PLUS RANGE REVIEW CASE TALKS MAKING A DIFFERENCE IN THE REGION READ CMME’S TOP TEN TIPS GUIDE TO ROAD BUILDING IN

PLUS RANGE REVIEW CASE TALKS MAKING A DIFFERENCE IN THE REGION READ CMME’S TOP TEN TIPS GUIDE TO ROAD BUILDING IN

The major news stories and company moves this month.

CASE CE on the development of its region-ready skid steers and backhoes.

CMME looks at how one heavy lift company is taking on the challenge on electrifying operations.

Maintaining uptime of machines is integral to Egypt’s ‘Toshka’ vital irrigation megaproject.

30_NEW RELEASES

The latest releases from the world of construction machinery.

The best way to keep road projects on track.

34_THE ACCIDENTAL

Yanmar steps up to help a campaign to save empty houses in Japan.

36_THE LAST WORD Hoist and Crane provides the power to a unique tourist attraction.

10 SPOTTED ZE135! Hitachi’s ZE135 electric excavator zeros in on Stockholm.

Suddenly election fever is hitting some key markets. With the UK Prime Minister surprising many by announcing an early election based on a set of economic results that are best summed up as not as bad it was, but not as good as it could be, there should be no doubt that the promises of spending that comes with a change or renewal of those in power is critical to construction.

With major elections in India, the UK and the US it is notable how far-reaching the impact of these political events can have on various industries. Among these, the construction machinery industry stands out as one that is particularly sensitive to the outcomes of elections. In this letter, I will delve into how the electoral processes and results in these three significant nations can shape the future of construction machinery, influencing everything from market demand to regulatory environments. India, one of the fastest-growing economies in the world, has a booming construction sector. The 2024 general elections played a critical role in determining the trajectory of infrastructure development.

Political parties often use infrastructure promises as a key component of their campaigns, pledging new roads, bridges, and urban development projects to gain voter support. The construction machinery industry, which supplies the essential equipment for these projects, stands to benefit significantly from any increase in infrastructure spending. However, changes in government can lead to shifts in policy priorities and funding allocations. A new administration or more likely an emboldened Modi might, as promised, accelerate existing projects or introduce new initiatives to boost the economy, as well as boosting demand

for construction machinery. Conversely, political instability or a roll-back in policy direction could delay projects, affecting industry growth, as well as trade.

In the UK, the 2024 election arrives as the nation is still navigating the post-Brexit landscape. Construction has faced challenges related to labour shortages, scaling back of national projects like the HS2 rail link and the UK government’s much-heralded, and lesser seen housing programme, as well as supply chain disruptions, which have been exacerbated by Brexit. As has been the case for several elections, the result will influence how these issues are addressed, particularly immigration policies and trade agreements.

Political commitments to infra projects, such as housing and green energy directly impact the demand for construction machinery. The industry will be closely watching the election outcomes to gauge future market conditions and investment opportunities. This is particularly true in the US, where the 2024 elections will be crucial for the industry. The Biden administration’s focus on the Infrastructure Investment and Jobs Act has boosted federal investment and the economy. But a continuation or expansion will depend heavily on the results.

A Trump win, as unpredictable as his first administration proved, is no guarantee that US manufacturers will resurge globally.

Stephen White Head of Content, CMME stephen.white@cpitrademedia.com

Stephen White Head of Content, CMME stephen.white@cpitrademedia.com

GROUP

MANAGING DIRECTOR

RAZ ISLAM

raz.islam@cpitrademedia.com

+971 4 375 5471

DIRECTOR OF FINANCE & BUSINESS OPERATIONS

SHIYAS KAREEM

shiyas.kareem@cpitrademedia.com

+971 4 375 5474

PUBLISHING DIRECTOR

ANDY PITOIS andy.pitois@cpitrademedia.com

+971 4 375 5473

EDITORIAL

HEAD OF CONTENT

STEPHEN WHITE stephen.white@cpitrademedia.com

+971 58 584 5818

EDITORIAL ASSISTANT

PRIYANKA RAINA priyanka.raina@cpitrademedia.com

+971 4 375 5478

ADVERTISING

SALES MANAGER

BRIAN FERNANDES brian.fernandes@cpitrademedia.com

+971 4 375 5479

DESIGN

ART DIRECTOR SIMON COBON simon.cobon@cpitrademedia.com

DESIGNER PERCIVAL MANALAYSAY percival.manalaysay@cpitrademedia.com

MARKETING

EVENTS EXECUTIVE

MINARA SALAKHI minara.s@cpitrademedia.com

+971 4 433 2856

CIRCULATION & PRODUCTION

DATA & PRODUCTION MANAGER

PHINSON MATHEW GEORGE phinson.george@cpitrademedia.com

+971 4 375 5476

DIGITAL

ABDUL BAEIS

abdul.baeis@cpitrademedia.com

UMAIR KHAN umair.khan@cpitrademedia.com

FOUNDER

DOMINIC DE SOUSA (1959-2015)

PUBLISHED BY

The Volvo EC550E delivers up to 35% more tonnes per hour, boosting profits. The perfect partner for a Volvo 35-40T Articulated hauler. A new hydraulic system provides exceptional power for heavy-duty digging. Backed up by outstanding support from Volvo Services, the EC550E gives you the power to dig – and keep on digging. Talk to your local Volvo dealer today.

INFRASTRUCTURE

EBRD to loan $255mn for construction of key road project in Armenia

CONSTRUCTION

Larsen & Toubro wins design and build hospital contract

INFRASTRUCTURE

Works on 23km long Desheng tunnel complete

CONSTRUCTION

Veolia subsidiary wins $320mn contract for desalination plant

CONSTRUCTION

Arada and Minor Hotels launch Anantara Sharjah Residences

ANALYSIS: Building Sustainable and Secure Data Centres in the GCC

FINANCE

Emaar’s Q1 revenue reaches US $1.8bn

Extremely strong start for 2024 includes 16% growth on profitability year-on-year

INFRASTRUCTURE

RTA launches survey to study and ease traffic in Dubai

PROPERTY

Symbolic announces residential project in Al Furjan

Sky Garden residences will feature ‘greened’ balconies, smart home management and generously-sized apartments

SUSTAINABILITY

Abu Dhabi invests in material recovery facility

Tadweer Group closes bidding for reprocessing plant set to play a crucial role in diverting emirate’s waste from landfill

OPERATIONS

Saudi Red Sea Authority issues marina licences

The boating facilities have achieved certification for technical procedures, quality of service, and sustainability

APPOINTMENT

Daniel King appointed to lead AESG’s cost management service in the UAE

PROPERTY

INFRASTRUCTURE

Abu

CONSTRUCTION

Shapoorji Pallonji wins Roshn residential contract

The firm will develop 429 units in the Riyadh community with an emphasis on sustainability and reduced utility costs

DMT launches ‘Plan Capital Survey’

INDUSTRY

appoints Arup for spatial planning of

CMEC AWARDED CONTRACT FOR 20,000 SAUDI

Saudi Arabia’s National Housing Company (NHC) has awarded a contract to China Machinery Engineering Corporation (CMEC) for the construction of 20,000 residential units. These will be built for key community projects throughout the Kingdom.

UAE-based total facilities management service provider

Al Shirawi Machinery has had the honour of welcoming the top executives from HD Hyundai Construction Equipment at its upcoming facility at Dubai Investment Park. The distributor said “it was a day of strategic conversations and a shared vision for the future.”

The tour of the facility included participation from Cheol Gon Choi, Chief Executive Officer, Edward Song, Chief Strategy Officer, and other distinguished Directors of the HD Hyundai Construction Equipment team, as well as Thani Al Shirawi, Chief Executive Officer, and other esteemed directors from the Al Shirawi Machinery team.

