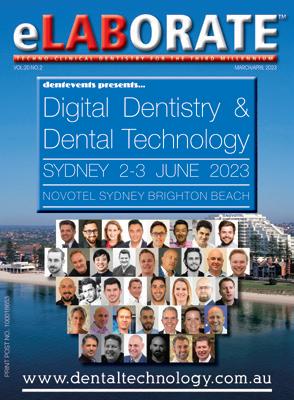

SYDNEY 2-3 JUNE 2023

NOVOTEL SYDNEY BRIGHTON BEACH

TWO DAYS OF LECTURES AND WORKSHOPS ON DIGITAL DENTISTRY FOR DENTISTS, SPECIALISTS, DENTAL TECHNICIANS AND DENTAL PROSTHETISTS

TWO DAYS OF LECTURES AND WORKSHOPS ON DIGITAL DENTISTRY FOR DENTISTS, SPECIALISTS, DENTAL TECHNICIANS AND DENTAL PROSTHETISTS

TWO DAYS OF LECTURES AND WORKSHOPS ON DIGITAL DENTISTRY FOR DENTISTS, SPECIALISTS, DENTAL TECHNICIANS AND DENTAL PROSTHETISTS

TWO DAYS OF LECTURES AND WORKSHOPS ON DIGITAL DENTISTRY FOR DENTISTS, SPECIALISTS, DENTAL AND DENTAL

REGISTER NOW and SAVE!

SPONSORS

INDUSTRY SUPPORTERS

THE

If you build it... will they come? In the 100-year history of the International Dental Show celebrated in March, the answer has always been a resounding yes. But in the immediately post-COVID world of trade exhibitions and events the world over, nothing is any longer a given.

By Joseph AllbeuryCertainly there was no shortage of dental companies to exhibit - in fact, 1,788 companies exhibited from 60 countries - but would the traditionally huge number of visitors once again return?

Travel restrictions were still in place for countries like China, air travel remains hellishly expensive, many people are still worried about getting sick while others are taking a wait a little longer and see approach.

For me, my personal mental health rehabilitation journey is always buoyed by repeating experiences I enjoyed preCOVID in the post-COVID world. Hence, when I booked my ticket, I had a lot riding on IDS returning as a tour de force - after all, this event is the greatest dental show on earth, right?

Fortunately, I was relieved, elated in fact, to see that the IDS experience has returned as amazing as ever!

The party we always throw on the night before IDS begins for anyone from Australia and New Zealand to attend went off without a hitch. The beer hall we always use as the venue was even staffed by the same surly waiters from four years prior. And we pulled a respectable crowd of our own.

Nothing like the main event, however.

In 2023, IDS succeeded in attracting 120,000 visitors from 162 countries to the Cologne fair grounds to see the latest and greatest that dentistry has to offer. It was packed! Covering 180,000 square metres, the 40th edition of the event in its 100th year didn’t disappoint. The last full size event in 2019 pulled an additional 40,000 people, but for all intents and purposes apart from that, it was bigger [10,000 square metres bigger] and better than ever... with wider aisles and the brand new Hall 1 with high ceilings similar to what we see at exhibition halls in Australia.

And all the halls were packed with everything dental has on offer - the best, the worst, the latest, the greatest. Home!

By the end of it, I didn’t even mind overpaying by around 400% for a very average hotel room. After all, that’s all part of the IDS experience.

Face-to-face, live and in person conferences and trade shows have survived COVID and returned in force as one of the most loved components of the dental world where you can meet up with friends and network with colleagues, learn and share experiences across the profession.

Our own Digital Dentistry & Dental Technology 2023 event is being staged in Sydney on June 2-3 and is a great way to see the latest tech from IDS and to catch up with your friends and colleagues for some fun while enjoying a first class education program. I hope to see you there!

Joseph Allbeury, Editor and Publisher

Joseph Allbeury, Editor and Publisher

H3D is an Australian PhD research spinout whose mission is to make custom-fit medical devices accessible for everyday people through their AI CAD product, AutoDesign. Based in Copenhagen, H3D is developing dental AI CAD in partnership with Modern Dental Pacific and Andent. H3D’s entry into dental follows their strong success in the audio industry where they have become the AI CAD market leader. Mimicking their successful approach in Audio, H3D are focusing on dental labs rather than clinics. The company’s motto is “built with labs, for labs” and there is a strong emphasis on quality. This is welcome news for dental labs, who have been increasingly neglected as dental CAD companies prioritise clinics and chairside. “Labs are the gold standard in terms of quality levels and our ambition is to create the world’s best AI CAD, so partnering with them was a natural choice for us,” said Damian Png, Director of the Dental Business Unit. H3D’s AI CAD boasts an order acceptance rate of >90% in the audio market, enthusiastic product reviews and a 100% customer retention rate. They work with iconic brands, such as Sennheiser, Amplifon and Formlabs. “H3D’s AI CAD designs look very promising - high quality standards, fast turnaround times and competitive pricing,” explained Matt Smith, General Manager at Andent. Labs see H3D’s AI CAD as a solution to the labour shortage of CAD technicians, which will ultimately help them scale their businesses. Currently, design takes a CAD technician 10-20 minutes per order. However, there is an industry-wide shortage of CAD technicians, so labs are forced to reject new business. “H3D’s AI CAD has the potential to be hugely impactful for our industry. It will enable us to significantly increase our production and overcome the capacity issues caused by the shortage of CAD designers. It will also facilitate the transition from thermoformed to digital splints, resulting in better quality products for dentists and patients,” said James Squirrell, CEO of Modern Dental Pacific. With H3D’s AI CAD, 100s of orders can be processed within 5 minutes. It’s so simple to use that it can be operated any lab staff. As the dental industry continues to embrace digital dentistry, H3D sees AI CAD further accelerating the trend towards intraoral scanners and 3D printing. “We’re regularly approached by 3D printing companies, IoS companies and resellers. For them, CAD is holding back the industry, so solving this bottleneck is hugely important,” said Iain Mcleod, CEO at H3D. H3D’s AI CAD for splints will be released in Q3 2023, with crowns, dentures and aligners following shortly. The company is currently accepting expressions of interest for their Innovators program (visit https://tinyurl.com/53nvncz7), which provides early access to the AI CAD product, as well as discounted pricing. For more info, visit www.h3d.ai

By Terry Whitty

By Terry Whitty

This year’s International Dental Show (IDS 2023) was back in full swing with the halls overflowing with exhibitors and plenty of hungry punters, all wanting to see the latest and greatest dentistry has on offer after the effective gap of 4 years during the COVID meltdown (there was a small IDS in 2021 but Australians were locked out). Although the numbers were slightly lower - 120,000 vs 160,000 in 2019 - the place was still abuzz and there was plenty to see for everyone. Anything and everything was on display and there were even more halls to see - so many in fact that I can honestly say it was a real effort to get around in the 5 days of the show.

If there was a theme for IDS 2023, it would definitely be Artificial Intelligence (AI) and automation. At every turn, there were posters and artwork touting AI and automation. Just about everyone in software is incorporating some sort of AI in some way. 3Shape use it in their Automate design service, Shining 3D in their intraoral scanning software, Adravision use it in x-ray software, etc, etc.

There were also numerous automation add-ons to existing equipment and lots of fancy expensive robot arms designed to replace manual intervention. imes-icore, for example, showed a system where thermoformed invisible aligners were taken up by a robotic arm and placed into one of their mills for cutting, then removed and the exercise continually repeated. And that’s only one example.

