As the year comes to a close what stands out to me over the last twelve eventful months is the global drive towards incorporating new technology. Like any Bauma year, 2022 saw great excitement at the show in October where the themes of low emissions, electrification, digitisation, automation, and the jobsite of the future were prominent enough to believe that they are now more than simply buzzwords. Emphasising this point even further, this year’s Bauma had the largest display of electric machines on record.

In the Middle East, however, it should be noted that machine usage continues to be largely driven by price rather than having the latest high-tech features. Yet, the second most notable theme of the year, the ongoing development of Saudi Arabia and the proliferation in planned mega projects there, is evidence that greater discussion is, at least, now being had in the region around sustainability and what can be done to seriously tackle long-term low emissions targets.

A third dominant feature of the last twelve months has been the ever-increasing presence of Chinese manufacturers on the global stage. At Bauma, for example, the large number of Chinese companies in the access division was conspicuous. These days it is also becoming less uncommon to see these companies dotted around the Middle East in the guises of their various types of heavy machinery. Reflecting the shift that is taking place, both in attitudes and in an operational sense, as many Western manufacturers are now setting up production bases in such emerging markets, this month’s cover story features one of those Chinese manufacturers that has been doing its upmost to get a piece of the pie in this region. In fact, Liugong Machinery

has had an incredibly productive year on the international front recently hitting some seriously impressive milestones.

Amongst all of that, it’s been a year of firsts for us all here at CMME. In May, we launched the very first dedicated Construction Machinery awards for the Middle East region. With over 5000 votes it showed that there is well and truly an appetite to celebrate the machines at the heart of the region’s landmark projects. On the back of this, we brought to you our very first machinery-specific website in September, which I’m proud to say is the only portal in the region to focus exclusively on construction machinery. It was a year too, when we broke new ground, not just by having the very first person on the front cover of this publication, – the highly impressive CEO of Bobcat, Scott Park - but the first female too - which was none other than the world’s premier IPAF trained operator, Lamya Alaydaroos.

No doubt, as a certain health pandemic starts to become a somewhat distant memory in most parts of the world it can be argued that we should go into this coming year with even more positivity than the one we are leaving. For now, I would like to take this opportunity to wish you all a blessed and peaceful Christmas season and may the New Year bring you happiness, health and prosperity.

Mark Dowdall Editor, CMMEmark.dowdall@cpitrademedia.com

GROUP

MANAGING DIRECTOR

RAZ ISLAM raz.islam@cpitrademedia.com +971 4 375 5471

MANAGING PARTNER

VIJAYA CHERIAN vijaya.cherian@cpitrademedia.com +971 4 375 5713

DIRECTOR OF FINANCE & BUSINESS OPERATIONS

SHIYAS KAREEM shiyas.kareem@cpitrademedia.com +971 4 375 5474

PUBLISHING DIRECTOR

ANDY PITOIS andy.pitois@cpitrademedia.com +971 4 375 5473

EDITOR

MARK DOWDALL mark.dowdall@cpitrademedia.com +971 4 375 5496

SALES MANAGER BRIAN FERNANDES brian.fernandes@cpitrademedia.com +971 4 375 5479

ART DIRECTOR SIMON COBON simon.cobon@cpitrademedia.com

DESIGNER PERCIVAL MANALAYSAY percival.manalaysay@cpitrademedia.com

EVENTS EXECUTIVE MINARA SALAKHI minara.s@cpitrademedia.com +971 4 433 2856

SOCIAL MEDIA EXECUTIVE DARA RASHWAN dara.rashwan@cpitrademedia.com

CIRCULATION

MANAGER PHINSON MATHEW GEORGE phinson.george@cpitrademedia.com +971 4 375 5476

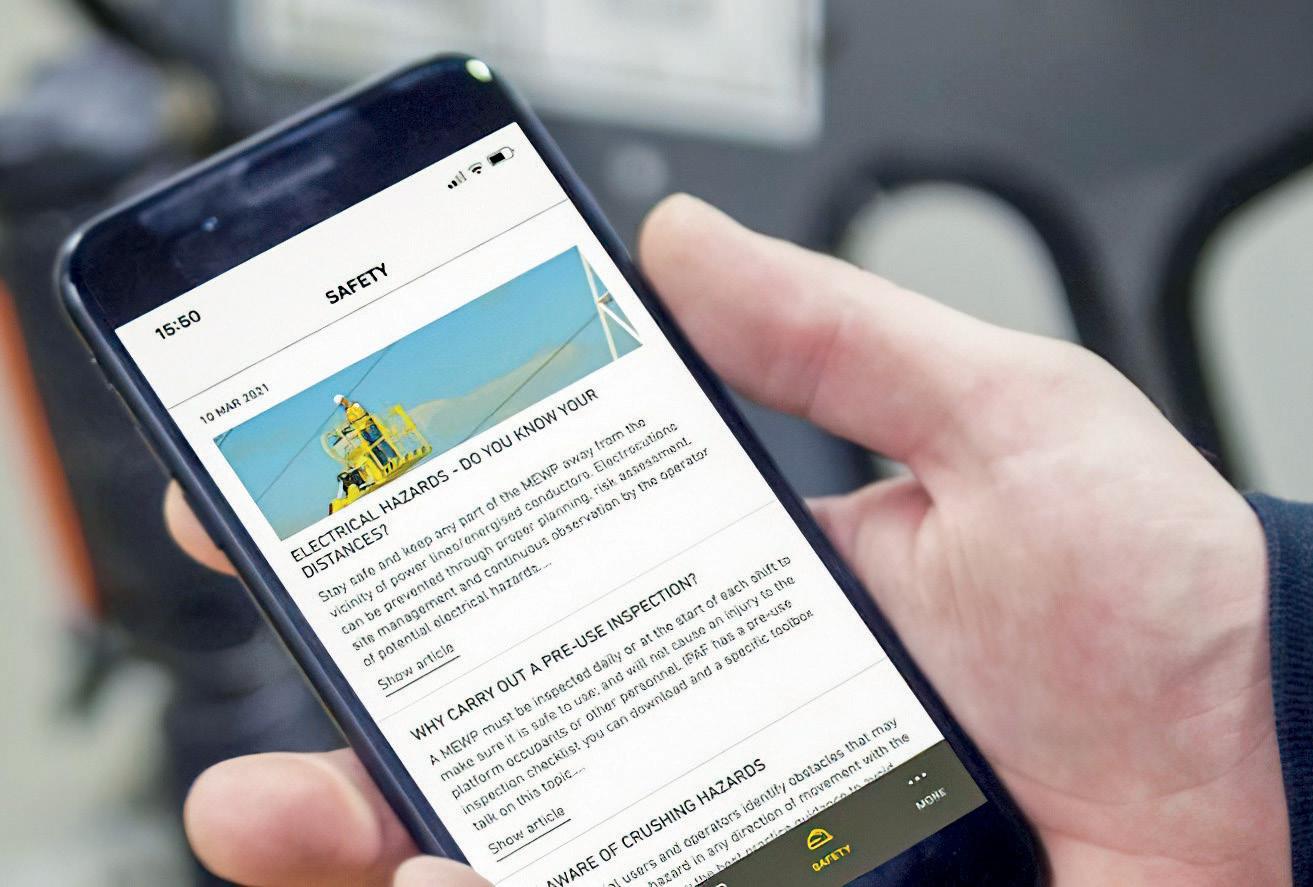

IPAF has announced that its ePAL mobile app for operators of mobile elevating work platforms (MEWPs) and mast-climbing work platforms (MCWPs) has now surpassed a quarter of a million first-time downloads.

The milestone follows the global roll-out of the ePal app earlier this year. The app which had initially been launched in June 2021, allows digital certification of training, including IPAF’s Powered Access Licence (PAL) Card.

Through the app IPAF can communicate safety messages to operators around the globe whilst users can store and share training certification, log machine time, and report incidents or near-misses to IPAF’s portal.

The app is available in all territories where IPAF certifies training, and according to the organisation is now in more than 160 countries worldwide.

Peter Douglas, IPAF’s CEO and Managing Director, said: “We developed ePAL in partnership with our member firm Trackunit in part to offer operators and supervisors a digital tool to share training certification and log equipment time, and also as part of our ongoing digitalisation project. We are streamlining processing of IPAF licences and have significantly reduced the carbon footprint involved in sending hundreds of thousands of plastic PAL Cards and paper certificates all around the globe each year.”

He added, “We have been rolling the app out since mid-2021, and while the emphasis was on newly certified training candidates in the first few months, take-up has snowballed and now it is encouraging to see that ePAL is being downloaded by ever increasing numbers of people around the world.

Eight units of SANY equipment, including truck mixers, batching plants, loaders and telehandlers have been delivered to Iraq to support the construction of the Nasiriyah International Airport, the manufacturer has announced.

