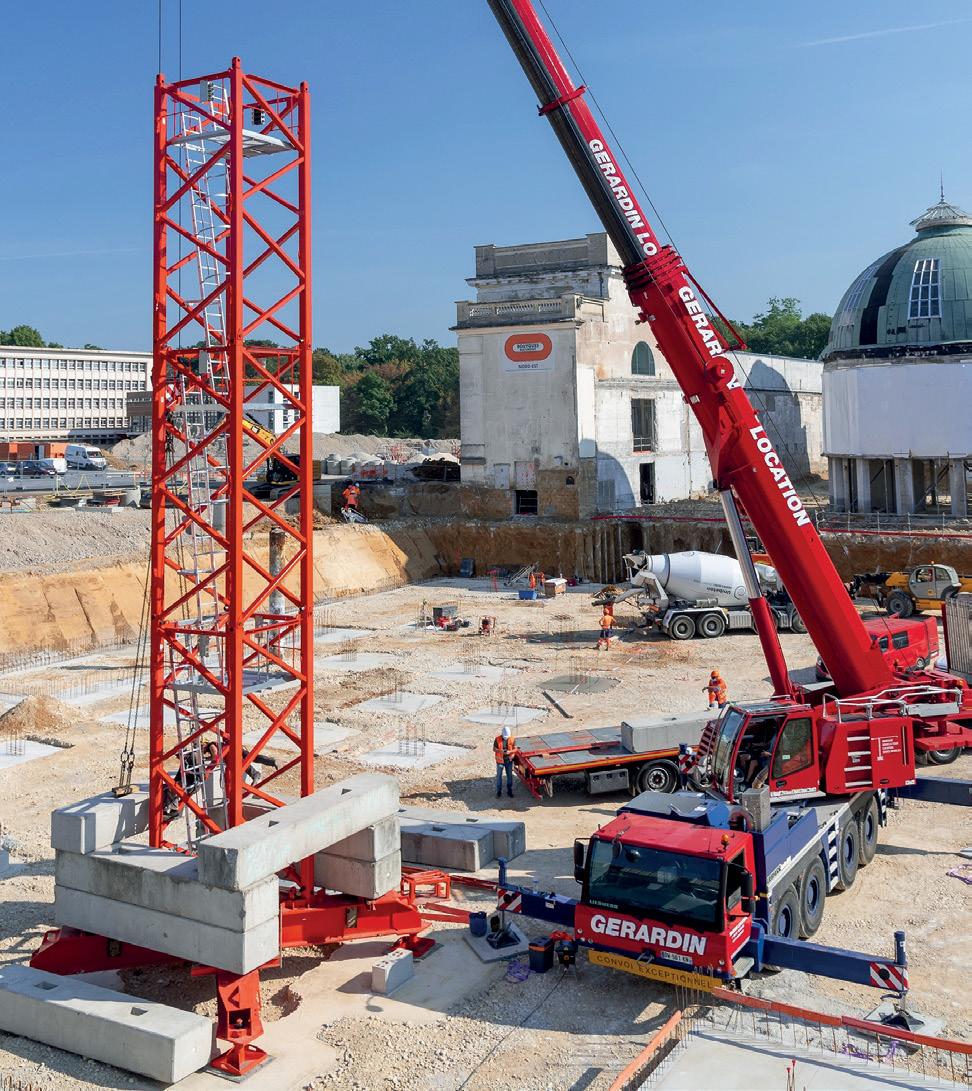

A pivotal aspect of the project is the installation of the

tower crane, known for its robust design and lifting capability.

Orion Contracting Co. (OCC), based in the dynamic Ras Al Khaimah Economic Zone (RAKEZ), has embarked on an ambitious project to construct a G+3 Labour Accommodation in the Al Hamra Industrial Area. This project, initiated in March 2024, is expected to demonstrate progress and efficiency by bringing together cutting-edge technology and strategic planning. Established in 2008 by a team of seasoned engineers, OCC has carved a niche for itself in the industry by leveraging innovative technologies and methodologies. The company’s ethos revolves around pushing the boundaries of conventional construction practices, offering unique concepts, designs, and execution strategies to not only meet but exceed client expectations. Its portfolio, rich with industrial and commercial construction projects, demonstrates a firm commitment to excellence and innovation.

a substantial jib length of 75 meters and a 16 ton capacity, are strategically designed to encompass the entire project area efficiently, ensuring timely completion within the stringent six-month timeline.

A pivotal aspect of the project is the erection of a Wolff 7532.16, a tower crane known for its robust design and lifting capability. The entire process, from the erection sequence to operational deployment, adhered to the stringent guidelines set forth in the manufacturer’s manual, ensuring both efficiency and safety. The foundation for the crane was meticulously prepared in collaboration with reputed third-party consultants, highlighting the unwavering commitment to safety and durability.

