SASKATCHEWAN

2021

THE VOICE OF THE OIL INDUSTRY IN SASKATCHEWAN

PUBLICATIONS MAIL AGREEMENT #40934510

saskatchewanoilreport.com

Petroleum Technology Research Centre’s Aquistore Project stores carbon dioxide Southeast College offers new Heavy Equipment Operator program

How to develop EOR technologies more efficiently with a stage-gated approach

LARGEST NETWORK.

BUSINESS WIRELESS Stay connected with customers and employees on Saskatchewan’s largest LTE and Wi-Fi networks. • Unlimited Canada-wide data* usage with Business VIP plans • No data overage charges • Free unlimited Wi-Fi with SaskTel selectWI-FI, SK’s largest Wi-Fi network • Unlimited text messaging in Canada, the US, and most of the Caribbean • Flexible, competitive wireless plans built with your needs in mind It’s the wireless solution your business needs. *Speed reduced to 2 Mbps after 20 GB or 50GB depending on chosen plan

sasktel.com/businessvip

IN THIS ISSUE

SASKATCHEWAN Oil Report is published by:

Message from the Premier of Saskatchewan, Scott Moe – 8

DEL Communications Inc. Suite 300, 6 Roslyn Road, Winnipeg, MB R3L 0G5 www.delcommunications.com

Message from the Saskatchewan Minister of Energy and Resources, Hon. Bronwyn Eyre – 10

President & CEO: DAVID LANGSTAFF Managing Editor: CINDY CHAN cindy@delcommunications.com

Message from Canada’s Minister of Natural Resources, Hon. Seamus O’Regan – 12

Advertising Sales Manager: DAYNA OULION dayna@delcommunications.com

Petroleum Technology Research Centre’s Aquistore Project stores carbon dioxide – 16

Advertising Sales Representatives: COLIN JAMES | ROSS JAMES | MICHELLE RAIKE DAN ROBERTS | ANTHONY ROMEO

The power of geothermal power generation – 18

Production services provided by: S.G. Bennett Marketing Services

Southeast College offers new Heavy Equipment Operator program – 22

Creative Director / Layout & Design: KATHLEEN CABLE

Brother’s Specialized Coating Systems Ltd.: Thriving and striving for the future – 24

Cover Photo Courtesy of: PETROLEUM TECHNOLOGY RESEARCH CENTRE

How to develop EOR technologies more efficiently with a stage-gated approach – 26 CER analysis shows the U.S. continues to be major supplier of oil to Canada while imports dropped in 2020 – 28 PTRC investigating the utilization of CO2 extensively in Saskatchewan’sheavy oil zone – 30 Carbon reporting: Coming soon to the supply chain – 32 Wicehtowak Limnos Consulting Services: A 100-per cent Indigenous-owned company – 35

INDEX TO ADVERTISERS

Fluor Canada: Positioned for growth, committed to building a better future – 36

© 2021 DEL Communications Inc. All rights reserved. Contents may not be reproduced by any means, in whole or in part, without the prior written permission of the publisher. While every effort has been made to ensure the accuracy of the informationcontained in and the reliability of the source, the publisher in no way guarantees nor warrants the information and is not responsible for errors, omissions or statements made by advertisers. Opinions and recommendations made by contributors or advertisers are not necessarily those of the publisher, its directors, officers or employees. Publications mail agreement #40934510 Return undeliverable Canadian addresses to: DEL Communications Inc. Suite 300, 6 Roslyn Road, Winnipeg, MB R2L 0G5 Email: david@delcommunications.com PRINTED IN CANADA | 05/2021

Annugas Compression Consulting Ltd..........................................13

Level Best Technologies Ltd..............................................................22

B & B Oilfield Hauling + Integrity Oilfield Hauling Ltd............... 29

Netzsch Canada, Inc.................................................................20 & 21

Brother’s Specialized Coating Systems Ltd....................................5

Petroleum Technology Research Centre............................ 14 & 15

Deep Earth Energy Production..................................................6 & 7 Department of Economy....................................................................9

Pumps & Pressure Inc.........................................................................17 Right Choice Energy Services Inc....................................................31

Fast Trucking Service Ltd...................................................................25 Fluor Canada Ltd...............................................................................IBC Good To Go Trucking..........................................................................19

SaskTel......................................................................................................3 SIMSA.....................................................................................................33

Goodwater Machine Shop (1986) Ltd............................................19

Southeast College..............................................................................23

Graham...............................................................................................IFC

Transcourt Tank Leasing....................................................................27

IFR Workwear Inc...........................................................................OBC

Wicehtowak Limnos Consulting Services LP.................................11

4 Saskatchewan Oil Report 2021

“Industry Leading Quality & Service Since 1987”

100% Canadian Owned. Specialists in Internal & External Coating Applications.

Lining Systems for Abrasion, Corrosion & High Heat Applications, Plural Spray Applications CSA Z245.30 , NACE Level 3, Pipe, Tanks, Vessels, Bends & Valves

6150 - 76 Avenue, Edmonton, AB T6B 0A6 Phone (780) 440-2855 Fax (780) 440-1050

www.brotherscoating.com sales@brotherscoating.com

About DEEP: DEEP is a Saskatchewan privately held corporation with a mission to develop Saskatchewan’s geothermal resources for power generation. DEEP’s vision is to be a producer of secure stable and sustainable energy. DEEP is developing a unique geothermal (or earth heat) power facility in southern Saskatchewan. This project will establish the first geothermal power facility in Canada. DEEP will harness high-quality geothermal resources with existing drilling and power generation technologies to establish a long-term renewable baseload (24 hours a day, 365 days a year) power supply. DEEP’s long-term goal is to develop 100s of megawatts (MW) of baseload power facilities from small scalable and repeatable 5-20 MW power plants each which could power up to 5,000 to 20,000 households.

DEEP | EARTH | ENERGY | PRODUCTION

Environmental Benefits: Once operating geothermal power plants produce almost zero emissions. Additionally the surface footprints of plants are small and do not compare to wind farms or large nuclear or coal power plants.

Economic Benefits: Geothermal power can be the lowest levelized cost of electricity when compared to other renewable. When combined with abundant government incentives such as those in Germany and the USA geothermal becomes a high revenue power production system. In addition the production cost fluctuations associated with commodity based energy sources such as coal, natural gas, oil and nuclear do not apply to geothermal.

Advantages: Geothermal has many advantages over other traditional power sources and other renewable energy sources. These advantages include economic, environmental and supply benefits.