The machines were delivered to China State Construction Engineering Corporation (CSCEC) to be used on the project, which involves the construction of a terminal building designed for a capacity of 750,000 passengers per year. Also inlcuded is an air traffic control building, a cargo building, a 25-km airport express way, some auxiliary facilities and the renovation of the runway.

Egyptian contractor Orascom Construction has acquired the country’s first two Potain MCR 295 luffing jib tower cranes.

The 16t cranes with 60m jib at the end were purchased from local Potain dealer IDP, who had erected the cranes to support the development of Cairo’s Maspero Triangle district.

“The Potain brand’s reputation for quality in urban development and innovative technology gave us the trust and confidence to expand our fleet with the new MCR 295 cranes. We are proud to have the first units in Egypt working on this prestigious project,” said Hossam Mounir, Equipment Deputy Director at Orascom Construction.

The 75-acre area by the River Nile is home to several highprofile buildings, including the Radio and Television Union Maspero building, the Foreign Ministry building, the Dar al-Maarif building, the Italian Consulate, and the Ramses Hilton Hotel.

Given the limited space, Orascom Construction said it needed cranes that were not only reliable, consistent, and high performing, but which could also work efficiently on a confined jobsite, helping to meet delivery deadlines.

IDP and Potain erected the cranes with an initial 37m height under hook and they will reach a final height under hook of 150m. The cranes will remain on site for approximately three years.

“We were impressed by the speed and professionalism with which the IDP field service team and Potain technicians erected the cranes on site, and they have since been proving their worth on this upscale project as world-class machines,” Mounir added.

States and Europe,” said CEO Cho Young-cheul at the ceremony.

Hyundai Doosan Infracore has celebrated the production of its 500,000th environmentally friendly small-sized G2 engine with a ceremonial event at its Incheon G2 factory, in South Korea.

The production and shipping of its 500,000th 1.8 to 3.4L grade small-sized G2 engine, comes as the plant completes ten years in business following its first production in October 2012 when the G2 engine plant was first built.

The ceremony was attended

by more than 70 employees including Hyundai Doosan Infracore CEO and President Cho Young-cheul, CEO and Vice President Oh Seunghyun, Engine Business Head Kim Joong-soo, and Labor Union Head Yoo Joon-mo.

“The G2 engine is a highefficiency, environmentally friendly engine produced with our very own technology and will be a key player that competes with global engine makers in markets such as the United

Speaking about the future vision for G2 engines he added, “We need to create a systematic production system in order to reach total production of one million engines in the next five years, which will require twice the current speed. Please also work on creating synergy between our three construction equipment companies as these engines will be applied to Hyundai Genuine’s forklifts and other vehicles along with Hyundai Doosan Infracore and Hyundai Construction Equipment’s excavators developed on a new integrated platform.”

Hyundai Doosan Infracore’s G2 engine satisfies EU Stage V and is used in various types of construction equipment.

The company says it plans to increase yearly capacity which is currently at 70,000 engines to 100,000 engines going forward by creating and expanding new productions externally.

Allison Transmission has become the exclusive provider of transmissions for Xuzhou Construction Machinery Group’s (XCMG) newest all-terrain cranes, which it expects will lead to additional growth for the company outside North America.

The manufacturer of vehicle propulsion solutions had been providing XCMG with the Allison 4970 Specialty Series (SP) transmission since its initial integration in the new XCA400L8 all-terrain cranes in July 2022.

“XCMG and Allison have had a successful partnership for more than 10 years. Beginning with 60-tonne cranes, to 100- and 130-tonnes, and now with our latest 300- to 500-tonne all-terrain cranes, Allison has always delivered reliable performance and high-quality products,” said Ma Qingjie, Deputy General Manager, XCMG Crane Sales.

BYRNE GROUP APPOINTS STEVE CAYGILL AS CHIEF

Equipment rental specialist, Byrne Group has announced the appointment of Steve Caygill to the role of Chief Commercial Officer, moving from his previous role within the company.

Wirtgen has launched a new automation technology designed to improve efficiency in the areas of soil stabilisation and cold recycling. By enabling precise, automatic steering, its new AutoTrac is said to increase process efficiency among Wirtgen wheeled recyclers resulting in high degrees of environmental compatibility. According to Wirtgen, AutoTrac steers the machine precisely based on established parameters within centimetres whilst it allows consistent utilisation of the machine’s ideal working width. AutoTrac relies, among other things, on various global navigation satellite systems (GNSS) for precise control.

Wet processing experts CDE, in partnership with Gulf Center United Industrial Equipment Co. and KAK-LAMOR JV/C, has announced plans to supply two contaminated soils wash plants to support the clean-up effort of an estimated 114km2 of polluted land in Kuwait.

As part of the deal CDE will design and engineer a turnkey wash plant for each of the North Kuwait Excavation, Transportation and Remediation (NKETR Zone 1) and South Kuwait Excavation, Transportation and Remediation (SKETR Zone 1) projects.

The two 100t/h and 140t/h solutions will process and remediate the coarse soil fraction

to eliminate contaminants and recover high-quality washed construction sand and aggregates suitable for reuse.

Following the destruction of some 700 oil wells in the early 1990s, approximately 26,000,000m3 of soil was contaminated with

crude oil, signalling the launch of one of the most extensive remediation programmes involving the cooperation and expertise of a consortium of international partners.

Working alongside industrial and engineering services firm

CNH Industrial has announced that effective December 31, 2022, it will cease all Construction Equipment sales activities in China.

Heavy-lifting specialist, Mammoet has completed the delivery and installation of the three “largest-capacity gas turbines” in the UAE, the company has announced.

The turbines were transported and installed as part of the Fujairah F3 Power Plant project, a 2.4GW plant, which will be the largest independent combined cycle power plant in the UAE.

Samsung C&T Corporation, the EPC contractor of the project had earlier awarded Mammoet with the receiving, transport, lifting and installation scope of the power plant components, Abu Dhabi Ports’ Fujairah

Terminals, operating at the Port of Fujairah under a concession agreement, was selected as the most suitable port for the receiving and handling of over-dimensional cargo, due to its location as it avoided the the mountains of Fujairah, the company said.

In total 105 power plant components needed to be transported 23km from the Port of Fujairah to the project site.

The route had an overhead bridge with a maximum clearance of 7.3m, while some of the components, such as the gas turbines, needed a clearance of 7.5m, including the trailers.

For 2021, sales of construction equipment in China totalled approximately $88 million. CNH

Industrial says it does not expect to incur significant resulting charges. The move is part of the company’s ongoing turnaround plan for its global construction business.

Gulf Center United Industrial Equipment Co., CDE’s longstanding partner in Kuwait, and KAKLAMOR JV/C, CDE wet processing technology will be utilised for the treatment of up to 800,000 tons of contaminated soil per year.

“The scale and ambition of this remediation programme cannot be understated,” said Ruchin Garg, CDE’s Regional Manager, Middle East & Africa.

He added, “It is a true test of our engineering excellence and a demonstration of how robust and effective CDE technology is at processing contaminated soils. This is a field in which CDE has an established track record of success.”

Dubai-based Alonsa Electric Group, has announced the launch of a comprehensive line of Goodyear engine oils throughout the Middle East, Africa, and Asia.

Featuring 72 kinds of lubricants including over 300 SKus (stock keeping units), the products were unveiled during the Automechanika 2022 Convention at Dubai World Trade Centre.

Regarding the new products, Sunil Khanchandani, Managing Director of Alonsa Electric Gulf FZCO said, “We are excited to bring our advanced lubricant solutions to Automechanika 2022. The

MENA region has always had a strong automotive enthusiast culture, and we look forward to sharing the latest oil and lubrication technology with vendors and consumers.”

Goodyear is said to have developed a proprietary formulation using 100% virgin synthetic-based oil technology combined with additive packages and blending practices.

The company says its latest products are exclusively tested in ISO 17025 laboratories while its lubricants are created in subcontracted blending factories in the United Arab Emirates, Europe, and Malaysia.

