PLUS IT’S YOUR CALL THE LIFE OF AN AUCTION CALLER

RENTAL REPORT

WHAT NEXT FOR THE SECTOR?

MACHINERY LAUNCH

PLUS IT’S YOUR CALL THE LIFE OF AN AUCTION CALLER

RENTAL REPORT

WHAT NEXT FOR THE SECTOR?

MACHINERY LAUNCH

A SPECIAL LOOK AT JCB’S NEW KIT LAUNCH IN DUBAI, INCLUDING THE LATEST 3CX

Kanoo Cranes lifting requirements with knowledgeable combined experience of more than 50 years with Mobile cranes,Crawler cranes, Tower cranes and

• SMIE-Anti collision

• JASO

• SPIERINGS

• MAEDA

Our Focus is to provide engineered crane solutions to the Construction, Oil and Gas and Industrial markets.

06_NEWS

The major news stories and company moves this month.

12_THE MAGIC MACHINE

JCB introduces the latest iteration of the 3CX and talks to CMME about staying ahead of the competition.

16_TIME TO CALL IT

CMME finds out what life is like as an auction caller.

22_RENTAL ROUNDTABLE

The future of the rental market in the UAE and Saudi Arabia looks set to see the two locked together.

30_NEW RELEASES

The latest releases from the world of construction machinery.

32_TOP TEN TIPS: PILING RIGS

The best advice for setting up your piling rig

34_TURKEY EARTHQUAKE

Survivors discuss rebuilding their lives a year on from the disaster.

36_LAST WORD Mammoet trials an all-round view for its mobile crane fleet.

As you may have heard by now, Construction Machinery is returning to Saudi Arabia with the inaugural Saudi Arabia Heavy Equipment and Trucks (HEAT) Show this November –and I cannot wait!

The HEAT Show which will be held in Dammam is an evolution of our Construction Machinery Show and it will be my first event in the Kingdom for over five years, and so much has changed since last one in Jeddah.

The Kingdom of Saudi Arabia’s ambitious infrastructure projects have always been a focal point of discussion in our industry, but this event marks a seminal moment, not just for Saudi Arabia but for the entire Middle East’s construction machinery sector.

Saudi Arabia, with its Vision 2030, has boldly set the stage for unprecedented growth and innovation in construction and infrastructure development. The HEAT Show, set against this backdrop, is not merely an exhibition but a testament to the Kingdom’s pivotal role in shaping the future of the construction machinery and heavy equipment landscape.

The show promises a great opportunity for manufacturers, dealers, and service providers to showcase the latest in heavy machinery, trucks, and construction equipment. More than that, I hope it can be a melting pot for ideas, technology transfer, and partnerships that could redefine industry standards.

As the leading voice for the construction equipment sector in the Middle East, Construction Machinery Middle East is excited to announce its support for the HEAT Show. I believe this event will be a cornerstone for not only understanding the current market dynamics but also for forecasting the future trends that will

govern our industry. The timing could not be better either.

As Saudi Arabia accelerates its construction and infrastructure projects, the demand for heavy equipment and trucks is at an all-time high. The HEAT Show will offer a unique lens through which we can view the innovations and solutions poised to meet this growing demand.

We encourage our readers, from industry veterans to newcomers, to come to this event. Whether you’re looking to expand your business network, explore the latest technologies, or simply gain insights into the Saudi Arabian and wider Middle Eastern markets, the HEAT Show is where you need to be this November.

Obviously, Construction Machinery Middle East is committed to bringing you comprehensive coverage of the event, including exclusive interviews, product launches, and expert analyses. Personally, I believe that the insights and contacts gained from the HEAT Show will be instrumental in driving our industry forward, fostering innovation, and encouraging higher standards across the board.

Before we head to Dammam though, there is the Construction Machinery ME Awards in Dubai. The event site is now live, so it’s time to get your nominations uploaded ahead of the voting campaign in May!

Advanced Crawler Excavators

Owners Pride Wheeled Excavators Wheel Loaders

Advanced Crawler Excavators

Owners Pride Wheeled Excavators Wheel Loaders

FINANCIAL

Government commits new capital to RAK Properties

INFRASTRUCTURE

Works begin on Zuluf water treatment plant says Fisia Italimpianti

CONSTRUCTION

RTA to launch WO-RK co-working space at BurJuman metro station

INFRASTRUCTURE

Cooling contract worth $187mn awarded for Diriyah

INFRASTRUCTURE

Abu Dhabi’s Taweelah desalination plant begins operations

ANALYSIS: Construction costs in the Middle East set to rise by up to 7% in 2024

INTERVIEW: Sustainable growth

INTERVIEW: Building the Blueprint for a Sustainable Tomorrow

DIVERSITY

AECOM celebrates UN’s #InvestInWomen theme on International Women’s Day Achieving gender equality in all aspects of life is more crucial than ever if we want to create prosperous economies and a sustainable planet

PROPERTY

Eagle Hills International launches Bahrain JV

New entity backed by $4bn funding from Abu Dhabi titan and local investment consortium

INFRASTRUCTURE

AD Ports Group inks deal for 60% stake in Tbilisi Dry Port

CONSTRUCTION

New beaches announced for Yas Bay Waterfront

CONSTRUCTION

Kingdom City sold for US $240mn Kingdom Holding Company will retain partial interest via new owner’s real estate fund

EVENT

LOGISTICS

Bahri begins build on new logistics centre at Jeddah Islamic Port Designed to cater to a broad spectrum of storage needs, Bahri Logistics Center features temperature-controlled areas and handling services

CONSTRUCTION

Deals worth US $2.6bn finalised for Sultan Haitham City Oman completes more than 35 development and partnership agreements for Phase One of the prestigious urban development

1 May 2024

Dubai / UAE

REGISTER NOW

Heavy Equipment and Truck Show to take place in Dammam 18-21 Nov 2024

CONSTRUCTION

RIB Software survey reveals positive outlook for 2024

CONSTRUCTION

Oman to partner with ICC for new building codes

The Heavy Equipment and Truck (HEAT) Show, a premier event in the world of commercial vehicles and heavy machinery, is set to take place from 18-21 November 2024 at the Dhahran Expo in Dammam, Saudi Arabia.

The landmark exhibition, the largest of its kind in Saudi Arabia, is strategically positioned in the epicentre of the oil and gas industry and aims to showcase the latest in heavy equipment, trucks, and transportation solutions, reflecting the need for dynamic innovations at a time of unprecedented growth in the Kingdom.

Over four days, the HEAT Show will bring together manufacturers, distributors, industry experts, and key stakeholders from across the region and beyond to explore the latest trends, technologies, and advancements in heavy machinery and vehicles. The event is designed to encourage business opportunities, networking, and knowledge exchange, catering to

the growing demands and challenges of the exciting Saudi Arabian market. The exhibition serves as an international platform, welcoming attendees from diverse sectors such as construction, logistics, and energy. This gathering is an ideal opportunity for professionals to source new technology and forge strategic partnerships that are vital for industry advancement. Moreover, the event is carefully tailored to address the specific needs of the construction and oil & gas sectors, showcasing specialized heavy equipment and vehicles. Attendees will have the chance to discover cutting-edge technologies and innovative solutions aimed at enhancing operational efficiency, safety, and sustainability. Furthermore, the event features live demonstrations, allowing participants to witness firsthand the power and capabilities of the latest heavy machinery and trucks, adding a dynamic and interactive element to the exhibition experience.

CRANES WOLFF AND ZAMIL

TARGET 300 CRANE

RENTAL FLEET AFTER AGREEING SAUDI MANUFACTURING DEAL

Mammoet has entered into a strategic partnership with Aertssen Machinery Services (AMS) bringing two of the biggest names in heavylift operations together in the major oil and gas producing country. The collaboration between heavy transport specialist Mammoet and the renowned Belgian-origin heavy-lifting company marks a pivotal moment in the two companies’ histories in the Middle East.

The new partners said they had join forces to meet the increasing demands of Qatar’s growing market, driven by robust capital and operational expenditures in the energy sector.

Wolffkran, the leading crane manufacturer, has partnered with the Zamil Group, a major Saudi investment holding company.

Agreed in early February in Riyadh, this joint venture aims to establish a WOLFF crane manufacturing facility in Saudi Arabia and amass a rental fleet of 300 cranes,ccc.

Duncan Salt, CEO of Wolffkran Holding AG, expressed pride in leading the way in Saudi Arabia’s dynamic construction sector, citing the current construction boom as a prime opportunity for local production. Dr. Peter Schiefer, owner and Wolffkran Board member, lauded the synergy the partnership with Zamil Group, known for its strong local presence and expertise in construction, real estate, and steel construction, promises.