As a lab owner in Australia, automation and AI options that help counter both the shortage of skilled labour and the increasing cost are of enormous interest.

As far as technology goes, without a doubt the most prolific of all the products on show at IDS 2023 was 3D printing, period. Not only was there a plethora of different brands of 3D printers, I was actually amazed at how many companies had “private labelled” well-known brands of printers just to make sure they had a 3D printer of their own on their stand. There were also more resin companies than you could poke a stick at, more peripherals such as washing units and curing units and just more 3D printing tech all ‘round.

One highlight was at the ASIGA stand. ASIGA launched their new resin tank called UltraGloss that allows any material to be printed with a glossy finish. Simple as it may sound, this is quite an astonishing breakthrough as most resins come out of a printer with a slightly rough feel. Not with UltraGloss, however, you can really see the difference especially if you’re printing things like splints and

surgical guides. The time saving will be really significant when it comes to post finishing and as an ASIGA user myself, I can’t wait to use these in my lab (they fit any ASIGA printer).

Shining 3D showed off their new fully automatic cutting, washing and drying all-in-one unit called FabWash and this is really a smart compact piece of equipment. After printing, the build platform is removed from the printer and placed into the FabWash. The printed parts will be automatically removed from the build platform, they will be washed and then dried without any intervention. This is really an innovative piece of equipment and saves a lot of time.

Speaking of automation, as mentioned earlier, its really the next big thing in dental 3D printing and there were glimpses of it at IDS. Formlabs displayed a new Automation Ecosystem consisting of some new hardware called Form Auto that basically retrofits to your Formlabs 3 or 3+ printer which can remove printed parts and then prep the machine ready for the next print. The new flexible Quick Release build platform assists with part removal and the new Fleet Control software helps you manage the whole thing.

Heygears showed off their new fully automatic UltraCraft A3D printer and this really is a step up as it is a dual projector DLP printer that has the part removal system fully built in, plus a resin filling system and automated software so you can run this printer non-stop 24/7! Of course you can also add a resin pump station to it for larger volumes and coming soon is a fully automated wash and cure system - it’s really amazing.

Resin suppliers for 3D printing were also in abundance. There were so many companies selling resins it was hard to keep up. Notably, resins for printing dentures, both the bases and the teeth,

were on the rise and everyone of course were touting theirs as the best, newest, strongest; well I think you get the idea anyway. Asiga, Dentca, Crowntec, Dreve, Asiga Myerson and many others all had new resins. From a practical point of view,

regardless of the physical and optical properties of the cured resins, probably the most important factor is actually how it sits into the regulatory framework that oversees its use. In Australia, this lies with the TGA so a lot of resins are not yet registered in Australia. And the time and expense to register a resin for long term Class IIa in mouth use will mean a lot of them will never grace our shores.

The other big area where companies are investing a lot of money towards is resins for permanent chairside restorations. Now don’t get too excited yet; in reality, these don’t replace ceramics, well not yet anyway, perhaps in many years to come. They are actually positioned as a “patient option” alongside ceramics and case selection is as important as restoration design.

For example, it’s unlikely you’re going to make a posterior bridge for a bruxer when most of these material only have flexural strength of sub 150 Mpa and to put that into perspective, e.max is around 400 Mpa. Materials are getting better all the time but at the moment, most are monolithic only as is to be expected as you can only print one shade at a time.

However, DWS had a very interesting system called Photoshade Adaptive Gradient Technology which gives the restoration the appearance of having multiple areas of the shade at differing levels. This is done with some clever resin changing technology as it will print lighter areas, then change or mix the resin and continue to the darker areas.

Another really interesting material was from Korea that has some unique properties allowing it to change colour depending on how it is cured. The wavelength of the cure will determine what shade you will end up with. You could theoretically block out areas of a crown and cure them at one wavelength and other areas at a different wavelength to create a polychromatic restoration, really interesting stuff!

Apart from 3D printing, tech wise, the well-established market of desktop milling continued to evolve. There were an abundance of powerhouse milling machine companies like Zirkonzahn, Amann Girrbach, DGSHAPE, imes-icore and VHF - in fact, all the well-known brands - but of note were the many new Asian manufacturers starting to make a noise. Aidite, Upcera, UP3D and Aurum - just to mention a few - are all offering lots of features at prices that really show great value. Some are even promising metal milling, a big ask from a desktop machine. These brands are rising quickly in quality, however, as with anything new, you must check out the track record first before diving in, but definitely keep an eye on them.

DGSHAPE from Japan showed it’s new DWX-53DC mill, a large robust unit that is a “do all” dry mill that’s been beefed up for high speed acrylic work, ideally suited to denture production. A newly designed spindle, a new 4mm high cutting speed tool and a brand new compartmentalised design really make this one worth a look.

All the CAM softwares associated with all the milling machines have had upgrades with AI and features like automated nesting and tool path generation are really the standard along with complex shapes such as full arch work is now much easier to process.

Face scanning is now starting to really grow legs with two brands of note really standing out. Ray’s RayFace and Shining 3D’s MetiSmile offer the ability to capture a 3D extraoral scan of a patient patients face/head in full colour. This really starts to open up the “virtual patient” concept where treatment planning, diagnosis, treatment planning and communication can all be done prior to treatment starting. Merge a face scan with an intraoral scan and a CBCT and you really have some powerful records to manipulate and measure. Face scans can be imported into popular CAD software such as exocad and 3Shape so expect to see much more of this in the very near future.

With 1788 exhibitors from 60 countries at IDS, there was so much more than just technology to see. The tools of the trade for every genre of dentistry were on display – if it’s used in a dental surgery or dental laboratory or for at-home oral care, there were myriad options on display across the 180,000 square metres of exhibition space.

Undeniably, however, the “age of the machines” is here and has permeated everywhere in dentistry and dental technology and it’s only going to get better, faster and cheaper... and far more automated. The benefits are real and the learning curve can be steep, but the journey is fun and very rewarding. And, if you’re not involved, you will simply be left behind.

The next IDS - the 41st International Dental Show - is scheduled to take place from 25 to 29 March 2025.

For a preview of some of the latest from IDS 2023, don’t forget to register for Digital Dentistry and Dental Technology 2023 in Sydney from June 2-3. Register at www.dentaltechnology.com.au

By Matthias Zimmerer, Application Engineer, CDT, Certified exocad trainer, Schütz Dental

By Matthias Zimmerer, Application Engineer, CDT, Certified exocad trainer, Schütz Dental

Looking back to how I used to manufacture splints makes me wonder what I would have done with all that time I could have saved in polishing.

3D printing is quite possibly the main manufacturing process used for splints today. 3D printed splint materials are tough with some being hard and rigid and others softer with a memory for patient compliance and comfort. The output will vary from printer to printer but all 3D printed splints must go through a polishing process to bring them to a gloss finish. So, regardless of how smooth the parts are after printing, there is always the need for manual surface polishing (or should I say “was”).

Polishing is a time consuming process and if, like me, you take your time and care to achieve a high gloss finish, then we share the same view that this will always be the first evaluation checkpoint on whether the product has been manufactured to a high quality or not.

The second evaluation checkpoint is patient fit. Polishing removes material and thus alters the surfacing of the splint away from patient geometry. To manufacture a true-to-CAD splint and then manually adjust the surfacing to get to that desired glossy finish always left me feeling that the splint was no longer a true representation of my carefully thought through CAD design, but now a unique creation of its own.