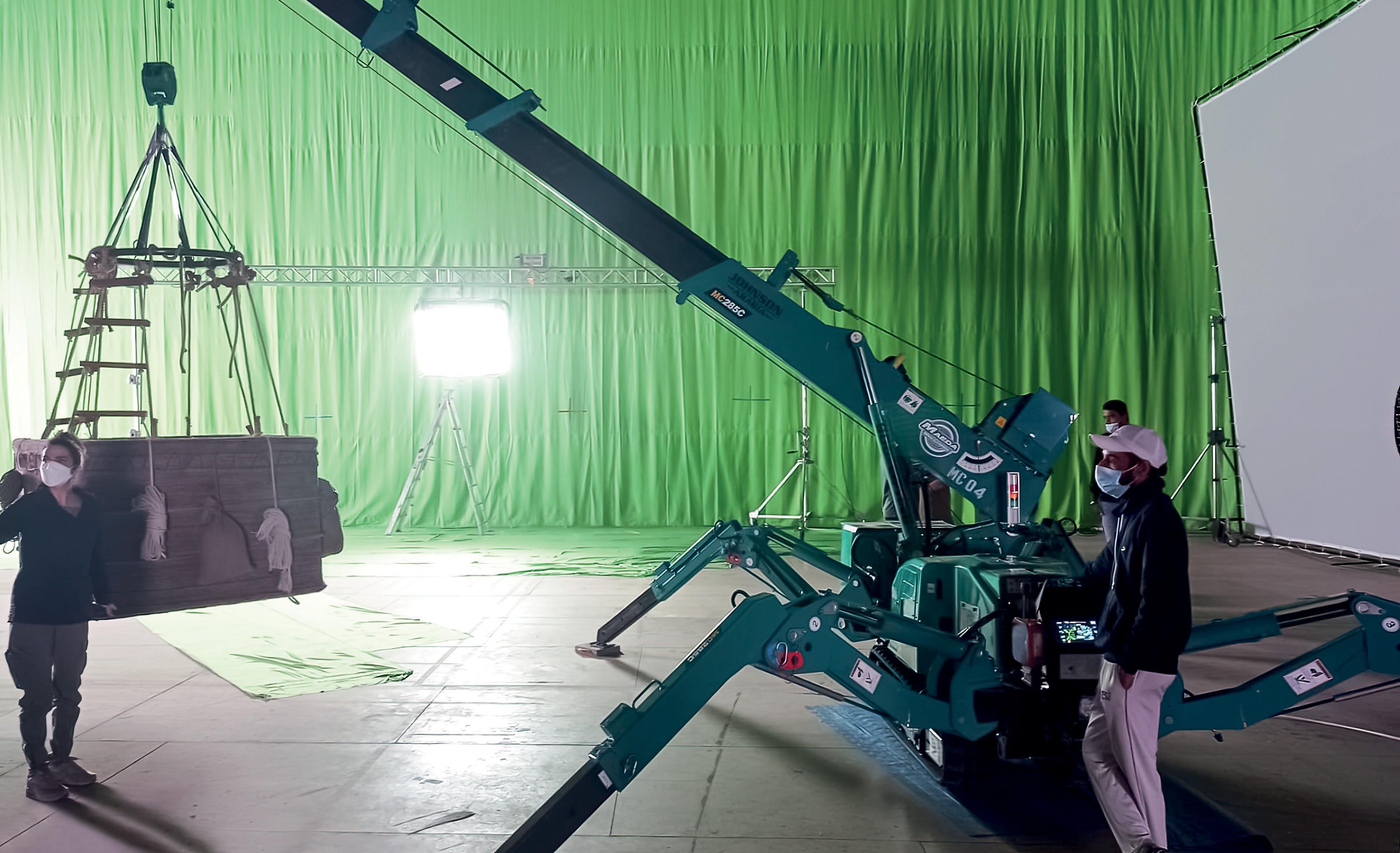

Restricted access cranes, like the Maeda Spider Cranes, rented out by Johnson Arabia in the GCC, is what the industry currently needs for many of the projects in the place of heavier machines that usually have a larger footprint. Spider cranes are compact, safe, and versatile in the way they can be used from rough terrains to tight stairways.

Speaking about some of the latest projects these cranes have been involved in, Johnson Arabia’s executive manager for UAE and Oman, Mohammed Fareed explains: “Our team will often recommend these spider cranes for projects in

power stations, hospitals, malls tight urban locations and even movies! The main reason being, they are compact enough to fit through standard door frames and have the ability to lift up to eight tonnes with its outriggers set up for load stability.”

He adds, “Glazing companies can use these spider cranes on sites from inside the structure and not need to schedule time for the use of a tower or mobile crane and this helps with project timelines as well.”

Johnson Arabia’s recent project is a perfect example of this where a 300 kg radiator needed to be lifted inside a power station and the MC 405 Maeda crane was used. The major challenge of this project was the weight of the

radiator and the fact that the roofing on the building was complete so no mobile crane would be able to access it. The only solution was to position a spider crane outside with its “arm” on the inside for this lift. Due to the compact size and the team’s perfect engineering, they were able to perform this lift successfully and with ease.

Another project that was done in recent months was an indoor art installation. Since the interior was fully finished and the art piece was schedule to be installed after, the best option to lift and place this

heavy piece was a spider crane. The crane was easily brought in through the doors, the lift was completed, and the team was able to leave with no impact to the existing interiors.

Finally, these spider cranes are perfect for movie sets or events where the spaces are confined by the studios but there is a need for these lifts as part of the story line of event requirement. So whether it’s a construction project or the next blockbuster, Spider cranes are the new way to lift.

The Maeda Spider Cranes have the ability to lift up to 8 tonnes

“Our team will often recommend these spider cranes for projects in power stations, hospitals, malls, tight urban locations and even movies!”A Maeda Spider Crane was deemed as the most suitable piece of equipment for a recent indoor art installation that was completed after the interior had already been finished.

“If a machine cannot work because it is waiting for parts, it becomes a drain on resources rather than helping the customer to earn money. This is something we absolutely want to avoid”

Volvo Construction Equipment (Volvo CE) aims to deliver the industry’s highest levels of customer uptime and profitability. Besides the reliable build of its machines, the added value of its services, and the competence of its dealers, parts availability plays a vital role.

“If a machine cannot work because it is waiting for parts, it becomes a drain on resources rather than helping the customer to earn money. This is something we absolutely want to avoid,” says Jesper Uhlin, Service Market Manager for the Middle East at Volvo CE.

In 2006 Volvo Group sought to reduce delivery times to dealers in the Middle East from the Central Distribution Centre

(CDC) in Ghent, Belgium, by establishing a Regional Distribution Centre (RDC) in the strategic location of the Jebel Ali Free Zone in Dubai, UAE.

The 8,000 m2 warehouse stocks around 50,000 spare parts for five Volvo entities in the region: Volvo CE, Volvo Trucks, Volvo Buses, Renault Trucks, and Mack Trucks. Volvo CE parts constitute just under a third of the inventory with approximately 12,000 part numbers.

The top 500 fast moving parts for Volvo CE are maintained at 93% availability, while overall availability hovers at 88%. Parts on backorders are recovered within 11 days of placing orders with the CDC in Ghent.

The site in Jebel Ali has excellent road network connections within UAE and to other Gulf countries so that almost 75% of shipments can be transported to dealers by truck, simplifying and shortening the logistics.

The RDC coordinates with Volvo CE dealers using the Syncron based MMI

tool, which helps both dealers and the warehouse to replenish the right quantities at the right time. This avoids dealers having to maintain excess inventory, improving the health of the stock.

Since its opening, Volvo Group has invested considerably in the RDC in Dubai, while its staff are constantly striving for continuous improvement. Whereas in 2013 the lead time for parts available in stock was 168 hours or five days from order to dispatch, today it is under eight hours.

Since 2017, the RDC has extended the cut-off time for stock orders from 1pm to 2pm for local dealers and from 7am to 9am for international dealers. Stock orders before these cut-off times are picked, packed, and dispatched on the same day by 4pm.

Vehicle off-road (VOR) orders, meanwhile, have a cut-off time of 3pm and are still dispatched on the same day. The RDC has dedicated staff to handle these kinds of orders. They are identified by the red colour of their uniforms and are given the highest priority in picking and utilisation of resources. These staff are also trained on end-to-end processes and are empowered to take decisions by themselves to ensure efficiency.

If the part is not available in the RDC, a direct ship process follows where the orders are transmitted to the CDC in Ghent and delivered directly to the dealer. This helps

reduce the lead time to process VOR orders and ensures uptime for customers.

The Japanese improvement methodology Kaizen has been a vital tool in the RDC’s success. “We put a lot of efforts into ‘going to Gemba’, which is spending time on the shop floor to see the real problems we face, talk to everybody involved, and truly understand what is going on,” says Humera Shaikh, Director of the RDC.

The next stage is value stream mapping. The team maps all the processes step-bystep to see what can be done to reduce time from order to dispatch, eliminating any hindrances or waste.

“For example, we have a very clean, traffic flow. We have one way traffic and stations set up so we don’t have lots of machines driving around and colliding. We also have a pull, rather than a push, system for ordering so that orders do not accumulate in one station,” Shaikh explains.

The team has also established a flawless process for import documentation, so that no trucks are waiting at border crossings due to incomplete paperwork.

Today, the RDC is considered a benchmark in quality and safety for the entire Volvo Group, and has received awards and accolades, including ‘Platinum level’ in the Volvo Production System (VPS) assessment and the Group Trucks Operations (GTO) Quality Award in 2018, and the Volvo Health, Safety & Wellbeing Award in 2020.