“Saudi Arabia is currently experiencing a construction boom and we are proud to be pioneering this dynamic market with local tower crane production,” said Duncan Salt, CEO of Wolffkran Holding AG, at the signing of the contract at the Private Sector Forum 2024 in Riyadh.

“In the Zamil Group, we have found a strong partner for this project,” said Dr. Peter Schiefer, owner and member of the Board of Directors of Wolffkran Holding AG. “A partnership that will create many synergy effects.”

The long-established family business based in Khobar not only has an excellent local network, but also has many years of experience in the construction, real estate, and steel construction sectors.

The two partners said that they are currently looking for a suitable location in The Kingdom for the state-of-the-art production facility as their step. .

When it’s hard. When it’s painful. When it’s loud. TADANO Rough-terrain crane GR series has it covered. Demonstrating impressive robustness and high performance, our line-up from 13t to 145t rough-terrain cranes feature state-of-the-art technology to handle even the most demanding requirements. With efficient motors, the longest boom in its class (GR-1000EX-4), compact design and smart assistant systems, everything is on board for maximum success. The GR series: maximum flexibility for your success.

www.tadano.com

Ritchie Bros. has partnered with a leading banking group in the MENAT region, Emirates NBD, to provide a financing option that allows customers the opportunity to purchase items without having to pay in one lump sum.

“As a trusted global marketplace for insights, services, and transaction solutions, Ritchie Bros. is constantly looking at ways to make acquiring heavy machinery easy for buyers,” said the company in a statement.

According to the UAE

Construction Equipment Market Report 2023, the country has seen a surge in investments in public infrastructure to boost sales of road construction equipment. This has contributed to the rising demand for heavy machinery, leading to more companies searching for financially flexible ways to source equipment for their projects. The Dubai government has allocated 8% of total expenditures to construction projects. This is a 34% increase on the spending planned versus

2023, which shows a strong commitment to developing infrastructure, thus raising the need for more heavy machinery and financing methods to supply the demand for these machines.

Shirin Bazargan, Regional Operations Manager at Ritchie Bros.’ Dubai office, outlined the process of using the financing service through Emirates NBD: “We worked closely with Emirates NBD to ensure the process of securing financing when purchasing our machines was as seamless as possible. Getting your equipment financed is as easy as filling in the online form on the Emirates NBD website, getting a call back from a banking representative to confirm if the machine you chose is eligible for financing, and signing the contract once your request is approved.”

“We are excited to be continuing our collaboration with a dynamic partner like Emirates NBD to give our clients access to a broader range of equipment.

Terex Rough Terrain Cranes has agreed to appoint Zahid Tractor as its authorised distributor for Saudi Arabia. Zahid Tractor will offer the complete portfolio of Terex Rough Terrain Cranes and provide local parts, service, and technical support, the two companies confirmed. Zahid Tractor was established in 1967 and has evolved into three core business units – Construction Machinery, Commercial Vehicles and Rental. One of the biggest distributors in KSA, the company serves several industries, including construction and infrastructure, industrial, logistics and warehousing, agriculture, transportation, petroleum, mining, and quarry and aggregates. They provide excellence in customer solutions through a highly motivated workforce in partnership with leading global quality suppliers, such as Caterpillar, Ingersoll Rand, UD Trucks and Doosan.

WakeCap has launched VerifyTime, a cloud-based workforce management solution that automates, verifies, and streamlines manual timekeeping processes on construction sites. Where hours, equipment, and other costs must be measured, a role that falls to the site team and can be prone to errors. VerifyTime replaces conventional timekeeping, promising a new level of transparency. Built on WakeCap’s sensor technology hardware and data analytics software, it collects data via a knob attached to standard worker safety helmets. An easy-to-install network connects the site to WakeCap’s secure cloud network. VerifyTime delivers ‘at-your fingertips’ data in an easy-to-understand visual dashboard format to site owners and payroll managers.

The recent ARA Show in New Orleans played host to a unique and challenging contest organised by Genie, a notable event that has captured the attention of the equipment rental industry. At the heart of the competition was the aim to win a Genie® GTH-5519 telehandler, along with a new telehandler auger attachment—a prize that was claimed by Jared Hicks, General Manager of Bootheel Parts & Equipment based in Poplar Bluff, Missouri, after a rigorous two-day endurance test.

Contestants were required to stand on podiums around the Genie machine for as long as possible during the show, from February 19th to 21st, with additional time credits for correctly answering trivia questions. Hicks emerged

victorious with a total of 18 hours, 40 minutes, and 40 seconds, showcasing not only physical stamina but also quick thinking and a broad knowledge base.

On his win, Hicks shared

his strategy and excitement, emphasizing the physical and mental preparation that went into the competition.

The significance of the victory was not just personal but

also professional, as the prize telehandler promises to be a valuable asset for his company, Bootheel Parts & Equipment, which serves a diverse clientele including contractors, homeowners, and event planners in the tri-state area. The competition also highlighted the personal touch and customercentric approach of local businesses like Bootheel Parts & Equipment, which has been a fixture in its community for over two decades.

Keith Hovey, from Genie, commented on the intention behind the competition—to demonstrate the resilience of their telehandler family through a test of human endurance and intellect. The event was not just about the toughness of machinery but also celebrated the spirit and dedication of those in the industry.

The Metro Line 3 in Panama is setting new standards for public infrastructure projects in Latin America. And that’s not only because this project is the largest construction project since the expansion of the Panama Canal. After commissioning of the new line, planned for 2026, traffic congestion in the city should be reduced significantly. At the same time, the population will have access to fast, efficient and sustainable public transportation that will offer considerably shorter travel times than before. Both of these factors mean enormous gains in quality of life for the region’s residents.

The new 34 km railway between the stations of Albrook and Ciudad del

Futuro is predominantly designed as an above-ground monorail. However, a 6 km section that crosses the Panama Canal will run underground. A tunnel boring machine is being used to construct the required tunnel for this section. But before the machine can start its work, a starter shaft is needed first. The HPH joint venture – comprising Hyundai Engineering & Construction, Posco and Hyundai Engineering Co., Ltd. – tasked BAUER Fundaciones Panama S.A., a subsidiary of BAUER Spezialtiefbau GmbH, with the diaphragm wall work. The scope of service also included installing barrettes along with jet grouting work.

Bauer’s work on this section of project began in July 2023 and is planned to continue until October

2024. The work is divided into two phases: In the first phase, which has already been completed, Bauer constructed 4,837 m3 of diaphragm wall for the starter shaft.

“In the second phase, the elevated railway section will be connected with the underground section using the cut and cover method. An additional 12,000 m3 of diaphragm wall still need to be constructed for this phase,” explains Alejandro de la Rosa, Project Manager at Bauer Panama. For both work phases, the equipment in use included two MC duty-cycle crane and two BC cutter units from Bauer Maschinen, several KR rigs from KLEMM Bohrtechnik as well as a BE 500 plant from BAUER MAT Slurry Handling Systems.

“Good planning and organization, as always, are crucial for success,” emphasizes Alejandro de la Rosa. The biggest challenges were the tight schedule and tough soil conditions. Cutting work in stone with strengths of up to 195 MPa was particularly difficult. In some cases, the diaphragm walls were also embedded up to a depth of 15 m in weathered and solid rock. To categorise the rock classes, 57 drillings were carried out in advance.

The project manager proudly reports: “Thanks to a fantastic team and excellent effort, we have been able to manage these challenges without a problem. We are currently running on time and are optimistic that we will be able to finish the work according to schedule.”

In the ultra-competitive world of construction machinery, JCB wants to claim it has once again set a benchmark with the launch of its latest machinery in the Middle East market.

Since 1964, JCB has been at the forefront of creating large track machines, and today, its comprehensive range of both tracked and wheeled machines caters to the global market’s diverse needs. The launch event in Dubai, a display of JCB’s enduring commitment to refreshing its line-up, showcased he evolution of the iconic 3CX range of backhoe loaders and introduced the robust JS 385 HD excavator.

Last month, JCB unveiled its updated 3CX range of backhoe loaders alongside its new heavy-duty excavators at the Jebel Ali Shooting Range in Dubai, marking a leap forward in its offering in terms of machinery innovation and efficiency for the Middle East market.