Baseload Power: Unlike other renewable geothermal provides constant baseload power. Where wind power is only produced when it is windy, and solar power is only produced when it is sunny, geothermal can be produced 365 days of the year.

www.deepcorp.ca

INFO@DEEPCORP.CA | SASKATOON, SK | 639.638.0484

Message from the Premier of Saskatchewan

SCOTT MOE

O

n behalf of the Government of Saskatchewan, it is my pleasure to welcome you to the 2021 edition of the Saskatchewan Oil Report. The past year has been enormously challenging for Saskatchewan and the entire world. The COVID-19 pandemic is an unprecedented crisis in our time. Every sector of society has been affected by the crisis. Every industry has felt the impact. The province’s oil and gas sector was hit hard by a steep reduction in demand caused by the pandemic and the damaging effects of an international price war. There has been tremendous uncertainty for energy companies and the families they support. But I strongly believe better days are ahead. As we move through 2021, Saskatchewan’s vaccination program will pick up steam, and life will slowly return to normal. The province’s economy is poised for a significant comeback, in part because we managed to keep more businesses open during the pandemic than any other jurisdiction in Canada. We’re starting from a good position, and the fundamental strengths of our economy have not changed. We are fortunate in Saskatchewan to have an energy sector that remains a powerhouse in our economy and in our communities. The importance of oil and gas to Saskatchewan’s wellbeing is underappreciated. The industry accounts for 16 per cent of our province’s GDP and supports nearly 30,000 families in dozens of communities. Energy companies pay taxes to well over 100 municipalities in the province, in addition to contributing hundreds of millions of dollars in taxes and royalties to provincial coffers. Our government understands the important role the oil and gas sector plays in supporting quality of life in Saskatchewan. That is why we will always stand up for the industry and the communities and families supported by the industry. An example of this commitment was in April 2020, when we implemented a series of relief measures for the provincial oil and gas sector, in response to the economic down-

8 Saskatchewan Oil Report 2021

turn resulting from COVID-19 and the price war. Following the announcement of these relief measures, the Government of Saskatchewan launched the Accelerated Site Closure Program (ASCP) to help address the abandonment and reclamation of inactive oil and gas wells and facilities. In partnership with the federal government and the Saskatchewan Research Council (SRC), the program is putting hundreds of people back to work. The ASCP, now well underway, applies $400 million in federal funding for the abandonment and reclamation of up to 8,000 inactive oil and gas wells and facilities. The program is expected to support approximately 2,100 full-time equivalent jobs over two years. Our government is ensuring Indigenous businesses, communities and people benefit from the program through the First Nations Stewardship Fund and the Indigenous Business Credit Pool. Our government will be relying on our Growth Plan to kickstart our economy and ensure another decade of growth. One of the objectives in our Growth Plan is the expansion of oil production in the province to 600,000 barrels per year by 2030. Demand for oil around the world is expected to grow in the years ahead. Saskatchewan can help meet that grow ing demand. Saskatchewan’s oil is among the most sustainably produced oil in the world. Our producers are the very best in the world at what they do. You can expect our government to defend and promote Saskatchewan’s oil and gas sector in the years ahead. On behalf of the Government of Saskatchewan, thank you for the many contributions you make to our province. We’re counting on you as we begin the next chapter in Saskatchewan’s growth story.

Scott Moe Premier

“Saskatchewan is just a great place to do business, the government stands by its word, and that stability is attractive to investors.” ~ Grant Strem, Chairman & CEO of Proton Technologies

Best Place to Pilot and Test New Technologies Saskatchewan offers the competitive cost structure, a stable regulatory environment, and royalty and incentive programs to help get your project off the ground. Saskatchewan has what the world needs. Discover the opportunities.

thinksask.ca/invest |

Message from the Saskatchewan Minister of Energy and Resources

HON. BRONWYN EYRE

O

n behalf of the Ministry of Energy and

Helium is also taking off in the province, with im-

Resources, I am pleased to join with

portant projects in the works from North American

Premier Moe in offering welcoming re-

Helium Inc. and Royal Helium. In fact, Saskatchewan

marks for the 2021 edition of the Sas-

will soon be home to the largest helium purifica-

katchewan Oil Report.

tion operation in Canada. It is being constructed by

Certainly over the course of the last year, the oil

North American Helium near Battle Creek, SK, and is

and gas sector has experienced significant challeng-

expected to be operational by July. Royal Helium is

es. In response, the Government of Saskatchewan

currently drilling of three wells near Climax.

implemented several, key relief measures, including

As we begin to emerge and recover from the CO-

extending mineral rights exploration timelines and

VID-19 pandemic, our oil and gas sector will play a

reducing the industry portion of the oil and gas ad-

substantial role in strengthening and building Sas-

ministration levy.

katchewan’s economy. In 2019, the oil and gas sec-

In May 2020, our government also launched the

tor produced over 490,000 barrels of oil per day, the

Accelerated Site Closure Program (ASCP), with the

value of provincial oil and gas production was over

important goal of getting Saskatchewan service

$10 billion, and the sector supported over 30,000

companies re-engaged and workers back on the job.

Saskatchewan jobs.

Now in the sixth month of a 30-month program, the

In November of 2019, we released Saskatchewan’s

ASCP has allocated $300 million and issued more

Growth Plan: The Next Decade of Growth, which in-

than $98 million in contracts to licensees, which

cludes ambitious targets that include increasing oil

hire service companies to complete abandonment

production by 25 per cent, to 600,000 barrels per

and reclamation activities. The ASCP has engaged

day, and increasing the value of Saskatchewan ex-

307 Saskatchewan-based service companies to date

ports by 50 per cent over the next decade.

across every oil and gas region of the province. Com-

Despite signs of growth, challenges to the oil and

pleted so far have been 724 well abandonments, 175

gas sector remain, including the impact of the fed-

flowline abandonments, 39 facility decommissions,

eral Carbon Tax, the federal Clean Fuel Standard and

and 1,434 site remediation and reclamation activities.

the federal Environmental Impact Assessment Act

Saskatchewan has also welcomed a number of

(Bill C-69). As a government, we continue to strongly

new, innovative projects over the past year. These in-

advocate for, and promote, the sector and its work-

clude the Prairie-LiEP Critical Mineral Joint Venture,

ers, as we call for more cautious, common-sense

a two-stage pilot project that will produce lithium

federal regulation and policies.

hydroxide from Saskatchewan oilfield brines, and

Saskatchewan remains committed to being a

Proton Technologies’ hydrogen production project,

strong environmental steward, while growing our

a first-of-its-kind project in the world that extracts

economy. v

hydrogen from existing oil reservoirs and leaves carbon dioxide in the ground.

10 Saskatchewan Oil Report 2021

• 100% Indigenous owned consulting company • Environmental potash services monitoring/testing/assessments • Project management / stakeholder engagement • Security services 24/7

#234, 400 Broad Street, regina, SK S4r 1X3

P: 306-596-1119

e: sverot@wlcs.ca

Message from Canada’s Minister of Natural Resources

HON. SEAMUS O’REGAN

I

t’s been a tough year. The double whammy of a pandemic and global oil price war hit companies, families and communities hard. It hasn’t been easy, especially for our oil and gas workers. But through it all, we’ve

seen your resilience. You’ve been front and centre in Canada’s pandemic response. Your products are used in life-saving equipment,

tects the environment while advancing reconciliation with Indigenous peoples. In Canada, good projects get done in a good way: • TMX. We approved it, we bought it and we’re building it. It’s already created over 7,000 jobs. • NGTL 2021. We approved it, and thousands more jobs will be created in Alberta.

such as petroleum for ventilators and masks. Your sector

• Line 3. We approved it, creating another 7,000 jobs.

has powered and heated hospitals, schools and homes.

The International Energy Agency tells us that demand for

Just as you were there for Canadians, our government

oil and gas will continue to grow for the next two decades,

was there for you. Since March of last year, we’ve provided

even as we invest in other sources of energy. Canada will

more than $2.8 billion in targeted support for the oil and

supply that demand under our world-leading environ-

gas sector, with a laser-like focus on jobs. From cleaning up

mental regulations, as we build our low-emissions energy

orphan and inactive wells, to providing much-needed li-

future.

quidity, to launching the $750m Emissions Reduction Fund, we supported roughly tens of thousands of jobs while lowering emissions and improving competitiveness.