Quality is measured in parts per million (PPM), which indicates failures in a million order lines. Failures can occur due to picking inaccuracies, packing discrepancies, or damage of goods in transit.

In January 2014 the RDC’s quality performance level was at 3,500 PPM. Today, it is just 225 PM. This means only one error for every 4,500 order lines and the RDC is handling an average of 3,000-3,500 lines per week. Volvo CE parts constitute

approximately 1,000 lines per week.

Safety also plays a vital role in maintaining short lead times and high quality. So far the RDC has gone eight years with no lost time due to accidents – a remarkable achievement.

“Safety is a cornerstone of Volvo’s brand identity,” Shaikh says. “It is important to us to instil a mindset where everyone takes care of themselves and those around them.”

To encourage staff to identify and report unsafe conditions and behaviour, and take immediate action to rectify them, the RDC has gamified the process. Staff participate in a ‘safety race’ competition, where each team is awarded one point for problem detection and two points for problem-solving. The teams’ progress is then visualised on a symbolic racetrack.

“The safety race has been a great way to get everybody engaged with the topic of safety and involved in suggesting and implementing improvements for the benefit of all staff,” she adds.

The next step for Volvo CE is to share the lessons learned from the RDC with certain dealers and help them to implement the same continuous improvement methodology that has proved so successful for Shaikh and her colleagues.

“There is a limit to how much we can do to decrease lead times within our

operations, but we can improve our endto-end thinking with dealers, together as an extended enterprise,” she explains.

“We can do similar value stream mapping with them to have a clear picture of what happens after the parts reach them. How can they make the lead time shorter for the customer to purchase the part? How can they improve quality? Are there any constraints in terms of packaging? Is there anything we could do at the RDC to further improve the packaging and logistics setup

for them? We can also help them arrange parts in the way we have done based on machine movements and introduce initiatives to improve safety awareness.”

In some cases, Volvo CE can get parts to dealers quicker, cheaper, and with less environmental impact by bypassing the RDC and shipping them directly from the supplier.

“Where dealers only need a few small parts, the RDC offers a simple, convenient, and reliable service to replenish their inventory. However, for really heavy parts, such as undercarriage parts, or extremely high-volume parts, such as filters, it makes sense to skip two stages in the chain – the CDC in Ghent and RDC in Dubai – and ship parts directly to the dealer,” Uhlin explains.

“This is used quite a lot in the Middle East and, when used correctly, has a positive impact on logistics, pricing, lead time, resources, and carbon footprint. It’s all about balancing dealer stock levels and optimizing logistics flows,” he continues.

Whether parts go through the RDC or directly to dealers from the supplier, Volvo CE is pursuing different approaches according to customer needs and striving for continuous improvement to ensure high-quality parts are always available to them, so that their machines stay up and running and earning.

“It is important to us to instil a mindset where everyone takes care of themselves and those around them”

It is no secret that one of the major changes in the compact equipment sector in the Middle East over the last several years has been the significant growth in the compact track loader market with the machine’s powerful pushing, digging and lifting performance; exceptional traction; minimal ground disturbance and attachment versatility just a few reasons why these machines have become so popular.

Given its long history in the compact equipment space, US manufacturer Gehl, is better placed than most to observe the transition that is taking place, having over the years developed a range of equipment from skid-steers to compact track loaders, telehandlers to excavators, and backhoe loaders to articulated loaders. It is also no stranger to the Middle East, first entering the region through its Israeli dealer New Feldman almost 60 years ago, and later on through MEDCO in Saudi Arabia. All of this was before it was acquired by Manitou, which would later become Manitou Group, in 2008.

“It’s very interesting when you look globally,” says Benoît Renard, Managing Director of Manitou Middle East. “For example, in the biggest skid steer and compact loaders market, which is the US, you see the trends where traditionally skid steers were 65% to 70% of the market and compact track

loaders made up the rest. But for the past five years this trend has been changing and now you have more compact track loaders being sold in that part of the world.”

In the Middle East the usage rate for skid steers is even higher, he explains, despite compact track loaders offering even more stability and the ability to do so much more on sand.

“For people who are used to working with skid steers, it’s hard to change that mentality but if you look at the pure operation of the machine itself, it often makes much more sense to go for a track loader.

“We have the perfect range of products with those compact tracks and although they are only made in the US for the moment, not in Manitou Group’s other plant in India, I think what we see in the US, we can replicate in this region.”

The shift from East to West has become a trend of its own in recent years and when Manitou Group acquired a factory in India about five years ago, it did so, knowing that the move would allow the company to better supply the Middle East region in the most efficient way possible.

Once it acquired the former Terex Equipment Private Limited factory, close to Delhi in Greater Noida, it quickly began producing AC products for the region. First backhoe loaders, then skid steers and now telehandlers, all of which are both Gehl and Manitou branded.

“The target was Southeast Asia, Middle East, and South America,” says Renard. “In terms of pricing, it’s very competitive so this is less costly to produce but we keep the same level of robustness that you can find in our other factories. Next year, we will introduce new products made in India where we will again enhance the quality of backhoe loaders and telehandlers. Our US team was highly involved in the new products to come, replicating the same standards and production processes that they have over there. It’s a common work between the different sites.”

Famous for its telehandlers, Manitou Group is the only major manufacturer in the world to offer the 17 metres, four-tonne solution made in India, while, on the smaller side of its portfolio it officially released the GCT (Gehl Compact Telehandler) at the recent Bauma trade fair, designed for users who want a machine that can both be easy to handle and transport between sites.

At less than two metres wide and over two metres high, the model is among the most compact on the market, with a transportable weight of less than three tonnes that allows the machine to be transported on a simple trailer, making it highly desirable for work in tight spaces such as entering buildings or maneuvering on renovation sites.

Describing it as a “game changer,” Renard explains its size means it can easily be put on a trailer giving the owner the autonomy

The compact track loader has become increasingly important in the Middle East due to its exceptional traction and minimal ground disturbance.

and independence to target both agriculture and landscaping.

“It’s a very compact telehandler that you can have with a skid steer carriage, so even customers that already use skid steers can switch to this telehandler because the attachments and the carriage remain the same. Plus, you have the outreach that you don’t have on the basic skid steer.”

Although not yet available in the GCC, Renard says it is only a matter of time before these kinds of machines follow the lead

of trucks and buses that are already using stage five in the region. In the meantime, the models have been added to both Gehl and Manitou’s offering in Israel where a thriving agricultural market has existed for a number of years.

Boom Agriculture in Israel is a highly developed industry despite the fact that the geography of the country is not naturally conducive to agriculture with more than half of the land area made up of desert. As of 2016, the kibbutz community was providing Israel with about 40% of its agricultural produce. In a country that produces up to 95% of its own food requirements, supplementing this with imports of grain, oilseeds, meat, coffee, cocoa and sugar it is easy to see why this is by far Gehl’s most dominant market in the Middle East.

Dubai, to its credit, is also beginning to make some headway in boosting the agricultural economy in the Middle East, with the world’s largest vertical farm opening up in 2022. The 30,658sqm vertical hydroponic farm has been designed to produce more than 1,000,000kg of high-quality leafy greens annually, while requiring 95% less water than conventional agriculture.

“At first sight when you look at Gulf countries, we don’t consider agriculture. But I was even in Saudi Arabia a few weeks back. And I was impressed. It has the largest dairy farm in the world,” Renard says.

“With all of this, you have to look for compact machines that are competitive in terms of pricing. Agriculture here definitely has big potential in the coming years, even more with the population growing.”

Against that backdrop it is no surprise that Manitou Group takes its ownership of Gehl very seriously and among the group’s extensive line-up at Bauma, this year, twelve new articulated loader models were launched under both the Gehl AL (Articulated Loader) and Manitou MLA (Manitou Loader Articulated) brands.

“We share the same expectations for both brands,” says Renard. “If you look at Oriental Trading Company (OTC) in Qatar, for example, you can see that they are working very well with Gehl instead of Manitou.”

Explaining further, he points out the ways in which both brands best complement each other. Material handling and people elevation is naturally in Manitou’s DNA while Gehl’s focus lies more in earth moving equipment and basic applications. With the experience and expertise of both, each brand continues to offer their own individual customer portfolio a host of new products and ranges.

“Even customers that already use skid steers can switch to this telehandler because the attachments and the carriage remain the same”

Mr. Qing, Liugong has just had one of its most successful years globally. What do you put that down to and how has that transmitted to the Middle East region?