However, my splint production took an enormous leap forward when Asiga contacted me to tell me about their brand new UltraGLOSS™ trays.

At first I thought that Asiga was exaggerating, but they have never oversold any aspect of their products so far so maybe what they were telling me was true. They told me that all I needed to do was to change the resin tray in my existing Asia printer to a new tray and I will print with a glossy finish on my splints.

I have been 3D printing and designing digitally for many years and as an exocad trainer, I see lots of technology and user hacks to improve the output. So I was sceptical at first, but I was happy to give it a go, so they sent me some UltraGLOSS™ trays.

The UltraGLOSS™ trays arrived and I ran a print with the new Detax Freeprint Splintmaster TAFF material.

The parts were glossy out of the resin but this is nothing new, although they did appear different. The real shock came after washing the splints in IPA. It was a surreal experience–the splints had retained the glossy surface and more so after post curing in my NK Optik Otoflash. Unbelievable!

The results were so impressive it made me look into optimising further to reduce support points from the splint while printing.

After a couple of trials, I now 3D print splints at an angle of 10˚ from vertical on two small connection points to anchor the splint to the build platform. The anchor points can be added in exocad (or your preferred design program) or, alternatively in Composer using the sprue function in the “Add support” dialog. Printing at this angle also removes the need for support points in most cases.

Digital dentistry has been in my blood for many years now and I have not seen a technology development quite like this since I started 3D printing. In-fact, I would refer to this as being the most disruptive development in dentistry this past decade.

All I did was change the resin tray to Asiga’s UltraGLOSS™ tray and I started to produce glossy splints direct from the printer. If I want to print models with a matt surface, then I just change the tray back to their standard tray.

Put simply, with Asiga’s new UltraGLOSS™ trays, you remove the need for manual polishing, increase productivity and most important of all, retain geometry compliance for patient comfort and fit.

Matthias Zimmerer is a trained dental technician and takes great pleasure in integrating new technologies into existing, well-established processes. He sees many possibilities for change and further development in digital dental technology, which he puts to the test every day. Matthias has been working for Schütz Dental since 2018 as an exocad certified consultant for exocad Dental CAD software and is also active in technical support.

Asiga, a 3D printer manufacturer located in Sydney, Australia manufacture 3D printers for direct additive manufacturing in industries including dentistry, audiology, medical modelling, jewellery and more. Having the ability to output predictable and accurate 3D printed parts is essential for these industries, ensuring production continuity. Asiga 3D printers offer an open material architecture providing compatibility with more than 500 materials from many industry leading 3D printing polymer manufacturers. For more info, visit www.asiga.com

DGSHAPE has released the DWX-52D Plus dry dental milling machine and DWX-42W Plus wet dental milling machine. These advanced milling devices offer users a suite of new and improved milling features.

The DWX-52D Plus brings a new level of efficiency and precision to milling zirconia, PMMA and other materials. Engineered for smooth production, the DWX-52D Plus boasts an impressive 190% reduction in friction and vibration, yielding enhanced output quality on significantly thinner margins and on PMMA materials. In addition, the DWX-52D Plus’s stronger spindle easily holds 3.0 mm and 4.0 mm burs, reducing the time needed for the roughing process. New CAM strategies combine with these improvements to boost overall production speeds.

The DWX-42W Plus provides everything users need for easy, fast and accurate wet milled production. Its stronger system efficiently handles ceramics and hybrid ceramics with zirconia. The included burs can mill 50 or more sintered zirconia units each,

while new roughing and finishing tools last up to 100% longer than previous tools. A nozzle has been added to the DWX-42W Plus’s spindle base for improved coolant flow and all nozzles have new extensions that ensure accuracy. These improvements along with new CAM strategies yield up to a 24% reduction in milling time for hybrid ceramic materials.

“With features that improve accuracy while reducing production time, the DWX-52D Plus and DWX-42W Plus each represent a significant step forward in digital dental milling technology,” said Hisashi Bito, DGSHAPE Corporation’s President of Operations. “As dental professionals worldwide increasingly move to digital milling workflows, DGSHAPE remains dedicated to offering advanced milling solutions that make wet and dry milling workflows easier, more efficient and more precise than ever before.”

For more information on the complete line of DGSHAPE dental products and accessories and to find an authorised reseller in your area, visit www.rolanddg.com.au

Zirkonzahn M2 Dual Teleskoper milling units have a specific mission: to guarantee high-precision milling of all common soft and hard dental material blanks (zirconia, resin, wax, sinter metal, cobalt-chrome alloy, titanium, Raw-Abutments®, glass ceramic and composite).

The M2 Dual Teleskoper features high stability due to the proven 5+1-axis simultaneous milling technology with orbit and opposed rotary axes. Also hard-to-reach areas – such as undercuts and divergences – can be milled without difficulty. Conceived as a stand-alone solution, it is possible to start milling and calibration processes as well as load elaboration tools directly from the machine, via the integrated PC with touchscreen. The machine is provided with two spaciously designed, optimally illuminated and easily accessible milling chambers which gives the user the freedom to mill dry and wet restorations

NEW! M2 DUAL TELESKOPER MILLING UNIT

Teleskoper Orbit (Ø 125 mm) Ø 95mm Orbit (can be upgraded to the Teleskoper Orbit)

Extra-large Teleskoper Orbit: for the elaboration of material blanks with Ø 95 mm, 98 mm, 106 mm or even 125 mm, mini zirconia blanks for single crowns as well as glass ceramic and Raw-Abutments ® blanks. Discs can be removed and reinserted later at exactly the same position with high precision in micron range – particularly useful for adjusting the friction of telescopic jobs and for the two stage production of immediate restorations in case of implant-supported prostheses (Double Milling technique)

in series without in-between cleaning. The left chamber is equipped with the extra-large Teleskoper Orbit (ø 125 mm), whereas the right with a ø 95 mm orbit. The separate and contamination-protected tool chamber with tool magazine (x21) and automatic tool changer function, also offers space for up to two additional tool magazines with 21 slots each. In this way, the milling unit allows up to 63 milling burs to be tidily and safely stored. Moreover, the optical detection tool guarantees a secure tool selection, resulting in greater safety and precision. Finally, the automatic self-cleaning and dry function and the Cleaning Kit with shower and suction system always ensure a clean, ready-touse milling chamber.

Thanks to the M2/M2 Dual upgrade kit, the M2 Dual Teleskoper milling unit can be also upgraded to the M2 Dual Double Teleskoper milling unit by integrating an additional Teleskoper Orbit.

The highlight in terms of flexibility is the extra-large Teleskoper Orbit, a new extra-large orbit with a diameter of 125 mm. In combination with special interchangeable holders, material blanks with a diameter of 95, 98, 106 or even 125 mm can be processed in the same orbit. Oversized bridges, which would not fit in normal blanks, can be now easily positioned and milled. In just one milling process, bite splint production also doubles and a much larger number of crowns can be manufactured. With the new Teleskoper Orbit, by means of special holders, up to 9 glass ceramics blanks or 6 Raw-Abutments® blanks or 7 small zirconia blanks (size 1) for producing single crowns in different colours

can now be milled in just one process. Moreover, blanks can be removed from the orbit and reinserted later at the same position with high precision in themicron range. This is particularly helpful for adjusting the friction of telescopic jobs or for the two-stage production of immediate restorations in case of implant-supported prostheses (with the Double Milling technique).