Canada will lead the way. Because there is no path to netzero without your industry. Canada is the fourth largest producer of oil and gas in

And today, our oil and gas workers are leading Canada’s

the world. It’s the biggest part of our economy. What that

economic recovery. Oil exports are at pre-pandemic vol-

means is we have hundreds of thousands of workers who

umes, oil prices have risen sharply, rig counts are edging

know how to build energy infrastructure – and lots of it.

upwards and so is capital investment. It’s a good reminder that the windshield is bigger than the rear-view mirror.

Engineers. Trades workers. Scientists. Investors. The people who made Canada the world’s fourth largest producer

The oil and gas sector remains Canada’s largest private-

of oil are the same people who will build our low-emissions

sector investor in clean technology – by far. You fund

energy future. The same people who will build renewables.

promising innovations, from carbon fibres for ultra-light

The same people who will help meet our climate targets.

electric vehicles to carbon capture and hydrogen produc-

We are determined to leave no energy worker or en-

tion technologies. These are the innovations that investors

ergy-producing region behind. Because this is our family

are looking for. Because the market is moving.

business. You are those workers. And in oil-producing prov-

Investors around the world are increasingly making clear choices. They’re putting their money into businesses, industries and jurisdictions that are taking meaningful climate action. And they’re divesting from those that, in their view, are not. The good news is that you’re already taking meaningful

inces like yours and mine, our friends and neighbours are too. The future we build has to be inclusive. We need to build back better and smarter. Your ingenuity, determination and hard work will make that happen. You will lead us in our common mission:

action. Canadian oil and gas is already produced under

• Net-zero emissions by 2050;

some of the most stringent environmental regulations in

• A prosperous economy that creates jobs, jobs, jobs;

the world, and we’ve built on that with a regulatory system

• A low-emissions future that leaves no one behind.

that provides the certainty investors are looking for. Our re-

I know this is a lot. It’s ambitious.

view process is open, transparent and predictable. It pro-

But we’re Canada. This is what we do. v

12 Saskatchewan Oil Report 2021

Energy Processing Ad

12/13/05

4:16 PM

Page 1

JACK!

IT’S ABOUT TIME

Jack knows time is money PAYS FOR ITSELF

INSTALLATION

YOUR TIME

The increase in oil/ gas production is immediately measureable not only in time, but real dollars.

It only takes a few hours to have your compressor up and running, practically eliminating production downtime.

Our safety qualified installers will perform maintenance checks when required, onsite, saving you the trip in.

– 4 WEEKS

– 1 DAY

– ZERO

www.annugas.com Toll Free

1.866.ANNUGAS

COMPRESSION

CONSULTING

ANNUGAS ANNUGAS PRODUCTION PRODUCTION ENHANCER ENHANCER ®

LTD.

The leader in developing sustainable and environmentally responsible energy.

HEAVY OIL HEAVY OIL HEAVY OIL HEAVY OIL HEAVY ENHANCED OIL RECOVERY ENHANCED OIL RECOVER CO 2 STORAGE & UTILIZATION CO 2 STORAGE & UTILIZ GEOTHERMAL ENERGY GEOTHERMAL ENERGY GEOT LITHIUM EXTRACTION LITHIUM EXTRACTION LITHIU

Y OIL HEAVY OIL HEAVY OIL HEAVY OIL HEAVY OIL H RY ENHANCED OIL RECOVERY ENHANCED OIL RECO ZATION CO 2 STORAGE & UTILIZATION CO 2 STORAGE THERMAL ENERGY GEOTHERMAL ENERGY GEOTHER UM EXTRACTION LITHIUM EXTRACTION LITHIUM EX

Accelerating innovation and research to reduce the carbon footprint and increase production of subsurface energy. Aquistore Illustration

Visit us at ptrc.ca

Petroleum Technology Research Centre’s Aquistore Project stores carbon dioxide

Monitoring equipment with Boundary Dam Power Station in background.

T

he Petroleum Technology Research Centre’s (PTRC) Aquistore Project is an ongoing carbon dioxide storage

The pipeline, monitoring building, and injection well (left of picture) at Aquistore.

PTRC was founded to help establish

developed in that program made the

the capacity in the province of Sas-

PTRC the logical choice for designing

katchewan to conduct oil and gas re-

a similar MMV program for deep sa-

search, and that rapidly expanded to

line storage at Aquistore.

project that is measuring, monitor-

include CO2 storage and monitoring

“We took the expertise we gained

ing and verifying injected CO2 from

when the Weyburn and Midale fields

in Weyburn to Aquistore,” Nickel says.

SaskPower’s Boundary Dam Carbon

began injecting CO2 to improve oil

“The Aquistore site a few kilometres

Capture Facility near Estevan, Sask.

production in the year 2000.”

from Boundary Dam is made to have

Its goal is demonstrate the scientific

The knowledge and expertise de-

a lot more measurement and monitor

and economic feasibility of deep sa-

veloped over the 15 years of Weyburn-

systems in operation than you would

line CO2 geological formation stor-

Midale research led the PTRC into

on a commercial site, just for the pur-

age and provide information for other

establishing and managing the CO2

poses of investigating all these types

jurisdictions and companies that are

storage component of the Boundary

of systems and eventually helping

planning to do the same.

Dam CCS Facility, Aquistore, which

other projects understand what mon-

began capturing CO2 in 2014.

itoring is needed and what is not.”

Established in 1998, the PTRC is funded by the Saskatchewan govern-

According to Erik Nickel, director

ment, private sector industry part-

of operations for the PTRC, the plan-

• To advance surface and subsurface

ners and the Government of Canada.

ning for Aquistore began in 2010,

carbon dioxide monitoring technol-

It originates and manages research

when SaskPower was in the process of

projects in enhanced oil recovery re-

building the CO2 capture facility out-

• To advance our understanding and

search and carbon management in

side Estevan. As the Weyburn Project

mitigate uncertainties of long-term

Saskatchewan.

progressed from 2000 to 2015 that

Aquistore has four main goals:

ogies;

stored carbon dioxide;

According to Norm Sacuta, director

the best practices for measurement,

• To demonstrate carbon dioxide stor-

of communications for the PTRC, “The

monitoring and verification (MMV)

age in deep saline formations as a

16 Saskatchewan Oil Report 2021

permanent, safe and viable strategy to reduce emissions; and • To reduce operational costs for emerging commercial CCS operations via Aquistore’s integration in an industrial-scale, full-chain CCS project. So how does Aquistore work? According to Nickel, CO2 is captured at the Boundary Dam coal-fired power plant using what is called a “postcombustion” capture system.

of kilometres, you have a big storage tank, and you can push CO2 into it. The carbon dioxide creates a plume for this ever-expanding circle of CO2. As it reaches further, pressures dissipate. In some cases, the CO2 dissolves into the water and/or into the rock. “If we can demonstrate and prove it’s safe to capture CO2 and dispose of it into this kind of rock formation, that is a real solution for mitigating CO2 emissions,” Sacuta says. “Sas-

katchewan and Canada are early to the game, and other projects in the United States have now also started to operate on an industrial scale. This hasn’t happened on-shore in Europe yet, but they’re interested in seeing what our project tells them scientifically that can be applied to other projects.” For more information, visit ptrc.ca/projects/ co2-eor-and-storage/aquistore. v

“The CO2 is made about 99 per cent pure and pressurized and put

Toll Free: 1-888-430-9359

into a pipeline. Most of that goes to Weyburn for enhanced oil recovery,” Nickel says. “About 400 to 600 tonnes