In the last year the highlight for Liugong Group has been the performance of our overseas business which has increased by more than 50% despite Covid and continued lockdowns in China. As one of the first in the Chinese construction machinery industry to venture overseas, LiuGong has been a pioneer in overseas manufacturing, with operations in seven major global regions. LiuGong has also set industry benchmarks for electric products and R&D while the company’s entire product lines have gone overseas, and our electric loader has debuted on the international market.

In the Middle East, although we have had to adjust our dealerships, we successfully introduced our drilling machine to the region. These are machines that attach to the chassis of an excavator and are hugely important for digging the foundation for buildings and bridges. It also reflects a demand in the region that continues to come from buildings and infrastructure segments. With Egypt and Saudi Arabia investing hugely in infrastructure now, too, this has

“That we have sold more wheel loaders than anyone else is obviously a milestone. Three years ago, we reached 400,000 units and since then we have exceeded 500,000 units globally making Liugong the largest wheel loader producer in the world”

brought increased demand for our machines.

Among the highlights of the last twelve months, excavator sales have been the highest among all product lines, wheel loaders continue to hold the largest market share in India while the highest growth rates in general is in Indonesian and Latin American markets. We are also seeing record sales in the emerging, mature, and aftermarket segments.

This obviously reflects how the perception of Chinese manufacturers continues to

The company has exceeded over half a million units sold since it first started production of the wheel loader.

improve. How has this changed and what is it that Liugong is doing to further strengthen the company’s appeal?

Yes, that is true. I can say that 10 years ago when I was a sales manager here, many clients doubted Chinese products when it came to quality of the machine, its performance and even after sales support. But nowadays it is more accepted that these products don’t just give a better price. They are good quality too.

I think because Liugong has been many

years in the business we can say we now have a very reliable product that many customers have already tested. A large part of our success, however, is thanks to our R&D centre. We have the national authorised Earthmoving Equipment R&D Centre that sets the standard for all Chinese manufacturers producing earthmoving equipment. It is through these standards that we have been able to improve our machines over the years giving better performance with lower cost and fuel consumption.

Globally, you have hit some other pretty impressive milestones in the last couple of years too. In particular, in the wheel loader segment?

Yes, it is true that we are most well-known for the wheel loader. That we have sold more wheel loaders than anyone else is obviously a milestone. Three years ago, we reached 400,000 units and since then we have exceeded 500,000 units globally making Liugong the largest wheel loader producer in the world. We produced the first Chinese wheel loader in 1966 so it started all the way back then.

Nowadays, Liugong not only has wheel loaders, but our product lines have expanded to 17 different segments including road construction machinery, earth moving equipment such as excavators and motor graders, skid steers and backhoe loaders. We also have mining equipment including screeners, crushers, and mining dumpers

emerging

product

while the latest

potential

line is agricultural machinery.

“Our product lines have expanded to 17 different segments including road construction machinery, earth moving equipment such as excavators and motor graders, skid steers and backhoe loaders”

These days it also seems to be a lot easier for Chinese manufacturers to enter the region. How did Liugong first enter the region and what were the main challenges you faced in establishing your presence here?

We started non-officially as a trading company in 1995, in Egypt, but we officially signed a distributor agreement for the first time, in Morocco, in 2003. Although we don’t currently have a dealer in the UAE, it serves as an ideal headquarters for the Middle East and North Africa region due to its geographical location and logistical conveniences.

Our market is mainly in Saudi Arabia and even Iran although political reasons influence the economy much more in this region and that has been one of the main obstacles that we have faced in growing our presence here. Although the currency exchange rate compared to other regions is quite stable the demand can be very much affected by political issues. Unfortunately sanctions in Iran as well as in North African countries such as Libya and Sudan have an effect and do make it difficult to do business in these places at this moment.

Mr.Qing, you’ve spent time working in some of the lesser highlighted areas of Africa and the Middle East. In terms of product development, what are some of the key trends you have observed? That’s right. Ten years ago I worked here as a

sales manager before I moved to Russia where I stayed for five years. This was followed by Kazakhstan for three years and Africa for one year before recently moving back to the UAE. In both Russia and Kazakhstan, the wheel loader accounts for 60% of the total quantity of machines which is mainly due to the strong Chinese influence that exists. This is because of the proximity of the countries. Here in the Gulf the excavator continues to attract the highest levels of demand on the back of a greater influence from Europe and America.

Chinese manufacturers have been growing in popularity in the Middle East due to improved machine qualityand economical price.

This is followed by the backhoe loader and then the wheel loader in third.

In fact, the top three wheel loader manufacturers every year can produce about 30,000 units globally. But if we are to look at other machines like the bulldozer, we will see that it is no more than about 2000 units per year so whilst this is also popular in the Middle East it is much smaller than the other segments.

Finally, can you explain how the Liugong’s wide offering of machines across all segments and classes helped to provide value to its customers?

If we take the wheel loader, for example, we have many different options. If customers want the economy-based one that compares with Indian and other Chinese manufacturers we can give them that while we also have the middle class and high-class configuration models that can compete with Caterpillar and the world’s other leading brands. As well as this, 20 years ago we started cooperating with German manufacturers where we use their transmission and axel to help guarantee the performance and quality of our product.

Through 30 years of development of our overseas market we have a full range of products especially in earth moving equipment we offer more than others. We believe this, added to our quick response to customer demands and after sales service ultimately makes life easier for our clients.

Indonesia is located near the equator and has abundant rainfall and forestry resources that provide sufficient raw materials for the development of timber and the industry’s industrial chain. With the channel advantages of local dealers, LiuGong Indonesia has made great progress in growing its forestry customer base.

In an “isolated” forest area where signal is almost lost, several LiuGong 915 FM excavators are busy in logging operations. This has been the case since the beginning of June. To arrive here, you have to travel in an off-road vehicle up a bumpy mountain road for more than 2 hours, then switch over to a speedboat that will take you through an Amazon-like rainforest waterway for over 30 kilometers.

The customer is one of the

top-five forestry contractors in Sumatra, with a current fleet of over 400 units of construction machinery and equipment. He first purchased a LiuGong 908 excavator in July 2021 year for sugarcane field operations. However, the first batch of equipment appeared to be “unsuitable”. LiuGong Indonesia immediately sent technical personnel to the site to conduct research and make adaptations to the equipment. The improved equipment worked well for the working conditions, and the customer followed up with the purchase of bulldozers, excavators, and other equipment for palm and other forestry projects. He now has

almost the entire line of LiuGong equipment, including nearly 20 LiuGong 915E FM excavators dedicated to forestry operations. The 915E FM is a professional forestry excavator specially

developed for logging, collecting and transporting wood under harsh working conditions such as forests and wetlands, etc. It is equipped with a Cummins engine and highly coordinated hydraulic system to realize sufficient output and smooth movement. To be reliable and durable in tough environments, it adopts reinforced configurations like enhanced grab, biliteral idler support and full track guards. In addition, 915E FM uses special protection for forestry and 960-mmwide single-grouser track. The minimum ground clearance is up to 600mm to ensure higher safety and low grounding pressure for convenient travelling in the forest.

ON THE BACK OF THE LAUNCH OF THE NEW XP700 TRELLEBORG WHEEL SYSTEMS HAS BEGUN TAKING ITS FIRST ORDERS FOR THE LOW INTENSITY MATERIAL HANDLING TYRE. IN THE FINAL PART OF OUR TYRE SERIES, BUSINESS DEVELOPMENT MANAGER, YASIN

The new XP700 was first announced in October. In what way is this tyre offering something new to customers in this region?

Not all customers in the Middle East require a forklift tyre for medium, high or maximum intensity. Each machine or industry will require a different performance from their tyres and this is why Trelleborg has produced the XP700 tyre for low intensity material handling applications. With this latest addition

to the Trelleborg Wheel Systems’ portfolio we can now comfortably help our customers meet the maximum intensity requirements of a steel factory or the low intensity requirements of an individual forklift owner renting his machine for a two-hour job.

The XP700 is specifically tailored for low intensity material handling applications. In terms of design differences to other tyres what does this mean?

The new XP700 tyre features deep lugs for enhanced traction and a compact lateral block design to minimise vibration. It is designed to perfectly match the needs of low intensity material handling

operations by delivering reliability, adequate load capacity and good steering ability, while minimising downtime to keep costs under control.

In today’s multitude of material handling operations, we recognise that having the right solution is key to maximising efficiency. As a tyre expert, Trelleborg’s latest launch of the new XP700 tyre completes our offering by following the release of the XP800 for medium and the XP1000 for maximum intensity application.

Typically, how do you best define low intensity material handling application?

This involves applications that are not in constant

use and only require the forklift to be used for a few hours each day. Also, when the forklift carries a lower load than maximum load capacity of the machine or when it runs in a short distance from truck to warehouse for example, the new XP700 tyre proves itself as the most cost-effective tyre in its class. Long mileage, low energy consumption and excellent cut resistance all deliver a solid performance at the right price.

to be used for a particular type of work?

