The Volvo EC550E delivers up to 35% more tonnes per hour, boosting profits. The perfect partner for a Volvo 35-40T Articulated hauler. A new hydraulic system provides exceptional power for heavy-duty digging. Backed up by outstanding support from Volvo Services, the EC550E gives you the power to dig – and keep on digging. Talk to your local Volvo dealer today.

The major news stories and company moves this month.

CMME joins contractor and access equpiment suppler on site at a mall redevelopment in Dubai.

Italy’s foremost concrete pump specialist looks at its growing importance for the region’s work-sites.

The Chinese powerhouse’s range continues to be re-shaped in the UAE to meet new demands.

30_NEW RELEASES

The latest releases from the world of construction machinery.

32_TOP TEN TIPS: WASTE REDUCTION

How best to minimise waste while on site.

34_SAUDI MOVERS AND SHAKERS

The equipment companies making moves inthe Kingdom.

40_THE LAST WORD

Enter the exoskeleton?

10 SPOTTED MCT185!

Topless crane from Potain transforms Istanbul sky- and shore-line.

There’s always been something deeply nostalgic about walking onto a construction site for me, and it had been a while since I’ve had the chance to visit one. So when I was invited last month to a mall revitalisation project in Dubai, I couldn’t resist.

Growing up in a family with its roots firmly planted in the construction business, stepping onto that site felt like stepping back into my past — a world where the hum of machinery and the camaraderie of workers always brought projects to life.

In fact, one of my first jobs, was being the labourer to a team of shop-fitters on major store and mall renovations in the South of England. And while it was often heavy and hard work done late on Saturday nights and early Sunday mornings (while many of my friends were still out partying), I always enjoyed the feeling of seeing behind the curtain.

With memories of those long-gone teen years coming back to be, the site visit, hosted by ISG and Spider Plus, was more than just a tour. It was a reminder of why I love this industry so much.

The sight of heavy equipment working in harmony, the precision with which tasks were executed, and the clear partnership between contractor and equipment rental company were striking.

Seeing Spider Plus’s equipment and teams in action alongside ISG’s own skilled workforce wasn’t just impressive; it was a testament to how crucial a strong contractor-rental relationship is to a project’s success.

As a contractor, you can have the bestlaid plans and a skilled team, but without the right tools and machinery at your

disposal, efficiency can lag. And without commumication at all levels you are pretty much doomed to fail.

The trust and synergy between ISG and Spider Plus on this site were palpable. Spider Plus’s ability to provide the right equipment at the right time allowed ISG to meet tight timelines, delivering top-quality results.

This partnership ensured that the revitalisation process was not only smooth but on track to meet the client’s ambitious goals.

(And all done while the rest of the mall remained in use and oblivious to the work behind the screens.)

There’s something awe-inspiring about how modern construction technology and equipment have evolved, and yet the fundamentals of the industry remain the same: teamwork, trust, and precision. Walking through that construction site, watching the MEWP and spider crane machinery in motion, and seeing the fruits of this partnership reminded me of why I fell in love with construction in the first place.

In an era, where speed and efficiency are key, it’s heartening to see that strong relationships between contractors and equipment companies like Spider Plus can still deliver tangible, high-quality results for clients and end-users alike.

Stephen White Head of Content, CMME stephen.white@cpitrademedia.com

GROUP

MANAGING DIRECTOR

RAZ ISLAM

raz.islam@cpitrademedia.com

+971 4 375 5471

DIRECTOR OF FINANCE & BUSINESS OPERATIONS

SHIYAS KAREEM

shiyas.kareem@cpitrademedia.com

+971 4 375 5474

PUBLISHING DIRECTOR ANDY PITOIS andy.pitois@cpitrademedia.com

+971 4 375 5473

EDITORIAL

HEAD OF CONTENT

STEPHEN WHITE

stephen.white@cpitrademedia.com

+971 58 584 5818

EDITORIAL ASSISTANT

PRIYANKA RAINA

priyanka.raina@cpitrademedia.com

+971 4 375 5478

ADVERTISING

SALES MANAGER

BRIAN FERNANDES

brian.fernandes@cpitrademedia.com

+971 4 375 5479

DESIGN

ART DIRECTOR SIMON COBON simon.cobon@cpitrademedia.com

DESIGNER PERCIVAL MANALAYSAY percival.manalaysay@cpitrademedia.com

MARKETING

SOCIAL MEDIA EXECUTIVE

FRANZIL DIAS franzil.dias@cpitrademedia.com

+971 4 433 2856

CIRCULATION & PRODUCTION

DATA & PRODUCTION MANAGER

PHINSON MATHEW GEORGE phinson.george@cpitrademedia.com

+971 4 375 5476

DIGITAL

ABDUL BAEIS abdul.baeis@cpitrademedia.com

UMAIR KHAN umair.khan@cpitrademedia.com

FOUNDER

DOMINIC DE SOUSA (1959-2015)

PUBLISHED BY

FINANCE

Sobha Realty complete US $230mn Sukuk Tap

INDUSTRY

AtkinsRéalis opens new office in Dubai

TECHNOLOGY

Bentley Systems acquires 3D Geospatial company Cesium

CONSTRUCTION

First guests expected at AMAALA in 2025 says RSG

INFRASTRUCTURE

Two new bridges open on Al Khail Road

EVENTS: Heavy Equipment and Truck Show to take place in Dammam 18-21 Nov 2024

INFRASTRUCTURE

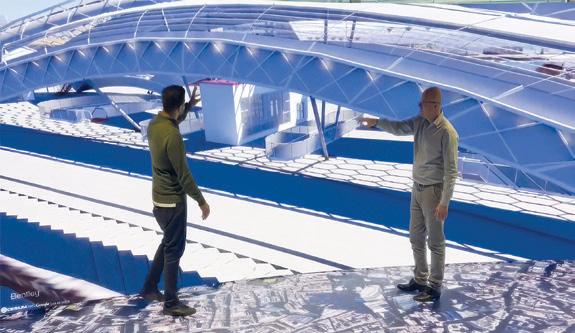

Design revealed for Al Maktoum International Airport

The project is expected to begin the planning phase in 2024, with Phase I due to be delivered by 2032

PROPERTY

ENERGY

New solar ‘mega project’ announced for Qatar

The new project will boost Qatar’s PV solar power production capacity to about 4,000MW

INDUSTRY

Trimble to host Connected Construction Conference

Some of the key topics include: data management in construction; future trends and emerging technologies; connected construction, and resilience and adaption challenges

PROPERTY

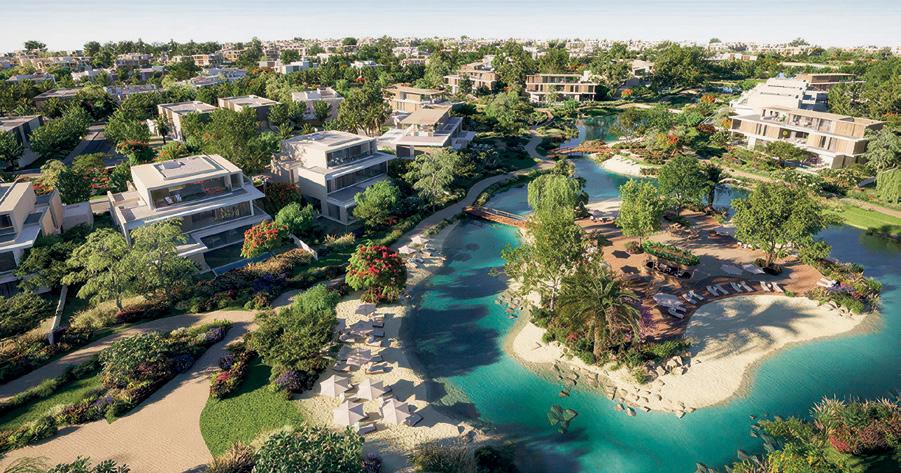

Meraas showpiece releases

200 new villas

Meraas is committed to achieving LEED Community certification for The Acres and the community is designed with this aspiration in mind

SUSTAINABILITY

JLL and Mashreq partner for LEED Zero Carbon status

The building’s Net Zero carbon status was realised through carbon emissions avoided or offset from the building’s annual operational energy and occupant transportation over a year

ENERGY

ENERGY

Barakah Plant commences operations for Unit 4

CONSTRUCTION

UAE and Jordan partner for key rail project

EGA implements digital greenhouse gas tracking PROPERTY

JAN DE NUL GROUP

WINS $220MN

MARINE CONTRACT

Nakheel has awarded a US $220mn contract for marine works on Palm Jebel Ali to Jan De Nul Dredging. Part of the international Jan De Nul Group, the company will be responsible for dredging, land reclamation, beach profiling and sand placement, directly supporting the construction of villas across all fronds.