The launch event showcased the evolution of JCB’s flagship 3CX range, which includes the base model 3CX, the enhanced 3CX Plus, and the topof-the-line 3CX PRO. Each model is designed with specific operational needs in mind, from the 55kW naturally-aspirated diesel engine of the 3CX to the turbocharged 68kW engine powering the 3CX Plus and 3CX PRO models.

The 3CX series promises versatility and efficiency, featuring options like a general purpose or six-inone front shovel, fixed or extending dipper arms, and various bucket and hammer pipework options. Notably, the 3CX PRO model introduces seatmounted servo controls for unprecedented control and visibility, alongside a suite of standard features aimed at enhancing productivity and fuel efficiency.

Richard Brooks, Group Product Innovation Director at JCB, highlighted the significant

investment behind this new range, emphasising JCB’s commitment to maintaining its leadership in the backhoe loader market. According to Brooks, these updates are set to make the JCB 3CX range even more operator-friendly, significantly improving efficiency, productivity, and operator comfort.

The backhoe loader, celebrating 70 years of production, remains one of the construction industry’s most versatile and sought-after machines. JCB says its new range not only commemorates this legacy but also sets a new standard for the future, optimising the combination of the loading shovel, forklift, excavator, and tool carrier into one machine.

As the construction sector continues to evolve, JCB claims the updated 3CX backhoe loaders and the new JS385LC HD excavator are poised to lead the way, offering cutting-edge solutions that promise to transform worksite operations and contribute to the industry’s sustainable development goals.

JCB’s backhoe loaders have become synonymous with versatility and performance and the 3CX, 3CX Plus, and 3CX PRO models represent the culmination of seven decades of product evolution, designed to meet the modern demands of construction professionals. With the construction industry booming and the market for backhoe loaders surpassing 100,000 units in 2023, JCB wants its latest offerings to lead the charge in terms of innovation in the market.

The 3CX series, renowned for its loader and excavator capabilities, now features enhanced models tailored for the non-legislative market, which comprises up to 65% of the opportunity in the large track excavator segments. From 8 tons to 240 tons, the 3CX range is engineered for durability, higher productivity, better fuel efficiency, and lower cost of ownership, all while ensuring operator safety and comfort.

“It’s where it started for us. We are 70 years into making backhoe loaders and through those 70 years we’ve learned just a little bit about manufacturing backhoe loaders and what we’ve worked out that is innovation is the key to keeping that product alive”

“The backhoe loader business is where it all started for JCB. So, it’s an enormous pleasure to launch these products,” said Ed Lovatt, Regional Manager- Export Sales at JCB “It’s where it started for us. We are 70 years into making backhoe loaders and through those 70 years we’ve learned just a little bit about manufacturing backhoe loaders and what we’ve worked out that is innovation is the key to keeping that product alive.”

He adds that JCB has been working on making the product better and more productive, more efficient and more comfortable for operators. The market where it leads is vast, he adds, at over 100,000 units in 2023. Driven by JCB’s India and Brazilian powerful manufacturing setup, the biggest proportion of the market is the non legislated market sector which JCB makes up 80% of the market it dominates.

“Market share is not the only barometer because we know the future growth for the backhoe loader business is going to come. From the non-legislative markets and we expect the exponential growth that we’ve seen over the past few years to continue and we of course want to be at the lead of that growth,” Lovatt remarks.

“You see that backhoe loaders sold from our competitors are just previous generation machines. This is from the ground up, a new product that has been developed specifically to meet the customer needs in your region.”

At the heart of JCB’s new offerings is the desire to enhance productivity without compromising on fuel efficiency or the operator’s comfort and safety. The ability of the new 3CX series to load a 20-ton lorry in under five minutes is a demonstration of a rate and as yet unmatched efficiency. This impressive performance is not just limited to loading. The backhoe loader moves material up to 20% faster than a conventional 13-ton excavator, showcasing its superior design and engineering.

Moreover, the new easy shift transmission enables the backhoe loader to reach speeds of 40 kilometers an hour, significantly reducing travel times to job sites. This feature alone positions the backhoe loader as a versatile and indispensable piece of machinery capable of handling various tasks with ease and precision. Despite the speed on the ground, the fuel efficiency is perhaps the standout feature of the new Tier-3 machines. According to JCB, operators will save over 44 barrels or 8,800l of fuel over three years

“Fuel remains by far the biggest cost from our customers of owning and operating a machine. So that is a substantial contribution on our part to drive down the running cost of machines and that is a 24 percent saving versus the leading competitors.”

JCB’s introduction of the latest 3CX backhoe loader series marks a significant milestone for the machine-type especially for the Middle East market. Known for its robust machinery lineage that dates back to 1964, JCB continues to lead machinery standards with a blend of innovation, durability, and efficiency.

JCB’s focus on the excavator end of the 3CX series has led to groundbreaking improvements. With the ability to perform at 150 tons per hour, the new series rivals even the best of the eight-and-a-half-tonne excavator families available in the market. The added advantage of a 5.7L deep depth

“We tasked ourselves to design a machine that has higher durability, a stronger top, better productivity better fuel efficiency, a lower cost of ownership”

and the introduction of servo controls for ease of operation emphasize JCB’s dedication to enhancing user experience and machine capability.

The transition to the new 3CX series signifies JCB’s evolution in response to market demands. Replacing the older models with the new 3CX, 3CX X, and 3CX PRO, JCB introduces machines equipped with higher-powered engines, air conditioning as standard, and innovative features such as six-in-one buckets and seat-mounted servo control driver interfaces.

These upgrades are not merely about enhancing machine performance but are also geared towards lowering the cost of ownership and improving fuel efficiency, which is crucial in today’s environmentally conscious market, says the British brand.

Key to the backhoe loader’s versatility is its comprehensive line of attachments, making it a true tool carrier product. JCB’s commitment to providing attachment solutions ensures that the backhoe loader remains productive across various industry sectors, including construction, maintenance, utilities, and even agriculture.

The introduction of single loader lever controls, a tilting steering column for easy access, and the smooth ride system underscores JCB’s focus on making the machines more user-friendly. These innovations not only make the operation of these machines easier but also significantly enhance the operator’s comfort and the machine’s overall productivity.

Alongside the updated backhoe loaders, JCB also introduced the JS385LC HD in Dubai, a heavy-duty excavator designed for the mining, quarrying, and civil engineering sectors. This new model builds on the success of the JS370, featuring a range of strengthened and reinforced elements to ensure durability and reliability under tough operating conditions. Powered by JCB’s six-cylinder Dieselmax 672 engine, the JS385LC HD offers impressive power

and efficiency, with advanced hydraulic systems and multiple operating modes to suit various applications. Its design emphasizes operator comfort and visibility, with a deluxe air-conditioned cab and an intelligent control system for easy monitoring and maintenance.

“JCB has been making a large track machines since 1964. That is 60 years of product evolution and development. And today, we have a comprehensive range of both tracked and wheeled machines to meet to our Global Market needs,” said global product manager James Allen. “In the non-legislative markets, that makes up to 65% of the opportunity in the large tractor excavator sites and JCB today has a comprehensive range that spans from are tons of 240 tons to meet our customers needs with tough and strong machines. But we always want to do better.

The JS 385 HD is a machine that has been re-engineered from the successful JS 370 to meet the rigorous expectations of today’s construction challenges. With strengthened structures and high-spec features as standard,

the JS 385 HD is equipped with a new dig end for handling larger capacity buckets and working harder than ever before. Its enhanced engine horsepower and system pressures allow for unparalleled productivity, making it the ultimate tool for tough markets.

“We wanted to make a machine stronger and better in the largest of the weight sector up to 40 times and we tasked ourselves to design a machine that has higher durability, a stronger top, better productivity better fuel efficiency, a lower cost of ownership. It also had to be a machine that was still the really comfortable and bet safe to use and I’m delighted to introduce to you the new machine.”

JCB’s latest offerings reflect a forwardlooking vision that prioritizes innovation, sustainability, and user experience. By introducing these advanced models to the Middle East market, JCB reinforces its commitment to supporting the region’s construction industry with machinery that meets the highest standards of efficiency, safety, and environmental responsibility.

“Jason Mamoa gets into this big fight action scene and all you can hear in the background is my auctioneering chant as the sale continues and the fists fly”

From the very start, Euro Auctions wanted to use the American parade style auction format at all its sale sites and as a result has always flown auctioneers in from the USA. Territory Manager for the Middle East, CMME’s Stephen White interviews Matt Hostetter, one of those ‘flying’ auctioneers.