HD Hyundai CE is one of the world’s leading equipment brands. Now backed by Al Shirawi’s aftersales and support in the UA (the two firms formally announced their partnership at the start of 2024) it is determined to see its performance match its reputation.

Jason Byun SVP Head of OverseasSales Hyundai Construction Equipment said at the time: “Hyundai is making remarkable return to the UAE. We will work closely to revive bonds with our customers.”

Al Shirawi Machinery believes it is now at the head of empowering the construction sector with cutting-edge wheel excavators, crawler excavators, wheel loaders, and robust kit tailored for every scale and scope of project.

According to the distributor: “Every machine they offer is infused with HD Hyundai’s commitment to “Comfort Intelligence” – combining advanced technology with user-centric design to ensure efficiency, safety, and comfort.

“The visit was more than a tour — it was a reaffirmation of their shared commitment. They’re setting the stage for future advancements the industry. At Al Shirawi, they don’t just sell equipment; they build partnerships that construct tomorrow’s landmarks.”

According to NHC, this agreement is one of several with major international construction companies. It will entail building different facilities, including medical care establishments, schools, and retail stores. The concept throughout is to create vibrant regional hubs with a full range of lifestyle amenities for residents.

Emrill has announced that it is making significant progress towards its sustainability targets for 2024. The organisation is on course to meet its goals in critical areas of environmental impact reduction, demonstrating Emrill’s commitment to sustainability in complete alignment with the UAE’s vision for a greener future. Emrill’s sustainability strategy includes ambitious targets over a 10-year period. The organisation aims to reduce its carbon footprint by 15 per cent, reduce waste generation at its head office and stores by 20 per cent, reduce water usage by 15 per cent, and divert 15% of waste from its head office and stores from landfills. Emrill has set quarterly targets of 0.5 per cent to ensure it achieves these goals and has established a points system to monitor and encourage continuous improvement.

Central to Emrill’s sustainability strategy is the launch of ‘United for Sustainability’, which builds on the success of ‘Together for Sustainability’. These programmes comprise several targeted sustainability initiatives that aim to reduce the environmental impact of Emrill’s operations and improve efficiencies for clients while enhancing the overall performance of buildings and communities.

In 2023, Emrill achieved significant reductions in CO2 emissions, with a decrease of 801 tonnes of CO2e, equivalent to removing 664 cars from the roads or providing the CO2 absorption of 138,000 mature trees. Additionally, Emrill reduced water consumption by over 2.25 million litres, which is the equivalent of filling more than 162 Olympic-sized swimming pools.

Al Habtoor Motors, the sole distributor of JAC Motors in the UAE said it will introduce ready-mix trucks later this year after unveiling its latest fleet of JAC commercial vehicles at a launch event at the Al Habtoor Grand Resort in Dubai.

The Promate and Workmate set new benchmarks for reliability, versatility, and innovation in the country’s commercial vehicle segment, executives told invited industry guests.Set close to the beach, the event showcased

a range of light and heavyduty trucks and commercial vehicles, “highlighting the latest innovations in the commercial vehicles sector to company delegates and key stakeholders,” said the distributor.

Specially curated and tested for the UAE market ahead of the launch, the trucks compliment the existing range of light commercial vehicles like the Sunray & M4 minibuses and cargo vans as well as the light trucks, which are already

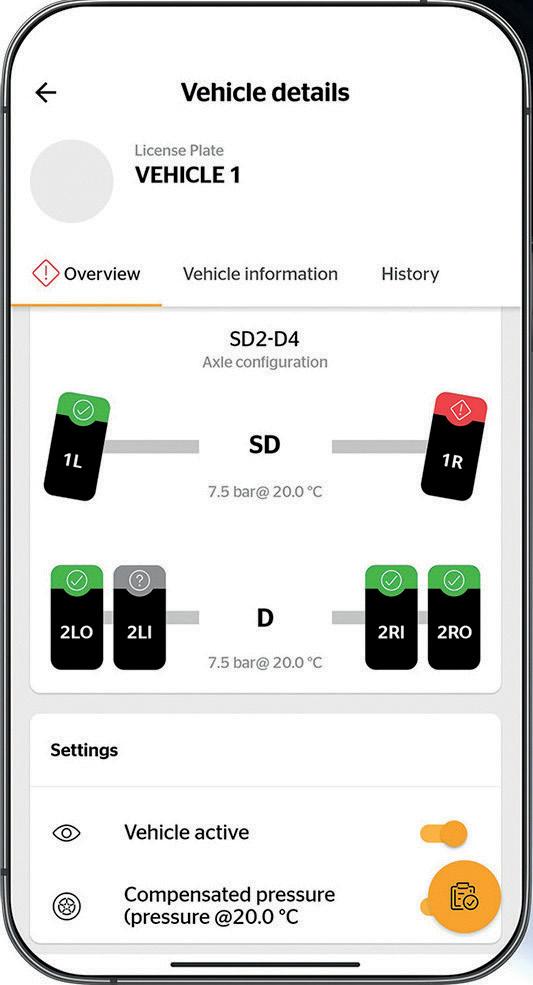

Continental has launched ContiConnect Lite, a new app version for digital tyre management. ContiConnect Lite creates a bridge between tire sensors and professional tire management and offers a free-of-charge gateway to selected ContiConnect features. Continental is delivering its OTR tyres with a Bluetooth-enabled sensor ex factory. “Digital tyre management contributes to greater safety, efficiency and sustainability, especially in the areas of earthmoving, agriculture, and at ports”, says Martijn Oosterbaan, Head of Product Management at Continental Specialty Tires. Thanks to a Bluetooth-enabled sensor, the tyre data can be read directly via smartphone.

“This makes access to digital tyre management particularly easy,” says Oosterbaan.

popular in this market.

The WORKMATE 4146 on display at the launch is a 6x4 41 GVWT truck packs a Cummins EURO V engines, which produce about 460 hp and 2,300Nm of torque and a manual transmission under the hood and each vehicle will feature newly designed ergonomic dashboards and air suspensions, which should improve the driving experience and minimise driver fatigue, said Wassef, adding that a readymixer variant is also on the way.

In terms of performance, all these vehicles have been equipped with powerful and technically advanced engines and latest transmissions, capable of serving several different applications and in the harshest conditions, whilst still maintaining both reliability and excellent fuel efficiency. The vehicles also excel in their loading capabilities to transport several tons of materials with absolute ease.

AL AIN’S ROADS

UPGRADE REACHES

HALF-WAY STAGE

Al Ain City Municipality has completed 47% of the work on Phase 1 of the extensive Infrastructure and Road Upgrade Project in the Al Amerah area. Project construction began in the third quarter of 2023, at a total budget of US $35.3mn. The three-phase project is part of a comprehensive plan to develop roads and sustainable infrastructure in Al Ain’s residential neighborhoods. It is also the largest single upgrade to the district’s roads network in the modern history of Al Ain and is part of a larger, ongoing civic enterprise to improve accessibility and access. Al Ain City Municipality explained that the project works cover numerous ley operations, including: road reconstruction; the creation of ample parking lots; storm drainage network improvement; laying down new sidewalks and walkways; resurfacing; fresh lane demarcation; lighting network upgrade; and speed bump installation.

Rokbak will make its inaugural appearance at Le Dig Tour, France’s premier construction machinery roadshow, this summer. The 28 tonne (30.9 US ton) Rokbak RA30 articulated hauler will be at several Le Dig Tour events – May 30th–31st in Rennes, June 6–7th in Mulhouse and September 19–20th in Brignoles.

Rokbak’s participation in Le Dig Tour underscores the company’s plans to expand its presence in France and build valuable partnerships with dealers and customers. Joining editions of the expo in the north, east and south of France will offer attendees the chance to engage directly with the Rokbak brand and the RA30.