GLOBAL’ CHALLENGE

Al-Bahar, the authorised dealer of Caterpillar products and services across the UAE, Oman, Bahrain, Kuwait, and Qatar, has successfully concluded its entry-level Internal Challenge, a segment of the Global Dealer Technician Challenge (GDTC) hosted by Caterpillar. The competition, dubbed “Heroes of the Trade,” took place over four intense days at Al-Bahar’s Regional Training Centre in Sharjah, UAE. The event saw four top technicians battle it out, with two emerging victorious to represent Al-Bahar at the Regional Qualifiers in Dubai this November.

The Heavy Equipment and Truck Show (HEAT) is proud to announce the participation of Tata Motors, a leading global automotive manufacturer at this year’s event.

Scheduled to take place from 1821 November at the Dhahran Expo in Dammam, Tata Motors will showcase a wide range of advanced cargo and passenger mobility solutions, including heavy-duty tippers, trucks and tractors all equipped with latest technology and engineered to meet the evolving needs of the region’s customers.

A trusted brand with a strong legacy, Tata Motors remains a leader in delivering innovative solutions for the global logistics and construction industries. As a leading player in the commercial vehicle industry, Tata Motors’ participation is poised to provide valuable insights into the future of commercial

vehicles and heavy machinery.

Sharing his thoughts, Raz Islam, Managing Director, CPI Trade Media, said, “We are thrilled to welcome Tata Motors to HEAT show 2024. Their participation marks a major highlight and reflects the company’s long-term commitment to the Middle Eastern market. Attendees will have a unique opportunity to explore Tata Motors’ cutting-edge innovations, each set to establish new benchmarks for reliability and performance.”

Commenting on the company’s participation, Anurag Mehrotra, Head – International Business, Tata Motors Commercial Vehicles, said, “Saudi Arabia remains a vital market for Tata Motors, and the HEAT show presents an excellent opportunity to engage with stakeholders and demonstrate our commitment towards developing solutions that meet the evolving needs of our customers.”

Jan De Nul Dredging is expected to complete the entire scope of marine works at Palm Jebel Ali in two years. The first eight fronds of the project are expected to be siteready by the first quarter of 2025, allowing for the commencement of villa infrastructure and civil works, the firm said in a statement.

“At Al-Bahar, we are dedicated to fostering a culture of excellence within our service network, as our technicians are our main advantage serving our customers better,” said Mr. Ibrahim Elaian, Vice President of Service at Al-Bahar. “The Global Dealer Technician Challenge provided a phenomenal platform for our technicians to showcase their expertise, dedication, and commitment to continuous learning. We are incredibly proud of all participants, and we’re confident that our champions will shine brightly at the regional level.”

The competition tested the technicians across a variety of skills, including machine diagnostics, practical service applications, and an in-depth understanding of aftermarket support offerings.

Held from 24th to 28th June 2024, the Internal Challenge concluded with an award ceremony celebrating the achievements of all four participants.

The ceremony served as a platform to recognise their dedication and hard work throughout the demanding challenge.

Looking to sell your surplus excavator, crane, truck or other heavy equipment for a great price? Sell in THE equipment month of the year:

• MASSIVE auctions across industries & geographies

• INCREDIBLE bidder & buyer momentum to benefit from

• MULTIPLE selling platforms to choose from - reserved & unreserved auctions, online marketplace

Dubai (UAE) September 24 & 25

Online Marketplace platform: Marketplace-E Middle-East

Metso has been awarded a significant order to deliver grinding mills to a copper mining project in Africa.

The order, valued at approximately EUR 20 million, has been recorded in the company’s Minerals segment for the third quarter of 2024.

The scope of Metso’s delivery includes energy-efficient HIGmill high-intensity stirred mills, along with auxiliary equipment and services. The HIGmill is renowned for its advanced and energy-efficient fine and ultra-

fine grinding capabilities, making it a key component of Metso’s portfolio of stirred mills designed to meet diverse customer needs.

Metso brings extensive experience to this project, having installed over 8,000 grinding mills globally. The company is also recognised for manufacturing and delivering some of the world’s largest SAG/ AG and ball mills. The HIGmill™ technology, which is part of Metso’s Planet Positive offering, leverages gravitational forces and GrindForce™ rotor technology

to achieve a finer grind, thereby enhancing mineral liberation.

Charles Ntsele, Vice President of Minerals Sales for Africa at Metso, expressed his enthusiasm for the project, highlighting Metso’s commitment to providing sustainable and efficient grinding solutions that align with the customer’s needs.

Metso is at the forefront of sustainable innovation, offering end-to-end solutions that improve energy and water efficiency, increase productivity, and reduce environmental risks in the aggregates, minerals processing, and metals refining industries. The company, headquartered in Espoo, Finland, employs over 17,000 people across nearly 50 countries, with sales reaching approximately EUR 5.4 billion in 2023. Metso is listed on the Nasdaq Helsinki.

The order, valued at approximately EUR 20 million, has been recorded in the company’s Minerals segment for the third quarter of 2024.

Åkerströms Björbo has introduced a new virtual training tool designed to significantly enhance personal safety during heavy lifting operations. It has developed state-of-the-art VR simulators that provide a realistic and secure training environment for crane operators. These proprietary simulators meet the stringent demands and standards of the Swedish industry, enabling operators to practice essential tasks such as precision driving, handling load swings, and safely maneuvering around suspended loads. The comprehensive training tool features several modules, culminating in a final exam where participants receive a detailed performance summary.

“With our VR training, operators can perform risky maneuvers in a safe, visual world that is designed to be authentic and engaging, optimizing the learning experience,” says Magnus Kenger, Business Developer at Åkerströms.

Whenever a Volvo Penta engine is sold, a partnership begins. Almost ten years ago, the first Eco Log 580E Harvester was fitted with the first Volvo Penta engine ever installed in a forestry application and sold to Swedish forestry specialists Nitta Rundvirke AB. In 2024, when Nitta Rundvirke ordered another harvester, the Eco Log 590G with the latest D8 EU Stage V Volvo Penta engine, the sale marked a new milestone in the companies’ long-standing relationship, as well as the delivery of the 1,000th Eco Log machine powered by Volvo Penta.

Develon will hold its inaugural Customer Demo Days, highlighting its cutting-edge excavators and other advanced machinery. Known for offering more innovative features than many competitors, Develon’s equipment continues to set new standards in the industry.

One standout at the event will be the new DX225LC-7X, the company’s first ‘Smart’ crawler excavator, designed to enhance operator efficiency and productivity.

Equipped with Full Electric Hydraulic (FEH) technology as standard, the DX225LC-7X enables faster, more efficient operations.

Another highlight is the new DA45-7 4x4 articulated dump truck (ADT), which shares the front

truck and cab unit with Develon’s market-leading DA30-7 and DA45-7 6x6 models. Modifications have been made to the rear dumper unit, giving the 4x4 DA45-7 the capability of a two-axle ADT, with twin rear wheels and a dumper

Al Ghurair Foods, a prominent food processing company in the UAE, has commenced the construction of the region’s first state-of-theart Corn Starch Manufacturing Plant at Khalifa Economic Zones Abu Dhabi (KEZAD). This landmark facility marks a significant milestone in enhancing the UAE’s food production capabilities and supporting the nation’s National Strategy for Food Security.

Situated on a sprawling 13.6-hectare site in KEZAD Area

A – Al Ma’mourah, the new plant is poised to serve both local and international markets. It will be equipped with cutting-edge technologies designed to produce a variety of products, including native and modified starches,

glucose syrups, and maltodextrin. These products will cater to a wide range of sectors, such as food and beverages, pharmaceuticals, and various industrial applications.