For info, visit www.zirkonzahn.com or call +39-0474-066-663 (in the Italian time zone).

100 % FUNCTION AND AESTHETICS, A SYMBIOSIS OF TITANIUM AND ZIRCONIA

- Digital acquisition of the oral situation with the Face Hunter 3D facial scanner and PlaneSystem®

- Production of prototypes in Multistratum® Flexible resin on titanium bases and insertion in the patient’s mouth

- Design of the titanium bars in Zirkonzahn.Modellier and fabrication of the fi nal Prettau® 2 Dispersive® zirconia structures

- Temporary cementation of the structures on the titanium bars; evaluation of aesthetics and functional parameters on the patient

- Minimal veneering of the gingival area with Fresco Gingiva and characterisation with ICE Stains 3D by Enrico Steger

- Anodisation and cementation of the titanium bars into the zirconia structures

Amann Girrbach brings a new material to market following 15 years of zirconia development work: Zolid Bion is the name of the new high-performance zirconia, which optimises the aesthetics and natural appearance of restorations without compromising on safety. Crowns can also be sintered in just 45 minutes - a property Zolid Bion offers as the first zirconia in its class.

Zirconia is the CAD/CAM material par excellence and an indispensable part of routines in dental practices and laboratories. For almost two years now, so-called 3D zirconias have been increas ingly appearing on the market, which offer numerous advantages, particularly with regard to aesthetics in the area of the incisal edge. Until now, however, compromises often had to be made in the interests of safety. Amann Girrbach has brought Zolid Bion to market, a new material unifying aesthetics and safety. “This further improves workflow for users. Zolid Bion is based on 15 years of zirconia development work in Austria and is more versatile than any other material. We are proud to offer users a real game changer with this innovative zirconia,” says a delighted Melanie Röschmann, Director Global Business Unit - Consuma bles at Amann Girrbach. Zolid Bion zirconia is characterised by a smooth colour gradient and increased translucency in the incisal area, giving restorations an even more natural appearance. The zirconia is also available in 16 Vita shades and in two bleach variants as well as in different blank heights.

Thanks to the raw materials used by Amann Girrbach, a strength of over 1,100/± 150 MPa can be guaranteed over the entire cross-section of the blank. “In terms of planning and application, this means absolute freedom and safety. From minimally invasive veneers and monolithic anterior crowns to long-span

bridges on implants - users no longer have to choose between different materials, but can cover a wide range of indications with Zolid Bion,” said Ms Röschmann and adds: “Additional safety is also provided by the new acrylic frame, which is now featured throughout the entire Zolid portfolio. This can prevent unsightly chipping and fractures and ensures safe handling during millingand in all milling systems.” The topic of safety is rounded off by a comprehensive 10-year warranty on all Zolid materials.

minutes

mann Girrbach covers the entire dental workflow with its products and services. The company develops innovative materials, as well as sintering furnaces, for zirconia and sintered metal restorations. The latest product from this category is the Therm DRS high-speed furnace.

“Thanks to its innovative design, our Therm DRS sintering furnace allows extremely fast sintering cycles. Crowns made of Zolid Bion can thus be sintered in just 45 minutes - and without any sacrifice in terms of aesthetics or safety. So Zolid Bion is the first material in its class to achieve such speeds,” Ms Röschmann emphasised. To rule out the possibility of high-speed sintering having any negative impact on material properties, the company collaborated closely with the renowned Ludwig Maximilian University of Munich in developing the Therm DRS. Joint in-vitro studies were carried out, all of which arrived at a very positive outcome. “The studies show that high-speed sintering leads to high mechanical strength, high fatigue strength and long-term stability. In addition, no significant influence of aging when compared to conventional sintering could be ascertained. This allows extremely efficient processing for the user, especially for small restorations and makes everyday laboratory and practice work much easier over the long term,” Ms Röschmann said.

zirconia

Workflows for fabricating Full and Partial dentures digitally

SYDNEY - JUL 22 |

MELBOURNE - AUG 5

This event is both a lecture documenting why you should choose digital dentures today as the optimal solution for your dental practice or denture clinic together with a LIVE systematic run-through of the process for fabricating both full and partial digital dentures. You will be able to follow Sam Dias as he explains the step-by-step process he uses in his four clinics across Sydney every day.

A demonstration of accurate intraoral scanning and prosthetic design ensures that the outcome won’t be compromised while saving time and money for you and your patient.

The session will conclude with a Q&A session discussing options leading to self-design or aided design as well as the finishing and polishing process. This course will cover the following...

1. Impression vs Scanning

A discussion and slide presentation comparing intraoral scanning and traditional impressions including a live scan of dentures will be shown. The scanning process will be shown step-by-step and the many different impression techniques currently used will be reviewed and details of how these can be carried on to the digital world shown.

2. Adding mesh and articulator adjustment

Combining multiple scans and adjusting the setup of the virtual articulator will be shown.

3. Wizard and model analysis

Wizards and model analysis tools will be explained.

4. Digital denture teeth selection

How to select the correct digital denture teeth library will be discussed as well as the use of the measure tool plus patient notes and extra scans. Denture teeth library options and applications will be discussed.

5. Digital denture teeth setups

6 HOURS CPD

Digital denture teeth setup tips and tricks for faster and more effortless setups will be detailed.

6. Denture base design

Key principles to bear in mind when designing your denture bases plus a guide to troubleshooting.

7. 3D printing

3D printing techniques plus a guide to material selection and achieving better outcomes.

8. Carded denture teeth

Step-by-step bonding technique with tips and tricks.

9. Staining technique

Techniques for staining and filling in the gaps.

10. Finishing and polishing

Tips to achieve a great final outcome.

Discussion + Q&A Session

The biggest and best event in dentistry is over for another two years and if you missed it, don’t despair... because eLABORATE has it covered!

Rather than only writing about what’s new at IDS 2023 in Cologne, Germany, we asked our technical editor, Terry Whitty and our favourite prosthetist, Sam Dias, to document the best of what they saw on video.

All the videos are available now at www.dentevents.tv/channel/ids2023 or scan the QR code below:

You can sign up for free through the website or simply use your existing Dental Community login to sign in and watch them all at your leisure.

“This was eLABORATE’s first foray into video reporting and we learnt a lot during the process,” said eLABORATE publisher Joseph Allbeury. “We mostly need to get better at sound!

“Overall, the videos give a unique perspective on what two Australians found interesting at the IDS in March and have presented it in a more indepth way than how the pages of eLABORATE can alone.”

Apart from these videos recorded at IDS, Dentevents.tv features hundreds of videos related to dentistry with more being continually added.

“Dentevents.TV is a dedicated video streaming service for the dental profession that we built during the first COVID-19 lockdown,” Mr Allbeury said. “We encourage you to watch the videos but also to add your own videos based around dentistry. The more the merrier!”

IDS 2025 is next on again in Cologne, Germany from March 25-29, 2025. Visit www.ids-cologne.de for more details.

Watch all the IDS videos 24/7 at www.dentevents.tv/channel/ids2023

Question 1. The main drawback for printed zirconia at this time is...

a. The crowns look lifeless.

b. Long post-processing times.

c. The printed and cured binder material is toxic.

d. The printers can only print resin.