“The 30 tonne trucks are a major part of the French ADT market due to ease of transportation to sites,” says Paul Culliford, Rokbak Regional Sales Manager EMEA,

Construction works on what is said to be China’s longest single-bore, double-track railway tunnel is complete according to China Railway No.2 Group. The firm notes that the 23km-long Desheng tunnel took 10 years to build and sits at 3,000m above sea level.

The tunnel is part of the Chengdu-Huangshengguan section of the Sichuan-Qinghai Railway. Passenger trains on the section are expected to travel at speeds of up to 200km/h and freight trains at up to 120km/h. Designed with the assistance of China Railway Eryuan Engineering

Group, the tunnel’s maximum buried depth is 750m. It is close to an active fault zone and passes through 17 parasitic folds and one fault, with the construction team dealing with earthquakes, landslides and debris flows during construction, the firm noted.

The Chengdu-Huangshengguan section of the railway is 276km long, while the Sichuan-Qinghai Railway is 836km long, and is one of eight high-speed lines connecting the north of the country to the south.

The Desheng tunnel is due to enter service later this year, the firm noted.

projects in France and deliver new benchmarks in both performance and total cost of ownership.”

Paul, who is multilingual, is looking forward to engaging with customers and explaining firsthand the capabilities of the Rokbak product line, which also includes the larger capacity 38 tonne (41.9 US ton) RA40 articulated dump truck.

“We will be on the ground during Le Dig Tour with an operator to display the RA30, allowing people to get up close and see exactly what we’re talking about via live demonstrations,” explains Paul. “With its increasing popularity and recognition, Le Dig Tour is a great way to meet customers and show them what Rokbak has to offer.” who will be part of the Rokbak team attending Le Dig Tour events. “Rokbak trucks are robust and reliable articulated haulers that will benefit construction

José Cuadrado has been appointed global CEO at Yanmar Compact Equipment (Yanmar CE). Cuadrado replaces Giuliano Parodi who, for the last six years, has successfully led the transformation of Yanmar CE into a global leader – and who is now transferring to manage the Yanmar Group’s strategy division.

As part of a wider reorganisation designed to establish the company as a market leader in its field, Barbara Caporali has been appointed commercial director of Yanmar CE Europe, Middle East and Africa region. Caporali is now responsible for a range of commercial activities, including

dealer sales, key account sales, network development and demand planning. Her arrival is part of a regional reorganisation of the commercial department that is designed to improve the company’s capabilities, gain market share and propel Yanmar CE towards its objective of becoming a compact equipment leader in the EMEA.

Caporali has spent almost the entirety of her two-decade career at construction equipment company CNH Industrial, where she has held a number of leadership roles that encompass sales, network development and marketing. Her most recent position was Head of Network Development Europe.

The ZE135 electric excavator, developed in a JV between HCME and KTEG, has taken centre stage on the first leg of a unique European tour, headlined “Powering the Future”. The 14-tonne zero-emission machine was joined by two smaller electric models, the Hitachi ZX856EB and ZX55U-6EB, in a test held under cold climatic conditions on a significant infrastructure project in Stockholm. Power was supplied by a 300kVA/422kWh battery charging unit that has been developed by Alfen NV, the Dutch supplier of mobile energy storage systems. When contractor Bäckströms was asked by Delvator – the country’s Hitachi dealer – to participate in a project featuring

three new electric excavators, the CEO Jerry Magnusson’s response was immediate: “We were incredibly happy, with three main reasons why we agreed to cooperate so quickly.

“Firstly, the City of Stockholm will implement a low emission zone in part of the city centre – where many of our machines work – at the end of this year. The second reason is that we aim to stay ahead of our customers’ requirements and satisfy them before they ask for a different solution. And finally, our group has set sustainable goals and indicated how these will be met – and the test is an important part of this programme.”

The contractor approached its customer, energy provider Stockholm Exergi, to check if it was willing for the

ZE135 and charging unit to work on a cooling system project in the city’s rejuvenated Meatpacking District.

“We’re aiming to get as close to zero primary energy use as possible and therefore the selection of the supplier and equipment for projects such as this are a top priority,” says Stockholm Exergi Construction Manager Johan Schröder. “The ZE135 is quieter than conventional machines, we’re happy with the zero emissions and there’s even an onsite charging unit.”

The ZE135 was a welcome addition to Bäckströms’ fleet to help install a 500m stretch of cooling pipes for Stockholm Exergi in February and March. The electric excavator was selected to excavate the trenches, lay

the two-way pipes and backfill ready for the completion of the contract. The portable battery charging unit is a vital piece of supporting equipment for the electric excavators. It is compact, easily transportable and convenient for an urban job site such as the Meatpacking District.

Bäckströms Project Support Anton Silvennoinen explains: “The ZE135 is used for about 3.5 hours each morning, and when the operator goes for lunch, we use the faster DC cable and recharge the machine’s battery in about 45 minutes. The work continues until the end of the day, then we leave the machine connected to the slower AC cable overnight – it’s ready for work the next morning.”

“CASE Construction Equipment isn’t just building machines; it is crafting solutions specifically designed to thrive in this demanding region”

CASE Construction Equipment (CE) isn’t just selling machines; it is investing in the future of the Middle East. By providing high-quality, efficient equipment, innovative solutions, and exceptional customer service, CASE empowers contractors to build communities and contribute to the region’s ongoing development.

CASE Construction Equipment’s (CE) dedication extends beyond the initial purchase. It offers comprehensive aftermarket support, ensuring your equipment remains operational and productive throughout its lifecycle. A network of qualified technicians and a readily available supply of parts minimises downtime and keeps projects on schedule.

With a surge in infrastructure and construction projects across the Middle East, CASE CE has seen a high demand for its skid steer loaders and backhoe loaders. These machines are favoured due to their adaptability and superior performance, catering to the diverse needs of the region’s construction activities. From infrastructure development to intricate urban construction, these machines tackle a wide range of tasks efficiently.

In 2023, CASE CE introduced the new V-series Backhoe loaders, which received a complete cab redesign inspired by Italian models. The new cab offers better air conditioning performance and includes a cooler box, ensuring operator comfort during long, hot summers.

The backhoe loaders are equipped with a specially designed cooling package to operate in temperatures up to +50°C. The inline cylinder design of the backhoe boom enhances the transfer of power, making it robust and reliable. The hydraulic system, designed with customer needs in mind, operates at a lower pressure of 205 bar, reducing the load on the pump and increasing the longevity and reliability of the already robust gear pump. This design choice, coupled with larger hydraulic ram cylinders, allows the loaders to carry more load, improving reliability and lowering the total cost of ownership (TCO). For the customer it is a win-win with fewer failures, as well as the lower TCO.

The skid steer loaders from CASE CE are particularly popular for several reasons. Designed to operate efficiently in the extreme heat of the Middle East, they feature a specially designed cooling package that allows them to work in

ambient temperatures of up to +50°C. This capability is crucial for maintaining productivity in the region’s harsh climate.

Additionally, the double radial arm booms deliver class-leading breakout forces and lift capacities, significantly improving cycle times. The design also includes remotely mounted engine filters, fuel filters, and engine oil drains in a dedicated service area, enhancing safety and reducing downtime by making maintenance quick and easy.

To further increase versatility, CASE CE has incorporated additional hydraulic auxiliary options, enabling skid steer loaders to carry larger and more powerful attachments. This flexibility allows the machines to adapt swiftly to various work applications.

Navigating tight spaces and uneven terrain is a frequent challenge in the

region. The compact size and superior maneuverability of CASE skid steers make them ideal for navigating congested areas and complex job sites.

A range to meet market demands

CASE CE has tailored its strategy and products to meet the unique environmental and economic challenges of the Middle East. The equipment is engineered to withstand the region’s extreme heat and rugged terrain, ensuring durability and reliability. The company’s focus on practical innovation and operator comfort further enhances the appeal of their machines in this market.