13.55T

The project involved the lifting of precast insulated walls weighing between 3.825 to 13.55 tons

The G+3 Labour Accommodation project involves the lifting and installation of precast insulated walls weighing between 3.825 to 13.55 tons, a task demanding precision, expertise, and the right equipment. OCC’s choice of Wolffkran Arabia for this critical operation underscores the importance of experience and innovation in handling such intricate tasks.

Wolffkran Arabia has always distinguished itself from the competition with its tailored solutions and expert guidance, proving instrumental in selecting the ideal tower crane for the project. While alternatives suggested the deployment of five to six cranes, Wolffkran Arabia optimised with a proposal to utilise just three tower cranes. These cranes, boasting

The project’s execution phase was marked by meticulous planning and adaptation. The foundation layout, tailored based on extensive soil reports, facilitated the optimal placement of the Wolff 7532.16 tower cranes. Fellow German firm Liebherr’s LTM 1150, a 150t mobile was deployed to enable the erection, and despite the considerable challenge posed by the 120 ton ballast weight required to stabilise the cranes, the team’s expertise and strategic planning ensured seamless installation and operation.

The choice of WOLFFKRAN 7532.16 models for this project was driven by their unmatched capacity and reach, capable of handling the maximum precast wall panel load with exceptional efficiency. Originating from Germany, these cranes symbolise the pinnacle of engineering excellence, combining robust performance with precision handling. As the project progresses, it serves as a vivid illustration of OCC’s and Wolffkran Arabia’s professional approaches to construction. By harnessing the power of cuttingedge crane technology and strategic planning, they are not just building structures but laying the foundation for future advancements in the construction industry of RAK and beyond.

The challenges of contributing to decarbonisation and meeting societal expectations are driving a profound transformation of the global mining industry. The industry has to become more sustainable but must also address energy security concerns and ensure that commodities are affordable.

The long-term trend of reducing the preponderance of coal was interrupted in 2022. In fact, coal demand reached a historic peak of 8bn tons driven by both its availability and its relatively low price compared to gas. Most countries, including the EU, US and Japan, saw demand for coal return to the downward trend but China, India and Indonesia continued to drive demand for coal through 2023.

We expect the transformation of the industry to continue apace. The global demand for coal is projected to decrease slightly to 6bn tons in 2030 before falling to just 1bn tons in 2050. Coal will be replaced by energy transition minerals as the main driver of revenue between 2030 and 2040.

Amid the geopolitical unrest in the Middle East and the continued aggression in Ukraine by Russia, gold has once again emerged as a beacon for investors seeking stability. Central banks globally have ramped up their gold reserves, using the precious metal as a shield against inflation and the uncertainties bred by ongoing conflicts. In

2023, the allure of gold strengthened, with its price soaring by 6.26 percent.

However, the spotlight doesn’t shine on gold alone. Critical minerals like copper have seen a spike in demand for entirely different reasons. As the world pivots towards a greener future, these minerals have become indispensable to the global green energy transition. A McKinsey report projects a surge in annual copper demand to 36.6 million tonnes, driven by global electrification efforts. Copper’s versatility is evident in its wide range of applications –from powering 100,000 mobile phones and 400 computers to facilitating the operation of about 40 cars and distributing electricity to approximately 30 homes. Furthermore, solar power systems rely on 5.5 tonnes of copper for every megawatt of capacity they deliver.

Despite the essential role of nickel in electric vehicles (EVs) – a boon for the nascent Saudi automotive industry, for instance - its market price has suffered, leading to the closure of several mining operations in Australia in recent weeks. This contrast in the fortunes of copper and nickel highlights the complex dynamics at play in the commodities market.

Shifting the focus to the Middle East, a region that accounts for 32.8 percent of the world’s oil and 29.1 percent of global gas supplies, the narrative is slowly changing. Traditionally known for its vast oil reserves, the Middle East is gradually diversifying its economy. Saudi Arabia, in particular, has made significant strides in

“The Kingdom covers nearly 2 million sq. km and is one of the world’s top 15 countries by area, with a relatively little developed mining industry. The potential is huge”

reducing oil production as part of its “Vision 2030,” emphasizing renewable energy investments. This shift has contributed to a 30 percent rise in global oil prices due to the altered supply and demand dynamics.

The Kingdom’s effort to bolster its renewable energy generation capacity by 21 percent in 2021, along with the recent announcement that it has doubled its estimated mineral wealth to US$2.5 trillion, signifies a broader economic transformation. This reorientation away from oil underscores the region’s rich tapestry of natural resources, including phosphates, potash, limestone, marble, kaolin, and salt, along with significant reserves of fertilizers.

Moreover, the Middle East’s mineral wealth is not limited to traditional resources. For instance, Iran’s GolGohar Iron Ore Mine and Saudi Arabia’s Ma’aden showcase the region’s mining capabilities, highlighting significant reserves of precious and industrial metals.