Speaking on the occasion, Mohamed Al Khadar Al Ahmed, CEO of KEZAD Group, expressed his support for the project: “KEZAD Gcommends Al Ghurair on the groundbreaking of the plant. Al Ghurair’s vision aligns with our own, as well as that of Abu Dhabi’s leadership, in enhancing food security across the region and creating new job opportunities. This cutting-edge facility will significantly bolster our domestic production capabilities, and we at KEZAD Group are proud to be part of this transformative journey.”

section similar to rigid dump trucks (RDTs) in the 40-tonne class.

The DA45-7 delivers enhanced performance, versatility, operator comfort, and easier maintenance compared to its predecessors. Also featured at the event is the

2-tonne DX20ZE-7 electric miniexcavator, which combines low noise and zero emissions with the performance and features typical of Develon’s next-generation DX-7 Series mini-excavators.

Develon wheel loaders, celebrated for their productivity, efficiency, comfort, and safety, were also on display. New features, such as parallel lift, cooling seats, and joystick steering across all models, reflect the company’s commitment to innovation.

The DL80-7 and DL85-7 models represent the compact wheel loader range at the event.

Develon’s Demo Days provides attendees with a hands-on experience of the latest kit.

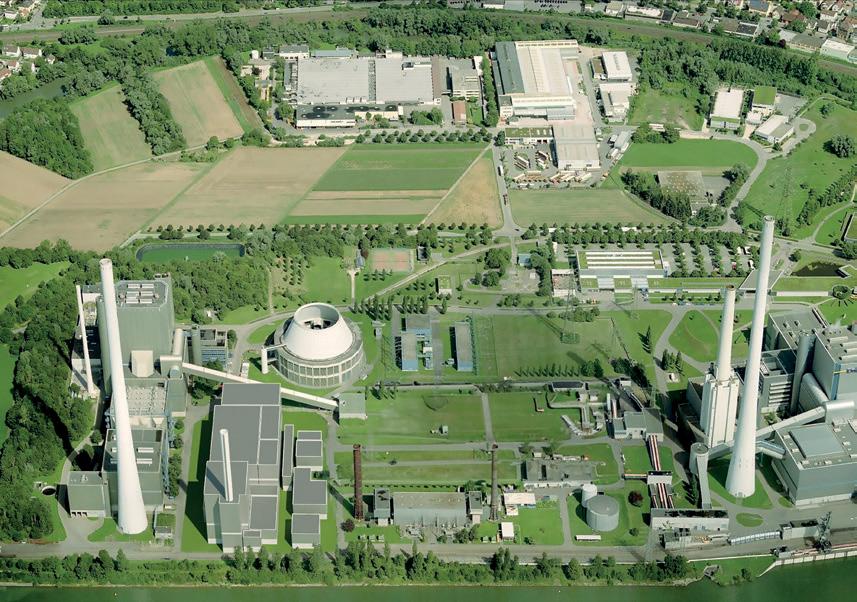

Mammoet, a global leader in heavy lifting and transport, has commenced work on the construction of a new combined cycle gas turbine (CCGT) power plant in Altbach/Deizisau, Germany.

This project, led by energy company EnBW, represents a significant step toward the future use of low-CO2 or green hydrogen by the 2030s. Initially, the plant will transition from coal to gas for electricity and heat production starting in 2026, ensuring an uninterrupted energy supply to both households and industry in the region.

Securing a reliable and competent partner was critical for this project, given its importance in maintaining continuous energy supply during the transition, said EnBW.

Mammoet was reportedly selected because of its tailored

engineering concept, comprehensive studies, and proven experience in power plant construction.

The company had previously demonstrated its expertise in dismantling Block 1 of the EnBW Neckarwestheim nuclear power plant, further solidifying its suitability for this significant undertaking.

Mammoet’s service package for the project includes just-in-time delivery, handling and unloading of components, interim storage, and the installation of key elements such as Heat Recovery Steam Generator (HRSG) modules, generators, turbines, and transformers.

Both locals and tourists witnessed a new Potain MCT 185 topless tower crane on the skyline of Istan-dul after the crane was deployed at the Tersane Istanbul project. Following its installation, it was expected to provide a boost to the construction process of the transformative coastal destination project within Turkey’s capital.

Purchased by the main contractor, Görgülü İnşaat, through Potain’s local dealer AHS VINÇ, the crane is set to remain on-site for a year, ensuring its pivotal role in the development’s progress.

To maximise the crane’s impact from the outset, a specialised

team of three engineers from Zhang-jiagang, China, traveled to Turkey to oversee the crane’s commissioning. Led by Zhang Yuanxiong, Manitowoc’s field service manager, the team ensured a seamless setup and provided comprehensive hands-on training to the local crew.

“We covered common operating issues and how to resolve them, as well as the importance of maximising uptime through regular inspections, fault diagnosis, and preventive maintenance. Learning in real-time, on the job helped the crew to understand much faster and will give them the confidence to get the most out of their new purchase,” said Zhang.

The Potain MCT 185 offers robust capabilities, with an 8-ton maximum capacity and an impressive 65-meter jib. The crane can handle up to 1.5 tons at the jib end, making it highly efficient for the project’s needs. Its design, featuring minimized component dimensions and weight, simplifies assembly and is tailored for urban and infrastructure projects.

This crane, like other Chinabuilt MCT models from Potain, stands out for its ease of transport, as-sembly efficiency, productivity, and reliability.

The Tersane Istanbul development is a landmark project situated along Istanbul’s historic and scenic waterline. This

242,000 square meter project aims to rejuvenate the old Ottoman shipyards, transforming them into a vibrant urban hub. The development will include luxury waterfront residences that blend historical charm with modern amenities, offering a variety of food, retail, and entertainment options set against the picturesque Golden Horn backdrop.

The addition of the Potain MCT 185 crane is expected to significantly accelerate the construction timeline, bringing the vision of Tersane Istanbul closer to reality. As this dynamic urban hub takes shape, the crane will play a crucial role in ensuring the project’s success and timely completion.

Experience exuberant engine power, timeless quality, and long-term durability that deliver unrivaled results. Ready to conquer any construction site, the DX400LC-7M embodies Develon’s pioneering spirit and unwavering commitment to excellence. Your next combat awaits—are you ready to take over your goal with the DX400LC-7M?

For more information and exclusive offers, contact us today. SCANIA

The redevelopment project involved several technically demanding tasks, including managing the ground bearing pressures and the precise placement of cranes on the building’s posttensioned slab.

“You’ve got to be passionate about what you do, or you won’t last. It’s a high-pressure job, but when you work with trusted partners, it makes all the difference”

In the highly competitive retail landscape of Dubai, the redevelopment of a major shopping mall is a logistically challenging and demanding operation requiring careful planning and laser-like precision.

One project to revitalise a major shopping destination showcases the combined strengths of Spider Plus and ISG Middle East. Since February 2024, the partnership has been instrumental in overcoming the complex challenges posed by the large-scale project, from dismantling heavy structures to installing critical MEP (Mechanical, Electrical, and Plumbing) features. This collaboration not only highlights the technical prowess of both companies but also underscores the importance of shared values and a commitment to excellence.

The partnership between Spider Plus and ISG began with a clear focus on addressing the specific needs of the mall’s redevelopment. Joe Duffy, Executive Manager at Spider Plus, recalls, “We started visiting the site in February 2024. The plan was to renew the second part of the mall, and ISG asked us to propose the exact equipment they needed. We began by proposing several models of spider cranes and access equipment tailored to the

unique challenges presented by the site.”

This initial collaboration quickly evolved as Spider Plus expanded its role from merely supplying equipment to providing critical technical support. One of the key challenges was the demolition of a large internal bridge, a task that required precision and careful planning. Spider Plus proposed the URW-706-2 spider crane, which proved to be a pivotal solution for dismantling the façade cladding and the complex internal structures.

The redevelopment project involved several technically demanding tasks, including managing the ground bearing pressures and the precise placement of cranes on the building’s post-tensioned slab. Duffy highlighted the meticulous approach required: “When removing sections of the bridge, we had to be very precise about where the cranes were placed to avoid any structural damage.”