• Pressure Washers

of CO2 per day goes to the Aquistore

• Fluid Handling Equipment

site. At the site, there is a metering

• Air Compressors

system that measures the volume, as well as several pressure gauges, both

• Chemical Pumps

at the surface and down the injec-

• Wastewater Treatment

tion well. The injected CO2 goes down

• Commercial Vehicle Wash Equipment

through the middle of the metal tubing, which is held in place by a cement casing that is CO2-resistant.” Nickel likens the injection well to a big straw going into a Slurpee, and then a smaller straw inside of it. “We inject through the smaller straw, which is the tubing. It goes down into the Slurpee more than 3.4 kilometres

HEAD OFFICE: Red Deer 403-347-9770 7018 Johnstone Drive Red Deer, AB T4P 3Y6 Fax: 403-343-7922 Email: sales@pumpsandpressure.com

• Steam Truck Fabrication • Well Pumps

• Sewage Pumps • Air Dryers

• Parts Washers

• Parker Hydraulics

underground,” he explains. “CO2 at this temperature and pressure is in a state that is neither a liquid nor a gas; it’s called a super critical state, which means it flows like a gas but has the

PUMP & COMPRESSOR DIVISION www.pumpsandpressure.com

properties of a liquid.” From there, it runs out into the formation and essentially pushes back the saline water that is naturally in the formation. “When you push something underground, it’s not like a big cave. We are talking about highly porous rock that contains water,” Nickel says. “If you take a rock like a sandstone, you can push things through it. If you take several hundreds of metres of that rock

BRANCH OFFICES: Saskatoon 306-242-6622

610A-51 Street E.,Saskatoon, SK S7K 7K3 Fax: 306-934-8204

Calgary 403-263-7207 #50, 5200-64 Avenue S.E., Calgary, AB T2C 4V3 Fax: 403-263-7206

Edmonton 780-430-9359 6707-75 Street N.W., Edmonton, AB T6B 1T6 Fax: 780-437-0550

Lethbridge 403-328-0504 2801 - 2nd Avenue N., Lethbridge, AB T1H 6S2 Fax: 403-328-0542

Grande Prairie 780-539-9939 11307-98 Avenue, Grande Prairie, AB T8V 5A5 Fax: 780-539-9907

Brandon 204-728-9303 622 Richmond Avenue E., Brandon, MB R7A 7G8 Fax: 204-728-9305

and spread it laterally over hundreds Saskatchewan Oil Report 2021 17

The power of geothermal power generation

power facilities from small, scalable and repeatable 20 MW power plants, each which could power up to 20,000 households. This project is being advanced by local world-class oilfield experts from Saskatchewan and Alberta, as well as a powerful board and management team and various strategic advisors such as George Lafond (government/Indigenous

relations)

and the Hon. Rob Norris, a former Saskatchewan cabinet minister. Construction of the facility is slated to commence in the fall of 2021 and be completed by March 2023. The project is the first step in Canada’s significant energy transition to clean

D

eep Earth Energy Production Corp. is developing Canada’s first geothermal power facility with a con-

tract to sell power to SaskPower.

power. The first 20-megawatt field in Canada. DEEP will harness high-

would offset 114,000 metric tonnes of

quality geothermal resources with

carbon dioxide a year, equal to emis-

existing drilling and power generation

sions from 32,000 cars annually.

technologies to establish a long-term

Geothermal power has many ben-

renewable baseload (24 hours a day,

efits, such as:

According to the DEEP website

365 days a year) power supply. DEEP’s

• Baseload – Geothermal is the only

(deepcorp.ca), this project will estab-

long-term goal is to develop hun-

renewable energy source that can

lish the first geothermal power facility

dreds of megawatts (MW) of baseload

produce baseload power 24-7.

18 Saskatchewan Oil Report 2021

• Green – Zero carbon-based fuel consumption and facilities have a small footprint that doesn’t interfere with bird migration. • Ongoing supply – With proper reservoir management, geothermal resources will not run out, meaning plants fuelled by this energy source can run indefinitely. • Building on innovation – The DEEP project will build on Saskatchewan’s world-class drilling technology and expertise. In 2018, DEEP successfully drilled the first of the six deepest wells being drilled into the Canadian side of the Williston Sedimentary Basin to test

geothermal power generation.

sults indicate that temperature and

hot formation brine for geothermal

Extended ~60-day testing of the

potential flow rates from the geother-

power generation. DEEP drilled and

geothermal system commenced in

mal reservoir in the Deadwood For-

completed its first horizontal well in

January 2021 to refine the reservoir

mation are sufficient to support mul-

October 2020, which is the first well

model, lateral well length and array

tiple geothermal power facilities.

in the world to be drilled and hydrau-

spacing on subsurface field develop-

lically stimulated for the purpose of

ment plans. Drilling and testing re-

For more information, visit deepcorp.ca. v

ONE CALL FOR ALL YOUR OIL FIELD NEEDS

Ag & Oilfield Pressure Welding, Repairs & Services

www.gOOdtOgOkiNdERsLEY.CA Celebrating 30 years in Kindersley!

• • • • • • • • •

QC Program & Weld Procedures Licenced Contractor Consulting Shop & Mobile Welding Lease Maintenance Pumpjack Repairs & Maintenance Tex Gates & Fence Panels Full Machine Shop Services Certified ‘B’ Pressure Welding

• Custom Fabricating & Design • Isnetworld & Complyworks Members • Field Service Crews • Pumpjack Inspections • Snow Dozing & Plowing • Lease Mowing & Maintenance • Equipment Rental • Ag Equipment Repairs

306-456-2560 Located in Weyburn Oilfield – Highway 35 South Box 28, Goodwater, SK S0C 1E0 goodwatermachine@sasktel.net www.goodwatermachine.ca Saskatchewan Oil Report 2021 19

NETZSCH Pumps

The right pump for your job – from one source! NEMO® Progressing Cavity Pumps, TORNADO® Rotary Lobe Pumps and NOTOS™ Multiple Screw Pumps to meet your requirements. n n n n

Wide range of flow rates and pressures Proven dependability in the harshest conditions Low pulsation, steady flow in direct proportion to speed Wide range of materials available

www.pumps.netzsch.com

n Transfer n Multiphase n Injection n Pipeline n Oil Extraction n Lubrication n Sump n Caisson

NETZSCH Canada, Inc Tel: 705-797-8426 email: ntc@netzsch.com

Southeast College offers new Heavy Equipment Operator program BY CINDY CHAN

S

outheast College is bring-

Southeast College has been around

ing innovation and safety

for 45-plus years, covering the south-

together with its new Heavy

east region of Saskatchewan, accord-

“We offer a wide variety of full-time

Equipment Operator pro-

ing to Jody Holzmiller, vice-president

credit programs. Some of the pro-

of education and training for the col-

grams at Southeast College include

gram.

lege. In those four decades, a lot has changed in terms of their programs.