Hi Matt. We are happy to have you running our sales at Euro Auctions, but would you tell us a little bit about your background and how you got into Auctioneering. I come from a family of auctioneers. My grandfather was an auctioneer. My dad, my uncle, my cousins, my sisters are all auctioneers. My family has a small auction company outside of Pittsburgh, Pennsylvania in the USA, where we auction for all kind of assets including real estate,

and business liquidations. So, when I’m not traveling or working for Euro Auctions, I am helping my family’s business grow.

Working for Euro Auctions for 15 years, how have things changed in that time? When I started there were three sale sites. Leeds in the UK, Dromore in Northern Ireland, and Dormagen in Germany, and four sales at each site, each year. It was great to come into a young company and watch it grow and it’s been a lot of fun, getting to travel the world, meeting people from all different backgrounds, all different cultures, and selling some really cool gear.

How did you get involved with Euro Auctions?

My dad, used to do some contract auctioneering for Yoder & Frey, which is now owned by the Keys family and Euro Auctions. I came out of high school and also started doing some contract auctioneering

for Yoder & Frey, doing a little bit of everything, including ring man, driving the truck around on auction day and if they need somebody to hold that pole out there, I would do whatever needed doing. Then I got a, a phone call from this super long international number that I didn’t recognise and it was the Euro Auctions head office offering me a trial at the Leeds sale in the UK. I came over, did a couple test runs, got to meet the Keys family, and I was hired. Then they just kind of kept me on staff as a regular guy in rotation. As the older auctioneers decided that they didn’t want to travel as much, like us youngsters, they kind of faded away and I just stuck around.

Could you just talk about auction school as that is not really a thing that we have over here?

So, I went to auction school with my sister when I was 15 years old, before I even graduated high school. In the US there’s probably 15 to 20 auction academies where they teach you about the business, about auction setups, removals, accounting, the business backend, giving you a broad overview of the auction business. And finally they teach you the fast talking, or the auction chant, which you then personalise and create your own style.

Could you give us a bit of a breakdown of the auctioneering chant and what you’re saying?

When you go to auction school, they teach you a very basic chant of - I’m bid five. That is a standard chant, which goes like this: I’m bid five. What do you bid? 10? So I’m bid five. What do you bid? 10? So I’m bid five. He bid 10, would you bid 10. Would he bid ten. Would he bid 10.

And after some time of using that chant, it t turns from that to: I’m bid five. Would

Hostetter says he admires Euro Auctions owners, the Keys family: “On sale day, these guys sweep up the yard, they’ll go turn a wrench onto a machine, they will drive a machine over the ramp”

you bid 10? Those words turn into more of a sound and the main chant, which you then use to set the tone and pace of the delivery and rhythm.

How does the British style of chant differ?

That is a little slower: And at 500 pounds. 500 at 550, 600, at 600 pounds now 650. 700 at 700, 750, 800, at 800 pounds, and so on, focusing on what has been bid. Whilst the American style is more about asking for that next bid, with more rhythm,

building the excitement. The American style would be: I got 500, I’m five 50, pop on five 50 now. 600. 600 bid. Sir, I could have been on 600, no, seven. It’s 700 on seven. Seven, seven now. 800 sir. 800. We give eight. So there’s more of excitement there. Teasing the bids out of the crowd.

You always seem to get one extra bid as the machine’s leaving the ramp. How is that?

As the auctioneer you kind of set a pace, set your tone. You can gauge people a little more too because you know, you’re more relaxed and calling some people out or you know, or calling out the ring men as well tickling that last bid.

Of all the stuff you’ve sold over the years, could you tell us either the highest value or a couple of the most memorable items that you might have sold?

For Euro Auctions, I sold the SUV that Usain Bolt, the Olympian, used for the London Olympics. It wasn’t anything fancy. It was a Lexus SUV but it was Usain Bolts, so it had some providence with it. I also got to sell some Hollywood memorabilia including the jumpsuit that Elvis Presley wore at Madison Square Garden in the sixties for

“As the auctioneer you kind of set a pace, set your tone. You can gauge people a little”

one of his concerts. That was pretty unique because it was the whole jumpsuit, with belt, buckle and the cape and totalled up and the high bidder paid $1,000,000 for it. That was pretty, pretty unique.

There must be a lot of opportunity in the USA, but , what’s made you stick to Euro Auctions?

The Keys family who own Euro Auctions are a great family to work for. On sale day, these guys sweep up the yard, they’ll go turn a wrench onto a machine, they will drive a machine over the ramp, they will jump start a dead tractor, they’ll do whatever needs to be done. They’re not above anybody and that is a truly great quality. It’s really amazing to see those guys just roll up their sleeves and work with everybody.

I also really love being behind a mic and the variety that you get with every Euro Auctions sale is incredible and I get all the selling time I need or want. And that is why I’ve decided to keep my roots in Euro Auctions, and I’ve been blessed that they’ve been wanting me back year after year.

The part of the auction that we find a lot of fun is ‘bid catching’, but do you think calleers from other countries could

cut it in the US ? It seems to be another level out there.

Oh yes, you guys are world class. The Euro Auctions team have come a long way over the 15 years I’ve been working with you. One of the main things is the real big connection the team has with the bidders, which few buyers or sellers probably know.

I’m tempted to recommend it to the new reps that come on board or other staff within the company – put yourself outside your comfort zone and do a bit of a ‘bid catching’, stand in front of the crowd, connecting with the audience – it is definitely useful to build rapport with customers and it looks good fun...This is your 15th year with Euro Auctions. What are some of the biggest changes you’ve seen in that time. What are biggest progressions the company’s made?

Firstly, just the sheer number of auctions, the size of the auctions, the frequency of the auctions, the location of the auctions. That is what has changed. Sheer progression. Euro auctions is always innovating. Staying ahead of the curve. They are world class at organising ‘off site’ sales. They’re willing to step out and bringing new tools, and new ways of doing business to their buyers

and sellers. The magazine that comes out now is an example, as is the online 24 /7 marketplace. They’re always trying to stay on the cutting edge, by bringing new tools to their buyers, to their sellers, and that way they give a good service and provide good value for that service.

Before we do finish, I recently heard that your career almost took a different path as a movie star with Jason Momoa, the movie star.

I feared you’d mention that. It was actually a little before Covid, and I didn’t even know who Jason Mamoa was. They were filming a movie in Pittsburgh, near where I live, and they were looking for an auctioneer for this fundraising charity auction scene. I applied, went down for a casting and they picked me for the role. We filmed all day. I sold a whole bunch of different things, but a lot of that is still laying on the editing floor because I never made the movie. But I am still in the movie, be it voice only. My voice invites the bad guy on stage, there is some dialogue, he leaves the stage and he and Jason Mamoa gets into this big fight action scene and all you can hear in the background is my auctioneering chant as the sale continues and the fists fly. I was hardly movie star material!

All the Nice Features of Previous Model Bodily Succeeded, Even Nicer Things to Come.

The equipment rental market in the UAE has experienced significant fluctuations, particularly highlighted by the influx of machines in 2017 and 2018 which saw the market reach saturation. This overflow, primarily affecting the UAE market, has quickend a trend of equipment migration towards Saudi Arabia. While this addreses a vital need within the kingdom, the shift has brought its own set of challenges, from plummeting rental rates to concerns over equipment quality and sustainability.

During the Rental Roundtable held during the Access and Handling Summit, Wayne Taylor, Managing Director, Safelift told the audience that the rental rates for equipment such as a 16-meter diesel boom have seen a dramatic declines from highs of $8,500-$9,000 per month in 2018-2019 to lows of around $1,000. This price drop, while potentially beneficial for short-term rentals, places significant pressure on rental companies, squeezing margins and potentially impacting the quality of service and maintenance, he said.

“We’re seeing a lot of migration of equipment from the UAE to Saudi and it’s probably needed here. I think we’ve seen the rental rates hit rock bottom and that doesn’t help anyone, certainly doesn’t help rental companies,” he commented.

Conversely, Saudi Arabia presents a burgeoning market for construction and equipment rental, driven by its ambitious mega projects and giga projects. The Kingdom’s focus on decarbonisation and sustainable development, although commendable, poses a dilemma for equipment rental markets. The migration of older, less efficient equipment from the UAE does not align with these green initiatives, raising concerns about the environmental impact and the overall sustainability of the construction sector.

Imtiyaz Abedi, Operations Director at Dayim Rental, represented the viewpoint from the Saudi rental powerhouse.