Tim Doherty, Project Manager at ISG Middle East, echoed the importance of this precision. He described the process of dismantling and rebuilding key structural elements, noting the use of 11 Mobile Elevated Work Platforms (MEWPs) provided by Spider Plus. These units were crucial in navigating the mall’s height restrictions and

weight limitations, especially in areas with ceiling heights reaching 15 meters. “Spider Plus supplied units that were lightweight but still capable of reaching the necessary height,” Doherty noted.

The spider cranes provided by Spider Plus also played a critical role in dismantling the front façade, where traditional scaffolding was not feasible. “We couldn’t use scaffolding due to the nature of the works. The spider crane allowed us to remove the façade with precision, reducing the risk and time involved,” Doherty said.

One of the most significant challenges of the mall redevelopment was conducting extensive construction work within a mall that remained open for business. This presented unique logistical and operational difficulties, requiring careful coordination to ensure that construction activities did not disrupt the mall’s daily operations or inconvenience shoppers.

Doherty elaborated on the complexities of working in a live environment: “We were working in a mall that was still open to the public, which meant we had to be incredibly mindful of noise, dust, and safety. The work had to be done in such a way that it minimized any impact on the mall’s operations.” This challenge

was further compounded by the need to transport heavy machinery and materials through public spaces without causing significant disruption.

Spider Plus’s equipment played a crucial role in overcoming these challenges. The spider cranes and MEWPs provided were not only versatile but also compact enough to be maneuvered through the mall’s restricted spaces. “One of the advantages of the spider cranes is their ability to work in confined spaces and be easily relocated as needed, which was essential

in a busy, operational mall,” explained Mohammed Shaheen. Sales Engineer at Spider Plus.

The teams had to work outside of peak hours, often during the night, to carry out the more disruptive tasks. This required an additional layer of coordination to ensure that the work could proceed efficiently without extending the project timeline.

“We had to be flexible with our scheduling and often work overnight to avoid interfering with the mall’s daily activities,” Doherty added.

One of the most challenging tasks was the removal of a large steel and concrete bridge within the mall, described by Doherty as a “ginormous lump of steel.”

This operation required careful planning and execution, as any mistake could have led to significant delays or accidents. “We had to back prop the steel, cut it into sections, and then methodically lift each piece off,” Doherty explained. Thanks to the collaboration between ISG and Spider Plus, this high-risk task was completed without any incidents, highlighting the efficiency and safety of the operation.

When delivering projects at any scale, ISG emphasises meticulous planning and execution; ensuring that every aspect of the project is right from the start.

“ We’re not just about delivering equipment; we’re about solving problems. If there’s an issue, we’re there to fix it immediately”

Doherty explained to CMME that this approach had to be implemented in the lead up to a mobilisaton that presented technical and logistical challenges onsite, adding that: “We don’t build it and then find out something is wrong. We ensure that everything is right from the first moment — whether it’s the design, the choice of materials, or the placement of equipment.”

Consequently, the close collaboration with Spider Plus has proven instrumental in achieving this goal on this project. The spider cranes and other equipment were not just delivered; they were integrated into a well-thought-out strategy that addressed potential challenges before they could become issues, said Duffy.

Building trust with partners creates a foundation for effective collaboration and mutual success, and has long been a cornerstone of ISG’s operational ethos. The collaboration between ISG and Spider Plus is not new; it’s a relationship built on trust and mutual respect over several years. Doherty, a veteran of similar projects in Europe but a relative newcomer to the Middle East, spoke highly of the partnership.

“Spider Plus has been a trusted partner of ISG for years. Their responsiveness and ability to provide the right equipment and support are invaluable,” he said.

Eddie Nobrega, Regional Sales Manager of Spider Plus echoed this sentiment, emphasizing the company’s commitment to not just supplying equipment but also providing ongoing support. “We’re not just about delivering equipment; we’re about solving problems. If there’s an issue, we’re there to fix it immediately,” Nobrega stated. He also highlighted the advantages of Spider Plus’s large fleet, which allows them to quickly replace any faulty equipment without causing significant delays to the project.

One of the key elements of their successful collaboration has been the responsiveness of Spider Plus to ISG’s needs. Doherty shared how the project’s tight schedule necessitated quick reactions to any issues that arose.

“We have a WhatsApp group for immediate communication. If a machine breaks down, it’s reported, and Spider Plus is on site to fix it right away. This kind of responsiveness is crucial when every hour counts,” he said. Nobrega added that the ability to swap out equipment quickly has been a major advantage. “If something becomes irreparable on site, we can replace it within a day. That flexibility ensures that the project stays on track, even if issues arise,” he explained.

ISG’s on-going commitment to being an Ethical Employee extends to its subcontractors and partners, ensuring that

all parties adhere to the highest standards of integrity, fairness, and responsibility. Doherty emphasized the importance of working with subcontractors who share ISG’s values, particularly in terms of fair labour practices and environmental stewardship.

This ethical approach is also characterised through the partnership with Spider Plus. The transparency and accountability that defined their collaboration remain in line with ISG’s broader commitment to ethical practices.

“We don’t just work with any supplier. We choose partners like Spider Plus who share our commitment to doing the right thing, not just in terms of project outcomes, but also in how we achieve those outcomes,” Doherty added.

Environmental responsibility is a growing concern in the construction industry, and Doherty also spoke about the importance of minimizing the project’s carbon footprint, a goal supported by the use of Spider Plus’s dual-fuel MEWPs, which can operate on both electricity and diesel. “These dual-fuel machines are brilliant for our sustainability goals. We track all our electricity usage, and using electric machines wherever possible helps us reduce our carbon footprint,” he explained.

As the project nears completion, both companies can reflect on the success of their collaboration. Doherty pointed out that ISG’s focus on getting things “right the first time” has been key to their successful partnership with Spider Plus. “We’ve worked closely from the pre-construction stage to ensure everything is done right the first time. This cohesive work between our teams has been critical,” he said. Nobrega concluded by emphasizing the importance of enjoying the work despite the pressures involved. “You’ve got to be passionate about what you do, or you won’t last. It’s a high-pressure job, but when you work with trusted partners, it makes all the difference,” he said.

Latest Generation of "Intelligence Power Control" System Hyundai’s newly developed remote management system

Leveling %12

Daily Fuel Efficiency

%9

Truck Loading %15

50T-Leading CWT for Best Stability

Reversible Cooling Fan for Cooling Efficiency

CIFA has been expanding its market coverage by appointing new dealers in areas that were previously uncovered.

In August 2024, CIFA (Compagnia Italiana Forme Acciaio) announced a strategic partnership with Al Marwan Machinery, a leading provider of heavy machinery in the UAE’s key markets of Dubai and the Northern Emirates, as well as Oman, This exclusive and exciting new dealership agreement allows Al Marwan to distribute CIFA’s full range of products across the region, including concrete pumps, batching plants, mixers, and advanced concrete machinery. The deal is a potential game-changer for contractors and to explore the story behind the deal and understand CIFA’s strategy for the Middle East, CMME sat down with Wajih Eit, General Manager of CIFA Middle East, to discuss the opportunities, challenges, and technological innovations that are shaping the company’s success in the region.

The Middle East has long been a hub of significant infrastructure and urban development projects, and the demand for high-quality concrete machinery has never been higher. CIFA has been a global

leader in concrete machinery since its founding in 1928. Known for its relentless focus on innovation and quality, CIFA has grown to become one of the world’s largest manufacturers of concrete equipment.

According to Wajih Eit, CIFA sees immense potential in the region, where ongoing investments in mega projects and future vision programmes are driving growth: “The Middle East market remains dynamic and promising. Despite the different challenges in this region, opportunities are considerable, especially with the huge volume of concrete required for important projects launched under each country’s future vision programmes.”

The newly secured partnership with Al Marwan Machinery, marks a significant milestone in the company’s Middle East expansion. The exclusive dealership agreement ensures that customers in Dubai, the Northern Emirates and Oman now have access to world-class concrete machinery. Eit adds enthusiastically: “We are thrilled to be partnering with Al Marwan. They are one of the top heavy machinery companies in the region, known for their strong customer relationships and excellent after-sales service. This partnership will help us reach a wider

audience and ensure that CIFA’s products are supported by top-tier service.”

The partnership comes at a time of rapid transformation in the construction industries within the UAE and Oman, where there is an increasing demand for machinery that offers greater efficiency, sustainability, and precision.