As Middle Eastern nations pivot towards renewables and other commodities, the global mining landscape is witnessing the entry of global companies into the region, drawn by its untapped mineral potential. This transition presents a unique opportunity for investors to diversify their portfolios and tap into the Middle East’s burgeoning mining sector.

In conversation with The Market Online, Farah Mourad, a Senior Research Analyst at financial service Equiti, elaborated on the Middle East’s investment potential. Mourad pointed out the diverse economic

landscape within the region, from energydependent nations to those focusing on tourism and financial services. The surge in non-oil trade, spurred by initiatives like Saudi Arabia’s Vision 2030, has significantly attracted foreign investment, indicating a fertile ground for businesses.

Moreover, Australia’s Metal Bank’s foray into the Middle East through exploratory rights in Jordan showcases the promising mining prospects in the region. The company’s successful identification of

copper mineralization underlines the rich mineral resources available for exploration and development.

As the Middle East continues to evolve, embracing renewable energy and diversifying its economy, the region represents a burgeoning market for investors. With robust GDP growth forecasts and a strategic location, the Middle East offers a compelling mix of risk and opportunity for those looking to broaden their investment horizons.

“The Kingdom has begun to explore the potential of its mineral wealth, currently estimated at $1.3 to $1.5 trillion in value,” Ali Alireza, managing director of Haji Husein Alireza & Co. told Arab News. “This is an important key towards reducing the country’s high dependence on oil and fossil fuels.

“The Kingdom covers nearly 2 million sq. km and is one of the world’s top 15 countries by area, with a relatively little developed mining industry. The potential is huge.”

To kickstart this process, Alireza explains, Saudi Arabia passed a law in June 2020 to attract foreign investors into the Kingdom’s mining business. The law, which came into effect in January 2021, aids the country in exploring mineral resources worth around $1.3 trillion, according to Invest Saudi.

This is all part of a campaign to attract nearly $200 billion in investments in mining by 2030.

According to the Ministry of Industry and Mineral Resources, the Kingdom possesses more than 20 different types of minerals, including gold, copper, iron, granite and marble.

In March last year, the ministry announced indicative timelines for the bidding cycles of five new mineral exploration opportunities that were showcased at the Future Minerals Forum 2023 in January in Riyadh. This action underlines a strategic shift in the Kingdom’s policy towards the discovery and extraction of minerals and metals that will aid the country’s transition towards green energy.

“New industries in a world trying to transition into a clean energy environment create new needs and opportunities in the mining sector,” adds Alireza. “In this regard, Saudi mines are rich in such minerals as required, for instance, in battery transition in cars as well as other vital minerals for powering electricity generating turbines etc. Saudi Arabia’s interest in the mining industry is not limited to within its shores, but complements it with international alliances such as that with Brasil’s Vale SA

and also the recent agreement with Japan to develop rare earth mining in Saudi Arabia and in other markets.”

The development of the Kingdom’s mining industry is contingent on foreign deals and investment. The Vale deal marks Saudi Arabia’s first major foray into mining, and comes via Manara Minerals, a new venture between the Kingdom’s Public Investment Fund and the Saudi Arabian Mining Company, known as Ma’aden. Khashoggi, who participated in the

As the Middle East continues to evolve, embracing renewable energy and diversifying its economy, the region represents a burgeoning market for investors.

second Future Minerals Forum in Riyadh in January and was subsequently appointed to the National Mining Council of Saudi Arabia, pointed out the Kingdom is investing in mining companies that are using very advanced technologies. “Technology is becoming an important tool for the mining industry because you can use it for mapping, for operating machinery remotely without having people self-operate machinery. Such technologies can also be used efficiently in Saudi Arabia,” he said.

The Forum this year featured some of the biggest names in mining, including the CEO of the world’s largest mining company, BHP’s Mike Henry. Also present was Dominic Barton, chairman of the Anglo-Australian multinational company Rio Tinto – the world’s second-largest metals and mining corporation. The attendance of such figures showed the Kingdom’s growing place in the world’s mining industry. However, as Khashoggi stressed: “The mining industry in Saudi Arabia is still in its infancy.”

“The Kingdom has begun to explore the potential of its mineral wealth, currently estimated at $1.3 to $1.5 trillion in value”

INSTALLATION

Situated some 90km south of Kuwait City in the Al-Khiran area along the Arabian Gulf, the visionary Sabah Al Ahmad Sea City (SAASC) is a sprawling metropolis of man-made islands and waterways that will eventually house over 250,000 residents.

Considered one of the largest real estate developments in the world, over 3,000 contractors from 20 countries are working 24/7 and to date have delivered five phases of the planned tenphase project.

With construction gaining pace, developer La’ Ala Al-Kuwait Real Estate Company, the firm behind the pioneering project, has partnered with CDE, a leading supplier of sand and aggregate washing solutions, to help meet its busy production schedule.