“You have a lot of migration and I think it is going to still continue from what I’ve heard. I think it is hurting the UAE because a lot of machines are being moved to Saudi as it’s picking up,” he said. “The good thing is machines are coming, the market is still largely under-supplied. But, again, the quality is a big concern.

“We have to set some things straight, with all the Giga projects and mega projects in Saudi, everybody wants to take part, While this is very good are we actually following the path that projects want to take on. We are talking about decarbonisation and new technologies but if we keep dumping in older and older kit that we should actually get disposed, then we are not solving the problem, right.”

Despite the challenges, the demand for construction equipment in both markets

“We’re seeing a lot of migration of equipment from the UAE to Saudi and it’s probably needed here. I think we’ve seen the rental rates hit rock bottom and that doesn’t help anyone, certainly doesn’t help rental companies”

remains high. In Saudi Arabia, the supply of machines is keeping up with this demand, yet the influx of equipment from the UAE raises questions about quality standards. This scenario underscores the need for a balanced approach to equipment rental, one that considers not just the immediate demand but also the long-term sustainability and efficiency of construction practices.

“We have to deliver what the customer wants and what the customer deserves,” urged Abedi expressing his concern that deadlines of events such as the World Expo and the FIFA World Cup will add pressure to the market for equipment in Saudi Arabia. “The size of the market can definitely double quickly over the next few years. The projects that we have cant just be called amibitious anymore. Because there are deadlines to meet.”

He adds that the demography and size of the population of Saudi Arabia is also changing. The project pipeline seemingly extending far into the next decade.

“It implies that there is a lot more construction to come and if you take into account the values of those projects and break that down by spend on plant and machinery you will get an idea of what is needed,” he said, adding that while incountry suppliers like his are investing in their own fleets, the Saudi rental players will not be able to do it all themselves.

“We are realistic and we want others to come. Let’s compete. Let’s play. We cannot be better without competition.”

Joe Keely, Executive Manager, AWP, Johnson Arabia agreed there was an opportunity for rental houses like his to participate in the booming market.

“I think there is also possibly one benefit you see with more competition is the

development of the market overall,” he continued.

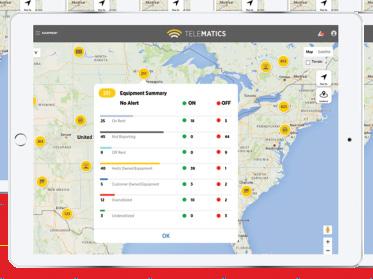

The equipment rental market in the Middle East, then, is at a crossroads, with significant opportunities for growth and innovation, but at the same time, rental companies are navigating a delicate balance between competitive pricing and maintaining high standards of equipment quality and sustainability. However, the adoption of new technologies, such as telematics and IoT, offers a path forward,

enabling better fleet management, predictive maintenance, and ultimately, more sustainable construction practices.

“If you look at the Middle East in general, and this goes for the UAE as well, development and the maturity of the market, increases the willingness to accept new or different technologies,” said Keely. “Playing off what Wayne said I think, at the minute, the market in the UAE has enough equipment. Too much in some types, but in certain applications, there isn’t enough of certain types of technology or machine types. In low-level access for example, we just don’t have enough equipment. In terms of facility maintenance, we, as an industry have not tapped into that fully. Part of that is an evolution that is needed in the FM companies and that is something we need to do as rental companies. FM companies in the region as a rule growing as third party providers. It didn’t really exist before people didn’t really maintain buildings like they are now. It’s just maturity overall.”

Wayne Taylor believes that there is work to be done at the end-user level.

“I think we need to still better educate customers,” he affirmed. “I always say to people why are we selling safely cheaply and why are people discounting safety? You know, we’re putting people at, sometimes 180 foot up in the air, and people don’t want to pay the price for it. And I say to all sales people do not sell on price, but unfortunately in the UAE everyone seems to sell on price and utilization is King. It’s not king.”

The future of the equipment rental market in the UAE and Saudi Arabia will depend on the ability of companies to adapt to these changing dynamics. By embracing new technologies and sustainable practices, the sector can potentially overcome the

current challenges, ensuring a robust and resilient market capable of supporting the region’s ambitious construction projects.

John Maddern, Operations Director at Sales & Rentals at Al Laith says that his company has brought in a specialised lowlevel solution via his long partnership LG in Africa. The softly-spoken South African is a relative newcomer to the market joining Al Laith in their rental and retail solutions division.

“So as a newcomer, I can share just a high-level sense of it that I don’t think there is anywhere in the world that I’ve seen opportunity like the Middle East. The reality of a market is that (the choice of equipment) is driven by your return on investment.”

He added that his own experience of introducing new equipment has been largely positive if the right approach is taken.

“The approach to take is centred around solution selling as opposed to just putting product in. So that is around engaging with customers, finding an all-round solution in a space that we not used to looking at through construction to light Industrial facilities, and even oil and gas.

“I look at the market and I can see a lot more opportunities. Yes, there’s a massive pricing issue that may deter you from buying certain products, but there should be specialised products and niche products. Through JLG and in terms of low level, we have gone to non-power, push around product which is a very specialised product that requires a very specialised approach in the market. We are working with customers quite closely, it requires volume, but it is certainly a really good product that puts safety innovation into that space…. It was a bit of a slog last year, we bought 82 units to get the machine into the market – I think people looked at us like we were crazy – but

I’m pleased to say that we have over 80% utilisation today moving into spaces that we never imagined.”

Maddern also believes that technologies such as IoT that could also enhance the market of rental equipment.

“One of the probably good things that came out of Covid for you was that I had some time to use my 20 years experience in powered access space to apply it to IoT. There are massive, massive benefits to be gained and I think businesses can leverage

from IoT and AI. There is a big connection between the two. There are ways to leverage AI to close your sources of information and get all of it onto one platform.”

The question is how much can technology help to push back against the low pricing in the market?

“We are seeing that movement,” said Joe Keely. “Partly as a result of Saudi Arabia and I think when organisations and people really do pressure you, technologies will need to be adopted. This will come from the government to a certain extent, as they really pressured that there will be an investment by people and that will then make a difference on what people are charging. There’s two ways that you need to look at IoT. The implementation of these cyber-fiscal systems will be both a benefit for us, for the manufacturers and their research arms and ultimately the enduser but by linking all those three things together we will all be looking for different things. But if you are saving 20% of the number of machines you need, you might pay 10% more per machine.”

“The development and the maturity of the market, increases the willingness to accept new or different technologies,” said

“Turnover is vanity, profit is sanity. I’m old school. I think it comes down to brass tacks,” commented Safelift’s Wayne Taylor. “I agree that there’s lots of ways of using technology today and looking at costs, but I feel, the lower the rental price, the higher the utilisation, the more the cost. I think what people don’t look at is what is the actual cost of renting? And that’s what we’ve got to start looking at and walking away from poor deals. I look at are these people, and asking myself when are they actually going to pay me and when are they going to pay me. (If you want higher prices) this needs to about looking at your customer base and changing your customer base if you need to.”

Volvo CE works collaboratively with customers on tailored CO2 reduction programmes to continually reduce their carbon footprint over time.

As construction contractors and quarry operators in the Gulf face increasing pressure to mitigate the impacts of fuel prices and emissions on both their bottom line and the environment, Volvo Construction Equipment is building on the inherent fuel efficiency of its machines with tailored CO2 reduction programmes.

Volvo Construction Equipment (Volvo CE) has a strong reputation for producing among the most fuel efficient machines on the market. Our wheel loaders, for example, incorporate a remarkable blend of advanced engine technology, optimal powertrain configuration, Optishift, enhanced cooling systems, intelligent load-sensing hydraulics, Eco-pedal system and auto engine shutdown. This winning combination maximises performance while minimising energy losses and fuel consumption. Nevertheless, we recognise that more can be done in collaboration with our authorised Volvo

dealers to help customers get the best out of their machines. This entails minimising the total cost of ownership and operation (TCO), while reducing environmental impact – an endeavour that is becoming increasingly important in the Gulf.

Fuel expenses constitute a significant portion of operating costs, particularly when machinery operates over long shifts or runs almost continuously to meet strict project deadlines or production targets. Although the Gulf region has historically benefited from lower diesel prices than other parts of the world, the pressure on construction contractors and quarry operators has increased.

High global post-pandemic demand, economic uncertainty, and the rise in global crude oil prices resulting from the Russia-Ukraine conflict have led to fuel costs becoming a growing concern. This is especially the case in UAE, where diesel prices have become higher than in other Gulf nations since deregulation in 2015.