Educational Assistant, Electrical (both Level 1 and 2 apprentice), Food Ser-

Phone/Fax 306-634-6001 P.O. Box 1652 Estevan, SK S4A 1C8

vice Cook, Office Administration, Hairstylist, Heavy Equipment and Truck and Transport Technician, Industrial

Dave Gallaway Pay Young Nolan LaCoste

306-461-4322 306-861-9986 306-461-4323

Fluid Levels / Dynamometers / Acoustic Buildups Fall Off Tests / Foam Depression Tests Sales and Service of Casing Compressors and Acoustic Fluid Level Equipment 22 Saskatchewan Oil Report 2021

Mechanic, Welding and a two-year Practical Nursing program,” Holzmiller says. “We also recently started offering a Powerline Technician program, making Southeast College the first regional college in the Saskatchewan system

to offer all four levels of an appren-

students weren’t getting enough seat

14-days, make a pile of money, are

ticeship program,” Holzmiller adds.

time, and they were also lacking in

off for a week and come back broke,”

general job and life skills,” Holzmiller

she explains. “That is one of the top-

says.

ics we’ve been working with them on

Southeast College’s Estevan campus will be offering the first intake of the

to try and make the program richer

newly redeveloped Heavy Equipment

The new Heavy Equipment Opera-

Operator training in the early spring of

tor program has been extended from

2021. According to Holzmiller, South-

six weeks to 12 weeks to accommodate

With the introduction of the new

east College used to broker that pro-

those needs and standards. The pro-

state-of-the-art simulators, the pro-

gram from Saskatchewan Polytechnic

gram will include 240 hours of simu-

gram will benefit aspiring operators

five to six years ago until they decided

lation time, as well as an additional

by giving them experience to build the

not to offer that program anymore.

six weeks of in-seat work experience,

muscle memory required to operate

Later on, they partnered with another

Holzmiller says. The school purchased

an actual piece of equipment, while

college out of Brandon, Assiniboine

eight modern, up-to-date simulators

being safe at the same time.

Community College. Hearing from

for the program. Holzmiller also says

“If something goes wrong on a real

industry and recognizing a need,

the program will teach the students

piece of equipment, it is very expen-

Southeast College approached the

about the industry as well as some

sive to fix, not to mention a safety con-

Saskatchewan Heavy Construction As-

general life skills such as how to bud-

cern,” Holzmiller says. “The simulators

sociation to see if they wanted to form

get, how to be a reliable employee,

will give them that added experience

a partnership to build a new program.

etc.

before they get on to the site and op-

“The program is different than what

“What we’ve heard a lot of the time

currently exists, based on feedback

was that people get out on to the job

from the industry. They recognized the

site, work their first two-week shift of

around those life skills.”

erate actual equipment.” For more information, visit southeastcollege.org.v

SAFETY TRAINING WHERE YOU NEED IT. WHEN YOU NEED IT.

H2S ALIVE | CONFINED SPACE | GROUND DISTURBANCE FALL ARREST | CPR AND 1ST AID | AND MUCH MORE! Visit southeastcollege.org for a full listing. Don’t see what you need, give us a call at 1-866-999-7372!

Saskatchewan Oil Report 2021 23

Brother’s Specialized Coating Systems Ltd.: Thriving and striving for the future

B

rother’s Specialized Coating Systems Ltd. has been serving the oil and gas, water and wastewater treat-

focused on making sure our staff and

nizations: NACE and SSPC. These two

all visitors to our plant are follow-

organizations have recently merged

ing mandated protocols and safety

to become one entity called AMPP.

to protect themselves and others,”

This streamlines the industry pro-

ment industries for the past 34 years.

says Brian Payne, general manager

cesses and standards that have been

Located in Edmonton, Alta., Brother’s

of Brother’s.

relied on by industry from these two

has garnered a solid reputation from

Brother’s has still managed to

organizations.

Industry for being one of Western

maintain

reputation

Having their own in-house quality

Canada’s most trusted provider of

throughout the industry for their high

program, NACE Level 3 Inspectors

high-quality protective coating so-

level of service, communication and

and SSPC Train the Trainer, enables

lutions, to ensure their investment

quality. These values are still driven

Brother’s to maintain a higher level

remains protected from corrosion,

throughout the company with well-

of quality that customers have come

erosion and harsh environmental

trained, long-term employees who

to expect from them over the years.

conditions.

provide consistent output each time,

Being a smaller shop allows Brother’s

allowing the quality to stay the same

to have their eyes and hands on each

with each job completed.

and every job that comes through.

Brother’s has been providing, in shop, specialized internal and exter-

a

positive

nal applications for equipment such

“The staff at Brother’s take their jobs

Brother’s is dedicated to safety by

as fabricated pipe spools, pipelines,

seriously; they take a lot of pride in

maintaining COR status through the

pressure vessels and tanks. They also

the work they do and they genuinely

Alberta Construction Safety Asso-

do below grade pipeline coatings as

care about the products we deliver to

ciation. They are also registered with

per CSA Z245.30 specification.

our customers. The end results mat-

vendor management systems such

Just as in any other industry during

ter and it shows. If you have had work

as ComplyWorks, ISNetworld and

this past year and with COVID-19 pro-

done by Brother’s in the past 15 to 20

Avetta.

tocols in place, Brother’s has had to

years, those same craftsmen are do-

“As a company that has strong val-

adjust to the new norms of how busi-

ing that same level of quality here to-

ues with safety, Brother’s makes it a

ness is being conducted.

day,” says Payne.

priority to get all of their staff and cli-

“It has been a challenging year to

Brother’s follows industry standard

say the least. We have been highly

protocols set out by two main orga-

24 Saskatchewan Oil Report 2021

ents home safe to their families each and every day,” says Payne.

Brother’s applies a complete range of internal and external liquid spray on coatings. When putting together a coating specification, each coating has a chemical, temperature, pressure and abrasion resistance that must be considered for the specified service. Brother’s is approved by all the major coating suppliers as an approved applicator for their materials. This allows them access to a number of qualified technical individuals and laboratories that can assist in making the best recommendations for the requested service environment no matter how challenging. Brother’s works with an array of industry partners, ranging from engineers to fabricators to end-users and owners. Their quality does not discriminate and they provide the same level of quality and service to all of their clients. Payne says, “We take pride in telling our customers what they need to know and not what they want to hear. This isn’t always an easy conversation; however, we are not doing our job if we don’t have that conversation. What is important is that they have all the correct information and the best recommendation in order to make an informed buying decision when putting together a job scope.” The experienced staff at Brother’s can assist in design applications by providing input for lengths, configuration, pre-blast issues and access points to various pieces of equipment. Brother’s has some new advancements in the works coming in 2021, starting with a new field division. They started out as both a shop and field company back in 1987 and that continued into the 2000s. “We previously specialized in vessel and small tank linings in the field,” says Payne. Fast forward to 2021. With an everchanging market, the demand and

inquiries to Brother’s for field crews has been bigger with each passing year. “We have owners and industry partners who have really pushed us into getting back to the field. We are making the commitment and investment to get back out there and perform the same quality and service that we have always been known for. We look forward to working with our

industry partners and owners in providing field applied solutions to help protect their investments.” Providing the best possible solutions to your inquiry, discussing the design parameters or keeping you updated along the way on the delivery schedule, Brother’s maintains that these are all important aspects of a successful job being completed to reach the desired outcome. v

Carnduff, SK S0C 0S0 p: (306) 482-3244 e. info@fasttruckingservice.com www.fasttruckingservice.com

Specializing in oilfield hauling and heavy hauling. Celebrating over 60 years of service in the oil industry! Saskatchewan Oil Report 2021 25

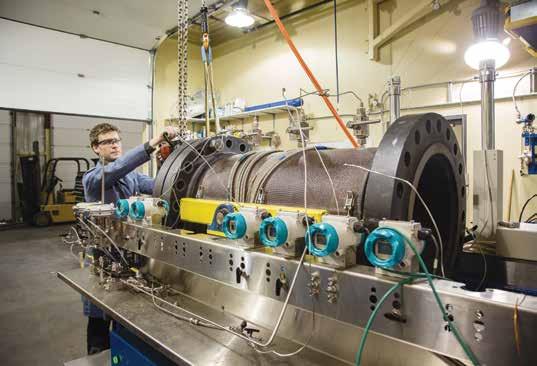

How to develop EOR technologies more efficiently with a stage-gated approach BY PETRO NAKUTNYY, DIRECTOR OF OPERATIONS, EOR PROCESSES, SASKATCHEWAN RESEARCH COUNCIL next stage or identify if further work is required, cycling the technology back through the previous stage. This process prioritizes early evaluation of factors that are most likely to cause a technology to fail. If a technology is not likely to succeed, it can be cancelled at the lowest possible cost in time and resources. First, a comprehensive roadmap is developed that can realistically take a new technology or concept from the drawing table all the way to the field. It’s a six-step approach that SRC has applied to several new technology developments and start-ups. These six steps are, of course, tailored to the experiment goals.