In its current phase, some 1.35 million cubic metres of in-spec beach sand is required by the middle of 2024 to meet production targets.

“Plant optimisation and up-time is key to deliver upon targets of this magnitude,” CDE’s Area Sales Manager, Mr James Murphy said.

“The material specifications for the desired beach sand are quite stringent. Pair this with feed material that varies greatly, and you can see the need for

an adaptable solution in order to keep up with production demands.”

A pre-existing wash plant set-up that was reaching the end of its operational life was employed on site for over a decade. A configuration of bucket wheel classifiers and tracked screens, the system was unable to adapt to variations in the raw feed material and was operating beyond its efficiency range, resulting in the loss of high-value sand to tailings ponds.

Mr Mark Dunglison, Director for Planning & Design, Earthworks & Marine at the La’ Ala Al-Kuwait Real Estate Company, said the system had served the project well but a more modern solution was needed to sustain the momentum behind the project.

“It played an important role in getting the project to where it is today, but our production demands required a more adaptable solution.

“We’re working with dry feed material excavated from below sea-level, which can be highly variable, and so we needed a solution that could respond to these variations and deliver consistent output without disruption to the production schedule.

“Traditionally, most wash plants work with fresh water or some sort of brackish water. At this site we’re dealing with salt water, which has salinity of up to 35,000ppm (parts per million). It’s very corrosive. The plant had to be able to work with high saline levels.”

In response, CDE proposed a solution comprising its M5500 modular wash plant, which integrates feeding, screening, washing and stockpiling on a single chassis; the EvoWash 151, a compact sand washing system that screens and separates smaller sand and gravel fractions through integrated high-frequency dewatering screen, sump and hydrocyclones; a configuration of six Infinity™ fine screens; and an efficient water management and recycling system to recover up to 90% of process water for immediate reuse.

“Our solution is built around improving fine screening capabilities and optimising product blending to maintain high material throughout and improve product yield,” explained CDE’s Regional Manager for the Middle East & Africa, Mr Ruchin Garg.

“The varying feed can be managed remarkably well by blending more or less of the fine product into the target beach sand. The ability to fine tune ensures optimum plant utilisation and maximum up-time. The net result being a higher overall yield.”

With the capacity to process up to 435 tonnes per hour, the CDE wash plant is delivering over 2,500 tonnes of fine sand for pipe bedding and almost 1,800 tonnes of coarse beach sand every day as part of ambitious targets to deliver 1.3 million cubic metres of inspec beach sand by the summer.

The wash plant processes 6,000 tonnes daily, boosts yield and expeditestargetsproduction 6,000

To address high levels of salinity, CDE introduced a series of additional measures to protect the plant.

“CDE added additional protective measures to the pipework, to the tanks, wherever they could. Stainless steel non-corrosive products, rubber linings, special coatings, and more are all carefully considered to ensure this plant can work in a very extreme saline environment,” Mr Dunglison said.

“We explored a variety of solutions with different suppliers, but CDE’s approach won out,” Mr Dunglison explained. “The team demonstrated real technical expertise and understanding of our needs when they proposed an alternative approach to what others were recommending.”

On average, the plant is receiving and processing over 6,000 tonnes of feed material every day.

Commenting on the environmental benefits of the plant, Mr Dunglison said, “We’re more efficient in our diesel use. The flocculant that we’re using within the thickener allows water to be recycled, which we didn’t have previously. It means we require significantly less top-up water. This is good because it limits how much we need to draw from the natural environment and any we discharge back into the water course is well within EPA tolerance.”

“This solution is our purpose in action,” Mr Ruchin Garg added.

“We’re driven to create our best world, a ton at a time. That means maximising the potential of natural resources in the most sustainable way possible, with greater efficiency and less waste than ever before.”

A central feature of the solution is the integration of CDE’s plant management app, CDE SmartTech. Mr Dunglison said the innovation underlying the app is in keeping with the vision of the Sabah Al Ahmad Sea City.

“The ability to monitor the operation and health of the plant in real time with in-depth data is highly valued and demonstrates real commitment to innovation. It’s providing us with important metrics to be able to measure production against forecasts, and we’re very pleased to say that the plant is helping us exceed our targets.”

CDE SmartTech enables customers to understand their plant’s performance, schedule maintenance and easily order parts. It enables operators, managers, and owners to make informed decisions to increase productivity, improve operational efficiency and maximise up-time.

INVESTING IN AN ARTICULATED HAULER IS A SIGNIFICANT DECISION AND ONE NOT TO

Articulated haulers play a crucial role in various applications from commercial construction projects to quarries, mines and infrastructure developments. The best ADTs offer efficient transportation of heavy loads across challenging terrain and easy manoeuvrability on tight, tricky sites. Before investing in an articulated dump truck, it’s essential to consider several factors to ensure that the machine aligns with your specific needs and operational requirements. With its trucks designed and built

for the toughest jobs and roughest sites, Scottish articulated hauler manufacturer Rokbak outlines five key considerations that should be integral to your purchasing decision.