Moreover, Gulf governments are exerting greater pressure on those in the construction industry to reduce energy consumption for the sake of the environment. For instance, the UAE Cabinet’s approval of the National Building Regulations and Standards at the end of 2022 mandates carbon footprint reduction, while the “We The UAE 2031”

national plan supports the country’s aspirations to be a champion for carbon reduction and neutrality.

Similarly, the Saudi Green Initiative, aligned with Saudi Arabia’s Vision 2030, and Qatar’s National Climate Change Action Plan both set national targets to reduce and avoid greenhouse emissions within the next seven years.

Machine data enables Volvo CE to monitor fuel consumption improvements throughout a CO2 production programme. Regardless of the solution, we and our dealers follow a four-step process – Insight, Analyse, Improve, and Sustain – to identify areas for improvement, implement initiatives for fuel and emissions savings, and continually measure and enhance performance. The advantage of this approach is its tailored nature, designed to align with specific customer requirements and budget considerations. If a ready-made solution is not available, it also presents an opportunity for us to collaborate with customers and develop custom solutions.

This is a shared journey we embark on together for the sake of our planet, and we believe that combining our machines with tailored services and collaborating with our customers as partners will lead to even greater accomplishments and accelerated progress. Change starts here!

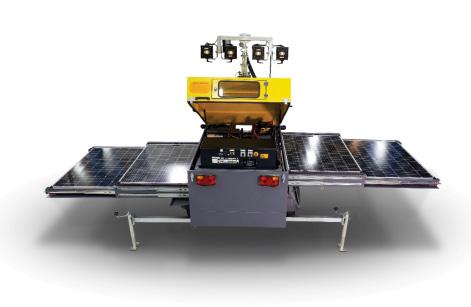

The latest releases from the world of construction machinery. EVERYTHING YOU NEED TO

A look at the people that Bobcat has helped since the disaster.

Top ten tips to mobilise piling rigs safely and efficiently.

Mammoet wants to give operators a birdseye view.

WHY GET IT?

NEW ARCHITECTURE PROVIDES HIGHLY CUSTOMISED SYSTEMS AND UPGRADEABILITY PATHS TO GROW WITH A CONTRACTOR’S NEEDS.

Topcon Positioning Systems has announced the latest evolution of the company’s road construction and resurfacing technology with the introduction of the MC-Max Asphalt Paving and MC-Max Milling solutions. The systems offer modularity, simplified configurations and advanced feature sets to increase productivity in asphalt paving and cold milling applications for construction companies and projects of all sizes.

The MC-Max Asphalt Paving and MCMax Milling systems, which are made up of GNSS receivers, total stations, displays, and other high-precision sensors, are built with the new MC-X machine control platform. This architecture provides highly customized systems and upgradeability paths to grow with a contractor’s needs.

Users choose from entry-level 2D systems that follow a reference, such as a string or a curb, or automated solutions that track a paver or miller in 3D for improved road smoothness in less time and with lower costs. Contractors can automatically pave and mill at variable depths, providing a better driving experience. The solutions also include MC-X licensing options, providing customers with further flexibility to meet their specific project and budget requirements. The new solutions are currently compatible with OEM CAN-based systems and will be expanded to include compatibility with additional aftermarket systems.

WITH AN EXPANDED RANGE OF SOLUTIONS, BOBCAT WANTS TO MOVE ON FROM DOOSAN INDUSTRIAL VEHICLE (DIV) BRANDING

Bobcat will once again use LogiMAT to showcase its latest material handling products, including the re-branded Doosan Industrial Vehicle (DIV) lineup machines for the first time.

The global rebranding and integration of Doosan Industrial Vehicle (DIV) under the Bobcat brand with its range of forklift trucks and warehouse equipment started in 2023.

From 1st January 2024, all of the company’s material handling equipment has been produced in the signature Bobcat colours – white and orange, and this year’s edition of the leading international trade fair will see the first showcasing of the extensive lineup of material handling products all under the Bobcat umbrella.

“The Bobcat brand is world famous for an extensive range of compact machines, which are used in construction, the agricultural sector, landscaping, demolition and many other industries. Bobcat loaders and telehandlers, which can be equipped with attachments such as pallet forks, buckets, grabs, bale clamps or dump hoppers, are often used for material handling and logistics tasks. So the addition of a complete range of IC and electric forklift trucks and warehouse equipment

is a natural extension to the Bobcat range,” explained the company in a statement.

At LogiMAT 2024. Bobcat’s product display will include diesel and electric forklifts, reach trucks and warehouse equipment such as pallet trucks and stackers. The display will also include Bobcat’s TL25.60 super compact telehandler, which allows work in tight spots without compromising performance, thanks to the machine’s compact dimensions and excellent manoeuvrability.

“We have broadened our portfolio to meet the needs of our customers,” added Scott Park, CEO and Vice Chairman of Doosan Bobcat. “With an expanded range of solutions, we’re empowering even more customers to accomplish more.”

The Bobcat range for the logistics and material handling market includes various lines: a series of diesel forklift trucks with lifting capacities from 2 to 16 ton; a series of LPG forklift trucks with lifting capacities from 2 to 7 ton and a series of electric forklift trucks with lifting capacities from 1.2 to 10 ton. The latter segment also includes a line of electric forklifts with three wheels for light work from 1.2 to 2 ton. Warehouse solutions also include pallet trucks, stackers and reach trucks.

SPECIFICATIONS

TL25.60 SUPER COMPACT TH

Rated Capacity: 2500kg

Lifting height: 5.9m

Rated power (ISO 14396): 54.6kW

Max reach: 3.3m

Unladen weight: 4308kg

INVENTHOR 6.2 SHREDDER, A STANDALONE MACHINE, IN COMBINATION WITH THE SELECTOR 800.2 OR WITH THE NEW BASKET SYSTEM

Economical pressure, changing legal frameworks and growing quality requirements: the recycling and waste disposal industry is placing increasingly high demands on providers of processing solutions. Doppstadt will demonstrate how these can be implemented at the International Trade Fair for Environmental and Wastewater Technologies (IFAT) in Munich from 13 to 17 May.

Under the motto “it’s not a booth, it’s a recycling plant”, Doppstadt’s presentation goes beyond a regular trade fair stand. Instead, the company is deliberately presenting a practical recycling plant in some areas and demonstrating various facets of processing with its solutions. In this way, Doppstadt demonstrates concrete and tried-and-tested solutions for the current and future challenges facing the industry.

“After the excellent experience we had with the concept in 2022, it was very easy for us to make the decision for a large stand in the outdoor area of the trade fair once again,” said Michael Zeppenfeldt, Sales Manager Germany at Doppstadt Umwelttechnik GmbH. “We have

the space we need to present our solutions in the best possible way and at the same time focus on the needs of our customers.”

The aim of putting the customer at the centre of attention is not only reflected in the positioning of the stand on the outdoor area, but also in its architecture. This time, the company is deliberately incorporating the daily challenges faced by customers. “We are simulating the working environment of our customers and underpinning our expertise in processing technology in this way,” said Zeppenfeldt.

The trade fair appearance is characterised by flexible, future-proof and economical solutions. In terms of future-proofing and flexibility, Doppstadt presents its INVENTHOR 6.2. The INVENTHOR is up to any current and future shredding task - as a stand-alone machine, in combination with the SELECTOR 800.2 or with the new basket system.

The Doppstadt solution is also available with an electric drive. The INVENTHOR 6.2 has an optimised folding hopper, which makes loading by wheel loader or excavator even more user-friendly.

The enhanced SM 620.3 screening machine fulfils the requirement for economic efficiency. Under the motto “Simply efficient screening”, the SM 620.3 is precisely customised to meet customer

requirements. In practice, it offers the same performance as its predecessor model with increased efficiency at an attractive price.

At IFAT Munich, Doppstadt will also be showcasing its grinder line in various applications. The AK is characterised by its broad and expandable range of applications. The mobile-modular treatment solutions that Doppstadt is presenting under the new brand name MMPC are also economical, legally compliant and flexible. “We see a lot of potential for our solutions on the international markets,” said Zeppenfeldt.

One of the focused points at IFAT is the processing of commercial, mixed construction site and biowaste. Zeppenfeldt explained: “Our Mobile Modular Processing Concept MMPC is based on the modular principle. Here, mobile machines are combined to enable broader and deeper value creation.”