“This is a significant step forward for CIFA,” Eit explains. “We’re not just keeping pace with industry trends — we’re leading the way. Working with Al Marwan allows us to bring the most advanced concrete solutions to our customers, backed by exceptional support.”

CIFA’s reputation as a trusted manufacturer has been built over decades, Eit explains “We are one of the oldest manufacturers of concrete equipment in the world, with over 95 years of experience. All of our manufacturing plants are based in Italy, ensuring the highest quality. We offer a full line of products, from batching plants and mixers to pumps. We also specialise in equipment for underground and mining work, such as shotcrete machines, as well as our fully electric Energya series.”

CIFA’s extensive product range and strong commitment to quality give it a unique foothold in the Middle East, where demand for reliable, highperformance machinery is rapidly increasing. The construction market has experienced significant changes in recent years, and CIFA has adapted to meet these evolving demands. Eit notes that the region is undergoing a transformation that requires new approaches to construction: “Over the past decade, we’ve seen a surge in

the

95

and comprehensive

range

large-scale infrastructure and residential projects. But what’s really interesting is the growing focus on sustainability and the adoption of advanced technologies like automation and smart systems.”

He highlights how diversification away from oil dependency has influenced construction needs: “Countries are no longer just focused on oil; they’re investing in various sectors, which has led to an increased demand for innovative and efficient construction solutions. That’s where CIFA really shines — we can provide advanced, energy-efficient machinery that meets these new challenges.”

Eit acknowledges that while the Middle East has faced political and economic fluctuations, the overall trend remains positive: “There have been ups and downs, but the direction is clear. The construction market is evolving, and it suits our strengths, particularly our ability to offer cutting-edge, sustainable solutions.”

CIFA has seen impressive growth in the Middle East, with the past 12 months being especially successful. Eit attributes this success to an ability to quickly adapt to changing conditions and respond to the needs of the market: “A lot of this comes down to our flexibility. We have a dedicated regional strategy that allows us to adapt quickly, and that’s helped us maintain a competitive edge.”

The opening of a new branch in Dubai in 2023 has also been a game-changer for the company: “Having a fully dedicated team for sales and after-sales support in Dubai has brought us much closer to our customers,” Eit says. “We’ve been able to provide faster, more personalised support to our dealer network and end-users, which has been crucial for our growth.”

CIFA has also expanded its presence in the region by appointing new dealers

in previously uncovered areas. “We’ve increased our market coverage, and with several large-scale projects ongoing, we are optimistic about the future,” Eit adds.

The Middle East’s harsh climate, with extreme temperatures and arid conditions, poses unique challenges for construction machinery. However, CIFA’s equipment is designed to meet these conditions head-on.

“CIFA is the only manufacturer that offers both hydraulic open pumping circuits and electronic closed pumping circuits,” says Eit. “This gives us a real advantage in the region because we can offer the most suitable solution based on the customer’s needs. The open circuit system is especially well-suited for high temperatures—it’s easy to operate and maintain.”

He emphasises the durability of the machinery: “Almost 90% of our truck pumps in the region are fitted with open circuit systems, and many of them have been in operation for over 30 years. Our equipment is built to withstand these tough conditions and keep delivering excellent performance.”

CIFA has built its reputation on innovation, and its products incorporate advanced technologies designed to improve efficiency and productivity on large-scale construction projects. Eit highlights some key innovations.

“Our SMARTRONIC system is a standout feature. It includes advanced stability control, automatic RPM engine speed adjustment, and maximum boom extension control. These features help

operators manage the machinery more effectively and boost overall performance.”

In addition to SMARTRONIC, CIFA’s CIFA CONNECT system offers remote monitoring of machine performance and maintenance needs. “CIFA CONNECT allows fleet managers to track all their equipment in real time from a single control room. It’s an invaluable tool for improving efficiency and ensuring that the machinery is running at peak performance.”

CIFA has also made strides in sustainability with its Energya series, the world’s first fully

Delivering equipment on time is crucial for largescale projects, and CIFA has worked hard to ensure that its supply chain can meet the demands of the fast-paced Middle Eastern market.

electric truck mixer. “The Energya series represents the future of construction equipment,” says Eit. “It offers significant reductions in fuel consumption and CO2 emissions without compromising on performance. For companies looking to reduce operational costs and their environmental footprint, it’s a practical and forward-thinking solution.”

Delivering equipment on time is crucial in a fast-paced market where large-scale projects often operate on tight schedules. CIFA has developed a robust supply chain strategy to meet these demands: “As many of our products are mounted on trucks, lead times are often dictated by their availability. We’ve invested heavily in purchasing directly from European truck suppliers to solve this challenge. We also keep a large stock of ready-to-deliver machines in Italy, Dubai, and at dealers’ yards across the region.”

This strategy ensures that CIFA can meet the needs of its customers, even for urgent project requirements. “It’s a complex approach, but it’s necessary to ensure we can deliver high-quality equipment on time, especially in a region as fast-moving as the Middle East,” Eit says.

With its new partnership with Al Marwan Machinery and its dedication to innovation and customer service, CIFA is well-positioned to continue to take market share, he adds.

“We’re very optimistic about the future. The market is evolving, and we’re excited to lead the way. With our advanced technology, strong local presence, and excellent partnerships, we’re confident that we’ll see major success in the years to come.”

Last October,

an agreement with

heralding the start of a robust strategic partnership aimed at strengthening its position within the heavy equipment sector.

“We are investing in advanced diagnostic tools, increasing parts availability, and enhancing technician training to ensure optimal service and faster turnaround times for our customers”

As the construction and heavy machinery sectors in the Middle East continue to expand and evolve, LiuGong Machinery, a major Chinese manufacturer, is making significant strides in the region. This growth is underscored by a newly minted partnership with Dubai-based Gargash General Trading, a collaboration that promises to reshape the landscape of construction equipment in the UAE. Following a successful launch, the partnership between the two companies continues to see the introduction of new products poised to meet the market’s diverse needs. Something both companies are well used to.

LiuGong Machinery, founded in 1958, has been a prominent force in the machinery industry, establishing itself with the introduction of China’s first modernized wheel loader in 1966. Over the past 65 years, LiuGong has evolved from a domestic pioneer to a global enterprise, currently offering over 30 product lines that span various engineering applications.

The company’s strategic vision for globalization, launched in 2002, has been instrumental in its expansion. LiuGong now operates over 30 overseas subsidiaries, four international manufacturing facilities, and five R&D centers worldwide. This extensive network, coupled with over 300 dealers, enables LiuGong’s innovative products to reach more than 170 countries.

The company’s “Total Globalisation, Total

Solution, and Total Intelligence” strategy reflects its commitment to becoming a world-class enterprise. This ambitious approach aligns perfectly with its latest venture in the Middle East, emphasising the potential of the newly formed partnership with Gargash General Trading.

A Strategic Alliance with Gargash GT

In October of the 2023, Gargash General Trading and LiuGong Machinery formalised a significant distribution agreement. The partnership was celebrated in a grand signing ceremony marking the beginning of a robust strategic relationship aimed at enhancing Gargash’s footprint within the heavy equipment sector. This move follows Gargash’s recent deal with Korean concrete pump specialist KCP, highlighting the company’s strategic own approach to expanding its portfolio.

Gargash General Trading, a wellestablished player in the UAE’s heavy equipment market, sought this partnership to address the increasing demand for high-quality construction machinery. The decision to align with LiuGong was driven by the need to offer a comprehensive range of equipment that meets the diverse requirements of the UAE construction sector. Coinciding with the end of an exciting first year for the Gargash-LiuGong partnership, the two firms are introducing four key product categories into the UAE market: Backhoe Loaders (BHLs), Skid Steer Loaders (SSLs), Single Drum Rollers (SDRs), and Mini Excavators. Each of these products has been tailored to address specific needs and challenges of infrastructure and earthmoving projects within the region.

“It is essential for Gargash to offer this range of light equipment, so our customers have a one-stop shop for all of their needs”

LiuGong’s Backhoe Loaders are designed to tackle a wide range of applications with efficiency and versatility. These machines are equipped with features such as a 6-in-1 bucket, an extendable stick, side shifter, and extra hydraulic lines. This robust configuration allows for flexibility in handling various tasks, from excavation to material handling. The Backhoe Loaders are engineered for ease of operation and maintenance, which is crucial for the demanding conditions of the UAE construction environment.