Question 2. Printing Lithium Disilicate is promising but at this time the machinery is...

a. Not able to print veneers.

b. Only able to print veneers.

c. Expensive for the average user.

d. Only available in 110 volts.

Question 3. Most quality printers available in dentistry today...

a. Will not be able to print hybrid ceramic crowns.

b. Can only print bridges.

c. Will be able to print hybrid ceramic crowns.

d. Are too expensive.

Question 4. Hybrid ceramic crowns are currently monolithic however..

a. Can be stained and glazed to characterise them.

b. They can be layered with porcelain.

c. They will never look like a tooth.

d. This will never change in the future.

Question 5. For shades, some companies are experimenting with...

a. Laser-based resins.

b. Changing resins at different times of the print cycle to get polychromatic restorations.

c. Not worrying about shade at all.

d. None of the above.

LQuestion 6. Many older patients are looking for...

a. An outcome regardless of cost.

b. An economic solution but want function and aesthetics.

c. Porcelain teeth only for aesthetics.

d. None of the above.

Question 7. The two master models were articulated according to the...

a. CBCT Scan.

b. Incisive papilla.

c. Clinical bite registration.

d. Bennet angle.

Question 8. Vita MFT means...

a. My Favourite Teeth.

b. Multi Flavoured Teeth.

c. Multi Functional Teeth.

d. Myofunctional Teeth.

Question 9. In the molar region, the lingualised MFT teeth helped...

a. Finding Centric and establishing Buccal contacts.

b. Establish the patients OVD.

c. Retain the denture with clasps.

d. Shade taking a lot.

Question 10. The internal colours were applied using the...

a. Cotton swab

b. Dreve DentureArt System

c. Superglue

d. All of the above

entistry as a profession is well-known for adopting new technologies and often well ahead of the curve when it comes to Star Trek-like advancements. Intraoral scanning, CAD/CAM manufacturing, CBCT and digital x-ray just to name a few... and of course the latest and greatest craze, 3D printing.

Although 3D printing has been around since the 1980s, in the last 5 years or so it has really come into its own as the next big thing in manufacturing. The 3D printing option has changed dramatically as newer, progressively lower cost machines have come to market that are physically smaller, more user friendly and designed for dental.

The latest new wave of “additive manufacturing” or desktop 3D printing has the whole of dentistry whipped into a frenzy of amazing expectation. The

truth is, 3D printing is a great technology and can be adapted well for some dental applications. However, as with all marketing, it tends to gloss the results and instead of trying to polish a wet cigar, they defiantly roll it in glitter which actually can give people false expectations.

Certainly 3D printing works well for models, surgical guides, splints, sleep appliances, orthodontic aligner manufacturing, dentures and lots of other polymer-based appliances, but what about directly printing crowns and bridges?

To answer that, we would have to ask many questions. What is the case proposed?; What material do we want to use?; Where will we print it (chairside or lab side)?; How long is post-processing and is the resultant crown viable aesthetically?; Are the physical properties up to the level we would expect for a long-term restoration?; and is it economically viable? Phew!

Firstly, let’s look at dentally-focused materials that can currently be 3D-printed.

Lithium Disilicate is a well-known and loved material. It grew to fame via the e.max brand from Ivoclar. It’s a glass ceramic and aesthetically, some say it cannot be beaten as a monolithic restoration. It has a flexural strength of about 400 MPa and a flexural modulus of approximately 70,000 MPa!

One company of note, LITHOZ from Austria, is investing heavily into creating lithium disilicate 3D printed restorations and are making a big noise about it. The printing of lithium disilicate opens up great possibilities, especially with restorations such as veneers which traditionally can be time consuming and technique and ability dependent, however it could possibly be used for all areas where lithium disilicate is used currently.

LITHOZ called their printing technology LCM, or Lithography Ceramic Manufacturing and it’s definitely something to watch in the future. However, the current technology to print lithium disilicate comes with a hefty price tag so to get an affordable chairside solution may still be a long way off.

Zirconia is in a similar situation. There are a few companies dabbling in printable zirconia technology and yes, there are printers that can print zirconia. However, the post processing time required currently leaves this technology in a similar bag as lithium disilicate. It’s currently not possible to have a patient sit down, do a quick scan and print an all-ceramic crown in a few minutes; however this will change in the future.

For all glass ceramics, 3D printing materials is the main reason you won’t see a chairside solution for some time as printing and post processing is very time consuming as mentioned before. The ceramic is in a liquified form with a binder holding the ceramic particles together and this “mix” is laid down layer-by-layer.

Once the part is printed, the binder needs to be removed, usually by heat over time and the glass ceramic or ceramic also needs to be crystalised or sintered to create the restoration ready for finishing.

At present, this is a fairly long process so it’s not viable to be used chairside. Dental labs are experimenting with this technology and while it’s in its infancy, there may possibly be some advantages to the process. Traditional milling or pressing (which can involve 3D printed models) of ceramics will remain the most viable process for some time yet. In fact, many companies are trying to make chairside milling even more viable.

Probably no material group is as polarising as hybrid composites to create a definitive 3D printed crown. Some people will think it’s a great idea whilst others find themselves running in the opposite direction. Let’s be clear here, we’re talking about a crown at the moment; we’re not including any bridgework here as that will open up a completely different can of worms.

The materials used for 3D printing hybrid composites vary widely from one company to the next, however all are starting to show great promise as a restorative material. Most are nanofilled ceramic composites. Seremco, for example, have a product called Crowntec that has a flexural strength of 135 MPa and an elastic modulus of 4000 MPa which seems to be one of the category leaders. They suggest this product is for permanent crowns, inlays, onlays and temporary bridges. The elastic modulus is key here, notice it is 4000 Mpa.

Formlabs describes their permanent crown material as “a toothcoloured, ceramic-filled resin for 3D printing permanent single crowns, inlays, onlays and veneers. Permanent Crown Resin produces high strength, long term restorations with an accurate and precise fit, available in four VITA Classical* shades. Low water

absorption and a smooth finish ensure restorations made from Permanent Crown Resin have a low tendency to age, discolour or accumulate plaque”. They state the flexural strength is 116 MPa and a Flexural modulus of 4090 MPa.

SprintRay describes their new material in partnership with Bego as “a new hybrid nanoceramic, FDA-cleared Class II resin for 3D printed definitive full crowns, partial crowns, and veneers. Ceramic Crown is a ceramic dominant material, with over 50% inorganic ceramic content, for high strength and resistance to wear making SprintRay Ceramic Crown a go-to material for definitive 3D crowns”. Flexural strength of 136 MPa and a Flexural modulus of 7600 MPa.

I think you can see a pattern here regarding the flexural strength and flexural modulus. Remembering a higher flexural modulus indicates a material is more resistant to bending, while a lower flexural modulus indicates a material has a higher tendency to bend when a given amount of bending stress is applied.

Does all this mean the crown will have the mechanical properties to be suitable for long term use? This will no doubt be a point of debate for many, but in the correct circumstances, it could well be the case.

So what about the aesthetics of these materials? Unfortunately all of these materials are monochromatic as they are usually printed from one shade of resin, for example A2, A3 etc. However, after curing, they can be stained and manipulated in many ways to characterise them, so this is an option. For highly aesthetically demanding cases, however, they may not be suitable.

There are companies working on techniques to improve the printing. Of note is the company DWS with their technique called Photoshade Adaptive Gradient Technology which gives the restoration the appearance of having multiple areas of the shade at differing levels.