Core flood.

I

The approach starts with identifying

t’s OK to fail in technology devel-

develop their technologies and eval-

opment. But it’s important to do it

uate technical, market and commer-

quickly and move on.

cial factors. This helps our clients save

the mechanisms and possible failure factors, so that they can be addressed as soon as possible. If it makes sense to proceed, the next step is designing

When industry is developing

time and accelerate adoption. We

new technologies to apply in the field,

operate across the whole spectrum

there are a lot of factors that go into

of technology readiness levels, from

the process — from concept to com-

concept-feasibility to field commer-

mercialization. At different points

tal design, including factors such as

cial pilots.

model size, aspect ratio, injection and

and performing small and large-scale experiments. It is very important to choose the appropriate experimen-

along the way, specialized expertise

Stage-gating technology develop-

can be useful to keep the process on

ment creates a roadmap for evaluat-

Once the experimental setup is

track and reduce development costs,

ing the field and the proposed tech-

chosen and prepared, several of the

as well as make the most efficient use

nology at key points during the pro-

experiments are run and what is of-

of time. This helps to de-risk the tech-

cess. SRC has developed fast-to-fail

ten found is that the initial idea needs

nology development process.

tools that allow us to quickly test new

significant modification for the technology to succeed.

production wells.

The Saskatchewan Research Coun-

ideas and identify any showstoppers.

cil (SRC) uses a stage-gated approach

The review will either confirm the

The next step is numerical simu-

to help small-to-medium enterprises

technology is ready to advance to the

lation and because it’s already been

26 Saskatchewan Oil Report 2021

tested it at a larger scale, now it’s a lot easier to predict field performance. After this, the field pilot is planned, which often involves selecting a location and providing monitoring to help determine how successful the technology is and/or what could be changed to make it even better. An important part of this stagegated approach is the use of custom, large-scale physical models in the experiments. These 3D models are designed and built by SRC’s experts

Universal test sands.

and can be tailored to the process and specific application. These mod-

lowed SRC to take many technologies

approach will continue to be there to

els provide the capacity to scale up to

from basically an idea to the field in

support industry in these important

field conditions, which also reduces

under five years — much faster than

endeavors.

experimental uncertainty and re-

the industry average.

duces the risk of unexpected issues at site.

So, keep going — the world needs

SRC’s Enhanced Oil Recovery team has provided science-based

new technologies, tools and tech-

solutions to industry since 1986. View

Of course, none of this is valuable

niques to help accelerate innovation

the complete article on SRC’s blog at

unless it works. This approach has al-

in the field. And SRC’s stage-gated

https://www.src.sk.ca/blog. v

Our diversified fleet will meet your equipment demands! It’s what we know… just ask!

Warren McDonell Jason Hugo wmcdonell@transcourt.com jhugo@transcourt.com When it comes to Leasing, Financing or Sales. It's what we know. 403.606.0880 Just Ask! 780.913.2700 Transcourt.com

Saskatchewan Oil Report 2021 27

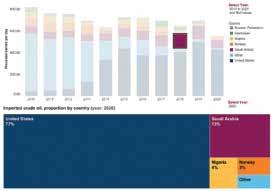

CER analysis shows the U.S. continues to be major supplier of oil to Canada while imports dropped in 2020 SUPPLIED BY CANADA ENERGY REGULATOR

T

decreased to $58.89 per barrel. he United States supplied nearly four out of every five barrels of oil imported into Canada in 2020 while • Imports into Quebec decreased from 203 Mb/d to 153 Mb/d in 2020, and all came from the U.S. while costs decrude imports fell 20 per cent due to lower demand creased to $52.92 per barrel. during the COVID-19 pandemic, according to the lat• Imports into Ontario decreased from 97 Mb/d to 43 Mb/d, est analysis from the Canada Energy Regulator (CER). and all came from the U.S. in 2020. Costs decreased to Imports of crude oil decreased to 555,000 barrels per day $53.37 per barrel. v (b/d), down from 693,000 b/d in 2019 with 77 per cent of total crude imports coming from the U.S. in 2020, up from 72 per cent in 2019. Of the remaining crude imports, 13 per cent came from Saudi Arabia, four per cent from Nigeria, three per cent from Norway and the remainder from several other countries. While Canada exports nearly 6.5 times more oil than it imports, it still relies on oil imports to feed refineries in the Atlantic Provinces, Quebec and Ontario. Less than one third of Canadian crude oil is processed by Canadian refineries for a variety of reasons, such as lack of pipeline access to domestic supplies, specific product requirements of refineries, or because it costs less to import. Most of the oil Canada imports is transported by marine tanker and pipeline, with small volumes being imported by rail. The CER produces neutral and fact-based energy analysis to inform the energy conversation in Canada. Market Snapshots are part of a portfolio of publications on energy supply, demand and infrastructure that the CER publishes regularly as part of its ongoing market monitoring. “The source for Canada’s crude oil imports has changed dramatically over the past decade. The United States has moved from a bit player in 2010 to a major supplier today, with the majority of oil imported into Canada coming from our southern neighbour,” says Darren Christie, Chief Economist, Canada Energy Regulator.

QUICK FACTS • The total cost of imported oil fell 40 per cent over the previous year to $11.5 billion, reflecting the lower volumes and decline in global crude prices. • Imports into Newfoundland and Labrador decreased from 106 Mb/d to 29 Mb/d in 2020, and all came from the U.S. while costs decreased to $77.87 per barrel. • Imports into New Brunswick decreased in 2020 to 245 Mb/d from 278 Mb/d, half of which came from the U.S. while costs 28 Saskatchewan Oil Report 2021

We operate the following equipment to relocate well site trailers and oilfield equipment from lease to lease or to wherever our customers need us to be. • Tri Drives • Low Trombone Trailers • Tandem Winch Tractors with Tri Axle Trailers

• 40-Ton Picker & Trailer

We not only supply our services to the oilfield, but have a lot of experience delivering equipment to Potash and Mining Sites. We take care of all permits and pilots as required. We have also been known to help a farmer out a time or two! Give Bruce a call @ 306-485-7535. Rates available upon request.