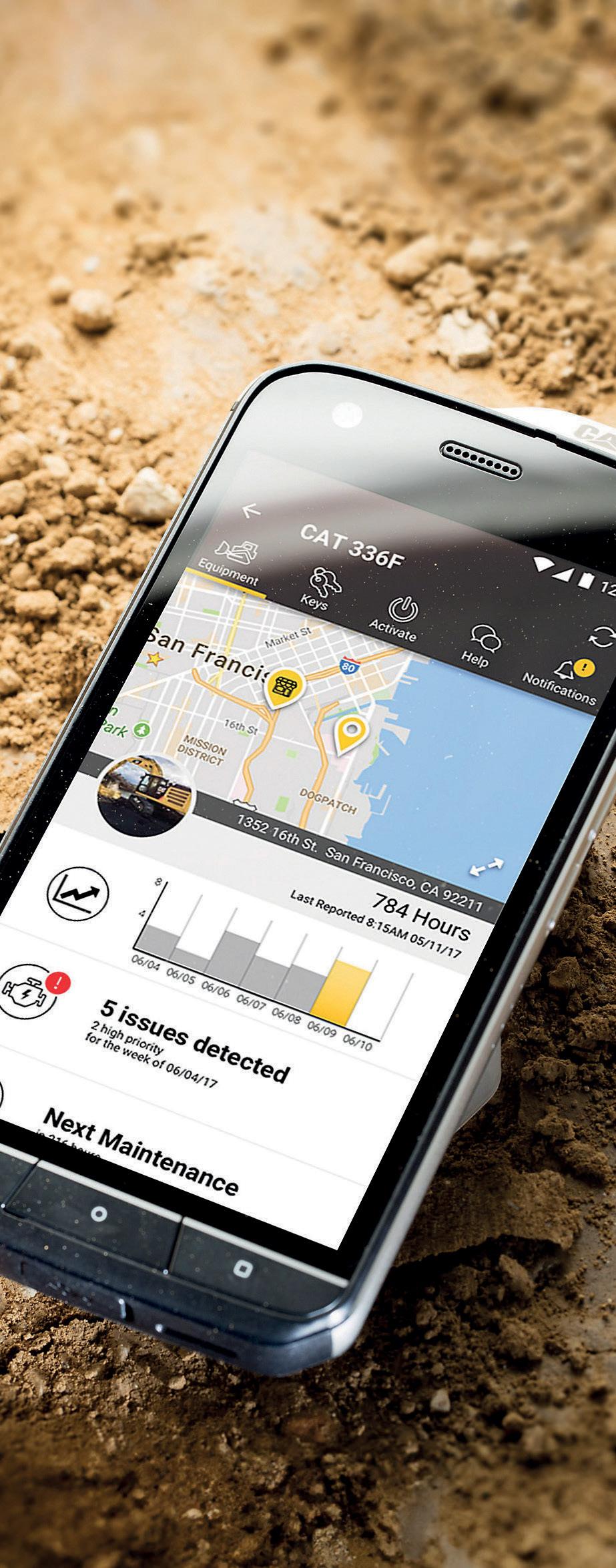

CASE CE continuously incorporates technological advancements into its equipment to benefit Middle Eastern customers. These innovations focus on

improving reliability, ease of maintenance, and fuel efficiency. CASE CE is committed to introducing new technologies that cater to the region’s specific needs, ensuring their equipment remains at the forefront of construction solutions.

To ensure high levels of customer service, CASE CE leverages a robust dealer network, frequent customer visits, and tailored solutions. The company’s aftermarket support infrastructure in the Middle East includes a network of qualified technicians and readily available parts, minimizing downtime and maximizing equipment lifespan.

CASE CE adheres to stringent environmental regulations, focusing on enhancing the energy efficiency and

“The compact size and superior maneuverability of CASE skid steers make them ideal for navigating congested areas and complex job sites”

emissions profiles of their equipment. As a global company, CASE CE is prepared to implement solutions developed for other markets to meet customer demands in the Middle East.

Operator and maintenance training are crucial for maximising equipment efficiency and longevity. A recent study published in the Construction Management Journal found that 25% machine failures were caused due to the operators exceeding the machine limits. On the maintenance side, 45% of all machine failures were due to poor periodic maintenance with 30% of failures due to not enforcing a daily inspection report. CASE CE therefore provides comprehensive training programs to ensure operators are well-versed in using and maintaining their machines. Proper training helps reduce operational costs and machine downtime, significantly improving overall performance.

This approach demonstrates how CASE CE’s dedication extends beyond selling equipment. The company invests in the future of the Middle East by providing high-quality, efficient machines, innovative solutions, and exceptional customer service. By understanding the specific challenges of the region and adapting their strategy accordingly, CASE CE empowers construction professionals to succeed, contributing to the ongoing development of the Middle East.

The Middle East construction landscape presents a unique set of hurdles. Scorching heat, rugged terrain, and economic considerations all demand equipment that’s as resilient as it is efficient. CASE Construction Equipment isn’t just building machines; it is crafting solutions specifically designed to thrive in this demanding region.

CASE CE understands that operator well-being directly impacts productivity. Their backhoe loaders and skid steers, like the V-Series, boast extra-large cabs for ample legroom and superior ergonomics. This translates to reduced fatigue and increased focus, even under a relentless sun.

The battle against heat doesn’t end with comfort. CASE CE equips their machines with a strategically positioned cooling system throughout the cab.

CASE CE machines are also built with high-quality materials and robust engineering to withstand the rigors of Middle Eastern terrain. This translates to fewer breakdowns and lower maintenance costs, keeping projects on schedule and within budget.

Fuel costs are a significant concern in the region and CASE CE prioritises fuelefficient engines and technologies that deliver optimal performance without compromising on power. This translates to reduced operating expenses and a healthy bottom line for construction companies.

CASE CE actively researches and analyses the evolving needs of the Middle East construction industry. This allows the manufacturer to tailor its product offerings and services to address specific challenges faced by regional customers.

The Middle East requires strong design, highly reliable, machines that are easy to maintain with low TCO. A truly global company, CASE CE continues to serve several markets in the region by meeting all safety and emission regulations, and ensures It is ready to meet any customer’s requirement, in any market, and whenever the customer needs world class equipment and support.

“If you want to be a leader in the market, you must ensure that you are leading this whole transition and are at the forefront for your customers”

Mammoet believes it zero-emission lifting and transport on site is now practical and help its customers reduce the carbon footprint of projects.

“If you ask me what my main vision is, I want us to redefine the construction site - at least at small scale initially - where we have electric or hydrogen cars, electric cranes, electric trucks, and have all this equipment cross-link and charge each other,” chimes Mammoet Head of Sustainability Mathias Hoogstra.

“An energy hub or energy balancing system would know where to direct power efficiently during a project. Equipment with the lowest energy would be fed by the equipment with the highest, or when required powered by additional external sources like hydrogen or bio-fuel generators. So, by design, we focus on exchanging energy as efficiently as possible and becoming zero-emission on site”.

As a leader in heavy lifting and transportation, Mammoet sees sustainability as an important factor in the future of its industry. But given the huge loads it deals with; electrifying fleets of cranes and selfpropelled trailers has for years felt like a pipe dream.

Thanks to recent developments, the company can now credibly offer a whole project solution without tailpipe emissions – using equipment that it has already introduced to the market. The sustainable revolution is gathering pace in heavy industry, with large rewards on offer for those nimble enough to adapt.

Hoogstra continues: “You see now, in government legislation but also in the tendering process, solutions that are adhering to zero emissions score more points. In the past this was the case, but the delta is becoming more and more significant in the value chain.

“I wouldn’t say the whole flood wave is already there, but the first change is starting. If you want to be a leader in the market, in my opinion, you must ensure that you are leading this whole transition and are at the forefront for your customers.”

Rafael Martinez, Sales Manager for the civil sector at Mammoet, has noticed the requirement for sustainable heavy lifting and transport growing over a number of years.