Joining is an investment in your future and that of the Dental Technology profession

Joining is an investment in your future and that of the Dental Technology profession

Joining is an investment in your future and that of the Dental Technology profession

JOIN HERE www.australiandentaltechnicians.com.au

Joining is an investment in your future and that of the Dental Technology profession

Joining is an investment in your future and that of the Dental Technology profession

JOIN HERE www.australiandentaltechnicians.com.au

JOIN HERE www.australiandentaltechnicians.com.au

Joining is an investment in your future and that of the Dental Technology profession

JOIN HERE www.australiandentaltechnicians.com.au

Joining is an investment in your future and that of the Dental Technology profession

JOIN HERE www.australiandentaltechnicians.com.au

JOIN HERE www.australiandentaltechnicians.com.au

Joining is an investment in your future and that of the Dental Technology profession JOIN HERE www.australiandentaltechnicians.com.au

JOIN HERE www.australiandentaltechnicians.com.au

No matter whether you are just starting out as a student, need advice with a business startup or want to expand your business into a more dynamic organisation, the ADTA has diverse skills, knowledge and a vast network of experience on offer at your service.

No matter whether you are just starting out as a student, need advice with a business startup or want to expand your business into a more dynamic organisation, the ADTA has diverse skills, knowledge and a vast network of experience on offer at your service.

No matter whether you are just starting out as a student, need advice with a business startup or want to expand your business into a more dynamic organisation, the ADTA has diverse skills, knowledge and a vast network of experience on offer at your service.

No matter whether you are just starting out as a student, need advice with a business startup or want to expand your business into a more dynamic organisation, the ADTA has diverse skills, knowledge and a vast network of experience on offer at your service.

No matter whether you are just starting out as a student, need advice with a business startup or want to expand your business into a more dynamic organisation, the ADTA has diverse skills, knowledge and a vast network of experience on offer at your service.

No matter whether you are just starting out as a student, need advice with a business startup or want to expand your business into a more dynamic organisation, the ADTA has diverse skills, knowledge and a vast network of experience on offer at your service.

No matter whether you are just starting out as a student, need advice with a business startup or want to expand your business into a more dynamic organisation, the ADTA has diverse skills, knowledge and a vast network of experience on offer at your service.

No matter whether you are just starting out as a student, need advice with a business startup or want to expand your business into a more dynamic organisation, the ADTA has diverse skills, knowledge and a vast network of experience on offer at your service.

The ADTA has strong representation within the TGA's Dental Sector Working Group (DSWG) and is well equipped to guide members through the process when listing devices on the ARTG. Members will be kept up to date with pertinent information.

The ADTA has strong representation within the TGA's Dental Sector Working Group (DSWG) and is well equipped to guide members through the process when listing devices on the ARTG. Members will be kept up to date with pertinent information.

The ADTA has strong representation within the TGA's Dental Sector Working Group (DSWG) and is well equipped to guide members through the process when listing devices on the ARTG. Members will be kept up to date with pertinent information.

The ADTA has strong representation within the TGA's Dental Sector Working Group (DSWG) and is well equipped to guide members through the process when listing devices on the ARTG. Members will be kept up to date with pertinent information.

The ADTA has strong representation within the TGA's Dental Sector Working Group (DSWG) and is well equipped to guide members through the process when listing devices on the ARTG. Members will be kept up to date with pertinent information.

The ADTA has strong representation within the TGA's Dental Sector Working Group (DSWG) and is well equipped to guide members through the process when listing devices on the ARTG. Members will be kept up to date with pertinent information.

The ADTA has strong representation within the TGA's Dental Sector Working Group (DSWG) and is well equipped to guide members through the process when listing devices on the ARTG. Members will be kept up to date with pertinent information.

The ADTA has strong representation within the TGA's Dental Sector Working Group (DSWG) and is well equipped to guide members through the process when listing devices on the ARTG. Members will be kept up to date with pertinent information.

An industry managed Certification and Conformity scheme specifically for Dental Laboratories, this scheme identifies those that have demonstrated their capabilities against a national standard and displayed their commitment to maintaining quality within dental technology.

An industry managed Certification and Conformity scheme specifically for Dental Laboratories, this scheme identifies those that have demonstrated their capabilities against a national standard and displayed their commitment to maintaining quality within dental technology.

An industry managed Certification and Conformity scheme specifically for Dental Laboratories, this scheme identifies those that have demonstrated their capabilities against a national standard and displayed their commitment to maintaining quality within dental technology

An industry managed Certification and Conformity scheme specifically for Dental Laboratories, this scheme identifies those that have demonstrated their capabilities against a national standard and displayed their commitment to maintaining quality within dental technology.

An industry managed Certification and Conformity scheme specifically for Dental Laboratories, this scheme identifies those that have demonstrated their capabilities against a national standard and displayed their commitment to maintaining quality within dental technology.

An industry managed Certification and Conformity scheme specifically for Dental Laboratories, this scheme identifies those that have demonstrated their capabilities against a national standard and displayed their commitment to maintaining quality within dental technology

An industry managed Certification and Conformity scheme specifically for Dental Laboratories, this scheme identifies those that have demonstrated their capabilities against a national standard and displayed their commitment to maintaining quality within dental technology

An industry managed Certification and Conformity scheme specifically for Dental Laboratories, this scheme identifies those that have demonstrated their capabilities against a national standard and displayed their commitment to maintaining quality within dental technology.

Stay informed with regular news from within the profession, association, search or post an ad in the classifieds, and adopt useful information from articles into your place of business.

Stay informed with regular news from within the profession, association, search or post an ad in the classifieds, and adopt useful information from articles into your place of business.

Stay informed with regular news from within the profession, association, search or post an ad in the classifieds, and adopt useful information from articles into your place of business.

Stay informed with regular news from within the profession, association, search or post an ad in the classifieds, and adopt useful information from articles into your place of business.

Stay informed with regular news from within the profession, association, search or post an ad in the classifieds, and adopt useful information from articles into your place of business.

Stay informed with regular news from within the profession, association, search or post an ad in the classifieds, and adopt useful information from articles into your place of business.

Stay informed with regular news from within the profession, association, search or post an ad in the classifieds, and adopt useful information from articles into your place of business.

Stay informed with regular news from within the profession, association, search or post an ad in the classifieds, and adopt useful information from articles into your place of business.

Reach like minded and interested parties by posting your Vacancies or Classifieds within the ADTA marketplace.

Reach like minded and interested parties by posting your Vacancies or Classifieds within the ADTA marketplace.

Reach like minded and interested parties by posting your Vacancies or Classifieds within the ADTA marketplace.

Reach like minded and interested parties by posting your Vacancies or Classifieds within the ADTA marketplace.

Reach like minded and interested parties by posting your Vacancies or Classifieds within the ADTA marketplace.

Reach like minded and interested parties by posting your Vacancies or Classifieds within the ADTA marketplace.

Reach like minded and interested parties by posting your Vacancies or Classifieds within the ADTA marketplace.

Reach like minded and interested parties by posting your Vacancies or Classifieds within the ADTA marketplace.

Take advantage of exclusive industry offerings as they are made available to ADTA members.

Take advantage of exclusive industry offerings as they are made available to ADTA members.

Take advantage of exclusive industry offerings as they are made available to ADTA members.

Take advantage of exclusive industry offerings as they are made available to ADTA members.

Take advantage of exclusive industry offerings as they are made available to ADTA members.