EXPERIENCE GOES ALONG WAY

Safety is our #1 concern! We are equipped to provide reliable transportation and expertise to move drilling rigs and all oilfield equipment throughout the oil patch in Saskatchewan, Manitoba and Alberta. • 8 x 8 Rig Tractor

• Rock Truck Commanders

• Tri Drives

• Tandem Winch Tractors

• 420” Bed Trucks • 1 Ton and Trailer • Pilot Trucks

• 8 x 8 Bed Trucks • Loaders

• Many Wheeled Combinations

• Planetary Tractors with Hydraulic Wheels Box 178, Carnduff, SK S0C 0S0 Dispatch: 306-485-7535 (Bruce) Email: info@bboilfield.ca www.bboilfield.ca

Email:

Box 144, Carnduff, SK S0C 0S0 Dispatch: 306-339-7136 info@integrityoil.ca www.integrityoil.ca

CHECK OUT OUR NEW WEBSITE

PTRC investigating the utilization of CO2 extensively in Saskatchewan’s heavy oil zone

M

att Nasehi, the manager of operations at the Petroleum Technology Research Cen-

tre, has seen the nature of heavy oil research and development change fundamentally in the last twenty years. “When PTRC was formed,” he says, “we were provided with a couple of main directives – to improve the recovery of oil from heavy oil in the province, which was averaging less than seven per cent of the oil-inplace, and lessen the environmental footprint of that oil production

Saskatchewan as a centre for carbon

leader on this topic (see: https://ptrc.

through new technologies that use

dioxide utilization and storage – yes,

ca/pub/docs/OfficialWhitePaper%20

less energy, water and other resourc-

for enhanced oil recovery, but also

Final.pdf).

es.”

for emissions reductions.”

The first few years of research at PTRC, starting in 1999, focused definitively on those two goals, but then a funny thing happened on the way to the forum, so to speak. Pan-Canadian, then the operators of the Weyburn oil field in southeastern Saskatchewan (nowhere near the heavy oil fields along the border with central Alberta) decided to start injecting carbon dioxide into their

PTRC would go on the develop a

Alberta Carbon Trunk Line to centre

second CO2 storage project, Aquis-

Alberta,” says Nasehi, “there may be

tore, which is discussed in another

ample opportunities for stretching

article in this edition of the Saskatch-

that pipeline to the Lloydminster area

ewan Oil Report, but with the rising

and other sources there adding to

interest in CO2 storage and utilization

the supply, for possible storage and

around the world, research into uses

utilization in and below the heavy oil

for such emissions has continued to grow. It was only a matter of time before PTRC decided to wed its interest

depleted oil wells to increase produc-

in heavy oil research with CO2 utiliza-

tion. That fateful decision altered the

tion. The result is a planned program

direction of research at the PTRC.

in injecting carbon dioxide from ex-

“It was an interesting transformation that resulted from the Pan-Ca-

“With the recent completion of the

isting sources in the heavy oil zone into the oilfields underground.

reservoirs.” PTRC is in the developmental stages of a research consortium into expanding CO2 use in the area. Researchers at both University of Regina and the Saskatchewan Research Council have already been funded by PTRC to conduct work into cyclic solvent injection in the Lloydminster

nadian decision, and from the interest

With the publication this past Oc-

it raised in both the PTRC and among

tober of a white paper called CCS

government and researchers,” says

Potential in the Heavy Oil Regions of

sions from heavy oil production in

Nasehi. “The subsequent 15-year re-

Saskatchewan and Alberta, PTRC is

Western Canada is a very real possi-

search program helped establish

positioning itself to be the research

bility going forward.” v

30 Saskatchewan Oil Report 2021

area. “I think utilizing much of the emis-

CONSTRUCTION & MAINTENANCE SERVICES MECHANICAL: ■ Fabrication of the following piping: • Carbon Steel, Stainless Steel & Chromoly Piping • Threaded Piping • HDPE & Fiberglass Piping ■ Blasting & Painting ■ Hydrotesting ■ Torqueing ■ Vessel Modifications ■ Equipment Installations ■ Demolition

STRUCTURAL: ■ Cutting & Capping of Piling ■ Fabrication & Installation of the following: • Structural Pipe Racks • Stairways & Landings • Safety Ladders • Platforms • Stiles ■ Equipment Bases ■ Torqueing ■ Blasting & Painting ■ Demolition

CIVIL: ■ Excavations, Backfilling & Gravelling ■ Concrete Framing & Placement for: • Tank & Equipment Bases • Concrete Pile Caps • Concrete Piling ■ Grouting (Cementitious and Epoxy) ■ Demolition MISCELLANEOUS: ■ Plant Turnarounds & Maintenance ■ Hot Shot Services ■ Safety Services

HEAD OFFICE: P.O. Box 236, 7 Brock Drive Brock Industrial Park, Moose Jaw, SK S6H 4N8

FIELD OFFICE/SHOP: 315 Evanston Drive, Weyburn, SK S4H 0Y9

306-693-3030

www.rcesi.com

Carbon reporting: Coming soon to the supply chain BY ERIC ANDERSON

Saskatchewan Minister of Energy and Resources Bronwyn Eyre addresses the Saskatchewan oil and gas supply chain.

T

he drive to sustainability and ESG reporting will be arriving in our supply chain soon. It is a parade we can either be in front of, within, behind or under – and being in front of it is more profitable. Simply put, sustainability is a broad term for any company’s efforts to “do better.” A more focused report is environmental, social and governance, or “ESG”, as it spotlights three specific pillars that are crucial to today’s business managers and investors. However, sustainability and ESG are sometimes used interchangeably. The big new piece to many of us is these reports include carbon reduc32 Saskatchewan Oil Report 2021

tion or “net zero” initiatives and climate change. In my role as executive director of the Saskatchewan Industrial and Mining Suppliers Association (SIMSA), I have had numerous conversations with resource-sector owner-company executives about net zero or carbon reporting being required of the supply chain in the near future. For more public proof, in a Feb. 2, 2021 news item from Bloomberg, it was reported that “Looking toward other 2021 goals, Nutrien is releasing a ‘comprehensive’ environmental, social and governance plan in May that highlights a push into sustainability,

Magro said. The plan will also include an idea of how much capital is needed for its goals.” Read more at bloomberg.com/news/articles/2021-02-18/ nutrien-eyes-potash-sales-in-regions-where-prices-are-strongest. In the JWN story (jwnenergy.com/ article/2021/2/3/esg-becoming-integrated-into-oil-and-gas-supply-ch), it is revealed that “Bringing the supply chain on board is key to oil and gas operators meeting their ESG goals, as their service and supply partners are in the field doing the physical work and interacting with local communities.” This broad initiative is heavily driven

Pump up your business profile with a SIMSA membership. The Saskatchewan Industrial and Mining Suppliers Association (SIMSA) helps global resource companies in the industrial, mining, and energy sectors make their supply chains better, more responsive, and smarter.

Could your company benefit from having its profile listed on our supplier database? Visit www.sksd.ca and find out how you can join over 230 Saskatchewan-based suppliers who already enjoy the many advantages of a SIMSA membership.