We believe its first about understanding the variety of material handling operations and to do this we need to define intensity parameters as follows:

• Load capacity: Trelleborg tyres fall fully under recommended load carrying capacities as indicated by the main worldwide technical organisations.

• Working time: Working solid tyres non-stop can potentially cause a buildup of heat and reduce lifespan.

First of all, we need to clearly differentiate industries to understand the main trends in the material handling tyre market, but also to define the industry sub segments.

Material handling machines are as various as battery countered balanced forklifts, electric motor narrow aisle forklifts, engine counter balanced forklifts, port equipment and airport ground support equipment. These machines are working in different industries such as food & beverage (bottling companies, breweries), warehousing & logistic (online retail stores, automotive parts warehouse), heavy industry (steel, aluminum factories), oil & gas industries (oil extraction platform, oil fields) but also in port & harbors and airports.

• Average Speed: High speeds may cause internal stress and deformation leading to overheating, compromising tyre performance.

• Cycle length: Long distances prevent dissipation of heat generated during operations which can create dangerous separation within the tyre.

• Cornering: Repetitive vehicle cornering produces excessive torque on the tyre, increasing the likelihood of deformation.

Based on this, the owner can opt for maximum intensity application pattern, that includes Pit Stop Line (XP1000), high intensity application pattern (Premia), medium intensity application pattern (XP800) and low intensity application pattern (XP700)

What is the market like currently for material handling tyres in the Middle East?

The Middle East material handling tyres market is quite different from one country to another, due to its internal dynamics, local industry and the type of

forklift and lifting equipment you can find. The UAE includes big logistic hubs and multiple free zones, which along with huge ports capacity and some of the busiest airports in the world, make it a significant market for material handling tires. On top of this, Saudi Arabia is a huge country in its own right with an important national industrial footprint, and a very strong oil & gas and petro chemical businesses. The growth potential of the country is very promising while Qatar is also growing fast. The FIFA World Cup 2022 has been of the main drivers for the need of new material handling equipment. Then there are other countries such as Bahrain and Oman that might appear to be smaller are also important as you can find key industry segments there too.

Have you started taking orders for this tyre yet in the Middle East or do you plan to in the near future?

With the official launch in October 2022, XP700 has been already ordered by our clients in the region. XP700 is already available in 21 x sizes that are the main tyre sizes that covers most of the fitment of the main forklift and material handling machines.

As Trelleborg Wheel Systems, we have our own warehouse facility in the UAE, this is helping us to carry stock to launch the product in the next weeks in the region. Our production facility in Sri Lanka is working hard since the launch of the new XP700 tyres to produce and ship our brand-new product to the region.

What are the main trends you are seeing in what customers are looking for in this segment?

How does Trelleborg ensure its customers make the right choice when choosing the correct tyre

Wave upon wave on new generation machinery is constantly changing even the most basic aspects of access and handling. But do you know the working practices this equipment requires and how to reap maximum return from this strongly mechanised culture?

The Access & Handling Summit assesses the impact of increasingly ‘smart’ machines, bound together by the Internet of Things, and presents detailed accounts of safe, efficient working – always focusing on real-world applications and the routes to best practice.

There is also a unique showcase of the latest equipment and inaction demonstrations of features and capabilities.

The event presents you with an opportunity to interact with regional industry decision makers and influencers. There are several innovative ways to sponsor, from interactive live polls to session background branding, and from lead generation campaigns to presentations. Contact us now for detailed information.

The one-day conference will feature high quality dialogue and provocative discussions; we will be hosting leading names from across the region, providing a terrific opportunity to see how the realities behind the major debates are progressing.

Mark Dowdall | +971 58 297 7094 mark.dowdall@cpitrademedia.com

Andy Pitois | +971 4 375 5473 andy.pitois@cpitrademedia.com

Brian Fernandes | +971 4 375 5479 brian.fernandes@cpitrademedia.com

Italian manufacturer, Tesmec has developed a green trencher prototype that fits into the path of full electric machines for underground stringing, expanding the range of zero-emission solutions for urban cable-laying sites.

The e-Sidecut is the prototype version with full electric power supply of a sidecut sc4p, a small trencher for optical fibre excavations in urban areas.

According to the company, E-Sidecut mounts a 358Vdc electric power pack that recharges in twelve hours or four hours while the electric motor works with an

operating speed of 3000 rpm. Additionally, the new electric modular architecture doubles the tank to wheel efficiency compared to traditional machine based on combustion engine, reducing the acoustic impact. It also costs less to operate compared to when using fossil fuels.

“In the trencher industry this is the first step towards the concept of an extensive range of trenchers for urban application,” said Marco Paredi, Trencher Business Unit Director in a statement.

“These are objectives outlined in the Tesmec sustainability path and in line with the Group’s ESG strategy, which sees the prioritisation of a green approach across all product lines,” he added.

Tesmec trenchers and surface miners can be used for a range of applications including pipelines, bulk excaavation, mining, energycables and fiber optic.The company took part in Bauma, in October, where it also presented its latest smart sustainable solutions and digital connected systems. At the event it showcased its integrated solutions for cable laying, surveying and digital mapping as well as trenchers and underground stringing. The e-Sidecut provided one of its event highlights.

JLG Industries, Inc., has introduced an all-new vertical mast lift series for both indoor and outdoor use, the company has announced..

The new JLG E18MCL model has been designed for construction and industrial applications that require outdoor and indoor capable machines while the E18MML has been rated for indoor use only, making it most suitable for sensitive flooring and finish work applications, including maintenance.

Equipped with solid, non-marking tires the E18MCL has a scissor-style steering that similar to JLG scissor lifts for quick familiarisation and reliable control through tight areas like doorways.

The E18MML is equipped with caster wheels and has Point & Go steering, the same as the more traditional vertical lift steering style on JLG’s predecessor models.

JLG’s E18 models are said to offer two times more duty cycles than the marketleading competitive machines. Due to the batteries being mounted under the platform, the E18s also are designed with improved machine weight distribution for efficient loading and unloading.

According to Misty Mason, JLG’s product manager, “The new E18 vertical lift series from JLG has been engineered to provide the most important features and benefits: Maximised durability, ease of serviceability and enhanced productivity — while keeping operator safety, confidence and comfort in mind.”

Doosan has launched a new Waste and Recycling Kit for the company’s DL-7 range of wheel loaders with the aim of improving working conditions for operators.

The first kit of its type for this product range is designed to help operators work safely in hazardous conditions during waste handling and recycling applications, such as contending with airborne dust, dirt and other dangerous particulates and materials.

The kit has been made available for all Doosan wheel loader models from the DL200-7 through to the DL480-7, which is the segment of the Doosan range that is most widely used in this kind of environment.

According to the manufacturer, a range of new safety features are provided in the kit, including the windshield guards, rim covers, road light protection and other protective covers, a fine mesh air intake cover and solid tyres. Several of these features will be optional to allow customers tailor their wheel loaders for their specific applications.

Doosan says it is also preparing an aftermarket version of the kit for those customers who decide to install the kit at a later date. In addition, the company is providing a wider fin air conditioner condenser as standard to facilitate easy cleaning and maintenance.

For maximum performance and versatility all of the new DL-7 wheel loaders are equipped as standard with a 3rd spool valve with settable flow and detent function, providing a constant flow for hydraulically driven attachments. The new kit was shown for the firs time at the Doosan stand at Bauma, where it was installed and displayed on a new generation DL280-7 wheel loader.

The DL-7 wheel loader range from Doosan offers a complete line of next generation machines driven by powerful new Stage V compliant engines, which the company says, provides higher productivity, increased fuel efficiency and a low cost of ownership.

According to Doosan, “the DL200-7 to DL480-7 models feature redesigned buckets offering up to 7% more capacity for easier and faster loading with standard bucket capacities from 2.0 to 4.8 m3. ” This provides increased productivity for a very wide range of material-handling applications.

As well as waste and recycling, these include the transport and delivery of soil, sand, aggregates and other materials in industry, for applications in construction, demolition, mining and quarrying. Doosan is also offering a wider choice of options to provide more work tools for a better match with applications, further increasing output.

The Z-kinematic lift arm in DL-7 wheel loaders delivers high breakout forces and lifting capacities, especially for heavy materials, and a large dump angle for efficiently unloading sticky materials. An optional high lift arm is available where higher dump heights and increased versatility are required.

The DL-7 loaders are said to have smooth and responsive hydraulics and auxiliary hydraulic connections. Operators can comfortably control hydraulic attachments via the proportional switch on the joystick. Various bias and radial tyre options are also available from la range of global manufacturers, to cover the widest possible range of conditions and applications.

In addition, the new wheel loaders come with a selection of counterweights including 300, 400 or 500 kg depending on the application.