“Low or zero-emission conditions are becoming more common these days”, says Martinez. “There are sometimes very specific needs to drive down the carbon impact of projects, originated by local particularities or restrictions by public entities, like projects within congested urban environments, or environmentally protected areas. In Europe, this is something we are already seeing for tunnels”.

Martinez is clear that we have reached the point where there is no turning back, and this is something that all companies must implement to succeed.

“It can go faster in some sectors and countries, slower in others. Ultimately, we are all on this trajectory and all businesses must adapt and prepare. From a public opinion perspective, no-one will be able to sell the need for more diesel-powered machines on-site. It is starting to become more important, and in certain cases it becomes key,” he continues. “In fact, projects that generate significant carbon emissions find it more and more difficult to secure funding from large financial institutions”.

Mammoet has been investing in ways to make its equipment less diesel-reliant, to give its customers greater choice when it comes to alternative power sources and help those customers to realize benefits such as smoother permitting procedures and a lower cost of borrowing.

This has led to the scenario where, using existing equipment such as the electric SPMT transporter and the SK series of cranes, Mammoet can now offer a tailpipe emissions-free solution that could serve the entire site lifting and transport scope of a project. It’s a vision that, just a few years ago, would have seemed impossible, considering the long working hours required.

“I would say we are proving ourselves now,” says Hoogstra. “We were developing for specific markets; and from this we are

Mammoet says it has been investing in ways to make its equipment less diesel-reliant, to give its customers greater choice when it comes to alternative power sources.

now seeing that we can combine different solutions to make a whole project more sustainable, whatever the demand is.

For example, we can now execute the marshalling and pre-assembly scopes of an offshore wind farm emissions-free.

“Our focus in the civil sector is to make sure that the movements of large items, such as viaducts and bridges, can be carried out with zero emissions using hydraulics that are powered by electricity. We installed a tunnel section recently in Belgium, of 850

tonnes, and did it fully electric. So, we can do it and can scale up fast to make sure we can do more”.

The Self-Propelled Modular Transporters (SPMTs) play a key part in many of its heavy lifting projects. It made sense to look at how to electrify this key piece of equipment and offer a net zero heavy transport solution. Mammoet consulted with a trusted supplier to make an existing diesel power pack fully electric, and the first ePPU (electric Power Pack Unit) prototype was

“You see now, in government legislation but also in the tendering process, solutions that are adhering to zero emissions score more points”

tested in Mammoet’s yard in Schiedam, the Netherlands. When comparing capabilities, there is no significant difference between electric and diesel powered SPMTs. Both offer an industry-standard 40 tonnes per axle line. The power packs are the same size and fit in the same position on the transporters. They also operate in the same way, driving the hydraulics and powertrain.

In terms of charging, the pack can go from 0 to 100% in approximately five and a half hours, meaning it can charge overnight – no significant change from the current scenario, where transporters generally lie idle at night.

“New technology like the ePPU are helping to breathe new life into existing Mammoet equipment,” says Niek Bezuijen, Global Sustainability Advisor at Mammoet.

“We nominated an old power pack to upgrade, which didn’t work as efficiently anymore. From a sustainability perspective, we thought: why don’t we retrofit it and make it electric because this results in a tailpipe zero-emission solution, and less waste?

“By reusing this equipment, we avoid the carbon impact of discarding it, the production cycle needed to create an allnew electric replacement, and – of course – the diesel emissions that the former equipment would have emitted when used.”

The goal of Mammoet’s work is to offer its customer a range of options for lowering the carbon impact of projects. So, it is looking into zero-emission operations, of all kinds.

“A hydrogen power feasibility test was carried out by skidding a single electrical transformer. The hydraulic system uses a hydrogen generator to perform the skidding operation. This solution emits only water vapour. For practical reasons it is more favorable to do the operation electrically, via the grid, or with a battery,” says Bezuijen. “In remote areas, it is often still possible to bring a battery pack, because jacking and skidding at the lower tonnages doesn’t require much energy – this is what we discovered with the test using hydrogen, in fact. We performed the same test with the battery, and to put an electrical transformer in place we only used seven kilowatt-hours (kWh). To put that into perspective, a Tesla has around 60 or 70kWh of battery, so we only used 10% of that”.

Electric-powered cranes have been a focus for some time. It has engineered zeroemission offshore wind and onshore wind cranes, and the SK series of cranes has been a staple of its fleet for over a decade. The SK range is notable among ring cranes in that its hydraulics run from an electric motor, powered by a generator. The SKs are great for construction projects that require a ring crane to be on site for a long period of time.

But what about projects needing faster and shorter crane mobilisation? To address this challenge, Mammoet recently developed a 100t mobile crane with a fully electric cab.

The company is primed to offer its customer a range of options for lowering the carbon impact of projects.

“This LTM 1095 crane was four years old,” says Bezuijen. “We decided to do a retrofit and use it as an opportunity to learn more about the electrification of our equipment. We also wanted to push the market for these types of cranes towards zero emission. The upper carrier (the cab) is fully electric. It has a 105kWh battery inside, so we can run

basically a normal working day with it. We conducted some tests a couple of months ago and the crane is now ready to operate.”

“The crane’s pre-existing engine was actually still in good condition, so we were able to use it to breathe new life into another crane in the fleet whose drivetrain was approaching end-of-life, and again reduce waste”.

One of the biggest barriers for these technologies is budget. This is something that Mammoet is mindful of and has considered in its vision for sustainability. Through innovation, it wants to support heavy industry to find energy savings to offset the potential costs of going green. Hoogstra believes the transition to electric, hydrogen and biofuel powered equipment - and a change in mindset - hold the answer: “In previous years, we were looking to reduce usage of diesel on site. Now, we are taking a step further to monitor energy usage in an electric power environment and actively steer on efficient execution. We are conducting tests with our range of electric equipment to determine typical power usage per shift. This will help our customers to put appropriate and costeffective electricity infrastructure in place, best suited to the project at hand.”

All that remains, is to put these plans into action, says Hoogstra: “We are looking forward to speeding up the whole process based on the needs of our customers. As such, we are looking for participants among our customer base that want to work with us and take these steps together.”

As the Euro Auctions Group continues its global expansion, the opening of its new Middle East corporate HQ in Abu Dhabi for the 24th of June sale will attract a global audience of buyers and sellers of used construction machinery and commercial vehicles.

Attracting vendors from across the Gulf, India, China and East Asia, the Abu Dhabi

site invites sellers seeking a world audience to trade with Euro Auctions. And while online buying is strong at all Euro Auctions sales, it is still the preference of Middle East buyers to attend live sales and bid in person on the day.

Operating 12 global auction sites for the disposal of construction equipment and commercial vehicles in the Middle East, Europe, Australia, Canada and the USA and the new Euro Auctions

‘Gulf HQ’ is the next step in that global expansion, making the Euro Auctions Group the largest privately owned auction business in the world.

With the appetite to be the biggest in the Gulf, Richard Sweatt, Country Manager for the Middle East and Asia, comments.

“We are delighted to welcome the world to our new facility in Abu Dhabi. As a global business, Euro Auctions has experienced rapid growth in the last two years with expansion in North America with the acquisition of the Michener Allen group in Canada, the business now spans 4 continents, with auction sites in 8 countries, operating 12 sites and selling over 150,000 lots each year.”

“This new site in the Khalifa Economic Zone

in Abu Dhabi is pivotal to our expansion plans in EMEA and East Asia. We are planning 4 to 6 live sales per year on this site, specialising in the sale of high value construction machinery and commercial vehicles and Abu Dhabi provides us with the opportunity and the appetite to further develop within this region.”

“The value of individual lots is increasing at each sale, selling high value, quality units, and we are also seeing many new consignors as our customers see the benefits of selling with us. At recent sales, many items sold for more than $100,000, notably bulldozers and dump trucks, with good 70t and 80t excavators fetching high prices. We are also seeing good consignments coming from outside of the UAE to meet the demand for fresh and low hours machines that buyers in the GULF want.”