LiuGong’s Mini Excavators cater to the growing demand for compact and

maneuverable equipment in the market. With models ranging from 1.8 to 5 tons, these excavators are ideal for road maintenance and other construction tasks requiring agility and precision. The 2.7-ton model is also available in a fully electric version, addressing sustainability goals by reducing fuel consumption and emissions.

Like the Mini-Excavators, LiuGong’s Skid Steer Loaders offer a balance of power and agility, making them suitable for both large-scale construction projects and smaller operations despite their size. In fact, their compact design and powerful lifting capacity allow them to perform efficiently in tight space s while handling heavy-duty tasks. This versatility

makes them a valuable addition to any construction fleet.

The Single Drum Rollers from LiuGong stand out due to their advanced compaction technology. With a double frequency vibration system, a 12-ton operating weight, and a 30-ton compaction weight—the highest in the market—these rollers ensure efficient and seamless compaction. This performance is crucial for contractors in the UAE, where highquality compaction is essential for road and infrastructure projects.

According to Mahmoud Darras, Sales Manager - Heavy Equipment, Gargash

General Trading, the introduction of these products the rising demand for highquality machinery in the UAE. LiuGong’s reputation for durability and performance in large earthmoving equipment is being effectively extended to these new product categories. This strategic move allows Gargash to offer a comprehensive suite of construction equipment, positioning itself as a one-stop shop for diverse machinery needs.

LiuGong’s emphasis on low total cost of ownership (TCO), durability, and compliance with market standards further enhances the appeal of its products in the UAE, says Darras. These attributes, coupled with extended warranty programmes and

robust aftersales support, differentiate LiuGong’s offerings from existing solutions in the market.

Darras adds: “To complete the product range and fulfil the market need for all types of construction equipment, it is essential for Gargash to offer this range of light equipment, so our customers have a one-stop shop for all of their needs.”

Gargash General Trading has implemented several strategies to ensure that LiuGong’s products are supported effectively in the UAE. This includes maintaining a high availability of spare parts through a well-established supply chain, supported by LiuGong’s regional warehouse in Jebel Ali Free Zone. With

more than 100,000 SKUs, this warehouse is critical in ensuring prompt service and parts availability.

As Darras stresses: “Gargash is working closely with Liugong to ensure a flawless supply chain of spare parts and keep the availability of essential parts above 90%.”

Additionally, Gargash is investing in expanding its service network, establishing new service centers, and upgrading existing facilities. Advanced diagnostic tools and enhanced technician training are part of this effort to provide optimal support and faster turnaround times for customers.

Training and support programmes for operators and technicians are also a priority. LiuGong’s team of engineers is available in the region to introduce new products and ensure that local technicians are trained and certified to handle these machines effectively.

The partnership between LiuGong Machinery and Gargash General Trading is set to have a lasting impact on the Middle East’s heavy equipment market. By combining LiuGong’s innovative products with Gargash’s established market presence and support infrastructure, the collaboration aims to address current and future demands in the construction sector.

“We are investing in advanced diagnostic tools, increasing parts availability, and enhancing technician training to ensure optimal service and faster turnaround times for our customers,” Darras explains to CMME

Customer feedback will play a crucial role in the continuous improvement of these products. Gargash and LiuGong are committed to actively gathering and analysing customer insights to refine and enhance their offerings, ensuring that they meet the evolving needs of the market. As LiuGong continues to advance its global strategy and expand its presence in the Middle East, the collaboration with Gargash General Trading will be a key driver in shaping the future of construction machinery in the market. With a focus on quality, innovation, and comprehensive support, the two firms are well-positioned to build on their impressive start within the UAE’s dynamic construction landscape.

“By working closely with Liugong, we ensure that customer insights directly influence future product iterations, allowing us to tailor solutions that meet evolving market needs and deliver superior performance.”

WHY GET IT?

THE NEW DX10Z-7 PROVIDES A SIGNIFICANTLY IMPROVED PERFORMANCE COMPARED TO THE PREVIOUS DX10Z MODEL IT REPLACES.

The DX10Z-7 is compact and easy to transport, offering a width of only 730 mm when the tracks and the front blade are fully retracted, allowing the machine to pass through doors. The hydraulically expandable undercarriage provides the DX10Z-7 with one of the widest stances in the mini-excavator segment.

Supplying an output of 7.6 kW (10.35 HP), the well proven D722 engine powers the DX10Z-7, providing dependable reliability, as well as low vibration and noise levels that are essential for working in confined areas in construction, rental, demolition, landscaping and many other applications.

The increased performance of the DX10Z-7 is based around a new 1.45 m boom design and increased arm length (from 810 to 890 mm), resulting in a significantly enhanced working range compared to the DX10Z.

WHY GET IT?

NIFTYLIFT’S FIRST STRAIGHT BOOM PLATFORM, WAS CREATED IN RESPONSE TO CUSTOMER DEMAND FOR A STREAMLINED, LOWER-COST

Niftylift has made a splash at this year’s Vertikal Days exhibition, launching two new product, including its first-ever straight boom platform, the HR22 SE, and an upgraded version of its popular HR12 4x4. These new models represent the company’s commitment to expanding its range and delivering cutting-edge solutions to the construction and industrial sectors.

The HR22 SE, Niftylift’s first straight boom platform, was created in response to customer demand for a streamlined, lower-cost option that maintains the company’s reputation for high-performance engineering. This all-electric model offers a maximum vertical reach of 19.7 meters (65 ft) and horizontal outreach of 18.8 meters (62 ft), making it ideal for construction and other industrial applications where reach, manoeuvrability, and low emissions are key factors.

According to Niftylift Managing Director

John Keely, the HR22 SE combines the company’s focus on reliability and affordability with features such as a zero-emissions drive, low-noise operation, and a robust design that suits congested workspaces. The unit can operate for up to five days on a single charge, thanks to its 8 x 400 Ah batteries, and includes advanced technology like the award-winning SiOPS system to prevent accidental machine operation.

Alongside the HR22 SE, Niftylift also introduced an upgraded HR12 4x4 model, further enhancing one of the company’s best-selling ranges. The modified boom provides an increased horizontal outreach of 6.4 meters (21 ft) and a working height of 12.1 meters (39 ft 6 in), while the four-wheel drive system ensures smooth operation on rough terrain.

Powered by Niftylift’s Gen2 Plug-In Hybrid system, the HR12 4x4 offers the flexibility of op-erating either via a fuel-efficient EU stage V-compliant engine or a zero-emissions electric mode, giving operators more choices for diverse work environments.

Both launches highlight Niftylift’s commitment to expanding its product line and meeting customer needs. “These new models are not only about extending our reach—literally and figuratively—but also about providing more efficient and versatile solutions,” says john Keely.”

BOTH MODELS COME EQUIPPED WITH THE INTELLIGENT TEOS OPERATING SYSTEM, WHICH ENHANCES EASE OF USE AND OPERATIONAL EFFICIENCY.

Terex Rough Terrain Cranes has expanded its TRT Series with the introduction of two new models, the TRT 100 and TRT 60. These additions follow the recent launch of the TRT 80L, further broadening the company’s range of user-friendly and durable cranes.

The TRT Series is known for its advanced features, and the new TRT 100 and TRT 60 models are no exception. Both models come equipped with the intelligent TEOS operating system, which enhances ease of use and operational efficiency. The compact design, four steering modes, and proportional full power telescoping boom provide flexibility and precision, making these cranes suitable for a variety of applications including ports, construction, infrastructure, mining, energy, and general lifting tasks. These cranes also feature the Eco Mode function, which optimises fuel consumption,

and the T-Link telematics platform, offering real-time data monitoring for improved fleet management. Additionally, the models include LED lights and a spacious, tiltable cabin with large glass surfaces, ensuring operator comfort and visibility.

The TRT 100, with a maximum capacity of 100 tonnes and a main boom length of 47 metres, is designed for heavy-duty lifting tasks. It includes a 17-metre jib stowed on the crane’s side, which can be easily attached to extend reach. A self-removable counterweight further enhances operational efficiency, stability, and transportability.