1. Capacity and load handling

One of the primary factors to consider is the truck’s hauling capacity. You need to assess typical load capacity and weight to ensure that the equipment chosen can handle the demands of the specific application. Rokbak offers two hauler models, the RA40 is the largest with a gross power of 331 kW (444hp), a maximum torque of 2,225 Nm and a 38-ton payload. It is a popular choice for major infrastructure projects, with its effective power

to weight ratio enabling the fast movement of heavy-duty materials. Like the RA40, the 28-ton RA30, with a gross power of 276 kW (370hp) and a maximum torque of 1880 Nm, also benefits from a transmission retardation system, a fully adaptable drivetrain and easy maintenance to suit a variety of different job sites.

Consideration of the type and size of material being handled allows the truck’s load-carrying body to be specified correctly to ensure optimum payload, load retention and longevity. Body options such as side extensions for lighter materials, tailgates for free-flowing material retention and additional liner plates for highly abrasive or large blasted rocks are all popular choices. Matching

Articulated haulers can move large amounts of material over challenging terrain in tough conditions

the hauler to existing complementary equipment ensures onsite efficiencies and safety.

Articulated haulers are designed to navigate challenging terrain, but the extent of their capabilities can vary. Both the RA30 and RA40 provide excellent performance in all hauling conditions, from muddy terrain to slippery slopes and the scorching heat to sub-zero temperatures. It’s important to evaluate the application and climate the truck will be used in, as well as consider the materials that will be transported and the topography of the site, including slope gradients, ground conditions and potential obstacles. Rokbak trucks offer top-level off-road performance. Choosing a hauler that can handle the specific conditions of the site is crucial for optimal efficiency and safety.

Operating costs, including fuel consumption and maintenance, are significant considerations for any heavy equipment investment. Efficiency in the use of power is as important as having a highperformance truck. Rokbak articulated haulers, for example, are built to perform while also setting new standards for total cost of ownership and a commitment to sustainability as part of the Volvo Group’s journey to net-zero. A lean-burning, highperforming engine and responsive transmission shift control are good for low fuel consumption and environmental impact – as well as increased uptime and extended service intervals. An adaptable, perfectly balanced drivetrain provides performance and productivity in all hauling conditions, while meeting worldwide emission standards with low cost of operation.

High-level, user-friendly retardation systems, as found in Rokbak trucks, facilitate control of the machine and allow the operator to manage the safety and speed of the hauler – increasing efficiency and reducing wear-and-tear with shorter cycle times on the haul route. Machine owners should also look for strong after-sales support and assess the availability of spare parts and maintenance services. A well-supported machine will lead to increased uptime and lower operating costs throughout the equipment’s lifecycle.

The well-being of operators is paramount in any heavy equipment operation. Features such as ergonomic design, operator visibility and the quality of the cabin environment provide a comfortable and safe workspace that not only enhances productivity, but also contributes to employee satisfaction and retention. A planetary gear transmission – as found in the RA40 to deliver smooth, efficient gear shifting – also increases operator comfort. Haulers equipped with safety features such as stability systems with traction control, body tip inhibits and advanced braking mechanisms help to ensure a secure working environment.

Modern articulated haulers often come equipped with advanced technology and telematics solutions. These features can provide valuable insights into machine performance, fuel efficiency and maintenance needs – helping machine owners to manage their operating costs. The RA30 and RA40 are linked to the Rokbak Haul Track telematics system, providing customers with complete visibility and control of the hauler, enabling you to monitor and manage fleets effectively.

“Consideration of the type and size of material being handled allows the truck’s load-carrying body to be specified correctly to ensure optimum payload, load retention and longevity”

In the picturesque setting of Cornwall, home to ancient legends and enchanting landscapes, the mining industry is deeply rooted in the history and identity of this English county. Littlejohns Pit is an iconic and living symbol of a centuries-old industrial legacy, where China clay and sand have been longtime hallmarks in shaping the local landscape.

Amid this scenery, Brookland Sand & Aggregates Ltd of Saint Austell shines as a virtuous example of cooperation and sustainability. Since March 2010, the company has sold over 2.3 million tons of sand and aggregates to both local and national customers, showing a significant reach beyond Cornwall’s borders. With one-third of its business run outside the county and a substantial sales volume in the London market as well, Brookland Sand & Aggregates Ltd has established itself as a leader in its field.

The company processes “Stent”, a by-product

of kaolin mining, into environmental-friendly secondary sand, and aggregates. This commitment is the reflection of a deep sense of ecological consciousness aimed at preserving natural resources and reducing the environmental impact - principles that find a strong ally in BKT, a leading Off-Highway tyre manufacturer. BKT provides Brookland Sand & Aggregates Ltd with tyres that are vital for ensuring not only safe, but also continuous operations, thus avoiding downtime and maximizing production efficiency.