*These services are in development. Members will be advised when these benefits are available. opment.

*These services are in development. Members will be advised when these benefits are available.

Take advantage of exclusive industry offerings as they are made available to ADTA members.

*These services are in development Members will be advised when these benefits are available

*These services are in development Members will be advised when these benefits are available

Take advantage of exclusive industry offerings as they are made available to ADTA members.

*These services are in development. Members will be advised when these benefits are available.

*These services are in development Members will be advised when these benefits are available

Take advantage of exclusive industry offerings as they are made available to ADTA members.

*These services are in development Members will be advised when these benefits are available opment

*These services are in development. Members will be advised when these benefits are available.

This is done with some clever resin changing technology as it will print lighter areas then change or mix the resin and continue to the darker areas. This is in its infancy, but it’s heading in the right direction.

The 3D printed permanent crown in its current state is not so much a replacement for a traditional ceramic restoration but as a new option of treatment. If the case selection is carefully evaluated and the expectation of the aesthetics is not highly demanding, then it’s quite possible the 3D-printed permanent crown is arguably a treatment option today.

Terence Whitty is a well-known dental technology key opinion leader and lectures nationally and internationally on a variety of dental technology and material science subjects. He is the founder and owner of Fabdent, a busy dental laboratory in Sydney specialising in high tech manufacturing. Using the latest advances in intra- and extra-oral scanning, CAD/ CAM, milling, grinding and 3D printing, most specialties are covered including ortho, fixed and removable prosthetics, computerised implant planning and guidance, TMD, sleep appliances and paediatrics.

By Daniel Lavrin, Dental Technician and Denturist

By Daniel Lavrin, Dental Technician and Denturist

Listening to what patients want and need is a crucial factor for a successful rehabilitation. When it comes to dentures, many older patients are looking for an economic solution. On the other hand, what they don’t want, is a denture that lacks functionality and aesthetics. The following user report profiles how to accomplish efficient and economic aesthetics and fuctionality with an established treatment protocol and denture teeth of choice.

A72-year-old female patient presented in the office because she could not eat properly with her removable prosthetics. The partial denture in the lower jaw broke several times and was uncomfortable and unstable. Because of that, she stopped wearing it. Despite the age-appropriate bone atrophy, the remaining teeth, 32 and 33, did not show any signs of inflammation. Tooth 32 had a mobility of one.

The patient wanted to keep both teeth and refused implants, which would have distributed the forces more evenly. The disadvantages of an uneven load and the accelerating effect on her remaining teeth were explained.

In case of necessary extractions at a later stage, an easy denture teeth addition to the new partial denture could be provided, which was satisfactory to the patient. She was currently only using the full denture in the upper, which did not function well, as the occlusal forces were unbalanced.

She desired an improvement of aesthetics and eating conditions with new prosthetics. Her limited budget made an economic solution necessary. Based on these factors, VITA Multi Functional Teeth (VITA MFT) were chosen for the new full denture in the upper and a partial denture in the lower to guarantee aesthetics and functionality for an ideal price-performance ratio.

After anatomic impressions of the upper and lower jaw, models were fabricated on which individual trays were created for the mucodynamic impression.

Master models were manufactered to be able to produce fitting bite registration plates with a wax rim to record the position of the mandible in relation to the maxilla and to transfer the midline, the canine position, the incisal length and expansion of the buccal corridor. According to the clinical bite registration, the two master models were articulated and the model analysis was performed.

VITA MFT Anterior was used for the set up in the anterior area. For a budget denture tooth, the anterior sets are very aesthetic. They are designed naturally in morphology and texture. The anatomical structure is simulated with neck, dentine and enamel layers, which leads to a three-dimensional play of light and colour. Tooth axis and coordinated angle characteristics, according to the aesthetic rules, make a quick match of the front teeth possible. Due to the position of the remaning canine and incisor, all lower teeth were used in addition to the natural incisor 32 to provide stability while eating with the new denture. So altogether, there were five lower central incisors established. The set up was performed edge-to-edge to the remaining natural teeth to improve the aesthetics of the upper smile line.

In the molar region, the lingualized VITA MFT Posterior easily enabled finding the centric position and establishing buccal contacts, due to the multifunctional occlusal surface design. The lingualisation of the teeth offered more space for the tongue and a more stable function on the atrophied jaw ridges. Extra care was also taken during the contouring of the lower lingual aspect to implement space and free movement of the tongue. During the try in, a final bite registration was taken with the set ups in order to recheck static and dynamic occlusion in the articulator.

After a successful clinical try in and final anatomical contouring, the prosthetics were transferred into polymer. First, the set ups were duplicated with hydrocolloid. Then the teeth were cleaned, conditioned and repositioned in the hydrocolloid index. Before the flasking of the denture base with the autopolymerizsing and pourable Castdon Resin (Dreve Dentamid, Germany), internal colours of the DentureArt System (Dreve Dentamid, Germany) were applied into the flask to simulate the appearance of the gingival anatomy. After the polymerisation, finishing and polishing was performed. The new rehabilitations were inserted intraorally and checked by the practitioner and the patient. Both were very satisfied with the lifelike appearance and functional integration. The patient’s requirements of an economical, aesthetic and functional rehabilitation were all met.

Daniel qualified as a Dental Technician in Paris and then achieved qualifications in denturism with the Ontario College Advanced Diploma for the Denturist. He was awarded his UK Diploma qualification in Clinical Dental Technology via the Royal College of Surgeons of England.

Solid, standard prosthetic with excellent cost e ciency

• Easy and intuitive setup

• Secure, solid and esthetic results

• Reliably reproduced tooth shades

NOW available in all

VITA classical A1–D4® shades!

D printers have reached a level where all the quality brands work very well and will give consistent, reliable results, provided you choose a machine suited to the task you require it to complete.

Moving forward, if there is one word that describes the future direction of 3D printing, it’s automation . And whilst it is easy to focus on printers that run continually by automating the removal of objects from the build platform once printing is complete, automation can actually be applied to all aspects of the process. After all, automation is designed to both increase efficiency and also to complete tasks that humans may want to avoid.

The latter is very important because 3D printing, for all its hype and glory, is actually a very messy business and the more you can automate, the better. If, through automation, we can avoid contact with the resins that tend to be sticky and smelly in a liquid state, then this is really a plus.

Overall, equipment for post-process washing and curing of 3D printed objects is still a bit of a mixed bag. Some manufacturers have novel equipment for these processes while others, unfortunately, have nothing at all.

Shining 3D Dental have taken steps to address this much maligned aspect of printing by adding a taste of automation to these processes with the introduction of the FabWash automatic post processing washing station and the FabCure 2 curing unit.

Firstly, a quick mention of the Shining 3D AccuFab-L4D and AccuFab-L4K MSLA 3D printers because they match with these products very well. For a full review of the L4D series printer see eLABORATE Vol. 20 No. 1 Jan/Feb 2023.

The FabWash unit is a cleverly thought out piece of equipment indeed. It’s the first fully automated washing and drying system designed to make things easy during the post processing segment of 3D printing.

The process is extremely simple as all you do is fill the machine with solvent and then remove the build platform from the AccuFab printer with the parts you have just printed and slide it into place in the FabWash unit.

Simply press the button on the front of the unit and the process will begin. The build platform is lowered into the wash unit and a sharp blade moves slowly across, separating the printed parts which drop into a basket within the solvent tank.