SPECIFICATIONS

INVENTHOR 6.2

Engine: MTU 6R1000 Daimler OM 936

Output: 260 kW (354 HP) @ 1,700 rpm

Capacity: 7.700cm3

Tank capacity: 500l

Shaft/drum length: 2,200mm

Before operating piling equipment, ensure all operators have received comprehensive training on the specific model they will be using. Understanding the machinery’s capabilities, limitations, and safety features is crucial to prevent accidents and ensure efficient operation. 01

ENSURE PROPER TRAINING

Before starting work., look for signs of wear and tear, check fluid levels, inspect hydraulic systems, and ensure all safety devices are functional. Preplanning should include consideration of mobile maintenance and refuelling stations so that such operations can be brought to the rig and conducted without tracking the rig backwards and forwards to fixed maintenance or refuelling points.

05

PUT SAFETY FIRST

Implement strict safety protocols, including wearing appropriate personal protective equipment (PPE), securing the work area, and ensuring all safety features on the equipment are engaged. Always be aware of the surroundings to avoid accidents with nearby structures or personnel.

OPTIMISE POSITIONING AND ALIGNMENT

Ensure the piling equipment is correctly positioned and aligned before starting the piling operation. Accurate positioning is critical to achieving the desired pile installation accuracy and load-bearing capacity.

LEARN THE RIGHT WAY

Adhere to the manufacturer’s operating guidelines and load capacities. Overloading or improper use can cause equipment damage or failure, leading to delays and increased project costs.

06

KEEP THE NOISE DOWN

Piling operations can generate significant noise and vibrations, which may affect nearby structures and communities. Use vibration monitoring equipment and implement noise reduction measures to minimize impact, especially in urban areas.

09

07

08

KEEP ACCURATE RECORDS

Maintain detailed logs of the piling process, including pile locations, depths, materials used, and any issues encountered. This documentation is essential for project management, quality control, and future reference.