Brookland Sand & Aggregates Ltd‘s approach toward innovation and reliability in its day-to-day operations greatly benefits from its employees’ professional experience and personal stories. One such key figure is Alfie Johns, whose ties to the area and the mining industry go far beyond his current role. “I grew up in this area being born in a village not far from here. Ever since we went to school, working in this area has been among the top employment opportunities,” Alfie says. “It runs in the family: my

grandfather, my father, they have all worked in the clay industry, which is now also part of our business.”

This deep sense of belonging and dedication is apparent in the care and attention Alfie puts into his job, especially when it comes to choosing the right equipment to ensure safe and efficient operations. The decision to rely on BKT tyres not only reflects a business choice, but also the pursuit of a family legacy tied to the land and its processing.

Alfie adds another aspect that speaks for the effectiveness of BKT tyres in Brookland Sand & Aggregates Ltd’s daily operations: “We have relied on BKT for about 6 or 7 years, and now we are testing a three-star tyre on our dump trucks to increase their durability. Their impressive performance over the years has only confirmed my confidence in the brand. We particularly appreciate their wear resistance and versatility under changeable weather conditions - qualities that are essential to our operations. Trust, reliability and cost-effectiveness are the pillars when it comes to choosing our tyres.”

The weather impact on daily operations is a central theme for Brookland Sand & Aggregates Ltd, which considers weather conditions as one of its main challenges. “On rainy days our sandy roads turn into slippery, heavy paths, while the sun dries them out, leaving behind thick layers of dust,” Alfie explains, emphasising how the company must constantly adapt to these variables. “Despite such challenges, our commitment to sustainability and environmental compliance remains steadfast. We always ensure that our operations are both efficient and environmentally responsible.”

This environmental awareness in combination with the need to operate effectively at all weather conditions, makes the choice of BKT tyres a key component in Brookland’s operational strategy. “My previous positive experience with BKT has reinforced the decision to adopt them here at Brookland as well. Their reliability in a variety of different conditions from heavy rain to drought enables us to proceed with our operations without any interruptions, while keeping our commitment to efficiency and sustainability.”

“Trust, reliability and cost effectiveness are the pillars when it comes to choosing our tyres”

First-hand testimony from those working in the field is of key importance for understanding the actual value of the company’s choices. Jake Cleave, owner Marshall Claeve’s son and a young dump truck driver at Brookland, is one of the company’s newest workforces, who brings in all the enthusiasm and dedication that reflects his family’s generational commitment to the industry. “I have been working here for about three years, and I can say that using BKT tyres has significantly improved our operational efficiency,” Jake says. “Their grip and stability even at the most adverse weather conditions make it possible for us to maintain operational continuity without downtime.”

Jake goes on and highlights how sustainability is at the core of Brookland’s business: “The reusability of by-products in our production cycle is not only an economic benefit but also contributes to reducing the environmental impact of our operations. And in BKT, we have found a partner who shares our vision of a more sustainable future.”

Brookland Sand & Aggregates Ltd has chosen BKT tyres from the EARTHMAX range to meet the needs

of their daily operations. Prominent among the patterns employed are EARTHMAX SR45, EARTHMAX SR50, and EARTHMAX SR49. EARTHMAX SR 45 M is an All Steel radial tyre specifically designed for rigid dump trucks, which provides excellent traction and is ideal for long-distance operations.

The EARTHMAX SR 50 (L-5) meanwhile is an All Steel radial tyre specifically designed for loaders. The durable casing and sidewall protectors are ideal for the most demanding operations. EARTHMAX SR 50 is made of a special cut-resistant compound that reduces wear ensuring a longer tyre life. Operators also appreciate its excellent traction combined with stability, and comfortable ride.

On the other hand, EARTHMAX SR 49 (L-4) is an All Steel radial tyre designed for loaders and dozers, low profile dump trucks (LPDTs) and LHD loaders. EARTHMAX SR 49 ensures excellent performance in demanding mining operations where excellent traction and stability are an essential requirement. The tyre has a directional design and is made of a particularly cut-resistant compound that provides excellent durability.

MANITOWOC SAYS IT HAS COMPLETED ITS LATEST GENERATION OF POTAIN LUFFING JIB CRANES WITH THE LAUNCH OF THE MR 309 AND MR 329.

Manitowoc has launched two new Potain luffing jib cranes: the MR 309 and MR 329. The jib can be mounted horizontally, section by section, while the reduced windvane spans make installation on tight jobsites easier. Accessible platforms and steps promote secure and efficient worker movement, and the counterjib ballast is installed at working height. The positioning of the ballast is made easier thanks to slinging rings and a self-centering system. A redesigned luffing mechanism further streamlines assembly, while an integrated jib-end basket further promotes more secure installation, inspection, and maintenance. Finally, the Potain CCS decreases commissioning time, helping the cranes to get to work faster.