Apollo Tyres has launches two new radial tyres for compact construction equipment such as telescopic handlers, compact loaders and backhoe loaders.

The Terra Pro 1044 and Terra Pro 1045 steel belted radial tyres are engineered for tough conditions, offering increased robustness and stability, the company said.

All Terra Pro tyres feature a steel belt and a tie bar, making the tyres stable during loading and lifting while a sidewall protector and special cut and crack resistant compound improves robustness while working in mud or on debris.

The Terra Pro 1045 features a symmetrical tread consisting of alternating hexagons, helping with “stability in all directions even on slopes.” The hexagons are designed for even wear and good wear resistance especially while turning with heavy loads. The symmetrical design also allows for equal traction driving forward and backward while the traction pattern of the Terra Pro 1044 ensures traction on soft underfoot conditions like mud.

Husqvarna Construction, part of Husqvarna Group, has launched its first electric drill motors to be equipped with Embedded Connectivity, a technology designed to produce rich data analytics and insights into the health of its equipment, The DM 400 and DM 430 singlephase 3.2 kW drill motors both offer the new technology, which is an enhanced version of Husqvarna Fleet Services. It includes key performance alerts and allows for continuous wireless updates of the machine’s software.

The tools themselves have a durable all-aluminum casing with a solid feel and a compact design to make them usable when drilling in narrow corners. The carrying handle also works as an impact guard and is easy to remove when needed, giving extra clearance in tight spaces.

Commenting on the new launches, Jeff Bennett, General Manager at Husqvarna Construction, said, “In this ever-changing world of technology and the Internet of Things, it has been essential for operators of equipment to be able to collect and analyze information on the usage of the product and how to enhance its outcome. The new DM 400 / DM 430 are designed for rough handling and heavy drilling jobs. But, they’re also very easy to handle in any drilling conditions you can think of. They can be termed as truly dependable workhorses built to make the operator proud.”

The typical Husqvarna features include the LED load indicator and the SmartStart (half speed) button, and the quick connection to the new Husqvarna DS 500 stand, which is designed to fit together with DM 400 / DM 430. In addition, the three-speed gearbox makes it easy to adjust the RPMs for core bit diameters from 55 to 350 mm for DM 400, and 100 to 450 mm for DM 430.

The need for power is global and it is growing. From dense urban cities to remote communities, operations and industries of all types require robust, reliable, flexible and fully integ power systems, that are available on demand.

Cummins Power Generation has looked beyond today’s challenges to help you meet your future needs by developing the next generation of power – an ever-expanding range of power system solutions that are reliable, flexible and user friendly. Supported by next-level global Cummins sales and service support that ensures you’re covered no matter where your business takes you.

Learn more at cummins.com/generators

“It cut through much higher, faster than what our customer has ever encountered, resulting in a very successful outcome”Tata Hitachi recently used a KDC 30 Drum Cutter for a tunnel construction project in Northern India.

Innovation, technology, and new ways of doing things aren’t always the first things that come to mind when discussing today’s emerging markets and the surrounding narrative of the change that is taking place. Instead, what tends to lead the way is talk of greater exports, lower production costs and shorter supply times. All while construction equipment based predominantly on price rather than value eats up the market share. A closer look, however, at some of the latest equipment that is now being used in these regions, reveals that the adoption of technology, or the more premium-led industry accessories, is not quite as slow as some would believe. In fact, in some cases, it is actually happening at an even quicker rate than that of the Middle East.

Attachment specialist Auger Torque is a notable example, having earned a reputation of finding new solutions to old problems, and doing so by providing equipment that can do the required job with the upmost levels of efficiency. In the last twelve months several of its attachments have started to gain recognition in the Indian market while presently the company is preparing to ship its Scrap Shear attachment directly from the Netherlands as part of an agreement with multinational conglomerate Tata

Group. The tool, which is expected to be delivered in January, will first arrive in Calcutta where it will be fitted on a Tata Hitachi ZAXIS 370 LCH Excavator before the full unit is transported all the way to Delhi to be commissioned.

“There is a huge drive for the recycling of vehicles and chassis,” explains International Business Development Manager for Auger Torque, Rohan Saldanha. “One of the key things is steel recycling is currently a huge focus for the Indian industry as a whole.”

To proceed with one steel recycling project project, Ramky Enviro Engineer Ltd, working in conjunction with Tata Hitachi, needed a Scrap Shear that could help prepare the site in the most timeefficient way. As part of its evaluation Tata Group looked at two things in particular: One was how fast the jaw opened and closed; the other was the cylinder at the top part of the Shear that allowed it to close. Firstly, the cycle of opening and closing for the Auger Torque Shear takes just 3.3 to 3.6 seconds compared to others in the market which can take anywhere from 5.6 to 6.8 seconds.

Secondly, one of the key features of the Auger Torque Shear is the four-chamber cylinder, which is said to result in 25% higher crushing power, almost one and a half times more than anyone else in the market.

“This was a key selling point for this product” Saldanha explains, “but this is validated by the fact that the customer could see the value in it. That was the key thing.”

Saldanha recognises that customers are choosing products and solutions based on value and efficiency, signalling that growing economies in Southeast Asia and North Africa are now seeing, at least, some changes to the traditional way of thinking. In what is one of the fastest growing emerging markets in the world the Shear at Tata Group is expected to be just the first of several purchases over the next twelve months.

Continuing on that same journey in India with Tata Hitachi, Auger Torque recently sold three Drum Cutters following significant interest from the Border Roads Organisation (BRO), the Indian Army and the National Highways Authority of India.

One of these Drum Cutters (the DC30) has already been deployed with Tata Hitachi in a key area of Kashmir that has become increasingly important to the government’s infrastructure development plans.

Given the mountainous terrain in Northern India, tunnel construction and profiling is vital to improving roadworks in the region, and whilst traditionally a combination of drilling and blasting was used to build tunnels there are potential disadvantages of this method when it comes to safety, the lack of precise control and the amount of pollution that is generated. On this particular project, the Auger Torque Drum Cutter was used as localization machinery in addition to the Tunnel Boring Machine (TBM) to profile the tunnel surface.

“That was one of the key elements for using our drum cutters for this job. It cut through much higher, faster than what our customer has ever encountered, resulting in a very successful outcome for the client,” says Saldanha.

The Auger Torque transverse Drum Cutter range, which has been making sizeable headway in emerging markets, is designed to work on a wide range of excavators from 2-60T and is most suitable for rocky terrain excavation trenching and surface scaling in severely adverse terrain conditions. It is particularly advantageous for tunnel profiling, trenching, road works and demolition works

“It’s quite unique,” says Saldanha explaining how the Drum Cutter shaves the rock and creates a surface for vehicles to reach up and shave off the tunnels of the walls. Such drum cutters are also used in existing tunnels where the surface needs to be reconstructed over a period of time. As part of the surface profiling process the surface of the tunnel or existing rock is shaved off, a netting system is used on the external surface, and a surface partner is used to spray across it, hardening the tunnel surface and preventing any debris from falling down as a result.

Meanwhile, road organizations in India have increasingly been turning to a standard tool that is already used widely across the UK’s busiest highways, the Variable Mulcher. Designed to work on the side of highways or busy roads, mulchers cut and chop vegetation into small particles with the latest purchases indicating that there is a growing willingness among emerging markets to

In the Middle East, Dubai based company RRT Contracting, recently purchased Auger Torque 25,000Max auger drive units. Paired with helical piles, these were used for greenhouse foundations. The company installed 600 helical piles (screws that fit into the ground to stabilize loads for building) using a 25,000 max drill aided with Auger Torque’s first unit of In-Site. This new In-Site range of data driven tools gives operators knowledge and insight whilst out in the field. A plug and play tool, with one power cable, sensor plugs and a handled touchscreen device, the In-Site range of products improves accuracy, precision and efficiency. In this case, it helped the operator install the screws without any deviation and ensure accurate alignment whilst removing the need to have three people present do one particular hole.

catch up with some of the trends in more established economies like the UK.

The KDC 30 Drum Cutter is designed to penetrate rock at low vibration and noise levels while it can operate underwater in up to 25m water depth .

“One of the key things,” says Saldanha, “is that if you use a brush cutter, you don’t know what’s on the ground, whether there will be bricks or rock or something else that might cause damage. The Mulcher is robust enough to take it as it’s got a cover which allows the drum to run it in high RPM, which in doing so prevents debris from flying back to the operator.” He adds, “They can localise the cut away from the

road into an area that can be easily cordoned off. It’s a very quick and effective tool because you don’t have to stop the traffic on the side of the road.”

With any success in introducing new ideas there can also be a positive knockon effect. Auger Torque continues to demonstrate the importance of value driven decisions, challenging beliefs that in this part of the world, only conservatism exists. The year ahead promises to accentuate this even further.