“The Euro Auctions strength is in its network of sale sites and our teams of sales managers who are globally connected. We attract good consignors and vendors because of our ability to sell to a large global audience, with over 250,000 unique clients and selling into over 100 countries, we are able to attract a very serious buying audience.”

“In the last 6 months we have seen a huge upturn in interest from buyers coming to us for the first time, as well as an increase in the number of vendors using Euro Auctions who have never previously sold at auction before. So, this is a real testimony to the trust that sellers put in us to achieve the best price possible with Euro Auctions always achieving true market value for the sellers equipment.”

“In Abu Dhabi we are seeing a changing audience, with buyers coming to us from across Europe, Africa

and East Asia and we are seeing trade coming from the America’s and Canada. We are seeing new buyers and new sellers in volume at all our recent sales and the trend shows no sign of letting up.”

“We want sellers to sell with us, and we want buyers to buy from us because, not only do we offer some of the most competitive rates of commission in our sector, but we have one of the best facilities thus attracting the best machines and the best inventory for our buyers.”

In Egypt, Volvo excavators and articulated haulers are currently contributing to the creation of a vast canal network for a modern irrigation system.

Many contractors engaged in Egypt’s agricultural gamechanger ‘Toshka Project’ are relying on dependable, efficient Volvo machines provided by GB Auto. These machines are built for high uptime and are contributing to the timely and cost-effective completion of earthwork excavations on the irrigation megaproject.

In south Egypt, deep in the desert, massive amounts of excavation are taking place with the contribution of machinery from Volvo Construction Equipment (Volvo CE) to create high-pressure canals and basins stemming from a key section of the Nile River. Redirecting a significant share of the country’s allotted water supply from the Nile, the canals will develop and extend agricultural projects to provide much-needed crop irrigation.

Known as the ‘Toshka Project’, this megaproject is located to the west of the major Egyptian cities of Aswan and Abu Simbel and the vast reservoir of Lake Nasser across the Nile. As one of the largest man-made lakes in the world with a surface area of 2,030 m2 (5,250 km2), Lake Nasser is an ample resource to supply the modern irrigation system setup in the desert, which consists of centre pivot – or waterwheel and circle – crop irrigation.

Toshka is a multi-phase project aiming to add 600,000 acres to the current agricultural patch of Egypt, which will expand into a million acres in the near future. It involves the construction of a 50 km main transfer canal and four additional 18-26 km long side branches to transport water from Lake Nasser to the Toshka Depression.

Here, desert is transformed into agricultural land, with the water supply fuelling centre pivot irrigation systems. As the world’s largest wheat importer, Egypt annually relies on importing 50% of its needs of wheat from abroad. The Toshka Project increases Egypt’s harvest and secures an independent cultural cycle of wheat, lessening the necessity for importation from other countries, with a national target of production predicted to secure around 70% of Egypt’s needs by 2030 considering annual population growth.

Hundreds of Volvo machines are assisting on the Toshka Project supplied through GB Auto, which has been the exclusive Volvo CE dealer in Egypt since 1999. Around 30 contractors operate on different sections of the Toshka Project, with Volvo excavators and articulated haulers removing and transporting huge amounts of earthworks to create the artificial waterways.

Challenging environments

GB Auto and Volvo CE’s prominence on the Toshka Project is due in part to the success of the articulated haulers on the Suez Canal expansion. This megaproject, developed in Egypt in 2014 and 2015, has heavily contributed to the global trade and logistics industry by dramatically shortening transit times of ships and cargo vessels passing through.

“The Suez Canal Corridor Area Project required safe earthworks solutions across huge sites, and so we suggested the Volvo articulated hauler concept to our customers,” explains Amre Sheta, vice-president of construction equipment sales at GB Auto. “The results of the Suez Canal expansion project were able to be demonstrated to contractors for Toshka when it came to equipment selection and encouraged them to place their trust in us

“It is truly an honour and a privilege for Volvo contributing our expertise and innovative solutions to help shape a sustainable and transformative future for Egypt”

and Volvo as a solid success partner.”

In Egypt, increasing temperatures and heightened droughts resulting from climate change, plus the restriction of importation through the impact of global conflicts have generated a need for irrigated cropland. The Toshka Project, conceived in the 1990s and formally resumed in 2016, will now implement a regular wheat harvest cycle in the country from October to April, with additional crops grown out of season. Wheat is extremely important to Egyptian civilisation. It is a country of 110 million people where the word for bread – ‘eish’ –means ‘life’. Egypt produces between 250 to 275 million loaves daily, with government officials estimating that citizens consume almost 100 billion every year.

“It is truly an honour and a privilege for Volvo to play a vital role along with GB Auto in the Toshka Project, contributing our expertise and innovative solutions to help shape a sustainable and transformative future for Egypt,” says Michael Moulaert, commercial manager for Egypt at Volvo CE. Volvo excavators and articulated haulers secure the scope of work for this type of megaproject. Achieving peak performance with minimal fuel consumption, the EC300D crawler excavator, for example, excels in the tough conditions of the Toshka Project. The machine’s engine boasts heightened horsepower and fuel efficiency, complemented by its electro-hydraulic system, ensuring superb control and faster cycle times. Operators using the EC480D crawler excavator, meanwhile, experience

enhanced digging forces, shorter cycle times, and improved hydraulics.

Tailored for demanding off-road tasks in heavy-hauling scenarios, the Volvo A45G articulated hauler delivers consistent productivity and reliability. The A45G minimises maintenance needs, extends service intervals, and facilitates easy access to service points, collectively increasing uptime, reducing maintenance expenses, and minimising total cost of ownership and operation (TCO). Engineered for optimal

efficiency, the Volvo A45G aims to achieve maximum productivity while minimising the cost per ton.

Intrinsic to Volvo CE product design is a commitment to safety, with an aim to consistently decrease the risk of accidents and fostering safer job sites for everyone involved. Volvo CE continues to innovate in this space, getting the job done with much higher safety precautions.

Keeping downtime to a minimum

The remoteness of the Toshka Project, the difficulties of the terrain, and tight deadlines means heavy-duty performance and high uptime are essential for contractors and their Volvo machines. Obstacles of rocky topography, rich in materials, mean demanding excavation work. At a certain section, 9 km of rigid barrier was removed in order to secure the waterflow.

“Our Volvo CE customers involved in the Toshka Project need the highest uptime with the highest capacity of performance,” says Amre. “When you’re working in the middle of the desert, fuel and oil consumption, together with supply and availability of spare parts, become even more vital.”

Providing a solid foundation of aftersales with a high service team response rate, GB Auto opened a dedicated service centre in the closer urban area of Aswan, a twohour drive from the Toshka site vicinity. It is from here, instead of 750 km away from the country’s capital Cairo, that GB Auto can closely liaise with contractors to supply spare parts and technical support efficiently, when and where needed.

With rising fuel costs being an even greater factor in this type of environment, the key to fuel efficiency lies in achieving the optimal ratio of tonnes per litre –maximising productivity while minimising fuel consumption. Volvo CE offers a robust Fuel Efficiency Guarantee for its excavators, articulated haulers, and wheel loaders, with the money-saving fuel efficiency of these machines underscoring a commitment to customers’ low TCO and promoting higher productivity.

The objective of the Toshka Project to ultimately use the resources of the Nile River to minimise the importation of wheat is another chapter in Egypt’s economic recovery pathway, which has focused on improving infrastructure, including road and rail networks, and agricultural developments. The longest river in the world remains an invaluable source of life for Egyptians as it was for their ancient ancestors, now thanks in part to the contribution of GB Auto and Volvo CE.

WHY GET IT?