The MR 309 and MR 329 have been introduced with maximum capacity variants of 16t or 25t. Despite sharing a common 60m jib and a 3.4t capacity at the tip, their distinct pivot and mast configurations result in differing heights under pivot and load curves.

The MR 309, with its 2m pivot and mast configuration, achieves a height under pivot of 49.2 m, reaching a maximum capacity of 4.3t at 5 m. In contrast, the MR 329, featuring a 2.45m pivot and mast configuration, attains a height under pivot of 55.2m, with a maximum capacity of 4.7t at 55m. In addition, the new cranes address the need for a strongly reduced out-of-service radius (9.5 m to 12 m) and decreased anchorage frame requirements.

WHY GET IT?

NEW LINE-UP IS YANMAR CE’S MOST AMBITIOUS AND CUTTING-EDGE RANGE OF COMPACT MACHINERY IN DECADES.

Yanmar Construction Equipment (Yanmar CE) says it is ushering in a new era of construction technology this spring at Intermat 2024. Hosted at the Parc des Expositions de Villepinte in Paris, Yanmar CE is set to reveal its most groundbreaking range of compact machinery in recent decades, promising to transform the landscape of construction equipment with innovative all-electric models. Yanmar CE is leading the sustainable transformation in construction machinery with the debut of its all-electric lineup, comprising the SV17e mini excavator, V8e wheel loader, and C08e tracked carrier. These models are designed to provide zero emissions without compromising on power or performance, showcasing Yanmar’s commitment to a carbon-neutral future.

The SV17e mini excavator features a 23.5 kWh electric power capacity and an aircooled 48V system designed to enhance

the operator experience with its superior digging, lifting, and carrying capabilities.

The V8e wheel loader, suitable for allterrain applications, boasts an 800-litre bucket capacity and comes with optional fast charging, enhancing its efficiency on tight job sites. Completing the trio, the compact C08e carrier is perfect for navigating narrow spaces, equipped with a robust 11.5 kWh battery. Yanmar CE is also introducing the SV86-7 and SV1007 midi excavators, which represent the next generation in their class. Designed for tight spaces and featuring minimal rear overhangs, these excavators provide exceptional performance in the 8-10 tonne segment, maintaining a compact footprint. Intermat 2024 also features the ‘90s Skills Challenge,’ a unique event hosted by Yanmar to engage and connect with operators through the You Operator Club. Participants will have the opportunity to demonstrate their dexterity with mini excavators in a thrilling race against time and competitors. Aligned with the Yanmar Green Challenge, Yanmar CE aims to achieve zero greenhouse gas emissions by 2050.

SPECIFICATIONS

SV17E MINI EXCAVATOR

Motor: Air-cooled 48V

Power: 23kWh

Weight: 1.8tI

Tear-out force: 12.5kN

Digging depth: 1.67m

THE WORLD’S LARGEST TRACK LOADER CAN DO IT ALL – CLEAR, LOAD, DIG, CARRY, FILL AND MORE – EVEN IN TOUGH OR SLICK GROUND CONDITIONS.

The new Cat 973 Track Loader combines unmatched versatility with up to 10 percent better fuel efficiency, more productivity, cab improvements and optional Payload technology. The 205 kW crawler loader has an operating weight of 29,892 kg and replaces the 973K worldwide. It joins the 953 (119 kW) and 963 (151 kW) in the Cat track loader line.

The 973 is the largest track loader in the industry, but still offers agility and ease of operation. The updated cab features a suspension seat and adjustable armrests/ controls. An intuitive 10-inch (254 mm) touchscreen dash display is easy to use and features a standard High Definition rearview camera. Slope Indicate helps make operation easier by showing machine mainfall and cross slope right on the display. Select joystick or V-lever and pedal steering for transmission controls and either

joystick or 2-lever implement controls. The joystick option provides familiar controls for operators experienced with skid steers/ compact track loaders. With either control scheme, operators can set implement response – fine, normal, coarse – to match operator preference or application. Repetitive lift, lower, rack, dump and float functions can be preset to make jobs like truck loading easier. Smoother implement and steering response, and improved steering performance provide more controllability.

The 973 is powered by a Cat C9.3B engine. Fuel consumption is reduced up to 10 percent with the Auto Mode that will adapt the engine speed to the load. Eco Mode will use even lower speed for further reduction in fuel consumption in lighter duty applications. Power Mode will keep engine speed high for a feel of readily available power at all times.

An optional Performance Series bucket boosts productivity up to 20 percent. An optional Fusion Quick Coupler enables fast attachment changes. A variety of buckets, forks and other tools can be shared among track loaders, wheel loaders and other Fusion compatible machines. Buckets come from

the factory with Advansys™ bucket tips/ adapter/locking system. Advansys tips are built for maximum productivity and the lowest bucket lifecycle cost. Hammerless retention system means safe, fast removal and installation without special tools.