The TRT 60, designed for lighter but still demanding tasks, has a maximum capacity of 60 tonnes and a main boom length of 42.5 metres. It features a stowable jib that extends from 8 to 15 metres, providing additional reach when needed.

A key innovation in the new models is the introduction of Terex’s ‘IdeaLift’ system. This feature optimises load lifting capabilities using asymmetric outriggers. The crane automatically selects the best lifting capacity based on the specific formation of the

outriggers, whether they are fully extended or partially retracted. This innovation enhances safety and efficiency during operations.

Giancarlo Montanari, General Manager of Terex Rough Terrain Cranes, expressed confidence in the new models, stating, “We are diligently expanding our product offering to ensure our portfolio possesses the capacity and flexibility to address daily lifting challenges in the modern working environment. The marketplace is highly competitive, but I have great confidence in our dedicated team members and the superior Italian craftsmanship behind every crane produced at our Crespellano manufacturing centre of excellence.”

SPECIFICATIONS

TRT 100

Main Boom Length: 47m

Jib Length: 17m

Capacity: 100t

Radius: 2.5m

LOWER YOUR COSTS

Effective waste management can reduce the amount of materials purchased and lessen disposal fees, while also enhancing project timelines and labour productivity.

The use of BIM also improves collaboration among project stakeholders, reducing the likelihood of errors and rework, both of which contribute to construction waste.

Proper storage and handling of materials on-site are critical to minimising waste. Designating specific areas for storing different types of materials, using pallets, shelves, and bins to keep materials off the ground, and protecting materials from weather conditions are all effective strategies.

By providing training on proper material handling, storage, and recycling techniques, construction firms can enhance workers’ skills and reduce waste. Regular training ensures consistent implementation of best practices across the jobsite.

PREFABRICATION IS AN OPTION

By segregating waste at the source, you can improve the quality of recyclable materials and reduce disposal costs. Establishing recycling stations and partnering with local recycling facilities ensures that materials are processed and reused.

09

ALWAYS ON TIME

By reducing the need for on-site storage and lowering the risk of damage, theft, and deterioration, JIT delivery helps to streamline project schedules and improve productivity.

KEEP TRACK OF WASTE

Regular jobsite waste audits are essential for identifying waste issues and improving material use. Engaging field staff, supervisors, and other stakeholders in the process encourages ownership and accountability for waste reduction.

By manufacturing components in a controlled factory environment, material waste is minimised, and the need for on-site rework is reduced. Prefabricated components can be quickly assembled on-site, reducing construction time and minimising disruption. 05 08 07 10 06

The construction landscape of Saudi Arabia is undergoing a remarkable transformation as the Kingdom embarks on an unprecedented wave of infrastructure projects. Driven by Vision 2030, a strategic initiative aimed at diversifying the economy and reducing dependency on oil, the country is rapidly evolving into a global construction hub. With mega-projects like Neom, the Red Sea Project, and King Salman International Airport, the Saudi market for construction machinery and heavy equipment is booming. As the Kingdom prepares for the Heavy Equipment and Truck Show (HEAT Show) this November, it’s clear that the sector is on an upward trajectory.

The HEAT Show is poised to showcase the latest innovations in heavy equipment, trucks, and machinery, drawing industry leaders from across the globe to Riyadh. The event will provide an invaluable opportunity for manufacturers, contractors, and industry stakeholders to network and explore the machinery and equipment propelling Saudi Arabia’s ambitious developments. Here’s a snapshot of the major international players making moves in the Saudi construction machinery market.

Raimondi Cranes, the Italian tower crane manufacturer, recently marked a significant milestone, with 70 of its cranes deployed across the Kingdom. These cranes are integral to projects spanning sectors like healthcare, hospitality, residential, education, and infrastructure, all key to Vision 2030. General Manager Wael Hasan notes, “The demand for tower cranes in Saudi Arabia is experiencing remarkable growth, thanks to the country’s push for economic diversification.”

Among Raimondi’s fleet, the MRT159 and MRT294 models stand out for their impressive lifting capabilities, catering to the growing infrastructure needs. As Saudi Arabia continues its ambitious development plans, Raimondi is set to play an even bigger role in the Kingdom’s progress.

In an exciting development for Saudi Arabia’s rapidly expanding construction sector, Rapid Access has announced the opening of its newest depot in Neom. This is the company’s fourth depot in Saudi Arabia and the eleventh across the Middle East, reinforcing its commitment to improving equipment accessibility and

service delivery in the region.

Neom, a visionary city under development in the Tabuk province, is a key area for growth and innovation. The new facility will enhance Rapid Access’s ability to provide Mobile Elevating Work Platforms (MEWP) to support construction and industrial projects in the region.

Waleed Isaac, Managing Director for Rapid Access in the Middle East and International, remarked, “Our commitment to invest in Neom is evident with the launch of our comprehensive Service and Engineering Center in Tabuk. We are witnessing the fastest evolution of a visionary project and are proud to be associated with it.”

Raimondi Cranes currently have 70 of its cranes deployed across the Kingdom 70

Ahmad Othman, Country Manager for Saudi Arabia and Bahrain, added that the depot will be equipped with a robust fleet of machines and highly trained engineers to ensure clients receive the best levels of support. This expansion underscores Rapid Access’s dedication to continuous growth, ensuring they are well-positioned to serve the Kingdom’s ambitious projects, such the King Salman International Airport project. Mace has been appointed to lead the delivery of what will be one of the world’s largest airports upon its completion in 2030. Spanning 57 square kilometres and capable of handling over 100 million passengers annually, this six-runway

airport is a testament to Saudi Arabia’s global ambitions.

Davendra Dabasia, CEO of Mace Consult, emphasised the project’s importance: “King Salman International Airport is a gamechanging infrastructure programme.”

The consultancy’s role will encompass everything from project management to sustainability, aligning with the Kingdom’s commitment to a greener future. set to be one of the world’s largest airports upon its completion in 2030. Spanning 57 square kilometres and capable of handling over 100 million passengers annually, this six-

runway airport is a testament to Saudi Arabia’s global ambitions.

Davendra Dabasia, CEO of Mace Consult, emphasised the project’s importance: “King Salman International Airport is a gamechanging infrastructure programme.”

The consultancy’s role will encompass everything from project management to sustainability, aligning with the Kingdom’s commitment to a greener future. A determination that is already making an impact on the equipment and vehicles coming into the market.

For instance, in a significant step towards greener transportation in Saudi Arabia, the first battery-electric truck from Mercedes-Benz Trucks, the eActros 300 L 4x2, has been unveiled in the Kingdom.

Launched at the EV Auto Show in Riyadh by Juffali Commercial Vehicles (JVC), the authorised General Distributor for Mercedes-Benz Trucks, the eActros represents a leap forward in Saudi Arabia’s sustainability journey.

Heiko Schulze, CEO of Juffali Commercial Vehicles, expressed the significance of the launch: “The eActros in Saudi Arabia represents a milestone for sustainable transportation in the region.” The truck, equipped with advanced systems like Stability Control Assist and Active Brake Assist, delivers both enhanced safety and a quieter, emission-free operation. With a battery capacity of 336 kWh and a range of up to 300 km, the eActros is designed to meet the Kingdom’s growing demand for sustainable transport options in line with

2030.

The introduction of the eActros underscores Saudi Arabia’s commitment to green logistics, a key pillar of its broader goals for economic and environmental sustainability. This electric truck is part of the Kingdom’s shift towards greener, more efficient freight transport, and will undoubtedly play a pivotal role as Saudi Arabia continues its drive towards a cleaner future.

In line with Vision 2030’s focus on improving industry standards, WakeCap, a leading provider of workforce safety solutions, is setting new benchmarks in construction safety. The company’s technology, which allows real-time monitoring of workers, is transforming how safety is managed on Saudi construction sites. With government support, WakeCap is helping establish new safety protocols that are fast becoming the norm in the Kingdom’s booming construction sector.

“This aligns perfectly with our mission to transform safety protocols in the construction industry and beyond, leveraging WakeCap’s capabilities to forge a safer, more secure working environment for all.”

WakeCap’s growing influence is further

underscored by the Ministry’s involvement in NCOSH, where WakeCap is positioned as a key player in shaping future occupational safety and health regulations in Saudi Arabia.