THE NEW RANGE ALSO ALLOWS BOBCAT TO COVER A FIFTH SEGMENT WITH 27, 35 AND 39 M ROTARY TELEHANDLERS WITH A HEAVIER LIFT CAPACITY OF UP TO 8 TONNE.

A new lineup of Bobcat rotary telehandlers – featuring the manufacturer’s patented panoramic cab, which offers unrivalled visibility – was on display at INTERMAT in Paris. The latest range comprises nine Stage V models with lifting heights of between 18 and 39 m that have been designed for European markets, and four Stage IIIA machines with lifting heights of 18 to 26 m that have been developed for use in the Middle East and Africa.

Bobcat has launched the new range of Rotary Telehandlers for markets in Europe and the Middle East and Africa. The new range offers nine Stage V powered models for the European market, covering lifting heights from 18 to 39 m and lifting capacities from 5 to 8 tonne. These are complemented by four Stage IIIA machines for sale in the Middle East and Africa, for lifting heights from 18 to 26m and lifting capacities from 5 to 6T.

The models with lifting heights from 18 to 26m are Deutz engine powered, with the higher lift models from 27 to 39m powered by Volvo engines. The same engine manufacturers are common to both the Stage IIIA and Stage V models, allowing easier maintenance and training.

One of the key aspects of the new line of rotary telehandlers is the patented panoramic cab offering the best visibility on the market and a wide range of features, including:

Inside the cab, all the Bobcat rotary telehandlers are equipped with a new dashboard with a 7 or 12In display offering a choice of three different views: the classic real-time load chart; a new boom dynamic load chart – showing only the area in which the operator can move safely with a load – and, thirdly, a 360° view from above.

The cab also offers additional interior finishes, including a new courtesy LED light behind the operator’s seat for better illumination within the cab. When not in use, the remote control system for the telehandler can now be stored inside a new dedicated compartment. A new LED light has also been inserted under the left armrest, which is activated by opening

the door and lights the floor area to make it easier when entering the cab.

With the core models available in the new rotary telehandler range, Bobcat offers a choice of solutions for four key lifting height segments, namely 18m, 21-22m, 25-26m and 30-32m, with a competitive choice in terms of machine capacities at these heights. Bobcat also offers additional models in these segments each with an additional 1 tonne in lift capacity.

The new range also allows Bobcat to cover a fifth segment with 27, 35 and 39m rotary telehandlers with a heavier lift capacity of up to 8 tonne.

MARKET INTEL TELEHANDLER MARKET CONTINUES TO GROW

The rotary telehandler market continues to grow worldwide and more than 4,500 machines were sold in 2023. The industry is heavily concentrated in Europe (85%) –with Italy, Germany, France and the Benelux countries accounting for 76% of the European market. North America.

WHY GET IT?

THE ZX390TC-7 HAS A ROBUST 25 CM LONGER UNDERCARRIAGE THAN THE STANDARD ZX350LC-7, AND IS SUPPLIED WITH AN ADDITIONAL 1.4-TONNE COUNTERWEIGHT.

Based on a Hitachi ZX350LC-7 standard excavator, with Zaxis-7 technology and Stage V-compliant engine, the new ZX390TC-7 tool carrier model has been specially adapted to work with larger working tools, and can be used for secondary demolition works.

Larger boom and bucket cylinders, and a one-class-higher reinforced linkage, enable the ZX390TC-7 to carry fivetonne tools, such as hydraulic shears for crushing that would normally be used by larger machines. It is equipped with a full hydraulic control system, suitable for use with all attachments, which can be changed within seconds from the operator’s seat. The model on display at Paris-Nord Villepinte (stand 6H039) is fitted with an OilQuick OQ80 automatic quick coupler system and Demarec crusher attachment. For added stability, the ZX390TC-7 has a robust 25 cm longer undercarriage than the standard ZX350LC-7, and is supplied with an additional 1.4-tonne counterweight. To ensure the safety of operators, the machine has side impact protection and a demolition-spec cab with FOPS guard level 2 and high-spec P5A safety glass.

FAST-ERECTING CRANE OFFERS MAXIMUM LIFTING CAPACITY WITH MINIMUM SPACE REQUIREMENTS.

With a radius of 55 m and a hook height of up to approx. 66 m, the Liebherr 125 K is currently the largest fast-erecting crane on the market. A well thought-out assembly system and low logistics costs make the Liebherr fast-erecting cranes particularly useful for shorter projects. The 125 K is, for example, ideal for work on construction projects such as multistory residential buildings, bridges and industrial facilities. It can be operated with a mobile energy storage system if the on-site power supply is insufficient. The 125 K offers an initial hook height of approx. 29.5 m as standard. Five tower sections can be inserted to reach a total hook height of approx. 42 m. This allows the crane to handle larger construction projects as well. If the hook height still isn’t sufficient, a 30° luffed jib position enables

the crane to reach a hook height of 66m. The crane has a maximum load capacity of 8,000kg and can lift up to 1,300kg with the jib head at a radius of 55m. Its exceptional flexibility is also demonstrated by its five radius options, ranging from 35m to 55m. The fast-erecting crane can be transported to site by trailer or semi-trailer with the appropriate axles. It travels as a complete unit so that it can be erected directly on site. No other tools are needed as assembly is achieved by means of low-maintenance rope kinematics. Construction site conditions are becoming increasingly tight and therefore require tower cranes to have compact dimensions to match. With its 3.2 m slewing radius, the Liebherr 125 K fasterecting crane fits into very small spaces, something unique for a crane of this size. Due to its variable slewing radius, which can be extended to 4m, the number of transportable ballasts can be reduced. In addition to familiar features such as the Micromove fine positioning mode, Load-Plus and Speed2Lift, further improvements includes new lighting with LED floodlights and radio remote control.

SPECIFICATIONS

LIEBHERR 125 K

Total hook height: 42m

Hook height plus jib: 66m

Maximum load capacity: 8t

Radius: 55m

Slewing radius: 3.5m

PROPER PLANNING AND PREPARATION

REGULAR MAINTENANCE CHECKS

Choose equipment specifically designed for road construction tasks such as excavators, graders, rollers, and paving machines. Ensure each piece of machinery is suited to the scale and specifics of the project, considering factors like engine power, capacity, and adaptability to local conditions.

Begin with thorough planning. Assess the project requirements, including the type of road, materials needed, and the terrain. Use this information to choose the right machinery and equipment layout plan that maximises efficiency and minimizes movement on site. 01 04 03 02

Conduct regular maintenance checks to avoid machinery breakdowns that can delay the project. Implement a routine maintenance schedule that includes checking fluids, filters, seals, and mechanical parts.

Ensure that all machinery operators are adequately trained not only in operation but also in daily maintenance and safety procedures. Well-trained operators can work more efficiently and safely, reducing the risk of accidents and machinery damage.

USE TECHNOLOGY AND AUTOMATION

Embrace technology such as GPS and machine control systems to enhance precision in tasks like grading and layering. Automation can significantly improve accuracy, speed up the construction process, and reduce material waste.

MONITOR PROGRESS AND ADJUST ACCORDINGLY

Keep track of progress using project management tools and adjust the use of machinery as needed. This might involve reallocating resources to different parts of the project or adjusting timelines based on the productivity and availability of specific equipment.

Prioritise safety by enforcing strict safety protocols and providing personal protective equipment. Ensure all machinery has up-todate safety features, and that emergency procedures are in place and understood by all team members.

EFFECTIVE COMMUNICATION

Maintain clear and open communication across all levels of the project team. Use communication tools effectively to coordinate between operators, supervisors, and the project management team to keep everyone informed and engaged.

ENVIRONMENTAL CONSIDERATIONS

After project completion, review the performance of the machinery and the effectiveness of the operating strategies. Gather feedback from operators and supervisors to identify areas for improvement and lessons learned for future projects. 09

Use machinery in a way that minimizes environmental impact. This includes managing noise levels, reducing emissions with newer or well-maintained machines, and ensuring proper handling and disposal of construction waste.