The parts are then agitated by a magnetically coupled impeller for a programable pre-determined time and washed for a squeaky clean result. After washing, the basket is raised automatically and the parts can dry off.

On the front panel is a simple illuminated switch and options to cut, wash and dry; wash and dry only; or just cut - it sounds like my local hairdresser - but rest assured, it does it all very, very well. Also, you can customise the program settings to suit your material and everything can be updated via WiFi so you will never be out of date.

Of course, you can use this unit with other brands of printers, but the cut function would not be available as it’s made to fit the Shining 3D printers alone. Nevertheless, the wash and dry function would still be very useful.

After the cut, clean and dry, you can then use the FabCure 2 light curing unit. This is a standard procedure and the known mechanical properties can be improved when a sufficient postcuring time is applied to achieve homogeneous polymerisation in both deep and superficial layers of the 3D printed object. The FabCure 2 unit is a lighting system of 30 multidirectional LED’s emitting powerful UV light that instantly penetrates deep into the surface of the part to be cured. With a power of 70 W, these LED’s provide a high power curing cycle ensuring an efficient curing process.

It also has an inbuilt heating module with multiple temperature sensors. The curing chamber heats up quickly to 60℃, accelerating the curing and ultimately enhancing the optical and mechanical properties of the cured parts. The FabCure 2 heating system precisely controls ambient temperatures to 60℃. The chamber volume is a huge 120 mm x 180 mm so there is room for a large number of printed parts.

FabCure 2 provides optimal curing parameters for Shining 3D resins, which can be updated via the wireless network. With an up-to-date cloud-based smart material library, the FabCure 2 is always synchronised. The FabCure 2 is equipped with Wi-Fi which enables over-the-air updates to deploy the latest firmware and configurations. Customised curing parameter settings are also supported for 3rd party resins so you can dial in your preferred resin curing cycle for your favourite resins and it will cure all resins regardless of whether they are 385 nm or 405 nm.

The Shining 3D FabWash all-in-one solution for cut, wash and dry together with the FabCure 2 is a godsend for all 3D printer users out there.

Terence Whitty is a well-known dental technology key opinion leader and lectures nationally and internationally on a variety of dental technology and material science subjects. He is the founder and owner of Fabdent, a busy dental laboratory in Sydney specialising in high tech manufacturing. Using the latest advances in intra- and extra-oral scanning, CAD/ CAM, milling, grinding and 3D printing, most specialties are covered including ortho, fixed and removable prosthetics, computerised implant planning and guidance, TMD, sleep appliances and paediatrics.

Awell-designed occlusal surface, particularly in a mouthguard designed for higher impacts, is vital to unlock the full protective capability of the appliance. While both the occlusal designs described here can be achieved by articulating and reheating after forming, we fortunately have the Occluform 3 for quickly creating high quality occlusal schemes in mouthguards. The advantages of incorporating the Occluform 3 into the mouthguard thermoforming process are multiple. The time alone saved by removing the need to re-

articulate is substantial but this technique also yields technical improvements by negating the need to heat the material a second time, thereby risking distortion of the formed mouthguard.

Adding the occlusion this way is performed while the material is in a hot plastic state immediately after the material has formed, with the exception of the Playsafe Triple foils - these are imprinted 60 seconds after forming, when the foil has slightly cooled. The foils are then allowed to complete the cooling cycle with the opposing model in place before final finishing.

Figure 9 (left). With the occlusal opening set, after the final layer is formed, bring the Bite Spacer down into the hot foil (allow 60 seconds delay for Playsafe Triple foils). This will create a plane with point contacts as well as displace the material buccally and incisally for added protection (“Buccal Shield”).

Figure 10. Leave in place until the cooling cycle has completed, then release the Bite Spacer from the Face Chuck arms, raise the opposing model and gently remove the reusable Bite Spacer - the occlusion is completed.

Peter Herring is a dental technician, prosthetist and a regular contributor to eLABORATE. He is the Australasian and Indonesian distributor for Erkodent products and spends his time between offices in Perth and Bali. He also operates a busy Australian lab dedicated to thermoformed appliances. He can be contacted at pjh@erkodent.com.au or for general enquires, call Freecall 1800-242-634.

Information contained in this section is provided by the manufacturers or distributors. eLABORATE does not assume responsibility for the accuracy of the data.

The Smile Lite MDP2 Mobile Dental Photography by Prof. Louis Hardan - the ultimate evolution in mobile dental photography – is here. It’s equipped with three groups of next generation “SunLike“ LEDs and each group can be lit up individually. A dimmer function gives you the possibility to set four different illumination levels. The increased light power is perfect

for posterior shots and the new integrated ergonomic handle provides stable support. The back of the Smile Lite MDP2 is equipped with a universal adapter that is adjustable and fits any smartphone with a width between 55-85mm.

Available: Alphabond Dental Tel: (02) 9417-6660

info@alphabond.com.au

www. alphabond.com.au

Available in a range of options, Fiber Force is the ideal product to reinforce any appliance. Pink Fiber Force Mesh is used primarily to fabricate reinforcement frameworks for newly constructed dentures, but can also be used for repairing dentures. Pink Fiber Force Braided Rope is excellent as a denture repair material as well as to

reinforce provisional and final fixed bridges or to reinforce orthotic appliances. Pink Fiber Force LC light cure resin is used in the framework fabrication process to create tissue stops.

Available: Alphabond Dental Tel: (02) 9417-6660

info@alphabond.com.au

www. alphabond.com.au

The MPF Composite Warming Palette is designed to bring composite to a more malleable consistency which aids manipulation when restoring small or long span restorations, especially when extensive gingival adaption in hybrid cases is required. The Makrolon polycarbonate palette case has stable UV properties that

prevents direct UV light from polymerising the composite within the tray. The LCD display shows the temperature of the actual glass plate which can be adjusted up or down.

Available: Alphabond Dental Tel: (02) 9417-6660

info@alphabond.com.au

www. alphabond.com.au

Scantist 3D is an extraoral scan spray to optimise the recording quality for CAD/CAM scans, camera/video recordings, structured light scans, blue light scans, etc. It evaporates / sublimates automati cally after application. It contains no pigments and no titanium dioxide (TiO2) and causes no contamination of the object, environment or user. It creates a non-slip surface and the ultra thin layer thickness results in a very fine homogeneous coating. Efficient and economical thanks to application using a special valve and fine nozzle. It adheres to all mate rials - even on very smooth surfaces and has no corrosive effect.

Available: Alphabond Dental Tel: (02) 9417-6660

info@alphabond.com.au www.alphabond.com.

The new Shining 3D DSEX PRO GOLD Scanner combines amazing performance with unbeatable value

• Model Scanning

• Impression Scanning

• Colour Scanning

• Texture Scanning

• Articulator Scanning

• Compatible with every major 3D printer, Mill and Software

• Crown and Bridge, Implants, Digital Dentures, Partials, Orthodontics

BUY BEFORE JUNE 30 FOR INSTANT ASSET TAX WRITE OFF !

Contact us today and we will show you how to integrate Affordable Digital Dental Technology into your business.

1300 878 336

Ceramill Matik opens up a still unique segment within the digital dental world. The machine frees today‘s modern dental technicians from unproductive secondary tasks that previously took up to 40 percent of their working time. This now allows the dental technician to concentrate 100 percent on the essentials: dental technology per se and the creation of value in the laboratory.