Purpose-built Low Ground Pressure (LGP), Waste Handling/Demolition and Ship Hold arrangements are factory equipped with specialized undercarriage, guarding and other features designed to take on the toughest tasks. The 973 Steel Mill package includes a specialised cab, insulated steel fuel tank, high temperature undercarriage and insulation throughout the machine, making it suitable for handling slag.

SPECIFICATIONS

CAT 973 TRACK LOADER

Weight: 30t

Power: 205 kW

Overall Machine Length: 7.5m

Machine Height: 3.5m

Bucket Capacity: 3.8m3

Building a tower crane is a sophisticated engineering feat that requires a team of skilled professionals, including engineers, crane operators, and construction workers. Adhering to safety standards and regulations throughout the process is paramount to ensure the safety of all workers and the surrounding area.

The first step involves detailed planning and design. Engineers must determine the crane’s required height, lifting capacity, and reach based on the construction project’s specifics. Considerations also include wind load, the weight of materials to be lifted, and the crane’s proximity to other structures.

BUILD ON A STRONG FOUNDATION

The site must be prepared to support the crane’s weight. This often involves constructing a large concrete foundation that can take several weeks to cure. The foundation must be precisely leveled and capable of supporting the crane’s load to prevent tipping.

Before construction can begin, it’s necessary to obtain all relevant permits from local authorities. This includes permits for construction, operation, and sometimes road closures for the assembly process.

TRANSPORT AND LOGISTICS IS VITAL

Tower crane components are manufactured off-site and transported to the construction site. This logistic operation requires careful planning, especially for large components that might need special transportation permits.

The operator’s cabin and the crane’s machinery, including the hoist, trolley, and slewing unit, are installed. The machinery must be carefully tested to ensure it operates correctly under load.

Once the tower is erected, the horizontal jib (the part of the crane that carries the load) and the counterjib (which holds the counterweights) are attached. Their balance is crucial for the crane’s stability.

09

Before the crane is put into operation, it undergoes rigorous inspection and testing. This includes static and dynamic load testing to ensure it can safely carry the maximum load.

START AT THE BASE

07 10 06 AHEAD FOR HEIGHTS

Finally, operators must be trained to use the crane safely. This training covers operating procedures, safety protocols, and emergency response procedures.

The crane is assembled on-site, starting with the base section attached to the foundation. Mobile cranes are often used to lift the tower sections, jib, and counterjib into place. The assembly process must follow the manufacturer’s guidelines precisely. 05 08

Euro Auctions’ Richard Sweatt says the powerhouse auctioneers’ new site has the potential to be the biggest operation in the Gulf selling used construction machinery.

The Euro Auctions Group, operators of auction sites for industrial plant and construction equipment in the Middle East, Europe, Australia, Canada and the USA, believe they have the appetite to make the Euro Auctions site in Abu Dhabi the biggest auction site in the region, and will open its doors to the new sales arena on 24 June.

Planning four to six live sales per year in the Khalifa Industrial Zone in Abu Dhabi, specialising in used and unused construction machinery and commercial vehicles, the Euro Auctions Group plans regular sales of high value construction machinery.

Having expanded its operation, moving from Dubai to Abu Dhabi, the Euro Auctions sale business sits on a site of over 43,000 square metres with facilities for handling all aspects associated with the sale of heavy construction machinery and commercial vehicles. With the appetite to be the biggest in the region, Richard Sweatt, Country Manager for the Middle East and Asia, comments.

“Euro auctions has experienced rapid growth in the last two years with expansion in North America with the acquisition of the Michener Allen group in Canada, the business now spans 4 continents, with auction sites in 8 countries, operating 12 sites and selling over 150,000 lots each year.”

“As a result, we see the Middle East as being pivotal in our global expansion and moving our operating base from Dubai to Abu Dhabi provides us with the opportunity and the appetite to further develop within this region.”

“Our business has been steadily growing in the Middle East and we see month-by-month sales increases with our outreach to buyers and consignors wishing to sell with Euro Auctions. We

have worked hard in the last couple of years to develop our brand and we are now seeing exciting consignments of good fresh, young machinery and equipment come to our site for sale to a global audience.”

“The Euro Auctions strength is in its network of sale sites and our teams of sales managers and country managers who are globally connected and we attract good consignors and vendors because of our ability to sell to a large global audience. With over 250,000 unique clients on our database and selling into over 100 countries globally, we are able to attract a very serious buying audience.”

“Currently all types of machinery is in demand, with the good, fresh, young machines attracting the eye of the buyer. Our last sale in February was our biggest to date, with the exciting news that at the next auction in June we will be raising the curtain on our new office accommodation and supportive infrastructure, which mirrors the standard of all other Euro Auction sale sites globally.”

“In the last six months we have seen a huge upturn in interest from buyers coming to us for