10

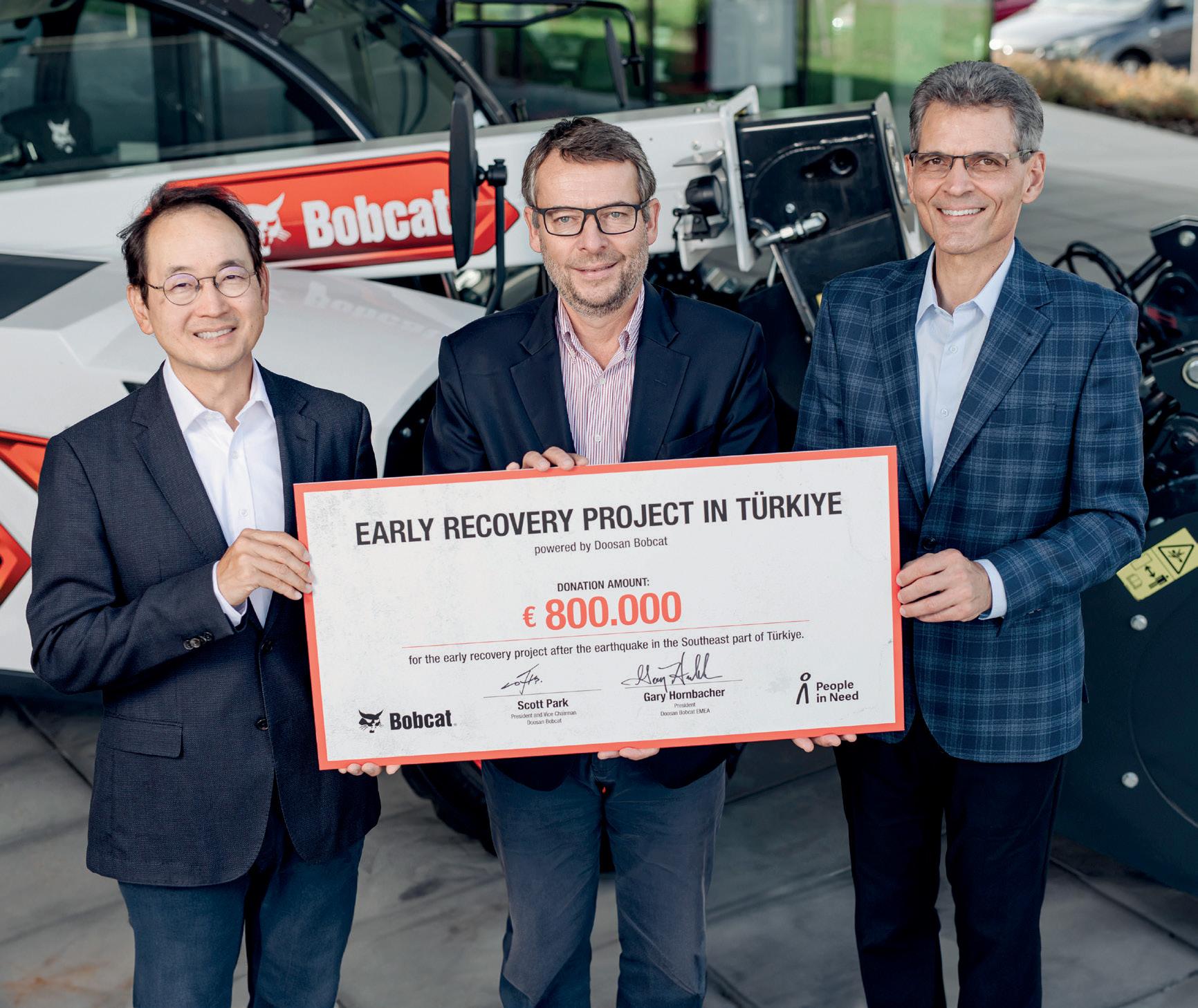

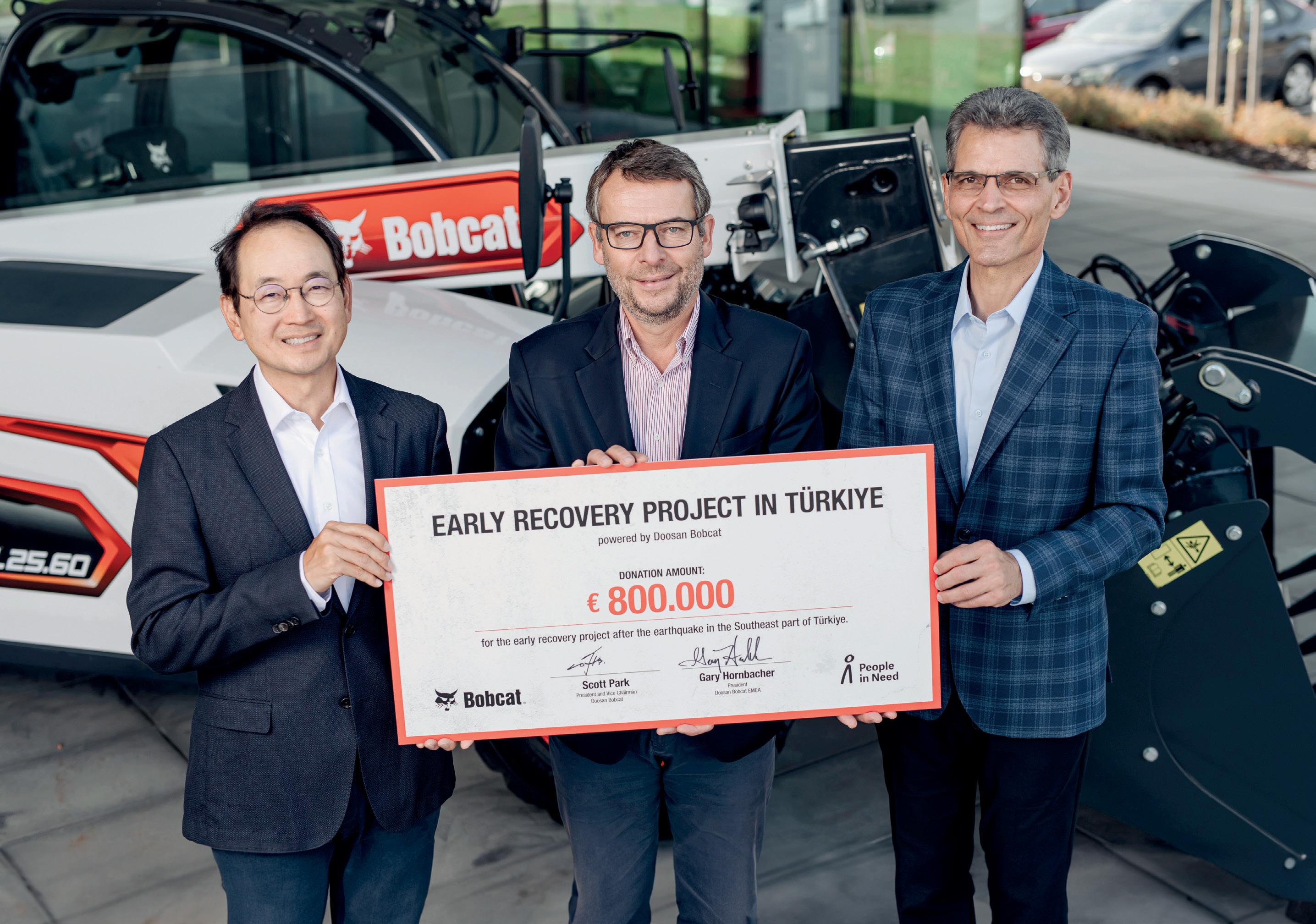

One year after the tragic earthquakes of February 6, 2023, which shook Turkey to its core, leaving over nine million people affected and more than 240,000 buildings in ruins, the journey towards recovery and rebuilding has been poignant and inspiring. In an ambitious move to kickstart the revival of Turkey’s local economy and community life, Doosan Bobcat, in partnership with People in Need — a globally recognised humanitarian organisation — initiated an 800,000 EUR grant aimed at supporting the heart of Turkey’s economy: its nano- and micro-enterprises.

This early recovery project was not just about financial assistance; it was a beacon of hope for those whose lives were upended by the natural disaster. The collaboration between Doosan

Bobcat and People in Need has so far supported 553 businesses, providing them not only with the means to rebuild but also to rekindle the spirit of enterprise that is crucial for the sustenance of local economies and communities.

Scott Park, Vice Chairman and CEO at Doosan Bobcat, emphasised the significance of this initiative, noting that the support extended to nano- and micro-enterprises has been vital in reviving essential services and fortifying local value chains. This effort, according to Park, is set to impact thousands of lives positively, reiterating Doosan Bobcat’s commitment to aiding the affected communities in tangible ways.

“In the aftermath of the devastating earthquake that struck Southeast Turkey, Doosan Bobcat committed to assist nano- and micro-enterprises in restoring their businesses. In partnership with People in Need, we have successfully extended aid to 553 businesses, fostering the revival of vital connections and the fortification of local value chains. This ongoing initiative is poised to reach

hundreds of businesses and positively impact the lives of thousands of people,” said Scott Park, Vice Chairman and CEO at Doosan Bobcat.

Šimon Pánek, Director and Co-Founder of People in Need, highlighted the critical role of small businesses in the economic fabric of local communities. The financial support provided has been instrumental in helping over 500 businesses bounce back, thereby aiding more than 2,000 individuals in resuming their lives and livelihoods post-disaster.

“Doosan Bobcat has demonstrated its commitment to empowering communities to recover and rebuild. In partnership with People in Need, Doosan Bobcat is providing essential financial support to small businesses that are the backbone of the local economy. This funding is helping local people and their businesses resume operations and provide essential services to their communities. Since the start of the program, our funding has helped over 500 businesses and more than 2000

individuals,” said Šimon Pánek, Director and CoFounder of People in Need.

Personal stories of resilience and hope underscore the profound impact of this project. Volkan used to have a three-storey lighting showroom that was reduced to rubble. He refused to let the tragedy define his future. Venturing into the new marketplace, Volkan reopened his shop, ready to contribute to Adıyaman’s recovery. People in Need recognized Volkan’s resilience and offered a timely cash grant, allowing him to replenish his lighting supplies and jumpstart his business once again. As Volkan’s clientele grew, so did his optimism.

“My old restaurant was completely destroyed, and I couldn’t save anything from there. I managed to get a container and started by placing tables and chairs around my container-based restaurant and now can accommodate 40 customers,” said Gündüz. “Thanks to funding I was able to purchase the cooking materials and equipment, allowing me to start my work again. I now have one parttime and two full-time employees.

The collaboration between Doosan Bobcat and People in Need has so far supported 553 businesses

“Though I experienced a complete loss, my hope remains intact. I’m steadfast in my commitment to regain what I’ve lost,” said Volkan.

Similarly, Vedat Gündüz, a restaurant owner, and Emine Çelik, a toast shop owner, shared how the support helped them restart their ventures, emphasizing the motivation and solidarity derived from their communities and the aid received.

Seeing them working and making money to support their families is what’s keeping me motivated to work and continue this journey.”

Toast shop owner Emine Çelik:

“Despite the sorrows and challenges, my outlook is positive. I’m a strong woman, and I will do whatever it takes to support my family and achieve our dreams. The grant was like a medicine for me—a lifeline—it allowed me to purchase the necessary equipment and tools for my shop, along with the materials needed for toasts. I was able to stand on my feet again.”

These narratives of resilience, determination, and community support are reflective of the

broader recovery efforts in the earthquake-stricken regions of Turkey. As Gary Hornbacher, President for the EMEA region at Doosan Bobcat, remarked, the project illustrates the profound resilience of the human spirit and the significant impact of collaborative efforts in restarting businesses, creating job opportunities, and facilitating a return to normalcy for local communities.

“All the stories that we hear from the beneficiaries of the early recovery project illustrate the resilience and determination, values that we hold dear. Our donation has already made a huge impact by restarting people’s businesses and creating job opportunities to help the local communities return to their everyday lives. It is through these partnerships that we can make a real difference,” said Gary Hornbacher, President for the Europe, Middle East and Africa (EMEA) region at Doosan Bobcat.

One year on, the journey of recovery in Turkey highlights the power of partnership, resilience, and hope. Through the combined efforts of Doosan Bobcat, People in Need, and the resilient spirit of the Turkish people, the path towards rebuilding lives and communities continues with renewed strength and optimism.

In a collaborative effort to enhance road safety and protect both drivers and pedestrians, Mammoet has teamed up with Rietveld, a specialist in fleet management and vehicle safety systems. The partnership aims to develop an innovative safety system for mobile cranes, with ongoing tests currently being conducted on a new Liebherr LTM 1070-4.2 70t model. The joint project seeks to address the growing demand for stringent safety measures in the operation of mobile cranes, prompted by tighter safety regulations. It integrates three distinct safety technologies to provide comprehensive protection during the movement and maneuvering of cranes on roads and construction sites.

indicates the location of the detected movement. The final element of the safety system, known as the ‘Halo’, projects a visible light boundary on the ground around the crane, clearly marking a safe zone for nearby individuals. This feature is particularly useful in noisy environments where hearing protection is necessary, as it provides a visual warning that is both intuitive and immediate.

The camera system will give the operator a full 360o-view from both inside and outside the cab 360˚

The first component of the system is Rietveld’s OmniVue 360° camera system, which utilises multiple cameras installed around the crane's chassis to create a panoramic view. This technology offers drivers both first-person and third-person perspectives, significantly enhancing their awareness of the crane’s surroundings and improving safety for pedestrians and other road users. Adding another layer of safety, the system incorporates sensors that monitor the vicinity of the crane, detecting people and obstacles within a predefined safety radius. Upon detection of a potential hazard, the driver is immediately alerted through an acoustic signal, and an LED warning panel

Ferdi Kivanc, project coordinator EMD, Mammoet, is optimistic about the project, highlighting the potential for these technologies to significantly reduce accidents and improve crane operator confidence: “By combining these three systems, Mammoet will improve safety, minimise accidents and damage, and give greater confidence to crane operators to create safer working environments. We see this as a system that will not only enhance crane safety, but also operator training in the future. Initial tests are promising, and I am very proud of the results.”

Frank Kanters, account manager, Rietveld, noted the uniqueness of the safety solution:“When Mammoet approached us, we were delighted to offer our expertise. By working with its engineers to test the integration of technologies, we have created something unique in crane safety solutions. We look forward to developing the system further and progressing to eventual rollout.”

With its compact design and light weight the applicators reach challenging project sites with ease. The improved LWSE hi-frequency motor and the compact control unit are also suitable for expanding to wire sawing and core drilling units, handing out a wide range of applications to construction sites.

Optimized drain intervals

Extended equipment life

Now you can increase significant savings through a dedicated tool developed and managed by TotalEnergies.

Presenting, LubAnac is a Fleet Management System, to reduce your vehicle maintenance costs through oil analysis that:

Reduces downtime of your fleet

Optimizes the maintenance

Increases the lifetime of your vehicles

Reduces total cost of ownership (TCO)