The government’s strategy to mandate safety and security across the construction and related sectors will be closely supported by WakeCap’s technology, which enhances emergency response times and provides robust data for compliance and incident investigation.

The technology facilitates real-time monitoring of workers’ conditions, enabling instant alerts in the event of emergencies, significantly reducing response times. Moreover, the data collected by WakeCap ensures ongoing compliance with safety regulations and plays a critical role in investigating incidents, identifying root causes, and implementing preventative measures.

NAZ Industries, the largest semi-trailer manufacturer in the Middle East, has its sights set on Saudi Arabia. With a new production facility in Dubai and plans for further expansion, NAZ is targeting the sale of 4,000 trailers in Saudi this year. CEO Adel Mir stated that the new facility will significantly increase production capacity, ensuring that NAZ meets the rising demand in the Kingdom’s construction and logistics sectors.

Since its establishment in 2001, NAZ products have gained a reputation in KSA for their quality and durability. Thousands of visitors have flocked to our exhibition stands at BIG5 Riyadh and BIG-5 Dubai, underscoring the high demand for our offerings. This enthusiasm has driven NAZ to focus more intently on the KSA market.

NAZ recently opened a new 350,000 sqm production facility in Dubai Investment Park 2 (DIP-2). It is also planning a second location which is three times bigger than its main facility. With the new addition to its current facilities it is targeting a production capacity of 12,000 trailers per year, says NAZ Industries CEO Adel Mir. “Our plan is to reach production and delivery of 12,000 trailers per year. The demand is there and we are working to expand in order to meet the demand. Our new facility in DIP-2 can deliver 3,200 units a year in 2 shifts,” he says.

operations in the Kingdom earlier this year. The platform is already registering major players such as El-Seif Engineering and AIC Steel, ensuring swift access to lifting equipment for Saudi’s megaprojects. Founder Andrei Geikalo commented, “Our launch in Saudi Arabia was a natural step, given the Kingdom’s $1 trillion worth of infrastructure projects.”

Wolffkran, the German crane manufacturer, has also joined forces with Saudi’s Zamil Group to establish a local crane production facility and rental fleet. With a planned production of 150 cranes per year, this partnership is poised to support Saudi’s numerous megaprojects, including those in Riyadh, Dammam, and Neom.

Wolffkran and Zamil Group plan to manufacture 150 cranes per year

“Our facility in freezone which is still under construction, can deliver 4,500 units in two shifts. We have a supply contract with one of the most reputed steel factories in the region and we can get approximately 3,500 chassis of standard trailers from them every year. Once the chassis are built, they will be shifted to our own facilities for the completion of trailers.”

Responding to Saudi Arabia’s rapid digital transformation, MYCRANE, the first online platform for crane rental, launched

The collaboration is a strategic response to the Kingdom’s construction boom, enhancing local manufacturing and crane availability, says Duncan Salt, CEO of Wolffkran Holding AG, expressing pride in leading the way in Saudi Arabia’s dynamic construction sector, citing the current construction boom as a prime opportunity for local production.

“Saudi Arabia is currently experiencing a construction boom and we are proud to be pioneering this dynamic market with local tower crane production,” said Salt at the signing of the contract at the Private Sector Forum 2024 in Riyadh.

The long-established family business

based in Khobar not only has an excellent local network, but also has many years of experience in the construction, real estate, and steel construction sectors. With the tower crane division, the company is adding another line of business to its broad portfolio.

“In the Zamil Group, we have found a strong partner for this project,” added Dr. Peter Schiefer, owner and member of the Board of Directors of Wolffkran Holding AG. “A partnership that will create many synergy effects.”

Terex Rough Terrain Cranes has named Zahid Tractor & Heavy Machinery as its authorised distributor in Saudi Arabia, expanding its presence in the region. Ajit S Nair, Head of Sales at Terex, said, “Saudi Arabia is a very important market for us.”

Zahid Tractor, a key player in the Kingdom’s infrastructure development, will offer Terex’s full range of cranes and provide local service and support.

Cummins Arabia meanwhile has signed a Memorandum of Understanding with Al Rasheed Co., signalling its intention to expand into Saudi Arabia’s defence sector. As part of this partnership, Cummins will introduce sustainable power solutions tailored to the needs of

the sector, reinforcing its commitment to the Kingdom’s Vision 2030 objectives.

Leveraging its rich history and expertise in serving the defence segment, Cummins Arabia is set to introduce reliable power solutions tailored to meet the unique demands of the sector. This strategic partnership is poised to unlock the potential for delivering unparalleled solutions and services to the Kingdom.

Ahmed Alghamdi, Country Leader of Cummins Arabia, commented on the partnership, saying, “Our collaboration with Al Rasheed Co. opens up new horizons for Cummins Arabia, significantly expanding our footprint within the Kingdom. This partnership goes beyond a mere agreement; it reflects our steadfast commitment to local investment and the advancement of technologies that promote a sustainable future.

“Our upcoming launch of the USD 2 million Dyno Test Cell facility in Dammam is a testament to this commitment. Every initiative and investment we undertake is aligned with the objectives of Vision 2030, ensuring that our contributions play a pivotal role in supporting the country’s ambitious and forwardthinking plan.”

18th - 21st November 2024

12,000sqm

WHILE EXOSKELETONS WON’T HAVE YOU FIGHTING KAIJU LIKE IN PACIFIC RIM, THEY’RE STILL A BIG STEP TOWARDS A SAFER, STRAIN-FREE WORKDAY

eobear recently initiated a trial looking into using exoskeletons to reduce repetitive stress injuries in manual work environments. Establishing an in-house ergonomics working group, comprised of operational staff and technicians, the company aimed to enhance the ergonomics of subsidence drilling by mitigating strain from repetitive tasks. They first employed mechanical means using a hierarchical risk reduction approach, before trialling assistive exoskeleton tech. Geobear’s subsidence management strategy involves drilling with progressively larger bits before inserting a 12 mm injection tube into the ground to inject a geopolymer resin, combatting subsidence. Whether conducted manually or using a driving tube, this process requires repeated bending and movement in a downwards direction. The exoskeleton, weighing 2.4 kg and composed of a plastic frame with a bicep-mounted pulley system, is designed to alleviate strain on the shoulders and neck during intensive work, such as continuous overhead tasks. Geobear piloted the exoskeleton with a group of its technicians in the UK for live field testing. Feedback from the working group highlighted significant challenges, particularly with movement restriction. The exoskeleton works by shifting strain from the arms to the operator’s core, promoting correct posture. While perfect for tasks at shoulder level and above, during operations such as driving the injection tube into the ground, operators needed to lean forward. With the exoskeleton

on, this caused discomfort. Additionally, the test group noted issues with the exoskeleton’s size, measuring 950 mm by 450 mm. This sizing posed challenges for larger operators, especially during the downward-facing drilling tasks. These concerns show that while the suit might be suited for horizontal or vertical subsidence works, such as in tunnels, there was an increased risk of injury during downward drilling tasks.

There is future potential for exoskeleton technology in various operational scenarios, particularly in horizontal and upward drilling tasks. Further trials with tool-balancing exoskeletons such as the Hilti EXO-T-22 could enhance ergonomics by reducing fatigue, shoulder strain and lower back pain through software that balances tool weights using a back-mounted winch. However, using this exoskeleton in cramped conditions, such as between residential properties, might be challenging. Geobear is already pursuing advancements beyond exoskeleton trials. Efforts include modifying drill stands for manual attachment with off-road capabilities and reducing strain from carrying larger weights. There are also efforts to enhance tube driving efficiency through new tips designed for driving into clay, reducing vibration, manual labour and the potential for musculoskeletal injuries. By continuously seeking innovative solutions, and investing in R&D testing, companies can show commitment to continuous improvement in the health and safety of their people in the field.

Putzmeister Concrete Pumps GmbH · www.putzmeister.com

Putzmeister Middle East

Jumeirah Lakes Towers (JLT) · 2406 Fortune Tower Cluster C

P.O. Box 337508 · Dubai, U.A.E.

Tel: +971 (0) 4 454 27 83 · Fax: +971 (0) 4 454 27 82

Mr. Mohammad Sabah +971 526700057

Mr. Binoj Syamala +971 526700016

•

•