Our Saskatchewan Supplier Database is a tool that helps link resource companies in need with qualified, capable Saskatchewan-based suppliers so that they can connect, innovate and grow together.

www.sksd.ca Database funding sponsors

by companies such as BlackRock – a company that manages over $4 trillion in funds and influences/indexes over $8 trillion. Notably, during my conversations with the owners for whom SIMSA members do work, BlackRock’s CEO’s – Larry Fink’s - annual letter to CEOs is often mentioned by the owners. The review of Larry Fink’s 2021 letter to CEOs (blackrock.com/corporate/ investor-relations/larry-fink-ceo-letter) by GlobalScan reveals what our owner clients have been hearing, will likely then following and eventually expecting of us. GlobalScan stated that the 2021 BlackRock letter has a few key themes: 1. The start of a “tectonic shift” toward net zero. 2. The inseparability of social and environmental issues. 3. The critical importance of data and disclosure. 4. The maturing connection between

sustainability and financial performance. So, the key implications for our owner customers are (and thus eventually their supply chain) that net zero commitments are now a requirement – a business-critical issue. Furthermore, transparency and reporting remains the thread underpinning all of this. In short, some time in the future during bid reviews, your sustainability or ESG report will likely be as important as your safety report; it will be a critical item to be addressed. Some owners are also discussing the incorporation of your sustainability or ESG report into the broader concept of safety, as it is perceived as “do no harm to people or the environment.” ESG will likely become like our safety culture. In short, if you and/or your services reduce the owners’ carbon footprint more than your competitors does, you will win more bids. Prior to COVID, this reporting was

probably going to be a requirement for the supply chain in about five years. However, COVID accelerated a few things globally, one of which is the sustainability or ESG reporting requirement. This could start showing up as a requirement in as little as a year from now. As such, in our ongoing effort to be a world-class supplier of goods and services fulfilling the needs of industry, SIMSA has begun a review of the required changes, needs and reporting. SIMSA will strive to provide related information and services to all our members, to assist them in becoming leaders in their ESG initiatives. Every great success story begins with the phrase “they started”, and then features a series of learning, tripping and refocusing events. Similarly, SIMSA will start on this journey and probably learn, trip and refocus a few times – but we will get there. v

SUITE 300, 6 ROSLYN ROAD, WINNIPEG, MANITOBA, CANADA

www.delcommunications.com

THE KEY TO PUBLISHING SUCCESS. We offer outstanding personal service and quality in the areas of:

• Creative Design • Advertising Sales • Trade Publications • Video Production & Editing • Qualified Sales & Editorial Team 34 Saskatchewan Oil Report 2021

Wicehtowak Limnos Consulting Services: A 100-per cent Indigenous-owned company BY JOSH MONTANA, OPERATIONS SUPERVISOR AND ENGAGEMENT LEAD

W

icehtowak Limnos Consulting Services (WLCS) is wholly owned by George

Gordon Developments (GGDL) and ultimately owned by the George Gordon First Nation (100-per cent Indigenously owned company), which is one of the largest nations within the Treaty 4 territory. WLCS has worked with various crown

corporations,

proponents

and worldwide companies within the pipeline, potash and oil and gas sectors completing security, labour, environmental/Indigenous monitoring and elder services. One of our more interesting and recent scopes of services has been advice to government and proponent in the service of creating Indigenous engagement policies and procedures, as well as creating Indigenous benefits plans for large capital projects. WLCS will bring diversity to your project with a traditional lens while successfully

completing

projects

safely, on budget and on time. We pride ourselves on being a Saskatchewan get it done company who is accountable, reliable, hard working, and authentic. v

Saskatchewan Oil Report 2021 35

Fluor Canada: Positioned for growth, committed to building a better future BY MADISON MCLENNAN, COMMUNICATIONS SPECIALIST, FLUOR CANADA LTD.

I

n 2019, Fluor marked its 70-year

detailed engineering, procurement,

solutions required to keep facilities

anniversary in Canada and cel-

transportation and logistics, modu-

running reliably, safely and cost-ef-

ebrated the legacy it has built

larization,

direct-hire

fectively. Its proven work processes

of successfully executing in-

construction, construction manage-

and project execution models are

dustrial projects across the country.

ment, commissioning, start-up, op-

scaled to fit for streamlined execution

Headquartered in Calgary, Alberta

erations and maintenance. Its teams

of projects ranging from $1,000 work

to best serve the oil and gas indus-

provide comprehensive professional

orders to $50 million improvements,

try in Western Canada, the company

and technical services to deliver safe,

making its offering suitable for own-

serves clients and employs person-

well-executed, capital‑efficient proj-

ers of varying sizes of assets.

nel from coast to coast.

ects.

fabrication,

In recent years, Fluor has been

Fluor provides local, regional and

While major greenfield projects are

a major participant on several suc-

international clients with full-service

signature to Fluor’s brand, the major-

cessful Canadian mega-projects that

technical and professional capabili-

ity of its project portfolio encompass-

have required optimal integration

ties, which include economic evalua-

es brownfield, small-capital projects.

and co-ordination of project teams.

tions, conceptual engineering, feasi-

The company has a 25-year history

Project owners frequently employ

bility studies, program management,

of delivering the tactical, innovative

Fluor’s

36 Saskatchewan Oil Report 2021

exceptional

program

and

project management capabilities on

including energy transition (carbon

ress and sustainability. In combina-

these challenging and complex proj-

capture, hydrogen, biofuels, liquified

tion with that, Fluor has committed

ects. Fluor’s construction offering cov-

natural gas, small modular reactors,

to achieving net zero by the end of

ers the ability to perform open site

etc.), pipelines, life sciences, high-

2023 in an effort to address the com-

construction management activities

demand metals and infrastructure.

pany’s impact on climate change and

through Fluor Canada, as well as self-

In-house subject matter experts in

demonstrate to its stakeholders the

perform construction services using

these areas, backed by proven tech-

importance of managing its green-

Fluor Constructors Canada Ltd. This

nology solutions, make Fluor a global

house gas emissions.

provides clients with flexibility in ex-

leader in diverse energy solutions.

ecution to support a project’s cost and

At the core of Fluor’s vision is to

Part of this vision also focuses on

positively contribute to the industries

the diversity of Fluor’s teams. Fluor

and communities in which we work.

With the vision to Build a Better Fu-

fosters a high-performance culture

Accordingly, the company is commit-

ture, Fluor is continuing to expand its

with purpose by advancing its di-

ted to growing regional businesses.

presence in growing markets outside

versity, equity and inclusion efforts

Fluor’s $2-billion average annual

of the traditional oil and gas sector,

and actively promoting social prog-

spend with Canadian contractors

schedule objectives.

Saskatchewan Oil Report 2021 37

Fluor is committed to delivering high-quality, safe and costeffective project solutions that enhance the value of its clients’ assets and increase their longterm business success. and suppliers represents more than 5,700 companies. Through meaningful engagement with community and Indigenous partners, Fluor aims to foster relations that help grow local economies. Understanding that when communities thrive so do their businesses and residents, Fluor’s charitable contributions, support of STEAM education initiatives, and employee volunteerism has significantly shaped its company culture. Fluor is committed to delivering high-quality, safe and cost-effective project solutions that enhance the value of its clients’ assets and increase their long-term business success. Industry leaders turn to Fluor to design and build the projects of all sizes, scopes and complexities. In response, Fluor provides solutions that deliver safe, well-executed, and capital-efficient projects to clients across Canada and around the world. Working with its clients, Fluor consistently delivers results with the quality and safety that clients expect. v

Please support the advertisers who help make this publication possible. 38 Saskatchewan Oil Report 2021

Design • Construct • Deliver

Industry leaders turn to Fluor to design and build the world’s toughest projects. In response, we provide solutions that deliver safe, well-executed, and capital-efficient projects to clients across Canada and around the world. Working with our clients, we consistently deliver results with the quality and safety they expect.

www.fluor.com © 2021 02 21 2 1 FFlluo lu uor o Co Corpo rpo orat ration ion on n. All Rig ig ght hts hts ts Re Resse Rese ser erved ed.. F or iss a regi Fl Flu egi eg gist sste tte ered d se serrvi rvvviice cce e mar mark of FFluo l r Corp luo orrpo or oraatio tion. n. n. AD ADC A D DC CA2 A20 A 2 20 0532 53 1

PROUDLY SUPPLYING THE OIL & GAS INDUSTRY SINCE 2005

STYLE 109 ULTRASOFT® 9 OZ CSA DELUXE COVERALLS

STYLE 102 ULTRASOFT® 7 OZ DELUXE COVERALLS