REVIEW AND REFLECT

05 08 07 10 06

YANMAR CE LENDS

A HAND TO A SWEDISH MAN WHO HAS

DEDICATED

HIMSELF TO SAVING AKIYAS, JAPANESE HOMES LEFT EMPTY TO FALL INTO DISREPAIR

Anton Wörmann has a lot going for him – clever, cheerful, charming and –that dream of young people everywhere – a model AND social media sensation. As if all that weren’t enough, he has also, quite by accident, stumbled onto a solution to a pressing social problem in his adopted home of Japan: making the 10 million abandoned homes in the country cool.

Japan is an outlier in many ways, but the phenomenon of homes being left empty to fall into disrepair – even in exclusive areas of major cities – is uniquely Japanese. Known as ‘akiya’ (meaning ‘vacant homes’), their abandonment is the result of several factors, including Japan’s declining

population, urbanisation, inheritance issues and simply Japan’s preference for all things new. Put simply, old buildings are not valued, not valuable – and certainly not cool.

Ready for take off

But that perception is starting to change – ever since 31 year old Anton, just for fun, started filming the renovation of his own akiya in 2020, and posting his triumphs and mishaps on social media. While doing up old properties is commonplace around the world, it’s virtually unheard of in Japan, so when Anton started publicising renovating his akiya – bought because it was cheaper than renting – it caused a sensation.

“I posted my first reel in English and just forgot about it,” says Anton. “Then a couple of days later a friend texted me from Paris to say ‘Hey dude –you’ve gone viral on TikTok! That was pretty cool

– and within days I had 50,000 followers – and a million subscribers in a couple of months – which was insane! So I just carried on making content.”

Today, Anton has more than a million followers in total on Instagram, TikTok, Facebook and YouTube – with audiences of all ages drawn from the US, Europe – evenly split between men and women. What makes his content so popular is the compelling combination of learning about Japanese culture, the oddity of these properties being so cheap and Anton’s engaging and cheerful TV skills.

And in his spare time…

As his popularity grew Anton received thousands of comments and questions from viewers about how to renovate akiyas – too many for him to attempt to answer. So his response was to capture all his learnings in print and write a best selling book on

the subject – called ‘Free houses in Japan’. Okay, so the houses aren’t free, but they can be bought for a fraction of what an equivalent property would cost anywhere else in the Western world.

As fun as it is to watch Anton’s adventures – he’s now on his fourth akiya – it has started to raise the profile of the very real – and growing – social problem akiya’s represent. (Their number is forecast to double to 20 million by 2030.)

“Japanese people love new things,” says Anton. “A house that is 30 or 40 years old is considered old – and unlike everywhere else in the Western World – their values don’t appreciate. In fact they fall until utlimately they are considered trash. Added to that, there is no renovation culture. Admittedly, many of them are ugly, but many are pretty – and I’ve even seen beautiful 150 year old townhouses abandoned. It’s really sad to see them so neglected.”

Anton doesn’t just return his akiyas to their previous state, he also makes them more sustainable; adding insulation, improving earthquake resistence and generally modernising them – all the while retaining their special character. And as they still don’t have a high value even after restoratation, Anton hasn’t sold his renovated akiyas, but rather rents them out to tourists. All-in-all, he’s come a long way from being the boy who helped his parents renovate their 150 year old home in Stockholm, Sweden…

“I think my reels show that we don’t need to buy new-new-new all the time – with all the concrete and raw materials that go with it,” says Anton. We

need to start valuing older homes – it’s a much more sustainable message and better for the planet. I’m happy to be a part of that movement. I didn’t expect any of it – it’s changed my life in so many ways.”

The likes of international investors and American documentary makers are all queueing up to support his efforts to save akiyas (even Yanmar CE lent him a compact excavator) – but is that what he really wants? Does he just want to be an influencer on social media – or would he rather be an activist that started a movement to save Japan’s unloved houses?

The unlikely radical

“What I’m doing is really not complicated – anyone could do it,” Anton says. “As long as I’m able to inspire people then I’m happy. I think someone needs to promote the many benefits of saving old houses, debunk the myths and show people how it can be done,” he says. “If people like what I do I’ll keep doing it. People in Japan and the Japanese media are starting to get interested –doing up akiyas is slowly becoming a thing. And in a strange way I think it needs to be a foreigner that shines a light on the great potential of saving old homes in Japan.”

With his popularity growing even Anton’s Japanese friends no longer think he’s crazy. While Do It Yourself renovation might not be the complete answer to Japan’s problem of abandoned homes, those that are renovated will help save resources and remove eyesores from local communities.

ELECTRIC MACHINERY A FUTURE-READY SERIES

Yanmar Compact Equipment (Yanmar CE) has launched a trio that includes fully electric wheel loader, mini-excavator, and tracked carrier, which together are the vanguard of the construction sites of tomorrow. The zero emission and cordless-in-use V8e, SV17e and C08e matches the output of Yanmar CE’s renowned internal combustion engine (ICE) compact equipment, ensuring seamless integration into a broad scope of applications. From landscaping and utility to urban and indoor construction, operators can be sure that these machines are ready to tackle even the toughest demands, all while exceeding the most stringent emission legislations, claims the firm.

Wrecently to form the centrepiece of a new and daring action-packed show - The Legend of the Trebuchet - the castle needed a way to provide the correct tensioning for this monster of ancient and medieval warfare. Hearing the call to arms, Hoist & Winch duly supplied a Hadef electric winch offering 1500kg pulling force (safe working load) with supporting frame and foundations. The trebuchet is an authentic recreation of one of the biggest and most deadly war machines of all time. Using a long rotating arm and the principles of leverage to launch projectiles from a sling, a trebuchet is essentially a huge catapult. It was powerful enough to hurl rocks that could breach castle walls. Sometimes it would even launch manure and dead animals into besieged castles to spread disease. It remained a warfare weapon until the 15th century, when gunpowder and cannons came to the fore.

After an initial site survey to discuss the requirements of this highly unusual application and specify the winch design features, Hoist & Winch returned to oversee a test fire of the trebuchet and measure its pulling force with a load cell and site tractor. Once complete, Hoist & Winch was in position to make a formal offer, comprising fully specified winch, mounting frame and foundation.

The Hadef electric winch offers up to 1500kg of pulling force

At the centre is a Hadef 400V, three-phase, 50Hz electric winch that delivers 1.5t pulling force from its 25m rope length. Control is via a lowvoltage radio remote with backup plug-in pendant. Features of note include: a pressure roller for the wire rope drum; fourposition top/bottom geared limit switches; a galvanised steel mounting frame for the winch; and electrical enclosures with IP66 protection rating.

In the lead-up to a new show - The Legend of the Trebuchet - Warwick Castle needed a highperformance electric winch to ensure reliable and repeatable tensioning of the trebuchet prior to launch.. The choice was a Hadef electric-powered wire-rope winch, delivered and installed by Hoist & Winch as part of a turnkey project.

Following order receipt and drawing approval, Hoist & Winch commenced on-site installation and commissioning, a process that included individual hydraulic pull tests of the resin anchor bolts for the winch frame. Test firing of the trebuchet also took place with measurement of the pulling force using a load cell for the LOLER (Lifting Operations and Lifting Equipment Regulations) certificate. Hoist & Winch also took care of customer handover training and issue of the LOLER Thorough Examination report.

When it’s hard. When it’s painful. When it’s loud. TADANO Rough-terrain crane GR series has it covered. Demonstrating impressive robustness and high performance, our line-up from 13t to 145t rough-terrain cranes feature state-of-the-art technology to handle even the most demanding requirements. With efficient motors, the longest boom in its class (GR-1000EX-4), compact design and smart assistant systems, everything is on board for maximum success. The GR series: maximum flexibility for your success.