Tower cranes allow construction project managers to complete some of the most difficult, intricate projects on any job site, dealing effectively with things like lifting and placing steel beams in place, transporting building materials, moving heavy equipment and more. With a growing population in the Middle East and continued investment in infrastructure, the tower cranes segment in the region is seeing a steady rise in the use of luffing jib cranes over some of the more traditional types such as hammerheads and flat-top cranes.

A luffing tower crane is ideal for congested areas, allowing operators to complete the task at hand even when space is limited on either side of the site. It achieves this through its ability to raise or lower its jib, allowing the operator to reduce the slewing radius as a result. The latest example of this comes in one of Dubai’s most vibrant districts, Jumeirah Lake Towers where two new Raimondi LR213s were recently installed for the construction of a 40-storey mixeduse tower. The cranes will remain on site for approximately two years. Upon completion, the new tower will feature 330 residential units alongside commercial spaces.

“We rented these two luffers to the project contractor, M/S Bu Haleeba Contracting, after carefully evaluating the jobsite specifications and the client’s requirements. Rising in one of the most densely populated and

congested neighbourhoods of Dubai, the site’s surrounding towers were the key aspects considered during site planning phase, and choosing the suitable crane model,” says Wael Hasan, Middle East Commercial Director, Raimondi Cranes.

Luffing jib cranes were chosen to avoid collision and overfly of surrounding properties, paired with the LR213’s good lifting capacity. The two LR213s, having a maximum lifting capacity of 14 tonnes, are currently at work onsite with a tower mast of 36m and a jib length of 50m. Equipped with a 55kW hoisting winch with a drum capacity of 880m, the cranes are said to have the ability to lift at a maximum speed up to 104 meters per minute.

In the early site mapping stages, climbing plans were drawn up, as the luffers need to reach a final height of 163m. The tightly built-up surroundings of the Dubai jobsite meant that no external climbing would be possible, thereby necessitating an internal climbing plan.

Hasan explains it was essential to study each stage of the internal climbing, noting that “Raimondi is one of the few manufacturers that offer the possibly to have a 14t maximum lifting capacity luffer with an internal climbing mast section of 39m height, that allows placement of connection collars at 13-metre distance. Each crane can be climbed every third floor, reducing climbing operations and consequently boosting site productivity. A great advantage in the Middle East as usually internal climbs occur every two floors.”

At Wolfkrran Arabia, the demand for luffing jib cranes has also been on the rise with the company’s operations director,

Jeff Watson explaining that the evergrowing appetite for modular construction continues to be a significant driver.

“There is a lot of demand for highcapacity luffing cranes. There’s a lot of high-capacity luffing tower cranes these days because everything is going modular. More and more, everything is being built off site or built on site in modules and then lifted up into place,” he says.

“But in general there are a lot more projects starting to happen again in the Middle East

In the last twelve months Liebherr tower cranes have been put to use on both a museum construction project in Saudi Arabia and the 1915 Canakkale Bridge project in Turkey, which is the longest suspension bridge in the world, connecting Europe and Asia.

Notably, Liebherr has expanded its Fibre crane family this year with extremely powerful machines – and for the first time beyond the EC-B series. The 258 HC-L 10/18 Fibre luffing jib crane, the 1188 EC-H 40 Fibre high-top crane and the 520 EC-B 20 Fibre and 370 EC-B 16 Fibre flat-top cranes were newly launched on the market and were all made available to the Middle East region.

By using the fibre rope, the lifting capacities can be increased by up to 43 percent compared to the steel rope versions. In addition, the fibre rope has a longer service life, offers an easier handling and does not require lubrication.

In addition, the successful EC-B series was expanded. Newly introduced to the market were the 470 EC B in a 16- and 20-tonne version, the 300 EC-B 12 Fibre and the 270 EC-B 12.

Liebherr says it has designed the NC-B series especially for pricesensitive markets and customers making it a viable option for many in the Middle East. The NC-B 12-70 flat-top crane is suitable for both in-situ concrete construction sites and precise lifts with heavy precast elements due to its long reach. The machine offers a maximum jib length of 70 metres, a peak load of 2,000kg and a maximum lifting capacity of twelve tonnes. Liebherr will also offer a more powerful hoist as an option in future.

and demand for cranes has been picking up. There’s been a lot more inquiries for Wolffkran cranes, a lot of tenders and there’s been a few things announced. Things are looking a lot better than one year ago.”

In terms of the product side of things Wolffkran recently launched the new 8076 compact trolley jib crane prototype at Bauma. Initially announced in 2021, Wolffkran’s first saddle jib crane in the 800 mt class has a reduced tower top and an impressive tip load capacity of 8.4 tonnes at 80 metres.

In partnership with local rental company Wiesbauer the crane had to be erected under realistic work site conditions from a single location with the smallest amount of effort possible and as quickly as possible. The 8076 was erected with a hook height of 44.1 metres, while the heaviest component was the counter jib, with an all-up weight of 27.3 tonnes. While the Middle East awaits the arrival of the 8076 to the region, the trend of bigger is better seems here to stay for the foreseeable future according to Ahmad

Wraikat, regional manager, Kanoo Cranes.

“Many companies in the Middle East are looking for much bigger luffing cranes than before especially all the tender jobs,” Wraikat explains, before adding:

“There is a strong demand for high-end villa projects in Dubai. They require the smaller luffing cranes, which before would have been considered big, but not anymore.

“There will be more and more inquiries for these bigger cranes because many project designs are starting to make life

easier by incorporating big steel members or precast panels. So this also means bigger cranes to lift them. So this is where the focus now lies.”

One of the most recent leading additions to the tower crane market, Wraikat points out, has been the Jaso J200, a topless crane that is ideal for congested sites as it can work at a reduced height. Long known for their low-tops; the Jaso flattops were added in 2021 with the J200.12 providing 12t capacity and the J200.10,

a 10t machine. Booms on both models start at 30m and can be increased in 2.5m increments up to 67.5m.

These Flat Top crane models were introduced to renew the T Series of the Top Line range, which previously only consisted of High-Top cranes. With the J200’s filling a niche between its lower tonnage and higher tonnage series Low Tops, Jaso remains a strong advocate of this type of crane, combining the benefits of High Top and Flat Top designs.

Wael can you describe how Raimondi has grown its presence in the Middle East region in 2022?

We have seen a significant boost of commercial activity over the past 12 months in the MENA region, with the majority of cranes been deployed in UAE, Qatar, and Algeria.

As a result of an increase in expenditure in the infrastructure sector from governments, we were able to contribute to the construction of key mixed-use developments around the region. It’s worth mentioning three major developments due to size. Firstly, the continuation of our partnership with UAE-based developer Arada for the construction of Sharjah newest megacity, Aljada, where we’ve erected more than 30 cranes. Second, in Doha, Qatar, 11 Raimondi cranes working on the construction of a luxurious residential waterfront, and third was the massive development of 2300 new housing units in Algeris, Algeria, with five flat-tops onsite.

In terms of tower crane development in which areas are you currently seeing the most change in the industry?

Due to the nature and dimensions of the latest projects, in the Middle East we are noticing an increase in demand for cranes with bigger lifting capacities, both in the flat-top and luffing jib crane category. We are proud to supply our clients high performance machines, such as the two recently launched Raimondi Class 110 and Class 150 series. We are very pleased about ConCore, the newly designed control system developed by Raimondi, as it will facilitate operations such as crane calibration and zoning.

The technology provides extensive, detailed, and prompt diagnostics thereby reducing site downtime and increasing productivity. This will also boost jobsite safety as commissioning operations will now mostly occur at the ground level.

Still on the note of safety, as it remains one of the major factors of importance in the region and a top priority for us. The new crane stairs reduce risk and facilitate operator climbing.

One of the biggest boons to our customers is the new Raimondi crane cab, Lumina. It now includes a pneumatic seat that stabilises according to operator body weight.

What are you most looking forward to in 2023, both globally and in the Middle East?

With Raimondi’s recent launch of 14 new models of flat-tops, we’re looking forward to receiving some of these new machines for one of Arada’s most awaited projects. Raimondi Middle East is looking forward to supporting Arada on the build of Jouri Hills, part of the exclusive Jumeirah Golf Estates, a world-class residential golf destination offering luxury homes and leisure facilities in the heart of new Dubai.

We have already placed an order of ten additional cranes to Raimondi headquarters, which will include a mixed of Raimondi MRTs and Ts. The latter ones will be equipped - for the first time in the Middle East - with Lumina, the newly designed Raimondi crane cab which we expect to generate great enthusiasm among crane operators in the region.

We’re looking at the upcoming year with excitement and positivity especially with the delivery of Raimondi’s newest product. The modularity of components, the increased tip-load, and the spacious crane cab will add extra value to our fleet.